SINGER 14U22 User Manual

'Riokjioi«»!

14

U12

Operator’s

Guide

SINGER

Professional 14U12

PREFACE

Thank you for your purchase of this sewing machine.

This machine will provide you with excellent performance in sewing from light to heavy material (lawn to

denim). Please refer to this booklet for proper use and optimum service.

Safety Cautions:

• Be sure that the electrical voltage of the socket outlet (wall receptacle) is the same as the rated

voltage of the motor.

• Disconnect the power-line plug from the socket outlet when changing needles, presser feet or

throat plates, or when leaving the machine unattended. This eliminates the possibility of

starting the machine by accidentally pressing the speed controller.

• Do not pull the fabric while you are stitching as this may deflect the needle, causing it to break.

• Before cleaning your machine, disconnect the power-line plug from the socket outlet.

• Do not attempt to adjust the motor belt. Contact your nearest Service Center should any

adjustment be required.

• Handle the foot controller with care and avoid dropping it on the floor. Be sure not to place

anything on top of it.

• When sewing closely watch the area being sewn to avoid injuries from needles and knives.

• Use only the handle to lift and move the machine.

* A Trademark of The Singer Company

Copyright © 1981 The Singer Company

All rights reserved throughout the World

CONTENTS

Page

1. Principal parts

2. Preparation prior to sewing.........................................................................................................................

3. Threading the machine .......................................................................................................................‘. 4

• Setting up the thread guide holder......................................................................................................... 4

• How to open looper cover ..................................................................................................................... 5

• How to remove cylinder cover.............................................................................................................. 5

• How to thread your machine correctly................................................................................................. 6

• How to change threads ........................................................................................................................ 9

4. Chain off and test sew................................................................................................................................... 9

5. How to adjust thread tension .................................................................................................................... 10

6. How to adjust stitch length.......................................................................................................................... 11

7. Free arm sewing (Tubular work)................................................................................................................ 12

8. Adjustment of presser foot pressure............................................................................................................ 13

9. How to replace needle................................................................................................................................ 13

10. Adjustment of overedge seam width......................................................................................................... 14

.......................................................

..............

.......................................................................

2

3

11. How to replace knives................................................................................................................................. 16

12. Lubrication.................................................................................................................................................. 17

13. Reasons for poor stitches and how to make adjustment............................................................................. 18

14. Relationship between cloth, thread and needle.......................................................................................... 19

15. Accessories................................................................................................................................................. 20

16. Specification of the 14U12 machine......................................................................................................... 20

