Page 1

3RW30/3RW40 Soft Starters

© Siemens AG 2008

Catalog News LV 1 N • January 2008

www.siemens.com/automation

Page 2

Related catalogs Contents

© Siemens AG 2008

Low-Voltage Controls and

Distribution

SIRIUS

·

SENTRON · SIVACON

Order No.:

Catalog

E86060-K1002-A101-A7-7600

Technical Information incl.

Low-Voltage

Controls and Components

for Applications according to UL

Order no.:

E86060-K1816-A101-A1-7600

Industrial Communication

Industrial Communication

for Automation and Drives

Order No.:

E86060-K6710-A101-B6-7600

E86060-K6710-A121-A2-7600

SICUBE

System Cubicles and

Cubicle Air-Conditioning

Order No.:

E86060-K1920-A101-A3-7600

Systems · Controlgear: Contactors and contactor assemblies,

solid-state switching devices · Protection equipment · Load

feeders, motor starters and soft starters · Monitoring and

control devices

LV 1

LV 1 T

LV 16 SIRIUS 3RV17 and 3RV18 circuit breakers according to

IK PI

IK PI N

LV 50 System cubicles · Cubicle modifications · Cubicle expansion

signaling devices · Transformers · Power supplies · Planning

and configuration with SIRIUS · Power Management System ·

SIVACON Power, distribution boards, busway and cubicle

systems

power distribution · Air circuit breakers, molded case circuit

breakers, switch disconnectors

distribution· BETA low-voltage circuit protection

UL 489 · SIVACON Components for 8US Distribution Systems

according to UL 508A · SENTRON 3WL5 air circuit breakers/

non-automatic air circuit breakers according to UL 489/IEC

SENTRON 3VL Molded Case Circuit Breakers according to

UL 489/IEC · ALPHA Devices according to UL Standard ·

BETA Devices according to UL standard

PROFINET/Industrial Ethernet · Industrial Mobile

Communicaton

ET 200 distributed I/Os · AS-Interface to EN 50295/IEC 61158 ·

Remote operation with SINAUT Telecontrol · Routers ·

ECOFAST system

components

Cubicle solutions in applications · Cubicle air-conditioning ·

Special colors

· Detecting devices · Commanding and

· SENTRON switching and protection devices for

· Software for power

·

· PROFIBUS to IEC 61158/EN 50170 · SIMATIC

· Accessories · Special cubicles

SIDAC

Reactors and Filters

Order No.:

E86060-K2803-A101-A4-7600

SIVACON 8PS

CD-K, BD01, BD2

Busbar Trunking Systems

up to 1250 A

Order No.:

E86060-K1870-A101-A3-7600

Automation & Drives

The A&D Offline Mall

CD-ROM:

E86060-D4001-A110-C6-7600

DVD:

E86060-D4001-A510-C6-7600

A&D Mall

Internet:

http://www.siemens.com/

automation/mall

Catalog-PDF

Internet:

http://www.automation.

siemens.com/cd

Registered trademarks Technical Assistance

LV 60 Commutating reactors for converters · Mains reactors for fre-

LV 70 Busbar trunking systems, overview · CD-K system

CA 01 All Automation and Drives products,

quency converters

Ferrite output reactors · Iron-core smoothing reactors · Smoothing air-core reactors · Filter reactors · Application-specific

reactors

Sinewave filters

(25 A to 40 A)

BD2 system (160 A to 1250 A)

including those in the catalogs listed above.

All Automation and Drives products,

including those in the catalogs listed above.

All catalogs for low-voltage controls and distribution can be

downloaded as PDF files.

· Radio interference suppression filters · dv/dt filters ·

· Iron-core output reactors ·

· BD01 system (40 A to 160 A) ·

All product designations may be registered trademarks or

product names of Siemens AG or other supplying

companies. Third parties using these trademarks or product

names for their own purposes may infringe upon the rights of

the trademark owners.

Further information about low-voltage controls is available on

the Internet at:

http://www.siemens.com/lowvoltage

Expert technical assistance for

Low-voltage controls and

electrical installation.

Tel.: +49 (9 11) 8 95-59 00

Fax: +49 (9 11) 8 95-59 07

E-Mail: technicalassistance@siemens.com

Page 3

3RW30/3RW40

© Siemens AG 2008

SIRIUS Soft Starters

Catalog News

LV 1 N · 01/2008

Invalid LV 1 · 2008 and LV 1 T · 2008,

Chapter 6, Load Feeders, Motor Starters

and Soft Starters,

Section: 3RW30 and 3RW40 Soft Starters

Contact your local Siemens

representative for further information

© Siemens AG 2008

The products and systems listed in this catalog are manufactured

using a certified quality

management system

which complies with

EN ISO 9001 (for the

Certificate Register No.

see the Appendix).

The TÜV certificate is

recognized in all IQ Net

countries.

s

Page 4

© Siemens AG 2008

Page 5

Introduction

© Siemens AG 2008

1

Siemens Automation and Drives. Welcome.

Sharpen your competitive edge. Totally Integrated Automation.

Integrated energy distribution from a single source.

Totally Integrated Power.

Low-Voltage Controls and Distribution - The basis for progressive

solutions.

SIRIUS Industrial Controls

Low-Voltage Power Distribution

Systems

2

AS-Interface

ECOFAST System

SIRIUS Safety Integrated

PROFIBUS

SIRIUS Modular System

Power Supplies

11

4AV Non-Stabilized Power Supplies

6EP Stabilized Power Supplies

- SITOP

- LOGO!Power

Engineering Software

12

Planning and Configuration with SIRIUS

Motor Starter ES

ECOFAST ES

SIMOCODE ES

Soft Starter ES

Controls –

3

Contactors and Contactor Assemblies

3RT, 3TB, 3TF Contactors for Switching Motors

3RA13, 3RA14, 3TD, 3TE Contactor Assemblies

3RT, 3RH, 3TB, 3TC, 3TH, 3TK Contactors for Special Applications

3RH, 3TH Contactor Relays · 3RT Coupling Relays

3TX7, 3RS18 Coupling Relays · LZS, LZX

3TG10 Power Relays/Miniature Contactors

Controls –

4

Solid-State Switching Devices

For resistive loads:

3RF20, 3RF21, 3RF22 Solid-State Relays

3RF23, 3RF24 Solid-State Contactors · 3RF29 Function Modules

For switching motors:

3RF24 Solid-State Contactors and Solid-State Reversing Contactors

Protection Equipment

5

3RV Motor Starter Protectors

3RB2 Solid-State Overload Relays

3RU1 Thermal Overload Relays

Load Feeders, Motor Starters and Soft Starters

6

3RW Soft Starters

3RA Fuseless Load Feeders

3RA71 Load Feeders with Safety Integrated

AS-Interface Motor Starters and Soft Starters

ET 200S, ET 200pro Motor Starters

ET 200S Safety Motor Starter Solutions Local / PROFIsafe

ECOFAST Motor Starters and Soft Starters

3RE Encapsulated Starters

Monitoring and Control Devices

7

SIMOCODE 3UF Motor Management and Control Devices

LOGO! Logic Modules · 3RP, 3RT19 Timing Relays

3UG Monitoring Relays for Electrical and Additional Measurements

3RS10, 3RS11 Temperature Monitoring Relays

S I R I U S I n d u s t r i a l C o n t r o l s

3RN1 Thermistor Motor Protection

3TK28 Safety Relays

3RS17 Interface Converters

Detecting Devices

8

3SE2, 3SE3, 3SE5, 3SF1 Position Switches

3SF1 Hinge Switches

3SE6 Magnetically Operated Switches

Plug-In Relays ·

Power Management System

13

System Overview

- SIMATIC powercontrol

- SIMATIC powercost

SIVACON Power Distribution Boards,

14

Busway Systems and Cubicle Systems

S8, 8PV and 8PT Power Distribution Boards and Motor Control

Centers , 8PS Busbar Trunking Systems · 8MC, 8MF Cubicle

Systems, 8MR, 8ME Cubicle Air-Conditioning

ALPHA 630-DIN Floor-Mounted Distribution Boards · ALPHA FIX

Terminal Blocks; ALPHA 8HP Molded-Plastic Distribut ion Systems

Components for 8US, 8UC, 4NC Distribution Systems:

SENTRON Switching and Protection Devices

15

for Power Distribution

3WL Air Circuit Breakers

SENTRON Switching and Protection Devices

16

for Power Distribution

3VL, 3VF2 Molded Case Circuit Breakers

SENTRON Switching and Protection Devices

17

for Power Distribution

3KA, 3KE, 3LD Switch Disconnectors

3KL, 3KM, 3NJ6 Switch Disconnectors with Fuses

3NP, 3NJ4, 3NJ5 Fuse Switch Disconnectors

L o w - V o l t a g e P o w e r D i s t r i b u t i o n

Software for Power Distribution

18

Dimensioning with SIMARIS design

Configuring, Visualizing and Controlling with SIMATIC

Configuring, Visualizing and Controlling with SENTRON

9

10

Commanding and Signaling devices

3SB2, 3SB3, 3SF5 Pushbutton Units and Indicator Lights

3SE7, 3SF2 Cable-Operated Switches

3SE2, 3SE3 Foot Switches

8WD4 Signaling Columns

8WD5 Integrated Signal Lamps

Transformers

Single-Phase Transformers

Three-Phase Transforme r s

BETA Low-Voltage Circuit Protection

19

Miniature Circuit Breakers (MCBs)

Residual Current Protective Devices

...

Low-Voltage Fuse Systems

SITOR Semiconductor Fuses

SR 60 Busbar Systems

Overvoltage Protection Devices

Socket Outlets

Measuring Devices

Appendix

20

Glossary · Training · Ordering notes · Further documentation ·

Standards and approvals · Quality management · Online

services · Customer support · Software licenses · Subject index

Order number index including export markings ·

Terms and conditions of sale and delivery

Page 6

Explanations

© Siemens AG 2008

■

General information

Things you should know about Catalog LV 1 · 2008 and Technical Information LV 1 T · 2008

Catalog LV 1 · 2008 contains selection- and orderrelevant data under the topic headings "Overview",

"Benefits", "Application", "Selection and ordering

data", "Accessories", "Options" and "More information".

Delivery time class (DT)

} Preferred type

A 2 working days

B 1 week

C 3 weeks

D 6 weeks

X On request

Preferred types are available immediately from

stock, i.e. are dispatched within 24 hours.

Normal quantities of the products are usually delivered within the specified time following receipt of

your order at our branch.

In exceptional cases, the actual delivery time may

differ from that specified.

Price units (PU)

The price unit defines the number of units, sets or

meters to which the specified price and weight

apply.

Packaging sizes (PS)

The packaging size defines the number, e.g. of

units, sets or meters, for outer packaging.

Only the quantity defined by the packaging size or

a multiple thereof can be ordered!

Price groups (PG)

Each product is assigned to a price group.

Weight

The defined weight in kg refers to the price unit

(PU).

Dimensions

All dimensions in mm.

The topics "Design", "Function", "Integration", Configuration", "Programming",

"Technical specifications", "Characteristic curves", "Schematics" and "Dimensional drawings" can be found if required in the Technical Information

LV 1 T · 2008.

The Technical Information LV 1 T is saved as a PDF file on the

CD-ROM which is enclosed with this catalog (inside front cover).

The delivery times apply up to the ramp at Siemens AG (products ready for

dispatch). The transport times depend on the destination and type of shipping.

The standard transport time for Germany is 1 day.

The delivery times specified here represent the state of 10/2007. They are permanently optimized. Up-to-date information can be found at

http://www.siemens.com/automation/mall.

Note:

For transformers, delivery time class B is applicable to an order quantity of up

to 5 units. For an order quantity of more than 5 units, delivery time class C is

applicable instead of delivery time class B.

