Singer SEQS-6000 Instruction Manual

F-1

INSTRUCTION MANUAL

63

F-2

“IMPORTANT SAFETY INSTRUCTIONS”

“When using an electrical appliance, basic safety precautions should always be followed, including the following.”

“Read all instructions before using this sewing machine.”

“DANGER--

1. “ This sewing machine should never be left unattended when plugged in. Always unplug this sewing machine from the electric

outlet immediately after using and before cleaning.”

“WARNING

1. “Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near children.”

2. “ This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance

by a person responsible for their safety. Children should be supervised to ensure that they do not play with the appliance.”

3. “ Use this sewing machine only for its intended use as described in this manual. Use only attachments recommended by the

manufacturer as contained in this manual.”

4. “ Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped

or damaged, or dropped into water. Return the sewing machine to the nearest authorized dealer or service center for

examination, repair, electrical or mechanical adjustment.”

5. “ If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualied persons in

order to avoid a hazard.”

6. “ Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing machine and foot

control free from the accumulation of lint, dust, and loose cloth.”

7. “Never drop or insert any object into any opening.”

8. “ Indoors use only.”

9. “Do not operate where aerosol (spray) products are being used or where oxygen is being administered.”

10. “To disconnect, turn switch to the off („0“) position, then remove plug from outlet.”

11. “ Switch off or unplug the appliance when leaving it unattended, unplug the appliance before carrying out maintenance or

replacing lamps.”

12. “Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.”

13. “Keep ngers away from all moving parts. Special care is required around the sewing machine needle.”

14. “Never sew with a damaged needle plate as this can cause needle to break.”

15. “Do not use bent needles.”

16. “Do not pull or push fabric while stitching. It may deect the needle causing it to break.”

17. “ Switch the sewing machine off (“0”) when making any adjustments in the needle area, such as threading needle, changing

needle, threading bobbin, or changing presser foot, etc.”

18. “ Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or when making any other user

servicing adjustments mentioned in the instruction manual.”

19. “ To avoid electrical shock never put the machine nor the mains cable or mains plug into water or other liquids.”

20. “ The LED lamp maximum power is 0.3w, maximum voltage is DC 5v, if the LED lamp is damaged, you should not use the

product and send it to the manufacture or service agent to repair or replace at once.”

21. “ Attention the following to avoid injury:

- Unplug the foot controller of the appliance when leaving it unattended:

- Unplug the foot controller of the appliance before carrying out any maintenance.”

“CAUTION

To reduce the risk of electric shock:”

To reduce the risk of burns, re, electric shock, or injury to persons: ”

-

Moving parts-To reduce risk of injury, switch off before servicing. Close cover before operating

-

-

machine.”

“SAVE THESE INSTRUCTIONS”

“This product is for household use, or equivalent.”

FOOT CONTROL (USA & Canada only)

Use Model YC-485 EC or Model JF-1000 with this sewing machine.

POLARIZED PLUGS CAUTION (USA & Canada only)

This appliance has a polarized plug (one blade wider than the other). To reduce the risk of electric shock, this plug is intended

to t in a polarized outlet only one way. If the plug does not t fully in the outlet, reverse the plug. If it still does not t, contact a

qualied electrician to install the proper outlet. Do not modify the plug in any way.

This appliance complies with EEC Directive 2004/108/EC covering the electromagnetic compatibility.

Please note that on disposal, this product must be safely recycled in accordance with relevant National legislation

relating to electrical/ electronic products. If in doubt please contact your retailer for guidance.

SINGER and FUTURA QUARTET are exclusive trademarks of The Singer Company Limited S.à r.l. or its Afliates.

©2011 The Singer Company Limited S.à r.l. or its Afliates. All rights reserved.

TABLE OF CONTENTS

1. GETTING TO KNOW YOUR MACHINE

Machine identication ---------------------------------------------------2

Accessories ----------------------------------------------------------------3

Setting up your machine -----------------------------------------------4

Spool pins ------------------------------------------------------------------4

Winding bobbin -----------------------------------------------------------5

Threading the bobbin thread ------------------------------------------6

Threading the top thread -----------------------------------------------7

Using automatic needle threader ------------------------------- 8 - 9

Needle, thread and fabric chart ------------------------------------ 10

Adjusting top thread tension ---------------------------------------- 11

Changing presser foot ------------------------------------------------ 11

Control panel function ------------------------------------------ 12 - 13

Functions of operation switch panel ------------------------------- 14

2. STARTING TO SEW

Quick reference table of stitch length and width --------- 15 - 16

Straight stitching ------------------------------------------------- 17 - 18

Keeping seams straight, Inserting zippers and piping

Hand-look quilt stitch -------------------------------------------------- 18

Zigzag stitching --------------------------------------------------------- 19

Adjusting stitch width and length, Satin stitch

Placement of patterns

Blind stitch --------------------------------------------------------------- 20

Multi-stitch zigzag ------------------------------------------------------ 21

Stretch stitches --------------------------------------------------- 22 - 25

Straight stretch stitch, Ric-rac stitch,

Honeycomb stitch, Overedge stitch, Feather stitch,

Pin stitch, Ladder stitch, Blanket stitch (1), (2),

Slant pin stitch, Slant overedge stitch,

Greek key stitch, Entredeux stitch, Criss-cross stitch,

Crossed stitch

Decorative Stitching --------------------------------------------------- 25

Continuous patterns --------------------------------------------------- 26

Sewing on a button ---------------------------------------------------- 26

Buttonholes -------------------------------------------------------- 27 - 29

Using buttonhole foot, Procedure, Corded buttonholes

Buttonholing with hard-to-sew fabrics

3. PREPARATION FOR EMBROIDERY SEWING

Before attaching embroidery unit ---------------------------- 30 - 31

Attaching embroidery foot, Inserting the bobbin,

Threading the top thread, Extension table,

Attaching embroidery unit -------------------------------------------- 32

Removing embroidery unit ------------------------------------------- 32

Securing fabric in embroidery hoop ------------------------------- 33

Using fabric and stabilizer ------------------------------------- 34 - 35

Preparing the machine before installing the hoop ------------- 36

Attaching and removing embroidery hoop ----------------------- 36

Installation of software ------------------------------------------ 37 - 38

Operation switches when embroidery unit is attached ----------39

Operation switches, Thread tension control

Troubleshooting -------------------------------------------------- 40 - 43

Helpful information for embroidering with Futura

Multi hoop ---------------------------------------------------------- 44 - 47

Helpful messages when embroidering --------------------------- 48

4. OTHER THINGS YOU SHOULD KNOW

Presser foot lifter ------------------------------------------------------- 49

Feed dog control ------------------------------------------------------- 49

Converting to free-arm sewing ------------------------------------- 49

Performance checklist ------------------------------------------------ 50

Cleaning hook area and feed dogs -------------------------------- 51

Oiling inside the face cover ------------------------------------------ 52

Special accessories --------------------------------------------- 53 - 58

Helpful messages ------------------------------------------------ 59 - 60

For European version

Sewing machine

Dimensions: 567 mm × 240 mm × 317 mm

Mass of the equipment: 10.8 kg

Embroidery unit

Dimensions: 504 mm × 411 mm × 141 mm

Mass of the equipment: 3.0 kg

Rated Voltage: 230 V ~

Rated Frequency: 50 Hz

Rated input: 64 W

Using ambient temperature: Normal temperature

Acoustic noise level: less than 70 db(A)

1

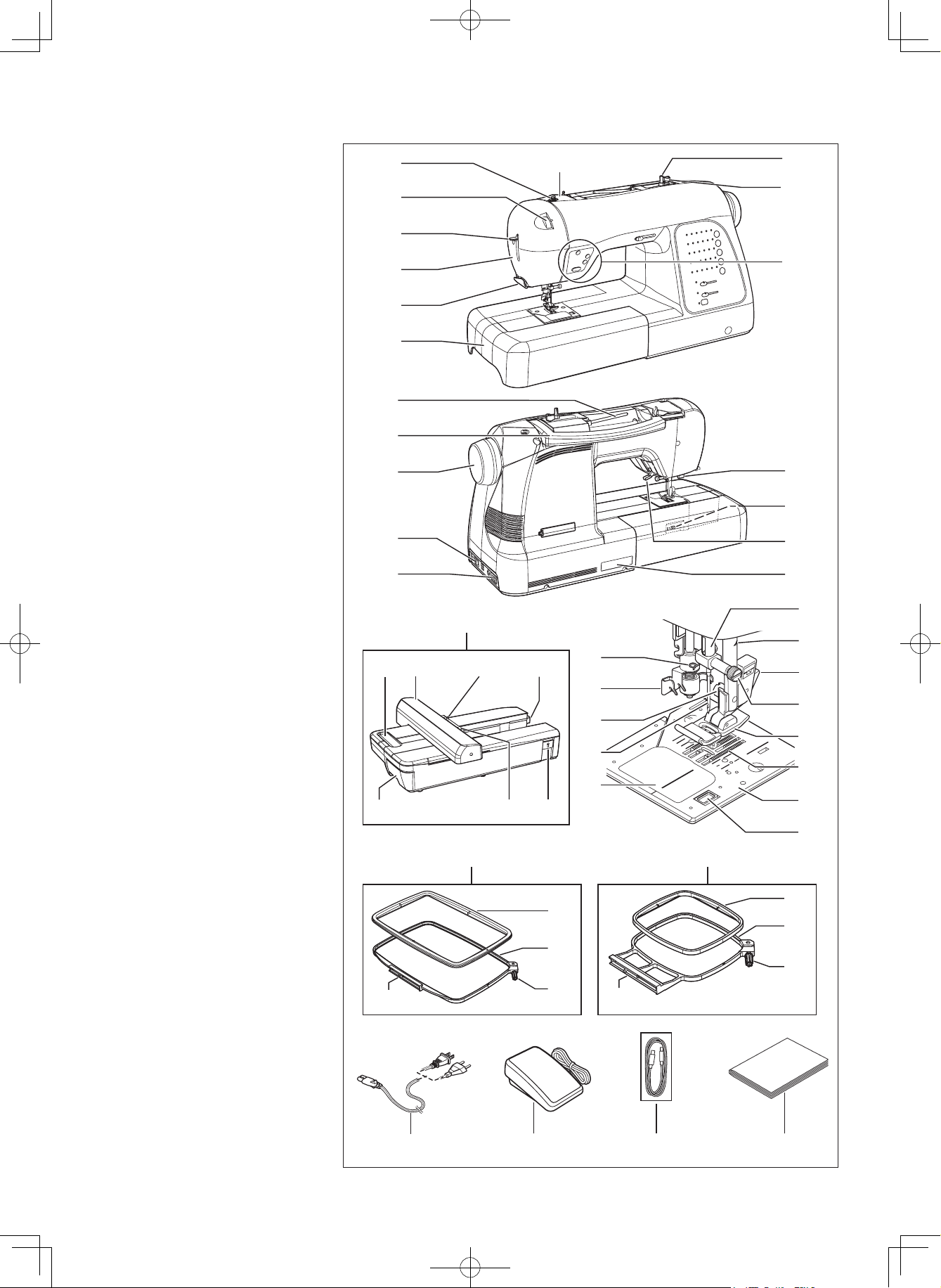

1. GETTING TO KNOW YOUR MACHINE

MACHINE IDENTIFICATION

1. Pre-tension guide

2. Bobbin winding tension disk

3. Thread tension control

4. Threading lever

5. Face cover

6. Thread cutter/holder

7. Extension table (Accessory box)

8. Bobbin winder spindle

9. Bobbin winder latch

10. Operation buttons

11. Horizontal spool pin

12. Handle

13. Hand wheel

14. Power/light switch

15. Cord socket

16. Buttonhole lever

17. Feed dog control

18. Presser foot lifter

19. Identication plate

20. Thread guide

21. Twin thread guide

22. Presser foot screw

23. Needle

24. Bobbin cover plate

25. Needle bar

26. Alternate thread cutter

27. Foot release button

28. Needle clamp screw

29. General purpose foot

30. Feed dogs

31. Needle plate

32. Bobbin cover release button

33. Embroidery unit

34 Hoop release lever

35. Carriage

36. Handle

37. Accessory drawer

38. Hoop bracket

39. Release lever

40. Connector

41. Large hoop

42. Inner frame

43. Outer frame

44. Hoop adjusting screw

45. Hoop mounting plate

46. Small hoop

47. Power line cord

48. Foot control

49. USB cable

50. Instruction manual

NOTE: Be sure the USB cable is

attached to your machine when

doing embroidery.

