Page 1

SMA Solar Technology AG

Solar Inverters

FLX Series

Installation Guide / Installationsanleitung / Guide d’installation / Guía de instalacion /

Guida all’installazione

www.SMA.de

Page 2

Choice of Language - Sprachauswahl - Choix de la langue - Selección de idioma Scelta della lingua

Page 4

Seite 51

Page 103

Página 151

Pagina 201

English UK

Deutsch

Français

Español

Italiano

L00410568-03_2q / Rev. date: 2014-06-20 1

Page 3

Safety and Conformity

Safety and Conformity

Safety Message Types

The following symbols are used in this document:

DANGER

Indicates a potentially hazardous situation which could

result in death.

WARNING

Indicates a potentially hazardous situation which could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which could

result in minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTICE

Indicates important information, including situations

which may result in damage to equipment or property.

General Safety

All persons installing and servicing inverters must be:

Trained and experienced in general safety rules

•

for work on electrical equipment.

Familiar with local requirements, rules and

•

regulations for the installation.

NOTICE

Before installation

Check for damage to equipment and packaging. If in

doubt, contact the supplier before commencing installation.

CAUTION

Installation

For optimum safety, follow the steps described in this

document. Keep in mind that the inverter has 2 voltage

carrying sides; the PV input and the AC grid.

WARNING

Disconnecting the inverter

Before starting work on the inverter, switch off AC at the

mains switch and PV using the PV load switch. Ensure

that the device cannot be unintentionally reconnected.

Use a voltage tester to ensure that the unit is disconnected and voltage free. The inverter can still be charged

with very high voltage at hazardous levels even when it

is disconnected from AC grid and solar modules. Wait at

least 8 minutes following disconnection from grid and

PV panels before proceeding.

For safe disconnection of DC current, turn off the PV load

switch (1).

L00410568-03_2q / Rev. date: 2014-06-20

Page 4

Safety and Conformity

CAUTION

Maintenance and modification

Only authorised personnel are permitted to modify the

inverter. To ensure personal safety, use only original

spare parts available from the supplier. If non-original

spare parts are used, compliance with CE guidelines in

respect of electrical safety, EMC and machine safety is

not guaranteed.

The temperature of the cooling racks and components

inside the inverter can exceed 70 ºC. Observe the danger

of burn injury.

DC voltages up to 1000 V are present in a PV system even

when the inverter is disconnected from the AC grid. Faults

or inappropriate use may lead to electric arcing.

WARNING

PV modules generate voltage when exposed to light.

WARNING

Do not work on the inverter while disconnecting DC and

AC.

The short-circuit current of the photovoltaic panels is only

slightly higher than the maximum operating current and

depends on the level of solar irradiation.

Conformity

Go to the download area at www.SMA.de, Approvals and

Certifications, for information.

See also 5 Technical Data.

CE marking - This symbol certifies the conformity of

the equipment with the requirements of the

applicable EC directives

L00410568-03_2q / Rev. date: 2014-06-20

Page 5

Contents

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Software Version

1.3 Spare Parts

1.4 Unpacking

1.5 Identification of Inverter

1.6 Installation Sequence

1.7 Return and Disposal

1.7.1 Return 8

1.7.2 Disposal 8

1.8 Overview of Installation Area

2 Installation

2.1 Environment and Clearances

2.2 Mounting the Mounting Plate

2.3 Mounting the Inverter

2.4 Removing the Inverter

2.5 Access to the Installation Area

6

6

6

7

7

7

7

7

9

10

10

11

12

13

13

2.6 AC Grid Connection

2.7 RS-485 or Ethernet Connections

2.8 Options

2.9 Closure

2.10 PV Connection

2.10.1 Protection Rating for PV Modules 17

3 Initial Setup and Start

3.1 User Interface

3.1.1 Operation Modes 18

3.1.2 Security Level 18

3.1.3 Preparation for Master Inverter

3.1.4 Manual PV Configuration 19

3.2 Display

3.2.1 Initial Setup via Display

3.2.2 Turn PV Load Switch On 23

3.2.3 Start-up 23

3.2.4 Autotest Procedure

14

15

15

15

16

18

18

19

19

20

23

3.3 Web Interface

3.3.1 Prepare for Setup 23

3.3.3 Setup Wizard 24

3.3.4 Web Interface 30

4 L00410568-03_2q / Rev. date: 2014-06-20

23

Page 6

Contents

3.3.5 Plant, Group and Inverter Views 31

3.3.6 Autotest Procedure 32

4 Service

4.1 Troubleshooting

4.2 Maintenance

5 Technical Data

5.1 Specifications

5.1.1 Inverter Specifications 37

5.2 Derating Limits

5.3 Conformity

5.4 Installation Conditions

5.5 Cable Specifications

5.6 Torque Specifications

5.7 Mains Circuit Specifications

5.8 Auxiliary Interface Specifications

5.9 RS-485 and Ethernet Connections

33

33

36

37

37

41

41

42

43

45

46

46

47

L00410568-03_2q / Rev. date: 2014-06-20 5

Page 7

1

Introduction

1Introduction

1.1 Purpose of the Manual

The Installation Guide provides information required to

install and commission the FLX series inverter.

Additional resources available:

User Guide, for information required in monitoring

•

and setup of the inverter, via the display or web

interface.

Design Guide, for information required for

•

planning use of the inverter in a diversity of solar

energy applications.

Sensor Interface Option Installation Guide, for

•

installation and commissioning of the sensor

interface option.

GSM Option Kit Installation Guide, for information

•

required to install a GSM option, and set up data

upload or messaging from the inverter.

PLA Option Guide, for information required to

•

install and set up PLA option for connecting radio

ripple control receiver to the inverter.

Fan Installation Instruction, for information

•

required to replace a fan.

These documents are available from the download area at

www.SMA.de, or from the supplier of the solar inverter.

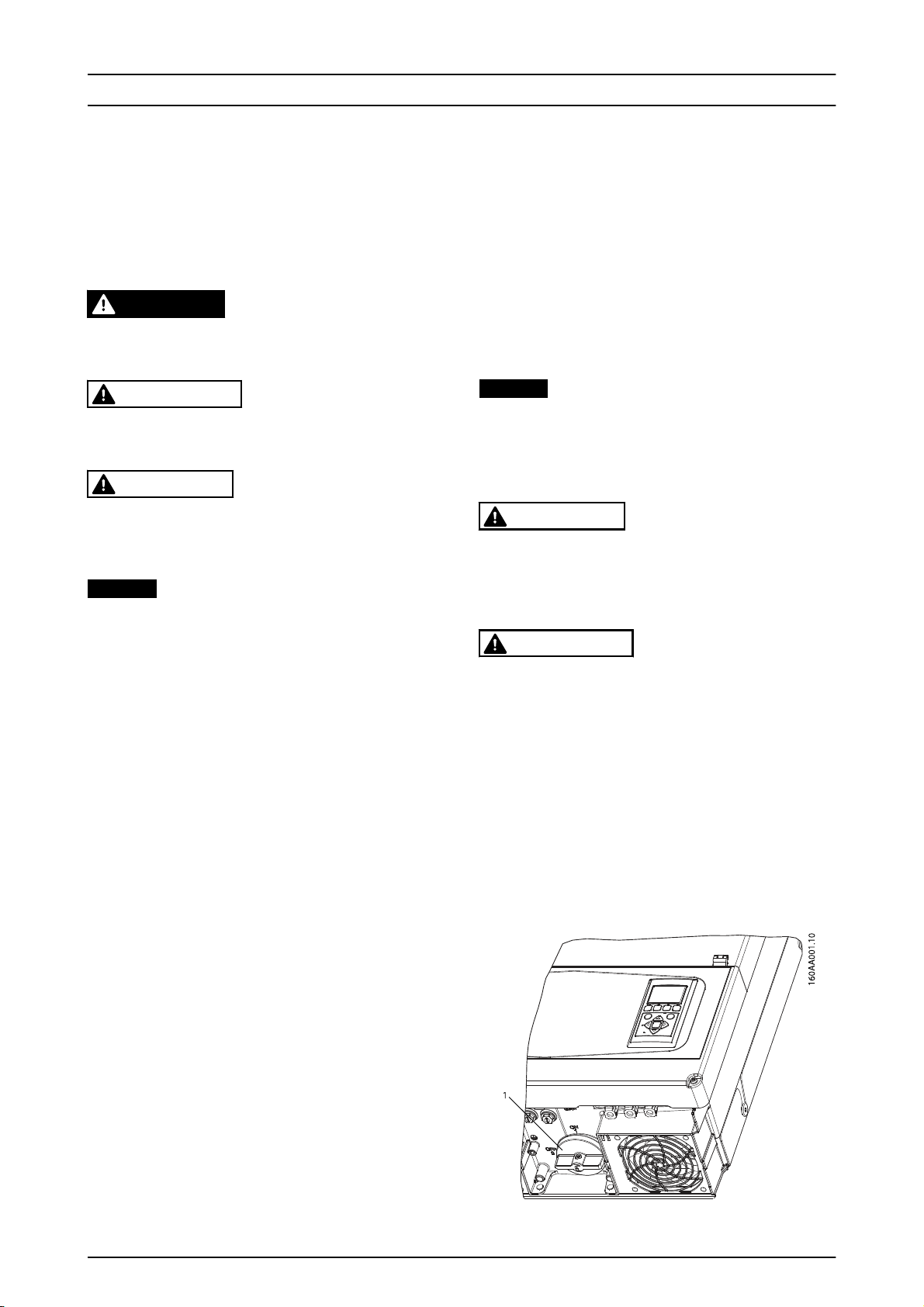

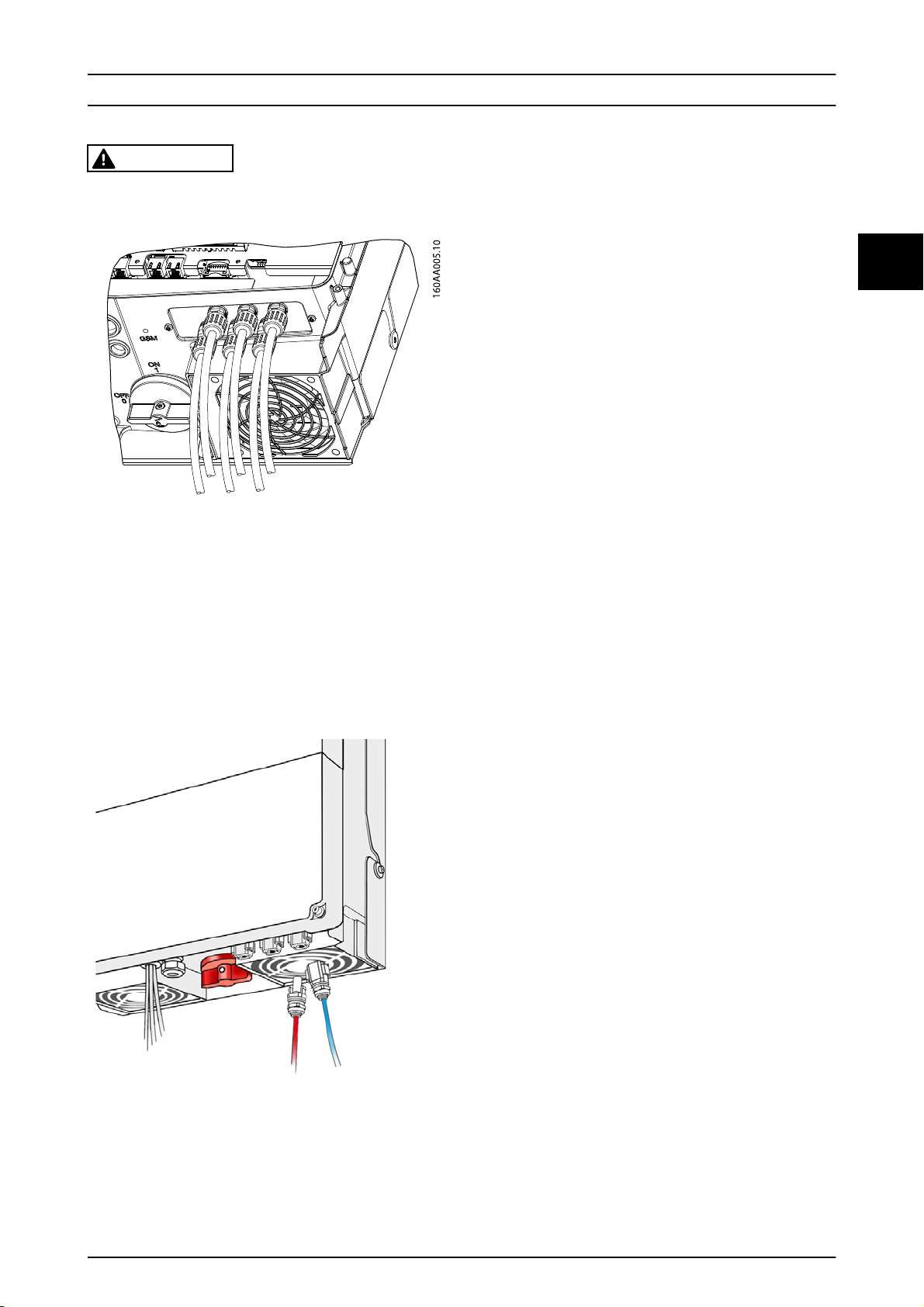

Illustration 1.1 FLX Series Inverter

The FLX series inverters feature:

IP65 enclosure

•

PV load switch

•

Sunclix connectors for PV input

•

Manual access via the display, for configuration

•

and monitoring of the inverter.

Ancillary service functionalities. Refer to the FLX

•

Series Design Guide for details.

Access via web interface, for configuration and

•

monitoring of the inverter.

1.2 Software Version

This manual is applicable for inverter software 2.05 and

onwards. To see the software version, via the display or

web interface (inverter level), go to [Status → Inverter →

Serial no. and SW ver. → Inverter].

NOTICE

Software version at manual release is 2.05. Information

about current software version is available at

www.SMA.de.

6 L00410568-03_2q / Rev. date: 2014-06-20

Page 8

Introduction

1.3 Spare Parts

Contact SMA Solar Technology AG for information about

spare parts, part numbers, and ordering.

1.4 Unpacking

Contents:

Inverter

•

Mounting plate

•

Accessories bag, containing: 3 mounting screws, 2

•

cable glands, 2 rubber cups, 1 earthing screw,

and 1 security label for France.

4 to 6 Sunclix mating parts depending on the

•

number of MPPT for FLX Pro 5-17.

Installation guide, booklet format

•

Quick guide, poster format

•

The following items are not supplied:

Security screws, M5 x 8-12, optional (not available

•

as product from SMA Solar Technology AG)

1.5 Identification of Inverter

1.6 Installation Sequence

1. Pay special attention to 1.1 Safety Message Types.

2. Install the inverter according to 2.1 Environment

and Clearances, 2.2 Mounting the Mounting Plate

and 2.3 Mounting the Inverter.

3. Open the inverter according to 2.5 Access to the

Installation Area.

4. Install AC according to 2.6 AC Grid Connection.

5. Install RS-485 or Ethernet, if used, according to

2.7 RS-485 or Ethernet Connections.

6. Install options, if any, according to the installation

guide supplied with the option.

7. Close the inverter according to 2.5 Access to the

Installation Area.

8. Install PV according to 2.10 PV Connection.

9. Turn on AC at the mains switch.

10. Set language, master mode, time, date, installed

PV power, country, and grid code:

For setup via the web interface, refer to

•

3.3 Web Interface.

For setup via the display, refer to

•

3.2 Display.

11. Turn on PV by turning on the PV load switch.

Refer to 2.10.1 Connection of PV.

12. Verify the installation by comparing with the

autodetection result in the display, as described

in 2.10 PV Connection.

13. The inverter is now in operation.

For installation and setup of multiple FLX Pro inverters in

master-follower configuration:

Perform steps 2–9 and 11 for each inverter.

•

Perform step 10 on the inverter planned as

•

master.

Perform step 12.

•

1 1

Illustration 1.2 Product Label

The product label on the side of the inverter shows:

Inverter type

•

Important specifications

•

Serial number, located under the bar code, for

•

inverter identification.

L00410568-03_2q / Rev. date: 2014-06-20 7

1.7 Return and Disposal

When replacing an inverter, it can either be returned to

your distributor, to SMA Solar Technology AG directly, or

disposed of according to local and national regulations.

SMA Solar Technology AG is committed to its policy of

environmental responsibility, and therefore appeals to end

users who are disposing of inverters to follow local

environmental legislation and to seek safe, responsible

means of disposal.

Page 9

1

Introduction

1.7.1 Return

For return to SMA Solar Technology AG, the inverter

should always be in its original packaging or equivalent

packaging. If the product is returned as a result of inverter

failure, contact your SMA Solar Technology AG inverter

supplier.

For return shipment and details, contact SMA Solar

Technology AG hotline.

1.7.2 Disposal

In case of end of service life, the inverter can be returned

to your distributor, to SMA Solar Technology AG directly,

or disposed of in the respective country. The shipping to

the distributor or SMA Solar Technology AG is paid by the

sender. Recycling and disposal of the inverter must be

done according to the rules and regulations applicable in

the country of disposal. All the inverter packaging material

is recyclable.

