Page 1

BT 200 04/00 English

BT 200

Physical Bus Test Device

for PROFIBUS-DP

Table of Contents

1 DESCRIPTION .............................................. 2

2 COMMISSIONING ......................................... 4

3 NORMAL MODE ........................................... 5

3.1 WIRING TEST ........................................................6

RROR MESSAGES OF THE WIRING TEST.................7

3.2 E

4 SPECIALIST MODE .................................... 10

4.1 OPERATOR CONTROL ..........................................10

4.2 STATION (RS 485) TEST .....................................12

RANCH TEST.....................................................13

4.3 B

ISTANCE...........................................................15

4.4 D

4.5 REFLECTION TEST...............................................16

ERVICE.............................................................17

4.6 S

5 LOG MODE ................................................. 18

6 SAMPLE APPLICATIONS .......................... 20

7 MAINTENANCE AND TROUBLE-

SHOOTING..................................................... 24

7.1 CHARGING STATUS OF THE BATTERY ....................24

HANGING THE BATTERY .....................................24

7.2 C

ELF-TESTS........................................................25

7.3 S

7.4 ERROR CORRECTION TABLE.................................26

8 ACCESSORIES AND REPLACEM ENT

PARTS ............................................................ 27

9 TECHNICAL DATA ..................................... 28

(S)J31069-D0075-U001-A2-6318 Page 1

Page 2

English 04/00 BT 200

1 Description

Purpose of the BT 200

The BT 200 offers diagnostics for PROFIBUSDP systems without having to use additional

measuring aids (e.g., PC or oscilloscope).

BT 200 - version 2

Version 2 of the BT 200 offers additional

functions.

• Log function

• 6-language user interface

• Test of the PROFIBUS-DP master inter-

face

• Indication of the master’s address

• Wiring test with stations connected

• New, reasonably-priced compact char-

ging device

(S)J31069-D0075-U001-A2-6318Page 2

Page 3

BT 200 04/00 English

Operator control elements and display

Fig. 1 BT 200 operator control elements and display

1) PROFIBUS-DP connection (9-pin sub D)

2) LC display (2 x 16 characters )

3) ON/OFF button

4) Charging socket for plug connector/charging device

5) TEST key (start test)

6) CURSOR keys

7) OK key (various functions)

8) ESCAPE key (terminate)

9) Charging contacts for charging device

(S)J31069-D0075-U001-A2-6318 Page 3

Page 4

English 04/00 BT 200

2 Commissioning

Before initial commissioning , chec k your delivery, and charge the battery.

Scope of delivery

The delivery includes:

- 1 BT 200

- 1 battery

- 1 test plug connector (wiring test)

- 1 test cable, length: 2 m (station test)

- 1 user’s guide

Charging the battery

- Open the battery compartment (see

chapter on changing the battery), and

check to determine whether the battery is

installed. Install the battery if necessary.

- Charge battery of the BT 200 via char-

ging shell (approx. 4 hours).

U Attention!

The battery is always delivered uncharged.

The charging shell is not included and must

be ordered separately.

- Measuring cannot be performed during

the charging procedure.

(S)J31069-D0075-U001-A2-6318Page 4

Page 5

BT 200 04/00 English

3 Normal Mode

The BT 200 is turned on with the ON/OFF

button.

Keep the ON/OFF button pressed until you

see a reaction on the display.

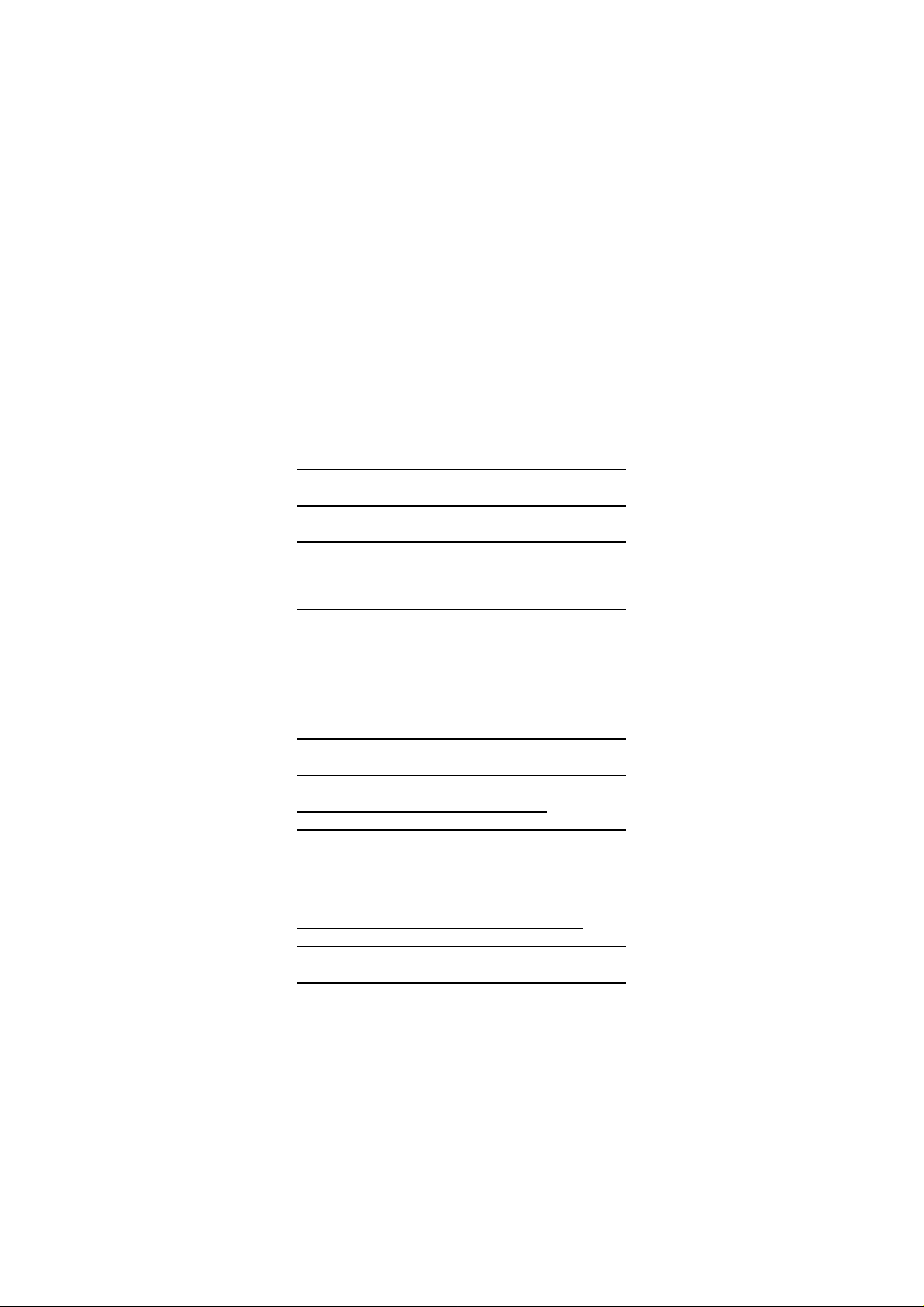

Standby display

The following display appears for approx. 2

seconds after the device is turned on.

Battery display

The battery capacity display is then shown for

approx. 2 seconds.

Operational display

After the battery display disappears, the BT

200 assumes normal mode and displays the

start screen for the wiring test.

Only the wiring test can be performed in normal mode.

When the BT 200 is in log mode (the cursor

looks different), an extra screen appears after

each test.

Energy saver mode

If no keys are pressed for approx. 3 minutes

and no measurements are being performed,

the BT 200 goes off automatically.

(S)J31069-D0075-U001-A2-6318 Page 5

Page 6

English 04/00 BT 200

3.1 Wiring Test

Principle of measuring

The wiring test for a bus segment is performed between the BT 200 and the test plug

connector. During the installation phase, a

test can be performed from connector to connector. See figure 2. The test connector is

always installed on the one end of the bus

segment.

Short circuits can also be determined outside

the test path. The bus segment may only be

equipped with a terminating resistor at the

beginning and at the end.

Fig. 2 S t ep-by-step measuring principle

Performing the test

The test can be performed with or without

stations connected.

The test is started by pressing the TEST key.

One of the following two messages is displayed if the test was concluded successfully.

For one terminating resistor (as long as installation has not been completed, only one

terminal resistor is present)

After installation has been concluded, two resistors must be inserted.

The test is concluded by pressing the OK key,

and a new wiring test can be started.

The wiring test can also be concluded or terminated at any time by pressing the ESC key.

(S)J31069-D0075-U001-A2-6318Page 6

Page 7

BT 200 04/00 English

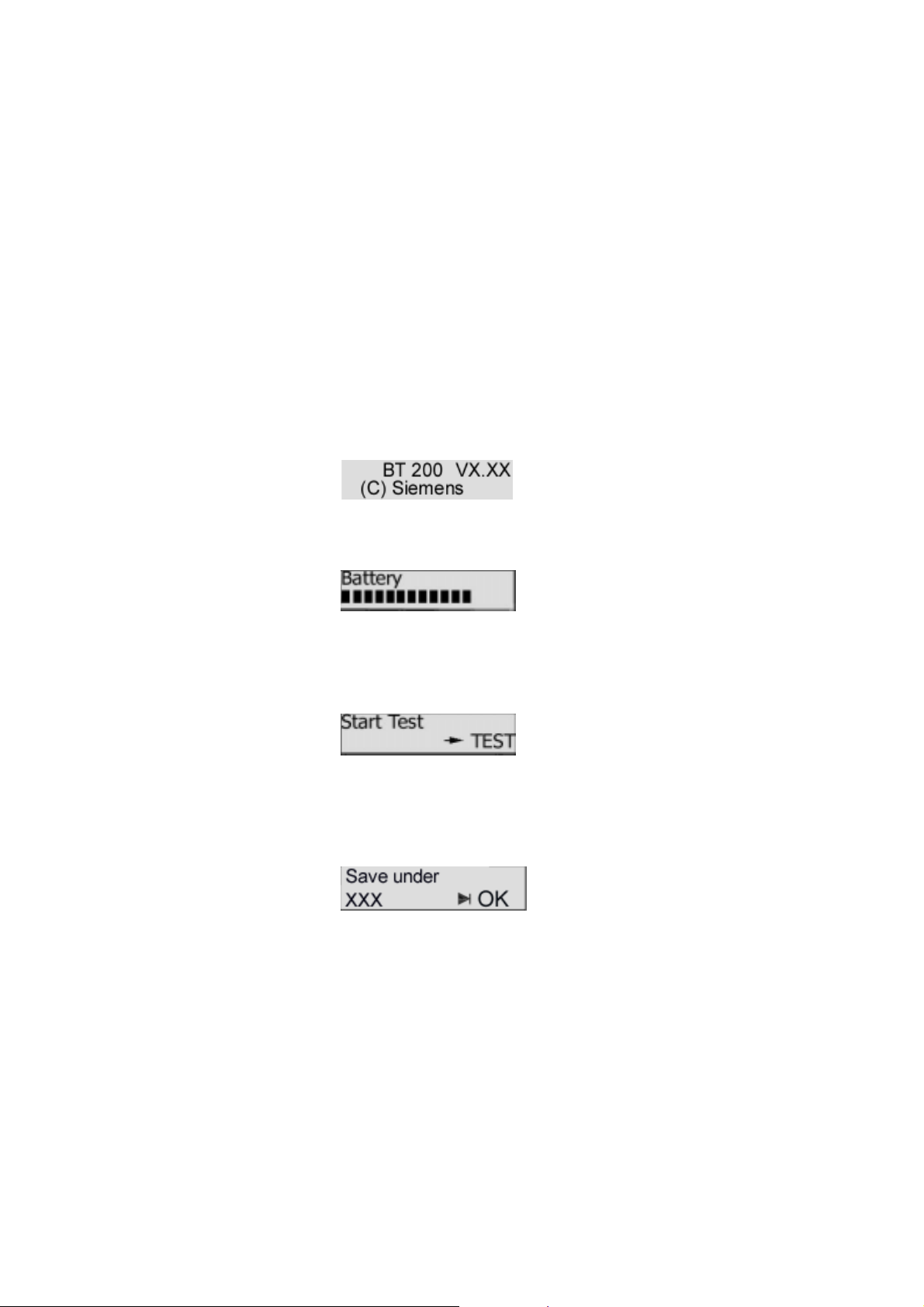

3.2 Error Messages of the Wiring Test

Station test

Check to determine whether the power supply

has been turned off for all stations and power

components.

Wire mix-up

Exchange the cores in the corresponding plug

connector.

U The wiring test must be performed each

time a new PROFIBUS plug connector is

connected. Otherwise an even number

of wire mix-ups will not be recognized.

Short circuit

Locate and correct the short circuit.

