Page 1

TopPage

MODEL SELECTION CODE DESTINATION

UX-B800

A

Australia

UX-B800A

SERVICE MANUAL

No. 00ZUXB800ASME

FACSIMILE

CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

[1] Caution........................................................... 1-1

[2] Specifications ................................................. 1-2

[3] Operation panel.............................................. 1-3

[4] Transmittable documents ............................... 1-5

[5] Installation ...................................................... 1-6

[6] Scan to E-mail.............................................. 1-10

[7] Clearing paper jams..................................... 1-12

[8] Quick reference guide .................................. 1-13

CHAPTER 2. ADJUSTMENTS

[1] Adjustments ................................................... 2-1

[2] Diagnostics and service soft switch ............... 2-2

[3] Troubleshooting ........................................... 2-40

[4] Error code table............................................ 2-41

CHAPTER 3. MECHANISM BLOCKS

[1] General description ........................................ 3-1

[2] Ink jet printer .................................................. 3-3

[3] Disassembly and assembly procedures......... 3-5

CHAPTER 4. DIAGRAMS

[1] Block diagram ................................................ 4-1

[2] Wiring diagram ............................................... 4-2

[3] Point-to-point diagram.................................... 4-3

MODEL

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Circuit description ..........................................5-1

[2] Circuit description of control PWB ................5-2

[3] Circuit description of LIU PWB ....................5-13

[4] Circuit description of power supply PWB...... 5-15

[5] Circuit description of CIS unit ......................5-15

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] Control PWB circuit .......................................6-1

[2] LIU PWB circuit ...........................................6-14

[3] Power Supply PWB circuit...........................6-19

[4] Operation Panel PWB circuit .......................6-21

CHAPTER 7. OTHER

[1] Protocol .........................................................7-1

[2] Power on sequence.......................................7-2

[3] Service tools ..................................................7-3

[4] Rewriting version up the FLASH ROM ..........7-6

Parts Guide

UX-B800A

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

UX-B800A

UX-B800A

CHAPTER 1. GENERAL DESCRIPTION

[1] Caution

1. Caution for Battery replacement

Service Manual

(Danish) ADVARSEL !

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the equipment manufacturer.

Discard used batteries according to manufacturer's instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

2. Precautions for using Lead-Free Solder

1. Employing lead-free solder

The Control PWB, LIU PWB, Power Supply PWB and Operation Panel PWB of this model employs lead-free solder.

This is indicated by the "LF" symbol printed on the PWB and in the service manual.

The suffix letter indicates the alloy type of the solder.

Example:

(French) ATTENTION

Il y a danger d'explosion s' il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d'un type recommandé par le constructeur.

Mettre au rébut les batteries usagées conformément aux

instructions du fabricant.

(Swedish) VARNING

Explosionsfare vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

(German) Achtung

Explosionsgefahr bei Verwendung inkorrekter Batterien.

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Hersteller angegebenen Anweisungen.

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free solder

When repairing a PWB with the "LF" symbol, only lead-free solder should be used. (Using normal tin/lead alloy solder may

result in cold soldered joints and damage to printed patterns.)

As the melting point of lead-free solder is approximately 40°C higher than tin/lead alloy solder, it is recommended that a

dedicated bit is used, and that the iron temperature is adjusted accordingly.

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is higher and has poorer melting point (flow), to prevent damage to the

land of the PWB, extreme care should be taken not to leave the bit in contact with the PWB for an extended period of time.

Remove the bit as soon as a good flow is achieved.

The high content of tin in lead free solder will cause premature corrosion of the bit.

To reduce wear on the bit, reduce the temperature or turn off the iron when it is not required.

Leaving different types of solder on the bit will cause contamination of the different alloys, which will alter their

characteristics, making good soldering more difficult.

It will be necessary to clean and replace bits more often when using lead-free solder. To reduce bit wear, care should be

taken to clean the bit thoroughly after each use.

1 – 1

Page 3

[2] Specifications

UX-B800A

Print cartridge yield

1, 2

:

Replacement cartridge: SHARP UX-C80B

Ink Save mode ON: Approx. 800 A4 pages

Ink Save mode OFF: Approx. 480 A4 pages

(The initial cartridge has the same yield as the above replacement cartridge.)

Paper tray capacity:

Approx. 200 A4 sheets (60 to 80 g/cm

2

) (At room temperature; maximum stack height should not be

higher than the line on the tray)

Recording system: Thermal inkjet

Print resolution: 600 x 600 dpi

Effective printing width: 203 mm max.

Scan to E-mail: Yes; requires an Internet connection and a router, switch, or hub to connect the machine. LAN cable

(10Base-T straight-through cable) must be purchased separately.

LAN interface: 10Base-T IEEE802.3

File formats: Tiff (G4), PDF (G4)

Memory capacity

2

:

Approx. 100 average pages

Modem speed: 14,400 bps with auto fallback to lower speeds.

Transmission time

2

:

Approx. 6 seconds

Compatibility: ITU-T (CCITT) G3 mode

Compression scheme: MR, MH, MMR

Storable transmission destinations: Rapid Keys: 36 A, B, C keys: 3(e-mail only)

Speed Dial numbers: 63

Telephone function: Yes (cannot be used if power fails)

Effective scanning width: 208 mm max.

Applicable telephone line: Public switched telephone network

Reception modes: AUTO, MANUAL, TEL/FAX

Automatic document feeder:

A4: 20 sheets max. (60 - 80 g/cm

2

. paper; temperature: 18 - 28°C; humidity: 45 - 65% RH)

Input document size: Automatic feeding:

Width: 148 to 210 mm

Length: 140 to 297 mm

Manual feeding:

Width: 70 to 210 mm

Length: 140 to 356 mm

Scanning Resolution: Standard: 203 x 98 dpi

Fine: 203 x 196 dpi

Super fine: 203 x 391 dpi

Halftone: 203 x 196 dpi

Halftone (grayscale): 64 levels

Contrast control: Automatic/Dark selectable

Copy function: Single/Multi/Sort (99 copies/page)

Display: LCD display, 20 digits x 2 lines

Power requirements: 230-240 V AC, 50 Hz

Power consumption: Standby: 6.0 W, Maximum: 40 W

Operating temperature: 15 - 32°C

Humidity: 25 - 80% RH

Dimensions (without attachments): Width: 380 mm

Depth: 280 mm

Height: 156 mm

Weight (without attachments): Approx. 4.5 kg

1

lnk Save mode is initially turned off. To turn on Ink Save mode.

2

Based on Sharp Standard Chart at standard resolution, excluding time for protocol signals (i.e., ITU-T phase C time only).

As a part of our policy of continuous improvement, SHARP reserves the right to make design and specification changes for product improvement

without prior notice. The performance specification figures indicated are nominal values of production units. There may be some deviations from

these values in individual units.

1 – 2

Page 4

UX-B800A

[3] Operation panel

PQRS

1

JKLGHI

TUV

DEFABC

MNO

WXYZ

2

01 02 03 04 05 06 07 08 09 10 11

12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 27 28 29 30 31

32 35 36

33/G1

9

Note: Affix the Rapid Key labels as shown above.

34/G2

3

DEL

B'CAST

1110

45

SECURE

DUPLEX

12

13

14 15

FUNCTION

RESOLUTION/

RECEPTION MODE

SPEED DIAL

HOLD

SPEAKER

16

76

8

COPY/HELP STOP

UP

ZA

REDIAL

DOWN

17

18

1. Number key: Use to dial numbers.

2. SCAN TO E-MAIL key: Press to send a document

to

an e-mail recipient.

3. Display:

you operate the machine.

This displays messages to help

4. A, B, C keys: An e-mail address can be stored in

each

key for one-touch selection.

5. RESOLUTION/RECEPTION key:

is in the feeder, press to adjust the scanning resolution.

At any other time, press to select the reception mode.

When a document

6. FUNCTION key: Press this key followed by the arrow

keys to select special functions and settings.

7. COPY/HELP key: When a document is in the feeder,

press to make a copy. At any other time, press to print the

Help List.

8. STOP key: Press to cancel an operation before it is

completed.

9. Group keys: Multiple fax or e-mail destinations can be

stored in each key for one-touch selection.

10. Rapid keys/Letter keys: A fax number or e-mail address

can be stored in each of these keys for one-touch selection

(attach the Rapid Key labels). When entering text, the keys

are used as letter keys.

