Page 1

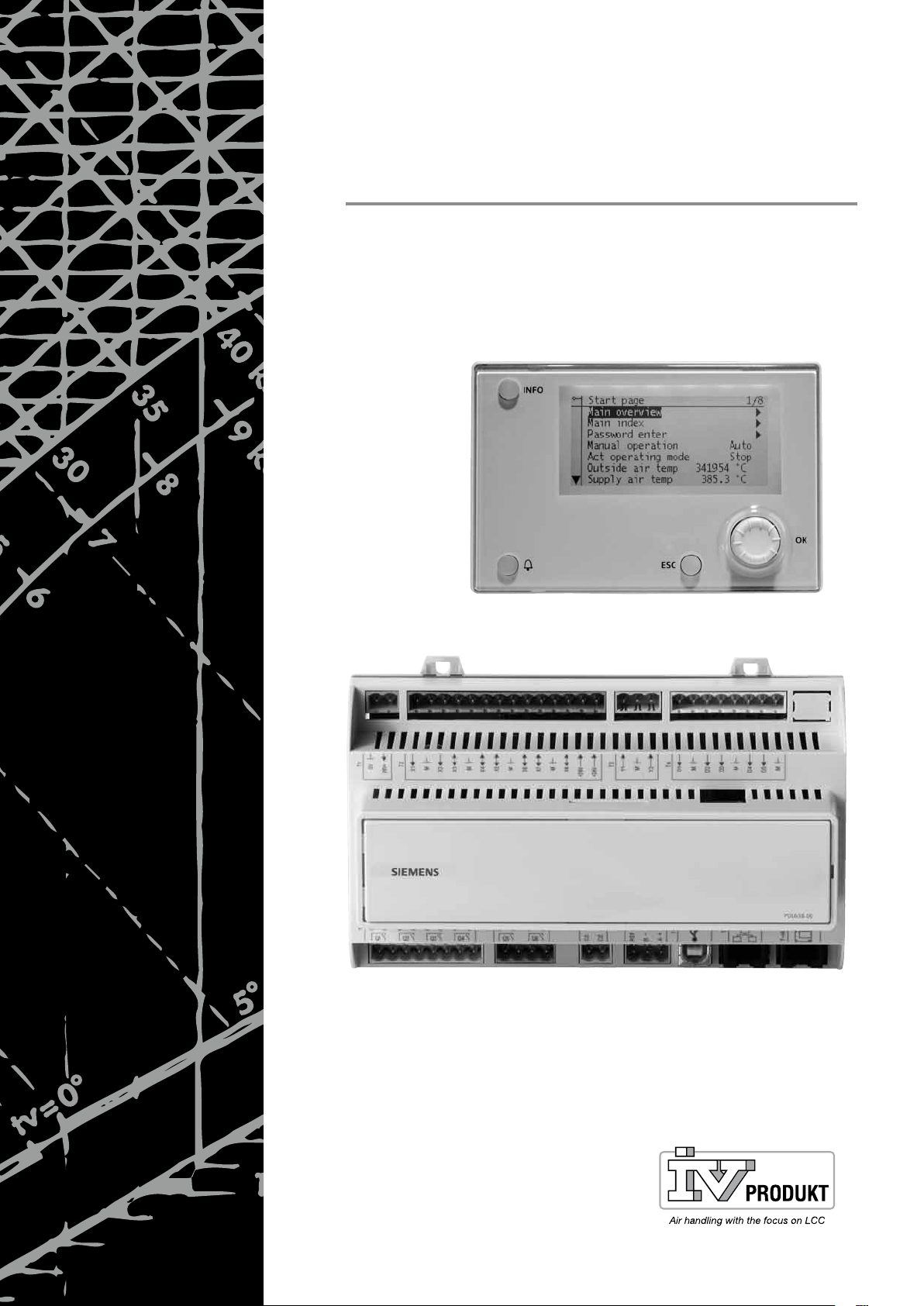

Control Equipment

Siemens Climatix

Basis Document Climatix Control System

Page 2

Page 3

Content

1 About this document ..............................................................................7

1.1 Revision history.........................................................................................7

1.2 Referenced documents.............................................................................7

1.3 Before you start.........................................................................................7

2 Philosophy of air handling units ...........................................................9

2.1 Overview ...................................................................................................9

2.2 Properties..................................................................................................9

2.3 Safety......................................................................................................10

2.4 Packing, transport and storage...............................................................11

2.5 Maintenance and service........................................................................11

2.6 Environmental protection and waste management.................................11

2.7 Abbreviations ..........................................................................................11

3 Function overview ................................................................................12

3.1 General ...................................................................................................12

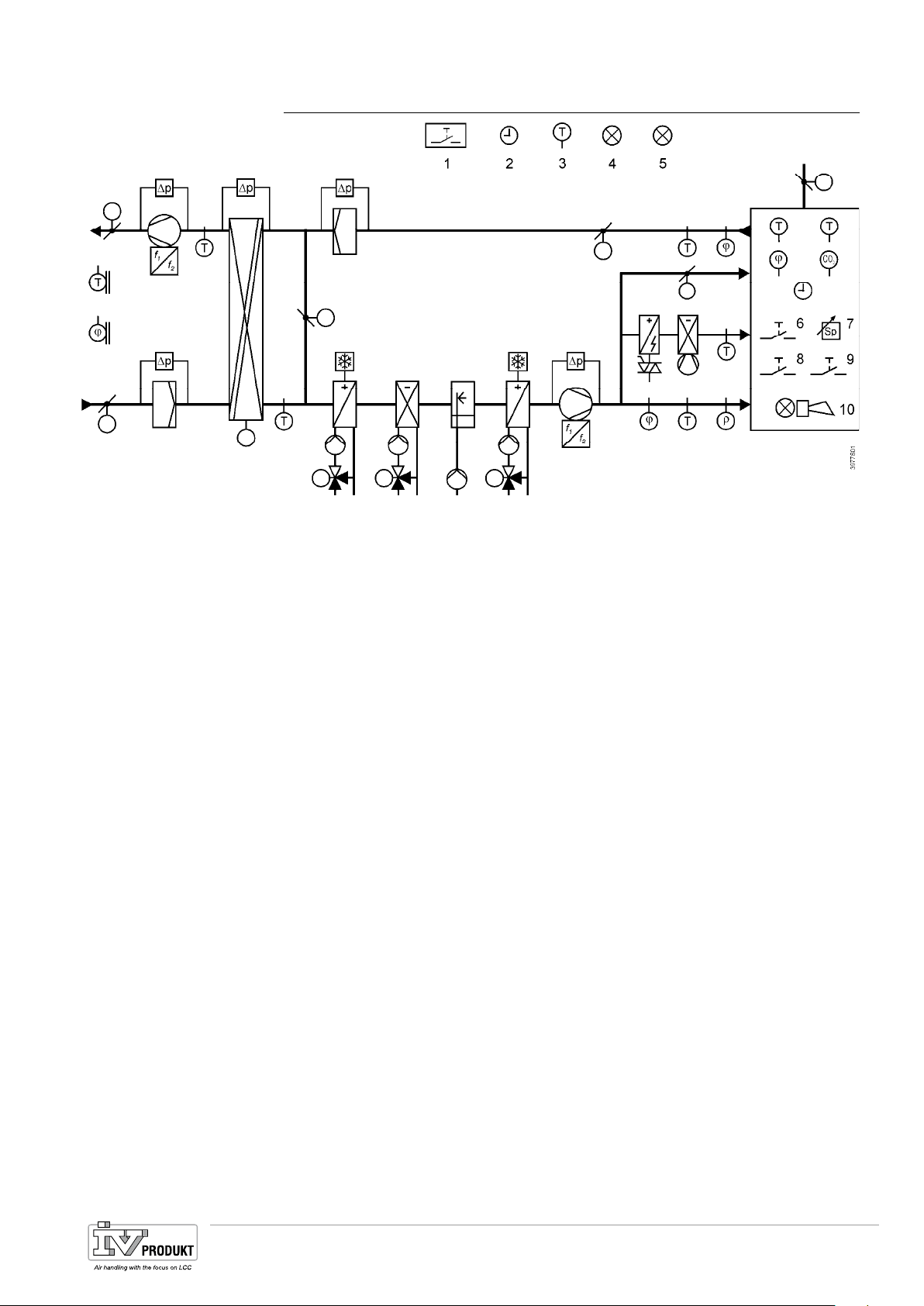

3.2 Diagram standard AHU...........................................................................13

3.3 Workflow diagram ...................................................................................14

4 Hardware overview ...............................................................................15

4.1 Basic controller (POL638x).....................................................................15

4.2 Extension module (POL955)...................................................................18

4.3 Inbuild HMI..............................................................................................20

4.4 External HMI (DM) ..................................................................................20

4.5 Room unit................................................................................................25

5 Functions...............................................................................................33

5.1 Global functions ......................................................................................33

5.2 Operating mode ......................................................................................35

5.3 Damper control........................................................................................46

5.4 Fan control ..............................................................................................50

5.5 Temperature control................................................................................59

5.6 Heat recovery damper ............................................................................67

5.7 Heat recovery (Plate, wheel, water)........................................................69

5.8 Heating / Heating 2 .................................................................................73

5.9 Electrical heating / Electrical heating 2...................................................77

5.10 Cooling / Cooling 2..................................................................................79

5.11 Humidity control ......................................................................................83

5.12 Air quality control.....................................................................................90

5.13 Auxiliary functions ...................................................................................91

5.14 Alarm handling (Alarm outputs) ..............................................................93

6 Detail pages: Inputs and outputs.........................................................95

6.1 General ...................................................................................................95

6.2 Analog outputs ........................................................................................95

6.3 Digital outputs .........................................................................................98

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 3

Page 4

6.4 Multistate outputs..................................................................................100

6.5 Analog inputs.........................................................................................102

6.6 Digital inputs..........................................................................................106

7 Detail pages: Controller......................................................................110

7.1 Loop controller ......................................................................................110

7.2 Cascade controller ................................................................................111

8 Detail pages: Time switch program...................................................114

8.1 General..................................................................................................114

8.2 Week scheduler.....................................................................................114

8.3 Day scheduler .......................................................................................115

8.4 Calendar (exception and fixed off)........................................................115

9 Communication ...................................................................................118

9.1 General..................................................................................................118

9.2 Modbus..................................................................................................119

9.3 LON.......................................................................................................124

9.4 BACnet..................................................................................................128

9.5 Room units ............................................................................................131

10 Application Info ...................................................................................135

11 Save / restore parameters ..................................................................136

12 Onboard WEB functionalities ............................................................139

13 System settings...................................................................................141

13.1 Password settings.................................................................................141

13.2 Change passwords ...............................................................................141

13.3 Language Support.................................................................................142

13.4 Target ....................................................................................................142

13.5 Daylight saving time..............................................................................143

13.6 HMI (operating unit) ..............................................................................145

13.7 Diagnostics............................................................................................145

13.8 Diag object handler ...............................................................................146

14 SD card and modem ...........................................................................148

14.1 SD card functions (Update application) ................................................148

14.2 Modem / SMS .......................................................................................149

15 Configuration.......................................................................................152

15.1 Configuration 1......................................................................................154

15.2 Configuration 2......................................................................................159

15.3 Configuration I/Os .................................................................................167

15.4 Check config I/Os..................................................................................176

Page 4

16 Examples..............................................................................................177

17 HMI........................................................................................................177

17.1 Overview ...............................................................................................177

17.2 Start page..............................................................................................177

17.3 Main index.............................................................................................177

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 5

17.4 Main overview .......................................................................................178

17.5 Configuration.........................................................................................178

17.6 Configuration 1......................................................................................178

17.7 Configuration 2......................................................................................180

17.8 Configuration I/Os.................................................................................184

17.9 Check config I/Os..................................................................................188

17.10 Global functions ....................................................................................189

17.11 Inputs ....................................................................................................189

17.12 Operating mode ....................................................................................191

17.13 Damper control......................................................................................194

17.14 Fan control ............................................................................................195

17.15 Temperature control..............................................................................197

17.16 Humidity control ....................................................................................206

17.17 Air qualtity control..................................................................................208

17.18 Auxiliary.................................................................................................209

17.19 Loop controllers.....................................................................................209

17.20 Operation hours ....................................................................................210

17.21 Alarm handling (Alarm outputs) ............................................................211

17.22 Outputs..................................................................................................212

18 Time scheduler....................................................................................213

18.1 Week schedulers...................................................................................213

18.2 Detail pages: Analog outputs ................................................................214

18.3 Detail pages: Digital outputs .................................................................215

18.4 Detail pages: Multistate outputs............................................................216

18.5 Detail pages: Analog inputs...................................................................217

18.6 Detail pages: Digital inputs....................................................................219

19 Alarming...............................................................................................222

19.1 General .................................................................................................222

19.2 Alarm list detail......................................................................................223

19.3 Alarm list ...............................................................................................224

19.4 Alarm history .........................................................................................224

19.5 Alarm list / history settings ....................................................................225

19.6 Alarm lists..............................................................................................226

20 Appendices..........................................................................................230

20.1 Point tables ...........................................................................................230

20.2 Diagnostic tables for check I/O .............................................................232

20.3 Navigation illustrations..........................................................................235

20.4 Parameter list room unit........................................................................239

Index 241

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 5

Page 6

Page 6

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 7

1 About this document

1.1 Revision history

Version Date Changes Section Pages

V1.0 02.07.2009 New document --- --V1.02 18.01.2010 New sub section

New sub section

Revised

4.5 – Room unit

20.4 – Parameter list room device

19.6 – Alarm lists

1.2 Referenced documents

Document title Type of document Document no.

Climatix Controllers POL6XX Documentation on basics CB1P3903en

Climatix Controllers POL63y.XX/XXX Data sheet CB1Q3230de

Climatix Extension Module POL955 Documentation on basics CB1P3920en

Climatix AHU ext. module 14 I/O POL955.XX.XXX Data sheet CB2N3262de

Climatix BACnet communication modules POL904.00/XXX,

POL908.00/XXX

Climatix communication BACnet MS/TP module

POL904.00/xxx

Climatix LON communication module POL906.00/XXX Documentation on basics CB1P3931en

Climatix communication LON module POL906.00/XXX Data sheet CB1Q3931de

Climatix MODBUS communication module POL902.00/XXX Documentation on basics CB1P3934en

Climatix communication MODBUS module POL902.00/XXX Data sheet CB1Q3934de

Documentation on basics CB1P3933en

Data sheet CB1Q3932de

1.3 Before you start

25-33

242-244

229-232

1.3.1 Trademarks

The table below lists the third-party trademarks used in this document and their

legal owners. The use of trademarks is subject to international and domestic provisions of the law.

