Page 1

EN

PV Inverter

SUNNY BOY 1200/1700

Installation Guide

SB12-17-IA-en-52 | IMEN-SB11_17 | Version 5.2

Page 2

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Notes on this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Scope of Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Appropriate Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Explanation of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3.1 Symbols on the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3.2 Symbols on the Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

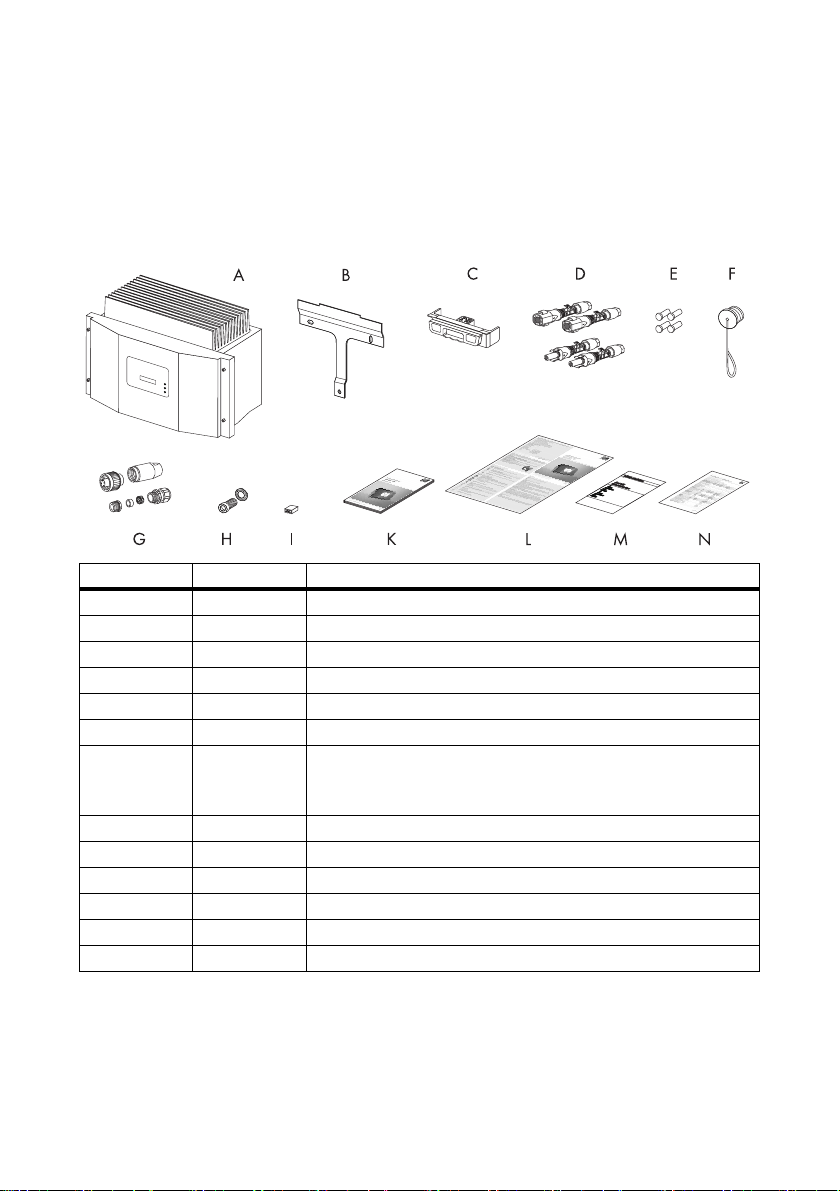

3.1 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Identifying the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Mounting the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Selecting the Mounting Location. . . . . . . . . . . . . . . . . . . . . . . . 16

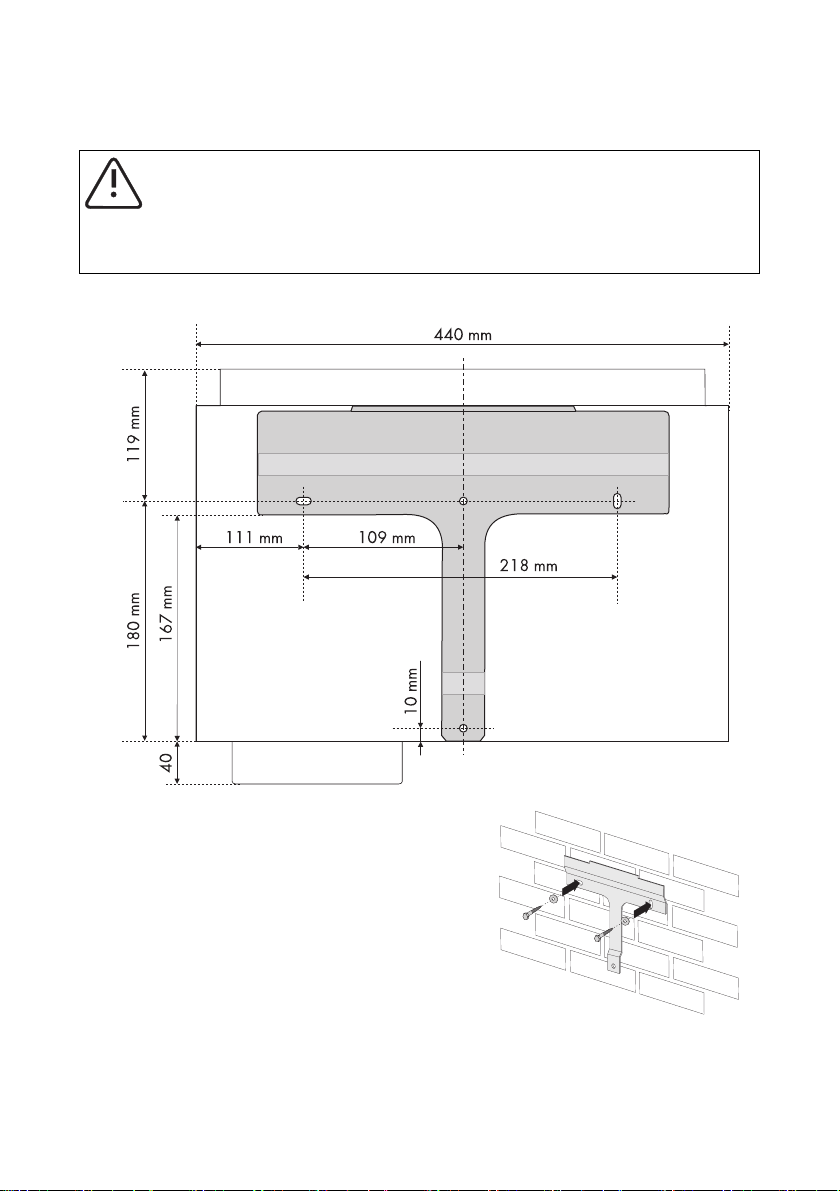

4.3 Mounting the Inverter with Wall Mounting Bracket . . . . . . . . . 18

5 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

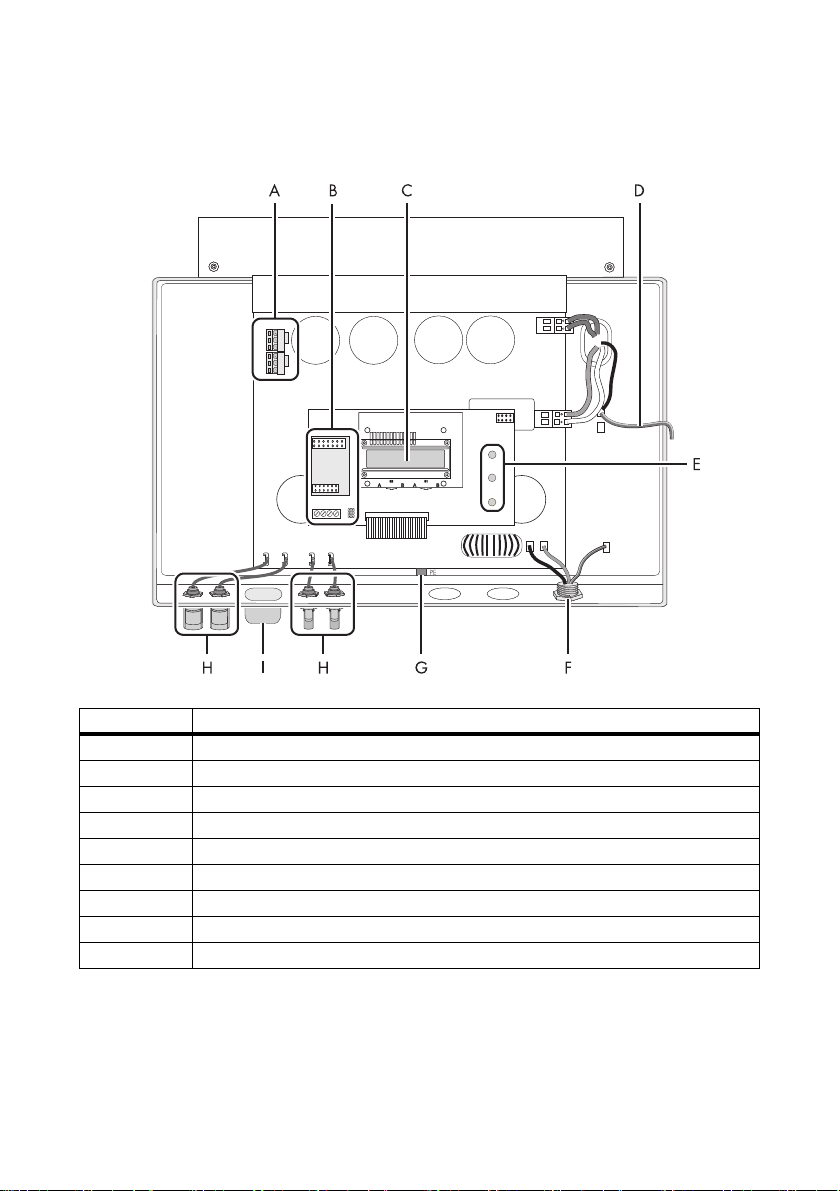

5.1 Overview of the Connection Area . . . . . . . . . . . . . . . . . . . . . . 20

5.1.1 Exterior View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1.2 Interior View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Connection to the Public Grid (AC) . . . . . . . . . . . . . . . . . . . . . 22

