Siemens Ardoptix PT 140 AF4, Ardoptix PT 140 AF1, Ardoptix PT 143 AF4, Ardoptix PT 143 AF1 Operating Manual

Page 1

Two-colour Pyrometer

PT 14x

7MC3040-...

Operating Manual

03/2017

Page 2

Page 3

Two-colour Pyrometer PT

Ident.-Nr.: 106 7393

PT14x_si_en.doc

Stand: 21.03.2017

830 hm / 810 het

Page 4

Copyright prohibits the reproduction or distribution of this instruction

manual, including text, photographs or images contained herein, in whole

or in part, for any purpose whatsoever, without prior consent of the author. This applies to any form of mechanical or electronic reproduction as

well as to electronic transmission in any form through any

medium.

Please note:

Unless otherwise stated in this instruction manual, the instruments

described herein are subject to change without prior notice, particularly

modifications for the sake of technological advancement.

Siemens AG

Digital Factory

Customer Services DF&PD

DF CS SD OP ITM

Telefon +49 (911) 750-9600

Fax +49 (911) 750-9609

Email: sirent.industry@siemens.com

Office/Testing

Warehouse/Counter service

Breslauer Str. 5

Gundelfinger Str. 20

90766 Fürth

90451 Nürnberg

Germany

Germany

Page 5

s

Operating manual

Contents

1 Product Numbers Ardoptix PT .................................................. 1

2 Miscellaneous ............................................................................. 2

2.1 Informationen about this manual ........................................................ 2

2.2 Explanation of symbols ....................................................................... 2

2.3 Liability and Warranty ......................................................................... 2

2.4 Copyright ............................................................................................ 3

3 Safety .......................................................................................... 3

3.1 Intended use ....................................................................................... 3

3.2 User’s responsibility ................................ ................................ ............ 4

3.3 Electromagnetic Compatibility ............................................................ 4

4 Scope of delivery ........................................................................ 4

5 General Description ................................................................... 4

5.1 Intended Use ...................................................................................... 4

5.2 Operating Controls and Display .......................................................... 4

6 Charging the batteries ............................................................... 5

7 Preparing the pyrometer for measurements ............................ 6

7.1 General Information ............................................................................ 6

7.2 Diopter compensation ......................................................................... 6

7.3 Brightness control to protect the eye .................................................. 6

7.4 Focusing the pyrometer ...................................................................... 6

7.5 Align the pyrometers ........................................................................... 7

7.6 Performing a measurement ................................ ................................ 7

7.7 Automatic switch-off ........................................................................... 8

8 Setting parameters at the pyrometer (basic configuration) .... 8

9 Menu ............................................................................................ 9

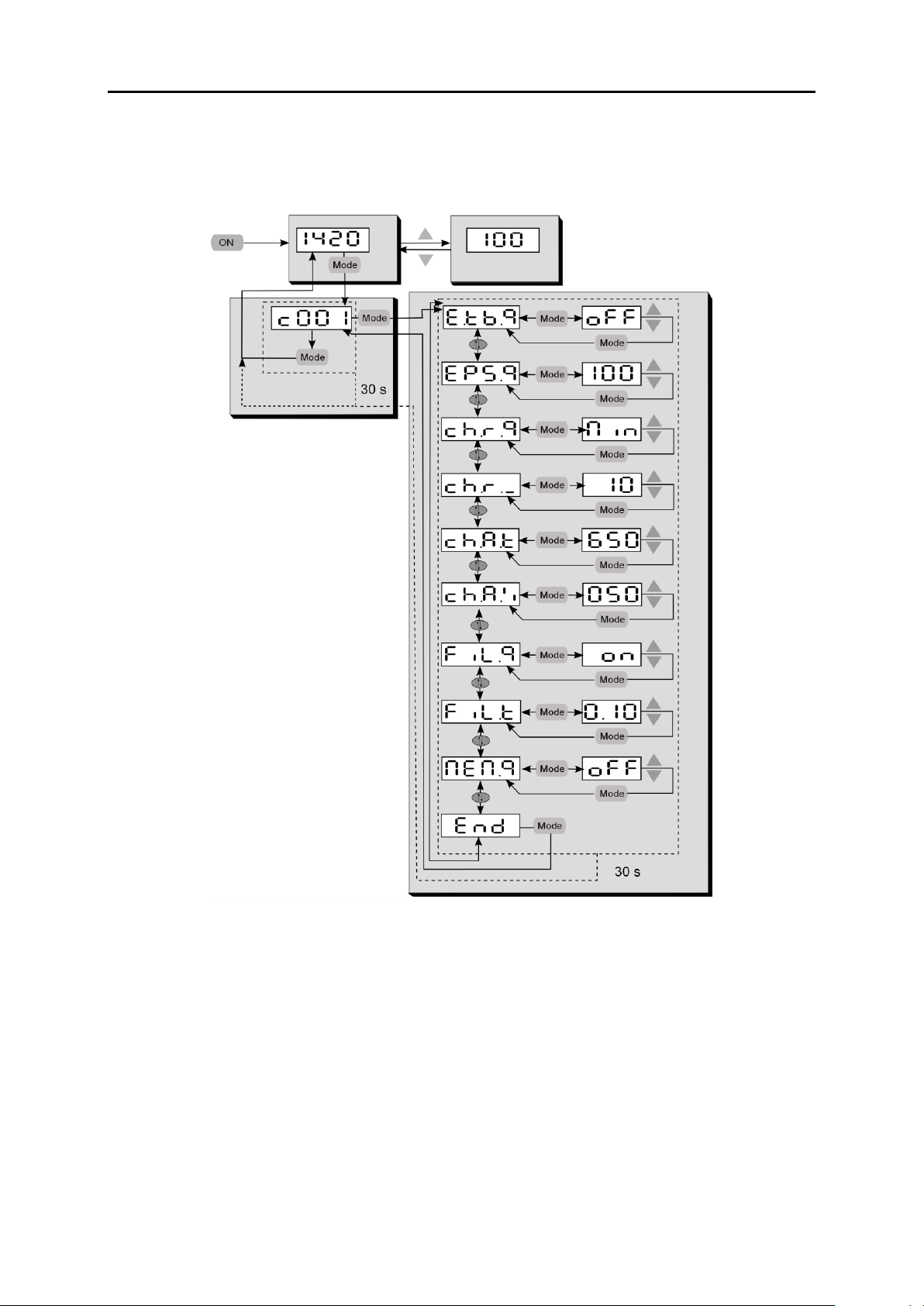

9.1 Measurement two-colour/ratio mode configuration layer C001.......... 9

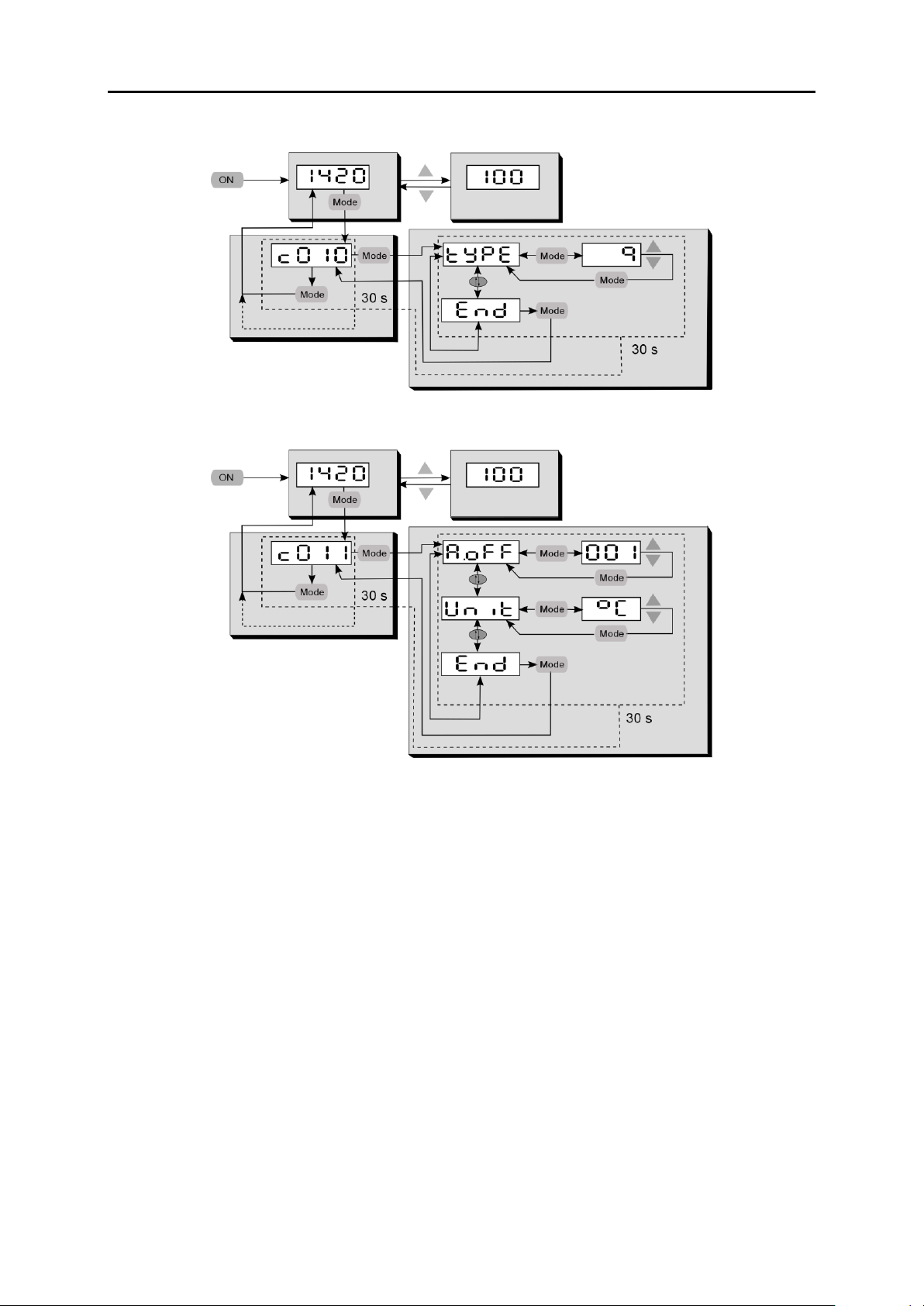

9.2 Configuration data acquisition configuration layer C010 ................... 10

9.3 General function configuration layer C011 ....................................... 10

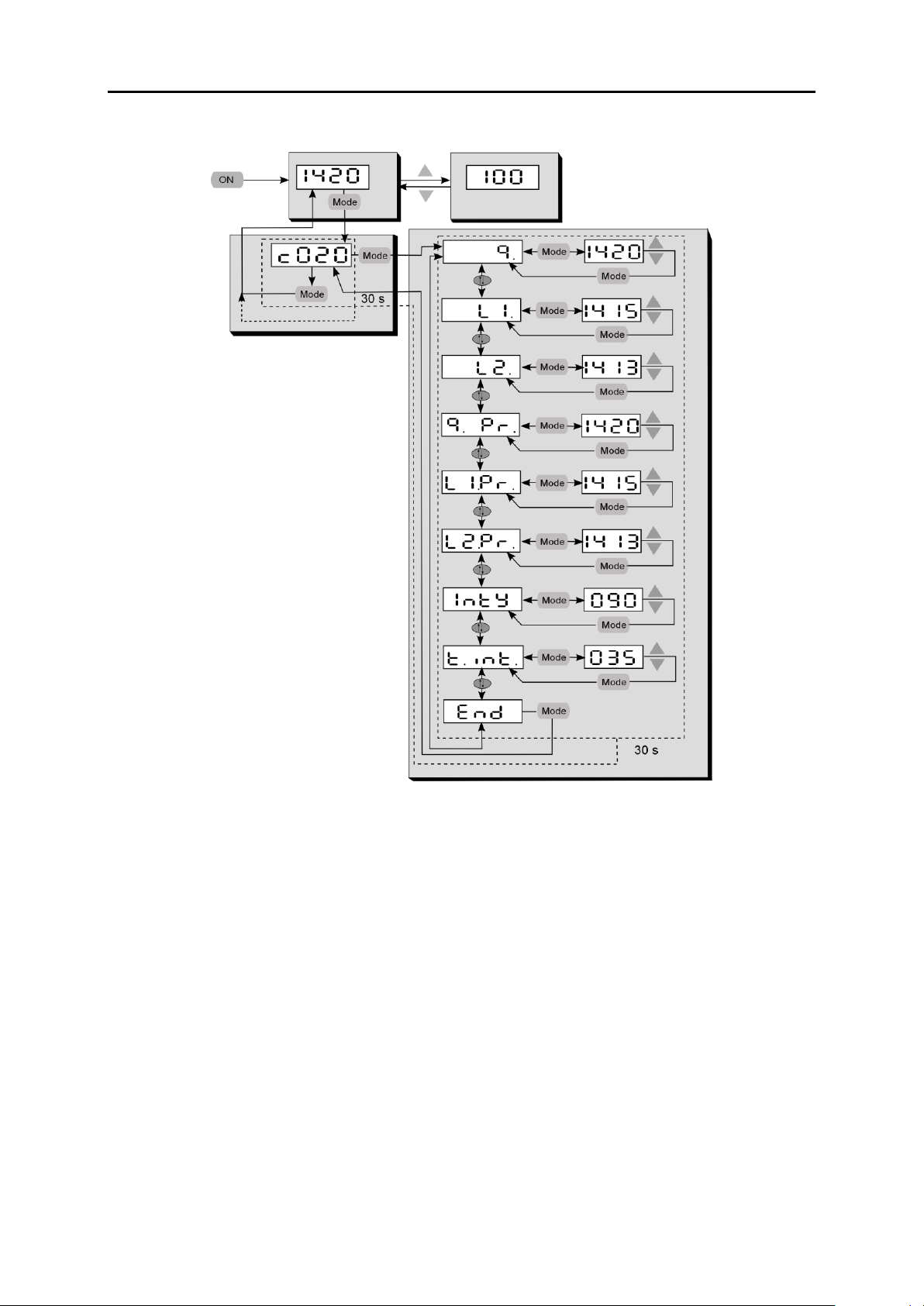

9.4 Displayed temperature readings configuration layer C020 ............... 11

10 Setting the Emissivity Ratio (two-colour/ratio mode) ............ 11

11 Initializing emissivity ratio constants ..................................... 12

11.1 Define number of emissivity ratio constants in array ........................ 12

11.1.1 Store and assign emissivity ratio constants .................................. 12

11.2 Select the emissivity ratio constant ................................................... 12

12 Determining and Setting Emissivity (Spectral mode) ............ 13

13 Initializing emissivity factors (Spectral mode) ....................... 13

13.1 Define number of emissivity constants in array ................................ 13

13.1.1 Store and assign emissivity constants .......................................... 14

13.2 Select the emissivity constant ........................................................... 14

14 Further configuration ............................................................... 14

15 Configuration – signal conditioning ....................................... 14

15.1.1 Transmission factor (spectral mode) ............................................ 14

15.1.2 Background Temperature Compensation (Spectral mode) .......... 15

15.1.3 Temperature offset using linear interpolation ............................... 15

15.1.4 Smoothing function ................................ ................................ ....... 16

15.2 Min/Max memory .............................................................................. 17

15.2.1 Min/Max Memory .......................................................................... 17

