Page 1

SINGER

INSTRUCTION ROOK

l£Ilo

' 1

&s

Page 2

PREFACE

Thank you for your purchase of this Combination Overiock, Chain Stitch and Cover Stitch

Sewing Machine. This machine, that is intended for househoid use wiii provide you with

exceiient performance in sewing from iight to heavy materiai (iawn to denim).

Piease refer to this Instruction Book for proper use and optimum service. To get the most

out of your sewing machine, read the entire Instruction Book before attempting to operate

the machine. Then famiiiarize yourseif with the machine by foiiowing the instruction Book

page by page.

To ensure that you are aiways provided with the most modern sewing capabiiities, the

manufacturer reserves the right to change the appearance, design or accessories of this

sewing machine when considered necessary without notification or obiigation.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always

be followed, including the following: Read the instruction carefully before you

use the machine.

ADANGER - To reduce the risk of electric shock:

* The appliance should never be left unattended when plugged in.

* Always unplug this appliance from the electric outlet immediately after using

and before cleaning.

* Always unplug this sewing machine from the electric outlet immediately

after using and before cleaning, removing covers, relamping, lubricating

or when making any other user servicing adjustments mentioned in the

instruction manual.

A WARNING - To reduce the risk of burns, fire, electric shock or

injury to persons:

* Do not allow this appliance to be used as a toy. Close attention is necessary

when this appliance is used by or near children and infirm persons.

* Use this appliance only for its intended use as described in this manual. Use

only attachments recommended by the manufacturer as contained in this

manual.

* Never operate this appliance if it has a damaged cord or plug, if it is not

working properly, if it has been dropped or damaged, or dropped into water.

Return the appliance to the nearest authorized dealer or service center for

examination, repair, electrical or mechanical adjustment.

* Never operate the appliance with any air openings blocked. Keep

ventilation openings of the sewing machine and foot control free from the

accumulation of lint, dust, and loose cloth.

* Keep fingers away from all moving parts. Special care is required around

the sewing machine needle and cutter.

* Always use the proper stitch plate. The wrong plate can cause the needle

to break.

* Do not use bent needles.

* Do not pull or push fabric while stitching. It may deflect the needle causing

it to break.

* Switch the sewing machine off “ O “ when marking any adjustments in the

needle area, such as threading needle area, such as threading needle,

changing needle, threading looper, or changing presser foot and the like.

Page 4

Never drop or insert any object into any opening.

Do not use outdoors.

Do not operate where aerosol (spray) products are being used or where

oxygen is being administered.

To disconnect, turn all controls to the off “ O “ position, then remove plug

from outlet.

Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

Use only identical replacement parts. See instructions for servicing double

insulated appliances.

If oil gets in eyes, immediately, rinse the oil out with water. If you swallow

oil by mistake, immediately consult a medical doctor.

Close cover before operating machine.

Keep the instructions at a suitable place close to the machine and hand it

over if you give the machine to a third party.

Use the machine only in dry locations. Don’t use the machine if it’s wet or

in humid environment.

SAVE THESE INSTRUCTIONS

This overlook sewing machine is intended for household use only.

* The machine may only be used with foot pedal type 4C-326G/ 4C-316C/

4C-345G/ 4C-326C manufactured by Wakaho. Never place anything on

the pedal.

* European contact window provided.

* The sound pressure level at normal operation is smaller than 76dB(A).

* SERVICING DOUBLE-INSULATED PRODUCTS (USA and Canada

version excepted) In a double-insulated product, two systems of insulation

are provided instead of grounding. No grounding means is provided on a

double-insulated product nor should a means for grounding be added to

the product. Servicing a double-insulated product requires extreme care

and knowledge of the system and should and only be done by qualified

service personnel. Replacement parts for a double-insulated product must

be identical to those parts in the product. A double-insulated product is

marked with the words DOUBLE INSULATION or DOUBLE INSULATED.

The symbol 0 may also be marked on the product.

Page 5

TABLE OF CONTENTS

Page

1. Principal parts....................................................................................................................................................... 5

2. Accessories........................................................................................................................................................... 7

3. Needle information............................................................................................................................................... 7

4. How to open looper cover..................................................................................................................................... 8

5. Principal parts behind the looper cover................................................................................................................ 8

6. Preparation prior to sewing................................................................................................................................... 8

7. Preparation for threading.................................................................................................................................... 10

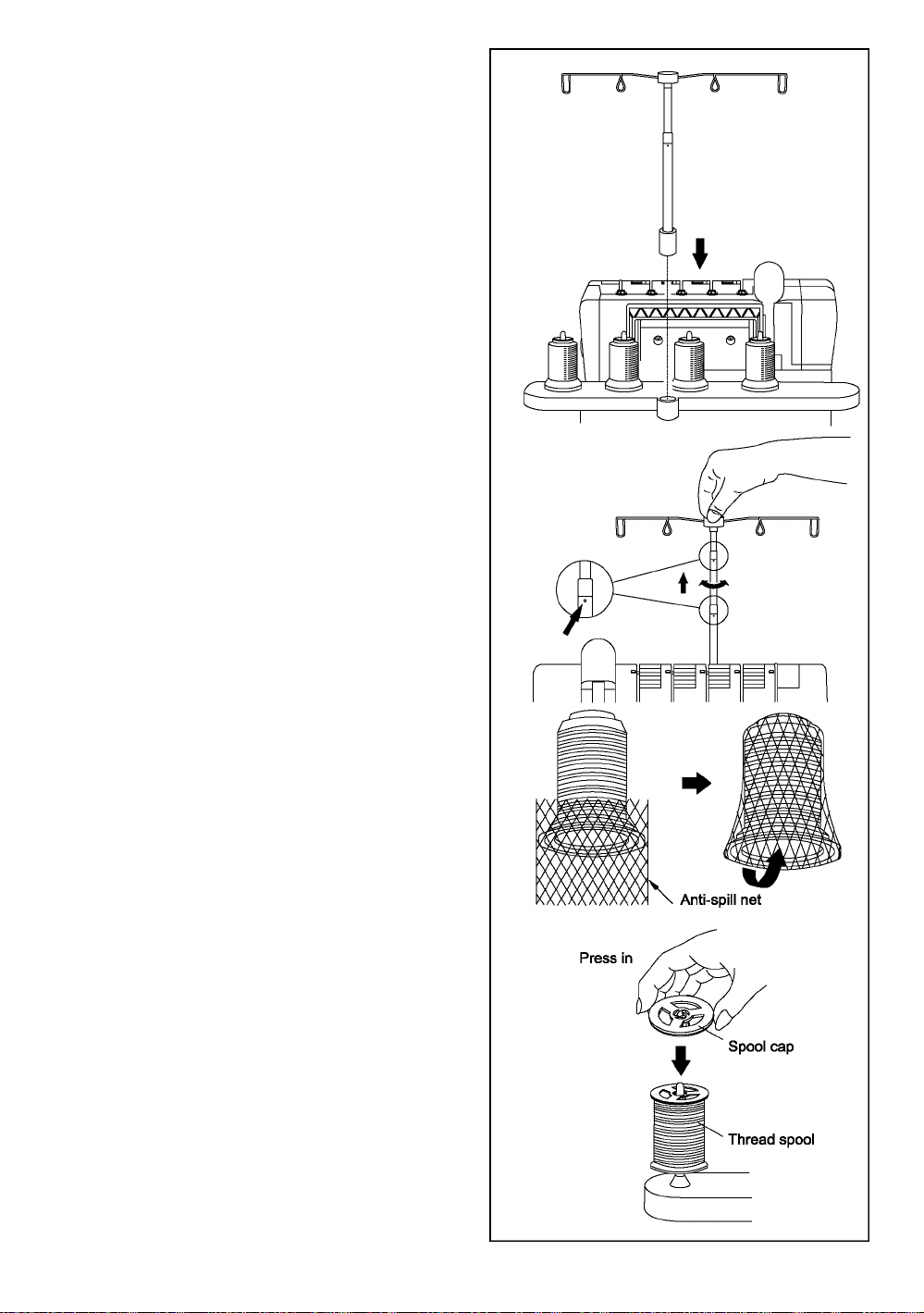

* Setting Up the Thread Guide Holder........................................................................................................... 10

* Anti-spill Net.................................................................................................................................................... 10

* Spool Cap....................................................................................................................................................... 10

8. How to remove and insert needles..................................................................................................................... 11

* Needle Position.............................................................................................................................................. 11

* To Remove Needle(s)..................................................................................................................................... 11

* To Insert Needles(s)....................................................................................................................................... 11

9. Selection of stitches............................................................................................................................................ 12

10. Handy reference chart........................................................................................................................................ 12

11. How to sew a cover stitch................................................................................................................................... 13

12. Threading the machine....................................................................................................................................... 16

* Threading Diagram: Three Thread Cover/Chain Stitch............................................................................... 16

* Tension Color Code: Cover Stitch................................................................................................................... 16

* Three-Thread Cover Stitch Suggested Tension Settings............................................................................ 25

* Threading Diagram: Cover Stitch - Two Thread Narrow................................................................................. 26

* Tension Color Code: Two Thread Narrow Cover............................................................................................ 26

* Threading Diagram: Cover Stitch - Two Thread Wide.................................................................................... 32

* Tension Color Code: Two Thread Wide Cover............................................................................................... 32

* Two-Thread Cover Stitch Suggested Tension Settings

* Threading Diagram: Chain Stitch.................................................................................................................... 39

* Tension Color Code: Chain Stitch................................................................................................................... 39

* Double Chain Stitch Suggested Tension Settings

13. How to change threads: tie on method............................................................................................................... 46

14. How to adjust the stitch length............................................................................................................................ 47

15. How to adjust the presser foot pressure............................................................................................................. 47

16. Differential feed.................................................................................................................................................. 48

17. Machine maintenance........................................................................................................................................ 49

18. Snap-on type presser foot.................................................................................................................................. 51

19. Troubleshooting chart......................................................................................................................................... 52

20. Relationship between cloth, thread and needle.................................................................................................. 53

21. Specification....................................................................................................................................................... 54

..............................................................................

......................................................................................

