Shop fox W1690 User Manual

MODEL W1690

DELUXE CEILING-MOUNTED

AIR FILTER

OWNER'S MANUAL

(FOR MODELS MANUFACTURED SINCE 02/03)

Phone: (360) 734-3482 • Online Technical Support: techsupport@woodstockint.com

COPYRIGHT © FEBRUARY, 2003 BY WOODSTOCK INTERNATIONAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

V1.12.16

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

#4946CR Printed in China

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property

damage from negligence, improper training, machine modifications or

misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

TABLE OF CONTENTS

PAGE

INTRODUCTION ............................................................................................................. 2

Woodstock Service and Support ........................................................................................... 2

Warranty and Returns ...........................................................................................................3

Specifications ............................................................................................................ 3

SAFETY .......................................................................................................................... 4

Additional Safety Instructions for Air Filters ..........................................................................6

ELECTRICAL .................................................................................................................. 7

110V Operation .....................................................................................................................7

Extension Cords ....................................................................................................................7

Grounding ..............................................................................................................................7

About Your New Deluxe Ceiling-Mounted Air Filter ..............................................................2

Standard Safety Instructions ..............................................................................................4-5

INTRODUCTION

SAFETY

ELECTRICAL

INSTALLATION ............................................................................................................... 8

Unpacking ..............................................................................................................................8

Box Contents .........................................................................................................................8

Shop Preparation ...................................................................................................................9

Dust System ..........................................................................................................................9

Beginning .............................................................................................................................10

Table-Top Mount .................................................................................................................10

Hanging Mount ....................................................................................................................11

Flush Mount .........................................................................................................................12

Overview ..............................................................................................................................13

Control Panel .......................................................................................................................13

Remote Control ...................................................................................................................13

Troubleshooting ...................................................................................................................14

Filters ...................................................................................................................................15

OPERATION ................................................................................................................. 13

MAINTENANCE ............................................................................................................ 15

INSTALLATION

OPERATION

MAINTENANCE

CLOSURE ..................................................................................................................... 16

Parts Breakdown and Parts List .....................................................................................17-18

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

-

1-

PARTS

INTRODUCTION

INTRODUCTION

Your new SHOP FOX® Model W1690 Deluxe Ceiling-Mounted Air Filter has been specially designed to

provide many years of trouble-free service. Close attention to detail, ruggedly built parts and a rigid

quality control program assure safe and reliable operation.

When used in conjunction with a dust collector system, the W1690 Deluxe Ceiling-Mounted Air Filter

efficiently removes fine wood particles in the air that many dust collectors cannot. Your unit has

key features like a 5-micron outer filter, a washable 1-micron inner filter, three fan speeds, 110V

operation, remote control functions, and a compact design. For further features and details, refer to

the Specifications section on Page 3.

Woodstock International, Inc. is committed to customer satisfaction in providing this manual. It is our

intent to include all the information necessary for safety, ease of assembly, practical use and durability

of this product.

If you need the latest edition of this manual, you can download it from http://www.shopfox.biz.

If you still have questions after reading the latest manual, or if you have comments please contact us at:

About Your New Deluxe

Ceiling-Mounted Air Filter

Woodstock International, Inc.

Attn: Technical Support Department

P.O. Box 2309

Bellingham, WA 98227

Woodstock Service and Support

We stand behind our machines! In the event that a defect is found, parts are missing or questions arise

about your machine, please contact Woodstock International Service and Support at 1-360-734-3482 or

send e-mail to: tech-support@shopfox.biz. Our knowledgeable staff will help you troubleshoot problems,

order parts or arrange warranty returns.

-2-

Warranty and Returns

Woodstock International, Inc. warrants all SHOP FOX® machinery to be free of defects from workmanship

and materials for a period of 2 years from the date of original purchase by the original owner. This

warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents,

lack of maintenance, or to repairs or alterations made or specifically authorized by anyone other than

Woodstock International, Inc.

INTRODUCTION

INTRODUCTION

Woodstock International, Inc. will repair or replace, at its expense and at its option, the

machine or machine part which in normal use has proven to be defective, provided that the original

owner returns the product prepaid to the

designated by our Bellingham, WA office, with proof of their purchase of the product within 2 years,

and provides Woodstock International, Inc. reasonable opportunity to verify the alleged defect through

inspection. If it is determined there is no defect, or that the defect resulted from causes not within the

scope of Woodstock International Inc.'s warranty, then the original owner must bear the cost of storing

and returning the product.

