Page 1

14

U32A

Operator’s

Guide

Page 2

14U 32A

PREFACE

Thank you for your purchase of this sewing machine.

This machine will provide you with excellent performance in sewing from light to heavy material (lawn to

denim). Please refer to this booklet for proper use and optimum service.

Safety Cautions:

Be sure that the etectrical voitage of the socket ©utlet (wail, receptacle) is the same as the rated

smltage of the motor.

o ïJiscoîiîiect ihe power-ime ptug îrom the socket outlet rohen ciiangiag needles, presser idet or

throat pistes, or when ieindiig the machine imattended. This eliminakes the possibilitv of

starting the machine by accidentally pressing the speed coiitroÎIer.

® IJo not piiii the fabric while yon are stitching as this may deflect the needle, causing it to break.

« Before deanliig your maciime, disconnect the powenhiie plug from the socket mitiet,

® ÎJO not attempt to adjust tîîe motor belt, tiontact your nearest Service Center sltoiiki any

adj'ustnient be reipiifed.

® Handle the foot controHer with care and avoid dropping it on the floor. Be sure not to place

anytliliig on top of it.

o When, sewing ciose.15' watch the area being sewn, to avoid injuries from needles and knives.

® Do not lîoid the free amt wften lifting or moving tiie niadiine.

★ A Trademark of THE SINGER COMPANY

Copyright © 1988 SINGER SEWING MACHINE COMPANY

All Rights Reserved Trhoughout The World

Page 3

CONTENTS

Page

1. Principal parts..............................................................................................................................................2

2. Preparation prior to sewing..........................................................................................................................3

3. Threading the machine ................................................................................................................................4

• Setting up the thread guide holder.........................................................................................................4

• How to open looper cover ......................................................................................................................4

• How to remove cylinder cover................................................................................................................4

• How to thread your machine correctly....................................................................................................5

• How to change threads .......................................................................................................................... 8

4. Chain off and test sew................................................................................................................................. 8

5. How to adjust thread tension .......................................................................................................................9

6. How to adjust stitch length........................................................................................................................ 10

7. How to do rolled hemming (Throat plate available at additional cost) ................................................... 11

8. Free arm sewing (Tublar work)................................................................................................................ 13

9. Margin lines.............................................................................................................................................. 13

10. How to replace needle............................................................................................................................... 14

11. How to replace knives............................................................................................................................... 14

12. Adjustment of presser foot pressure.......................................................................................................... 15

13. Reasons for poor stitches and how to make adjustment........................................................................... 16

14. Relationship between cloth, thread and needle......................................................................................... 17

15. Accessories................................................................................................................................................ 18

16. Specification of the 14U 32A machine..................................................................................................... 18

