Page 1

006001 +

PARTS & SERVICE

Part number 514252-200

March 2014

Page 2

Page 3

SERVICE & PARTS

MANUAL

A38E

Aerial Work Platform

Nameplate

The Serial Number of the Work

Platform is also stamped on the

inside of the Chassis, close to the

Steering Cylinder.

When contacting Snorkel for service or parts information, sure to include the MODEL and SERIAL

NUMBERS from the equipment nameplate.

The A38E work platform meets and exceeds the requirements of both:

En280:2001 and ANSI A92.5 (1992)

iA38E Work Platform

Page 4

WARNING

U

p

R

i

g

h

t

A

B

3

8

C

All personnel shall carefully read, understand and follow all safety rules and operating

instructions before operating or performing maintenance on any Snorkel aerial work platform.

Safety Rules

Electrocution Hazard Tip Over Hazard

THIS MACHINE IS NOT

INSULATED!

NEVER elevate the platform or drive

the machine while elevated unless

the machine is on a firm, level

surface.

ollision Hazard Fall Hazard

NEVER position the platform

without first checking for overhead

obstructions or other hazards.

NEVER climb, stand, or sit on

platform guardrails or midrail.

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material

used for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures, buildings etc.). All other uses of the aerial work platform are prohibited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a

safe distance from live parts of

electrical equipment!

NEVER get closer than the minimum distance recommended by your National Regulations.

Exceeding the specified permissible maximum load is prohibited! See “Platform Capacity” for details.

The use and operation of the aerial work platform as a lifting tool or a crane is prohibited!

NEVER exceed the manual force allowed for this machine. See “Manual Force” for details.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or

debris; and avoiding them.

OPERATE machine only on surfaces capable of

supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. “Beaufort Scale” for details.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level surface.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete structures,

etc., is prohibited!

Dismantling the entry gate or other railing components is prohibited! Always make certain that the entry gate is closed and securely

locked!

It is prohibited to keep the entry gate in an open position when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on

the platform is prohibited!

NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and dam-

aged cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its working

range.

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen

gas.

Modifications to the aerial work platform are prohibited or permissible only at the approval by Snorkel .

AFTER USE, secure the work platform from unauthorized use by turning the keyswitch off and removing key.

The driving of MEWP’s on the public highway is subject to regulations made under the Road Traffic Acts.

ALWAYS use a full body harness, prior to raising the platform, as recommended by the Health and Safety Executive (H1/05/05)

ii A38E Work Platform

Page 5

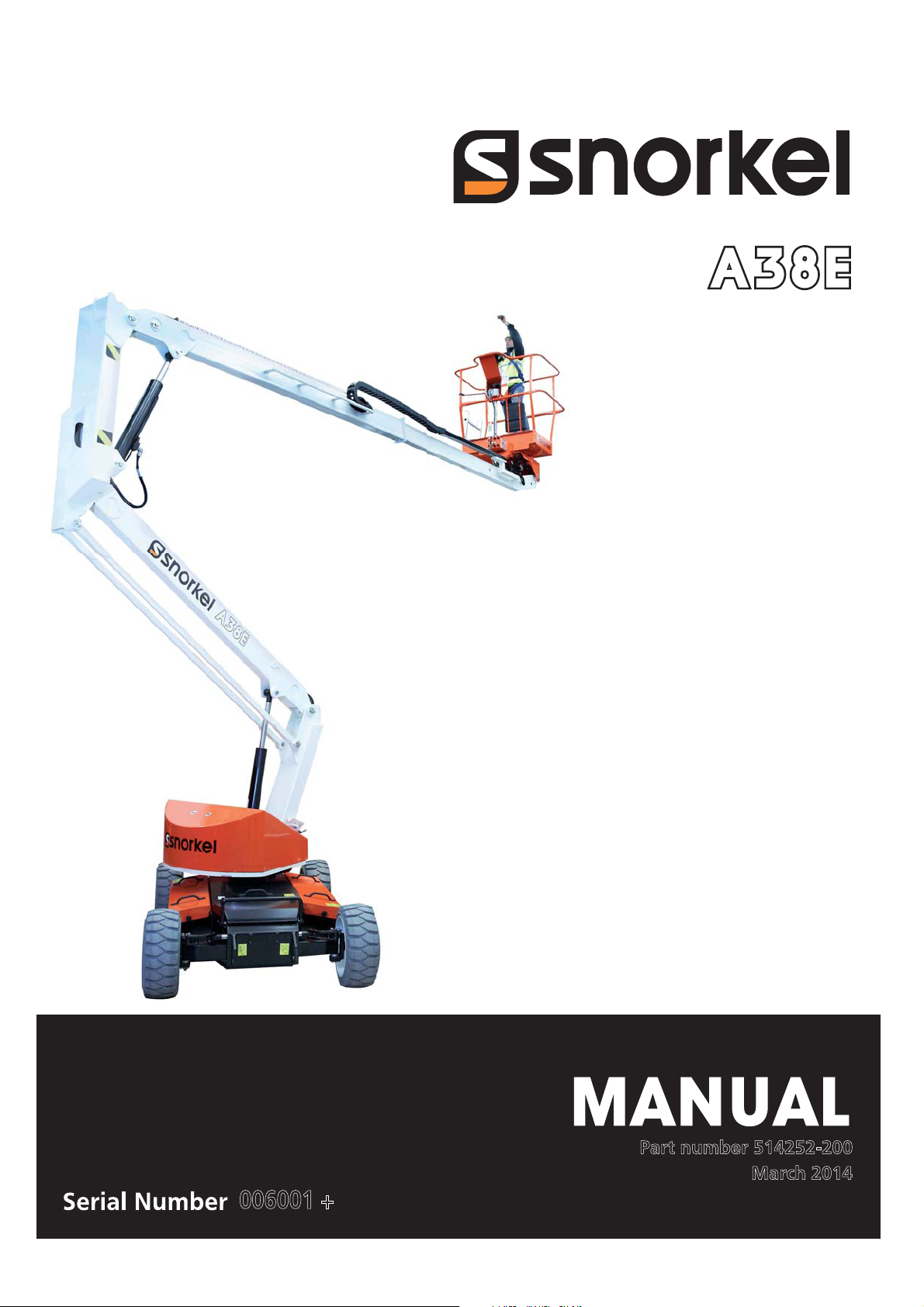

Harness attachment points are provided in the platform and the manufacturer recommends the usage of a fall

Safety Rules

restraint harness, especially where required by national safety regulations.

All harness attachment points on SNORKEL vehicles have been tested with a force of 3,650 lbs (16.3 KN)

per person.

See below examples of harness attachment points used on SNORKEL vehicles with their corrosponding rating;

Harness attachment point Type 1. is rated for one

lanyard attachment per loop as shown in the

illustrations depending upon platform occupancy rating

(see operators manual & decals).

Top View Top View

Top View

Type 1.

Type 2.

2 lanyard

attachments

Harness attachment point Type 2. is rated for two

lanyard attachments per loop as shown in the

illustrations depending upon platform occupancy rating

(see operators manual & decals).

Top View

2 lanyard

attachments

Harness attachment point Type 3. is rated for one

lanyard attachment per loop as shown in the

illustrations depending upon platform occupancy rating

(see operators manual & decals).

Front View

1 lanyard

attachment

Top View

1 lanyard

attachment

1 lanyard

attachment

Type 3.

Harness attachment point Type 4. is rated for one

lanyard attachment per loop as shown in the

illustrations depending upon platform occupancy rating

(see operators manual & decals).

1 lanyard

attachment

Type 4.

NOTE: There can be more harness attachment points per machine than the

maximum number of occupants allowed in a platform. Refer to

the platform decal & specifications table listed in the operators

manual for the correct occupancy rating before use.

iiiA38E Work Platform

Page 6

NOTES:

iv A38E Work Platform

Page 7

Foreword

Introduction

HOW TO USE THIS MANUAL

This manual is divided into 7 Sections,

The right hand pages of each Section is marked with a black

section number printed at the top corner of each page which

can be used as a quick guide.

SPECIAL INFORMATION

D A N G E R

Indicates an imminently hazardous situation which, if not avoided, will

result in severe injury or death.

W A R N I N G

Indicates a potentially hazardous situation which, if not avoided, could

result in severe injury or death.

C A U T I O N

Indicates a potentially hazardous sit uation which, if not avoided, may

result in minor or moderate injury.

General Description & Machine Specifications.

Information on the preparation for use, shipment,

Introduction &

Specifications

Machine Preparation

forklifting, transporting and storage.

Operation

Operating Instructions & Safety Rules.

1.0

2.0

3.0

WORKSHOP PROCEDURES

C A U T I O N

Detailed descriptions of standard workshop

procedures, safety principles and service operations

are not included. Please note that this manual does

contain warnings and cautions against some specific

service methods which could cause personal inju

could damage a machine and make it unsafe.

Please understand that these warnings cannot cover

all conceivable ways in which service, whether or not

recommended by Snorkel, can be done, or the possible

hazardous consequences of each conceivable way,

nor could Snorkel investigate all ways. Anyone using

service procedures or tools, whether or not recom-

mended by Snorkel, must satisfy themselves

thoroughly that neither personal safety no

safety will beorjeopardised.

Notes: Give helpful information.

All information contained in this manual is based on the

t product information available at the time of printing.

lates

We reserve the right to make changes at any time without

notice. No part of this publication ma

stored in retrieval system, or transmitted, in any form by

any means, electronic, mechanical, photocopying,

recording, or otherwise, without prior written permission of

the publisher. This includes text, figures and tables.

y be reproduced,

ry,

r machine

Maintenance

Preventative Maintenance & Service Intervals.

Troubleshooting

Causes of and Solutions to typical problems.

Schematics

Schematics and Valve Block Diagram with

description and location of components.

Illustrated Parts

4.0

5.0

6.0

Breakdown

Complete parts lists with illustrations.

7.0

vA38E Work Platform

Page 8

NOTES:

Foreword

vi A38E Work Platform

Page 9

Section

No.

Contents

Table of Contents

Page

No.

Section

No.

Section

i

Page

No.

1.0 Introduction & Specifications

1.0 Introduction ........................................................ 1-1

Purpose ..........................................................1-1

Scope ..............................................................1-1

1.1 General Information .......................................... 1-1

Platform ..........................................................1-1

Control Box ....................................................1-1

Elevating Assembly ..................................... 1-1

Rotation Gear ................................................ 1-1

Drive & Steer Systems .................................1-2

Power System ................................................1-2

Control System ............................................. 1-2

Chassis ...........................................................1-2

A38E Purpose & Limitations ...................... 1-2

1.2 Specifications ..................................................... 1-3

1.3 Notes .....................................................................1-4

2.0 Machine Preparation

2.1 Preparation For Use ......................................... 2-1

2.2 Preparation For Shipment ............................... 2-1

2.3 Forklifting The Work Platform ........................ 2-1

2.4 Lifting The Work Platform ................................ 2-1

2.5 Transport by Truck .............................................2-1

2.6 Manual Brake Release ......................................2-2

2.7 Storage .................................................................2-2

2.8 Notes .....................................................................2-3

3.0 Operation

3.0 Introduction ........................................................ 3-1

General Functioning .....................................3-1

Driving ........................................................... 3-1

Steering .......................................................... 3-1

Operating the Booms ...................................3-1

Design Features ............................................3-2

3.1 Safety Rules & Precautions ............................. 3-3

3.2 Controls & Indicators .......................................3-4

3.3 Pre-Operation Inspection .................................3-6

System Function Inspection .......................3-6

3.4 Opertaion ............................................................ 3-7

Elevating & Lowering

A38E Work Platform ................................. 3-7

Travel With The Work Platform

Lowered ..................................................... 3-7

Travel With The Work Platform

Elevated ..................................................... 3-8

Levelling ........................................................ 3-8

Emergency Situations &

Emergency Override .................................3-8

Emergency Lowering ......................3-8

Control From Ground Level ........................ 3-9

After Use Each Day ..................................... 3-9

Manual Rotation ...........................................3-9

Manual Telescopic Retraction ....................3-9

3.5 Notes .....................................................................3-11

The

4.0 Maintenance

4.0 Introduction ........................................................ 4-1

Tools Required ..............................................4-1

4.1 Preventative Maintenance ............................... 4-1

Preventative Maintenance

Table Key ....................................................4-2

Preventative Maintenance

Report ..........................................................4-2

4.2 Battery Maintenance .........................................4-3

Battery Inspection & Cleaning ...................4-3

Battery Charging .......................................... 4-3

Battery Cell Equalization ............................. 4-4

4.3 Temperature Correction For

Electrolyte Readings ......................................4-4

4.4 Lubrication ......................................................... 4-5

Grease Fittings .............................................. 4-5

Slew Ring .......................................................4-5

Pivot Pins .......................................................4-5

Hydraulic Oil Tank & Filter ......................... 4-5

4.5 Setting Hydraulic Pressures ............................ 4-6

Main Relief Valve ..........................................4-6

Slew Cross-Line Relief Valve ...................... 4-7

4.6 Maintenance on Elevating Assembly ............. 4-7

Installation of Elevating Assembly

Support ......................................................

