Page 1

FUJI-Reader

Service Manual

SP

Troubleshooting

© Siemens AG 2003

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

English

Print No.: SPB7-420.840.52.01.02 Doc. Gen. Date: 01.03

Replaces: n.a.

Page 2

CR-IR347/CR-IR347P

Service Manual

Troubleshooting (MT)

Page 3

Contents Maintenance Troubleshooting

CR-IR347 Service Manual – Contents

Troubleshooting (MT)

1. Overview of Troubleshooting ...................................................................................... MT1-1

1.1 Flow of Troubleshooting ................................................................................... MT1-1

1.2 How to Understand Error Log........................................................................... MT1-3

2. Error Codes List ........................................................................................................... MT2-1

3. Format of Detail Information ....................................................................................... MT3-1

3.1 Supplementary Explanation of Detail Information.......................................... MT3-17

3.2 Format of Abort Code ........................................................................................MT3-18

4. Error Code Analysis Flow (Mechanism)..................................................................... MT4-1

03A2, 13A1, 13A2, 23A1, 23A2 .......................................................................... MT4-1

13A4, 13A5 .......................................................................................................... MT4-2

0.1

13A6, 13A7 .......................................................................................................... MT4-3

13A8, 23A8 .......................................................................................................... MT4-4

13A9, 23A9 .......................................................................................................... MT4-5

13AA, 23AA......................................................................................................... MT4-6

13AD .................................................................................................................... MT4-7

03B1, 23B1 .......................................................................................................... MT4-8

03B2, 23B2 .......................................................................................................... MT4-9

03B3 .................................................................................................................... MT4-10

03B4, 03B5, 03B6 ...............................................................................................MT4-11

03B7 .................................................................................................................... MT4-12

03BC, 23BA, 23BB, 23BC ..................................................................................MT4-13

03BF, 23BD, 23BE, 23BF ...................................................................................MT4-14

03C1 .................................................................................................................... MT4-15

03C0, 03C2 ..........................................................................................................MT4-16

03C6, 03C8, 03CA, 23C6 .................................................................................... MT4-17

03C7, 03C9, 03CB, 23C7 .................................................................................... MT4-18

03CC ....................................................................................................................MT4-19

009-058-03

08.30.2002 FM3476

03CD ....................................................................................................................MT4-20

03D3 .................................................................................................................... MT4-22

03D5 .................................................................................................................... MT4-23

13E1, 13E2, 13E4, 13E5, 13E9, 23E1, 23E2, 23E4, 23E5, 23E9 ....................... MT4-25

13E3, 23E3 ..........................................................................................................MT4-26

03E8, 23E6, 23E7, 23E8 ..................................................................................... MT4-27

03EE, 03EF, 23EA, 23EB, 23EC, 23ED .............................................................MT4-28

23F1, 23F2...........................................................................................................MT4-29

13F3, 23F3...........................................................................................................MT4-30

CR-IR347

Service Manual

0.1

Page 4

Contents Maintenance Troubleshooting

5. Error Code Analysis Flow (Scanner) .......................................................................... MT5-1

0532, 2542, 2570 ................................................................................................. MT5-1

0534, 1533, 2543, 2544, 2571, 2572, 2573, 2574 ............................................... MT5-2

0536, 2535, 2545, 2546 ....................................................................................... MT5-3

0537, 2547, 2575 ................................................................................................. MT5-4

0538, 2530, 2548, 2576 ....................................................................................... MT5-5

0563, 2560, 2561, 2564 ....................................................................................... MT5-6

6. Error Code Analysis Flow (Electrical) ........................................................................ MT6-1

7. Checkout Flowcharts ................................................................................................... MT7-1

7.1 Checking the SK1 .............................................................................................. MT7-2

0.2

7.2 Checking the SK2 .............................................................................................. MT7-4

7.3 Checking the SK3 .............................................................................................. MT7-6

7.4 Checking the Ground Connections.................................................................. MT7-8

7.5 Checking the SL1 ...............................................................................................MT7-10

7.6 Checking the SL2 ...............................................................................................MT7-12

7.7 Checking the SL4 ...............................................................................................MT7-14

7.8 Checking the SL5 ...............................................................................................MT7-16

7.9 Checking the SM1 ..............................................................................................MT7-18

7.10 Checking the SN1 .............................................................................................. MT7-20

7.11 Checking the SN2 .............................................................................................. MT7-22

7.12 Checking the SN3 .............................................................................................. MT7-24

7.13 Checking the SN4 .............................................................................................. MT7-26

7.14 Checking the SZ1 (SED08D) ............................................................................. MT7-28

7.15 Checking the SZ2 ............................................................................................... MT7-30

7.16 Checking the SZ3 ............................................................................................... MT7-32

7.17 Checking the SZ4 ............................................................................................... MT7-34

7.18 Checking the ML1 ..............................................................................................MT7-36

7.19 Checking the ML2 ..............................................................................................MT7-38

7.20 Checking the MM1 ............................................................................................. MT7-40

7.21 Checking the MN1 .............................................................................................. MT7-42

7.22 Checking the MN2 .............................................................................................. MT7-44

7.23 Checking the MN3 .............................................................................................. MT7-46

7.24 Checking the MN4 .............................................................................................. MT7-48

7.25 Checking the MZ1 ..............................................................................................MT7-50

7.26 Checking the MZ2 ..............................................................................................MT7-52

7.27 Checking the MZ3 ..............................................................................................MT7-54

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.2

Page 5

Contents Maintenance Troubleshooting

7.28 Checking the MZ4 ..............................................................................................MT7-56

7.29 Checking the PL1 ...............................................................................................MT7-58

7.30 Checking the SVL1 ............................................................................................ MT7-60

7.31 Checking the SOLK1 ......................................................................................... MT7-62

7.32 Checking the BCRK1 .........................................................................................MT7-64

7.33 Checking the BCRN1 .........................................................................................MT7-66

7.34 Checking the Erasure Lamps (LAMP1-LAMP5) .............................................. MT7-68

7.35 Checking the Polygon (POL) ............................................................................ MT7-70

7.36 Checking the Laser (LDD) .................................................................................MT7-72

7.37 Checking the Start Point Detector (SYN) ......................................................... MT7-74

7.38 Checking the Photomultiplier (PMT08D) ......................................................... MT7-76

0.3

7.39 Checking the Photomultiplier (PMR08C) .........................................................MT7-78

7.40 Checking the Voltages ...................................................................................... MT7-80

7.41 Checking the Boards .........................................................................................MT7-82

7.42 Checking the HDD.............................................................................................. MT7-84

7.43 Checking the Monitor ........................................................................................MT7-86

8. Circuit Diagram ............................................................................................................ MT8-1

9. Priority Checks to Be Conducted upon Trouble Occurrence ................................... MT9-1

10. Making Analyses of Image Abnormalities .................................................................MT10-1

10.1 Making Analyses in Accordance with Error Codes ........................................MT10-1

10.2 Making Analyses in the Virtual Image Generation Mode ...............................MT10-1

[1] Vertical streaks ............................................................................................. MT10-2

[2] Horizontal streaks ........................................................................................ MT10-3

[3] Other image abnormalities ..........................................................................MT10-4

10.3 Reference Data - Typical Image Abnormalities ...............................................MT10-5

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.3

Page 6

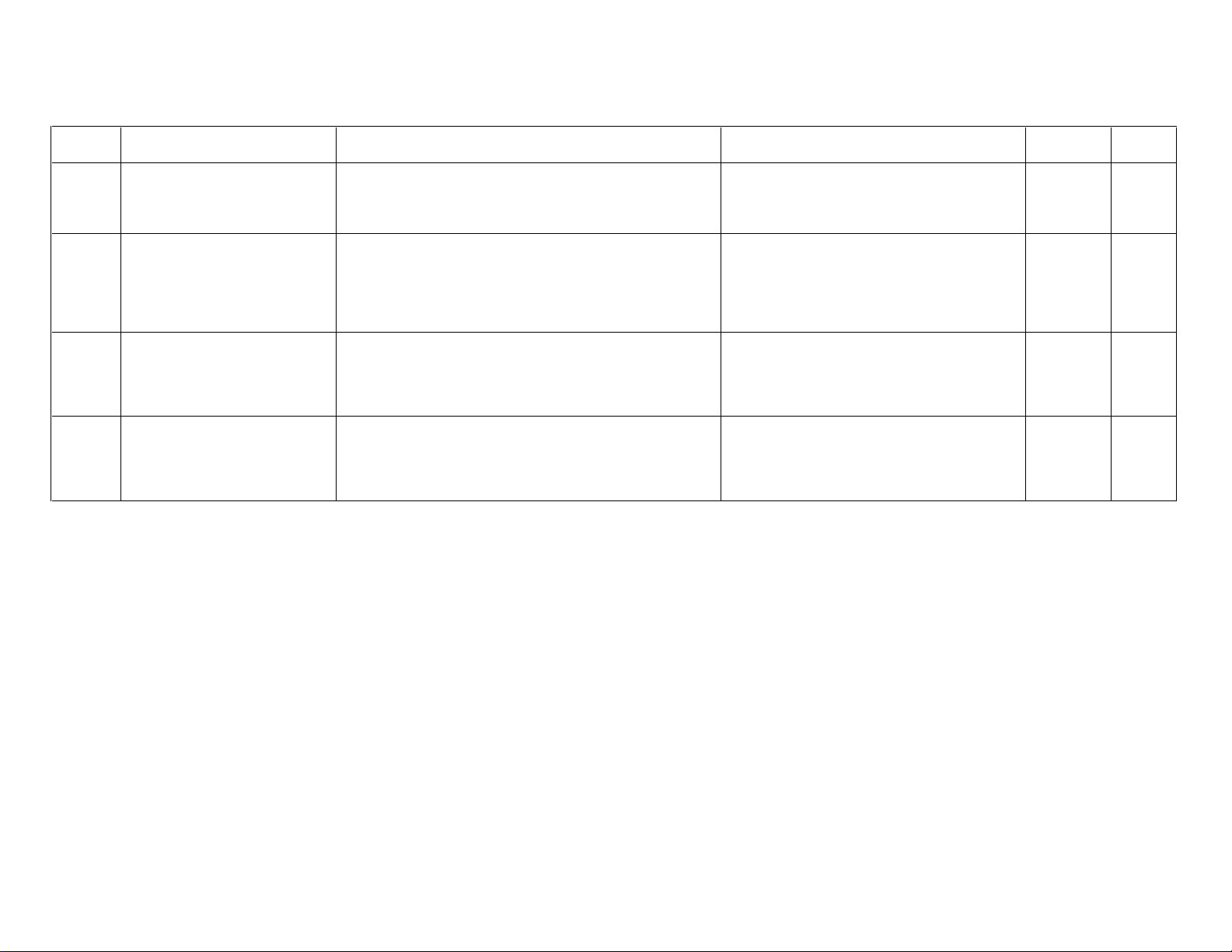

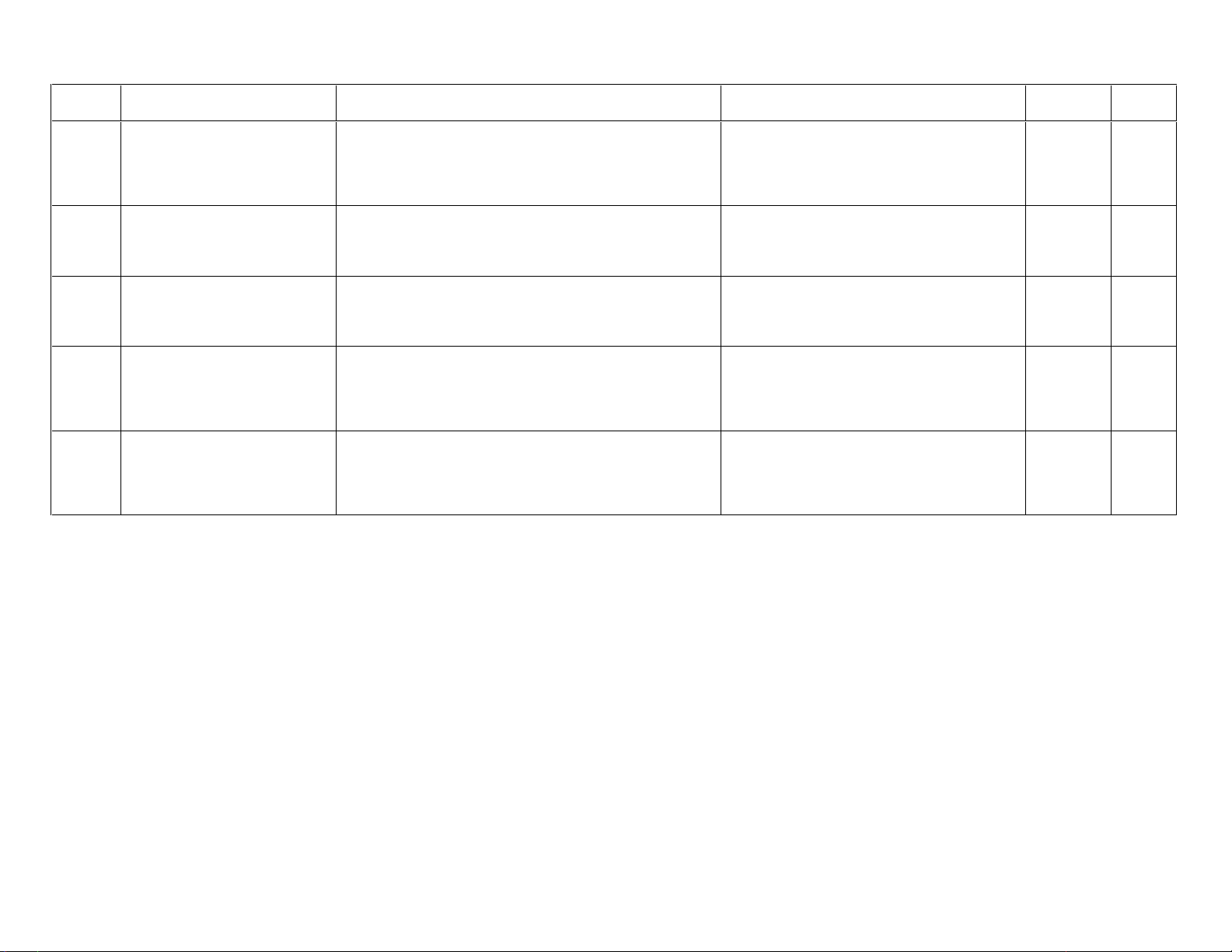

Troubleshooting (MT) Control Sheet

Control Sheet

Issue date

10/10/2000 00 New release (FM2732) All pages

05/15/2001 01 Corrections (FM3052) MT - 12–47, 53, 54, 63, 64, 64.1,

08/30/2001 02 Support for “plus” (support for software MT - 29, 32, 33, 36, 43, 46, 52,

08/30/2002 03 Error Code List, Analysis Flow, and other All pages

Revision number Reason Pages affected

MT - 1

64.2, 68, 102, 103, 105, 106

version A04) (FM3142) 57, 59-62, 62.1-62.2, 67, 122

information added (FM3476)

