Sharp XL-520W,CP-520 Service Manual

– 1 –

XL-520W/CP-520

CONTENTS

Page

SAFETY PRECAUTION FOR SERVICE MANUAL ........................................................................................................... 2

SPECIFICATIONS ............................................................................................................................................................. 2

NAMES OF PARTS ........................................................................................................................................................... 3

OPERATION MANUAL ...................................................................................................................................................... 5

DISASSEMBLY.................................................................................................................................................................. 7

REMOVING AND REINSTALLING THE MAIN PARTS..................................................................................................... 8

ADJUSTMENT ................................................................................................................................................................... 9

BLOCK DIAGRAM ........................................................................................................................................................... 16

SCHEMATIC DIAGRAM / WIRING SIDE OF P.W.BOARD............................................................................................. 20

VOLTAGE ........................................................................................................................................................................ 28

NOTES ON SCHEMATIC DIAGRAM .............................................................................................................................. 29

TYPE OF TRANSISTOR AND LED ................................................................................................................................. 29

WAVEFORMS OF CD CIRCUIT...................................................................................................................................... 30

TROUBLESHOOTING (CD SECTION) ........................................................................................................................... 31

FUNCTION TABLE OF IC................................................................................................................................................ 36

REPLACEMENT PARTS LIST/EXPLODED VIEW

XL-520W

CP-520

XL-520W and CP-520 constitute XL-520W.

SERVICE MANUAL

SHARP CORPORATION

No. S0780XL520W//

• In the interests of user-safety the set should be restored to its original

condition and only parts identical to those specified should be used.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

XL-520W/CP-520

– 2 –

Cassette deck section

Frequency response: 50 - 14,000 Hz (Normal tape)

Signal/noise ratio: 50 dB

Wow and flutter: 0.25 % (WRMS)

Type: 2-way [12 cm (4-3/4") woofer and 2 cm

(13/16") tweeter]

Rated input power: 20 W

Maximum input power: 40 W

Impedance: 4 ohms

Dimensions: Width; 160 mm (6-5/16")

Height; 240 mm (9-1/2")

Depth; 183 mm (7-1/4")

Weight: 1.8 kg (4.0 lbs.)/each

General

Power source: AC110/127/220/230-240 V, 50/60 Hz

Power consumption: 98 W

Dimensions: Width; 160 mm (6-5/16")

Height; 240 mm (9-1/2")

Depth; 300 mm (11-13/16")

Weight: 3.7 kg (8.2 lbs.)

Amplifier section

Output power: PMPO; 320 W (total)

MPO; 56 W (28 W + 28 W) (10% T.H.D)

RMS; 40 W (20 W + 20 W) (10% T.H.D)

Input terminals: Video/Auxiliary (audio signal);

500 mV/47 kohms

Output terminals: Speakers; 4 ohms

Headphones; 16-50 ohms

(recommended; 32 ohms)

Tuner section

Frequency range: FM; 88 - 108 MHz

AM; 531 - 1,602 kHz

Compact disc player section

Type: Compact disc player

Signal readout: Non-contact, 3-beam semi-conductor

laser pickup

D/A Converter: 1-bit D/A converter

Filter: 8-times oversampling digital filter

Frequency response: 20 - 20,000 Hz

Wow and flutter: Unmeasurable

(less than 0.001% W.peak)

SPECIFICATIONS

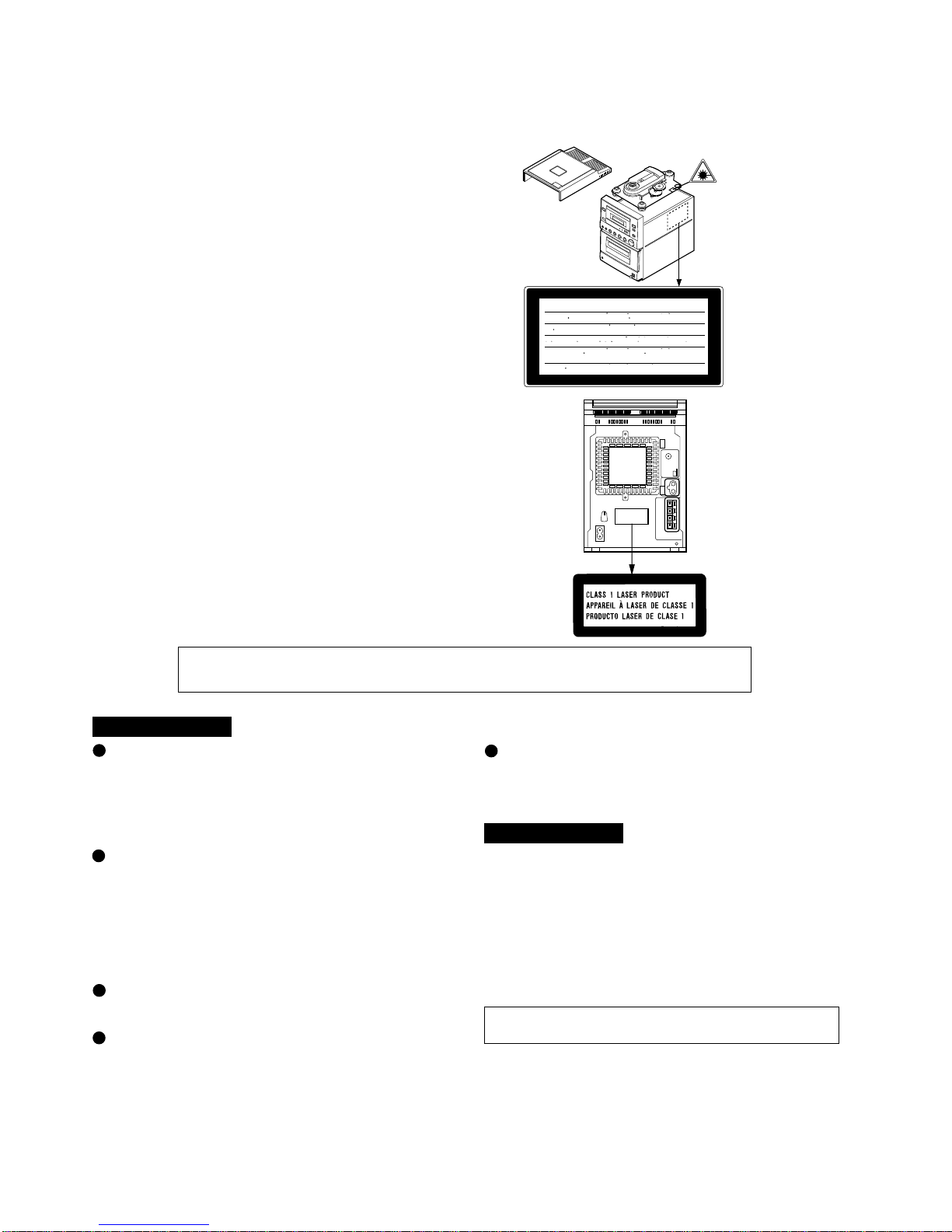

SAFETY PRECAUTION FOR

SERVICE MANUAL

Precaution to be taken when replacing and servicing the

Laser Pickup.

The AEL (Accessible Emission Level) of Laser Power Output

for this model is specified to be lower than Class I Requirements.

However, the following precautions must be observed during

servicing to protect your eyes against exposure to the Laser

beam

(1) When the cabinet has been removed, the power is turned

on without a compact disc, and the Pickup is on a position

outer than the lead-in position, the Laser will light for several

seconds to detect a disc. Do not look into the Pickup Lens.

(2) The Laser Power Output of the Pickup inside the unit and

replacement service parts have already been adjusted prior

to shipping.

(3) No adjustment to the Laser Power should be attempted

when replacing or servicing the Pickup.

(4) Under no circumstances look directly into the Pickup Lens

at any time.

(5) CAUTION - Use of controls or adjustments, or performance

of procedures other than those specified herein may result

in hazardous radiation exposure.

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

Specifications for this model are subject to change without

prior notice.

XL-520W

CAUTION-INVISIBLE LASER RADIATION WHEN OPEN. DO NOT STARE INTO

BEAM OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

VARNING-OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD. STIRRA

EJ IN I STRALEN OCH BETRAKTA EJ STRALEN MED OPTISKA INSTRUMENT.

ADVERSEL-USYNLIG LASERSTRALING VED ABNING. SE IKKE IND I

STRALEN-HELLER IKKE MED OPTISKE INSTRUMENTER.

VARO! AVATTAESSA OLET ALTTIINA NAKYMATON LASERSATEILYLLE.

ALA TUIJOTA SATEESEEN ALAKA KATSO SITA OPTISEN LAITTEEN LAPI.

VARNING-OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD.

STIRRA EJ IN I STRALEN OCH BETRAKTA EJ STRALEN GENOM OPTISKT

INSTRUMENT.

ADVERSEL-USYNLIG LASERSTRALING NAR DEKSEL APNES. STIRR IKKE

INN I STRALEN ELLER SE DIREKTE MED OPTISKE INSTRUMENTER.