5.2.1 Conditions for the AC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.2 Connecting the Inverter to the Public Grid (AC) . . . . . . . . . . . . . . . . . . . . . . 24

5.2.3 Connecting additional grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installation Guide SB12-17-IA-en-52 3

Page 4

Table of Contents SMA Solar Technology AG

5.3 Setting the Display Language . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.4 PV generator connection (DC) . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4.1 Conditions for the DC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4.2 Assembling the DC Plug Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.4.3 Opening the DC Plug Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.4.4 Connecting the PV Generator (DC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.5 Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.6 Setting the Grid and Country Parameters . . . . . . . . . . . . . . . . . 36

5.6.1 Setting the Installation Country . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.6.2 Setting Stand-alone Grid Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.1 Commissioning the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.2 Display Messages during Initialization . . . . . . . . . . . . . . . . . . . 39

6.3 Self-Test in accordance with DK 5940, Ed. 2.2

(applies to Italy only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3.1 Starting the Self-Test by Tapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3.2 Completion of the Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7 Opening and Closing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2 Opening the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3 Closing the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8 Maintenance and Cleaning. . . . . . . . . . . . . . . . . . . . . . . . 50

8.1 Checking the Electronic Solar Switch for Wear . . . . . . . . . . . . 50

9 Failure Search. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.1 LED Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.2 Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4 SB12-17-IA-en-52 Installation Guide

Page 5

SMA Solar Technology AG Table of Contents

9.3 Red LED is Glowing Continuously. . . . . . . . . . . . . . . . . . . . . . . 56

9.3.1 Checking the PV Generator for a Ground Fault . . . . . . . . . . . . . . . . . . . . . . 57

9.3.2 Checking the Functioning of the Varistors . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.1 Dismantling the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.2 Packing the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.3 Storing the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.4 Disposing of the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.1 Sunny Boy 1200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.2 Sunny Boy 1700 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

12 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

13 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Installation Guide SB12-17-IA-en-52 5

Page 6

Table of Contents SMA Solar Technology AG

6 SB12-17-IA-en-52 Installation Guide

Page 7

SMA Solar Technology AG Notes on this Manual

1 Notes on this Manual

1.1 Scope of Validity

This manual describes the assembly, installation, commissioning and maintenance of the following

SMA inverters:

• Sunny Boy 1200 (SB 1200)

• Sunny Boy 1700 (SB 1700)

Store this manual where it can be accessed at all times.

1.2 Target Group

This manual is for qualified personnel. The tasks described in this manual may only be performed by

qualified personnel.

1.3 Additional Information

You will find further information on special topics such as designing a line circuit breaker or the

description of the operating parameters in the download area at www.SMA.de/en.

Refer to the user manual for detailed information on operating the inverter.

Installation Guide SB12-17-IA-en-52 7

Page 8

Notes on this Manual SMA Solar Technology AG

1.4 Symbols Used

The following types of safety precautions and general information are used in this manual:

DANGER!

G

"DANGER" indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING!

"WARNING" indicates a hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION!

"CAUTION" indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury!

NOTICE!

"NOTICE" indicates a situation that can result in property damage, if not avoided.

Information:

Information provides tips that are valuable for the optimal installation and operation of

your product.

☑ This symbol indicates the result of an action.

8 SB12-17-IA-en-52 Installation Guide

Page 9

SMA Solar Technology AG Safety

2 Safety

2.1 Appropriate Usage

The Sunny Boy is a PV inverter, which converts the DC current of the PV generator to AC current and

feeds it into the public grid.

Principle of a PV plant with this Sunny Boy

Th e Su nny Boy may onl y be o per ate d wi th P V ge ner ato rs ( modu les and cabling) of protection classII.

Do not connect any sources of energy other than PV modules to the Sunny Boy.

When designing the PV system, ensure that the values comply with the permitted operating range of all

components at all times. The free design program "Sunny Design" (www.SMA.de/en/SunnyDesign)

will assist you. The manufacturer of the PV modules must have approved the modules for use with this

Sunny Boy device. You must also ensure that all measures recommended by the module manufacturer

for long-term maintenance of the module properties are taken (see also Technical Information "Module

Technology", in the download area of www.SMA.de/en).

Do not use the Sunny Boy for purposes other than those described here. Alternative uses,

modifications to the Sunny Boy or the installation of components not expressly recommended or sold

by SMA Solar Technology AG void the warranty claims and operation permission.

Installation Guide SB12-17-IA-en-52 9

Page 10

Safety SMA Solar Technology AG

Certified Countries

The Sunny Boy 1200/1700 (with according configuration) fulfill the requirements specified in the

following standards and directives (dated: 12/2010):

SB 1200 SB 1700

• AS4777 (2005) • AS4777 (2005)

• C10/C11 (05.2009) • C10/C11 (05.2009)

• CER/06/190 (10.2006)* • CER/06/190 (10.2006)

• DK 5940 Ed.2.2 (02.2006)** • DK 5940 Ed.2.2 (02.2006)**

• EN 50438:2008*** • EN 50438:2008***

• G83/1-1:2008 • G83/1-1:2008

• IEEE929 • IEEE929

• PPC:2006 • PPC:2006

• PPDS:2009 • PPDS:2009

• RD 1663/2000 (2000) • RD 1663/2000 (2000)

• RD 1663/661 • RD 1663/661

• VDE 0126-1-1 (02.2006) • VDE 0126-1-1 (02.2006)

• UTE C15-712-1**** • UTE C15-712-1****

* On request

** only applies to SB 1200-IT/SB 1700-IT

*** does not apply to national standard deviations of EN 50438

**** Firmware version 3.06 and higher

SMA Solar Technology AG can preset special grid parameters for other countries/installation

locations according to customer request, after evaluation by SMA Solar Technology AG. You can

make later modifications yourself by changing software parameters with respective communication

products (e.g. Sunny Data Control or Sunny Explorer) (see section 5.6”Setting the Grid and Country

Parameters” (page36)). To change grid-relevant parameters, you need a personal access code - the

so-called SMA Grid Guard Code. The application form for the personal access code is located in the

download area at www.SMA.de/en, in the "Certificate" category for each inverter.

10 SB12-17-IA-en-52 Installation Guide

Page 11

SMA Solar Technology AG Safety

2.2 Safety Precautions

DANGER!

Danger to life due to high voltages in the inverter!

• All work on the inverter may be carried out by qualified personnel only.

• T he a ppl iance is not to b e us ed b y ch ildren o r pe rso ns w ith re duced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction.

• Children should be supervised to ensure that they do not play with the appliance.

DANGER!

Danger of burn injuries due to hot enclosure parts.

• Do not touch enclosure during operation.

• Only touch the lid during operation.

NOTICE!

Dust and water in the Sunny Boy can damage the inverter!

Once the Electronic Solar Switch has been pulled out, the inverter only provides protection

rating IP21. The inverter is then no longer protected against water and dust. In order that

the protection rating IP65 is also provided during a temporary decommissioning, proceed

as follows:

• Release and disconnect all DC connectors.

• Open all DC connectors and remove the cables.

• Close all DC inputs with the corresponding DC connectors and the sealing plug

provided.

• Securely attach the Electronic Solar Switch again.

Installation Guide SB12-17-IA-en-52 11

Page 12

Safety SMA Solar Technology AG

NOTICE!

Damage to the inverter due to moisture and dust intrusion

If the Electronic Solar Switch is not plugged in or incorrectly plugged in during operation,

moisture and dust can penetrate the inverter.

If the Electronic Solar Switch is not correctly plugged in, this can cause contacts to wear in

the Electronic Solar Switch or the Electronic Solar Switch might fall down. This can result in

yield loss and damage to the Electronic Solar Switch.

Always plug in the Electronic Solar Switch as described in the following:

• Do not tighten the screw in the Electronic Solar Switch.

• Firmly plug in the Electronic Solar Switch until it is flush with the enclosure.

• Ensure that the maximum distance between the Electronic Solar Switch and the

enclosure is 1 mm.

Grounding the PV Generator

Comply with the local requirements for grounding the modules and the PV generator.

SMA Solar Technology AG recommends connecting the generator frame and other

electricity conducting surfaces so that there is continuous conduction and to ground them

in order to achieve maximum protection of the system and personnel.