Page 4

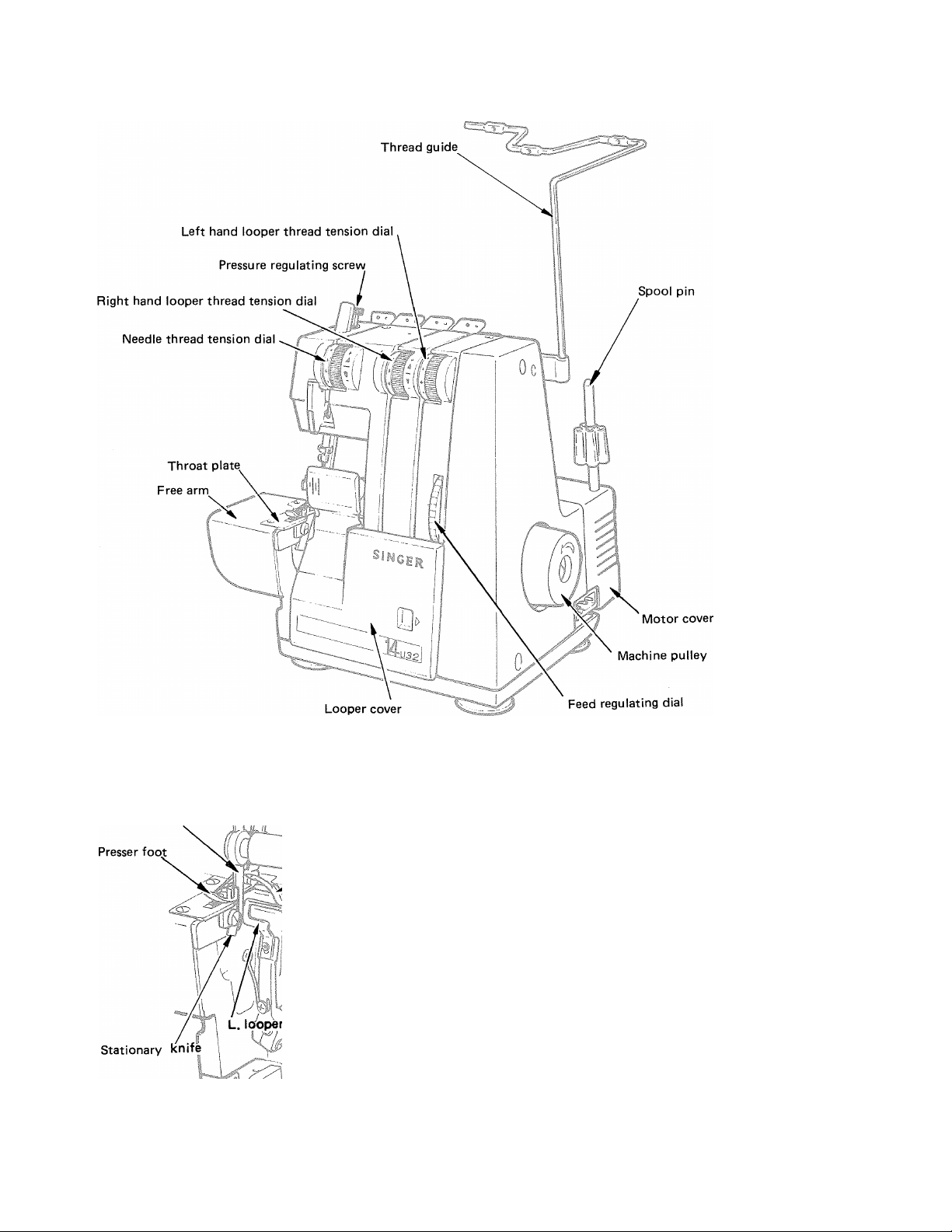

1. Principal parts

• Machine with looper cover opened

Movable knife

Rj looperi

Page 5

2. Preparation prior to sewing

Connect the machine plug to the electrical receptacle of your machine and the power line plug to the wall

receptacle.

Controller

Machine

\

plug

Power line plug wall receptacle

To run the machine and control the speed, press the speed controller. The harder you press, the faster the

machine will sew. To stop the machine from sewing, remove your foot from the speed controller.

Caytion:

• Be sure that the electrical voltage of the socket outlet (wa!! receptacle! is the same as the rated voltage of

the motor.

® Handle the foot controller with care and avoid dropping it on the floor. Be sure not to place anything

on top of it.

® Disconnect the power-line plug from the socket outlet vvhen changing needles, presses feet or throat

plates, or vtfhen leaving the rnachirie linattended. This eliminates the possibility of startiing the rtiaehine

by accidentally pressing the speed controller.

• Before cleaning your machine, cJiscorinect the power-line plug from the socket outlet.

