Shop fox W1711, W1677 User Manual

MODEL W1677/W1711 SERIES

LEFT-TILT TABLE SAW

#5674TR

W1677EXT1 Shown

OWNER'S MANUAL

Phone: (360) 734-3482 • Online Technical Support: tech-support@shopfox.biz

COPYRIGHT © JULY, 2002 BY WOODSTOCK INTERNATIONAL, INC. REVISED MAY, 2007 (TR).

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in Taiwan

This manual provides critical safety instructions on the proper setup,

operation, maintenance and service of this machine/equipment.

Failure to read, understand and follow the instructions given in this

manual may result in serious personal injury, including amputation,

electrocution or death.

The owner of this machine/equipment is solely responsible for its safe

use. This responsibility includes but is not limited to proper installation in a safe environment, personnel training and usage authorization, proper inspection and maintenance, manual availability and

comprehension, application of safety devices, blade/cutter integrity,

and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property

damage from negligence, improper training, machine modifications or

misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Table of Contents

INTRODUCTION..................................................................... 2

Woodstock Technical Support .................. 2

W1677 Series Specifications ................... 3

W1711 Series Specifications ................... 4

Controls and Features ........................... 5

SAFETY ..................................................................................... 6

Standard Safety Instructions ................... 6

Specific Safety Instructions for Table Saws .. 8

Avoiding Potential Injuries ...................... 9

Kickback ......................................... 11

Common Terms ................................. 12

ELECTRICAL .......................................................................... 13

220V Operation ................................. 13

Extension Cords ................................ 13

Grounding ....................................... 13

SETUP ......................................................................................14

Unpacking ....................................... 14

Inventory ........................................ 14

Shop Fox Classic Fence Inventory .......... 15

Shop Fox Original Fence Inventory .......... 16

Machine Placement ............................ 17

Cleaning Machine ............................... 17

Mobile Base ..................................... 18

Assembly ......................................... 18

Test Run .......................................... 22

MAINTENANCE .................................................................... 38

V-Belts ........................................... 38

Cleaning ......................................... 38

Table & Base .................................... 38

Lubrication ...................................... 38

SERVICE .................................................................................. 39

General .......................................... 39

Blade Tilt Stop Bolts ........................... 39

Blade Alignment ................................ 40

Miter Slot Parallel to Blade ................... 41

Shimming Wings ................................ 42

Splitter Adjustment ............................ 43

Angle Pointer ................................... 44

Miter Gauge ..................................... 44

Replacing V-Belts ............................... 45

Adjusting Fence ................................ 45

W1677 Wiring Diagram ........................ 46

W1711 Wiring Diagram ........................ 47

Troubleshooting ................................. 48

PARTS ...................................................................................... 50

Table/Body Breakdown ........................ 50

Motor/Trunnion Breakdown ................... 52

Guard/Miter Gauge Breakdown .............. 54

Warranty ................................................................................56

SAFETYINTRODUCTION

SetupELECTRICAL MAINTENANCE

OPERATIONS

OPERATIONS .........................................................................23

General .......................................... 23

Blade Height .................................... 23

Feed Rate ....................................... 23

Blade Selection ................................. 24

Changing Blades ................................ 25

Through vs. Non-Through Cuts ............... 26

Rip Cuts .......................................... 27

Blade Tilt/Bevel Cuts .......................... 27

Cross Cuts ....................................... 28

Miter Cuts ....................................... 28

Dado Cuts ........................................ 29

Rabbet Cuts ..................................... 31

Resawing ......................................... 33

Aftermarket Safety Accessories .............. 36

Shop-Made Safety Accessories................ 37

SERVICE PARTS

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

W1677/W1711 10" Table Saw

INTRODUCTION

INTRODUCTION

Woodstock Technical Support

Your new SHOP FOX® machine has been specially designed to provide many years of trouble-free service. Close attention to detail, ruggedly built parts and a rigid quality control program assure safe and

reliable operation.

Woodstock International, Inc. is committed to customer satisfaction. Our intent with this manual is to

include the basic information for safety, setup, operation, maintenance, and service of this product.

We stand behind our machines! In the event that questions arise about your machine, please contact

Woodstock International Technical Support at (360) 734-3482 or send e-mail to: tech-support@shopfox.

biz. Our knowledgeable staff will help you troubleshoot problems and process warranty claims.

If you need the latest edition of this manual, you can download it from http://www.shopfox.biz.

If you have comments about this manual, please contact us at:

Woodstock International, Inc.

