Singer NP050101, NP050103 Service Manual

SINGER

INDUSTRIAL

PRODUCTS

Needle

Catalog

SERVICE

Positioner

Numbers

I.

MANUAL

for

the

SINGER

and

—

Underbed

NP050101

Thread

and

Trimmer

NP050103

'A Trade

Mark

ofThe

Fordetails,

Industrial Products Division, 30 Rockefeller Plaza, New York, N.Y. 10020

Singer

Company

call

your

Industrial

Copyright

All

Rights

Sales

©1967

Reserved

Office,

or write The

THE

INDUSTRIAL

by The Singer Company

Throughout

SINGER

the

World

Singer

Company,

PRODUCTS

COMPANY

DIVISION

Printed

in U.S.A.

TABLE

OF

CONTENTS

Paragraph

SECTION

SECTION

SECTION

Title

I -

GENERAL

1-1 PURPOSE 1

1-2

1-3

II -

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

III -

FEATURES 2

BASIC COMPONENTS 2

INSTALLATION

GENERAL INFORMATION 3

PREPARATION

POWER

OPERATING

SEWING

COMMUTATOR SENSOR 10

POSITIONER

TRIMMER

T

RIMMER

THREAD

OPERATION

INFORMATION

OF SEWING

TRANSMITTER

SWITCHES

HEAD

CONTROL

PACK

SOLENOID

WIPER

ASSEMBLY.

TABLE

CONSOLE

ASSEMBLY

Page

16

19

3

3

4

10

11

13

SECTION

SECTION

3-1

3-2

3-3

IV -

4-1

4-2

V -

5-1

GENERAL INFORMATION 20

PRE-OPERATING CHECKS 20

OPERATION 20

SERVICING

GENERAL

CLEANING INSTRUCTIONS 22

TROUBLESHOOTING

GENERAL

5-2 Needle Not

5-3

5-4

5-5

5-6

Faulty

Bobbin Thread

Needle

Needle

TrimmingorDouble

Thread

Thread Pulls

AND

INFORMATION

INFORMATION

ADJUSTMENTS

Positioning

Cut

Too

Cut

Too Short 25

Out

Properly

Short

TriggeringofSolenoid

of

Needle

Assembly

...