For multi-unit packing and reusable packaging see Appendix

■

Order number index

Order number index with export regulation

Order number Export regulation Page

3R

3RA N N 6/5, 6/11

3RP N N 6/5

3RT N N 6/5, 6/10

3RU19 00-1 N N 6/10

3RU19 00-2 N N 6/10

3RW30 0 N N 6/4

3RW30 1 N N 6/4

3RW30 2 N N 6/4

3RW30 3 EAR99 N 6/4

3RW30 4 EAR99 N 6/4

3RW40 2 N N 6/7 ... 8

3RW40 3 N N 6/7 ... 8

3RW40 4 N N 6/7 ... 8

3RW40 5 N N 6/9

3RW40 7 N N 6/9

3RW49 N N 6/10 ... 11

4

ECCN AL

Siemens LV 1 N SIRIUS Soft Starters · 1/2008

Order number Export regulation Page

ECCN AL

3S

3SB N N 6/10

3SX N N 6/10

3Z

3ZX on request 6/5, 6/11

Page 7

3RW30/3RW40

© Siemens AG 2008

SIRIUS Soft Starters

Catalog

Technical Information

3RW Soft Starters

General data

6/2 - Overview

3RW30 for standard applications

6/3 - Overview

6/3 - Application

6/4 - Selection and ordering data

3RW40 for standard applications

6/6 - Overview

6/6 - Application

6/7 - Selection and ordering data

3RW Soft Starters

3RW30 for standard applications

6/12 - Function

6/12 - Technical specifications

6/21 - Characteristic curves

6/21 - More information

3RW40 for standard applications

6/23 - Function

6/24 - Technical specifications

6/34 - Characteristic curves

6/35 - More information

Project planning aids

6/37 - Dimensional drawings

6/39 - Schematics

Siemens LV 1 N SIRIUS Soft Starters ·

01/2008

Page 8

3RW Soft Starters

© Siemens AG 2008

General data

■

Overview

The advantages of the SIRIUS soft starters at a glance:

• Soft starting and smooth ramp-down

1)

• Stepless starting

• Reduction of current peaks

• Avoidance of mains voltage fluctuations during starting

• Reduced load on the power supply network

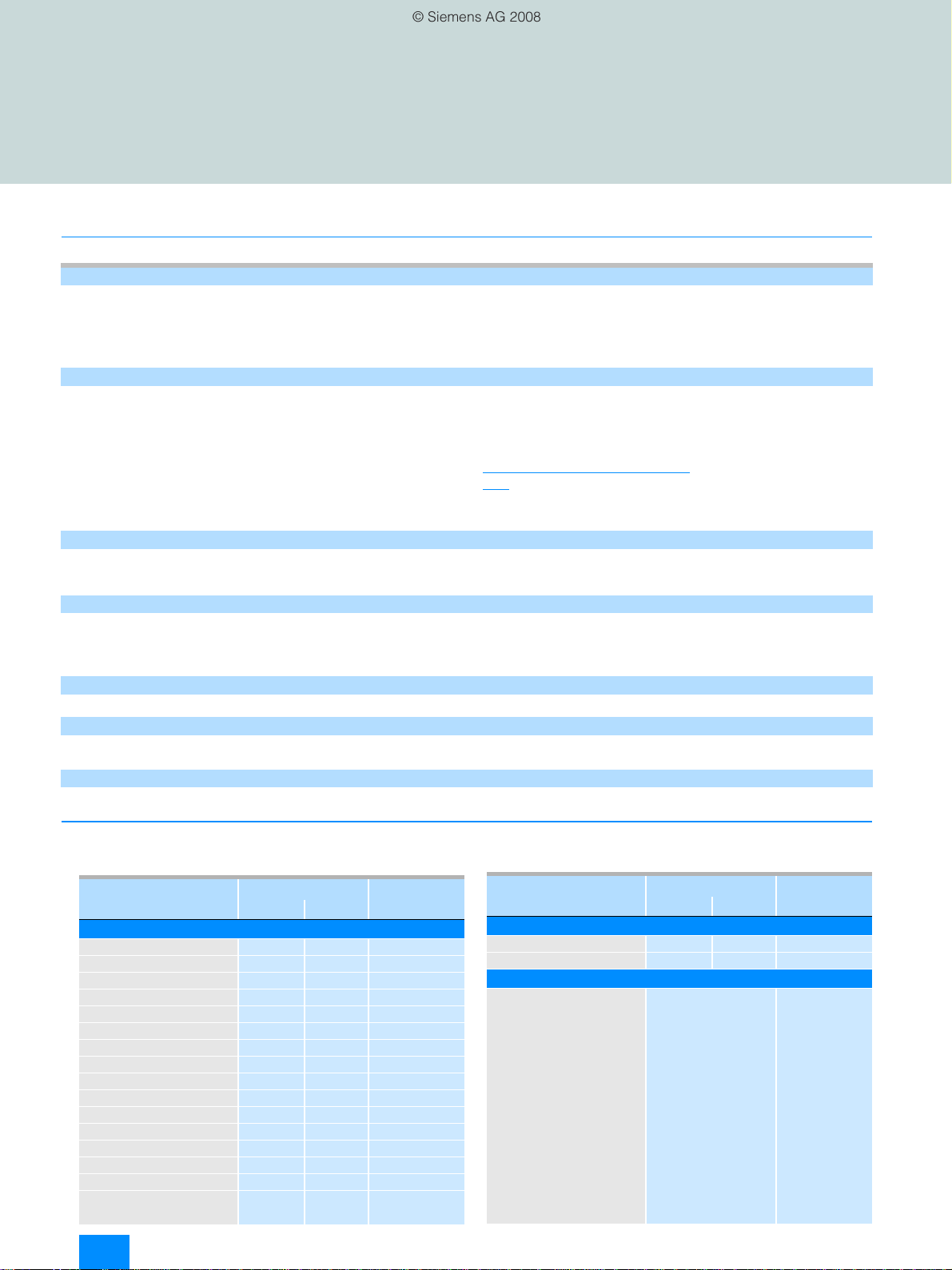

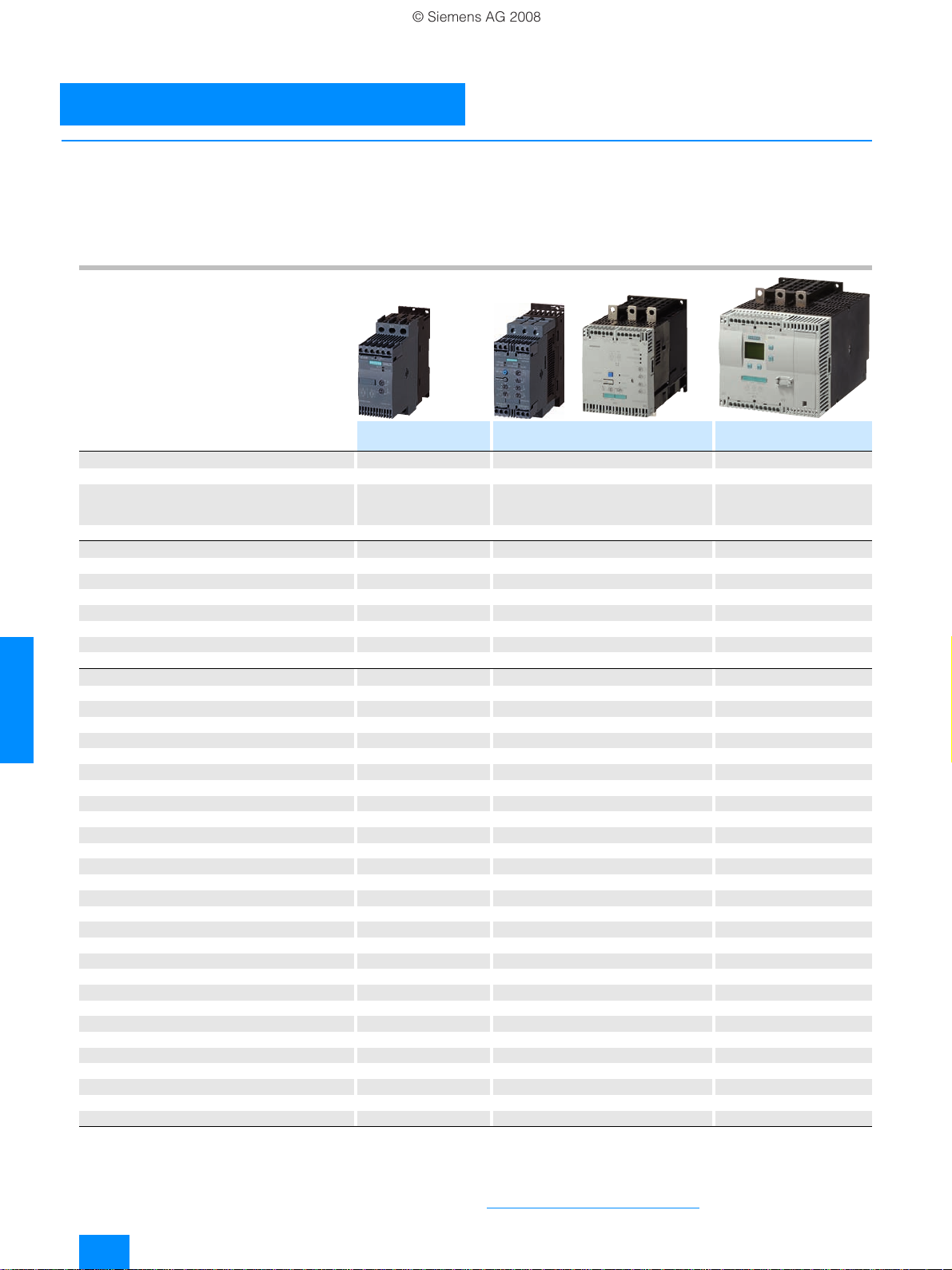

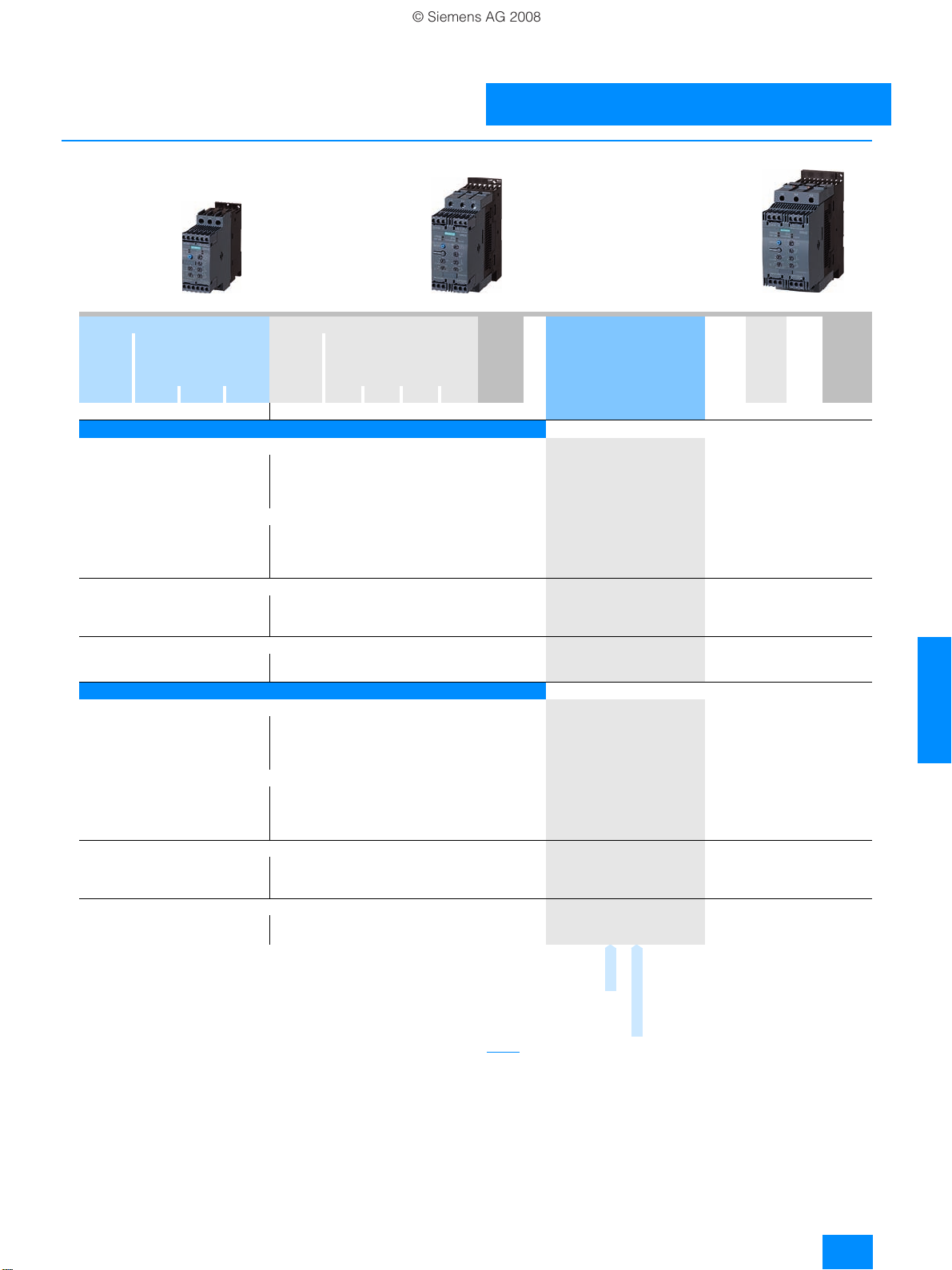

SIRIUS 3RW30 SIRIUS 3RW40 SIRIUS 3RW44

Standard applications Standard applications High-Feature applications

Rated current up to 40 °C A 3...106 12.5 ... 432 29 ... 1214

Rated operational voltage V 200 ... 480 200 ... 600 200 ... 690

Motor rating at 400 V

• Inline circuit kW 1.5 ... 55 5.5 ... 250 15 ... 710

• Inside-delta circuit kW -- -- 22 ... 1200

Ambient temperature °C -25 ... +60 -25 ... +60 0 ... +60

Soft starting/ramp-down ✔

Vol t a g e ramp ✔✔ ✔

Starting/stopping voltage % 40 ... 100 40 ... 100 20 ... 100

Starting and ramp-down time s 0...20 0...20 1...360

Torque control -- -- ✔

Starting/stopping torque %-- -- 20...100

Torque limit % -- -- 20 ... 200

Ramp time s -- -- 1 ... 360

Integral bypass contact system ✔ ✔ ✔

6

Intrinsic device protection -- ✔✔

Motor overload protection -- ✔ ✔

Thermistor motor protection -- ✔

Integrated remote RESET -- ✔

Adjustable current limiting -- ✔✔

Inside-delta circuit -- -- ✔

Breakaway pulse -- -- ✔

Creep speed in both directions of rotation -- -- ✔

Pump ramp-down -- -- ✔

DC braking -- -- ✔

Combined braking -- -- ✔

Motor heating -- -- ✔

Communication -- -- with PROFIBUS DP (optional)

External display and operator module -- -- (optional)

Operating measured value display -- -- ✔

Error logbook -- -- ✔

Event list -- -- ✔

Slave pointer function -- -- ✔

Trace function -- -- ✔

Programmable control inputs and outputs -- -- ✔

Number of parameter sets 1 1 3

Parameterization software (Soft Starter ES) -- -- ✔

Power semiconductors (thyristors) 2 controlled phases 2 controlled phases 3 controlled phases

Screw terminals ✔ ✔ ✔

Spring-loaded terminals ✔✔ ✔

UL/CSA ✔ ✔ ✔

CE marking ✔✔ ✔

Soft starting under heavy starting conditions -- -- ✔4)

Configuring support

✔ Function is available; -- Function is not available.

