Page 1

TopPage

SERVICE MANUAL

CODE: 00ZMXFN23/S1E

DIGITAL MULTIFUNCTIONAL SYSTEM

OPTION

FINISHER

MODEL

CONTENTS

[1] PRODUCT OUTLINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . 3-1

[4] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] TROUBLE CODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] DISASSEMBLY AND ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] SIGNAL LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

MX-FN23

[10] ACTUAL WIRING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

[2] SPECIFICTIONS

1. Basic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

[3] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External and Internal View . . . . . . . . . . . . . . . . . . . . . . . 3-1

2. Detectors and Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3. Motors, Solenoids, Gate, PWB, Switch and Fan . . . . . .3-3

[4] ADJUSTMENTS

1. General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

2. List of adjustment items . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

3. Details of adjustment and setting . . . . . . . . . . . . . . . . . .4-1

[5] TROUBLE CODE

1. Trouble code list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

2. Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

[6] OPERATIONAL DESCRIPTIONS

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Outline of the transport path . . . . . . . . . . . . . . . . . . . . . 6-1

3. Offset mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

4. Staple mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

5. Electrical section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

[7] MAINTENANCE

1. Maintenance system table. . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] DISASSEMBLY AND ASSEMBLY

1. External view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Paper entry, alignment, staple. . . . . . . . . . . . . . . . . . . . 8-2

3. Paper delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

4. Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

5. Fan disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

[9] SIGNAL LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] ACTUAL WIRING CHART . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Page 3

MX-FN23 PRODUCT OUTLINE 1 – 1

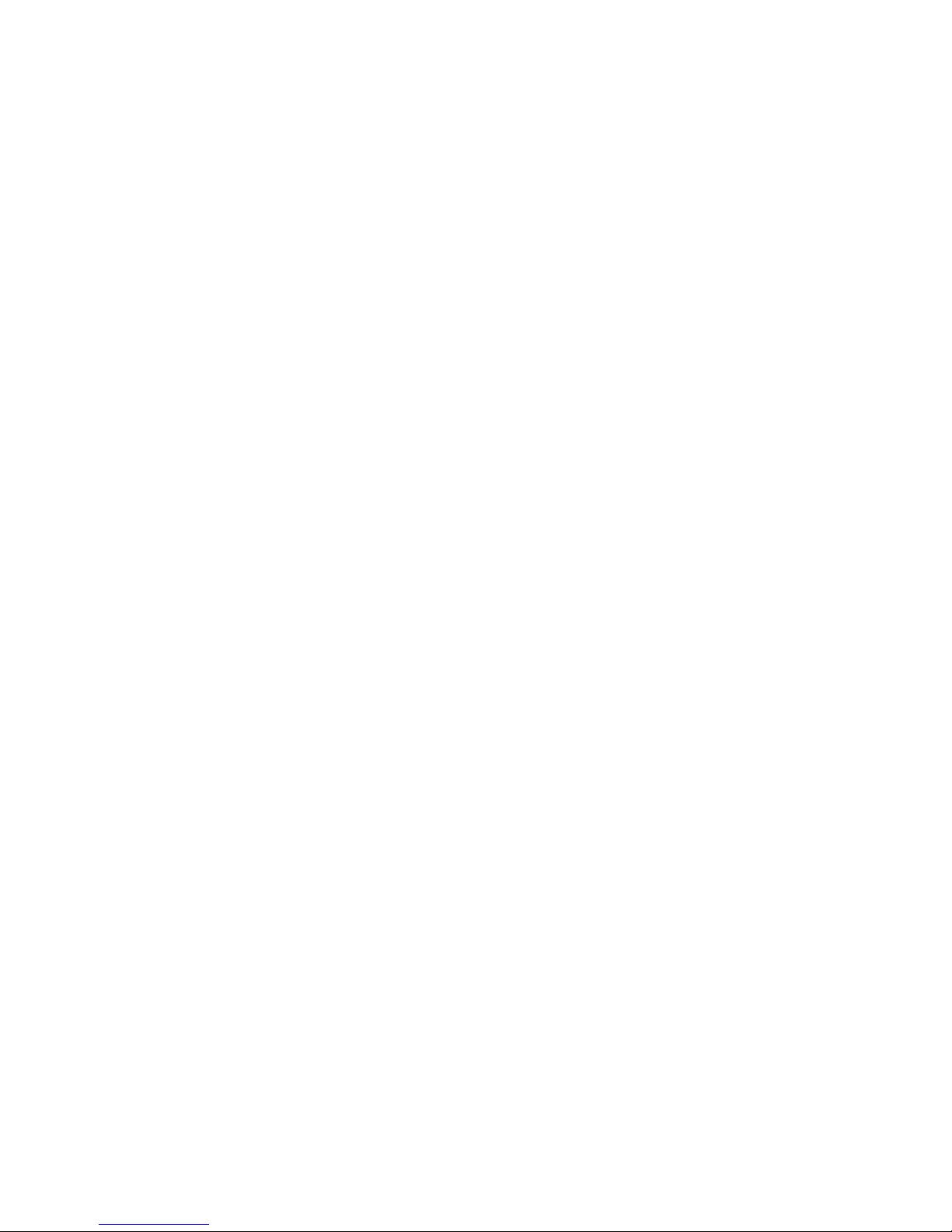

[1] PRODUCT OUTLINE

The FN-23 is a post-processing unit of output paper from a copier, a printer, or a fax machine, which is installed to the machine below.

It is provided with the offset function which discharges output paper by shifting copy by copy, and the staple function (only one position stapling).

Since it is installed to the center tray of the machine, there is no extra space for installation.

The finisher needs a staple cartridge as a consumable part. (Staple cartridge (About 5,000 staples x 3 pcs.) MX-SCX1)

Applicable model MX-M264U/M314U/M354U

MX-M264N/M314N/M354N

Finisher

[MX-FN23]

Staple cartridge

Digital multifunctional system

[MX-M264U/M314U/M354U]

[MX-M264N/M314N/M354N]

Page 4

MX-FN23 SPECIFICTIONS 2 – 1

[2] SPECIFICTIONS

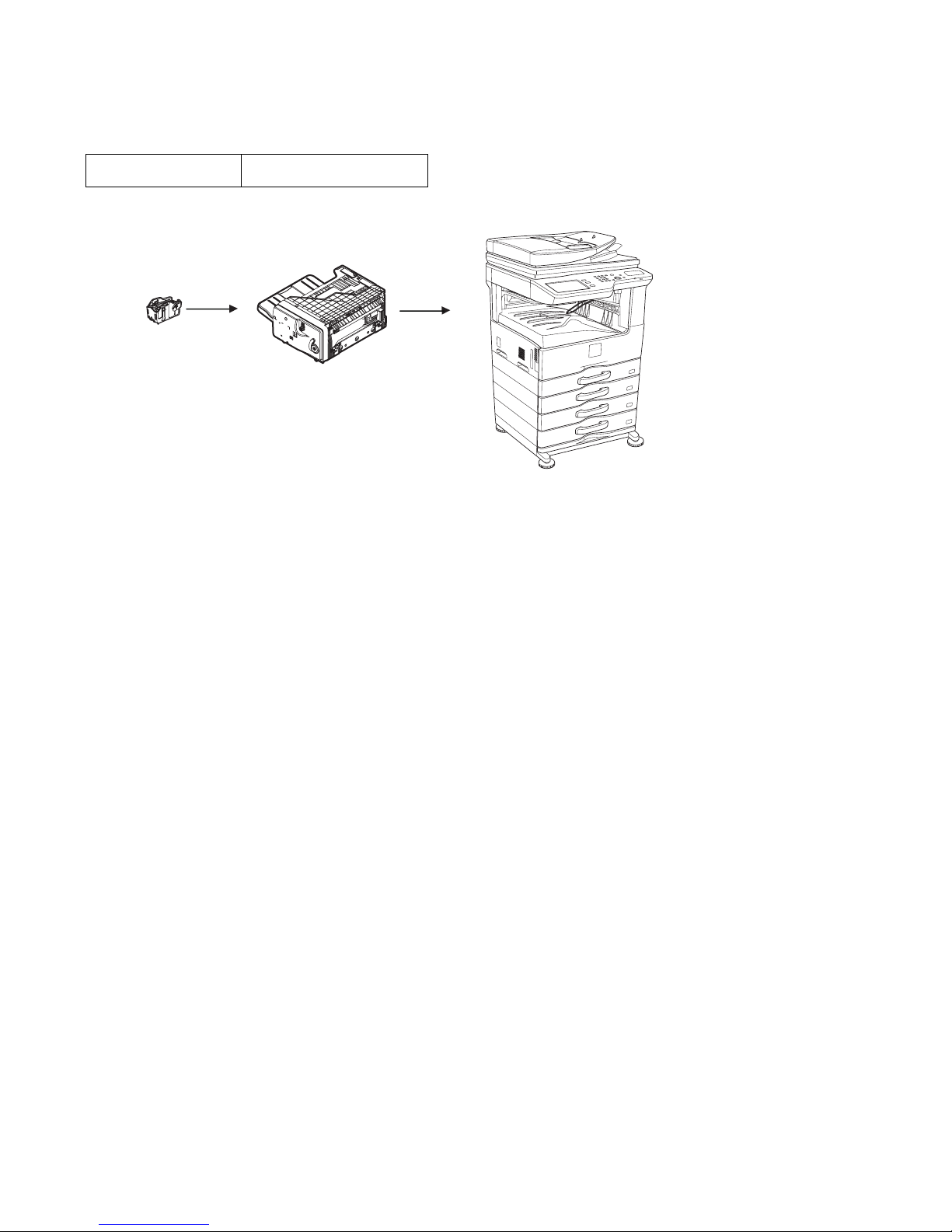

1. Basic specifications

(1) Basic specifications

*1: China only

Model name MX-FN23

Name Finisher

Type Built-in type

Paper transport reference Center reference

Loading method Lifting method offset tray

Mode Non-sort offset sort, staple sort

Power consumption About 49W

Power source Supplied from the main unit

Dimensions (W x D x H mm) 472 x 461 x 199mm (When the paper delivery tray is extended: Width 619mm)

Occupying size Conforms to the main unit.

Weight 13.0kg (including the connection unit, excluding the second paper delivery unit.)

Stacker section

Offset quantity 30mm

Stacking

capability

Non-sort Bottom direction (Y) : 25mm or less

Paper exit direction (X) : 25mm or less

Offset Bottom direction (Y) : 25mm or less

Paper exit direction (X) : 25mm or less

Staple alignment (Shift in a job) X,Y : 2.5mm

Paper exit

storage capacity

Non-staple

mode

250 sheets or 35.5mm or less (A3, B4, 11 x 17, 8.5 x 14, 8.5 x 13, 8K*)

500 sheets or 71mm or less (A4, A4R, B5, B5R, 8.5 x 11, 8.5 x 11R, 16K*, 16KR*)

*: 8K, 16K, and 16KR are valid only for China.

100 sheets or 35.5mm or less (A5, A5R, 5.5 x 8.5, 5.5 x 8.5R, B6R, Postcard, OHP, Label sheet, Envelope (20 sheets))

Note: Offset is disabled for Postcard, OHP, Label, Tab paper and Envelope.