2 1

3

4

5

6

7

11

12

13

14

15

33

34

3837 39

41

45

8

9

10

16

17

18

19

25

26

20

4036 35

27

21

28

22

29

23

30

24

31

32

46

42

42

43

43

44

44

45

2

47

48 50

49

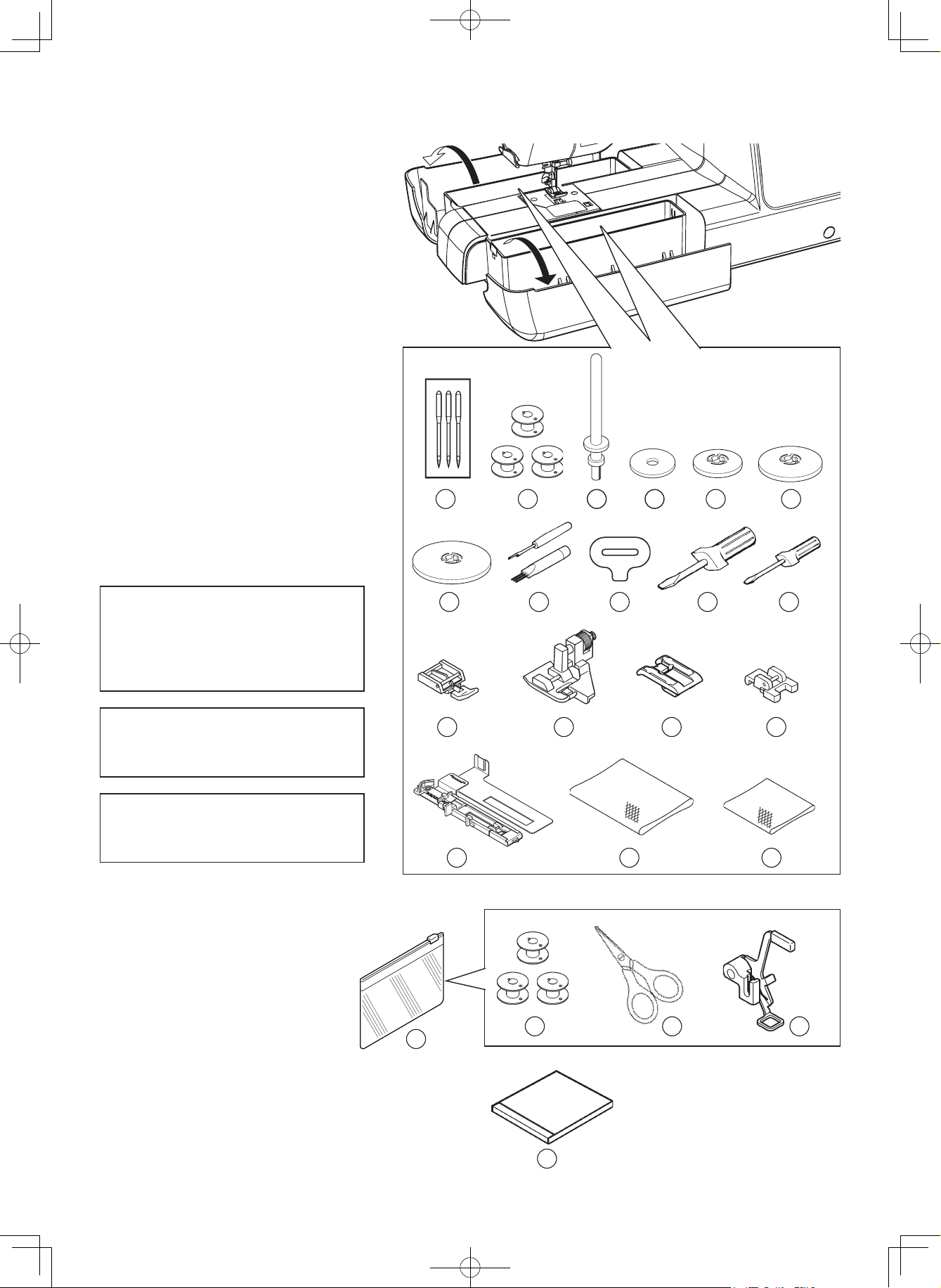

ACCESSORIES

FOR SEWING MACHINE

1. Needles

2. Bobbins

3. Auxiliary spool pin

4. Spool pin felt discs

5. Spool pin cap (mini)

6. Spool pin cap (small)

7. Spool pin cap (large)

8. Buttonhole opener/Brush

9. Screwdriver for needle plate

10. Screwdriver (large)

11. Screwdriver (small)

12. Zipper foot

13. Blind hem foot

14. Satin foot

15. Button sewing foot

16. Buttonhole foot and underplate

17. Thread spool net (long)

18. Thread spool net (short)

1 2 5 6

3 4

The Foot that comes on your

Sewing machine is called the

General Purpose Foot and will

be used for the majority of your

sewing.

The Satin Foot (14) is another

very useful foot and should be

used for most decorative sewing.

When purchasing additional

bobbins, be sure they are Class

I5 J.

FOR EMBROIDERY

19. Vinyl bag

20. Bobbins

21. Scissors

22. Embroidery presser foot

23. Embroidery software CD

7 8

12

13

9 10 11

14 15

16 17 18

20

21

19

22

FUTURA embroidery is a “system” in which your

computer software communicates designs to your

embroidery machine. The FUTURA embroidery

designs are accessed via your computer by installing

the FUTURA software.

To install the FUTURA software, refer to the CD insert

for more information.

23

3

SETTING UP YOUR MACHINE

Be sure to wipe off any surplus oil from needle plate area

before using your machine the rst time.

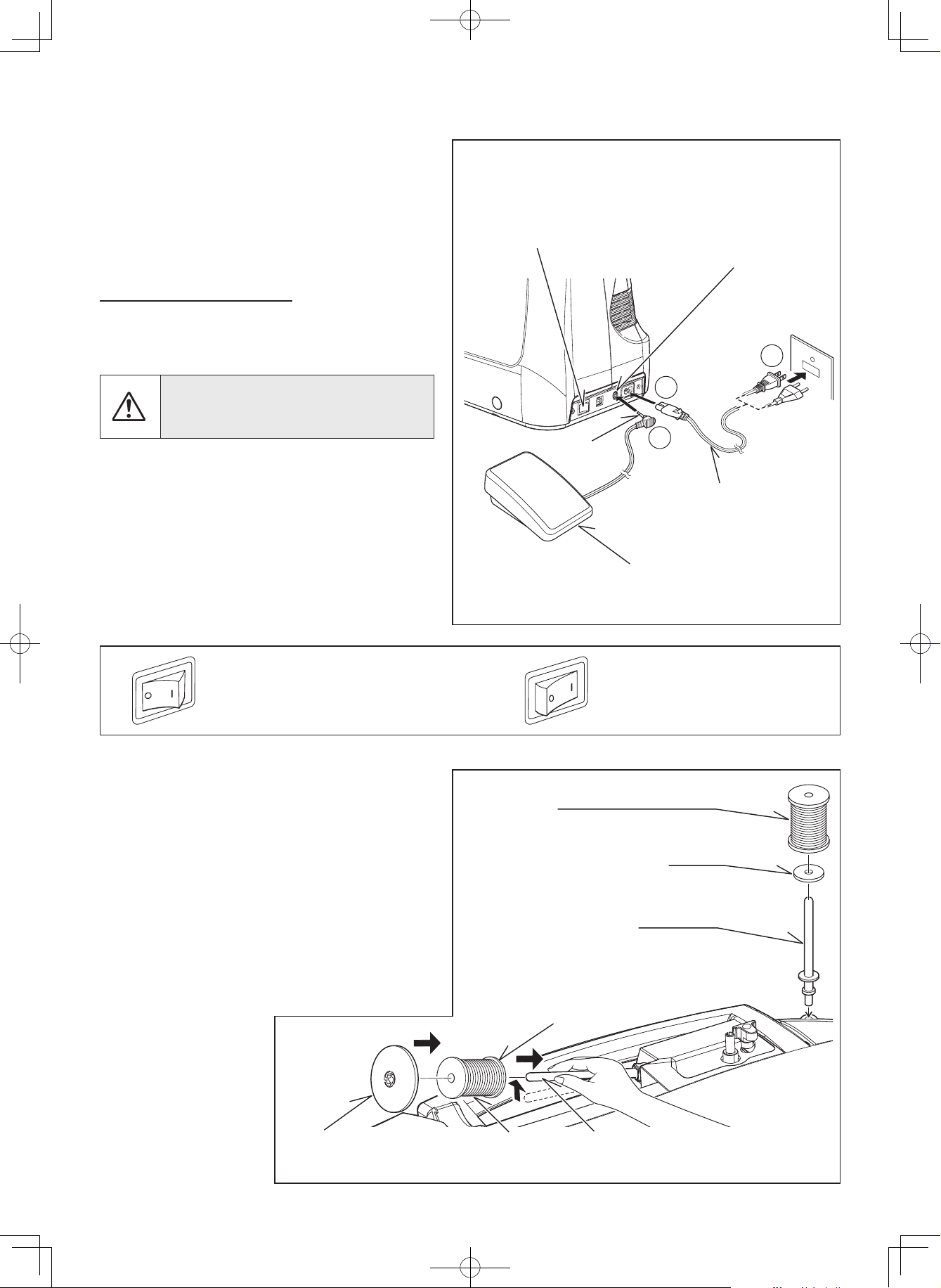

POWER LINE CORD/FOOT CONTROL

Connect the plug of the power line cord into the cord

socket (1) and your wall outlet (2) as illustrated.

Connect the foot control plug into the machine socket (3),

when using sewing machine only.

NOTE: In sewing mode, the machine can be operated

either with or without the foot control (see page

14).

Always disconnect the machine from power

supply by removing the plug from the walloutlet.

POWER/LIGHT SWITCH

Your machine will not operate until the power/light switch

is turned on. The same switch controls both the power and

the light.

When servicing the machine, or when changing needles

or lights, etc., the machine must be disconnected from the

power supply.

Set power/light switch at “OFF”

Pin

Machine socket

2

1

3

Power line cord

Foot control

Power/light switch “OFF” Power/light switch “ON”

SPOOL PINS

HORIZONTAL SPOOL PIN for normal

thread spool

Place thread spool on the pin and secure with a spool cap

to ensure smooth ow of thread.

VERTICAL SPOOL PIN for large thread

spool

Attach the spool pin. Place felt disc over it. Place a thread

spool on the spool pin.

