Page 1

I^ofmufnd

-..«y, ».n'-L.-» ijg ' " iS ^

i Jt'' ~ ’ ,

■v'-c-^V'. 'f -*

'A ii

14

n

U11/13

mu

—

Mil

w

L'>

: \'

Operator’s

Guide

M—HHmH

•r

im

mggBggHm

——

V^O*''

m

SINGER

Page 2

Professional 14U11/13

PREFACE

Thank you for your purchase of this sewing machine.

This machine will provide you with excellent performance in two thread overedging, two thread chain stitch

ing (14U13) and interlocking (safe.ty stitching)(14U13) from light to heavy material (lawn to denim). Please

refer to this booklet for proper use and optimum service.

Safety Cautions:

• Be sure that the electrical voltage of the socket outlet (wall receptacle) is the same as the rated

voltage of the motor.

• Disconnect the power-line plug from the socket outlet when changing needles, presser feeet or

throat plates, or when leaving the machine unattended. This eliminates the possibility of start

ing the machinery by accidentally pressing the speed controller.

*

• Do not pull the fabric while you are stitching as this may deflect the needle, causing it to break.

• Before cleaning your machine, disconnect the power-line plug from the socket outlet.

• Do not attempt to adjust the motor belt. Contact your nearest Service Center should any

adjustment be required.

• Handle the foot controller with care and avoid dropping it on the floor. Be sure not to place

anything on top of it.

• When sewing closely watch the area being sewn to avoid injuries from needles and knives.

• Use only the handle to lift and move the machine.

* A Trademark of The Singer Company

Copyright ©1982 The Singer Company

All right reserved throughout the World

Page 3

CONTENTS

1. Principal parts............................................................................................................................................. 2

Page

2. Preparation prior to sewing

3. Threading the machine

• Setting up the thread guide holder

• How to open looper cover..................................................................................................................... 5

• How to remove cylinder cover.............................................................................................................. 5

• How to thread your machine correctly.................................................................................................. 6

• How to change threads ........................................................................................................................ 10

4. How to sew................................................................................................................................................ 11

5. Chain off and test sew................................................................................................................................. 13

6. How to adjust thread tension ..................................................................................................................... 14

7. How to adjust stitch length......................................................................................................................... 15

8. Free arm sewing (Tubular work)................................................................................................................ 16

9. Adjustment of presser foot pressure........................................................................................................... 17

10. How to replace needle.............................................................................................................................. 17

11. Adjustment of overedge seam width.......................................................................................................... 18

......................................................

.............................................................................................................................

.......................................................................................................

...................

..............................................

3

4

4

12. How to replace knives................................................................................................................................. 20

13. Lubrication................................................................................................................................................ 21

14. Reasons for poor stitches and how to make adjustment........................................................................... 22

15. Relationship between cloth, thread and needle .

16. Accessories................................................................................................................................................. 24

17. Specification of the 14U11/13 machine ................................................................................................... 24

...

.................................................................................... 23