Page 6

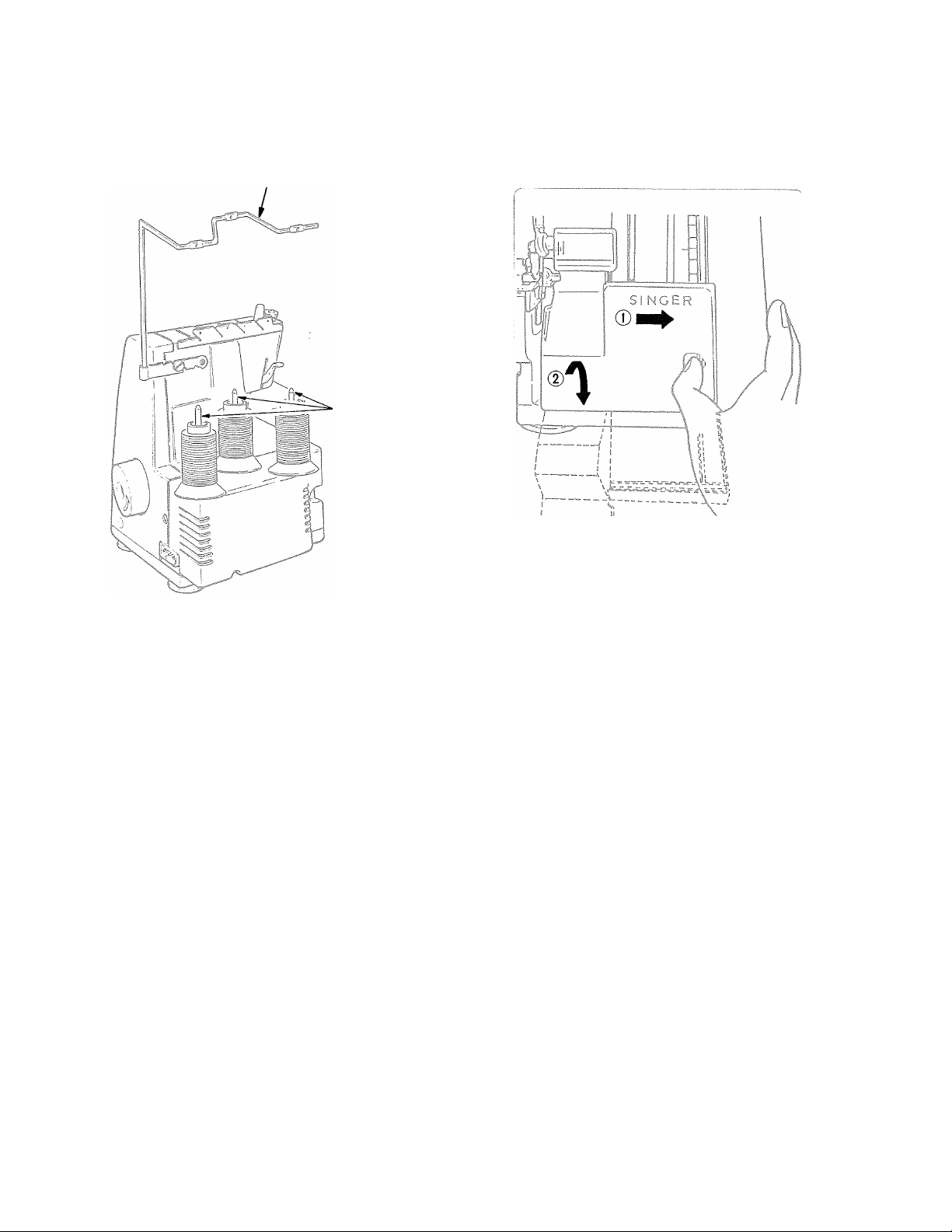

• Setting up the thread guide holder

Thread guide

Spool pin

• How to open looper cover

Swing thread guide up as far as it will go so that

thread guide holes are located just above the spool

pins.

Place the thread on the spool stand as shown

above.

® How to remove cylinder cover

II

^Ll

\

Cylinder cover

0 Push the cover to the right as

far as it will go and

0 Pull cover down toward you.

Be sure looper cover is closed when sewing.

To replace cover

r\

/

Throat

plate

(D While pulling the cylinder cover to the left,

(D Lift cover upward and off the machine.

* Do not hold the cylinder cover when inoviiig the rnachirie.

Place the upper on the cover under the throat

plate and press cover downward to the right.