Spool

Felt disc

Vertical spool pin

Thread retaining slit

4

Spool pin cap

Spool Spool pin

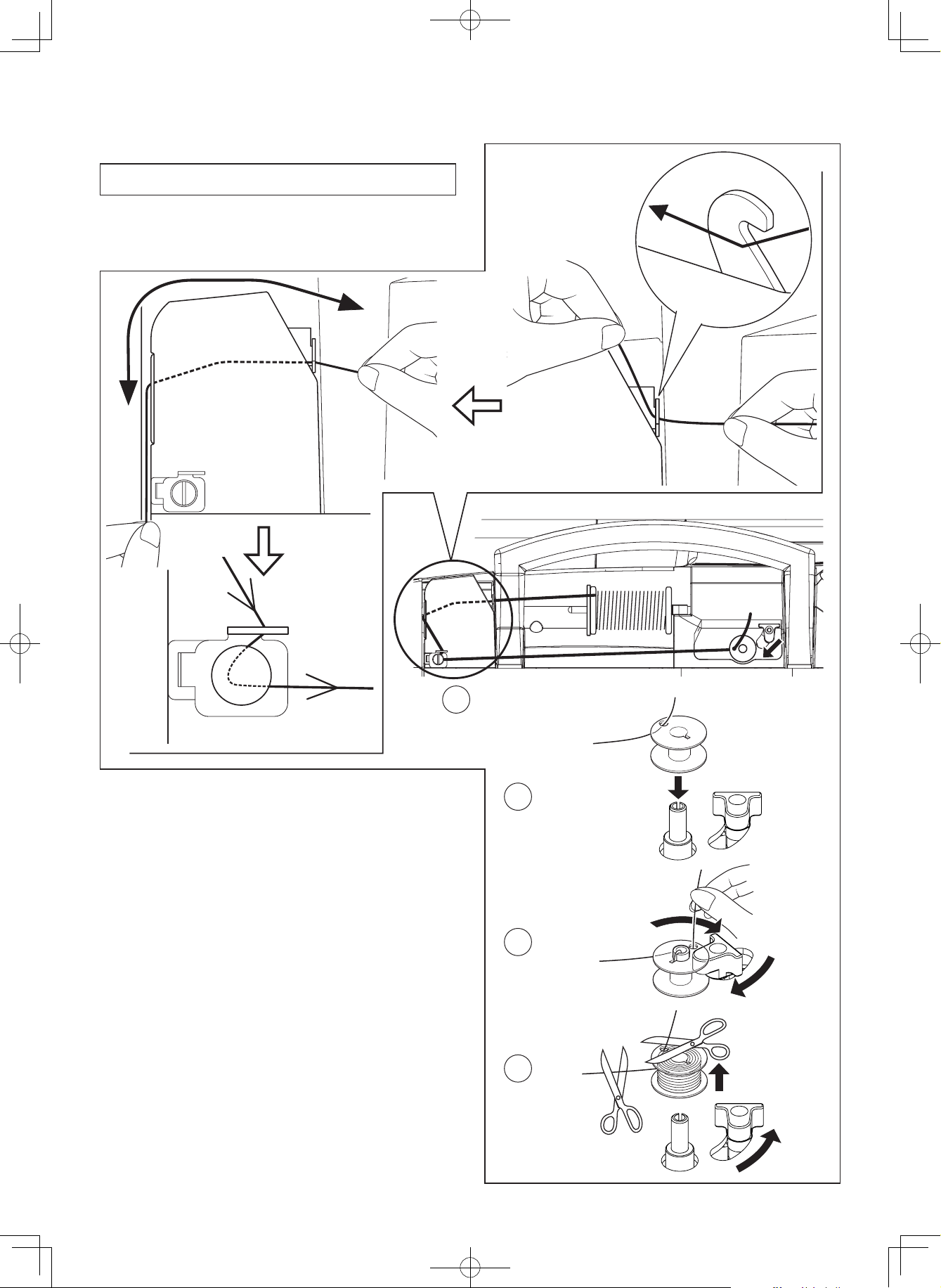

WINDING BOBBIN

Be sure to use Class 15 J bobbins.

1. Place a spool of thread on the spool pin, and secure it with

the spool pin cap. Pull the thread out from the spool and

place it through thread guides as shown in illustration.

1

2. Put end of thread through the hole in bobbin as shown.

Place bobbin onto the bobbin winder spindle as far as it

can go.

3. Holding onto the end of the thread, push the bobbin winder

latch against the bobbin until it clicks and bobbin starts to

rotate.

4. Bobbin will disengage automatically and the winding

mechanism will stop when the bobbin is full. Remove the

wound bobbin and cut the thread tail.

2

3

4

5

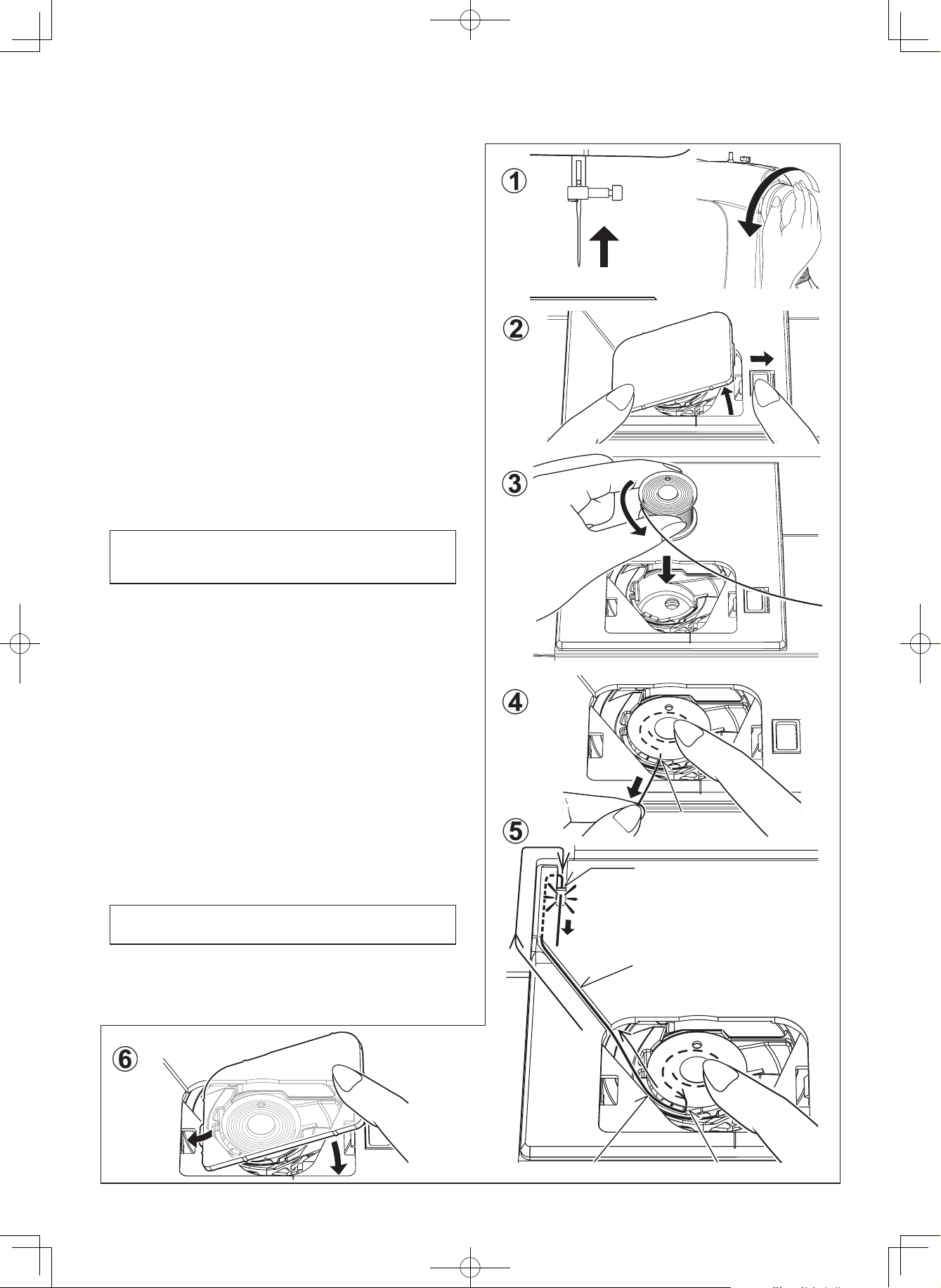

THREADING THE BOBBIN THREAD

1. Raise the needle to its highest position by rotating the hand

wheel counter clockwise (toward you).

2. Remove the bobbin cover plate by pushing the release

button to the right. Bobbin cover will pop up sufciently to

allow you to remove the cover.

3. Insert the bobbin making sure the bobbin rotates counter-

clockwise when you pull the thread.

NOTE: This is a very important step. The bobbin

must rotate counterclockwise when thread is pulled.

4. Pull thread through the slot (A) and then to the left.

5. With a finger held gently on top of the bobbin, pull the

thread until it stops in the slot (B). Then pull the thread

along the groove on the needle plate until it is snipped with

cutter on the top left.

NOTE: Sewing can be started without having to pull

up the bobbin thread.

6. Replace the clear bobbin cover plate onto the needle plate.

A

Cutter

Groove

6

AB

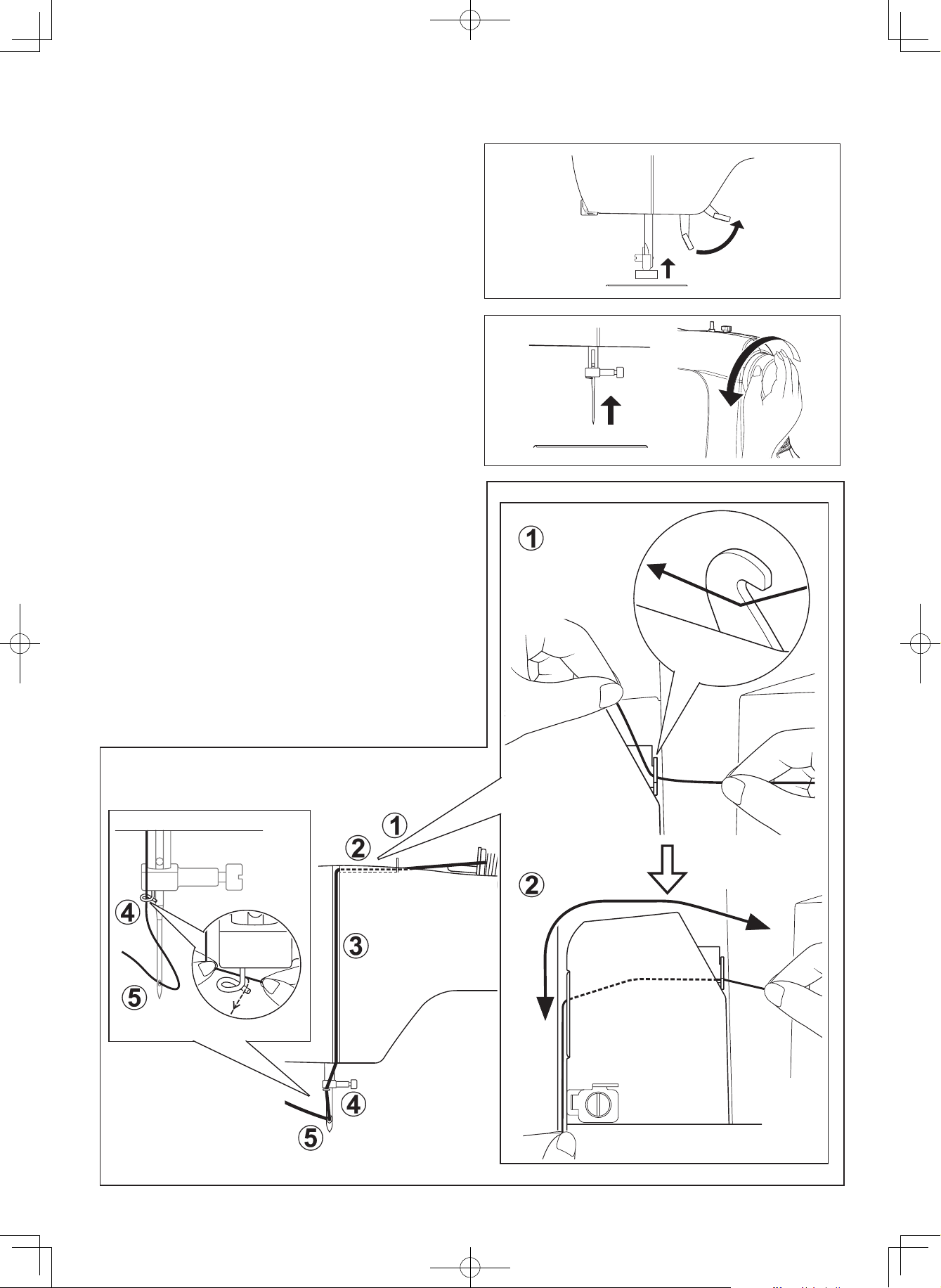

THREADING THE TOP THREAD

A. Raise the presser foot lifter. Always be sure to raise the

presser foot lifter before threading the top thread. (If the

presser foot lifter is not raised, correct thread tension

cannot be obtained.)