Page 4

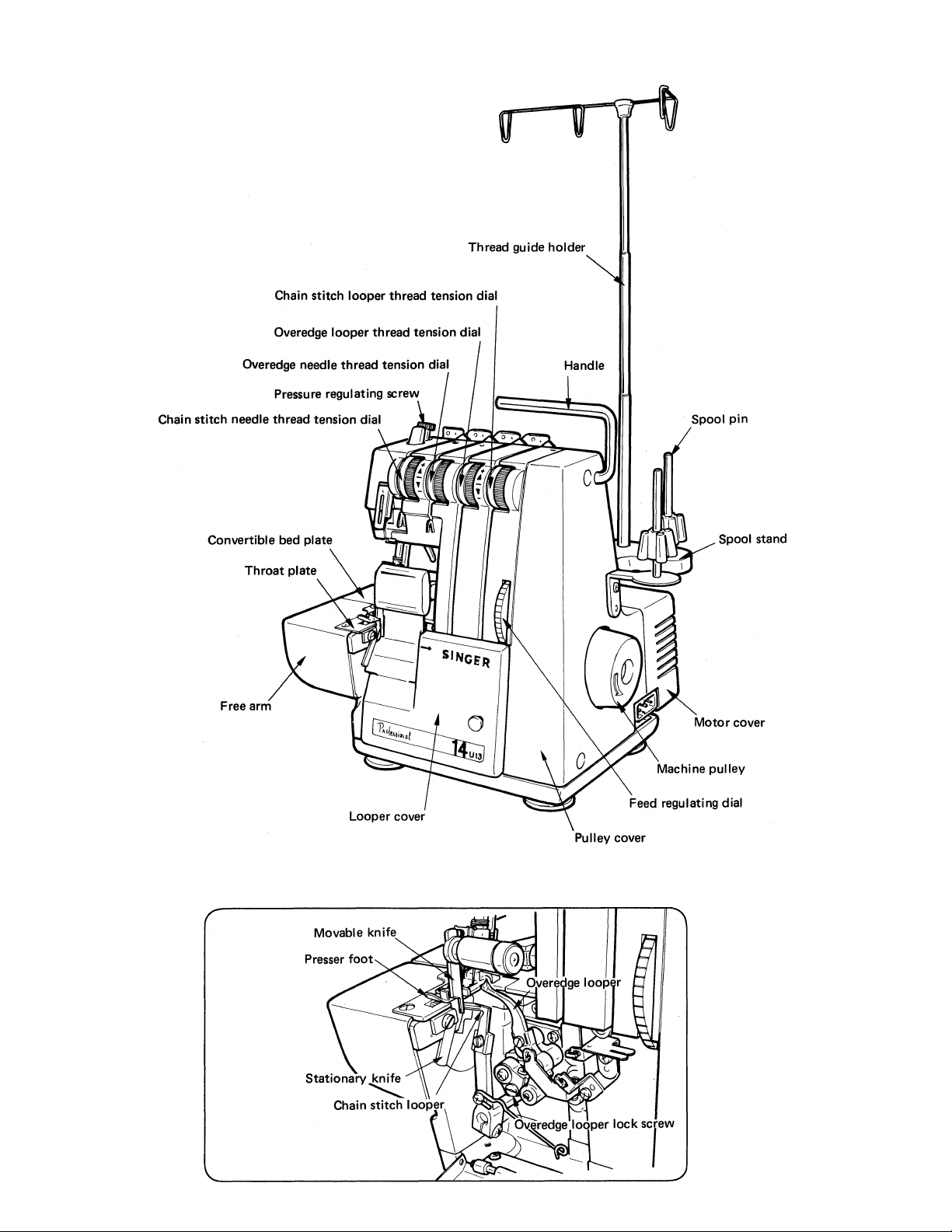

1. Principal parts

• Machine with looper cover opened

Page 5

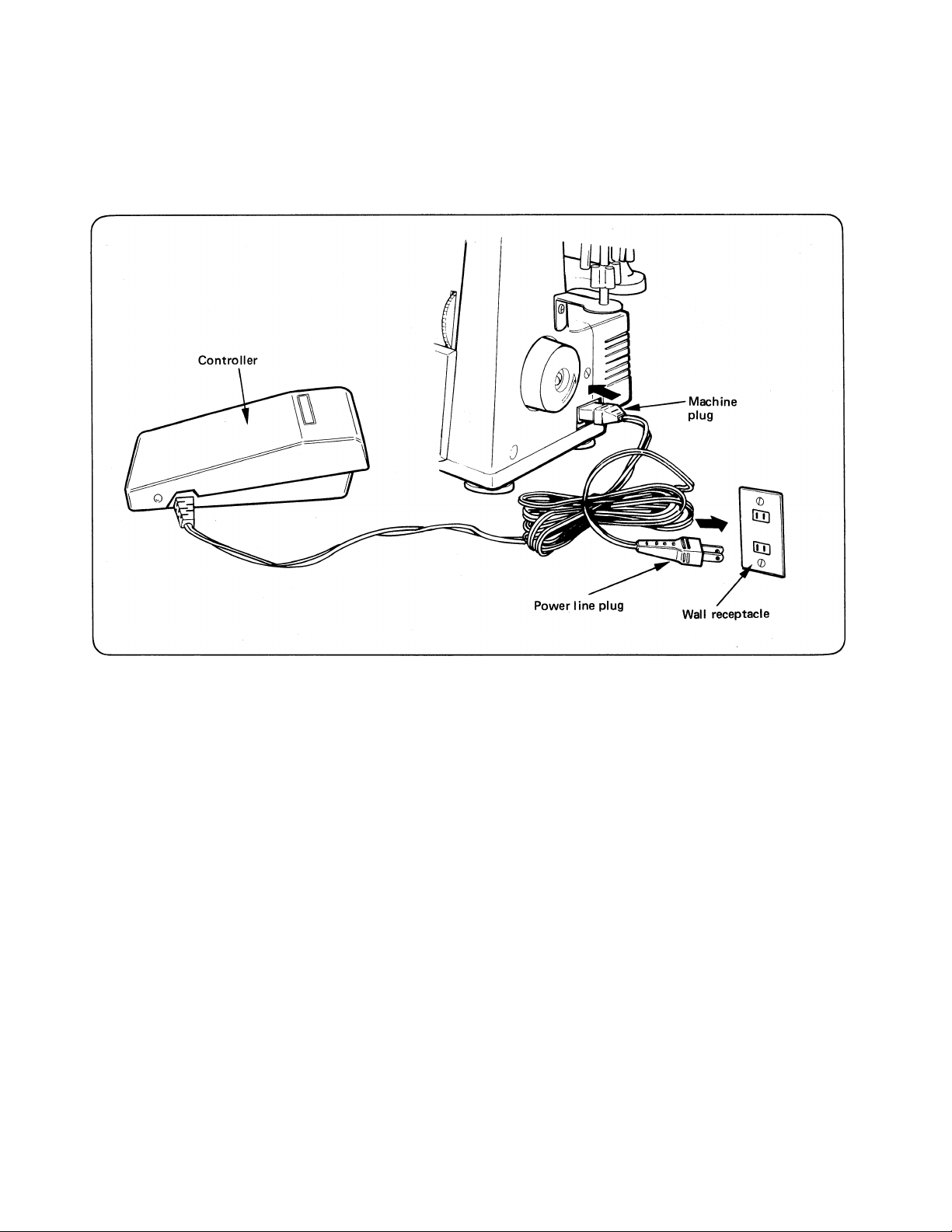

2. Preparation prior to sewing

Connect the machine plug to the electrical receptacle of your machine and the power line plug to the wall

receptacle.

To run the machine and control the speed, press the speed controller. The harder you press, the faster the

machine will sew. To stop the machine from sewing, remove your foot from the speed controller.

Caution:

• Be sure that the electrical voltage of the socket outlet (wall receptacle) is the same as the rated voltage of

the motor.

> Handle the foot controller with care and avoid dropping it on the floor. Be sure not to place anything

on top of it.

• Disconnect the power-line plug from the socket outlet when changing needles, presser feet or throat

plates, or when leaving the machine unattended. This eliminates the possibility of starting the machine by

accidentally pressing the speed controller.

Before cleaning your machine, disconnect the power-line plug from the socket outlet.

