Page 1

C62

LEVEL 2.5

REPAIR DOCUMENTATION

V 1.1

V1.1 Page 1 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 2

TABLE OF CONTENTS:

INTRODUCTION..........................................................................................................................................3

1

2 IO-CONNECTOR.............................................................. FEHLER! TEXTMARKE NICHT DEFINIERT.

3 RTC BATTERY...........................................................................................................................................11

4 TRANSISTOR SOT-323 (FOR LEDS)......................................................................................................16

TRANSISTOR SOT-323 (FOR VIBRA) ...................................................................................................21

5

FUSE .............................................................................................................................................................26

6

7 VOLTAGE SUPRESSOR ............................................................................................................................31

8 TRANSISTOR SOT-223 ..............................................................................................................................36

9 ZENER DIODE.............................................................................................................................................41

10 LED COLOR YELLOW............................................................................................................................46

V1.1 Page 2 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 3

1 Introduction

The C62 is a triple band (EGSM900/GSM1800/GSM1900) handportable phone with a Li-Ion

battery. There are three different colour variants. The colours are Eagle White, Pigeon Blue

and Cherry Red. For every colour, there are eight different keymat variants: Latin, Chinese

Stroke, Hebrew, Cyrillic, Thai, Bopomofo, Arabic and Greek.

Partnumber on IMEI label:

C62: S30880-S9230-Axxx,

where xxx may be any number from 100, 101, 102...

This manual is intended to help you carry out repairs on level 2.5, meaning limited

component repairs. Failure highlights are documented and should be repaired in the local

workshops.

It must be noted that all repairs have to be carried out in an environment set up according to

the ESD (Electrostatic Discharge Sensitive Devices) regulations defined in international

standards.

If you have any questions regarding the repair procedures or technical questions about the

spare parts do not hesitate to contact our technical support team in Kamp-Lintfort, Germany:

Tel.: +49 2842 95 666

Fax: +49 2842 95 4302

E-mail: st-support@siemens.com

V1.1 Page 3 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 4

2 IO-Connector

2.1 Affected Units

2.1.1 Type: C62

2.1.2 Affected IMEIs / Date Codes: All / All

2.1.3 Affected SW-Versions: All

2.2 Fault Description

2.2.1 Fault Symptoms for customers:

Charging problems.

Problems with external loudspeaker or microphone

when using a car kit.

Problems with accessories connected at the system

connector.

Problems with SW booting.

2.2.2 Fault Symptom on GSM-Tester:

This fault cannot be detected with a GSM-Tester.

2.3 Priority:

........ Mandatory

⌧ ........ Repair

........ Optional

........ Not Yet Defined

2.4 Repair Documentation

2.4.1 Description of procedure:

V1.1 Page 4 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 5

2.4.1.1 Diagnosis

Check the system connector visually. Watch for oxidation and dry

joints!

2.4.1.2 Repair by component change

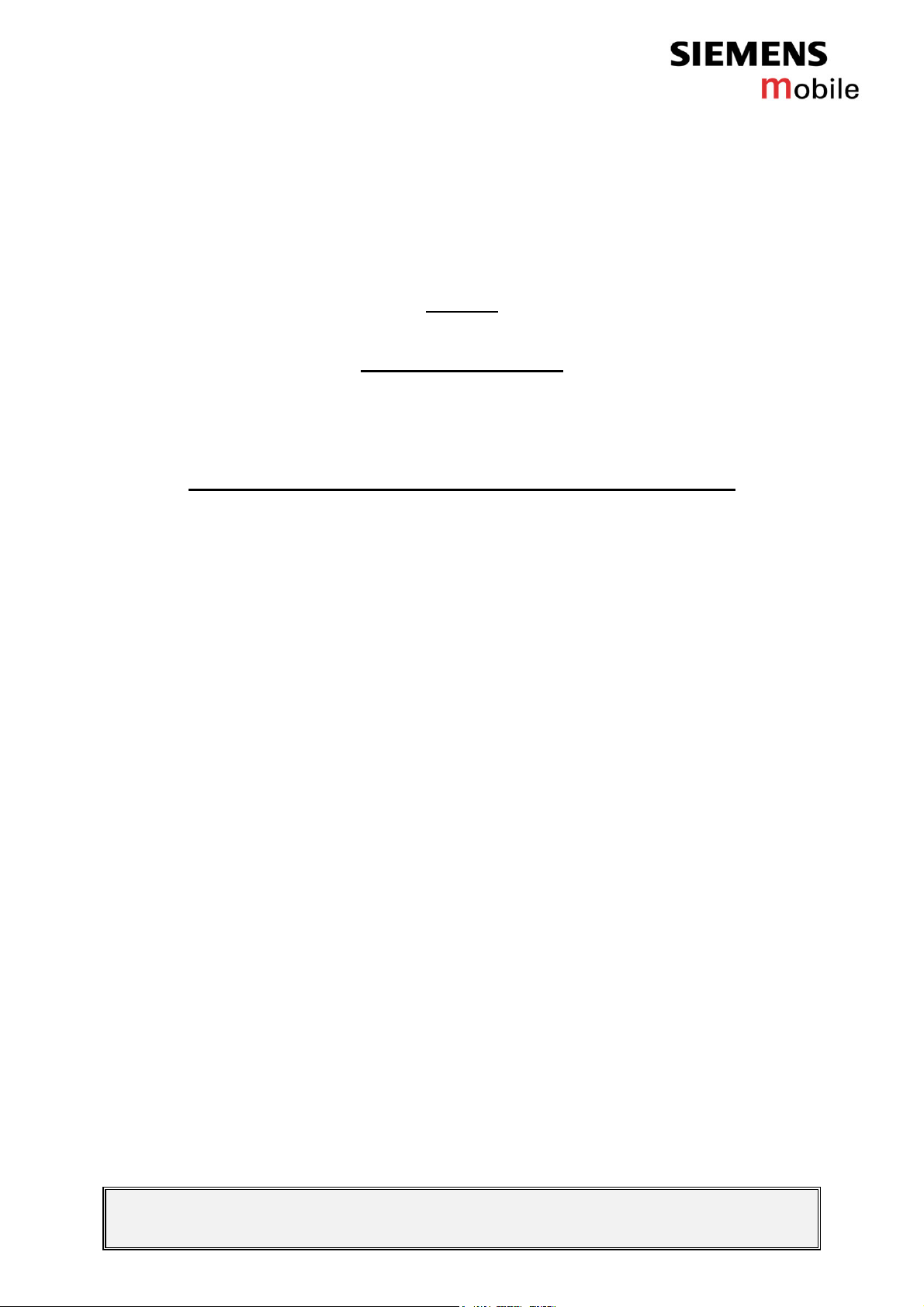

# Figure Instruction Note

1

Use a hot air blower to

remove the defective

system connector.

Avoid excessive heat!

Watch out for the

surrounding

components!!

Figure 2-1

2

Figure 2-2

3

Remove the defective

connecter.

Add solder on the pads.

