Page 1

Company Confidential Siemens Com

Copyright 2005© Siemens AG

Service Repair Documentation

Level 2.5 – CL75

Release Date Department Notes to change

1.0 23.08.2005 COM MD CC GRM T New document

Service Repair Documentation

Level 2.5 – CL75

Page 1 of 12

Page 2

Company Confidential Siemens Com

Copyright 2005© Siemens AG

Table Of Contents

1. CL75 Board Layout ....................................................................................4

2. System Connector.......................................................................................5

3. LED.............................................................................................................6

4. Battery Connector.......................................................................................7

5. Backup Battery............................................................................................8

6. Microphone.................................................................................................9

7. Speaker Spring..........................................................................................10

8. IRDA.........................................................................................................11

9. Hall IC.......................................................................................................12

Service Repair Documentation

Level 2.5 – CL75

Page 2 of 12

Page 3

Company Confidential Siemens Com

Copyright 2005© Siemens AG

Introduction

This Service Repair Documentation is intended to carry out repairs on Siemens

repair level 2.5. The described failures shall be repaired in Siemens authorized local

workshops only.

All repairs have to be carried out in an ESD protected environment and with ESD

protected equipment/tools. For all activities the international ESD regulations have to be

considered.

Assembling/disassembling has to be done according to the latest CL75 Level 2 repair

documentation. It has to be ensured that every repaired mobile Phone is checked

according to the latest released General Test Instruction document (both documents

are available in the Technical Support section of the C-market).

Check at least weekly C-market for updates and consider all CL75 related Customer

Care Information.

If you have any questions regarding the repair procedures or technical questions

spare not hesitate to contact our technical support team in Kamp-Lintfort, Germany:

Tel.: +49 2842 95 4666

Fax: +49 2842 95 4302

e-mail:

st-support@klf.siemens.de

Service Repair Documentation

Level 2.5 – CL75

Page 3 of 12

Page 4

Company Confidential Siemens Com

y

p

g

Copyright 2005© Siemens AG

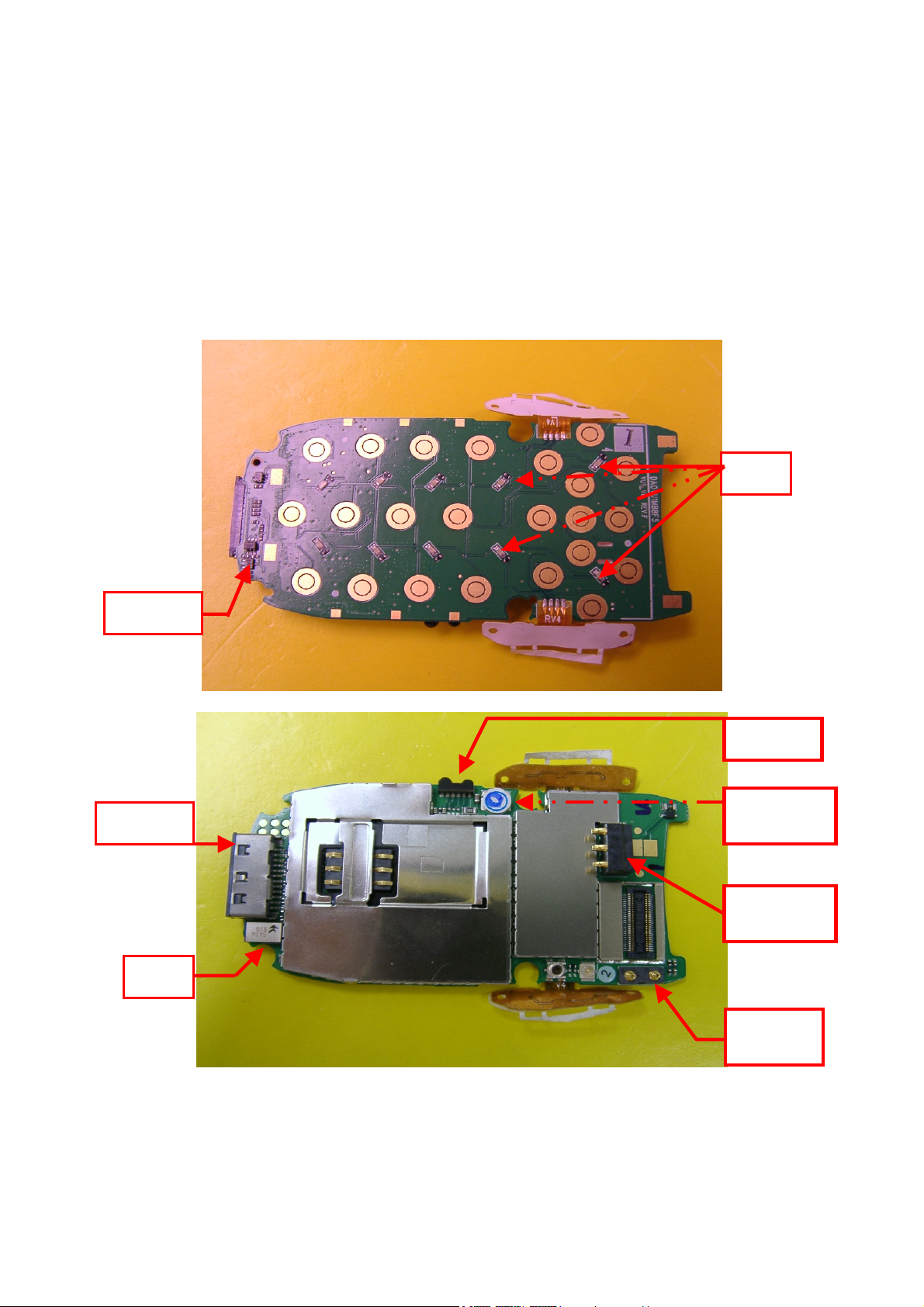

1. CL75 Board Layout

Jigs, Tools and working materials for all described repairs:

- Hot air blower

- Soldering gun

- Tweezers

- Flux

- Solder

LED

Hall IC

IO Jack

MIC

IRDA

Backup

Batter

Battery

Connector

Speaker

rin

S

Page 4 of 12

Service Repair Documentation

Level 2.5 – CL75

Page 5

Company Confidential Siemens Com

Copyright 2005© Siemens AG

2. System Connector

Fault Symptoms

Customer:

Charging Problems

Problems with external loudspeaker or microphone when using a car kit

Problems with accessories connected at the system connector

IO connector problems

Watch for oxidation and

damaged pad of the IO

connector

Okay

Check for dust inside the

IO connector

Not okay

Not okay

Not okay

Check the status of IO

connector visually.

Exchange

IO

connector

Not okay

Use the resistor test

function of a multimeter to

check connection between

spring contacts and

soldering contacts. The

value must be ~0Ω

Okay

Connector IO Jack

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Re-solder new component afterwards.

E-commerce order number: C39334-Z97-C448

Soldering temperature: 240 – 255°C

IRIS Diagnose Code: 46100 Interface/ Charging Connector/ Mechanical Damage

47300 Interface/ Data Interface/ Mechanical Damage

4B100 Interface/ Headset Connector/ Mechanical Damage

Page 5 of 12

Service Repair Documentation

Level 2.5 – CL75

GRT:

No Support

SCRAP don’t send

back to WSC

Clean IO

connector

- Check for twisted or

bended contacts

- Check for dry joints

Level 2 Repair

Page 6

Company Confidential Siemens Com

N

Copyright 2005© Siemens AG

3. LED

Fault Symptoms

Customer:

Keypad illumination does not work

LED’s Problems

Watch for oxidation and

damaged pads of the LED’S

Not okay

Check the status of the

LED's visually

Exchange

Keypad LED

Not okay

Use the diode test

function of a multimeter

to check the status of

the diode. The typical

voltage drop on the

diode is 1.7 V when

testing the diode

function with the

multimeter.

LED

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards. Attention: Remove Metal Dome Sheet before!!!

E-commerce order number: V20810-U6208-D670

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 36000 Keys/Illumination

GRT:

No Support

okay

okay

okay

ot okay

SCRAP don´t send

back to

- Check for dry joints

WSC

Level 2 Repair

Page 6 of 12

Service Repair Documentation

Level 2.5 – CL75

Page 7

Company Confidential Siemens Com

Copyright 2005© Siemens AG

4. Battery Connector

Customer:

Mobile does not switch on

Not okay

Exchange

battery

connector

Not okay

Connector Battery

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components!

E-commerce order number: C39334-Z97-C486

Soldering temperature: 240 – 255°C

IRIS Diagnose Code: 91500 Functionality / Switch Off Problems / Battery Contacts Damage

Battery connector

problems

Watch for oxidation and

damaged pad of the

battery connector

Okay

Check for dust inside the

battery connector

Check the status of battery

connector visually.