Page 6

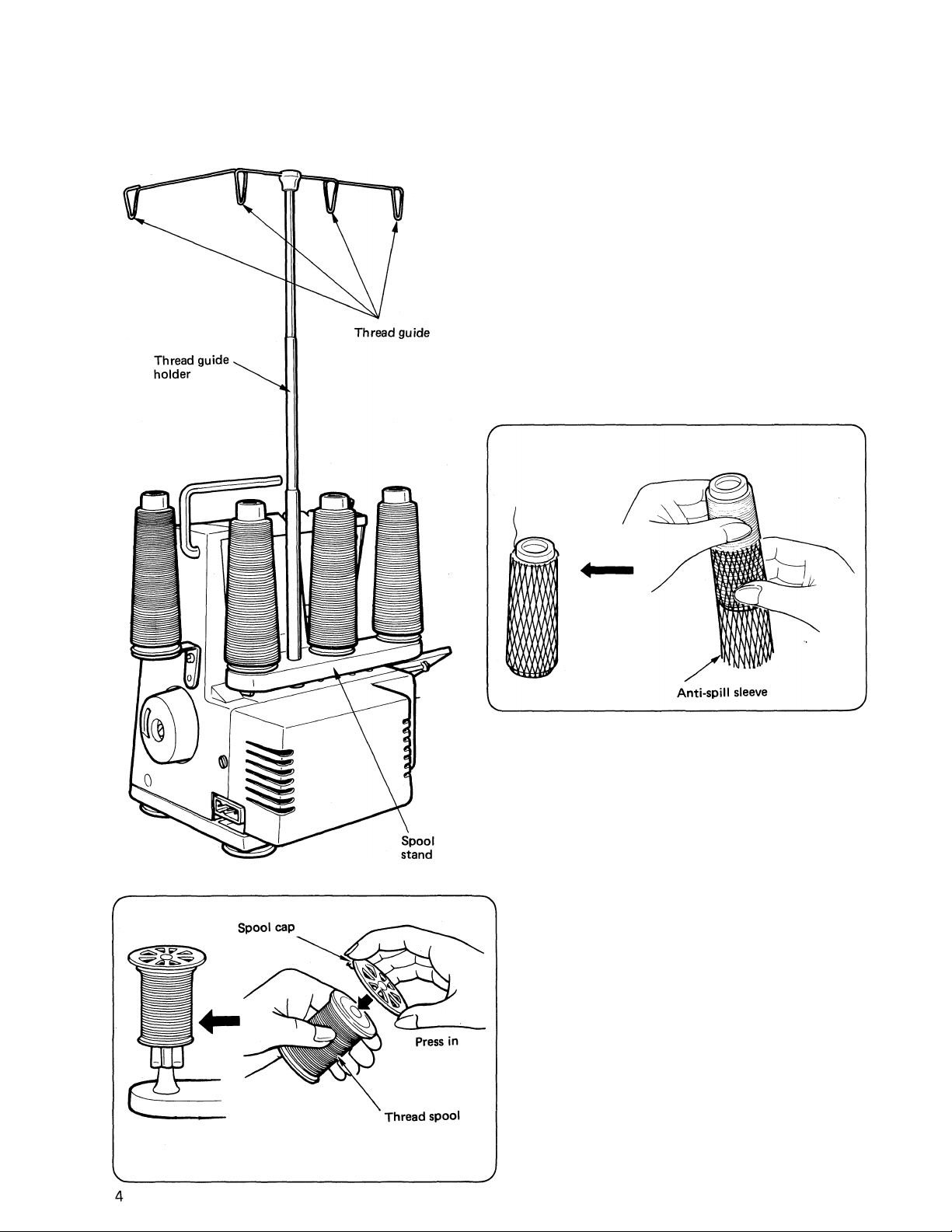

3. Threading the machine

• Setting up the thread guide holder

Extend the thread guide holder as far as possible and set

the thread guides so that they are located right above

the spool pins.

Place the thread on the spool stand as shown in the

figure at the left.

When using synthetic threads that easily spill off the

cop (cone) slip the anti-spill sleeve furnished with the

machine over the thread from the bottom of the cop

(cone) leaving the thread end hanging free at the top of

the anti-spill sleeve as shown above.

When using a reel type thread spool, fit the

spool cap supplied with the machine onto

the thread spool as shown at left.

Page 7

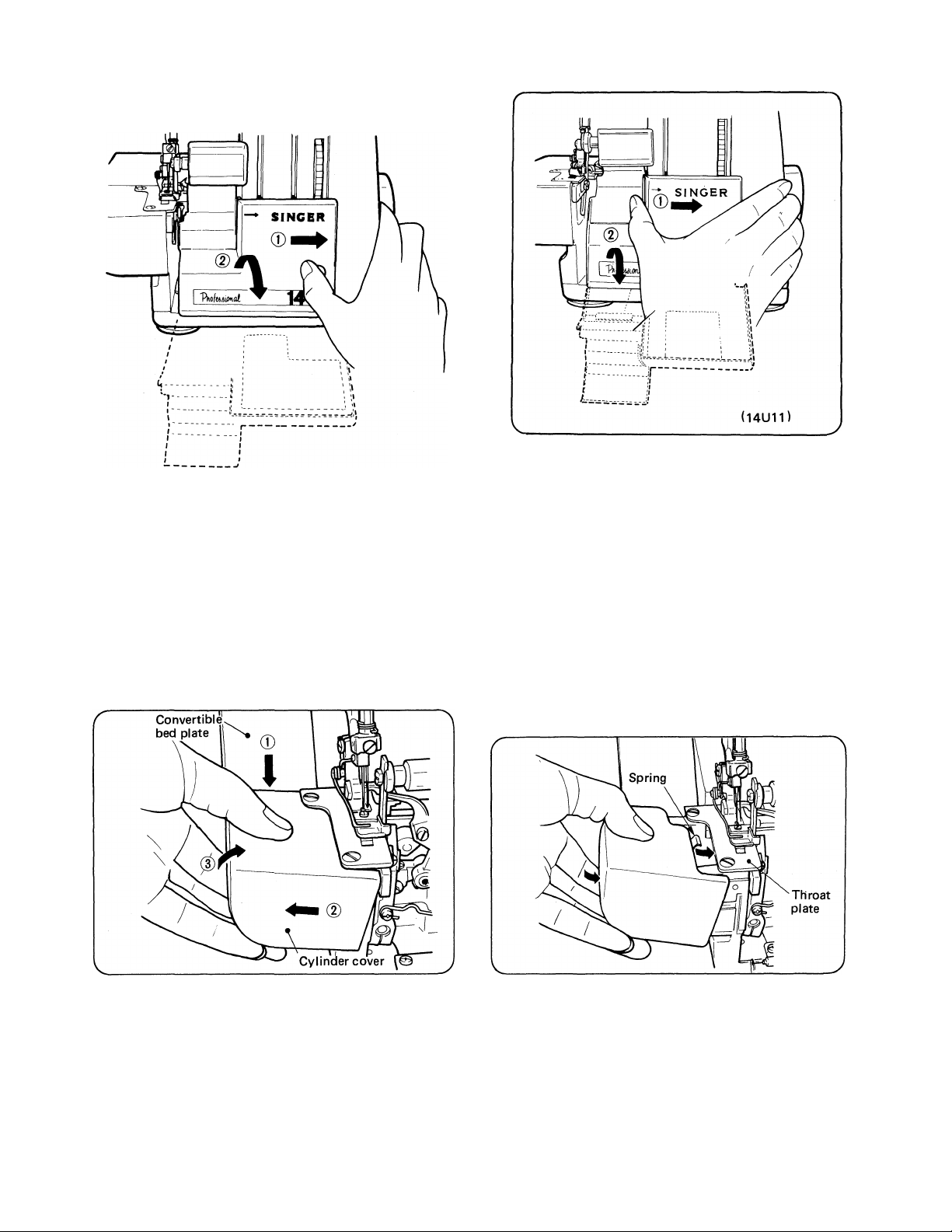

Be sure looper cover is closed when sewing.

