Page 1

3 Year Guarantee

*Register online within 30

days. Terms & Conditions apply

Garantie de 3 ans

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

Conditions Générales d’utilisation

3 Jahre Garantie

*Registrieren Sie sich innerhalb von 30

Tagen online. Es gelten die allgemeinen

Geschäftsbedingungen

3 años de garantía

*Regístrese online dentro de 30 días.

Se aplican los términos y condiciones

3 anni di garanzia

*Registrarsi on-line entro 30 giorni.

Termini e Condizioni si applicano

3 Jaar Garantie

*Registreer online binnen 30 dagen.

Algemene voorwaarden van toepassing

www.silverlinetools.com

Page 2

R

E

L

I

V

N

L

I

S

POWER

R

E

E

A

G

N

677293

Arc Welder

Arc Welder

Poste à souder à l'arc

Lichtbogenschweißgerät

Soldadora por arco

Saldatrice ad arco

Lasmachine

40-100A

www.silverlinetools.com

Page 3

1

5

2

4

2

3

Page 4

®

Arc Welder

English .................. 4

Français ................ 8

Deutsch ................. 12

Español ................. 16

Italiano .................. 20

Nederlands ............ 24

40-100A

www.silverlinetools.com

3

Page 5

GB

GB

Description of Symbols

The rating plate on your tool may show symbols. These represent important

information about the product or instructions on its use.

Wear hearing protection

Wear eye protection

Wear breathing protection

Wear head protection

Wear hand protection

Read instruction manual

Class I construction (Protective earth)

Risk of electrocution

Conforms to relevant legislation and safety standards

Environmental Protection

Waste electrical products should not be disposed of with household

waste. Please recycle where facilities exist. Check with your local

authority or retailer for recycling advice

Specification

Input voltage: ............................................. 230V

Frequency: .................................................50Hz

Rated duty cycle: ........................................ 10%

Amps @ 60% duty cycle: ........................... 28A

Current range: ............................................ 40-100A

No load voltage: ......................................... 48V

Insulation class: .......................................... H

Electrode size: ............................................ 1.6-2.5mm

Max welding thickness: .............................. 5mm

Fuse rating: ................................................ 13A

Case Protection Rating: .............................. IP21S

Protection Class: ........................................

Weight: ....................................................... 13kg

The sound intensity level for the operator may exceed 85dB(A) and

sound protection measures are necessary.

As part of our ongoing product development, specifications of

Silverline products may alter without notice.

Carefully read and understand this manual and any label attached to the tool

before use. Keep these instructions with the product for future reference. Ensure

all persons who use this product are fully acquainted with this manual.

Even when used as prescribed it is not possible to eliminate all residual risk

factors. Use with caution. If you are at all unsure of the correct and safe manner in

which to use this tool, do not attempt to use it.

General Power Tool Safety

Warnings

WARNING Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

Work Area Safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents

b) Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control

Electrical Safety

a) Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will reduce risk of electric

shock

b) Avoid body contact with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded

c) Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock

d) Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords increase the risk of electric

shock

e) When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock

f) If operating a power tool in a damp location is unavoidable, use a

residual current device (RCD) protected supply. Use of an RCD reduces

the risk of electric shock

NOTE: The term “residual current device (RCD)” may be replaced by the

term “ground fault circuit interrupter (GFCI)” or “earth leakage circuit breaker

(ELCB)”.

Personal Safety

a) Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired

or under the influence of drugs, alcohol or medication. A moment of

inattention while operating power tools may result in serious personal injury

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate conditions will reduce personal

injuries

c) Prevent unintentional starting. Ensure the switch is in the off-position

before connecting to power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites accidents

d) Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result

in personal injury

e) Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used. Use

of dust collection can reduce dust-related hazards

Power Tool Use & Care

a) Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at the

rate for which it was designed

4

4

Page 6

Arc Welder677293

b) Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and must

be repaired

c) Disconnect the plug from the power source and/or the battery pack

from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally

d) Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to operate

the power tool. Power tools are dangerous in the hands of untrained users

e) Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool’s operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly maintained power tools

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control

g) Use the power tool, accessories and tool bits etc. in accordance with

these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for operations different from

those intended could result in a hazardous situation

Service

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained

Welding Safety

• Welding produces toxic fumes and can reduce oxygen levels in the work area.

Always work in a well ventilated area. Avoid inhaling welding fumes and use a

suitable respirator where appropriate.

• Some metal parts may have galvanised, lead, cadmium, or other coatings.

Attempting to weld through these coatings can produce highly toxic fumes.

Always remove all coatings before welding.

• If you experience irritation to the lungs, throat, or eyes whilst welding, STOP

IMMEDIATELY and seek fresh air.

• Welding produces extremely high levels of UV light. To prevent eye damage,

ALWAYS wear an approved welding face mask. Under no circumstances look

directly at the arc

• If there is a possibility of other people approaching the work area, erect suitable

screening to protect them from the light / glare.

• To prevent skin damage, ALWAYS wear a suitable fire-proof long sleeve jacket,

heat proof gloves, and cap. Keep covered up.

• Always remove any flammable materials (e.g. cigarette lighter, matches) from

your clothing before welding.

• Always keep a fire extinguisher nearby when welding. Sparks and accidental

contacts can cause fires.

• Only weld when all workpieces and work area are dry.

• Do not weld sealed containers (e.g. fuel tanks, air tanks, oil drums).

• The heat generated from welding can cause sealed containers to burst without

warning.

• Be aware of transferred heat. Metal parts can conduct heat away from the work

area, and cause ignition of flammable materials.

• Be aware that welded parts will remain hot for some time after joining.

• Allow to cool fully before handling or leaving unattended.

• Never weld in the presence of flammable gasses, liquids, or dust

• Always ensure that you have a responsible person nearby to alert you to any

fire, or to call help in an emergency.

• Use of welding machines will create powerful magnetic fields. This may disturb

the operation of sensitive electronic equipment. Pacemaker wearers should

consult a doctor before using a welding machine.

• Do not overload power supply. Check your mains wiring is capable of delivering

the required currents (see specification) safely.

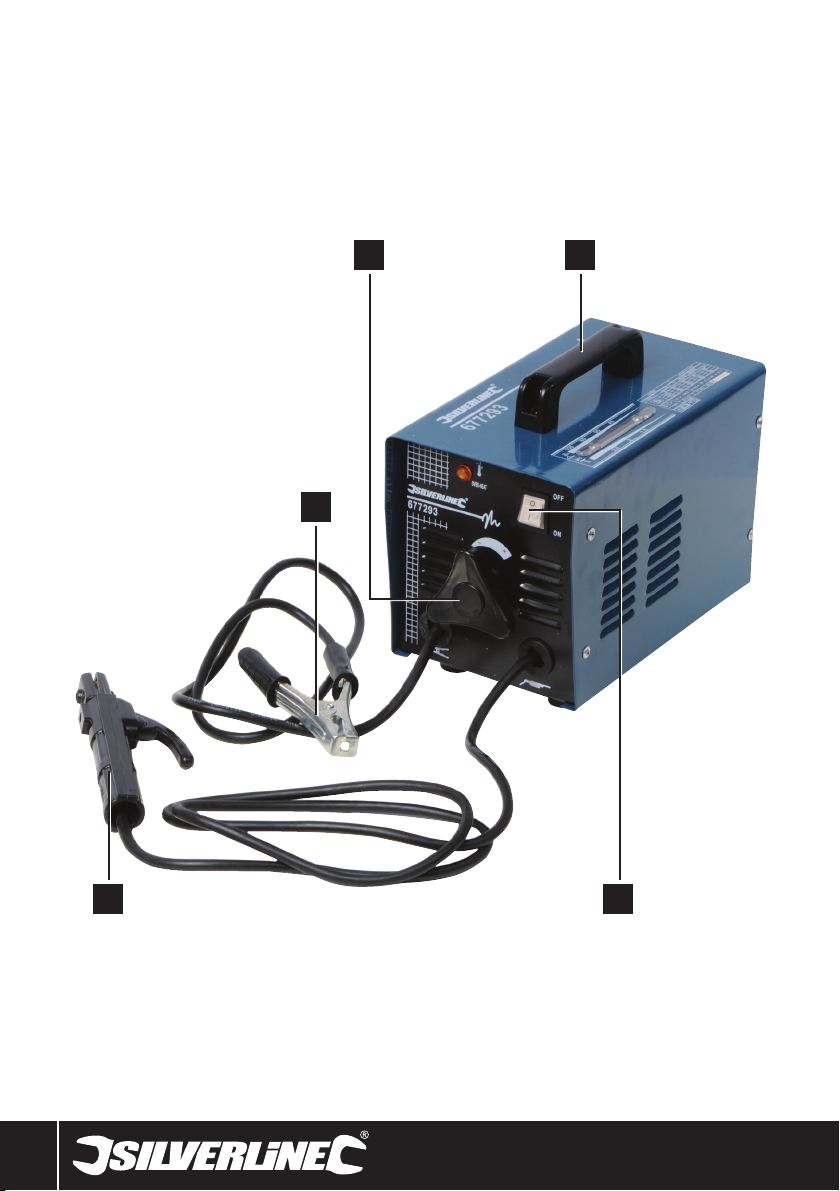

Product Familiarisation

1 Current Control Knob

2 Carry Handle

3 Power Switch

4 Electrode Clamp

5 Earth Clamp

Accessories

Welding Mask (inc. handle and visor)