A frequent cause (e.g., of shield short circuits)

is the incorrect application of shield braiding in

the plug connectors.

(S)J31069-D0075-U001-A2-6318 Page 7

Page 8

English 04/00 BT 200

Line or shield break

Possible error causes:

• Interruption of several cores

• Interruption of cores and shield

• Test plug connector not connected

To obtain a correct measuring result for shield

break, the shield may not be connected with

ground.

With all four messages, first check the plug

connectors/connections in question. If these

are okay, replace the line.

(S)J31069-D0075-U001-A2-6318Page 8

Page 9

BT 200 04/00 English

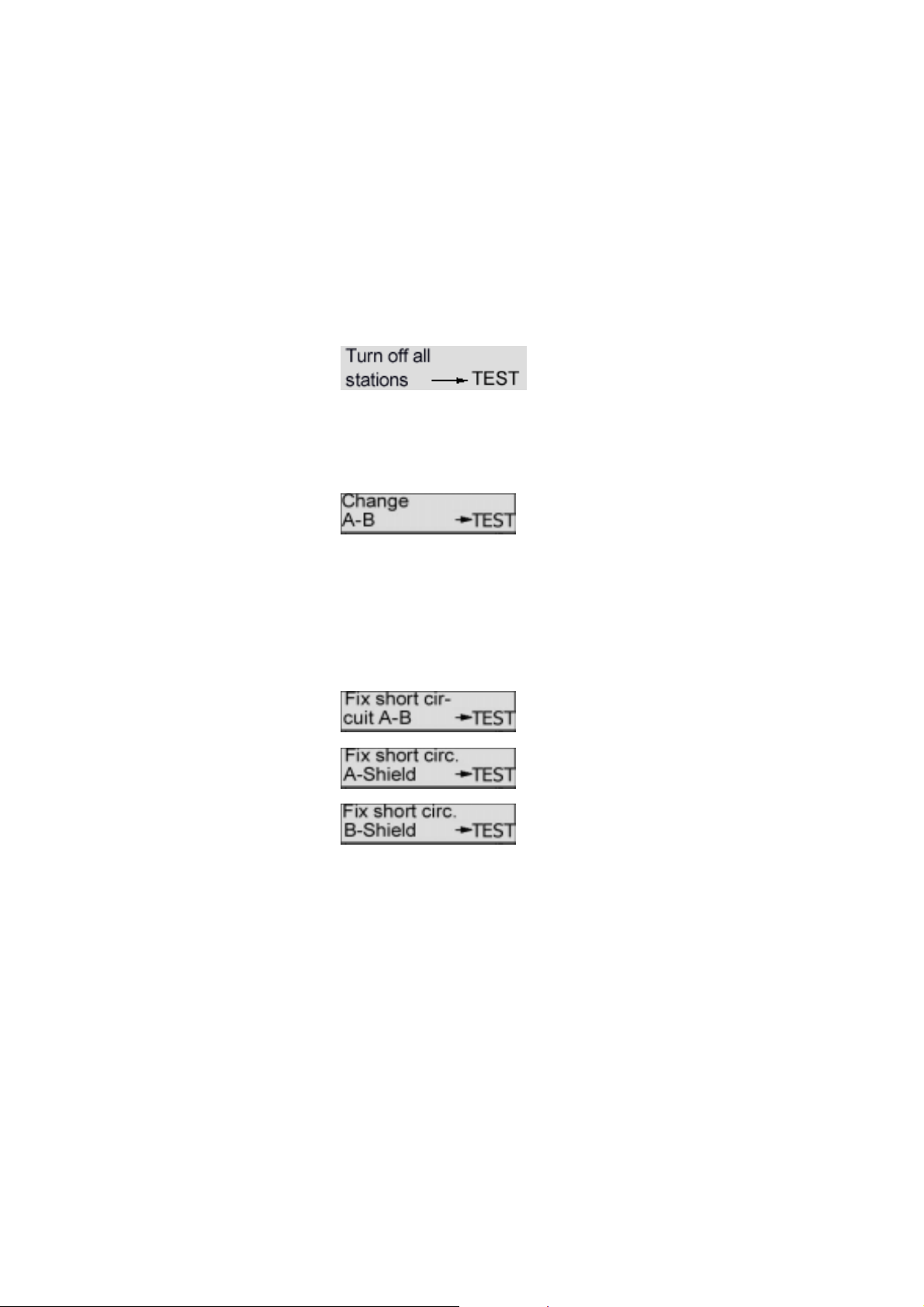

None or more than two terminating resistors

Page with the "→""←" keys.

Place a terminating resistor at the beginning

and end of the bus segment.

Page with the "→""←" keys.

Remove or deactivate all terminating resistors

except the two at the beginning and end of

the bus segment.

(S)J31069-D0075-U001-A2-6318 Page 9

Page 10

English 04/00 BT 200

4 Specialist Mode

You can switch from normal mode to specialist mode by pressing ESC and OK at the same time.

The following functions are available in specialist mode.

- Wiring test. See normal mode.

- Station test (RS 485 test)

- Branch test

- Distance measurement

- Reflection test

- Service menu

4.1 Operator Control

The BT 200 is menu-controlled via the input

keys of the sealed keyboard (figure 1).

Cursor

The current cursor position in the display is

shown as a flashing arrow and indicates the

function which is being performed.

If the BT200 is in log mode, the cursor position is shown with a modified arrow.

(S)J31069-D0075-U001-A2-6318Page 10

Page 11

BT 200 04/00 English

Menu items

Menu items are selected with the cursor and

activated with the OK key. The ESC key can

be used to terminate a running function or to

jump back to the higher-level menu item.

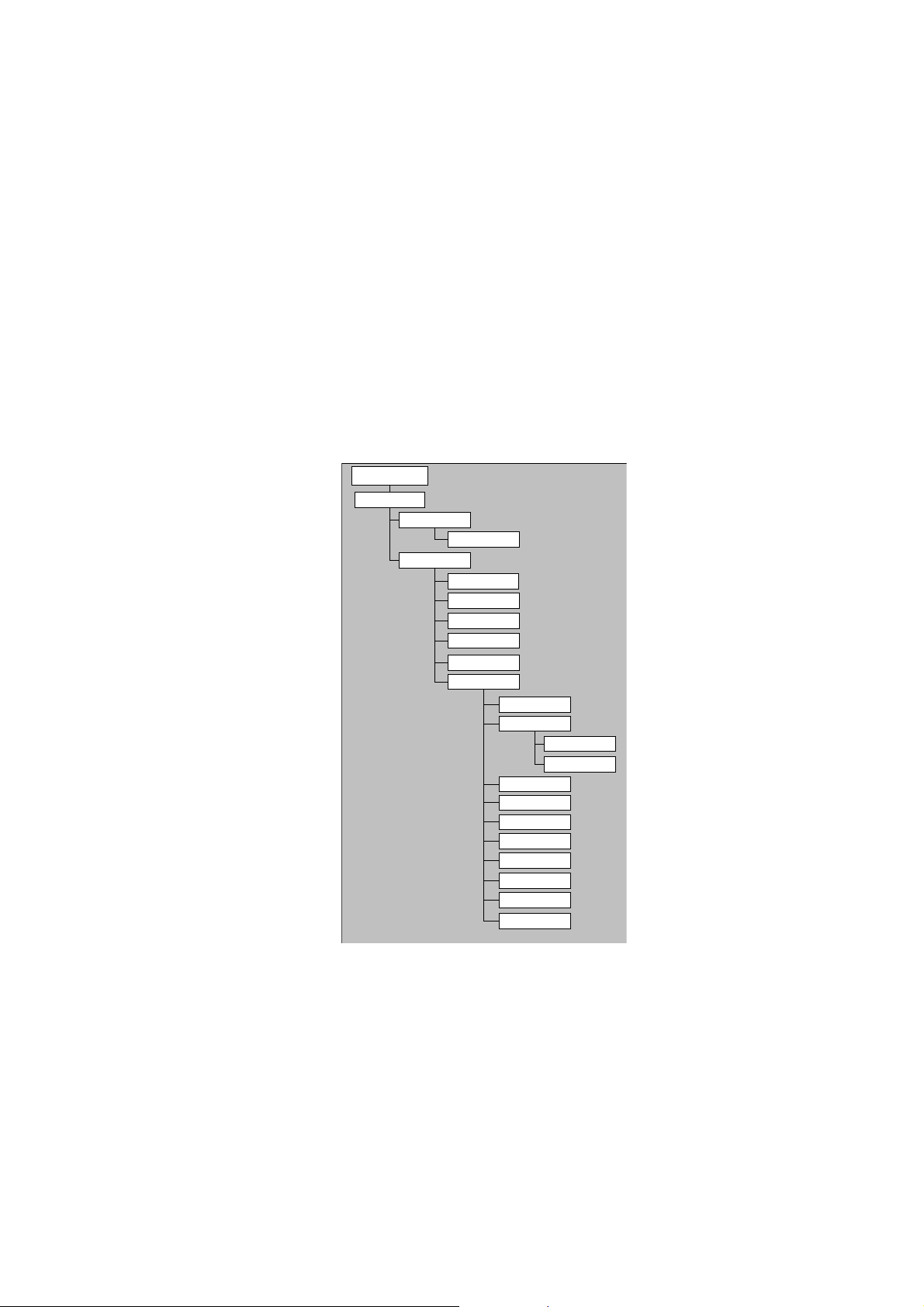

Menu structure

START

Battery test

N mode

s comde

(Normal mode)

Wiring

(Specalist mode)

Wiring

RS485

Branch

Distance

Reflection

SERVICE

(Test)

(Test)

(Test)

(Test)

(Measurement)

(Test)

(Settings)

Language

Settings

Baud rate

Resistance

Log mode

Communication

Battery

Contrast

Calibration

Deleting

FW version

Self test

Fig. 3 Menu st ructure

(S)J31069-D0075-U001-A2-6318 Page 11

Page 12

English 04/00 BT 200

4.2 Station (RS 485) Test

This test is used to test the RS 485 interface

of a single slave or master.

Performing the test

Disconnect bus connector from the station.

Establish point-to-point connection between

station and BT 200. See figure 4.

U Only the included test cable may be used for

this connection.

station

Fig. 4 P oi n t -to-point connection

Turn on the station since the test must be

performed with an active station. The master

must be in "RUN" mode.

Start station test.

Set address of the station to be tested as

shown below.

Test results

Possible test results are listed below.

- RS 485 okay (slave okay)

- RS 485 defective. (No continuous signal

receipt; repeat test.)

- No response (nothing at all received)

- 5 V : (corresponding measured value)

- RTS signal (YES or NO)

(S)J31069-D0075-U001-A2-6318Page 12

Page 13

BT 200 04/00 English

4.3 Branch Test

This can be used to check the availability of

all slaves on PROFIBUS or to address an in-

dividual slave.

The branch test can also be performed beyond repeaters/LWL.

Performing the test

Disconnect all masters from the bus (e.g., PG,

OP and CP). See figure 5.

Caution: The bus termination must remain

ensured.

Connect BT 200 to the bus.

Set the baud rate configured on the bus on

the BT 200.

Set the desired address for individual slave

test.

Set address to "000" for the total test.

Confirm with OK the address (slave or master) which was detected by the BT 200.

Fig. 5 Measuri ng pri nc i pl e of the branc h test

(S)J31069-D0075-U001-A2-6318 Page 13

Page 14

English 04/00 BT 200

Test results

During the total branch test, each available

slave is indicated in a list of available stations

(i.e., LIFE LIST).

- LIFE LIST

For an individual test

- No response (e.g., no station with this

bus address on the bus.)

- Faulty station (e.g., a slave number has

been assigned twice.)

(S)J31069-D0075-U001-A2-6318Page 14

Page 15

BT 200 04/00 English

4.4 Distance

Distance measurement can only detect lines

longer than 15 m. No distance measurement

can be performed when repeaters are used.

Performing the test

Turn off the power supply of all bus stations.

Connect test plug connector to one end of the

line and the BT 200 to the other end. (Turn

off resistor for BT 200.)

Start distance measurement.

After the start, the BT 200 requests three values which must be entered on the keyboard.

- Loop resistance (default = 110 Ω/km)

The default value can be changed via

menu item Service.

- Number of 12-Mbaud plug connec-

tors/devices with longitudinal inductivity

- Resistance value per connector/device

(default = 0.32 Ω)

After entry of the last value and confirmation

with OK, measurement is performed.

Measurement results

The following appears on the display.

The following error messages can occur during measurement.

- No resistor inserted.

- Display "0 m" (no plausible length deter-

mined)

- More than 1 resistor inserted.

Possible causes of errors:

- Distance < 15 m

- Stub lines, located on the measuring path

Correct the error, and repeat the measurement.