• How to remove cylinder cover

(14U13)

® Push the cover to the right as

far as it will go and

(D Pull cover down toward you.

To replace cover

® Push convertible bed plate down and

(2) While pulling the cylinder cover to the left,

d) Lift cover upward and off the machine.

*

* Be sure to lower the plate.

* Do not hold the cylinder cover when moving the machine.

Place the upper spring on the cover under the

throat plate and press cover downward to the

right.

Page 8

• How to thread your machine correctly

Correct sewing cannot be obtained when machine is threaded incorrectly.

Threading is diagrammed on the inner side of the looper cover and identified with colors on the various

thread guides.

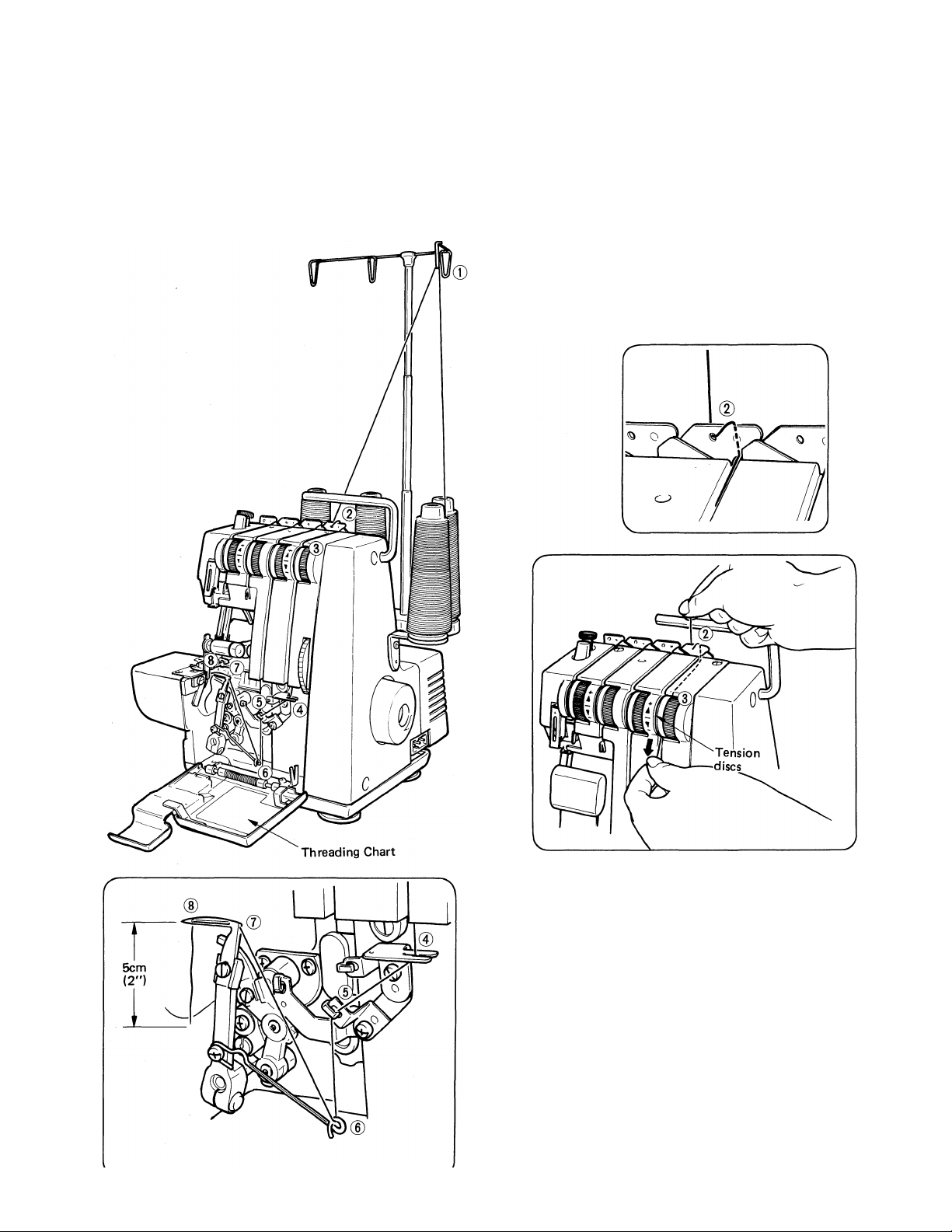

(1) Open looper cover. Thread the chain stitch looper in the order 0 to (8) as indicated in the figure below,

(threading points marked in yellow) (14U13 only).

Wind thread around thread

guide when threading @ as

shwon in figure below.

While holding thread with finger, pass it

between the tension discs and pull thread

down to make certain it is properly located

in between the tension discs.

• Use tweezer provided in the accessory set when

threading looper thread hole ©, ®.

•

• Draw about 5cm (2 inches) of thread from the

looper thread hole.