Figure 2-3

V1.1 Page 5 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 6

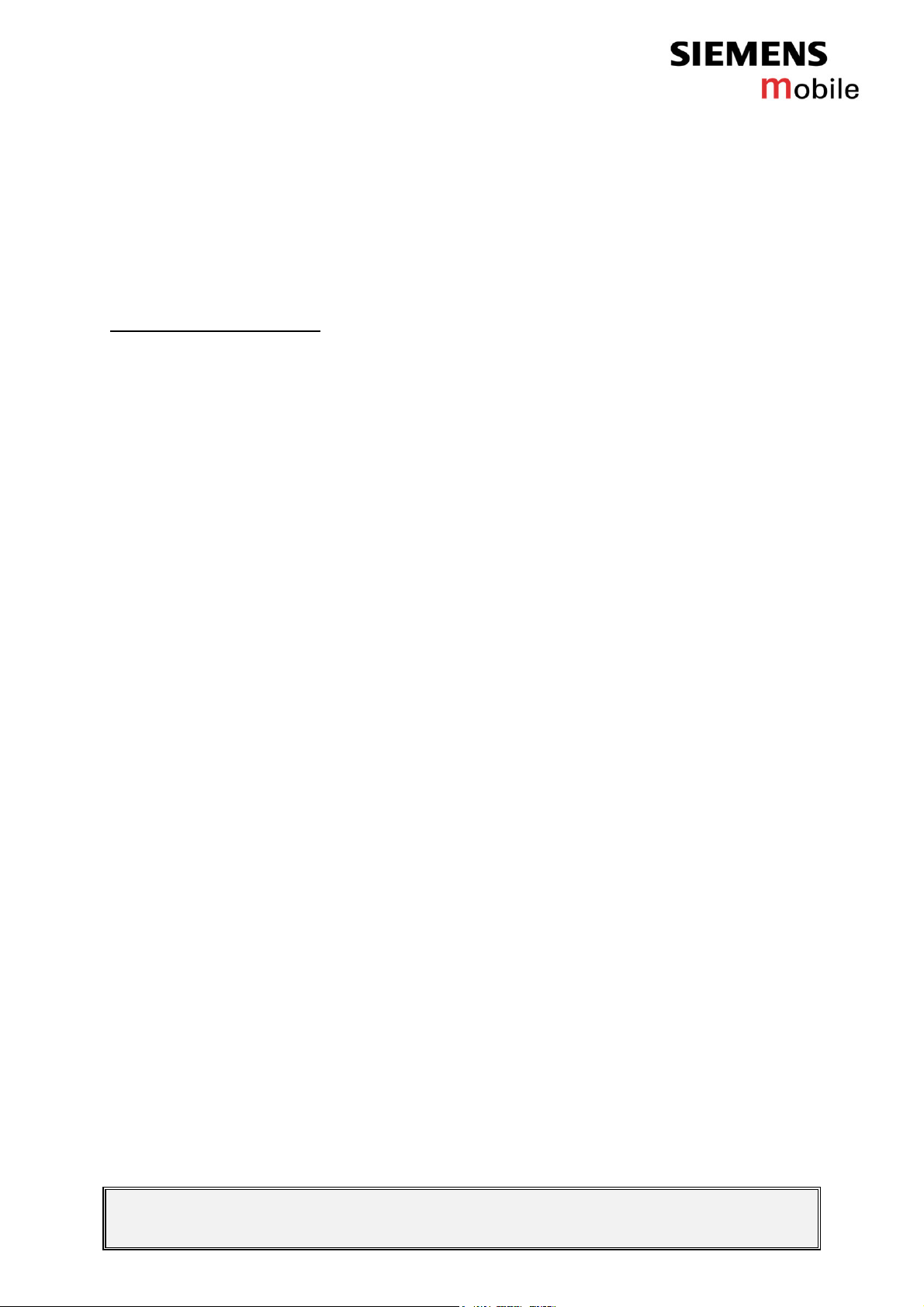

4

Figure 2-4

5

Add flux on the pads.

Re-solder the new

system connector by

using a hot air blower.

Check that the

connector is straight and

exactly in right place.

Figure 2-5

6

Figure 2-6

2.4.1.3 Repair by SW-Booting

Not possible!

New connector is in its

place.

2.4.1.4 Test

Charging problems can be discovered by measuring the voltage

between pins 1 (Power) and 2 (GND). Voltage should be between 5V

and 9,5V if system connector is working.

V1.1 Page 6 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 7

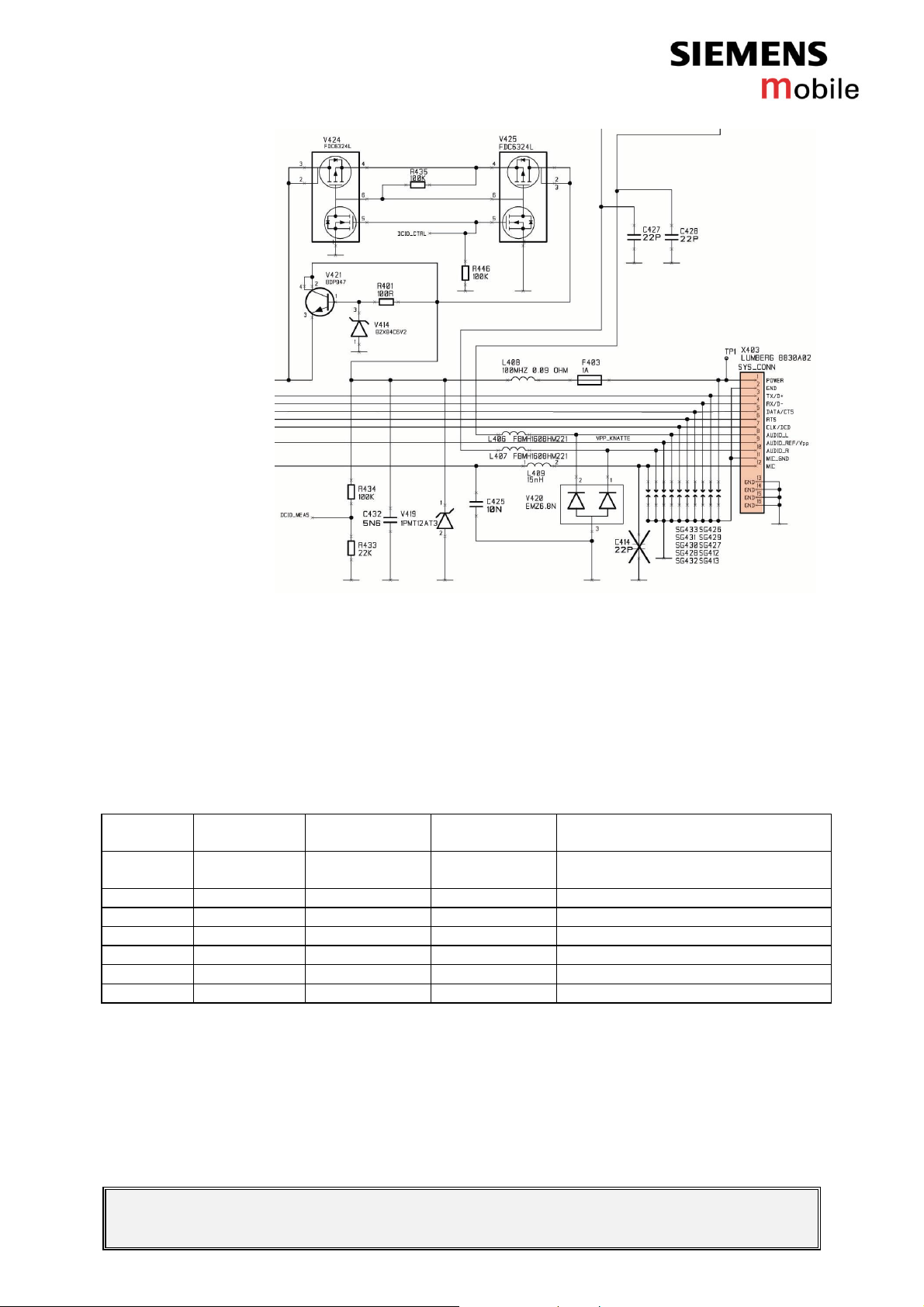

Circuit diagram of system connector

Test if accessories function well.

In order to detect an accessory when plugged into the system

connector, the following pins on the connector are used in the

detection scenario: POWER, TX/D+, RX/D-, DATA/CTS, CLK/DCD and

RTS. Table 1 shows the pins and their possible use in a detection

scenario.

Table 1: Accessory coding options

Pin No. Signal name Default level Default

1 POWER L(Z) Off Open or charge source (Set by

2 GND GND -

3 TX/D+ H(Z) Out High/Low (Set by Phone)

4 RX/D- L(Z) In Open, Tx or high (Set by accessory)

5 DATA/CTS H(Z) In Open, Tx or low (Set by accessory)

6 RTS H(Z) In Open, Tx or low (Set by accessory)

7 CLK/DCD H(Z) In Open, Tx or low (Set by accessory)

Possible coding options

direction

accessory)

The different coding options for the supported accessories can be seen

in Table 2.