Trademarks Legal owner

BACnet American National Standard (ANSI/ASHRAE 135-

1995)

LonLink™

LON® / LonManager®

LonMark®

LonTalk®

LonWorks®

MODBUS® The MODBUS Organization, Hopkinton, MA, USA

All product names listed in the table are registered (®) or not registered (™)

trademarks of the owner listed in the table. We forgo the labeling (e.g. using the

symbols ® and ™) of trademarks for the purposes of legibility based on the reference in this section.

Echelon Corporation

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 7

Page 8

1.3.2 Copyright

This document may be duplicated and distributed only with the express permission

of Siemens, and may only be passed on to authorized persons or companies with

the required technical knowledge.

1.3.3 Quality assurance

These documents were prepared with great care.

• The contents of all documents are checked at regular intervals.

• All necessary corrections are included in subsequent versions.

• Documents are automatically amended as a consequence of modifications and

corrections to the products described.

Please make sure that you are aware of the latest document revision date.

If you find any lack of clarity while using this document, or if you have any criticisms

or suggestions, please contact the product manager in your nearest branch office.

Addresses for Siemens RCs are available at www.siemens.com/sbt.

1.3.4 Document use / request to the reader

Before using our products, it is important that you read the documents supplied

with or ordered at the same time as the products (equipment, applications, tools

etc.) carefully and in full.

We assume that persons using our products and documents are authorized and

properly trained and have the requisite technical knowledge to use our products as

intended.

Additional information on products and applications is available:

• On the intranet (for Siemens employees only) at

https://workspace.sbt.siemens.com/content/00001123/default.aspx

• At your

next Siemens branch office www.siemens.com/sbt or at your system

suppliers.

• From the support team in the headquarters fieldsupport-

zug.ch.sbt@siemens.com if no local POC is available.

Siemens assumes no liability to the extent allowed under the law for any losses

resulting from a failure to comply with the aforementioned points or for the improper

compliance of the same.

Page 8

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 9

2 Philosophy of air handling units

2.1 Overview

Climatix OEM controller

product range

Climatix 6xx controller

product range

With the Climatic controller product range for OEM, Siemens is supporting the

trend within the industry to integrate applications for air conditioning and refrigeration technology into the devices at the factory and to lower in this way the costs of

plant installation and commissioning.

The Climatix product range covers all application segments: From standard controllers for simple, cost-optimized HVAC applications such as fan coils to more challenging, communicating applications, up to and including freely programmable

controllers for complex solutions using AHU or chillers that demand a maximum

amount of flexibility for communications and extensions.

All Climatix POL6xx controllers are freely programmable and can be programmed

accordingly for the corresponding use such as ventilation, refrigeration or district

heating.

Various standard applications were created to help OEM customers speed up timeto-market and benefit from our application knowledge and experience in integrating

into the building automation and control system.

The applications are based on years of experience in the corresponding application

segments, are checked and tested and equipped with the required communication

interfaces such as BACnet, LON and Modbus.

The standardization in turn significantly lowers costs at OEM, reduces support expenses as well and guarantees integration into Siemens building automation and

control systems.

2.2 Properties

Climatix standard AHU

application

The application includes all standard as well as special ventilation functions which

can be selected for the OEM and defined using the operator unit (HMI).

The OEM loads the generated parameter file at the end of line test so that the

AHUs are ready to install.

Authorized personnel are also able to enable additional functions in the field to

make it possible to add any desired extensions.

The AHU standard application stands out with its flexible hardware and software,

but also thanks to the standardization of integration.

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 9

Page 10

Use with other components

2.3 Safety

All equipment that is connected to the system must be CE marked and comply with

the Machine Safety Directive.

2.3.1 Requirements regarding personnel for installation and

start-up

Installation and start-up of POL 63X may only be carried out by qualified personnel

who have relevant technical expertise and who are well acquainted with all the

safety and installation regulations.

2.3.2 Safety regulations

The following safety regulations do not relate solely to POL 63X but also to the

regulator’s surroundings (e.g. control panel) and the technical plant in the property.

Observe all safety directions and comply with the corresponding general safety

regulations in order to prevent personal injury and damage to property.

• Safety devices may not be removed, bypassed or taken out of operation.

• Apparatus and system components may only be used in a technically fault-free

state. Faults that can affect safety must be rectified immediately.

• Observe the required safety instructions against excessively high contact

voltages.

• The plant may not be in operation if the standard safety devices are out of

operation or if their effects are influenced in some other way.

• All handling that affects the prescribed disconnection of the protective extra-low

voltage (AC 24 V) must be avoided.

• Disconnect the supply voltage before opening the apparatus cabinet. Never

work when the power is on!

• Avoid electromagnetic and other interference voltages in signal and connection

cables.

• Assembly and installation of system and plant components may only be

performed in accordance with corresponding installation instructions and

instructions for use.

• The following equipment must be protected against static charging: electronic

components, open printed circuit boards, freely accessible connectors and

apparatus components that are connected with the internal connection.

In this context, also observe necessary protective measures such as earthing,

potential equalisation, conducting surfaces (avoid highly insulating materials), etc.

Page 10

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 11

Packing

Transportation

Storage

Cleaning

Faults

2.4 Packing, transport and storage

The required packing of the system for storage and transport is dependent on the

mechanical and climate conditions.

Use the original packaging from Siemens or from the supplier when mechanical

and climate conditions have an impact on transport.

During transport under particularly difficult conditions, a special package must be used.

If the equipment is not to be installed immediately, store it in a well ventilated area,

protected against high temperatures, humidity, dust and metal particles.

• For storage and transport, the limit values specified in data sheet CE2Q3226

always apply.

Contact your supplier or Siemens in the event of any uncertainty.

• Damage that arises as a result of incorrect packing, storage or transport is not

the responsibility of Siemens.

2.5 Maintenance and service

All that is required to maintain POL63x is regular cleaning. System components

that are arranged within the control panel are most easily separated from dust and

dirt in conjunction with the prescribed maintenance checks.

Diagnostics, the rectifying of faults and restarting may only be carried out by

authorised staff. This also applies to work within the control panel (e.g. inspections,

replacing fuses).

In the event of unauthorised interventions, Siemens cannot undertake to honour

any guarantees. The responsibility for any damage that occurs in the system and

any consequential damage rests with whoever caused the damage.

2.6 Environmental protection and waste

Environmental

protection

Waste management

management

Process unit POL 63X has no negative impact on the environment.

The apparatus includes electrical and electronic components and when discarded

must not be handled together with household waste. Always observe local regu-

lations!

2.7 Abbreviations

HMI Human Machine Interface (operating unit)

KP Gain factor (P-effect)

LED Light emitting diode

NC Normally Closed (opening contact)

NO Normally Open (closing contact)

SD Secure device

TN Integral action time (I-time)

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 11

Page 12

3 Function overview

3.1 General

Scope of delivery

Control functions

Implemented communications

Remote o

vice

peration, ser-

• 49 inputs and outputs are available on the base controller POL63x and a maximum of 2 POL955.00/ALG extension modules.

• All functions and the positioning of I/Os are freely configurable on the operator

unit without programming.

• Sensor types (Pt1000, LGNi1000, Ni1000, NTC10k) and the areas for active

sensors are freely selectable.

• Step-by-step configuration. Functions that can no longer be selected are automatically hidden in later steps.

• Disabled functions are hidden on operator units (HMI; HMI4Web) and for comm.

• Support of various languages (currently English, German and Swedish).

• The operating units are password protected and connected over the bus. A sin-

gle HMI possible for multiple controllers.

• Application software update and controller firmware with backup of plant parameters using the SD card.

• Download preconfigured plants using SD cards or a PC with the Saphir Scope

Tool.

• USB interface as the standard connection between the controller and PC.

• Supply air, room and return air and cascade control with optional limitation of

supply air.

• Summer/winter compensation of setpoint.

• External setpoint default or setpoint shift.

• Night start of plant when room temperature with separate setpoint is too low (too

high).

• 4 different heat recovery variants.

• 4 heating registers (2 warm water, 2 electric registers with up to 3 steps, or 0-

10V DC) with up to 3 included in the heating sequence.

• Limitation of electric register dependent on fan speed (stage).

• Preheating for the warm water register, including frost sensor and/or detector.

• 2 cooling registers (cold water or up to 3 stages or analog DX).

• Limitation of direct expansion evaporator dependent on fan speed (stage).

• Shut off cooling register when the outside air temperature is too low.

• Cooling recovery.

• Fresh air and exhaust air damper control.

• Fire damper control with autotest function.

• Extract air fan can be disabled.

• Stepped (maximum 3 steps), frequency controlled or modulating analog controll-

ed fans.

• Emergency off function.

• Time switch catalog with daily, weekly and annual program.

• Modbus RTU or TCP (master, Energy Meter EM24 from Carlo Gavazzi).

• Modbus RTU or TCP (Slave).

• BACnet IP and MSTP.

• LON.

• OPC via TCP/IP or modem.

• Web HMI. (for POL 638.xx only) automatically configured when configuring the

plant.

• Saphir Scope Tool via modem, TCP/IP or LON.

• Alarm messages per e-mail or SMS (GSM modem required).

Page 12

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 13

Legend

Heat recovery

3.2 Diagram standard AHU

The figure displays a schematic of the entire functional scope for the standard AHU

application. All aggregates, sensors and functions are selected and configured

when configuring the air handling unit.

− Fire detector

− Time switch program

− Free temperature sensor

− Free alarm display

− Display of certain operating modes

− Occupancy button

− Setpoint settings

− Emergency button

− Acknowledge alarm

− Alarm display

Heat recovery can be implemented in the following ways:

– Rotary heat exchanger.

– Plate heat exchanger.

– Water heat exchanger.

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 13

Page 14

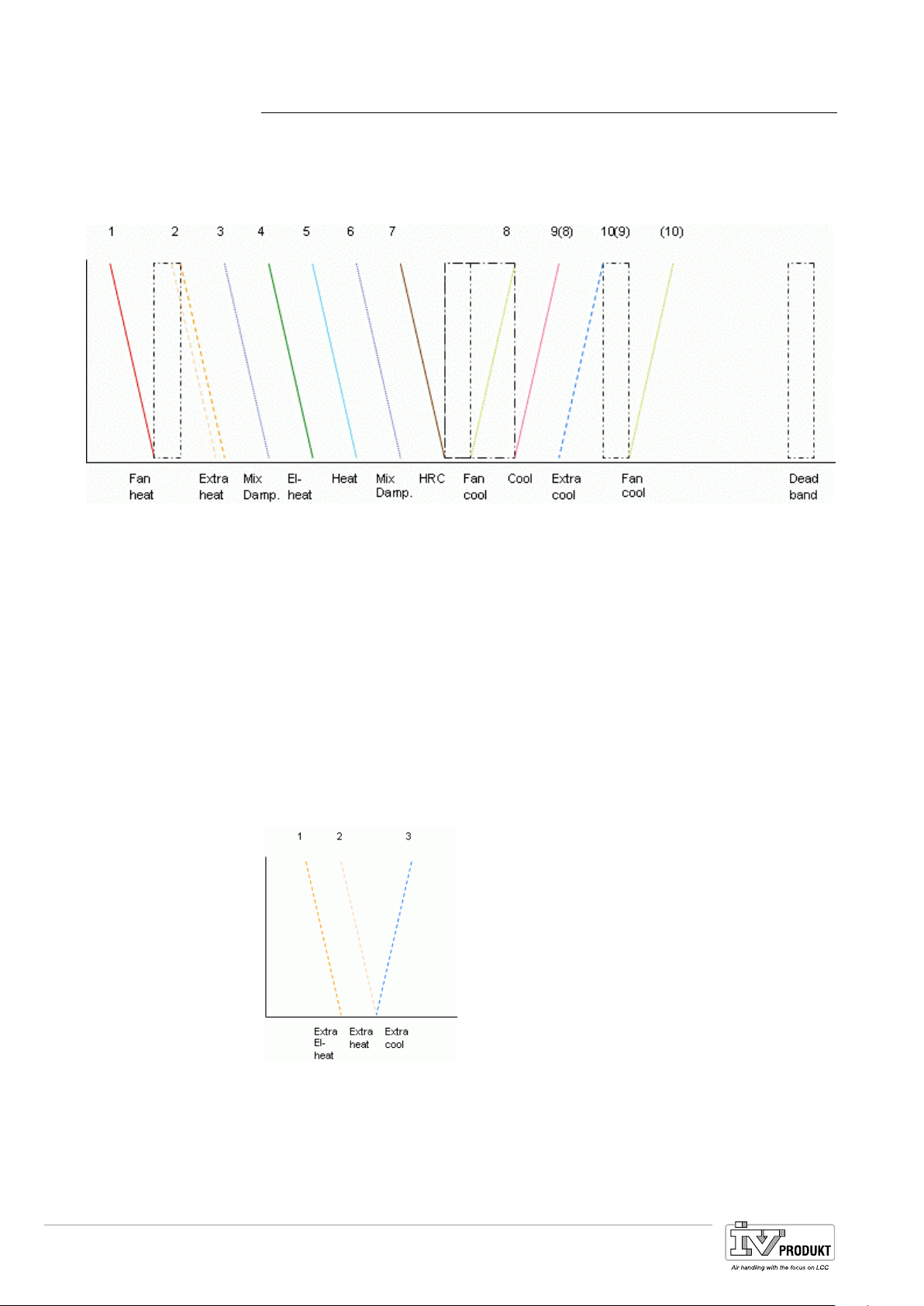

3.3 Workflow diagram

With all aggregates

Legend

Stand alone

• Mixing dampers have changeable placement.

• Fan cooling have changeable placement.

• Deadband between heating and cooling can be changed.

• Fanheat and Fancool have their own changeable deadband.

The figure displays a schematic of all possible sequences included in the application. Individual sequences and series are set automatically during configuration or

for sequence 3, 6 mix damper and 8, 9 fan cool, cooling by configuring the sequence.

