Sharp XLMP-150-E, XLMP-150-H Service manual

XL-MP150H/MP150E

SERVICE MANUAL

No. S3525XLMP150H

MICRO COMPONENT SYSTEM

Illustration XL-MP150H

Illustration XL-MP150E

(XL-MP150H Only)

(XL-MP150H Only)

CONTENTS

PRECAUTIONS FOR USING LEAD-FREE SOLDER

CHAPTER 1. GENERAL DESCRIPTION

[1] SAFETY PRECAUTION FOR SERVICE

MANUAL........................................................1-1

[2] IMPORT ANT SERVICE NOTES (FOR U.K.

ONLY)............................................................1-2

[3] SPECIFICATIONS.........................................1-2

[4] NAMES OF PARTS.......................................1-4

CHAPTER 2. ADJUSTMENTS

[1] ADJUSTMENT ..............................................2-1

[2] TEST MODE..................................................2-2

[3] Standard Specification of Stereo System

Error Message Display Contents...................2-4

CHAPTER 3. MECHANICAL DESCRIPTION

[1] REMOVING AND REINSTALLING THE

MAIN PARTS.................................................3-1

[2] DISASSEMBLY.............................................3-3

CHAPTER 4. DIAGRAMS

[1] BLOCK DIAGRAM.........................................4-1

MODEL

XL-MP150H Micro Component System consisting of XLMP150H (main unit) and CP-MP150H (speaker system).

MODEL

XL-MP150E Micro Component System consisting of XLMP150E (main unit) and CP-MP150E (speaker system).

• In the interests of user-safety the set should be restored to its original condition and only parts identical to those specified be used.

• Note for users in U.K.

Recording and playback of any material may require consent which

SHARP is unable to give. Please refer particularly to the provisions

of Copyright Act 1956, the Dramatic and Musical Performers Protection Act 1956, the Performers Protection Acts 1963 and 1972

and to any subsequent statutory enactments and orders.

CHAPTER 5. CIRCUIT DESCRIPTION

[1] WAVEFORMS OF CD CIRCUIT.................... 5-1

[2] VOLTAGE.......................................................5-2

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] NOTES ON SCHEMATIC DIAGRAM.............6-1

[2] TYPES OF TRANSISTOR AND LED.............6-1

[3] WIRING SIDE OF PWB/SCHEMATIC DIA-

GRAM ............................................................6-2

CHAPTER 7. FLOWCHART

[1] TROUBLESHOOTING...................................7-1

CHAPTER 8. OTHERS

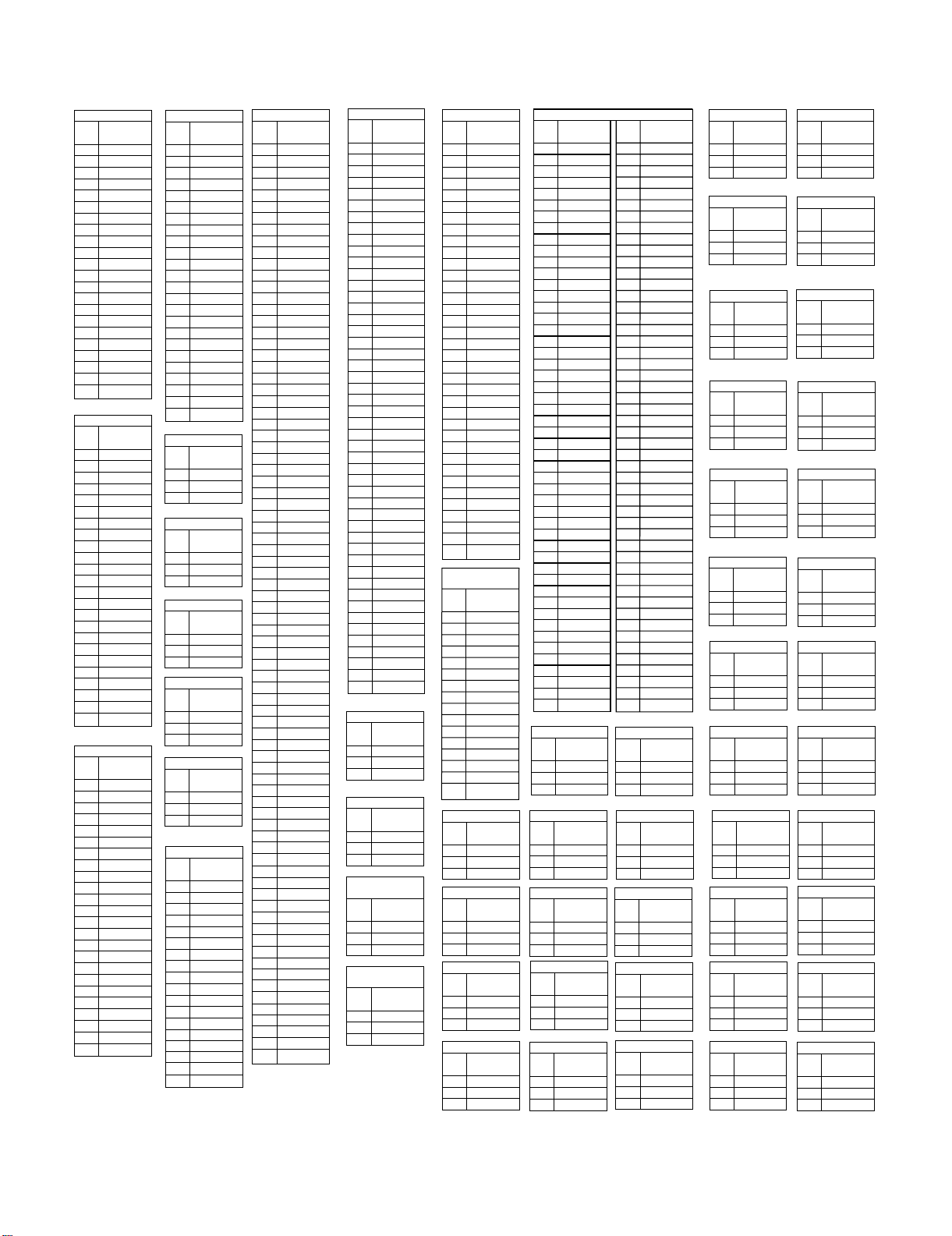

[1] FUNCTION TABLE OF IC..............................8-1

[2] FL DISPLAY..................................................8-11

[3] WIRING OF PRIMARILY SUPPLY LEADS

(FOR U.K. ONLY)................... ... .... ... ... ......... 8-12

Parts Guide

XL-MP150H

XL-MP150E

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

XL-MP150H/MP150E

AudioXL-MP150H/MP150EService ManualXLMP150HMarketE

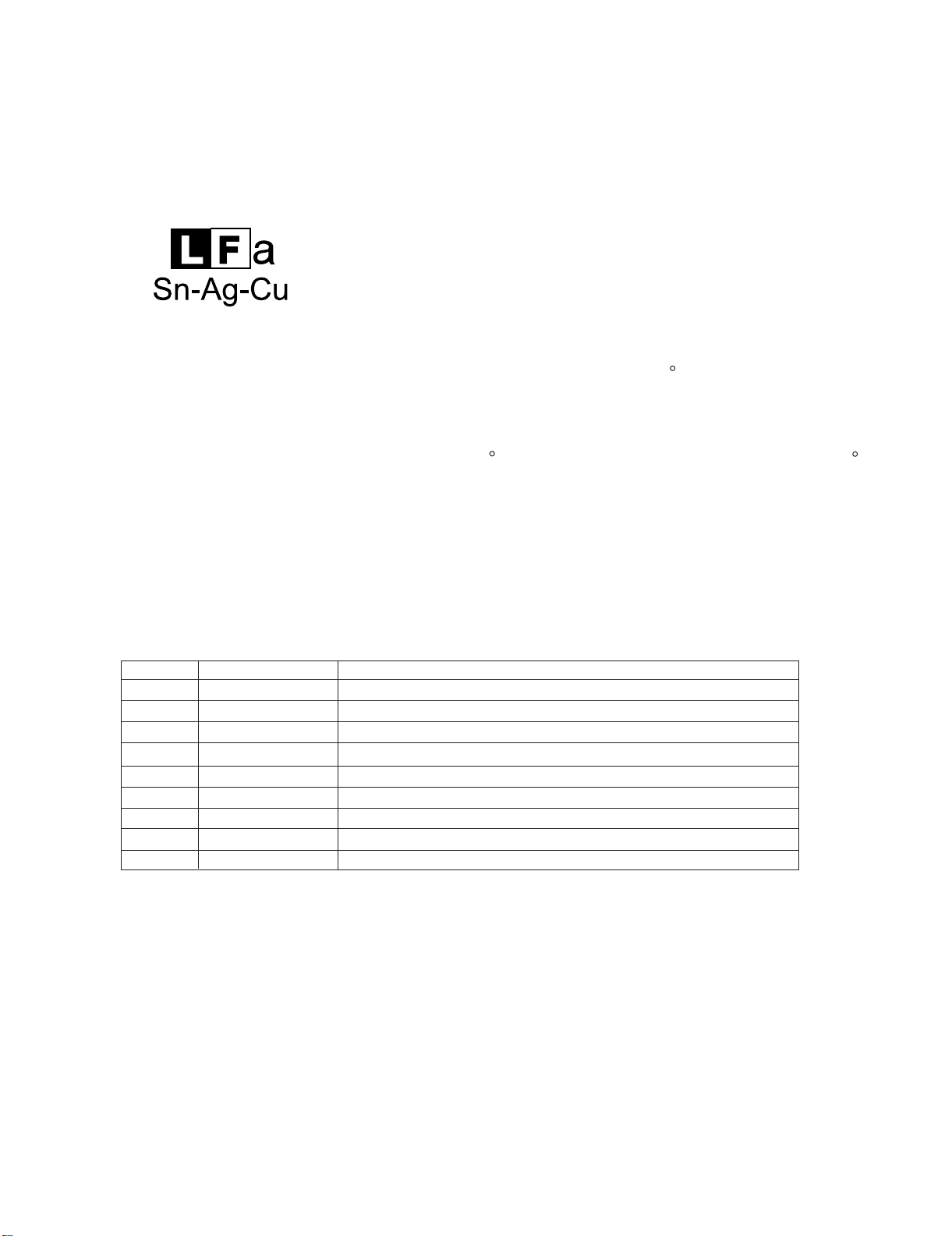

PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

"MAIN,DISPLAY,TERMINAL,SWITCH,USB,POWER,JACK,TUNER,CD MP3,CD MOTOR (PWB ONLY),

CD CHANGER MOTOR (PWB ONLY) PWB" of this model employs lead-free solder.

The LF symbol indicates lead-free solder, and is attached on the PWB and service manuals. The alphabetical character

following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free wire solder

When fixingthe PWB solderedwith the lead-free solder, apply lead-free wiresolder. Repairing with conventional lead wire solder

may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 C, we recommend you to use a

dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station

or service branch in your area.

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 C which is higher than the conventional lead solder by 40 C,

and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of

time. However, Since the land may be peeled off or the maximum heat-resistance temperature of parts may be exceeded,

remove the bit from the PWB as soon as you confirm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corrected. Make sure to turn on and off the

power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use

of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Ref No.

PWB-A 92LPWB6285MANS

PWB-A 92LPWB6287MANS

PWB-B

PWB-B

PWB-D

PWB-E

PWB-F

Parts No.

92LPWB6285PWRS

92LPWB6287PWRS

92LPWB6289TUNSPWB-C

92LPWB6291TUNSPWB-C

92LPWB6285CDUS

QPWBF0027AWZZ

QPWBF1055AWZZ

MAIN (A1),DISPLAY (A2),TERMINAL (A3),SWITCH (A4)/USB(A5) [XL-MP150H]

MAIN (A1),DISPLAY (A2),TERMINAL (A3),SWITCH (A4) /USB(A5)[XL-MP150E]

POWER (B1),JACK (B2) [XL-MP150H]

POWER (B1),JACK (B2) [XL-MP150E]

TUNER [XL-MP150H]

TUNER [XL-MP150E]

CD MP3

CD MOTOR (PWB ONLY)

CD CHANGER MOTOR (PWB ONLY)

Description

i

XL-MP150H/MP150E

Laser Diode Properties

Material: GaAIAs

Wavelength: 795 nm

Emission Duration: continuous

Laser Output: max. 0.6 mW

Note for users in Australia:

Copyright may exist in material you wish to record. Copying or broadcasting such material without permission of the relevant licensees or

owners of the copyright is prohibited by law. SHARP is not in a position to authorise the copying or broadcasting of copyright materials

and nothing in this OPERATION MANUAL should be implied as giving that authority.

For other countries:

Audio-visual material may consist of copyrighted works which must

not be recorded without the authority of the owner of the copyright.

Please refer to the relevant laws in your country.

AudioXL-MP150H/MP150EService ManualXLMP150HMarketE

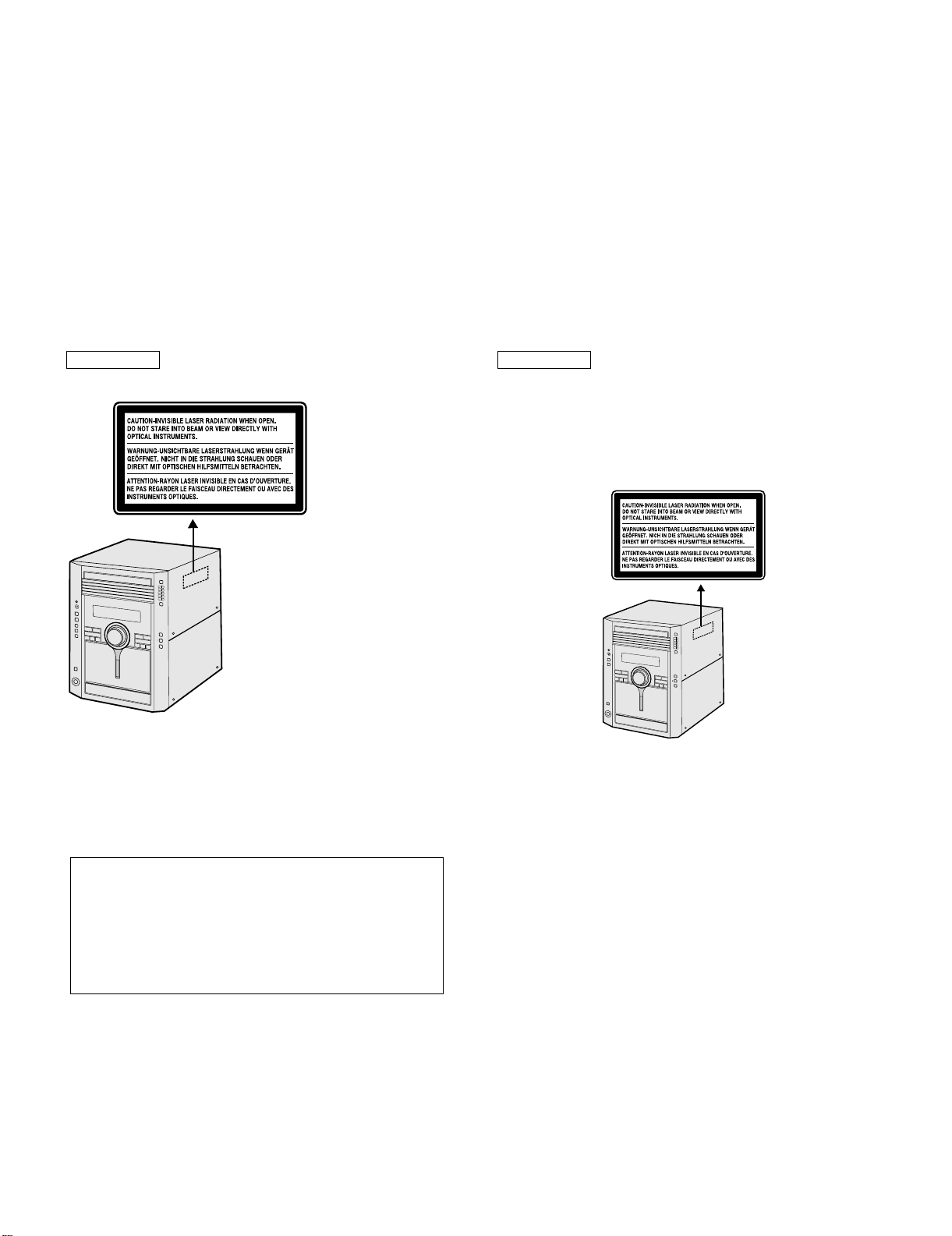

CHAPTER 1. GENERAL DESCRIPTION

[1] SAFETY PRECAUTION FOR SERVICE

MANUAL

Precaution to be taken when replacing and servicing the Laser Pickup.

The AEL (Accessible Emission Level) of Laser Power Output for this model is specified to be lower than Class 1 Requirements. However, the following precautions must be observed during servicing to protect your eyes against exposure to the Laser beam.

1) When the cabin et has been removed, the power is turned on without a compact disc, and th e Pickup is on a position out er than the lead-in position, the Laser will light for several seconds to detect a disc. Do not look into the Pickup Lens.

2) The Laser Power Output of the Pickup inside the unit and replacement service parts have already been adjusted prior to shipping.

3) No adjustment to the Laser Power should be attempted when replacing or servicing the Pickup.

4) Under no circumstances look directly into the Pickup Lens at any time.

5) CA UTION - Use of controls or adjustments, or performance of procedures other than those specified herein may result in hazardous radiation

exposure.

XL-MP150H

Laser Diode Properties

Material: GaAIAs

Wavelength: 795 nm

Emission Duration: continuous

Laser Output: max. 0.6 mW

ADVERSEL-SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING.

SE IKKE IND I STRÅLEN-HELLER IKKE MED OPTISKE INSTRUMENTER.

VARO!AVATTAESSA OLET ALTTIINANÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE ÄLÄ TUIJOTA SÄTEESEEN ÄLÄKÄ KATSO SITÄ

OPTISEN LAITTEEN LÄPI.

VARNING-SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA

DEL ÄR ÖPPNAD. STIRRA EJ IN I STRÅLEN OCH BETRAKTA EJ

STRÅLEN GENOM OPTISKT INSTRUMENT.

XL-MP150E

VAROITUS! LAITTEEN KÄYTTÄMINEN MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA TAVALLA SAATTAA

ALTISTAA KÄYTTÄJÄN TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE.

VARNING - OM APPARATEN ANVÄNDS PÅ ANNAT SÄTT ÄN

I DENNA BRUKSANVISNING SPECIFICERAS. KAN

ANVÄNDAREN UTSÄTTAS FÖR OSYNLIG LASERSTRÅLNING, SOM ÖVERSKRIDER GRÄNSEN FÖR

LASERKLASS 1.