Laeser Diode Properties

Material: GaAlAs

Wavelength: 780 nm

Emission Duration:continuous

Laser Output: max. 0.6 mW

CP-520

– 3 –

XL-520W/CP-520

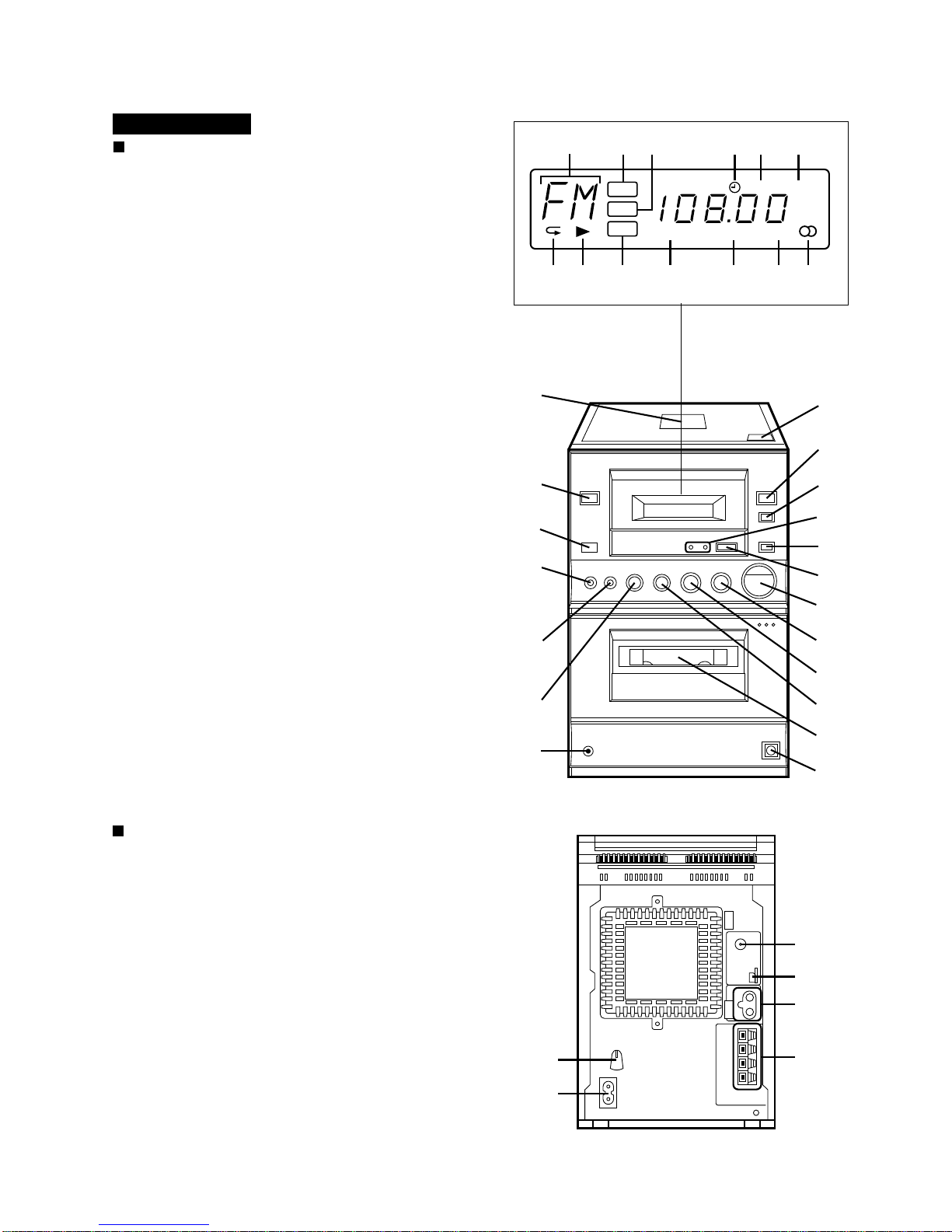

NAMES OF PARTS

Front Panel

1. Functin/Band/Track Number Indicator

2. Volume Indicator

3. Extra Bass/Equalizar Indicator

4. Timer Indicator

5. Record Indicator

6. Sleep Indicator

7. Repeat Indicator

8. Play Indicator

9. Video/Auxiliary Indicator

10. Random Indicator

11. Memory Indicator

12. FM Stereo Mode Indicator

13. FM Stereo Indicator

14. CD Compartment

15. On/Stand-by Switch

16. Remote Control Sensor

17. Record Pause/Beat Cancel Button

18. Memory/Set Button

19. (CD) Track Down/Review Button

(TAPE) Rewind Button

(TUNER) Preset Down Button

20. Headphone Socket

21. CD Eject Button

22. Function Selector Button

23. Band Selector Button

24. 3D Surround Mode Indicators

25. Extra Bass/Equalizer Mode Button

26. 3D Surround Mode Button

27. Volume Up/Down Buttons

28. (CD) Play/Pause Button

(TAPE) Play Button

(TUNER) Tuning Up Button

29. (CD/TAPE) Stop Button

(TUNER) Clear Button

30. (CD) Track Up/Cue Button

(TAPE) Fast Forward Button

(TUNER) Preset Up Button

31. Cassette Compartment

32. CD Digital Output Socket (Optical)

Rear Panel

1. AC Voltage Selector

2. AC Power Input Socket

3. FM 75 ohms Aerial Socket

4. AM Loop Aerial Input Socket

5. Video/Auxiliary (Audio Signal) Input Sockets

6. Speaker Terminals

XL-520W

VOL

EQ

AUX

RANDOM MEMORY ST

REC SLEEP

kHz

MHz

123 456

8 9 10 11 12 137

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

1

2

3

4

5

6

XL-520W/CP-520

– 4 –

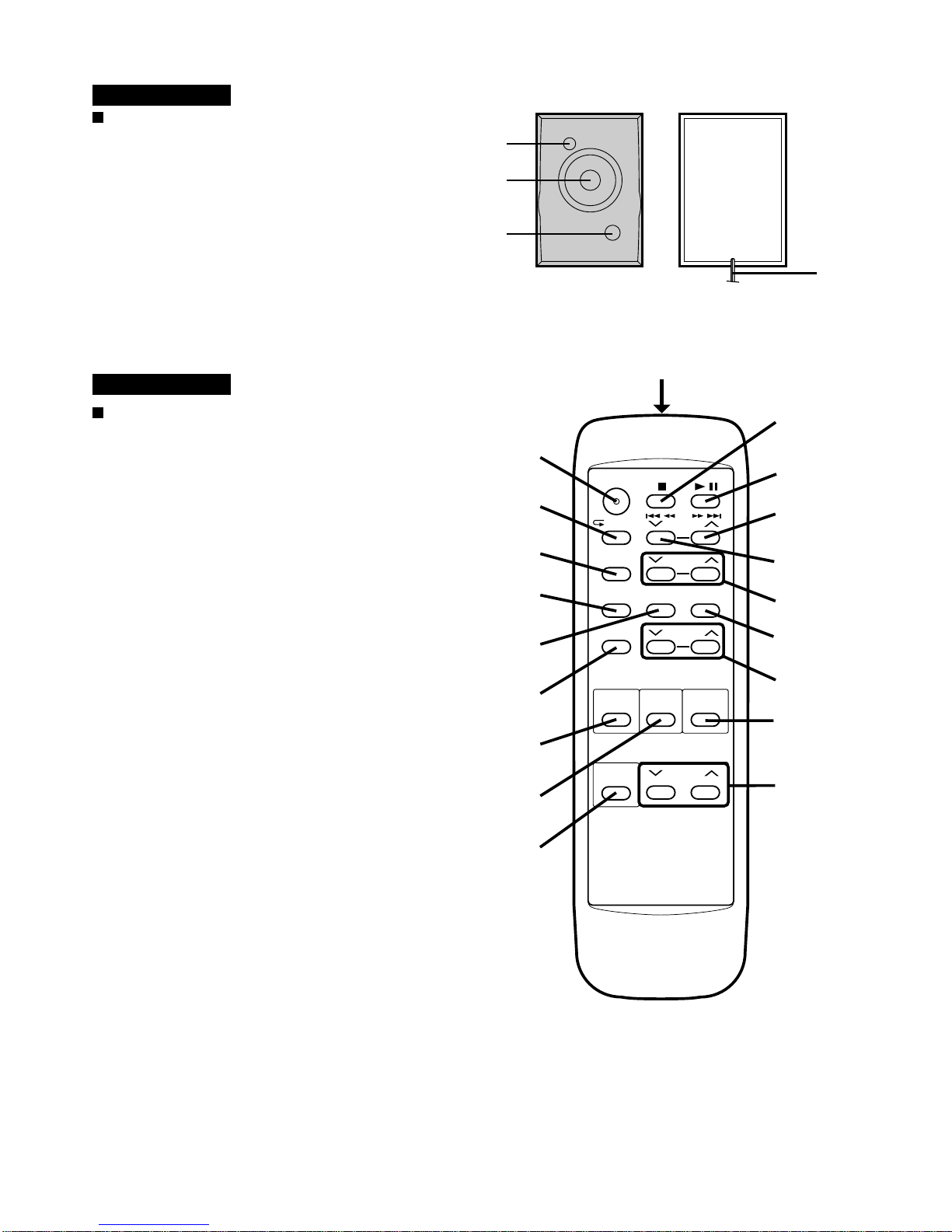

Speaker Section

1. Tweeter

2. Woofer

3. Bass Reflex Duct

4. Speaker Wire

Remote Control

1. Remote Control Transmitter LED

2. On/Stand-by Button

3. (CD) Repeat/Random Button

4. (CD/TUNER) Memory/Set Button

5. (CD/TUNER) Clear Button

6. Timer/Set Button

7. Sleep Button

8. (CD/TAPE) Stop Button

9. (CD) Play/Pause Button

(TAPE) Play Button

10. (CD) Track Up/Cue Button

(TAPE) Fast Forward Button

(TUNER) Preset Up Button

11. (CD) Track Down/Review Button

(TAPE) Rewind Button

(TUNER) Preset Down Button

12. Tuning Up/Down Buttons

13. Timer Button

14. Timer Up/Down Buttons

15. Function Selector Button

16. Band Selector Button

17. 3D Surround Mode button

18. Extra Bass/Equalizer Mode Button

19. Volume Up/Down Buttons

CP-520

XL-520W

1

2

3

4

ON/

STAND-BY

/RANDOM

TIMER/

SET

PRESET

MEMORY/

SET

TUNING

TIMER

VOLUME

CLEAR

SLEEP

FUNCTION

BAND

X-BASS/

EQUALIZER

TIMER

3D

SURROUND

1

8

9

10

11

12

13

14

18

19

2

3

4

5

6

7

15

16

17

– 5 –

XL-520W/CP-520

OPERATION MANUAL

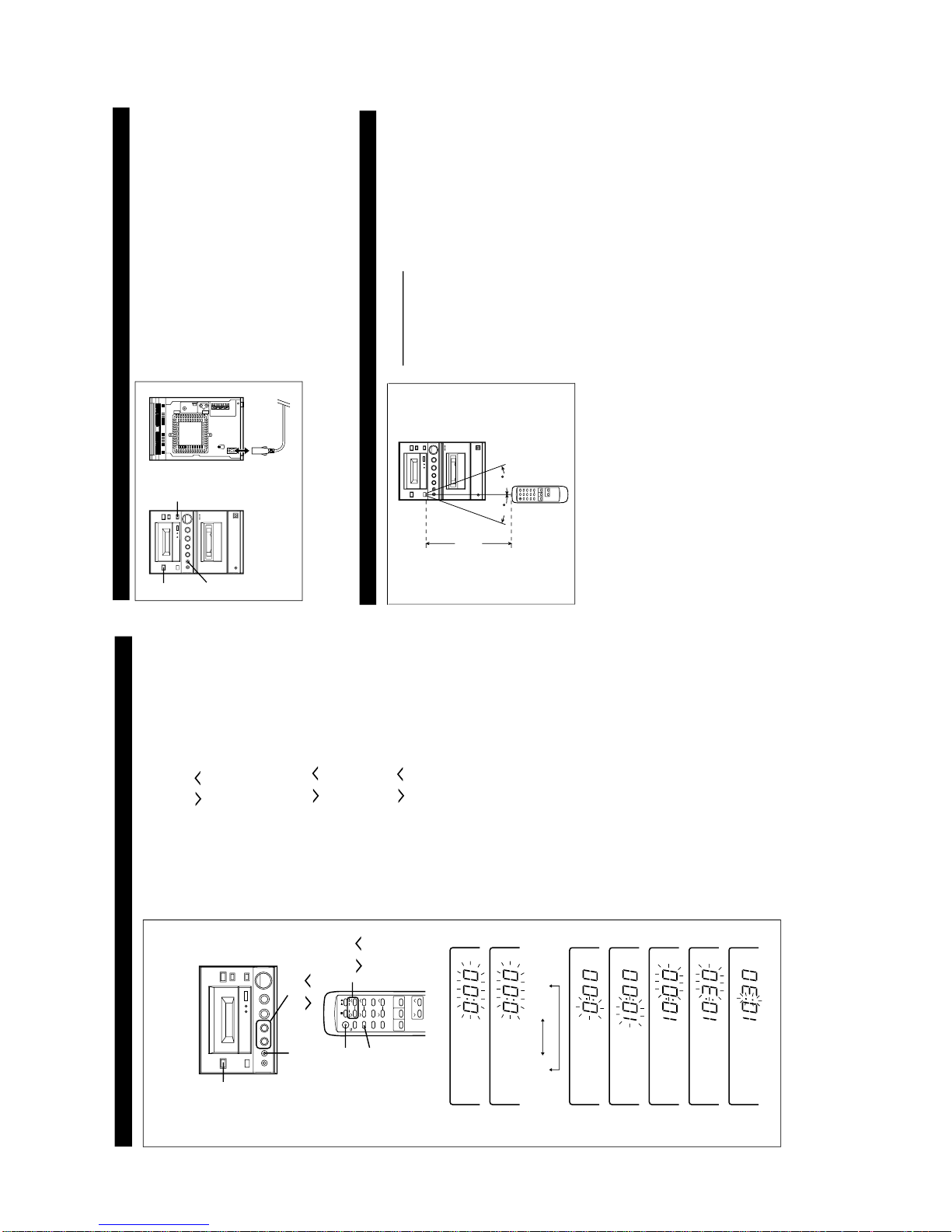

SETTING THE CLOCK

1

Press the ON/STAND-BY button to enter the stand-by mode.

2

Press the MEMORY/SET button.

3

Press the PRESET ( or ) button to select the time display

mode.

"0:00" → Th e 24-hour di splay will appe ar.

(0:00 - 23:59)

"AM 12:00" → The 12-hour display will appear.

(AM 12:00 - PM 11:59)

● Note that this can only be set when the unit is first installed

or it has been reset (see page 6).

4

Press the MEMORY/SET button.

5

Press the PRESET ( or ) button to adjust the hour.

● Press the PRESET button once to advance the time by 1 hour.

Hold it down to advance continuously.

● When the 12-hour display is selected, "AM" will change auto-

matically to "PM".

6

Press the MEMORY/SET button.

7

Press the PRESET ( or ) button to adjust the minutes.

● Press the PRESET button once to advance the time by 1

minute. Hold it down to change the time in 5 minute intervals.

● The hour setting will not advance even if minutes advance from

"59" to "00".

8

Press the MEMORY/SET button.

● The clock starts operating from "0" seconds. (Seconds are not

displayed.)

Note:

● In the event of a power failure or when the AC power lead is

disconnected, the clock display will go out.

When the AC power supply is restored, the clock display will

flash on and off to indicate the time when the power failure

