Siemens TLE5250 Datasheet

2.5-A High Performance Smart Power

Stepper-Motor Driver with Diagnostic Interface

Overview

Features

• Single phase driver for stepper motor 2.5 A

• Low ON-resistance (typical 0.3 Ω)

• Wide supply range 6 V to 45 V

• Wide current range 10 mA to 3 A

• Fast nominal/actual comparator for micro

stepper mode

• Wide temperature range

• Short circuit protection

• Under voltage shutdown

• Overtemperature shutdown

• Serial diagnostic interface

• Fast freewheeling diodes

• TTL-compatible inputs

TLE 5250

SPT-IC

P-SIP-15-1

Type Ordering Code Package

TLE 5250 Q67000-A9103 P-SIP-15-1

Description

TLE 5250 is a monolithic IC in Smart Power technology for controlling and regulating the

motor current in one phase of a bipolar step ping motor. The re are other appli cations in

driving DC motors and inductive loads that are operated on constant current.

The device has TTL-compatible logic inputs, include s a H-bridge with integrated, fa st

free-wheeling diodes plus dynamic limiting of the motor current by a chopper mode. The

nominal current can be set continuously by a cont rol voltage. Microstep mode can be

produced by applyin g a sinusoidal c ontrol voltage. T wo TLE 5250s, wi th a minimum of

external circuitry and a single supply voltage, form a complete system - that can be

driven direct by an MC- for two-phase, bipolar stepping motors with output current of up

to 2.5 A per phase. The outputs of the IC are internally protected against shorted to

ground, supply voltage and shorted load. The output stages are also disabled by

undervoltage and overtemperature. All fault functions can be detected by the internal

diagnostics, which can be read out serially.

