Page 1

XL-30H/30W

SERVICE MANUAL

No. S5046XL30HW//

MICRO COMPONENT SYSTEM

Illustration: XL-30H

Illustration: XL-30W

MODEL

XL-30H Micro Component System consisting of XL-30H (main unit)

and CP-XL40H (speaker system).

MODEL

XL-30W Micro Component System consisting of XL-30W (main unit)

and CP-XL40H (speaker system).

• In the interests of user-safety the set should be restored to its original

condition and only parts identical to those specified should be used.

• Note for users in U.K.

Recording and playback of any material may require consent,

which SHARP is unable to give. Please refer particularly to the

provisions of Copyright Act 1956, the Dramatic and Musical

Performers Protection Act 1956, the Performers Protection Acts

1963 and 1972 and to any subsequent statutory enactments and

orders.

XL-30H

XL-30W

CONTENTS

Page

SAFETY PRECAUTION FOR SERVICE MANUAL .......................................................................................................... 2

IMPORTANT SERVICE NOTES (XL-30H FOR U.K. ONLY)............................................................................................ 3

VOLTAGE SELECTION (FOR XL-30W)........................................................................................................................... 3

AC POWER SUPPLY CORD AND AC PLUG ADAPTOR (FOR XL-30W)....................................................................... 3

SPECIFICATIONS ............................................................................................................................................................ 4

NAMES OF PARTS .......................................................................................................................................................... 5

OPERATION MANUAL..................................................................................................................................................... 6

DISASSEMBLY............................................................................................................................................................... 10

REMOVING AND REINSTALLING THE MAIN PARTS.................................................................................................. 11

ADJUSTMENT................................................................................................................................................................ 13

TEST MODE ................................................................................................................................................................... 14

ERROR LIST .................................................................................................................................................................. 18

NOTES ON SCHEMATIC DIAGRAM ............................................................................................................................. 19

TYPES OF TRANSISTOR AND LED.............................................................................................................................. 19

BLOCK DIAGRAM .......................................................................................................................................................... 20

SCHEMATIC DIAGRAM ................................................................................................................................................. 24

WIRING SIDE OF P.W.BOARD...................................................................................................................................... 30

WAVEFORMS OF CD CIRCUIT..................................................................................................................................... 37

TROUBLESHOOTING .................................................................................................................................................... 38

FUNCTION TABLE OF IC .............................................................................................................................................. 44

LCD SEGMENT .............................................................................................................................................................. 52

PARTS GUIDE/EXPLODED VIEW

PACKING METHOD (XL-30H FOR U.K. ONLY)

SHARP CORPORATION

– 1 –

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

XL-30H/30W

SAFETY PRECAUTION FOR SERVICE MANUAL

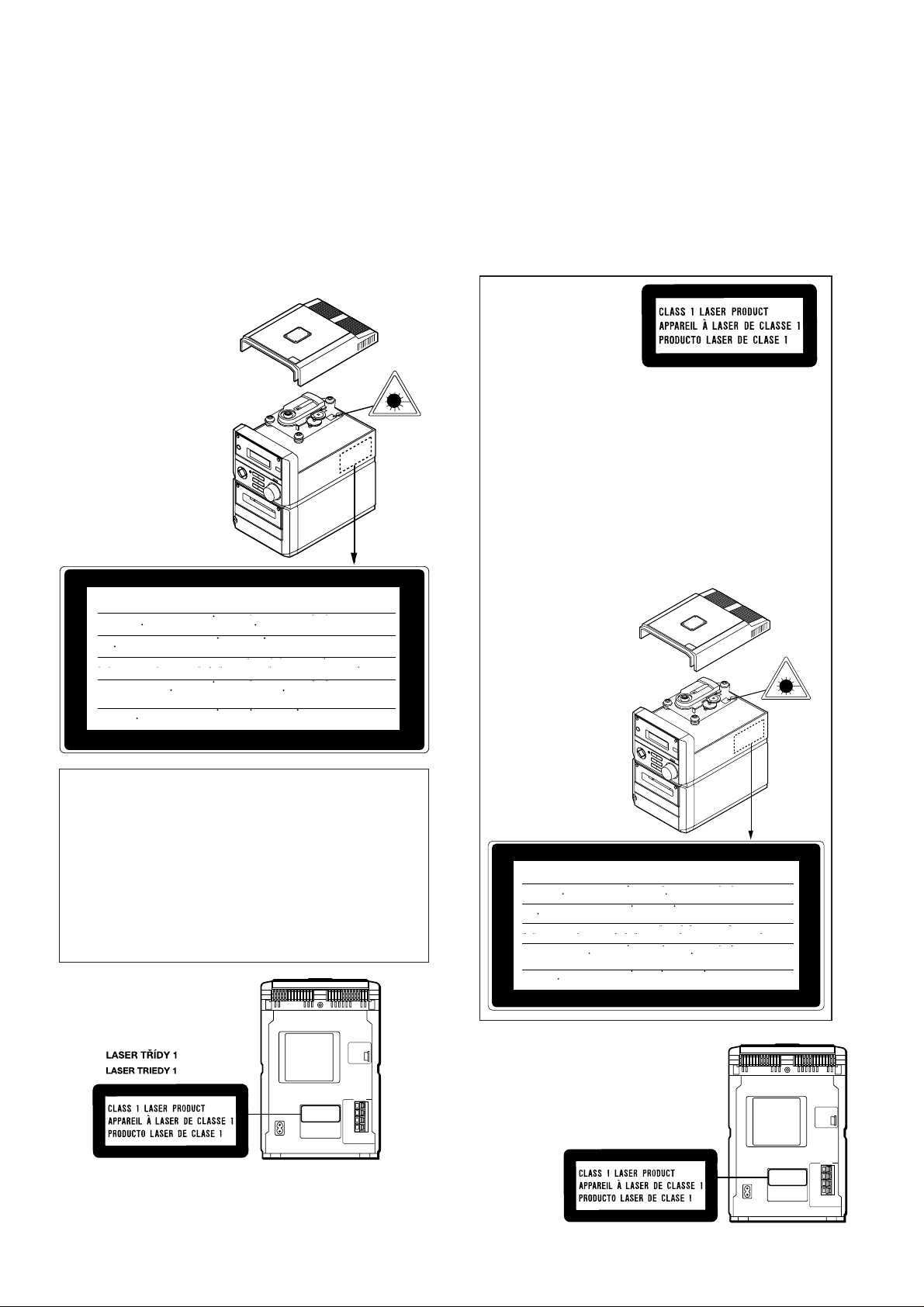

Precaution to be taken when replacing and servicing the Laser Pickup.

The AEL (Accessible Emission Level) of Laser Power Output for this model is specified to be lower than Class I Requirements.

However, the following precautions must be observed during servicing to protect your eyes against exposure to the Laser beam

(1) When the cabinet has been removed, the power is turned on without a compact disc, and the Pickup is on a position outer than

the lead-in position, the Laser will light for several seconds to detect a disc. Do not look into the Pickup Lens.

(2) The Laser Power Output of the Pickup inside the unit and replacement service parts have already been adjusted prior to shipping.

(3) No adjustment to the Laser Power should be attempted when replacing or servicing the Pickup.

(4) Under no circumstances look directly into the Pickup Lens at any time.

(5) CAUTION - Use of controls or adjustments, or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

Laser Diode Properties

Material: GaAIAs

Wavelength: 780 nm

Emission Duration: continuous

Laser Output: max. 0.6 mW

CAUTION-INVISIBLE LASER RADIATION WHEN OPEN. DO NOT STARE INTO

BEAM OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

VARNING-OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD. STIRRA

EJ IN I STRALEN OCH BETRAKTA EJ STRALEN MED OPTISKA INSTRUMENT.

ADVERSEL-USYNLIG LASERSTRALING VED ABNING. SE IKKE IND I

STRALEN-HELLER IKKE MED OPTISKE INSTRUMENTER.

VARO! AVATTAESSA OLET ALTTIINA NAKYMATON LASERSATEILYLLE.

ALA TUIJOTA SATEESEEN ALAKA KATSO SITA OPTISEN LAITTEEN LAPI.

VARNING-OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD.

STIRRA EJ IN I STRALEN OCH BETRAKTA EJ STRALEN GENOM OPTISKT

INSTRUMENT.

ADVERSEL-USYNLIG LASERSTRALING NAR DEKSEL APNES. STIRR IKKE

INN I STRALEN ELLER SE DIREKTE MED OPTISKE INSTRUMENTER.

● This Micro Component System is classified

as a CLASS 1 LASER product.

● The CLASS 1 LASER PRODUCT label is located on the rear cover.

● Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation

exposure.

As the laser beam used in this compact disc

player is harmful to the eyes, do not attempt to

disassemble the cabinet. Refer servicing to

qualified personnel only.

Laser Diode Properties

Material: GaAIAs

Wavelength: 780 nm

Emission Duration: continuous

Laser Output: max. 0.6 mW

VAROITUS! LAITTEEN KÄYTTÄMINEN MUULLA

KUIN TÄSSÄ KÄYTTÖOHJEESSA MAI NI TULLA

TAVALLA SAATTAA ALTI STAA KÄYTTÄJÄN

TURVALLI SUUSLUOKAN 1 YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE LASERSÄTEIL YLLE.

VARNING - OM APPARATEN ANVÄNDS PÅ ANNAT

SÄTT ÄN I DENNA BRUKSANVI SNI NG SPECI FI

CERAS. KAN ANVÄNDAREN UTSÄTTAS FÖR

OSYNLIG LASERSTRÅLNING, SOM ÖVERSKRIDER

GRÄNSEN FÖR LASERKLASS 1.

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

(XL-30H for Europe)

CAUTION-INVISIBLE LASER RADIATION WHEN OPEN. DO NOT STARE INTO

BEAM OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

VARNING-OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD. STIRRA

EJ IN I STRALEN OCH BETRAKTA EJ STRALEN MED OPTISKA INSTRUMENT.

ADVERSEL-USYNLIG LASERSTRALING VED ABNING. SE IKKE IND I

STRALEN-HELLER IKKE MED OPTISKE INSTRUMENTER.

VARO! AVATTAESSA OLET ALTTIINA NAKYMATON LASERSATEILYLLE.

ALA TUIJOTA SATEESEEN ALAKA KATSO SITA OPTISEN LAITTEEN LAPI.

VARNING-OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD.

STIRRA EJ IN I STRALEN OCH BETRAKTA EJ STRALEN GENOM OPTISKT

INSTRUMENT.

ADVERSEL-USYNLIG LASERSTRALING NAR DEKSEL APNES. STIRR IKKE

INN I STRALEN ELLER SE DIREKTE MED OPTISKE INSTRUMENTER.

(FOR XL-30W)

CAUTION

Use of controls, adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

As the laser beam used in this compact disc player

is harmful to the eyes, do not attempt to disassemble the cabinet. Refer servicing to qualified personnel only.

(XL-30H for U.K.)

– 2 –

Page 3

XL-30H/30W

IMPORTANT SERVICE NOTES (XL-30H FOR U.K. ONLY)

Before returning the unit to the customer after completion of a

repair or adjustment it is necessary for the following withstand

voltage test to be applied to ensure the unit is safe for the

customer to use.

Setting of Withstanding Voltage Tester and set.

Set name set value

Withstanding Voltage Tester

Test voltage 4,240 VPEAK

3,000 VRMS

Set time 6 secs

Set current(Cutoff current) 4 mA

Unit

Judgment

OK: The “GOOD” lamp lights.

NG: The “NG” lamp lights and the buzzer sounds.

WITHSTANDING

VOLTAGE TESTER

AC

OUT

SHORT-CIRCUT

AC POWER

SUPPLY CORD

PROBE

UNIT

CONNECT THE PROBE

TO GND OF CHASSIS

SCREW TERMINAL

VOLTAGE SELECTION (FOR XL-30W)

The voltage selector is located on the rear panel of the unit. If adjustment is necessary, use a screwdriver in order to turn the selector

in either direction until the correct voltage figure is displayed in the window.

AC POWER SUPPLY CORD AND AC PLUG ADAPTOR (FOR XL-30W)

QACCA0001SJ00

QACCB0001SJ00

QACCE0001SJ00

QACCL0002AW00

QPLGA0253AFZZ

QPLGA0250AFZZ

– 3 –

Page 4

XL-30H/30W

XL-30H/30W

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

SPECIFICATIONS

● General

Power source:

(For XL-30H)

Power source:

(For XL-30W)

Power consump-

tion: (For XL-30H)

Power consumption: (For XL-30W)

Dimensions:

Weight:

● Amplifier section

Output power:

(XL-30H for Europe)

Output power:

(XL-30H for U.K.)

Output power:

(For XL-30W)

Output terminals:

● Tuner section

Frequency range:

(For XL-30H)

Frequency range:

(For XL-30W)

AC 230 V, 50 Hz

AC 110 - 127/220 - 240 V,

50/60 Hz

26 W

28 W

Width; 160 mm (6-5/16")

Height; 241 mm (9-1/2")

Depth; 249 mm (9-13/16")

2.7 kg (6.0 lbs.)

PMPO; 28 W (total)

MPO; 14 W (7 W + 7 W)

(DIN 45 324)

RMS; 10 W (5 W + 5 W)

(DIN 45 324)

RMS; 10 W (5 W + 5 W)

(10 % T.H.D.)

MPO; 14 W (7 W + 7 W)

(10 % T.H.D.)

RMS; 10 W (5 W + 5 W)

(10 % T.H.D.)

Speakers; 4 ohms

Headphones; 16-50 ohms

(recommended; 32 ohms)

FM; 87.5-108 MHz

AM; 522-1,620 kHz

FM; 88-108 MHz

AM; 531-1,602 kHz

● Compact disc player section

Type: Compact disc player

Signal readout: Non-contact, 3-beam semi-

conductor laser pickup

D/A converter: 1-bit D/A converter

Filter: 8-times oversampling digital

filter

Frequency response:

20 - 20,000 Hz

Wow and flutter: Unmeasurable

(less than 0.001% W. peak)

● Cassette deck section

Frequency response: 50 - 14,000 Hz (Normal tape)

Signal/noise ratio: 50 dB

Wow and flutter:

0.3 % (DIN 45 511)

(XL-30H for Europe)

Wow and flutter:

0.25 % (WRMS)

(XL-30H for U.K./XL-30W)

CP-XL40H

Type: Full range speaker system

Speakers: 10 cm (4") full-range speaker

Rated input power:

Maximum input power:

5 W

10 W

Impedance: 4 ohms

Dimensions: Width; 145 mm (5-3/4")

Height; 240 mm (9-1/2")

Depth; 191 mm (7-1/2")

Weight: 1.3 kg (2.9 lbs.)/each

Specifications for this model are subject to change without

prior notice.