B. Turn the hand wheel counter clockwise (toward you) until

the needle is in its highest position.

C. Thread the machine with your left hand while rmly gripping

the thread with your right hand in the following order as

illustrated.

* Guide the thread through thread guides (1 & 2), and then

pull it down along the groove (3).

* Guide the thread into the thread guide (4).

* Pass the thread through the eye of the needle (5) from

front to back. (See following page for instructions on

operation of the Automatic Needle Threader.)

IMPORTANT:

To verify that the machine is threaded properly in the

tension discs, do this simple check:

1.) With the presser foot raised, pull the thread towards

the back of the machine. You should detect only

a slight resistance and little or no deection of the

needle.

2.) Now lower the presser foot and again pull the thread

towards the the back of the machine. This time you

should detect a considerable amount of resistance

and much more deflection of the needle. If you do

not detect the resistance you have mis-threaded the

machine and need to re-thread it.

7

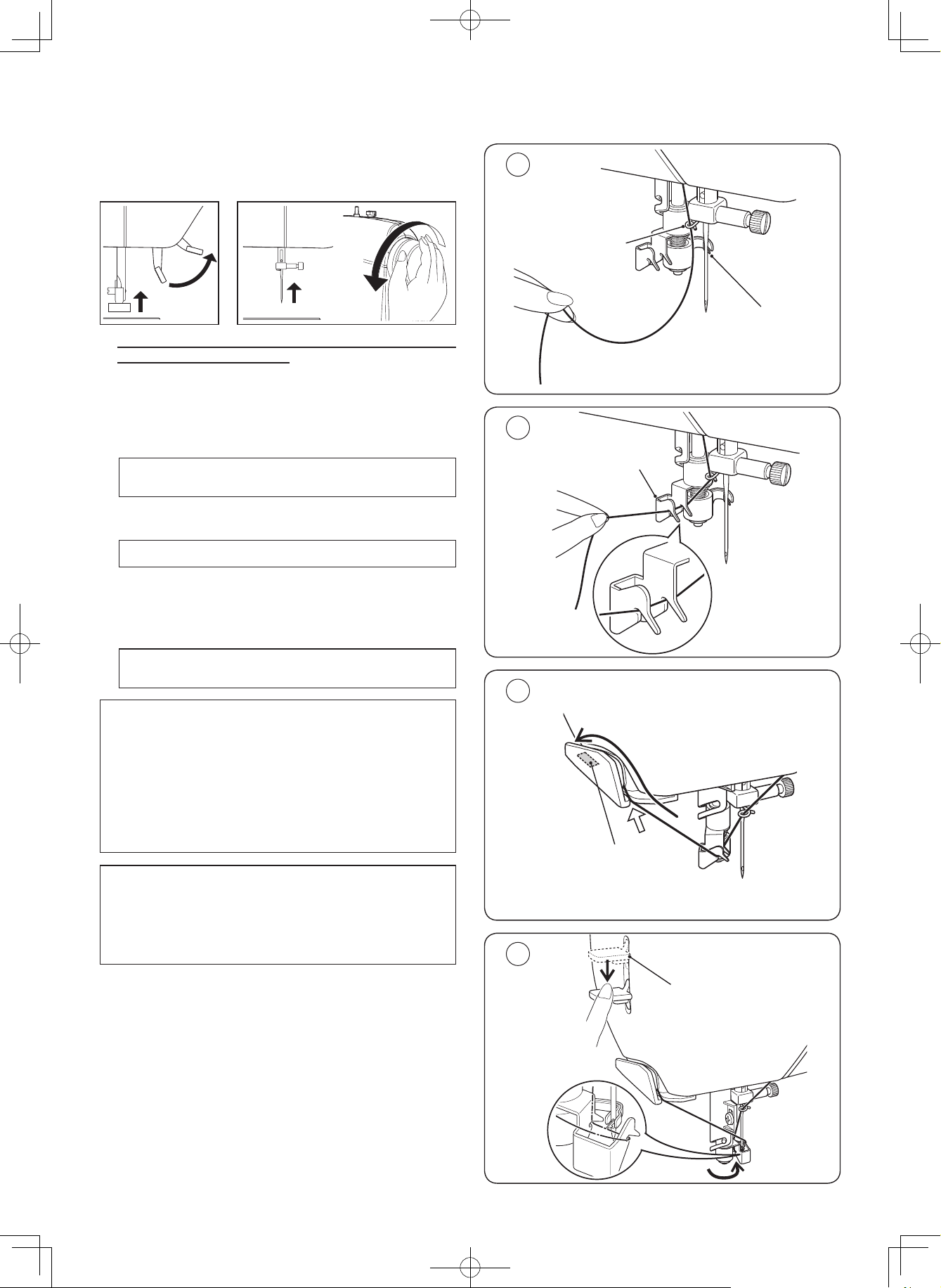

USING AUTOMATIC NEEDLE THREADER

Be sure to raise the presser foot lifter and raise the needle

to its highest position before threading.

1. Thread the machine with your left hand while gripping the

thread with your right hand. Hook thread to the thread

guide on the needle bar and pull it toward you leaving

about 4” (10 cm) clear.

2. Hook thread into the twin thread guides (A and B).

3. Pull thread gently into the thread cutter/holder to cut and

hold it in place.

Don’t pull thread with strong force or thread may

be pulled off from needle hole after threading.

4. Pull down the threading lever to its lowest position until the

twin thread guide rotates and stops.

Make sure that the guide doesn’t touch fabric, etc.

1

Thread guide

Threading hook

2

Twin thread guide

5. Release the threading lever and needle will be threaded

automatically. If it should not return to the original position,

raise it gently by hand.

6. Pull thread loop away from you.

If the needle has not been threaded correctly, rethread from STEP 1.

NOTE:

For smooth threading, it is recommended that

the machine be set for straight stitch (in center

needle position) when using the automatic needle

threader.

Heavy thread cannot be threaded through fine

needle.

Don’t lower the threading lever while the machine is

in operation or the threading hook may be broken.

IMPORTANT: If the needle cannot be threaded with the

Automatic Needle Threader due to particular qualities

of the thread, or if the thread is too thick for the

needle being used, then manually thread the needle

after hooking the thread through the thread guide on

the needle bar.

3

4

A

B

Thread cutter/holder

Threading lever

8

5

6

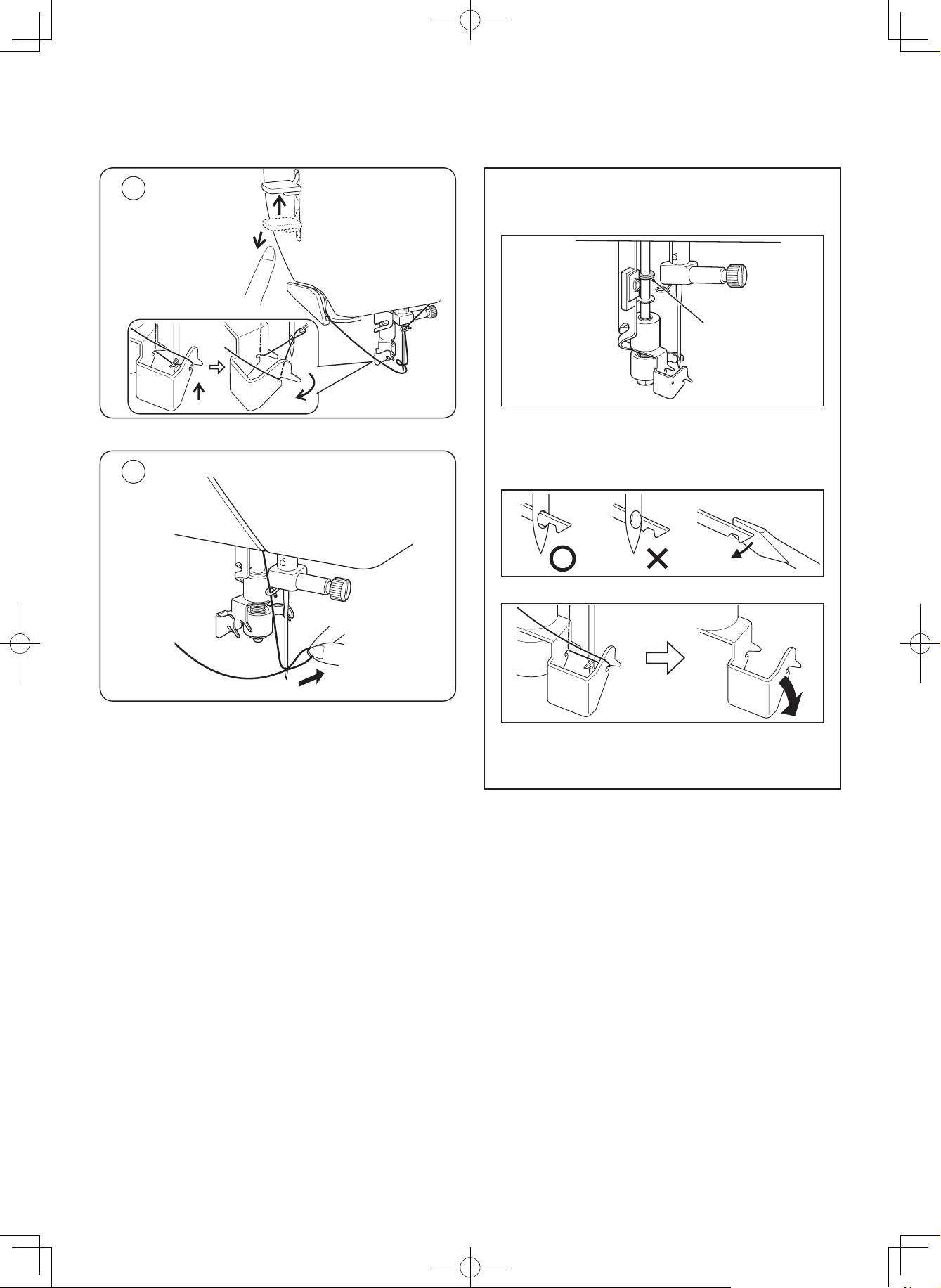

HELPFUL SUGGESTIONS:

Put a drop of sewing machine oil onto the felt disc,

if the machine is used after a long interval.

Felt disc

If the threading hook is deviated from needle hole,

adjust the position of the hook using a small screw

driver.

If the threading hook cannot catch thread, adjust

the vertical position by bending the twin thread

guide.

9

NEEDLE, THREAD AND FABRIC CHART

Your fabric will determine the choice of a needle and thread.

The following table is a practical guide to needle and thread

selection. Always refer to it before a new sewing project.

Generally, the same size and type of thread is used in the

bobbin as in the upper thread.

FABRICS THREAD NEEDLES

The fabrics below can be of any

ber: cotton, linen, silk, wool,

synthetic, rayon, blends. They

are listed as examples of weight.