occurred or when the AC power lead was disconnected.

ON/

STAND-BY

ON/

STAND-BY

MEMORY/

SET

MEMORY/

SET

PRESET

( / )

PRESET

( / )

AM 12:000:00

2

3

4

5

6

7

8

If this happens, follow the procedure below to change the clock

time.

To change the clock time:

1

Press the ON/STAND-BY button to enter the stand-by mode.

2

Perform steps 4 - 8 above.

To change the time display mode:

1

Perform steps 1 - 3 in the section "RESETTING THE MICRO-

COMPUTER", on page 6.

2

Perform steps 1 - 8 above.

In this example, the clock is set for the 24-hour

(0:00) system.

PREPARATION FOR USE

15

15

■

Remote control

Notes concerning use:

● Replace the batteries if control distance decreases or operation

becomes erratic.

● Periodically clean the transmitter LED on the remote control

and the sensor on the main unit with a soft cloth.

● Exposing the sensor on the main unit to strong light may in-

terfere with operation. Change the lighting or the direction of

the unit.

● Keep the remote control away from moisture, excessive heat,

shock, and vibrations.

0.2 m - 6 m

(8" - 20')

RESETTING THE MICROCOMPUTER

Reset the microcomputer under the following conditions:

● To erase all of the stored memory contents (clock and timer

settings, tuner and CD presets).

● If the display is not correct.

● If the operation is not correct.

1

Press the ON/STAND-BY button to enter the stand-by mode.

2

Unplug the AC power lead from the AC INPUT socket on this

unit.3Whilst pressing down the MEMORY/SET button and the X-

BASS/EQUALIZER button, plug the AC power lead into the

AC INPUT socket on this unit.

1

2,3

3

3

Caution:

● The operation explained above will erase all data stored in

memory, such as clock and timer settings, tuner and CD pres-

ets.

XL-520W/CP-520

– 6 –

(Continued)

■

AM/FM interval (span)

The International Telecommunication Union (ITU) has established

that member countries should maintain either a 10 kHz or a 9

kHz interval between broadcasting frequencies of any AM station.

The illustration shows the 9 kHz interval zones (regions 1 and

3), and the 10 kHz interval zone (region 2).

This product is not equipped with a span selector. However, it

will be adjusted to 9 kHz AM interval (50 kHz FM interval) when

shipped from the factory.

Before using the unit, be sure to set it for the AM tuning interval

(span) used in your area.

To check the tuning span currently selected:

1

Press the ON/STAND-BY button to turn the power on.

2

Press the FUNCTION button until "FM" or "AM" appears in

the display.3Press the BAND button to select the AM band.

● If "AM 531 kHz" is displayed, it means that the radio has been

adjusted for a 9 kHz span. If "AM 530 kHz" is displayed, it

means that the radio has been adjusted for a 10 kHz span.

To change from a 9 kHz AM (50 kHz FM) interval to a

10 kHz AM (100 kHz FM) interval:

1

Press the ON/STAND-BY button to enter the stand-by mode.

2

Hold down the BAND button and the ■ button for at least 4

seconds. Release the buttons when "AM SP 10 kHz" and "FM

SP 100 kHz" are displayed alternately.

● The unit will return to the clock display.

To return to a 9 kHz AM (50 kHz FM) interval:

1

Press the ON/STAND-BY button to enter the stand-by mode.

2

Hold down the BAND button and the ■ button for at least 4

seconds. Release the buttons when "AM SP 9 kHz" and "FM

SP 50 kHz" are displayed alternately.

● The unit will return to the clock display.

Cautions:

● When the unit is left for approximately 14 hours after the span

has been switched and AC power lead disconnected, it will be

automatically returned to a 9 kHz span. If this happens, set

the span again.

● When the span is switched, any stations that are memorised

will be cancelled.

ON/

STAND-BY

BAND

FUNCTION

kHz

kHz

kHz

kHz

[9 kHz → 10 kHz]

[10 kHz → 9 kHz]

kHz

kHz

kHz

kHz

(4 seconds)

(4 seconds)

– 7 –

XL-520W/CP-520

1 Top Cabinet 1. Screw .................. (A1) x4 7-1

2. Socket ................. (A2) x3

3. Screw .................. (A3) x1

2 Side Panel 1. Screw .................. (B1) x7 7-1

(Left/Right)