11. BROADCAST key: Press to send to multiple fax or e-mail

destinations.

12. SECURE key: Press to use the fax secure receive function.

13. DUPLEX key: Use to scan two-sided documents

for transmission and copying.

14. SPEED DIAL key: Press to select a fax or e-mail

destination stored in a 2-digit Speed Dial number.

15. HOLD key: Press to put a phone call on hold.

16. SPEAKER key: Press to listen to the line and fax tones

through the speaker when faxing.

Note: This is not a speakerphone. It cannot be used for

speaking.

17. START/MEMORY key: Press after dialing to send a fax.

Press before dialing to send a fax through memory. Press in

the date and time display to show the percentage of memory

currently used.

18. Arrow key: Use to scroll through and select settings, and

to search for stored destinations.

1 – 3

Page 5

Letter keys

Use these keys when the display prompts you to enter

a name, e-mail address, or other text.

14 523

DEL

6

B'CAST

SECURE

UX-B800A

DUPLEX

1. SYMBOL key: Press to enter a symbol (the character

appearing on the right side of each letter key). Press again

to return to normal letter entry mode.

6. DEL key: Press to delete the character marked by the

2. Caps Lock key: Press to enter upper case letters.

Press again to return to lower case letter entry.

3. SHIFT key: Hold down to temporarily change case.

4. Letter keys: Use to enter letters.

5. @ key, .com key: Press to enter "@" and ".com" when

entering an e-mail address.

Monitoring phone conversations

When speaking through the handset, you can press to allow a third

person to listen to the conversation through the speaker. (To turn off the

speaker, press the key again.)

To adjust the volume of the speaker when monitoring a conversation, press

or (the volume reverts to the lowest setting each time the handset

is replaced).

Note that the speaker cannot be used for speaking; it is only for listening.

To avoid feedback (a loud howling sound), be sure to turn off the speaker

SPEAKER

(press once again) before you replace the handset.

SPEAKER

cursor. When the cursor is to the right of a line of text, press

to backspace and clear characters. (The cursor can be moved

by pressing or .) To delete all entered characters, hold

down until all characters are cleared.

1 – 4

Page 6

UX-B800A

h

[4] Transmittable documents

1. Document Sizes

Normal size Width 148 - 210 mm

Length 140 - 297 mm

(Max.)

(Max.)

(Min.)

140mm

70mm

[Special size]

Use document carrier sheet for smaller documents.

• With special sizes, only one sheet can be fed into the machine at a

time. Insert next page into feeder as current page is being scanned.

A4 size

210mm

[Normal size]

297mm

210mm

[Special size]

2. Paper Thickness & Weight

356mm

5. Automatic Document Feeder Capacity

Number of pages that can be placed into the feeder at as follows:

Normal size: max. ADF 20 pages

• Temperature: 18 ~ 28°C

• Humidity: 45 ~ 65%

Special size: single sheet only (manual feed)

NOTE

• When you need to send or copy more pages than the feeder

limit, place additional pages in feeder when last page in feeder is

being scanned.

• Place additional pages carefully and gently in feeder. If force is

used, double-feeding or a document jam may result.

6. Readable Width & Length

The readable width and length of a document are slightly smaller than

the actual document size.

Note that characters or graphics outside the effective document scanning range will not be read.

• Readable width

208mm, max

10 sheets 1 sheet (Manual)

Paper weight 20 lbs.

(74.3 g/m

at the environment

23 ± 5°C

55 ± 10%

Paper thickness (ref.) 0.09 mm 0.06 mm ~ 0.18mm

Paper size A4 (210 mm x 297 mm)

Feeder capacity A4: 10 sheets max.

2)

14 lbs. ~ 42 lbs.

2

(52 g/m

~ 157g/m2)

3. Document Types

• Normal paper

Documents handwritten in pencil (No. 2 lead or softer), fountain

pen, ball-point pen, or felt-tipped pen can be transmitted.

Documents of normal contrast duplicated by a copying machine

can also be transmitted.

• Diazo copy (blue print)

• Diazo copy documents of a normal contrast may be transmitted.

• Carbon copy

A carbon copy may be transmitted if its contrast is normal.

4. Cautions on Transmitting Documents

• Documents written in yellow, greenish yellow, or light blue ink cannot be transmitted.

• Ink, glue, and correcting fluid on documents must be dry before the

documents can be transmitted.

• All clips, staples and pins must be removed from documents before

transmission.

• Patched (taped) documents should be copied first on a copier and

then the copies used for transmission.

• All documents should be fanned before insertion into the feeder to

prevent possible double feeds.

Readable widt

• Readable length

This is the length of the document sent minus 4mm from the top

and bottom edges.

4mm

Readable length

4mm

1 – 5

Page 7

[5] Installation

Attach the document exit tray and

flip out the extension.

Pull the received document tray extension

all the way out.

1. Site selection

Take the following points into consideration when selecting a site for

this model.

ENVIRONMENT

• The machine must be installed on a level surface.

• Keep the machine away from air conditioners, heaters, direct sunlight, and dust.

• Provide easy access to the front, back, and sides of the machine.

In particular, keep the area in front of the machine clear, or the original document may jam as it comes out after scanning.

• The temperature should be between 15 - 32°C.

• The humidity should be between 25% and 80% (without condensation).

ELECTRICITY

AC 230-240 V, 50 Hz, earthed AC outlet is required.

Caution!

• Connection to a power source other than that specified will cause

damage to the equipment and is not covered under the warranty.

• If your area experiences a high incidence of lightning or power

surges, we recommend that you install a surge protector for the

power and telephone lines. Surge protectors can be purchased at

most telephone specialty stores.

If the machine is moved from a cold to a warm place...

Condensation may form on the reading glass if machine is moved from

a cold to a warm place, this will prevent proper scanning of documents

for transmission. Turn on the power and wait approximately 2 hours

before using machine.

TELEPHONE JACK

A standard telephone jack must be located near the machine. This is

the telephone jack commonly used in most homes and offices.

• Plugging the fax machine into a jack which is not a standard analog

telephone jack, may result in damage to the machine or your telephone system.