1 – 1

XL-MP150H/MP150E

PROBE

AC

OUT

UNIT

SHORT-CIRCUIT

AC POWER

SUPPLY CORD

CONNECT THE PROBE

TO GND OF CHASSIS

SCREW

WITHSTANDING

VOLTAGE TESTER

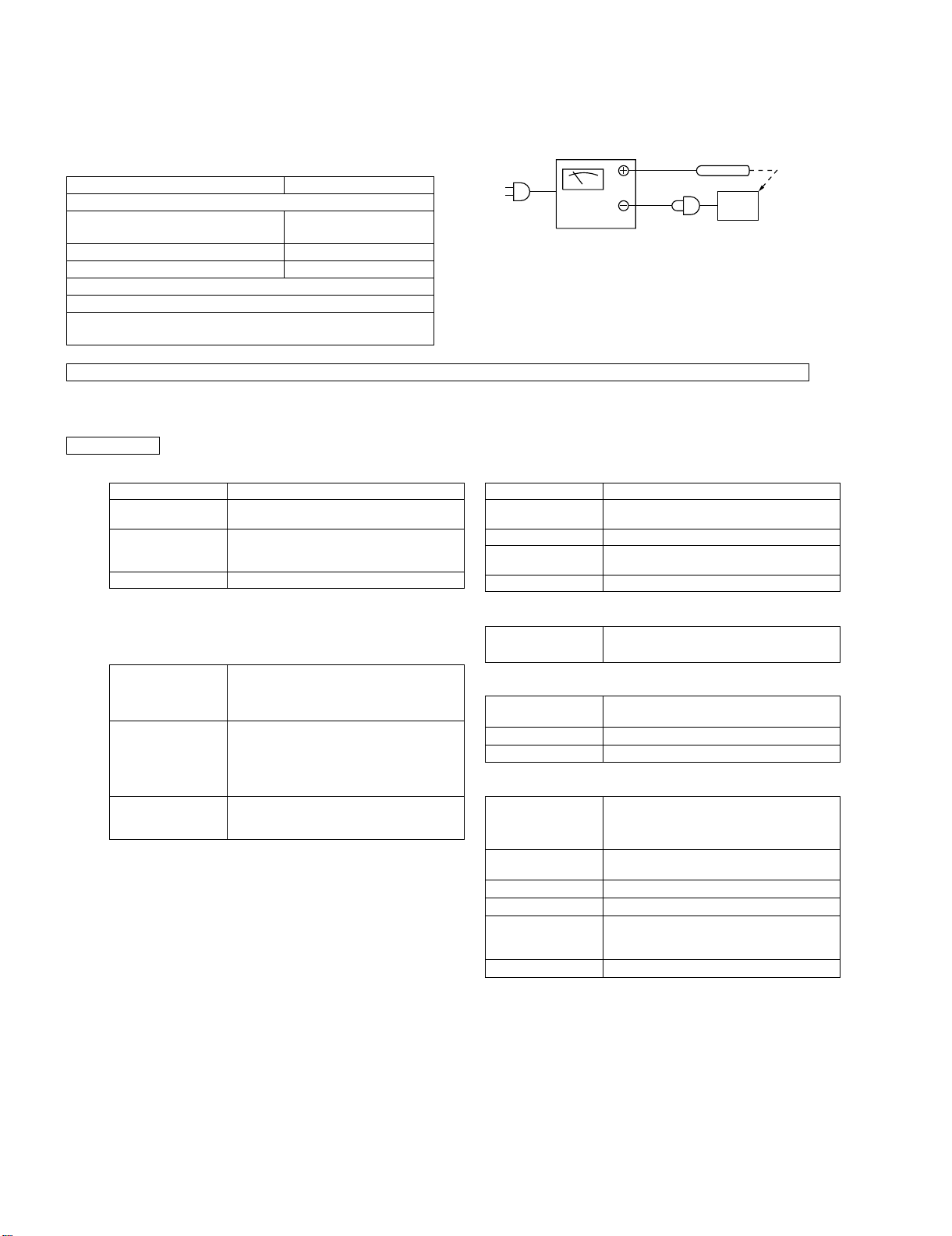

[2] IMPORTANT SERVICE NOTES (FOR U.K.

ONLY)

Before returning the unit to the customer after completion of a repair or

adjustment it is necessary for the following withstand voltage test to be

applied to ensure the unit is safe for the customer to use.

Setting of Withstanding Voltage Tester and set.

Set name set value

Withstanding Voltage Tester

Test voltage 4,240 VPEAK

3,000 VRMS

Set time 6 secs

Set current (Cutoff current) 4 mA

Unit

Judgment

OK: The “GOOD” lamp lights.

NG: The “NG” lamp lights and the buzzer sounds.

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER TO THE OPERATION MANUAL.

[3] SPECIFICATIONS

XL-MP150H

General■

Power source AC 230 V, 50 Hz

Power

consumption

Dimensions Width: 185 mm (7-1/4")

Weight 6.1 kg (13.4 lbs.)

( * )This power consumption value is obtained when the demonstra-

tion mode is cancelled in the power stand-by mode.

Amplifier

■

Output power PMPO: 752 W (total)

Output terminals Speakers: 6 ohms

Input terminals Video/Auxiliary (audio signal):

Power on:100 W

Power stand-by: 0.6 W(*)

Height: 260 mm (10-1/4")

Depth: 307 mm (12")

MPO: 376 W (188 W + 188 W) (DIN 45 324)

RMS: 200 W (100 W + 100 W) (DIN 45 324)

RMS: 160 W (80 W + 80 W) (DIN 45 500)

Headphones: 16 - 50 ohms

(recommended: 32 ohms)

Subwoofer pre-out (audio signal):

200 mV/10 k ohms at 70 Hz

500 mV/47 k ohms

USB input: USB type

CD player

■

Type 5-disc multi-play compact disc player

Signal readout Non-contact, 3-beam semiconductor laser

D/A converter 1-bit D/A converter

Frequency

response

Dynamic range 90 dB (1 kHz)

Tuner

■

Frequency range FM: 87.5 - 108 MHz

Cassette deck

■

Frequency

response

Signal/noise ratio 50 dB (recording/playback)

Wow and flutter 0.35 % (DIN 45 511)

Speaker

■

Type 2-way type speaker system

Maximum input

power

Rated input power 100 W

Impedance 6ohms

Dimensions Width: 185 mm (7-1/4")

Weight 3.1 kg (6.8 lbs.)/each

pickup

20-20,000Hz

AM: 522 - 1,620 kHz

50 - 14,000 Hz (normal tape)

5 cm (2") tweeter

13 cm (5-1/8") woofer

200 W

Height: 260 mm (10-1/4")

Depth: 260 mm (10-1/4")

1 – 2

XL-MP150H/MP150E

XL-MP150E for U.K.

General

■■

Power source AC 230 - 240 V, 50 Hz

Power

consumption

Dimensions Width: 185 mm (7-1/4")

Weight 6.1 kg (13.4 lbs.)

( * )This power consumption value is obtained when the demonstra-

tion mode is cancelled in the power stand-by mode.

Amplifier

■

Output power

Output terminals Speakers: 6 ohms

Input terminals Video/Auxiliary (audio signal):

■

CD player

Type 5-disc multi-play compact disc player

Signal readout Non-contact, 3-beam semiconductor laser

D/A converter 1-bit D/A converter

Frequency

response

Dynamic range 90 dB (1 kHz)

Power on:100 W

Power stand-by: 0.6 W(*)

Height: 260 mm (10-1/4")

Depth: 307 mm (12")

PMPO: 752 W (total)

MPO: 376 W (188 W + 188 W) (DIN 45 324)

RMS: 200 W (100 W + 100 W) (DIN 45 324)

RMS: 160 W (80 W + 80 W) (DIN 45 500)

Headphones: 16 - 50 ohms

(recommended: 32 ohms)

Subwoofer pre-out (audio signal):

200 mV/10 k ohms at 70 Hz

500 mV/47 k ohms

USB input: USB type

pickup

20 - 20,000 Hz

Tuner

Frequency range FM: 87.5 - 108 MHz

AM: 522 - 1,620 kHz

■

Cassette deck

Frequency

response

Signal/noise ratio 50 dB (recording/playback)

Wow and flutter 0.35 % (WRMS)

Speaker

■

Type 2-way type speaker system

Maximum input

power

Rated input power 100 W

Impedance 6ohms

Dimensions Width: 185 mm (7-1/4")

Weight 3.1 kg (6.8 lbs.)/each

50 - 14,000 Hz (normal tape)

5 cm (2") tweeter

13 cm (5-1/8") woofer

200 W

Height: 260 mm (10-1/4")

Depth: 260 mm (10-1/4")

XL-MP150E for Australia/New Zealand

General

■

Power source AC230-240V,50Hz

Power

consumption

Dimensions Width: 185 mm (7-1/4")

Weight 6.4 kg (14.1 lbs.)

Amplifier

■

Output power

Output terminals Speakers: 6 ohms

Input terminals Video/Auxiliary (audio signal):

CD player

■

Type 5-disc multi-play compact disc player

Signal readout Non-contact, 3-beam semiconductor laser

D/A converter 1-bit D/A converter

Frequency

response

Dynamic range 90 dB (1 kHz)

100 W

Height: 260 mm (10-1/4")

Depth: 307 mm (12")

MPO: 376 W (188 W + 188 W) (10% T.H.D.)

RMS: 200 W (100 W + 100 W) (10% T.H.D.)

RMS: 160 W (80 W + 80 W) (0.9% T.H.D.)

Headphones: 16 - 50 ohms

(recommended: 32 ohms)

Subwoofer pre-out (audio signal):

200mV/10kohmsat70Hz

500 mV/47 k ohms

USB input: USB type

pickup

20 - 20,000 Hz

Tuner

■

Frequency range FM: 87.50 - 108.00 MHz

AM: 522 - 1,620 kHz

Cassette deck

■

Frequency

response

Signal/noise ratio 50 dB (recording/playback)

Wow and flutter 0.3 % (WRMS)

Speaker

■

Type 2-way type speaker system

Maximum input

power

Rated input power 100 W

Impedance 6ohms

Dimensions Width: 185 mm (7-1/4")

Weight 3.1 kg (6.8 lbs.)/each

50 - 14,000 Hz (normal tape)

5 cm (2") tweeter

13 cm (5-1/8") woofer

200 W

Height: 260 mm (10-1/4")

Depth: 260 mm (10-1/4")

Specifications for this model are subject to change without prior

notice.