12 SB12-17-IA-en-52 Installation Guide

Page 13

SMA Solar Technology AG Safety

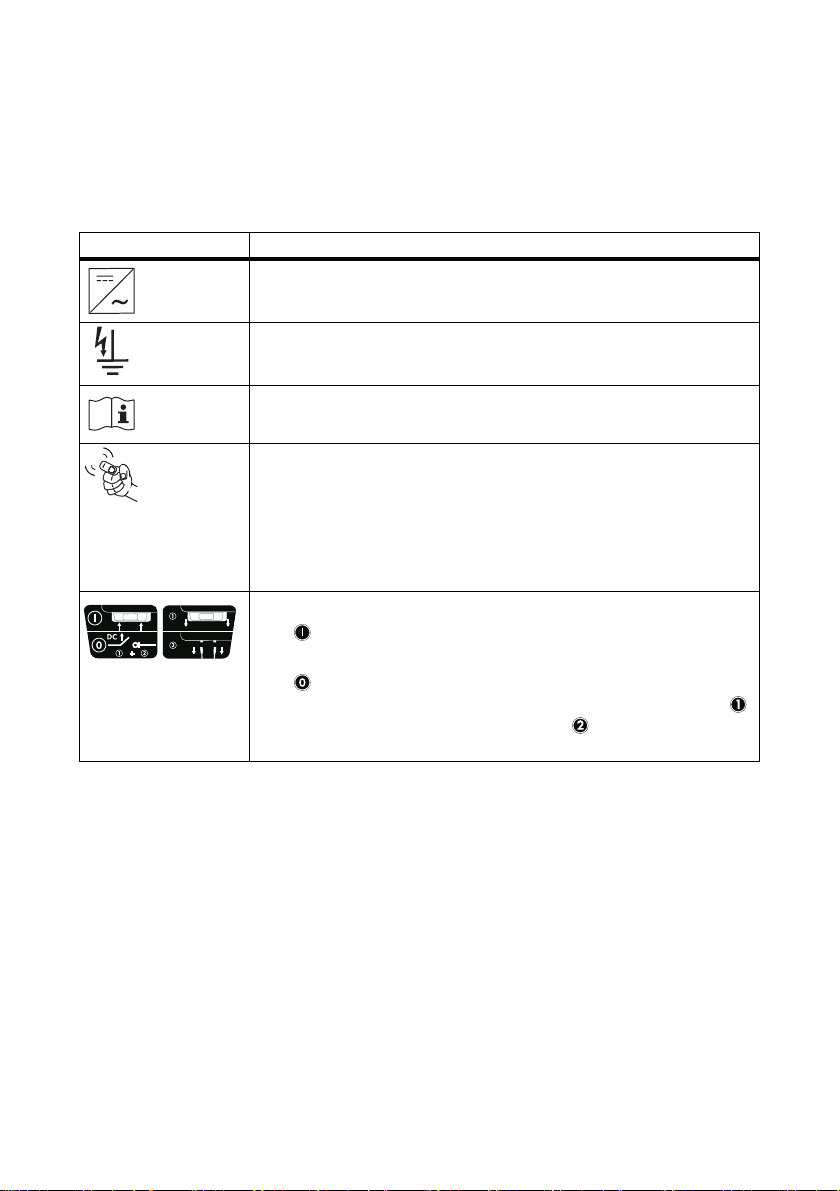

2.3 Explanation of Symbols

This chapter contains an explanation of all symbols found on the inverter and type label.

2.3.1 Symbols on the Inverter

Symbol Explanation

Operation display.

Indicates the operation condition of the inverter.

Ground fault or varistor defective.

Read section 9.3”Red LED is Glowing Continuously” (page56).

Disturbance or fault.

Read section 9”Failure Search” (page52).

You can operate the display by tapping it:

• 1 tap: the backlight is switched on, or the display switches to the next

screen.

• 2 taps in quick succession: the inverter shows the display messages

from the initialization phase again (see section 6.2”Display

Messages during Initialization” (page39)).

Electronic Solar Switch (ESS) DC load disconnection unit

• When the Electronic Solar Switch is plugged in, the DC circuit is

closed.

• To interrupt the DC circuit and disconnect the inverter securely

under load, you have to first pull out the Electronic Solar Switch

and then remove all DC plug connectors , as described in section

7.2”Opening the Inverter” (page45).

Installation Guide SB12-17-IA-en-52 13

Page 14

Safety SMA Solar Technology AG

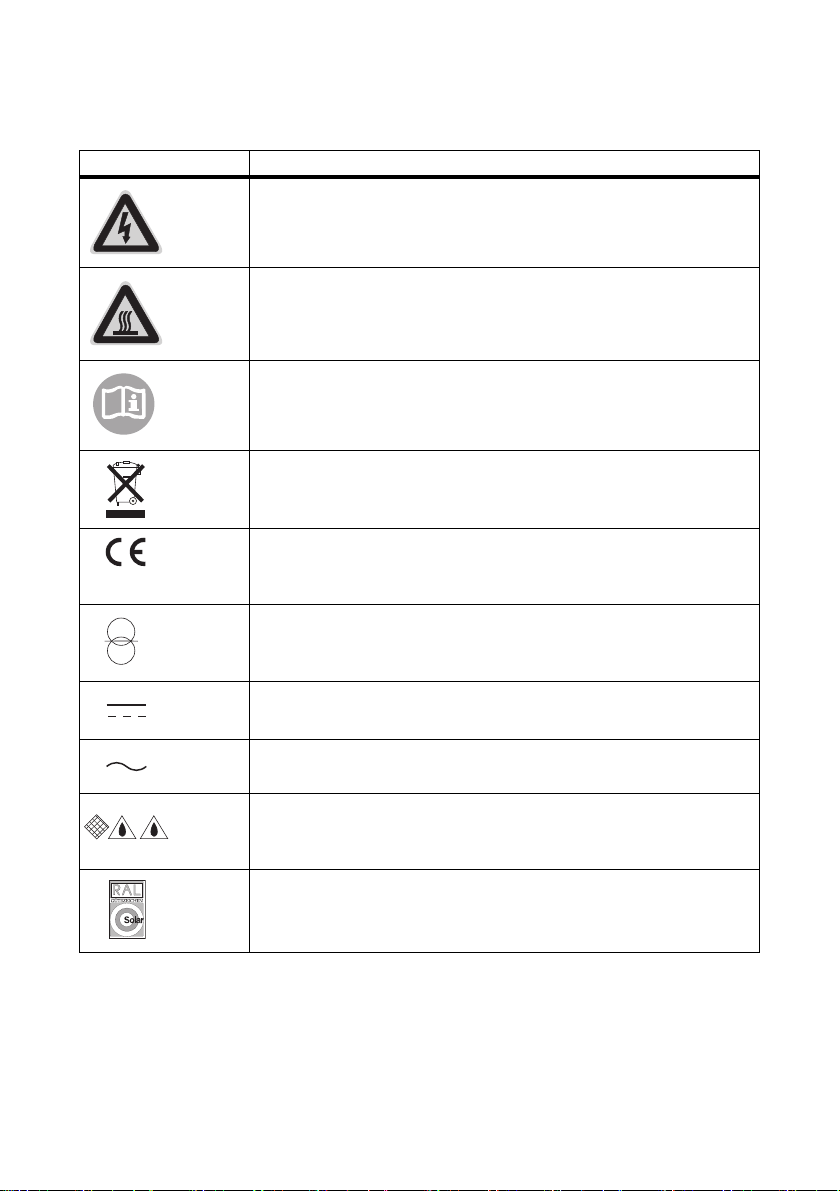

2.3.2 Symbols on the Type Label

Symbol Explanation

Beware of dangerous electrical voltage.

The inverter operates at high voltages. All work on the inverter must be

carried out by qualified personnel only.

Beware of hot surface.

The inverter can become hot during operation. Avoid contact during

operation.

Observe all documentation that accompanies the inverter.

The inverter must not be disposed of with the household waste. For more

information on disposal, see section 10.4”Disposing of the Inverter”

(page62).

CE mark.

The inverter complies with the requirements of the applicable EC

guidelines.

The inverter has a transformer.

Direct Current (DC)

Alternating current (AC)

Protection rating IP65.

The inverter is protected against penetration by dust particles and water

jets from any angle.

RAL quality mark for solar products.

The inverter complies with the requirements of the German Institute for

Quality Assurance and Labeling.

14 SB12-17-IA-en-52 Installation Guide

Page 15

SMA Solar Technology AG Unpacking

3 Unpacking

3.1 Scope of Delivery

Check the delivery for completeness and for any visible external damage. Contact your dealer if

anything is damaged or missing.

Object Quantity Description

A 1Sunny Boy

B 1 Wall mounting bracket

C 1 Electronic Solar Switch (ESS)

D 4 DC plug connectors (2 x positive/2 x negative)

E 4 Sealing plugs for DC plug connectors

F 1 Protective cap for AC socket on inverter

G 1 AC connection socket: socket unit, threaded sleeve, pressure

screw PG13.5, sealing ring PG13.5, fastening case PG13.5,

cable gland PG16

H 1 M6x12 cylinder head screw and locking washer

I 1Jumper

K 1 Installation guide

L 1 User manual

M 1Set of documents with explanations and certificates

N 1 Supplementary sheet with inverter factory settings

3.2 Identifying the Inverter

You can identify the inverter by the type label. The type label is on the right side of the enclosure.

The serial number (Serial No.) and the type (Type / Model) of the product, as well as device-specific

characteristics are specified on the type label.

Installation Guide SB12-17-IA-en-52 15

Page 16

Mounting the Device SMA Solar Technology AG

4 Mounting the Device

4.1 Safety

DANGER!

Danger to life due to fire or explosion!

Despite careful construction, electrical devices can cause fires.

• Do not mount the inverter on flammable construction materials.

• Do not mount the inverter in areas where highly flammable materials are stored.

• Do not mount the inverter in areas with a risk of explosion.

CAUTION!

Danger of burn injuries due to hot enclosure parts.

• Mount the inverter in such a way that the enclosure cannot be touched inadvertently.

CAUTION!

Risk of injury due to the heavy weight of the inverter.

• Take the inverter's weight of approx. 25 kg into account for mounting.

4.2 Selecting the Mounting Location

Consider the following points when selecting where to install:

• The installation method and mounting location must be suitable for the inverter's weight and

dimensions (see section 11”Technical Data” (page63)).

• Mount on a solid surface.

• The mounting location must at all times be clear and have safe access without the use of

additional aids such as scaffolding or lifting platforms. Any possible service actions are

otherwise limited.

• Vertical installation or tilted backward by max. 45°.

• The connection area must point downward.

• Never install the device with a forward tilt.

16 SB12-17-IA-en-52 Installation Guide

Page 17

SMA Solar Technology AG Mounting the Device

• Never install the device with a sideways tilt.

• Do not install horizontally.

• Install at eye level in order to allow operating state to be read at all times.

• To ensure optimal operation, the ambient temperature should be below 40 °C.

• Do not expose the inverter to direct sunlight to avoid a power reduction due to excessive

heating.

• I n a l ivi ng a rea, do n ot m oun t th e unit on pla ste rbo ard wal ls ( or s imilar) in o rde r to avo id a udible

vibrations. The inverter can make noises when in use which may be perceived as a nuisance in

a living area.

• Observe the minimum clearances to walls, other

inverters or objects as shown in the diagram in

order to ensure sufficient heat dissipation and

sufficient space for the removal of the Electronic

Solar Switch.

Multiple inverters installed in areas with high ambient temperatures

If necessary, increase the clearances and make sure there is enough ventilation to ensure

sufficient cooling of the inverters.

Installation Guide SB12-17-IA-en-52 17

Page 18

Mounting the Device SMA Solar Technology AG

4.3 Mounting the Inverter with Wall Mounting Bracket

CAUTION!

Risk of injury due to the heavy weight of the inverter.

• Take the inverter's weight of approx. 25 kg into account for mounting.