Hammer & Brush

Unpacking Your Tool

• Carefully unpack and inspect your tool. Fully familiarise yourself with all its

features and functions

• Ensure that all parts of the tool are present and in good condition. If any parts

are missing or damaged, have such parts replaced before attempting to use

this tool

Assembly

Assembling the mask

1. Carefully slot the handle into the fixing slots on the mask. Ensure both

nibs engage for a secure fit

2. Remove protective wrapping from the visor and slot the visor into

place. Take care not to scratch the visor, and ensure the visor engages

fully with the clips so that it fully covers the viewing panel and cannot

be dislodged

Connecting to a Power Supply

• ONLY connect this welder to a power supply capable of providing the specified

voltage

• If connecting to a generator, check the specification of the generator first

Before Use

• Always wear appropriate personal protective equipment for the job that you

are to do. Use of this machine requires a welding mask, gloves, heat resistant

clothing and, if appropriate, a respirator

• Always ensure that you have an appropriate fire extinguisher near to the work

area

• Always inspect your machine for damage or wear. Pay particular attention to

leads and cables. If any damage is found DO NOT USE

• Check that all casings or covers are properly closed and secured

• Position the welder to ensure that it will not move, or tip, in use. Ensure that

there is at least 500mm of clear space around the welder, to allow proper

ventilation

Operating Instructions

Warning: Always unplug the welding machine from the mains supply and allow to

cool fully before attempting to fit or replace any part

Setting the machine

• To achieve a good quality weld the Current Control Knob (1) must be set

correctly

• Turning the control knob clockwise will increase the welding current, turning the

knob anti-clockwise will reduce the welding current

Welding rod selection

• In order to produce a good quality weld, the correct type of welding rod must be

used. Welding rods are available in a variety of thicknesses and materials, and

with a range of coatings

• Refer to rod manufacturers guidelines to select the correct rod for your

requirements

Duty Cycle

• This machine is not designed to weld constantly. Excessive continuous welding

will cause overheating and damage to internal components

www.silverlinetools.com

www.silverlinetools.com

5

5

Page 7

GB

GB

• The duty cycle (see specifications) defines the number of minutes, in every ten

minutes, that the machine can weld

• For a duty cycle of 30%, the machine may be used for 3 minutes, then must be

allowed 7 minutes to cool

• If the duty cycle is exceeded, the machine will automatically cut out

• Using the machine at reduced current settings and maintaining good ventilation

will maximise the duty cycle

Thermal cut-out

• This machine is equipped with a thermal cut-out. If the machine is overloaded,

or used beyond its duty cycle, it will automatically shut down

• Allow the machine to cool. The cut-out will automatically reset once the

machine is ready for use

Preparing to weld

• Ensure that parts to be joined are clean, and free from rust, paint, or other

finishes

• All parts should be well supported, with a gap of approximately 1mm where

you intend to form the welded joint

• Check that there are no flammable materials in the vicinity of the work area

• Attach the Earth Clamp (5) to a cleaned area of one of the parts, as near as

practical to where the joint will be

• Squeeze the Electrode Clamp (4), to open the jaws. Place an electrode into

the jaws, and release. The electrode should be firmly gripped, with the clamp

contacting the clean metal part (not the coated part)

• Ensure that there is a responsible person, and an operable fire extinguisher

at hand

• Connect the machine to the mains power supply

Welding

WARNING: Using a welder correctly is a technical skill. A welder used incorrectly

can be highly dangerous. The information presented below is general guidance

only. If you are not entirely

• Move the Power Switch (3) to the 'ON' position

• Hold the Electrode Clamp (4) in one hand, and the face mask in the other

• Position the rod at an angle of approx 80˚ to the surface, with the tip is approx

30mm away from the metal

• Hold the mask over your face, and tap the rod against the metal

• An arc should strike between the metal, and the tip. Try to hold the tip of the rod

a distance away from the metal equal to the rod thickness. Maintain the arc for

1-2 seconds, then move the rod away

• Allow the weld to cool slightly, and move the mask away from your face. If the

settings were correct, a round 'spot' weld should have formed

• If the weld has not fully penetrated the metal, increase the current setting. If a

hole has been made in the metal, reduce the current setting

• Practice making 'spot' welds until you are confident using the machine, and

selecting settings

• To form a 'seam' weld, maintain the arc for longer, and slowly move the rod

forward at the same time. The speed at which the rod is moved is crucial to

achieving a good weld

• If the machine settings are correct, the arc should be steady, and produce a

crackling sound. Be aware that you will have to gradually move the electrode

clamp closer to the metal as the rod is used up

• Once the weld bead is complete, remove excess and splatters using a chipping

hammer or wire brush. Do not attempt to weld over beads unless properly

cleaned

• Creating neat, high quality welds is a skill that takes time to master. Practice

and good preparation will help to make satisfactory welds

Troubleshooting

Should you experience any problem with the welder please make the

following checks:-

• That the welding current is correct for the diameter and type of electrode in use

• That if the power supply is on, the power indicator light in the ON/OFF switch

is on. If the power indicator light is not on there is a power supply problem (for

example a circuit breaker may have blown)

• That the correct voltage is being used as indicated on the rating plate

• That you have not exceeded the duty cycle and the thermal cut-out is in

operation

• That the cables are undamaged and that there is nothing causing a short circuit

• That all circuit connections are correct. You should pay particular attention

to the work clamp, making sure that it is correctly attached to the workpiece

and that there is no grease, paint or other contaminate that could cause a bad

connection

Maintenance

WARNING: Always remove the plug from the mains power supply before carrying

out any maintenance/cleaning.

Cleaning

• Keep your machine clean at all times. Dirt and dust will cause internal parts

to wear quickly, shortening the machine’s service life. Clean the body of your

machine with a soft brush, or dry cloth. If available, use clean, dry, compressed

air to blow through the ventilation holes

Disposal

• Do not dispose of power tools, or other waste electrical and electronic

equipment, with household waste

• Contact your local waste disposal authority for information on the proper way

to dispose of tools

6

6

Page 8

Silverline Tools Guarantee

This Silverline product comes with a 3 year

guarantee

Register this product at www.silverlinetools.com within 30 days of

purchase in order to qualify for the 3 year guarantee. Guarantee period

begins according to the date of purchase on your sales receipt.

Terms & Conditions

Guarantee period becomes effective from the date of retail purchase as

detailed on your sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the

stockist where it was purchased, with your receipt, stating details of the

fault. You will receive a replacement or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date,

your name, address and place of purchase before any work can be

carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools

to establish if the deficiencies are related to material or manufacturing of

the product.

Carriage will not be refunded. Items for return must be in a suitably clean

and safe state for repair, and should be packaged carefully to prevent

damage or injury during transportation. We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorized

repair agents.

The repair or replacement of the product will not extend the period

of guarantee

Defects recognised by us as being covered by the guarantee shall be

corrected by means of repair of the tool, free of charge (excluding carriage

charges) or by replacement with a tool in perfect working order.

Retained tools, or parts, for which a replacement has been issued, will

become the property of Silverline Tools.

EC Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorised by: Silverline Tools

Declares that the

Name/ model: Arc Welder

Type/ serial no: 677293

Net installed power: 40 - 100A

Conforms to the following Directives:

• Low voltage directive 2006/95/EC

• EMC Directive 2004/108/EC

• ROHS Directive 2002/95/EC

• EN60974-1:2005

• EN60974-6:2003

• EN60974-10:2007

• EN61000-3-11:2000, EN61000-3-12:2005

Arc Welder677293

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee

Registration button. You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created

in PDF format for you to print out and keep with your purchase.

The repair or replacement of your product under guarantee provides

benefits which are additional to and do not affect your statutory rights as

a consumer.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline

Tools that the deficiencies were due to faulty materials or workmanship

within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will

replace it with a functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating

instructions eg blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding

sheets, cutting discs and other related items.

Accidental damage, faults caused by negligent use or care, misuse,

neglect, careless operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools

components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its

authorized repair agents.

Claims other than the right to correction of faults on the tool named in

these guarantee conditions are not covered by the guarantee.

The technical documentation is kept by: Silverline Tools

Notified body: TUV Rheinland

Place of declaration: Shanghai, China

Date: 11/11/11

Signed by:

Director

Name and address of Manufacturer or Authorised representative:

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ United Kingdom

www.silverlinetools.com

www.silverlinetools.com

7

7

Page 9

F

Description des symboles

La plaque signalétique figurant sur votre outil peut présenter des symboles. Ces

symboles constituent des informations importantes relatives au produit ou des

instructions concernant son utilisation.

