Page 1

TopPage

SERVICE MANUAL

CODE: 00ZMXFN10/S1E

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM OPTION

SADDLE STITCH FINISHER

PUNCH MODULE

PAPER PASS UNIT

MX-FN10

MX-PNX5 A/B/C/D

MODEL

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] UNPACKING AND INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . 3-1

* For how to unpacking and installation, refer to the installation manual.

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . . . . 4-1

[5] OPERATIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] DISASSEMBLY AND ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

MX-RBX3

CONTENTS

[9] SELF DIAG MESSAGE AND TROUBLE CODE. . . . . . . . . . . . . . . 9-1

[10] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

[1] PRODUCT OUTLINE

1. Product outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2. Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

[2] SPECIFICATIONS

1. MX-FN10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2. MX-PNX5 A/B/C/D . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

3. MX-RBX3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Part names and functions. . . . . . . . . . . . . . . . . . . . . . .4-1

[5] OPERATIONAL DESCRIPTION

1. Straight paper exit mode. . . . . . . . . . . . . . . . . . . . . . . .5-1

2. Non staple mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

3. Rear on position staple mode . . . . . . . . . . . . . . . . . . . .5-2

4. 2-position staple mode . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5. Front one position staple mode. . . . . . . . . . . . . . . . . . .5-3

6. Saddle motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

7. Punch process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

[6] DISASSEMBLY AND ASSEMBLY

1. Saddle finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

2. Paper Transport Section (MX-RBX3) . . . . . . . . . . . . . .6-7

3. Punch section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

[7] MAINTENANCE

1. Maintenance System Table . . . . . . . . . . . . . . . . . . . . . 7-1

[8] ADJUSTMENTS

1. Finisher/saddle unit and Punch unit . . . . . . . . . . . . . . 8-1

2. Punch unit (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

[9] SELF DIAG MESSAGE AND TROUBLE CODE

1. Interface transport unit. . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. Punch unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

3. Transport section except for the saddle. . . . . . . . . . . . 9-2

4. Process tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

5. Load tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

6. Staple unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

7. Saddle transport load section . . . . . . . . . . . . . . . . . . . 9-4

8. Saddle staple unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9. Saddle folding section . . . . . . . . . . . . . . . . . . . . . . . . 9-5

10.Other sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

[10] ELECTRICAL SECTION

1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Page 3

MX-FN10 PRODUCT OUTLINE 1 – 1

MX-FN10

Service Manual

[1] PRODUCT OUTLINE

1. Product outline

This unit is installed to the following machines to perform the after-process of output paper from a copier, or a fax machine. The output paper is

passed to the saddle finisher by the interface unit (MX-RBX3). Each sheet is discharged one by one by the offset function.

1) 3 kinds of auto staple functions:

There are 3 staple positions available. (One position in the front, one position at the back, 2 positions at the center)

2) Saddle stitch function: Up to 15 sheets of paper can be stapled at the center and folded into two and discharged.

3) Punch function (Option):

By installation of a puncher unit, paper can be punched to make holes for a binder. (Applicable for 64 – 128g/m

2

. OHP films cannot be

used.)

The saddle stitch finisher requires staple cartridge as a consumable part.

(Staple cartridge (About 5000 staples x 3) MX-SCX1, Staple cartridge (for saddle) (About 2000 staples x 3) AR-SC3)

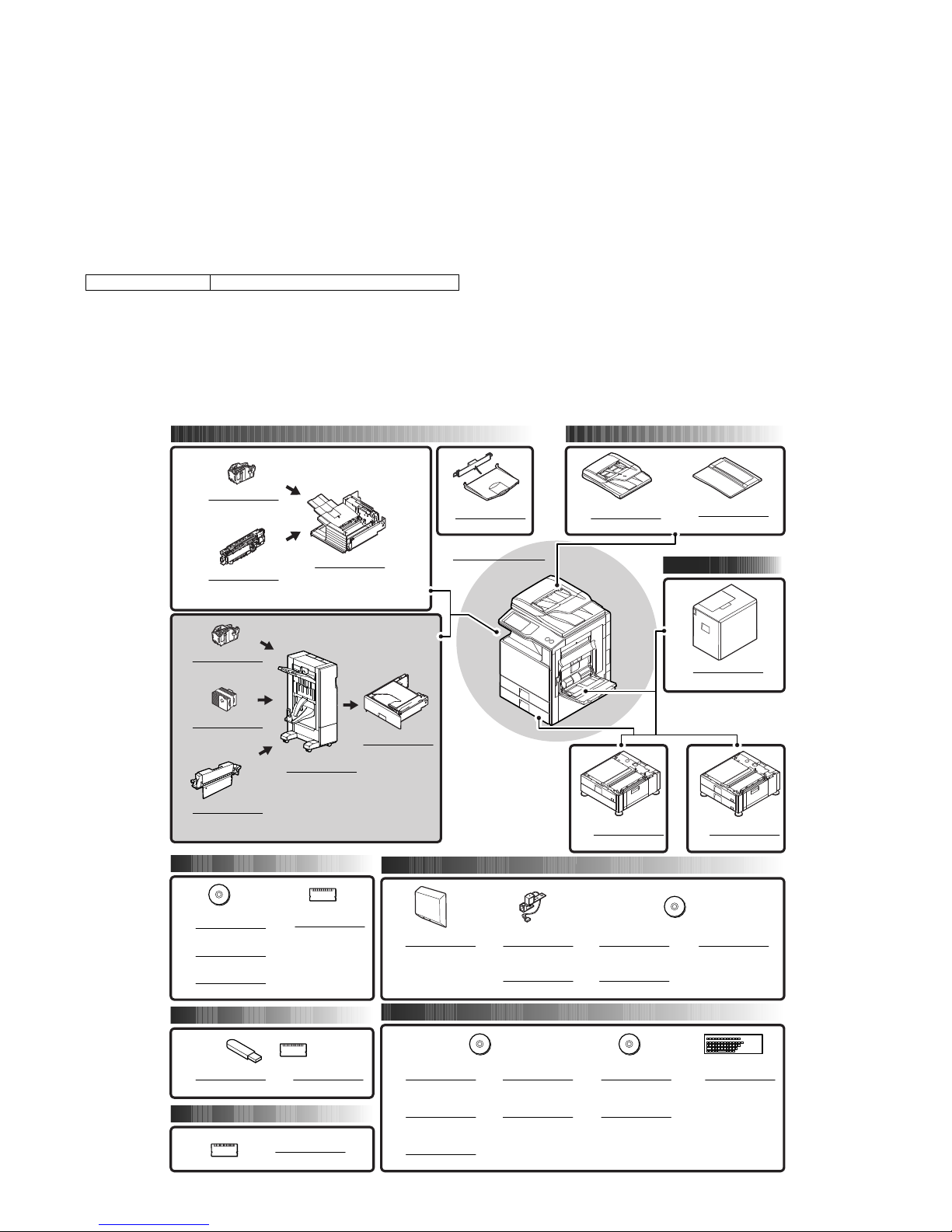

2. Configuration

1) When installing this unit, the paper feed desk (MX-DEX6/DEX7) and the interface unit (MX-RBX3) must be installed together.

2) This unit cannot be installed with the finisher (MX-FNX9) simultaneously.

Applicable models MX-2600N/3100N/2600G/3100G

Paper exit system Document feeder system

Printer expansion

Memory

Authentication/Security

Application/Solution

Image send expansion

Paper feed system

DIGITALFULL COLOR

MULTIFUNCTIONALSYSTEM

MX-2600N/3100N

MX-2600G/3100G

MX-SCX1

FINISHER

MX-FNX9

LARGE CAPACITYTRAY

MX-LCX1

STAND/2x 500 SHEET

PAPERDRAWER

MX-DEX7

PUNCH MODULE

STAPLECARTRIDGE

MX-SCX1

STAPLECARTRIDGE

STAPLECA

(For saddle)

RTRIDGE

MX-PNX1

A/B/C/D

AR-SC3

PUNCH MODULE

MX-PNX5

A/B/C/D

PRINTER

EXPANSIONKIT

MX-PBX3

EXPANSION

MEMORY BOARD

MX-SMX3

PS3 EXPANSION KIT

MX-PKX1

STAMPUNIT

AR-SU1

STAMPCARTRIDGE

AR-SV1

INTERNET FAX

EXPANSIONKIT

MX-FWX1

NETWORK SCANNER

EXPANSIONKIT

MX-NSX1

APPLICATION

INTEGRATIONMODULE

MX-AMX1

XPS EXPANSION KIT

MX-PUX1

BARCODE FONT KIT

AR-PF1

DATA SECURITY KIT

MX-FR10U

DATA SECURITY KIT

MX-FR10

SHARPDESK

5 LICENSE KIT

MX-USX5

KEYBOARD

MX-KBX1

APPLICATION

COMMUNICATIONMODULE

MX-AMX2

EXTERNAL

ACCOUNT MODULE

MX-AMX3

SADDLE STITCH

FINISHER

MX-FN10

PAPERPASS UNIT

MX-RBX3

REVERSING

SINGLE PASS FEEDER

MX-RPX2

DOCUMENT COVER

MX-VRX1

FACSIMILE

EXPANSIONKIT

MX-FXX2

EXIT TRAY UNIT

MX-TRX1

SHARPDESK

1 LICENSE KIT

MX-USX1

SHARPDESK

10 LICENSE KIT

MX-US10

SHARPDESK

50 LICENSE KIT

MX-US50

SHARPDESK

100 LICENSE KIT

MX-USA0

DIGITALFULL COLOR

MULTIFUNCTIONALSYSTEM

MX-2600N/3100N

MX-2600G/3100G

STAND/1x 500 SHEET

PAPERDRAWER

MX-DEX6

Page 4

MX-FN10 SPECIFICATIONS 2 – 1

MX-FN10

Service Manual

[2] SPECIFICATIONS

1. MX-FN10

A. Basic specifications

B. Finishing section

C. Saddle stitch section

D. Consumable parts

Type Console type finisher

Loading method Moving offset tray and saddle stitch exit tray

Transport speed 26/31/35/45/50 ppm

Transport reference Center reference

Mode types Non-staple, staple, saddle stitch/bi-folding

Paper sizes allowed for offset A3, B4, A4, A4R, B5, B5R, 8K, 16K, 16KR, 11" x 17", 8.5" x 14", 8.5" x 13.5", 8.5" x 13.4", 8.5" x 13", 8.5" x 11",

8.5" x 11"R, 7.25" x 10.5"R

Offset quantity 30mm, 1.2 inch

Tray type (Number of trays) Upper tray: Lift-up/down offset tray

Lower tray: Book tray for saddle stitch

Paper exit direction Face down

Paper exit paper size A3W, A3, B4, A4, A4R, B5, B5R, A5R, 8K, 16K, 16KR

12" x 18", 11" x 17", 8.5" x 14", 8.5" x 13.5", 8.5" x 13.4", 8.5" x 13", 8.5" x 11", 8.5" x 11"R, 5.5" x 8.5"R,

7.25" x 10.5"R

Power consumption 70W

Power source Supplied from the host machine power (DC24V/DC5V)

External dimensions (W x D x H) When the paper exit tray is on the storge position: 497 x 631 x 988 (mm), 19-9/16 x 24-53/64 x 38-57/64 (inch)

When the paper exit tray is on the pull-out position: 656 x 631 x 988 (mm), 25-13/16 x 24-53/64 x 38-57/64 (inch)

Occupying dimensions (W x D) When the tray is on pull-out position: 656 x 631 (mm), 25-13/16 x 24-53/64 (inch)

* Distance from the main unit: 300mm, 11 13/16 inch

Weight Approx. 40kg (88 lbs)

Installation/maintenance Installed by service personnel

Optional detection Auto detection supported

Packaged items Parts for mounting, operational sheet, staple directional instruction label, punch directional instrucrtion label,

installation cautionary note

Capacity of paper exit and load Non-staple: 1,000 sheets (Small size) Max. 500 sheets for A5R, 5.5" x 8.5"R (Plain paper 60 to 105g/m2 (16 to

28 lbs) or equivalent)

500 sheets (Large size) (Plain paper 60 to 80g/m

2

(16 to 21 lbs) or equivalent)

Staple sort: 50 sets * (Max. 50 sets for small size, one-position stapling at the rear)

Max: 1,000 sheets (Small size)

500 sheets (Large size)

*: Less than 1,000 sheets and less than 30 sets depending on the use environment and paper curl.

Large size: A3W, A3, B4, 8K, 12" x 18", 11" x 17", 8.5" x 14", 8.5" x 13.5", 8.5" x 13.4", 8.5" x 13"

Small size: A4, A4R, B5, B5R, A5R, 16K, 16KR, 8.5" x 11", 8.5" x 11"R, 5.5" x 8.5"R, 7.25" x 10.5"R

Offset function Provided

Paper size which can be stapled A3, B4, A4, A4R, B5, B5R, 8K, 16K, 16KR, 11" x 17", 8.5" x 14", 8.5" x 13.5", 8.5" x 13.4", 8.5" x 13", 8.5" x 11",

8.5" x 11"R

Ejectable paper size Determinate

size

AB type A3W, A3, B4, A4, A4R, B5, B5R, A5R, 8K, 16K, 16KR

Inch type 12" x 18", 11" x 17", 8.5" x 14", 8.5" x 13.5", 8.5" x 13.4", 8.5" x 13", 8.5" x 11"R,

8.5" x 11", 5.5" x 8.5"R, 7.25" x 10.5"R, 5.5" x 8.5"R

Indeterminate

size

AB type 148 x 100 to 432 x 297

Inch type 5 1/2" x 5 1/2" to 17" x 11 5/8"

Paper weight Thin paper:

Plain paper:

Heavy paper:

55 to 59g/m

2

(15 to 16 lbs)

60 to 105g/m

2

(16 to 28 lbs)

106 to 256g/m

2

(28 to 68 lbs)

Quantity of paper to be stapled (Max.) 50 sheets (Small size, 90g/m

2

(24 lbs))

25 sheets (Large size, 90g/m

2

(24 lbs))

Stapling 3 kinds (One in the front, one at the back, two positions)

Staple supply Staple cartridge replacement

Staple detection Staple empty detection: Provided (Nearly empty: 20 pcs. remained)

Manual stapling No

Stapling type 2-position stapling (center stapling), face down

Folding location Center folding

Paper size A3, B4, A4R, 8K, 16KR, 11" x 17", 8.5" x 14", 8.5" x 11"R

Weight of paper applicable for saddle stitch

60 to 105g/m2 (106 to 209g/m2 (cover 1 sheet)), 16 to 28 lbs (28 to 110 lbs (cover 1 sheet))

Quantity of paper to be stapled 10 sets (11 to 15 sheets), 15 sets (6 to 10 sheets), 20 sets (1 to 5 sheets)