1 Fan heating 7 Heat recovery

2 Heating 2 or Electro heating 2 8 Fan cooling

3 Mixing dampers 9 (8) Cooling

4 Electro Heating 10(9) Cooling 2

5 Heating (10) Fan cooling

6 Mixing dampers DB Dead band

Extra sequences can be placed in the normal sequence (above) or as an own

sequence (stand alone):

Legend

Page 14

1 Electro Heating 2

2 Heating 2

3 Cooling 2

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 15

4 Hardware overview

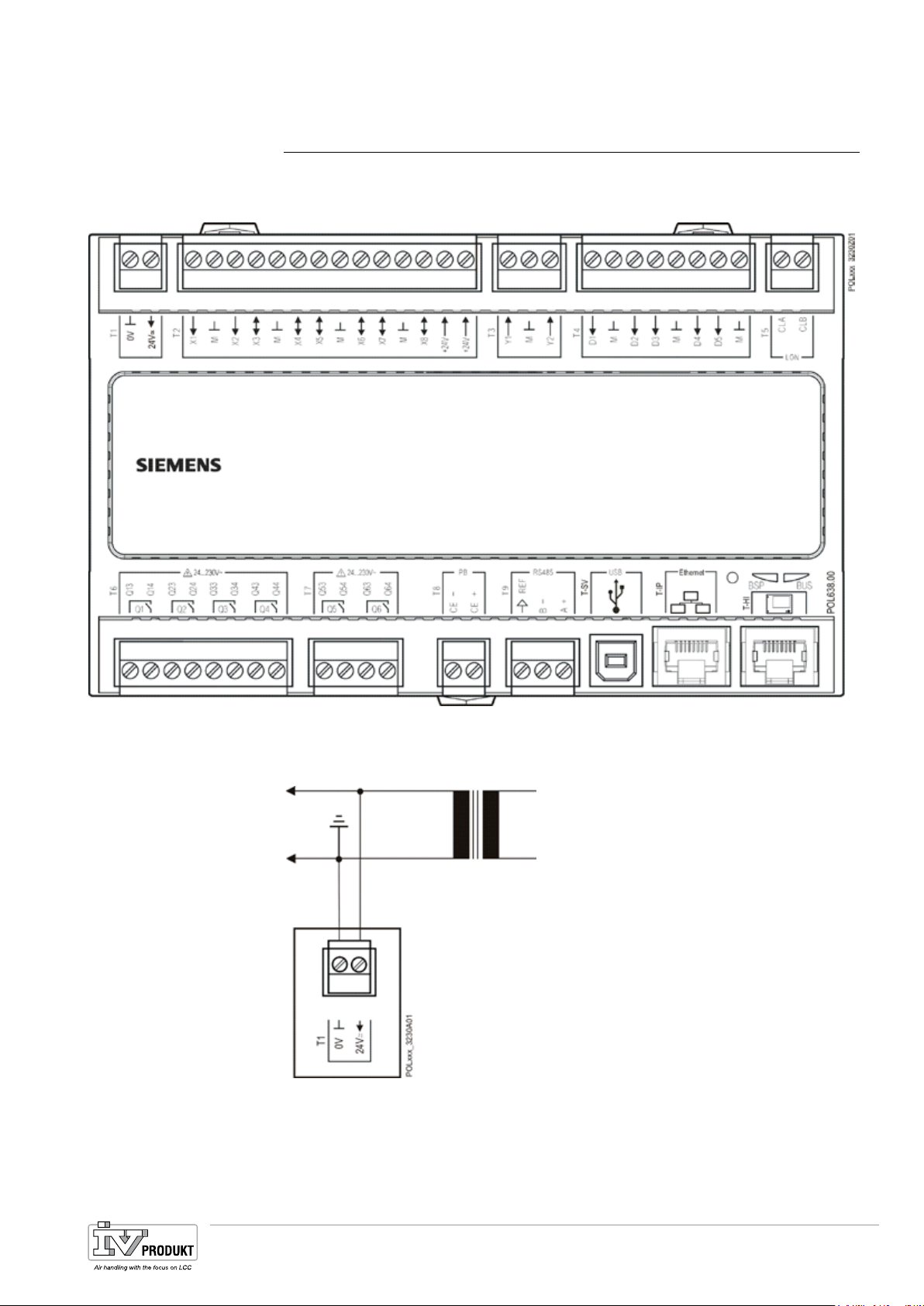

4.1 Basic controller (POL638x)

The exact designation of inputs / outputs in the program or HMI is available in the

point table in the appendix.

Connection instruction

Power supply

Digital inputs

To connect external components to the process unit, these instructions must be

followed.