Page 6

s

Operating manual

15.2.2 Double Maximum Memory with hold time ..................................... 17

15.2.3 Double Maximum Memory with hold time "Combined" ................. 18

15.2.4 Automatic Temperature Detection (ATD) ..................................... 18

16 Setting Parameters at the device ............................................ 22

16.1 Configuration layers ................................................................ .......... 22

16.1.1 Temperature measurement using two-colour/ratio mode ............. 23

16.1.2 Temperature measurement lambda 1 .......................................... 24

16.1.3 Temperature measurement lambda 2 .......................................... 25

16.1.4 Configuration I/O .......................................................................... 27

16.1.5 General Functions ........................................................................ 28

16.1.6 Displayed temperature readings ................................................... 29

17 Software CellaView .................................................................. 29

18 PC Interface .............................................................................. 29

19 Remote configuration .............................................................. 30

19.1 Main Menu ........................................................................................ 31

19.2 View Current Configuration............................................................... 31

19.3 Submenus ........................................................................................ 32

19.3.1 Configure two-colour/ratio mode .................................................. 32

19.3.2 Lambda 1 ..................................................................................... 32

19.3.3 Lambda 2 ..................................................................................... 33

19.3.4 Quick access to emissivity / signal smoothing / operating mode .. 33

19.3.5 I/O Signal Configuration ............................................................... 33

19.3.6 Automatic temperature data output .............................................. 35

19.4 User Recalibration ............................................................................ 36

20 Maintenance ............................................................................. 38

20.1 Cleaning the pyrometer lens/protective glass ................................... 38

21 Accessories .............................................................................. 39

21.1 Supplementary lens .......................................................................... 39

22 Theory of Non-Contact Temperature Measurements ............ 40

22.1 Emissivity .......................................................................................... 40

22.2 Temperature measurement using spectral mode ............................. 41

22.3 Temperature measurement using two-colour/ratio mode ................. 41

22.4 Emissivity Coefficient Table – Spectral Mode ................................... 42

23 General technical data ............................................................. 43

24 Technical Data PT 140 (650 – 1700 °C) .................................... 43

24.1 Field of View Diagrams PT 140 (650 – 1700 °C) .............................. 43

25 Technical Data PT 140 (750 – 2400 °C) .................................... 45

25.1 Field of View Diagrams PT 140 (750 – 2400 °C) .............................. 45

26 Technical Data PT 143 (650 – 1700 °C) .................................... 46

26.1 Field of View Diagrams PT 143 (650 - 1700°C) ................................ 46

27 Technische Daten PT 143 (MB 750 - 2400°C).......................... 47

27.1 Field of View Diagrams PT 143 (MB 750 - 2400°C) ......................... 47

29 Dimensions ............................................................................... 48

30 Shipping, Packaging and Disposal ......................................... 49

30.1 Inspecting your shipment .................................................................. 49

30.2 Packaging ......................................................................................... 49

30.3 Disposal of used apparatus .............................................................. 49

31 Copyright .................................................................................. 50

Page 7

s

Operating manual

32 Default settings ........................................................................ 51

32.1 Temperature measurement (Configuration layer: C001)............. 51

32.2 Temperature measurement Lambda 1 /2(Configuration layer: C002) .. 52

32.3 Temperature measurement Lambda 2(Configuration layer: C003) ...... 53

32.4 General Functions (Configuration layer: C010) ........................... 53

32.5 General Functions (Configuration layer: C011) ........................... 54

Page 8

s

Operating manual

Page 9

s

Operating manual

1

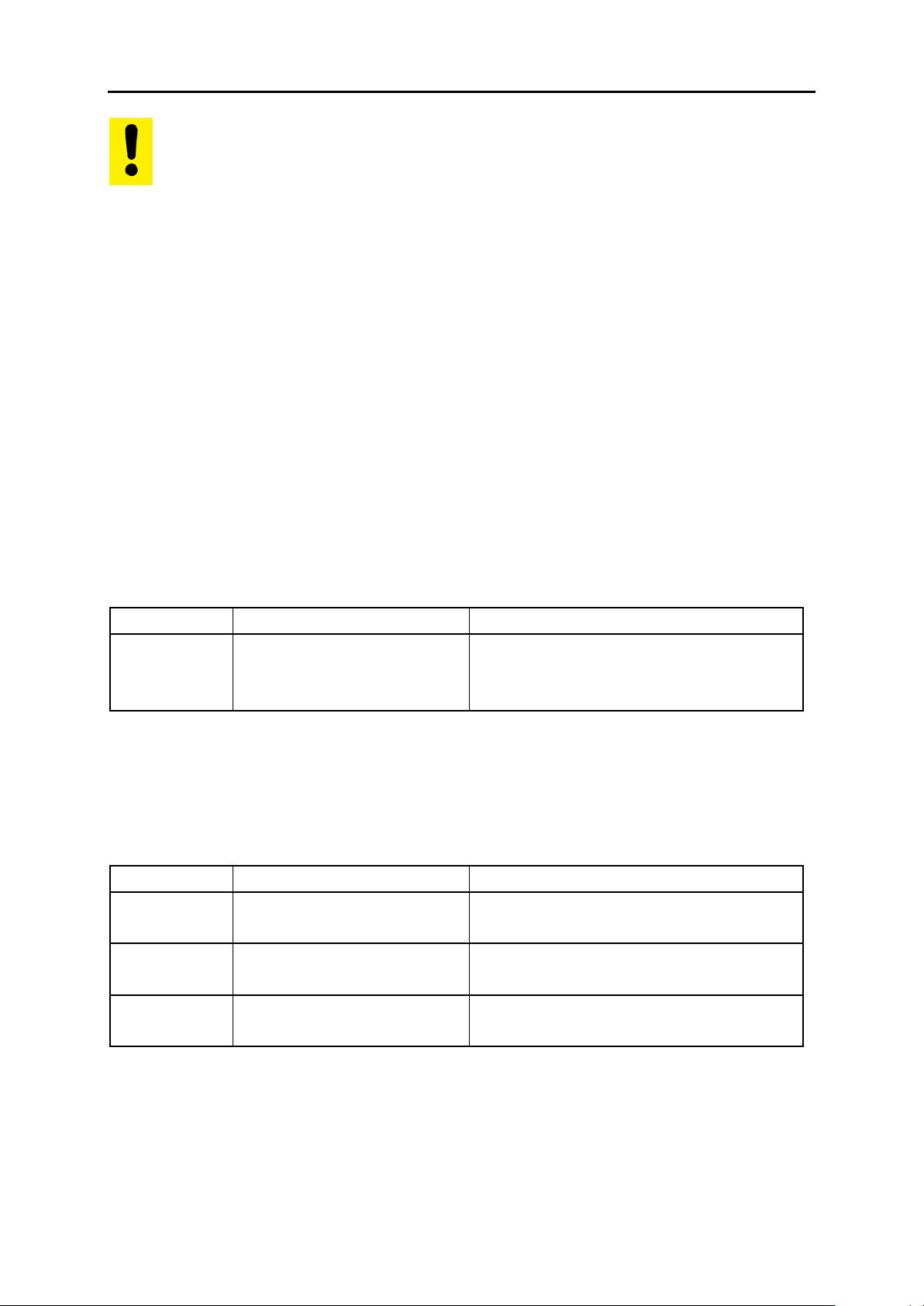

1 Product Numbers Ardoptix PT

Pyrometer

Temperarute range

Product number

Ardoptix PT 140 AF1

MB: 650-1700 °C, D=80:1 (St.-Optic)

7MC3091-1AB40

Ardoptix PT 140 AF4

MB: 750-2400 °C, D=150:1 (St.-Optic)

7MC3091-1AB20

Ardoptix PT 143 AF1

MB: 650-1700 °C, DV=230:1, DH=45:1

(St.-Optic)

7MC3091-1AB43

Ardoptix PT 143 AF4

MB: 750-2400 °C, DV=350:1, DH=50:1

(St.-Otic)

7MC3091-1AE43

Page 10

s

Operating manual

2

2 Miscellaneous

2.1 Informationen about this manual

The Operating Manual shall enable the user to properly install the

pyrometer and those accessories which are necessary.

