Page 1

042011

25A PLASMA ARC CUTTING MACHINE

PLASMA30i

IN TRODUCTION

The PLASMA30i is an inverter current power source machine, designed for cutting

electrically conductive materials (metals and alloys) using the plasma arc procedure. The

plasma gas may be air or nitrogen. The lightweight portable inverter plasma cutter has

many features that enable the user to easily cut most all metals.

Page 2

1

Introduction............................................................................................................................... Front Cover

Table of Contents ...................................................................................................................................... 1

Safety Information ..................................................................................................................................2-3

Specifications ............................................................................................................................................ 4

Features .................................................................................................................................................... 5

Description of Equipment .......................................................................................................................6-7

Assembling the Unit/Start-up Guide .......................................................................................................... 8

Plasma Cutting .......................................................................................................................................... 9

Troubleshooting/Consumable Replacement ........................................................................................... 10

Maintenance ............................................................................................................................................ 11

Replacement Parts .................................................................................................................................. 12

Wiring Diagram........................................................................................................................................ 13

Warranty/Service and Repair .................................................................................................................. 14

TABLE OF CONTENTS

Page 3

2

MUST READ INSTRUCTIONS BEFORE USE

Read, understand and follow all safety messages

and instructions in this manual. Safety messages in

this section ofthe manual contain a signal word with

a three-part message and, in some instances, an

icon.

The signal word indicates the level of the hazard in

a situation.

DANGER

Indicates an Imminently hazardous Situation which,

if not avoided, will result in death or serious injury to

the operator or bystanders.

WARNING

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury

to the operator or bystanders.

CAUTION

Indicates a potentially hazardous situation which, if

not avoided, may result in moderate or minor injury

to the operator or bystanders.

IMPORTANT

Indicates a situation which, if not avoided, may

result in damage to the welding equipment.

Safety messages in this section contain three

different type styles.

• Normal type states the hazard.

• Bold type states how to avoid the hazard.

• Italic type states the possible consequences of

not avoiding the hazard.

An icon, when present, gives a graphical

description of the potential hazard.

Plasma Arc Cutting

DANGER

• Electric welding or plasma cutting cause ultra

violet rays and weld spatter

Bystanders will be exposed to ultraviolet rays

and weld spatter.

Wear welding helmet with appropriate shade

lens while using electric welders or plasma

cutters.

Do not allow bystanders while welding or

cutting.

Wear safety shield and protective clothing.

Ultraviolet rays will burn eyes; weld spatter can

cause injury.

WARNING

• Plasma cutting produces heat, sparks, hazard

of electric shock and/or hazardous vapors

Wear appropriate gloves, helmets or goggles

and other protective clothing.

Follow all instructions and safe practices while

welding or cutting.

Keep bystanders away from immediate area.

Byproducts of plasma cutting can cause burns or

other bodily injury.

SAVE THESE INSTRUCTIONS

SAFETY INFORMATIO N

Page 4

3

Risk of Electrical Shock

WARNING

• Electrical shock can result when contacting

live electrode or internal components

• Electrical shock can result from absence of

grounding prong

Do not touch electrode or internal components

without protection.

Disconnect power before servicing.

Do not remove the grounding prong in any

electrical plug.

Electrical shock can cause injury

Risk of Explosion

WARNING

• Plasma cutting causes sparks that can cause

explosion

Use caution and proper procedures when

welding.

Avoid sparks if gasoline vapor and other fuels

are present.

Electrical shock, flames and explosion can cause

serious injury

Electrical and Magnetic Fields

WARNING

• Plasma cutting may cause localized Electrical

and Magnetic Fields around cables and power

sources

• The magnetic fields created by high currents

may affect the operation of medical

equipment.

Route the electrode and work cables together.

Do not place your body between the

electrode/torch and work cables.

Never coil the electrode/torch lead around

your body.

Do not work next to welding/cutting power

source.

Electrical shock and Magnetic fields can cause

injury.

Disposal of Equipment

IMPORTANT

• Disposal of electrical equipment can be

hazardous to the environment

Contact local regulations prior to disposal

Improper disposal can cause an environmental

hazard

SAFETY INFORMATIO N cont’d

Page 5

4

This machine is a constant direct current power sour

ce,

designed for cutting electrically conductive materials (metals

and alloys) using the plasma arc procedure. The plasma

gas may be air or

nitr

ogen

EXPLANATION OF THE TECHNICAL

SPECIFICATIONS LISTED ON THE

MACHINE PLATE

EN 60974.1 The machine has been built according to

EN 50199 this European

standar

ds.