1 – 3

XL-MP150H/MP150E

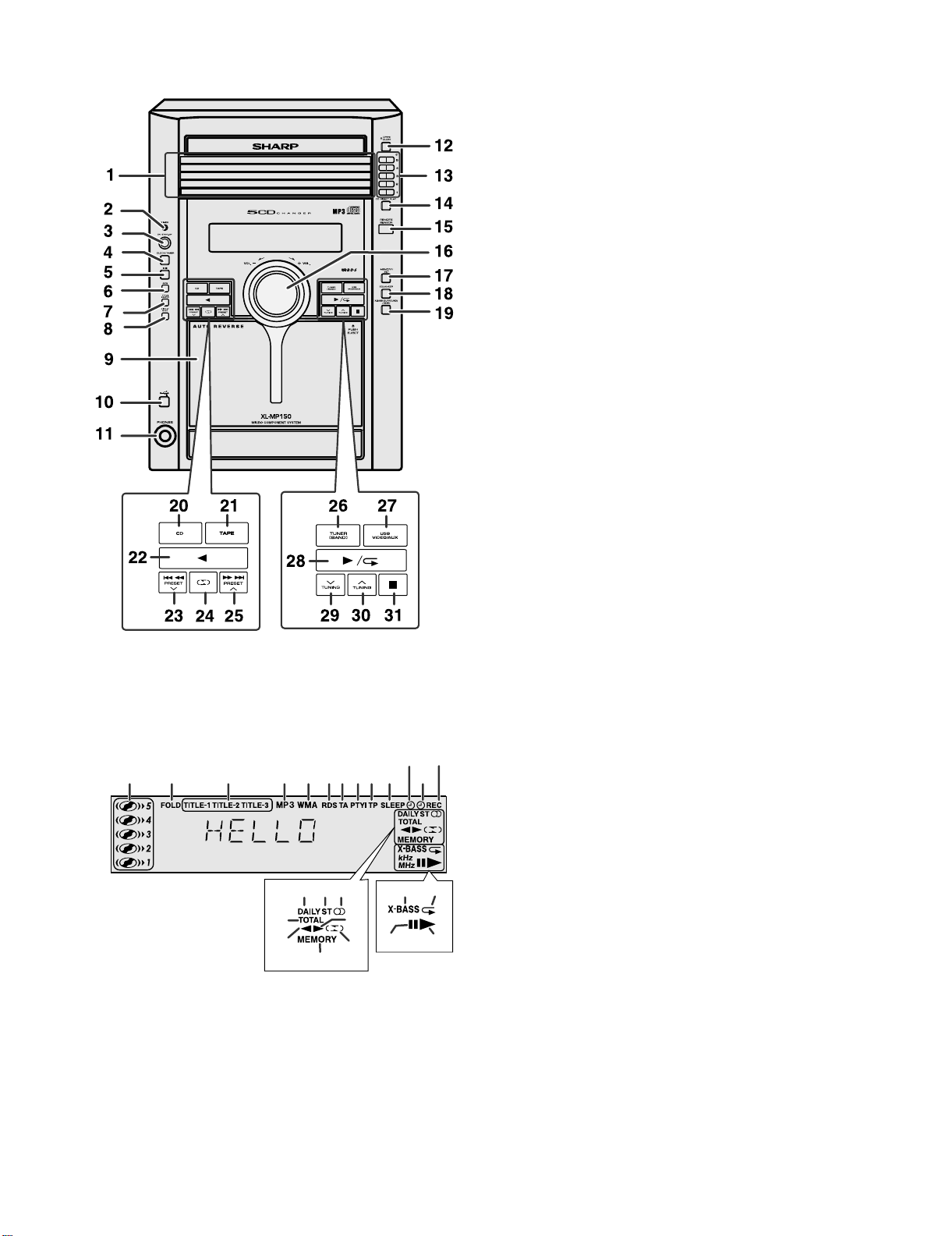

[4] NAMES OF PARTS

/

USB

CD

Front panel

1.■Disc Trays

2. Timer Indicator

3. On/Stand-by Button

4. Clock/Timer Button

5. Tape Record Pause Button

6. RDS ASPM (Auto Station Programme Memory) Button

7. RDS Programme Type/

Traffic Information Search Button

8. RDS Display Mode Select Button

9. Cassette Compartment

10. USB Socket

11. Headphone Socket

12. Disc Tray Open/Close Button

13. Disc Number Select Buttons

14. Disc Direct Play Button

15. Remote Sensor

16. Volume Control

17. Memory/Set Button

18. Equalizer Mode Select Button

19. Extra Bass (Surround)/ Demo Mode Button

20. CD Button

21. Tape Button

22. Tape Reverse Play Button

23. DiscTrack Down or Fast Reverse,Tape Rewind,Tuner Preset

Down,Time Down Button

24. Tape Reverse Mode Select Button

25. Disc Track Up or Fast Forward, Tape Fast Wind,

Tuner Preset Up, Time Up Button

26. Tuner (Band) Button

27. USB/Video/Auxiliary Button

28. Disc Play or Repeat, Tape Forward Play Button

29. Tuning Down Button

30. Tuning Up Button

31. Disc or Tape Stop Button

Illustration XL-MP150H

12 3 456789101112

22 23

24

14

21

15 16 17

20

18

19

13

25

Display

1.■Disc Number Indicators

2. MP3/WMA Folder Indicator

3. MP3/WMATitle Indicators

4. MP3 Indicator

5. WMA Indicator

6. RDS Indicator

7. Traffic Announcement Indicator

8. Dynamic PTY Indicator

9. Traffic Programme Indicator

10. Sleep Indicator

11. Timer Play Indicator

12. Timer Recording Indicator

13. Tape Record Indicator

14. MP3/WMA Total Indicator

15. Daily Timer Indicator

16. FM Stereo Mode Indicator

17. FM Stereo Receiving Indicator

18. Tape Forward Play Indicator

19. Tape Reverse Mode Indicator

20. Memory Indicator

21. Tape Reverse Play Indicator

22. Extra Bass Indicator

23. Disc Repeat Play Indicator

24. Disc Pause Indicator

25. Disc Play Indicator

Illustration XL-MP150H

1 – 4

XL-MP150H/MP150E

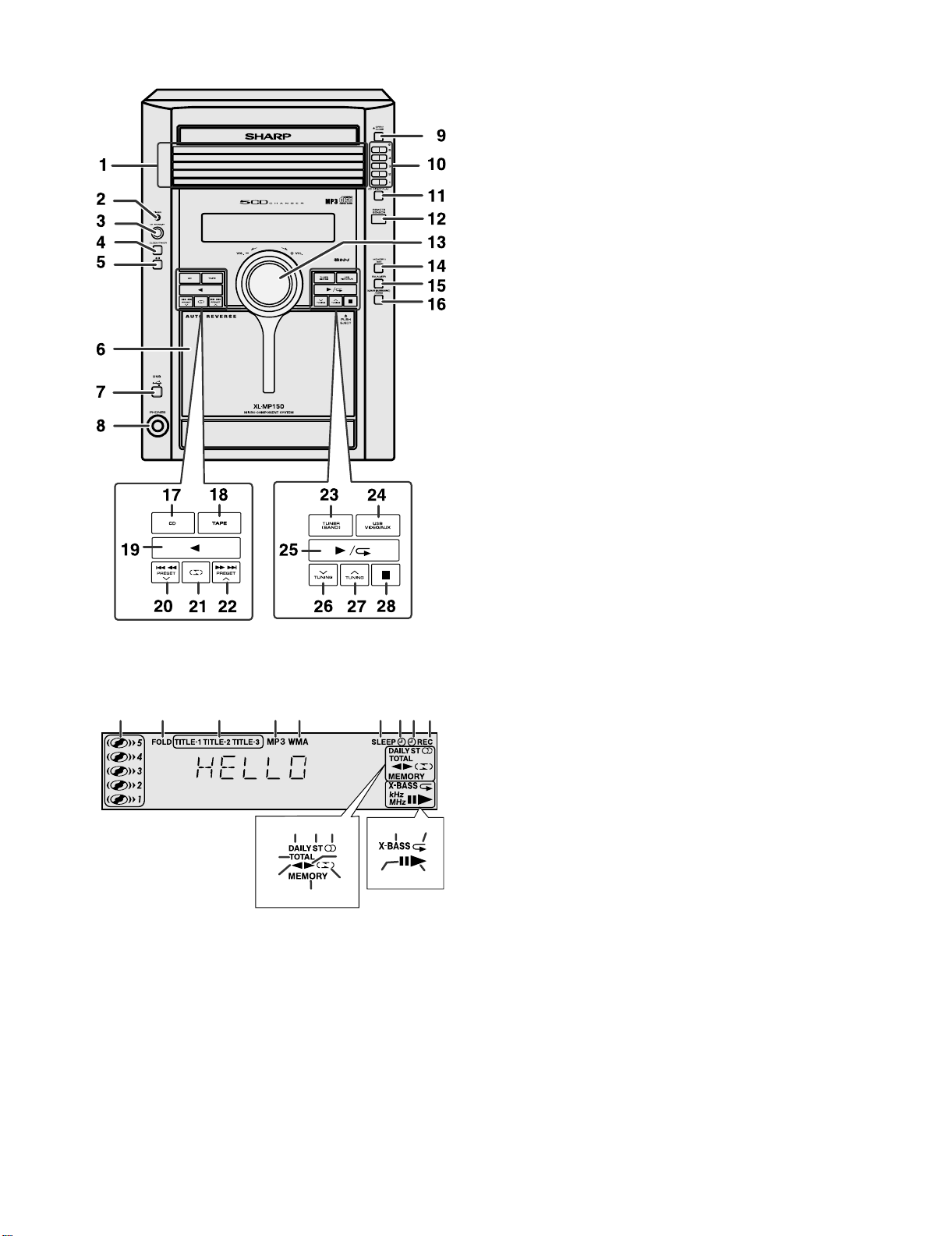

Front panel

■

1. Disc Trays

2. Timer Indicator

3. On/Stand-by Button

4. Clock/Timer Button

5. Tape Record Pause Button

6. Cassette Compartment

/

7. USB Socket

8. Headphone Socket

9. Disc Tray Open/Close Button

10. Disc Number Select Buttons

11. Disc Direct Play Button

12. Remote Sensor

13. Volume Control

14. Memory/Set Button

15. Equalizer Mode Select Button

16. Extra Bass (Surround)/ Demo Mode Button

17. CD Button

18. Tape Button

19. Tape Reverse Play Button

20. DiscTrack Down or Fast Reverse,Tape Rewind,Tuner Preset

Down,Time Down Button

21. Tape Reverse Mode Select Button

22. Disc Track Up or Fast Forward, Tape Fast Wind,

Tuner Preset Up, Time Up Button

23. Tuner (Band) Button

24. USB/Video/Auxiliary Button

25. Disc Play or Repeat, Tape Forward Play Button

26. Tuning Down Button

27. Tuning Up Button

28. Disc or Tape Stop Button

Illustration XL-MP150E

12 3 45 6789

18 19

20

21

10

17

11 12 13

16

14

15

Illustration XL-MP150E

Display

■

1. Disc Number Indicators

2. MP3/WMA Folder Indicator

3. MP3/WMATitle Indicators

4. MP3 Indicator

5. WMA Indicator

6. Sleep Indicator

7. Timer Play Indicator

8. Timer Recording Indicator

9. Tape Record Indicator

10. MP3/WMA Total Indicator

11. Daily Timer Indicator

12. FM Stereo Mode Indicator

13. FM Stereo Receiving Indicator

14. Tape Forward Play Indicator

15. Tape Reverse Mode Indicator

16. Memory Indicator

17. Tape Reverse Play Indicator

18. Extra Bass Indicator

19. Disc Repeat Play Indicator

20. Disc Pause Indicator

21. Disc Play Indicator

1 – 5

XL-MP150H/MP150E

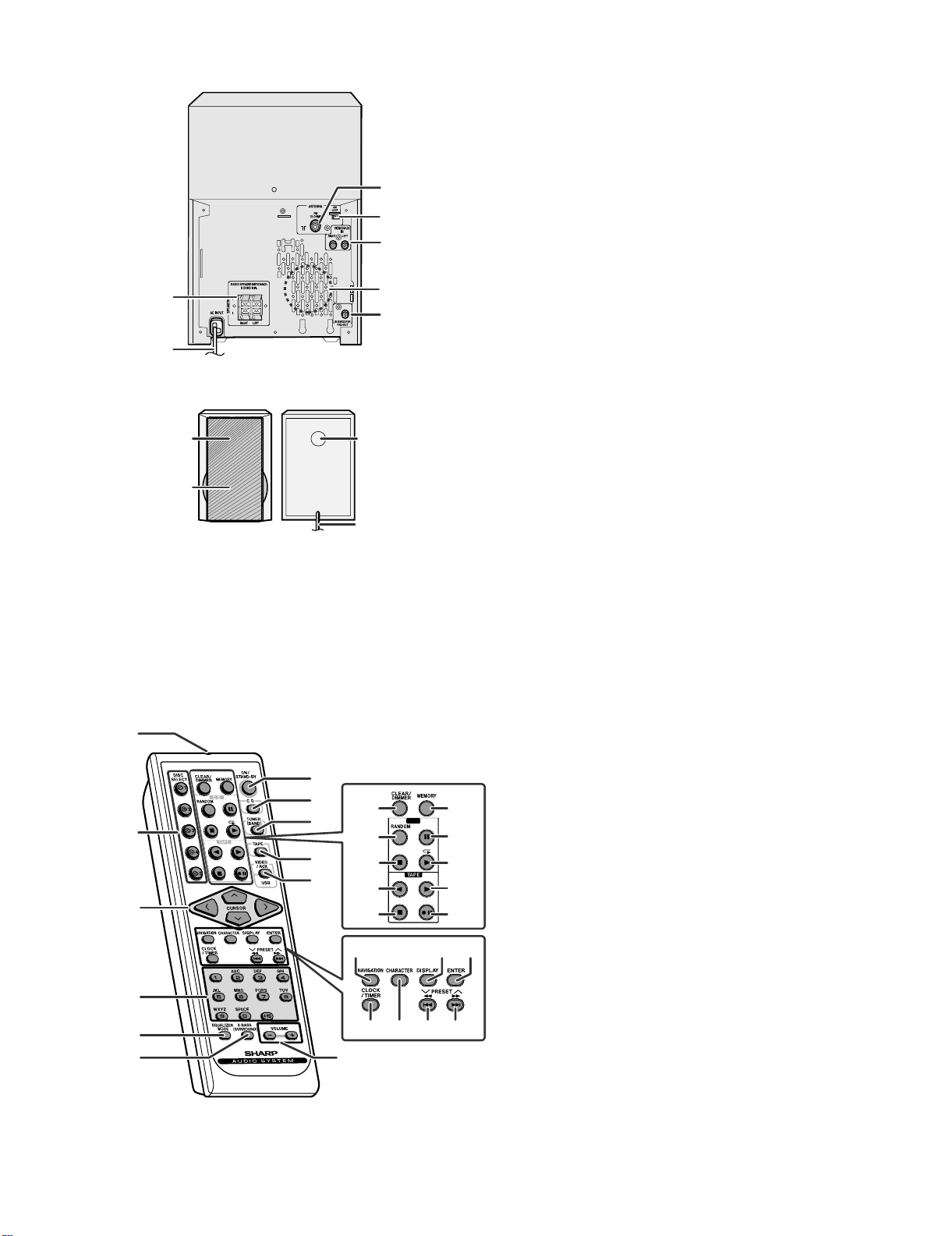

Rear panel

1.■Speaker Terminals

2. AC Power Lead

3. FM 75 Ohm Aerial Terminal

4. AM Loop Aerial Socket

3

4

5. Video/Auxiliary (Audio Signal) Input Sockets

6. Cooling Fan

7. Subwoofer Pre-output Socket

5

1

6

7

2

Speaker system

1

3

1.■Tweeter

2. Woofer

3. Bass Reflex Duct

4. Speaker Wire

2

4

Remote control■

1. Remote Control Transmitter

2. Disc Number Select Buttons

3. Cursor Buttons

4. Character Input/Disc Direct Search Buttons

1

7

8

13

2

3

9

10

11

14

15

16

17

23

CD

18

19

20

21

22

24 25

4

5

6

26 27 28 29

12

5. Equaliser Mode Select Button

6. Extra Bass (Surround) Button

7. Power On/Stand-by Button

8. CD Button

9. Tuner (Band) Button

10. Tape Button

11. Video/Auxiliary/USB Button

12. Volume Up and Down Buttons

13. Disc Clear/Dimmer Button

14. Disc Random Button

15. Disc Stop Button

16. Tape Reverse Play Button

17. Tape Stop Button

18. Memory Button

19. Disc Pause Button

20. Disc Play or Repeat Button

21. Tape Forward Play Button

22. Tape Record Pause Button

23. MP3/WMA Navigation Mode Select Button

24. MP3/WMA Display Button

25. Enter Button

26. Clock/Timer Button

27. Character Button

28. Disc Track Down or Fast Reverse, Tape FastWind,

Tuner Preset Down,Time Down Button

29. DiscTrack Up or Fast Forward, Tape Fast Wind,

Tuner Preset Up,Time Up Button

1 – 6

AudioXL-MP150H/MP150EService ManualXLMP150HMarketE

CHAPTER 2. ADJUSTMENTS

[1] ADJUSTMENT

1. MECHANISM SECTION

• Driving Force Check

Torque Meter Specified Value

Play: TW-2111 Over 80 g

• Torque Check

Torque Meter Specified Value

Play: TW-2111 30 to 80 g.cm

Fast forward: TW-2231 70 to 180 g.cm

Rewind: TW-2231 70 to 180 g.cm

2. TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

• AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

Test Stage Frequency Frequency

Display

AM IF 450 kHz 1,620 kHz T351 *1

AM Band

— 522 kHz (fL): T306

Coverage

AM Tracking 990 kHz 990 kHz (fL): T303 *1

*1. Input: Antenna Output: TP302

*2. Input: Antenna Output: TP301

FM ANTENNA

TERMINAL

TUNER PWB-C

20

IC302

TP301

C393

AM BAND

COVERAGE fL

Setting/

Adjusting

Parts

1.1 ± 0.1 V

SO301

ANTENNA

FE301

AM TRACKING fL

T306

AM

LOOP

CNP302

T303

Instrument

Connection

*2

XL-MP150H/MP150E

• Tape Speed

Test Tape Adjusting

Point

Normal

speed

MTT-111 Variable

Resistor in

motor.

TAPE MECHANISM

Variable Resistor in motor

Figure 1

3. CD SECTION

• Adjustment

Since this CD system incorporates the following automatic adjustment functions, readjustment is not needed when replacing the

pickup. Therefore, different PWBs and pickups can be combined

freely.

Each time a disc is changed, these adjustments are performed

automatically. Therefore, playback of each disc can be performed

under optimum conditions.

Items adjusted automatically

1) Offset adjustment (The offset voltage between the head amplifier

output and the VREF reference voltage is compensated inside the

IC.)

* Focus offset adjustment

* Tracking offset adjustment

2) Tracking balance adjustment

3) Gain adjustment (The gain is compensated inside the IC so that the

loop gain at the gain crossover frequency will be 0 dB.)

* Focus gain adjustment

* Tracking gain adjustment

Specified

Value

Connection

3,000 ± 30 Hz Speaker Ter-

minal (Load

resistance: 6

ohms)

Tape

Motor

Instrument

IC303

L354

R356

R357

TP302

T351

AM IF

Figure 2 ADJUSTMENT POINTS

Notes:

1. Description of the "FM IF Adjustment" is not carried on this Manual.

It is because the IF coil in the FM front end section has been best

adjusted in the factory so that its further adjustment is not needed

at the field. When replacing the FM front end assembly, no adjustment is needed either.

2. The parts in the FM front end section are prepared in a complete

unit, so you can't obtain each part individually.

4. CD ERROR CODE DESCRIPTION

Error Explanation

01 When Pickup set inner position, inner switch cannot detect

'ON' level for 10 secs.

10* CAM error. Can't detect CAM switch when CAM is moving.

11* When it detect cam operation error during initialize process.

20* TRAY error. Can't detect TRAY switch when TRAY is mov-

ing.

21* When it detect TRAY operation error during initialize pro-

cess.

31 When it change to CD function, DSP cannot read initial data.

* 'CHECKING'

If Error is detected, 'CHECKING' will be displayed instead of 'ERCD**'. 'ER-CD**' display will only be displayed when error had been

detected for the 5th times.

2 – 1

XL-MP150H/MP150E

[2] TEST MODE

• Setting the test mode

During stand-by mode, press ON/STAND-BY button while pressing

down the button and X-BASS/DEMO button. then, press the CD

button to enter the test mode.

C D T E S T

OPEN/CLOSE operation is using manual. IL isn’t done

<< >>,<< >>buttons make pick's slide possible.

A

to page 2-3

<<PLAY>> key input.

Do TOC IL. Do normal play.

When these following key is input into PLAY key, track number can be appoint directly.

<< 1>> key: Track 4

<< 2>> key: Track 9

<< 3>> key: Track 15

IL isn’t done

IL isn’t done

<<MEMORY>>

key input.

Adjustment result automatically will

display as below for each 2 sec:

a) "FOF_XXXX"

b) "TOF_XXXX"

c) "TBAL_XX"

d) "TGAN_XX"

f) "FGAN_XX"

g) "RFLS_XX"

<<STOP>> key input.

STOP

explanation:

a) Focus off set = "FOF_XXXX"

b)Tracking off set = "TOF_XXXX"

c)Tracking balance = "TBAL_XX"

d)Tracking Gain = "TGAN_XX"

f) Focus Gain = "FGAN_XX"

g) RF level shift = "RFLS_XX"

VOL — Last memory

P.GEQ — FLAT

X-BASS — OFF

To cancel: Power OFF

––––––––

2 – 2

A

<<MEMORY/SET>> key input.

Laser ON.

<<MEMORY/SET>> key input.

Tracking OFF play at that specific point.

<<MEMORY/SET>> key input.

Tracking ON play from that specific point.

XL-MP150H/MP150E

<<MEMORY/SET>> key input.

Adjustment result automatically will display as below for each 2 sec:

a) "FOF_XXXX"

b) "TOF_XXXX"

c) "TBAL_XX"

d) "TGAN_XX"

f) "FGAN_XX"

g) "RFLS_XX"

<<STOP>> key input.

STOP

Sliding the PICKUP with<< >>, << >> button must only be

in STOP mode.

explanation:

a) Focus off set = "FOF_XXXX"

b)Tracking off set = "TOF_XXXX"

c)Tracking balance = "TBAL_XX"

d)Tracking Gain = "TGAN_XX"

f) Focus Gain = "FGAN_XX"

g) RF level shift = "RFLS_XX"

VOL — Last memory

P.GEQ — FLAT

X-BASS — OFF

To cancel: Power OFF

2 – 3

XL-MP150H/MP150E

[3] Standard Specification of Stereo System Error Message Display Contents

Error Contents DISPLAY Notes

CD Pickup Mechanism Error. 'ER-CD01' PU-IN SW Detection NG.

CD Changer Mechanism Error. 'ER-CD**' (*) 10: CAM SW Detection NG during normal operation

CD DSP Communication Error. 'ER-CD31' DSP COMMUNICATION ERROR.

Focus Not Match/IL Time Over. 'NO DISC'

TUNER PLL Unlock.

(*) CHECKING:

If CD changer mechanism error is detected, 'CHECKING' will be display instead of 'ER-CD**'. 'ER-CD**' display will only be display when error had

been detected for the 5 th times.

Speaker abnormal detection and +B PROTECTION display

In case speaker abnormal detection or +B PROTECTION had occurred, the unit will aut omatically enter to stand-by mode and Timer indicator will

flashing as below.

Example:In case of speaker abnormal

87.50

FM MHz

11: CAM SW Detection NG during initialize process

20:TRAY SW Detection NG during normal operation

21:TRAY SW Detection NG during initialize process

PLL Unlock.

ON

ON

FLASHINGFLASHING

TIMER

LED OFF OFF

NO. 2

1 FRAME

OFF

NO. 1NO. 1

OFF

NO. 2

(REPEAT)

NO. 1 : +B PROTECTION

NO. 2 : Speaker abnormal

BEFORE TRANSPORTING THE UNIT

The following process need to be taken after set tapering/parts replacement.

1. Press the ON/STAND-BY button to enter stand-by mode.

2. While pressing down the button and the X-BASS/DEMO button, press the ON/STAND-BY button. The Micro Computer version number will

be displayed as "AU******".

3. Press OPEN/CLOSE button until "WAIT"--> "FINISHED" appears.

4. Unplug the AC cord and the unit is ready for transporting.

2 – 4

AudioXL-MP150H/MP150EService ManualXLMP150HMarketE

CHAPTER 3. MECHANICAL DESCRIPTION

XL-MP150H/MP150E

[1] REMOVING AND REINSTALLING THE

MAIN PARTS

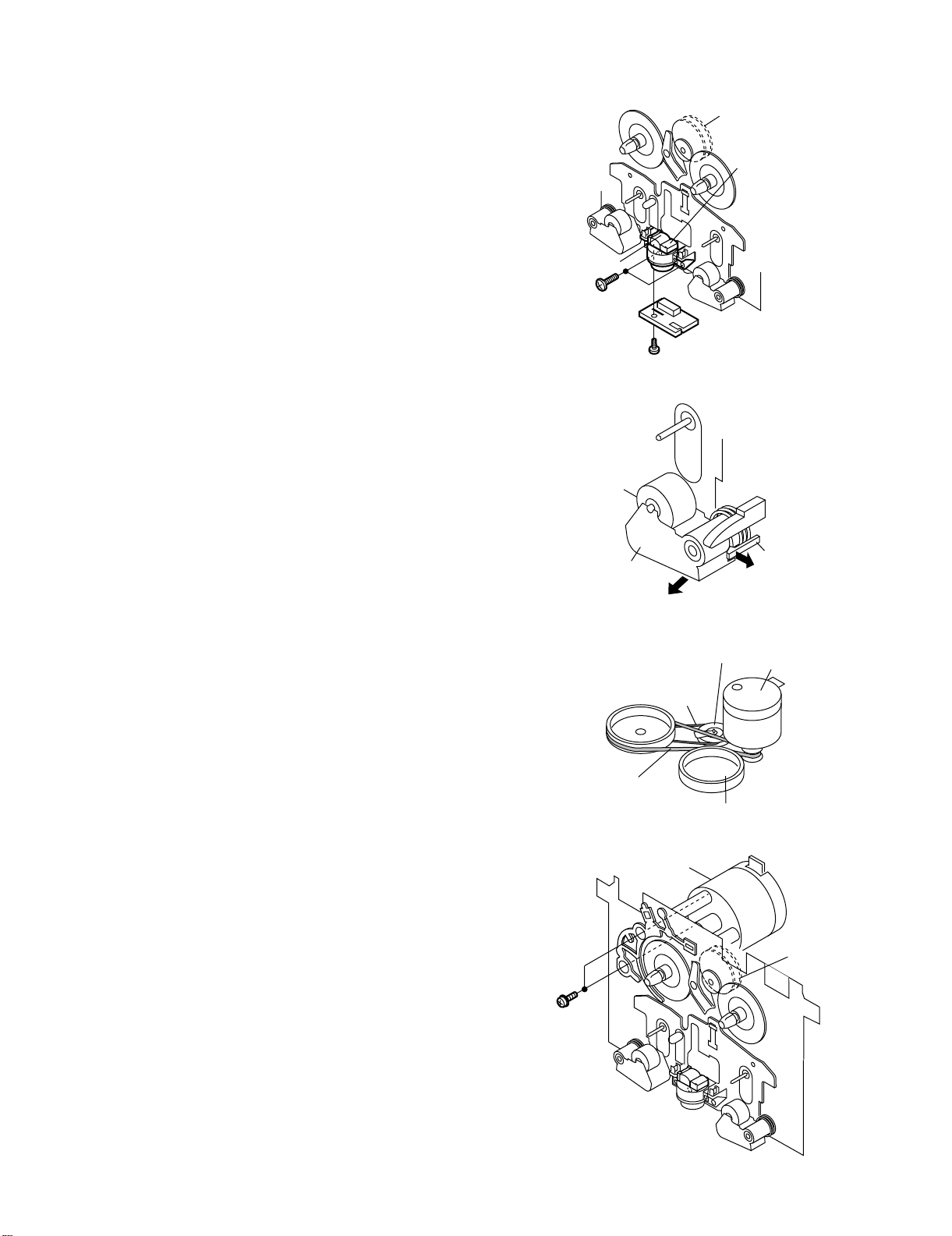

1. TAPE MECHANISM SECTION

Perform steps 1 to 5, 1 1 of the disassembly method to remove the t ape

mechanism.(see page 3-3,3-4)

1.1. How to remove the Record/Playback Head (See Fig. 1)

1. When you remove the screws (A1) x 2 pcs and (A2) x 1 pc., the

record/playback head can be removed.