– 4 –

Page 5

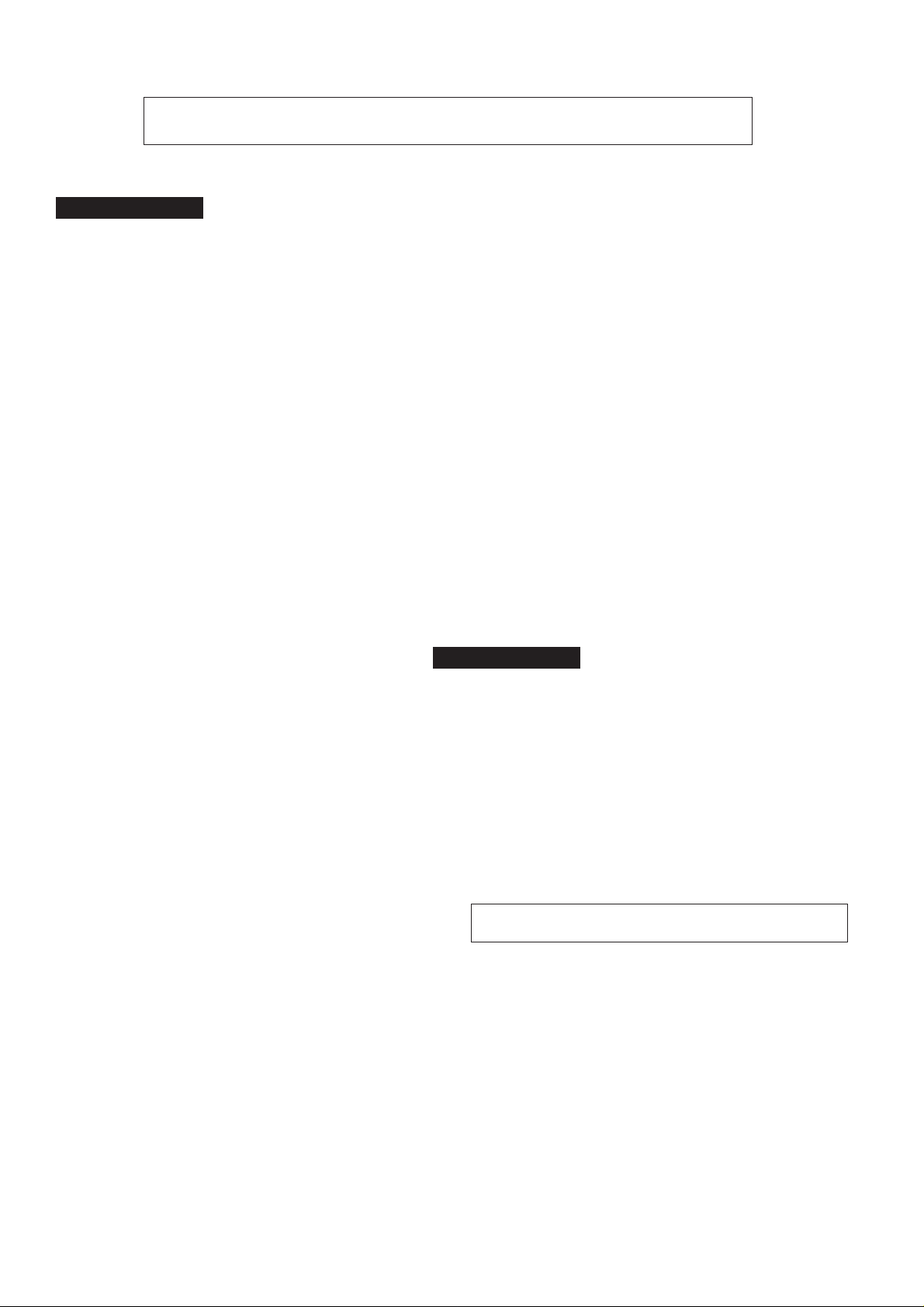

XL-30H/30W

p

XL-30H/30W

■ Front panel

1. Timer Indicator

2. Record Indicator

3. Sleep Indicator

4. (CD) Repeat Indicator

5. (CD) Play Indicator

6. (CD) Random Indicator

7. (CD/TUNER) Memory Indicator

8. FM Stereo Mode Indicator

9. FM Stereo Indicator

10. CD Compartment

11. On/Stand-by Button

12. (CD/TAPE) Stop Button

(TUNER) Memory Clear Button

13. Record Pause Button

14. Bass/Treble Selector Button

15. Memory/Set Button

16. Clock/Timer/Sleep Button

17. Band Selector Button

18. (CD) Review Button

(TAPE) Rewind Button

(TUNER) Tuning Down Button

19. Function Selector Button

20. Headphone Socket

21. CD Eject Button

22. Remote Control Sensor

23. Volume Select Button

24. (CD) Play/Pause Button

(TAPE) Play Button

25. Jog Dial

26. (CD) Cue Button

(TAPE) Fast Forward Button

(TUNER) Tuning Up Button

27. Volume/Jog Dial Selector Button

28. Cassette Compartment

XL-30H

NAMES OF PARTS

10

11

12

13

14

15

16

17

18

19

20

1

1

5

4

6

7

3

2

9

8

21

22

23

24

25

26

27

28

2

3

■ Rear panel

1. AC Power Input Socket

2. FM/AM Loop Aerial Socket

3. S

eaker Terminals

XL-30W

■ Rear panel

1. Voltage Selector

2. AC Power Input Socket

3. FM 75 ohms Aerial Socket

4. AM Loop Aerial Socket

5. Speaker Terminals

3

4

1

5

2

– 5 –

Page 6

XL-30H/30W

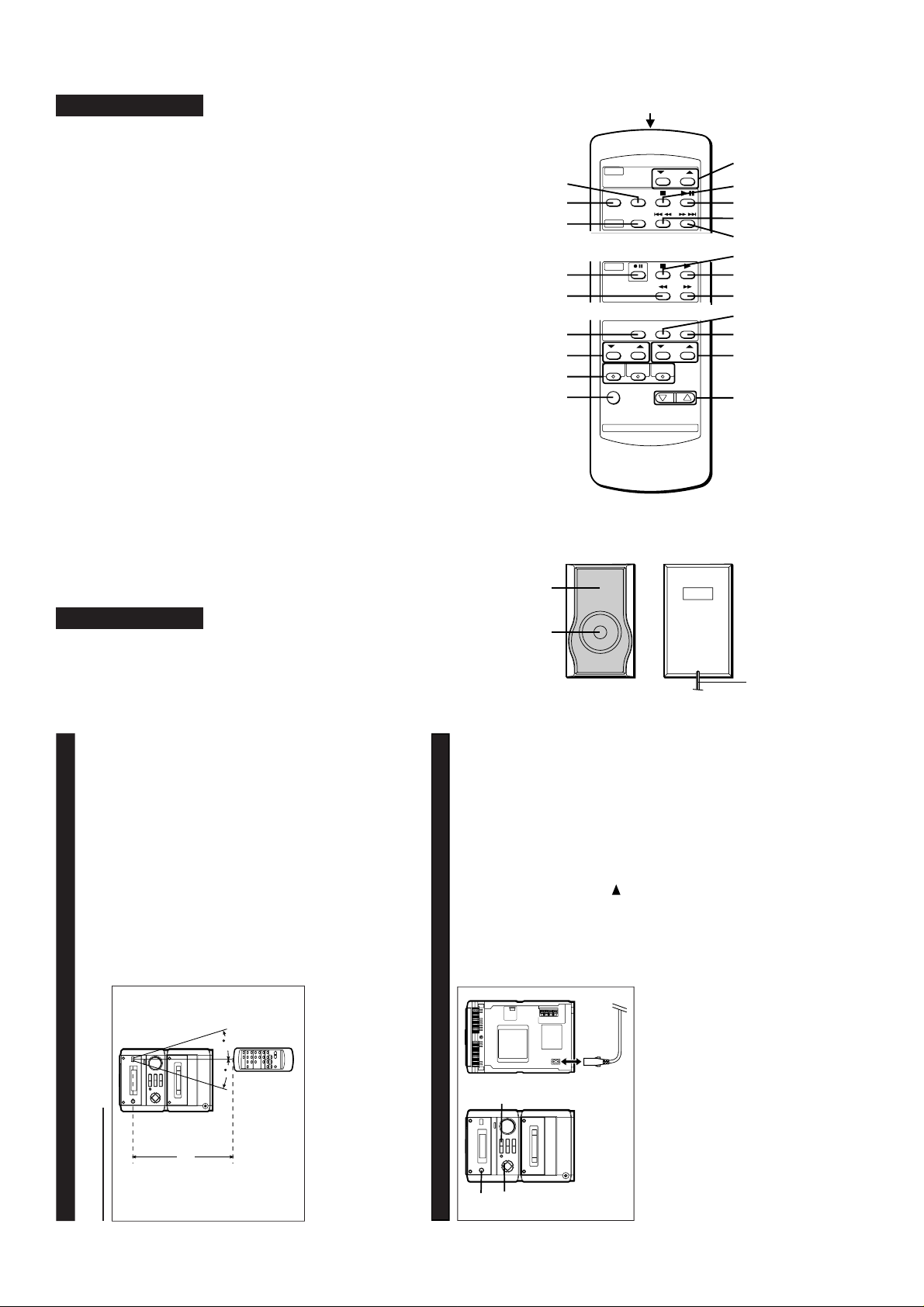

PREPARATION FOR USE

15

15

Notes concerning use:

● Replace the batteries if the operating distance is

reduced or if the operation becomes erratic.

● Periodically clean the transmitter LED on the re-

mote control and the sensor on the main unit

with a soft cloth.

● Exposing the sensor on the main unit to strong

light may interfere with operation. Change the

lighting or the direction of the unit.

● Keep the remote control away from moisture,

excessive heat, shock, and vibrations.

0.2m - 6m

(8” - 20”)

■ Remote control

1

2

3

3

4

5

10

11

2

6

7

8

9

12

13

14

20

22

15

16

17

18

19

21

1

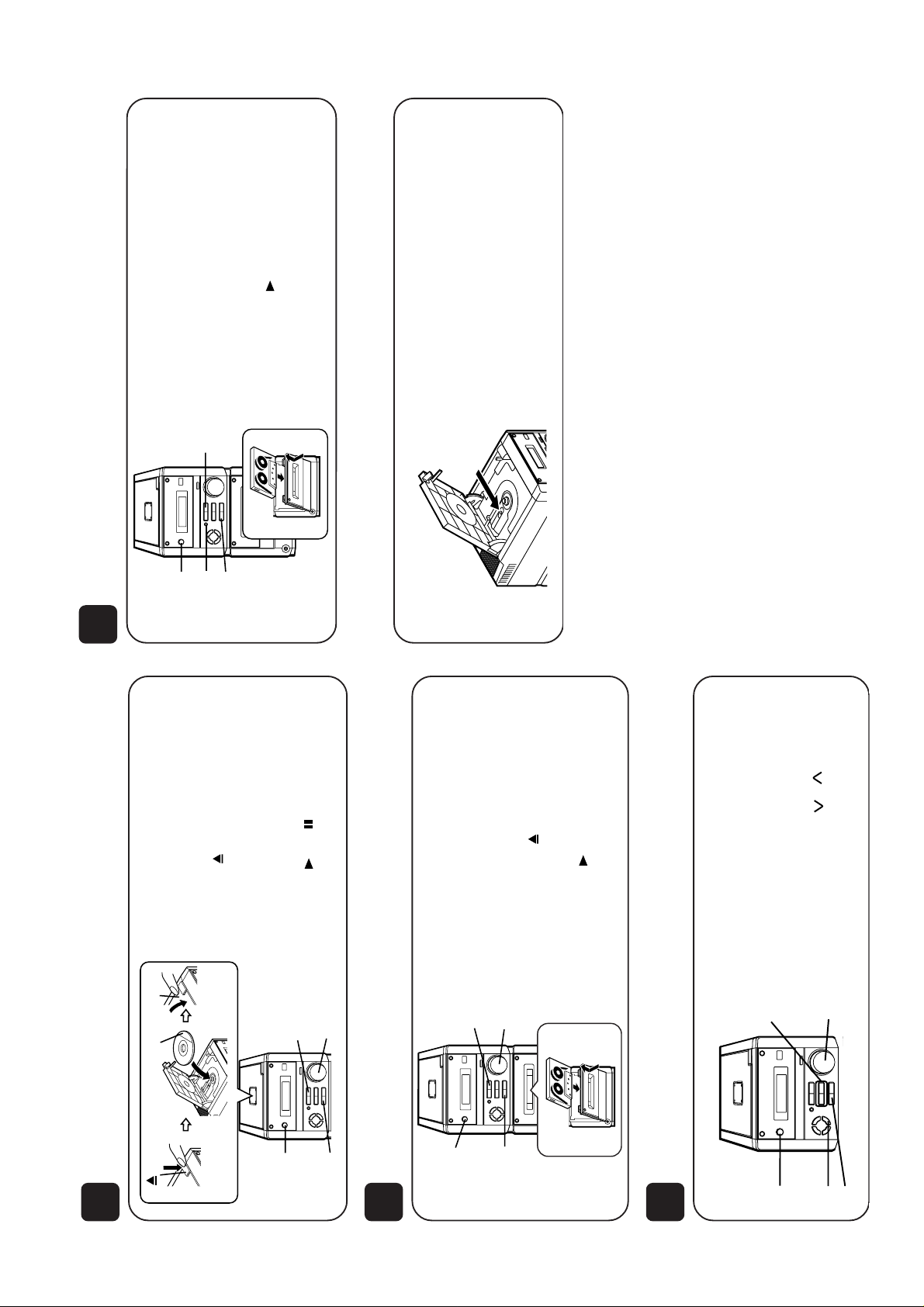

RESETTING THE MICROCOMPUTER

1

3

3

2,3

AC INPUT

Reset the microcomputer under the following

conditions:

● To erase all of the stored memory contents (clock

and timer settings, and tuner and CD presets).

● If the display is not correct.

● If the operation is not correct.

1

Press the ON/STAND-BY button to enter the

stand-by mode.

2 Unplug the AC power lead from the AC INPUT

socket on this unit.

3 Whilst pressing down the MEMORY/SET but-

ton and the button, plug the AC power lead

into the AC INPUT socket on this unit.

Caution:

● The operation explained above will erase all data

stored in memory, such as clock and timer set-

tings, and tuner and CD presets.

XL-30H/30W

■ Remote control

1. Remote Control Transmitter LED

● Tuner control section

2. Preset Up/Down Buttons

● CD control section

3. Clear Button

4. Random/Repeat Button

5. Memory Button

6. Stop Button

7. Play/Pause Button

8. Track Down/Review Button

9. Track Up/Cue Button

● Tape control section

10. Record Pause Button

11. Rewind Button

12. Stop Button

13. Play Button

14. Fast Forward Button

● Common section

15. Sleep Button

16. Bass Up/Down Buttons

17. Function Selector Buttons

18. On/Stand-by Button

19. Timer Button

20. Clock Button

21. Treble Up/Down Buttons

22. Volume Up/Down Buttons

CP-XL40H

1. Bass Reflex Duct

2. Full-Range Speaker

3. Speaker Wire

OPERATION MANUAL

– 6 –

Page 7

XL-30H/30W

SETTING THE CLOCK

1

Press the CLOCK/TIMER/SLEEP button to en-

ter the time check mode.

2

Within 3 seconds, press the MEMORY/SET but-

ton.

3

Turn the jog dial to select the time display mode.

0:00 AM 12:00

“0:00” → The 24-hour display will appear.

(0:00 - 23:59)

“AM 12:00” → The 12-hour display will appear.

(AM 12:00 - PM 11:59)

● Note that this can only be set when the unit is

first installed or it has been reset.

4

Press the MEMORY/SET button.

5

Adjust the hour by turning the jog dial.

● When the jog dial is turned one click clockwise,

the time will increase by 1 hour. When it is turned

one click anti-clockwise, the time will decrease

by 1 hour.

Keep turning the jog dial to change the time con-

tinuously.

● When the 12-hour display is selected, “AM” will

change automatically to “PM”.

(Main unit operation)

In this example, the clock is set for the 24-hour

(0:00) system.

CLOCK/TIMER/

SLEEP

MEMORY/SET

Jog dial

6

Press the MEMORY/SET button.

7

Adjust the minutes by turning the jog dial.

● When the jog dial is turned one click clockwise,

the time will increase by 1 minute. When it is

turned one click anti-clockwise, the time will de-

crease by 1 minute.

Keep turning the jog dial to change the time con-

tinuously.