Page 7

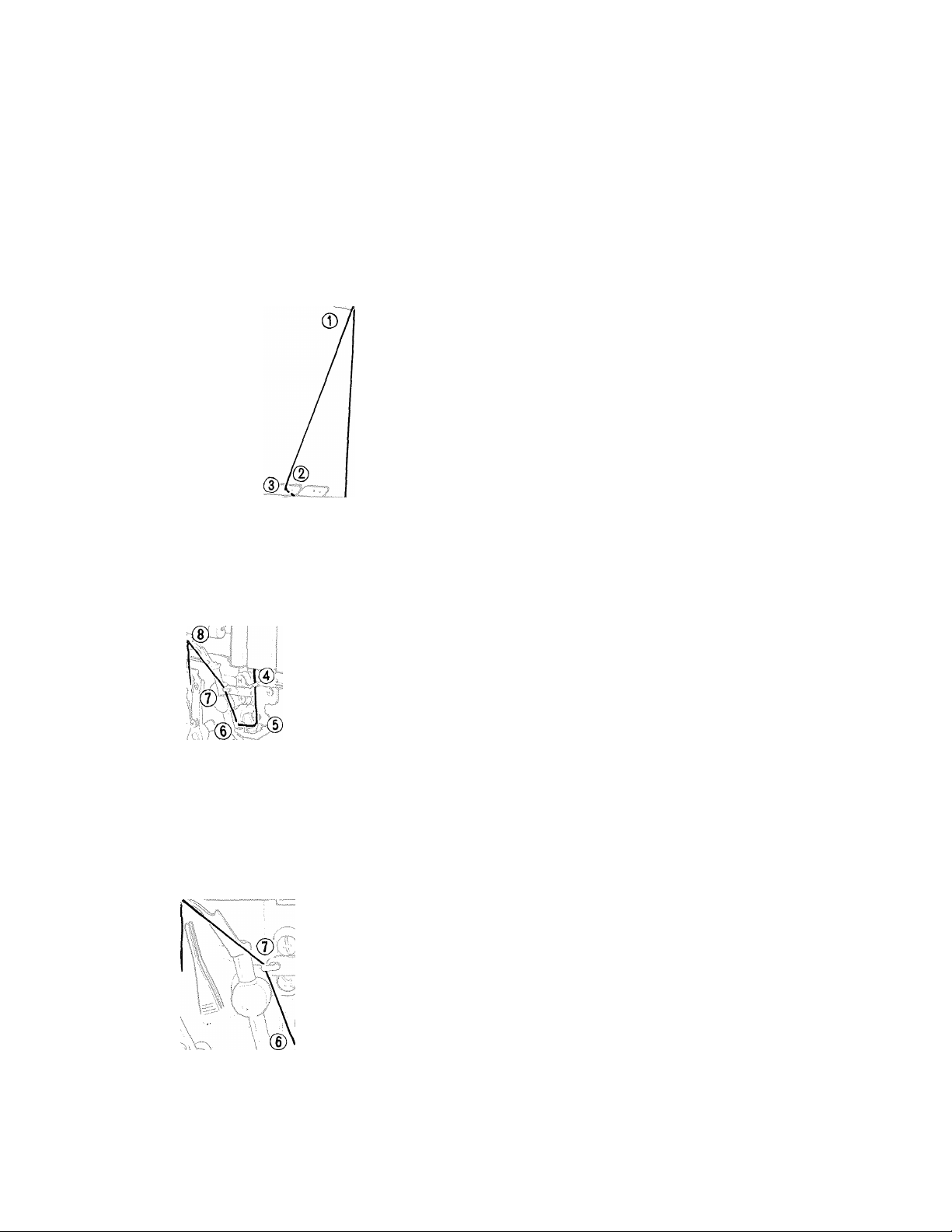

9 How to thread your machine correctly

Correct sewing cannot be obtained when machine is threaded incorrectly.

Threading is diagrammed on the inner side of the looper cover and identified with colors on the various

thread guides.

(1) Open looper cover. Thread the right looper in the order 0 to (8) as indicated in the figure below,

(threading points marked in orange)

Threading Chart

01

/

y

Tension'

discs

/

Use tweezers provided in the accessory set when

threading looper thread hole 0

Draw about 5cm (2 inches) of thread from the

looper thread hole.

Page 8

(2) Thread left looper in sequence from @ to 0 (marked in yellow color). Cylinder cover must also be

removed when threading this part. (Refer to page 4 for cylinder cover removal).

Tension discs

Turn machine pulley toward you

until left looper is at left as far

as it will go and thread looper

thread hole (£) from left to

right. (Use tweezers provided in

your accessory set).