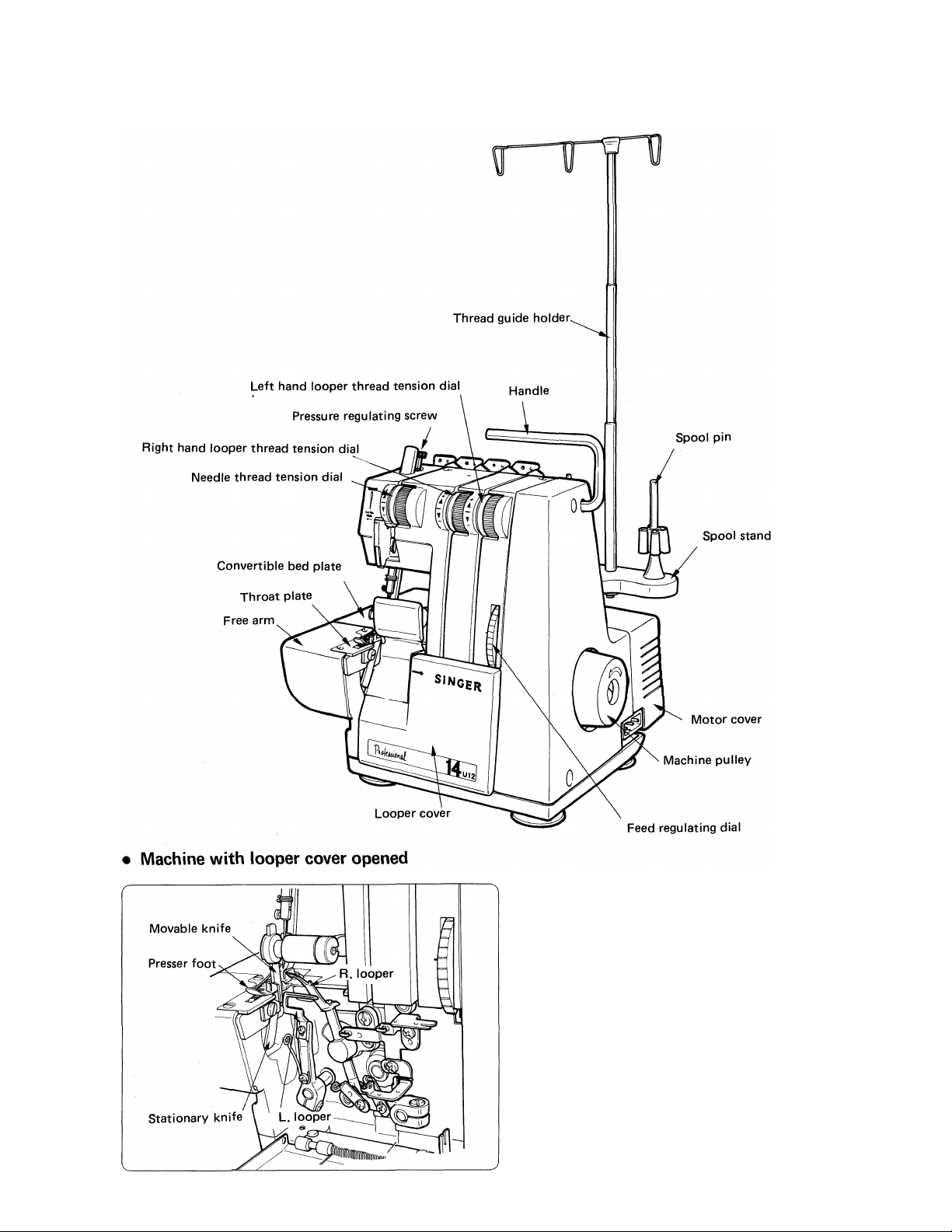

1. Principal parts

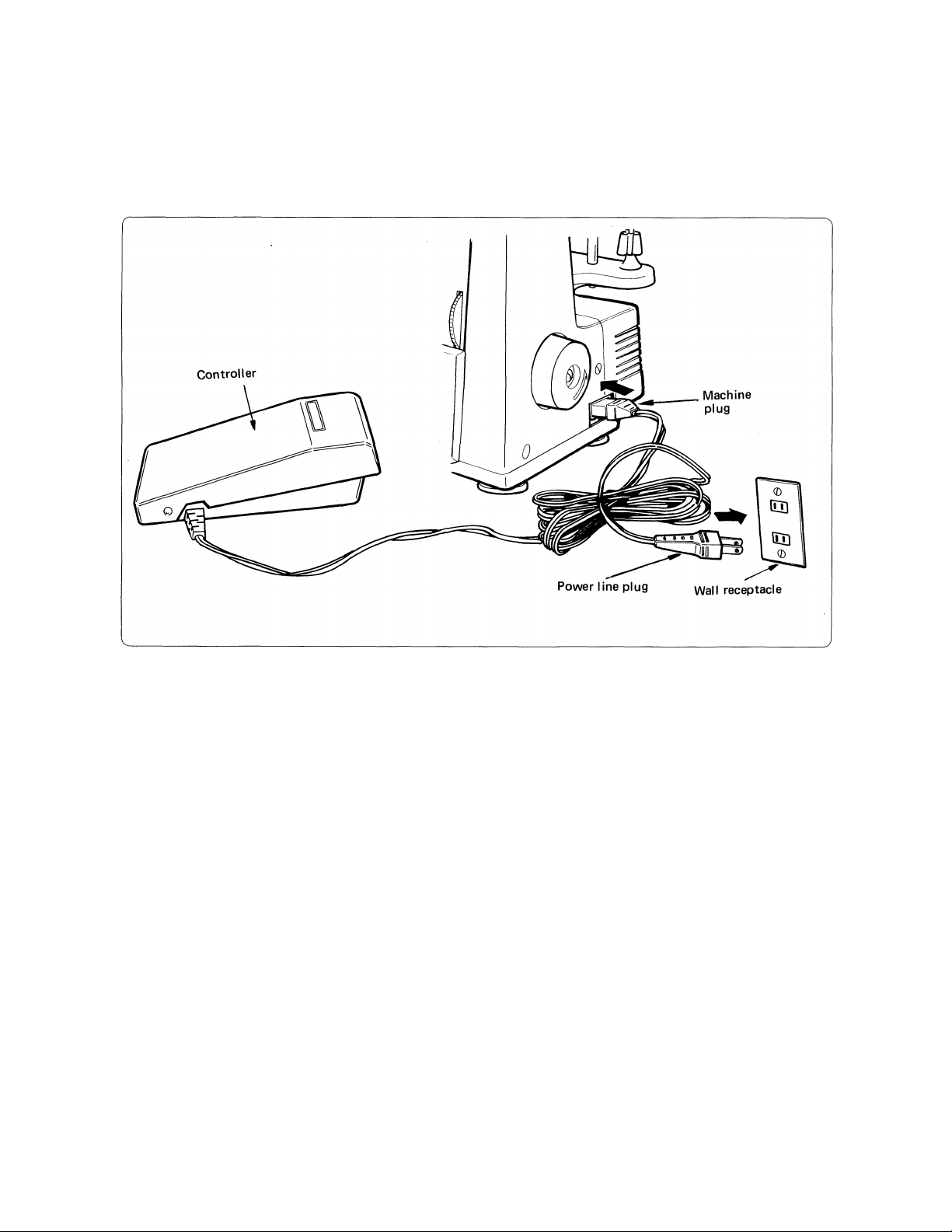

2. Preparation prior to sewing

Connect the machine plug to the electrical receptacle of your machine and the power line plug to the wall

receptacle.

To run the machine and control the speed, press the speed controller. The harder you press, the faster the

machine will sew. To stop the machine from sewing, remove your foot from the speed controller.

Caution:

• Be sure that the electrical voltage of the socket outlet (wall receptacle) is the same as the rated voltage of

the motor.

• Handle the foot controller with care and avoid dropping it on the floor. Be sure not to place anything

on top of it.

• Disconnect the power-line plug from the socket outlet when changing needles, presser feet or throat

plates, or when leaving the machine unattended. This eUminates the possibihty of starting the machine by

accidentally pressing the speed controller.

Before cleaning your machine, disconnect the power-line plug from the socket outlet.