V1.1 Page 7 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 8

Table 2: Accessory coding table

RX/D- DATA/CTS CLK/DCD RTS Description

OPEN OPEN OPEN OPEN Default: No accessory connected

TX/D+ GND OPEN TX/D+ Headset

TX/D+ GND GND TX/D+ Headset with PTT pressed

HIGH OPEN GND OPEN Car Kit portable

2.4.2 List of needed material

2.4.2.1 Components

System connector female 12pin SMD

Part Number: L36197-F5121-F730

2.4.2.2 Jigs and Tools

Hot air blower

Tweezers

Inspection lamp

2.4.2.3 Special Tools

None

2.4.2.4 Working materials

Flux

Solder

2.4.3 Drawings

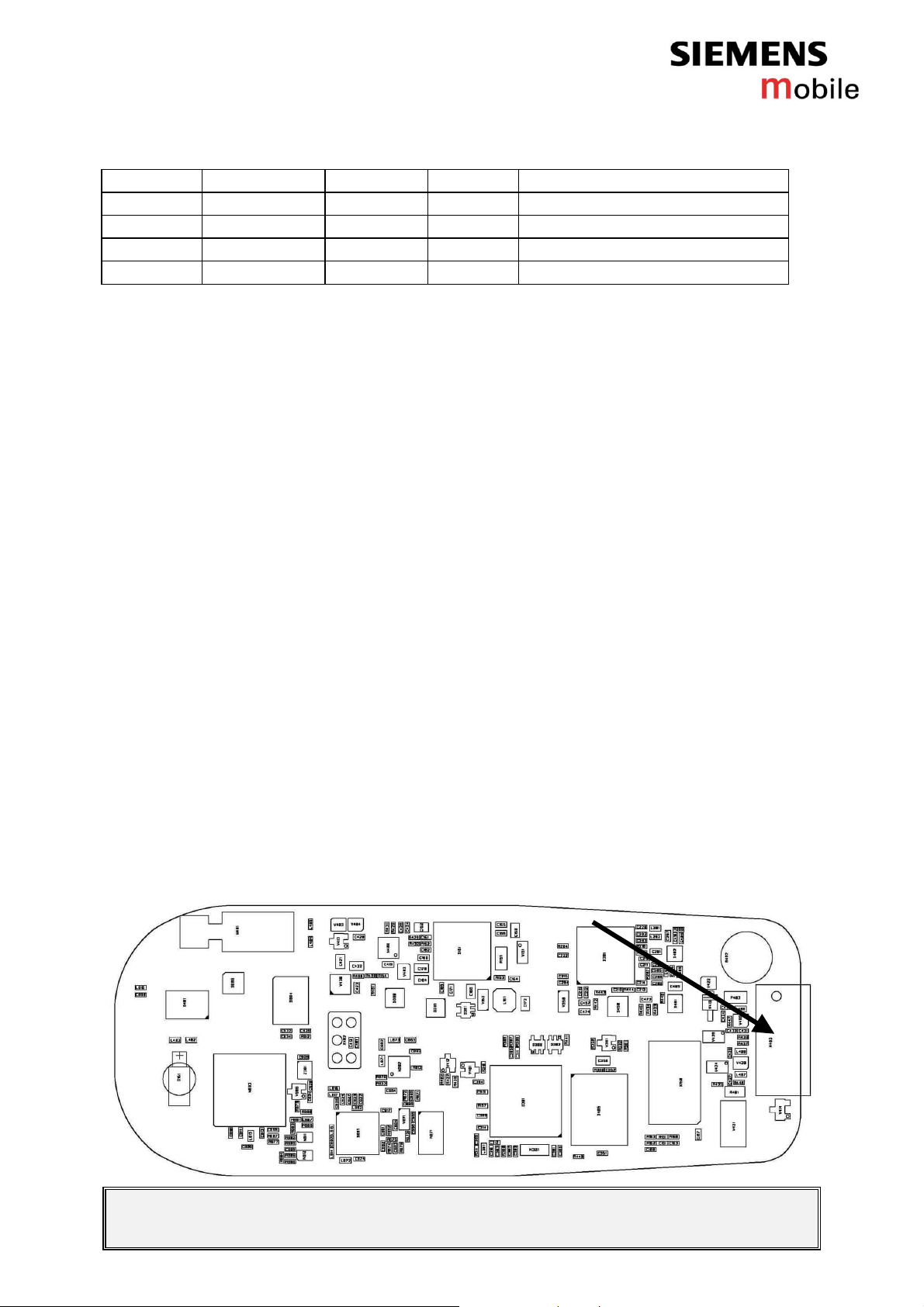

Figure 1: C62 board, system connector side

V1.1 Page 8 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 9

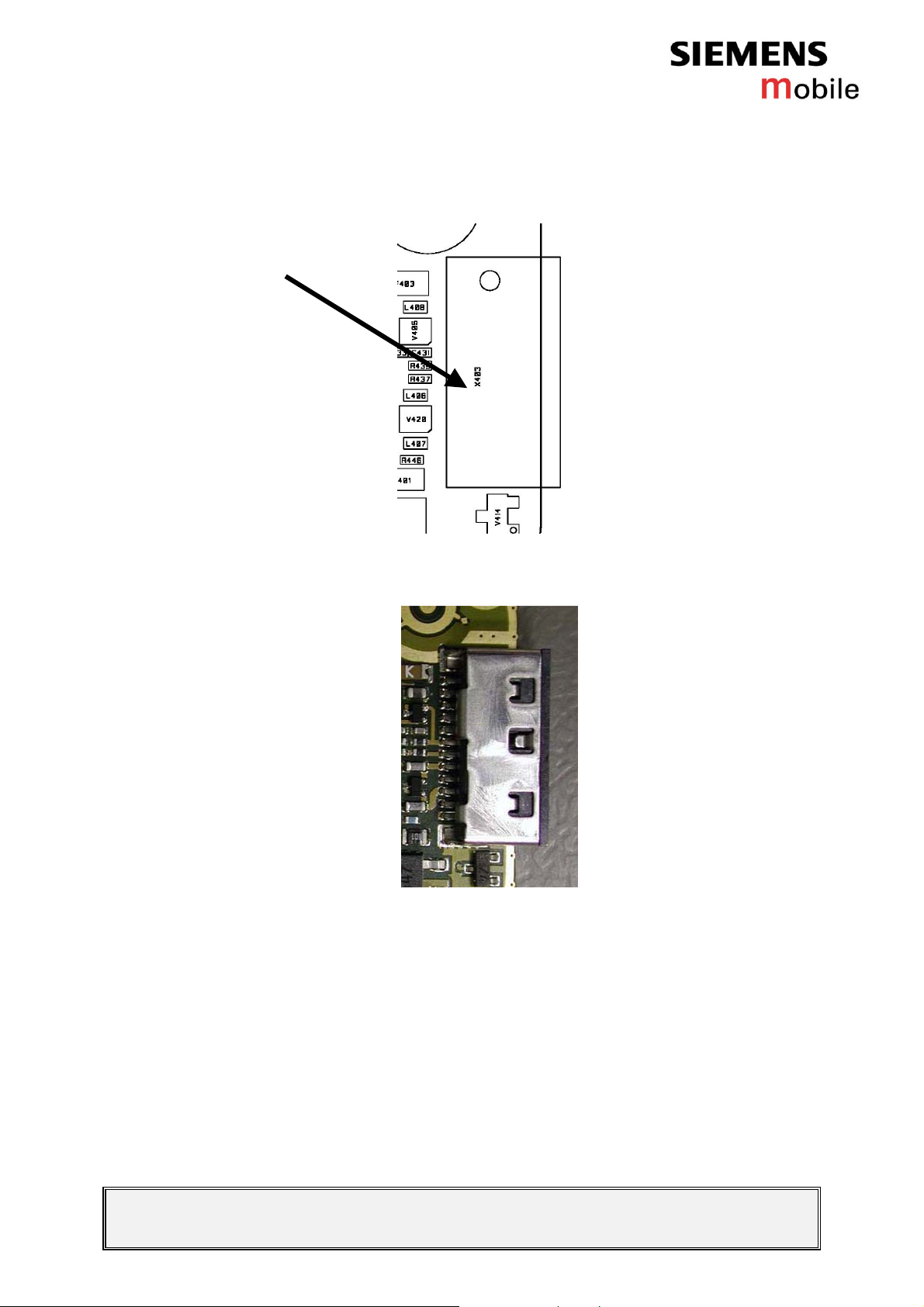

Figure 2: C62 system connector placement (top view)