Before starting installation, be sure to read and understand this entire

manual, in particular the chapter on safety! The instructions contained in

this manual, especially those concerning safety, as well as site-specific

regulations governing UV radiation must be complied with at all times!

2.2 Explanation of symbols

Important safety-related references in this manual are marked with a

symbol.

CAUTION!

This symbol indicates important information which, if neglected, might

result in pyrometer damage, malfunction or breakdown.

PLEASE NOTE !

This symbol points out guidelines which should be heeded for efficient

and trouble-free operation.

2.3 Liability and Warranty

All information compiled in this manual is in accordance with applicable

regulations. The statements made are based on state-of-the-art technology and reflect our extensive knowledge and many years of experience.

PLEASE NOTE !

Always carefully read this Operating Manual before beginning any

work on or with the instrument, especially prior to installation and

initial setup! The Manufacturer shall not be held liable for any

damages or malfunctions arising from a disregard of the warnings

and instructions contained herein.

This Operating Manual must be retained for future use. Please ensure

that all persons who wish to operate the instrument have access to this

manual.

Page 11

s

Operating manual

3

2.4 Copyright

This Operating Manual should be treated as confidential. It is solely intended for use by persons involved with the instrument. This manual may

not be made available to a third party without prior Manufacturer’s con-

sent. Please contact the Manufacturer if the need should arise.

PLEASE NOTE !

The data, texts, charts, drawings, images or other representations contained in this manual are copyright-protected and furthermore, subject to

intellectual property rights. Violators will be prosecuted. Unauthorised

use and copyright infringement will be subject to penalty by law.

Reproductions of any kind, in whole or in part, as well as the exploitation

or disclosure of this manual’s content without the explicit written approval

of the Manufacturer are expressly prohibited by law. Violations shall be

subject to compensation claims by the Manufacturer. The right to claim

additional indemnities remains reserved.

3 Safety

This chapter outlines all important safety aspects to be considered for

optimum employee protection and to ensure safe and reliable operations.

3.1 Intended use

The pyrometer is solely intended for non-contact measurement of temperatures as described in this manual. Any other use is not intended.

Operational safety can only be ensured when the instrument is used for

its intended purpose.

CAUTION !

It is prohibited to use the pyrometer for any other purpose beyond what

is specified in this manual. Using the instrument in any other manner will

be considered as improper.

The Manufacturer/Authorised Agent shall not be held liable for any damages or loss resulting from such unintended or improper use; in this case

the risk is solely borne by the user.

Page 12

s

Operating manual

4

3.2 User’s responsibility

The pyrometer may only be used when it is in perfect working condition.

3.3 Electromagnetic Compatibility

The devices comply with the essential safety requirements of the Electromagnetic Compatibility Directive 2014/30/EU (EMC Act).

4 Scope of delivery

Make sure that all of the following components have been included with

your shipment:

Pyrometer

Carrying case

Power supply

Calibration certificate

Software CellaView (Download Version)

USB cable

5 General Description

5.1 Intended Use

The Ardoptix PT series provides efficient pyrometers for non-contact

temperature measurements.

The two-colour pyrometer Ardoptix PT 14x measures the intensity of infrared radiation at two different wavelengths. The ratio of these two intensities is proportional to the temperature. The Ardoptix PT 14x is used

for temperature measurement from 650 °C to 2400 °C. These instruments serve a broad range of applications which include the iron and

steel producing industry as well as the metal, glass, cement and chemical industries.

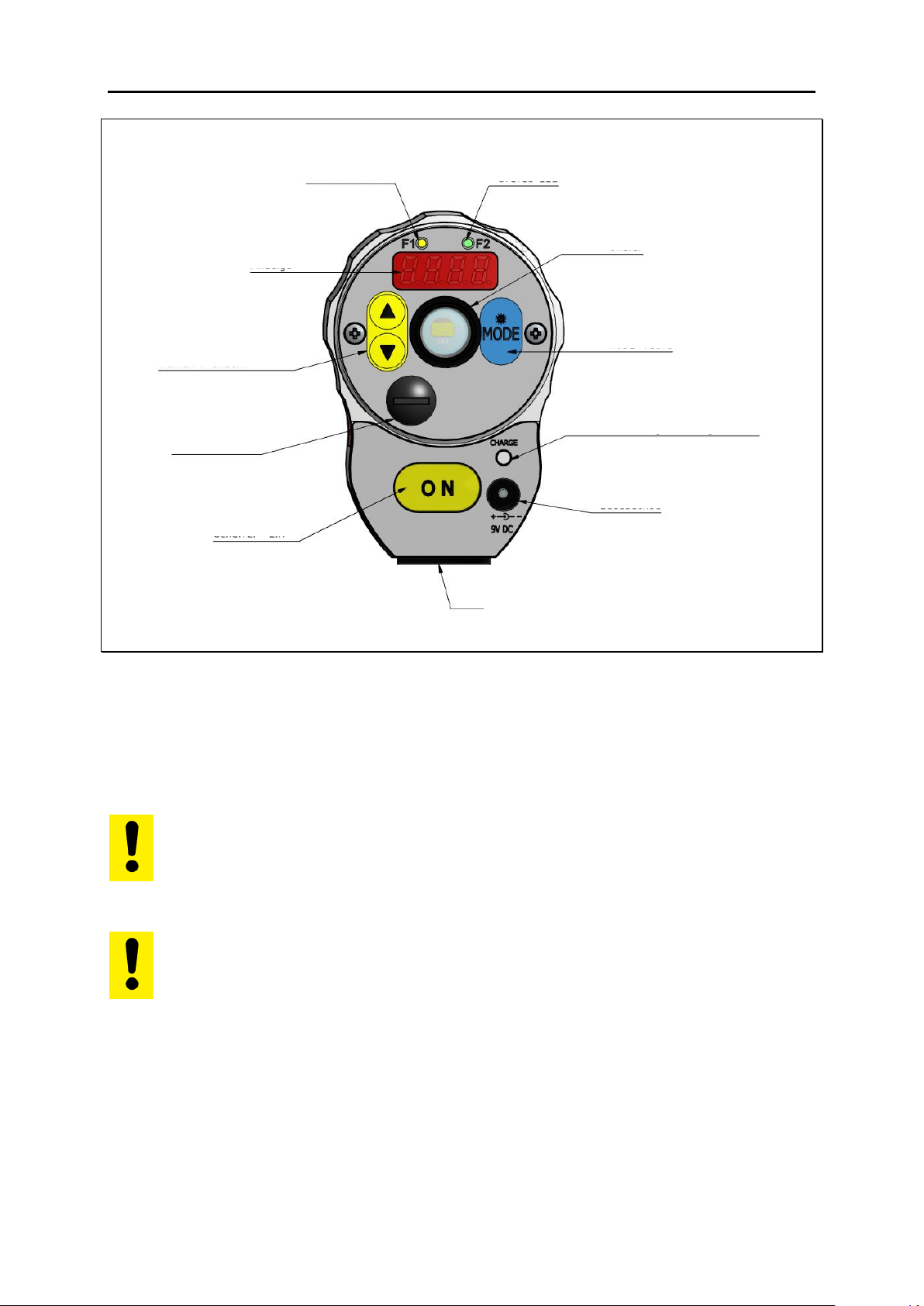

5.2 Operating Controls and Display

The rear panel of the Ardoptix has a 4-digit display and 4 push-buttons.

The display normally indicates the currently measured temperature. During configuration (using the push-buttons), the display will show the parameter you are setting. Whenever the display shows a parameter, the

F1 Parameter LED (yellow) will light up. During a running measurement,

the F2 Status LED (green) will light up.

Page 13

s

Operating manual

5

6 Charging the batteries

Connect the battery charging socket of the Ardoptix to the provided power supply (9 V DC). The charge indicator lights as long as the batteries

are being charged. A complete charging cycle takes approx. 15 hours.

Parameter LED

Status LED

Ocular

Mode key

Charge indicator

Charging socket

¼“ Tripod thread

Switch „ON“

USB connection

Parameter

select / change

Display

Only use the power supply which comes with the pyrometer. Do not use any other power supply as this may cause

irreparable damage to the device.

The charger is only for charging the battery.

The rechargeable battery is only charged when the pyrometer is switched off.

Page 14

s

Operating manual

6

7 Preparing the pyrometer for measurements

7.1 General Information

The pyrometer’s field of view must remain unobstructed. Any obstruction

may lead to measurement errors.

7.2 Diopter compensation

7.3 Brightness control to protect the eye

7.4 Focusing the pyrometer

To ensure precise temperature measurement, the pyrometer

must be correctly focused on the target object

The pyrometer offers diopter compensation to adjust the sighting device to the

user’s vision. Turn the ring until you see

a sharp image of the target spot indication in the viewfinder.

Instruments with a measuring range of

> 2000 °C are equipped with a polarisation

filter to control brightness and protect the

user’s eye.