Attn: Technical Documentation Manager

P.O. Box 2309

Bellingham, WA 98227

Email: manuals@woodstockint.com

-2-

W1677/W1711 10" Table Saw

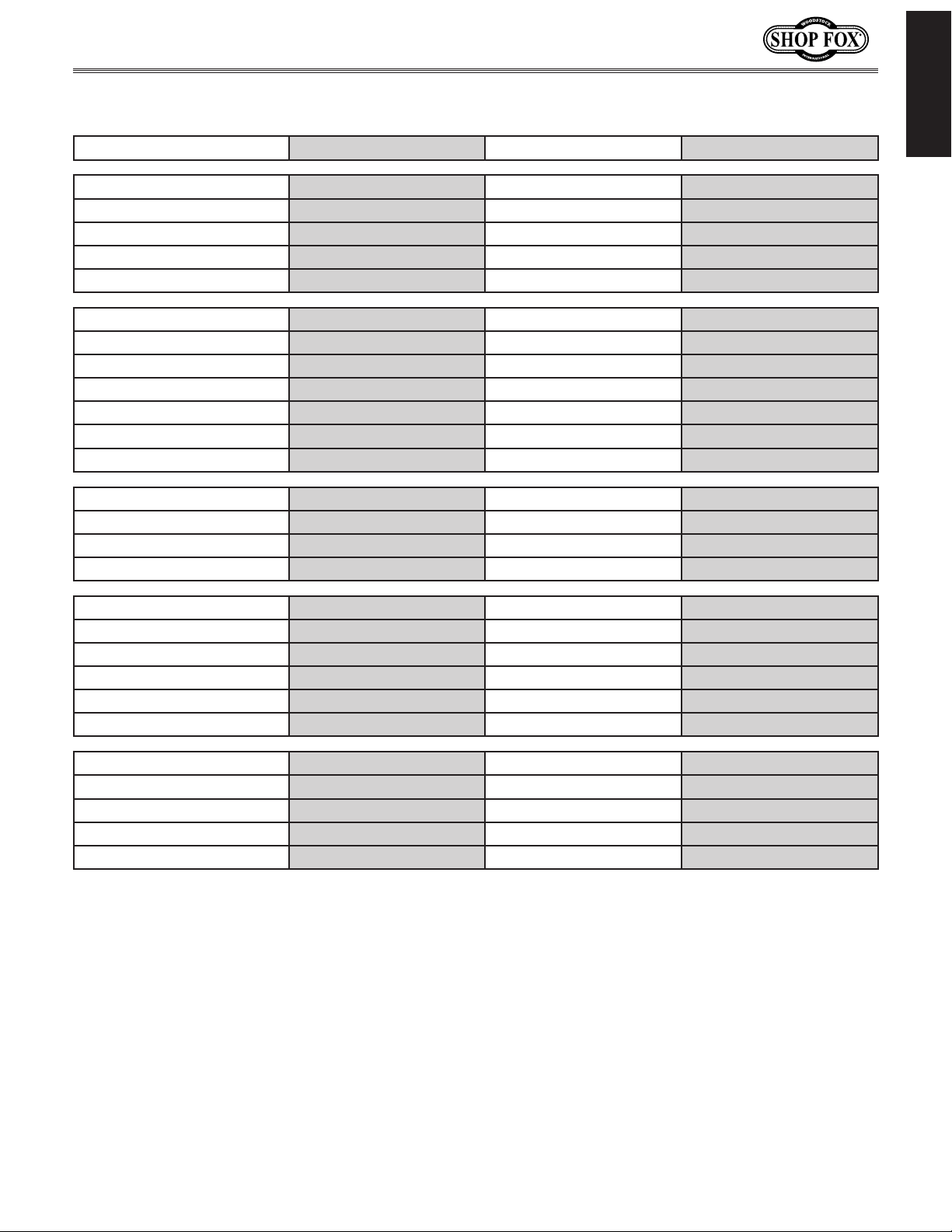

W1677 Series Specifications

Model Number W1677 W1677EXT1 W1677EXT2

INTRODUCTION

Motor

Voltage

Phase

Amps

Speed

Table Size (full assembly)

Table Height

Overall Machine Size

Footprint Size

Weight

Fence

Long Rails & Extension Table

Maximum Rip Right of Blade

Maximum Rip Left of Blade

Maximum Depth of Cut at 90°

Maximum Depth of Cut at 45°

Maximum Blade Diameter

Arbor Size

Arbor Speed

Rim Speed

Blade Tilt (Left)

Maximum Dado Width

3 HP 3 HP 3 HP

220V 220V 220V

Single-Phase Single-Phase Single-Phase

18 18 18

3450 RPM 3450 RPM 3450 RPM

1

⁄8" x 27" 841⁄8" x 27" 841⁄8" x 27"

40

34" 34" 34"

56"L x 34"W 84"L x 34"W 84"L x 34"W

1

⁄2"L x 201⁄2"W 201⁄2"L x 201⁄2"W 201⁄2"L x 201⁄2"W

20

410 lbs. 500 lbs. 500 lbs.

Shop Fox Classic Shop Fox Classic Shop Fox Original

No Yes Ye s

26" 52" 49"

8" 8" 8"

3" 3" 3"

1

⁄8" 21⁄8" 21⁄8"

2

10" 10" 10"

5

⁄8"

5

⁄8"

5

⁄8"

4200 RPM 4200 RPM 4200 RPM

11,000 FPM 11,000 FPM 11,000 FPM

0° – 45° 0° – 45° 0° – 45°

13

⁄16"

13

⁄16"

13

⁄16"

Miter Slot Size

Dust Port Size

Country of Origin

Assembly Time (approx.)

Warranty

3

⁄4"W x 3⁄8"H

3

⁄4"W x 3⁄8"H

3

⁄4"W x 3⁄8"H

4" 4" 4"

Taiwan Taiwan Taiwan

60 Minutes 90 Minutes 90 Minutes

2 Year 2 Year 2 Year

-3-

W1677/W1711 10" Table Saw

W1711 Series Specifications

INTRODUCTION

Model Number W1711 W1711EXT W1711EXT1 W1711EXT2

Motor

Voltage

Phase

Amps

Speed

Table Size (full assembly)

Table Height

Overall Machine Size

Footprint Size

Weight

Fence

Long Rails & Extension Table

Included Mobile Base

Included Steelex Blade

Maximum Rip Right of Blade

Maximum Rip Left of Blade

Maximum Depth of Cut at 90°

Maximum Depth of Cut at 45°

5 HP 5 HP 5 HP 5 HP

220V 220V 220V 220V

Single-Phase Single-Phase Single-Phase Single-Phase

25 25 25 25

3450 RPM 3450 RPM 3450 RPM 3450 RPM

1

⁄8" x 27" 841⁄8" x 27" 841⁄8" x 27" 841⁄8" x 27"

40

34" 34" 34" 34"

56"L x 34"W 84"L x 34"W 84"L x 34"W 84"L x 34"W

1

⁄2"L x 201⁄2"W 201⁄2"L x 201⁄2"W 201⁄2"L x 201⁄2"W 201⁄2"L x 201⁄2"W

20

410 lbs. 500 lbs. 500 lbs. 500 lbs.

Shop Fox Classic Shop Fox Classic Shop Fox Classic Shop Fox Original

No Yes Yes Yes

No No Yes Yes

No No Yes Yes

26" 52" 52" 49"

8" 8" 8" 8"

3" 3" 3" 3"

1

⁄8" 21⁄8" 21⁄8" 21⁄8"

2

Maximum Blade Diameter

Arbor Size

Arbor Speed

Rim Speed

Blade Tilt (Left)

Maximum Dado Width

Miter Slot Size

Dust Port Size

Country of Origin

Assembly Time (approx.)