©

5cm

(2 inches)

—L

Turn machine pulley toward you

until the looper is at right as far

as it will go passing the thread

under the throat plate, then

using a tweezer, thread the

looper thread hole ©from front

to back. Draw about 5cm (2

inches) of thread from thread

hole.

Page 9

(3) Thread the needle thread in the order® to © (green mark).

Threading of needle eye ©becomes easier when the movable knife is set at the nonoperating position

(See figure on page 14 for movable knife non-operating position).

](D

Tension discs'

(4) When needle thread is not correctly

threaded between the tension discs,

it will lie loose on the underside of

the material as shown in figure at

right.

Topside

Underside

Page 10

• How to change thread

When you wish to change the needle

thread, left looper thread or right

looper thread with a different thread,

the following steps will make the

changing convenient.

(1) Cut the thread near the spool and

tie the end to the thread you wish

to change to as shown in figure at

right.

(2) Raise presser foot.

(3) Turn the tension dials down

toward the minus (—) sign until

the dial stops and draw the thread

out so that the tie knot of the

threads extend about 5cm (2

inches) from the presser foot.

When drawing needle thread

through the needle eye, stop the

tie knot before the needle eye, cut

the thread and pass it through the

needle eye.

Tie knot

Cloth,,

When the machine is completely threaded,

turn the machine pulley toward you 2 or 3

turns while holding the 3 threads applying a

slight tension as shown in figure at left.

After chaining off, make a test stitch on a

sample of your fabric so that you can adjust

the thread tensions correctly.

After completing the seam, chain off approx.

5 cm (2 inches) as shown in figure at left and

cut thread with scissors.

Page 11

5. Mow to adjust thread tension

Adjust thread tension to suit the type of material and size of the thread used. The thread tension dial

on this machine are a one-tum system and as the number on the thread tension dials increases, the thread

tension become tighter.

® Correct thread tension

Be sure the threads are correctly threaded since otherwise proper thread tension cannot be obtained (See

page 5).

Right looper thread

Needle thread

Topside

Underside

When each of the dials are set to the stand

ard settings shown in the table, correct

tension can be obtained. Slight adjustments

may give better thread tensions.

Thread Tension

Needle thread

123456789

Fabric

A;

-3/

"■'bo

-Left looper

thread

Right

Looper Thread

123456789

Left

Looper Thread

123456789

Light

Weight

Medium

Weight

Heavy

Weight

-

Page 12

When the right looper thread

lie on the underside of fabric.

/

Needle thread

Right looper"^

thread

Topside

'Left looper

thread

Underside

When the left looper thread

appears on the top.

Left looper

thread

\

Right \oo<per /

thread J

Needle^

thread

Topside Underside

When the needle thread tension is too loose.

/

Rightlooper f > \ /

th read - j

Left looper------------ ¿leedle

thread thread

Topside .

Underside

Turn right looper dial (orange

color) toward the plus sign (+).

Or, turn the left looper dial

(yellow) toward the Minus

sign (-).

Turn left looper dial (yellow)

toward the plus sign (+).

Or, turn the right looper dial

(orange) toward the minus

sign (—).

The feed regulator dial on this machine is pre-set to

Feed

Regulator

dial

3mm for normal sewing condition. Since the adjust

ment can be made easily, adjust the stitch length to

4mm when sewing heavy weight fabrics such as

quilting and to 2mm when sewing light weight

fabrics such as lining fabric, crepe, etc. and you will

obtain excellent seams without puckerings.

Turn the needle thread tension

dial (green) toward the plus

sign (+).

Or, turn both right and left

looper dials (orange and

yellow) toward the minus sign

(-).

10

Page 13

(Throat plate available at additional cost)

1. Fabric, needle and thread

Fabric; Light to medium weight (See page 17)

• Rolled hemming is done by rolling the fabric and overedging (seam width 1.5mm), and is not

suited for heavy or stiff fabrics.

Needle: Singer Cat. No. 2054 (#10), #14.

Thread: A variety of thread combinations can be used for rolled hemming.