Removal of Elevating Assembly

Support ....................................................... 4-7

4.7 Switch Adjustments ............................................ 4-8

Tilt Sensor ..................................................... 4-8

Boom Rest Limit Switch ... ...........................4-8

4.8 Hydraulic Manifold ........................................... 4-10

Removal ......................................................... 4-10

Disassembly ..................................................4-10

Cleaning & Inspection .................................4-10

Assembly .......................................................4-10

Installation .....................................................4-10

4.9 Hydraulic Pump ................................................. 4-12

Removal ......................................................... 4-12

Installation .....................................................4-12

4.10 Traction Motor Maintenance .......................... 4-12

Inspecting the Drive Motor ........................4-12

4.11 Electric Motor .................................................... 4-14

Troubleshooting ...........................................4-14

Disassembley ................................................ 4-14

Inspection ......................................................4-14

Reassembley ................................................. 4-14

Maintenance Intervals & Procedures ....... 4-15

4.12 Drive Reduction Gearbox .................................4-17

Changing the Oil ...........................................4-18

4.13 Torque Specifications ........................................4-18

4.14 Lower Lift Cylinder ............................................4-19

Removal ......................................................... 4-19

Disassembly ..................................................4-19

Cleaning & Inspection .................................4-19

Reassembly/Seal Replacement ...................4-20

.4-

7

IA38E Work Platform

Page 10

Section

i

Sect ion

No.

Contents

Table of Contents

Page

No.

Sect ion

No.

Page

No.

Installation .....................................................4-20

4.15 Upper Lift Cylinder ............................................4-21

Removal ......................................................... 4-21

Disassembly ..................................................4-21

Cleaning & Inspection .................................4-21

Reassembly/Seal Replacement ................... 4-21

Installation ........................

4.16 Telescopic Cylinder ........................................... 4-22

Removal .........................................................4-22

Disassembly ..................................................4-23

Cleaning & Inspection .................................4-23

Reassembly/Seal Replacement ................... 4-23

Installation .....................................................4-23

4.17 Steering Cylinder ........

Removal .........................................................4-23

Disassembly ..................................................4-23

Cleaning & Inspection .................................4-24

Reassembly/Seal Replacement ................... 4-24

Installation .....................................................4-24

4.18 Master Levelling Cylinder ............................... 4-25

Removal ..............................

Disassembly ..................................................4-25

Cleaning & Inspection .................................4-25

Reassembly/Seal Replacement ................... 4-25

Installation .....................................................4-25

4.19 Slave Levelling Cylinder ..................................4-26

Removal ......................................................... 4-26

Disassembly .............................

Cleaning & Inspection .................................4-26

Reassembly/Seal Replacement ................... 4-26

Installation .....................................................4-27

Bleeding the Master/Slave

Levelling Circuit ........................................4-27

4.20 Adjustment Of Overcentre Valves .................... 4-28

4.21 Replacing GP400 control module ....................4-29

4.22 Calibration of load cell ...................................4-30

.............................4-22

.......................................4-23

........................... 4-25

.....................4-26

5.0 Troubleshooting

7.0 Illustrated Parts Breakdown

7.0 Introduction ........................................................7-1

7.1 Index ..............

7.2 Illustrated Parts Breakdown .......................... 7-2

F inal Assembly A38E ................. ................................ 7-2

Chassis Ass embly .......................................................... 7-4

A38 PG Parts Assembly .................... ..... ....... .. ... .......... 7-6

Booms and Posts Assembly ..... .......... ............ ..... .......... 7-8

Cage and Cradle Assembly.................................................... 7-

Cage and Cradle Assembly (Rotator) ................................... 7-

Wheel Hub Assembly .......................................................... 7-

Drive Reduction Gear box Assembly .................................. 7-

Traction Motor Assembly (514274-000)............................. 7-

Traction Motor Assembly (512944-000).............................

Motor / Pump Assembly..................................................

Re ar & Front Wheel Kit .................................................

Worm Drive Unit & Slew Bearing.......................................

Manifold

Lower Lift Cylinde r Assembly.............................................

Upper Lift Cylinder Assembly ............................................

Telescopic Cylinder Assembly.............................................

St eeri ng Cylinder Assembly................................................

Master / Slave Cylinder Assembly......................................

Lower Control Box Assembly ............................................ 7-

Upper Control Box Assembly (CE)..................................... 7-

Upper Control Box Assembly (ANSI).................................

Cables & Electrical Components..........................................

Hose Ass embly...................................................................

Decal Kit - ANSI Version ...............................................

Decal Kit - CE Version ....................................................

Options List ..........................................................................

Block Assem

....................................................... 7-1

bly ...............................................

77-

7-

77-

7-

7-

77-

7-

7-

77-

7-

7-52

7-54

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

5.0 Introduction ........................................................5-1

General Procedure ........................................ 5-1

Special Tools .... ............................................ 5-2

Adjustment Procedures .......... ..................... 5-2

Checking Pump Preasure...............................5-2

Diagnostics using Ezcal display......... .......... 5-2

5.1 Troubleshooting Guides ....... .................... 5-4

5.2

I/O Matrix ..................................................... 5-3

Replacing the GP400 Control module ....... 5-6

GP400 I/O Allocations...............................

Notes ........................................................

5-7

5-8

6.0 Schematics

6.0 Introduction ........................................................6-1

6.1 Electrical Schematics ........................................6-3

6.2 Hydraulic Schematics ....................................... 6-6

II A38E Work Platform

Page 11

NOTES:

Contents

Section

i

IIIA38E Work Platform

Page 12

Section

i

NOTES:

Contents

IV A38E Work Platform

Page 13

Introduction & Specifications

Section

1.0

1.0 Introduction

PURPOSE

The purpose of this Service & Parts Manual is to

provide instructions and illustrations for the operation

and maintenance of the A38E Work Platform

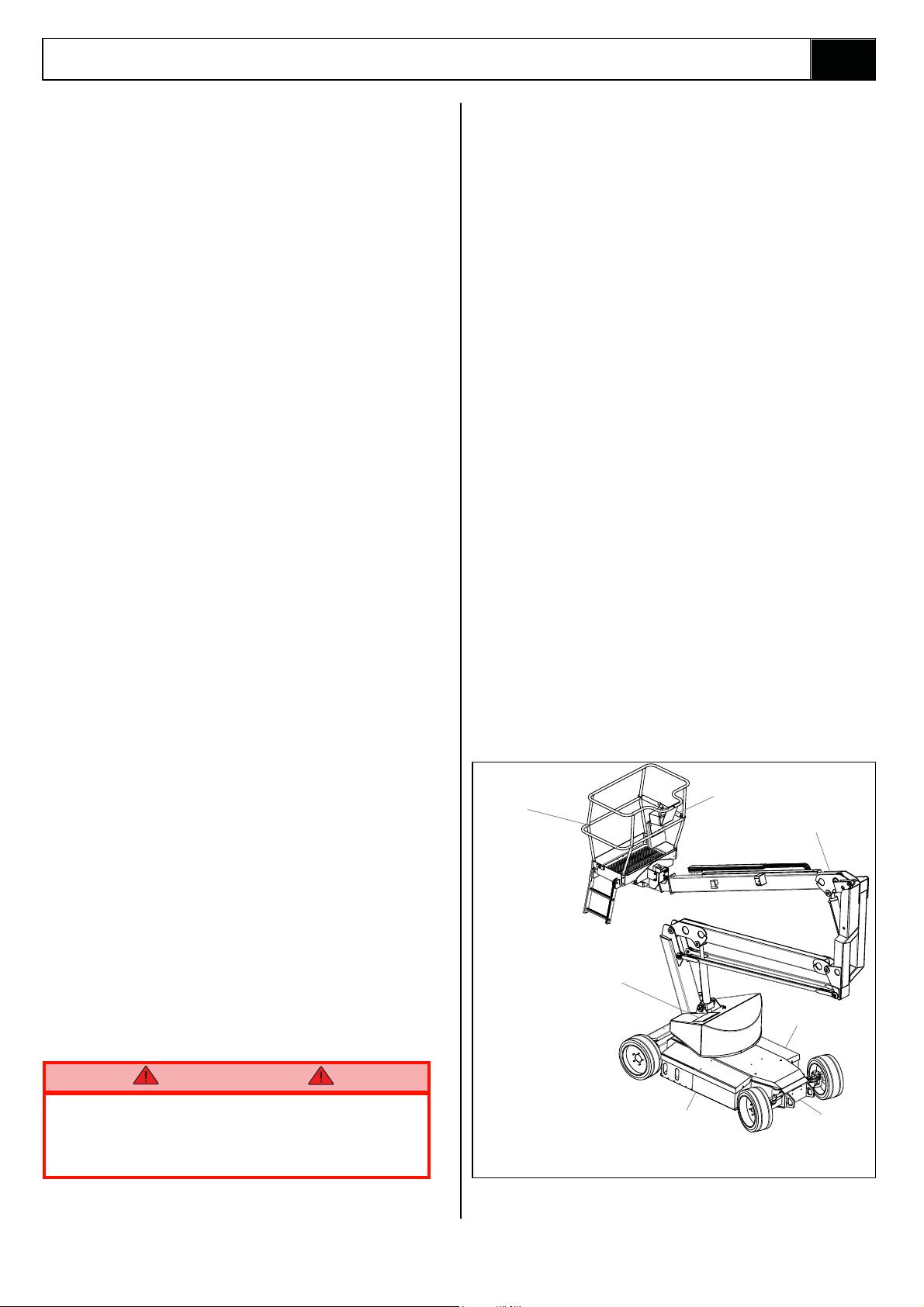

manufactured by Snorkel. (See Figure 1-1).

SCOPE

The manual includes the procedures and

responsibilities which must be strictly adhered to for

proper operation, maintenance, adjustment, and

repair of this product. The Maintenance Section

further covers preventative maintenance and trouble

shooting.

1.1 General Information

The A38E is a quickly deployable self propelled aerial

work platform, designed to raise a specified number

of operators with hand tools to a work height of up

to 13.45 m (44.12ft.) i.e. a platform floor height of

11.45 m (37.56 ft.). It is designed to provide mobility

with the Platform in the raised or lowered position,

although travel with the Platform raised is limited to

a low speed. The boom assembly and telescope

functions are operated by a hydraulic pump driven

by a DC electric motor. Two DC electric traction

motors coupled to two braked gearboxes regulate

the drive function.

