Page 1

LC-30HV4E

SERVICE MANUAL

S32X6LC30HV4E

LCD COLOUR TELEVISION

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

LC-30HV4E

CONTENTS

Page

» IMPORTANT SERVICE SAFETY PRECAUTION .....2

» SPECIFICATIONS................................................4

» OPERATION MANUAL ........................................ 5

» DIMENSIONS ....................................................11

» REMOVING OF MAJOR PARTS........................13

»

ADJUSTMENT PROCEDURES (AVC System) ..

» UPGRADING INSTALLED PROGRAMS ...........27

» ADJUSTMENT PROCEDURES (Display) .........29

» MAJOR IC INFORMATIONS..............................33

» TROUBLE SHOOTING TABLE ..........................53

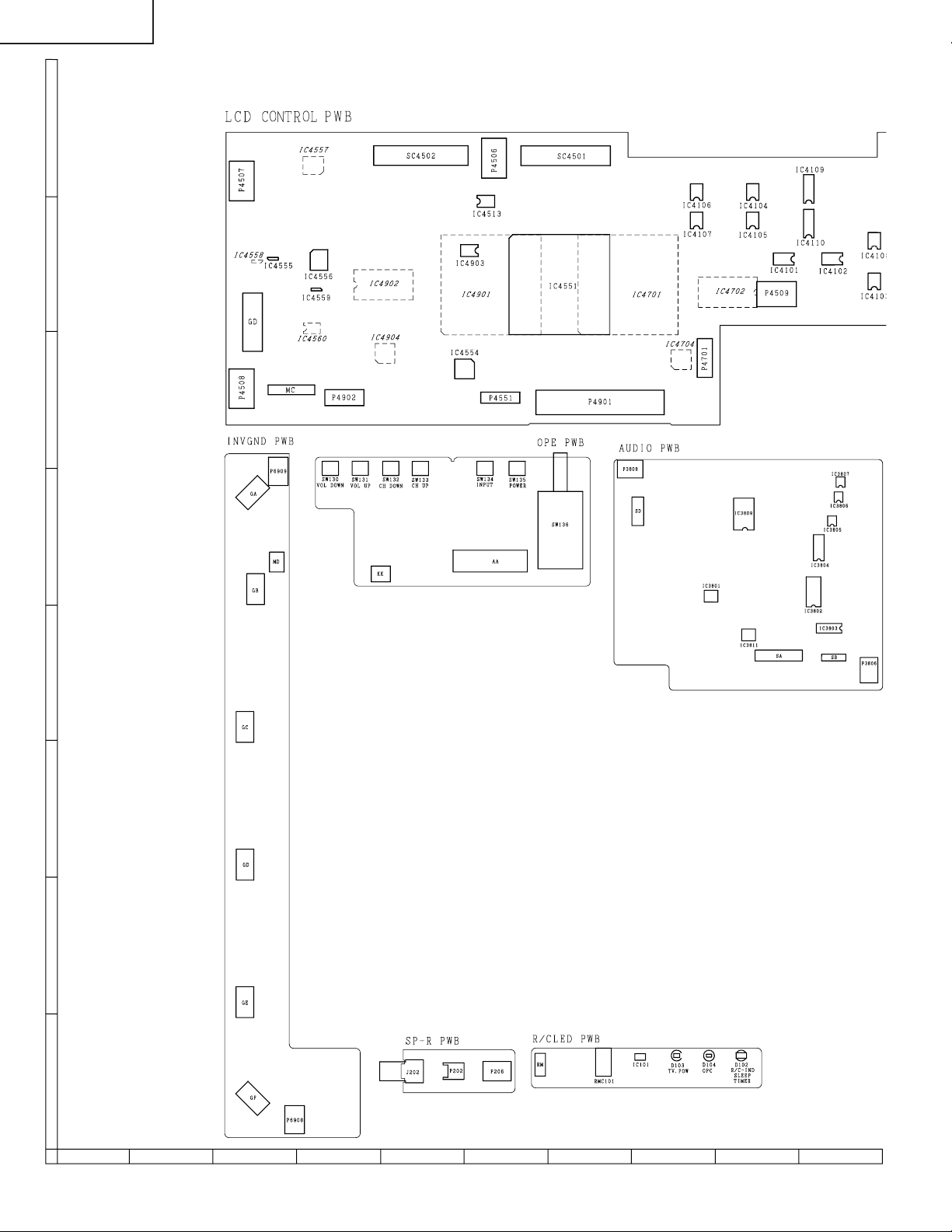

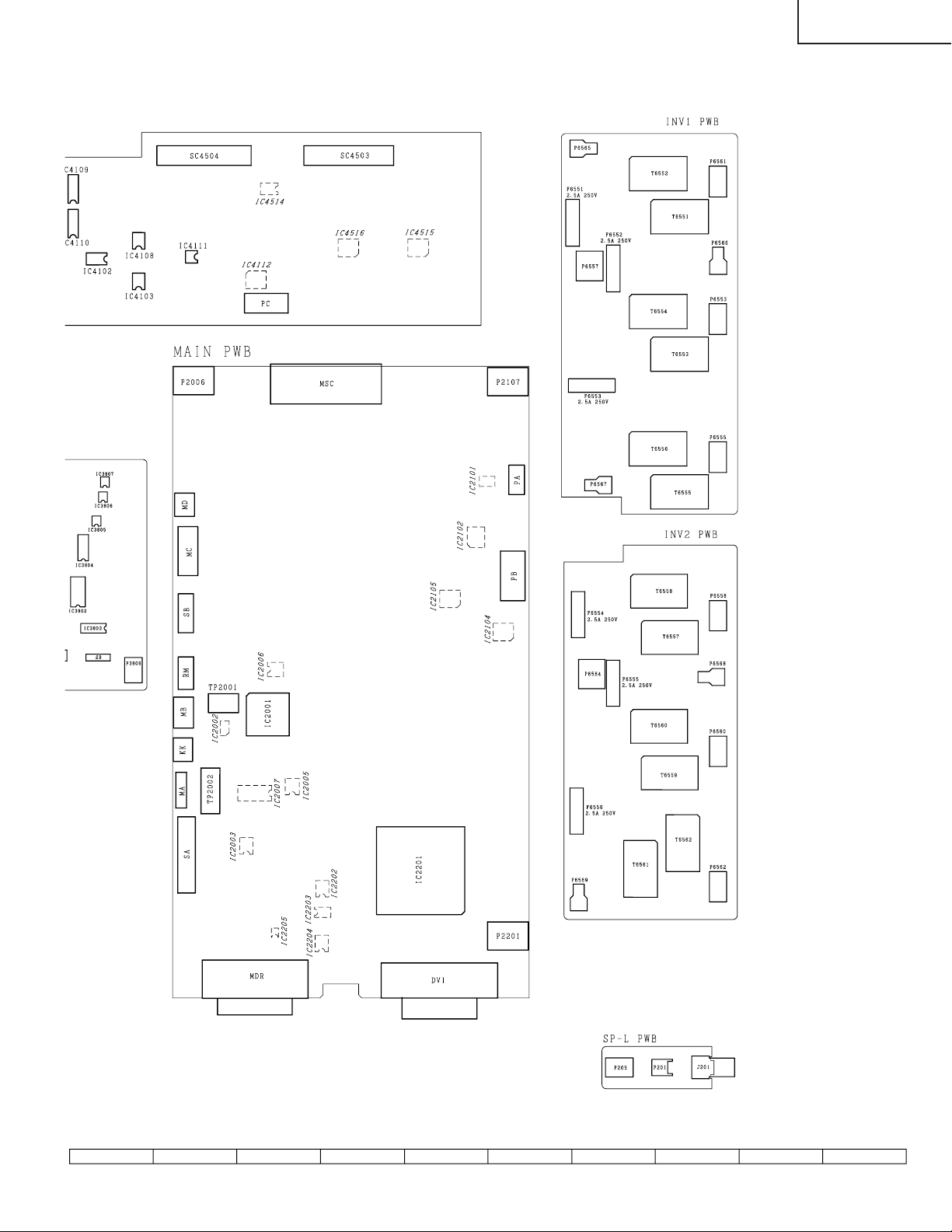

» CHASSIS LAYOUT.............................................64

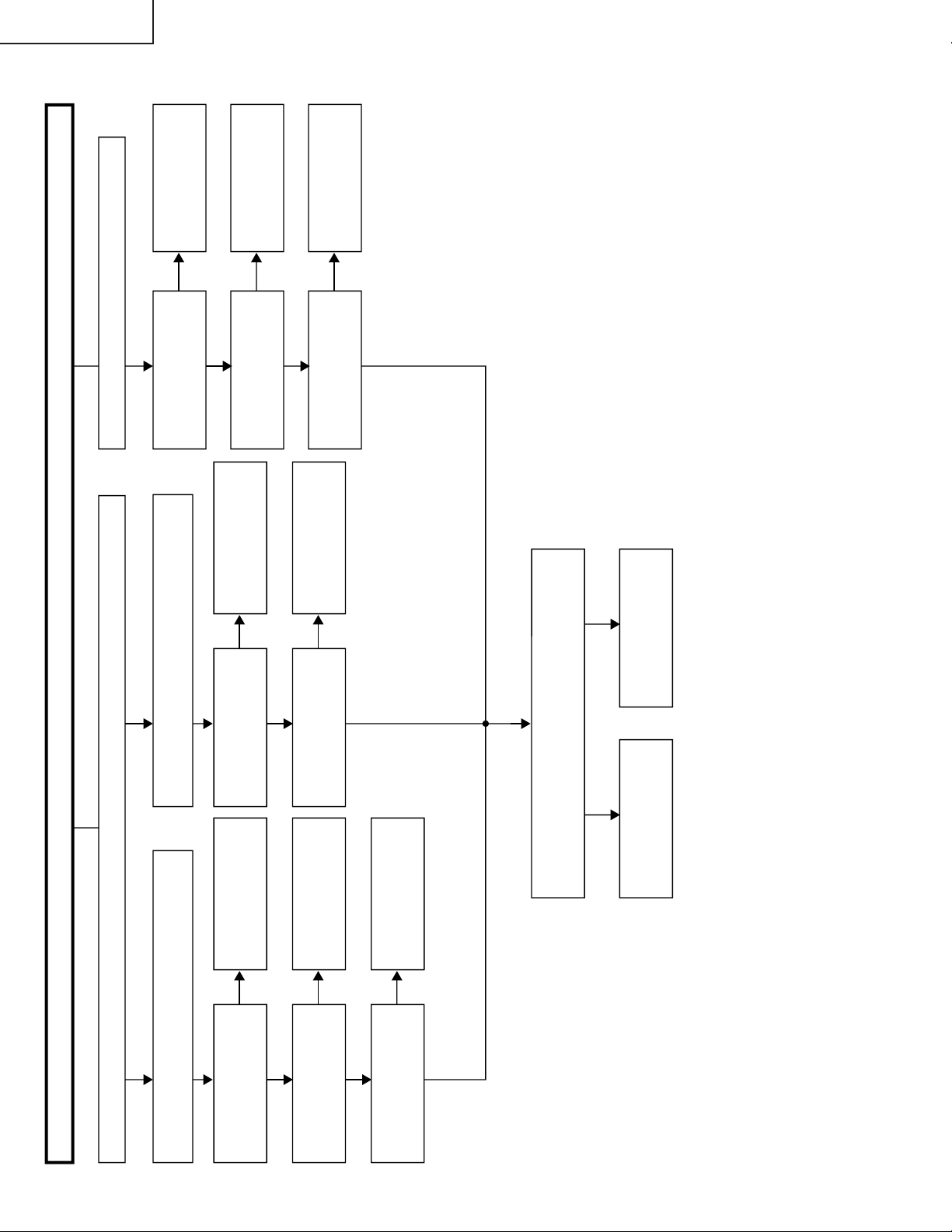

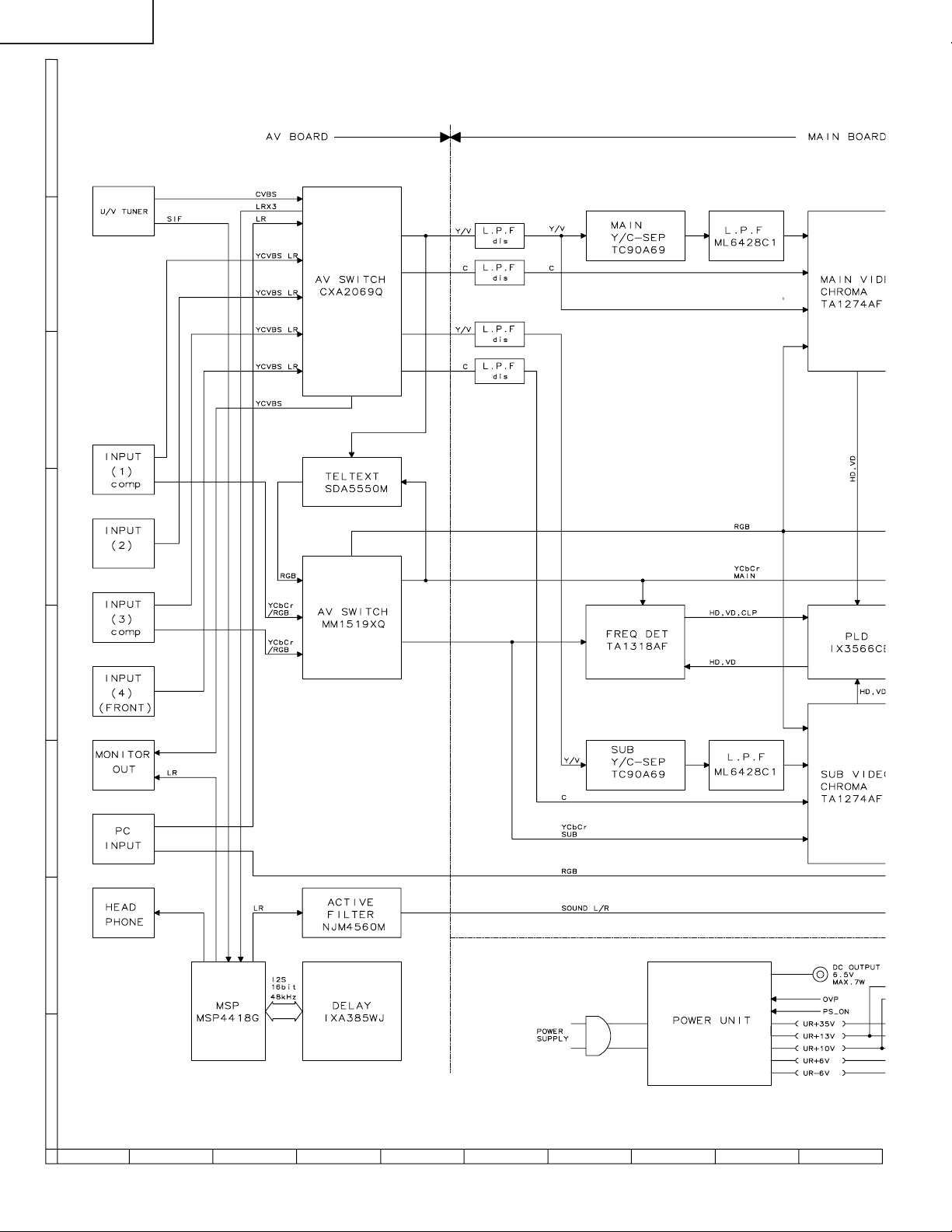

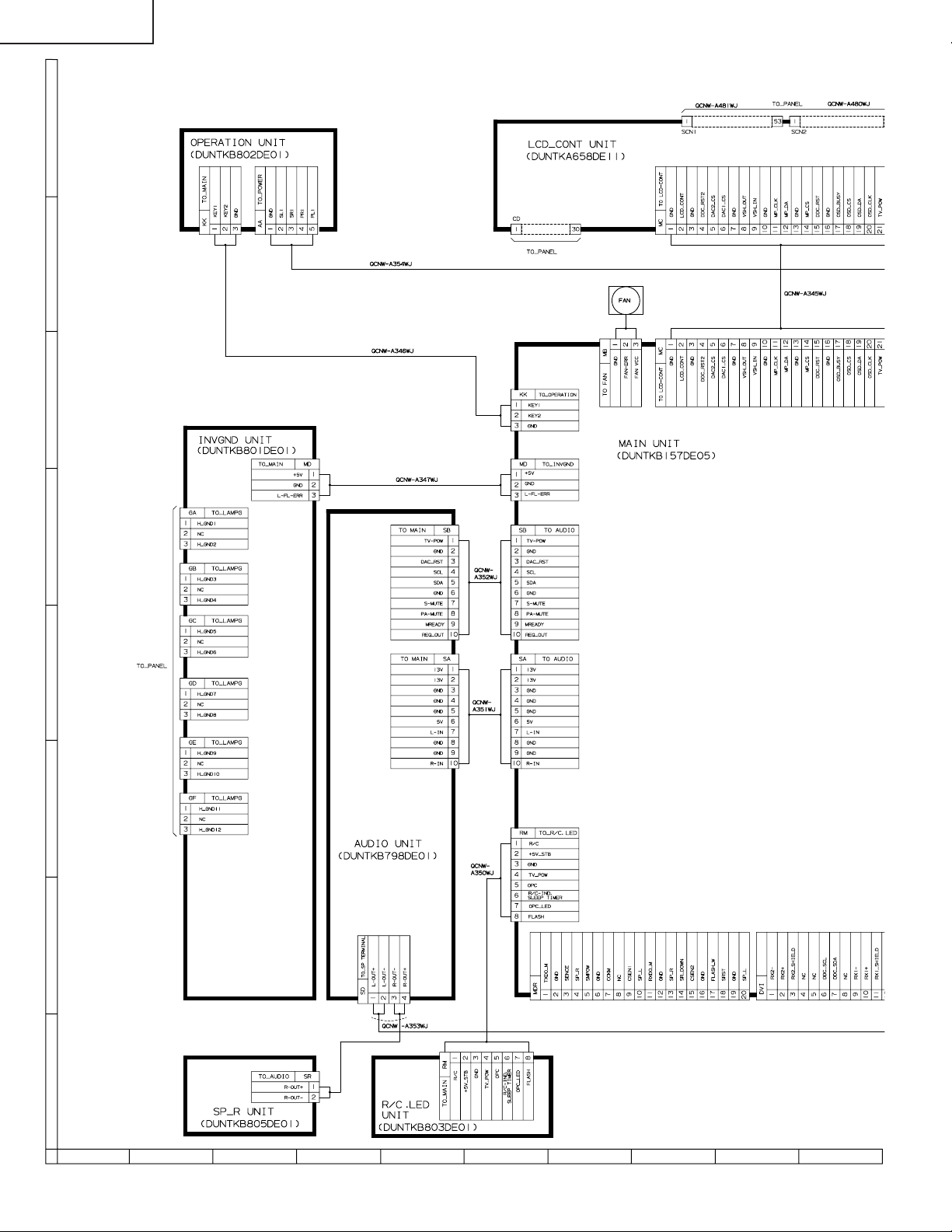

» SYSTEM BLOCK DIAGRAM (AVC System) ...... 68

» SIGNAL FLOW BLOCK DIAGRAM

(AVC System).....................................................70

20

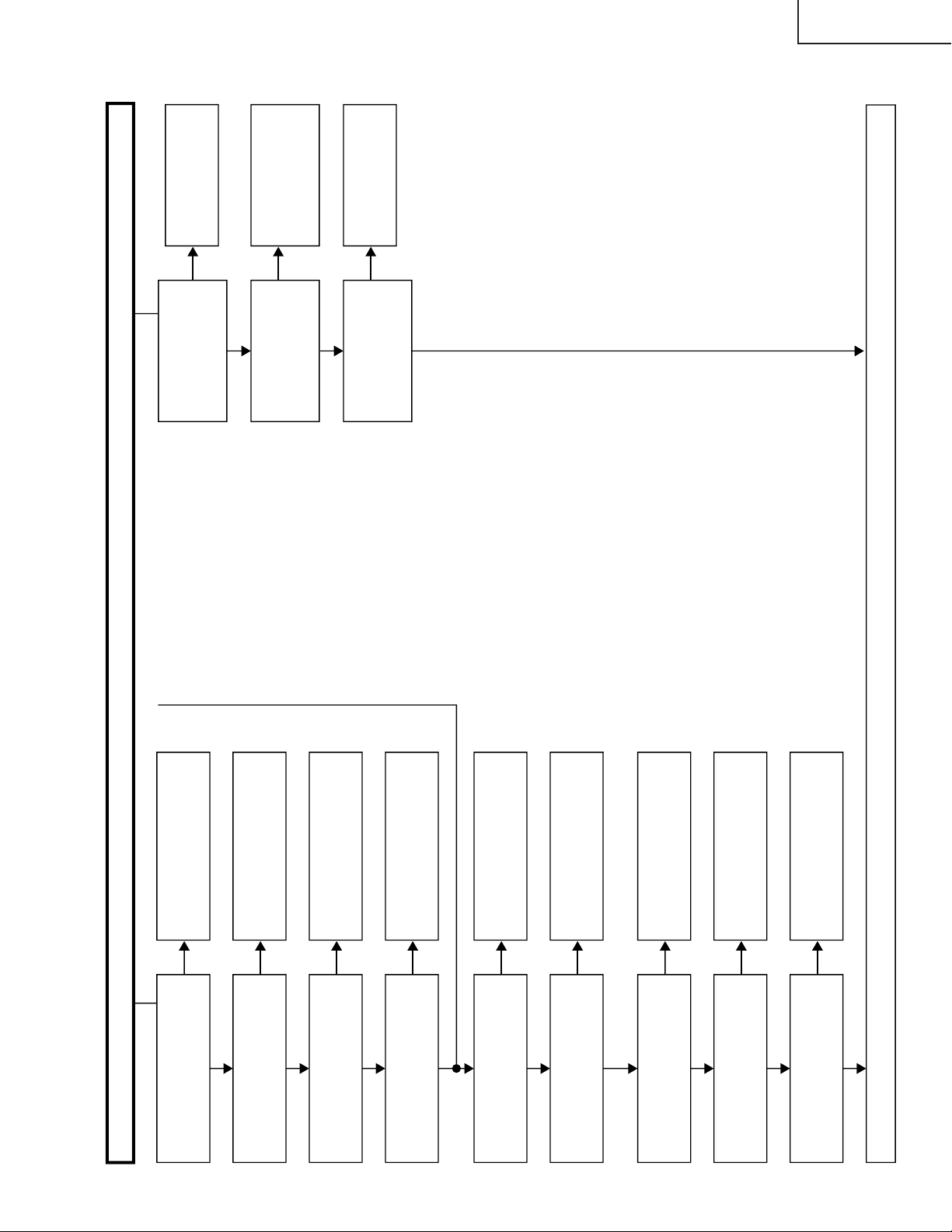

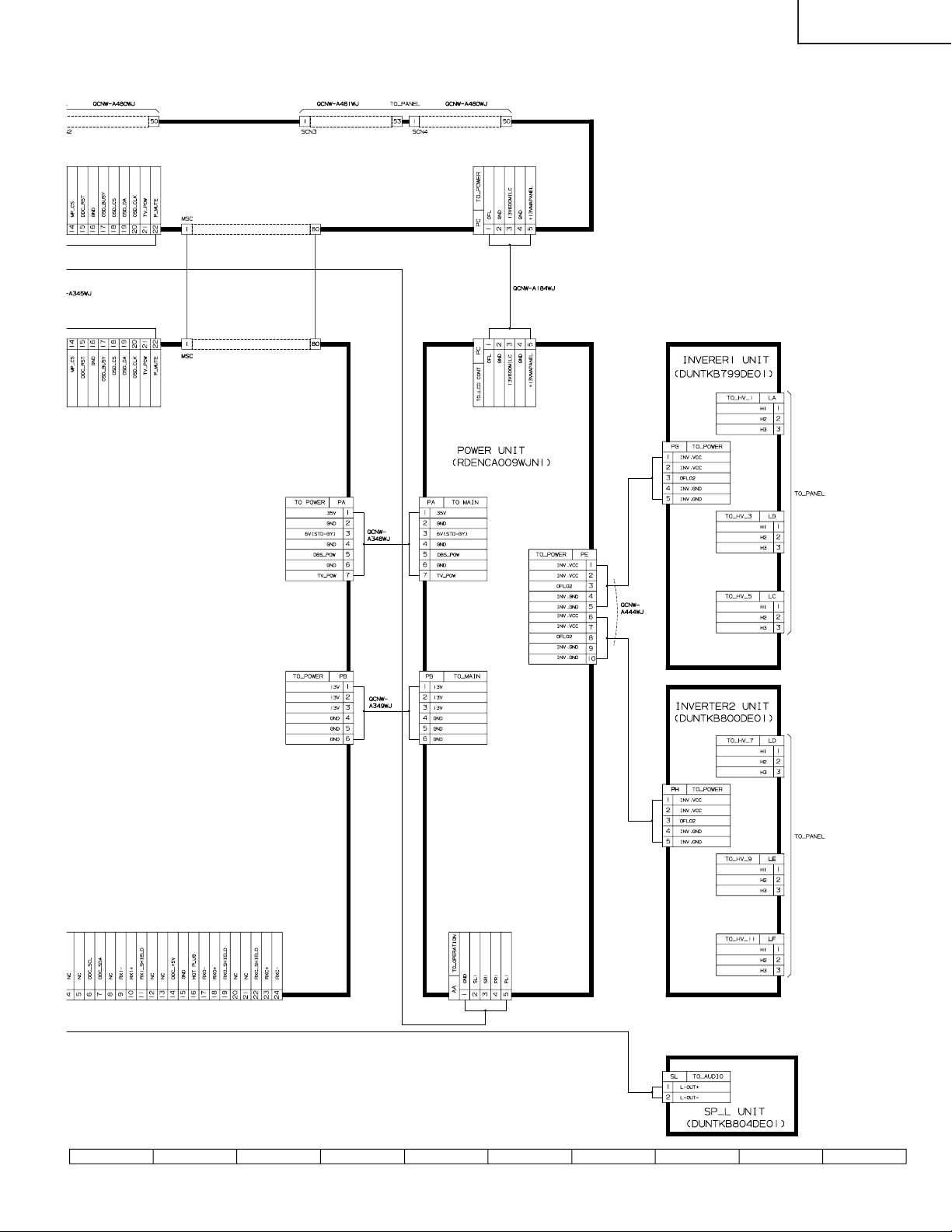

» POWER SYSTEM BLOCK DIAGRAM

(AVC System).....................................................72

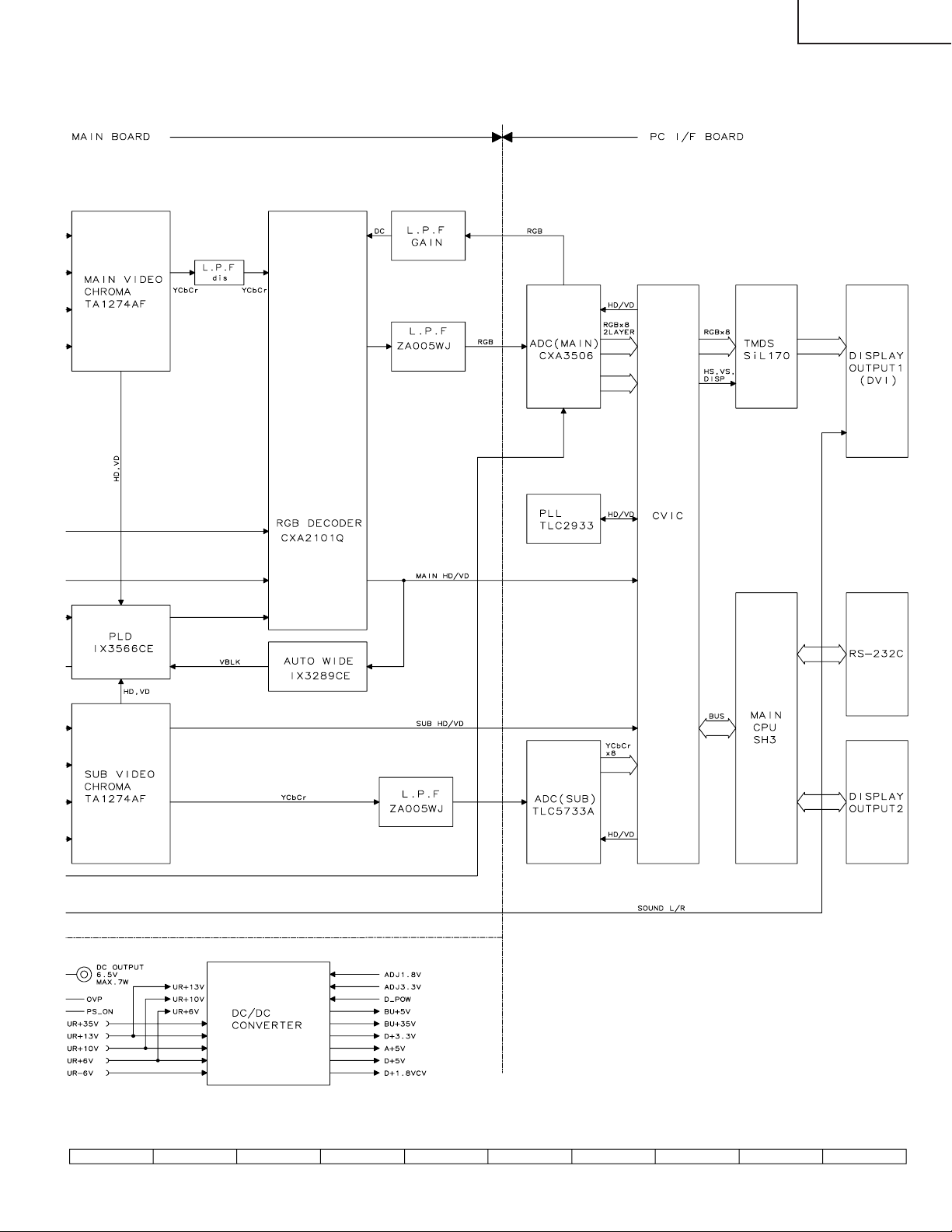