38

44

Page 6

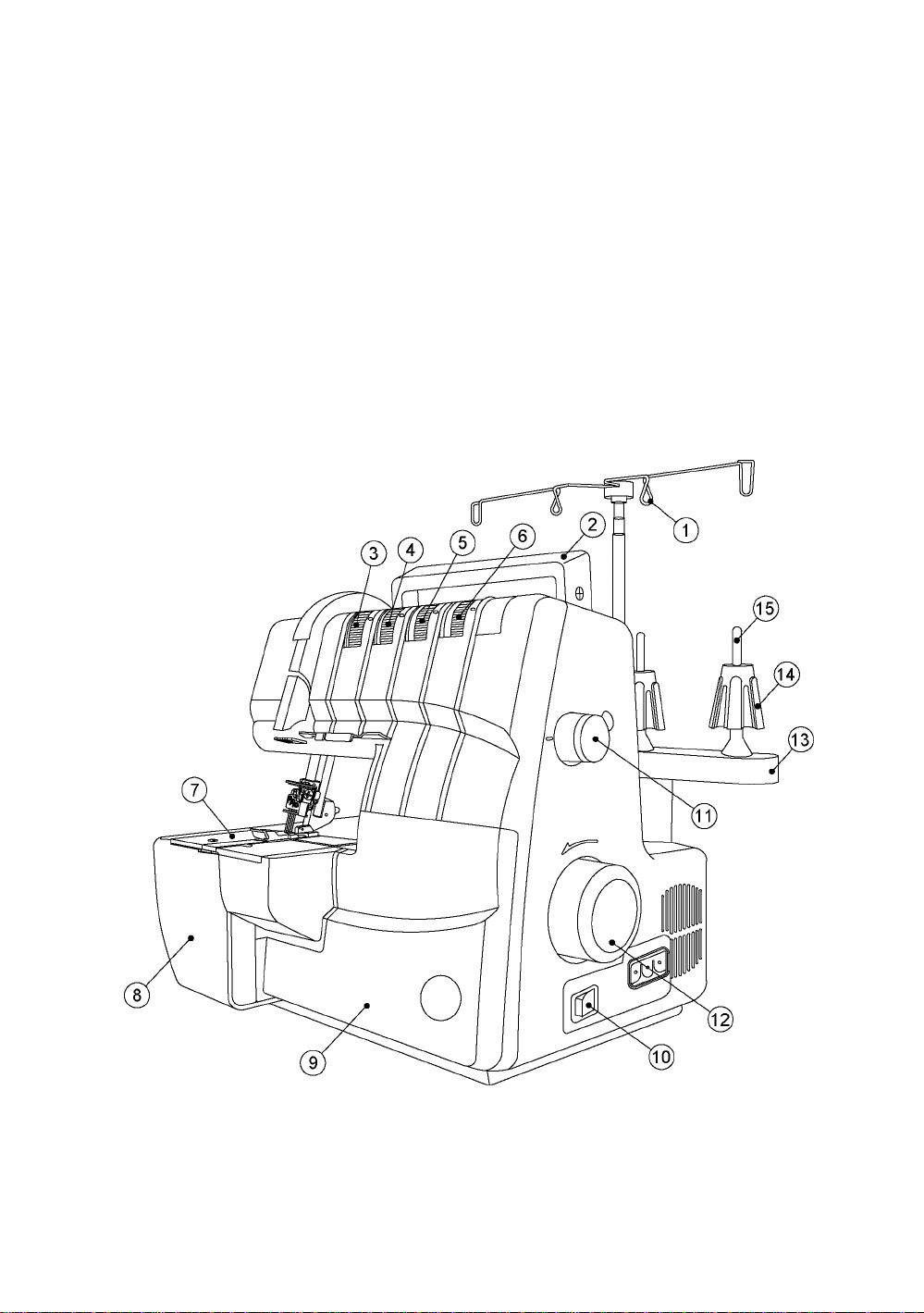

1. PRINCIPAL PARTS

1. Thread Guides and Holder

2. Handle

3. Left Needle Thread Tension Dial (blue)

4. Middle Needle Thread Tension Dial (green)

5. Right Needle Thread Tension Dial (red)

6. Chain Stitch Looper Thread Tension Dial (yellow)

7. Throat Plate

8. Cloth Plate

9. Looper Cover

10. Power & Light Switch

11. Stitch Length Dial

12. Handwheel

13. Spool Stand

14. Cone Adaptor

15. Spool Pin

Page 7

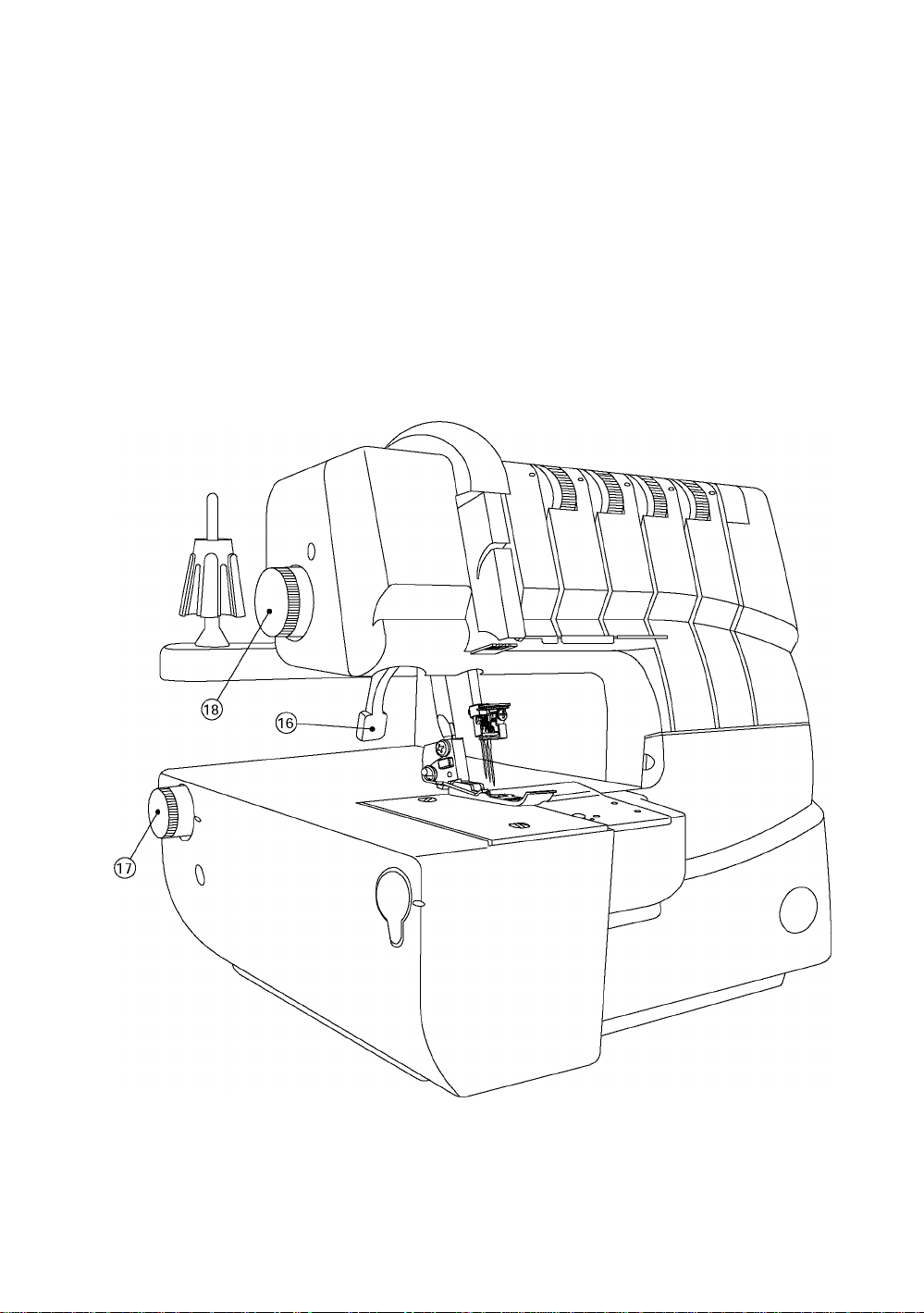

16. Presser Bar Lifter and Tension Release

17. Differentiai Feed Adjusting Diai

18. Foot Pressure Adjusting Diai

Page 8

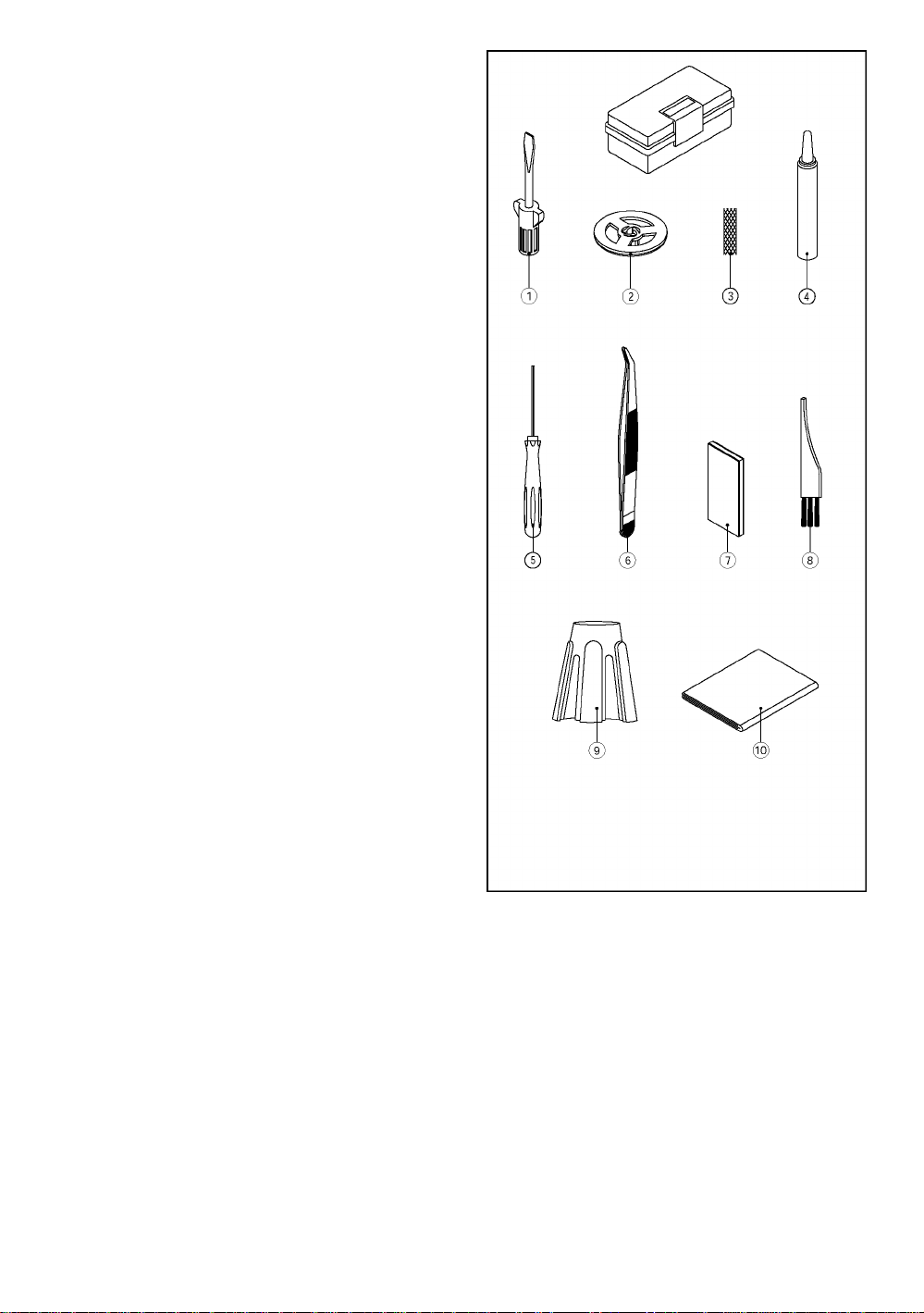

2. ACCESSORIES

Accessories are contained in the accessory case

1. Screw Driver (iarge size) 1

2. Thread Unwinder Spooi Cap 4

3. Anti-Spili Net 4

4. Oiier 1

5. Aiien Screw Driver (smali) 1

6. Tweezers 1

7. Needie Set 1

8. Brush 1

9. Spooi Holder 1

10. Machine Cover 1

3. NEEDLE INFORMATION

' This cover stitch uses a flat shank industrial needle

that eliminates the possibility of inserting the needle

backwards.

' Do not attempt to use a standard household sewing

machine needle of any size or type in this cover

stitch.

’ SINGER 2022 Needles size 14/90 are furnished

with the machine.

' Only use SINGER 2022 Needles size 14/90 and

11/80 as supplied in the accessory case.