(S)J31069-D0075-U001-A2-6318 Page 15

Page 16

English 04/00 BT 200

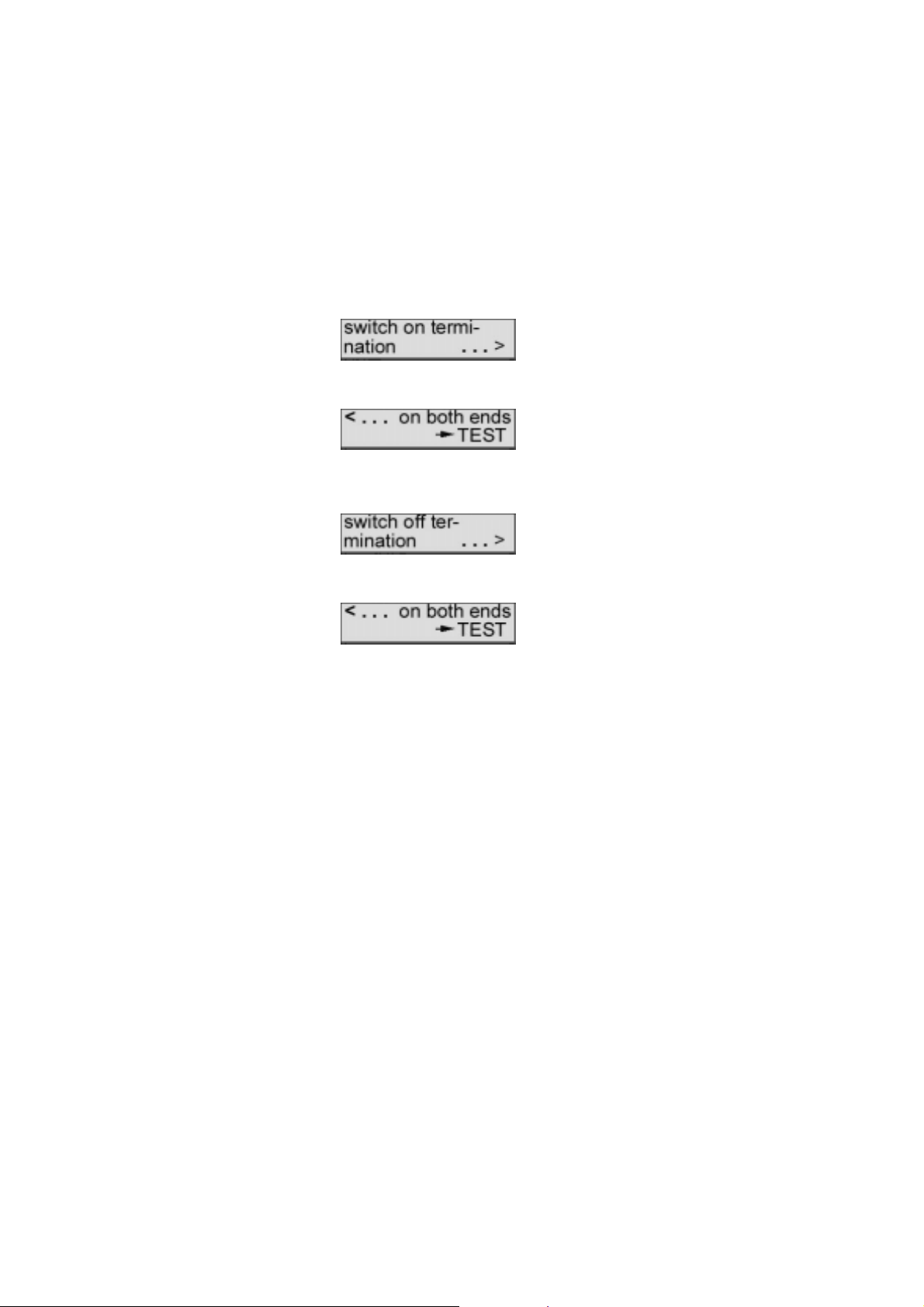

4.5 Reflection Test

The reflection test can be used to determine a

faulty location (e.g., short circuit) or to confirm

the distance measurement (not via repeater).

Reflections can occur, for example, in the following situations:

- Stub lines exist.

- Too many terminating resistors have be-

en inserted, or none have been inserted.

- Change to a wrong type of cable occurs

within the measuring path.

Performing the test

Disconnect master from the bus, and make

sure that:

- the bus termination has power

- no bus communication occurs

- no test plug connector is connected.

Connect BT 200 to one end of the line.

Start reflection measurement.

Test results

If no reflection (i.e., fault) is detected, the following message appears.

If a reflection is detected, the following message appears.

The number in the display specifies the distance in meters from the measuring point to

the faulty point.

If the distance of the reflection measurement

corresponds to a previous distance measurement, this distance measurement is confirmed. The wiring of the bus segment which

was measured is correct.

(S)J31069-D0075-U001-A2-6318Page 16

Page 17

BT 200 04/00 English

4.6 Service

Settings

The following settings can be changed in the

Service menu.

- Language (German/English/French/

- Italian/Spanish/Portuguese)

- Loop resistance (50 to 200 Ω/km)

- Baud rate (9600 baud to 12 Mbaud)

- Contrast (↑↓)

- Log mode (on/off)

Communication

Activate the interface for data transmission for

the log function.

Displays

The Service menu gives you the following information.

- Firmware version

- Battery capacity

Hardware test

This tests the internal hardware.

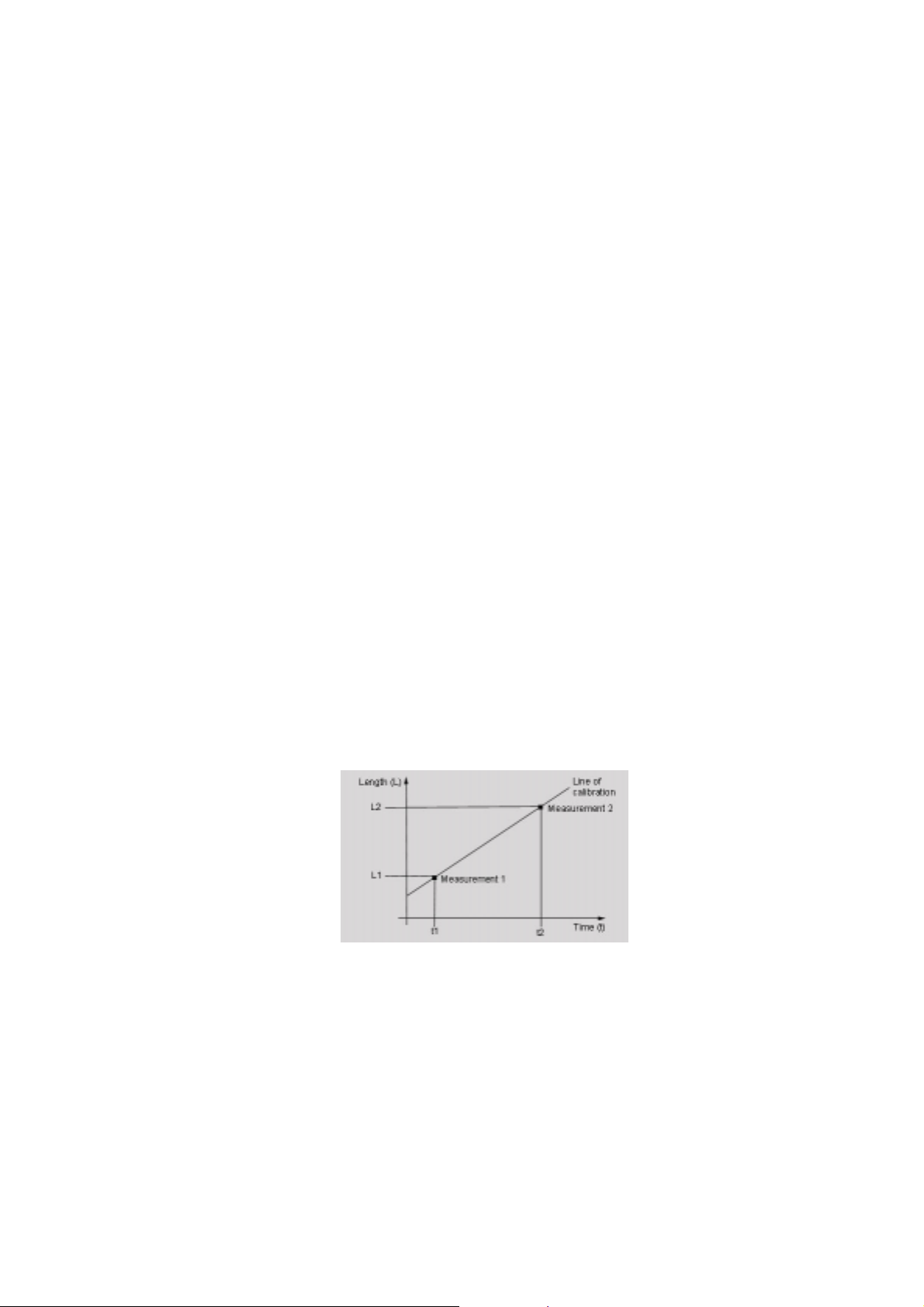

Calibration

Calibration is not necess ary when the standard type-A PROFIBUS cable is used.

The accuracy of distance and reflection measurement is achieved by calibration with 2 test

cables of different known lengths.

Fig. 6 P rinciple of calibration

(S)J31069-D0075-U001-A2-6318 Page 17

Page 18

English 04/00 BT 200

5 Log Mode

In log mode, performed tests are stored on

the BT 200. Later this inform ation can be

transferred over a serial interface to a PC with

log SW.

Log mode can be enabled and disabled in the

SERVICE menu.

Log mode remains set even when the BT 200

is turned off. This mode remains on until the

setting in the SERVICE menu is changed

again.

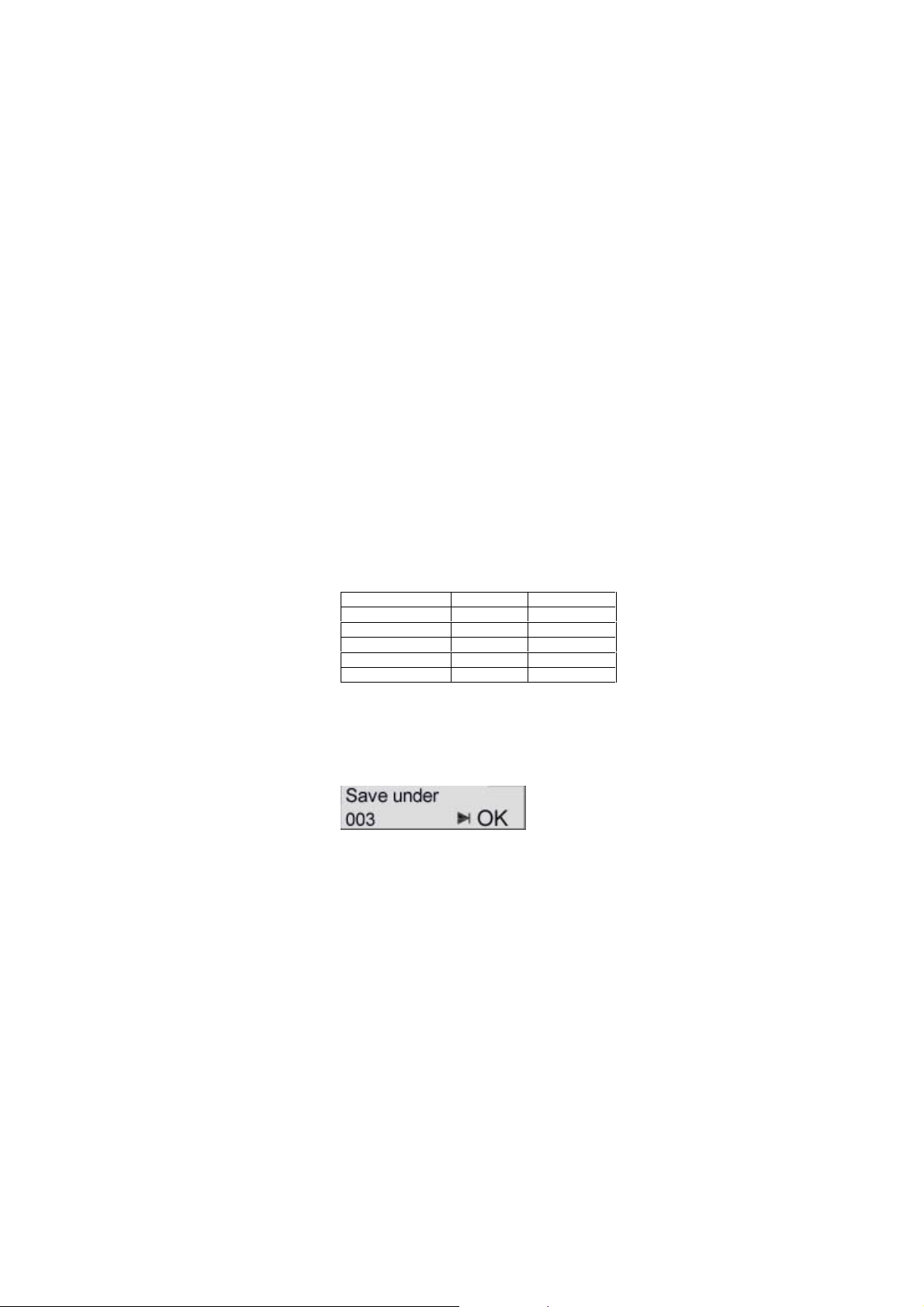

An identifier (X0 ..X999) is assigned to each

test to be stored on the BT 200.

