Page 1

FUJI-Reader

Service Manual

SP

General Information

© Siemens AG 2003

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

English

Print No.: SPB7-420.840.51.01.02 Doc. Gen. Date: 01.03

Replaces: n.a.

Page 2

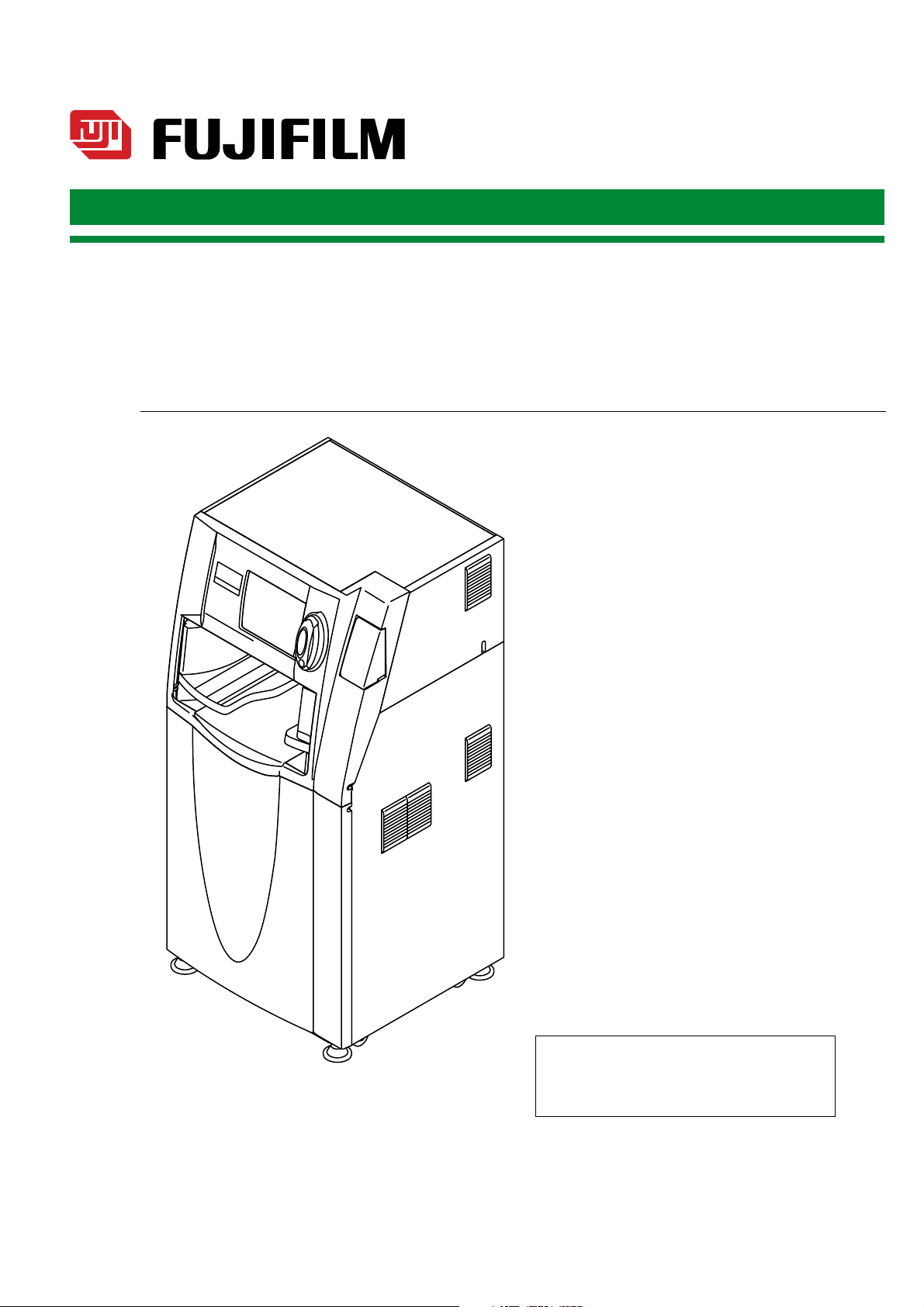

FUJI COMPUTED RADIOGRAPHY

CR-IR347 (FCR 5000MA)

CR-IR347P (FCR 5000MA plus)

Service Manual

Document No. 009-058-03

1 st Edition - Oct. 20, 2000

Revised Edition - Aug. 30, 2002

Fuji Photo Film Co., Ltd.

Printed in Japan

Page 3

0.1

The relationship between mR (milliroentgen), which is the unit of radiation,

and µC/kg (micro-coulomb/kilogram), which is the SI derived unit of radiation,

is as follows.

1 mR = 0.258 µC/kg

FCR® is a registered trademark of Fuji Photo Film Co., Ltd.

<No part of this manual may be reproduced or transmitted.>

Copyright© 2000-2002 by Fuji Photo Film Co., Ltd.

All rights reserved. No part of this publication may be reproduced, stored

in a retrieval system, or transmitted in any form or by means, electronic,

mechanical, photocopying, recording or otherwise, without the prior written

permission of Fuji Photo Film Co., Ltd. Miyanodai Technology Development

Center.

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.1

Page 4

1. Getting Started

■ Scope

This Service Manual is applicable to Fuji Computed Radiography CR-IR347 and CR-IR347P.

The machine is categorized as Class 1 according to IEC classification.

◆

NOTES

• Differences between the CR-IR347 and CR-IR347P are as follows.

The CR-IR347 may be connected to the ID-T741.

The CR-IR347P may be connected to the CR-IR348CL and ID-T741.

• Units with serial number #5001 or later are called “CR-IR347P”.

■ Notation of Unit Symbols

For notation of unit symbols, metric units set forth in the International Systems of Units (SI)

are used, as a rule. However, metric units that are allowed in the Measurement Law, not in

the SI, are used in some cases.

◆

0.2

■ Notation of Warnings, Cautions, etc.

WARNING

Used when death or serious injury may occur if the instruction is not observed.

CAUTION

Used when minor or medium levels of physical injury may be incurred if the instruction is

not observed.

Also used when the machine may suffer serious trouble (such as unrecoverable or

difficult-to-recover trouble).

◆

INSTRUCTION

Used when the machine may suffer damage, or any failure or malfunction may occur, if

the instruction is not observed.

◆

NOTE

Used to indicate the matters that need attention during steps of the procedure.

◆

◆

REFERENCE

Used to indicate terminology or supplemental explanations.

Used to indicate the chapter or section you should refer to.

■ Notation in the Manual

In this service manual, the term “CR-IR347” represents the “FCR5000MA”.

009-058-00

009-058-02

10.10.2000 FM2732

08.30.2001 FM3142

CR-IR347

Service Manual

0.2

Page 5

■ Notation of Symbols

• Check/Adjustment indicator: Indicates that it is necessary to check or adjust the installa-

tion location when the part or component removed is to be

reinstalled.

This indicator is placed in the illustration that depicts the

CHECK

procedures for removing the parts and components.

When you see this indicator, refer to its relevant “■ Check/

Adjustment Procedures.”

• Half-punch indicator: Indicates that it is necessary to align the half-punches when

installing the parts or components.

However, it is not indicated for the half-punches for improving ease of assembly or preventing erroneous assembly

procedures.

■ Servicing Instruments and Tools That Require Inspection/Calibration

The machine should be installed and serviced by use of servicing instruments and tools that

have been inspected and calibrated as appropriate.

0.3

If the machine were serviced using servicing instruments and tools that have not been

inspected and calibrated, proper performance of the machine could not be guaranteed.

Servicing instruments and tools that require inspection/calibration are as listed below.

Inspection/calibration procedures should be performed in accordance with the inspection/

calibration manuals described in the ECN Information.

● Instruments and tools that require inspection/calibration

Name

Dosimeter

Steel rule (150mm)

Steel rule (300mm)

Digital tester

Calipers

Push-pull gauge

✻: A block gauge for use in inspection requires calibration.

Inspection Calibration Servicing instrument inspection/calibration manual No.

–

❍

❍

❍

❍ (✻)

❍

❍

–

–

ECO NO. FCR - A014

❍

–

❍

TR7H0002.EPS

009-058-02

009-058-00

08.30.2001 FM3142

10.10.2000 FM2732

CR-IR347

Service Manual

0.3

Page 6

2. Safety Precautions

Warnings and cautions regarding the procedures should be observed to avoid possible

physical hazards and serious accidents that may occur during installation and servicing.

Labels that describe relevant precautions are attached on the machine.

The instructions on such labels should also be observed during procedures.

2.1 Working Precautions

■ Power Supply

● Unless otherwise instructed in the Service Manual, be sure to turn OFF the power of the

machine and unplug the power plug before servicing. With the power plug still plugged,

you may experience electric shock, burn, or secondary damage due to short circuit even

when the machine is powered OFF. It should be noted, however, that some servicing

procedures, such as voltage measurement, cannot be performed under power-OFF

condition. In such cases, use due care to avoid electric shock, burn, or secondary

damage due to short circuit, as instructed in this manual.

0.4

● To restart or reboot the machine, power it OFF and wait more than five seconds before

powering it ON again. If the machine is powered ON within five seconds, it may

automatically shut down for protection against overcurrent and overvoltage.

■ Drive Mechanism

● Be sure to turn OFF the power before servicing the gears, cams, belts, and other drive

mechanism parts. Otherwise, your body or clothing may be entangled.

However, there may be cases where the procedures cannot be performed under power-

OFF condition. In such cases, use due care to avoid entanglement of your hand, foot,

hairs, and clothing with any rotating mechanism, as instructed in this manual.

■ Heavy Objects

Exercise due care regarding your working posture to avoid back pain during removal and

installation of heavy objects.