SINGER 2022

Overlook needle

Page 9

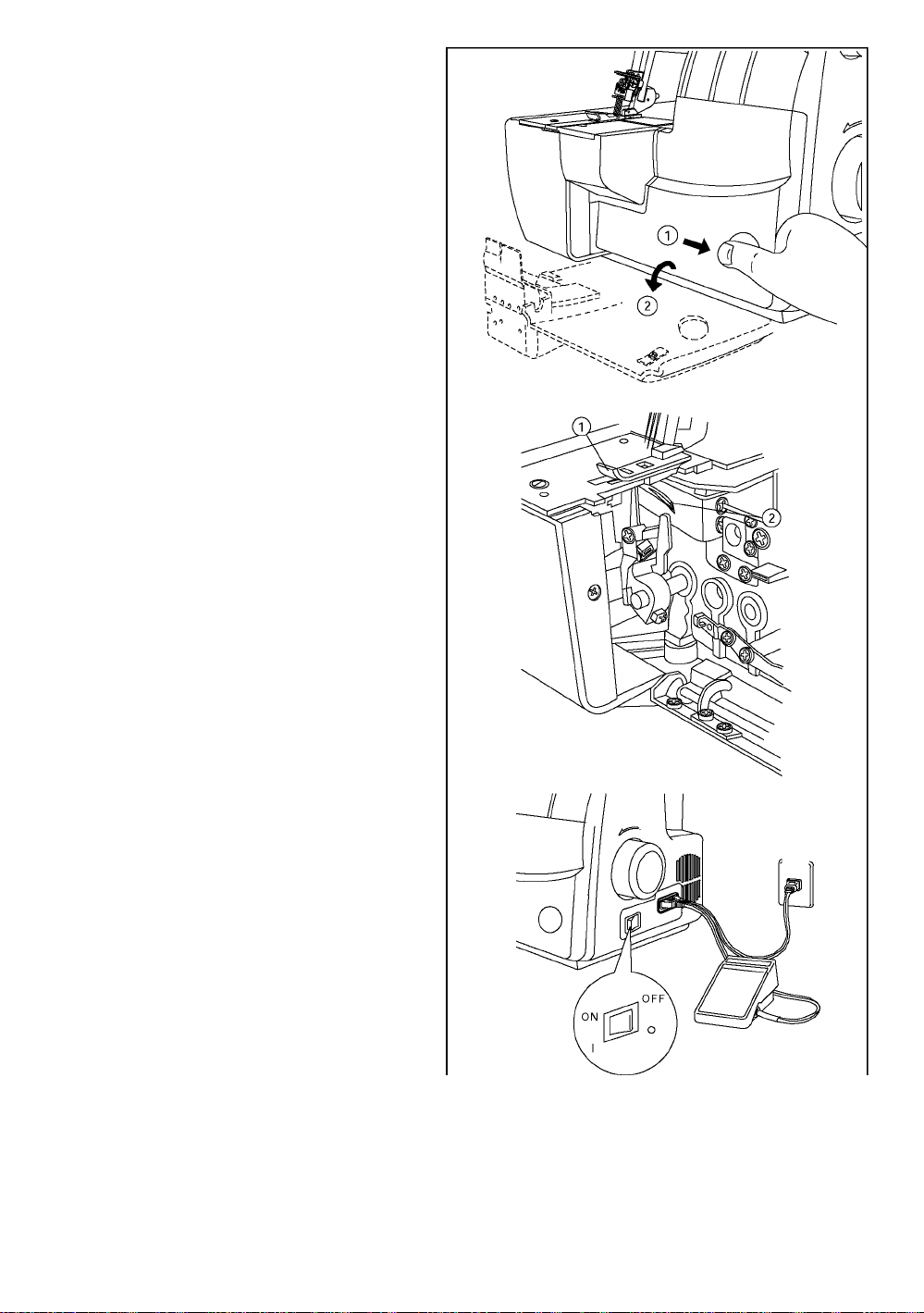

4. HOWTO OPEN LOOPER COVER

Caution:

A

Push the cover to the right as far as it wiii go.

Puii cover down toward you.

A

Be sure to turn off power switch.

Caution:

|\ Be sure iooper cover is ciosed when

sewing.

5. PRINCIPAL PARTS BEHIND THE

LOOPER COVER

1. Chain/Cover Looper

6. PREPARATION PRIOR TO SEWING

' Connect the controlier/eiectric piug to the

machine receptacle.

’ Plug power line into eiectric outlet.

' Power Switch: Push "i" mark side to turn “ON”

Push "O" mark side to turn “OFF”

' To run the machine and controi the speed, press

the controlier.

' The harder you press, the faster the machine

wiii sew.

' To stop the machine from sewing, remove your

foot from the controiier.

WARNING:

Use only foot controller provided with this machine.

(Type 4C-316B for U.S.A. & CANADA only)

Be sure to make reference to “Warning” on following

Page.

Page 10

POLARIZED PLUG INFORMATION (FOR U.S.A. & CANADA ONLY)

This appliance has a polarized plug (one blade wider than the other). To reduce the risk of

electric shock, this plug is intended to fit in a polarized outlet only way. If the plug does not fit

fuily in the outlet, reverse the plug. If it still does not fit contact a qualified electrician to instail

the proper outlet. Do not modify the piug in any way.

A

Warning:

' Be sure that the eiectrical voitage of the eiectric outlet (wall receptacle) is the same as the

rated voltage of the motor.

' Handle the foot controller with care and avoid dropping it on the floor. Be sure not to place

anything on top of it when not in use.

' Disconnect the power line plug from the electric outlet when changing needles, presser feet or

when leaving the machine unattended. This eiiminates the possibility of starting the machine

by accidentally pressing the controller.

Page 11

7. PREPARATION FOR THREADING

Setting Up the Thread Guide Hoider

• Take out the thread guide from the top of

Styrofoam, and insert it as shown on the right

iiiustration.

• This machine is shipped with the thread guide

hoider on the top of styrofoam.

• Fuiiy extend the thread guide hoider.

• The two joints on the teiescope wili ciick into

place when they are correctiy positioned.

• Center the thread guides above the spooi pins.

• Place thread over the cone adapters on the

spool pins.

Note: Your new machine is threaded to sew

Triple Cover Stitch. Refer to Page 45 for

instructions on tying on to the threads.

Anti-spili Net

• When using synthetic threads that easily spill off

the cone, slip the anti-spill net furnished with the

machine over the thread from the bottom of the

cone leaving the thread end hanging free at the

top the anti-spill net as shown at right.

Spool Cap

• When using a regular thread spool, fit the spool

cap supplied with the machine onto the thread

spool as shown at right.

10

Page 12

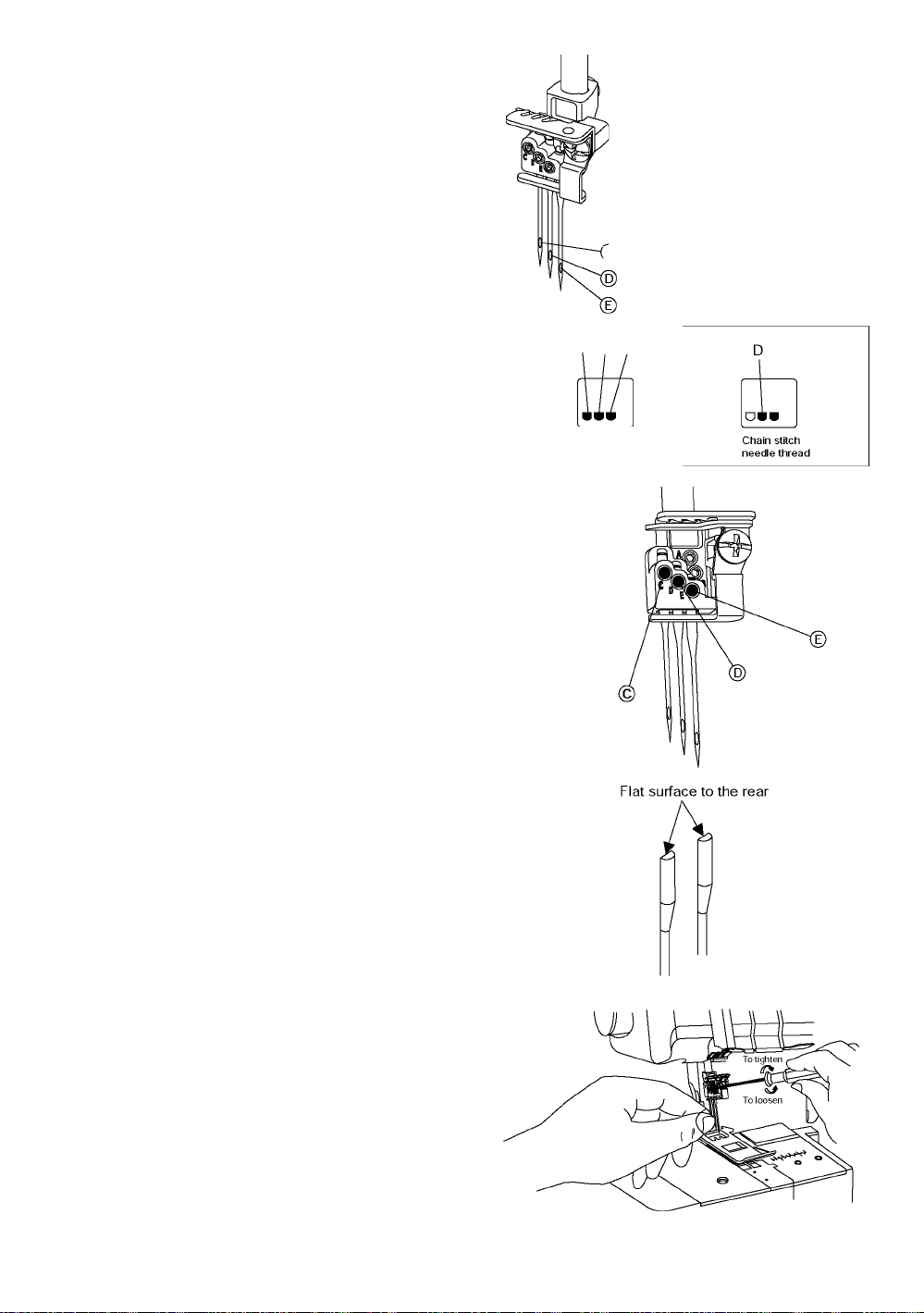

8. HOWTO REMOVE AND INSERT NEEDLES

Needle Position

• With this machines, three needies can be inserted to

the needie clamp as shown in the drawing.

• The Instruction Book refers to different needie positions

by iliustrating the needle clamp at right.

Note: When all cover stitch needles are inserted,the left

needle will be slightly higher than the others.

To Remove Needle(s)

Caution:

Be sure to disconnect the machine from the

A

• Turn the hand wheel toward you until the needles are at

their highest position.

• Place a thick piece of fabric [such as felt] under the

presser foot. Lower the needles halfway into the fabric.

• Loosen, but do not remove the needle set screws

with the small alien screwdriver. Hold the needles with

your fingers and raise the needle bar. The needles will

remain in the fabric.

electric outlet before removing needle(s).

C. Cover stitch left needle

D. Cover stitch middle needle

E. Cover stitch right needle

C

Cover stitch right needle

Cover stitch middle needle-|—I

/ Chain stitch needle

Cover stitch left needle -

C D E

Vo

Left, middle and right cover

stitch needle thread

Attention:

After removing the specific needle which is not currently to

be used for sewing, remember to fasten the set screw in

the screw hole of the needle clamp and to Just fasten tight

into the hole. Please do not over-tighten the screw into the

hole or the needle clamp will be damaged.