1

Name Content Life Product name

Staple cartridge Staple cartridge x 3 5000 x 3 MX-SCX1

Staple cartridge (for saddle) Staple cartridge x 3 2000 x 3 AR-SC3

: '10/Jun/21

1

Page 5

MX-FN10 SPECIFICATIONS 2 – 2

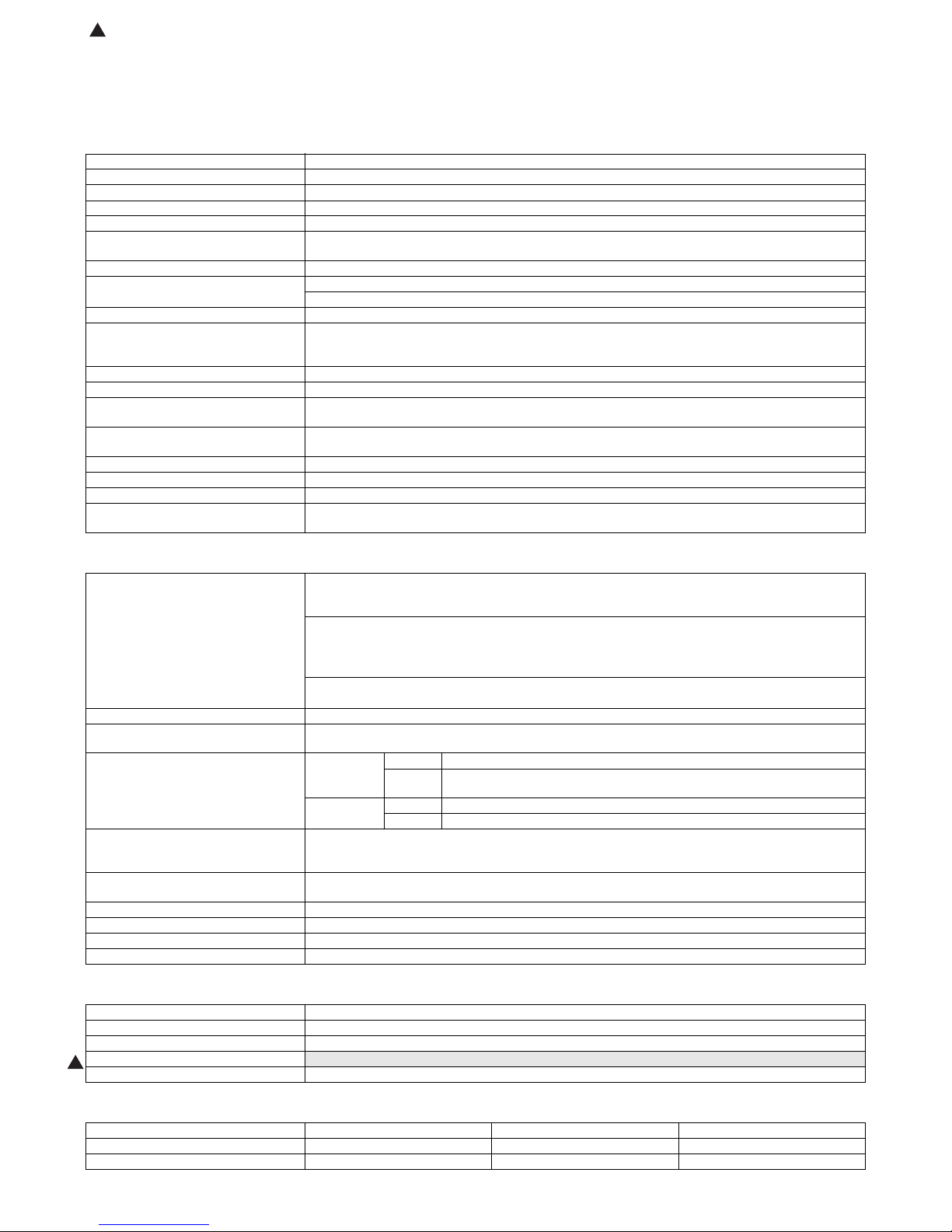

2. MX-PNX5 A/B/C/D

*1: Auto switching: 2 holes/3 holes

Kind of hole punch

Type Punch unit for saddle finisher

Punch type 2 holes / 3 holes / 4 holes / 4 holes (wide)

A punch unit that provides all of these 4 types can be installed.

Transport speed 26, 31, 35, 45, sheets/min.

Transport reference Center reference

Punch dust full detection Provided

Paper exit direction Face down

Paper weight Plain paper: 60 to 105g/m

2

(16 to 28 lbs)

Thin paper: 55 to 59g/m

2

(15 to 16 lbs)

Heavy paper: 106 to 256g/m

2

(28 to 68 lbs)

Puchable paper size 2 holes

(MX-PNX5A)

A3, B4, A4, A4R, B5, B5R, 11" x 17", 8.5" x 14", 8.5" x 13.5", 8.5" x 13.4", 8.5" x 13", 8.5" x 11",

8.5" x 11"R, 8K, 16K, 16KR

3 holes *1

(MX-PNX5B)

3 holes: A3, A4, 11" x 17", 8.5" x 11"

2 holes: 8.5" x 14", 8.5" x 13.5", 8.5" x 13.4", 8.5" x 13", 8.5" x 11"R, 7.25" x 10.5"R

4 holes

(MX-PNX5C)

A3, A4

4 holes (wide)

(MX-PNX5D)

A3, B4, A4, A4R, B5, B5R, 11" x 17", 8.5" x 14", 8.5" x 13.5", 8.5" x 13.4", 8.5" x 13", 8.5" x 11",

8.5" x 11"R

Power source Supplied from the finisher

External dimensions (W x D x H) 120.2 x 600.4 x 244.2 (mm), 4-23/32 x 23-5/8 x 9-39/64 (inch)

Weight Approx. 3.5kg (7.7 lbs)

Packaged items Parts for mounting, instructional label for garbage pickup

Kind Hole position

Hole

size

Kind Hole position

Hole

size

2 holes

(MX-PNX5A)

A: 801mm

B: 123mm

6.5mm 4 holes

(MX-PNX5C)

A: 801mm

B: 123mm

6.5mm

2/3 holes

(MX-PNX5B)

2 holes A: 1081mm

B: 123mm

8.0mm 4 holes

(wide)

(MX-PNX5D)

A: 701mm

B: 123mm

C: 211mm

6.5mm

3 holes A: 701mm

B: 123mm

ABA

B

A

A

ABA

B

C

ABA

Page 6

MX-FN10 SPECIFICATIONS 2 – 3

3. MX-RBX3

Type Paper pass unit

Paper reception reference Center referance

Receiving speed 65 to 450mm/sec (20 to 50cpm)

Receiving and sending speed 20 to 50cpm

Paper weight Thin paper:

Plain paper:

Heavy paper:

55 to 59g/m

2

(15 to 16 lbs)

60 to 105g/m

2

(16 to 28 lbs)

106 to 256g/m

2

(28 to 68 lbs)

Transportable paper sizes A3W, A3, B4, A4, A4R, B5, B5R, A5R, 16K, 16KR

12" x 18", 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R, 5.5" x 8.5"R, 7.25" x 10.5"R

External dimensions (W x D x H) 555 x 535 x 165 (mm), 21 27/32 x 21 1/16 x 6 1/2 (inch)

Weight Approx. 7kg (15.4 lbs)

Power source Supplied by saddle finisher

Power consumption Included with saddle finisher power consumption

Interface Mechanical: Fixed to the main unit with screws.

Electrical: Cable connection from the finisher

Control: Controlled by the communication command from the main unit through the finisher.