The pyrometer is equipped with focusable

optics. Turn the lens until the target object

and the target marker (distinctly marked in

the viewfinder) both appear in sharp focus

simultaneously

Page 15

s

Operating manual

7

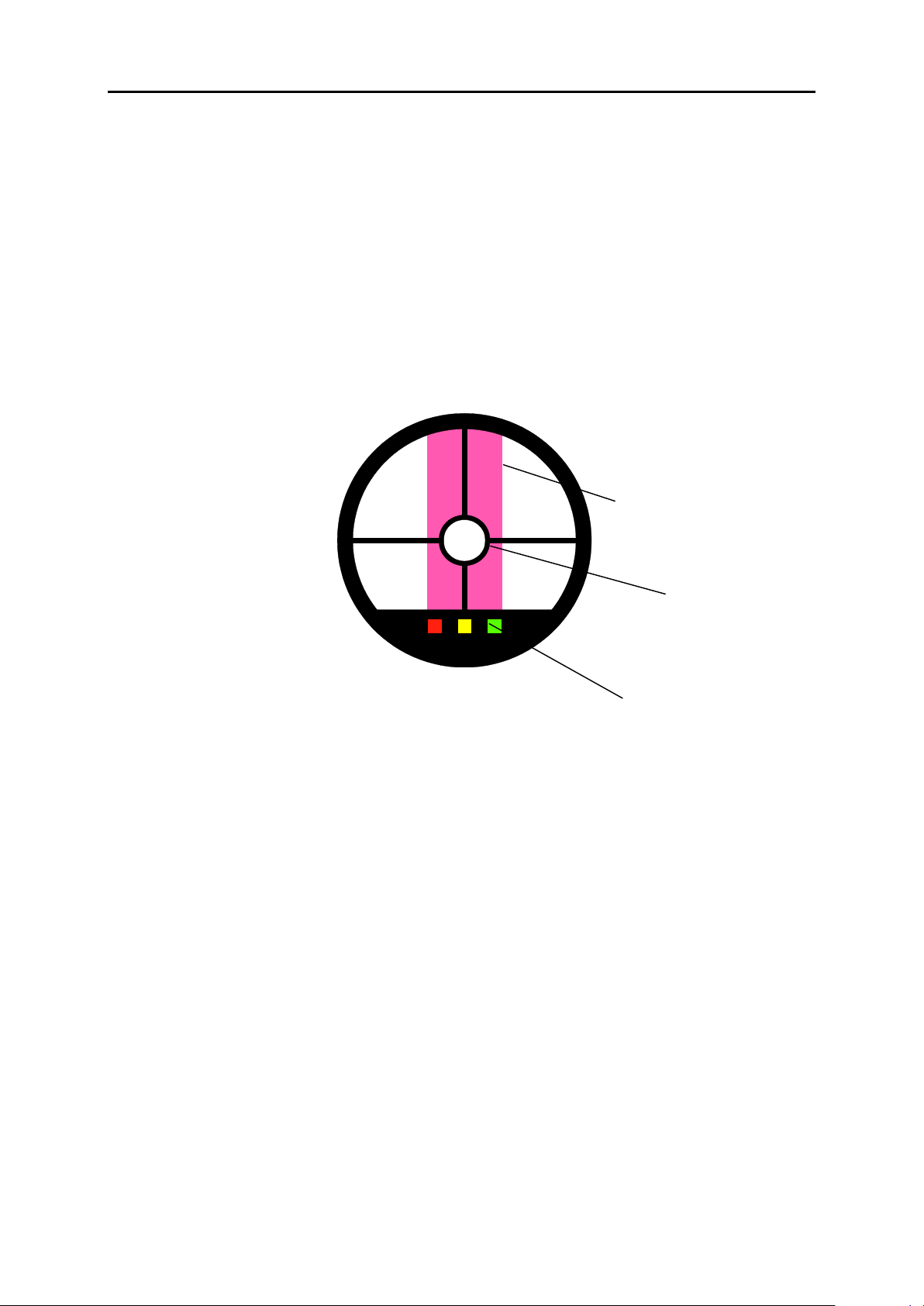

7.5 Align the pyrometers

Direct the Ardoptix to the object to be measured. The target marker in

the through-the-lens sighting device indicates the size of the target. (see

technical data/ course of target). When measuring with a two-colour pyrometer, the object to be measured is not required to fill the complete

measurement area. The integrated traffic light function in the viewfinder

signals an inadmissible partial illumination and the measurement is

stopped.

7.6 Performing a measurement

Press the ON button to switch on the device. If necessary adjust the ratio

correction. Focus the target marker at the diopter correction switch and

adjust the pyrometer lens to the correct measuring distance.

Measurement is in progress as long as you press the ON button. The

temperature (depending on the configured mode) is displayed on the

rear panel when you release the ON button. As an option, the measurement readings can be transmitted via interface.

1) Traffic light indicates

2) Measurement area

3) Target object

2

3

1

The amount of thermal radiation emitted from an object depends on the specific radiation properties of the material and its

surface. Non-contact temperature measurement requires that

you determine the material constant (emissivity) of the target

object prior to first-time use

Page 16

s

Operating manual

8

7.7 Automatic switch-off

In the default setting, the Ardoptix switches off automatically after 2

minutes if none of the control keys are pressed. Automatic switch-off can

be configured from 1 – 60 minutes. The Ardoptix measures continuously

when it is in "automatic disconnection deactivated" mode.

8 Setting parameters at the pyrometer (basic configura-

tion)

Use the buttons ▲▼ and the „MODE" button on the rear panel to access

and configure parameters. With these buttons you can view and adjust

all settings required for operating the pyrometer.

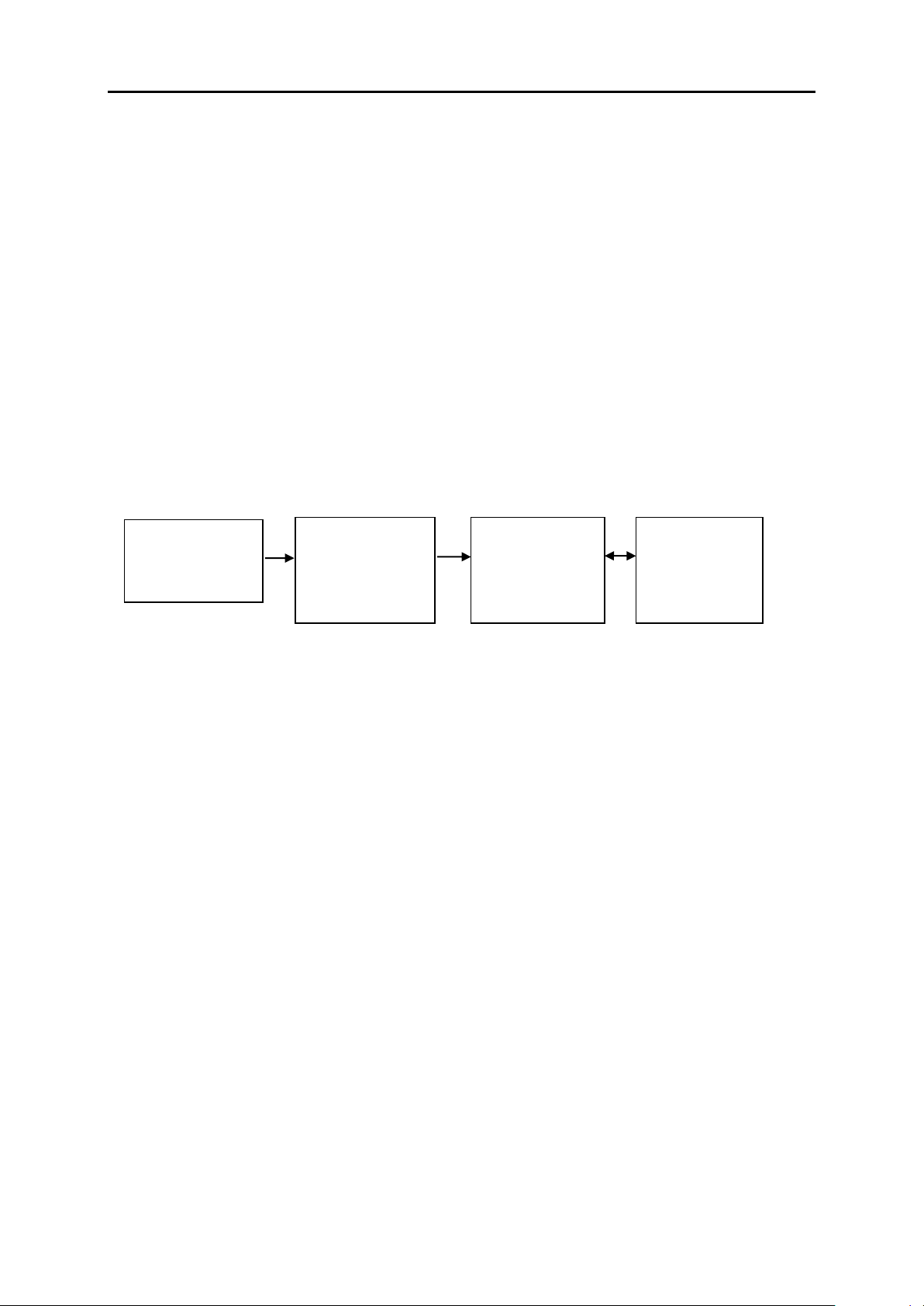

Menu structure:

1. Press the MODE button while in normal operating mode to switch

to "configuration layer" mode.

2. Use ▲▼ to select the configuration layer for the parameter you

wish to set.

3. Press MODE to confirm. Press ▲▼ to select the particular parameter.

4. Press MODE to confirm. Press ▲▼ to adjust the parameter value.

5. Press MODE again to end. Press ▲▼ to select END.

Whenever a control key has not been pressed within 30 seconds, the pyrometer will automatically return to normal operating mode. The modified

value is applied.

Normal

operating mode

(temperature)

Select

config. layer

C000-

C999

Select

parameter

EPS1

Adjust

parameter

99.9

MOD

MOD

MOD

▲▼

▲▼

▲▼

Key lock may have been activated at the terminal. When selecting the configuration layer you will be prompted to enter an access code with

P000

. To obtain full access to parameter set-

tings, enter

P100

otherwise you will only be able to view pa-

rameters but not change them.

Page 17

s

Operating manual

9

9 Menu

9.1 Measurement two-colour/ratio mode configuration layer

C001

In the default configuration, certain parameter settings will be

hidden. If required, you can have them shown

Page 18

s

Operating manual

10

9.2 Configuration data acquisition configuration layer C010

9.3 General function configuration layer C011

Page 19

s

Operating manual

11

9.4 Displayed temperature readings configuration layer C020

10 Setting the Emissivity Ratio (two-colour/ratio mode)

When the radiation properties of the target object’s surface (emissivity)

differ at two different wavelengths, or when interferences in the field of

view—such as dust or steam—do not weaken the signal to the same degree at each wavelength, the pyrometer can be adjusted by setting the

ratio of these two emissivity coefficients.

During normal operating mode, the emissivity ratio can

be set at the pyrometer using the ▲▼ buttons. When

simultaneously pressing the MODE key, the display

shows the current measuring temperature while the

emissivity ratio coefficient continues to be adjusted in the

background. This is an easy way to determine the emissivity ratio when the object temperature is known. The

modified values are directly adopted.

Page 20

s

Operating manual

12

11 Initializing emissivity ratio constants

The Ardoptix lets you store up to 10 emissivity ratio factors. Before you

perform a new measurement, simply use the ▲▼ control keys to select

your preconfigured emissivity factor. When you select a stored emissivity

ratio factor, the display will briefly show the preconfigured factor for that

emissivity ratio factor.

11.1 Define number of emissivity ratio constants in array

Before you configure the pyrometer with emissivity ratio factors, you

must define the size/length of the array. This is the number of emissivity

ratio you would like the array to contain (10 maximum). Using parameter

E.TB.Q, enter the total number.

Measurement two-colour/ratio mode configuration layer C001

Parameter

Function

Explanation

E.TB.Q

Enter desired number

of elements in array

If E.TB.1 = OFF, then use

▲▼ keys to manually set emissivity ratio

11.1.1 Store and assign emissivity ratio constants

Next, assign a value to each emissivity ratio constant in the index.

Measurement two-colour/ratio mode configuration layer C001

Parameter

Function

Explanation

E. 01

Emissivity ratio

Memory position 1

z. B. 100.5 %

E. 02

Emissivity ratio

Memory position 2

z. B. 101 %

E. 03

Emissivity ratio

Memory position 3

z. B. 101.5 %

11.2 Select the emissivity ratio constant

The memory position can optionally be set using the menu.

Once you have configured the emissivity ratio parameter,

the pyrometer will maintain this specific setting. The pyrometer will always operate with this value unless you

change the setting.

Page 21

s

Operating manual

13

Measurement two-colour/ratio mode configuration layer C001

Parameter

Function

Explanation

E.IDX

Memory position

Shows current selected emissivity ratio constant, e.g. E. 02

12 Determining and Setting Emissivity (Spectral mode)

In pyrometry, the specific radiation characteristics of the measured object

will influence the generated temperature data. In order to produce accurate and reliable temperature readings, the pyrometer must be configured according to the specific material constant (emissivity).

In spectral operation mode, emissivity can be set at the pyrometer using

the ▲▼ buttons. This changed setting will apply immediately to the current temperature measurement

13 Initializing emissivity factors (Spectral mode)

The Ardoptix lets you store up to 10 emissivity factors for lambda 1 and

lambda 2. Before you perform a new measurement, simply use the ▲▼

control keys to select your preconfigured emissivity factor. When you select a stored emissivity factor, the display will briefly show the preconfigured factor for that emissivity factor.

13.1 Define number of emissivity constants in array

Before you configure the pyrometer with emissivity factors, you must define the size/length of the array. This is the number of material constants

you would like the array to contain (10 maximum). Using parameter

E.TB.1/ E.TB.2, enter the total number.