Port de protection auditive

Port de lunettes de sécurité

Port de masques respiratoires

Port du casque

Port de gants

Lire le manuel d’instructions

Construction de classe I (Mise à la terre)

Risque d’électrocution

Conforme à la réglementation et aux normes de sécurité pertinentes

Protection de l’environnement

Les produits électriques usagés ne doivent pas être jetés avec les

ordures ménagères. Veuillez les recycler dans les centres prévus à

cet effet. Pour de plus amples informations, veuillez contacter votre

municipalité ou point de vente

Caractéristiques techniques

Tension : ..................................................... 230 V~

Fréquence : ................................................ 50 Hz

Cycle opératoire nominal : .......................... 10%

Ampérage à 60% du cycle opératoire : .......28 A

Variations de courant nominal : .................. 40-100 A

Tension à vide : .......................................... 48 V

Classe d’isolation : ..................................... H

Diamètre de l’électrode : ............................ 1,6-2,5 mm

Epaisseur max. de soudure : ...................... 5 mm

Valeur nominale du fusible : ....................... 13 A

Degré de protection : .................................. IP21S

Classe de protection : .................................

Poids : ....................................................................13 kg

L’intensité sonore peut dépasser 85 dB(A) et il est recommandé que

l’opérateur prenne des mesures de protection sonore.

Du fait de l’évolution constante de notre développement produits,

les spécifications des produits Silverline peuvent changer sans

Lisez attentivement ce manuel ainsi que toute étiquette apposée sur l’outil et

assurez-vous d’en comprendre le sens avant utilisation. Rangez ces consignes

avec l’outil, pour référence ultérieure. Assurez-vous que toute personne venant à

utiliser cet outil ait attentivement pris connaissance de ce manuel.

Sachez qu’utiliser un outil conformément aux prescriptions ne garantit pas

l’élimination de tous les facteurs de risque. Procédez avec prudence. N’utilisez pas

cet outil si vous avez des doutes quant à la manière sûre et correcte de procéder.

notification préalable.

Consignes générales de

sécurité relatives aux appareils

électriques

AVERTISSEMENT Veuillez lire l’intégralité des consignes de sécurité et des

instructions. Le non-respect de ces consignes et instructions peut entraîner un

risque de choc électrique, d’incendie et/ou se traduire par des blessures graves

Veuillez conserver ces instructions et consignes de sécurité pour référence

ultérieure.

L’expression « appareil électrique » employée dans les présentes consignes

recouvre aussi bien les appareils filaires à brancher sur le secteur que les

appareils sans fils fonctionnant sous batterie.

Sécurité sur la zone de travail

a) Maintenir une zone de travail propre et bien éclairée. Des zones

encombrées et mal éclairées sont sources d’accidents.

b) Ne pas utiliser d’outils électriques dans des environnements explosifs,

tels qu’à proximité de liquides, de gaz ou de poussières inflammables.

Les appareils électriques produisent des étincelles susceptibles d’enflammer

la poussière ou les vapeurs présentes.

c) Eloigner les enfants et les passants pendant l’utilisation d’un appareil

électrique. Ceux-ci peuvent provoquer une perte d’attention et faire perdre

la maîtrise de l’appareil.

Sécurité électrique

a) Voir ‘Branchement sur le secteur’ pour s’informer des conditions de

sécurité lorsque que vous branchez votre appareil sur le secteur. Ne pas

suivre les consignes peut engendrer un accident fatal.

b) Eviter le contact corporel avec les surfaces mises à la terre telles que

tuyaux, radiateurs, cuisinières et réfrigérateurs. Le risque de décharge

électrique est plus important si le corps est mis à la terre.

c) Ne pas exposer l’appareil électrique à la pluie ou à l’humidité.

L’infiltration d’eau dans un appareil électrique accroît le risque de décharge

électrique.

d) Ne pas maltraiter le cordon électrique. Ne jamais utiliser le cordon

électrique pour porter, tirer ou débrancher l’appareil. Protéger le

cordon électrique de la chaleur, du contact avec l’essence, des bords

tranchants et pièces rotatives. Un cordon électrique endommagé ou

entortillé accroît le risque de décharge électrique.

Sécurité des personnes

a) Rester vigilent et faire preuve de bon sens lors de la manipulation de

l’appareil. Ne pas utiliser un appareil électrique lorsque l’on se trouve

dans un état de fatigue, ou sous l’influence de drogues, d’alcool ou

de médicaments. Un moment d’inattention pendant l’utilisation d’un outil

électrique peut se traduire par des blessures graves.

b) Porter un équipement de protection approprié. Toujours porter une

protection oculaire. Le port de masque à poussières, chaussures de

sécurité antidérapantes, casque de sécurité et protections antibruit adaptés

aux différentes conditions de travail réduit le risque de blessures corporelles.

c) Eviter tout démarrage accidentel. S’assurer que l’interrupteur

marche-arrêt soit en position d’arrêt avant de brancher l’appareil sur

l’alimentation secteur ou d’installer la batterie, de prendre l’appareil ou

de le transporter. Porter un appareil électrique tout en maintenant le doigt

posé sur l’interrupteur ou brancher un appareil électrique dont l’interrupteur

est sur la position de marche est source d’accidents.

d) Enlever toute clé et tout instrument de réglage avant de mettre

l’appareil électrique en marche. Une clé ou un instrument de réglage

laissé fixé à un élément en rotation de l’appareil électrique peut entraîner des

blessures physiques.

e) Ne pas essayer d’atteindre une zone hors de portée. Se tenir toujours

en position stable permettant de conserver l’équilibre. Cela permet de

mieux contrôler l’appareil électrique dans des situations inattendues.

f) Porter des vêtements appropriés. Ne pas porter de vêtements amples

ou des bijoux pendants. Eloigner cheveux, vêtements et gants des

pièces en mouvement. Les vêtements amples, les bijoux pendants et

cheveux longs peuvent être happés par les pièces en rotation.

8F8

Page 10

Poste à souder à l’arc677293

g) Si l’appareil est pourvu de dispositifs destinés au raccord

d’équipements d’extraction et de récupération de la poussière/sciure,

s’assurer qu’ils soient bien fixés et utilisés correctement L’utilisation de

ces dispositifs peut réduire les risques dus à la poussière.

Utilisation et entretien des appareils électriques

a) Ne pas forcer sur l’appareil électrique. Utiliser l’appareil électrique

approprié au travail à effectuer. Un appareil électrique adapté et employé

au rythme pour lequel il a été conçu permettra de réaliser un travail de

meilleure qualité et dans de meilleures conditions de sécurité.

b) Ne pas utiliser un appareil électrique dont l’interrupteur marche-arrêt

est hors service. Tout appareil électrique dont la commande ne s’effectue

plus par l’interrupteur marche-arrêt est dangereux et doit être réparé.

c) Débrancher l’appareil électrique ou démonter sa batterie avant

d’effectuer tout réglage ou changement d’accessoire et avant de le

ranger. De telles mesures préventives réduiront les risques de démarrage

accidentel.

d) Ranger les appareils électriques inutilisés hors de portée des enfants

et ne pas permettre l’utilisation de cet appareil aux personnes

non habituées à son maniement ou n’ayant pas lu les présentes

instructions. Les appareils électriques sont dangereux dans les mains

d’utilisateurs inexpérimentés.

e) Veiller à l’entretien des appareils électriques. Vérifier que les éléments

rotatifs soient bien alignés et non grippés. S’assurer de l’absence

de pièces cassées ou endommagées susceptibles de nuire au bon

fonctionnement de l'appareil. Si l’appareil électrique est endommagé,

le faire réparer avant toute utilisation. De nombreux accidents sont dus à

l’utilisation d’appareils électriques mal entretenus.

f) Veiller à ce que les outils de coupe soient tenus affûtés et propres. Des

outils de coupe bien entretenus, aux tranchants bien affûtés, sont moins

susceptibles de se gripper et sont plus faciles à contrôler.

g) Utiliser l’appareil électrique, les accessoires et outils à monter

conformément à ces instructions, en tenant compte des conditions de

travail et de la tâche à réaliser. Toute utilisation d’un appareil électrique

autre que celle pour laquelle il a été conçu peut entraîner des situations

à risque.

Révision

a) Ne faire réparer votre appareil électrique que par un réparateur qualifié

utilisant uniquement des pièces de rechange identiques. Cela permet de

maintenir la sécurité d’utilisation de l’appareil électrique.

Consignes de sécurité relatives à

la soudure

• La soudure peut produire de la fumée toxique et réduire le taux d’oxygène

présent dans la zone de travail. Travaillez toujours dans un endroit bien ventilé.

Evitez d’inhaler la fumée émise par la soudure et portez un masque respiratoire

lorsque l’activité s’y prête.

• Certaines parties métalliques peuvent être galvanisées ou revêtues de plomb,

de cadmium ou d’autres revêtements. Souder sur ces revêtements peut

produire de la fumée hautement toxique. Décapez toujours la surface avant de

procéder au soudage.

