Page 1

SINAMICS S210

Servo Drive System

www.siemens.com/sinamics-s210Unrestricted © Siemens 2019-2020

Unrestricted © Siemens 2019

Page 2

SINAMICS S210 Servo Drive System, positioning within

SINAMICS “Discontinuous Motion” Portfolio

Basic: SINAMICS V90

Servo Drive System

Single axis AC/AC drive with

basic functionality and connectivity

for standard numeric and motion

controllers

Unrestricted © Siemens 2019

Page 3

Midrange: SINAMICS S210

Servo Drive System

Single axis AC/AC drive with high

dynamic and performance for

motion applications in the mid range

segment.

High-End: SINAMICS S120

Servo Drive

Modular DC/AC multi axis system

with most advanced drive based

technology and connectivity to high

end numeric and motion controllers

Page 3

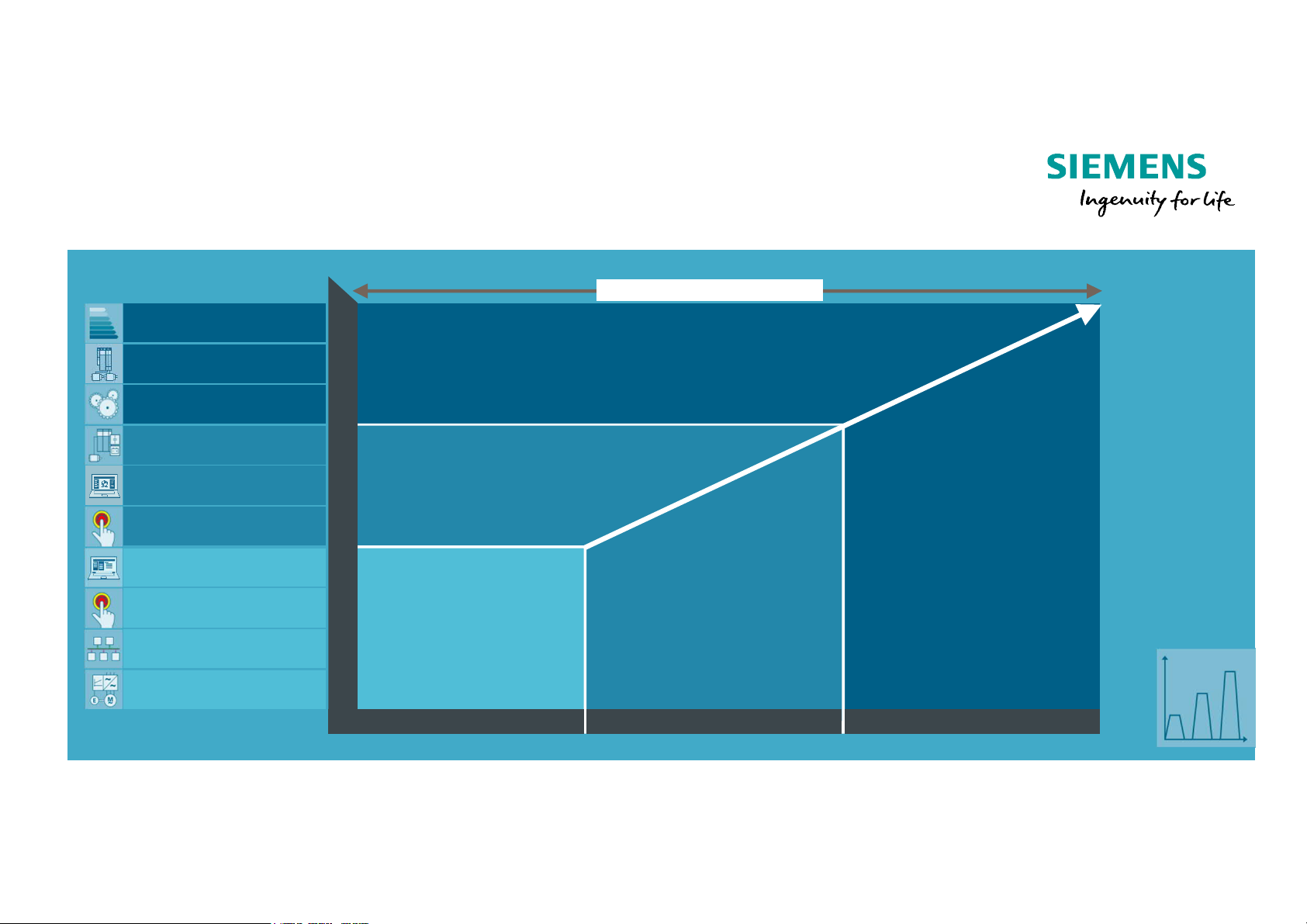

The scalable SINAMICS Drives Portfolio

for „Discontinuous Motion“

Engineered with TIA Portal

Energy Recovery

Multiaxis, Direct Drives

DCC / TEC

DC Coupling

(only 3-AC units)