EN 50192

N°..................... Serial

number

.

Always indicate this for any request

regarding the machine.

....... Single-phase static

transformer-r

ectifier

frequency

converter

.

.................... Drooping

characteristic.

................. Suitable for plasma

cutting.

TORCH TYPE ......Type of torch that may be used with

this

machine.

U0.

PEAK ....

Secondary open-circuit voltage. Peak value.

X .....................

Percentage duty

cycle.

The duty cycle expresses the

percentage

of

10 minutes for which the machine may work

at a certain current I2 and

voltage

U2 without

overheating.

I2 ......................

Cutting

curr

ent.

U2 ....................Secondary voltage at cutting current I2.

This voltage is measured when

cutting

with the gas nozzle in contact with

the

work piece.

If this distance increases, the cutting

voltage also increases and the duty cycle

X% may drop.

U1 ....................Rated supply

voltage

1~ 50/60Hz ...... 50- or 60-Hz single-phase power

supply

.

The machine is equipped with

automatic

voltage change.

I1 Max ............. Max. absorbed current at the

correspon

ding

current I2 and voltage U2.

I1 eff ................This is the maximum value of the

actual

current absorbed, considering the

duty

cycle. This value usually corresponds

to

the

capacity of the fuse (delayed type)

to

be

used as a protection for

the equipment.

IP23 S . ............ Protection rating for the housing.

Grade 3 as the second digit means

that

this

equipment may be stored, but it is not

suitable for use outdoors in the rain, unless

it is protected.

S ...................

Suitable for working in hazardous

enviro

nments.

SPECIFICATIONS+

Power+Input+

!!

Voltage!

115!or!230!Volt!

Phase!!

Single!Phase!

Frequency!

50/60!Hertz!

Current!

30!Amps!115!Volt!

!!

20!Amps!230!Volt!

Power+Output+

!!

Duty!Cycle/Rated!Output!

100%!@!19!Amps!

!!

60%!@22!Amps!

!!

35%!@!25!Amps!

Output+Control+

Adjustable!5!‐!25!Amps!

Torch+Cable+Length+

12!Feet!

Ground+Cable+Length+

12!Feet!

Power+Input+Cord+

8!Feet!

Dimensions+

!!

Height!

16!Inches!

Width!

8!Inches !

Depth!

16!Inches!

Weight++

!!

Base!Unit!

29!

Shipping!

33!

SPE CIFICATIONS

Page 6

5

FEATURES

• Inverter portable 30 amp plasma cutter.

• Either 110 volt of 230 volt input with automatic switching.

• Low input amperage requirement.

• Inverter technology allows the plasma cutter to be lightweight (29 Ib.) and still able to perform many

cutting applications.

• The adjustable amperage output of a minimum of 5 amps, allows the cutting of one layer of material

without cutting the second layer.

• The maximum of 25 amps will cut 3/8" steel and sever 1/2".

• Pilot self restart function allows the unit to cut perforated or grid metal.

• Low air pressure LED.

• Air regulator and filter.

• The PLASMA30i includes plasma cutter, torch assembly, ground cable, spare nozzle and electrode.

• Industry-leading technical support of over 30 years of experience by calling 800-ABC-WELD to

speak with a live expert.

Page 7

6

DES CRIPTIO N OF EQ UIPMENT

A Power

cord

B Compressed air fitting (1/4" female gas thread)

C Main power

switch “0” = off “l” = on

D Main power

led

E Pressure regulator

knob (Lift to adjust)

F Pressure gauge

G Thermostat LED

H Ground

cor

d

I Water

trap

L Low air pressure LED

M Cutting current regulator

knob

N Blocked LED; lights when hazardous

conditions

arise.

O LED that lights when the

"SELF-RESTART

PILOT"

function is

active

P Push-button to activate and deactivate the

"SELF-

RESTART

PILOT"

function.

Q Plasma

tor

ch (includes consumable parts).

Q

Page 8

7

THERMAL PROTECTION

This system comes equipped with the following safety

devices:

Overload cutout:

To avoid overload while

cutting.