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

MT - 1

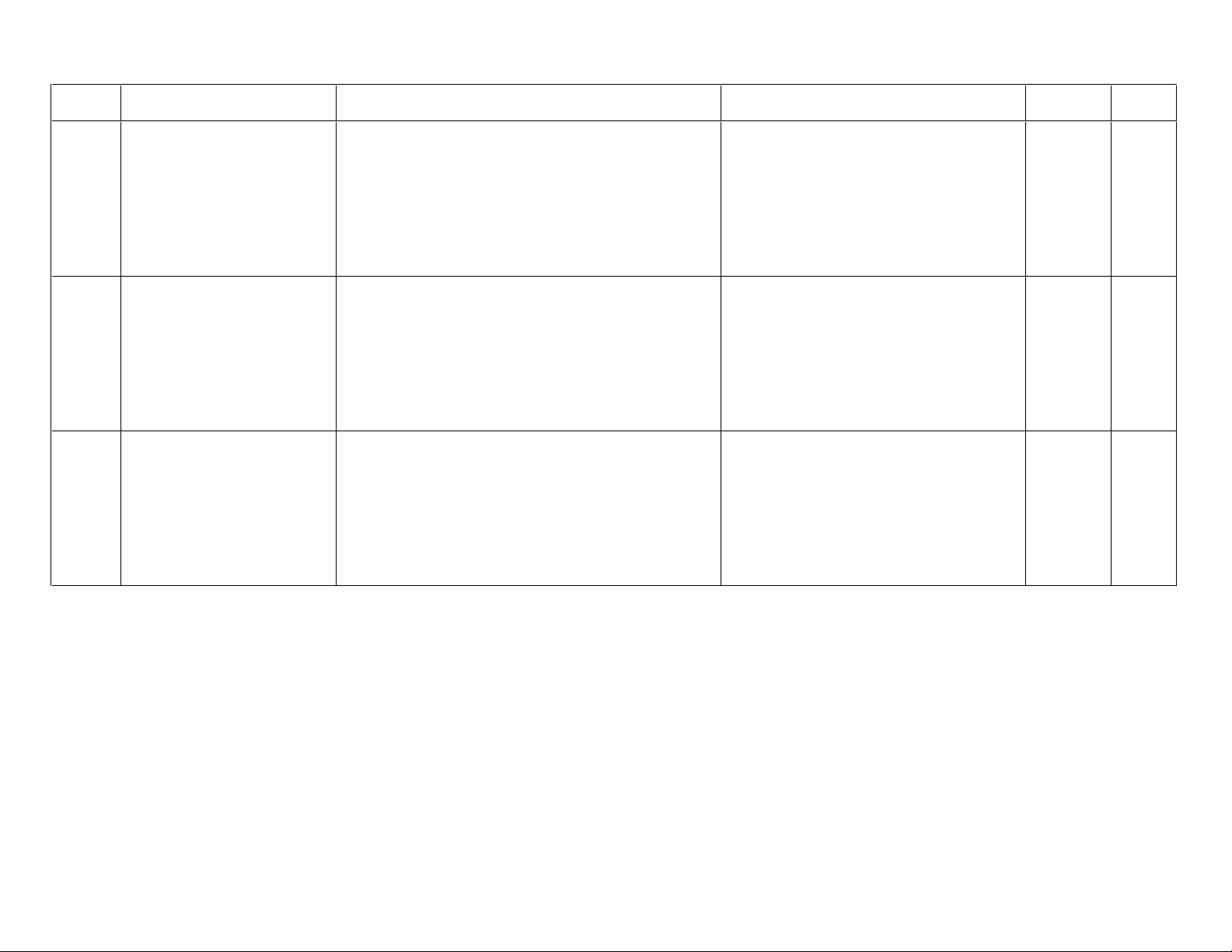

Page 7

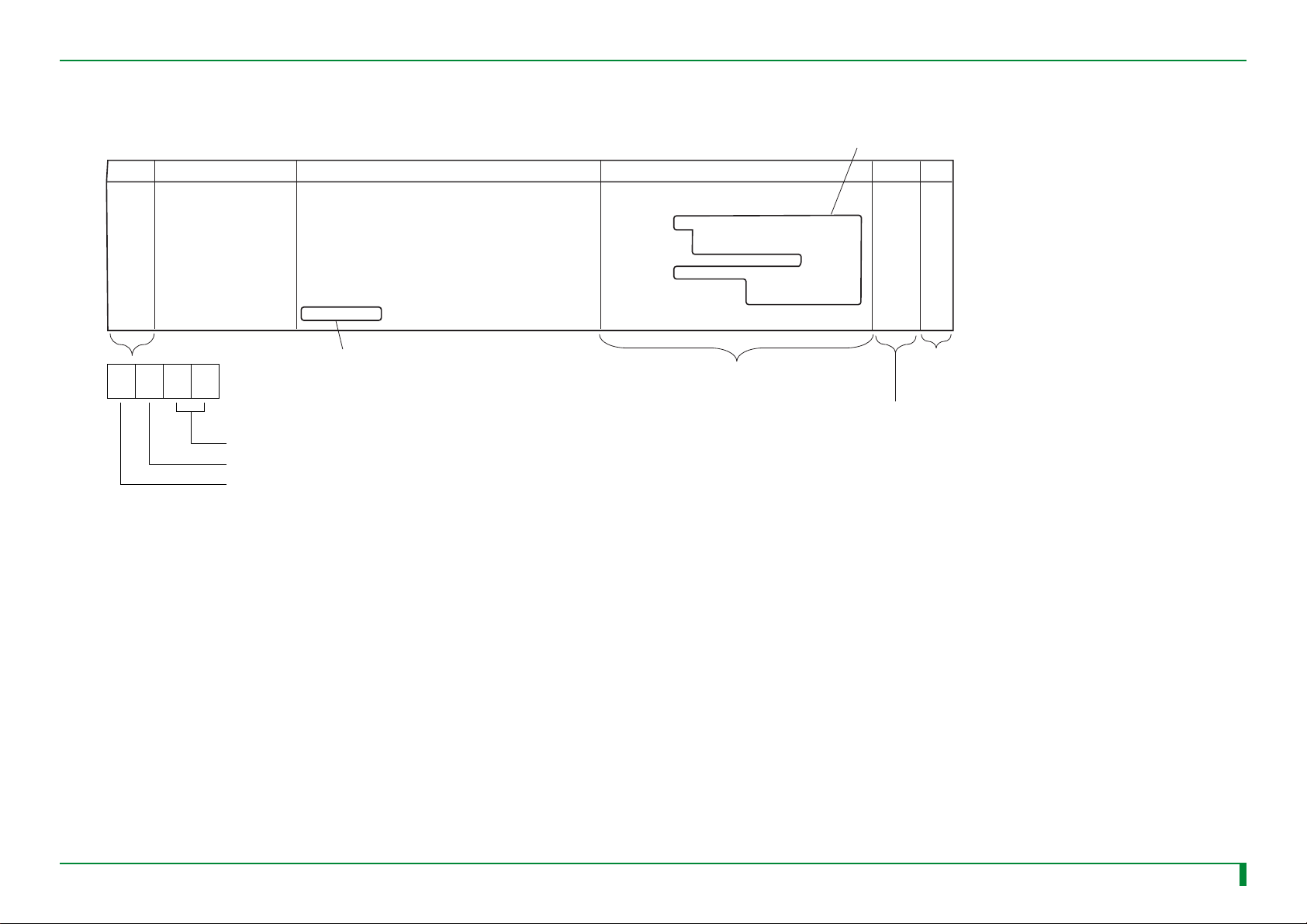

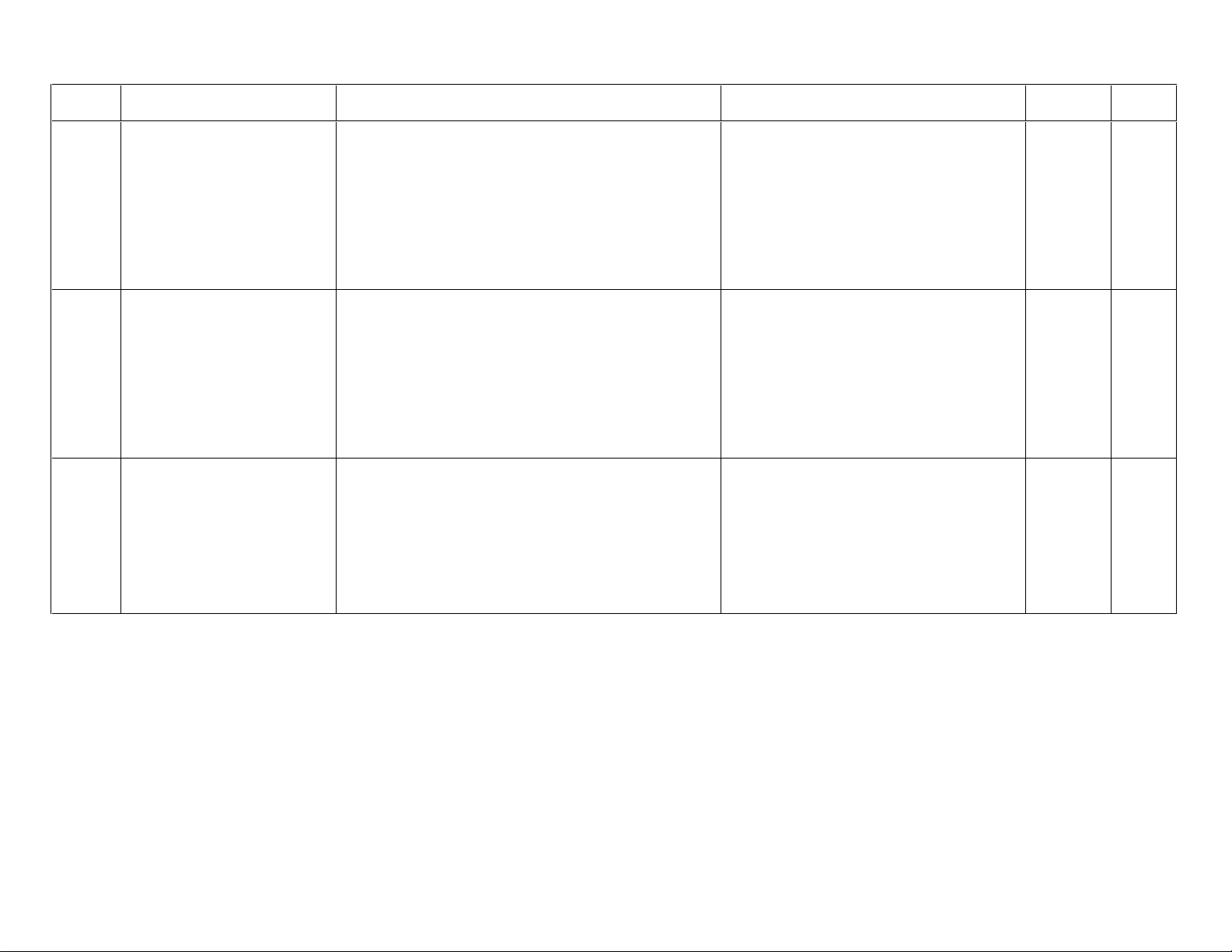

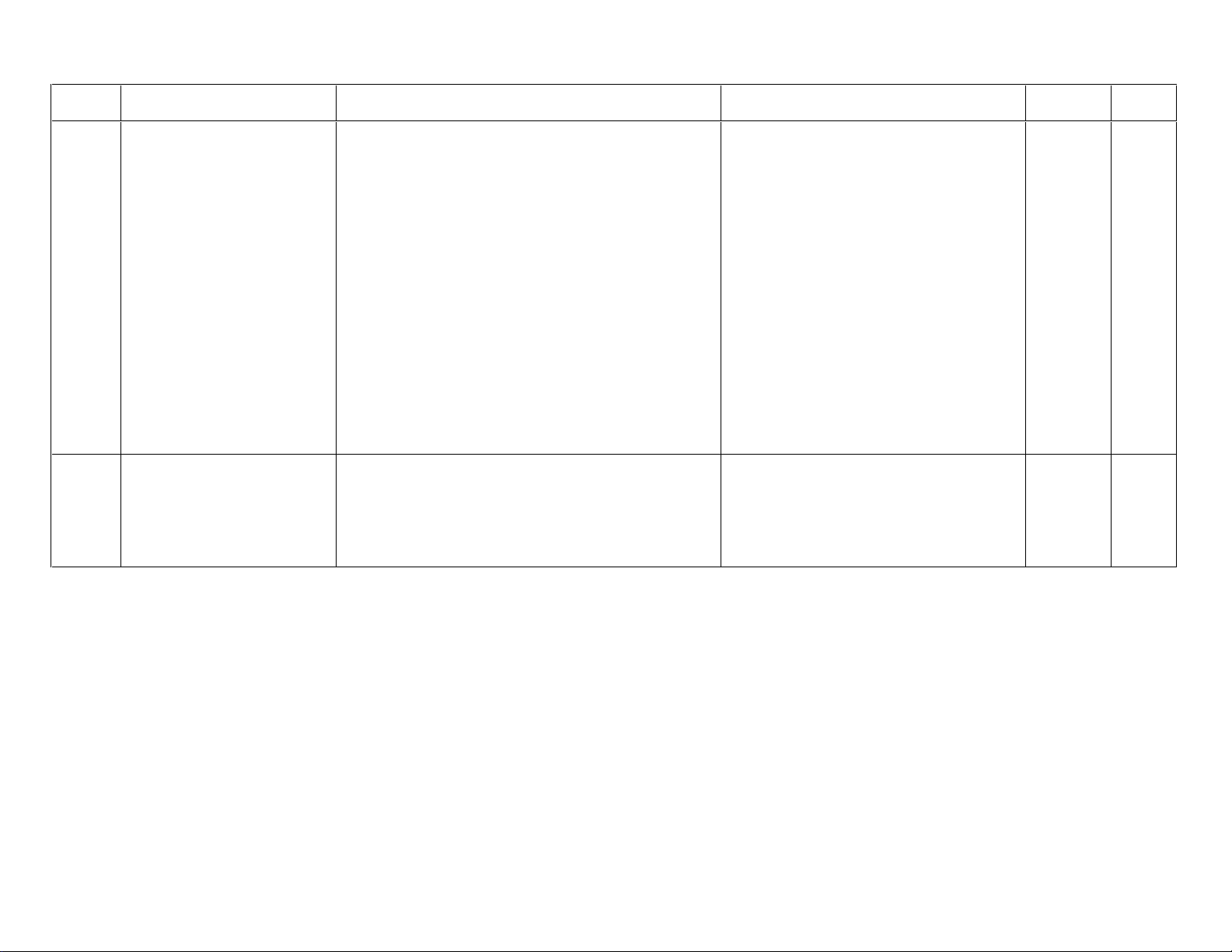

MT1 - 1

Code

Analysis

flow

Detail

Code

Name

Error code

Significance/Occurrence Condition Probable Cause/Remedy

Error name

Reference destination,

such as analysis flow,

check flow, etc.

Summary of the error Presumable cause of

error and remedy

MT4-12

7.1

Reference page or reference section number

Reference page

<Error Code Analysis Flow>

MT - 1

P

MT4- 1

MT4-1

FR7H2731.EPS

Section number

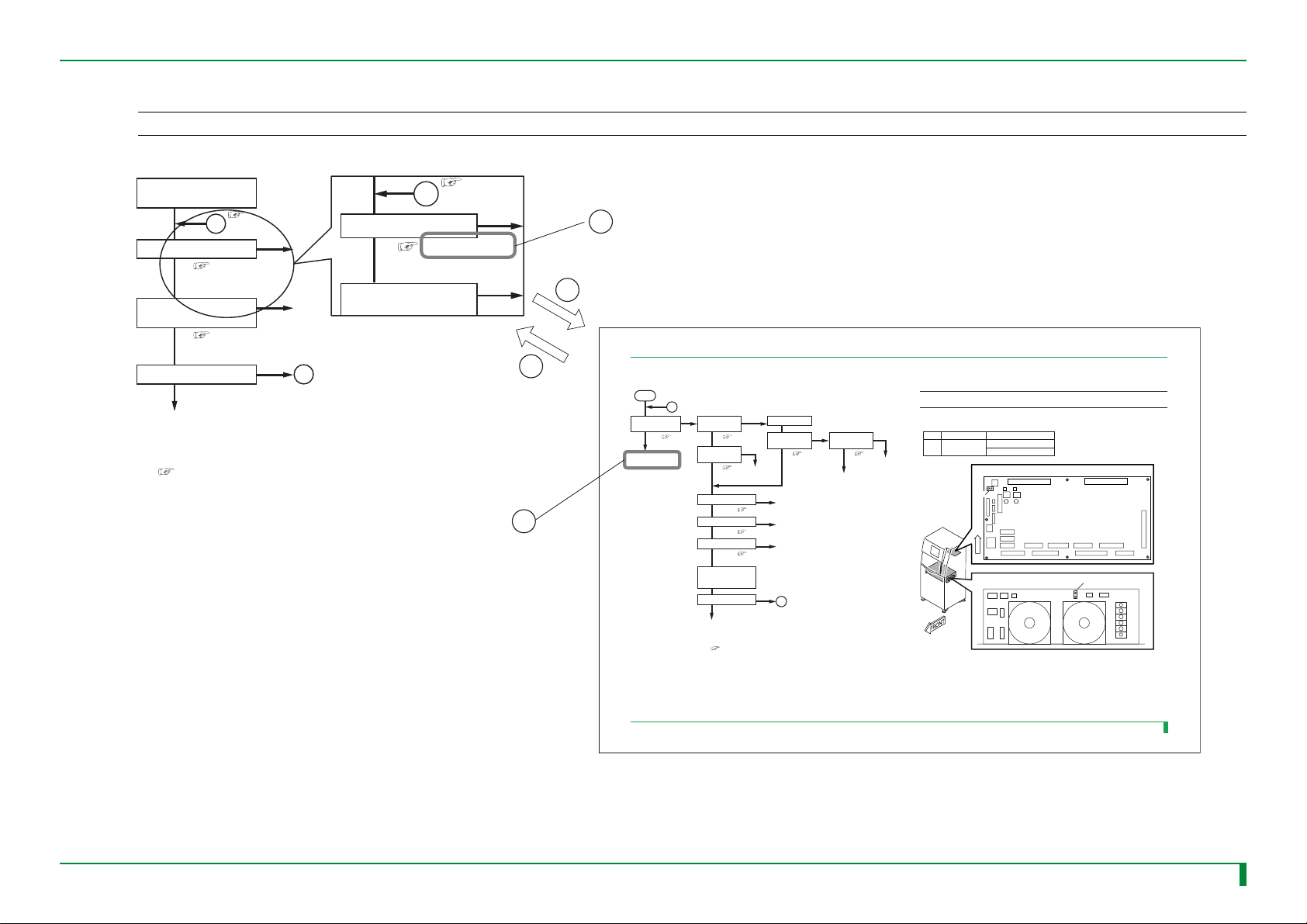

Error Code Analysis Flow (Mechanism)

03A2, 13A1, 13A2, 23A1, 23A2

■ Error Occurrence Conditions

03A2 Cassette hold release error

13A1 Cassette setting error 1

During routine/initialization/error handling (cassette hold check), the cassette

hold solenoid (SOLK1) is turned OFF, but the cassette hold sensor (SK3) does

not transition from Open to Close within 0.5 sec (TK14), and retry operation is

performed six times or more (NK12).

13A2 Cassette hold release error

During routine/initialization/error handling (cassette hold release check), the

cassette hold solenoid (SOLK1) is turned ON, but the cassette hold sensor

(SK3) does not transition from Close to Open within 0.5 sec (TK14), and retry

operation is performed six times or more (NK11).

23A1 Cassette hold failure retry

During routine/initialization/error handling (cassette hold check), the cassette

hold solenoid (SOLK1) is turned OFF to hold the cassette, but the cassette hold

sensor (SK3) does not transition from Open to Close within 0.5 sec (TK14).

23A2 Cassette hold release failure retry

During routine/initialization/error handling (cassette hold release check 2), the

cassette hold solenoid (SOLK1) is turned ON to release the cassette hold, but the

cassette hold sensor (SK3) does not transition from Close to Open within 0.5 sec

(TK14), and retry operation is performed.

■ I/O Locations

Cassette

Cassette set unit

■ Preparations

1. Turn OFF and uncover the machine.

2. Check for dirt and other foreign matter (lead character marking chips, etc.)

inside the machine. Any foreign matter must be removed.

■ Analysis Flow

Note the error log with

the M-Utility.

Is the sensor (SK3) normal?

Replace the components in the order indicated below:

1. SNS08C board

2. DRV08A board

3. CPU90E board

4. MTH08C board

5.SK3

6.SOLK1

Replace the sensor (SK3).

Is the solenoid (SOLK1)

normal?

Does the error recur?

“7.3 Checking the SK3”

“1.2 How to View the Error Log”

“7.31 Checking the SOLK1”

Replace the solenoid (SOLK1).