Once you have configured the emissivity parameter, the

pyrometer will maintain this specific setting. The pyrometer will always operate with this value unless you change

the setting.

To determine the correct setting of the emissivity of a comparative measurement is carried out by a contact measurement. In

order to minimize measurement differences between the two

different physical measuring methods, the comparison measurement is almost the same time and performs at the same

measuring point as possible.

Page 22

s

Operating manual

14

Temperature measurement lambda 1 (Configuration layer: C002)

Parameter

Function

Explanation

E.TB.1

Enter desired number

of elements in array

If E.TB.1 = OFF, then use

▲▼ keys to manually set emissivity

13.1.1 Store and assign emissivity constants

Next, assign a value to each material constant in the index (E. 01, E.

02 etc.).

Temperature measurement lambda 1 (Configuration layer: C002)

Parameter

Function

Explanation

E. 01

Emissivity

Memory position 1

z. B. 75 %

E. 02

Emissivity

Memory position 2

z. B. 60 %

E. 03

Emissivity

Memory position 3

z. B. 50 %

13.2 Select the emissivity constant

The memory position can optionally be set using the menu.

Temperature measurement lambda 1 (Configuration layer: C002)

Parameter

Function

Explanation

E.IDX

Memory position

Shows current selected emissivity constant,

e.g. E. 02

14 Further configuration

15 Configuration – signal conditioning

15.1.1 Transmission factor (spectral mode)

The pyrometer has to be adjusted for the transmission properties of any

supplementary lens and/or protective window screwed onto the pyrometer. Set the pyrometer for the specific transmission factor (a percentage

value) which is indicated either in the product’s data sheet or on the lens

itself. This is parameter TAU.1 and can be accessed at configuration

layer C002/C003. If you are not using any auxiliary lens or protective

window, set the parameter to 100.0.

Parameters for lambda 2 are identical to lambda 1. See Chapter 16.1.3

Page 23

s

Operating manual

15

15.1.2 Background Temperature Compensation (Spectral mode)

Thermal radiation reflected from the surrounding will require that you

make an additional correction when the reflected radiation is strong

compared to the natural radiation of the target. This applies to object surfaces which have very low emissivity or when the temperature of the object is lower than the temperature of its surroundings.

The background radiation reflected from the object consists of the following factors:

Background temperature

Background size

The capability of the background material to reflect infrared radia-

tion

To ensure that the measurement is not distorted and that the temperature readings are completely accurate, you should activate "background

temperature compensation" (switch on C002 or C003 / BAC.1).

Now enter the temperature value of the ambient source of radiation

(BAC.T) and its influence as a percentage (BAC.%). The influence in

percent stands for the size and the capability of the material to emit infrared radiation. You will have to determine these variables first.

15.1.3 Temperature offset using linear interpolation

When necessary, Ardoptix PT allows you to program an offset for the

temperature reading reported. The offset correction can be configured

Source of extraneous radiation

Example: furnace 950 °C

Target object TO = 900 °C

Emissivity e < 1

Reflection s > 0

Furnace radiation T

Back

= 950 °C

Page 24

s

Operating manual

16

individually with a minimum of 2 and a maximum of 10 interpolating

points (X/Y nodes). This information is stored in a user-defined temperature-indexed lookup table and used for signal conditioning. For values

lower than the 1st node and higher than the last node, the first and last

linear segments are extrapolated. Enter the nodes in ascending order.

Use the rear panel display to access this function via C001 / LIN.1.

15.1.4 Smoothing function

When the target object’s temperature is erratic, it makes sense to

smooth these temperature fluctuations in order to stabilize the signal.

The greater the time constant t

98,

(user-definable), the lower the effect of

these fluctuations on the yielded temperature reading. The pyrometer’s

response time is proportional to the time constant. Set signal smoothing

via parameter C001 / FIL.Q.

analogue

output

signal

time

output signal without

smoothing

output signal with

smoothing

X4

X3

X1

X2

Y1

Y2

Y3

Y4

Temperature before offset

Temperature after offset

Page 25

s

Operating manual

17

15.2 Min/Max memory

The pyrometer features a data memory to store minimum and maximum

(peak) temperature readings. This feature can be configured in one of

the following modes:

Memory off

Store minimum value (single)

Store maximum value (single)

Store double max. value for cyclical processes

ATD function (Only available in pyrometer with ATD function)

15.2.1 Min/Max Memory

In this mode—also called peak picker—the pyrometer determines the

highest or lowest temperature reading and keeps the temperature reading. The value is stored until you press the ON button again. Additionally,

you can define the smoothing filter setting.

15.2.2 Double Maximum Memory with hold time

In this operating mode the pyrometer continuously detects the maximum

temperature reading. This value is stored for the duration of the configured hold time and is displayed on the rear panel. In mid-sequence – after 50% lapse of the hold time – a second internal peak picker starts.

When the hold time has expired without finding a new max value, the

output signal decreases to the value of the second peak temperature (if it

turned out being lower than the first peak).

This memory mode serves to detect the maximum temperature of objects moving periodically past the pyrometer lens. The temperature reading is kept for the duration of the configured holding time when the pyrometer does not detect any hot object. The holding time should be configured to approximately 1.5 times as long as the cycle of the moving targets. This ensures that a temperature measurement gap is avoided and

temperature changes are detected quickly.

Page 26

s

Operating manual

18

target object in the pyrometer’s field of view

holdtime

time

temp. reading with double max. buffer

temp. measurement without double max. buffer

15.2.3 Double Maximum Memory with hold time "Combined"

The function of the double maximum memory "combined" is similar to

that of the double maximum memory. However, the hold time starts

when the spectral temperature is at its highest point. Displayed is the

corresponding two-colour temperature. If the spectral temperature decreases during the hold time, the corresponding two-colour temperature

is only displayed when the hold time has elapsed. If the spectral temperature rises during the hold time, the corresponding two-colour temperature is directly displayed.

15.2.4 Automatic Temperature Detection (ATD)

The ATD function allows a very easy and fully automatic capture of the

temperature. As soon as the pyrometer is switched on and aimed at a

hot object, the measurement starts automatically. The threshold value to

detect a hot object is adjustable. Depending on the configuration, the

measurement ends either after a selectable period or when there is no

longer a hot object in the pyrometer's measurement area. At the end of

the measurement the captured value is displayed until a new measuring

object is detected. To eliminate unrealistic measurement differences, it is

possible to check the determined measured value for plausibility in relation to the previous measured value and to filter it out. The new measured value can also be averaged with a weighting factor to eliminate

large jumps between the measured values.

Page 27

s

Operating manual

19

Threshold limits

The start of a measuring cycle is determined automatically and is dependent on the following variables:

Parameter

Function

Limit 1 (LI. 1)

Before beginning the measurement, the

temperature reading must have been lower

than Limit 1 at least once.

If Auto reset is activated (A.RST= ON),

Limit 1 will be ignored

Limit 2 (LI. 2)

Limit 2 must be exceeded at least for the

duration of the time delay (T.DEL).

Time Delay (T.DEL):

See Limit 2

When the conditions are fulfilled, the sampling time can begin (T.ACT).

Page 28

s

Operating manual

20

Parameter

Function

Sampling time

(T.ACT)

During the sampling time the temperature is

detected and stored as a temperature value.

Display and output of temperature reading [ANO]

The parameter ANO (normal display mode) defines which temperature

value is saved during sampling.

Parameter

Function

Display mode (ANO)

„T=0“ displays the lower temperature range

limit during the measurement.

„T.HLD“ indicates the previous tempera-

ture reading during the current measurement.

The green status LED indicates that a measurement is currently in process.

Average weighting [F-PR] Plausibility check

When the sampling time has ended, an average value is calculated for

recorded measuring cycles. The temperature reading is weighted with

the previously saved average value and added.

Parameter

Function

Weighted average

(F-PR)

Factor for average weighting. If you enter

100%, averaging will be off.

The smaller you set the F-PR factor, the stronger the weighting will be.

When the averaging function is activated (F-PR <100%) a plausibility

check will be performed. The difference in temperature between the current reading and the previously stored average is determined. If this deviation is greater than the plausibility threshold TSP, the transmitted data will be „0“ and the average value will remain unchanged.

Enter the upper threshold and lower threshold for the permissible deviation separately.

The parameter T.ACT= 0 automatically recognizes the

end of the discontinuous process (measured temperature

< L2). The pyrometer then shows "Auto" instead of the time

under parameter T.ACT.

Page 29

s

Operating manual

21

Parameter

Function

Plausibility (TSP_)

Permitted temperature difference for a valid

measurement when the new value is lower

than the stored measured value.

Plausibility (TSP~)

Permitted temperature difference for a valid

measurement when the new value is higher

than the stored measured value.

If a measuring cycle does not start during the period T.OUT the saved

average will be deleted and reinitialized when the next cycle begins.

Parameter

Function

Timeout

(T.OUT)

Time cycle for deleting average value (in

minutes)

At the end of the measuring cycle the pyrometer displays the averaged

temperature value (or the invalid reading „----“ ).

Cut-off interval [T.DIS]

A cut-off interval (time lag) begins after the measuring time has ended.

This cut-off interval must expire before the next measurement can start

with the cycle starting conditions described above.

Parameter

Function

Cut-off interval

(T.DIS)

The interval between one completed sampling and the start of a new sampling.

Timeout [T.OUT]

If a measuring cycle does not start during the period T.OUT, the saved

average will be deleted and reinitialized when the next cycle begins.

Parameter

Function

Timeout (T.OUT):

Time out for average function (in minutes)

Autoreset Function [A.RST]

Activate auto reset for the ATD function to run cyclically. Limit 1 will then

be ignored.

Normally, for a new measuring cycle to start, the detected temperature

must have dropped below Limit 1. If, however, you wish to measure a

Page 30

s

Operating manual

22

continuous process (continuous material flow), you must activate Auto

Reset. Limit 1 will then be ignored. Sampling will continue (restarting automatically and producing temperature readings cyclically) as long as

Limit 2 is exceeded for the time period defined by T.DEL.

Parameter

Function

Autoreset (A.RST):

Autoreset on/off

Parameter Set Li2 check on tAct [CH.L.2]

When this parameter is set to ON (CH.L.2=on), the detected temperature must exceed Limit 2 during the entire measuring time (TACT) in

order for the pyrometer to generate a valid temperature reading. The

measurement is discarded when the value falls below Limit 2.

The display shows „----“

Parameter

Function

Set Li2 check on tAct (CH.L.2)

on/off

16 Setting Parameters at the device

In addition to the configuration possibilities described, many parameters

can be adjusted at the rear panel using push buttons. These settings can

be accessed via configuration layers.

16.1 Configuration layers

The configuration layers are structured as follows:

C001 Temperature measurement two-colour/ratio mode

C002 Temperature measurement lambda 1

C003 Temperature measurement lambda 2

C010 I/O configuration (LED / Buzzer)

C011 General function

C020 Display temperature readings

The following chart lists all parameters. In the factory default configuration, certain parameters and configuration layers will not be accessible

by control key. This is meant to simplify pyrometer operation for the user.

These parameters are indicated by. If required, remote access to these

parameters can be enabled via PC interface or at configuration layer

C011. Open the user calibration menu (Menu mode: Full).

Some parameter settings will be hidden if their basic function has been

deactivated. For example, you will not be able to adjust the smoothing

Page 31

s

Operating manual

23

time of the filter if the filter has been turned off or switched to automatic

mode.