• When mounting the bracket, use fastening material suitable for the material.

1. Use the wall mounting bracket as a drilling template and mark the positions of the drill holes.

2. Attach the wall mounting bracket to the wall using

appropriate screws and washers.

18 SB12-17-IA-en-52 Installation Guide

Page 19

SMA Solar Technology AG Mounting the Device

3. Use the upper mounting clips to fit the inverter in the

wall mounting bracket so that it cannot be pushed

out of the wall mounting bracket from the side.

4. If a second grounding conductor is required in the

country of installation, you need to ground the

inverter and secure it against being lifted out of

place, as described in section 5.2.3”Connecting

additional grounding” (page27).

5. . If a second grounding conductor is not required,

secure the inverter against being lifted out of place

using the enclosed M6x12 screw.

6. Check to ensure the inverter is firmly fastened.

☑ The inverter is now mounted to the wall.

Installation Guide SB12-17-IA-en-52 19

Page 20

Electrical Connection SMA Solar Technology AG

5 Electrical Connection

NOTICE!

Electrostatic discharges can damage the inverter!

Internal components of the inverter can be irreparably damaged by static discharge.

• Ground yourself before touching a component.

5.1 Overview of the Connection Area

5.1.1 Exterior View

The following figure shows the assignment of the individual connection areas on the bottom of the

inverter.

Object Description

A DC connectors for connecting the PV strings

B Socket for connecting the Electronic Solar Switch (ESS) DC load disconnection unit

C Enclosure opening with sealing plugs for communication

D Socket for AC Connection

20 SB12-17-IA-en-52 Installation Guide

Page 21

SMA Solar Technology AG Electrical Connection

5.1.2 Interior View

The following illustration shows the various components and connection areas of the open inverter.

Object Description

A Varistors

B Connection area and sockets for optional communication via RS485 or radio

C Display

D PE connection cable for the lid

E Operating status LEDs

F Socket for AC Connection

G Tab for grounding the cable shield with RS485 communication

H DC plug connectors

I Electronic Solar Switch (ESS) socket

Installation Guide SB12-17-IA-en-52 21

Page 22

Electrical Connection SMA Solar Technology AG

5.2 Connection to the Public Grid (AC)

5.2.1 Conditions for the AC Connection

Connection requirements of the utility operator

Comply with the connection requirements of your utility operator!

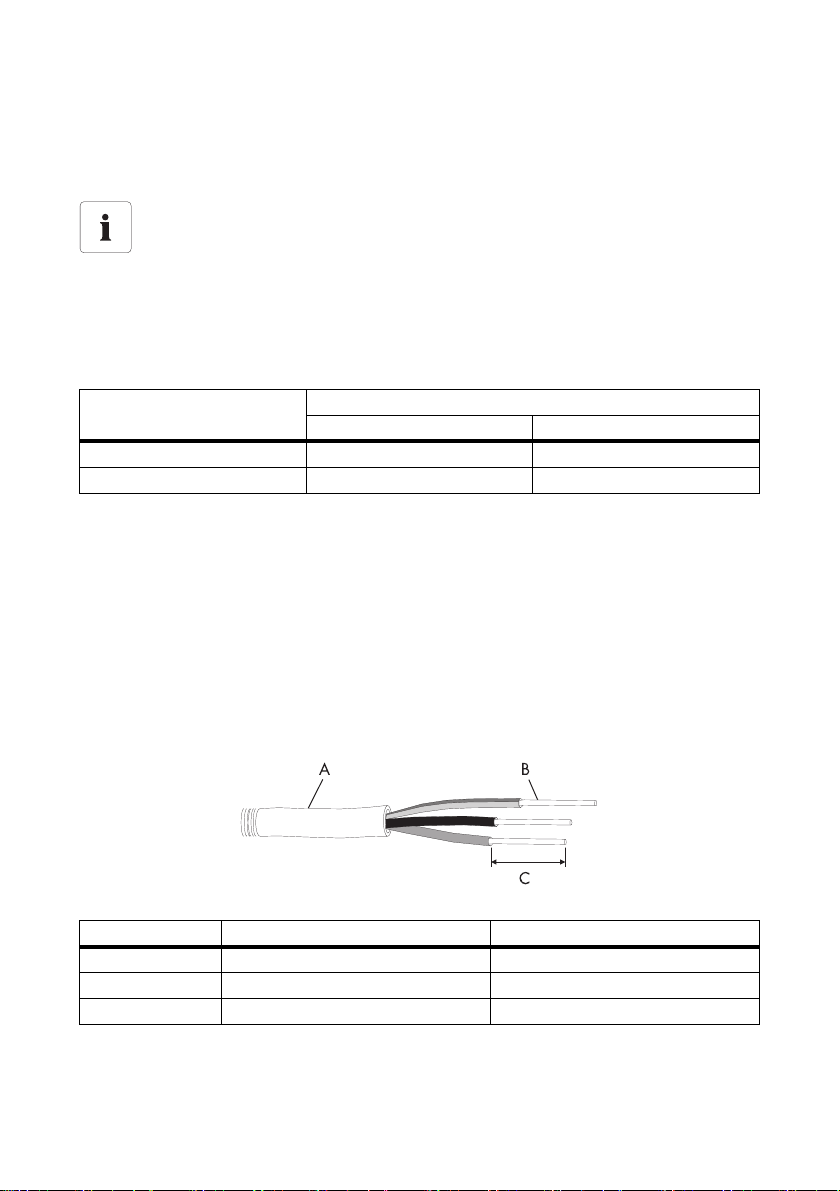

Cable Sizing

The conductor cross-sectional area should be dimensioned so output losses do not exceed 1 % at

nominal power.

The maximum wire lengths relative to the conductor cross-section are shown in the following table.

Conductor cross-section Maximum wire length

SB 1200 SB 1700

1.5 mm² 18 m 15 m

2.5 mm² 30 m 22.5 m

The conductor cross-sectional area required in individual cases depends on the following factors

among others:

• Ambient temperature,

•Routing method,

•UV resistance,

•Conduction losses,

• Valid installation guidelines of the respective country (of the installation location).

Cable Requirements

Position Description Value

A External diameter 9 mm …17 mm

B Conductor cross-section max. 2.5 mm²

C Strip insulation 4 mm … 5 mm

22 SB12-17-IA-en-52 Installation Guide

Page 23

SMA Solar Technology AG Electrical Connection

Load Disconnection Unit

You must install a separate line circuit breaker for each inverter in order to ensure that the inverter

can be securely disconnected under load. The maximum permissible rating is located in section

11”Technical Data” (page63).

De tai led inf orm ation an d ex amp les for the rating o f a l ine cir cuit breaker can be found in the Technical

Information "Line Circuit Breaker" in the SMA Solar Technology AG download area at

www.SMA.de/en.

DANGER!

Danger to life due to fire.

When more than one inverter is connected to the same line circuit breaker, the protective

function of the line circuit breaker is no longer guaranteed. It can result in a cable fire or

the destruction of the inverter.

• Never connect several inverters to a single line circuit breaker.

• Comply with the maximum permissible fuse protection of the inverter when selecting

the circuit breaker.

DANGER!

Danger to life due to fire.

When a generator (inverter) and a consumer are connected to the same line circuit

breaker, the protective function of the line circuit breaker is no longer guaranteed. The

current from the inverter and the grid can accumulate to overcurrent, which is not detected

by the line circuit breaker.

• Never connect loads between the

inverter and the line circuit breaker

without protection.

• Always protect consumers separately.

NOTICE!

Damage to the inverter by using screw type fuse elements as a load

disconnection unit!

A screw type fuse element, e.g. D system (Diazed) or D0 system (Neozed) is not a circuit

breaker, and may not be used as a load disconnection unit. A screw type fuse element is

only used as cable protection.

When disconnecting under load using a screw type fuse element, the inverter can be

damaged.

• U se o nly a lo ad disco nnec tin g sw itc h or a lin e ci rcu it b rea ker as a load disconnecting

unit.

Installation Guide SB12-17-IA-en-52 23

Page 24

Electrical Connection SMA Solar Technology AG

5.2.2 Connecting the Inverter to the Public Grid (AC)

Overview AC connection socket

Object Description

A Socket element

B Threaded sleeve

C Sealing ring PG13.5

D Fastening case PG13.5

E Pressure screw for PG 13.5 (for a cable diameter between 9 mm … 13.5 mm)

F Cable gland PG 16 (for a cable diameter between 13.5 and 17 mm)

Procedure

1. Choose an appropriate screw fitting for the AC cable.

2. Check the grid voltage and compare with "V

The exact operating range of the inverter is specified in the operating parameters. The

corresponding document is located in the download area at www.SMA.de/en, in the

"Technical Description" category of the respective inverter.

3. Switch off the line circuit breaker, secure against reconnection, and make sure no voltage is

present.

4. Strip approx. 30 mm from the AC cable.

5. Shorten L and N by 5 mm.

6. Strip the wires of the cable by 4 to 5 mm.

24 SB12-17-IA-en-52 Installation Guide

" on the type label.

AC nom

Page 25

SMA Solar Technology AG Electrical Connection

7. Pass the pressure screw and/or cable gland and socket tube over the AC cable.

Size used Procedure

PG13.5 • Push the sealing ring into the

fastening case.

• Lead the pressure screw

PG13.5 and the fastening

case including the sealing

ring over the AC cable.

• Lead threaded sleeve over

the AC cable.

PG16 • Pass the cable gland PG16

over the AC cable.

• Lead threaded sleeve over

the AC cable.

8. Insert the protective earth PE (green-yellow) in the

screw terminal with the earth sign on the socket

element and tighten the screw.

9. Insert the neutral conductor N (blue) in the screw

terminal 1 on the socket and tighten the screw.

10. Place phase L (brown or black) into screw

terminal2 on the socket insert and tighten the

screw.

11. Terminal 3 on the socket element remains unused.

12. Make sure the wires are securely connected.

Installation Guide SB12-17-IA-en-52 25

Page 26

Electrical Connection SMA Solar Technology AG

13. Screw the threaded sleeve onto the socket element.

14. Tighten the pressure screw or cable gland tightly onto the threaded sleeve.

Size used Procedure

PG13.5

The fastening case along with the sealing ring is pressed into the threaded

sleeve and can no longer be seen.