22

24

24

24

24

25

LIST

OF

ILLUSTRATIONS

Figure

1 S

2 Sewing Table

3 Operating Switches 5

4

5 Foot

6

7 Slo-Sew Switch 8

8 Operating

9

lOA

&B Positioner Control Console 12

1lA & B

nC

IID

12 Setting of

13

14A

&B

15

16 Operating Controls

inger

Heel

Knee

Commutator

Trim

Trim

Thread

Trimmer

Trimmer

Thread Wiper J9

Needle

Sewing

Switch

Trim

Trim

Pack Thread Picker Installation 14

Pack Thread Picker Installation 15

Picker

Solenoid

Solenoid

Positioner

Machine

Top

Installation 6

Switch Installation.• 7

Switch Installation 8

Switches

Sensor

Assembly

Adjustment

Trimmer

Knife

Assembly

Adjustments

Title

and

and

Underbed

Wiring

Procedure

Trimmer

Data

Equipped

Page

1

4

9

11

15

16

17

18

21

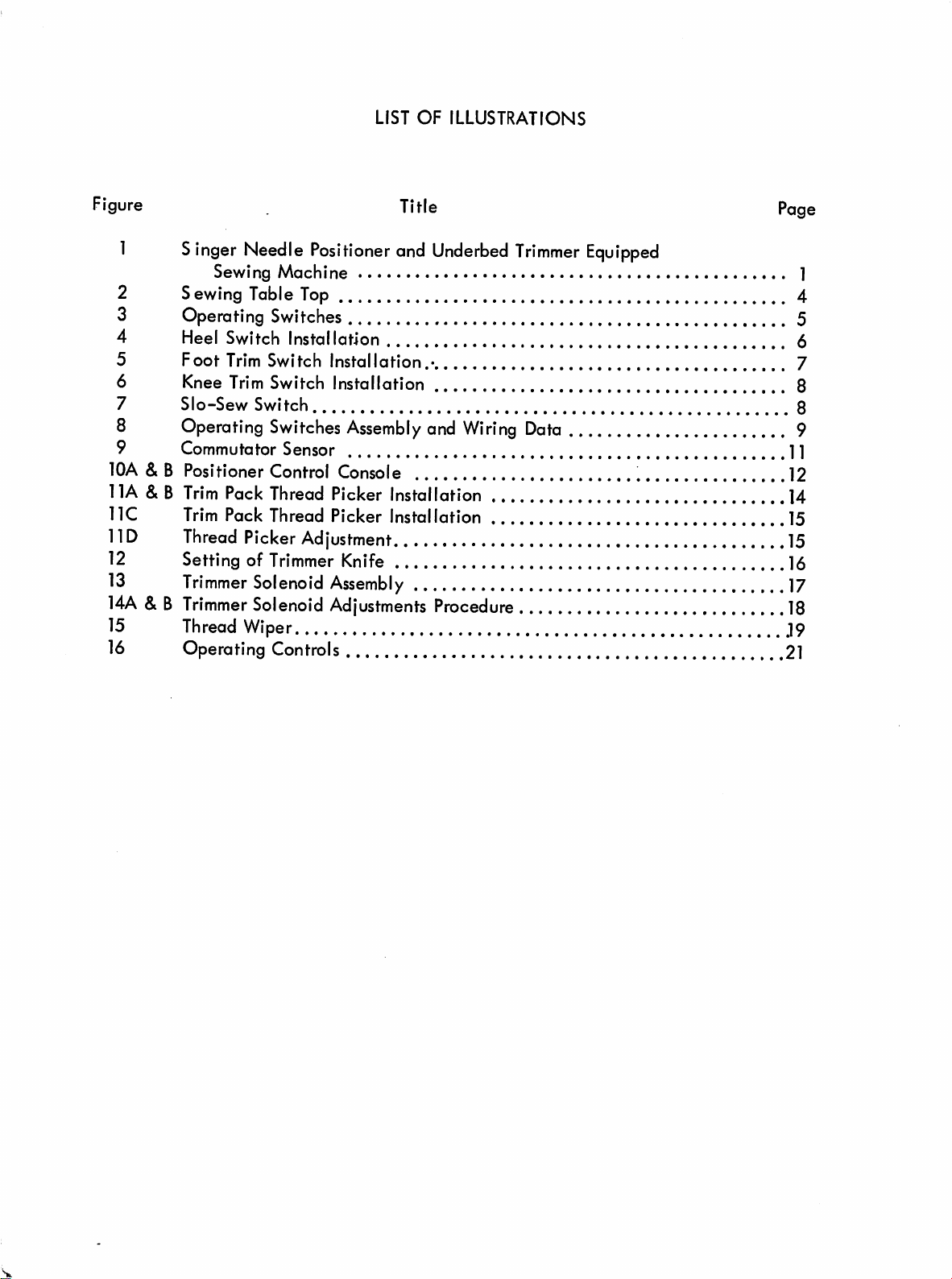

Catalog

Catalog

No,

NP050101 refers to

No.

NP050103

refers to

Machine

Machine

Nos, 281-41

No.

281-61.

and

281-43.