Stapling mode 30 section, or 250 sheets, or 35.5mm or less (fixed size paper greater than A4R) (Documents in mixed sizes with the same

width)

30 section, or 500 sheets, or 71mm or less (fixed size paper smaller than A4R)

Note: Stapling heavy paper is only available for front and back cover.

Paper empty detection YES

Paper delivery tray full detection YES

Staple section

Binding position Rear one position binding

Binding quantity 50 sheets (A4, A4R, B5, B5R, 8.5 x 11, 8.5 x 11R, 16K*1, 16KR*1)

30 sheets (A3, B4, 11 x 17, 8.5 x 14, 8.5 x 13, 8K*1)

Mixed load (same width) stapling: 30 sheets

Staple loading method Staple cartridge (5000 staples) (MX-SCX1)

Staple empty detection YES

Manual staple mode NO

Page 5

MX-FN23 SPECIFICTIONS 2 – 2

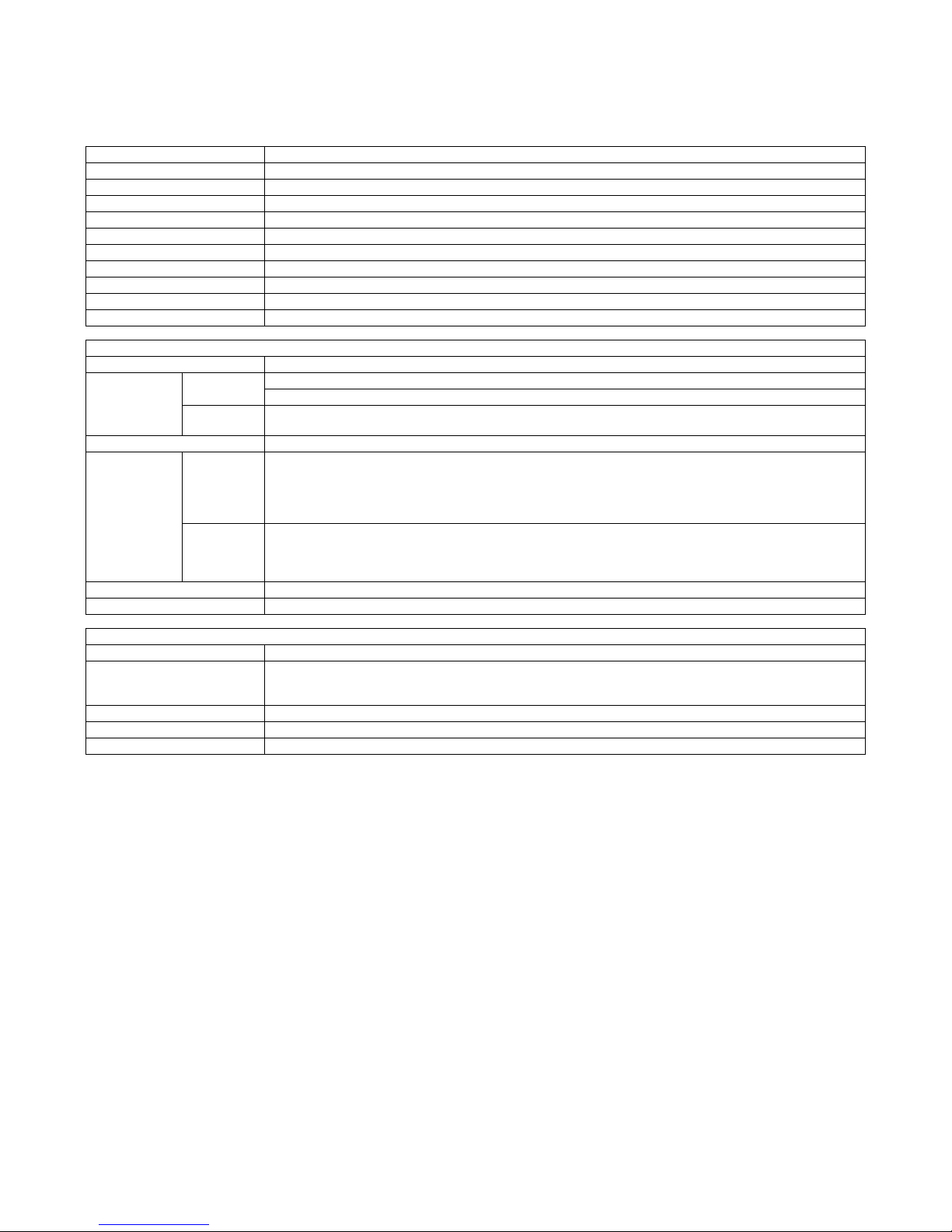

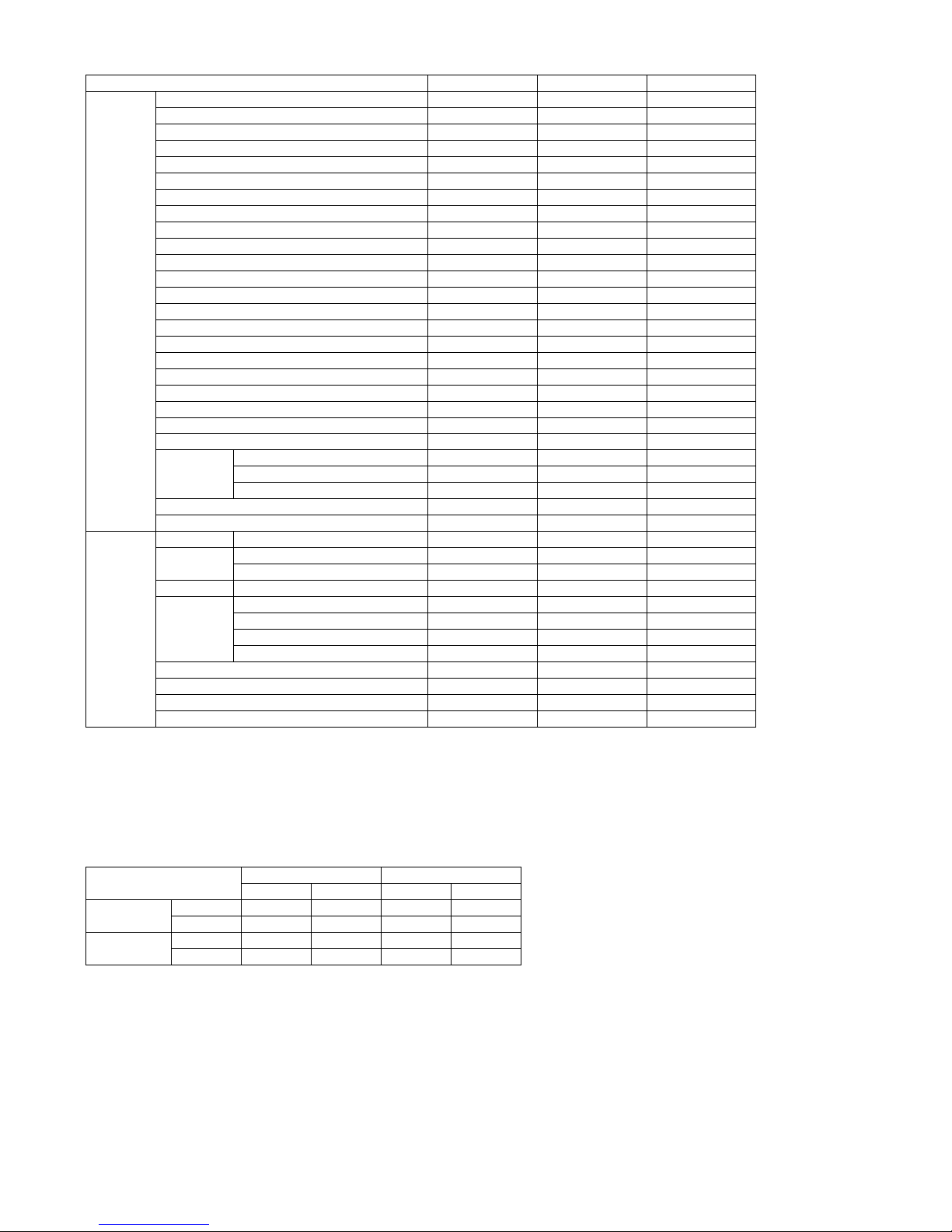

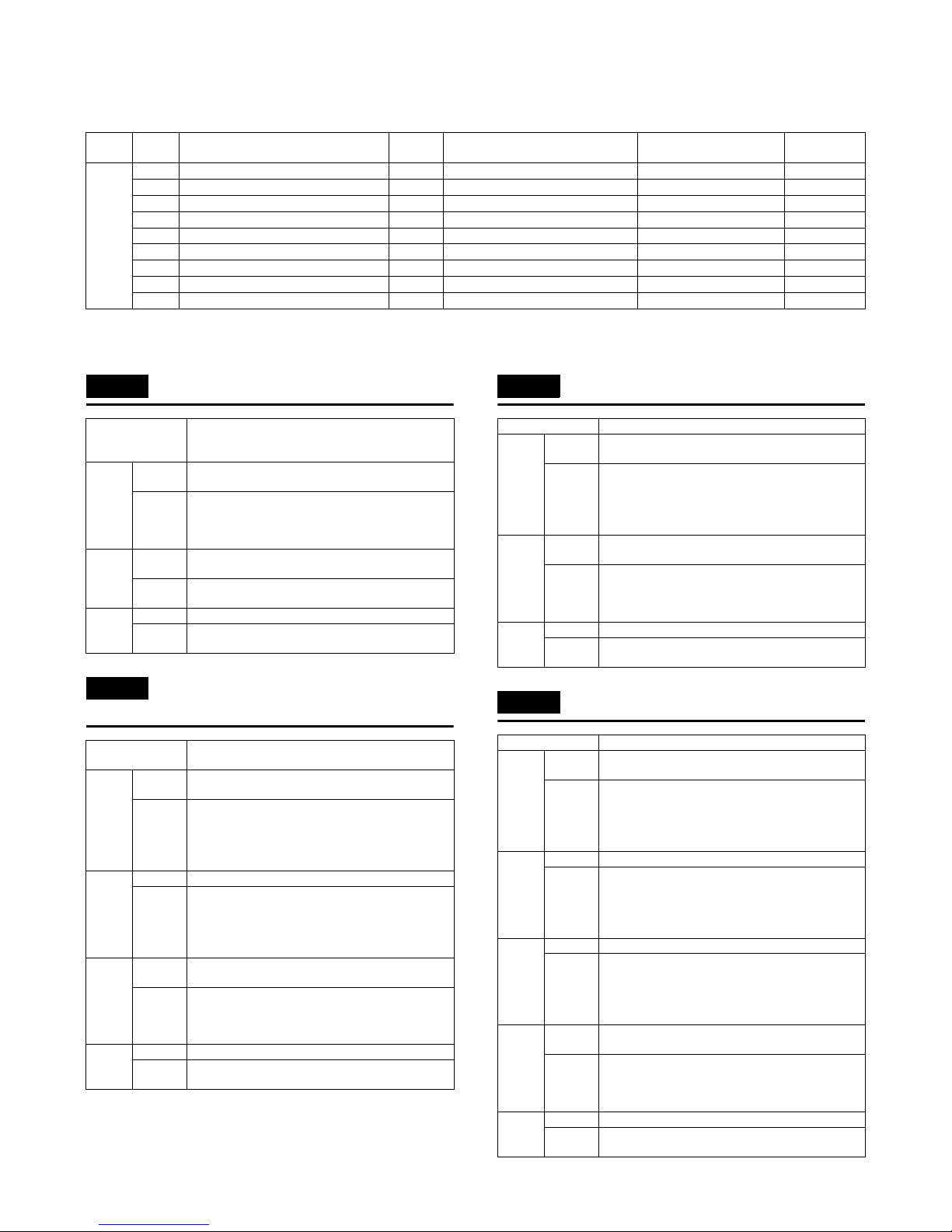

(2) Usable Paper size/weight

*1: Paper is passed, but alignment is not assured.