The LED G (see fig 1) lights when

active.

Pneumatic:

➡

Located on the torch inlet to prevent low air

pressure. The LED L lights when tripped (see fig.1).

Electrical:

1) In the event of a short-circuit between the nozzle

and

electrode during arc

striking

2) In the event of a short-circuit between the contacts

of

the

reed relay on circuit 22 (see exploded drawing).

3) When the electrode is worn to the point it must

be

replaced.

These conditions block the machine, and are

signaled

by

the lit LED N .

4) In addition, this machine is equipped with

automatic

selection of the supply voltage and the following

protections:

A) 230V Power supply: during start-up, the machine

remains blocked

(LED N lit) if the voltage is below

200V. After start-up, the machine runs at as low

as 180V.

B) 115V Power supply: during start-up, the machine

remains blocked

(LED N lit) if the voltage is below

100V. After start-up, the machine runs at as low

as 90V.

Lightweight and Variable Input Voltage Selections

The plasma cutter is able to operate on either 115 volt or 230

volt service using its automatic voltage input feature. The

advanced inverter design requires much less amperage

input thus saving on electricity costs. This along with its

lightweight design, allows it to be used anywhere there is

electric service and compressed air available.

Adjustable Arc Control

The PLASMA30i adjustable output arc control allows the

user to easily cut thin metal, up to 3/8” and sever up to.1/2”.

With the adjustable output control, the cutting arc can be

adjusted to cut one layer of material without cutting the

second layer. This can be extremely useful in the

automotive sector where an outer panel may be removed

without cutting through an inner panel.

Many industrial segments will benefit using the PLASMA30i

because of its multiple input, lightweight design and

adjustable arc feature. The plasma cutter eliminates the

need of using oxygen acetylene cutting techniques that not

only would be cumbersome to move, also more costly.

WARNING

• Do not remove or short-circuit the safety

devices.

• Use only original spare parts.

• Always replace any damaged parts of the

machine with original materials.

• Use only torches type CP40.

• Do not run the machine without its housings.

This would be dangerous to the operator and

anyone else in the work area, and would prevent

the machine fr

om

being cooled properly.

DES CRIPTIO N OF EQUIPMENT cont ’d

Page 9

8

INSTALLATION

Make sure that the supply voltage is either 115 volts and a

minimum of 30 amp service or 230 volt and a minimum of 20

amp service. When mounting a plug, make sure it has an

adequate

capa

city, and that the "yellow/green conductor"

of the power

supply cable is connected to the ground or

“earth” terminal. The blue and brown wires need to be

connected to each of the other pins on the plug.

WARNING

Only skilled personnel should install the machine. All

connections must be carried out according to current

regulations.

See complete listing of safety messages at the beginning of

this manual.

The machine must be installed by qualified personnel.

All connections must be made in compliance with

current safety standards and full observance of safety

regulations (see CEI 26-23 - IEC-TS 62081).

Connect the air supply to the fitting B .

• If the system air contains a considerable amount

of

moisture and oil, it is best to use a drying filter to

avoid

excessive oxidation and wear of the consumer

parts,

damaging the torch and reducing the cutting

speed

and

quality

.

If the air supply comes from a pressure regulator of a

com

pressor or centralized system, the regulator must be set

to

an output pressure of no more than 8 bar (0.8 Mpa) or

116 PSI. If

the

air supply comes from a compressed air

cylinder, the

cylin

der must be equipped with a pressure

regulator. Never connect a compressed air cylinder

directly to the r

egu

lator on the machine! The pressure

could exceed

the capacity of the regulator, which might

explode!

1)

Connect the power cord A : the yellow-green cable

wir

e

must be connected to an efficient grounding

terminal of the plug. The remaining brown and blue

wires must be connected to the supply voltage.

2) Amperage requirements

• 230V 20 amp service.

• 115V 30 amp service.

3) The absorbed current I

1

may be determined a l s o by

reading the technical specifications shown on the

machine under the available supply voltage

U1.

4) Any extension cords must be sized appropriately for

current

I, but are not recommended.

ASS EMBLING THE UN IT/STAR T UP GU IDE

Page 10

9

T U V

W

Fig. 3

Fig. 4

Fig. 2/A

Fig. 2/B

1. Turn the machine on “l” using the switch C . The warning

lamp D will light to indicate that the machine is on.