1.2. How to remove the Pinch Roller (See Fig. 2)

1. Carefully bend the pinch roller pawl in the direction of the arrow

<A>, and remove the pinch roller (B1) x 1 pc., in the direction of the

arrow <B>.

NOTE: When installing the pinch roller, pay attention to the spring

mounting position.

1.3. How to remove the Belt (See Fig. 3)

1. Remove the main belt (C1) x 1 pc., from the motor side.

2. Remove the FF/REW belt (C2) x 1 pc.

1.4. How to remove the Motor (See Fig. 4)

1. Remove the screws (D1) x 2 pcs., to remove the motor.

Erase Head

(A1)x2

Ø2x6mm

Pinch Roller

(B1)x1

(A2)x1

Ø2x9mm

Figure 1

Pull

Figure 2

<B>

Clutch Ass'y

Record/Playback

Head

<A>

Pinch

Roller

Pawl

(D1)x2

Ø2.6x5mm

Main Belt

(C1)x1

FF/REW

Belt

(C2)x1

Figure 3

Motor

FF/REW

Clutch

Flywheel

Motor

Clutch Ass'y

3 – 1

Figure 4

XL-MP150H/MP150E

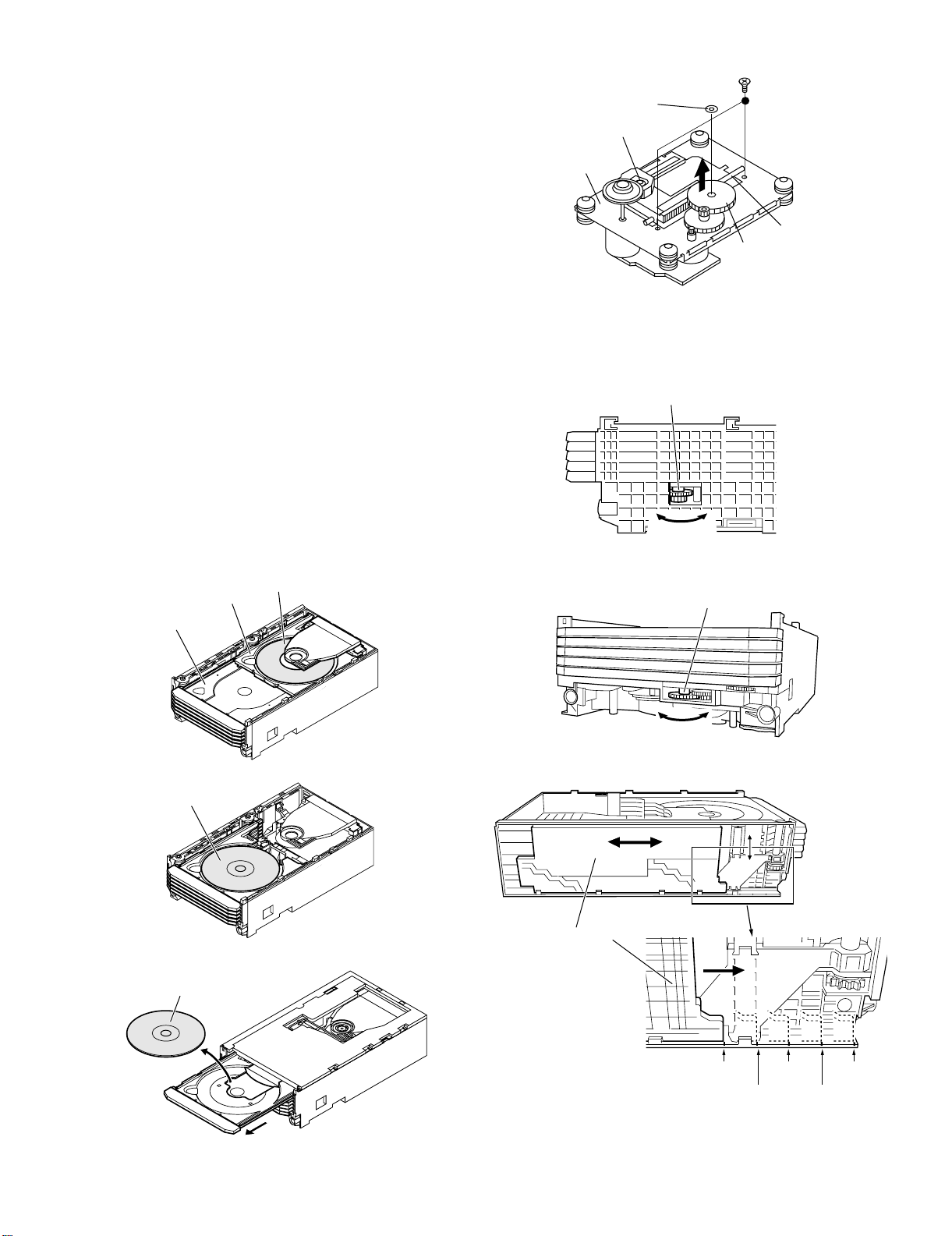

2. CD MECHANISM SECTION

Perform steps 1 to 3, 14,15 of the disassembly method to remove the

CD mechanism.(see page 3-3,3-4)

2.1. How to remove the Optical Pickup (See Fig. 1)

1. Remove the screws (A1) x 2 pcs and shaft (A2) x 1 pc.

2. Remove the stop washer (A3) x 1 pc and gear (A4) x 1 pc.

3. Remove the optical pickup.

NOTE: After pulling out the optical pickup connector, wrap the tip of it

with conductive aluminium foil or the like to protect the optical

pickup from the static electricity.

Stop Washer

(A3) x1

Optical Pickup

CD

Mechanism

(A1) x2

ø2.6 x5mm

Gear

(A4) x1

Shaft

(A2) x1

2.2. How to remove CD Disc (See Fig. 2~6)

1. When CD is at play position, rotate reduction gear C clock-wise as

shown in Figure 2 until disk tray is at ‘STOCK’ position, then rotate

the gear further to eject the disk tray (Figure 6) so that CD can be

removed from the tray.

2. In another case, if CD mechanism is at tray No. 1 play position and

to remove CD located in tray No. 3, the procedure is as follows:

If the gear up down board is located at tray No. 1 position, then

rotate Reduction gear C clock-wise until Disc tray is at ‘STOCK’

position. Rotate reduction gear D clock-wise (Figure 3) to move the

CD mechanism to tray No. 3 position. This is confirmed by checking the gear up down board position base on the marking as indicated on the main chassis as shown in Figure 4.

• Usually changer is covered with top plate. As for reference purpose, we exclude the top plate for easy viewing. (Figure 5,6)

CD Disc

Disc Tray

Guide Tray

Figure 1

Reduction gear C

Front

Rear

Figure 2

Reduction gear D

Up Down

CD Disc

CD Disc

Remove CD from tray.

CD At 'PLAY' position.

CD At 'STOCK' position.

Figure 5

Tray eject

Figure 6

3 – 2

Gear up down board

Figure 3

Figure 4

Mark 1

(DISC 1)

Mark 2 Mark 4

(DISC 2)

Mark 3 Mark 5

(DISC 3)

(DISC 5)

(DISC 4)

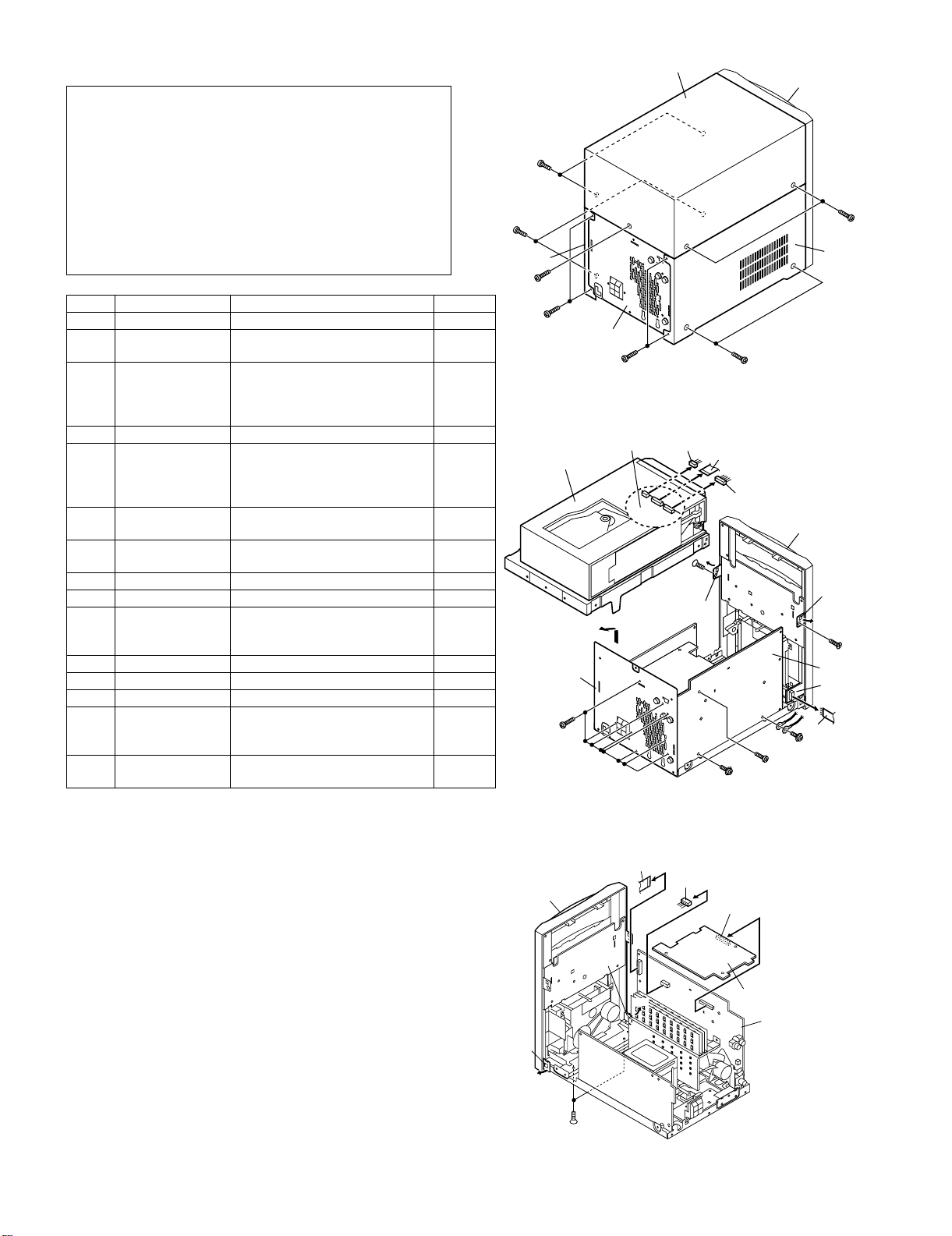

[2] DISASSEMBLY

(A1) x2

ø3x12mm

(A1) x2

ø3x12mm

(B1) x2

ø3x10mm

(B1) x2

ø3x8mm

(B1) x2

ø3x8mm

(B1) x2

ø3x8mm

(A1) x1

ø3x12mm

Front Panel

Top Cabinet

Rear

Panel

Side Panel

(Left)

Side Panel

(Right)

(F2) x1

(E1) x2

ø3x10mm

Front Panel

Turner PWB

Main PWB

Pull

(E2) x1

(E3) x1

Pull

Hook

(E4)x1

Hook

(E4)x1

Caution on Disassembly

Follow the below-mentioned notes when disassembling the unit and

reassembling it, to keep it safe and ensure excellent performance:

1) Take cassette tape and compact disc out of the unit.

2) Be sure to remove the power supply plug from the wall outlet

before starting to disassemble the unit.

3) Take off nylon bands or wire holders where they need to be

removed when disassembling the unit. After servicing the unit,

be sure to rearrange the leads where they were before disassembling.

4) Take sufficient care on static electricity of integrated circuits and

other circuits when servicing.

STEP REMOVAL PROCEDURE FIGURE

1 Top Cabinet 1. Screw............................(A1) x 5 1

2 Side Panel (Left/

Right)

3 CD Changer unit 1. Screw............................(C1) x 2

4 Rear Panel 1. Screw............................(D1) x 8 2

5 Front Panel 1. Screw............................(E1) x 3

6 Tuner PWB 1. Screw.............................(F1) x 1

7 Main PWB 1. Screw............................(G1) x 2

8 Power PWB 1. Screw............................(H1) x 4 4

9 Terminal PWB 1. Screw.............................(J1) x 1 4

10 Display PWB 1. Knob..............................(K1) x 1

11 Tape Mechanism 1. Screw.............................(L1) x 4 5

12 Jack PWB 1. Screw............................(M1) x 1 5

13 USB PWB 1. Screw............................(N1) x 1 5

14 CD MP3 PWB

(Note 1)

15 CD Mechanism 1. Screw............................(Q1) x 4

Note 1:

After removing the connector for the optical pickup from the connector,

wrap the conductive aluminium foil around the front end of the connector so as to protect the optical pickup from electrostatic damage.