PG16 • Retighten the lock nut of the

cable gland.

☑ The AC connection socket has been screwed together.

15. If the AC connection socket is not immediately connected to the inverter, close the AC socket on

the inverter with the protective cap provided.

16. Insert the AC connection socket into the AC socket

on the inverter. Remove the protective cap

beforehand as required.

17. Turn the threaded ring of the AC connection socket

tightly onto the AC socket on the inverter. The

threaded ring serves to seal and relieve strain on

the AC connection socket.

☑ The AC cable is now connected to the inverter.

DANGER!

Danger to life due to high voltages in the inverter.

• Do not switch on the line circuit breaker until the PV generator has been connected

and the inverter is securely closed.

26 SB12-17-IA-en-52 Installation Guide

Page 27

SMA Solar Technology AG Electrical Connection

5.2.3 Connecting additional grounding

If a second grounding conductor, additional grounding or potential equalization is required, you may

also ground the inverter on the enclosure.

Additional grounding overview

Object Description

A M6x12 cylinder head screw (included in the scope of delivery)

B Washer

C Terminal lug (M6) with grounding conductor

D Locking washer (included in scope of delivery)

E Metal shackle on the underside of the enclosure

F Wall bracket of the inverter

Procedure

1. Fit the washer, terminal lug with grounding

conductor and locking washer onto the cylinder

head screw. The toothing of the locking washer

must face toward the metal shackle.

2. Insert the cylinder head screw into the metal

shackle on the underside of the enclosure and

screw into the wall bracket. Tighten the cylinder

head screw using a torque of 6 Nm.

3. Check that the contact between the grounding

conductor and the enclosure is in accordance with

the regulations valid for the country of installation.

Installation Guide SB12-17-IA-en-52 27

Page 28

Electrical Connection SMA Solar Technology AG

5.3 Setting the Display Language

You can set the language of the display using the switches on the underside of the display assembly

inside the inverter.

Procedure

1. Open the inverter as described in section 7.2”Opening the Inverter” (page45).

2. Set the switches for the required language, as

shown below.

Language Switch S2 Switch S1

German B B

English B A

French A B

Spanish A A

For type SB 1200-IT/1700-IT inverters, the following switch settings apply for firmware version

3.06 and higher:

Language Switch S2 Switch S1

German B B

Italian B A

French A B

English A A

3. Close the inverter as described in section 7.3”Closing the Inverter” (page48).

☑ The display language has now been set.

28 SB12-17-IA-en-52 Installation Guide

Page 29

SMA Solar Technology AG Electrical Connection

5.4 PV generator connection (DC)

5.4.1 Conditions for the DC Connection

Use of Adaptors

Adaptors (branch connectors) must not be visible or freely accessible in the immediate

surroundings of the inverter.

• The DC current flow may not be interrupted via adaptors.

• Observe the procedure for disconnecting the inverter as described in section

7.2”Opening the Inverter” (page45).

• Requirements for the PV modules of the connected strings:

– Same type

–Same number

– Identical alignment

– Identical tilt

• The connecting cables from the PV modules must be fitted with plug connectors. You will find

the necessary DC plug connector for DC connection in the delivery.

• The following limiting values at the DC input of the inverter may not be exceeded:

Inverter Maximum input voltage Maximum input current

SB 1200 400 V (DC) 12.6 A (DC)

SB 1700 400 V (DC) 12.6 A (DC)

DANGER!

Risk of lethal electric shock or fire.

The maximum possible input current per string is limited by the plug connectors used. If the

plug connector is overloaded, an electric arc may occur and there is a fire risk.

• Ensure that the input current for each string does not exceed the maximum flow

current of the plug connectors used.

Installation Guide SB12-17-IA-en-52 29

Page 30

Electrical Connection SMA Solar Technology AG

5.4.2 Assembling the DC Plug Connector

In order to connect to the inverter, all connecting cables of the PV modules must be equipped with the

DC plug connectors provided.

To assemble the DC plug connectors, proceed as detailed below. Ensure the plug connectors have

the correct polarity. The DC plug connectors are marked with "+" and " − ".

Cable requirements:

• Use a PV1-F cable.

Procedure

1. Insert stripped cable into the plug up to the limit.

2. Press the clamping clip downward until you hear an

audible click.

3. Ensure the cable is correctly in place.

Result Action

☑ If the conductors are visible in the hollow

cavity of the clamp, the cable is in the

correct position.

30 SB12-17-IA-en-52 Installation Guide

• Proceed to step 4.

Page 31

SMA Solar Technology AG Electrical Connection

Result Action

☑ If the conductors are not visible in the

hollow cavity of the clamp, the cable is not

• Declamp the clamping clip. Use a

screwdriver with a width of 3.5 mm.

in the correct position.

• Remove cable and start again from step 1.

4. Push the threaded joint to the thread and screw into place with a torque of 2 Nm.

☑ The DC plug connectors are now assembled and can be connected to the inverters, as

described in section 5.4.4”Connecting the PV Generator (DC)” (page33).

Installation Guide SB12-17-IA-en-52 31

Page 32

Electrical Connection SMA Solar Technology AG

5.4.3 Opening the DC Plug Connector

1. Screw the threaded joint off.

2. To release the plug connector, slot a screw driver

into the side catch mechanism and lever out.Use a

screwdriver with a width of 3.5 mm.

3. Carefully pull the DC plug connector apart.

4. Declamp the clamping clip. Use a screwdriver with

a width of 3.5 mm.

5. Remove the cable.

☑ The cable is now removed from the DC plug connector.

32 SB12-17-IA-en-52 Installation Guide

Page 33

SMA Solar Technology AG Electrical Connection

5.4.4 Connecting the PV Generator (DC)

DANGER!

Danger to life due to high voltages in the inverter.

• Before connecting the PV generator, ensure that the line circuit breaker is switched

off.

NOTICE!

Excessive voltages can destroy the measuring device.

• Only use measuring devices with a DC input voltage range up to at least 1000 V.

1. Disconnect the line circuit breaker and secure against re-connection.

2. Pull the Electronic Solar Switch downward, slightly

toward the wall.

3. Check the connection cables of the PV modules for

co rre ct pola rit y an d that th e ma ximum in put vo lta ge

of the inverter is not exceeded.

At an ambient temperature above 10 °C, the open

circuit voltage of the PV modules must not be more

than 90 % of the maximum inverter input voltage.

Otherwise, check the system design and the PV

mo dul e co nne cti on. If this i s no t do ne, the max imu m

inverter input voltage can be exceeded at low

temperatures.

NOTICE!

Exceeding the maximum input voltage can destroy the inverter!

If the voltage of the PV modules exceeds the maximum input voltage of the inverter, it can

be destroyed by the overvoltage. All warranty claims become void.

• Do not connect strings with an open circuit voltage greater than the maximum input

voltage of the inverter.

• Check the system design.

Installation Guide SB12-17-IA-en-52 33

Page 34

Electrical Connection SMA Solar Technology AG

4. Check the strings for ground faults, as described in section 9.3.1”Checking the PV Generator

for a Ground Fault” (page57).

DANGER!

Risk of lethal electric shock.

• Do not connect strings with ground faults.

•First, rectify the ground fault in the respective string.

5. Check the DC plug connector for correct polarity and connect it.

To release the plug connectors see section 7.2”Opening the Inverter” (page45).

6. To create the sealing on the inverter, all the DC

inputs that are not needed must be closed as

follows:

– Insert the sealing plugs provided into the DC

plug connectors that are not required.

Do not insert the sealing plus into the DC inputs

on the inverter.

– Insert the DC plug connectors with sealing plugs

into t he correspo nding DC inputs on th e inver ter.

34 SB12-17-IA-en-52 Installation Guide

Page 35

SMA Solar Technology AG Electrical Connection

7. Check the Electronic Solar Switch for wear, as

described in section 8.1”Checking the Electronic

Solar Switch for Wear” (page50) and reattach it

firmly.

NOTICE!

Damage to the inverter due to moisture and dust intrusion

If the Electronic Solar Switch is not plugged in or incorrectly plugged in during operation,

moisture and dust can penetrate the inverter.

If the Electronic Solar Switch is not correctly plugged in, this can cause contacts to wear in

the Electronic Solar Switch or the Electronic Solar Switch might fall down. This can result in

yield loss and damage to the Electronic Solar Switch.

Always plug in the Electronic Solar Switch as described in the following:

• Do not tighten the screw in the Electronic Solar Switch.

• Firmly plug in the Electronic Solar Switch until it is flush with the enclosure.

• Ensure that the maximum distance between the Electronic Solar Switch and the

enclosure is 1 mm.

☑ The PV generator is now connected.

Installation Guide SB12-17-IA-en-52 35

Page 36

Electrical Connection SMA Solar Technology AG

5.5 Communication

The inverter is equipped with a slot for communication interfaces in order to communicate with special

data a cquisi tion device s (e.g. Sunny WebBox ) or a PC with corre sponding software (e.g. Sunny Data

Control or Sunny Explorer).

Refer to the communication interface manual for a detailed wiring diagram and a description of the

mounting.

5.6 Setting the Grid and Country Parameters

Changing Grid-Relevant and Country Parameters

To change grid-relevant parameters, you need a personal access code - the so-called

SMA Grid Guard Code. The application form for the personal access code is located in

the download area at www.SMA.de/en, in the "Certificate" category for each inverter.

Ensure that you discuss the changes to these parameters with your utility operator.

A detailed description of the operating parameter for the inverter is available in the download area

at www.SMA.de/en in the category "Technical Description" of the respective inverter.

5.6.1 Setting the Installation Country

Using the "Default" parameter you can set the installation country and/or the grid connection

standard valid for the country via a communication device (e.g. Sunny WebBox) or a PC with

appropriate software (e.g. Sunny Data Control or Sunny Explorer). This, however, is only required if

the inverter was origi nally o rdered for anoth er country. You can see the standard to which the invert er

was set upon delivery from the type label and the supplementary document provided with the factory

settings.

36 SB12-17-IA-en-52 Installation Guide

Page 37

SMA Solar Technology AG Electrical Connection

5.6.2 Setting Stand-alone Grid Operation

To operate the inverter in a Sunny Island system, you must set the inverter via the "Default" parameter

to off-grid ("OFF-Grid") operation.