2. Press the torch trigger briefly to open the flow of

compressed air. Since the arc is not lit, air leaves the torch

for only 5 sec.

3. Now adjust the pressure, shown on the pressure gauge F

to 3.5 bar or 50 psi Lift the knob to adjust. Clockwise will

increase and counterclockwise will decrease. Then lock

the knob by pressing it downward.

4. Connect the grounding clamp to the work piece. The

cutting circuit must not be deliberately placed in direct or

indirect contact with the protective wire except in the work

piece.

If the work piece is deliberately grounded using the

protective conductor, the connection must be as direct as

possible and use a wire of at least the same size as the

cutting current return wire, and connected to the work

piece at the same point as the return wire using the return

wire clamp or a second grounding clamp placed in the

immediate vicinity. Every precaution must be taken to

avoid stray currents.

5. Use the knob M to adjust the cutting current from 5 to 25 A

based on the work at hand.

6. Make sure that the ground clamp and the work piece are in

good electrical contact, especially with painted or oxidized

metal or with insulated coating; connect the clamp as close

as possible to the cutting area.

Do not connect the grounding clamp to the part of

the material that is to be removed.

7. Press the torch trigger to strike the pilot arc. If cutting does

not begin within 2 seconds, the pilot arc goes out; press

the trigger again to re-strike it.

8. Begin cutting as shown in fig. 2a, avoid starting as shown

in fig. 2b

9. Hold the torch upright while cutting.

10. When you have finished cutting and released the trigger,

air will continue to leave the torch for approximately 40

seconds to allow the torch to cool down.

It is best not to turn the machine off until this cooldown period is complete.

• To cut perforated or grid metal, activate the "Pilot self

restart" function using the push-button P (LED O lit). When

you have finished cutting, holding this push-button down

will cause the pilot arc to restart automatically.

Use this function only if necessary to avoid

unnecessary wear on the electrode and nozzle.

•

Should you need to make holes or begin cutting from the

center of the work piece, you must hold the torch at an

angle and slowly straighten it so that the nozzle does not

spray molten metal (see fig. 3). This must be done when

making holes in pieces more than 3 mm or ~.118” thick.

(12 gauge = .105”)

• Should you need to cut several layers of metal, as are

normally used in auto body work, adjust the cutting current

to the minimum values.

For currents between 5 and 10 A it may be helpful to set

the intake pressure to approximately 2 bar or 29 psi.

Turn the machine off when the task is completed.

PLASMA CUT TING - INTRO DUCTION

Page 11

10

INSUFFICIENT PENETRATION

This error may be caused by the

following:

• High speed. Always make sure that the arc fully

pene

trates

the work piece and is never held at a forward angle of more

than 10 -15°. This will avoid incorrect

consump

tion of the

nozzle and burns to the nozzle

holder

.

• Excessively thick work pi ece (see cutting speed

dia

grams, fig. 5).

• Grounding clamp not in good electrical contact with

the

work piece.

• Worn nozzle and electrode.

• Cutting current too low.

NOTE: When the arc does not penetrate, the

molten

metal scraps obstruct the nozzle.

THE CUTTING ARC GOES OFF

This error may be caused

by:

• Worn nozzle, electrode or swirl ring.

• Air pressure too high.

• Supply voltage too low.

REPLACING CONSUMABLE PARTS

Always shut off the machine before replacing

consu

mer parts.

• The electrode must be replaced when it has a crater in the

center approximately 1 mm deep (.039”) or slightly over

1/32”.

• The gas nozzle must be replaced when the hole is no

longer smooth and the cutting capacity is diminished.

• The swirl ring must be replaced when some areas are

blackened. Due to its small size, it is very important to

position it correctly during assembly (see fig. 4).

• The nozzle holder must be replaced when the insulating

part is deteriorated

Make sure that the electrode T, the swirl ring U and

the

gas nozzle V are mounted correctly, and that

the

nozzle holder W is firmly tightened.

If any of these parts are missing, this will interfer

e

with smooth operation of the machine and,

especial

ly,

jeopardize operator safety

SHORTER LIFE OF CONSUMABLE PARTS

This error may be caused by:

• Oil or dirt in the arc intake,

• Unnecessarily long pilot arc,

• Low arc pressure.