To Insert Needles(s)

• Hold the needle with the flat surface to the back.

• Insert the needle into the needle socket as far as it

will go.

• When inserting a needle, if you first lower it down

into the hole in the throat plate it will line up with the

needle socket. Then direct it upwards

This machine uses SINGER 2022 needles.

Do not use Standard Household Needles.

11

Page 13

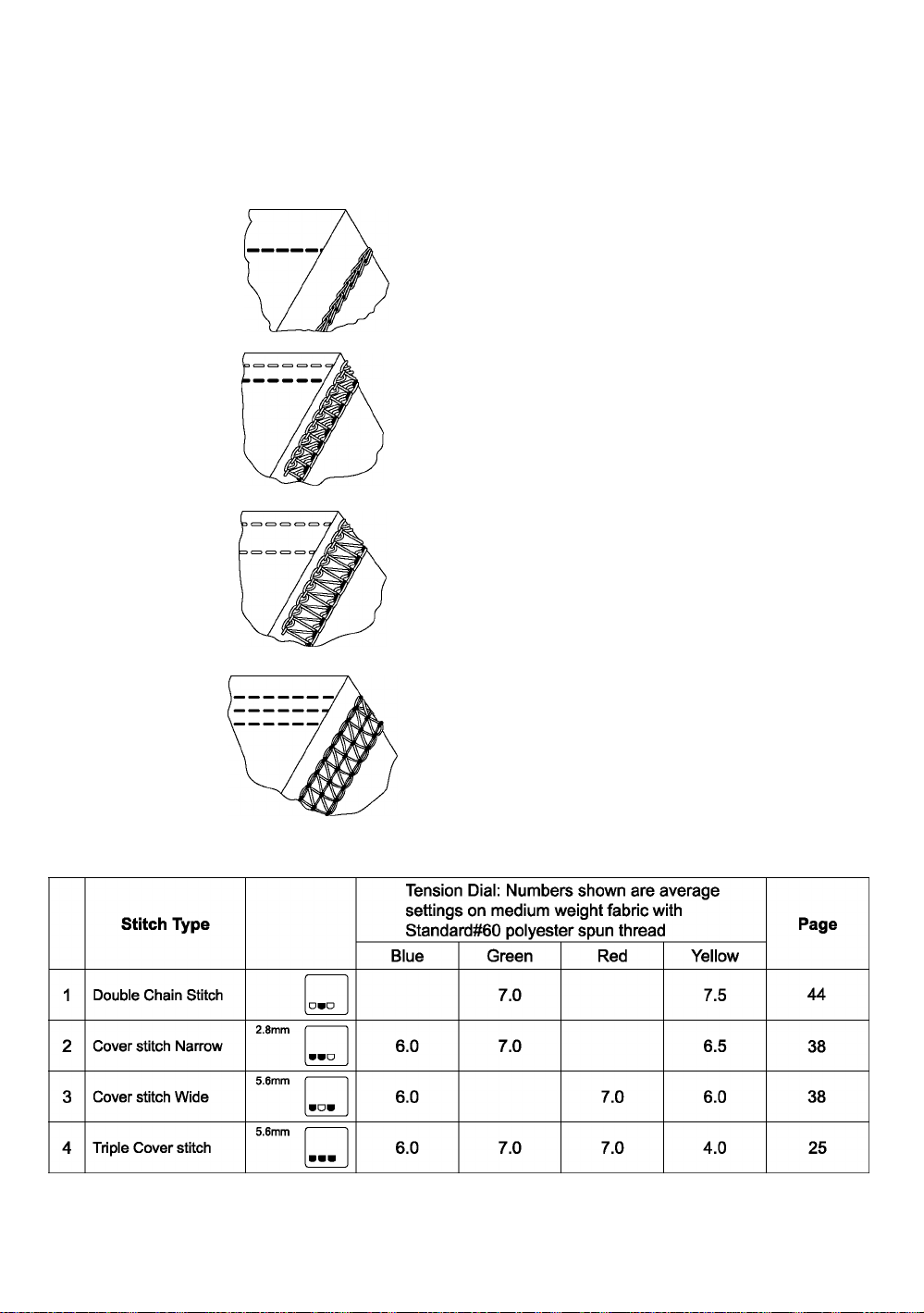

9. SELECTION OF STITCHES

This machine is capable of producing 4 types of stitches according to the combination of needie positions, threading

methods, tension adjustment.

Stitch Type

1. Double

Chain Stitch

2. Cover Stitch

Narrow

(2.8mm)

3. Cover Stitch

Wide (5.6mm)

4. Triple Cover

Stitch

(5.6mm)

A1-needie 2-thread straight stitch is

used for construction or decorative

stitching. Seams also can be sewn at

desired distance from edge of fabric

by disengaging the right iooper and

movabie knife.

2-needie, 3-thread cover stitch is

suitabie for stretchy fabrics such as

knits, etc.

A narrow seam is formed by using ieft

and middle needles.

2-needle 3-thread cover stitch is

suitable for stretchy fabrics such as

knits, etc.

A wide seam is formed by using left

and right needles.

3-needle 4-thread cover stitch is

suitable for stretchy fabrics such as

knits, etc.

A triple seam is formed by using left,

middle, and right needle.

Reference

Page

44

38

38

25

10. HANDY REFERENCE CHART

The thread tension becomes tighter as the diais are turned to higher numbers. The tension settings shown on this page as weli as throughout

the instruction book are suggested guides. Adjust thread tensions to suit the fabric and size of thread of thread used. For best results make

tension adjustments in smali increments of no greater than haif a number at a time.

* When chainstitching under conditions given in No.1, set stitch iength to over 2mm.

* When cover stitching under conditions given in No.2,3,4, set stitch iength to over N (2.5mm).

12

Page 14

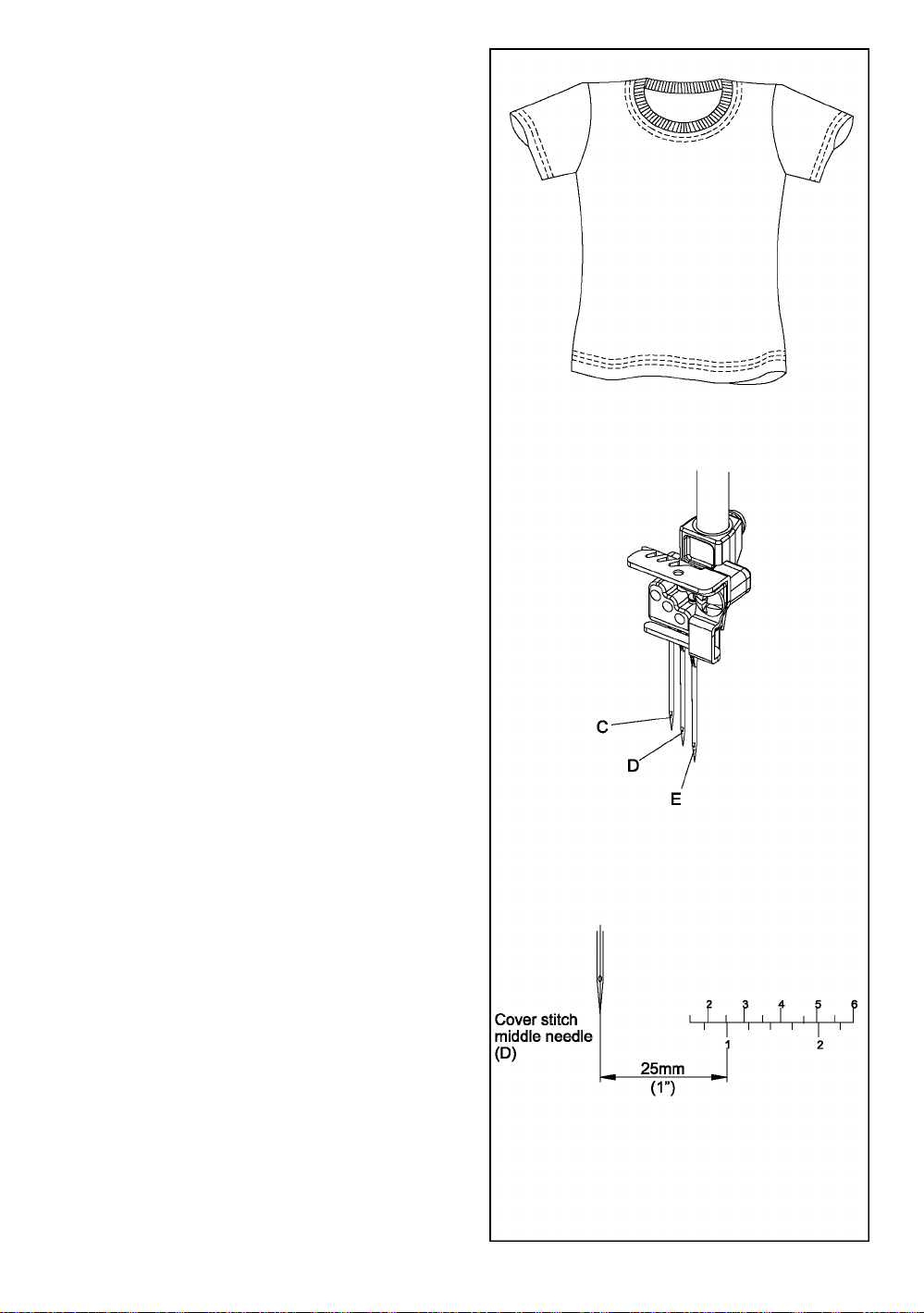

11. HOWTO SEW A COVER STITCH

This machine can produce a 3-thread 5.6 mm wide

bottom cover stitch.

The cover stitch can be used for covering, binding

or top-stitching necklines and for hemming the

bottom, of T-shirts and sweatsuits, etc. in addition

to flat joining seams (plain seaming).

The cover stitch is most suitable for stretchy

fabrics such as knit.

It also can be used In woven fabrics such as

denim, but careful attention must be paid to the

tension settings or there is the possibility of thread

breakage and or skipping.

If you experience skipping or thread breakage

sewing denim change needles first and then adjust

the tensions little by little (1/4 number at a time).

Machine Set up

Caution:

A

• Open looper cover. (See page 8)

• For Triple 5.6mm cover stitch, install cover stitch

right needle (E), cover stitch middle needle (D) and

cover stitch left needle (C).

• Pass thread through needles (E), (D) and (C) and

thread cover stitch looper [yellow].

• The graduations on seam guide plate indicate the

distance from cover stitch middle needle.

Use It as a guide when positioning fabric edge.

• Close looper cover.

Be sure to turn off power switch.

