Somat SP-60S Manual

somat®

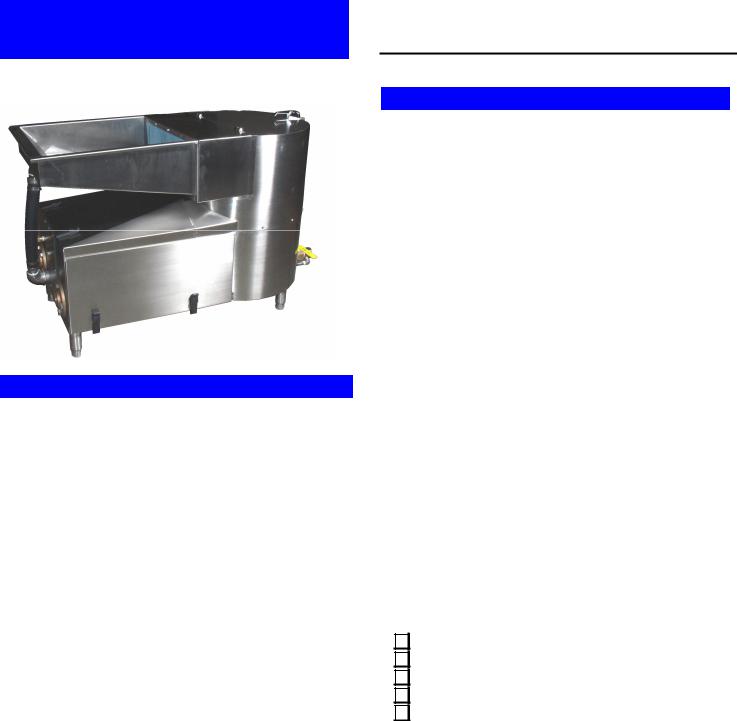

Super 60 Remote Waste Pulping System

Description

Standard SOMAT® Model SP-60S pulper constructed of stainless steel with a hinged stainless steel lid, water flushed tray, horizontal drive, and internal valve package. The Som-A-Trol® control panel is pre-wired and contains the water level control. A push button station is also included.

Benefits:

As much as 8 to 1 (87.5%) volume reduction

Reduced labor costs

Better sanitation

Water conservation

Improved operator morale

Reduced silverware loss

Processes tough plastics, plus a wide variety of waste

Operation: Foodservice waste enters the pulping tank via the tray where it is mixed with water, forming a slurry of 5% solids and 95% water. The slurry is pumped to a remote Hydra-Extractor®, where the water is removed, resulting in a greatly reduced volume. The resulting semidry pulp is discharged into a haul-away container. The extracted water is recovered and returned to the pulper for re-use.

Somat® equipment provides an economic and efficient answer to cutting the high and ever increasing costs associated with waste handling.

Manufactured with pride by Somat® Company of Lancaster, Pennsylvania, USA, originators of waste pulping systems and specialists in waste reduction technology.

Approval:

Patent No. US 6,776,365 |

08/17/04 |

|

|

UL Listed Product |

File: E-194205 |

Item No.

SOMAT® Model: SP-60S

Technical Specifications

Pulper: 25 1/2” diameter, 35.5” high, polished stainless steel tank with water flushed tray, hinged lid and associated proximity switch. Horizontally mounted pulping and pumping system, integrated with one 6 HP TEFC motor. This unit is supported by four neoprene vibration mounts that isolate it from the stainless steel frame. A urethane vibration-absorbing gasket is located between the pulping tank and pulper shell. Rubber hoses further isolate vibrations from the end plate where external connections are made. Stainless steel shrouds totally enclose the drive system and water manifolds. Adjustable legs provide 6” floor-to-frame clearance. All customer connections are external. 5 HP slurry booster pump (not shown).