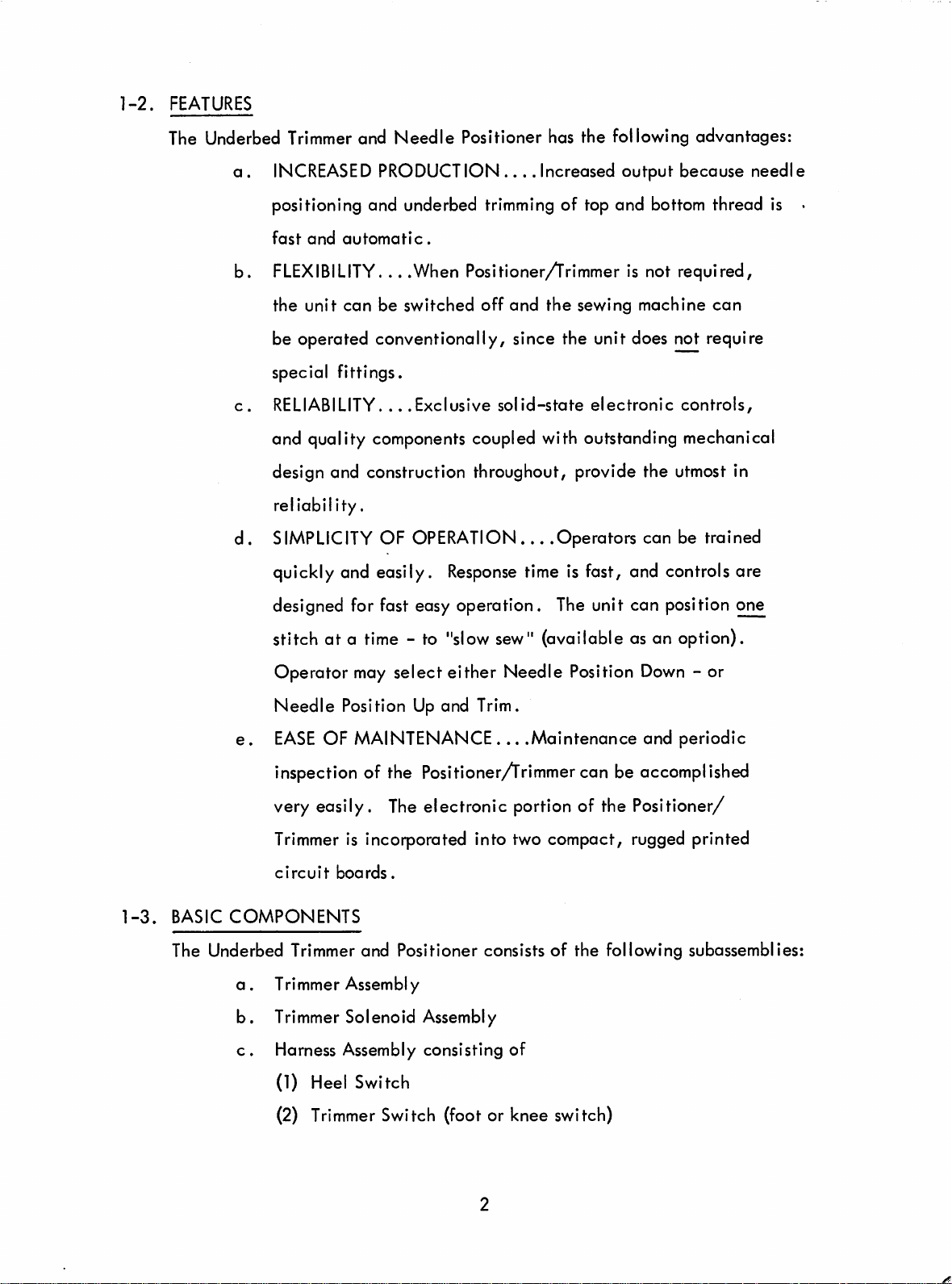

PURPOSE

The

Underbed

The

Singer

operator

needle

SECTION

Trimmer

Co.toIncrease

working

and

on apparel manufacturing.

cut

top

and

and

bottom

1 -

GENERAL

Needle

the

Positioner,

efficiency,

threadsbyhand.

INFORMATION

figure1,has

speed

The

and

accuracy

operator

Instead

need

the

been

developed

ofa

not position the

operator

touches a knee switch or a foot treadle and the positioner/trimmer does this auto

matically,

bottom threads of material being sewn.

TRIM

PACK

ASSEMBLY

THREAD

thus

PICKER

(HIDDEN)

accomplishing

automatic

positioning,

and

trimmingofboth

COMMUTATOR

SFWCJOR

sewing

merely

POSITIONER

CONSOLE

by

machine

top

and

SOLENOID

PACKAGE

y

Figure 1... .SINGER Needle Positioner and Underbed

Trimmer

Equipped Sewing Machine

1-2.

FEATURES

The Underbed

a.

b.

c.

d.

Trimmer

INCREASED

and

Needle

PRODUCTION

Positioner has the following advantages:

....

Increased output because needle

positioning and underbed trimming of top and bottom thread is •

fast

and

automatic.

FLEXIBILITY....When Positioner/Trimmer is not required,

the

unit

con be switched

off

and

the

sewing machine

can

be operated conventionally, since the unit does not require

special fittings.

RELIABILITY.

...

Exclusive

solid-state

electronic

controls,

and quality components coupled with outstanding mechanical

design and construction throughout, provide the utmost in

reliability.

SIMPLICITY

quickly and easily.

OF OPERATION... .Operators con be trained

Response

time is fast, and controls are

designed for fast easy operation. The unit can position one

1-3.

stitch at a time - to "slowsew" (available as an option).

Operator may select either Needle Position

Needle

e.

EASE

inspection of the

very easily.

Trimmer

circuit

BASIC

The Underbed Trimmer and Positioner consists of the following subossemblies:

COMPONENTS

a.

Trimmer Assembly

b.

Trimmer Solenoid Assembly

c.

Harness Assembly consisting of

(1) Heel Switch

Position

Up

and Trim.

OF MAINTENANCE... .Maintenance and periodic

Positioner/Trimmer

The

electronic portion of the Positioner/

can be

is incorporated into two compact, rugged printed

boards.

Down

- or

accomplished

(2) Trimmer Switch (foot or knee switch)

(3)

Slow

Sew

Switch (optional)

d.

Needle

e.

Commutator Sensor Assembly

f.