8 L00410568-03_2q / Rev. date: 2014-06-20

Page 10

Introduction

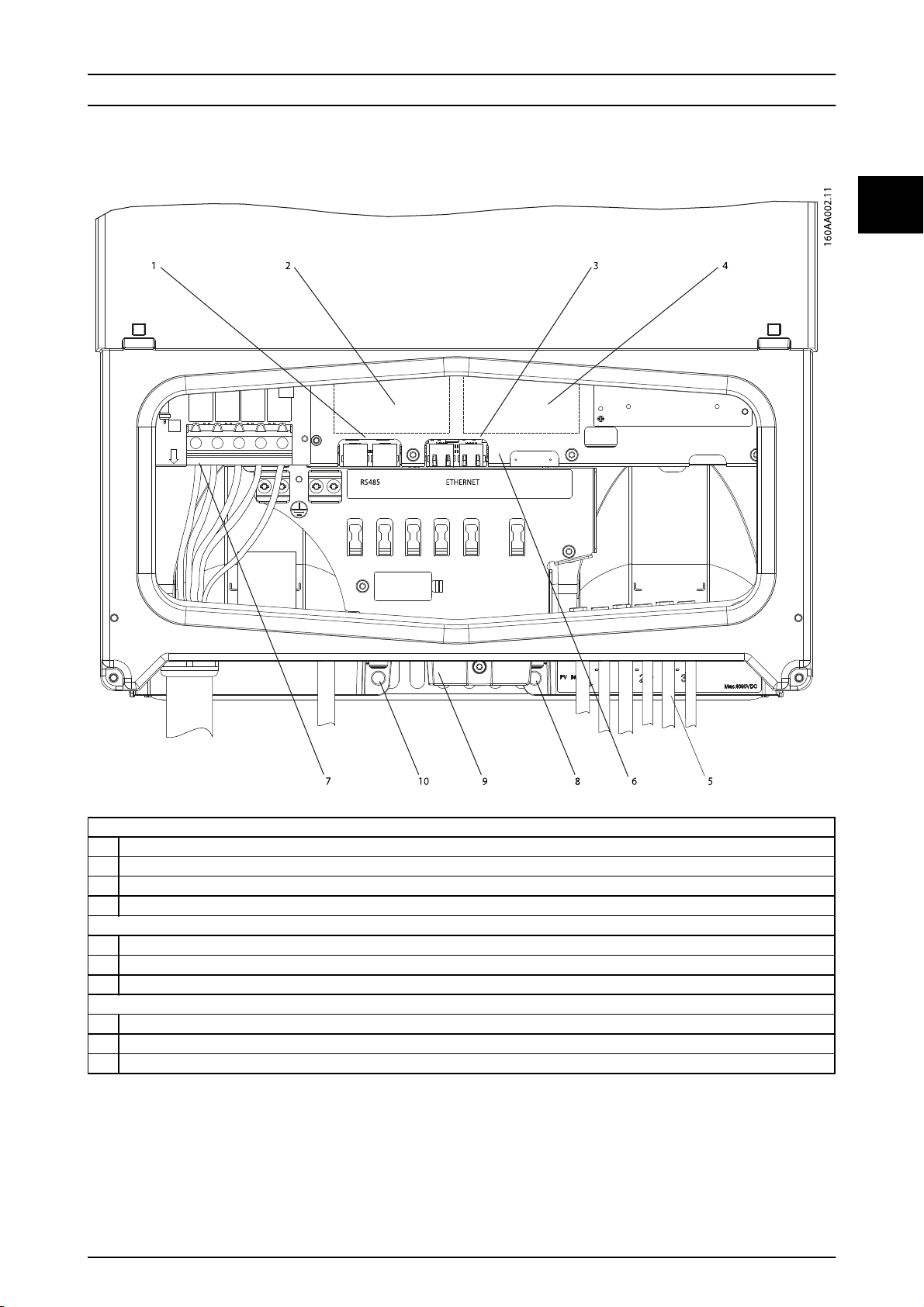

1.8 Overview of Installation Area

1 1

PELV (Safe to touch)

1 RS-485 interface

2 Option slot A (can be used for GSM option, optional sensor interface, or PLA option)

3 Ethernet interface

4 Option slot A (can be used for GSM option, optional sensor interface, or PLA option)

Live Part

5 PV connection area

6 Communication board

7AC terminal

Other

8 Security screw position

9PV load switch

10 Security screw position

Illustration 1.3 Overview of Installation Area

L00410568-03_2q / Rev. date: 2014-06-20 9

Page 11

2

Installation

2 Installation

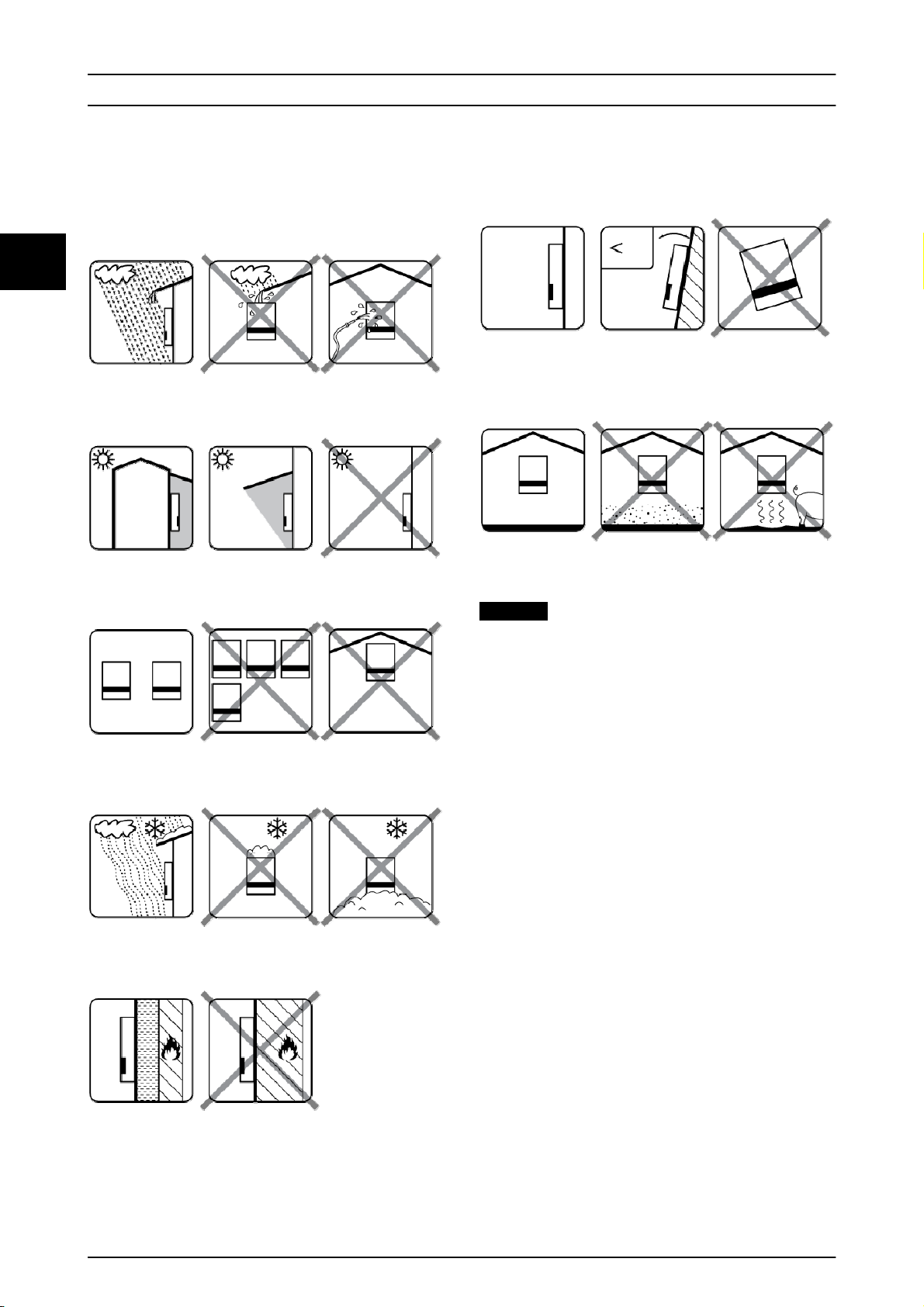

2.1 Environment and Clearances

Illustration 2.6 Mount Upright on Vertical Surface. Tilt of up to

10 degrees is permitted

Illustration 2.1 Avoid Constant Stream of Water

Illustration 2.2 Avoid Direct Sunlight

Illustration 2.3 Ensure Adequate Air Flow

Illustration 2.4 Ensure Adequate Air Flow

Illustration 2.7 Prevent Dust and Ammonia Gases

NOTICE

When planning the installation site, ensure that inverter

product and warning labels remain visible. For details,

refer to 5 Technical Data.

Illustration 2.5 Mount on Non-flammable Surface

10 L00410568-03_2q / Rev. date: 2014-06-20

Page 12

Installation

2

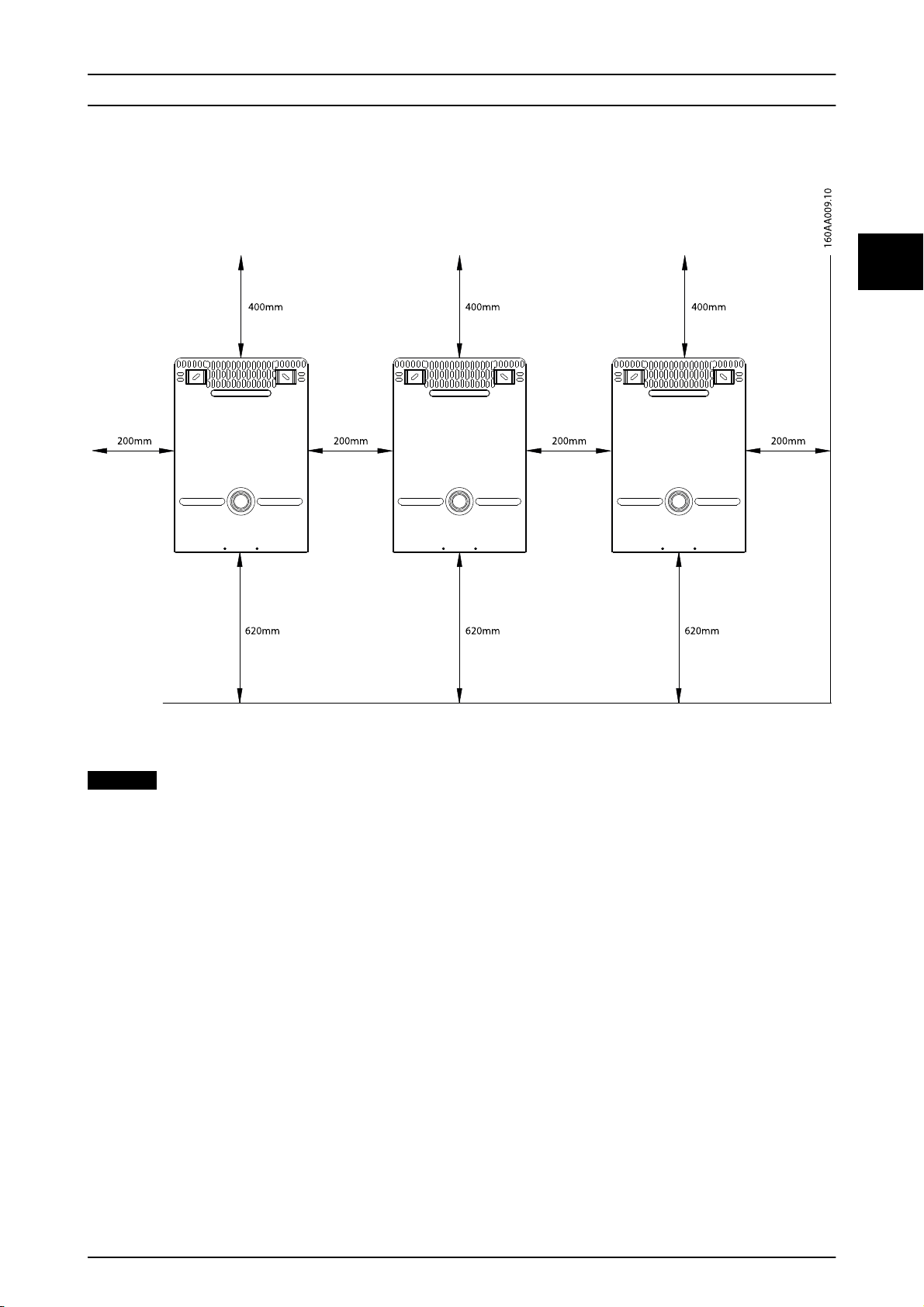

2.2 Mounting the Mounting Plate

2

Illustration 2.8 Safe Clearances

NOTICE

Ensure 620 mm base clearance for adequate airflow.

L00410568-03_2q / Rev. date: 2014-06-20 11

Page 13

2

Installation

Illustration 2.10 Mounting the Mounting Plate

Illustration 2.9 Mounting Plate

NOTICE

Use of the mounting plate delivered with the inverter is

mandatory.

Mount the mounting plate:

Mount in the defined environment.

•

Use screws and rawl plugs that can safely carry

•

the weight of the inverter.

Ensure that the mounting plate is correctly

•

aligned.

Observe safe clearances when installing one or

•

more inverters, to ensure adequate airflow.

Clearances are specified in Illustration 2.8 and the

mounting plate label.

Mounting multiple inverters in a single row is

•

recommended. Contact the supplier for

guidelines, when mounting inverters in more

than one row.

Ensure adequate clearance at the front, for

•

service access to the inverter.

.

2.3 Mounting the Inverter

CAUTION

For safe handling of the inverter, 2 people must carry

the unit, or a suitable transport trolley must be used.

Wear safety boots.

Procedure:

1. Lift the inverter. Locate the slots on the side of

the mounting plate.

Illustration 2.11 Position the Inverter

12 L00410568-03_2q / Rev. date: 2014-06-20

Page 14

Installation

2

2. On the inverter, position the side screws against

the mounting plate slots.

3. Push the inverter as shown so the side screws

slide into the 2 lower slots, then the 2 upper

slots. See Illustration 2.12 and Illustration 2.13.

1. Use 2 security screws, M5 x 8-12 (not supplied).

2. Insert screws through the pre-drilled anti-theft

holes (see Illustration 1.3), through the mounting

plate to the wall.

3. Tighten screws.

2.4 Removing the Inverter

Procedure:

1. Perform removal in the reverse order of

mounting.

2. Lift the inverter. 2 people must carry the unit.

3. With a firm grip at the base of the inverter, lift

and slide the inverter out of the mounting plate

slots.

4. Lift the inverter free of the mounting plate.

2.5 Access to the Installation Area

CAUTION

Observe ESD safety regulations. Discharge any electrostatic charge by touching the grounded enclosure,

before handling any electronic component.

2

Illustration 2.12 Slide into Slots

Illustration 2.13 Detail of Sliding into Slot

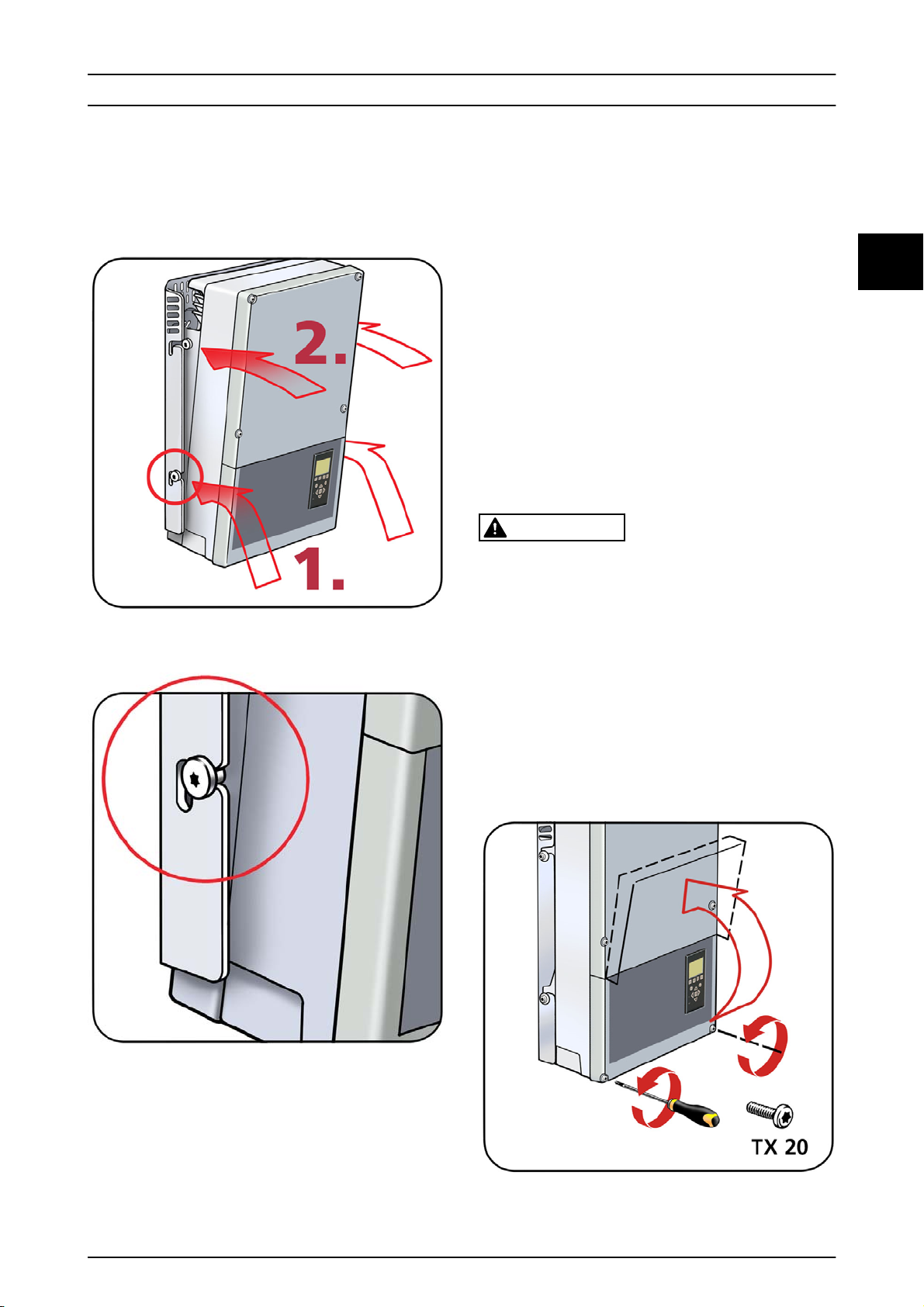

Procedure:

1. To open the cover, loosen the 2 lower front

screws using a TX 20 screwdriver. The screws

cannot fall out.

2. Lift the cover 180 degrees. A magnet holds the

cover open.

3. To close the cover, lower it into place and fasten

the 2 front screws.

4. Check that the 4 side screws sit securely in the

mounting plate slots.

