Siemens SINUMERIK 828D, SINUMERIK 840DE sl, SINUMERIK 840D sl Operating Manual

_

_

A

SINUMERIK SINUMERIK 840D sl/828D HMI sl Milling

SINUMERIK

SINUMERIK 840D sl/828D HMI sl Milling

Operating Manual

Valid for

Control System

SINUMERIK 840D sl/840DE sl/828D

Software Version

NCU system software for 840D sl/840DE sl/828D with

HMI sl 2.6

Preface

Introduction

_____________

Setting up the machine

_____________

Execution in manual mode

Machining the workpiece

Simulating machining

Creating G code program

Creating a ShopMill program

Programming technological

functions (cycles)

User variables

Teaching in a program

Tool management

Program management

Setting up drives

HT 8

PCU321

Easy Message

Easy Extend

Service Planner

Ladder add-on tool

larms, error messages, and

system alarms

Appendix

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

A

06/2009

6FC5398-7CP20-0BA0

Legal information

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Ordernumber: 6FC5398-7CP20-0BA0

Ⓟ 07/2009

Copyright © Siemens AG 2009.

Technical data subject to change

Preface

Structure of the documentation

The SINUMERIK documentation is organized in three parts:

● General documentation

● User documentation

● Manufacturer/service documentation

Information on the following topics is available at

http://www.siemens.com/motioncontrol/docu:

● Ordering documentation

Here you can find an up-to-date overview of publications.

● Downloading documentation

Target group

Benefits

Links to more information for downloading files from Service & Support.

● Researching documentation online

Information on DOConCD and direct access to the publications in DOConWEB.

● Compiling individual documentation on the basis of Siemens contents with the My

Documentation Manager (MDM), refer to http://www.siemens.com/mdm.

My Documentation Manager provides you with a range of features for generating your

own machine documentation.

● Training and FAQs

Information on our range of training courses and FAQs (frequently asked questions) is

available via the page navigation.

This documentation is intended for users of milling machines running the HMI sl software.

The operating manual familiarizes users with the operator controls and operating commands.

It instructs users on how to respond to faults and take corrective action.

HMI sl Milling

Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

3

Preface

Standard scope

This documentation only describes the functionality of the standard version. Extensions or

changes made by the machine tool manufacturer are documented by the machine tool

manufacturer.

Other functions not described in this documentation might be executable in the control.

However, no claim can be made regarding the availability of these functions when the

equipment is first supplied or in the event of servicing.

For the sake of simplicity, this documentation does not contain all detailed information about

all types of the product and cannot cover every conceivable case of installation, operation, or

maintenance.

Terms

The meanings of some basic terms are given below in this documentation.

Program

A program is a sequence of instructions to the CNC which combine to produce a specific

workpiece on the machine.

Contour

Technical Support

The term contour refers generally to the outline of a workpiece. More specifically, it refers to

the section of the program that defines the outline of a workpiece comprising individual

elements.

Cycle

A cycle, e.g. rectangular pocket milling, is a subroutine defined in HMI sl for executing a

frequently repeated machining operation.

If you have any technical questions, please contact our hotline:

Europe/Africa

Phone +49 180 5050 222

Fax +49 180 5050 223

€0.14/min. from German landlines, mobile phone prices may differ.

Internet http://www.siemens.com/automation/support-request

America

Phone +1 423 262 2522

Fax +1 423 262 2200

E-mail mailto:techsupport.sea@siemens.com

HMI sl Milling

4 Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

Preface

Asia/Pacific

Phone +86 1064 719 990

Fax +86 1064 747 474

E-mail mailto:adsupport.asia@siemens.com

Note

Country-specific telephone numbers for technical support are provided under the following

Internet address:

http://www.automation.siemens.com/partner

Questions about the manual

If you have any queries (suggestions, corrections) in relation to this documentation, please

fax or e-mail us:

Fax +49 9131- 98 2176

E-mail mailto:docu.motioncontrol@siemens.com

A fax form is available in the appendix of this document.

Internet address

http://www.siemens.com/motioncontrol

HMI sl Milling

Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

5

Preface

HMI sl Milling

6 Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

Table of contents

Preface ......................................................................................................................................................

1 Introduction..............................................................................................................................................

1.1 Product overview .........................................................................................................................

1.2 Operator panel fronts ...................................................................................................................

1.2.1 Overview ......................................................................................................................................

1.2.2 Keys of the operator panel...........................................................................................................

1.3 Machine control panels ................................................................................................................

1.3.1 Overview ......................................................................................................................................

1.3.2 Controls on the machine control panel ........................................................................................

1.4 User interface...............................................................................................................................

1.4.1 Screen layout ...............................................................................................................................

1.4.2 Status display...............................................................................................................................

1.4.3 Actual value window ....................................................................................................................

1.4.4 T,F,S window ...............................................................................................................................

1.4.5 Current block display ...................................................................................................................

1.4.6 Operation via softkeys and buttons .............................................................................................

1.4.7 Entering or selecting parameters.................................................................................................

1.4.8 Pocket calculator..........................................................................................................................

1.4.9 Context menu...............................................................................................................................

1.4.10 Touch operation ...........................................................................................................................

1.4.11 Changing the user interface language.........................................................................................

1.4.12 Entering Asian characters............................................................................................................

1.4.13 Protection levels...........................................................................................................................

1.4.14 Online help in HMI sl....................................................................................................................

3

17

17

18

18

19

24

24

24

27

27

28

31

32

33

34

35

37

39

39

40

40

42

44

2 Setting up the machine............................................................................................................................

2.1 Switching on and switching off.....................................................................................................

2.2 Approaching a reference point.....................................................................................................

2.2.1 Referencing axes .........................................................................................................................

2.2.2 User agreement ...........................................................................................................................

2.3 Operating modes .........................................................................................................................

2.3.1 General ........................................................................................................................................

2.3.2 Channel switchover......................................................................................................................

2.4 Settings for the machine ..............................................................................................................

2.4.1 Switching over the coordinate system (MCS/WCS) ....................................................................

2.4.2 Switching the unit of measurement..............................................................................................

2.4.3 Setting the work offset .................................................................................................................

2.5 Measuring the tool .......................................................................................................................

2.5.1 Measuring a tool manually...........................................................................................................

2.5.2 Measuring the tool length with the workpiece as reference point................................................

2.5.3 Measuring radius or diameter ......................................................................................................

2.5.4 Measuring a tool with an electrical tool probe..............................................................................

2.5.5 Calibrating the electrical tool probe .............................................................................................

2.6 Measuring the workpiece zero .....................................................................................................

HMI sl Milling

Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

47

47

48

48

49

50

50

52

53

53

53

55

57

57

58

58

59

61

62

7

Table of contents

2.6.1 Overview ..................................................................................................................................... 62

2.6.2 Sequence of operations ..............................................................................................................

2.6.3 Examples with manual swivel .....................................................................................................

2.6.4 Setting the edge ..........................................................................................................................

2.6.5 Edge measurement.....................................................................................................................

2.6.6 Measuring a corner .....................................................................................................................

2.6.7 Measuring a pocket and hole......................................................................................................

2.6.8 Measuring a spigot......................................................................................................................

2.6.9 Aligning the plane........................................................................................................................

2.6.10 Defining the measurement function selection.............................................................................

2.6.11 Corrections after measurement of the zero point .......................................................................

2.6.12 Calibrating the electronic workpiece probe .................................................................................

64

65

66

68

71

73

79

84

86

87

88

2.7 Work offsets ................................................................................................................................

2.7.1 Display active zero offset ............................................................................................................

2.7.2 Displaying the work offset "overview" .........................................................................................

2.7.3 Displaying and editing base zero offset ......................................................................................

2.7.4 Displaying and editing settable zero offset .................................................................................

2.7.5 Displaying and editing details of the zero offsets........................................................................

2.7.6 Deleting a work offset..................................................................................................................

2.7.7 Measuring the workpiece zero ....................................................................................................