■ Safety Devices

Safety devices (such as fuses, circuit breakers, interlock switches, panels, and covers)

should always be enabled. Never attempt to make any alteration or modification that may

impair their safety features.

009-058-00

10.10.2000 FM2732

CR-IR347

Service Manual

0.4

Page 7

■ Optical Parts

Observe the following rules when servicing the optical parts. Otherwise, the image quality

may be degraded.

● Before removing the protective housings, be sure to turn OFF the high-voltage switch (HV

switch). If the machine is powered ON with any of the protective housings removed, the

photomultiplier will be damaged.

● Never remove the scanning optics unit covers. If the covers are removed, the image

quality may degrade.

● For dust removal procedures, observe the instructions described in the manual.

● Some high-voltage parts, such as the photomultiplier, may not be sufficiently discharged

even after power is turned OFF. When servicing such parts, exercise due care to avoid

electric shock hazards (not to touch the connector and terminal carelessly).

■ Other Working Precautions

● Do not remove or install any part or component while the machine is powered, because of

possible electric shock hazards.

● When performing checks or adjustments under the powered condition, exercise due care

against electric shock or other hazards.

0.5

● Do not touch the parts (such as erasure lamps) that remain at high temperature because

you may suffer burns.

● When servicing the scanning optics unit and printed circuit boards, be sure to wear an

antistatic wristband to remove static electricity built on the human body. Static electricity

may cause damage to the printed circuit boards.

● Secure the machine onto the floor in place by use of its adjustable feet or retainers.

● Keep clean the product labels, safety standards labels, product serial number indications,

and so forth attached on the machine, and do not peel them or put another label over

them.

● Before powering ON the machine after completion of the servicing procedures, make sure

that all the parts, screws, connectors, and so forth that were removed have been reinstalled as appropriate, and that no tool is left in the machine.

009-058-00

10.10.2000 FM2732

CR-IR347

Service Manual

0.5

Page 8

2.2 Precautions Against Laser Radiation

As indicated by the Certification and Indication Label attached on the rear cover of the

machine for overseas use, the machine complies with the U.S. Federal Regulations

concerning laser safety. The image reader incorporates a laser with a maximum output of 60

mW (Class 3B, semiconductor laser wavelength of 660 nm, red visible light), but you will not

be exposed to any hazard if you perform tasks as instructed in this manual.

■ Precautions Against Laser Exposure

Observe the following precautions to avoid laser exposure.

● Procedures that require precautions against laser exposure

When performing the following procedures, observe the instructions exactly as described

in this manual to avoid laser exposure. After the procedures are completed, put the

removed protective housings and screws back exactly in their original position to prevent

leakage of a laser beam out of the machine.

• Removal and reinstallation of the scanning optics unit.

• Replacement and cleaning of subscanning unit parts.

● Preventive maintenance for keeping the machine in compliance

0.6

In order to keep the machine in compliance, perform preventive maintenance programs

described in “Preventive Maintenance Volume” at intervals specified.

● Things that should not be done to avoid laser exposure

Observe the following precautions to avoid laser exposure.

• Never attempt to perform procedures other than instructed in this manual because you

may be exposed to laser beam radiation.

• Do not reflect a laser beam by placing a mirror or the like in the laser beam path.

• Do not alter the light path of a laser beam.

• Do not replace optical parts while the laser is energized.

• Do not attempt to make optical axis adjustment in the field. Although the semiconductor

laser beam is red visible light, field adjustment of the optical axis cannot be done.

009-058-00

009-058-00

10.10.2000 FM2732

10.10.2000 FM2732 (1)

CR-IR347

Service Manual

0.6

Page 9

■ Protective Housings Against Laser Exposure

Even when the protective housings are removed for servicing, laser beams will never leak

out from the machine unless the optical path is intentionally changed. However, if the optical

path is changed inadvertently during optics-related procedures, the service engineer or other

people around the machine may be possibly exposed to laser radiation. During opticsrelated procedures, carefully perform the procedures while checking the instructions

described in this manual, and after the procedures are completed, restore the protective

housings removed back exactly where they were.

● Protective Housing of the Machine

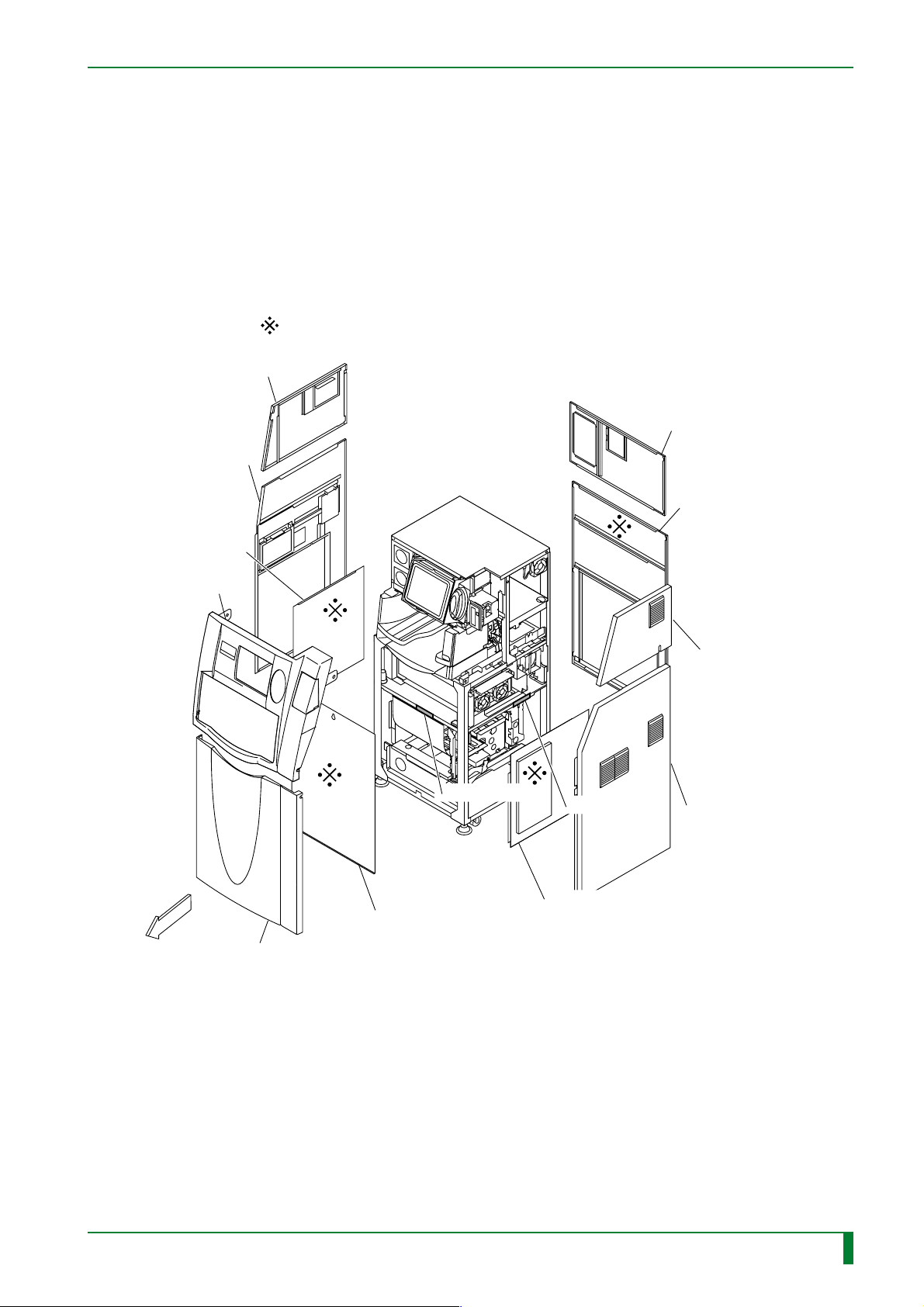

The removable protective housings of the machine are illustrated below. The four covers

marked by

Upper left-hand side cover

Lower left-hand side cover

in the illustration below are protective housings against laser exposure.