2. How to exchange throat plate

o

A throat plate for rolled hem stitching is available

at additional cost. By exchanging the ordinary

overedge throat plate on the machine with a

rolled hemming throat plate by the following

procedure, the machine can be used for rolled hem

stitching.

o

nr

o

Rolled hemming

throat plate

1. First of all, always disconnect the power line plug from

the receptacle.

2. Turn the hand wheel towards you until the needle is at

its highest point.

3. Lift the Presser foot.

4. Remove the cylinder cover, (see page 4).

5. Unscrew the throat plate screw (1) and remove the

throat plate.

6. Install the ordinary overedge throat plate and replace

the screw (1).

7. Replace the cylinder cover (See paged).

Ordinary overedge

throat plate

be ~ c : I ' - '

11

Page 14

3. How to adjust thread tension

1. Standard rolled hem stitching

Set each dial to the standard settings shown in the table for correct tension. For adjustments refer to

page 9, Item 5. How To Adjust Thread Tension.

Thread Tension!

^0/

Stitching

Needle Thread

123456789

123456789

Right

Looper Thread

123456789

Standard

Rolled hem

Rolled hem

Variation

2. Right looper thread wrapped rolled hem stitching (rolled hem variation)

® Correct thread tension

Right looper

(orange dial)

For light and medium weight fabrics which are difficult

Needle thread

(green dial)

Topside

\ \

Left looper thread

(yellow dial)

Underside

to roll, a fine seam can be obtained by this stitching.

Left

Looper Thread

To correctly adjust the thread tension, first set the dials to the standard settings shown in the above

chart and adjust to proper tension. Next set the dials as follows from the above standard thread tension

dial settings.

a. Turn the right looper thread tension dial (orange) towards the minus (—) sign half settings.

b. Turn the left looper thread tension dial (yellow) towards plus (+) sign 2 — 3 settings.

When the right looper

thread is too loose

1

Needle thread

Right looper^

thread

Topside

Turn right looper thread tension

dial (orange) towards the plus

(+) sign.

\ \

Left looper

thread

Underside

When the left looper

thread is too loose

/

Needle thread

Right looper -

thread

\

Topside //

Turn left looper thread tension

dial (yellow) towards the plus

(+) sign.

Or, turn right looper thread ten

sion dial (orange) towards the

minus (—) sign.

Left looper

thread

Underside

When the needle thread

is too loose

Right looper

thread

Topside

Underside

Turn needle thread dial (green)

towards the plus (+) sign.

Or, turn both right and left

looper dials (orange and yellow)

towards the minus (—) sign.

\

Left looper

thread \

\

Needle thread

12

Page 15

4. How to sew and cautions

1. Stitch length adjustment (See page 10)

For rolled hemming, set the feed regulator dial to “2” or “F” and a fine seam can be obtained.

2. Sewing

• See page 8, “4. Chain off and test sewing”.

• For rolled hemming, if a slight tension is applied to the material in the sewing direction, a finer seam

finish can be obtained.

• At the start of sewing, slightly pull the end of the chain off so it will not be entangled in the stitch.

• The overedge stitch width for rolled hemming is approximately 1.5mm and cannot be adjusted,

Inthis case, note that the fabric cut width is 3.5mm (adjusted at shipment).

8. Free arm seeving fTyblar work!

This is a free arm machine and is suited for tubular

work.

This is especially convenient for finishing hard-toreach areas such as arm holes and overcasting

cuffs.

Slip tubular work onto the free arm and sew.

Use margin lines on looper cover.

Thick line on extreme right is 5/8 inch from center

of needle.

13

Page 16

10, Homi to replace needle

Needle set

screw

Use Singer needle Cat. No. 2054 Available in

sizes (#10), #14.

To remove the needle:

Replace

\

Remove

Flat surface to the rear

• Be sure the power line plug is disconnected

from the wall receptacle.

• Turn the machine pulley toward you until

the needle is at its highest position. Loosen

the needle set screw with a coin and remove

needle.

To replace the needle:

• Insert the needle into the needle bar hole as

far as it will go with flat surface to the rear

and securely tighten the needle set screw.