1. Screw............................(B1) x 8 1

2. Hook..............................(C2) x 2

3. Socket...........................(C3) x 2

4. Flat Cable......................(C4) x 1

2,3

2. Flat Cable......................(E2) x 2

3. Socket...........................(E3) x 1

4. Hook..............................(E4) x 2

2. Socket...........................(F2) x 1

2,4

2. Socket...........................(G2) x 4

2. Screw............................(K2) x 8

3. Flat Cable......................(K3) x 1

1. Screw............................(P1) x 4

2. Flat Cable......................(P2) x 2

3. Socket...........................(P3) x 1

2. Screw............................(Q2) x 4

XL-MP150H/MP150E

2

Figure 1

CD Servo PWB

CD Changer

3

Unit

2

3

4

5

Rear Panel

6

(D1) x8

ø3x8mm

6

7

(C3) x1

(C1) x1

ø3x10mm

Hook

(C2)x1

Figure 2

(C4) x1

Pull

(G1) x1

ø3x10mm

(C3) x1

(F1) x1

ø3x8mm

Front Panel

(E2) x1

(E1) x1

ø3x10mm

Hook

(C2)x1

Pull

(C1) x1

ø3x10mm

Main PWB

Headphones

PWB

Figure 3

3 – 3

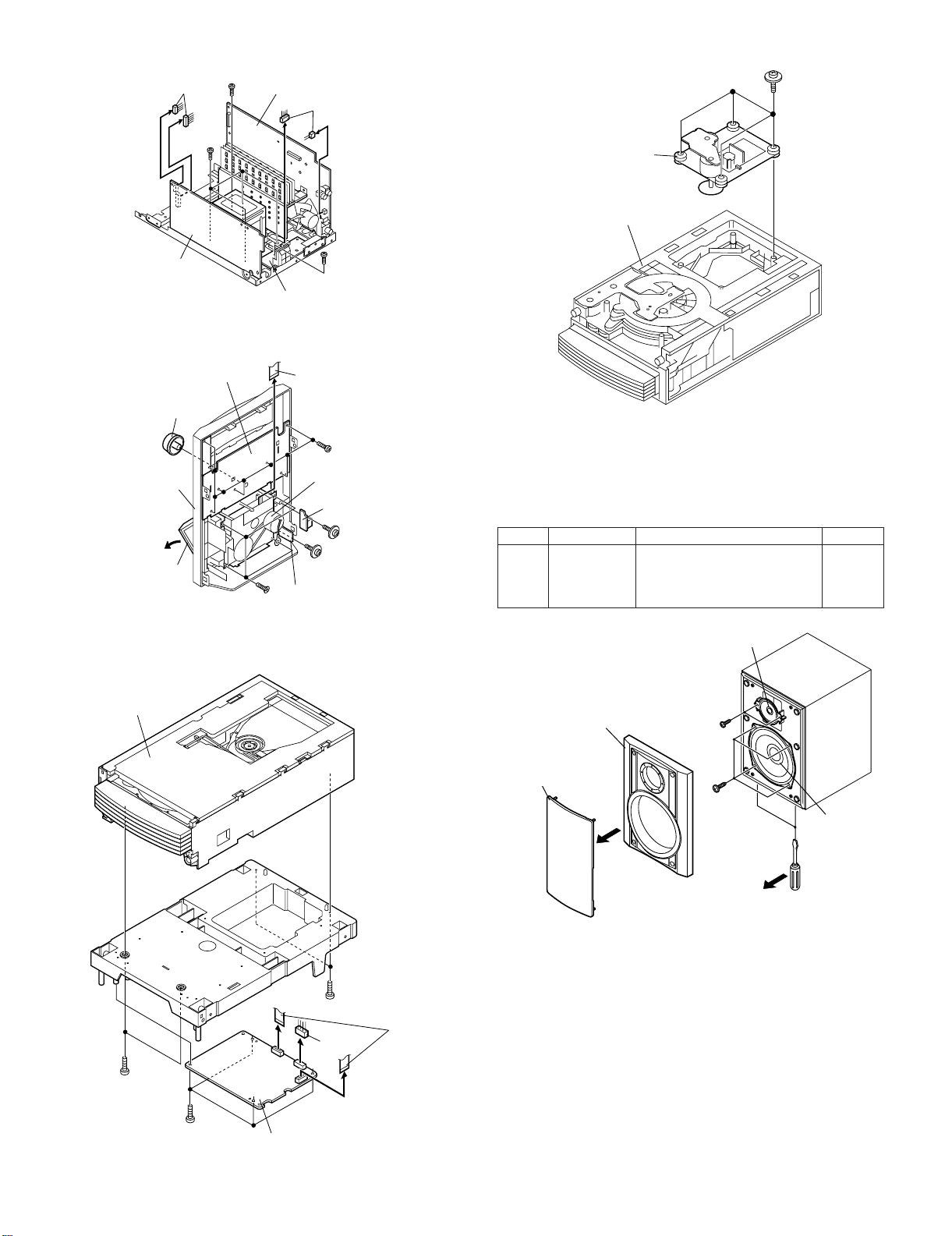

XL-MP150H/MP150E

STEP REMOVAL PROCEDURE FIGURE

1Woofer/

Tweeter

1. Net Frame.................(A1) x1

2. Front Panel...............(A2) x1

3. Screw........................(A3) x2

4. Screw........................(A4) x4

8

Screwdriver

Net Frame

(A1)x1

(A3)x2

ø3x10mm

(A4)x4

ø4x16mm

Woofer

Front Panel

(A2)x1

Tweeter

(G2) x2

(H1) x4

ø4x6mm

Power PWB

(G1) x1

ø3x8mm

Figure 4

Main PWB

(G2) x2

Terminal PWB

(J1) x1

ø3x8mm

CD Mechanism

CD Changer

Unit

(Q2) x4

Special

Front Panel

Cassette

Holder

CD Changer

Unit

(K1) x1

Display PWB

Figure 5

(L1) x4

ø3x10mm

(K3) x1

(K2) x8

ø2.6x8mm

Tape

Mechanism

(M1) x1

Special

JACK PWB

USB PWB

(N1) x1

ø3x10mm

Figure 7

(Q1) x2

ø3x10mm

(P1) x4

ø3x10mm

CD MP3 PWB

Figure 6

(Q1) x2

ø3x10mm

(P3) x1

Figure 8

(P2) x2

3 – 4

-MEMO-

XL-MP150H/MP150E

3 – 5

XL-MP150H/MP150E

N

B

AudioXL-MP150H/MP150EService ManualXLMP150HMarketE

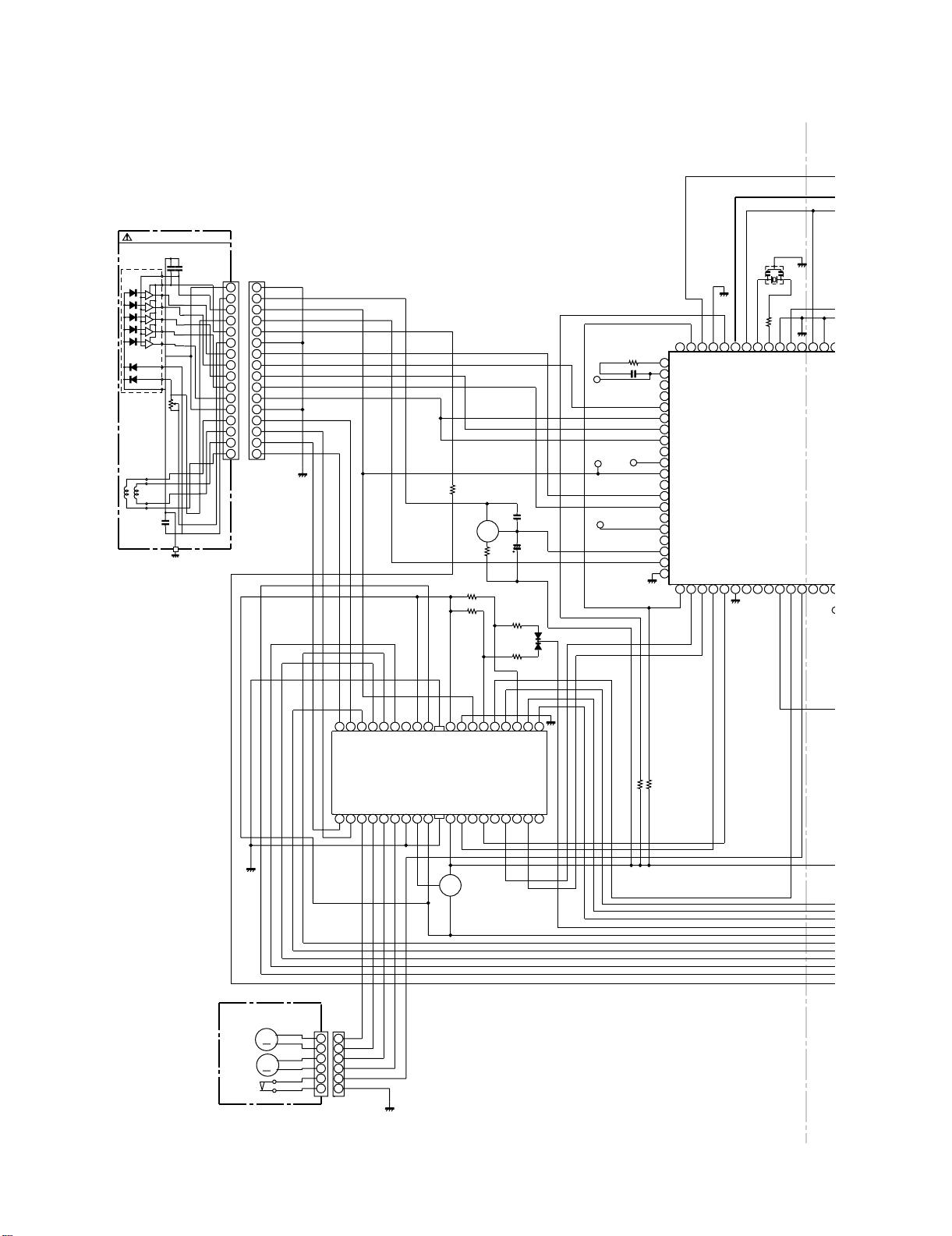

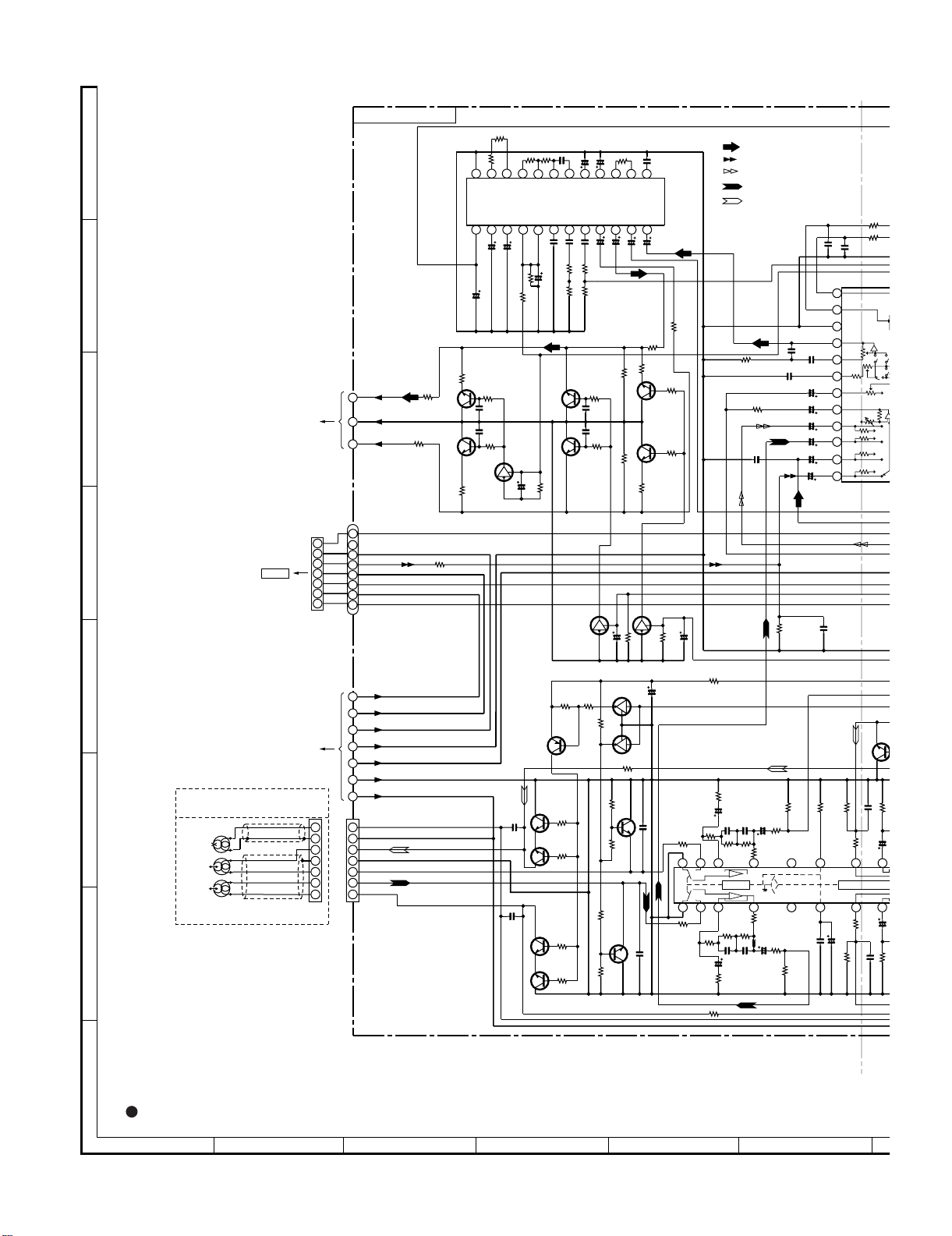

CHAPTER 4. DIAGRAMS

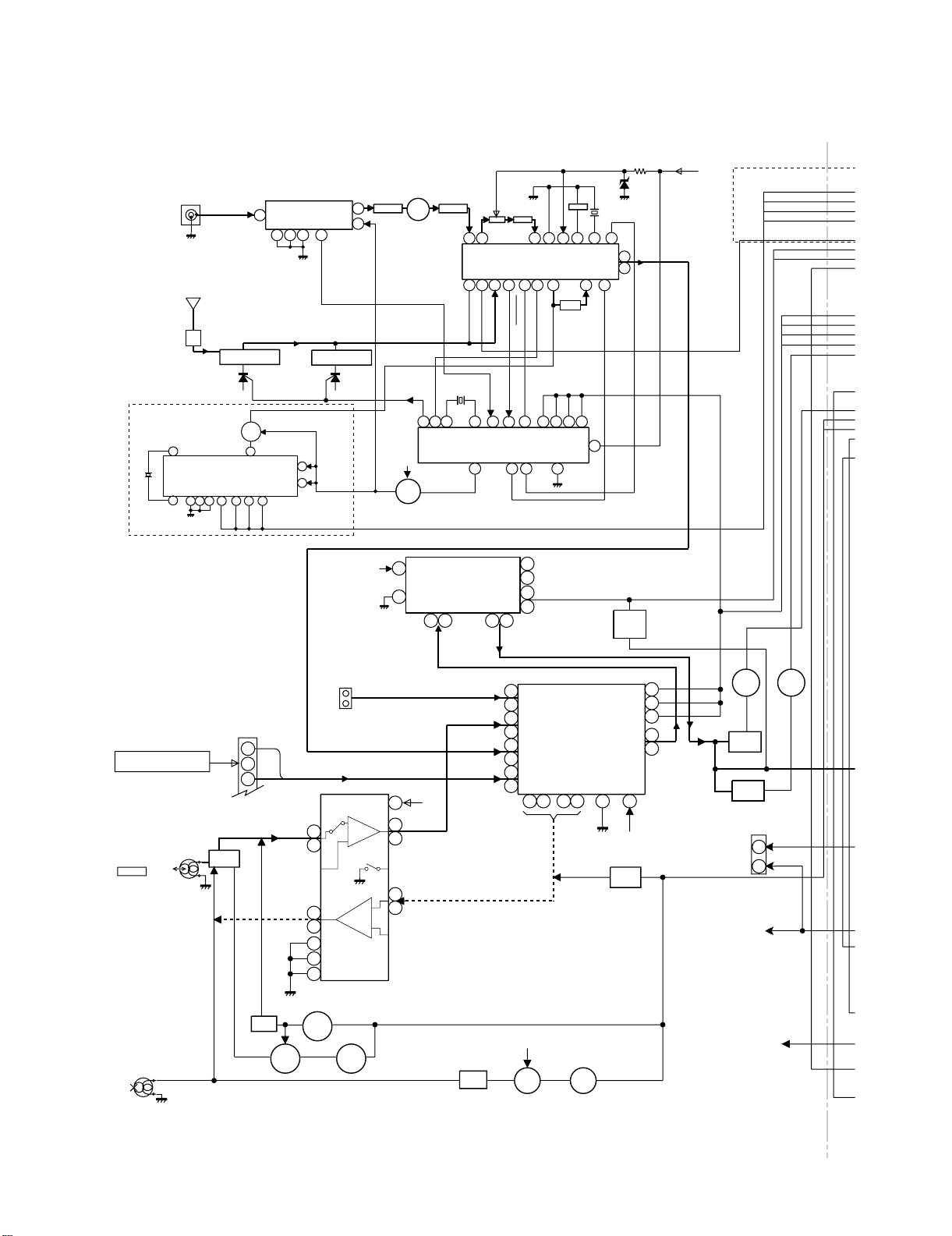

[1] BLOCK DIAGRAM

ANTENNA

TERMINAL

SO301

AM LOOP

ANTENNA

L341

BALUN

ICT21

LC72723

RDS DECODER

8

XOUT

VSSD

TEST

XIN

9

10

74

H ONLY

VSSA

13

AM

TRACKING

QT21

MPX IN

RST

RDDA

14

15

2

RDCL

8

RDS-ID/

16

FE301

FM FRONT END

VDDA

3

11

VDDD

READY

3762

FOUT

AM BAND

COVERAGE

FM IF

1

CF301

5

FM IF DET./

FM MPX./AM IF

VT

+B

FM

Q360

SWITCHING

+B5

13

12

CF302

Q301

IC303

LA1832S

4.5MHZ

1220

+B5

FM

IC602

IXA043AW

NEW SOUND

23 24

RIN

T351

AM IF

OUT

AM MIX

VSM

AM OSC IN

X352

FM IN

OSC

FM/AM

IC302

LC72131

PLL(TUNER)

21 22

LIN

AM RF IN

AM IN

1516

ROUT

CF352

AM OSC OUT

910

LOUT

AM IF

10

IF OUT

STEREO

MO/ST

19

20

SW1

16

17

SW2

CF351

10.7MHz

895427117

FM

DET

GND

FM+B

FM/AM

OUT

162421201523

18

L354

LOW PASS

FILTER

CL

DO

DI

CE

34

51

622 11

217

ST FM

VCO

MPXIN

12

17

X351

456kHz

13

L

MO/ST

R

FM/AM

ZD351

5.1V

L

14

R

NS_SW1

Q609

Q605

Q606

+B5

HONLY

+

-20dBATT

FROM CD SECTION

CNP3

REC /P.B. HEAD

L-CH

TAPE

R-CH

AC BIAS

ERASE

HEAD

CNS3

SWITCHING

Q101Q104

1

2

3

SWITCHING

Q105

Q106

L(TA)

R(TA)

L REC

R REC

+B5

Q112

L

R

JK690

2

23

REC

9

16

11

12

15

Q114

SWITCHING

VIDEO/AUX

P.B

H/N

SWITCHING

Q113

L

9

R

16

L

10

TAPE

15

R

L

CD

11

14

R

L

12

R

13

TUNER

+B5

13

4

L

PB

21

R

L

REC

7

18

R

IC101

AN7345K

PLAYBACK AND RECORD

/PLAYBACK AMP.

+B5

BIAS

OSC

Q111

L103

Q109

SWITCHING

DI

CE

IC601

LC75341

CLK

AUDIO P ROCESSOR

17

BIAS

Q110

3

Q107

Q108

MUTING

BIAS

+B5

718 8 23

1

2

24

R

21

L

4

REC/PLAY

Q607

Q601

Q602

Q603

Q604

CNS3

TO CD/MP3 SECTION

7

+B4

+B7(A_+5V)

5

+B8(SW_+5V)

+B10

Q608

LD_+8V

M_+8V

U

Figure 4-1 BLOCK DIAGRAM (1/6)

4 – 1

+B10

+

+B_PROTECT

+B8(SW_+5V)

+B1

+B5

RDS_RST

RDS_READY

RDS_RDDA

RDS_RDCL

TUN_SM

NS_SW2

NS_SW1

UNSW5.6

+B_PROTECT

D_GND

SP_DET

S-MUTE

M_+13V

A_+10V

SW_5V

AC_RLYCON

SP_RLY

REC/PLAY

T_BIAS

P_IN

-20dB

CE

CLK

DI

DO

VF1

-VF

VF2

CNP701B

E : 25PIN

H:29PIN

XL-MP150H/MP150E

29

28

HONLY

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

TO DISPLAY SECTION

-20dBATT

18

ON

08

+8V

8V

+B1

+B5

L

R

M_+13V

A_+10V

14

VL-

VL+

5

2

IC855

+B_PROTECT

VF2

-VF

VF1

IC854

UNSW_5.6V

P_IN

KIA78L05

VOLTAGE

REGULATOR

SP DET

IC901

STK412-490

POWER AMP.