1)

Only soft starting available for 3RW30.

2)

Optional up to size S3 (device variant).

3)

Available for 3RW40 2. to 3RW40 4.; optional for 3RW40 5. and 3RW40 7..

4)

Calculate soft starter and motor with size allowance where required.

1)

Win-Soft Starter, electronic selection slider ruler, Technical Assistance ++49 911 895 5900

• Reduction of the mechanical load in the operating mechanism

• Considerable space savings and reduced wiring compared

with conventional starters

• Maintenance-free switching

• Very easy handling

• Fits perfectly in the SIRIUS modular system

✔ ✔

2)

3)

5)

Not possible in inside-delta circuit.

6)

Trace function with Soft Starter ES software.

✔

✔

4)

4) 5)

4) 5)

6)

More information can be found on the Internet at

http://www.siemens.com/softstarter

6/2

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

Page 9

66

■

© Siemens AG 2008

Overview

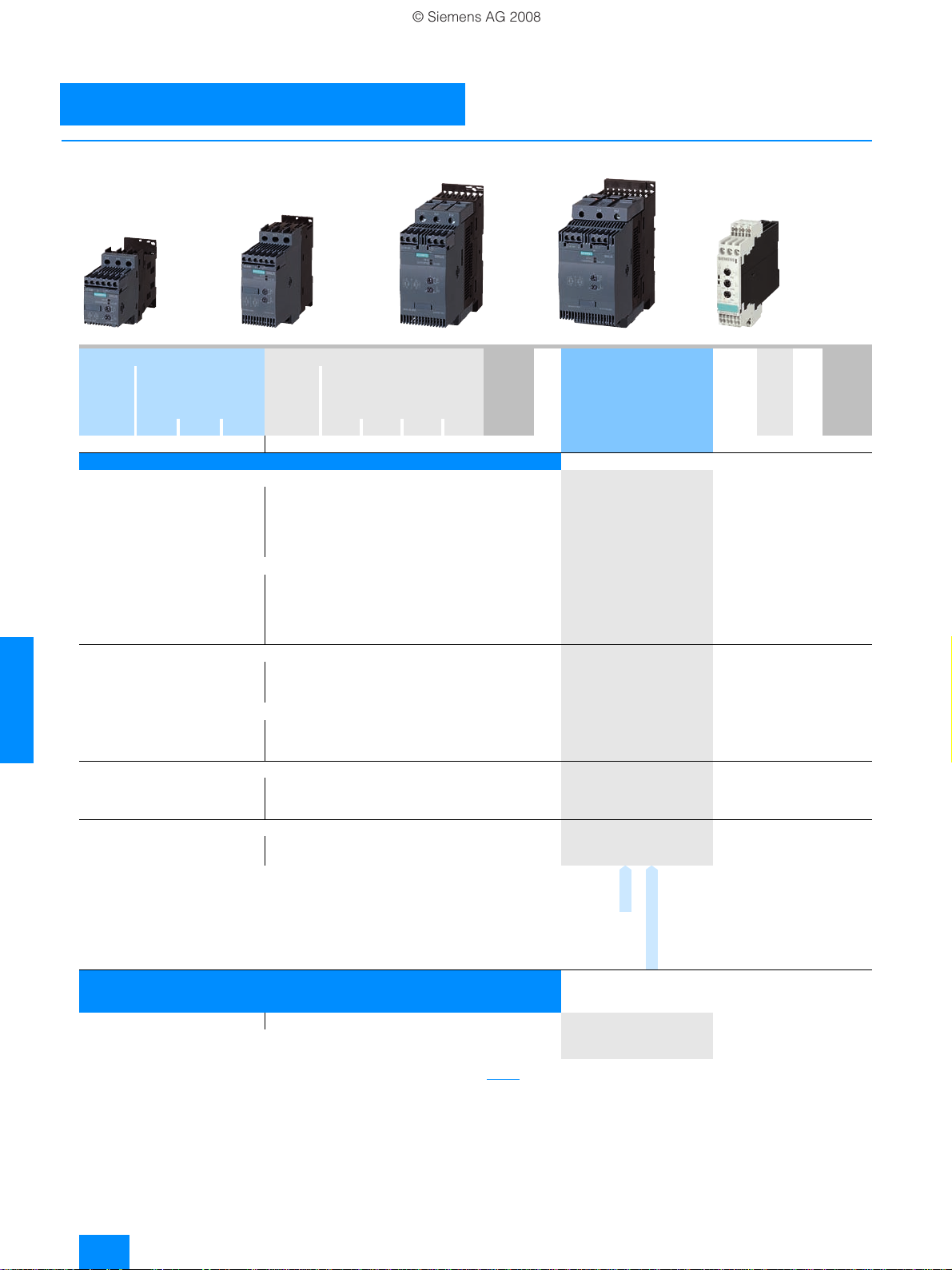

The SIRIUS 3RW30 soft starters reduce the motor voltage

through variable phase control and increase it in ramp-like mode

from a selectable starting voltage up to mains voltage. During

starting, these devices limit the torque as well as the current and

prevent the shocks which arise during direct starts or wye-delta

starts. In this way, mechanical loads and mains voltage dips can

be reliably reduced.

Soft starting reduces the stress on the connected equipment

and results in lower wear and therefore longer periods of troublefree production. The selectable start value means that the soft

starters can be adjusted individually to the requirements of the

application in question and unlike wye-delta starters are not

restricted to two-stage starting with fixed voltage ratios.

The SIRIUS 3RW30 soft starters are characterized above all by

their small space requirements. Integrated bypass contacts

mean that no power loss has to be taken into the bargain at the

power semiconductors (thyristors) after the motor has started

up. This cuts down on heat losses, enabling a more compact

design and making external bypass circuits superfluous.

Various versions of the SIRIUS 3RW30 soft starters are available:

• Standard version for fixed-speed three-phase motors, sizes

S00, S0, S2 and S3, with integrated bypass contact system

• Version for fixed-speed three-phase motors in a 22.5 mm

enclosure without bypass

Soft starters rated up to 55 kW (at 400 V) for standard

applications in three-phase networks are available. Extremely

small sizes, low power losses and simple start-up are just three

of the many advantages of this soft starter.

3RW Soft Starters

3RW30

for standard applications

■

Application

The 3RW30 soft starters are suitable for soft starting of threephase asynchronous motors.

Due to two-phase control, the current is kept at minimum values

in all three phases throughout the entire starting time. Due

to continuous voltage influencing, current and torque peaks,

which are unavoidable in the case of wye-delta starters, for

instance, do not occur.

Application areas

•Pumps

•Heat pumps

• Hydraulic pumps

• Presses

• Conveyors

• Roller conveyors

• Screw conveyors

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

6/3

Page 10

3RW Soft Starters

© Siemens AG 2008

3RW30

for standard applications

■

Selection and ordering data

per PU

approx.

kg

3RW30 18-1BB14 3RW30 28-1BB14 3RW30 38-1BB14 3RW30 47-1BB14 3RW30 03-2CB54

Ambient temperature 40 °C Ambient temperature 50 °C Size DT Order No. Price

Rated

operational current I

A kWkWkWA hphphphp

Rated operational voltage Ue200 ... 480 V

• With screw terminals

3.6 0.75 1.5 -- 3 0.5 0.5 1.5 -- S00 } 3RW30 13-1BB@4 1 1 unit 131 0.580

6.5 1.5 3 -- 4.8 1 1 3 -- S00 }

92.24 -- 7.8 2 2 5 -- S00 }

12.5 3 5.5 -- 11 3 3 7.5 -- S00 }

17.6 4 7.5 -- 17 3 3 10 -- S00 }

• With spring-loaded terminals

3.6 0.75 1.5 -- 3 0.5 0.5 1.5 -- S00 B 3RW30 13-2BB@4 1 1 unit 131 0.580

6.5 1.5 3 -- 4.8 1 1 3 -- S00 B

92.24 -- 7.8 2 2 5 -- S00 B

12.5 3 5.5 -- 11 3 3 7.5 -- S00 B

17.6 4 7.5 -- 17 3 3 10 -- S00 B

• With screw terminals

25 5.5 11 -- 23 5 5 15 -- S0 } 3RW30 26-1BB@4 1 1 unit 131 0.690

32 7.5 15 -- 29 7.5 7.5 20 -- S0 }

6

38 11 18.5 -- 34 10 10 25 -- S0 }

• With spring-loaded terminals

25 5.5 11 -- 23 5 5 15 -- S0 B 3RW30 26-2BB@4 1 1 unit 131 0.690

32 7.5 15 -- 29 7.5 7.5 20 -- S0 B

38 11 18.5 -- 34 10 10 25 -- S0 B

• With screw-type or spring-loaded terminals

45 11 22 -- 42 10 15 30 -- S2 B3RW30 36-@BB@4 1 1 unit 131 1.200

63 18.5 30 -- 58 15 20 40 -- S2 B

72 22 37 -- 62 20 20 40 -- S2 B

• With screw-type or spring-loaded terminals

80 22 45 -- 73 20 25 50 -- S3 B3RW30 46-@BB@4 1 1 unit 131 1.710

106 30 55 -- 98 30 30 75 -- S3 B

Order No. supplement for connection types

• With screw terminals 1

• With spring-loaded terminals

Order No. supplement for rated control supply voltage U

• 24 V AC/DC 0

• 110 ... 230 V AC/DC 1

Rated power of

three-phase induction

motors for rated

1)

operational voltage U

e

230 V 400 V 500 V 200 V 230 V 460 V 575 V

3)

e

Rated

operational cur-

1)

I

rent

e

Rated power of three-phase

induction motors for rated

operational voltage U

2)

s

e

3RW30 14-1BB@4 1 1 unit 131 0.580

3RW30 16-1BB@4 1 1 unit 131 0.580

3RW30 17-1BB@4 1 1 unit 131 0.580

3RW30 18-1BB@4 1 1 unit 131 0.580

3RW30 14-2BB@4 1 1 unit 131 0.580

3RW30 16-2BB@4 1 1 unit 131 0.580

3RW30 17-2BB@4 1 1 unit 131 0.580

3RW30 18-2BB@4 1 1 unit 131 0.580

3RW30 27-1BB@4 1 1 unit 131 0.690

3RW30 28-1BB@4 1 1 unit 131 0.690

3RW30 27-2BB@4 1 1 unit 131 0.690

3RW30 28-2BB@4 1 1 unit 131 0.690

3RW30 37-@BB@4 1 1 unit 131 1.200

3RW30 38-@BB@4 1 1 unit 131 1.200

3RW30 47-@BB@4 1 1 unit 131 1.710

per PU

2

PU

PS* PG Weight

(UNIT,

SET, M)

Soft starters for easy starting conditions and high switching frequency,

rated operational voltage U

rated control supply voltage U

30.551.1 -- 2.6 0.5 0.5 -- -- 22.5 mm

• With screw terminals } 3RW30 03-1CB54 1 1 unit 131 0.207

• With spring-loaded terminals A

1)

Stand-alone installation.

2)

Soft starter with screw terminals: delivery time class } (preferred type).

3)

Main circuit connection: screw terminals.

6/4

200 ... 400 V,

e

24 ... 230 V AC/DC

s

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

3RW30 03-2CB54 1 1 unit 131 0.188

Note:

Selection of the soft starter depends on the rated motor current.