CONTROL BOX

The control box is permanently fitted at the front

centre of the platform. It features a Joystick which

will provide proportional control for raising or

lowering either of the

retracting the Telescopic Boom, rotating (slewing)

the entire Booms & Posts Assembly or driving.

A safety feature which is incorporated into the

Joystick’s operation is the Interlock Switch. This

must be activated at all times while operation is

required. This allows for one-handed operation. A

complete explanation of control functions can be

found in Section 3.

two booms, extending or

ELEVATING ASSEMBLY

The platform is raised and lowered by a combination

of two steel lift booms and one telescopic boo

each of which is operated by a hydraulic cylinder

which in turn is actuated by hydraulic power from the

motor driven pump. Solenoid operated valves control

to which cylinder the hydraulic oil is directed. Each

cylinder features an integral holding valve to prevent

uncontrolled descent in the case of a hose burst.

m,

ROTATION GEAR

The Booms & Posts Assembly can be rotated to

provide up to 5.6 m (18.4 ft.) of side outreach,

measured from the centreline of rotation to the front

of the Platform. This is do

hydraulic motor driving a Worm Drive Unit, around a

large diameter Slew Gear.

1.

ne by means of an integral

6.

2.

PLATFORM

The platform is large enough for a specified number

of operators and has a free-draining perforated floor

with 150 mm (5.9inches) toe boards. Hand rails are

constructed from steel tubing and a safety drop-bar is

provided at the entrance. Safety harness anchor points

are also fitted in the floor of the platform. The primary

Control Box is fitted permanently within this platform.

W A R N I N G

DO NOT begin using the machine until the

platform entrance drop bar is in the fully

lowered position.

7.

1. Pl atform

2. Elevating Assembly

3. Chassis

4. Power Module

5. Control Module

6. Platform Control Box

7. Lower Control Box

Figure 1-1: A38E Work Platform

5.

3.4.

1-1A38E Work Platform

Page 14

Section

1.1

Introduction & Specifications

DRIVE & STEER SYSTEMS

The A38E Work Platform is restricted to low speed

drive when the Platform is raised above the Boom

Rest Limit Switch. The Traction controller controls the

application of drive from the Joystick by means of two

ction Motors, which are assembled to the drive

Tra

wheels via a Drive Reduction Gearbox.

Steering of the A38E Work Platform is controlled by

a double acting cylinder. An Operator can Steer left

or right by depressing the Rocker Switches on top of

the Joystick, while activating the Interlock Switch.

POWER SYSTEM

The power system incorporates eight 6V batteries

driving the drive traction motors, or the 4kW (5.4HP)

electric motor which in turn drives the hydraulic

pump. The application of this hydraulic pressure is

performed by the Control System.

CONTROL SYSTEM

The machine is provided with fully proportional

controls by means of the interaction between a

P600, electron tor om ci contro l a dna rel proportional

joystick. The P600 and motor controller regulate the

drive motor/pump speed and hence the flow of oil

reaching the cylinders, the Worm Drive Unit or the

Drive Reduction Gearbox. It regulates the direction of

flow of the hydraulic oil via the solenoid valves located

on the manifold block, and it also monitors the operation of all switches on the machine via the machine

harness system.

The motor control units are located, in the left hand

chassis mo

hydraulic tank. This is accessible by removing the

main cover.

dule. The manifold block is located on the

A38E PURPOSE & LIMITATIONS

The purpose of the A38E work platform is to provide a

quickly deployable variable height work platform. It is

capable of lifting a specified number of people with work

tools up to an upper limit of 215 kg (ANSI 475 lbs) in

total. The unit will provide the ability to reach over

obstacles but must be used on firm level ground.

See Specification table on page 1-3.

The platform must only be used on firm level or slightly

uneven ground capable of supporting the maximum load

generated under the four wheels. Do not use on soft or

severely sloping ground.

DANGER

NOTE: It should be recognised that if the tilt

switch senses a degree of slope greater than

3º the elevating circuits will lockout and

sound a warning alarm. The Emergency

Override should then be used, to lower the

Elevating Assembly.

CHASSIS

The chassis is a structural frame designed to support

all the components of the A38E Work Platform.

1-2 A38E Work Platform

Page 15

Introduction & Specifications

1.2 Specifications

ITEM METRIC IMPERIAL (ANSI)

Duty Cycle 45% of 8 hour shift 45% of 8 hour shift

Platform Size

Max. Platform Capacity 2

Indoors

Outdoors

Maximum Working Height

Maximum Platform Height

Min. Platform Floor Height

Max. Working Outreach

Platform Height At

Maximum Outreach

Stowed Dimensions

Length

Width

Height

Ground Clearance 0.12 m 0.39 ft

heel Base x Gauge 2.00 m x 1.27 m 6.56 ft x 4.16 ft

W

Rotation

Unloaded Weight

With Load/ Max Weight

Drive Speed Stowed 0 - 4 km/h 0 - 2.49 mph

Drive Speed Elevated

Maximum Gradeability 36% 36%

Inside Turning Radius

Outside Turning Radius 2.40 m 7.87 ft

Power Source

System Voltage Control 12V 12V

Battery Charger

Hydraulic Oil Tank Capacity

Max. Hydraulic Pressure

Hydraulic Oil Grade

Cylinder Types

Control System

Wheels/Tyres

Braking

Table 1-1: Specifications

0.58 m x 1.3 m (inside gaurdrails) 1.77 ft x 4.3 ft (inside gaurdrails)

15 kg 475 lbs

2 People 2 People

1 People

13.45 m

11.45 m

0.65 m

6.10 m 20.00 ft

5.40 m 17.72 ft

4.04 m

1.50 m

2.00 m

362 degrees non-continuous 362 degrees non-continuous

3,770 kg 7

3,985kg 8,840 lbs

0 - 0.4 km/h 0 - 0.25 mph

0.40 m 1.31 ft

48V DC 4kW, 8 X 6V 210Ah Batteries 48V DC 5.4HP, 8 X 6V 210Ah Batteries

Auto Dual AC input 100-240V ~ 50/60Hz 18A

Output 48V, 25A

25 Litres 6.5 Gallons US

145 bar 2105 psi

ISO #46 ISO #46

2 Double Acting Lift Cylinders With

Lock Valves And Manual Emergency

Lowering Facility.

1 Double ActingTelescopic Cylinder

Refer to Section 5 of the Service &

Parts Manual

One handed Proportional Joystick

Operating Energy Efficient Motor

Control System

400 mm Diameter Steel Disc Wheel

With Solid All Surface Tyres

Automatic Spring Applied

Hydraulic Release

Auto Dual AC input 100-240V ~ 50/60Hz 18A

Output 48V, 25A

2 Double Acting Lift Cylinders With

Lock Valves And Manual Emergency

1 Double ActingTelescopic Cylinder

Refer to Section 5 of the Service &

One handed Proportional Joystick

Operatin

15.75 inch Diameter Steel Disc Wheel

With Solid All Surface Tyres

Automatic Spring Applied

2 People

44.12 ft

37.56 ft

2.13ft

13.25 ft

4.92 ft

6.56 ft

,826 lbs

Lowering Facility.

Parts Manual

g Energy Efficient Motor

Control System

Hydraulic Release

Section

1.2

Max Noise Lev el

69.5 dB(A) 69.5 dB(A)

1-3A38E Work Platform

Page 16

Section

1.3

NOTES:

Introduction & Specifications

1-4 A38E Work Platform

Page 17

Machine Preparation

2.1 Preparation for use

CAUTION

Read, understand and follow all operating

instructions before attempting to operate the

machine.

2.2 Preparation for Shipment

1. Lubricate machine per lubrication instructions in

Section 4.4, Maintenance.

2. Fully lower the platform and make sure the

machine is stowed securely.

3. Check that the hydraulic oil level is adequate

and that it is not over filled.

Check that the batteries are charged and disconnect

the batteries usin

This prevents excessive power drain prior to next

using the machine.

g the Battery Disconnect Plug.

FORKLIFT

HERE

Section

2.1

Front Lifting /

Tie-down Lug

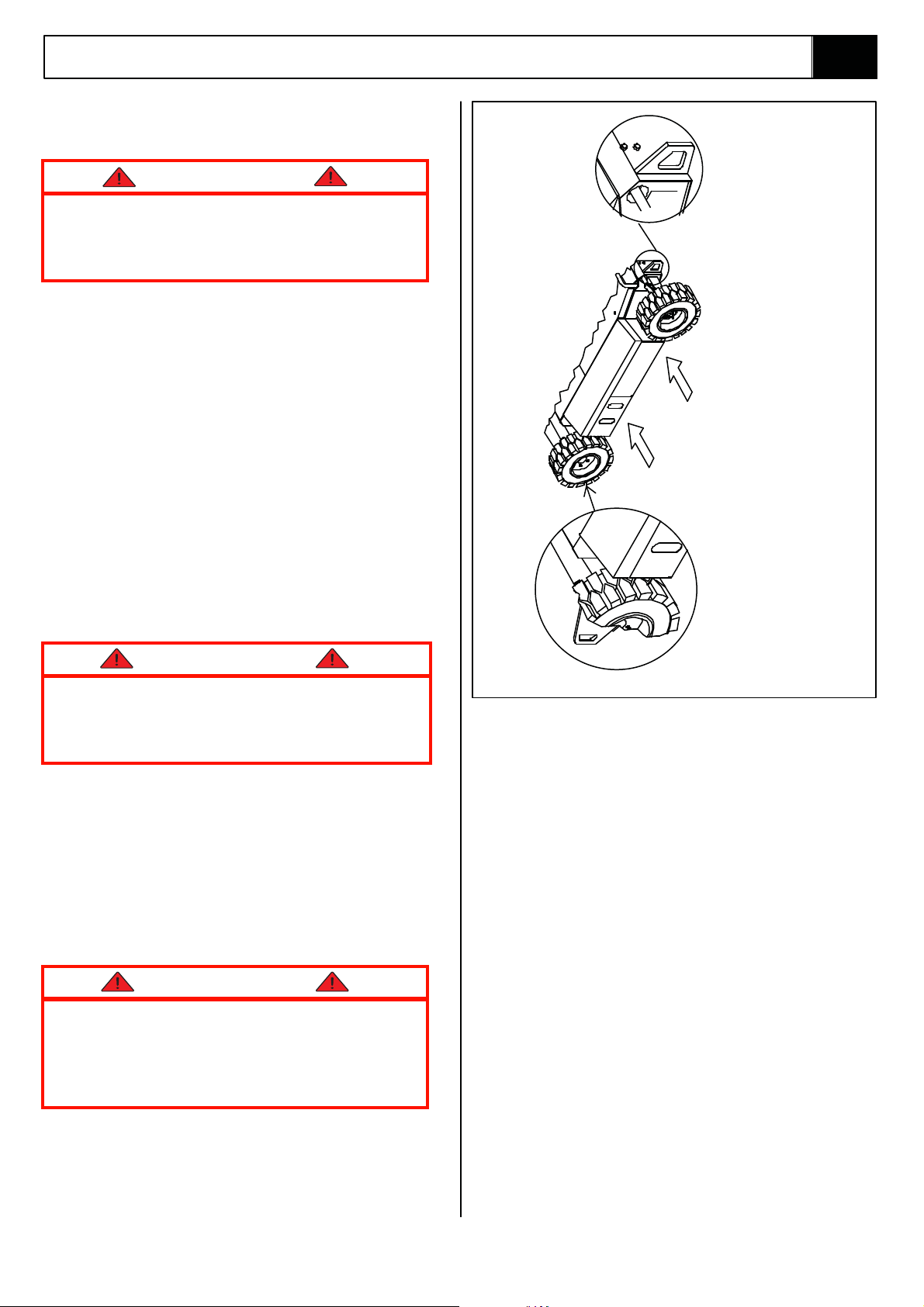

2.3 Forklifting the Work Platform

CAUTION

The A38E is not designed to be consistently

forklifted. This operation can be used for very

short distances only.