X1...X8

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 15

Page 16

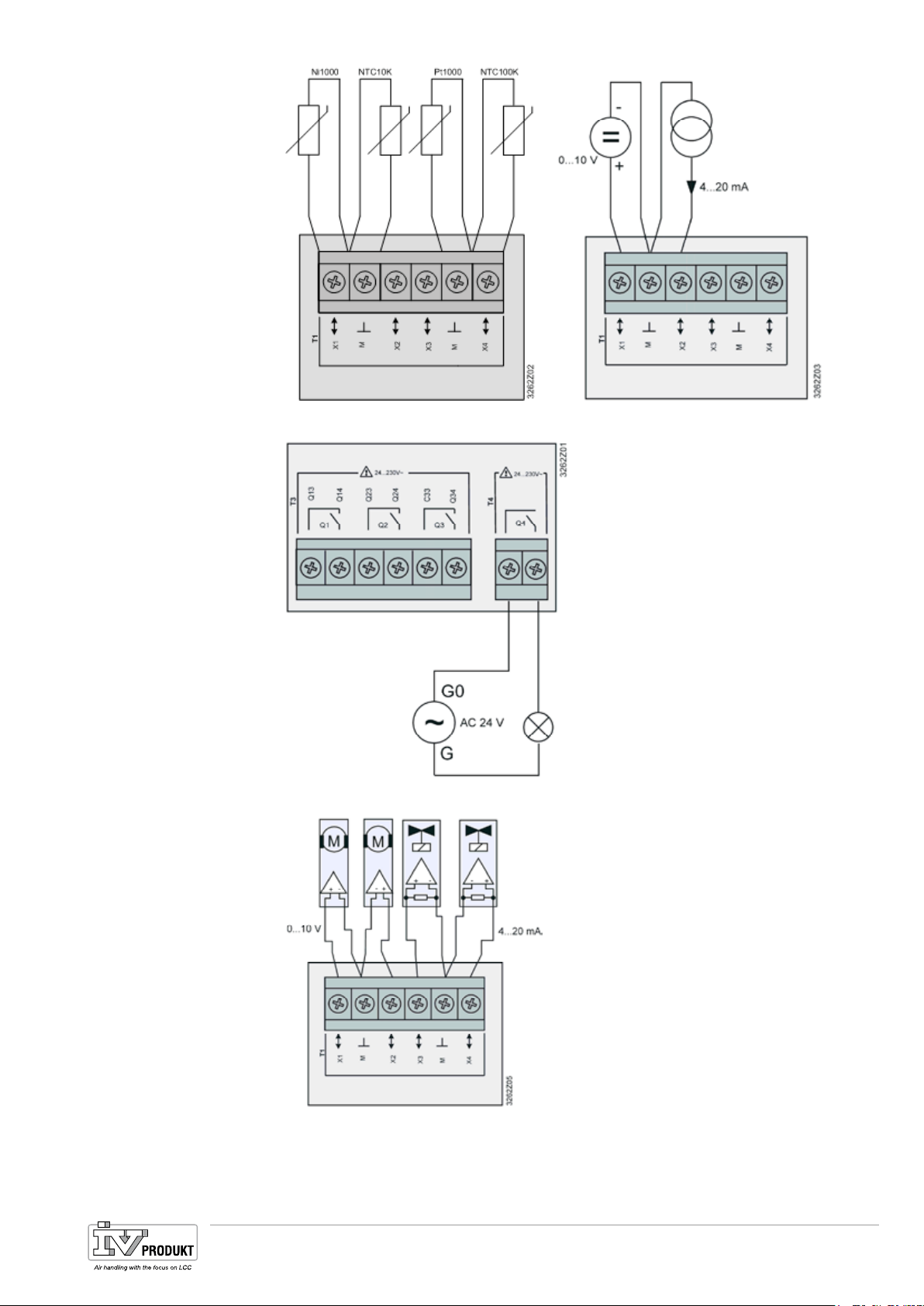

Analog inputs

Analog outputs

X1...X8

X3...X8

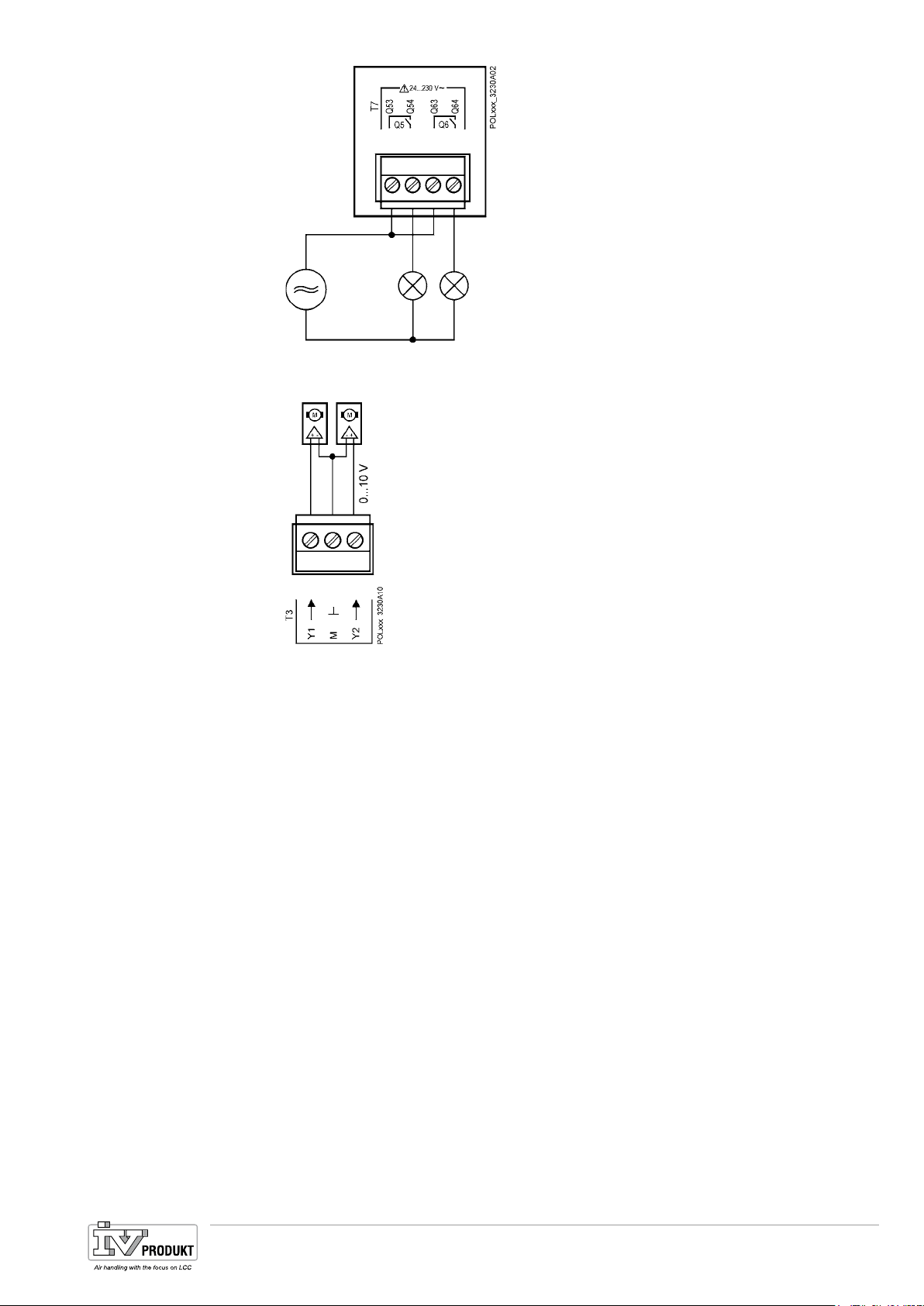

Relay outputs

Page 16

Q1...Q6

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 17

Analog outputs

Y1, Y2

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 17

Page 18

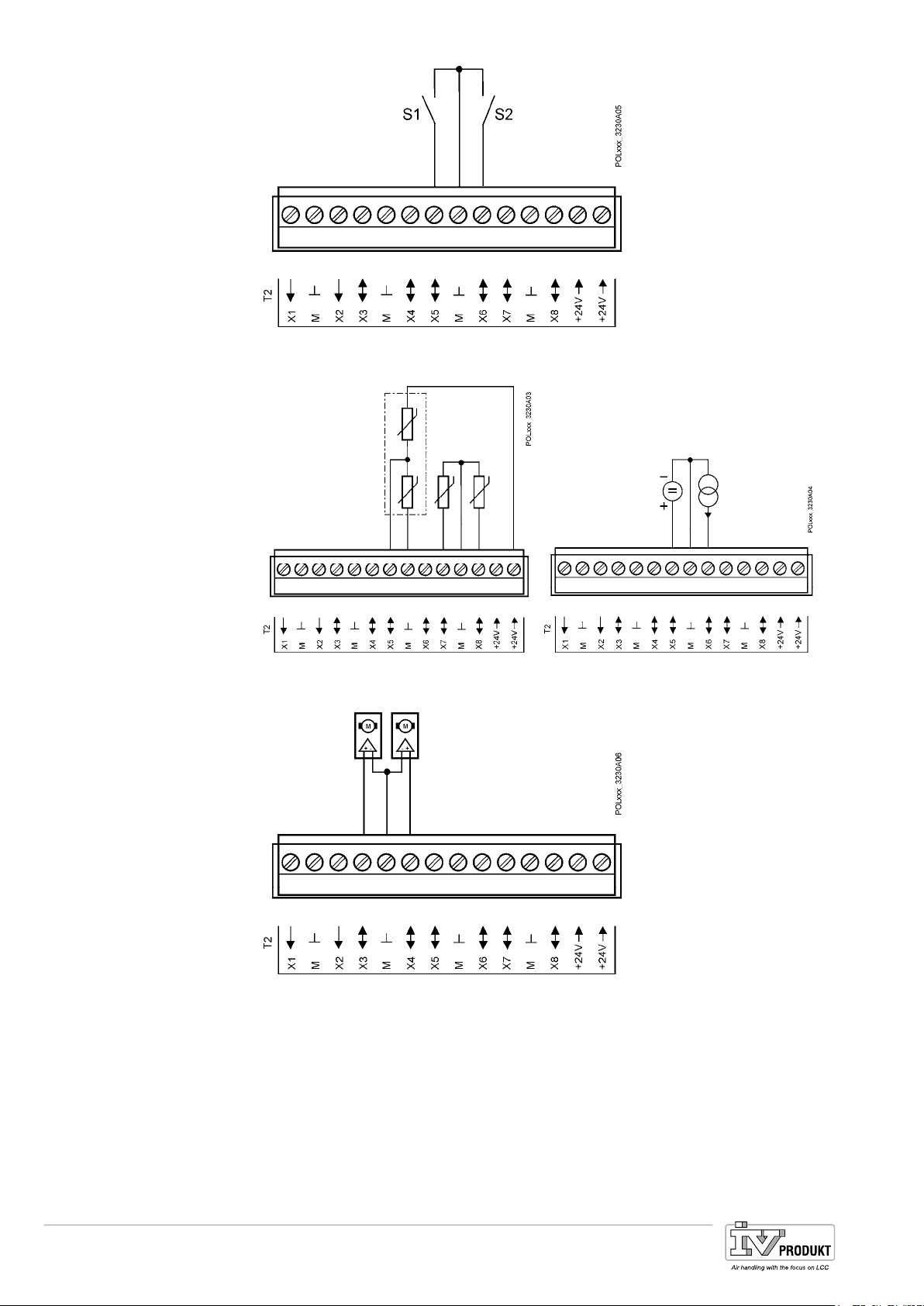

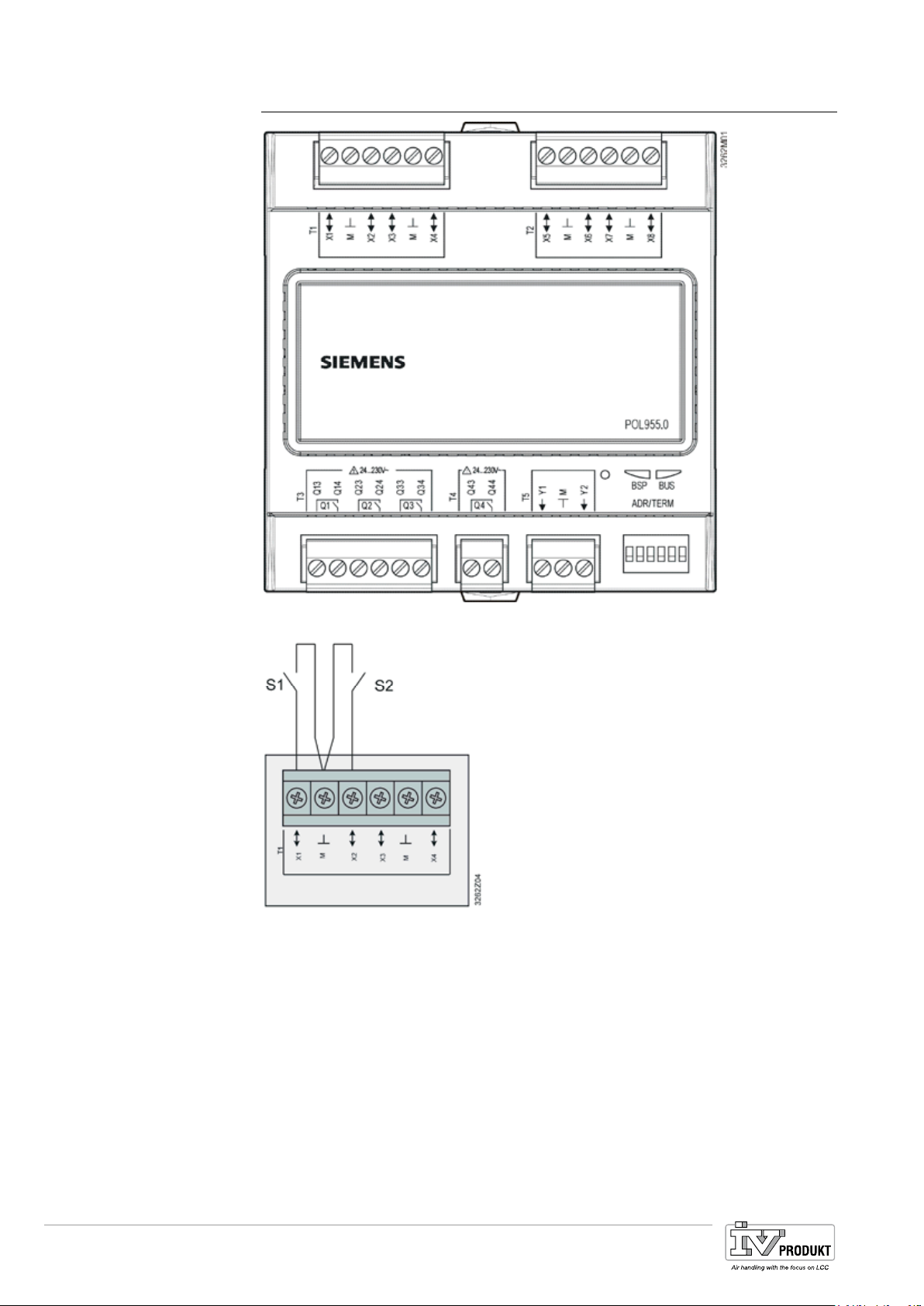

4.2 Extension module (POL955)

Digital inputs

Analog inputs

X1...X8

X1...X8

Page 18

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 19

Relay outputs

Analog outputs

Q1...Q4

X1...X8

Analog outputs

Y1...Y2

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 19

Page 20

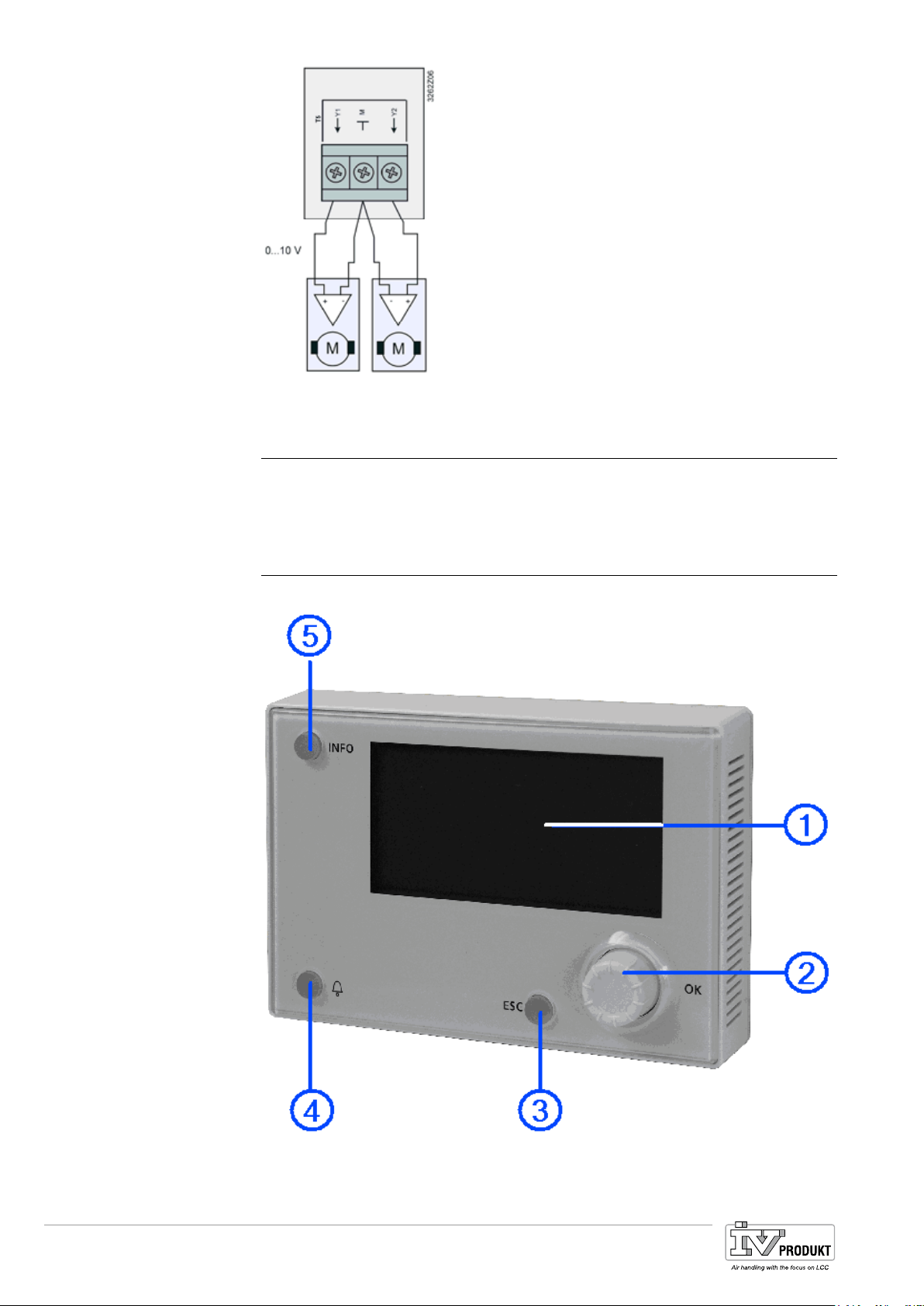

4.3 Inbuild HMI

Implemented at a later date.

4.4 External HMI (DM)

Operator elements

The external operator unit includes the following operating elements:

Page 20

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 21

Additional information

1. Display

Displays menus, parameters, parameter values, commands, etc.

2. Setting know

• Select menu, parameters, parameter values: Turn.

• Change parameter values: Turn.

• Go to lower levels or to setting pages: Press.

• Exit setting pages and assume changed values: Press.

• Go to password handling page: Press long.

3. ESC button

• Go to the next higher level: Press.

• Exit setting pages and reject changed values: Press.

• Go to start page: Press long.

• Go back to last active page (after going to password handling page using

the setting knob): Press.

• Go back to last active page (after going to Main Index page using the Info

button): Press.

4. Alarm button

LED:

• Off: No alarm.

• Blinking: Alarm pending.

• Lit continuously: Pending acknowledged alarm.

Press button:

• Go to last alarm.

• Go to alarm list (displays pending alarms and alarm history).

• Go to alarm history.

• Go to alarm settings.

• Acknowledge and reset alarms in the alarm list or alarm history.

For more information, refer to section

19

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 21

Page 22

Alarming. page 222.

5. Info but

ton

• Go to Main Index page: Press.

• Go to HMI basis page: Press long.

Page 22

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 23

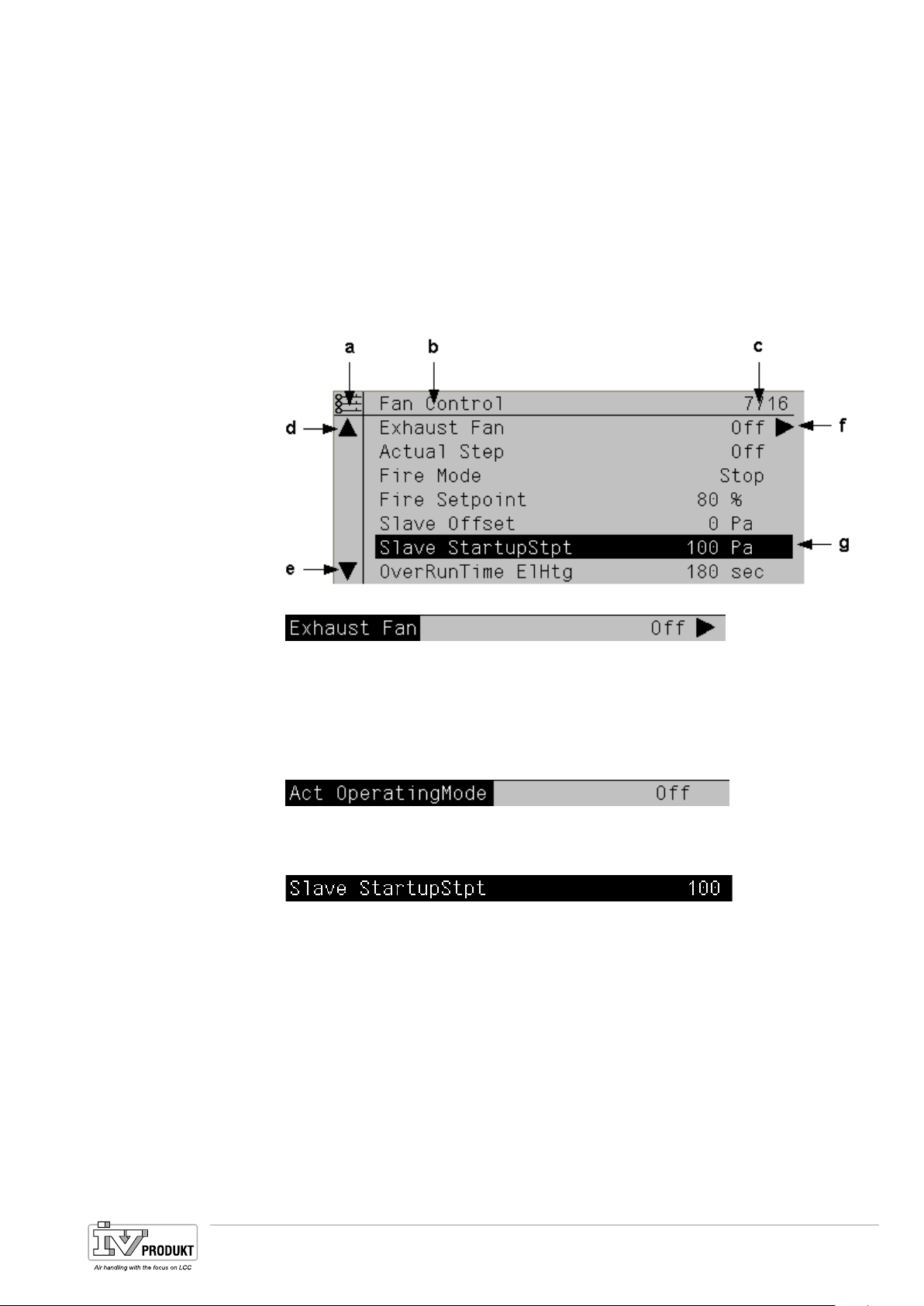

Display

Display design:

a Present access levels:

- No symbol: No Level

- 1st key: Level 6

- 2nd key: Level 4

- 3rd key: Level 2.

b Title of displayed pages.

c 7: Number of selected lines; 16: Number of available lines for the page.

d Page includes additional lines above ---> You can scroll up.

e Page includes additional lines below ---> You can scroll down.

f Another level is located below this line. You can go to it.

g Currently selected line.

