Page 1

GLOBAL PRODUCT SUPPORT

CLINITEK® AUWi™ System PM Checklist

UF-1000i and Track Preventive Maintenance Guide

Purpose

This document provides a list of scheduled preventive maintenance procedures to be performed at the

recommended frequencies.

Disclaimer

Institution Name:

System Serial No.:

Cycle Count:

(if applicable)

Frequency:

Warranty: Contract: On Demand:

The CLINITEK AUWi Preventive Maintenance on the UF-1000i and Track is based upon a 6 month PM

cycle. The 6 month PM cycle is based upon an average sample count of 15000 samples. The PM cycle

may need to be increased for customers that run samples far in excess of 15,000/6 months. Examples

are high volume Quest and BRL sites.

The installation and servicing of the equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates, or who are otherwise authorized by

Siemens or one of its affiliates to provide such services. Assemblers and other persons who are not

employed by or otherwise directly affiliated with or authorized by, Siemens or one of its affiliates are

directed to contact one of the local offices of Siemens or one of its affiliates before attempting

installation or service procedures.

Semi-annual:

Product & Model:

Annual:

BIOHAZARD

Wear personal protective equipment and use universal precautions.

Special Instructions for Siemens Personnel

To complete the tasks listed in this checklist, refer to the system’s Service Guide for procedural

information.

Order UF-1000i PM Kit 10713799.

DPUA-A07.831.02.02.02 Page 1 of 3

Page 2

GLOBAL PRODUCT SUPPORT

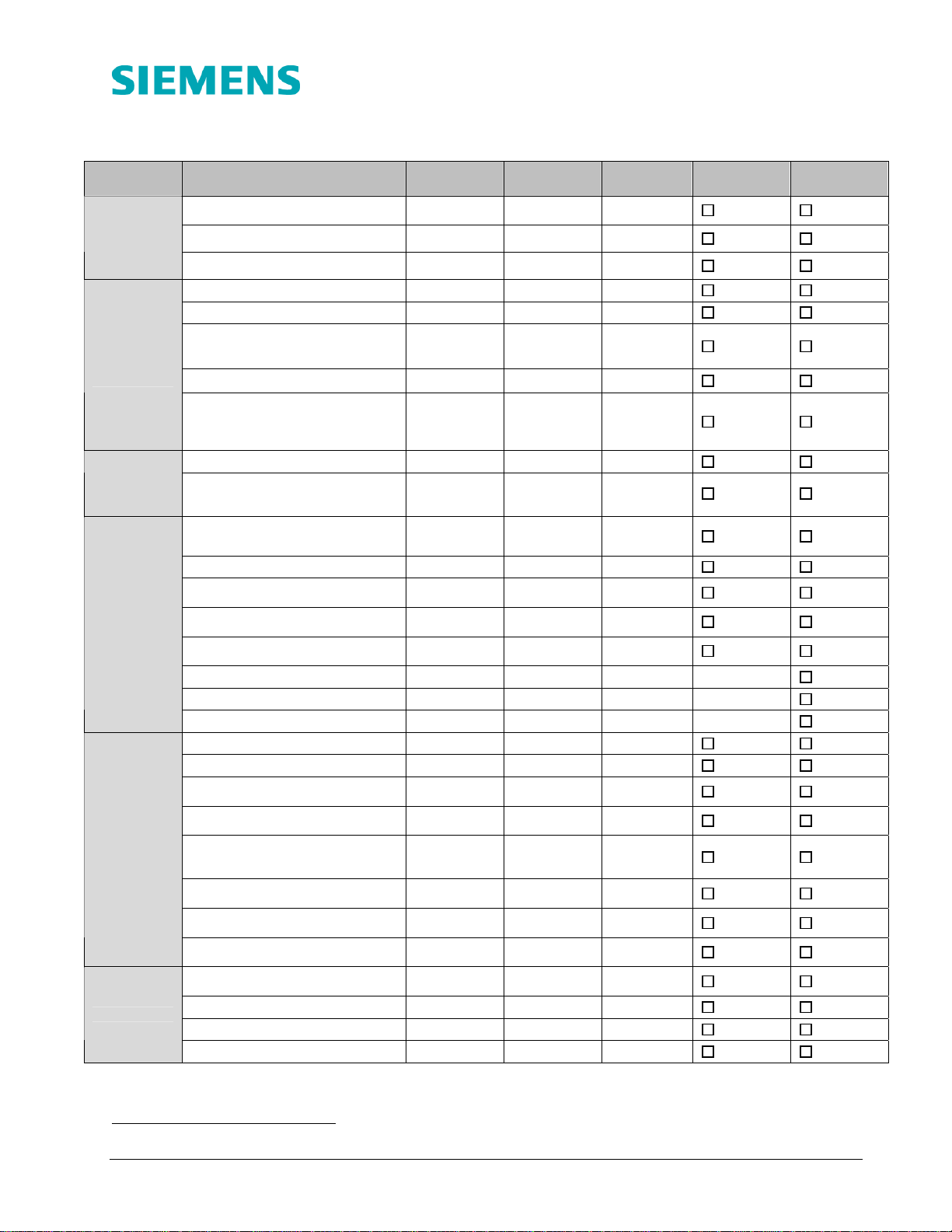

Tasks Completed

System Item

Review purpose of PM with the

customer.

Pre-check

Sample

Aspiration

Unit

Reaction

Unit

Pneumatic

Unit

Hydraulic

Other

Interview the operator.

Verify instrument operation.

Clean the Sample Aspiration Pipette.