*2: Paper is passed and stapling is performed, but alignment is not assured.

*3: For heavy paper of 129g/m

2

or more, alignment is not assured.

*4: Available only for the front cover and the back cover.

*5: Can be output but in not supported.

*6: Comply to "Paper typesetting".

*7: Custom size.

Normal paper exit Offset Staple mode

Paper size 11" x 17" Yes Yes Yes

8.5" x 14" (216 x 356) Yes Yes Yes

8.5" x 13.4" (216 x 340) Yes No No

8.5" x 13" (216 x 330) Yes Yes Yes

8.5" x 11" Yes Yes Yes

8.5" x 11"R Yes Yes Yes

7.25" x 10.5"R Yes*

1

No No

5.5" x 8.5"R Yes*

1

No No

5.5" x 8.5" Yes*

1

Yes *

1

No

A3 Yes Yes Yes

B4 Yes Yes Yes

A4 Yes Yes Yes

A4R Yes Yes Yes

B5 Yes Yes Yes

B5R Yes No Yes

A5R Yes*

1

No No

A5 Yes*

1

Yes *

1

No

B6R Yes*

1

No No

8K Yes Yes Yes

16K Yes Yes Yes

16KR Yes No Yes

A6R Yes*

1

No No

Envelope Commercial10 (4-1/8" x 9-1/2") Yes*

1

No No

International DL (110mm x 220mm) Yes*

1

No No

International C5 (162mm x 229mm) Yes*

1

No No

Extra Yes*

1

No No

Custom*

7

Yes *

1

No No

Paper type Thin paper 56-59g/m

2

Yes *

1

Yes *

1

Yes *

2

Plain paper 60-90g/m

2

Yes Yes Yes

Recycled paper Yes Yes Yes

Heavy paper Max. 200g/m

2

Yes *3 Yes *

3

Yes *

4

Envelope Commercial10 (4-1/8" x 9-1/2") Yes*

1

No No

International DL (110mm x 220mm) Yes*

1

No No

International C5 (162mm x 229mm) Yes*

1

No No

Monarch Yes*

1

No No

OHP Yes*

1

No No

Label sheet (SF-4A3F) Yes*

1

No No

Tab paper Yes*

5

No No

User settings 1-7 Yes*

6

Yes Yes

AB System (mm) Inch Systm (inch)

Min. Max. Min. Max.

Bypass tray

X 140 432 5-1/2 17

Y 100 297 5-1/2 11-5/8

Duplex

X 182 432 8-1/2 17

Y 182 297 7-1/4 11-5/8

Page 6

MX-FN23 EXTERNAL VIEW AND INTERNAL STRUCTURE 3 – 1

DS)Options

[3] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External and Internal View

No. Name Function/Operation

1 Paper delivery extension tray When making copy or print of a size longer than B5R, pull this section out.

2 Paper delivery tray Copied or printed paper is discharged to this tray.

3 Finisher upper paper guide Only the lead edge section of switch-backed paper is discharged to this section, and then transported to the switch-back

section.

4 Finisher connection lock pawl This pawl locks the finisher to the machine.

By turning the separation lever, this pawl operates to release lock of finisher.

5 Staple cartridge Staples are stored in this cartridge. (Consumable part)

6 Separation lever When replacing a staple cartridge or removing jam paper, turn this lever to the left and slide the whole finisher to the left.

7 JAM cancel knob When a jam occurs in the finisher, turn this knob to remove the jam paper.

1 2 3

47 456

Page 7

MX-FN23 EXTERNAL VIEW AND INTERNAL STRUCTURE 3 – 2

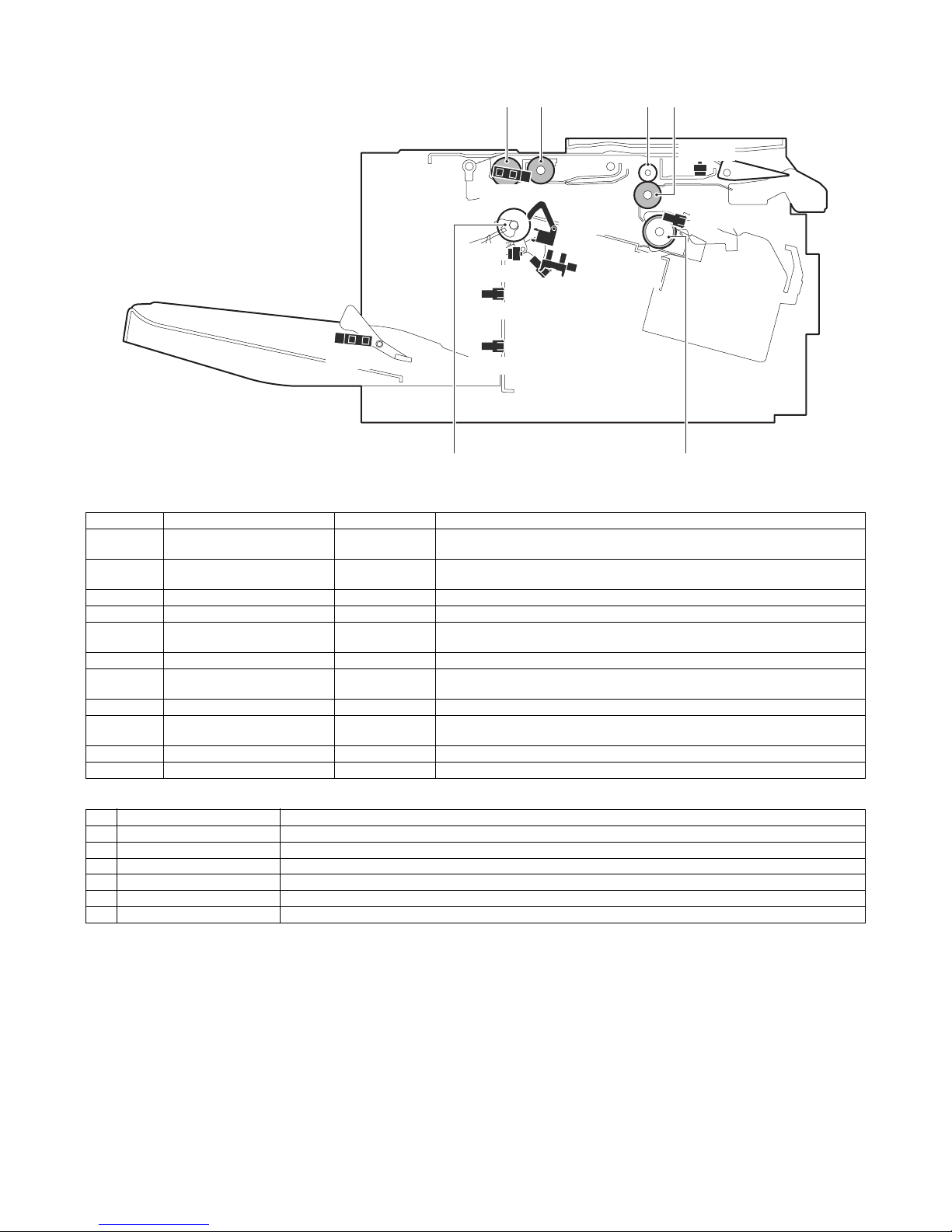

2. Detectors and Rollers

Detectors

Rollers

Signal name Name Type Function/Operation

FAPHPS-F Paper alignment plate home

position sensor F

Transmission type Detects the home position of the paper alignment plate on the front side.

FAPHPS-R Paper alignment plate home

position sensor R

Transmission type Detects the home position of the paper alignment plate on the rear side.

FDRPS Delivery roller position sensor Transmission type Detects that the delivery roller is in the home position.

FDTLLS Delivery tray lower limit sensor Transmission type Detects the lower limit position of the paper delivery tray.

FDTPD Paper delivery tray paper

detector

Paper on the paper delivery tray is detected.

FPLD Paper level detector Transmission type Detects the paper height position of the paper delivery tray (movable section).

FPLS Paper level sensor Reflection type Detects the paper height position of the paper delivery tray (movable section) during a

staple job.

FPPD1 Paper pass detector Reflection type Detects paper entry in the finisher.

FPRD Paper rear edge detector Transmission type Detects that the rear edge of paper transported to the compiler reaches the rear edge of

the compiler.

FSTPD Staple tray paper detector Transmission type Detects paper presence in the staple compiler.

FTPS Delivery tray position sensor Detects the intermediate position of the paper delivery tray.

No. Name Function/Operation

1 Paper delivery roller Discharges paper from the staple compiler to the paper delivery tray.

2 Take-up roller Transports paper which is transported into the staple compiler to the rear edge plate.

3 Paper entry roller (Idle) Applies a pressure to paper and the transport roller to give a transport power of the transport roller to paper.