Navigation lines

Display line

Setting lines

Set discrete parameter

values.

On navigation lines, the object is highlighted in black when selected. It displays the

present value for a component in front of the navigation arrow.

Navigation:

• Select line: Turn setting knob.

• Switch to level below: Press setting knob.

The object is also highlighted in black when selected for display lines (read only). It

displays the present value for a component.

The parameter name and its present value are highlighted in black for the parameter setting lines.

Set value:

• Select line: Turn setting knob.

• To switch setting page: Press setting knob.

• Set the parameter value on the setting page: Turn setting knob.

• Exit setting page and assume changed parameter values: Press setting knob.

• Exit setting page without saving parameter values: Press ESC.

When only one value is selectable:

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 23

Page 24

Set analog parameter

values.

The checked off line (Fire Setpoint) displays the presently set value. Changed as

follows:

• Select new value: Turn setting knob.

• Assume new value (and exit setting page): Press setting knob.

or

• Retain old value (and exit setting page): Press ESC button.

When multiple values can be selected:

Checked off lines display presently selected values. Changed as follows:

• Select a value: Turn setting knob.

• Select/deselect value: Press setting knob.

• Assume new selection:

– Select Done: Turn setting knob.

– Select Done: Press setting knob.

or

• Retain old value (and exit setting page): Press ESC button.

Page 24

The scale displays minimum and maximum adjustable values.

Present value changed as follows:

• Adjust number under the arrow

• Move arrow to the left: Turn continuously via a increments of ten

(9--->0 or 0--->9).

• Move arrow to right: Do not turn for about 1 second.

• Assume new value (and exit setting page): Press setting knob.

or

• Retain old value (and exit setting page): Press ESC button.

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

: Turn setting knob.

Page 25

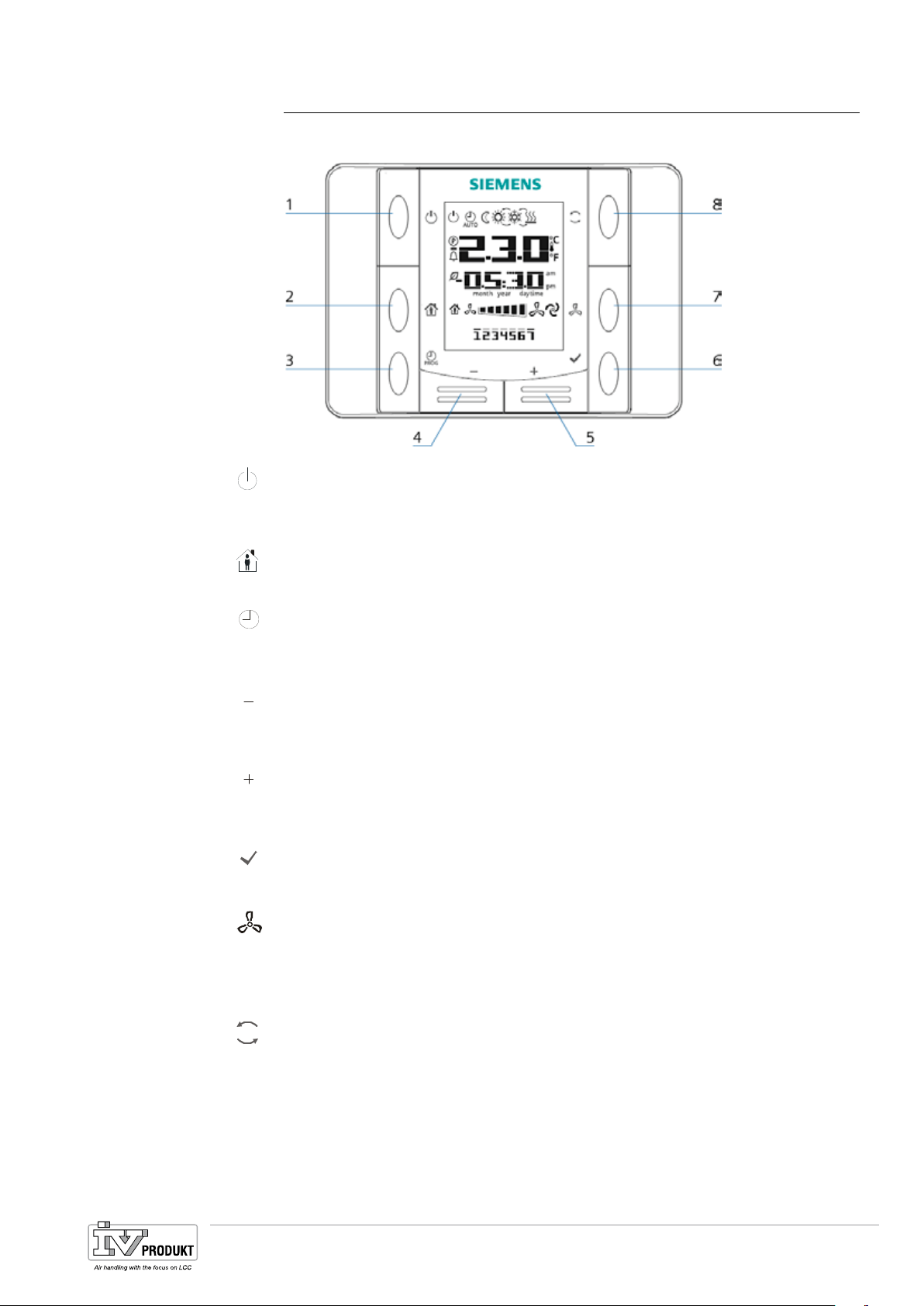

4.5 Room unit

Operating elements

P R OG

The room unit has the following operating elements:

6. (1) On/Off

• Button to changeover from OFF to ON state. Buttons 2-8 are locked and

the display is switched off in the OFF state.

7. (2) Occupancy

• Button to switch on/off a programmed occupancy mode

8. (3) Program

• Long press: Set date and time on the room unit.

• Short press: Change the scheduler program.

9. (4) Minus

• Button to adjust the temperature setpoint. Each push of the button lowers

the temperature setpoint by 0.1 °C/1.0 F or by 0.5 °C/1.0 °F.

10. (5) Plus

• Button to adjust the temperature setpoint. Each push of the button increases the temperature setpoint by 0.1 °C/1.0 F or by 0.5 °C/1.0 °F.

11. (6) OK

• Key to confirm date/time and scheduler program entries.

12. (7) Fan

• Button to adjust plant stage.

Press: The speed is increased by one stage each time you press the button.

13. (8) Mode

It is cyclical: 1-2-3-Auto-1-2-3-Auto, etc.

• Button to select between a maximum of three energy modes: Auto, comfort

and economy.

Press: The mode changes each time you press the button and displayed

with the corresponding symbol.

It is cyclical: Auto – Comfort – Economy – Auto, etc.

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 25

Page 26

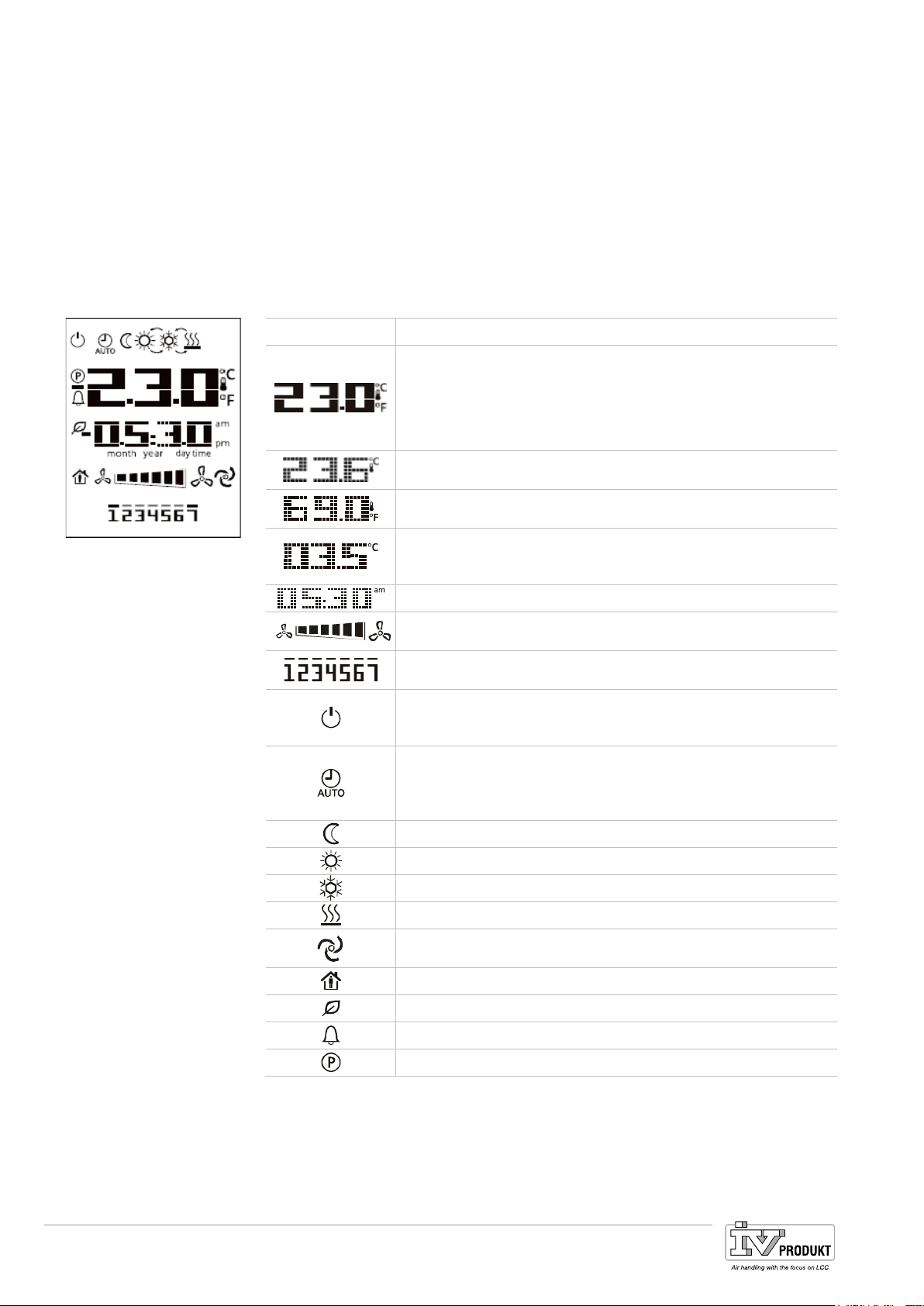

Display

The display shows:

• Selected temperature display

– exhaust temperature, or

– the given room device temperature, or

– mixed room temperature

• Setpoint shift

• Energy mode

• Plant stage

• Time

• Day of the week

The table below displays and explains all the symbols available on the display.

Display

Meaning

Temperature display range

Displays exhaust temperature for the given room device

temperature or the mixed room temperature in °C or °F.

Temperature in °C

Resolution 0.1 °C

Temperature in °F

Resolution 1.0 °F

Setpoint shift

Can be displayed/changed to °C or to °F

Resolution 0.1°C/1.0F or 0.5°C/1.0F

Time

Plant stage

Day of week display (POL822.60/xxx only)

1=Monday

ON/OFF

The device does not fully shut down with OFF, but rather

goes to standby.

Auto mode active

The controller overrides the room device when the symbol

blinks (see 5.2.2 Prioritization operating modes...)

Buttons 1, 2, 5 and 8 are locked.

Economy mode active

Comfort mode active

Cooling

Heating

Automatic plant control

Occupancy mode

Energy tracking

Alarm display

Parameter mode

Page 26

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 27

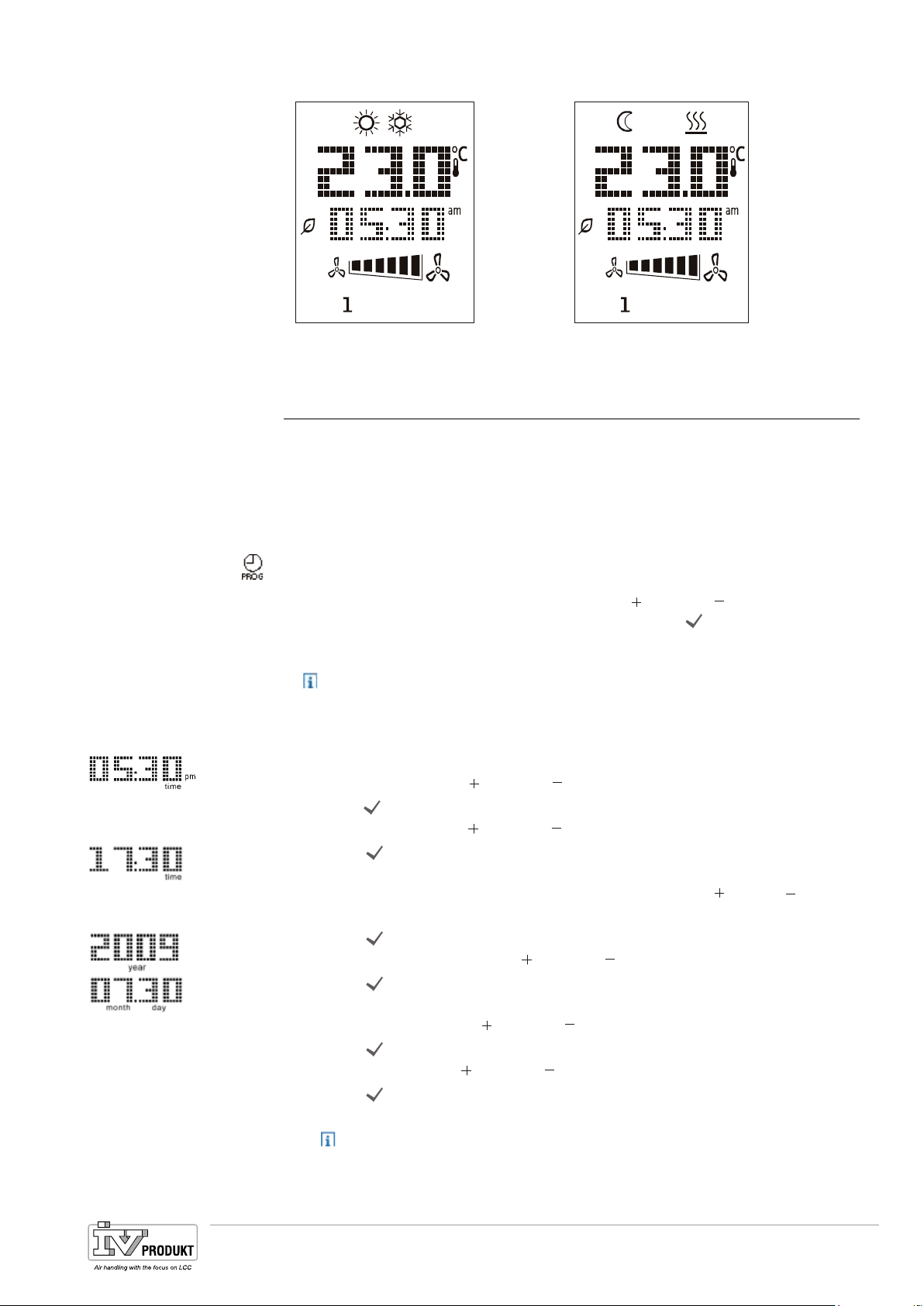

Sample displays

Date and time

Comfort mode, cooling Economy mode, heating

4.5.1 Startup behavior

The room unit initializes automatically after the room unit is connected to the controller and the communication is operating (commissioning is completed). First, all

the symbols appear, then the symbol

returns to normal after a short period. The displays state on P__ if communication

is not properly established (e.g. incorrect room unit address).