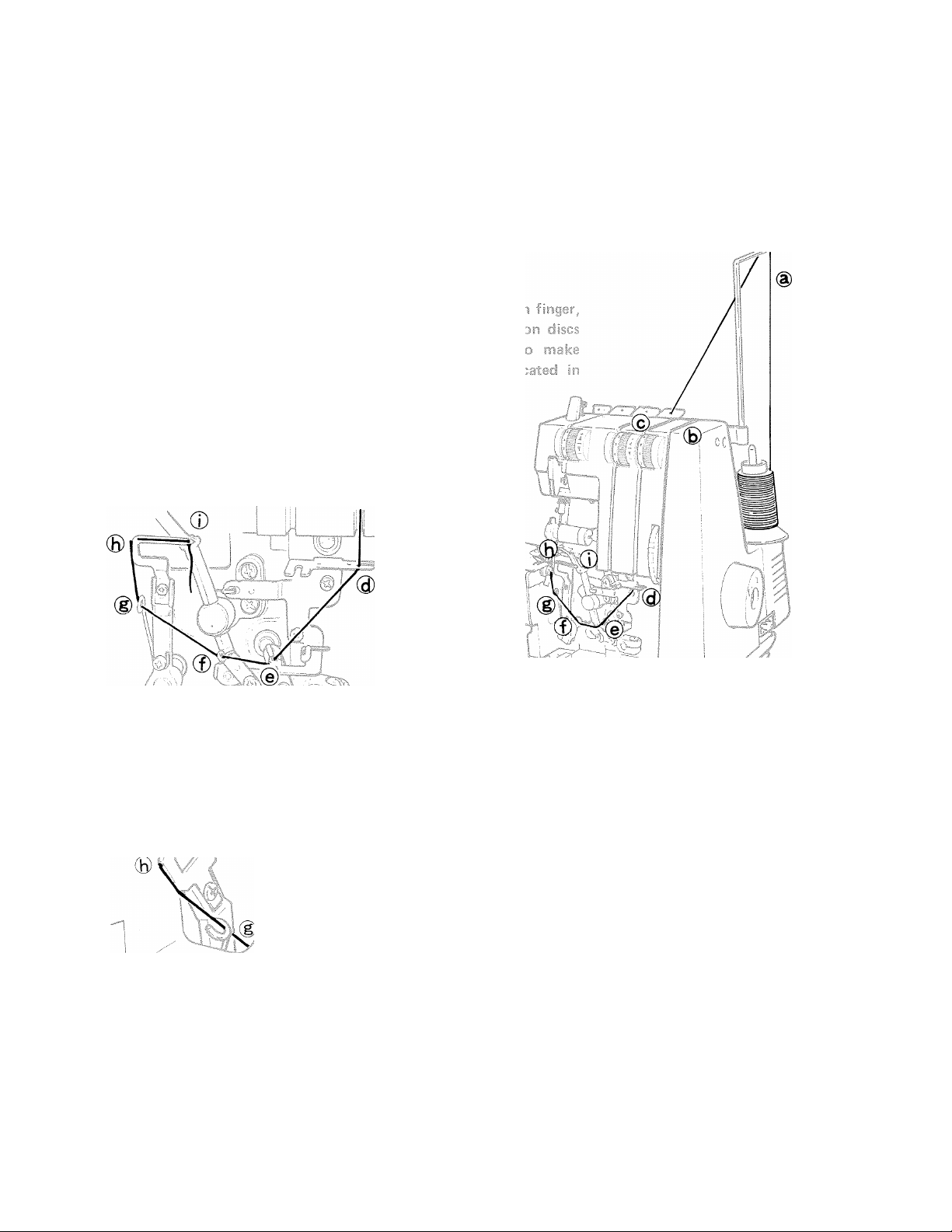

11, How to replace kriices

The stationary knife should be changed when it becomes dull.

(1) Be sure that the power line plug is disconnected from the wall receptacle.

(2) Open the looper cover and set the movable knife in the non-operating position.

(3) Loosen the stationary knife set screw and remove the stationary knife.

J

Movable

knife

holder

Push the movable knife holder to the

right as far as it will go and turn the knob

in the direction shown.

14

As shown above, the movable knife

will be in a non-operating position.

Page 17

(4) Place a new stationary knife in the groove of the stationary knife holder, align the cutting edge level with

the top surface of the throat plat and tighten set screw.