3 Back Board 1. Screw .................. (C1) x4 7-1

(With Power 2. Socket ................. (C2) x2

Amp. PWB) 3. Flat Wire .............. (C3) x1

4 Main PWB 1. Screw .................. (D1) x3 7-2

2. Socket ................. (D2) x2

5 Front Panel 1. Screw .................. (E1) x2 7-2

6 Display PWB/ 1. Screw .................. (F1) x6 7-2

CD Servo PWB 2. Socket ................. (F2) x2

7 Power Supply PWB 1. Screw .................. (G1) x5 7-2

8 Jack PWB 1. Screw .................. (H1) x1 7-3

9 Tape Mechanism 1. Screw .................. (J1) x4 7-3

10 CD Mechanism 1. Screw .................. (K1) x3 7-4

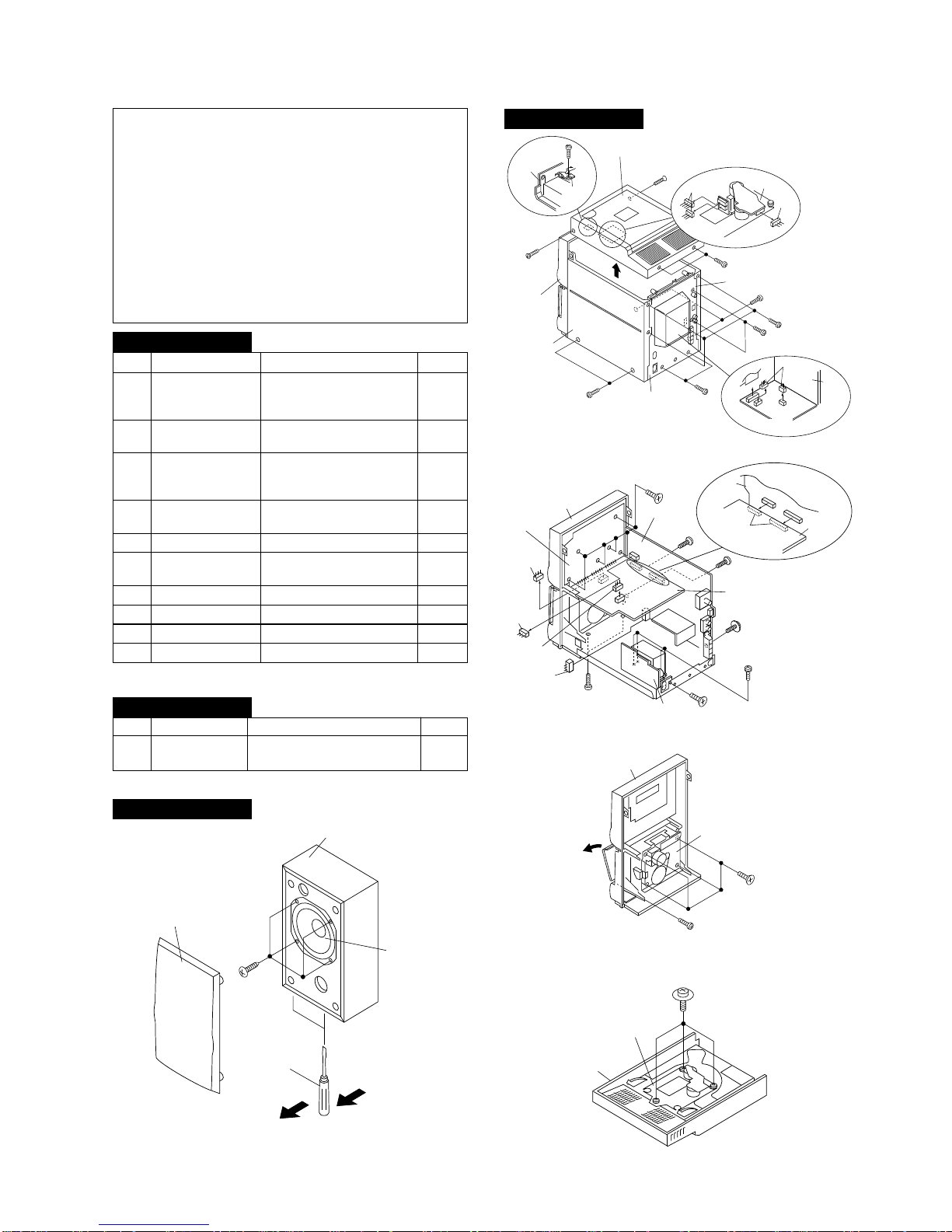

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need be

removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were

before disassembling.

4. Take suffcient care on static electricity of integrated

circuits and other circuits when servicing.

Figure 7-2

Figure 7-3

STEP REMOVAL

PROCEDURE

FIGURE

Figure 7-1

XL-520W

STEP

REMOVAL PROCEDURE FIGURE

1 Woofer 1. Net........................... (A1) x1 7-5

3. Screw ...................... (A2) x4

CP-520

(A1)x1

ø3x12mm

(A1)x1

ø3x12mm

(B1)x2

ø3x10mm

(C1)x2

ø3x10mm

(B1)x2

ø3x10mm

(C1)x2

ø3x10mm

(C2)x2

(B1)x3

ø3x10mm

(A1)x2

ø3x10mm

(A2)x2

(A2)x1

CD

Mechanism

(A3)x1

ø3x10mm

Swicth

PWB

Top Cabinet

Top

Cabinet

Side Panel

(Right)

Front

Panel

Rear

Panel

Back

Board

Power Amp PWB

Side Panel

(Left)

(c3)x1

(F1)x6

ø3x10mm

(D1)x1

ø3x10mm

(D1)x1

ø3x10mm

CD Servo PWB

Main PWB

Power Supply

PWB

Front Panel

Display PWB

(G1)x4

ø4x6mm

(D1)x1

ø3x10mm

(G1)x1

ø3x10mm

(E1)x2

ø3x10mm

(F2)x1

(D2)x1

(D2)x1

(F2)x1

(D2)x2

CD Servo

PWB

Main

PWB

CD Mechanism

(K1)x3

ø2.6x10mm

Top Cabinet

(A2)x4

ø4x12mm

Net

(A1)x1

Woofer

Speaker Box

Screw

driver

Direction of handle

XL-520W

Figure 7-4

CP-520

Figure 7-5

Tape MechanismOpen

(J1)x4

ø3x10mm

Front Panel

(H1)x1

ø3x10mm

XL-520W/CP-520

– 8 –

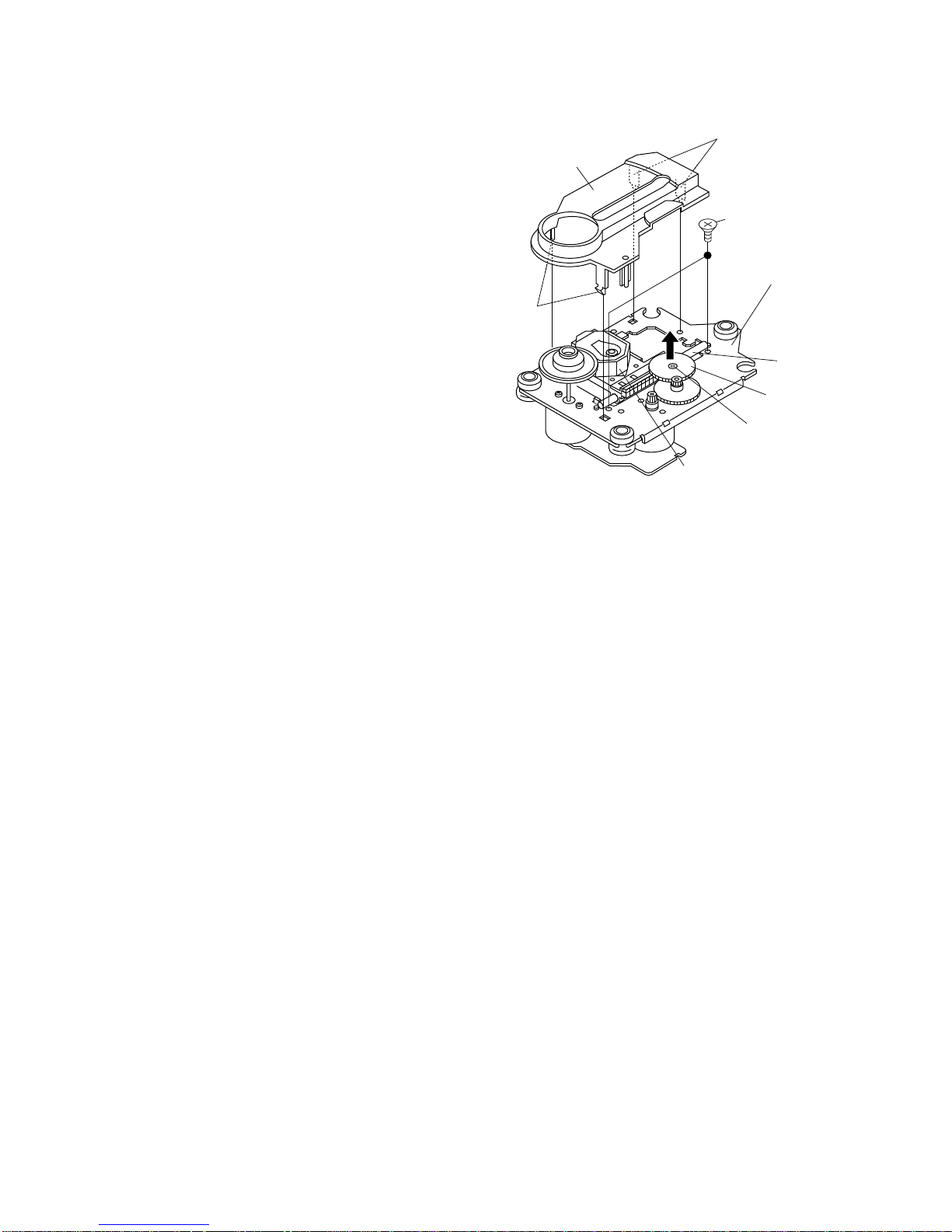

Figure 8

How to remove the pickup (See Fig. 8)

1. Remove the mechanism cover, paying attention to the

pawls (A1) x 4 pcs.

2. Remove the screws (A2) x 2 pcs., to remove the shaft (A3)

x 1 pc.

3. Remove the stop washer (A4) x 1 pc., to remove the gear

(A5) x 1 pc.

4. Remove the pickup.

Note:

After removing the optical pickup connector wrap the front

end of connector in conductive aluminium foil so as to

prevent damage of optical pickup by static electricity.

REMOVING AND REINSTALLING THE MAIN PARTS

CD MECHANISM SECTION

Perform steps 1,to 5 of the disassembly method to remove the

CD mechanism.