You have several possibilities to set the inverter to stand-alone grid operation:

• Setting via Sunny WebBox

or

• Setting via Sunny Data Control or Sunny Explorer.

DANGER!

Danger to life due to high voltages in the event of outage of the power

distribution grid.

If you set the inverter to stand-alone grid operation, it does not fulfill any country-specific

standards and regulations. Therefore, if there is an outage of the power distribution grid,

there is a danger of back-feed.

• Never operate the inverter directly on the power distribution grid when set to

stand-alone grid operation.

Installation Guide SB12-17-IA-en-52 37

Page 38

Commissioning SMA Solar Technology AG

6 Commissioning

6.1 Commissioning the Inverter

1. Check the following requirements before commissioning:

– The inverter is firmly fastened.

– Correct connection of the AC cable (grid)

– Full connection of the DC cables (PV strings)

–DC inputs that are not needed are closed with the corresponding DC plug connectors and

sealing plugs.

– The enclosure lid is securely screwed in place

– The Electronic Solar Switch (ESS) is securely plugged

–The line circuit breaker is laid out correctly

2. Switch on the line circuit breaker.

☑ Green LED glows: commissioning has been successful.

or

☑ Green LED flashes when there is insufficient irradiation: network connection conditions have

not yet been reached. Wait for sufficient irradiation.

or

☑ The red or yellow LED is glowing or flashing: there has been an error. Proceed to step 3.

A Green LED Operation

B Red LED Ground fault or varistor

defective

C Yellow LED Disturbance

Self test in accordance with DK 5940, Ed. 2.2 for initial commissioning

(applies to Italy only)

The Italian DK 5940 standard requires that an inverter can first operate on the power

distribution grid when the disconnection times for overvoltage, undervoltage, minimum

frequency and maximum frequency have been checked.

Restart the self-test as described in the following section 6.3”Self-Test in accordance with

DK 5940, Ed. 2.2 (applies to Italy only)” (page40). The test takes approx. 8 minutes.

3. Read section 9”Failure Search” (page52) and if necessary eliminate the fault or disturbance.

38 SB12-17-IA-en-52 Installation Guide

Page 39

SMA Solar Technology AG Commissioning

6.2 Display Messages during Initialization

After startup of the inverter, the display shows the inverter

type.

After 5 seconds, or when you tap again on the enclosure

cover, the firmware version of the internal processors is

displayed.

After a further 5 seconds, or when you tap again, the

configured country standard is displayed

(example: “GER/VDE0126-1-1”).

Show display messages again

In order to show the display messages from the initialization phase again during

operation,tap twice on the enclosure cover.

Installation Guide SB12-17-IA-en-52 39

Page 40

Commissioning SMA Solar Technology AG

6.3 Self-Test in accordance with DK 5940, Ed. 2.2 (applies to Italy only)

6.3.1 Starting the Self-Test by Tapping

You can start testing the disconnection times by tapping on the enclosure lid. Prerequisite here is that

the country configuration of the inverter has been set to Italy (IT/DK5940) or "trimmed". Proceed as

follows for checking the disconnection times:

1. Connect the PV generator with the inverter. The inverter can only initialize if the PV generator

produces enough power. It is therefore not possible to test the disconnection times at night.

2. Connect the inverter on the AC side. For this, you have to create the AC connection (AC plug

or direct connection) and/or switch on the line circuit breaker of the grid cable (fuse or

automatic circuit breaker).

3. The inverter is now in the initialization phase, i.e. all 3 LEDs are glowing at the same time.

Start the self-test immediately after all 3 LEDS have gone out by tapping once on the display

of the inverter.

4. The question on whether you would like to start the

test sequence appears in the display. Tap on the

display again within 30 seconds in order to confirm

the question.

Once you have started the test sequence, the inverter checks the disconnection times for overvoltage,

undervoltage, maximum frequency and minimum frequency one after the other. During the tests, the

inverter shows the values in the display which are described in section 6.3.2”Completion of the SelfTest” (page40).

6.3.2 Completion of the Self-Test

Note the values which are displayed during the self-test. These values must be entered into a test

protocol. The test results of the individual tests are displayed 3 times one after the other. The

respective display message is displayed for 10 seconds. During the test sequence, the inverter will not

react to tapping.

The self-test changes the upper and lower shut-down thresholds for each protective function on a linear

basis with a modification of 0.05 Hz/s and 0.05 Vn/s for the frequency and voltage monitoring. As

soon as the actual measurement value is outside the permitted range (altered shut-down threshold),

the inverter disconnects itself from the grid. In this way, the inverter determines the reaction time and

checks itself.

40 SB12-17-IA-en-52 Installation Guide

Page 41

SMA Solar Technology AG Commissioning

Overvoltage Test

The inverter begins with the overvoltage test. During the

test sequence, the voltage limit applied is shown in the

display of the inverter.

The voltage limit is reduced successively until the shutdown threshold is achieved and the inverter disconnects

from the grid.

Once the inverter has disconnected from the grid, the display successively shows the following values

one after the other:

•Disconnection value,

•Calibration value,

•Reaction time,

• Present grid voltage.

Installation Guide SB12-17-IA-en-52 41

Page 42

Commissioning SMA Solar Technology AG

Undervoltage Test

After the overvoltage test, the inverter performs the

undervoltage test. During the test sequence, the current

calibration value of the voltage limit applied is shown in

the display of the inverter.

The voltage limit is increased successively until the shutdown threshold is achieved and the inverter disconnects

from the grid.

Once the inverter has disconnected from the grid, the display successively shows the following values

one after the other:

•Disconnection value,

•Calibration value,

•Reaction time,

• Present grid voltage.

42 SB12-17-IA-en-52 Installation Guide

Page 43

SMA Solar Technology AG Commissioning

Maximum Frequency

In the thi rd s tep , the inv ert er t est s th e ma xim um f requenc y.

During the test sequence, the frequency limit applied is

shown in the display of the inverter.

The frequency limit is reduced successively until the shutdown threshold is achieved and the inverter disconnects

from the grid.

Once the inverter has disconnected from the grid, the display successively shows the following values

one after the other:

•Disconnection value,

•Calibration value,

•Reaction time,

• Present grid frequency.

Installation Guide SB12-17-IA-en-52 43

Page 44

Commissioning SMA Solar Technology AG

Minimum Frequency

In the last step, the inverter tests the minimum frequency.

During the test sequence, the frequency limit applied is

shown in the display of the inverter.

The frequency limit is increased successively until the shutdown threshold is achieved and the inverter disconnects

from the grid.

Once the inverter has disconnected from the grid, the display successively shows the following values

one after the other:

•Disconnection value,

•Calibration value,

•Reaction time,

• Present grid frequency.

When the inverter has carried out the 4 tests, it switches to MPP operation mode ("MPP"). The original

calibration values are then re-set and the inverter automatically connects to the grid. If you would like

to carry out the test again, you have to disconnect the inverter, in other words you have to disconnect

it on the AC and DC sides and then later re-activate it. You can then restart the self-test as described

in the following section 6.3.1”Starting the Self-Test by Tapping” (page40). The inverter begins the

test sequence again, as described in section 6.3.2”Completion of the Self-Test” (page40).

44 SB12-17-IA-en-52 Installation Guide

Page 45

SMA Solar Technology AG Opening and Closing

7 Opening and Closing

7.1 Safety

DANGER!

Risk of lethal electric shock.

Observe the following before opening the inverter:

• Ensure the AC side is not live.

• Ensure the DC side is not live.

NOTICE!

Electrostatic discharges can damage the inverter!

Internal components of the inverter can be irreparably damaged by electrostatic

discharge.

• Ground yourself before touching a component.

7.2 Opening the Inverter

1. Disconnect the line circuit breaker and secure against re-connection.

2. Pull the Electronic Solar Switch downwards, slightly

towards the wall.

3. Using a current probe, ensure that there is no

current to all DC cables.

☑ If there is a current present, check the

installation.

Installation Guide SB12-17-IA-en-52 45

Page 46

Opening and Closing SMA Solar Technology AG

4. Unlock all the DC plug connectors: Use a

screwdriver with a width of 3.5 mm.

– Insert a screwdriver into one of the side slits (1).

– Disconnect the DC plug connectors (2).

DANGER!

Danger to life due to unsafe disconnection from the PV generator!

A secure separation from the PV generator is only guaranteed after pulling off the

Electronic Solar Switch and all DC plug connectors.

• Remove all DC plug connectors to

completely disconnect the PV generator

from the inverter.

5. Pull out the AC plug.

46 SB12-17-IA-en-52 Installation Guide

Page 47

SMA Solar Technology AG Opening and Closing

6. Check whether all LEDs and the display have gone out.

DANGER!

Danger to life due to high voltages in the inverter.

The capacitors in the inverter require 15 minutes to discharge.

• Wait 15 minutes before opening the inverter.

7. Ensure that there is no voltage at the DC plugs at

the inverter.

☑ If there is a voltage present, check the

installation.

8. Remove all screws from the enclosure lid and pull

the lid forward smoothly.

9. Remove the protective conductor (PE) connection

from the lid by loosening the locking device of the

PE connection on the lid.

☑ The inverter is now open and is not live.

Installation Guide SB12-17-IA-en-52 47

Page 48

Opening and Closing SMA Solar Technology AG

7.3 Closing the Inverter

1. Reconnect the protective conductor (PE) connection to the enclosure lid.

2. Secure the enclosure lid of the inverter by evenly

tightening the 4 lid screws.

3. Check the DC plug connector for correct polarity and connect it.

To release the plug connectors see section 7.2”Opening the Inverter” (page45).

4. Close all unnecessary DC inputs as described in section 5.4.4”Connecting the PV Generator

(DC)” (page33) to seal the inverter.

5. Pull out the AC plug.

48 SB12-17-IA-en-52 Installation Guide

Page 49

SMA Solar Technology AG Opening and Closing

6. Check the Electronic Solar Switch for wear, as

described in section 8.1”Checking the Electronic

Solar Switch for Wear” (page50) and reattach it

firmly.

NOTICE!