Installation/maintenance Installed by service personnel

Optional detection Auto detection supported

Packaged items Parts for mounting, installation cautionary note

Page 7

MX-FN10 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 1

MX-FN10

Service Manual

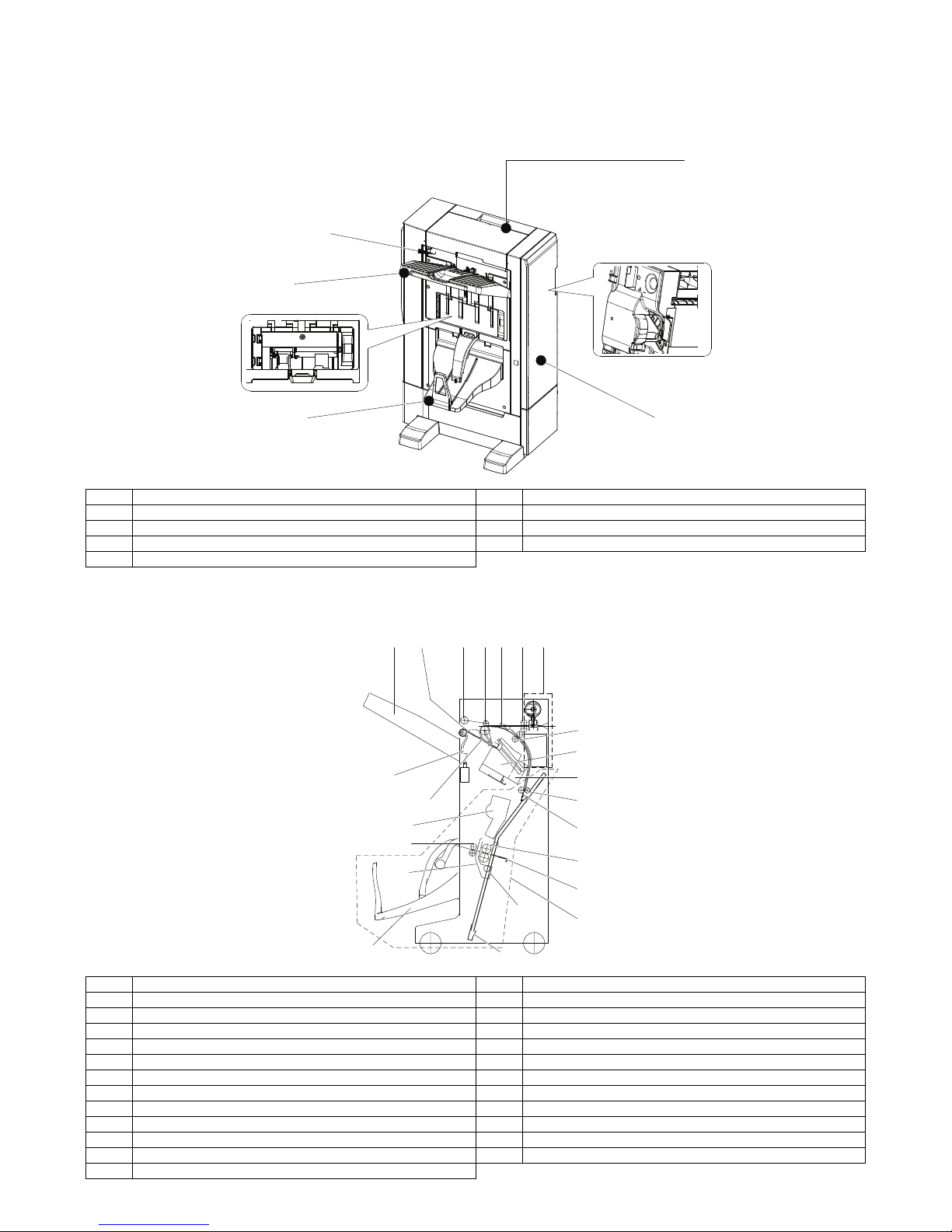

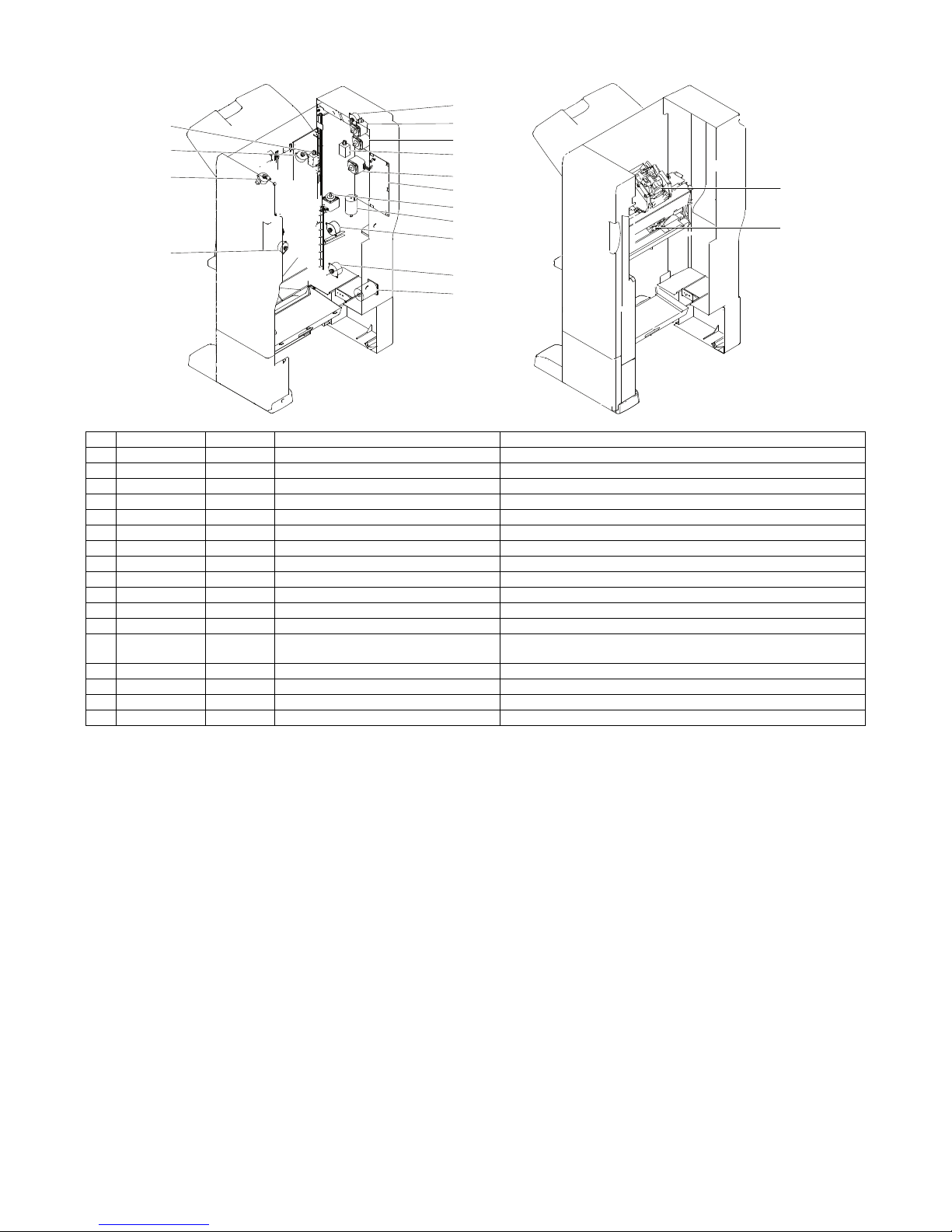

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Part names and functions

A. External view

B. Internal structure

(1) Finisher section

No. Name No. Name

1 Staple compiler 5 Offset tray

2 Top cover 6 Saddle stitch tray

3 Edge binding staple section 7 Center binding staple section

4 Front cover

No. Name No. Name

1 Paper exit tray 13 Saddle No. 2 transport roller

2 Alignment plate 14 Paper rear edge holder

3 Paper exit roller 15 Saddle staple unit

4 Process roller 16 Saddle paper exit roller

5 Flapper 17 Folding roller

6 Inlet port transport roller 18 Saddle alignment plate

7 Punch section 19 Saddle No. 3 transport roller

8 Paper holding lever 20 Paper pushing plate

9 Scrabble belt 21 Saddle section

10 Saddle No. 1 transport roller 22 Paper lead edge pushing plate

11 Gripper unit 23 Saddle stitch tray

12 Edge binding staple unit

3

7

1

6

5

4

2

8

9

18

19

15

16

1

23

22

10

11

14

12

17

20

21

13

234567

Page 8

MX-FN10 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 2

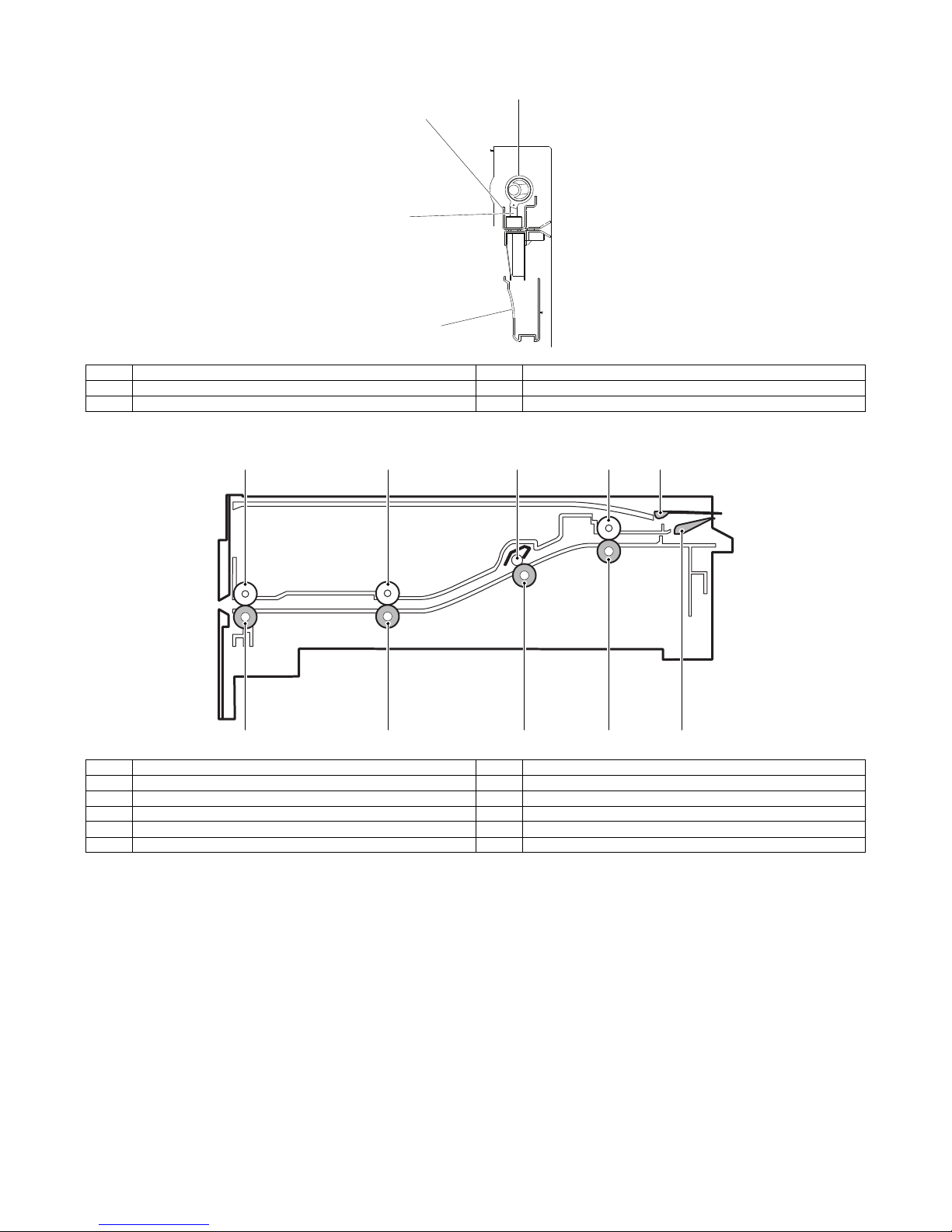

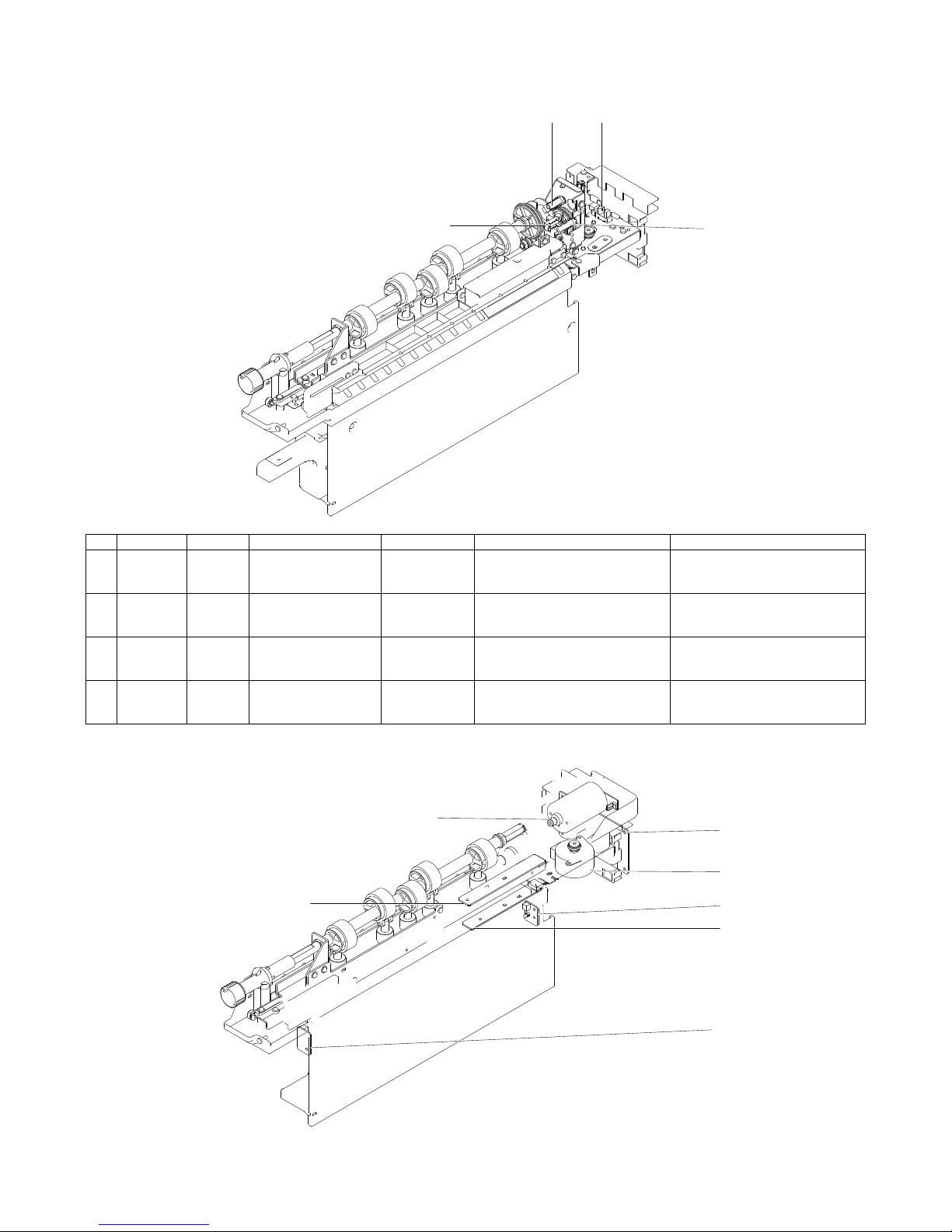

(2) Punch section (Option: MX-PNX5 A/B/C/D)

(3) Interface transport section (MX-RBX3)

No. Name No. Name

1 Cam 3 Punch

2 Dice 4 Dust box

No. Name No. Name

1 Paper exit roller 6 Paper exit front roller

2 Paper exit front roller 7 Inlet port rear roller

3 Inlet port rear roller shaft 8 Inlet port roller

4 Inlet port roller 9 Reverse flapper

5 Paper exit roller 10 Upper guide flapper

1

2

3

4

1

5

2

6

4

8

9

10

3

7

Page 9

MX-FN10 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 3

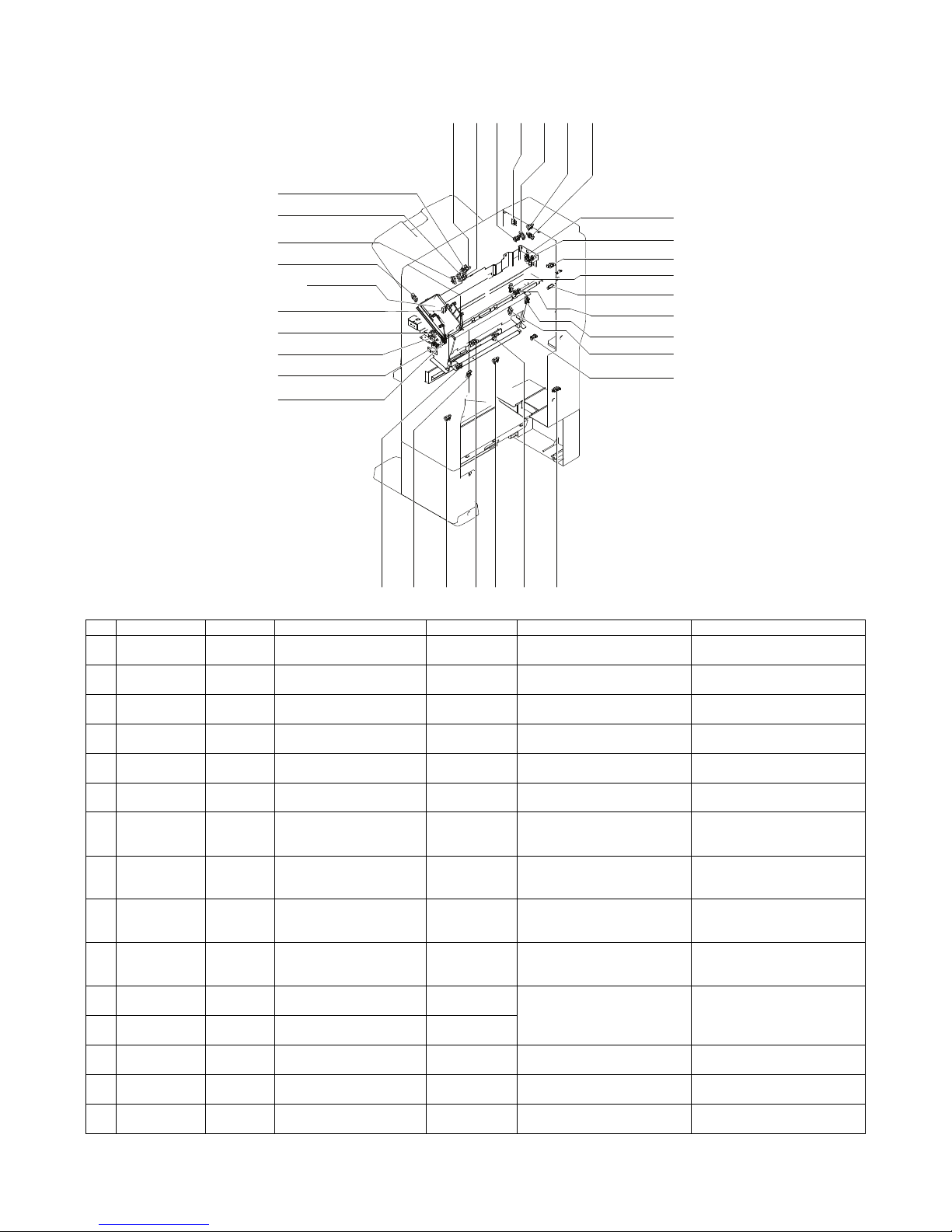

C. Finisher and saddle section

(1) Sensor and switch

No. Code Signal Name Type Function/Operation Output

1 PINS FPPD1 Finisher Paper Pass

Detector 1

Photointerrupter Paper detection at the inlet port of

the finisher

When there is paper, TP1

becomes HI level.

2 EMPS FATPD Finisher Paper Alignment

Tray Paper Detector

Photointerrupter Paper detection on the process

tray

When there is paper, TP26

becomes HI level.

3 SFTEMPS FDTPD Finisher Paper Delivery Tray

Paper Detector

Photointerrupter Paper detection on the load tray When there is paper, TP116

becomes LO level.

4 BDINS FPPD2 Finisher Paper Pass

Detector 2

Photointerrupter Paper detection at the inlet port of

the saddle process section

When there is paper, TP11

becomes HI level.

5 BDOUTS FPPD3 Finisher Paper Pass

Detector 3

Photointerrupter Paper detection at the saddle

paper exit section

When there is paper, TP8

becomes HI level.

6 BDEMPS FSPOD Finisher Saddle Paper

Delivery Tray Paper Detector

Photointerrupter Paper detection on the saddle

load tray

When there is paper, TP4

becomes LO level.

7 BDPASS FSATPD Finisher Saddle Paper

Alignment Tray Paper

Detector

Photointerrupter Paper detection in the saddle

process section

When there is paper, TP4

becomes LO level.

8 RUDS FDRHS Finisher Delivery Roller

Homeposition Sensor

Photointerrupter Detection of the upper standby

position of up/down movement of

the bundle exit roller

When the roller is at the upper

standby position, TP12 becomes

LO level.

9 FJOGHPS FPAPHS_F Finisher Paper Alignment

Plate Homeposition Sensor

(Front)

Photointerrupter Detection of the front side

alignment guide home position

When at home position, TP9

becomes LO level.

10 RJOGHPS FPAPHS_R Finisher Paper Alignment

Plate Homeposition Sensor

(Rear)

Photointerrupter Detection of the rear side

alignment guide home position

When at home position, TP10

becomes LO level.

11 LVLS FPLD Finisher Paper Level

Detector

Photointerrupter Detection of paper surface

position on the load tray by the

combination of both sensor

outputs

* Refer to the separate table

outside the column.