5. Release the inverter.

Anti-theft Protection (Optional)

To protect the inverter against theft, fasten as follows:

L00410568-03_2q / Rev. date: 2014-06-20 13

Illustration 2.14 Loosen Front Screws and Lift Cover

Page 15

2

Installation

2.6 AC Grid Connection

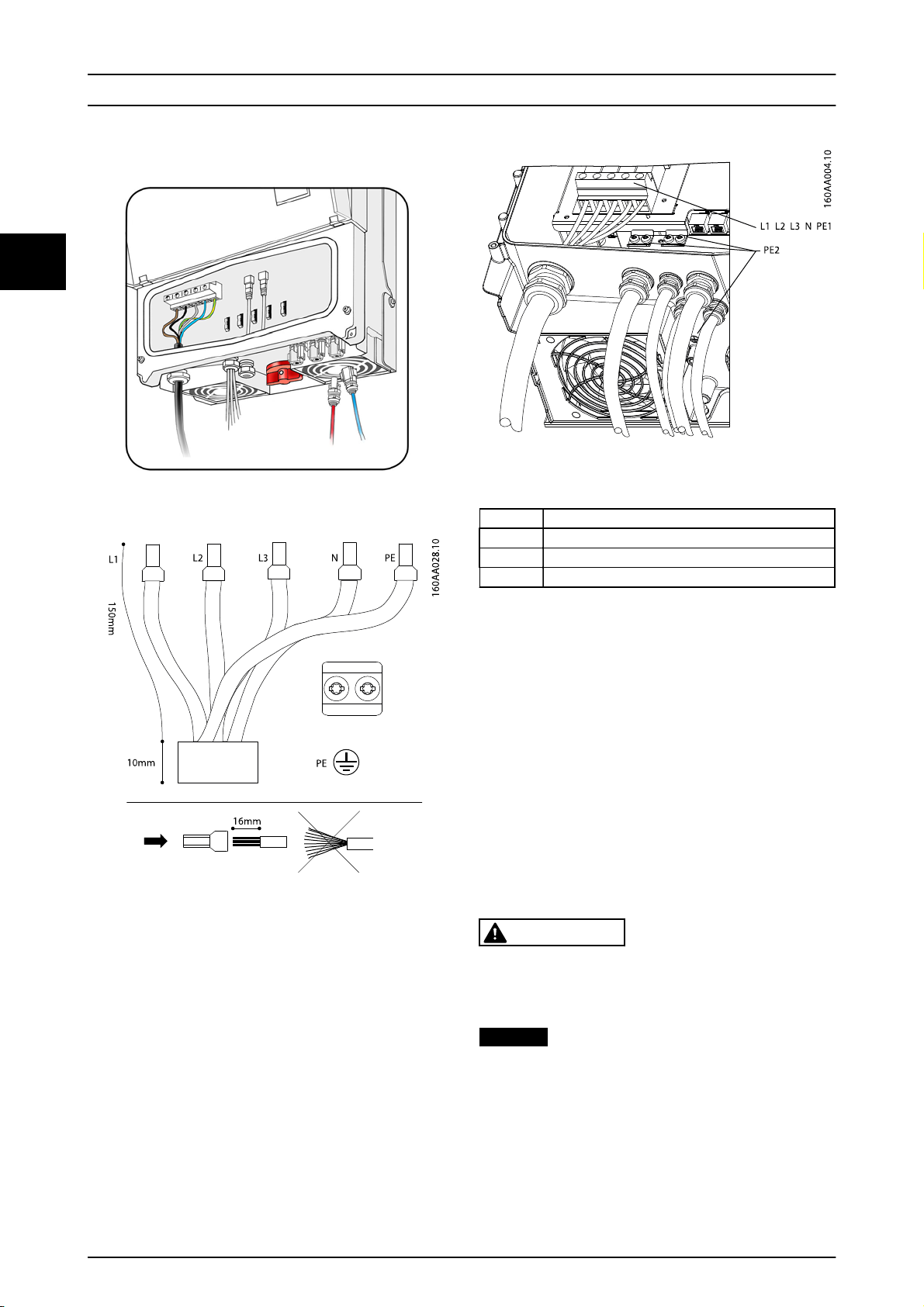

Illustration 2.17 AC Connection Area

Illustration 2.15 Installation Area

L1, L2, L3 3 mains wires

NNeutral wire

PE1 Primary protective earth

PE2 Secondary protective earth

Illustration 2.16 AC Cable Wire Strip

On the AC cable, strip insulation on all 5 wires. The PE wire

must be longer than the mains and neutral wires. See

Illustration 2.16.

1. Verify that the inverter rating matches the grid.

2. Ensure that main circuit breaker is released, and

take precautions to prevent reconnection.

3. Open the front cover.

4. Insert the cable through the AC gland to the

terminal blocks.

5. Connect the 3 mains wires (L1, L2, L3), the

neutral wire (N) and the protective earth wire (PE)

to the terminal block with the respective

markings.

6. Optional: Make an extra PE connection at the

secondary PE earthing points.

7. All wires must be properly fastened with the

correct torque. See 5.6 Torque Specifications.

CAUTION

Check that all wiring is correct. Connecting a phase wire

to the neutral terminal may permanently damage the

inverter.

NOTICE

Tighten all screws and glands thoroughly.

14 L00410568-03_2q / Rev. date: 2014-06-20

Page 16

Installation

2

NOTICE

This product may generate DC current exceeding 6 mA,

into the external grounded PE wire. Where a residual

current-operated protective (RCD) or monitoring (RCM)

device is used for protection in case of direct or indirect

contact, only an RCD or RCM of Type B is allowed on the

supply side of this product. When applying an RCD it

must have a 300 mA sensitivity to avoid tripping. IT

systems are not supported.

NOTICE

For fuse and RCD information, refer to 5 Technical Data.

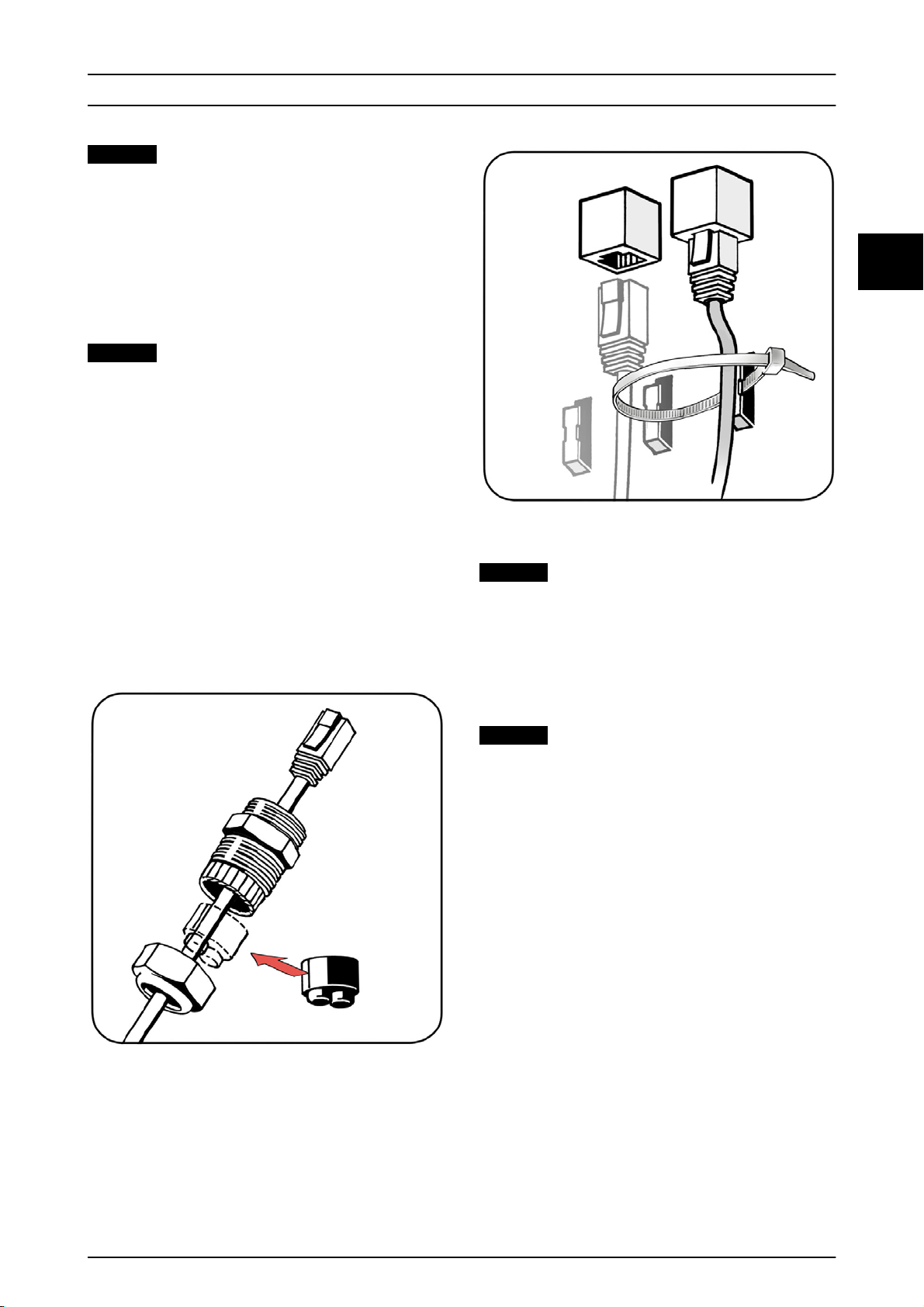

2.7 RS-485 or Ethernet Connections

Before connecting RS-485 or Ethernet cables, refer to

requirements in 5.9 RS-485 and Ethernet Connections.

2

Procedure:

1. Do not remove the RJ-45 connector.

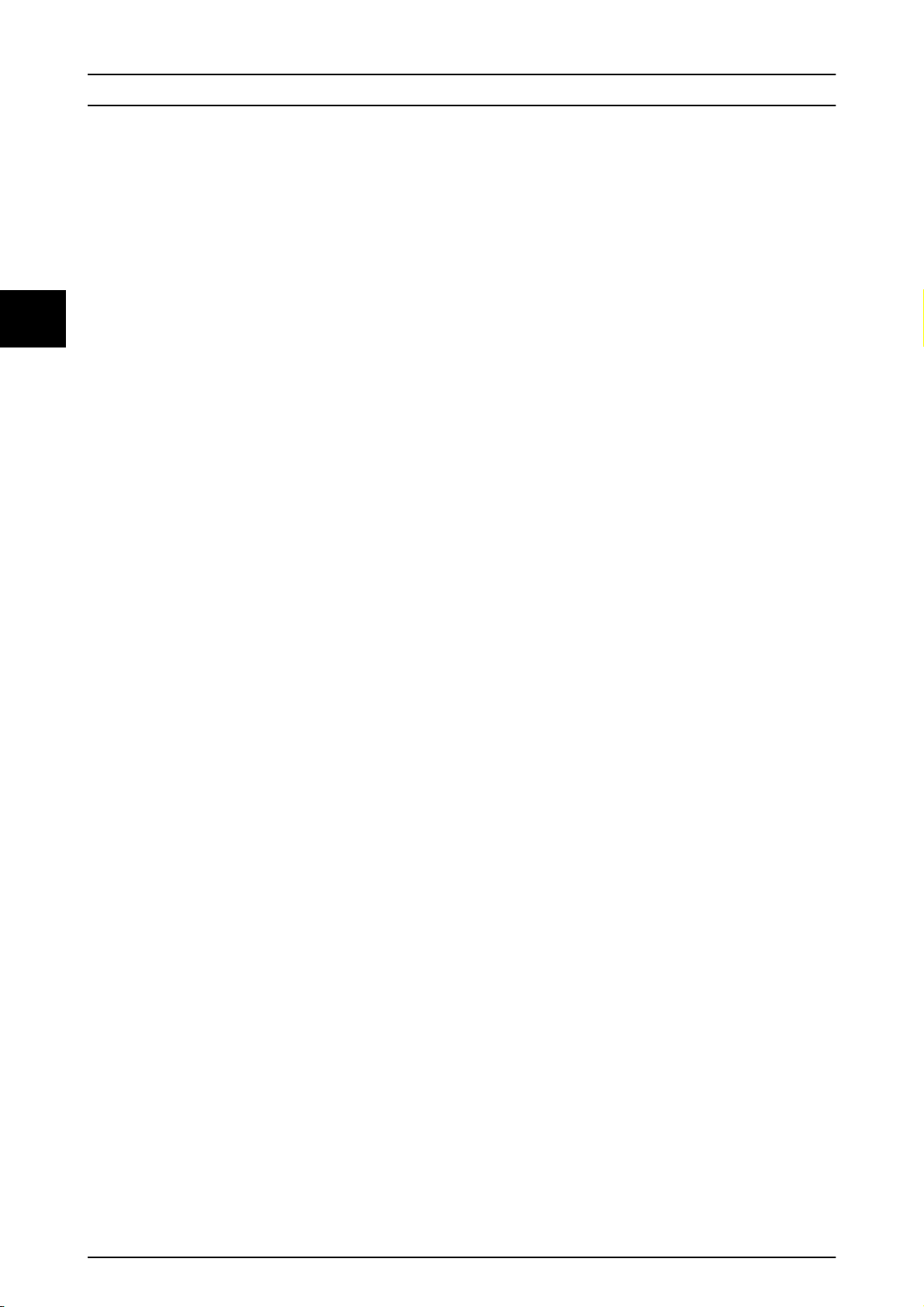

2. Guide the cables through the base of the inverter

via cable glands. See Illustration 2.18.

3. Plug into the RS-485 or Ethernet connector.

4. Fasten cables with cable ties to ensure a durable

connection over time. See Illustration 2.19.

Illustration 2.19 Fasten with Cable Ties

NOTICE

Tighten all screws and glands thoroughly.

2.8 Options

To install options, refer to the respective option installation

guide.

NOTICE

Tighten all screws and glands thoroughly.

2.9 Closure

1. Close the cover of the inverter installation area.

Fasten the 2 front screws.

2. Turn on AC power.

Illustration 2.18 Guide Through Cable Glands

L00410568-03_2q / Rev. date: 2014-06-20 15

Page 17

2

Installation

2.10 PV Connection

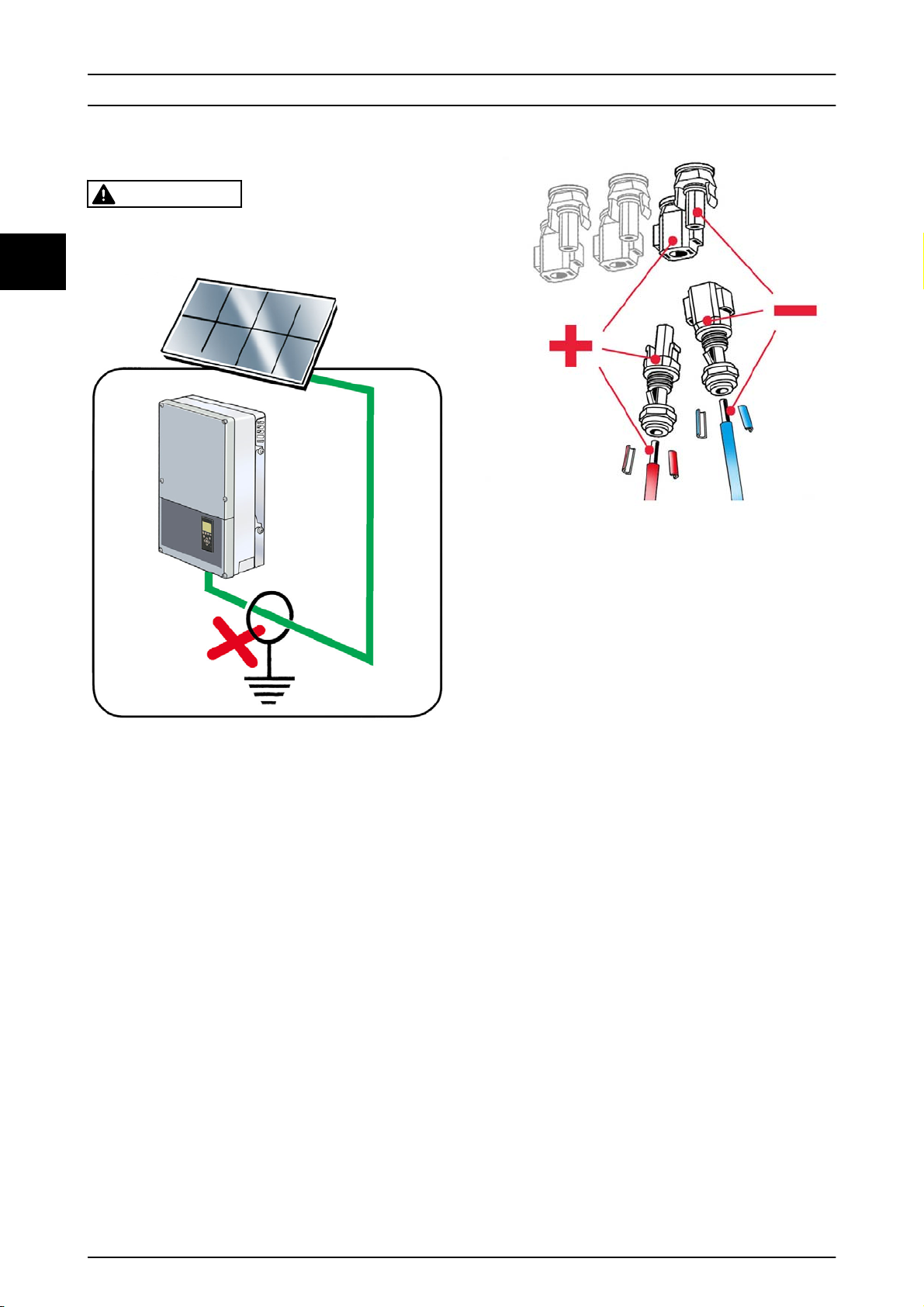

WARNING

PV modules generate voltage when exposed to light.

Do NOT connect PV to earth.

Illustration 2.21 Correct Polarity: Mounting Sunclix Connector

on Cable

Illustration 2.20 Do Not Connect PV to Earth

Use a suitable voltmeter that can measure up to 1000 V

DC.

1. Mount Sunclix connectors (not supplied) on the

PV cables, according to Illustration 2.21.

2. Verify the polarity and maximum voltage of the

PV arrays by measuring the PV open-circuit

voltage. See Illustration 2.21.

The PV open-circuit voltage must not

•

exceed 1000 V DC. The inverter is

protected against reversed polarity and

will not generate power until the

polarity is correct. Reversed polarity

damages neither the inverter nor the

connectors.

1. Measure the DC voltage between the positive

terminal of the PV array and earth (or the green/

yellow PE cable).

The voltage measured should

•

approximate zero. If the voltage is

constant and not zero, there is an

insulation failure somewhere in the PV

array.

2. Locate and fix the failure before continuing.

3. Repeat this procedure for all arrays. Uneven distribution of input power on the PV inputs is

permitted, if:

The individual input is not overloaded.

•

The maximum permissible load per

input is 8000 W.

The maximum short-circuit current of

•

the PV modules at STC (Standard Test

Conditions) does not exceed 13.5 A per

input.

16 L00410568-03_2q / Rev. date: 2014-06-20

Page 18

Installation

2

CAUTION

PV installation

Unused PV inputs may not be short-circuited.