This is Woodstock International, Inc.'s sole written warranty and any and all warranties that may be

implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited

to the duration of this written warranty. We do not warrant that

with the provisions of any law or acts. In no event shall Woodstock International, Inc.'s liability under

this warranty exceed the purchase price paid for the product, and any legal actions brought against

Woodstock International, Inc. shall be tried in the State of Washington, County of Whatcom. We shall

in no event be liable for death, injuries to persons or property or for incidental, contingent, special or

consequential damages arising from the use of our products.

Every effort has been made to ensure that all

standards. We reserve the right to change specifications at any time because of our commitment to

continuously improve the quality of our products.

SHOP FOX

®

factory service center or authorized repair facility

SHOP FOX

SHOP FOX

®

machinery meets high quality and durability

®

machinery complies

SHOP FOX

®

Specifications

Motor ...............................................1⁄5 HP, 115V, 60 Hz, 1200 RPM, Single-Phase

1

Motor Amperage ..................................HI = 3 Amps, MID = 2

Motor Low Speed ..............................................................................750 RPM

Motor Medium Speed ..................................................................... 960 RPM

Motor High Speed .........................................................................1200 RPM

Fan Low Speed Sound Rating ................................................................... 62 dB

Fan Medium Speed Sound Rating ...........................................................67 dB

Fan High Speed Sound Rating ...............................................................69 dB

Air Flow at Low Speed .................................................................... 556 CFM

Air Flow at Medium Speed ............................................................... 702 CFM

Air Flow at High Speed .................................................................. 1044 CFM

Primary Filter .............................................................................. 5-Micron

Secondary Filter ........................................................................... 1-Micron

Unit Dimensions (L x W x H) ................................................ 30

Shipping Weight .......................................................................................................64 lbs.

Installed Weight .................................................................................55 lbs.

-3-

⁄2 Amps, LO = 2 Amps

1

⁄4" x 241⁄8" x 121⁄8"

SAFETY

READ MANUAL BEFORE OPERATING MACHINE.

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

RESULT IN PERSONAL INJURY.

SAFETY

1. Thoroughly read the instruction manual before operating your machine. Learn the applications,

2. Keep work area clean and well lit. Clutter and inadequate lighting invite potential hazards.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury.

This symbol is used to alert the user to useful information about proper

NOTICE

operation of the equipment, and/or a situation that may cause damage

to the machinery.

Standard Safety Instructions

limitations and potential hazards of this machine. Keep manual in a safe, convenient place for future

reference.

3. Ground all tools. If a machine is equipped with a three-prong plug, it must be plugged into a

three-hole grounded electrical receptacle or grounded extension cord. If using an adapter to aid in

accommodating a two-hole receptacle, ground using a screw to a known ground.