LightWeight

MediumWeight

MediumHeavy

Knits Bonded Knits

Batiste

Chiffon

Crepe

Corduroy

Flannel

Gabardine

Gingham

Linen

Muslin

Wool Crepe

Bonded Wovens

Canvas

Coating

Denim

Duck

Sailcloth

Double Knit

Jersey

Tricot

Cotton-wrapped

Polyester

100% Polyester

* Mercerized Size 60

Cotton-wrapped

Polyester

100% Polyester

* Mercerized Size 50

Nylon

Cotton-wrapped

Polyester

100% Polyester

* Mercerized Size 40

* "Heavy Duty"

Cotton-wrapped

Polyester

Polyester

Nylon

* For best sewing results, always use a Singer Branded Needle.

TYPE SIZE

2000 or 2020

red

shank

2000 or 2020

red

shank

2000 or 2020

red

shank

2001 or 2045

yellow

shank

11/80

orange

band

14/90

blue

band

16/100

purple

band

18/110

yellow

band

11/80

orange

band

14/90

blue

band

16/100

purple

band

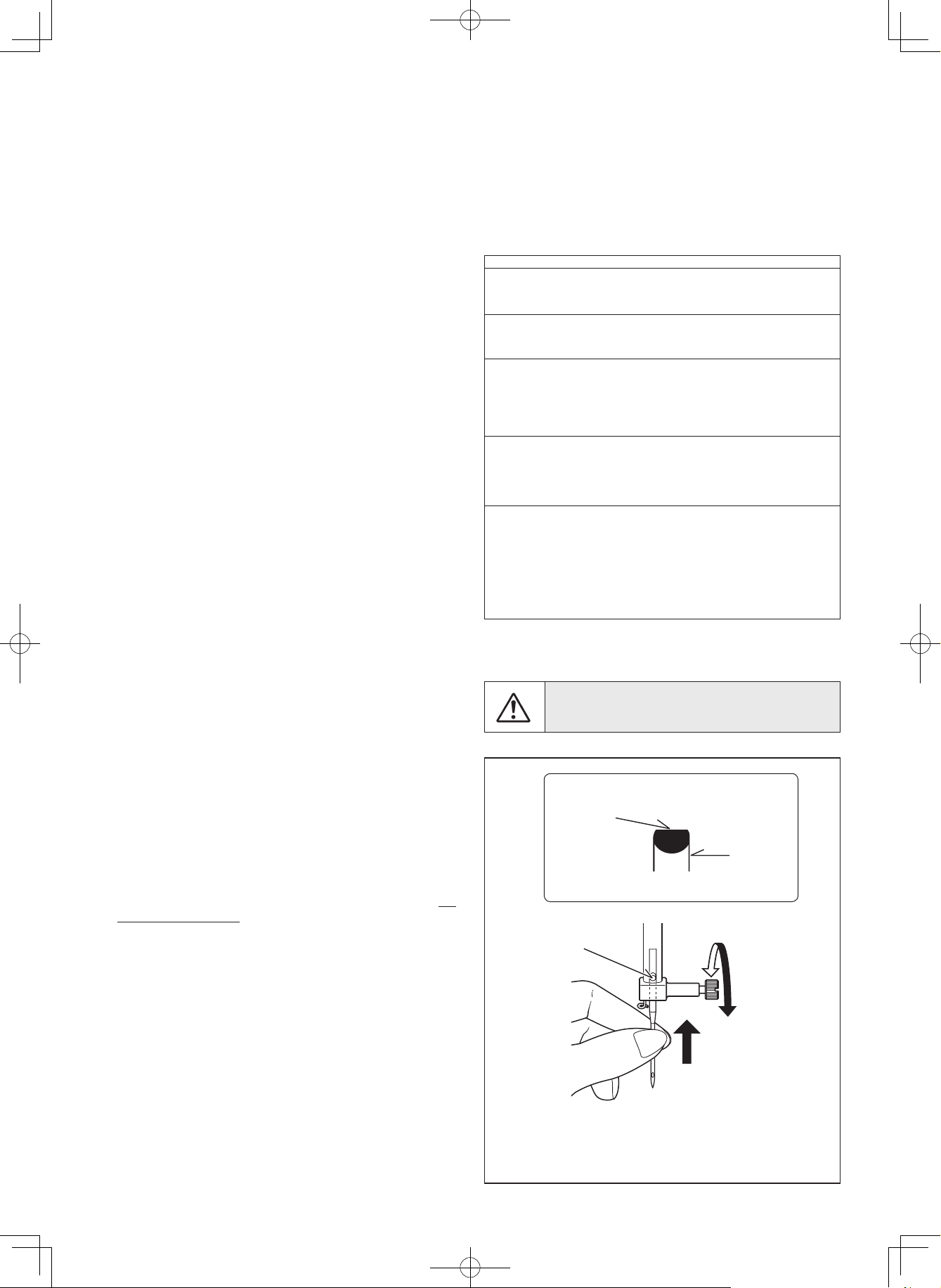

Changing the needle

1. Raise the needle bar to its highest position by turning the

hand wheel counter clockwise (toward you).

2. Loosen the needle clamp screw by turning it toward you.

3. Remove the needle by pulling it downward.

4. Insert the new needle into the needle clamp with the at

side toward the back.

5. Push the needle up as far as it can go.

6. Tighten the needle clamp screw firmly with the screw

driver.

Always disconnect the machine from power

supply by removing the plug from the wall-outlet.

Flat side

Needle

Pin

Flat

side

toward

the

back

10

ADJUSTING TOP THREAD TENSION

90% of your sewing will be accomplished with the word “S”

exposed on the tension control dial on top of the machine.

Under side

Helpful Hint: A slight adjustment to a higher number or a

lower number may improve sewing appearance.

STRAIGHT STITCHING

The correct appearance of your stitching is largely determined

by the balanced tension of both top and bobbin threads. The

tension is well balanced when these two threads ‘lock’ in the

middle of layers of the fabric you are sewing.

If, when you start to sew, you nd that the stitching is irregular,

you will need to adjust the tension control. Do this, however,

only after you have determined that the machine is correctly

threaded (see page 7).

Make all adjustments with presser foot ‘down’.

A balanced tension (identical stitches both top and bottom) is

usually only desirable for straight stitch sewing.

ZIGZAG, SATIN STITCH, DECORATIVE and

BUTTON HOLE SEWING

For zigzag sewing, satin stitch and decorative stitch functions,

thread tension should be less than that for straight stitch

sewing.

Well balanced

Top side

Top stitch too tight Top stitch too loose

It is recommended for buttonholes to set thread tension at E.

You will always obtain a nicer stitch and less puckering when

the upper thread appears slightly on the bottom side of your

fabric.

BOBBIN TENSION

The bobbin tension has been correctly set at the factory,

so you do not need to adjust it.

CHANGING PRESSER FOOT

Be sure the needle is in the highest position. Raise presser

foot lifter.

1. Push presser foot release button to remove the foot.

2. Place the desired foot on the needle plate aligning the

presser foot pin with the foot holder.

3. Lower the presser foot lifter so that the foot holder snaps

on the foot.

Decrease tension Increase tension

Presser foot lifter

3

1

Foot release button

2

Foot holder

11

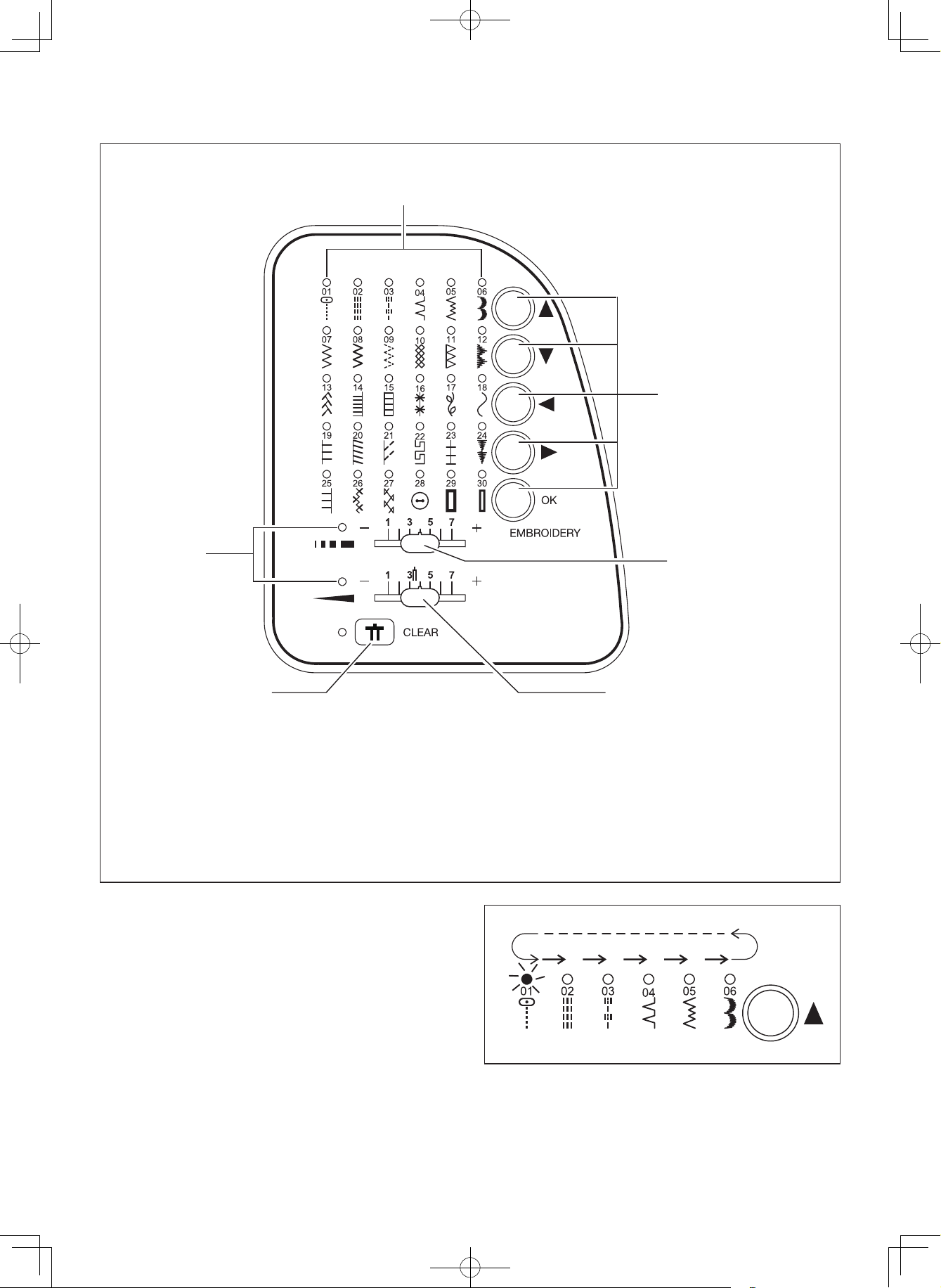

LED indicator

Pattern selection buttons

LED indicator

Twin needle mode button

Stitch width/needle position control

Stitch length control

*NOTE: The provided scales and numbers on the length and width controls are for reference only

and do not represent actual sewing parameters of length and width.

CONTROL PANEL FUNCTIONS

Pattern selection buttons

Turn on the power switch and the LED indicator above the straight

stitch pattern will be lit. At this point you may sew Straight Stitch.

To select other patterns, push the pattern selection button to

the right of the row that contains your desired pattern. Stop

when the LED indicator above your pattern is lit.