Thread

Positioner Assembly

Wiper

Assembly

2-1.

2-2.

SECTION

GENERAL

This

Section will describe the physical installation of the subossemblies that

INFORMATION

up the complete Underbed

n -

INSTALLATION

Trimmer

This machine should operate from

110-115 volt source

and Positioner.

CAUTION

only.

:

Electricity should be shut off during

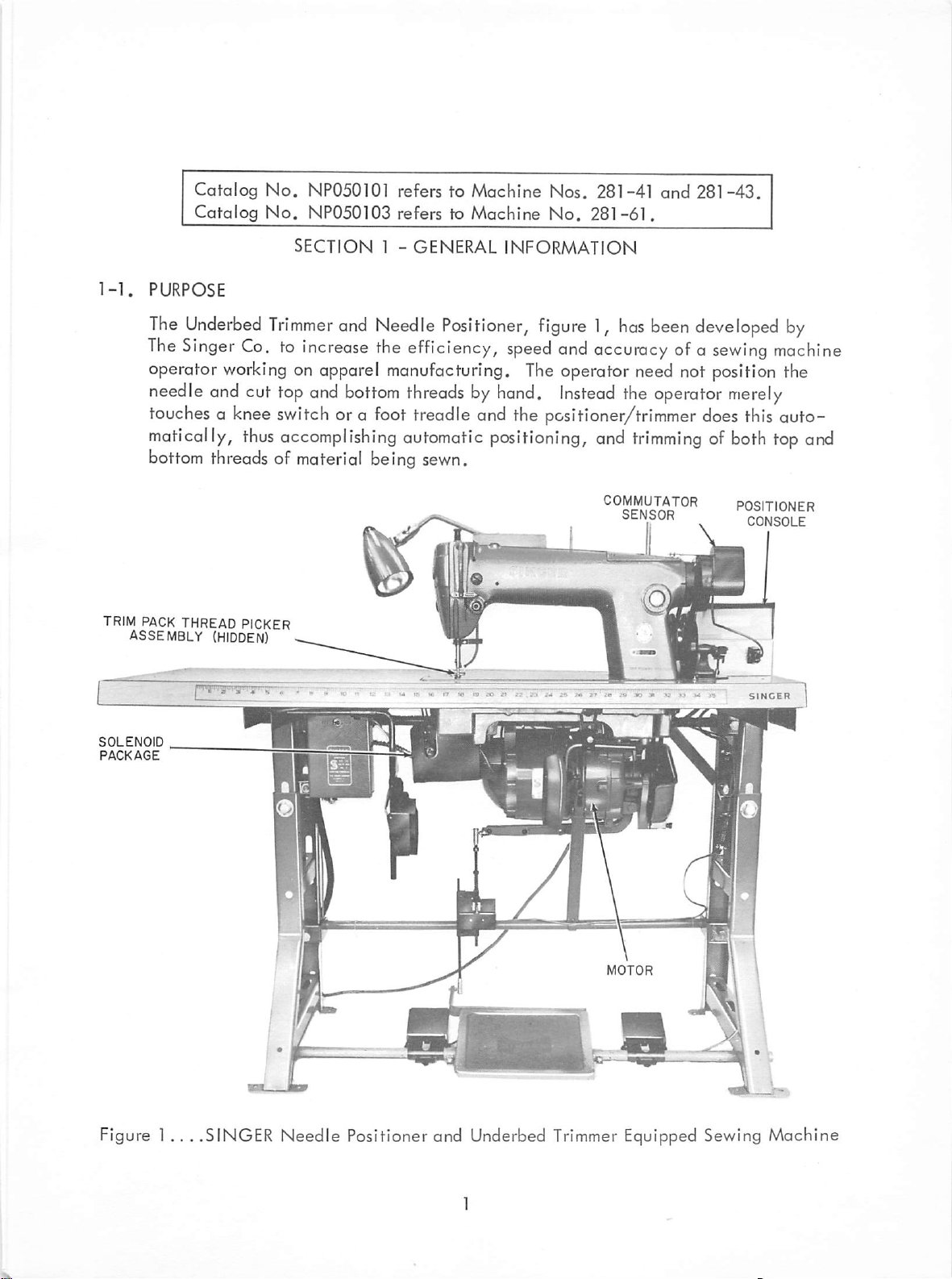

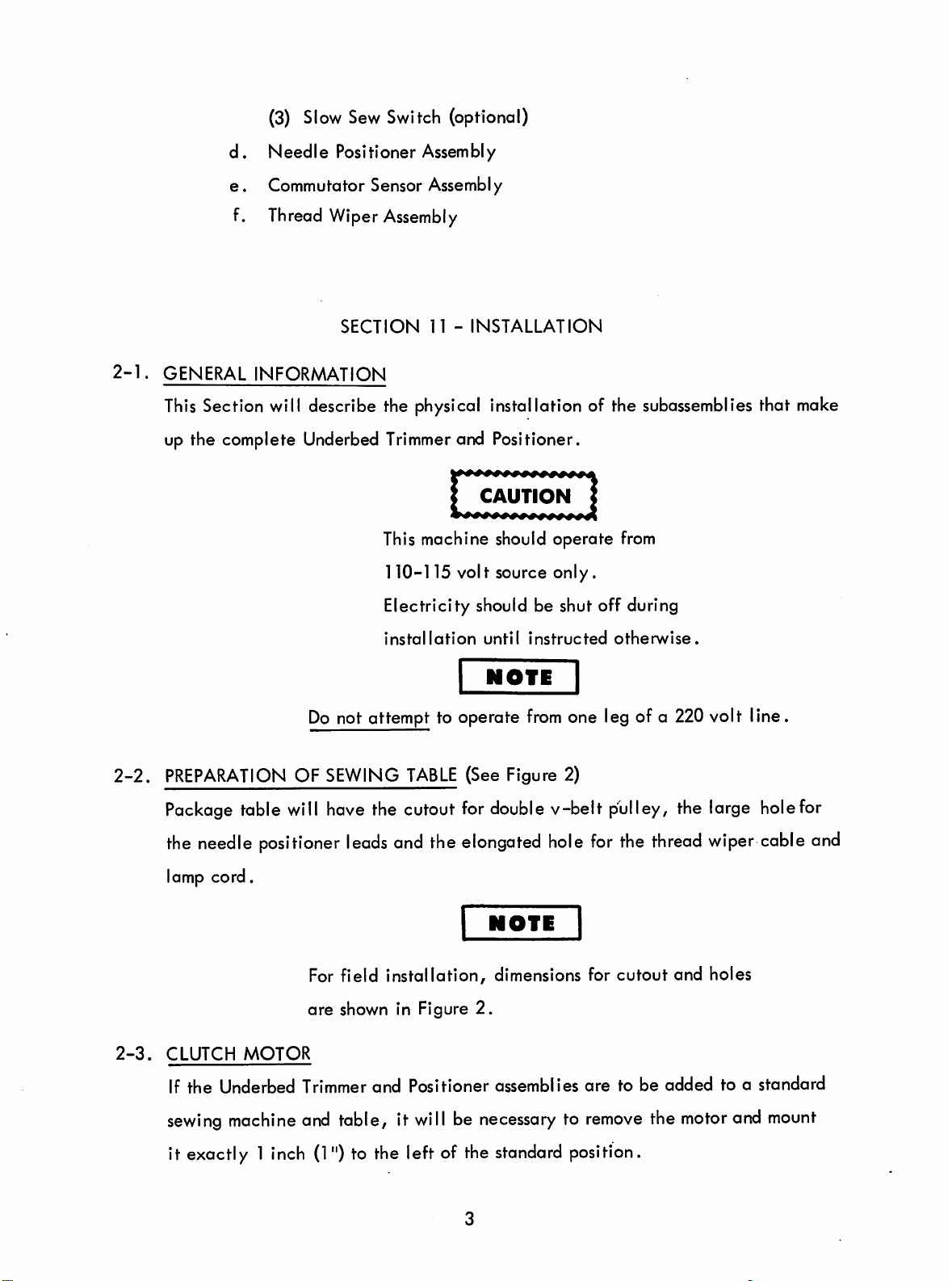

PREPARATION

installation

Do

not attempt to operate

OF SEWING

TABLE

until

instructed

NOfE

from

(See Figure 2)

otherwise.

one leg of a 220 volt line.

make

Package table will have the cutout for double v-belt pulley, the large holefor

the

2-3.

needle

lamp cord.

CLUTCH

If the Underbed Trimmer and Positioner assemblies

sewing

positioner

MOTOR

machine

leads

For field

are

shown in Figure

and

table, it

and the elongated

NOTE

installation,

will

dimensions for

2.

be

necessarytoremove

hole

for

the

thread

cutout

are

to be added to a standard

the

it exactly 1 inch (1") to the left of the standard position.

wiper

and holes

motor

and

cable

mount

and

MACH

3-1/4

NE

3/8

MIN

TABLE

1-1/2

DIA.

RIGHT

HOLE

SIDE

OF

TABLE

BELT

SLOT

4-7/8

8-15/16

5-13/16

(3)

(.228

NO.IDRILL

I"

DEEP

DIA.