Semiconductor Group 1 1998-02-01

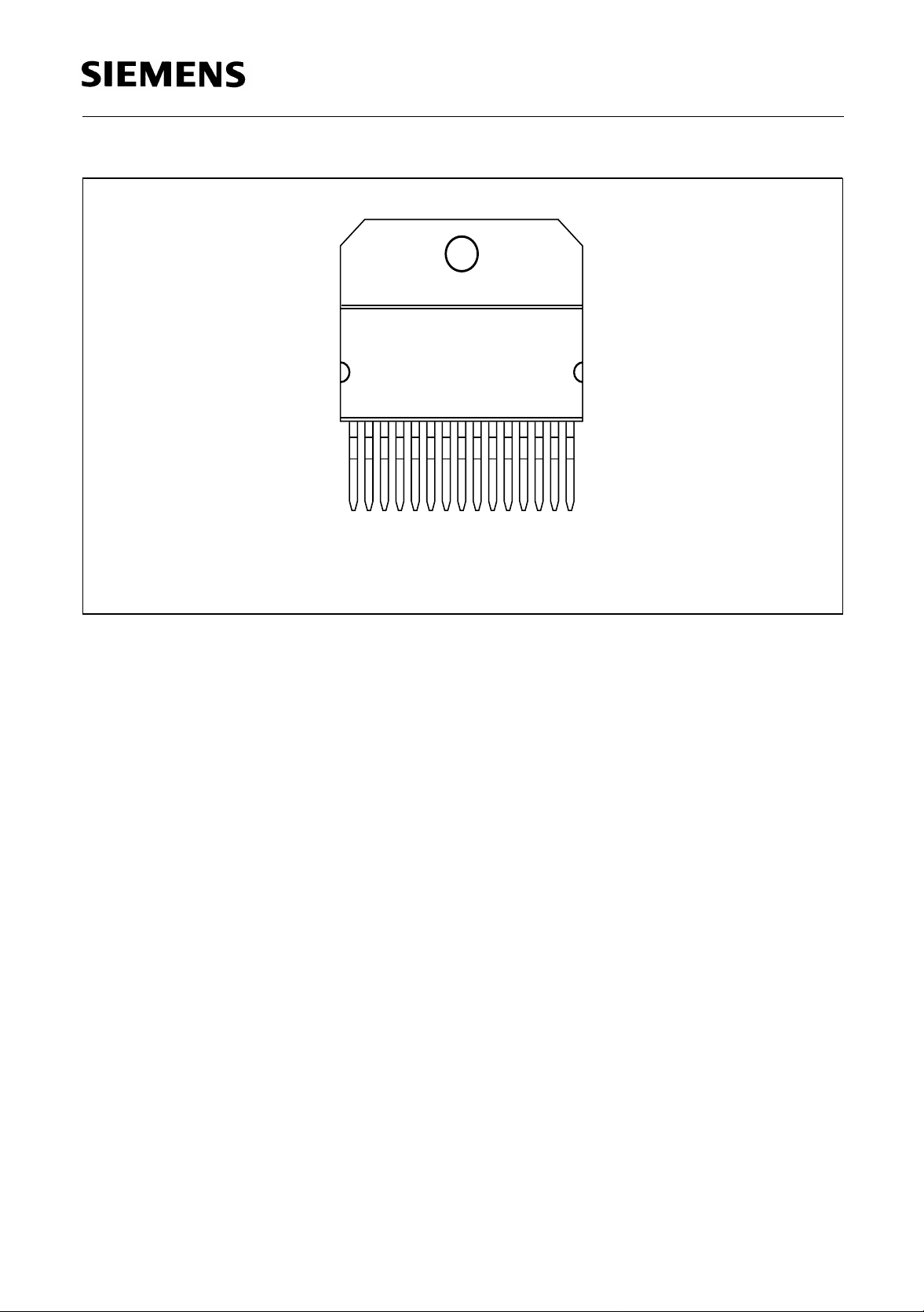

PH

DIAG

EN

TLE 5250

151

S

V

Q1

Q1

GND

Sense

Sense

Q2

S

V

Q2

AEP01471

RS

ACT

NOM

Figure 1 Pin Configuration (top view)