UX-B800A

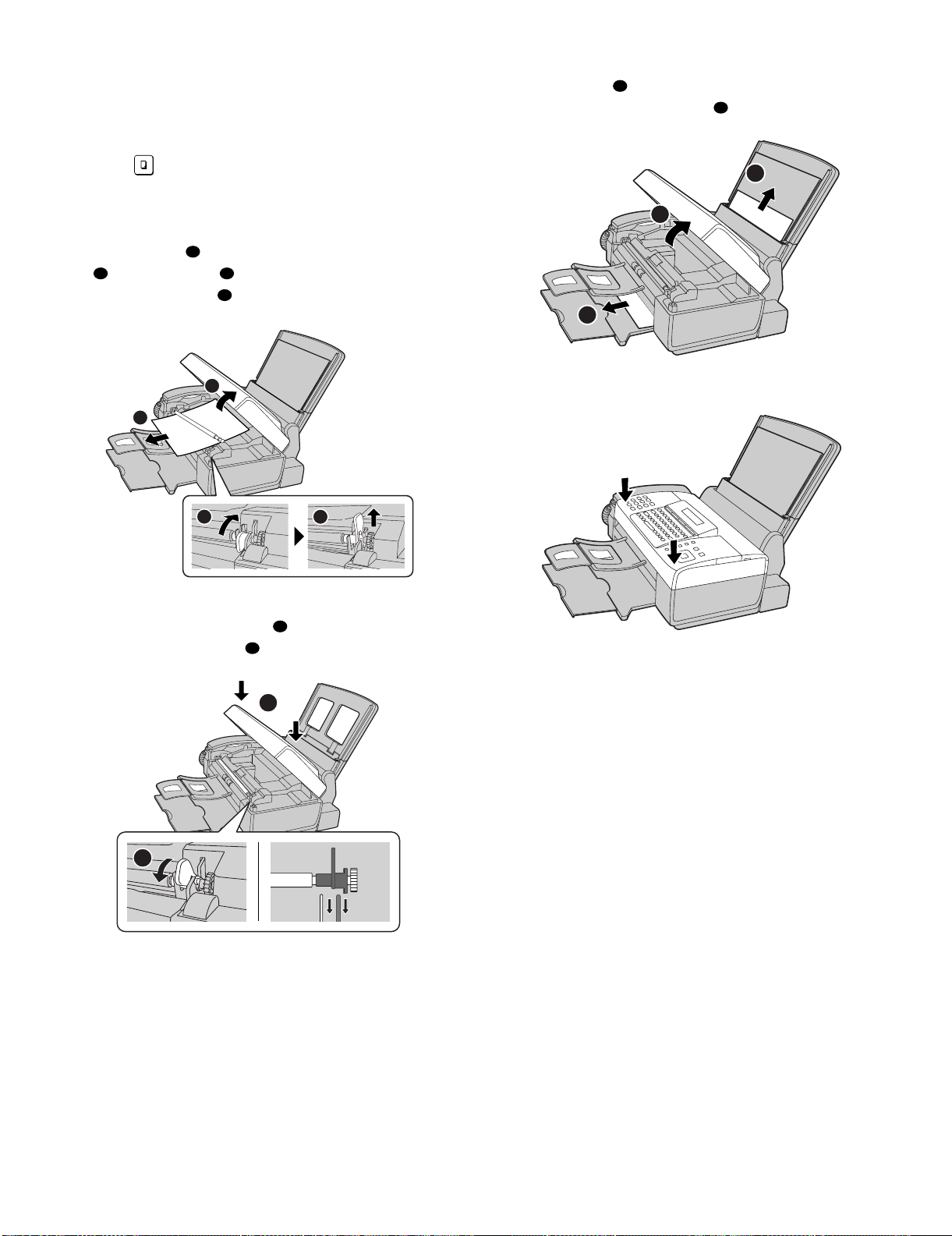

2) Close the cover.

3. Connect the handset

4. Attaching the tray

1) Attach the received document tray

2. Removing the packing tape

1) Open the cover ( ) and remove the tape ( ). (Do not install

the print cartridge yet.)

1 2

2

2) Attach the paper tray

1

1 – 6

Page 8

UX-B800A

5. Loading Paper

Approximately 200 sheets of A4-size paper (60 - 80 g/m2) can be

loaded in the paper tray (at room temperature; maximum stack height

should not be higher than the line on the tray).

1) Fan the paper, and then tap the edges against a flat surface to

even the stack.

2) Pull the paper plate forward and insert the stack of paper into the

tray, print side up.

6. Connecting the power cord

Caution! Remove all packing tape before plugging in the power

cord, or machine to the machine may result.

• The power outlet must be installed near the equipment and must be

easily accessible.

Plug the plug adapter into a 230-240 V, 50 Hz, earthed (3-prong) AC

outlet.

The stack must not be

higher than this line.

• If paper remains in the tray, take it out and combine it into a single stack with the new paper.

• Printing on the reverse side of the paper may result in poor print

quality.

• Do not use paper that has already been printed on or is curled.

• Remove received faxes and other printed output before about

50 sheets accumulate in the received document tray (otherwise

the sheets may scatter).

If at any time the display shows [ADD PAPER &] / [PRESS START

KEY], check the paper tray. If the tray is empty, add paper. If there is

paper in the tray, take it out and then reinsert it.

When finished, press .

• The display will show [CHECK CARTRIDGE] until you install the

print cartridge.

When disconnecting the machine, always disconnect the phone line

before you disconnect the power cord. When re-connecting the

machine, always connect the power cord before connecting the

phone line.

It is recommended that you install surge protectors for the power and

telephone lines. Surge protectors can be purchased at most telephone specialty sotres.

7. Installing the print cartridge

Print cartridge yield

SHARP UX-C80B replacement cartridge

Ink Save mode OFF: Approx. 480 A4 pages

Ink Save mode ON: Approx. 800 A4 pages (The initial cartridge has

the same yield as the replacement cartridge.)

• Ink Save mode is initially turned off. To turn on Ink Save mode.

Caution! Do not open the cover while the machine is printing.

Note: Keep ink cartridges sealed in their packages until you are ready

to install them. It is recommended that you do not use a cartridge that

has been left unused for a long time after opening, as the print quality

may be considerably degraded.

• Make sure the machine's power cord is plugged in and paper is

loaded in the paper tray.

1) Open the cover (grasp the finger grip).

If the display shows [PRINTER ERROR] or [PRINTER ERROR/

CHECK PAPER], open the cover and check for jammed paper.

Remove any jammed paper and close the cover.

1 – 7

Page 9

2) Remove only the tape from the new cartridge.

• Make sure all tape is removed.

• CAUTION! DO NOT touch the gold contact area on the cartridge.

UX-B800A

5) Close the cover, pressing firmly on both front corners.

Display: [CHANGE CARTRIDGE]/[1=NEW, 2=OLD].

6) Press (NEW) if the cartridge you installed is new.

Display: [NEW CARTRIDGE?] / [OK:PRESS START]

Press (OLD) if the cartridge you installed is old.

3) Make sure the cartridge holder is in the position shown. Place your

fingers on top of the holder and open the holder release.

• CAUTION! DO NOT touch the gold contact area or pull on the

cable.

• If you are replacing the cartridge, remove the old cartridge. If

you are going to use the old cartridge again, place it in an airtight container (containers for this purpose can be purchased at

most office supply stores).

4) Insert the new print cartridge ( ). Close the holder ( ), making sure it clicks into place.

1

2

2

7) Press .

If you selected "OLD" in the previous step, this completes the

installation procedure. (Note: If you find that print quality is not satisfactory, align the print cartridge.)

If you selected "NEW", the machine will print an alignment page.

Continue with the steps below.

8) In the alignment page, locate the line that is closest to a straight

line.

In this example, "15" is closest to a straight line.

9) Enter the number of the straightest line with the number keys.

• To clear a mistake, press .

1

10)Press .

The machine is initially set to print high quality images, which require

more ink. If you prefer to use less ink and speed up drying time,

change the "INK SAVE MODE" setting to "ON".

1 – 8

Page 10

UX-B800A

8. Connecting the Phone Line

Connect the phone line cord to the TEL. LINE socket and a wall telephone socket (use the provided adapter if needed).

Wall phone socket

TEL.

SET

TEL.

LINE

TEL. LINE

socket

The machine is initially set for tone dialing. If you are on a pulse dial

line, change the "DIAL MODE" setting.

It is recommended that you install surge protectors for the power and

telephone lines. Surge protectors can be purchased at most telephone specialty stores.

1 – 9

Page 11

[6] Scan to E-mail

FUNCTION

STOP

The Scan to E-mail feature lets you scan a document and directly send

the image to an e-mail recipient.

• This saves you the trouble of scanning the document into a computer and sending the scanned file using an e-mail program.

• The scanned document is sent as an attachment to an e-mail message. The attached file can be in TIFF or PDF format.

Requirements

To use Scan to E-mail, you must.

• Have an Internet connection.

• Have a broadband router or LAN switch/hub through which you can

connect the machine to the Internet (the router is usually connected

to a cable modem or DSL modem).

A typical setup is shown below.

UX-B800A

Automatic assignment of IP addresses is normally performed by a

DHCP server, which may be a computer, router, or other device on

the network. (Most routers used on home networks contain a DHCP

server.)

If your network requires that a static (permanent) IP address be

assigned to the machine, see Network Settings to enter the IP address

and related information.

2. Checking your IP address and the connection

To check the machine's IP address and verify that the machine is able

to communicate on the network, follow these steps.

1) Press , then until [NETWORK SETTING] appears.

2) 2 Press , then to show [NETWORK INFORMA-

TION]

Internet

Cable/DSL

modem

LAN cable

LAN ports

(Hub/Switch)

WAN port

Router

LAN cable

LAN cable

LAN cable

Note: The Scan to E-mail function is not compatible with mail servers that require security protection (SSL).

1. Connecting the Machine

The machine is connected using an Ethernet cable (not included).

Please purchase a 10Base-T straight-through (regular) cable that supports 10Base-T.

Connect one end of the cable to the LAN port on the machine.

Connect the other end to a LAN port on your router, switch, or hub.

• If you are uncertain which port to connect the cable to, see the

manual for the router, switch or hub.

• The connections can be made with all devices powered on.

• For other questions about how the machine should be connected,

consult your Internet service provider.

1. IP address

The machine requires an IP address to communicate on the Internet.

If your network is set up to automatically assign IP addresses, you do

not need to do anything; the machine will automatically receive an IP

address when it is connected.

3) 3 Press .