“15. Removing and Installing the PC Boards” in the “Checks,

Replacement, and Adjustment of Parts” volume

“4.7 Cassette Hold Sensor (SK3)” in the “Checks, Replacement,

and Adjustment of Parts” volume

“4.6 Cassette Hold Solenoid (SOLK1)” in the “Checks,

Replacement, and Adjustment of Parts” volume

During routine/initialization/error handling (cassette hold release check), the

cassette hold solenoid (SOLK1) is turned ON, but the cassette hold sensor (SK3)

does not transition from Close to Open within 0.5 sec (TK14), and retry operation

is performed six times or more (NK11).

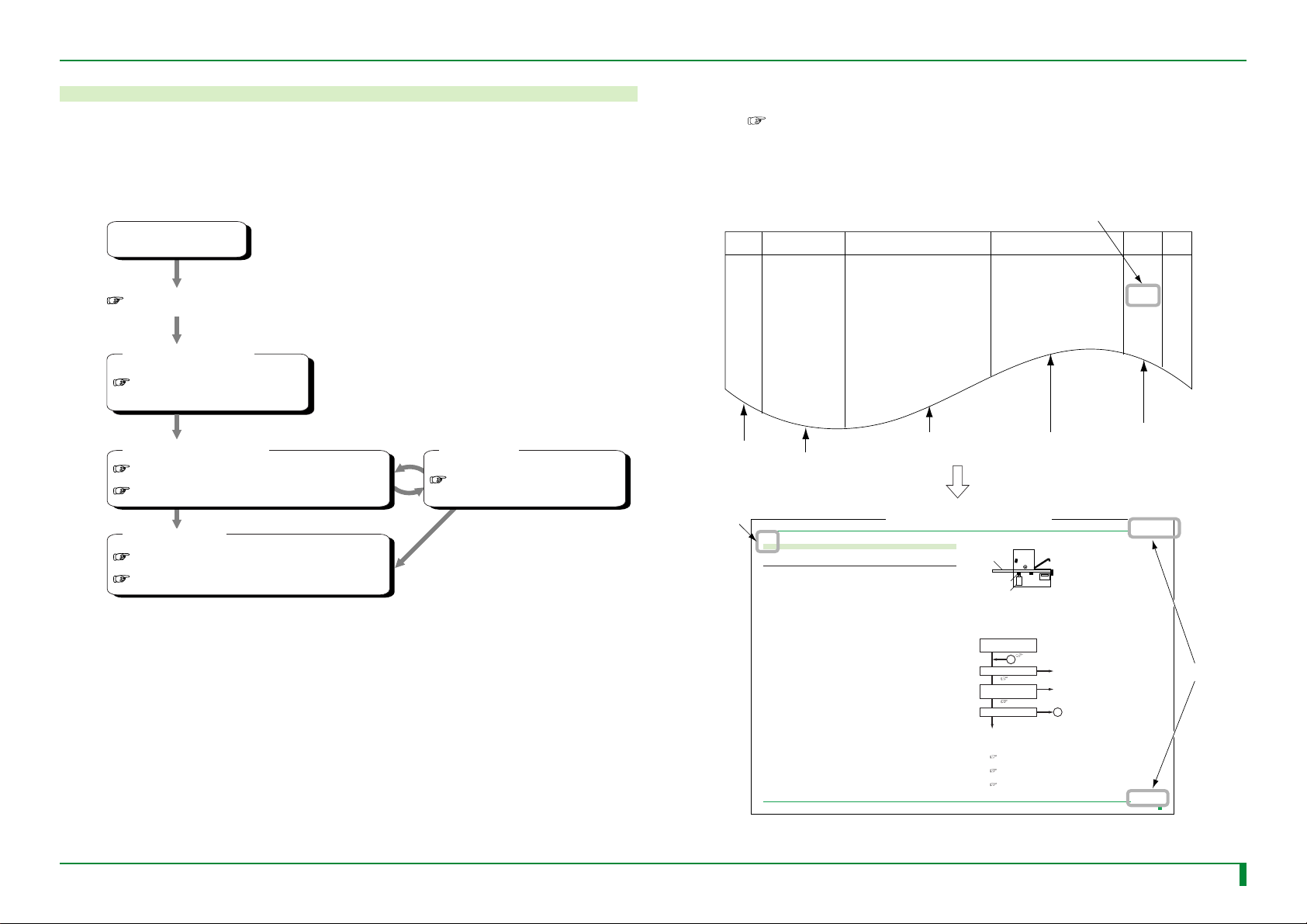

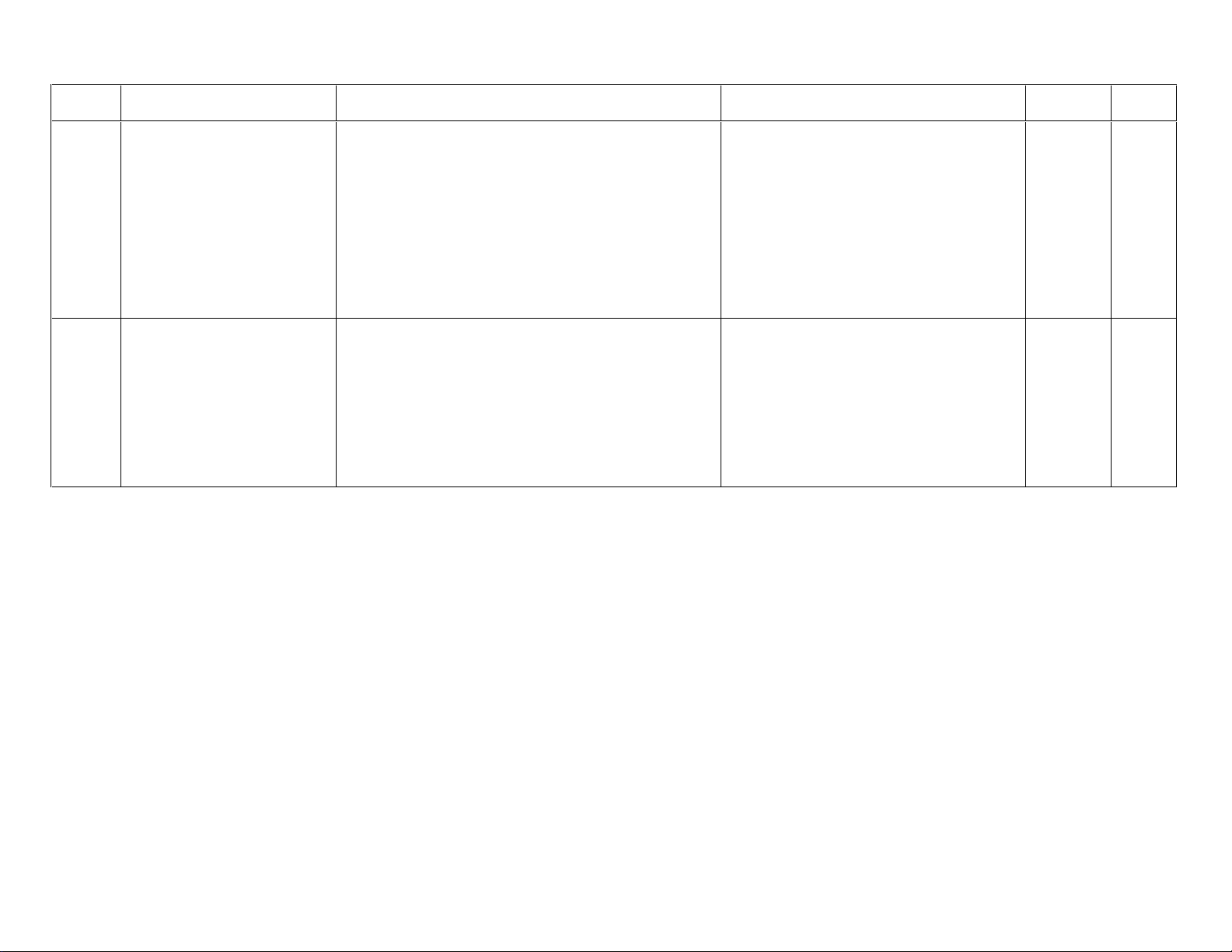

1. Overview of Troubleshooting

1.1 Flow of Troubleshooting

■ Overall Flow

When a trouble occurs, refer to the Troubleshooting Volume along the flow shown below to take

remedial action, such as parts replacement, as needed.

Trouble occurred

“9. Priority Checks to Be Conducted upon Trouble Occurrence”

009-058-03

08.30.2002 FM3476

<Error code is displayed>

“2. Error Code Table”

<Error Code Analysis Flow>

“4. Error Code Analysis Flow (Mechanism)”

“5. Error Code Analysis Flow (Scanner)”

<Remedial Action>

“Checks, Replacement, and Adjustment of Parts Volume”

“Service Parts List Volume”

<Check Flow>

“7. Check Flow”

FR7H2730.EPS

CR-IR347

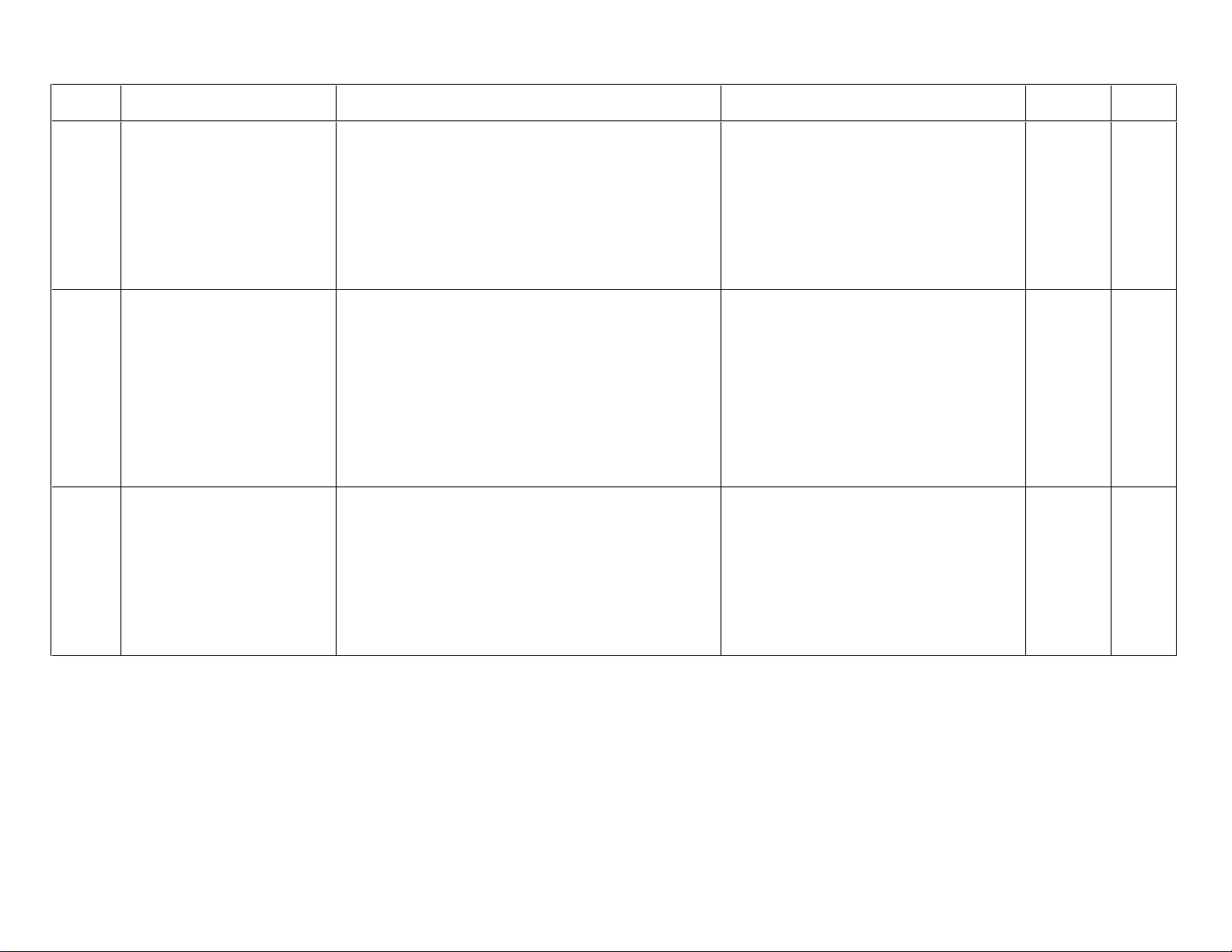

■ How to Use the Analysis Flow

(1) Check the error code.

“1.2 How to Understand Error Log”

(2) Refer to the Error Code Table.

If any reference page is found in the “Error Code Analysis Flow” column of the Error Code

Table, proceed to its relevant error code analysis flow.

4.

009-058-00

10.20.2000 FM2731

Service Manual

Service Manual

SK3

SOLK1

FR7H2101.EPS

1

N

Y

N

Y

N

Y

1

FR7H2201.E

MT - 1CR-IR347

MT1 - 1

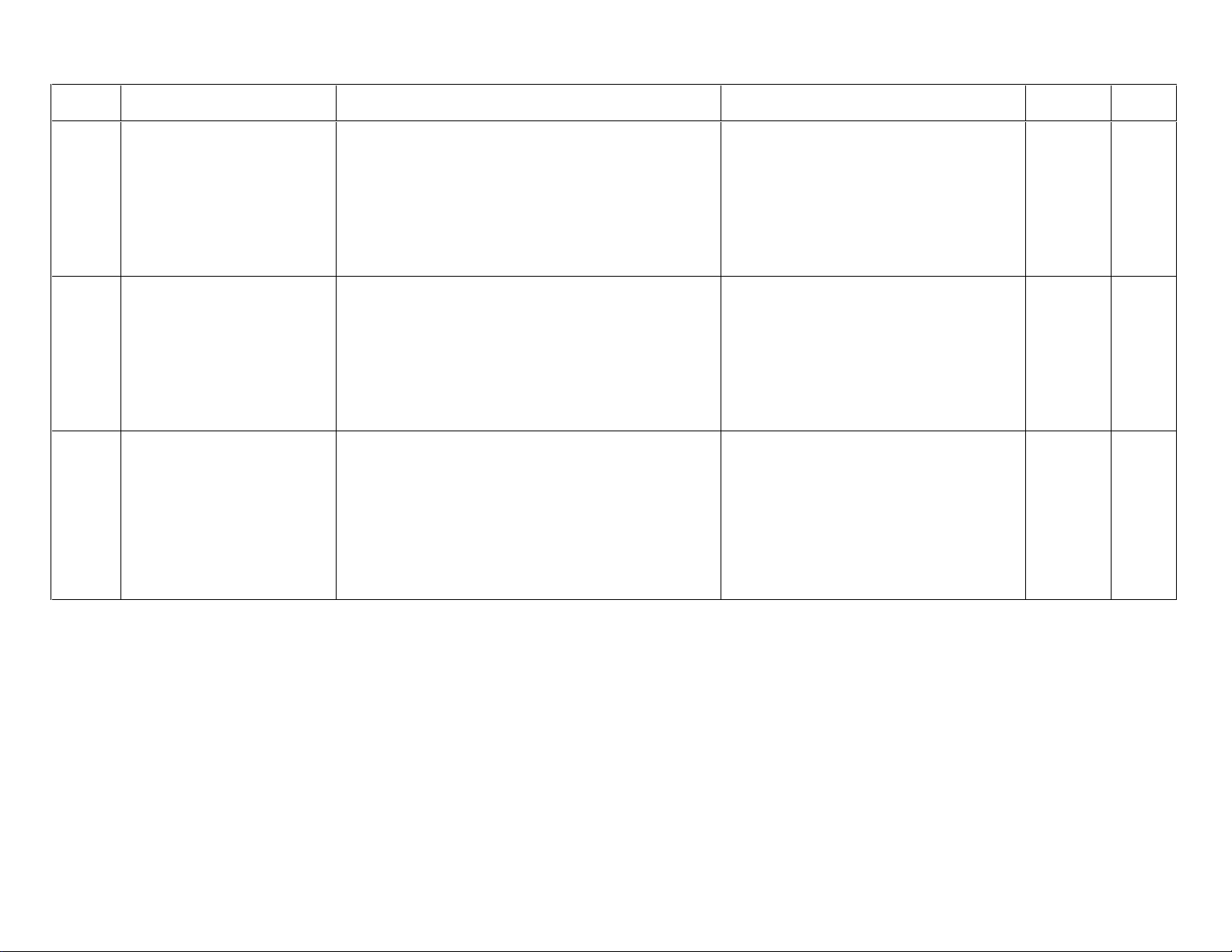

Page 8

MT1 - 2

a

(3) Troubleshoot according to the analysis flow.

◆

NOTE

◆

When troubleshooting, refer to the Check Flow that describes the checking procedures for troubleshooting individual I/O parts, as well as “Check, Replacement, and Adjustment of Parts” volume.

<Error Code Analysis Flow>

“

Note the error log with

the M-Utility.

“

1.2 How to View the Error Log"

1

Is the sensor (SK1) normal? Replace the sensor (SK1).

“

7.1 Checking the SK1

Y

Is the solenoid (SOLK1)

normal?

“

Y

Does the error recur?

N

”

N

Replace the solenoid (SOLK1).

7.31 Checking the SOLK1

N

Is the sensor (SK1) normal?

Is the solenoid (SOLK1)

normal?

”

1

Y

Y

Replace the PC boards in the following order:

1. SNS08C board

2. DRV08A board

3. CPU90E board

4. MTH08C

board

“15. Removing and Installing the PC Boards”

in the “Checks, Replacement, and Adjustment of Parts” volume

Return to the Error Analysis Flow section

number page or indicated page.

1.2 How to

1

N

N

“

7.1 Checking the SK1

Proceed to the section number page.

A

”

A

<Check Flow>

MT 7- 2

[2] Checking with the M-Utility

[3]

Replace any

blown fuse.

FR7H2301.EPS

[6] [ENT] → [4] [ENT] → [3] [ENT]

◆

CHECKS

◆

1. Check that the sensor is “open” when its light path is not blocked.

2. Check that the sensor is

[3] Checking the voltage

Voltage

+5V

[4] Checking the mechanism

• SK1 replacement

“4.3 Cassette Ejection Sensor (SK1)” in the “Checks, Replacement, and Adjustment” volume

Standard value

4.75–5.25 V

SNS08C board

CN4

F

R

O

N

T

Power supply unit (JPS-6)

“

closed” when its light path is blocked.