12 LVLHPS FPHHD Finisher Paper Hold

Homeposition Sensor

Photointerrupter

13 GRPHPS FGHPS Finisher Gripper Home

Position Sensor

Photointerrupter Gripper arm HP position

detection

When at home position, TP10

becomes LO level.

14 SLDHPS FSSHPS Finisher Stapler Shift Home

Position Sensor

Photointerrupter Detection of the edge stapler unit

home position in the FR direction

When at home position, TP7

becomes HI level.

15 TOPCOVS FCD2 Finisher Cover Detector 2 Photointerrupter Detection of open/close of the

upper JAM release cover

When the cover is closed, TP15

becomes LO level.

33 - 37

20

23

16

18

4

19

29

1

14

15810311732

27

11

12

9

32

13

30

28

26

62422572125

Page 10

MX-FN10 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 4

Separate table

16 SFTCLKS FTLMRS Finisher Tray Lift Motor

Rotation Sensor

Photointerrupter Detection of abnormality such as

the load tray motor lock.

The output is switched between

HI and LO according to the shift

speed of the load tray lifting and

descending.

17 SFTUPLMT FTULD Finisher Tray Upper Limit

Detector

Photointerrupter Detection of the upper limit

position of up/down shift area of

the paper load tray

When at the upper limit position,

TP1 becomes LO level.

18 SFTDNLMT FTLLD Finisher Tray Lower Limit

Detector

Photointerrupter Detection of the lower limit of up/

down shift area of the paper load

tray

When at the lower limit position,

TP3 becomes LO level.

19 SFTSDNLMT FTPS Finisher Tray Position

Sensor

Photointerrupter Detection of large size paper tray

full

When at the intermediate

position, TP2 becomes LO level.

20 BNDBRDHP FSPHS Finisher Saddle Plate

Homeposition Sensor

Photointerrupter Detection of the saddle pushing

plate home position

When at home position, TP10

becomes LO level.

21 BNDJOGHPS FSAPHS Finisher Saddle Alignment

Plate Homeposition Sensor

Photointerrupter Detection of the saddle alignment

guide home position

When at home position, TP10

becomes LO level.

22 RENDHPS FSPGHS Finisher Saddle Paper Guide

Homeposition Sensor

Photointerrupter Detection of the saddle movable

pushing plate home position

When at home position, TP10

becomes LO level.

23 BNDSLDHPS FSSSHPS Finisher Saddle Stapler Shift

Home Position Sensor

Photointerrupter Detection of the edge stapler unit

home position in FR direction

When at home position, TP7

becomes HI level.

24 BNDR3S FSRHS Finisher Saddle Roller

Homeposition Sensor

Photointerrupter Detection of the saddle process

section transport roller (No. 3

roller) home position

When at home position, TP7

becomes HI level.

25 BNDBRDCLKS FSMRS Finisher Saddle Motor

Rotation Sensor

Photointerrupter Detection of abnormality of the

saddle pushing plate shift speed

control and the motor lock, etc.

The output is switched between

HI and LO according to the speed

of the pushing plate motor.

26 JOGPOSS FSSSW2 Finisher Stapler Safety

Switch 2

Photointerrupter Detection of the edge stapler

clinchable position

When at the clinchable position,

TP7 becomes HI level.

27 GRPOUTS FPDD Finisher Paper Delivery

Detector

Photointerrupter Detection of the gripper arm exit

complete position

When at the gripper exit complete

position, TP7 becomes HI level.

28 FDOORS FCD1 Finisher Cover Detector 1 Photointerrupter Detection of the front door cover

open/close

When the front cover is closed,

TP15 becomes LO level.

29 JOINTS FCD Finisher Connection

Detector

Photointerrupter Detection of connection of the

finisher with the main unit

When connected to the main unit,

TP15 becomes LO level.

30 FDOORSW FSSW1 Finisher Safety Switch 1 Micro switch Detection of open/close of the

jam release cover in the front

section

When the cover is closed, TP15

becomes LO level.

31 STPLSAFESW FSSSW1 Finisher Staple Safty Switch 1Micro switch Assuring the safety against

insertion of a foreign material in

the lift guide section

When the cover is closed, TP15

becomes LO level.

32 BNDSTPRESW FSSCS Finisher Saddle Staple

Cover Sensor

Micro switch Detection of open/close of the

saddle stapler staple replacement

cover

When the cover is closed, TP15

becomes LO level.

33 STPHPS FSSHS Finisher Saddle Staple

Homeposition Sensor

- Detection of the stapling

mechanism home position

(Sensor built in the stapler unit)

When at the home (standby)

position, TP51 becomes HI level.

34 STPEMPS FSSES Finisher Saddle Staple

Empty Sensor

- Detection of staple empty (sensor

built in the stapler unit)

When staple empty, TP53

becomes LO level.

35 STPSLFPS FSLS Finisher Staple Lead Sensor - Detection of stapling enable state

after completion of staple feed

(sensor built in the stapler unit)

When in the READY state, TP52

becomes HI level.

36 BNDSTPHP FSHS Finisher Staple

Homeposition Sensor

- Dete ction the stapling mechanism

home position (sensor built in the

stapler unit)

When at the home (standby)

position, TP51 becomes HI level.

37 BNDSTPEMP FSED Finisher Staple Empty

Detector

- Detection of staple empty (sensor

built in the stapler unit)

When staple empty, TP53

becomes LO level.

LVL S LV LH PS

Status

TP71 TP13

LO LO Detection of a low position of the paper surface on the load tray.

LO HI Detection of retraction of the paper surface lever.

HI LO Detection of the paper surface position on the load tray.

HI HI Detection of a high position of the paper surface on the load tray.

No. Code Signal Name Type Function/Operation Output

Page 11

MX-FN10 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 5

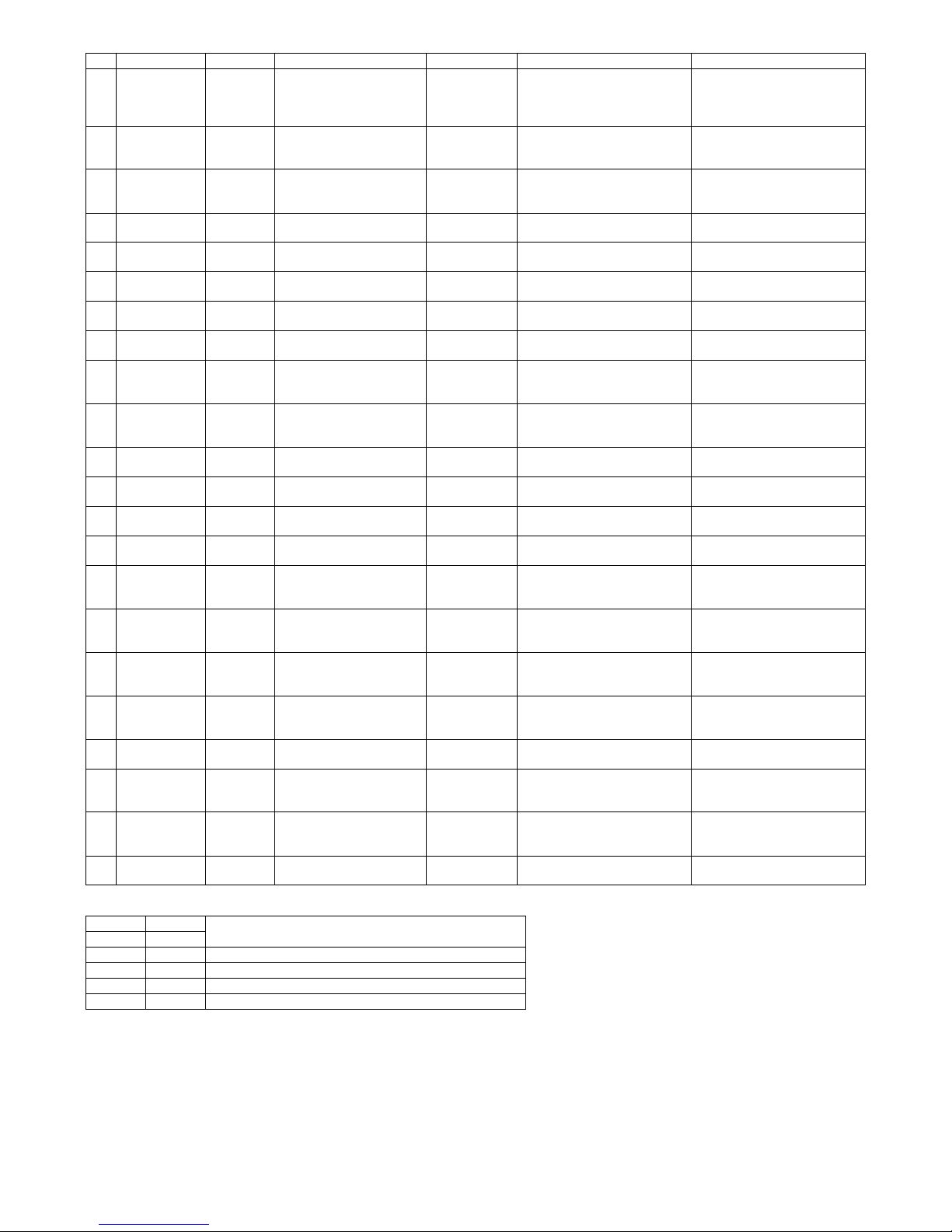

(2) Motor and PWB

No. Code Signal Name Function

1 FEEDMOT1 FPTM1 Finisher Paper Transport Motor 1 Drives the inlet port roller and the feed roller.

2 FEEDMOT2 FPTM2 Finisher Paper Transport Motor 2 Drives the feed roller and the scrabbling belt.

3 GRPMOT FGM Finisher Gripper Motor Shifts the gripper arm in the exit/save direction.

4 ROMOT FDRLM Finisher Delivery Roller Lift Motor Drives the bundle exit roller up and down.

5 SIFTMOT FTLM Finisher Tray Lift Motor Drives the paper load tray up and down.

6 FJOGMOT FPAM-F Finisher Paper Alignment Motor F Drives the alignment guide on the front side.

7 RJOGMOT FPAM-R Finisher Paper Alignment Motor R Drives the alignment guide on the rear side.

8 BNDJOGMOT FSPAM Finisher Saddle Paper Alignment Motor Drives the saddle alignment guide.

9 RENDMOT FSPM Finisher Saddle Positioning Motor Drives the saddle folding position guide.

10 BNDR3MOT FSPTM Finisher Saddle Paper Transport Motor Drives No. 3 paper transport roller.

11 SLDMOT FSSM Finisher Stapler Shift Motor Shifts the stapler unit in the FR direction.

12 BNDBRDMOT FSDM Finisher Saddle Motor Drives the saddle folding plate.

13 LVLSOL FPHS1 Finisher Paper Holding Solenoid 1 Drives the lever for paper holding and detection of the paper surface in

the load tray.

14 PPRSSOL FPHS2 Finisher Paper Holding Solenoid 2 Holds paper in the process section.

15 Finisher Control PWB Controls the finisher.

16 BNDSTPLMOT FSM Finisher Staple Motor Drives the stapling mechanism. (Stapler unit built-in motor)

17 STPLMOT FSDSM Finisher Saddle Staple Motor Drives the stapling mechanism. (Stapler unit built-in motor)

13

7

6

8

4

1

2

14

3

15

11

16

17

5

10

9

12

Page 12

MX-FN10 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 6

D. Punch section (Option: MX-PNX5 A/B/C/D)

(1) Sensor

(2) Motor and PWB

No. Code Signal Name Type Function/Operation Output

1 PNCHPOS FPPS Finisher Punch Paper

Position Sensor

Photointerrupter Detects the punch rotating position. When at home position, TP47 on the

control PWB of the finisher becomes

HI level.

2 PNCHHP FPCHPS Finisher Puncher Cam

Home Position Sensor

Photointerrupter Detects the lower limit position on the

3-hole side in the 2/3-hole punch.

When at the lower limit position, TP48

on the control PWB of the finisher

becomes HI level.

3 PNCHCLK FPMRS Finisher Punch Motor

Rotation Sensor

Photointerrupter Controls the punch position and

detects the motor lock.

When at home position, TP49 on the

control PWB of the finisher becomes

HI level.

4 SLDHP FPHPS Finisher Puncher Home

Position Sensor

Photointerrupter Detects the home position of the

punch position horizontal resist

correction mechanism.

When at home position, TP49 on the

control PWB of the finisher becomes

HI level.

2

14

3

1

3

2

6

5

7

4

Page 13

MX-FN10 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 7

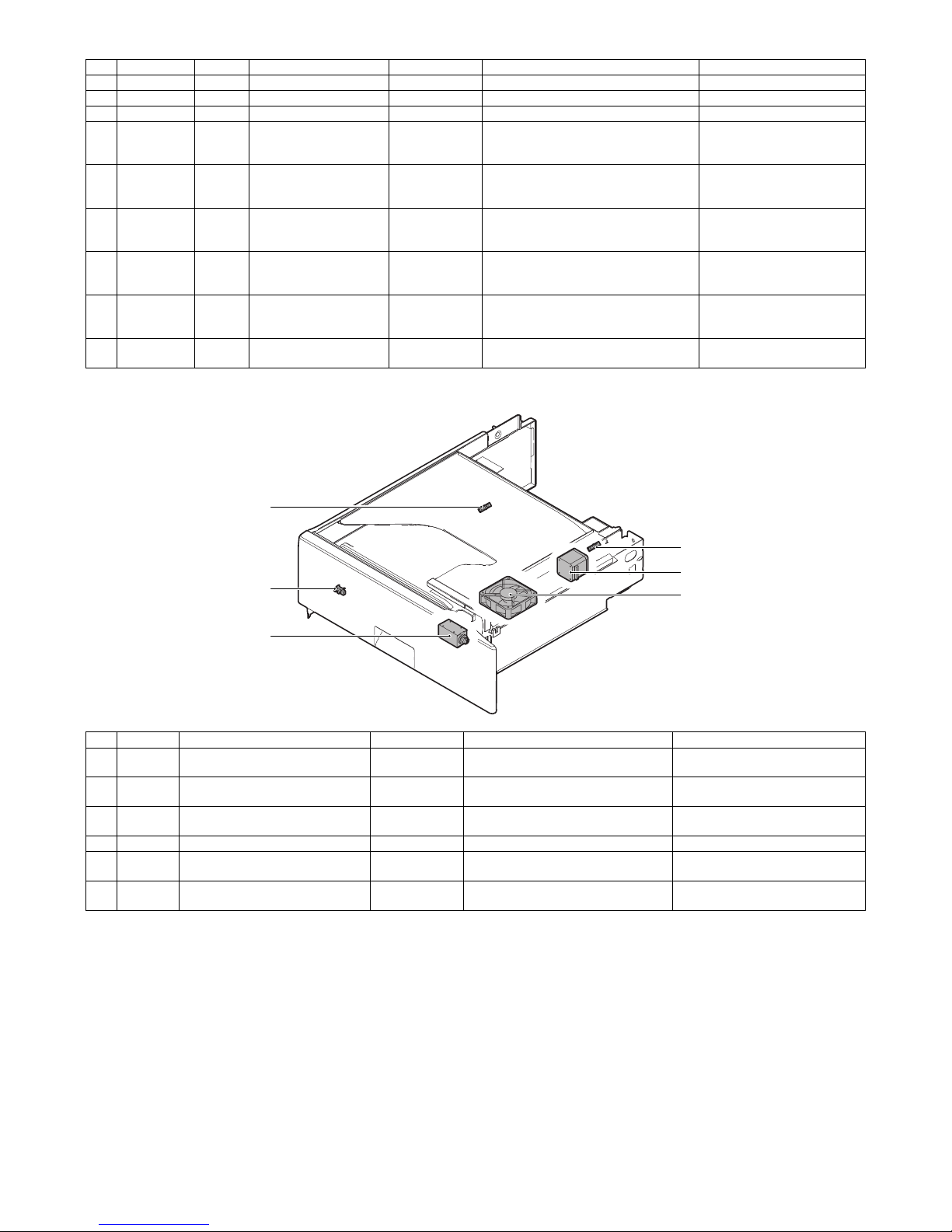

E. Interface transport section (MX-RBX3)

No. Code Signal Name Type Function/Operation Output

1 PNCH_MOT FPM Finisher Punch Motor Drives the punch unit up and down.

2 SLDMOT FPSM Finisher Punch Shift Motor Shifts the punch unit to the center of paper.

3 Punch Control PWB Controls the punch.

4, 5 REGTIMS FPTS Finisher Punch Timing

Sensor

Transmission

type photo

sensor

Detects the lead edge and the rear edge of

paper to be punched.