13

Page 15

Additional Information About Cover Stitch

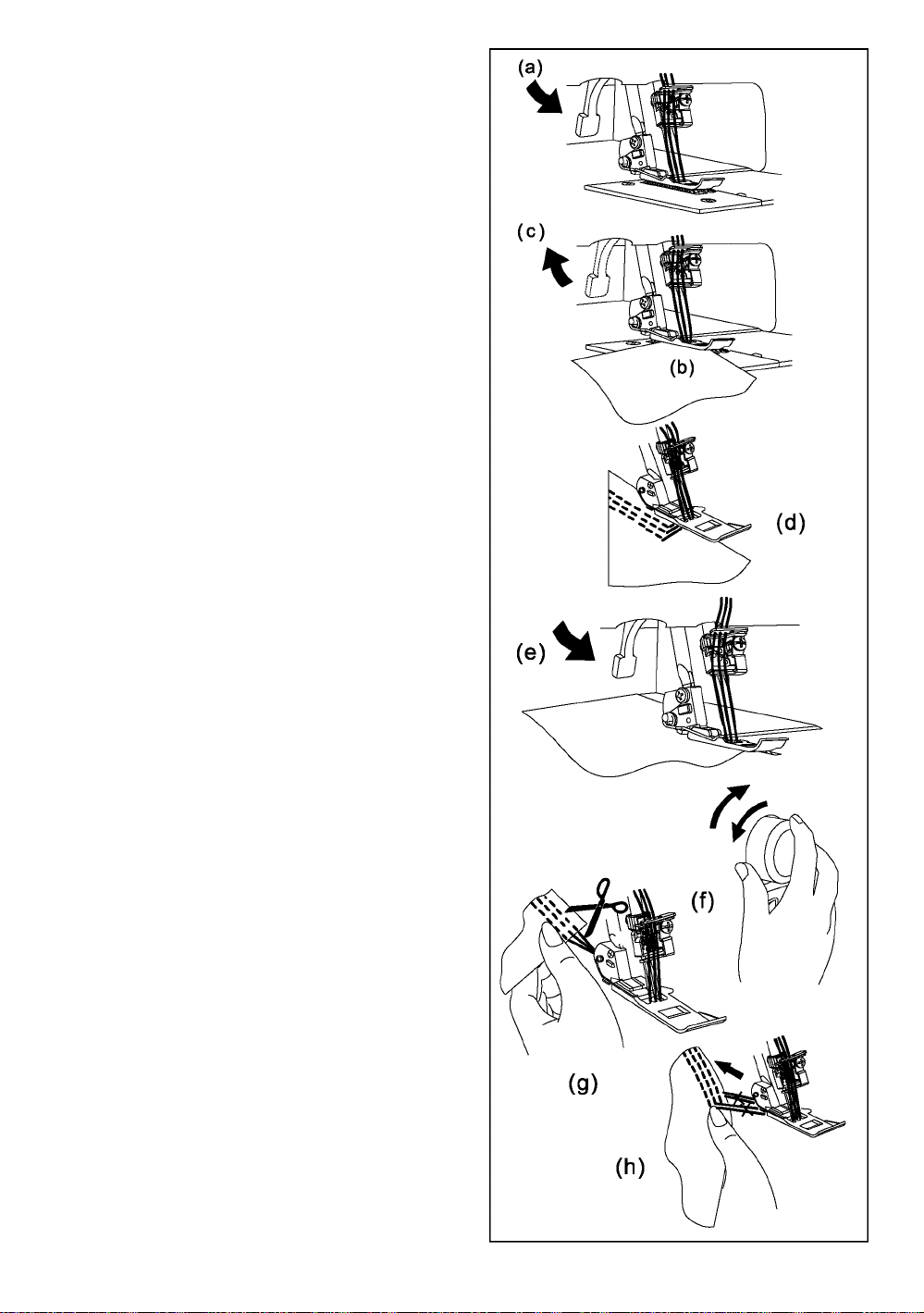

At start of sewing

• Raise presser foot, (a)

Place fabric under presser foot behind the needle, (b)

Lower presser foot, (c)

Note:

When you start to sew from the middle of the fabric,

place the fabric at the desired starting point of sewing,

(d)

At end of sewing

stop sewing when the fabric is not under

the needles

Raise presser foot, (e)

Turn the hand wheel toward you one circle

(counter-clockwise), then turn away from you

one circle back, (Clockwise) stopping with

needles in the highest position, (f)

Place your thumb on the stitches, then pull out

the fabric lightly to rear of machine and cut the

threads, (g)

Note:

The instructions are given when sewing cover

stitches because it is not possible to chain-off

when doing a cover stitch, (h)

14

Page 16

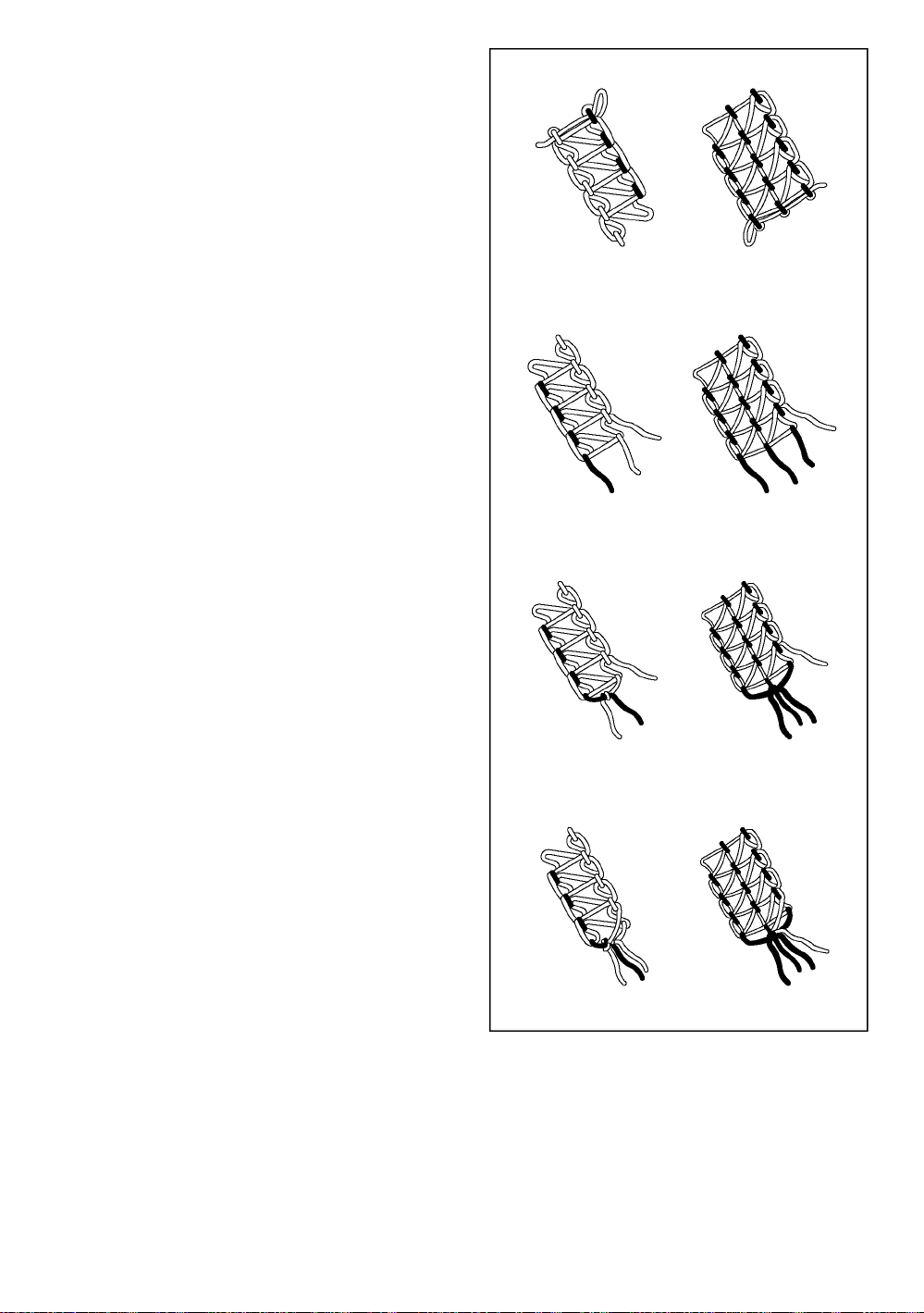

Securing the Seam End

• Since the seams formed by cover stitch unravei

when the iooper thread is pulied out at the end

of sewing, secure the seam end in the foliowing

manner.

When sewing through to the edge of fabric, among

the threads coming out of the fabric edge, knot

the needie threads (2 or 3 threads) together first,

as shown on the right iliustration. Then, tie these

threads with the Iooper threads.

When sewing is stopped haifway, puil out the

needie threads (2 or 3 threads) on the underside of

the fabric and knot the threads in the same manner

as described above.

Cut extra threads.

Note: Normaiiy, the seams at the start of sewing do

not unravel, but it is safe to secure the seam

end foliowing the same steps as described

when sewing through to the edge of fabric.

15

Page 17

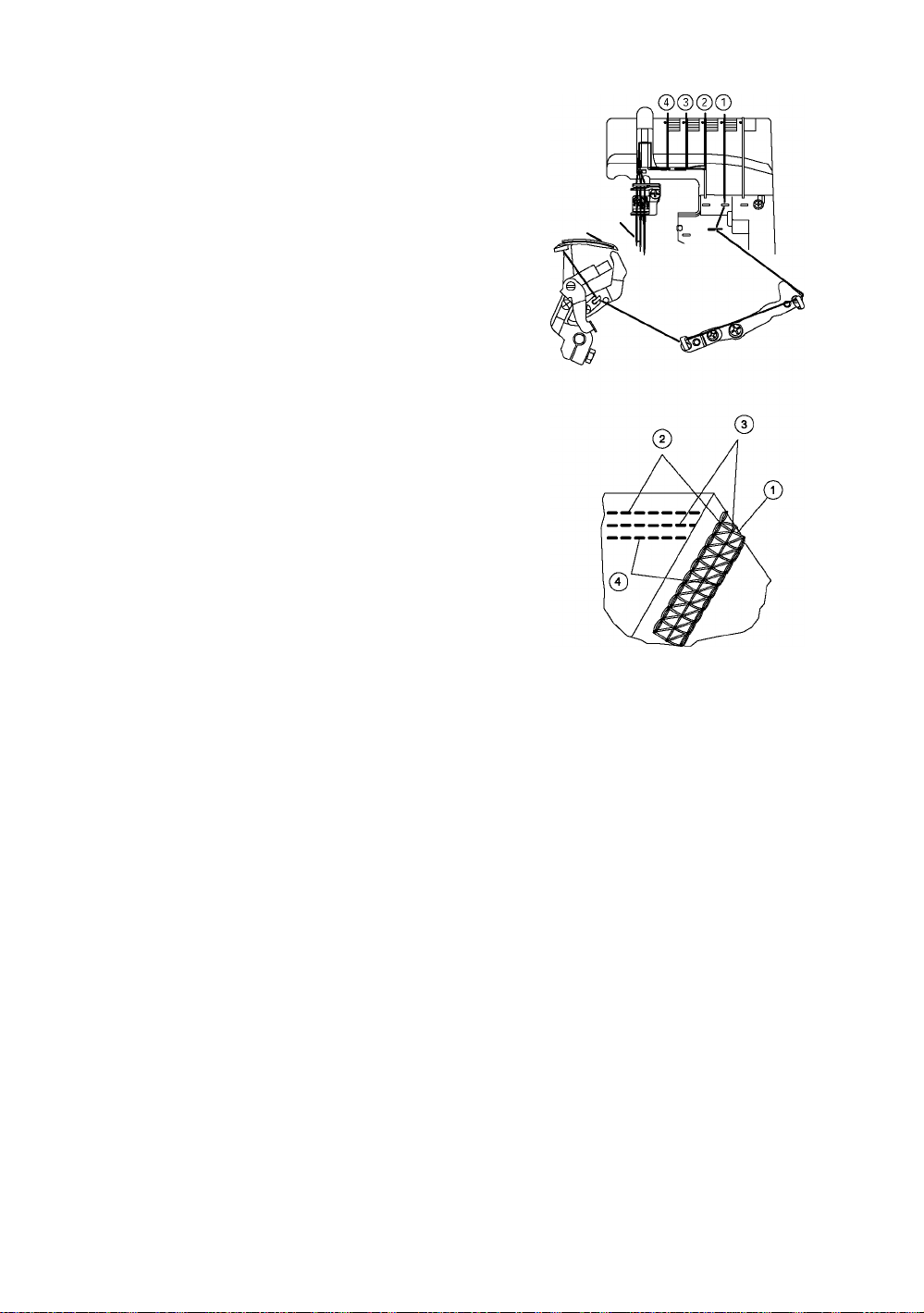

12. THREADING THE MACHINE

Threading Diagram:

Three Thread Cover Stitch

• A color coded threading diagram is located Inside

the looper cover for quick reference.