Figure 3: C62 system connector

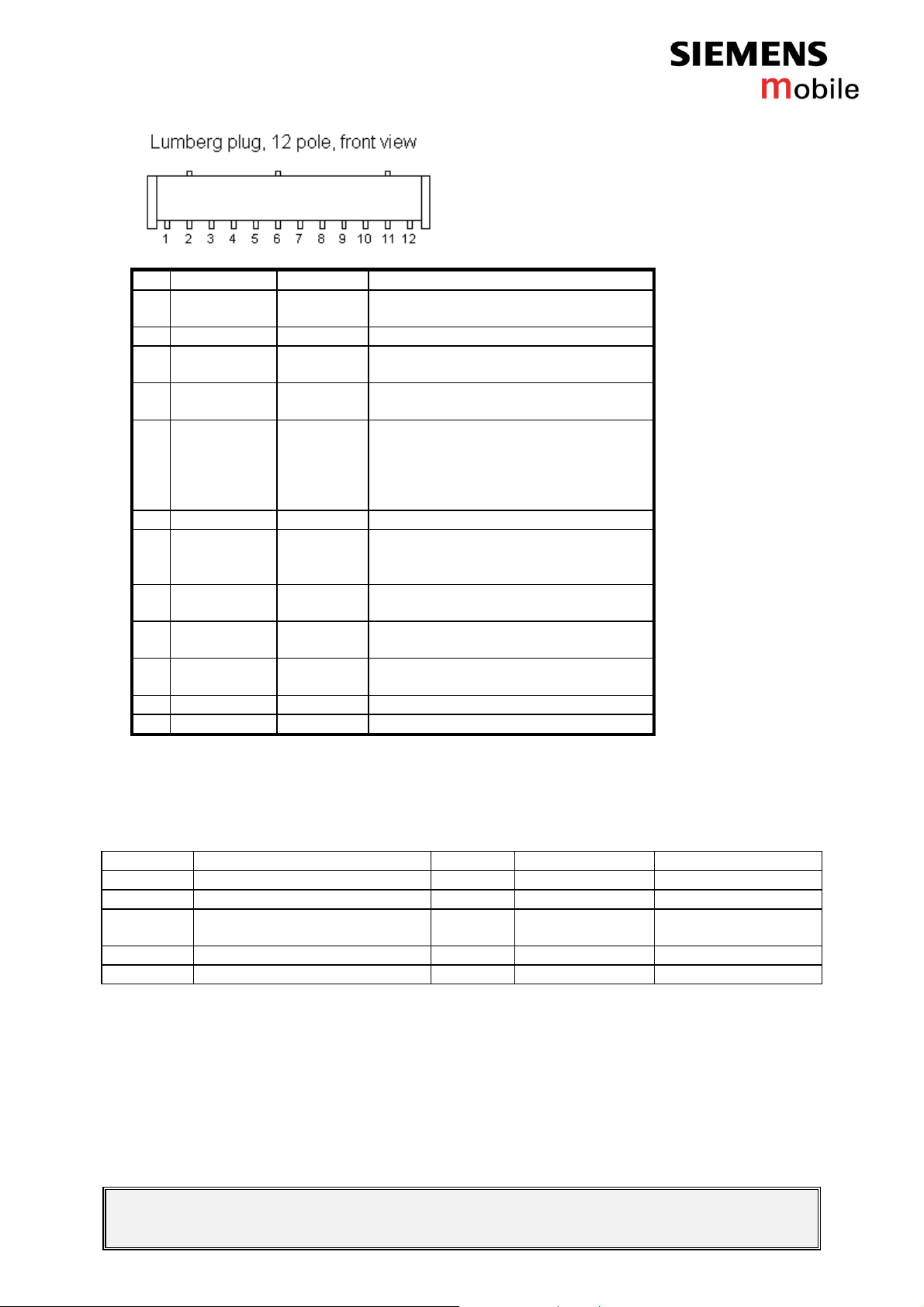

Table 3: Siemens C62 system connector pin description

V1.1 Page 9 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 10

Pin Name IN/OUT Notes

1 POWER I Charging Current

2 GND Common GND

3 TX O Serial interface, used for Flash

programming and ITP commands

4 RX I Serial interface, used for Flash

programming and ITP commands

5 DATA/CTS I/O Serial interface, used for AT-

commands.

Data line for accessory bus.

Use as CTS in data operation.

Used for accessory detection

6 RTS I Used for accessory detection

7 CLK/DCD I/O Serial interface, used for AT-

commands.

Used for accessory detection

8 Audio L O Dual -ended (other end is Audio R)

output for external receiver (mono)

9 Audio_Ref/V

PP

I Used for 12V flash programming

voltage

10 Audio R O Dual -ended (other end is Audio L)

output for external receiver (mono)

11 Gnd_Micro GND external microphone

12 Micro I Input for external microphone

Table 4: Lumberg signal levels

Pin no. Signal name Level Min [V] Max [V]

3 TX/D+ VOH VOL 2.17 0 3.00 0.20

4 RX/D- VIH VIL 2.10 0 3.60 0.48

5 DATA/CTS VIH VIL

V

OH VOL

2.10 0 2.17 0 3.30 0.46 3.00 0.42

6 RTS VIH VIL 2.10 0 3.30 0.46

7 CLK/DCD VIH VIL 2.10 0 3.30 0.46

V1.1 Page 10 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 11

3 RTC battery

3.1 Affected Units

3.1.1 Type: C62

3.1.2 Affected IMEIs / Date Codes: All / All

3.1.3 Affected SW-Versions: All

3.2 Fault Description

3.2.1 Fault Symptoms for customers:

The clock is reset when battery is switched off and on.

3.2.2 Fault Symptom on GSM-Tester:

This fault cannot be detected with a GSM-tester.

3.3 Priority:

........ Mandatory

⌧

........ Repair

........ Optional

........ Not Yet Defined

3.4 Repair Documentation

3.4.1 Description of procedure:

3.4.1.1 Diagnosis

Check the RTC battery visually. Watch for dry joints!