Illustration 2.22 DC Connection Area

1. On the inverter turn the PV load switch into off

position.

2. Connect the PV cables using Sunclix connectors.

Ensure correct polarity, see Illustration 2.21.

Attach Sunclix mating part to PV cable.

•

Connect to each PV input in the PV

•

connection area with a 'click'.

2.10.1 Protection Rating for PV Modules

The inverter must only be operated with PV modules of

protection class II, compliant to IEC 61730, application class

A.

Module voltage rating must be more than 480 V (typical

module voltage rating is 1000 V). This does not prevent

the use of strings with lower operating voltage.

Only connect PV modules to the inverter. Other energy

sources are not allowed.

2

Illustration 2.23 Connect to PV Input

L00410568-03_2q / Rev. date: 2014-06-20 17

Page 19

Initial Setup and Start

3 Initial Setup and Start

3

3.1 User Interface

The user interface comprises:

Local display. Enables manual setup of the

•

inverter.

Web interface. Enables access to multiple

•

inverters via Ethernet.

Choose an interface to set up and start the inverter, either

via

Display

•

3.2 Display

3.2.1 Initial Setup via Display

or

Web interface

•

3.3 Web Interface

3.3.4 Web Interface

Do not touch the other interface during the setup and

start-up processes.

For access and menu information, refer to the FLX Series

User Guide.

resistance between the PV arrays and earth. Meanwhile, it

also monitors the grid parameters. When the grid

parameters have been within the specifications for the

required amount of time (depends on grid code), the

inverter starts to energise the grid.

On grid (Green LED on)

The inverter is connected to the grid and energises the

grid. The inverter disconnects when:

it detects abnormal grid conditions (dependent

•

on grid code), or

an internal event occurs, or

•

insufficient PV power is available (no power is

•

supplied to the grid for 10 minutes).

The inverter then enters connecting mode or off grid

mode.

Fail Safe (Red LED flashing)

If the inverter detects an error in its circuits during the selftest (in connecting mode) or during operation, the inverter

goes into fail safe mode, disconnecting from grid. The

inverter will remain in fail safe mode until power has been

absent for a minimum of 10 minutes, or the inverter has

been shut down completely (AC+PV).

3.1.1 Operation Modes

The inverter has 4 operation modes, indicated by LEDs.

For more information on the LEDs, refer to the FLX Series

User Guide.

Off grid (LEDs off)

When no power has been delivered to the AC grid for

more than 10 minutes, the inverter disconnects from the

grid and shuts down. 'Off grid - standby' is the default

night mode. 'Off grid - sleep' is the night mode for lowest

energy consumption.

Off grid - standby mode (LEDs off)

•

The inverter is disconnected from grid. User and

communication interfaces remain powered for

communication purposes.

Off grid - sleep mode (LEDs off)

•

The inverter is disconnected from grid. User,

communication, and option interfaces are

powered down.

Connecting (Green LED flashing)

The inverter starts up when the PV input voltage reaches

250 V. The inverter performs a series of internal self-tests,

including PV autodetection and measurement of the

3.1.2 Security Level

3 predefined security levels filter user access to menus and

options.

Security levels:

Level [0]: General access. No password is required.

•

Level [1]: Installer or service technician. Password

•

access required.

Level [2]: Installer or service technician. Password

•

extended access required.

Throughout the manual, a [0], [1] or [2] inserted after the

menu item indicates the minimum security level required

for access.

When logged on to the web interface as Admin, access is

at security level [0].

Access to levels [1] and [2] requires a service logon,

comprising a user ID and a password.

18 L00410568-03_2q / Rev. date: 2014-06-20

Page 20

Initial Setup and Start

3

The service logon provides direct access to a

•

specific security level for the duration of the

current day.

Obtain the service logon from SMA Solar

•

Technology AG.

Enter the logon via the display, or the web

•

interface logon dialog.

When the service task is complete, log off at

•

[Setup → Security].

The inverter automatically logs the user off after

•

10 minutes of inactivity.

Security levels are similar on the display and the web

interface.

A security level grants access to all menu items at the

same level as well as all menu items of a lower security

level.

3.1.3 Preparation for Master Inverter

The master mode feature allows 1 inverter to be appointed

as master inverter for the inverter network.

The master inverter accesses the other inverters in the

network, enabling:

Settings and data replication to the rest of the

•

network, enabling easy commissioning and data

management.

Control of power at plant level (control of

•

ancillary services).

Data retrieval from the network, for graphical

•

display on the web interface, upload to a data

warehouse, or export to a PC.

Before enabling master mode, ensure that the following

requirements are met:

No other master inverters are present in the

•

network.

Ethernet connection from PC to inverter RJ-45

•

interface, using a patch cable (network cable

cat5e, crossed or straight through). See 2.7 RS-485

or Ethernet Connections.

Installed sensor interface option, with sensors

•

installed, when sensor data are required.

Location closest to the router, in a daisy chain

•

network topology.

3.1.4 Manual PV Configuration

Set up the inverter for manual PV configuration:

Via the display, security level 1, at [Setup → Setup

•

details → PV configuration].

Via the web interface, security level 0, at [Inverter

•

level: Setup → Setup details → PV configuration].

When the inverter is set to manual PV configuration, the

autodetection is subsequently overridden.

To set the configuration manually via the display:

1. Turn on AC to start the inverter.

2. Obtain the installer password from the distributor.

Go to [Setup → Security → Password], and enter

the password.

3.

Press [Back]. Use the arrows to navigate to [Setup

→ Setup details → PV configuration].

4.

Select manual PV configuration mode, at: [Setup

→ Setup details → PV configuration → Mode:

Manual].

5. Set up the PV input configuration to match the

wiring, at: [Setup → Setup details → PV configuration].

PV input 1: Individual, Parallel or Off

•

PV input 2: Individual, Parallel or Off

•

PV input 3: Individual, Parallel or Off

•

3.2 Display

NOTICE

The display activates up to 10 seconds after power up.

The integrated display on the inverter front gives the user

access to information about the PV system and the

inverter.

The display has 2 modes:

1.

Normal: The display is in use.

2.

Power saving: After 10 minutes of display

inactivity the back light of the display turns off to

save power. Reactivate the display by pressing

any key.

3

After enabling master mode, perform a network scan to

verify that all follower inverters are connected to the

master inverter. To initiate the scan, go to [Setup →

Inverter details → Master mode → Network].

L00410568-03_2q / Rev. date: 2014-06-20 19

Page 21

3

Initial Setup and Start

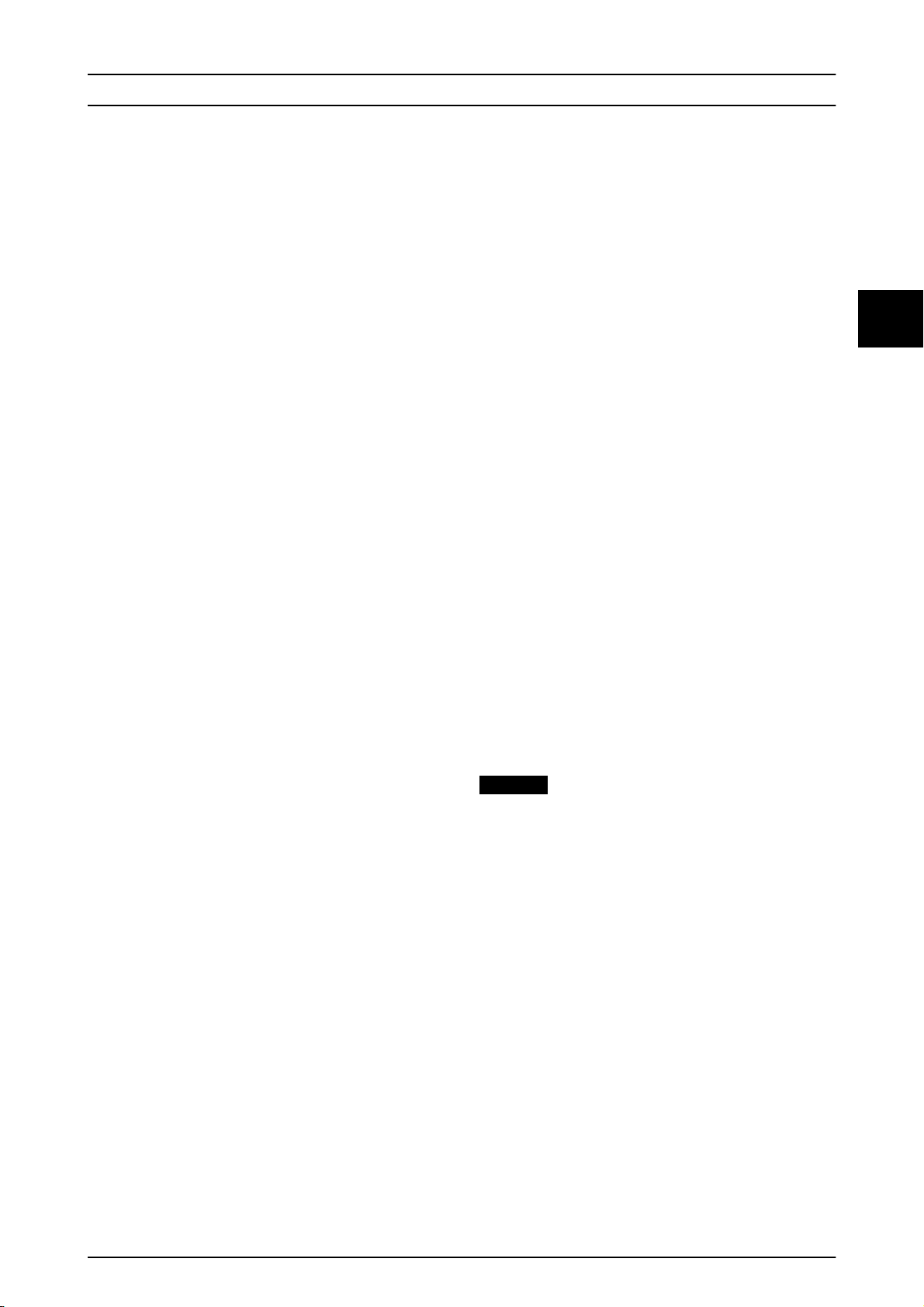

Illustration 3.1 Overview of Display Buttons and Functionality

Key Function LED

F1

F2

F3

F4

Home

OK

Arrow up

Arrow

Down

Arrow Right

Arrow Left

Back

On - Green

LED

Alarm - Red

LED

Table 3.1 Overview of Display Buttons and Functionality

View 1/View 2 - Screen

Status Menu

Production Log Menu

Setup Menu

Return to View Screen

Enter/select

A step up/increase value

A step down/decrease

value

Moves cursor right

Moves cursor left

Return/de-select

Flashing = Fail safe

The inverter is

configured as master.

This icon appears in the

top right corner.

The inverter is a

follower, connected to a

master. This icon

appears in the top right

corner.

When keys F1-F4 are

selected, the LED above

the key will light up

On/flashing = On grid/

Connecting

The menu structure is divided into 4 main sections:

1.

View - presents a short list of information, read

only.

2.

Status - shows inverter parameter readings, read

only.

3.

Log - shows logged data.

4.

Setup - shows configurable parameters, read/

write.

See the following sections for more detailed information.

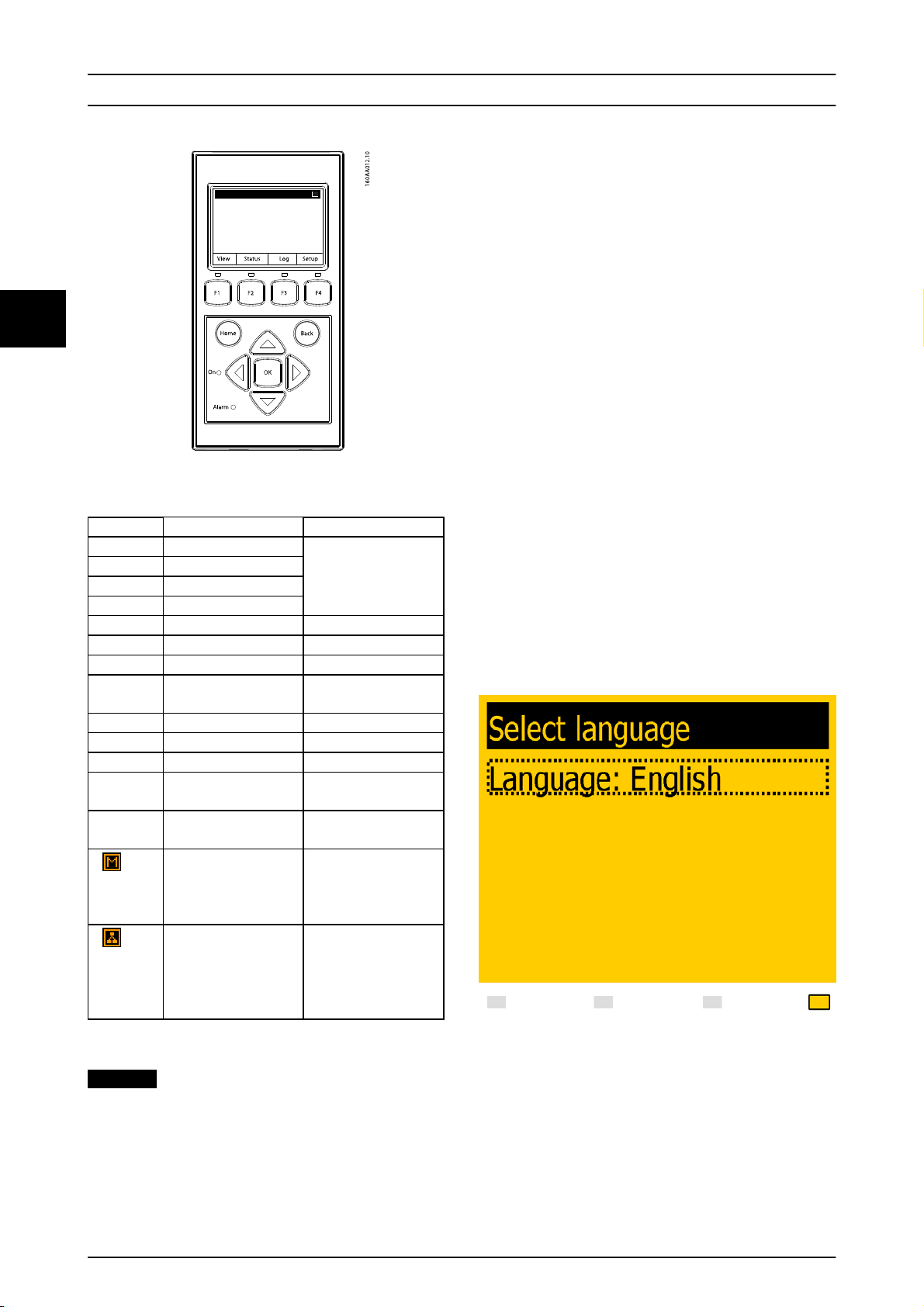

3.2.1 Initial Setup via Display

The inverter is shipped with a predefined set of settings

for different grids. All grid-specific limits are stored in the

inverter and must be selected at installation. It is always

possible to see the applied grid limits in the display.

After installation, check all cables and then close the

inverter.

Turn on AC at the mains switch.

IP address can be found in the display during commissioning.

When prompted by the display select language. This

selection has no influence on the operating parameters of

the inverter and is not a grid code selection.

Illustration 3.2 Select Language

NOTICE

The contrast level of the display can be altered by

pressing the arrow up/down button while holding down

The language is set to English at initial start-up. To change

this setting press the [OK] button. Press [

through the languages. Select language by pressing [OK].

the F1 button.

20 L00410568-03_2q / Rev. date: 2014-06-20

] to scroll down

▼

Page 22

Initial Setup and Start

3

NOTICE

To use the default language (English) simply press the

[OK] button twice to select and accept.

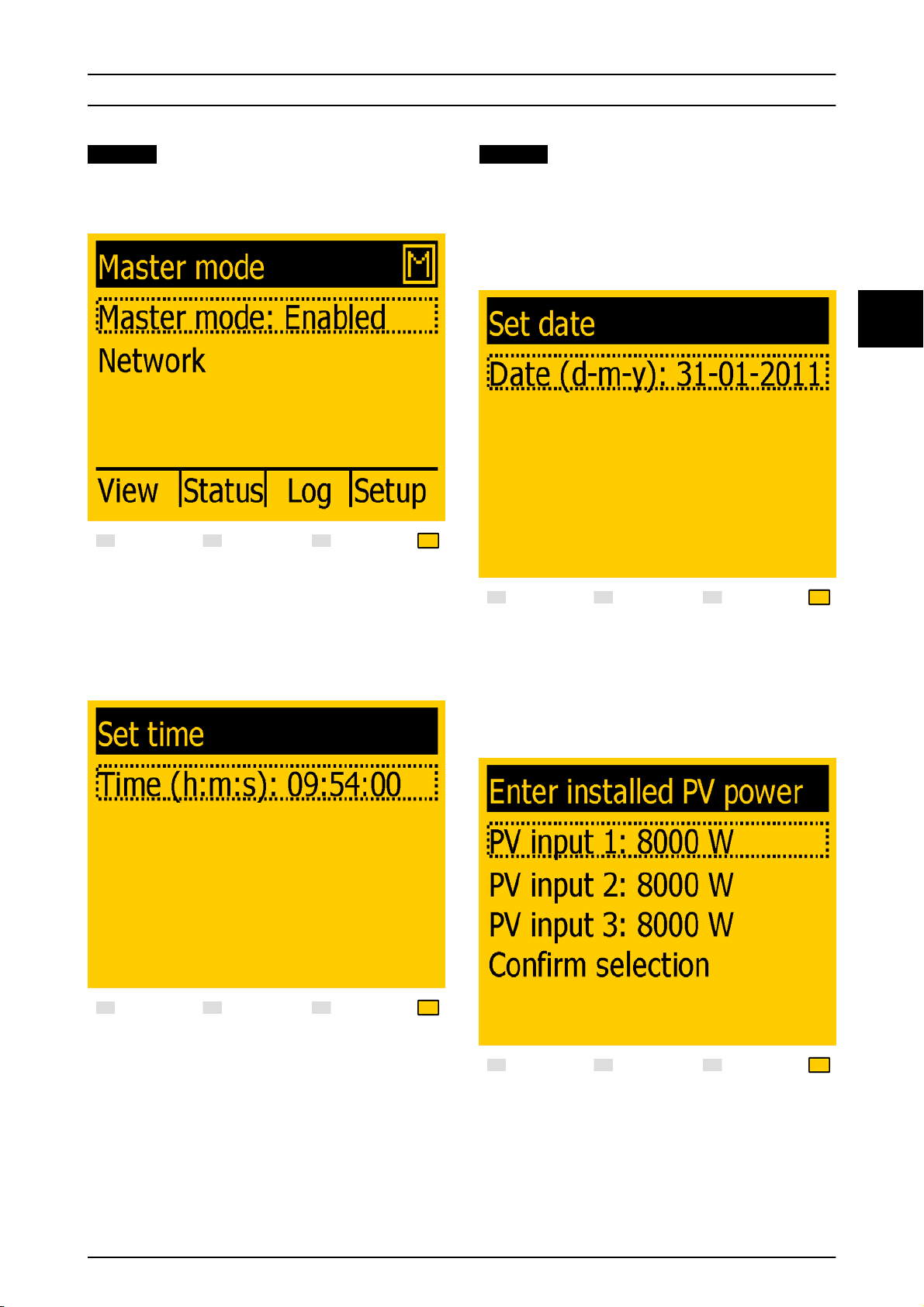

Illustration 3.3 Master Mode

NOTICE

Set the time and date accurately. The inverter uses this

information for logging. If an incorrect time/date is

accidentally set, correct it immediately in the set date

and time menu [Setup → Inverter details → Set date and

time].