When there is paper, TP54 on

the control PWB of the finisher

becomes LOW level.

4, 5 SIZE_B5R FPES1 Finisher Punch Paper

Edge Sensor 1

Transmission

type photo

sensor

Detects the paper edge on the rear of the

machine in the width direction of E5R and

EXE-R size.

When there is paper, TP55 on

the control PWB of the finisher

becomes LOW level.

4, 5 SIZE_A4R FPES2 Finisher Punch Paper

Edge Sensor 2

Transmission

type photo

sensor

Detects the paper edge on the rear side of

the machine in the width direction of LGL,

LTR-R, FS, and A4R size.

When there is paper, TP55 on

the control PWB of the finisher

becomes LOW level.

4, 5 SIZE_B4R FPES3 Finisher Punch Paper

Edge Sensor 3

Transmission

type photo

sensor

Detects the paper edge on the rear side of

the machine in the width direction of EXE,

B4, and B5 size.

When there is paper, TP55 on

the control PWB of the finisher

becomes LOW level.

4, 5 SIZE_A3 FPES4 Finisher Punch Paper

Edge Sensor 4

Transmission

type photo

sensor

Detects the paper edge on the rear side of

the machine in the width direction of A3,

A3 wide, and A4 size.

When there is paper, TP55 on

the control PWB of the finisher

becomes LOW level.

6, 7 DUST FPDFS Finisher Punch Dust Full

Sensor

Photointerrupter Detects full of the punch dust box. When full, TP2 on the punch

PWB remains HI level.

No. Signal Name Type Function/Operation Output

1 PDPPD1 Interface transport unit inlet port

sensor

Photointerrupter Interface inlet port paper detection LO light is interrupted when paper is

provided.

2 PDPPD2 Interface transport unit outlet port

sensor

Photointerrupter Interface outlet port paper detection LO light is interrupted when paper is

provided.

3 PDCS Interface transport unit cover sensor Photointerrupter Interface cover open detection Light is interrupted when the cover is

open.

4 PDPTM Interface transport motor Paper transport roller drive

5 PDPGS Interface reverse path solenoid Drive of the flapper which selects the

path in the finisher and the reverse path

6 PDCF Interface fan Temperature rise protection fan in the

finisher inlet port section

2

3

5

6

4

1

Page 14

MX-FN10 OPERATIONAL DESCRIPTION 5 – 1

MX-FN10

Service Manual

[5] OPERATIONAL DESCRIPTION

1. Straight paper exit mode

1) The transport motor and the transport motor 2 are driven at the

paper exit speed of the main unit, and paper is discharged

from the main unit.

At that time, the paper exit roller goes into the nip state.

2) The inlet port sensor turns on, and the paper rear edge

reaches the specified position. Then the speed of the transport

motor and the transport motor 2 is changed to the inside-themain unit speed.

3) The inlet port sensor turns OFF and the paper rear edge

reaches the specified position. Then the speed of the transport

motor is changed to the paper exit speed of the main unit, and

the speed of the transport motor 2 is changed to the stack tray

paper exit speed.

4) When the paper rear edge goes out of the paper exit roller, the

speed of the transport motor 2 is changed to the paper exit

speed of the main unit.

2. Non staple mode

1) The transport motor and the transport motor 2 are driven at the

paper exit speed of the main unit, and paper is discharged

from the main unit.

2) The inlet port sensor turns on, and the paper rear edge

reaches the specified position. Then the speed of the transport

motor and the transport motor 2 is changed to the inside-themain unit speed.

3) The inlet port sensor turns OFF and the paper rear edge

reaches the specified position. Then the speed of the transport

motor is changed to the paper exit speed of the main unit.

4) When the paper rear edge reaches the reverse position for

storing to the process tray, the transport motor 2 is temporarily

stopped. Then the transport motor 2 reverses to store paper in

the process tray.

5) When paper is stored in the process tray, the alignment plate

reciprocates to align paper.

Page 15

MX-FN10 OPERATIONAL DESCRIPTION 5 – 2

6) Reception of paper in the process tray is repeated until the

specified number of sheet for a bundle is stacked. (1 - 5)

7) When all the sheets of paper in a bundle are discharged to the

process tray, the paper bundle is discharged to the stack tray

by the gripper.

3. Rear on position staple mode

1) The transport motor and the transport motor 2 are driven at the

paper exit speed of the main unit, and paper is discharged

from the main unit.

2) The inlet port sensor turns on, and the paper reaches the

specified position. Then the speed of the transport motor and

the transport motor 2 is changed to the inside-the-main unit

speed.

3) The inlet port sensor turns OFF and the paper rear edge

reaches the specified position. Then the speed of the transport

motor is changed to the paper exit speed of the main unit.

4) When the paper rear edge reaches the reverse position for

storing to the process tray, the transport motor 2 is temporarily

stopped. Then the transport motor 2 reverses to store paper in

the process tray.

5) When paper is stored in the process tray, the alignment plate

reciprocates to align paper.

6) Reception of paper in the process tray is repeated until the

specified number of sheet for a bundle is stacked. (1 - 5)

7) When all the sheets of a bundle are discharged to the process

tray, stapling is performed.

8) After stapling, the paper bundle is discharged to the stack tray

by the gripper.

Page 16

MX-FN10 OPERATIONAL DESCRIPTION 5 – 3

4. 2-position staple mode

1) The transport motor and the transport motor 2 are driven at the

paper exit speed of the main unit, and paper is discharged

from the main unit.

2) The inlet port sensor turns on, and the paper reaches the

specified position. Then the speed of the transport motor and

the transport motor 2 is changed to the inside-the-main unit

speed.

3) The inlet port sensor turns OFF and the paper rear edge

reaches the specified position. Then the speed of the transport

motor is changed to the paper exit speed of the main unit.

4) When the paper rear edge reaches the reverse position for

storing to the process tray, the transport motor 2 is temporarily

stopped. Then the transport motor 2 reverses to store paper in

the process tray.

5) When paper is stored in the process tray, the alignment plate

reciprocates to align paper.

6) Reception of paper in the process tray is repeated until the

specified number of sheet for a bundle is stacked. (1 - 5)

7) When all the sheets of a bundle are discharged to the process

tray, stapling at the first position is performed. After completion

of the first stapling, the staple unti is shfited to the second staplingposition and the second stapling is performed.

8) After completion of the second stapling, the paper bundle is

discharged to the stack tray by the gripper.

5. Front one position staple mode

1) The transport motor and the transport motor 2 are driven at the

paper exit speed of the main unit, and paper is discharged

from the main unit.

2) The inlet port sensor turns on, and the paper reaches the

specified position. Then the speed of the transport motor and

the transport motor 2 is changed to the inside-the-main unit

speed.

Page 17

MX-FN10 OPERATIONAL DESCRIPTION 5 – 4

3) The inlet port sensor turns OFF and the paper rear edge

reaches the specified position. Then the speed of the transport

motor is changed to the paper exit speed of the main unit.

4) When the paper rear edge reaches the reverse position for

storing to the process tray, the transport motor 2 is temporarily

stopped. Then the transport motor 2 reverses to store paper in

the process tray.

5) When paper is stored in the process tray, the alignment plate

reciprocates to align paper.

6) Reception of paper in the process tray is repeated until the

specified number of sheet for a bundle is stacked. (1 - 5)

7) When all the sheets of a bundle are discharged to the process

tray, stapling is performed.

8) After stapling, the paper bundle is discharged to the stack tray

by the gripper.