• If the machine has automatically received an IP address and is

able to communicate, [IP ADDRESS/DHCP: ON] will appear on

the top line of the display, followed by the IP address on the bot-

tom line. To show the machine's host name, press .

• If a static IP address has been entered in the machine and the

machine is able to communicate, [IP ADDRESS/DHCP: OFF]

will appear on the top line of the display, followed by the IP

address on the bottom line. To show the machine's host name,

press .

• If the machine was unable to receive an IP address automatically, or if the router locked up after the machine received an IP

address, [IP ADDRESS/DHCP: FAIL] / [192.168. 1 .201] will

appear. "192.168. 1 .201" is an IP address that is assigned to

the machine for diagnostic purposes when connection fails (it

cannot be used for regular communication).

• If [NOW CONNECTING/CHECK LATER] appears, press

to exit. Make sure the cable is connected correctly, wait briefly,

and then repeat the procedure again.

3. If the machine is unable to communicate...

• Check the Ethernet cable. Are the connections secure? Are you

using straight-through (not crossover) cable for 10Base-T?

• There may be a problem in the router or other device to which

the machine is connected. Try removing and then restoring the

power to the router (see the manual for the router).

• If [IP ADDRESS/DHCP: FAIL] appears, remove and then reinsert the Ethernet cable plug, and repeat the procedure to check

the machine’s IP address. If the same message appears, check

the device that acts as the DHCP server on your network (try

removing and restoring the power). If your router is your DHCP

server, make sure that DHCP is enabled in the router settings. If

your network does not have a DHCP server, set a static IP

address as explained.

• If a static IP address has been set, make sure that the network

settings are correct.

1 – 10

Page 12

UX-B800A

Setting Description

SENDER

NAME

Enter the sender name that will appear in the e-mail message

(max. of 50 characters). When finished, press .

SENDER

ADDRESS

Enter your sender e-mail address (max. of 128 characters). When

finished, press . (Note: Be sure to enter your actual e-mail

address. Return e-mail and undelivered mail repor ts will be sent to

this address. In addition, some STMP servers reject outgoing email if a valid sender e-mail address is not entered.)

E-MAIL

SUBJECT

Enter a default subject (max. of 128 characters). When finished,

press .

E-MAIL

MESSAGE

Enter a default message (max. of 256 characters). When finished,

press .

FILE FORMAT This sets the default format of the file that is created when you

scan a document. Press for TIFF or for PDF.

Initial setting: TIFF

SMTP SERVER Enter the host name or IP address of your outgoing (SMTP) mail

server (max. of 60 characters). When finished, press .

2. E-mail Settings

Before the Scan to E-mail function can be used, you must configure

the e-mail settings.

The e-mail settings specify your outgoing mail server, as well as your

sender name, sender address, and other items that appear in the email message to which scanned image files are attached.

• It is easiest to configure the e-mail settings in the machine's Web

page. The machine's Web page can be accessed from any computer on the same network as the machine.

• The e-mail settings can also be configured using the machine's

operation panel.

Note: If your Internet service provider requires that you configure

"SMTP Authentication" or "POP before SMTP" settings, you must use

the Web page.

If you do not know your SMTP server name or the settings that are

required, ask your Internet service provider.

1. Accessing the machine's Web page

To access the Web page, you will need to know the machine's host

name or IP address (usually it is most convenient to use the host

name).

To check the machine's host name or IP address, follow the procedure

in Checking your IP address and the connection, or print the Network

Settings List.

Type in the host name or IP address of the machine in the Address bar

of the Web browser on your computer.

The Web page menu will appear. Select E-mail Setup and configure

the settings. For explanations of the settings, click Help in the Web

page menu.

Note: If the Web page is used while the machine is in operation

(except for voice calls using the handset), machine operation may

become unstable.

3. E-mail settings

Enter the required information for each setting as explained below.

This is done in step 4 of the procedure on the previous page.

• The sender address and SMTP server settings are required. The

other settings are optional.

• Use the letter keys to enter text. For information on using the letter

keys.

• The e-mail subject, e-mail message, and file format that you enter

below are default settings. They will be used if you do not specify

these items at the time of transmission.

2. Using the machine's operation panel to configure the settings

Follow the steps below to display the e-mail settings, and then configure each setting as explained in the table on the next page.

1) Press , then until [E-MAIL SETTING] appears.

FUNCTION

2) Press , then repeatedly until the setting that you

wish to configure appears.

3) Press . (Note: This step is not necessary for the "FILE

FORMAT" setting.)

4) Enter the required information for the setting as explained in the

table on the next page.

5) After configuring the setting, the next e-mail setting will appear in

the display. You can configure the next setting, or press to

exit.

STOP

1 – 11

Page 13

[7] Clearing paper jams

2

1

2

UX-B800A

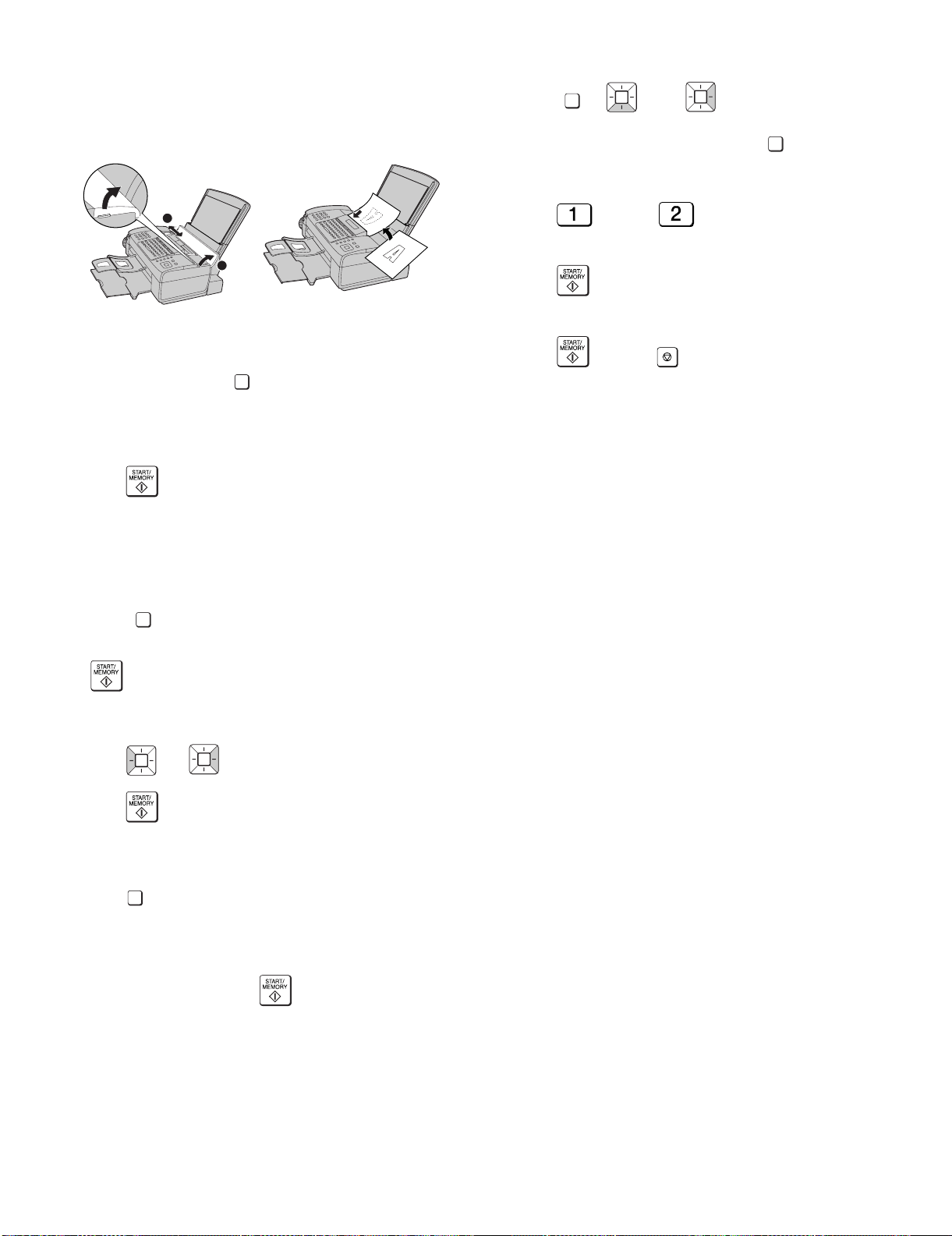

2. Clearing jammed printing paper

1. Clearing a jammed document

If the original document doesn't feed properly during transmission or

copying, or [DOCUMENT JAMMED] appears in the display, first try

pressing . If the document doesn't feed out, remove it as

explained below.

Important: Do not try to remove a jammed document without releasing it as explained below. This may damage the feeder mechanism.

1) Open the cover ( ). Rotate the lever so that points straight up

COPY/HELP

1

2 3

( ), and pull it up ( ). Pull the roller out to the right, and

remove the document ( ).

4

4

1

2

3

1) Open the cover ( ). Pull the jammed paper forward or backward

out of the machine as appropriate ( ), taking care not to tear it.

2) Close the cover, pressing down firmly on both front corners.

1

2

2) Replace the white roller, inserting the left end first. Push the lever

down and rotate it back down ( ). Close the cover, pressing

firmly on both front corners ( ).

1

2

2

1

1 – 12

Page 14

UX-B800A

FUNCTION

[8] Quick reference guide

7. Storing Destinations

1. Fax / Scan to E-mail Transmission

Place your document (up to 20 pages) face down in the document

feeder.

2

1

2. Sending a Fax by Normal Dialing

1. Lift the handset or press .

2. Dial the fax number.

3. Wait for the reception tone (if a person answers, ask them to press

their Start key).

4. Press .

SPEAKER

3. Using a Rapid Key (fax/e-mail)

Press the Rapid Key for the destination.

1. Press , , then .

2. Press an unused Rapid Key, or press and enter an

SPEED DIAL

unused 2-digit Speed Dial number (01 to 63). (For an e-mail destination, you can also press the A, B or C key and go to Step 4.)

3. Press for fax or for e-mail.

4. Enter the fax number or the e-mail address.

5. Press .

6. Enter a name with the letter keys.

7. Press and then .

STOP

4. Using a Speed Dial number (fax/e-mail)

1. Press .

2. Enter the appropriate 2-digit Speed Dial number and press

SPEED DIAL

.

5. Searching for a destination (fax/e-mail)

1. Press or until the desired destination appears.

2. Press .

6. Receiving Faxes

RESOLUTION/

RECEPTION MODE

Press until the desired reception mode appears in the dis-

play.

AUTO mode: The machine automatically answers and receives faxes.

MANUAL mode: Answer all calls (even faxes) by picking up the hand-

set. To begin fax reception, press .

TEL/FAX mode: The machine automatically answers and receives

faxes. Voice calls are signalled by a special ringing sound.

1 – 13

Page 15

(step 1) Select "OPTION SETTING".

KEY : FUNCTION , , ,

DISPLAY: OPTION SETTING PRESS KEY

(step 2) Select "DIAL MODE".

KEY: , , , ,

DISPLAY: DIAL MODE

1: TONE, 2: PULSE

(step 3) Select, using "1" or "2".

KEY:

DISPLAY: TONE

KEY:

DISPLAY: PULSE

(step 4) End, using the "STOP" key.

(Press the STOP key three times.)

KEY:

1

2

STOP

1

Press or to select

HIGH,MIDDLE,LOW

,or

OFF

.

(Make sure has not been

pressed, the handset is not lifted,

and a document is not loaded in the

feeder.)

•

The ringer will ring once at the

selected level.

2

If you selected "

OFF OK ?

"toturn

off the ringer, press .

SPEAKER

START/

MEMORY

UX-B800A

CHAPTER 2. ADJUSTMENTS

[1] Adjustments

1. General description

Since the following adjustments and settings are provided for this

model, make adjustments and/or setup as necessary.

2. Adjustments of output voltage (FACTORY ONLY)

1. Install the power supply unit in the machine.

2. Set the recording paper and document.

3. When the document is loaded, power is supplied to the output

lines. Confirm that outputs are within the limits below.

2.1. Output voltage settings

1

15

CNLIU CNSP

CNPRT1 CNPRT2

CNCRMT

CNPW

CNLAN

CNENC CNFDMT

1

8

CNPN

CNSCANMT

CNCIS

CONTROL PWB

UX-B800A

4. Settings

Service Manual

4.1. Dial mode selector

DIAL mode (Soft Switch No. SW-9 Data No. 8)

Use this to set the fax machine to the type of telephone line you are

on.

• The factory setting is “TONE”.

18

CNPW

POWER SUPPLY PWB

Output Voltage limits

+5V 4.75 - 5.25V

+30V 27.0 - 33.0V

Pin No. CNPW

1 +30V

2 +30V

3MG

4MG

5DG

6DG

7+5V

8+5V

3. IC protectors replacement

ICPs (IC Protectors) are installed to protect the CIS and Ope amp. circuit. ICPs protect various ICs and electronic circuits from an overcurrent condition.

The location of ICPs are shown below:

CNPN

CNSCANMT

IC600

CNCIS

FU900

CNLAN

CNENC CNFDMT

CNPW

CONTROL PWB

(TOP VIEW)

1) FU900 (KAB5002) is installed in order to protect overcurrent +24V

supply. If FU900 is open, replace it with a new one.

LIU PWB

CNLIU

115

CNLIU CNSP

CNPRT1 CNPRT2

CNCRMT

5. Volume adjustments

5.1. Speaker volume

1

2

•

SPEAKER

Press .

Press or to select

HIGH,MIDDLE

SPEAKER

Press again to turn off the

speaker.

5.2. Ringer volume

2 – 1

,or

LOW

.

Page 16

UX-B800A

SOFT SWITCH MODE

SW123=00100100

Switch No.

12345678:DataNo.

SW =

SW1 =

[1] key

SW12 =

[2] key

SW123=00100100

[3] key

Cursor position

SW124=00000000

[START/MEMORY] key

SW125=00000000

SW123=00100100

[START/MEMORY] key

SW123=00100100

SW123=00100100

[>] or [#] key

SW124=00000000

With the cursor on data 8

[>] or [#] key

SW124=00000000

[>] or [#] key

SW124=00000000

SW124=00000000

[<] or [ ] key

SW123=00100100

With the cursor on data 1

[<] or [ ] key

SW123=00100100

[<] or [ ] key

SW124=00000000

[UP] or [4] key

SW123=00100100

SW125=00000000

[UP] or [4] key

SW124=00000000

[DOWN] or [6] key

SW125=00000000

SW123=00100100

[DOWN] or [6] key

[2] Diagnostics and service soft switch

1. Entering the diagnostic mode 2. Diagnostic items description

2.1. SOFT SWITCH MODE

FUNCTION

Press

display will appear

ROM:TF64

Then press the

Select the desired item with the

with the rapid key.

Enter the mode with the

•

specifications)

(Diag

FUNCTION

9 8

alternately.

: ROM version

START/MEMORY

START/MEMORY

9 8

7

7

key.

and the key or select

UP DOWN

key

key.

ROM:

TF64

, and

the

following

In this mode, the soft switches are set and the soft switch list is printed.

2.1.1 Operation

Soft switch mode screen

UP

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

START/MEMORY

DOWN

COUNTRY NAMEDIAG MODE

START/MEMORY

SOFT SWITCH MODE

ROM & RAM CHECK

AGING MODE

PANEL CHECK MODE

CHECK PATTERN MODE

SIGNAL SEND MODE

MEMORY CLEAR

SHADING MODE

AUTO FEEDER MODE

FLASH MEMORY CHECK

MEMORY SET MODE

CIS ADJUSTING MODE

SHARP CHART AGING

ASF AGING

IJP LIST MODE

LIFE MODE

LIFE CLEAR MODE

SECURE PASS LIST

2.1.2 Switch number selection and data setting

1. Enter three digits of a soft switch number to set the switch number.

Of a switch number of unexacting soft switch is entered, key error

buzzer sounds to reject the input.

2. Press [START/MEMORY] key moves the cursor to the data number

1 of the former soft switch. If the switch number is the final, pressing [START/MEMORY] key will exit the soft switch mode.

