Siemens SINUMERIK 840D sl Ctrl-Energy, SINUMERIK 828D Ctrl-Energy System Manual

SINUMERIK

SINUMERIK 840D sl / 828D

Ctrl-Energy

Valid for

Control system

SINUMERIK 840D sl / 840DE sl / 828D

Software Version

CNC Software 4.7 SP1

Preface

Fundamental safety

instructions

1

System Manual

Introduction

Ctrl-E Analysis

Ctrl-E Profiles

Reactive power

compensation

Flux reduction

User know-how

Appendix

2

3

4

5

6

7

A

01/2015

6FC5397-0EP40-5BA2

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: 6FC5397-0EP40-5BA2

Ⓟ 07/2015 Subject to change

Copyright © Siemens AG 2011 - 2015.

All rights reserved

Preface

SINUMERIK documentation

SINUMERIK documentation

The SINUMERIK documentation is organized in the following categories:

● General documentation

● User documentation

● Manufacturer/service documentation

Additional information

You can find information on the following topics at www.siemens.com/motioncontrol/docu:

● Ordering documentation/overview of documentation

● Additional links to download documents

● Using documentation online (find and search in manuals/information)

Please send any questions about the technical documentation (e.g. suggestions for

improvement, corrections) to the following address:

docu.motioncontrol@siemens.com

My Documentation Manager (MDM)

Under the following link you will find information to individually compile OEM-specific machine

documentation based on the Siemens content:

www.siemens.com/mdm

Training

For information about the range of training courses, refer under:

● www.siemens.com/sitrain

SITRAIN - Siemens training for products, systems and solutions in automation technology

● www.siemens.com/sinutrain

SinuTrain - training software for SINUMERIK

FAQs

You can find Frequently Asked Questions in the Service&Support pages under Product

Support. http://support.automation.siemens.com

Ctrl-Energy

System Manual, 01/2015, 6FC5397-0EP40-5BA2 3

Preface

SINUMERIK

You can find information on SINUMERIK under the following link:

www.siemens.com/sinumerik

Hotline and Internet address

Technical Support

You will find telephone numbers for other countries for technical support in the Internet under

http://www.siemens.com/automation/service&support

EC Declaration of Conformity

The EC Declaration of Conformity for the EMC Directive can be found on the Internet at:

http://support.automation.siemens.com/WW/view/de/10805517/134200

Ctrl-Energy

4 System Manual, 01/2015, 6FC5397-0EP40-5BA2

Table of contents

Preface.........................................................................................................................................................3

1 Fundamental safety instructions...................................................................................................................7

1.1 General safety instructions.......................................................................................................7

1.2 Industrial security.....................................................................................................................7

2 Introduction...................................................................................................................................................9

3 Ctrl-E Analysis............................................................................................................................................11

3.1 SENTRON PAC3200/4200....................................................................................................12

3.1.1 Hardware................................................................................................................................12

3.1.2 Commissioning the Power Monitoring Device........................................................................13

3.1.3 Commissioning the PAC PROFIBUS expansion module (840D sl).......................................14

3.1.4 Commissioning the expansion module PAC PROFINET (828D)...........................................15

3.2 Commissioning the PLC for SENTRON PAC........................................................................15

3.2.1 SINUMERIK 840D sl..............................................................................................................15

3.2.1.1 Commissioning the PLC with PROFIBUS..............................................................................15

3.2.1.2 Commissioning the PLC with PROFINET..............................................................................19

3.2.2 SINUMERIK 828D..................................................................................................................22

3.3 Commissioning the PLC for Ctrl-E Analysis...........................................................................23

3.3.1 Configuring the energy consumption display for SINUMERIK 840D sl..................................23

3.3.1.1 PLC user program for SINUMERIK 840D sl programming....................................................27

3.3.2 Configuring the display of energy consumption for SINUMERIK 828D.................................29

3.3.2.1 Programming the PLC user program for SINUMERIK 828D.................................................33

3.4 Commissioning the HMI for Ctrl-E Analysis...........................................................................37

3.4.1 Changing display texts of the auxiliary systems.....................................................................37

3.5 Long time measurement.......................................................................................................38

3.6 Power display in the status line of the "Machine" operating area..........................................38

4 Ctrl-E Profiles.............................................................................................................................................39

4.1 Commissioning the PLC for Ctrl-E Profiles............................................................................39

4.1.1 Overview................................................................................................................................39