Startdrive Integration

+ Webserver

Basic & Extended

Safety incl. PROFIsafe

TIA Portal Integration

Safety:

STO via terminal

PROFINET, serial com.,

e.g. Modbus, PTI

*)

Performance & drive functions

V90

+ 1FL6

S210

+ 1FK2

S120 / S120M

+ 1FK7, 1FT7 , 1PH8, 1FG1,

2

Servo Control

Unrestricted © Siemens 2019

Page 4

Basic Midrange High-End

2

+ additional motors

Page 4

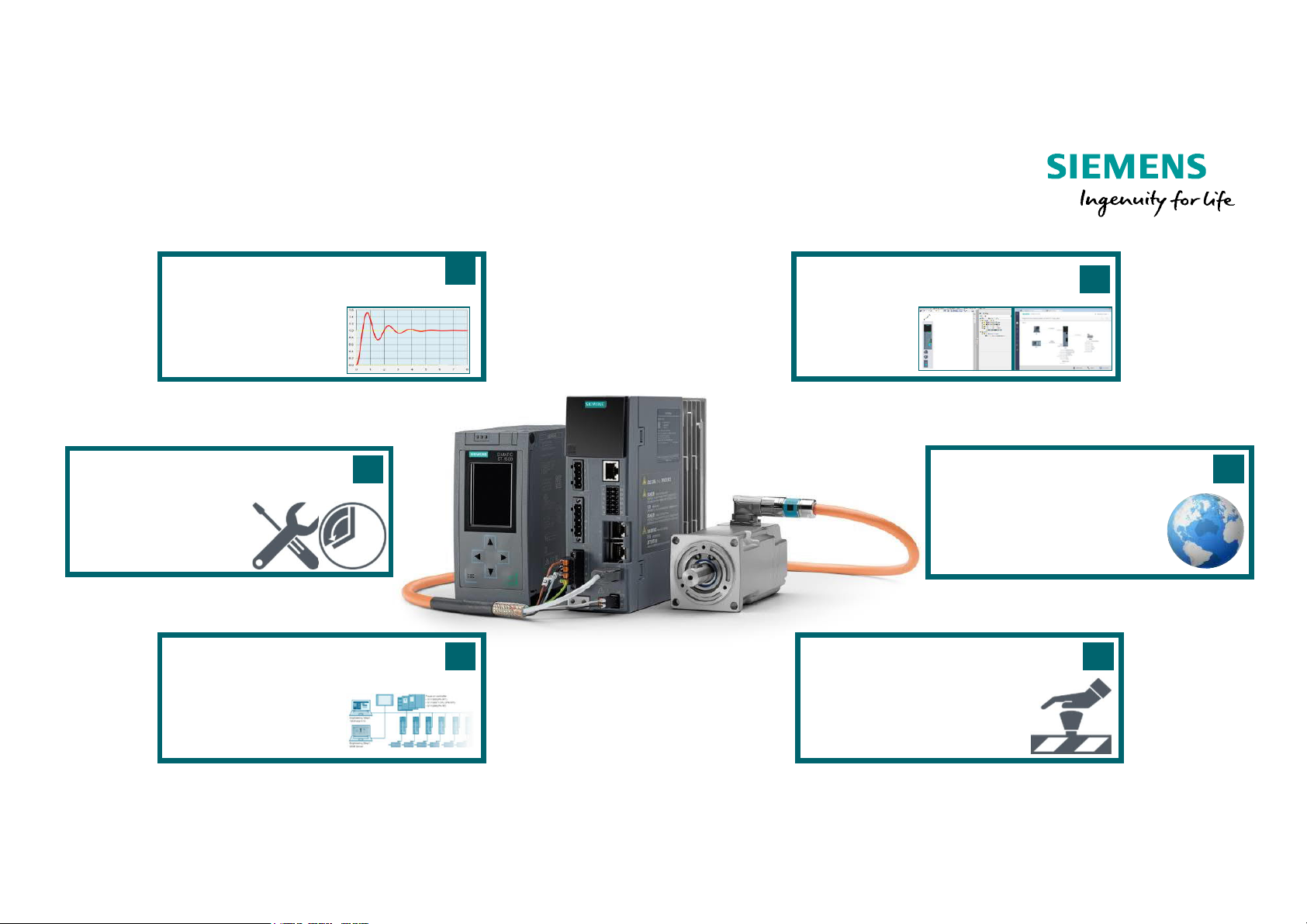

SINAMICS S210 Servo Drive System

Easy, High Performant, Safe

Compact design High Performance

Simple installation with

One Cable Connection for

the motor

Optimal together with

SIMATIC controller

+

Easy commissioning

+

via TIA Portal*)(>= V15.1)

or

High

Dynamic

+

Webserver

Ready for world wide

+

markets

+

Integrated Safety

+

Functionality

Unrestricted © Siemens 2019

Page 5

Page 5

SINAMICS S210 Servo Drive System

The top highlights of the System

Feature / Function Benefits

SIMOTICS S-1FK2

SIMOTICS S-1FK2

Unrestricted © Siemens 2019

Page 6

SINAMICS S210

• Dedicated S-1FK2 motor(HD/CT)

• Fast Current Controller (62,5 µs)

• Fast PROFINET IRT (250 µs)

• DC-Coupling (for 3-AC units)

• Basic & Extended Safety

integrated functions via

PROFIsafe

• Integrated Webserver

• “One Button Tuning”

• TIA Portal (V15.1) integrated

• TIA Selection Tool integrated

• One-Cable-Connection (OCC)

• Integrated EMC Filter

• Integrated Braking Resistor

• 1AC 230V (200-240V) 0.05 – 0.75kW

• 3AC 400V (200-480V) 0.4 – 7kW

• UL Certification

u

u

u

u

u

High

Dynamic

• Increase

performance

• Fulfill high

demands for

safety

• Easy

engineering

• Safes time on

installation

• Ready for world

wide markets

Page 6

Added Value

with SINAMICS S210 Servo Drive System

System advantages

PROFINET

Industrial Ethernet

The certified integrated safety

functions help to ensure to

realize a practicable protection

of personnel and machinery

