Page 1

STÖBER CombiDrive

SIEMENS Micromaster integrated

Installation and Commissiong instructions

It ist essential to read and comply with these

instructions prior to installation and commissioning!

®

01/2001

Page 2

Contents

Safety precautions................................................................................................ ..1

1. OVERVIEW ..................................................................................................... ..2

2. INSTALLATION............................................................................................... ..3

3.OPERATING INFORMATION ........................................................................... 10

4. CLEAR TEXT DISPLAY MODULE & SYSTEM PARAMETERS............................. 15

5. FAULT CODES ............................................................................................... 30

6. SPECIFICATIONS............................................................................................ 31

7. SUPPLEMENTARY INFORMATION................................................................ 34

8. ACCESSOIRES................................................................................................ 37

Page 3

8

Safety Precautions

d

s

e

s

n

r

d

s

r

o

s

e

r

g

e

e

a

t

s

d

e

n

s

e

n

e

l

e

d

e

t

n

,

e

e

e

f

e

s

y

Before installing and putting this equipment into operation, please read these safety precautions and

warnings carefully and all the warning signs attached to the equipment. Make su re that the warning signs

are kept in a legible condition and replace missing or damaged signs.

WARNING

This equipment contains hazardous voltages an

controls hazardous rotati ng mec hanical part s. Los

of life, severe personal i njury or property damag

can result if the instructions contained in thi

manual are not followed.

Only suitable qualified personnel should work o

this equipment, and only after becoming familia

with all safety notices, installation, operation an

maintenance procedures contai ned in this manual.

The successful and safe operation of thi

equipment is dependent upon its proper handling,

installation, operation and m ai nt enance.

• The CombiDrive

• ALWAYS isolate the equipment from the powe

supply before starting any work on it.

• The dc-link capacitor remains charged t

dangerous voltages even when the power i

removed. For this reason it is not perm issibl

to open the equipment until one minute afte

the power has been turned off. When handlin

the open equipment it should be noted that liv

parts are exposed. Do not touch these liv

parts.

• The equipment must not be connected to

supply via an ELCB (Earth Leakage Circui

Breaker - see DIN VDE 0160, section 6.5).

• The following terminals can carry dangerou

voltages even if the inverter is inoperative:

-the power supply terminals L1, L2, L3.

-the motor terminals U, V, W.

• Ensure that the inverter’s cover has been fi tte

correctly before applying mains power to th

CombiDrive®. If a Braking Unit has bee

supplied, ensure that the term inal connection

fitted to the underside of the cover mat

correctly with those on the inverter whe

refitting the cover.

• Only qualified personnel may connect, st art t h

system up and repair faults. These personne

must be thoroughly acquainted with all th

warnings and operating procedures containe

in this manual.

• Certain parameter settings may cause th

motor to restart automatically after an inpu

power failure.

• This equipment must not be used as a

‘emergency stop’ mechani sm (see EN 60204

9.2.5.4).

®

operates at high voltages.

CAUTION

• Children and the general public must b

prevented from accessing or approaching t h

equipment!

• This equipment may only be used for th

purpose specified by the manufacturer.

Unauthorised modifications and the use o

spare parts and accessori es that are not sold

or recommended by the manufacturer of th

equipment can cause fires, electric shock

and injuries.

• Keep these operating instruc tions within eas

reach and give them to all users!

European Low Voltage & EMC Directives

The CombiDrive® product complies with the requirements of the Low

Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC.

The units are certified for compliance with the followi ng standards:

EN 60204-1 Safety of machinery - E l ectrical equipment of

machines

EN 60146-1-1 Semiconductor convert ers - General

requirements and line commutated converters

BS EN50081-2: 1995 Generic Emission St andard - Industrial

Environment

BS EN50082-2: 1995 Generic Immunity St andard - Industrial

Environment

®

Proviso: The CombiDrive

an OPm2 is connected.

European Machinery Directive

The CombiDrive® product (combined inverter and motor ass embly) is

suitable for incorporation into machinery.

The CombiDrive

which it is incorporated has been certified to be in c ompliance with the

provisions of the European Directive 89/392/EEC.

Note: Only valid for machinery to be operated in the European

®

must not be put into serv ice until the machi nery i nto

Community.

European EMC Directive

When installed according to the recommendations described in this

manual, the Co mb iD ri ve

defined by the EMC Product Standard for Power Drive Systems

EN61800-3.

does not meet CE requirements when

®

fulfills all requirements of the EMC directive as

05.02.01

© STÖBER plc 199

Page 4

English 2. Installation

8

1. OVERVIEW

The CombiDrive® is an integrated motor/inverter for variable speed applications.

The inverter is microproc ess or -c ontr olled and us es s tate of the ar t IG BT tec hnology for r eliability and flex ibility.

A special pulse-width modulation method with ultrasonic pulse frequency permits extremely quiet motor

operation. Inverter and motor protection is provided by comprehensive protective functions.

Features:

• Easy to install and commission.

• Closed loop control using a Proportional, Integral (PI) control loop function.

• High starting torque with programmable starting boost.

• Remote control capability via RS485 serial link using the USS protocol.

• Ability to control up to 31 CombiDrive

• Optional remote control capability via RS485 serial link using PROFIBUS-DP.

• Factory default parameter settings pre-programmed for European and North American requirements.

• Output frequency (and hence motor speed) can be controlled by one of four methods:

(1) Built-in potentiometer.

®

via the USS protocol.

(2) High resolution analogue setpoint (voltage or current input).

(3) Fixed frequencies via binary inputs.

(4) Serial interface.

• Built-in dc injection braking.

• Acceleration/deceleration times with programmable smoothing.

• Single signal relay output incorporated.

• External connection for optional Clear Text Display (OPm2) or for use as external RS485 interface.

• Fast Current Limit (FCL) for reliable trip-free operation.

• Optional factory-fitted resistive braking unit (also available as a separate post-sale option).

• Optional motor brake and interface.

• Integral class A or class B filter options.

05.02.01

2

© STÖBER plc 199

Page 5

2. Installation English

y

e

2. INSTALLATION

WARNING

To guarantee the safe operation of the equipment it must be installed and commissioned b

qualified personnel only.

Take particular note of the general and regional installation and safety regulations regarding

work on high voltage installations (e.g. VDE), as well as the relevant regulations r egarding th

correct use of tools and personal protective gear.

Use the lifting eyes provided if the motor has to be lifted. Do not lift machine s ets (e.g. built- on

gearboxes, fan units) by suspending the individual machines!

If the PROFIBUS option has been fitted, remove the PROFIBUS module before attaching

cables or chains to the lifting eyes.

Always check the capacity of the hoist before lifting any equipment.

2.1 Wiring Guidelines to Minimise the Effects of EMI

The CombiDrive® are designed to operate in an industrial environment where a high level of Electro Magnetic

Interference (EMI) can be expected. Usually, good installation practices will ensure safe and trouble free

operation. However, if problems are encountered, the following guidelines may prove useful. In particular,

grounding of the system 0V at the inverter, as described below, may prove effective.

(1) Ensure that all equipment is well earthed using short, thick earthing c able connec ted to a c ommon s tar

point or busbar. It is particularly important that any control equipment that is connected to the inverter

(such as a PLC) is connected to the s ame earth or st ar point as the inv erter via a s hort, thick link. Flat

conductors (e.g. metal brackets) are preferred as they have lower impedance at high frequencies.

(2) Wherever possible, use screened leads for connections to the contr ol circuitry. Terminate the ends of

the cable neatly, ensuring that long strands of unscreened wire are not left visible.

(3) Separate the control cables from the power connections as much as possible, using separate trunking,

etc. If control and power cables cross, arrange the cables so that they cross at 90°.

(4) Ensure that contactors in the cubicle are suppressed, either with R-C s uppressors for AC contactors

or ‘flywheel’ diodes for DC contactors, fitted to the coils. Varistor suppressor s are als o effectiv e. This

is particularly important if the contactors are controlled from the relay connection on the CombiDrive

(5) Use screened or armoured cables for the power c onnections and ground the screen at both ends v ia

the cable glands.

On no account must safety regulations be compromised when installing the

CombiDrive

®

!

®

.

© STÖBER plc 1997

3

05.02.01

Page 6

English 2. Installation

8

e

e

2.2 Mechanical Installation

Figures 1 and 2 show dimensional information for all CombiDrive® variants.

Note: ‘Case size’ refers to the type of inverter box mounted on the motor. ‘Motor frame’ refers to the motor

frame size only.

®

Remove or tighten down screw-in lifting eyes prior to using the CombiDrive

Stable foundations or mounting conditions, exact alignment of the motors and a well-balanced tr ansmission

element are essential for quiet, vibration-free running. If necessary, insert shims under the motor's feet to

prevent strain, or balance the whole rotor and transmission element.

Always use the correct tools for fitting and removing transmission elements (coupling halv es, pulleys, pinions,

etc.).