Measurement point

SNS08C CN4 1-2

JPS-6 DCOUT2 1-2

1

TR7H2087.EPS

2

DC OUT2

2

1

FR7H2501.EPS

B

B

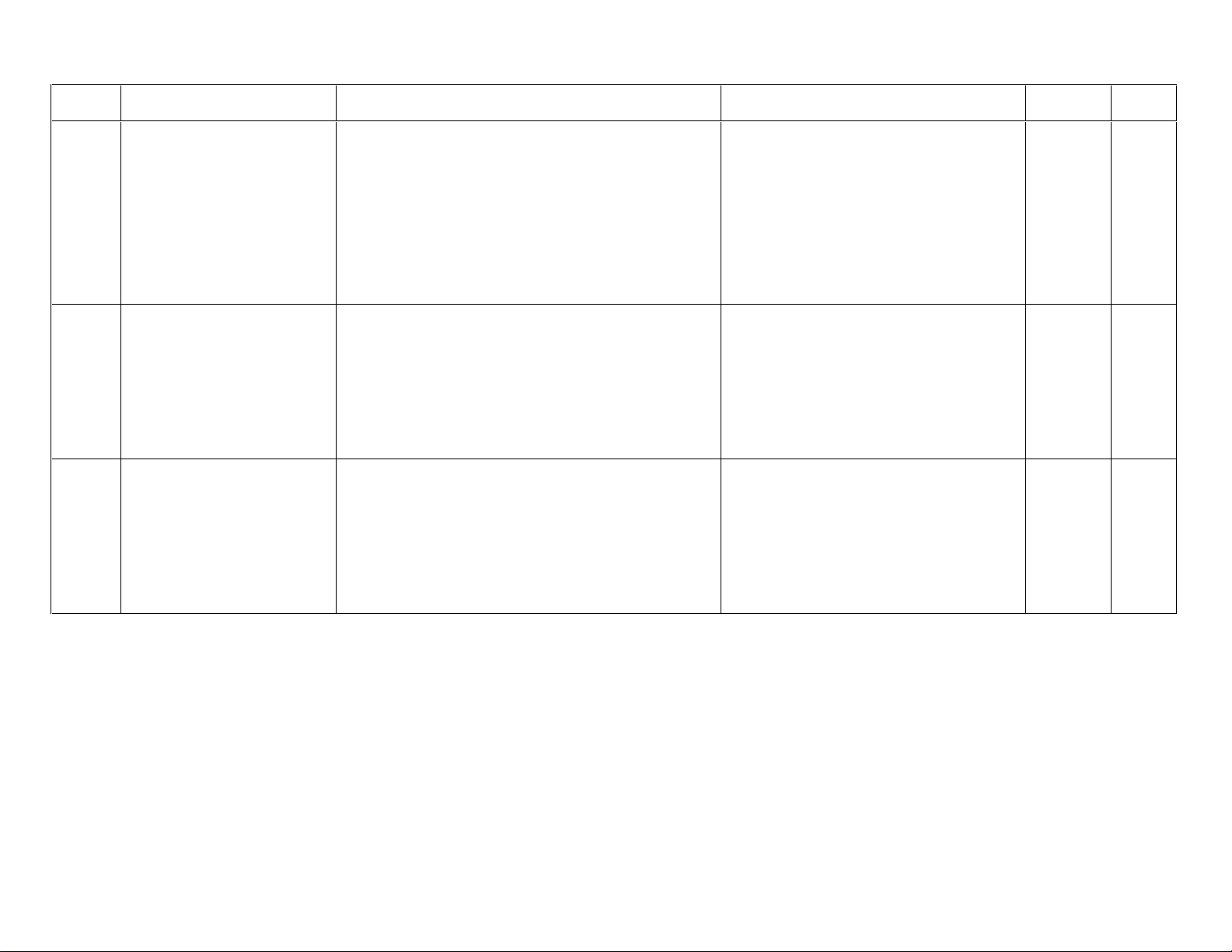

7.1 Checking the SK1

[1] Analysis Flow

START

A

Does the M-Utility

indicate that the sensor

operation is normal?

Y

Return to the error code

nalysis flow.

Are the SNS08C

N

board voltages

normal?

[2]

Is the SNS08C

board fuse normal?

Are the cables normal?

Is the mechanism normal?

Is the sensor normal?

Remove and reinstall the

CPU90E board and

connectors.

Does the error recur?

Replace the PC boards in the following order:

1. SNS08C board

2. CPU90E board

3. MTH08C board

Y

Y

Y

Y

Y

Y

N

Power OFF.

Are the power supply

[3]

N

[7]

Replace any

blown fuse.

N

[5], [6]

N

[4]

N

“Checks, Replacement, and Adjustment of Parts”

volume

N

“15. Removing and Installing the PC Boards” in the “Checks,

Replacement, and Adjustment of Parts” volume

NN

unit (JPS-6) voltages

normal?

Y

[3]

Replace any faulty cable.

Repair the mechanism.

Check the sensor.

A

Are the fuses for the

power supply unit

(JPS-6) normal?

Y

Replace the power

supply unit (JPS-6).

N

009-058-03

08.30.2002 FM3476

CR-IR347

009-058-00

10.20.2000 FM2731

Service Manual

CR-IR347

Service Manual

MT7 - 2

FR7H2732.EPS

MT1 - 2

Page 9

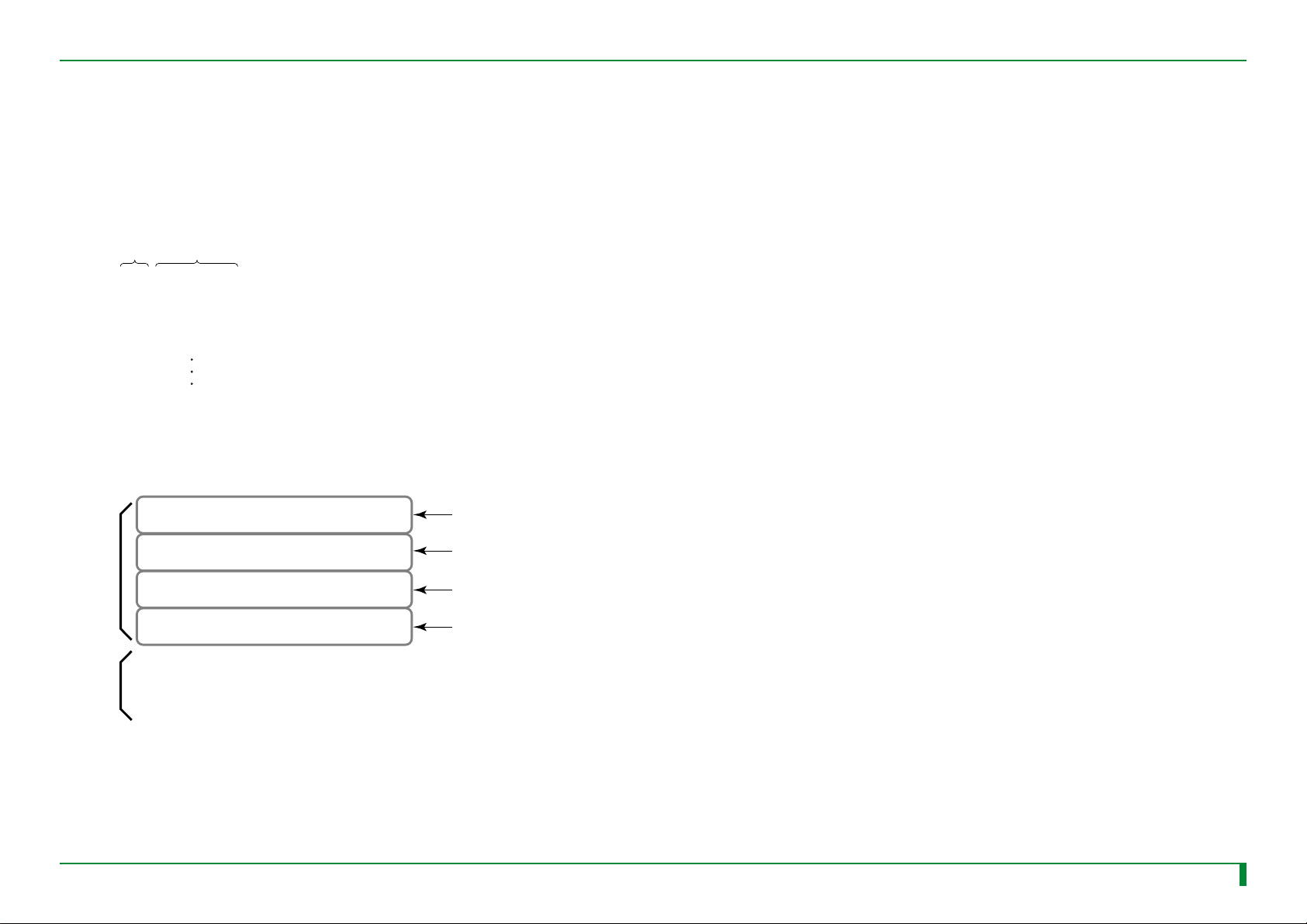

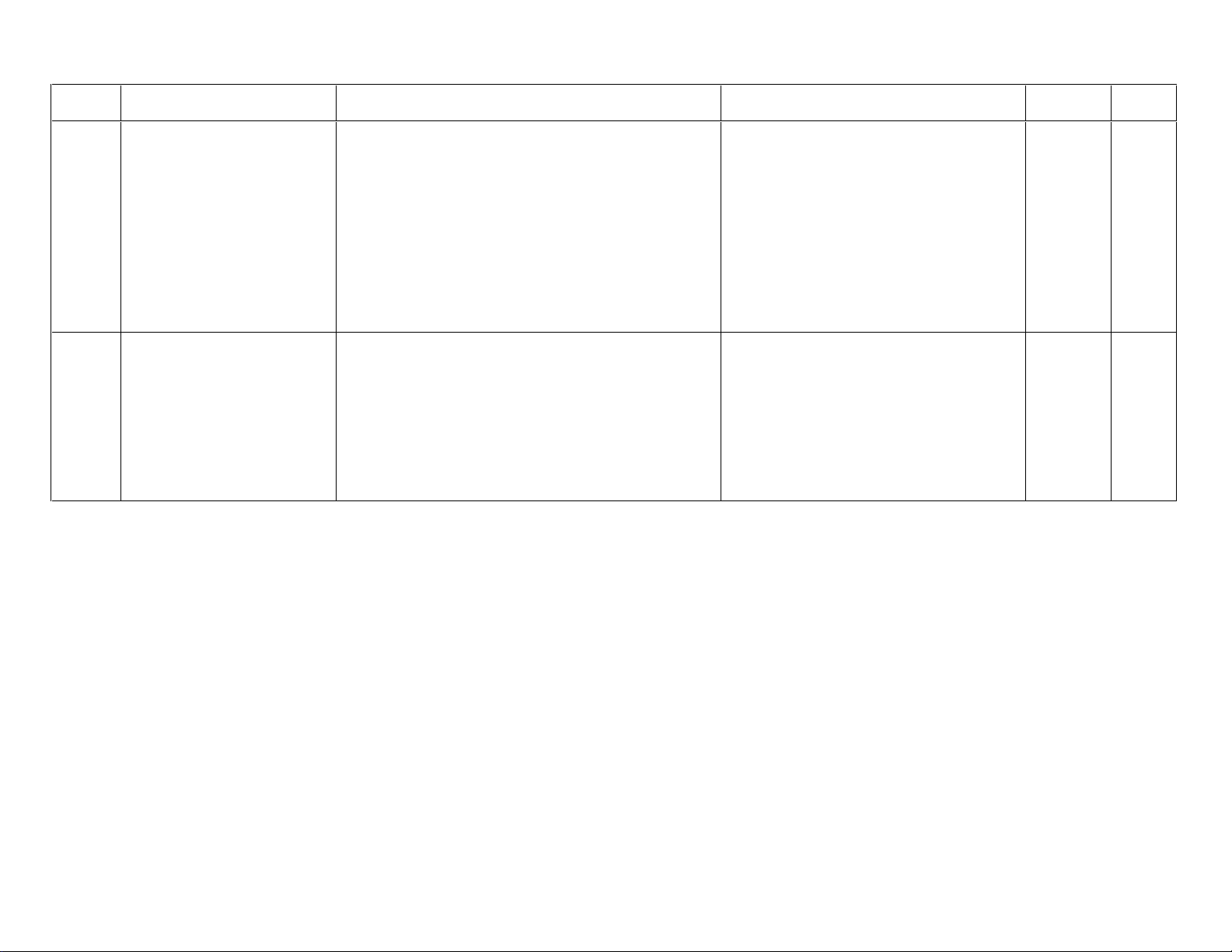

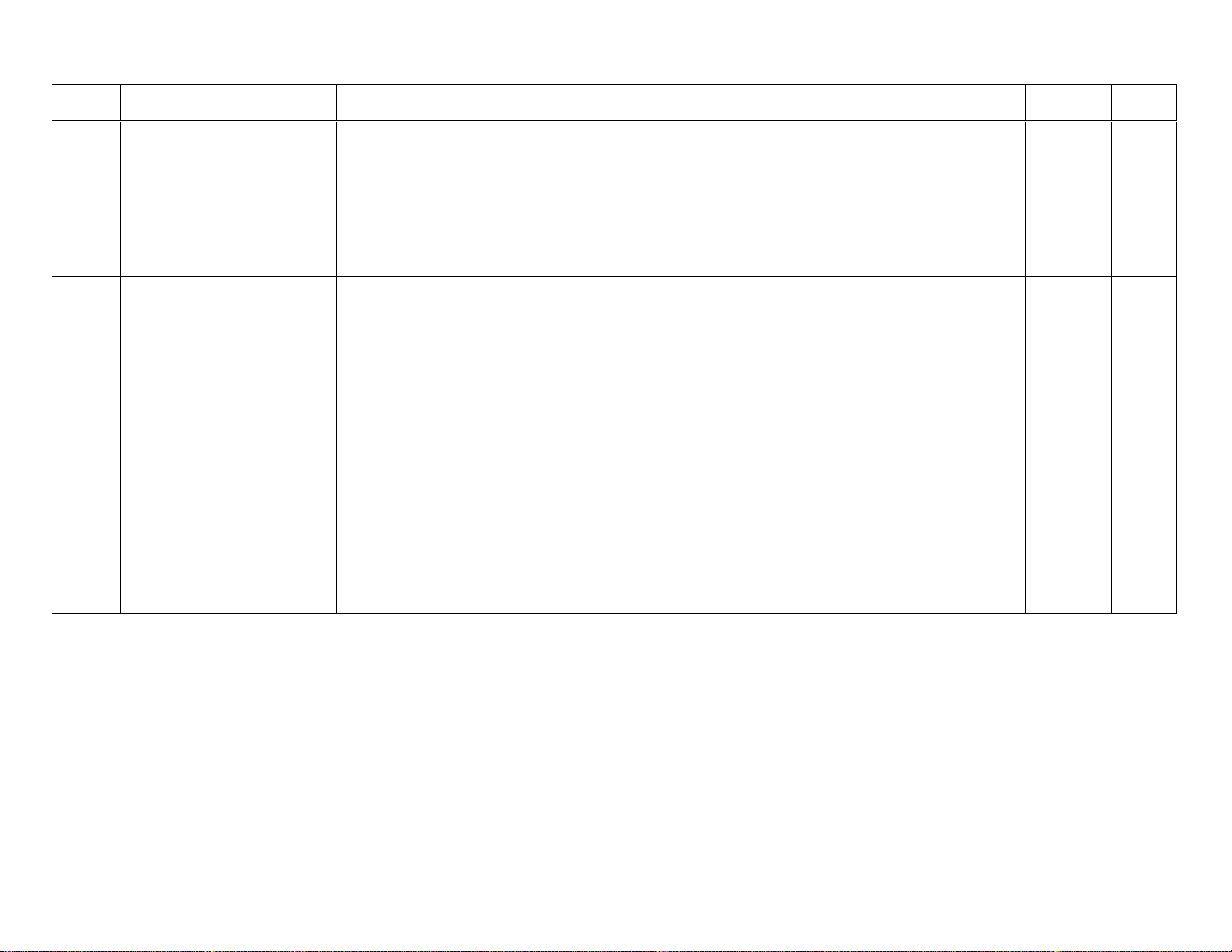

1.2 How to Understand Error Log

When an error code is displayed, check the error log.