The SIRIUS 3RW30 solid-state soft starters are designed for

easy starting conditions. J

deviating conditions or increased switching frequency, it may be

Load

< 10 x J

. In the event of

Motor

necessary to choose a larger device.

Siemens recommends the use of the selection and simulation

program Win-Soft Starter. For information about rated currents

for ambient temperatures > 40 °C, see technical specifications

(see Technical Information LV 1 T).

* You can order this quantity or a multiple thereof.

Page 11

66

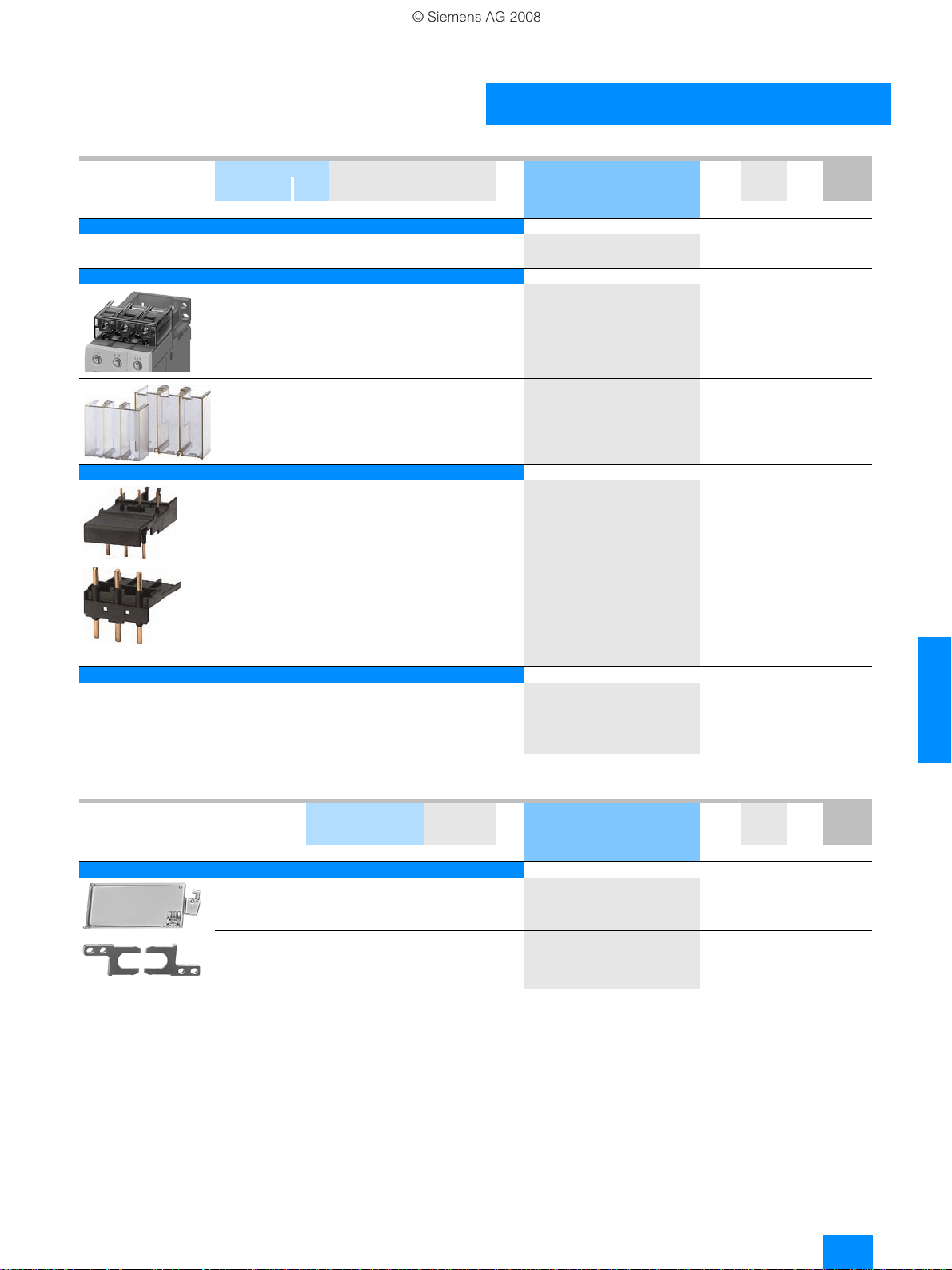

Accessories

© Siemens AG 2008

For soft starters Motor starter protectors DT Order No. Price

Typ e Size Size

Auxiliary terminals

Auxiliary terminals, 3-pole

3RW30 4. S3 B3RT19 46-4F 1 1 unit 101 0.035

Covers for soft starters

Terminal covers for box terminals

Additional touch protection to be fitted at the box

terminals (2 units required per device)

3RW30 3. S2 } 3RT19 36-4EA2 1 1 unit 101 0.020

3RW30 4. S3 }

Terminal covers for cable lugs and busbar connections

For complying with the phase clearances and as touch

protection if box terminal is removed

(2 units required per contactor)

3RW30 4. S3 } 3RT19 46-4EA1 1 1 unit 101 0.040

Link modules to motor starter protectors

3RW30 13,

3RW30 14,

3RW30 16,

3RW30 17,

3RW30 18

3RW30 26 S0 S0 }

3RW30 27,

3RW30 28

3RW30 36 S2 S2 }

3RW30 37,

3RW30 38

3RW30 46,

3RW30 47

S00 S0 }

S2 D

S3 D

S3 S3 }

Operating instructions1)

For soft starters

3RW30 1.

3RW30 2.

3RW30 3.

1)

The operating instructions are included in the scope of supply.

3RW30 4.

S00

S0

S2

S3

3RW Soft Starters

3RW30

for standard applications

PU

per PU

3RT19 46-4EA2 1 1 unit 101 0.025

3RA19 21-1A 1

3RA19 21-1A 1

3RA19 31-1D 1

3RA19 31-1A 1

3RA19 41-1D 1

3RA19 41-1A 1

3ZX10 12-0RW30-2DA1

PS* PG Weight

(UNIT,

SET, M)

10 units

10 units

5 units

5 units

5 units

5 units

per PU

approx.

kg

101 0.028

101 0.028

101 0.041

101 0.033

101 0.042

101 0.072

Covers and push-in lugs (only for 3RW30 03)

3RP19 02

3RP19 03

* You can order this quantity or a multiple thereof.

Version Functionality

Sealable covers For securing against

Push-in lugs for

screw mounting

Functions

unauthorized

adjustment of

setting knobs

Use DT Order No. Price

For devices

with 1 or

2 CO contacts

For devices

with 1 or

2 CO contacts

3RP19 02 1 5 units 101 0.004

}

3RP19 03 1 10 units 101 0.002

}

per PU

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

PU

PS* PG Weight

(UNIT,

SET, M)

per PU

approx.

kg

6/5

Page 12

3RW Soft Starters

© Siemens AG 2008

3RW40 for standard applications

■

Overview

SIRIUS 3RW40 soft starters have all the same advantages as the

3RW30 soft starters.

The SIRIUS 3RW40 soft starters are characterized above all by

their small space requirements. Integrated bypass contacts

mean that no power loss has to be taken into the bargain at the

power semiconductors (thyristors) after the motor has started

up. This cuts down on heat losses, enabling a more compact

design and making external bypass circuits superfluous.

At the same time this soft starter comes with additional

integrated functions such as adjustable current limiting, motor

overload and intrinsic device protection, and optional thermistor

motor protection. The higher the motor rating, the more

important these functions because they make it unnecessary to

purchase and install protection equipment such as overload

relays.

Internal intrinsic device protection prevents the thermal

overloading of the thyristors and the power section defects this

can cause. As an option the thyristors can also be protected by

semiconductor fuses from short-circuiting.

Thanks to integrated status monitoring and fault monitoring, this

compact soft starter offers many different diagnostics options.

Up to four LEDs and relay outputs permit differentiated

monitoring and diagnosis of the operating mechanism by

indicating the operating state as well as for example mains or

phase failure, missing load, non-permissible tripping time/class

setting, thermal overloading or device faults.

Soft starters rated up to 250 kW (at 400 V) for standard

applications in three-phase networks are available. Extremely

small sizes, low power losses and simple start-up are just three

of the many advantages of the SIRIUS 3RW40 soft starters.

"Increased safety" type of protection EEx e according to

ATEX directive 94/9/EC

The 3RW40 soft starters size S6, S10 and S12 are suitable for

6

starting explosion-proof motors with "increased safety" type of

protection EEx e;

see Catalog LV 1 "Appendix" –> "Standards and approvals" –>

"Type overview

areas (ATEX explosion protection)".

of approved devices for explosion-protected

■

Application

The SIRIUS 3RW40 solid-state soft starters are suitable for soft

starting and stopping of three-phase asynchronous motors.

Due to two-phase control, the current is kept at minimum values

in all three phases throughout the entire starting time and

disturbing direct current components are eliminated in addition.

This not only enables the two-phase starting of motors up to

250 kW (at 400 V) but also avoids the current and torque peaks

which occur e.g. with wye-delta starters.

Application areas

•Pumps

•Heat pumps

• Hydraulic pumps

• Presses

• Conveyors

• Roller conveyors

• Screw conveyors

• Escalators

• Piston compressors

• Screw compressors

• Small fans

• Centrifugal blowers

•Bow thrusters

•Stirrers

•Extruders

• Lathes

• Milling machines

6/6

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

Page 13

66

■

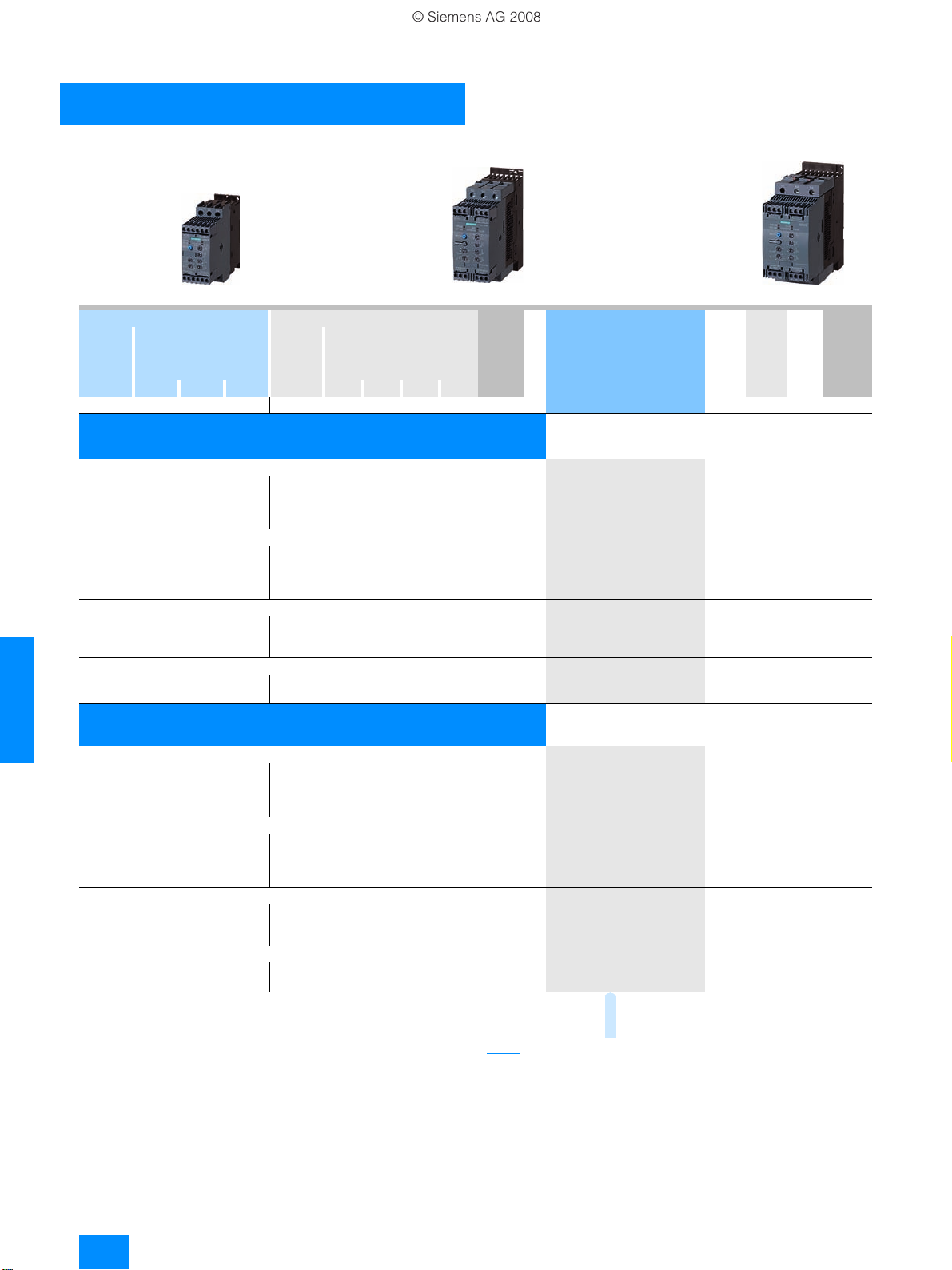

3RW40 28-1BB14 3RW40 38-1BB14 3RW40 47-1BB14

© Siemens AG 2008

Selection and ordering data

3RW Soft Starters

3RW40

for standard applications

Ambient temperature 40 °C Ambient temperature 50 °C Size DT Order No. Price

Rated

operational current I

A kW kW kW A hp hp hp hp kg

Rated power of

three-phase induction

motors for rated

1)

operational voltage U

e

230 V 400 V 500 V 200 V 230 V 460 V 575 V

e

Rated

operational cur-

1)

rent I

e

Rated power of three-phase

induction motors for rated

operational voltage U

e

per PU

PU

PS* PG Weight

(UNIT,

SET, M)