16.1.1 Temperature measurement using two-colour/ratio mode

(Configuration layer: C001)

Parameter

Function

Explanation

E.TB.Q

Array size

Use array with 1-10 entries or enter material

constant directly into the pyrometer

EPS.Q

Ratio correction

E.IDX

Memory position

Customize the array; assign a value to each

of the ratio correction in the array. Possible

indexes depend on the size of the array

E. 01

Assign ratio correction

constants

Customize the array; assign a value to each

of the ratio correction in the array. Possible

indexes depend on the size of the array

CH.R.Q

Plausibility check ratio

mode

OFF off

MIN deactivation when below limit

MI.MA. deactivation when below or above limit

CH.R._

Relative limit min.

Relative lower limit [%] , two-colour temp.

reading invalid (signal intensity)

CH.R.~

Relative limit max.

Relative upper limit [%] , two-colour temp.

reading invalid (signal intensity)

CH.A.T

Absolute min. temp.

Absolute lower limit, two-colour temp. reading

invalid

CH.A.%

Absolute minimum

Emissivity

Absolute lower limit [%], two-colour temp.

reading invalid

LIN.Q

Temperature offset

using linear

OFF off

2-10 number of nodes used

L. X1

node x 1 - 10

Signal input (initial value) node n

L. Y1

node y 1 - 10

Signal output (resulting value) node n

FIL.Q

Smoothing filter

OFF

ON

FIL.T

Smoothing time

Time in seconds t98

MEM.Q

Min/Max memory

OFF off

MIN lowest (min.)temperature, single

MAX highest (max.) temperature, single

DBL.M double maximum

DIS.M ATD function

MEM.T

Hold time for Min/Max

Hold time in sec.

FIL.M

Smoothing filter for

min/max*

OFF OFF

ON ON

FIL.T

Smoothing time*

Time t98 in sec.

T.DEL

time delay **

For ATD function, see Chap. 15.2.4

T.ACT

Sampling time **

For ATD function, see Chap. 15.2.4

T.DIS

cut-off interval **

For ATD function, see Chap. 15.2.4

T.OUT

Timeout**

For ATD function, see Chap. 15.2.4

LI. 1

Limit 1**

For ATD function, see Chap. 15.2.4

LI. 2

Limit 2**

For ATD function, see Chap. 15.2.4

F-PR

Average weighting **

For ATD function, see Chap. 15.2.4

TSP~

Plausibility

threshold **

For ATD function, see Chap. 15.2.4

Page 32

s

Operating manual

24

TSP~

Plausibility

threshold **

For ATD function, see Chap. 15.2.4

MEM.T

Hold time for Min/Max

Hold time in sec.

FIL.M

Smoothing filter for

min/max*

OFF OFF

ON ON

FIL.T

Smoothing time*

Time t98 in sec.

END

End

Exit menu

*

Only available with Min/Max and Double Max modes

**

Only available with ATD function

16.1.2 Temperature measurement lambda 1

(Configuration layer: C002)

In the factory default configuration, all parameter settings for digital inputs and outputs will be hidden.

Parameter

Function

Explanation

E.TB.1

Array size

Use array with 1-10 entries or enter material

constant directly into the pyrometer

EPS.1

Emissivity factor L1

Enter material constant directly into the pyrometer

E.IDX

Memory position

Choose an entry from the material constants

array

E. 01

Assign material

constants

Customize the array; assign a value to each

of the material constants in the array. Possible

indexes depend on the size of the array

TAU.1

Transmittance factor

L1

BAC.1

Ambient temperature

compensation

BAC.T

Temp. of ambient

source of radiation

BAC.%

Influence of ambient

IR radiation

The reflected thermal radiation from the surroundings as a portion of the total IR radiation

collected by the sensor in %

LIN.1

Temperature offset

using linear

OFF off

2-10 number of nodes used

L. X1

node x 1 - 10

Signal input (initial value) node n

L. Y1

node y 1 - 10

Signal output (resulting value) node n

FIL.1

Smoothing filter

OFF smoothing not activated

ON simple smoothing

FIL.T

Smoothing time

time t98 in sec for simple smoothing

MEM.1

Min/Max memory

OFF off

MIN lowest (min.)temperature, single

MAX highest (max.) temperature, single

DBL.M double maximum

DIS.M ATD function

MEM.T

Hold time for Min/Max

Hold time in sec.

FIL.M

Smoothing filter for

min/max*

OFF OFF

ON ON

FIL.T

Smoothing time*

Time t98 in sec.

Page 33

s

Operating manual

25

T.DEL

time delay **

For ATD function, see Chap. 15.2.4

T.ACT

Sampling time **

For ATD function, see Chap. 15.2.4

T.DIS

cut-off interval **

For ATD function, see Chap. 15.2.4

T.OUT

Timeout**

For ATD function, see Chap. 15.2.4

LI. 1

Limit 1**

For ATD function, see Chap. 15.2.4

LI. 2

Limit 2**

For ATD function, see Chap. 15.2.4

F-PR

Average weighting **

For ATD function, see Chap. 15.2.4

TSP~

Plausibility

threshold **

For ATD function, see Chap. 15.2.4

TSP~

Plausibility

threshold **

For ATD function, see Chap. 15.2.4

ANO

Mode of display **

T=0 show lower limit of temp. range dur-

ing running measurement

T.HLD Hold previous temp. reading during

running measurement

A.RST

Auto reset**

For ATD function, see Chap. 15.2.4

CH.L.2

Set Li2 check on tAct**

For ATD function, see Chap. 15.2.4

END

End

Exit menu

*

Only available with Min/Max and Double Max modes

**

Only available with ATD function

16.1.3 Temperature measurement lambda 2

(Configuration layer: C003)

By default, some parameters are suppressed to facilitate operation.

Parameter

Function

Explanation

E.TB.

Array size

Use array with 1-10 entries or enter material

constant directly into the pyrometer

EPS.2

Emissivity factor L2

Enter material constant directly into the pyrometer

E.IDX

Memory position

Choose an entry from the material constants

array

E. 01

Assign material

constants

Customize the array; assign a value to each of

the material constants in the array. Possible

indexes depend on the size of the array

TAU.2

Transmittance factor

L2

BAC.2

Ambient temperature

compensation

BAC.T

Temp. of ambient

source of radiation

BAC.%

Influence of ambient

IR radiation

The reflected thermal radiation from the surroundings as a portion of the total IR radiation

collected by the sensor in %

LIN.2

Temperature offset

using linear

OFF off

2-10 number of nodes used

Page 34

s

Operating manual

26

L. X1

node x 1 - 10

Signal input (initial value) node n

L. Y1

node y 1 - 10

Signal output (resulting value) node n

FIL.2

Smoothing filter

OFF smoothing not activated

ON simple smoothing

FIL.T

Smoothing time

time t98 in sec for simple smoothing

MEM.1

Min/Max memory

OFF off

MIN lowest (min.)temperature, single

MAX highest (max.) temperature, single

DBL.M double maximum

DIS.M ATD function

MEM.T

Hold time for Min/Max

Hold time in sec.

FIL.M

Smoothing filter for

min/max*

OFF OFF

ON ON

FIL.T

Smoothing time*

Time t98 in sec.

T.DEL

time delay **

For ATD function, see Chap. 15.2.4

T.ACT

Sampling time **

For ATD function, see Chap. 15.2.4

T.DIS

cut-off interval **

For ATD function, see Chap. 15.2.4

T.OUT

Timeout**

For ATD function, see Chap. 15.2.4

LI. 1

Limit 1**

For ATD function, see Chap. 15.2.4

LI. 2

Limit 2**

For ATD function, see Chap. 15.2.4

F-PR

Average weighting **

For ATD function, see Chap. 15.2.4

TSP~

Plausibility

threshold **

For ATD function, see Chap. 15.2.4

TSP~

Plausibility

threshold **

For ATD function, see Chap. 15.2.4

ANO

Mode of display **

T=0 show lower limit of temp. range dur-

ing running measurement

T.HLD Hold previous temp. reading during

running measurement

A.RST

Auto reset**

For ATD function, see Chap. 15.2.4

CH.L.2

Set Li2 check on tAct**

For ATD function, see Chap. 15.2.4

END

End

exit menu

*

Only available with Min/Max and Double Max modes

**

Only available with ATD function

L1 stands for lambda 1, meaning the temperature reading from

lambda 1

L2 stands for lambda 2, meaning the temperature reading from

lambda 2

Page 35

s

Operating manual

27

16.1.4 Configuration I/O

(Configuration layer: C010)

In the factory default configuration, all parameter settings for digital inputs and outputs will be hidden.

Parameter

Function

Explanation

TYPE

Operating mode/

measuring technique

Q ratio mode (quotient)

L1 Lambda 1

L2 Lambda 2

LED.

LED (green)

OFF OFF

ON ON

LED.S

LED: define source

RDY Status LED indicates ‘ready’

L1 Lambda 1

L1.PR Lambda 1 without peak picker

L2 Lambda 2

L2.PR. Lambda 2 without peak picker

Q Two-colour/ratio mode

Q. PR. Two-colour/ratio mode without peak

picker

TU Inner device temperature

1NTY. Signal intensity

M.TR.1 Triggered by ATD function Lambda 1*

M.TR.2 Triggered by ATD function Lambda 2*

M.TR.Q Triggered by ATD function two-

colour/ratio mode*

DIRT Dirt Alert

A.AC.1 Measuring time ATD Lambda 1*

A.AC.2 Measuring time ATD Lambda 2 *

A.AC.9 Measuring time ATD

two colour/ratio mode *

LED.F

LED function

LVL. Switch direction “Level” (LED acti-

vated if limit exceeded)

LVL.- Switch direction “Level” (LED / out-

put inverted)

RN6. Switch direction “Range” (LED acti-

vated if range exceeded)

RN6- Switch direction “Range” (LED / out-

put inverted)

LED.T

LED switching

threshold

Temperature limit

(only available at function “Level”)

LED.H

LED signal threshold

Hysteresis +/- relative to signal threshold

(only available at function “Level”)

LED._

LED lower limit of

range

Lower limit of range for switch signal

(only available function “range”)

LED.~

LED upper limit of

range

Upper limit of range for switch signal

(only available function “range”)

LED.L

LED delay time

LED.M

LED hold time

BU2.

Buzzer

OFF OFF

ON ON

BUZ.S

Buzzer: define source

RDY Status LED indicates ‘ready’

L1 Lambda 1

L1.PR Lambda 1 without peak picker

L2 Lambda 2

L2.PR. Lambda 2 without peak picker

Q Two-colour/ratio mode

Q. PR. Two-colour/ratio mode without peak

picker

Page 36

s

Operating manual

28

TU Inner device temperature

1NTY. Signal intensity

M.TR.1 Triggered by ATD function Lambda 1*

M.TR.2 Triggered by ATD function Lambda 2*

M.TR.Q Triggered by ATD function two-

colour/ratio mode*

DIRT Dirt Alert

A.AC.1 Measuring time ATD Lambda 1*

A.AC.2 Measuring time ATD Lambda 2 *

A.AC.9 Measuring time ATD

two colour/ratio mode *

BU2.F

Buzzer function

LVL. Switch direction “Level” (LED acti-

vated if limit exceeded)

LVL.- Switch direction “Level” (LED / out-

put inverted)

RN6. Switch direction “Range” (LED acti-

vated if range exceeded)

RN6- Switch direction “Range” (LED /

output inverted)

BU2.T

Buzzer switching

threshold

Temperature limit

(only available at function “Level”)

BU2.H

Buzzer signal

threshold

Hysteresis +/- relative to signal threshold

(only available at function “Level”)

BU2._

Buzzer lower limit of

range

Lower limit of range for switch signal

(only available function “range”)

BU2.~

Buzzer upper limit of

range

Upper limit of range for switch signal

(only available function “range”)

BUZ.L

Buzzer delay time

BU2.M

Buzzer hold time

END

End

exit menu

*

Only available with ATD function

16.1.5 General Functions

(Configuration layer: C011)

Parameter

Function

Explanation

A.OFF

Auto switch-off

OFF automatic switch-off function deac-

tivated

1-60 time period in minutes for auto

switch-off delay

A.STR.