0.7

Upper rear cover

Left-hand inner cover

Upper front cover

FRONT

Lower front cover

HHS label #2

Light protect plate

HHS label #2

Right-hand inner cover

Lower rear cover

Upper right-hand side cover

Lower right-hand side cover

FR7H0001.EPS

009-058-00

10.10.2000 FM2732

CR-IR347

Service Manual

0.7

Page 10

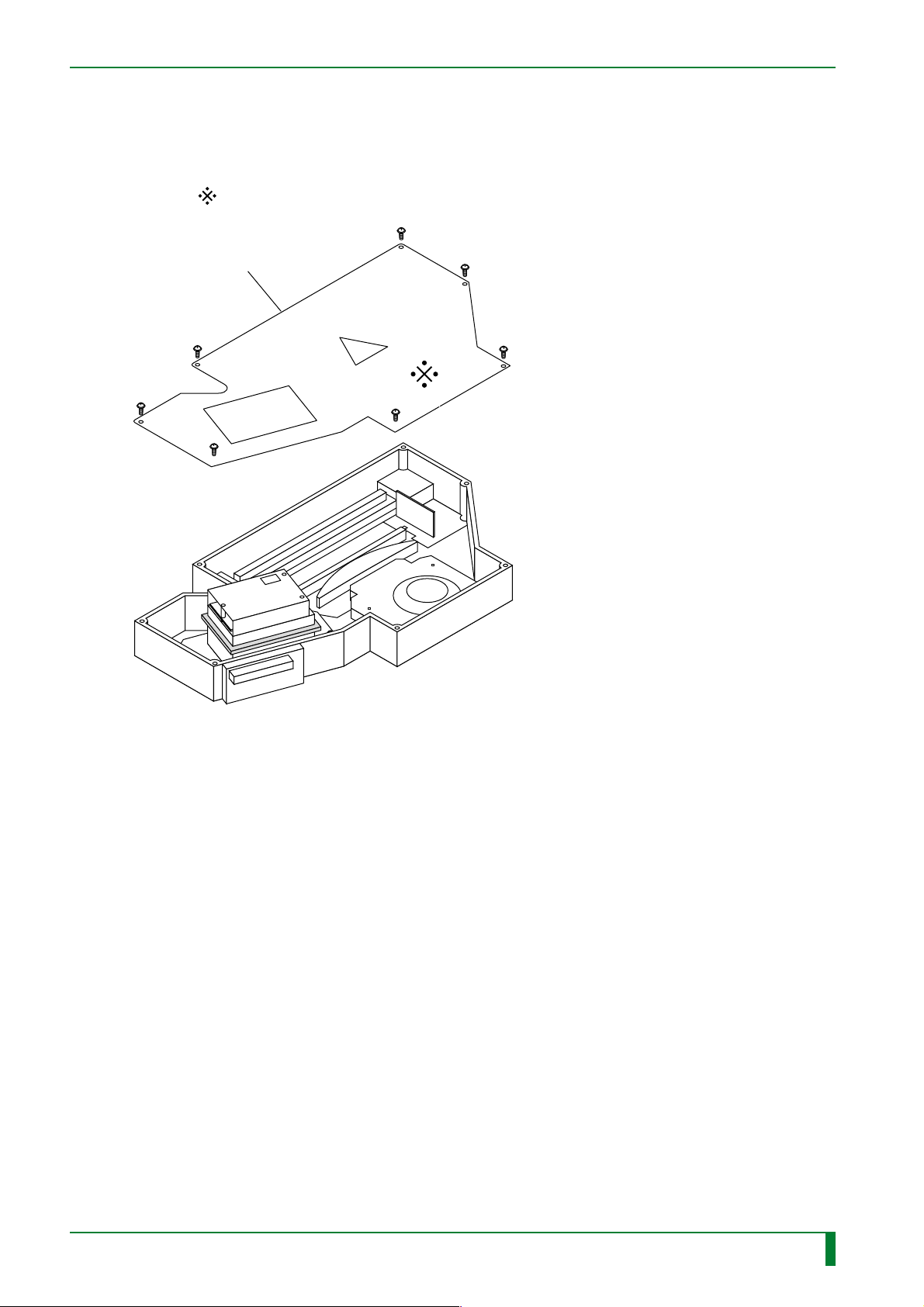

■ Scanning optics unit protective housing

The removable protective housing for the scanning optics unit is shown below. The

protective housing for laser radiation exposure prevention consists of the cover that is

marked

in the figure below.

Top cover

0.8

FR7H0015.EPS

009-058-00

10.10.2000 FM2732

CR-IR347

Service Manual

0.8

Page 11

BLANK PAGE

0.9

009-058-00

10.10.2000 FM2732

CR-IR347

Service Manual

0.9

Page 12

2.3 Safety Labels and Other Labels

2.3.1 Laser Precaution Labels

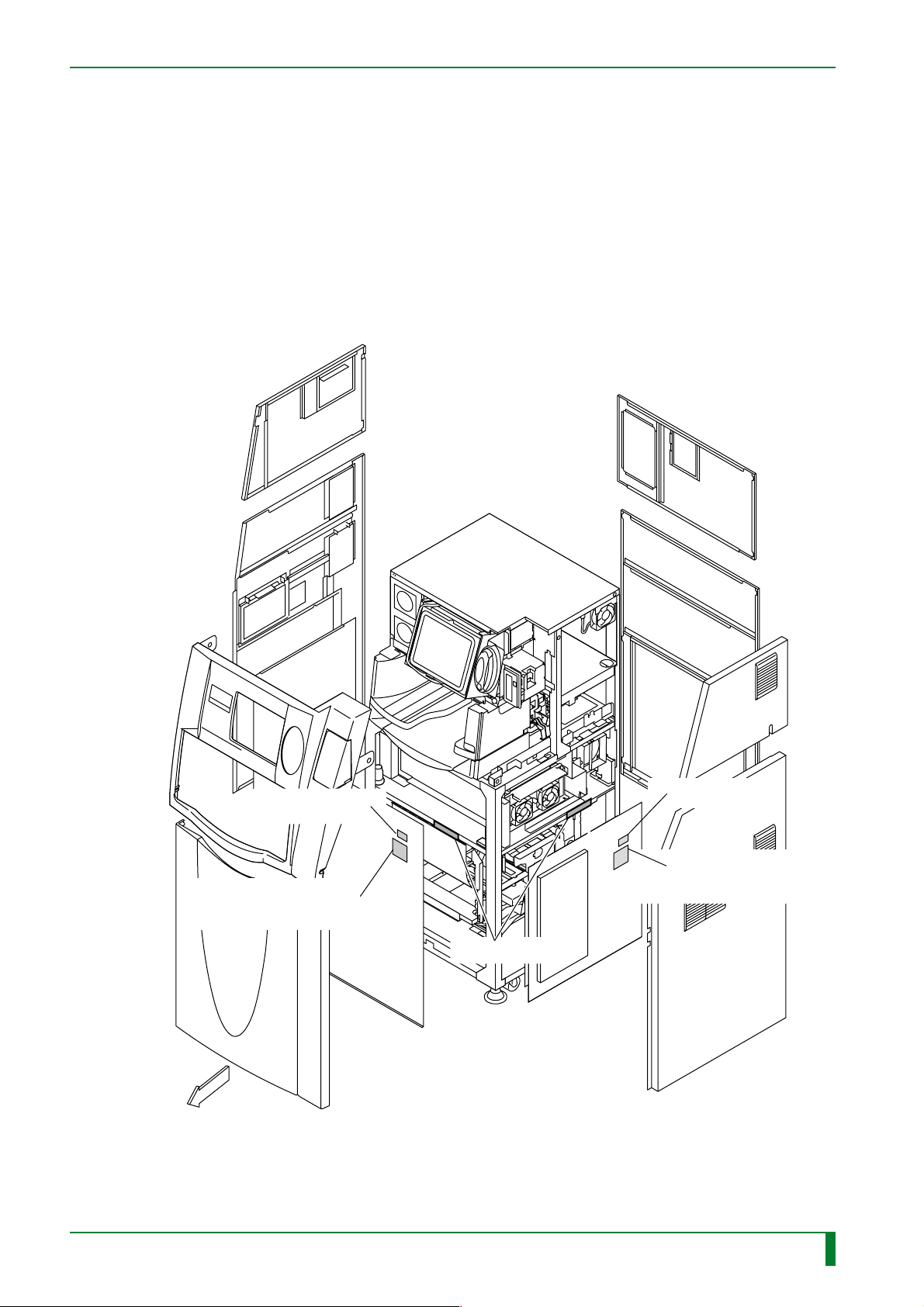

■ Precaution Label Attachment Locations

Below are illustrated the protective housings and attachment locations of laser precaution

labels, as specified in Part 1-J, Federal Regulations Code “Title 21” issued by the FDA of the

U.S.