Rated operational voltage Ue 200 ... 480 V2)

• With screw terminals

12.5 3 5.5 -- 11 3 3 7.5 -- S0 } 3RW40 24-1BB@4 1

25 5.5 11 -- 23 5 5 15 -- S0 }

32 7.5 15 -- 29 7.5 7.5 20 -- S0 }

38 11 18.5 -- 34 10 10 25 -- S0 }

• With spring-loaded terminals

12.5 3 5.5 -- 11 3 3 7.5 -- S0 B 3RW40 24-2BB@4 1

25 5.5 11 -- 23 5 5 15 -- S0 B

32 7.5 15 -- 29 7.5 7.5 20 -- S0 B

38 11 18.5 -- 34 10 10 25 -- S0 B

• With screw-type or spring-loaded terminals

45 11 22 -- 42 10 15 30 -- S2 B 3RW40 36-@BB@4 1

63 18.5 30 -- 58 15 20 40 -- S2 B

72 22 37 -- 62 20 20 40 -- S2 B

• With screw-type or spring-loaded terminals

80 22 45 -- 73 20 25 50 -- S3 B 3RW40 46-@BB@4 1

106 30 55 -- 98 30 30 75 -- S3 B

3RW40 26-1BB@4 1

3RW40 27-1BB@4 1

3RW40 28-1BB@4 1

3RW40 26-2BB@4 1

3RW40 27-2BB@4 1

3RW40 28-2BB@4 1

3RW40 37-@BB@4 1

3RW40 38-@BB@4 1

3RW40 47-@BB@4 1

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 1.350

131 1.350

131 1.350

131 1.900

131 1.900

Rated operational voltage Ue 400 ... 600 V

• With screw terminals

12.5 -- 5.5 7.5 11 -- -- 7.5 10 S0 B 3RW40 24-1BB@5 1

25 -- 11 15 23 -- -- 15 20 S0 B

32 -- 15 18.5 29 -- -- 20 25 S0 B

38 -- 18.5 22 34 -- -- 25 30 S0 B

• With spring-loaded terminals

12.5 -- 5.5 7.5 11 -- -- 7.5 10 S0 B 3RW40 24-2BB@5 1

25 -- 11 15 23 -- -- 15 20 S0 B

32 -- 15 18.5 29 -- -- 20 25 S0 B

38 -- 18.5 22 34 -- -- 25 30 S0 B

• With screw-type or spring-loaded terminals

45 -- 22 30 42 -- -- 30 40 S2 B 3RW40 36-@BB@5 1

63 -- 30 37 58 -- -- 40 50 S2 B

72 -- 37 45 62 -- -- 40 60 S2 B

• With screw-type or spring-loaded terminals

80 -- 45 55 73 -- -- 50 60 S3 B 3RW40 46-@BB@5 1

106 -- 55 75 98 -- -- 75 75 S3 B

Order No. supplement for connection types

• With screw terminals 1

• With spring-loaded terminals

Order No. supplement for rated control supply voltage U

•24VAC/DC 0

• 110 ... 230 V AC/DC 1

1)

Stand-alone installation without auxiliary fan.

2)

Soft starter with screw terminals: delivery time class } (preferred type).

3)

Main circuit connection: screw terminals.

3)

s

Note:

Selection of the soft starter depends on the rated motor current.

The SIRIUS 3RW40 solid-state soft starters are designed for

easy starting conditions. J

deviating conditions or increased switching frequency, it may be

3RW40 26-1BB@5 1

3RW40 27-1BB@5 1

3RW40 28-1BB@5 1

3RW40 26-2BB@5 1

3RW40 27-2BB@5 1

3RW40 28-2BB@5 1

3RW40 37-@BB@5 1

3RW40 38-@BB@5 1

3RW40 47-@BB@5 1

2

<10xJ

Load

necessary to choose a larger device. Siemens

use of the selection and simulation program

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

. In the event of

Motor

recommends the

Win-Soft Starter.

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 1.350

131 1.350

131 1.350

131 1.900

131 1.900

For information about rated currents for ambient temperatures

> 40 °C, see technical specifications.

per PU

approx.

* You can order this quantity or a multiple thereof.

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

6/7

Page 14

3RW Soft Starters

3RW40 28-1TB04 3RW40 38-1TB04 3RW40 47-1TB04

© Siemens AG 2008

3RW40

for standard applications

Ambient temperature 40 °C Ambient temperature 50 °C Size DT Order No. Price

Rated

operational current I

A kW kW kW A hp hp hp hp kg

Rated power of

three-phase induction

motors for rated

1)

operational voltage U

e

230 V 400 V 500 V 200 V 230 V 460 V 575 V

e

Rated

operational cur-

1)

rent I

e

Rated power of three-phase

induction motors for rated

operational voltage U

e

per PU

PU

PS* PG Weight

(UNIT,

SET, M)

per PU

approx.

Rated operational voltage Ue 200 ... 480 V2),

with thermistor motor protection,

rated control supply voltage U

• With screw terminals

12.5 3 5.5 -- 11 3 3 7.5 -- S0 } 3RW40 24-1TB04 1

25 5.5 11 -- 23 5 5 15 -- S0 }

32 7.5 15 -- 29 7.5 7.5 20 -- S0 }

38 11 18.5 -- 34 10 10 25 -- S0 }

• With spring-loaded terminals

12.5 3 5.5 -- 11 3 3 7.5 -- S0 B 3RW40 24-2TB04 1

25 5.5 11 -- 23 5 5 15 -- S0 B

32 7.5 15 -- 29 7.5 7.5 20 -- S0 B

38 11 18.5 -- 34 10 10 25 -- S0 B

• With screw-type or spring-loaded terminals

45 11 22 -- 42 10 15 30 -- S2 B 3RW40 36-@TB04 1

63 18.5 30 -- 58 15 20 40 -- S2 B

72 22 37 -- 62 20 20 40 -- S2 B

• With screw-type or spring-loaded terminals

80 22 45 -- 73 20 25 50 -- S3 B 3RW40 46-@TB04 1

6

106 30 55 -- 98 30 30 75 -- S3 B

Rated operational voltage Ue 400 ... 600 V,

24 V AC/DC

s

3RW40 26-1TB04 1

3RW40 27-1TB04 1

3RW40 28-1TB04 1

3RW40 26-2TB04 1

3RW40 27-2TB04 1

3RW40 28-2TB04 1

3RW40 37-@TB04 1

3RW40 38-@TB04 1

3RW40 47-@TB04 1

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 1.350

131 1.350

131 1.350

131 1.900

131 1.900

with thermistor motor protection,

3)

24 V AC/DC

s

1 unit

3RW40 26-1TB05 1

3RW40 27-1TB05 1

3RW40 28-1TB05 1

3RW40 26-2TB05 1

3RW40 27-2TB05 1

3RW40 28-2TB05 1

3RW40 37-@TB05 1

3RW40 38-@TB05 1

3RW40 47-@TB05 1

2

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 0.770

131 1.350

131 1.350

131 1.350

131 1.900

131 1.900

Note:

Selection of the soft starter depends on the rated motor current.

The SIRIUS 3RW40 solid-state soft starters are designed for

easy starting conditions. J

deviating conditions or increased switching frequency, it may be

necessary to choose a larger device. Siemens

use of the selection and simulation program

Load

<10xJ

. In the event of

Motor

recommends the

Win-Soft Starter.

rated control supply voltage U

• With screw terminals

12.5 -- 5.5 7.5 11 -- -- 7.5 10 S0 B 3RW40 24-1TB05 1

25 -- 11 15 23 -- -- 15 20 S0 B

32 -- 15 18.5 29 -- -- 20 25 S0 B

38 -- 18.5 22 34 -- -- 25 30 S0 B

• With spring-loaded terminals

12.5 -- 5.5 7.5 11 -- -- 7.5 10 S0 B 3RW40 24-2TB05 1

25 -- 11 15 23 -- -- 15 20 S0 B

32 -- 15 18.5 29 -- -- 20 25 S0 B

38 -- 18.5 22 34 -- -- 25 30 S0 B

• With screw-type or spring-loaded terminals

45 -- 22 30 42 -- -- 30 40 S2 B 3RW40 36-@TB05 1

63 -- 30 37 58 -- -- 40 50 S2 B

72 -- 37 45 62 -- -- 40 60 S2 B

• With screw-type or spring-loaded terminals

80 -- 45 55 73 -- -- 50 60 S3 B 3RW40 46-@TB05 1

106 -- 55 75 98 -- -- 75 75 S3 B

Order No. supplement for connection types

• With screw terminals 1

• With spring-loaded terminals

1)

Stand-alone installation without auxiliary fan.

2)

Soft starter with screw terminals: delivery time class } (preferred type).

3)

Main circuit connection: screw terminals.

For information about rated currents for ambient temperatures

> 40 °C, see technical specifications.

6/8

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

* You can order this quantity or a multiple thereof.

Page 15

3RW Soft Starters

66

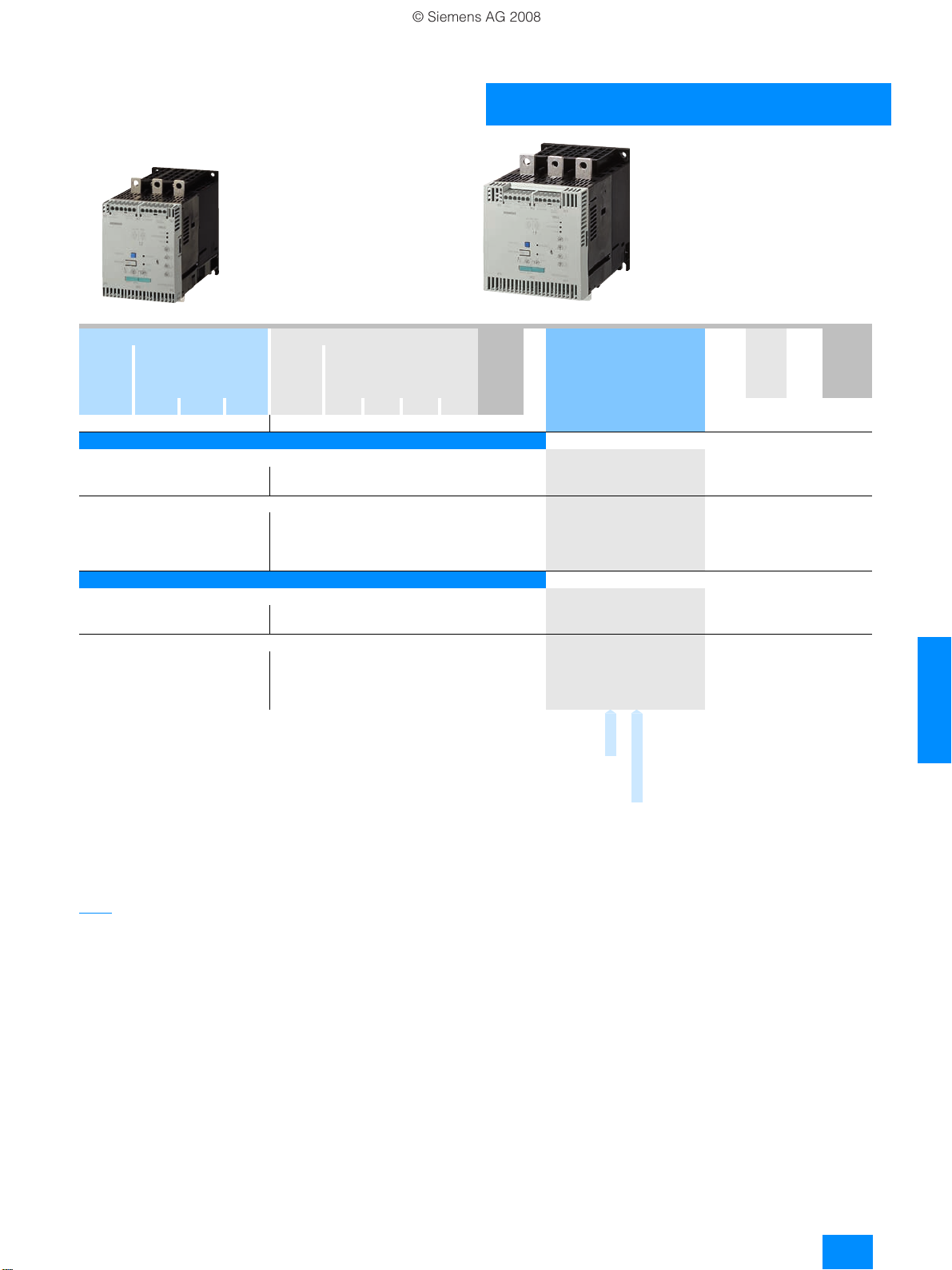

3RW40 56-6BB44 3RW40 76-6BB44

© Siemens AG 2008

for standard applications

3RW40

Ambient temperature 40 °C Ambient temperature 50 °C Size DT Order No. Price

Rated

operational current I

A kW kW kW A hp hp hp hp kg

Rated power of

three-phase induction

motors for rated

1)

operational voltage U

e

230 V 400 V 500 V 200 V 230 V 460 V 575 V

e

Rated

operational cur-

1)

rent I

e

Rated power of three-phase

induction motors for rated

operational voltage U

e

per PU

PU

PS* PG Weight

(UNIT,

SET, M)