The following table shows the maximum

number of tests which can be stored and their

identifiers.

Type of Test ID Letter Max. Number

Wiring test V 128

Station test T 128

Branch test S 10

Distance meas. E 10

Reflection test R 10

Storing the tests

After each test, the following prompt with the

next available identifier appears on the display.

The identifier can be changed with the cursor

or accepted with OK.

If you manually enter an identifier which has

already been assigned, it will be overwritten.

(S)J31069-D0075-U001-A2-6318Page 18

Page 19

BT 200 04/00 English

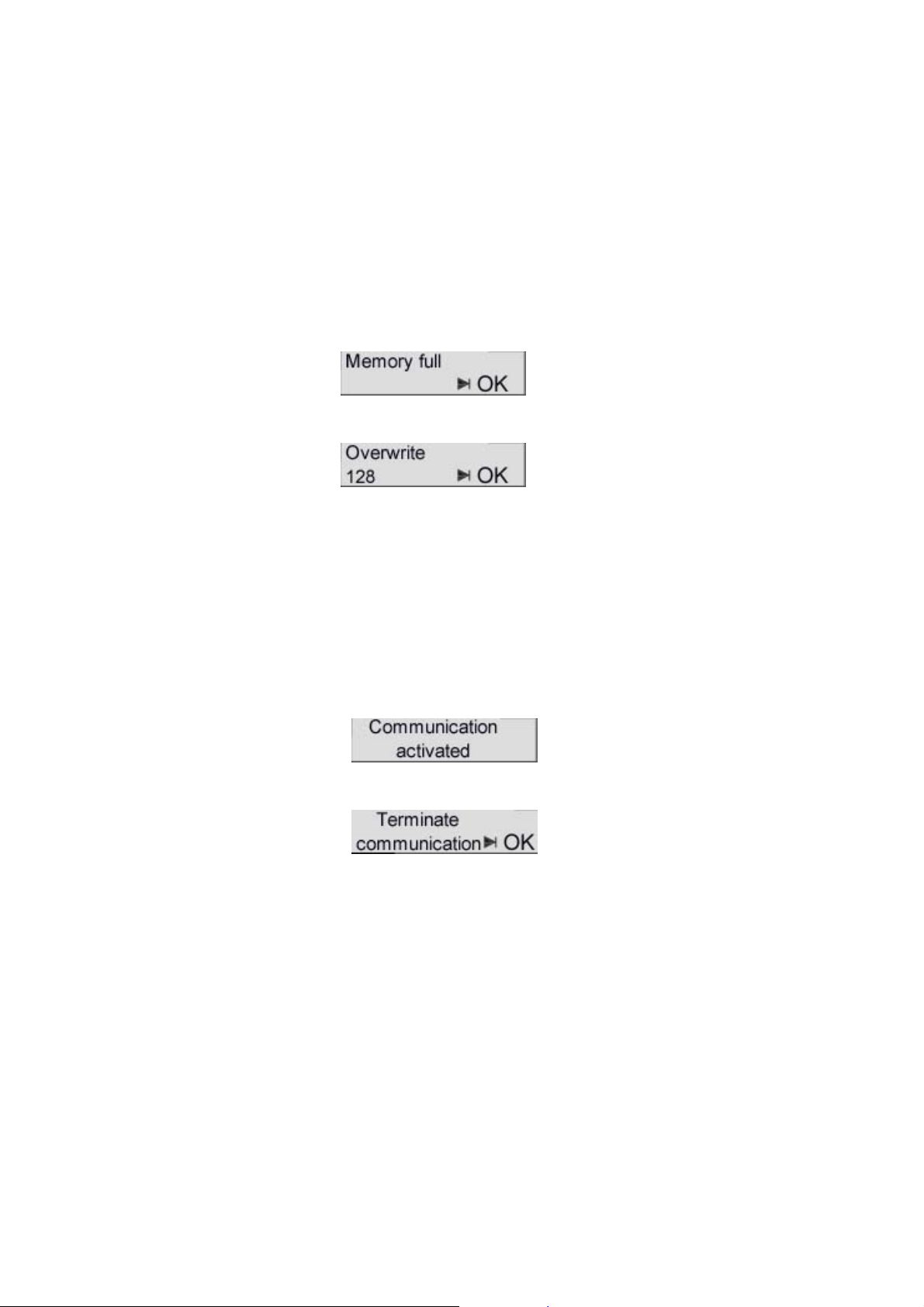

Memory full

This display appears when the maximum

number of tests to be stored is reached.

After you confirm with OK, the last selected

identifier appears which you can then

overwrite.

This identifier cannot be changed. The last

test result is overwritten.

Transferring tests to a PC

The test data are stored in non-volatile memory (i.e., they can be transferred to the PC

even after the BT 200 is turned off).

Before starting the transmission to the PC,

connect the included "log" cable to a COM

interface of the PC and to the 9-pin sub D

socket of the BT 200.

The transmission is activated with the

SERVICE menu and indicated on the display.

Communication can be terminated with the

ESC key. The following display appears.

OK terminates communication.

ESC terminates "termination" of communication.

Deleting the test data

The test data can be deleted with the

SERIVCE menu.

(S)J31069-D0075-U001-A2-6318 Page 19

Page 20

English 04/00 BT 200

6 Sample Applications

Testing the complete PROFIBUS-DP

• No master may be connected to the bus.

• The "life list" can also be generated with a re-

peater and optical paths.

• Parts of the system can be tested in advance

without the master for their bus functionality.

Fig. 7 S am pl e test 1

(S)J31069-D0075-U001-A2-6318Page 20

Page 21

BT 200 04/00 English

Wiring test for connected stations

• Stations no longer need to be removed from the

bus.

(Stations must be powered down!)

(Measurement not possible over repeater)

Fig. 8 S am pl e test 2

(S)J31069-D0075-U001-A2-6318 Page 21

Page 22

English 04/00 BT 200

Wiring test of a segment via PG socket on the

repeater

Fig. 9 S am pl e test 3

(S)J31069-D0075-U001-A2-6318Page 22

Page 23

BT 200 04/00 English

Wiring test of a segment behind a repeater and

with terminator

Fig. 10 Sample test 4

(S)J31069-D0075-U001-A2-6318 Page 23

Page 24

English 04/00 BT 200

7 Maintenance and Trouble-

Shooting

7.1 Charging Status of the Battery

The charging status of the battery is indicated

for approximately 2 seconds during startup.

This display then disappears.

The charging status can also be indicated via

the service menu during operation.

If the battery goes dead during operation, the

charging status begins to flash.

Standard values

If you want to reset all values to their status

on delivery, keep both cursor keys pressed

for approx. three seconds after switch-on.

7.2 Changing the Battery

Fig. 11 Changing the battery

(S)J31069-D0075-U001-A2-6318Page 24

Page 25

BT 200 04/00 English

7.3 Self-Tests

The BT 200 performs self-tests automatically

and on request (hardware test).

- Internal RS 485 driver test

The test is performed each time the station and branch test is called.

- RAM test

A cyclic RAM test is performed.

- Flash EPROM test

A cyclic EPROM test is performed.

- RS 485 driver test

The individual tests (e.g., RAM test, flash

EPROM test and display key test) can also be

selected in specialist mode via service menu HW test.

If an error is detected during the self-test, you

must proceed as shown in the error correc-

tion table.

(S)J31069-D0075-U001-A2-6318 Page 25

Page 26

English 04/00 BT 200

7.4 Error Correction Table

Fault during startup

Display Fault Reason Effect Correc-

tion

None No dis-

play after

switch-on

If possible:

"internal

error"

message

Fault during operation

Display Fault Reason Effect Correc-

Battery

display

flashes

before.

None Device

Internal

driver

defect

After

switchon, "internal

error"

message

appears.

Device

goes off.

goes off.

Internal

driver is

defective.

Battery

dead

RAM/

EPROM

error

display/

keyboard

defective

Battery is

dead.

Time with

no user

activity

was

exceeded.

HW defect

Hardware

does not

start up.

No measuring

possible

No measuring

possible

None Press

No station/

branch

test

possible

Charge

battery

or install

new

battery.

Replace

BT 200.

tion

Charge

battery/

install

new

one.

ON/

OFF

button.

Replace

BT 200.

(S)J31069-D0075-U001-A2-6318Page 26

Page 27

BT 200 04/00 English

8 Accessories and Replacement

Parts

The following components can be ordered under

their MLFB number.

Designation/Picture MLFB Number

Test connector

6EP8106-0AC20

Log kit

for Win95/98/NT4

• CD-ROM in

Ger/Eng/French

• Cable

6ES7193-8MA00-0AA0

Plug-in charger w. power

pack for: 230 V AC

110 V AC

Battery with connection

cable

Test-cable station test

9-pin sub D on

9-pin sub D (1 to 1)

(S)J31069-D0075-U001-A2-6318 Page 27

6ES7193-8LA00-0AA0

6ES7193-8LB00-0AA0

6EP8106-HA01

6EP8106-OHC01

Page 28

English 04/00 BT 200

9 Technical Data

General

Dimensions 210 * 100 * 55 mm

Weight 400 g

Battery capacity

Life

Voltage supply NiCd, 4.8 V battery

Display LCD, 2 * 16 charac-

Baud rate 9600 Bd to 12 MBd

Protection class IP 20

Measuring accuracy Length measurement

Environmental Requirements

Operating temperature + 5°C to +45°C

Storage temperature -20°C to +60°C

Relative humidity Maximal 95% / 24°C

Air pressure

operation

storage

≥ 720 mAh

≥ 8 h

ters

(+/-3m)

Middle 75% / 17°C

(without

condensation)

795 to 1080 hPa

660 to 1080 hPa

EMC guidelines

CE labeling DIN EN 61326-1:

1998

EN 50 081-1

EN 50 082-2

Physical Requirements

Vibration during operation IEC 1131-2

Shock stress during operation IEC 1131-2

Free fall IEC 1131-2/68-2-32

Certifications

UL

CSA

Order number

(S)J31069-D0075-U001-A2-6318Page 28

6ES7 181-0AA010AA0

Page 29

BT 200 04/00 English

Abbreviations

Bd

Baud (1 Bd = 1 character (bit/second)

BT

CP

EMC

MBd

NiCd

NN

OP

PG

RTS

Physical bus test device

Communications processor

Electromagnetic compat ibi lity

6

1 MBd = 10

Nickel cadmium

Miles above sea level

Operator panel

Programmer

Request to send

baud

Info Info Info Info Info Info Info

This document can be downloaded free of charge

from the Internet under the following URL:

http://www.ad.siemens.de/simatic-cs

Continuous current information on SIMATIC products

is available on the Internet under:

http://www.ad.siemens.de/simatic

SIMATIC Customer Support can be reached under:

Tel. +49 (911) 895 7000

Fax. +49 (911) 895 7002

(S)J31069-D0075-U001-A2-6318 Page 29

Page 30

English 04/00 BT 200

(S)J31069-D0075-U001-A2-6318Page 30

Page 31

BT 200 04/00 Deutsch

BT 200

Busphysik-Testgerät

für PROFIBUS-DP

Inhaltsverzeichnis

1 BESCHREIBUNG ......................................... 2

2 INBETRIEBNAHME ...................................... 4

3 NORMALMODUS ......................................... 5

3.1 VERDRAHTUNGSTEST.............................................6

EHLERMELDUNGEN DES VERDRAHTUNGSTESTS ......7

3.2 F

4 SPEZIALISTENMODUS ............................. 10

4.1 BEDIENUNG.........................................................10

4.2 TEILNEHMER- (RS485) TEST...............................12

TRANGTEST ......................................................13

4.3 S

NTFERNUNG......................................................15

4.4 E

4.5 REFLEXIONS-TEST...............................................16

ERVICE.............................................................17

4.6 S

5 PROTOKOLLIERMODUS ........................... 18

6 ANWENDUNGSBEISPIELE ....................... 20

7 WARTUNG UND FEHLERBEHEBUNG ..... 24

7.1 LADEZUSTAND DES AKKUS...................................24

KKU-WECHSEL .................................................24

7.2 A

7.3 SELBST - TESTS..................................................25

EHLERBEHEBUNGSTABELLE................................26

7.4 F

8 ZUBEHÖR UND ERSATZTEILE ................ 27

9 TECHNISCHE DATEN ................................ 28

(S)J31069-D0075-U001-A2-6318 Page 1

Page 32

Deutsch 04/00 BT 200

1 Beschreibung

Zweck des BT 200

Das BT 200 bietet Diagnosemöglichkeiten für

PROFIBUS-DP-Systeme ohne zusätzliche

Meßhilfsmittel, wie PC oder Oszilloskop.