12

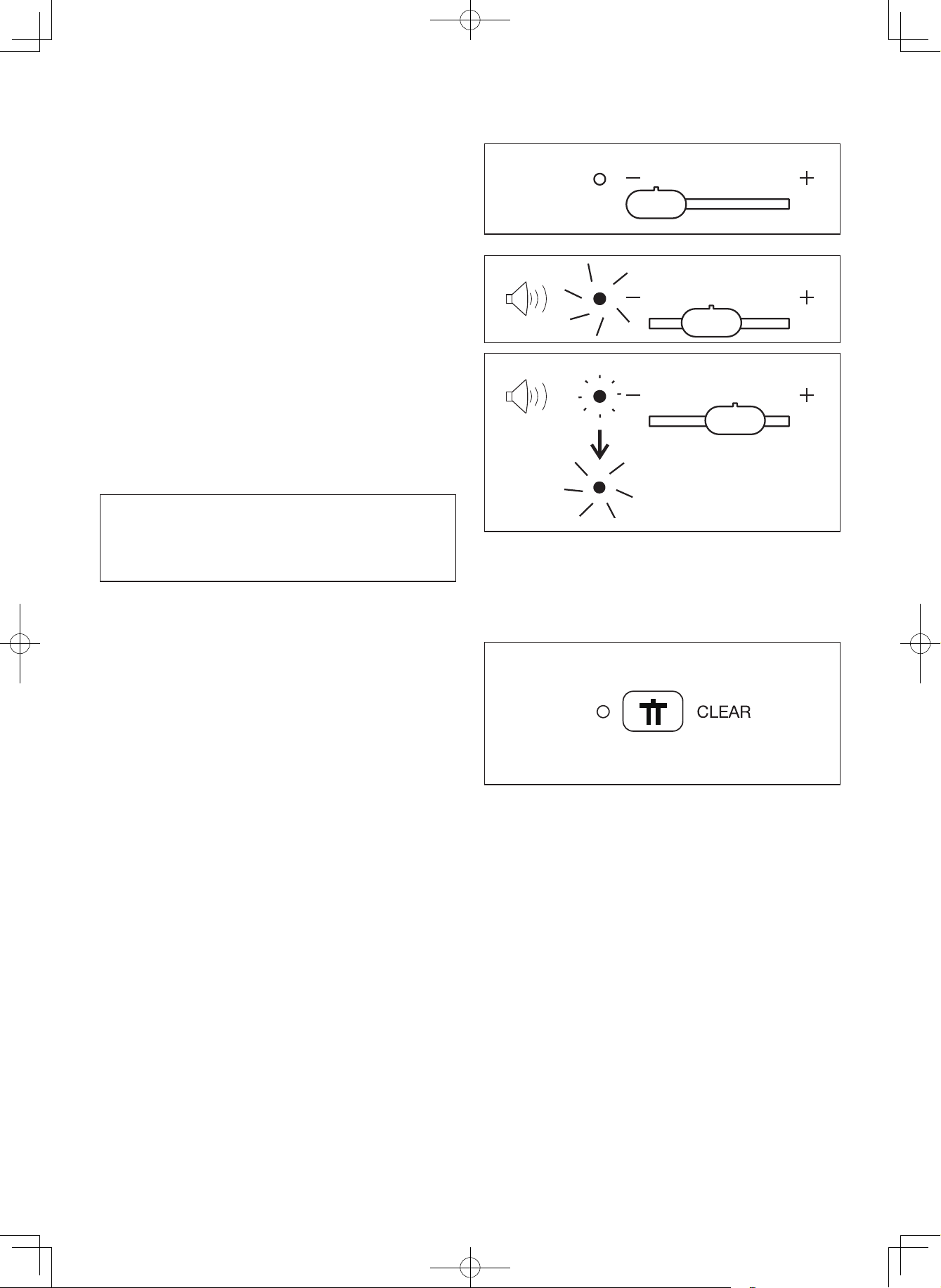

Stitch length and width/needle position controls

*Auto/Default settings

Your sewing machine will produce most of your stitching

requirements at an Auto/Default Stitch Length and Width. When

a pattern is selected, it will automatically sew at default settings of

stitch length, width and needle position for straight stitch.

Auto (preprogrammed) default settings are easily determined

by moving the Stitch Length and Width / Needle Position

Control Knob. The LED Indicator next to the Control will light

in orange without blinking and a beep will sound indicating you

are at the Auto / Default Position.

*Manual settings

Once you have determined the Auto / Default position you can

manually change the length, width or straight stitch needle

postition according to your preference. Starting at the Auto

position, slide the control knob left or right to locate each of

the potential adjustments. At each manual adjustment point,

the LED will blink 3 times in green and a beep will sound.

The LED will light in red beyond the potential adjustment range.

NOTES: 1. Some patterns offer more opportunities for

manual adjustments than others.

2. An alternate method of determining

available adjustments is to move the

control knobs while sewing slowly.

Twin needle mode button

The width setting for twin needle sewing can be activated if it is

available for the selected pattern. The LED turns on when twin

needle sewing is activated.

Width setting for twin needle sewing can be activated, if it

is available for a selected pattern. LED turns on when twin

needle sewing is activated.

13

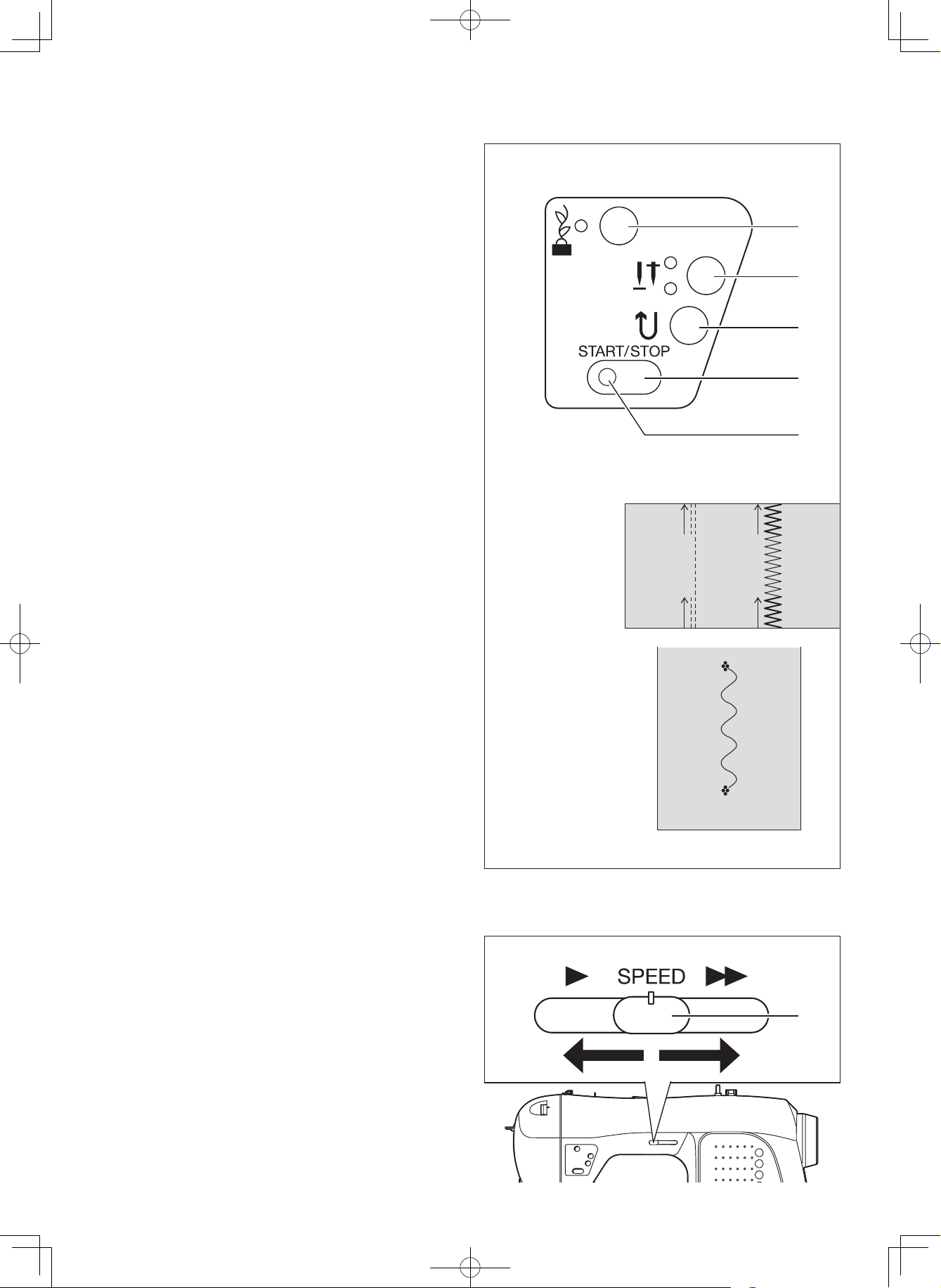

FUNCTIONS OF OPERATION SWITCH

PANEL

1. TACKING STITCH MODE BUTTON

Push this button and tacking stitch can be done with LED lit.

The sewing machine makes 4 tiny tacking stitches to tie off

the sewing on all patterns. The position of the tacking stitches

will be at the exact spot in the pattern where the tacking stitch

button is pushed.

1

2

2. NEEDLE STOP POSITION SELECTOR BUTTON

When the machine is turned on, needle is set at its up-stop

position with upper LED lamp lit. When the button is pushed,

needle is set at its down-stop position with lower LED lamp

lit. Push it again and it will return to its up-stop position with

upper LED lamp lit.

3. REVERSE STITCH BUTTON

Reverse sewing is carried out by pushing the reverse stitch

button. The machine will sew 4 stitches in reverse and stop.

4. START/STOP BUTTON

When the Start/Stop button is pushed, the machine starts

slowly, and when the button is pushed once more, the

machine stops.

However, when foot control is plugged, the Start/Stop button

will be inactive.

LED INDICATOR

5.

Green light indicates machine is ready to start.

Red light indicates machine is operating.

Flashing red light indicates a problem or an error.

* Flashing for 2 - 3 seconds shows that an incorrect

operation was made.

* Continuous flashing indicates that the machine

malfunctions.

3

4

5

Reverse stitch function

for straight and zigzag

stitches

Tacking stitch function

for tie-off of other

stitches

6. SPEED CONTROL LEVER

Sliding the lever sets desired sewing speed. When foot control

is used, the lever serves as a top speed limiter.