MIN.

I

HOLES)

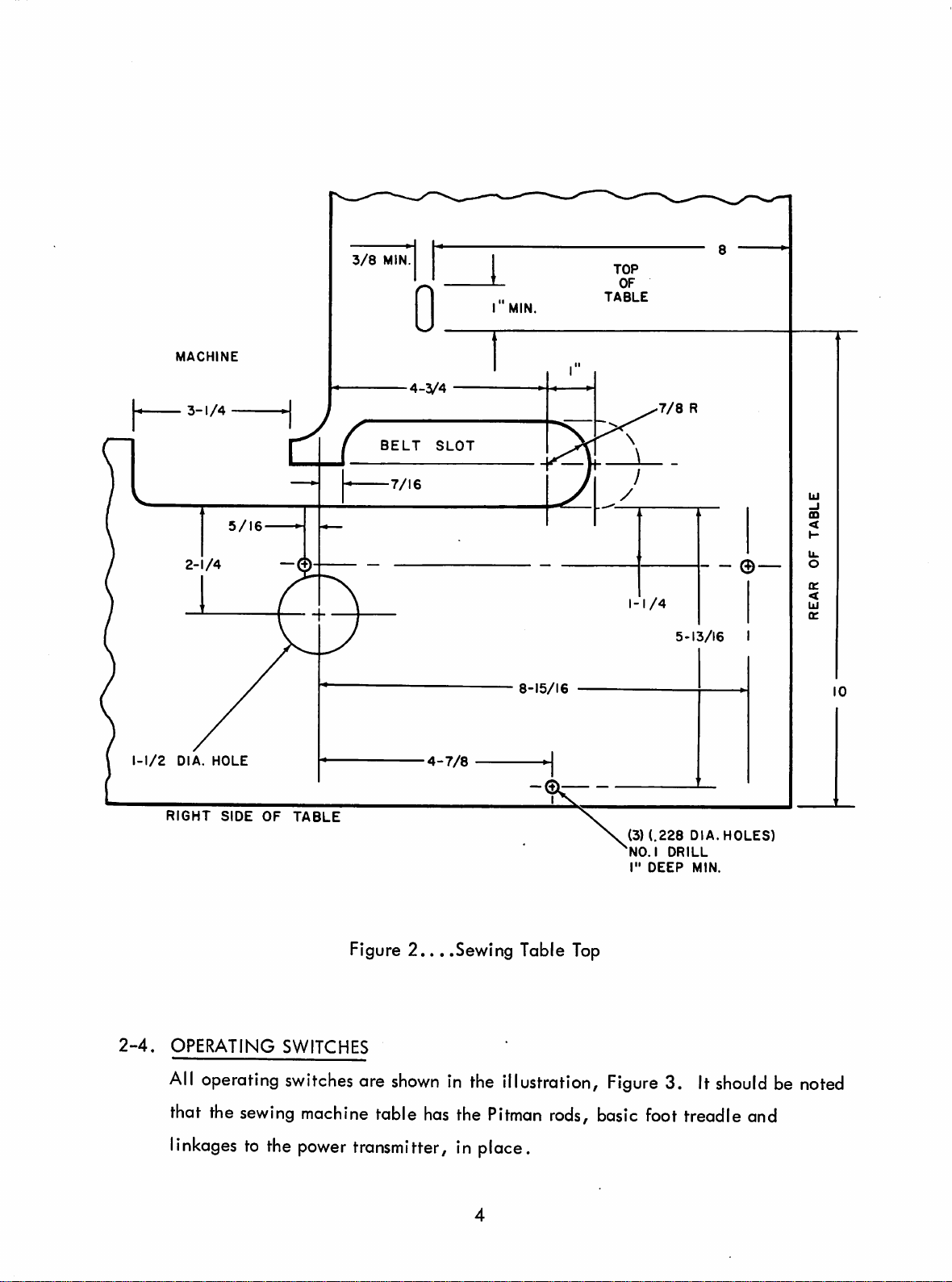

2-4.

OPERATING

All

operofing

that the

sewing

linkages to the

Figure

SWITCHES

switches

ore

machine table

power

transmitter, in place.