BT200 Version 2

Das BT 200 Version 2 bietet zusätzlich

• Protokollierfunktion

• 6-sprachige Bedienoberfläche

• Test der PROFIBUS-DP-Master Schnitt-

stelle

• Anzeige der Master-Adresse

• Verdrahtungstest mit angeschlossenen

Teilnehmern

• neues, kostengünstiges KompaktLadegerät

(S)J31069-D0075-U001-A2-6318Page 2

Page 33

BT 200 04/00 Deutsch

Bedienelemente und Anzeige

Bild 1 Bedienelemente u. Anzeige

1) PROFIBUS-Anschluß (9-polig, Sub-D)

2) LC - Display (2x16 Zeichen)

3) EIN / AUS-Taste

4) Ladebuchse für Stecker/Ladegerät

5) TEST-Taste (Test starten)

6) CURSOR-Tasten

7) OK-Taste (verschiedene Funk tionen)

8) ESCAPE-Taste (Abbruch)

9) Ladekontakte für Ladegerät

(S)J31069-D0075-U001-A2-6318 Page 3

Page 34

Deutsch 04/00 BT 200

2 Inbetriebnahme

Vor der ersten Inbetriebnahme ist der Lieferumfang zu kontrollieren und der Akku aufzuladen.

Lieferumfang

Zum Lieferumfang gehören:

- 1 BT 200

- 1 Akku

- 1 Prüfstecker (Verdrahtungstest)

- 1 Prüfkabel, Länge 2m (Teilnehmertest)

- 1 Bedienungsanleitung

Akku laden

- Akku-Fach öffnen (siehe Kap. Akku-

wechsel) und kontrollieren, ob der Akku

eingesetzt ist (ggf. eins etzen).

- Eingesetzten Akku des BT 200 über

Ladegerät aufladen (ca. 4 Stunden).

U Achtung!!

Der Akku wird immer in entladenem Zustand

ausgeliefert !

Das Ladegerät gehört nicht zum Lieferumfang

und muß separat bestellt werden.

- "Während des Ladevorgangs ist kein

Messbetrieb zulässig"

(S)J31069-D0075-U001-A2-6318Page 4

Page 35

BT 200 04/00 Deutsch

3 Normalmodus

Mit der ON/OFF-Taste wird das BT 200 eingeschaltet.

Die ON/OFF-Taste muß solange gedrückt

bleiben, bis am Display eine Reaktion erfolgt.

Bereitschaftsanzeige

Nach dem Einschalten erscheint für ca. 2

Sek. die Bereitschaftsanzeige.

Akku-Anzeige

Anschließend wird für ca. 2 Sek. die AkkuKapazitäts-Anzeige eingeblendet.

Betriebsanzeige

Nach Verlöschen der Akku-Anzeige wechselt

das BT 200 in den Normalmodus und zeigt

das Startfenster für den Verdrahtungstest an.

Im Normal-Modus kann nur der Verdrahtungstest durchgeführt werden.

Befindet sich das BT 200 im Protokolliermodus (erkennbar am verändertem Cursor), erscheint nach jedem Test die zusätzliche Abfrage

Stromspar-Modus

Wird ca. 3 Minuten lang keine Taste gedrückt

oder keine Messung durchgeführt, schaltet

das BT 200 automatisch ab.

(S)J31069-D0075-U001-A2-6318 Page 5

Page 36

Deutsch 04/00 BT 200

3.1 Verdrahtungstest

Meßprinzip

Der Verdrahtungstest für ein Bussegment erfolgt zwischen BT 200 und dem Prüfstecker.

Während der Installationsphase kann von

Stecker zu Stecker geprüft werden (Bild 2).

Der Prüfstecker ist dabei immer an dem einem Ende des Bussegmentes aufgesteckt.

Kurzschlüsse können auch außerhalb der

Teststrecke festgestellt werden. Das Bussegment darf nur am Anfang und am Ende

mit einem Abschlußwiderstand versehen sein.

Bild 2 Schrittweises Meßprinzip

Durchführung

Der Test kann mit oder ohne angeschlossene

Teilnehmer durchgeführt werden. Der Test

wird durch Drücken der TEST-Taste gestartet.

Bei erfolgreich abgeschlossenem Test erscheint eine der beiden Meldungen:

bei einem Abschlußwiderstand (solange die

Installation nicht abgeschlossen ist, ist nur ein

Abschlußwiderstand vorhanden)

nach Abschluß der Installation müssen zwei

Widerstände eingelegt sein.

Durch Drücken der OK-Taste wird der Test

beendet und ein neuer Verdrahtungstest kann

gestartet werden.

Der Verdrahtungstest kann auch durch Drükken der ESC-Taste beendet oder jederzeit

abgebrochen werden.

(S)J31069-D0075-U001-A2-6318Page 6

Page 37

BT 200 04/00 Deutsch

3.2 Fehlermeldungen des Verdrahtungstests

Teilnehmerprüfung

Bitte kontrollieren Sie, ob bei allen Teilnehmern und Netzkomponenten die Spannungsversorgung ausgeschaltet ist.

Leitungsdreher

Tauschen Sie die Adern im entsprechenden

Anschlußstecker.

U Der Verdrahtungstest muß jeweils nach

Anschluß eines neuen PROFIBUSsteckers durchgeführt werden. Andernfalls kann eine geradzahlige Anzahl von

Leitungsdrehern nicht erkannt werden!

Kurzschluß

Lokalisieren und beheben Sie den Kurz-

schluß.

Häufige Ursachen z.B bei Schirmschlüssen

sind unsachgemäß aufgelegte Schirmgeflechte in den Steckern.

(S)J31069-D0075-U001-A2-6318 Page 7

Page 38

Deutsch 04/00 BT 200

Leitungs- oder Schirmbruch

Mögliche Fehlerursachen:

• Unterbrechung mehrerer Adern

• Unterbrechung von Adern und Schirm

• Prüfstecker nicht gesteckt

Um ein korrektes Meßergebnis für den Bruch

Schirm zu erhalten, darf der Schirm nicht mit

der Erde verbunden sein.

Bei allen vier Meldungen überprüfen Sie

zuerst die in Frage kommenden Stecker/

Anschlüsse. Sind diese in Ordnung, tauschen

Sie die Leitung aus.

(S)J31069-D0075-U001-A2-6318Page 8

Page 39

BT 200 04/00 Deutsch

Keine- oder mehr als zwei Abschlußwiderstände

Mit den Tasten "→""←" blättern

Setzen Sie jeweils am Anfang und am Ende

des Bussegments einen Abschlußwiderstand

ein.

Mit den Tasten "→""←" blättern

Entfernen bzw. deaktivieren Sie alle Abschlußwiderstände bis auf die zwei am Anfang und Ende des Bussegments.

(S)J31069-D0075-U001-A2-6318 Page 9

Page 40

Deutsch 04/00 BT 200

4 Spezialistenmodus

Durch gleichzeitiges Drücken von ESC und

OK wird vom Normalmodus in den Speziali-

stenmodus umgeschaltet.

Im Spezialistenmodus stehen folg end e Funktionen zur Verfügung:

- Verdrahtungstest (siehe Normalmodus).

- Teilnehmertest (RS485-Test)

- Strangtest

- Entfernungsmessung

- Reflexionstest

- Service-Menü

4.1 Bedienung

Die Bedienung des BT 200 erfolgt menügesteuert über die Eingabetasten der Folientastatur (Bild 1).

Cursor

Die aktuelle Cursor-Position im Display wird

durch einen blinkenden Pfeil angezeigt und ist

die Funktion, die ausgeführt wird.

Befindet sich das BT 200 im Protokolliermodus, wird die Cursor-Position durch einen geänderten Pfeil angezeigt.

(S)J31069-D0075-U001-A2-6318Page 10

Page 41

BT 200 04/00 Deutsch

Menüpunkte

Menüpunkte werden mit dem Cursor angewählt und über die OK-Taste aktiviert. Mit der

ESC-Taste kann eine laufende Funktion abgebrochen werden oder ein Rücksprung in

den übergeordneten Menüpunkt erfolgen.

Menüstruktur

START

Akku-Test

N-Modus

S-Modus

(Normal-Modus)

Verdrahtung

(Spezialisten-Modus)

Verdrahtung

RS485

Strang

Entfernung

Reflexion

SERVICE

Einstellungen

Protokollmodus

Kommunikation

(Test)

(Test)

(Test)

(Test)

(Messung)

(Test)

(Einstellungen)

Sprache

Baudrate

Widerstand

Akku

Kontrast

Kalibrierung

Löschen

FW-Version

Selbst-Test

Bild 3 Menüstruktur

(S)J31069-D0075-U001-A2-6318 Page 11

Page 42

Deutsch 04/00 BT 200

4.2 Teilnehmer- (RS485) Test

Mit diesem Test wird die RS485-Schnittstelle

eines einzelnen Slave oder Master getestet:

Durchführung

Busstecker vom Teilnehmer abziehen.

Punkt-zu-Punkt-Verbindung zwischen Teilnehmer und dem BT 200 herstellen

(siehe Bild 4).

U Für diese Verbindung darf nur das mitgelie-

ferte Prüfkabel verwendet werden !

Bild 4 Punkt zu Punkt Verbindung

Teilnehmer einschalten (der Test muß bei aktivem Teilnehmer durchgeführt werden).

Teilnehmertest starten. Der Master muß auf

Betriebsart "RUN" stehen.

Testergebnisse

Folgende Testergebnisse sind möglich:

- RS 485 o.k. (Teilnehmer in Ordnung)

- RS 485 defekt (kein kontinuierlicher Si-

gnalempfang; Test wiederholen)

- Keine Antwort (überhaupt nichts

empfangen

- 5 V : (entsprechender Meßwert)

- RTS-Signal (JA oder NEIN)

(S)J31069-D0075-U001-A2-6318Page 12

Page 43

BT 200 04/00 Deutsch

4.3 Strangtest

Damit kann die Erreichbarkeit aller am

PROFIBUS befindlichen Slaves überprüft

oder ein einzelner Slave angesprochen werden.

Der Strangtest kann auch über Repeater/LWL

hinweg durchgeführt werden.

Durchführung

Alle Master vom Bus abziehen, z.B. PG, OP,

CP (siehe Bild 5).

Bitte beachten: Der Busabschluß muß gewährleistet bleiben.

BT 200 an den Bus anschließen.

Die am Bus projektierte Baudrate am BT 200

einstellen.

Für Slave-Einzeltest gewünschte Adresse

einstellen.

Für Gesamttest Adresse "000" einstellen.

Mit "OK " die vom BT 200 erkannte Adresse

(Slave oder Master) bestätigen.

Bild 5 Meßprinzip des Strangtests

(S)J31069-D0075-U001-A2-6318 Page 13

Page 44

Deutsch 04/00 BT 200

Testergebnisse

Beim Gesamtstrangtest wi rd jeder erreichbare

Slave in einer Liste der erreichbaren Teilnehmer (LIFE LIST) angezeigt.

- LIFE LIST

Bei einem Einzeltest

- Keine Antwort (z.B. kein Teilnehmer mit

der eingestellten Busadresse am Bus)

- Fehlerhafter Teilnehmer (z.B. doppelt

vergebene Slave-Nummer).

(S)J31069-D0075-U001-A2-6318Page 14

Page 45

BT 200 04/00 Deutsch

4.4 Entfernung

Mit der Entfernungsmessung können nur

Leitungsleitungen über 15m Länge ermittelt

werden. Die Entfernungsmessung ist nicht

über Repeater möglich.

Durchführung

Versorgungsspannung aller Bustei lne hmer

ausschalten.

Prüfstecker an ein Ende und BT 200 an das

andere Leitungsende stecken (Abschlußwiderstand bei BT 200 abschalten).

Entfernungsmessung starten.

Nach dem Start werden vom BT 200 drei

Werte abgefragt, die über die Tastatur einzugeben sind:

- Schleifenwiderstand (Standard = 110 Ω/km)

Der Standardwert kann über den Menüpunkt Service geändert werden.

- Anzahl der 12 MBaud-Stecker/Geräte mit

Längsinduktivität

- Widerstandswert pro Stecker/Gerät

(Standard = 0,32 Ω)

Nach Eingabe des letzten Wertes und Bestätigung mit OK wird die Messung durchgeführt.

