Somat eCorect ET-100w Installation Manual

OPERATION / INSTRUCTION MANUAL

AND

GENERAL INFORMATION

eCorect ET-100w

Somat Company 165 Independence Ct Lancaster, Pa 17601 800-237-6628 www.somatcompany.com

SAFETY

INSTRUCTIONS

READ THE MANUAL COMPLETELY BEFORE ATTEMPTING TO OPERATE THE UNIT.

HIGH VOLTAGE! DO NOT PERFORM ANY REPAIRS TO MOTORS OR CONTROL SYSTEMS WITHOUT TURNING OFF THE MAIN POWER.

ALWAYS TURN THE MAIN POWER OFF AND LET ALL MOTORS COME TO A STANDSTILL BEFORE DOING ANY MAINTENANCE ADJUSTMENTS OR CLEANING OF THE UNIT.

BEFORE STARTING, BE SURE ALL PERSONNEL ARE CLEAR OF MOVING PARTS.

KNOW LOCATION AND FUNCTIONS OF ALL START/STOP BUTTONS AND SAFETY SWITCHES.

DURING PERIODIC MAINTENANCE, CHECK ALL SAFETY SWITCHES TO BE SURE THEY ARE OPERATING PROPERLY.

DO NOT REMOVE OR ALTER GUARDS.

DO NOT REMOVE SAFETY LABELS. IF LABELS ARE MISSING OR DESTROYED, CONTACT FACTORY FOR REPLACEMENT.

DO NOT OBSTRUCT ELECTRICAL PANELS OR PUSH BUTTONS.

GOOD HOUSEKEEPING IS THE MOST IMPORTANT SAFETY PROCEDURE.

IMPORTANT

The Instruction Manual is important to the proper operation and maintenance of your SOMAT® System. It should be readily available to those who are responsible for the operation and performance of the SOMAT® equipment.

Due to the high cost of preparing replacement manuals, a charge will be made for duplicate

manuals beyond those furnished with the original shipment.

For ordering duplicate manuals, please contact:

SERVICE DEPARTMENT

SOMAT COMPANY

165 Independence Court, Lancaster, PA 17601 USA Telephone 717-397-5100, Fax 717-291-0877 1-800-23-SOMAT (1-800-237-6628)

Internet: www.somatcompany.com parts@somatcompany.com

LIMITED WARRANTY

SOMAT COMPANY warrants each new product manufactured by it to be free from defects in material and workmanship under normal use and service, which does not include normal wear of parts, ("normal use and service", with respect to Pulpers, Presses, water Hydra-Extractors, Waste Handling and Processing Systems, shall mean the handling only of waste items of the types listed in the SOMAT® Quotation or Sales Order therefore and within the LIMITATIONS THEREIN set forth), its obligation under this warranty being limited to repairing or replacing any part or parts thereof, free of charge INCLUSIVE of labor to remove and replace, f.o.b. factory from which shipped, which shall, within one year from initial start-up of the SOMAT® System or from date of original installation of the product if not a system, or eighteen months from date of shipment, whichever shall first occur, be returned to SOMAT® at the factory from which shipped, with transportation charges prepaid, and which SOMAT's examination shall disclose to its satisfaction to have been thus defective. This warranty shall not apply to any product or part which shall have been repaired or altered by any person not employed or retained by SOMAT®, so as in the judgment of SOMAT® to affect its operation and reliability, nor which has been installed, operated, or maintained contrary to SOMAT® OPERATION or PREVENTIVE MAINTENANCE INSTRUCTION MANUALS or to other written instructions or drawings approved by SOMAT®, nor which has been subject to misuse, negligence, or accident. This warranty shall not apply should the SOMAT® System be initially started up without a duly authorized SOMAT® representative present.

EXCEPT AS HEREIN EXPRESSLY STATED, NO WARRANTY, EXPRESS, IMPLIED OR BY LAW, (INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), IS MADE BY SOMAT; AND IN ANY EVENT SOMAT’S LIABILITY, WHETHER IN CONTRACT, TORT, STRICT LIABILITY, OR UNDER ANY WARRANTY, OR OTHERWISE, SHALL NOT EXCEED THE PURCHASE PRICE RECEIVED BY IT AND SHALL IN NO EVENT INCLUDE ANY CONSEQUENTIAL, INCIDENTAL, PUNITIVE OR OTHER SPECIAL DAMAGES.

NO CHANGE IN THIS WARRANTY AND LIMITATION OF LIABILITY AND NO SUBSTITUTE THEREFORE (WHETHER INCORPORATED IN A PURCHASE ORDER OR OTHERWISE) SHALL BE EFFECTIVE UNLESS SPECIFICALLY SET FORTH IN A WRITTEN INSTRUMENT SIGNED BY AN OFFICER OF SOMAT®.

Rev. 08/01/00

PRECAUTIONS:

1.The unit shall be installed in accordance with national and local wiring regulations and all applicable codes.