The rotors are dynamically balanced with the full featherkey inserted as standard. Since 1991 the type of

balance has been marked on the drive end of the shaft (shaft end face). F denotes balanced with full

featherkey; H denotes balanced with half featherkey. Bear in mind the type of balance used when fitting the

transmission element.

Poor running characteristics can arise in cases where the trans mission elements have a length ratio of hub

length to length of shaft end < 0.8 and they run at speeds of > 1500 rpm. In such cases r ebalancing may be

necessary, e.g. by reducing the dis tance by whic h the featherk ey protr udes fr om the tr ansmis s ion element and

the shaft surface.

.

WARNING

Take suitable precautions to prevent transmission elements from being touched. If th

CombiDrive

secured in position to prevent it from flying off while the shaft is rotating.

Please check the following prior to commissioning:

• The rotor turns freely without rubbing.

• The motor is assembled and aligned properly.

• The transmission elements are adjusted correctly (e.g. belt tension) and the transmission element is

suitable for the given operating conditions.

• All electrical connections, mounting screws and connecting elements are tightened and fitted correctly.

• All protective conductors are installed properly.

• Any auxiliary equipment that might be fitted (e.g. brakes) is in working order.

• Protection guards are installed around all moving and live parts.

• The maximum speed (see rating plate) is not exceeded. Note that the maximum speed is the highest

operating speed permitted for short periods. Remember that motor noise and vibration are wors e at this

speed and bearing life is reduced.

The above list is not meant to be exhaustive - additional checks may also be required.

®

is started up without a transmission element attached, the featherkey must b

05.02.01

4

© STÖBER plc 199

Page 7

2. Installation English

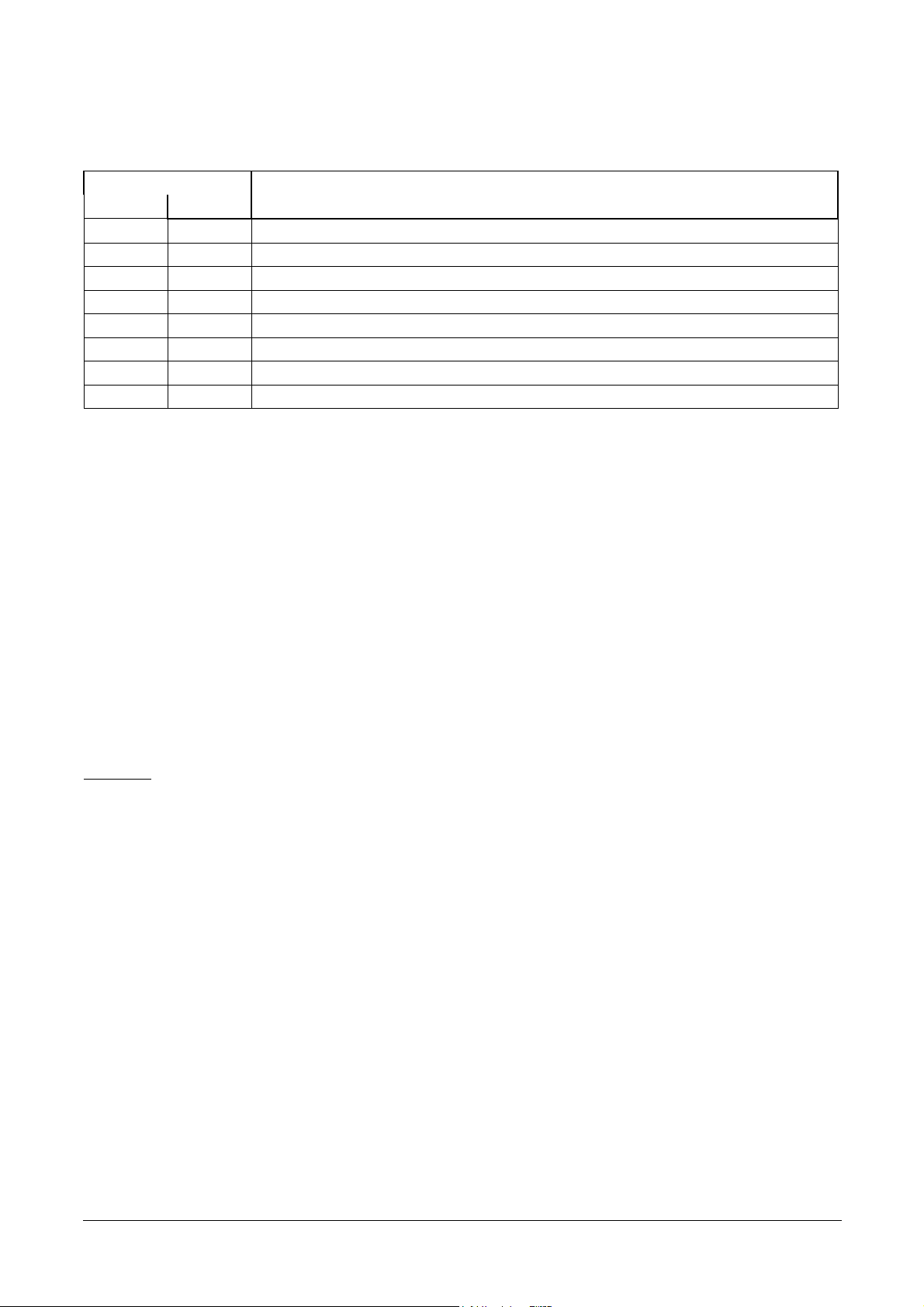

CombiDrive® – Dimension (Only dimensions of the motor, total dimensions of the gear motor see

MGS-catalog, Impr.-No. 440 637)

qx = Max. dimension; Given either through the inverter or through the fan cowl.

single-phase

three-phase

Motor-type

71 K 0,25 kW PM 25/1 122 182 237

71 L 0,37 kW PM 37/1 122 182 237

80 K 0,55 kW PM 55/1 122 193 259,5

80 L 0,75 kW PM 75/1 122 193 259,5

Motor-type

71 L 0,37 kW PM 37/3 122 182 237

80 K 0,55 kW PM 55/3 122 193 259,5

80 L 0,75 kW PM 75/3 122 193 259,5

90 K 1,1 kW PM 110/3 171 201 296

90 L 1,5 kW PM 150/3 171 201 296

100 K 2,2 kW PM 220/3 171 234 328,5

100 L 3,0 kW PM 300/3 171 234 328,5

112 K 4,0 kW PM 400/3 171 248,5 353

132 K 5,5 kW PM 550/3 171 264,5 372,5

132 L 7,5 kW PM 750/3 171 264,5 372,5

Motor

output rating

Motor

output rating

Inverter type Width (b)

Inverter type Width (b)

Dimension

w´

Dimension

w´

qx

qx

Dimension in mm

Installation notes

The position of the inverter related to the gearbox, see MGS-catalog (Impr.-No. 440 637).

The rotation of the terminal box is not possible.

© STÖBER plc 1997

5

05.02.01

Page 8

English 2. Installation

8

c

l

2.3 Electrical Installation

Remove the four M5 cross-head screws on the inverter's cover to access the electrical terminals (see Figure 3

and Figure 4).

Notes: (1) Refer to the electrical data table for cable sizes (see section 6).

(2) We recommend introducing a `drip loop' when connecting the mains and c ontrol c ables (see

Figure 5).

CAUTION

The printed circuit boards contain CMOS components that are particularly sensitive to stati

electricity. For this reason, avoid touc hing the boards or components with your hands or meta

objects.

Mains Connector *

L1 L2 L3

Jumpers for

PI Input Type

Default = V

V

I

Control Cable Connector

(PL800)

112

Jumpers for

Analogue Input Type

Default = V

JP303

JP303

JP302

V

I

LED

(Green)

1 4

OPm2 Connector

(SK200)

JP303

JP301

JP300

LED

(Yellow)

-+

Contr ol

Potentiometer

(R314)

IMPORTANT

Ensure that the following tightening torques are used:

Electrical terminal screws: 1.1 Nm

Access cover retaining screws: 4.0 Nm

Gland hole covers: 1.0 Nm

Jumper in ‘V’ positi on = voltage input (default)

Not e:

Jumper in ‘I’ position = current input

Figure 1: Electrical Connection Diagram

05.02.01

Check that the supply voltage is correct for t he

*

COMBIMASTER used by referring to the voltage

code part of t he or der number (see section 6).

© STÖBER plc 199

6

Page 9

2. Installation English

h

2.3.1 Mains Cable Connections

Ensure that the power source supplies the correct voltage and is designed for the necessary current. Ens ure

that the appropriate circuit-breakers with the s pecified current rating are connected between the power supply

and CombiDrive

®

(see section 6).

Use Class 1 60/75oC copper wire only.

Use a 4-core screened cable (for cross-section of each c ore see section 6). If crimp terminals are used then

they must be insulated. If crimps are not used, the strip length must not exceed 5 mm.

Feed the power cable into the inverter via the gland hole nearest to the motor shaft (see Figure 3). Connect the

power leads to terminals L1, L2, L3 and the separate earth.