● Machine

0.10

EN 60825-1: 1996

Class 3B panel label

FRONT

HHS label #1

HHS label #1

EN 60825-1: 1996

Class 3B panel label

HHS label #2

FR7H0002.EPS

009-058-00

10.10.2000 FM2732

CR-IR347

Service Manual

0.10

Page 13

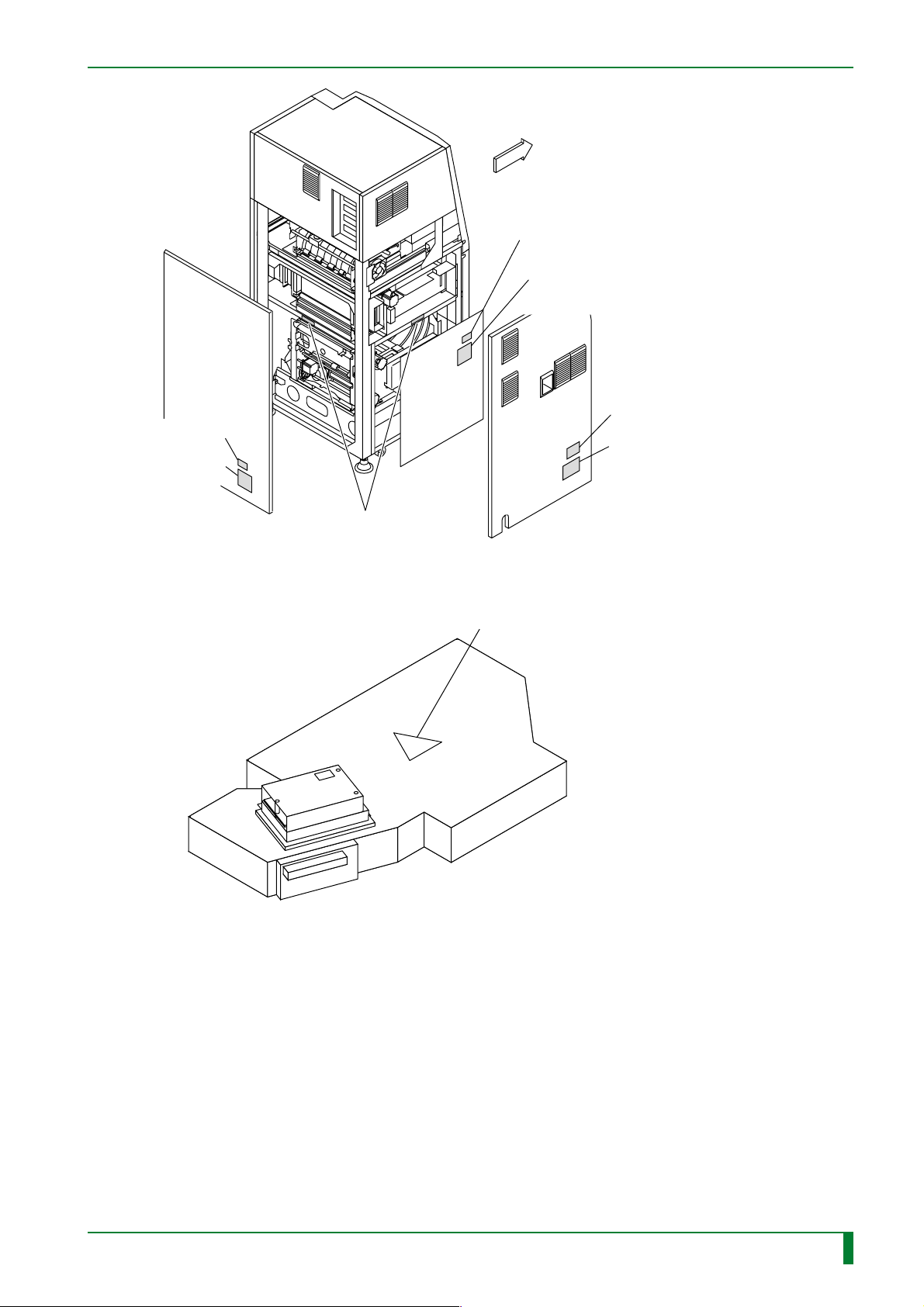

HHS label #1

EN 60825-1: 1996

Class 3B panel label

0.11

FRONT

HHS label #1

EN 60825-1: 1996

Class 3B panel label

HHS certification and identification label

EN 60825-1: 1996

Class 1 product label

HHS label #2

● Scanning Optics Unit

FR7H0003.EPS

EN 60825-1: 1996 warning label

FR7H0015.EPS

009-058-00

10.10.2000 FM2732

CR-IR347

Service Manual

0.11

Page 14

Safety Precautions

26-30, NISHIAZABU 2-CHOME, MINATO-KU,

26-30, NISHIAZABU 2-CHOME, MINATO-KU,

■ List of Precaution Labels

● HHS Certification and Identification Label

CR-IR347 CR-IR347P

0.12

FUJI PHOTO FILM CO., LTD.

26-30, NISHIAZABU 2-CHOME, MINATO-KU,

TOKYO 106-8620, JAPAN

MODEL

SERIAL No.

MANUFACTURED

This product complies with

21 CFR Chapter 1. Subchapter J.

CR-IR 347

● HHS Label #1

DANGER

Laser radiation when open

AVOID DIRECT EXPOSURE TO BEAM

● HHS Label #2

DANGER

Laser radiation

when open external cover

AVOID DIRECT EXPOSURE TO BEAM

FPE

FR7H0004.EPS

FR7H0005.EPS

FR7H0006.EPS

FUJI PHOTO FILM CO., LTD.

26-30, NISHIAZABU 2-CHOME, MINATO-KU,

TOKYO 106-8620, JAPAN

MODEL

SERIAL No.