Forklift from the side by lifting under the chassis

modules as per Figure 2-1. When lifting the A38E

with a forklift, great care should be taken not to

damage the right or left hand modules as these

contain sensitive equipment.

2.4 Lifting the Work Platform

CAUTION

See specifications (Section 1.2) for the

weight of the work platform and be certain

tha

t lifting apparatus is of adequate capacity

to lift the platform.

The A38E may be lifted by an overhead hoist/crane in

the following manner:

Four lifting straps capable of safely supporting the

total weight of the A38E ( (3,770 Kg /7,430 lbs CE

Rear Lifting /

Tie-down Lug

Figure 2-1: Forklifting & Lifting the A38E

Version & 4,010 Kg /8,840 lbs ANSI Version) and at

least 250 cm (8 ft.) long are required. This minimum

length is important to ensure the correct lifting an

The straps should be positioned at the Lifting/Tie

Down Lugs as shown in Figure 2-1. Great care must

be taken to avoid damage to any of the components

of the machine.

gle.

2.5 Transport by Truck

The A38E is normally carried upon a suitably rated

transportation vehicle. Because of the high

gradeability of the A38E it will be capable of driving

directly on to most vehicles. If however the loading

slope is greater than the gradeability or the batteries

have been depleted sufficiently a winch sho

used. The procedure when using a winch is to

disengage the gearbox from the drive wheels using

the Allen key release, and then winch the machine on

to the vehicle in its freewheel state.

Refer to Section 2.6 which follows.

uld be

2-1A38E Work Platform

Page 18

Section

2.6

Machine Preparation

When the A38E is on the Truck it should then be

made secure.

1. Chock the wheels of the A38E.

2. Secure the work platform to the transport

vehicle with chains or straps of adequate load

capacity attached to the lifting lugs on the

chassis.

CAUTION

Overtightening of the chains or straps through

tie down lugs may result in damage to the

Work Platform.

2.6 Manual Brake Release

CAUTION

Perform this operation only when the machine

will not operate under its own power and it is

necessary to move the mach

winching onto a trailer for transportation.

Ensure the machine is on level ground before

commencing this operation and use wheel

chocks as appropriate to prevent the machine

from rolling inadvertently.

Do not exceed 3 mph. Faster speeds will

damage drive components and void warranty.

1. Ensure that the Platform is fully lowered and

that the Elevating Assembly is slewed (rotated)

such that the platform is stowed above the drive

wheels. Turn the Upper Control Box to the OFF

tion and remove the key.

posi

2. Attach a chain/cable of sufficient capacity for

towing the machine to the front or rear lifting/tie

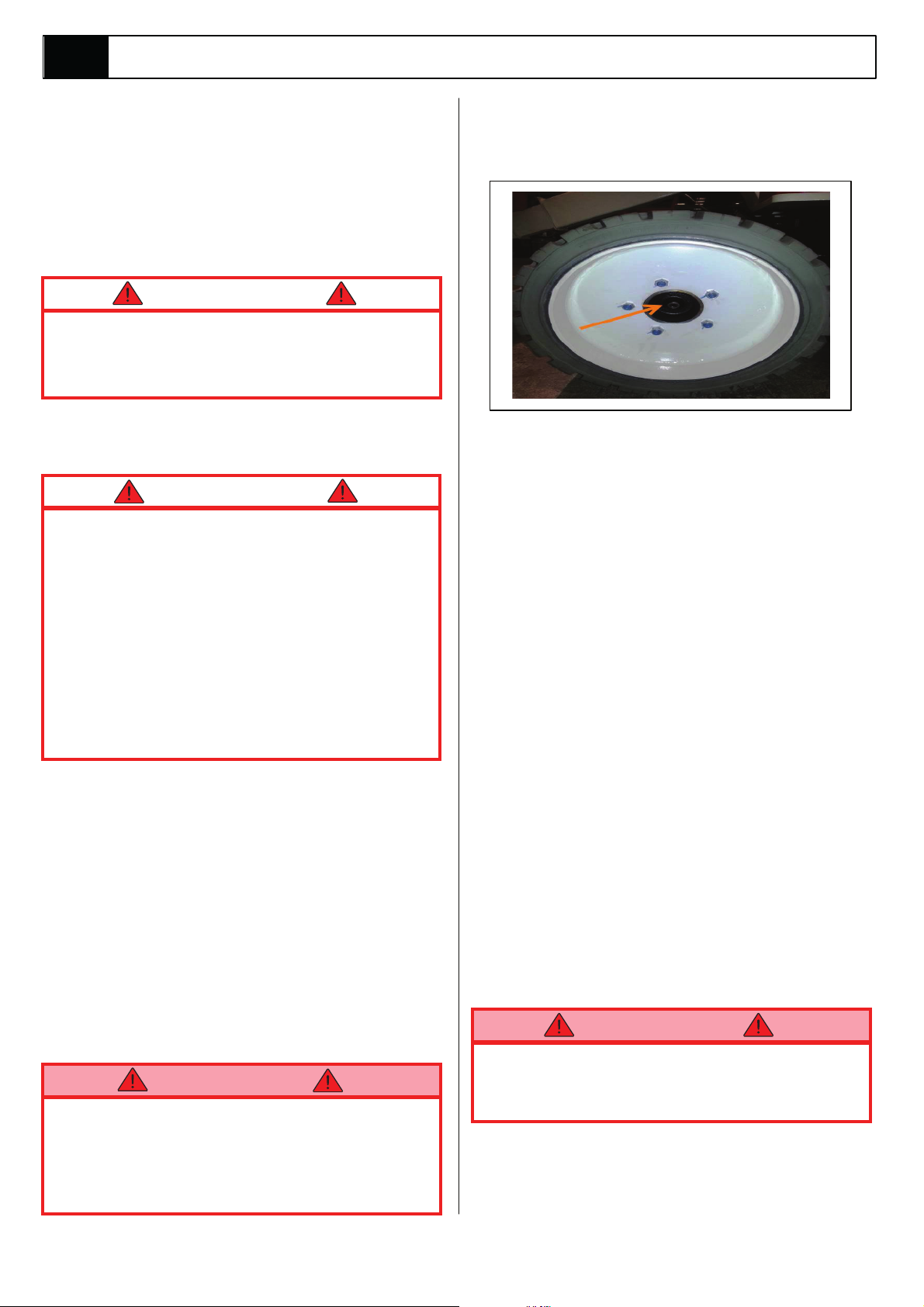

down lugs. Take up the slack in the chain/cable.

3. Locate the Allen head socket screws located in

the centre of the two drive (rear) wheels and

using a 6 mm Allen key, turn each one

clockwise to its full extent. The machine is now

in freewheel mode.

WARNING

DO NOT leave the machine unattended or

attempt to operate the A38E Work Platform

until the Brake Rele

re-engaged.

ase Screws

ine, or for

have bee

n

4. When towing is completed, turn both Allen head

socket screws in a counter clockwise direction

until they rest firmly against the locking circlip.

Figure 2-2 : Manual Brake Release

2.7 Storage

No preparation is required for storage when the Work

Platform is in regular use. Regular maintenance per

Table 4-1 should be performed.

If the work platform is to be placed in long term

storage (dead storage) use the following preservation

procedure.

PRESERVATION

1. Clean painted surfaces. If the painted surface is

damaged, repaint.

2. Fill the hydraulic tank to operating level with the

platform fully lowered. Fluid should be visible

on the Di

hydraulic fluid be drained.

3. Coat exposed portions of cylinder rods with a

preservative such as multipurpose grease and

wrap with barrier material.

4. Coat all exposed unpainted metal surfaces with

preservative.

BATTERIES

1. Disconnect the batteries.

2. Disconnect the battery leads and secure to the

chassis.

Care should be taken, while disconnecting the

battery leads, that a short circuit does not occur.

i.e. grounding to the chassis with a

3. Remove the batteries and place in alternate

service. Battery efficiencies are best realised

when used consistently.

p Stick. It is not recommended that the

WARNING

spanner.

2-2 A38E Work Platform

Page 19

NOTES:

Machine Preparation

Section

2.7

2-3A38E Work Platform

Page 20

Section

2.7

NOTES:

Machine Preparation

2-4 A38E Work Platform

Page 21

Operation

Section

3.0

3.0 Introduction

GENERAL FUNCTIONING

WARNING

Before beginning to operate the machine it is a

mandatory requirement to read, fully understand

and follow the Operators Manual.

The A38E Lift and Steer functions are operated by

utilising a battery powered electric motor which

drives a hydraulic pump. The pump supplies oil

under pressure to the various platform functions.

electrically activated solenoid valves (the control

of which solenoid valve activates and the rate at

electrical circuit, and its components).

The Drive function is operated by utilising two drive

motors which

Motor Controller.

NOTE:

An Interlock Trigger Switch is an integral part of the

Joystick. This must be depressed for the functions to

operate. This will energise the Line Contactor and enable

electrical control. (This safety feature prevents

inadvertent activation of all powered functions, in the

case of accidental movement of the Joystick.)

DRIVING

Platform controls provide variable speeds for the

drive function through the use of a Joystick. This is

achieved using a motor control unit which varies the

speed of the two DC electric traction motors. To drive

the A38E there are a number of steps which need be

taken. First the operator should ensure that neither of

the Emergency Stop Buttons are pressed, then the

Keyswitch on the ground control panel should be

turned to the

Momentarily operate the drive

the A38E will be able to drive.

The machin

to the angle of the Joy-

position, while the

depressed. The speed range within which the machine

will drive is deter-mined by whether or not the booms

are raised.

are controlled by a Electronic Traction

‘PLATFORM CONTROL’ position.

function switch and

e will then drive at a speed proportional

stick

from the neutral (centre)

Joystick Interlock Switch is

If a boom is raised off the Boom Rest Limit Switch

the current to the drive motors will be reduced leading

to a significantly slower drive speed. This is a safety

feature. The drive wheels are driven by two DC

electric traction motors coupled to two braked

gearboxes. When the Joystick is in the neutral

position the brake chamber is free of oil and the

internal spring within the gearbox maintains the

braking pressure. Upon moving the Joystick the

brake chambers will receive a flow of pressurised

oil which will release the brakes.

STEERING

Platform controls also provide a steering function

through the use of ‘Rocker’ activated Steering

Switches in the Joystick. This is achieved by using the

tla yb wolf ciluardyh eht seirav hci 006P wh ering

the voltage to the pump. To steer the A38E there are

a number of steps which need be

First the operator should ensure that neither of the

Emergency Stop Buttons are pressed, then the

Keyswitch ground control Panel should be turned to

‘PLATFORM CONTROL’ position.

the

Momentarily operate the drive function switch to drive

and the A38E will also be able to steer. To steer the

machine the Rocker should be pushed to the left or

the right, while the Joystick Interlock Switch is

depressed. Steering left or right will energise the

steering coils and allow oil to enter the full bore side

or annular side of the steering cylinder, there by

turning the wheels in the chosen direction. The

orientation of the Platform to the Chassis will

determine the direction the machine will travel when

the Joystick is engaged.

NOTE:

Steering is not self-centring. The wheels must be

returned to the straight ah

Steering Switch.

ead position by operating the

taken.

OPERATING THE BOOMS

Boom functions, including the telescopic and slewing

functions, can be operated either from the Platform

Controls or the Chassis Controls.

The Platform controls provide variable speeds for the

boom functions through the use of a Joystick. This is

deeps eht seirav hcihw 006P na gnisu deveihca

of the motor/pump unit and increases

the flow of oil to the different functions. This control

t receives a control signal from the Joystick on the

uni

upper controls, the speed of the motor will increase

as the Joystick is pushed further away from the

neutral (centre) position.

or decreases

3-1A38E Work Platform

Page 22

Section

3.0

Operation

It will be noticed that on the Upper Control Box a set

of switches are used to alternate functions. Each

function will have it’s corresponding graphicand lamp.