Use a 4 - 5 mm cross-tip screwdriver to tighten the terminal screws.

2.3.2 Control Cable Connections

CAUTION

The control and power supply cables must be laid separately. They must not be fed throug

the same cable conduit/trunking.

Use screened cable for the control lead.

Feed the control cable into the inverter via the appropriate gland hole (s ee Figure 3). Unplug connector block

PL800 from the PCB and connect the control wires in acc ordance with the inform ation given in F igures 4a and

4b (also see Figure 3).

IMPORTANT: A wire link must be fitted between control terminals 5 (DIN1) and 8 (P15+) otherwise the

CombiDrive

®

will not operate when control potentiometer R314 is used. The wire link must be

removed when operation via a run/stop switch is required.

Plug the connector block back into the PCB, refit the cover and tighten the four securing screws.

Rel ay

(24 V dc, 1 A max.)

P10+0VAIN+AIN-DI N1DIN2

123456

Power Supply

for

Analogue Input

1234

0V

N (- )

For USS

Protocol

5V

(250 mA max.)

P (+)

RL1B

RL1C

(COM)

(0 - 10 V or 0 - 20 mA)

(NO)

PI +ve Input

P15+PI-PI+

8

9101112

OR

Power Supply

(+15 V, max. 50 mA)

DIN3

7

Dig it al

Inputs

(7.5 - 33 V, max. 5 mA)

Analogue

Input

(0/2 - 10 V or

0/4 - 20 mA)

(+10 V, max. 10 mA)

PL800

Control Terminals

Figure 4a: Control Terminal Connections

© STÖBER plc 1997

SK200

Telephone Socket

(FCC 68 Type 4/4)

7

05.02.01

Page 10

English 2. Installation

8

3

1. 8 mm ma x.

1

2

OR

Figure 4b: Connecting Control Wires to PL800

1

3

2

Figure 2: Cable Connections with Drip Loop

05.02.01

© STÖBER plc 199

8

Page 11

2. Installation English

, V,

)

V

V

V

V

A

A

+

)

)

3

V

t

ype

2.3.3 Block Diagram

PE

3 AC 380 - 500 V

SI

Power supply for

PI feedback

transducer or

other load

PI -ve Inpu

PI +ve Input

: 0 - 10

2 - 10

I: 0 - 20 m

4 - 20 m

-

24 V

+

OR

OR

Relay

Connections

Connections for

Serial Link or OPm2

OR

PL800

AIN

AIN-

DIN1

DIN2

DIN

RL1B

RL1C

SK200

5V

0V

N (-

P (+

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

+10V (10 mA max.

0

A/D

+15

A/D

RS485

PE

CPU

I

V

JP302 JP303

JP300 JP301

PI Input T

Analogue Input Type

PE

PE

~

M

3 ~

L1, L2, L3

3 ~

U

GR

ZK

WR

W

AD

CPU

GR

M

RS485

SI

WR

ZK

Analogue to Digital Converter

Microprocessor

Rect if ier

Mot or

Serial Interface

Mai ns Fuse

Inverter

DC Link Capacitor

Figure 3: Block Diagram

© STÖBER plc 1997

9

05.02.01

Page 12

English 3. Operating Information

8

r

k

e

3. OPERATING INFORMATION

WARNING

The equipment must not be switched on until after its cover has been fitted and the cove

screws have been tightened to the correct torque.

After the power has been turned off, you must always wait one minute so that the dc-lin

capacitors can discharge. Do not remove the cover until this time has elapsed.

All settings must only be entered by qualified personnel, paying particular attention to th

safety precautions and warnings.

3.1 General

(1) The CombiDrive® does not have a main power switch and is therefore live when the mains supply is

connected.

(2) When delivered, the inverter has a frequency setpoint range of between 0 Hz and 50 Hz. Regar dless

of its initial position, internal potentiometer R314 must be turned fully counter-clockwise before the

CombiDrive

R314 can be accessed by removing the right-hand gland hole cover (see Figure 3).

(3) Parameter settings can only be changed by using either the serial interface (SK200) or an optional

Clear Text Display (OPm2). Refer to the parameter list in section 4 for a full description of each

available parameter.

Connecting a serial link or the OPm2 to the serial interface is made simple by removing the appropriate gland

hole cover (see Figure 3) and plugging a suitably terminated interface cable into the telephone soc ket

(SK200).

(4) Analogue input type selection is determined by jumpers JP300 and JP301. JP300 closed selects

current input, JP301 closed (default) selec ts voltage input. T hese jumpers can only be ac cess ed while

the cover is removed (see Figure 3).

(5) If the CombiDrive

change P077 from 0 to 1 (requires OPm2).

®

can be started.

®

is run unloaded (e.g. for test purposes) and vibration or trip conditions occur,

3.2 Basic Operation

There are two basic modes of operation for the CombiDrive®. Neither mode requires the use of an OPm2 or

serial link connection:

(1) Using the internal potentiometer only:

(a) For forward rotation, ensure that a link is fitted between DIN1 (pin 5) and P15+ (pin 8) on PL800 (see

Figure 4a). For reverse rotation, connect the link to DIN2 (pin 6) instead of DIN1.

(b) Apply mains power. The green and yellow LEDs will illuminate to show that power is applied. Turn

potentiometer R314 fully counter-clockwise, otherwise the CombiDrive

(c) Turn the potentiometer clockwise until the yellow LED extinguishes. This indicates that power is now

applied to the motor. Continue turning clockwise to increase the speed of the motor.

(d) Turn the potentiometer counter-clockwise to reduce the speed of the motor . Turning the potentiometer

fully counter-clockwise causes the motor to slow to a complete stop. Check that both LEDs are

illuminated (STANDBY mode).

05.02.01

10

®

cannot be started.

© STÖBER plc 199

Page 13

3. Operating Information English

(2) Using a combination of the internal potentiometer and a run/stop switch:

(a) Connect a run/stop switc h between DIN1 (pin 5) and P15+ (pin 8) on PL800 (see Figur e 4a) if

forward rotation is required. If reverse rotation is required instead, connect the s witch to DIN2

(pin 6) instead of DIN1.

IMPORTANT

In either case, if a link has been fitted between pin 5 and pin 8 it must be remov ed before the

run/stop switch is fitted.

(b) Apply mains power. The green and yellow LEDs will illuminate to show that power is applied.

(c) Set the external run/stop switch to ON.

(d) Turn potentiometer R314 clockwise to set the required motor speed.

(e) Stop the motor by setting the external on/off switch to OFF. When the switch is set to ON

again, it will run at the speed previously set using the potentiometer.

3.3 Operation - External Analogue Control

The method of setting up the CombiDrive® for use with external analogue voltage control is des cribed below.

This method can use both the internal potentiometer and external analogue voltage control. It does not require

the use of an OPm2 or serial link connection.

(1) Connect a 4.7 kΩ potentiometer to the control terminals as shown in Figure 3 or connect pin 2 (0V) to pin 4

(AIN-) and a 0 - 10 V signal between pin 2 (0V) and pin 3 (AIN+).

(2) Ensure that a link is fitted between pin 5 (DIN1) and pin 8 (P15+).

(3) Check that voltage input is selected by ensuring that the jumper is fitted to JP301.

(4) Refit the cover, tighten the cover screws to the correct torque and then apply mains power to the inverter.

(5) Turn the external potentiometer (or adjust the analogue control voltage) until the desired frequency is

achieved. The unit will not switch on until a minimum of 2 V has been applied.

Note

The frequency set by the external voltage is added to the frequency set by the internal potentiometer.

As with Basic Operation (2), a run/stop switch can be used to start and stop the motor, or the direction of

rotation can be changed by connecting the link to DIN2 instead of DIN1.

3.4 Operation - Digital Control

This method of operation requires either a Clear Tex t Display (OPm2) or a se rial link connection. Fo r a basic

startup configuration using digital control, proceed as follows:

(1) Remove the link that connects control terminal 5 to terminal 8 (if one has been fitted).

(2) Connect control terminal 5 to terminal 8 via a s imple on/off switch. This sets up the inver ter for clock wise

rotation (default). If counter-clockw ise operation is required, connect a s witch between contr ol terminals 6

and 8.

(3) Connect the OPm2 or serial link to SK200. Refit the cov er, tighten the cover screws to the correct torque

and then apply mains power to the inverter.

(4) Set parameter P006 to 000 to specify digital setpoint.

(5) Set parameter P005 to the desired frequency setpoint.

(6) Set the external on/off switch to ON or pr ess the ON button on the OPm2 (set P007 = 001 to use the

OPm2). The CombiDrive

®

will now run at the frequency set by P005.

3.5 Stopping the Motor

Via the external on/off switch: setting the switch to OFF overrides the setting on the potentiometer and

causes the motor to come to a controlled stop.

Via the potentiometer: turning the potentiometer counter-clockwise until the input voltage drops below 1 V

causes the motor to slow to a stop.