(5) Return the movable knife to its original position.

Same height

Stationary

knife set

screw

Stationary knife

12. Acijustfiierit of presser foot pressore

Pressure regulating thumb screw

Less pressure

More pressure

The presser foot pressure of this machine is

preadjusted at the factory to suit the sewing of

medium weight fabrics.

It may become necessary to adjust the pressure

in the case of delicate or heavy weight fabric.

For light weight fabric

(as shown at left).

Heavy weight fabric (as shown at left).

Decrease the pressure

Increase the pressure

15

Page 18

Whenever sewing difficulty is encoutered, make the adjustments as noted below.

Condition

When the fabric is not fed.

When the needle breaks.

» Insufficient presser foot pressure.

® Needle not inserted properly.

Reason

* Fabric being pulled too hard.

® Loose needle set screw.

When the thread breaks. ® Incorrect threading.

® Bent needle or needle point

damaged.

® Thread tension too tight.

® Thread tangled.

® Needle inserted incorrectly.

When stitches skip.

® Needle bent or needle point

damaged.

® Needle set loosely.

Method of Adjustments

(reference pages)

® Increase presser foot pressure

(page 15).

® Insert needle correctly or replace

with correct needle (page 14).

® Do not pull the fabric by hand.

Use hand only to guide the fabric.

® Tighten screw firmly.

® Thread machine correctly

(page 5).

® Change to correct needle

(page 14).

® Adjust tension (page 9).

® Thread correctly (page 5).

® Insert needle correctly (page 14).

® Replace with correct needle

(page 14).

® Set needle firmly in position

(page 14).

When stitches are

irregular.

When fabric puckers

When the machine does

not operate.

When motor is excessively

noisy or when sparking is

excessive.

® Incorrect threading.

® Thread machine correctly

(page 5).

® Wrong needle used.

® Insufficient presser foot

pressure.

® Thread tension not balanced.

® Thread tension too tight.

® Threading incorrect or tangled.

® Power line plug not connected.

® Motor damaged.

® Controller damaged.

® Use Singer Cat. 2054 #14.

® Increase presser foot pressure

(page 15).

® Adjust tensions (page 9).

® Adjust tension (page 9).

® Thread correctly (page 5).

® Connect with power source.

® Change carbon brush.*

® Have your Singer representative

repair and service the controller.

® Motor damaged. ® Change carbon brush.*

* Have your Singer representative

replace the carbon brush.

16

Page 19

eloth, thread and needle

Type of Fabric

Lightweight

Lawn, Organdy,

Voil, Crepe, etc.

Medium Weight

Muslin, Sheersucker,

Satin, Gabardine

Broadcloth, etc.

Heavy Weight

Oxford, Denim

Tweed, Corduroy

Serge

Type of Thread

Cotton #100

Silk #100

Spun #80 - #90

Tetron #80 — #100

Cotton #60 — #80

Silk #50

Spun #60 — #80

Tetron #60 — #80

Cotton #40 — #60

Silk #40 - #60

Spun #60 — #80

Needle

Singer Cat. No. 2054

(#10) #14

#14

#14

Knit

Tricot

Jersey

Wool (woven, knit)

Tetron #50 — #80

Spun #80 - #90

Tetron #60 — #80

Spun #60 “ #80

Tetron #60 — #80

Cotton #60 — #80

Spun #60 -- #80

Tetron #50 — #60

Wooley nylon

Wooley tetron

(#10) #14

#14

#14

17

Page 20

15„ Accessories

1. Needle set

2. Tweezers

16= Specification of the 14U32A machine

Item Specification

Sewing speed 1,300 spm maximum

Stitch length (feed amount)

Overedge stitch width

Needle bar stroke

Presser foot rise

Needle Singer Cat. No. 2054 (#10) #14

Number of threads

Machine dimensions

Weight

1 ~ 5 mm

3.5 mm

25 mm

5 mm

3

width 257 mm x depth 231mm x height 313 mm

5.0 kg

18

Page 21

6L

01AI31M

Page 22

MEMO

20

Page 23

Page 24

Form U3864 (788)

Part No. 379210-002

Printed in Japan

Loading...

Loading...