4.1.2 Automatic state machine PLC functions................................................................................40

4.1.3 Checking the energy-saving states........................................................................................42

4.1.4 PLC user program..................................................................................................................43

4.1.5 Interface signals 840D sl........................................................................................................44

4.1.5.1 Signals for controlling energy-saving profiles.........................................................................44

4.1.5.2 Signals for parameterization..................................................................................................45

4.1.6 Interface signals 828D...........................................................................................................46

4.1.6.1 Signals for controlling energy-saving profiles.........................................................................46

4.1.6.2 Signals for parameterization..................................................................................................47

4.2 Creating and editing energy-saving profiles...........................................................................48

Ctrl-Energy

System Manual, 01/2015, 6FC5397-0EP40-5BA2 5

Table of contents

5 Reactive power compensation...................................................................................................................53

6 Flux reduction.............................................................................................................................................55

7 User know-how...........................................................................................................................................57

7.1 Commissioning user screen forms.........................................................................................57

A Appendix.....................................................................................................................................................59

A.1 Overview................................................................................................................................59

Index...........................................................................................................................................................61

Ctrl-Energy

6 System Manual, 01/2015, 6FC5397-0EP40-5BA2

Fundamental safety instructions

1.1 General safety instructions

WARNING

Risk of death if the safety instructions and remaining risks are not carefully observed

If the safety instructions and residual risks are not observed in the associated hardware

documentation, accidents involving severe injuries or death can occur.

● Observe the safety instructions given in the hardware documentation.

● Consider the residual risks for the risk evaluation.

WARNING

Danger to life or malfunctions of the machine as a result of incorrect or changed

parameterization

As a result of incorrect or changed parameterization, machines can malfunction, which in turn

can lead to injuries or death.

● Protect the parameterization (parameter assignments) against unauthorized access.

● Respond to possible malfunctions by applying suitable measures (e.g. EMERGENCY

STOP or EMERGENCY OFF).

1

1.2 Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With this in mind, Siemens’

products and solutions undergo continuous development. Siemens recommends strongly that

you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state-of-the-art industrial security concept. Third-party products that may be in use should also

be considered. For more information about industrial security, visit this address (http://

www.siemens.com/industrialsecurity).

To stay informed about product updates as they occur, sign up for a product-specific

newsletter. For more information, visit this address (http://support.automation.siemens.com).

Ctrl-Energy

System Manual, 01/2015, 6FC5397-0EP40-5BA2 7

Fundamental safety instructions

1.2 Industrial security

WARNING

Danger as a result of unsafe operating states resulting from software manipulation

Software manipulation (e.g. by viruses, Trojan horses, malware, worms) can cause unsafe

operating states to develop in your installation which can result in death, severe injuries and/

or material damage.

● Keep the software up to date.

You will find relevant information and newsletters at this address (http://

support.automation.siemens.com).

● Incorporate the automation and drive components into a holistic, state-of-the-art industrial

security concept for the installation or machine.

You will find further information at this address (http://www.siemens.com/

industrialsecurity).

● Make sure that you include all installed products into the holistic industrial security concept.

Ctrl-Energy

8 System Manual, 01/2015, 6FC5397-0EP40-5BA2

Introduction

The topics of energy efficiency and energy saving are also playing an increasingly important

role in the machine tool environment.

With SINUMERIK Ctrl-Energy, Siemens is offering an extensive range of components,

functions, software tools and services to increase the efficiency of machine tools.

Ctrl-Energy

You will find an overview of the complete range of functions under the following link:

www.siemens.com/sinumerik/ctrl-energy

Acquisition, evaluation, and control of energy consumption

The functions Ctrl-E Analysis to acquire and evaluate the energy consumption of the machine

and Ctrl-E Profiles, to control energy-saving states of the machine are available in SINUMERIK

Operate. Additional energy-saving functions or user know-how on this topic can be added in

this area of SINUMERIK Operate.

2

Ctrl-Energy

System Manual, 01/2015, 6FC5397-0EP40-5BA2 9

Introduction

Ctrl-Energy

10 System Manual, 01/2015, 6FC5397-0EP40-5BA2

Ctrl-E Analysis

In order to sensitize users to the topic of energy efficiency, the power and energy data of the

machine are first acquired.

Acquiring and evaluating energy consumption

A control system with SINUMERIK Operate without a connected measuring instrument

determines the power directly from the drives and displays this.