4 Paper entry roller Transports paper (which is transported from the copier) to the staple compiler.

5 Rear edge take-up roller Drives paper (which is transported to the staple compiler) to the rear edge plate.

6 Paper delivery roller (Idle) Gives a transport power of the transport roller to paper.

FPLD

FPLS

FPPD1

FPRD

FSTPD

FDTPD

FAPHPS-F

FAPHPS-R

FDRPS

12 34

56

FDTLLS

FTPS

Page 8

MX-FN23 EXTERNAL VIEW AND INTERNAL STRUCTURE 3 – 3

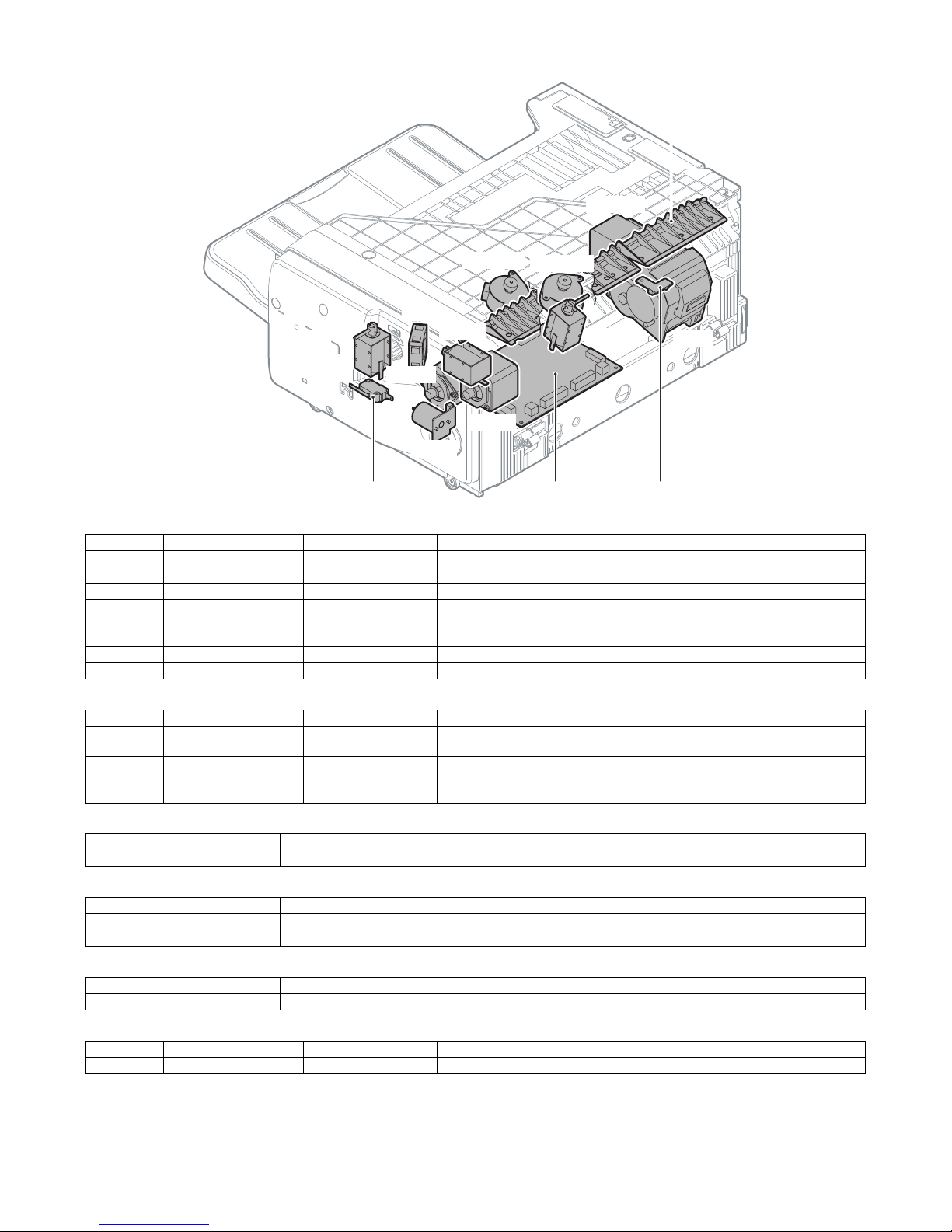

3. Motors, Solenoids, Gate, PWB, Switch and Fan

Motors

Solenoids

Gate

PWB

Switch

Fan

Signal name Name Type Function/Operation

FDRLM Delivery roller lift motor Stepping motor Moves the paper delivery roller up and down.

FPAM-F Paper alignment motor F Stepping motor Drives the paper alignment plate F.

FPAM-R Paper alignment motor R Stepping motor Drives the paper alignment plate R.

FPDM Paper delivery motor Stepping motor Drives the paper delivery roller and the take-up roller. Also moves the take-up roller up

and down.

FPTM Paper transport motor Stepping motor Drives the paper entry roller and the rear edge take-up roller.

FSM Stalpe motor Drives the staple unit.

FTLM Tray lift motor DC brush motor Drives the paper delivery tray (movable section).

Signal name Name Type Function/Operation

FARLS Alignment roller lift

solenoid

Electromagnetic solenoid Controls up-down movement of the rear edge take-up roller.

FPGS Paper gate solenoid Electromagnetic solenoid Drives the select gate of the paper transport path of paper transported to the switch-

back section and paper transported to the paper delivery tray.

FPS Paddle solenoid Electromagnetic solenoid Controls ON/OFF of the paddler rotation.

No. Name Function/Operation

1 Paper entry gate Selects the paper transport path to the switch back section and to the paper delivery tray.

No. Name Function/Operation

2 Control PWB Controls the operation of the finisher.

3 LED PWB Illuminates the staple unit.

No. Name Function/Operation

4 Safety switch Detects open/close of the front cover to turn ON/OFF the motor power.

Signal name Name Type Function/Operation

FCF Finisher cooling fan motor DC brush motor Cools the paper exit motor.

FDRLM

FPAM-F

FPAM-R

FPDM

FPTM

FSM

FTLM

FARLS

FPGS

FPS

FCF

1

24 3

Page 9

MX-FN23 ADJUSTMENTS 4 – 1

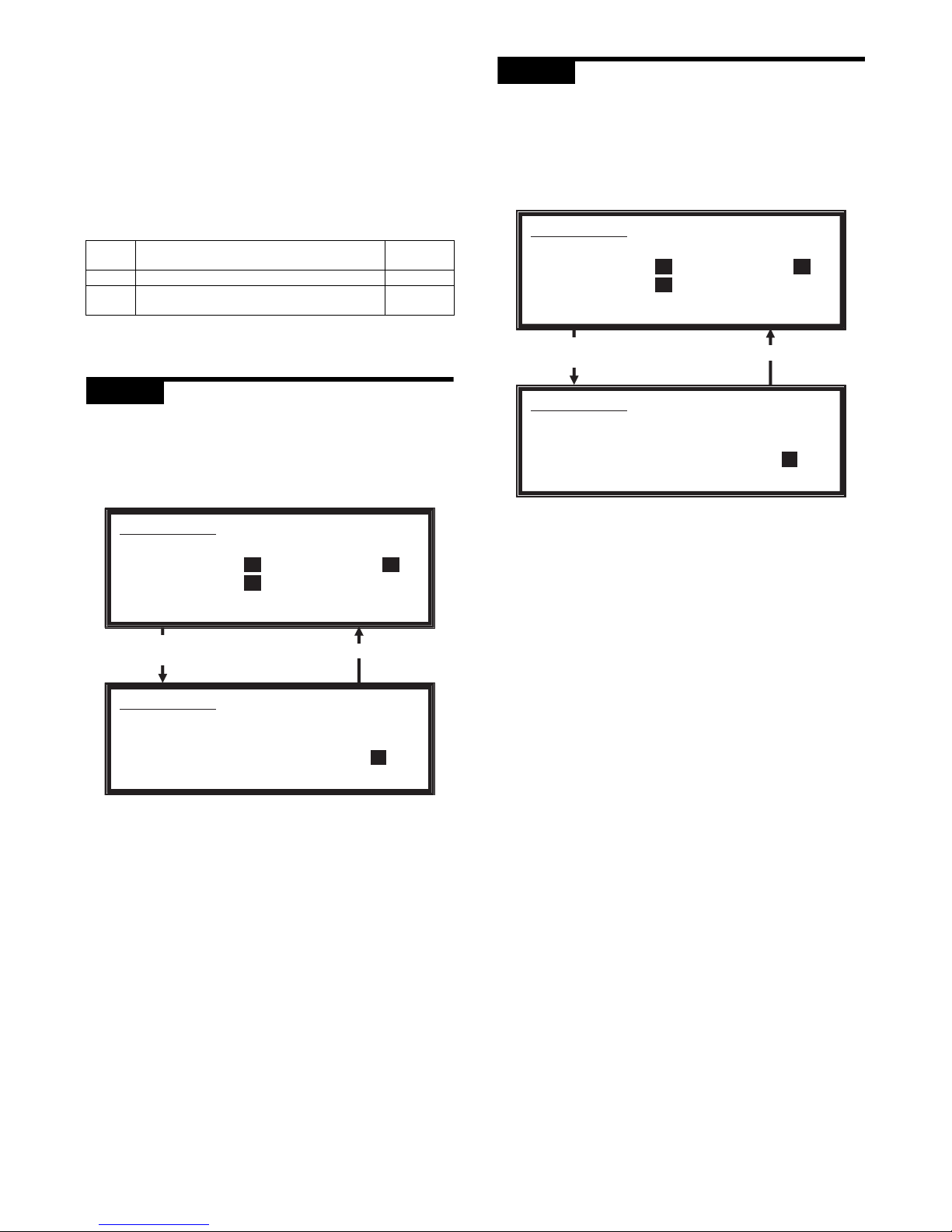

[4] ADJUSTMENTS

1. General

Perform an adjustments when a problem occurs.

If the adjustment value is changed when there is no trouble in the

machine, a trouble may be generated such as improper alignment

of paper, paper exit jam, attachment of roller marks on paper, etc.

2. List of adjustment items

3. Details of adjustment and setting

ADJ 1 Paper alignment width

adjustment

This adjustment is executed when a trouble occurs in paper alignment.

1) Execute Sim3-10.

2) Select "1: FPAM ADJUST".

3) Enter the set value with 10-key. (Press [C] key to clear the

entered values.)

Initial value: 50

When the adjustment value is increased by 1, the alignment

plate F/R width is narrowed by 0.419mm in alignment operation.

When the adjustment value is decreased by 1, the alignment

plate F/R width is widened by 0.419mm in alignment operation.

The alignment plate F and the alignment plate R cannot be

adjusted separately. The shift amount on the F side and that

on the R side are alternatively corrected everytime the adjustment value is increased by 1. (Correction with 51 for the F

side, and 52 for the R side. ... 59 for the F aide, and 60 for the

R side. Similar when the set value is decreased.) When, however, the alignment plate lower cannot be adjusted due to the

mechanism structure, adjust only on the R side without correcting both of the F and the R side.

4) Press [OK] key to save the set value.

5) After completion of the adjustment, make staple copies.

Alignment specification: Within 2.5mm

ADJ 2 Paper delivery roller

descending position

adjustment

This adjustment is executed when a paper exit jam occurs or when

roller marks of the paper delivery roller are attached to paper.

1) Execute Sim3-10.

2) Select "2: FDRLM ADJUST".

3) Enter the set value with 10-key. (Press [C] key to clear the

entered values.)

Initial value: 50

When the adjustment value is increased by 1, the shift amount

of the paper delivery roller is changed by 0.13mm toward the

pressure increasing side (*1).

When the adjustment value is decreased by 1, the shift

amount of the paper delivery roller is changed by 0.13mm

toward the pressure decreasing side (*1).

*1: The pressure increasing side means the direction to

increase the paper delivery roller pressure onto paper, and

the pressure decrease side means the direction to

decrease the paper delivery roller pressure onto paper.

4) Press [OK] key to save the set value.

Job No Adjustment items

Simulation

to be used

ADJ1 Paper alignment width adjustment 3-10

ADJ2 Paper delivery roller descending position

adjustment

3-10

SIMULATION 3-10

FINISHER SETTING. SELECT 1-2, AND PRESS START.

1: FPAM ADJUST 50 1

2: FDRLM ADJUST 50

SIMULATION 3-10

FINISHER SETTING. INPUT VALUE 40-60, AND PRESS

START.

1: FPAM ADJUST 50

Select 1 and

press [START] key.

Press [CUSTOM SETTINGS] key.

SIMULATION 3-10

FINISHER SETTING. SELECT 1-2, AND PRESS START.

1: FPAM ADJUST 50 2

2: FDRLM ADJUST 50

SIMULATION 3-10

FINISHER SETTING. INPUT VALUE 40-60, AND PRESS

START.

2: FDRLM ADJUST 50

Select 2 and

press [START] key.

Press [CUSTOM SETTINGS] key.

Page 10

MX-FN23 TROUBLE CODE 5 – 1

[5] TROUBLE CODE

1. Trouble code list

2. Details

F1-00 Finisher communication trouble

F1-03 Finisher delivery roller lift motor

trouble

F1-10 Finisher staple motor trouble

F1-15 Finisher tray lift motor trouble

MAIN

CODE

SUB

CODE

Content Section Operation mode Remedy NOTE

F1 00 Finisher communication trouble FIN When communicating Turn ON/OFF the power.

03 Finisher delivery roller lift motor trouble FIN When the roller is operating Check the connection state.

10 Finisher staple motor trouble FIN When the staple is operating Check the connection state.

15 Finisher tray lift motor trouble FIN When the tray is operating Check the connection state.

19 Finisher paper alignment motor F trouble FIN When the alignment plate is operating Check the connection state.

20 Finisher paper alignment motor R trouble FIN When the alignment plate is operating Check the connection state.

29 Finisher cooling fan trouble FIN When paper is delivered. Check the paper exit, etc.

37 Finisher RAM data trouble FIN When the RAM is accessed. Check the connection state.

50 Finisher incompatible trouble FIN When the power is turned ON Check the connection state.

Phenomenon Communication error with the finisher.

Communication line test error after turning ON the

power or canceling the exclusive simulation.

Case 1 Cause Connection trouble or disconnection of the connector

and the harness.

Check &

Remedy

Check the connector and the harness in the

communication line.

Connect the connector properly. Replace the

harness.

Case 2 Cause Finisher control PWB trouble. Control PWB (PCU)

trouble.

Check &

Remedy

Replace the finisher control PWB or the control PWB

(PCU).

Case 3 Cause Malfunctions caused by noises.

Check &

Remedy

Canceled by turning OFF/ON the power.

Phenomenon Up/down operation trouble of the paper delivery

roller.

Case 1 Cause Connection trouble or disconnection of the connector

and the harness of the motor

Check &

Remedy

Check the connection of the connector and the

harness in the motor line with the finisher control

PWB.

Connect the connector properly. Replace the

harness.

Case 2 Cause Delivery roller position sensor (FDRPS) trouble.

Check &

Remedy

Check to confirm that the FDRPS turns ON/OFF with

SIM3-2.

If it does not turn ON/OFF, check the connection of

the connector and the harness of the sensor.

Replace the sensor.

Case 3 Cause Motor lock, an overcurrent to the motor, intrusion of

foreign material.

Check &

Remedy

Select the FDRLM with SIM3-3 to check the

operation of the single unit.

Check to confirm that there is no foreign material in

the drive system.

Case 4 Cause Finisher control PWB trouble. Motor trouble

Check &

Remedy

Replace the finisher control PWB or the motor.

Phenomenon Staple motor operation trouble

Case 1 Cause Connection trouble or disconnection of the connector

and the harness of the staple unit.

Check &

Remedy

Check the connection of the connector and the

harness between the finisher control PWB and the

staple unit line.

Connect the connector properly. Replace the

harness.

Case 2 Cause Motor lock, an overcurrent to the motor, intrusion of

foreign material.

Check &

Remedy

Select the FSM with SIM3-3 to check the operation of

the single unit.

Check to confirm that there is no foreign material in

the staple unit.

Case 3 Cause Finisher control PWB trouble. Staple unit trouble.

Check &

Remedy

Replace the finisher control PWB or the staple unit.

Phenomenon Up/down operation trouble of the paper delivery tray

Case 1 Cause Connection trouble or disconnection of the connector

and the harness of the motor

Check &

Remedy

Check the connection of the connector and the

harness in the motor line with the finisher control

PWB.

Connect the connector properly. Replace the

harness.

Case 2 Cause Paper level detector (FPLD) trouble.

Check &

Remedy

Check to confirm that the FPLD turns ON/OFF with

SIM3-2.

If it does not turn ON/OFF, check the connection of

the connector and the harness of the sensor.

Replace the sensor.

Case 3 Cause Delivery tray lower limt sensor (FDTLLS) trouble.

Check &

Remedy

Check to confirm that the FDTLLS turns ON/OFF

with SIM3-2.

If it does not turn ON/OFF, check the connection of

the connector and the harness of the sensor.

Replace the sensor.

Case 4 Cause Motor lock, an overcurrent to the motor, intrusion of

foreign material.

Check &

Remedy

Select the FTLM with SIM3-3 to check the operation

of the single unit.

Check to confirm that there is no foreign material in

the drive system.

Case 5 Cause Finisher control PWB trouble. Motor trouble

Check &

Remedy

Replace the finisher control PWB or the motor.

Page 11

MX-FN23 TROUBLE CODE 5 – 2

F1-19 Finisher paper alignment motor F

trouble

F1-20 Finisher paper alignment motor R

trouble

F1-29 Finisher cooling fan trouble

F1-37 Finisher RAM data trouble

F1-50 Finisher incompatible trouble

Phenomenon Operation trouble of the paper alignment plate F

Case 1 Cause Connection trouble or disconnection of the connector

and the harness of the motor

Check &

Remedy

Check the connection of the connector and the

harness in the motor line with the finisher control

PWB.

Connect the connector properly. Replace the

harness.

Case 2 Cause Paper alignment plate home position sensor F

(FAPHPS-F) trouble.

Check &

Remedy

Check to confirm that the FAPHPS-F turns ON/OFF

with SIM3-2.

If it does not turn ON/OFF, check the connection of

the connector and the harness of the sensor.

Replace the sensor.

Case 3 Cause Motor lock, an overcurrent to the motor, intrusion of

foreign material.

Check &

Remedy

Select the FPAM-F with SIM3-3 to check the

operation of the single unit.

Check to confirm that there is no foreign material in

the drive section and the alignment plate.

Case 4 Cause Finisher control PWB trouble. Motor trouble

Check &

Remedy

Replace the finisher control PWB or the motor.

Phenomenon Operation trouble of the paper alignment plate R

Case 1 Cause Connection trouble or disconnection of the connector

and the harness of the motor

Check &

Remedy

Check the connection of the connector and the

harness in the motor line with the finisher control

PWB.

Connect the connector properly. Replace the

harness.

Case 2 Cause Paper alignment plate home position sensor R

(FAPHPS-R) trouble.

Check &

Remedy

Check to confirm that the FAPHPS-R turns ON/OFF

with SIM3-2.

If it does not turn ON/OFF, check the connection of

the connector and the harness of the sensor.

Replace the sensor.

Case 3 Cause Motor lock, an overcurrent to the motor, intrusion of

foreign material.

Check &

Remedy

Select the FPAM-R with SIM3-3 to check the

operation of the single unit.

Check to confirm that there is no foreign material in

the drive section and the alignment plate.

Case 4 Cause Finisher control PWB trouble. Motor trouble

Check &

Remedy

Replace the finisher control PWB or the motor.

Phenomenon When the finisher cooling fan is operating, the lock

signal is not canceled in a certain time.

Case 1 Cause Improper connection or disconnection of the fan

connector and harness.

Check &

Remedy

Check the connector and harness of the finisher

control PWB and the fan line.

Connect the connector securely. Replace the

harness.

Case 2 Cause Motor lock, an over current to the motor, intrusion of

a foreign material.

Check &

Remedy

Select the FCF with SIM03-03 and check the

operation of the single unit.

Case 3 Cause Finisher control PWB trouble, fan trouble.

Check &

Remedy

Replace the finisher control PWB or the staple unit.

Phenomenon Backup RAM operation trouble

Case 1 Cause Finisher control PWB trouble. EEPROM trouble.

Check &

Remedy

Replace the finisher control PWB or the EEPROM.

Phenomenon Connection of a finisher incompatible with the

machine is detected.

Case 1 Cause Connection of a finisher incompatible with the

machine is detected.

Check &

Remedy

Connect the MX-FN23 to the machine.

Page 12

MX-FN23 OPERATIONAL DESCRIPTIONS 6 – 1

[6] OPERATIONAL DESCRIPTIONS

1. General

This chapter describes the operations of the finisher.

The major operation modes are as follows:

• Offset mode

• Staple mode

In this chapter, the basic operations in the above two modes are described.

2. Outline of the transport path

The outline of the transport path is described below.

3. Offset mode

When the operation mode command is received from the copier,

the finisher starts the transport operation.

A. Reception of paper discharged from the main

unit

1) The paper delivery motor (FPDM) is driven in the paper delivery direction to lift the take-up roller. When a flapper solenoid

request (finisher paper pass) is received, the paper gate solenoid (FPGS) is turned ON to switch the paper pass gate to the

finisher side.

2) When paper enters the finisher, the paper transport motor

(FPTM) is driven at the machine paper delivery speed to

receive paper delivery from the machine.

3) When the rear edge of paper passes the paper delivery roller

of the machine, the paper transport motor (FPTM) is accelerated to 400mm/sec. After a lapse of a certain time, the paper

alignment motor F (FPAM-F) and the paper alignment motor R

(FPAM-R) are driven to make the paper alignment plate stand

by outside of paper. Then, the alignment roller lift solenoid

(FARLS) is turned ON to lift the rear edge take-up roller.

No. Name No. Name

1 Delivery movable tray 8 Paper pass detector

2 Paper delivery tray paper detector 9 Paper pass gate

3 Delivery paddler 10 Stapler

4 Paper delivery roller 11 Rear edge plate

5 Take-up roller 12 Paper rear edge detector

6 Paper alignment plate (F, R) 13 Rear edge take-up roller

7 Paper pass roller 14 Paper level actuator

45 7

10

31 6

11121314

2 8 9

Page 13

MX-FN23 OPERATIONAL DESCRIPTIONS 6 – 2

B. Paper alignment

1) When the rear edge of paper passes the paper pass roller, the

paper delivery motor (FPDM) is driven in the reversing direction at 400mm/sec, descending and rotating the take-up roller

to pull the paper rear edge to the rear edge plate.

2) After a lapse of time from detecting ON of the paper rear edge

detector (FPRD), the paper delivery motor (FPDM) is driven in

the paper delivery direction at 400mm/sec, lifting the take-up

roller and rotating the paper delivery roller. At the same time,

the delivery roller lift motor (FDRLM) is driven downward to

shift to the stand-by position of the paper delivery roller.

3) After the take-up roller is lifted, the paper alignment motor F

(FPAM-F) and the paper alignment motor R (FPAM-R) are

driven by a certain level to align paper to the front side or to the

rear side.

C. Paper delivery

1) After completion of alignment, the delivery roller lift motor

(FDRLM) is driven downward to lower the paper delivery roller

to the paper delivery position, discharging paper in the process

tray.

2) After detecting OFF of the paper rear edge detector (FPRD),

the paddle solenoid (FPS) is turned ON to shift to the delivery

paddler to the save position.