© STÖBER plc 1997

11

05.02.01

Page 14

English 3. Operating Information

8

3.6 If the Motor Does Not Start Up

Check the LEDs on the side of the inverter:

LED State CombiDrive

Green Yellow

ON ON Mains power on, CombiDrive® not running (STANDBY)

ON OFF CombiDrive® running, as per control commands (ON)

Flashing Flashing Current limit warning

Flashing ON CombiDrive® overtemperature

ON Flashing Motor overtemperature

OFF ON Other fault (e.g. tripped)

OFF Flashing Mains undervoltage

OFF OFF Mains supply fault (e.g. faulty external switch)

If a fault occurs: switch off, dis connect and then reconnec t the power and then switch on again. Switc h off if

the fault condition persists. Trips can be reset by connecting a switch to DIN3 (see parameter P053).

If a warning occurs: switch off, disconnect and reconnect the power and then switch on again.

In either of the above cases, if the fault/warning persists then further investigation requires an OPm2 or a serial

link connection.

®

Status

3.7 Local and Remote Control

The inverter can be controlled either loca lly (default), or remotely v ia a USS data line connected to the inter nal

RS485 telephone socket (SK200).

When local control is used (P910 = 0), the motor c an only be controlled via the internal potentiometer or the

control terminals. Control commands, setpoints or parameter changes received via the RS485 interface have

no effect.

For remote control, the serial interface is designed as a 2- wire connection for bi-direc tional data transmission.

Refer to parameter P910 in section 4 for the available remote control options.

When operating via remote control the inverter will not accept control commands from the terminals.

Exception: OFF2 or OFF3 c an be activated via parameter P051 to P053 ( refer to parameters P051 to P053 in

section 4).

Several CombiDrive

individually.

Note: If the inverter has been set up to operate via the serial link but does not run when an ON command is

received, try reversing the connections to terminals 3 and 4 on SK200.

For further information, refer to the following documents:

E20125-B0001-S302-A1 Application of the USS Protocol in SIMOVERT Units 6SE21 and

E20125-B0001-S302-A1-7600 Application of the USS Protocol in SIMOVERT Units 6SE21 and

®

can be connected to an external control unit at the same time and can be addressed

MICROMASTER (German)

MICROMASTER (English)

05.02.01

12

© STÖBER plc 199

Page 15

3. Operating Information English

–

3.8 Closed Loop Control

Closed loop control is only possible when an OPm2 or a serial link is connected to the CombiDrive®.

3.8.1 General Description

The CombiDrive® provides a Proportional/Integral (PI) control function for closed loop control ( see Figure 7) . PI

control is ideal for temperature or press ur e contr ol, or other applic ations where the c ontr olled var iable changes

slowly or where transient errors are not critical. This control loop is not suitable for use in systems where fast

response times are required.

Note: The closed loop function is not designed for speed control, but can be us ed for this prov ided that fast

response times are not required.

When closed loop PI control is enabled (P201 = 002), all setpoints are calibrated between zero and 100%, i.e.

a setpoint of 50.0 = 50%. This allows general purpose control of any process variable that is actuated by motor

speed and for which a suitable transducer is available.

Setpoint

Acceleration/

Low Pass

Filter

Scaling

+

P

P202

Decel er ati on

Ramp

Mot or

M

Process

e.g. fan

P002, P003

Feedback

(e.g. duct pressure)

Transducer

P208

P205

P206

Feedback

Sampl e

Rat e

P211, P212

I

P203, P207

Closed Loop Mode Disabled

P201 = 000

Closed Loop Mode Enabled

P201 = 002

P210

Feedback

Monitor

Figure 7: Closed Loop Control

3.8.2 Hardware Setup

Connect the signal wire from the external feedback transducer to control terminal 10. Set jumper JP303 if

voltage input type is required (default) or set JP302 if current input type is required.

15 V dc power for the feedback transducer can be supplied from control terminal 8.

3.8.3 Parameter Settings

Closed loop control cannot be used unless P201 is fir st set to 001. Most of the parameters associated with

closed loop control are shown in Figure 7. Other parameters which are also associated with closed loop

control are as follows:

P001 (value = 007)

P061 (value = 012 or 013)

P210

P220

Descriptions of all closed loop control parameters are provided in section 4. For further detailed information

about PI operation, refer to the Siemens DA 64 Catalogue.

© STÖBER plc 1997

13

05.02.01

Page 16

English 4. Clear Text Display Module & System Parameters

8

E

4. CLEAR TEXT DISPLAY MODULE & SYSTEM PARAMETERS

4.1 Clear Text Display Module (OPm2)

This section only applies for users who intend using the optional Clear Text Display module (OPm2) to

control the operation of the CombiDrive

The OPm2 module provides a multi-language user-friendly interface to the CombiDr ive

®

.

®

. The display is menu-

driven and provides information in simple text form. It also includes built-in context-sensitive Help screens.

As well as enabling direct control of the motor, the OPm2 extends the functionality of the CombiDrive

®

by

providing access to a comprehens ive range of adjustable parameters. Setting these par ameters will allow you

to customise the operation of the CombiDrive

JOG

1

But to n

RUN / STOP

Inducator

2

STOPPED →

P000 F=0.00Hz

=0.0A RPM=0

I

V=0.0V

RUN

But to n

3

RUN STOP

®

to meet almost any application requirement.

M

▼

M

LCD

Scre en

P

▲

▼

FORWARD / REVERSE

But to n

6

Jog

STOP

4

But ton

Menu

P

UP / INCREASE

Freque ncy

7

MENU

5

But ton

1

Pressing thi s but ton while the motor is stopped causes i t to

start and run at the pr eset jog frequency. The motor stops as

soon as the button is rel eased. Pressing this butt on while t he

motor is running has no effect. Disabled if P007 or 123 = 0.

2

indi cates that t he motor is running.

Gre en

Flashing green

indicates that the motor is ramping up or

down.

indi cates that the motor is stationary.

Red

Flashing red

3

Press to star t the i nverter. Disabled if P007 or P121 = 0.

4

Press to stop t he i nverter.

5

Changes the display to show the menu opti ons. Pressi ng and

indi cates a fault condi tion.

holding this button down and then pressing the ∇ button

causes the Help screen to be displayed.

DOWN / DECREAS

Freque ncy

Parameterisation

6

Press to change the dir ection of rotat ion of t he motor.

But to n

8

9

REVERSE is indicated by a minus sign (values <100) or a

flashing decimal point (values > 100). Disabled i f P007 or

P122 = 0.

7

Press to INCREASE frequency. Used to change parameter

numbers or values to higher settings duri ng the

parameterisati on procedure. Disabled i f P124 = 0.

8

Press to DECREASE frequency. Used t o change parameter

numbers or values t o lower settings during the

parameterisati on procedure. Disabled i f P124 = 0.

9

Press to access par ameters. Disabled if P051 - P053 = 14

when using di gital inputs.

Figure 8: Clear Text Display Module (OPm2)

05.02.01

© STÖBER plc 199

14

Page 17

4. Clear Text Display Module & System Parameters English

R

4.2 System Parameters

The parameters listed here can only be accessed via the OPm2 or a serial link to the CombiDrive®. If the

CombiDrive

®

is to be operated only using analogue control within the 0 - 50 Hz frequenc y range then ac c es s to

these parameters is not required.

Note: The control buttons on the OPm2 (RUN, REVERSE and JOG) are disabled by default and cannot be

used until P007 has been set to ‘1’.

Access to parameters is determined by the value set in P009. Check that the key par ameters necessary for

your application have been programmed.

P009 options are:

0 = Only the parameters from P001 to P009 can be read and set.

1 = Parameters P001 to P009 can be set and all other parameters can only be read.

2 = All parameters can be set, but P009 resets to 0 the next time power is removed from the inverter.

3 = All parameters can always be set.

Note: In the following parameter table:

‘•' Indicates parameters that can be changed during operation.

‘✩✩✩' Indicates that the value of this factory setting depends on the rating of the motor.

Parameter Function Range

Description / Notes

[Default]

P000

Operating display - This displays the output selected in P001 on the second line of the

LCD screen.

If output frequency has been selected (P001 = 0) and the inverter is

OFF, the display alternates between the current frequency (F) and the

frequency that the inverter will run at when the RUN button is pressed

(S). If P001 is set to any other value then only the actual value is

displayed on this line of the display.

In the event of a fault, the relevant fault code (Fxxx) is displayed (see

section 5). In the event of a warning the display flashes.

P001 ••••

P002 ••••

Display mode 0 - 8

[0]

Ramp up time (seconds) 0 - 650.00

[10.00]

Display selection:

0 = Output frequency (Hz)

1 = Frequency setpoint (i.e. speed at which inverter is set to run)

(Hz)

2 = Motor current (A)

3 = DC-link voltage (V)

4 = Motor torque (% nominal)

5 = Motor speed (RPM)

6 = USS status (see section 7.2)

7 = Closed loop control setpoint (% of full scale)

8 = Output voltage

This is the time taken for the motor to accelerate from standstill to the

maximum frequency as set in P013.