6

GND

1

7

VH-

VH+

D801

VL-

VL+

+B3

D802

IC851

KIA7812AP

VOLTAGE

REGULATOR

IC852

KIA7810AP

VOLTAGE

REGULATOR

IC853

KIA7805AP

VOLTAGE

REGULATOR

Q850

EONLY

11

L-OUT

R-OUT

Q901

Q904

T4.0A L 250V

F801

T4.0A L 250V

T2A L 250V

T2A L 250V

Q801

REGULATOR

SP_RLY

Q905

F802

F804

F803

VOLTAGE

RL914

RELAY

PT801

POWER

TRANSFORMER

(MAIN)

T.F

DRIVER

Q906

+B3

FAN MOTOR

M971

M

SO901

SPEAKER TERMINAL

JK701

HEADPHONES

JK953

SUB WOOFER

OUT-PUT

F805

T2A L 250V

RL841

RELAY

+B7(A_5V)

EONLY

L841

LINE

FILTER

AC POWER

SUPPLY CORD

H : AC 230V,50 Hz

E : AC 230-240V,50 Hz

AC_RLY

Q841

RELAY

DRIVER

D842-D845

H ONLY

PT841

POWER

TRANSFORMER

(SUB)

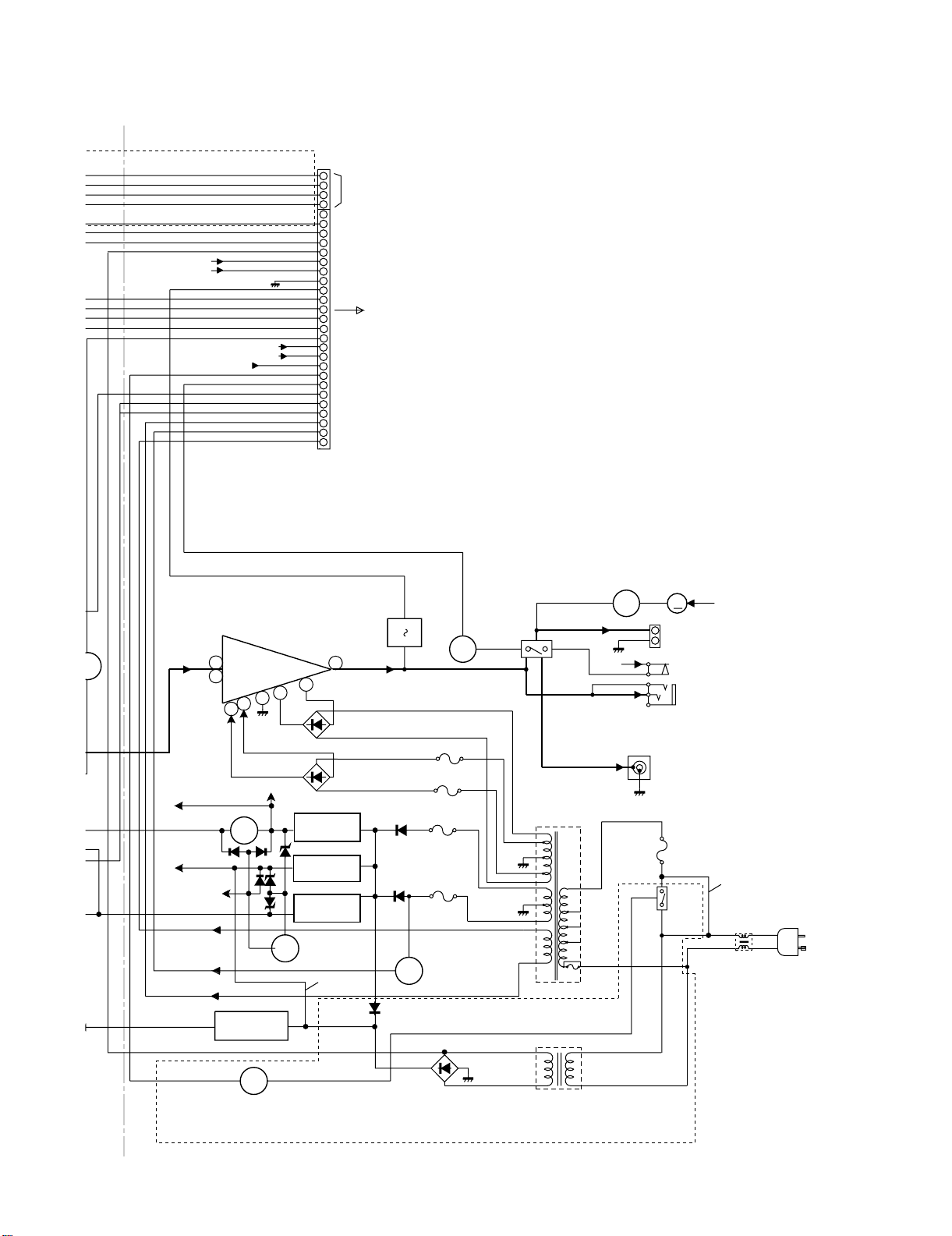

Figure 4-2 BLOCK DIAGRAM (2/6)

4 – 2

XL-MP150H/MP150E

M_+13V

+10V

SYSTEM

MICROCOMPUTE

TAPE MECHANISM Ass'y

CNP701A

E : 25PIN

H : 29PIN

CNP702

Q702

Q712

Q701

Q714

Q715

Q713

IC701

FL701

Q710

LED707

IXA060AW

363738394041424344454647484950

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81 82 83 84 85 86 87 88 89 90 91 92 93 94 9

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

8

7

6

5

4

3

2

1

T_SOL_B

SMUTE

SMUTE

T_FPSW

T_RUN_PULS

T_MOTOR

FPA

T1RUN

T_SOL

T_MOTOR

GND

T_SOL

DO

T_SOL_B

T_MOTOR

T_SOL_A/VOLLED

VSS

RESET

ILLU_LED

VDD

NS_SW2

NS_SW1

DIST

T_BIAS

T_REC/PLAY

-20dBATT

SP_RLY

AC_RLY

S30

7

1

4

5

2

3

6

CE

DO

CLK

DI

+B_PROTECT

H ONLY

D_GND

S_MUTE

REC/PLAY

T_BIAS

A+10V

M_+13V

SW_5V

SP_DET

SP_RLY

-20dB

VF2

-VF

-VF

P_IN

VF1

UNSW5.6

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

AC_RLY(H ONLY)

AC_RLY(H ONLY)

H ONLY

H ONLY

TO MAIN PWB

7

1

4

5

6

2

3

R. REC

F. REC

+MTR

-COM

M

+

-

END SW

+SOL

N.C. (OP PACK)

SOLENOID

TAPE

MOTOR

46474849

RDS_RDCL

RDS_RDDA

RDS_READY

RDS_RST

RDS_RDCL

RDS_RDDA

RDS_READY

RDS_RST

FPB

S8S7S6S5S4S3S2

S1

G12

G11

G10

G9G8G7

G6

S30

S29

S28

S27

S26

S25

S24

S23

S22

S21

S20

S19(DIST1)

S18(DIST2)

S17(DIST3)

S16(DIST4)

S15

S14

S13

S12

S11

S10

VDD2

VLOAD

S9

89

10111213141516171819202122232425262728293031323334353637383940414243444546475051

FFNPNPP30

P29

P28

P27

P26

P25

P24

P23

P22

P21

P20

P19

P18

P17

P16

P15

P14

P13

P12

P11

P10

P09

P08

P07

P06

P05

P04

P03

P02

P01

G12

G11

G10

G09

G08

G07

G06

G05

G04

G03

VF2

FL DISPLAY

TUN_SM

NS_SW1

NS_SW2

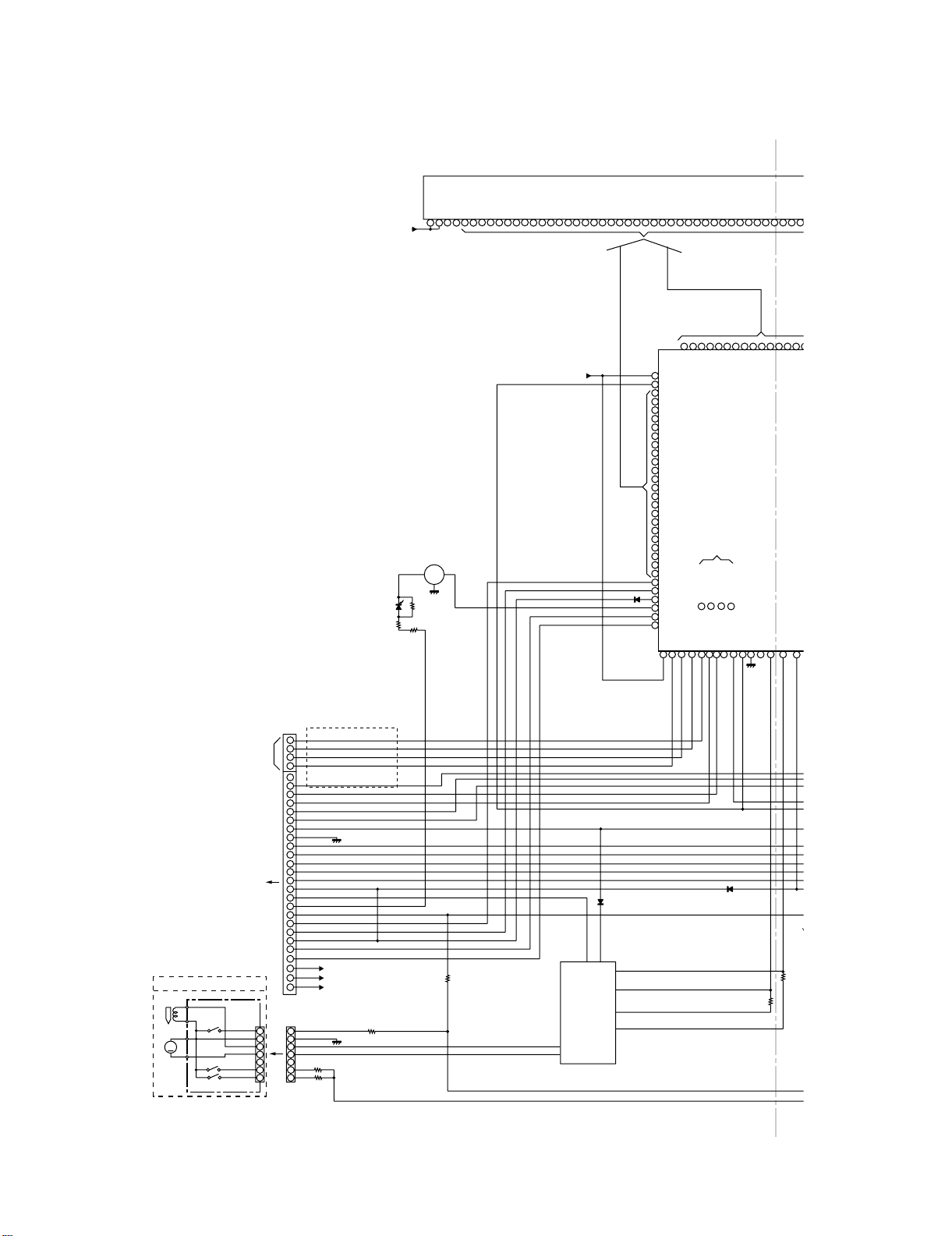

Figure 4-3 BLOCK DIAGRAM (3/6)

4 – 3

XL-MP150H/MP150E

S1

G09

G08

G07

G06

G05

G04

G03NXNX

G02

G01NPF

100

AVDD

KEY0

KEY1

KEY2

VOL_JOG

PROTECT

T_FPSW

TUN_SM/SPAN

T_RUN_PULS

DISCuCLAMESW

TRAY_SW1u2

CD_INTB

MP3_INTB

AVSS

XOUT

CD_CE

CD_DO(FLASHD0)

CD_DI(FLASHDI)

P_IN

PHOTO

SP_DET

REMOCON

MOTA+

MOTA-

VSS

VDD

VPP

CLK

124589

XIN

CE

DI

31323334353637383940

USB_CE

VF1

CNP704

TRAY SW1&2

CD_INTB

MP3_INTB

CD_CE

CD_DO

CD_DI

CD_CLK

USB_CE

CD_RESOUT

MOT_A+

MOT_APHOTO

GND

RESET

VPP

GND

+5V

+5V

BI705

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

5

4

3

2

1

TO CD/MP3 PWB

CNS5

4

3

2

1

TO CD/MP3 PWB

DISC & CLAMP SW

E:GND

+B

+B

CD_RESOUT

MOT_A+

MOT_A-

CD_CLK

CD_DI

CD_DO

CD_CE

Q719

CD_RESOUT

MOT_A+

MOT_A-

+B

+B

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

XL700

17

8.388MHz

18

19

20

21

22

23

24

25

26

27

28

29

30

TUN_SM(H ONLY)

1011121314

89 90 91 92 93 94 95 96 97 98 99

G9G8G7G6G5G4G3G2G1

G12

G11

G10

IC701

A060AW

YSTEM

OCOMPUTER

T_SOL_B

T_MOTOR

T_SOL_A/VOLLED

VSS

SMUTE

CD_CLK(FLASHCLK)

TIMERLED

SMUTE

LED701

+B +B

+B

VOLUME

+B

VR701

SW711

SW718

SW701

SW707

SW708

SW710

H-ONLY

+B

~

~

~

KEY2

KEY1

KEY0

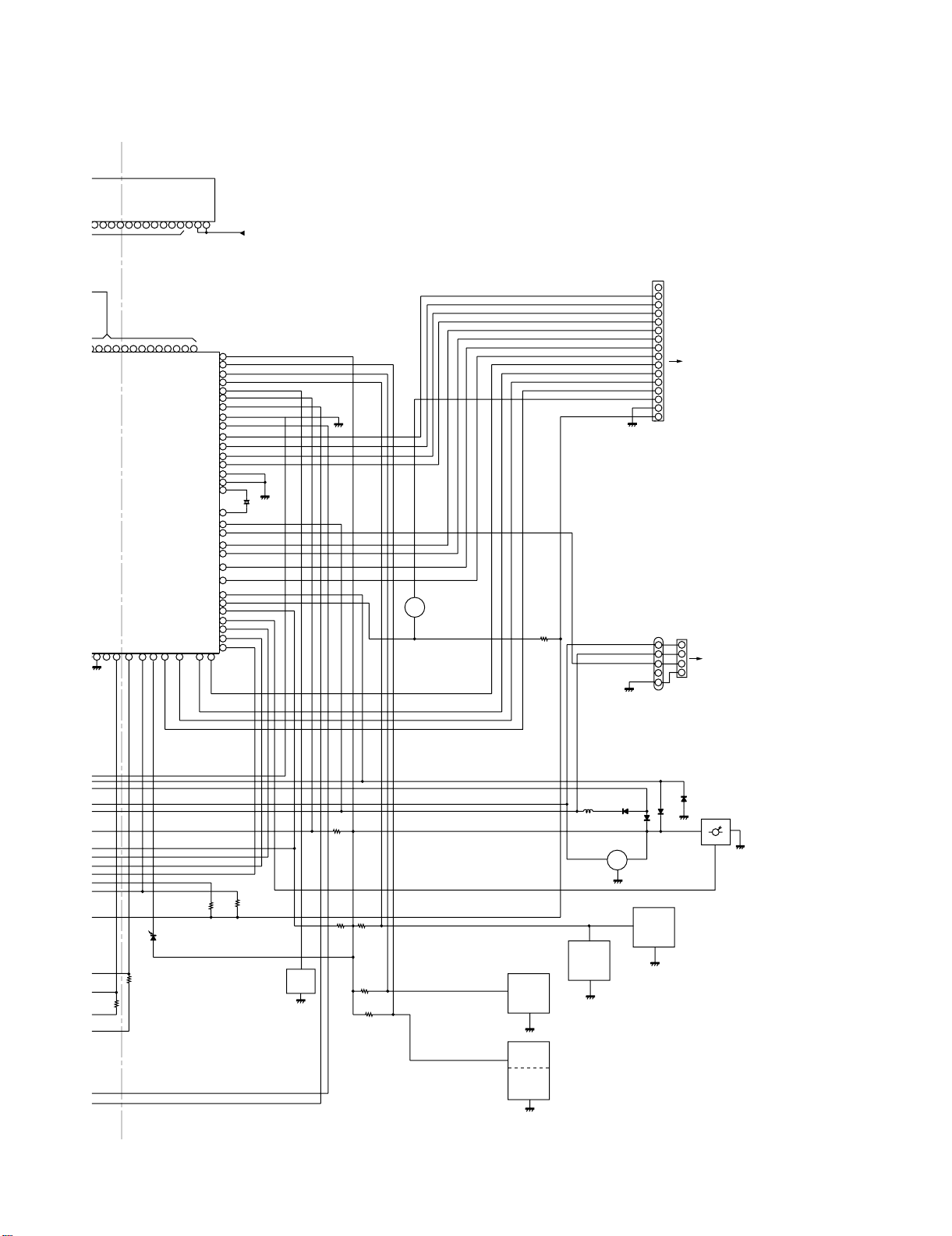

Figure 4-4 BLOCK DIAGRAM (4/6)

4 – 4

SW719

SW721

RX701

REMOTE

SENSOR

2013TH2E1

Q703

SW722

KEY

~

SW728

~

XL-MP150H/MP150E

MP3 DECODER/DIGITAL S

PROCESSOR

FOCUS/TRACKING/

SPIN/SLED DRIVER

TP

TP4

TP3

TP2

TP1

LA6261

LC78690ES2

9

10

11

12

13

14

15

16

17

18

19

20

21 22 23 24 25 26 27 28 29 30 31 32 33 34 3

80 79 78 77 76 75 74 73 72 71 70 69 68 67 6

8

7

6

5

4

3

2

1

7

8

9

10 11 12 13 14 15 16 17 18

1234

5

6

30

29

28 27 26 25 24 23 22 21 20 19

36 35 34 33

32

31

(MGND)

(MGND)

(MO_A-)

(DGND)

(DGND)

(DGND)

(DGND)

(MO_A+)

(MO_B+)

(MO_B-)

(LVDD)

(SVDD)

(AUVDD)

(MO_SPEED)

PVCC2

PGND2

SVCC

VREFIN

SGND

VO4-

VO5-

VO6+

VO6-

VO3-

VO2+

VO1+

VO2-

VO1-

PGND1

VIN1

REGOUT

VIN1G

VIN2

VIN3G

VIN2G

VCONT6

REV6

VIN3

MUTE

PVCC1

VO3+

VIN4

VIN4G

VO4+

VO5+

FWD6

VCONT5

REV5

FWD5

REGIN

TR-

FO+

FO-

TR+

GND

C

F

B

A

E

VR

VCC

PD

VREF

LD

GND

VREF

FDO

PDOUT1

SPDO

XOUT

SLCO

AVDD

RCHO

LRVSS

LRVDD

LCHO

XVDD

XIN

XVSS

AMUTEB

DOUT

DVDD

DVSS

DVDD1 8

C2F

FSEQ

DEFECT

PUIN

DMUTEB

VVDD1

PCKIST

PDOUT0

VVSS1

SLDO

TDO

AVDD

AVSS

JITTC

RFMON

LDS

LDD

TEIN

TE

TEC

FIN

EIN

FEC

DIN

BIN

CIN

AIN

PHLPF

LPF

RFOUT

EFMIN

+B

+B

+B+B

+B

+B

+B

+B

+B

GND

TR-

TR+

TR+

FO+

FO+

FO-

PD

VR

LD

F

C

B

A

E

VCC

TR-

VREF

GND

PUIN

SL+

SL-

SP-

SP+

(AGND)

16.9344MHz

6

5

4

2

1

3

9

10

11

12

13

14

15

16

8

7

4

3

2

6

5

1

9

10

11

12

13

14

15

16

8

7

4

3

2

6

5

1

PICKUP UNIT(306)

SLED

MOTOR

SPINDLE

MOTOR

+

+

-

-

PICKUP-IN

M

M

6

5

2

4

1

3

DRIVER

LASER

CNP1

XL1

Q2

CNP2

IC2

IC1

CNP3A

SW1A

M1A

M2A

Q1

Figure 4-5 BLOCK DIAGRAM (5/6)

4 – 5

XL-MP150H/MP150E

+B

Hz

(DGND)