2,...Sewing

shown

in the illustration.

has

the

Table

Pitman

Top

Figure

rods,

basic foot treadle and

3. It

should

be

noted

KNEE

TRIMMER

SWITCH

TREADLE

SWITCH

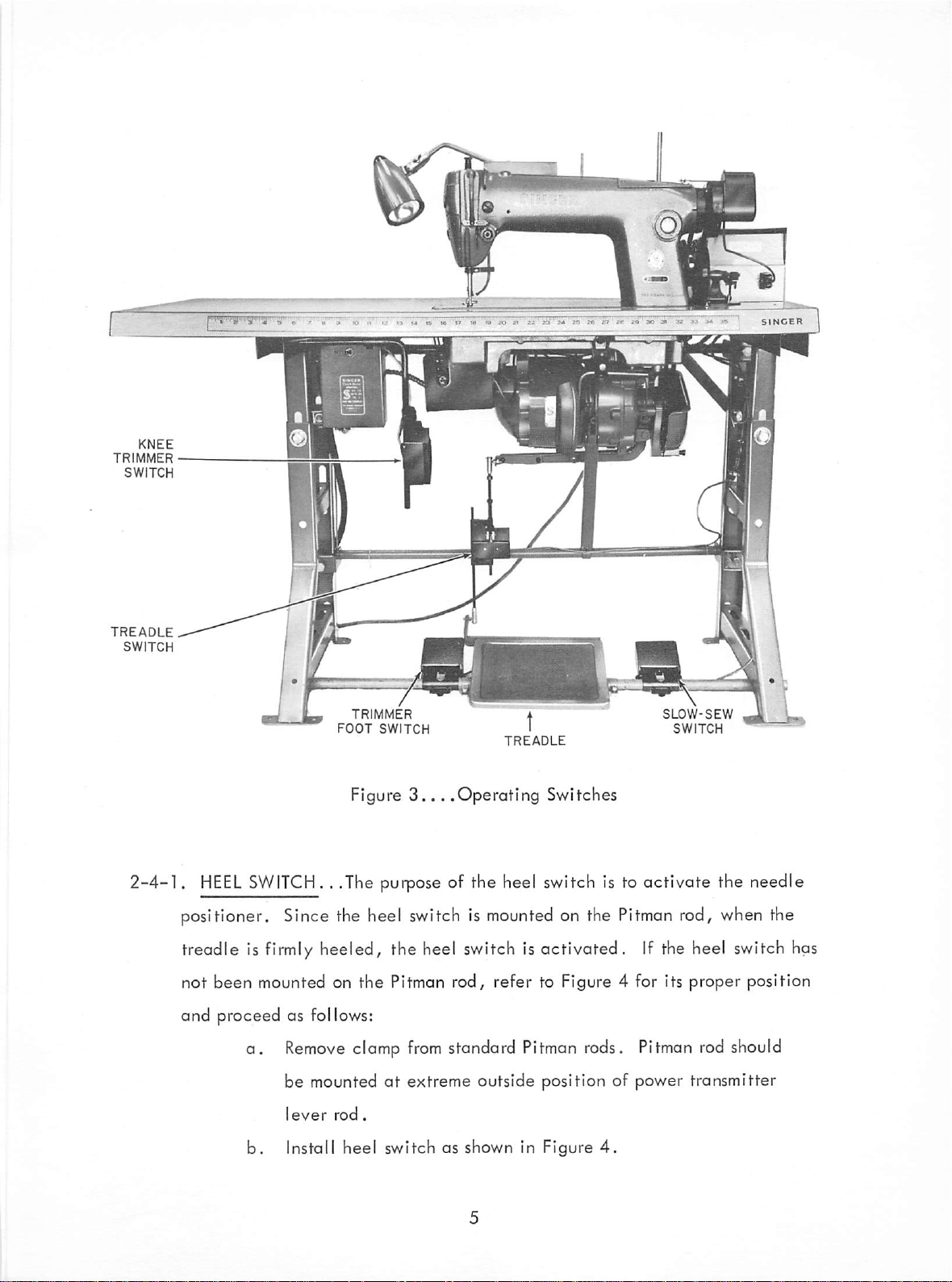

2-4-1.

TRIMMER

FOOT

SWITCH

HEEL

SWITCH.

Figure

. .The purpose of the heel switch is to activate the needle

3...

.OperaHng Switches

positioner. Since the heel switch is

TREADLE

mounted

on the Pitman rod, when the

SLOW-SEW

SWITCH

treadle is firmly heeled, the heel switch is activated. If the heel switch has

not

been

mounted on

and proceed as follows:

a.

Remove

be mountedatextreme outside position of power transmitter

b.

Install

the

clamp

heel

Pitman

from

switch

rod,

refer to Figure 4 for its proper position

standard Pitman rods. Pitman rod should

as shown in Figure

4.