Warranty

10" 10" 10" 10"

5

⁄8"

5

⁄8"

5

⁄8"

5

⁄8"

4200 RPM 4200 RPM 4200 RPM 4200 RPM

11,000 FPM 11,000 FPM 11,000 FPM 11,000 FPM

0° – 45° 0° – 45° 0° – 45° 0° – 45°

13

⁄16"

3

⁄4"W x 3⁄8"H

13

⁄16"

3

⁄4"W x 3⁄8"H

13

⁄16"

3

⁄4"W x 3⁄8"H

13

⁄16"

3

⁄4"W x 3⁄8"H

4" 4" 4" 4"

Taiwan Taiwan Taiwan Taiwan

60 Minutes 90 Minutes 90 Minutes 90 Minutes

2 Year 2 Year 2 Year 2 Year

-4-

W1677/W1711 10" Table Saw

Controls and Features

Take time to aquaint yourself with the controls

of your new table saw. They will be mentioned

frequently throughout the instructions in this

manual, and the better you know your machine,

the better you can make it perform. Figures 1

and 2 point out the key controls and their locations.

INTRODUCTION

For complete details regarding the controls of

the Shop Fox Classic fence, refer to the manual

included with the fence.

For complete details regarding the extension

tables, refer to the manual included with those

tables.

Miter Gauge

ON/OFF

Switch

Locking

Lever

Hairline

Indicator

Scale

Figure 1. Fence controls.

Blade Guard/Splitter

Fence

Blade Height Wheel

Lock Knobs

Blade Tilt Wheel

Figure 2. Machine controls.

-5-

W1677/W1711 10" Table Saw

SAFETY

READ MANUAL BEFORE OPERATING MACHINE.

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

SAFETY

NOTICE

RESULT IN PERSONAL INJURY.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury.

This symbol is used to alert the user to useful information about proper

operation of the equipment, and/or a situation that may cause damage

to the machinery.

Standard Safety Instructions

1. READ THROUGH THE ENTIRE MANUAL BEFORE STARTING MACHINERY. Machinery presents serious

injury hazards to untrained users.

2. ALWAYS USE ANSI APPROVED SAFETY GLASSES WHEN OPERATING MACHINERY. Everyday eyeglasses only have impact resistant lenses—they are NOT safety glasses.

3. ALWAYS WEAR AN NIOSH APPROVED RESPIRATOR WHEN OPERATING MACHINERY THAT PRODUCES

DUST. Wood dust is a carcinogen and can cause cancer and severe respiratory illnesses.

4. ALWAYS USE HEARING PROTECTION WHEN OPERATING MACHINERY. Machinery noise can cause

permanent hearing damage.

5. WEAR PROPER APPAREL. DO NOT wear loose clothing, gloves, neckties, rings, or jewelry which may

get caught in moving parts. Wear protective hair covering to contain long hair and wear non-slip

footwear.

6. NEVER OPERATE MACHINERY WHEN TIRED, OR UNDER THE INFLUENCE OF DRUGS OR ALCOHOL.

Be mentally alert at all times when running machinery.

7. ONLY ALLOW TRAINED AND PROPERLY SUPERVISED PERSONNEL TO OPERATE MACHINERY. Make

sure operation instructions are safe and clearly understood.

8. KEEP CHILDREN AND VISITORS AWAY. Keep all children and visitors a safe distance from the work

area.

9. MAKE WORKSHOP CHILD PROOF. Use padlocks, master switches, and remove start switch keys.

-6-

W1677/W1711 10" Table Saw

10. NEVER LEAVE WHEN MACHINE IS RUNNING. Turn power off and allow all moving parts to come to

a complete stop before leaving machine unattended.

11. DO NOT USE IN DANGEROUS ENVIRONMENTS. DO NOT use machinery in damp, wet locations, or

where any flammable or noxious fumes may exist.

12. KEEP WORK AREA CLEAN AND WELL LIT. Clutter and dark shadows may cause accidents.

13. USE A GROUNDED EXTENSION CORD RATED FOR THE MACHINE AMPERAGE. Undersized cords over-

heat and lose power. Replace extension cords if they become damaged. DO NOT use extension cords

for 220V machinery.

14. ALWAYS DISCONNECT FROM POWER SOURCE BEFORE SERVICING MACHINERY. Make sure switch is

in OFF position before reconnecting.

15. MAINTAIN MACHINERY WITH CARE. Keep blades sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

16. MAKE SURE GUARDS ARE IN PLACE AND WORK CORRECTLY BEFORE USING MACHINERY.

SAFETY

17. REMOVE ADJUSTING KEYS AND WRENCHES. Make a habit of checking for keys and adjusting

wrenches before turning machinery ON.

18. CHECK FOR DAMAGED PARTS BEFORE USING MACHINERY. Check for binding and alignment of

parts, broken parts, part mounting, loose bolts, and any other conditions that may affect machine

operation. Repair or replace damaged parts.

19. USE RECOMMENDED ACCESSORIES. Refer to the instruction manual for recommended accessories.

The use of improper accessories may cause risk of injury.

20. DO NOT FORCE MACHINERY. Work at the speed for which the machine or accessory was designed.

21. SECURE WORKPIECE. Use clamps or a vise to hold the workpiece when practical. A secured

workpiece protects your hands and frees both hands to operate the machine.

22. DO NOT OVERREACH. Keep proper footing and balance at all times.

23. MANY MACHINES WILL EJECT THE WORKPIECE TOWARD THE OPERATOR. Know and avoid condi-

tions that cause the workpiece to "kickback."

24. ALWAYS LOCK MOBILE BASES (IF USED) BEFORE OPERATING MACHINERY.

25. BE AWARE THAT CERTAIN DUST MAY BE HAZARDOUS to the respiratory systems of people and

animals, especially fine dust. Make sure you know the hazards associated with the type of dust you

will be exposed to and always wear a respirator approved for that type of dust.

-7-

W1677/W1711 10" Table Saw

Specific Safety Instructions for Table Saws

READ and understand this

entire instruction manual

SAFETY

1. Always use guard, splitter and anti-kickback pawls on all ''through-sawing'' operations. Through-

sawing operations are those when the blade cuts completely through the workpiece as in ripping or

crosscutting.

2. Always hold the work firmly against the miter gauge or the fence when cutting.

3. Always use a push-stick for ripping narrow stock.

4. Never perform any operation ''free-hand'' which means using only your hands to support or guide the

workpiece. Always use either the fence or the miter gauge to position and guide the work.

5. Never stand or have any part of your body in line with the path of the saw blade.

before using this machine.

Serious personal injury

may occur if safety and

operational information is

not understood and followed. DO NOT risk your

safety by not reading!