Additional consumption-relevant data can be retrieved and displayed at the control using the

additional SENTRON PAC Power Monitoring Device.

Depending on where the SENTRON PAC measuring transducer is installed, you have the

possibility of either measuring the power of the whole machine or only a specific load.

With an integrated measuring function, the energy consumption during a measuring period

can be acquired for all drives together with an additional measuring location – and the electrical

power drawn for a selected load can be recorded with respect to time.

Display of energy consumption

● The user can see a graphic of the current power consumption in the first status line of the

"Machine" operating area.

3

● Additionally, in the Ctrl-Energy initial display the user is shown the consumption in the form

of colored bars, which indicate the current power and the results of today's and yesterday's

long time measurement.

Maximum measuring time

The maximum measuring time for energy between start and stop as well as for an NC part

program is, as a result of the trace recording, 922 seconds (00:15:22).

Ctrl-Energy

System Manual, 01/2015, 6FC5397-0EP40-5BA2 11

Ctrl-E Analysis

3.1 SENTRON PAC3200/4200

3.1 SENTRON PAC3200/4200

3.1.1 Hardware

Hardware components

You require the following hardware in order to be able to use all of the "Ctrl-Energy" functions:

● SENTRON PAC3200 (Firmware ≥ V2.2.0)

http://support.automation.siemens.com/WW/view/de/25240652/130000

● SENTRON PAC4200 (Firmware ≥ V1.4.0)

http://support.automation.siemens.com/WW/view/de/31675630/130000

● SENTRON PAC - accessories

http://www.automation.siemens.com/btlv-static/

Lowvoltage_LV10-1_complete_German_2011.pdf

– Power Monitoring Device (page 11/27 ff)

– Current transformer (Page 11/39)

● The expansion modules must be temporarily removed in order to upgrade the firmware

using powerconfig.

● Protection/fusing of the supply and measuring voltages according to Configuration Manual

● Expansion module PAC PROFINET; order number 7KM 9300-0AE01-0AA0

● Expansion module PAC PROFIBUS; order number 7KM 9300-0AB01-0AA0

● PC software powerconfig (≥ V2.2)

http://support.automation.siemens.com/WW/view/de/50246395

● Current transformer depending on

– the connection type at the SENTRON PAC

– Accuracy requirements

– Currents

DANGER

Open current transformer circuits result in electric shock and arcing

If not observed, will cause death, serious injury or considerable property damage.

Only measure the current using external current transformers. DO NOT protect the

circuits using a fuse. Do not open the secondary circuit of the current transformer under

load. Short circuit the secondary current terminals of the current transformer before

removing this device. The safety information for the current transformers used must

be carefully followed.

Selection example

Catalog, Siemens LV 1/Accessories and spare parts:

Ctrl-Energy

12 System Manual, 01/2015, 6FC5397-0EP40-5BA2

References

Ctrl-E Analysis

3.1 SENTRON PAC3200/4200

For a three-phase measurement according to connection type 3P4W (four conductors,

unbalanced load, without voltage transformers, with three current transformers), accuracy

class 1, primary rated current 100 A, secondary rated current 1A, three window-type

transformers are recommended (4NC5117-0CC20).

Note

When measuring the complete machine, it is recommended that the current is sensed directly

after the main switch. For the voltage tap, please observe the usual protection/fusing.

Information on the installation, configuration and operation of the Power Monitoring Device

and the expansion module can be found in the following references:

● SENTRON PAC3200 Power Monitoring Device Manual

(Document order number A5E01168664A-05)

● SENTRON PAC4200 Power Monitoring Device System Manual

(Document order number A5E02316180A-03)

● PAC PROFIBUS DP, SWITCHED ETHERNET PROFINET Expansion Module Manual

(document order number A5E01168846A-06)

3.1.2 Commissioning the Power Monitoring Device

A detailed description of commissioning of the SENTRON PAC Power Monitoring Device is

provided in the corresponding manuals.

Preconditions

● The device has been installed.

● The optional expansion modules have been installed.

● The device has been connected in accordance with the possible connection methods.

● The battery has been inserted into the battery compartment (only for the SENTRON

PAC4200).