Page 9

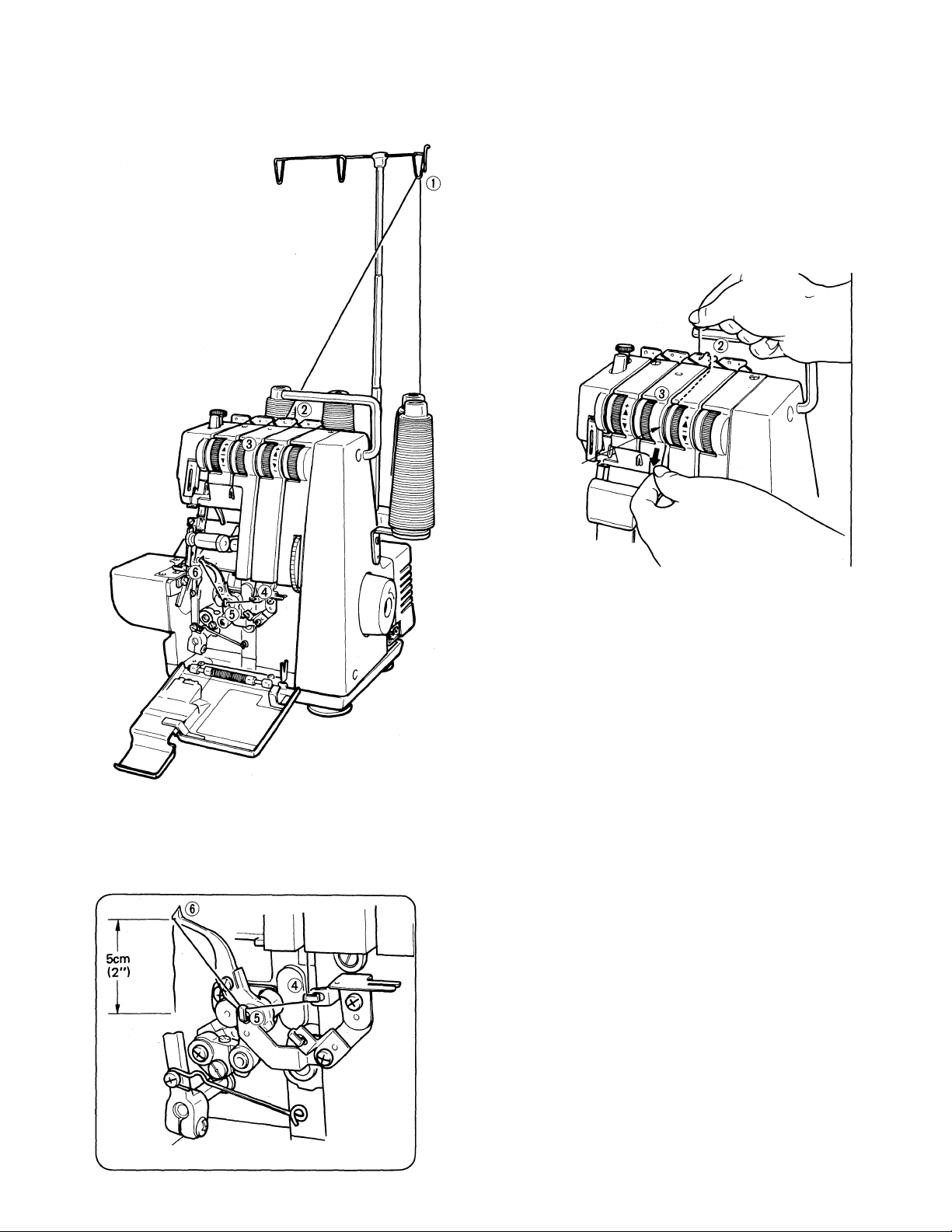

(2) Thread the overedge looper in sequence from 0 to (6) (marked in orange color).

Wind thread around thread

guide when threading (2) as

shown in figure below.

Tension

discs

While holding thread with finger,

pass it between the tension discs

and pull thread down to make

certain it is properly located in

between the tension discs.

Use tweezer provided in the accessory set when

threading looper thread hole (6).

Draw about 5cm (2 inches) of thread from the

looper thread hole.