• Thread the machine in the order 1 to 4 as shown

at right.

Tension Color Code: Cover Stitch

J

1. Cover stitch looper thread

2. Right needle thread...................... Red

3. Middle needle thread

4. Left needle thread

........................

..........

...................

Yellow

Green

Blue

16

Page 18

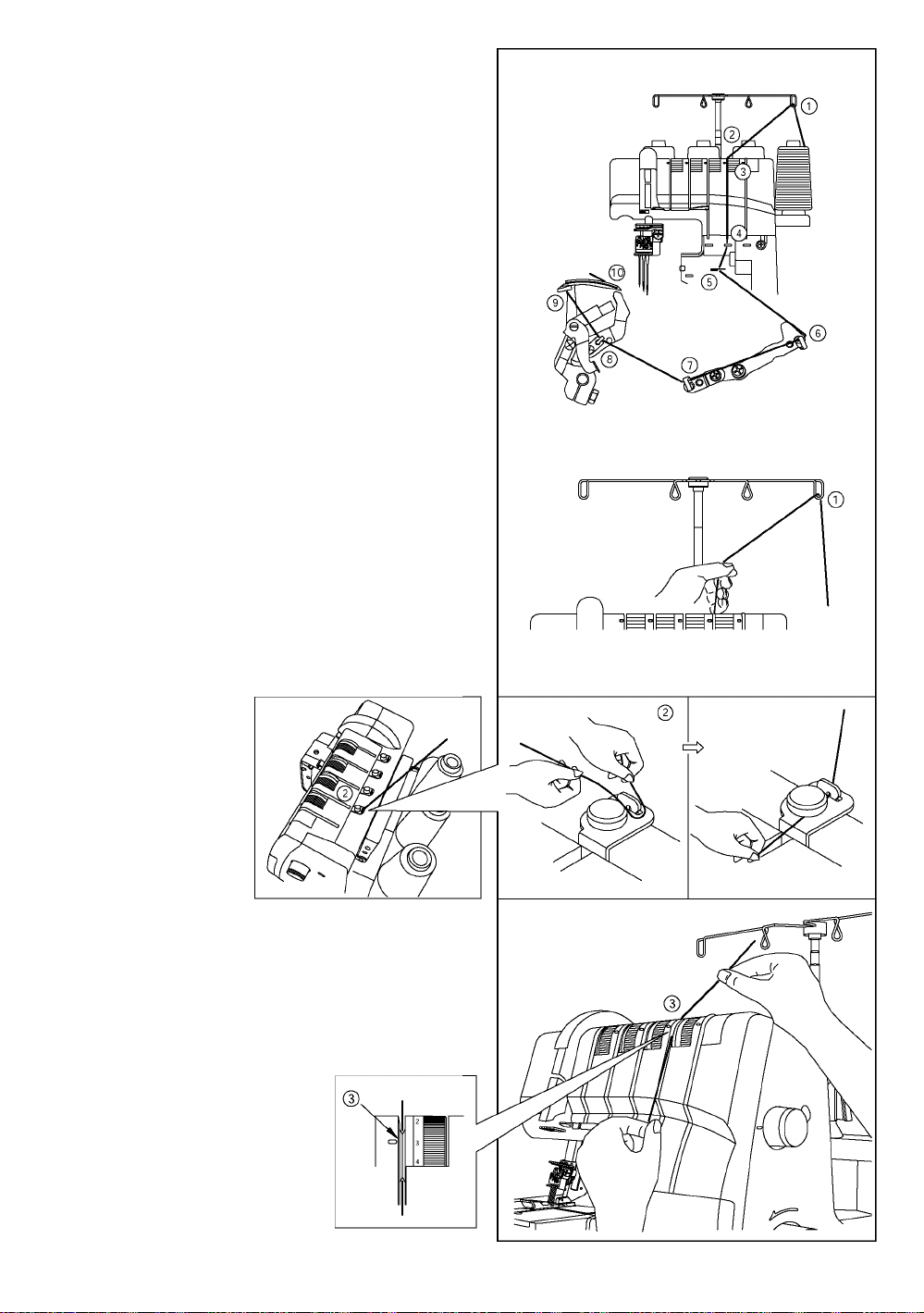

1) Threading the Chain Stitch/Cover Stitch Looper

(Yeiiow)

• Thread the chain stitch/cover stitch iooper as

indicated 1~10.

Raise Presser foot to reiease Tension discs

Pass thread from back to the front through the thread

guide 1.

Thread the top cover

thread guide by puiiin

the thread towards the

ieft untii it siips under

guide. Then puii threa

aiong the right side of

button as iliustrated.

Whiie hoiding thread with fingers, pass it between the

tension discs and puii thread down to make certain it is

properiy iocated in between the tension discs 3.

17

Page 19

Turn the hand wheel toward you until the chain stitch

iooper extends out 10mm from the throat piate edge.

Thread the iooper area of the machine foiiowing the

yeiiow color-coded thread guides 4~10.

Note: Use the tweezers provided in the accessory case

to aid in threading the Iooper.

Place the thread with the point of the tweezers through

threading guide 4.

Place the thread with the point of the tweezers through

the front slot of threading guide 5.

Place the thread with the point of the tweezers through

threading guide 6,7 and 8.

Thread the Iooper eye (A) from front to back.

Pull about 10cm (4 inches) of thread through the

Iooper. Position thread into V cutout (B) on threader.

Firmly hold thread tail with left hand and pull threader

lever (C) up into place (D).

18

Page 20

(2) Threading the Cover Stitch Right Needie

(Red) (E on needie ciamp)

• Thread the cover stitch right needie as

indicated 1-9.

Raise Presser foot to reiease Tension discs

Pass thread from back to the front through the thread

guide 1.

Thread the top cover

thread guide by puiiing

the thread towards the

ieft untii it siips under

guide. Then puii thread

aiong the right side of

button as iiiustrated.

19

Page 21

While holding thread with fingers, pass it between the

tension discs and pull thread down to make certain it is

properly located in between the tension discs 3.

Continue to thread points 4-8.

Note: Slip thread into the rear slot on thread guides 5.

Slip the thread into the slot of the Take-up Lever

Cover 6. Slip the thread into the right slots for

thread guides 7 and 8.

Before threading eye of needle, make sure thread is

in front of thread guide located on the bottom of the

needle clamp for Cover stitch.

Thread the eye of the right needle 9.

Note: Use of tweezers in the accessory case will

make needle eye threading easy.

Draw about 10cm (4 inches) of thread through

needle eye towards the rear of the machine.

Place the thread to the back under the presser foot.

20

Page 22

(3) Threading the Cover Stitch Middie/Chain Stitch Needle

(Green) (D on needle clamp)

• Thread the cover stitch middle/chain stitch needie as

indicated 1~9.

• Raise the Presser Foot to reiease Tension discs.

Pass thread from back to the front through the thread

guide 1.

Thread the top cover

thread guide by pulling

the thread towards the

left until it slips under

guide. Then pull thread

along the right side of

button as illustrated.

21

Page 23

While holding thread with fingers, pass it between the

tension discs and puli thread down to make certain it is

properly located in between the tension discs 3.

Continue to thread points 4-8.

Note: Slip thread into the middle slot of the thread

guide 5 and into the slot of take-up lever cover 6

Then continue by slipping thread into the middie

slot of the thread guides 7 and 8.

Before threading eye of needie, make sure thread is

in front of thread guide iocated on the bottom of the

needle clamp for Cover stitch and for Chain stitch.

Thread the eye of the right needie 9.

Note: Use of tweezers in the accessory case wiil

make needle eye threading easy.

Draw about 10cm (4 inches) of thread through

needle eye towards the rear of the machine.

Place the thread to the back under the presser foot.

22

Page 24

4) Threading the Cover Stitch Needies

(1) Threading the Cover Stitch Left Needle

(Blue) (C on needle clamp)

• Thread the cover stitch left/chain stitch needie as

indicated 1~9.

• Raise Presser foot to reiease Tension discs.

Pass thread from back to the front through the thread

guide 1.

©

Thread the top cover

thread guide by puiiing

the thread towards the

ieft untii it siips under

guide. Then puii thread

aiong the right side of

button as iiiustrated.

Whiie hoiding thread with finger, pass it between the

tension discs and puii thread down to make certain it

is properiy iocated in between the tension discs 3.

23

Page 25

Continue to thread points 4~8.

Note: Siide thread into front slot on thread guide 5

and the slot of take-up lever over 6. Then slip

thread Into left slots of thread guides 7 and 8.

Before threading eye of needle, make sure thread is

in front of thread guide located on the bottom of the

needle clamp.

Thread the eye of the left needle 9.

Note: Use of tweezers In the accessory case will

make needle eye threading easy.

Draw about 10cm (4 inches) of thread through

needle eye to hang free.

Place the thread to the back, under the presser foot.

24

Page 26

Three-Thread Cover Stitch Suggested Tension Settings

Note: * These are suggested tension settings oniy.

* Tension settings are effected by;

1) Type and thickness of fabric

2) Needie size

3) Size, type and fiber content of thread

* Stitch iength for cover stitch should be set at

over N (2.5mm).

Correct Balance

• Set each tension diai to settings shown at right

and test sew on a sampie of your fabric.

How to Balance

• When the cover stitch looper thread is too ioose;

-Turn the cover stitch iooper thread tension diai

(yellow) toward a higher number.

• When the cover stitch left needle thread tension is

too loose;

-Turn the cover stitch left needle thread tension dial

(blue) toward a higher number.

-Or, turn cover stitch looper thread tension dial

(yellow) toward a lower number.

• When the cover stitch middle needle thread tension

is too loose;

-Turn the cover stitch middle needle thread tension

dial (green) toward a higher number.

-Or, turn cover stitch looper thread tension dial

(yellow) toward a lower number.

• When the cover stitch right needle thread tension is

too loose;

-Turn the cover stitch right needle thread tension

dial (red) toward a higher number.

-Or, turn the cover stitch looper thread tension dial

(yellow) toward a lower number.

NEEDLE POSITION

STITCH LENGTH N~4

Cover stitch right needle thread

Cover stitch

Left needle thread

Topside

Cover stitch

looper Thread

Polyester

Woolly nylon 6.0 7.0 7.0 0

Cover stitch right needie thread Cover stitch middle

Cover stitch

Left needle thread

Topside

Cover stitch right needle thread

Cover stitch

Left needle thread

Topside

Cover stitch right needle thread Cover stitch middle

Cover stitch

Left needle thread

Topside

Cover stitch right needle thread Cover stitch middle

Blue Green Red Yellow

6.0 7.0 7.0 4.0

Cover stitch middle

needle thread

Cover stitch

looper thread

Underside

Tension Dial

needle thread

Cover stitch

looper thread

Underside

Cover stitch middle

needle thread

Cover stitch

looper thread

Underside

needle thread

Cover stitch

looper thread

Underside

needle thread

• When the top surface of fabric bulges between

needle threads and the seams on the underside of

the fabric becomes tight;

- Turn the cover stitch looper thread tension dial

(yellow) toward a lower number.