3. Threading the machine

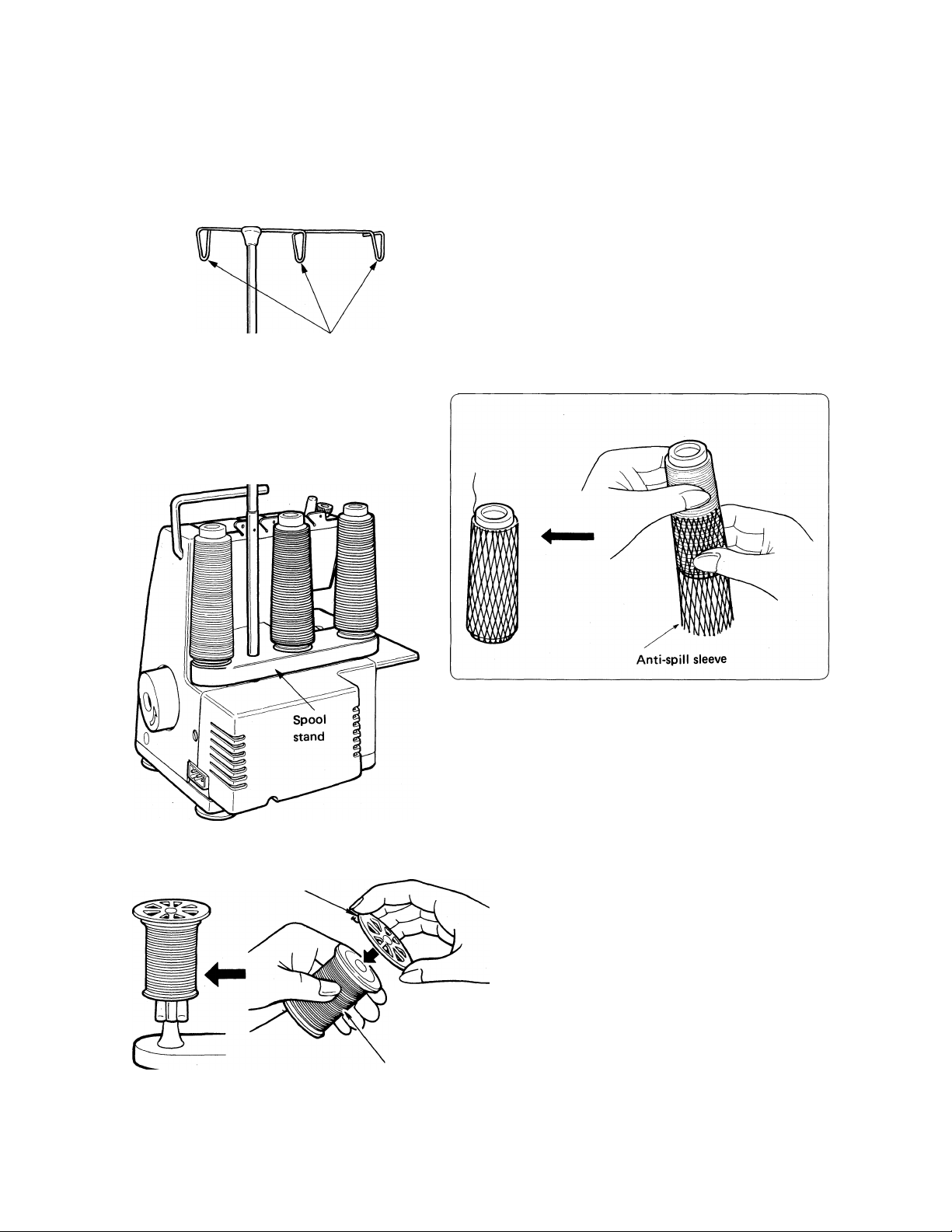

• Setting up the thread guide holder

Thread guide

Thread guide

holder

Extend the thread guide holder as far as possible and set

the thread guides so that they are located right above

the spool pins.

Place the thread on the spool stand as shown in the

figure at the left.

Spool cap

When using synthetic threads that easily spill off the

cop (cone) slip the anti-spill sleeve furnished with the

machine over the thread from the bottom of the cop

(cone) leaving the thread end hanging free at the top of

the anti-spill sleeve as shown above.

When using a reel type thread spool, fit the

spool cap supplied with the machine onto

the thread spool as shown at left.

Press in

Thread spool

• How to open looper cover

* Be sure looper cover is closed when sewing.