Setting the ramp up time too short can cause the inverter to trip (fault code

F002 - overcurrent).

Frequency

f

max

0 Hz

amp up

time

(0 - 650 s)

Time

© STÖBER plc 1997

15

05.02.01

Page 18

English 4. Clear Text Display Module & System Parameters

8

R

4

4

Parameter Function Range

[Default]

P003 ••••

Ramp down time (seconds) 0 - 650.00

[25.00]

P004 ••••

Smoothing (seconds) 0 - 40.0

[0.0]

Description / Notes

This is the time taken for the motor to decelerate from maximum frequency

(P013) to standstill.

Setting the ramp down time too short can cause the inverter to trip (fault

code F001 - overvoltage).

This is also the period for which DC injection braking is applied (see P073)

Frequency

f

max

0 Hz

amp down

time

(0 - 650 s)

Time

Used to smooth the acceleration/deceleration of the motor (useful in

applications where it is important to avoid ‘jerking’, e.g. conveyor

systems, textiles, etc.).

Smoothing is only effective if the ramp up/down time exceeds 0.3 s.

Frequency

f

max

(P013)

P002 = 10 s

P005 ••••

P006

Digital frequency setpoint (Hz) 0 - 120.00

[50.00]

Frequency setpoint source

selection

0 - 2

[1]

0 Hz

P00

= 5 s

Total acceleration time

= 15 s

P00

= 5 s

Time

Note: The smoothing curve for deceleration is based on the ramp

up gradient (P002) and is added to the ramp down time set

by P003. Therefore, the ramp down time is affected by

changes to P002.

Sets the frequency that the inverter will run at when operated in digital

mode. Only effective if P006 set to ‘0’.

Sets the control mode of the inverter.

0 = Digital. The inverter runs at the frequency set in P005.

If P007 is set to zero, the frequency may be adjusted by setting

any two of digital inputs P051 - P053 to values of 11 and 12.

1 = Analogue. The frequency is set via an analogue input signal

or the internal potentiometer.

2 = Fixed frequency or motor potentiometer. Fixed frequency is

only selected if the value of at least one binary input (P051 P053) = 6, 17 or 18.

Notes: (1) If P006 = 1 and the inverter is set up for remote

control operation, the analogue inputs remain active

(added to the serial setpoint).

(2) Motor potentiometer setpoints via digital inputs

are stored when P011 = 1.

05.02.01

16

© STÖBER plc 199

Page 19

4. Clear Text Display Module & System Parameters English

Parameter Function Range

[Default]

P007

P009 ••••

P011

P012 ••••

Keypad control 0 - 1

[0]

Parameter protection setting 0 - 3

[0]

Frequency setpoint memory 0 - 1

[0]

Minimum motor frequency (Hz) 0 - 120.00

[0.00]

Description / Notes

0 = The RUN, REVERSE and JOG buttons are disabled. Control is

via digital inputs (see parameters P051 - P053). ∆ and ∇ may

still be used to control frequency provided that P124 = 1 and a

digital input has not been selected to perform this function.

1 = OPm2 buttons are enabled (can be individually disabled

depending on the setting of parameters P121 - P124). The

digital inputs for RUN, JOG and ∆ / ∇ are disabled.

Determines which parameters can be adjusted:

0 = Only parameters from P001 to P009 can be read/set.

1 = Parameters from P001 to P009 can be set and all other

parameters can only be read.

2 = All parameters can be read/set but P009 automatically

resets to 0 when power is removed.

3 = All parameters can be read/set.

0 = Disabled

1 = Enabled. The setpoint alterations made with the ∆ / ∇ buttons or

digital inputs are stored even when power has been removed

from the inverter.

Sets the minimum motor frequency (must be less than the value of

P013).

P013 ••••

P014 ••••

P015 ••••

P016 ••••

P017 ••••

Maximum motor frequency (Hz) 0 - 120.00

[50.00]

Skip frequency 1 (Hz) 0 - 120.00

[0.00]

Automatic restart after mains

failure.

Start on the fly 0 - 2

Smoothing type 1 - 2

0 - 1

[0]

[0]

[1]

Sets the maximum motor frequency.

A skip frequency can be set with this parameter to avoid the effects of

mechanical resonance. Frequencies within +/-(value of P019) of this

setting are suppressed. Stationary operation is not possible within the

suppressed frequency range - the range is just passed through.

Setting this parameter to ‘1’ enables the inverter to restart

automatically after a mains break or ‘brownout’, provided the run/stop

switch is still closed or the link is fitted, P007 = 0 and P910 = 0, 2 or 4.

0 = Disabled

1 = Automatic restart

Allows the inverter to start onto a spinning motor.

Under normal circumstances the inverter runs the motor up from 0 Hz.

However, if the motor is still spinning or is being driven by the load, it will

undergo braking before running back up to the setpoint - this can cause an

overvoltage trip. By using a flying restart, the inverter ramps up the output

voltage at the setpoint for the period defined by P020.

0 = Normal restart

1 = Flying restart after power up, fault or OFF2 ( if P018 = 1).

2 = Flying restart every time (useful in circumstances where the

motor can be driven by the load).

1 = Continuous smoothing (as defined by P004).

2 = Discontinuous smoothing. This provides a fast unsmoothed

response to STOP commands and requests to reduce frequency.

Note: P004 must be set to a value > 0.0 for this parameter to have

any effect.

© STÖBER plc 1997

17

05.02.01

Page 20

English 4. Clear Text Display Module & System Parameters

8

Parameter Function Range

[Default]

P018 ••••

P019 ••••

P020

P021 ••••

P022 ••••

Automatic restart after fault 0 - 1

[0]

Skip frequency bandwidth (Hz) 0 - 10.00

[2.00]

Flying start ramp time (seconds) 0.50 - 25.0

[5.0]

Minimum analogue frequency

(Hz)

Maximum analogue frequency

(Hz)

0 - 120.00

[0.00]

0 - 120.00

[50.00]

Description / Notes

Automatic restart after fault:

0 = Disabled

1 = The inverter will attempt to restart up to 5 times after a fault.

If the fault is not cleared after the 5th attempt, the inverter

will remain in the fault state until reset.

There is an increasing time delay between each restart

attempt.

Frequencies set by P014, P027, P028 or P029 that are within +/- the

value of P019 are suppressed.

Used in conjunction with P016 (set longer times if persistent F002

trips occur).

Frequency corresponding to the lowest analogue input value, i.e.

0 V / 0 mA or 2 V / 4 mA. This can be set to a higher value than P022

to give an inverse relationship between analogue input and frequency

output (see diagram in P022).

Frequency corresponding to the highest analogue input value, i.e.

10 V / 20 mA, determined by P023. This can be set to a lower value

than P021 to give an inverse relationship between analogue input and

frequency output.

i.e.

f

P021

P022

P023 ••••

P024 ••••

Analogue input type 0 - 2

[2]

Analogue setpoint addition 0 - 2

[0]

P022

P021

V / I

Note: The output frequency is limited by values entered for

P012/P013.

Selects analogue input type according to the setting of jumpers

JP300/JP301:

JP301 closed OR JP300 closed

0 = 0 V to 10 V 0 mA to 20 mA

1 = 2 V to 10 V 4 mA to 20 mA

2 = [2 V* to 10 V] 4 mA* to 20 mA

* The inverter will come to a controlled stop if V < 1 V or 2 mA.

WARNING: The motor can automatically run without a

potentiometer or voltage source connected

between pins 3 and 4.

With P023=2, the motor will automatically start

when V exceeds 2 V. This equally applies to

analogue and digital control (i.e. P006 = 0 or 1).

If the inverter is not in analogue mode (P006 = 0 or 2), setting this

parameter to ‘1’ causes the analogue input value to be added.

0 = No addition.

1 = Addition of the analogue setpoint (defined by P023) to the

fixed frequency or the motor potentiometer frequency.

2 = Scaling of digital/fixed setpoint by analogue input (P023) in

the range 0 - 100%.

Note: By selecting a combination of reversed negative fixed

frequency settings and analogue setpoint addition, it is

possible to configure the inverter for ‘centre zero’ operation

with a +/-5 V supply or a 0 - 10 V potentiometer so that the

output frequency can be 0 Hz at any position, including the

centre position.