Components include: 304 stainless steel pulper tank, investment cast 17-4 stainless steel security ring and rotating blade, three replaceable stationary blades on the security ring, stainless steel impeller with replaceable stainless steel pumping vanes. The one-piece rotating blade is hardened to 46 Rockwell C and can be easily resharpened.

Valve Package: Pre-piped bronze valves mounted on manifolds completely enclosed in stainless steel shrouds.

Som-A-Trol® (Electrical Control Panel): Wall mounted, UL approved, NEMA 4 stainless steel enclosure. Included are all necessary power, control and water level components, pre-wired to a terminal strip. A push button station is included with the panel or mounted on the unit.

Options Available:

Trough connection

Slurry siphon break

Prison package

Special electrical characteristics

Second year warranty

Electrical Characteristics: 208/230/460 volt, 3 phase, 60 Hz.

Capacity: 1000 pounds per hour of foodservice waste mix, consisting of: food scraps, plastic flatware, paper, milk cartons, Styrofoam, aluminum foil, cardboard, polyethylene bags and all types of plastic containers and packaging.

Finish: All exterior surfaces are polished stainless steel.

Equipment only is supplied by SOMAT® Company; installation, piping, and wiring are not included.

Somat Company Division of ITW Food Equipment Group LLC 165 Independence Court

Lancaster, PA 17601 USA

Phone: 717-397-5100 800-237-6628 Fax: 717-291-0877

www. somatcompany.com

somat® |

SP-60S |

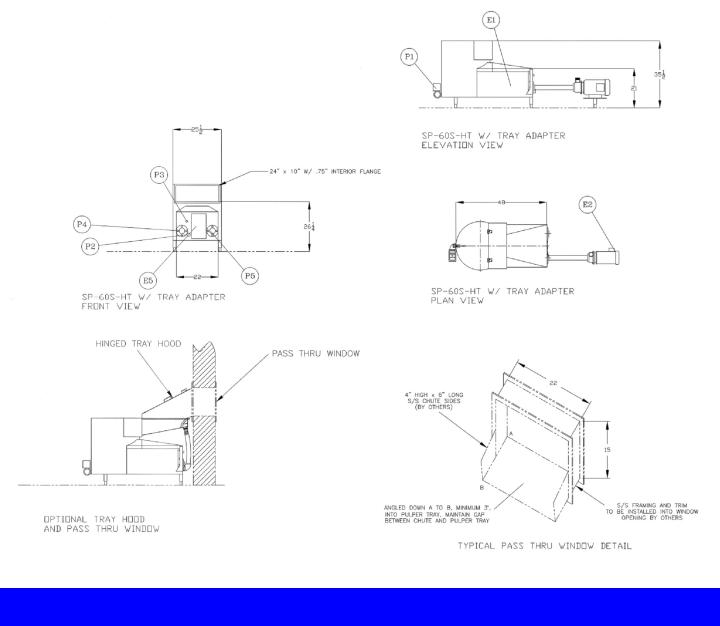

HT Specs / Tray Options |

|

Remote Pulping System |

|

Somat® Model SP-60S-FS

Utility Connections

E1- Pulper Drive Motor |

|

P1- Drain Valve Outlet (MOV) |

(2”) |

E2- Slurry Pump Motor |

|

P2- Return Water Outlet |

(1 ½”) |

E3- N/A |

|

P3- Fresh Water Inlet |

(½”) |

E4- N/A |

|

P4- Slurry Outlet |

(2”) |

E5- Junction Enclosure |

|

P5- Return Water Inlet |

(2”) |

|

Dimensions |

|

|

|

|

|

|

Height: 35.5” (902mm) |

|

Equipment weight: 410# (186kg) |

|

Length: 53.5” (1359mm) |

|

Operating weight: 530# (241kg) |

|

Width: 25.5” (648mm) |

|

Crated weight: 756# (343kg) |

|

|

|

Crated volume: 80 Cu. Ft. (2.8 Cu Meters) |

|

Loading...

Loading...