» PC I/F BLOCK DIAGRAM (AVC System) ..........74

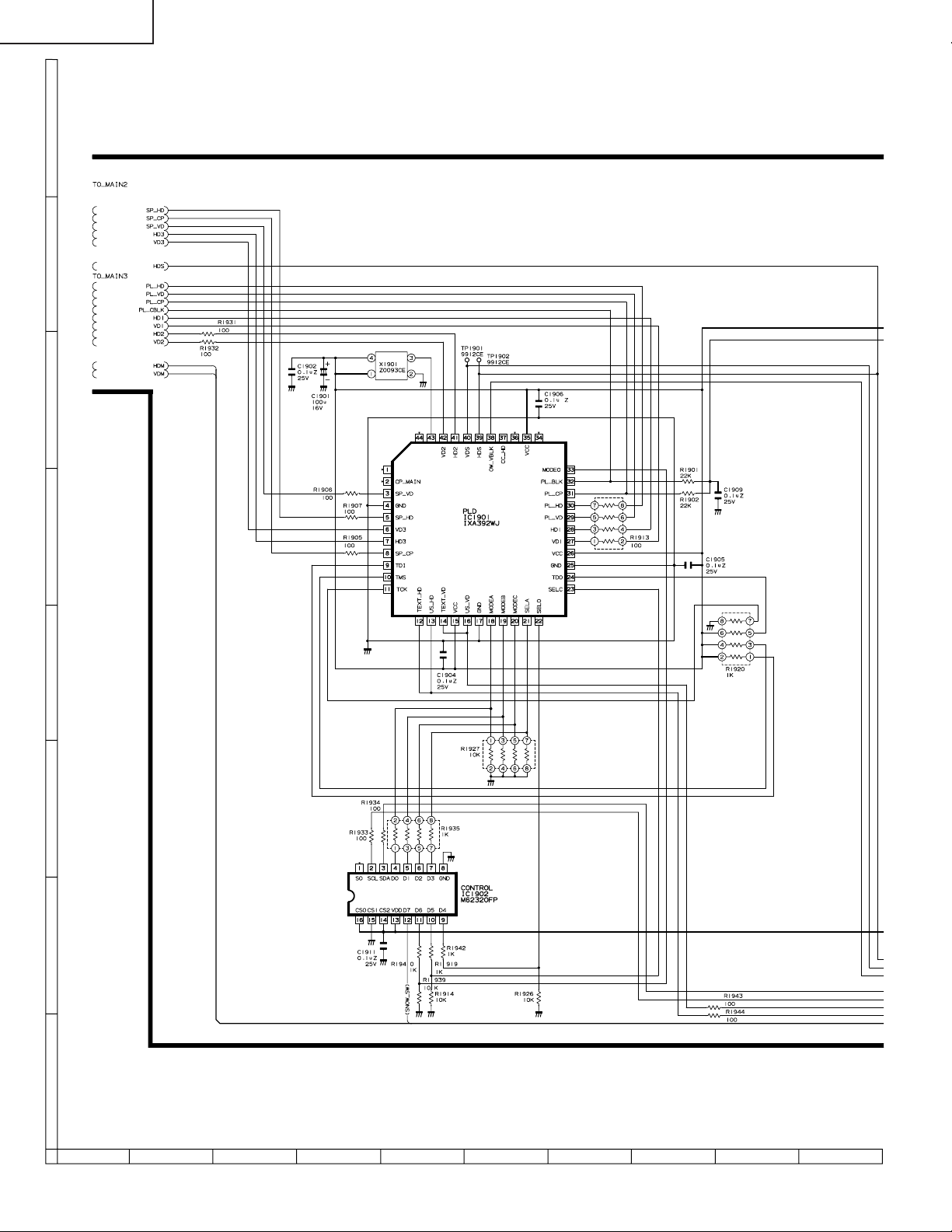

» SIGNAL BLOCK DIAGRAM (Display)................ 76

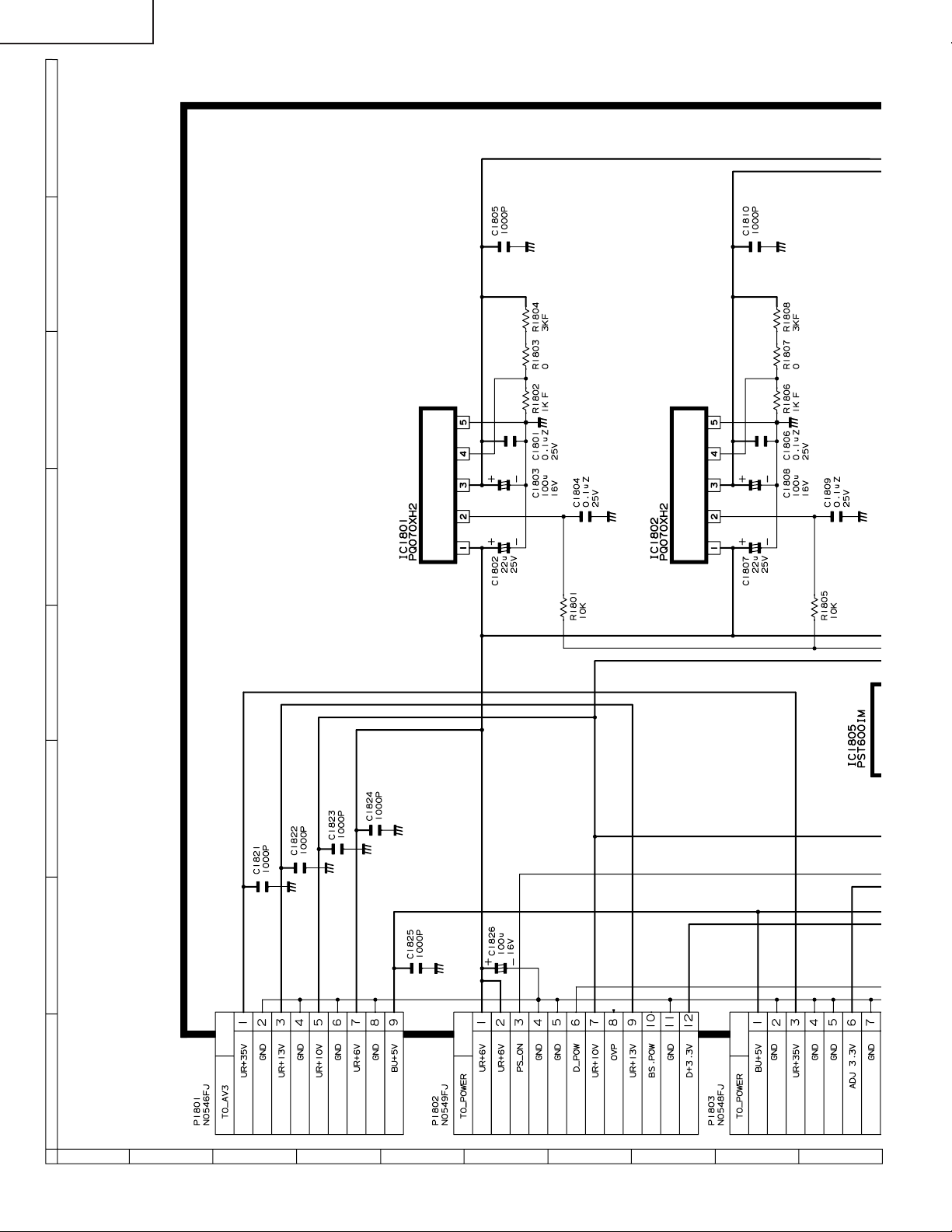

» POWER UNIT BLOCK DIAGRAM (Display) ...... 78

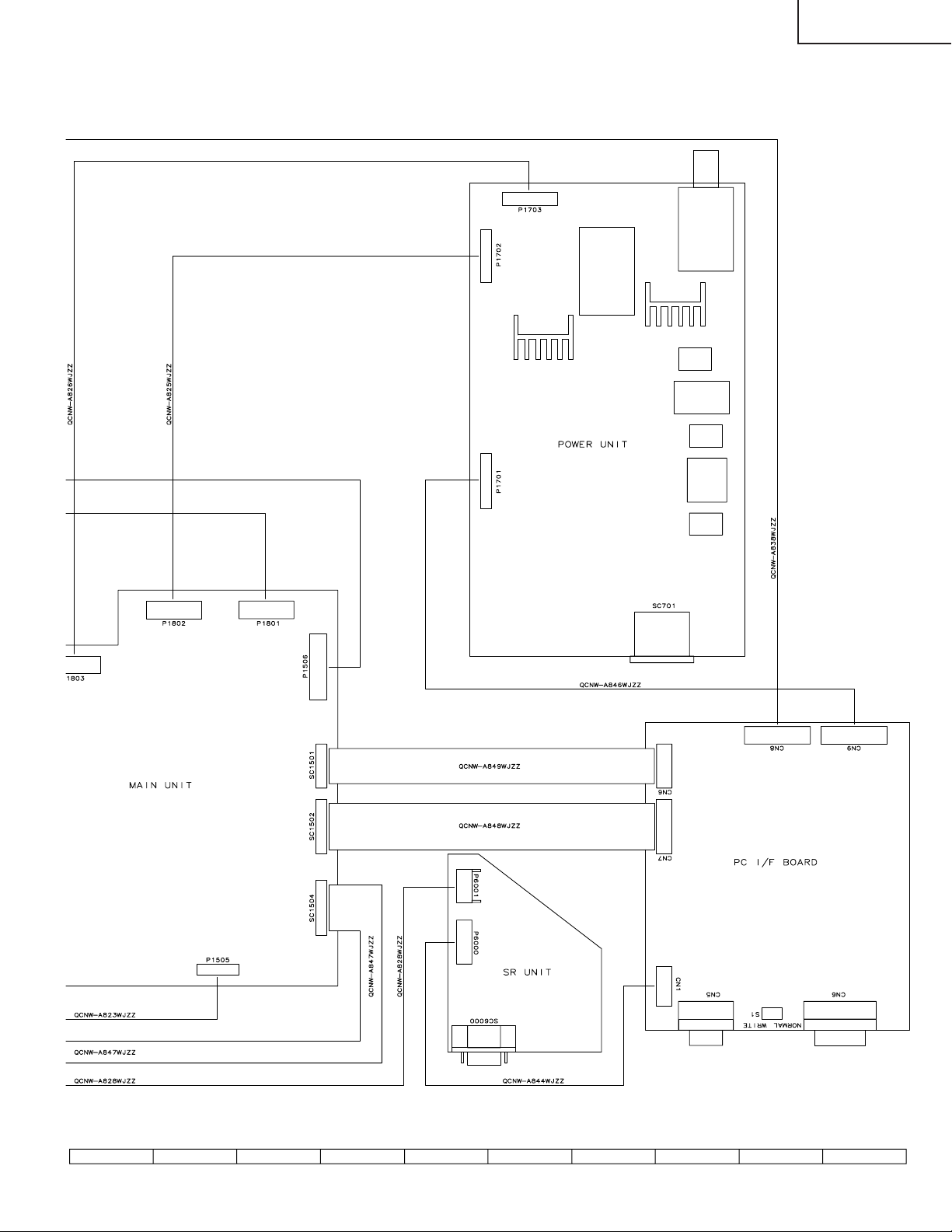

» OVERALL WIRING DIAGRAM (AVC System) ... 80

» OVERALL WIRING DIAGRAM (Display)............ 84

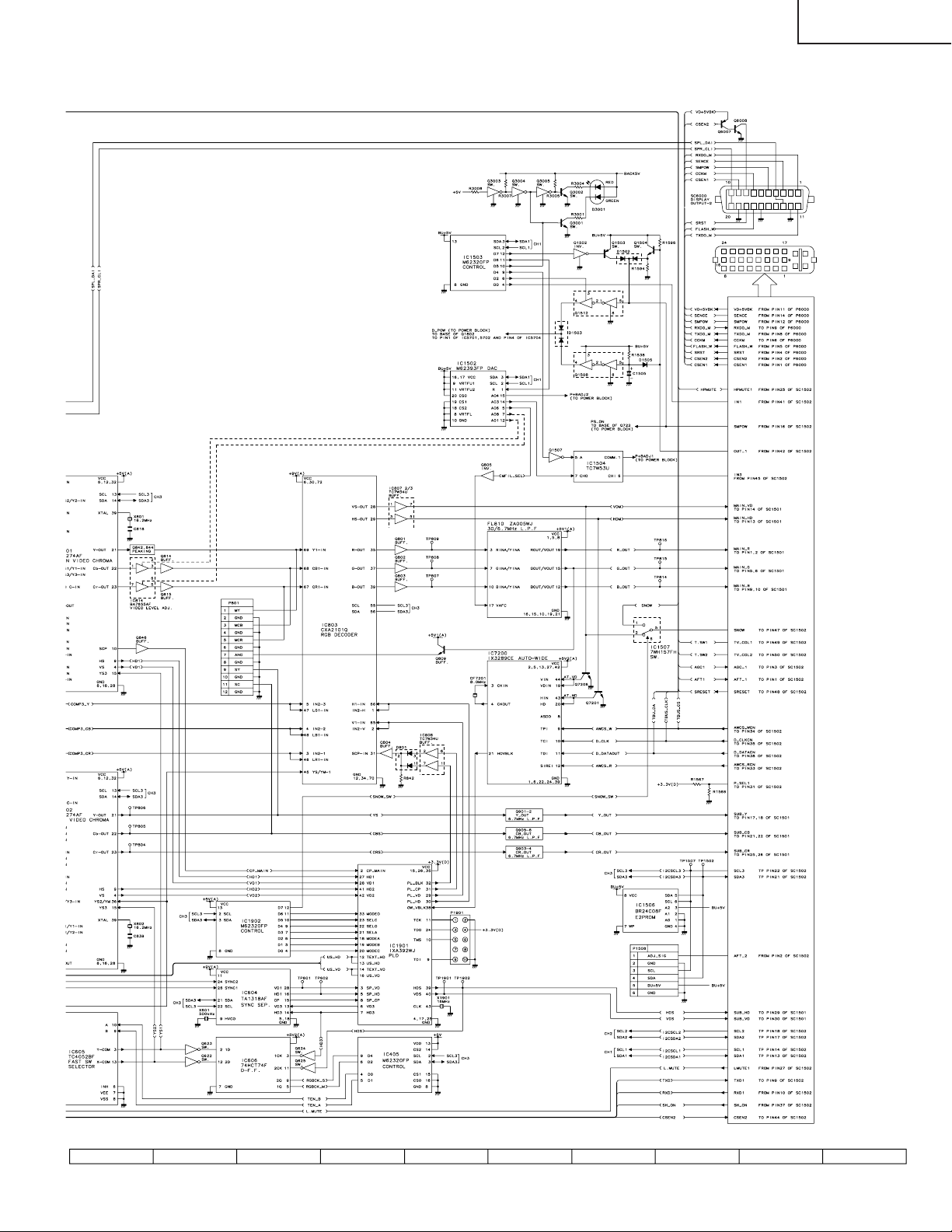

» DESCRIPTION OF SCHEMATIC DIAGRAM ..... 86

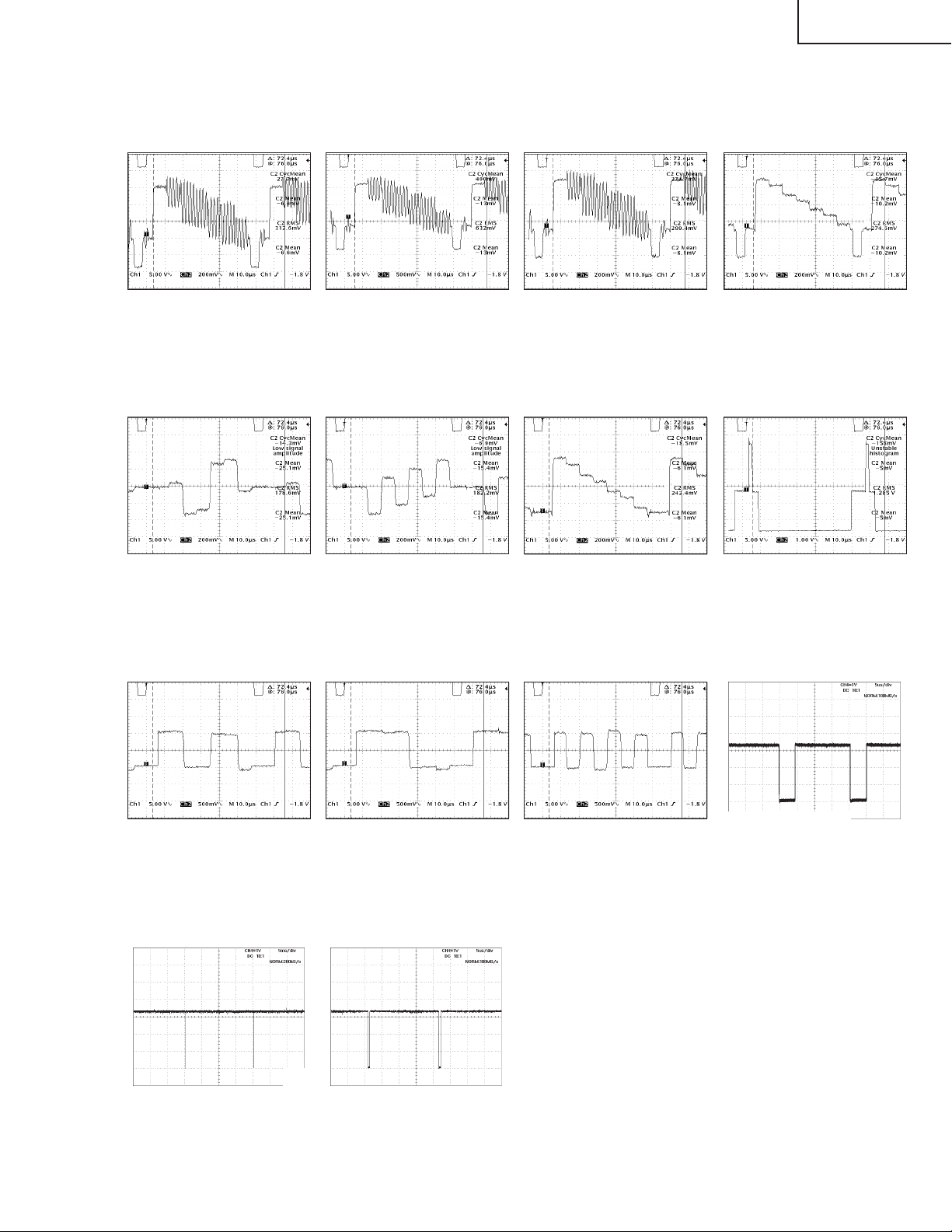

» WAVEFORMS .................................................... 87

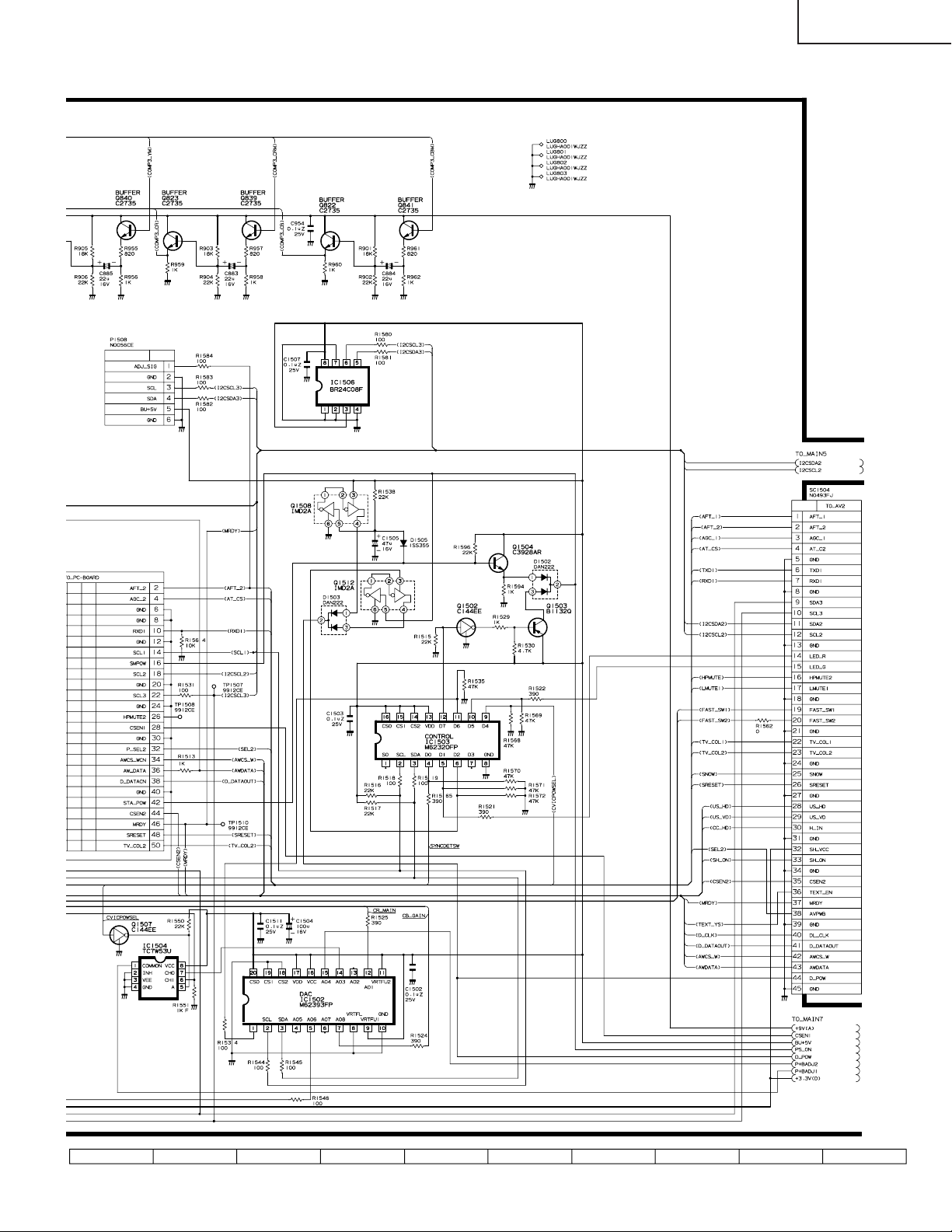

» SCHEMATIC DIAGRAM..................................... 88

» PRINTED WIRING BOARD ASSEMBLIES...... 161

» PARTS LIST .....................................................205

» PACKING OF THE SET ...................................247

Page

SHARP CORPORATION

Page 2

LC-30HV4E

2

2

IMPORTANT SERVICE SAFETY PRECAUTION

Ë

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

» Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

All checks must be repeated with the AC cord plug

CAUTION: FOR CONTINUED PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE.

AVC SIDE: F701 (T2AL, 250V)

LCD SIDE: F1(T3.15AL, 250V), F3 (T2AL, 250V)

F6551, F6552, F6553, F6554, F6555, F6556 (T2.5AL,

250V)

connection reversed. (If necessar y, a nonpolarized