05.02.01

18

© STÖBER plc 199

Page 21

4. Clear Text Display Module & System Parameters English

Parameter Function Range

[Default]

P027 ••••

P028 ••••

P029 ••••

P031 ••••

P032 ••••

P035

P041 ••••

P042 ••••

P043 ••••

P044 ••••

P045

P046 ••••

P047 ••••

P048 ••••

P050

Skip frequency 2 (Hz)

Skip frequency 3 (Hz) 0 - 120.00

Skip frequency 4 (Hz) 0 - 120.00

Jog frequency right (Hz) 0 - 120.00

Jog frequency left (Hz) 0 - 120.00

Reverse motor direction 0 - 1

Fixed frequency 1 (Hz) 0 - 120.00

Fixed frequency 2 (Hz) 0 - 120.00

Fixed frequency 3 (Hz) 0 - 120.00

Fixed frequency 4 (Hz) 0 - 120.00

Inversion fixed setpoints for

fixed frequencies 1 - 4

Fixed frequency 5 (Hz) 0 - 120.00

Fixed frequency 6 (Hz) 0 - 120.00

Fixed frequency 7 (Hz) 0 - 120.00

Inversion fixed setpoints for

fixed frequencies 5 - 7

0 - 120.00

[0.00]

[0.00]

[0.00]

[5.00]

[5.00]

[0]

[5.00]

[10.00]

[15.00]

[20.00]

0 - 7

[0]

[25.00]

[30.00]

[35.00]

0 - 7

[0]

Description / Notes

See P014.

See P014.

See P014.

Jogging is used to advance the motor by small amounts. It is

controlled via the JOG button or with a non-latching switch on one of

the digital inputs (P051 to P053).

If jog right is enabled (DINn = 7), this parameter controls the frequency at

which the inverter will run when the switch is closed. Unlike other setpoints, it

can be set lower than the minimum frequency.

If jog left is enabled (DINn = 8), this parameter controls the frequency at which

the inverter will run when the switch is closed. Unlike other setpoints, it can be

set lower than the minimum frequency.

0 = Normal direction control.

1 = Direction control is reversed.

Valid if P006 = 2 and P053 = 6 or 18 or P051 = P052 = P053 = 17.

Valid if P006 = 2 and P052 = 6 or 18 or P051 = P052 = P053 = 17.

Valid if P006 = 2 and P051 = 6 or 18 or P051 = P052 = P053 = 17.

Valid if P006 = 2 and P051 = P052 = P053 = 17.

Sets the direction of rotation for the fixed frequency:

FF 1 FF 2 FF 3 FF 4

P045 = 0 ⇒⇒ ⇒⇒

P045 = 1 ⇐ ⇒⇒⇒

P045 = 2 ⇒ ⇐ ⇒⇒

P045 = 3 ⇒⇒ ⇐ ⇒

P045 = 4 ⇒⇒ ⇒⇐

P045 = 5 ⇐⇐⇒⇒

P045 = 6 ⇐⇐⇐⇒

P045 = 7 ⇐⇐⇐⇐

⇒ Fixed setpoints not inverted.

⇐ Fixed setpoints inverted.

Valid if P006 = 2 and P051 = P052 = P053 = 17.

Valid if P006 = 2 and P051 = P052 = P053 = 17.

Valid if P006 = 2 and P051 = P052 = P053 = 17.

Sets the direction of rotation for the fixed frequency:

FF 5 FF 6 FF 7

P050 = 0 ⇒⇒ ⇒

P050 = 1 ⇐ ⇒⇒

P050 = 2 ⇒ ⇐ ⇒

P050 = 3 ⇒⇒ ⇐

P050 = 4 ⇒⇒ ⇒

P050 = 5 ⇐⇐⇒

P050 = 6 or 7 ⇐⇐⇐

⇒ Fixed setpoints not inverted.

⇐ Fixed setpoints inverted.

© STÖBER plc 1997

19

05.02.01

Page 22

English 4. Clear Text Display Module & System Parameters

8

Parameter Function Range

[Default]

P051 Selection control function, DIN1 0 - 19

(terminal 5), fixed frequency 3 [1]

or binary fixed frequency bit 0.

P052 Selection control function, DIN2 0 - 19

(terminal 6), fixed frequency 2. [2]

or binary fixed frequency bit 1.

P053 Selection control function, DIN3 0 - 19

(terminal 7), fixed frequency 1 [10]

or binary fixed frequency bit 2.

Description / Notes

Function of P051 to P053

Value

Input disabled

0

ON right

1

ON left

2

Reverse

3

OFF2 *

4

OFF3 *

5

Fixed frequencies 1 - 3

6

Jog right

7

Jog left

8

Remote operation

9

Fault code reset

10

Increase frequency **

11

Decrease frequency **

12

Disable analogue input

13

(setpoint is 0.0 Hz)

Disable the ability to change

14

parameters

Enable dc brake

15

Do not use

16

Binary fixed frequency control

17

(fixed frequencies 1 - 7)

As 6, but input high will also

18

request RUN *

External trip/PTC

19

Function,

low state

Off

Off

Normal

OFF2

OFF3

Off

Off

Off

Local

Off

Off

Off

Analogue

on

‘P’ Enabled

Off

Off

Off

Yes (F012)

Function,

high state

On right

On left

Reverse

On

On

On

Jog right

Jog left

Remote

Reset on

rising edge

Increase

Decrease

Analogue

disabled

‘P’ Disabled

Brake on

On

On

No

P056

P058 ●

Digital input debounce time 0 - 2

[0]

RUN command delay (seconds) 0.0 - 650.0

[0.0]

* See section 3.7.

** Only effective when P007 = 0.

Binary Coded Fixed Frequency Mapping

(P051, P052, P053 = 17)

DIN3 (P053) DIN2 (P052) DIN1 (P051)

STOP 000

RUN to FF1 (P041) 0 0 1

RUN to FF2 (P042) 0 1 0

RUN to FF3 (P043) 0 1 1

RUN to FF4 (P044) 1 0 0

RUN to FF5 (P046) 1 0 1

RUN to FF6 (P047) 1 1 0

RUN to FF7 (P048) 1 1 1

Use a fast response time only when a ‘clean’ input signal

is used, e.g. from a PLC. Use a slow response time to

allow filtering of the signal if a noisy input (e.g. a switch) is

used.

0 = 12.5 ms

1 = 7.5 ms

2 = 2.5 ms

Sets a time delay before the RUN command takes effect.

This parameter affects run commands from all sources

except the RUN button on the OPm2 (this activates the

drive immediately)..

05.02.01

20

© STÖBER plc 199

Page 23

4. Clear Text Display Module & System Parameters English

t

t

f

Parameter Function Range

[Default]

P061

P062

P063

P064

Selection relay output RL1 0 - 13

[6]

Electro-mechanical brake option

control

External brake release delay

(seconds)

External brake stopping time

(seconds)

0 - 4

[0]

0 - 20.0

[1.0]

0 - 20.0

[1.0]

Description / Notes

Value Relay function Active

0 No function assigned (relay not active) Low

1 Inverter is running High

2 Inverter frequency 0.0 Hz Low

3 Motor run right has been selected High

4 External brake on (see parameters P063/P064)

5 Inverter frequency less than or equal to minimum

1

Low

Low

frequency

6 Fault indication

2

Low

7 Inverter frequency greater than or equal to setpoint High

8 Warning active

3

Low

9 Output current greater than or equal to P065 High

10 Motor current limit (warning)

11 Motor over temperature (warning)

3

3

Low

Low

12 Closed loop motor LOW speed limit High

13 Closed loop motor HIGH speed limit High

1

External brake requires 24 V (max.) dc slave relay.

2

Inverter switches off (see parameter P930 and section 5).

3

Inverter does not switch off (see parameter P931).

4

‘Active low’ = relay OPEN. ‘Active high’ = relay CLOSED.

This enables or disables the electro-mechanical brake option.

Operation is the same as for P061 = 4, except that the brake control

voltage is supplied directly.

0 = Disabled

1 - 3 = Do not use

4 = Enabled

Only effective if the relay output is set to control an external brake (P061

= 4) or the electro-mechanical brake option is used (P062 = 4). In this

case when the inverter is switched on, it will run at the minimum

frequency for the time set by this parameter before releasing the brake

control relay and ramping up (see illustration in P064).

As P063, only effective if the relay output is set to control an external

brake (P061 = 4) or the electro-mechanical brake option is used (P062 =

4). This defines the period for which the inverter continues to run at

the minimum frequency after ramping down and while the external

brake is applied.

4

ON OFF

f

min

t

P063

A

B

A = Brake applied

P064

B = Brake removed

A

Notes: (1) Settings for P063 and P064 should be slightly longer

than the actual time taken for the external brake to

apply and release respectively.

(2) Setting P063 or P064 to too high a value, especially

with P012 set to a high value, can cause an

overcurrent warning or trip as the inverter attempts to

move a locked motor shaft.

© STÖBER plc 1997

21

05.02.01

Page 24

English 4. Clear Text Display Module & System Parameters

8

Parameter Function Range

[Default]

P065

Current threshold for relay (A) 0 - 99.9

[1.0]

P071 ••••

P072 ••••

P073 ••••

Slip compensation (%) 0 - 200

[0]

Slip limit (%) 0 - 500

[250]

DC injection braking (%) 0 - 250

[0]

P074 ••••

I2t motor derating 0 - 1

[1]

P077

Control mode 0 - 2

[0]

Description / Notes

This parameter is used when P061 = 9. The relay switches on when

the motor current is greater than the value of P065 and switches off

when the current falls to 90% of the value of P065 (hysteresis).