3

To enable master mode go to the Inverter details menu

[Setup → Inverter details → Master mode] and set master

mode to Enabled.

Illustration 3.4 Set Time

Illustration 3.5 Set Date

Set date as prompted by the display. Press [OK] to select.

Press [

pressing [OK].

] to scroll up through the numbers. Select by

▲

Set time as prompted by the display. Press [OK] to select

number. Press [

by pressing [OK].

The clock is 24-hour format. The inverter accounts for

daylight saving automatically.

] to scroll up through the numbers. Select

▲

L00410568-03_2q / Rev. date: 2014-06-20 21

Illustration 3.6 Installed PV Power

Enter the amount of installed PV power for each of the PV

inputs. When a group of PV inputs are connected in

Page 23

Initial Setup and Start

parallel, enter average installed PV power for each PV

input, as shown in the examples.

3

PV String Configuration

Example 1: PV1, PV2 and PV3 are each set

to individual mode.

Nominal PV power installed:

PV 1: 6000 W PV 1: 6000 W

PV 2: 6000 W PV 2: 6000 W

PV 3: 3000 W PV 3: 3000 W

Example 2: PV1 and PV2 are set to

parallel mode and have a total of 10 kW

PV power installed. PV3 is set to

individual mode and has nominal 4 kW

PV power.

Example 3: PV1 and PV2 are set to

parallel mode and have a total of 11 kW

PV power installed. PV3 is set to [Off] and

has no PV installed.

Table 3.2 Examples of Installed PV Power

Enter this value for

“Installed PV power”

PV 1: 5000 W

PV 2: 5000 W

PV 3: 4000 W

PV 1: 5500 W

PV 2: 5500 W

PV 3: 0 W

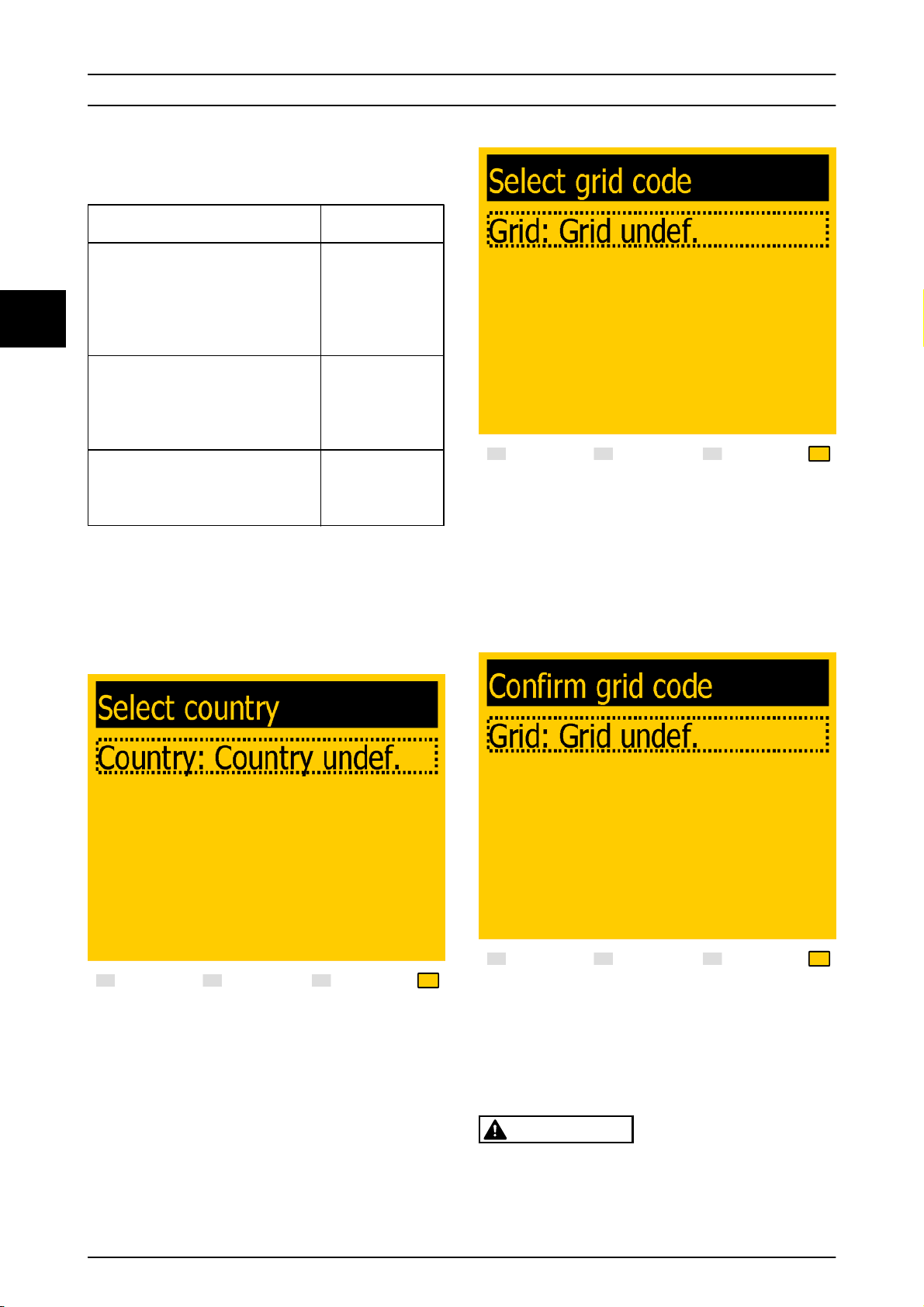

The display will now show ‘Select country’. The setting is

‘undefined’ at initial start-up. Press [▼] to scroll down

through the list of settings. To select the desired setting,

press [OK].

Illustration 3.8 Select Grid Code

The display will now show ‘Select grid code’. The grid code

is set to ‘undefined’ at initial start-up. To select the grid

code, press [OK]. Press [

] to scroll down through the list.

▼

Select the grid code for the installation by pressing [OK]. It

is very important to choose the correct grid code.

Illustration 3.9 Confirm Grid Code Selection

Illustration 3.7 Select Country

To confirm, select the grid code again and press [OK]. The

settings for the chosen grid code have now been

activated.

WARNING

Correct selection of grid code is essential to comply with

local and national standards.

22 L00410568-03_2q / Rev. date: 2014-06-20

Page 24

Initial Setup and Start

3

NOTICE

If the 2 grid code selections do not match, they will be

cancelled and it will be necessary to repeat this step. If

an incorrect grid code is accidentally accepted at the

first selection, simply accept the “Grid: Undefined” in the

confirm grid code screen. This cancels the grid code

selection and enables a new selection.

NOTICE

Access on security level 2 is granted for 5 hours after

setup completion. Logout must be performed before

leaving the site. If an incorrect grid code is selected

twice, it can be changed within the 5 hours. Access on a

higher level is possible by locking the configuration and

logging on again using a 24-hour password. Only

authorised personnel is allowed to configure the

inverter. Changes will be logged and SMA Solar

Technology AG accepts no liability for damage caused by

changing the inverter configuration.

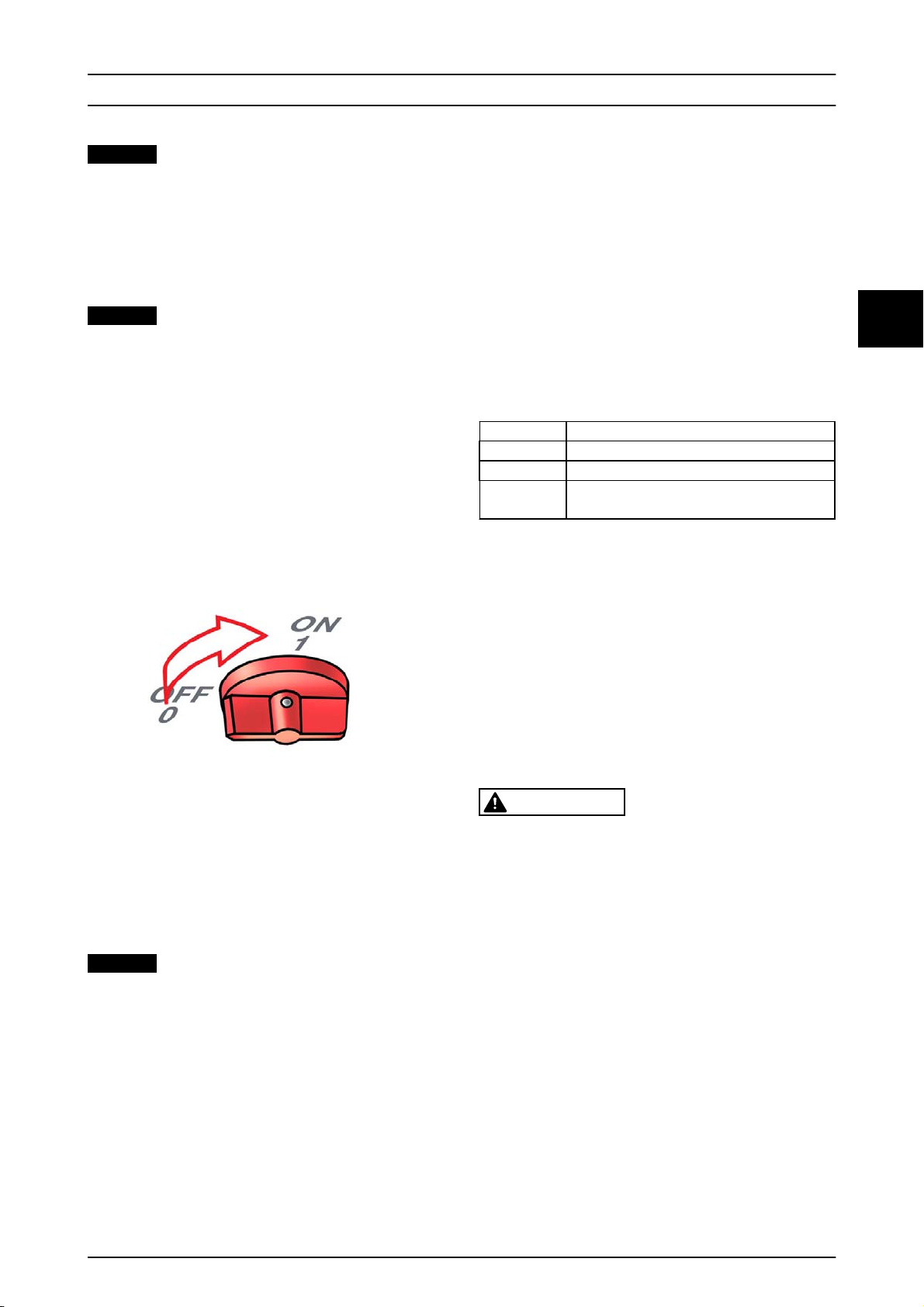

3.2.2 Turn PV Load Switch On

3.3 Web Interface

These instructions describe the web interface, which

facilitates remote access to the inverter.

Refer to the download area at www.SMA.de for the newest

instructions.

For all text entries, the software supports characters

compatible with Unicode.

For inverter name, no spaces are permitted.

For plant, group and inverter name, only the following

characters are supported:

Letters abcdefghijklmnopqrstuvwxyz

Capital letters ABCDEFGHIJKLMNOPQRSTUVWXYZ

Numbers 0123456789

Special

characters

- _.

3.3.1 Prepare for Setup

Ensure that the following items are ready before

commencing setup:

Master inverter is designated and prepared, see

•

3.1.3 Preparation for Master Inverter.

Ethernet connection from PC to inverter is

•

established, see also 2.7 RS-485 or Ethernet

Connections.

3

Illustration 3.10 Turn the PV Load Switch On

3.2.3 Start-up

The inverter starts automatically if sufficient solar

irradiation is available. The start-up will take a few minutes.

During this period, the inverter performs a self-test.

NOTICE

The inverter is protected against reversed polarity. The

inverter does not generate power until any reversed

polarity is corrected.

3.2.4 Autotest Procedure

For certain grid codes, an automatic test of the inverter

can be initialised by activating the inverter autotest

procedure:

Via the display, go to [Setup → Autotest] and

•

press [OK].

3.3.2 Initial Setup via Web Interface

CAUTION

Change the Web Server logon and password of the

master inverter immediately for optimal security when

connecting to the Internet. To change the password go

to [Setup → Web Server → Admin].

Setup Sequence

1. Ensure that the master inverter is designated and

prepared, see 3.1.3 Preparation for Master Inverter.

2. On the PC, wait until Windows reports limited

connectivity (if no DHCP is present). Open the

Internet browser and ensure that pop-ups are

enabled.

3. Type 1 of the following options in the address

field:

L00410568-03_2q / Rev. date: 2014-06-20 23

Page 25

Initial Setup and Start

3

For Windows XP and older Windows

•

versions: http://invertername, where

'invertername' is the final 10 digits of

the serial number.

For Windows 7 and newer Windows

•

versions: http://IP address. The IP

address can be found in the display.

It is not possible to use the installation wizard with

Windows 7 and 8.

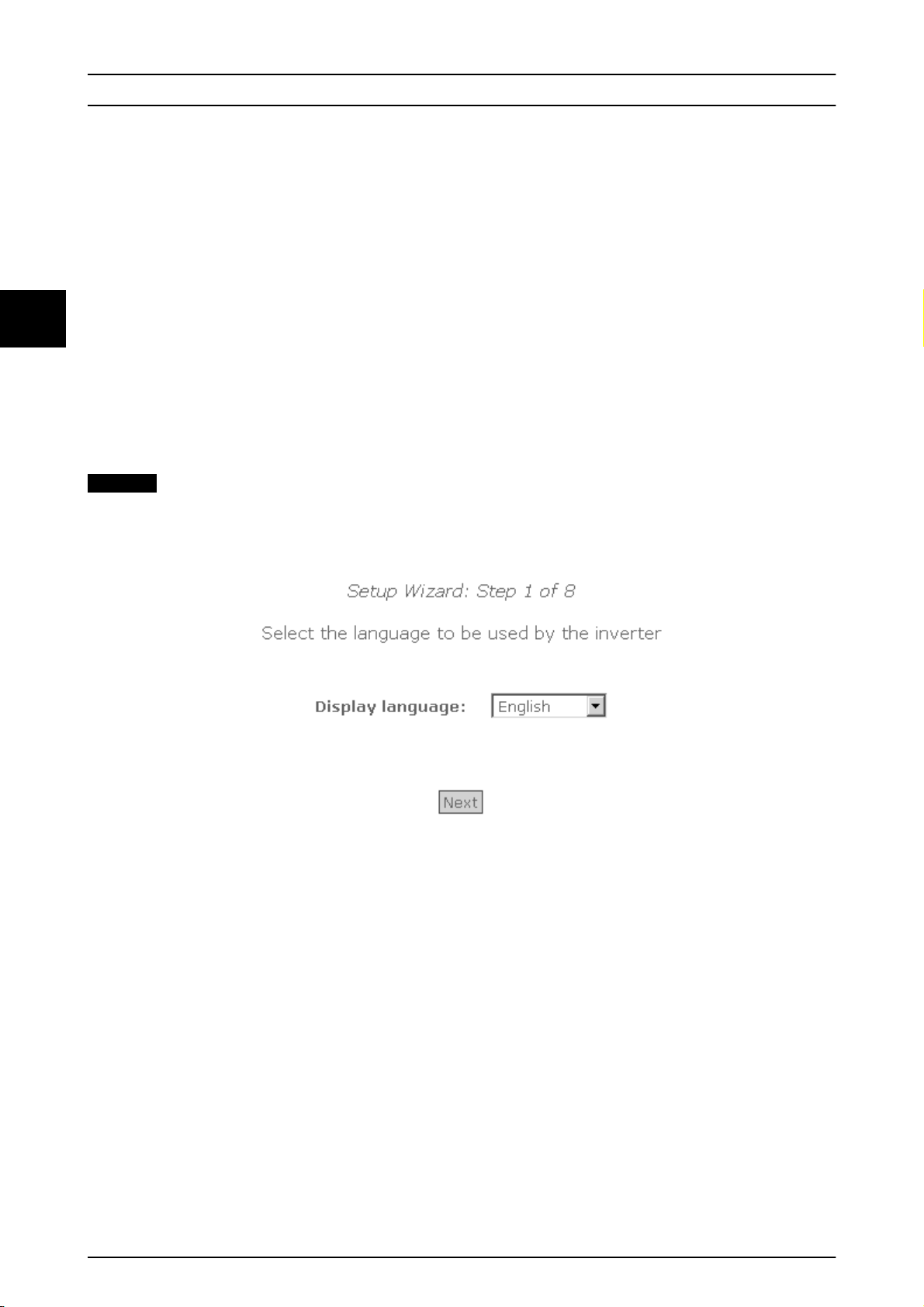

3.3.3 Setup Wizard

Step 1 of 8: Display language

Select display language.

The default language is English.

•

NOTICE

This selection defines the language in the display, not

the grid code.

Find the serial number marked on the product label on the

side of the inverter enclosure. See Illustration 1.2.

1. The web interface logon dialog opens.

2. Type 'admin' in the user and password fields, and

click ‘Log in’.

3. At initial logon the inverter runs a setup wizard.

Illustration 3.11 Step 1 of 8: Display Language

To change the language setting later, go to [Setup → Setup Details].