Semiconductor Group 2 1998-02-01

TLE 5250

Pin Definitions and Functions

Pin No. Symbol Function

1 DIAG Open-drain diagnostics output

2 PH Input for determining source/sink on outputs Q1 and Q2; when

Enable = Low, this pin serves as clock input for reading out

diagnostics

3 EN Input for activating or turning off device (all output transistors

turned off); Enable High = output active, Enable

Low = diagnostics

4, 12

V

S

Supply voltage of IC

5, 6 Q1 Power output with integrated free-wheeling diodes

7, 9 Sense Actual-current output: shared, open-source output of sink

transistors

8 GND Ground

10, 11 Q2 Power output with integrated free-wheeling diodes

13 RS Determines turning back on of sink transistor by internally

driven, external RC element or external TTL trigger signal

14 NOM Input for reference potential (nominal current) for nominal/

actual comparator

15 ACT Input for actual current for nominal/actual comparator

Semiconductor Group 3 1998-02-01

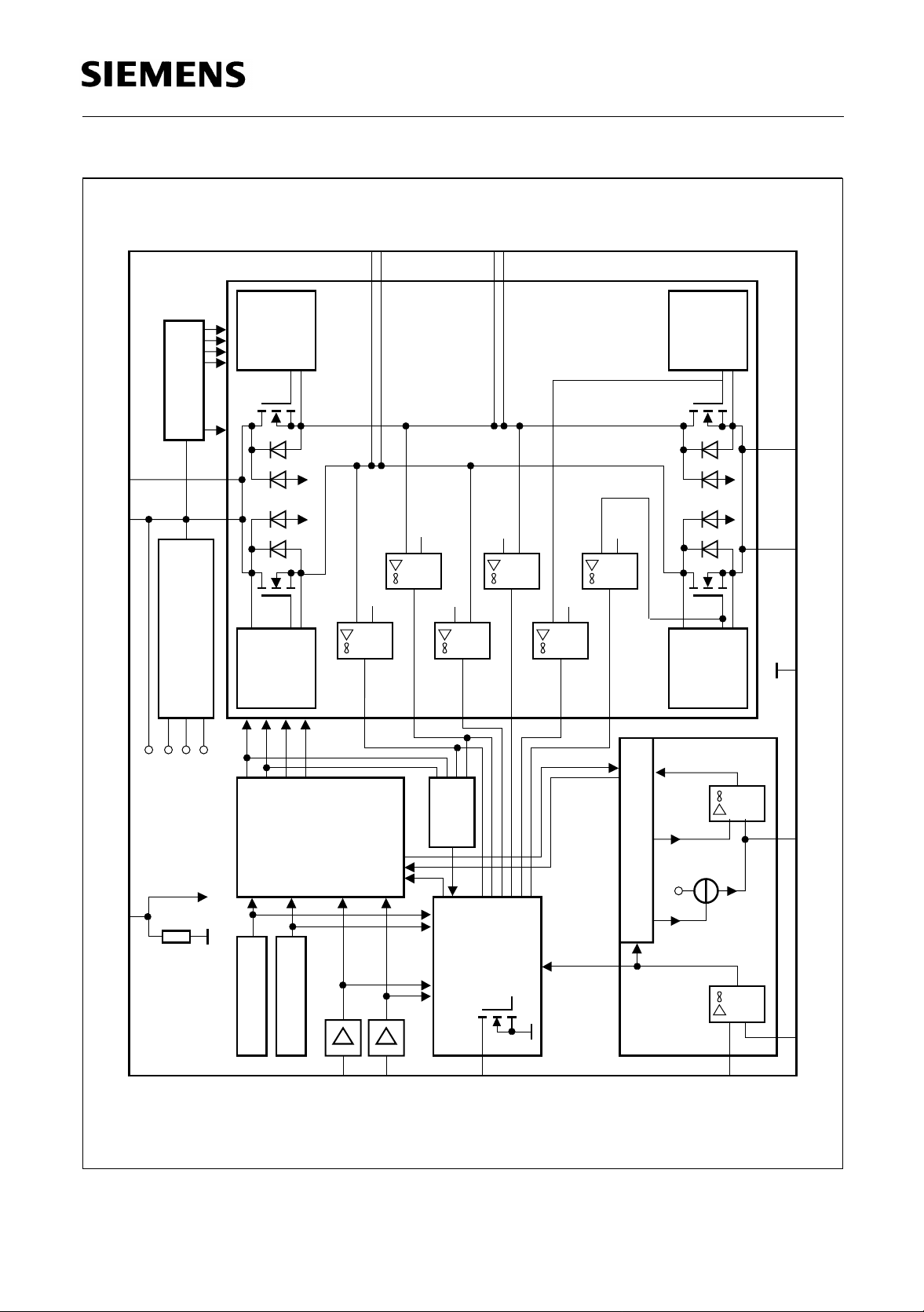

TLE 5250

Charge Pump

S

412

S

VV

Bandgap/Bias

-6 V

S

V

Driver 2

T2T1

Driver 1

Q1

5

6

-1.5 V

S

V

+

-

Q1 High

H-Bridge

-1.5 V

S

V

-

+

Q2 High

Q2

10

Output Stage

3 V

+

3 V

-

+

Q2 Low

Q1 Low

11

-

5 V

-

+

G on T4

5 V

-

+

G on T5

Driver 4

T4

T3

Driver 3

AEB01468

9

Sense

7

Sense

GND

T1

T2

T3

T4

CC1

CC2

S

V

Bias

V

V

16

Cooling Pin

Undervoltage

Overtemperature

Figure 2 Block Diagram

Logic

Functional

3

Enable

2

Phase

Overload

Diagnostics

Logic

1

Diagn

Chop Logic

ref

V

Charge

Off/Ι

Nom/Act

PWM Logic

1 mA

Comp

14

-

+

+

-

Nominal

13 8

15

Actual RC/Sync

Semiconductor Group 4 1998-02-01

TLE 5250

Application

Two TLE 5250 drivers are required to operate a bipolar stepping motor. To implement

full-step operation, a squarewave voltage with the required stepping frequency is applied

to the phase in put of the upper drive r, and the s ame squarewave voltage, bu t offset in

phase by 90°el, to the phase input of the lower driver. Motor-current limiting is produced

by a DC signal that is applied to both nominal-current inputs. In microstep operation the

nominal current tracks sinusoidally and synchronously with the required stepping

frequency. This produces a sinusoidal current in the motor windings to ensure very

smooth running and a high stepping frequency. If an instantaneous nominal value (sine

or cosine) is held on the second driver, it is possible to set a certain angle of rotation while

the motor is stationary. The motor current produced by this depends on nominal voltage

and sense resistance (normally 0.5 Ω), i.e.