The inverter can estimate the amount of slip in an

asynchronous motor at varying loads and increase its

output frequency to compensate. This parameter `fine

tunes' the compensation for different motors in the range

0 - 200% of the inverter's nominal estimate.

This limits the slip of the motor to prevent `pull-out'

(stalling), which can occur if slip is allowed to increase

indefinitely. When the slip limit is reached, the inverter

reduces the frequency until the level of slip is acceptable.

This stops the motor by applying a DC current. This causes heat to be

generated in the motor rather than the inverter and holds the shaft

stationary until the end of the braking period. Braking is effective for

the period of time set by P003.

The DC brake can be activated using DIN1 - DIN3 (braking is active

for as long as the DIN is high - see P051 - P053).

WARNING: Frequent use of long periods of dc injection

braking can cause the motor to overheat.

If DC injection braking is enabled via a digital

input then DC current is applied for as long as the

digital input is high. This causes heat in the

motor.

0 = Disabled

2

1 = Enabled. Causes an F074 trip if the motor I

t calculation reaches its

limit. The time taken to trip is dependent on the difference between

the overload current and the nominal motor current rating stored in

P083 - typically a 150% overload will result in a switch-off in 1-2

minutes.

WARNING: For safety-critical applications, it is recommended

that a motor PTC is used to protect the motor from

overheating.

Controls the relationship between the speed of the motor and the

voltage supplied by the inverter.

0 = Linear voltage/frequency.

Use this curve for synchronous motors or motors connected

in parallel.

1 = Linear voltage/frequency with energy saving.

Output voltage is reduced at low load (not recommended for

dynamic loads).

2 = Quadratic voltage/frequency relationship.

This is suitable for centrifugal pumps and fans.

V

N

V

max

VN (P084)

0/1

2

f

(P081)

N

05.02.01

22

f

© STÖBER plc 199

Page 25

4. Clear Text Display Module & System Parameters English

Parameter Function Range

[Default]

P078 ••••

P079 ••••

P081

P082

P083

P084

P085

P086 ••••

P087

P089 ••••

P091 ••••

P092 ••••

Continuous boost (%) 0 - 250

[100]

Starting boost (%) 0 - 250

[0]

Nominal frequency for motor

(Hz)

Nominal speed for motor (RPM)

Nominal current for motor (A)

Nominal voltage for motor (V)

Nominal power for motor

(kW/hp)

Motor current limit (%) 0 - 250

Motor PTC enable 0 - 1

Stator resistance (Ω)

Serial link slave address 0 - 30

Serial link baud rate 3 - 7

0 - 120.00

[]

0 - 9999

[]

0.1 - 99.9

[]

0 - 1000

[]

0 - 100.0

[]

[150]

[0]

0.01-

100.00

[]

[0]

[6]

Description / Notes

Operates continuously over the whole frequency range.

For many applications it is necessary to increase low frequency

torque. This parameter sets the start-up voltage at 0 Hz to adjust the

available torque for low frequency operation. 100% setting will

produce rated motor current at low frequencies.

WARNING: If P078 is set too high, overheating of the motor

and/or an overcurrent trip (F002) can occur.

For drives which require a high initial starting torque, it is possible to

set an additional current (added to the setting in P078) during

ramping. This is only effective during initial start up and until the

frequency setpoint is reached.

Note: This increase is in addition to P078, but the total is limited to

250%.

‘These parameters are set in the factory and should not be changed

under normal circumstances.

The motor current can be limited with this parameter. If the set value

is exceeded, the output frequency is reduced until the current falls

below this limit. During this process, both LEDs will flash (see section

3.6).

Change this parameter only when the PTC option is fitted.

0 = Disabled

1 = Motor PTC enabled

Note: If P087 = 1 and the PTC input goes high then the inverter will

trip (fault code F004). Note that if the internal PTC gets too

hot, the inverter will trip (fault code F005).

Set in the factory. Do not adjust!

Up to 31 CombiDrive

controlled by a computer or PLC using the USS protocol. This

parameter sets a unique address for the inverter.

Sets the baud rate of the RS485 serial interface (USS protocol):

3 = 1200 baud

4 = 2400 baud

5 = 4800 baud

6 = 9600 baud

7 = 19200 baud

Note: Some RS232 to RS485 converters are not capable of

baud rates higher than 4800.

®

can be connected via the serial link and

© STÖBER plc 1997

23

05.02.01

Page 26

English 4. Clear Text Display Module & System Parameters

8

Parameter Function Range

[Default]

P093 ••••

P094 ••••

P095 ••••

P099 ••••

P101 ••••

P111

P112

P113

P121

P122

Serial link timeout (seconds) 0 - 240

[0]

Serial link nominal system

setpoint (Hz)

USS compatibility 0 - 2

Communication adapter type 0 - 1

Operation for Europe or USA 0 - 1

Inverter power rating (kW/hp) 0.0 - 10.00

Inverter type 1 - 8

COMBIMASTER model 24 - 29

Enable/disable RUN button 0 - 1

Enable/disable

FORWARD/REVERSE button

0 - 120.00

[50.00]

[0]

[0]

[0]

[]

[8]

[-]

[1]

0 - 1

[1]

Description / Notes

This is the maximum permissible period between two incoming data

telegrams. This feature is used to turn off the inverter in the event of a

communications failure.

Timing starts after a valid data telegram has been received and if a

further data telegram is not received within the specified time period,

the inverter will trip and display fault code F008.

Setting the value to zero switches off the control.

Setpoints are transmitted to the inverter via the serial link as

percentages. The value entered in this parameter represents 100%

(HSW = 4000H).

0 = Compatible with 0.1 Hz resolution

1 = Enable 0.01 Hz resolution

2 = HSW is not scaled but represents the actual frequency value to

a resolution of 0.01 Hz (e.g. 5000 = 50 Hz).

0 = Option module not present

1 = PROFIBUS module (enables parameters relating to PROFIBUS)

This sets the inverter for European or USA supply and motor

frequency:

0 = Europe (50 Hz)

1 = USA (60 Hz)

Note: After setting P101 = 1 the CombiDrive

factory defaults. i.e. P944 = 1 to automatically set P013 =

60 Hz, P022 = 60 Hz, P081 = 60 Hz, P082 = 1680 rpm and

P085 will be displayed in hp.

Read-only parameter that indicates the power rating of the inverter in

kW. e.g. 0.55 = 550 W

Note: If P101 = 1 then the rating is displayed in hp.

Read-only parameter.

1 = MICROMASTER series 2 (MM2)

2 = CombiDrive

3 = MIDIMASTER

4 = MICROMASTER Junior (MMJ)

5 = MICROMASTER series 3 (MM3)

6 = MICROMASTER Vector (MMV)

7 = MIDIMASTER Vector (MDV)

8 = CombiDrive

Read-only parameter.

24 = CM150/3

25 = CM220/3

26 = CM300/3

27 = CM400/3

28 = CM550/3

29 = CM750/3

0 = RUN button disabled.

1 = RUN button enabled (only possible if P007 = 1).

0 = FORWARD/REVERSE button disabled.

1 = FORWARD/REVERSE button enabled (only possible if P007 = 1).

®

®

series 2

®

must be reset to

05.02.01

24

© STÖBER plc 199

Page 27

4. Clear Text Display Module & System Parameters English

Parameter Function Range

[Default]

P123

P124

P125

P131

P132

P134

P135

P137

P140

P141

P142

P143

P151 ••••

P152 ••••

P201

P202 ••••

Enable/disable JOG button 0 - 1

[1]

Enable/disable ∆ and ∇ buttons

Reverse direction inhibit 0 - 1

Frequency setpoint (Hz)

Motor current (A)

DC link voltage (V)

Motor RPM

Output voltage (V)

Most recent fault code 0 - 9999

Most recent fault code -1 0 - 9999

Most recent fault code -2 0 - 9999

Most recent fault code -3 0 - 9999

Green LED function 0 - 5

Yellow LED function 0 - 5

PI closed loop mode 0 - 2

P gain (%) 0.0 - 999.9

0 - 1

[1]

[1]

0.00 -120.00

[-]

0.0 - 99.9

[-]

0 - 1000

[-]

0 - 40000

[-]

0 - 1000

[-]

[-]

[-]

[-]

[-]

[4]

[5]

[0]

[1.0]

Description / Notes

0 = JOG button disabled.

1 = JOG button enabled (only possible if P007 = 1).

0 = ∆ and ∇ buttons disabled.

1 = ∆ and ∇ buttons enabled (only possible if P007 = 1).

Note: This applies for frequency adjustment only. The buttons can

still be used to change parameter values.

0 = Reverse direction disabled. Inhibits reverse commands from

ALL sources (reverse RUN commands result in forward rotation)

1 = Normal operation (FORWARD/REVERSE operation allowed)

Read-only parameters. These are copies of the values selected

by P001 but can be accessed directly via the serial link.

The last recorded fault code (see section 5) is stored in this

parameter. It is cleared when the inverter is reset.

This is a copy of the code stored in P930.

This parameter stores the last recorded fault code prior to that stored

in P140/P930.