Rated operational voltage Ue 200 ... 460 V2)

• With screw-type or spring-loaded terminals

134 37 75 -- 117 30 40 75 -- S6 B 3RW40 55-@BB@4 1

162 45 90 -- 145 40 50 100 -- B

• With screw-type or spring-loaded terminals

230 75 132 -- 205 60 75 150 -- S12 B 3RW40 73-@BB@4 1

280 90 160 -- 248 75 100 200 -- B

356 110 200 -- 315 100 125 250 -- B

432 132 250 -- 385 125 150 300 -- B

3RW40 56-@BB@4 1

3RW40 74-@BB@4 1

3RW40 75-@BB@4 1

3RW40 76-@BB@4 1

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

131 4.900

131 6.900

131 8.900

131 8.900

131 8.900

131 8.900

Rated operational voltage Ue 400 ... 600 V3)

• With screw-type or spring-loaded terminals

134 -- 75 90 117 -- -- 75 100 S6 B 3RW40 55-@BB@5 1

162 -- 90 110 145 -- -- 100 150 B

• With screw-type or spring-loaded terminals

230 -- 132 160 205 -- -- 150 200 S12 B 3RW40 73-@BB@5 1

280 -- 160 200 248 -- -- 200 250 B

356 -- 200 250 315 -- -- 250 300 B

432 -- 250 315 385 -- -- 300 400 B

Order No. supplement for connection types

• With screw terminals 6

• With spring-loaded terminals 2

Order No. supplement for the rated control supply voltage U

• 115 V AC 3

• 230 V AC 4

1)

Stand-alone installation.

2)

Soft starter with screw terminals: delivery time class } (preferred type).

3)

Soft starter with screw terminals: delivery time class A.

4)

Main circuit connection: busbar connection.

5)

Control by way of the internal 24 V DC supply and direct control by means

of PLC possible.

4)

5)

s

3RW40 56-@BB@5 1

3RW40 74-@BB@5 1

3RW40 75-@BB@5 1

3RW40 76-@BB@5 1

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

131 4.900

131 6.900

131 8.900

131 8.900

131 8.900

131 8.900

Note:

Selection of the soft starter depends on the rated motor current.

The SIRIUS 3RW40 solid-state soft starters are designed for

easy starting conditions. J

deviating conditions or increased switching frequency, it may be

necessary to choose a larger device. Siemens

use of the selection and simulation program

Load

<10xJ

. In the event of

Motor

recommends the

Win-Soft Starter.

For information about rated currents for ambient temperatures

> 40 °C, see technical specifications.

per PU

approx.

* You can order this quantity or a multiple thereof.

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

6/9

Page 16

3RW Soft Starters

© Siemens AG 2008

3RW40

for standard applications

Accessories

For soft starters Versio n DT Order No. Price

Typ e Size

Box terminal blocks for soft starters

For round and ribbon cables

3RW40 5. S6 • Up to 70 mm

3RW40 7. S12 • Up to 240 mm

Auxiliary terminals

Auxiliary terminals, 3-pole

3RW40 4. S3 B3RT19 46-4F 1

Covers for soft starters

Terminal covers for box terminals

Additional touch protection to be fitted at the box terminals

(2 units required per device)

3RW40 3. S2 } 3RT19 36-4EA2 1

3RW40 4. S3 }

3RW40 5. S6 }

3RW40 7. S12 }

Terminal covers for cable lugs and busbar connections

3RW40 4. S3 For complying with the phase

3RW40 5. S6 }

3RW40 7. S12 }

2

• Up to 120 mm

clearances and as touch protection

if box terminal is removed

(2 units required per contactor)

2

2

per PU

} 3RT19 55-4G 1

} 3RT19 56-4G 1

} 3RT19 66-4G 1

3RT19 46-4EA2 1

3RT19 56-4EA2 1

3RT19 66-4EA2 1

3RT19 46-4EA1 1

}

3RT19 56-4EA1 1

3RT19 66-4EA1 1

PU

(UNIT,

SET, M)

PS* PG Weight

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

per PU

approx.

kg

101 0.230

101 0.260

101 0.676

101 0.035

101 0.020

101 0.025

101 0.030

101 0.040

101 0.040

101 0.070

101 0.130

Sealing covers

3RW40 2. to

3RW40 4.

3RW40 5. and

3RW40 7.

6

Modules for RESET

1)

Modules for remote RESET, electrical

Operating range 0.85 ... 1.1 x Us,

power consumption AC 80 VA, DC 70 W,

ON period 0.2 s ... 4 s,

switching frequency 60/h

3RW40 5. and

3RW40 7.

Mechanical RESET comprising

3RW40 5. and

3RW40 7.

Cable releases with holder for RESET

For Ø 6.5 mm holes in the control panel;

max. control panel thickness 8 mm

3RW40 5. and

3RW40 7.

S0,

S2,

S3

S6,

S12

S6,

•24...30VAC/DC } 3RU19 00-2AB71 1

S12

• 110 ... 127 V AC/DC }

• 220 ... 250 V AC/DC }

S6,

• Resetting plunger, holder and former } 3RU19 00-1A 1

S12

• Suitable pushbutton IP65, Ø 22 mm,

12 mm stroke

• Extension plunger A

S6,

• Length 400 mm } 3RU19 00-1B 1

S12

• Length 600 mm }

3RW49 00-0PB10 1

}

}

3RW49 00-0PB00 1

3RU19 00-2AF71 1

3RU19 00-2AM71 1

3SB30 00-0EA11 1

B

3SX13 35 1

3RU19 00-1C 1

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

1 unit

131 0.005

131 0.010

101 0.066

101 0.067

101 0.066

101 0.038

102 0.020

102 0.004

101 0.063

101 0.073

1)

Remote RESET already integrated in the soft starters 3RW40 2. to

3RW40 4..

6/10

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

* You can order this quantity or a multiple thereof.

Page 17

3RW Soft Starters

66

© Siemens AG 2008

for standard applications

3RW40

For soft starters Motor starter protectors

Typ e Size

Size

Link modules to motor starter protectors

3RW40 24,

3RW40 26

3RW40 27,

3RW40 28

3RW40 36 S2 S2 }

3RW40 37,

3RW40 38

3RW40 46,

3RW40 47

S0 S0 } 3RA19 21-1A 1

S2 D

S3 D

S3 S3 }

Fans (to increase switching frequency and for device mounting in

positions different from the normal position)

3RW40 2. S0 } 3RW49 28-8VB00 1

3RW40 3.,

3RW40 4.

S2,

S3

Operating instructions1)

For soft starters

3RW40 2.

3RW40 3.

3RW40 4.

3RW40 5.

1)

The operating instructions are included in the scope of supply.

Spare parts

3RW40 7.S6S12

For soft starters Ver sion DT Order No. Price

Typ e Size Rated control supply

S0

S2

S3

voltage U

s

Fans

Fans

3RW40 5.-.BB3 . S6 115 V AC } 3RW49 36-8VX30 1

3RW40 5.-.BB4 . S6 230 V AC }

3RW40 7.-.BB3 . S12 115 V AC }

3RW40 7.-.BB4 . S12 230 V AC }

DT Order No. Price

3RA19 31-1D 1

3RA19 31-1A 1

3RA19 41-1D 1

3RA19 41-1A 1

3RW49 47-8VB00 1

}

3ZX10 12-0RW40-1AA1

3ZX10 12-0RW40-2DA1

3RW49 36-8VX40 1

3RW49 47-8VX30 1

3RW49 47-8VX40 1

per PU

per PU

PU

PS* PG Weight

(UNIT,

SET, M)

10 units

5 units

5 units

5 units

5 units

1 unit

1 unit

PU

PS* PG Weight

(UNIT,

SET, M)

1 unit

1 unit

1 unit

1 unit

per PU

approx.

kg

101 0.028

101 0.041

101 0.033

101 0.042

101 0.072

131 0.010

131 0.020

per PU

approx.

kg

131 0.300

131 0.300

131 0.500

131 0.500

* You can order this quantity or a multiple thereof.

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

6/11

Page 18

3RW Soft Starters

© Siemens AG 2008

3RW30 for standard applications

■

Function

The space required by the compact SIRIUS 3RW30 soft starter

is often only about one third of that required by a wye-delta

assembly of comparable rating. This not only saves space in the

control cabinet and on the standard mounting rail but also does

away completely with the wiring work needed for wye-delta

starters. This is notable in particular for higher motor ratings

which are only rarely available as fully wired solutions.

At the same time the number of cables from the starter to the

motor is reduced from six to three. Compact dimensions, short

start-up times, easy wiring and fast commissioning make

themselves felt as clear-cut cost advantages.

The bypass contacts

operation by an integrated solid-state arc quenching system.

This prevents damage to the bypass contacts in the event of a

fault, e.g. brief disconnection of the control voltage, mechanical

shocks or life-related component defects on the coil operating

mechanism or main contact spring.

The new series of devices comes with the "polarity balancing"

control method, which is designed to prevent direct current

components in two-phase controlled soft starters. On two-phase

controlled soft starters the current resulting from superimposition

of the two controlled phases flows in the uncontrolled phase.

This results for physical reasons in an asymmetric distribution of

the three phase currents during the motor ramp-up. This

phenomenon cannot be influenced, but in most applications it is

non-critical.

Controlling the power semiconductors results not only in this

asymmetry, however, but also in the previously mentioned direct

current components which can cause severe noise generation

on the motor at starting voltages of less than 50 %. The control

method used for these soft starters eliminates these direct

current components during the ramp-up phase and prevents the

braking torque which they can cause.

of these soft starters are protected during

It creates a motor ramp-up that is uniform in speed, torque and

current rise, thus permitting a particularly gentle, two-phase

starting of the motors. At the same time the acoustic quality of

the starting operation comes close to the quality of a threephase controlled soft starter. This is made possible by the ongoing dynamic harmonizing and balancing of current half-waves

of different polarity during the motor ramp-up. Hence the name

"polarity balancing".

• Soft starting with voltage ramp; the starting voltage setting

range U

from 0 s to 20 s.

is 40 % to 100 % and the ramp time tR can be set

s

• Integrated bypass contact system to minimize power loss

• Setting with two potentiometers

• Simple mounting and start-up

• Mains voltages at 50/60 Hz, 200 to 480 V

• Two control voltage versions 24 V AC/DC and 110 to 230 V AC/DC

• Wide temperature range from -25 °C to +60 °C

• The built-in auxiliary contact ensures user-friendly control and

possible further processing within the system (for status

graphs see page 6/22).

6

■

Technical specifications

Typ e 3RW30 1. , 3RW30 2. 3RW30 3. , 3RW30 4.

Control electronics

Rated values Terminal

Rated control supply voltage A1/A2 V 24 110 ... 230 24 110 ... 230

• Tolerance %

Rated control supply current

• STANDBY mA <50 6 20 <50

• During pick-up mA

•ON mA

Rated frequency Hz

• Tolerance %

Control input

IN ON/OFF

Power consumption with version

•24VDC mA approx. 12

• 110/230 V AC mA

Relay outputs

Output 1 ON 13/14 Operating indication (NO)

Rated operational current A

Protection against overvoltages

Short-circuit protection

Operating indications LED

Off

Start

Bypass

Error signals

• 24 V DC: U < 0.75 x Us or U > 1.25 x U

• 110 ... 230 V AC:U < 0.75 x U

Electrical overloading of bypass

(reset by removing IN command)

Missing mains voltage, phase failure, missing load

Device fault

or U > 1.15 x U

s

s

s

±20 -15/+10 ±20 -15/+10

< 100 15 < 4000 < 500

< 100 15 20 <50

50/60

±10

AC: 3/6; DC: 1.5/3

3 AC-15/AC-14 at 230 V,

1 DC-13 at 24 V

A

Protection by means of varistor through contact

4 A gL/gG operational class;

6 A quick (fuse is not included in scope of supply)

DEVICE

Green Off Green Off

Green Green flashing Green Green flashing

Green Green Green Green

Off Red Off Red

Off Red Off Red

Yellow Red -- --

Green Red Green Red

Red Red Red Red

STATE/BYPASSED/

FAILURE

DEVICE

STATE/BYPASSED/

FAILURE

6/12

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

Page 19

3RW Soft Starters

66

NSB0_01897

10°

10°

10°10°

© Siemens AG 2008

Typ e 3RW30 1. ... 3RW30 4.