USE this and other machinery with caution

and respect. Always consider safety first,

as it applies to your individual working

conditions. No list of safety guidelines can

be complete—every shop environment is

different. Failure to follow guidelines could

result in serious personal injury, damage

to equipment or poor work results.

6. Never reach behind or over the blade with either hand for any reason.

7. Move the rip fence out of the way when crosscutting with the miter gauge.

8. Always use multiple light passes when cutting deep non-through cuts.

9. Never attempt to free a stalled saw blade without first turning the saw OFF.

10. Provide adequate support to the rear and sides of the saw table for wide or long workpieces.

11. Avoid kickbacks. A condition in which a piece of wood is thrown back towards an operator at a high

rate of speed. Usually is caused by the stock becoming trapped between the stationary face of the

rip fence and the rotating side of the saw blade. Do not operate the machine until you know what

a kickback is and how to avoid it.

12. Avoid awkward operations and hand positions where a sudden slip could cause your hand to move

into the blade.

13. Avoid cutting warped stock or stock that may contain loose knots, nails or any other defects. These

conditions may cause kickback.

-8-

W1677/W1711 10" Table Saw

Avoiding Potential Injuries

SAFETY

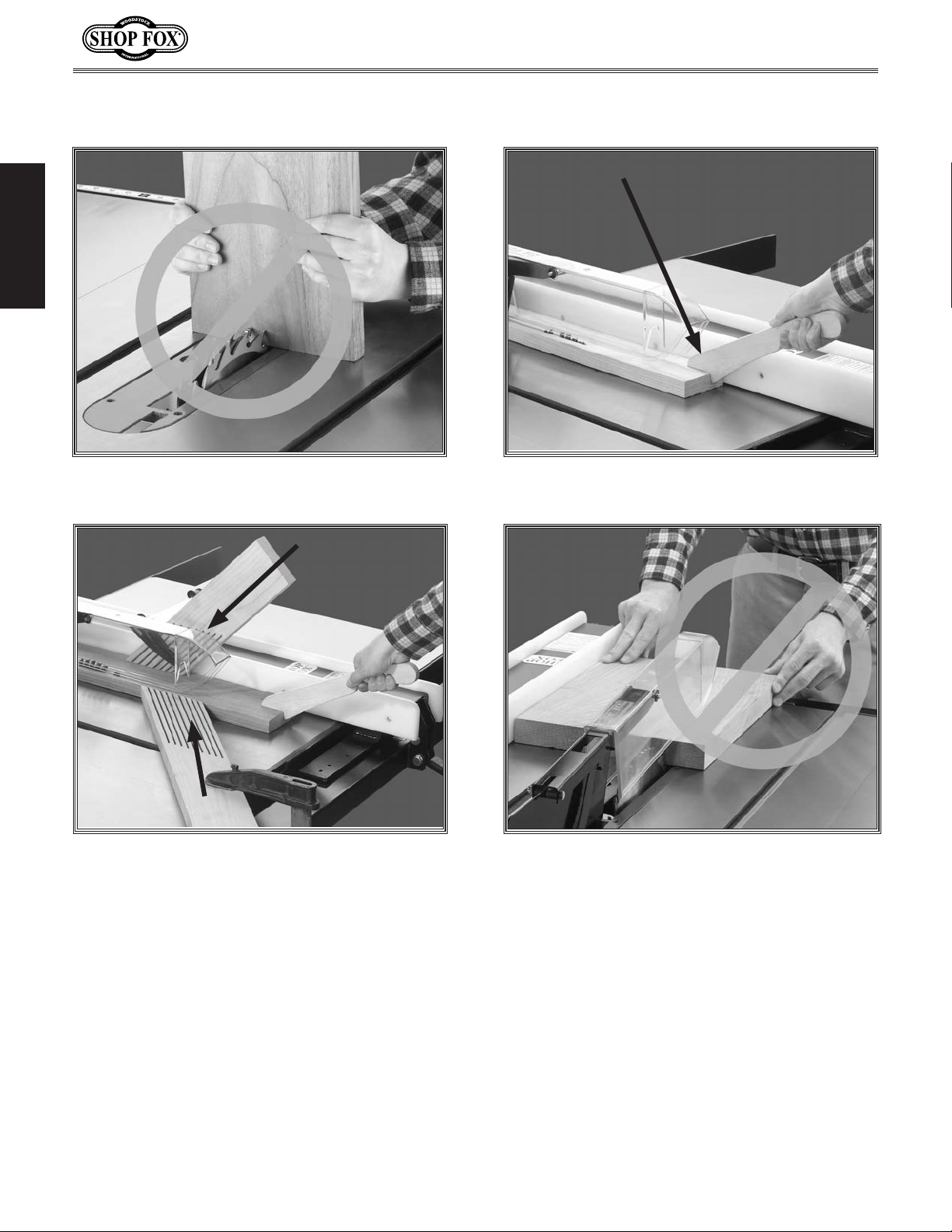

Figure 3. Unplug saw before changing blades.

Figure 4. Never use the rip fence as a guide when

cutting with the miter gauge.

Figure 5. Do not freehand cuts.

Figure 6. Do not make through cuts without the

blade guard/splitter in place.

-9-

W1677/W1711 10" Table Saw

Avoiding Potential Injuries

SAFETY

Figure 7. Do not make unstable cuts. Figure 9. Use a push stick when ripping

narrow pieces.

Figure 8. Use featherboards when possible

to protect against kickback.

Figure 10. Do not stand directly behind blade

when making a cut.

-10-

W1677/W1711 10" Table Saw

Kickback

Kickback occurs when the blade launches the workpiece toward the front of the saw. This happens so

quickly the operator rarely has time to respond. He or she can be killed, severely hurt or have his/her

hand forced into the moving blade. Kickback is one of the most serious dangers that can occur with a

table saw. In order to protect yourself from kickback, it is essential to educate yourself about why and

how it happens. Below is a list of ways to protect yourself from kickback.

SAFETY

• Do not stand directly behind the

workpiece. Should a kickback occur, the

workpiece may be launched at a high rate of

speed in the direction from which it came.

If you are standing behind the workpiece, it

will hit you. Instead, stand off to the side in

a location where you are still able to maintain total control.

• Do not use the rip fence as a guide when

crosscutting with the miter gauge. The

workpiece may pinch the blade, causing

kickback. Use the miter gauge and the rip

fence by themselves—never together.