Damage to the inverter due to moisture and dust intrusion

If the Electronic Solar Switch is not plugged in or incorrectly plugged in during operation,

moisture and dust can penetrate the inverter.

If the Electronic Solar Switch is not correctly plugged in, this can cause contacts to wear in

the Electronic Solar Switch or the Electronic Solar Switch might fall down. This can result in

yield loss and damage to the Electronic Solar Switch.

Always plug in the Electronic Solar Switch as described in the following:

• Do not tighten the screw in the Electronic Solar Switch.

• Firmly plug in the Electronic Solar Switch until it is flush with the enclosure.

• Ensure that the maximum distance between the Electronic Solar Switch and the

enclosure is 1 mm.

7. Switch on the line circuit breaker.

8. Check whether the display and the LEDs indicate

normal operating mode (see section

6”Commissioning” (page38)).

☑ The inverter is now closed and in operation.

Installation Guide SB12-17-IA-en-52 49

Page 50

Maintenance and Cleaning SMA Solar Technology AG

8 Maintenance and Cleaning

Check for proper inverter operation at regular intervals. Impurities such as dust or pollen can cause

heat accumulation that can lead to yield losses. Also check the inverters and the cables for visible

external damage. Undertake repairs if necessary.

8.1 Checking the Electronic Solar Switch for Wear

Check the Electronic Solar Switch for wear before plugging it in. Depending on the shape of the

Electronic Solar Switch, you can estimate the wear on either the metal tongues (shape A) or on the

plastic (shape B).

Result Action

☑ The metal tongues in the Electronic Solar

Switch are undamaged and not discolored

(A).

or

☑ The plastic in the Electronic Solar Switch is

undamaged (B).

1. Securely attach the Electronic Solar Switch

handle.

2. Commission the inverter as described in

section 6”Commissioning” (page38).

50 SB12-17-IA-en-52 Installation Guide

Page 51

SMA Solar Technology AG Maintenance and Cleaning

Result Action

☑ The metal tongues in the Electronic Solar

Switch have a brown discoloration or are

burned through (A).

or

☑The plastic in the Electronic Solar Switch

shows thermal deformation (B).

Th e El ectroni c So lar Switch c an n o longer rel iab ly

disconnect the DC side.

1. Replace the Electronic Solar Switch handle

before attaching it again (for the order

number see section 12”Accessories”

(page69).

2. Commission the inverter as described in

section 6”Commissioning” (page38).

Installation Guide SB12-17-IA-en-52 51

Page 52

Failure Search SMA Solar Technology AG

9 Failure Search

If the inverter displays blink codes or error messages other than those described in the following

section, contact the SMA Serviceline.

In the user manual provided, you will also find a description of the display messages during operation,

the status messages and measuring channels.

Do not try to carry out repairs other than those described here. Instead, use the SMA Solar

Technology AG 24-hour replacement service (the inverter will be ready for dispatch within 24 hours

and sent to a forwarding agency) and repair service

9.1 LED Codes

Green Red Yellow Status

Glows continuously Is not glowing Is not glowing OK (feeding operation)

Glows continuously Is not glowing Ground fault or varistor

defective

Glows continuously OK (initialization)

Flashes quickly

(3 x per second)

Flashes slowly

(1 x per second)

Briefly goes out

(Approx. 1x per

second)

Is not glowing Is not glowing Is not glowing OK (nighttime deactivation)

Is not glowing Is not glowing OK (stop)

Glows continuously Is not glowing Ground fault or varistor

defective

Is not glowing Is not glowing OK (waiting, grid monitoring)

Glows continuously Is not glowing Ground fault or varistor

defective

Is not glowing Is not glowing OK (derating)

Glows continuously Is not glowing Ground fault or varistor

defective

Glowing/flashing Disturbance

Glows continuously Is not glowing Ground fault or varistor

defective

Glowing/flashing Ground fault or varistor

defective and disturbance

52 SB12-17-IA-en-52 Installation Guide

Page 53

SMA Solar Technology AG Failure Search

9.2 Error Messages

Wh en a dis tur ban ce o ccu rs, the i nverter generates a message, which dep end s on the ope rat ing mod e

and the type of the detected disturbance.

Message Description and corrective measure

!PV-Overvoltage!

!DISCONNECT DC!

ACVtgRPro The 10-minute-average grid voltage is no longer within the permissible

Bfr-Srr Internal measurement comparison fault or hardware defect.

Overvoltage at DC input.

Overvoltage can destroy the inverter.

Corrective measures

Disconnect the inverter from the grid immediately.

1. Turn off the line circuit breaker.

2. Remove the Electronic Solar Switch.

3. Disconnect all the DC plug connectors.

4. Check DC voltage:

– If the DC voltage exceeds the maximum input voltage, check the

plant design or contact the person who installed the PV

generator.

– If the DC voltage is under the maximum input voltage, reconnect

the inverter to the PV generator as described in section 5.4”PV

generator connection (DC)” (page29).

If the message occurs again, disconnect the inverter again and contact

the SMA Serviceline (see section 13”Contact” (page70)).

range. This can have the following causes:

• The grid voltage at the connection point is too high.

• The grid impedance at the connection point is too high.

The inverter disconnects to assure compliance with the voltage quality of

the grid.

Corrective measures

Check the grid voltage at the connection point of the inverter:

• If, due to the local grid conditions, the grid voltage is 253 V or

more, ask the utility operator whether the voltage at the feed-in

point can b e adjus ted, or whet her it would a gree to an al teration of

the threshold value of the ACVtgRPro parameter to monitor the

voltage quality.

• If the grid voltage is continually within the acceptable range and

this error is still displayed, contact the SMA Serviceline.

Corrective measures

• If this fault occurs often, contact the SMA Serviceline.

Installation Guide SB12-17-IA-en-52 53

Page 54

Failure Search SMA Solar Technology AG

Message Description and corrective measure

EEPROM Transition disturbance while data is being written or read from EEPROM.

The data is not relevant for safe operation

The disturbance has no effect on the performance of the inverter.

EEPROM dBh EEPROM data is defective, the device has switched off because the loss

of data has disabled important functions of the inverter.

Corrective measures

• Contact the SMA Serviceline.

EeRestore One of the duplicate data sets in the EEPROM is defective and has been

reconstructed without loss of data.

• The error message only serves to inform you and has no effect on

the performance of the inverter.

Fac-Bfr

Fac-Srr

FacFast

The grid frequen cy is n o longe r within the perm issib le rang e ("Bfr" or "Srr"

is an internal message of no relevance for the user).

For safety reasons, the inverter disconnects itself from the grid.

Corrective measures

• Check the grid connection and contact the utility operator if

necessary

• If the grid frequency is within the tolerance range, yet "Fac-Bfr",

"Fac-Srr" or "FacFast" faults are still being displayed, contact the

SMA Serviceline.

Imax

overcurrent

Overcurrent on the AC side. This fault code is displayed if the current in

the AC grid is larger than specified.

Corrective measures

• Check the system design and grid conditions.

K1-Close

K1-Open

Fault during relay test.

Corrective measures

• Contact the SMA Serviceline if this problem occurs often or several

times in succession.

MSD-FAC

MSD-VAC

MSD-Timeout

Internal measurement comparison fault or hardware defect.

Corrective measures

• If this fault occurs often, contact the SMA Serviceline.

Offset The "Offset" operating condition is a normal operating condition that

occurs prior to grid monitoring. If "Offset" is displayed as an error, then

there is a disturbance in the data logging.

Corrective measures

• If this fault occurs often, contact the SMA Serviceline.

54 SB12-17-IA-en-52 Installation Guide

Page 55

SMA Solar Technology AG Failure Search

Message Description and corrective measure

Riso The electrical insulation between the PV plant and ground is faulty. The

re sis tance be twe en the DC plu s and/or DC m inus con nec tion and ground

is outside the defined limit range.

Corrective measures

• Check the plant insulation.

• Check the plant for ground faults as described in section

9.3.1”Checking the PV Generator for a Ground Fault” (page57).

ROM The inverter's firmware is faulty.

Corrective measures

• If this fault occurs often, contact the SMA Serviceline.

Shutdown Temporary inverter fault.

Corrective measures

• Contact the SMA Serviceline.

Vac-Bfr

Vac-Srr

The grid voltage is no longer within the permissible range ("Bfr" or "Srr" is

an internal message of no relevance for the user). This code can be

caused by any of the following conditions:

• Grid disconnected (line circuit breaker, fuse),

•AC cable is broken or

• AC cable is highly resistive

For safety reasons, the inverter disconnects itself from the grid.

Corrective measures

• Check the grid current and grid connection on the inverter.

• If the grid voltage lies outside the acceptable range because of

local grid conditions, ask the utility provider if the voltage can be

adjusted at the feed-in point or if it would agree to changes in the

values of the monitored operational limits (operating parameters:

Uac-Min and Uac-Max).

• If the grid frequency is within the tolerable range, yet "Vac-Bfr," or

"Vac-Srr" faults are still being displayed, please contact the SMA

Serviceline.

Installation Guide SB12-17-IA-en-52 55

Page 56

Failure Search SMA Solar Technology AG

Message Description and corrective measure

VpvMax

Vpv-Max

Overvoltage at DC input. The inverter may be damaged.

Corrective measures

Immediately disconnect the inverter from the grid.

1. Turn off the line circuit breaker.

2. Remove the Electronic Solar Switch.

3. Disconnect all the DC plug connectors.

4. Check DC voltage:

– If the DC voltage exceeds the maximum input voltage, check the

plant design or contact the person who installed the PV

generator.

– If the DC voltage is under the maximum input voltage, reconnect

the inverter to the PV generator as described in section 5.4”PV

generator connection (DC)” (page29).

If the message occurs again, disconnect the inverter again and contact

the SMA Serviceline (see section 13”Contact” (page70)).

Watchdog

Watchdog Srr

Internal program run fault.

Corrective measures

• If this fault occurs often, contact the SMA Serviceline.

9.3 Red LED is Glowing Continuously

If the red LED of the status display is continuously on during operation, there is either a ground fault

in the PV generator or at least one of the varistors for the overvoltage protection is defective.

Procedure

1. Check for ground faults in the PV generator as described in section 9.3.1”Checking the PV

Generator for a Ground Fault” (page57).