V

M

V[]

=

---------------------- -

I

nom

R

S

V[]

Ω[]

The actual voltage should be thoroughly filtered for precise current regulation, especially

in microstep operation. So the actual input is accessible, and an RC element is

R

necessary between the Sense output and Actual input. The resistance

should

R

correspond to the internal resistance of the nominal-current input-voltage source to

prevent additional voltage offset on the nominal/actual comparator.

Circuit Description

Outputs

Outputs Q1 and Q2 are fed by push-pul l output stages. Four integrated free-wheeli ng

diodes referred to ground or the supply voltage protect the integrated circuit against

reverse voltages from an inductive load.

Enable and Phase

V

Outputs Q1 and Q2 ca n be dis abled by a voltage

V

sink transistors are enabled by

Inh

≥ 2V.

of ≤ 0.8 V on the Enable pin. The

Inh

The voltage on the Phase input d etermines the phase of the ou tput current. Ou tput Q1

V

acts as a sink for

For output Q2 this is reversed: sink for

≤ 0.8 V and as a source for VPh≥ 2V.

Ph

V

≥ 2 V and source for VPh≤ 0.8 V.

Ph

The sink transistors are chopped. Low signal on the Enable pin plus a clock signal on the

Phase pin enable readout of the multiplexer.

Semiconductor Group 5 1998-02-01

TLE 5250

Nominal-Current Input

The peak current in the motor windi ng is defined by the voltage on the Nomin al input.

This is compared by a fast comparator to the voltage drop on the actual-current sensor.

If the nominal current is exceeded, the sin k transistors of the output s are turned off by

the logic.

RC/Sync Input

The outputs are turned on by the signal applied to the RC input. Synchronization is

possible by TTL signal or chopper mode with an external RC combination.

Chopper Mode

After the supply voltage is applied, capacitor CT is charged with constant current of

1 mA. A regulator limits the maximum voltage on the capacitor to 2.3 V. As a result of the

rising current in the motor winding, the voltage on the actual sensor increases. Once the

value defined by the nominal-current input is exceeded, the fast c omparator resets an

RS flipflop. Thus sink transistors T3 and T4 are turned off by the logic. The charge

current is turned off and the parallel RT discharges CT.

The internal logic is designed so that capacitor CT is always charged before the

discharge operation is triggered. This guarantees a constant charge time, even for very

small coil currents (see Figure 7).

Sync Operation

If a sync signal with TTL le vel is app lied to the RC inp ut, the nega tive edge will set the

RS flipflop - by way of the combined Schmitt trigger and monoflop - if the voltage on the

current sensor is smaller than the nominal value on the nominal-current input. As in

chopper mode, the appropriate output transistors conduct. They are again turned off by

resetting the RS flipflop when the voltage on th e current sensor becomes gre ater than

the nominal value (see Figure 8).

Output-Stage Control

This part of the circuit handles turn-off of the output stages when the output is shorted to

ground. There is sep arate current mon itoring for this purpos e in the s ource trans istors.

The temperature of the output stages is also monitored. If this exceeds 175 °C, all output

stages are turned off, and then turned on again when the temperature drops.

Undervoltage also causes turn-off of the transistors in the output stages. These possible

fault states are stored in the diagnostics register.

Semiconductor Group 6 1998-02-01

TLE 5250

Diagnostics

The information from the dif ferent parts of the circuit is colle cted in the di agnostics a nd

stored in the fault logic. The information is read out on the Diagnostics output (open

collector).

The fault logic consists of a 16-bit multiplexer that switches information in three

categories through to the Diagnostics output.

Bit 0 always appears inv erted on DIAG when EN is High. This means that, if there is

overcurrent on the upper transistor, undervoltage or overtemperature, it will be signaled

immediately on the Diagnostics output. DIAG changes from High to Low.

Bit 1: check bit.

Bits 2, 3, 4 and 5 ind icate th e mome ntary sta tus of t he comp arator s on the two outpu ts

(see Figure 2). Cha nges in the statu s of the comparator s for output monitoring can be

observed on DIAG when EN is Low and the counter of the multiplexer is on 2, 3, 4 or 5.

This is necessary for detecting underload.

Bits 6, 7, 8, 9

The monoflop generates a s hort s trobe sign al w hen the EN edge changes from High to

Low. The status of the comparators for outp ut monitoring is stored with this si gnal and

can be read out in bits 6, 7, 8 and 9.