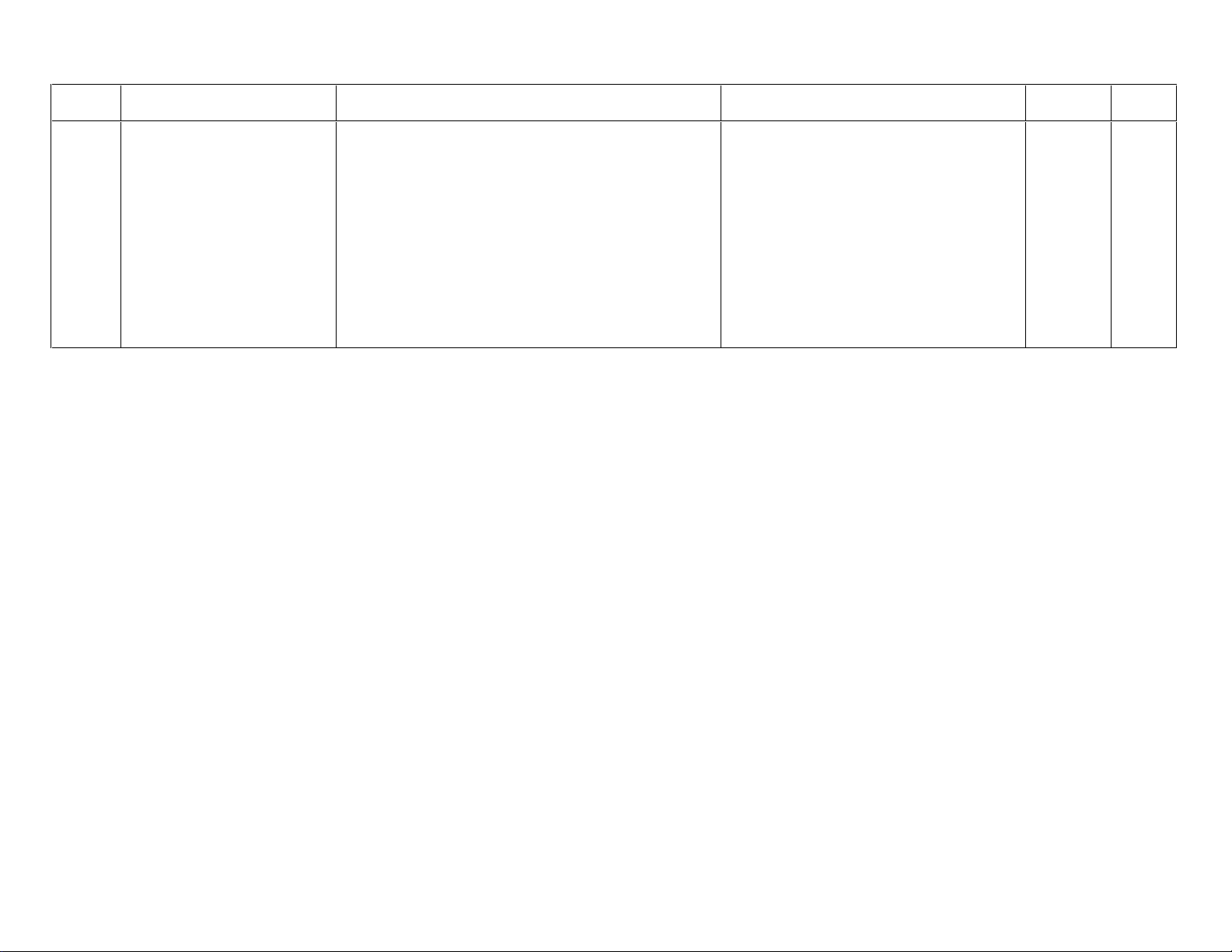

■ How to Understand the Error Log List

When multiple errors occurred, the error at the beginning that occurred at the same time (with a

margin of about 2-4 minutes) is the most likely cause that is directly responsible for the trouble.

Check the error log to see which is the error at the beginning.

● Error log format

Error code Occurrence date

CODE DATE

03EF 2000.10.18 17:13

001000000000000001-0-0-011-0000101101.------

--.1.0.0.9.0.0.0.0000.0000.0000

23EB 2000.10.18 17:13

111000000000000001-0-0-011-0000101101.------

--.1.0.0.9.0.0.0.0000.0000.0000

● How to identify the error code at the beginning

In the error log example shown below, those denoted by “A” and “B” are errors that occurred at the

same time (with a margin of about 2 minutes), the error at the beginning for “A” is “23EB”.

Error codes displayed on the screen

CODE DATE

03EF 2000.10.18 17:13

001000000000000001-0-0-011-0000101101.------

--.1.0.0.9.0.0.0.0000.0000.0000

23EB 2000.10.18 17:13

111000000000000001-0-0-011-0000101101.------

A

B

--.1.0.0.9.0.0.0.0000.0000.0000

23EB 2000.10.18 17:13

111000000000000001-0-0-011-0000101101.------

--.1.0.0.9.0.0.0.0000.0000.0000

23EB 2000.10.18 17:13

111000000000000001-0-0-011-0000101101.------

--.1.0.0.9.8.8.8.0000.0000.0000

23E1 2000.10.18 16:55

1110000000000000000000001101000110010.------

--.1.0.0.0.0.0.0.0000.0000.0000

13A8 2000.10.18 16:55

11110000000000000000-0001110000110010.------

--.1.0.0.6.3.1.0.0000.0000.0000

03C2 2000.10.18 16:24

11100000000000000100-0001001000111010.000001

40.1.5.0.A.0.0.1.0000.0000.0000

13B8 2000.10.18 16:07

001000000000000001-0-0-011-1000101111.------

--.1.5.0.0.0.0.0.0000.0000.0000

0.END 1.NEXT 2.BEFORE (DEFAULT=1) :

FR7H2733.EPS

Error code that occurred last

Error code that

occurred third

Error code that

occurred second

Error code at the beginning:

It should be analyzed first.

FR7H2734.EPS

MT1 - 3

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

MT1 - 3

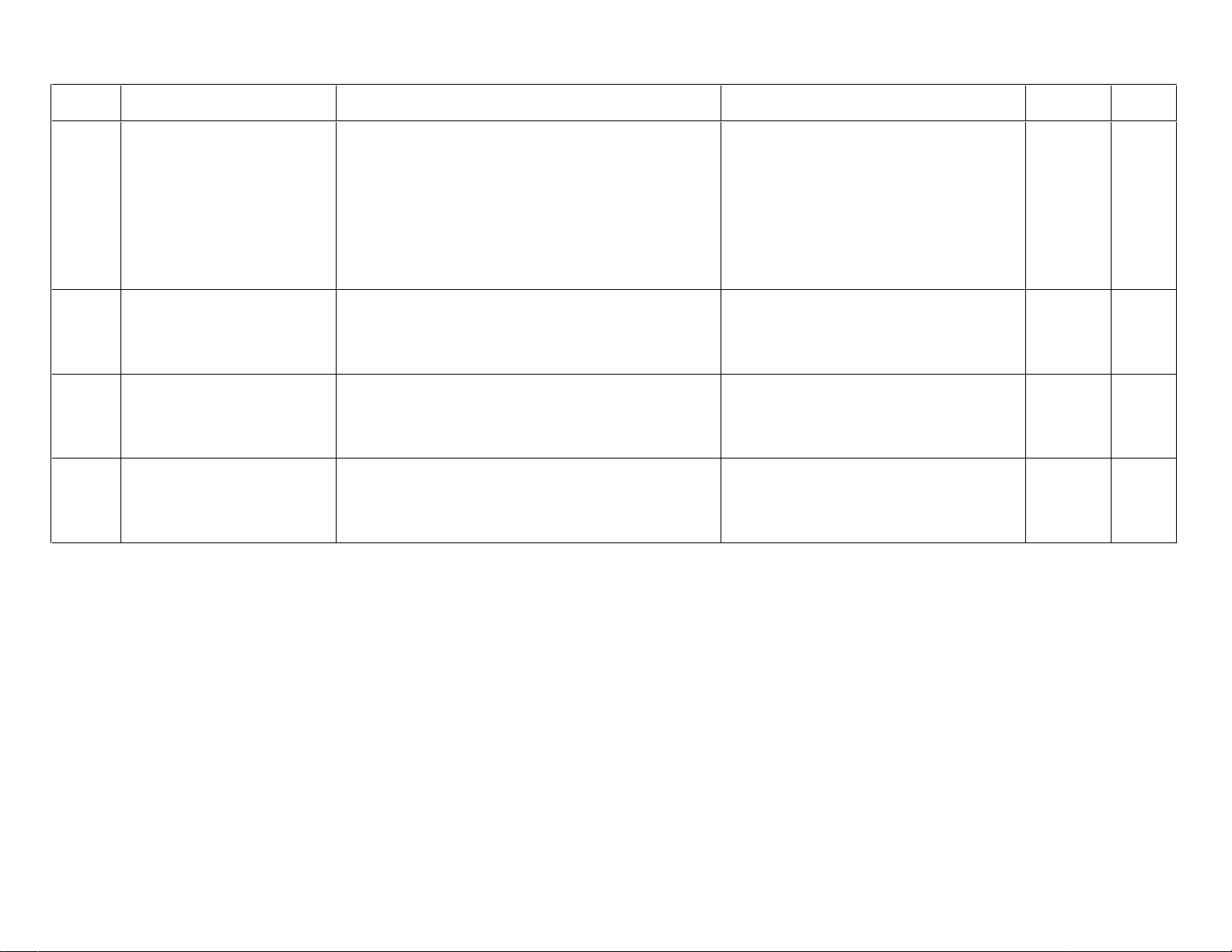

Page 10

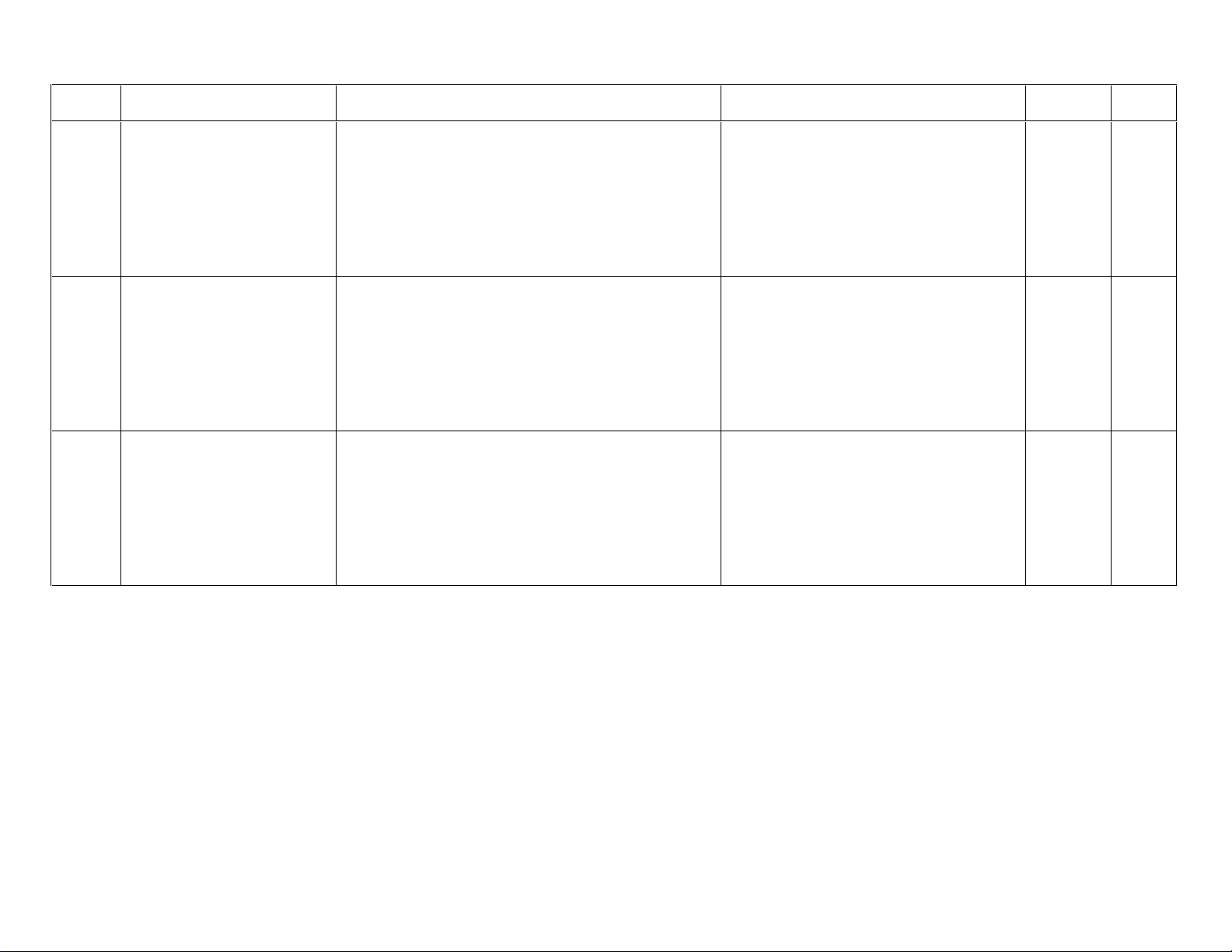

● Error code

An example of error code format is presented below.

Code Name

03BC

Side-positioning HP

operation error

[During initialization/normal processing]

Although the MN1 turned ON, the SN1 failed to close,

allowing the maximum retry count (NN51) to be exceeded.

<I/O name>

• MN1; Side-positioning motor

• SN1; Side-positioning mechanism home position sensor

<Reference>

MD-8.2.8/8.5.2

Significance/Occurrence Condition

Probable Cause/Remedy

• Perform the analysis flow for

Error 03BC (MT-4).

• Check the MN1 (MT-7.2/MU-4.6/SP-07).

• Check the SN1 (MT-7.10/MU-4.6/MC-8.4).

• Check the side-positioning conveyor

mechanism (MD-5.4/MC-8).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

Indicates the reference volume

abbreviation and section number.

Analysis

flow

Detail

D-5MT4-13

MT1 - 4

Indicates the reference volume

abbreviation and section number.

XYZZ

Hexadecimal notation

00-FF: Reference number according to error classification

0-9, A-F: Error classification

0-3: Error level

X: Error level

• FATAL error: 0

Error where the normal processing cannot be resumed.

It is necessary to troubleshoot and take remedial action immediately.

• WARNING: 1, 2, 3

Errors where the processing may be resumed by performing retry

operation, etc.

This category includes an error that is merely logged as history information

and an error where the processing is resumed but its error code is displayed

on screen.

ZZ: Reference number

Managed according to the error classification

The checks to be performed are listed in random

order. Judge the target machine condition and

change the order of checks as needed to begin

by checking on the most probable error cause.

Y: Error classification

0: OS (operating system software), CPU, library

1: Overall control, information gathering function,

output destination control function

2: Panel control

3: Conveyor-related control

4: Image processing related (reading)

5: Scanner control

6: Undefined

7: IDT interface control

See “Section 2.3,

Format of Detail Information”.

Indicates the reference page for

“Analysis Flow” in this volume.

8: Printer interface control

9: Undefined

A: ID information setup function

B: Network output image processing

C: FINP control

D: DICOM control

E: Undefined

F: Other (software install, version update, etc.)