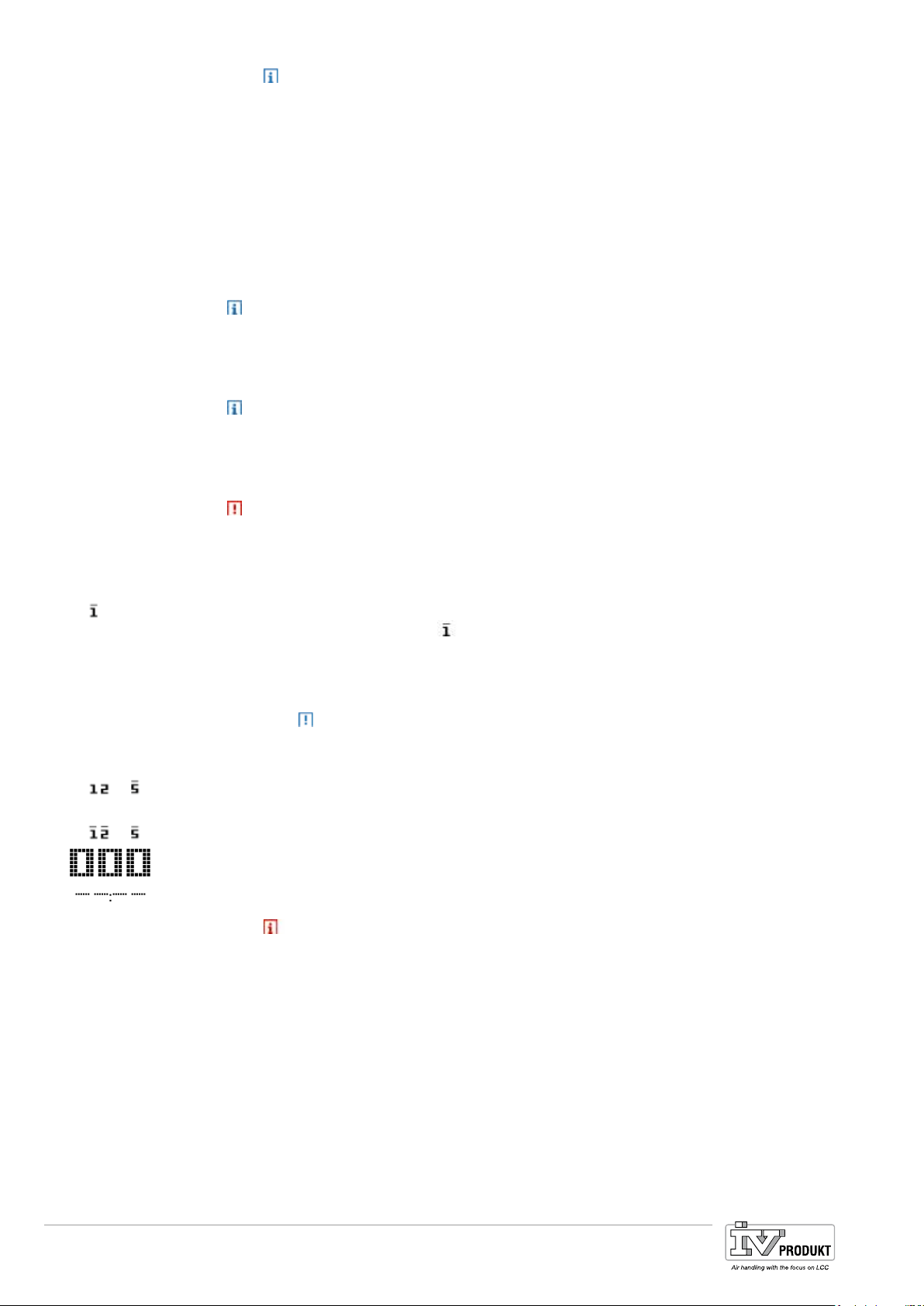

User presses the PROG button long (more than 1 second) to enter data and time.

The following applies:

• Flashing parameters can be changed using the

• Changes can (and must) be completed by pressing the

play automatically goes to the next adjustable parameter.

Please note: This is cyclical. The clock blinks again after changing and con-

firming the month and day. You can exit the menu at this point by pressing

the PROG button.

1. Press PROG button long (hour display blinks), then

set the hour with the

2. Taste

set minutes with the

Press OK (the hour is saved and the minute display flashes), then

3. Press

OK button (minutes are saved and the entire time display flashes),

plus and minus buttons.

plus and minus.

then

set the time display format (12/24 hour display; use the

buttons)

4. Press

set the desired year with the

5. Press

OK (the display format is saved and the year display flashes), and

OK (the year is saved and the display shows the month/day display,

the month display blinks), and

set the month with the

6. Press

set the day with the

7. Press

OK (the month and saved and the day display flashes), and

OK (month and day is saved; display returns to the time).

plus and minus buttons.

plus and minus buttons.

8. Press PROG (the display returns to normal).

The display returns automatically to normal when the PROG is not pressed

within one minute.

appears on the display. The display

P__

plus and minus buttons.

OK button. The dis-

plus or minus

plus and minus buttons.

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 27

Page 28

Scheduler function

Program time switch

catalog

Select days of the week

Please note: The room unit does not have an internal clock. The precise time is

periodically synchronized with the controller (master).

The weekly and daily schedule for the time switch catalog (so-called "scheduler")

can be programmed:

• for all 7 days of the week.

• Daily with up to 6 switching entries (referred to as "Entry")

You can do the following when setting up the entries

• determine a switching time and

• select the state to be run in Auto mode.

Possible state assignments (e.g. 0=Off, 1=EcoSt1, 2=ComfSt1, etc.) are predefined as part of the controller configuration. A max. 7 states are possible.

The selected operation is automatically run at the defined time after the entry is

setup.

The following button assignments are enabled when programming the scheduler:

• PROG —> Cancel.

• OK. —> Confirm.

The workflow includes explanations of the individual steps from a technical viewpoint. As a practical matter, individual steps may not be needed, while others must

be repeated, etc. As a result, we are listing an example in this section that illustrates a practical example on programming a room unit.

1. Press PROG

(the display goes to

display through the days of the week).

and flashes; Press plus or minus to quickly cycles the

2. Select weekday with plus and minus (1=Monday), then confirm selection

with OK.

Note: The same settings apply to the selected days. You must proceed

through the entire instruction chain to program different settings for certain

days.

3. Conduct weekdays through day 7 as per step 2.

4. 1 time (!) press the plus button.

You now see the selected days; a flashing bar appears above the numbers.

5. Confirm selected weekdays: 1 time (!) press OK.

The display changes to the first entry page, the state is "00X", time is 00:00

:Do not change the time for this entry!

Three entries per day are prepared and may vary depending on the configured

plant, e.g. State 001 at 00:00 am, state 002 at 08:00 am, state 001 at 6:00 pm. The

entries do not need to be entered in chronological order.

The following illustrates how to create a new (the fourth) entry.

Page 28

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 29

Change schedule

and/or state

Add schedules

Delete schedule

Hints

6. Press plus or minus to select the entry to be changed; click OK to confirm.

Entry is selected, hour display flashes.

7. Set hours to "XX" with plus or minus, then

Press OK.

The minute display flashes.

8. Set minutes to "XX" with plus or minus, then

Press OK.

The state display flashes.

9. Set command to "X" with plus or minus, then

Press OK.

Entry display is static.

10. If other entries required: Repeat steps 6 to 9; you must enter a status each

time.

11. After the final entry: Press OK (status line is idle), then

Finish programming with PROG.

12. Press plus to select entry "Status 000 —:— ", then

Press OK,

the hour display flashes

Then start over at step 7 above.

13. Press plus or minus to select the entry for deletion; click OK to confirm.

Entry is selected, hour display flashes.

14. Disable entry by setting the hour to —:X X,

with X X = any number available in the minute display.

Then press OK

the entry display changes to 000 and —:—

15. If no other changes required:

After the final entry: Press OK (status line is idle), then

Finish programming with PROG.

Up to 7 states can be programmed depending on configuration. They can be assigned, for example, as follows:

Hints

Access levels

Example 1 Example

2

0 = OFF 4 = ComfSt2 0 = OFF

1 = EcoSt1 5 = EcoSt3 1 = Stage 1

2 = ComfSt1 6 = ComfSt3 2 = Stage 2

3 = EcoSt2

Press PROG at any time to return to a previous page when programming the

scheduler.

The room unit returns to normal if no entry is made for longer than 1 minute.

Parameter programming is lost through the last OK, if you return to the normal

page. The same applies when no entries are made on the room unit for more than

1 minute.

4.5.2 Parameters

The room unit distinguishes between 3 access levels:

• Level 6 End users (password 1000).

• Level 4 Service operator (password 2000).

• Level 2 OEM (password 6000).

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 29

Page 30

Group and overall lists

Hints

Parameter mode

Room unit parameter list

The parameters are compiled into three groups.

All available values in the parameter lists affect the application (see

Parameter list room unit , page 239).

includes...

20.4 –

Group

…

Room

S

settings and acknowledge (change be changed depending on the

password).

The most important present values (read only).

U

The main setpoints (may be changed depending on the password).