General procedure when commissioning the device

● Connected the supply voltage

● Parameterizing SENTRON PAC

● Connect the measuring voltage

● Connect the current to be measured

● Check the displayed measured values

● Check the polarity and phase assignment of the measuring transducer

Ctrl-Energy

System Manual, 01/2015, 6FC5397-0EP40-5BA2 13

Ctrl-E Analysis

3.1 SENTRON PAC3200/4200

Parameterizing SENTRON PAC

You have the option of parameterizing the measuring device in the following ways:

● Using the input keys and display of the SENTRON PAC

● Using a PC connected to the SENTRON PAC, which has the software this has been

supplied (powerconfig).

After booting select the language and the measuring device is then ready for operation.

3.1.3 Commissioning the PAC PROFIBUS expansion module (840D sl)

To communicate via Profibus, the SENTRON PROFIBUS module in combination with Sentron

PAC3200/4200 must be parameterized differently.

1. Select SENTRON PAC "Settings" > "PROFIBUS modules".

- OR For SENTRON PAC4200, select "Settings" > "Expansion modules" > "MOD1" >

"PROFIBUS MODULE".

2. Press "Enter".

You obtain the following information in the subsequent window:

– Order number

– Serial number of the SENTRON PROFIBUS module

– Firmware version of the SENTRON PROFIBUS module

– PROFIBUS ADDR.:

The DP address of module is displayed here.

3. Press "Enter".

This means that you have the option of entering the same PROFIBUS address as in the

automation system.

Ctrl-Energy

14 System Manual, 01/2015, 6FC5397-0EP40-5BA2

3.2 Commissioning the PLC for SENTRON PAC

3.1.4 Commissioning the expansion module PAC PROFINET (828D)

To communicate via PROFINET, the SENTRON SWITCHED ETHERNET PROFINET module

in combination with Sentron PAC3200/4200 must be parameterized differently.

1. Select SENTRON PAC "Settings" > "SWITCHED ETHERNET".

- OR Select SENTRON PAC "Settings" > "Expansion modules" > "MOD1" > "SWITCHED

ETHERNET".

2. Press "ENTER".

You obtain the following information in the subsequent window:

– Order number

– Serial number of the SENTRON SWITCHED ETHERNET PROFINET module

– Firmware version of the SENTRON SWITCHED ETHERNET PROFINET module

– The first character of the NameOfStation of the SENTRON SWITCHED ETHERNET

PROFINET module that can be a maximum of 26 characters

– IP-ADDR.:

The IP address of the module is displayed here.

Ctrl-E Analysis

3. Using the menu item "- ->", open the next window and obtain among other things the

information about the SUBNET address of the module.

Specifying/changing the device name

The device name can only be entered (it must be specified) using the powerconfig software

in the submenu "Expansion slot1".

● Sentron PAC3200: pac3200-pn22

● Sentron PAC4200: pac4200-pn21

The next time that the 828D boots, the 828D IO controller assigns the correct IP address to

the expansion module according to the device name:

● pac4200-pn21 --> 192.168.214.21

● pac3200-pn22 --> 192.168.214.22

3.2 Commissioning the PLC for SENTRON PAC

3.2.1 SINUMERIK 840D sl

3.2.1.1 Commissioning the PLC with PROFIBUS

PROFIBUS is commissioned with the PLC Toolbox 4.6 or higher.

Ctrl-Energy

System Manual, 01/2015, 6FC5397-0EP40-5BA2 15

Ctrl-E Analysis

3.2 Commissioning the PLC for SENTRON PAC

Preconditions

● Configure the hardware, save and compile the project

● Generating the system data for the PLC

● Install the Toolbox software, which also contains the libraries for the PLC basic program of

an NCU 7x0.3.

Note

PLC Toolbox 4.6SP1 requires STEP 7 V5.5 SP3 or higher.

Procedure

You are on the main screen of the SIMATIC Manager.

1. Select the "File" > "Open" menu and then click on the "Libraries" tab.

2. Select the library for the PLC basic program "bp7x0_46" and confirm the dialog with "OK".

3. You have inserted the library and selected the PLC program under "PLC-First-Startup 840D

sl" > "SINUMERIK" > "PLC317F-3 PN/DP " > "S7 Program".

