Page 1

Illustration: XL-505H/CP-505

XL-505H,505E,507E/CP-505,505E,507

SERVICE MANUAL

No. S7752XL505HE/

XL-505H

XL-505E

XL-507E

CP-505

CP-505E

CP-507

• Note for users in UK

Recording and playback of any material may require consent

which SHARP is unable to give. Please refer particularly to the

provisions of Copyright Act 1956, the Dramatic and Musical

Performers Protection Act 1956, the Performers Protection Acts

1963 and 1972 and to any subsequent statutory enactments and

orders.

CONTENTS

SAFETY PRECAUTION FOR SERVICE MANUAL .......................................................................................................... 2

IMPORTANT SERVICE NOTES (XL-505E FOR UK/XL-507E ONLY)............................................................................. 3

SPECIFICATIONS ............................................................................................................................................................ 3

NAMES OF PARTS .......................................................................................................................................................... 4

OPERATION MANUAL..................................................................................................................................................... 6

DISASSEMBLY................................................................................................................................................................. 7

REMOVING AND REINSTALLING THE MAIN PARTS.................................................................................................... 8

ADJUSTMENT.................................................................................................................................................................. 9

BLOCK DIAGRAM .......................................................................................................................................................... 16

SCHEMATIC DIAGRAM / WIRING SIDE OF P.W.BOARD............................................................................................ 20

VOLTAGE ....................................................................................................................................................................... 26

NOTES ON SCHEMATIC DIAGRAM ............................................................................................................................. 27

TYPE OF TRANSISTOR AND LED ................................................................................................................................ 27

WAVEFORMS OF CD CIRCUIT..................................................................................................................................... 28

TROUBLESHOOTING (CD SECTION) .......................................................................................................................... 29

FUNCTION TABLE OF IC .............................................................................................................................................. 34

LCD SEGMENT .............................................................................................................................................................. 41

REPLACEMENT PARTS LIST/EXPLODED VIEW

PACKING OF METHOD (XL-505E FOR UK/XL-507E ONLY)

XL-505H and CP-505 constitute XL-505H.

XL-505E and CP-505E constitute XL-505E.

XL-507E and CP-507 constitute XL-507E.

• In the interests of user-safety the set should be restored to its

original condition and only parts identical to those specified be

used.

Page

SHARP CORPORATION

– 1 –

Page 2

XL-505H,505E,507E/CP-505,505E,507

CAUTION-INVISIBLE LASER RADIATION WHEN OPEN. DO NOT STARE INTO

BEAM OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

VARNING-OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD. STIRRA

EJ IN I STRALEN OCH BETRAKTA EJ STRALEN MED OPTISKA INSTRUMENT.

ADVERSEL-USYNLIG LASERSTRALING VED ABNING. SE IKKE IND I

STRALEN-HELLER IKKE MED OPTISKE INSTRUMENTER.

VARO! AVATTAESSA OLET ALTTIINA NAKYMATON LASERSATEILYLLE.

ALA TUIJOTA SATEESEEN ALAKA KATSO SITA OPTISEN LAITTEEN LAPI.

VARNING-OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD.

STIRRA EJ IN I STRALEN OCH BETRAKTA EJ STRALEN GENOM OPTISKT

INSTRUMENT.

ADVERSEL-USYNLIG LASERSTRALING NAR DEKSEL APNES. STIRR IKKE

INN I STRALEN ELLER SE DIREKTE MED OPTISKE INSTRUMENTER.

VAROITUS! LAITTEEN KÄYTTÄMINEN MUULLA KUIN

TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA TAVALLA SAATTAA

ALTISTAA KÄYTTÄJÄN TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE.

VARNING - OM APPARATEN ANVÄNDS PÅ ANNAT SÄTT

ÄN I DENNA BRUKSANVISNING SPECIFICERAS. KAN

ANVÄNDAREN UTSÄTTAS FÖR OSYNLIG

LASERSTRÅLNING, SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

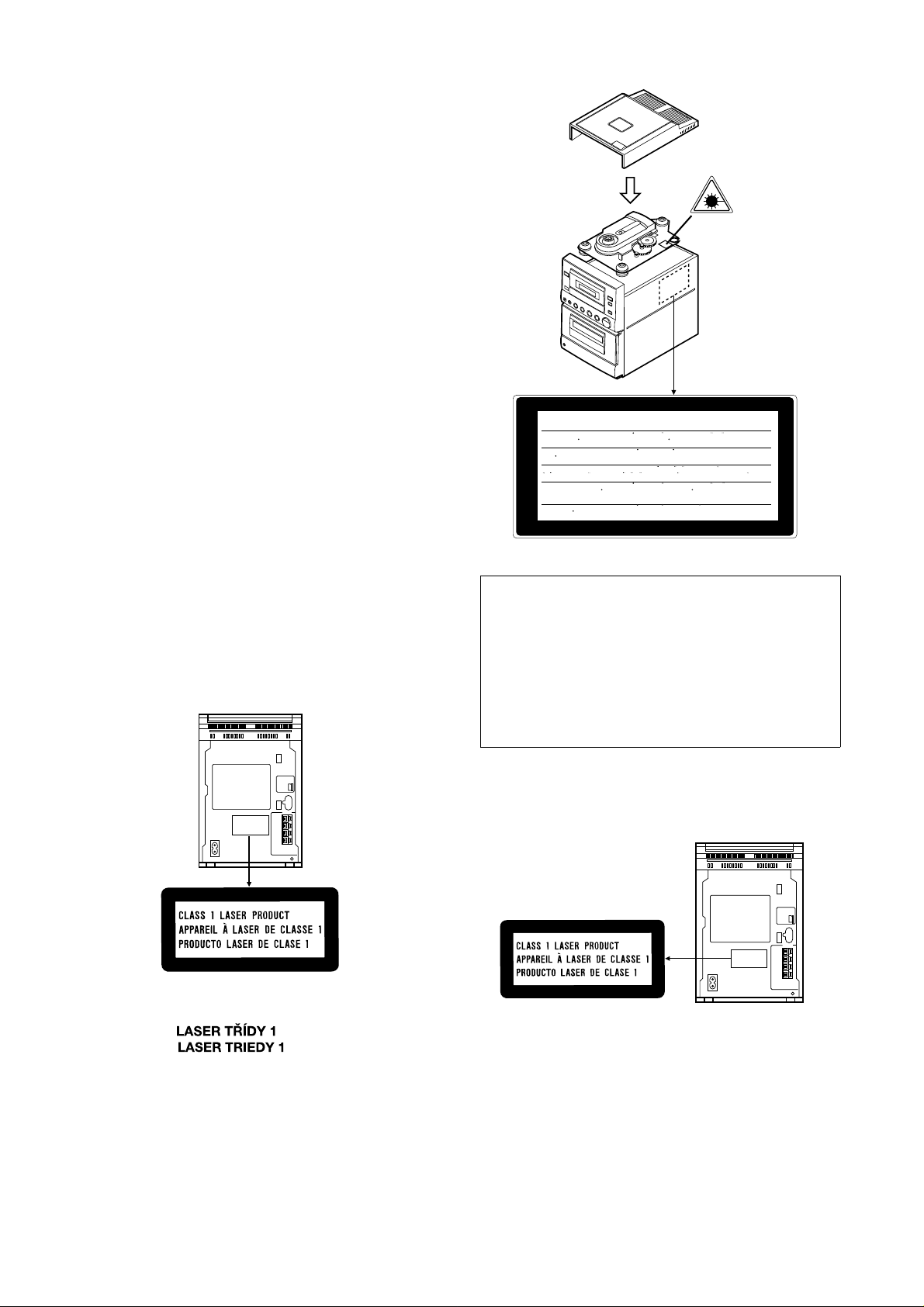

SAFETY PRECAUTION FOR

SERVICE MANUAL

Precaution to be taken when replacing and servicing the

Laser Pickup.

The AEL (Accessible Emission Level) of Laser Power Output

for this model is specified to be lower than Class I Requirements.

However, the following precautions must be observed during

servicing to protect your eyes against exposure to the Laser

beam

(1) When the cabinet has been removed, the power is turned

on without a compact disc, and the Pickup is on a position

outer than the lead-in position, the Laser will light for several

seconds to detect a disc. Do not look into the Pickup Lens.

(2) The Laser Power Output of the Pickup inside the unit and

replacement service parts have already been adjusted prior

to shipping.

(3) No adjustment to the Laser Power should be attempted

when replacing or servicing the Pickup.

(4) Under no circumstances look directly into the Pickup Lens

at any time.

(5) CAUTION - Use of controls or adjustments, or performance

of procedures other than those specified herein may result

in hazardous radiation exposure.

(XL-505H)

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

(XL-505E/507E)

– 2 –

Page 3

IMPORTANT SERVICE NOTES (XL-505E FOR UK/XL-507E ONLY)

Before returning the unit to the customer after completion of a

repair or adjustment it is necessary for the following withstand

voltage test to be applied to ensure the unit is safe for the

customer to use.

Setting of Withstanding Voltage Tester and set.

Set name set value

Withstanding Voltage Tester

Test voltage 4,240 VPEAK

3,000 VRMS

Set time 6 secs

Set current(Cutoff current) 4 mA

Unit

Judgment

OK: The “GOOD” lamp lights.

NG: The “NG” lamp lights and the buzzor sounds.

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

XL-505H,505E,507E/CP-505,505E,507

WITHSTANDING

VOLTAGE TESTER

AC

+

OUT

-

SHORT-CIRCUIT

AC POWER

SUPPLY CORD

PROBE

UNIT

CONNECT THE PROBE

TO GND TERMINAL

OF PHONO TERMINAL

SCREW

OF CHASSIS

SPECIFICATIONS

XL-505H/505E/507E

General

Power source: AC 230 V, 50 Hz

Power consumption: 52 W

Dimensions: Width; 160 mm (6-5/16")

Height; 240 mm (9-1/2")

Depth; 250 mm (9-7/8")

Weight: 2.6 kg (5.7 lbs.)

Amplifier section

Output power: PMPO; 28 W (total)

(XL-505H/505E) MPO; 14 W (7 W + 7 W) (DIN 45 324)

RMS; 10 W (5 W + 5 W) (DIN 45 324)

Output power: MPO; 14 W (7 W + 7 W) (10 % T.H.D.)

(XL-507E) RMS; 10 W (5 W + 5 W) (10 % T.H.D.)

Output terminals: Speakers; 4 ohms

Headphones; 16-50 ohms

(recommended; 32 ohms)

Tuner section

Frequency range: FM; 87.5 - 108 MHz

AM; 522 - 1,620 kHz

Compact disc player section

Type: Compact disc player

Signal readout: Non-contact, 3-beam semi-conductor

laser pickup

D/A Converter: 1-bit D/A converter

Filter: 8-times oversampling digital filter

Frequency response: 20 - 20,000 Hz

Wow and flutter: Unmeasurable

(less than 0.001% W.peak)

Cassette deck section

Frequency response: 50 - 14,000 Hz (Normal tape)

Signal/noise ratio: 55 dB

(XL-505H/505E)

Signal/noise ratio: 50 dB

(XL-507E)

Wow and flutter: 0.3 % (DIN 45 511)

(XL-505H/505E)

Wow and flutter: 0.25 % (WRMS)

(XL-507E)

CP-505/505E/507

Type: Full range speaker system

Speakers: 10 cm (4") full-range speaker

Rated input power: 5 W

Maximum input power: 10 W

Impedance: 4 ohms

Dimensions: Width; 145 mm (5-3/4")

(CP-505/507) Height; 240 mm (9-1/2")

Depth; 183 mm (7-1/4")

Dimensions: Width; 145 mm (5-3/4")

(CP-505E) Height; 240 mm (9-1/2")

Depth; 133 mm (5-1/4")

Weight: 1.1 kg (2.4 lbs.)/each

(CP-505/507)

Weight: 1.0 kg (2.2 lbs.)/each

(CP-505E)

Specifications for this model are subject to change without

prior notice.