MANUFACTURED

This product complies with

21 CFR Chapter 1. Subchapter J.

CR-IR 347P

FIT

FR7H0021.EPS

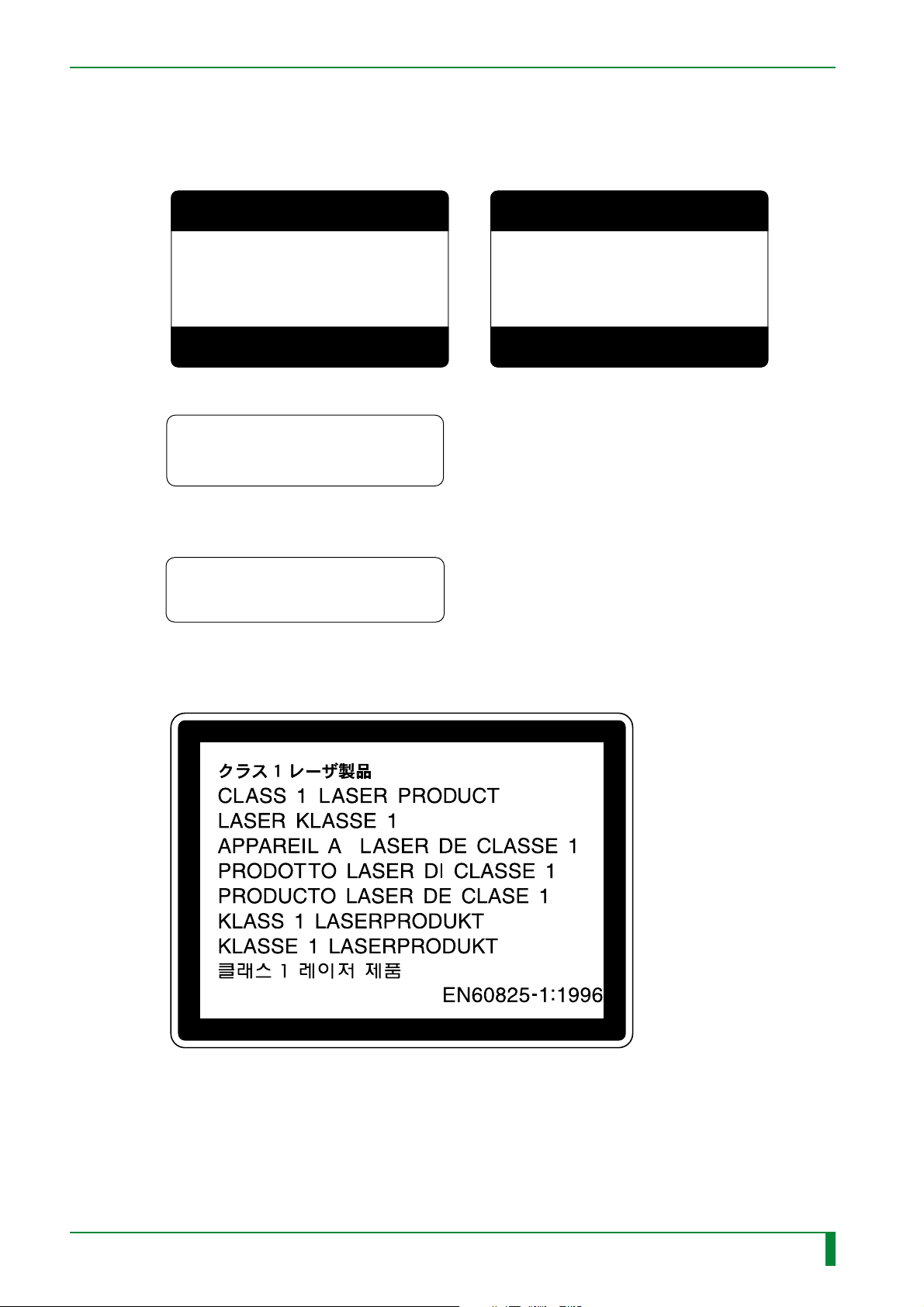

● EN 60825-1: 1996 Class 1 Product Label

FR7H0007.EPS

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.12

Page 15

● EN 60825-1: 1996 Class 3B Panel Label

0.13

● EN 60825-1: 1996 Warning Label

FR7H0016.EPS

FR7H0008.EPS

009-058-00

10.10.2000 FM2732

CR-IR347

Service Manual

0.13

Page 16

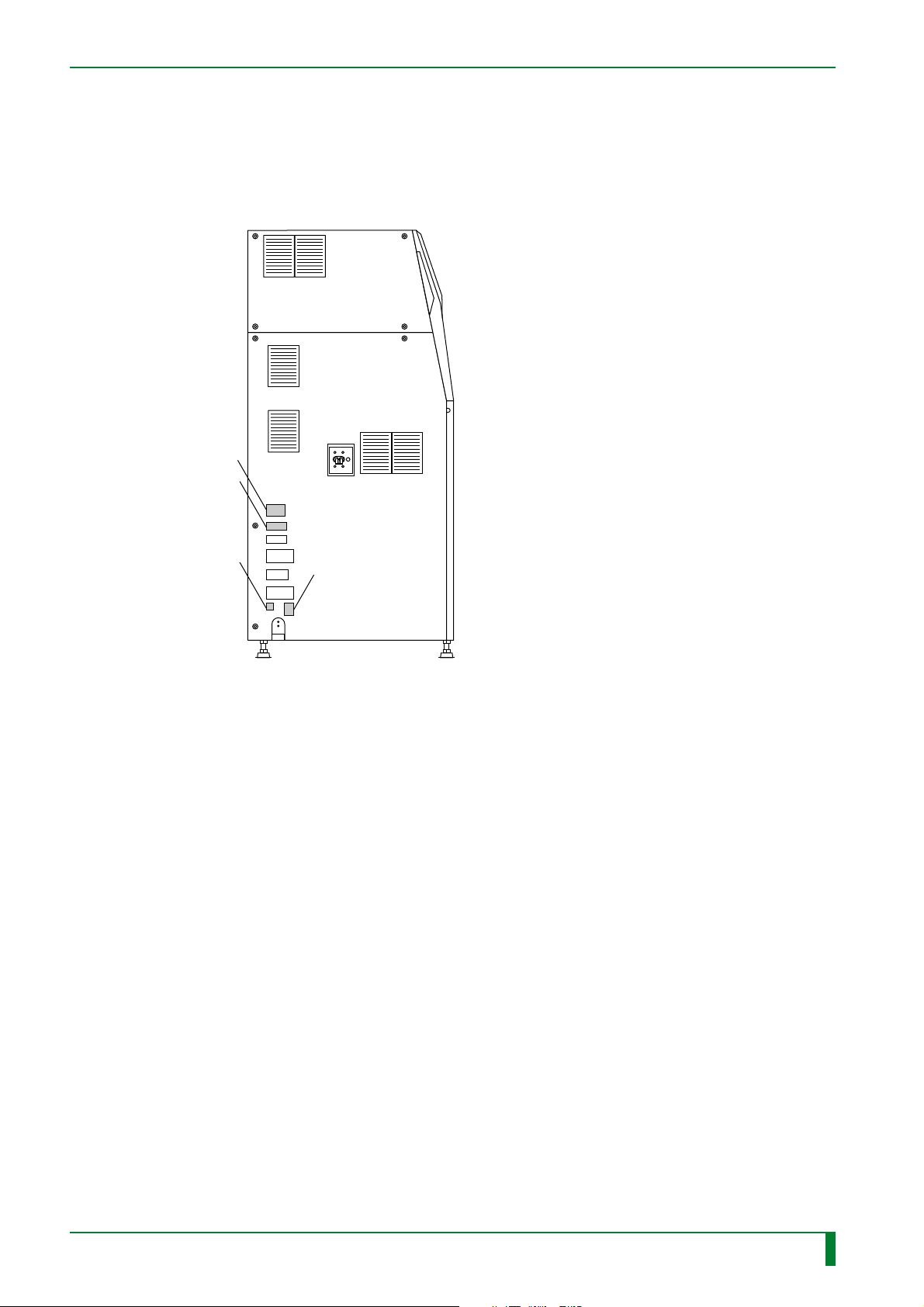

2.3.2 Other Labels

■ Label Attachment Locations

Left-hand side

Rating indication label

Manufacturer label

0.14

Compliance sticker

Electric shock

caution label

FR7H0009.EPS

009-058-00

10.10.2000 FM2732

CR-IR347

Service Manual

0.14

Page 17

Safety Precautions

■ List of Other Labels

● Ratings Indication Label

CR-IR347 CR-IR347P

0.15

● Manufacturer Label

FR7H0011.EPS

● Compliance sticker

EXAMINED

GOOD

FUJI KIKI

FR7H0012.EPS

● Electric shock caution label

FR7H0010E.EPS

FR7H0022E.EPS

009-058-03

08.30.2002 FM3476

FR7H0013.EPS

CR-IR347

Service Manual

0.15

Page 18

3. Specifications of the Machine

3.1 Dimensions, Weight, and Center of Gravity

■ Dimensions

W730xD700xH1565 (mm)

730

0.16

■ Weight

280 kg approx.

■ Center of Gravity

Height: 720 mm

From the right-hand side: 365 mm

From the rear: 385 mm

700

1565

Unit: mm

FR7H0018.EPS

009-058-00

009-058-00

10.10.2000 FM2732

10.10.2000 FM2732 (1)

CR-IR347

Service Manual

0.16

Page 19

3.2 Machine Moving and Fixing Means

■ Moving Means

• Caster x 4 (omnidirectional, no brake attached)

■ Fixing Means

• Adjustable foot x 4

3.3 Environmental Requirements

■ Atmospheric Requirements

Operation Non-operation During transit

Temperature

Relative

humidity

Atmospheric

pressure

15–30 °C0–45 °C -10–50 °C

40–80 %

700–1,030 hPa 500–1,030 hPa

10–90 % 10–90 %

(Without condensation)

0.17

The above environmental requirements during non-operation

and during transit do not apply to IPs (Imaging Plates).

■ Floor (Installation Area) Vibration Requirements

10 to 55 Hz in frequency and 0.0075 mm or less in amplitude.

■ Floor Levelness

10 mm/m (1/100 of inclination) or less for both front and rear and both right and left

■ Floor Flatness

10 mm or less

■ Variable Magnetic Field

0.3 gauss p-p or less

TR7H0001.EPS

009-058-00

009-058-00

10.10.2000 FM2732 (1)

10.10.2000 FM2732

CR-IR347

Service Manual

0.17

Page 20

3.4 Electrical Specifications

■ Frequency

50Hz/60Hz, single-phase, common specification

■ Line Voltage

120-240 V A C ±10%

■ Power Capacity

0.8 kVA

■ Power Cord

100 V: 3.5 m.

200 V: 15 m.

■ Rated Amperage

120-240 VAC, 50/60Hz: 6.7A-3.3A

0.18

■ Overload Protection

100 V/200 V: 15 A.

■ Power Consumption

0.8 kVA.

■ Grounding (Overseas)

Use a separate cable kit specifically designed for local use, and securely insert the power

plug into an indoor polarized receptacle.

3.5 Other Specifications

■ Maximum Heat Generation

800 wh.

■ Noise

Standby: 55 dB or less.

Operation: 60 dB or less

Single-shot noise: 70 dB or less

■ Warm-up Time

Approx. 4 minutes.

009-058-02

009-058-00

08.30.2001 FM3142

10.10.2000 FM2732

CR-IR347

Service Manual

0.18

Page 21

3.6 Installation and Servicing Spaces

■ Installation space requirements

The space required for installation varies depending on whether the machine is anchored.

● When the machine is not anchored ● When the machine is anchored

Height: 1800 or more

Height: 1800 or more

0.19

Rear

Machine

Front

50 or more

700 or more

■ Servicing space requirements

Furnish the following space for servicing purposes.

Height: 1900 or more

Rear

700 or more

Rear

700 or more 700 or more200 or more 200 or more

Machine

Front

100 or more

700 or more

Unit: mm

FR7H0019.EPS

600 or more

Front

Machine

700 or more

700 or more

Unit: mm

FR7H0020.EPS

009-058-00

10.10.2000 FM2732

CR-IR347

Service Manual

0.19

Page 22

3.7 Preliminary W ork

Before starting the grounding procedures, make sure that the place where the machine is to

be installed meets the criteria set forth in “SSS Installation Site Requirements.”

Before the machine is transferred, preinstallation procedures should be completed for necessary electrical utility, water supply/drain piping, waste solution disposal, and air-conditioning

system installation work.

■ Electrical Work (Overseas)

For more detail, local rules and regulations should be complied with.

● For 200V power supply

An independent branch circuit assigned specifically for the machine should be provided via a

15A circuit breaker .

A predetermined ground wiring should be implemented for the ground polarity of the recep-

tacle.

● For 100V power supply

A predetermined ground wiring should be implemented for the ground polarity of the recep-

tacle.

0.20

■ Installation site conditions

Avoid the following installation sites:

• Places where the temperature changes drastically

• Places near heat sources such as heaters

• Places where water leakage or equipment submersion may occur

• Places where any corrosive gas ma y be generated

• Dusty places

• Places where the machine is subject to constant or excessive vibration/shock

• Places exposed to direct sunlight

009-058-02

009-058-00

08.30.2001 FM3142

10.10.2000 FM2732

CR-IR347

Service Manual

0.20

Page 23

BLANK PAGE

0.21

009-058-00

10.10.2000 FM2732

CR-IR347

Service Manual

0.21

Page 24

Notation of Board Names in Manual

4. Notation of Board Names in Manual

Information about modifications to the boards installed in the machine is summarized here.

Unless spelled out or enumerated in the manual, board names shall be replaced as follows.

0.22

Change to boards installed

MTH08C → MTH08D

MMA90A → DIM08A

MMB90A → DIM08A

CPU90F → LAN90B

Summary of change

● Features of the MTH08D board

• DIP switch (S1) was added.

• The fuse was changed to a replaceable glass tube type.

• The subject to be protected by the fuse was changed.

● Features of the DIM08A board

• Memory module for the MTH08D board.

• The procedure for its removal/reinstallation was changed

to horizontal detachment.

• Shipped as installed in the machine.

● Features of the LAN90B board

• To install the LAN90B board, it is necessary that the bracket

located on the rear side of the controller be version D or later.

TR7H0003.EPS

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.22

Page 25

BLANK PAGE

0.23

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.23

Page 26

Contents Maintenance Machine Description

CR-IR347 Service Manual – Contents

Machine Description (MD)

1. Machine Overview ........................................................................................................ MD-2

1.1 Features .............................................................................................................. MD-2

1.2 System Configuration........................................................................................ MD-4

1.3 External Machine Components and Their Names .......................................... MD-10

1.4 Internal Machine Components.......................................................................... MD-12

1.4.1 Unit arrangement ................................................................................... MD-12

1.4.2 Roller arrangement and conveyance path .......................................... MD-13

1.4.3 I/O arrangement diagram and function descriptions ......................... MD-14

1.4.4 PC board arrangement diagram ........................................................... MD-18

1.5 System Block Diagram ...................................................................................... MD-20

0.24

1.6 Power Supply Related Fuse Block Diagram.................................................... MD-22

2. Software ........................................................................................................................ MD-26

2.1 Software Terms and Definitions ....................................................................... MD-26

2.2 Image Data Flow (1) ........................................................................................... MD-28

2.3 Image Data Flow (2) ........................................................................................... MD-30

2.4 Startup Control Descriptions ............................................................................ MD-34

3. Electrical ....................................................................................................................... MD-36

3.1 Power supply unit (JPS-6)................................................................................. MD-36

3.2 Erasure Unit........................................................................................................ MD-38

3.3 Information on Board LEDs .............................................................................. MD-40

4. Scanner ......................................................................................................................... MD-44

4.1 Scanner Components ........................................................................................ MD-45

4.2 Scanner Operation Descriptions ...................................................................... MD-46

5. Mechanical .................................................................................................................... MD-48

5.1 Cassette Set Unit ............................................................................................... MD-50

5.2 IP removal unit ................................................................................................... MD-51

5.3 Erasure Conveyor ........................................................................................... MD-51.2

5.4 Side-Positioning Conveyor .............................................................................MD-51.3

5.5 Subscanning Unit ............................................................................................ MD-51.5

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.24

Page 27

Contents Maintenance Machine Description

6. ***This chapter is intentionally blank*** ................................................................... MD-51.9