Use the resistor test

function of a multimeter to

check connection between

spring contacts and

soldering contacts. The

value must be ~0Ω

GRT:

No Support

Not okay

Not okay

Okay

SCRAP don’t send

back to WSC

Clean battery

connector

- Check for twisted or

bended contacts

- Check for dry joints

Level 2 Repair

Service Repair Documentation

Level 2.5 – CL75

Page 7 of 12

Page 8

Company Confidential Siemens Com

r

Copyright 2005© Siemens AG

5. Backup Battery

Customer:

Customer parameter (date and time) are not saved

when battery is removed

Not okay

Exchange

backup

battery

Backup Battery

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Re-solder new component afterwards.

E-commerce order number: V39328-F2705-Z2

Soldering temperature: 240 – 255°C

IRIS Diagnose Code: C8100 Settings/ General / Clock / Date

Backup battery

problems

Watch for oxidation and

damaged pad of the

backup battery

Check the status of backup

battery visually.

Okay

Okay

Level 2 Repai

GRT:

No Support

Not okay

SCRAP don’t send

back to WSC

- Check for dry joints

Service Repair Documentation

Level 2.5 – CL75

Page 8 of 12

Page 9

Company Confidential Siemens Com

r

Copyright 2005© Siemens AG

6. Microphone

Customer:

Customer parameter (date and time) are not saved

when battery is removed

not okay

Exchange

microphone

Microphone

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components!

E-commerce order number: C39254-Z6-C139

Soldering temperature: 240 – 255°C

IRIS Diagnose Code: 73110 Acoustics/ Transmitting / Microphone / No Function

73130 Acoustics/ Transmitting / Microphone / Mechanical damage

73140 Acoustics/ Transmitting / Microphone / Noise

Microphone problems

Watch for oxidation and

damaged around

microphone.

Okay

Check the status of

microphone visually.

Okay

Level 2 Repai

GRT:

No Support

Not okay

SCRAP don’t send

back to WSC

Service Repair Documentation

Level 2.5 – CL75

Page 9 of 12

Page 10

Company Confidential Siemens Com

Copyright 2005© Siemens AG

7. Speaker Spring

Fault Symptoms

Customer:

No ring tone under correct setting.

Speaker spring’s

problems

Watch for oxidation and

damaged pad of the

speaker spring

not okay

Check the status of speaker

spring visually.

Okay

Okay

Exchange

speaker

spring

Level 2 Repair

Speaker Spring

Use tweezers to remove defective component. Avoid excessive heat! Watch surrounding components!

Re-solder new component afterwards.

E-commerce order number: C39334-Z97-C487

Soldering temperature: 240 – 255°C

IRIS Diagnose Code: 74000 Acoustics/ Ringer / No Function

41300 Acoustics/ Ringer / Mechanical Damage

Page 10 of 12

Service Repair Documentation

Level 2.5 – CL75

GRT:

No Support

Not okay

SCRAP don’t send

back to WSC

- Check for twisted or

bended contacts

- Check for dry joints

Page 11

Company Confidential Siemens Com

Copyright 2005© Siemens AG

8. IRDA

Fault Symptoms

Customer:

No infrared connection possible.

IRDA problems

Watch for oxidation and

damaged pad of the IRDA

not okay

Check the status of IRDA

visually.

okay

Exchange

IRDA

Not okay

Use the resistor test

function of a multimeter to

check connection between

spring contacts and

soldering contacts. The

value must be ~0Ω

IRDA

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Re-solder new component afterwards.

E-commerce order number: V20810-U6208-D670

Soldering temperature: 240 – 255°C

IRIS Diagnose Code: 41100 Interfaces/ IRDA / No Function

41300 Interfaces/ IRDA / Mechanical Damage

GRT:

No Support

not okay

Okay

SCRAP don’t send

back to WSC

- Check for dry joints

Level 2 Repair

Service Repair Documentation

Level 2.5 – CL75

Page 11 of 12

Page 12

Company Confidential Siemens Com

r

Copyright 2005© Siemens AG

9. Hall IC

Fault Symptoms

Customer:

No infrared connection possible.

Hall IC problems

Watch for oxidation and

damaged pad of the Hall IC

Not okay

Check the status of Hall IC

visually.

okay

Exchange

Hall IC

Not okay

Power on the handset and

use voltage test in multimeter

to measure pin2 output with a

magnet closing (high to low)

and removing (low to high).

Hall IC

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Re-solder new component afterwards.

E-commerce order number: V20810-U6207-D670

Soldering temperature: 240 – 255°C

IRIS Diagnose Code:

GRT:

No Support

Not okay

Okay

SCRAP don’t send

back to WSC

- Check for dry joints

Level 2 Repai

Service Repair Documentation

Level 2.5 – CL75

Page 12 of 12

Loading...

Loading...