C

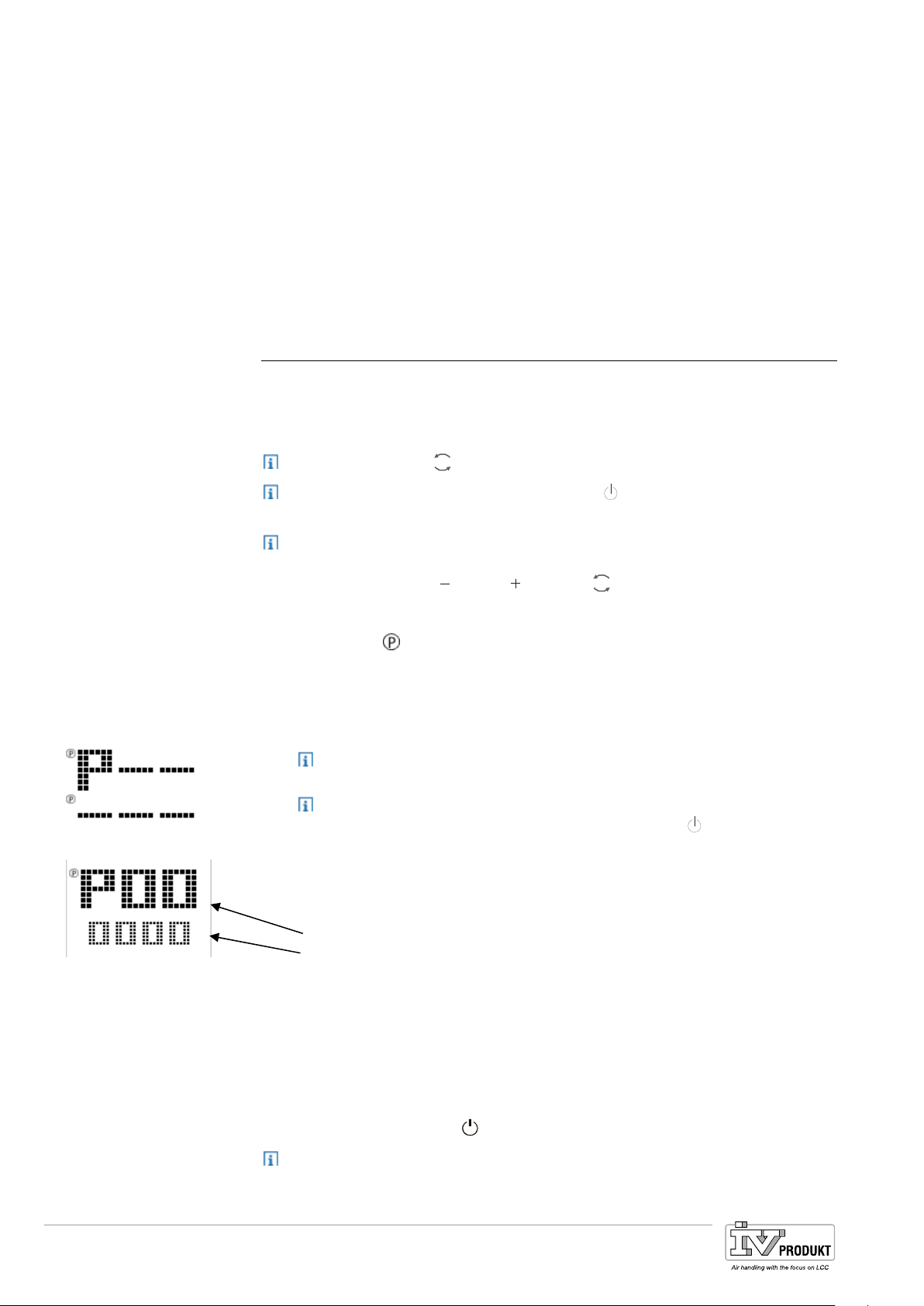

4.5.3 Edit function parameters (parameterization mode)

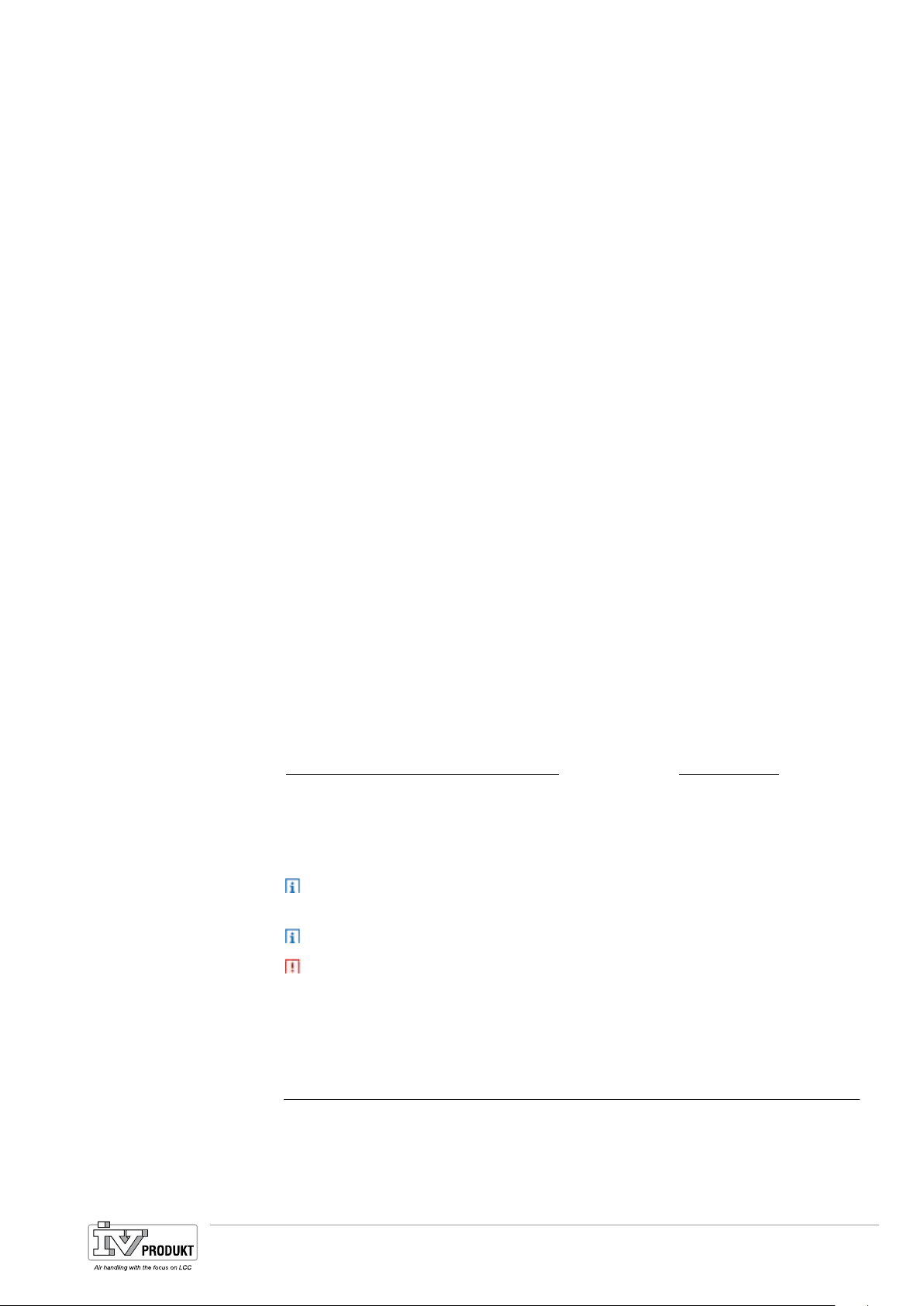

The function parameters available in the room unit are edited in parameter mode.

The appropriate password required to access it. The following descriptions are

therefore directed in the main toward service personnel.

Use the mode button

In the parameter mode, use the On/Off button to cancel or generally go back

to the previous page.

The room unit returns to normal if no entry is made for longer than 1 minute.

1. Simultaneous press

goes to password entry pages for parameter mode, the first position for the

password flashes.

The symbol

parameter is displayed.

2. Press plus or minus for the first position of the password, then

press Mode.

The first position is saved, the second flashes.

3. Repeat step 2 for the other positions.

After the correct password, after entering the final position, a parameter

group (A, C, S) must be selected on a new page.

For an false password or missing group name, the error message to the

side appears and the first position flashes. Press On/Off

enter the password.

4. Select a group with plus or minus, then press Mode to confirm.

The following is displayed. The following applies:

• Letter = Parameter group.

• Upper line = Parameter-ID.

• Lower line = Parameter value.

5. Press plus or minus to select parameter ID and then press Mode to set the

parameter value.

For RW (read/write) access, the parameter value flashes and can be edited;

the parameter ID line continues to flash for lower rights.

6. Use plus or minus to set parameter value, then

press Mode to confirm.

The insert mark returns to the parameter ID line.

7. Press parameter mode

The room unit parameter list includes all room unit parameters that can be

read/described (see

20.4 – page 239).

to confirm an entry.

minus, plus and mode.

On/Off to exit.

to cancel and re-

Page 30

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 31

Diagnostic mode

Room device parameters

4.5.4 Edit room unit parameters (diagnostic mode)

Room unit parameters for the room unit are edited in diagnostic mode. They impact

only the room unit where the setting is entered and saved. The following descriptions are therefore directed exclusively toward service personnel.

Use the mode button

Use the On/Off button to cancel or generally go back to the previous page.

The room unit returns to normal if no entry is made for longer than 1 minute.

The following local parameters can be viewed/edited in diagnostics mode.

1. Simultaneously press

The display goes to the first diagnostic pages; the following is displayed

• Software version (3 digit) and

• Build number (4 digit).

2. Press

mode.

The display goes to the parameter 1 KNX connectivity (RO)

(parameter overview: see following table)

This parameter cannot be changed (display only).

3. Select additional parameters (0…9) with

Proceed as follows to change a parameter:

• Select parameter (

• Press

mode (parameter value flashes).

• Enter new parameter value with

• Press

mode (parameter flashes).

4. As soon as all parameters are (re-)set: Press

appears.

The individual addresses of multiple HMI devices connected to a network can-

not be the same!

No Room unit parameter/description

001 connectivity (RO)

The KNX connectivity page displays

• OK to indicate that the process bus is active

This is the cases if any data frames are received over the past 70 seconds.

• NG if the process bus is not active.

002

003

004

005

individual addresses – Line address (RW) - (X.1.1).

Address range: 0...15 (is generated automatically, see parameter 9).

individual addresses – address range (RW) - (1.X.1).

Address range: 0...15 (is generated automatically, see parameter 9).

individual addresses – device range (RW) - (1.1.X).

Address range: 1...252 (is generated automatically, see parameter 9).

geographic address apartment (RW) - (X.1.1).

Numbering range for apartment: 1...126.

Default value set to 5 (only requires change if multiple controllers are operated with room devices on one bus) see as well Main Index > Integrations >

Room units Settings > Room zone.

to confirm an entry.

on/off, minus, plus and mode.

minus or plus.

minus or plus, parameter flashes).

minus or plus.

on/off until the main page

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 31

Page 32

Alarm display

No Room unit parameter/description

006

geographic address room (1.X.1).

Numbering range for room: 1...14.

007

Default value set to 1.

geographic address sub zone (RW)(1.1.X).

Numbering range for sub zone: 1...15.

This value must be changed from default 1 to 2 for two room units on the

same controller.

008

¨

Network error recognition on/off (RW).

Parameter to turn on/off the network error recognition function, with

0 = off (P__ is displayed when no data frames are received in the last 70

seconds and the function is turned on).

1 = On.

NET flashes, when no data frames are received over the past 70 seconds

and the function is turned on.

Timeout Network error recognition during parameter initialization: 30

seconds.

009 Automatic assignment of individual addresses on/off (RW).

0 = The room unit uses the unit devices as a fixed assigned individual ad-

dress.

1 = Automatic addressing on the process bus

The room unit changes as required (e.g. for address conflict on the

process bus) the individual address via DAA mechanism (Detect And

Avoid mechanism)

Default value 1 = automatic addressing

When the controller sends an alarm to the room unit, the

• Alarm is displayed

• Depending on parameterization, the alarm number, including the grouping, flash-

es, or only the alarm is displayed

A = Alarm switched off,

B = Normal alarm,

C = Warning

Details see

19.6 – Alarm lists and 9.5 – Communication room unit

Page 32

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 33

5 Functions

5.1 Global functions

5.1.1 General

This section describes special functions that related to the application as a whole.

Prerequisites

Parameters

Parameter Range Function

Su-Wi calculation

Manual mode

Enable manual alarm

Enable comm test Function not yet available.

Communication test Function not yet available.

None.

Main Index > Global functions

– Summer

– Winter

– Auto

– Manual

– No

– Yes

Displays present status for summer and winter operation.

Go to page to parameterize summer/winter

changeover.

Displays whether one of the outputs is not in auto

mode (intervention via HMI), a sensor is out of service or the manual operation mode is not on auto.

Go to page with all digital inputs, e.g. to set the

alarm class for enabled manual alarm.

– Auto mode: No element in manual mode or out

of service.

– Manual mode: At least one element is in manual

operation or out of service.

Enables an alarm if when Manual mode = Manual.

– No alarm trigger.

– Alarm trigger.

5.1.2 Summer Winter changeover

Prerequisite

Function

None.

It decides whether the plant is in summer or winter operation based on various options (hardware input, date, temperature). This information is required (as an option) to shut down humidification in summer, to changeover the Combi Coils and to

changeover temperature control (Tmp control mode = RmSplyC Su or RtSplyC Su).

A hardware input enabled for the changeover (Main Index > Configuration > Configuration 1 > Su/Wi input = Yes) has the highest priority (Signal 1 = Summer).

The temperature or date can affect the changeover depending on parameterization. Both criteria must be met when both are enabled. There is no changeover and

the plant in continuously in winter operation when no criterion is enabled.

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 33

Page 34

Parameter

Main Index > Global functions > Su/Wi calculation

Parameter Range Function

State

Su/Wi input

– Winter

– Summer

– Winter

– Summer

Status of Summer/Winter changeover:

– Winter operation is enabled.

– Summer operation is enabled.

Status of input on hardware side for changeover.

Go to page with all digital input settings. For example, you can change the input’s direction of control

there.

– Winter operation enabled: Signal 0.

– Summer operation enabled: Signal 1.

Outs air tmp damped Damped outside air temperature.

Summer date / time *.* *:* Set date and time for changeover to summer op-

eration.

Example:

23:30 01.Apr ---> Changeover on April 1 at 11:30

pm.

– Asterisks only (*.* *:*): Changeover date is not

relevant; changeover occurs based on temperature.

– Permissible time entries:

*:* ---> 00:00

*:20 ---> 00:20

10:* ---> 10:00.

– Date entry:

Allowed: 15.May

Not allowed by month: Odd / Even.

Winter date / time *.* *:* Set date and time for changeover to winter opera-

tion.

Example:

10:40:00 PM 01.Oct ---> Changeover on October

1 at 10:40 pm.

Note: See summer date / time

Time constant 0…36000 [h] Time constant to calculate dampened (determined

over this period) outside air temperature. Set this

value for the short period to 0 to reset the damp-

ened or assume present outside air temperature.

Outs air tmp summer -64...64 [°C] Changes over to summer operation when the

damped outside air temperature is greater than this

value.

Outs air tmp winter -64...64 [°C] Changes over to winter operation when the

damped outside air temperature is less than this

value.

Page 34

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 35

5.2 Operating mode

5.2.1 General

Purpose

Function to set and display all settings for the operating mode in question, i.e. start

conditions, switch-off conditions, operating mode. The plant may also be control

using the HMI.

Prerequisites

Parameterization

None.

None.

The configuration in Configuration1 and Configuration2 provide the various ways to

switch on the plant.

Displays/settings

Main Index > Unit > Operating Mode

Parameter Range Function

Actual

Manual operation

– Off

– On/Comfort

– Economy.

– Na

– Osstp

– NightClg

– UnOcc

– NightKick

– FireDamper

– Fire

– Stop.

– OverRun

– StartUp

– Auto

– Off

– Stage 1

– Stage 2

– Stage 3

– Auto

– Off

– Eco St1

Plant operating state:

– Plant is switched off.

– Plant operating in Comfort Mode.

– Plant operating in Economy Mode.

– Available operating mode, currently unused.

– Optimum start (boost function active).

– Night cooling, active.

– Not used (temperature start at night) heating or

cooling active.

– Night kick active for the plant to update the duct

temperature.

– Fire damper test running.

– Plant in fire mode (depending on the parameteri-

zation of Fire mode).

– Plant stopped and locked(Controller in Startup-

Phase, Configuration not Done; HighClass

Alarm; Emergency Stop).

– Fan overrun.

– Plant in start-up routine.

Manual plant operation via HMI (only possible for

Tsp function <> Steps+Tmp).

– Auto mode: Time switch catalog, night cooling,

etc., can switch on the plant.

– Plant off.

– Plant operating in stage 1 (using setpoint stage 1

for analog controlled plants).

– Plant operating in stage 2 (using setpoint stage 2

for analog controlled plants).

– Plant operating in stage 3 (using setpoint stage 3

for analog controlled plants).

Manual plant operation via HMI (only possible for

Tsp function = Steps+Tmp).

– Auto mode: Time switch catalog, night cooling,

etc., can switch on the plant.

– Plant off.

– Plant operating in Economy at stage 1 (using

setpoint stage 1 for analog controlled plants).

Manual operation (cont.)

– Comf St1 – Plant operating in Comfort mode at stage 1 (us-

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 35

Page 36

Parameter Range Function

– Eco St2

– Comf St2

–

– Eco St3

– Comf St3

ing setpoint stage 1 for analog controlled plants).

– Plant operating in Economy at stage 2 (using

setpoint stage 2 for analog controlled plants).

– Plant operating in Comfort mode at stage 2 (us-

ing setpoint stage 2 for analog controlled plants).

– Plant operating in Economy at stage 3 (using

setpoint stage 3 for analog controlled plants).

– Plant operating in Comfort mode at stage 3 (us-

ing setpoint stage 3 for analog controlled plants).