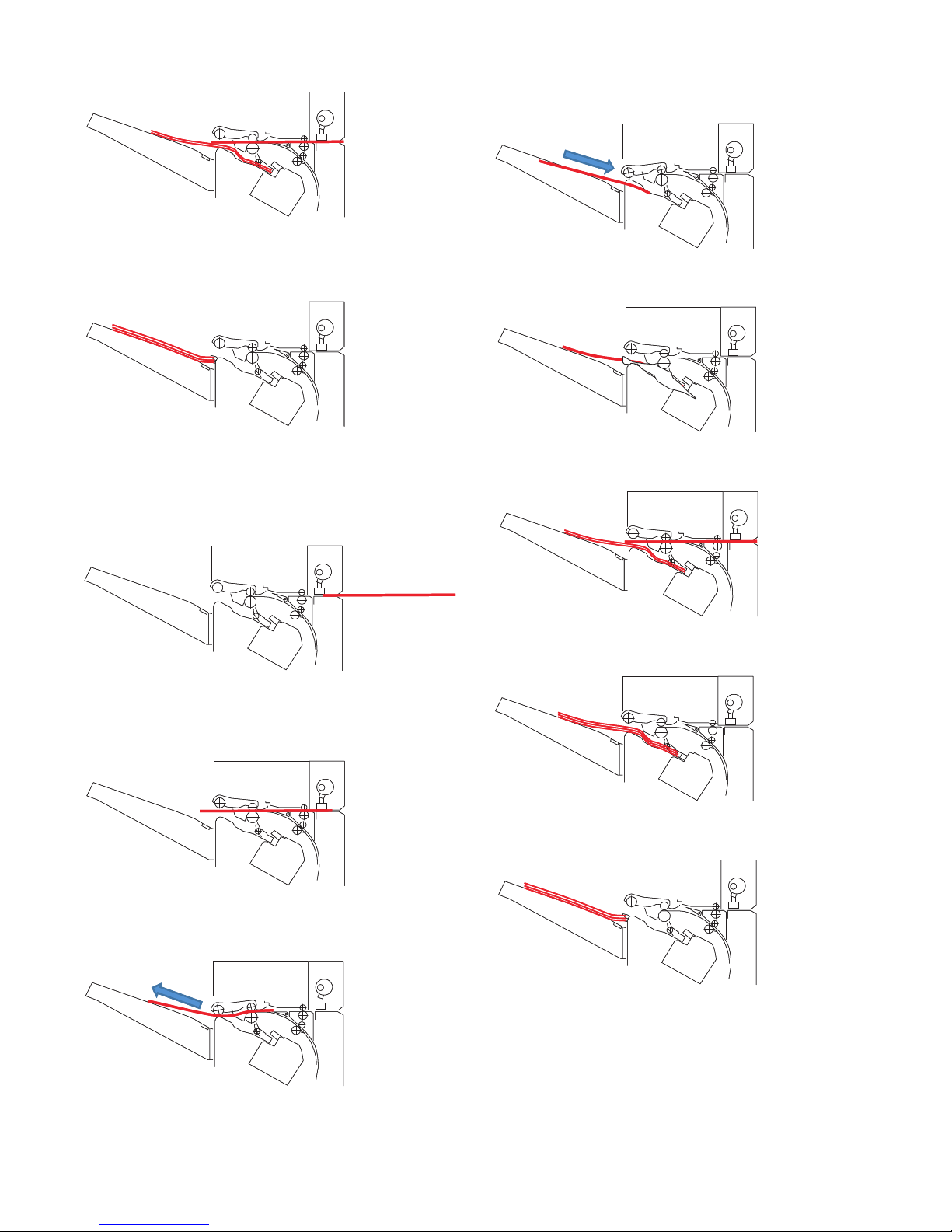

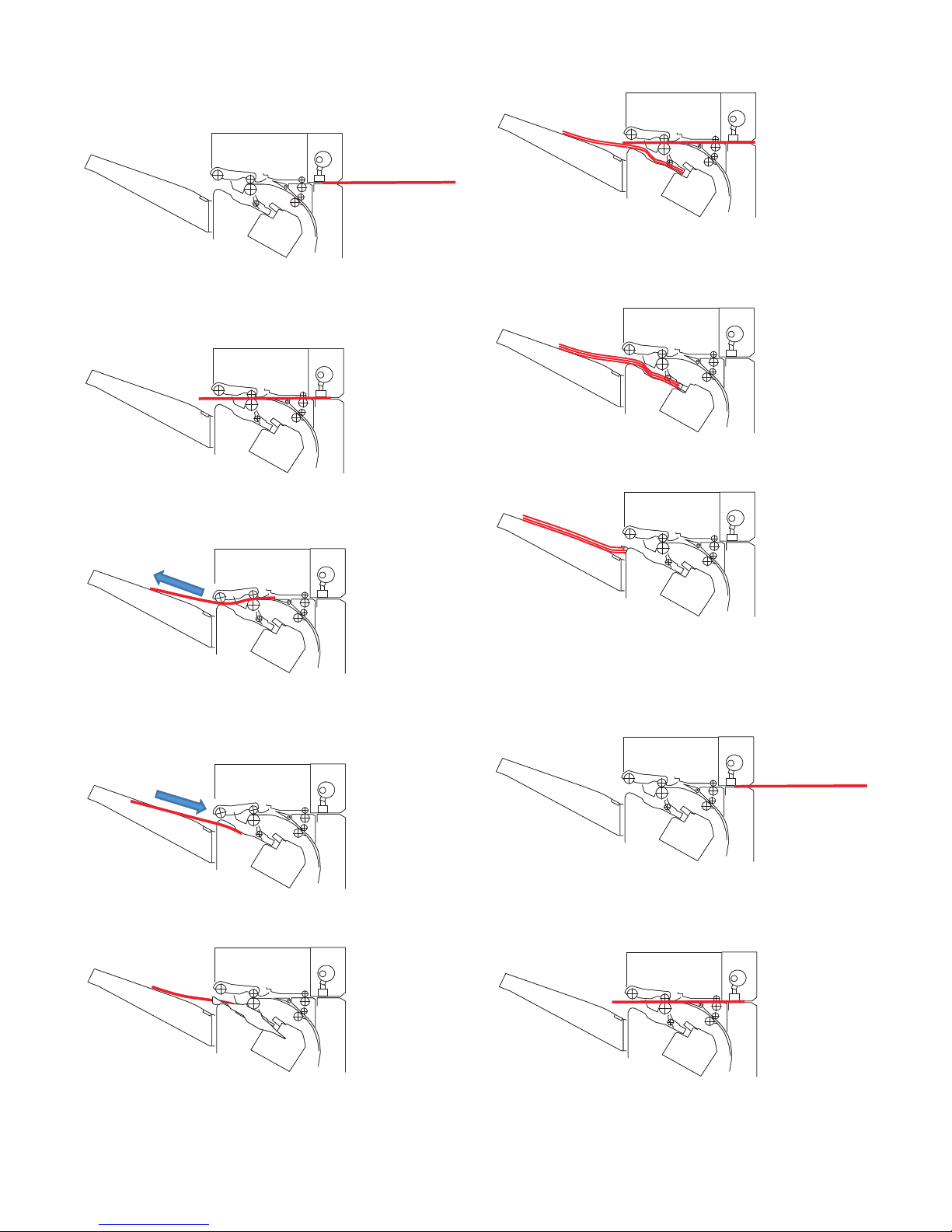

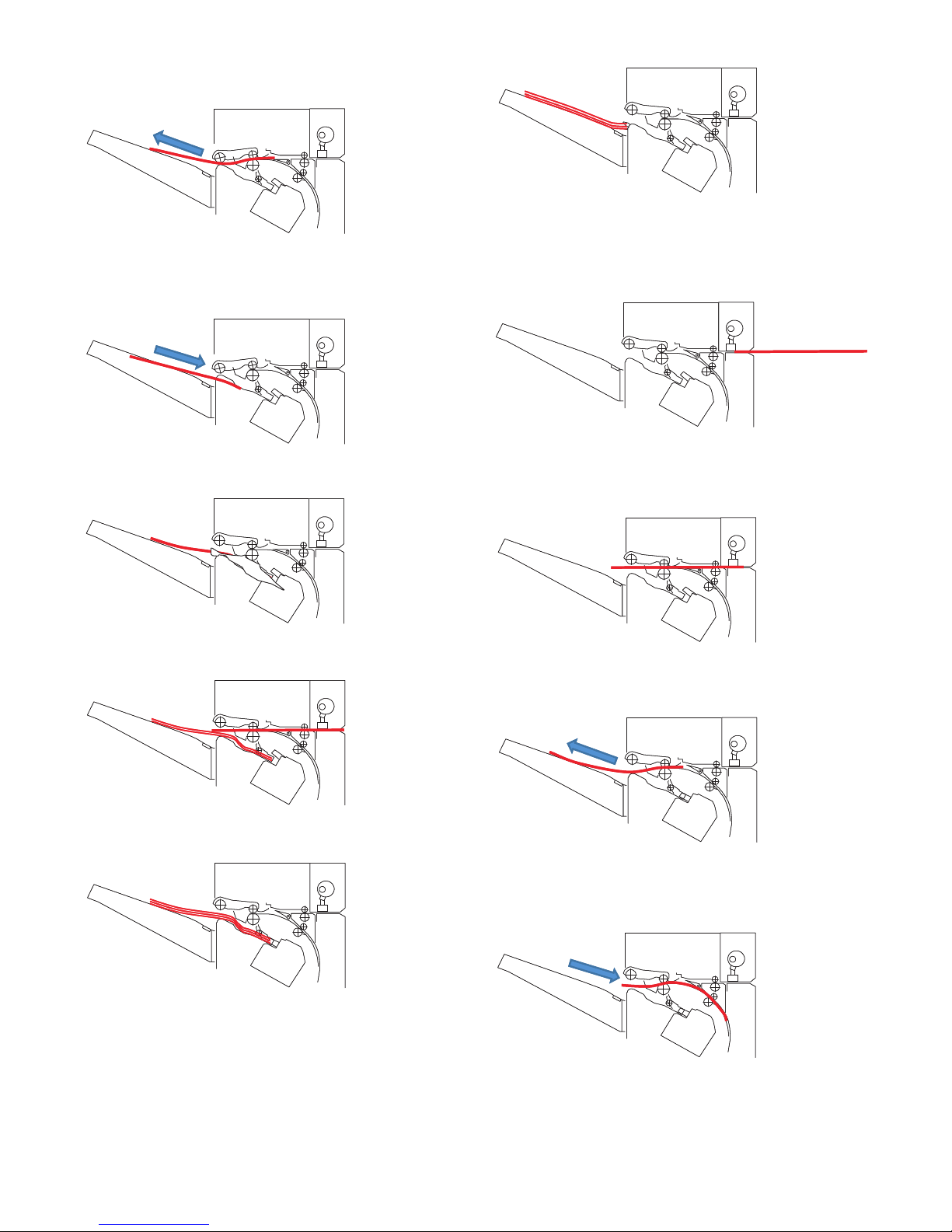

6. Saddle motor

1) The transport motor and the transport motor 2 are driven at the

paper exit speed of the main unit, and paper is discharged

from the main unit.

2) The inlet port sensor turns on, and the paper reaches the

specified position. Then the speed of the transport motor and

the transport motor 2 is changed to the inside-the-main unit

speed.

3) The inlet port sensor turns OFF and the paper rear edge

reaches the specified position. Then the speed of the transport

motor is changed to the paper exit speed of the main unit.

4) When the paper rear edge reaches the reverse position for

storing to the saddle process tray, the transport motor 2 is temporarily stopped. Then the transport motor 2 reverses to store

paper in the saddle process tray.

Page 18

MX-FN10 OPERATIONAL DESCRIPTION 5 – 5

5) When paper is stored in the saddle process tray, the alignment

plate reciprocates to align paper.

6) Reception of paper in the saddle process tray is repeated until

the specified number of sheet for a bundle is stacked. (1 - 5)

7) When all the sheets of a bundle are discharged to the saddle

process tray, stapling is performed.

8) After completion of stapling, the paper stopper is lowered to

shift the paper bundle to the paper folding position.

Page 19

MX-FN10 OPERATIONAL DESCRIPTION 5 – 6

9) Start the pushing plate motor to fold the paper bundle and discharge it.

10) The paper bundle is discharged to the saddle stack tray by the

saddle exit motor.

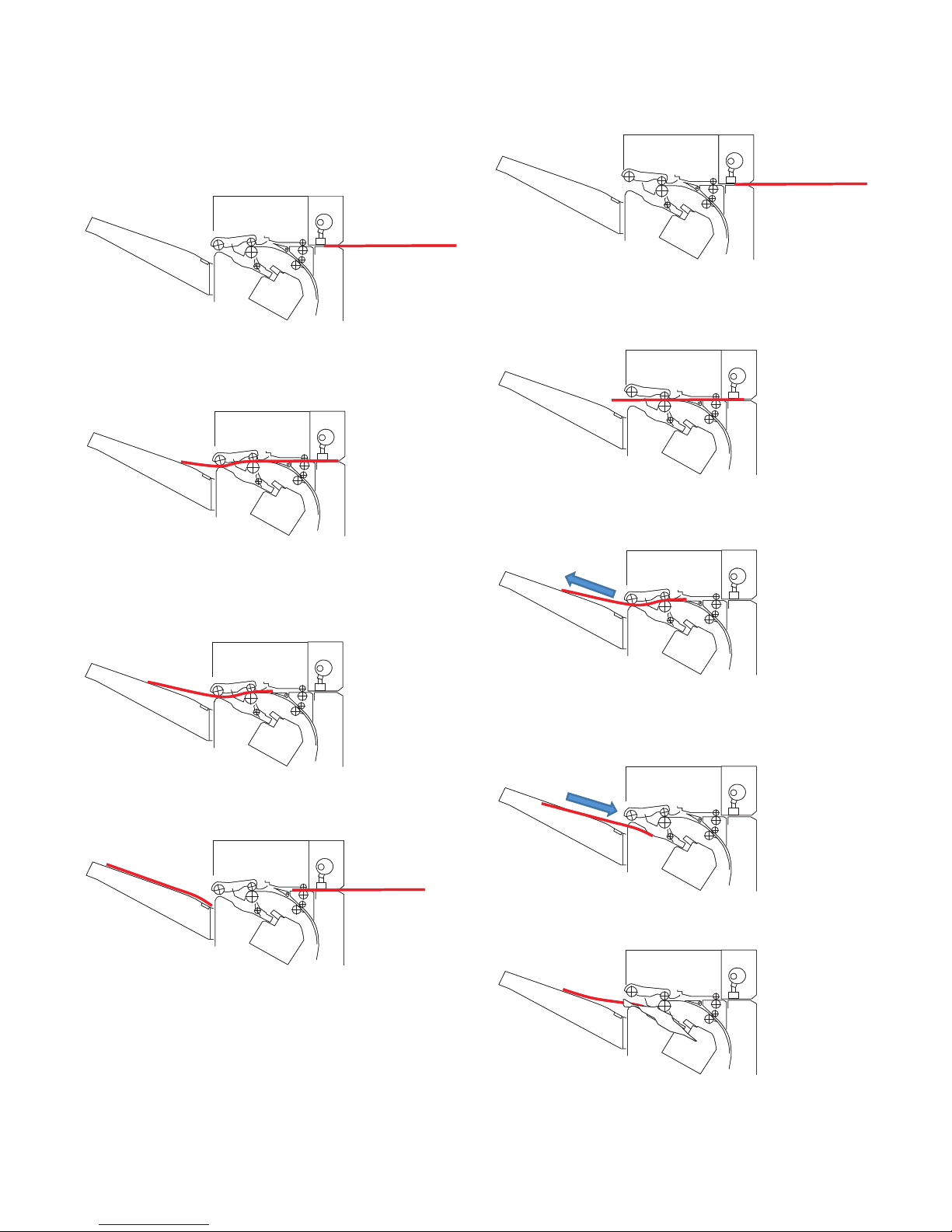

7. Punch process

1) When the paper lead edge passes the paper rear edge detection sensor, the punch horizontal registration motor is booted

to start the horizontal registration.

2) After starting horizontal registration, when the horizontal registration sensor detects the side edge, it is shifted by the specified distance to stop the punch horizontal registration motor.

3) When the paper rear edge passes the paper rear edge detection sensor, the transport motor and the transport motor 2 are

stopped to stop paper.

4) When paper is stopped, the punch motor is booted to punch at

the paper rear edge.

5) After completion of punching, the transport motor and the

transport motor 2 are booted to start paper transport, executing the specified after-process.

Page 20

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 1

MX-FN10

Service Manual

[6] DISASSEMBLY AND

ASSEMBLY

1) Turn off the main power, and disconnect the connector of the

saddle finisher.

2) Open the front door, and release the lock.

Remove the saddle finisher from the main unit.

1. Saddle finisher

A. External outfit control items

(1) Load tray

1) Remove the load tray.

(2) Saddle paper holding lever

1) Remove the movable lever.

2) Remove the fixing lever.

(3) Saddle tray

1) Remove the saddle tray.

Page 21

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 2

(4) Front cabinet

1) Remove the front lower cover.

2) Open the front door, and remove the front cabinet.

(5) Rear cabinet upper

1) Remove the rear cabinet upper.

(6) Rear cabinet lower

1) Remove the front lower cover. (See (4).)

2) Remove the rear cabinet upper. (See (5).)

3) Remove the foot cover.

4) Remove the rear cabinet lower.

(7) Upper door

1) Remove the front cabinet. (See (4).)

2) Remove the rear cabinet upper. (See (5).)

3) Remove the upper door.

(8) Right cabinet

1) Remove the front cabinet. (See (4).)

2) Remove the rear cabinet. (See (5).)

3) Remove the right cabinet.

Page 22

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 3

(9) Right lower cover

1) Loosen the screw [1].

2) Remove the right lower cover.

(10) Side guide upper

1) Remove the load tray. (See (1).)

2) Remove the saddle paper holding lever. (See (2).)

3) Remove the saddle tray. (See (3).)

4) Remove the front cabinet. (See (4).)

5) Remove the rear cabinet upper. (See (5).)

6) Put the load tray supporting plate (front) [1] and the load tray

supporting plate (rear) [2] outside of the rail groove.

Note: When the load tray is on the top position, lower the load

tray by manually turning the load tray lift motor rotation

shaft (counterclockwise) so that the sensor flag attached

to the supporting plate (rear) does not make contact with

the load tray upper limit sensor.

7) Open the center binding staple replacement door, and release

the center binding staple lock.

8) Disconnect two connectors on the left side of the side guide

upper.

9) Remove the side guide upper.

(11) Side guide lower

1) Remove the side guide upper. (See (10).)

2) Remove the side guide lower.

NOTE: When assembling, place the polyester film (2 positions) on

each side of the side guide lower and attach.

[1]

[1]

[2]

Page 23

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 4

B. Transport section

(1) Center binding stapler unit removal

1) Remove the harness duct and the center binding staple

replacement door switch.

2) Remove the center binding harness guide and the upper and

lower stapler connection parts.

3) Remove the center binding stapler earth wire fixing screw.

4) Remove the center binding stapler unit fixing screw. (5 positions)

5) Pull out the center binding stapler unit.

(2) Center binding stapler removal

1) Remove the unit frame.

2) Slide the stapler to the front, and remove the connector and

the earth wire fixing screw.

Page 24

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 5

3) Remove the stapler fixing screws (3 positions).

4) Remove the stapler.

(3) Edge binding stapler removal

1) Slide the stapler to the front.

2) Remove the latch for connection of the main unit.

3) Remove two stapler fixing screws from the hole in circle in the

figure below.

At that time, shift the stapler and fit the screw with the hole

position.

4) Remove the stapler.

(4) Saddle pushing plate motor gear box removal

1) Remove the grip, the E-ring, and the bearing which are fixing

each gear shaft.

Page 25

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 6

2) Remove the interface cable facing part.

Remove the gear box fixing screw.

3) Remove the gear box.

(5) Transport motor assembly

1) Remove the rear cabinet upper. (See A-(5).)

2) Remove the screw, and remove the transport motor assembly.

(6) Load tray lift motor gear box

1) Remove the rear cabinet upper. (See A-(5).)

2) Remove the saddle finisher control PWB fixing part. (See C(2).)

3) Remove the gear box.

C. PWB section

(1) Saddle finisher control PWB

1) Remove the rear cabinet upper. (See A-(5).)

2) Remove the PWB fixing screw, and disconnect each connector, release the PWB holding pawl, and remove the PWB.

Page 26

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 7

(2) Saddle finisher control PWB fixing parts

1) Remove the control PWB. (See (1).)

2) Remove the screw, and remove the PWB fixing part.

2. Paper Transport Section (MX-RBX3)

A. Paper Pass Unit

1) Pull out the paper pass unit, and remove the screw.