Pickup Unit

( A2 ) x2

ø2.6 x6mm

( A1 ) x2

CD Mechanism

Shaft

( A3 ) x1

Gear

( A5 ) x1

StopWasher

( A4 ) x1

Mechanism Cover

( A1 ) x2

– 9 –

XL-520W/CP-520

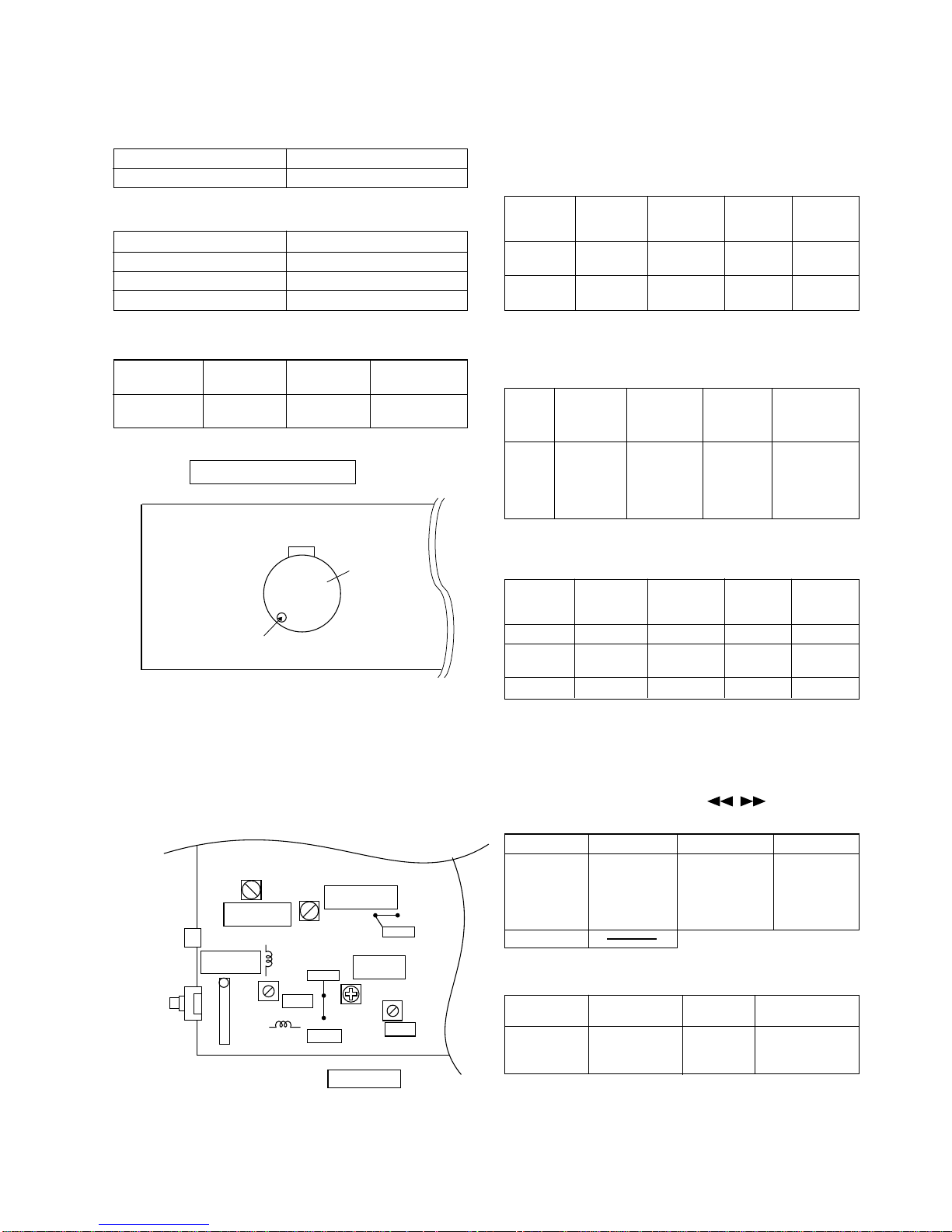

MECHANISM SECTION

• Driving Force Check

Torque Meter

Specified Value

Play: TW-2412 Over 80 g

• Torque Check

Torque Meter

Play: TW-2111 30 to 70 g. cm

Fast forward: TW-2231 50 to 140 g.cm

Rewind: TW-2231 50 to 140 g.cm

Specified

Value

Adjusting

Point

Instrument

Connection

Test Tape

MTT-111 Motor 3,000 ± Headphone

90 Hz Socket

ADJUSTMENT

Specified Value

• Tape Speed

Figure 9-1 ADJUSTMENT POINT

TAPE MECHANISM

M901

Motor

Volume in motor

Figure 9-2 ADJUSTMENT POINTS

SO301

ANTENNA

TERMINAL

MAIN PWB

CNP301

L302

IC301

1

T302

TP301

TP302

T304

FM IF

AM IF

AM

TRACKING fL

T306

AM BAND

COVERAGE fL

FM MUTE

LEVEL

T351

VR351

L303

FM BAND

COVERAGE fL

FM RF

fL: Low-range frequency

fH: High-renge frequency

IF 450 kHz 1,602 kHz T351 *1

Band — 531 kHz (fL): T306 *2

Coverage 1.1 ± 0.1 V

Tracking 990 kHz 990 kHz (fL): T302 *1

Test Stage

Frequency Frequency

Display

Setting/

Adjusting

Parts

Instrument

Connection

Adjusting

Parts

Instrument

Connection

Display

Frequency

98.00 MHz 98.00 MHz VR351* Input: SO301

(25 dBµV) Output: Speaker

Terminal

TUNER SECTION

• FM RF

Signal generator: 1 kHz, 75 kHz dev., FM modulated

Band — 87.50 MHz (fL): L303 *1

Coverage 3.4 ± 0.1 V

RF 98.00 MHz 98.00 MHz L302 *2

(10-30 dB)

Test Stage

Frequency

Frequency

Display

Setting/

Adjusting

Parts

Instrument

Connection

*1. Input: Antenna, Output: TP301

*2. Input: Antenna, Output: Speaker Terminal

• Detection

Signal generator: 10.7 MHz, FM sweep generator

IF 10.7 MHz 98.00 MHz T304(Turn Input: Pin 1 of

the core of IC301

T304 fully Output: TP302

counterclockwise.

Test

Stage

Frequency

Frequency

Display

Setting/

Adjusting

Parts

Instrument

Connection

*1. Input: Antenna, Output: Speaker Terminal

*2. Input: Input is not connected, Output: TP301

• Setting the Test Mode

Keeping the BAND button and MEMORY button pressed, turn

on POWER. Then, the frequency is initially set in the memory

as shown in Table. Call it with the , button to use it

for adjustment and check of tuner circuit.

Preset No.

FM

Preset No.

AM

1 87.50 MHz 6 531 kHz

2 108.00 MHz 7 1,602 kHz

3 98.00 MHz 8 990 kHz

4 90.00 MHz 9 603 kHz

5 106.00 MHz 10 1,404 kHz

11~40

• FM Mute Level

Signal generator: 1 kHz, 40 kHz dev., FM modulated

*Adjust so that an output signal appears.

• AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

XL-520W/CP-520

– 10 –

Figure 10-2

Figure 10-3

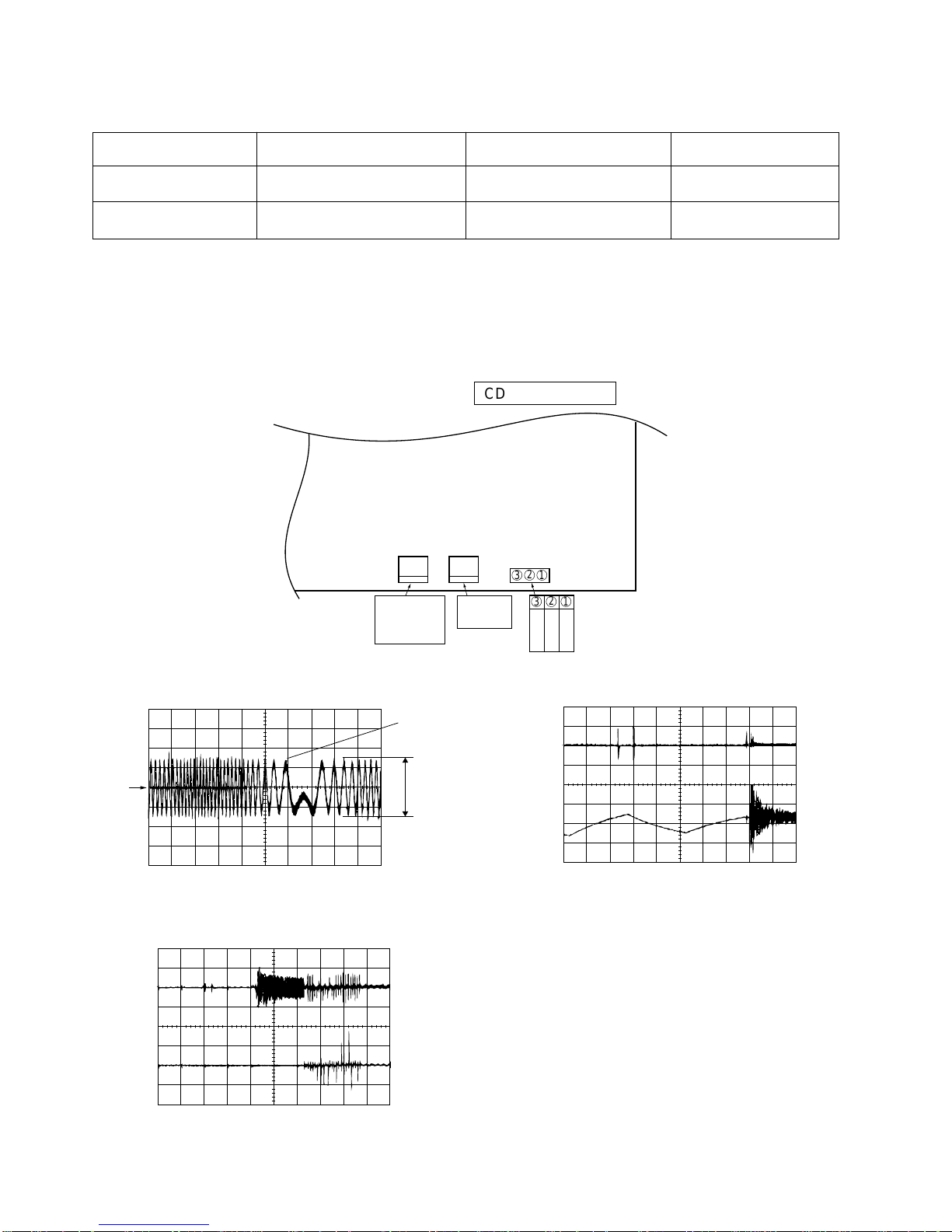

1. This CD unit need adjustment as follow.

CD SECTION

Figure 10-4

CD Test Mode

Adjustment Part

Value/Adjusting Method

Instrument Connection

Step 1 VR803 (Focus Offset) DC + 40 mV (FEI>VRO) FEI (R826) and VRO

(1-Pin of TP801)

Step 4 VR802 (Tracking Error Balance) *1 (See Fig. 9-2) TSO (3-Pin of TP801)

and VRO (1 Pin of TP801)

*1: Adjust to obtaiin vertically symmetrical waveform (Fig. 10-2) with respect toreference DC level. The reference level is VRO

(Approx DC 2.1V).

2. This CD unit have the following automatic adjustment function. Automatic adjustment item.

2-1: Focus Servo Gain (Fig. 10-3)

Focus Gain Adjustment is performed when disc is changed.

2-2: Tracking Servo Gain (Fig. 10-4)

Tracking Gain Adjustment is performed when disc is changed and disc is playbacked.