adaptor plug must be used only for the purpose of

completing these checks.)

Any reading of 35V peak (this corresponds to 0.7

mA. peak AC.) or more is excessive and indicates a

potential shock hazard which must be corrected

before returning the monitor to the owner.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks:

1. Inspect all lead dress to make certain that leads are

not pinched, and check that hardware is not lodged

between the chassis and other metal parts in the

receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

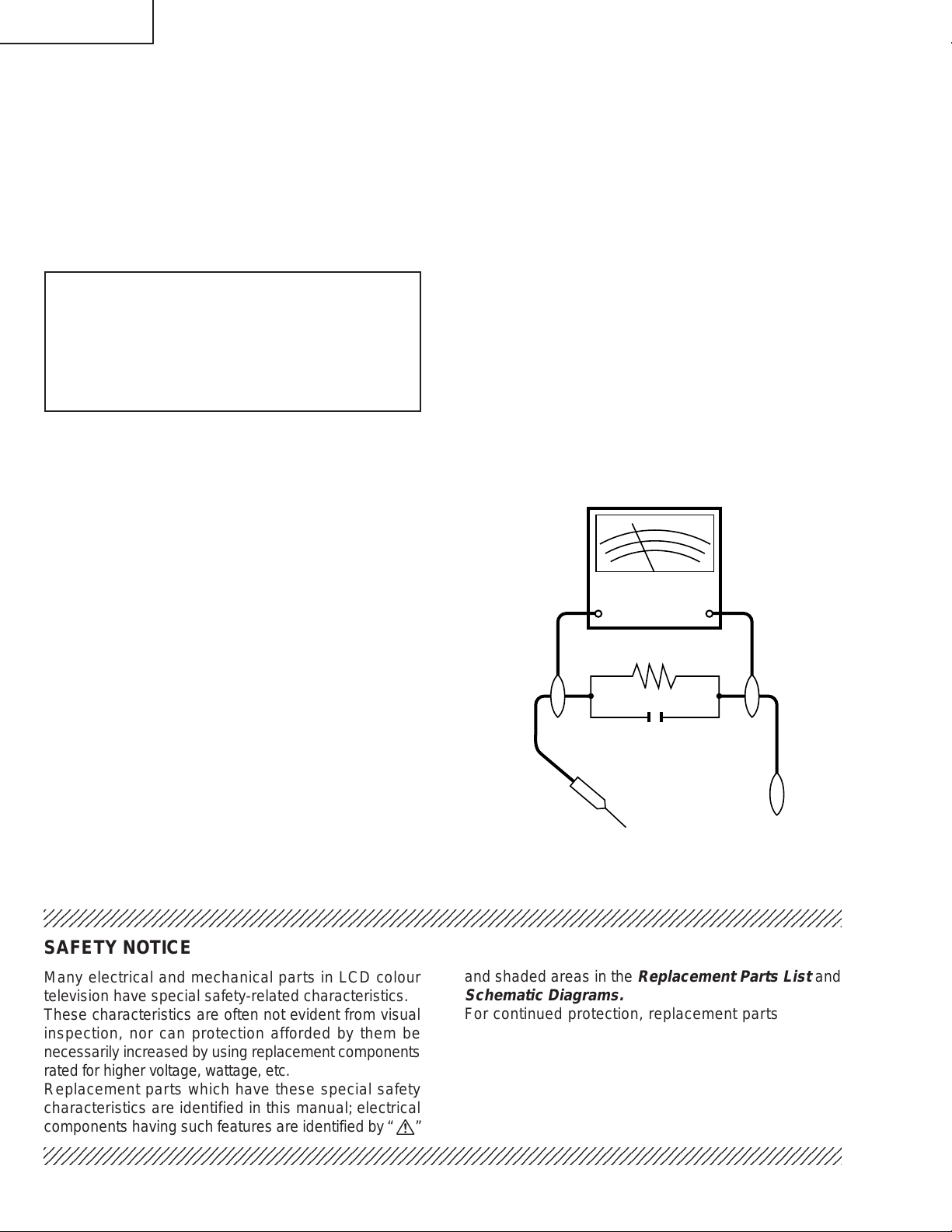

» Plug the AC cord directly into a 220~240 volt A C outlet.

» Using two clip leads, connect a 50k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series

with all exposed metal cabinet parts and a known

earth ground, such as electrical conduit or electrical

ground connected to an earth ground.

» Use an AC voltmeter having with 5000 ohm per volt,

TO EXPOSED

METAL PARTS

or higher, sensitivity or measure the A C voltage drop

across the resistor.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

DVM

AC SCALE

50k ohm

10W

0.15 µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in LCD colour

television have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage , w attage , etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

and shaded areas in the

Schematic Diagrams.

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of a substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock, fire or other hazards.

components having such features are identified by “ å”

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

Replacement Parts List

and

Page 3

LC-30HV4E

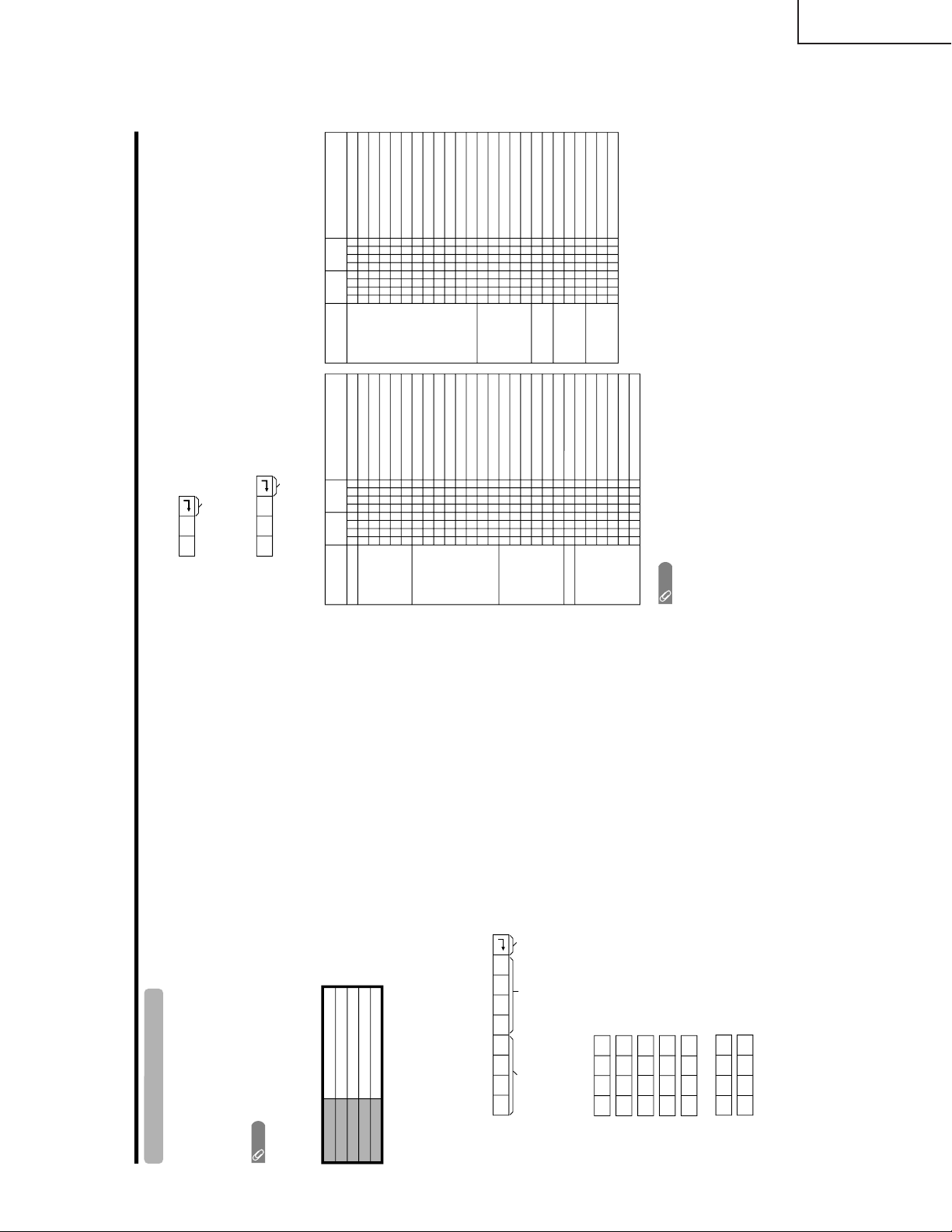

Precautions for using lead-free solder

1 Employing lead-free solder

"PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the

PWBs and service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend

you to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit,

contact our service station or ser vice branch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead

solder by 40°C, and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, Since the land may be peeled off or the maximum heat-resistance

temperature of parts may be exceeded, remov e the bit from the PWB as soon as you confirm the steady soldering

condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on

and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No, ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

3

Page 4

LC-30HV4E

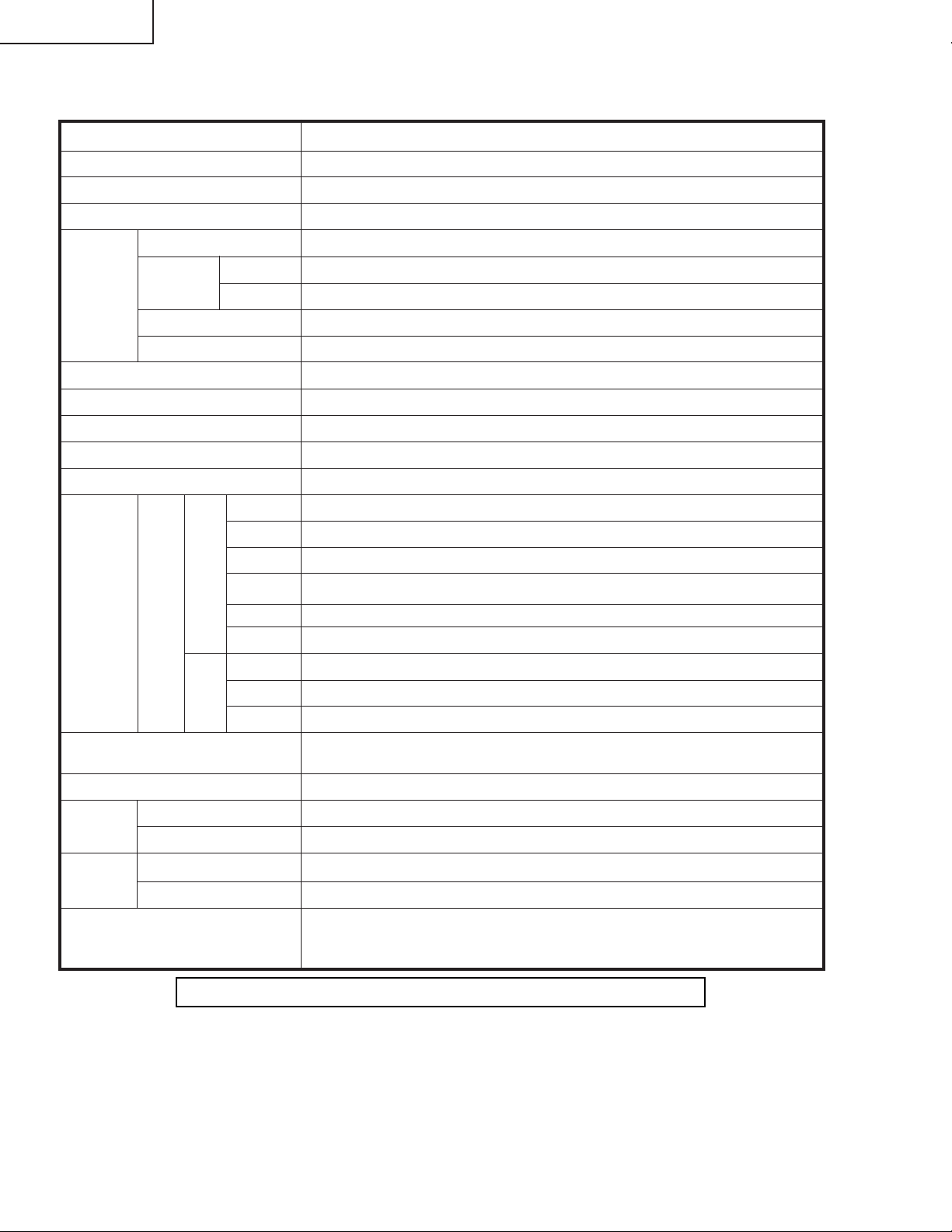

SPECIFICATIONS

Item 30" LCD COLOUR TV, Model:LC-30HV4E

LCD panel 30" Advanced Super View & BLACK TFT LCD

Number of dots 2,949,120 dots (1280 × 768 × 3 dots)

Video Colour System PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

TV

Function

TV-standard (CCIR)

Receiving

Channel

VHF/UHF

CATV

B/G, D/K, I, L/L’

E2–E69ch, F2–F10ch, I21–I69ch, IR A–IR Jch

Hyper-band, S1–S41ch

TV-Tuning System

STEREO/BILINGAL NICAM/IGR

Brightness 430 cd/m

Backlight 60,000 hours (at Save1)

Viewing angles H : 170° V : 170°

Audio amplifier 10W × 2

Speakers Ø 8 cm 2pcs

Terminals SCART (AV in, RGB in, TV out)

OSD language

AVC

System

Rear INPUT 1

INPUT 2

INPUT 3

ANTENNA 75 Ω Din Type

AV OUTPUT Audio (Variable, Fixed), S-VIDEO out, AV out

DC OUTPUT DC6.5V 7W MAX

Front

INPUT 4 S-VIDEO, AV in

PC

Headphones

Auto Preset 99 ch, Auto Label, Auto Sort

2

SCART (AV in/out, S-VIDEO in, AV Link)

SCART (AV in/out, S-VIDEO in, RGB in), Component

15 Pin mini D-Sub, Audio in (Ø 3.5mm jack)

Ø 3.5mm jack

English/German/French/Italian/Spanish/Dutch/Swedish/Portuguese/Greek/

Finnish/Russian/Turkish

Power Requirement

Power

Consumption

Weight

Accessories

AVC System

Display

AVC System

Display

AC 220–240 V, 50/60 Hz

32 W (0.7 W Standby)

109 W (0.9 W Standby) (Method IEC60107)

5.4 kg (w/o stand), 5.5 kg (with stand)

15.7 kg (w/o stand), 19.5 kg (with stand)

Operation manual, Remote control unit (× 1), System cable ( × 1), AC cord

(× 2), LR6 (“AA” size) Alkaline battery (× 2), Stand unit (× 1), Cable clamp

(× 1)

Specifications are subject to change without prior notice.

4

Page 5

OPERATION MANUAL

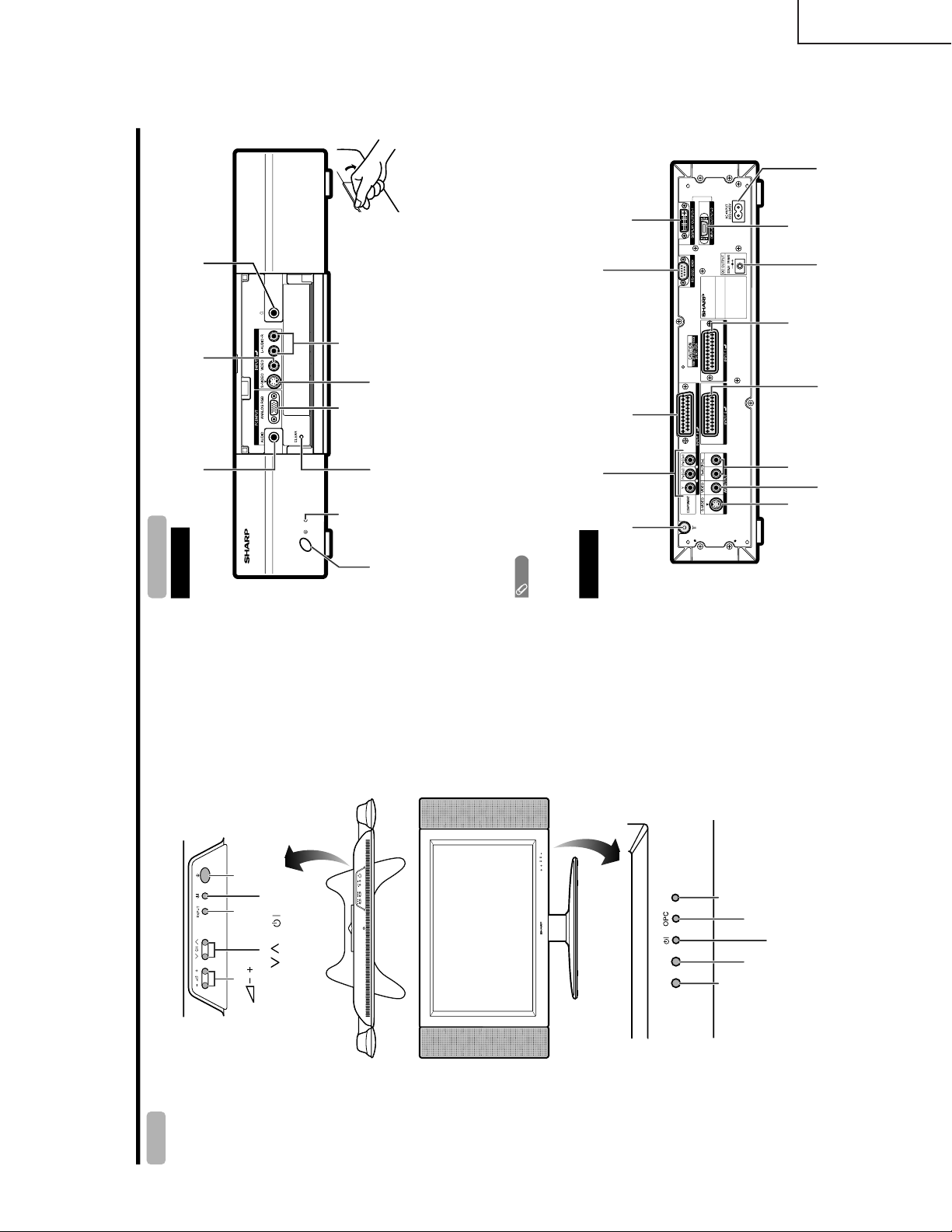

Part names

OPC indicator*

STANDBY/ON indicator

MAIN POWER

button

OPC sensor

Remote control sensor

indicator

Display

STANDBY/ON button

(

)

INPUT

button

VOLUME buttons

(

/

)

CHANNEL buttons

(CH

/

)

Remote control sensor

*OPC: Optical Picture Control

INPUT 1 terminal

(SCART)

INPUT 3 terminals (Y, P

B

(C

B

)

,

P

R

(C

R

))

INPUT 2 terminal (SCART)

AV OUTPUT terminal

(S-VIDEO)

DISPLAY OUTPUT1 terminal

AC INPUT terminal

CLEAR*

POWER button

RS-232C terminal

INPUT 4 terminal (S-VIDEO)

PC INPUT terminal (AUDIO)

INPUT 4 terminals (AUDIO)

INPUT 3 terminal (SCART)

AV OUTPUT terminal

(VIDEO)

AV OUTPUT terminals

(AUDIO)

PC INPUT terminal

(ANALOG RGB)

* If the AVC System is switched on but it does not appear to be operating corr ectly, it may need resetting. In this

case, press CLEAR, shown in the diagram, lightly with the end of a ballpoint pen or other pointed object.

This will reset the System as shown below.

• AV MODE resets to USER.

• TV channel resets to channel 1.

• Dual screen resets to normal.

• Audio setting initialises.

• SRS resets to OFF.

• Image position is initialised.

NOTE

• Pressing CLEAR will not work if the System is in standby mode (indicator lights red).

• Pressing CLEAR will not delete channel preset or password. See page 60 for clearing the password when you know it.

See page for initialising to the factory preset values when you forget your password.

ANTENNA INPUT terminal

AVC System

STANDBY/ON indicator

DISPLAY OUTPUT2

terminal

INPUT 4 terminal (VIDEO)

(How to open the door)

Front view

Rear view

Headphone

DC OUTPUT terminal

(Terminal for expanded

functionality in the near

future.)

(When connecting headphones,

the sound from the speakers is

muted.)

LC-30HV4E

5

Page 6

LC-30HV4E

PreparationPart names

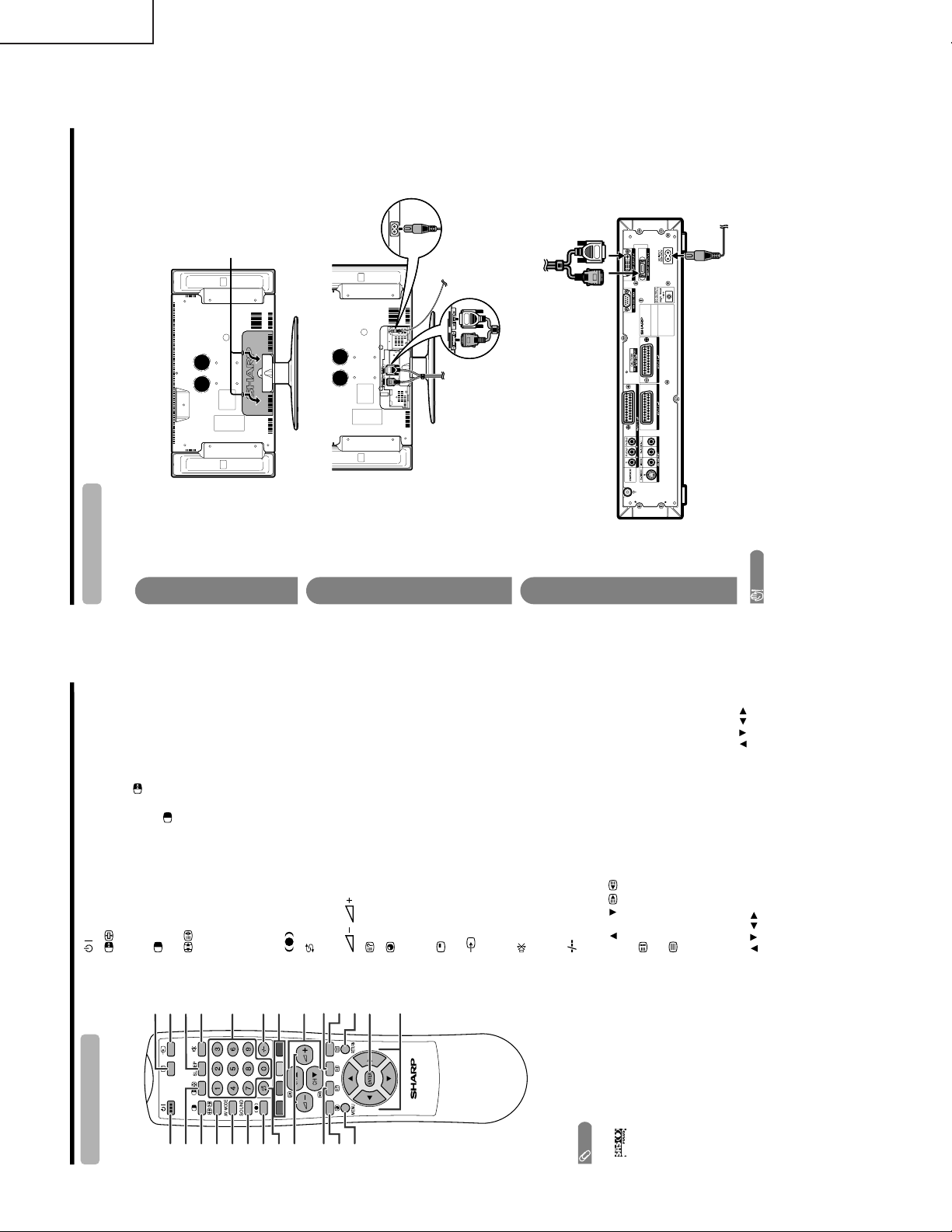

1 (STANDBY/ON)

To switch the power on and off.

2

(FREEZE/HOLD for TELETEXT)

TV/External input mode: Change the still image mode.

TELETEXT mode: Freeze a multi-page on screen while other

pages are automatically updated. Press

again to return to the

normal image.

3

(DUAL screen)

Set the dual picture mode. Press

again to return to normal view.

4

(WIDE MODE/ T/B/F)

TV/External input mode: Change the wide image mode.

TELETEXT mode: Set the area of magnification. (full/upper half/

lower half)

5 AV MODE

Select a video setting: AV MODE (STANDARD, DYNAMIC, MOVIE,

GAME, USER), PC MODE (STANDARD, USER)

6 SOUND

Select the sound multiplex mode.

7

(SRS and FOCUS)*

Select SRS and FOCUS sound system.

8

(Flashback)

Press to return to the previous channel in normal viewing mode.

Press to return to the previous page in TELETEXT mode.

9

/

(VOLUME)

Set the volume.

10

(Reveal hidden for TELETEXT)

TELETEXT mode: Display hidden characters.

11

(SUBPAGE for TELETEXT)

TELETEXT mode: Change the picture mode for sub-page selecting.

12 MENU

Display the MENU screen.

13

(CHANNEL INFORMATION)

Display the channel information and time.

14

(INPUT SOURCE)

Select an input source. (TV, INPUT 1, INPUT 2, INPUT 3, INPUT 4,

PC)

15 SLEEP

Set the Sleep timer.

16

(MUTE)

Mute the sound.

17 0 – 9

TV/External input mode: Set the channel.

TELETEXT mode: Set the page.

18

(Digit for channel select)

Change the digits of the selected TV channel.

19 Colour (RED/GREEN/YELLOW/BLUE)

TELETEXT mode: Select a page.

20 CH

/CH

(

/

)

TV/External input mode: Select the channel.

TELETEXT mode: Set the page.

21

(TOP Overview for TELETEXT)

TELETEXT mode: Display an index page for CEEFAX/FLOF

information. TOP Overview for TOP programme.

22

(TELETEXT)

Select the TELETEXT mode. (all TV image, all TEXT image, TV/TEXT

image)

23 RETURN

MENU mode: Return to the previous menu screen.

24 ENTER

Execute a command.

Return to the initial image position after moving with

/

/

/

.

25

/

/

/

(Cursor)

Select a desired item on the setting screen.

Move the picture on the screen.

1

2

3

4

5

6

7

8

9

10

11

12

14

15

13

16

17

18

19

20

21

22

23

24

25

NOTE

• When using the r emote contr ol unit, point it

at the Display.

*

is a trademark of SRS Labs, Inc.

FOCUS technology is incorporated under

license from SRS Labs, Inc.

Remote control unit

AC INPUT

110V–240V

DISPLAY INPUT2 DISPLAY INPUT1

System cable

AVC System (rear view)

AC cord

Display (rear view)

AC cord

System cable

(GREY)

Connect the plug firmly

until the hooks on both

sides click.

(WHITE)

Connect the plug into the

terminal and secure it by

tightening the thumb screws.

(GREY) (WHITE)

Setting the System

After putting the Display and the AVC System in place, connect the system cables and AC cords. Use the

cable clamp for bundling the cables.

Press down the two

upper hooks to remove

the cover toward you.

Connecting the system cable and the AC cord to the Display

1

2

3

Removing the terminal cover

Connecting the system cable and the AC cord to the AVC System

CAUTION

• TO PREVENT RISK OF ELECTRIC SHOCK, DO NOT TOUCH UN-INSULATED PARTS OF ANY CABLES WITH THE

AC CORD CONNECTED.

6

Page 7

Preparation

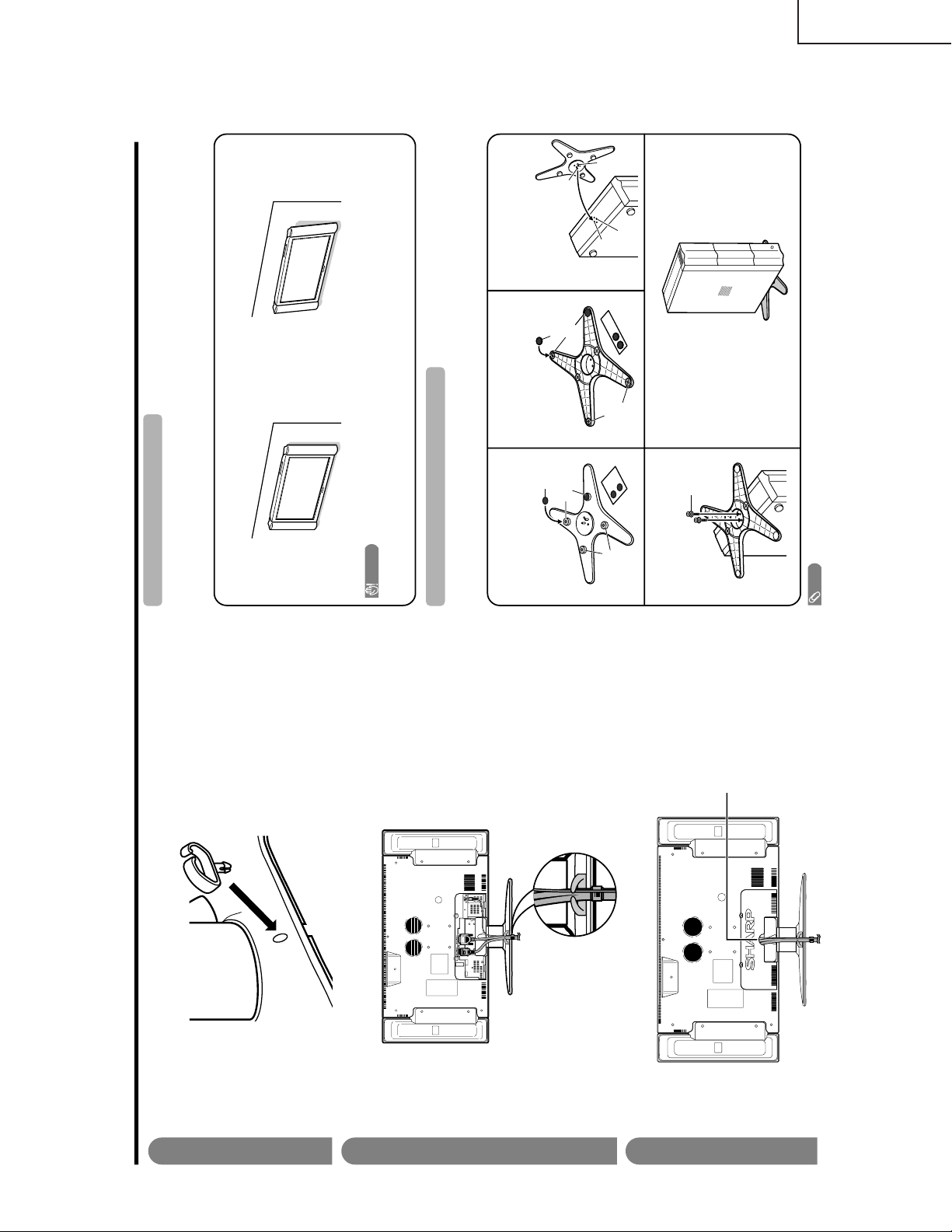

4

5

6

Attaching the clamp to the leg of the Display

Bundling the cables with the clamp

Closing the terminal cover

Display (rear view)

Cables come out from

the small opening.

Setting the Display on the wall

Setting the AVC System with the stand

CAUTION

• Installing the LCD Colour TV requires special skill that should only be performed by qualified service personnel.

Customers should not attempt to do the work themselves. SHARP bears no responsibility for improper mounting or

mounting that results in accident or injury.

1

Using an optional bracket to mount the Display

• You can ask a qualified service personnel about using an optional AN-37AG1 bracket to mount the Display

to the wall.

• Carefully read the instructions that come with the bracket before beginning work.

Vertical mounting Angular mounting

Hanging on the wall

AN-37AG1 wall mount bracket. (See the bracket instructions for details.)

How to install the AVC System vertically using the stand unit.

• Use the supplied stand unit for installing the AVC System vertically in an upright position.

Stick each spacer to the

stand as shown.

Peel each spacer

away from the

paper and attach

to the four bulging

areas on the stand.

2

Attach each cushion to

the stand as shown.

3

Fit the stand to the AVC

System.

Peel each cushion

away from the

paper and attach

to the four areas at

the bottom.

Insert the stand into the AVC

System, making sure that the

thick and thin bulges of the

stand align with the big and

small holes on the AVC

System.

Stand

spacer

Bulge

Stand cushion

Thin bulge

Thick

bulge

Big hole

Small

hole

4

Attach the stand using the

stand screws as shown.

Stand screw

The AVC System installed

vertically with the stand.

NOTE

• When mounting the AVC System vertically, always use the supplied stand. Be careful not to block vent holes when

standing up directly on the floor or a flat surface as this can result in equipment failure.

Attaching point

Attaching point

Bulge

LC-30HV4E

7

Page 8

LC-30HV4E

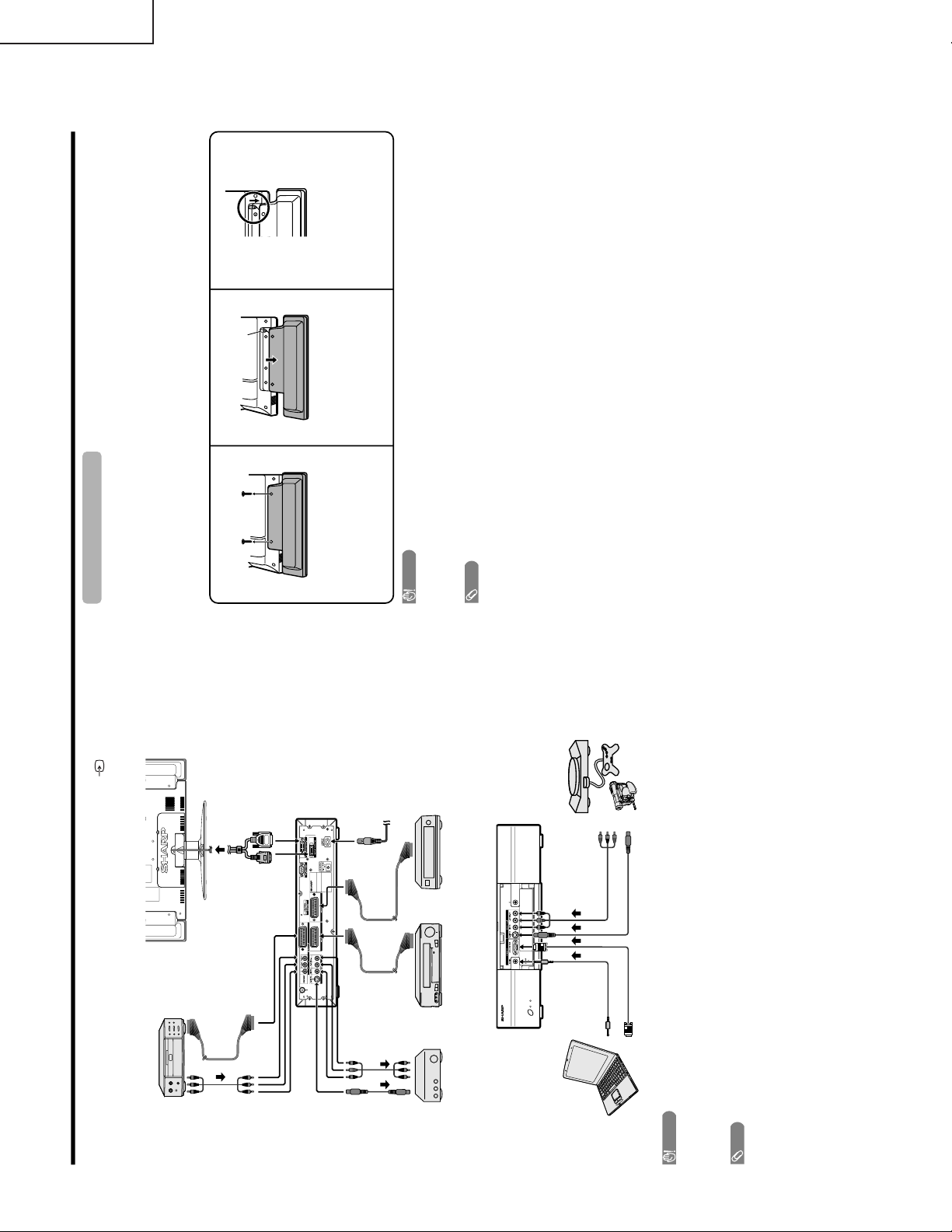

Using external equipment

Display

(rear view)

DVD player

AVC System

(rear view)

AVC System

(front view)

AV Receiver

(Built-in Tuner Amp)

VCR Decoder

Game console/CamcorderPC

You can connect many types of external equipment to your System, like a decoder, VCR, DVD player, PC, game

console and camcorder. To view external source images, select the input source from on the remote

control unit or INPUT on the Display.

CAUTION

• To protect all equipment, always turn off the AVC System before connecting to a decoder, VCR, DVD player, PC, game

console, camcorder or other external equipment.

• The S-video signal only outputs when “INPUT2” or “INPUT3” is selected for “Y/C”, or when from the INPUT 4 terminal (S-

VIDEO). Only the S-video signal can output from the INPUT 4 terminal (S-VIDEO).

NOTE

• Please refer to the relevant operation manual (DVD player, PC, etc.) carefully before making connections.

Removing the speakers

This unit has detachable type speakers.

You can detach the system speakers when using external amplifier/speakers.

Before detaching (or attaching) speakers, unplug the AC cord from the AC outlet.

Before attaching/detaching speakers

• Before performing work make sure to turn off the System.

• Before performing work spread cushioning over a flat surface to lay the Display on. This will prevent it from

being damaged.

CAUTION

• The speaker terminals on the Display is only for the attached speakers. Do not connect any third party plug or speaker to

the terminal.

• Insert the speaker plug completely into the terminal.

• Do not handle or move the Display by the speakers.

NOTE

• Perform the same steps for both left and right speakers.

• To attach the speakers, perform the above steps in reverse order.

123

Unfasten the screws used to

secure the speakers in place.

Take hold of the speaker and

slowly slide it sideways.

(The speaker plug is still

inserted, so make sure not to

pull the speaker too far.)

Remove the speaker plug from

the terminal on the Display.

(Do not remove the plug by

pulling the cord.)

Now the speaker can be

detached from the Display.

Speaker

plug

8

Page 9

LC-30HV4E

RS-232C port specifications

Return codeCommand 4-digits Parameter 4-digits

PC Control of the System

• When a program is set, the display can be controlled from the PC using the RS-232C terminal.

The input signal (PC/video) can be selected, the volume can be adjusted and various other adjustments and

settings can be made, enabling automatic programmed playing.

•

Attach an RS-232C cable cross-type (commercially available) to the supplied Din-D/sub RS-232C for the

connections.

NOTE

• This operation system should be used by a person who is accustomed to using PC.

Communication conditions

Set the RS-232C communications settings on the PC to match the display’s communications conditions. The

display's communications settings are as follows:

Baud rate:

Parity bit:

Data length:

Stop bit:

Flow control:

9,600 bps

8 bits

None

1 bit

None

Appendix

Command format

Communication procedure

Send the control commands from the PC via the RS-232C connector.

The Display operates according to the received command and sends a response message to the PC.

Do not send multiple commands at the same time. Wait until the PC receives the OK response before sending

the next command.

Eight ASCII codes e CR

Command 4-digits:Command. The text of four characters.

Parameter 4-digits:Parameter 0 – 9, x, blank, ?

Parameter

Input the parameter values, aligning left, and fill with blank(s) for the remainder. (Be sure that four values are input for the

parameter.)

When the input parameter is not within an adjustable range,

“ERR” r

eturns. (Refer to “Response code format”.)

No problem to input any numerical value for

“x” on the table.

When “?” is input for some commands, the present setting value responds.

C1 C2 C3 C4 P1 P2 P3 P4

0055

100

– 30

0009

0

????

?

Commands

P

I

I

I

I

I

I

I

I

I

I

I

I

I

A

A

A

A

A

A

V

H

H

V

V

C

P

POWER OFF (STANDBY)

INPUT SWITCHING (TOGGLE)

TV (CHANNEL FIXED)

TV (CHANNEL SELCTION) (1

– 99)

INPUT1 – 4 (1 – 4)

PC

INPUT1 (CVBS)

INPUT1 (RGB)

INPUT2 (CVBS)

INPUT2 (Y/C)

INPUT3 (CVBS)

INPUT3 (Y/C)

INPUT3 (RGB)

INPUT3 (COMPONENT)

TOGGLE

STANDARD

DYNAMIC

MOVIE

GAME

USER

VOLUME (0 – 60)

H-POSITION (AV) (10– 10)

H-POSITION (PC) (90– 90)

V-POSITION (AV) (30– 30)

V-POSITION (PC) (60– 60)

CLOCK ( 90 – 90)

PHASE ( 20 – 20)

POWER SETTING

INPUT SELECTION A

INPUT SELECTION B

AV MODE

SELECTION

VOLUME

POSITION

O

T

T

T

A

P

N

N

N

N

N

N

N

N

V

V

V

V

V

V

O

P

P

P

P

L

H

W

G

V

V

V

C

P

P

P

P

P

P

P

P

M

M

M

M

M

M

L

O

O

O

O

C

S

R

D

D

D

D

D

1

1

2

2

3

3

3

3

D

D

D

D

D

D

M

S

S

S

S

K

E

0

x

0

*

*

x

0

1

0

1

0

1

2

3

0

1

2

3

4

5

*

*

*

*

*

*

*

_

_

*

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

*

*

*

*

*

*

*

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

*

*

*

*

*

*

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

CONTROL ITEM COMMAND PARAMETER

CONTROL

CONTENTS

W

W

W

W

W

W

W

W

W

W

W

W

S

S

S

S

S

T

T

D

C

C

T

T

D

TOGGLE

NORMAL

FULL 14:9

ZOOM 14:9

PANORAMA

FULL

CINEMA 16:9

CINEMA 14:9

NORMAL

FULL

DOT BY DOT

CINEMA

TOGGLE

OFF

SRS

FOCUS

SRS FOCUS

DUAL SCREEN OFF

DUAL SCREEN ON

DIRECT CHANNEL (1

– 99)

CHANNEL UP

CHANNEL DOWN

TEXT OFF

TEXT ON (TOGGLE)

DIRECT PAGE JUMP (100

– 899)

WIDE MODE

SRS

DUAL SCREEN

CHANNEL

TEXT

I

I

I

I

I

I

I

I

I

I

I

I

R

R

R

R

R

W

W

C

H

H

E

E

C

D

D

D

D

D

D

D

D

D

D

D

D

S

S

S

S

S

I

I

C

U

D

X

X

P

E

E

E

E

E

E

E

E

E

E

E

E

S

S

S

S

S

N

N

H

P

W

T

T

G

0

1

2

3

4

5

6

7

8

9

1

1

0

1

2

3

4

0

1

*

x

x

0

1

*

_

_

_

_

_

_

_

_

_

_

0

1

_

_

_

_

_

_

_

*

_

_

*

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

*

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

CONTROL ITEM COMMAND PARAMETER

CONTROL

CONTENTS

NOTE

• If an underbar (_) appears in the parameter column, enter a space.

• If an asterisk (*) appears, enter a value in the range indicated in brackets under CONTROL CONTENTS.

Return code (0DH)

Response code format

Normal response

Problem response (communication error or incorrect command)

Return code (0DH)

OK

ERR

9

Page 10

LC-30HV4E

Appendix

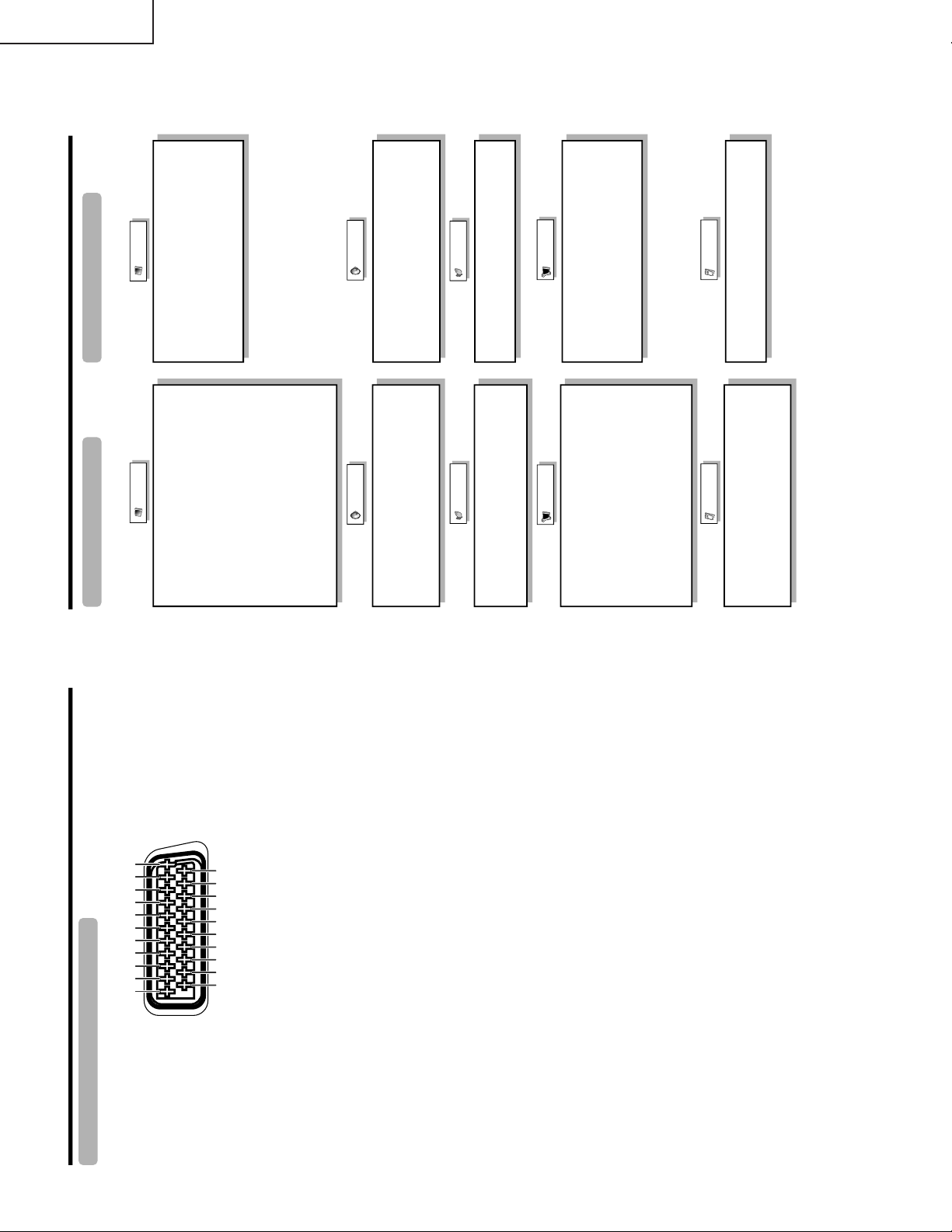

SCART (INPUT 1)

1. Audio right output

(TV Monitor out)

2. Audio right input

3. Audio left output

(TV Monitor out)

4. Common earth for audio

5. Earth for blue

6. Audio left input

7. Blue input

8. Audio-video control

9. Earth for green

10. Not used

11. Green input

12. Not used

13. Earth for red

14. Not used

15. Red input

16. Red/Green/Blue control

17. Earth for video

18. Earth for Red/Green/Blue

control

19. Video output

(TV Monitor out)

20. Video input

21. Plug shield

SCART (INPUT 2)

1. Audio right output

2. Audio right input

3. Audio left output

4. Common earth for audio

5. Earth

6. Audio left input

7. Not used

8. Audio-video control

9. Earth

10. AV LINK control

11. Not used

12. Not used

13. Earth

14. Not used

15. Chroma S-Video input

16. Not used

17. Earth for video

18. Earth

19. TV Monitor output

20. Video input/S-video input

21. Plug shield

SCART (INPUT 3)

1. Audio right output

2. Audio right input

3. Audio left output

4. Common earth for audio

5. Earth

6. Audio left input

7. Blue input

8. Audio-video control

9. Earth

10. Not used

11. Green input

12. Not used

13. Earth

14. Not used

15. Red input/Chroma S-Video

input

16. Red/Green/Blue control

17. Earth for video

18. Earth

19. TV Monitor output

20. Video input/S-video input

21. Plug shield

1 3 5 7 9 111315171921

2 4 6 8 101214161820

Connecting pin assignments for SCART

Various audio and video devices may be connected via the SCART terminals.

Basic adjustment settings

AV input mode menu items

List of AV menu items to help you with

operations

Contrast

Brightness

Colour

Tint

Sharpness

Advanced

C.M.S.

Colour Temp

Black

Monochrome

Film Mode

I/P Setting

DNR

Picture

Power Save

No Signal off

No Operation off

Auto Installation

Programme Setup

Child Lock

Position

WSS

4:3 Mode

Full Mode

Rotate

Language

Treble

Bass

Balance

Surround.

Input Select

Audio Out

Cool Climate

Colour System

Audio

Power control

Setup

Option

PC input mode menu items

List of PC menu items to help you with

operations

Contrast

Brightness

Red

Green

Blue

C.M.S.

Picture

Power Save

Power Management

Input Signal

Auto Sync.

Fine Sync.

Rotate

Language

Audio

Power control

Setup

Option

Treble

Bass

Balance

Surround

Audio Out

Cool Climate

10

Page 11

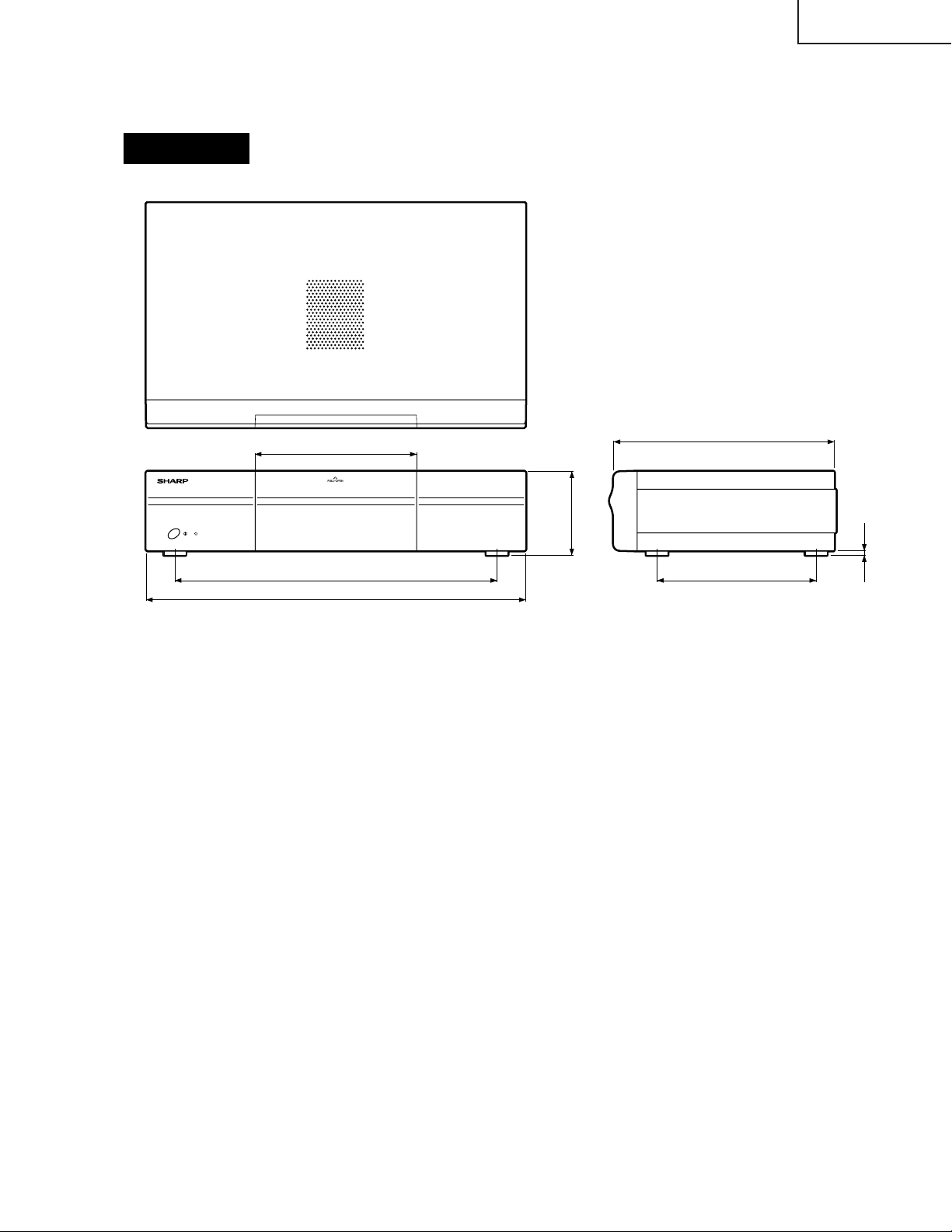

DIMENSIONS

LC-30HV4E

AVC System

183

365

430

Unit: mm

250

95

5

180

11

Page 12

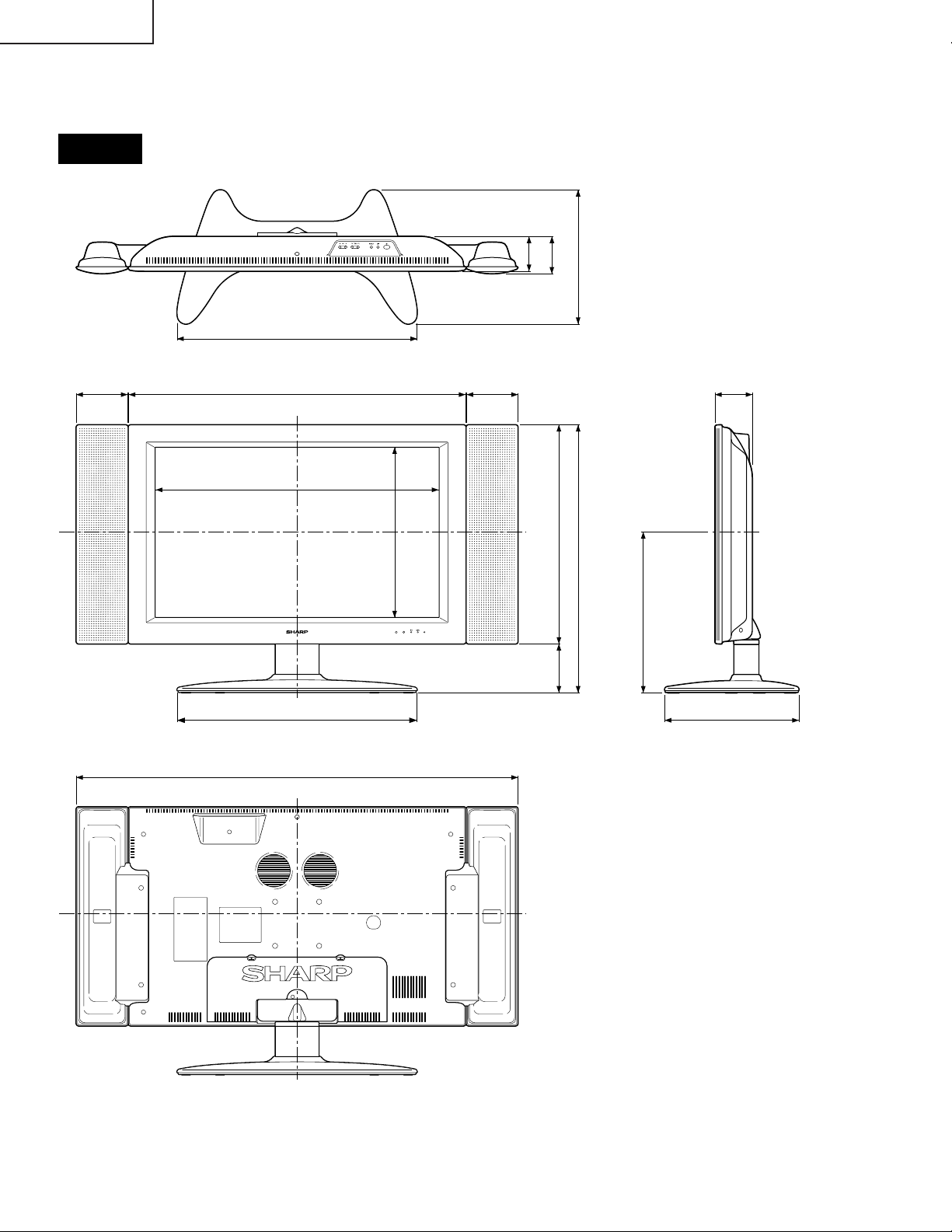

LC-30HV4E

Display

545

117.5 117.5

643

766

385

Unit: mm

79

84.5

305608

84.5

497

545

1002

364

111

305

12

Page 13

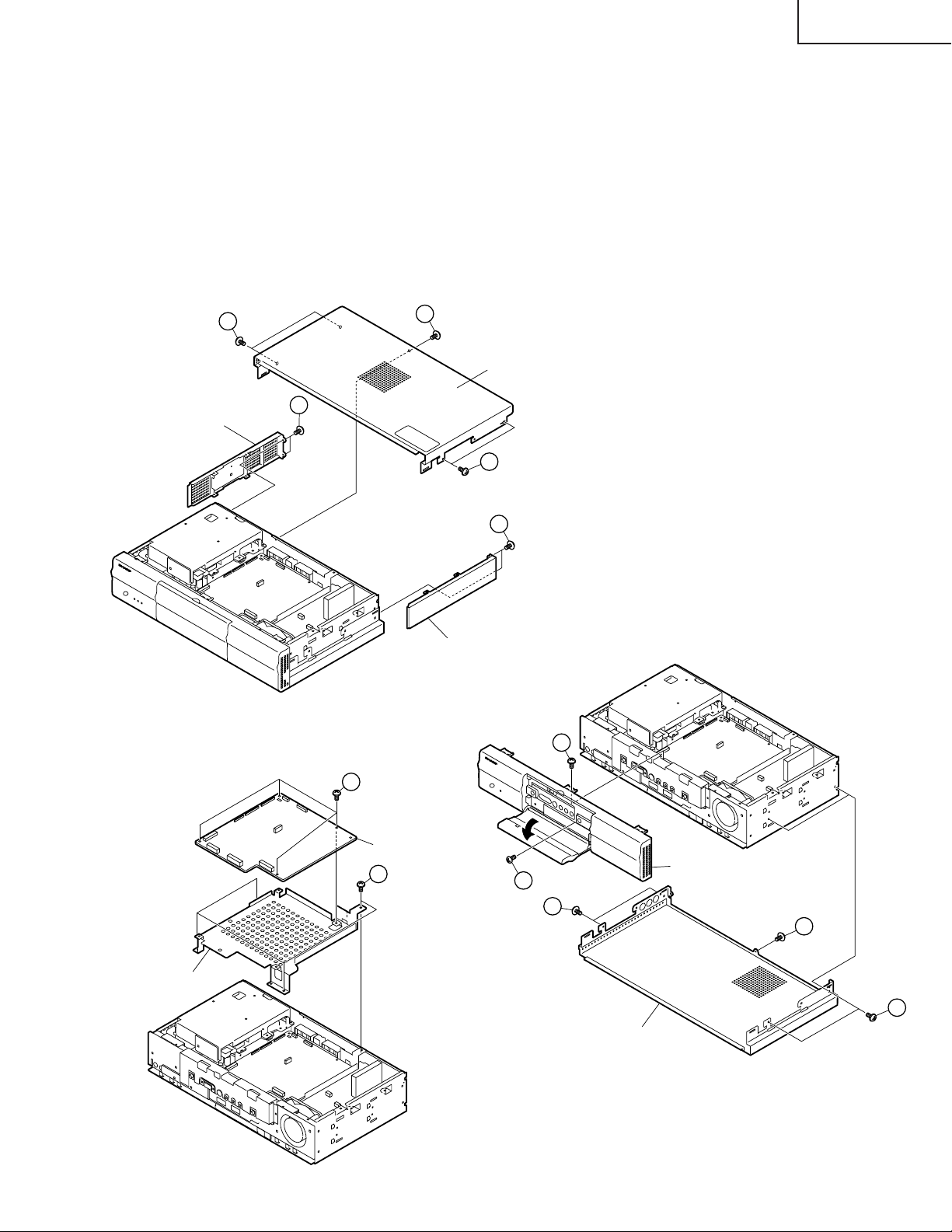

REMOVING OF MAJOR PARTS

Ë Ë

Ë AVC System

Ë Ë

1. Remove the five top cabinet retaining screws and slide the top cabinet backward to remove it.

2. Remove the four side cover retaining screws on both the right and left sides and slide the side covers

backward to remove them.

3. Remove the one front panel retaining screws and remove the front panel.

4. Remove the five bottom cabinet retaining screws and slide the bottom panel backward to remove it.

5. Remove the four screws securing the main PWB angle and remove the angle upward.

6. Remove the four screws securing the main PWB to the angle and remove the main PWB.

LC-30HV4E

1

Side Cover (L)

1

Top Cabinet

2

1

2

Side Cover (R)

3

Main PWB angle

6

Main PWB

5

3

Front panel

4

4

4

Bottom panel

13

Page 14

LC-30HV4E

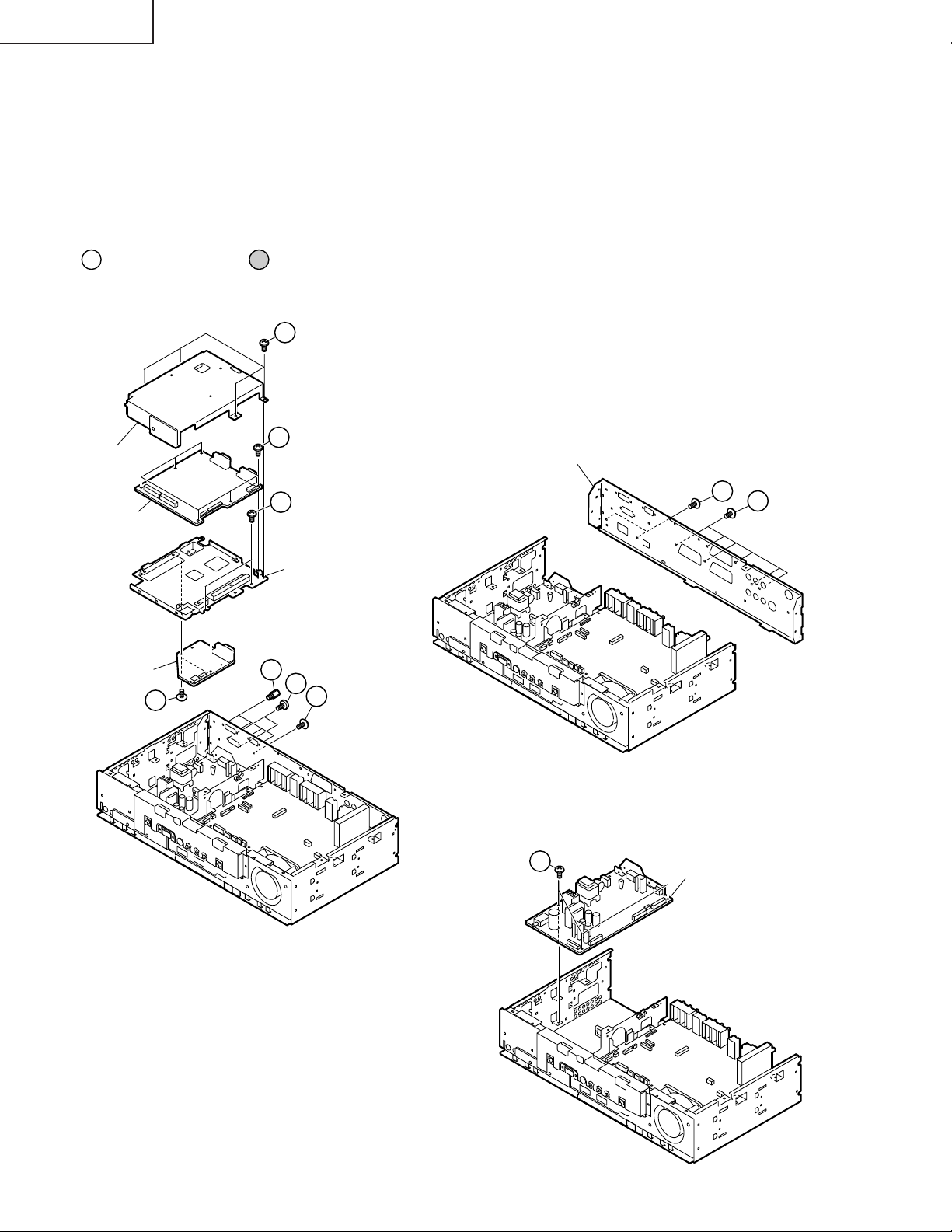

7. Remove the system/control terminal retaining:

7-1. Remove the four hex head screws securing the terminals of the system and control cables (white).

7-2. Remove the two screws securing the terminal of the system cable (gray).

7-3. Remove the two rear chassis retaining screws.

8. Remove the PC I/F and SR units:

8-1. Remove the four PC I/F top shield retaining screws and remove the shield.

8-2. Remove the six PC I/F unit retaining screws and remove the unit.

8-3. Remove the two PC I/F bottom shield retaining screws and remove the angle.

8-4. Remove the two SR unit retaining screws and remove the SR unit.

9. Remove the 8 rear cabinet retaining screws and remove the rear chassis.

9

: XBPSN30P06000, 9 : XEBSF30P08000)

(

10. Remove the three power supply board retaining screws and remove the power supply board.

8-1

8-2

PC I/F unit shield

Rear chassis

PC I/F unit

SR unit

8-4

8-3

PC I/F unit angle

7-1

7-2

7-3

10

9-2

Power unit

9-1

14

Page 15

11. Remove the AV unit:

11-1. Remove the five AV unit retaining screws and remove the AV unit.

11-2. Remove the three AV unit angle retaining screws and remove the angle.

12. Remove the fan:

12-1. Remove the two cooling fan retaining screws and remove the cooling fan.

13. Remove unit from the front chassis:

13-1. Remove the two hex head screws and four screws securing the front shield to the front chassis and

remove the front shield.

13-2. Remove the four screws securing the front unit and remove the unit.

11-1

AV unit

AV unit angle

11-2

LC-30HV4E

Cooling Fan

13-2

12-1

13-1

13-1

Front Shield

15

Front unit

Page 16

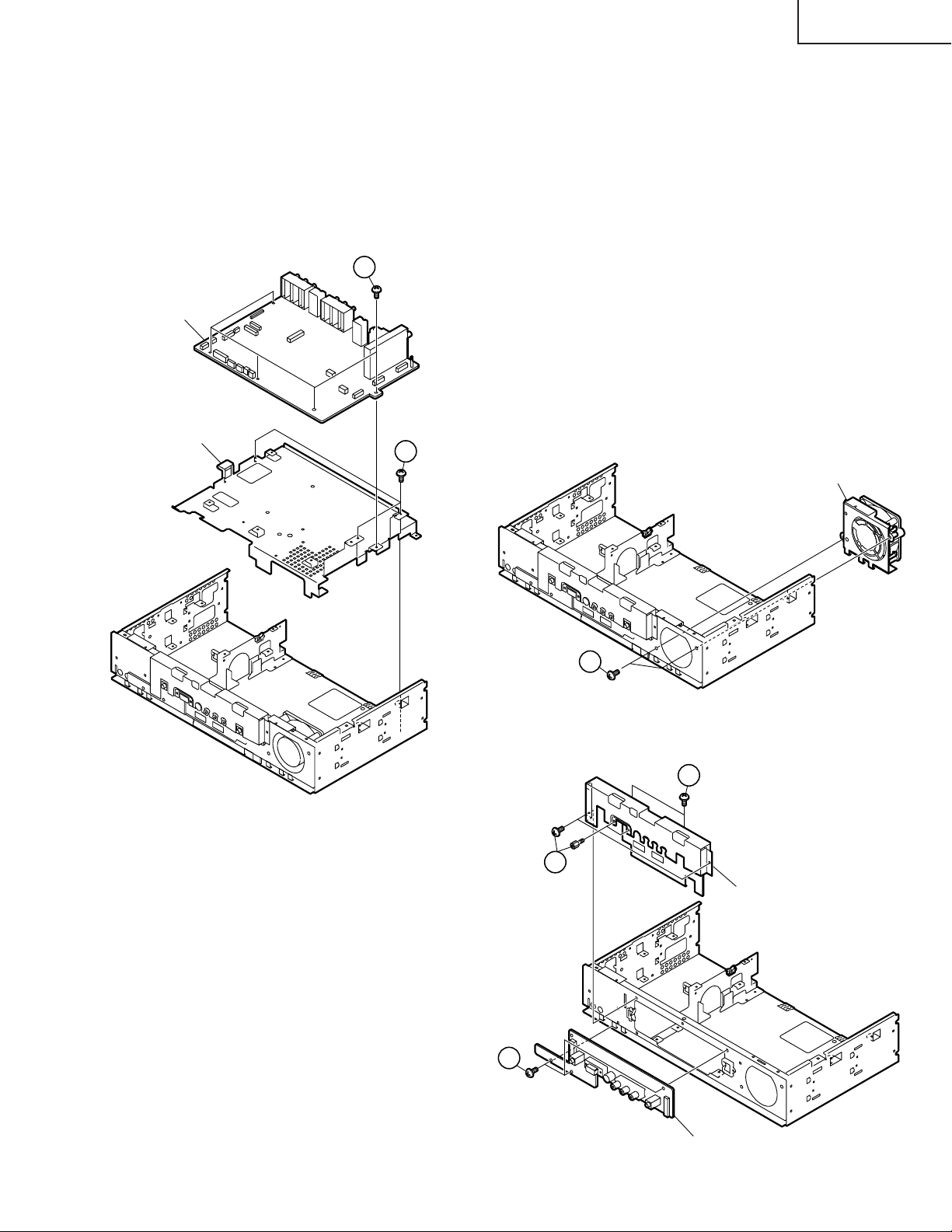

LC-30HV4E

Ë Ë

Ë Display

Ë Ë

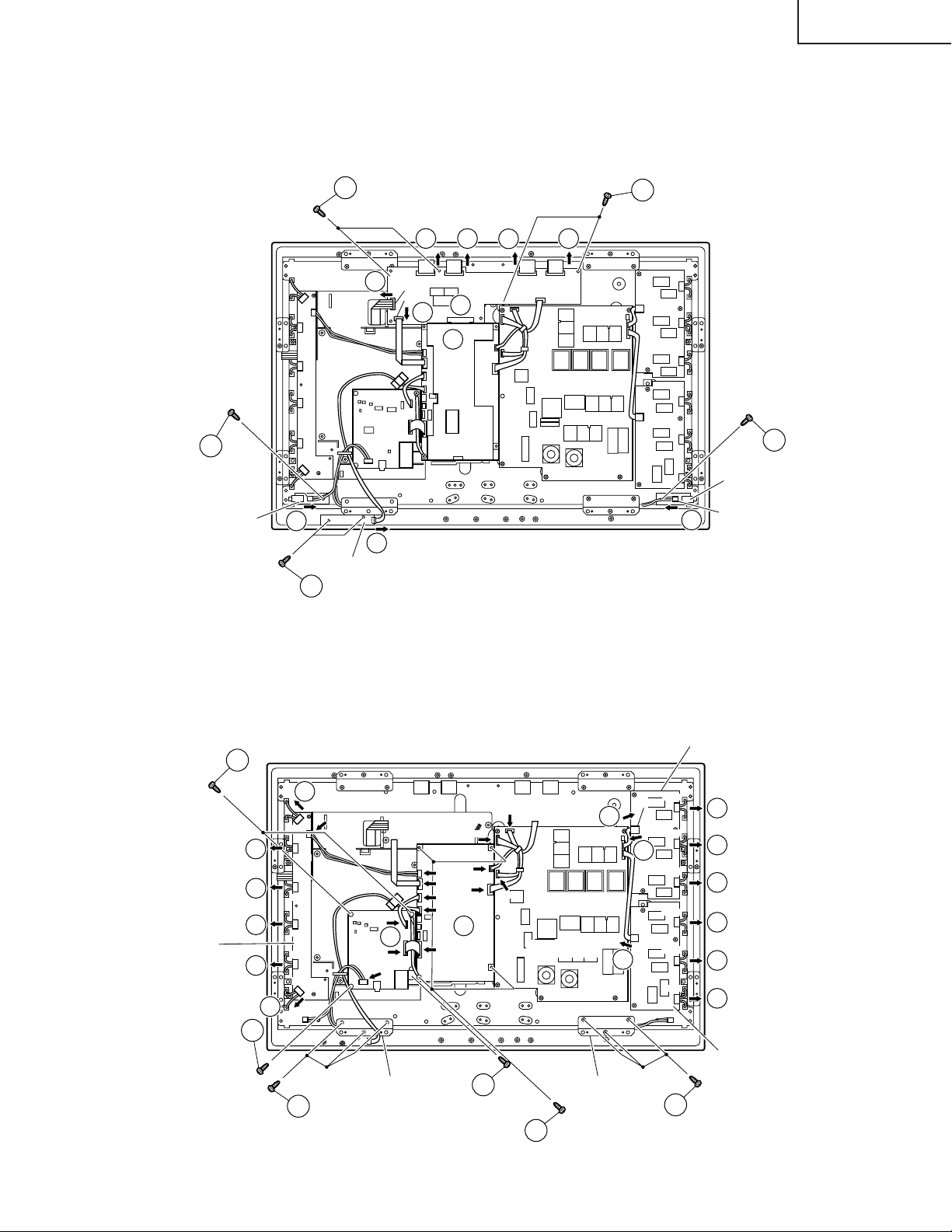

1. Take off bottom terminal cover.

2. Take off the speaker by removing 4 screws and disconnecting speaker terminals.

3. Take off the table stand by removing 6 screws.

4. Take off the rear cabinet by removing 18 screws and releasing the front cabinet's 6 hooks.

Speaker

4

Rear Cabinet

4

4

Speaker

2

4

4

4

2

3

Terminal Cover

2

4

4

4

Table Stand

1

2

4

5. Take off the operation cover assembly by removing 2 screws and detaching the connector.

6. Take off the center angle by removing 8 screws and disconnecting 1 lead wire from the fan.

5

Operation Cover Ass'y

5

P131

P130

5

6

P2103

6

Center Angle

6

16

Page 17

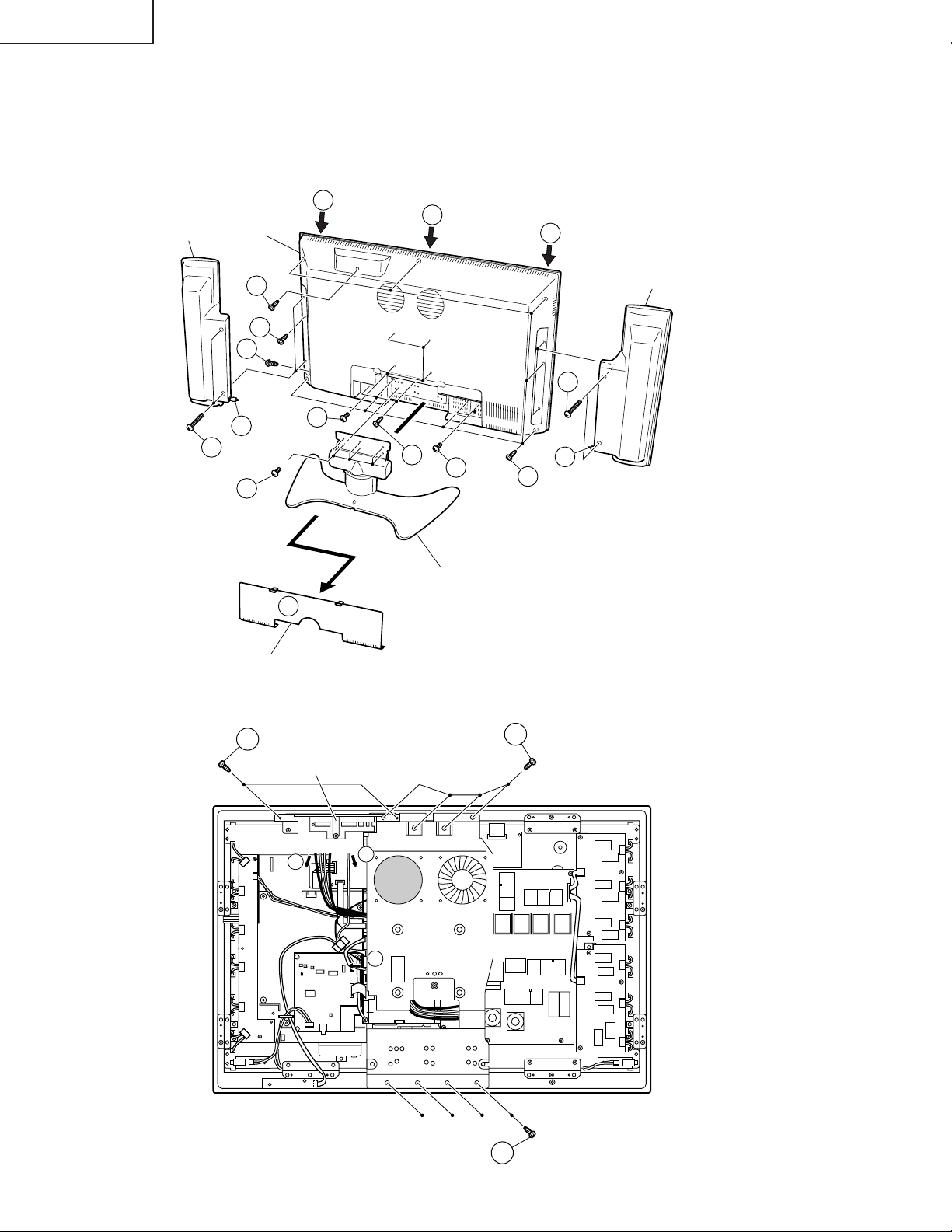

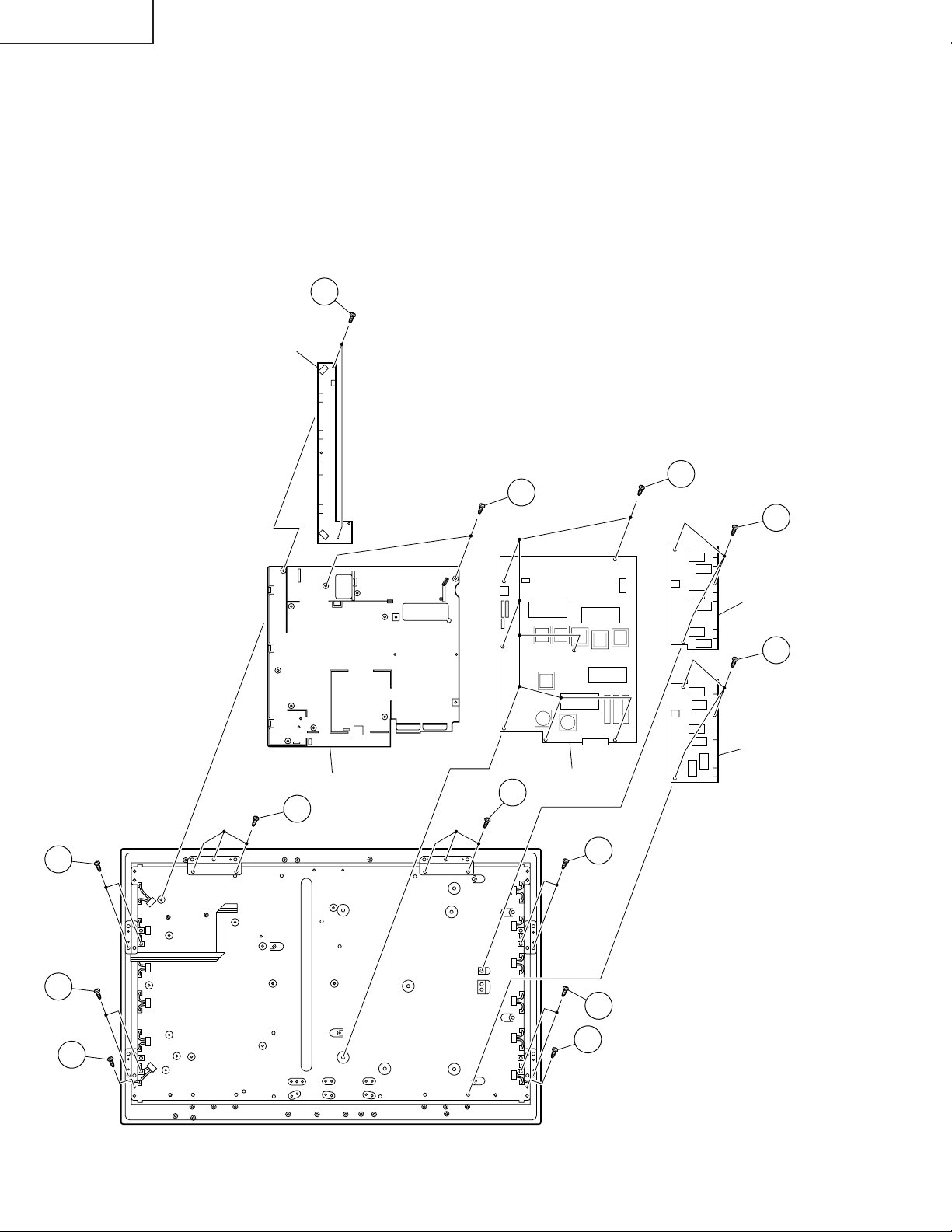

7. Take off the LCD control PWB by detaching 7 connectors and removing 4 screws.

8. Take off the R/C, LED PWB by detaching one connector and removing 2 screws.

9. Take off the speaker (L) PWB by detaching one connector and removing one screw.

10.Take off the speaker (R) PWB by detaching one connector and removing one screw.

LC-30HV4E

9

Speaker(L)

PWB

P201

9

8

7

7

8

R/C,LED PWB

SC4502

SC4551

SC491

7

7

7

7

LCD

control

7

7

SC4503

7

13

Main

PWB

10

Speaker(R)

PWB

P202

10

11.Take off the main PWB by detaching 8 connectors and removing 4 screws.

12.Take off the audio PWB assembly by detaching 3 connectors and removing 4 screws.

13.Take off the 2 reinforcement angles by removing 3 screws from each angle.

14.Detach each connector.

Inverter-1 PWB

12

Inverter

GND PWB

14

14

14

14

14

P6901

P6902

P6903

P6904

P6905

P6906

P6907

Audio

PWB

P3804

P3802

12

P3801

P2106

SC2001

P2002

P2003

P2104

11

Main

PWB

CN4

P2101

P2102

CN5

CN3

Power Unit

14

CN7

14

P6565

14

P6564

P6551

P6553

P6555

P6558

P6560

P6562

14

12

Reinforcement angle

13

15

Reinforcement angle

13

11

14

14

14

14

14

14

Inverter 2 PWB

17

Page 18

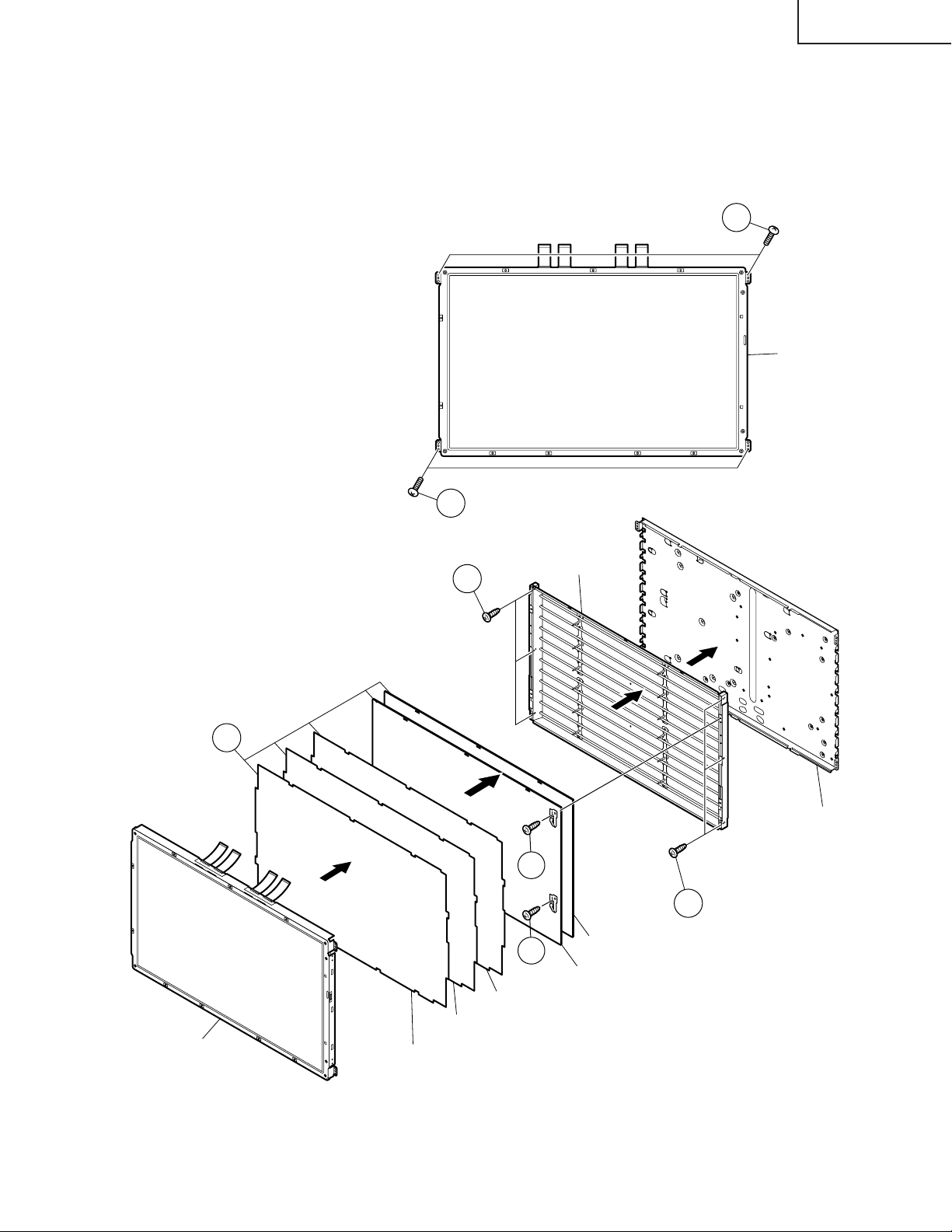

LC-30HV4E

15.Take off the inverter GND PWB by removing 2 screws.