• Only use sharp, clean blades. Sharp blades

will cut the material easier, reducing the

chance that the blade will get jammed up

while cutting the workpiece. Always replace

or sharpen your dull blades. Blades covered

in resin are just as likely to cause kickback

as a dull blade.

• Never freehand a cut with the table saw.

The small twists or turns that are inherent

with freehand cuts will cause kickback.

• Keep your table saw clean. Buildup of

wood chips or dust, or any other objects

that may obstruct an otherwise smooth cut,

has the potential to cause kickback.

• Cutting warped stock or stock with loose

knots, nails, or other defects will cause

kickback.

• Do not reach behind the blade to pull the

workpiece through the cut. In the event

of a kickback, your hand may be pulled

into the moving blade.

• Use push sticks or push paddles when-

ever possible. Using one or two push sticks

when ripping can decrease operator injury

in the event of kickback. Push sticks and

push paddles create a barrier between

your hands and the workpiece.

• Be aware that small cutoff pieces are

easily kickbacked if loose near the blade.

Use a zero-clearance table insert whenever

possible.

• Always use the blade guard/splitter

when making through-cuts. The blade

splitter has anti-kickback pawls that dig

into the workpiece in the event of a kickback. Removing the guard/splitter greatly

increases the risk of danger from kickback.

• Always feed material into the blade at

the proper feed rate. Feeding material

into the blade too fast may cause a kickback. Listen to the blade and the motor

during a cut. If either one is struggling,

decrease the feed rate.

• Consider aftermarket or shop-made

accessories to increase your level of safety. Many of these items are designed to

stop the board during a kickback or reduce

the chance of kickback by stabilizing the

board during a cut.

-11-

W1677/W1711 10" Table Saw

Common Terms

In order to increase user safety awareness and understanding, we have provided a list of common terms

associated with table saws. We will refer to many of these terms throughout this manual, so the time you

spend learning these terms will result in an increased knowledge of table saw applications.

Arbor

The shaft underneath the table on which

SAFETY

the blade mounts.

Bevel

An angled cut on the edge of a board that reaches both faces of the board.

Crosscut

To cut across the grain of a piece of stock.

Dado

A slot cut partially through the thickness of the

stock either with or against the grain.

Feed Rate

The speed at which the stock is pushed into the

moving blade.

Flush

A condition when two or more surfaces are perfectly flat and parallel to each other, so that

their touching edges have an even surface.

Kerf

The width of the material that a blade removes

from the workpiece.

Non Through-Cut

A cut that does not pass through the top of the

workpiece—i.e. a dado or rabbet cut. This type

of cut is more dangerous than a through cut

because it requires the operator to remove the

blade guard/splitter assembly.

Examples:

Dado Cutting: Page 29

Rabbet Cutting: Page 31

Resawing: Page 33

Outfeed Side

The opposite side of the table that the workpiece

is fed into the blade. Usually supplemented with

an aftermarket or shop-made table to catch a

freshly cut workpiece.

Positive Stop

A bolt or pin that can be adjusted to stop a moving part at a predetermined location. This table

saw has positive stops for tilting the blade.

Rabbet

An L-shaped cut along the edge of a workpiece.

Rip Cut

To cut along the grain of stock (see Page 27).

Kickback

The event in which the stock is ejected from the

blade at a high rate of speed toward the operator. Usually caused by binding the blade or by

a blade condition that forces the momentum of

the blade to push the stock away.

Miter Cut

An angled cut across the face or end of a board.

Usually cut to match another board of a corresponding angle so that each cut piece fits perfectly into the other, thus changing the direction of the workpiece.

Straightedge

An object with a perfectly straight edge that

is used to compare against another object to

determine whether it is straight.

Through-Cut

A cut that passes completely through the top

of the workpiece. The blade guard MUST be

installed for safest operation.

Examples:

Rip Cuts: Page 27

Crosscutting: Page 28

Miter Cuts: Page 28

Blade Tilt/Bevel Cuts: Page 27

-12-

W1677/W1711 10" Table Saw

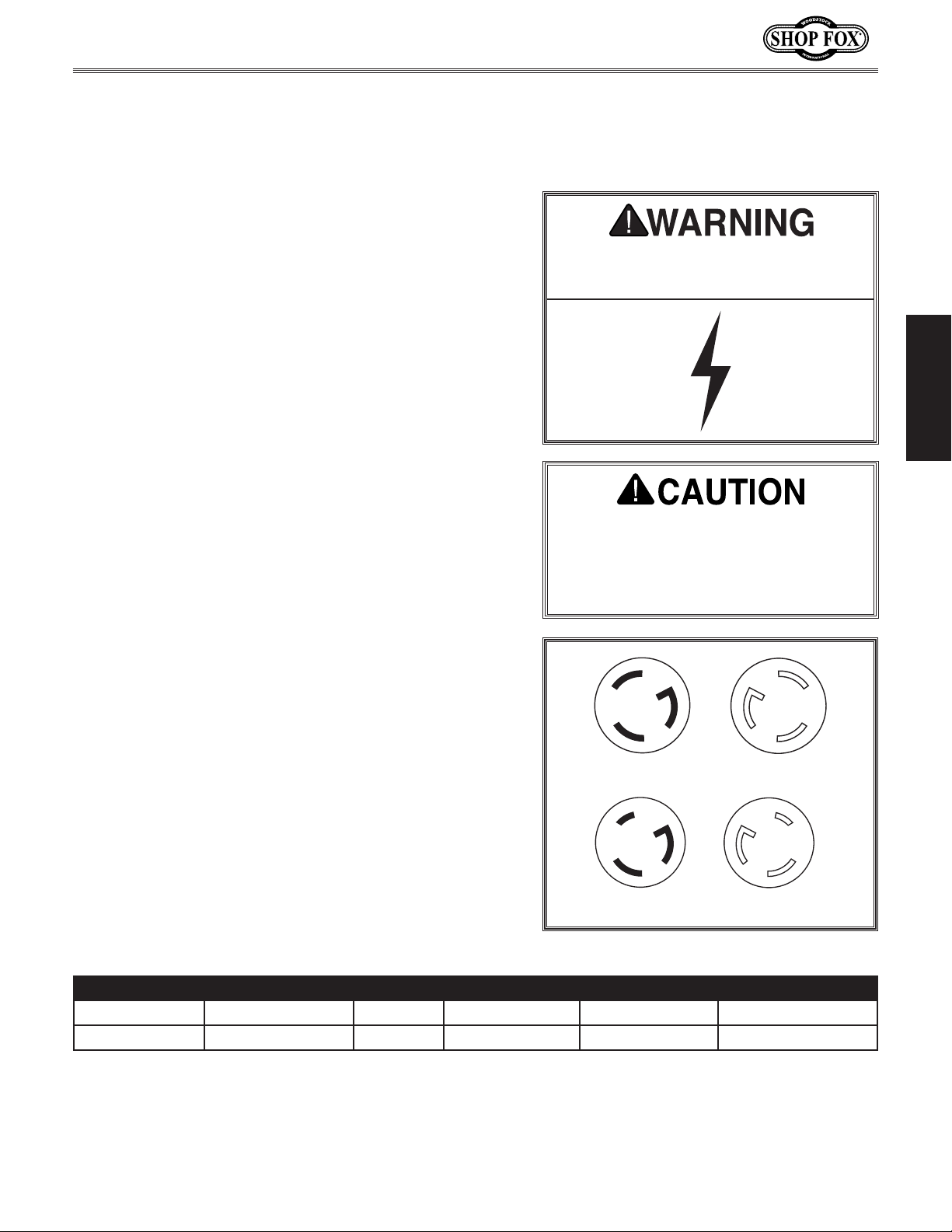

L6-20 R

ELECTRICAL

220V Operation

The Model W1677/W1711 is prewired for 220V operation.

Always connect this machine to a dedicated circuit with a

verified ground, using the recommended circuit size and

power connection method stated below.

Never replace a circuit breaker with one of higher amperage without consulting a qualified electrician to ensure

compliance with wiring codes. If you are unsure about

the wiring codes in your area or plan to connect your

machine to a shared circuit, you may create a fire hazard—consult a qualified electrician to reduce this risk.

Extension Cords

We do not recommend using an extension cord with your

machine. If you have no other choice, use the following

guidelines:

• Use cords rated for Standard Service

• Never exceed a length of 50 feet

• Ensure cord has a ground wire and pin

• Do not use cords in need of repair

Electrocution or severe shock could

occur if machine is not grounded.

ELECTRICAL

Replacing an existing circuit breaker

with one rated for higher amperage

may result in a fire. Get help from an

electrician if your circuit is too small

for the machine.

Grounding

This machine must be grounded! Verify that any existing electrical outlet and circuit you intend to plug into

is actually grounded. If it is not, it will be necessary to

run a separate copper grounding wire, of the appropriate size, from the outlet to a known ground. Under no

circumstances should you connect your machine to an

ungrounded power source or electrocution or severe

shock could occur.

Figure 11. Plug & receptacle examples.

Model Operating Voltage Amp Draw Min. Circuit Size Plug/Receptacle Extension Cord

W1677 Series 220V 18 Amps 20A NEMA L6-20 12 Gauge

W1711 S er ie s 220V 25 Amps 30A NEMA L6-30 8 Gauge

-13-

L6-20 P

L6-30 P

L6-30 R

SETUP

Unpacking

Your new table saw has been carefully packaged for safe

transporting. When unpacking, remove the red shipping

braces that hold the saw to the pallet. If you notice the

machine has been damaged, please contact your authorized SHOP FOX

The following is a description of the main components

shipped in the table saw box. Lay the components out

to inventory them. Note: Some parts and hardware may

already be installed on the machine. Make sure to check

the machine when you use this inventory list.

®

dealer immediately.

Inventory

W1677/W1711 10" Table Saw

A

Box Inventory (Figures 12 & 13) Qty

A. Saw Base Unit ..............................................1

B. Extension Wings ............................................2

SETUP

C. Cabinet Cover ..............................................1

D. Lock Knob ...................................................1

E. Handwheel ..................................................1

F. Miter Gauge ................................................1

G. Blade Guard/Splitter ................................ ......1

H. Dado Table Insert ..........................................1

I. Standard Table Insert .....................................1

J. Dust Port ....................................................1

K. Arbor Wrench...............................................1

L. Support Shaft ...............................................1

M. Blade Guard Brackets .....................................2

N. Handwheel Handle ........................................1

O. Switch Support Bracket ...................................1

Hardware and Tools Qty

5

• Flat Head Screw

• Flat Washer

5

• Hex Nut

⁄16"-18 (Switch Bracket) .......................1

• Tap Screws 10-24 x

• Set Screws

• Hex Bolt

5

5

⁄16"-18 x 11⁄2" (Brackets on Shaft) ..........2

• Flat Washers

• Lock Washers

5

• Hex Nuts

• Hex Bolts

⁄16"-18 (Brackets on Shaft) ..................2

5

⁄16"-18 x 1" (Guard/Splitter Install) .......2

• Flat Washers

⁄16"-18 x 1" (Switch Bracket) .......1

5

⁄16" (Switch Bracket) ......................1

3

⁄8" (Dust Port) .....................4

⁄16"-18 x 3⁄8" (Brackets on Shaft) .........2

5

⁄16" (Brackets on Shaft) ..................4

5

⁄16" (Brackets on Shaft) .................2

5

⁄16" (Guard/Splitter Install) .............2

• Hex Wrenches 3, 4, 8mm .........................1 each

• Flat Wrench ................................................1

Figure 12. Saw base unit.

C

B

F

G

H

J

K

M

L

I

O

Figure 13. Table saw loose parts.