Time switch program

– Off

– Stage 1…Stage 3

Displays current command for time switch catalog

(for Tsp function = Steps only).

Jumps to page to parameterize time switch catalog.

Time switch program

From BACS

– Off

– Eco

– Comf

– Auto

– Off

– Stage 1

– Stage 2

– Stage 3

– Auto

– Off

– Eco St1

– Comf St1

– Eco St2

– Comf St2

– Eco St3

– Comf St3

Displays present command for time switch catalog.

(for Tsp function = Steps+Tmp only).

Jumps to page to parameterize time switch catalog.

Displays plant command from BMS (for TspFunction <> Steps+Tmp only). The value may also be

operated using HMI even when communication not

connected.

– Auto mode: Time switch catalog, night cooling,

etc., can switch on the plant.

– Plant off.

– Plant operating in stage 1 (using setpoint stage 1

for analog controlled plants).

– Plant operating in stage 2 (using setpoint stage 2

for analog controlled plants).

– Plant operating in stage 3 (using setpoint stage 3

for analog controlled plants).

Displays plant command from BMS (for TspFunction = Steps+Tmp only). The value may also be

operated using HMI even when communication not

connected.

– Auto mode: Time switch catalog, night cooling,

etc., can switch on the plant.

– Plant off.

– Plant operating in Economy at stage 1 (using

setpoint stage 1 for analog controlled plants).

– Plant operating in Comfort mode at stage 1 (us-

ing setpoint stage 1 for analog controlled plants).

– Plant operating in Economy at stage 2 (using

setpoint stage 2 for analog controlled plants).

– Plant operating in Comfort mode at stage 2 (us-

ing setpoint stage 2 for analog controlled plants).

– Plant operating in Economy at stage 3 (using

setpoint stage 3 for analog controlled plants).

Plant operating in Comfort mode at stage 3 (using

setpoint stage 3 for analog controlled plants).

Page 36

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 37

Parameter Range Function

External control

Roomunit op mode

– Auto

– Off

– Stage 1

–

– Stage 2

– Stage 3

– Auto

– Comfort

– Standby

Displays current plant command from hardware

plant switch.

– Auto mode: Time switch catalog, night cooling,

etc., can switch on the plant.

– Plant off.

– Plant operating in stage 1 (using setpoint stage 1

for analog controlled plants).

– Plant operating in stage 2 (using setpoint stage 2

for analog controlled plants).

– Plant operating in stage 3 (using setpoint stage 3

for analog controlled plants).

Displays present plant command from room unit

– Auto mode: Time switch catalog, night cooling,

etc., can switch on the plant.

– Plant operating in Comfort Mode.

– Plant is in standby.

– Plant operating in Economy Mode.

– Economy.

Night kick exh tmp

--- Starts plant to update sensor values for return-air

controlled plant and activated night cooling or UnitStart TmpDelta.

(Temperature difference start). Jumps to page to

parameterize night kick.

Night cooling

--- Night cooling (free cooling). Jumps to page to parameterize night cooling.

Tmp start

--- Starts plant at night based on temperature difference. Jumps to page to parameterize temperature

difference start.

Boost

--- Boost plant start. Jumps to page to parameterize

boost plant start.

Power up delay

0…36000 [s] Delayed plant start after controller restart.

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 37

Page 38

5.2.2 Prioritize various operating modes and switch-on sequences

OpMode

Display of various operating modes: Disabled functions and elements are ignored.

Page 38

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 39

Start sequence

Plant start sequence. Disabled functions and elements are ignored.

Fire

Conditions to trigger a fire alarm.

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 39

Page 40

Stop

Conditions that stop the plant:

Configuration

by Download

No

Configuration 1

Done

Configuration 2

Done

Configuration I/

O

Done

Configuration

I/O Doubled

No Fault

Configuraion

I/O not

configured

OK

Yes

Not Done

Not Done

Not Done

Fault

Not OK

Controller

Power up

Emergency

Stop

Alarm

High Class

0

Release Stop

Aktiv

Passive

Aktiv

Inaktiv

Aktiv

Inaktiv

STOPP

Page 40

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 41

5.2.3 Time switch program

Prerequisite

A time switch catalog is enabled:

Main Index > Configuration > Configuration 1 > TSP function <> No

Function

The plant is controlled via the time switch program.

Parameter

Main Index > Unit > Operating mode > Time switch program

Parameter Range Function

Schedule

– Off

– Stage1…Stage3

Present plant operating mode from the time switch

catalog for Tsp function <= Steps. Goes to details

page to parameterize time switch catalog.

Schedule – Off

– Eco St1…Eco St3

– Comf St1…Comf St3

Calendar exception – Passive

– Active

Present plant operating mode from the time switch

catalog for Tsp function = Steps+Tmp. Goes to details page to parameterize time switch catalog.

Calendar for vacation and holidays. The entry for

the exception day of the scheduler is enabled when

this entry is enabled. Goes to details page to parameterize time switch catalog.

Calendar fix off – Passive

– Active

Additional calendar to switch off the plant. Goes to

details page to parameterize second calendar.

5.2.4 External Control (parameterize plant switch)

Prerequisite

The external plant switch is enabled:

Main Index > Configuration > Configuration 1 > Ext control input <> None

Function

Plant operation via external plant switch, presence detectors or buttons (Ext control

input 1, Ext control input 2). The plant can be switched to auto mode, a set stage or

to off depending on parameterization and configuration. The command defaulted

here is only enabled when no higher priority command is not active, e.g. Manual

Operation is enabled via HMI.

Parameter

Main Index > Unit > Operating mode > External control

Parameter Range Function

Actual mode

– Auto

– Off

– Stage 1

– Stage 2

– Stage 3

Actual plant operating mode as triggered by the plant switch.

– Auto mode: Time switch catalog, night cooling, etc., can

switch on the plant.

– Plant off.

– Plant operating in stage 1 (using setpoint stage 1 for analog

controlled plants).

– Plant operating in stage 2 (using setpoint stage 2 for analog

controlled plants).

– Plant operating in stage 3 (using setpoint stage 3 for analog

controlled plants).

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 41

Page 42

Parameter Range Function

Tmp stpt input 1

– Comfort

– Economy.

Applied temperature setpoint at the active input Ext control

input 1; enabled only for Tsp function = Steps+Tmp.

– Comfort setpoint.

– Economy setpoint.

Note: The present temperature setpoint is determined by the

value from Tmp stpt input 2 if both inputs are enabled.

Tmp stpt input 2

– Comfort

– Economy.

Applied temperature setpoint at the active input Ext control

input 2; enabled only for Tsp function = Steps+Tmp.

– Comfort setpoint.

– Economy setpoint.

See not for Tmp stpt input 1!

Off delay 0…23.0 [h]

Switch-off delay. Plant goes to auto mode after the delay.

Notes:

– Off delay = 0 ---> The present command is pending as long

as the impacted input is enabled. This is mandatory for

plant switches.

– Off delay > 0 ---> Is used exclusively for external buttons or

presence detectors that requires resetting the plant to auto

mode after a set period.

Fan steps

– Auto

– Off

– 1Step

– 2Step

– 3Step

Select fan step:

– Auto mode.

– Plant off.

– Plant operating in stage 1 (using setpoint stage 1 for analog

controlled plants).

– Plant operating in stage 2 (using setpoint stage 2 for analog

controlled plants).

– Plant operating in stage 3 (using setpoint stage 3 for analog

controlled plants).

Start/stop function

– Off

– On

Define input functions:

– Each pulse on the input start the Timer Off delay.

– The first pulse on the input starts the Timer Off delay and

sets the command. The next pulse resets to auto mode.

The same applies when the timer expires.

Fan steps function

• Main Index > Configuration > Configuration 1 > Ext control input = One --->

Only input Ext control input 1 is enabled. The command set with fan steps is issued when Ext control input 1 = On.

• Main Index > Configuration > Configuration 1 > Ext control input = Two --->

Both inputs Ext control input 1 and Ext control input 2 are enabled. In this case:

– Ext control input 1 = Off and Ext control input 2 = Off ---> Command = Auto

mode.

– Ext control input 1 = Off and Ext control input 2 = Off ---> Command = 1Step.

– Ext control input 1 = Off and Ext control input 2 = On ---> Command = 2Step.

– Ext control input 1 = On and Ext control input 2 = On ---> Command as de-

termined by fan step.

Page 42

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 43

Start/stop function and of

f

delay

• Start/stop function = Off and Off delay = 0 ---> The command is issues as long

as the signal is pending.

• Start/stop function = Off and Off delay > 0 ---> The command is issued during

the off delay period for a pulse at the input. The timer restarts for each new

pulse on the input.

• Start/stop function = On and Off delay = 0 ---> The command is issued for a

pulse on the input and then reset against at the next pulse.

• Start/stop function = On and Off delay > 0 ---> The command is issued for a

pulse on the input and then reset against at the next pulse or after the off delay

period.

5.2.5 Night kick function

Prerequisite

Function automatically enabled when the following conditions are met:

– Non room sensor available and

– the return tmp sensor is not parameterized as saved and

– Night cooling or start is enabled based on the temperature difference:

Main Index > Configuration > Configuration 1 > Room tmp sensor = No

and

Main Index > Configuration > Configuration 1 > Exh air tmp sensor = Yes

Und

Main Index > Configuration > Configuration 2 > Night cooling = Yes

Main Index > Configuration > Configuration 2 > Tmp start <> No

Function

Plant kick ramps up the plant after a longer period of inoperation to update the

measured return temperature in the duct.

This temperature is used as the decision-making criterion to start night cooling or

temperature difference start and should be kept updated as much as possible.

Parameter

Main Index > Unit > Operating mode > Night kick exh tmp

Parameter Range Function

Kick time

00:00...23:59 Time to execute kick.

Example:

23:00 Kick is run at 11:00 pm.

*:* Time is not relevant; the interval applies accordingly.

Interval time 0.0…36000.0 [h] Interval time to execute kick.

Example:

3.0 Run every 3 hours.

0.0 Interval is not relevant; kick time applies accordingly.

On time 0...36000 [s] Kick period.

Example

Kick time = 23:00 / Interval time = 3 / On time = 300

---> The plant is switched-on for 300 seconds if the plant has been off for at least 3

hours as of 11:00 pm.

Note

Kick time = *:* and interval time = 0.0 h ---> No plant kick is triggered.

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 43

Page 44

5.2.6 Night cooling (Free Cooling)

Prerequisite

Function

Note

Night cooling (free cooling) is enabled.

Main Index > Configuration > Configuration 2 > Night cooling <> No

Night cooling cools down a building at night using cool outside air without auxiliary

energy for high daytime temperatures.

• Night cooling is switched on in the following cases:

– Outside air temperature is greater than the lower level: Out tmp > Min outs

tmp

and

– Outside air temperature is less than the difference from room temperature and

switch-on differential: Out tmp < Room tmp - Delta

and

– Room temperature is greater than the sum of the room setpoint and hystere-

sis: Room tmp > Room tmp setpoint + hysteresis.

• Night cooling is switched off in the following cases:

– Timer Min run time = 0

and

– Plant switches on.

or

– Outside air temperature is less than the difference from room temperature and

switch-off differential: Out tmp > Room tmp – 1 or

– Room temperature is less than or equal to room setpoint: Room tmp <= Room

tmp setpoint

The function is disabled for faulty outside air or room temperature.

Parameter

Main Index > Unit > Operating mode > Night cooling

Parameter Range Function

Room tmp setpoint

-64.0…64.0 [°C] Room setpoint for night cooling. Setpoint applies to return air

for night cooling with a return air sensor.

Hysteresis 0.0…64.0 [°C] Hysteresis for switch on.

Delta 1.0…64.0 [°C] Minimum difference between room and outside air tempera-

ture.

Min outs tmp -64.0…64.0 [°C] Minimum outside air temperature to activate night cooling.

Min run time 0…999 [min] Minimum runtime after a start.

5.2.7 Temperature difference start

Prerequisite

Function

Plant start by temperature difference is enabled:

Main Index > Configuration > Configuration 2 > Tmp start <> No

Plant night start based on temperature difference prevents the building from cooling down or heating up too much. It is controlled to a separate setpoint for heating

and cooling.

The heating and or cooling start can be enabled separately:

Main Index > Configuration > Configuration 2 > Tmp start

Page 44

The function can be implemented using a return air sensor if no room sensor is

available.

Basis Document Siemens Climatix Control System

BDCX.100820.01GB

Page 45

Cooling demand

Heating demand

Note

The plant night start by temperature difference for cooling demand occurs when

the following conditions are met:

– Room tmp > Start stpt cooling und

– Timer Minimum off time = 0

The shutdown occurs for:

– Room tmp < Start stpt cooling - Hysteresis

The plant night start by temperature difference for heating demand occurs when

the following conditions are met:

– Room tmp > Start stpt heating und

– Timer Min off time = 0

The shutdown occurs for cooling demand occurs for:

Room tmp > Start stpt heating + Hysteresis

The function when the room temperature sensor (return air sensor) fails.

Parameter

Main Index > Unit > Operating mode > Tmp start

Parameter Range Function

Start stpt cooling

-64.0….64.0 [°C] Start temperature for cooling.

Cooling setpoint -64.0….64.0 [°C] Cooling setpoint.

Start stpt heating -64.0…64.0 [°C] Start temperature for heating.

Heating setpoint -64.0….64.0 [°C] Heating setpoint.

Hysteresis 0.1…64.0 [°C] Shutdown hysteresis.

Minimum off time 0…999 [min] Minimum switch-off time after active heating or cooling.

Min run time 0.0…..999.0 [min] Minimum runtime after a start.

5.2.8 Boost function (boost plant start)

Prerequisite:

Function

Boost is enabled:

Main Index > Configuration > Configuration 2 > Boost <> No

Boost ensures a comfortable room temperature when the plant is switched on normally.

The heating and or cooling start can be enabled separately:

Main Index > Configuration > Configuration 2 > Boost

Cooling demand

Heating demand

Note

The function can be implemented using a return air sensor if no room sensor is

available.

Boost for cooling demand occurs when the following conditions are met:

– Room tmp > Start stpt cooling + Hysteresis and

– Time to normal start via the time switch program < Compensation time

The shutdown occurs for:

– Room tmp < Start stpt cooling

Boost for heating demand occurs when the following conditions are met:

– Room tmp < Start stpt heating - Hysteresis and

– Time to normal start via the time switch program < Compensation time

The shutdown occurs for: