Page 1

SERVICE MANUAL

CODE: 00ZMXFDX1/S1E

FOLDING UNIT

MODEL

CONTENTS

[1] SPECIFICATION

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

2. Paper Size/Type/Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[2] MAINTENANCE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

[3] REPLACEMENT AND ADJUSTMENT

1. BEFORE YOU BEGIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

2. COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

3. FEED MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

4. UPPER EXIT SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

5. UPPER STOPPER MOTOR/HP SENSOR, FEED SENSOR . . . . . . . 3 - 2

6. FOLD TIMING SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

7. LOWER STOPPER MOTOR/HP SENSOR, RELAY BOARD . . . . . . . 3 - 2

8. LEADING EDGE SENSOR, LOWER EXIT SENSOR . . . . . . . . . . . . . 3 - 2

9. ANTI-STATIC BRUSH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

10. FOLD ROLLER MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

11. MAIN CONTROL BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

12. PSU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

13. UNEVEN FOLDING ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

MX-FDX1

[4] SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

[5] DETAILS

1. OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

2. Z-FOLDING UNIT PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

3. DRIVE LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

4. ELECTRICAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

MX-FDX1

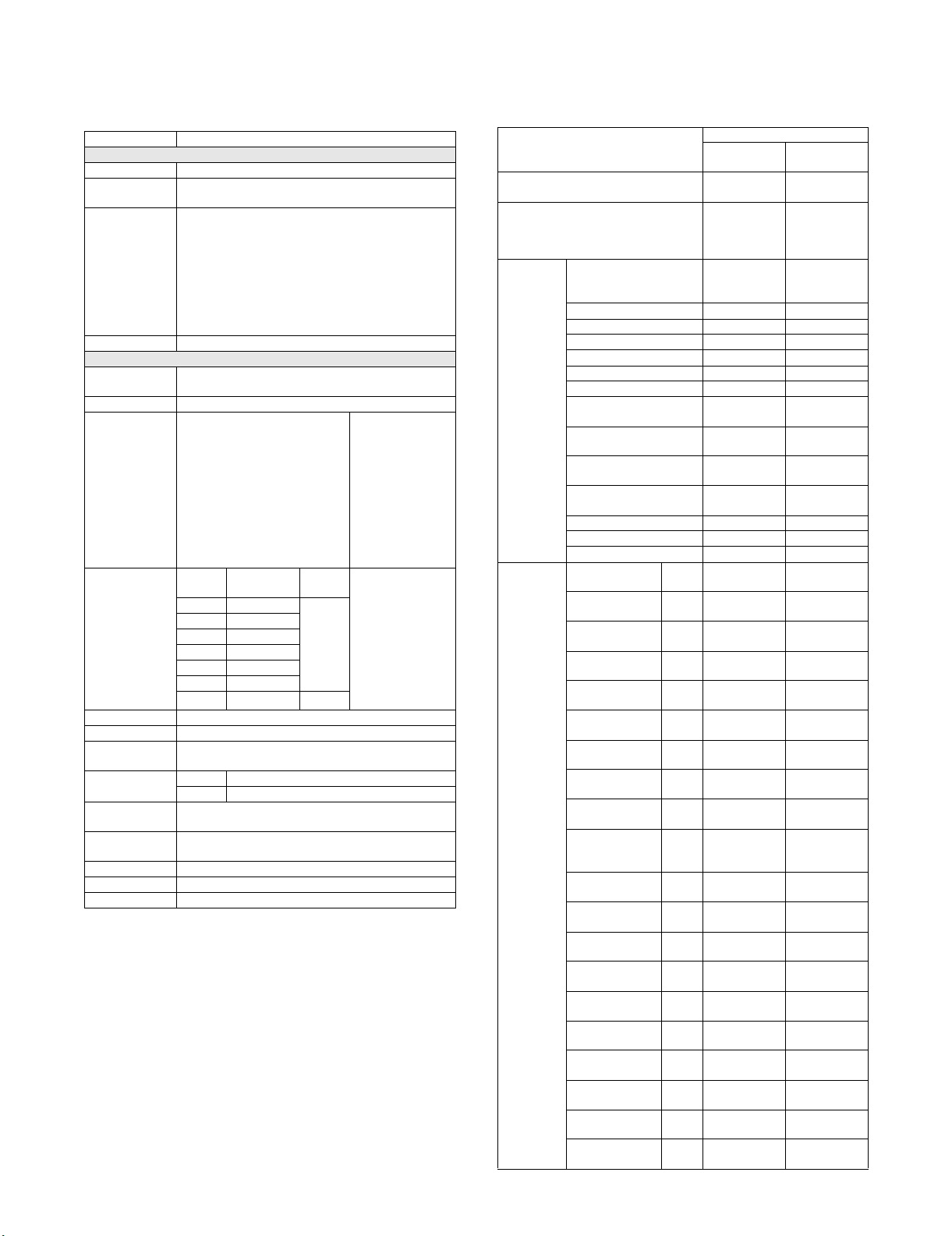

[1] SPECIFICATION

Service Manual

1. General

Form Floor type

Transport speed 85-110 sheets/minute (A4, 8.5"x11")

Transport

alignment

Paper Size

(Through pass)

Paper Weight 52g/m

Processing

performance

Folding Type Z-folding

Adjustment of

Folding Position

(1st time)

Adjustment of

Folding Position

(2nd time)

Paper size A3, B4, A4-R, 11"x17", 8.5"x14", 8.5"x11"-R

Paper weight 60-90g/m

Reversing

mechanism

Reliability MCBJ In compliance with the main unit.

Life Straight pass section: 5 years or 24,000K

Power

Consumption

Power Source 120W

Dimensions 177mm(W) x 634mm(D) x 980mm(H)

Weight 53.2kg or less

Through Pass Section

Center alignment

All papers that can be fed from the main unit or inserter.

A3W, A3, B4, A4, A4-R, B5, B5-R, A5, A5-R, 8K, 16K,

16KR, 12"x18", 11"x17", 9"x12", 8.5"x14" , 8.5"x13.4",

8.5"x13", 8.5"x11", 8.5"x11"-R, 5.5"x8.5", 5.5"x8.5"-R,

7.25"x10.5"R, SRA3 (320x450mm), SRA4,

318x234.75mm, 312.5x220mm, 318x469.5mm,

312.5x440mm, Postcard

* A5/5.5"x8.5" are fed from Inserter Tray of Inserter

Unit.

2

- 300g/m2,16lbs Bond-170lbs Index

50 sheets/minute (A4R, 8.5"x11"-R)

Available (±4mm), Adjustment

pitch 0.1mm, Controlled by the

main unit.

8.5x14 -4 - 33

8.5x11 Impossible ---

None

MCBF In compliance with the main unit.

(Folding section: 5 years or 6,000K)

AC100 - 240V (In-let type, Original cable)

Folding Section

Adjustment

Size

range (mm)

A3R -4 - 23 0.1mm

B4R -4 - 38

A4R -4 - 8

12x18 -4 - 3

11x17 -4 - 18

2

,16lbs-24lbs Bond

Pitch

When folding paper

in half, if you set +

value (default is 0

mm), edge of

paper which is

folding side moves

to outside, if you

set - value, edge of

paper which is

folding side moves

to inside.

When folding paper

to one-quarter, If

you set + value

(default is 2mm

inside), edge of

paper moves to

inside, If you set value, edge of

paper moves to

outside.

2. Paper Size/Type/Weight

Through

Minimum paper weight 52g/m

Maximum paper weight 300g/m

Paper type Thin paper Yes

Plain paper Yes Yes

Recycled paper Yes Yes

Colored paper Yes Yes

Letter head Yes Yes

Pre-printed paper Yes Yes

Pre-punched paper Yes Yes

Heavy paper1

(106-128g/m

Heavy paper2

(129-176g/m

Heavy paper3

(177-205g/m

Heavy paper4

(206-300g/m

Tab paper Yes No

Transparency paper Yes No

Label paper Yes No

Paper size 12"x18" (A3W) 305

Ledger (11"x17") 279

Ledger (11"x17")

Z folding

Legal (8.5"x14") 216

Legal (8.5"x14")

Z folding

Mexican Legal

(8.5"x13.4")

Foolscap

(8.5"x13")

Letter (8.5"x11") 279

Letter R

(8.5"x11"R)

Letter R

(8.5"x11"R)

Z folding

Invoice

(5.5"x8.5")

Invoice R

(5.5"x8.5"R)

Exective R

(7.25"x10.5")

9x12 (A4W) 305

A3 297

A3 Z folding 297

B4 257

B4 Z folding 257

A4 297

A4-R 210

2

)

2

)

2

)

2

)

pass section

(40lbs bond)

(140lbs index)

(100lbs cover)

(Even 52g/m

is possible)

x457

x432

279

x216

x356

216

x178

216

x340

216

x330

x216

216

x279

216

x140

216

x140

140

x216

184

x266

x229

x420

x210

x364

x182

x210

x297

Folding Unit

2

2

Ye s N o

Ye s N o

Ye s N o

Ye s N o

Ye s N o

Ye s Ye s

-Yes

Ye s Ye s

-Yes

Ye s N o

Ye s N o

Ye s N o

Ye s Ye s

-Yes

Ye s -

Ye s N o

Ye s N o

Ye s N o

Ye s Ye s

-Yes

Ye s Ye s

-Yes

Ye s N o

Ye s Ye s

2

Folding

section

60g/m2

(16lbs bond)

90g/m2

24lbs Bond

No

MX-FDX1 SPECIFICATION 1 – 1

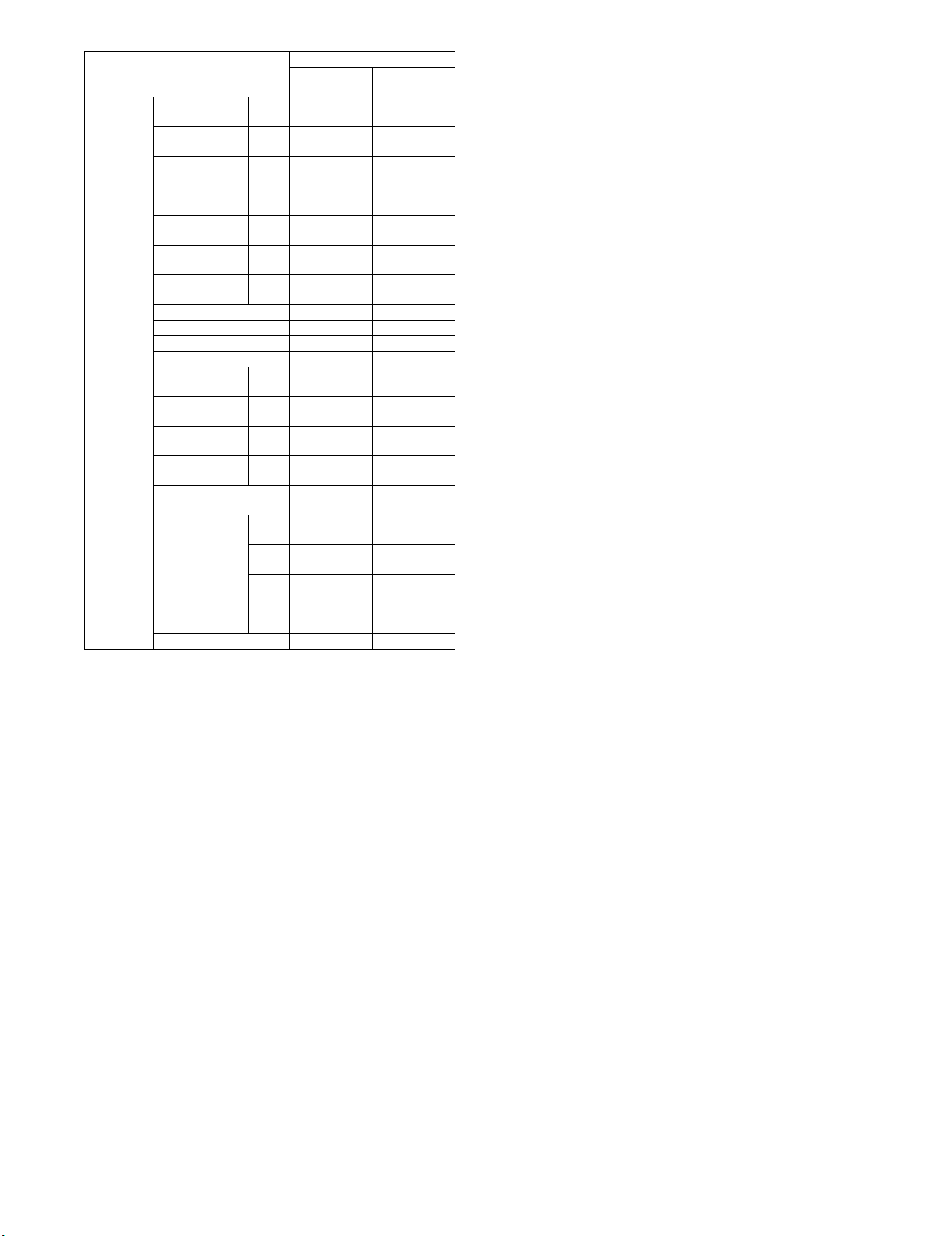

Page 3

Paper size A4-R Z folding 210

x148

B5 257

x182

B5-R 182

x257

A5 210

x148

A5-R 148

x210

SRA3 320

x450

SRA4 320

x225

318x234.75mm Yes No

312.5x220mm Yes No

318x469.5mm Yes No

312.5x440mm Yes No

8K 270

x390

16K 270

x195

16K-R 195

x270

Postcard 100

x148

Special-Custom size Yes No

Folding Unit

Through

pass section

-Yes

Yes No

Yes No

Yes -

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Folding

section

(Custom Range) min

Main

max

Main

min

Sub

max

Sub

Special-Size uncertain Yes No

100 (4.0) -

320 (12.5) -

140 (5.5) -

470 (18.5) -

MX-FDX1 SPECIFICATION 1 – 2

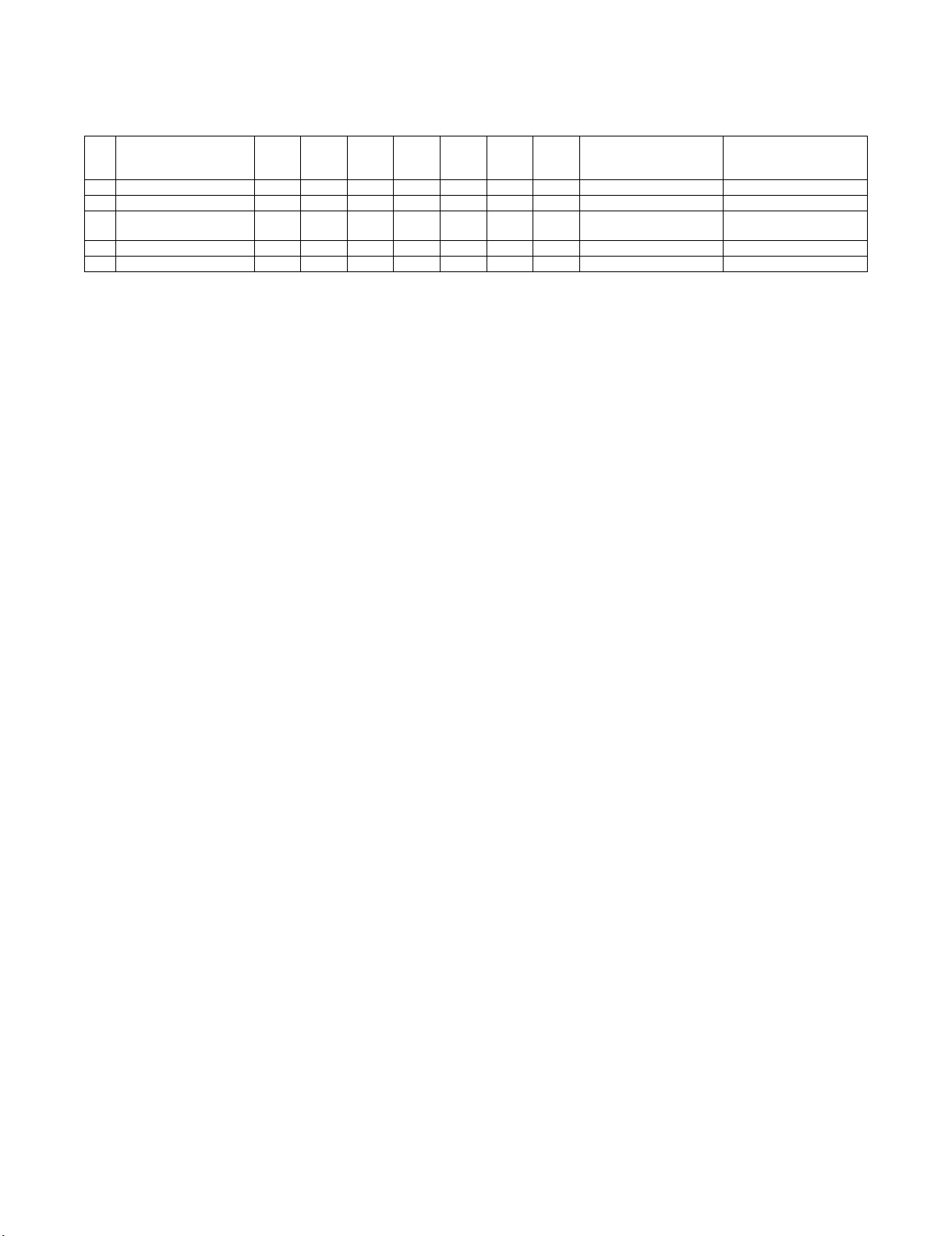

Page 4

MX-FDX1

[2] MAINTENANCE LIST

✕: Check {: Clean S: Replace U: Adjust ✩: Lubricate : Shift position

(Clean, replace, or adjust as needed.)

Service Manual

No. Part name

1 Reflection type sensor ✕ {{{{{{ Clean by air

2 Sensor reflection plate ✕ {{{{{{ Clean by air

3 Folding roller ✕ {{{{{{Folding mode counter

4 Transport guide plate ✕ {{{{{{

5 Gear ✕✕✕✕✕✕✕ UKOG-0307FCZZ

When

calling

500K 1000K 1500K 2000K 2500K 3000K Life judgement (Reference)

every 200K

Tool, oil, chemicals

Procedure

Treatment after procedure

When there is dirt, wipe

with wet cloth and water.

MX-FDX1 MAINTENANCE LIST 2 – 1

Page 5

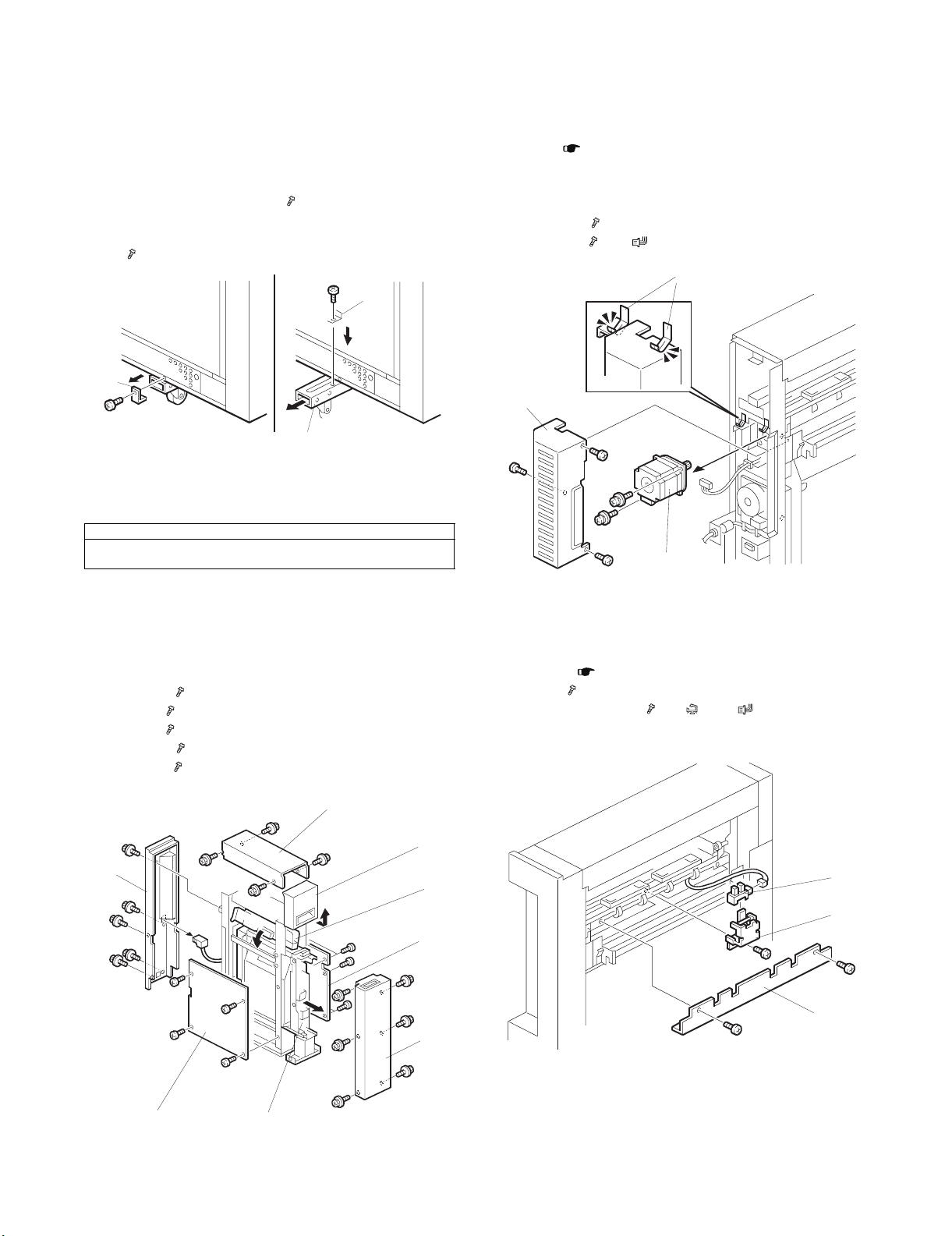

[A]

[B]

[C]

MX-FDX1

[3] REPLACEMENT AND ADJUSTMENT

Service Manual

1. BEFORE YOU BEGIN

1) Disengage the Z-folding unit from the machine.

2) Disengage the Z-folding unit from the finisher (or cover sheet

feeder).

3) At the bottom on the sides of the Z-folding unit:

• Remove the lock bracket [A] ( x 1).

• Pull out the foot extension [B].

• Re-attach the bracket [A] to lock the foot in the open position

( x 1).

[A]

[A]

[B]

Reinstallation

Do this procedure in the opposite sequence to retract and lock the

extensions below the Z-folding unit.

CAUTION

The Z-folding unit is not stable, with or without the feet extended. Do your

work carefully; do not tilt the unit.

3. FEED MOTOR

• Pull the Z-folding mechanism out of the unit, but not fully.

Remove: ( 2. COVERS)

• Left cover

• Right cover

• Rear cover

[A] Motor cover ( x 3)

[B] Feed Motor ( x 2, x 1, timing belt x 1)

[C]

[A]

[B]

2. COVERS

• Open the front door [A].

• Lift the horizontal transport plate [B] to the left until it locks on the

left side.

• Pull out the Z-fold mechanism [C].

[D] Front cover ( x 6)

[E] Top cover ( x 4)

[F] Left cover ( x 4)

[G] Right cover ( x 5)

[H] Rear cover ( x 6)

[E]

[A]

[H]

[B]

[G]

[D]

Reinstallation

Confirm that the motor cover is below the leaf springs at [C].

4. UPPER EXIT SENSOR

• Left cover ( 2. COVERS)

[A] Bracket ( x 2)

[B] Upper exit sensor unit ( x 1, x 1, x 1)

[C] Upper exit sensor

[F]

[C]

MX-FDX1 REPLACEMENT AND ADJUSTMENT 3 – 1

Page 6

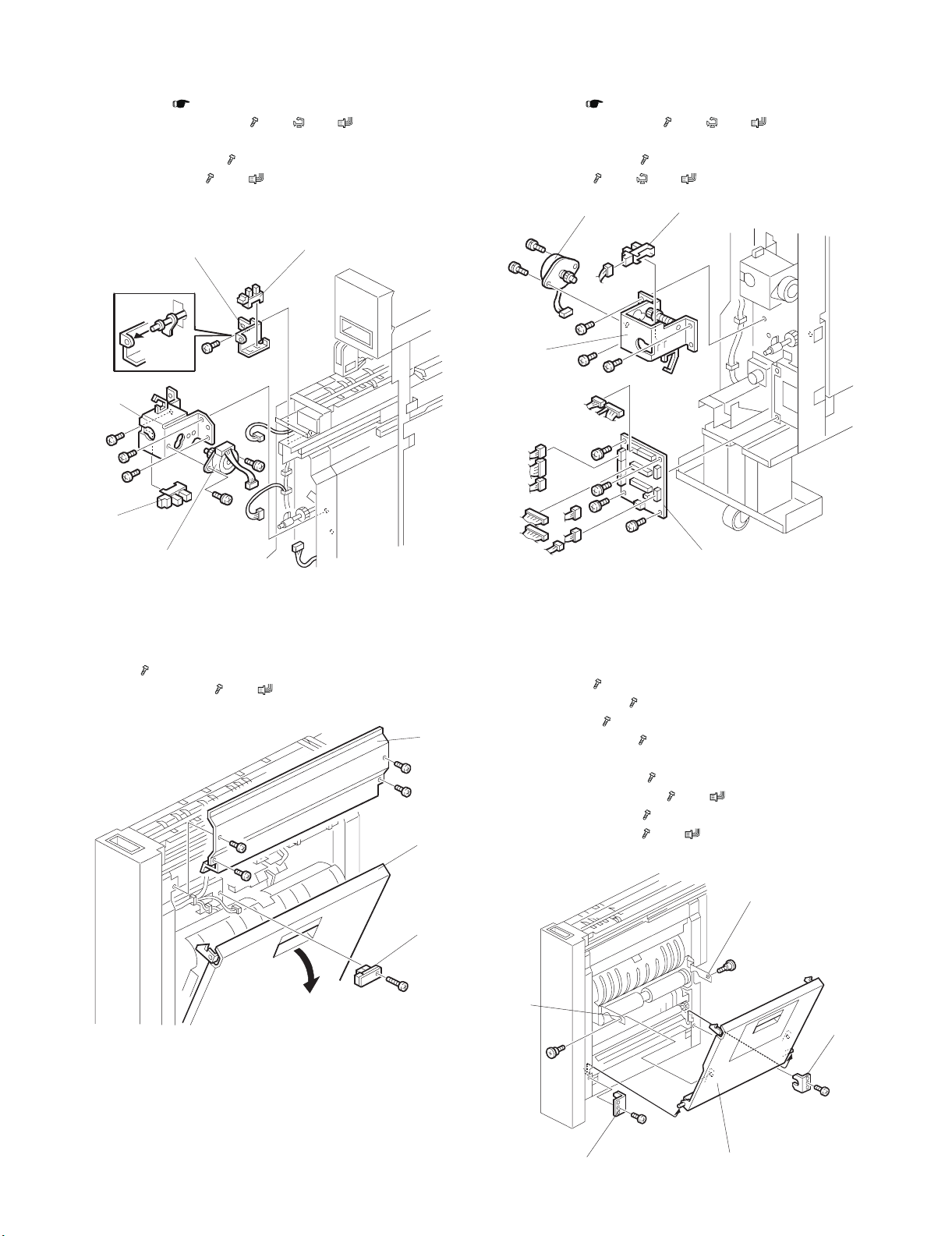

5. UPPER STOPPER MOTOR/HP

SENSOR, FEED SENSOR

• Front cover ( 2. COVERS)

[A] Upper stopper motor unit ( x 3, x 2, x 2)

[B] Upper stopper motor HP sensor

[C] Upper stopper motor ( x 2)

[D] Feed sensor unit ( x 1, x 1)

[E] Feed sensor

7. LOWER STOPPER MOTOR/HP SENSOR, RELAY BOARD

• Front cover ( 2. COVERS)

[A] Lower stopper motor unit ( x 3, x 2, x 2),

[B] Lower stopper HP sensor

[C] Lower stopper motor ( x 2)

[D] Relay board ( x 4, x 3, x 10)

[C]

[B]

[D]

[E]

[A]

[B]

[C]

6. FOLD TIMING SENSOR

• Pull the Z-fold mechanism out of the unit.

[A] Open the right vertical transport unit cover.

[B] Plate ( x 4)

[C] Fold timing sensor ( x 1, x 1)

[B]

[A]

[A]

[D]

8. LEADING EDGE SENSOR, LOWER EXIT SENSOR

• Pull out the Z-folding mechanism.

• Open the right vertical transport cover [E].

[A] Left link arm ( x 1)

[B] Left corner bracket ( x 1)

[C] Right link arm ( x 1)

[D] Right corner bracket ( x 1)

[E] Vertical transport cover.

[F] Lower fold roller cover ( x 2)

[G] Leading edge sensor unit ( x 1, x 1)

[H] Leading edge sensor ( x 1)

[I] Lower exit sensor unit ( x 1, x 1)

[J] Lower exit sensor

[C]

[A]

[B]

MX-FDX1 REPLACEMENT AND ADJUSTMENT 3 – 2

[C]

[D]

[E]

Page 7

[G]

[H]

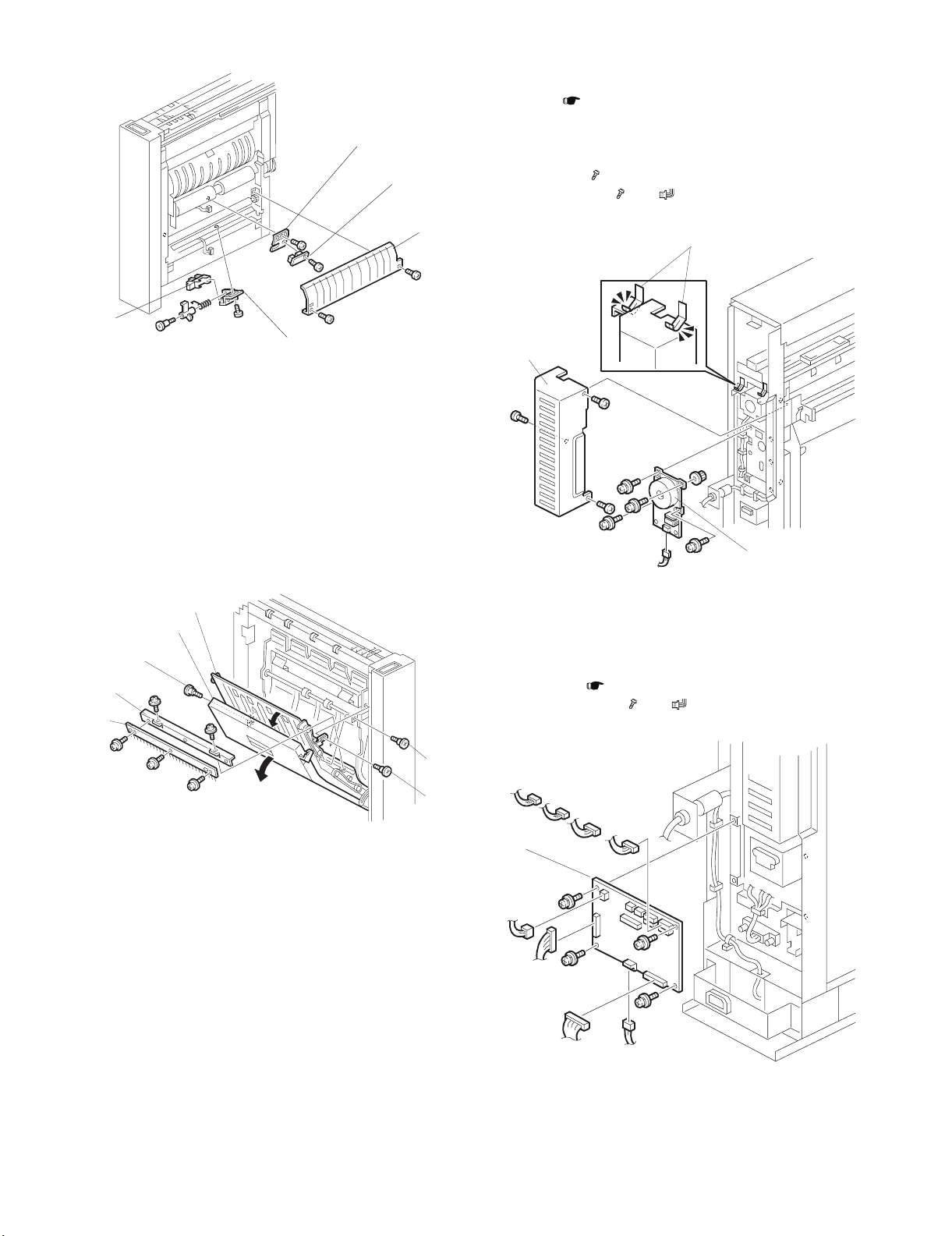

10. FOLD ROLLER MOTOR

• Pull the Z-folding mechanism out of the unit, but not fully.

Remove: ( 2. COVERS)

• Left cover

• Right cover

• Rear cover

[A] Motor cover ( x 3)

[B] Fold roller motor ( x 4, x 1, timing belt x 1)

[J]

[I]

9. ANTI-STATIC BRUSH

• Pull out the Z-folding mechanism.

• Open the left vertical transport cover [A].

• Open the vertical transport assembly [B].

Remove:

[C] Left link screw

[D] Right link screw

[E] Link screw

[F] Bracket

[G] Anti-static brush

[B]

[A]

[C]

[F]

[G]

[F]

[C]

[A]

[B]

Reinstallation

Make sure that the motor cover is below the leaf springs [C].

11. MAIN CONTROL BOARD

Remove:

• Rear cover. ( 2. COVERS)

[A] Main control board ( x 4, x 8)

[D]

[E]

[A]

MX-FDX1 REPLACEMENT AND ADJUSTMENT 3 – 3

Page 8

12. PSU

• Open the front door.

• Pull the Z-fold mechanism out of the unit.

Remove:

• Left cover and right cover. ( 2. COVERS)

[A] Base top cover ( x 3).

[B] Base left cover ( x 2).

[C] Base right cover ( x 2).

• Make a mark at the positions of the connectors, then disconnect them.

NOTE:

These connectors do not have different colors. To help you

connect them again correctly, make marks on them.

[D] Power supply unit (PSU) ( x4, x 2).

• Pull the PSU out of the right side of the bottom.

[E] Power supply board ( x 6, x 3).

[A]

B. Z-FOLD ADJUSTMENT SCREWS

The adjustment of the 1st fold is done by turning an adjustment

screw linked to the paper stopper.

Pull out the Z-fold mechanism.

Open the right cover to see the adjustment screw located at [A].

This is the screw used to adjust the 1st fold.

[A]

[B]

[D]

[C]

13. UNEVEN FOLDING ADJUSTMENT

A. OVERVIEW

Printed Side (1 Side)

1st Fold

[E]

Open the left cover to see the screw located at [B].

This is the screw used to adjust the 2nd fold.

[B]

2nd Fold

This procedure describes how to correct uneven folding (D) in

paper folded with the Z-Fold unit. Before doing this procedure,

please note the names and positions of the 1st and 2nd Fold.

Section [5]-2 provides a full description of how Z-folding is done.

MX-FDX1 REPLACEMENT AND ADJUSTMENT 3 – 4

D

Page 9

C. Z-FOLD ADJUSTMENT PROCEDURE

(1) 1st Fold Adjustment

1) Print one A3 copy and send it through the Z-fold unit.

2) Open the 2nd fold (2).

3) Turn the paper over so the edge (3) is aligned with the crease

of the 2nd fold.

1

9) After the adjustment is completed, use a screw driver to hold

the screw in position, then retighten the nut you loosened in

Step 5). Do not turn the screw.

(2) 2nd Fold Adjustment

1) Print one A3 copy and send it through the Z-fold unit.

2) Open the folded sheet at the 1st fold (1) then lay it down flat.

3) Stand the sheet on its end so the edge (3) is up and the crease

of the 1st fold is facing out.

2

1

3

3

4) Open the right door and locate the screw that adjusts the 1st

fold (see previous page).

5) Use a phillips screwdriver to turn the screw [A] to the left to

loosen the nut.

• If the corner is over the right edge, turn the screw to the

right.

• If the corner is over the left edge, turn the screw to the left.

NOTE:

• The illustration above shows the corner over the right

edge.

• You can see the pointer [B] change position on the

notches of the adjustment scale as you turn the screw.

1

2

3

3

4) Open the left door and locate the screw that adjusts the 2nd

fold (see previous page).

5) Use a phillips screwdriver to turn the screw [A] to the left to

loosen the nut.

• If the corner is over the right edge, turn the screw to the

right.

• If the corner is over the left edge, turn the screw to the left.

NOTE:

• The illustration shows the corner over the right edge.

• You can see the pointer [B] change position on the

notches of the adjustment scale as you turn the screw.

[A]

[B]

6) Close the Z-Fold unit.

7) Do another test print.

8) If the 1st fold is still misaligned, repeat this procedure until the

alignment is correct.

MX-FDX1 REPLACEMENT AND ADJUSTMENT 3 – 5

[B]

[A]

Page 10

6) Close the Z-Fold unit.

X

X

X

7) Do another test print.

8) If the 1st fold is still misaligned, repeat this procedure until the

alignment is correct.

9) After the adjustment is completed, use a screw driver to hold

the screw in position, then retighten the nut you loosened in

Step 5). Do not turn the screw.

D. Z-FOLD ADJUSTMENT REFERENCE TABLE

(1) 1st Fold Adjustment

Turn screw right

Turn screw left

(2) 2nd Fold Adjustment

Turn screw right

NOTE:

A one-notch adjustment on the scale means the alignment is corrected by about 1 mm.

Turn screw left

MX-FDX1 REPLACEMENT AND ADJUSTMENT 3 – 6

Page 11

MX-FDX1

[4] SERVICE TABLES

Service Manual

Perform the folding position adjustment on the administrator adjustment menu of the system setting.

లˍ୬պ౾

(B)

(A)

లˎ୬պ౾

1) Press [SYSTEM SETTING] key on the operation panel and log

in as the administrator.

(Password: admin/default)

2) Press [Administrator Adjustment] key and select [Option

Adjustment] on the administrator adjustment menu.

4) Adjust the paper folding position.

Adjustment condition

First folding

position

Adjust the

length of (A).

When the adjustment value is increased, the folding

edge position is shifted to the upper edge from the

position of 1/2.

(Example) When the adjustment value is increased:

3) Select [Folding Unit] from the option adjustment menu.

Second folding

position

Adjust the

length of (B).

When the adjustment value is increased, the folding

edge position is shifted from the first folded position.

(Example) When the adjustment value is increased.

MX-FDX1 SERVICE TABLES 4 – 1

Page 12

MX-FDX1

[5] DETAILS

Service Manual

1. OVERVIEW

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

2. Z-FOLDING UNIT PAPER PATH

A. PAPER PATH WITH NO FOLDING

The feed rollers [1] feed the paper from the main machine into the

Z-folding unit.

If Z-folding was not used for the job, the sheet feeds above the

closed junction gate [2].

The upper exit sensor [3] detects the leading and trailing edge of

the unfolded sheet.

The upper exit rollers [4] feed the unfolded sheet out of the Z-folding unit and into the finisher.

[1]

[4]

[3]

[2]

14

1 Front Door Sensor 14 Grip Rollers

2 Junction Gate 15 Lower Stopper

3 Feed Rollers 16 Leading Edge Sensor

4 Feed Sensor 17 Vertical Feed Rollers - 1

5 Fold Timing Sensor 18 Anti-Static Brush

6 Pinch Idle Roller 19 1st Fold Roller

7 Upper Stopper 20 Vertical Feed Rollers - 2

8 Upper Stopper Path Sensor 21 Upper Stopper HP Sensor

9 3rd Fold Roller 22 Pinch Feed Roller

10 2nd Fold Roller 23 Vertical Feed Rollers - 3

11 Lower Stopper HP Sensor 24 Vertical Feed Rollers - 4

12 Lower Exit Rollers 25 Upper Exit Sensor

13 Lower Exit Sensor 26 Upper Exit Rollers

13

MX-FDX1 DETAILS 5 – 1

Page 13

B. PAPER PATH WITH Z-FOLDING

The feed rollers [1] feed the paper from the main machine into the

Z-folding unit.

The junction gate solenoid energizes and opens the junction gate

[2]. The junction gate sends the sheet down into the Z-folding paper

path.

The upper and lower stopper motors move the upper stopper [3]

and lower stopper [4] to the positions for the paper size that was

used for the job.

The feed sensor [5] detects the leading edge and trailing edge of

the sheet. The pinch idle roller solenoid (upper) pulls the pinch idle

roller [6] away from the pinch feed roller [7] and the paper can fall

between the pinch rollers.

The anti-static brush [8] removes static electricity from the sheet.

When the fold timing sensor [9] detects the trailing edge of the

sheet, it energizes the pinch idle roller solenoid (lower). This

pushes the pinch idle roller [6] against the opposite pinch feed roller

[7].

The lower stopper [10] stops the sheet and buckles it slightly

toward the nip [11] of the 1st and 2nd fold rollers.

[1]

[3]

[4]

[9]

[8]

[6]

[7]

[5]

[2]

[1]

[5]

[7]

[9]

[6]

[3]

[11]

[8]

[4]

The pinch feed roller [1] turns and feeds the sheet down against the

lower stopper [2]

At the correct time, the fold roller motor switches on and turns the:

• 1st fold roller [3]

• 2nd fold roller [4]

• 3rd fold roller [5]

The sheet continues to buckle until it feeds into the nip [6] of the 1st

and 2nd fold rollers. These two rollers fold the sheet.

The leading edge sensor [7] detects the leading edge of the sheet:

• When the leading edge goes by while the paper feeds down (to

the lower stopper).

• When the leading edge goes by again while the paper feeds up

into the nip of the 1st and 2nd fold rollers.

If the leading edge sensor does not detect the leading edge at the

correct time, this sensor signals a jam.

At the correct time, the pinch idle roller [8] is pulled away from the

pinch feed roller [9] by the pinch idle roller solenoid (upper).

[10]

[2]

The 1st fold roller [1] and 2nd fold roller [2] continue to turn. This

feeds the edge of the 1st fold up until it hits the upper stopper [3].

The sheet lifts the feeler of the upper stopper path sensor [4]. This

sensor:

• Detects when the sheet comes to the upper stopper path.

• Detects when the sheet goes out of the upper stopper path.

The upper stopper sensor detects a jam if it does not detect that the

sheet comes and goes at the correct times.

When the sheet feeds between the 1st and 2nd fold rollers, this

pushes the first fold against the upper stopper. The sheet buckles

down into the gap between the 2nd fold roller [5] and 3rd fold roller

[6]. The second fold is made when the sheet feeds between the

2nd and 3rd feed rollers.

[3]

[4]

[1]

[6]

[2]

[5]

MX-FDX1 DETAILS 5 – 2

Page 14

The 2nd and 3rd fold rollers [1] continue to turn and feed the sheet

1

2

3

9

4

10

11

12

13

5678

down.

The feeler of the upper stopper path sensor [2] falls and the sensor

detects that the sheet is gone. The fold rollers feed the folded sheet

to the lower exit rollers [3].

The lower exit sensor [4] detects the leading edge and trailing edge

of the sheet. If the trailing edge is not detected during the correct

time interval, the sensor detects a jam.

The grip rollers [5] feed the folded sheet to the four pairs of vertical

feed rollers [6].

The upper exit sensor [7] detects the leading edge and trailing edge

of each folded sheet. If the leading and trailing edge are not

detected during the correct time interval, this sensor detects a jam.

The upper exit rollers [8] feed the folded sheet into the finisher.

At the correct time:

• The upper stopper motor lifts the upper stopper [9] until the upper

stopper sensor [10] detects that the upper stopper is at its home

position. This stops the motor.

• The lower stopper motor lowers the lower stopper [11] until the

lower stopper sensor [12] detects that the lower stopper is at its

home position. This stops the motor.

[8]

[7]

[6]

[9]

[2]

[10]

3. DRIVE LAYOUT

1 Feed Motor

2 Feed Rollers

3 Fold Roller Motor

4 Lower Exit Rollers

5 Grip Rollers

6 3rd Fold Roller

7 2nd Fold Roller

8 1st Fold Roller

9 Vertical Feed Rollers - 1

10 Vertical Feed Rollers - 2

11 Vertical Feed Rollers - 3

12 Vertical Feed Rollers - 4

13 Upper Exit Rollers

[1]

[3]

[4]

[12]

[11]

[5]

MX-FDX1 DETAILS 5 – 3

Page 15

4. ELECTRICAL COMPONENTS

A. OVERVIEW

S7

M1

M2

S9

4

S4

3

S3

SOL1

S1

SOL3

SOL2

S2

M4

S8

S5

S6

1

B. ELECTRICAL COMPONENT SUMMARY

Motors

No. Name Description

M1

STPASS_M

M2

ZFLD_M

M3

ZLSTPP_M

M4

ZUSTPP_M

PCBs

No. Name Description

PCB1 Main Control Board Controls the operation of the Z-

PCB2 PSU Supplies the dc power for the Z-

PCB3 Surge Protector

PCB4 Interface Board Motors and sensor interface board.

Feed Motor Drives the feed rollers and exit

Fold Roller Motor Drives the 1st, 2nd, and 3rd fold

Lower Stopper

Motor

Upper Stopper

Motor

Board

rollers of the Z-folding unit.

rollers.

Raises and lowers the lower

stopper. It 1) Raises the upper

stopper to the proper position for the

size of the paper selected for the

job, and 2) Lowers the lower stopper

until the lower stopper sensor

detects that the lower stopper is at

its home position where it remains

until the start of the next job.

Lowers and raises the upper

stopper. It 1) Lowers the upper

stopper to the proper position for the

size of the paper selected for the

job, and 2) Raises the upper stopper

until the upper stopper sensor

detects that the upper stopper is at

its home position where it remains

until the start of the next job.

folding unit.

folding unit.

Fuse and surge protector board.

2

1 Interface Board

2 Power Supply Unit

3 Surge Protector Board

4 Main Control Board

M1 Feed Motor

M2 Fold Roller Motor

M3 Lower Stopper Motor

M4 Upper Stopper Motor

S1 Feed Sensor

S2 Fold Timing Sensor

S3 Front Door Sensor

S4 Leading Edge Sensor

S5 Lower Exit Sensor

S6 Lower Stopper HP Sensor

S7 Upper Exit Sensor

S8 Upper Stopper HP Sensor

S9 Upper Stopper Path Sensor

SOL1 Junction Gate Solenoid

SOL2 Pinch Idle Roller Solenoid - Lower

SOL3 Pinch Idle Roller Solenoid - Upper

M3

Sensors

No. Name Description

S1

ZFEED

S2

ZPRSTM

S3

UPDOOR

S4

ZPRTTM

Feed Sensor Detects the leading edge and trailing

Fold Timing Sensor (1) Detects the leading edge of the

Front Door Sensor Detects when the top cover of the Z-

Leading Edge

Sensor

edge of the sheet at the top of the

paper path before Z-Folding. When

the feed sensor detects the leading

edge, it energizes the pinch idle

roller solenoid. The solenoid pulls

the pinch idle roller away from the

pinch feed roller so the paper can

fall below these opposing rollers.

sheet and energizes the pinch idle

roller solenoid (upper) to pull the

pinch idle roller away from the pinch

feed roller so the sheet falls through

the gap between these rollers. (2)

Detects the trailing edge of the sheet

and energizes the pinch idle roller

solenoid (lower) to push the pinch

idle roller against the pinch feed

roller.

folding unit is closed and signals an

alert that the cover is open. The unit

cannot be used until this cover is

closed.

Mounted above the lower stopper.

The leading edge sensor 1) detects

the leading edge of the sheet when

drops onto the lower stopper, 2)

detects the leading edge again when

the paper is pulled up into the nip of

the 1st and 2nd fold rollers. If the

leading edge sensor does not detect

the edge at the prescribed times, it

will signal an error.

MX-FDX1 DETAILS 5 – 4

Page 16

Sensors

No. Name Description

S5

ZEXII1

S6

LSTPPRHP

S7

ZEXIT3

S8

HSTPPRHP

S9

HSTPPRPS

Lower Exit Sensor Mounted below the lower exit rollers.

Lower Stopper HP

Sensor

Upper Exit Sensor 1) Detects the leading/trailing edges

Upper Stopper HP

Sensor

Upper Stopper Path

Sensor

Detects the leading/trailing edges of

the folded sheet as it passes below.

If these edges do not pass at the

times prescribed for the selected

paper size, the sensor will signal a

jam alert.

Detects the lower stopper when it

reaches its home position and turns

off the lower stopper motor.

of each sheet unfolded sheet after it

passes over the closed junction

gate, 2) Detects the leading/trailing

edge of each folded sheet as it

leaves the vertical feed path below.

If the edges do not go by for the time

prescribed for the paper size, the

sensor will send a jam alert.

Detects the upper stopper when it

reaches its home position and turns

off the upper stopper motor.

Mounted below the upper stopper. 1)

When the feeler of the upper stopper

path sensor detects the paper when

the crease of the first fold stops at

the upper stopper, it delays long

enough so the 1st/2nd feed rollers

can continue to rotate and buckle

the trailing edge of the paper below

at the nip of the 2nd/3rd feed rollers,

then the sensor switches off the 1st/

2nd feed rollers and switches on the

2nd/3rd feed roller pair. The 2nd/3rd

feed rollers pull the buckle into the

nip and create the 2nd crease. 2)

Detects the paper when it leaves the

upper stopper path and signals an

error if the paper does not leave at

the prescribed time.

Solenoids

No. Name Description

SOL1

FLPPR_S

SOL2

ZPRES_S

SOL3

ZEST_S

Junction Gate

Solenoid

Pinch Idle Roller

Solenoid (Lower)

Pinch Idle Roller

Solenoid (Upper)

Opens and closes the junction gate

solenoid. When not energized, the

junction gate remains closed and

paper passes over the back of the

closed junction gate and through the

Z-folding unit. When energized it

opens the junction gate which

guides paper down and into the

paper path of the Z-folding unit.

Attached to the pinch idle roller, this

solenoid pushes the pinch idle roller

and closes the gap between the

pinch idle/pinch feed rollers when

the fold timing sensor at the above

the pinch idle roller detects the

trailing edge of the sheet so the

rollers can pinch and stop the paper

in the paper path.

Attached to the pinch idle roller, this

solenoid pulls the pinch idle roller

away from the pinch feed roller

when the feed sensor at the top of

the Z-fold paper path detects the

leading edge of the sheet so the

paper can drop between these

opposing rollers.

MX-FDX1 DETAILS 5 – 5

Page 17

C. BLOCK DIAGRAM

Straight pass

motor

F1

Folding motor

Upper stopper

motor

Lower stopper

motor

Flapper solenoid

Pressure solenoid

Separation solenoid

Drawer unit

Drawer connector

CP1 CP4

PBA-CONT PBA-CN

To LOGIC

DC5V

DC-DC CONVERTOR

FUZE1

CP3

CP2

CP5

CP1

DC24V

N

DC POWER SUPPLY

L

MX-FDX1 DETAILS 5 – 6

AC100V - 240V

PBA-SP

(AC FILTER)

N

F1 F2

L

AC INLET

AC100V - 240V

Page 18

D. ACTUAL WIRING CHART

Upper stopper motor

Paper feed motor

Lower stopper motor

Flapper solenoid

Paper exit sensor 1

Upper stopper

home position

sensor

Lower stopper

home position

sensor

Upper stopper

section pass

sensor

Paper feed

sensor

Paper exit

Z-folding motor

Pressure solenoid

Separation solenoid

sensor 3

Frame side Slide side

Pressure sensor

Complex cable

Power source

Separation sensor

Cover open/close

sensor

Main unit or

front stage unit

Main unit or

front stage unit

Rear stage unit

MX-FDX1 DETAILS 5 – 7

Page 19

y

LEAD-FREE SOLDER

The PWB’s of this model employs lead-free solder. The “LF” marks indicated on the PWB’s and the Service Manual mean “Lead-Free” solder.

The alphabet following the LF mark shows the kind of lead-free solder.

Example:

<Solder composition code of lead-free solder>

Solder composition

Sn-Ag-Cu

Sn-Ag-Bi

Sn-Ag-Bi-Cu

Sn-Zn-Bi

Sn-In-Ag-Bi

Sn-Cu-Ni

Sn-Ag-Sb

Bi-Sn-Ag-P

Bi-Sn-Ag

5mm

Lead-Free

Solder composition

code (Refer to the

table at the right.)

a

(1) NOTE FOR THE USE OF LEAD-FREE SOLDER THREAD

When repairing a lead-free solder PWB, use lead-free solder thread.

Never use conventional lead solder thread, which may cause a breakdown or an accident.

Since the melting point of lead-free solder thread is about 40°C higher than that of conventional lead solder thread, the use of the

exclusive-use soldering iron is recommended.

Solder composition code

a

b

z

i

n

s

p

(2) NOTE FOR SOLDERING WORK

Since the melting point of lead-free solder is about 220°C, which is about 40°C higher than that of conventional lead solder, and its soldering

capacity is inferior to conventional one, it is apt to keep the soldering iron in contact with the PWB for longer time. This may cause land

separation or may exceed the heat-resistive temperature of components. Use enough care to separate the soldering iron from the PWB when

completion of soldering is confirmed.

Since lead-free solder includes a greater quantity of tin, the iron tip may corrode easily. Turn ON/OFF the soldering iron power frequently.

If different-kind solder remains on the soldering iron tip, it is melted together with lead-free solder. To avoid this, clean the soldering iron

tip after completion of soldering work.

If the soldering iron tip is discolored black during soldering work, clean and file the tip with steel wool or a fine file.

COPYRIGHT©XXXX BYSHARP CORPORATION

COPYRIGHT©XXXX BYSHARP CORPORATION

ALL RIGHTS RESERVED.

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

form or byanymeans, electronic, mechanical,

an

photocopying, recording, or otherwise, without

prior written permission of the publisher.

Page 20

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

(English) Caution !

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

Mettre au rebut les batteries usagées conformément aux

(Swedish) VARNING

(German) Achtung

Explosionsgefahr bei Verwendung inkorrekter Batterien.

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

le constructeur.

instructions du fabricant.

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

Hersteller angegebenen Anweisungen.

CAUTION FOR BATTERY DISPOSAL

(For USA, CANADA)

THIS PRODUCT CONTAINS A LITHIUM PRIMARY

(MANGANESS DIOXIDE) MEMORY BACK-UP BATTERY

THAT MUST BE DISPOSED OF PROPERLY. REMOVE THE

BATTERY FROM THE PRODUCT AND CONTACT YOUR

LOCAL ENVIRONMENTAL AGENCIES FOR INFORMATION

ON RECYCLING AND DISPOSAL OPTIONS.

CE PRODUIT CONTIENT UNE PILE DE SAUVEGARDE DE

MÉMOIRE LITHIUM PRIMAIRE (DIOXYDE DE MANGANÈSE)

QUI DOIT ÊTRE TRAITÉE CORRECTEMENT. ENLEVEZ LA

PILE DU PRODUIT ET PRENEZ CONTACT AVEC VOTRE

AGENCE ENVIRONNEMENTALE LOCALE POUR DES

INFORMATIONS SUR LES MÉTHODES DE RECYCLAGE ET

“BATTERY DISPOSAL”

“TRAITEMENT DES PILES USAGÉES”

DE TRAITEMENT.

Page 21

COPYRIGHT 2007 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic; mechanical; photocopying; recording or otherwise

without prior written permission of the publisher.

Trademark acknowledgements

Microsoft

Corporation in the U. S.A. and other countries.

Windows

Windows®

and

U.S.A. and other countries.

IBM and PC/AT are trademarks of International Business Machines Corporation.

Acrobat

reserved. Adobe, the Adobe logo, Acrobat, and the Acrobat logo are trademarks

of Adobe Systems Incorporated.

All other trademarks and copyrights are the property of their respective owners.

®

Windows® operating system is a trademark or copyright of Microsoft

®

95, Windows®

XP, Windows®

Internet Explorer®

®

Reader Copyright® 1987-2002 Adobe Systems Incorporated. All rights

98, Windows® Me, Windows NT®

Vista, Windows®

2000 Server, Windows®

4.0, Windows® 2000,

are trademarks or copyrights of Microsoft Corporation

Server 2003

in the

SHARP CORPORATION

Digital Document System Group

CS Promotion Center

Yamatokoriyama, Nara 639-1186, Japan

2007 May Printed in Japan

Loading...

Loading...