FR1H1316.EPS

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

MT1 - 4

Page 11

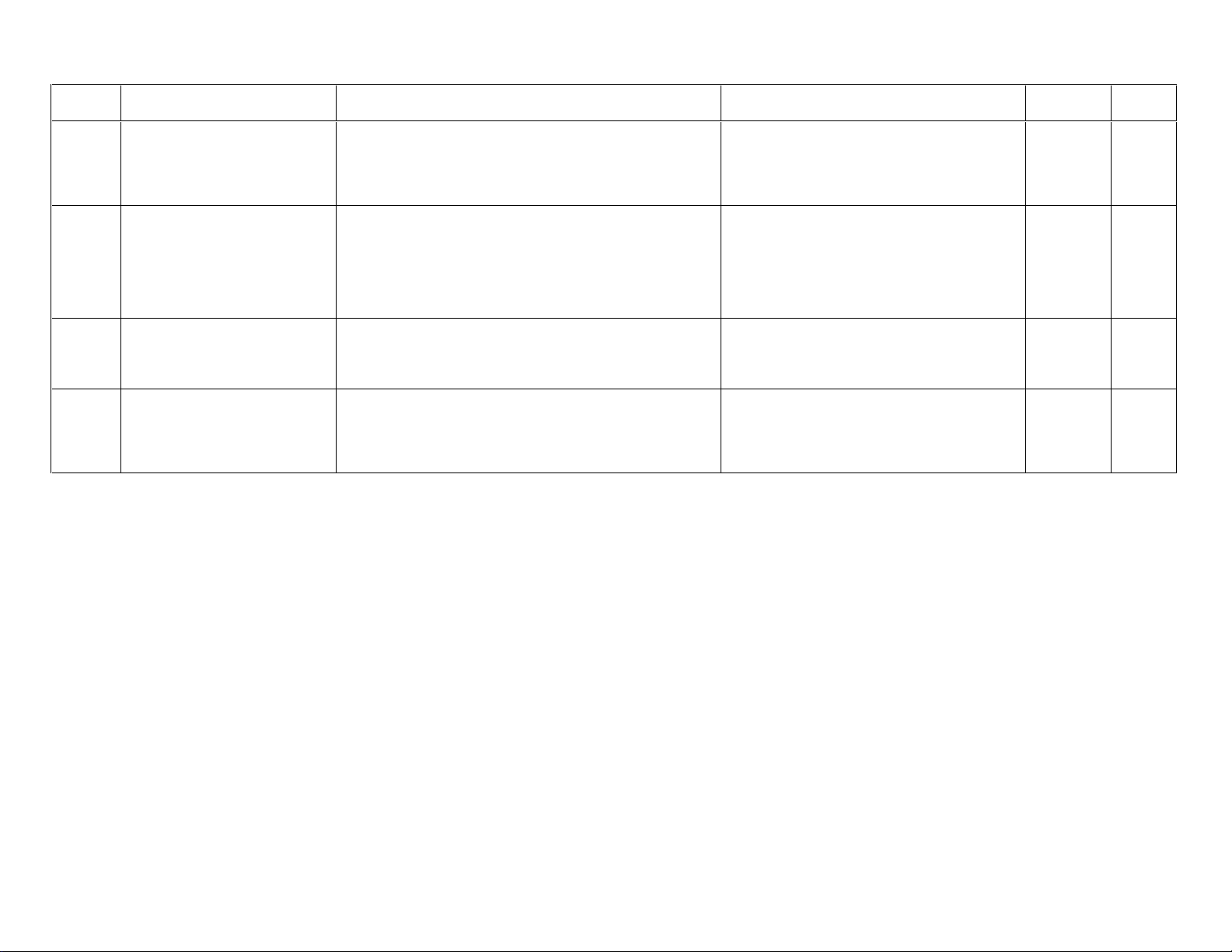

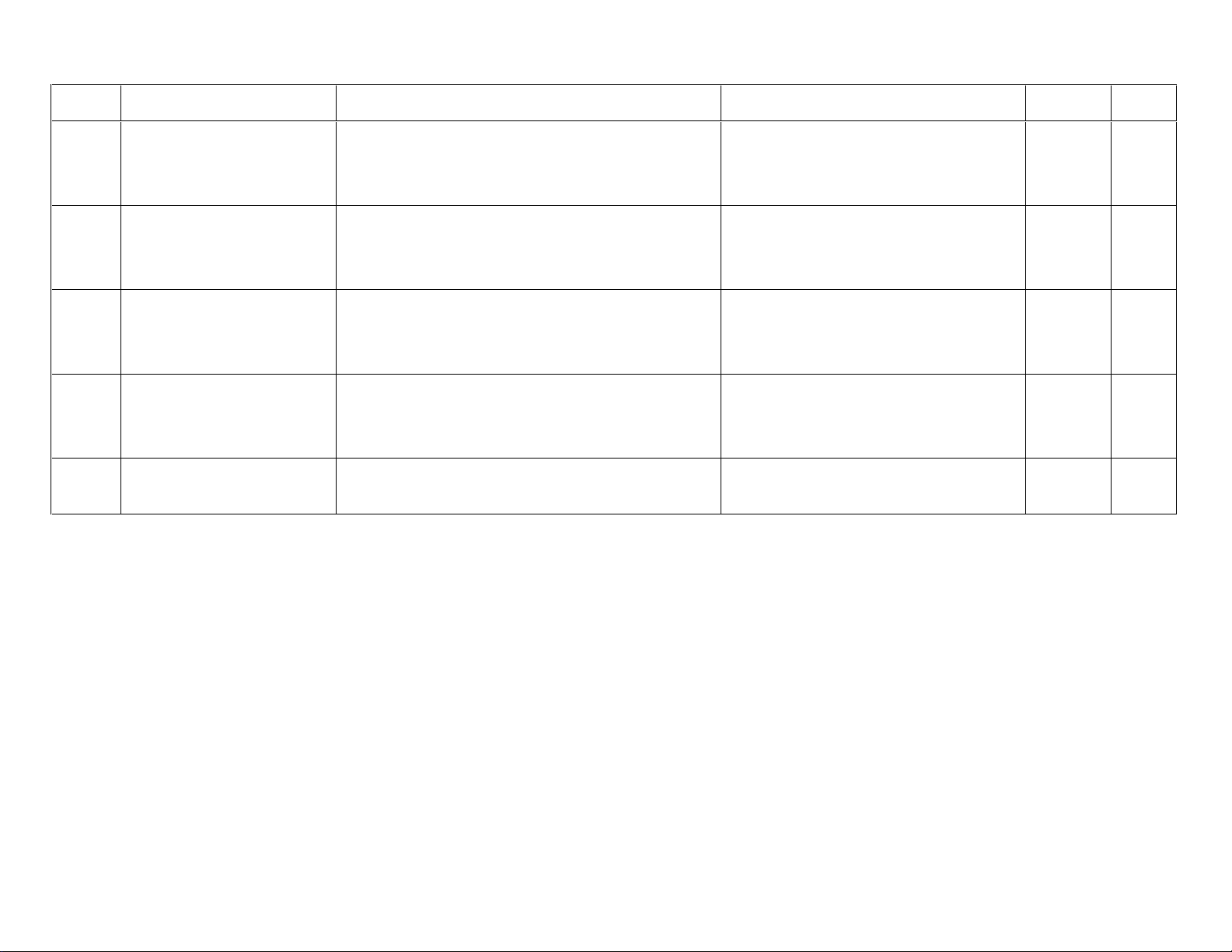

2. Error Codes List

MT2-1

Code

0100

0101

0102

0110

Name Significance/Occurrence Condition

Board insertion position error

ID information control system

initialization error

Common data control system

initialization error

Image control system

initialization error

[During initialization]

The board insertion slot position was found to be abnormal when it was checked.

[During initialization/normal processing]

The ID information control system (IMM) was found to be abnormal.

[During initialization]

An error was detected in the common data control system (CDM).

[During initialization/normal processing]

An error was detected in the image control system (IDM).

Probable Cause/Remedy

• Check the board insertion location (MC-15).

• Check for improper board setup (MC-15).

• Check the board (MT-7.41).

• Check for an improper software update (MU-A1.2).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

Analysis

flow

- A-8

-

-

-

Detail

F

F

F

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-1

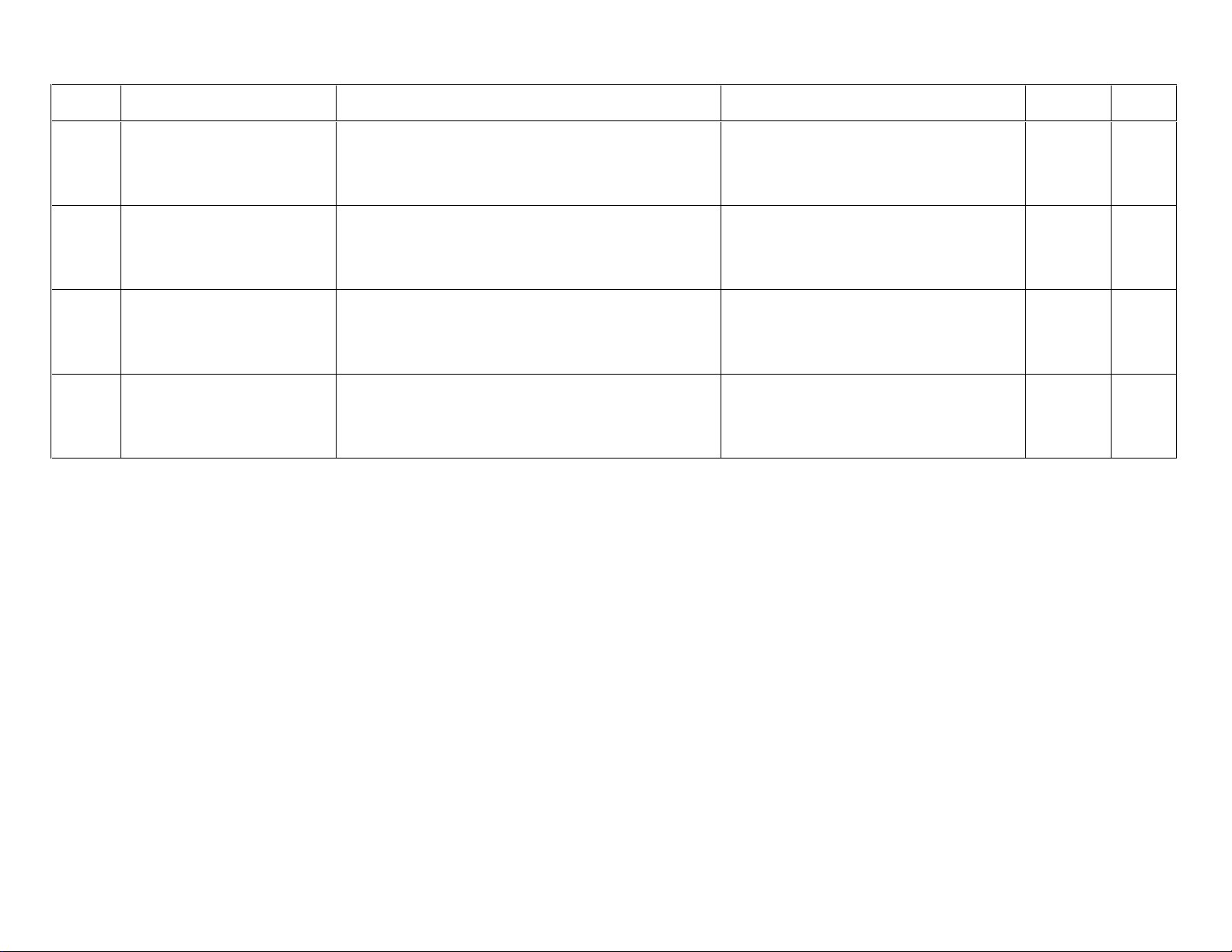

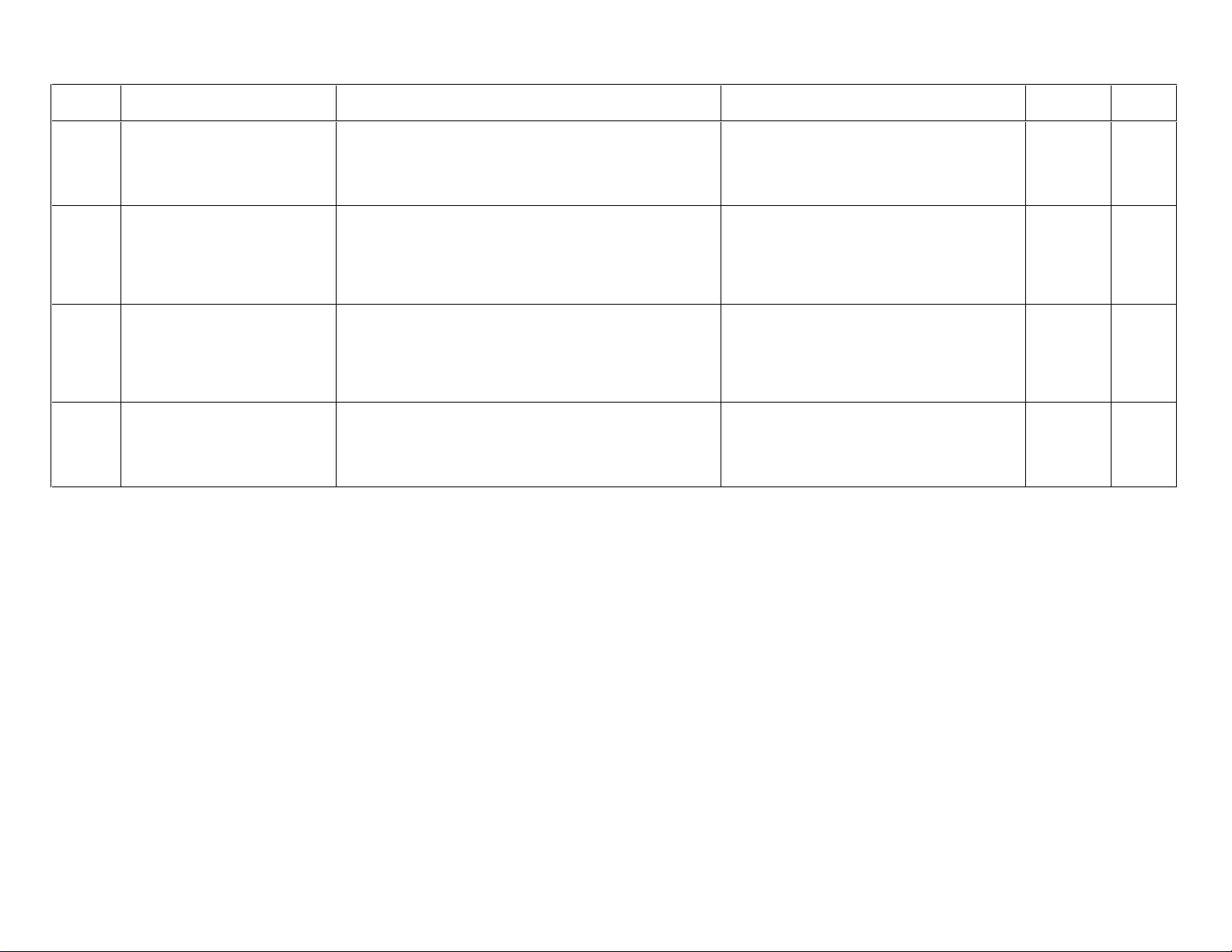

Page 12

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-2

Analysis

flow

Detail

0111

0112

0113

0120

HD image display area

initialization error

No effective option

Not enough common memory

File open error

[During initialization/normal processing]

An error was detected in the HD image display area.

[During initialization/normal processing]

An error was detected when shared memory allocation was attempted for option

configuration.

[During initialization]

It was detected that the capacity of the common memory is insufficient.

[During initialization]

An error was detected when an attempt was made to open a configuration file

(NETMASKS).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the MMA90A and MMB90A/DIM08A board

(MT-7.41/MC-15/IN-5.5).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the MMA90A and MMB90A/DIM08A board

(MT-7.41/MC-15/IN-5.5).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

-

-

- E-5

-

A-1

F

F

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-2

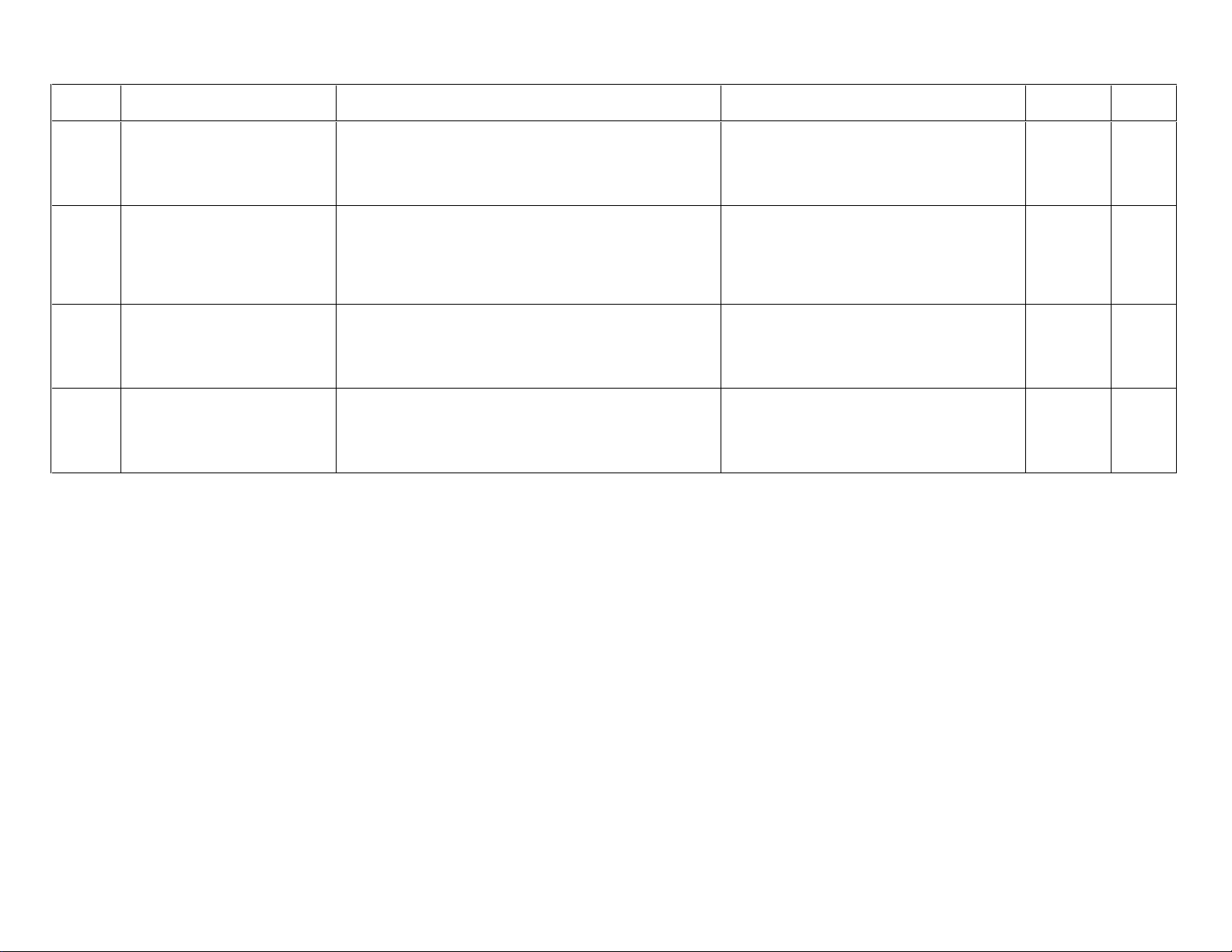

Page 13

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-3

Analysis

flow

Detail

0121

0122

0123

0130

File read error

File close error

File format error

File open error

[During initialization]

An error was detected when an attempt was made to read a configuration file

(NETMASKS).

[During initialization]

An error was detected when an attempt was made to close a configuration file

(NETMASKS).

[During initialization]

An error was found in the format of a configuration file (NETMASKS).

[During initialization]

An error was detected when an attempt was made to open a configuration file

(HOSTS ADDRESS).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the configuration settings (MU-4.2).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

-

-

-

-

A-1

A-1

A-1

A-1

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-3

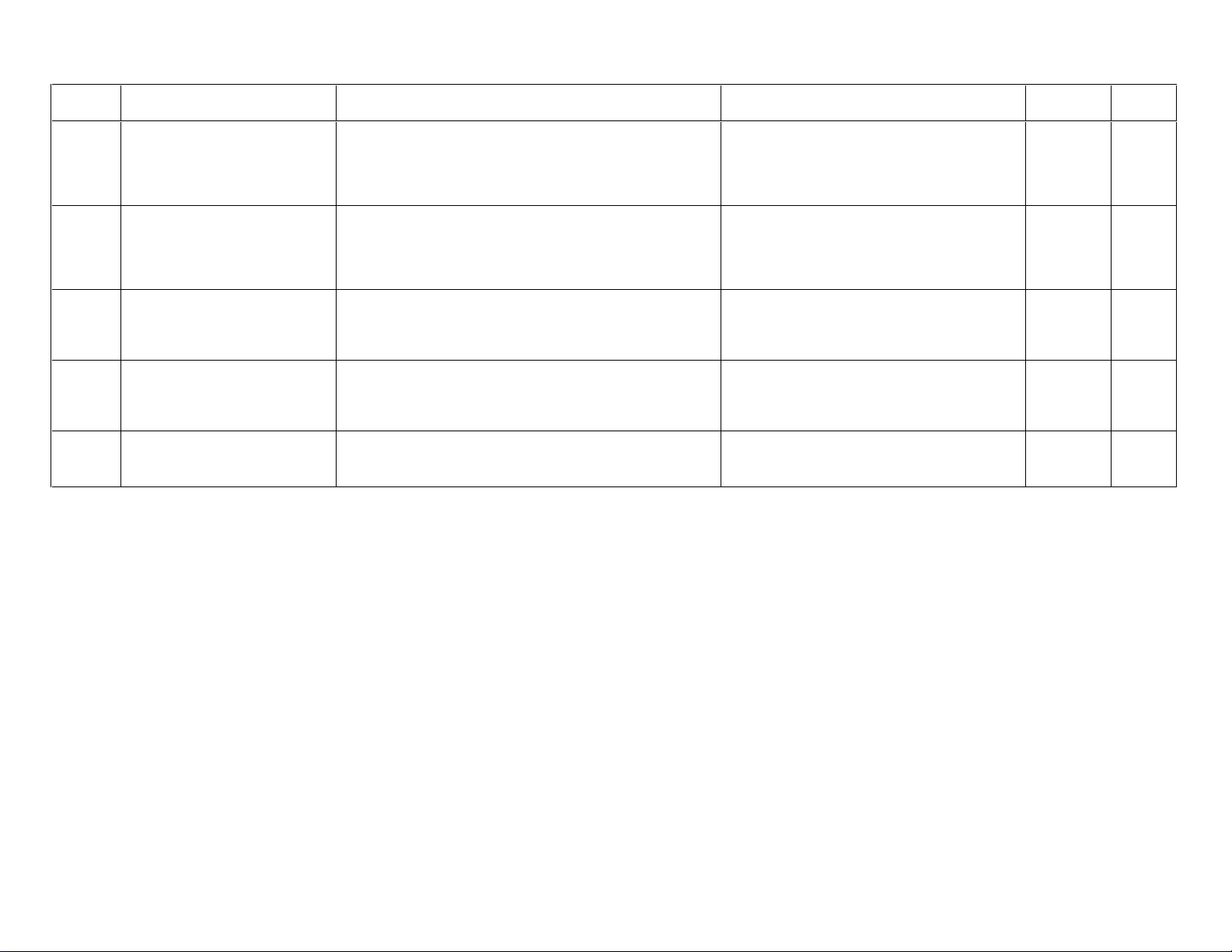

Page 14

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-4

Analysis

flow

Detail

0131

0132

0133

0134

0140

File read error

File close error

File format error

File setting value error

Boot line-related error

[During initialization]

An error was detected when an attempt was made to read a configuration file

(HOSTS ADDRESS).