– 3 –

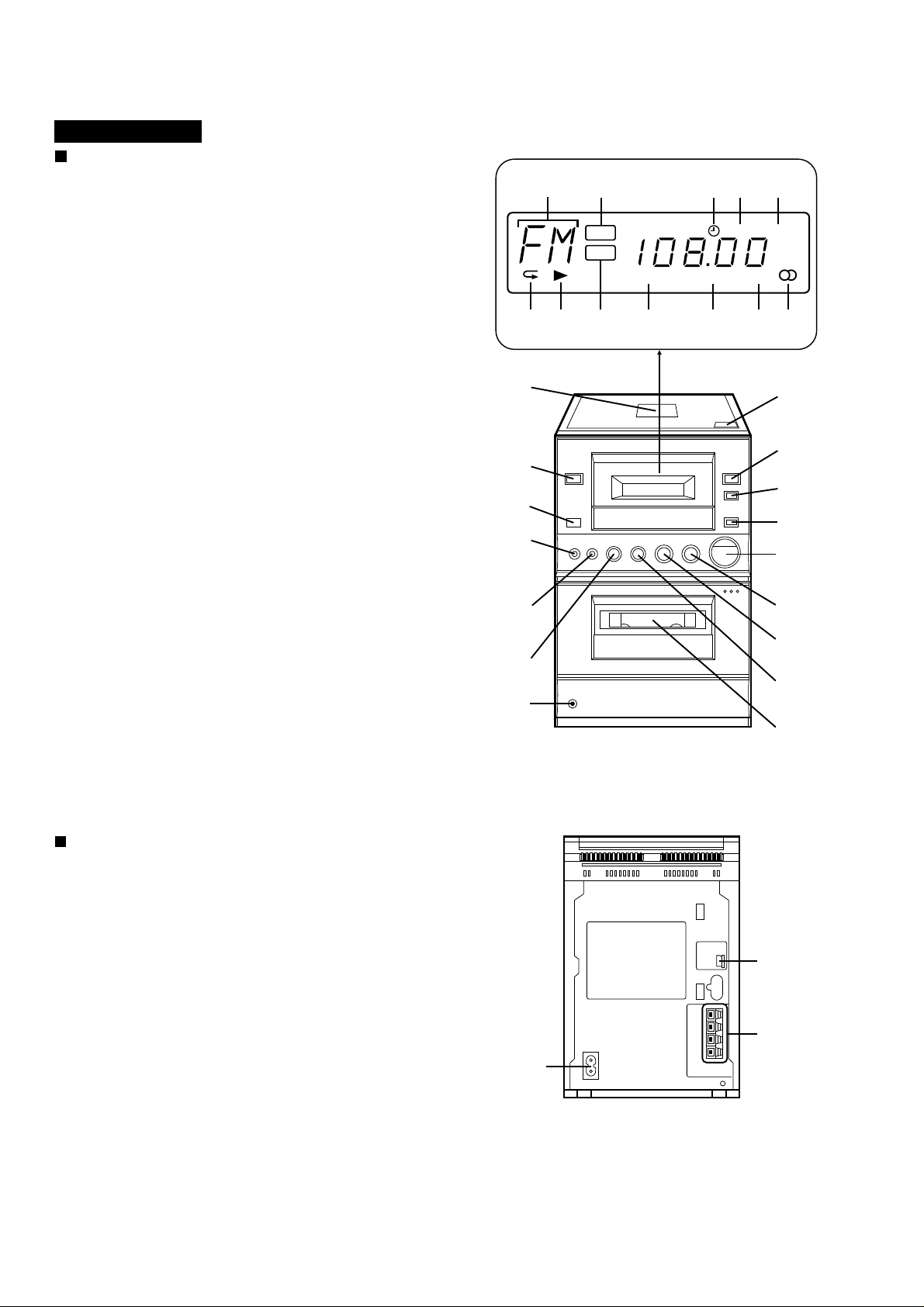

Page 4

VOL

EQ

RANDOM MEMORY ST

REC SLEEP

kHz

MHz

2

3

4

5

6

78

91011

12

13

1

20

22

15

16

17

18

19

23

24

25

26

27

14

21

28

2

3

1

XL-505H,505E,507E/CP-505,505E,507

XL-505H/505E/507E

Front Panel

1. Function/Band/Track Number Indicator

2. Volume Indicator

3. Timer Indicator

4. Record Indicator

5. Sleep Indicator

6. Repeat Indicator

7. Play Indicator

8. Extra Bass/Equalizer Indicator

9. Random Indicator

10. Memory Indicator

11. FM Stereo Mode Indicator

12. FM Stereo Indicator

13. CD Compartment

14. On/Stand-by Switch

15. Remote Control Sensor

16. Record Pause/Beat Cancel Button

17. Memory/Set Button

18. (CD) Track Down/Review Button

(TAPE) Rewind Button

(TUNER) Preset Down Button

19. Headphones Socket

20. CD Eject Button

21. Function Selector Button

22. Band Selector Button

23. Extra Bass/Equalizer Mode Button

24. Volume Up/Down Buttons

25. (CD) Play/Pause Button

(TAPE) Play Button

(TUNER) Tuning Up Button

26. (CD/TAPE) Stop Button

(TUNER) Clear Button

27. (CD) Track Up/Cue Button

(TAPE) Fast Forward Button

(TUNER) Preset Up Button

28. Cassette Compartment

NAMES OF PARTS

Rear Panel

1. AC Power Input Socket

2. FM/AM Loop Aerial Socket

3. Speaker Terminals

– 4 –

Page 5

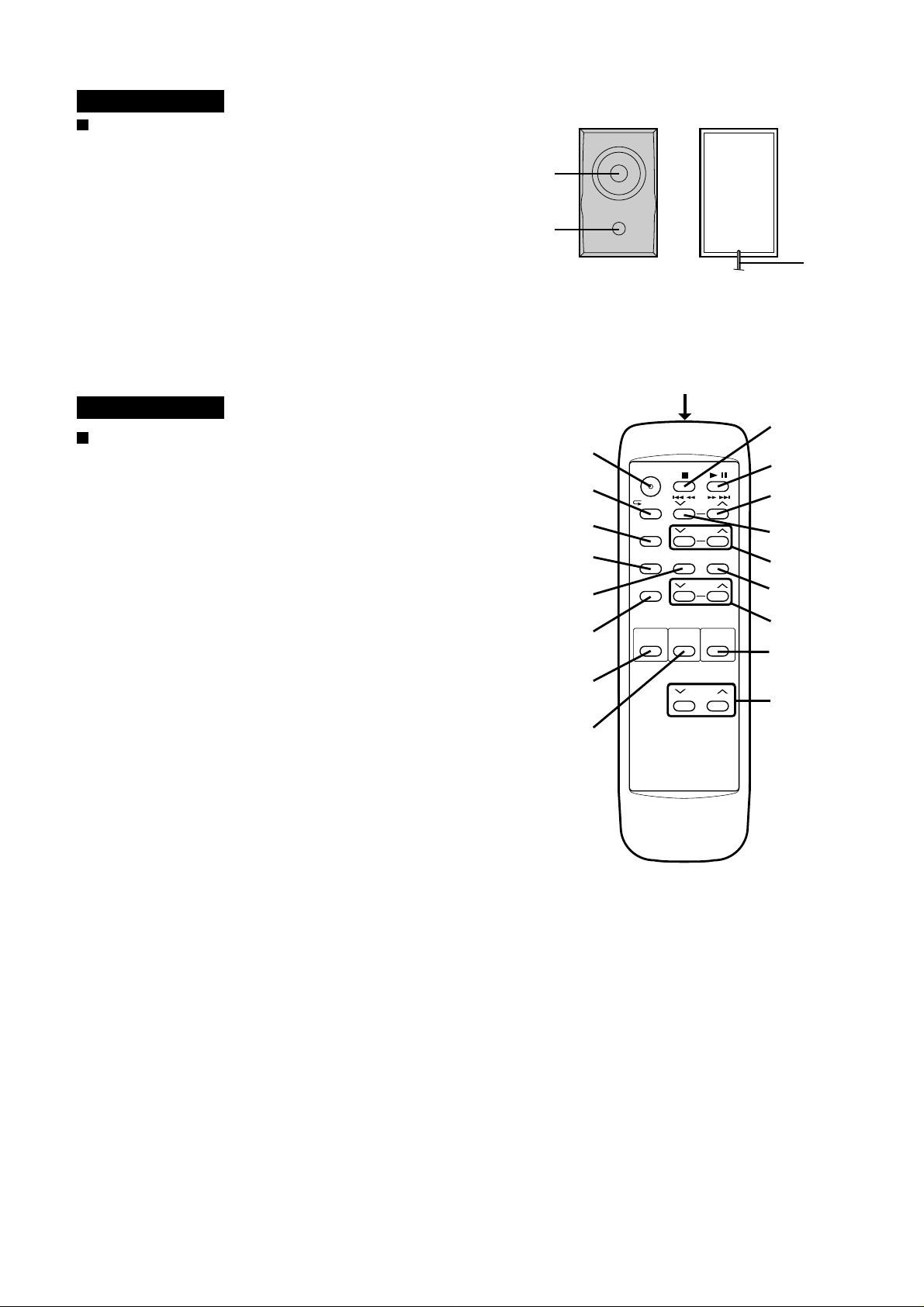

CP-505/505E/507

Speaker Section

XL-505H,505E,507E/CP-505,505E,507

1. Full-Range Speaker

2. Bass Reflex Duct

3. Speaker Wire

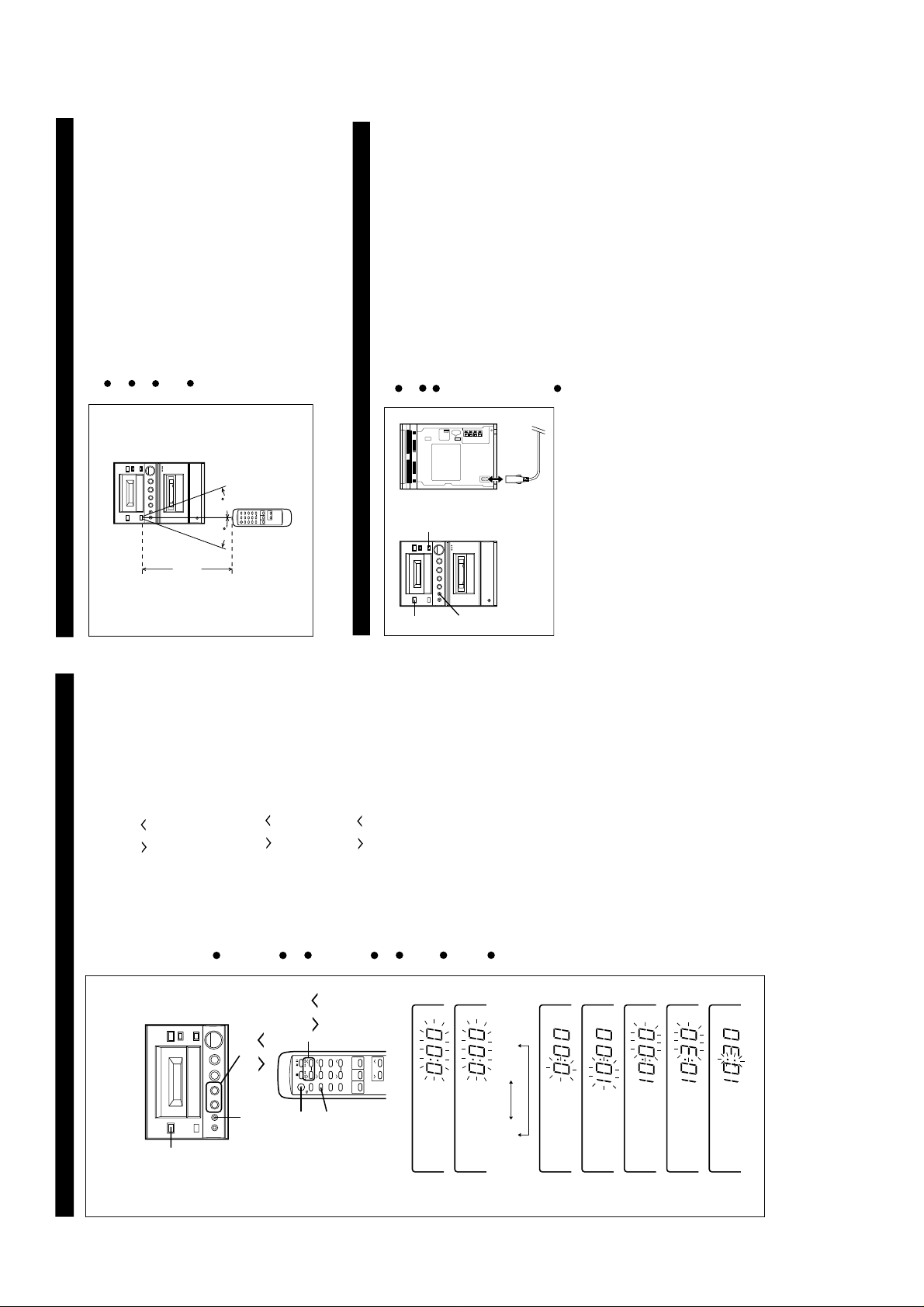

XL-505H/505E/507E

Remote Control

1. Remote Control Transmitter LED

2. On/Stand-by Button

3. (CD) Repeat/Random Button

4. (CD/TUNER) Memory/Set Button

5. (CD/TUNER) Clear Button

6. Timer/Set Button

7. Sleep Button

8. (CD/TAPE) Stop Button

9. (CD) Play/Pause Button

(TAPE) Play Button

10. (CD) Track Up/Cue Button

(TAPE) Fast Forward Button

(TUNER) Preset Up Button

11. (CD) Track Down/Review Button

(TAPE) Rewind Button

(TUNER) Preset Down Button

12. Tuning Up/Down Buttons

13. Timer Button

14. Timer Up/Down Buttons

15. Function Selector Button

16. Band Selector Button

17. Extra Bass/Equalizer Mode Button

18. Volume Up/Down Buttons

1

2

3

1

8

2

3

4

5

6

7

ON/

STAND-BY

/RANDOM

MEMORY/

SET

CLEAR

SLEEP

FUNCTION

TIMER/

SET

BAND

PRESET

TUNING

TIMER

EQUALIZER

TIMER

X-BASS/

9

10

11

12

13

14

17

15

VOLUME

18

16

– 5 –

Page 6

XL-505H,505E,507E/CP-505,505E,507

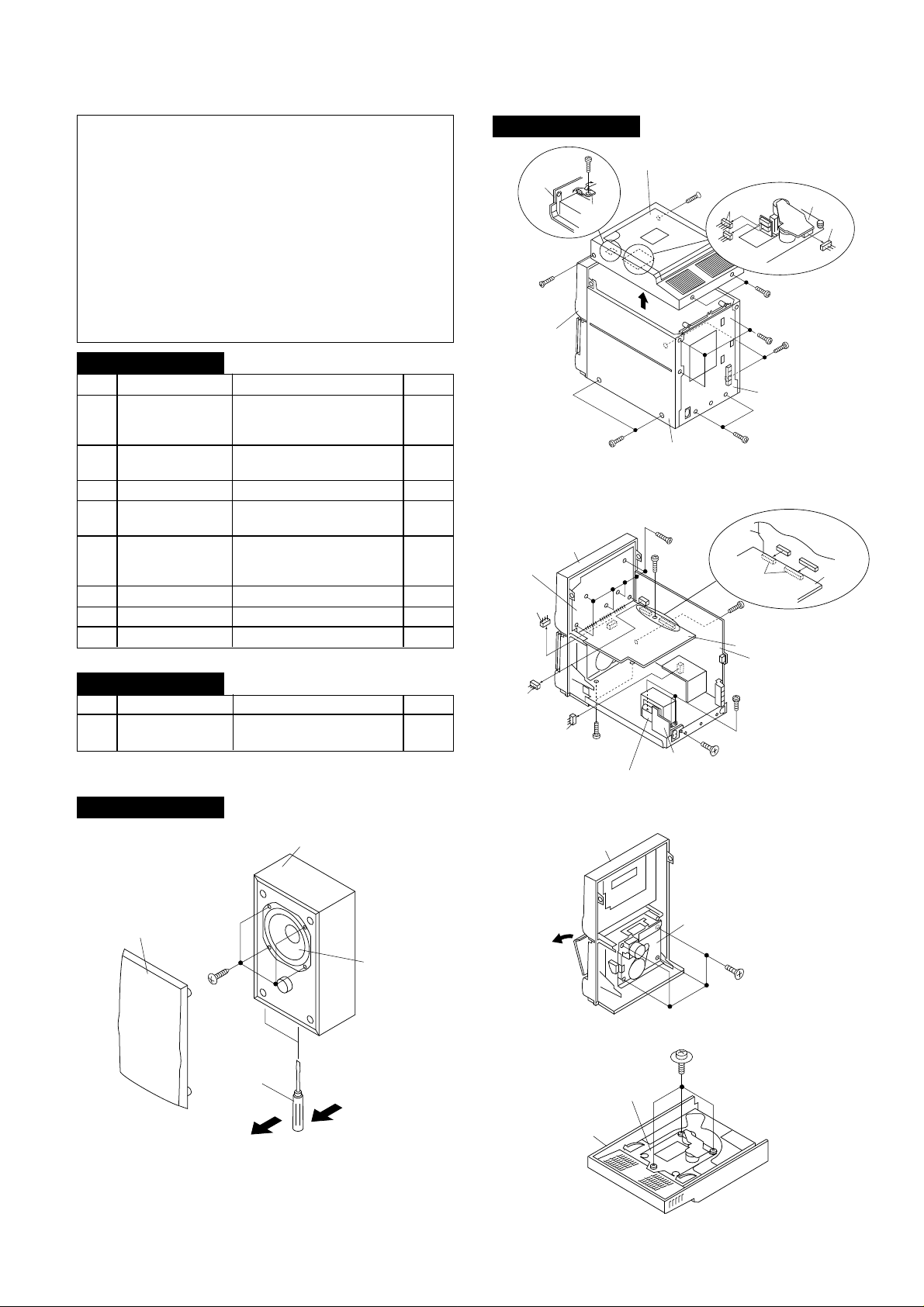

SETTING THE CLOCK

1

Press the ON/STAND-BY switch to enter the stand-by mode.

2

Press the MEMORY/SET button.

3

Press the PRESET ( or ) button to select the time display

mode.

"0:00" → The 24-hour disp lay will appe ar.

(0:00 - 23:59)

"AM 12:00" → The 12-hour display will appear.

(AM 12:00 - PM 11:59)

Note that this can only be set when the unit is first installed

or it has been reset (see page 14).

4

Press the MEMORY/SET button.

5

Press the PRESET ( or ) button to adjust the hour.

Press the PRESET button once to advance the time by 1 hour.

Hold it down to advance continuously.

When the 12-hour display is selected, "AM" will change auto-

matically to "PM".

6

Press the MEMORY/SET button.

7

Press the PRESET ( or ) button to adjust the minutes.

Press the PRESET button once to advance the time by 1

minute. Hold it down to change the time in 5 minute intervals.

The hour setting will not advance even if minutes advance from

"59" to "00".

8

Press the MEMORY/SET button.

The clock starts operating from "0" seconds. (Seconds are not

displayed.)

Note:

In the event of a power failure or when the AC power lead is

disconnected, the clock display will go out.

When the AC power supply is restored, the clock display will

flash on and off to indicate the time when the power failure

occurred or when the AC power lead was disconnected.

ON/

STAND-BY

ON/

STAND-BY

MEMORY/

SET

MEMORY/

SET

PRESET

( / )

PRESET

( / )

AM 12:000:00

2

3

4

5

6

7

8

If this happens, follow the procedure below to change the clock

time.

To change the clock time:

1

Press the ON/STAND-BY switch to enter the stand-by mode.

2

Perform steps 4 - 8 above.

To change the time display mode:

1

Perform steps 1 - 3 in the section "RESETTING THE MICRO-

COMPUTER", on page 14.

2

Perform steps 1 - 8 above.

In this example, the clock is set for the 24-hour

(0:00) system.

PREPARATION FOR USE

15

15

Notes concerning use:

Replace the batteries if control distance decreases or operation

becomes erratic.

Periodically clean the transmitter LED on the remote control

and the sensor on the main unit with a soft cloth.

Exposing the sensor on the main unit to strong light may in-

terfere with operation. Change the lighting or the direction of

the unit.

Keep the remote control away from moisture, excessive heat,

shock, and vibrations.

0.2 m - 6 m

(8" - 20')

RESETTING THE MICROCOMPUTER

Reset the microcomputer under the following conditions:

To erase all of the stored memory contents (clock and timer

settings, tuner and CD presets).

If the display is not correct.

If the operation is not correct.

1

Press the ON/STAND-BY switch to enter the stand-by mode.

2

Unplug the AC power lead from the AC INPUT socket on this

unit.3Whilst pressing down the MEMORY/SET button and the X-

BASS/EQUALIZER button, plug the AC power lead into the

AC INPUT socket on this unit.

1

2,3

3

3

Caution:

The operation explained above will erase all data stored in

memory, such as clock and timer settings, tuner and CD pres-

ets.

OPERATION MANUAL

– 6 –

Page 7

DISASSEMBLY

(D1)x6

ø3x10mm

(E1)x1

ø3x10mm

(D1)x1

ø3x10mm

CD Servo PWB

Main PWB

Power Supply

PWB

Power

Transformer

Front Panel

Display PWB

(F1)x3

ø4x8mm

(F1)x1

ø3x10mm

(D1)x2

ø3x10mm

(D2)x1

(E2)x1

(D2)x1

(E2)x2

CD Servo

PWB

Main

PWB

Tape MechanismOpen

(G1)x4

ø3x10mm

Front Panel

CD Mechanism

(H1)x3

ø2.6x10mm

Top Cabinet

Caution on Disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need be

removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were

before disassembling.

4. Take suffcient care on static electricity of integrated

circuits and other circuits when servicing.

XL-505H/505E/507E

STEP REMOVAL

1 Top Cabinet 1. Screw...................(A1) x4 7-1

2 Side Panel 1. Screw...................(B1) x7 7-1

(Left/Right)

3 Back Board 1. Screw ................... (C1) x2 7-1

4 Front Panel 1. Screw................... (D1) x9 7-2

5 Main PWB/ 1. Screw...................(E1) x1 7-2

Display PWB/ 2. Socket..................(E2) x3

CD Servo PWB

6 Power Supply PWB 1. Screw................... (F1) x4 7-2

7 Tape Mechanism 1. Screw...................(G1) x4 7-3

8 CD Mechanism 1. Screw...................(H1) x3 7-4

PROCEDURE

2. Socket..................(A2) x3

3. Screw...................(A3) x1

2. Socket..................(D2) x2

FIGURE

XL-505H,505E,507E/CP-505,505E,507

XL-505H/505E/507E

(A3)x1

ø3x10mm

Top

Cabinet

(A1)x1

ø3x10mm

Front

Panel

Swicth

PWB

(B1)x2

ø3x10mm

Top Cabinet

Side Panel

Figure 7-1

(A1)x1

ø3x10mm

(A2)x2

(C1)x2

ø3x10mm

(B1)x3

ø3x10mm

Rear Panel

CD

Mechanism

(A1)x2

ø3x10mm

(B1)x2

ø3x10mm

(A2)x1

CP-505/505E/507

STEP

1 Speaker 1. Net....................... (A1) x1 7-5

REMOVAL PROCEDURE FIGURE

2. Screw .................. (A2) x4

CP-505/505E/507

Speaker Box

Net

(A1x1)

(A2)x4

ø4x15mm

Screw

driver

Direction of handle

Figure 7-5

Speaker

Figure 7-2

Figure 7-3

Figure 7-4

– 7 –

Page 8

XL-505H,505E,507E/CP-505,505E,507

Pickup Unit

( A2 ) x2

ø2.6 x6mm

( A1 ) x2

CD Mechanism

Shaft

( A3 ) x1

Gear

( A5 ) x1

StopWasher

( A4 ) x1

Mechanism Cover

( A1 ) x2

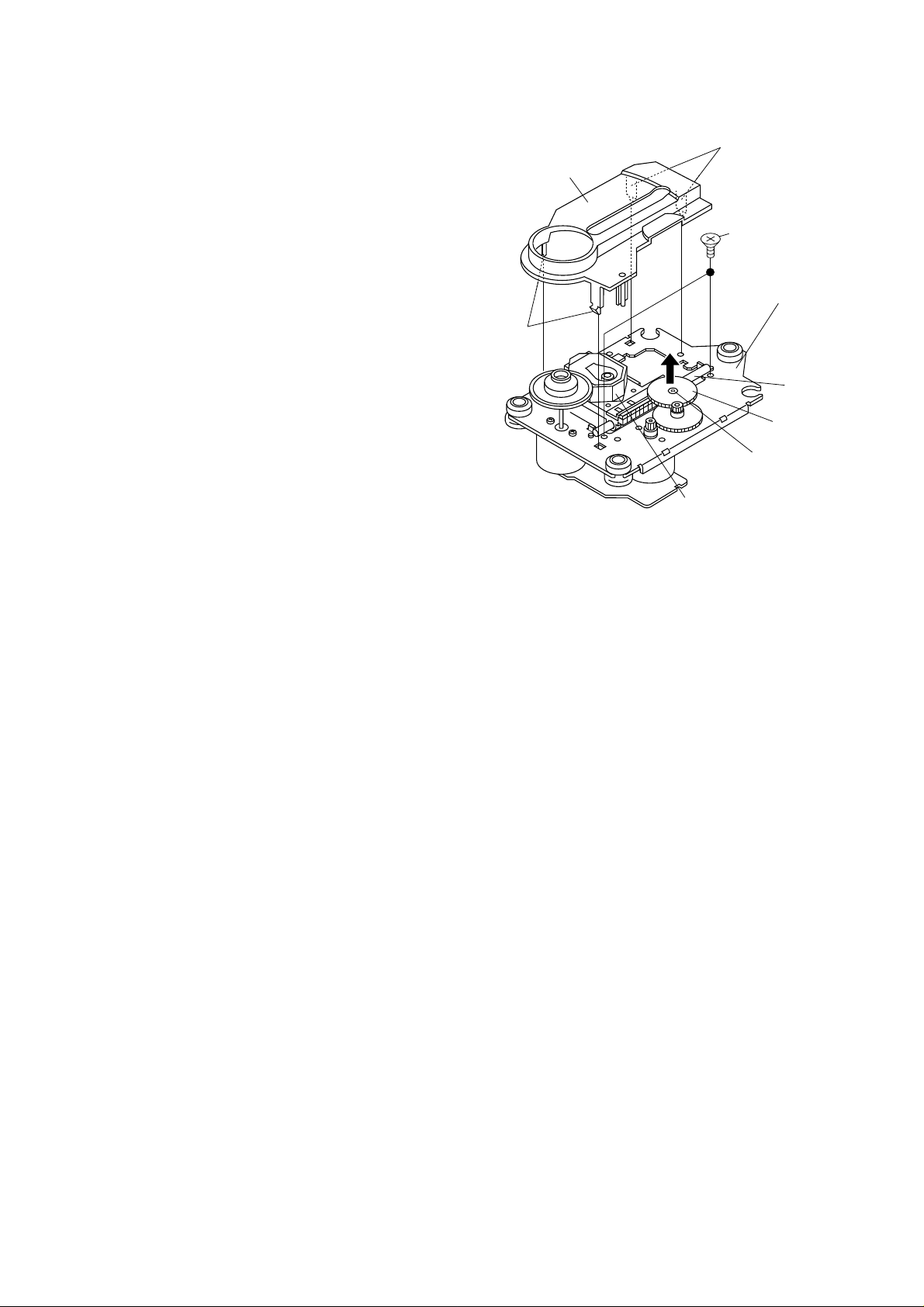

REMOVING AND REINSTALLING THE MAIN PARTS

CD MECHANISM SECTION

Perform steps 1 and 8 of the disassembly method to remove

the CD mechanism.

How to remove the pickup (See Fig. 8)

1. Remove the mechanism cover, paying attention to the

pawls (A1) x 4 pcs.

2. Remove the screws (A2) x 2 pcs., to remove the shaft (A3)

x 1 pc.

3. Remove the stop washer (A4) x 1 pc., to remove the gear

(A5) x 1 pc.

4. Remove the pickup.

Note:

After removing the optical pickup connector wrap the front

end of connector in conductive aluminium foil so as to

prevent damage of optical pickup by static electricity.

Figure 8

– 8 –

Page 9

ADJUSTMENT

MECHANISM SECTION

• Driving Force Check

Torque Meter

Play: TW-2412 Over 80 g

• Torque Check

Torque Meter

Play: TW-2111 30 to 70 g. cm

Fast forward: TW-2231 50 to 140 g.cm

Rewind: TW-2231 50 to 140 g.cm

• Tape Speed

Test Tape

MTT-111 In Motor 3,000 ± Headphones

Adjusting

Point

TAPE MECHANISM

Specified Value

Specified Value

Specified

Value

Instrument

Connection

90 Hz

XL-505H,505E,507E/CP-505,505E,507

TUNER SECTION

fL: Low-range frequency

fH: High-renge frequency

• FM RF

Signal generator: 1 kHz, 75 kHz dev., FM modulated

Test Stage Frequency

Band — 87.50 MHz (fL): L303 *1

Coverage 3.4 ± 0.1 V

RF 98.00 MHz 98.00 MHz L302 *2

(10~30 dB)

*1. Input: Antenna, Output: TP301

*2. Input: Antenna, Output: Speaker Terminal

• Detection

Signal generator: 10.7 MHz, FM sweep generator

Frequency Frequency

Test

Stage

IF 10.7 MHz 98.00 MHz T304(Turn Input: Pin 1 of

Frequency

Display

Display

Setting/

Adjusting

Parts

Setting/

Adjusting

Parts

the core of IC301

T304 fully Output: TP302

counterclockwise.

Instrument

Connection

Instrument

Connection

CNP301

ANTENNA

M901

Motor

Volume in motor

Figure 9-1 ADJUSTMENT POINT

T302

AM BAND

T306

AM

TRACKING

L302

FM BAND

COVERAGE

1

IC301

T304

FM IF

L303

COVERAGE

TP301

FM RF

MAIN PWB

FM MUTE

LEVEL

VR351

TP302

T351

AM IF

• AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

Test Stage

IF 450 kHz 1,620 kHz T351 *1

Band — 522 kHz (fL): T306 *2

Coverage 1.1 ± 0.1 V

Tracking 990 kHz 990 kHz (fL): T302 *1

Frequency Frequency

Display

Setting/

Adjusting

Parts

Instrument

Connection

*1. Input: Antenna, Output: Speaker Terminal

*2. Input: Input is not connected, Output: TP301

• Setting the Test Mode

Keeping the BAND button and MEMORY button pressed, turn

on POWER. Then, the frequency is initially set in the memory

as shown in Table. Call it with the , button to use it

for adjustment and check of tuner circuit.

Preset No.

1 87.50 MHz 6 522 kHz

2 108.00 MHz 7 1,620 kHz

3 98.00 MHz 8 603 kHz

4 90.00 MHz 9 1,404 kHz

5 106.00 MHz 10 990 kHz

11~40

FM

Preset No.

AM

• FM Mute Level

Signal generator: 1 kHz, 40 kHz dev., FM modulated

Frequency

98.00 MHz 98.00 MHz VR351*1 Input: CNP301

Display

(25 dBµV) Output: Speaker

Adjusting

Parts

Instrument

Connection

Terminal

Adjust so that an output signal appears.

Figure 9-2 ADJUSTMENT POINTS

– 9 –

Page 10

XL-505H,505E,507E/CP-505,505E,507

FET

FSO

1

2

CD SECTION

1. This CD unit need adjustment as follow.

CD Test Mode

Step 1 VR803 (Focus Offset) DC + 40 mV (FEL>RFO) FEI (R826) and VRO

Step 4 VR802 (Tracking Error Balance) *1 (See Fig. 10-1) TSO (3-Pin of TP801)

*1: Adjust to obtaiin vertically symmetrical waveform (Fig. 10-1) with respect toreference DC level. The reference level is VRO

(Approx DC 2.1V).

2. This CD unit have the following automatic adjustment function. Automatic adjustment item.

2-1: Focus Servo Gain (Fig. 10-2)

Focus Gain Adjustment is performed when disc is changed.

2-2: Tracking Servo Gain (Fig. 10-3)

Tracking Gain Adjustment is performed when disc is changed and disc is playbacked.

VRO

Adjustment Part

TSO

SYMMETRICAL

1

UP AND DOWN

Value/Adjusting Method

Instrument Connection

(1-Pin of TP801)

and VRO (1 Pin of TP801)

TSO

TS2O

Figure 10-1

Figure 10-3

Figure 10-2

1

2

CD SERVO PWB

VR802 VR803

TP801

321

TRACKING

ERROR

FOCUS

OFFSET

BALANCE

Figure 10-4 ADJUSTMENT POINTS

– 10 –

321

T

N

S

C

O

V

R

O

Page 11

XL-505H,505E,507E/CP-505,505E,507

TEST MODE

The Test Mode for this microcomputer has two variations, namely "regular Test Mode" for adjustment and measurement and "selfdiagnosis Test Mode" for self-judgment in final inspection of products.

1. Entering the Test Mode

To enter the each Test Mode, press the POWER key, holding down the following two keys in the regular standby mode (power

off state). In this case only the main unit keys are valid. The Test Mode is not set even when the remote controller POWER

key is turned on.

[Regular Test Mode]

1. CD Test Mode (TEST 1)

2. Tuner Test Mode (TEST 3)

3. Electronic volume Test Mode (TEST 4)

4. Timer Test Mode (TEST 5)

5. LCD Test Mode (TEST 6)

[Self-diagnosis Test Mode]

1. Key input diagnosis TEST Mode (TESTA)

2. CD Test Mode (TEST 1)

1. Step 1 Mode

When the CD Test Mode is set, the following display lights, and the CD pickup slides to the innermost periphery.

After lighting for 1.5 sec

When the following operation key is pressed in this state, the following operation is performed.

"POWER" ................The Test Mode is set to off, power is turned off, and the mode is changed to the regular standby mode.

"FF/FWD" ................After the pickup returns once to the innermost periphery, the pickup slides to the external periphery while

.................................this key is held down.

"REW/REV" .............After the pickup returns once to the innermost periphery, the pickup slides to the internal periphery while

.................................this key is held down. However, input is invalid if PU-IN is on.

"PLAY".....................Shift to Step 2

"STOP" ....................Invalid

* In case of mode entry the pickup is moved to the internal periphery. At this time entry of any key other than POWER key is

disabled until shift of pickup to the internal periphery is completed. If PU-IN SW ON cannot be detected while waiting for 10

seconds, the slide motor is stopped, the following error is displayed, and entry of any key other than POWER key is disabled.

– 11 –

Page 12

XL-505H,505E,507E/CP-505,505E,507

2. Step 2 Mode

When the PLAY key is pressed in the mode above, the laser lighting is turned on. In this state the laser is only turned on,

and other operations are not performed.

When the following operation key is pressed in this state, the following operation is performed.

"POWER" ................The Test Mode is set to off, power is turned off, and the mode is changed to the regular standby mode.

"FF/FWD" ................While this key is held down, the pickup slides to the external periphery.

"REW/REV" .............While this key is held down, the pickup slides to the internal periphery. However, if PU-IN is on, entry is

.................................invalid.

"PLAY".....................Shift to Step 3

"STOP" ....................Return to Step 1

3. Step 3 Mode

While the laser is lighting, the focus servo is turned on, and focus search is performed. If focusing failure occurs, focus search

is repeated until focusing is attained.

When the following operation keys are pressed in this state, the following operations are performed.

"POWER" ................The Test Mode is set to off, power is turned off, and the mode is changed to the regular standby mode.

"FF/FWD" ................While this key is held down, the pickup slides to the external periphery.

"REW/REV" .............While this key is held down, the pickup slides to the internal periphery. However, if PU-IN is on, entry is

.................................invalid.

"PLAY".....................If focusing has been attained, the process proceeds to Step 4. Unless focusing has been attained,

.................................reception is inhibited.

"STOP" ....................Return to Step 1

4. Step 4 Mode

The disc is rotated and CLV is locked while the tracking servo is off.

The time display indicates always "0:00".

When the following operation keys are pressed in this state, thefollowing operations are performed.

"POWER" ................The Test Mode is set to off, power is turned off, and the mode is changed to the regular standby mode.

"FF/FWD" ................While this key is held down, the pickup slides to the external periphery.

"REW/REV" .............While this key is pressed, the pickup slides to the internal periphery. However, if PU-IN is on, entry is

.................................invalid.

"PLAY".....................Shift to Step 5

"STOP" ....................Return to Step 1

– 12 –

Page 13

XL-505H,505E,507E/CP-505,505E,507

5. Step 5 Mode

The tracking servo is turned on, groove is traced, mute is set to off, and playback is started. Even when the outermost

periphery of disc is reached in playback mode, it does not stop. The LCD display indicates playback lapse time as in case

of regular CD playback.

When the following operation keys are pressed in this state, the following operations are performed.

"POWER" ................The Test Mode is set to off, power is turned off, and the mode is changed to the regular standby mode.

"FF/FWD" ................While this key is held down, the pickup slides to the external periphery.

"REW/REV" .............While this key is held down, the pickup slides to the internal periphery. However, if PU-IN is on, entry is

.................................invalid.

"PLAY".....................Invalid

"STOP" ....................Return to Step 1

Other cautions

• While the CD lid OPEN is detected, entry into any step later than Step 2 is disabled. If CD lid OPEN is detected in any step

higher than Step 2, return to Step 1 is done.

• TOC IL is not performed in the Test Mode.

• The key operation, excepting that specified above, is the same as that of regular operation (CD). Only the FUNCTION key

is input-inhibited.

• Syncro REC with REC key input is also invalid in this mode.

3. Tuner Test Mode (TEST 3)

1. Outline of tuner (radio) Test Mode

The tuner Test Mode is intended to store adjustment/measurement frequency in the preset memory CH without frequency

adjustment by the adjusting personnel when the tuner is adjusted in the production line.

2. Details of tuner Test Mode

When power is turned on with the POWER key while the MEMORY/SET key and BAND key are held down together in

POWER OFF state, the frequency for adjustment/measurement of specific destination specified by the AREA terminal is

preset-stored in the preset memory CH (the frequency to be preset-stored for specific destination is explained in the Item

C). When the tuner Test Mode is started up, it is started with FM. FM is FM STEREO only.

When the REW key is pressed while the preset memory CH is 1CH, the highest CH is found as in case of regular mode. When

the FF key is pressed while the preset memory CH is highest CH, 1CH is found.