3) After a lapse of time from detecting OFF of the paper rear

edge detector (FPRD), the paper delivery motor (FPDM) is

decelerated to decelerate paper delivery. At the same time, the

paper alignment motor F (FPAM-F) and the paper alignment

motor R (FPAM-R) are driven to shift the paper alignment plate

to the home position.

The alignment roller lift solenoid (FARLS) is turned OFF to

descend the rear edge take-up roller.

4) After the paper passes the paper delivery roller, the delivery

roller lift motor (FDRLM) is driven upward to lift the paper delivery roller to the home position.

5) After lifting the paper delivery roller, the paddle solenoid (FPS)

is turned OFF to rotate the paper delivery paddler one turn and

to press paper with the paper level actuator.

6) When there is the next paper, repeat the procedures from "A-

2)". In the same bundle, however, the alignment direction of

the paper alignment plate is the same. When the bundle is

changed, the alignment position is changed to the opposite to

that of the previous bundle.

7) If there is no paper following, each actuator is turned OFF to

complete the transport operations.

4. Staple mode

When the operation mode command is received from the copier,

the finisher starts the transport operation.

A. Reception of paper discharged from the main

unit

1) The paper delivery motor (FPDM) is driven in the paper delivery direction to lift the take-up roller. When a flapper solenoid

request (finisher paper pass) is received, the paper gate solenoid (FPGS) is turned ON to switch the paper pass gate to the

finisher side.

2) When paper enters the finisher, the paper transport motor

(FPTM) is driven at the machine paper delivery speed to

receive paper delivery from the machine.

3) When the rear edge of paper passes the paper delivery roller

of the machine, the paper transport motor (FPTM) is accelerated to 400mm/sec. After a lapse of a certain time, the paper

alignment motor F (FPAM-F) and the paper alignment motor R

(FPAM-R) are driven to make the paper alignment plate stand

by outside of paper.

Page 14

MX-FN23 OPERATIONAL DESCRIPTIONS 6 – 3

B. Paper alignment and stapling

1) When the rear edge of paper passes the paper pass roller, the

paper delivery motor (FPDM) is driven in the reversing direction at 400mm/sec, descending and rotating the take-up roller

to pull the paper rear edge to the rear edge plate.

2) After a lapse of time from detecting ON of the paper rear edge

detector (FPRD), the paper delivery motor (FPDM) is driven in

the paper delivery direction at 400mm/sec, lifting the take-up

roller and rotating the paper delivery roller.

3) After a lapse of a certain time from detecting ON of the paper

rear edge detector (FPRD), the paper alignment motor F

(FPAM-F) or the paper alignment motor R (FPAM-R) is driven

by a certain level depending on the paper to be aligned to align

paper to the staple position.

4) After completion of alignment, the alignment roller lift solenoid

(FARLS) is turned OFF to descend the rear edge take-up

roller. If two or more sheets of paper are aligned, the alignment

motor operated in procedure 3) to shift the paper alignment

plate to the home position. The operations from [A-2] are

repeated for the specified number of sheets. After completion

of alignment of the specified number of sheets, the staple

motor (FSM) is driven to perform stapling.

C. Paper delivery

1) After stapling, the paper alignment motor R (FPAM-R) and the

paper alignment motor F (FPAM-F) are driven to separate the

paper alignment plate 3mm away from paper. At the same

time, the delivery roller lift motor (FDRLM) is driven downward

by a certain level to shift the paper delivery roller to the paper

delivery position, discharging the paper bundle from the process tray.

2) After detecting OFF of the paper rear edge detector (FPRD),

the paddle solenoid (FPS) is turned ON to shift to the delivery

paddler to the save position.

3) After a lapse of time from detecting OFF of the paper rear

edge detector (FPRD), the paper delivery motor (FPDM) is

decelerated to decelerate paper delivery. At the same time, the

paper alignment motor F (FPAM-F) and the paper alignment

motor R (FPAM-R) are driven to shift the paper alignment plate

to the home position.

The alignment roller lift solenoid (FARLS) is turned OFF to

descend the rear edge take-up roller.

4) After the paper passes the paper delivery roller, the delivery

roller lift motor (FDRLM) is driven upward to lift the delivery

roller to the home position.

5) After lifting the paper delivery roller, the paddle solenoid (FPS)

is turned OFF to rotate the paper delivery paddler one turn and

to press paper with the paper level actuator.

6) When there is the next paper, repeat the procedures from "A-

2)".

7) If there is no paper following, each actuator is turned OFF to

complete the transport operations.

Page 15

MX-FN23 OPERATIONAL DESCRIPTIONS 6 – 4

5. Electrical section

A. Overall block diagram

CPU

)

7

13

2/S

8

H(

(STA457C)

(2SB1240 x4)

+24V

+24V

+24V

P-GND

FG

WSSF

FAPHPS-R

FPRD

FAPHPS-F

FSTPD

FDTLLS

FPLD

FDRPS

+5V

+5V

+5V

+5V

+5V

+5V

+5V

+5V

+5V

+5V

+5VR

FTPS

FPPD1

S-GND

MX-FN23

FDTPD

FPLS

+24VR

+24VR

+24V

Paper alignment motor F

Delivery roller lift motor

Paper delivery motor

Paper transport motor

Paper alignment motor R

H bridge circuit

Tray lift motor

Paddle solenoid

Paper gate solenoid

Alignment roller lift solenoid

Transistor array

Fan motor drive circuit

Not installed

LED PWB UN

Illumination of the staple unit

Cooling fan motor

RxD-FIN

+3.3V+5V

+24V

+24VR

TxD-FIN

DSR-FIN

/DTR-FIN

/RES-FIN

FINDET

Input buffer

Input buffer

Output buffer

Output buffer

Input buffer

3-terminal Reg

Input buffer

Safety switch

On-board

writing circuit

Main unit

FPAPD

FDRLPD

FPDPD

FPTPD

STLK

FCF-LD

FSL

FPAM-F

FPAM-R

FDRLM

FPDM

FPTM

FSM

FSHPS

FSED

FSLD

FTLM

FPGS

FPS

FARL S

FCF

FSL

+24V

+24V

+24VR

+24VR

+5V

+24VR

+5VR

(TD62003APG)

Paper rear edge detector

Paper alignment plate home

position sensor F

Staple tray paper detector

Paper level detector

Delivery tray lower limit sensor

Delivery tray position sensor

Paper pass detector

Delivery roller position sensor

Paper alignment plate home

position sensor R

Paper delivery tray paper detector

Paper level sensor

IF MAIN PWB UN

Sensor

in put

circuit

Chopping

circuit

(STA7101M)

Chopping

circuit

(STA7101M)

Chopping

circuit

(STA7101M)

Chopping

circuit

(STA7101M)

(STA7101M)

Chopping

circuit

H bridge circuit

Staple Motor

Staple home position sensor

Staple empty detector

Staple lead detector

Staple unit

(RQJ0602EGDQS)

Page 16

MX-FN23 MAINTENANCE 7 – 1

[7] MAINTENANCE

1. Maintenance system table

5: Check {: Clean s: Replace U: Adjust I: Lubricate

No. Part name 75K 150K 225K 300K 375K 450K 525K 600K Remark

1 Rear edge take-up roller 55555555Replace as needed.

Supply of service parts

2 Staple cartridge Replace at every 5K. Replacement is made by the user.

1

2

Page 17

MX-FN23 DISASSEMBLY AND ASSEMBLY 8 – 1

[8] DISASSEMBLY AND

ASSEMBLY

1. External view

A. Finisher

1) Remove the hand screw from the finisher connection connector on the side of the machine, and remove the machine connection harness from the finisher.

2) Open the front cover. Remove the resin clip, and remove the

front cover.

3) Remove the screw, and remove the left cabinet of the

machine.

4) Open the front cabinet of the machine.

5) Remove the screw, and remove the front cabinet lower and the

connection cabinet.

6) Release the lock with the separation lever, and slide the finisher to the left.

7) Remove the connection plate, and slide the finisher toward

you.

8) Remove the finisher.

Page 18

MX-FN23 DISASSEMBLY AND ASSEMBLY 8 – 2

B. Main PWB cover

1) Remove the screw, and remove the main PWB cover.

C. Front cabinet

1) Remove the screw, and remove the separation lever. Remove

the screw, and remove the front cabinet.

D. Rear cabinet

1) Remove the screw, and remove the rear cabinet.

E. Paper entry paper guide unit

1) Remove the screw, and remove the paper entry paper guide

unit.

F. Upper paper guide

1) Remove the screw, and remove the upper paper guide.

2. Paper entry, alignment, staple

A. Staple cartridge

1) Open the front cover.

2) Turn the separation lever to the left to separate the finisher

from the machine.

3) Pull the lever of the staple case to remove the staple case.

NOTE: When installing the staple case, push it until it locks.

Page 19

MX-FN23 DISASSEMBLY AND ASSEMBLY 8 – 3

4) Remove the staple cartridge.

NOTE: When installing the staple cartridge, push it until it locks.

NOTE: If there is any staple remaining in the staple cartridge, the

cartridge cannot be removed.

B. Staple motor

1) Remove the main PWB cover.

2) Disconnect the connector, remove the screw, and remove the

staple motor.

C. Paper gate solenoid

1) Remove the front cabinet.

2) Disconnect the connector, remove the screw, and remove the

paper gate solenoid mounting plate unit.

3) Remove the screw, and remove the paper gate solenoid.

NOTE: After fixing the paper gate solenoid, the plunger must be in

contact with the molt (F/R) of the paper entry lower PG in

the free state.

Press the plunger with your finger to check to confirm that it

is in contact with the molt (F/R) of the paper entry upper

PG.

D. Safety switch

1) Disconnect the connector, remove the screw, and remove the

safety switch.

E. Paper pass detector

1) Remove the paper entry paper guide unit.

2) Remove the upper paper guide.

3) Remove the screw, remove the mounting plate, and disconnect the connector. Remove the screw, and remove the paper

entry detector.

Page 20

MX-FN23 DISASSEMBLY AND ASSEMBLY 8 – 4

F. Paper rear edge detector

1) Disconnect the connector, remove the screw, and remove the

upper stay right unit.

2) Remove the screw, and remove the ST paper entry paper

guide lower.

3) Remove the paper rear edge detector, and disconnect the connector.

G. Paper transport motor

1) Disconnect the connector, remove the screw, and remove the

harness holder.

2) Disconnect the connector, remove the screw, and remove the

paper transport motor.

H. Rear edge take-up roller

1) Remove the E-ring, the pulley, the belt, and the parallel pin.

2) Disconnect the connector, remove the screw, and remove the

take-up solenoid mounting plate unit.

Page 21

MX-FN23 DISASSEMBLY AND ASSEMBLY 8 – 5

3) Remove the E-ring, the tray paper entry collar, and the parallel

pin, and remove the rear edge take-up roller.

I. Alignment roller lift solenoid

1) Disconnect the connector, remove the screw, and remove the

roller lift solenoid.

NOTE: After fixing the roller lift solenoid, the plunger must be in

contact with the rear edge regulation plate in the free state.

Press the plunger with your finger to check to confirm that

the clearance between the take-up roller and the rear edge

regulation plate is 10 - 12mm.

J. Paper alignment motor F

1) Remove the JAM release knob, the one-way coupling, the

Mylar, the pulley, the SP pin, the E-ring, and the bearing, and

remove the paper entry roller.