Auto temp. data ouput

OFF automatic temp. data output is off

ON temp. data output at PC terminal

A.CYC.

Cycle for auto temp.

data output

Select cycle time in s

ADDR.

Device address

Enter address of device for non-terminal

mode

DISP.

Display control

"ON" Display panel indicates "on"

IA1 Indicated temperature reading ac-

cording to operating mode

UNIT

temperature unit

°( degrees Celsius

°F degrees Fahrenheit

MENU

Menu-Mode

NORM With marked parameter are

shown

FULL All parameters are shown

END

End

exit menu

Page 37

s

Operating manual

29

16.1.6 Displayed temperature readings

(Configuration layer: C002)

Parameter

Function

Explanation

Q.

Temp. reading

Quotient

Shows current temperature reading in twocolour mode

L1.

Temp. reading

Lambda1

Actual temperature reading lL 1

L2.

Temp. reading

Lambda1

Actual temperature reading L 2

Q. PR.

Temp. reading Quotient Pre

Shows current temperature reading in twocolour/ratio mode prior to peak picker

L1.PR.

Temp. reading Lambda1 Pre

Shows current temperature reading for L1

prior to peak picker

L2.PR.

Temp. reading Lambda 2 Pre

Shows current temperature reading for L2

prior to peak picker

1NTY.

Signal-Intensity

Calculated signal intensity

T.INT.

Inner temperature

Current inner temp. of device

END

Ende

Menü verlassen

17 Software CellaView

The software CellaView can be used for representation, analysis and ar-

chiving of measured values of your pyrometer.

You can download the CellaView software here:

http://www.industry.siemens.com/services/global/de/sirent/verkauf/Documents/software/cellaview.zip

18 PC Interface

The Ardoptix features a USB port to enable data communication to a PC

for remote device configuration and temperature monitoring. Either use

the CellaView software or use another standard terminal program.

The USB port is on the back of the pyrometer, covered by a protective

cap. The pyrometer is supplied with a standard USB cable.

A Windowsoperating system released prior to Windows7 will not automatically identify the Ardoptix as the peripheral device. The required

driver is included in the CellaView.zip or use the link www.prolific.com.tw

to download the PL 2303 driver.

When using the CellaView software no additional parameter must be set.

For more information on CellaView, please refer to the software instruction manual.

Page 38

s

Operating manual

30

If you are using a terminal program such as HyperTerminal, set parameters for the serial interface as follows:

When using a terminal software, e.g. Hyperterminal, enter the parameters manually as follows:

57600 Baud / 8 Data bits / odd parity / 1 stop bit /

no handshake

After enabling the interface and selecting parameter settings, the pyrometer will automatically transmit data via serial interface (autoprint activated).

19 Remote configuration

Pyrometer setup and temperature monitoring can be configured from a

PC running a simple serial terminal such as HyperTerminal. Many key

parameters can be easily accessed from a keyboard. Additional functions and settings can be programmed from cascading submenus, as

shown in the menu navigation chart below:

To set the pyrometer to the terminal mode, simultaneously hold down the

Ctrl key and press the E key twice in rapid succession.

A help menu will appear on the screen.

Main Menu

Submenu 1

Submenu 2

Execute the

command

Execute the

command

Execute the

command

press

[RETURN]

or [ESC]

press

[RETURN]

or [ESC]

press

[RETURN]

Select [KEY]

Select [KEY]

Backspace

Backspace

Enter

Enter

Enter

[ESC]

[ESC]

Serial communication starts approximately 2 seconds after the

data terminal ready (DTR) control signal is enabled at the interface. Activate this signal in the terminal program or device configuration

Page 39

s

Operating manual

31

Direct commands have an assigned key. Example: E for epsilon (ratio

correction). Submenu settings are shown in brackets. Example[Quotient]

19.1 Main Menu

After starting the terminal program or after entering „H“ the main menu

will appear

----------------------------------------------------------------->H

-----------------------------------------------------------------Mainmenu

-----------------------------------------------------------------0: [QUOTIENT] E: Quick access EPSILON

1: [LAMBDA 1] A: Quick access FILTER

2: [LAMBDA 2] T: Quick access TYPE of measure

C: [I/O]

K: [CALIBRATION]

H: Show this help-site J: Show diagnosis

W: Show ambient temperature Q: Show calibration data

X: Show measure temperatures P: Show channel parameters

------------------------------------------------------------------

19.2 View Current Configuration

Command „P“ shows you how your Ardoptix PT is currently configured.

------------------------------------------------------------------

- PT 143 AF1 650-1700C - 00/00112 - Job - 21.10.13 -

- PT40SW101/0 QP 0,95/1,05um Version 01.02 10.07.13 -

------------------------------------------------------------------

Qu range .... 650.0 - 1700.0 C DISPLAY source ....... quotient

Qu epsilon ratio ...... 100.0 %

Qu check L2 rel.limit 10.00 %

Qu abs.limit 650 C @ 50.00 %

Qu linearization .......... off

Qu filter .......... 0.10 s

Qu memory type ............ off GRN.LED source ... ready-signal

GRN.LED function level/signal

Unit .................. Celsius GRN.LED delay time ... 0.00 s

Terminal assigned to ...... USB GRN.LED hold time .... 0.00 s

Autoprint ......... on (cyclic) BUZZER source ............ off

Print cycle time ..... 0.1 s

Protocol address .......... 001

Display ........... temperature

Key lock .................. off

----------------------------------------------------------------->

At the top left, there is a list of data acquisition parameters for the two

colour reading (Quotient). The right-side column shows LED/BuzzerConfiguration. At the bottom left you will find general settings.

Page 40

s

Operating manual

32

19.3 Submenus

19.3.1 Configure two-colour/ratio mode

Press key "0“ to access the data acquisition parameters for the quotient.

-----------------------------------------------------------------Submenu QUOTIENT

------------------------------------------------------------------

Qu epsilon ratio ...... 100.0 %

Qu check L2 rel.limit 10.00 %

Qu abs.limit 650 C @ 50.00 %

Qu linearization .......... off

Qu filter .......... 0.10 s

Qu memory type ............ off

C: [CONFIG EPSILON TABLE]

E: Epsilon

U: [Q-CHECK]

L: [LINEARIZATION]

F: Filter

M: [MEMORY]

P: Show parameter

Q: Show calibration data

O: Show signal intensity

X: Show measure temperatures

Y: Show premax measure temps.

ESC: Back to MAIN-MENU

----------------------------------------------------------------->QUOTIENT >

19.3.2 Lambda 1

Press key „1“ to access all data acquisition parameters for Lambda 1.

-----------------------------------------------------------------Submenu LAMBDA 1

------------------------------------------------------------------

L1 epsilon ............ 99.0 %

L1 transmission ....... 100.0 %

L1 backc. ................. off

L1 linearization .......... off

L1 filter .......... 0.10 s

L1 memory type ............ off

C: [CONFIG EPSILON TABLE]

E: Epsilon

T: Transmission

B: Background-Compensation

L: [LINEARIZATION]

F: Filter

M: [MEMORY]

P: Show parameter

Q: Show calibration data

X: Show measure temperatures

Y: Show premax measure temps.

ESC: Back to MAIN-MENU

----------------------------------------------------------------->LAMBDA 1 >

Page 41

s

Operating manual

33

19.3.3 Lambda 2

Press key „2“ to access all data acquistion parameters for Lambda 2.

-----------------------------------------------------------------Submenu LAMBDA 2

------------------------------------------------------------------

L2 epsilon ............ 99.0 %

L2 transmission ....... 100.0 %

L2 backc. ................. off

L2 linearization .......... off

L2 filter .......... 0.10 s

L2 memory type ............ off

C: [CONFIG EPSILON TABLE]

E: Epsilon

T: Transmission

B: Background-Compensation

L: [LINEARIZATION]

F: Filter

M: [MEMORY]

P: Show parameter

Q: Show calibration data

X: Show measure temperatures

Y: Show premax measure temps.

ESC: Back to MAIN-MENU

----------------------------------------------------------------->LAMBDA 2 >

19.3.4 Quick access to emissivity / signal smoothing / operating

mode

Use keys "E", "T", „B“ und "F" to access and change the emissivity set-

ting, smoothing filter and measuring mode.

19.3.5 I/O Signal Configuration

Press „C“ to access and adjust all settings regarding LED and buzzer.

-----------------------------------------------------------------Submenu I/O

-----------------------------------------------------------------C: [STATUS LED CONTROL]

D: [BUZZER CONTROL]

M: [OPTIONS]

ESC: Back to MAIN-MENU

----------------------------------------------------------------->I/O >

The LED and buzzer configuration are grouped in submenus where each

can be accessed for further configuration.

LED-Control:

Page 42

s

Operating manual

34

-----------------------------------------------------------------Submenu CONTROL LED

-----------------------------------------------------------------GRN.LED source ... ready-signal

GRN.LED function level/signal

GRN.LED delay time ... 0.00 s

GRN.LED hold time .... 0.00 s

S: Set source

F: Set function

D: Set delay time

O: Set hold time

ESC: Back to MAIN-MENU

----------------------------------------------------------------->I/O >LED CONTROL >

Set status LED source:

0: Off

1: Ready-Signal

2: Lambda 1

3: Lambda 1 premax

4: Lambda 2

5: Lambda 2 premax

6: Quotient

7: Quotient premax

8: Signal intensity

9: Dirt Alert

10: Ambient Temperature

11: Lambda 1 ATD Trigger

12: Lambda 2 ATD Trigger

13: Quotient ATD Trigger

14: Lambda 1 ATD tAct

15: Lambda 2 ATD tAct

16: Quotient ATD tAct

-----------------------------------------------------------------Your choice>

Buzzer-control:

-----------------------------------------------------------------Submenu CONTROL 2

------------------------------------------------------------------

BUZZER source ............ off

S: Set source

ESC: Back to MAIN-MENU

----------------------------------------------------------------->I/O >BUZZER CONTROL >S

Set buzzer control source:

0: Off

1: Ready-Signal

2: Lambda 1

3: Lambda 1 premax

4: Lambda 2

5: Lambda 2 premax

6: Quotient

7: Quotient premax

8: Signal intensity

9: Dirt Alert

10: Ambient Temperature

11: Lambda 1 ATD Trigger

12: Lambda 2 ATD Trigger

Page 43

s

Operating manual

35

13: Quotient ATD Trigger

14: Lambda 1 ATD tAct

15: Lambda 2 ATD tAct

16: Quotient ATD tAct

-----------------------------------------------------------------Your choice>

In the submenu "Options" you can program a keylock. If keylock is activated and you wish to change a parameter setting, enter Code P100

for full access. If you enter an incorrect code, you can view the configuration but you will not be able to change the setting.

-----------------------------------------------------------------Submenu OPTIONS

------------------------------------------------------------------

Autoprint ......... on (cyclic)

Print cycle time ..... 0.1 s

Protocol address .......... 001

Display ........... temperature

Key lock .................. off

Unit .................. Celsius

A: Set autoprint function

T: Set output cycle time

P: Set protocol-address

D: Set display function

E: Set key lock

F: Set unit Celsius/Fahrenheit

R: Switch off pyrometer

ESC: Back to MAIN-MENU

----------------------------------------------------------------->I/O >OPTIONS >

19.3.6 Automatic temperature data output

For continuous serial transmission of temperature data, you must activate automatic temperature data output.

