Somat SP-75, SP-75S Specifications

somat® |

|

Item No_______________________________ |

|

|

|

|

|

SOMAT Model: SP-75S |

Remote Waste Pulping System |

|

|

|

Technical Specifications |

|

|

|

Description

Standard SOMAT® Model SP-75S HT high tank pulper, hinged lid with limit switch, water flushed feed tray, 3 HP or 5 HP slurry pump, valve package, Som- A-Trol® control panel with water level control, push button station.

Benefits

As much as 8 to 1 (87.5%) volume reduction

Reduced labor cost

Better sanitation

Water conservation

Improved operator morale

Reduced silverware loss

Pulper: 30” diameter, 39.5” high polished stainless steel tank with water flushed feed tray, hinged lid with limit switch, 3/8” thick stainless steel slurry chamber, 7 ½ HP TEFC direct drive motor, internal junk box and cutting mechanism, HyPoint cutting mechanism, stainless steel, consists of 1 piece security ring with 3 stationary, replaceable top cutters and impeller with 2 replaceable rotating cutters.

Valve Package: All valves required for proper operation (fresh water, tray flush and drain lines).

Som-A-Trol® (Electrical Control Panel): UL approved. Includes all necessary electrical components prewired to a terminal strip; water level control and push button station, in a NEMA 4 stainless steel enclosure.

Options Available:

Feed trough connection

Feed tray cover

Special electrical characteristics

Under Dish Table unit

Special Requirements:

Dual water level control and motor operated valve with controls. Required if more than one pulper operating with a single Hydra-Extractor.

Stainless Steel Dam. Required when pulper is located higher (one level minimum) than the Hydra-Extractor.

Processes a wide variety of waste |

Electrical Characteristics: 208/230/460 volt, 3 |

||

Operation: Foodservice waste enters the pulping |

Phase, 60 Hertz |

||

Capacity: 1250 pounds per hour of foodservice |

|||

tank via the feed tray where it mixes with water, is |

|||

processed and |

made into a slurry. The slurry, |

waste mix, consisting of food scraps, plastics, milk |

|

consisting of 5% solids and 95% water, is |

cartons, paper, aluminum foil and cardboard. |

||

automatically transported through a pipeline to the |

Finish: All exterior surfaces, except where polished |

||

Hydra-Extractor®, where water is removed and the |

|||

resultant semi-dry pulp is discharged into a haul- |

stainless steel, are prime coated and finished with |

||

away container. |

The extracted water is recovered |

two coats of enamel paint. |

|

and returned to the pulping tank for re-use. |

|

||

Somat equipment provides an economic and |

Equipment only is supplied by SOMAT Company; installation, piping and |

||

efficient answer to cutting the high and ever |

wiring not included. |

||

increasing costs associated with waste handling. |

|

||

Manufactured by Somat Company of Lancaster, |

|

||

Pennsylvania, originators of waste pulping systems |

|

||

and specialists in waste reduction technology. |

Somat Company |

||

|

|

||

Approval: |

|

Division of ITW Food Equipment Group LLC |

|

|

165 Independence Court |

||

|

|

Lancaster, PA 17601 USA |

|

|

|

Tel: 717-397-5100 Fax: 717-291-0877 |

|

|

|

1-800-237-6628 |

|

|

|

||

|

|

www.somatcompany.com |

|

6/14/05 |

|||

|

|||

somat® |

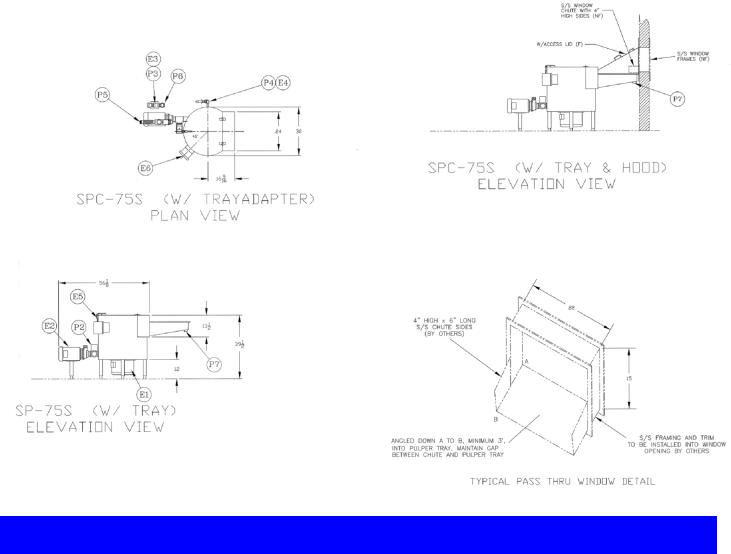

SP-75S-HT Specs / Tray Options |

||

Remote Pulping System |

|

||

|

|

|

|

|

|

|

|

Somat® Model SP-75S HT

Utility Connections

E1- Pulper Drive Motor |

P1- N/A |

|

E2- Slurry Pump Motor |

P2- Drain Valve Outlet (MOV) |

(2”) |

E3- Return Line MOV |

P3- Return Water Inlet |

(2”) |

E4- Fresh Water Solenoid |

P4- Fresh Water Inlet |

(3/4”) |

E5- Limit Switch |

P5- Slurry Outlet |

(2”) |

E6- Junction Enclosure |

P6- Return Water To Tray |

(1 ½”) |

|

P7- Tray Flush |

(1 ½”) |

Dimensions |

|

|

|

|

|

Tank Height: 39.5” (1004mm) |

Equipment weight: 525 lbs. (238 kg) |

|

Length: 56” (1423mm) (Excluding tray / trough) |

Operating weight: 745 lbs. (338 kg) |

|

Width: 30” (762mm) (Excluding external piping) |

Crated weight: 850 lbs. (386 kg) |

|

|

Crated volume: 85 cu. ft. |

|

6/14/05

Loading...

Loading...