2.8 Monitoring axis and spindle data ................................................................................................

2.8.1 Specify working area limitations..................................................................................................

2.8.2 Editing spindle data.....................................................................................................................

2.9 Displaying setting data lists.........................................................................................................

2.10 Handwheel assignment.............................................................................................................

2.11 MDA ..........................................................................................................................................

2.11.1 Loading an MDA program from the Program Manager ............................................................

2.11.2 Saving an MDA program...........................................................................................................

2.11.3 Executing an MDA program......................................................................................................

2.11.4 Deleting an MDA program.........................................................................................................

3 Execution in manual mode.....................................................................................................................

3.1 General......................................................................................................................................

3.2 Selecting a tool and spindle ......................................................................................................

3.2.1 T, S, M windows........................................................................................................................

3.2.2 Selecting a tool..........................................................................................................................

3.2.3 Starting and stopping a spindle manually .................................................................................

3.2.4 Position spindle .........................................................................................................................

89

90

91

92

93

93

95

96

97

97

98

99

100

101

101

102

103

103

105

105

105

105

106

107

108

3.3 Traversing axes.........................................................................................................................

3.3.1 Traverse axes by a defined increment......................................................................................

3.3.2 Traversing axes by a variable increment ..................................................................................

3.4 Positioning axes ........................................................................................................................

3.5 Swiveling ...................................................................................................................................

3.6 Simple face milling of workpiece...............................................................................................

3.7 Default settings for manual mode .............................................................................................

4 Machining the workpiece .......................................................................................................................

4.1 Starting and stopping machining...............................................................................................

4.2 Selecting a program ..................................................................................................................

HMI sl Milling

109

109

110

111

112

116

119

121

121

122

8 Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

Table of contents

4.3 Testing a program......................................................................................................................123

4.4 Displaying the current program block ........................................................................................

4.4.1 Current block display .................................................................................................................

4.4.2 Displaying a basic block.............................................................................................................

4.4.3 Display program level ................................................................................................................

4.5 Correcting a program .................................................................................................................

4.6 Repositioning axes.....................................................................................................................

4.7 Starting machining at a specific point ........................................................................................

4.7.1 Use block search .......................................................................................................................

4.7.2 Continuing program from search target .....................................................................................

4.7.3 Simple search target definition...................................................................................................

4.7.4 Defining an interruption point as search target..........................................................................

4.7.5 Entering the search target via search pointer ............................................................................

4.7.6 Parameters for block search in the search pointer ....................................................................

4.7.7 Block search mode ....................................................................................................................

4.8 Intervening in the program sequence ........................................................................................

4.8.1 Program control..........................................................................................................................

4.8.2 Skip blocks.................................................................................................................................

4.9 Overstore ...................................................................................................................................

4.10 Editing a program.......................................................................................................................

4.10.1 Searching in programs...............................................................................................................

4.10.2 Replacing program text..............................................................................................................

4.10.3 Copying/pasting/deleting a program block.................................................................................

4.10.4 Renumber program....................................................................................................................

4.10.5 Editor settings ............................................................................................................................

124

124

125

126

127

128

129

129

131

132

133

133

135

135

137

137

138

140

141

141

142

144

145

145

4.11 Displaying G Functions and Auxiliary Functions........................................................................

4.11.1 Selected G functions..................................................................................................................

4.11.2 All G functions............................................................................................................................

4.11.3 Auxiliary functions ......................................................................................................................

4.12 Displaying the program runtime and counting workpieces ........................................................

4.13 Setting for automatic mode ........................................................................................................

5 Simulating machining.............................................................................................................................

5.1 Overview ....................................................................................................................................

5.2 Simulation before machining of the workpiece ..........................................................................

5.3 Simultaneous recording before machining of the workpiece .....................................................

5.4 Simultaneous recording during machining of the workpiece .....................................................

5.5 Different views of a workpiece ...................................................................................................

5.5.1 Plan view....................................................................................................................................

5.5.2 3D view ......................................................................................................................................

5.5.3 Side view....................................................................................................................................

5.6 Editing the simulation display.....................................................................................................

5.6.1 Blank display..............................................................................................................................

5.6.2 Showing and hiding the tool path...............................................................................................

5.7 Program control during the simulation .......................................................................................

5.7.1 Changing the feedrate ...............................................................................................................

5.7.2 Simulating the program block by block ......................................................................................

147

147

149

150

152

153

155

155

157

158

159

160

160

160

161

161

161

162

162

162

163

HMI sl Milling

Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

9

Table of contents

5.8 Changing and adapting a simulation graphic............................................................................ 164

5.8.1 Enlarging or reducing the graphical representation..................................................................

5.8.2 Panning a graphical representation ..........................................................................................

5.8.3 Rotating the graphical representation.......................................................................................

5.8.4 Modifying the viewport ..............................................................................................................

164

164

165

166

5.9 Displaying simulation alarms.....................................................................................................

6 Creating G code program ......................................................................................................................

6.1 Graphical programming.............................................................................................................

6.2 Program views ..........................................................................................................................

6.3 Program structure .....................................................................................................................

6.4 Basics........................................................................................................................................

6.4.1 Machining planes ......................................................................................................................

6.4.2 Current planes in cycles and input screens ..............................................................................

6.4.3 Programming a tool (T) .............................................................................................................

6.5 Generating a G code program ..................................................................................................

6.6 Blank input ................................................................................................................................

6.7 Machining plane, milling direction, retraction plane, safe clearance and feedrate (PL, RP,

SC, F)........................................................................................................................................

6.8 Selection of the cycles via softkey ............................................................................................

6.9 Calling technology functions .....................................................................................................

6.9.1 Hiding cycle parameters............................................................................................................

6.9.2 Setting data for cycles...............................................................................................................

6.9.3 Checking cycle parameters.......................................................................................................

6.9.4 Changing a cycle call ................................................................................................................

6.9.5 Additional functions in the input screens...................................................................................

167

169

169

169

172

173

173

173

174

175

176

177

178

182

182

182

182

183

184

6.10 Measuring cycle support ...........................................................................................................

7 Creating a ShopMill program .................................................................................................................

7.1 Program views ..........................................................................................................................

7.2 Program structure .....................................................................................................................

7.3 Basic information.......................................................................................................................

7.3.1 Machining planes ......................................................................................................................

7.3.2 Polar coordinates ......................................................................................................................

7.3.3 Absolute and incremental dimensions ......................................................................................

7.4 Creating a ShopMill program ....................................................................................................

7.5 Program header ........................................................................................................................

7.6 Generating program blocks.......................................................................................................

7.7 Tool, offset value, feed and spindle speed (T, D, F, S, V) ........................................................

7.8 Defining machine functions .......................................................................................................

7.9 Call work offsets........................................................................................................................

7.10 Repeating program blocks ........................................................................................................

7.11 Specifying the number of workpieces .......................................................................................

7.12 Changing program blocks .........................................................................................................

185

187

187

191

192

192

192

193

194

196

197

198

200

201

202

203

204

HMI sl Milling

10 Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

Table of contents

7.13 Changing program settings........................................................................................................204

7.14 Selection of the cycles via softkey .............................................................................................

7.15 Calling technology functions ......................................................................................................

7.15.1 Additional functions in the input screens ...................................................................................

7.15.2 Checking input parameters........................................................................................................

7.15.3 Setting data for technological functions .....................................................................................

7.15.4 Changing a cycle call .................................................................................................................

7.16 Measuring cycle support ............................................................................................................

8 Programming technological functions (cycles).......................................................................................

8.1 Drilling ........................................................................................................................................

8.1.1 General ......................................................................................................................................

8.1.2 Centering (CYCLE81) ................................................................................................................

8.1.3 Drilling (CYCLE82).....................................................................................................................

8.1.4 Reaming (CYCLE85) .................................................................................................................

8.1.5 Deep-hole drilling (CYCLE83)....................................................................................................

8.1.6 Boring (CYCLE86) .....................................................................................................................