D

E

N

-14-

W1677/W1711 10" Table Saw

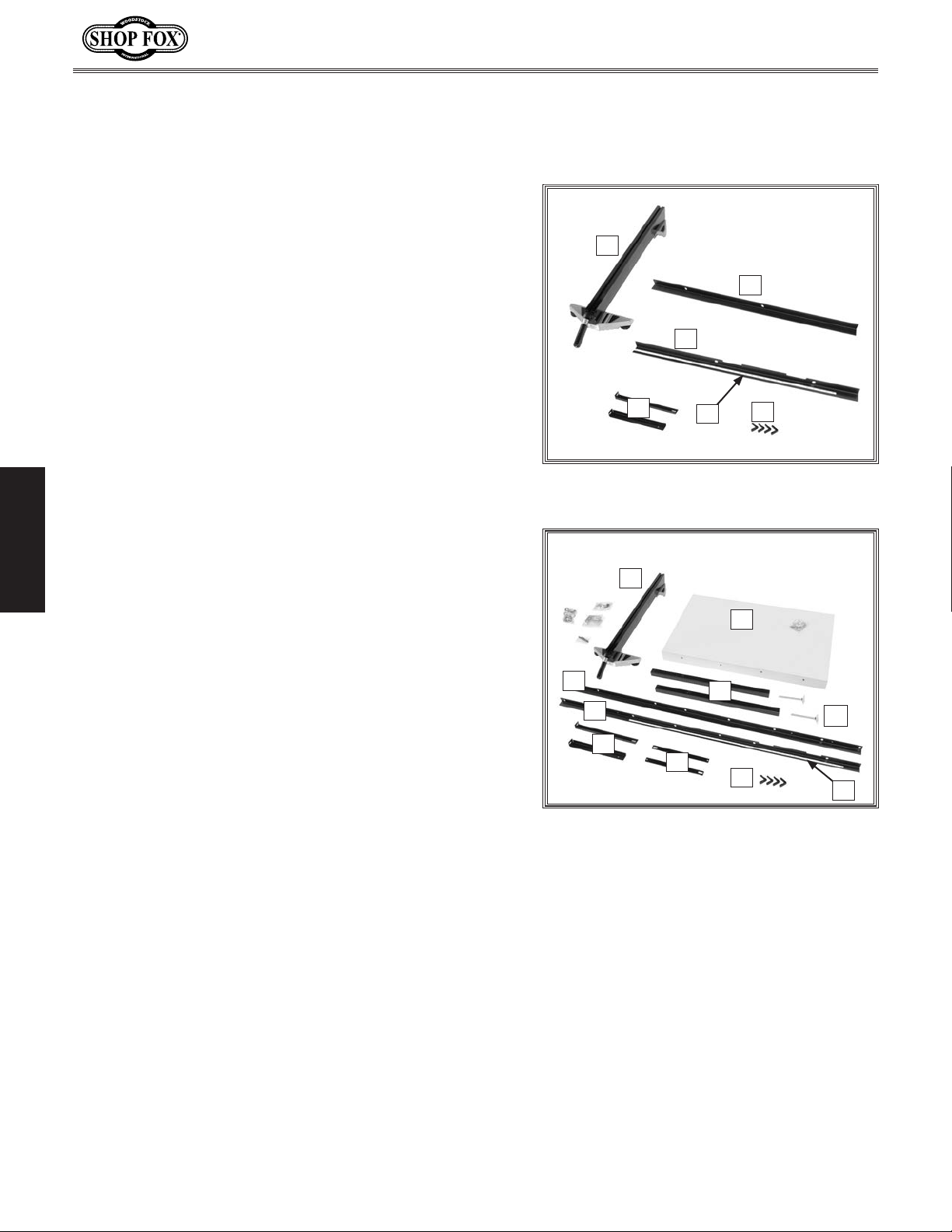

Shop Fox Classic Fence

Inventory

Depending on which model you purchased, your saw will

come with standard length rails or with long rails. The

Shop Fox Classic fence includes extra hardware for mounting it to other brands of table saws.

The inventory list below and Figures 14 & 15 show only

the hardware needed to mount the fence to your saw. To

avoid confusion, we suggest removing any items not listed

here from your immediate work area.

C

B

D

A

E

Inventory Needed for Your Saw

Standard Rails (Figure 14): Qty

A. Fence Assembly ............................................1

B. Front Rail 46

C. Back Rail 46

D. Front Rail Rectangular Tube 54" .........................1

E. Scale .........................................................1

Long Rails (Figure 15): Qty

A. Front Rail Rectangular Tube 84" .........................1

B. Extension Table ............................................1

C. Legs ..........................................................2

D. Feet ..........................................................2

E. Front Rail 72"...............................................1

F. Back Rail 72" ...............................................1

G. Fence Assembly ............................................1

H. Leg Braces ..................................................2

I. Scale .........................................................1

Common Rail/Table Mounting Hardware:

• Hex Bolts

• Flat Washers

• Hex Bolts

• Flat Washers

1

⁄2" ...........................................1

1

⁄2" ............................................1

3

⁄8-16 x 1" (Rail/Table) ........... 4

3

⁄8" (Rail/Table) ............... 4

1

⁄4-20 x 3⁄4" (Rail/Tube) .......... 4

1

⁄4" (Rail/Tube) ................ 4

Figure 14. Classic fence inventory for

standard rails.

A

B

E

F

G

H

Figure 15. Classic fence inventory for long

rails.

Additional Hardware Only for Long Rail Setup:

1

• Hex Bolts

• Flat Washers

• Hex Bolts

• Flat Washers

• Hex Nuts

• Hex Nuts

• Wood Screws

• Fender Washers

• Hex Bolts

• Flat Washers

• Flat Washers

• Wood Screws #8 x

⁄4-20 x 3⁄4" (Rail/Tube) .......... 3

1

⁄4" (Rail/Tube) ................ 3

3

⁄8"-16 x 13⁄4" (Rail/Ext Table) .. 8

3

⁄8" (Rail/Ext Table) ......... 16

3

⁄8"-16 (Rail/Ext Table) ........... 8

1

⁄2" (Feet Jam Nuts) ............... 2

1

⁄4" x 3⁄4" (Brace/Ext Table) . 2

1

3

⁄8"-16 x 3⁄4" (Brace/Leg) ........ 2

⁄4" (Brace/Ext Table) ..... 2

3

⁄8" (Brace/Leg) ............... 2

3

⁄8" (Spacers for Brace/Leg) . 8

3

⁄4" (Leg/Ext Table) ... 12

C

SETUP

D

I

-15-

Shop Fox Original Fence

Inventory

Depending on which model you purchased, your saw will

come with standard length rails or long rails. The Shop

Fox Original fence includes extra hardware for mounting it

to other brands of table saws.

W1677/W1711 10" Table Saw

A

The inventory list below and Figures 16 & 17 show only

the hardware needed to mount the fence to your saw. To

avoid confusion, we suggest removing any items not listed

here from your immediate work area. The hardware list

below is categorized by application.