[During initialization]

An error was detected when an attempt was made to close a configuration file

(HOSTS ADDRESS).

[During initialization]

An error was found in the format of a configuration file (HOSTS ADDRESS).

[During initialization]

An error was found in the settings contained in a configuration file (HOSTS

ADDRESS).

[During initialization]

An error was detected in the backup memory data.

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the configuration settings (MU-4.2).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Check the configuration settings (MU-4.2).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Check the CPU90E board (MT-7.41/MC-15.3). -

-

-

-

-

A-1

A-1

A-1

A-1

F

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-4

Page 15

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-5

Analysis

flow

Detail

0141

01A0

01A1

01A2

Routing information-related

error

ID information read error

ID information update error

Image data close error

[During initialization]

An error was found in the settings contained in a configuration file

(ROUTING/HOSTS ADDRESS).

[During initialization/normal processing]

An error was detected when an attempt was made to read ID information.

[During initialization/normal processing]

An error was detected when an attempt was made to update ID information.

[During initialization/normal processing]

An error was detected when an attempt was made to close an image data file.

• Check the configuration settings (MU-4.2).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the MMA90A and MMB90A/DIM08A board

(MT-7.41/MC-15/IN-5.5).

• Check the HDD (MT-7.42/MC-11).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the MMA90A and MMB90A/DIM08A board

(MT-7.41/MC-15/IN-5.5).

• Check the HDD (MT-7.42/MC-11).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

-

-

-

-

F

D

D

D

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-5

Page 16

Code

01A3

0200

Name Significance/Occurrence Condition

EQUIP file format error

Image data close error

[During initialization]

An error was found in the format contained in a configuration file (EQUIPMENT).

[During U-Utility mode]

An error was detected when an attempt was made to delete an image queued for

processing.

Probable Cause/Remedy

• Check the configuration settings (MU-4.2).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the MMA90A and MMB90A/DIM08A board

(MT-7.41/MC-15/IN-5.5).

• Check the HDD (MT-7.42/MC-11).

MT2-6

Analysis

flow

-

-

Detail

D

-

0301

0302

File open error

File format error

[During initialization]

An error was detected when an attempt was made to open a subsystem (IPH) file

on the HDD.

[During initialization]

An error was found in the data format of a subsystem (IPH) file on the HDD.

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

-

-

D-1

D-1

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-6

Page 17

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-7

Analysis

flow

Detail

0303

0304

0311

0312

0322

File setting value error

File read error

FPMC device error

Motor stop time-out

SNS device error

[During initialization]

An error was found in the setting data contained in a subsystem (IPH) file on the

HDD.

[During initialization]

An error was detected when an attempt was made to read a subsystem (IPH) file

on the HDD.

[During initialization]

An error was detected when an attempt was made to initialize the FPMC device

for the CPU memory (CPU90E board).

[During initialization/normal processing]

Although a pulse motor drive request or stop request was issued, a timeout

occurred because the target pulse motor could not be driven or stopped.

[During initialization]

An error was detected when an attempt was made to initialize the SNS device.

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the CPU90E board (MT-7.41/MC-15.3). - D-3

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Check the CPU90E board (MT-7.41/MC-15.3). -

-

-

- D-3

D-1

D-1

D-3

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-7

Page 18

Code

03A2

Name Significance/Occurrence Condition

Cassette hold release error

[During initialization/normal processing/M-Utility mode/abnormality processing]

Although the SOLK1 turned ON, the SK3 failed to open, allowing the maximum

retry count (NK11) to be exceeded.

<I/O name>

• SOLK1; Cassette hold solenoid

• SK3; Cassette hold sensor

<Reference>

MD-8.6.2

Probable Cause/Remedy

• Perform the analysis flow for Error 03A2 (MT-4).

• Check the SOLK1 (MT-7.31/MU-4.6/MC-4.6).

• Check the SK3 (MT-7.3/MU-4.6/MC-4.7).

• Check the cassette set unit mechanism (MD-5.1/MC-4).

• Check the cassette.

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT2-8

Analysis

flow

MT4-1

Detail

D-5

03A8

03B0

Nonstandard initialization IP

size

IP feed/load conveyor

remaining IP discharge

impossible

[During initialization]

When the IP size was checked, the CLOSE time combination of the SM1 did not

agree with the IP size data stored in the machine.

<I/O name>

• SM1; Before-BCR IP sensor

<Reference>

MD-8.2.4 (IP identification condition table)

[During initialization]

When the machine was searched for IPs, the remaining IP process could not be

performed for one of the following reasons:

• Cassette detection was not achievable.

• The CMOS information was abnormal.

<Reference>

MD-8.5.8

• Check the IP and cassette.

• Check the MM1 (MT-7.20/MU-4.6/MC-6.14).

• Check the MN3 (MT-7.23/MU-4.6/SP-07).

• Check the SM1 (MT-7.9/MU-4.6/SP-05).

• Check the cassette set unit mechanism (MD-5.1/MC-4).

• Check the IP removal unit mechanism (MD-5.2/MC-5).

• Check the side-positioning conveyor mechanism

(MD-5.4/MC-8).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Check the SK1 (MT-7.1/MU-4.6/MC-4.3).

• Check the SK2 (MT-7.2/MU-4.6/MC-4.9).

• Clear the backup memory and then perform a reset (IN-17).

• Check the cassette.

• Check the cassette set unit mechanism (MD-5.1/MC-4).

-

- D-5

D-5

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-8

Page 19

Code

03B1

Name Significance/Occurrence Condition

IP feed conveyance error

[During initialization/normal processing]

Although the MN3/MM1/ML2 was turned ON, the SM1 did not close and a timeout

occurred.

<I/O name>

• MN3/MM1/ML2; IP transport motor

• SM1; Before-BCR IP sensor

<Reference>

MD-8.2.3

Probable Cause/Remedy

• Perform the analysis flow for Error 03B1 (MT-4).

• Check the MN3 (MT-7.23/MU-4.6/SP-07).

• Check the MM1 (MT-7.20/MU-4.6/MC-6.14).

• Check the ML2 (MT-7.19/MU-4.6/MC-5.22).

• Check the SM1 (MT-7.9/MU-4.6/SP-05).

• Check the IP removal unit mechanism (MD-5.2/MC-5).

• Check the side-positioning conveyor mechanism

(MD-5.4/MC-8).

• Check the fuse (F11) for the power supply (JPS-6)

(MD-1.6/MT-7.40/MC-13.2).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT2-9

Analysis

flow

MT4-8

Detail

D-5

03B2

IP load conveyance error

[During initialization/normal processing]

Although the ML2/MM1/MN3 turned ON, a timeout occurred because the SK2

failed to close.

<I/O name>

• ML2/MM1/MN3; IP transport motor

• SK2; Cassette IN sensor

<Reference>

MD-8.2.16/8.2.17/8.4.1

• Perform the analysis flow for Error 03B2 (MT-4).

• Check the ML2 (MT-7.19/MU-4.6/MC-5.22).

• Check the MM1 (MT-7.20/MU-4.6/MC-6.14).

• Check the MN3 (MT-7.23/MU-4.6/SP-07).

• Check the SK2 (MT-7.2/MU-4.6/MC-4.9).

• Check the IP removal unit mechanism (MD-5.2/MC-5).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT4-9

D-5

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-9

Page 20

Code

03B3

Name Significance/Occurrence Condition

Side-positioning conveyor

entrance conveyance error

[During initialization/normal processing]

Although the MN3 turned ON, the SN3 did not close after the SM1 closing.

Therefore, a retry operation was performed.

<I/O name>

• MN3; IP transport motor

• SM1; Before-BCR IP sensor

• SN3; Side-positioning IP sensor

<Reference>

MD-8.2.6

Probable Cause/Remedy

• Perform the analysis flow for Error 03B3 (MT-4).

• Check the MN3 (MT-7.23/MU-4.6/SP-07).

• Check the SN3 (MT-7.12/MU-4.6/MC-8.8).

• Check the side-positioning conveyor mechanism

(MD-5.4/MC-8).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT2-10

Analysis

flow

MT4-10

Detail

D-5

03B4

03B5

Restored IP load low-speed

conveyance error

Restored IP load high-speed

conveyance error

[During normal processing/abnormality processing]

Although the MN3/MM1/ML2 turned ON, the SL2 did not open.

<I/O name>

• MN3/MM1/ML2; IP transport motor

• SL2; Cassette inlet IP sensor

<Reference>

MD-8.3.1

[During normal processing/abnormality processing]

Although the MN3/MM1/ML2 turned ON, the SL2 did not close.

<I/O name>

• MN3/MM1/ML2; IP transport motor

• SL2; Cassette inlet IP sensor

<Reference>

MD-8.3.1

• Perform the analysis flow for Error 03B4 (MT-4).

• Check the MN3 (MT-7.23/MU-4.6/SP-07).

• Check the MM1 (MT-7.20/MU-4.6/MC-6.14).

• Check the ML2 (MT-7.19/MU-4.6/MC-5.22).

• Check the SL2 (MT-7.6/MU-4.6/SP-04).

• Check the IP removal unit mechanism (MD-5.2/MC-5).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Perform the analysis flow for Error 03B5 (MT-4).

• Check the MN3 (MT-7.23/MU-4.6/SP-07).

• Check the MM1 (MT-7.20/MU-4.6/MC-6.14).

• Check the ML2 (MT-7.19/MU-4.6/MC-5.22).

• Check the SL2 (MT-7.6/MU-4.6/SP-04).

• Check the IP removal unit mechanism (MD-5.2/MC-5).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT4-11 D-5

MT4-11 D-5

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-10

Page 21

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-11

Analysis

flow

Detail

03B6

IP feed/load conveyor

remaining IP discharge error

[During initialization]

• Although the ML2/MM1/MN3 turned ON, the SL2 did not open.

• Although the ML2/MM1/MN3 turned ON, the SM1 did not open.

• Although the ML2 turned ON, the SL2 did not open.

• An error was found in the CMOS information.

<I/O name>

• ML2/MM1/MN3; IP transport motor

• SL2; Cassette inlet IP sensor

• SM1; Before-BCR IP sensor

<Reference>

MD-8.5.6/8.5.8/8.5.10

• Perform the analysis flow for Error 03B6 (MT-4).

• Check the ML2 (MT-7.19/MU-4.6/MC-5.22).

• Check the MM1 (MT-7.20/MU-4.6/MC-6.14).

• Check the MN3 (MT-7.23/MU-4.6/SP-07).

• Check the SL2 (MT-7.6/MU-4.6/SP-04).

• Check the SM1 (MT-7.9/MU-4.6/SP-05).

• Check the IP removal unit mechanism (MD-5.2/MC-5).

• Check the side-positioning conveyor mechanism

(MD-5.4/MC-8).

• Clear the backup memory and then perform a reset (IN-17).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT4-11 D-5

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-11

Page 22

Code

03B7

Name Significance/Occurrence Condition

Side-positioning conveyor

remaining IP discharge error

[During initialization]

• Although the MN3 and MZ1 turned ON to reverse for the purpose of moving

the remaining IP in the before-reading conveyor, the SM1 did not close. Or

when the MN3 turned ON for feed conveyance after the SM1 close, the SN3

did not close.

• Although the MN3 turned ON for feed conveyance to search for a remaining

IP in the before-reading conveyor, the SN3 did not close.

[During initialization/normal processing]

Although the ML2/MM1/MN3 turned ON for feed conveyance to move the

remaining IP in the before-reading conveyor, the SM1 did not open.

Or when the MN3 turned ON for feed conveyance after the SM1 close, the SN3

did not close.

<I/O name>

• ML2/MM1/MN3; IP transport motor

• MZ1; Subscanning motor

• SM1; Before-BCR IP sensor

• SN3; Side-positioning IP sensor

<Reference>

MD-8.5.6

Probable Cause/Remedy

• Perform the analysis flow for Error 03B7 (MT-4).

• Check the MN3 (MT-7.23/MU-4.6/SP-07).

• Check the MZ1 (MT-7.25/MC-10.6).

• Check the SN3 (MT-7.12/MU-4.6/MC-8.8).

• Check the SM1 (MT-7.9/MU-4.6/SP-05).

• Check the SZ1 (MT-7.14/MC-10.11).

• Check the side-positioning conveyor mechanism

(MD-5.4/MC-8).

• Check the subscanning unit mechanism (MD-5.5/MC-10).

• Clear the backup memory and then perform a reset (IN-17).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT2-12

Analysis

flow

MT4-12 D-5

Detail

03B8

009-058-03

08.30.2002 FM3476

IP position information error

[During initialization]

The machine's CMOS information (IP found) did not agree with the remaining IP

search result (no IP).

<Reference>

MD-8.5.8/8.5.10

CR-IR347 Service Manual [ 2. ] MT2-12

• Clear the backup memory and then perform a reset (IN-17).

• Turn the power OFF and then back ON to achieve

automatic discharge, clear the backup memory,

and then perform a reset (IN-17).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

-

D-5

Page 23

Code

03BC

Name Significance/Occurrence Condition

Side-positioning HP

operation error

[During initialization/normal processing]

Although the MN1 turned ON, the SN1 failed to close, allowing the maximum retry

count (NN51) to be exceeded.

<I/O name>

• MN1; Side-positioning motor

• SN1; Side-positioning mechanism home position sensor

<Reference>

MD-8.2.8/8.5.2

Probable Cause/Remedy

• Perform the analysis flow for Error 03BC (MT-4).

• Check the MN1 (MT-7.21/MU-4.6/SP-07).

• Check the SN1 (MT-7.10/MU-4.6/MC-8.4).

• Check the side-positioning conveyor mechanism

(MD-5.4/MC-8).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT2-13

Analysis

flow

MT4-13

Detail

D-5

03BF

03C0

Side-positioning grip

operation error

IP pre-reading conveyance

error

[During initialization/normal processing]

Although the MN2 turned ON, the SN2 failed to close, allowing the maximum retry

count (NN61) to be exceeded.

<I/O name>

• MN2; Grip release motor

• SN2; Grip release home position sensor

<Reference>

MD-8.2.11/8.5.1

[During initialization/normal processing]

Although the MN3 turned ON, the SZ1 closed before the SN1 closing.

<I/O name>

• MN3; IP transport motor

• SN1; Side-positioning mechanism home position sensor

• SZ1; IP leading edge sensor

• Perform the analysis flow for Error 03BF (MT-4).

• Check the MN2 (MT-7.22/MU-4.6/MC-8.2).

• Check the SN2 (MT-7.11/MU-4.6/MC-8.5).

• Check the side-positioning conveyor mechanism

(MD-5.4/MC-8).

• Check the power supply (JPS-6) (MT-7.40/MC-13.1).

• Check the fuse (F9/F12) for the power supply (JPS-6)

(MD-1.6/MT-7.40/MC-13.2).

• Clear the backup memory and then perform a reset (IN-17).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Perform the analysis flow for Error 03C0 (MT-4).

• Check the MN3 (MT-7.23/MU-4.6/SP-07).

• Check the SN1 (MT-7.10/MU-4.6/MC-8.4).

• Check the SZ1 (MT-7.14/MC-10.11).

• Check the side-positioning conveyor mechanism

(MD-5.4/MC-8).

• Check the subscanning unit mechanism (MD-5.5/MC-10).

• Check the IP.

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT4-14

MT4-16

D-5

D-5

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-13

Page 24

Code

03C1

Name Significance/Occurrence Condition

IP reading conveyance error

[During normal processing]

Although the MZ1 turned ON, the SN3 did not open.

[During secondary erasure]

Although the MZ1 and MN3 turned ON, the SN3 did not open.

<I/O name>

• MZ1; Subscanning motor

• SN3; Side-positioning IP sensor

• MN3; IP transport motor

<Reference>

MD-8.2.11

Probable Cause/Remedy

• Perform the analysis flow for Error 03C1 (MT-4).

• Check the MZ1 (MT-7.25/MC-10.6).

• Check the MN3 (MT-7.23/MU-4.6/SP-07).

• Check the SN3 (MT-7.12/MU-4.6/MC-8.8).

• Check the subscanning unit mechanism (MD-5.5/MC-10).

• Check the power supply (JPS-6) (MT-7.40/MC-13.1).

• Check the fuse (F3/F4) for the power supply (JPS-6)

(MD-1.6/MT-7.40/MC-13.2).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT2-14

Analysis

flow

MT4-15 D-5

Detail

03C2

Reading IP leading edge

detection error

[During normal processing]

Although the MZ1 turned ON, the SZ1 did not close.

<I/O name>

• MZ1; Subscanning motor

• SZ1; IP leading edge sensor

<Reference>

MD-8.2.11

• Perform the analysis flow for Error 03C2 (MT-4).