Meßergebnis

Am Display erscheint folgende Anzeige

Während der Messung können folgende

Fehlermeldungen auftreten:

- Kein Widerstand eingelegt

- Anzeige “0 m“ (keine plausible Länge

ermittelt)

- Mehr als 1 Widerstand eingelegt

Mögliche Fehlerursachen:

- die Entfernung < 15m

- Stichleitungen innerhalb der Meßstrecke

Beseitigen Sie den Fehler und wiederholen

Sie die Messung.

(S)J31069-D0075-U001-A2-6318 Page 15

Page 46

Deutsch 04/00 BT 200

4.5 Reflexions-Test

Der Reflexionstest kann zur Ermittlung einer

Störstelle z.B. Kurzschluß, oder zur Bestätigung der Entfernungsmessung herangez oge n

werden (nicht über Repeater).

Reflexionen können z.B. auftreten, wenn:

- Stichleitungen vorhanden sind.

- zu viele Abschlußwiderstände oder keine

eingelegt sind.

- Innerhalb der Meßstrecke der Wechsel

auf einen ungeeigneten Kabeltyp erfolgt.

Durchführung

Master vom Bus nehmen und sicherstellen

dass:

- der Busabschluss mit Spannung versorgt

ist.

- daß kein Busverkehr stattfindet.

- kein Prüfstecker gesteckt ist

BT 200 an einem Leitungsende

anschließen.

Reflexionsmessung starten.

Testergebnis

Wird keine Reflexion (Störung) erkannt, erscheint die Meldung:

Wird eine Reflexion erkannt, erscheint die

Meldung:

Die angezeigte Zahl gibt die Entfernung in

Metern von der Meßstelle zur Störstelle an.

Stimmt die Entfernung der Reflexionsmessung mit einer vorangegangenen Entfernungsmessung überein, ist diese Entfernungsmessung bestätigt. Eine Störstelle in

der Verdrahtung des gemessenen Bussegmentes liegt nicht vor.

(S)J31069-D0075-U001-A2-6318Page 16

Page 47

BT 200 04/00 Deutsch

4.6 Service

Einstellungen

Im Service-Menü können folgende Einstellungen geändert werden:

- Sprache

(Deutsch/Englisch/Französisch/Italienisc

h/Spanisch/Portugiesisch)

- Schleifenwiderstand (50 - 200 Ω/km)

- Baudrate (9600 Baud - 12 MBaud)

- Kontrast (↑↓)

- Protokolliermodus (Ein/Aus)

Kommunikation

Aktivieren der Schnittstelle zur Datenübertragung für die Protokollierfunktion

Anzeigen

Im Service-Menü stehen Ihnen folgende Anzeigen zur Verfügung:

- Firmwa re - Version

- Akku - Kapazität

Hardware-Test

Damit kann die interne Hardware getestet

werden.

Kalibrierung

Bei Standard-PROFIBUS-Kabel Typ A ist keine Kalibrierung nötig.

Die Genauigkeit von Entfernungs- und Reflexionsmessung wird durch die Kalibrierung mit

2 verschieden langen Testleitungen mit bekannten Längen erreicht.

Bild 6 Prinzip der Kalibrierung

(S)J31069-D0075-U001-A2-6318 Page 17

Page 48

Deutsch 04/00 BT 200

5 Protokolliermodus

Im Protokolliermodus werden durchgeführte

Tests im BT 200 gespeichert und können

später per serieller Schnittstelle zu einem PC

mit Protokollier-SW übertragen werden.

Der Protokolliermodus kann über das

SERVICE-Menü ein- und ausgeschaltet werden.

Der Protokolliermodus bleibt auch nach Abschaltung des BT 200 eingestellt, bis die Einstellung im SERVICE-Menü wieder geändert

wird.

Jeder im BT 200 abzuspeichernde Test wird

mit einer Kennung versehen (0 ..999).

Die folgende Tabelle zeigt die maximal mögliche Anzahl von abzuspeichernden Tests und

die zugehörigen Kennungen:

Test-Art max.Anzahl

Verdrahtungstest 128

Teilnehmertest 128

Strangtest 10

Entfernungsmessung

Reflexionstest 10

10

Tests speichern

Nach jedem durchgeführten Test erscheint im

Display die Abfrage „Speichern unter“ mit der

nächsten freien Kennung.

Die Kennung kann per Cursor verändert oder

mit OK übernommen werden.

Wird bei manueller Eingabe eine Kennung

gewählt, die schon vergeben ist, so wird diese

überschrieben.

(S)J31069-D0075-U001-A2-6318Page 18

Page 49

BT 200 04/00 Deutsch

Speicher voll

Ist die maximale Anzahl der zu speichernden

Tests erreicht, so erscheint die Anzeige

Nach OK erscheint die zuletzt ausgewählte

Kennung und wird zum Überschreiben angeboten.

Diese Kennung kann nicht verändert werden,

das letzte Testergebnis wird überschrieben.

Tests an PC übertragen

Die Testdaten werden nicht flüchtig abgespeichert, d.h. sie können auch nach einem

Ausschalten des BT200 zum PC übertragen

werden.

Um die Übertragung zum PC zu starten,

muß das mitgelieferte Protokollier-Kabel an

eine COM-Schnittstelle des PC‘s und an die

9pol. Sub-D-Buchse des BT200 angeschlossen werden.

Die Übertragung wird über das SERVICEMenü aktiviert und im Display angezeigt.

Mit der ESC-Taste kann der Abbruch der

Kommunikation eingeleitet werden. Im Display erscheint die Abfrage:

Mit OK wird die Kommunikation abgebrochen.

Löschen der Testdaten

Die Testdaten können über das SERVICEMenü gelöscht werden.

(S)J31069-D0075-U001-A2-6318 Page 19

Page 50

Deutsch 04/00 BT 200

6 Anwendungsbeispiele

Testen des gesamten PROFIBUS-DP

• Es darf kein Master am Bus angeschlossen

sein.

• Die "Life-List" kann auch über Repeater und

optische Strecken hinweg erzeugt werden.

• Anlagenteile können vorab ohne Master auf

Funktionsfähigkeit des Busses geprüft werden.

Bild 7 Testbeispiel 1

(S)J31069-D0075-U001-A2-6318Page 20

Page 51

BT 200 04/00 Deutsch

Verdrahtungstest bei angeschlossenen Teilnehmern

• Teilnehmer brauchen nicht mehr vom Bus abge-

zogen werden

(Teilnehmer müssen spannung sfrei se in)

(Messung nicht über Repeater möglich)

Bild 8 Testbeispiel 2

(S)J31069-D0075-U001-A2-6318 Page 21

Page 52

Deutsch 04/00 BT 200

Verdrahtungstest eines Segments über

PG-Buchse am Repeater

Bild 9 Testbeispiel 3

(S)J31069-D0075-U001-A2-6318Page 22

Page 53

BT 200 04/00 Deutsch

Verdrahtungstest eines Segments hinter

einem Repeater und mit Terminator

Bild 10 Testbeispiel 4

(S)J31069-D0075-U001-A2-6318 Page 23

Page 54

Deutsch 04/00 BT 200

7 Wartung und Fehlerbehebung

7.1 Ladezustand des Akkus

Der Ladezustand des Akkus wird beim Anlauf

für ca. 2 Sekunden angezeigt. Danach wird

die Anzeige ausgeblendet.

Der Ladezustand kann während des Betriebs

zusätzlich über das Service-Menü angezeigt

werden.

Wird der Akku während der Betriebszeit leer,

wird der Ladezustand blinkend angezeigt.

Standardwerte

Wollen Sie alle Werte auf den Auslieferungszustand zurücksetzen, müssen Sie nach dem

Einschalten beide Cursor-Tasten für ca. drei

Sekunden gedrückt halten.

7.2 Akku-Wechsel

Bild 11 Akkuwechsel

(S)J31069-D0075-U001-A2-6318Page 24

Page 55

BT 200 04/00 Deutsch

7.3 Selbst - Tests

Das BT 200 führt automatisch und auf Anfor-

derung (Hardware Test) Selbsttests durch:

- Interner RS485 – Treiber – Test:

nach jedem Aufruf des Teilnehmer- und

Strang-Tests wird der Test durchgeführt.

- RAM-Test:

ein zyklischer RAM-Test wird durchgeführt

- Flash-EPROM-Test:

ein zyklischer EPROM-Test wird durchgeführt.

- RS485-Treiber-Test

Die einzelnen Tests, wie RAM-Test, FlashEPROM-Test und Display-Tasten-Test können auch aus dem Spezialisten-Modus über

das Service-Menü – HW-Test ausgewählt

werden.

Wird während des Selbsttests ein Fehler erkannt muß entsprechend der Fehlerbehe-

bungstabelle vorgegangen werden.

(S)J31069-D0075-U001-A2-6318 Page 25

Page 56

Deutsch 04/00 BT 200

7.4 Fehlerbehebungstabelle

Störung beim Anlauf

Anzeige Störung Grund Auswir-

kung

keine Keine

Anzeige

nach

dem Einschalten

Akku

entladen

kein

Hochlauf

der Hardware

Behebung

Akku

laden /

neuen

Akku

einlegen

wenn

möglich:

kommt

Meldung

"interner

Fehler"

Störung im Betrieb

Anzeige Störung Grund Auswir-

Akkuanzeige

blinkt

vorher

keine Gerät

interner

Treiber

defekt

nach Einschalten

erscheint

Meldung

"interner

Fehler"

Gerät

schaltet

sich aus

schaltet

sich aus

interner

Treiber

ist defekt

RAM/

EPROM

-Fehler

Display/

Tastatur

defekt

Akku ist

leer

Zeit

ohne

Bedienung

überschritten

HW

defekt

kein

Meßbetrieb

möglich

kung

kein

Meßbetrieb

möglich

keine ON/OFF

Kein

Teinehmer/

StrangTest

möglich

BT 200

austauschen

Behebung

Akku

laden /

neuen

einlegen

-Taste

drücken

BT 200

austauschen

(S)J31069-D0075-U001-A2-6318Page 26

Page 57

BT 200 04/00 Deutsch

8 Zubehör und Ersatzteile

Die folgenden Komponenten können unter Angabe

der entsprechenden MLFB-Nr. bestellt werden.

Bezeichnung/Bild MLFB-Nummer

Prüfstecker

6EP8106-0AC20

Protokollierkit

für Win 95/98/NT4

• CD-ROM in D/E/F

• Kabel

6ES7193-8MA00-0AA0

Steckerladegerät mit

Netzteil für:

230 V AC

110 V AC

Akku mit Anschlußkabel 6EP8106-0H A01

Prüfkabel für Teilnehmer

Test

9-polig-Sub-D auf

9-polig-Sub-D (1 zu 1)

(S)J31069-D0075-U001-A2-6318 Page 27

6ES7193-8LA00-0AA0

6ES7193-8LB00-0AA0

6EP8106-OHC01

Page 58

Deutsch 04/00 BT 200

9 Technische Daten

Allgemein

Abmessungen 210 * 100 * 55 mm

Gewicht 400 g

Akkukapazität

Betriebsdauer

Spannungsversorgung NiCd-Akku 4,8 V

Anzeige LCD, 2 * 16 Zeichen

Baudrate 9600 Bd … 12 MBd

Schutzart IP 20

Meßgenauigkeit Längenmessung +/-

Umgebungsbedingungen

Betriebstemperatur + 5°C bis +45°C

Lagertemperatur -20°C bis +60°C

Relative Luftfeuchtigkeit Maximal 95% / 24°C

Zul. Betriebshöhe (über NN) -1000m bis +2000m

EMV-Richtlinien

CE-Kennzeichnung DIN EN 61326-1:

≥ 720 mAh

≥ 8 h

3m

Mittel 75% / 17°C

(ohne Betauung)

1998

EN 50 081-1

EN 50 082-2

Mechanische Bedingungen

Schwingung im Betrieb IEC 1131-2

Schockbeanspruchung im

Betrieb

Freifall IEC 1131-2/68-2-32

Zulassungen

UL

CSA

Bestellnummer

(S)J31069-D0075-U001-A2-6318Page 28

IEC 1131-2

6ES7 181-0AA010AA0

Page 59

BT 200 04/00 Deutsch

Abkürzungen

Bd

Baud (1Bd = 1 Zeichen(Bit)/Sekunde)

BT

CP

EMV

MBd

NiCd

NN

OP

PG

RTS

Busphysik-Testgerät

Kommunikations-Prozessor

Elektromagnetische Verträglichkeit

6

1MBd = 10

Nickel-Cadmium

Normal Null (Meereshöhe)

Operator Panel

Programmiergerät

Request to send

Baud

Info Info Info Info Info Info Info

Diese Doku können Sie im Internet kostenfrei unter

der folgenden URL downloaden:

http://www.ad.siemens.de/simatic-cs

Ständig aktuelle Informationen zu den

SIMATIC-Produkten erhalten Sie im Internet unter:

http://www.ad.siemens.de/simatic

Den SIMATIC Customer Support erreichen Sie unter:

Tel. +49 (911) 895 7000

Fax. +49 (911) 895 7002

(S)J31069-D0075-U001-A2-6318 Page 29

Page 60

Deutsch 04/00 BT 200

(S)J31069-D0075-U001-A2-6318Page 30

Page 61

BT 200 04/00 Les français

BT 200

Testeur de physique de bus

pour DP PROFIBUS

Sommaire

1 DESCRIPTION .............................................. 2

2 MISE EN SERVICE ....................................... 4

3 MODE STANDARD ....................................... 5

3.1 TEST DU CÂBLAGE.................................................6

ESSAGES D’ERREURS DU TEST DU CÂBLAGE ..........7

3.2 M

4 MODE SPÉCIALISTE ................................. 10

4.1 COMMANDE.........................................................10

4.2 TEST DE LA STATION (RS485)..............................12

EST DE LA PHASE...............................................13

4.3 T

ISTANCE...........................................................15

4.4 D

4.5 TEST DE LA RÉFLEXION ........................................16

AINTENANCE.....................................................17

4.6 M

5 MODE D’ENREGISTREMENT .................... 18

6 EXEMPLES D’APPLICATION .................... 20

7 MAINTENANCE ET ELIMINATION DES

ERREURS ...................................................... 24

7.1 ETAT DE CHARGE DE L’ACCUMULATEUR.................24

EMPLACEMENT DE L’ACCUMULATEUR ..................24

7.2 R

UTO-CONTRÔLES ...............................................25

7.3 A

7.4 TABLEAU D’ÉLIMINATION DES ERREURS..................26

8 ACCESSOIRES ET PIÈCES DE

RECHANGE ................................................... 27

9 CARACTÉRISTIQUES TECHNIQUES ....... 28

(S)J31069-D0075-U001-A2-6318 Page 1

Page 62

Les français 04/00 BT 200

1 Description

Utilité du BT 200

Le BT 200 offre des possibilités de diagnostic

pour les systèmes DP PROFIBUS sans auxiliaires de mesure complémentaire s, tel s que

PC ou oscilloscope.

BT200 Version 2

Le BT 200 version 2 offre de plus :

• fonction d'enregistrement

• interface utilisateur en 6 langues

• test de l'interface maître DP PROFIBUS

• affichage de l'adresse maître

• test du câblage avec les stations raccor-

dées

• nouveau chargeur compact peu coûteux

Page 2

(S)J31069-D0075-U001-A2-6318

Page 63

BT 200 04/00 Les français

Éléments de commande et afficheur

Fig 1 Él éments de commande et afficheur

10) Connexion PROFIBUS (à 9 pôles, sub-

miniature D)

11) Afficheur LCD (2x16 caractères)

12) Touche MARCHE/ARRET

13) Douille de charge pour connecteur/chargeur

14) Touche de TEST (démarrage du test)

15) Touches CURSEUR

16) Touche OK (différentes fonctions)

17) Touche ESC (abandon)

18) Contacts de charge pour chargeur

(S)J31069-D0075-U001-A2-6318 Page 3

Page 64

Les français 04/00 BT 200

2 Mise en service

Avant la première mise en service, il convient

de contrôler l'étendue de la livraison et de

charger l'accumulateur.

Etendue de la livraison

La livraison englobe :

- 1 BT 200

- 1 accumulateur

- 1 connecteur d'essai (test du câblage)

- 1 câble d'essai, longueur 2 m (test de la

station)

- 1 notice d'utilisation

Charge de l’accumulateur

- Ouvrir le compartiment de l'accumula-

teur (voir le chapitre remplacement de

l'accumulateur) et s'assurer que l'accumulateur est en place (l'i nsérer le cas

échéant).

- Charger l'accumulateur inséré dans le

BT 200 par l'intermédiaire du chargeur

(pendant env. 4 heures).

U Attention !!

L'accumulateur est toujours fourni à l'état déchargé !

Le chargeur ne fait pas partie de la livraison

et doit être commandé séparément.

- "Aucune mesure n'est autorisée pendant

la charge."

Page 4

(S)J31069-D0075-U001-A2-6318

Page 65

BT 200 04/00 Les français

3 Mode standard

Le BT 200 est mis en marc he avec la touche

ON/OFF.

La touche ON/OFF doit être maintenue enfoncée jusqu'à l'apparition d'une réaction à

l'écran.

Affichage de l'état d'attente

L'affichage de l'état d'attente apparaît pendant

env. 2 s après la mise en marche.

Affichage de capacité de l'accumulateur

L'affichage de la capacité de l'accumulateur

apparaît ensuite pendant env. 2 s.

Affichage de fonctionnement

Quand la mention de l'accumulateur a disparu

de l'écran, le BT 200 passe en mode standard

et affiche la fenêtre de démarrage du test du

câblage.

Le mode standard ne permet d'effectuer que

le test du câblage.

Si le BT 200 se trouve en mode d'enregistrement (reconnaissable à la modification du

curseur), la demande supplémentair e suivante apparaît après chaque test :

Mode d'économie de courant

Le BT 200 passe automatiquement hors circuit si l’on n’a ppu ie sur aucu ne touc he pendant env. 3 minutes ou que l’on n’effectue aucune mesure.

(S)J31069-D0075-U001-A2-6318 Page 5

Page 66

Les français 04/00 BT 200

3.1 Test du câblage

Principe de mesure

Le test de câblage d'un segment du bus s'effectue entre le BT 200 et le connecteur d'essai. Pendant la phase d'installation, le

contrôle peut s'effectuer d'un connecteur à

l'autre (figure 2). Le connecteur d'essai est

alors toujours branché sur l'une des extrémités du segment du bus. Les courts-circuits

peuvent aussi être constatés en-dehor s de la

section de test. Le segment de bus ne doit

être muni d'une résistance terminale qu'au

début et à l'extrémité.

Fig 2 Pri ncipe de mesure progressive

Réalisation

Le test peut être effectué avec ou sans stations raccordées. Pour démarrer le test, appuyer sur la touche TEST.

Lorsque le test est terminé avec succès, l'un

des deux messages suivants apparaît :

avec une résistance terminale (tant que l'installation n'est pas terminée, il n'y a qu'une résistance terminale)

après la fin de l'installation, les deux résistances doivent être mises en place.

Une pression de la touche OK permet de

mettre fin au test et de démarrer un nouveau

test du câblage.

On peut également mettre fin au test du câblage ou l'interrompre à tout moment en appuyant sur la touche ESC.

Page 6

(S)J31069-D0075-U001-A2-6318

Page 67

BT 200 04/00 Les français

3.2 Messages d’erreur du test du câblage

Contrôle des stations

Veuillez contrôler si l'alimentation électrique

est coupée sur l'ensemble des stations et de

composants du réseau.

Interversion des câbles

Remplacez les brins dans le connect eur

correspondant..

U Le test du câblage doit être effectué

après le raccordement de chaque nouveau connecteur PROFIBUS. Il est sinon

impossible de détecter un nombre pair

d'interversions des câbles !

Court-circuit

Localisez et éliminez le court-circuit.

La pose incorrecte de tresses de blindage

dans les connecteurs constitue p. ex. une

cause fréquente de courts-circuits.

(S)J31069-D0075-U001-A2-6318 Page 7

Page 68

Les français 04/00 BT 200

Rupture de câble ou de blindage

Causes possibles de défaut :

• Coupure de plusieurs brins

• Coupure de brins et du blindage

• Connecteur d'essai non enfiché

Afin d'obtenir un résultat de mesure correct

pour la rupture du blindage, ce dernier ne doit

pas être relié à la terre.

Pour les quatre messages, commencez par

vérifier les connecteurs/connexions concernés. S'ils sont en bon état, remplacez le câble.

Page 8

(S)J31069-D0075-U001-A2-6318

Page 69

BT 200 04/00 Les français

Absence de résistance terminale ou plus de deux

résistances terminales

Faire défiler avec les touches "→""←"

Insérez une résistance terminale à chaque

extrémité du segment du bus (début et fin).

Faire défiler avec les touches "→""←"

Retirez ou désactivez toutes les résistances

terminales, sauf celles se trouvant à chaque

extrémité du segment du bus.

(S)J31069-D0075-U001-A2-6318 Page 9

Page 70

Les français 04/00 BT 200

4 Mode spécialiste

Une pression simultanée sur les touches ESC

et OK permet de passer du mode standard en

mode spécialiste.

Le mode spécialiste permet de disposer des

fonctions suivantes :

- test du câblage (voir mode standard).

- test des stations (test RS485)

- test de la phase

- mesure de la distance

- test de la réflexion

- menu service

4.1 Commande

La commande du BT 200 est guidée par menu, via les touches d'entrée du clavier à

membrane (figure 1).

Curseur

La position momentanée du curseur sur

l'écran est signalée par une flèche clignotante

et correspond à la fonction en cours d'exécution.

Lorsque le BT 200 se trouve en mode d'enregistrement, la position du curseur est signalée

par une flèche modifiée.

Page 10

(S)J31069-D0075-U001-A2-6318

Page 71

BT 200 04/00 Les français

Fonctions du menu

Les fonctions du menu sont sélectionnées au

moyen du curseur et activées via la touche

OK. La touche ESC permet d'interrompre une

fonction en cours ou de revenir dans la fonction ascendante.

Structure du menu

START

Akku-Test

N-Modus

S-Modus

(Normal-Modus)

Câblage

(Mode Spécialiste)

Câblage

RS485

rúseau

Distance

Réflexion

SERVICE

Enregistrement

Communikation

(Test)

(Test)

(Test)

(Test)

(Messurage)

(Test)

(Réglagles)

Langue

Réglagles

Vitesse

Ajouter une

Akku

Contrast

Kalibrierung

Effacent

FW-Version

Selbst-Test

Fig 3 Structure du menu

(S)J31069-D0075-U001-A2-6318 Page 11

Page 72

Les français 04/00 BT 200

4.2 Test des stations (RS485)

Ce test permet de contrôler l'interface RS485

d'un esclave ou d'un maître individuel :

Réalisation

Débrancher le connecteur de bus de la station.

Etablir une connexion point par point entre la

station et le BT 200 (voir figure 4).

U Pour ce raccordement, utiliser uniquement le

câble d'essai fourni !

Fig 4 Conne xion point par poi nt

Mettre la station sous tension (le test doit être

effectué lorsque la station est active).

Démarrer le test de la station. Le maître doit

se trouver sur le mode opératoire " RUN".

Résultats du test

Les résultats de test suivants sont possibles :

- RS 485 o.k. (station en ordre)

- RS 485 défectueux (absence de récep-

tion continue de signaux ; réitérer le test)

- Absence de réponse (absence totale de

réception

- 5 V : (valeur de mesure correspondante)

- Signal DPE (OUI ou NON)

Page 12

(S)J31069-D0075-U001-A2-6318

Page 73

BT 200 04/00 Les français

4.3 Test de la phase

Il permet de vérifier si tous les esclaves se

trouvant sur le PROFIBUS sont jo ignables, ou

de contrôler la réaction d'un esclave indivi-

duel.

Le test de la phase peut également être effectué via répéteur/câble à fibres optiques.

Réalisation

Débrancher tous les maîtres du bus, p. ex

PG, OP, CP (voir figure 5).

Attention : la terminaison du bus doit rester

garantie.

Raccorder le BT 200 au bus.

Régler sur le BT 200 la vitesse de transmission configurée sur le bus.

Pour le test individuel des esclaves, régler

l'adresse souhaitée.

Pour le test global, régler l'adresse "000".

Confirmer par "OK" l'adresse reconnue par le

BT 200 (esclave ou maître).

Fig 5 Pri ncipe de mesure du test de la phase

(S)J31069-D0075-U001-A2-6318 Page 13

Page 74

Les français 04/00 BT 200

Résultats du test

Lors du test global de la phase, chaque es-

clave pouvant être joint est affiché dans une

liste des stations accessibles ("LIFE LIST").

- "LIFE LIST"

Lors d'un test individuel

- Absence de réponse (p. ex. pas de sta-

tion avec l'adresse de bus réglée sur le

bus)

- Station erronée (p. ex. numéro d'esclave

attribué en double).

Page 14

(S)J31069-D0075-U001-A2-6318

Page 75

BT 200 04/00 Les français

4.4 Distance

La mesure de la distance ne s'applique qu'à

des câbles d'une longueur supérieure à 15 m.

La mesure de la distance n'est pas possible

par l'intermédiaire d'un répéteur.

Réalisation

Couper la tension d’alimentation de toutes les

stations du bus.

Brancher le connecteur d'essai à une extrémité et le BT 200 à l'autre extrémité du câble

(couper la résistance terminale avec le BT

200).

Démarrer la mesure de la distance .