Simple engineering and high

performance with PROFINET,

Safety on the same bus,

PROFIenergy

Integrated engineering and

Unrestricted © Siemens 2019

Page 7

data management via TIA-Portal.

Standard operating philosophy.

One project file, therefore

consistency is always ensured.

Page 7

SINAMICS S210 Safety Integrated functions

according to EN 61800-5-2 functional safety

Functions for safe shutdown

PROFINET

Industrial Ethernet

Safe torque off (STO) Safe Stop 1 (SS1)

Safe Stop 2 (SS2) Safe Operating Stop (SOS)

Functions for safely monitoring motion

Safely-Limited Speed (SLS)

Safe Speed Monitor (SSM) Safe Direction (SDI)

Functions for safe brake management and diagnosis

Safe Brake Control (SBC)

Safe Brake Test (SBT)

Safely-Limited Acceleration (SLA)

Unrestricted © Siemens 2019

Page 8

Standard Safety Function

Extended Safety Function (available starting SINAMICS Firmware Version V5.1 SP1):

License required (via SINAMICS SD-Card)

Motor with safety encoder required (1FK2■■■-■■■■■-■S■■ or 1FK2■■■-■■■■■-■M■■)

Page 8

SINAMICS S210

3AC Devices – Line supply when DC-Link is used

û

ü

3 AC Bus

Terminal and

common DC

Busbar Terminal

included in

optional

6SL3260-2DC000AA0 terminal kit

Group fusing

When DC coupling is used, only group

fusing is allowed! For suggested fuses

please refer to manual of SINAMICS S210.

Therefore also the 3AC supply of the drives

(Terminal X1) must be connected via the

infeed AC busbar connectors (Terminal

included in optional Kit Order Number

6SL3260-2DC00-0AA0)

Unrestricted © Siemens 2019

ü

û

û

û

û

û

Line fusing

When DC coupling is used, single line

fusing is not allowed!

!

DC

infeed

like

BLM of

S120

!

û

û

Infeed of DC via DC Busbar

Using a common external DC supply, like a

SLM of SINAMICS S120 System to power

up the DC busbar of SINAMICS S210 is

not allowed!

If this is required, please use SINAMICS

S120 System instead!