• Si vous ressentez une irritation aux poumons, à la gorge ou aux yeux pendant le

soudage, ARRETEZ-VOUS IMMEDIATEMENT et sortez à l’air pur.

• La soudure produit des taux extrêmement élevés d’ultraviolets. Pour éviter

d’altérer votre vue, portez TOUJOURS un masque à souder agréé. Ne regardez

JAMAIS directement l’arc.

• Si d’autres personnes risquent de s’approcher de la zone de travail, installez un

écran approprié pour les protéger des ultraviolets / de la lumière éblouissante.

• Pour éviter les brûlures de la peau, portez TOUJOURS une veste ignifugée

à manches longues appropriée, des gants résistants à la chaleur et une

casquette. Restez bien couvert.

• Retirez toujours toute source de combustion (par exemple : briquet, allumettes)

de vos vêtements avant de souder.

• Gardez toujours un extincteur à proximité de la zone de soudure. Les étincelles

et les contacts accidentels peuvent provoquer des incendies.

• Soudez uniquement lorsque toutes les pièces à souder et la zone de travail

sont sèches.

• Ne soudez pas de conteneurs scellés (par exemple : réservoirs à essence ou à

air, citernes à pétrole). La chaleur produite par la soudure peut faire subitement

exploser les conteneurs scellés.

• Soyez conscient de la propagation de la chaleur. Les éléments métalliques

peuvent communiquer la chaleur à tout matériel se trouvant à proximité

de votre zone de travail, ce qui peut à son tour enflammer des matériaux

combustibles.

• Sachez que les pièces soudées resteront chaudes pendant quelques temps

après leur soudure. Laissez-les refroidir complètement avant de les manipuler

ou de vous en éloigner.

• Ne soudez jamais à proximité de gaz, de liquides ou de poussières

inflammables.

• Assurez-vous toujours qu’une personne responsable se trouve à proximité afin

de vous avertir en cas d’incendie ou d’appeler de l’aide en cas d’urgence.

• L’utilisation de postes à souder créera des champs magnétiques puissants,

susceptibles de perturber le fonctionnement des équipements électroniques

sensibles. Il est recommandé que les personnes portant un stimulateur

cardiaque consultent un médecin avant d’utiliser un poste à souder.

• Ne surchargez pas l’alimentation secteur. Vérifiez que votre installation

électrique peut fournir les courants requis en toute sécurité (voir les

caractéristiques techniques).

Présentation du produit

1 Bouton de réglage de courant

2 Poignée de transport

3 Bouton d’alimentation

4 Porte-électrode

5 Pince de masse

Accessoires

Masque de soudure (avec poignée et visière).

Marteau à piquer et Brosse

Assemblage

Assemblage du masque

1. Insérez avec précaution la poignée dans les fentes de fixation du masque.

Assurez-vous que les deux nervures aient bien été insérées.

2. Retirez l’emballage protecteur du verre et insérez le verre dans la fente

prévue à cet effet. Prenez soin de ne pas rayer le verre et assurez-vous que

celui-ci soit bien retenu par les petits crochets de retenue de manière à

recouvrir totalement la fente de visée et qu’il ne se déplace pas.

Branchement à une source d’alimentation électrique :

• Connectez uniquement le poste à souder à une source électrique capable de

fournir le voltage spécifié.

• Avant de le connecter à un générateur, vérifiez bien les caractéristiques

techniques de celui-ci.

Avant l’utilisation

• Portez toujours l’équipement de protection approprié au travail envisagé.

L’utilisation de cet appareil demande l’usage d’un masque de soudeur, de

gants, de vêtement résistant à la chaleur et, éventuellement, d’un masque de

protection.

• Gardez toujours un extincteur à proximité de la zone de soudure

• Inspectez toujours la machine, recherchez les signes de dommages et d’usure.

Prêtez une attention toute particulière aux fils électriques et câbles. En cas de

dommage, N’UTILISEZ PAS L’APPAREIL.

• Vérifiez que tous les boîtiers, carters et couvercles soient convenablement

fermés.

• Choisissez avec soin l’emplacement du poste à souder de manière qu’il reste

bien immobile et ne puisse se renverser à l’usage. Assurez-vous de maintenir

un espace vide d’au moins 50 cm de chaque côté du poste pour garantir la

bonne ventilation de l’appareil.

www.silverlinetools.com

www.silverlinetools.com

9

9

Page 11

F

Consignes d’utilisation

AVERTISSEMENT: Débranchez l’alimentation électrique du poste à souder et

laissez refroidir complètement avant de manipuler ou de remplacer une pièce.

Réglage de la machine

• Pour effectuer une soudure de bonne qualité, réglez correctement Bouton de

réglage de courant (1).

• Tourner le bouton de réglage dans le sens des aiguilles d’une montre augmente

le courant, dans le sens contraire des aiguilles diminue le courant.

Sélection d’électrode

• Pour obtenir une soudure de bonne qualité, il faut utiliser le bon type

d’électrode. Les électrodes sont disponibles dans des matériaux et des

diamètres variés, et dans une gamme de revêtements différents

• Referez-vous à la table de la taille des électrodes aux directives du fabricant

afin de choisir l’électrode qui répond à vos besoins.

Cycle d’utilisation

• Cette machine n’est pas conçue pour un usage ininterrompu. Toute opération de

soudage excessivement prolongée entraîne une surchauffe et une détérioration

des composants internes.

• Le cycle d’utilisation définit la durée maximale en minutes, sur une période de

dix minutes, pendant laquelle la machine peut fonctionner.

• Dans le cas d’un cycle d’utilisation de 10 %, la machine peut être utilisée

pendant 1 minute, avec une pause obligatoire de 9 minutes pour le

refroidissement.

• Si le cycle d’utilisation n’est pas respecté, la machine se déconnectera

automatiquement.

• Pour profiter au mieux du cycle d’utilisation, utilisez une configuration électrique

faible et une bonne ventilation de la zone de travail.

Coupure thermique automatique

• Cette machine est équipée d’un coupe-circuit thermique automatique. En

cas de surcharge, ou de dépassement du cycle d’utilisation, elle s’éteindra

automatiquement

• Laissez la machine refroidir. Le coupe-circuit thermique se réinitialisera

automatiquement dès que la machine pourra de nouveau être utilisée.

Préparation pour la soudure

• Assurez-vous que les pièces à souder sont propres, et qu’elles ne sont pas

recouvertes de rouille, de peinture ou de tout autre type de revêtements

• Toutes les parties devraient être bien maintenues afin qu’’il y ait un espace

d’environ 1mm entre les pièces que vous voulez souder

• Assurez-vous qu’il n’y a aucune source inflammable dans le voisinage de la

zone de travail

• Fixez la pince de masse (5) sur une partie nettoyée d’une des pièces à souder,

aussi près que possible de l’endroit où vous allez réaliser la soudure

• Appuyez sur le porte-électrode (4), pour l’ouvrir. Insérez-y une électrode et

relâchez-le. L’électrode doit être solidement fixée et sa partie métallique (et

non pas sa partie recouverte d’un revêtement) doit être en contact avec le

porte-électrode

• Assurez-vous qu’une personne responsable et qu’un extincteur en état de

marche, se trouvent à proximité

• Branchez l’appareil à votre source d’alimentation électrique

Soudure

AVERTISSEMENT: l’utilisation correcte d’un poste à souder est une technique.

L’utilisation incorrecte d’un poste à souder peut être extrêmement dangereuse.

Les informations présentées ci-dessous sont uniquement des conseils généraux.

Si vous n’êtes pas entièrement certain de votre capacité à utiliser cet outil en toute

sécurité, NE L’UTILISEZ PAS.

Positionnez le bouton de mise en Marche (3) sur la position 'ON'

• Saisissez le porte-électrode (4) dans une main, et le masque à souder dans

l’autre.

• Positionnez l’électrode à un angle d’environ 80˚ par rapport à la surface à

souder, en maintenant la pointe de l’électrode a environ 30mm du métal.

• Placez le masque à souder devant votre visage et frottez la pointe de l’électrode

sur le métal.

• Un arc devrait se produire entre le métal et la pointe de l’électrode. Essayez

d’éloigner la pointe de l’électrode du métal d’une distance égale à l’épaisseur

du diamètre de l’électrode. Maintenez cet arc pendant 1 à 2secondes, puis

déplacez l’électrode.

• Laissez refroidir légèrement la soudure et enlevez le masque à souder. Si les

réglages sont corrects, vous devriez avoir un point de soudure rond.

• Si la soudure n’a pas complètement pénétré le métal, augmentez l’intensité. Si

le métal a été percé, réduisez l’intensité

• Entrainez-vous à faire des soudures par points jusqu’à ce que vous vous sentiez

sûr de vous pour utiliser cet appareil et pour sélectionner les réglages.

• Pour réaliser un cordon de soudure, déplacez régulièrement l’électrode audessus de la surface à souder en conservant l’arc pendant plus longtemps. La

vitesse de déplacement de l’électrode est essentielle pour réaliser une bonne

soudure.