HELPFUL HINTS

• If the system air contains considerable amounts of moisture

and oil, it is best to use a drying filter to avoid excessive

oxidation and wear on consumable parts, damage to the

torch and a reduction in the speed and quality of the cutting.

• Make sure that the new electrode and nozzle to be mounted

are thoroughly clean and degreased.

• Always use original spare parts to avoid damaging the

torch.

TROUBLESHOOTING/

CON SUMABLE REPLACEM ENT

Page 12

11

MAINTENANCE

Always cut off the power supply to the machine before any

operation, which must always be carried out by qualified

personnel (CEI 26-29 / IEC 60974-4).

PLASMA CUTTER MAINTENANCE

In the case of maintenance inside the machine, make sure

that the switch C is in position O and that the power cord is

disconnected from the mains.

Even though the machine is equipped with an automatic

condensation drainage device that is tripped each time the

air supply is closed, it is good practice to periodically make

sure that there is no condensation accumulated in the water

trap I (fig.1).

It is also necessary to periodically clean the interior of the

machine from the accumulated metal dust, using compressed air.

PRECAUTIONS AFTER REPAIRS.

After making repairs, take care to organize the wiring so that

there is secure insulation between the primary and

secondary sides of the machine. In particular, make sure

that the casing 50 is mounted (see exploded drawing). Do

not allow the wires to come into contact with moving parts or

those that heat up during operation. Reassemble all clamps

as they were on the original machine, to prevent a

connection from occurring between the primary and

secondary circuits should a wire accidentally break or be

disconnected.

Also mount the screws with geared washers as on the

original machine.