V1.1 Page 11 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 12

3.4.1.2 Repair by component change

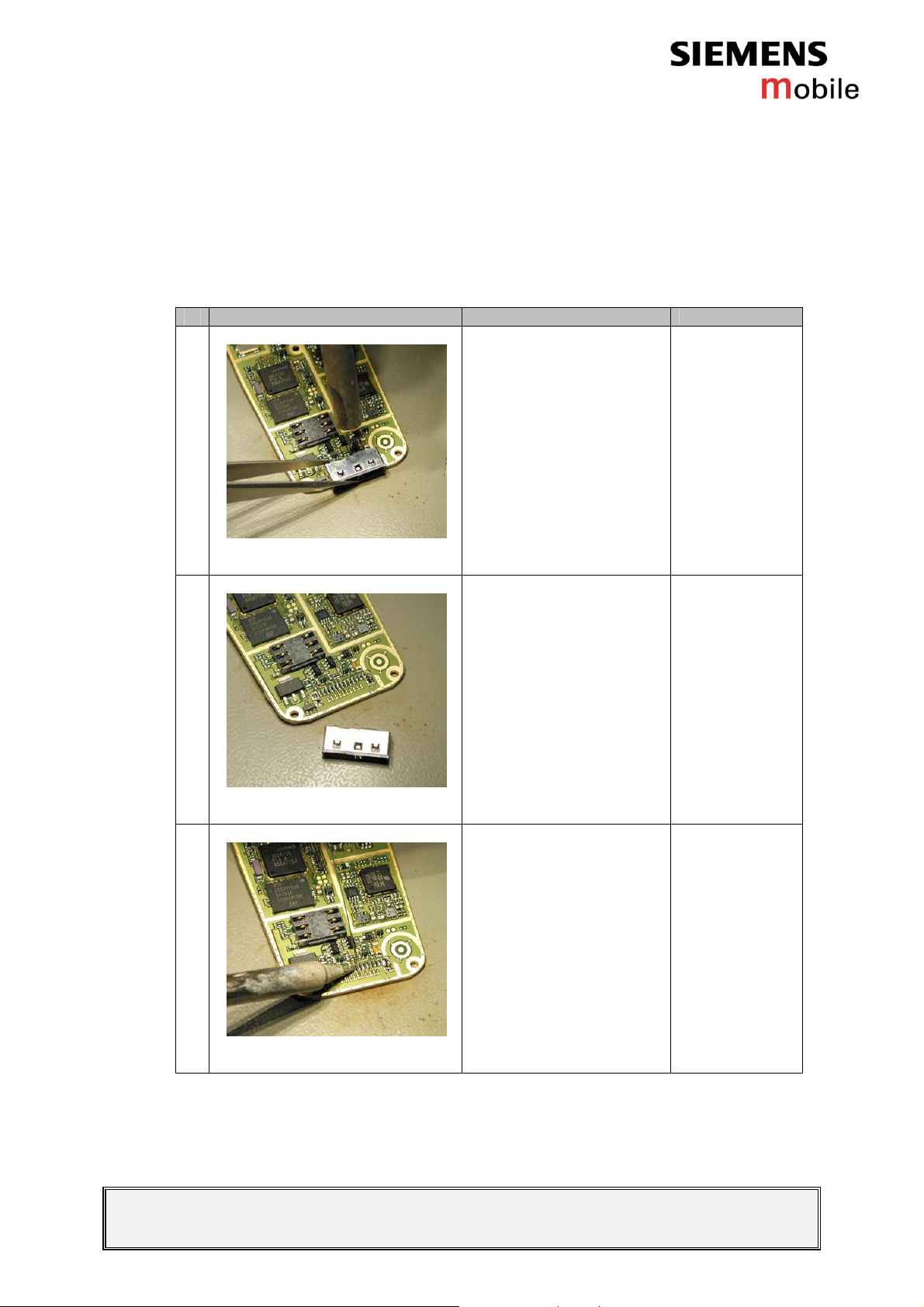

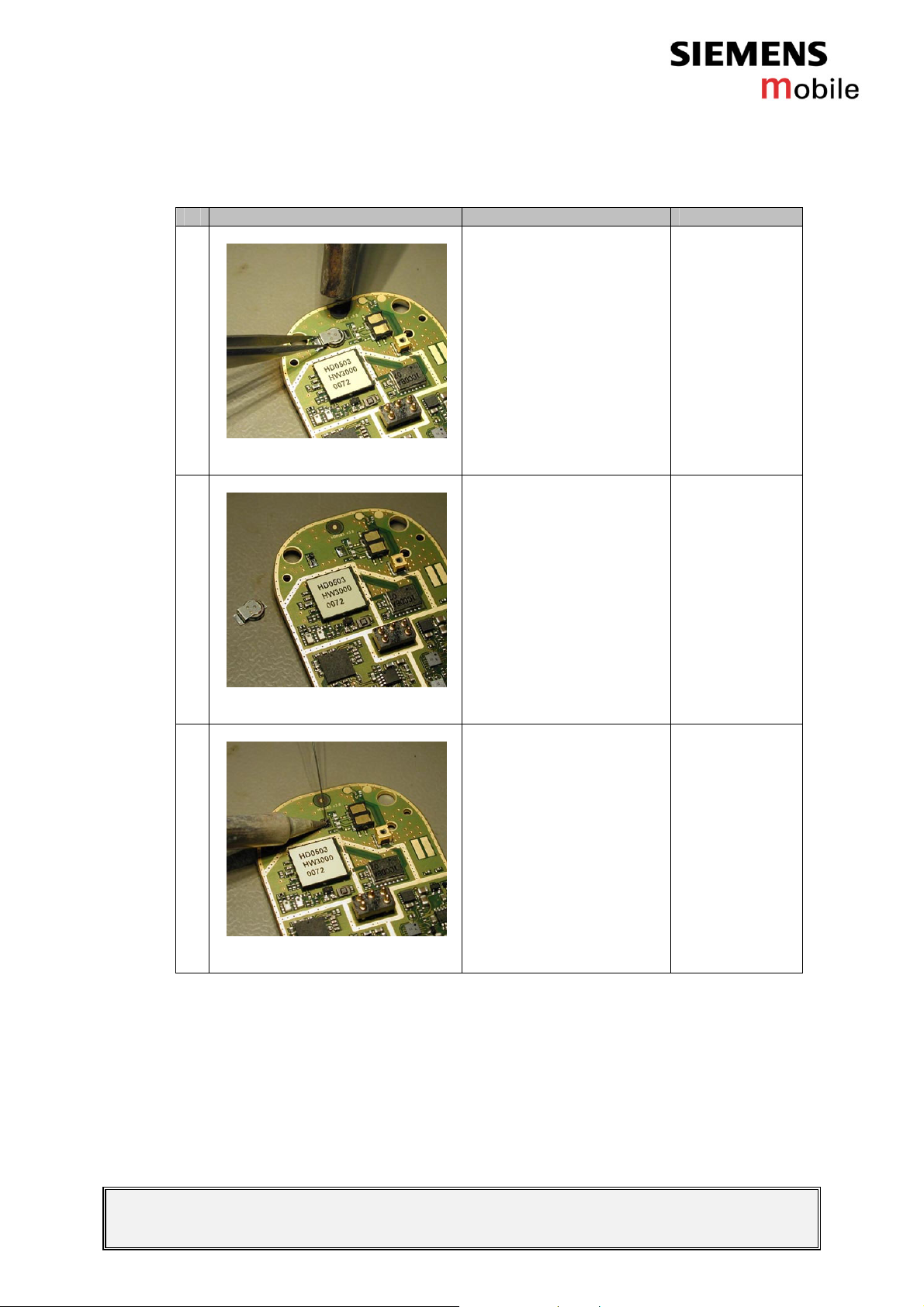

# Figure Instruction Note

1

Use a hot air blower to

remove the defective

RTC battery. Avoid

excessive heat!

Watch out for the

surrounding

components!

Figure 3-1

2

Figure 3-2

3

Figure 3-3

The defective RTC

battery is removed.

Add solder on the pads.

V1.1 Page 12 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

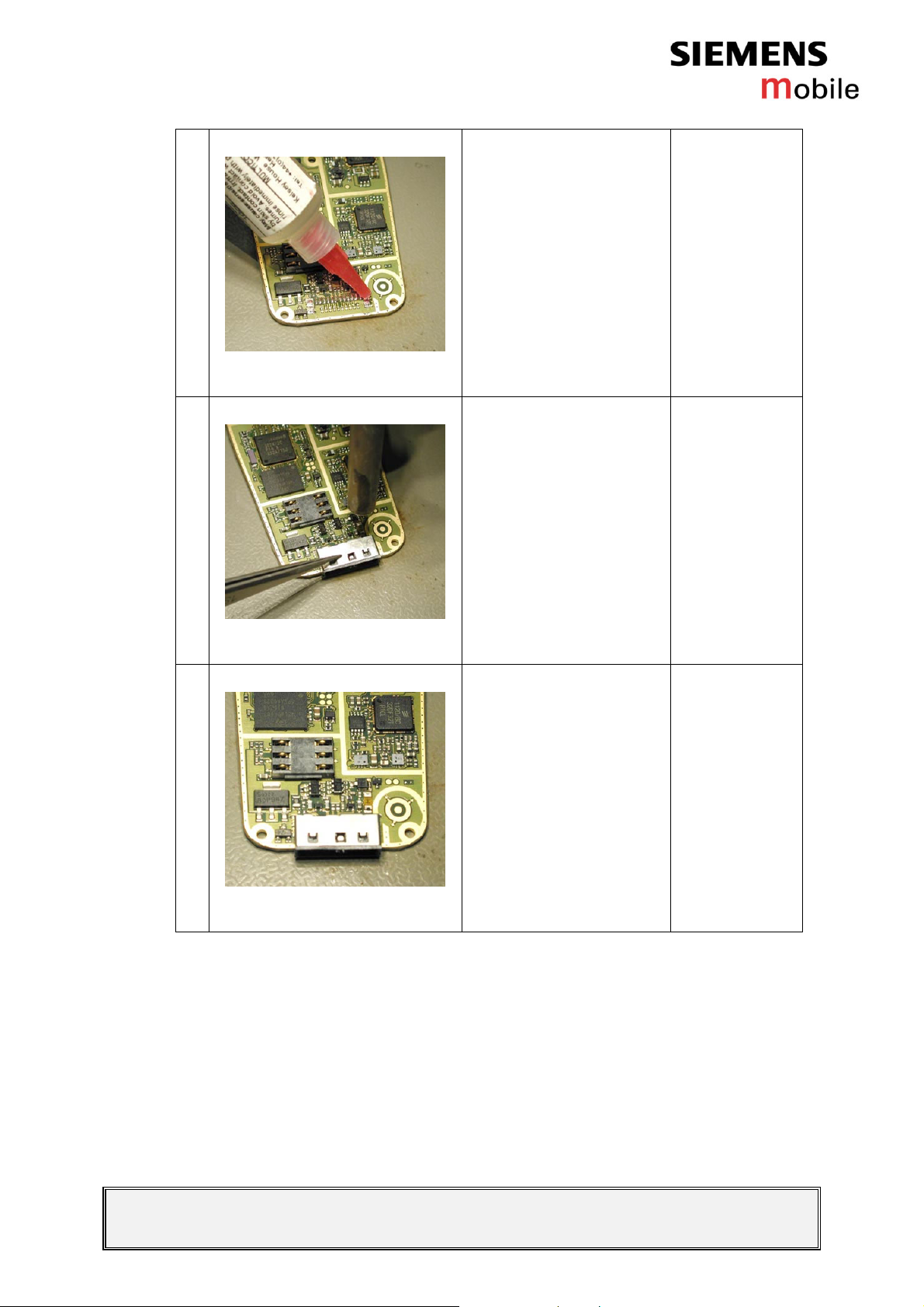

Page 13

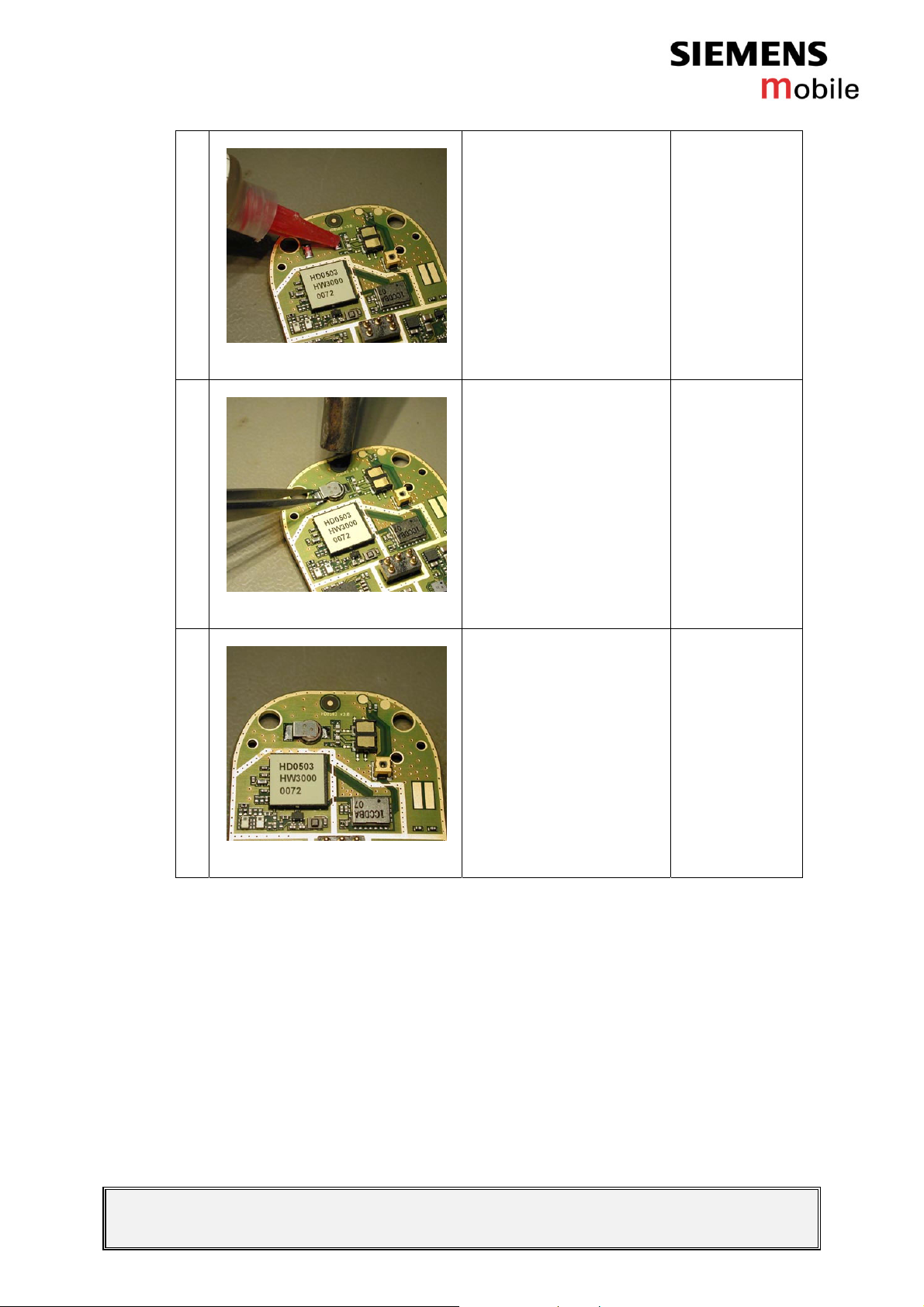

4

Figure 3-4

5

Figure 3-5

Add flux on the pads.