70 69 68 67 66 65 64 63 62 61

DVSS

DOUT

DVDD

VVSS2

DVDD1.8

VCOC2

VPDOUT2

AMUTEB

STDATA

1

90ES2

DIGITAL SIGNAL

SSOR

DVDD1.8

DVSS

DVDD

C2F

FSEQ

DEFECT

PUIN

DMUTEB

31 32 33 34 35 36 37 38 39 40

TP5

(DGND)

+B

VPREF2

LRSY

DATACK

DATA

TEST1

STCK

STREQ

TEST0

CONT0

CONT1

CONT2

INTB1

INTB0

RESB

DO

VDD3

VVDD2

DI

CL

CE

VVSS3

(DGND)

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

(DVDD)

DVSS

DVDD

CNP7

1

GND

RESET

(P26/BCLK)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

CNP6

1

VPP

2

+5V

3

4

CNP5

GND

TRAY SW2

TRAY SW1

CLAMP

DISC

PHOTO

CAM+

CAM-

(P25/SDAT)

TO DISPLAY PWB

GND

SI

SO

SCK

+5V

VPP

RESET

FROM DISPLAY PWB

1

2

3

4

5

6

+5V

7

TR+

8

TR-

9

10

11

CNP4

1

2

3

4

5

6

7

8

9

10

11

P71/INT1

CNB1

DGND

VCC

GND

CNP9

D+

D-

CNP8

+

-

+

-

2

1

1

2

3

4

TRAY SW2

TRAY SW1

CLAMP

RX1

PHOTO

INTERRUPTER

M

MOTOR

M

MAIN CAM

FROM ??? PWB

1

2

3

4

CNS8

SW3

SW2

SW1

SW4

DISC

M1

TRAY

M2

MOTOR

JK702

USB

4321

+B

(DVDD)

+B

DISC/CLAMP

TRAY SW1/SW2

CD_INT

MP3_INT

CD_CE

CD_DO

CD_DI

CD_CLK

USB_CE

CD_RES

MO_A+

MO_A-

PHOTO

GND

+5V+B

+B

(DGND)

(DGND)

+B

+B

+B

(DI)

(CL)

(RESt)

(CE)

(P27/LRCK)

Q4

(MGND)

Q3

+B

XL2

12MHz

(DGND)

+B

(+8V)

+B

48 47 46 45 44 43 42 41 40 39 38 37

P72/INT2

P30

1

2

3

4

5

6

7

8

9

10

11

12

R-CH

AGND

L-CH

DGND

+5V

MGND

+8V

P73/

INT3

RESt

XT1

XT2

VSS1

CF1

CF2

VDD1

P10

P11

P12

P13

(DI)

P31

P71/INT1

P70/INT0

IXA070AW

SYSTEM

MICROCOMPUTER

PWM0

P17

P16

P15

P14

13 14 15 16 17 18 19 20 21 22 23 24

(CL)

1

2

3

4

FROM MAIN PWB

5

6

7

IC3

P32

PWM1

P33/FILT

P34/FILT

VSS2

VDD2

VSS3

P00

D+

P27/LRCK

VDD3

P26/BCLK

P25/SDAT

P02

P01

(DGND)

D-

36

35

34

P24

33

P23

32

P22

31

P21

30

P20

29

P07

28

P06

27

P05

26

P04

25

P03

Q5

CNP3

Figure 4-6 BLOCK DIAGRAM (6/6)

4 – 6

XL-MP150H/MP150E

AudioXL-MP150H/MP150EService ManualXLMP150HMarketE

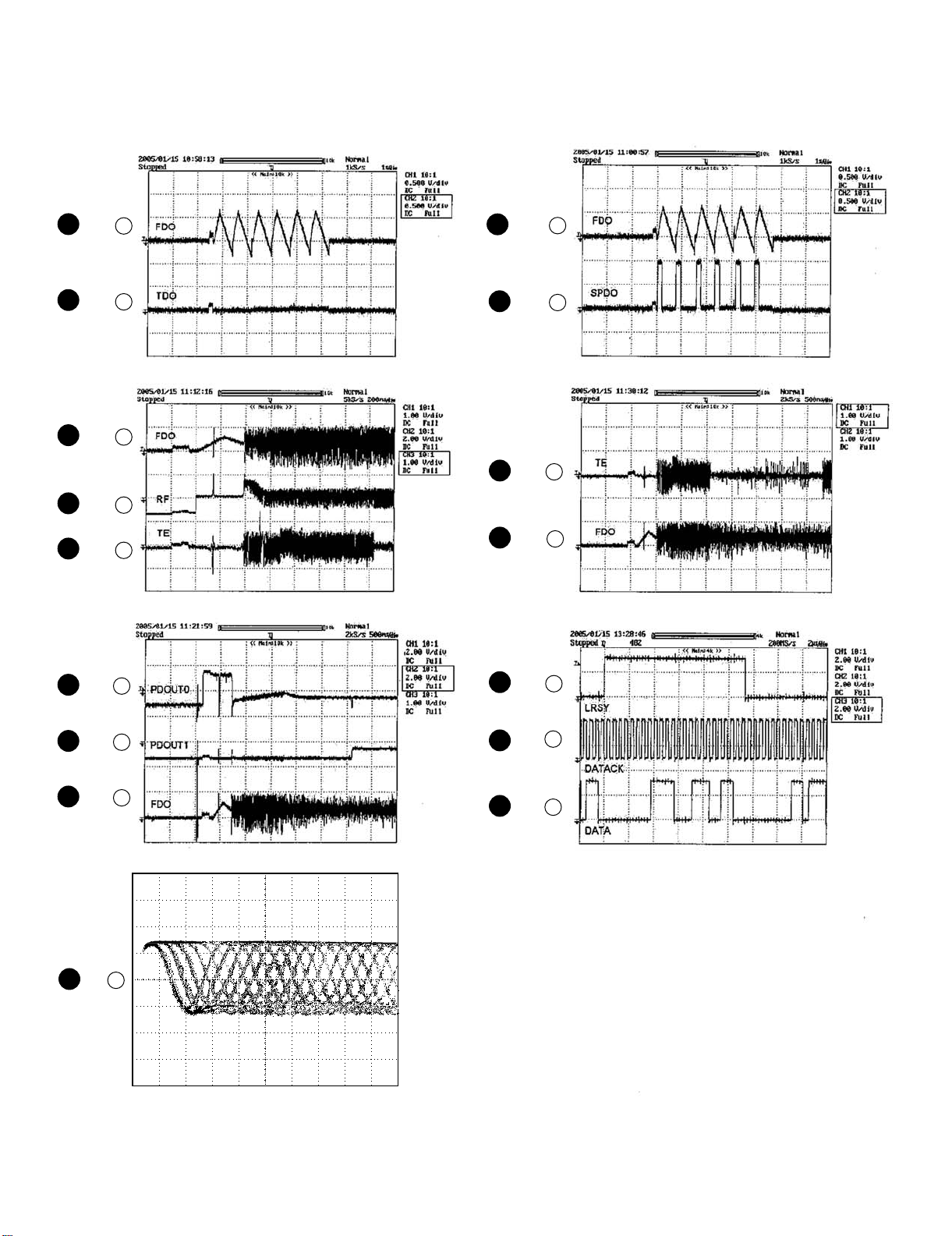

CHAPTER 5. CIRCUIT DESCRIPTION

[1] WAVEFORMS OF CD CIRCUIT

3

IC1

22

3

IC1

22

IC1

IC1

IC1

22

16IC1

28IC1

27IC1

23

5

2

2

3

10

9

25IC1

16IC1

22IC1

60IC1

59IC1

4

3

1

2

7

6

3

1

IC1 2

22IC1

Vp-p=1.0 V~1.3 V

0.5 mV/div,0.5 µsec/div

8

58IC1

5 – 1

[2] VOLTAGE

XL-MP150H/MP150E

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

IC302

VOLTAGE

2.57 V

0V

0V

0V

0V

5.13 V

10.18 V

4.75 V

0V

0V

5.23 V

0V

5.23 V

0V

0V

2.57 V

5.24 V

0V

0V

10.18 V

0V

2.57 V

IC303

VOLTAGE

2.11 V

6.10 V

2.11 V

2.11 V

0V

0V

5.10 V

3.00 V

5.03 V

0V

3.90 V

3.90 V

2.28 V

1.29 V

1.26 V

2.07 V

0V

2.20 V

2.04 V

1.29 V

2.40 V

2.40 V

5.02 V

3.52 V

IC101

VOLTAGE

0V

0V

0.57 V

1.95 V

1.61 V

0V

0V

0.58 V

3.39 V

3.38 V

0V

0V

6.84 V

4.11 V

0V

3.39 V

0.58 V

0V

0V

1.42 V

1.95 V

0.57 V

0V

0V

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

4

5

6

7

8

9

IC601

VOLTAGE

0V

0V

0V

4.97 V

4.93 V

4.94 V

4.94 V

4.96 V

4.94 V

4.94 V

4.94 V

4.94 V

4.94 V

4.94 V

4.94 V

4.94 V

4.95 V

4.94 V

4.94 V

4.93 V

4.96 V

4.96 V

9.91 V

0V

IC851

VOLTAGE

18.97 V

1.29 V

13.28 V

IC852

VOLTAGE

18.75 V

0V

9.92 V

IC853

VOLTAGE

18.97 V

0V

4.96 V

IC854

VOLTAGE

14.35 V

0.574 V

5.65 V

IC855

VOLTAGE

8.41 V

13.27 V

7.92 V

IC901

VOLTAGE

52.2 V

22.69 V

10.46 V

-10.61 V

-22.5 V

-52.1 V

0V

0V

0V

0V

0V

-50.5 V

50.6 V

0V

0V

-47.5 V

0V

0V

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

1

2

3

4

5

6

7

8

9

IC1

VOLTAGE

1.56 V

1.69 V

1.67 V

1.52 V

1.62 V

1.62 V

1.62 V

1.62 V

1.61 V

1.61 V

1.61 V

0V

1.61 V

1.61 V

1.61 V

1.61 V

1.61 V

3.20 V

0V

0V

3.20 V

1.62 V

1.61 V

1.61 V

1.62 V

0V

0V

2.88 V

0.98 V

3.12 V

3.16 V

3.23 V

0V

0V

3.22 V

3.22 V

0V

1.83 V

3.17 V

0V

3.21 V

0V

0V

2.97 V

2.94 V

0.93 V

3.21 V

3.22 V

3.22 V

3.21 V

3.21 V

3.21 V

0V

0V

0V

0V

0V

0V

0V

3.12 V

3.10 V

1.53 V

0V

0V

0V

1.83 V

0V

3.22 V

0V

0V

0V

1.28 V

1.41 V

3.08 V

1.58 V

3.17 V

0V

1.58 V

3.20 V

1.56 V

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

PIN

NO.

E

C

B

PIN

NO.

E

C

B

(H ONLY)

PIN

NO.

E

C

B

(H ONLY)

PIN

NO.

E

C

B

IC1

VOLTAGE

0V

3.18 V

3.3 V

0V

0V

2.64 V

3.3 V

3.3 V

0V

0V

0V

0V

2.98 V

2.97 V

0V

0V

0V

0V

3.3 V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

3.3 V

0V

0V

0V

0V

0V

0V

3.3 V

0V

0V

0V

0V

0V

0V

3.17 V

0V

1.79 V

Q301

VOLTAGE

0V

0V

0V

Q360

VOLTAGE

9.8 V

0V

9.8 V

QT21

VOLTAGE

1.98 V

5.17 V

2.56 V

Q841

VOLTAGE

0.12 V

0V

0.70 V

PIN

NO.

PIN

NO.

10

11

12

13

14

15

16

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

2

3

4

5

6

7

8

9

E

C

B

E

C

B

E

C

B

E

C

B

IC2

VOLTAGE

2.04 V

2.03 V

2.04 V

2.03 V

2.03 V

2.04 V

0V

4.15 V

4.80 V

3.23 V

1.61 V

1.61 V

1.61 V

1.61 V

1.61 V

1.61 V

1.61 V

1.61 V

4.30 V

4.30 V

3.07 V

3.17 V

3.17 V

2.84 V

1.61 V

0V

4.77 V

7.69 V

4.74 V

0V

0V

0V

0V

0V

2.03 V

2.03 V

1CT21

(H Only)

VOLTAGE

2.57 V

2.57 V

5.15 V

0V

2.66 V

2.66 V

0V

2.73 V

2.73 V

0V

5.16 V

5.16 V

0V

0V

0V

5.16 V

Q1

VOLTAGE

3.23 V

0V

3.19 V

Q2

VOLTAGE

4.76 V

3.23 V

4.11 V

Q3

VOLTAGE

1.83 V

3.23 V

2.32 V

Q4

VOLTAGE

0V

0V

3.00 V

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

VOLTAGE

5V

5V

5V

5V

1.33 V

5V

5V

0V

2.967 V

4.94 V

4.96 V

3.93 V

1.684 V

0V

0V

2.328 V

2.709 V

4.63 V

0.96 V

0V

1.604 V

4.6 V

4.6 V

1.828 V

4.96 V

5V

4.86 V

0V

0V

0V

4.95 V

0V

0V

4.96 V

2.026 V

4.96 V

11.64 V

13.28 V

13.28 V

0V

4.64 V

4.8 V

4.63 V

4.64 V

4.64 V

0V

1.628 V

1.088 V

0V

-0.6 V

Q101

VOLTAGE

0V

0V

0.69 V

Q102

VOLTAGE

0V

0V

0.70 V

Q103

VOLTAGE

0V

0V

0.69 V

Q104

VOLTAGE

0V

0V

0.69 V

Q105

VOLTAGE

0V

0V

0V

IC701

PIN

NO.

100

PIN

NO.

PIN

NO.

PIN

NO.

C

PIN

NO.