7. ***This chapter is intentionally blank*** ................................................................. MD-51.11

8. Mechanical Control Flowcharts .................................................................................. MD-52

8.1 Viewing the Control Flowcharts ....................................................................... MD-52

8.2 Normal Operation Flowcharts........................................................................... MD-54

8.2.1 Cassette insertion .................................................................................. MD-56

8.2.2 IP feed ..................................................................................................... MD-62

8.2.3 IP length measurement ......................................................................... MD-70

8.2.4 IP Identification ...................................................................................... MD-74

8.2.5 Cleaning guide grip ............................................................................... MD-78

0.25

8.2.6 Side-Positioning Conveyance .............................................................. MD-80

8.2.7 Cleaning Guide Grip Release ............................................................... MD-84

8.2.8 Side-positioning ..................................................................................... MD-88

8.2.9 CSL/IDT information confirmation ....................................................... MD-92

8.2.10 Preparations for reading ....................................................................... MD-94

8.2.11 Reading ................................................................................................... MD-96

8.2.12 CSL/IDT information confirmation 2 ....................................................MD-104

8.2.13 After-reading conveyance ..................................................................... MD-106

8.2.14 Before-erasure conveyance .................................................................. MD-108

8.2.15 Erasure conveyance ..............................................................................MD-112

8.2.16 After-erasure conveyance ..................................................................... MD-114

8.2.17 IP loading ................................................................................................ MD-118

8.2.18 Erasure confirmation ............................................................................. MD-124

8.2.19 Cassette ejection ...................................................................................MD-126

8.3 Secondary Erasure Flowcharts ........................................................................MD-128

8.3.1 Backward loading ..................................................................................MD-130

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.25

Page 28

Contents Maintenance Machine Description

8.4 Step Operation Flowcharts ...............................................................................MD-132

8.4.1 Feed/load step operation ...................................................................... MD-132

8.4.2 Side-positioning step operation ...........................................................MD-142

8.5 Initialization Flowcharts ....................................................................................MD-146

8.5.1 Side-positioning grip home positioning ..............................................MD-148

8.5.2 Side-positioning unit home positioning ..............................................MD-152

8.5.3 Mirror ascent ..........................................................................................MD-156

8.5.4 Initialization subscanning grip confirmation ...................................... MD-158

8.5.5 Cleaning guide HP positioning .............................................................MD-162

8.5.6 IP search ................................................................................................. MD-166

8.5.7 Suction cup HP positioning .................................................................. MD-176

0.26

8.5.8 Feed/load conveyance IP processing .................................................. MD-180

8.5.9 Cassette hold release confirmation .....................................................MD-184

8.5.10 Before-reading standby IP processing ................................................MD-188

8.5.11 Subscanning grip HP positioning ........................................................ MD-194

8.5.12 Empty cassette ejection ........................................................................MD-204

8.5.13 Mirror descent ........................................................................................MD-206

8.5.14 Initialization cassette hold release ....................................................... MD-208

8.6 Abnormality Process Flowcharts ..................................................................... MD-210

8.6.1 Abnormality process (cassette ejection 1) ..........................................MD-210

8.6.2 Abnormality process (cassette ejection 2) ..........................................MD-212

8.6.3 Abnormality process (cassette not detected) ..................................... MD-216

8.6.4 Abnormality process (recovered IP loading) ...................................... MD-217

8.6.5 Abnormality process (high dose) .........................................................MD-218

8.6.6 Abnormality process (IP generation/type mismatch detection) ........MD-219

8.6.7 Abnormality process (lamp failure) ..................................................... MD-220

8.6.8 Abnormality process (IDT line failure) ................................................. MD-221

8.6.9 Abnormality process (ID information not registered) ........................ MD-222

009-058-03

08.30.2002 FM3476

8.6.10 Abnormality process (BCR retry) .........................................................MD-223

CR-IR347

Service Manual

0.26

Page 29

Contents Maintenance Machine Description

BLANK PAGE

0.27

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.27

Page 30

Contents Maintenance Troubleshooting

Troubleshooting (MT)

1. Overview of Troubleshooting ...................................................................................... MT1-1

1.1 Flow of Troubleshooting ................................................................................... MT1-1

1.2 How to Understand Error Log........................................................................... MT1-3

2. Error Codes List ........................................................................................................... MT2-1

3. Format of Detail Information ....................................................................................... MT3-1

3.1 Supplementary Explanation of Detail Information.......................................... MT3-17

3.2 Format of Abort Code ........................................................................................MT3-18

4. Error Code Analysis Flow (Mechanism)..................................................................... MT4-1

03A2, 13A1, 13A2, 23A1, 23A2 .......................................................................... MT4-1

13A4, 13A5 .......................................................................................................... MT4-2

0.28

13A6, 13A7 .......................................................................................................... MT4-3

13A8, 23A8 .......................................................................................................... MT4-4

13A9, 23A9 .......................................................................................................... MT4-5

13AA, 23AA......................................................................................................... MT4-6

13AD .................................................................................................................... MT4-7

03B1, 23B1 .......................................................................................................... MT4-8

03B2, 23B2 .......................................................................................................... MT4-9

03B3 .................................................................................................................... MT4-10

03B4, 03B5, 03B6 ...............................................................................................MT4-11

03B7 .................................................................................................................... MT4-12

03BC, 23BA, 23BB, 23BC ..................................................................................MT4-13

03BF, 23BD, 23BE, 23BF ...................................................................................MT4-14

03C1 .................................................................................................................... MT4-15

03C0, 03C2 ..........................................................................................................MT4-16

03C6, 03C8, 03CA, 23C6 .................................................................................... MT4-17

03C7, 03C9, 03CB, 23C7 .................................................................................... MT4-18

03CC ....................................................................................................................MT4-19

009-058-03

08.30.2002 FM3476

03CD ....................................................................................................................MT4-20

03D3 .................................................................................................................... MT4-22

03D5 .................................................................................................................... MT4-23

13E1, 13E2, 13E4, 13E5, 13E9, 23E1, 23E2, 23E4, 23E5, 23E9 ....................... MT4-25

13E3, 23E3 ..........................................................................................................MT4-26

03E8, 23E6, 23E7, 23E8 ..................................................................................... MT4-27

03EE, 03EF, 23EA, 23EB, 23EC, 23ED ............................................................. MT4-28

23F1, 23F2........................................................................................................... MT4-29

13F3, 23F3........................................................................................................... MT4-30

CR-IR347

Service Manual

0.28

Page 31

Contents Maintenance Troubleshooting

5. Error Code Analysis Flow (Scanner) .......................................................................... MT5-1

0532, 2542, 2570 ................................................................................................. MT5-1

0534, 1533, 2543, 2544, 2571, 2572, 2573, 2574 ............................................... MT5-2

0536, 2535, 2545, 2546 ....................................................................................... MT5-3

0537, 2547, 2575 ................................................................................................. MT5-4

0538, 2530, 2548, 2576 ....................................................................................... MT5-5

0563, 2560, 2561, 2564 ....................................................................................... MT5-6

6. Error Code Analysis Flow (Electrical) ........................................................................ MT6-1

7. Checkout Flowcharts ................................................................................................... MT7-1

7.1 Checking the SK1 .............................................................................................. MT7-2

0.29

7.2 Checking the SK2 .............................................................................................. MT7-4

7.3 Checking the SK3 .............................................................................................. MT7-6

7.4 Checking the Ground Connections.................................................................. MT7-8

7.5 Checking the SL1 ...............................................................................................MT7-10

7.6 Checking the SL2 ...............................................................................................MT7-12

7.7 Checking the SL4 ...............................................................................................MT7-14

7.8 Checking the SL5 ...............................................................................................MT7-16

7.9 Checking the SM1 ..............................................................................................MT7-18

7.10 Checking the SN1 .............................................................................................. MT7-20

7.11 Checking the SN2 .............................................................................................. MT7-22

7.12 Checking the SN3 .............................................................................................. MT7-24

7.13 Checking the SN4 .............................................................................................. MT7-26

7.14 Checking the SZ1 (SED08D) ............................................................................. MT7-28

7.15 Checking the SZ2 ...............................................................................................MT7-30

7.16 Checking the SZ3 ...............................................................................................MT7-32

7.17 Checking the SZ4 ...............................................................................................MT7-34

7.18 Checking the ML1 ..............................................................................................MT7-36

7.19 Checking the ML2 ..............................................................................................MT7-38

7.20 Checking the MM1 ............................................................................................. MT7-40

7.21 Checking the MN1 ..............................................................................................MT7-42

7.22 Checking the MN2 ..............................................................................................MT7-44

7.23 Checking the MN3 ..............................................................................................MT7-46

7.24 Checking the MN4 ..............................................................................................MT7-48

7.25 Checking the MZ1 ..............................................................................................MT7-50

7.26 Checking the MZ2 ..............................................................................................MT7-52

7.27 Checking the MZ3 ..............................................................................................MT7-54

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.29

Page 32

Contents Maintenance Troubleshooting

7.28 Checking the MZ4 ..............................................................................................MT7-56

7.29 Checking the PL1 ...............................................................................................MT7-58

7.30 Checking the SVL1 ............................................................................................ MT7-60

7.31 Checking the SOLK1 ......................................................................................... MT7-62

7.32 Checking the BCRK1 .........................................................................................MT7-64

7.33 Checking the BCRN1 .........................................................................................MT7-66

7.34 Checking the Erasure Lamps (LAMP1-LAMP5) .............................................. MT7-68

7.35 Checking the Polygon (POL) ............................................................................ MT7-70

7.36 Checking the Laser (LDD) ................................................................................. MT7-72

7.37 Checking the Start Point Detector (SYN) .........................................................MT7-74

7.38 Checking the Photomultiplier (PMT08D) ......................................................... MT7-76

0.30

7.39 Checking the Photomultiplier (PMR08C) .........................................................MT7-78

7.40 Checking the Voltages ...................................................................................... MT7-80

7.41 Checking the Boards .........................................................................................MT7-82

7.42 Checking the HDD.............................................................................................. MT7-84