Ctrl-Energy

16 System Manual, 01/2015, 6FC5397-0EP40-5BA2

3.2 Commissioning the PLC for SENTRON PAC

4. Copy the sources, modules and symbols to the PLC program

Ctrl-E Analysis

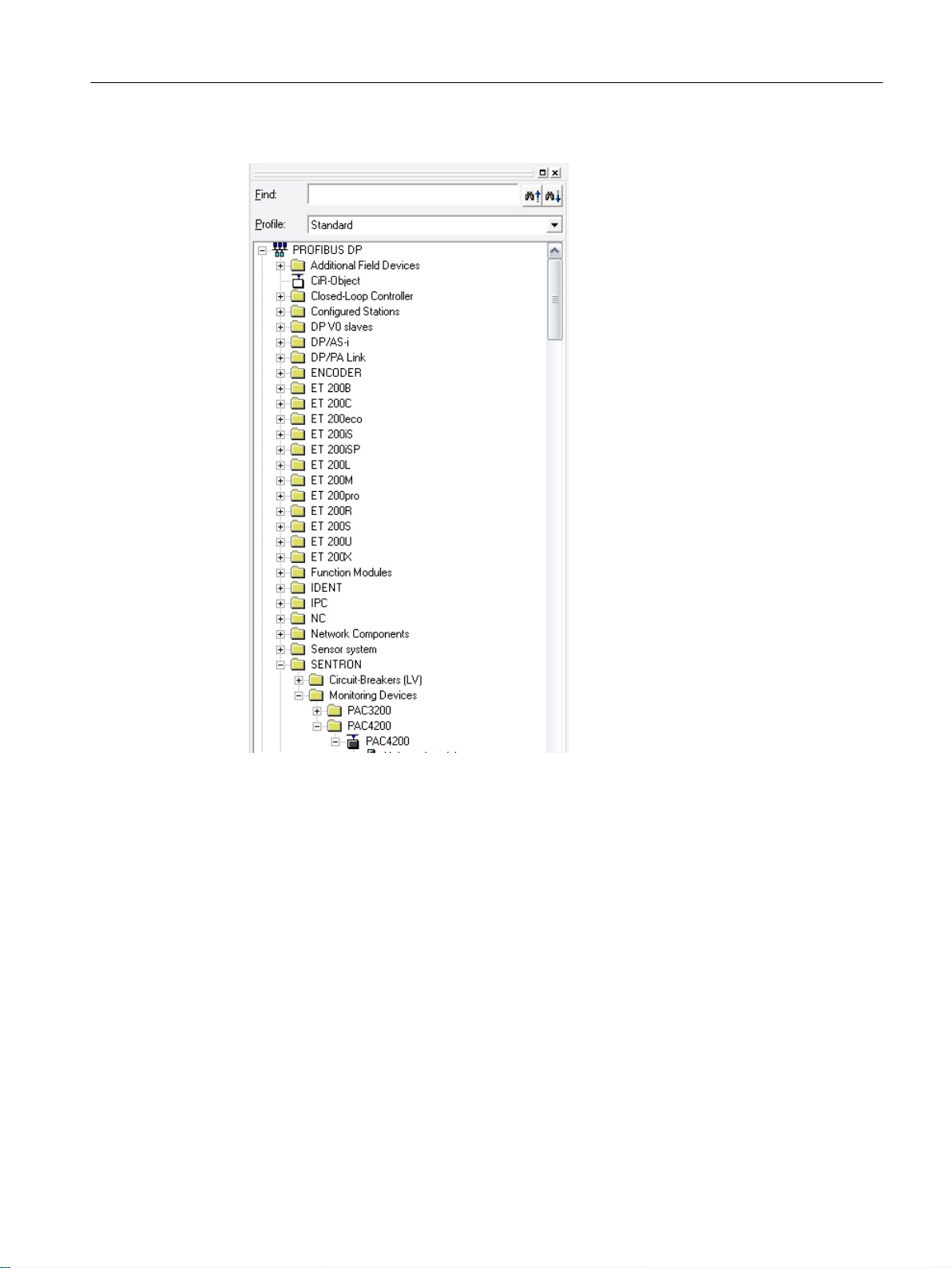

Figure 3-1 Hardware catalog after incorporating the GSD file

Ctrl-Energy