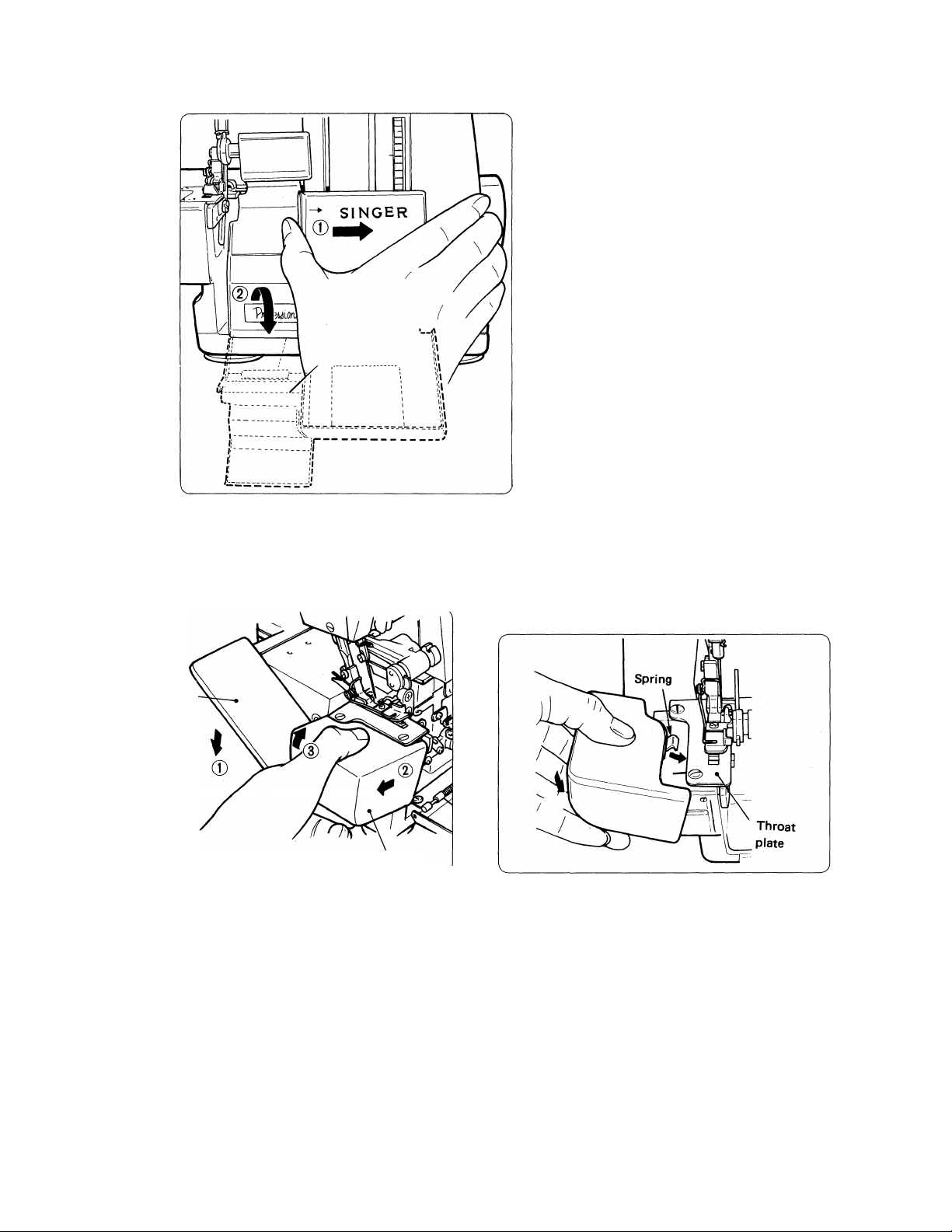

(1) Push the cover to the right as

far as it will go and

(D Pull cover down toward you.

• How to remove cylinder cover

Convertible

bed plate

Cylinder cover

0 Push convertible bed plate down and

@ While pulling the cylinder cover to the left,

(D Lift cover upward and off the machine.

To replace cover

Place the upper spring on the cover under the

throat plate and press cover downward to the

right.

* Be sure to lower the plate.

* Do not hold the cylinder cover when moving the machine.

• How to thread your machine correctly

Correct sewing cannot be obtained when machine is threaded incorrectly.

Threading is diagrammed on the inner side of the looper cover and identified with colors on the various

thread guides.

(1) Open looper cover. Thread the right looper in the order 0 to (§) as indicated in the figure below,

(threading points marked in orange)

Wind thread around thread

guide when threading (2) as

shown in figure below.

While holding thread with finger, pass it

between the tension discs and pull thread

down to make certain it is properly located

in between the tension discs.

• Use tweezer provided in the accessory set when

threading looper thread hole (8) .

• Draw about 5cm (2 inches) of thread from the

looper thread hole.

Loading...

Loading...