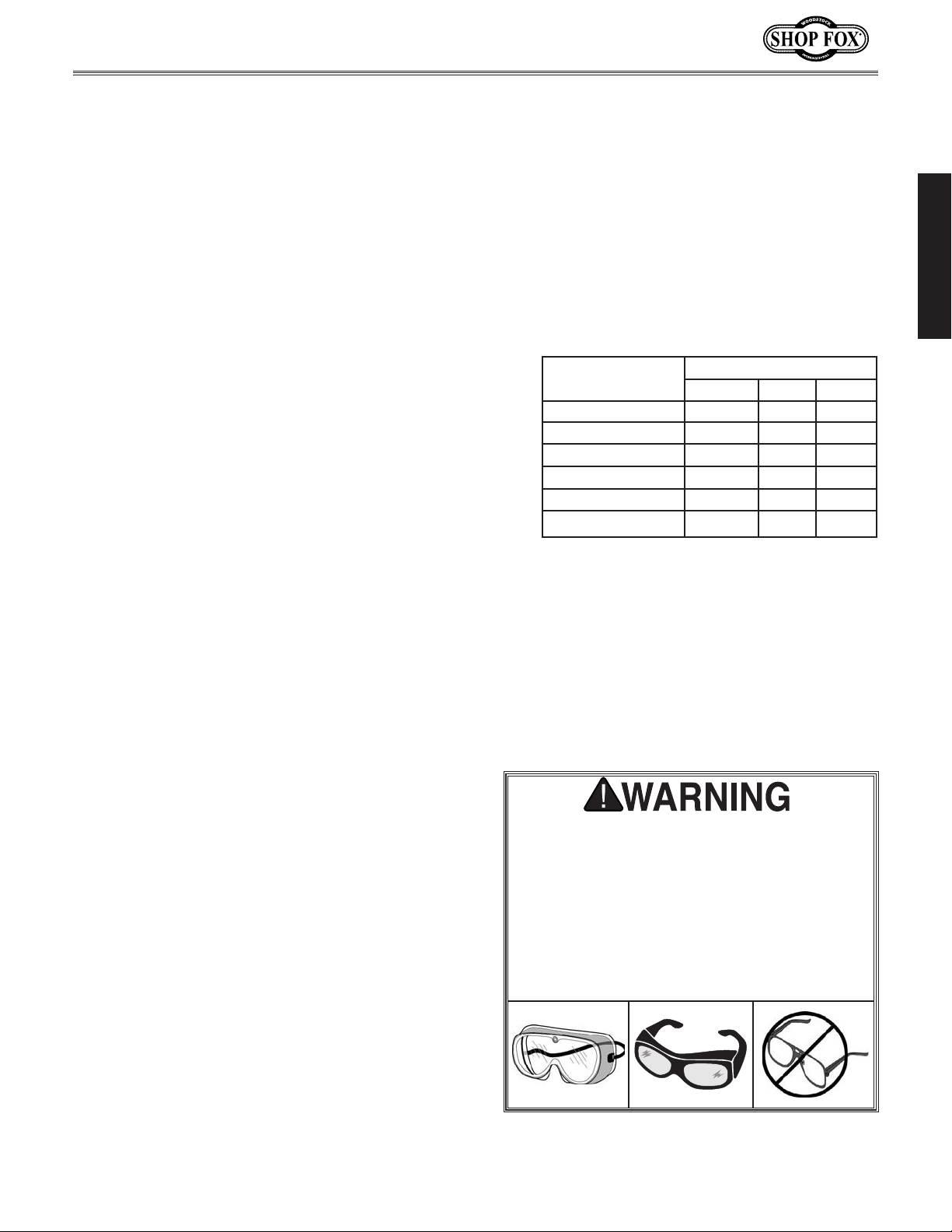

4. Wear eye protection at all times. Use safety glasses with side shields or safety goggles that meet

the appropriate standards of the American National Standards Institute (ANSI).

5. Avoid dangerous environments. DO NOT operate this machine in wet or open flame environments.

Airborne dust particles could cause an explosion and severe fire hazard.

6. Ensure all guards are securely in place and in working condition.

7. Make sure the machine power switch is in the OFF position before connecting power to

machine.

8. Keep the work area clean, free of clutter, grease, etc.

9. Keep children and visitors away. Visitors should be kept at a safe distance while operating unit.

10. Childproof your workshop with padlocks, master switches or by removing starter keys.

11. Stop and disconnect the machine when cleaning, adjusting or servicing.

-4-

12. DO NOT force tool. The machine will do a safer and better job at the rate for which it was

designed.

13. Use correct tool. Do not force machine or attachment to do a job for which it was not designed.

14. Wear proper apparel. Do not wear loose clothing, neck ties, gloves, jewelry, and secure long hair

away from moving parts.

15. Remove adjusting keys, rags, and tools. Before turning the machine on, make it a habit to check

that all adjusting keys and wrenches have been

removed.

16. Avoid using an extension cord. But if you must,

examine the extension cord to ensure it is in good

condition. Use

length and gauge of extension cord needed for your

particular needs. The amp rating of the motor can be

found on its nameplate. If the motor is dual voltage,

be sure to use the amp rating for the voltage you

will be using. If you use an extension cord with an

undersized gauge or one that is too long, excessive

heat will be generated within the circuit, increasing

the chance of a fire or damage to the circuit.

Always use an extension cord that uses a ground pin

and connected ground wire. Immediately replace a

damaged extension cord.