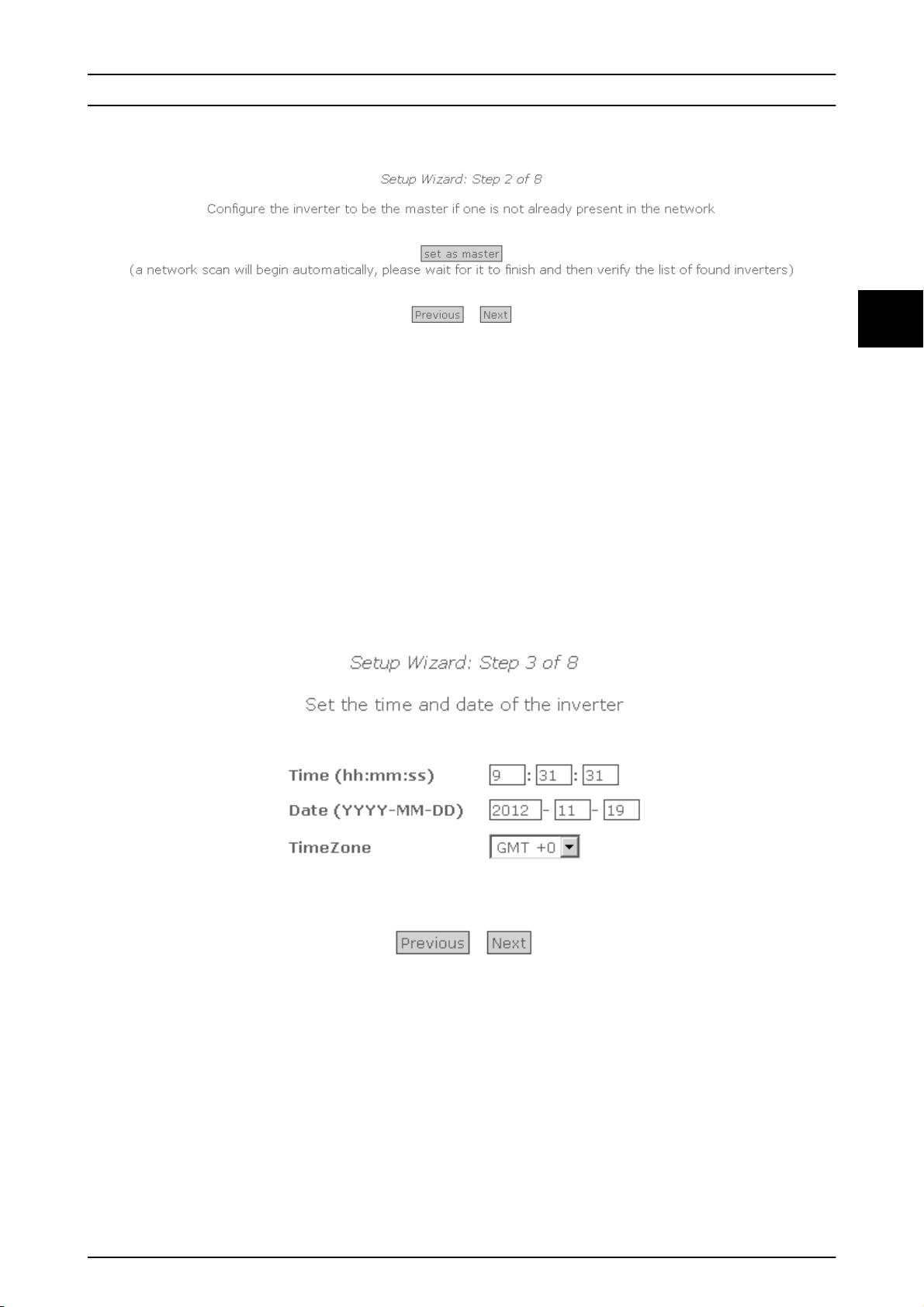

Step 2 of 8: Master setting

To set up a master inverter, click on ‘Set as master’.

A scan runs to identify inverters in the network.

•

A pop-up window shows the inverters successfully identified.

•

Click [OK] to confirm that the correct number of inverters has been found.

24 L00410568-03_2q / Rev. date: 2014-06-20

Page 26

Initial Setup and Start

3

Illustration 3.12 Step 2 of 8: Master Setting

To change this setting later, go to [Inverter level: Setup → Inverter details].

Step 3 of 8: Time and date

Enter:

Time in 24-hour format

•

Date

•

Time zone

•

3

Accuracy is important, because date and time are used for logging purposes. Adjustment for daylight savings is automatic.

Illustration 3.13 Step 3 of 8: Time and Date

To change these settings later, go to [Inverter level: Setup → Set date and time].

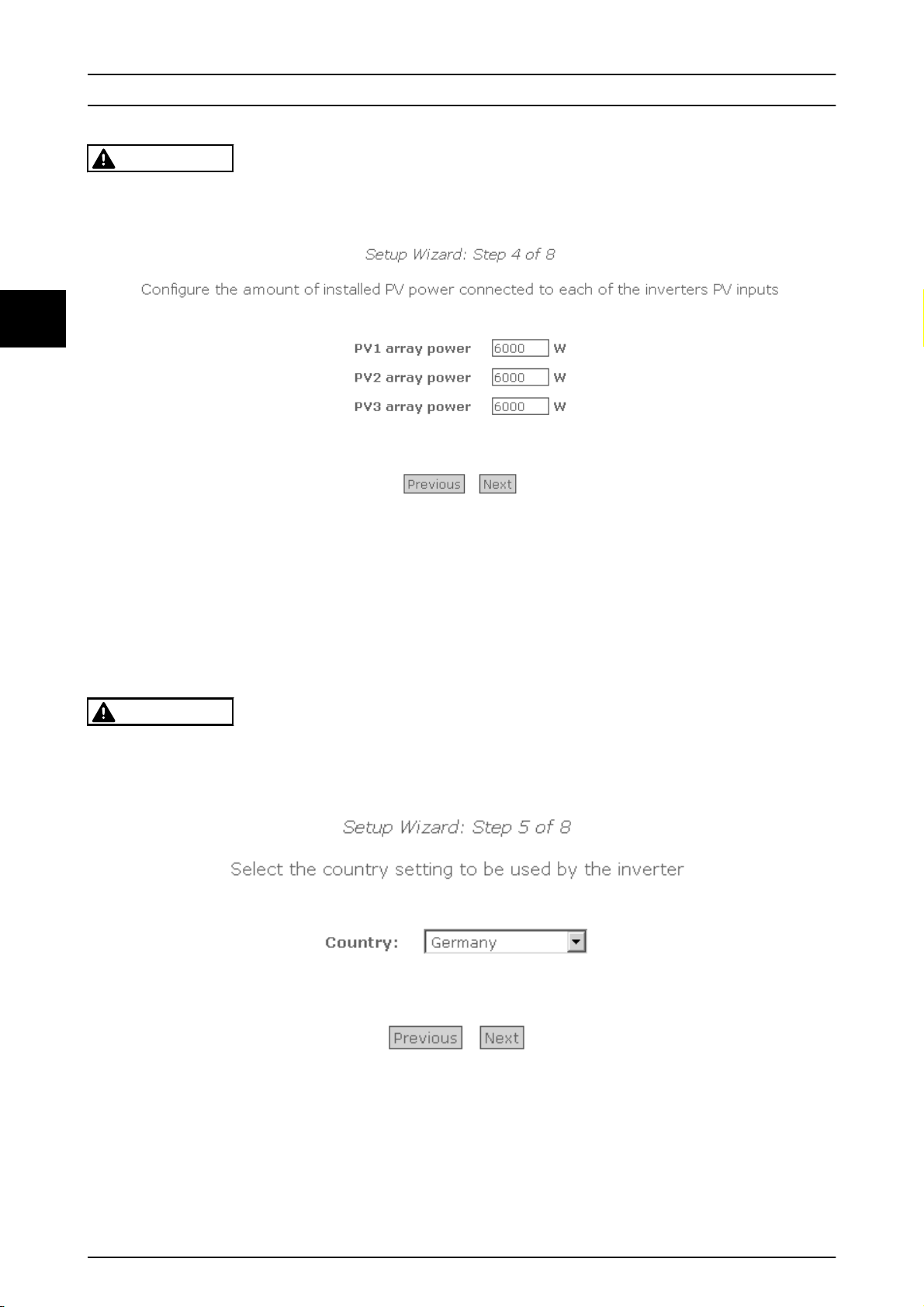

Step 4 of 8: Installed power

For each PV input, enter installed PV power.

The installed PV power values are used to calculate performance ratio. For more information refer to the FLX Series Design

Guide.

L00410568-03_2q / Rev. date: 2014-06-20 25

Page 27

3

Initial Setup and Start

CAUTION

Incorrect setting can have serious consequences for

production efficiency.

Illustration 3.14 Step 4 of 8: Installed Power

To change the installed power, go to [Inverter level: Setup → Calibration, PV Array].

Step 5 of 8: Country of Installation

Select the setting to match the location of the installation.

CAUTION

Correct selection is essential to comply with local and

national standards.

Illustration 3.15 Step 5 of 8: Country of Installation

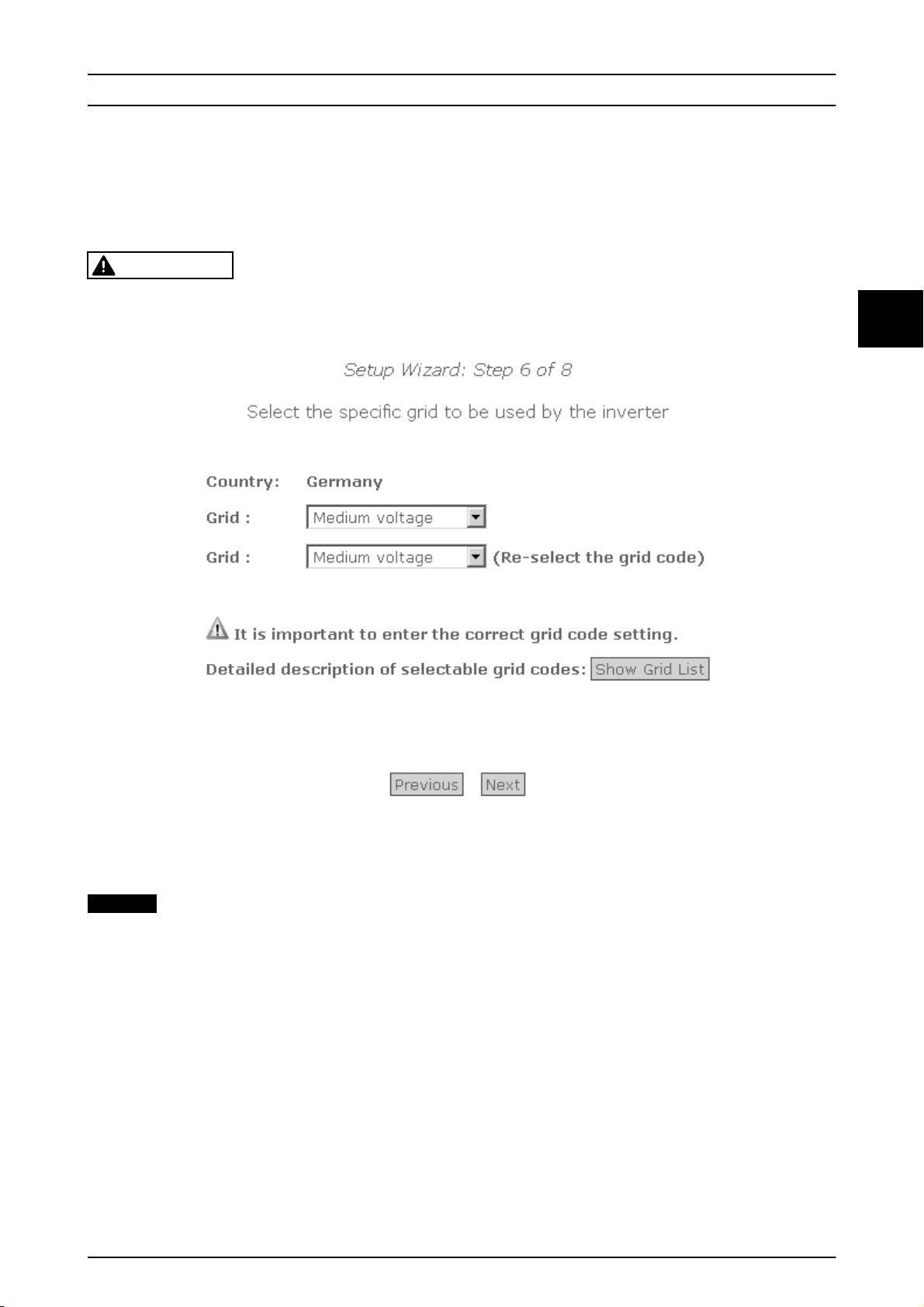

Step 6 of 8: Grid code

Select the grid code to match the location of the installation.

26 L00410568-03_2q / Rev. date: 2014-06-20

Page 28

Initial Setup and Start

3

The default setting is [undefined].

•

Select the grid code again, to confirm.

The setting is activated immediately.

•

CAUTION

Correct selection is essential to comply with local and

national standards.

3

Illustration 3.16 Step 6 of 8: Grid Code

NOTICE

If the initial and confirmation settings are different,

grid code selection is cancelled, and

•

the wizard recommences step 5.

•

If initial and confirmation settings match, but are

incorrect, contact service.

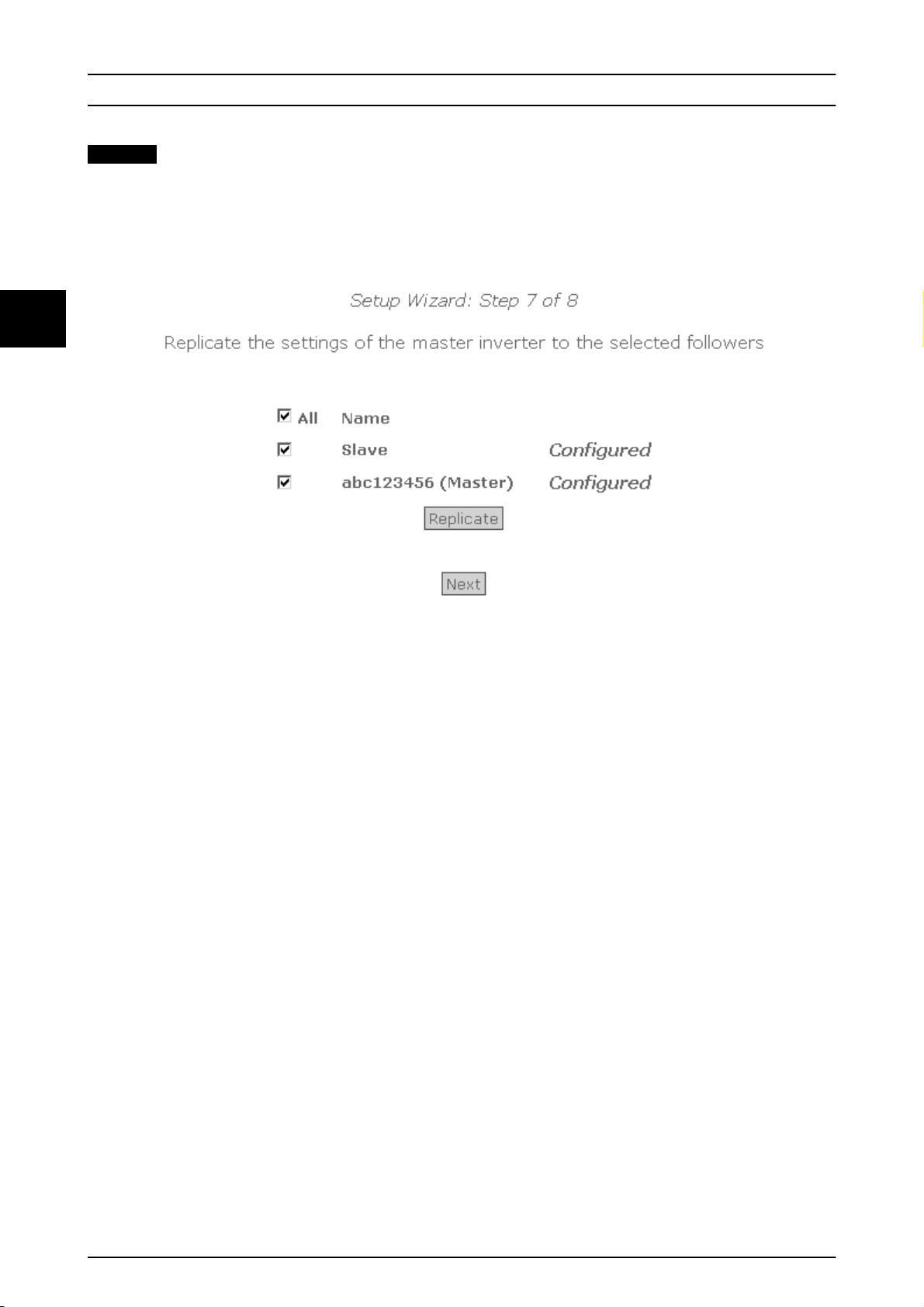

Step 7 of 8: Replication

This step is available for a master inverter with followers connected. To replicate the settings from steps 1–6 to other

inverters in the same network:

Select inverters.

•

Click [Replicate].

•

L00410568-03_2q / Rev. date: 2014-06-20 27

Page 29

3

Initial Setup and Start

NOTICE

When the PV configuration, installed PV power and PV

array area of follower inverters in the network differ

from that of the master, do not replicate. Set up the

follower inverters individually.