TSO

VRO

1

SYMMETRICAL

UP AND DOWN

FEI

FSO

1

2

TSO

TS2O

1

2

Figure 10-1 ADJUSTMENT POINTS

VR802 VR803

TP801

TRACKING

ERROR

BALANCE

FOCUS

OFFSET

T

S

O

N

C

V

R

O

321

321

CD SERVO PWB

– 11 –

XL-520W/CP-520

TEST MODE

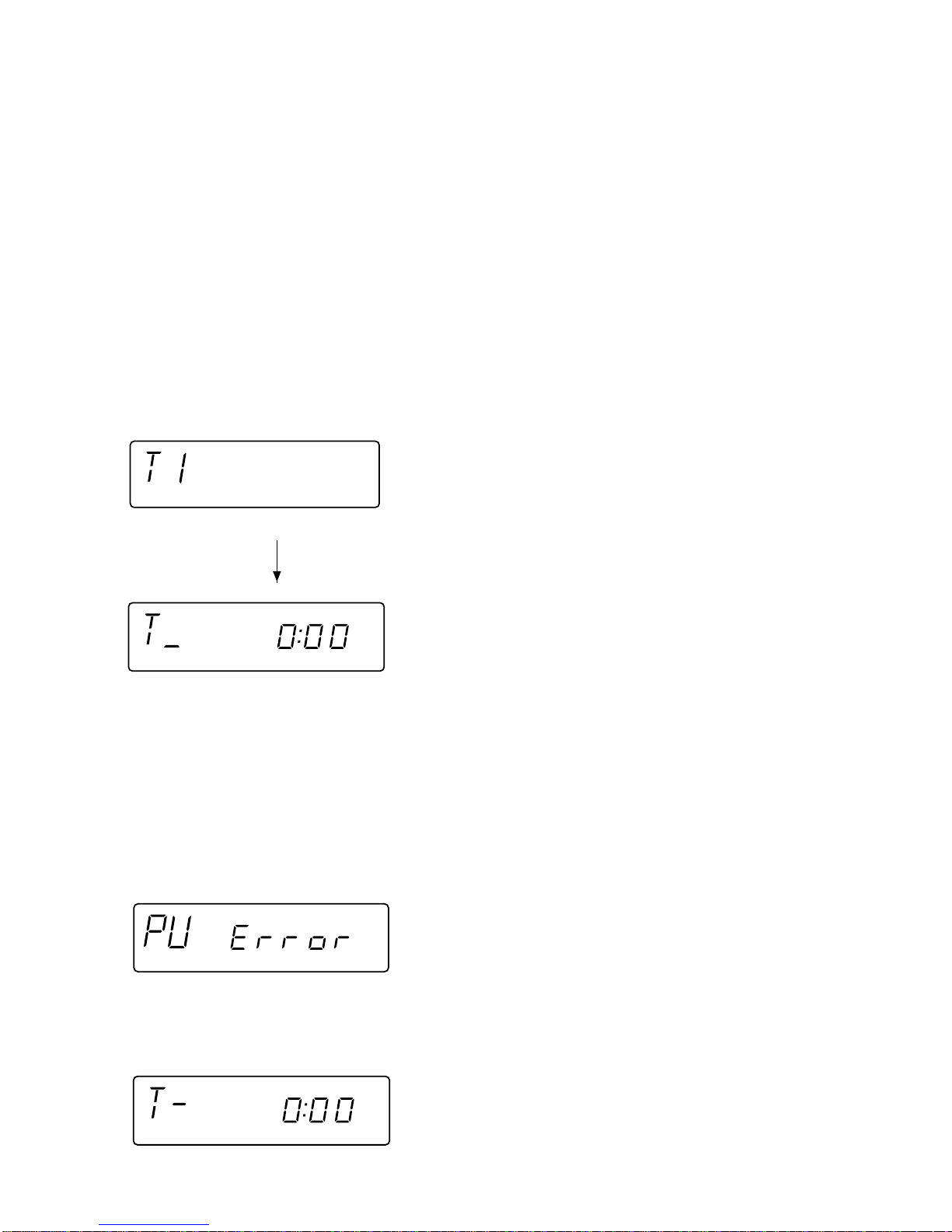

The Test Mode for this microcomputer has two variations, namely "regular Test Mode" for adjustment and measurement and "selfdiagnosis Test Mode" for self-judgment in final inspection of products.

1. Entering the Test Mode

To enter the each Test Mode, press the POWER key, holding down the following two keys in the regular standby mode (power

off state). In this case only the main unit keys are valid. The Test Mode is not set even when the remote controller POWER

key is turned on.

[Regular Test Mode] [Holding Down Keys]

1. CD Test Mode (TEST 1)………………………… Stop + Play

2. Tuner Test Mode (TEST 3)……………………… Memory/Set + Band Selector

3. Electronic volume Test Mode (TEST 4)…………Stop + Extra Bass/Equalizer Mode

4. Timer Test Mode (TEST 5)……………………… Fast Forward + Function Selector

5. LCD Test Mode (TEST 6)…………………………Memory/Set + Function Selector

[Self-diagnosis Test Mode]

1. Key input diagnosis TEST Mode (TESTA)………Play + Record Pause

2. Step 2 Mode

When the PLAY key is pressed in the mode above, the laser lighting is turned on. In this state the laser is only turned on,

and other operations are not performed.

2. CD Test Mode (TEST 1)

1. Step 1 Mode

When the CD Test Mode is set, the following display lights, and the CD pickup slides to the innermost periphery.

After lighting for 1.5 sec

When the following operation key is pressed in this state, the following operation is performed.

"POWER" ................The Test Mode is set to off, power is turned off, and the mode is changed to the regular standby mode.

"FF/FWD" ................After the pickup returns once to the innermost periphery, the pickup slides to the external periphery while

.................................this key is held down.

"REW/REV" .............After the pickup returns once to the innermost periphery, the pickup slides to the internal periphery while

.................................this key is held down. However, input is invalid if PU-IN is on.

"PLAY".....................Shift to Step 2

"STOP" ....................Invalid

* In case of mode entry the pickup is moved to the internal periphery. At this time entry of any key other than POWER key is

disabled until shift of pickup to the internal periphery is completed. If PU-IN SW ON cannot be detected while waiting for 10

seconds, the slide motor is stopped, the following error is displayed, and entry of any key other than POWER key is disabled.

XL-520W/CP-520

– 12 –

When the following operation key is pressed in this state, the following operation is performed.

"POWER" ................The Test Mode is set to off, power is turned off, and the mode is changed to the regular standby mode.

"FF/FWD" ................While this key is held down, the pickup slides to the external periphery.

"REW/REV" .............While this key is held down, the pickup slides to the internal periphery. However, if PU-IN is on, entry is

.................................invalid.

"PLAY".....................Shift to Step 3

"STOP" ....................Return to Step 1

3. Step 3 Mode

While the laser is lighting, the focus servo is turned on, and focus search is performed. If focusing failure occurs, focus search

is repeated until focusing is attained.

When the following operation keys are pressed in this state, the following operations are performed.

"POWER" ................The Test Mode is set to off, power is turned off, and the mode is changed to the regular standby mode.

"FF/FWD" ................While this key is held down, the pickup slides to the external periphery.

"REW/REV" .............While this key is held down, the pickup slides to the internal periphery. However, if PU-IN is on, entry is

.................................invalid.

"PLAY".....................If focusing has been attained, the process proceeds to Step 4. Unless focusing has been attained,

.................................reception is inhibited.

"STOP" ....................Return to Step 1

4. Step 4 Mode

The disc is rotated and CLV is locked while the tracking servo is off.

The time display indicates always "0:00".

When the following operation keys are pressed in this state, thefollowing operations are performed.

"POWER" ................The Test Mode is set to off, power is turned off, and the mode is changed to the regular standby mode.

"FF/FWD" ................While this key is held down, the pickup slides to the external periphery.

"REW/REV" .............While this key is pressed, the pickup slides to the internal periphery. However, if PU-IN is on, entry is

.................................invalid.

"PLAY".....................Shift to Step 5

"STOP" ....................Return to Step 1

5. Step 5 Mode

The tracking servo is turned on, groove is traced, mute is set to off, and playback is started. Even when the outermost

periphery of disc is reached in playback mode, it does not stop. The LCD display indicates playback lapse time as in case

of regular CD playback.

– 13 –

XL-520W/CP-520

When the following operation keys are pressed in this state, the following operations are performed.

"POWER" ................The Test Mode is set to off, power is turned off, and the mode is changed to the regular standby mode.

"FF/FWD" ................While this key is held down, the pickup slides to the external periphery.

"REW/REV" .............While this key is held down, the pickup slides to the internal periphery. However, if PU-IN is on, entry is

.................................invalid.

"PLAY".....................Invalid

"STOP" ....................Return to Step 1

Other cautions

• While the CD lid OPEN is detected, entry into any step later than Step 2 is disabled. If CD lid OPEN is detected in any step

higher than Step 2, return to Step 1 is done.

• TOC IL is not performed in the Test Mode.

• The key operation, excepting that specified above, is the same as that of regular operation (CD). Only the FUNCTION key

is input-inhibited.

• Syncro REC with REC key input is also invalid in this mode.

3. Tuner Test Mode (TEST 3)

1. Outline of tuner (radio) Test Mode

The tuner Test Mode is intended to store adjustment/measurement frequency in the preset memory CH without frequency

adjustment by the adjusting personnel when the tuner is adjusted in the production line.

2. Details of tuner Test Mode

When power is turned on with the POWER key while the MEMORY/SET key and BAND key are held down together in

POWER OFF state, the frequency for adjustment/measurement of specific destination specified by the AREA terminal is

preset-stored in the preset memory CH (the frequency to be preset-stored for specific destination is explained in the Item

C). When the tuner Test Mode is started up, it is started with FM. FM is FM STEREO only.

When the REW key is pressed while the preset memory CH is 1CH, the highest CH is found as in case of regular mode. When

the FF key is pressed while the preset memory CH is highest CH, 1CH is found.

The RADIO (TUNER) BAND key (or TUNER/BAND key on the remote controller) is valid.

As in case of regular mode, selection of band, FM MONO/STEREO mode is enabled by pressing the RADIO (TUNER) BAND

(or TUNER/BAND ) key.

Exiting the tuner Test Mode, When the destruction data is stored in the memory in the tuner Test Mode, AC supply is

interrupted in the Test Mode and the AC supply is recovered, all the memory is cleared with the destruction data in case of

start-up.

(Countermeasures so that the Test Mode memory does not remain when AC supply is restored after power supply failure

occurred once in the Test Mode.) The memory is not cleared when AC supply is turned off after POWER OFF.

FUNCTIONkey is not accepted in the tuner test mode. In case of exit from the tuner Test Mode through the backup mode

upon occurrence of power failure the frequency data stored in the preset memory for adjustment/measurement is erased.

(As a result the preset memory CH becomes empty.)

The display indication is the same as that in case of regular operation.

The following display lights for one second when the tuner TEST mode is turned on

XL-520W/CP-520

– 14 –

Test Mode operation specification

3. Preset frequencies for various destinations (random preset memory)

BAND (CH)

1 FM 87.5MHz

2 FM 108.0MHz

3 FM 98.0MHz

4 FM 90.0MHz

5 FM 106.0MHz

• The unit used in the table above is Hz. K represents 1,000 times, and M represents 1,000,000 times.

• The hatched data shown in the table are not stored in the memory.

• FM is stereo mode.