25

Cover stitch

Left needle thread

Topside Underside

Cover stitch

looper thread

Page 27

Threading Diagram: Cover Stitch - Two Thread Narrow

Tension Color Code: Two Thread Narrow Cover

1. Cover Stitch Looper

2. Middle Needle Thread (D)...........................Green

3. Left Needle Thread (C)

4. Remover Needle (E)

....................................

...............................

Yellow

Blue

1) Threading the Chain Stitch/Cover Stitch Looper

(Yeliow)

• Thread the chain stitch/cover stitch looper as

indicated 1~10.

Raise Presser foot to release Tension discs.

Pass thread from back to the front through the thread

guide 1.

Thread the top cover

thread guide by pulling

the thread towards the

left until it slips under

guide. Then pull thread

along the right side of

button as illustrated.

26

Page 28

While holding thread with fingers, pass it between the

tension discs and pull thread down to make certain It Is

properly located in between the tension discs 3.

Turn the hand wheel toward you until the chain stitch

looper extends out 10mm from the throat plate edge.

Thread the looper area of the machine following the

yellow color-coded thread guides 4~10.

Note: Use the tweezers provided in the accessory case

to aid In threading the looper.

Place the thread with the point of the tweezers through

threading guide 4.

Place the thread with the point of the tweezers through

the front slot of threading guide 5.

Place the thread with the point of the tweezers through

threading guide 6,7 and 8.

Thread the looper eye (A) from front to back.

Pull about 10cm (4 inches) of thread through the

looper. Position thread into V cutout (B) on threader.

Firmly hold thread tall with left hand and pull threader

lever (C) up into place (D).

B

Sk

C

27

Page 29

(2) Threading the Cover Stitch Middie/Chain Stitch Needle

(Green) (D on needle clamp)

• Thread the cover stitch middle/chain stitch needie as

indicated 1~9.

• Raise the Presser Foot to reiease Tension discs.

Pass thread from back to the front through the thread

guide 1.

Thread the top cover

thread guide by pulling

the thread towards the

left until it slips under

guide. Then pull thread

along the right side of

button as illustrated.

While holding thread with fingers, pass it between the

tension discs and pull thread down to make certain it is

properly located in between the tension discs 3.

28

Page 30

Continue to thread points 4-8.

Note: Slip thread into the middle slot of the thread

guide 5 and into the slot of take-up lever cover 6.

Then continue by slipping thread into the middie

slot of the thread guides 7 and 8.

Before threading eye of needie, make sure thread is

in front of thread guide located on the bottom of the

needle clamp for Cover stitch and for Chain stitch.

Thread the eye of the right needle 9.

Note: Use of tweezers in the accessory case will

make needle eye threading easy.

Draw about 10cm (4 inches) of thread through

needle eye towards the rear of the machine.

Place the thread to the back under the presser foot.

29

Page 31

Threading the Cover Stitch Needies

(3) Threading the Cover Stitch Left Needie

(Blue) (C on needle clamp)

• Thread the cover stitch left/chain stitch needie as

indicated 1~9.

• Raise Presser foot to reiease Tension discs.

Pass thread from back to the front through the thread

guide 1.

©

Thread the top cover

thread guide by puiiing

the thread towards the

ieft untii it siips under

guide. Then puii thread

aiong the right side of

button as iiiustrated.

Whiie hoiding thread with finger, pass it between the

tension discs and puii thread down to make certain it

is properiy iocated in between the tension discs 3.

30

Page 32

Continue to thread points 4~8.

Note: Siide thread into front slot on thread guide 5

and the slot of take-up lever over 6. Then slip

thread Into left slots of thread guides 7 and 8.

Before threading eye of needle, make sure thread is

in front of thread guide located on the bottom of the

needle clamp.

Thread the eye of the left needle 9.

Note: Use of tweezers In the accessory case will

make needle eye threading easy.

Draw about 10cm (4 inches) of thread through

needle eye to hang free.

Place the thread to the back, under the presser foot.

31

Page 33

Threading Diagram: Cover Stitch - Two Thread Wide

Tension Coior Code: Two Thread Wide Cover

1. Cover Stitch Looper

2. Middle Needle Thread (E)...........................Red

3. Left Needle Thread (C)

4. Remover Needle (D)

....................................

...............................

Yellow

Blue

1) Threading the Chain Stitch/Cover Stitch Looper

(Yeilow)

• Thread the chain stitch/cover stitch looper as

indicated 1~10.

Raise Presser foot to release Tension discs.

Pass thread from back to the front through the thread

guide 1.

Thread the top cover

thread guide by pulling

the thread towards the

left until it slips under

guide. Then pull thread

along the right side of

button as illustrated.

32

Page 34

While holding thread with fingers, pass it between the

tension discs and pull thread down to make certain It Is

properly located in between the tension discs 3.

Turn the hand wheel toward you until the chain stitch

looper extends out 10mm from the throat plate edge.

Thread the looper area of the machine following the

yellow color-coded thread guides 4~10.

Note: Use the tweezers provided in the accessory case

to aid In threading the looper.

Place the thread with the point of the tweezers through

threading guide 4.

Place the thread with the point of the tweezers through

the front slot of threading guide 5.

Place the thread with the point of the tweezers through

threading guide 6,7 and 8.

Thread the looper eye (A) from front to back.

Pull about 10cm (4 inches) of thread through the

looper. Position thread into V cutout (B) on threader.

Firmly hold thread tall with left hand and pull threader

lever (C) up into place (D).

B

Sk

C

33

Page 35

(2) Threading the Cover Stitch Right Needie

(Red) (E on needie ciamp)

• Thread the cover stitch right needie as

indicated 1-9.

Raise Presser foot to reiease Tension discs

Pass thread from back to the front through the thread

guide 1.

Thread the top cover

thread guide by puiiing

the thread towards the

ieft untii it siips under

guide. Then puii thread

aiong the right side of

button as iiiustrated.

34

Page 36

While holding thread with fingers, pass it between the

tension discs and pull thread down to make certain it is

properly located in between the tension discs 3.

Continue to thread points 4-8.

Note: Slip thread into the rear slot on thread guides 5.

Slip the thread into the slot of the Take-up Lever

Cover 6. Slip the thread into the right slots for

thread guides 7 and 8.

Before threading eye of needle, make sure thread is

in front of thread guide located on the bottom of the

needle clamp for Cover stitch.

Thread the eye of the right needle 9.

Note: Use of tweezers in the accessory case will

make needle eye threading easy.

Draw about 10cm (4 inches) of thread through

needle eye towards the rear of the machine.

Place the thread to the back under the presser foot.

35

Page 37

3) Threading the Cover Stitch Needies

(1) Threading the Cover Stitch Left Needle

(Blue) (C on needle clamp)

• Thread the cover stitch left/chain stitch needie as

indicated 1~9.

• Raise Presser foot to reiease Tension discs.

Pass thread from back to the front through the thread

guide 1.

©

Thread the top cover

thread guide by puiiing

the thread towards the

ieft untii it siips under

guide. Then puii thread

aiong the right side of

button as iiiustrated.

Whiie hoiding thread with finger, pass it between the

tension discs and puii thread down to make certain it

is properiy iocated in between the tension discs 3.

36

Page 38

Continue to thread points 4~8.

Note: Siide thread into front slot on thread guide 5

and the slot of take-up lever over 6. Then slip

thread Into left slots of thread guides 7 and 8.

Before threading eye of needle, make sure thread is

in front of thread guide located on the bottom of the

needle clamp.

Thread the eye of the left needle 9.

Note: Use of tweezers In the accessory case will

make needle eye threading easy.

Draw about 10cm (4 inches) of thread through

needle eye to hang free.

Place the thread to the back, under the presser foot.

37

Page 39

Two-Thread Cover Stitch Suggested Tension Settings

Note: * These are suggested tension settings oniy.

NEEDLE POSITION

mmu mum

* Tension settings are effected by;

1) Type and thickness of fabric

2) Needie size

3) Size, type and fiber content of thread

* Stitch iength for cover stitch should be set at

over N (2.5mm).

Correct Baiance

• Set each tension diai to settings shown at right

and test sew on a sample of your fabric.

How to Balance

• When the cover stitch iooper thread is too ioose;

-Turn the cover stitch Iooper thread tension dial

(yellow) toward a higher number.

Cover stitch

Iooper thread

Underside

Cover stitch

Iooper thread

Underside

N~4

STITCH LENGTH

Cover stitch right needie thread

Cover stitch

Left needie thread

Topside

Cover stitch

Iooper Thread

Polyester 6.0 7.0 5.0

Woolly nylon 6.0 7.0 0

Cover stitch

Iooper Thread

Polyester 6.0 7.0 4.0

Woolly nylon 6.0 7.0 0

Cover stitch

Left needie thread

Blue Green Red Yellow

Blue Green Red Yellow

Cover stitch right needie thread

V Topside

Tension Dial

Tension Dial

When the cover stitch left needle thread tension

is too loose;

-Turn the cover stitch left needle thread tension

dial (blue) toward a higher number.

-Or, turn cover stitch Iooper thread tension dial

(yellow) toward a lower number.

When the cover stitch right needle thread tension

is too loose;

-Turn the cover stitch right needle thread tension

dial (green) or (blue) toward a higher number.

- Or, turn the cover stitch Iooper thread tension

dial (yellow) toward a lower number.

When the top surface of fabric bulges between

needle threads and the seams on the underside

of the fabric becomes tight;

- Turn the cover stitch Iooper thread tension dial

(yellow) toward a lower number.

38

Cover stitch

Left needle thread

Cover stitch

Left needle thread

Cover stitch

Left needle thread

V

Topside

Cover stitch right needle thread

Jlopside

Cover stitch right needle thread

Topside Underside

Underside

Cover stitch

Iooper thread

Cover stitch

Iooper thread

Cover stitch

Iooper thread

Page 40

Threading Diagram: Chain Stitch

• A color coded threading diagram is located inside

the looper cover for quick reference.

• Remove Left (C) and Right (E) Needle

• Thread the machine in the order 1 to 2 as shown

at right.

Tension Coior Code: Chain Stitch

1. Chain stitch looper thread

2. Chain stitch needle thread (D)... Green

............

Yellow

39

Page 41

1) Threading the Chain Stitch/Cover Stitch Looper

(Yeiiow)

• Thread the chain stitch/cover stitch iooper as

indicated 1~10.

Raise Presser foot to reiease Tension discs

Pass thread from back to the front through the thread

guide 1.

Thread the top cover

thread guide by puiiin

the thread towards the

ieft untii it siips under

guide. Then puii threa

aiong the right side of

button as iliustrated.

Whiie hoiding thread with fingers, pass it between the

tension discs and puii thread down to make certain it is

properiy iocated in between the tension discs 3.

40

Page 42

Turn the hand wheel toward you until the chain stitch

iooper extends out 10mm from the throat piate edge.

Thread the iooper area of the machine foiiowing the

yeiiow color-coded thread guides 4~10.

Note: Use the tweezers provided in the accessory case

to aid in threading the Iooper.

Place the thread with the point of the tweezers through

threading guide 4.

Place the thread with the point of the tweezers through

the front slot of threading guide 5.

Place the thread with the point of the tweezers through

threading guide 6,7 and 8.

Thread the Iooper eye (A) from front to back.

Pull about 10cm (4 inches) of thread through the

Iooper. Position thread into V cutout (B) on threader.

Firmly hold thread tail with left hand and pull threader

lever (C) up into place (D).