Page 10

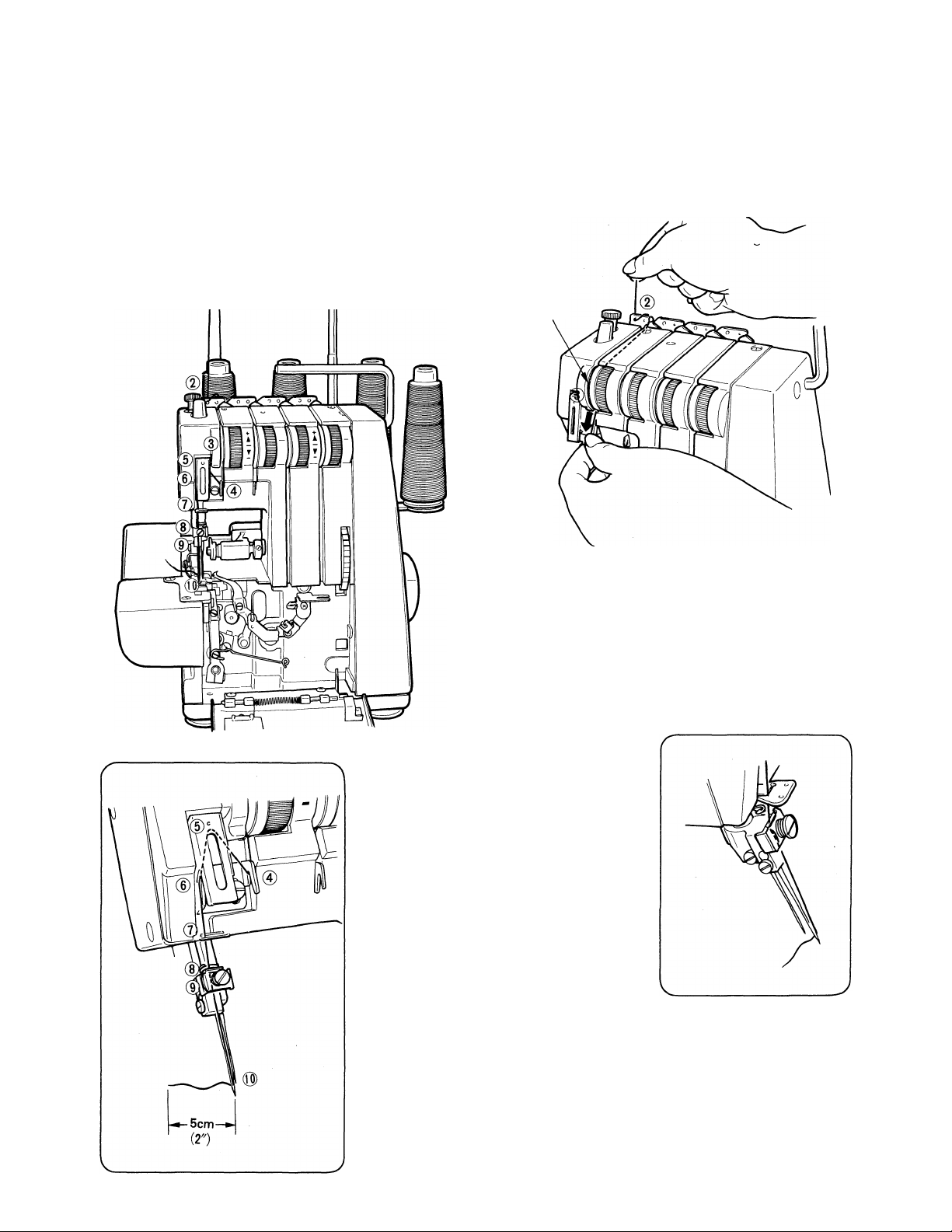

(3) Thread the overedge needle thread in the order ® to (7) (green mark).

Threading of needle eye (7) becomes easier when the movable knife is set at the nonoperating position

(See figure on page 18 for movable knife non-operating position).

Wind thread around thread

guide when threading (2) as

shown in figure below.

Tension

discs

While holding thread with finger, pass it

between the tension discs and pull thread

down to make certain it is properly located

in between the tension discs.

Use tweezer provided in the accessory set when

threading looper thread hole (7) .

• Draw about 5cm (2 inches) of thread from the

looper thread hole.

Page 11

(4) Thread the chain stitch needle thread in the order (I) to @ (blue mark).(14U13 only)

Wind thread around thread

guide when threading (2) as

shown in figure below.

Tension

discs

While holding thread with finger, pass it

between the tension discs and pull thread

down to make certain it is properly located

in between the tension discs.

• Lower needle bar as for as it

will go when threading (5) .

• Use tweezer to thread eye

•

• Draw about 5cm (2 inches)

of thread from needle eye.

Page 12

(5) Check to see that thread tension dials are properly threaded (especially needle thread).

When needle thread is not correctly threaded between the tension discs, it will lie loose on the underside

of the material as shown in figure.

0

• How to change thread

The thread is pre-set at the factory

before shipment.

When you wish to change the thread

with a different thread, the following

steps will make the changing con

venient.

(1) Cut the thread near the spool and

tie the end to the thread you wish

to change to as shown in figure at

right.

(2) Raise presser foot.

(3) Turn the tension dials down

toward the minus (-) sign until

the dial stops and draw the thread

out so that the tie knot of the

threads extend about 5cm (2

inches) from the presser foot.

(4) When drawing needle thread

through the needle eye, stop the

tie knot before the needle eye, cut

the thread and pass it through the

needle eye.

10

Page 13

4. How to sew

This sewing machine will allow the following 3 different kinds of stitch formations obtainable by simple

adjustments.

1. Safety Stitch Formation (14U13 only)

Safety stitch can be obtained when all 4 threads are

used. The stitches are attractive and can be sewn on all

kind of fabrics from light weight to heavy weight.

(Application) Inserting sleeves into shirts, blouse, and

dresses as well as sewing sides together.

2, Two Thread Chain Stitch Formation (14U13 only)

A useful two thread chain stitch can be obtained

when needle thread for chain stitch and looper

thread for chain stitch are used.

When you wish to obtain a tight seam, sew another

row of stitches next to the previously row.

(Application) Binding knit wear, jersey, etc.

When chain stitching, be sure to disengage the overedge looper so that it does not move, in the following

manner.

Also place the movable knife in a non operating position as required. (See Page 18)

• The overedge looper is disengaged as follows.

With the screw driver turn the overedge looper

screw in direction of arrow shoym in figure until

the screw comes off the overedge looper driving

lever (back).

Ensure the screw is completely out of engagement

with the driving lever by pulling the screw outward

with fingers.

Press down the released overedge looper so that

it is in its lowest position.

(Make sure overedge looper does not move by

turning machine pulley towards you slowly.)

11

Page 14

To re-engage overedge looper, lift overedge looper driv

ing lever (front) up as far as it will go as shown in figure

and while pressing the overedge looper lock screw

tighten it in the direction of arrow shown in figure

at left.

When sewing with movable knife in non-operating position, sewing can be performed more conveniently by

installing the chain stitch seam width gage in place of the knife cover.

3. Overedge Stitch Formation

12

Attractive overedge seams can be obtained when needle

thread for overedge and looper thread for overedge are

used.

(Application) Overedging of suit, blouse, slacks, etc.

Page 15

5. Chain off and test sew

When the machine is completely threaded,

place a piece of the fabric to be sewn complete

ly under the presser foot.

Hold the needle thread with a slight tension as

shown in figure at left and turn the machine

pulley towards you 2 or 3 turns.

After threading for the first time or when

rethreading due to thread breakage during

sewing, repeat the above.

Thread cutter

After completing the seam,

chain off approx. 5cm (2 inches)

as shown in figure at left and

cut thread with the thread cut

ter on the presser foot.

13

Page 16

6. How to adjust thread tension

Adjust thread tension to suit the type of material and size of the thread used. Tension becomes tighter as

the tension dial is turned up toward the plus sign (+).

• Correct thread tension

Be sure the threads are correctly threaded since otherwise proper thread tension cannot be obtained (See

page 6).

Correct chain stitch. (14U13 only)

• How to obtain correct thread tension.

When the chain stitch needle thread tension is weak.(14U13 only)

Correct overedge stitch

Topside

Underside

14

Turn the chain stitch needle thread tension

dial (blue) toward the plus sign (+), or chain

stitch looper thread tension to minus sign

(-).

Page 17

When the overedge needle thread is tight but

overedge looper thread tension is weak.

When the overedge needle thread tension is weak

but the overedge looper thread tension is tight.

—

—

Overedge

looper dial

(orange)

+ i\i'

m

A

=

liljj

TEUZT, l =

Overedge

needle dial

(green)

Topside

+

A

▼

“r

Either turn the overedge needle thread tension

dial (green) toward the minus sign (-) or turn

the overedge looper thread tension dial (orange)

toward the plus sign (+).