Illustration 3.17 Step 7 of 8: Replication

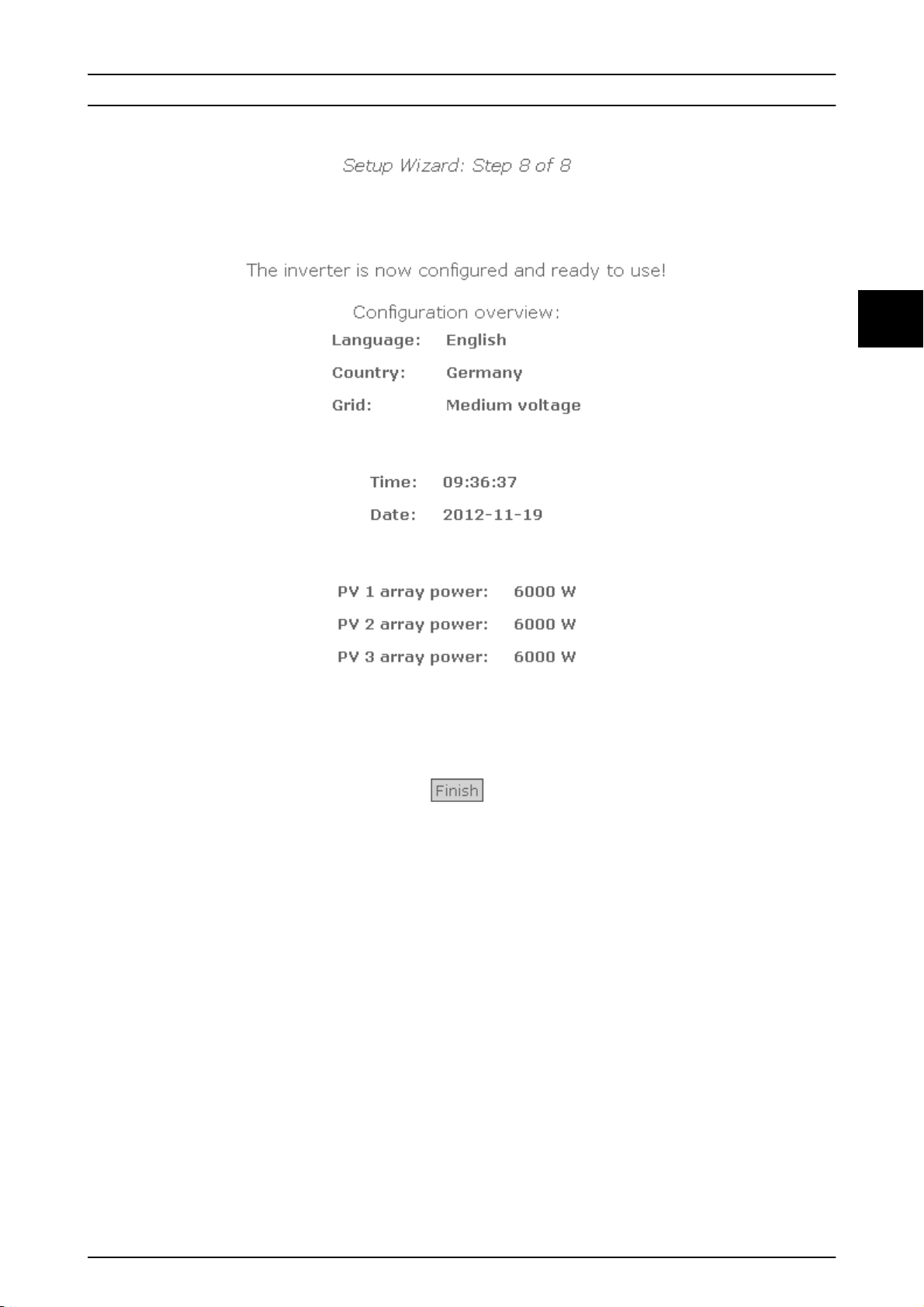

Step 8 of 8: Inverter start-up

The wizard displays an overview of the setup configuration.

Click on [Finish] to start up the inverter. Start-up will commence when solar irradiation is sufficient.

The start-up sequence, including self-test, takes a few minutes.

28 L00410568-03_2q / Rev. date: 2014-06-20

Page 30

Initial Setup and Start

3

3

Illustration 3.18 Step 8 of 8: Inverter start-up

To change the setup later, access the inverter via the web interface or the display, at inverter level.

To change the name of the inverter, go to [Inverter level: Setup → Inverter details].

•

To enable master mode, go to [Inverter level: Setup → Inverter details].

•

L00410568-03_2q / Rev. date: 2014-06-20 29

Page 31

3

Initial Setup and Start

3.3.4 Web Interface

The web interface overview is structured as follows.

Illustration 3.19 Overview

1.

Plant name: Displays the current plant name:

Click on the plant name to display the

•

plant view.

Change the plant name at [Setup →

•

Plant details].

2.

Group menu: Displays groups of inverters:

Inverters join group 1 by default.

•

Click on a group name to display the

•

group view, and a list of inverters in the

group.

Change the group name via [Setup →

•

Inverter details] in the inverter view.

3.

Group members: Displays the inverter names in

the group currently selected. The default inverter

name is based on the serial number.

Click on an inverter name to display the

•

inverter view.

Change the name of the inverter via

•

[Setup → Inverter details] in the inverter

view.

4.

Main menu: This menu corresponds to the

inverter display main menu.

5.

Submenu: The submenu corresponds to the main

menu item currently selected. All submenu items

belonging to a particular main menu item are

displayed here.

6.

Content area: The main menu and submenus of

the web interface are identical to the menus in

the inverter display. The submenu content

displayed here corresponds to the submenu

selected: [Overview]. On some pages, a horizontal

menu is provided for improved readability.

7.

Footer: Options in the footer bar:

Language: Opens a pop-up window.

•

Click on the country flag to change the

language of the web interface to the

desired language for the active session.

Contact: Opens a pop-up window,

•

which displays SMA Solar Technology

AG contact information.

Logout: Opens the login/logout dialog

•

box.

Security level: Displays the current

•

security level as explained in the section

Security Levels.

30 L00410568-03_2q / Rev. date: 2014-06-20

Page 32

Initial Setup and Start

3

NOTICE

The content of the main menu changes depending on

which view is currently selected: the plant, a group of

inverters, or an individual inverter.

3.3.5 Plant, Group and Inverter Views

The overview screens for plant view, group view, and

inverter view display the same overall status information.

3

Illustration 3.20 Overall Plant Status

L00410568-03_2q / Rev. date: 2014-06-20 31

Page 33

3

Initial Setup and Start

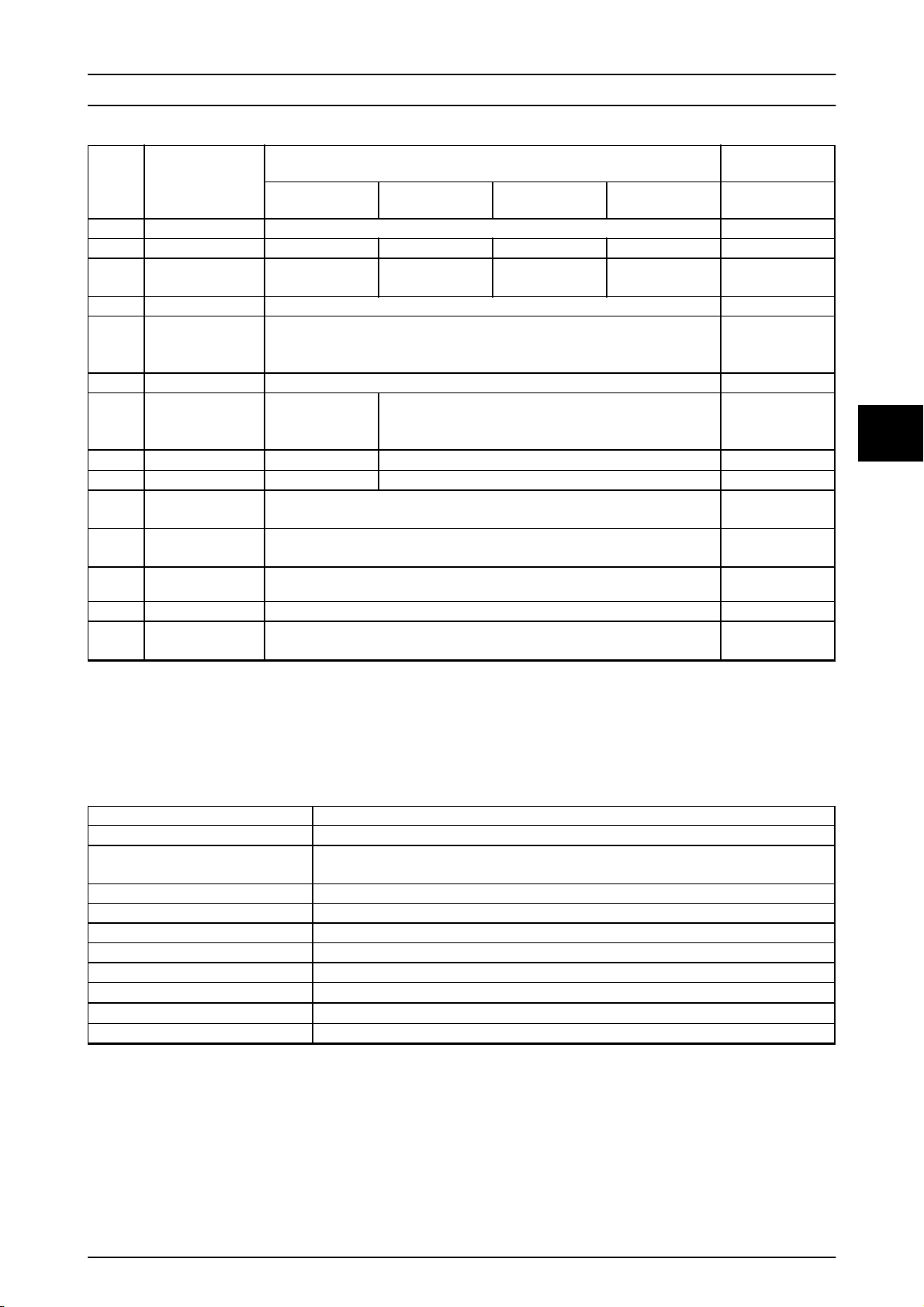

Item Unit View Description

Plant and

Group

Overall plant status - x

Current production kW x x Real time energy production level

Yield today kWh x x Cumulative yield for the day

Total revenue Euro x x Cumulative revenue earned since initial startup

Total CO

Performance ratio % x x Real time performance ratio

Total yield kWh x x Cumulative yield since initial startup

Power limit adjustment % x Maximum power limit as % of nominal inverter AC output rating

saving kg x x Cumulative CO2 saved since initial startup

2

Inverter

x

Red: Plant PR <50%, or:

Any inverter in the network

- in fail safe mode, or

- missing from the scan list, no contact with the master

Yellow: Any inverter in the network

- with PR <70%, or

- in Connecting or Off grid mode

Green: Plant PR ≥70%, and

- all inverters with PR ≥70%, and

- all inverters in On grid mode

Red: Inverter PR <50%, or inverter has an error

Yellow: Inverter PR between 51% and 70%, or inverter in Connecting

mode

Green: No errors, and

- inverter PR ≥70%, and

- inverter in On grid mode

Table 3.3 Information Displayed in Plant View, Overview Screen

NOTICE

To calculate performance ratio PR, an irradiation sensor

is required, see [Setup → Calibration].

3.3.6 Autotest Procedure

For certain grid codes, an automatic test of the inverter

can be initialised by activating the inverter autotest

procedure:

Via the web interface, go to [Inverter level: Setup

•

→ Setup details → Autotest] and click on [Start →

Test].

32 L00410568-03_2q / Rev. date: 2014-06-20

Page 34

Service

4

4Service

4.1 Troubleshooting

here. When the inverter enters the On grid mode, the most

recent event is cleared and is shown as 0.

This guide provides tables showing messages appearing in

the inverter display, known as events. The tables contain

descriptions as well as which actions to take, when an

event arises. For the full event list, refer to the FLX Series

User Guide.

To view events, go to the Log menu and enter the

The event code is made up of 2 elements: the group

classifier and the event ID. The group classifier describes

the general type of the event, while the event ID is used

to identify the specific event.

Table 4.1 is an overview of how the tables of inverter

events are constructed and how to use them.

Eventlog menu. The latest event registered by the inverter,

as well as a list of the 20 most recent events, is shown

Event Type

-

ID Status message Description Action DNO Hotline PV

201 Tpower_high. The internal temperature of the

inverter is too high.

Table 4.1 How to Read the Event Tables

Event Type

ID

Display

Description

Action

DNO

Hotline

PV

Indicates whether the event relates to grid, PV, internal or fail safe issues.

The specific event ID.

Text shown in display.

Description of the event.

Description of which action to take prior to contacting any other parties.

If the prescribed action has not identified the malfunction, contact the DNO for further assistance.

If the prescribed action has not identified the malfunction, contact the inverter hotline for further assistance.

If the prescribed action has not identified the malfunction, contact the PV supplier for further assistance.

Check the inverter is not covered and that the

ventilation duct is not blocked. If not, call installer.

-x -

4

Grid-related Events

ID Status

Description Action DNO Hotline PV

message

1–6 Grid voltage too low. Call the installer and inform about the grid-phase voltage.

Check voltage and AC installation, if the voltage is zero

check the fuses.

7–9 Grid voltage average over 10

minutes too high.

10–15 Grid voltage too high.

16–18 The inverter has detected a

voltage peak on the grid.

19–24 Grid frequency too low or too

high.

25–27 Loss of mains, Phase-to-phase

voltages too low.

28–30 Loss of mains, ROCOF out of

range.

31–33 DC grid current too high. For occurrence several times daily, contact installer.

Call the installer and inform about the grid-phase voltage.

Check that the installation is correct according to the installation guide. If so, then increase the mean voltage limit

according to section Functional Safety.

Call the installer and inform about the grid-phase voltage.

Check voltage and AC installation.

Call the installer and inform about the grid frequency.. x - -

Call the installer and inform about the voltage on all three

phases.

Check the phase-to-phase voltages and the AC installation.

If the event reoccurs several times each day, contact the

DNO.

Installer: Perform on-site grid analysis.

x- -

x- -

x- x- -

x- -

x- -

-x -

L00410568-03_2q / Rev. date: 2014-06-20 33

Page 35

Service

4

ID Status

Description Action DNO Hotline PV

message

34–37 Residual Current Monitoring Unit

(RCMU) has measured an

excessive current.

40 AC grid notOKThe AC grid has been out of

range for more than 10 minutes

(frequency and/or voltage).

41–43 The inverter has detected that

grid voltage was below a certain

level.

47 PLA below

threshold

48–53 Grid

frequency

too low or

too high

54–56 DC grid current too high (stage

246 A grid event was detected and

The inverter disconnects from

grid if PLA is below 3% of

nominal power.

Call the installer and inform about the grid frequency.

2).

inverter was stopped by the

redundant safety circuit.

Turn both DC and AC off and wait until the display turns

off. Then turn on DC and AC and observe if the event

reoccurs. If the event reoccurs, call the installer.

Installer: Visual inspection of all PV cables and modules.

Call the installer and inform about Frequency, SW version

and Grid code setting

Installer: Check the AC installation.

If this event is reported several times each day, contact the

installer.

Installer: Perform on-site grid analysis.

Contact the DNO and obtain status on active power

reduction (PLA).

Check the AC installation.

For occurrence several times daily, contact installer.

Installer: Perform on-site grid analysis.

A grid event was detected and inverter was stopped by the

redundant safety circuit. Check the event log. If the majority

of entries are of type 246, call the service department.

Otherwise wait 24 hours and check again.

-x -

x- -

x- -

x- -

x- -

-x -

Table 4.2 Grid-related Events

PV-related Events

ID Status

Description Action DNO Hotline PV

message

100-102 PV negative Input current is negative, polarity

incorrect.

103-105 PV current is

too high/

waiting.

112-114 PV config fault Call the installer.

115 PV ISO too low The resistance between ground and

116-118 PV wrong polarity Call the installer.

121-123,

125

258 PV voltage too

PV ISO low PV1, PV2, PV3, multiple

high/waiting

Too many PV modules connected in

parallel. Should only appear on newly

installed systems.

PV is too low for the inverter to start

up. This will force the inverter to make

a new measurement after 10 minutes

have passed.

(related to 115)

PV voltage is too high. Check that installation and layout correspond

Call the installer.

Installer: Check polarity, if correct, call service.

Call the installer.

Installer: Check no. of strings in parallel and

current ratings. Has the current limit been

exceeded? Has the inverter derated on PV

current? Reconnect strings in parallel, possibly

install a second inverter.

Installer: Call service.

Make a visual inspection of all PV cables and

modules for correct installation according to

the installation guide. The event could indicate

that the PE connection is missing.

Installer: Call service.

Call the installer.

Installer: Call service.

to recommendations in the manuals.

-- x

-x x

-- x

-x x

-x x

-x x

-x x

Table 4.3 PV-related Events

34 L00410568-03_2q / Rev. date: 2014-06-20

Page 36

Service

4

Internal Events

ID Status

Description Action DNO Hotline PV

message

201–208 The internal temperature of the

inverter is too high.

209, 210 Voltage on DC bus is too high. Reset the inverter by disconnecting DC and AC,

211 Fan rpm low Fan speed is too low. Is the inverter fan blocked?

212 DC bus

balance

timeout

213–215 Internal error Voltage measured

216–221 Current measured on AC side is too

224 RCMU over

range

225–240 Failure in Memory/ EEPROM. Restart the inverter. If event persists, call the

241, 242,

249

243, 244 Internal error. -x 247 FSP plausi-

248, 251 Self test failed

252-254 Current measured on AC side is too

255–257 Islanding protection trip. Call the installer.

260 The resistance between ground and

261-262 PV current measurements failed. Call the installer.

Internal communication error. - x -

bility fault

FSP fail safe

Inverter unable to balance DC bus. Call the installer.

before and after the relay differs by

more than 20 V.

high.

A wire is broken in the RCMU. Call the installer.

A plausibility fault has occurred in

the functional safety processor.

The self-test has failed. - x -

high.

PV is too low for the inverter to start

up. This will force the inverter to

make a new measurement after 10

minutes have passed.

Check the inverter is not covered and that the

ventilation duct is not blocked. If not, call the

installer.

using the switches. If the event is repeated, call

the installer. Installer:

Check the maximum PV voltage using the display

to see if it is above the limits.

Yes: Clean the fan, No: Call the installer.

Installer: Call service.

Call the installer.

Installer: Call service.

Call the installer.

Installer: Call service.

Installer: If self-test does not complete

successfully, call service partner.

installer.

Installer: Call service.

Check event log for other grid events (1-55) and

follow the instructions for these events. If the

event persists, call the installer.

Call the installer.

Installer: Call service.

Installer: Call service.

Call the installer.

Installer: Call service.

Installer: Call service.

-x -

-x -

-x -

-x -

-x -

-x -

-x -

-x -

-x -

-x -

-x -

-x -

-x x

4

Table 4.4 Internal Events

L00410568-03_2q / Rev. date: 2014-06-20 35

Page 37

4

Service

Events Caused by the Self-test

ID Description Action DNO Hotline PV

264-271 Measurement circuit test failed. Restart the inverter. If event persists, call the installer.

Installer: Call service.

352 RCMU self-test failed. Call the installer.

353 Current sensor test failed. -x 356-363 Transistor and relay test failed, or inverter

relay has failed (contact assumed welded).