• Si les réglages de l’appareil sont corrects, l’arc devrait être régulier et devrait

produire un crépitement. Sachez qu’il faudra progressivement rapprocher le

porte-électrode du métal au fur et à mesure que l’électrode s’use.

• Une fois la soudure terminée, enlevez les résidus et les éclaboussures

de soudure à l’aide d’un marteau à piquer les soudures ou d’une brosse

métallique. Ne tentez pas de souder par-dessus ces résidus à moins qu’ils aient

été convenablement nettoyés.

• La réalisation de soudures régulières et de haute qualité est une technique

dont la maitrise demande du temps. La pratique et une bonne préparation

permettront de réaliser des soudures satisfaisantes.

En cas de problème

• Vérifiez que le courant de soudure soit correctement paramètre fonction du

diamètre et le type d’électrode.

• Vérifiez que le courant soit ‘on’, et que l’indicateur lumineux du bouton

d’alimentation soit ‘on’. S’il ne l’est pas, il y un problème avec la prise (par

exemple à cause d’un fusible).

• Vérifiez que le voltage adéquate soit utilisé (comme indiqué sur la plaque).

• Vérifiez que vous n’avez pas dépassé le cycle d’utilisation ou provoquer la

coupure thermique automatique.

• Vérifiez que les câbles ne soient pas endommagés et qu’il n’y a rien qui puisse

causer un court-circuit.

• Vérifiez toutes les connections, particulièrement aux niveaux des pinces. Elles

doivent être fixées correctement sur la pièce de travail. Assurez- vous qu’il n’y

a pas de graisse ou de peinture ou autre saleté qui puisse causer une mauvaise

connection.

Entretien

Nettoyage

• Débranchez l’appareil de l’alimentation secteur avant de le nettoyer

• Gardez votre appareil propre. Enlevez toujours la poussière ou les particules et

assurez-vous que les trous de ventilation ne soient jamais bouchés. Utilisez

un pinceau doux ou un chiffon sec pour nettoyer l’appareil, et si c’est possible,

débouchez les trous de ventilation avec de l’air comprimé sec et propre.

Recyclage

• Ne jetez pas vos appareils ni autres équipements électriques et électroniques

usagés avec les ordures ménagères.

• Contactez la collectivité chargée de la collecte des déchets pour de plus amples

informations concernant le recyclage de ce type de déchet.

10F10

Page 12

Garantie Silverline Tools

Ce produit Silverline bénéficie d’une garantie

de 3 ans

Enregistrez ce produit à www.silverlinetools.com dans les 30 jours suivant

l’achat afin de bénéficier de la garantie de 3 ans. La période de garantie

commence à partir de la date d’achat figurant sur votre facture d’achat.

Conditions de Garantie des Outils Silverline

La période de garantie prend effet à compter de la date de l’achat en

magasin, comme indiqué sur votre facture d’achat.

VEUILLEZ CONSERVER VOTRE FACTURE D’ACHAT.

Si ce produit est défectueux pendant les 30 jours qui suivent l’achat,

retournez-le au magasin où vous l’avez acheté, avec votre facture, en

expliquant en détail le problème. Le produit sera remplacé ou vous serez

remboursé(e).

Si ce produit est défectueux après cette période de 30 jours,

retournez-le à :

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Royaume Uni

Toute demande de service sous garantie doit être soumise pendant la

période de garantie.

Avant toute intervention sous garantie, vous devez présenter la facture

d’achat originale sur laquelle doivent figurer la date d’achat, votre nom,

votre adresse et le lieu d’achat.

Vous devez expliquer en détail la défaillance nécessitant réparation.

Les demandes de service sous garantie faites pendant la période de

garantie seront vérifiées par Silverline Tools pour établir si la défaillance du

produit est liée à un vice de matériau ou de fabrication.

Les frais de port ne seront pas remboursés. Les articles retournés doivent

être convenablement propres et sûrs pour être réparés et devraient être

emballés soigneusement pour éviter tout dommage ou toute blessure

pendant le transport. Nous pouvons refuser les livraisons qui ne sont pas

convenables ou sûres.

Toute intervention sera effectuée par Silverline Tools ou ses agents de

réparation agréés.

La réparation ou le remplacement du produit ne dépassera pas la période

de garantie.

Les anomalies que nous reconnaissons être couvertes par la garantie

seront rectifiées par la réparation de l’outil, sans frais (hormis les

frais de port) ou par son remplacement par un outil en parfait état de

fonctionnement.

Les pièces ou les outils remplacés deviendront la propriété de

Déclaration de conformité CE

Le soussigné : Mr Darrell Morris

Autorisé par : Silverline Tools

Déclare que le produit :

Nom/modèle : Poste à souder à l'arc

Nº de série/Type : 677293

Puissance nette installée : 40 - 100A

Est conforme aux directives suivantes :

• Directive sur les basses tensions 2006/95/CE

• Compatibilité électromagnétique 2004/108/CE

• Directive RoHS 2002/95/CE

• EN60974-1:2005

• EN60974-6:2003

• EN60974-10:2007

• EN61000-3-11:2000, EN61000-3-12:2005

Poste à souder à l’arc 677293

Enregistrement de votre achat

Visitez silverlinetools.com, sélectionnez le bouton d’enregistrement

et saisissez :

• Vos informations personnelles

• Les informations concernant le produit et l’achat

Vous recevrez le Certificat de garantie en format PDF. Veuillez l’imprimer et

le conserver avec votre achat.

Silverline Tools.

La réparation ou le remplacement de votre produit sous garantie vous

apporte des avantages ; ces avantages s’ajoutent à vos droits statutaires

en tant que consommateur sans les affecter aucunement.

La présente garantie couvre:

La réparation du produit, s’il peut être vérifié, à la satisfaction de Silverline

Tools, que les défaillances du produit ont été provoquées par un vice de

matériau ou de fabrication au cours de la période de garantie.

Si une pièce n’est plus disponible ou n’est plus fabriquée, Silverline Tools la

remplacera par une pièce de rechange opérationnelle.

Utilisation de ce produit dans l’UE.

La présente garantie ne couvre pas:

Silverline Tools ne garantit pas les réparations nécessaires du produit

engendrées par :

L’usure normale provoquée par l’utilisation conforme aux instructions

d’utilisation, par exemple les lames, les charbons, les courroies, les

ampoules, les batteries, etc.

Le remplacement de tout accessoire fourni tel que les forêts, les lames, les

feuilles abrasives, les outils de coupes et les autres articles associés.

Les dommages et les défaillances accidentels causés par une utilisation ou

un entretien négligent, une mauvaise utilisation, un manque d’entretien ou

une utilisation ou une manipulation imprudente du produit.

L’utilisation du produit à des fins autres que son utilisation domestique

normale.

Le moindre changement ou la moindre modification du produit.

L’utilisation de pièces et d’accessoires qui ne sont pas des composants

véritables de Silverline Tools.

Une installation défectueuse (sauf si l’installation a été réalisée par

Silverline Tools).

Les réparations ou les modifications réalisées par des tiers autres que

Silverline Tools ou ses agents de réparation agréés.

Les demandes de service autres que le droit de rectifier les défaillances

de l’outil indiquées dans ces conditions de garantie ne sont pas couvertes

par cette garantie.

La documentation technique est conservée par : Silverline Tools

Organisme notifié : TUV Rheinland

Lieu de la déclaration : Shanghai, Chine

Date : 11/11/11

Signature :

Directeur général

Nom et adresse du fabricant ou de son représentant agréé :

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ Royaume-Uni

www.silverlinetools.com

www.silverlinetools.com

11

11

Page 13

D

Beschreibung der Symbole

Auf dem Leistungsschild des Werkzeugs sind möglicherweise Symbole abgebildet.

Sie vermitteln wichtige Informationen über das Produkt oder dienen als

Gebrauchsanweisung.

Gehörschutz tragen

Augenschutz tragen

Atemschutz tragen

Kopfschutz tragen

Schutzhandschuhe tragen

Handbuch sorgfältig lesen

Schutzklasse I (Schutzleiter)

Lebensgefahr durch Stromschlag!

Erfüllt die entsprechenden rechtlichen Vorschriften und

Sicherheitsnormen

Umweltschutz

Elektroaltgeräte dürfen nicht über den Haushaltsmüll entsorgt

werden. Nach Möglichkeit bitte über entsprechende Einrichtungen

entsorgen. Lassen Sie sich bezüglich der sachgemäßen Entsorgung

von Elektrowerkzeugen von der zuständigen Behörde oder dem

Händler beraten.

Technische Daten

Eingangsspannung: .................................... 230 V~

Frequenz: ................................................... 50 Hz

Nenneinschaltdauer: .................................. 10 %

Einschaltdauer:........................................... 28 A bei 60 %

Regelbereich: ............................................. 40-100 A

Leerlaufspannung: ..................................... 48 V

Isolierklasse: .............................................. H

Schweißdraht: ............................................ 1.6-2.5 mm

Max. Schweißnahtdicke: ............................5 mm

Netzabsicherung: ....................................... 13 A

Schutzart: ................................................... IP 21S

Clase de protección: ...................................