3. Data number selection

a) Pressing [>] or [#] key moves the cursor to the right. If the cursor

is on data number 8, pressing [>] or [#] key shifts the cursor to data

number 1 of the next switch number. If the switch number is the

final, pressing [>] or [#] key will exit the soft switch mode.

b) Pressing [<] or [ ] key moves the cursor to the left. If the cursor

is on data number 1, pressing [<] or [ ] key shifts the cursor to

data number 8 of the former switch number. If the switch number is

001, pressing [<] or [ ] key do not move the cursor.

c) Pressing [UP] or [4] key moves the cursor to the data number 1

of the next soft switch. If the switch number is 001, pressing [UP] or

[4] key shifts the cursor to data number 1.

d) Pressing [DOWN] or [6] key moves the cursor to the data number 1 of the former soft switch. If the switch number is the final,

pressing [down] or [6] key will exit the soft switch mode.

2 – 2

Page 17

e) Pressing [8] key moves the cursor to the data number 1 of the

To finish this mode, press [STOP] key

04:PANEL KEY TEST

1

[1] key

[2]Key

2

SPEAKER

Go to a) or b).

..... (other key)

[SPEAKER] key

Start by pressing the

[START/MEMORY] key

PRINTING

DIAG MODE

05:CHECK PATTERN

10th former soft switch.

SW123=00100100

SW113=00000000

[8] key

SW103=00000000

[8] key

f) Pressing [2] key moves the cursor to the data number 1 of the

10th next soft switch.

SW123=00100100

SW133=00000000

[2] key

SW143=00000000

[2] key

2.1.3 Data setting

Press the [1] key, and the data to the position of the cursor will be

changed to 1.

Press the [0] key, and the data to the position of the cursor will be

changed to 0.

2.1.4 Outputting method of soft switch list

In the soft switch mode, press [COPY/HELP] key, and the soft switch

list will be printed.

2.1.5 Storage of data

In the following cases, the data if the soft switches set will be stored.

• It is shifted to set the next soft switch by pressing [START/MEMORY] key.

• If is shifted to set the former soft switch with the [<] or [UP] or [4]

key.

• It is shifted to set the next soft switch with the [>] or [DOWN] or [6]

key.

• If is shifted to set the 10th former soft switch with the [8] key.

• It is shifted to set the 10th next soft switch with the [2] key.

2.2. ROM & RAM check

To check the sum value of Firmware or RAM.

No. Device Alarm Buzzer Remarks

1

2 SDRAM 3 times <Short

ROM

(PROGRAM FLASH)

Main

1 time <Short

sound>

sounds>

UX-B800A

2.4. PANEL CHECK MODE

This is used to check whether each key is normally operated or not.

After the test, the test result will be printed.

2.4.1 Flow

Press any key except [STOP] key. At this time, the name of each key

will be displayed every push of the key.

a) When all keys can be inputted, the following message will be displayed.

ALL KEY OK !!

Then the screen will be all displayed in black (refer to (2))and the test

result will be printed.

b) If any key skipped, the following message will be displayed.

KEY ERROR !!

A key name that is not pressed yet is displayed so that this test can be

continued.

At that time, pressing the [STOP] key will exit this mode. And the result

will be printed.

2.4.2 Black screen

2.2.1 Display

DIAG MODE

02:ROM & RAM CHECK

2.2.2 Result printing

After checking, the results print starts.

2.3. AGING MODE

A total of 10 sheets of check patterns are printed at 1-hour intervals.

This mode is exited when executed to the end (after 9 hours) or by

pressing the [STOP] key.

DIAG MODE

03:AGING MODE

WAITING

Start checking by pressing

[START/MEMORY] key

Start by pressing the

[START/MEMORY] key

SDRAM : OK

PRINTING

PRINTING

03:AGING MODE

Display during the aging

mode interval

2.5. CHECK PATTERN MODE

Printing the pattern.

2 – 3

Page 18

UX-B800A

AUTO FEEDER

[START/MEMORY] key

without document

DIAG MODE

09:AUTO FEEDER MODE

Only the sensor that is activated is displayed

DIAG MODE

A4 (A4 )

DIAG MODE

A4 (A4 ORG)

DIAG MODE

()

Set document

[START/MEMORY] key

without document

WAIT A MOMENT

DIAG MODE

10:FLASH MEM. CHECK

FLASH CHECK

PRESS START OR STOP

[START/MEMORY] key

[STOP] key

Next daig mode

[START/MEMORY] key

PRINTING

Start

DIAG MODE

11:MEMORY SET MODE

MEMORY SET MODE

xxxxxxxx= [ ]

[START/MEMORY] key

Address entry screen

Entry of memory address (8 digits)

MEMORY SET MODE

1234ABCD=4C [L]

Hex

number

Character

code

• Change of memory contents: 2-digit entry in hex number

• Move down the address of the referenced memory by one: [<] or [UP] key

• Move up the address of the referenced memory by one: [>] or [DOWN] key

• Dump list print: [COPY/HELP] key

• Back to the address entry screen: [STOP] key

The contents of the memory are displayed

in hex number and character code.

2.6. SIGNAL SEND MODE

The specified signals are transmitted in the following sequence to

check the modem.

1. Press the [START/MEMORY] key, and no signals with the loop

state starts.

[1] No signals (making the loop)

[2] 14400BPS (V.17)

[3] 12000BPS (V.17)

[4] 9600BPS (V.17)

[5] 7200BPS (V.17)

[6] 9600BPS (V.29)

[7] 7200BPS (V.29)

[8] 4800BPS (V.27ter)

[9] 2400BPS (V.27ter)

[10] 300BPS (FLAG)

[11] 2100Hz (CED)

[12] 1100Hz (CNG)

DIAG MODE

06:SIGNAL SEND MODE

[START/MEMORY] Key

SIG SEND MODE

V.17 7200bps V.17 9600bps

[START/MEMORY] Key

V.29 9600bps V.29 7200bps

2100 Hz (CED TONE) FLAG (300bps)

[ENTER]Key

1100 Hz (CNG)

[START/MEMORY] Key

[START/MEMORY] Key

[START/MEMORY] Key

[ENTER]Key

CML ON

[START/MEMORY] Key

V.17 14400bps

[START/MEMORY] Key

[START/MEMORY] Key

V.17 12000bps

[START/MEMORY] Key

V.27ter 4800bps

[START/MEMORY] Key

[START/MEMORY] Key

V.27ter 2400bps

2.9. AUTO FEEDER MODE

Inserting and discharging the document can check the auto feeder.

1. The information of document sensor (A4 sensor) and ORG sensor

is displayed when the documents are inserted to the Auto Feeder.

Press the [START/MEMORY] key, and feeding documents is

started.

2. Press [STOP] key to exit the mode.

2.10. FLASH MEMORY CHECK

Read/write of the flash memory is checked.

The result is printed after completion of check.

Be sure to clear the memory after execution.

2. Pressing the [START/MEMORY] key during transmitting CNG signal, or pressing the [STOP] key will stop the output of signal and

exit the mode.

2.7. MEMORY CLEAR

Clear the back-up memory including the soft switches, registration

data. After executing this mode, the memory clear report is printed.

Note: The following data is not cleared. Values for Printer life including

the adjusted value of printing void.

DIAG MODE

07:MEMORY CLEAR

Start by pressing the

[START/MEMORY] key

2.8. SHADING MODE

Shading waveforms are stored.

Set a shading sheet and press the [START/MEMORY] key to start

shading.

DIAG MODE

08:SHADING MODE

Start by pressing the

[START/MEMORY] key

MEMORY CLEARD

PRINTING

TOTAL SHADING

2.11. MEMORY SET MODE

It is possible to read or write the memory contents.

When 8 digits of physical address are entered, the data of that address

is displayed.

When 2 digits of data are entered after entering 8 digits of address and

a key is pressed, the contents can be rewritten.

Rewriting is enabled only in the range of addresses 00000000 to

007FFFFF.

If the memory is rewritten, the machine may malfunction.

Press the [STOP] key on the address entry screen to exit the mode.

2 – 4

Page 19

2.12. CIS ADJUSTING MODE

Start by pressing the

[START/MEMORY] key

MACH.COUNT=0123456789

DIAG MODE

16:LIFE MODE

STAND-BY state

Press

FUNKTION

Start by pressing the

[START/MEMORY] key

DIAG MODE

17:LIFE CLEAR MODE

Start by pressing the

[START/MEMORY] key

DIAG MODE

18:SECURE PASS LIST

In this mode, the position of Scanner motor is moved from the home

position up to the specified value. And document reading lamp is

turned on.

DIAG MODE

12:CIS ADJUST

[START/MEMORY] key

CIS ADJUST MODE

The motor will move to the specified position and the reading lamp is lit on.

[START/MEMORY] key

Press the [STOP] key to exit the mode.

2.13. SHARP CHART AGING

SHARP CHART is printed continuously.

UX-B800A

2.16. LIFE MODE

MACHINE PAGE COUNT is displayed.

Press the [STOP] key to exit the mode.

• LIFE MODE can also be checked by the following operation.

2.17. LIFE CLEAR MODE

MACHINE DOT COUNT and MACHINE PAGE COUNT are cleared.

DIAG MODE

13:SHARP CHART AGING

Start by pressing the

[START/MEMORY] key

SHARP CHART AGING

PRINTING P.1

Press the [STOP] key for interruption.

2.14. ASF AGING

The recording paper is fed continuously.

DIAG MODE

14:ASF AGING

Start by pressing the

[START/MEMORY] key

ASF AGING

Press the [STOP] key for interruption.

2.15. IJP LIST MODE

Maintenance data of the printer is output.

MACHINE DOT COUNT Machine total dot count

MACHINE PAGE COUNT Machine total page count

CARTRIDGE DOT COUNT Cartridge-by-cartridge dot count

IDLE MAINTENANCE COUNT Maintenance information

INSTALL MAINTENANCE

COUNT

BEGIN OF JOB MAINTENANCE

COUNT

THRESHOLD MAINTENANCE

COUNT

POJ MAINTENANCE COUNT Maintenance information

SWATH START TEMPERA-

TURE

FUSE MEMORY VALUE Cartridge information

VPH ON TIME Cartridge information

CARTRIDGE CHANGE COUNT Cartridge replacement count

JAM COUNT Jam count

NOZZLE CLEAN COUNT Nozzle cleaning count

CALIBRATION ENVIRONMENT

TEMPERATURE

CALIBRATION PRINT HEAD

TEMPERATURE

TEMPERATURE MODE Temperature control information

Maintenance information

Maintenance information

Maintenance information

Temperature control information

Environmental temperature information

Cartridge temperature information

2.18. SECURE PASS LIST

Print the SECURE PASS LIST.

DIAG MODE

15:IJP LIST MODE

Start by pressing the

[START/MEMORY] key

PRINTING

2 – 5

Page 20

UX-B800A

3. How to make soft switch setting

To enter the soft switch mode, press the following key entries in sequence.

Press

FUNCTION

9 8 START/MEMORYSTART/MEMORY

DATA No. 1 2 3 4 5 6 7 8

SW001 = 0 0 0 0 0 0 0 0

SW001 = 1 0 0 0 0 0 0 0

SW001 = 1 0 0 0 0 0 0 0

SW001 = 1 0 0 0 0 0 0 0

SW001 = 1 0 0 0 0 0 0 0

SW002 = 0 0 0 0 0 0 0 0

SW300 = 0 0 0 0 0 0 0 0

7

Press 1 or key.

Press or key.

Press or key.

Bit1 - 8 are set.

Press key during setting.

Soft SW002 - SW300 are set.

To finish the settings halfway between

SW001 and SW300, press the STOP

key. In this case, the setting being done

to the SW No. on display will be nullified

while settings done to the preceding

SW No. remain in effect.

When the COPY/HELP key is pressed, the

contents of soft switches are printed.

0

<

>

START/MEMORY

0

1

0

The soft switch mode is terminated.

2 – 6

Page 21

4. Soft switch description

4.1. Soft switch

UX-B800A

SW

NO.

SW

1

SW

2

SW

3

SW

4

SW

5

SW

6

DATA

NO.

1Reserved 0

2Reserved 0

Receive mode FAX TEL TEL/

3

4

5Reserved 1

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2 Forced 4800BPS reception Yes No 0

CED tone signal interval 75ms 500ms 750ms 1000ms

3

4

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1 Length limitation of receive No limit Receive 1.5m 0

2 Footer print Yes No 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7 CSI transmission Not transmitted Transmitted 0

8 Action when RTN is received No communication error Communication error 0

1Reserved 1

2 Dial pausing (sec/pause) 4sec 2sec 0

3 Pulse format of D.P. N+1 N 0

4 DIS receive acknowledgement dur-

ing G3 transmission

5 Non-modulation carrier for V29

transmission mode

6Reserved 0

7 Protocol monitor Yes No 0

8 Line monitor Yes No 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved

1Reserved 0

2Reserved 0

3 Digital cable equalizer for Reception Yes No 0

4 Sender's information transmit No Yes 0

5Reserved 1

6Reserved 0

7Reserved 0

8Reserved 0

ITEM

No.30011

No.40101

No.30011

No.40101

Twice NSF: Once

Yes No 0

Switch setting and function

10

FAX

FAX

DIS: Twice

Initial

setting

0

0

0

0

0

0

Remarks

2 – 7

Page 22

UX-B800A

SW

NO.

SW

7

SW

8

DATA

NO.

1 H2 mode No Yes 0

2 Reserved 1

3 ECM mode No Yes 0 OPTION

4 ECM MMR mode No Yes 0

Signal transmission level 1

5

6

7

8

Recall interval (FAX) 0

1

2

3

4

Recall times (FAX) 0

5

6

7

8

ITEM

Switch setting and function

10

Binary input

No. = 8 4 2 1

5678(DataNo.)

EX1111

eg. -8dBm

Binary input

No. = 8 4 2 1

1234(DataNo.)

EX0101

eg. 5 minutes

Binary input

No. = 8 4 2 1

5678(DataNo.)

EX0010

eg. 3 times

Initial

setting

1

1

1

1

0

1

0

1

0

Remarks

Setting:

N = 1 to 9

Setting:

N = 1 to 9

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Sort copy function Yes No 0 PRINT SETUP

SW

9

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Dial mode Pulse Tone 0

1 Reserved 1

2 Reserved 0

3 CNG detection Yes No 1 OPTION

4 Number of CNG detection 3 pulses 2 pulses 0

SW

5 Signal detect time in TEL/FAX mode 3sec 1sec 0

10

6 Reserved 0

CNG detection time after ringing

7

8

1 Reserved 0

2 Reserved 1

3 Time display format 24hours 12hours-AM/PM 1

4 Date display format Month-Day-Year Day-Month-Year 0

SW

11

Pseudo ringing time at TEL/FAX

automatic switching mode

5

6

7 Reserved 0

8 CED detection time 500ms 1000ms 0

No. 7 0 0 1 1

No. 8 0 1 0 1

No. 5 0 0 1 1

No. 6 0 1 0 1

20sec 10sec 30sec No limit

0

0

15sec 30sec 60sec 120sec

0

0

OPTION

2 – 8

Page 23

UX-B800A

SW

NO.

SW

12

SW

13

SW

14

SW

15

SW

16

SW

17

DATA

NO.

1 MH fixed Yes No 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Key tone OFF ON 0 OPTION

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

Modem speed No. 5 No.6 No. 7 No. 8

5

6

7

8

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 1

5 Reserved 1

6 Reserved 0

7 Reserved 0

8 Reserved 1

1 Digital cable equalizer for transmis-

sion

2 Reserved

3 Reserved 0

4 Flash send time Long time Short time 0 OPTION

Flash short time 90ms 100ms 110ms 125ms

5

6

Flash long time 250ms 230ms 270ms 280ms

7

8

1 Reserved 0

2 Reserved 1

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 1

7 Reserved 0

8 Reserved 0

ITEM

V.17 14400bps 1000

V.17 12000bps 1010

V.17 9600bps 1001

V.17 7200bps 1011

V.29 9600bps 0001

V.29 7200bps 0011

V.27ter 4800bps 0010

V.27ter 2400bps 0000

Yes N o 0

No. 50011

No. 60101

No. 70011

No. 80101

Switch setting and function

10

Initial

setting

1

0

0

0

0

0

0

0

0

Remarks

2 – 9

Page 24

UX-B800A

SW

NO.

SW

18

SW

19

SW

20

SW

21

SW

22

SW

23

DATA

NO.