8.1.7 Tapping (CYCLE84, 840)...........................................................................................................

8.1.8 Drill and thread milling (CYCLE78)............................................................................................

8.1.9 Positioning and position patterns...............................................................................................

8.1.10 Arbitrary positions (CYCLE802).................................................................................................

8.1.11 Line position pattern (HOLES1).................................................................................................

8.1.12 Circle position pattern (HOLES2)...............................................................................................

8.1.13 Repeating positions ...................................................................................................................

8.2 Milling .........................................................................................................................................

8.2.1 Face milling (CYCLE61) ............................................................................................................

8.2.2 Rectangular pocket (POCKET3)................................................................................................

8.2.3 Circular pocket (POCKET4).......................................................................................................

8.2.4 Rectangular spigot (CYCLE76)..................................................................................................

8.2.5 Circular spigot (CYCLE77).........................................................................................................

8.2.6 Multi-edge (CYCLE79)...............................................................................................................

8.2.7 Longitudinal groove (SLOT1).....................................................................................................

8.2.8 Circumferential groove (SLOT2)................................................................................................

8.2.9 Open groove (CYCLE899).........................................................................................................

8.2.10 Long hole (LONGHOLE) - only for G code programs................................................................

8.2.11 Thread milling (CYCLE70).........................................................................................................

8.2.12 Engraving (CYCLE60) ...............................................................................................................

206

210

210

210

211

211

212

215

215

215

216

218

219

220

223

225

229

232

233

234

236

237

238

238

240

244

248

250

252

254

257

260

266

268

272

8.3 Contour milling ...........................................................................................................................

8.3.1 General ......................................................................................................................................

8.3.2 Representation of the contour....................................................................................................

8.3.3 Creating a new contour..............................................................................................................

8.3.4 Creating contour elements.........................................................................................................

8.3.5 Changing the contour.................................................................................................................

8.3.6 Contour call (CYCLE62) - only for G code program ..................................................................

8.3.7 Path milling (CYCLE72) .............................................................................................................

8.3.8 Contour pocket/contour spigot (CYCLE63/64) ..........................................................................

8.3.9 Predrilling contour pocket (CYCLE64).......................................................................................

8.3.10 Milling contour pocket (CYCLE63).............................................................................................

8.3.11 Residual material contour pocket (CYCLE63) ...........................................................................

8.3.12 Milling contour spigot (CYCLE63)..............................................................................................

8.3.13 Residual material contour spigot (CYCLE63) ............................................................................

HMI sl Milling

Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

277

277

277

279

281

285

286

287

290

291

294

296

298

300

11

Table of contents

8.4 Further cycles and functions ..................................................................................................... 302

8.4.1 Swiveling plane/tool (CYCLE800).............................................................................................

8.4.2 Swiveling tool (CYCLE800).......................................................................................................

8.4.2.1 Swiveling tool/preloading milling tools - only for G code program (CYCLE800).......................

8.4.2.2 Swiveling tool/orienting milling tools - only for G code program (CYCLE800)..........................

8.4.3 High-speed settings (CYCLE832).............................................................................................

8.4.4 Subroutines ...............................................................................................................................

302

310

310

311

312

314

8.5 Further cycles and functions ShopMill ......................................................................................

8.5.1 Transformations ........................................................................................................................

8.5.2 Translation.................................................................................................................................

8.5.3 Rotation.....................................................................................................................................

8.5.4 Scaling.......................................................................................................................................

8.5.5 Mirroring ....................................................................................................................................

8.5.6 Straight or circular machining....................................................................................................

8.5.7 Programming a straight line ......................................................................................................

8.5.8 Programming a circle with known center point .........................................................................

8.5.9 Programming a circle with known radius ..................................................................................

8.5.10 Helix ..........................................................................................................................................

8.5.11 Polar coordinates ......................................................................................................................

8.5.12 Straight polar.............................................................................................................................

8.5.13 Circle polar ................................................................................................................................

8.5.14 Obstacle ....................................................................................................................................

9 User variables........................................................................................................................................

9.1 Overview ...................................................................................................................................

9.2 R parameters ............................................................................................................................

9.3 Displaying global user data (GUD) ...........................................................................................

9.4 Displaying channel GUDs .........................................................................................................

9.5 Displaying local user data (LUD) ..............................................................................................

9.6 Displaying program user data (PUD) ........................................................................................

316

316

317

318

319

320

321

323

324

325

326

327

327

329

330

331

331

332

333

335

336

337

9.7 Searching for user data.............................................................................................................

9.8 Defining and activating user variables ......................................................................................

10 Teaching in a program...........................................................................................................................

10.1 Overview ...................................................................................................................................

10.2 General sequence.....................................................................................................................

10.3 Inserting a block ........................................................................................................................

10.3.1 Input parameters for teach-in blocks.........................................................................................

10.4 Teach-in via window..................................................................................................................

10.4.1 General......................................................................................................................................

10.4.2 Teach in rapid traverse G0........................................................................................................

10.4.3 Teach in straight G1..................................................................................................................

10.4.4 Teaching in circle intermediate and circle end point CIP..........................................................

10.4.5 Teach-in A spline ......................................................................................................................

10.5 Editing a block...........................................................................................................................

10.6 Selecting a block .......................................................................................................................

10.7 Deleting a block.........................................................................................................................

HMI sl Milling

337

338

341

341

341

342

343

344

344

345

346

346

346

348

349

350

12 Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

Table of contents

11 Tool management.................................................................................................................................. 353

11.1 Lists for the tool management....................................................................................................

11.2 Magazine management .............................................................................................................

11.3 Tool types...................................................................................................................................

11.4 Tool dimensioning ......................................................................................................................

11.5 Tool list.......................................................................................................................................

11.5.1 Additional data ...........................................................................................................................

11.5.2 Creating a new tool ....................................................................................................................

11.5.3 Measuring the tool .....................................................................................................................

11.5.4 Managing several cutting edges ................................................................................................

11.5.5 Delete tool..................................................................................................................................

11.5.6 Loading and unloading tools......................................................................................................

11.5.7 Selecting a magazine.................................................................................................................

11.6 Tool wear ...................................................................................................................................

11.6.1 Reactivating a tool .....................................................................................................................

11.7 Tool data OEM ...........................................................................................................................

11.8 Magazine....................................................................................................................................

11.8.1 Positioning a magazine..............................................................................................................

11.8.2 Relocating a tool ........................................................................................................................

11.9 Sorting tool management lists....................................................................................................

11.10 Filtering the tool management lists ............................................................................................

11.11 Displaying tool details ................................................................................................................

353

354

354

356

363

365

366

368

368

369

370

371

372

375

376

377

379

379

381

382

383

11.12 Changing a tool type ..................................................................................................................

12 Program management...........................................................................................................................

12.1 Overview ....................................................................................................................................

12.1.1 NC memory................................................................................................................................

12.1.2 Local drive..................................................................................................................................

12.1.3 USB drives .................................................................................................................................

12.2 Opening and closing the program..............................................................................................

12.3 Executing a program..................................................................................................................

12.4 Creating a directory/program/job list/program list ......................................................................

12.4.1 Creating a new directory............................................................................................................

12.4.2 Creating a new workpiece..........................................................................................................

12.4.3 Creating a new G code program................................................................................................

12.4.4 Creating a new ShopMill program..............................................................................................

12.4.5 Storing any new file....................................................................................................................

12.4.6 Creating a Joblist .......................................................................................................................

12.4.7 Creating a program list...............................................................................................................

12.5 Creating templates .....................................................................................................................

12.6 Displaying the program in the Preview. .....................................................................................

12.7 Selecting several directories/programs......................................................................................

12.8 Copying and pasting a directory/program ..................................................................................

12.9 Deleting a program/directory......................................................................................................

12.9.1 Deleting a program/directory......................................................................................................

384

385

385

388

388

389

390

391

393

393

394

395

396

396

397

399

400

401

401

403

405

405

HMI sl Milling

Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

13

Table of contents

12.10 Moving a directory/program ...................................................................................................... 406

12.11 Renaming file and directory properties .....................................................................................