The RADIO (TUNER) BAND key (or TUNER/BAND key on the remote controller) is valid.

As in case of regular mode, selection of band, FM MONO/STEREO mode is enabled by pressing the RADIO (TUNER) BAND

(or TUNER/BAND ) key.

Exiting the tuner Test Mode, When the destruction data is stored in the memory in the tuner Test Mode, AC supply is

interrupted in the Test Mode and the AC supply is recovered, all the memory is cleared with the destruction data in case of

start-up.

(Countermeasures so that the Test Mode memory does not remain when AC supply is restored after power supply failure

occurred once in the Test Mode.) The memory is not cleared when AC supply is turned off after POWER OFF and FUNCTION

selection. In case of exit from the tuner Test Mode through the backup mode upon occurrence of power failure

the frequency data stored in the preset memory for adjustment/measurement is erased. (As a result the preset

memory CH becomes empty.)

The display indication is the same as that in case of regular operation.

The following display lights for one second when the tuner TEST mode is turned on

– 13 –

Page 14

XL-505H,505E,507E/CP-505,505E,507

Test Mode operation specification

3. Preset frequencies for various destinations (random preset memory)

BAND (CH)

1 FM 87.5MHz

2 FM 108.0MHz

3 FM 98.0MHz

4 FM 90.0MHz

5 FM 106.0MHz

6 AM 522 kHz

7 AM 1620 kHz

8 AM 990 kHz

9 AM 603 kHz

10 AM 1404 kHz

• The unit used in the table above is Hz. K represents 1,000 times, and M represents 1,000,000 times.

• The hatched data shown in the table are not stored in the memory.

• FM is stereo mode.

Note: Keys which are effective in Test Mode

• Main unit keys: VOLUME UP/DOWN, BAND, TUNING UP, POWER, MEMORY, CLEAR,

PRESET UP/DOWN

• Remote controller keys:

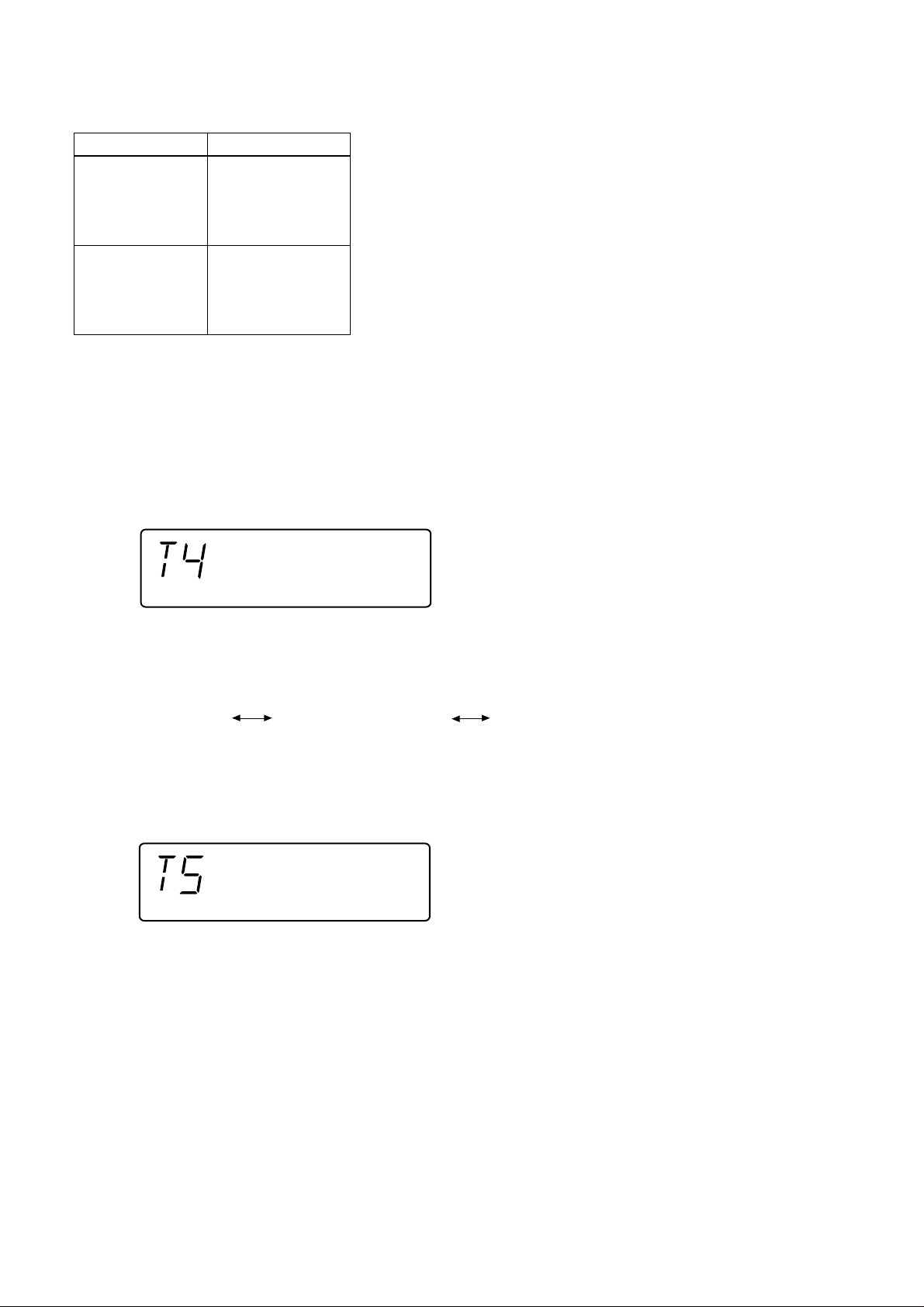

4. Electronic volume Test Mode (TEST 4)

After the Test Mode is set, the following display lights for one second.

VOL UP/DOWN, BAND, TUNING UP/DOWN, POWER, MEMORY, CLEAR, PRESET UP/DOWN

When this mode has been set, -14dB (STEP17) is set, the preset equalizer is set to FLAT (EQ-3), the SRS mode is set to OFF,

and the start-up function is set to Tape.

1. The display is the same as that indicated in case of regular operation excepting when Test Mode is set.

2. The volume control with the Volume UP/DOWN key is only the following 3 steps, differing from the volume control in the regular

operation mode.

Volume — ∞ (STEP 0) Volume — 14dB (STEP 17) Volume — 0 (STEP 24)

3. The preset equalizer and SRS are switched if key operation is performed.

5. Timer Test Mode (TEST 5)

When the Test Mode is set, the following display lights for one second.

The current time and timer time are set in the following procedure, and timer playback is performed.

1. The present time is set to 1:00, the timer is set to ON time 1:02, OFF time 1:12, Function is set to Tape, Volume is set to STEP8.

One minute is counted in increments of second, and timer playback is performed. One step of Fade-in/out in this mode is

performed for 0.5 sec.

The display is the same as that appears in the regular timer operation.

2. After completion of timer playback test "TEST-5" indication (which appears when the mode is set) appears again and Standby

state is set. PLAY key entry is waited. If an entry is detected, the SLEEP timer is set to 2 minutes, and Function is set to Tape,

so that playback is started at once. Volume is set to STEP8, and 10 seconds are counted down in decrements of second. One

step of Fade-out is 0.5 sec.

The display is the same as that appears in the regular sleep playback mode.

3. After completion of SLEEP test, the Test Mode is turned off, and regular standby mode is set, so that the Test Mode ends.

– 14 –

Page 15

XL-505H,505E,507E/CP-505,505E,507

6. LCD Test Mode (TEST 6)

When the LCD Test Mode is set, all the LCD segments light.

7. Key input diagnosis Test Mode (TEST A)

When the Test Mode is set, the following display appears.

In this Test Mode checking as to whether all the main unit keys can be detected is performed. Accordingly, when this mode

is set, checking is performed so as to examine whether the POWER key was pressed last after all the following keys were

pressed. If the result is OK, the following OK is displayed. If any one of keys was not pressed, an error is indicated. When the

POWER key is pressed, exit from the mode is made irrespective of whether the termination is normal or abnormal, and the

standby mode is set.

All the models using this microcomputer do not have the same keys. The entry of the following keys is detected depending on

the combination of simultaneously pressed keys when this mode is set. Key pressing order is not fixed. Pressing of all keys

must be detected.

1. In case of "PLAY" + "REC PAUSE"

Since the model does not have RDS and SRS, all the keys to be detected are the following 11 keys.

PLAY, VOL , VOL , BAND, G-EQ, FUNCTION, MEMORY/SET, REC PAUSE, REW/REV, FF/FWD, STOP

<

<

OK/NG indication of test result must be as follows.

NG indication

OK indication

– 15 –

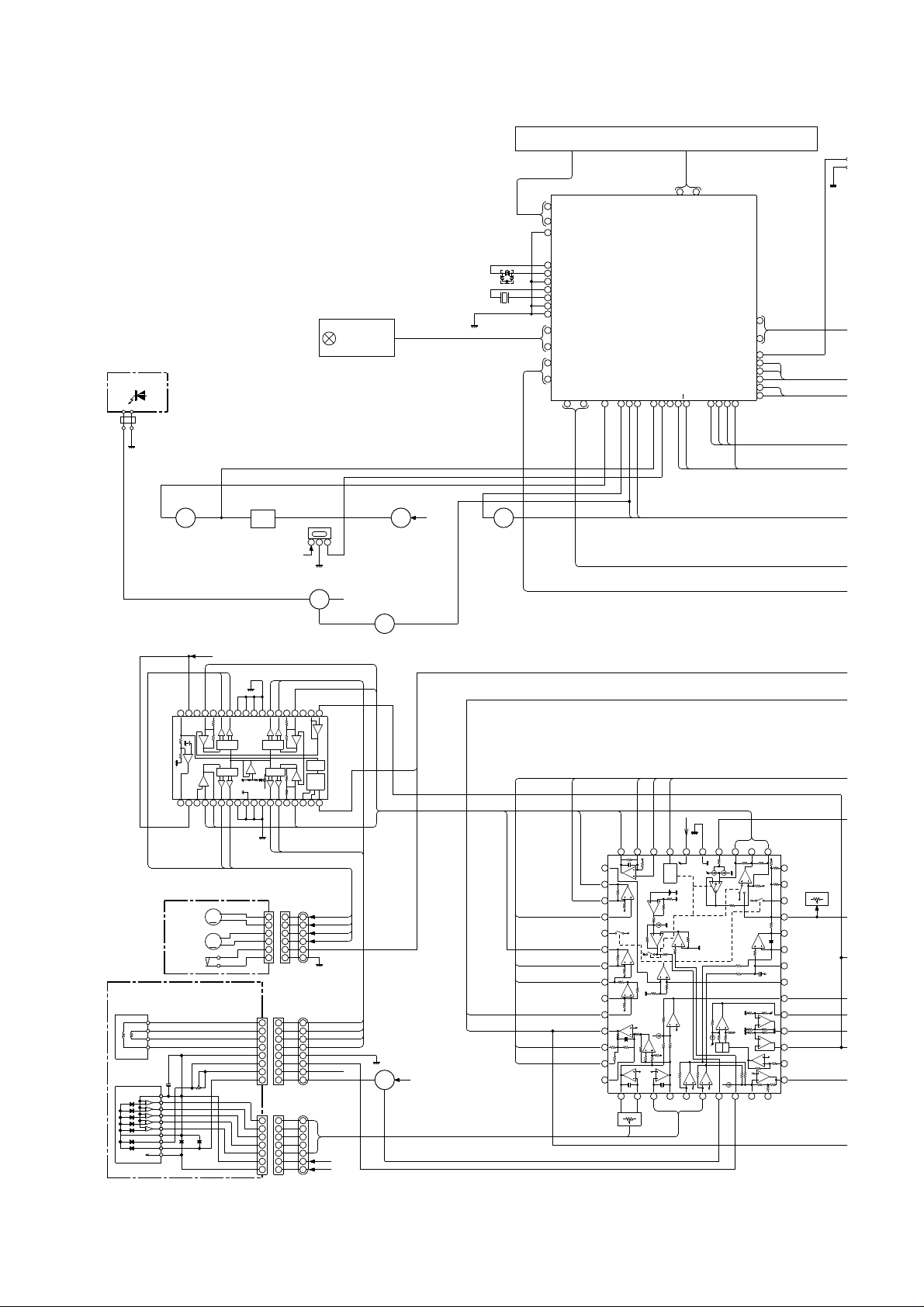

Page 16

XL-505H,505E,507E/CP-505,505E,507

KEY

SW702-SW707

SW710-SW714

SW718

LED704-LED712

FW701

SWITCHING

Q701

RESET

Q702

Q703

RX701

321

µ-CON +5V

X701

X702

SYS STOP

REMOCON

RESET

M+12V

Q704 Q705

SWTCHING

LCD

LCD701

COM3

1

~

~

4

COM0

5

VLC3

9

OSC2

10

OSC1

11

VSS

XI

12

13

XO

14

MMOD

15

VREF

17

KEY1

~

~

19

POWER

21

F.P

~

~

23

CAM SW

~

DI

25 31 32 34 35 36 37 38 39 40 41 45 46 47 48

~

IC701

IX0189AW

P-CONT

CE

P-MUTE

RESET

CD+B

REMOCON

CLE

SYS STOP

SEG7

STEREO

~

7493

~

SEG26

62

BUS3

~

~

57

PU-IN

56

LID-SW

55

BIAS

54

B-CAN

53

REC

52

MOT

CEE

CD RES

BUCK

R-MUTE

SOL

51

SD

ACTUATOR

TR+

FO+

FO–

TR–

1/2VCC

GND

MON

VCC

18 17 16 15 14 13 12 11 10

Reg5V

19 20 21 22 23 24 25 26 27

M802

SPINDLE

SW801

PU-IN

C4A

C

F

B

A

E

C2A C3A

LD

VCC

–

+

M801

SLED

VR1A

NC

+

–

+

(S+6.2VLINE)