7.43 Checking the Monitor ........................................................................................MT7-86

8. Circuit Diagram ............................................................................................................ MT8-1

9. Priority Checks to Be Conducted upon Trouble Occurrence ................................... MT9-1

10. Making Analyses of Image Abnormalities .................................................................MT10-1

10.1 Making Analyses in Accordance with Error Codes ........................................MT10-1

10.2 Making Analyses in the Virtual Image Generation Mode ...............................MT10-1

[1] Vertical streaks ............................................................................................. MT10-2

[2] Horizontal streaks ........................................................................................ MT10-3

[3] Other image abnormalities ..........................................................................MT10-4

10.3 Reference Data - Typical Image Abnormalities ...............................................MT10-5

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.30

Page 33

Contents Maintenance Troubleshooting

BLANK PAGE

0.31

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.31

Page 34

Contents Maintenance Checks, Replacement and Adjustment of Parts

0.32

Checks, Replacement and Adjustment of Parts (MC)

1. Check/Adjustment Procedures for Each Unit............................................................ MC-2

2. Table of Contents ......................................................................................................... MC-4

3. Removing and Installing the Covers .......................................................................... MC-8

4. Removing and Installing the Cassette Set Unit ......................................................... MC-10

4.1 Cassette Set Unit ............................................................................................... MC-10

4.2 Shutter ................................................................................................................ MC-12

4.3 Cassette Ejection Sensor (SK1) ....................................................................... MC-14

4.4 Barcode Reader (BCRK1).................................................................................. MC-16

4.5 Pulling Out the Tray ........................................................................................... MC-20

4.6 Cassette Hold Solenoid (SOLK1) ..................................................................... MC-26

4.7 Cassette Hold Sensor (SK3) ............................................................................. MC-32

4.8 Claw Guide Assembly ....................................................................................... MC-34

4.9 Cassette IN Sensor (SK2) .................................................................................. MC-40

4.10 Rubber Roller ..................................................................................................... MC-50

4.11 Guide Plate ......................................................................................................... MC-52

4.12 Guide Stoppers .................................................................................................. MC-64

4.13 Movable Guides ................................................................................................. MC-66

5. Removing and Installing the IP Removal Unit ........................................................... MC-74

5.1 IP Removal Unit.................................................................................................. MC-74

5.2 IP Leak Valve (SVL1).......................................................................................... MC-78

5.3 Suction Cup HP Sensor (SL1)........................................................................... MC-80

5.4 Timing Belt (for IP Conveyance)....................................................................... MC-86

5.5 Guide Plate A...................................................................................................... MC-90

5.6 Rubber Rollers C and D..................................................................................... MC-92

5.7 Rubber Roller (Large) ........................................................................................ MC-94

5.8 Guide Plate D...................................................................................................... MC-96

5.9 Guide Plates B and C......................................................................................... MC-98

5.10 Supports (for IP Removal Arm) ........................................................................ MC-100

5.11 Suction Cups ......................................................................................................MC-104

5.12 IP Suction Pump (PL1) ...................................................................................... MC-108

5.13 Inch/Metric Sensor (SL4) ...................................................................................MC-110

5.14 Suction Sensor (SL5)......................................................................................... MC-112

5.15 Receiver Rollers .................................................................................................MC-114

5.16 Guide Plates E, F, and G ................................................................................... MC-118

5.17 Suction Cup Driving Motor (ML1) .....................................................................MC-120

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.32

Page 35

Contents Maintenance Checks, Replacement and Adjustment of Parts

5.18 Timing Belt (for Suction Cup Drive) ................................................................. MC-122

5.19 Shaft (for Suction Cup Drive)............................................................................ MC-124

5.20 IP Removal Unit Upper Assembly ....................................................................MC-128

5.21 Rubber Roller A.................................................................................................. MC-130

5.22 IP Transport Motor (ML2) ..................................................................................MC-132

5.23 Shaft (for IP Conveyance) .................................................................................MC-134

5.24 Rubber Roller B.................................................................................................. MC-136

6. Removing and Installing the Erasure Conveyor ....................................................... MC-138

6.1 Erasure Lamp Assembly ...................................................................................MC-138

6.2 Erasure Conveyor ..............................................................................................MC-140

0.33

6.3 Cleaning Roller Assembly................................................................................. MC-144

6.4 Cleaning Rollers................................................................................................. MC-146

6.5 Erasure Lamps (LAMP1-LAMP5) ......................................................................MC-148

6.6 Erasure Thermostatic Switch (TSW2) ..............................................................MC-150

6.7 Erasure Thermostatic Switch (TSW1) ..............................................................MC-152

6.8 Erasure Cooling Fan (FANM1) ..........................................................................MC-154

6.9 Sockets ...............................................................................................................MC-156

6.10 Timing Belts ....................................................................................................... MC-160

6.11 Lamp House Assembly ..................................................................................... MC-164

6.12 Filter ....................................................................................................................MC-166

6.13 Reflection Plate .................................................................................................. MC-168

6.14 IP Transport Motor (MM1) ................................................................................. MC-170

6.15 Rubber Rollers (Upper) ..................................................................................... MC-172

6.16 Light Protect Plates ...........................................................................................MC-174

6.17 Rubber Rollers (Lower) .....................................................................................MC-176

6.18 Guide Plates .......................................................................................................MC-178

7. Pulling Out and Pushing In the Scanner Unit ............................................................MC-182

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.33

Page 36

Contents Maintenance Checks, Replacement and Adjustment of Parts

8. Removing and Installing the Side-Positioning Conveyor ......................................... MC-188

8.1 Side-Positioning Conveyor ...............................................................................MC-188

8.2 Grip Release Motor (MN2) ................................................................................. MC-192

8.3 Barcode Reader (BCRN1).................................................................................. MC-194

8.4 Side-Positioning Mechanism HP Sensor (SN1) .............................................. MC-196

8.5 Grip Release HP Sensor (SN2) ......................................................................... MC-198

8.6 Cleaning Guide Drive Motor (MN4)................................................................... MC-200

8.7 BCR08A Board ...................................................................................................MC-202

8.8 Side-Positioning IP Sensor (SN3)..................................................................... MC-204

8.9 Cleaning Guide HP Sensor (SN4) ..................................................................... MC-206

0.34

8.10 Cleaning Guide Assembly................................................................................. MC-208

8.11 Shaft (for Cleaning Guide Assembly) .............................................................. MC-214

8.12 Guide Plate C...................................................................................................... MC-218

8.13 Timing Belt (for IP Conveyance)....................................................................... MC-220

8.14 Guide Plate G ..................................................................................................... MC-222

8.15 Rubber Rollers (Rear) ........................................................................................MC-226

8.16 Wires (Left Side)................................................................................................. MC-230

8.17 Wires (Right Side) ..............................................................................................MC-234

8.18 Timing Belt (for Side-Positioning Mechanism) ...............................................MC-240

8.19 Shaft (for Grip Release) .....................................................................................MC-246

9. Removing and Installing the Scanning Optics Unit .................................................. MC-250

9.1 Adjusting the Format .........................................................................................MC-250

9.2 Shading and Sensitivity Corrections ...............................................................MC-254

9.3 Checking for Image Problems ..........................................................................MC-258

9.4 Removing and Installing the Scanning Optics Unit........................................ MC-262

9.5 LD Assembly ......................................................................................................MC-266

9.6 Polygon Assembly .............................................................................................MC-270

9.7 SYN08A Board.................................................................................................... MC-274

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.34

Page 37

Contents Maintenance Checks, Replacement and Adjustment of Parts

0.35

10. Removing and Installing the Subscanning Unit ........................................................MC-278

10.1 Driving-Side Grip Release HP Sensor (SZ2).................................................... MC-278

10.2 Mirror HP Sensor (SZ4) ..................................................................................... MC-280

10.3 Rubber Belt and SUS Belt ................................................................................. MC-282

10.4 Kapton® Belt ......................................................................................................MC-284

10.5 Flywheel ..............................................................................................................MC-286

10.6 Subscanning Motor MZ1 (FFM) ........................................................................ MC-288

10.7 PMT08D Board ................................................................................................... MC-292

10.8 PMR08C Board ................................................................................................... MC-296

10.9 Light-Collecting Guide Assembly (for Front Surface) ....................................MC-300

10.10 Light-Collecting Guide Assembly (for Back Surface) .................................... MC-308

10.11 Light-Collecting Mirror and IP Leading-Edge Sensor (SZ1/SED08D) ........... MC-320

10.12 Glass Guide ........................................................................................................ MC-326

10.13 Lower Rubber Rollers........................................................................................ MC-332

10.14 Mirror Driving Motor (MZ4)................................................................................ MC-336

10.15 Driving-Shaft Grip Motor (MZ2) ........................................................................ MC-338

10.16 Driven-Shaft Grip Motor (MZ3).......................................................................... MC-342

10.17 Driven-Side Grip Release HP Sensor (SZ3) .....................................................MC-346

10.18 Subscanning Unit Controller Assembly ..........................................................MC-348

10.19 SCN08D/SCR08D Board ....................................................................................MC-354

10.20 PHV08D Board.................................................................................................... MC-358

11. Removing and Installing the Hard Disk Drive (HDD) ................................................ MC-360

11.1 Setting HDD ........................................................................................................ MC-361

11.2 Hard Disk Drive (HDD) ....................................................................................... MC-362

12. Removing and Installing the Floppy Disk Drive (FDD) .............................................MC-372

12.1 Setting FDD ........................................................................................................ MC-372