This parameter stores the last recorded fault code prior to that stored

in P141.

This parameter stores the last recorded fault code prior to that stored

in P142.

0 =Off

1 =On

2 = Fault mode: On = Tripped

Flashing = Warning

3 = Running mode:On = Motor running

Flashing = Inverter on but motor

stationary

4 = Default mode (see table in section 3.6)

5 = Not used

0 =Off

1 =On

2 = Fault mode: On = Tripped

Flashing = Warning

3 = Running mode:On = Motor running

Flashing = Inverter on but motor

stationary

4 = Not used

5 = Default mode (see table in section 3.6)

0 = Normal operation (closed loop control disabled).

1 = Not used

2 = Closed loop control using PI input for transducer feedback.

Proportional gain.

© STÖBER plc 1997

25

05.02.01

Page 28

English 4. Clear Text Display Module & System Parameters

8

Parameter Function Range

[Default]

P203 ••••

P205 ••••

P206 ••••

P207 ••••

P208

P210

P211 ••••

P212 ••••

P220 ••••

P331

P332

I gain (%) 0.00 -

99.99

[0.00]

Sample interval (x 25 ms) 1 - 2400

[1]

Transducer filtering 0 - 255

[0]

Integral capture range (%) 0 - 100

[100]

Transducer type 0 - 1

[0]

Transducer reading (%) 0.0 - 100.0

[-]

0% setpoint 0.00-

100.00

[0.00]

100% setpoint 0.00-

100.00

[100.00]

PI frequency cut-off 0 - 1

[0]

Analogue mode 0 - 4

[2]

Fine adjustment (%) 0 - 100

[10]

Description / Notes

Integral gain.

0.01% corresponds to the longest integral response time.

Sampling interval of feedback sensor.

0 = Filter off.

1 - 255 = Low pass filtering applied to transducer.

Percentage error above which integral term is reset to zero.

0 = An increase in motor speed causes an increase in sensor

voltage/current output.

1 = An increase in motor speed causes a decrease in sensor

voltage/current output.

Read only. Value is a percentage of full scale of the PI input.

Value of P210 to be maintained for 0% setpoint.

Value of P210 to be maintained for 100% setpoint.

0 = Normal operation

1 = Switch off inverter at or below minimum frequency.

0 = Internal potentiometer only

1 = External analogue input only

2 = Internal potentiometer + external analogue input

3 = Internal potentiometer fine, external input coarse

4 = Internal potentiometer coarse, external input fine

Percentage of fine tuning adjustment for P331 = 3 or 4.

P700

P701 ••••

P702

P723

P880

State of digital inputs 0 - 7

[-]

Specific to PROFIBUS-DP. See PROFIBUS Handbook for further

details. (Access only possible with P099 = 1.)

DIN3 DIN2 DIN1

0 =0 0 0

1 =0 0 1

2 =0 1 0

3 =0 1 1

4 =1 0 0

5 =1 0 1

6 =1 1 0

7 =1 1 1

Specific to PROFIBUS-DP. See PROFIBUS Handbook for further

details. (Access only possible with P099 = 1.)

05.02.01

26

© STÖBER plc 199

Page 29

4. Clear Text Display Module & System Parameters English

Parameter Function Range

[Default]

P910 ••••

Local/Remote mode 0 - 4

[0]

P918 ••••

P922

P923 ••••

Software version 0.00 -

99.99

[-]

Equipment system number 0 - 255

[0]

P927 ••••

P928 ••••

P930

P931

P944

Most recent fault code 0 - 9999

[-]

Most recent warning type 0 - 9999

[-]

Reset to factory default settings 0 - 1

[0]

Description / Notes

Sets the inverter for local control or remote control over the serial link:

0 = Local control

1 = Remote control (and setting of parameter values)

2 = Local control (but remote control of frequency)

3 = Remote control (but local control of frequency)

4 = Local control (but remote read and write access to

parameters and facility to reset trips)

Note: When operating the inverter via remote control (P910 = 1

or 3), the analogue input remains active when P006 = 1

and is added to the setpoint.

Specific to PROFIBUS-DP. See PROFIBUS Handbook for further

details. (Access only possible with P099 = 1.)

Contains the software version number and cannot be changed.

You can use this parameter to allocate a unique reference number to

the inverter. It has no operational effect.

Specific to PROFIBUS-DP. See PROFIBUS Handbook for further

details. (Access only possible with P099 = 1.)

The last recorded fault code (see section 5) is stored in this

parameter. It is cleared when the inverter is reset.

The last recorded warning is stored in this parameter until power is

removed from the inverter:

002 = Current limit active

003 = Voltage limit active

005 = Inverter over temperature (internal PTC)

Set to ‘1’ and then press P to reset all parameters except P101 to the

factory default settings.

P947

P958

P963

P967

P968

P970

P971 ••••

EEPROM storage control 0 - 1

[1]

Specific to PROFIBUS-DP. See PROFIBUS Handbook for further

details. (Cannot be accessed unless P099 = 1.)

0 = Changes to parameter settings (including P971) are lost when

power is removed.

1 = Changes to parameter settings are retained during periods

when power is removed.

IMPORTANT

Take care not to exceed the EEPROM write cycle limit of

50,000/parameter (approx.) when using the serial link to update

parameters, otherwise data loss or corruption may occur. Read cycles

are unlimited.

© STÖBER plc 1997

27

05.02.01

Page 30

English 5. Fault Codes

8

5. FAULT CODES

Fault codes are only available when an OPm2 is connected to the CombiDrive®.

®

In the event of a failure, the CombiDrive

fault that occurred is stored in parameter P930. e.g. ‘0003' indicates that the last error was F003.

Fault Code Cause Corrective Action

F001

F002

F003

F004

F005

F006

F008

F009

F010

F011

F012

F013

F018

F030

F031

F033

F036

F074

F106

F112

F151 - F153

F201

F212

Overvoltage Check whether supply voltage is within the limits indicated on the rating plate.

Overcurrent Check motor lead and motor for short-circuits and earth faults.

Overload Check whether the motor is overloaded.

Overheating of motor

(monitoring with PTC)

Inverter overtemperature

(internal PTC)

Power module overtemperature Check that the ambient temperature is not too high.

USS protocol timeout Check the serial interface.

Undervoltage Check that the power supply is supplying enough voltage to the inverter.

Initialisation fault / Parameter loss * Check the entire parameter set. Set P009 to `0000' before power down.

Internal interface fault * Switch off power and switch on again.

External trip Source of trip is digital input (configured as an external trip input) going low -

Programme fault * Switch off power and switch on again.

Auto restart after fault Automatic restart after fault (P018) is pending.

PROFIBUS link failure Check the integrity of the link.

Option module link failure Check the integrity of the link.

PROFIBUS configuration error Check the PROFIBUS configuration.

PROFIBUS module watchdog trip Replace PROFIBUS module

Motor overtemperature by I2t

calculation

Parameter fault P006 Parameterise fixed frequency(ies) and/or motor potentiometer on the digital

Parameter fault P012/P013 Set parameter P012 < P013.

Digital input parameter fault Check the settings of digital inputs P051 to P053.

P006 = 1 while P201 = 2 Change parameter P006 and/or P201.

Parameter fault P211/P212 Set parameter P211 < P212.

switches off and a fault code appears on the LCD screen. The last

Increase the ramp down time (P003).

Check whether the required braking power is within the specified limits.

Increase the ramp-up time (P002).

Reduce the boost set in P078 and P079.

Check whether the motor is obstructed or overloaded.

Check if motor is overloaded.

Check the connections to the PTC.

Has P087 been set to 1 without a PTC being connected?

Check that the ambient temperature is not too high.

The motor speed may be too low for a given load.

Check the settings of the bus master and P091 - P093.

Check whether the timeout interval is too short (P093).

check the external source.

WARNING: The motor shaft may start to rotate at any time.

Check that the motor current does not exceed the value set in P083.

inputs.

* Ensure that the wiring guidelines described in section 2.1 have been complied with.

When the fault has been corrected, restart the inverter and the motor will run if the fault has been cleared.

05.02.01

28

© STÖBER plc 199

Page 31

6. Specifications English

6. SPECIFICATIONS

CSA-single-phase device

Model PM25/1 PM37/1 PM55/1 PM75/1

Motor frame size: 4 pole 71K 71L 80K 80L

Motor output rating: 0.25 kW 0.37 kW 0.55 kW 0.75 kW

Operating input voltage: 1ø AC 208 - 240 V

Operating input frequency: 47 - 63 Hz

Output frequency: 0 - 150 Hz

Output frequency with.

OPm2 or serial link: 4 pole

0 - 140 Hz

Input current: 3.2 A

rms

0 - 140 Hz 0 - 140 Hz 0 - 140 Hz

4.6 A

rms

Main fuse: 10 A 16 A

Min lead cross-secti on:

1 mm

2

CSA-three-phase device

Model PM37/3 PM55/3 PM75/3 PM110/3 PM150/3