PIN

NO.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

E

C

B

E

C

B

E

B

E

C

B

E

C

B

VOLTAGE

0.29 V

0.28 V

0.23 V

0.25 V

0.33 V

4.53 V

-28.79 V

-26.24 V

-15.65 V

-28.78 V

-28.78 V

-20.88 V

-28.78 V

-10.3 V

-10.28 V

-12 V

-20.91 V

-25.99 V

-28.78 V

-25.98 V

-18.28 V

-10.25 V

-26.15 V

-25.98 V

-28.78 V

-23.34 V

-26.14 V

-26 V

-4.66 V

-28.9 V

-23.49 V

-25.96 V

-26.1 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

-25.93 V

Q106

VOLTAGE

0V

0V

0V

Q107

VOLTAGE

0V

0V

0.65 V

Q108

VOLTAGE

0V

0V

0.65 V

Q109

VOLTAGE

9.92 V

0.2 V

9.87 V

Q110

VOLTAGE

0V

9.87 V

0V

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

Q111

VOLTAGE

0.18 V

0.18 V

0V

Q112

VOLTAGE

7.98 V

7.93 V

7.26 V

Q113

VOLTAGE

0V

0V

3.54 V

Q114

VOLTAGE

0V

0V

3.54 V

Q601

VOLTAGE

0V

0V

0.71 V

Q602

VOLTAGE

0V

0V

0.71 V

Q607

VOLTAGE

3.78 V

3.74 V

0V

Q801

VOLTAGE

41.5 V

28.98 V

29.55 V

Q850

VOLTAGE

0V

4.72 V

0V

Q901

VOLTAGE

0V

5.11 V

0V

Q902

VOLTAGE

0V

5.16 V

0V

Q903

VOLTAGE

0V

5.01 V

0V

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

Q904

VOLTAGE

0V

5.02 V

0V

Q905

VOLTAGE

0V

0V

0.80 V

Q906

VOLTAGE

4.96 V

0V

0V

Q701

VOLTAGE

13 V

1V

13 V

Q702

VOLTAGE

13 V

0V

13 V

Q703

VOLTAGE

0V

4.75 V

0V

Q710

VOLTAGE

4.75 V

0V

0V

Q712

VOLTAGE

0V

4.75 V

0V

Q713

VOLTAGE

13 V

0V

13 V

Q714

VOLTAGE

0V

4.78 V

0V

Q715

VOLTAGE

13 V

0V

13 V

Q719

VOLTAGE

0V

4.95 V

0V

5 – 2

XL-MP150H/MP150E

-MEMO-

5 – 3

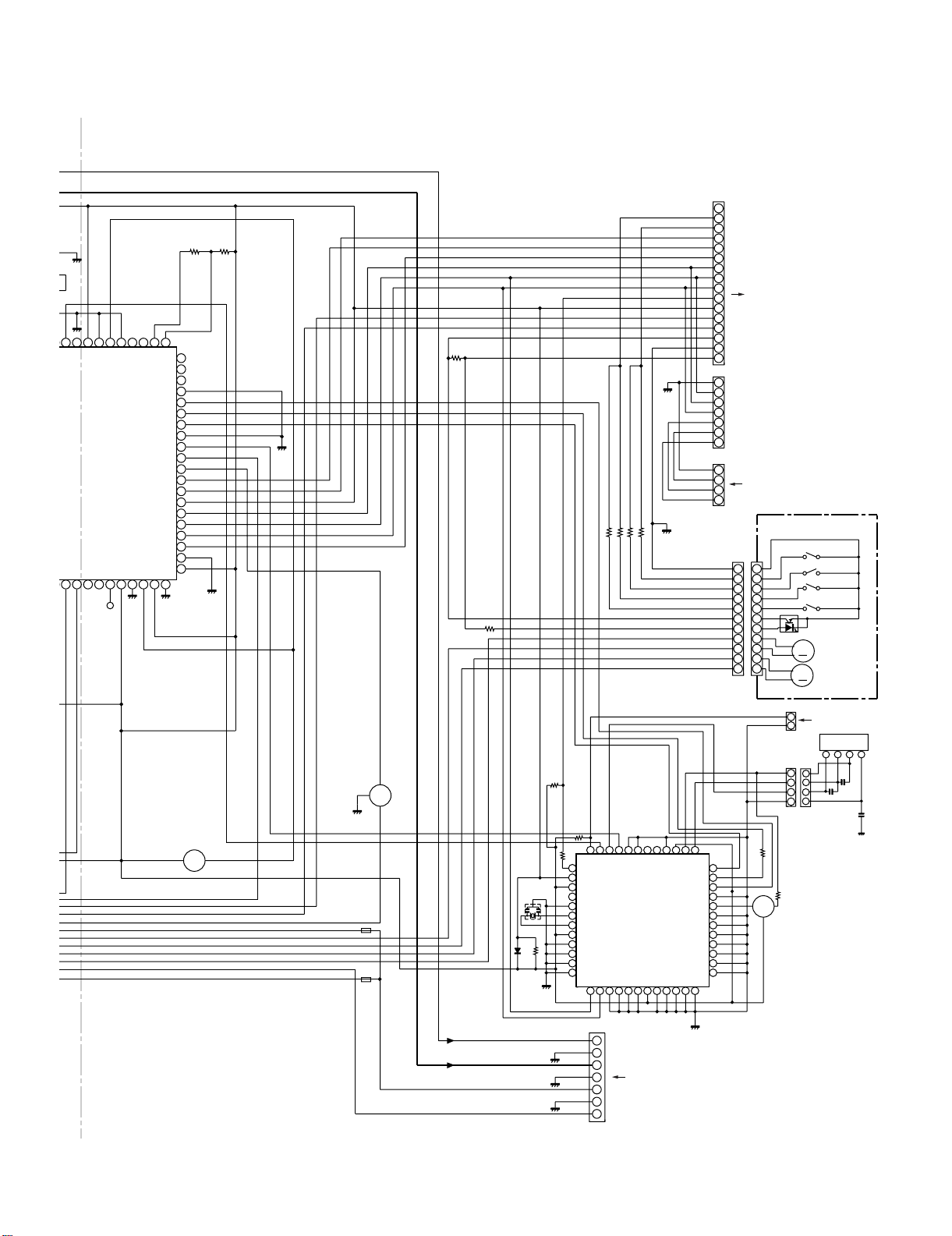

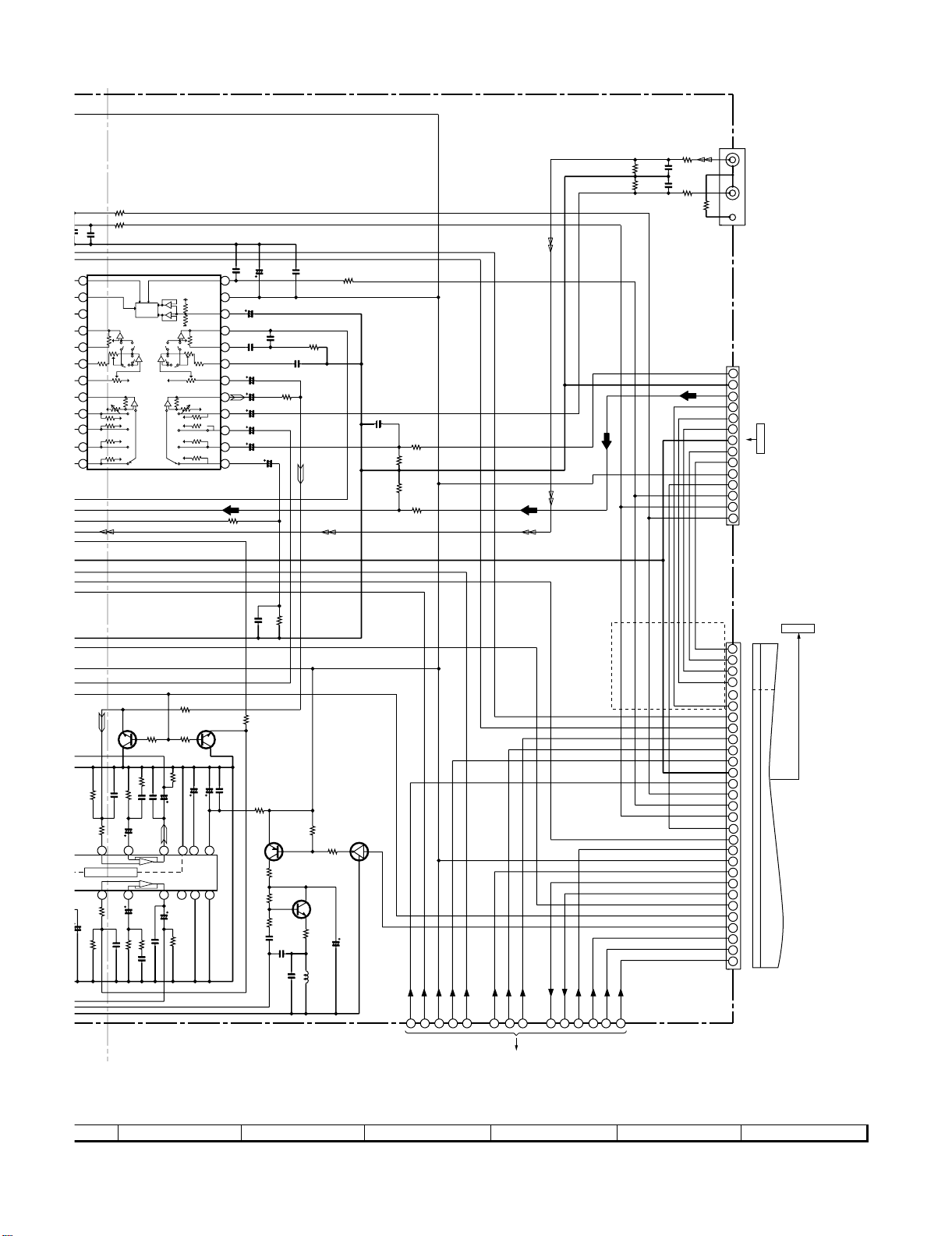

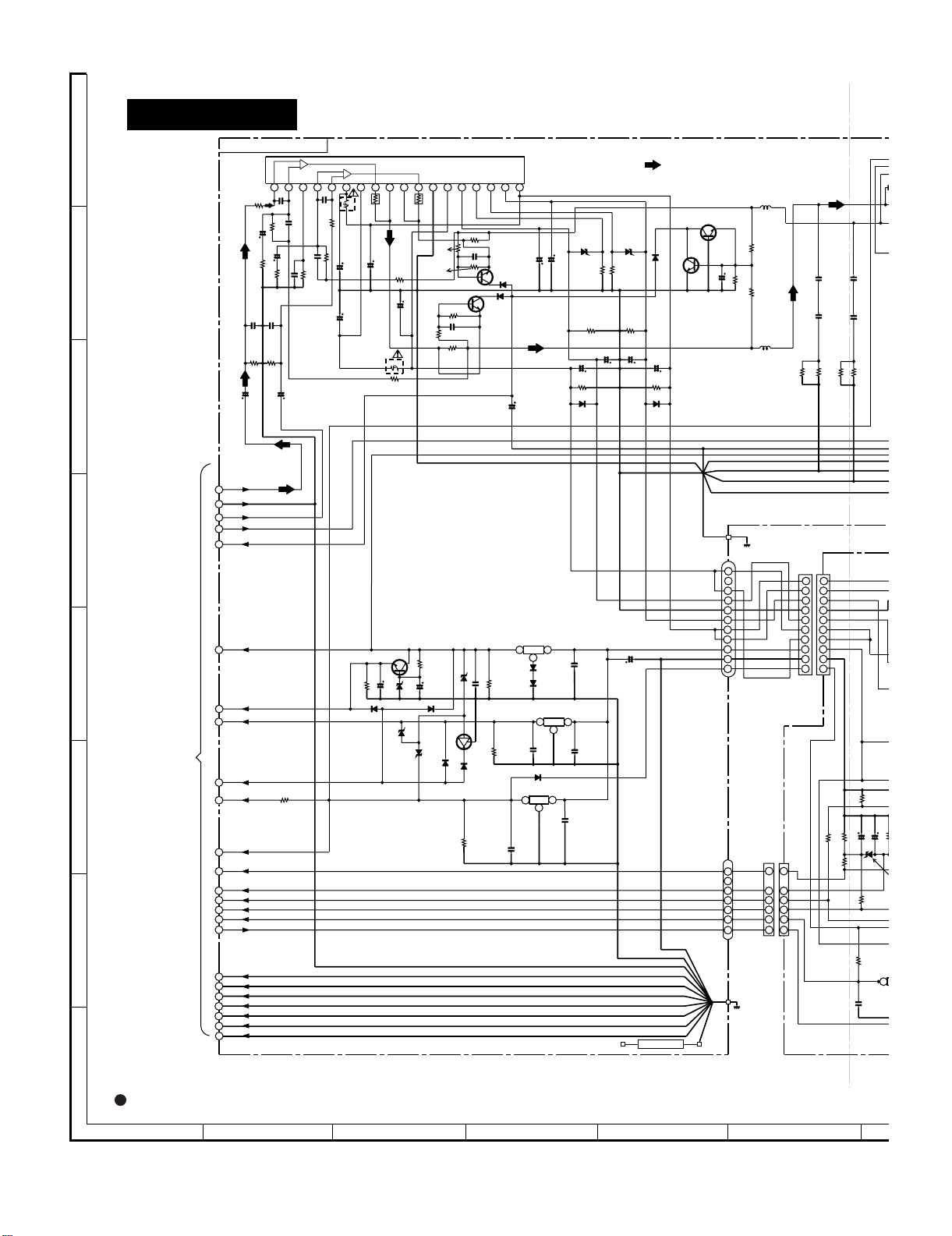

AudioXL-MP150H/MP150EService ManualXLMP150HMarketE

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS LAYOUT

[1] NOTES ON SCHEMATIC DIAGRAM

XL-MP150H/MP150E

•Resistor:

To differentiate the units of resistors, such symbol as K and M are

used: the symbol K means 1000 ohm and the symbol M means

1000 kohm and the resistor without any symbol is ohm-type resistor. Besides, the one with “Fusible” is a fuse type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this symbol P

means pico-farad and the unit of the capacitor without such a symbol is microfarad. As to electrolytic capacitor, the expression

“capacitance/withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board for this model

are subject to change for improvement without prior notice.

REF. NO DESCRIPTION POSITION

SW1 CLAMP ON—OFF

SW1A PICKUP IN ON—OFF

SW2 TRAY SW1 ON—OFF

SW3 TRAY SW2 ON—OFF

SW4 DISC ON—OFF

SW701 ON/STAND-BY ON—OFF

SW702 CLOCK/TIMER ON—OFF

SW703 REC/PAUSE ON—OFF

SW704 PRESET UP ON—OFF

SW705 PRESET DOWN ON—OFF

SW706 REVERSE PLAY ON—OFF

SW707 REVERSE MODE ON—OFF

SW708 DISPLAY MODE [XL-MP150H] ON—OFF

SW709 PTY/TI SEARCH [XL-MP150H] ON—OFF

SW710 ASPM [XL-MP150H] ON—OFF

SW711 USB/VIDEO/AUX ON—OFF

• The indicated vo ltage in each section is the one measured by Digital Multimeter between such a section and the chassis with no signal given.

1. In the tuner section,

indicates AM

indicates FM stereo

2. In the main section, a tape is being played back.

3. In the deck section, a tape is being played back.

4. In the power section, a tape is being played back.

5. In the CD section, the CD is stopped.

• Parts marked with “ ” ( ) are important for

maintaining the safety of the set. Be sure to replace these parts

with specified ones for maintaining the safety and performance of

the set.

REF. NO DESCRIPTION POSITION

SW712 TUNER (BAND) ON—OFF

SW713 PLAY/REPEAT ON—OFF

SW714 TUNING/TIME DOWN ON—OFF

SW715 TUNING/TIME UP ON—OFF

SW716 STOP ON—OFF

SW717 CD ON—OFF

SW718 TAPE ON—OFF

SW719 MEMORY/SET ON—OFF

SW720 EQUALISER ON—OFF

SW721 X-BASS/DEMO ON—OFF

SW722 DIRECT PLAY ON—OFF

SW723 DISC 1 ON—OFF

SW724 DISC 2 ON—OFF

SW725 DISC 3 ON—OFF

SW726 DISC 4 ON—OFF

SW727 DISC 5 ON—OFF

SW728 OPEN/CLOSE ON—OFF

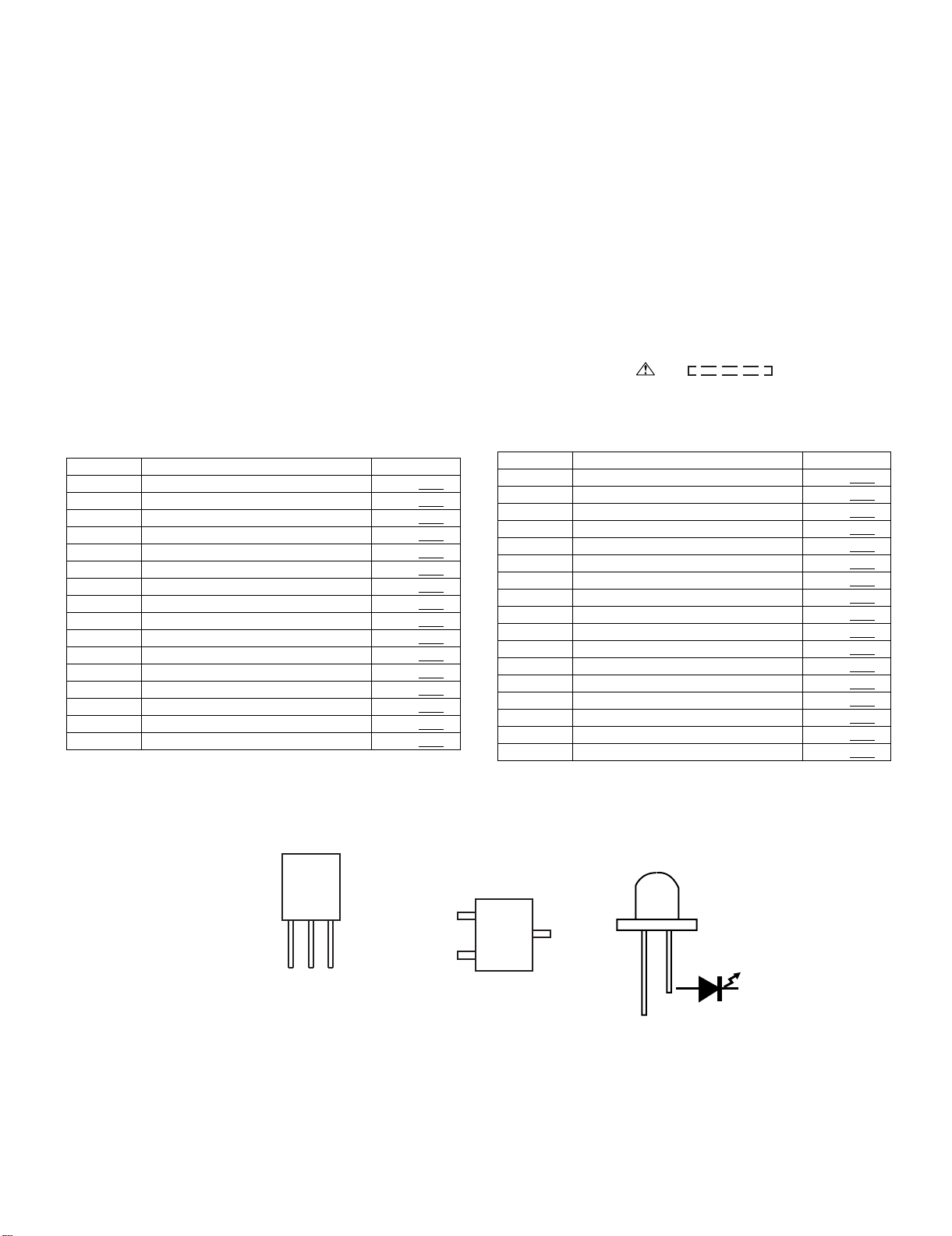

[2] TYPES OF TRANSISTOR AND LED

FRONT

VIEW

EC B

(S) (G) (D)

(1) (2) (3)

KTA1271 Y

KTA1273 Y

KTA1274 Y

KTC3199 GR

KTC3200 GR

KTC3203 Y

2SC380 O

KTC2026

B

(3)

VIEW

E

(1)

KTA1504 Y

KTA1504 GR

KTC3875 GR

KRA102 S

KRA107 S

KRC104 S

KRC102 S

6 – 1

TOP

FRONT

VIEW

C

(2)

SLR343VC3F

XL-MP150H/MP150E

L

2

+

C125

R133

C127

C

R132

C128

[3] WIRING SIDE OF PWB/SCHEMATIC DIAGRAM

MAIN PWB-A1(1/2)

+B

A

SOUND

IC602

IXA043AW

NEW

B

R619

L_CH

2

CNS3

1

2

3

4

5

6

7

7

6

5

4

3

2

1

3

4

BI601

1

2

3

4

5

6

7

8

5

6

7

8

9

10

11

7

6

5

4

3

2

1

CNP101

R-CH

CD_A_GND

L-CH

CD_D_GND

+5V

CD_M_GND

LD+8V

ERASE

M_GND

T2_R2

A_GND

T2_R1

T2_L1

T2_L2

C

TO MAIN PWB(2/2)

H:6-4 2 - D

E:6-6 2 - D

D

CNP3

6-17 11 - G

TO CD/MP3 PWB

E

TO MAIN PWB(2/2)

H:6-4 2 - G

E:6-6 2 - G

TAPE MECHANISM

Ass'y(212)

F

R-CH

(212-1)

HEAD

L-CH

RECORD/PLAYBACK/ERASE

CNS101

330

Q605

A_GND

R_CH

CD_M_GND

CD_D_GND

CD_A_GND

A_GND(AUDIO)

D_GND

TAPE_A_GND

M_GND

KTC3875 GR

R618

330

Q606

KTC3875 GR

12K

R650

R646

1.5K

+B +B

+B

G

R670

15K

R673

101112

eala-

eala-

VROUT

V+ GND

OUT

VREF-

VREF-

13 14 15 16 17 18 19 20 21 22 23

C671

3.3/16

+B

C672

47/16

12K

R649

R647 R617

2.2K

C645

0.001

C644

0.001

R648

2.2K

2

3

Q609

KRA107 S

C610

22/50

C104

180P

(CH)

C103

180P

15K

VRIN

IN

R671

1

BASS-

C670

10K

R669

27K

VROUT

SW1

1/50

33K

R672

0V

0V

0V

0V

0V

0V

C676

0.068

(ML)

R668

22K

VRIN

BASS-

C3OUT

FIL

SW2

eala-

0.001

C668

R664

C669

10/50

Q603

KTC3875 GR

22K

R655

KRA102 S

R146

10K

9.3V

9.3V

Q112

KTA1504 GR

Q102

KTC3200 GR

R104

2.2K

0.7V

R106

0.7V

3.3K

Q104

KTC3200 GR

Q103

KTC3200 GR

0.7V

R105

3.3K

0.7V

Q101

KTC3200 GR

Q604

Q608

8.6V

C3IN

HFFILL

0

R665

R103

2.2K

C667

33K

KTC3875 GR

C675

Cr

HFFILR

0.001

R662

R147

10K

R148

4.7K

10/50

C666

2.2K

C637

0.001

C638

R616

R663

0

0.001

2.2K

3

+B

1/50

C674

Ca

ROUT

0.001

C664

33K

2

C640

KRC104 S

0V

2

0V

2

0V

4.7K

R110

4.7K

R109

0V

R107

47K

R667

22K

MOUT

LOUT

C665

10/50

2.7K

R615

R614

1

2.2/50

Q113

0V

KRC104 S

R112

R108

47K

0V

0V

Q105

KTC3875 GR

R620

1

1

0V

0V

10/50

Q601

2.7K

Q114

15K

Q106

123456789

MIN

RIN

24

C662

10/50

R623

KTC3875 GR

Q602

KTC3875 GR

2