This selector switch indicates to the Controller which

function is required and by using the Joystick the

speed of this selected function can be adjusted.

The boom functions on the chassis controls provide

proportional control for each function by way of an

analog rocker switch, the desired function can be

activated by holding on

controls and and operating the analog rocker, the

one of four switches on the

the four switchs act as both selector & enable

switches.

The use of these functions is further explained

throughout this Section.

DESIGN FEATURES

The A38E Series Work Platform has the following

features:

The drive speed is limited to a ‘creep speed’ when

operating the Work Platform while the machine is

elevated.

The energy-efficient motor control units provides

long battery life and smooth proportional control of

the boom and drive functions.

All cylinders are fitted with hydraulic hose-burst

protection interlocks.

The on-board charger is fully automatic and

charges the batteries efficiently and economically.

If the work platform starts to become unstable and

the Tilt Sensor is activated an alarm will sound in

the upper control box. In this situation power is

partially cut to the upper controls to prevent any

boom movements (i.e. UP, TELE OUT) that might

increase instability. An emergency override switch

is fitted to allow the booms to be lowered at a

controlled speed to bring the machine back to a

stable position.

In the event of a power loss the two Boom Lift

Cylinders are fitted with emergency lowering

valves which allow the booms to be lowered at a

controlled speed by an operator on the ground.

A Master Cylinder/Slave Cylinder levelling system

ensures that the Platform remains level throughout

the entire working cycle of the machine.

A manual rotation facility is fitted to allow rotation of

the Elevating Assembly in the event of power loss.

HOUR METER & BATTERY CHARGE

INDICATOR.

The A38E Series Work Platform is equiped with a

display in the chassis control panel which displays

total hours run & an Indication of remaining battery

charge.

LOAD SENSI NG

The A38E is fitted with a load sensing system designed to comply with the requirements of :

BS EN 280 : 2001

If a load equivelent to 99% of safe working load is

lifted an overload lamp will illuminate on the platform

control box.

If a load which is greater than the safe working load by

is present in the basket all machine functions will

10%

cease to operateand an acoustic warning will sound.

In order to return

les

s than the safe working load must be present in the

basket and

re-cycled by pushing the emergency stop button and

releasing it again.

to normal operation a load equal to or

the power must be re-cycled, power can be

3-2 A38E Work Platform

Page 23

Operation

Section

3.1

3.1 Safety Rules and Precautions

WARNING

Before using the A38E Work Platform it is

imperative to read, understand and follow the

following Safety Rules and Precautions.

NEVER operate the machine unless you have been

fully trained in its safe use, are medically fit and have

read and fully understood these instructions.

NEVER leave the A38E unattended with the Platform

in the raised position.

ALWAYS position the machine on firm level ground

with a minimum bearing capacity of 78 kg /cm

(1109 psi).

CHECK that no

the machines range of movement.

DO NOT work within 3 metres (10 feet) of live

overhead cables. Set up warning tape barrier at the

safe distance.

(THIS MACHINE IS NOT INSULATED).

DO NOT exceed the safe working load of 215 kg,

(ANSI 475 lbs)

CE=max. 1 persons Outdoor + Tools 135Kg

2 person Indoor + Tools 55Kg

(ANSI=max. 2 person Indoor/Outdoor)

See specification table on page 1-3 .

overhead obstructions exist within

2

DO NOT use in winds exceeding 12.5 m/s (28 mph Beaufort Force 6)

NEVER change or modify operating or safety

systems.

INSPECT the machine thoroughly for cracked welds,

loose hardware, hydraulic leaks, damaged control

cable, loose wire connections and wheel bolts.

NEVER climb down an elevating assembly with

platform elevated.

NEVER perform service on or in the elevating

assembly while the platform is elevated without first

blocking the elevating assembly.

NEVER recharge batterie

flame; batteries under charge emit highly explosive

hydrogen gas.

SECURE the work platform against unauthorised use

by turning Keyswitch off and removing key from

switch.

NEVER replace any component or part with anything

other than original Snorkel replacement parts without

Snorkel’s consent.

NEVER leave the machine unattended while the

Gearbox Drive is disengaged.

s near sparks or open

NEVER sit, stand or climb on guard rail or midrail of

the platform.

NEVER use ladders or scaffolding on the platform.

DO NOT use the ma

application involving additional loads or forces. The

maximum side force must not exceed 200N

Outdoors / 400N Indoors, (ANSI = 90 ft. lbs).

DO NOT increase wind loadings by fitting items such

as sign boards, flags etc. to the cage or boom.

DISTRIBUTE all loads evenly on the platform. See

Table 1-1 for maximum platform load.

NEVER use damaged equipment. (Contact Snorkel

Ltd. for instructions).

NEVER attach overhanging loads or increase the

size

of the working platform.

chine as a crane or for any other

3-3A38E Work Platform

Page 24

Section

3.2

Operation

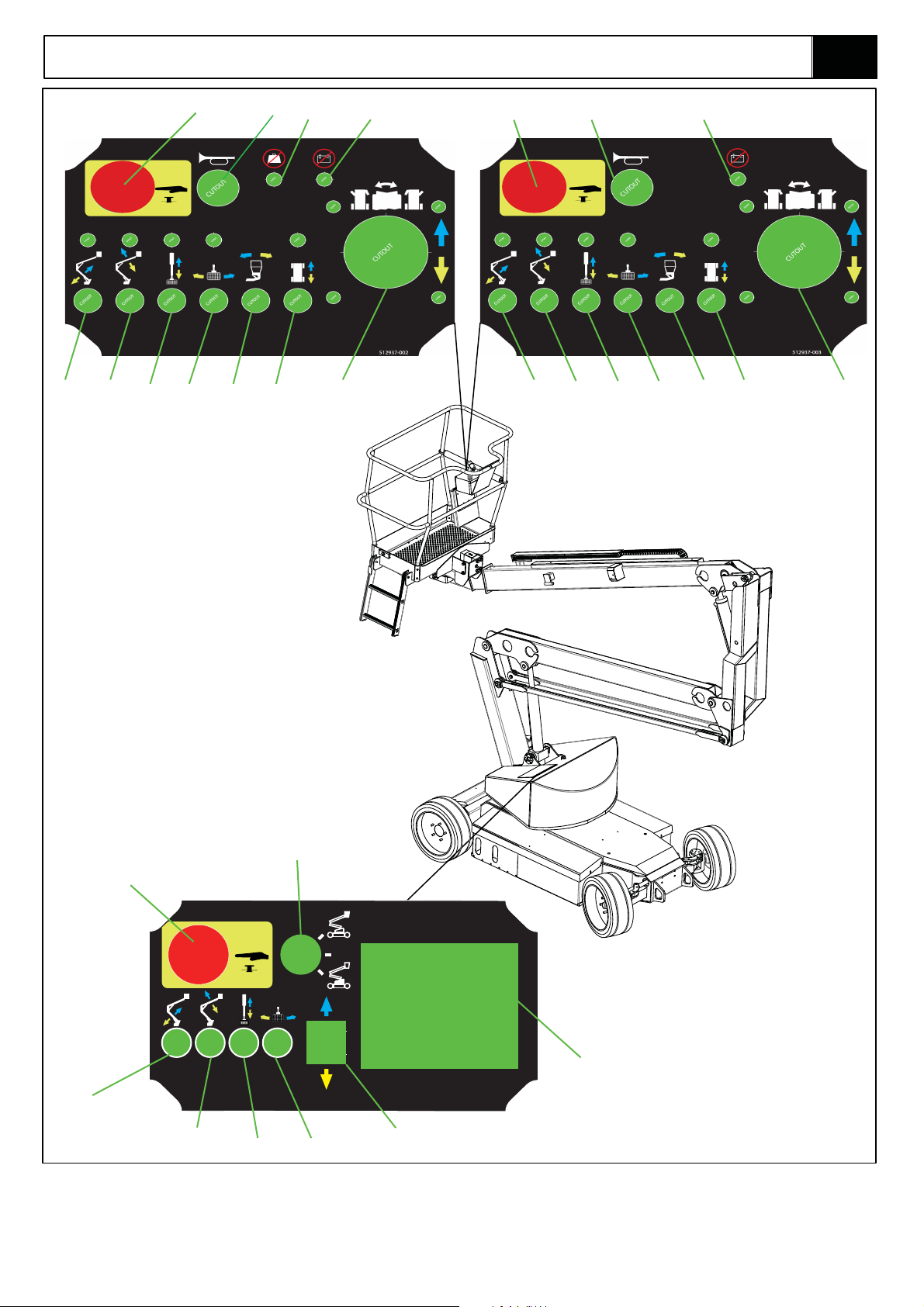

3.2 Controls and Indicators

The controls and indicators for operation of the A38E

Work Platform are shown in Figures 3-1 & 3-2. The

name and function of each control and indicator are

listed in Tables 3-1. The index numbers in the figure

correspond to the index numbers in the table. The

operator should know the location of each

control and indicator and have a thorough

knowledge of the function and operation of each

before attempting to operate the unit.

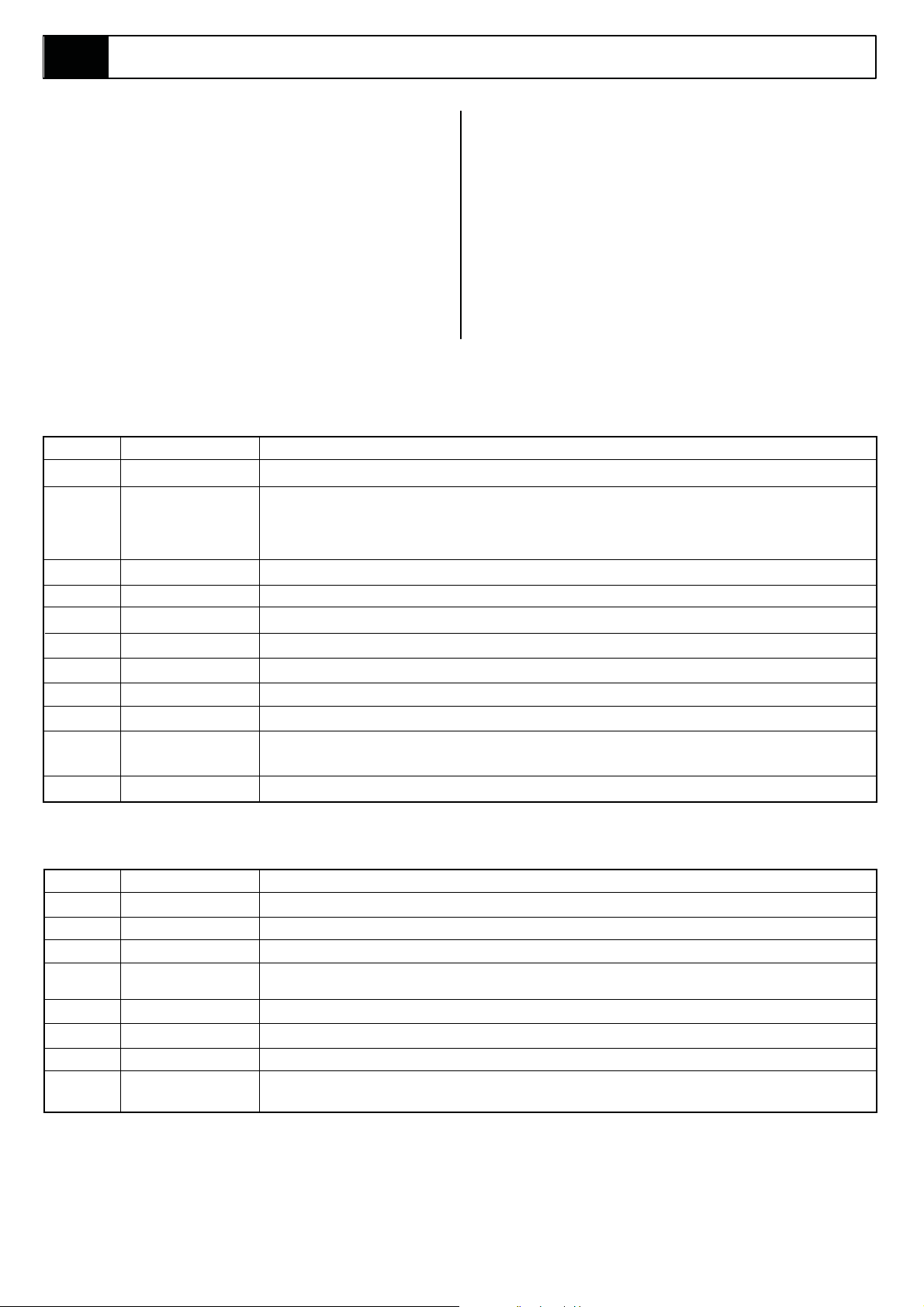

Table 3-1: Controls and Indicators

Platform Controller*

INDEX NO. NAME FUNCTION

1 Emergency Stop Cuts all Platform control functions when pushed, twist to release.

2 Platform Level Operate switch and hold while using joystick to level the platform.

Note: Platform Cylinders will keep the platform level during normal operation, if the

Platform goes out of level over time this function will return the platform to level.

3 Upper Boom Operate switch to engage Upper Boom lift functions (Up & Down)

4

5 Drive Operate switch to engage Drive functions (Forward & Reverse)

6 Horn Operate switch and hold to sound

7 Slew (Rotate) Operate switch to engage Slew functions (Clockwise & Counter Clockwise)

Low Boom

Operate switch to engage Lower Boom lift functions (Up & Down)

the horn.

8 Warning Lamp Low battery warning lamp. Machine must be charged.

9 Telescope Operate switch to engage Telescope functions (Extend & Retract)

10

11

Joystick Depress deadman switch and select joystick forward or reverse to enable a selected

function.

Overload warning lampWarning Lamp

Chassis Control

INDEX NO. N

1

2 Upper Boom Operate switch and hold to engage and enable Upper Boom lift functions (up & down)

3 Lower Boom Operate switch and hold to engage and enable Lower Boom lift functions (up & down)

4

5 Telescope Operate switch and hold to engage and enable Telescope functions (extend & retract)

6

8 Display In normal operation displays battery life and hour run. Can also be used to display

AME FUNCTION

mergen

E

Slew (Rotate) Operate switch and hold to engage and enable Slew functions (clockwise & counter

Key Switch Turns the machine OFF/ON and selects Platform or Chassis controls

Rocker Switch Use with “enable” switches to activate the selected f un

cy Stop

Cuts

all m

Clockwise.

diagnostics.

achine functions

ction7

Note:

Yellow and Blue direction arrows are included on the Control Panel to show the operator which way each

function will move when the joystick is moved in a particular direction.

3-4 A38E Work Platform

Page 25

Operation

CUTOUT

CUTOUT

CUTOUT

CUTOUT

CUTOUT

CUTOUT

Section

3.2

(CE)

4 4

3

1

7

6

11 8

2

5 109

1

512937-000

6

9

8

7 5 10

23

(ANSI)

3

1

6

0

8

512940-000

2

5

4

7

Figure 3-1: Controls & Indicators

3-5A38E Work Platform

Page 26

Section

3.3

Operation

3.3 Pre-Operation Inspection

W A R N I N G

Carefully read, understand and follow all

safety rules and operating instructions.

Perform the following steps each day before

use. DO NOT perform service on Work

Platform with the platform elevated unless the

elevating assembly is properly supported.

1. Remove module covers and inspect for

damage, oil leaks or missing parts.

2. Check the level of the hydraulic oil with the

platform fully lowered and the Telescopic Boom

fully retracted. Oil should be visible on the filler

cap dip stick. If ne

No. 46 hydraulic oil.

3. Check that the electrolyte level in the batteries

is correct. (Battery Maintenance, Section 4.3)

4. Verify batteries are charged.

5. Check that the A.C. extension cord has been

disconnected from charger.

6. Carefully inspect the entire machine for

damage such as cracked welds or structural

members, loose or missing parts, oil leaks,

damaged cables or hoses, loose connections

and tyre damage.

7. Move machine, if necessary, to unobstructed

are

a where machine can be fully elevat

8. Visually inspect the cylinders, hoses and cables

for damage. Check for missing or loose parts.

cessary top-up using ISO

ed.

15. Operate the manual telescopic retraction

system using the Handpump to test that it will

work. (Not required on

16. LOWER each boom until the Elevating

is fully stowed. Turn Keyswitch on the Lower

ANSI machines).

Assembly

Control box to the ‘LOWER CONTROL SELECTION’.

Climb into the

Platform and check that the

Platform is level.

If not adjust as shown in

Section of this manual. Repeat all the above

tests from the Platform Controls. Push the

Emergency Stop Button to identify that

functions will indeed cease when depressed.

Bring the machine back to the stowed position

and retract the Telescopic Cylinder.

17. PRESS the Service Horn to see that it is

operational

pressing the Joystick Interlock Switch slowly

PUSH the Joystick to DRIVE FORWARD, and

then PULL to DRIVE REVERSE, to check for

speed and proportional control. The farther you

push or pull the Joystick the faster the machine

will travel.

18. PUSH the Steering Switch RIGHT and then

LEFT to check for steering control.

19. RAISE the Elevating Assembly until the Boom

Rest Limit Switch is no longer activated and

then repeat the Drive Fun

speed (‘CREEP SPEED’) should be available.

The System Function Inspection is then complete.

. Select the DRIVE function. While

W A R N I N G

the Platform Levelling

ction test. Only low

SYSTEM FUNCTION INSPECTION

9. Turn both Chassis and Platform Emergency

Stop switches ON (rotate clockwise).

10. Turn Keyswitch on the Lower Control box to

the ‘LOWER CONTROL SELECTION’.

11. Using the chassis control switches, fully

ELEVATE Booms no. 1 & 2 and EXTEND the

Telescope.

12. SLEW the Elevating Assembly through 180

degrees in both directions.

13. Visually inspec

cage mounting/structure, lift cylinders, cables

and hoses for leaks, damage or erratic

operation. Check for missing or loose parts

such as nuts, bolts and circlips.

14. Test that the Emergency Lowering Valves on

each of the Lift Cylinders is operating correctly

as detailed in Section 3.4. PUSH the

Emergency Stop Button to identify that

functions will indeed cease when depressed.

t the elevating assembly and

If there are any concerns about the safe use

or operation of the A38E following this

Pre-Ope

ration Inspection DO NOT USE

THE A38E WORK PLATFORM. Contact your

supplier or Snorkel’s Product Support

Department.

3-6 A38E Work Platform

Page 27

Operation

Section

3.4

3.4 Operation

NOTE: Before operating the A38E Work Platform

it is imperative that the Pre-Operation Inspection

(Section 3.3) has been completed and any

deficiencies have been corrected. The operator

must also understand the functions of all the

controls before operating the machine.

ELEVATING & LOWERING THE A38E

WORK PLATFORM

Before beginning any operation involving the Elevating

Assembly the following checks should be carried out.

When the A38E has been thoroughly inspected the

elevating assembly can then be used.

W A R N I N G

LOOK up and around for obstructions before

performing the lift function.

ENSURE that the Elevating Assembly is

clear of the Chassis before engaging the

Slew operation.

DO NOT overload the platform

DO NOT operate within 3 metres (10 feet) of

any electrical power cables. THIS WORK

PLATFORM IS NOT INSULATED.

Cordon off the area within the platform’s

working area to keep passers-by clear of

the booms.

NOTE: Chas

1. Ensure the ‘CONTROL SELECTION KEYSWITCH’

is selected to ‘UPPER CONTROL’ and

emergency stop buttons are released (twisted clock-

wise).

Enter Platform through the entrance at the side

2.

of the A38E and ensure that the drop bar is in

the lowered position. Lock the Entry Step in the

raised position.

3. Before using the machine all local Safety

Regulations involving helmets and restraining

devices should be observed. Safety harness

lanyards, not exceeding 1 m (3 ft.) in length,

should be attached to anchor points in cage

floor.

4. Select “ LOWER BOOM ” on function selector

switch.Check for overhead obstructions and when

when satisfied squeeze the Joystick Interlock

control on.

sis controls are for service use only.

both

Slowly move the Joystick forwardto ELEVATE

the lower boom.

The further the joystick is moved, the faster.

the boom will move.

to

the Interlock at

required.

5. Select “UPPER BOOM ”, “TELESCOPE” or

“ROTATE” as required using the ‘Function

Selector Switches’ and operate as described

above. For boom functions the controls will

again be forward for UP and backward for

DOWN.

6. To rotate (SLEW) RIGHT the Controller

Joystick should be moved forward. Conversel

to rotate (SLEW) LEFT move the Controller

Joystick backward.

7. To ”TELESCOPE” IN the Controller Joystick

should be moved forward. Conversely to

”TELESCOPE” OUT move the Controller

Joystick backward.

8. Before lowering, check beneath the cage floor

for obstructions, operate as described above,

moving the Joystick back to lower the Booms.

Pressure must be applied

all times while operation is

TRAVEL WITH WORK PLATFORM

LOWERED

1. Verify that the chassis Emergency Stop Button

is in the

and that the Keyswitch is turned to the

‘UPPER CONTROL’position.

2. Climb into the Platform and check that the

Platform Emergency Stop Button is in the ‘ON’

position,

depressed. Ensure that the

lowered

3. Check that the route is clear of persons,

obstructions, pot holes or ledges and is capable

of supporting the wheel loads. Also, check that

the clearances above, below and to the side of

the Work Platform are sufficient.

4. Grasp the Joystick so that the Interlock Switch

is depressed (releasing this Interlock Switch will

cut power to the Joystick). Slowly push or pull

the Joystick to FORWARD or REVERSE to

travel in the desired direction. The farther you

push or pull the Joystick from the centre the

faster the machine will travel.

‘ON’ position (turn clockwise)

and that the Drive function button is

drop bar is in the

position.

y

3-7A38E Work Platform

Page 28

Section

3.4

Operation

5. To “STEER” the A38E activate the Interlock

Switch while pushing the Steering Switch LEFT

or RIGHT to turn the wheels. Observe the tyres

while manoeuvring to ensure proper direction.

NOTE:

Steering is not self-centring. The wheels must be

returned to the straight ahead position by operating

the Steering Switch.

TRAVEL WITH WORK PLATFORM

ELEVATED

W A R N I N G

Travel with platform elevated ONLY on firm

and level surfaces. Platform motion is

exaggerated whil

surfaces.

NOTE:

The Work Platform will travel at reduced speed when

in the elevated position.

1. Check that the route is clear of persons,

obstructions, pot holes or ledges and is capable

of supporting the wheel loads. Also, check that

the clearances above, below and to the side of

the Work Platform are sufficient.

2. Operate the Drive function switch.

3. Grasp the Joystick so that the Interlock Switch

is depressed (releasing this Interlock Switc

cut power to the Joystick). Slowly push or pull

the Joystick to FORWARD or REVERSE to

travel in the desired direction. The farther you

push or pull the Joystick from the center the

faster the machine will travel.

e travelling on uneven

h will

C A U T I O N

If the machine comes to a halt and the Tilt

Alarm sounds, immediately lower the

Platform and move the machine to a level

location before re-elevating the Platform.