12.12 Backing up data ........................................................................................................................

12.12.1 Generating the archive via series startup .................................................................................

12.12.2 Reading in an archive ...............................................................................................................

12.12.3 Generating an archive in the Program Manager.......................................................................

12.13 EXTCALL ..................................................................................................................................

13 Setting up drives....................................................................................................................................

13.1 Overview ...................................................................................................................................

13.2 Setting up drives .......................................................................................................................

14 HT 8.......................................................................................................................................................

14.1 HT 8 overview ...........................................................................................................................

14.2 Traversing keys .........................................................................................................................

14.3 Machine control panel menu .....................................................................................................

14.4 Virtual keyboard ........................................................................................................................

14.5 Calibrating the touch panel .......................................................................................................

15 PCU321.................................................................................................................................................

15.1 Overview ...................................................................................................................................

15.2 Basic Functions .........................................................................................................................

407

408

408

410

410

412

415

415

415

419

419

422

423

424

426

429

429

430

16 Easy Message.......................................................................................................................................

16.1 Overview ...................................................................................................................................

16.2 Activating Easy Message ..........................................................................................................

16.3 Creating/editing a user profile ...................................................................................................

16.4 Setting-up events ......................................................................................................................

16.5 Logging an active user on and off.............................................................................................

16.6 Displaying SMS logs .................................................................................................................

16.7 Making settings for Easy Message ...........................................................................................

17 Easy Extend ..........................................................................................................................................

17.1 Overview ...................................................................................................................................

17.2 Enabling a device......................................................................................................................

17.3 Activating and deactivating a device.........................................................................................

17.4 Commissioning Easy Extend ....................................................................................................

18 Service Planner .....................................................................................................................................

18.1 Performing and monitoring maintenance tasks.........................................................................

18.2 Set maintenance tasks..............................................................................................................

431

431

432

433

434

436

437

438

439

439

440

441

442

443

443

445

HMI sl Milling

14 Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

Table of contents

19 Ladder add-on tool................................................................................................................................. 447

19.1 PLC diagnostics .........................................................................................................................

19.2 Structure of the user interface....................................................................................................

19.3 Control options ...........................................................................................................................

19.4 Displaying PLC properties .........................................................................................................

19.5 Displaying and editing NC/PLC variables ..................................................................................

19.6 Displaying and editing PLC signals ...........................................................................................

19.7 Displaying information on the program blocks...........................................................................

19.8 Downloading a PLC user program.............................................................................................

19.9 Editing the local variable table ...................................................................................................

19.10 Creating a new block .................................................................................................................

19.11 Editing block properties..............................................................................................................

19.12 Inserting and editing networks ...................................................................................................

19.13 Editing network properties .........................................................................................................

19.14 Displaying and editing symbol tables.........................................................................................

19.15 Inserting/deleting a symbol table ...............................................................................................

19.16 Searching for operands..............................................................................................................

19.17 Displaying the network symbol information table.......................................................................

447

448

449

450

451

452

453

454

455

456

458

458

460

461

462

462

464

19.18 Displaying/canceling the access protection ...............................................................................

19.19 Displaying cross references.......................................................................................................

20 Alarms, error messages, and system alarms.........................................................................................

20.1 Displaying alarms.......................................................................................................................

20.2 Displaying an alarm log..............................................................................................................

20.3 Displaying messages .................................................................................................................

20.4 Sorting, alarms, faults and messages........................................................................................

20.5 PLC and NC variables ...............................................................................................................

20.5.1 Displaying and editing PLC and NC variables...........................................................................

20.5.2 Saving and loading screen forms ..............................................................................................

20.5.3 Load symbols.............................................................................................................................

20.6 Version .......................................................................................................................................

20.6.1 Displaying version data..............................................................................................................

20.6.2 Save information ........................................................................................................................

20.7 Logbook .....................................................................................................................................

20.7.1 Displaying and editing the logbook ............................................................................................

20.7.2 Making a logbook entry..............................................................................................................

20.8 Creating screenshots .................................................................................................................

465

465

467

467

469

470

471

472

472

475

476

477

477

478

479

480

480

481

HMI sl Milling

Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

15

Table of contents

20.9 Remote diagnostics................................................................................................................... 482

20.9.1 Setting remote access...............................................................................................................

20.9.2 Permit modem...........................................................................................................................

20.9.3 Request remote diagnostics......................................................................................................

20.9.4 Exit remote diagnostics.............................................................................................................

482

484

484

485

A Appendix................................................................................................................................................

A.1 Feedback on the documentation...............................................................................................

A.2 Overview ...................................................................................................................................

Index......................................................................................................................................................

487

487

489

491

HMI sl Milling

16 Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

Introduction

1.1 Product overview

The SINUMERIK controller is a CNC (Computerized Numerical Controller) for machine tools.

You can use the CNC to implement the following basic functions in conjunction with a

machine tool:

● Creation and adaptation of part programs

● Execution of part programs

● Manual control

● Access to internal and external data media

● Editing of data for programs

● Management of tools, zero points and further user data required in programs

● Diagnostics of controller and machine

Operating areas

The basic functions are grouped in the following operating areas in the controller:

1

([HFXWHSDUWSURJUDPVPDQXDOFRQWURO

(GLWLQJRIGDWDIRUSURJUDPV

7RROPDQDJHPHQW

&UHDWLQJDQGDGDSWLQJRISDUWSURJUDPV

$FFHVVWRLQWHUQDODQGH[WHUQDOGDWDPHGLD

$ODUPGLVSOD\6HUYLFHGLVSOD\

$GDSWLQJRIWKH1&GDWDWRWKHPDFKLQH

V\VWHPVHWWLQJ

2SHUDWLQJDUHDV

0$&+,1(

3$5 $ 0(7 (5

352*5$0

352*5$0

0$1$*(5

',$*126,6

67$5783

HMI sl Milling

Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

17

Introduction

1.2 Operator panel fronts

1.2 Operator panel fronts

1.2.1 Overview

Introduction

The display (screen) and operation (e.g. hardkeys and softkeys) of the HMI sI user interface

occurs via the panel front.