In the submenu “Options”, command “A" activates (on) / deactivates

(off) this function.

If ATD is activated, the temperature data will only be transmitted after

successful completion of measurement.

If ATD is deactivated, press command "T" to select the cycle time in

which the current temperature data are transmitted through the serial interface.

When automatic temperature data output is activated, the pyrometer will

not display the parameter settings when it is switched on. Instead, the

pyrometer will instantly begin transmitting data.

Page 44

s

Operating manual

36

Temperature data format

two-colour/ratio Lambda 1 – Lambda 2 (one cycle):

Byte

Negative Temperature

Positive Temperature

Temperature exceeds

measuring range

Temperature falls below

measuring range

1

Space

Space

Space

Space

2

Minus symbol -

Space

Minus symbol -

Minus symbol -

3

Digit 1000

Digit 1000 O U

4

Digit 100

Digit 100 V N

5

Digit 10

Digit 10 E D

6

Digit 1

Digit 1 R E

7

Decimal point .

Decimal point .

Space

R

8

Decimal place

Decimal place

Space

Space

9

Space

Space

Minus symbol -

Minus symbol -

10

Unit C or F

Unit C or F

Space

Space

11

Tabulator

Tabulator

Tabulator

Tabulator

12

Space

Space

Space

Space

13

Minuszeichen -

Space

Minus symbol -

Minus symbol -

14

Digit 1000

Digit 1000 O U

15

Digit 100

Digit 100 V N

16

Digit 10

Digit 10 E D

17

Digit 1

Digit 1 R E

18

Decimal point .

Decimal point .

Space

R

19

Decimal place

Decimal place

Space

Space

20

Space

Space

Minus symbol -

Minus symbol -

21

Unit C or F

Unit C or F

Space

Space

22

Tabulator

Tabulator

Tabulator

Tabulator

23

Space

Space

Space

Space

24

Minuszeichen -

Space

Minus symbol -

Minus symbol -

25

Digit 1000

Digit 1000 O U

26

Digit 100

Digit 100 V N

27

Digit 10

Digit 10 E D

28

Digit 1

Digit 1 R E

29

Decimal point .

Decimal point .

Space

R

30

Decimal place

Decimal place

Space

Space

31

Space

Space

Minus symbol -

Minus symbol -

32

Unit C or F

Unit C or F

Space

Space

33

Carriage Return

Carriage Return

Carriage Return

Carriage Return

The cycle time in which the temperature reading is transmitted can be

set via parameter ACYC (minimum cycle duration is 0.1 second).

19.4 User Recalibration

If ever required, the pyrometer can be recalibrated. Go to Submenu Calibration. Press command „K“ and then enter the password „100“ to ac-

cess the calibration menu.

All signs/symbols are ASCII coded; preceding zeros will be

transmitted

Page 45

s

Operating manual

37

------------------------------------------------------------------

-----------------------------------------------------------------Submenu CALIBRATION

------------------------------------------------------------------

Name .... "Pyrometer PT Series"

Menu mode ............. default

1: [LAMBDA 1 CALIBRATION]

A: Reset settings to factory default

E: Set menu mode

S: Set pyrometer name

Z: End Calibration-Mode

ESC: Back to MAIN-MENU

----------------------------------------------------------------->CALIBRATION >

You can reset all configurations you have made to your pyrometer and

restore the factory default settings using command "A". This also applies

to data acquisition parameters, LED and buzzer.

Press command "E" if you would like to view all parameters which are

otherwise hidden. Because this list of menu items is quite long (Chapter

16), we only recommend this for advanced users. If you intend to carry

out measurements of molten metal only, it makes sense to maintain the

factory configuration. This will keep those parameters, which will not require adjustment, hidden

Command "S" enables the user to enter a short word to designate the

measurement location/task. This text can be accessed from the Main

Menu by pressing "Q".

-----------------------------------------------------------------Submenu LAMBDA 1

------------------------------------------------------------------

L1 range .... 0.0 - 1000.0 C

L1 User calibration ....... off

L1 User def. offset +0.00000

L1 User def. factor +1.00000

A: Set L1 - extended-range

B: Set L1 User-Cal. On/Off

ESC: Back to MAIN-MENU

----------------------------------------------------------------->CALIBRATION >LAMBDA 1 >

Use command "A" to reconfigure the pyrometer‘s measuring range. The

range can be adjusted to be either larger or smaller than the factoryconfigured range. When customizing the temperature range, make sure

that upper and lower temperatures you enter are compatible with the pyrometer’s actual working range.

Use key "B" for direct access to enable adjustments to the Ardoptix PT.

Page 46

s

Operating manual

38

If you make a mistake while making the adjustments, simply enter offset=0.0 und factor=1.0, or set User Calibration to „off“.

20 Maintenance

20.1 Cleaning the pyrometer lens/protective glass

A false temperature reading will be generated when the lens/protective

glass is dirty. Therefore check the lens periodically and clean it, if necessary.

Dust can be removed by simply blowing it away or by using a soft brush.

A special lens cleaning cloth is ideal, but any soft, clean, lint-free cloth

will be suitable.

If the lens is quite dirty, use a very mild liquid detergent and rinse carefully with clear water while holding the pyrometer down. Apply as little pressure as possible to avoid scratching the lens.

Make sure to turn off the pyrometer before removing or attaching the

lens. Failure to do so may result in damage to the instrument!

T

actual

Actual temperature

Influence of factor (slope)

Influence of offset

T

target

User calibration Pyrometer PT

To recalibrate your Ardoptix, you will require a calibration furnace and a reference standard

Protect the pyrometer against high ambient temperatures, high

air humidity, high voltage and strong electromagnetic fields.

Never point the lens directly towards the sun

Page 47

s

Operating manual

39

21 Accessories

Description

Type

Item No.

Protective glass M46

70146

120314

USB Cable

VK 11/D

1009677

Power supply

1053975

Carrying case

PT 110/A

1052289

Supplementary lens

PZ 20/O-50

514744

Supplementary lens

PZ 20/O-63

514985

Supplementary lens

PZ 20/O-75

513840

Supplementary lens

PZ 20/O-120

514973

21.1 Supplementary lens

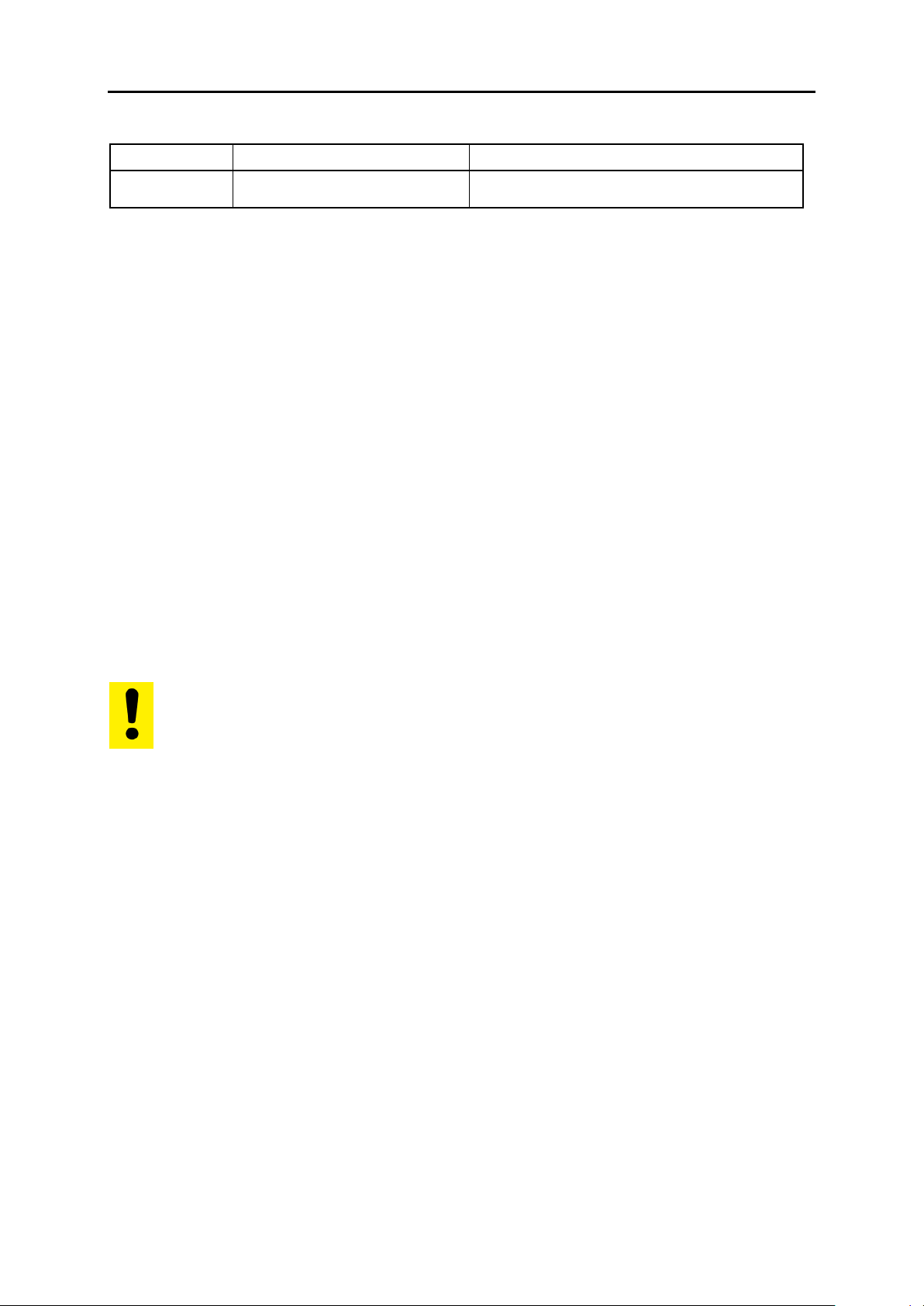

Pyrometer

Supplementary lens

Type

PZ 20/O-50

PZ 20/O-63

PZ 20/O-75

PZ 20/O-120

distance

[mm]

spot

size

Ø in mm

distance

[mm]

spot

size

Ø in mm

distance

[mm]

spot size

Ø in mm

distance

[mm]

spot

size

Ø in mm

PT 140 AF 1

36-41

0.65-0.9

45 - 54

0.8 – 1,1

52 - 63

1.9 – 0.4

84 - 112

1.7 – 2.1

PT 140 AF 4

36-41

0.35-0.45

45 - 54

0.4 – 0.6

52 - 63

0.45 – 0.7

84 - 112

0.7 – 1.1

Pyrometer

Supplementary lens

Type

PZ 20/O-50

PZ 20/O-63

PZ 20/O-75

PZ 20/O-120

distance

[mm]

Mess-

fleck

in mm

distance

[mm]

spot size

in mm

distance

[mm]

spot size

in mm

distance

[mm]

spot size

in mm

PT 143 AF 1

h

36-41

1.2 – 1.6

45 - 54

1.4 – 1.2

52 - 63

1.6 – 2.4

84 - 112

2.4 – 3.8

v

0.2 – 0.3

0.4 – 0.4

0.5

0.5 – 0.8

PT 143 AF 4

h

35 - 41

1.0 – 1.4

45 - 54

1.3 – 1.8

52 - 63

1.4 – 2.1

84 - 112

2.1 – 3.4

v

0.2

0.2 – 0.3

0.3 – 0.4

0.4 – 0.6