PLATFORM LEVELLING

NOTE:

The Levelling function will only

Rest Limit Switch has been activated i.e. when the

Booms are stowed.

work when the Boom

The platform can be levelled from the Upper controls

using the levelling function, oper d oh ld thena eta

levelling switchon the upper control box (see fig3-1)

while moving the joystick forward or back to level the

platform. The switch should be operated in short

bursts to level the platform slowly.

EMERGENCY SITUATIONS &

EMERGENCY OVERRIDE

In any emergency situation, the first action to be taken

should be to hit the red “Emergency Stop”

button for instant cutout of all functions. It will then be

required to twist the button clockwise, this releases

the cutout and the machine can be operated again.

If the audible Tilt warning alarm sounds, normal

control functions will cease to operate. This will

due to the following problem ;

the machine is out of level i.e. Tilt Sensor has

been activated.

In this situation the only machine

operate are descent functions, descend to the ground

in a controlled manner and cycle the power (push and

release the emergency stop) to restore all functions,

move the machine to a level surface and continue

with normal operation.

Note that during emergency operation, controls

will operate at a fixed, slow speed and will not

allow the raising or extending of the Booms.

The Booms can be lowered or retracted.

functions that will

be

EMERGENCY LOWERING

C A U T I O N

When operating this function, extreme care

must be taken to ensur

carrying out the task does not become

trapped by the structure. DO NOT climb

down the Elevating Assembly to operate

these valves.

Should the machine become inoperable when

elevated, request a person on the ground to lower the

platform using the emergency lowering valves.

These are red knobs (push type) mounted at the

base of the 2 Main Hydraulic Lift Cylinders (See

Figure 3-2).

Operate the lower boom first by pushing slowly.

The boom will descend slowly. The speed

is controlled by retaining pressure on the valve -

e that the person

of descent

3-8 A38E Work Platform

Page 29

Operation

ens

ure a slow controlled rate of descent at all times.

Descent can be halted at any time by removing

pressure from the red knob.

Repeat the operation if necessary for the upper boom

when cylinder is in reach of the ground.

With both main booms lowered fully it should then be

possible to leave the platform safely.

Section

3.4

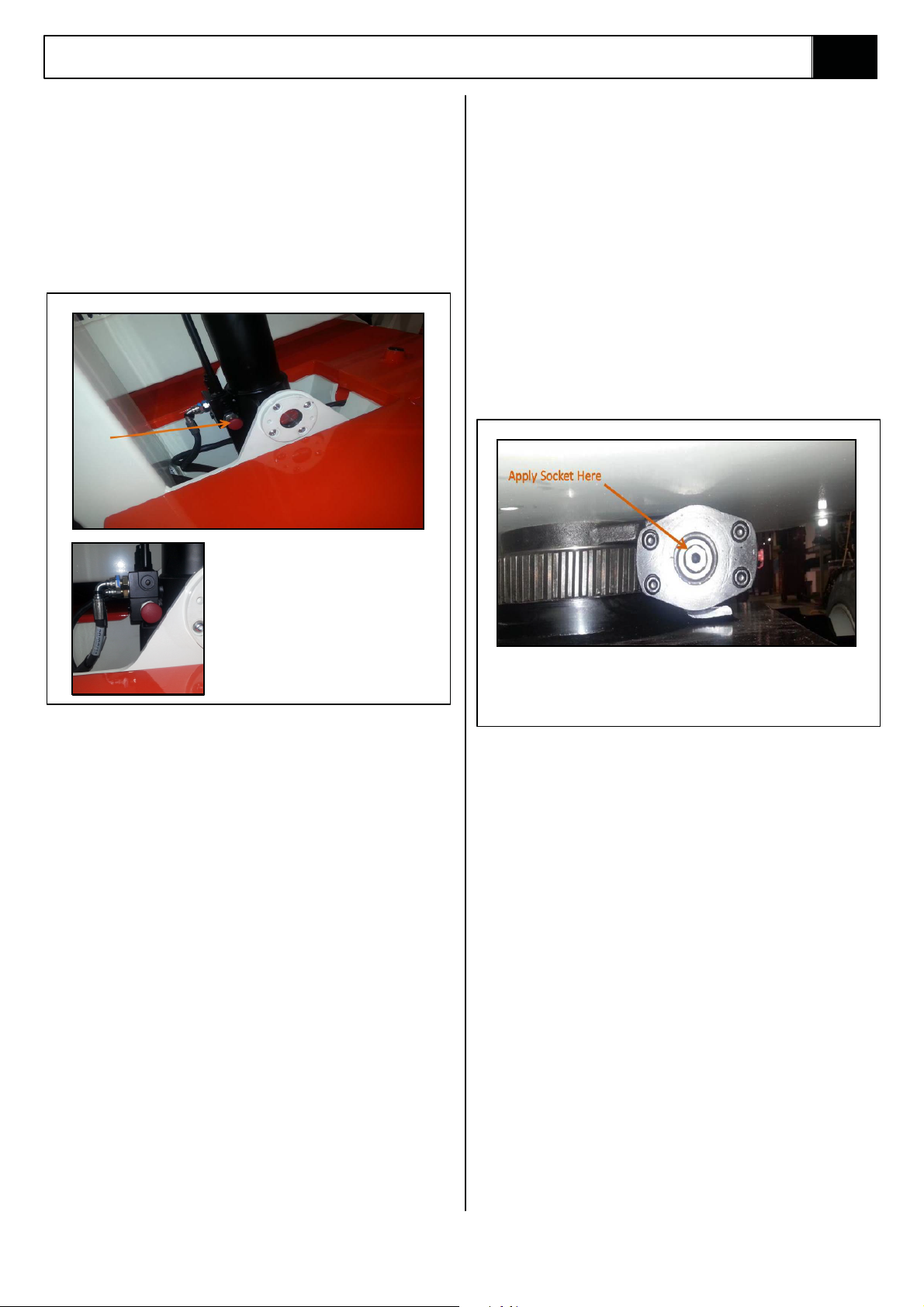

MANUAL ROTATION

1. Ensure booms are lowered as far as possible

using the emergency lowering valves, and that

the Emergency Stop Button is pressed to

prevent any accidental powered operation.

2. Apply a 7/8” socket wrench to shaft and turn to

rotate elevating assembly.

3. Remove wrench.

Before operating the Emergency

Lowering Valves the surrounding

area should first be cleared of any

potential obstructions. It is also

important that when the valve is

pushed, it is initially done slowly.

This is so that sudden movement

will not occur in the Elevating

Assembly, leading to a potentially

unstable machine.

Figure 3-2: Emergency Lowering

CONTROL FROM GROUND LEVEL

1. Chassis Controls are fitted at the base of the

Elevating Assembly. These should be used

when no operator is in the platform (for

maintenance/ service or inspection purposes),

or if the operator has become incapacitated.

For further information see Table 3-1.

2. Use the appropriate switch to raise or lower

Boom 1, Boom 2, Telescope or rotate as

required.

AFTER USE EACH DAY

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably

undercover, secure against vandals, children or

unauthorised operation.

3. Turn key switch to OFF and remove key to

prevent unauthorised ope

4. Recharge batteries in accordance with

instructions in section 4.2.

ration.

the

To rotate the Elevating Assembly first apply a 7/8”

socket wrench to the shaft and turn to rotate the

Elevating Assembly. When finished remove the wrench.

Figure 3-3: Manual Rotation

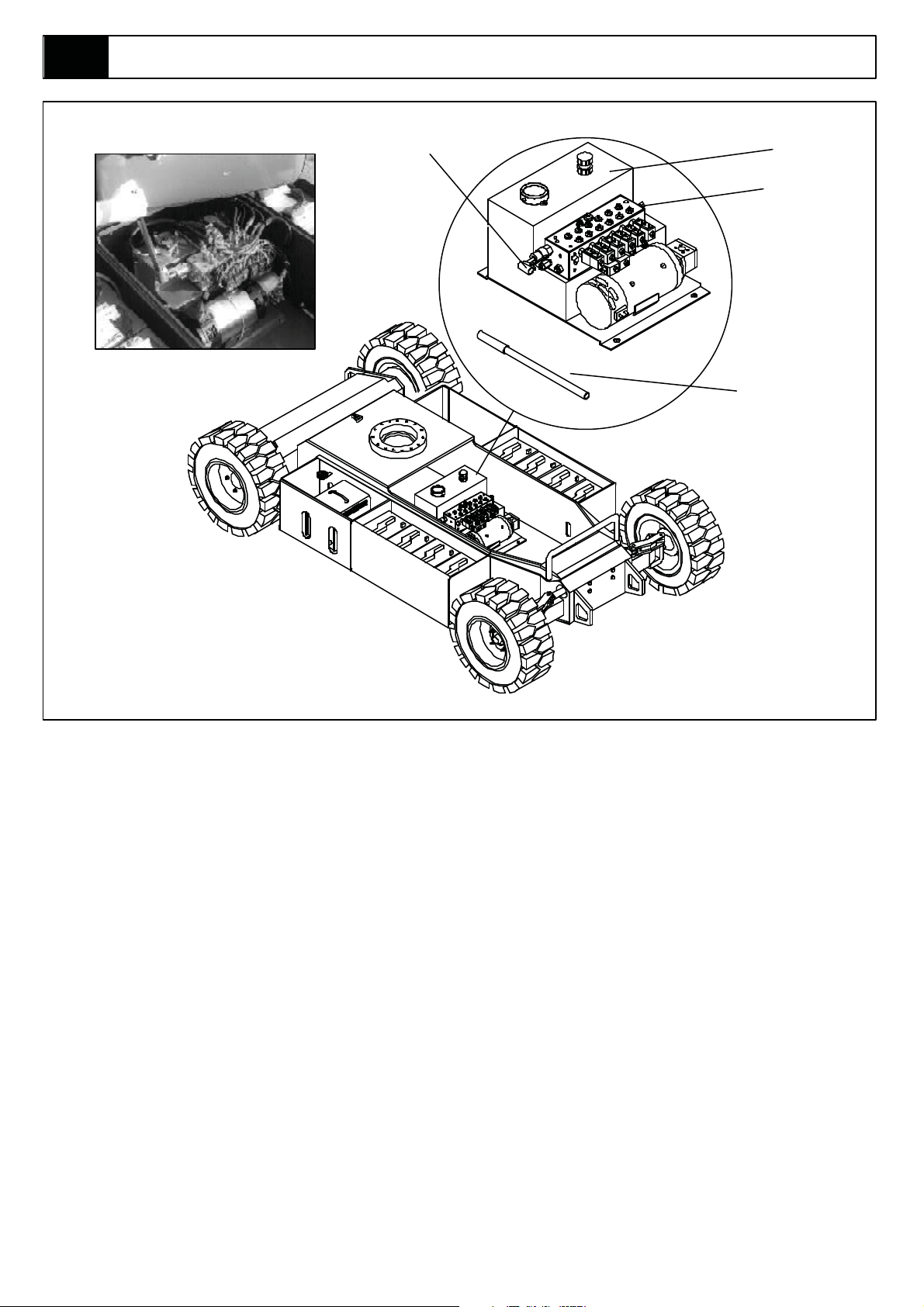

MANUAL TELESCOPIC RETRACTION

(SEE FIGURE 3-4)

NOTE:

Manual Tele Retraction is not required, and

not provided for ANSI machines.

In the event of loss of electrical power the Telescopic

Cylinder can be retracted as follows:

1. Remove the cover from the chassis body.

2. The Handpump is attached to the Main Manifold

Block. Remove the Handpump Handle from the

clips on the side of the Chassis and insert into

the Handpump Valve as shown in Figure 3-4.

3. Operate handpump to retract

the tele cylinder.

4. After use replace the Handpump Handle in the

clips provided.