2) Free the lock, to remove the paper pass unit.

(1) Paper transport unit entry sensor

1) Remove the paper pass unit.

2) Remove the paper transport unit entry sensor.

(2) Paper transport unit exit sensor

1) Remove the paper pass unit.

2) Remove the bracket, and remove the paper transport unit exit

sensor.

(3) Upper Guide Flapper

1) Remove the paper pass unit.

2) Open the upper transport unit, remove each parts, and remove

the reverse gate.

1

2

3

Page 27

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 8

(4) Interface Fan

1) Remove the paper pass unit.

2) Remove the bottom cover.

3) Remove the clamps, and disconnect the connector then

remove the interface fan.

* Install the interface fan so as the side with the label (A)

comes to the direction illustrated.

(5) Interface Transport Motor

1) Remove the paper pass unit.

2) Remove the bottom cover. (See (4).)

3) Disconnect the connector, then remove the interface transport

motor.

(6) Entry Reverse Pass Solenoid.

1) Remove the paper pass unit.

2) Remove the bottom cover. (See (4).)

3) Remove the front cover.

4) Remove the solenoid unit.

5) Remove each parts, then remove the entry reverse pass solenoid.

* Adjust so that the distance between the lower guide and the

upper guide flapper is 22mm with the solenoid plunger

pushed in. Install the entry reverse pass solenoid.

1

2

2

3

A

1

2

3

1

2

22mm

Page 28

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 9

(7) Entry Roller

1) Remove the paper pass unit.

2) Remove the bottom cover. (See (4).)

3) Remove the interface transport motor. (See (5).)

4) Remove the front cover. (See (6).)

5) Remove the stopper band, and the bracket, then remove the

upper guide unit.

* When installing, adjust so that the solenoid is fit with the

bracket adjustment reference. If the upper guide unit magnet lifts up, adjust the bracket for the magnet not to lift up.

6) Remove each parts, then remove the entry roller.

(8) Post Entry Roller

1) Remove the paper pass unit.

2) Remove the bottom cover. (See (4).)

3) Remove the front cover. (See (6).)

4) Remove the upper guide unit. (See (7).)

5) Remove the bracket, and remove the post entry roller unit.

6) Remove each parts, and remove the post entry roller.

(9) Pre Entry Roller

1) Remove the paper pass unit.

2) Remove the bottom cover. (See (4).)

3) Remove the front cover. (See (6).)

4) Remove the upper guide unit. (See (7).)

5) Remove each parts, and remove the pre entry roller.

2

2

3

1

Adjustment

reference

± 0.5

Page 29

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 10

(10) Exit Roller

1) Remove the paper pass unit.

2) Remove the bottom cover. (See (4).)

3) Remove the front cover (See (6).)

4) Remove the upper guide unit. (See (7).)

5) Remove the drawer bracket.

Remove each parts and remove the exit roller.

B. Reverse Tray Unit

(1) Reverse Flapper

1) Remove the paper pass unit.

2) Remove the reverse tray.

3) Remove each parts, and remove the reverse flapper.

C. Left Cabinet Unit

(1) Interface Transport Unit Cover Detection Sensor

1) Remove the paper pass unit.

2) Remove the reverse tray. (See B-(1).)

3) Free the lock, then remove the saddle stitch finisher.

4) Remove the left cover.

5) Disconnect the connector, and the sensor bracket. Remove

the interface transport unit cover detection sensor.

(2) Paper Pass PWB

1) Remove the paper pass unit.

2) Remove the reverse tray. (See B-(1))

3) Remove the left cover. (See C-(1).)

4) Remove allen screw, remove the interface PWB, then remove

the connector.

1

2

3

4

Page 30

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 11

3. Punch section

A. Punch drive section

(1) Punch motor removal

1) Remove the upper cover. (Remove two screws.)

2) Remove the rear blinding cover. (Remove two screws.)

3) Remove the jam process knob, the screw, and the sensor

holding part.

4) Remove the shaft reception part (front), the bearing, and the

screw, and remove the screw of the shaft reception part (rear).

5) Remove the shift.

6) Remove the screw and the motor.

a

a

Page 31

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 12

B. PWB section

(1) Punch control PWB

1) Turn the screw and remove the control PWB in the arrow

direction.

(2) Light receiving dust sensor 2

1) Pull out the punch dust box in the arrow direction.

2) Remove the screw which is fixing the sensor cover.

3) Pull out in the arrow direction [1], and remove in the arrow

direction [2].

4) Remove the screw which is fixing the dust sensor, and turn the

dust sensor in the arrow direction.

5) Remove the screw which is fixing the sensor cover.

6) Pull out the sensor cover <1> in the arrow direction.

7) Pull out in the arrow direction <1>, and remove the arrow

direction <2>.

8) Remove the screw which is fixing the dust sensor.

9) Remove the dust sensor in the arrow direction.

[2]

[1]

[2]

[1]

Page 32

MX-FN10 DISASSEMBLY AND ASSEMBLY 6 – 13

(3) Light receiving side registration sensor removal

1) Remove the screw which is fixing the registration sensor.

2) Remove the registration sensor cover in the arrow direction.

3) Remove the registration sensor in the same direction as the

cover.

(4) Light emitting registration sensor removal

1) Pull out the jam process knob in the arrow direction, and

remove the screw.

2) Remove two screws.

3) Remove the spring in the arrow direction.

4) Remove the harness duct in the arrow direction.

5) Separate the upper and the lower sections. (Pull up in the

arrow direction.)

6) Remove the screw, and remove the sensor cover in the arrow

direction.

7) Remove the registration sensor in the same direction as the

cover.

Page 33

MX-FN10 MAINTENANCE 7 – 1

MX-FN10

Service Manual

[7] MAINTENANCE

1. Maintenance System Table

: Check (Clean, replace, or adjust as necessary.) : Clean : Replace : Adjust ✩: Lubricate : Move position

No. Part name

When

calling

100K200K300K400K500K600K700K800K900K1000K110 0

K

Remark

1 Transport rollers

2 Transport paper guides

3Gears When checking, apply to the necessary

positions. (Specified positions)

4Belts

5 Knurled belt Replacement reference: Replace at

every 1000K of the finisher paper exit

count value.

6Sensors

7 Discharge brush

8 Stapler unit Replacement reference: Replace the unit at every 200K staple.

9 Stapler unit for saddle Replacement reference: Replace the unit at every 100K staple.

10 Punch unit Replacement reference: Replace the unit at every 1000K.

11 Staple cartridge User replacement for every 5000pcs.

12 Staple cartridge for saddle User replacement for every 2000pcs.

6

6

6

6

66 6666 6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

5

1

11

1

12

1

1

1

7

8

9

7

1

66 6 6 6 6

11110

Page 34

MX-FN10 ADJUSTMENTS 8 – 1

MX-FN10

Service Manual

[8] ADJUSTMENTS

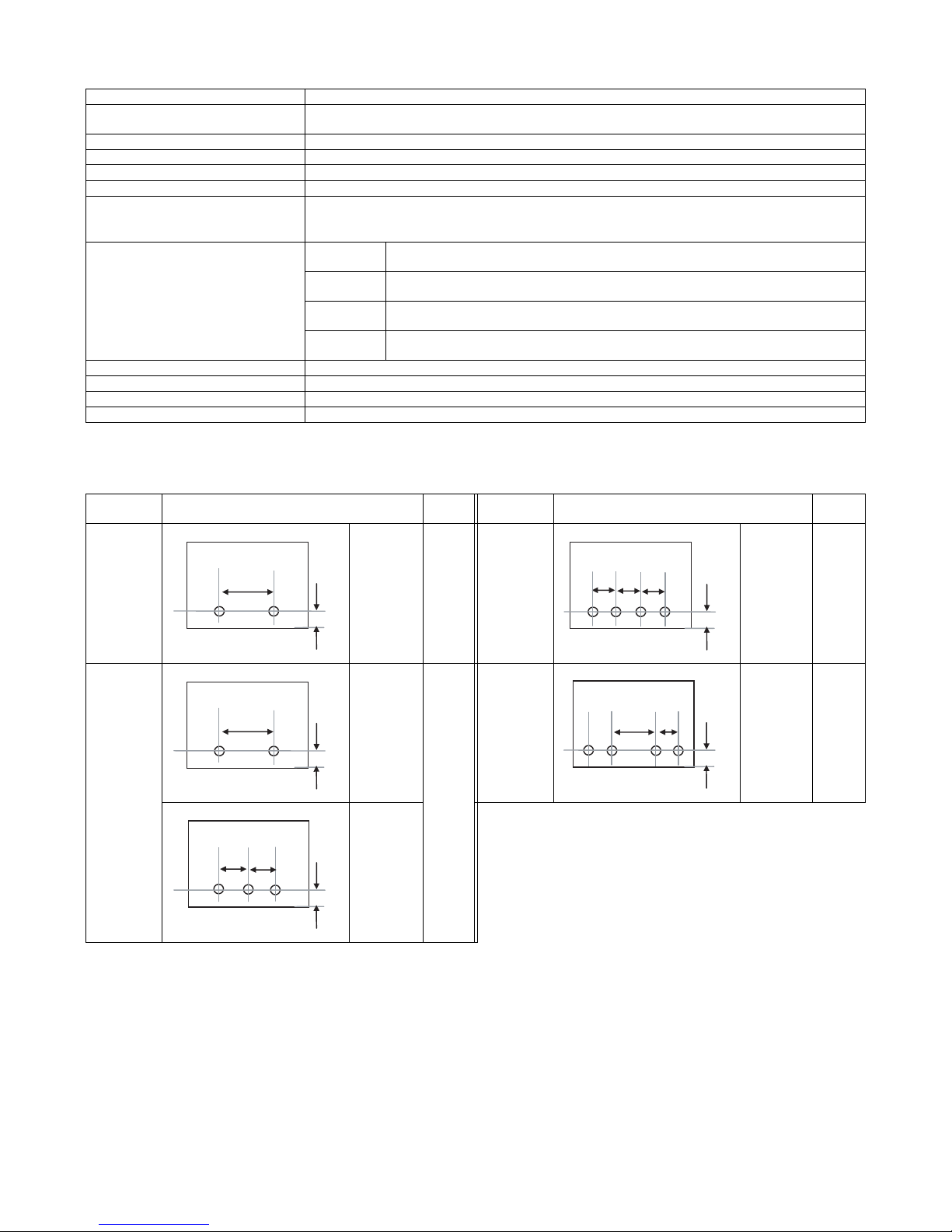

1. Finisher/saddle unit and Punch unit

1) Select "FINISHER ADJUSTMENT" in SIM 3-10.

2) Select a setup item and change the setup value.

Adjustable setup range is as follows.

<Set range and default value of each set value>

<Amount of change and change direction for each set value>

Item Display Item

Set

range

Default

A

SADDLE

POSITION

Saddle binding 25 - 75 50

B

FOLDING

POSITION

Saddle folding position

adjustment

25 - 75 50

C

FRONT

ADJUST

Alignment position

adjustment (Front)

35 - 65 50

D

REAR

ADJUST

Alignment position

adjustment (Rear)

35 - 65 50

E

STAPLE

REAR

Staple binding position

adjustment (Rear one

position)

25 - 75 50

F

STAPLE

REAR R

Staple binding position

adjustment (Rear one

position/ R system)

45 - 75 50

G

STAPLE

FRONT

Staple binding position

adjustment (Front one

position)

25 - 75 50

H

STAPLE

FRONT R

Staple binding position

adjustment (Front one

position/ R system)

25 - 55 50

I

STAPLE

BOTH

Staple binding position

adjustment (Two positions

center)

45 - 55 50

J

STAPLE

PITCH

Staple binding position

adjustment (Two positions

pitch)

35 - 62 50

K

PUNCH

CENTER

Punch center adjustment 35 - 65 50

OK

10key

SIMULATION NO.03-10

CLOSE

TEST

FINISHER ADJUSTMENT

0

50

A˖

:SADDLE POSITION

A

: FOLDING POSITION

B

: FRONT ADJUST

C

:REAR ADJUST

D

:STAPLE REARR

F

:STAPLE REAR

E

:STAPLE FRONT

G

:STAPLE FRONT R

H

:STAPLE BOTH

I

:STAPLE PITCH

J

: PUNCH CENTER

K

: PUNCH HOLE

L

:

:

:

:

:

:

:

:

:

:

:

:

50

50

50

50

50

50

50

50

50

50

50

50

OK

SIMULATION NO.03-10

CLOSE

TEST

FINISHER ADJUSTMENT

0

30

A˖

:SADDLE POSITION

A

: FOLDING POSITION

B

: FRONT ADJUST

C

:REAR ADJUST

D

:STAPLE REARR

F

:STAPLE REAR

E

:STAPLE FRONT

G

:STAPLE FRONT R

H

:STAPLE BOTH

I

:STAPLE PITCH

J

: PUNCH CENTER

K

: PUNCH HOLE

L

:

:

:

:

:

:

:

:

:

:

:

:

30

50

50

50

50

50

50

50

50

50

50

50

OK

L

PUNCH

HOLE

Punch hole position

adjustment

30 - 60 50

M

SADDLE_A

DJUST_

POS

Saddle alignment position

adjustment

35 - 65 50

N

GRIPPER_

POS

Gripper exit position

adjustment

35 - 65 50

Item Display Item Change Change direction

A SADDLE

POSITION

Saddle

binding

0.2mm Large value: The binding

position is lower than the

center.

Small value: The binding

position is upper than the

center.

B FOLDING

POSITION

Saddle

folding

position

adjustment

0.2mm Large value: The folding

position is lower than the

center.

Small value: The folding

position is upper than the

center.

C FRONT

ADJUST

Alignment

position

adjustment

(Front)

0.2mm Large value: The

alignment plate position is

shifted to the center.

Small value: The

alignment plate position is

shifted to the outside.

D REAR

ADJUST

Alignment

position

adjustment

(Rear)

0.2mm Large value: The

alignment plate position is

shifted to the center.

Small value: The

alignment plate position is

shifted to the outside.

ESTAPLE

REAR

Staple

binding

position

adjustment

(Rear one

position)

0.2mm Large va lue: The distance

between the staple

position and the paper

edge becomes longer.

Small value: The distance

between the staple

position and the paper

edge becomes shorter.

FSTAPLE

REAR R

Staple

binding

position

adjustment

(Rear one

position/ R

system)

0.2mm Large va lue: The distance

between the staple

position and the paper

edge becomes longer.

Small value: The distance

between the staple

position and the paper

edge becomes shorter.

GSTAPLE

FRONT

Staple

binding

position

adjustment

(Front one

position)

0.2mm Large va lue: The distance

between the staple

position and the paper

edge becomes shorter.

Small value: The distance

between the staple

position and the paper

edge becomes longer.

HSTAPLE

FRONT R

Staple

binding

position

adjustment

(Front one

position/ R

system)

0.2mm Large va lue: The distance

between the staple

position and the paper

edge becomes shorter.