Re-solder the new RTC

battery by using a hot air

blower and a soldering

iron if necessary. Check

that the RTC battery is

exactly in right place.

Watch surrounding

components!

6

Figure 3-6

3.4.1.3 Repair by SW-Booting

3.4.1.4 Test

Not possible!

Retest the handset after the repair.

If clock resets when battery is removed, RTC battery is faulty.

Measurement with voltage meter, the voltage should be 1.8V.

Note! If battery is empty, wait that it charges and voltage raises up to

1.8V.

New RTC battery is in its

place.

V1.1 Page 13 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 14

3.4.2 List of needed material

3.4.2.1 Components

RTC-battery SMD VA6

Part Number: L36145-K1310-X293

3.4.2.2 Jigs and Tools

Hot air blower

Soldering iron

Tweezers

3.4.2.3 Special Tools

None

3.4.2.4 Working materials

Flux

Solder

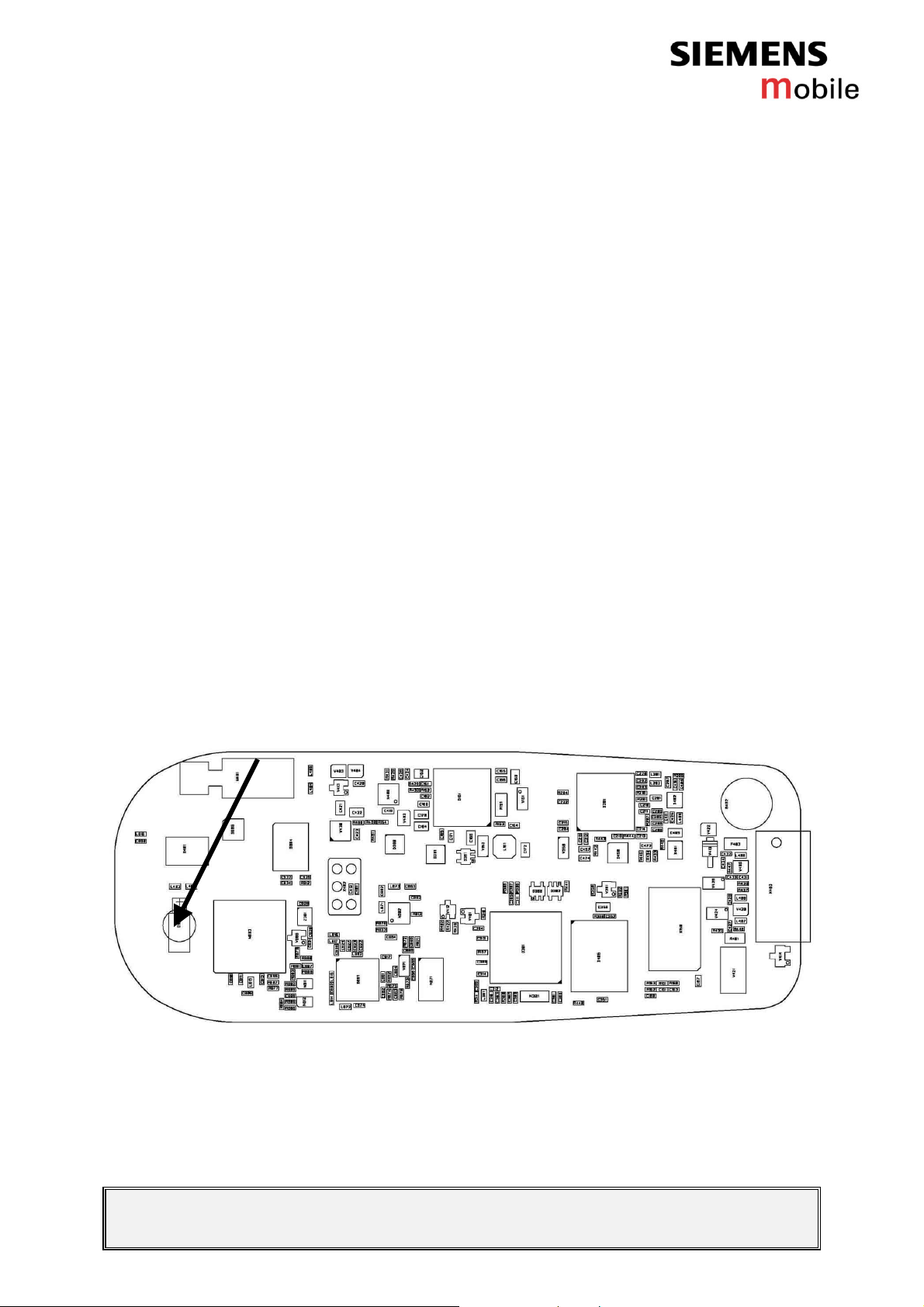

3.4.3 Drawings

Figure 1: C62 board, RTC battery side

V1.1 Page 14 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 15

Figure 2: C62 RTC battery placement (top view)