System Manual, 01/2015, 6FC5397-0EP40-5BA2 17

Ctrl-E Analysis

3.2 Commissioning the PLC for SENTRON PAC

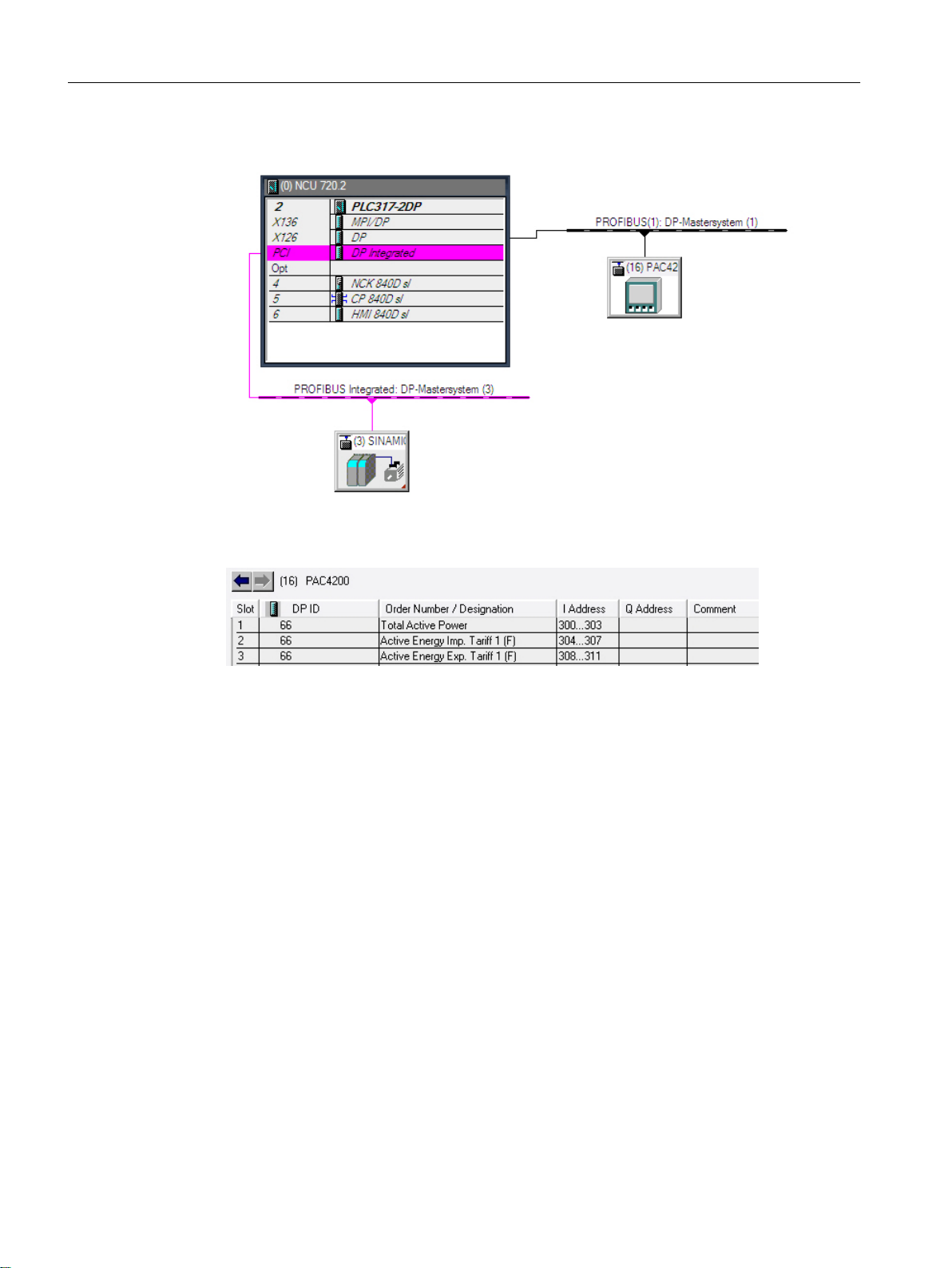

5. In HW Config, drag the selected module to the Profibus DP master system.

6. In the hardware catalog, open the required module and assign the subslots as shown in

the diagram.