• Check the IP.

• Check the MZ1 (MT-7.25/MC-10.6).

• Check the SZ1 (MT-7.14/MC-10.11).

• Check the subscanning unit mechanism (MD-5.5/MC-10).

• Check the power supply (JPS-6) (MT-7.40/MC-13.1).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the SCN08D board (MT-7.41/MC-10.19).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT4-16

D-5

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-14

Page 25

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-15

Analysis

flow

Detail

03C6

03C7

03C8

Drive shaft grip error

Driven shaft grip release

error

Drive shaft grip release error

[During initialization/normal processing]

Although the MZ2 turned ON, the SZ2 did not open.

<I/O name>

• MZ2; Driving-shaft grip motor

• SZ2; Driving-side grip release home position sensor

<Reference>

MD-8.2.11/8.5.4/8.5.11

[During initialization/normal processing]

Although the MZ3 turned ON, the SZ3 did not open.

<I/O name>

• MZ3; Driven-shaft grip motor

• SZ3; Driven-side grip release home position sensor

<Reference>

MD-8.2.10/8.2.11/8.5.4/8.5.11

[During initialization/normal processing]

Although the MZ2 turned ON, the SZ2 did not close.

<I/O name>

• MZ2; Driving shaft grip motor

• SZ2; Driving-side grip release home position sensor

<Reference>

MD-8.2.14/8.5.11

• Perform the analysis flow for Error 03C6/03C8/03CA (MT-4).

• Check the MZ2 (MT-7.26/MU-4.6/MC-10.15).

• Check the SZ2 (MT-7.15/MU-4.6/MC-10.1).

• Check the subscanning unit mechanism (MD-5.5/MC-10).

• Check the fuse (F2) for the power supply (JPS-6)

(MD-1.6/MT-7.40/MC-13.2).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Perform the analysis flow for Error 03C7/03C9/03CB (MT-4).

• Check the MZ3 (MT-7.27/MU-4.6/MC-10.16).

• Check the SZ3 (MT-7.16/MU-4.6/MC-10.17).

• Check the subscanning unit mechanism (MD-5.5/MC-10).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Perform the analysis flow for Error 03C6/03C8/03CA (MT-4).

• Check the MZ2 (MT-7.26/MU-4.6/MC-10.15).

• Check the SZ2 (MC-7.15/MU-4.6/MC-10.1).

• Check the subscanning unit mechanism (MD-5.5/MC-10).

• Check the fuse (F2) for the power supply (JPS-6)

(MD-1.6/MT-7.40/MC-13.2).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT4-17 D-5

MT4-18 D-5

MT4-17 D-5

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-15

Page 26

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-16

Analysis

flow

Detail

03C9

03CA

03CB

Driven shaft grip error

Drive shaft grip

self-diagnosis error

Driven shaft grip release

self-diagnosis error

[During initialization/normal processing]

Although the MZ3 turned ON, the SZ3 failed to close.

<I/O name>

• MZ3; Driven-shaft grip motor

• SZ3; Driven-side grip release home position sensor

<Reference>

MD-8.2.11/8.2.14/8.5.4/8.5.11

[During initialization]

Although the MZ2 turned ON, the SZ2 did not open.

<I/O name>

• MZ2; Driving-shaft grip motor

• SZ2; Driving-side grip release home position sensor

<Reference>

MD-8.5.11

[During initialization]

Although the MZ3 turned ON, the SZ3 did not open.

<I/O name>

• MZ3; Driven-shaft grip motor

• SZ3; Driven-side grip release home position sensor

<Reference>

MD-8.5.11

• Perform the analysis flow for Error 03C7/03C9/03CB (MT-4).

• Check the MZ3 (MT-7.27/MU-4.6/MC-10.16).

• Check the SZ3 (MT-7.16/MU-4.6/MC-10.17).

• Check the subscanning unit mechanism (MD-5.5/MC-10).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Clear the backup memory and then perform a reset (IN-17).

• Perform the analysis flow for Error 03C6/03C8/03CA (MT-4).

• Check the MZ2 (MT-7.26/MU-4.6/MC-10.15).

• Check the SZ2 (MT-7.15/MU-4.6/MC-10.1).

• Check the subscanning unit mechanism (MD-5.5/MC-10).

• Check the fuse (F2) for the power supply (JPS-6)

(MD-1.6/MT-7.40/MC-13.2).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Perform the analysis flow for Error 03C7/03C9/03CB (MT-4).

• Check the MZ3 (MT-7.27/MU-4.6/MC-10.16).

• Check the SZ3 (MT-7.16/MU-4.6/MC-10.17).

• Check the subscanning unit mechanism (MD-5.5/MC-10).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT4-18 D-5

MT4-17 D-5

MT4-18 D-5

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-16

Page 27

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-17

Analysis

flow

Detail

03CC

03CD

03D3

Mirror operation error

Conveyance error

(side-positioning return

conveyance)

Pre-erasure conveyance

error

[During normal processing]

The MZ4 turned ON, but the SZ4 did not open.

<I/O name>

• MZ4; Mirror drive motor

• SZ4; Mirror home position sensor

<Reference>

MD-8.5.13

[During normal processing]

The MZ1/MN3 turned ON, but the SN3 did not close.

<I/O name>

• MZ1; Subscanning motor

• MN3; IP transport motor

• SN3; Side-positioning IP sensor

<Reference>

MD-8.2.6

[During normal processing]

Although the MM1/MN3 turned ON, the SM1 failed to close. Therefore, a retry

operation was performed.

<I/O name>

• MM1/MN3; IP transport motor

• SM1; Before-BCR IP sensor

<Reference>

MD-8.2.14

• Perform the analysis flow for Error 03CC (MT-4).

• Check the light-collecting mirror arm mechanism.

• Check the MZ4 (MT-7.28/MU-4.6/MC-10.14).

• Check the SZ3 (MT-7.16/MU-4.6/MC-10.17).

• Check the subscanning unit mechanism (MD-5.5/MC-10).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Perform the analysis flow for Error 03CD (MT-4).

• Check the MZ4 (MT-7.28/MU-4.6/MC-10.14).

• Check the SZ3 (MT-7.16/MU-4.6/MC-10.17).

• Check the subscanning unit mechanism (MD-5.5/MC-10).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Perform the analysis flow for Error 03D3 (MT-4).

• Check the MM1 (MT-7.20/MU-4.6/MC-12.7).

• Check the MN3 (MT-7.23/MU-4.6/MC-8.2).

• Check the SM1 (MT-7.9/MU-4.6/SP-05).

• Check the side-positioning conveyor mechanism

(MD-5.4/MC-8).

• Check the erasure conveyor mechanism (MD-5.3/MC-6).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT4-19 D-5

MT4-20 D-5

MT4-22

D-5

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-17

Page 28

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-18

Analysis

flow

Detail

03D5

03E8

03EE

Erasure conveyance error

Suction cup moving error

Cleaning guide return

operation error

[During normal processing]

Although the MN3/MM1/ML2 turned ON, the SM1 failed to open.

<I/O name>

• MN3/MM1/ML2; IP transport motor

• SM1; Before-BCR IP sensor

<Reference>

MD-8.2.15

[During initialization/normal processing/M-Utility mode/abnormality processing]

Although the ML1 turned ON, the SL1 failed to close, allowing the maximum retry

count (NL51) to be exceeded.

<I/O name>

• ML1; Suction cup drive motor

• SL1; Suction cup home position sensor

<Reference>

MD-8.2.2/8.5.7

[During initialization/normal processing/M-Utility mode/abnormality processing]

Although the ML1 turned ON, the SL1 failed to close, allowing the maximum retry

count (NL51) to be exceeded.

<I/O name>

• ML1; Suction cup drive motor

• SL1; Suction cup home position sensor

<Reference>

MD-8.2.2/8.5.7

• Perform the analysis flow for Error 03D5 (MT-4).

• Check the MN3 (MT-7.23/MU-4.6/SP-07).

• Check the MM1 (MT-7.20/MU-4.6/MC-6.14).

• Check the ML2 (MT-7.19/MU-4.6/MC-5.22).

• Check the SM1 (MT-7.9/MU-4.6/SP-05).

• Check the erasure conveyor mechanism (MD-5.3/MC-6).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Perform the analysis flow for Error 03E8 (MT-4).

• Check the ML1 (MT-7.18/MU-4.6/MC-5.17).

• Check the SL1 (MT-7.5/MU-4.6/MC-5.3).

• Check the IP removal unit mechanism (MD-5.2/MC-5).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Perform the analysis flow for Error 03EE (MT-4).

• Check the SN4 (MT-7.13/MU-4.6/MC-8.9).

• Check the side-positioning conveyor mechanism

(MD-5.4/MC-8).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

MT4-23 D-5

MT4-27

MT4-28

D-5

D-5

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-18

Page 29

Code

03EF

0400

0401

0402

Name Significance/Occurrence Condition

Cleaning guide operation

error

File open error

File format error

File setting value error

[During normal processing]

The MN4 is turned ON, but the SN4 does not close, allowing the maximum retry

count (NL51) to be exceeded.

<I/O name>

• MN4; Cleaning guide drive motor

• SN4; Cleaning guide home position sensor

<Reference>

MD-8.2.7/8.5.5

[During initialization]

An error was detected when an attempt was made to open a subsystem file (IMG).

[During initialization]

An error was found in the format of a subsystem file (IMG).

[During initialization]

An error was found in the settings contained in a subsystem file (IMG).

Probable Cause/Remedy

• Perform the analysis flow for Error 03EF (MT-4).

• Check the MN4 (MT-7.24/MU-4.6/MC-8.6).

• Check the SN4 (MT-7.13/MU-4.6/MC-8.9).

• Check the side-positioning conveyor mechanism

(MD-5.4/MC-8).

• Check the DRV08A board (MT-7.41/MC-15.11).

• Check the SNS08C board (MT-7.41/MC-15.11).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

MT2-19

Analysis

flow

MT4-28

-

-

-

Detail

D-5

E-1

E-1

E-1

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-19

Page 30

Code

0403

Name Significance/Occurrence Condition

File read error

[During initialization]

An error was detected when an attempt was made to read a subsystem file (IMG).

Probable Cause/Remedy

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the HDD (MT-7.42/MC-11).

• Format the HDD and reinstall the software (MU-A1).

MT2-20

Analysis

flow

-

Detail

E-1

0410

0411

0412

0413

DSP4 device initialization

error

DSP4 device open error

DSP4 micro program boot

error

DSP4 micro program load

error

[During initialization]

An error was detected when an attempt was made to initialize the DSP4 device

(IMG07B board).

[During initialization]

An error was detected when an attempt was made to open the DSP4 device

(IMG07B board).

[During initialization]

An error was detected when an attempt was made to boot a micro program for the

DSP4 device (IMG07B board) from the HDD.

[During initialization]

An error was detected when an attempt was made to load a micro program into

the DSP4 device (IMG07B board).

• Check the CPU90E board (MT-7.41/MC-15.3). - E-2

• Check the CPU90E board (MT-7.41/MC-15.3). - E-2

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the IMG07B board (MT-7.41/MC-15.4).

• Check the HDD (MT-7.42/MC-11).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the IMG07B board (MT-7.41/MC-15.4).

• Check the HDD (MT-7.42/MC-11).

-

-

E-2

E-2

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-20

Page 31

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-21

Analysis

flow

Detail

0414

0415

0420

0421

DSP4 checksum error

DSP4 self-diagnosis error

DSP4 memory write error

DSP4 memory read error

[During initialization]

An error was found in the checksum on the micro program for the DSP4 device

(IMG07B board).

[During initialization]

An error was detected in the micro program self-diagnosis on the DSP4 device

(IMG07B board).

[During initialization/normal processing]

An error was detected when an attempt was made to write into the DSP4 device

(IMG07B board).

[During normal processing]

An error was detected when an attempt was made to read the DSP4 device

(IMG07B board).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the IMG07B board (MT-7.41/MC-15.4).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the IMG07B board (MT-7.41/MC-15.4).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the IMG07B board (MT-7.41/MC-15.4).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the IMG07B board (MT-7.41/MC-15.4).

- E-2

- E-2

- E-2

- E-2

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-21

Page 32

Code

0422

0423

Name Significance/Occurrence Condition

DSP4 image processing

error 1

DSP4 image processing

error 2

[During normal processing]

An image processing error was found in the DSP4 device (IMG07B board) when

image data was being read from the scanner.

[During normal processing]

An image processing error was found in the DSP4 device (IMG07B board) after an

image data read from the scanner.

Probable Cause/Remedy

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the IMG07B board (MT-7.41/MC-15.4).

• Check the SCN08D board (MT-7.41/MC-10.19).

• Check the MMA90A and MMB90A/DIM08A board

(MT-7.41/MC-15/IN-5.5).

• Check the cable (MT-7/SP-12).

• Check the fuse (F3/F4) for the power supply (JPS-6)

(MD-1.6/MT-7.40/MC-13.2).

• Check the MZ1/MZ2/MZ3

(MU-4.6/MC-10.6/MC-10.15/MC-10.16).

• Check the MN1/MN2/MN3 (SP-07/MC-8.2).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the IMG07B board (MT-7.41/MC-15.4).

• Check the SCN08D board (MT-7.41/MC-10.19).

• Check the MMA90A and MMB90A/DIM08A board

(MT-7.41/MC-15/IN-5.5).

• Check the cable (MT-7/SP-12).

• Check the fuse (F3/F4) for the power supply (JPS-6)

(MD-1.6/MT-7.40/MC-13.2).

• Check the MZ1/MZ2/MZ3

(MU-4.6/MC-10.6/MC-10.15/MC-10.16).

• Check the MN1/MN2/MN3 (SP-07/MC-8.2).

MT2-22

Analysis

flow

-

-

Detail

E-2

E-2

0425

009-058-03

08.30.2002 FM3476

DSP1 device initialization

error

[During initialization]

An error was detected when an attempt was made to initialize the DSP1 device

(BSP08A board).

CR-IR347 Service Manual [ 2. ] MT2-22

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the BSP08A board (MT-7.41/MC-15.5).

- E-2

Page 33

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-23

Analysis

flow

Detail

0426

0427

0428

0429

0430

0435

DSP1 device open error

DSP1 micro program boot

error

DSP1 micro program load

error

DSP1 checksum error

DSP1 self-diagnosis error

DSP1 memory write error

[During initialization]

An error was detected when an attempt was made to open the DSP1 device

(BSP08A board).

[During initialization]

An error was detected when an attempt was made to boot a micro program for the

DSP1 device (BSP08A board) from the HDD.

[During initialization]

An error was detected when an attempt was made to load a micro program into

the DSP1 device (BSP08A board).

[During initialization]

An error was found in the checksum on the micro program for the DSP1 device

(BSP08A board).

[During initialization]

An error was detected in the micro program self-diagnosis on the DSP1 device

(BSP08A board).

[During initialization/normal processing]

An error was detected when an attempt was made to write into the DSP1 device

(BSP08A board).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the BSP08A board (MT-7.41/MC-15.5).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the BSP08A board (MT-7.41/MC-15.5).

• Check the HDD (MT-7.42/MC-11).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the BSP08A board (MT-7.41/MC-15.5).

• Check the HDD (MT-7.42/MC-11).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the BSP08A board (MT-7.41/MC-15.5).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the BSP08A board (MT-7.41/MC-15.5).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the BSP08A board (MT-7.41/MC-15.5).

- E-2

-

-

- E-2

- E-2

- E-2

E-2

E-2

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-23

Page 34

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-24

Analysis

flow

Detail

0436

0437

0440

0441

DSP1 memory read error

DSP1 image processing

error 1

DSP2 device initialization

error

DSP2 device open error

[During normal processing]

An error was detected when an attempt was made to read the DSP1 device

(BSP08A board).

[During normal processing]

An image processing error was found in the DSP1 device (BSP08A board) when

image data was being read from the scanner.

[During initialization]

An error was detected when an attempt was made to initialize the DSP2 device

(BSP08A board).

[During initialization]

An error was detected when an attempt was made to open the DSP2 device

(BSP08A board).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the BSP08A board (MT-7.41/MC-15.5).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the BSP08A board (MT-7.41/MC-15.5).

• Check the SCN08D board (MT-7.41/MC-10.19).

• Check the MMA90A and MMB90A/DIM08A board

(MT-7.41/MC-15/IN-5.5).

• Check the cable (MT-7/SP-12).

• Check the fuse (F3/F4) for the power supply (JPS-6)

(MD-1.6/MT-7.40/MC-13.2).

• Check the MZ1/MZ2/MZ3

(MU-4.6/MC-10.6/MC-10.15/MC-10.16).

• Check the MN1/MN2/MN3 (SP-07/MC-8.2).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the BSP08A board (MT-7.41/MC-15.5).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the BSP08A board (MT-7.41/MC-15.5).

- E-2

-

- E-2

- E-2

E-2

009-058-03

08.30.2002 FM3476

CR-IR347 Service Manual [ 2. ] MT2-24

Page 35

Code

Name Significance/Occurrence Condition

Probable Cause/Remedy

MT2-25

Analysis

flow

Detail

0442

0443

0444

0445

0450

DSP2 micro program boot

error

DSP2 micro program load

error

DSP2 checksum error

DSP2 self-diagnosis error

DMA device open error

[During initialization]

An error was detected when an attempt was made to boot a micro program for the

DSP2 device (BSP08A board) from the HDD.

[During initialization]

An error was detected when an attempt was made to load a micro program into

the DSP2 device (BSP08A board).

[During initialization]

An error was found in the checksum on the micro program for the DSP2 device

(BSP08A board).

[During initialization]

An error was detected in the micro program self-diagnosis on the DSP2 device

(BSP08A board).

[During initialization]

An error was detected when an attempt was made to open the DMA device

(CPU90E board).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the BSP08A board (MT-7.41/MC-15.5).

• Check the HDD (MT-7.42/MC-11).

• Check the CPU90E board (MT-7.41/MC-15.3).

• Check the MTH08C/D board (MT-7.41/MC-15.1/MC-15.2).

• Check the BSP08A board (MT-7.41/MC-15.5).

• Check the HDD (MT-7.42/MC-11).