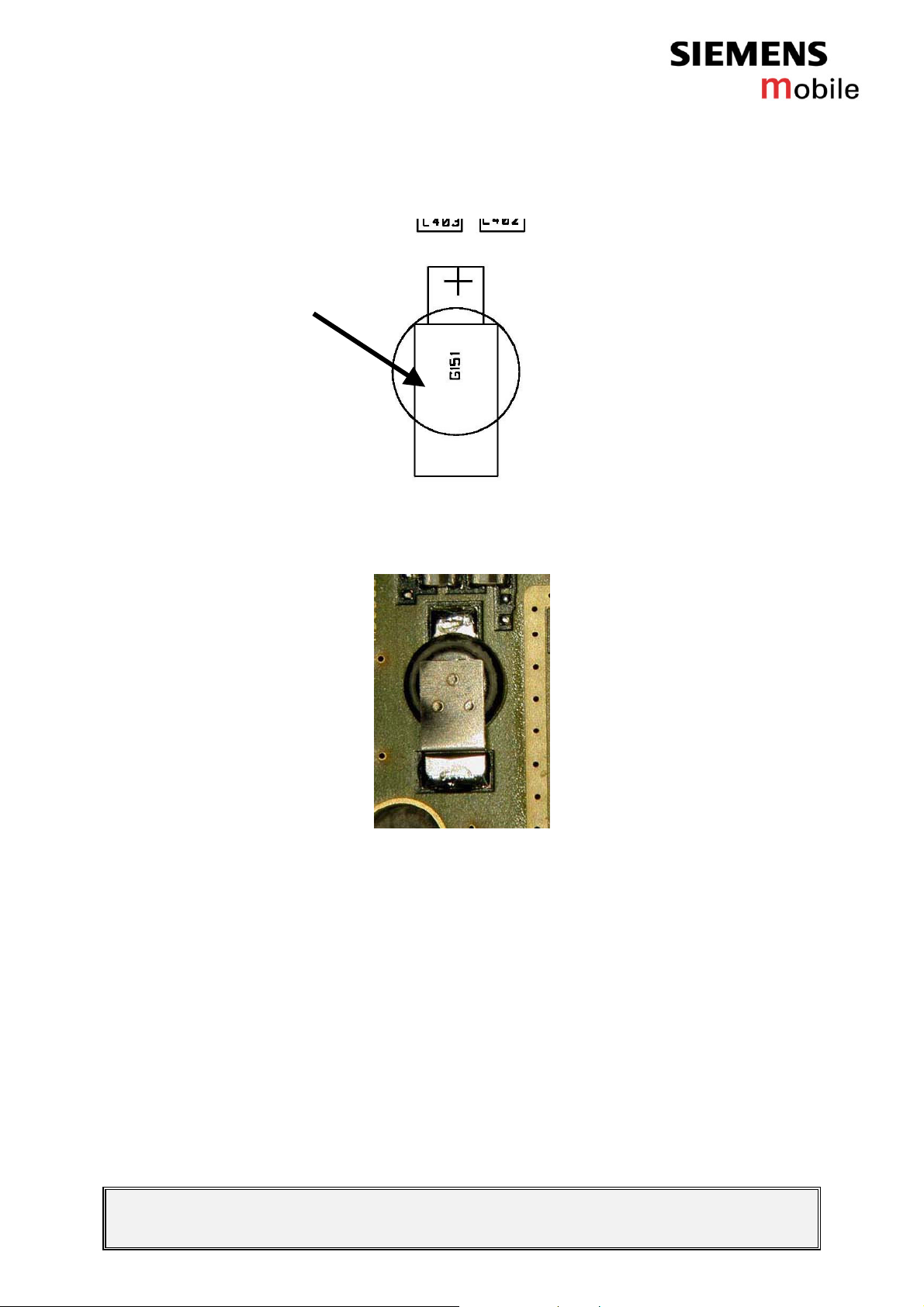

Figure 3: C62 RTC battery

V1.1 Page 15 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 16

4 Transistor SOT-323 (for LEDs)

4.1 Affected Units

4.1.1 Type: C62

4.1.2 Affected IMEIs / Date Codes: All / All

4.1.3 Affected SW-Versions: All

4.2 Fault Description

4.2.1 Fault Symptoms for customers:

4.2.2 Fault Symptom on GSM-Tester:

4.3 Priority:

........ Mandatory

⌧

........ Repair

........ Optional

........ Not Yet Defined

4.4 Repair Documentation

4.4.1 Description of procedure:

Display light does not work.

This fault cannot be detected with a GSM-tester.

4.4.1.1 Diagnosis

Check the transistor visually. Watch for dry joints!

V1.1 Page 16 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 17

4.4.1.2 Repair by component change

# Figure Instruction Note

1

Use a hot air blower to

remove the defective

transistor. Avoid

excessive heat!

Watch out for the

surrounding

components!

Figure 4-1

2

Figure 4-2

3

Figure 4-3

Add solder on the pads.

Add flux on the pads.

V1.1 Page 17 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 18

4

Figure 4-4

4.4.1.3 Repair by SW-Booting

4.4.1.4 Test

Re-solder the new

transistor by using a hot

air blower and a

soldering iron if

necessary. Watch

surrounding

components!

Not possible!

Retest the handset after the repair.

The circuit diagram of Transistor SOT-323 (for LEDs)

4.4.2 List of needed material

4.4.2.1 Components

TR NPN SOT323 SMD

Part number: L36197-F5122-F76

4.4.2.2 Jigs and Tools

Hot air blower

Soldering iron

Tweezers

V1.1 Page 18 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 19

4.4.2.3 Special Tools

None

4.4.2.4 Working materials

Flux

Solder

4.4.3 Drawings

Figure 1: C62 board, transistor SOT323 (for LEDs) side

Figure 2: C62 transistor SOT323 (for LEDs) placement (top view)

V1.1 Page 19 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 20

Figure 3: C62 transistor SOT323 (for LEDs)

V1.1 Page 20 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 21

5 Transistor SOT-323 (for Vibra)

5.1 Affected Units

5.1.1 Type: C62

5.1.2 Affected IMEIs / Date Codes: All / All

5.1.3 Affected SW-Versions: All

5.2 Fault Description

5.2.1 Fault Symptoms for customers:

5.2.2 Fault Symptom on GSM-Tester:

5.3 Priority:

........ Mandatory

⌧

........ Repair

........ Optional

........ Not Yet Defined

5.4 Repair Documentation

5.4.1 Description of procedure:

Vibrator does not work.

This fault cannot be detected with a GSM-tester.

5.4.1.1 Diagnosis

Check the transistor visually. Watch for dry joints!

V1.1 Page 21 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 22

5.4.1.2 Repair by component change

# Figure Instruction Note

1

Use a hot air blower to

remove the defective

transistor. Avoid

excessive heat!

Watch out for the

surrounding

components!

Figure 5-1

2

Figure 5-2

3

Figure 5-3

Add solder on the pads.

Add flux on the pads.

V1.1 Page 22 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 23

4

Figure 5-4

5.4.1.3 Repair by SW-Booting

5.4.1.4 Test

Re-solder the new

transistor by using a hot

air blower and a

soldering iron if

necessary. Watch

surrounding

components!

Not possible!

Retest the handset after the repair.

- GROUND+LEFT VIBRA PAD should have VBATT (4.2V).

- COILS L404, L405 should have resistance of 1.0 Ohm.

Change V413 if vibrator does not work after replacement.

The circuit diagram of Transistor SOT-323 (for vibra)

5.4.2 List of needed material

5.4.2.1 Components

TR NPN SOT323 SMD

Part number: L36197-F5122-F76

5.4.2.2 Jigs and Tools

Hot air blower

Soldering iron

Tweezers

V1.1 Page 23 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 24

5.4.2.3 Special Tools

None

5.4.2.4 Working materials

Flux

Solder

5.4.3 Drawings

Figure 1: C62 board, transistor SOT323 (for vibra) side

Figure 2: C62 transistor SOT323 (for vibra) placement (top

view)

V1.1 Page 24 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 25

Figure 3: C62 transistor SOT323 (for Vibra)

V1.1 Page 25 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 26

6 Fuse

6.1 Affected Units

6.1.1 Type: C62

6.1.2 Affected IMEIs / Date Codes: All / All

6.1.3 Affected SW-Versions: All

6.2 Fault Description

6.2.1 Fault Symptoms for customers:

6.2.2 Fault Symptom on GSM-Tester:

6.3 Priority:

........ Mandatory

⌧

........ Repair

........ Optional

........ Not Yet Defined

6.4 Repair Documentation

6.4.1 Description of procedure:

Charging does not work.

Accessories do not work.

This fault cannot be detected with a GSM-tester.

6.4.1.1 Diagnosis

Check the fuse visually. Watch for dry joints!

V1.1 Page 26 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 27

6.4.1.2 Repair by component change

# Figure Instruction Note

1

Use a hot air blower to

remove the defective

fuse. Avoid excessive

heat!

Watch out for the

surrounding

components!

Figure 6-1

2

Figure 6-2

3

Figure 6-3

Add solder on the pads.

Add flux on the pads.

V1.1 Page 27 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 28

4

Figure 6-4

6.4.1.3 Repair by SW-Booting

6.4.1.4 Test

Re-solder the new fuse

by using a hot air blower

and a soldering iron if

necessary. Watch

surrounding

components!

Not possible!

Retest the handset after the repair.

Measure resistance over fuse (F403), it should be 0 Ohm.

Measure transistor SOT-223 (V421) PIN1+GROUND, it should

be 6.2V (zener voltage), if it’s not, then the zener diode (V414)

is faulty.

Measure V421 PIN2+GROUND, it should be 8.3 V (charging

voltage, not charging mode), if it’s not, then the Voltage

suppressor (V419) is faulty.

Measure V421 PIN3+GROUND, it should be 5.7V (lowered

voltage), if it’s not, then the V421 is faulty.

The circuit diagram of Fuse

V1.1 Page 28 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 29

6.4.2 List of needed material

6.4.2.1 Components

Fuse low profile 1A 1206 SMD

Part number: L36197-F5122-F79

6.4.2.2 Jigs and Tools

Hot air blower

Soldering iron

Tweezers

6.4.2.3 Special Tools

None

6.4.2.4 Working materials

Flux

Solder

6.4.3 Drawings

Figure 1: C62 board, fuse side

V1.1 Page 29 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 30

Figure 2: C62 fuse placement (top view)

Figure 3: C62 fuse

V1.1 Page 30 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 31

7 Voltage supressor

7.1 Affected Units

7.1.1 Type: C62

7.1.2 Affected IMEIs / Date Codes: All / All

7.1.3 Affected SW-Versions: All

7.2 Fault Description

7.2.1 Fault Symptoms for customers:

7.2.2 Fault Symptom on GSM-Tester:

7.3 Priority:

........ Mandatory

⌧

........ Repair

........ Optional

........ Not Yet Defined

7.4 Repair Documentation

7.4.1 Description of procedure:

Charging does not work.

Accessories do not work.

This fault cannot be detected with a GSM-tester.

7.4.1.1 Diagnosis

Check the voltage supressor visually. Watch for dry joints!

V1.1 Page 31 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 32

7.4.1.2 Repair by component change

# Figure Instruction Note

1

Use a hot air blower to

remove the defective

voltage supressor. Avoid

excessive heat!

Watch out for the

surrounding

components!

Figure 7-1

2

Figure 7-2

3

Figure 7-3

Add solder on the pads.

Add flux on the pads.

V1.1 Page 32 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 33

4

Figure 7-4

7.4.1.3 Repair by SW-Booting

7.4.1.4 Test

Re-solder the new

voltage supressor by

using a hot air blow and

a soldering iron if

necessary. Watch

surrounding

components!

Not possible!

Retest the handset after the repair.

Measure resistance over fuse (F403), it should be 0 Ohm.

Measure transistor SOT-223 (V421) PIN1+GROUND, it should

be 6.2V (zener voltage), if it’s not, then the zener diode (V414)

is faulty.