Inventory Needed for Your Saw

Standard Rails (Figure 16): Qty

A. Shop Fox Original Fence ..................................1

B. Front Rail ...................................................1

C. Rear Rail ....................................................1

D. Scale .........................................................1

E. End Braces ..................................................2

SETUP

F. Rail End Covers ............................................4

Long Rails (Figure 17): Qty

A. Shop Fox Original Fence ..................................1

B. Extension Table ............................................1

C. Legs ..........................................................2

D. Feet ..........................................................2

E. Front Rail 72"...............................................1

F. Back Rail 72" ...............................................1

G. Scale .........................................................1

H. End Braces ..................................................2

I. Table Leg Braces ...........................................2

J. Rail End Covers ............................................4

Common Rail/Table Mounting Hardware:

• Hex Bolts

• Low Profile Hex Bolts

(F Rail/Main Table) ............................ 2

• Flat Washers

• Hex Bolts

• Flat Washers

• Hex Nuts

• Flat Hd Screw

• Flat Washer

• Hex Nut

• Fence Stop ......................................1

• Phlp Hd Screw 10-24 x 5/8" .................. 1

• Flat Washer #10 ................................ 1

3

⁄8-16 x 1" (R Rail/Main Table) .. 2

3

⁄8" (Rail/Main Table) ......... 8

3

⁄8-16 x 1" (End Braces) .......... 2

3

⁄8" (End Braces) ............... 2

3

⁄8"-16 (End Braces) ............... 2

1

⁄4"-20 x 5⁄8" (End Braces) .. 1

1

⁄4" (End Braces) ................ 1

1

⁄4"-20 (End Braces) ................ 1

3

⁄8-16 x 1"

B

C

E

D

F

Figure 16. Original fence inventory for

standard fence rails.

A

B

E

C

F

H

I

J

Figure 17. Original fence inventory for

long fence rails.

Additional Hardware Only for Long Rails:

3

• Hex Bolts

• Flat Washers

• Hex Nuts

• Hex Nuts

• Wood Screws

• Fender Washers

• Hex Bolts

• Flat Washers

• Flat Washers

• Wood Screws #8 x

⁄8"-16 x 13⁄4" (Rail/Ext Table) .. 8

3

⁄8" (Rail/Ext Table) ......... 16

3

⁄8"-16 (Rail/Ext Table) ........... 8

1

⁄2" (Feet Jam Nuts) ............... 2

1

⁄4" x 3⁄4" (Brace/Ext Table) . 2

1

3

⁄8"-16 x 3⁄4" (Brace/Leg) ........ 2

⁄4" (Brace/Ext Table) ..... 2

3

⁄8" (Brace/Leg) ............... 2

3

⁄8" (Spacers for Brace/Leg) . 8

3

⁄4" (Leg/Ext Table) ... 12

D

G

-16-

W1677/W1711 10" Table Saw

Machine Placement

• Floor Load: This machine distributes a

heavy load in a small footprint. Some floors

may require additional bracing to support

both machine and operator.

• Working Clearances: Consider the following

when establishing a location for your

machine:

— Existing and anticipated needs

— Size of material to be processed

— Space for auxiliary stands, work tables or

other machinery

— Room to perform maintenance inside the

cabinet.

• Lighting: Lighting should be bright enough

to eliminate shadow and prevent eye strain.

• Electrical: Electrical circuits must be

dedicated or large enough to handle

amperage requirements. Outlets must be

located near each machine, so high-traffic

areas are clear of power cords. Follow local

electrical codes for proper installation of

new lighting, outlets, or circuits.

USE helpers or power

lifting equipment to lift

this machine. Otherwise,

serious personal injury

may occur.

Cleaning Machine

The unpainted parts of your machine type are

coated with a shipping grease that protects

them from corrosion during shipment. This coating does its job well, but requires a little elbow

grease to remove.

The shipping grease can be cleaned off with a

solvent, petroleum or citrus-based degreaser.

DO NOT use chlorine-based solvents such as

brake parts cleaner or acetone—if you happen

to splash some onto a painted surface, you will

ruin the finish.

Here is one easy and popular method for cleaning the shipping grease: Soak the grease in

WD-40

scrape most of the grease off with a plastic

putty knife or other straight edge that won't

scratch the cast iron, re-soak, then wipe down

with a shop rag.

®

or a similar product, wait five minutes,

NEVER use gasoline or

other petroleum-based

solvents to clean with.

Most have low flash

points, which make them

extremely flammable.

A risk of explosion and

burning exists if these

products are used. Serious

personal injury may occur

if this warning is ignored!

SETUP

MAKE your shop “child

safe.” Ensure that your

workplace is inaccessible

to youngsters by closing

and locking all entrances

when you are away. NEVER

allow untrained visitors in

your shop when assembling, adjusting or operating equipment.

ALWAYS work in wellventilated areas far from

possible ignition sources

when using solvents to

clean machinery. Many

solvents are toxic when

inhaled or ingested. Use

care when disposing

of waste rags and

towels to be sure they

DO NOT create fire or

environmental hazards.

-17-

Mobile Base

If your model includes a mobile base kit, or you plan to

use an aftermarket mobile base kit for your saw, we recommend assembling the saw on the mobile base to avoid

heavy/awkward lifting later.

Assemble your mobile base equipment as detailed in

the instructions included with the mobile base, then put

the saw base unit on the mobile base before continuing

assembly.

Assembly

W1677/W1711 10" Table Saw

You can mount the extension wings yourself, but it is

easier with help.

Note: If you have a model with long rails and an extension table, leave the right wing off to make room for the

extension table.

To assemble your table saw, do these steps:

SETUP

1. Using the fasteners that come pre-installed in the

table, attach the extension wings to the table, as

shown in Figure 18. Do not completely tighten the

bolts at this point.

2. Place a straightedge across the table and the extension wings, and adjust each wing until it is flush

with the table, then tighten the bolts underneath to

secure the wing in place.

3. Check the overall flatness of the table and extension wing assembly with a straightedge, as shown in

Figure 19.

Figure 18. Extension wing attached to

table.

Figure 19. Checking overall table flatness

with a straightedge.

Note: If an extension wing tilts up or down at the

outside edges, shim it with masking tape or shim

stock (refer to Shimming Wings on Page 42).

4. Attach the switch bracket to the backside of the

left extension wing with the

head screw,

in Figure 20.

5

⁄16" flat washer, and 5⁄16" nut, as shown

5

⁄16"-18 x 1" Phillips flat

-18-

Figure 20. Attaching switch to extension

wing.

Loading...

Loading...