Small value: The distance

between the staple

position and the paper

edge becomes longer.

ISTAPLE

BOTH

Staple

binding

position

adjustment

(Two

positions

center)

0.2mm Large value: The staple

position is shifted to the

front side from the center.

Small value: The staple

position is shifted to the

rear side from the center.

Item Display Item

Set

range

Default

Page 35

MX-FN10 ADJUSTMENTS 8 – 2

NOTE: "A: SADDLE POSITION (Saddle binding position adjust-

ment)" and "B: FOLDING POSITION (Saddle folding position adjustment)"

The saddle binding position adjustment and the saddle

folding position adjustment can be executed in the system

setting menu. However, the adjustments in the system setting are based on the adjustment value of this simulation.

If, therefore, the adjustment value of this simulation is set

to an extreme level, the adjustment range in the system

setting may be narrowed. (Adjustment range in the system

setting 5.0mm)

If the adjustment range in the system setting is to narrow,

change the adjustment value of this simulation.

In general, when the saddle binding position and the saddle folding positions are adjusted to the center by this simulation, the above trouble will not occur.

2. Punch unit (option)

A. Punch unit and punch PWB destination setting

1) When the punch PWB is replaced, the destination must be set

accordingly.

2) Use the DIP switch and the push switch on the punch PWB to

set the destination.

3) The DIP switch setting and destinations are shown in the table

below.

4) Destination setting procedures

a) Check to confirm that the punch unit power is turned OFF.

b) Set the DIP switches 1, 2, and 4 to ON, then push and

hold the push switch and supply the power.

c) Set the DIP switch for a desired destination.

d) Push the push switch to fix the destination setting. (The

LED flashes.)

e) Check to confirm that the LED turns ON (fixed state), and

turn OFF the power of the punch unit.

f) Set all the DIP switches to OFF, and terminate the opera-

tion.

5) Checking the currently set destination

a) Check to confirm that the punch unit power is turned OFF.

b) Set the DIP switches 1, 2, and 4 to ON, then push and

hold the push switch and supply the power.

c) Set the DIP switches 1 and 4 to OFF. (In this case, only

the DIP switch 2 is set to ON.)

d) Push the push switch, and check the number of flashing of

the LED.

(Since the first cycle includes the first lighting of the LED,

count the number of flashing in the second cycle.)

e) Turn OFF the power of the punch unit.

f) Set all the DIP switches to OFF, and terminate the opera-

tion.

JSTAPLE

PITCH

Stap le

binding

position

adjustment

(Two

positions

pitch)

0.2mm Large value: The pitch of

two positions becomes

wider.

Small value: The pitch of

two positions becomes

narrower.

K PUNCH

CENTER

Punch

center

adjustment

0.2mm Large value: The hole

position is shifted to the

front side from the center.

Small value: The hole

position is shifted to the

rear side from the center.

L PUNCH

HOLE

Punch hole

position

adjustment

0.2mm Large value: The distance

between the hole position

and the paper edge

becomes shorter.

Small value: The distance

between the hole position

and the paper edge

becomes longer.

M SADDLE_

ADJUST_

POS

Saddle

alignment

position

adjustment

0.2mm Large value: The

alignment plate position is

shifted to the center.

Small value: The

alignment plate position is

shifted to the outside.

N GRIPPER_

POS

Gripper exit

position

adjustment

0.2mm Large value: The gripper

exit position is shifted to

the front.

Small value: The gripper

exit position is shifted to

the rear.

Item Display Item Change Change direction

Model Kind of punch

DIP switch

1234

MX-PNX5 (2-hole) 2-hole type OFF OFF OFF OFF

MX-PNX5 (2/3-hole) 2/3-hole type OFF OFF OFF ON

MX-PNX5

(4-hole France)

4-hole type

(France)

OFF OFF ON OFF

MX-PNX5

(4-hole Sweden)

4-holel type

(Sweden)

OFF OFF ON ON

㪦㪥

㪈㪉㪊㪋

㪚㪧㪬

㪣㪜㪛

㪧㫌㫅㪺㪿㩷㪧㪮㪙

㪛㪠㪧㩷㫊㫎㫀㫋㪺㪿

㪧㫌㫊㪿㩷㫊㫎㫀㫋㪺㪿

Page 36

MX-FN10 ADJUSTMENTS 8 – 3

NOTE: In the MX-PNX5 series, when the punch hole type (destina-

tion) is set with the DIP switch, the F1-32 error display is

made. Note that the error display is made because of

mechanical reasons and that it is not an actual error in the

case of the MX-PNX5.

B. Punch unit and punch PWB sensor adjustment

1) When the punch PWB is replaced, the following sensors must

be adjusted. (Punch dust detection must be executed in maintenance, too.)

Transport system, paper edge detection sensors

Punch timing sensor

Punch paper edge sensor 1

Punch paper edge sensor 2

Punch paper edge sensor 3

Punch paper edge sensor 4

Punch dust detection system

Punch dust sensor

2) The adjustment of each sensor is performed with the DIP

switch and the push switch on the punch PWB.

3) The DIP switch setting and the target adjustment sensors are

shown in the table below.

4) Transport pass system, paper edge detection system sensor

adjustment procedures

a) Check to confirm that the punch unit power is turned OFF.

b) Check to confirm that there is no paper and interruption

material in the sensor section.

c) Set the DIP switches 1, 2, and 3 to ON, then push and

hold the push switch and supply the power.

d) Set all the DIP switches to OFF according to the table

above.

e) Push the push switch and execute the adjustment. (The

LED flashes.)

f) Check to confirm that the LED flashes (fixed state), and

turn OFF the punch unit power.

5) Punch dust detection system sensor adjustment procedures

a) Check to confirm that the punch unit power is turned OFF.

b) Check to confirm that the dust box is normally set, and

that there is no punch dust in the dust box.

c) Set the DIP switches 1, 2, and 3 to ON, then push and

hold the push switch and supply the power.

d) Set the DIP switch 4 to ON and DIP switches 1, 2, and 3

to OFF according to the table above.

e) Push the push switch and execute the adjustment. (The

LED flashes.)

f) Check to confirm that the LED flashes (fixed state), and

turn OFF the punch unit power.

g) Set all the DIP switches to OFF, and terminate the opera-

tion.

6) Error display in case of an adjustment error

(Since the first cycle includes the first lighting of the LED, count

the number of flashing in the second cycle.)

LED flashing number Kind of punch

4 times 2-hole type

9 times 2/3-hole type

7 times 4-hole type (France)

8 times 4-holel type (Sweden)

Adjustment execution sensor

DIP switch

1234

Transport system, paper edge detection

system sensor (collective)

OFFOFFOFFOFF

Punch dust detection system OFF OFF OFF ON

㪦㪥

㪈㪉㪊㪋

㪚㪧㪬

㪣㪜㪛

㪧㫌㫅㪺㪿㩷㪧㪮㪙

㪛㪠㪧㩷㫊㫎㫀㫋㪺㪿

㪧㫌㫊㪿㩷㫊㫎㫀㫋㪺㪿

LED flashing number Error content

14 times Punch timing sensor adjustment error

15 times Punch paper edge sensor 4 adjustment error

16 times Punch paper edge sensor 3 adjustment error

17 times Punch paper edge sensor 2 adjustment error

18 times Punch paper edge sensor 1 adjustment error

19 times Dust sensor adjustment error

20 times

Adjustment value save failure (error) to

EEPROM

21 times

Page 37

MX-FN10 SELF DIAG MESSAGE AND TROUBLE CODE 9 – 1

MX-FN10

Service Manual

[9] SELF DIAG MESSAGE AND

TROUBLE CODE

1. Interface transport unit

2. Punch unit

Phenomenon The inlet port reverse pass solenoid does not operate

properly.

Case1 Cause Inlet port reverse solenoid trouble

Check &

Remedy

Perform the coil conduction test to check

conduction. If there is no conduction, replace.

Case2 Cause Electric cable, connector trouble

Check &

Remedy

Check conduction between connector

terminals. If there is no conduction, replace

the electric cable.

Case3 Cause Control PWB trouble

Check &

Remedy

If the solenoid does not work in the solenoid

single operation mode, replace the finisher

control PWB.

Case4 Cause Caught by foreign material.

Check &

Remedy

Check the guide. If it is caught, remove the

cause.

Phenomenon The interface transport motor does not operate

properly.

Case1 Cause Interface transport motor trouble

Check &

Remedy

Perform the coil conduction test to check

conduction. If there is no conduction, replace.

Case2 Cause Electric cable, connector trouble

Check &

Remedy

Check conduction between connector

terminals. If there is no conduction, replace

the electric cable.

Case3 Cause Finisher control PWB trouble

Check &

Remedy

If the motor does not operate in the motor

single operation mode, replace the finisher

control PWB.

Phenomenon The interface transport fan motor does not operation

properly.

Case1 Cause Interface transport fan motor trouble

Check &

Remedy

Perform the coil conduction test to check

conduction. If there is no conduction, replace.

Case2 Cause Electric cable, connector trouble

Check &

Remedy

Check conduction between connector

terminals. If there is no conduction, replace

the electric cable.

Case3 Cause Finisher control PWB trouble

Check &

Remedy

If the motor does not operate in the motor

single operation mode, replace the finisher

control PWB.

Phenomenon Paper jams frequently occur in the interface

transport section.

Case1 Cause Interface transport unit inlet port sensor

trouble

Check &

Remedy

Measure the voltage of TP89 on the finisher

control PWB. Check to confirm that the

voltage is 3.3V when there is no paper, and

3.3V 5% when there is some paper. If the

voltage is outside this range, replace the

sensor.

Case2 Cause Interface transport unit exit port sensor

trouble

Check &

Remedy

Measure the voltage of TP88 on the finisher

control PWB. Check to confirm that the

voltage is 1V or less when there is no paper,

and 3.3V 5% when there is some paper. If

the voltage is outside this range, replace the

sensor.

Case3 Cause Electric cable, connector trouble

Check &

Remedy

Check conduction between connector

terminals. If there is no conduction, replace

the electric cable.

Case4 Cause Finisher control PWB trouble

Check &

Remedy

When each sensor is turned ON/OFF, though

the sensor level is changed, if the

phenomenon is not canceled, replace the

finisher control PWB.

Phenomenon The punch unit is not recognized.

Case1 Cause Electric cable, connector trouble

Check &

Remedy

Check conduction between connector

terminals. If there is no conduction, replace

the electric cable.

Case2 Cause Control PWB trouble

Check &

Remedy

If the harness and the connector are normal,

replace the punch control PWB. If the trouble

still remains, replace the finisher control

PWB.

Phenomenon The punch motor does not operate properly.

(Punching is not performed properly.)

Case1 Cause Punch motor trouble

Check &

Remedy

Perform the conduction test of the coil. If

there is no conduction, replace.

Case2 Cause Punch HP sensor trouble

Check &

Remedy

Measure the voltage at CN 3.3pin on the

punch control PWB to confirm that it is 1V or

less when transmitting, and 5V 5% when

interrupted. If the voltage is outside the range,

replace the sensor.

Case3 Cause Punch positions sensor trouble

Check &

Remedy

Measure the voltage at CN 3.9pin on the

punch control PWB to confirm that it is 1V or

less when transmitting, and 5V 5% when

interrupted. If the voltage is outside the range,

replace the sensor.

Case4 Cause Punch clock sensor trouble

Check &

Remedy

Measure the voltage at CN 3.6pin on the

punch control PWB to confirm that it is 1V or

less when transmitting, and 5V 5% when

interrupted. If the voltage is outside the range,

replace the sensor.

Case5 Cause Electric cable, connector trouble

Check &

Remedy

Check conduction between connector

terminals. If there is no conduction, replace

the electric cable.

Case6 Cause Punch control PWB trouble

Check &

Remedy

If the motor does not operate properly in the

motor single operation mode, replace the

punch control PWB. If the trouble still

remains, replace the punch control PWB.

Phenomenon The horizontal shift motor does not operate properly.

Case1 Cause Horizontal shift motor trouble

Check &

Remedy

Check conduction of the coil. If there is no

conduction, replace.

Case2 Cause Horizontal shift HP sensor trouble

Check &

Remedy

Measure the voltage at CN 5.3pin on the

punch control PWB to confirm that it is 1V or

less when transmitting, and 5V 5% when

interrupted. If the voltage is outside the range,

replace the sensor.

Case3 Cause Electric cable, connector trouble

Check &

Remedy

Check conduction between connector

terminals. If there is no conduction, replace

the electric cable.

Case4 Cause Punch control PWB trouble

Check &

Remedy

If the motor does not operate properly in the

motor single operation mode, replace the

punch control PWB. If the trouble still

remains, replace the punch control PWB.

Phenomenon Paper jams frequently occur in the interface

transport section.

Page 38

MX-FN10 SELF DIAG MESSAGE AND TROUBLE CODE 9 – 2

3. Transport section except for the

saddle

4. Process tray

Phenomenon The rear edge sensor and the resist sensor do not

operate properly.

Case1 Cause Rear edge sensor trouble

Check &

Remedy

If ON/OFF operation is not made in the punch

single sensor check mode, replace the PWB

assembly on the light emitting side and the

light receiving side. If the trouble still remains,

replace the punch control PWB.

Case2 Cause Resist sensor (SIZE A3) trouble

Check &

Remedy

If ON/OFF operation is not made in the punch

single sensor check mode, replace the PWB

assembly on the light emitting side and the

light receiving side. If the trouble still remains,

replace the punch control PWB.

Case3 Cause Resist sensor (SIZE B4) trouble

Check &

Remedy

If ON/OFF operation is not made in the punch

single sensor check mode, replace the PWB

assembly on the light emitting side and the

light receiving side. If the trouble still remains,

replace the punch control PWB.

Case4 Cause Resist sensor (SIZE A4) trouble

Check &

Remedy

If ON/OFF operation is not made in the punch

single sensor check mode, replace the PWB

assembly on the light emitting side and the

light receiving side. If the trouble still remains,

replace the punch control PWB.

Case5 Cause Resist sensor (SIZE B5) trouble

Check &

Remedy

If ON/OFF operation is not made in the punch

single sensor check mode, replace the PWB

assembly on the light emitting side and the

light receiving side. If the trouble still remains,

replace the punch control PWB.

Case6 Cause Electric cable, connector trouble

Check &

Remedy

Check conduction between connector

terminals. If there is no conduction, replace

the electric cable.

Phenomenon The dust sensor does not operation properly.

Case1 Cause Dust sensor trouble

Check &

Remedy

If ON/OFF operation is not made in the punch

single sensor check mode, replace the PWB

assembly on the light emitting side and the

light receiving side. If the trouble still remains,

replace the punch control PWB.

Case2 Cause Electric cable, connector trouble

Check &

Remedy

Check conduction between connector

terminals. If there is no conduction, replace

the electric cable.

Phenomenon The punch backup RAM does not operate properly.

Case1 Cause Punch control PWB trouble

Check &

Remedy

If it does not operate properly in the punch