14

6

2. STARTING TO SEW

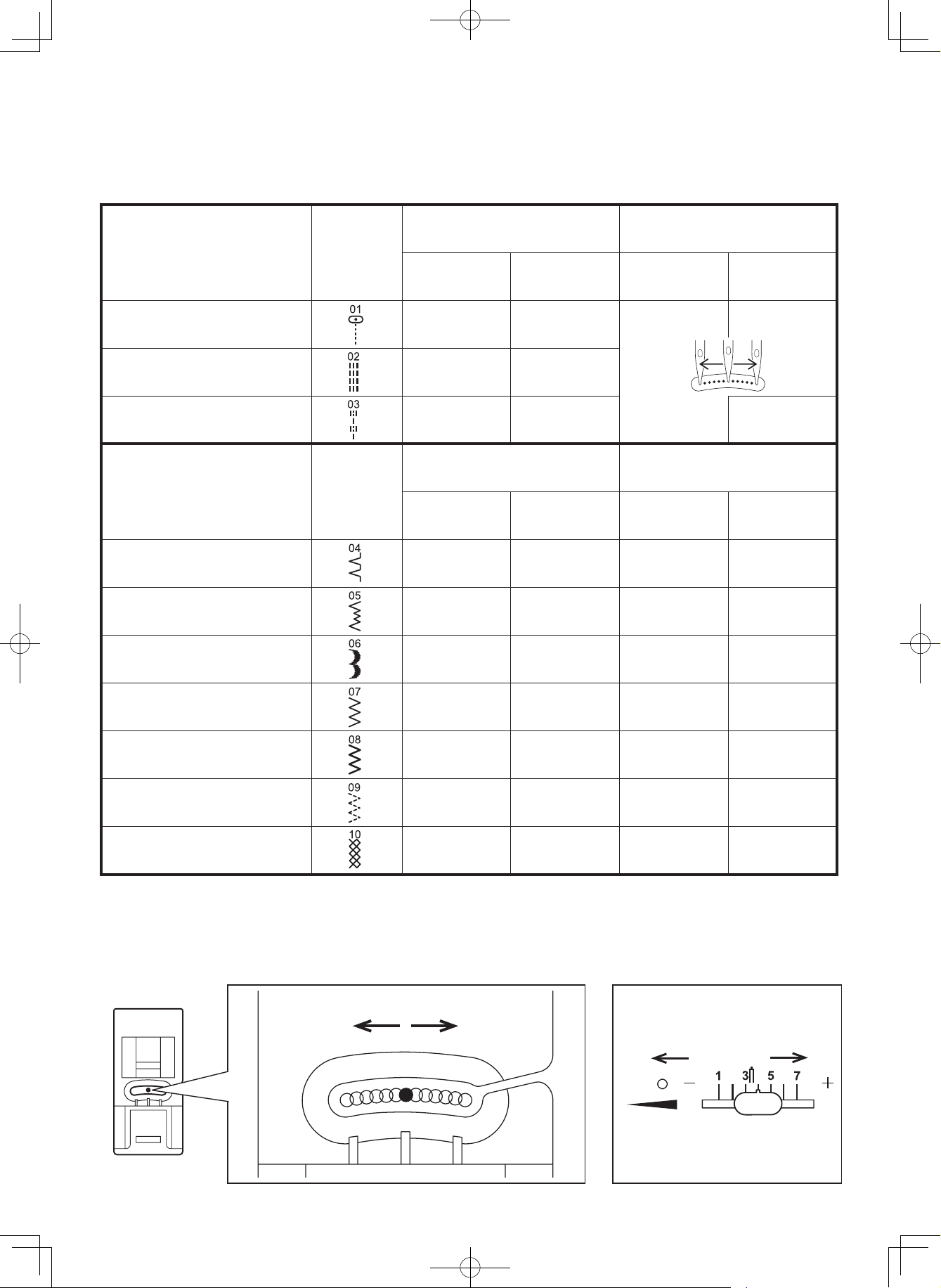

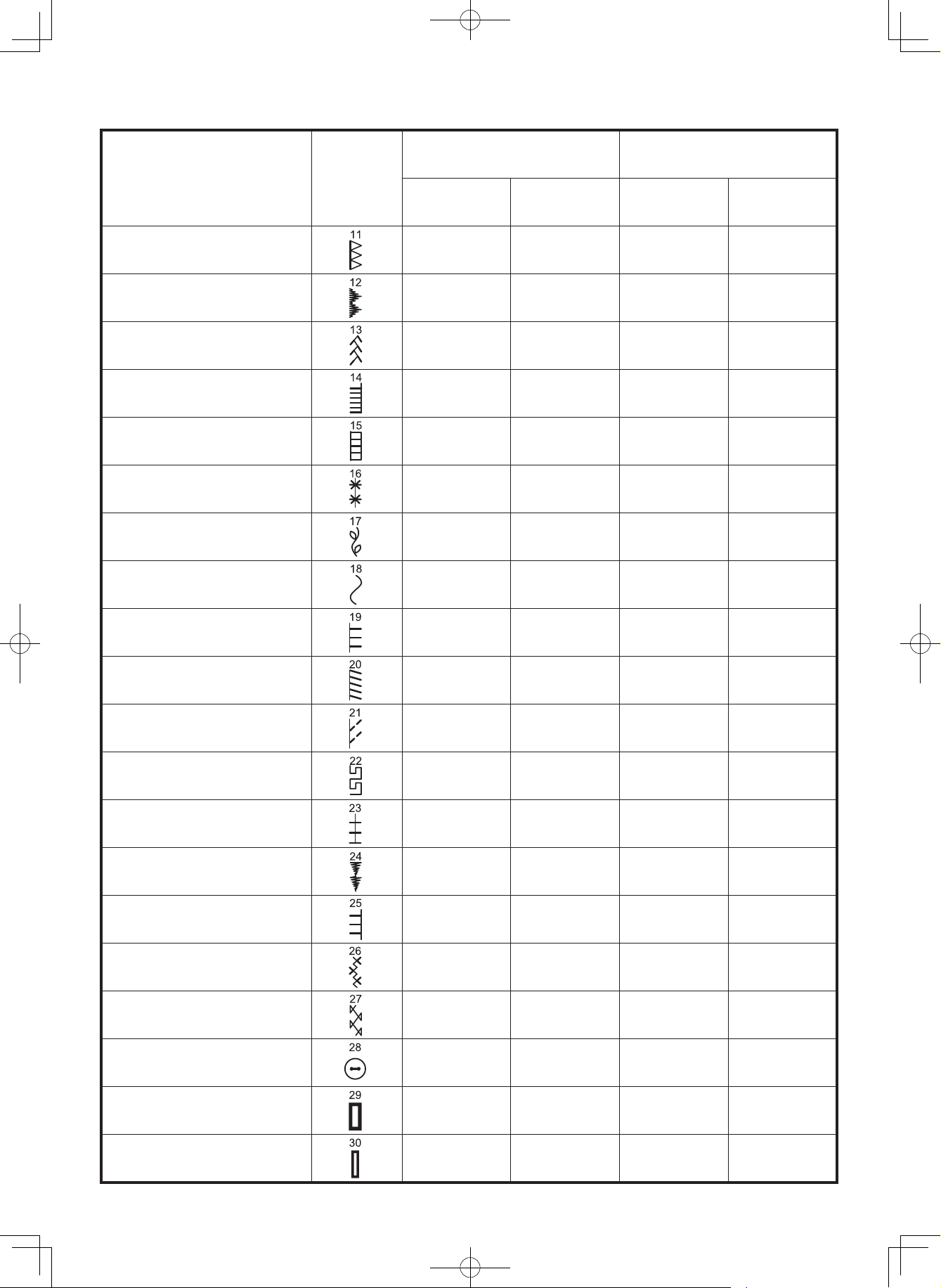

QUICK REFERENCE TABLE OF STITCH LENGTH AND WIDTH

LENGTH NEEDLE POSITION

STITCH SYMBOL

AUTO MANUAL AUTO MANUAL

STRAIGHT 2.5 0.5 ~ 4.8

STRAIGHT STRETCH 2.5 1.5 ~ 3.0

HAND-LOOK QUILT 2.5 2.0 ~ 4.0

LENGTH WIDTH

STITCH SYMBOL

AUTO MANUAL AUTO MANUAL

REGULAR BLINDHEM 2.0 1.0 ~ 3.0 3.0 1.0 ~ 6.0

STRETCH BLINDHEM 2.0 1.0 ~ 3.0 3.0 2.0 ~ 7.0

CRESCENT 0.5 0.5 ~ 1.5 7.0 3.5 ~ 7.0

ZIGZAG 2.0 0.5 ~ 3.0 5.0 0 ~ 7.0

CENTER LEFT - RIGHT

-

RIC-RAC 2.5 1.5 ~ 3.0 5.0 2.0 ~ 7.0

MULTI-STITCH ZIGZAG 1.5 0.3 ~ 2.5 6.0 2.5 ~ 7.0

HONEYCOMB 2.0 1.5 ~ 3.0 6.0 3.0 ~ 6.0

Adjusting needle position for straight stitch

13 needle positions are available for quilting, topstitching, etc.

Toward rightToward left

Toward rightToward left

Width control

15

STITCH SYMBOL

LENGTH WIDTH

AUTO MANUAL AUTO MANUAL

OVEREDGE

PYRAMID

FEATHER

PIN

LADDER

STAR

VINE

SERPENTINE

BLANKET (1)

2.5 1.5 - 3.0 3.5 3.5 - 7.0

0.5 0.5 - 1.5 7.0 3.5 - 7.0

2.0 1.0 - 3.0 6.0 3.0 - 6.0

2.5 1.5 - 3.0 3.0 1.0 - 7.0

2.5 1.5 - 3.0 3.5 1.0 - 7.0

3.0

-

5.0 5.0, 6.0

2.0 1.5 - 2.5 7.0 3.5, 7.0

1.8 0.8 - 2.5 7.0 3.5, 7.0

2.5 1.5 - 3.0 3.5 1.0 - 7.0

SLANT PIN

SLANT OVEREDGE

GREEK KEY

ENTREDEUX

ARROWHEAD

BLANKET (2)

CRISS-CROSS

CROSSED

BUTTON SEWING

2.0 0.8 - 2.5 3.5 1.0 - 6.0

2.0 1.0 - 3.0 5.0 1.0 - 7.0

2.5 1.3 - 2.5 5.0 3.5 - 7.0

2.5 1.5 - 3.0 3.0 2.0 - 7.0

0.5 0.5 - 1.5 7.0 3.5 - 7.0

2.5 1.5 - 3.0 3.5 1.0 - 7.0

2.0 1.5 - 3.0 6.0 3.0 - 6.0

2.5 1.0 - 3.0 4.0 2.0 - 6.0

0

-

3.0 2.0 - 4.5

WIDE BARTACK BUTTONHOLE

NARROW BARTACK BUTTONHOLE

16

0.5 0.5, 0.8 5.5

0.5 0.5, 0.8 3.5

-

-

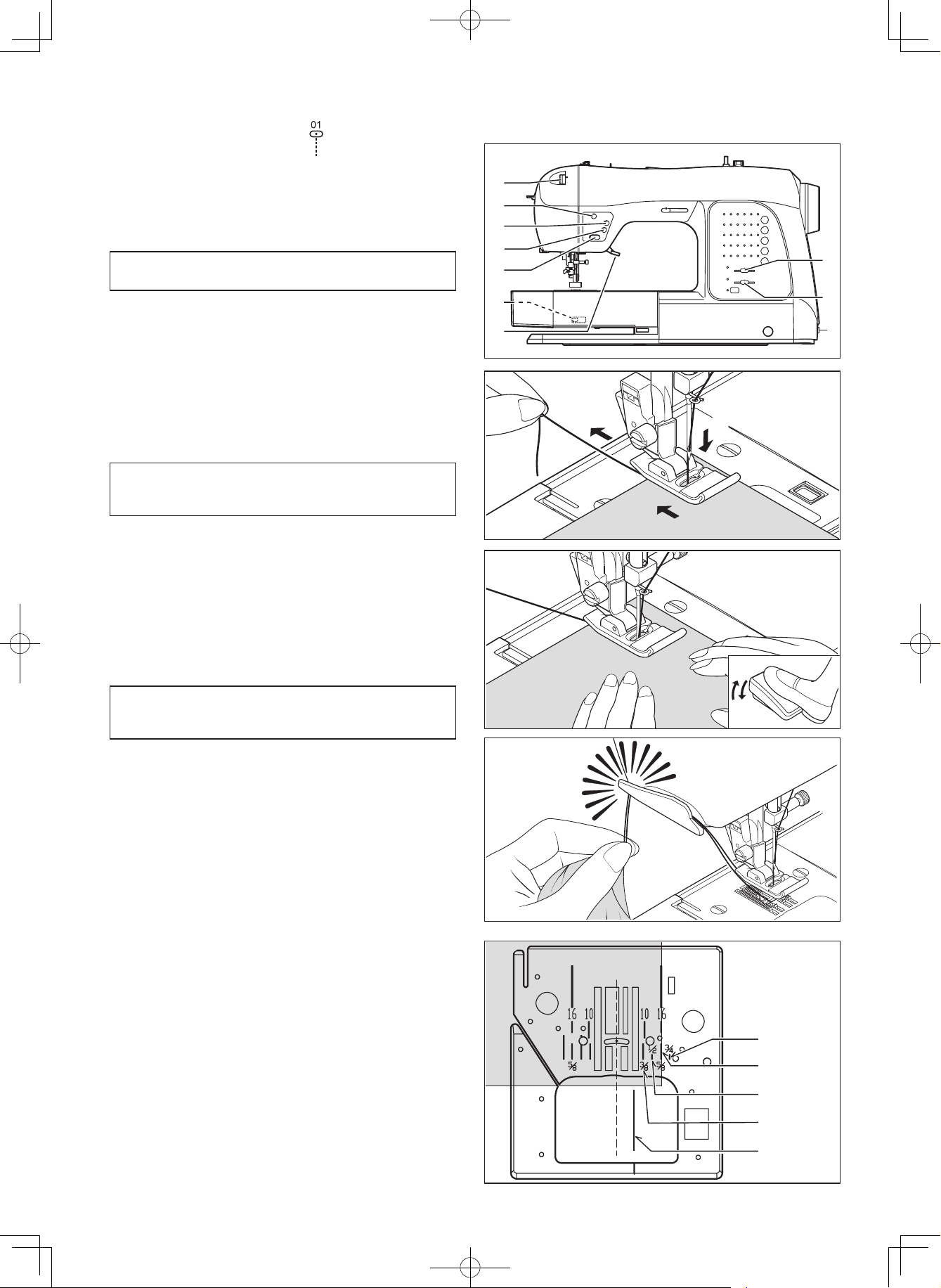

STRAIGHT STITCHING

Straight stitch is most frequently used for all types of sewing.