17. Keep proper footing and balance at all times.

TABLE 1 to determine the correct

Extension Cord Requirements

TABLE 1

Length and Gauge

Amp Rating 25ft 50ft 100ft

0-6 #16 #16 #16

7-10 #16 #16 #14

11-12 #16 #16 #14

13-16 #14 #12 #12

17-20 #12 #12 #10

21-30 #10 #10 No

SAFETY

18.DO NOT leave machine unattended. Wait until it comes to a complete stop before leaving the

area.

19. Perform machine maintenance and care. Follow lubrication and accessory attachment instructions

in the manual.

20. Keep machine away from open flame. Operating

machines near pilot lights and/or open flames

creates a high risk if dust is dispersed in the

area. Dust particles and an ignition source may

cause an explosion. Do not operate the machine

in high-risk areas, including but not limited to,

those mentioned above.

21. If at any time you are experiencing difficulties

performing the intended operation, stop using

the machine! Contact our service department or

ask a qualified expert how the operation should

be performed.

22. Habits—good and bad—are hard to break.

Develop good habits in your shop and safety will

become second-nature to you.

Always wear safety glasses or goggles

when operating equipment. Operating this

equipment creates the potential for flying

debris that can cause eye injury. Everyday

glasses or reading glasses only have impact

resistant lenses, they are not safety glasses.

Be certain the safety glasses you wear meet

the appropriate standards of the American

National Standards Institute (ANSI).

-5-

Additional Safety for Air Filters

INTENDED USE. This air filter is designed

SAFETY

HAZARDOUS DUST. Dust exposure may cause

LEAD PAINT DUST AND ASBESTOS FIBERS. DO

to capture dust from ambient air in a

woodworking shop for a short time after

cutting or sanding operations. DO NOT use

this air filter to collect particles of silica,

metal, lead paint, asbestos, or hazardous

bacterium. DO NOT allow this filter to collect

liquids, combustible fumes, burning or

smoking material, or toxic fumes.

cancer, birth defects, or long-term respiratory

damage. Be aware of the dust hazards

associated with each workpiece material, and

always wear a NIOSH-approved respirator to

reduce your risk.

NOT try to collect lead paint or asbestos

fibers with this machine. Due to the high

hazard to human health, these materials must

be collected with special equipment.

DISCONNECTING POWER SUPPLY. Turn the

switch OFF, disconnect the air filter from the

power supply, and allow the impeller to come

to a complete stop before leaving the machine

unattended or doing any service, cleaning,

maintenance, or adjustments.

REGULAR CLEANING. For best performance,

regularly check/clean the filters to avoid the

buildup of fine dust. Make sure to regularly

clean the surrounding area where the machine

is operated—excessive dust buildup on

overhead lights, heaters, electrical panels,

or other heat sources will increase the risk of

fire.

SUSPENDED DUST PARTICLES AND IGNITION

SOURCES. DO NOT operate the air filter in

areas where explosion risks are high. Areas

of high risk include, but are not limited to,

areas near pilot lights, open flames, or other

ignition sources.

DUST ALLERGIES. Dust from certain woods

may cause an allergic reaction in people and

animals. Make sure you know what type of

wood dust you will be exposed to in case

there is a possibility of an allergic reaction.

WEAR RESPIRATOR. Fine dust that is too small

to be caught in the filter will be blown into

the ambient air during operation. Wearing a

NIOSH approved respirator during this time

will reduce your risk of permanent respiratory

damage.

EMPTYING DUST. When removing dust from the

filters, turn OFF the switch, disconnect power,

and wear a respirator and safety glasses.

Empty dust away from ignition sources and

into an approved container.

USE this and other machinery with caution and respect. Always consider safety first, as it applies

to your individual working conditions. No list of safety guidelines can be complete—every shop

environment is different. Failure to follow guidelines could result in serious personal injury, damage to equipment or poor work results.

FIRE SUPPRESSION. Only operate the air filter

in locations that contain a fire suppression

system or have a fire extinguisher nearby.

IMPELLER HAZARDS. DO NOT place your hands

or tools inside the air filter housing during

operation for any reason. The powerful

suction could easily cause accidental contact

with the impeller which could cause serious

personal injury or damage to the machine.

OPERATING LOCATION. DO NOT operate the air

filter in rainy or wet locations—exposure to

water may create a shock hazard or decrease

the life of the machine.

-6-

Loading...

Loading...