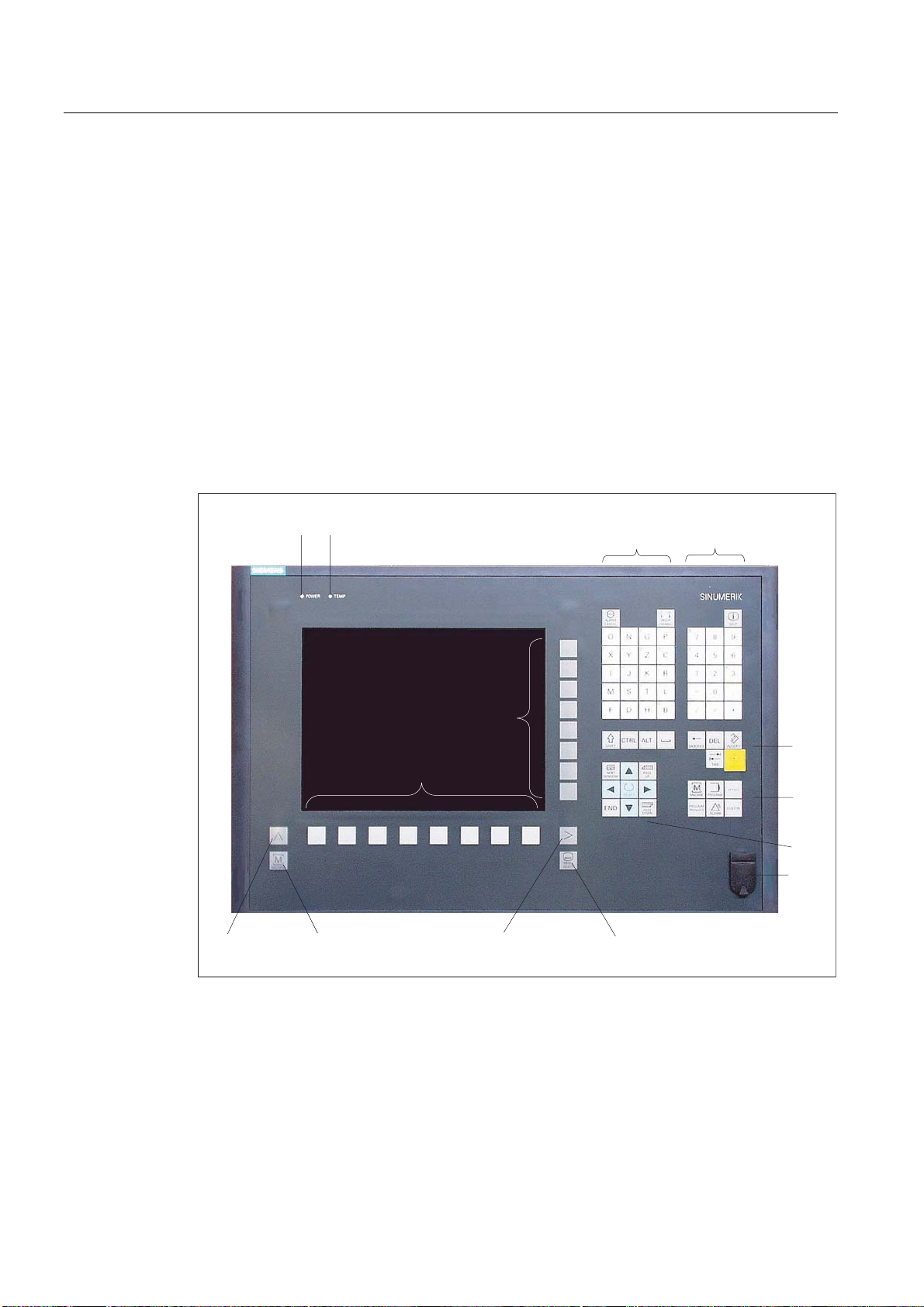

In this example, the OP 010 operator panel front is used to illustrate the components that are

available for operating the controller and machine tool.

Operator controls and indicators

(5)

(5)

HMI sl Milling

18 Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

Introduction

1.2 Operator panel fronts

1 Status LED: POWER

2 Status LED: TEMP

(illuminated LEDs indicate increased wear)

3 Alphabetic key group

4 Numerical key group

5 Softkeys

6 Control key group

7 Hotkey group

8 Cursor key group

9 USB interface

10 Menu select key

11 Menu forward button

12 Machine area button

13 Menu back key

Figure 1-1 View of OP 010 operator panel front

References

A more precise description as well as a view of the other operator panel fronts that can be