2) Remove the screw, and remove the upper stay left.

3) Remove the E-ring, and remove the pressure release drive

gear. Remove the E-ring, and slide the bearing, and remove

the paper delivery pressure release PG unit.

4) Remove the E-ring, the Mylar, the pulley, and the parallel pin.

Remove the E-ring, and slide the bearing, and remove the

paper delivery roller unit.

5) Disconnect the connector. Remove the screw, and remove the

compiler.

10 12mm0mm

Page 22

MX-FN23 DISASSEMBLY AND ASSEMBLY 8 – 6

6) Disconnect the connector. Remove the screw, and remove the

paper alignment motor F.

K. Paper alignment motor R

1) Disconnect the connector. Remove the screw, and remove the

paper alignment motor R.

L. Paper alignment plate home position sensor F

1) Remove the screw, remove the mounting plate, and disconnect the connector. Remove the paper alignment plate home

position F sensor from the mounting plate.

M. Paper alignment plate home position sensor R

1) Remove the screw, remove the mounting plate, and disconnect the connector. Remove the paper alignment plate home

position R sensor from the mounting plate.

N. Staple tray paper detector

1) Remove the screw, and remove the sensor holder and the rear

edge regulation plate.

2) Remove the screw, and remove the jogger F and the jogger R.

3) Remove the screw, and remove the alignment tray upper unit.

Page 23

MX-FN23 DISASSEMBLY AND ASSEMBLY 8 – 7

4) Remove the staple tray paper detector, and disconnect the

connector.

3. Paper delivery

A. Delivery roller position sensor

1) Remove the rear cabinet.

2) Remove the E-ring, and remove the pressure release drive

gear. Disconnect the connector, and remove the paper delivery roller position sensor.

B. Tray lift motor

1) Remove the front cabinet.

2) Remove the harness holder.

3) Disconnect the connector, remove the screw, and remove the

lift drive frame.

4) Remove the worm gear and the screw, and remove the tray lift

motor.

C. Paddle solenoid

1) Remove the E-ring, the paddler drive collar, the baring, the

gear, the parallel pin, the Mylar, the belt, and the pulley.

2) Remove the screw, and remove the EV frame unit.

3) Remove the screw, and remove the paddle solenoid.

Page 24

MX-FN23 DISASSEMBLY AND ASSEMBLY 8 – 8

NOTE: After fixing the paddle solenoid, the paddler solenoid arm

must be in contact with the paddler drive collar with the

plunger in the free state.

Press the plunger with your finger to check to confirm that

the clearance between the paddler solenoid arm and the

paddler drive collar is 0 - 1.5mm.

D. Delivery tray position sensor, Delivery tray

lower limit sensor

1) Remove the delivery tray position sensor and the delivery tray

lower limit sensor.

E. Paper delivery motor

1) Remove the compiler.

2) Remove the spring, the E-ring, the gear, and remove the

screw.

3) Disconnect the connector, remove the paper delivery motor

unit.

4) Remove the screw, and remove the paper delivery motor.

F. Delivery roller lift motor

1) Remove the screw, and remove the pressure release drive

cover. Remove the screw.

2) Disconnect the connector, and remove the delivery roller lift

motor.

0 - 1.5mm0mm

Page 25

MX-FN23 DISASSEMBLY AND ASSEMBLY 8 – 9

G. Paper level detector

1) Disconnect the connector, remove the paper level detector.

H. Paper level sensor

1) Disconnect the connector. Remove the screw, and remove the

paper level sensor.

I. Paper delivery tray paper detector

1) Remove the screw, and remove the tray upper cover.

2) Remove the paper delivery extension tray.

3) Remove the actuator. Remove the paper delivery tray paper

detector, and disconnect the connector.

4. Others

A. LED PWB

1) Remove the main PWB cover.

2) Remove the front cabinet.

3) Remove the paper entry paper guide unit.

4) Disconnect the connector, remove the screw, and remove the

LED cover. Remove the screw, and remove the LED PWB.

B. Main PWB

1) Remove the compiler.

2) Disconnect the connector, remove the screw, and remove the

main PWB.

Page 26

MX-FN23 DISASSEMBLY AND ASSEMBLY 8 – 10

5. Fan disassembly

1) Remove one screw from the bottom frame.

2) Disconnect the connector of the FAN.

3) Remove the FAN together with the mounting plate.

4) Remove two screws from the FAN mounting plate.

Page 27

MX-FN23 SIGNAL LIST 9 – 1

[9] SIGNAL LIST

Signal

name

Name Function/Operation

Connector level

Connector

No.

Pin

No.

NOTE

"L" "H"

FAPHPS-F Finisher paper alignment plate

home position sensor F

Detects the standby position (HP) of

the alignment plate F.

Other than

HP

HP CNF 17

FAPHPS-RFinisher paper alignment plate

home position sensor R

Detects the standby position (HP) of

the alignment plate R.

Other than

HP

HP CNF 18

FARLS Finisher alignment roller lift

solenoid

Up/down operation of the take-up

roller

Up Down CNF 13

FDRLM Finisher delivery roller lift motor Up/down operation of the delivery

roller

– – CNC 12-17

FDRLMA Finisher delivery roller lift motor

control signal (phase A)

Controls the delivery roller lift motor

(phase A).

– – CNC 15

FDRLM/A Finisher delivery roller lift motor

control signal (phase /A)

Controls the delivery roller lift motor

(phase /A).

– – CNC 13

FDRLMB Finisher delivery roller lift motor

control signal (phase B)

Controls the delivery roller lift motor

(phase B).

– – CNC 12

FDRLM/B Finisher delivery roller lift motor

control signal (phase /B)

Controls the delivery roller lift motor

(phase /B).

– – CNC 14

FDRPS Finisher delivery roller position

sensor

Detects the delivery roller position. Upper

limit

Other than

upper limit

CNC 18

FDTLLS Finisher delivery tray lower limit

sensor

Detects the lower limit position of the

paper delivery tray.

Other than

lower limit

Lower limit CND 25

FDTPD Paper delivery tray paper detector Paper on the paper delivery tray is

detected.

Paper

present

on the tray

Paper empty

on the tray

CNC 22

FPAM-F Finisher paper alignment motor F Operates the alignment plate F side. – – CNF 1-6

FPAM-FA Finisher paper alignment motor F

control signal (phase A)

Controls the alignment motor F.

(phase A)

– – CNF 4

FPAM-F/A Finisher paper alignment motor F

control signal (phase /A)

Controls the alignment motor F.

(phase /A)

– – CNF 2

FPAM-FB Finisher paper alignment motor F

control signal (phase B)

Controls the alignment motor F.

(phase B)

– – CNF 1

FPAM-F/B Finisher paper alignment motor F

control signal (phase /B)

Controls the alignment motor F.

(phase /B)

– – CNF 3

FPAM-R Finisher paper alignment motor R Operates the alignment plate R side. – – CNF 7-12

FPAM-RA Finisher paper alignment motor R

control signal (phase A)

Controls the alignment motor R.

(phase A)

– – CNF 10

FPAM-R/A Finisher paper alignment motor R

control signal (phase /A)

Controls the alignment motor R.

(phase /A)

– – CNF 8

FPAM-RB Finisher paper alignment motor R

control signal (phase B)

Controls the alignment motor R.

(phase B)

– – CNF 7

FPAM-R/B Finisher paper alignment motor R

control signal (phase /B)

Controls the alignment motor R.

(phase /B)

– – CNF 9

FPDM Finisher paper delivery motor Takes up and discharges paper on

the compiler tray.

– – CND 1-6

FPDMA Finisher paper delivery motor

control signal (phase A)

Controls the paper delivery motor

(phase A).

– – CND 4

FPDM/A Finisher paper delivery motor

control signal (phase /A)

Controls the paper delivery motor

(phase /A).

– – CND 2

FPDMB Finisher paper delivery motor

control signal (phase B)

Controls the paper delivery motor

(phase B).

– – CND 1

FPDM/B Finisher paper delivery motor

control signal (phase /B)

Controls the paper delivery motor

(phase /B).

– – CND 3

FPGS Finisher paper pass gate solenoid Selects the transport path of

reversed paper and discharged

paper from the main unit.

Reverse

path

Exit path

(To FIN side)

CND 20

FPLD Finisher paper level detector Detects the paper surface on the

paper delivery tray.

– Paper surface

detection

CNC 25

FPLS Finisher paper level sensor Detects the paper surface on the

paper delivery tray.

Paper

surface

detection

–CNA5

FPPD1 Finisher paper pass detector Detects paper which enters FIN. Paper

present

Paper empty CND 29

FPRD Finisher paper rear edge detector Detects the paper rear edge at the

center when taking paper into the

compiler tray.

Paper

present

Paper empty CNF 22

FPS Finisher paddle solenoid Rotates the paddler. – – CND 18 Rotates one turn

by ON–OFF.

FPTM Finisher paper transport motor Transports paper discharged from

the main unit.

– – CND 7-12

Page 28

MX-FN23 SIGNAL LIST 9 – 2

FPTMA Finisher paper transport motor

control signal (phase A)

Controls the transport motor

(phase A).

– – CND 10

FPTM/A Finisher paper transport motor

control signal (phase /A)

Controls the transport motor

(phase /A).

– – CND 8

FPTMB Finisher paper transport motor

control signal (phase B)

Controls the transport motor

(phase B).

– – CND 7

FPTM/B Finisher paper transport motor

control signal (phase /B)

Controls the transport motor

(phase /B).

– – CND 9

FCF Finisher cooling fan Cools the paper exit motor. OFF ON CND 15

FSED Finisher staple empty detector Detects empty of spare staples in

the stapler.

Staple

present

Staple empty CNC 10

FSHPS Finisher staple home position

sensor

Detects the standby position of the

stapler.

HP Out of home

position

CNC 8

FSLD Finisher staple lead detector Detects the staple position of the

stapler.

Ready Other than

Ready

CNC 9

FSM Finisher staple motor Stapling operation of paper bundle – – CNC 3-6

FSM+ Finisher staple motor control

signal (+ side)

Controls the staple motor (+ side). – – CNC 3, 4

FSM- Finisher staple motor control

signal (- side)

Controls the staple motor (- side). – – CNC 5, 6

FSSW Finisher safety switch Turns OFF the power when the front

door is opened to stop the motor.

––CNE1-2

FSTPD Finisher staple tray paper

detector

Detects paper empty on the

compiler tray.

Paper

empty

Paper present CNF 24-26

FTLM Finisher tray lift motor Up/down operation of the paper

delivery tray

– – CNF 13-14

FTLM+ Finisher tray lift motor control

signal (+)

Controls the tray lift motor (+ side). – – CND 13

FTLM- Finisher tray lift motor control

signal (-)

Controls the tray lift motor (- side). – – CND 14

FTPS Finisher delivery tray position

sensor

Detects the upper limit position of

the paper delivery tray.

Other than

upper limit

Upper limit CND 24

Signal

name

Name Function/Operation

Connector level

Connector

No.

Pin

No.