Note: Keys which are effective in Test Mode

• Main unit keys: VOLUME UP/DOWN, BAND, TUNING UP, POWER, MEMORY, CLEAR,

PRESET UP/DOWN

• Remote controller keys:

VOL UP/DOWN, BAND, TUNING UP/DOWN, POWER, MEMORY, CLEAR, PRESET UP/DOWN

4. Electronic volume Test Mode (TEST 4)

After the Test Mode is set, the following display lights for one second.

1 FM 87.5MHz

2 FM 108.0MHz

3 FM 98.0MHz

4 FM 90.0MHz

5 FM 106.0MHz

When this mode has been set, -14dB (STEP17) is set, the preset equalizer is set to FLAT (EQ-3), the SRS mode is set to OFF,

and the start-up function is set to Tape.

1. The display is the same as that indicated in case of regular operation excepting when Test Mode is set.

2. The volume control with the Volume UP/DOWN key is only the following 3 steps, differing from the volume control in the regular

operation mode.

Volume — ∞ (STEP 0) Volume — 14dB (STEP 17) Volume — 0 (STEP 24)

3. The preset equalizer and SRS are switched if key operation is performed.

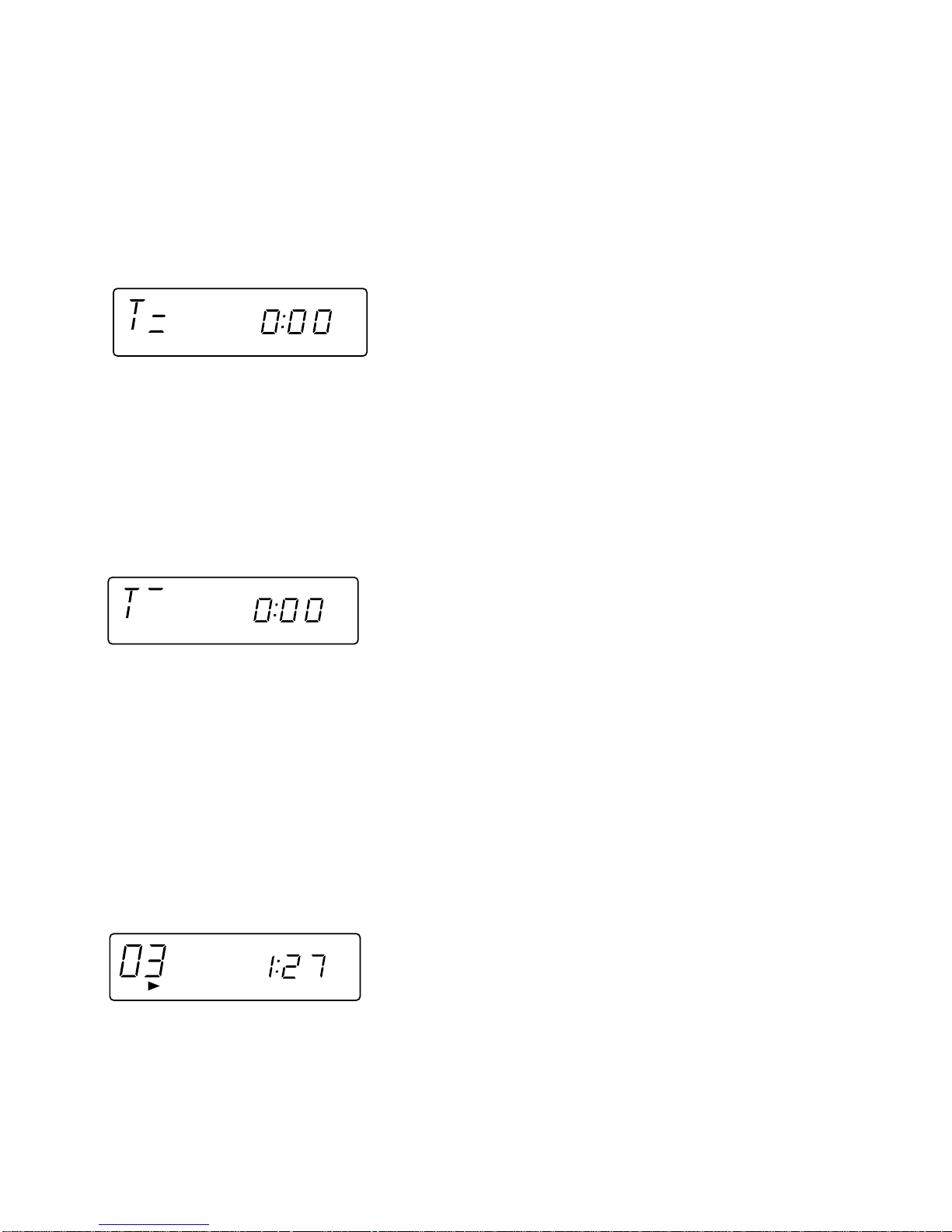

5. Timer Test Mode (TEST 5)

When the Test Mode is set, the following display lights for one second.

The current time and timer time are set in the following procedure, and timer playback is performed.

1. The present time is set to 1:00, the timer is set to ON time 1:02, OFF time 1:12, Function is set to Tape, Volume is set to STEP8.

One minute is counted in increments of second, and timer playback is performed. One step of Fade-in/out in this mode is

performed for 0.5 sec.

The display is the same as that appears in the regular timer operation.

2. After completion of timer playback test "TEST-5" indication (which appears when the mode is set) appears again and Standby

state is set. PLAY key entry is waited. If an entry is detected, the SLEEP timer is set to 2 minutes, and Function is set to

Tape, so that playback is started at once. Volume is set to STEP8, and 10 seconds are counted down in decrements of

second. One step of Fade-out is 0.5 sec.

The display is the same as that appears in the regular sleep playback mode.

3. After completion of SLEEP test, the Test Mode is turned off, and regular standby mode is set, so that the Test Mode ends.

6. LCD Test Mode (TEST 6)

When the LCD Test Mode is set, all the LCD segments light.

BAND (CH)

10 kHz SPAN

100 kHz SPAN

BAND (CH)

6 AM 531 kHz

7 AM 1,602 kHz

8 AM 990 kHz

9 AM 603 kHz

10 AM 1,404 kHz

6 AM 530 kHz

7 AM 1,620 kHz

8 AM 990 kHz

9 AM 600 kHz

10 AM 1,400 kHz

BAND (CH)

9 kHz SPAN

10 kHz SPAN

– 15 –

XL-520W/CP-520

In this Test Mode checking as to whether all the main unit keys can be detected is performed. Accordingly, when this mode

is set, checking is performed so as to examine whether the POWER key was pressed last after all the following keys were

pressed. If the result is OK, the following OK is displayed. If any one of keys was not pressed, an error is indicated. When the

POWER key is pressed, exit from the mode is made irrespective of whether the termination is normal or abnormal, and the

standby mode is set.

All the models using this microcomputer do not have the same keys. The entry of the following keys is detected depending on

the combination of simultaneously pressed keys when this mode is set. Key pressing order is not fixed. Pressing of all keys

must be detected.

1. In case of "SRS" + "REC PAUSE"

Since the model does not have RDS and SRS, all the keys to be detected are the following 12 keys.

PLAY, VOL , VOL , BAND, G-EQ, FUNCTION, MEMORY/SET, REC PAUSE, REW/REV, FF/FWD, STOP, SRS

OK/NG indication of test result must be as follows.

<

<

NG indication

OK indication

7. Key input diagnosis Test Mode (TEST A)

When the Test Mode is set, the following display appears.

XL-520W/CP-520

– 16 –

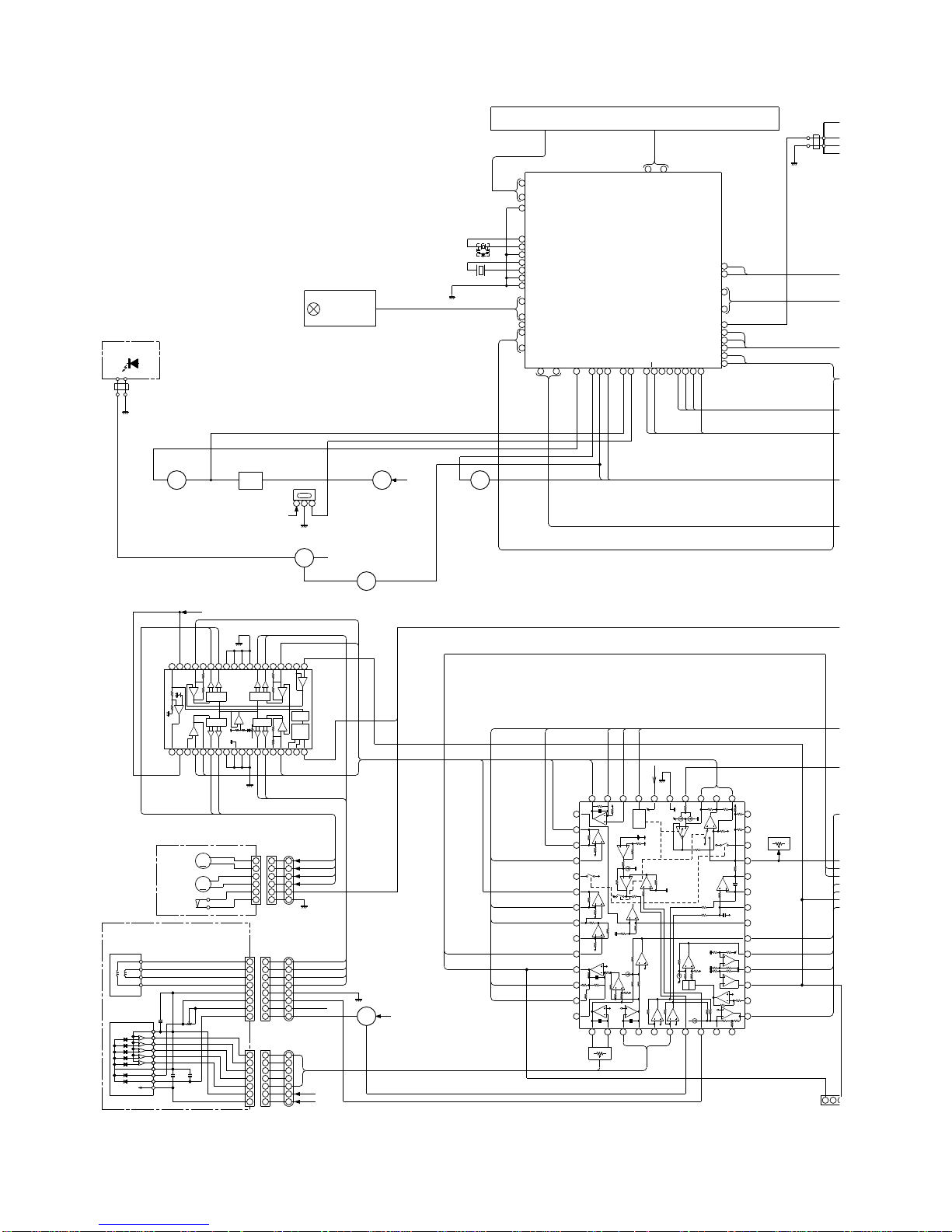

Figure 16 BLOCK DIAGRAM (1/4)