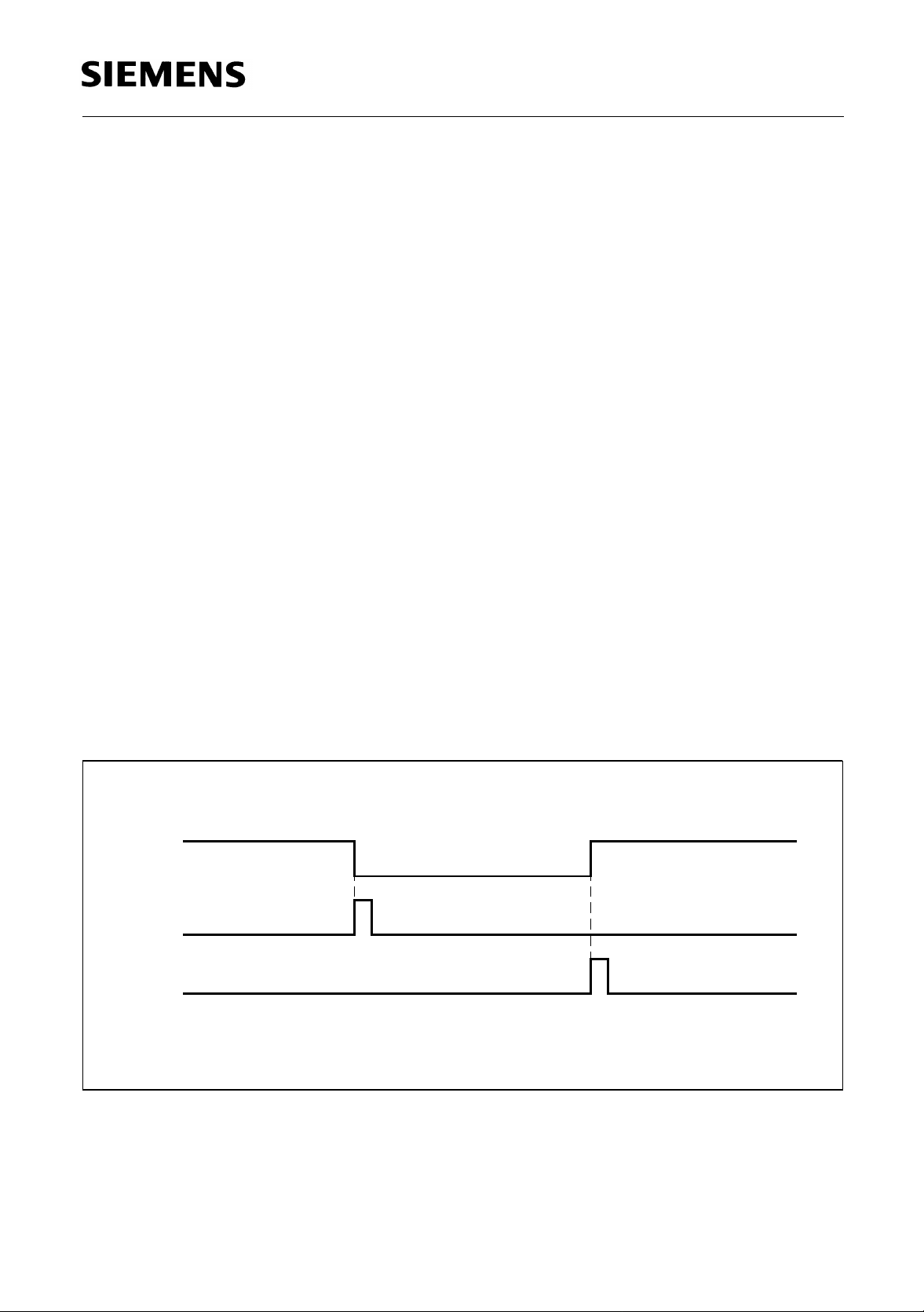

When Enable is Low, the Phase input is used as a cl ock input. As the edge rises, an

internal counter is incremented and the corresponding channel of the multiplexer is

switched through. As the edge f alls , the sign al is outp ut in verte d. Whe n Enab le is Hi gh,

the counter is reset to zero.

EN

Strobe

Reset

AED01467

Figure 3

Semiconductor Group 7 1998-02-01

Loading...

Loading...