Measure V421 PIN2+GROUND, it should be 8.3 V (charging

voltage, not charging mode), if it’s not, then the Voltage

suppressor (V419) is faulty.

Measure V421 PIN3+GROUND, it should be 5.7V (lowered

voltage), if it’s not, then the V421 is faulty.

The circuit diagram of Voltage suppressor

V1.1 Page 33 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 34

7.4.2 List of needed material

7.4.2.1 Components

Zener transient voltage supressor 12V max 1000W

Part number: L36197-F5122-F81

7.4.2.2 Jigs and Tools

Hot air blower

Soldering iron

Tweezers

7.4.2.3 Special Tools

None

7.4.2.4 Working materials

Flux

Solder

7.4.3 Drawings

Figure 1: C62 board, Voltage supressor side

V1.1 Page 34 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 35

Figure 2: C62 Voltage supressor placement (top view)

Figure 3: C62 voltage supressor

V1.1 Page 35 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 36

8 Transistor SOT-223

8.1 Affected Units

8.1.1 Type: C62

8.1.2 Affected IMEIs / Date Codes: All / All

8.1.3 Affected SW-Versions: All

8.2 Fault Description

8.2.1 Fault Symptoms for customers:

8.2.2 Fault Symptom on GSM-Tester:

8.3 Priority:

........ Mandatory

⌧

........ Repair

........ Optional

........ Not Yet Defined

8.4 Repair Documentation

8.4.1 Description of procedure:

Charging does not work.

This fault cannot be detected with a GSM-tester.

8.4.1.1 Diagnosis

Check the transistor visually. Watch for dry joints!

V1.1 Page 36 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 37

8.4.1.2 Repair by component change

# Figure Instruction Note

1

Use a hot air blower to

remove the defective

transistor. Avoid

excessive heat!

Watch out for the

surrounding

components!

Figure 8-1

2

Figure 8-2

3

Figure 8-3

Add solder on the pads.

Add flux on the pads.

V1.1 Page 37 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 38

4

Re-solder the new

transistor by using a hot

air blower and a

soldering iron if

necessary. Watch

surrounding

components!

Figure 8-4

8.4.1.3 Repair by SW-Booting

Not possible!

8.4.1.4 Test

Retest the handset after the repair.

Measure resistance over fuse (F403), it should be 0 Ohm.

Measure

transistor SOT-223 (V421) PIN1+GROUND, it should be

6.2V (zener voltage), if it’s not, then the zener diode (V414) is

faulty.

Measure V421

PIN2+GROUND, it should be 8.3 V (charging

voltage, not charging mode), if it’s not, then the Voltage

suppressor (V419) is faulty.

Measure V421 PIN3+GROUND, it should be 5.7V (lowered

voltage), if it’s not, then the V421 is faulty.

The circuit diagram of Transistor SOT-223

V1.1 Page 38 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 39

8.4.2 List of needed material

8.4.2.1 Components

Transistor NPN SOT-223

Part number: L36197-F5122-F77

8.4.2.2 Jigs and Tools

Hot air blower

Soldering iron

Tweezers

8.4.2.3 Special Tools

None

8.4.2.4 Working materials

Flux

Solder

8.4.3 Drawings

Figure 1: C62 board, transistor SOT-223 side

V1.1 Page 39 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 40

Figure 2: C62 transistor SOT-223 placement (top view)

Figure 3: C62 transistor SOT-223

V1.1 Page 40 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 41

9 Zener diode

9.1 Affected Units

9.1.1 Type: C62

9.1.2 Affected IMEIs / Date Codes: All / All

9.1.3 Affected SW-Versions: All

9.2 Fault Description

9.2.1 Fault Symptoms for customers:

9.2.2 Fault Symptom on GSM-Tester:

9.3 Priority:

........ Mandatory

⌧

........ Repair

........ Optional

........ Not Yet Defined

9.4 Repair Documentation

9.4.1 Description of procedure:

Charging does not work.

This fault cannot be detected with a GSM-tester.

9.4.1.1 Diagnosis

Check the zener diode visually. Watch for dry joints!

V1.1 Page 41 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 42

9.4.1.2 Repair by component change

# Figure Instruction Note

1

Use a hot air blower to

remove the defective

zener diode. Avoid

excessive heat!

Watch out for the

surrounding

components!

Figure 9-1

2

Figure 9-2

3

Figure 9-3

Add solder on the pads.

Add flux on the pads.

V1.1 Page 42 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 43

4

Re-solder the new zener

diode by using a hot air

blower and a soldering

iron if necessary. Watch

surrounding

components!

Figure 9-4

9.4.1.3 Repair by SW-Booting

Not possible!

9.4.1.4 Test

Retest the handset after the repair.

Measure resistance over fuse (F403), it should be 0 Ohm.

Measure transistor SOT-223 (V421) PIN1+GROUND, it should

be 6.2V (zener voltage), if it’s not, then the zener diode (V414)

is faulty.

Measure V421 PIN2+GROUND, it should be 8.3 V (charging

voltage, not charging mode), if it’s not, then the Voltage

suppressor (V419) is faulty.

Measure V421 PIN3+GROUND, it should be 5.7V (lowered

voltage), if it’s not, then the V421 is faulty.

The circuit diagram of Zener diode

V1.1 Page 43 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 44

9.4.2 List of needed material

9.4.2.1 Components

Zener diode 6.2V max 350mW SOT23 SMD

Part number: L36197-F5122-F78

9.4.2.2 Jigs and Tools

Hot air blower

Soldering iron

Tweezers

9.4.2.3 Special Tools

None

9.4.2.4 Working materials

Flux

Solder

9.4.3 Drawings

Figure 1: C62 board, zener diode side

V1.1 Page 44 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 45

Figure 2: C62 zener diode placement (top view)

Figure 3: C62 zener diode

V1.1 Page 45 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 46

10 LED color yellow

10.1 Affected Units

10.1.1 Type: C62

10.1.2 Affected IMEIs / Date Codes: All / All

10.1.3 Affected SW-Versions: All

10.2 Fault Description

10.2.1 Fault Symptoms for customers:

10.2.2 Fault Symptom on GSM-Tester:

10.3 Priority:

........ Mandatory

⌧

........ Repair

........ Optional

........ Not Yet Defined

10.4 Repair Documentation

No even light in the keymat or dark area in the

keymat.

LEDs are not lit.

This fault cannot be detected with a GSM-tester.

10.4.1 Description of procedure:

10.4.1.1 Diagnosis

Check the yellow LED visually.

Use the diode test function of a multimeter to check the status of the

diode.

V1.1 Page 46 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 47

The typical voltage drop on the diode is 1.7V when testing the diode

function with the multimeter.

10.4.1.2 Repair by component change

# Figure Instruction Note

1

Remove the domesheet

from the PWB.

Figure 10-1

2

Figure 10-2

3

Figure 10-3

Use a hot air blower to

remove the defective

yellow LED. Avoid

excessive heat!

Watch out for the

surrounding

components!

Add solder on the pads.

V1.1 Page 47 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 48

4

Figure 10-4

5

Figure 10-5

Add flux on the pads.

Place the LED according

to Fig.13-5, anode on

the right, cathode on the

left.

Direction of

the board in

the picture:

system

connector is at

the bottom

(See Fig.13-6)

6

Figure 10-6

7

Figure 10-7

Re-solder the new

yellow LED by using a

hot air blower and a

soldering iron if

necessary. Watch

surrounding

components!

V1.1 Page 48 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 49

8

Figure 10-8

10.4.1.3 Repair by SW-Booting

10.4.1.4 Test

Not possible!

Retest the handset after the repair.

Adding voltage (1.8V) on one of the LED, If LEDs work well, the

light is lid.

- If single LED is empty, one can be changed (LEDs are in

parallel connection).

- If all LEDs are empty, check TR SOT-323 (V412) with

voltage meter.

- Voltage over V412 should be over 0.5V.

Mount the domesheet in

its place. Use a new

domesheet if the old one

was damaged during

removal.

Use the the

dome sheet

Jig.

F30032-P333A1

- PIN1+GROUND (when light is on) voltage should be

1.6V.

- PIN3+GROUND (when light is on) voltage should be

VBATT-1.8V (2.8V).

The circuit diagram of the LED color yellow

V1.1 Page 49 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 50

10.4.2 List of needed material

10.4.2.1 Components

LED yellow 1.60x0.8x0.6mm SMD

Part number: L36197-F5122-F72

10.4.2.2 Jigs and Tools

Hot air blower

Soldering iron

Tweezers

10.4.2.3 Special Tools

None

10.4.2.4 Working materials

Flux

Solder

10.4.3 Drawings

Figure 1: C62 board, LED colour yellow side

V1.1 Page 50 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Page 51

Figure 2: C62 LED colour yellow placement (top view)

Figure 3: C62 LED colour yellow

V1.1 Page 51 of 51 ICM CCQ GRM

Company Confidential

Level 2,5 C62 Copyright 2002 Siemens AG 10/2003

Loading...

Loading...