2. If the red LED continu es to gl ow, check the varistors as described in section 9.3.2”Checking the

Functioning of the Varistors” (page59).

56 SB12-17-IA-en-52 Installation Guide

Page 57

SMA Solar Technology AG Failure Search

9.3.1 Checking the PV Generator for a Ground Fault

1. Disconnect the inverter from both the DC and AC connections as described in section

7.2”Opening the Inverter” (page45).

DANGER!

Risk of lethal electric shock.

• Only touch the cables of the PV generator on their insulation.

• Do not connect strings with ground faults to the inverter.

NOTICE!

Excessive voltages can destroy the measuring device.

• Only use measuring devices with a DC input voltage range up to at least 1000 V.

2. Measure the voltages between the positive pole of

the strings and the ground potential (PE).

3. Measure the voltages between the minus pole of

the strings and the ground potential (PE).

4. Measure the voltages between the plus pole and

the minus pole of each string.

☑ If the voltages measured are stable and the total of the voltages from the plus pole against

ground potential and the minus pole against ground potential of a string roughly

corresponds to the voltage between the plus pole and minus pole, then there is a ground

fault.

Installation Guide SB12-17-IA-en-52 57

Page 58

Failure Search SMA Solar Technology AG

Result Action

☑You have found a ground fault. • The installer of the PV generator must

remedy the ground fault in the affected

string. You can determine the location of the

ground fault as described below.

•Do not reconnect the faulty string.

• Close the inverter and commission it as

described in section 6.1”Commissioning

the Inverter” (page38).

☑You have found no ground fault. It is likely that one of the thermally monitored

varistors is defective.

• Check the varistors as described in section

9.3.2”Checking the Functioning of the

Varistors” (page59).

Location of the ground fault

The approximate position of the ground fault can be determined from the ratio of the measured

voltages between the plus pole against ground potential and the minus pole against ground

potential (PE).

Example:

In this case, the ground fault is between the second and third PV module.

☑ The ground fault check is finished.

58 SB12-17-IA-en-52 Installation Guide

Page 59

SMA Solar Technology AG Failure Search

9.3.2 Checking the Functioning of the Varistors

Varistors are wear parts. Their functional efficiency diminishes with age or following repeated

responses as a result of overvoltages. It is therefore possible that one of the thermally monitored

varistors has lost its protective function, and thus the red LED is lit.

Position of Varistors

You can determine the position of the varistors using the illustration below.

Observe the following allocation of the

terminals:

• Terminal A: outer terminal (varistor

connection with loop [crimp])

• Terminal B: middle terminal

• Terminal C: outer terminal (varistor

connection without loop [crimp])

Check the function of the varistors as described below:

1. Open the inverter as described in section 7.2”Opening the Inverter” (page45).

2. With the aid of a multimeter, determine for both

varistors in the installed state whether a conductive

connection exists between connectors B and C.

Result Action

☑There is a conducting connection. There is probably a different fault in the inverter.

• Contact the SMA Serviceline (see section

13”Contact” (page70)).

Installation Guide SB12-17-IA-en-52 59

Page 60

Failure Search SMA Solar Technology AG

Result Action

☑There is no conducting

connection.

The respective varistor is not working and must be

replaced.

Varistor failure is generally due to influences which affect

all varistors similarly (temperature, age, induced

overvoltage). SMA Solar Technology AG recommends

that you replace both varistors.

The varistors are specially manufactured for use in the

in ver ter and are not com mer cia lly ava ila ble . Th ey m ust b e

ordered directly from SMA Solar Technology AG (see

section 12”Accessories” (page69)).

• To replace the varistors, proceed to step 3.

NOTICE!

Destruction of the inverter due to overvoltage.

If varistors are missing, the inverter is no longer protected against overvoltages.

• Replacement varistors should be obtained as soon as possible.

•Do not ope rate th e inverter witho ut varistors in plants wit h a hig h risk of overvoltages.

3. Insert an insertion tool into the openings of the

terminal contacts (1).

☑The terminal clamps loosen.

If you do not receive an insertion tool for operating

the terminal clamps with your replacement

varistors, contact SMA Solar Technology AG. As

an alternative, the individual terminal contacts can

be operated using a 3.5 mm wide screwdriver.

4. Remove the varistor (2).

5. Insert new varistor (3).

The pole with the small loop (crimp) must be fitted

to terminal A when remounting.

6. Close the inverter as described in section

7.3”Closing the Inverter” (page48).

☑ The check and replacement of the varistors is

completed.

60 SB12-17-IA-en-52 Installation Guide

Page 61

SMA Solar Technology AG Decommissioning

10 Decommissioning

10.1 Dismantling the Inverter

CAUTION!

Risk of injury due to the heavy weight of the inverter.

• Remember that the inverter weighs approx. 25 kg.

1. Open the inverter as described in section 7.2”Opening the Inverter” (page45).

2. Remove all cables from the inverter.

3. Close the inverter with the 4 screws.

4. Loosen the lower screw between the inverter und

wall mounting bracket.

5. Remove the inverter upward from the wall mounting

bracket.

☑ The inverter is dismantled.

Installation Guide SB12-17-IA-en-52 61

Page 62

Decommissioning SMA Solar Technology AG

10.2 Packing the Inverter

If possible, always pack the inverter in its original packaging. If it is no longer available, you can also

use an equivalent box. The box must be capable of being closed completely and made to support

both the weight and the size of the inverter.

10.3 Storing the Inverter

Store the inverter in a dry place where ambient temperatures are always between − 25 °C and

+60°C.

10.4 Disposing of the Inverter

Dispose of the inverter at the end of its service life in accordance with the disposal regulations for

electronic waste which apply at the installation site at that time. Alternatively, send it back to

SMA Solar Technology AG with shipping paid by sender, and labeled "ZUR ENTSORGUNG"

("for disposal") (see section 13”Contact” (page70)).

62 SB12-17-IA-en-52 Installation Guide

Page 63

SMA Solar Technology AG Technical Data

11 Technical Data

11.1 Sunny Boy 1200

DC Input

Maximum DC power at cos φ = 1 P

Maximum DC voltage * V

MPP voltage range at 230 V AC V

DC nominal voltage V

Minimum DC voltage at 230 V AC V

Start voltage, adjustable V

Maximum input current I

DC

DC max

PV

DC nom

DC min

PV Start

PV max

1320 W

400 V

100 V … 320 V

120 V

100 V

120 V

12.6 A

Number of MPP trackers 1

Maximum number of parallel strings 2

Voltage ripple of input voltage V

pp

<10%

Internal consumption during operation < 4 W

* The maximum open circuit voltage, which can occur at a cell temperature of −10 °C, may not exceed the maximum input voltage.

AC Output

AC nominal power at 230 V AC, 50 Hz P

Maximum AC apparent power S

Nominal AC current I

Maximum output current I

AC nom

AC max

AC nom

AC max

Maximum fuse protection 16 A

Harmonic distortion of output current at

K

IAC

AC THD voltage < 2 %,

AC power > 0.5 AC nominal power

Nominal AC voltage V

AC voltage range V

AC grid frequency f

Operating range at AC grid frequency f

AC nom

AC

AC nom

AC

50 Hz: 45.5 Hz … 54.5 Hz

60 Hz: 55.5 Hz … 64.5 Hz

Power factor at nominal AC power cos φ 1

Overvoltage category III

Test voltage at 50 Hz 1.7 kV

Surge testing voltage 4 kV

Surge testing voltage with serial interface 6 kV

Internal consumption in night mode 0.1 W

1200 W

1200 VA

5.2 A

6.1 A

< 3 %

220 V / 230 V / 240 V

180 V … 265 V

50 Hz / 60 Hz

Installation Guide SB12-17-IA-en-52 63

Page 64

Technical Data SMA Solar Technology AG

Mechanical data

Width x height x depth 440 mm x 339 mm x 214 mm

Weight 23 kg

Climatic Conditions

Extended temperature range * − 25 °C … +60 °C

Extended humidity range * 0 % … 100 %

Extended air pressure range * 79.5 kPa … 106 kPa

Temperature range ** − 25 °C … +70 °C

Operation temperature range − 25 °C … +60 °C

Maximum operating altitude above mean sea

2000 m

level

* according to DIN EN 50178:1998-04, installation type C, class 4K4H

** according to DIN EN 50178:1998-04, transport type E, class 2K3

Features

Topology LF transformer

General data

Protection rating according to DIN EN 60529 IP65

Protection class I

Noise emission (typical) ≤ 41 dB(A)

Protective equipment

All-pole DC switch-disconnector Electronic Solar Switch,

DC plug system SUNCLIX

DC overvoltage protection Thermally monitored varistors

Personal protection (R

> 1 M Ω ) Insulation monitoring

iso

Pole confusion protection Short circuit diode

AC short circuit protection Current control

All-pole AC disconnection unit Automatic disconnection device SMA Grid

Guard 2.1, double design

Communication Interfaces

®

Bluetooth

Radio Optional

RS485, galvanically isolated Optional

64 SB12-17-IA-en-52 Installation Guide

Wireless Technology Optional

Page 65

SMA Solar Technology AG Technical Data

Electronic Solar Switch

Electrical service life in the event of a short circuit,

A minimum of 50 switching operations

with a nominal current of 35 A

Maximum switching current 35 A

Maximum switching voltage 800 V

Maximum PV power 12 kW

Protection rating when plugged IP65

Protection rating when unplugged IP21

Efficiency

Peak efficiency η

European efficiency η

Installation Guide SB12-17-IA-en-52 65

max

EU

92.1 %

90.9 %

Page 66

Technical Data SMA Solar Technology AG

11.2 Sunny Boy 1700

DC Input

Maximum DC power at cos φ = 1 P

DC

Maximum DC voltage * VDC

MPP voltage range at 230 V AC V

DC nominal voltage V

Minimum DC voltage at 230 V AC V

Start voltage, adjustable V

Maximum input current I

PV

DC nom

DC min

PV Start

PV max

max

1850 W

400 V

147 V … 320 V

180 V

139 V

180 V

12.6 A

Number of MPP trackers 1

Maximum number of parallel strings 2

Voltage ripple of input voltage V

pp

<10%