–

LEVEL

SHIFT

LEVEL

SHIFT

DMEO

M

M

SL+

SL–

987654321

––

++

+

–

++

––

28 29 30 31 32 33 34 35 36

SP+

SP–

+

SP+

SP–

–

SL+

+

SL–

PU-IN

–

GND

TR–

TR+

FO+

FO–

GND

PD

VR

LD

C

F

B

A

E

1/2V

+5V

GND

GND

++

LEVEL

SHIFT

LEVEL

SHIFT

VCC

6

5

4

3

2

1

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

SWITCHING

FMSO

TS2O

TR–

TR+

NC

GAIN1

––

–

+

–

+

++

––

STAND

GAIN4

FSO

FO+

FO–

6

6

5

5

4

4

3

3

2

2

1

1

BI803

CNP803

CNS803

BI801

CNS801

11

22

33

44

55

66

77

88

CNS802

BI802

11

22

33

44

55

66

77

T.S.D

Q707

-BY

TR–

TR+

FO+

FO–

GND

PD

VR

LD

GND

+–

PU-IN

1/2VCC

+5V

IC804

CD STB

SP+

SP–

SL+

SL–

A 12V

LED+B

Q706

SWITCHING

SWTCHING

Q801

P CONT

+5V

DMEN

TPI

DMEP

TNI

TRACKING

ERROR

BLANCE

VR802

SEL

TNO

DMEO

DFCT

25

FMSO

26

FMSM

27

FMSP

28

THLD

29

TS2O

30

TS2N

31

TS2P

32

TS1N

33

TS1P

34

TSO

35

TEL1

36

TEL2

37

38

TSN

39 40 41 42 43 44 45 46 47 48

TPO

LDO

PD

CD+5V

VCC

FNI

GND

OSCI

FPI

LDO

COSC

MDI

15161718192021222324

FSO

FSN

14

FEL2

FOCUS

OFFSET

13

FEL1

VR803

12

FHLD

FEI

11

10

FEO

FEN

9

FEP

8

DFIN

7

SBAD

6

RFRP

5

2VRO

4

VRO

3

RFI

2

RFO

1

RFT

RFN

IC801

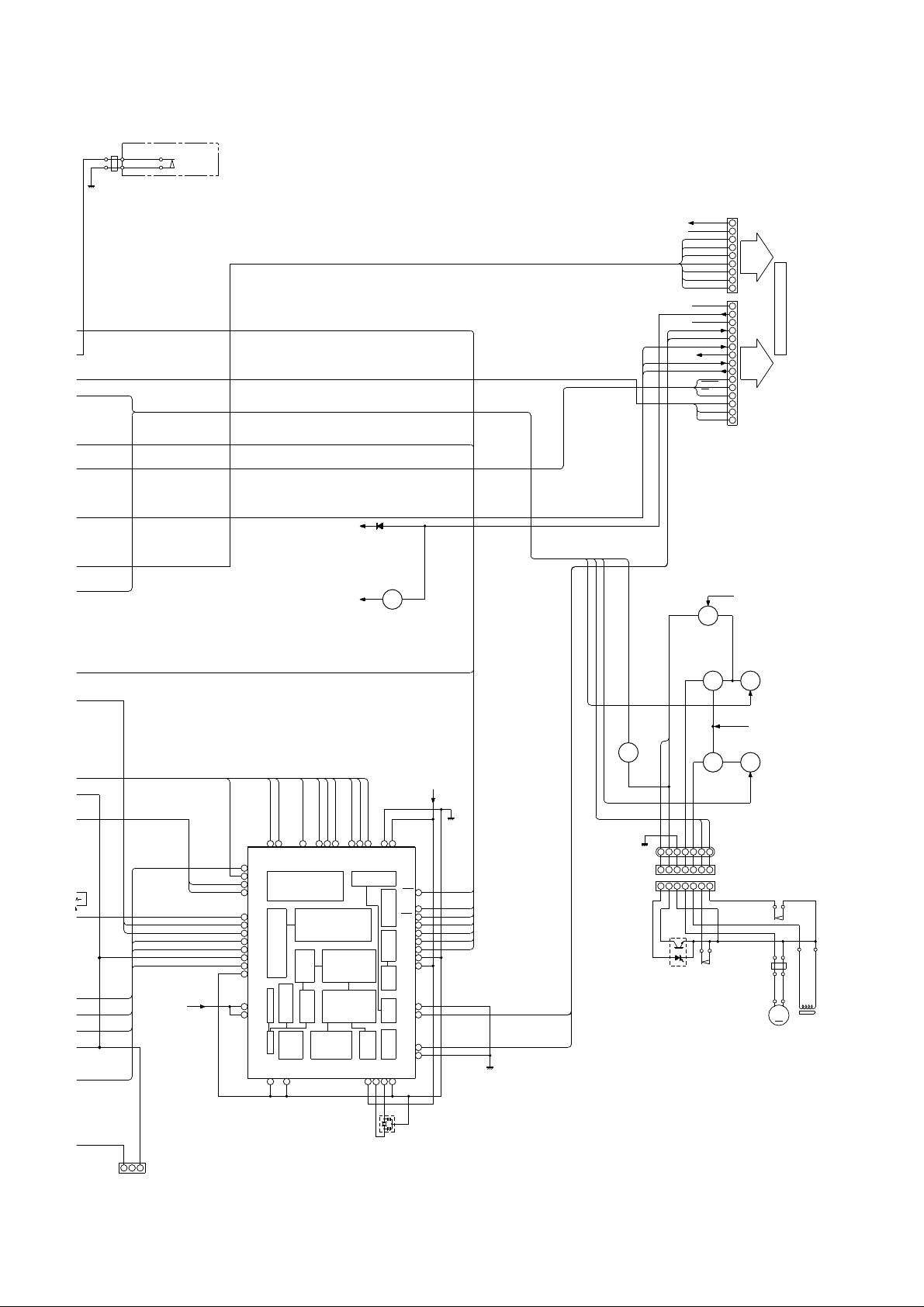

Figure 16 BLOCK DIAGRAM (1/4)

– 16 –

Page 17

XL-505H,505E,507E/CP-505,505E,507

FW702

SW701

CD EJECT

(S+6.2V)

S+6.2V

R-CH

L-CH

P MUTE

P CONT

CD+B

R-MUTE

FM ST

SD

REC

B-CAN

BIAS

µ-CON5V

Q906

SWTCHING

TAPE MOTOR

DRIVER

Q905

CNS603

1

2

3

4

5

6

7

8

9

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CNS602

SWTCHING

TO MAIN PWB

Q904

M 12V

D GND

VCL

VCE

VDI

CL

DO

CE

DI

M GND

A GND

A 12V

5V

Q861

REGULATOR

MOT

SOL

RUN PLS

PU IN

Q902

P.F

CAM SW

BI901

CNS901

CNP901

Q901

SW902

FW901

TAPE

M-12V

SWTCHING

CAM

M901

+

–

M

SOL901

SOLENOID

SWTCHING

Q903

SOLENOID

CD+5V

D-GND

2526272830323334363740

TKIC

TEL1

TEL2

ADRESS

EFM

AUDIO OUT

FMON

SERVO

STATUS

TGUH1

16K RAM

CORRECT

TGUL

TIMING

GENERATOR

OUT

DIGITAL

VDDX

XI

VDDD

GNDD

BUCK

CD BUS

INTERFACE

BUS3

BUS2

BUS1

BUS0

RAM

Q DATA

GNDD

VDDD

SUB

CODE

GNDA

CLOCK

GNDA

DA CONV

XO

GNDX

IC802

X801

RESET

21

RST

BUCK

19

CCE

CCE

18

BUS3

17

BUS2

16

BUS1

15

BUS0

14

13

G-GND

12

7

6

LO

2

RO

1

A-GND

CD L-CH

CD R-CH

US

SET

03

CD+5V

VRO

TSO

321

TP801

TEST POINT

42

43

44

47

48

49

50

51

52

53

54

58

59

FOCUS

SEL

TRACKING

FCSI

SERVO

FKIC

CONTROL

FEI

TESH

TEOF

SBAD

RFRP

VREF

A/D CONVERTOR

RFI

GNDA

VDDA

PDCNT

TMAX DET

STATUS

CLV SERVO

PLL

STATUS

TESTX

GNDD

65 67 77 78 79 80

FMFB

DMFC

DMPC

41

2VREF

DRIVER

7654321

7654321

7654321

SW901

PH901

RECORD

PREVENTION

Figure 17 BLOCK DIAGRAM (2/4)

– 17 –

Page 18

XL-505H,505E,507E/CP-505,505E,507

1

T302

AM ANT.

AM OSC.

T306

AM LOOP

ANTENNA

CNP301

1

2

FM

3

FM MUTE LEVEL

VR351

AM OSC OUT

24

IC303

LA1832

FM IF DET./

FM IF

FM MPX./AM IF

12 4

OUT

AM OSC

IN

23

AM MIX

IN

AM OSC

OUT

21

AM RF IN

AM IF IN

SD

GND

567

X351

FM/AM OUT

STEREO

FM DET

89

16

1718

MPX VCO

IF OUT

VCC

10 12

MPX IN

PHASE

15

R-CH OUT

14

L-CH OUT

13

PHASE

MO/ST

(AM/FM)

SWITCHING

Q351

R-MUTE

BF301

RECORD/PLAYBAK

HEAD

L-CH

R-CH

ERASE HEAD

+5V

12

16

15

IF IN

FM IN

AM IN

FM

MO/ST

IF REQ

FM

11

10

9

7

REC

IC102

6

L-OUT

ALC

12

7

R-OUT

NF

31

5

150K

–

+

MUTE

+

9

–

150K

11

NF

VOLTAGE

REGULATOR

ZD351

+5V

A-12V

8

10

ALC

2

A-GND

REC MUTE

L-CH

R-CH

AUDIO

+12V

FM+B

VOLTAGE

REGULATOR

Q105

Q106

SWITCHING

Q107

AUDIO +

Q360

REC

AM IF

AM MIX OUT

T351

CF352

RF AMP.

Q305

FM IF

T304

7

IC101

BA3126N

FM OSC

L303

VD302

8

REC SW

1

2

3

P/B SW

CONT

4

5

6

P/B SW

7

8

9

REC SW

FM RF

L302

VT

VD303

1

43

6

5

IC301

TA7358AP

FM FRONT END

AUDIO +12V

SWITCHING

Q171

VT

Q154

Q155

FM+B

B-CAN

CF302

9

BEAT CANCEL

SWITCHING

4.5MHz

SWITCHING

Q101-Q104

Q151

L151

BIAS OSC.