Clean the Aspiration Path.

Check the Sample Filter

semiannually.

Replace the Sample Filter yearly.

Clean the Rinse Cup.

Check the Rinse Cup Mounting Plate

semiannually.

Replace the Rinse Cup Mounting

Plate yearly.

Disassemble and clean the SRV.

Clean the Reaction Chamber,

including the overflow nipples and

white Teflon

Clean the Bellows semiannually.

Replace the Bellows unit yearly.

Clean the Drain Filter.

Check the pressure level

(0.26 MPa).

Check/Adjust the pressure level (0.05

MPa).

Check/Adjust the pressure level

(–0.053 MPa).

Replace the Vacuum Head yearly. 10378370 443-6865-6

Replace the Pressure Head yearly. 10378371 448-6866-0

Replace the Air Drier Tube yearly. 10712827 443-2606-1

Clean the Overflow Sensor.

Replace the Sheath Syringe body. 10378384 943-2234-1

Replace the Whole Urine Pump seal

every 30,000 cycles or yearly.

Replace the Charging Pump seal

every 30,000 cycles or yearly.

Replace the Waste Line Pinch

Tubing of the Rinse Cup

semiannually.

Replace the Pinch Line Tubing of the

Waste Chambers semiannually.

Replace the Pinch Tubing of the

charging lines semiannually

Clean the Flow Cell (using Sysmex

Service menus).

Clean inside of the system and

Sysmex work area.

Check the system for leaks.

Replace dirty or damaged tubing.

Lubricate Linear Sliders.

®

rings.

Siemens

Part #

— — —

— — —

— — —

— — —

10635175

10635174

— — —

10378354 366-1473-5

—

—

10378388 991-0542-3

— — —

— —

— —

— —

— — —

10378352 346-9357-8

10378352 346-9357-8

10329288 442-6486-5

10329288 442-6486-5

10377317 442-6483-4

10713983

Tool

— — —

— — —

— — —

— — —

*

Sysmex

Part #

BM145402

BL248407*

— —

— —

063-3001-0

Value

—

—

—

LL 0.24

UL 0.26

LL 0.045

UL 0.054

LL –0.050

UL –0.056

—

—

—

—

—

—

140 mm

250 mm

SED 40 mm

BAC 65 mm

—

1

/2 Year 1 Year

Review Review

Interview Interview

Check Check

Clean Clean

Clean Clean

Check Replace

Clean Clean

Check Replace

Clean Clean

Clean Clean

Clean Replace

Clean Clean

Check Check

Adjust Adjust

Adjust Adjust

No Action Replace

No Action Replace

No Action Replace

Clean Clean

Replace Replace

Replace Replace

Replace Replace

Replace Replace

Replace Replace

Replace Replace

Clean Clean

Clean Clean

Check Check

Replace Replace

Lube Lube

*

If the sample filter has not been retrofitted to the new version, replace with retrofit kit.

DPUA-A07.831.02.02.02 Page 2 of 3

Page 3

GLOBAL PRODUCT SUPPORT

System Item

Clean the IPU display.

IPU

Operation

Optical

Alignment

Temperature

General

Vacuum and clean the inside of the

IPU.

Back up data (Service menu).

Check/Adjust the Aspiration Pipette

position.

Check/Adjust the Sample Rotation

Unit position.

Check/Adjust the mixing speed –

Reaction Chamber.

Check/Adjust the mixing motor

position.

Check UF II Control measured data.

Check S-FSC with 7μm Latex

measured data.

Check B-FSC with 1μm Latex

measured data.

Check S-SFL with Fluorescence

Latex measured data.

Check S-SSC with Fluorescence

Latex measured data.

Check FLL and SSC %CV.

Check SED Reaction Chamber.

Check BAC Reaction Chamber.

Check Sheath Heater.

Check Photo-multiplier.

Check Pneumatic Unit duct.

Check room temperature.

Check engineering change records.

Perform operation check.

Re-confirm the measured data from

Pre-check.

Perform quality control.

Clean up (waste container, etc.).

Check accessories.

Siemens

Part #

— — —

— — —

— — —

— — —

— — —

— —

— — —

— — —

10377388 Duke 4070

10377389 Duke 4010

10377390 A7312

10377390 A7312

— —

— —

— —

— —

— —

— —

— —

— — —

— — —

— — —

— — —

— — —

— — —

Sysmex

Part #

Value

Target

1550 rpm

(1450–1650

rpm)

115 ±30 ch

%CV < 1.8%

90 ±30 ch

%CV < 4.0%

Single peak

120 ±30 ch

%CV < 6.0%

70 ±30 ch

%CV < 6.0%

< 1.5%

difference

31.5–36.5°C

37.5–42.5°C Check Check

33.5–38.5°C

33.0–37.0°C

15–32°C

below 30°C

1

/2 Year 1 Year

Clean Clean

Clean Clean

Back up Back up

Adjust Adjust

Adjust Adjust

Adjust Adjust

Adjust Adjust

Check Check

No Action

No Action

No Action

No Action

No Action

Check Check

Check Check

Check Check

Check Check

Check Check

Check Check

Check Check

Check Check

Check Check

Clean Clean

Check Check

Check

Check

Check

Check

Check

Trademark Information

CLINITEK and AUWi are trademarks of Siemens Healthcare Diagnostics.

Teflon is a trademark of E. I. DuPont de Nemours and Company.

Date Signature (Customer)

Print name

DPUA-A07.831.02.02.02 Page 3 of 3

Date Signature (FSE)

Print name

Loading...

Loading...