364 Neutral connection is damaged or missing. Call the installer. Installer: Check AC installation for failures

365 Earth wire failed. Call the installer.

Table 4.5 Events Caused by the Self-test

Installer: Call service.

on neutral connection. Call service.

Installer: Call service.

-x -

-x -

-x -

-x -

-x -

4.2 Maintenance

Normally, the inverter needs no maintenance or

calibration.

Ensure that the heat sink at the rear of the inverter is not

covered.

Clean the contacts of the PV load switch once per year.

Clean by cycling the switch to on and off positions 10

times. The PV load switch is located at the base of the

inverter.

For correct operation and long service life, ensure free air

circulation

around the heat sink at the top and side of the

-

inverter where the air exhausts, and

to the fan at the inverter base.

-

To clear obstructions, clean using pressurised air, a soft

cloth, or a brush.

WARNING

Temperature of the heat sink can exceed 70 °C.

36 L00410568-03_2q / Rev. date: 2014-06-20

Page 38

Technical Data

5

5 Technical Data

5.1 Specifications

5.1.1 Inverter Specifications

Nomen-

Parameter

clature

AC

|S| Rated apparent

power

P

ac,r

V

ac,r

I

acmax

cosphi

f

r

V

dc,r

V

dcmin

V

mppmin

V

mppmax

V

dcmax

V

dcstart

V

dcmin

I

dcmax

Rated active power

Active power at

cos(phi)=0.95

Active power at

cos(phi)=0.90

Reactive power

range

Nominal AC voltage

(AC voltage range)

Rated current AC 3 x 7.2 A 3 x 8.7 A 3 x 10.1 A 3 x 11.6 A 3 x 13 A

Max. current AC

AC current distortion

(THD at nominal

output power, %)

Inrush current 9.5 A / 10 ms

Power factor at

ac,r

100% load

Controlled power

factor range

Standby

consumption

Nominal grid

frequency (range)

DC

Max. PV input power

per MPPT

Nominal power DC 5.2 kW 6.2 kW 7.2 kW 8.3 kW 9.3 kW

Nominal voltage DC

/

MPP voltage - active

-

2)

tracking

power

MPP efficiency, static 99.9%

MPP efficiency,

dynamic

Max. DC voltage

Turn on voltage DC

Turn off voltage DC

Max. MPP current

/ rated

3)

FLX series

56789

5 kVA 6 kVA 7 kVA 8 kVA 9 kVA

1)

5 kW 6 kW 7 kW 8 kW 9 kW

4.75 kW 5.7 kW 6.65 kW 7.6 kW 8.55 kW

4.5 kW 5.4 kW 6.3 kW 7.2 kW 8.1 kW

0 - 3.0 kVAr 0 - 3.6 kVAr 0 - 4.2 kVAr 0 - 4.8 kVAr 0 - 5.4 kVAr

3P+N+PE - 230/400 V (+/- 20 %)

3 x 7.5 A 3 x 9.0 A 3 x 10.6 A 3 x 12.1 A 3 x 13.6 A

-----

>0.99

0.8 over-excited

0.8 under-excited

2.7 W

50 (

±

5 Hz)

5.2 kW 6.2 kW 7.2 kW 8 kW

715 V

220/250 - 800 V 220/260 - 800 V 220/300 - 800 V 220/345-800 V 220/390 - 800 V

99.7%

1000 V

250 V

220 V

12 A per PV input

5

L00410568-03_2q / Rev. date: 2014-06-20 37

Page 39

Technical Data

5

Nomenclature

Parameter

FLX series

56789

Max. short-circuit

current DC (at STC) 13.5 A per PV input

Min. on grid power 20 W

Efficiency

Max. efficiency 97.9% 97.9% 97.9% 97.9% 97.9%

Euro efficiency, V at

dc,r

96.1% 96.4% 96.4% 97.1% 97.2%

Other

Dimensions (H, W,

D), inverter / incl.

667 x 500 x 233 mm / 774 x 570 x 356 mm

packaging

Mounting

recommendation

Weight, inverter /

incl. packaging

Acoustic noise level

4

MPP trackers 2

Operation

temperature range

Nom. temperature

range

Storage temperature

Mounting plate

38 kg / 44 kg

-

-25..60 °C

-25..45 °C

-25..60 °C

Overload operation Change of operating point

Overvoltage

categories

Table 5.1 Specifications

1)

At rated grid voltage (V

2)

To utilise the full range, asymmetrical layouts must be considered

), Cos(phi)=1.

ac,r

including start-up voltage for at least 1 string. Achieving nominal

power will depend on configuration.

Nomen-

Parameter

clature

10 12.5 15 17

AC

|S| Rated apparent

power

P

ac,r

Rated active power

Active power at

cos(phi)=0.95

Active power at

cos(phi)=0.90

Reactive power

range

V

ac,r

Nominal AC voltage

(AC voltage range)

Rated current AC 3 x 14.5 A 3 x 18.2 A 3 x 21.7 A 3 x 24.7 A

1)

10 kVA 12.5 kVA 15 kVA 17 kVA

10 kW 12.5 kW 15 kW 17k W

9.5 kW 11.9 kW 14.3 kW 16.2 kW

9.0 kW 11.3 kW 13.5 kW 15.3 kW

0 - 6.0 kVAr 0-7.5 kVAr 0-9.0 kVAr 0-10.2 kVAr

3P+N+PE - 230/400 V (+/- 20 %)

Grid: OVC III

PV: OVC II

3)

At symmetric input configuration.

4)

SPL (Sound Pressure Level) at 1 m under normal operating

conditions. Measured at 25 °C.

FLX series

38 L00410568-03_2q / Rev. date: 2014-06-20

Page 40

Technical Data

5

Nomenclature

I

acmax

cosphi

ac,r

f

r

V

dc,r

/

V

dcmin

V

mppmin

V

mppmax

V

dcmax

V

dcstart

V

dcmin

I

dcmax

Parameter

FLX series

10 12.5 15 17

Max. current AC

AC current distortion

(THD at nominal

output power, %)

Inrush current 0.5 A / 10 ms

Power factor at

100% load

Controlled power

factor range

Standby

consumption

Nominal grid

frequency (range)

DC

Max. PV input power

per MPPT

Nominal power DC 10.4 kW 12.9 kW 15.5 kW 17.6 kW

Nominal voltage DC

MPP voltage - active

tracking

3)

power

2)

/ rated

-

MPP efficiency, static 99.9%

MPP efficiency,

dynamic

Max. DC voltage

Turn on voltage DC

Turn off voltage DC

Max. MPP current

Max. short-circuit

current DC (at STC) 13.5 A per PV input

3 x 15.1 A 3 x 18.8 A 3 x 22.6 A 3 x 25.6 A

-<2 %

>0.99

0.8 over-excited

0.8 under-excited

2.7 W

50 (

±

5 Hz)

8 kW

715 V

220/430 - 800 V 220/360 - 800 V 220/430 - 800 V 220/485 - 800 V

99.7%

1000 V

250 V

220 V

12 A per PV input

5

Min. on grid power 20 W

Efficiency

Max. efficiency 97.9% 98.0% 98.0% 98.1%

Euro efficiency, V at

dc,r

Other

Dimensions (H, W,

D), inverter / incl.

97.2% 97.3% 97.4% 97.6%

667 x 500 x 233 mm / 774 x 570 x 356 mm

packaging

Mounting

recommendation

Weight, inverter /

incl. packaging

Acoustic noise level

Mounting plate

38 kg / 44 kg 39 kg / 45 kg

4

-55 dB(A)

MPP trackers 2 3

Operation

temperature range

Nom. temperature

range

-25..60 °C

-25..45 °C

L00410568-03_2q / Rev. date: 2014-06-20 39

Page 41

Technical Data

5

Nomenclature

Parameter

FLX series

10 12.5 15 17

Storage temperature

Overload operation Change of operating point

Overvoltage

categories

Table 5.2 Specifications

1)

At rated grid voltage (V

2)

To utilise the full range, asymmetrical layouts must be considered

including start-up voltage for at least 1 string. Achieving nominal

power will depend on configuration.

), Cos(phi)=1.

ac,r

-25..60 °C

Grid: OVC III

PV: OVC II

3)

At symmetric input configuration.

4)

SPL (Sound Pressure Level) at 1 m under normal operating

conditions. Measured at 25 °C.

Parameter FLX series

Connector type Sunclix

Parallel mode Yes

Interface Ethernet (Web interface), RS-485

Options GSM Option Kit, Sensor Interface Option, PLA Option

PV Sweep Yes

Overload operation Change of operating point

Grid supportive functionality Fault ride-through

Active power control

Reactive power control

DC short-circuit protection Yes

5)

5)

Integrated, or via external device

Yes

Table 5.3 Inverter Features and Functionalities

5)

Remote control via external device.

Parameter FLX series

Electrical

Safety (protective class) Class I (grounded)

PELV on the communication and control card

Overvoltage categories Grid: OVC III

Functional

Islanding detection - loss

of mains

Voltage magnitude Disconnection, included

Frequency Disconnection, included

DC content of AC current Disconnection, included

Insulation resistance Connection prevented, included

RCMU - Type B Disconnection, included

Table 5.4 Safety Specifications

Disconnection

•

3-phase monitoring

•

ROCOF

•

Class II

PV: OVC II

40 L00410568-03_2q / Rev. date: 2014-06-20

Page 42

Technical Data

5

5.2 Derating Limits

To ensure that the inverters can produce the rated power,

measurement inaccuracies are taken into account when

enforcing the derating limits stated in Table 5.5.

(Limit = rated value + tolerance).

FLX series

5 6 7 8 9 10 12.5 15 17

Grid current, per phase 7.5 A 9.0 A 10.6 A 12.1 A 13.6 A 15.1 A 18.8 A 22.6 A 25.6 A

Grid power, total 5150 W 6180 W 7210 W 8240 W 9270 W 10300 W 12875 W 15450 W 17510 W

Table 5.5 Derating Limits

5.3 Conformity

International

Standards

Directive LVD 2006/95/EC

Directive EMC 2004/108/EC

Safety IEC 62109-1/IEC 62109-2

Integrated PV load switch VDE 0100-712

Functional Safety IEC 62109-2

EMC immunity

EMC emission

Utility interference EN 61000-3-2/-3 EN 61000-3-11/-12

CE Yes

Utility characteristics

S0 Energy Meter (option) EN62053-31 Annex D

Table 5.6 International Standards Compliance

5 6 7 8 9 10 12.5 15 17

FLX series

EN 61000-6-1

EN 61000-6-2

EN 61000-6-3

EN 61000-6-4

IEC 61727

EN 50160

5

L00410568-03_2q / Rev. date: 2014-06-20 41

Page 43

5

Technical Data

5.4 Installation Conditions

Parameter Specification

Temperature

Relative humidity 95 % (non-condensing)

Pollution degree PD2

Environmental class according to IEC IEC60721-3-3

Air quality - general ISA S71.04-1985

Air quality - coastal, heavy industrial and agricultural zones Must be measured and classified acc. to ISA S71.04-1985

Vibration 1G

Observe product ingress protection class IP65

Max. operating altitude 2000 m above sea level.

Installation Avoid constant stream of water.

−

25 °C - +60 °C (for temperature derating see the FLX Series Design Guide.)

3K6/3B3/3S3/3M2

Level G2 (at 75% RH)

PELV protection is effective up to 2000 m above sea level only.

Avoid direct sunlight.

Ensure adequate air flow.

Mount on non-flammable surface.

Mount upright on vertical surface.

Prevent dust and ammonia gases.

The FLX inverter is an outdoor unit.

Table 5.7 Conditions for Installation

Parameter Condition Specification

Mounting plate Hole diameter 30 x 9 mm

Alignment

Table 5.8 Mounting Plate Specifications

Perpendicular

5.4.1 France UTE Requirements

NOTICE

In France, observe the UTE C 15-712-1 and NF C 15–100

requirements.

For installation in France, apply warning label to front of

inverter.

Illustration 5.1 Warning Label

±

5° all angles

42 L00410568-03_2q / Rev. date: 2014-06-20

Page 44

Technical Data

5

5.5 Cable Specifications

NOTICE

Avoid power loss in cables greater than 1% of the

NOTICE

Table states only cable lengths less than 100 m.

nominal inverter rating by following the values stated in

the tables and illustrations.

Specification FLX series

AC cable maximum

length [m]

AC cable type 5-wire copper cable

AC cable outer diameter 18-25 mm

AC cable insulation strip Strip 16 mm length of insulation from all 5 wires

PE cable diameter Equal to or greater than diameter of AC phase cables

Table 5.9 AC Cable Specifications

1)

Using cable with a diameter less than 4 mm2 is not recommended.

AC cable size 5 6 7 8 9 10 12.5 15 17

2.5 mm

4 mm

6 mm

10 mm

16 mm

2

43 m 36 m 31 m 27 m 24 m 21 m

2

69 m 57 m 49 m 43 m 38 m 34 m 27 m

2

2

2

86 m 74 m 64 m 57 m 52 m 41 m 34 m 30 m

95 m 86 m 69 m 57 m 51 m

2)

Using cable with a diameter less than 6 mm2 is not recommended.

1) 1) 1)

Specification FLX series

DC cable type

DC cable length

Mating connector Sunclix PV-CM-S 2,5-6(+) / PV-CM-S 2,5-6(-)

DC cable size 4 mm

- 4.8 Ω /km

DC cable size 6 mm

- 3.4 Ω /km

2

2

Min. 1000 V, 13.5 A

< 200 m*

200-300 m*

2) 2)

92 m 81 m

5

Table 5.10 DC Cable Specifications

* The distance between inverter and PV array and back, plus the

cumulative length of the cables used for PV array installation.

Consider also the following when choosing cable type and

cross-sectional area:

Ambient temperature

•

Layout type (inside wall, under ground, free air

•

etc.)

UV resistance

•

L00410568-03_2q / Rev. date: 2014-06-20 43

Page 45

Technical Data

5

Illustration 5.2 FLX Series 5, Cable Losses [%] versus Cable

Length [m]

Illustration 5.3 FLX Series 6, Cable Losses [%] versus Cable

Length [m]

Illustration 5.5 FLX Series 8, Cable Losses [%] versus Cable

Length [m]

Illustration 5.6 FLX Series 9, Cable Losses [%] versus Cable

Length [m]

Illustration 5.4 FLX Series 7, Cable Losses [%] versus Cable

Length [m]

44 L00410568-03_2q / Rev. date: 2014-06-20

Illustration 5.7 FLX Series 10, Cable Losses [%] versus Cable

Length [m]

Page 46

Technical Data

5

5.6 Torque Specifications

Illustration 5.8 FLX Series 12.5, Cable Losses [%] versus Cable

Length [m]

Illustration 5.9 FLX Series 15, Cable Losses [%] versus Cable

Length [m]

Illustration 5.11 Overview of Inverter with Torque Indications

1

Parameter Tool Tightening Torque

1M16 cable gland

body

M16 cable gland,

compression nut

2M25 cable gland

body

M25 cable gland,

compression nut

3 Front screw Torx TX 20 1.5 Nm

Table 5.11 Nm Specifications 1

Wrench 19 mm 3.75 Nm

Wrench 19 mm 2.5 Nm

Wrench 27 mm 7.5 Nm

Wrench 27 mm 5.0 Nm

5

Illustration 5.10 FLX Series 17, Cable Losses [%] versus Cable

Length [m]

L00410568-03_2q / Rev. date: 2014-06-20 45

Page 47

5

Technical Data

Illustration 5.12 Overview of Inverter with Torque Indications

2

5.7 Mains Circuit Specifications

Parameter Tool Tightening Torque

1M32 cable gland

body

2M32 cable gland,

compression nut

3Terminals on AC

terminal block

4 PE Torx TX 20 or

Table 5.12 Nm Specifications 2

Wrench 42 mm 7.5 Nm

Wrench 42 mm 5.0 Nm

Pozidriv PZ2 or

Straight slot 1.0 x

5.5 mm

Straight slot 1.0 x

5.5 mm

2.0 - 4.0 Nm

2.2 Nm

FLX series

5 6 7 8 9 10 12.5 15 17

Maximum inverter current, I

Recommended blow fuse type gL/gG

Recommended automatic fuse type B or C

Table 5.13 Mains Circuit Specifications

*)

Always choose fuses according to national regulations.

acmax

*)

*)

7.5 A 9 A 10.6 A 12.1 A 13.6 A 15.1 A 18.8 A 22.6 A 25.6 A

10 A 13 A 13 A 13 A 16 A 16 A 20 A 25 A 32 A

16 A 16 A 16 A 20 A 20 A 20 A 25 A 25 A 32 A

5.8 Auxiliary Interface Specifications

Interface Parameter Parameter Details Specification

RS-485 and Ethernet Cable

RJ-45 connectors:

2pcs RJ-45 for RS-485

2pcs RJ-45 for Ethernet

Galvanic interface insulation Yes, 500 Vrms

Direct contact protection Double/Reinforced insulation Yes

Short-circuit protection Yes

RS-485 only Cable Max. cable length 1000 m

Max. number of inverter

nodes

Ethernet only Communication Network topology Star and daisy chain

Cable Max. cable length between

Max. number of inverters

Cable jacket diameter (

Cable type Shielded Twisted Pair (STP CAT 5e or

Cable characteristic impedance

Wire gauge 24-26 AWG (depending on mating

Cable shield termination Via metallic RJ-45 plug

inverters

⌀

)

2x5-7 mm

– 120

2)

Ω

SFTP CAT 5e)

100

Ω

metallic RJ-45 plug)

63

100 m

1)

100

Table 5.14 Auxiliary Interface Specifications

1)

Max. number of inverters are 100. If GSM modem is used for portal

upload, the number of inverters in a network is limited to 50.

46 L00410568-03_2q / Rev. date: 2014-06-20

2)

For outdoor use, we recommend outdoor burial type cable (if

buried in the ground) for both Ethernet and RS-485.

Page 48

Technical Data

5

Illustration 5.13 Auxiliary Interfaces

5.9 RS-485 and Ethernet Connections

RS-485

Terminate the RS-485 communication bus at both ends.

Termination is automatic when no RJ-45 plug is

•

inserted into the socket. The absence of a mating

connector enables both termination and bias.

In rare cases, bias is unwanted, but termination is

•

required. To terminate the RS-485 bus, mount a

100 Ω termination resistor into an RJ-45 field

mountable connector. Then insert the connector

(with resistor) into the unused RJ-45 connector.

The RS-485 address of the inverter is unique, and defined

at the factory.

1.

GND

2. GND

3.

RX/TX A (-)

4. BIAS L

5. BIAS H

6.

RX/TX B (+)

7. Not connected

8. Not connected