X352

VT

D GND

22

20

21

VSS

AOUT

X OUT

X IN

CE

IC302

LC72131

PLL CONTROLLER

SWITCHING

A-12V

Q152

SWITCHING

Q153

REC BIAS

CONT

AM IF IN

431

CF351

DI

CL

DO

6

5

L-IN

R-IN

Q172

SWITCHING

REC

Figure 18 BLOCK DIAGRAM (3/4)

– 18 –

Page 19

XL-505H,505E,507E/CP-505,505E,507

AUDIO +12V

CE

CL

REC RREC L

TAPE L TAPE R

TAPE

30

TUN R

TUN L

CD R

CD L

10

8

R2

19

L2

28

R1

L1

11

CE

25

24

D1

CL

23

31

NC

29

NC

27

AVSS

VSS

26

22

VSS

20

NC

18

NC

L-IN

R-IN

TUNER

CD

R-MUTE

STEREO

SD

DODI

Q601

MUTE

Q602

R-CH X-BASS/GRAPHIC EQUALIZER

TAPE RTAPE L

17 32

L3

R3

IC401

LC75394E

AUDIO PROCESSOR

FUNCTION CONTROL

VOL CONTROL

G-EQ CONTROL

LSELO

RSELO

14 35

L-CH X-BASS/GRAPHIC EQUALIZER

L-CH OUT

1

R-CH OUT

3

GND

2

IC601

4140

RF2C1

LF2C1

RF2C2

LF2C2

43

42

44

RF3C1

RF2C3

LF2C3

LF3C1

689

75

45

RF3C2

LF3C2

4

RF3C3

LVROUT

RVROUT

LF3C3

62

5251

RTOUT

RINVIN2

RVref

Vref

LVref

LTEST

RTEST

VDD

LTOUT

LINVIN2

53

6061

RVRIN

LVRIN

50

56

63

54

59

57

AUDIO +12V

58

55

+

SO601

SPEKER TERMINAL

–

CNP602

BIAS

B-CAN

REC

321

FM ST

CD+B

R-MUTE

SD

P CONT

A-GND

D+5V

M-GND

151413121110

M 12V

D-GND

A 12V

987654

P MUTE

CD L

CD R

TO CD SERVO PWB

VOLTAGE

REGULATOR

PRE CL

PRE CE

PRE DI

TUNER

CL CQCK

TUN DO

TUN CE

DI COIN

987654321

CD+6.2V

MECH +12V

AUDIO +12V

CNP603

REGULATOR

VOLTAGE

REGULATOR

Q607

VOLTAGE

Q605

Q604

Figure 19 BLOCK DIAGRAM (4/4)

– 19 –

P-CONT

Q606

Q608

CD+B

Q603

Q609

STAND-BY

7

VCC

4

F652

T1.25A

L 250V

F653

T800mA

L 250V

D651-D654

F651

T2.5A

L 250V

J601

HEADPHONES

CNP651

1

212

T651

POWER

TRANSFORMER

AC SOCKET

230V,50Hz

T.F

Page 20

XL-505H,505E,507E/CP-505,505E,507

A

D301

1SS133

D302

CNP301

1SS133

1

2

3

FM

C349

0.022

B

ANTENNA

AM LOOP

R320

T302

AM ANT.

AM

TRACKING

R321

T306

AM OSC.

AM BAND

COVERAGE

C337

0.022

C

C309

C308

0.022

C307

0.0047

C305

0.0047

R301

22

C304

0.01

(UJ)

D305

C319

18P

D

(CH)

321

BF301

BAND PASS FILTER

1SS133

C306

6.8P

12

R302

L302

C303

0.001

C318

3

E

RECORD/PLAYBACK

HEAD

L-CH

R-CH

F

ERASE HEAD

1

2

3

4

5

6

7

8

CNS101

CNP101

1

2

3

4

5

6

7

8

G

VD301-1

R319

KV1236Z2

33

22

R323

68K

FM BAND

COVERAGE

0.001

100K

VD303

4.7P

4

FM FRONT END

TA7358AP

C121

82P

C122

82P

100K

KV1236Z23F

R303

33K

KDV147C

5

C330

8.2P

(UJ)

VD301-2

C334

18P

(UJ)

RF AMP.

2SC535 C

6

R310

4.7K

Q305

FM IF

T304

R304

47K

FM RF

C311

C332

C331

0.022

0.047

C335

C336

18P

470P

(CH)

C316

C315

10/16

100P

R305

680

(UJ)

C314

C313

3.3P

L303

C312

33P

R306

15P

10

(CH)

8

7

IC301

HEAD SELECTOR

IC101

BA3126N

REC SW

1

C101

2

470P

3

R138

330

+B

0.3V

1

Q171

10.8V

Q172

KRC102 M

SWITCHING

P/B SW

CONT

4

5

6

P/B SW

7

8

9

REC SW

32

(0V)

BEAT CANCEL

BEAT CANCEL

(0V)

32

1

R140

10K

R139

2.7K

C102

470P

+B

(10.8V) 10.8V

KRA102 M

SWITCHING

+B +B

C333

0.022

C310

0.001

R324

100K

(CH)

22P

R307

47

R101

1K

R102

1K

Q154

SWITCHING

Q155

SWITCHING

0V

C342

+B

R336

4.7K

C317

0.022

R308

10K

VD302

KDV147C

9

C113

4.7/25

C151

180P

C152

0.001

R160

KTC3199 GR

5.6K

C156

0.022

KTC3199 GR

BEAT CANCEL

R309

R126

820

5.6K

R358

C343

8.2K

L353

1mH

0.022

VR351

10K(B)

FM MUTE

LEVEL

R351

5.6K

IC303

FM IF DET./

FM MPX./ AM IF

C351

0.022

321

CF302

+B

SWITCHING SWITCHING

Q101

KTC3199 GR

KTC3199 GR

0V

(0.15V)

(0.15V)

0.3V

(0.8V)

R121

4.7K

Q102

KTC3199 GR

SWITCHING

R122

C114

4.7/25

4.7K

C117

10/16

R151

47K

C153

0.0039

(ML)

R159

2SC2001 K

5.6K

BIAS OSC.

C154

0.027

(ML)

(0V)

L352

390

390

C119

0.01

C118

0.022

2.2/50

D102

1SS133

SWITCHING

C120

Q106

KTC3199 GR

REC MUTE

R363

3.3K

Q351

KRC104 M

SWITCHING

ZD351

UZ5.1BSB

C396

100/10

C395

0.022

VOLTAGE

REGULATOR

Q360

KTA1266 GR

R383

5.6K

+B

REC MUTE

R141

330

Q105

KTC3199 GR

C126

22/16

+B

C125

100/25

1SS133

680K

R135

Q107

KRC104 M

0.01

R384

5.6K

4.7V

1

R111

2.2K

R131

4.7K

D105

R132

1SS133

32

R133

4.7K

R134

100K

1

11.4V

R385

5.6K

C391

47/16

1K

32

R136

10K

R112

2.2K

D104

33P

C362

3.3/50

C361

0.022

C364

10/16

C363

0.022

C360

0.022

24

2223

21

FM AFC

AM RF IN

AM OSC IN

AM OSC OUT

LA1832

FM IF IN

REG

AM MIX OUT

123

R352

1K

33P

VT

TP301

22

X IN

IC302

LC72131

0V

(0.14V)

R117

22K

180

R119

SWITCHING

Q104

KTC3199 GR

R118

22K

R120

SWITCHING

Q152

KTA1266 GR

C155

47/16

KRC104 M

SWITCHING

X OUT

180

2

C350

0.022

+B

21

T351

AM IF

VSS

NC

C115

0.0022

C116

0.0022

R153

10K

Q153

CF352

C394

47/16

C392

0.001

R381

10K

R380

1.5K

C393

1/50

20

AOUT

1K

C376

220P

R115

15K

C129

4.7/25

C130

4.7/25

R116

15K

R154

10K

3

1

C352

10/16

C344

C397

0.022

R382

330

R386

330

C381

12P

(CH)

X352

4.5MHz

C382

(CH)

15P

PLL (TUNER)

C384

0.001

+B +B

Q103

0V

0.3V

(0.8V)

R123

4.7K

R124

4.7K

R125

100K

R152

100K

Q151

L151

330µH

VSM

AM IF IN

GND

4

567

321

C353

0.022

C380

1/50

R379

2.2K

18

19

PD

AIN

DI

CE

4321

5

C377

220P

C378

220P

R157

+B

150

R155

R156

56

150

C365

0.022

1920

SD

CL

C379

C106

C366

AM LOW CUT

C387

DO

6

R3711KR3721KR3731KR374

220P

R103

120

C103

330P

C104

330P

270P

R104

120

0.001

R350

C367

18

FM/AM OUT

STEREO

C354

0.022

1617

VDD

7

C105

270P

+B

2.7K

1/50

FM DET

8

R353

270

0.022

FM IN

MW

FM

C107

47/16

5

9

C108

47/16

TP302

C399

0.022

CF351

R393

1K

L351

100µH

C385

0.01

14

1213

15

NC

SW

AM IN

FM

MO/ST

10

11

98

R359

1.8K

R107

10K

REC./P.B.

EQUALIZER

3

150K

–

+

MUTE

+

–

150K

11

R108

10K

X351

17

VCC

9

+B

C398

R377

5.6K

IF IN

IF REQ

AMP.

470K

R357

R356

1K

MPX VCO

10

100/10

C386

330P

R365

10K

R360

4.7K

R105

150K

C109

0.015/50

IC102

BA3311L

6

C110

0.015/50

R106

150K

MPX IN

IF OUT

C369

56P

C368

1/50

PHASE

11

C357

2.2/50

C356

0.001

22P

C355

47K

R395

R109

3.9K

C111

10/16

ALC

R110

3.9K

C374

7

C358

0.018

1516

1/50

R-CH OUT

C370

1/50

C383

1

12

R355

3.3K

0.022

C112

10/16

R387

C373

1314

L-CH OUT

12

5.6K

+B

R127

3.9K

R129

3.3K

R128

3.9K

C371

1/50

C372

1/50

PHASE

R376

0.018

MO/ST

8

10

2

(AM/FM)

10K

C124

+B

R364

3.3K

R361

12K

R362

12K

+B

1SS133

+B

47/16

R130

3.3K

100µH

R391

R392

+B

D101

C123

R114

+B

FM+B

DO

CL

DI

CE

REC L

REC R

TAPE R

TAPE L

R113

3.3K

R137

4.7K

D106

1SS133

3.3K

MAIN PWB-A1

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page 27.

1

23456

Figure 20 SCHEMATIC DIAGRAM (1/4)

– 20 –

Page 21

FM SIGNAL

AM SIGNAL

PLAYBACK SIGNAL

RECORD SIGNAL

CD SIGNAL

XL-505H,505E,507E/CP-505,505E,507

505H: 0.047

505E/507E: 0.068

R412

5.6K

C414

R414

3.3K

33

34

R4

R3

32

NC

31

RINVTIN1

R2

30

NC

29

R1

28

AVSS

27

VSS

26

CE

25

D1

24

AUDIO PROCESSOR

CL

23

VSS

22

L1

21

NC

20

L2

19

NC

18

L3

17

LINVIN1

L4

14

16

15

R413

C411

22/16

3.3K

R411

5.6K

IC601

LA4600

VCC

4

7

T1.25A L 250V

F653

T800mA L 250V

R624

1K

0V23

1

Q609

KRC107 M

3

+B

13.5V

R628

100

C620

470/25

100P

3635

RSELO

LSELO

C413

100P

F652

4700/25

(HND)

R629

C616

C418

0.0012

RTIN

RF1C1

LTIN

LF1C1

1213

C417

1

2

3

820

C412

22/16

C406

TAPE R

TUN R

CD R

DI COIN

987654321

10

M 12V

OPT IN

TUN L

CD L

TAPE L

C601

33/16

C628

10/16

C625

10/16

CNP603CNP602

A GND

+B

R-MUTE

STEREO

BIAS

SD

A 12V

D GND

B-CAN

+B

+B

+B

A 12V

FM ST

R-MUTE

SD

CD+B

REC

P CONT

987654321

CNS602 CNS603

TO CD SERVO PWB

P23 12-B

P MUTE

CD L

CD R

A-GND

+B

D+5V

R634

1K

+B

+B

M 12V

M-GND

151413121110

TO CD SERVO PWB

D-GND

PRE CL

PRE CE

PRE DI

P23 12-A

TUN DO

CL CQCK

TUN CE

.4V

+B

5

FM+B

1

6

+B

DO

CL

DI

CE

REC L

REC R

TAPE R

TAPE L

R113

3.3K

R137

4.7K

D106

1SS133

3.3K

R114

1/50

R420

C404

1K

1/50

R418

1K

R416

C402

1K

1/50

R403

1K

R402

1K

R401

1K

R415

1K

C401

R417

1/50

1K

C403

1/50

C405

R419

1/50

1K

R627

10/16

R607

R616

10K

6.8K

6.8K

C622

C627

C624

0.022

0.022

0.022

R603

1K

(0.7V)

R604

(0.7V)

0V

1K

0V

R621

2SD2012 Y

22K

R623

22K

C621

100/25

C605

4.7/25

C606

4.7/25

R608

Q607

6.8V

D604

1SS133

C626

47/16

+B

REGULAYOR

10.9V

D603

1SS133

C603

Q601

0.001

KTC3199 GR

Q602

C604

0.001

KTC3199 GR

1K

13.5V6.2V

Q606

KTC3199 GR

7.5V

ZD602

10K

R625

UZ7.5BSC

(0V) 4.5V

10.9V 13.5V

Q605

2SD2012 Y

VOLTAGE

Q604

2SD2012 Y

11.5V

D602

1SS133

R620

47

UZ13BSA

33K

R617

C607

100/25

C608

22/25

0V

STAND-BY

D601

1SS133

1

2

13.5V

12.1V

ZD601

R601

10K

R615

6.8K

R602

10K

+B +B

C623

POWER AMP.