used may be found in the following literature

840D sl/840 Di sl Operator Components Manual

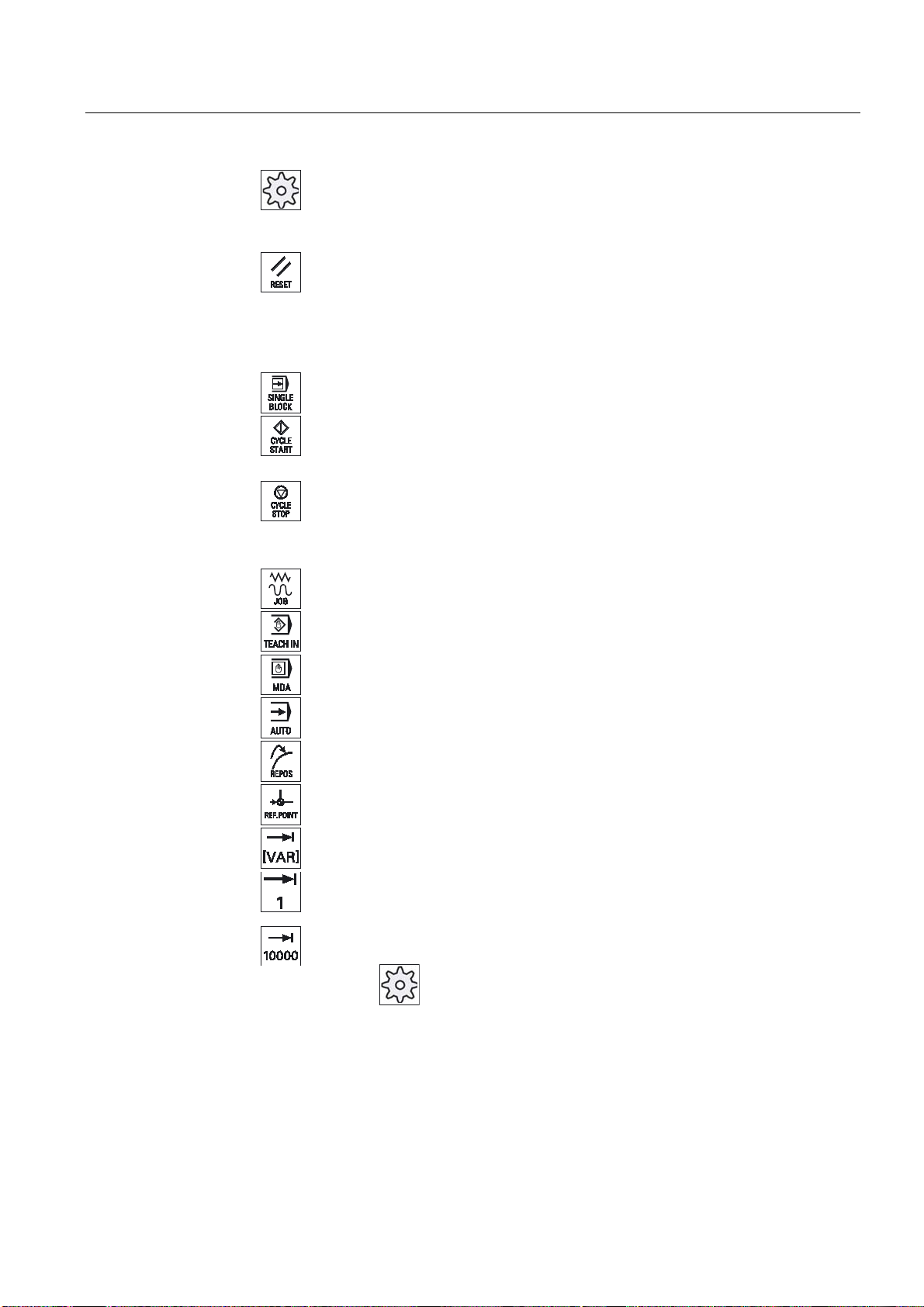

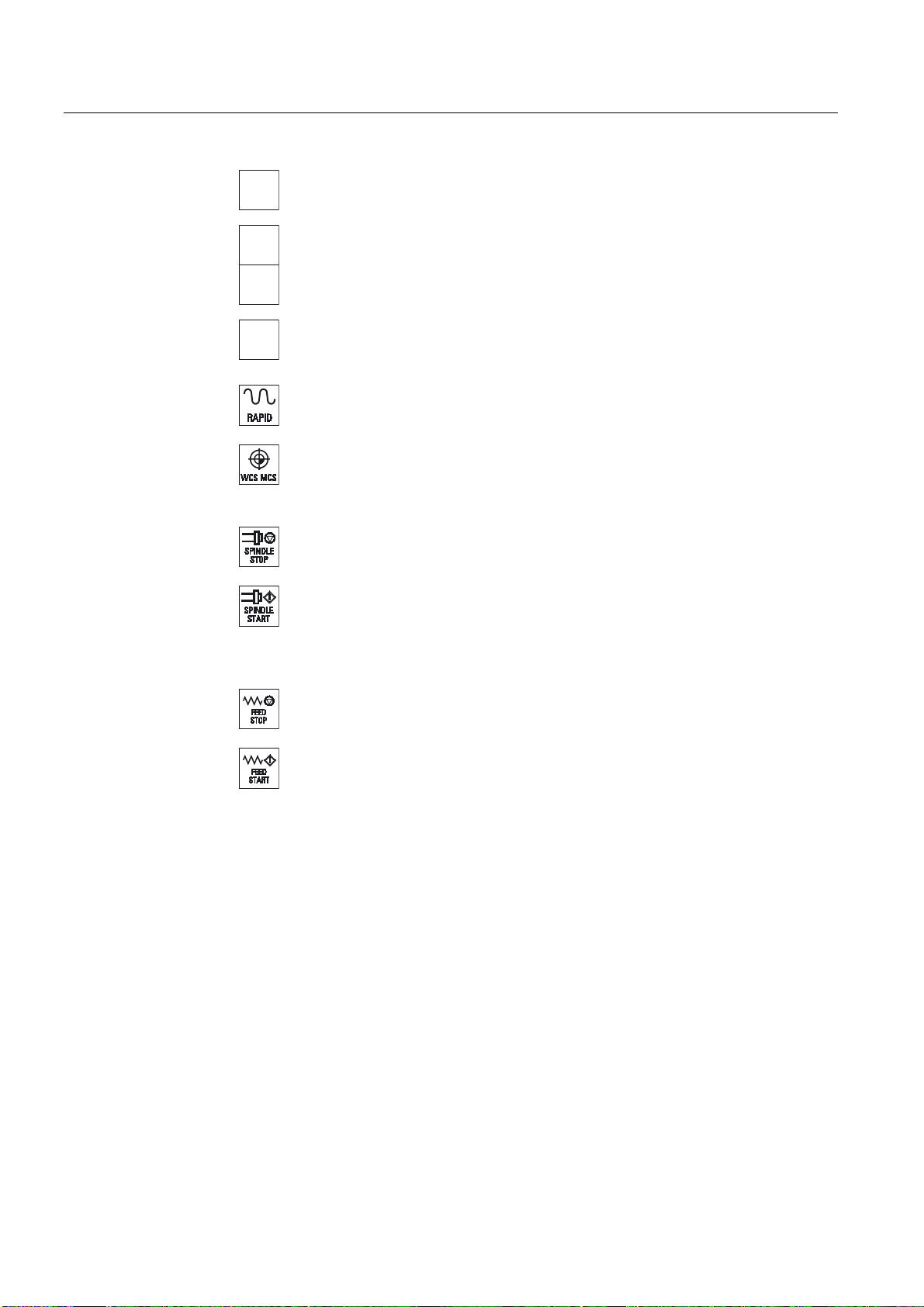

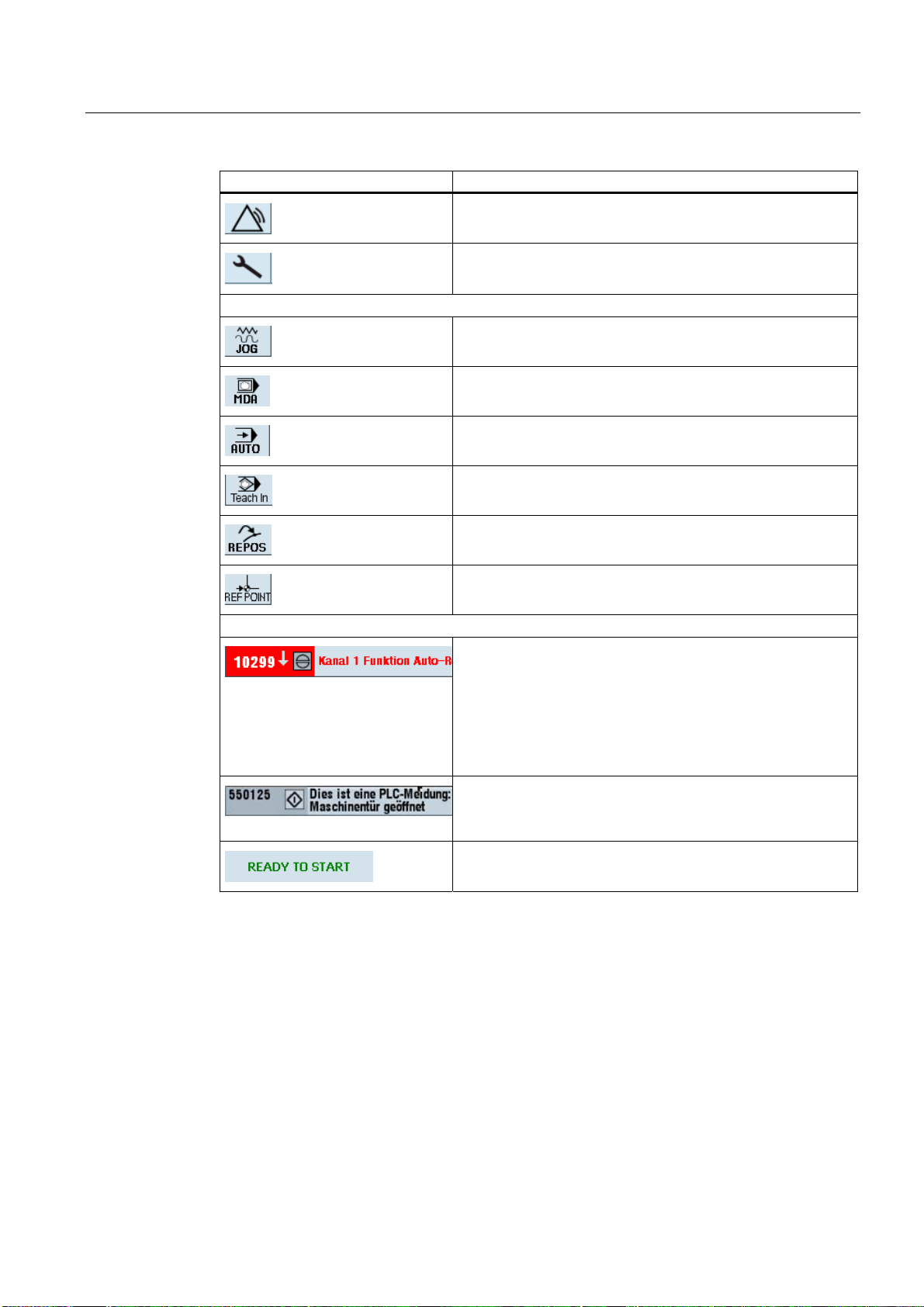

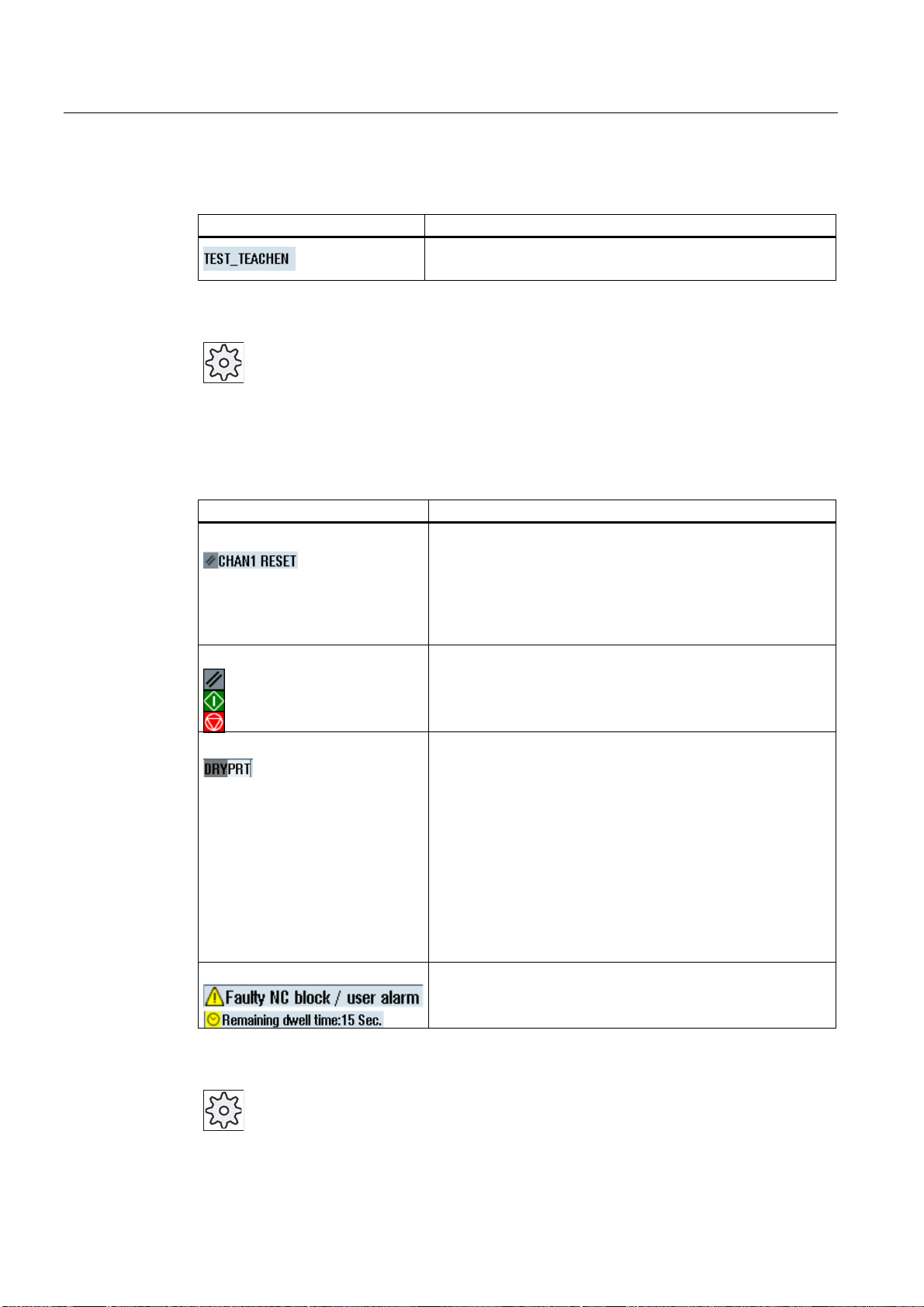

1.2.2 Keys of the operator panel

The following keys and key combinations are available for operation of the control and the

machine tool.

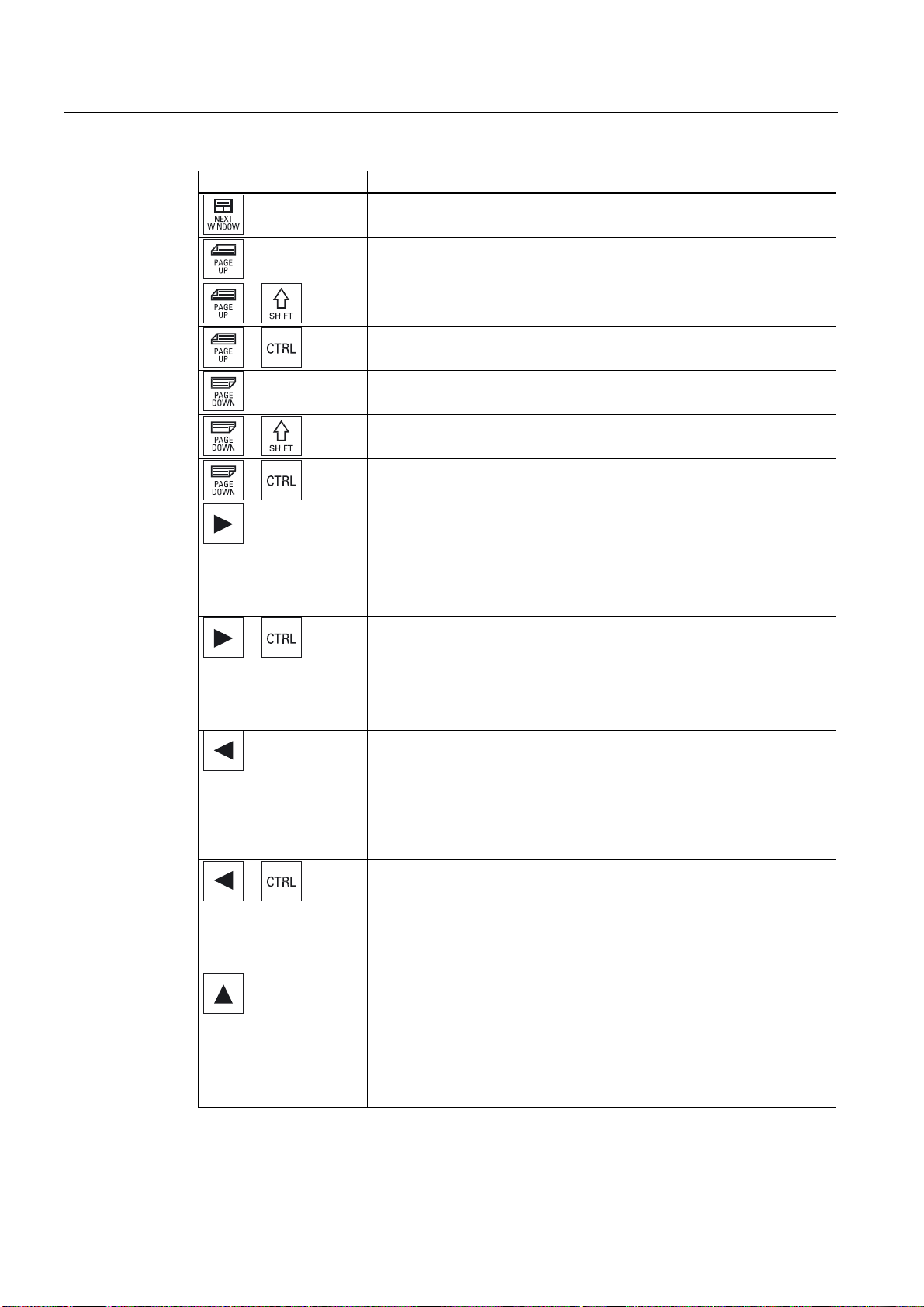

Keys and key combinations

Table 1- 1 Keys of the operator panel

Key Function

<ALARM CANCEL>

Cancel alarms and messages that are marked with this symbol.

<CHANNEL>

Select channel or continue.

HMI sl Milling

Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

<HELP>

Calls the context-sensitive online help for the selected window.

19

Introduction

1.2 Operator panel fronts

Key Function

<NEXT WINDOW>

+

+

+

+

+

+

Continue to next window.

<PAGE UP>

Scrolling upwards in a menu screen.

<PAGE UP> + <SHIFT>

Scrolling upwards in a menu screen, the cursor remains at its position.

<PAGE UP> + <CTRL>

Scrolling upwards in a menu screen, the cursor jumps into the first line.

<PAGE DOWN>

Scrolling downwards in a menu screen.

<PAGE DOWN> + <SHIFT>

Scrolling downwards in a menu screen, the cursor remains at its position.

<PAGE DOWN> + <CTRL>

Scrolling downwards in a menu screen, the cursor jumps into the last line.

<Cursor right>

• Edit mode:

Opens a directory or program (e.g. cycle) in the editor.

• Navigation mode:

Moves the cursor to the right by one character.

<Cursor right> + <CTRL>

• Edit mode:

Moves the cursor to the right by one word

• Navigation mode:

Moves the cursor in a table to the next cell to the right.

<Cursor left>

• Edit mode:

Closes a directory or program (e.g. cycle) in the editor. Changes that

have been made are accepted, functions just like "OK".

• Navigation mode:

Moves the cursor to the left by one character.