Gewicht: ..................................................... 13 kg

El nivel de intensidad sonora para el usuario puede exceder de 85

dB(A). Se recomiendan usar medidas de protección sonora.

Como parte de nuestra política de desarrollo de productos, los

datos técnicos de los productos Silverline pueden cambiar sin

Betreiben Sie das Gerät erst, wenn Sie diese Bedienungsanleitungen und alle

am Werkzeug angebrachten Etiketten sorgfältig gelesen und verstanden haben.

Bewahren Sie alle Anleitungen mit dem Gerät zum späteren Nachschlagen

auf. Vergewissern Sie sich, dass alle Benutzer dieses Produkts diese

Bedienungsanleitung vollständig verstanden haben.

Auch wenn dieses Gerät wie vorgeschrieben verwendet wird, ist es nicht möglich,

sämtliche Restrisiken auszuschließen. Mit Vorsicht verwenden. Sollten Sie sich in

irgendeiner Weise unsicher bezüglich der sachgemäßen und sicheren Benutzung

dieses Werkzeugs sein, verwenden Sie es nicht.

previo aviso.

Allgemeine Sicherheitshinweise

für Elektrowerkzeuge

WARNUNG! Lesen Sie alle Sicherheitshinweise und Anweisungen.

Versäumnisse bei der Einhaltung der Sicherheitshinweise und Anweisungen

können elektrischen Schlag, Brand und/oder schwere Verletzungen verursachen.

Bewahren Sie alle Sicherheitshinweise und Anweisungen für die Zukunft auf.

Der in den Sicherheitshinweisen verwendete Begriff „Elektrowerkzeug“ bezieht

sich auf netzbetriebene Elektrowerkzeuge (mit Netzkabel) und auf akkubetriebene

Elektrowerkze uge (ohne Netzkabel).

Arbeitsplatzsicherheit

a) Halten Sie Ihren Arbeitsbereich sauber und gut beleuchtet. Unordnung

oder unbeleuchtete Arbeitsbereiche können zu Unfällen führen.

b) Arbeiten Sie mit dem Elektrowerkzeug nicht in explosionsgefährdeter

Umgebung, in der sich brennbare Flüssigkeiten, Gase oder Stäube

befinden. Elektrowerkzeuge erzeugen Funken, die den Staub oder die

Dämpfe entzünden können.

c) Halten Sie Kinder und andere Personen während der Benutzung des

Elektrowerkzeugs fern. Bei Ablenkung können Sie die Kontrolle über das

Gerät verlieren.

Elektrische Sicherheit

a) Bitte entnehmen Sie sicherheitskritische Informationen zum

Stromanschluss dieses Gerätes dem Absatz „Anschluss an die

Stromversorgung“ unten. Nichtbefolgen dieser Anweisungen kann tödliche

Verletzungen zur Folge haben.

Der Anschlussstecker des Elektrowerkzeuges muss in die Steckdose

passen. Der Stecker darf in keiner Weise verändert werden.

Verwenden Sie keine Adapterstecker gemeinsam mit schutzgeerdeten

Elektrowerkzeugen. Unveränderte Stecker und passende Steckdosen

verringern das Risiko eines elektrischen Schlages.

b) Vermeiden Sie Körperkontakt mit geerdeten Oberflächen wie von

Rohren, Heizungen, Herden und Kühlschränken. Es besteht ein erhöhtes

Risiko durch elektrischen Schlag, wenn Ihr Körper geerdet ist.

c) Halten Sie Elektrowerkzeuge von Regen oder Nässe fern. Das Eindringen

von Wasser in ein Elektrowerkzeug erhöht das Risiko eines elektrischen

Schlages.

d) Zweckentfremden Sie das Kabel nicht, um das Elektrowerkzeug zu

tragen, aufzuhängen oder um den Stecker aus der Steckdose zu ziehen.

Halten Sie das Kabel fern von Hitze, Öl, scharfen Kanten oder sich

bewegenden Geräteteilen. Beschädigte oder verwickelte Kabel erhöhen

das Risiko eines elektrischen Schlages.

Sicherheit von Personen

a) Seien Sie aufmerksam, achten Sie darauf, was Sie tun, und gehen Sie

mit Vernunft an die Arbeit mit einem Elektrowerkzeug. Benutzen Sie

kein Elektrowerkzeug, wenn Sie müde sind oder unter dem Einfluss

von Drogen, Alkohol oder Medikamenten stehen. Ein Moment der

Unachtsamkeit beim Gebrauch des Elektrowerkzeuges kann zu ernsthaften

Verletzungen führen.

b) Tragen Sie persönliche Schutzausrüstung und immer eine Schutzbrille.

Das Tragen persönlicher Schutzausrüstung, wie Staubmaske, rutschfeste

Sicherheitsschuhe, Schutzhelm oder Gehörschutz, je nach Art und Einsatz

des Elektrowerkzeuges, verringert das Risiko von Verletzungen.

c) Vermeiden Sie eine unbeabsichtigte Inbetriebnahme. Vergewissern

Sie sich, dass das Elektrowerkzeug ausgeschaltet ist, bevor Sie es an

die Stromversorgung und/oder den Akku anschließen, es aufnehmen

oder tragen. Wenn Sie beim Tragen des Elektrowerkzeuges den Finger

am Schalter haben oder das Gerät eingeschaltet an die Stromversorgung

anschließen, kann dies zu Unfällen führen.

d) Entfernen Sie Einstellwerkzeuge oder Schraubenschlüssel, bevor Sie

das Elektrowerkzeug einschalten. Ein Werkzeug oder Schlüssel, der sich

in einem drehenden Geräteteil befindet, kann zu Verletzungen führen.

e) Vermeiden Sie eine unnatürliche Körperhaltung. Sorgen Sie für einen

sicheren Stand und halten Sie jederzeit das Gleichgewicht. Auf diese

Weise lässt sich das Elektrowerkzeug in unerwarteten Situationen besser

kontrollieren.

f) Tragen Sie geeignete Kleidung. Tragen Sie keine weite Kleidung oder

Schmuck. Halten Sie Haare, Kleidung und Handschuhe fern von sich

bewegenden Teilen. Lockere Kleidung, Schmuck oder lange Haare können

von sich bewegenden Teilen erfasst werden.

12D12

Page 14

Lichtbogenschweißgerät677293

g) Wenn Staubabsaug- und -auffangeinrichtungen montiert werden

können, vergewissern Sie sich, dass diese angeschlossen sind und

richtig verwendet werden. Verwendung einer Staubabsaugung kann

Gefährdungen durch Staub verringern.

Verwendung und Behandlung des Elektrowerkzeuges

a) Überlasten Sie das Gerät nicht. Verwenden Sie für Ihre Arbeit das dafür

bestimmte Elektrowerkzeug. Mit dem passenden Elektrowerkzeug arbeiten

Sie besser und sicherer im angegebenen Leistungsbereich.

b) Benutzen Sie kein Elektrowerkzeug, dessen Schalter defekt ist. Ein

Elektrowerkzeug, das sich nicht mehr ein- oder ausschalten lässt, ist

gefährlich und muss repariert werden.

c) Ziehen Sie den Stecker aus der Steckdose und/oder entfernen Sie den

Akku, bevor Sie Geräteeinstellungen vornehmen, Zubehörteile wechseln

oder das Gerät weglegen. Diese Vorsichtsmaßnahme verhindert den

unbeabsichtigten Start des Elektrowerkzeuges.

d) Bewahren Sie unbenutzte Elektrowerkzeuge außerhalb der Reichweite

von Kindern auf. Lassen Sie Personen das Gerät nicht benutzen, die

mit diesem nicht vertraut sind oder diese Anweisungen nicht gelesen

haben. Elektrowerkzeuge sind gefährlich, wenn sie von unerfahrenen

Personen benutzt werden.

e) Pflegen Sie Elektrowerkzeuge mit Sorgfalt. Kontrollieren Sie, ob

bewegliche Teile einwandfrei funktionieren und nicht klemmen,

ob Teile gebrochen oder so beschädigt sind, dass die Funktion des

Elektrowerkzeuges beeinträchtigt ist. Lassen Sie beschädigte Teile vor

dem Einsatz des Gerätes reparieren. Viele Unfälle haben ihre Ursache in

schlecht gewarteten Elektrowerkzeugen.

f) Halten Sie Schneidwerkzeuge scharf und sauber. Sorgfältig gepflegte

Schneidwerkzeuge mit scharfen Schneidkanten verklemmen sich weniger

und sind leichter zu führen.

g) Verwenden Sie Elektrowerkzeug, Zubehör, Einsatzwerkzeuge usw.

entsprechend diesen Anweisungen. Berücksichtigen Sie dabei die

Arbeitsbedingungen und die auszuführende Tätigkeit. Der Gebrauch von

Elektrowerkzeugen für andere als die vorgesehenen Anwendungen kann zu

gefährlichen Situationen führen.