● The hour setting will not advance even if min-

utes advance from “59” to “00”.

8

Press the MEMORY/SET button.

● The clock starts operating from “0” second. (Sec-

onds are not displayed.)

Note:

● In the event of a power failure or when the AC

power lead is disconnected, the clock display will

go out.

When the AC power supply is restored, the clock

display will flash on and off to indicate the time

when the power failure occurred or when the AC

power lead was disconnected.

If this happens, follow the procedure below to

change the clock time.

To change the clock time:

Perform steps 1, 2 and 4 - 8 above.

To change the time display mode:

1

Perform steps 1 - 3 in the section “RESETTING

THE MICROCOMPUTER”,.

2

Perform steps 1 - 8 above.

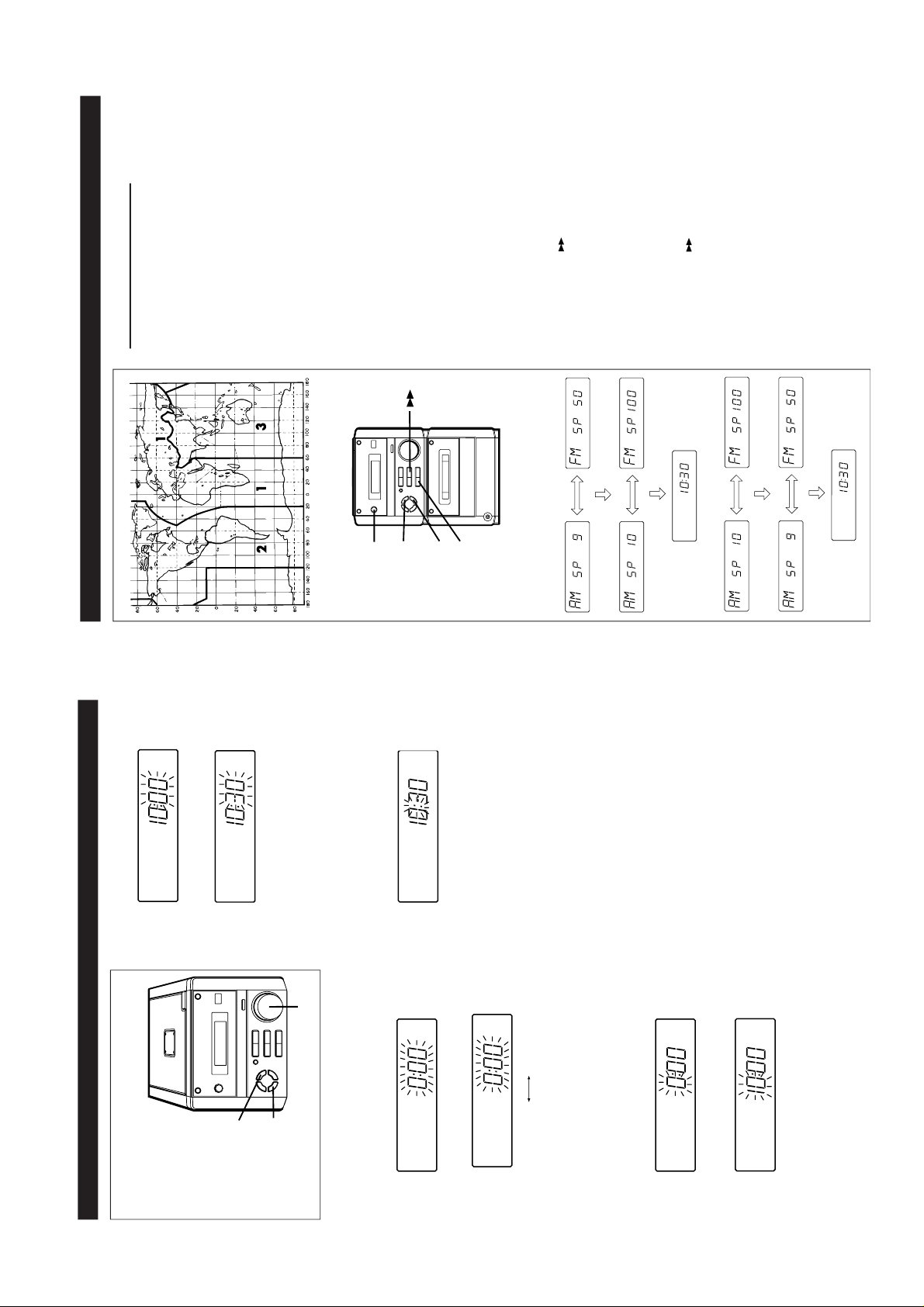

PREPARATION FOR USE (FOR XL-30W Only)

■ AM/FM interval (span)

The International Telecommunication Union (ITU)

has established that member countries should

maintain either a 10 kHz or a 9 kHz interval be-

tween broadcasting frequencies of any AM station.

The illustration shows the 9 kHz interval zones (re-

gions 1 and 3), and the 10 kHz interval zone (re-

gion 2).

This product is not equipped with a span selector.

However, it will be adjusted to 9 kHz AM interval

(50 kHz FM interval) when shipped from the fac-

tory.

Before using the unit, be sure to set it for the AM

tuning interval (span) used in your area.

To check the tuning span currently selected:

1

Press the ON/STAND-BY button to turn the

power on.

2

Press the FUNCTION button until “FM” or “AM”

appears in the display.3Press the BAND button to select the AM band.

● If “AM 531 kHz” is displayed, it means that the

radio has been adjusted for a 9 kHz span. If “AM

530 kHz” is displayed, it means that the radio

has been adjusted for a 10 kHz span.

To change from a 9 kHz AM (50 kHz FM) interval

to a 10 kHz AM (100 kHz FM) interval:

1

Press the ON/STAND-BY button to enter the

stand-by mode.

2

Hold down the button and the MEMORY/

SET button for at least 4 seconds. Release the

buttons when “AM SP 10 kHz” and “FM SP 100

kHz” are displayed alternately.

● The unit will return to the clock display.

To return to a 9 kHz AM (50 kHz FM) interval:

1

Press the ON/STAND-BY button to enter the

stand-by mode.

2

Hold down the button and the MEMORY/

SET button for at least 4 seconds. Release the

buttons when “AM SP 9 kHz” and “FM SP 50

kHz” are displayed alternately.

● The unit will return to the clock display.

Caution:

● When the unit is left for a few hours after the

span has been switched and AC power lead dis-

connected, it will be automatically returned to a

9 kHz span. If this happens, set the span again.

● When the span is switched, any stations that are

memorised will be cancelled.

MEMORY/

SET

FUNCTION

BAND

ON/

STAND-BY

kHz

kHz

kHz

kHz

kHz

kHz

kHz

kHz

– 7 –

Page 8

XL-30H/30W

Placing the system

20 cm (8")

10 cm (4")

10 cm (4")

10 cm (4")

3

1

Check the supplied accessories

Remote control × 1

AC power lead

(For U.K.)

× 1

FM/AM loop aerial ×1

2 “AA” size batteries (UM/SUM-3, R6, HP-7 or similar)

3

Replace the battery cover.

2

Putting batteries into the remote control

1

Remove the battery

cover.

2

Insert the batteries.

AC power lead

(For Europe)

× 1

FM aerial × 1

(For-XL30W)

Remote control × 1

AC power lead × 1

AM loop aerial ×1

(For-XL30H)

4

Connections

1 Connect the AM and FM aerials.

2 Connect the speaker system.

3 Connect the AC power lead.

2

1

3

1

2

FM aerial

AM loop

aerial

White line

Right speaker

Left speaker

1

2

RATED

LINE VOLTAGE

220Vı240V

AC 230 V, 50 Hz

(XL-30H for Europe)

AC 110V - 127V or 220V - 240V, 50/60 Hz

ANTENNA

LOOP

FM

75

OHMS

1

2

3

AM loop aerial

FM aerial

(For XL-30W)

AC 230 V, 50 Hz

(XL-30H for U.K.)

(For

XL-30H)

To an AC socket

(For XL-30W)

(For XL-30H/

XL-30W)

– 8 –

Page 9

XL-30H/30W

6

Listening to a tape

3

2

1

4

5

1

2

5

3

4

6

1

2

6

7

5

PUSH

CLOSE

3

CD EJECT

4

Label side up

1

Press the ON/STAND-BY button to turn

the power on.

2

Press the FUNCTION button until “FM” or

“AM” appears.

3

Press the BAND button to select FM ST,

FM or AM.4Press the TUNING ( or ) button to tune

into a station.

5

Adjust the VOLUME control.

1

Press the ON/STAND-BY button to turn

the power on.

2

Press the FUNCTION button until “Cd” or

“no dISC” appears.

3

Press the CD EJECT button to open

the CD compartment.

4

Place a CD on the spindle.

5

Close the CD compartment by pushing the

corner marked “PUSH CLOSE”.

6

Press the /CD button.

7

Adjust the VOLUME control.

5

Listening to a CD

Listening to the radio

7

1

Press the ON/STAND-BY button to turn

the power on.

2

Press the FUNCTION button until “TP”

appears.

3

Open the cassette door by pushing the

area marked “ PUSH EJECT”

4

Load a cassette.

5

Press the button.6Adjust the VOLUME control.

8

Recording from a CD

1

Press the ON/STAND-BY button to turn

the power on.

2

Press the FUNCTION button until “Cd” or

“no dISC” appears.

3

Load a CD and a recordable cassette.

4

Press the REC PAUSE button.

5

Press the button.

● Do not touch the laser pickup lens. If fingerprints

or dust accumulate on the pickup, clean it gently

with a dry cotton swab.

● CD pickup cleaning

1

2

5

3

4

– 9 –

Page 10

XL-30H/30W

CD Mechanism

(L1)x3

ø2.5x10mm

PWB Washer x3

Top Cabinet

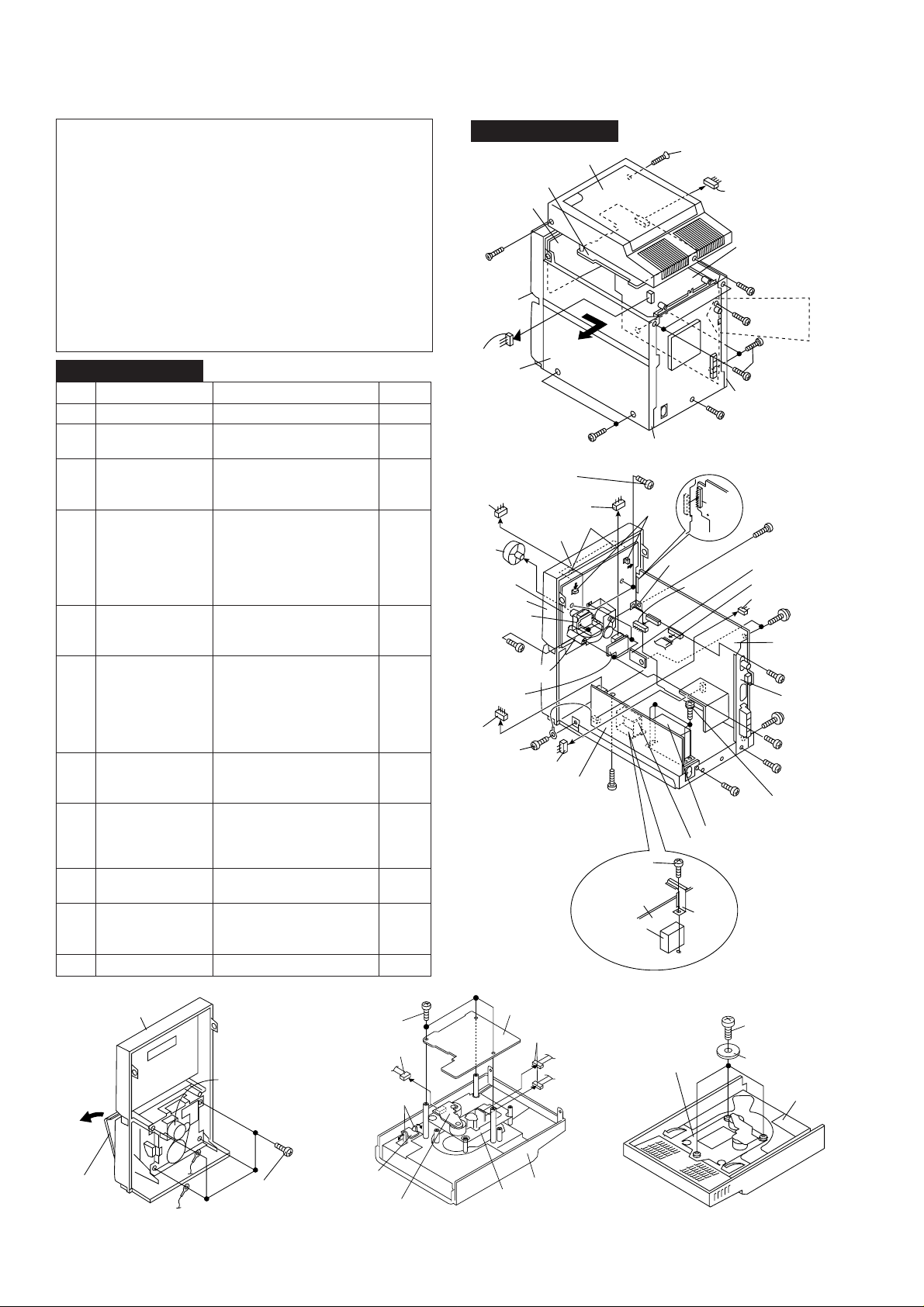

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need to

be removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were

before disassembling.

4. Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

XL-30H/30W

STEP REMOVAL

1 Side Panel

2 Top Cabinet 1. Screw .................. (B1) x1 10-1

Switch PWB 2. Socket ................. (B2) x2

3 Rear Panel 1. Screw .................. (C1) x1 10-1

4 Main PWB/ 1. Screw .................. (D1) x3 10-2

Headphones PWB 2. Screw .................. (D2) x2

5 Jog Switch PWB 1. Socket ................. (E1) x1 10-2

6 Display PWB/ 1. Screw .................. (F1) x2 10-2

LED PWB 2. Screw .................. (F2) x3

(With Jog Motor 3. Bracket ................ (F3) x1

Holder) 4. Socket ................. (F4) x1

7 Front Panel 1. Screw .................. (G1) x1 10-2

8 Power PWB 1. Screw .................. (H1) x4 10-2

9 Tape Mechanism 1. Open the cassette holder 10-3

10 CD PWB/ 1. Screw .................. (K1) x3 10-4

Open Close Switch 2. Hook .................... (K2) x2

PWB (Note) 3. Socket ................. (K3) x3

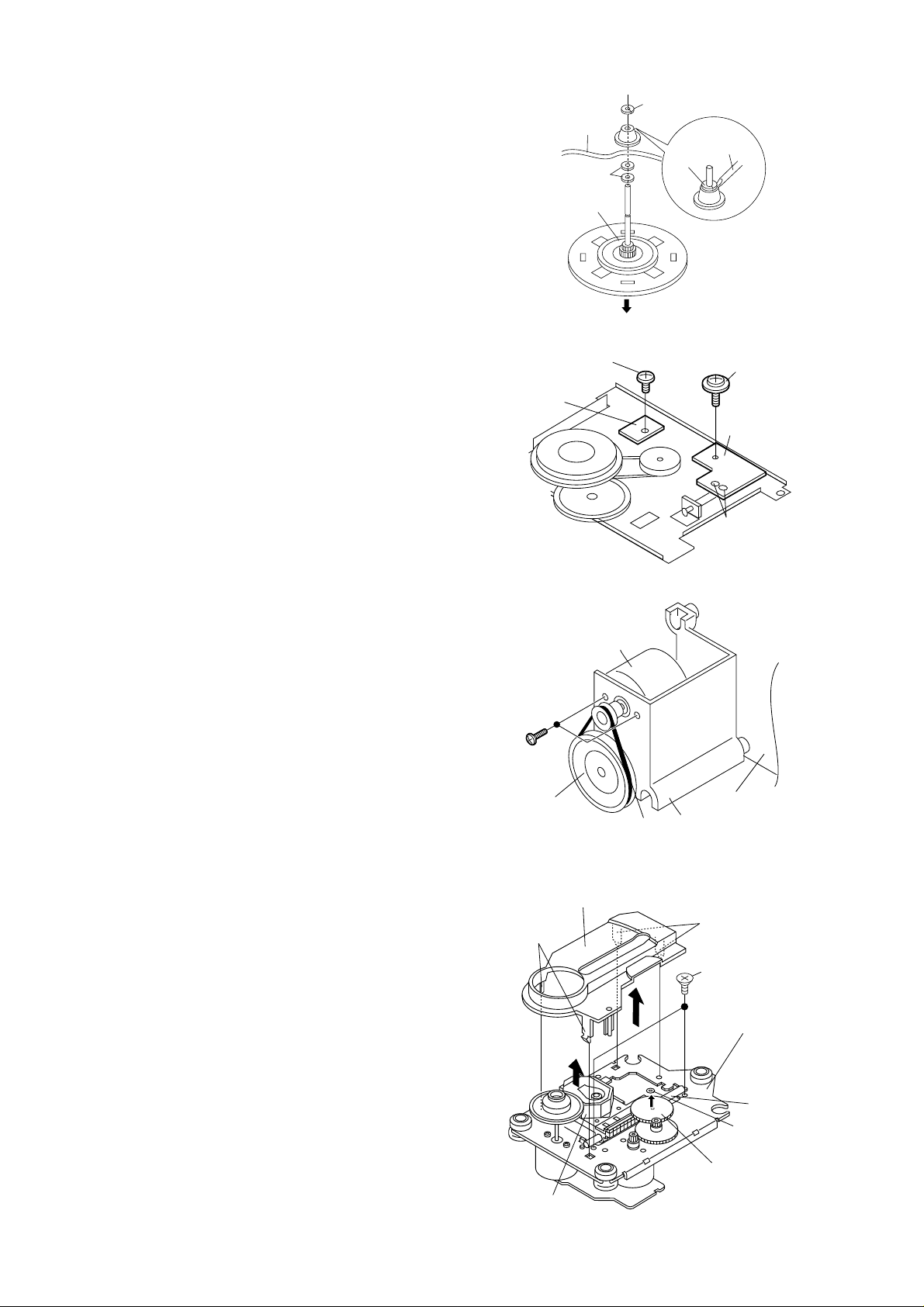

11 CD Mechanism 1. Screw .................. (L1) x3 10-5

(Left/Right)

PROCEDURE

1. Screw .................. (A1) x8 10-1

2. Screw .................. (C2) x1

(XL-30W ONLY)

3. Bracket ................ (D3) x1

4. Socket ................. (D4) x3

5. Flat wire............... (D5) x1

6. Socket ................. (D6) x1

2. Screw .................. (E2) x2

3. Knob .................... (E3) x1

5. Hook .................... (F5) x2

6. Hook .................... (F6) x2

2. Socket ................. (G2) x1

3. Screw .................. (G3) x1

2. Screw .................. (H2) x1

3. Screw .................. (H3) x1

4. Bracket ................ (H4) x1

2. Screw .................. (J1) x4

FIGURE

XL-30H/30W

Display

PWB

(A1)x1

ø3x10mm

Front

Panel

(B2)x1

Side Panel

(Right)

(E1)x1

(E3)x1

Display PWB

Front Panel

Jog Switch

PWB

(E2)x2

ø2.5x12mm

Jog Motor

Tape

Holder

Mechanism

PWB

(F4)x1

(G3)x1

ø3x6mm

Power PWB

Top Cabinet

CD PWB

(A1)x2

ø3x10mm

(F2)x2

ø2.5x10mm

LED

PWB

(D4)x1

(D4)x1

(F6)x2

Figure 10-1

(F5)x2

(G1)x1

ø3x8mm

(H3)x1

ø3x6mm

Power PWB

Sub Power

Transformer

Figure 10-2

(A1)x1

ø3x10mm

RearPanel

(F3)x1

(D4)x1

(B2)x1

Main PWB

(B1)x1

ø3x10mm

XL-30W Only

(C2)x1

ø3x10mm

(A1)x4

ø3x10mm

Side Panel

(Lift)

(C1)x1

ø3x10mm

(D6)x1

Main Power Transformer

Sub Power Transformer

(H4)x1

Headphones

PWB

(H2)x1

ø3x10mm

(D2)x1

ø3x8mm

(D5)x1

(G2)x1

Main PWB

(H1)x4

ø3x6mm

(D1)x2

ø3x10mm

(F2)x1

ø2.5x10mm

(D3)x1

(D1)x1

ø3x10mm

(F1)x3

ø2.5x14mm

(D2)x1

ø3x8mm

Open

Cassette

Holder

Front Panel

Figure 10-3

Tape

Mechanism

(J1)x4

ø2.5x10mm

(K1)x3

ø2.5x14mm

(K3)x1

(K2)x2

Open/Close

Switch PWB

CD Motor PWB

Figure 10-4

– 10 –

CD PWB

(K3)x2

Top Cabinet

CD Mechanism

Figure 10-5

Page 11

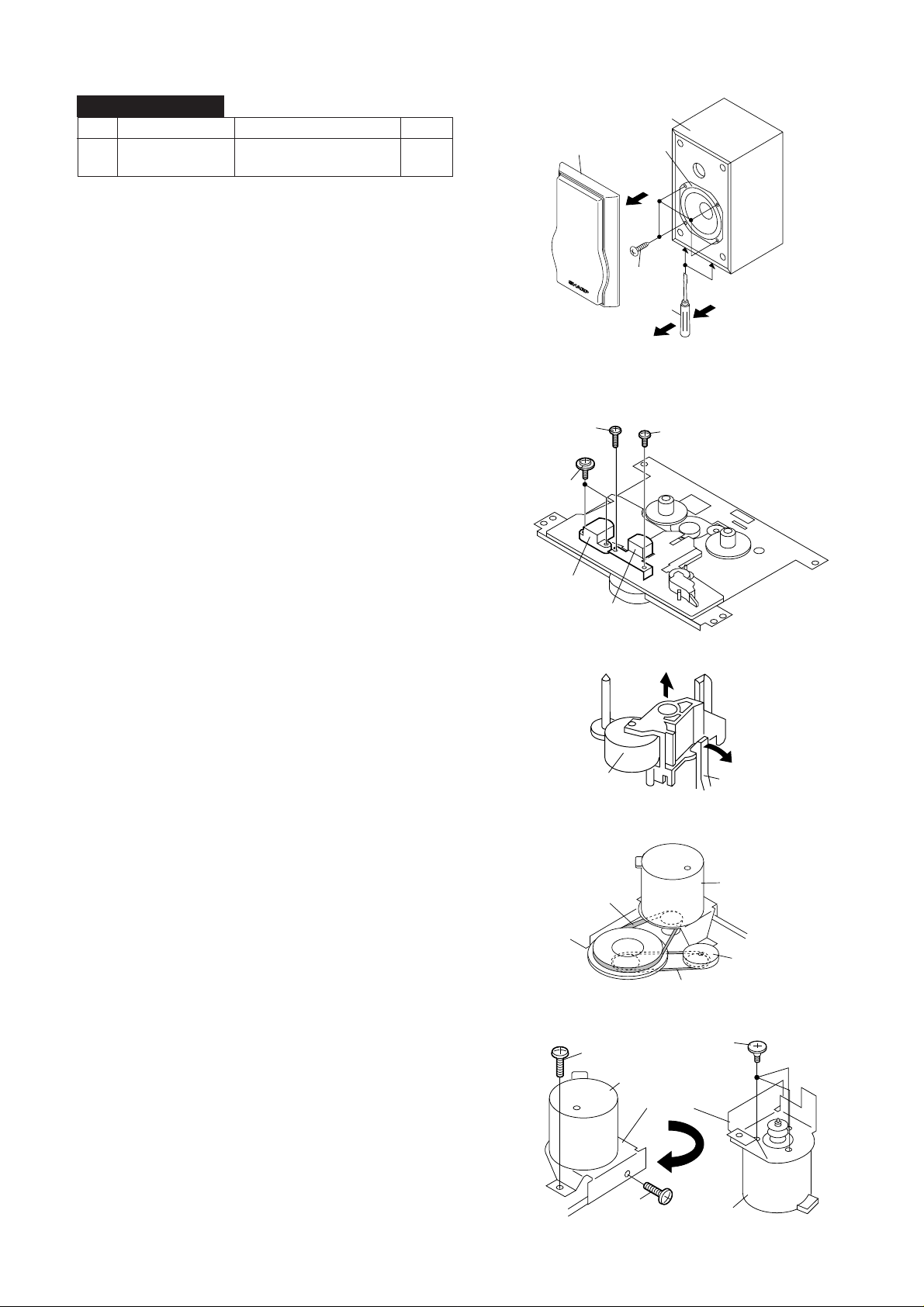

CP-XL40H

(A2)x4

ø4x12mm

(A1x1)

Woofer

Speaker Box

Driver

Direction of handle

Driver should be

pried away from

speaker Box.

Erase Head

Record/

Playback Head

(A1)x2

ø2x8mm

(A2)x1

ø2x3mm

(A2)x1

ø2x7mm

(D1)x1

ø2x4mm

(D2)x3

Special

Screw

Motor

Bracket

Motor

Motor

(D1)x1

ø2x4mm

STEP REMOVAL

1 Speaker 1. Front panel .......... (A1) x1 11-1

PROCEDURE

2. Screw .................. (A2) x4

FIGURE

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

REMOVING AND REINSTALLING THE MAIN PARTS

TAPE MECHANISM SECTION

Perform steps 1 to 7 and 9 of the disassembly method to

remove the tape mechanism. (See page 10.)

How to remove the record / playback and erase

heads (See Fig. 11-2.)

1. Remove the screws (A1) x 2 pcs., to remove the erase

head.

2. Remove the screws (A2) x 2 pcs., to remove the record/

playback head.

Note:

After replacing the heads and performing the azimuth

adjustment, be sure to apply screwlock.

XL-30H/30W

Figure 11-1

Figure 11-2

How to remove the pinch roller (See Fig. 11-3.)

1. Carefully bend the pinch roller pawl in the direction of the

arrow <A>, and remove the pinch roller (B1) x 1 pc.,

upwards.

How to remove the belts (See Fig. 11-4.)

1. Remove the main belt (C1) x 1 pc., from the motor pulley.

2. Remove the FF/REW belt (C2) x 1 pc., from the REW/FF

roller.

3. Put on the belts in the reverse order of removal.

Note:

When putting on the belt, ascertain that the belt is not twisted,

and clean it.

How to remove the motor

(See Figs. 11-5.)

1. Remove the main belt.

2. Remove the screws (D1) x 2 pcs., to remove the motor

3. Remove the screws (D2) x 3 pcs., to remove the motor.

Note:

When mounting the motor, pay attention to the motor mounting

angle.

bracket.

Pinch Roller

(B1)x1

Main Belt

(C1)x1

Figure 11-3

FF/REW Belt

(C2)x1

Figure 11-4

<A>

Pinch Roller

Pawl

Motor

REW/FF

Clutch

Figure 11-5

– 11 –

Page 12

XL-30H/30W

Stop

Washer

Driver

(E1)x1

Stop Washer

Mechanism

Chassis

Washerx2

Flywheel

How to remove the flywheel (See Fig. 12-1.)

1. Remove the belt.

2. Remove the stop washer (E1) x 1 pc., with a small precision

screwdriver to extract the flywheel from the capstan metal.

Note:

When the stop washer is deformed or damaged, replace it

with a new one.

How to reinstall the parts

Install each part in the reverse order of the removal with care.

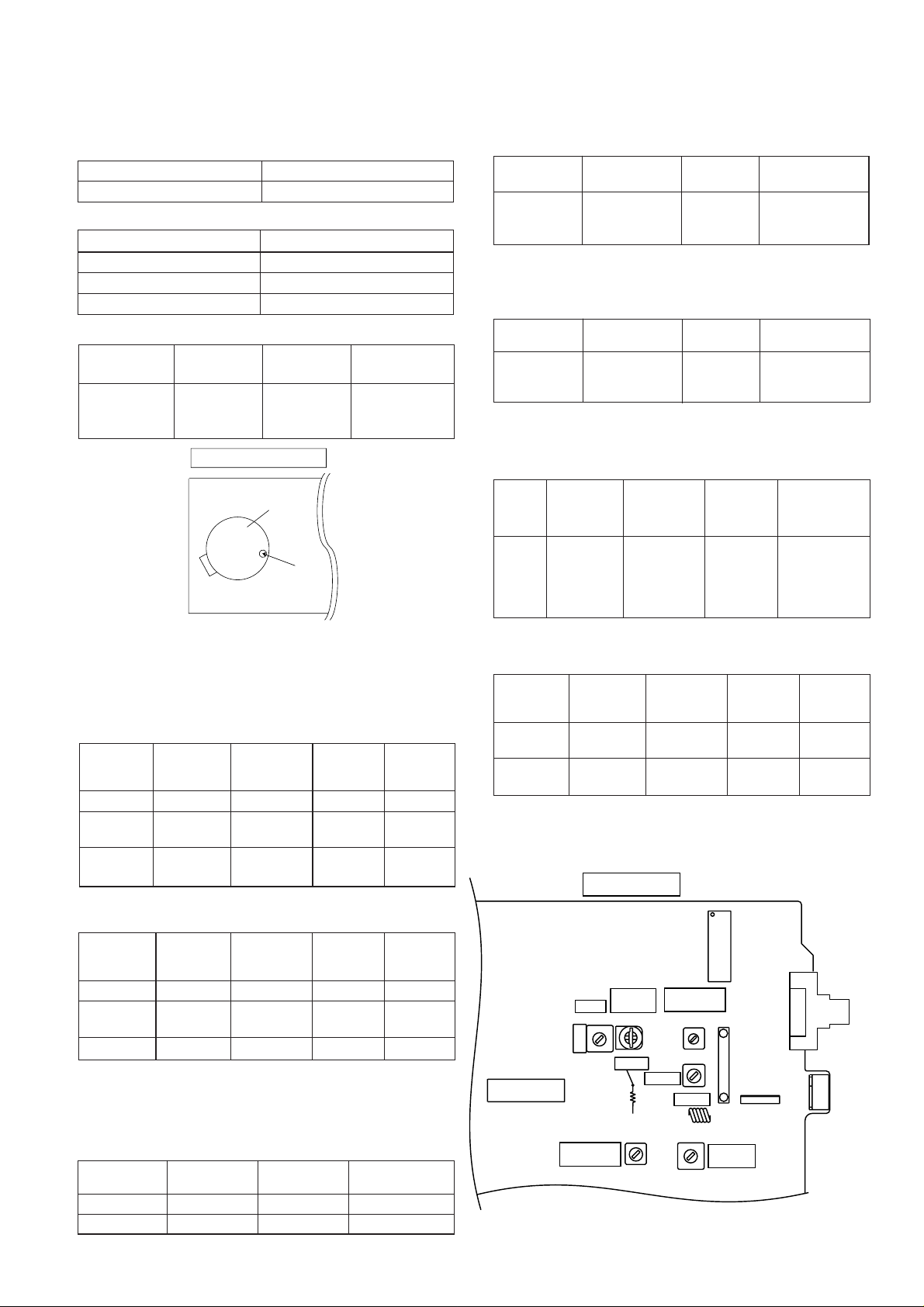

How to remove the tape mechanism PWB

(See Fig. 12-2.)

1. Remove the screws (F1) x 1 pc., to remove the tape

mechanism PWB.

2. Remove the screws (F2) x 1 pc.

3. Remove the solder joints (F3) x 2 pcs., to remove the tape

mechanism PWB.

(F1)x1

ø2x3mm

Tape

Mechanism

PWB

Figure 12-1

(F2)x1

ø2x8mm

Tape

Mechanism

PWB

How to remove the jog motor

(See Figs. 12-3.)

1. Remove the side panel and top cabinet.

2. Remove the jog belt (G1) x 1 pc., from the motor pulley.

3. Remove the screws (G2) x 2 pcs., to remove the jog motor.

Note:

When putting on the belt, ascertain that the belt is not twisted,

and clean it.

CD MECHANISM SECTION

Perform steps 1, 2 and 10, 11 of the disassembly method to

remove the CD mechanism.

How to remove the pickup (See Fig. 12-4)

1. Remove the mechanism cover, paying attention to the

pawls (A1) x 4 pcs.

2. Remove the screws (A2) x 2 pcs., to remove the shaft (A3)

x 1 pc.

3. Remove the stop washer (A4) x 1 pc., to remove the gear

(A5) x 1 pc.

4. Remove the pickup.

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

– 12 –

(G2)x2

ø2x5mm

Worm

Gear

(A1) x2

Pickup Unit

Figure 12-2

Jog Motor

Jog Belt

(G1)x1

Figure 12-3

Mechanism Cover

Figure 12-4

(F3)x2

Solder

Joint

Display PWB

Jog Motor

Holder

(A1) x2

(A2) x2

ø2.6 x6mm

CD Mechanism

Shaft

(A3) x1

StopWasher

(A4) x1

Gear

(A5) x1

Page 13

MECHANISM SECTION

• Driving Force Check

Torque Meter

Play: TW-2412 Over 80 g

• Torque Check

Torque Meter

Play: TW-2111 30 to 60 g. cm

Fast forward: TW-2231 55 to 140 g.cm

Rewind: TW-2231 55 to 140 g.cm

• Tape Speed

Test Tape

MTT-111 Variable 3,000 ± Headphone

Adjusting

Point

resistor in 90 Hz terminal

motor.(M901)

Specified Value

Specified Value

Specified

Value

Instrument

Connection

ADJUSTMENT

• FM Mute Level (For XL-30W)

Signal generator: 1 kHz, 40 kHz dev., FM modulated

Frequency

98.00 MHz 98.00 MHz VR351*1 Input: SO301

(25 dBµV) Output: Speaker

*1. Adjust so that an output signal appears.

• FM Mute Level (For XL-30H)

Signal generator: 1 kHz, 40 kHz dev., FM modulated

Frequency

98.00 MHz 98.00 MHz VR351*1 Input: CNP301

(30 dBµV) Output: Speaker

*1. Adjust so that an output signal appears.

Display

Display

Adjusting

Parts

Adjusting

Parts

XL-30H/30W

Instrument

Connection

Terminal

Instrument

Connection

Terminal

TAPE MECHANISM

M901

Tape

Motor

Variable

resistor

in motor

Figure 13-1 ADJUSTMENT POINT

TUNER SECTION

fL: Low-renge frequency

fH: High-renge frequency

• AM IF/RF (For XL-30H)

Signal generator: 400 Hz, 30%, AM modulated

Frequency Frequency

IF 450 kHz 1,620 kHz T351 *1

AM Band — 522 kHz (fL): T306 *2

Coverage 1.1 ± 0.1 V

AM 990 kHz 990 kHz T302 *1

Tracking

• AM IF/RF (For XL-30W)

Signal generator: 400 Hz, 30%, AM modulated

Test Stage Frequency

AM IF 450 kHz 1,602 kHz T351 *1

AM Band — 531 kHz (fL): T306 *2

Coverage 1.1 ± 0.1 V

AM Tracking 990 kHz 990 kHz T302 *1

*1. Input: Antenna, Output: Speaker Terminal

*2. Input: Input is not connected, Output: TP301

Span selectors are to be 9 kHz (AM), 50 kHz (FM).

• Check FM VT (XL-30H/30W)

Signal generator: 1 kHz, 40 kHz dev., FM modulated

Frequency

87.5 MHz 87.5 MHz 3.4 V ± 1.0 V TP301

108 MHz 108 MHz 7.8 V ± 1.0 V TP301

Display

Display

Setting/

Adjusting

Parts

Frequency

Display

Setting/

Adjusting

Parts

Check Point Instrument

Connection

Instrument

Connection

Instrument

Connection

• FM Detection (XL-30H/W)

Signal generator: 10.7 MHz, FM sweep generator

Frequency Frequency

Test

Stage

Display

Setting/

Adjusting

Parts

FM IF 10.7 MHz 98.00 MHz T304(Turn Input: Pin 1 of

the core of IC301

T304 fully

counterclockwise).

• FM RF (XL-30H/W)

Signal generator: 1 kHz, 75 kHz dev., FM modulated

Test Stage

Frequency

FM Band — 87.50 MHz (fL): L303 *1

Coverage 3.4 ± 0.1 V

FM RF 98.00 MHz 98.00 MHz L302 *2

(10~30 dB)

Frequency

Display

Setting/

Adjusting

Parts

*1. Input: Antenna, Output: TP301

*2. Input: Antenna, Output: Speaker Terminal

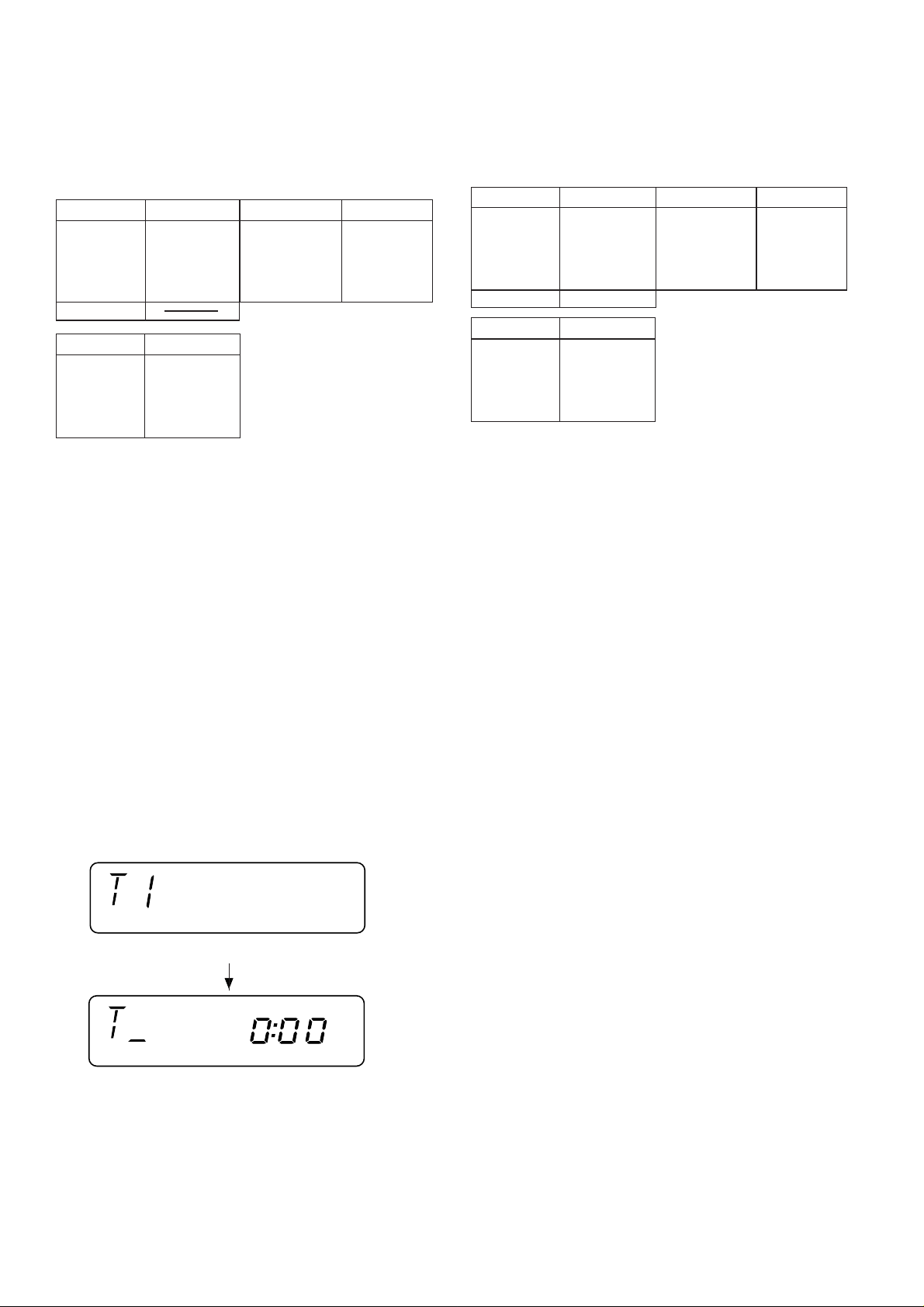

MAIN PWB

IC302

R336

T306

FM Band

Coverage fL

FM IF

L302

L303

T304

FM RF

T302

9

IC301

1

AM

Tracking

BF301

– 13 –

IC303

FM Mute

Level

AM IF

VR351

T351

CF352

AM Band

Coverage fL

TP301

Figure 13-2 ADJUSTMENT POINTS

Instrument

Connection

Instrument

Connection

SO301

ANTENNA

SOCKET

(XL-30W

Only)

CNP301

ANTENNA

SOCKET

Page 14

XL-30H/30W

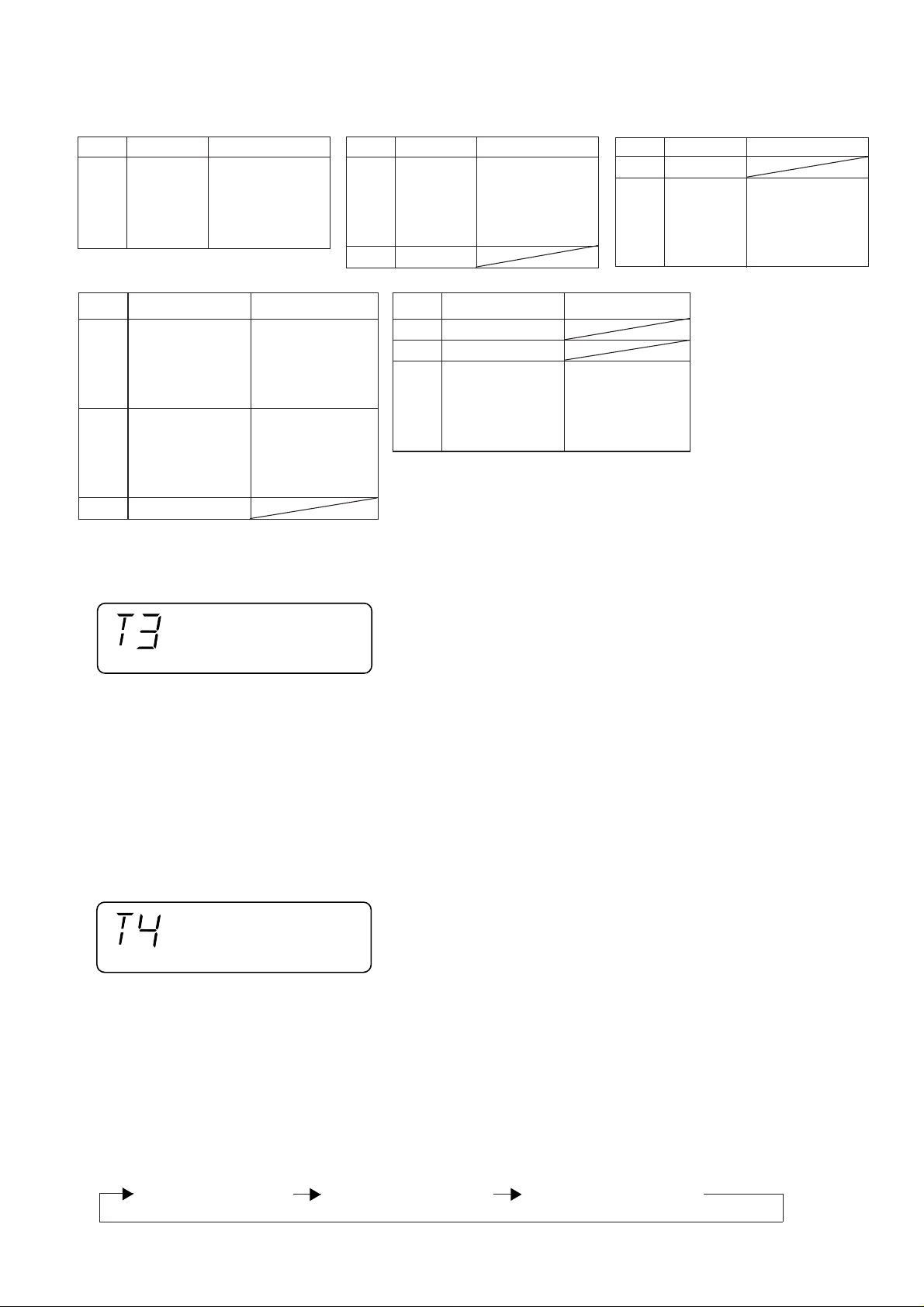

• Setting the Test Mode (For XL-30W)

Keeping the FF/FWD button and MEMORY button pressed,

turn on POWER. Then, the frequency is initially set in the

memory as shown in Table. Call it with the Jog volume button

by pressing the VOLUME/JOG button to use it for adjustment

and check of tuner circuit.

Preset No. FM STEREO

1 87.50 MHz 6 531 kHz

2 108.00 MHz 7 1,602 kHz

3 98.00 MHz 8 990 kHz

4 90.00 MHz 9 603 kHz

5 106.00 MHz 10 1,404 kHz

11~25

Preset No.

26 106.00 MHz

27 90.00 MHz

28 98.00 MHz

29 108.00 MHz

30 87.50 MHz

FM MONO

Preset No.

AM

• Setting the Test Mode (For XL-30H)

Keeping the FF/FWD button and MEMORY/SET button

pressed, turn on POWER. Then, the frequency is initially set

in the memory as shown in Table. Call it with the JOG DIAL

knob to use it for adjustment and check of tuner circuit.

Preset No. FM STEREO

1 87.50 MHz

2 108.00 MHz

3 98.00 MHz

4 90.00 MHz

5 106.00 MHz

11~25 ––––

Preset No. FM MONO

26 106.00 MHz

27 90.00 MHz

28 98.00 MHz

29 108.00 MHz

30 87.50 MHz

Preset No.

6 522 kHz

7 1,620 kHz

8 990 kHz

9 603 kHz

10 1,404 kHz

AM

TEST MODE

The test mode applied to this microcomputer has three modes, namely ordinary test mode to be used for adjustment or

measurement, aging test mode to be used for aging test, and self-diagnosis test mode for self-inspection in case of final product

inspection.

1. Turning on the test mode

To turn on the specific test mode, press the POWER button, holding down the following two buttons in the ordinary stand-by

mode (power off state). In this case only the main unit button is valid. Even when the POWER of remote control button is set

to on, the test mode is not turned on.

[Ordinary test mode]

1. CD Test Mode (TEST 1)…………………… Volume/JOG Dial Selector + FF/FWD

2. Tuner Test Mode (TEST 2)………………… Volume/JOG Dial Selector + Volume Select

3. Electronic volume Test Mode (TEST 3)……REW/REV + FF/FWD

4. Timer Test Mode (TEST 4)………………… FUNCTION + Volume Select

5. LCD Test Mode (TEST 5)……………………FUNCTION + FF/FWD

[Self-diagnosis Test Mode]

1. Button input diagnosis test mode (TEST6).…

2. CD Test Mode (TEST 1)

In the CD test mode the operation of each step is enabled even when the LID-SW is off. However, if focus cannot be set in step

3 or any error processing is started, it is impossible to proceed to the next step. When the error processing is started, operations

other than termination of test mode by pressing the POWER button or return to the step 1 by pressing the STOP button are inhibited.

1. Step 1 Mode

When the CD test mode is turned on, the following indication lights, the processing (until turning-off of CD STB terminal of CD

initialization operation flow) is executed, and the next button input is waited.

REW/REV + Volume Select

After lighting for one second

If the following operation buttons are pressed in this state, the operation is performed as follows.

"POWER".................The test mode is turned off, the power is turned off, and the ordinary stand-by mode is set.

"FF/FWD".................After the pickup returns once to the innermost periphery, it slides toward the outer periphery while this

button is held down.

"REW/REV"..............After the pickup returns once to the innermost periphery, it slides toward the inner periphery while this

button is pressed. However, if PU-IN is on, input is invalid.

"PLAY" .....................Shift to step 2

"STOP".....................Invalid

"REC PAUSE"..........Shift to step 5

– 14 –

Page 15

XL-30H/30W

* In case of initialization the pickup is moved toward the inner periphery. Any buttons other than "POWER" button are not

accepted until the shift of pickup to the inner periphery is completed at this time. If PU-IN SW ON cannot be detected within

10 seconds, the slide motor is stopped, and the following error indication appears. Press the POWER button to end the test

mode, or press the STOP button to return to step 1. Any other operations are inhibited.

2. Step 2 Mode

When the "PLAY" button is pressed in this mode, the laser lighting command LDON (8400) is sent, and the laser is turned on.

Other operations are not performed.

If the following buttons are pressed in this state, the operation is performed as follows.

"POWER" ................The test mode is turned off, the power is turned off, and the ordinary stand-by mode is set.

"FF/FWD" ................The pickup slides toward the outer periphery while this button is held down.

"REW/REV" .............The pickup slides toward the inner periphery while this button is held down. However, if PU-IN is on, input

is invalid.

"PLAY".....................Shift to step 3

"STOP" ....................Return to step 1

"REC PAUSE" .........Shift to step 5

3. Step 3 Mode

The laser is kept lighting. The processing (until turning-on of CLV servo of CD initialization operation flow) is executed, and

the next button input is waited. (The focus servo is turned on, and focus search is performed.)

The focus search is repeated until the focus is set.

When the following operation buttons are pressed in this state, the operation is executed as follows.

"POWER" ................The test mode is turned off, the power is turned off, and the ordinary standby mode is set.

"FF/FWD" ................The pickup slides toward the outer periphery while this button is held down.

"REW/REV" .............The pickup slides toward the inner periphery while this button is held down. However, if PU-IN is on, input

is invalid.

"PLAY".....................If the focus has been set, shift to step 4 is executed. If the focus has not been set, acceptance is inhibited.

"STOP" ....................Return to step 1

"REC PAUSE" .........Shift to step 5

*If the focus is disturbed after it has been set, the process returns to step 1.

4. Step 4 Mode

The CLV servo ON command (8600) sending operation is performed, and the next button input is waited. (The disc is rotated

to perform CLV locking.)

The time display indicates always "0:00".

When the following buttons are pressed in this state, the operation is executed as follows.

"POWER" ................The test mode is turned off, the power is turned off, and the ordinary standby mode is set.

"FF/FWD" ................The pickup slides toward the outer periphery while this button is held down.

"REW/REV" .............The pickup slides toward the inner periphery while this button is held down. However, if PU-IN is on, input

is invalid.

"PLAY".....................Shift to step 5

"STOP" ....................Return to step 1

"REC PAUSE" .........Shift to step 5

*If the focus is disturbed, the process returns to step 1.

– 15 –

Page 16

XL-30H/30W

5. Step 5 Mode

The CD initialization operation flow is executed to the end, the mute is set to off, and playback is started. Even when the

playback reaches the outermost periphery of disc, the operation does not stop. The LCD display indicates the playback past

time as in case of ordinary CD playback.

When the following operation buttons are pressed in this sate, the operation is executed as follows.

"POWER".................The test mode is turned off, the power is turned off, and the ordinary standby mode is set.

"FF/FWD".................The pickup slides toward the outer periphery while this button is held down.

"REW/REV"..............The pickup slides toward the inner periphery while this button is held down. However, if PU-IN is on, input

is invalid.

"PLAY" .....................Invalid

"STOP".....................Return to step 1

"FUNCTION"............Shift to step 6

"BAND" ....................Shift to step 7

*If the focus is disturbed, the process returns to step 1.

Other cautions

• TOC IL is not executed in the test mode.

• As for button operations other than those shown above, only the sound volume operation (with JOG) is accepted.

3. Tuner Test Mode (TEST 2)

1. Outline of tuner (radio) test mode

The tuner test mode is intended to store the adjustment and measurement frequencies in the preset memory CH without

frequency setting by adjusting personnel when the tuner section is adjusted in the production line.

2. Details of tuner test mode

When the power is turned on by using the "POWER" button while the "Volume/JOG Dial Selector" and "Volume Select"

buttons are held down in POWER OFF state, the frequency for adjustment and measurement of destination specified by the

AREA terminal is preset and stored in the preset memory CH. However, Ordinary 1 and Ordinary 2 are set to the designation

(destination selected by SPAN switching operation) set when the test mode is set. (As for frequencies to be preset and stored

for each destination, refer to item 3.)

The tuner test mode is started from preset No.1.

The operations of test mode are identical with the ordinary operations of TUNER function. However, FUNCTION switching

is invalid.

Since it is necessary to discard the content of preset memory when the tuner test mode is ended, "0000" or "1111" bits are

written in the memory to be checked in case of memory check (in case of initial setting) so that memory abnormality is detected

in case of initial setting so as to ensure memory initialization.

When the tuner test mode is turned on, the following indication lights for one second.

• The TUNER TEST2 mode is set as a result of Volume Select + POWER. -> IF AC is set to OFF in the TEST2 mode, the initial

state is restored.

When POWER is set to OFF, the memory of TEST2 mode is protected.

When the power is turned on again, the ordinary operation is enabled while the data is stored in the

memory (besides TUNER).

If AC OFF state is maintained in this state for about 1/2 day, start is executed in the initial state.

• To clear the whole memory, insert the AC cord, holding down MEMORY + PLAY.

– 16 –

Page 17

3. Preset frequencies for various destinations (random preset memory)

(For XL-30H)

CH

1 FM 87.50 MHz

2 FM108.00 MHz

3 FM FM 98.00 MHz

4 STEREO FM 90.00 MHz

5 FM106.00 MHz

(For XL-30W)

1 FM 87.50 MHz

2 FM108.00 MHz

3 FM STEREO FM 98.00 MHz

4 FM 90.00 MHz

5 FM106.00 MHz

6 AM 531 kHz

7 AM1602 kHz

8 AM AM 990 kHz

9 AM 603 kHz

10 AM1404 kHz

11-15 LW

BAND

Europe 2, 4

Ordinary 1,ChinaCH

BAND

6 AM 522 kHz

7 AM1620 kHz

8 AM AM 990 kHz

9 AM 603 kHz

10 AM1404 kHz

11-15 LW

16-20

21-25

26 FM106.00 MHz

27 FM 90.00 MHz

28 FM MONO FM 98.00 MHz

29 FM108.00 MHz

30 FM 87.50 MHz

Europe 2, 4CH

BAND

XL-30H/30W

CH

16-25

26 FM106.00 MHz

27 FM 90.00 MHz

28 FM FM 98.00 MHz

29 MONO FM108.00 MHz

30 FM 87.50 MHz

Ordinary 1,ChinaCHBAND

BAND

Europe 2, 4

• The hatched sections of the table are not stored in memory.

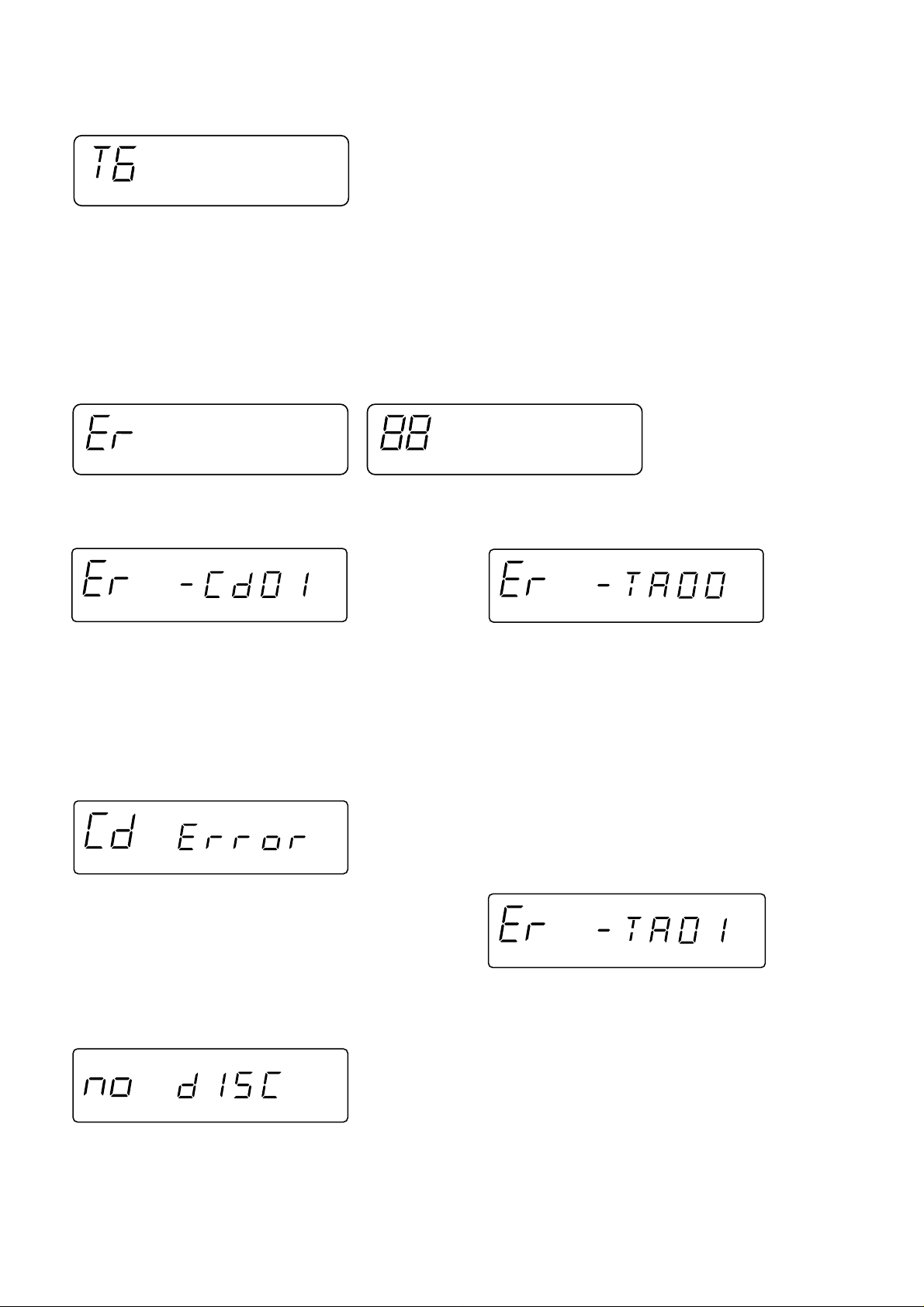

4. Electronic volume Test Mode (TEST 3)

When the test mode is set, the following indication lights for one second.

When this mode is set, BASS/TREBLE is set to 0 (0 dB) and SURROUND mode is set to off, and start-up function is set to CD

when volume is -14 dB (STEP 17). The button operations in the test mode are the same as those of ordinary operation excepting

sound volume UP/DOWN.

(1) The indication is the same as that of ordinary operation excepting test mode setting.

(2) The sound volume control with the sound volume UP/DOWN button is only the following 3 steps unlike the ordinary state.

Volume- ∞ (STEP 0) <-> Volume-14 dB (STEP 23) <-> Volume-0 (STEP 30)

(3) BASS/TREBLE and SURROUND are switched when button operation is performed.

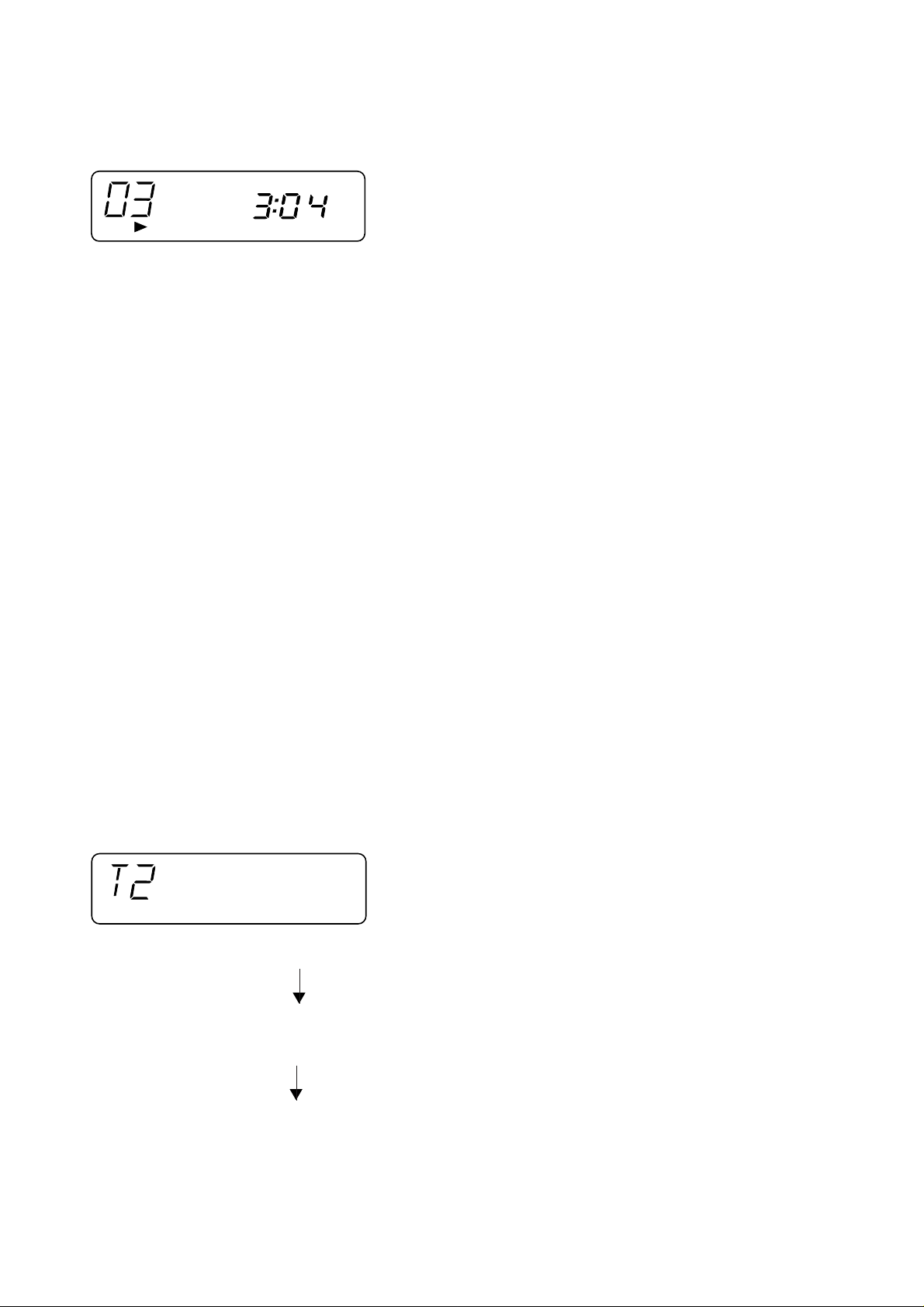

5. Timer test Mode (TEST 4)

When the test mode is set, the following indication lights for one second.

The current time and timer time are set in the following procedure to perform the timer playback.

1.Set the current time to 1:00, set the timer to ON time 1:02, set the function to Tape, and set volume STEP 8. One minute is counted

as one second, and the timer playback operation is performed. The fade-in (when playback is started) is executed at a rate of

one step for 0.5 sec. After completion of fade-in the fade-out is executed at a rate of one step for 0.5 sec (WAIT 1 sec inserted).

After completion of fade-out the power is turned off (after WAIT 1 sec), and the mode is changed to the standby mode.

The indication during operation is the same as that of ordinary timer operation.

6. LCD Test Mode (TEST 5)

When the LCD test mode is set, all the LCD segments are lighted. After that the indication is changed as follows according to

the "PLAY" button input.

Lighting of all segments Lighting of odd segments Lighting of even segments

– 17 –

Page 18

XL-30H/30W

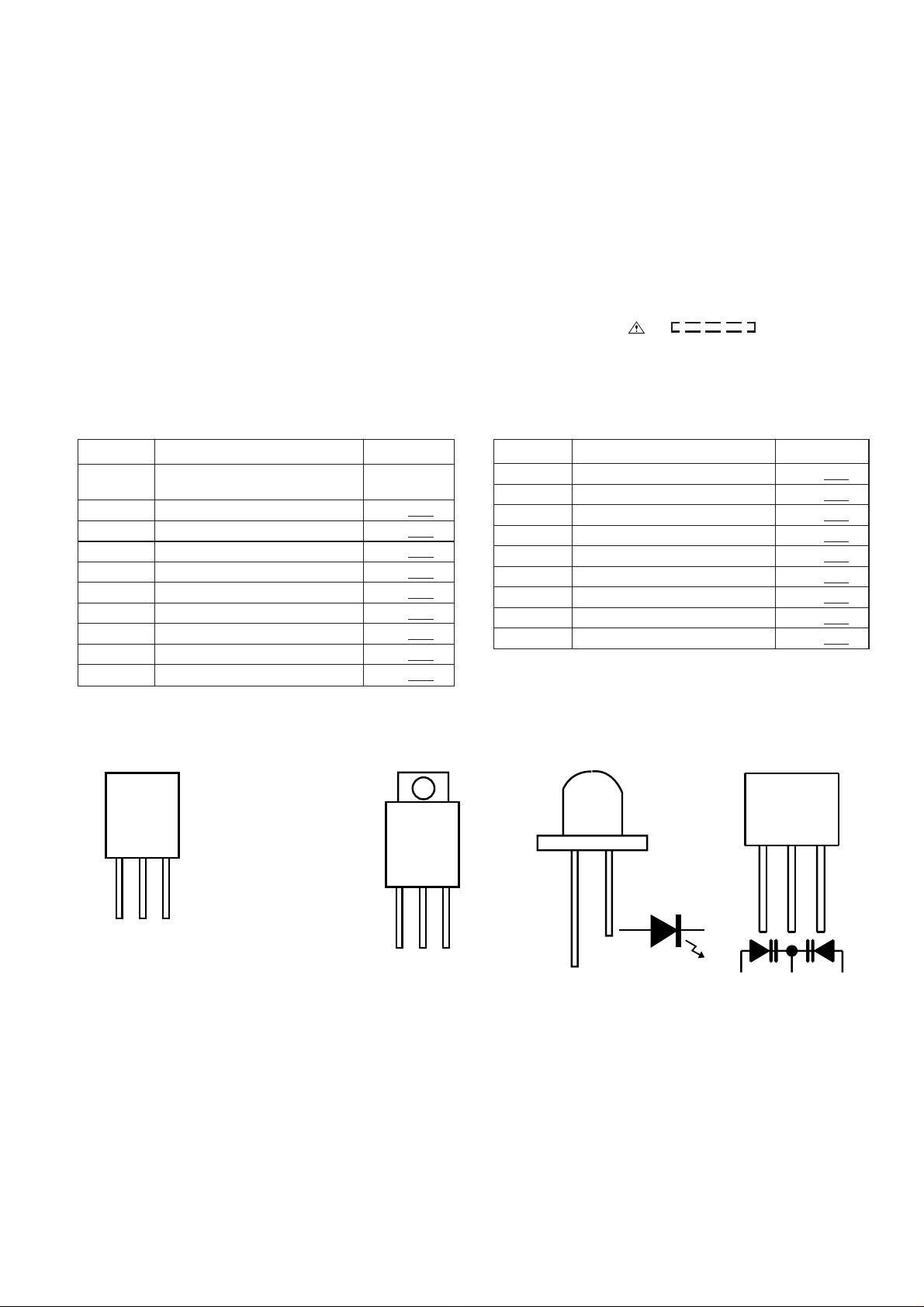

7. Key input diagnosis Test Mode (TEST 6)

When the test mode is set, the following indication appears.

This test mode is intended to check whether all the main unit buttons can be detected. Accordingly, in this test mode checking

as to whether the "POWER" button was pressed after all the buttons shown below were pressed is performed. If the result is

OK, OK is indicated. Even any one of keys was not pressed, an error is indicated. In case of OK termination or error termination

exit from this mode occurs when the "POWER" button is pressed next time, and the standby mode is set.

1. In case of "FF/FWD" + "REC PAUSE"

Since SURROUND and RDS are not provided, the following 11 buttons are detected as all buttons.

PLAY, JOG MODE, BAND, BASS/TREBLE, FUNCTION, MEMORY/SET, REC PAUSE, REW, FF, STOP, CLOCK/TIMER/

SLEEP.

The OK/NG indication of test result is as follows.

ERROR LIST

PU-IN SW detection error

Tape mechanism error 1

Error content ............The detection SW cannot detect ON

after a fixed period of time even if the

microcomputer controls the CD pickup

to return to the innermost position.

Probable cause........Defective or poorly connected PU-IN

SW or slide motor.

Action .......................Solve the problem and turn on the power

again.

CD read error

Error content ........... Disc data cannot be read properly or

even if it can be read, the disc is not a

playable one.

Probable cause....... The disc is loaded upside down, not CD-

DA, scratches, stains, etc.

Action ...................... Open the CD lid, then reload the disc

correctly. Remove the scratches or stains

on the disc.

NO DISC

Error content ........... Focusing is impossible.

Probable cause....... The disc is loaded upside down, not CD-

DA, scratches, stains, etc.

Action ...................... Open the CD lid, then reload the disc

correctly. Remove the scratches or stains

on the disc.

Error content ........... The detection SW "CAM-SW" cannot

detect ON (mechanism in operation) even

if the motor and solenoid are controlled

to play back, fast forward, rewind, or

record the tape.

Probable cause ....... Mechanism is in operation when this

message appears: Defective or poorly

connected CAM-SW. Mechanism stops:

Defective or poorly connected motor or

solenoid.

Action ...................... Solve the problem and turn on the power

again.

Tape mechanism error 2

Error content ........... Initialization cannot be completed when

the microcomputer controls the motor

and solenoid to initialize the tape

mechanism (to set the mechanism to the

stop mode). The detection SW "CAMSW" cannot detect OFF While the

mechanism is in operation.

Probable cause ....... Mechanism is in operation when this

message appears: Defective or poorly

connected CAM-SW. Mechanism stops:

Defective or poorly connected motor or

solenoid.

Action ...................... Solve the problem and turn on the power

again.

– 18 –

Page 19

NOTES ON SCHEMA TIC DIAGRAM

ECB

(1) (2) (3)

FRONT

VIEW

FRONT

VIEW

BCE

FRONT

VIEW

2SB562 C

2SC2001 K

2SC535 C

2SD468 C

KRA102 M

KRC102 M

KRC104 M

KRC107 M

KTA1266 GR

KTC3199 GR

2SD2012 Y

MPG3372X

HY2043

SVC348S

KDV147B

1 2 3

XL-30H/30W

• Resistor:

To differentiate the units of resistors, such symbol as K and

M are used: the symbol K means 1000 ohm and the symbol

M means 1000 kohm and the resistor without any symbol is

ohm-type resistor. Besides, the one with “Fusible” is a fuse

type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means micro-micro-farad and the unit of the

capacitor without such a symbol is microfarad. As to

electrolytic capacitor, the expression “capacitance/withstand

voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board for this

model are subject to change for improvement without prior

notice.

REF. NO

SW651 VOLTAGE SELECTOR 220-240V

(XL-30W Only)

NSW801 PICKUP IN ON—OFF

SW700 JOG ON—OFF

SW709 ON/STAND-BY ON—OFF

SW710 CLOCK/TIMER/SLEEP ON—OFF

SW711 TUNING UP ON—OFF

SW712 PLAY/CD PAUSE ON—OFF

SW713 VOLUME SELECT ON—OFF

SW721 MEMORY/SET ON—OFF

SW722 BASS/TREBLE ON—OFF

DESCRIPTION

POSITION POSITIONREF. NO

• The indicated voltage in each section is the one measured

by Digital Multimeter between such a section and the chassis with no signal given.

1. In the tuner section,

( ) indicates AM

< > indicates FM stereo

2. In the main section, a tape is being played back.

3. In the deck section, a tape is being played back.

( ) indicates the record state.

4. In the power section, a tape is being played back.

5. In the CD section, the CD is stopped.

• Parts marked with “ ” ( ) are important for

maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and

performance of the set.

DESCRIPTION

SW723 BAND ON—OFF

SW724 REC. PAUSE ON—OFF

SW725 STOP/CLEAR ON—OFF

SW726 TUNING DOWN ON—OFF

SW727 FUNCTION ON—OFF

SW728 VOLUME JOG ON—OFF

SW801 OPEN/CLOSE ON—OFF

SW901 FOOL PROOF ON—OFF

SW902 CAM ON—OFF

Figure 19 TYPES OF TRANSISTOR AND LED

– 19 –

Page 20

XL-30H/30W

ANTENNA

TERMINALS

FOR XL-30W

SO301

FM ANTENNA

TERMINALS

XL-30W

ONLY

ANTENNA

TERMINALS

BF301

BAND

PASS

FILTER

CNP301

AM

1

2

CNP301

1

AM/FM

2

3

FOR XL-30H

FM RF

VT

L302

VD303

FM FRONT END

TA7358AP

IC301

L341

BALUN

T306

AM OSC.

78654323211

T302

AM ANT

FM IF FM IF

CF303 T304

FM OSC

VT

L303

VD302

9

VD301-1

SVC348S

VD301-2

SVC348S

Q305

FM IF AMP.

Q306

FM MUTE LEVEL

VR351

10K(B)

AM OSC OUT

24

AM OSC OUT

FM IF IN

10.7MHz

CF302

3

1

FM IF

VT

D_GND

X352

4.5MHz

21

22

23

FM AFC

AM RF IN

AM OSC IN AM MIX OUT

FM IF DET./FM MPX./AM IF

LA1832

REG

AM IF

T351

AM MIX OUT

TP301

21

22

20

VSS

AOUT

IC302

X OUT

LC72131

X IN

NC

1 2 3 4

20

VSM

IC303

AM IF IN

4 3 2 1

5

AM IF IN

3

1

CF352

2

19

AIN

PLL CONTROLLER

CE

GND

DI

19

AM LOW CUT

SD

6

18

PD

CL

6

5

18

FM/AM OUT

7

CF351

FM IF

17

VDD

DO

STEREO

16

FM IN

FM

7

FM DET

8

MUTE

8

X351

456kHz

MPX IN

IF OUT

11

PHASE

15

R-CH OUT

14

16

17

MPX VCO

VCC

9

10

+5V

12

14

13

15

NC

SW

IF IN

AM IN

MO/ST

FM

IF REQ

9

10

11

13

MO/ST

L-CH OUT

PHASE

(AM/FM)

12

SWITCHING

+5V

FM RIPPLE

Q351

ZD351

MTZJ5.1B

A_GND

FM+B

FILTER

R_MUTE

A_12V

R-MUTE

Q360

A_12V

RECORD/

PLAYBACK

HEAD

L-CH

R-CH

ERASE

HEAD

M901

TAPE MOTOR

M

SOL901

SOLENOID

IC101

HEAD SELECTOR

BA3126N

BIAS OSC

Q151

L151

Q172

SWITCHING

7

6

5

4

3

2

1

CNS901

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

P.F

CAM SW

REC SW

P/B SW

CONT

IC101

P/B SW

REC SW

REC

SWITCHING

L-CH

CNP101

CNS101

L-CH

1

1

L-CH

2

2

A-GND

3

3

A-GND

4

4

R-CH

5

5

R-CH

6

6

ERASE

7

7

A-GND

8

8

PH901

PHOTE INTERRUPTER

CFW901

1

+

-

1

2

2

SW901

FOOL

PROOF

SW902

CAM

A-12V

Q171

SWITCHING

L-CH

R-CH

R-CH

CNP901

Q152

Q153

SOLENOID

DRIVER

M_GND

Q101-Q104

SWITCHING

A_12V

SWITCHING

REC BIAS

CONT

Q903

SWITCHING

Q902

SWITCHING

L-IN

IC102

REC./P.B.

EQUALIZER

AMP.

Q901

5

9

R-IN

RUN PLS

SOL

M_12V

TAPE MOTOR

Q905

DRIVER

NF

3

11

NF

SWITCHING

150K

+

MUTE ALC

+

-

150K

6

Q906

Q904

SWITCHING

L-OUT

IC102

BA3311L

7

U_CON5V

1

12

MOT

CNP703

10

R-OUT

8

2

ALC

A_12V

BIAS

B-CAN(NC)

1 2 3 4

REC MUTE

Q105

Q106

RUN_PLS

REC

MOT

SOL

U_CON 5V

6

5

7

TO DISPLAY PWB

D-GND

M_12V

8

9

A_12V

10

REC

TAPE SW

11

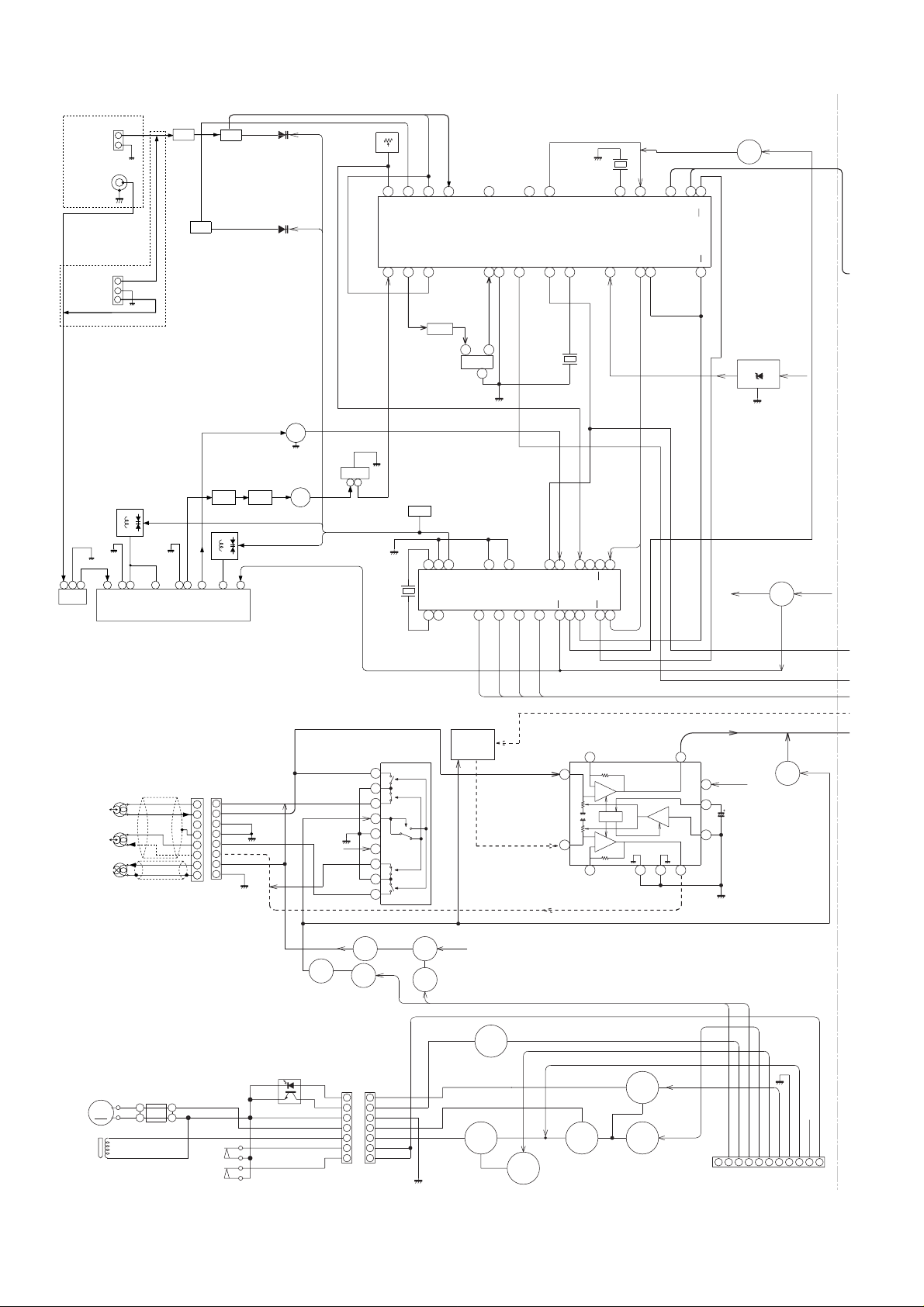

Figure 20 BLOCK DIAGRAM (1/4)

– 20 –

Page 21

XL-30H/30W

_

SD

9

FM ST

8

DO

7

CL

CD+B

P MUTE

P-STB

CE

DI

6

TO DISPLAY

5

PWB

4

3

2

1

CNS704

CD_6R2V

MECHA 12V

(M_12V)

AUDIO 12V

(A_12V)

MECH 12V

AUDIO 12V

(M 12V)

(A 12V)

MUTE

Q607

VOLTAGE

REGULATOR

Q605

Q604

VOLTAGE

REGULATOR

Q605

VOLTAGE

REGULATOR

Q604

Q601

Q602

Q606

Q608

CD+B

Q603

TE

12V

UTE

A_12V

STEREO

SD

REC L/R CH

TAPE L/R CH

5

6

REC

Q603

Q609

TAPE R

TUN R

CD R

CD L

TUN L

TAPE L

L-IN

R-IN

NF

F653

T1A L 250V

F653

T1A L 250V

FROM

DISPLAY

PWB

15

16

10

8

5

9

6

P-CONT

GND

LC75342M

7

CNP681

3

2

1

14

IC401

17

IC601

LA4600

POWER

AMP.

DISPLAY

3

22

1

REC R CH

11

13 12

10

FUNCTION/VOLUME EQUALIZER

19

20

REC L CH

L-CH OUT

1

R-CH OUT

3

21

18

2

VCC

4

CNS652

CNP652

1

1

2

2

GND

VOLTAGE REGULATOR

CNP681

USWD_5R6V

3

FROM

PWB

2

1

P_CONT

D_GND

FOR XL-30H

D651~D654

GND

Q683

3

VOLTAGE REGULATOR

Q682

2

CNP652

CNS652

3

1

9

22

D651~D654

Q683

D681~D684

1

8

23

R-CH OUT

7

24

Q682

Q681

6

25

L-CH OUT

T2.5A L 250V

5

26

L-CH

F651

T2.5A L 250V

Q681

SUB POWER

TRANSFORMER

F651

NC

28

A_12V

L-CH

RLY681

CE

VSS

LOGIC

VDD

29

+

SO601

SPEAKER

TERMINALS

+

J601

HEADPHONES

T651

MAIN POWER

TRANSFORMER

RLY681

T651

MAIN POWER

TRANSFORMER

4 3 2 1

27

T681

DI

30

CL

T.F

SO651

AC POWER

INPUT SOCKET

AC230V,50Hz

T.F

LF651

LINE

FILTER

220-240V

110-127V

SW651

VOLTAGE

SELECTOR

B

M_12V

9

10

A_12V

11

TAPE SW

1 2 3

6

D_GND

M_12V

CD_6R2V

CD R

M-GND

A-GND

CD L

4

5

TO CD SERVO PWB

7

CNP605

D681~D684

FOR XL-30W

Figure 21 BLOCK DIAGRAM (2/4)

– 21 –

T681

SUB POWER

TRANSFORMER

SO651

AC POWER INPUT SOCKET

AC110-127/220-240V,

50/60Hz

Page 22

XL-30H/30W

G

G

W

VCC

VCC

1

M_12V

SWITCHING

RESET

SWITCHING

Q708

Q701

1

2

2

1

D_GND

SWITCHING

Q707

Q706

D704-709

LED

CFW701

SWITCHING

Q709

Q702

Q703

A_12V

LED+B

D_GND

RX701

REMOTE

SENSOR

2

3

1

SW700

JOG

LCD701 LCD DISPLAY

5

24

93

94

SEG7

SEG6

IC701

CLOCK

RESET

33

32

92

91

SEG8

RUN_PLS

34

35

~

90

SEG9

BIAS

36

89

SEG10

B_CAN

37

88

SEG12

SEG11

POWER

SYS STOP

38

87

86

SEG13

REMOCON

39

40

85

SEG14

CLE

41

NC

84

SEG16

SEG15

JOG UP

JOG DOWN

42

83

43

82

SEG17

SURR

44

NC

81

SEG18

P_STB

45

80

SEG20

SEG19

P_MUTE

CD+B

46

79

78

SEG21

CLID_DW

CLID_UP

MVOL_DW

MVOL_UP

MVOL_IND

P_CONT

48

47

77

SEG22

SEG27

SEG28

SEG29

SEG30

SEG31

SEG32

SEG33

CCE

BUCK

BUS3

BUS2

BUS1

BUS0

CD_STB

CD_RES

PU_IN

BACK

LIGHT

DATA

49

NC

STEREO

76

SEG23

50

SD

75

74

SEG24

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

SE

SE

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

~

1 4

NC

NC

NCNCNCNCNC

100

99

98

97

95

COM3

1

COM2

2

3

4

5

6

7

8

9

X701

8MHz

X702

32.768kHz

SW709-SW710

KEY

SW711-SW713

SW721-SW728

CNS706

UP

1

CNP706

1

2

2

3

3

C

A

DOWN

B

10

11

12

13

14

15

16

17

18

19

CLID_PRO

NC

20

NC

NC

21

TAPE_SW

22

VSM

NC

23

VREF+

24

25

DI

96

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

COM1

COM0

VLC3

VLC2

VLC1

VDD

OSC2

OSC1

VSS

XI

XO

MMOD

VREF

CLID_SW

KEY1

KEY2

MODEL

DO

26

27

IX0027SJ

SYSTEM CONTROL

MICROCOMPUTER

CE

SOL

MOT

REC

CL

28

29

31

30

D_GND

U-COM VDD

U-CON+5V

SYS STOP

REMOCON

RESET

P CONT

3

TO

POWER

2

PWB

1

CNS707

+5V

DVSR

RO

DVDD

DVR

LO

DVSL

TEST1

TEST2

A_GND

TEST3

BUS0

BUS1

BUS2

BUS3

VDD

VSS

BUCK

/CCE

TEST4

/TSMOD

/RST

X801

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

+5V

16.93MHz

7879

XO

XVDD

TEST0

/HSO

2 3 4

1

77

XI

/UHSO

76

XVSS

EMPH

5

75

VDD

LRCK

6

PXO

VSS

74

7

SW801

OPEN/CLOSE

D_GND

73

72

71

70

PXI

VSS

TESIN

/DACT

TESI01

SERVO/SIGNAL

BCK

AOUT

DOUT

MBOV

IPF

8

11 12

9

10

CFW807

1

2

68

69

66

65

67

IO3

IO2

/CKSE

/DMOUT

IC802

TC9462F

CONTROL

SBOK

CLCK

VDD

VSS

15

13

16

14

64

IO1

DATA

17

IO0

SFSY

63

18

1

2

M_GND

62

VSS

VDD

SBSY

SPCK

19

M_GND

+5V

Q861

CD_6R2V

15

REG

REG.

14

REGINOUT

FMO

10

12

13

8

11

9

+

-

+

DMO

CD STB

SP+

SP-

234

6

5

7

- +

MUTE

-

+

SL-

SL+

IC804

CD

18

19

17

TRO

TA2109F

SBAD

FEO

FEN

VRO

RFRP

RFIS

RFGO

RFGC

AGCI

RFO

GND

RFN

LA6541D

+

-

+--

21

20

TR+

TR-

IC801

2VRO

22

M_GND

TEO

TEN

TEB

SEL

LDO

MDI

TN1

TPI

FPI

FNI

VCC

+

-

+

26

+ -

FO+

-

28

29

3

27

FOO

S

24

23

25

FO-

TEI

12

11

10

TEBC

9

SEL

8

7

6

E

5

F

4

B

3

A

2

1

CD +5V

IC804

LA6541D

FOCUS/

TRACKING/

RESET

RES

16

SPIN/SLED

DRIVER

54

51

56

25

55

DMO

2VREF

P2VREF

HSSW

26

52

53

FVO

ZDET

28

27

FMO

PDO

29

TEBC

TMAXS

30

50

RFGC

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

TMAX

VREF

TRO

FOO

TEZI

TEI

TSIN

SBAD

FEI

RFRP

RFZI

RFCT

AVDD

RFI

SLCO

AVSS

VCOF

VCOREF

PVREF

LPFO

LPFN

+5V

D_GND

SERVO PRE AMP.

SBAD

13

FEI

14

15

16

RFRP

17

18

RFI

19

RFGC

20

21

22

23

24

D_GND

60

59

61

57

58

SEL

FLGB

FLGA

FLGD

FLGC

SPDA

COFS

MONIT

VDD

TESI00

22

21

23

20

24

D_GND

+5V

Figure 22 BLOCK DIAGRAM (3/4)

– 22 –

Page 23

XL-30H/30W

LCD DISPLAY

5

24

~

NCNCNC

92

89

SEG8

91

SEG9

90

SEG10

88

SEG11

93

94

95

96

SEG7

SEG6

SEG5

SEG4

IC701

IX0027SJ

STEM CONTROL

ROCOMPUTER

CLOCK

MOT

REC

RESET

33

31

30

32

RUN_PLS

34

POWER

BIAS

B_CAN

38

36

37

35

87

86

SEG13

SEG12

REMOCON

SYS STOP

39

40

85

SEG14

CLE

41

NC

84

SEG16

SEG15

JOG UP

JOG DOWN

42

83

43

82

SEG17

SURR

44

NC

81

SEG18

P_STB

45

80

SEG20

SEG19

P_MUTE

CD+B

46

79

78

SEG21

CLID_DW

CLID_UP

MVOL_DW

MVOL_UP

MVOL_IND

P_CONT

48

47

77

SEG22

SEG27

SEG28

SEG29

SEG30

SEG31

SEG32

SEG33

CCE

BUCK

BUS3

BUS2

BUS1

BUS0

CD_STB

CD_RES

PU_IN

BACK

LIGHT

DATA

49

NC

STEREO

76

SEG23

50

SD

75

74

SEG24

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

SEG25

SEG26

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

MVOL_DW

MVOL_UP

M_12V

IC702

TA7291S

LOADING MOTOR DRIVER

1 2 3 4

NC

5

D_GND

6

CNP705

7

2

1

8

2

1

CNS705

9

M701

JOG MOTOR

M

CL ID_SW

CD_RES

CD_STB

TAPE_SW

M_12V

D_GND

U_CON5V

RUN_PLS

B_CAN

SD

STEREO

DO

CE

CD+B

P_MUTE

P_STB

CCE

BUCK

BUS3

BUS2

BUS1

BUS0

PU_IN

A_12V

SOL

MOT

REC

BIAS

CL

DI

CFW704

10

9

8

7

6

5

4

3

2

1

CNS702

11

10

9

8

7

6

5

4

3

2

1

CNP703

9

1

TO CD PWB

TO MAIN PWB

TO MAIN PWB

CD_6R2V

Q861

IC804

LA6541D

FOCUS/

TRACKING/

SPIN/SLED

DRIVER

ND

SL-

FMO

15

1112

14

13

+

REG

REGINOUT

-

REG.

+

LA6541D

+

-

RESET

+--

CD

RES

18

20

19

16

17

TR-

TRO

IC801

TA2109F

SERVO PRE AMP.

SBAD

SBAD

13

FEI

14

FEO

FEN

15

16

VRO

RFRP

17

RFRP

18

RFIS

RFI

19

RFGO

RFGC

20

RFGC

21

AGCI

22

RFO

23

GND

24

RFN

D_GND

SL+

10

21

TR+

2VRO

M_GND

9

IC804

22

M_GND

TEO

TEN

TEB

SEL

LDO

MDI

TN1

TPI

FPI

FNI

VCC

CL ID_SW

CD_6R2V

DMO

SP+

SP-

CD STB

1

6

FO-

26

5

+ -

FO+

234

VCC

MUTE

-

+

+

-

+

-

VCC

28

29

30

27

CD_6R2V

FOO

8

7

- +

24

23

25

CD_RES

CCE

BUCK

BUS3

BUS2

BUS1

BUS0

CD_STB

PU_IN

CNP702

CL ID_L

A_GND

CD_R

M_GND

M_12V

D_GND

CD_6R2V

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

FROM

DISPLAY

PWB

TO

MAIN PWB

CNS605

+

M

+

M

-

TR-

TR+

FO+

FO-

ACTUATOR

1/2VCC

C

F

B

A

E

GND

MON

LD

VCC

NM802

SPINDLE

MOTOR

NM801

SLED

MOTOR

NSW801

PICKUP IN

12

11

10

9

8

7

6

5

4

3

2

1

TEI

TEBC

SEL

E

F

B

A

CD +5V

SWITCHING

Q801

+5V

TRTR+

FO+

FO-

D-GND

VR

LD

VREF

+5V

SP+

6

SP-

5

SL+

4

SL-

3

PU-IN

2

M_GND

1

CNS803

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

PICKUP UNIT

TR-

1

TR+

2