Ctrl-Energy

18 System Manual, 01/2015, 6FC5397-0EP40-5BA2

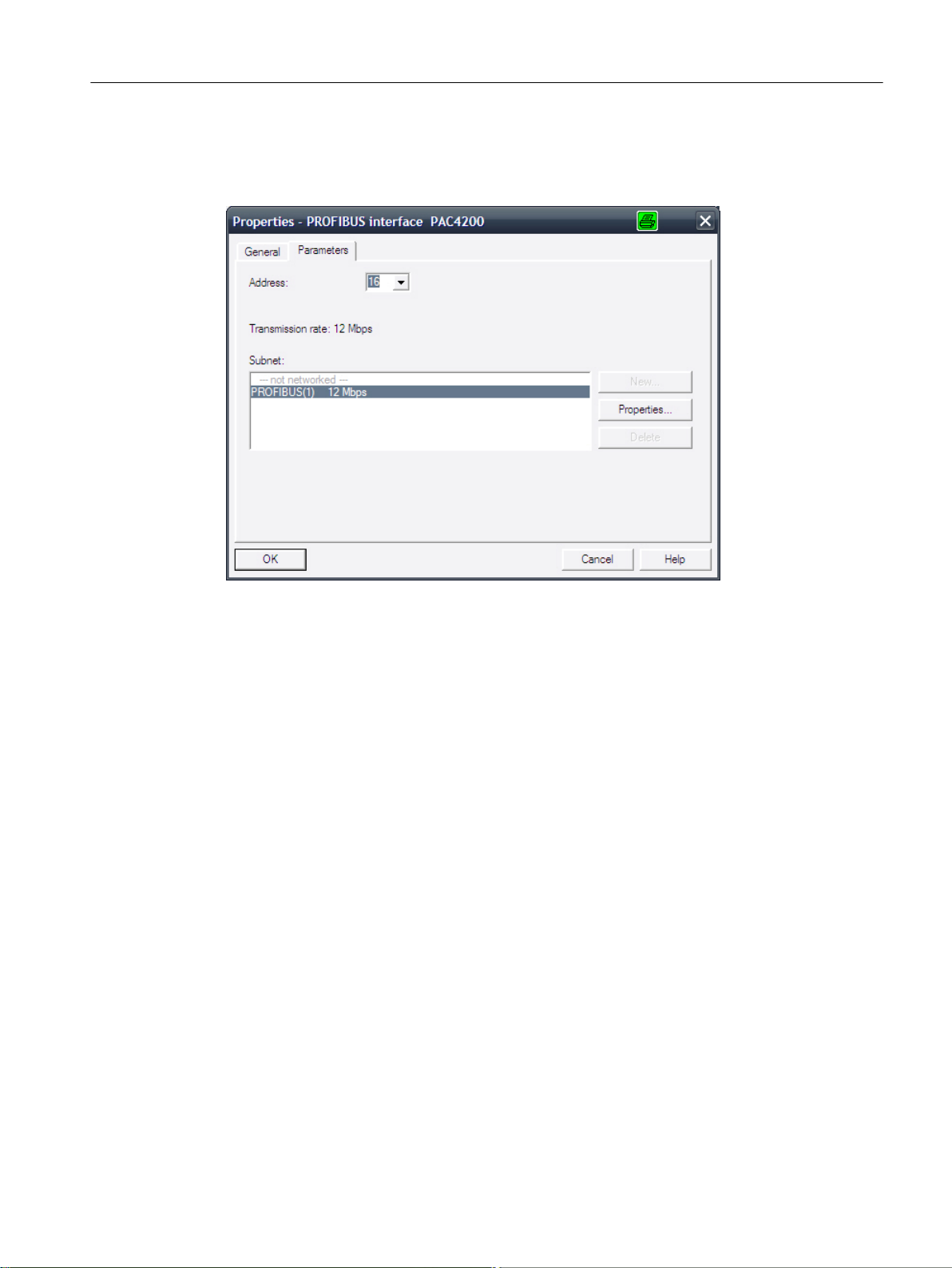

PROFIBUS interface

PROFIBUS must be configured with a data transfer rate of 12 Mbit/s.

Ctrl-E Analysis

3.2 Commissioning the PLC for SENTRON PAC

Setting the PROFIBUS address

Set the PROFIBUS address of the expansion module either directly at the SENTRON PAC or

enter using the powerconfig software.

References

Additional information about commissioning the PLC can be found in the following references:

CNC Commissioning Manual: NCK, PLC, drive / SINUMERIK 840D sl

3.2.1.2 Commissioning the PLC with PROFINET

PROFINET is commissioned with the PLC Toolbox 4.6 or higher. This requires SIMATIC STEP

7 V5.5SP3 or higher.

Preconditions

● Configure the hardware, save and compile the project

● Generating the system data for the PLC

● Install the Toolbox software, which also contains the libraries for the PLC basic program of

an NCU 7x0.3PN.

● GSDML for PAC PROFINET

http://support.automation.siemens.com/WW/view/de/50186868

Ctrl-Energy

System Manual, 01/2015, 6FC5397-0EP40-5BA2 19

Loading...

Loading...