2.The unit MUST be placed at least 8” from the wall

3.DO NOT pull or alter power cord. Pulling and misuse of the power supply cord can result in damage to the unit and cause electrical shock.

4.Ensure the electrical cord is properly grounded.

5.DO NOT place any materials on top of unit

6.DO NOT use water to clean the unit, use an approved stainless equivalent.

7.DO NOT alter the pre-programmed settings or disassemble the unit without first contacting Somat Company. Failure to do so may result in a voided warranty.

8.Turn off incoming power to unit and lockout breaker to perform any kind of maintenance or cleaning.

9.DO NOT open the input door during operation, it can cause odor issues and errors in the automated control and operation.

10.Ensure the unit and the area around the unit is clean. Proper maintenance of the unit is also highly recommended.

11.Please have ALL operators read this manual to ensure proper understanding of the unit and its operation.

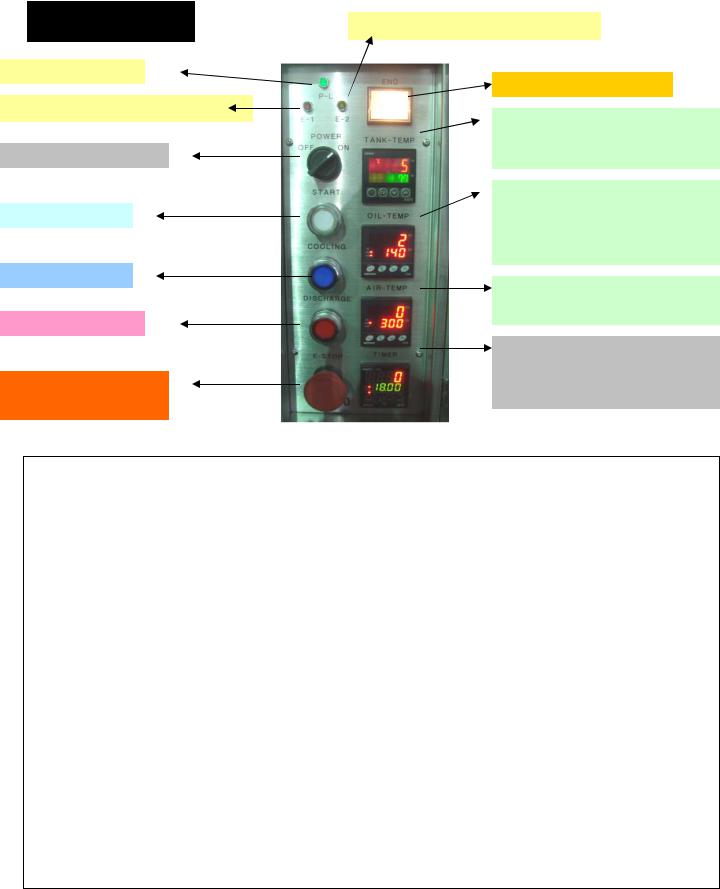

Control Panel

P-L Power Indicator

E-1 OVERLOAD Indicator (OIL-TEMP)

POWER ON/OFF switch

START button

COOLING button

DISCHARGE button

E-STOP

emergency stop button

E-2 OVERHEAT Indicator (AIR-TEMP)

END operation indicator

TANK-TEMP indicator

1st row: internal temperature

2nd row: Pre-set control temperature

OIL-TEMP indicator 1st row: Oil temperature

2nd row: Pre-set control threshold AL-H, L: Pre-set overheat control & switch temperature

AIR-TEMP indicator

Temperature of deodorizer

TIMER control

1st row: Operating hour

2nd row: Pre-set maximum operating hour for extra safety

DESCRIPTION

P-L light: Main power indicator (green light will be on with the start of operation)

E-1 Light: Overload Indicator of hot oil temperature. Activates when the hot oil exceeds the threshold settings.

E-2 Light: Overheat indicator for deodorizer. Activates when the deodorizer is overheated.

END Light: Indicates when the machine completes operation. The light will be off after discharging the content.

POWER switch: Main power switch

START button: To start operation

COOLING button: The light will be on when the cooling cycle of the machine starts after completion of operation cycles.

DISCHARGE button: To open the output door unit to discharge the content after completion of its operation.

E-STOP button. Emergency stop button to manually stop the machine or use it in case of emergency.

To release from Emergency mode, turn the switch clockwise

TANK-TEMP: Displays temperature of the internal reactor and pre-set control settings * (2nd row : 78~80)

2nd Row: Pre-set Value as a default factory setting

OIL-TEMP: Displays the temperature of hot oil and pre-set threshold of hot oil; (2nd row: 140) + 10

If it is overheated; E-2 light will be ON. AL-H/L (Overheat control temperature) *

AIR-TEMP: Displays temperature of deodorizer unit* 2nd row: 300) +up to 50 (ALH)

TIMER: Indicates pre-set operation hour (2nd row; 1800)*

Loading...

Loading...