Service

a) Lassen Sie Ihr Elektrowerkzeug nur von qualifiziertem Fachpersonal

und nur mit Original-Ersatzteilen reparieren. Damit wird sichergestellt,

dass die Sicherheit des Elektrowerkzeuges erhalten bleibt.

Sicherheitshinweise für

Schweißarbeiten

• Schweißen verursacht toxische Dämpfe und kann den Sauerstoffgehalt im

Arbeitsbereich reduzieren. Arbeiten Sie immer in einem gut belüfteten Bereich.

Vermeiden Sie das Einatmen von Schweißdämpfen und verwenden Sie

gegebenenfalls ein Atemschutzgerät.

• Einige Metallteile sind verzinkt oder mit Blei, Kadmium oder anderen

Materialien beschichtet. Beim Schweißen durch diese Beschichtungen können

extrem toxische Dämpfe entstehen. Vor dem Schweißen daher zunächst alle

Beschichtungen entfernen.

• Bei Lungen-, Hals oder Augenreizung während des Schweißens die

Schweißarbeiten sofort einstellen und an die frische Luft gehen.

• Schweißen erzeugt extrem starkes UV-Licht. Tragen Sie zur Vermeidung von

Augenschäden immer eine zugelassene Schweißmaske. Schauen Sie unter

keinen Umständen direkt in den Lichtbogen.

• Wenn sich andere Personen möglicherweise dem Arbeitsbereich nähern

könnten, stellen Sie entsprechende Schutzwände auf, damit sie vor Licht/

Blendung geschützt werden.

• Tragen Sie zur Vermeidung von Hautschäden immer eine geeignete feuerfeste,

langärmelige Jacke sowie hitzebeständige Schutzhandschuhe und Mütze. Den

Körper stets gut bedeckt halten.

• Entfernen Sie entzündliche Materialien (z.B. Feuerzeuge, Streichhölzer) immer

vor dem Schweißen aus der Kleidung.

• Halten Sie während des Schweißens immer einen Feuerlöscher griffbereit.

Funken und versehentlicher Kontakt können Brände auslösen.

• Schweißen Sie nur dann, wenn alle Werkstücke und der Arbeitsbereich trocken

sind.

• Keine verschlossenen Behälter (z.B. Kraftstofftanks, Lufttanks, Ölfässer)

schweißen. Die durch die Schweißarbeit erzeugte Hitze kann dazu führen, dass

verschlossene Behälter ohne Vorwarnung bersten.

• Achten Sie auf übertragene Wärme. Metallteile können die Wärme vom

Arbeitsbereich ableiten und brennbare Materialien entzünden.

• Bedenken Sie stets, dass geschweißte Teile nach der Bearbeitung noch

einige Zeit heiß bleiben. Die Teile vor der Handhabung, oder bevor diese

unbeaufsichtigt gelassen werden, völlig abkühlen lassen.

• Niemals in Gegenwart entzündlicher Gase, Flüssigkeiten oder Staub schweißen.

• Stellen Sie immer sicher, dass eine verantwortungsbewusste Person in der

Nähe ist, die vor Feuer warnen und im Notfall Hilfe rufen kann.

• Die Verwendung von Schweißgeräten erzeugt sehr starke magnetische

Felder. Diese könnten den Betrieb empfindlicher Elektronikeinrichtungen

beeinträchtigen. Träger von Herzschrittmachern sollten sich vor Gebrauch eines

Schweißgeräts von einem Arzt beraten lassen.

• Die Stromzufuhr nicht überlasten. Vergewissern Sie sich, dass Ihre

Netzstromversorgung die erforderliche Stromleistung sicher bereitstellen kann.

Geräteübersicht

1 Stromregler

2 Tragegriff

3 Netzschalter

4 Elektrodenhalter

5 Masseklemme

Zubehör

Schweißschild (mit Griff und Scheibe)

Schlackenhammer mit Drahtbürste

Auspacken des Gerätes

• Packen Sie Ihr Werkzeug vorsichtig aus und überprüfen Sie es. Machen Sie sich

vollständig mit all seinen Eigenschaften und Funktionen vertraut.

• Vergewissern Sie sich, dass sämtliche Teile des Werkzeugs vorhanden und in

einwandfreiem Zustand sind. Sollten Teile fehlen oder beschädigt sein, lassen

Sie diese ersetzen, bevor Sie das Werkzeug verwenden.

Montage

Schweißschild zusammensetzen

1. Schieben Sie den Griff vorsichtig in die Montageschlitze im Schweißschild

und vergewissern Sie sich, dass beide Stifte eingerastet sind.

2. Nehmen Sie die Scheibe aus der Verpackung und setzen Sie die Scheibe

in das Fenster ein. Gehen Sie dabei vorsichtig vor, damit die Scheibe nicht

zerkratzt wird und überprüfen Sie, dass die Scheibe fest sitzt und sich nicht

verschieben lässt. Die Scheibe muss das ganze Fenster abdecken.

Anschluss an die Stromversorgung

• Schließen Sie dieses Schweißgerät ausschließlich an ein Stromnetz an, das die

erforderliche Spannung bereitstellen kann.

• Prüfen Sie beim Anschluss an einen Generator zunächst die technischen Daten

des Generators.

Vor Inbetriebnahme

• Tragen Sie stets für die auszuführende Aufgabe geeignete persönliche

Schutzausrüstung. Für den Betrieb dieses Gerätes sind Schweißmaske,

Schutzhandschuhe, Hitzeschutzkleidung und gegebenenfalls eine

Atemschutzmaske erforderlichHalten Sie während des Schweißens immer

einen geeigneten Feuerlöscher griffbereit.

• Überprüfen Sie Ihr Gerät stets auf Schäden und Verschleiß. Richten Sie dabei

besondere Aufmerksamkeit auf Leitungen und Kabel. Sollten Sie Mängel

feststellen, verwenden Sie das Gerät nicht!

• Vergewissern Sie sich, dass sämtliche Gehäuseteile und Abdeckungen

ordnungsgemäß geschlossen und verriegelt sind.

• Stellen Sie das Schweißgerät so auf, dass es während des Betriebs nicht

verrutschen oder umfallen kann. Sorgen Sie dafür, dass der Raum um das

Schweißgerät mit einem Abstand von mindestens 50 cm freigehalten wird, um

angemessene Belüftung zu gewährleisten.

www.silverlinetools.com

www.silverlinetools.com

13

13

Page 15

D

Bedienungsanleitung

Warnhinweis: Trennen Sie das Schweißgerät stets vom Stromnetz und

lassen Sie es vollständig abkühlen, bevor Sie Teile anbringen oder ersetzen.

Gerät einstellen

• Um ein hochwertiges Schweißergebnis zu erzielen, muss der Stromregler (1)

richtig eingestellt sein.

• Drehen Sie den Stromregler im Uhrzeigersinn, um den Schweißstrom zu

erhöhen. Wenn Sie den Stromregler entgegen dem Uhrzeigersinn drehen, wird

der Schweißstrom verringert.

Elektrodenwahl

• Um ein hochwertiges Schweißergebnis zu erzielen, muss die richtige

Elektrodenart verwendet werden. Schweißelektroden sind in verschiedensten

Stärken und aus unterschiedlichen Materialien und Umhüllungen erhältlich.

• Für die Wahl der benötigten Elektrode verweisen wir auf die obige

Spezifizierungstabelle sowie die Angaben des Elektrodenherstellers.

Einschaltdauer

• Dieses Gerät ist nicht zum Dauerschweißen vorgesehen. Ein zu langer

Schweißbetrieb würde Überhitzung verursachen und Bauteile im Geräteinneren

beschädigen.

• Die Einschaltdauer (siehe technische Daten) legt in zehnminütigen Abständen

fest, wie viele Minuten lang mit dem Gerät geschweißt werden kann.

• Bei einer Einschaltdauer von 30 % darf das Gerät 3 Minuten lang zum

Schweißen eingesetzt werden und muss anschließend 7 Minuten lang

abkühlen.

• Bei einer Überschreitung der Einschaltdauer schaltet sich das Gerät selbsttätig

ab.

• Um eine maximale Einschaltdauer zu erzielen, sollte das Gerät mit geringeren

Stromeinstellungen bei guter Belüftung eingesetzt werden.

Thermoüberlastschutz

• Dieses Gerät verfügt über einen Thermoüberlastschutz. Bei einer Überlastung

oder einem zu langen Gebrauch des Geräts über die Einschaltdauer hinaus

schaltet es sich selbsttätig ab.

• Warten Sie, bis sich das Gerät abgekühlt hat. Der Überlastschutz wird

automatisch zurückgesetzt, sobald das Gerät wieder einsatzbereit ist.

Vorbereitung auf das Schweißen

• Sorgen Sie dafür, dass die zu schweißenden Teile sauber und frei von Rost, Lack

und anderen Oberflächenbeschichtungen sind.

• Alle Teile müssen fest abgestützt sein und es sollte eine etwa 1 mm breite

Lücke an der Stelle verlaufen, an der die Schweißnaht entstehen soll.