NOTE

"L" "H"

Page 29

MX-FN23 ACTUAL WIRING CHART 10 – 1

[10] ACTUAL WIRING CHART

CN-D

B30B-PHDSS-B

FPDMA

2187564910

31246

5

PHR-6

873154612

+5V

P-GND

+24V

CN-A

B09B-PASK-1

FINSTS

FINCMD

/FINCRDY

/FINSRDY

/RES-FIN

FPLS

S-GND

CN-B

B3P-VH

FTLM

FTLM+

Tray lift motor

Cooling fan motor

PHR-2

FTLM-

Safety switch

1

3

RES-FIN/

2

4

FWE

P31(TXD1)

CN-J

B12B-PH-K-S

765

+3.3V8MD2

+3.3V

11910

12

S-GND

P33(RXD1)

P35(SCLK1)

RES-FIN

S-GND

+5V

19

11121517181314162029222125232827262430

3

FPDM/A

FPDMB

FPDM/B

+24VR

+24VR

FPTMA

FPTM/A

FPTMB

FPTM/B

+24VR

+24VR

FLTM+

FTLM-

FCF

FPGS/

+24V

+5V

+5V

FTPS

FDTLLS

S-GND

S-GND

S-GND

FPPD1

Main unit

FPDMA

+24VR

FPDM/B

FPDMB

FPDM/A

+24VR

FPDM

Delivery roller lift motor

FPTM/B

+24VR

FPTMA

FPTM/A

FPTMB

+24VR

31264

PHR-6

5

FPTM

Paper transport motor

2

1

Paddle solenoid

FPAM-F/B

+24V

FPAM-FA

FPAM-F/A

FPAM-FB

+24V

12543

6

FPAM-F

Paper alignment motor F

SMR-06V-B SMP-06V-BC

FPAM-RA

+24V

FPAM-R/B

FPAM-RB

FPAM-R/A

+24V

12456

3

FPAM-R

Paper alignment motor R

SMP-06V-BCSMR-06V-B

SMR-03V-N SMP-03V-NC

+24V

3

1

lignment roller lift solenoid

FARLS/

FARLS

1

FAPHPS-F

FAPHPS-F

2

Paper alignment plate

home position sensor F

S-GND

PHR-3

3+5V

FAPHPS-R

1

FAPHPS-R

S-GND

2

PHR-3

3+5V

1

FPRD

S-GND

FPRD 2

179228-3

+5V3S-GND

1

2

FSTPD

Staple tray paper detector

PHR-3

FSTPD

+5VR

3

Paper rear edge detector

FPS-187

FPS-187

1 FSSW

1 +24V(OUT)

FSSW

+24V(OUT)

B2P-VH

CN-E

122

+5V

3

FPPD1

FPPD1

2

Paper pass detector

S-GND

179228-3

1+5V

/FINDET 9

Paper alignment plate

home position sensor R

42531

6

SMP-11V-NC SMR-11V-N

978

10

RxD-FIN

TxD-FIN

DSR-FIN

/DTR-FIN

/FINDET

/RES-FIN

+5V

S-GND

+24V

P-GND

SMR-03V-N

2

SMP-03V-NC

FPPD1

3

1

S-GND

+5V

RxD-FIN

TxD-FIN

/RES-FIN

/FINDET

+5V

S-GND

+24V

DSR-FIN

/DTR-FIN

5

813921

12311

4

P-GND

D-SUB 15pin

14

P-GND

7835641

S-GND

2

CN-C

LED+

LED-

B26B-PHDSS-B

FSM+

FSM-

FSM+

FSHPS

FSM-

FSLD

9161412171315

11

+24VR

10

+5V

FSED

FDRLM/A

FDRLMB

FDRLMA

FDRLM/B

+24VR18FDRPS

25212324222619

FPLD

20

+5V

S-GND

+5V

S-GND

FDTPD

S-GND

+5V

FSL-2

1

FSL

Illumination of the staple unit

FSL+

PHR-2

431

2 FSM+

FSM+

FSM-

179228-5

FSM-

Staple UN

S-GND

Staple home position sensor

FSED

FSLD

FSHPS

+5V

Staple lead detector

Staple empty detector

Stalpe motor

MOTOR

45132

SENSOR

179228-4

FDRLMA

+24VR

FDRLM/B

FDRLMB

FDRLM/A

+24VR

31246

5

PHR-6

FDRLM

1

FDRPS

FDRPS

2

Delivery roller position sensor

S-GND

179228-3

3

+5V

FDTPD

3

2

FDTPD

S-GND

Paper delivery tray paper detector

1

PHR-3

+5V

FPLD

FPLD

213 S-GND

179228-3

+5V

Paper level detector

S-GND

FDTPD

+5V

213

SMR-03V-N SMP-03V-NC

S-GND

FDTPD

+5V

213

SMR-03V-N SMP-03V-NC

P-GND

FCF-LD

FPS/

+24V

Paper delivery motor

FPS

FPS/

SMP-03V-NCSMR-03V-N

3

+24V 1

FPGS

Paper gate solenoid

FPGS/

SMP-02V-NCSMR-02V-N

2

+24V

1

FCF

P-GND

PALR-03VFPAP-03V-S

3

FCF-LD 2

FCF

1

FTPS

1

FTPS

S-GND

2

179228-3

3

+5V1FDTLLS2S-GND

FDTLLS

+5V

3

179228-3

+24V9FARLS/

+5V

B26B-PHDSS-B

CN-F

FPAM-FA

1257846

+24V

S-GND

+5V10+5V

FPRD

S-GND3FSTPD

FPAM-F/A

19

1211151318

17

FPAM-FB

16142021222623

24

FPAM-F/B

+24V

+24V

+24V

FPAM-RB

FPAM-R/A

FPAM-R/B

FPAM-RA

S-GND

FAPHPS-F

FAPHPS-R25S-GND

+5V_R

Delivery tray position sensor

Delivery tray lower limit

sensor

LED PWB UN

IF MAIN PWB UN

P-GND

3

P-GND

11

15 F-GND

FPLS

FPLS

213 S-GND

179228-3

+5V

Paper level sensor

HRS

DF11-4DS-2C

+DF11-4DP-SP1(05)

5V

1234

DF11-4DS-2C

HRS

321

GND

+DF11-4DP-SP1(05)

4

Paper entry sensor harness

Process tray harness

Front harness

Front harness

Machine interface harness

Tray paper

detection harness

Tray interface

harness

Rear harness

Page 30

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

COPYRIGHT©XXXX BYSHARP CORPORATION

ALL RIGHTS RESERVED.

The PWB’s of this model employs lead-free solder. The “LF” marks indicated on the PWB’s and the Service Manual mean “Lead-Free” solder.

LEAD-FREE SOLDER

The alphabet following the LF mark shows the kind of lead-free solder.

(1) NOTE FOR THE USE OF LEAD-FREE SOLDER THREAD

When repairing a lead-free solder PWB, use lead-free solder thread.

Never use conventional lead solder thread, which may cause a breakdown or an accident.

Since the melting-point of lead-free solder thread is about 40°C higher than that of conventional lead solder thread, the use of the

exclusive-use soldering iron is recommended.

(2) NOTE FOR SOLDERING WORK

Since the melting-point of lead-free solder is about 220°C, which is about 40°C higher than that of conventional lead solder, and its soldering

capacity is inferior to conventional one, it is apt to keep the soldering iron in contact with the PWB for longer time. This may cause land

separation or may exceed the heat-resistive temperature of components. Use enough care to separate the soldering iron from the PWB when

completion of soldering is confirmed.

Since lead-free solder includes a greater quantity of tin, the iron tip may corrode easily. Turn ON/OFF the soldering iron power frequently.

If different-kind solder remains on the soldering iron tip, it is melted together with lead-free solder. To avoid this, clean the soldering iron

tip after completion of soldering work.

If the soldering iron tip is discolored black during soldering work, clean and file the tip with steel wool or a fine filer.

Example:

5mm

Lead-Free

Solder composition

code (Refer to the

table at the right.)

<Solder composition code of lead-free solder>

Solder composition

Sn-Ag-Cu

Sn-Ag-Bi

Sn-Ag-Bi-Cu

Sn-Zn-Bi

Sn-In-Ag-Bi

Sn-Cu-Ni

Sn-Ag-Sb

Bi-Sn-Ag-P

Bi-Sn-Ag

a

b

z

i

n

s

p

Solder composition code

a

Page 31

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

le constructeur.

Mettre au rebut les batteries usagées conformément aux

instructions du fabricant.

(Swedish) VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

(German) Achtung

Explosionsgefahr bei Verwendung inkorrekter Batterien.

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Hersteller angegebenen Anweisungen.

(For USA, CANADA)

“BATTERY DISPOSAL”

THIS PRODUCT CONTAINS A LITHIUM PRIMARY

(MANGANESS DIOXIDE) MEMORY BACK-UP BATTERY

THAT MUST BE DISPOSED OF PROPERLY. REMOVE THE

BATTERY FROM THE PRODUCT AND CONTACT YOUR

LOCAL ENVIRONMENTAL AGENCIES FOR INFORMATION

ON RECYCLING AND DISPOSAL OPTIONS.

“TRAITEMENT DES PILES USAGÉES”

CE PRODUIT CONTIENT UNE PILE DE SAUVEGARDE DE

MÉMOIRE LITHIUM PRIMAIRE (DIOXYDE DE MANGANÈSE)

QUI DOIT ÊTRE TRAITÉE CORRECTEMENT. ENLEVEZ LA

PILE DU PRODUIT ET PRENEZ CONTACT AVEC VOTRE

AGENCE ENVIRONNEMENTALE LOCALE POUR DES

INFORMATIONS SUR LES MÉTHODES DE RECYCLAGE ET

DE TRAITEMENT.

CAUTION FOR BATTERY REPLACEMENT

CAUTION FOR BATTERY DISPOSAL

Page 32

All rights reserved.

Produced in Japan for electronic Distribution

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic; mechanical; photocopying; recording or otherwise

without prior written permission of the publisher.

Trademark acknowledgements

• Microsoft®, Windows®, Windows®98, Windows®Me, Windows NT®4.0,

Windows

®

2000, Windows®XP, Windows®Vista, Windows®Server 2003 and

Internet Explorer

®

are registered trademarks or trademarks of

Microsoft Corporation in the U.S.A. and other countries.

• PostScript is a registered trademark of Adobe Systems Incorporated.

• Macintosh, Mac OS, AppleTalk, EtherTalk, Laser Writer, and Safari are registered

trademarks or trademarks of Apple Computer, Inc.

• IBM, PC/AT, and Power PC are trademarks of International Business Machines

Corporation.

• Acrobat

®

Reader Copyright®1987- 2002 Adobe Systems Incorporated. All rights

reserved. Adobe, the Adobe logo, Acrobat, and the Acrobat logo are trademarks of

Adobe Systems Incorporated.

• PCL is a registered trademark of the Hewlett-Packard Company.

• Sharpdesk is a trademark of Sharp Corporation.

COPYRIGHT © 2012 BY SHARP CORPORATION

• All other trademarks and copyrights are the property of their respective owners.

SHARP CORPORATION

Business Solutions Group

CS Promotion Center

Yamatokoriyama, Nara 639-1186, Japan

2012 Jan. Produced in Japan for electronic Distribution

Loading...

Loading...