12.2 Floppy Disk Drive (FDD) ....................................................................................MC-372

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.35

Page 38

Contents Maintenance Checks, Replacement and Adjustment of Parts

0.36

13. Removing and Installing the Power Supply Unit (JPS-6) .........................................MC-374

13.1 Power Supply Unit (JPS-6) ................................................................................MC-374

13.2 Power Supply Unit Fuses ..................................................................................MC-378

14. Removing and Installing the Monitor .........................................................................MC-382

14.1 CRT (Monitor) .....................................................................................................MC-382

14.2 Fuse Between Power Supply Unit and CRT ....................................................MC-388

15. Removing and Installing the PC Boards .................................................................... MC-390

15.1 MTH08C Board ...................................................................................................MC-402

15.2 MTH08D Board ...................................................................................................MC-404

15.3 CPU90E Board.................................................................................................... MC-406

15.4 IMG07B Board ....................................................................................................MC-410

15.5 BSP08A Board.................................................................................................... MC-411

15.6 IMG08M Board ....................................................................................................MC-413

15.7 CPU90F Board (Optional) ..................................................................................MC-414

15.8 LAN90B Board (Optional).................................................................................. MC-416

15.9 HCP08A Board (Optional) ................................................................................. MC-417

15.10 IMG08H Board (Optional) ..................................................................................MC-418

15.11 SNS08C and DRV08A Boards ........................................................................... MC-420

15.12 VOL08A Board.................................................................................................... MC-427

15.13 LED08A Board ....................................................................................................MC-428

15.14 LED08B Board ....................................................................................................MC-428

15.15 BCR08A Board ...................................................................................................MC-429

15.16 SYN08A, PMT08D, PMR08C, SCN08D/SCR08D, and PHV08D boards .......... MC-429

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.36

Page 39

Contents Maintenance Checks, Replacement and Adjustment of Parts

BLANK PAGE

0.37

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.37

Page 40

Contents Maintenance Maintenance Utility

Maintenance Utility (MU)

1. Summary of Service Utility ............................................................................................ MU-2

(1) Maintenance Utility ............................................................................................... MU-2

(2) Configuration Setting ........................................................................................... MU-2

(3) Image Processing Parameter Adjustment .......................................................... MU-2

2. Mode Transitions ............................................................................................................. MU-4

(1) Initialization process mode .................................................................................. MU-5

(2) Routine process mode ......................................................................................... MU-5

(3) Abnormality process mode.................................................................................. MU-5

(4) User utility mode (U-Utility).................................................................................. MU-5

(5) Maintenance utility mode (M-Utility) ................................................................... MU-5

0.38

(6) End process mode ................................................................................................ MU-5

3. U-Utility (User Utility) ...................................................................................................... MU-6

(1) Functions of U-Utility............................................................................................ MU-6

(2) U-Utility tree........................................................................................................... MU-6

(3) U-Utility operation ................................................................................................. MU-7

(4) U-Utility commands .............................................................................................. MU-8

4. M-Utility (Maintenance Utility) ...................................................................................... MU-10

(1) Functions of M-Utility ......................................................................................... MU-10

(2) M-Utility tree ........................................................................................................ MU-10

(3) M-Utility operation .............................................................................................. MU-16

(4) Common Operating Procedures for M-Utility................................................... MU-19

(5) M-Utility commands ............................................................................................ MU-24

[1] ERROR LOG UTILITY.......................................................................................... MU-24

[1-1] LIST ......................................................................................................... MU-24

009-058-03

08.30.2002 FM3476

[1-1-1] ALL .............................................................................................. MU-24

[1-1-2] SUMMARY .................................................................................. MU-25

[1-2] CLEAR..................................................................................................... MU-26

[1-3] SAVE TO FD ............................................................................................ MU-27

[1-3-1] ERROR LOG ............................................................................... MU-27

[1-3-2] TRACE DATA .............................................................................. MU-28

[1-3-3] IOT DATA ..................................................................................... MU-29

CR-IR347

Service Manual

0.38

Page 41

Contents Maintenance Maintenance Utility

[1-4] SAVE TO HD ............................................................................................ MU-30

[1-4-1] ERROR LOG ............................................................................... MU-30

[2] CONFIGURATION SETTING ............................................................................... MU-32

[2-1] SYSTEM (IRSET.CFG) ............................................................................MU-32

[2-2] PRINT (FILMFMT.CFG) ........................................................................ MU-45.4

[2-3] REMOTE SWITCH (RMT_SW.CFG) ....................................................... MU-55

[2-4] EQUIPMENT (EQUIP) ............................................................................. MU-56

[2-5] LOCAL INTERFACE (INTERFACE) ........................................................ MU-58

[2-6] NETWORK HOST INTERFACE (DEVICE) ............................................. MU-58

[2-7] HOSTS ADDRESS (HOSTS) .................................................................. MU-60

0.39

[2-8] DISTRIBUTION (CODEDSTB) ................................................................ MU-62

[2-9] ROUTING (ROUTE) ................................................................................ MU-63

[2-10] NETMASKS (NETMASKS) ..................................................................... MU-64

[2-11] DICOM (Base on DICOM)....................................................................... MU-65

[3] TEST MODE ......................................................................................................... MU-66

[3-1] ROUTINE ................................................................................................. MU-66

[3-2] AUTO MODE ........................................................................................... MU-66

[3-2-1] READING & ERASURE .............................................................. MU-66

[3-2-2] PRIMARY ERASURE .................................................................. MU-67

[3-2-3] SECONDARY ERASURE ............................................................ MU-68

[4] ELECTRICAL UTILITY......................................................................................... MU-70

[4-1] ERASURE LAMP TEST .......................................................................... MU-70

[4-2] IMAGE MEMORY TEST .......................................................................... MU-70

[4-3] DSP TEST ................................................................................................MU-71

[4-4] LAN.......................................................................................................... MU-72

009-058-03

08.30.2002 FM3476

[4-4-1] ETHERNET MAC ADDRESS ...................................................... MU-72

[4-4-2] PING ............................................................................................ MU-72

[4-4-3] CPU90F DMA .............................................................................. MU-73

[4-5] HDD ......................................................................................................... MU-74

[4-5-1] WRITE-READ VERIFY ................................................................. MU-74

[4-6] FDD.......................................................................................................... MU-75

[4-6-1] WRITE-READ VERIFY ................................................................. MU-75

CR-IR347

Service Manual

0.39

Page 42

Contents Maintenance Maintenance Utility

[5] SCANNER UTILITY.............................................................................................. MU-76

[5-1] INITIALIZE ............................................................................................... MU-76

[5-2] POLYGON ............................................................................................... MU-76

[5-2-1] OFF .............................................................................................. MU-76

[5-2-2] ON ................................................................................................ MU-76

[5-3] LASER ..................................................................................................... MU-77

[5-3-1] OFF .............................................................................................. MU-77

[5-3-2] ON ................................................................................................ MU-77

[5-4] HV ............................................................................................................ MU-78

[5-4-1] OFF .............................................................................................. MU-78

0.40

[5-4-2] ON ................................................................................................ MU-78

[5-5] HV DATA .................................................................................................. MU-79

[5-5-1] FRONT......................................................................................... MU-79

[5-5-2] BACK ........................................................................................... MU-80

[5-6] FORMAT .................................................................................................. MU-81

[5-6-1] DEFAULT ..................................................................................... MU-81

[5-6-2] FREQ ADJUST ........................................................................... MU-82

[5-6-3] PIXEL ADJUST ........................................................................... MU-83

[5-7] SHADING/SENSITIVITY ......................................................................... MU-84

[5-7-1] REC MODE ................................................................................. MU-84

[5-7-2] CALCULATION ........................................................................... MU-85

[5-7-2-1] ST ................................................................................... MU-85

[5-7-2-2] HR................................................................................... MU-89

[5-7-2-3] HR (FOR MANUFACTURING) ....................................... MU-92

[5-7-3] SHADING/POLYGON CORRECTION......................................... MU-93

[5-7-4] SENSITIVITY DATA ..................................................................... MU-94

009-058-03

08.30.2002 FM3476

[5-7-5] HV DATA/ [5-7-6] PMT DATA ...................................................... MU-94

[5-8] DATA MANAGEMENT ............................................................................. MU-95

[5-8-1] SAVE SHADING AND POLYGON DATA .................................... MU-95

[5-8-2] SAVE SENSITIVITY DATA .......................................................... MU-95

[5-8-3] SAVE FORMAT DATA ................................................................. MU-96

[5-8-4] DISPLAY DATA ........................................................................... MU-97

[5-8-5] LOAD FROM FD.......................................................................... MU-98

[5-8-6] SAVE TO FD ................................................................................ MU-99

CR-IR347

Service Manual

0.40

Page 43

Contents Maintenance Maintenance Utility

[5-9] DIAGNOSTIC......................................................................................... MU-100

[5-10] VIRTUAL IMAGE ................................................................................... MU-101

[5-10-1] LIGHT ...................................................................................... MU-101

[5-10-2] LOG AMP ................................................................................ MU-102

[5-10-3] SCN08 INPUT .......................................................................... MU-102

[5-10-4] ROUTINE ................................................................................. MU-102

[5-11] BOTH SIDES ADDITIONAL .................................................................. MU-103

[5-11-1] FRONT ONLY .......................................................................... MU-103

[5-11-2] BACK ONLY ............................................................................ MU-103

[5-11-3] ROUTINE ................................................................................. MU-103

0.41

[6] MECHANICAL UTILITY ..................................................................................... MU-104

[6-1] INITIALIZE ............................................................................................. MU-104

[6-2] MOTOR .................................................................................................. MU-105

[6-2-1] NUMBER ................................................................................... MU-105

[6-2-2] PARAMETER ............................................................................. MU-105

[6-2-3] DRIVE ........................................................................................ MU-108

[6-2-4] STOP ......................................................................................... MU-108