Control times and parameters

Control times

Closing delay (with connected control voltage) ms <50

Closing delay (automatic/mains contactor mode) ms < 300

Mains failure bridging time

Control supply voltage ms 50

Mains failure response time

Load current circuit ms 500

Starting parameters

• Starting time s 0...20 7.5

• Starting voltage %

Start-up detection

Operating mode output 13/14

Rising edge at Start command ON

Falling edge at Off command

1)

Mains failure detection only in standby state, not during operation.

Typ e 3RW30 1.-. BB.4 ... 3RW30 4.-.BB .4

Power electronics

Rated operational voltage VAC 200 ... 480

To le ra n ce %

Rated frequency Hz

To le ra n ce %

Continuous duty at 40 °C (% of I

Minimum load (% of I

Maximum cable length between soft starter and motor m

Permissible installation height m

Permissible mounting position

(auxiliary fan not available)

1)

40 ... 100 40

No

-15/+10

50/60

±10

)%115

)%10 (at least 2 A)

e

e

300

5000

(derating from 1000, see characteristic curves); higher on request

3RW30

for standard applications

Factory default

Permissible ambient temperature

Operation °C -25 ... +60; (derating from +40)

Storage °C

Degree of protection

Typ e 3RW30 13 3RW30 14 3RW30 16 3RW30 17 3RW30 18

-40 ... +80

IP20 for 3RW30 1. and 3RW30 2. ;

IP00 for 3RW30 3. and 3RW30 4.

Power electronics

Load rating with rated operational current I

• According to IEC and UL/CSA1), for individual mounting, AC-53a

-at 40°C A 3.6 6.5 9 12.5 17.6

-at 50°C A

-at 60°C A

Power loss

• In operation after completed ramp-up with uninterrupted rated

operational current (40 °C) approx.

• During starting with 300 %

Permissible rated motor current and starts per hour

for normal starting (Class 10)

- rated motor current I

- starts per hour

- rated motor current

- starts per hour

1)

Measurement at 60 °C according to UL/CSA not required.

2)

With 300 % IM.

3)

For intermittent duty S4 with ON period = 30 %, Tu= 40 °C, stand-alone

installation vertical. The quoted switching frequencies do not apply for

automatic mode.

3)

3)

I

(40°C) W 6 13 20 20 29

M

2)

, starting time 3 s A 3.6 6.5 9 12.5 17.6

M

2)

I

, starting time 4 s A 3.6 6.5 9 12.5 17.6

M

e

3.3 6 8 12 17

3 5.5 7 11 14

W 0.25 0.5 1 2 4

1/h 200 87 50 85 62

1/h 150 64 35 62 45

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

6/13

Page 20

3RW Soft Starters

© Siemens AG 2008

3RW30

for standard applications

Typ e 3RW30 26 3RW30 27 3RW30 28

Power electronics

Load rating with rated operational current I

• According to IEC and UL/CSA1), for individual mounting, AC-53a

-at 40°C A 25.3 32.2 38

-at 50°C A

-at 60°C A

Power loss

• In operation after completed ramp-up with uninterrupted rated

operational current (40 °C) approx.

• During starting with 300 %

Permissible rated motor current and starts per hour

for normal starting (Class 10)

- rated motor current I

- starts per hour

- rated motor current

- starts per hour

1)

Measurement at 60 °C according to UL/CSA not required.

2)

With 300 % IM.

3)

For intermittent duty S4 with ON period = 30 %, Tu= 40 °C, stand-alone

installation vertical. The quoted switching frequencies do not apply for

automatic mode.

Typ e 3RW30 36 3RW30 37 3RW30 38 3RW30 46 3RW30 47

3)

3)

I

(40°C) W 47 55 64

M

2)

, starting time 3 s A 25 32 38

M

2)

I

, starting time 4 s A 25 32 38

M

Power electronics

Load rating with rated operational current I

• According to IEC and UL/CSA1), for individual mounting, AC-53a

-at 40°C A 45 65 72 80 106

-at 50°C A

-at 60°C A

Power loss

• In operation after completed ramp-up with uninterrupted rated

operational current (40 °C) approx.

• During starting with 300 %

Permissible rated motor current and starts per hour

for normal starting (Class 10)

- rated motor current I

- starts per hour

- rated motor current

6

- starts per hour

1)

Measurement at 60 °C according to UL/CSA not required.

2)

With 300 % IM.

3)

For intermittent duty S4 with ON period = 70 %, Tu= 40 °C, stand-alone

installation vertical. The quoted switching frequencies do not apply for

automatic mode.

3)

3)

I

(40°C) W 79 111 125 144 192

M

2)

, starting time 3 s A 45 63 72 80 106

M

2)

I

, starting time 4 s A 45 63 72 80 106

M

e

23 29 34

21 26 31

W 8 13 19

1/h 23 23 19

1/h 15 16 12

e

42 58 62.1 73 98

39 53 60 66 90

W 6 12 15 12 21

1/h 38 23 22 22 15

1/h 26 15 15 15 10

6/14

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

Page 21

3RW Soft Starters

66

NSB00479

© Siemens AG 2008

for standard applications

Soft starters Type 3RW30 1. 3RW30 2. 3RW30 3. 3RW30 4.

Conductor cross-sections

Screw terminals Main conductors

Front clamping point

connected

Rear clamping point

connected

Both clamping points

connected

•Solid mm22x(1...2.5);

• Finely stranded with end sleeve mm

• Stranded mm

• AWG cables

- solid or stranded AWG 2x(14...10) 2 x (14 ... 10) 1x(18...2) 1x(10...2/0)

-stranded AWG

•Solid mm

• Finely stranded with end sleeve mm

• Stranded mm

• AWG cables

- solid or stranded AWG -- -- 1x(16...2) 1x(10...2/0)

•Solid mm

• Stranded mm

• Finely stranded with end sleeve mm

• AWG cables

- solid or stranded AWG -- -- 2x(16...2) 2x(10...1/0)

2x(2.5...6)

acc. to IEC 60947

2

2 x (1.5 ... 2.5);

2x(2.5...6)

2

-- -- 1x(0.75...35) 1x(4...70)

1x8 1x8 -- --

2

-- -- 2 x (1.5 ... 16) 2x(2.5...16)

2

-- -- 1 x (1.5 ... 25) 1x(2.5...50)

2

-- -- 1 x (1.5 ... 35) 1x(10...70)

2

-- -- 2 x (1.5 ... 16) 2x(2.5...16)

2

-- -- 2 x (1.5 ... 25) 2x(10...50)

2

-- -- 2 x (1.5 ... 16) 2x(2.5...35)

2 x (1 ... 2.5);

2 x (2.5 ... 6)

acc. to IEC 60947;

max. 1 x 10

2 x (1 ... 2.5);

2x(2.5...6)

2 x (1.5 ... 16) 2x(2.5...16)

1x(0.75...25) 1x(2.5...35)

3RW30

• Tightening torque Nm

Tools

Degree of protection

Spring-loaded terminals Main conductors

•Solid mm21 ... 4 1...10 -- --

• Finely stranded with end sleeve mm

• AWG cables

- solid or stranded (finely stranded) AWG 16 ... 14 16 ... 10 -- --

-stranded AWG

Tools

Degree of protection

Busbar connections Main conductors

• With cable lug according to DIN 46234 or

max. 20 mm wide

-stranded mm2-- -- -- 2x(10...70)

- finely stranded mm

• AWG cables, solid or stranded AWG

Soft starters Type 3RW30 1. ... 3RW30 4 .

2 ... 2.5 2...2.5 4.5 6.5

18 ... 22 18 ... 22 40 58

lb.in

PZ 2 PZ 2 PZ 2 Allen screw 4 mm

IP20 IP20 IP20

2

1 ... 2.5 1 ... 6, end

16 ... 12 1x8 -- -DIN ISO 2380-

1A0; 5 x 3

IP20 IP20 -- --

2

-- -- -- 2x(10...50)

-- -- -- 2x(7...1/0)

sleeves without

plastic collar

DIN ISO 23801A0; 5 x 3

Conductor cross-sections

Auxiliary conductors (1 or 2 conductors can be connected):

Screw terminals

• Solid mm22 x (0.5 ... 2.5)

• Finely stranded with end sleeve mm

•AWG cables

- solid or stranded AWG 2x(20...14)

- finely stranded with end sleeve AWG

• Terminal screws

- tightening torque Nm 0.8 ... 1.2

Spring-loaded terminals

• Solid mm22x(0.25...2.5)

• Finely stranded with end sleeve mm

• AWG cables, solid or stranded AWG

2

lb.in

2

2 x (0.5 ... 1.5)

2x(20...16)

7 ... 10.3

2x(0.25...1.5)

2x(24...14)

(IP00 terminal

compartment)

-- --

-- --

IP20

(IP00 terminal

compartment)

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

6/15

Page 22

3RW Soft Starters

© Siemens AG 2008

3RW30

for standard applications

Typ e 3RW30 03

Control electronics

Rated values

Rated control supply voltage V 24 ... 230 AC/DC

• Tolerance %

Rated control supply current mA

Rated frequency at AC Hz

• Tolerance %

Starting time s

Starting voltage %

Ramp-down time s

Power electronics

Rated operational voltage VAC 200 ... 400

To le ra n ce %

Rated frequency Hz

To le ra n ce %

I

Continuous duty (% of

Minimum load

Maximum conductor length between soft starter and motor m

Degree of protection according to IEC 60529 IP20 (IP00 terminal compartment)

Permissible installation height m

Permissible mounting position

1)

)%100

e

(% of Ie); at 40 °C % 9

± 10

25 ... 4

50/60

± 10

0.1 ... 20 (adjustable)

40 ... 100 (adjustable)

0 ... 20 (adjustable)

± 10

50/60

±10

2)

100

5000

(derating from 1000, see characteristic curves); higher on request

10°

10°

10°10°

NSB0_01897

Permissible ambient temperature

Operation °C -25 ... +60; (derating from +40)

Storage °C

Load rating with rated operational current I

• According to IEC and UL/CSA1), for individual mounting, AC-53a

-at 40°C A 3

-at 50°C A

-at 60°C A

• According to IEC and UL/CSA

6

-at 40°C A 2.6

-at 50°C A

-at 60°C A

Power loss

• In operation after completed ramp-up with uninterrupted rated

operational current (40 °C) approx.

• At utilization of max. switching frequency W

Permissible starts per hour

• For intermittent duty S4, Tu= 40 °C, stand-alone installation vertical 1/h 1500

•ON period=70% %I

1)

, for butt-mounting, AC-53a

e

-40 ... +80

2.6

2.2

2.2

1.8

W 6.5

3

/s 300/0.2

e

Conductor cross-sections

Screw terminals • Main conductors

(1 or 2 conductors connectable)

For standard screwdriver

size 2 and Pozidriv 2

Spring-loaded terminals Main and auxiliary conductors

1)

The rated motor current (specified on the motor's name plate) should at

least amount to the specified percentage of the SIRIUS soft starter unit's

rated operational current I

e

- solid mm²

- finely stranded with end sleeve mm²

- stranded mm²

- AWG cables,

solid or stranded

- terminal screws

- tightening torque Nm

• Auxiliary conductors

- solid mm² 1 x (0.5 ... 4);

- finely stranded with end sleeve mm²

- AWG cables,

solid or stranded

- terminal screws

- tightening torque Nm

• Solid mm22x(0.25...1.5)

• Finely stranded with end sleeve mm

• AWG cables,

solid or stranded

.

1 x (0.5 ... 4);

2 x (0.5 ... 2.5)

1 x (0.5 ... 2.5);

2 x (0.5 ... 1.5)

-2x(20...14)

AWG

M3, PZ2

0.8 ... 1.2

7.1 ... 8.9

lb.in

2 x (0.5 ... 2.5)

1 x (0.5 ... 2.5); 2 x (0.5 ... 1.5)

AWG

2x(20...14)

M3, PZ2

0.8 ... 1.2

lb.in

7...8.9

2

2x(0.25...1)

2

2x(24...16)

mm

2)

If this value is exceeded, problems with line capacities may arise, which

can result in false firing.