Overedge

needle dial

(green)

Topside

Overedge

looper dial

(orange)

Either turn the overedge needle thread tension

dial (green) toward the plus sign (+) or turn the

overedge looper thread tension dial (orange)

toward the minus sign (-).

7. How to adjust stitch length

The feed regulator dial on this machine is pre-set

to 3mm for normal sewing condition. Since the

adjustment can be made easily, adjust the stitch

length to 4mm when sewing heavy weight fabrics

such as quilting and to 2mm when sewing light

weight fabrics such as lining fabric, crepe, etc.

and you will obtain excellent seams without

puckering.

15

Page 18

8. Free arm sewing (Tubular work)

As shown in figure at left, this machine becomes a free

arm machine simply by pushing the convertible bed

plate down making tubular work such as sewing sleeves

very easy.

This is especially convenient for finishing hard-to-reach

areas such as arm holes and overcasing trouser cuffs.

Slip tubular work

onto the free arm

and sew.

16

Page 19

9. Adjustment of presser foot pressure

The presser foot pressure of this machine is

preadjusted at the factory to suit the sewing of

medium weight fabrics.

It may become necessary to adjust the pressure

in the case of delicate or heavy weight fabric.

For hght weight fabric — Decrease the pressure

(as shown at left).

Heavy weight fabric — Increase the pressure

(as shown at left).

10. How to replace needle

Use Singer needle Cat. No. 2053. Available in

sizes #10, #11, #12 #14.

Needles for household machines can not be used.

To remove the needle:

• Be sure the power line plug is disconnected

from the wall receptacle.

• Turn the machine pulley toward you until

the needle is at its highest position. Loosen

the needle set screw with a screw driver and

remove needle.

To replace the needle:

• Insert the needle into needle bar as far as it

will go, with long groove toward you, as

shown in figure at left.

•

• Hold needle firmly so that its direction can

not change and securely tighten the needle set

screw.

17

Page 20

11. Adjustment of overedge seam width

The overedge seam width of this machine is set to 3.5mm (9/64 inches) for normal sewing condition, how

ever it can be increased up to 5mm (13/64 inches) for overedging heavy weight fabrics as instructed below.

If any problems arise in making the adjustment, call your Singer representative.

(1) Before making the adjustment, be sure that the power line plug is disconnected from the wall receptacle.

(2) Open the looper cover. (See page 5)

(3) Turn the machine pulley toward you, lower the movable knife as far as it will go and set it in the

nonoperating position as shown in figure below.

(4) Prjess down convertible bed plate and remove the cylinder cover. (See page 5)

(5) Loosen the 2 stationary knife holder set

screws with the hex-head wrench provided in

the accessories, move the stationary knife

holder to the right or left and tighten the

set screws.

(Wehn a wider seam is desired, move the

holder to the right and when a narrower

seam is desired, move the holder to the left).

Be sure to align the cutting edge of the

stationary knife level with the top surface of

the throat plate.

18

Page 21

(6) Replace the cylinder cover. (See page 5)

(7) Loosen the chaining-off finger set screw on the presser foot and adjust the fìnger to the cutting width

desired by moving it either to the right or left and tighten set screw.

(8) Return the movable knife to its original position.

(9) Test sew

Make a test sample first so that you can correctly adjust the position of the chaining-off finger, since an

improperly positioned finger may cause the cutting width to become narrower than the overedge seam

width, or become wider and cause the edge of the fabric to fold.

It may be necessary to re-adjust position of chaining-off fmger when other materials are used.