Après le démarrage, trois valeurs devant être

entrées par le clavier sont demandées par le

BT 200 :

- résistance de boucle (standard = 110 Ω/km).

La valeur standard peut être modif iée par la

fonction service.

- Nombre de connecteurs/appareils

12 Mbauds avec inductance série

- Valeur de la résistance par

connecteur/appareil

(standard = 0,32 Ω)

La mesure est effectuée après entrée de la

dernière valeur et confirmation avec OK.

Résultat de la mesure

L'affichage suivant apparaît à l'écran :

Les messages d'erreur suivants peuvent se

présenter pendant la mesure :

- Aucune résistance insérée

- Affichage “0 m“ (aucune longueur plausi-

ble déterminée)

- Plus d'une résistance insérée

Causes possibles d'erreurs :

- distance < 15 m

- lignes de branchement à l'intérieur du

segment de mesure

Eliminez l'erreur et renouvelez la mesure.

(S)J31069-D0075-U001-A2-6318 Page 15

Page 76

Les français 04/00 BT 200

4.5 Test de la réflexion

Le test de la réflexion peut être utilisé pour

rechercher une imperfection, p. ex. courtcircuit, ou pour confirmer la mesure de la

distance (pas via répéteur).

Les réflexions peuvent p. ex. survenir dans

les cas suivants :

- présence de lignes de branchement.

- Un trop grand nombre de résistances

terminales sont insérées, ou aucune.

- Le changement s'effectue sur un type de

câble inadéquat à l'intérieur du segment

de mesure.

Réalisation

Sortir le maître du bus et s'assurer des points

suivants :

- la terminaison de bus est alimentée en

tension ;

- aucune circulation ne s'effectue sur le

bus ;

- Aucun connecteur de bus n'est enfich é.

Raccorder le BT 200 à une extrémité du câble.

Démarrer la mesure de la réflexion.

Résultat du test

Si aucune réflexion (perturbation) n'est détectée, le message suivant apparaît :

Si une réflexion est détectée, le message suivant apparaît :

Le nombre affiché donne la distance en mètres du point de mesure au point de perturbation. Si la distance obtenue lors de la mesure

de la réflexion correspond à celle d'une mesure préalable, cette mesure de la distance

est confirmée. Il n'y a pas de perturbation

dans le câblage du segment de bus mesuré.

Page 16

(S)J31069-D0075-U001-A2-6318

Page 77

BT 200 04/00 Les français

4.6 Service

Réglages

Les réglages suivants peuvent être modifiés

sous le menu service :

- Langue

(allemand/anglais/français/italien/espagnol/portugais)

- Résistance de boucle (50 - 200 Ω/km)

- Vitesse de transmission (9600 bauds -

12 Mbauds)

- Contraste (↑↓)

- Mode d'enregistrement (activé/coupé)

Communication

Activation de l'interface de transmission des

données pour la fonction d'enregistrement

Affichage

Vous disposez des affichages suivants sous

le menu service :

- version de firmware

- capacité de l'accumulateur

Test du matériel

Il permet de contrôler le matériel interne.

Calibrage

Avec le câble PROFIBUS standard de type A,

tout calibrage est superflu.

La précision de la mesure de la distance et de

la réflexion est atteinte par le calibrage dans

des longueur connues avec 2 câbles-test de

longueur différentes.

Fig 6 Pri nc i pe du calibrage

(S)J31069-D0075-U001-A2-6318 Page 17

Page 78

Les français 04/00 BT 200

5 Mode d’enregistrement

Sous le mode d'enregistrement, les tests effectués sont mémorisés dans le BT 200 et

peuvent être ultérieurement transmis par interface série vers un PC comportant un logiciel d'enregistrement.

Le mode d'enregistrement peut être activé et

coupé via le menu SERVICE.

Le mode d'enregistrement reste également

réglé après la coupure du BT 200, jusqu'à la

modification du réglage sous le menu

SERVICE.

Chaque test devant être mémorisé dans le

BT 200 est doté d'un code (0 ..999).

Le tableau ci-après montre le nombre maximum possible de tests devant être mémorisés

et les codes correspondants :

Type de test Nombre max.

Test du câblage 128

Test de la station 128

Test de la phase 10

Mesure distance 10

Test de réflexion 10

Mémorisation des tests

Après la réalisation de chaque test, l'instruction "mémoriser sous" s'affiche à l'écran avec

le code suivant disponible.

Le code peut être modifié par curseur ou accepté par une pression sur OK.

Lors de la saisie manuelle, si l'on sélectionne

un code déjà attribué, il est écrasé.

Page 18

(S)J31069-D0075-U001-A2-6318

Page 79

BT 200 04/00 Les français

Mémoire pleine

Lorsque le nombre maximum de tests devant

être mémorisés est atteint, le message suivant s'affiche à l'écran :

Le dernier code sélectionné apparaît après

OK et est proposé pour écrasement.

Ce code ne peut pas être modifié, le dernier

résultat de test est écrasé.

Transmission des tests au PC

Les données de test ne sont pas mémorisées en mode volatile, c'est-à-dire qu'elles

peuvent également être transmises au PC

après une coupure du BT 200.

Pour démarrer la transmission au PC, il est

nécessaire de raccorder le câble d'enregistrement fourni à une interface COM du PC

et à la douille subminiature D à 9 broches

du BT 200.

La transmission est activée par le menu

SERVICE et affichée à l'écran.

La touche ESC permet d'amorcer l'interruption de la communication. La demande suivante s'affiche à l'écran :

La communication est interrompue lor squ e

l'on sélectionne OK.

Effacement des données de test

Les données de test peuvent être effacées

par le menu SERVICE.

(S)J31069-D0075-U001-A2-6318 Page 19

Page 80

Les français 04/00 BT 200

6 Exemples d’application

Contrôle de l'ensemble de la DP PROFIBUS

• Aucune maître ne doit être raccordé au bus.

• La "Life-List" peut être également générée via

répéteur et segments optiques.

• Le bon fonctionnement du bus peut être contrôlé

au préalable sans maître dans les différentes

parties de l'installation.

Page 20

Fig 7 Exem pl e de test 1

(S)J31069-D0075-U001-A2-6318

Page 81

BT 200 04/00 Les français

Test du câblage avec les stations raccordées

• Il n'est plus nécessaire de débrancher les stations du bus

(les stations doivent être hors tension)

(mesure impossible via répéteur).

Fig 8 Exem pl e de test 2

(S)J31069-D0075-U001-A2-6318 Page 21

Page 82

Les français 04/00 BT 200

Test du câblage d'un segment via douille PG sur

répéteur

Page 22

Fig 9 Exem pl e de test 3

(S)J31069-D0075-U001-A2-6318

Page 83

BT 200 04/00 Les français

Test du câblage d'un segment derrière un répéteur et avec résistance terminale

Fig 10 Exemple de test 4

(S)J31069-D0075-U001-A2-6318 Page 23

Page 84

Les français 04/00 BT 200

7 Maintenance et élimination des

erreurs

7.1 Etat de charge de l’accumulateur

L'état de charge de l'accumulateur est affiché

pendant env. 2 secondes à la mise en marche. L'affichage est ensuite supprimé.

L'état de charge peut en outre être affiché par

le menu service pendant le fonctionnement.

Si l'accumulateur se vide pendant le temps de

fonctionnement, l'affichage de l'état de charge

se met à clignoter.

Valeurs standard

Si vous souhaitez remettre toutes les valeurs

dans l'état à la livraison, vous devez maintenir

les deux touches du curseur enfoncées

pendant env. trois secondes après la mise en

marche.

7.2 Remplacement de l’accumulateur

Page 24

Fig 11 Remplacement de l’accumulateur

(S)J31069-D0075-U001-A2-6318

Page 85

BT 200 04/00 Les français

7.3 Auto-contrôles

Le BT 200 exécute des auto-contrôles auto-

matiquement et sur demande (test du matériel) :

- Test interne du pilote RS485 :

le test est réalisé après chaque demande

de test de la station et de la phase.

- Test RAM :

un test cyclique de la RAM est effectué.

- Test de la FEPROM :

un test cyclique de l'EPROM est réalisé.

- Test du pilote RS485

Les différents tests, tels test de RAM, test

FEPROM et test des touches de l'écran peuvent également être sélectionnés à partir du

mode spécial via la fonction service - test

matériel.

Si une erreur est détectée pendant l'autocontrôle, il convient de procéder selon le ta-

bleau d'élimination des erreurs.

(S)J31069-D0075-U001-A2-6318 Page 25

Page 86

Les français 04/00 BT 200

7.4 Tableau d'élimination des erreurs

Dérangement à la mise en marche

Affi-

chage

Néant Aucun

Eventuellement

affichage

message"dér

angement

interne"

Dérangement pendant le fonctionnement

Affi-

chage

Affichage

accu.

clignote

avant

Néant Appareil

Dérangement

affichage

après la

mise en

marche

Message

"dérangement

interne"

s'affiche

après

mise en

marche

Dérangement

Appareil

se met

hors

circuit

se met

hors

circuit

Motif Consé-

quence

Accumulateur

déchargé

Dérangement

RAM/

EPROM

Défaut

écran/

clavier

Motif Consé-

Accu

vide

Temps

sans com

mande

dépassé

Pas de

démarrage du

matériel

Aucune

mesure

possible

quence

Aucune

mesure

possible

Néant Appuyer

Remède

Charger

accu/

insérer

accu

neuf

Remplacer le

BT 200

Remède

Charger

accu/

insérer

accu

neuf

touche

ON/OFF

Pilote

interne

défectueux

Page 26

Pilote

interne

défectueux

(S)J31069-D0075-U001-A2-6318

Matériel

défectueux

Test

station/

phase

impossible

Remplacer le

BT 200

Page 87

BT 200 04/00 Les français

8 Accessoires & pièces de rechange

Vous pouvez commander les composants suivants

en indiquant le n° de référence correspondant.

Désignation/figure N° de référence

Connecteur d'essai

6EP8106-0AC20

Kit d'entregistrement pour

Win 95/9 8/NT4

• CD-ROM en D/E/F

• Câble

6ES7193-8MA00-0AA0

Chargeur à fiche avec bloc

d'alimentation pour :

230 V AC

110 V AC

Accumulateur avec câble

de raccordement

Câble d'essai pour test des

stations

Submin. D 9 broches sur

Subm. D 9 broches (1 / 1)

(S)J31069-D0075-U001-A2-6318 Page 27

6ES7193-8LA00-0AA0

6ES7193-8LB00-0AA0

6EP8106-0HA01

6EP8106-OHC01

Page 88

Les français 04/00 BT 200

9 Caractéristiques techniques

Généralités

Dimensions 210 * 100 * 55 mm

Poids 400 g

Capacité de l'accumulateur

Durée de service

Alimentation électrique Accu. NiCd 4,8 V

Affichage LCD, 2 * 16 caract.

Vitesse de transmission 9600 Bd … 12 MBd

Type de protection IP 20

Précision de mesure Mesure longueur +/-

Conditions environnantes

Température de service + 5°C bis +45°C

Température de stockage -20°C bis +60°C

Humidité relative de l'air Maxi 95% / 24°C

Haut. fonct. adm. (au-dessus

niveau de la mer)

≥ 720 mAh

≥ 8 h

3m

Moyenne 75% / 17°C

(sans rosée)

-1000m à +2000m

Directives EMV

Identification CE DIN EN 61326-1:

1998

EN 50 081-1

EN 50 082-2

Conditions mécaniques

Vibrations en service IEC 1131-2

Sollicitation aux chocs pendant le service

Chute libre IEC 1131-2/68-2-32

Homologations

UL

CSA

Référence

Page 28

(S)J31069-D0075-U001-A2-6318

IEC 1131-2

6ES7 181-0AA010AA0

Page 89

BT 200 04/00 Les français

Abréviations

Bd

Baud (1Bd = 1 caractère (bit)/seconde)

BT

CP

EMV

MBd

NiCd

NN

OP

PG

RTS =

DPE

Testeur de physique de bus

Processeur de communication

Compatibilité électromagnétique

6

1MBd = 10

Nickel cadmium

Zéro hydrographique (niveau de la mer)

Pupitre opérateur

Console de programmation

Request to send, demande pour émettre

bauds

Info Info Info Info Info Info Info

Vous pouvez télécharger la présente documentation

gratuitement sur Internet, sous l'adresse suivante :

http://www.ad.siemens.de/simatic-cs

Des informations actuelles sur les produit s SIM ATIC

sont disponibles en permanence sur le site Inter net

ci-dessous :

http://www.ad.siemens.de/simatic

Vous pouvez joindre le Service clientèle SIMATIC

sous les numéros suivants :

Tel. +49 (911) 895 7000

Fax. +49 (911) 895 7002

(S)J31069-D0075-U001-A2-6318 Page 29

Page 90

Les français 04/00 BT 200

Page 30

(S)J31069-D0075-U001-A2-6318

Loading...

Loading...