(2) Threading the Cover Stitch Middie/Chain Stitch Needie

(Green) (D on needie ciamp)

• Thread the cover stitch middle/chain stitch needle as

indicated 1~9.

• Raise the Presser Foot to release Tension discs.

Pass thread from back to the front through the thread

guide 1.

B

Sk

C

J

41

Page 43

Pass thread from back to the front through the thread

guide 1.

Thread the top cover

thread guide by puiling

the thread towards the

left until it siips under

guide. Then pull thread

along the right side of

button as illustrated.

While holding thread with fingers, pass it between the

tension discs and pull thread down to make certain it is

properly located in between the tension discs 3.

U © 1

/ /"f m

/ / ^ m

/ \.ry

T

0

1

42

Page 44

Continue to thread points 4~8.

Note: Slip thread into the middle slot of the thread

guide 5 and into the slot of take-up lever cover 6.

Then continue by slipping thread into the middle

slot of the thread guides 7 and 8.

Before threading eye of needle, make sure thread is

in front of thread guide located on the bottom of the

needle clamp for Cover stitch and for Chain stitch.

• Thread the eye of the right needle 9.

Note: Use of tweezers in the accessory case will

make needle eye threading easy.

• Draw about 10cm (4 inches) of thread through

needle eye towards the rear of the machine.

• Place the thread to the back under the presser foot.

43

Page 45

Double Chain Stitch Suggested Tension Settings

Note: * These are suggested tension settings oniy.

* Tension settings are effected by;

1) Type and thickness of fabric

2) Needie size

3) Size, type and fiber content of thread

* Stitch iength for double chain stitch should

be set at over 2mm.

Correct Balance

• Set each tension dial to settings shown at right

and test sew on a sample of your fabric.

NEEDLE POSITION

STITCH LENGTH 2-4

How to Balance

• When the chain stitch needle thread tension is

too loose;

-Turn the needle thread tension dial (green)

toward a higher number.

-Or, turn the chain stitch looper thread tension

dial (yellow) toward a lower number.

Fabric

Medium weight 7.0 7.5

Biue Green Red Yeilow

Tension Dial

44

Page 46

How to Sew

The double chain stitch is sewn with 2 threads, one

needie and one iooper.

Start and end of sewing

• When starting to sew, pull the thread chain

lightly to the rear of machine until the needle

penetrates the fabric.

• When starting to sew after threading the

machine, sew 2 ~ 3 cm on a scrap fabric and

chain-off to make a chain.

• At end of sewing, pull the fabric lightly to the

rear of machine and chain-off.

45

Page 47

13. HOWTO CHANGE THREADS:

TIE ON METHOD

To change thread type or color, clip thread near the

spool.

Place new thread on stand.

Tie new thread and old thread ends together with

a square knot. Clip thread taiis to 2~3cm (1 inch)

length. If clipped too short, threads may come untied.

Firmly pull both thread to test knot security.

Raise Presser foot to release Tension discs.

Pull the threads through the machine one at a time.

If threads do not pull easily, check for tangles on

thread guides or looping under thread stand.

When pulling thread through the needles, STOP

when the knot Is in front of the needle.

Cut the thread, and insert it through the needle.

46

Page 48

14. HOW TO ADJUST THE STITCH

LENGTH

The stitch length dial should be set on the N

setting for most sewing conditions.

Adjust the stitch length to N~ 4 when sewing

heavy weight fabrics.

Adjust the stitch length to 2~N when sewing

lightweight fabrics to obtain excellent seams

without puckering.

15. HOWTO ADJUST THE PRESSER

FOOT PRESSURE

The presser foot pressure of this machine is pre

adjusted at the factory to suit the sewing of medium

weight fabrics.

Most of the materials do not require adjustment of

presser foot pressure. However, there are some

instances where adjustment is necessary, such as

when sewing lightweight and heavyweight fabrics.

In such case, N for normal, 1 for the lightest pressure,

and 5 for the heaviest.

For lightweight fabric...Decrease the pressure

For heavyweight fabric...Increase the pressure

47

Page 49

16. DIFFERENTIAL FEED

• Differential feed is a system which “stretches” or

“gathers” the fabric, when the amount of feed of

front feed dogs in relation to the rear feed dogs is

changed.

• The differential feed ratio ranges from 1:0.6~1:2.0.

Adjustment is made by means of the differential

feed adjusting dial pictured at right.

• Use of differential feed is very effective in stretch

fabrics.

• Setting “N” is differential feed adjusting dial setting

for ratio 1:1.

To set the differential feed adjusting dial for gathering

• Set differential feed adjusting dial above setting “N”.

Setting of adjusting dial depends on material being

sewn as well as the amount of desired gather.

Therefore set dial to suit the fabric and test sew before

sewing your garment.

Note: For normal stitching, set differential feed

adjusting dial to graduation “N”.

To set the differential feed adjusting dial for stretch

• Set differential feed adjusting lever knob below

setting “N”.

48

Page 50

17. MACHINE MAINTENANCE

Cleaning the Machine

Danger:

y\ Before cleaning your machine, disconnect

A

power line piug from the wali receptacle.

Clean the lint from the looper area often with

a dry lint brush.

Oiling the Machine

Danger:

Before cleaning your machine, disconnect

A

power line plug from the wall receptacle.

The oiling points shown in the diagram, should

be oiled periodically.

Note: Use only sewing machine oil. Do not use

any other oil or damage could result.

49

Page 51

How to Exchange Light Bulb

Danger:

A

Always unplug before re-lamping.

Light bulb is available at your dealer shop.

Take old bulb to the dealer shop and ask for

same bulb.

If voltage Indicated on the electrical rating

plate of your machine is 120V, ask for light

bulb conforming to following specification.

- Bayonet type: 110~120V, 15W

• Glass shape: T-20

• Lamp cap: El2

• Overall length: 48mm

• Remove light cover screw and while pushing

the cover lightly to the rear, swing cover to

the left and remove from machine as shown

in the illustration. Turn bulb to the left to

remove. To replace the bulb, push bulb Into

the socket and turn to the right.

A

A

Caution:

Be sure the light bulb has cooled off before

changing with a new one.

Warning:

Replace the light cover first before connecting

the power line plug.

If voltage Indicated on the electrical rating

plate of your machine is 220-240V, ask

for light bulb conforming to following

specification.

Edison type (screw type): 220-240V, 15W

• Glass shape: T-22

• Lamp cap: El4

• Overall length: 56mm

Remove light cover screw and while pushing

the cover lightly to the rear, swing cover to

the left and remove from machine as shown

in the illustration. Turn bulb to the left to

remove. To replace the bulb, screw bulb Into

the socket and turn to the right.

50

Page 52

18. SNAP-ON TYPE PRESSER FOOT

• The following snap-on type presser foot

specially prepared for this machine are

available at extra-charge.

Note: Do not use presser foot made for other

machines. Use of such presser foot may

result In Interference with the needle and

can be hazardous.

• The snap-on type presser foot of this machine

permits easy removal and replacement.

Caution:

Be sure to disconnect the power line plug or

turn off the power switch when changing the

A

Removal

presser foot.

Raise presser foot and raise needle bar to its

highest position.

Press red colored lever (A) located on back

of clamp under the presser foot shank, raise

presser bar lifter to its High Lift position and

while holding the presser bar lifter in this

position, remove the presser foot plate.

Replacement

• Place presser foot plate on throat plate under

presser foot shank so that hinge pin (C) will fit

in slot (B) of the shank. Then lower presser bar

lifter.

• If presser foot plate can not be placed under

presser foot shank easily, raise presser bar lifter

to its High Lift position and while holding it in this

position, place presser foot plate under presser

foot shank. Then lower presser bar lifter.

• Raise presser bar lifter and make sure the

presser foot plate Is properly attached to the

presser foot shank.

•

51

Page 53

19. TROUBLESHOOTING CHART

Problem Solution

Page

Fabric does not feed well - Lengthen stitch length.

- Increase presser foot pressure for heavy weight fabric.

- Decrease presser foot pressure for lightweight fabric.

Needle breaks

- Insert needle correctly. 11

- Tighten needle set screw. 11

- Use a larger needle on heavy fabrics.

Thread breaks - Check threading.

16-45

- Cheek for tangled or caught thread.

- Insert needle correctly.

- Insert new needle, current needle may be bent or have a blunt

point. 7

- Use only high quality thread. 34

- Loosen thread tension. 12, 25, 38, 44

Stitch skip - Insert new needles, current needles may be bent or have a blunt 7

point. Use only Branded Style SINGER 2022 Needles. 11

- Tighten needle set screw. 11

- Insert needles correctly. 11

- Change type or size of needles.

16-45

- Check threading. 21

- Increase presser foot pressure.

- Use a high quality thread.

47

47

47

11

46

11

53

Irregular stitches

- Balance thread tension.

12,25,38,44

- Check for tangled or caught thread. 20

- Check threading.

16-45

Fabric puckers - Loosen thread tension. 12,25,38,44

- Check for tangled or caught thread.

- Use high quality lightweight thread.

46

53

- Shorten stitch length. 21

- Decease presser foot pressure for lightweight fabrics. 21

Fabric jams

- Close looper cover before sewing.

- Check for tangled or caught thread.

8

46

- Compress thick layers of fabric with conventional machine before

sewing.

Machine does not operate - Connect machine to power source. 8

52

Page 54

20. RELATIONSHIP BETWEEN CLOTH, THREAD AND NEEDLE

Type of Fabric Type of Thread Needle SINGER 2022

WOVEN

Lightweight

Lawn, Organdy, Voiie,

Crepe, etc.

Medium Weight

Musiin, Seersucker,

Satin, Gabardine,

Broadcioth, etc

Heavy Weight

Oxford, Denim, Tweed,

Serge,Corduroy

KNIT

Tricot Spun: #80 ~ #90

Cotton: #100

Siik/ Rayon: #100

Spun: #80 ~ #90

Poiyester: #80 ~ #100

Cotton: #60 ~ #80

Siik/ Rayon: #50

Spun: #60 ~ #80

Poiyester: #60 ~ #80

Cotton: #40 ~ #60

Siik/ Rayon: #40 ~ #60

Spun: #60 ~ #80

Poiyester: #50 ~ #80

Poiyester: #60 ~ #80

#11/80

#14/90, #11/80

#14/90

#11/80

Jersey Spun: #60 ~ #80

Poiyester: #60 ~ #80

Cotton: #60 ~ #80

Wool (woven, knit) Spun: #60 ~ #80

Poiyester: #50 ~ #60

Wooiiy nyion

Wooiiy Polyester

53

#14/90, #11/80

#14/90, #11/80

Page 55

21. SPECIFICATION

Item Specification

Sewing speed 1,300 spm maximum

Differential feed ratio 1:0.6 ~ 1:2 (with differential feed machine)

Cover stitch needle gauge Two needles: 2.8mm (narrow), 5.6mm (wide)

Triple needles: 5.6mm

Needle bar stroke 27mm

Pressure foot rise 4.5mm

Needle SINGER 2022 #90

Number of threads

Machine dimensions (mm)

Width 360

Depth 290

Height 300

Weight (kg) 7.3kgs

2-4

54

Page 56

RECYCLING

Do not dispose of electrical appliances as unsorted municipal waste, use separate collection

facilities.

Contact your local government for information regarding the collection systems available.

If electrical appliances are disposed of in landfills or dumps, hazardous substances can leak

into the groundwater and get into the food chain, damaging your health and well-being.

When replacing old appliances with new one, the retailer is legally obligated to take back

your old appliance for disposal at least for free of charge.

55

Page 57

G5P32

Loading...

Loading...