19

Page 22

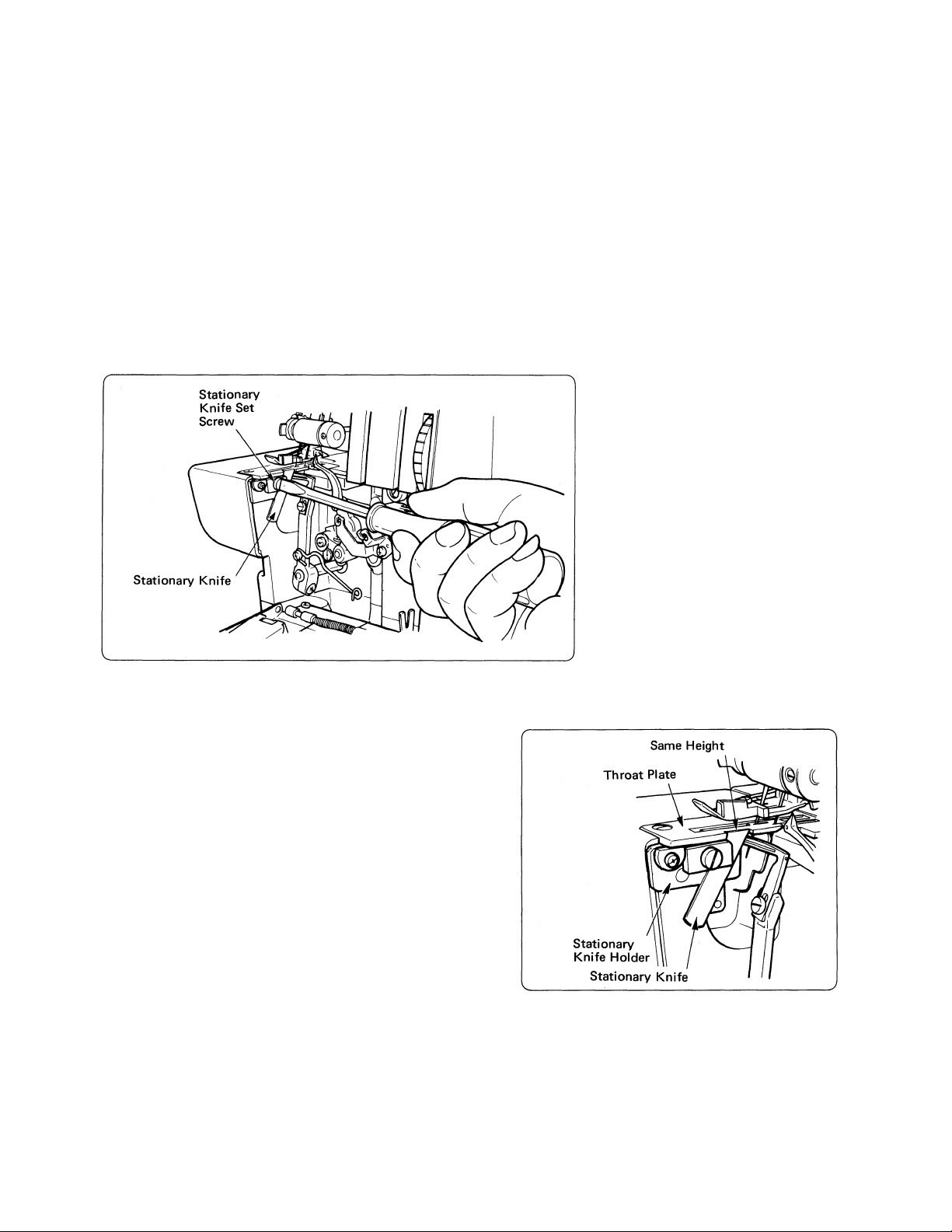

12. How to replace knives

The stationary knife should be changed when it becomes dull.

The stationary knife can be replaced according to the following steps, however if there are any difficulties

experienced, call your Singer representative to make the adjustment.

(1) Besure that the power line plug is disconnected from the wall receptacle.

(2) Open the looper cover and set the movable knife in the non-operating position (see page 18).

(3) Loosen the stationary knife set screw and remove the stationary knife.

(4) Place a new stationary knife in the groove of the

stationary knife holder, aUgn the cutting edge level

with the top surface of the throat plate and tighten

set screw.

(5) Return the movable knife to its original position.

• The movable knife on this machine has a carbide

alloy tip cutting edge and under normal use will

not required replacement.

20

Page 23

13. Lubrication

Special material is used for the important parts of this machine, therefore only occasional lubrication is

required. The oiling points shown on the figure below should be lubricated periodically.

21

Page 24

14. Reasons for poor stitches and how to make adjustment

Whenever sewing difficulty is encountered, make the adjustments as noted below.

Condition

When the fabric is not fed.

When the needle breaks.

When the thread breaks.

When stithces skip.

Reason

• Insufficient presser foot pressure.

• Needle not inserted properly.

• Fabric being pulled too hard.

• Loose needle set screw.

• Inccorect threading.

• Bent needle or needle point

damaged.

• Thread tension too tight.

• Thread tangled.

• Needle inserted incorrectly.

• Needle bent or needle point

damaged.

• Needle set loosely.

Method of Adjustments

(reference pages)

• Increase presser for pressure

(page 17).

• Insert needle correctly or replace

with correct needle (page 17).

• Do not pull the fabric by hand.

Use hand only to guide the fabric.

• Tighten screw firmly.

• Thread machine correctly (page

6).

• Change to correct needle

(page 17).

• Adjust tension (page 14).

• Thread correctly (page 6).

• Insert needle correctly (page 17).

• Replace with correct needle

(page 17).

• Set needle firmly in position

(page 17).

When stitches are

irregular.

When fabric puckers

When the machine does

not operate.

When motor is excessively

noisy or when sparking is

excessive.

• Incorrect threading.

• Wrong needle used.

• Insufficient presser foot

pressure.

• Thread tension not balanced.

• Thread tension too tight.

• Threading incorrect or tangled.

• Power line plug not connected.

• Motor damaged.

• Motor damaged.

• Thread machine correctly

(page 6).

• Use Singer Cat. 2053 #10, #11,

#12 #14.

• Increase presser foot pressure

(page 17).

• Adjust tensions (page 14).

• Adjust tension(page 14).

• Thread correctly (page 6).

• Connect with power source.

• Change Motor.*

• Change Motor.*

* Have your Singer representative

replace the carbon brush.

22

Page 25

15. Relationship between cloth, thread and needle

Type of Fabric

Lightweight

Lawn, Organdy,

Voil, Crepe, etc.

Medium Weight

Muslin, Soccer,

Satin, Gabardine

Broadcloth, etc.

Heavy Weight

Oxford, Denim

Tweed, Corduroy

Serge

Type of Thread

Cotton #100

Silk #100

Spun #80 - #90

Tetron #80 - #100

Cotton #60 — #80

Silk #50

Spun #60 — #80

Tetron #60 — #80

Cotton #40 - #60

Silk #40 - #60

Spun #60 — #80

Tetron #50 - #80

Needle

Singer Cat. No. 2053

#10

#11, #12 #14

#14

Knit

Tricot

Jersey

Wool (woven, knit)

Spun #80 — #90

Tetron #60 - #80

Spun #60 - #80

Tetron #60 - #80

Cotton #60 — #80

Spun #60 - #80

Tetron #50 - #60

Bulk tetron

Bulk nylon

#10, #11

#11, #12 #14

#11, #12 #14

23

Page 26

16. Accessories

(Accessory box)

1. Needle Set of 5 needles (Singer Cat. No. 2053 2 each #10 and 3 each #14 needles)

2. Screwdriver (medium size)

3. Hex-head wrench

4. Tweezer

5. Thread unwinder spool cap

6. Stationary knife

7. Brush

8. Oiler

9. Machine cover

10. Anti-spill sleeve

1

1

1

2(14U11),4(14U13)

1

1

1

1

2(14U11),4(14U13)

11. Chain stitch gage

1 (14U13 only)

17. Specification of the 14U11/13 machine

Item

Sewing speed

Stitch length (amount of feed)

Overedge stitch width

Needle bar stroke

1,500 spm maximum

2 - 5 mm (5/64" - 13/64") (5 to 12 s.pi.)

3.5-5 mm (Standard 3.5 mm) (9/64'' - 13/64")

27 mm (1 - 5/64")

Specification

Presser bar rise

Needle

Number of threads used

Size of machine

Weight of machine

24

5 mm (13/64")

Singer Cat. No. 2053 #10, #11, #12 #14

14U11....2,14U13....4

Width 257 mm X Depth 231 mm X Height 290 mm

(10-1/8" X 9-3/32" X 11-13/32")

14U11....8.1 kg. (17.8 lbs.), 14U13....8.5 kg. (18.7 lbs.)

Page 27

Page 28

Form U 3360

Part No. 409764-002

Printed in Japan

Loading...

Loading...