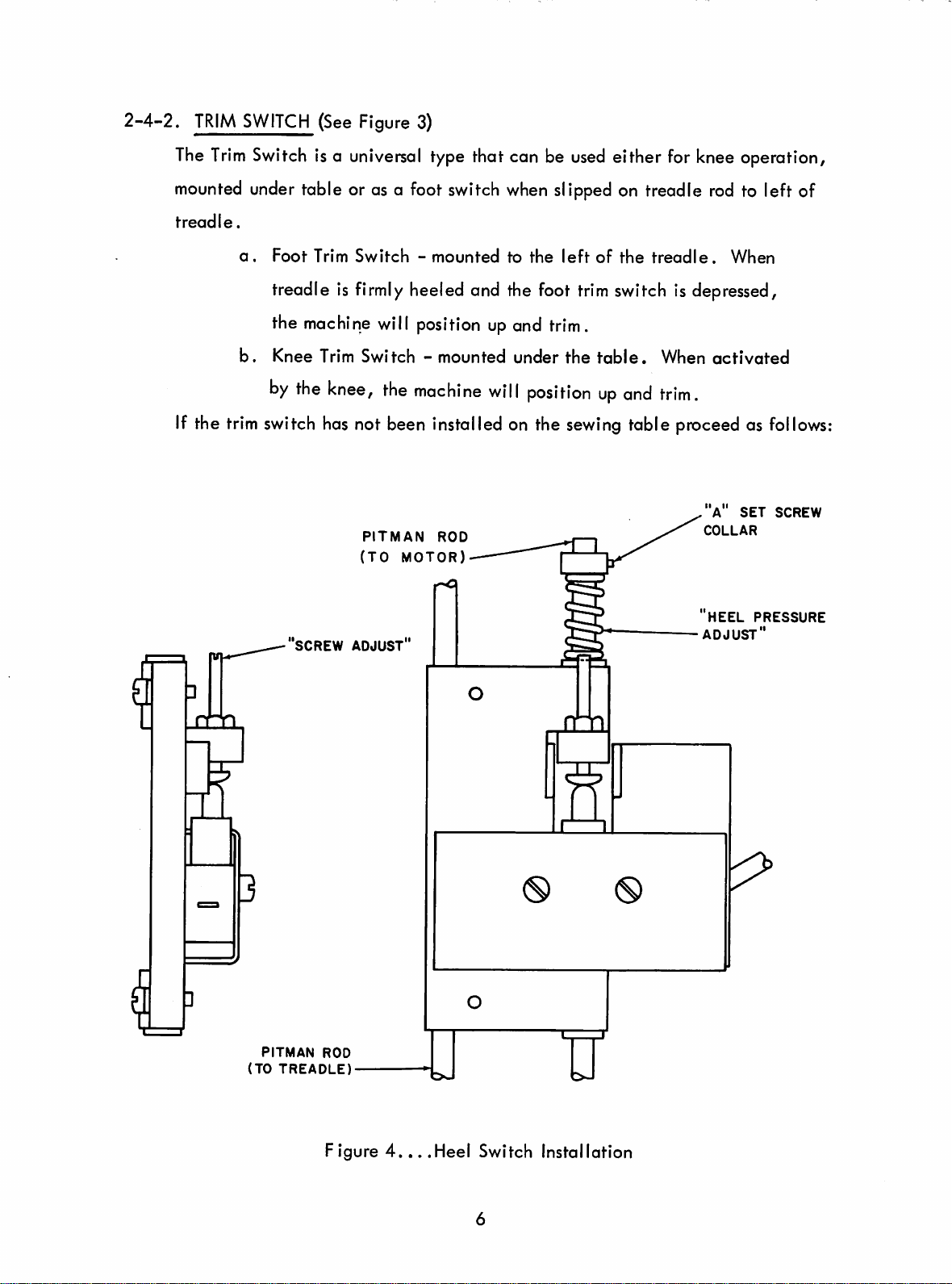

2-4-2.

The

TRIM

Trim

SWITCH

Switch

(See Figure 3)

isa

universal

type that can be

used

either for knee operation,

mounted

treadle.

If the

trim

under table or as a foot switch

a.

Foot

Trim

Switch-mounted

treadle is firmly heeled and the foot

when

slipped on treadle

to

the

left

trim

of

the

treadle.

switch is depressed,

the machine will position up and trim.

b.

Knee

Trim

by

the

Switch-mounted

knee,

the

machine

under

will

positionupand

the

table.

When

trim.

switch has not been installed on the sewing table proceed as

SCREW

PITMAN

(TO

ADJUST

ROD

MOTOR)

rod

to left of

When

activated

"a"

set

COLLAR

HEEL

adjust"

follows:

screw

PRESSURE

s

PITMAN

(TO

ROD

TREADLE)

Figure

4...

.Heel

Switch Installation

Loading...

Loading...