6/16

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

Page 23

3RW Soft Starters

66

© Siemens AG 2008

for standard applications

Standard Parameters

Electromagnetic compatibility according to EN 60947-4-2

EMC interference immunity

Electrostatic discharge (ESD) EN 61000-4-2 ±4 kV contact discharge, ±8 kV air discharge

Electromagnetic RF fields

Conducted RF interference

RF voltages and RF currents on cables

•Burst EN 61000-4-4 ±2kV/5kHz

•Surge

EMC interference emission

EMC interference field strength EN 55011 Limit value of Class A at 30 ... 1000 MHz,

Radio interference voltage

Radio interference suppression filters

Degree of noise suppression A (industrial applications) Not required

Degree of noise suppression B (applications for residential areas)

Control voltage

• 230 V AC/DC Not available

•24VAC/DC Not required for 3RW30 1. and 3RW30 2.;

1)

Degree of noise suppression B cannot be obtained through the use of

filters as the strength of the electromagnetic field is not attenuated by the

filter.

EN 61000-4-3 Frequency range: 80 ... 2000 MHz with 80 % at 1 kHz

EN 61000-4-6 Frequency range: 150 kHz ... 80 MHz with 80 % at 1 kHz

EN 61000-4-5 ±1 kV line to line

EN 55011 Limit value of Class A at 0.15 ... 30 MHz,

required for 3RW30 3 . and 3RW30 4. (see table)

Degree of severity 3: 10 V/m

Interference 10 V

±2 kV line to earth

limit value of Class B at 3RW30 2. ; 24 V AC/DC

limit value of Class B for 3RW30 2. ; 24 V AC/DC

1)

3RW30

Soft starter types Rated current

Soft starters Voltage range 200 ... 480 V

A A mm

3RW30 36 45 4EF1512-1AA10 50 16

3RW30 37 63 4EF1512-2AA10 66 25

3RW30 38 72 4EF1512-3AA10 90 25

3RW30 46 80 4EF1512-3AA10 90 25

3RW30 47 106 4EF1512-4AA10 120 50

1)

The radio interference suppression filter is used to remove the conducted

interference from the main circuit. The field-related emissions comply with

degree of noise suppression B.

Recommended filters

Filter types Rated current filters Terminals

1)

2

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

6/17

Page 24

3RW Soft Starters

NSB0_01936

M

3~

Q11

Q21

F1

© Siemens AG 2008

3RW30

for standard applications

Fuse assignment

The type of coordination to which the motor feeder with soft

starter is mounted depends on the application-specific

requirements. Normally, fuseless mounting (combination of

motor starter protector and soft starter) is sufficient.

Fuseless version

Soft starters Motor starter protectors

Rated

Q11 Q1 I

Typ e A Typ e kA A

Type of coordination 1

3RW30 03 3 3RV10 11-1EA10 50 4

3RW30 13 3.6

3RW30 14 6.5

3RW30 16 9

3RW30 17 12.5

3RW30 18 17.6

3RW30 26 25

3RW30 27 32

3RW30 28 38

3RW30 36 45

3RW30 37 63

3RW30 38 72

3RW30 46 80

3RW30 47 106

1)

The rated motor current must be considered when selecting the devices.

6

Fused version (line protection only)

current

Q1

Q11

M

3~

NSB0_01935

1)

400V +10% Rated

q max

2)

3RV10 21-1FA10 10 5

3RV10 21-1HA10 10 8

3RV10 21-1JA10 10 10

3RV10 21-1KA10 10 12.5

3RV10 21-1BA10 10 20

3RV10 31-4DA10 55 25

3RV10 31-4EA10 55 32

3RV10 31-4FA10 55 40

3RV10 31-4GA10 20 45

3RV10 41-4JA10 20 63

3RV10 41-4KA10 20 75

3RV10 41-4LA10 11 90

3RV10 41-4MA10 11 100

If type 2 coordination is to be fulfilled, semiconductor fuses must

be fitted in the motor feeder.

current

2)

The types of coordination are explained in more detail in Catalog LV 1,

"Load Feeders, Motor Starters and Soft Starters" ––> "Fuseless Load Feeders".

Soft starters Line protection, maximum Line contactors

Q11 F1 Q21

Typ e A Typ e A

Type of coordination 11): Iq= 65 kA at 480 V 10 %

3RW30 03

3RW30 13 3.6

3RW30 14 6.5

3RW30 16 9

3RW30 17 12.5

3RW30 18 17.6

3RW30 26 25

3RW30 27 32

3RW30 28 38

3RW30 36 45

3RW30 37 63

3RW30 38 72

3RW30 46 80

3RW30 47 106

1)

The types of coordination are explained in more detail in Catalog LV 1,

"Load Feeders, Motor Starters and Soft Starters" ––> "Fuseless Load

Feeders".

2)

Iq= 50 kA at 400 V.

6/18

Rated

current

2)

3 3NA3 805

3NA3 803-6 10 000 3RT10 15

3NA3 805-6 16 000 3RT10 15

3NA3 807-6 20 000 3RT10 16

3NA3 810-6 25 000 3RT10 24

3NA3 814-6 35 000 3RT10 26

3NA3 822-6 63 00 3RT10 26

3NA3 824-6 80 00 3RT10 34

3NA3 824-6 80 00 3RT10 35

3NA3 130-6 100 1 3RT10 36

3NA3 132-6 125 1 3RT10 44

3NA3 132-6 125 1 3RT10 45

3NA3 136-6 160 1 3RT10 45

3NA3 136-6 160 1 3RT10 46

Rated

current

3)

20 000 3RT10 15

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

Size (optional)

3)

3NA3 805-1 (NH00), 5SB2 61 (DIAZED), 5SE2 201-6 (NEOZED).

Page 25

66

© Siemens AG 2008

Fused version with 3NE1 SITOR fuses (semiconductor and line protection)

Soft starters All-range fuses Line contactors

Rated

Q11 F'1 Q21

Typ e A Ty pe A

Type of coordination 21): Iq= 65 kA at 480 V 10 %

3RW30 03

3RW30 13 3.6

3RW30 14 6.5

3RW30 16 9

3RW30 17 12.5

3RW30 18 17.6

3RW30 26 25

3RW30 27 32

3RW30 28 38

3RW30 36 45

3RW30 37 63

3RW30 38 72

3RW30 46 80

3RW30 47 106

1)

The types of coordination are explained in more detail in Catalog LV 1,

"Load Feeders, Motor Starters and Soft Starters" ––> "Fuseless Load Feeders".

The type of coordination "2" refers only to soft starters, not to any

components in the feeder.

2)

Iq= 50 kA at 400 V.

3)

No SITOR fuse required!

Alternatively: 3NA3 803 (NH00), 5SB2 21 (DIAZED), 5SE2 206 (NEOZED).

current

2)

3 3NE1 813-0

F’1

Q21

Q11

M

3~

NSB0_01937

Rated

current

3)

3NE1 813-0 16 000 3RT10 15

3NE1 813-0 16 000 3RT10 15

3NE1 813-0 16 000 3RT10 16

3NE1 813-0 16 000 3RT10 24

3NE1 814-0 20 000 3RT10 26

3NE1 803-0 35 000 3RT10 26

3NE1 020-2 80 00 3RT10 34

3NE1 020-2 80 00 3RT10 35

3NE1 020-2 80 00 3RT10 36

3NE1 820-0 80 000 3RT10 44

3NE1 820-0 80 000 3RT10 45

3NE1 021-0 100 00 3RT10 45

3NE1 022-0 125 00 3RT10 46

16 000 3RT10 15

Size (optional)

3RW Soft Starters

3RW30

for standard applications

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

6/19

Page 26

3RW30

NSB0_01938

M

3~

Q11

Q1

F3

NSB0_01939

M

3~

Q11

Q21

F1

F3

© Siemens AG 2008

for standard applications

Fused version with 3NE3 SITOR fuses (semiconductor protection by fuse, line and overload protection by motor starter protector;

alternatively, installation with contactor and overload relay possible)

Soft starters Semiconductor fuses, minimum Semiconductor fuses, maximum Semiconductor fuses, minimum

Q11 F3 F3 F3

Typ e A Ty pe A Typ e A Ty pe A

Type of coordination 21): Iq= 65 kA at 480 V 10 %

3RW30 03

3RW30 13 3.6 -- -- -- -- -- -- 3NE4 101 32 0

3RW30 14 6.5

3RW30 16 9

3RW30 17 12.5

3RW30 18 17.6

3RW30 26 25

3RW30 27 32

3RW30 28 38

3RW30 36 45

3RW30 37 63

3RW30 38 72

3RW30 46 80

3RW30 47 106

Soft starters Semiconductor fuses, max. Semiconductor fuses, min. Semiconductor fuses, max. Cylindrical fuses

Q11 F3 F3 F3 F3

Typ e A Ty pe A Ty pe A Typ e A Ty pe A

Type of coordination 21): Iq= 65 kA at 480 V 10 %

6

3RW30 03

3RW30 13 3.6

3RW30 14 6.5

3RW30 16 9

3RW30 17 12.5

3RW30 18 17.6

3RW30 26 25

3RW30 27 32

3RW30 28 38

3RW30 36 45

3RW30 37 63

3RW30 38 72

3RW30 46 80

3RW30 47 106

Soft starters Line contactors Motor starter protectors Line protection, maximum

Q11 Q21 Q1 F1

Typ e A Type A Ty pe A

Type of coordination 21): Iq= 65 kA at 480 V 10 %

3RW30 03

3RW30 13 3.6 3RT10 15 3RV10 21-1FA10

3RW30 14 6.5 3RT10 15 3RV10 21-1HA10

3RW30 16 9 3RT10 16 3RV10 21-1JA10

3RW30 17 12.5 3RT10 24 3RV10 21-1KA10

3RW30 18 17.6 3RT10 26 3RV10 21-1BA10

3RW30 26 25 3RT10 26 3RV10 31-4DA10

3RW30 27 32 3RT10 34 3RV10 31-4EA10

3RW30 28 38 3RT10 35 3RV10 31-4FA10

3RW30 36 45 3RT10 36 3RV10 31-4GA10

3RW30 37 63 3RT10 44 3RV10 41-4JA10

3RW30 38 72 3RT10 45 3RV10 41-4KA10

3RW30 46 80 3RT10 45 3RV10 41-4LA10

3RW30 47 106 3RT10 46 3RV10 41-4MA10

1)

The types of coordination are explained in more detail in Catalog LV 1,

"Load Feeders, Motor Starters and Soft Starters" ––> "Fuseless Load

Feeders". The type of coordination "2" refers only to soft starters, not to any

components in the feeder.

6/20

3RW Soft Starters

Rated

current

2)

3 -- -- -- -- -- --

-- -- -- -- -- -- 3NE4 101 32 0

-- -- -- -- -- -- 3NE4 101 32 0

-- -- -- -- -- -- 3NE4 101 32 0

-- -- -- 3NE3 221 100 1 3NE4 101 32 0

-- -- -- 3NE3 221 100 1 3NE4 102 40 0

-- -- -- 3NE3 222 125 1 3NE4 118 63 0

-- -- -- 3NE3 222 125 1 3NE4 118 63 0

-- -- -- 3NE3 224 160 1 3NE4 120 80 0

-- -- -- 3NE3 225 200 1 3NE4 121 100 0

3NE3 221 100 1 3NE3 227 250 1 -- -- --

3NE3 222 125 1 3NE3 225 200 1 -- -- -3NE3 224 160 1 3NE3 231 350 1 -- -- --

Rated

current

2)

3 -- -- -- 3NE8 015-1 25 00 3NE8 015-1 25 00 3NC1 010 10

-- -- -- 3NE8 015-1 25 00 3NE8 015-1 25 00 3NC2 220 20

-- -- -- 3NE8 015-1 25 00 3NE8 015-1 25 00 3NC2 220 20

-- -- -- 3NE8 015-1 25 00 3NE8 015-1 25 00 3NC2 220 20

-- -- -- 3NE8 015-1 25 00 3NE8 018-1 63 00 3NC2 250 50

-- -- -- 3NE8 003-1 35 00 3NE8 021-1 100 00 3NC2 263 63

3NE4 117 50 0 3NE8 017-1 50 00 3NE8 021-1 100 00 3NC2 263 63

3NE4 118 63 0 3NE8 018-1 63 00 3NE8 022-1 125 00 3NC2 280 80

3NE4 118 63 0 3NE8 020-1 80 00 3NE8 022-1 125 00 3NC2 280 80

3NE4 120 80 0 3NE8 020-1 80 00 3NE8 024-1 160 00 3NC2 280 80

3NE4 121 100 0 3NE8 021-1 100 00 3NE8 024-1 160 00 -- --

-- -- -- 3NE8 022-1 125 00 3NE8 024-1 160 00 -- --

-- -- -- 3NE8 022-1 125 00 3NE8 024-1 160 00 -- --

-- -- -- 3NE8 024-1 160 00 3NE8 024-1 160 00 -- --

Rated

current

2)

3 3RT10 15 3RV10 11-1EA10 4 3NA3 805

(optional) 400 V +10 % Rated

Siemens LV 1 N SIRIUS Soft Starters · 01/2008

Rated

current

Rated

current

Size Rated

Size Rated

current

current

5 3NA3 803-6 10 000

8 3NA3 805-6 16 000

10 3NA3 807-6 20 000

12.5 3NA3 810-6 25 000