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 1

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 1

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 1

3 Reserved 0

4 Reserved 1

5 Reserved 1

6 Reserved 0

7 Reserved 0

8 Reserved 0

Line density selection STAN-

1

2

Communication results printout Error

3

4

5

6 Caller ID function Yes No 0 OPTION

7 Activity report print Yes (When memory full) No (First data is cleared when

8 Day Light Saving (Summer time) No Yes 1

1 Activate Receive Fax to E-mail Yes No 0

2 Print setting of received fax for

Receive Fax to E-mail

3 Report setting for Receive Fax to E-

mail

4 Activate Secure Receive Yes No 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Ink Save Mode Setting ON OFF 0 PRINT SETUP

2 Receive Reduce Setting 100% Auto 0 PRINT SETUP

Paper Size LET-

3

4

5 Half tone copy print swath direction Single direction printing Both direction printing 1 PRINT SETUP

6 Reserved 0

7 Reserved 0

8 Reserved 0

ITEM

No. 1 0 0 1 1

No. 2 0 1 0 1

No. 300011

No. 400101

No. 510000

Print at error Always Print 0

Print at error Always Print 1

No. 3 0 0 1 1

No. 4 0 1 0 1

Switch setting and function

10

FINE S-FINE STAN-

DARD

Only

TER

Error/

Memory

A4 LEGAL LET-

Send

only

memory full)

DARD

No Print Always

TER

Initial

setting

0

0

0

0

1

0OPTION

0

1

Remarks

OPTION

(Only for Stan-

dard/Fine)

OPTION

(Only for A4)

2 – 10

Page 25

UX-B800A

SW

NO.

SW

24

SW

25

SW

26

SW

27

SW

28

SW

29

SW

30

DATA

NO.

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 1

6 Reserved 0

7 Reserved 0

8 Reserved 1

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 1

6 Reserved 0

7 Reserved 0

8 Reserved 1

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 1

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

ITEM

Switch setting and function

10

Initial

setting

Remarks

2 – 11

Page 26

UX-B800A

SW

NO.

SW

31

SW

32

SW

33

SW

34

SW

35

SW

36

SW

37

DATA

NO.

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4 Error criterion 10-20% 5-10% 0

EOL (End of Line) detection timer 13sec 25sec 5sec

5

6

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

ITEM

No. 5001

No. 6010

Switch setting and function

10

Initial

setting

0

0

0

Remarks

2 – 12

Page 27

UX-B800A

SW

NO.

SW

38

SW

39

SW

40

SW

41

SW

42

SW

43

DATA

NO.

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 1

3Reserved 1

4Reserved 0

5Reserved 0

6Reserved 0

7 Make/Break ratio in D.P. 40/60 33/67 0

8 Pre pause time in D.P. 320ms 50ms 0

Inter digit pause time No. 1 No. 2 No. 3

1

2

3

4

Change to PB from PB by key

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

DTMF detect time 50ms 80ms 100ms 120ms

1

2

3 Protection of remote reception

(5 ) detect

Remote operation code figure by

external TEL(0-9)

4

5

6

7

8Reserved 0

1Reserved 0

2Reserved 1

3Reserved

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

ITEM

800ms 0 0 0

840ms 0 0 1

880ms 0 1 0

900ms 0 1 1

1000ms 1 0 0

Not used 1 0 1

Not used 1 1 0

Not used 1 1 1

Yes No 1

No. 10011

No. 20101

Yes No 0

Switch setting and function

10

Binary input

No. = 8 4 2 1

4567(DataNo.)

EX0101

eg. Remote operation code is set "5 "

Initial

setting

0

0

0

0

0

0

1

0

1

1

Remarks

OPTION

2 – 13

Page 28

UX-B800A

SW

NO.

SW

44

SW

45

SW

46

SW

47

SW

48

SW

49

SW

50

DATA

NO.

1 Reserved 1

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 1

4 Reserved 0

5 Reserved 0

6 Reserved 1

7 Reserved 1

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

ITEM

Switch setting and function

10

Initial

setting

Remarks

2 – 14

Page 29

UX-B800A

SW

NO.

SW

51

SW

52

SW

53

SW

54

SW

55

SW

56

SW

57

DATA

NO.

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Busy tone detect when TEL/FAX

mode

7 Dial tone detect when TEL/FAX

mode

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 1

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 1

2 Reserved 0

3 Reserved 1

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 1

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 1

5 Reserved 0

6 Reserved 1

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 1

3 Reserved 0

4 Reserved 1

5 Reserved 0

6 Reserved 1

7 Reserved 0

8 Reserved

1 Reserved 0

2 Reserved 1

3 Reserved 0

4 Reserved 0

5 Reserved 1

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

ITEM

No Yes 0

No Yes 0

Switch setting and function

10

Initial

setting

1

Remarks

2 – 15

Page 30

UX-B800A

SW

NO.

SW

58

SW

59

SW

60

SW

61

SW

62

SW

63

SW

64

DATA

NO.

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 0

4Reserved 0

5Reserved 0

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 0

3Reserved 1

4Reserved 0

5Reserved 0

6Reserved 1

7Reserved 0

8Reserved 0

1Reserved 1

2Reserved 1

Ringer Volume OFF LOW MIDDLE HIGH

3

4

Speaker Volume LOW LOW MIDDLE HIGH

5

6

7Reserved 1

8Reserved 0

1Reserved 0

2Reserved 1

3Reserved 1

4Reserved 0

5Reserved 1

6Reserved

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 1

3Reserved 0

4Reserved 0

5Reserved 1

6Reserved 0

7Reserved 0

8Reserved 0

1Reserved 0

2Reserved 1

3Reserved 0

4Reserved 1

5Reserved 0

6Reserved 0

7Reserved 1

8Reserved 0

ITEM

No. 30011

No. 40101

No. 50011

No. 60101

Switch setting and function

10

Initial

setting

0

1

0

1

1

Remarks

2 – 16

Page 31

UX-B800A

SW

NO.

SW

65

SW

66

SW

67

SW

68

SW

69

SW

70

SW

71

DATA

NO.

1 Reserved 0

2 Reserved 1

3 Reserved 1

4 Reserved 0

5 Reserved 0

6 Reserved 1

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 1

3 Reserved 1

4 Reserved 0

5 Reserved 1

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 1

4 Reserved 0

5 Reserved 1

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 1

2 Reserved 0

3 Reserved 1

4 Reserved 1

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

ITEM

Switch setting and function

10

Initial

setting

Remarks

2 – 17

Page 32

UX-B800A

SW

NO.

SW

72

SW

73

SW

74

SW

75

SW

76

SW

77

SW

78

DATA

NO.

1 Reserved 0

2 Reserved 0

3 Reserved 1

4 Reserved 0

5 Reserved 1

6 Reserved 1

7 Reserved 1

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 1

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 1

7 Reserved 0

8 Reserved 0

1 Reserved 1

2 Reserved 1

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 1

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 1

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 1

4 Reserved 1

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 1

2 Reserved 0

3 Reserved 0

4 Reserved 1

5 Reserved 0

6 Reserved 1

7 Reserved 0

8 Reserved 0

ITEM

Switch setting and function

10

Initial

setting

Remarks

2 – 18

Page 33

UX-B800A

SW

NO.

SW

79

SW

80

SW

81

SW

82

SW

83

SW

84

SW

85

DATA

NO.

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 1

5 Reserved 0

6 Reserved 0

7 Reserved 1

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 1

2 Reserved 1

3 Reserved 1

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 1

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 1

8 Reserved 1

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

ITEM

Switch setting and function

10

Initial

setting

Remarks

2 – 19

Page 34

UX-B800A

SW

NO.

SW

86

SW

87

SW

88

SW

89

SW

90

SW

91

SW

92

DATA

NO.

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 1

5 Reserved 0

6 Reserved 0

7 Reserved 1

8 Reserved 1

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 1

4 Reserved 0

5 Reserved 1

6 Reserved 0

7 Reserved 1

8 Reserved 0

1 Reserved 0

2 Reserved 1

3 Reserved 1

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

ITEM

Switch setting and function

10

Initial

setting

Remarks

2 – 20

Page 35

UX-B800A

SW

NO.

SW

93

SW

94

SW

95

SW

96

SW

97

SW

98

SW

99

DATA

NO.

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 1

3 Reserved 0

4 Reserved 0

5 Reserved 1

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 1

3 Reserved 0

4 Reserved 0

5 Reserved 1

6 Reserved 1

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 1

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0

1 Reserved 0

2 Reserved 0

3 Reserved 0

4 Reserved 1

5 Reserved 1

6 Reserved 0

7 Reserved 0

8 Reserved 1

1 Reserved 0

2 Reserved 1

3 Reserved 0

4 Reserved 0

5 Reserved 0

6 Reserved 0

7 Reserved 0

8 Reserved 0