<Cursor left> + <CTRL>

• Edit mode:

Moves the cursor to the right by one word.

• Navigation mode:

Moves the cursor in a table to the next cell to the right.

<Cursor up>

• Edit mode:

Moves the cursor upwards.

• Navigation mode:

– Moves the cursor in a table to the next cell upwards.

– Moves the cursor in a menu screen upwards.

HMI sl Milling

20 Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

Introduction

1.2 Operator panel fronts

Key Function

<Cursor up> + <CTRL>

+

+

+

• Edit mode:

Moves the cursor upwards by one word.

• Navigation mode:

– Moves the cursor in a table to the beginning of the table.

– Moves the cursor in a menu screen to the beginning of the line.

<Cursor up> + <SHIFT>

Moves the cursor one paragraph upwards.

<Cursor down>

• Edit mode:

Moves the cursor downwards.

• Navigation mode:

– Moves the cursor in a table to the next cell downwards.

– Moves the cursor in a menu screen downwards.

<Cursor down> + <CTRL>

• Edit mode:

Moves the cursor downwards by one word.

• Navigation mode:

– Moves the cursor in a table to the end of the table.

– Moves the cursor in a menu screen to the end of a line.

+

+

+

+

+

<Cursor down> + <SHIFT>

Moves the cursor one paragraph downwards.

<SELECT>

Selects a listed value. Sets the value to "true".

<END>

Moves the cursor to the last entry field in a menu screen or a table.

<END> + <SHIFT>

Moves the cursor to the last entry.

<END> + <CTRL>

Moves the cursor to the last entry in the last line of the actual column.

<BACKSPACE>

• Edit mode:

Deletes a character selected to the left of the cursor.

• Navigation mode:

Deletes all of the selected characters to the left of the cursor.

<BACKSPACE> + <CTRL>

Deletes a word selected to the left of the cursor.

<TAB>

Indent the cursor by several characters.

<TAB> + <CTRL>

Moves the cursor to the right in the next cell. In so doing, also changes

into the next line to the lefthand cell.

HMI sl Milling

Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

21

Introduction

1.2 Operator panel fronts

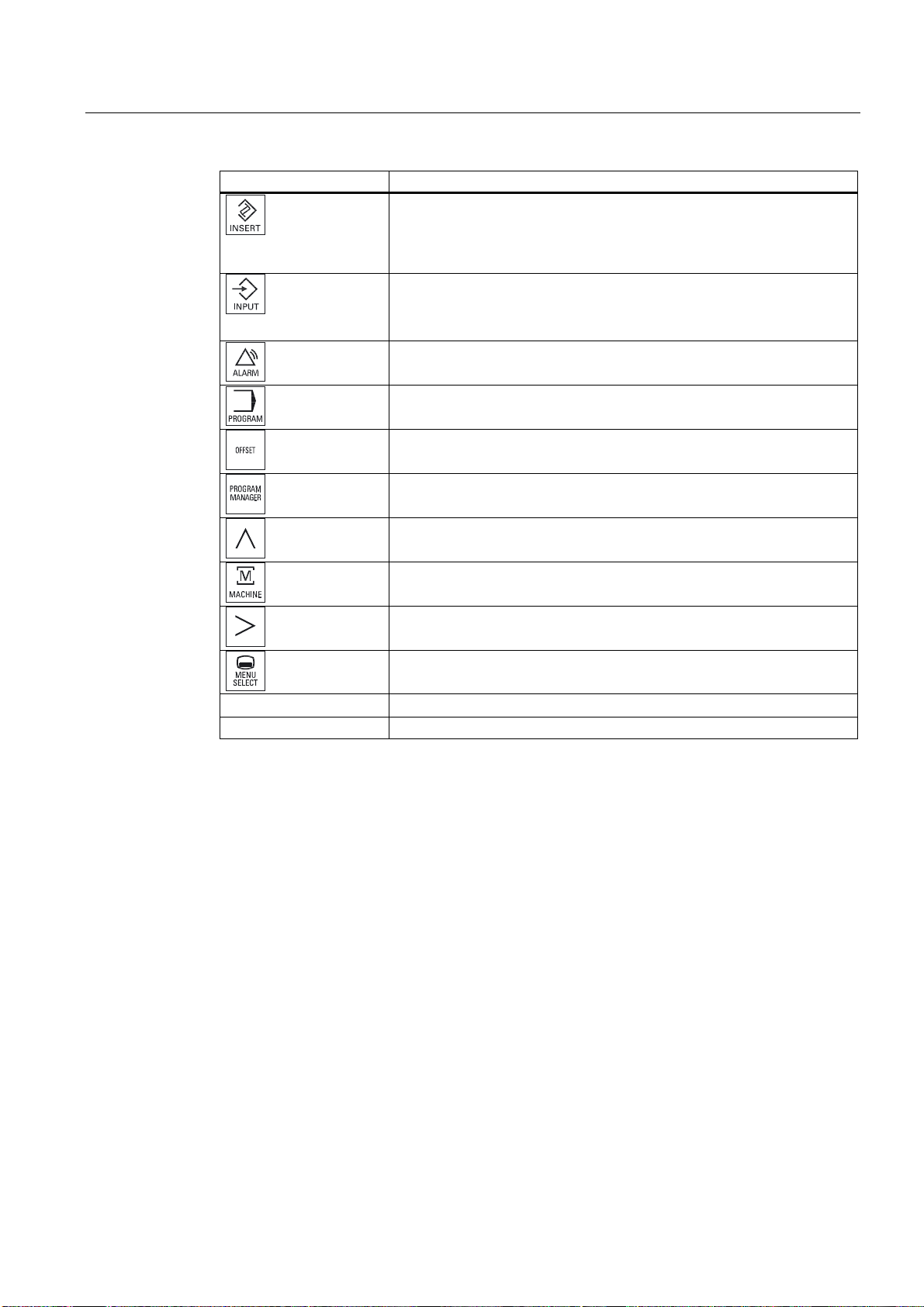

Key Function

<TAB> + <SHIFT>

+

+ <A>

+ <C>

+ <L>

+ <P>

+ <X>

+ <Y>

+ <V>

Moves the cursor to the left in the next cell. In so doing, also changes into

the next line to the righthand cell.

<SHIFT>

Press the Shift key to enter the upper character shown on the dual input

keys.

<CTRL> + <A>

Selects all entries in the actual window. (only in the editor and program

manager).

<CTRL> + <C>

Copies the selected content.

<CTRL> + <L>

The actual user interface scrolls through the installed languages.

<CTRL> + <P>

A screenshot of the actual user interface is created and saved as file.

<CTRL> + <X>

Cuts out the selected text. Text is located in the clipboard.

<CTRL> + <Y>

Changes that have been reset are reactivated. (only in the editor).

<CTRL> + <V>

Inserts text from the clipboard:

• To the actual cursor position

• Replaces selected text

+ + <S>

+ + <L>

+ <S>

+ + <>

+

<CTRL> + <ALT> + <S>

Creates a complete archive on an external data carrier (USB-FlashDrive).

<CTRL> + <SHIFT> + <L>

The actual user interface scrolls through all of the installed languages in

the inverse sequence.

<ALT> + <S>

Opens the Input Method Editor to enter Asian characters.

<ALT> + <SHIFT> + <D>

Backs up the log files on the USB-FlashDrive. If a USB-FlashDrive is not

inserted, then the files are backed-up in the manufacturer's area of the

CF-Card.

<DEL>

• Edit mode:

Deletes the first character to the right.

• Navigation mode:

Deletes all characters.

<DEL> + <CTRL>

• Edit mode:

Deletes the first word to the right.

• Navigation mode:

Deletes all characters.

HMI sl Milling

22 Operating Manual, 06/2009, 6FC5398-7CP20-0BA0

Introduction

1.2 Operator panel fronts

Key Function

<INSERT>

<Return> / <Enter> Accepts the entered value and moves the cursor into the next line/cell.