5. Reposition the cover on Chassis.

hence is

3-9A38E Work Platform

Page 30

Section

3.4

Operation

Hand Pump

Valve

Hydraulic

Tank

Valve Block

Hand Pump

Handle

Figure 3-4: Manual Telescopic Retraction

3-10 A38E Work Platform

Page 31

NOTES:

Operation

Section

3.5

3-11A38E Work Platform

Page 32

Section

3.5

NOTES:

Operation

3-12 A38E Work Platform

Page 33

Maintenance

Section

4.0

4.0 Introduction

!

W A R N I N GW A R N I N G

Be sure to read, understand and follow all

information in the

Operation Section of

this manual before attempting to operate or

perform service on any A38E Work Platform.

This section contains instructions for the

maintenance of the A38E Series Work Platform.

Procedures for scheduled maintenance and repair/

removal are included.

Referring to Section 3.0 and Section 6.0 will aid in

understanding the operation and function of the

various com

Platform and help in diagnosing and repair of the

machine.

Refer to Table 4-1, the Preventative Maintenance

Checklist for the recommended Maintenance

intervals.

ponents and systems of the A38E Work

TOOLS REQUIRED

!

4.1 Preventative Maintenance

(Table 4-1)

The complete inspection consists of periodic visual

and operational checks, together with all necessary

minor adjustments to assure proper performance.

Daily inspection will prevent abnormal wear and

prolong the life of all

maintenance schedule is to be performed at regular

intervals.

Inspection and maintenance shall be performed by

personnel who are trained and familiar with

mechanical and electrical procedures. Complete

scriptions of the procedures are in the text

de

following the table.

!

Before performing preventative maintenance

familiarise yourself with the operation of the

machine.

Ensure that the machine is fully secured

and supported when carrying out

maintenance procedures in the elevated

position.

systems. The inspection and

W A R N I N GW A R N I N G

!

The following is a list of items which may be required

to perform certain maintenance & repair procedures

on the A38E Work Platform.

1 x Multi-meter capable of reading Voltage, Ohms

and Amps.

1 x Hydraulic Pressure Gauge

- Range (0 - 3000 PSI)

1 x

Calibrator EZcal (Snorkel Part No: 504560-001)

Note:

EZcal Display can be used in place of the above

Calibrator, the calibrator may only be necessary

when working in the Platform as the EZ Display

is located within the ground Controls.

The Preventative Maintenance table has been

designed primarily to be used for machine service

and maintenance repair.

Please copy the following page and use this

table as a checklist when inspecting a machine

for service.

4-1A38E Work Platform

Page 34

Section

4.1

Maintenance

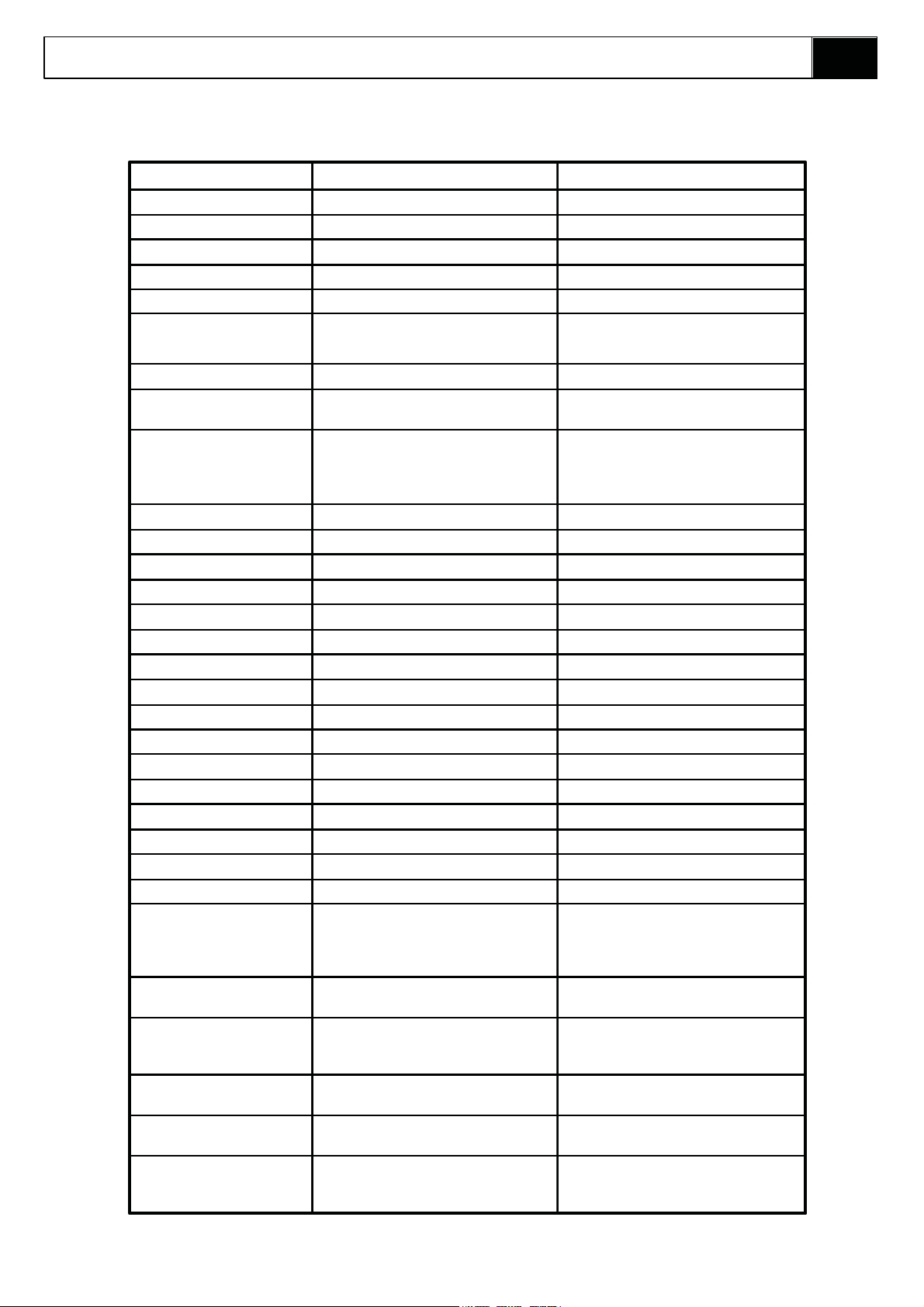

Preventative Maintenance Table Key

Interval

Daily = each shift or every day

10h/7d = every 10 hours or 7 days

50h/30d = every 50 hours or 30 days

250h/6m = every 250 hours or 6 months

500h/1y = every 500 hours or 1 year

1000h/2y = every 1000 hours or 2 years

Y=Yes/Acceptable

N=No/Not Acceptable

R=Repaired/Acceptable

Preventative Maintenance Report

Date : _______________________________

Owner : ______________________________

Model No : ____________________________

V.I.N No : _____________________________

Serial No :____________________________

Serviced By :__________________________

Service Interval :________________________

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Battery Check electrolyte level. Daily

System Check battery cable condition. Daily

Charge batteries. Daily

Check Charger condition &

operation. Daily

Check specific gravity. 50h/30d

Clean exterior. 250h/6m

Clean terminals. 250h/6m

Hydraulic Check oil level. Daily

Oil Drain and replace oil. 500h/1y

(ISO #46).

Hydrau e clean piWcil

Pump Check for hose fitting leaks. 50h/30d

Check for leaks at mating surfaces. 50h/30d

Check mounting bolts for proper 50h/30d

torque.

Hydraulic Check for leaks. Daily

System Check hose connections. 50h/30d

Check for exterior wear. 50h/30d

Change filter. 250h/6m

Emer. Open the emergency lowering Daily

Hydraulic valves and check for proper

System operation.

Control Check switch operation. Daily

Cable Check the exterior of cable for Daily

pinching, binding or cable wear.

Tyres / Check for damage. Daily

Wheels Check/torque nuts - 50h/30d

Front: 200 Nm (150 ft. lbs)

Rear: 130 Nm (95 ft. lbs)

Overload

System

Check/torque nuts - 220 Nm

(162 ft. lbs)

Calibrate system

50h/30d

50h/30d

500h/1y

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Steering Check Steering Cylinder for leaks. 50h/30d

Assembly Lubricate all pivot pins. 250h/6m

Check Links and Hubs. 250h/6m

Drive Check for operation. Daily

Motors Check for any foreign bodies. Daily

Check for wear of brushes. 500h/1y

Check that commutator or springs 500h/1y

are undamaged.

Check bearings for operation. 1000h/2y

Change oil in drive reduction

gearbox.(ref: sec 4.12)

Platform Check welds for cracks. Daily

Deck and Check condition of floor. Daily

Guardrails Check that securing bolts are Daily

Slew Grease slew gear. 10h/7d

System Check slew motor for leaks and 50h/30d

Slew Check torque on all bolts, 15 outer 50h/30d

System/ ring and 20 inner ring.

First Post Retorque to 220 Nm (160 ft. lbs).

Elevating Inspect for structural cracks. Daily

Assembly Check hoses for pinch or rubbing Daily

Lift Check cylinder rod for wear. 50h/30d

Cylinders Check pivot pin retaining rings. 50h/30d

Chassis

Assembly Daily

Entire Unit Function check Emergency stop Daily

tightened.

Check drop bar on cage entrance. Daily

mounting bolts for proper torque.

Check hardware and fittings for 250h/6m

proper torque.

points.

Check pivot pins for damage. 50h/30d

Check pivot pin retaining rings. 50h/30d

Check elevating assembly for 250h/6m

bending.

Check component mounting for 250h/6m

proper torque.

Check fasteners for proper torque. 250h/6m

Grease all fittings as section 4.4. 50h/30d

Check hoses for pinch or rubbing

points.

switches at control boxes.

Perform pre-operation inspection. Daily

Check for and repair collision Daily

damage.

Check for peeling, missing or Daily

unreadable decals. Replace.

Lubricate. 50h/30d

Grease all fittings. 50h/30d

Check for corrosion - Remove and 250h/6m

repaint.

500h/1y

DailyInspect for structural cracks

NOTE:

Recommend Bolt Torques are shown in Table 4-3,

Section 4.13.

Signature of Service Engineer

_____________________________

4-2 A38E Work Platform

Page 35

Maintenance

Section

4.2

4.2 Battery Maintenance

Electrical energy for the motor is supplied by eight 6

volt batteries wired in series to give a 48 volts DC

supply. Each of these batteries consist of three cells

which can supply a maximum voltage of 2.1V ea

=>6.3V per battery =>50.4V per battery pack. Proper

care and maintenance of the batteries and motor will

ensure maximum performance from the work

platform.

W A R N I N G

Hazard of explosive gas mixture. Keep

sparks, flames and smoking materials away

from batteries

Always wear

with batteries.

Battery fluid is highly corrosive. Rinse away

any spilled fluid thoroughly with clean water.

BATTERY INSPECTION AND

safety glasses when working

Basic Rule for maximum duty cycle of deep cycle

traction batteries

Always recharge Battery as soon as possible

after the low Battery L.E.D illuminates.

Allow the charger to charge the batteries until it

automatically shuts off.

BATTERY CHARGING

Batteries do not reach full potential until they have

been through 50 charge/discharge cycles (however

the rate at which the potential

tial, and the batteries will normally have 95% potential

after 15 charge/discharge cycles). Hence do not use

a new battery in a battery pack that already has more

than 15 cycles Charge batteries at the end of each

work shift or sooner if batteries have been

discharged. A battery is conside

cell if it has less than 80% of the potential of the other

batteries in the pack while

increases is exponen-

red to have a faulty

measured under load.

CLEANING

Check battery fluid level daily, especially if work

platform is being used in a warm, dry climate. If

required, add distilled water; use of tap water with a