MAINTENANC E

Page 13

12

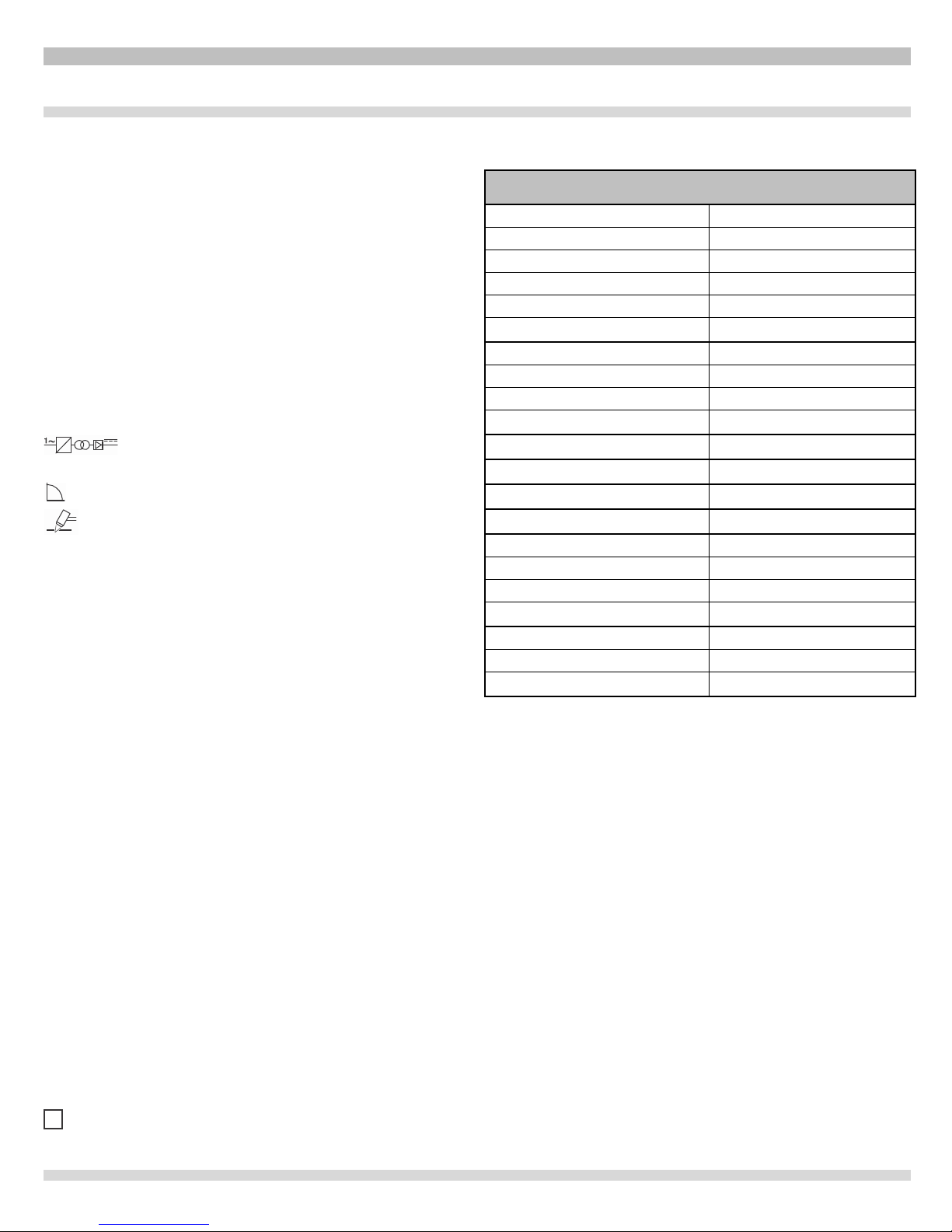

POS

PART

NUMBER

DESCRIPTION

1

CKSP3001

HOUSING

2

CKSP3002

HANDLE SUPPORT

3

CKSP3003

HANDLE

4

CKSP3004

RING NUT

5

CKSP3005

SUPPORT

6

CKSP3006

GAUGE

7

CKSP3007

REGULATOR

8

CKSP3008

FITTING

9

CKSP3009

SWITCH

10

CKSP3010

COVER

11

CKSP3011

POWER CORD

12

CKSP3012

CABLE OUTLET

13

CKSP3013

BACK PANEL

14

CKSP3014

FAN SUPPORT

15

CKSP3015

MOTOR WITH FAN

16

CKSP3016

INSIDE BAFFLE

17

CKSP3017

CHOKE

18

CKSP3018

RUBBER FOOT

19

CKSP3019

BOTTOM

20

CKSP3020

SOLENOID VALVE

21

CKSP3021

UNION ELBOW

22

CKSP3022

HIGH-FREQ. CIRCUIT

23

CKSP3023

FITTING

24

CKSP3024

TERMINAL BOARD

25

CKSP3025

STRAIN RELIEF

26

CKSP3026

RING NUT

27

CKSP3027

CABLE WITH CLAMP

28

CKSP3028

STRAIN RELIEF

29

CKSP3029

KNOB

30

CKSP3030

FRONT PANEL

31

CKSP3031

PANEL CIRCUIT

32

CKSP3032

PRESSURE SWITCH

33

CKSP3033

SUPPORT

34

CKSP3034

SUPPORT

35

CKSP3035

POWER CIRCUIT

36

CKSP3036

FILTER CIRCUIT

37

CKSP3037

FITTING

38

CKSP3038

FITTING

39

CKSP3039

FITTING

40

CKSP3040

TORCH CONNECTOR

41

CKSP3041

HANDGRIP w/PUSHBUTTON

42

CKSP3042

O.RING

43

PLASMA3006

TORCH BODY (HEAD)

44

PLASMA3004

ELECTRODE (PACK. 5 PCS.)

45

PLASMA3003

SWIRL RING (PACK. 2 PCS.)

46

PLASMA3002

NOZZLE (PACK. 5 PCS.)

47

PLASMA3001

NOZZLE HOLDER

48

CKSP3048

TORCH CABLE

49

PLASMA3007

COMPLETE TORCH

50

CKSP3050

COVER

51

CKSP3051

FRAME

52

CKSP3052

PROTECTION

53

CKSP3053

FRAME

REP LACEMENT PARTS – PART S LIST

WHEN ORDERING SPARE PARTS PLEASE STATE THE MODEL NUMBER

AND SERIAL NUMBER AND PART NUMBER NEEDED.