10

5

9

6

8

Q608

KRA102 M

11.5V

R619

47

Q603

KTC3199 GR

C420

270P

C422

0.018

4140

393837

RF2C1

RF1C3

RF1C2

IC401

LC75394E

LF1C2

LF1C3

LF2C1

11

10

C421

0.018

(ML)

C419

270P

0.0012

505H: 0.047

505E/507E: 0.068

C613

1000/25

0V

C614

1000/25

C615

0.022

+B

C652

0.1

C653

0.1

(ML)

C424

RF2C2

LF2C2

LF2C3

75

D652

RL204F

505H: 0.033

505E/507E: 0.039

505H: 0.033

505E/507E: 0.039

C426

C428

RF4C3

RF4C2

47

4342

44

48

45

46

C434

R480

0.0033

100K

RFS

49

C438

RVref

RF3C1

RF2C3

RF4C1

RF3C3

RF3C2

50

100P

51

52

53

54

55

56

C443

57

100/10

58

C439

59

10/16

60

C437

61

100P

62

63

64

C433

0.0033

LF4C3

505H: 0.033

505E/507E: 0.039

1

2

3

4

C436

100/10

C440

10/16

C435

100/10

R479

100K

SO601

SPEAKER

TERMINAL

SP_L-CH

SP_L-CH_GND

SP_R-CH_GND

SP_R-CH

689

C423

LF3C1

LF3C2

C425

RINVIN2

RTOUT

RVRIN

RTEST

RVROUT

Vref

VDD

LVROUT

LTEST

LVRIN

LTOUT

LINVIN2

LVref

LFS

LF3C3

LF4C2

LF4C1

2314

C427

505H: 0.033

505E/507E: 0.039

HEADPHONES PWB-A5

FW601

5

L-CH

L-CH

A_GND

R-CH

R-CH

1

F651

T1.25A

L 250V

D651

C651

RL204F

D654

RL204F

C654

0.1

0.1

RL204F

D653

POWER SUPPLY PWB-A6

When Servicing, pay attention as the area

enclosed by this line ( ) is directly

connected with AC main voltage.

C442

1/50

C441

1/50

C444

100/25

C445

0.022

CNP651

11

22

SO651

R662

330

HEADPHONES

R661

330

T651

POWER

TRANSFORMER

AC SOCKET

230V

50Hz

D402

1SS133

D401

1SS133

J601

T.F

7

8 9 10 11 12

Figure 21 SCHEMATIC DIAGRAM (2/4)

– 21 –

Page 22

XL-505H,505E,507E/CP-505,505E,507

2

DISPLAY PWB-A3

A

B

C

D

E

F

G

H

LED PWB-A4

LED710

204GDTR4

LED707

204GDTR4

LED704

204GDTR4

R704A

120

120

R703A

LED708

204GDTR4

LED705

LED711

204GDTR4

R704B

120

120

R703B

LED706

LED712

204GDTR4

LED709

204GDTR4

21

FW701

21

D720

+B

1SS133

R70C

3.3K

R70A

1K

R70B

1K

2

Q701

KRC102 M

4.9V

C710

0.01

+B

18

IC804:

FOCUS/TRACKING/

19

SPIN/SLIDE DRIVER

+B

TR+

FO+

FO–

TR–

ACTUATOR

C4A

1/2VCC

C

F

B

A

E

GND

MON

LD

C2A

VCC

R702A

120

204GDTR4

120

R702B

204GDTR4

3

0V

1

+B

17

16 15

VCC

Reg5V

–

+

20

21

R875

10K

M801

SLED

M802

SPINDLE

SW801

PU-IN

VR1A

3.3/50

D721

C3A

C711

1SS133

NC

+

R70E

–

+

–

M

M

100K

14 13 12

24

2322

+B

Q702

KTC3199 GR

4.9V

R70F

0.01

C712

SL+

SL–

11

–

+

–

+

+

+

–

–

GND

26

25

SP–

SP+

+

–

+

PU-IN

–

TR–

TR+

FO+

FO–

GND

VR

0.35V

R70J

10K

82

KTC3199 GR

C871

330/10

10

9

GND

+

–

27

28

SP+

SPSL+

SL–

GND

PD

LD

C

F

B

A

E

1/2V

+5V

Q703

8

VCC

1

2

3

4

5

6

7

R70G

R70H

10K

0.34V

3029

6

5

4

3

2

1

CNP803

1

2

3

4

5

6

7

8

UZ3.3BSB

1K

1.1V

TR+

765

+

––

R70K

––+

31

FO–

ZD701

120

+

–

++

6

5

4

3

2

1

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

STAND-BY

10.7V

TR–

3332

FO+

CNS803

CNS801

CNS802

STOP

/CLEAR

SW714

PRESET

UP

SW713

PRESET

DOWN

SW712

MEMORY

/SET

SW711

REC

/PAUSE

SW710

ON/

SW718

+B

R70M

100

+B

23

C713

1K

10/16

R70L

Q707

KTA1266 GR

10V

4321

NC

GAIN1

–

+

T.S.D

–

+

STAND

GAIN4

34

35

6

5

4

3

2

1

BI801 BI803

1

2

3

4

5

6

7

8

BI802

1

2

3

4

5

6

7

-BY

R80B

82K

R80C

+

–

36

82K

TRTR+

FO+

FOGND

PD

VR

LD

R721

10K

RX701

1

10.8V

CD STB

R874

10K

SP+

SPSL+

SL–

PU-IN

GND

R80A

R80F

82K

R717

3.9K

R718

2.7K

R719

1.8K

R720

1.8K

C714

470P

R798

47K

IC804

M56748FP

R873

4.7K

82K

R818

18

R799

2.2K

+B

C715

100/10

1SS133

+B

D723

KRC102 M

0V

2

R872 10K

R80E

82K

FUNCTION

X-BASS/

EQUALIZER

VOL DOWN

CD PAUSE/

TUNING UP

R722

10K

µ-COM VDD

µ-CON+5V

SYS STOP

REMOCON

RESET

D722

1SS133

Q704

2SD468 C

5.7V

6.3V

C716

47/16

Q706

3

3.2V

1

0V

+B

R871 10K

FMSO

TS2O

DMEO

FSO

Q801

2SA1015 GR

R80G

82K

LDO

SW707

BAND

SW706

SW705

VOL UP

SW704

SW703

PLAY/

SW702

+B

R801

22

C802

100/10

11.2V

R70R

100

UZ6.2BSC

R70N

(Fusible)

ZD702

P CONT

• NOTES ON SCHEMATIC DIAGRAM can be found on page 27.

1

23456

Figure 22 SCHEMATIC DIAGRAM (3/4)

LCD

LCD701

R708

5.6K

R709

3.9K

+B

R710

2.7K

L701

100µH

R711

1.8K

R712

1.8K

R713

10K

+B

+B

10

+B

330

R70P

C717

0.022

+B

C704

0.022

+B

+B

+B

PD PD

+B

R724

47K

+B

+B

C703

C701

47K

R723

0.6V

47K

R734

R725

47K

R726

1K

0.022

X702

(CH)

C702

(CH)

22P

22P

R728 1K

R730 1K

R731 1K

R732 1K

R729

10K

+B+B

Q705

KRA102 M

R709

1K

32

4.8V

5V

1

R735

47K

R736 47K

R737 47K

R738 47K

R739 47K

LED+B

M 12V

µ-CON+5V

GND

R810

2.2K

C807

(ML)

0.22

X701

R741 1K

R742 1K

R817

15K

R816

47K

– 22 –

4321

5

100

989796

99

95 94

COM3

1

COM2

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

DI

R743 1K

R744 1K

C811

22/16

C810

(ML)

0.1

R819

4.7K

R814

1M

R813

2.2K

R812

18K

R811

27K

R809

100K

C813

0.0022

TRACKING

ERROR

BALANCE

SEG0

COM1

COM0

VLC3

VLC2

VLC1

VDD

OSC2

OSC1

VSS

XI

XO

MMOD

VREF

AREA

KEY1

KEY2

POWER

VSM

F.P

RUN PLS

CAM SW

VREF+

DO

26

R745 1K

R823

100K

27

R803

93

SEG2

SEG4

SEG6

SEG1

SEG3

SEG5

SEG7

SYSTEM MICROCOMPUTER

N.C

VDI

VCL

VCE

CL

RESET

CE

29

28

R751 1K

R750 1K

R749 1K

R748 1K

R747 1K

R746 1K

+B

+B

C812

10/16

DMEO

DFCT

25

FMSO

26

FMSM

27

FMSP

28

THLD

29

TS2O

30

TS2N

31

C809

TS2P

0.015

32

TS1N

0.33

C808

33

TS1P

34

TSO

35

TEL1

36

TEL2

37

TSN

38

22K

TPO

R804

120K

VR802

F

100K(B)

B

A

E

LDO

9876

929190 89

SEG8

SEG9

SEG10

SEG11

IC701

IX0189AW

CD+B

P-CONT

P-MUTE

3433323130

473635

R756 1K

R755 1K

R754 1K

R753 1K

R820

33K

2324

DMEN

39 40

TPI

88

SEG12

SYS STOP

FUNC

48

R757 1K

22

DMEP

41

TNI

86

87

SEG13

SEG14

CLE

REMOCON

R759 1K

21

SEL

42

180K

R805

14

13121110

85

84 83

SEG15

STEREO

42

414049

R760 1K

+B

C820

0.0068

20

VCC

43

FNI

TNO

15

SEG16

SD

43

R761 1K

+B

16

82

SEG17

ID

44

19

GND

44

FPI

17

81

SEG18

DATA

45

C822

47/16

SEG19

CD RES

R764 1K

C821

OSCI

18

80 79 78

46

C823

10/16

0.022

45

LDO

19

SEG20

CEE

47

20

SEG21

CD STB

BUCK

1718

COSC

46

MDI

24

23

22

21

77

76

SEG25

75

74

SEG26

SEG23

SEG22

SEG24

73

SEG27

SEG28

72

SEG29

71

SEG30

70

SEG31

69

N.C

68

N.C

67

N.C

66

N.C

65

SRS1

64

SRS2

63

BUS3

62

BUS2

61

BUS1

60

BUS0

59

58

PU-IN

57

56

LID-SW

BIAS

55

B-CAN

54

REC

53

52

MOT

51

SOL

R-MUTE

504948

R767 1K

R766 1K

R765 1K

R821

18K

C824

0.056

(ML)

FSO

FSN

15

16

47

48

RFT

RFN

R829

470

IC801

TA2065F

SERVO AMP.

C825

0.039

(ML)

FEL2

14

FEL1

13

FHLD

12

FEI

11

FEO

10

9

FEP

8

DFIN

7

SBAD

6

RFRP

5

2VRO

4

VRO

3

RFI

2

RFO

1

R787

R781 1K

R780 1K

R779 1K

R778 1K

R777 10K

R776 1K

R775 1K

R774 1K

R773 1K

R772 1K

R771 1K

R770 1K

R827

150K

FEN

R838

12K

47K

+B

R822

330

FOCUS

OFFSET

R825

470K

C826

1/50

C831

0.056

C828

0.056

(ML)

C829

C830

47P

R837

3.9P

2.7K

VR803

100K(B)

C827

470P

R828

2.7K

C834

0.056

(ML)

C832

47/16

C833

220/10

212

220K

R826

(ML)

FW702

R788

TSO

1

47K

3

Page 23

CD LID SWITCH PWB-A7

FW702

1

SW701

CD EJECT

+B

+B

R794

47K

47K

M 12V

D GND

VCL

VCE

VDI

CL

DO

CE

DI

R787

212

47K

R788

CD STB

1 1K

0 1K

9 1K

8 1K

7 10K

6 1K

5 1K

4 1K

3 1K

2 1K

1 1K

0 1K

+B +B

R822

330

VR803

100K(B)

FOCUS

OFFSET

R825

220K

R826

470K

C826

1/50

27

C827

0K

470P

R828

2.7K

R837

2.7K

C831

(ML)

0.056

C832

47/16

C828

0.056

(ML)

C833

220/10

3.9P

C829

C830

47P

C834

(ML)

0.056

8

K

TSO

321

+B +B

D718

RL104A

+B

+B

+B

R830

220K

40

+B

R832

15K

R833

8.2K

C841

0.0047

C842

0.0033

0.0033

C844

0.022

C845

47/16

+B

R842

10K

R841

1K

R843

47K

R845

C847

2.2M

100P

C846

220/10

R846

C848

33K

0.01

C849

0.01

SERVO/SIGNAL CONTROL

C843

R844

220K

TC9284BF

41

42

43

44

45

46

47