Let’s begin by following the steps below.

1. SETTINGS

Presser foot - General Purpose Foot

Thread tension control - S

NOTE: Based upon the weight of the fabric, slight

“ne tuning” of the tension may be desired.

A. Thread tension control

B. Tacking stitch mode button

C. Needle up/down position selector button

D. Reverse stitch button

E. Start/stop button

F. Feed dog control (at rear side)

G. Presser foot lifter

H. Stitch length control

I. Stitch width control

J. Power/light switch

NOTE: Since a straight stitch has no width, the

stitch width control is used to change the needle

position.

2. Pull both threads under the presser foot toward the back of

the machine, leaving about 6” (15 cm) clear.

3. Place the fabric under the presser foot and lower the

presser foot lifter.

4. Turn the hand wheel counter clockwise (towards you) until

the needle enters the fabric.

5. Start the machine. Guide the fabric gently with your hands.

When reaching the edge of the fabric, stop the sewing

machine.

A

B

C

D

E

F

G

5

1

2

H

I

J

4

3

NOTE: The Needle Plate has both Metric and Inch

Markings as an aid for guiding your fabric when

sewing a seam.

6. First turn the handwheel counter clockwise (toward you)

until the needle is in its highest position, then raise the

presser foot. Draw the fabric to the rear and cut off excess

thread with the thread cutter located on the bottom of the

face cover, as shown.

KEEPING SEAMS STRAIGHT

To keep the seam straight, use one of the numbered guide

lines on the needle plate. The numbers indicate distance from

the needle at its center position.

The guide line on the bobbin cover plate is a ¼” (6mm) seam

guide line, used for piecing quilt blocks or for sewing narrow

seams.

6

3/4" (19 mm)

5/8" (16

1/2" (13

mm

mm

)

)

3/8" ( 9

1/4" ( 6

mm

mm

17

)

)

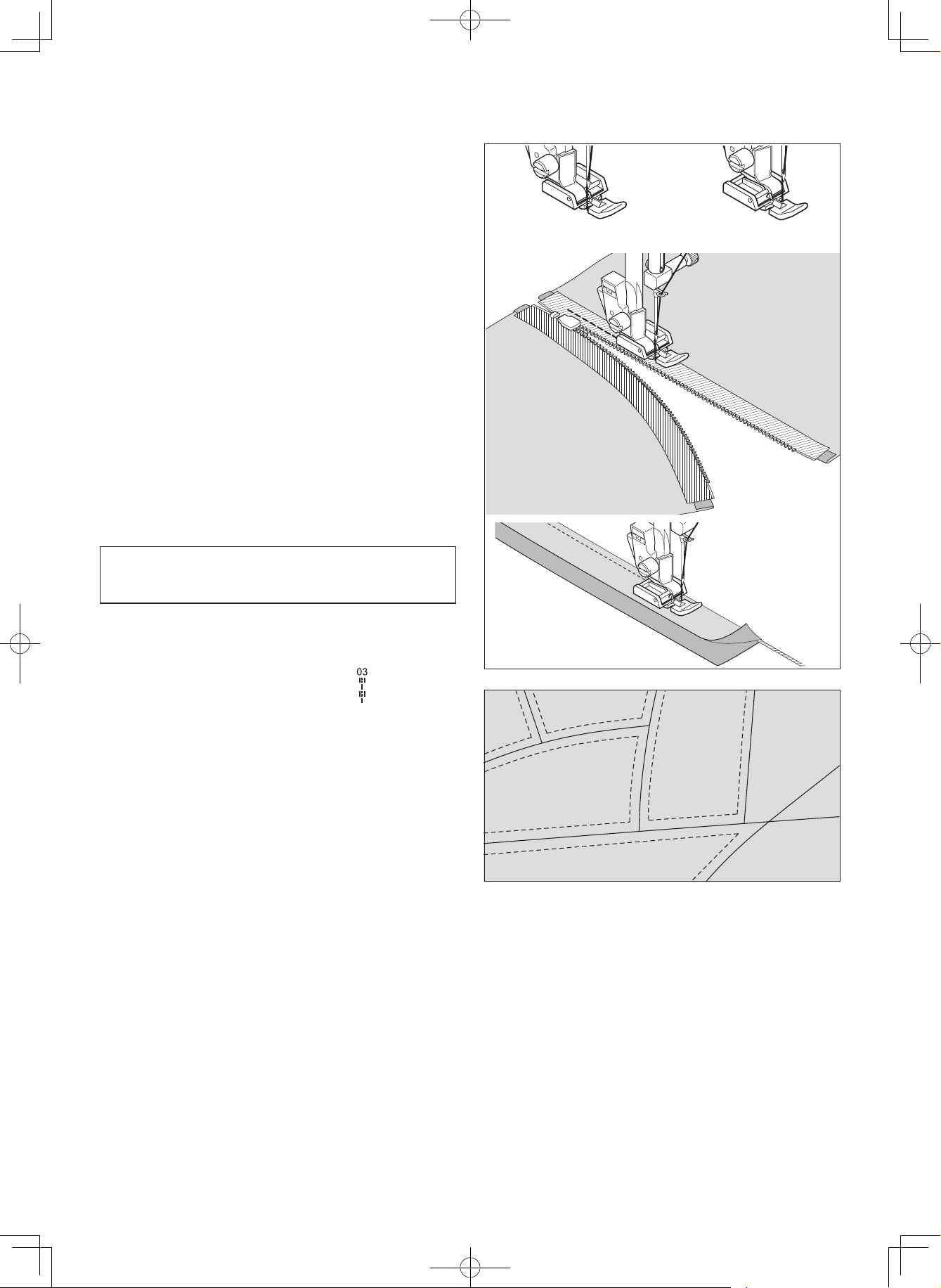

INSERTING ZIPPERS AND PIPING

Use the zipper foot to sew to the right or left of the zipper or to

sew close to a cord.

INSERTING ZIPPERS

To sew down the right side, attach left side of zipper foot to

presser foot holder so that the needle passes through the

opening on the left side of the foot.

To sew down the left side, attach right side of foot to foot

holder.

PIPING

Create a piping by covering a ller cord with a bias strip of fabric.

Attach the right side of the zipper foot to the foot holder so that

the needle passes through the right side of the zipper foot.

Baste the seam allowances together, enclosing the ller cord,

forming seam tape for the piping.

Needle to left of foot Needle to right of foot

Helpful Hint: Slight adjusting of the needle position to

sew closer to the piping may be accomplished with

the Stitch Width Control.

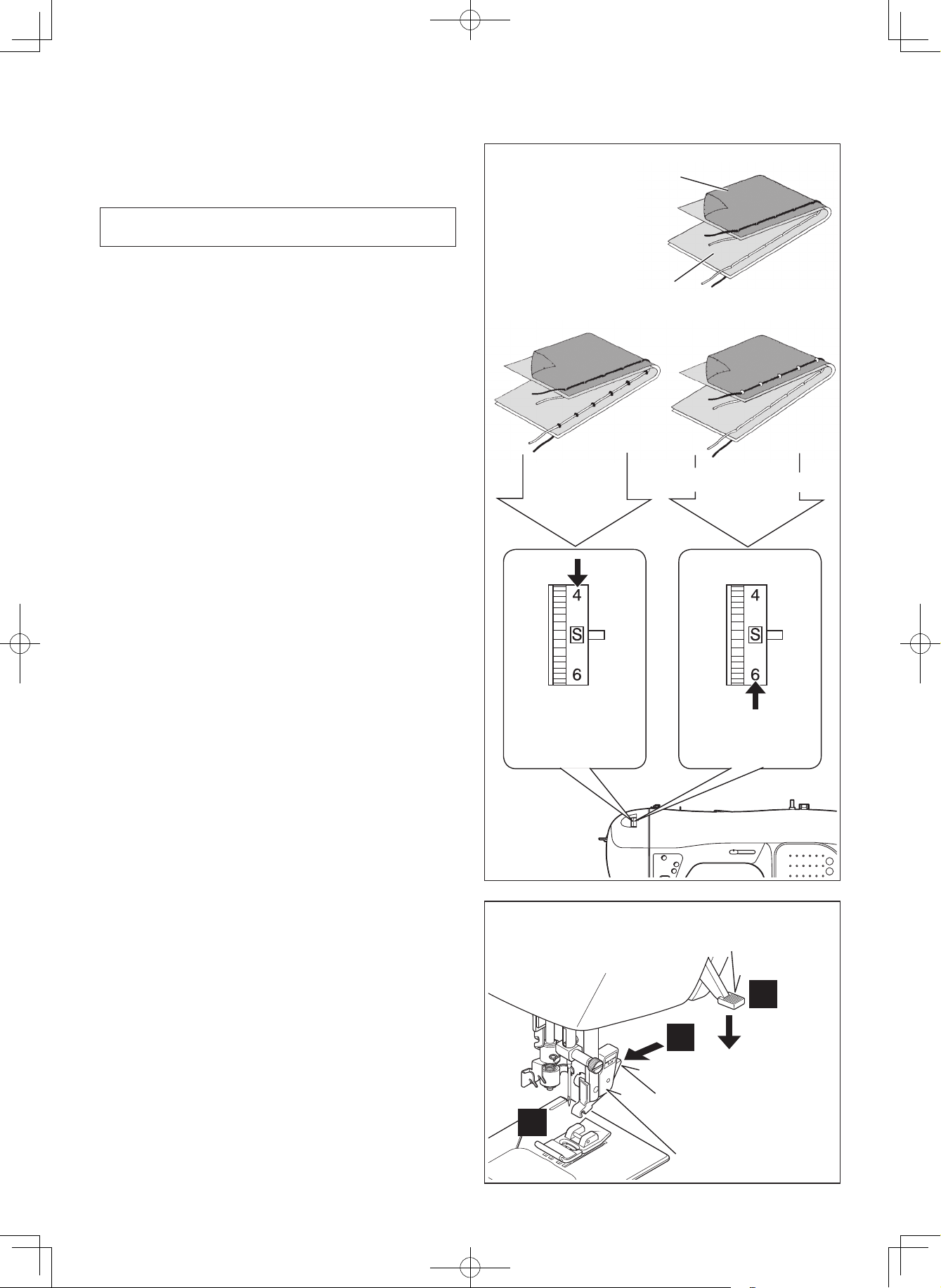

HAND-LOOK QUILT STITCH

This stitch is designed to look like hand sewing for topstitching

and quilting.

1. Thread bobbin with desired top stitching color.

2. Thread the needle with either invisible thread or with thread

that is a color which blends in with the fabric color, so it

doesn’t show.

3. Increase thread tension toward 6 or higher until you

achieve the desired appearance.

4. Set the stitich length at 4 (maximum).

5. Start to sew.

18

Loading...

Loading...