Page 14

13

CODIFICA COLORI

CABLAGGIO

ELETTRICO

WIRING DIAGRAM

COLOUR CODE

A NERO

BLACK

B ROSSO

RED

C

GRIGIO

GREY

D

BIANCO

WHITE

E VERDE

GREEN

F VIOLA

PURPLE

G

GIALLO

YELLOW

H BLU

BLUE

K

MARRONE

BROWN

J ARANCIO

ORANGE

I ROSA

PINK

CODIFICA COLORI

CABLAGGIO

ELETTRICO

WIRING DIAGRAM

COLOUR CODE

L

ROSA-NERO

PINK-BLACK

M GRIGIO-VIOLA

GREY-PURPLE

N

BIANCO-VIOLA

WHITE-PURPLE

O

BIANCO-NERO

WHITE-BLACK

P GRIGIO-BLU

GREY-BLUE

Q

BIANCO-ROSSO

WHITE-RED

R

GRIGIO-ROSSO

GREY-RED

S BIANCO-BLU

WHITE-BLUE

T NERO-BLU

B

LACK-BLUE

U

GIALLO-VERDE

YELLOW-GREEN

V AZZURRO

BLUE

WIRING D IAGRAM

Page 15

14

Snap-on Tools Company Limited Two (2) Year Warranty

Snap-on Tools Company (the “Seller") warrants only to original purchasers who use the Equipment in their business that

under normal use, care and service, the Equipment (except as otherwise provided herein) shall be free from defects in

material and workmanship for two years from the date of original invoice. Seller does not provide any warranty for

accessories used with the Equipment that are not manufactured by Seller. Seller limits torch assembly to a period of 30 days.

SELLER'S OBLIGATIONS UNDER THIS WARRANTY ARE LIMITED SOLELY TO THE REPAIR OR, AT SELLER'S

OPTION, REPLACEMENT OF EQUIPMENT OR PARTS WHICH TO SELLER'S SATISFACTION ARE DETERMINED TO BE

DEFECTIVE AND WHICH ARE NECESSARY, IN SELLER'S JUDGMENT, TO RETURN THIS EQUIPMENT TO GOOD

OPERATING CONDITION. NO OTHER WARRANTIES, EXPRESS OR IMPLIED OR STATUTORY, INCLUDING WITHOUT

LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, SHALL

APPLY AND ALL SUCH WARRANTIES ARE HEREBY EXPRESSLY DISCLAIMED.

SELLER SHALL NOT BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL COSTS OR DAMAGES

INCURRED BY PURCHASERS OR OTHERS (including, without limitations, lost profits, revenues, and anticipated sales,

business opportunities or goodwill, or interruption of business and any other injury or damage).

This warranty does not cover (and separate charges for parts, labor and related expenses shall apply to) any damage to,

malfunctioning, inoperability or improper operation of the Equipment caused by, resulting from or attributable to (A) abuse,

misuse or tampering; (B) alteration, modification or adjustment of the Equipment by other than Seller's authorized

representatives; (e) installation, repair or maintenance (other than specified operator maintenance) of the Equipment or

related equipment, attachments, peripherals or optional features by other than Seller's authorized representatives; (D)

improper or negligent use, application, operation, care, cleaning, storage or handling; (E) fire, water, wind, lightning or other

natural causes; (F) adverse environmental conditions, including, without limitation, excessive heat, moisture, corrosive

elements, dust or other air contaminants, radio frequency interference, electric power failure, power line voltages beyond

those specified for the Equipment. unusual physical, electrical or electromagnetic stress and/or any other condition outside of

Seller's environmental specifications; (G) use of the Equipment in combination or connection with other equipment,

attachments, supplies or consumables not manufactured or supplied by Seller; or (H) failure to comply with any applicable

federal, state or local regulation, requirement or specification governing welders and related supplies or consumables.

Repairs or replacements qualifying under this Warranty will be performed on regular business days during Seller's normal

working hours within a reasonable time following purchaser's request. All requests for Warranty service must be made during

the stated Warranty period. Proof of purchase date is required to make a Warranty request. This Warranty is nontransferable.

Snap-on Tools Company

Kenosha, Wisconsin 53141-1410

Technical Support Line 800-ABC-WELD

Customer Service and Technical Support 800-ABC-WELD

Monday – Friday 7:00 a.m. – 3:00 p.m. EST

Made in Italy

Snap-on and Wrench “S” are trademarks of Snap-on Incorporated.

©Snap-on Incorporated 2011. All Rights Reserved.

Printed in United States

Snap-on, 2801 80th St., Kenosha, WI 53143

www.snapon.com

WAR RANTY/S ERVICE AND REP AIR

Loading...

Loading...