û

Seite 9

Page 9

Motion Control

via SIMATIC S7 & SIMOTION controller and PROFINET

Motion Control

via SIMATIC

Distributed Controllers

SIMATIC ET 200 CPU

SINAMICS S210 follows as

the high dynamic drive!

Unrestricted © Siemens 2019

Page 11

Not in focus for S210!

1) Synchronization with specification of the synchronous position

2) Synchronization without specification of the synchronous position

Page 10

SINAMICS S210 servo drive system

Technical overview

SINAMICS S210

(6SL3210-5HB…) 1AC

(6SL3210-5HE…) 3AC

• Voltage: 1AC 200-240V and

3AC 200-480V

• Power: 50W-7.0kW

• PN IRT (250 µs), current cont. 62,5 µs,

PROFIsafe

• Safety functions: STO, SS1, SBC

Extended safety: SS1, SS2, SOS, SLS,

SSM, SLA, SDI, SBT

• Up to 6 devices can be connected via

DC link (only 3AC devices)

• Removable terminals

• DI: 1 F-DI (2 DI), 2 DI Measure Probes

• Side-by-side mounting

• Integrated EMC-Filter

• Integrated break resistor

• Integrated WEB-Server

Unrestricted © Siemens 2019

Page 13

SIMOTICS S-1FK2

(1FK21…) High Dynamic

(1FK22…) Compact

• Torque (M0): 0,16-40Nm

• High Dynamic (HD) and Compact (CT),

shaft height 20 to 100

• Encoder: 22 Bit Abs. Single or Multiturn

(battery-free)

• 300% overload

• Protection Degree: IP64, optional IP65

• With or without holding brake

• Plain or feather key shaft

• Rotatable, robust metal connector

• Ready to use in North-America

One Cable Connection

(6FX5002-8QN...) Standard

(6FX8002-8QN...) Trailing cable

• Individual cable lengths up to 50m can

be ordered

• SPEED- CONNECT fast connection

system with rotatable motor connector

• Flexible cables with small bending radii

• Trailing cable version available

(6FX800…)

• Small and compact M12 connector for

motor SH20/30mm (only 25mm in

height)

• Extension cables and mounting flange

available

Page 11

SINAMICS S210 servo drive system,

Easy, High Performant, Safe & Perfect together with SIMATIC.

Advantages of S210 servo drive system

SIMOTICS S-1FK2

SIMOTICS S-1FK2

SINAMICS S210

• High performance of drive and motor

• Fast installation of drive and motor via one cable

connection (OCC)

• Integrated basic & extended safety functions

• Easy engineering commissioning because now fully

integrated into the TIA-Portal*), “One Button Tuning”

and web server.

• Optimal together with SIMATIC controller like

SIMATIC S7-1500/T-CPU/ ET200 SP Open Controller.

• Now also integrated in the TIA Selection Tool (offline

Version)

Drives, motors and controllers.

All from a single source.

Unrestricted © Siemens 2019

Page 14

Matching perfectly.

Page 12

Reference MC Factory F80 Erlangen

New production line for SINAMICS S120 Motor-Modules

1

pulsar-351

Equip the material feeding conveyor for the new

SINAMICS S120 Motor Module production line

in MC Factory Erlangen F80. The S210/ S-1FK2

drive a linear axes. The linear axe lifts and

positioned the roller conveyor (1) which is

attached to it. In total there are 4 conveyor

stations with each 4 lifters. Products used:

SINAMICS S210 Servo Drive System and

SIMATIC ET200 SP open controller.

Please see application video here

1

Customer:

MC Factory F80 Erlangen (Germany)

Industry: Equipment manufacturing

Unrestricted © Siemens 2019

Page 15

Benefits:

• Comissioning: Very easy setup, Commissioning of the drive

already finished after 5 minutes! Thanks to One Button

Tuning and electronic type plate of the motor.

• Installation: Fast Installation with One Cable

• Controller: Works perfectly together with distributed

SIMATIC ET200 SP Open Controller

Page 13

SINAMICS S210 Servo Drive System

The new high dynamic Servo Drive System from Siemens

www.siemens.com/sinamics-s210

Unrestricted © Siemens 2019

Page 16

Subject to changes and errors. The information given in this docum ent only contains general descriptions and/or performance features which may

not always specifically reflect those desc ribed, or which may undergo modification in the course of further development of the products. The requested

performance features are binding only when they are expressly agreed upon in the concluded contract.

All product designations, product names, etc. may contain trademarks or other rights of Siemens AG, its affiliated companies or third parties.

Their unauthorized use may infringe the rights of the respective owner.

Loading...

Loading...