1

4

9

10

11

12

13

14

15

17

19

21

23

25 31 32 34 35 36 38 39 41 42 45 4640 44 47 48

51

52

53

54

55

56

63

64

57

62

5

321

987654321

18 17 16 15 14 13 12 11 10

28 29 30 31 32 33 34 35 36

19 20 21 22 23 24 25 26 27

8

7

6

5

4

3

2

1

88

77

66

55

44

33

22

11

7

6

5

4

3

2

1

77

66

55

44

33

22

11

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

9

10

11

12

13

14

15161718192021222324

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39 40 41 42 43 44 45 46 47 48

8

7

6

5

4

3

2

1

32

1

FSO

M+12V

µ-CON +5V

~

~

~

~

~

~

IX0189AW

IC701

~

PU-IN

BUS3

SRS1

SRS2

~

~

~

~

~

7493

SEG26

SEG7

COM0

COM3

DI

CE

LCD

LCD701

LID-SW

BIAS

B-CAN

REC

MOT

SOL

FW701

LED704 - LED712

SW710-SW714

SW718

SW702-SW708

KEY

RX701

RESET

Q701

SWITCHING

Q702

Q703

SWTCHING

A 12V

LED+B

P CONT

SWITCHING

SWITCHING

Q707

Q706

(S+6.2VLINE)

SL–

SL+

TR+

TR–

TS2O

IC804

CD STB

DMEO

SP+

SP–

FO+

FO–

GAIN4

LEVEL

SHIFT

LEVEL

SHIFT

LEVEL

SHIFT

LEVEL

SHIFT

VCC

++

––

––

++

––

++

––

++

STAND

-BY

T.S.D

GND

Reg5V

VCC

GND

GAIN1

NC

NC

+

–

+

–

–

+

–

+

+–

–

+

–

+

ACTUATOR

TR–

FO–

FO+

TR+

C4A

C2A C3A

VR1A

VCC

LD

MON

GND

E

A

B

F

C

1/2VCC

BI801

CNS801

TR–

GND

FO–

FO+

TR+

BI802

CNS802

1/2VCC

+5V

C

F

B

A

E

1/2V

+5V

+

–

+

–

M

M

M801

SLED

M802

SPINDLE

SW801

PU-IN

BI803

CNP803

CNS803

GND

PU-IN

SL–

SL+

SP–

SP+

Q801

SWTCHING

+5V

IC801

BLANCE

VR802

ERROR

TRACKING

FOCUS

OFFSET

VR803

TEST POI

FW702

CD+5V

FMSO

Q704 Q705

PD

VR

LD

VRO

TSO

SD

R-MUTE

TPO

REMOCON

RESET

REMOCON

SYS STOP

TR–

TR+

FO+

FO–

GND

PD

VR

LD

GND

PU-IN

SL–

SL+

SP–

SP+

X702

32.768kHz

DFCT

FMSO

FMSM

FMSP

THLD

TS2O

TS2N

TS2P

TS1N

TS1P

TSO

TEL1

TEL2

TSN

RFT

RFN

TPI

TNI

TNO

FNI

FPI

LDO

MDI

GND

VCC

SEL

DMEO

DMEN

DMEP

OSCI

COSC

FSO

FSN

FHLD

FEL1

FEL2

FEI

FEN

SBAD

FEO

FEP

DFIN

RFRP

2VRO

VRO

RFI

RFO

F.P

20

VSM

BUCK

CEE

CD RES

DATA

CLE

STEREO

SYS STOP

CD+B

P-CONT

P-MUTE

RESET

CAM SW

POWER

KEY1

VREF

MMOD

XO

XI

VSS

OSC1

OSC2

VLC3

X701

8MHz

PD

LDO

– 17 –

XL-520W/CP-520

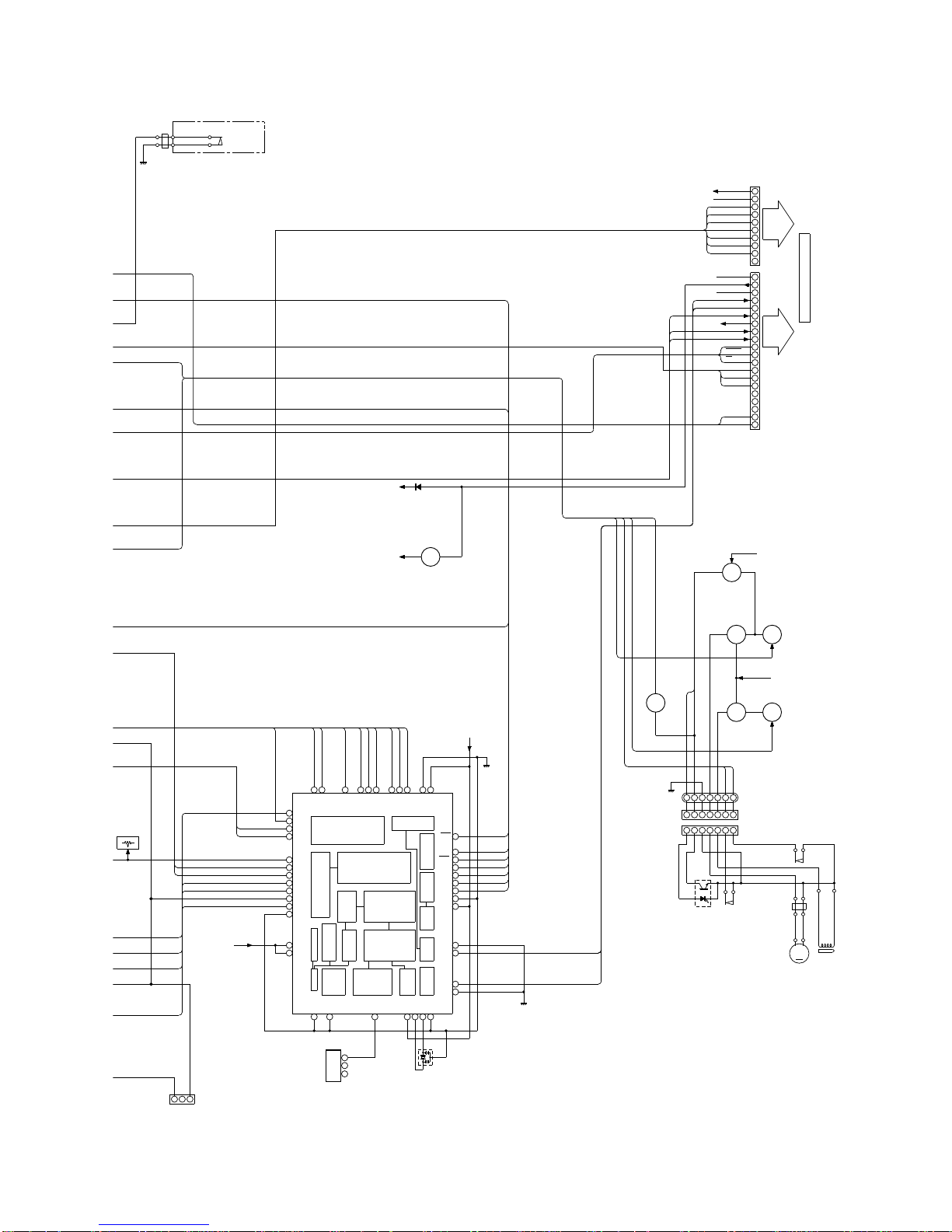

Figure 17 BLOCK DIAGRAM (2/4)

321

7

12

13

14

15

16

17

18

19

21

2526272830323334363740

41

42

43

44

47

48

49

50

51

52

53

54

58

59

65 67 7775 78 79 80

6

2

1

3

2

1

9

8

7

6

5

4

3

2

1

14

13

12

11

10

9

20

10

19

18

17

16

15

8

7

6

5

4

3

2

1

7654321

7654321

7654321

FOCUS

OFFSET

VR803

TEST POINT

TP801

DIGITAL

X801

J801

DIGITAL

OUT TO

MD/DAT

PDCNT

VDDA

GNDA

RFI

RFRP

VREF

SBAD

TEOF

TESH

FEI

FKIC

FCSI

SEL

2VREF

CCE

RST

BUCK

BUS3

BUS2

BUS1

BUS0

GNDD

VDDD

GNDA

RO

LO

GNDA

GNDX

XO

XI

VDDX

TESTX

GNDD

DA CONV

OUT

PLL

STATUS

AUDIO OUT

CLV SERVO

TMAX DET

STATUS

CODE

SUB

CLOCK

EFM

CORRECT

RAM

Q DATA

INTERFACE

CD BUS

16K RAM

ADRESS

A/D CONVERTOR

SERVO

STATUS

GENERATOR

TIMING

FOCUS

TRACKING

SERVO

CONTROL

CD+5V

FMFB

TGUH1

DMPC

DMFC

FMON

TKIC

TGUL

TEL1

TEL2

GNDD

VDDD

D-GND

CD+5V

FW702

SW701

CD EJECT

5V

(S+6.2V)

REGULATOR

Q861

TO MAIN PWB

CNS603

M 12V

D GND

VDI

DI

CE

CL

DO

VCE

VCL

CNS602

REC

R-MUTE

P CONT

P MUTE

S+6.2V

A GND

M GND

A 12V

SD

BIAS

B-CAN

FM ST

CD+B

L-CH

R-CH

SWTCHING

µ-CON5V

Q906

TAPE MOTOR

DRIVER

SWTCHING

Q905

M-12V

Q902

SWTCHING

SWTCHING

SOLENOID

DRIVER

CNP901

CNS901

BI901

SW902

CAM

PREVENTION

RECORD

SW901

PH901

FW901

–

+

SOLENOID

M

M901

TAPE

BUS0

BUS1

BUS2

BUS3

BUCK

CCE

RESET

G-GND

A-GND

CD R-CH

CD L-CH

Q904

P.F

CAM SW

Q901

Q903

VRO

TSO

SOL901

MOT

SOL

RUN PLS

IC802

PU IN

D

1

2

D

P

O

SRS1

SRS2

Loading...

Loading...