• Vergewissern Sie sich, dass sich keine brennbaren Materialien in der Nähe des

Arbeitsbereichs befinden.

• Befestigen Sie die Masseklemme (5) an einem gereinigten Bereich an einem

der zu schweißenden Teile, und zwar so nah wie möglich an der Stelle, wo die

Schweißnaht entstehen soll.

• Drücken Sie zum Öffnen der Backen den Elektrodenhalter (4). Setzen Sie eine

Elektrode zwischen die Backen und geben Sie den Griff frei. Die Elektrode sollte

nun fest eingespannt sein, wobei die Klammer nicht den beschichteten, sondern

nur den unbeschichteten Metallteil berühren darf.

• Stellen Sie sicher, dass sich eine verantwortungsvolle Person und ein

funktionstüchtiger Feuerlöscher in der Nähe befinden.

• Schließen Sie das Gerät ans Stromnetz an.

Schweißen

WARNHINWEIS: Die korrekte Benutzung eines Schweißgerätes ist eine technische

Fertigkeit. Ein falsch verwendetes Schweißgerät kann äußerst gefährlich sein. Die

nachfolgenden Informationen sind lediglich als allgemeine Hinweise zu verstehen.

Wenn Sie sich in irgendeiner Weise unsicher bezüglich der sicheren Verwendung

dieses Geräts sein sollten, benutzen Sie es nicht!

• Stellen Sie den Netzschalter (3) auf „ON“ („Ein“).

• Halten Sie den Elektrodenhalter (4) in einer Hand und den Schweißschild in

der anderen.

• Bringen Sie die Elektrode in einen Winkel von etwa 80˚ zur Oberfläche. Die

Spitze muss dabei ca. 3 cm vom Metall entfernt sein.

• Halten Sie den Schweißschild vor Ihr Gesicht und klopfen Sie die Elektrode

gegen das Metall.

• Ein Lichtbogen sollte zwischen dem Metall und der Spitze zünden. Versuchen

Sie, die Elektrodenspitze in einer Entfernung vom Metall zu halten, die der

Elektrodenstärke entspricht. Erhalten Sie den Lichtbogen etwa 1–2 Sekunden

aufrecht und führen Sie die Elektrode dann weg.

• Lassen Sie die Schweißstelle etwas abkühlen und entfernen Sie den

Schweißschild vor Ihrem Gesicht. Wenn die Einstellungen richtig waren, sollte

sich nun ein runder, geschweißter Punkt gebildet haben.

• Wenn die Schweißstelle das Metall nicht vollständig durchdrungen hat, müssen

Sie die Stromzufuhr mit dem Stromregler erhöhen. Wenn ein Loch im Metall

entstanden ist, muss die Stromzufuhr verringert werden.

• Machen Sie probeweise einige Schweißpunkte, bis Sie im Umgang mit dem

Gerät und mit der Wahl der Einstellungen sicher sind.

• Erhalten Sie den Lichtbogen länger aufrecht und führen Sie die Elektrode

gleichzeitig langsam vorwärts, um eine Schweißnaht zu schweißen. Die

Geschwindigkeit, mit der die Elektrode bewegt wird, ist für ein gutes Ergebnis

ausschlaggebend.

• Wenn das Gerät richtig eingestellt ist, sollte der Lichtbogen beständig sein

und ein knisterndes Geräusch erzeugen. Berücksichtigen Sie, dass Sie den

Elektrodenhalter mit zunehmender Elektrodenabnutzung stetig näher an das

Metall führen müssen.

• Entfernen Sie, wenn die Anwendung beendet ist, Überschuss und Spritzer mit

dem Schlackenhammer und der Drahtbürste. Schweißen Sie nur auf bereits

bestehenden Schweißpunkten, wenn diese gründlich gereinigt sind.

• Saubere, hochwertige Schweißergebnisse zu erzielen ist eine Fertigkeit, die

über längere Zeit erlernt werden muss. Übung und gute Vorbereitung führen

schließlich zu zufriedenstellenden Schweißergebnissen.

Störungsbehebung

Falls Störungen beim Betrieb des Schweißgerätes auftreten sollten, überprüfen

Sie bitte Folgendes:

• Dass der Schweißstrom für den benutzen Elektrodendurchmesser und die

verwendete Elektrodenart geeignet ist.

• Dass die Netzanschlussanzeige am Netzschalter beim Anschluss an die

Stromversorgung leuchtet. Wenn die Netzanschlussanzeige nicht leuchtet,

deutet dies auf ein Problem mit der Stromversorgung hin (z.B. könnte ein

Schutzschalter durchgebrannt sein).

• Dass die gemäß dem Leistungsschild richtige Spannung verwendet wird.

• Dass die Einschaltdauer nicht überschritten wurde und dass der

Thermoüberlastschutz betriebsfähig ist.

• Dass die Kabel nicht beschädigt sind und dass kein Kurzschluss ausgelöst

werden kann.

• Dass alle Stromkreisverbindungen funktionstüchtig sind. Achten Sie

insbesondere auf die Arbeitsklemme, die richtig am Werkstück angebracht

sein muss, sowie darauf, dass kein Fett, Farbe oder andere Verschmutzungen

vorhanden sind, die eine nicht leitende Verbindung verursachen könnten.

Wartung

WARNHINWEIS: Trennen Sie das Gerät stets vom Stromnetz, bevor Sie Wartungsoder Reinigungsarbeiten durchführen.

Reinigung

• Halten Sie Ihr Gerät stets sauber. Entfernen Sie regelmäßig Schmutz und Staub

und achten Sie darauf, dass die Lüftungsöffnungen nicht verstopfen. Reinigen

Sie das Gerätegehäuse mit einer weichen Bürste oder einem trockenen Tuch.

Die Lüftungsöffnungen mit sauberer, trockener Druckluft reinigen, sofern

verfügbar.

Entsorgung

• Elektrowerkzeuge oder andere elektrische und elektronische Altgeräte nicht

über den Hausmüll entsorgen.

• Lassen Sie sich von der zuständigen Behörde bezüglich der ordnungsgemäßen

Entsorgung von Elektrowerkzeugen beraten.

14D14

Page 16

Silverline-Tools-Garantie

Dieses Silverline-Produkt wird mit einer 3-JahresGarantie angeboten

Registrieren Sie dieses Produkt unter silverlinetools.com innerhalb von

30 Tagen nach dem Kauf, um die 3-Jahres-Garantie zu aktivieren. Der

Garantiezeitraum beginnt mit dem Kaufdatum auf Ihrem Kaufbeleg.

Garantiebedingungen

Der Garantiezeitraum beginnt mit dem Kaufdatum im Einzelhandel, das auf

dem Kaufbeleg angegeben ist.

BITTE BEWAHREN SIE IHREN KAUFBELEG AUF

Falls dieses Produkt innerhalb von 30 Tagen nach dem Kauf einen

Defekt aufweisen sollte, bringen Sie es bitte mit Ihrem Kaufbeleg zu dem

Fachhändler, bei dem es gekauft wurde, und informieren Sie ihn über die

Mängel. Das Gerät wird ersetzt oder der Kaufpreis zurückerstattet.

Falls dieses Produkt nach Ablauf von 30 Tagen nach dem Kauf einen Mangel

aufweist, senden Sie es an:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Großbritannien

Der Garantieanspruch muss während der Garantiezeit gestellt werden.

Sie müssen den Originalkaufbeleg mit Angabe des Kaufdatums einreichen

und Ihren Namen und Ihre Adresse sowie den Ort des Kaufs angeben, bevor

etwaige Arbeiten durchgeführt werden können.

Sie müssen genaue Angaben über den zu behebenden Defekt machen.

Alle innerhalb der Garantiefrist gemachten Forderungen werden von

Silverline Tools daraufhin überprüft werden, ob es sich bei den Mängeln um

einen Material- oder Fertigungsfehler handelt.

Versandkosten werden nicht zurückerstattet. Alle Produkte müssen sich

in sauberem und sicherem Zustand befinden und sorgfältig verpackt zur

Reparatur eingeschickt werden, um Schäden oder Verletzungen während

des Transports zu vermeiden. Die Annahme ungeeigneter oder unsicherer

Lieferungen kann von uns verweigert werden.

Alle Arbeiten werden von Silverline Tools oder seinen autorisierten

Reparaturwerkstätten durchgeführt.

Die Reparatur oder der Ersatz des Produkts führt nicht zur Verlängerung des

Garantiezeitraums.

Mängel, bei denen unsere Prüfung ergibt, dass sie unter die Garantie fallen,

werden durch kostenlose Reparatur des Werkzeugs (ohne Versandkosten)

oder Ersatz durch ein Werkzeug in einwandfreiem Zustand behoben.

Lichtbogenschweißgerät677293

Registrierung Ihres Kaufs

Gehen Sie auf silverlinetools.com, klicken Sie auf ‚Registrierung’ und

geben Sie Folgendes ein:

• Ihre persönlichen Angaben

• Produktdetails und Kaufinformationen

Sobald dieses Produkt registriert worden ist, wird Ihre