16.Take off the power PWB by removing 7 screws. Remove insulation sheet.

17.Take off the inverter-1 PWB by removing 3 screws.

18.Take off the inverter-2 PWB by removing 3 screws

19.Take off the 4 reinforcement angles by removing 2 screws from each angle.

20.Take off the 2 reinforcement angles by removing 3 screws from each angle.

21.Take off the chassis frame by removing 2 screws.

22.Take off the LCD panel assembly by removing 2 screws.

15

Inverter GND

PWB

21

16

17

19

19

22

Chassis Frame

20

Inverter-1 PWB

18

Inverter-2 PWB

Power Unit

20

19

19

22

18

Page 19

LC-30HV4E

23.Take off the LCD panel with panel shield by removing 4 screws.

24.Take off D-BEF sheet, prism sheet and diffusion sheet. Take off ITO sheet and diffusion panel by removing 2

screws.

25.Take off the panel shield by removing 6 screws.

23

LCD Panel

LCD Panel

24

23

25

Diffusion Sheet

Prism Sheet

D-BEF Sheet

24

24

Lamp

Panel Shield

25

Diffusion Panel

ITO Sheet

19

Page 20

LC-30HV4E

ADJUSTMENT PROCEDURES (AVC SYSTEM)

Preparation for adjustment

1. The product has been adjusted and optimized in the factory. If the product needs to be readjusted for some

reason, e.g., after parts replacement, follow the instructions shown below.

2. Control parameter values set in the in-process adjustment mode has been stored in the corresponding registers.

When the product is readjusted, the contents of the registers are changed. Bef ore readjustment, f actory settings

should be noted in case the contents of registers require to be restored.

3. Use a stabilized AC power supply.

4. To rewrite a program, you should note the items ("OSD MENU" and "Adjustment Values") you want to change

and initialize EEPROM, and then rewrite the changes into EEPROM.

How to enter the in-process adjustment mode

CAUTION: Exercise great care to hide the procedure in entering the in-process adjustment mode from the

customer. Inadvertent setting changes in this mode may cause a fatal error resulting in a program being

unrecoverable.

1. Entering the in-process adjustment mode:

Connect the system cable between the display and AVC system.

Turn on the main power while holding down the "INPUT" button and the "Volume (-)" button of the display

simultaneously. The system will be activated.

~If you see multiple lines of blue characters on the display, you are in the in-process adjustment mode. If not

(the normal activation screen opens), retry.

2. Accessing the inspection process mode:

After activation of the system, make adjustments according to the instructions indicated on the process adjustment

OSD menu screen.

Move to the General Process Adjustment (AVC System Section Process).

3. Restoring factory settings: (At the time of "INDUSTRY INIT" execution, please wait for about 30 seconds until

/// disappears.)

When the "INDUSTRY INIT" button is selected after activation of the system, factory channel setting remains

unchanged after the system exits from the in-process adjustment mode.

Changes made by the user will default to factory settings. Note that channel setting is also initialized.

4. Exiting from the in-process adjustment mode:

Unplug the power cable while the system is in the in-process adjustment mode to exit from the mode.

Take care not to press the "Power" button on the remote controller or the AVC system after using factory

settings to run the system.

5. OSD menu screen and menu items during manual adjustment:

~The layout and men u items of the OSD menu screen ma y some what vary depending on the program versions .

~Just rewriting a program does not cause settings to be "initial values". (Preparation for adjustment)

1. Button operation in the in-process adjustment mode

Cursor Up Move to the next page

Cursor Down Back to the previous page

Volume (+) Increase the setting by 1

Volume (-) Decrease the setting by 1

ENTER Execute the function

Cursor Left Increase the setting by 10

Cursor Right Decrease the setting by 10

Channel (Up) Move the cursor up

Channel (Down) Move the cursor down

INPUT Change input (Tuner -> Input 1 -> Input 2 ->Input 3 -> Input 4 -> PC ->)

20

Page 21

LC-30HV4E

CENTER Version

OSD Version

CVIC Version

TTXP V ersion

∫ ∫

∫ ∫

∫ ∫

∫ ∫

2001 06 21A

XXXXXXXX

XXXXXXXX

XXXXXXXX

∫

∫

∫

∫

Page Program version Colour system

TUNER NO SIG1/13 HDCP:ON EUROPE EUROPE

Main unit AV unitHDCPSource of input

2. In-process adjustment screen layout

6. Loading the backup data and setting HDCP when the PC I/F unit is replaced

Nearly all data including factory settings, user settings, and channel setting is stored in the PC I/F unit.

The product comes with EEPROM (IC1506) on the Main unit in case the PC I/F unit is replaced; original data

backed up on the EEPROM can be loaded to the new PC I/F unit.

∫ How to load the backup data

Select EEPROM RECOVER in the OSD menu (page 13/13) and turn the "Volume" key ON; then press

"ENTER".

∫ How to set HDCP

After completion of adjustments, select KEY WRITE "ON" in the OSD men u (page 1/13) for man ual adjustment

and turn the "Volume" key ON; then press "ENTER".

21

Page 22

LC-30HV4E

ËË

Ë Adjustment parameters

ËË

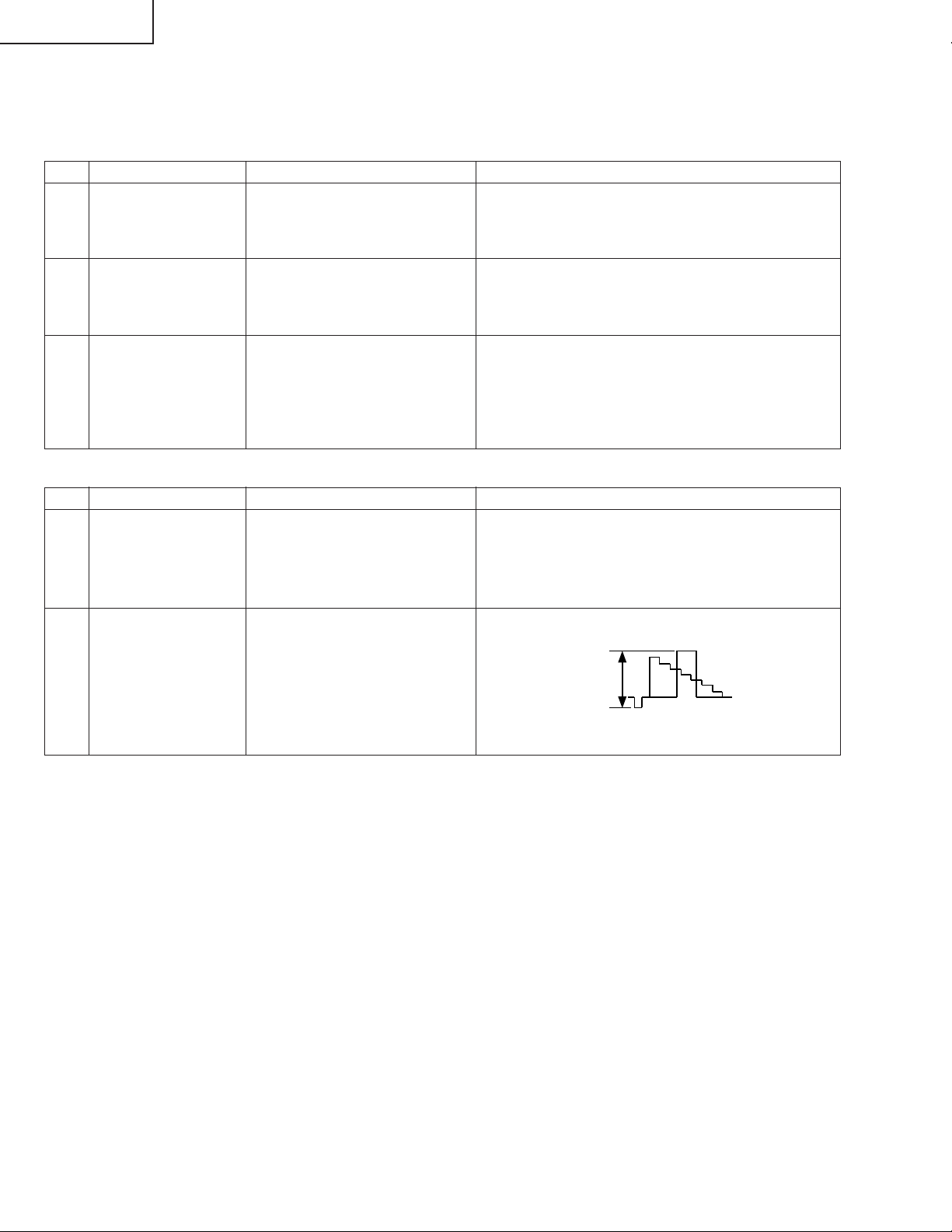

1) Analog adjustment

(1) AVC System voltage adjustment

Adjustment items Adjustment conditions Adjustment procedures

1 In-process adjustment

mode

(

Check the destination.

)

Enter the in-process adjustments mode.

Check that the destination is EUROPE.

2 AVC System 3.3V

adjustment

3 AVC System 1.8V

adjustment

Connect a DC voltmeter to TP4

at the opening on the top of the

PC I/F unit.

Move the cursor to the [Ë+Badj3.3V] line and adjust

the TP4 voltage to 3.30±0.01V.

Move the cursor to the [Ë+BAdj1.8V] line and press

"ENTER" key.

Adjustment is complete if [Ë+BAdj1.8V complete]

appears.

If "ERR" occurs, adjust pin (6) at CN9 on the PC I/F

unit so that 1.9V is reached.

(2) TUNER adjustment

Adjustment items Adjustment conditions Adjustment procedures

1 Setup 1. Set colour system to "PAL".

2. Select PAL source.

100% colour bar signal including 100% white, such

as split field colour bar

2 Tuner level adjustment Adjust TP1101 so that the Y signal without the chroma

Connect the oscilloscope to

TP1101.

component should be 1.00 ±0.02 Vp-p

1.0Vp-p

(between the bottom of sync signal and the white

peak).

22

Page 23

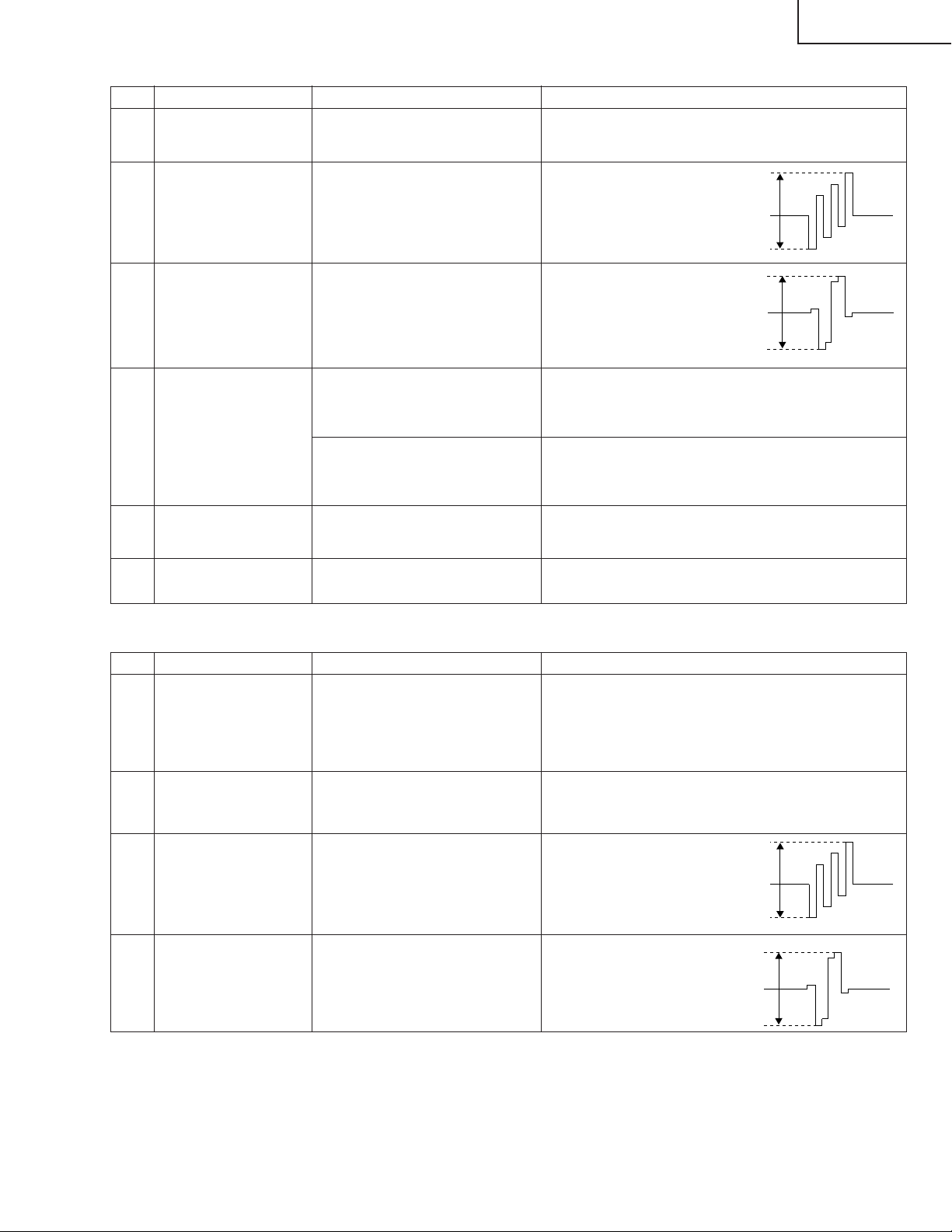

(3) PAL signal adjustment

Adjustment items Adjustment conditions Adjustment procedures

1 MAIN PAL Y LEVEL

adjustment

LC-30HV4E

Adjust pin (1) of P801 to 0.70 ±0.025 Vp-p.

2 MAIN PAL COLOR

GAIN adjustment

3 MAIN PAL Cr LEVEL

adjustment

4 MAIN CONTRAST

adjustment

Press the DUAL screen button. Select the special DUAL screen settings for adjustment

5 SUB PAL Y adjustment Adjust TB1274_SUB output (TP806) to

6 SUB PAL COLOR

GAIN adjustment

Adjust pin (3) of P801 to

0.53 ±0.025 Vp-p.

0.53V

Adjust pin (5) of P801 to

0.53 ±0.025 Vp-p.

0.53V

Adjust the output (TP815) of IC810 to have 0.90±0.025

Vp-p from the pedestal level.

(so that the same video source is reflected on MAIN/

SUB).

1.5 ±0.05 Vp-p.

Adjust TB1274_SUB output (TP805) to

1.13 ±0.05 Vp-p.

(4) SECAM signal adjustment

Adjustment items Adjustment conditions Adjustment procedures

1 Setup 1. Set colour system to SECAM.

2. Select SECAM source.

100% colour bar signal including 100% white, such

as split field colour bar.

2 MAIN SECAM Y

LEVEL adjustment

3 MAIN SECAM COLOR

GAIN adjustment

4 MAIN SECAM Cr

LEVEL adjustment

Adjust pin (1) of P801 to 0.70 ±0.025 Vp-p.

Adjust pin (3) of P801 to

0.53 ±0.025 Vp-p.

Adjust pin (5) of P801 to

0.53 ±0.025 Vp-p.

0.53V

0.53V

23

Page 24

LC-30HV4E

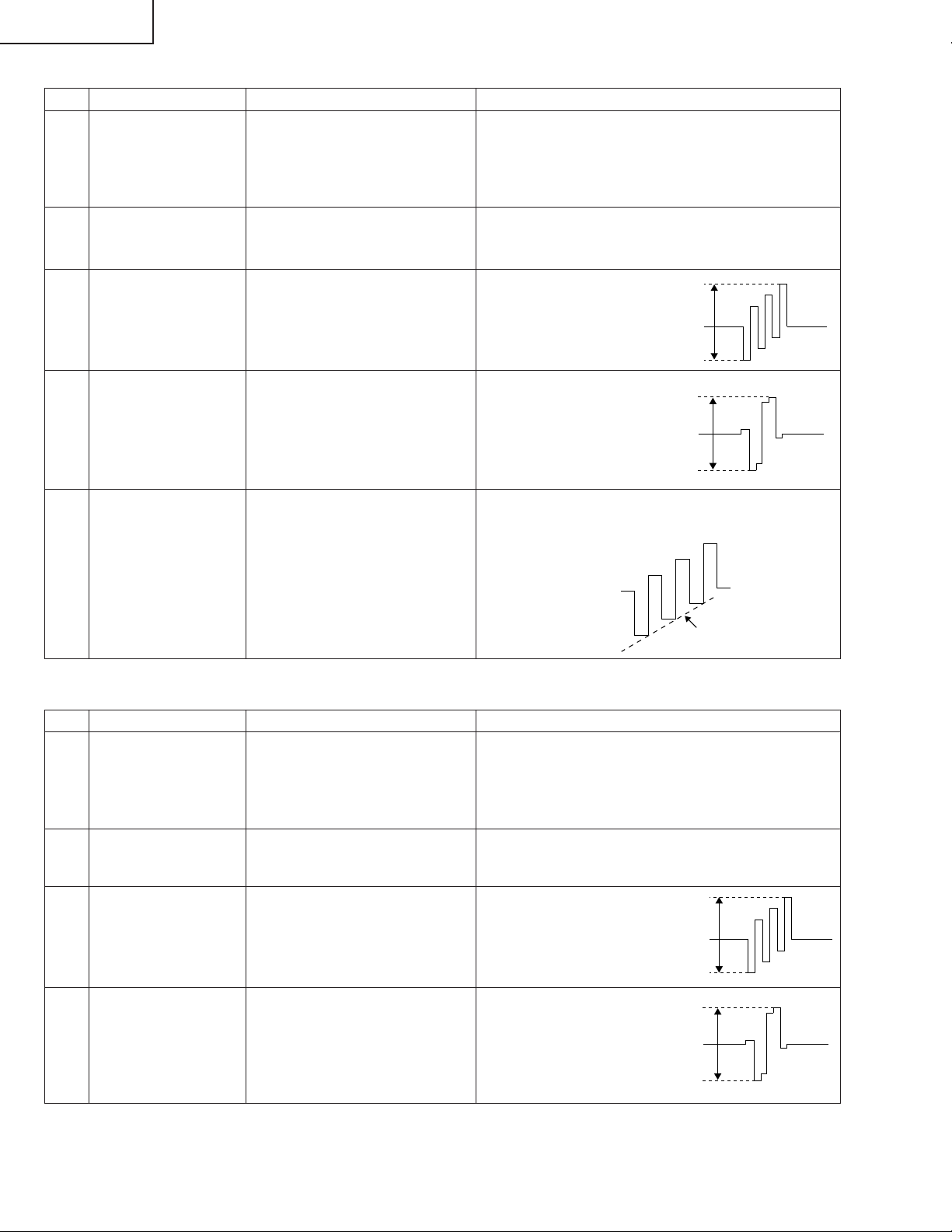

(5) N358 signal adjustment

Adjustment items Adjustment conditions Adjustment procedures

1 Setup 1. Set colour system to N358.

2. Select N358 source.

100% SMPTE colour bar or similar colour bar

signal including 100% white.

2 MAIN N358 Y

LEVEL

adjustment

3 MAIN N358 COLOR

GAIN adjustment

4 MAIN N358 Cr LEVEL

adjustment

5 MAIN N358 TINT

adjustment

Adjust pin (1) of P801 to 0.70 ±0.025 Vp-p.

Adjust pin (3) of P801 to

0.53 ±0.025 Vp-p.

0.53V

Adjust pin (5) of P801 to

0.53 ±0.025 Vp-p.

0.53V

Adjust TB1274_MAIN output (TP802) so that waveform

becomes as illustrated below:

Smoothed

(6) Component 15k Hz signal adjustment

Adjustment items Adjustment conditions Adjustment procedures

1 Setup 1. Select component 15k Hz.

2. Select component source.

100% SMPTE colour bar or similar colour bar

signal including 100% white.

2 MAIN COMP 15k Y

CONTRAST

adjustment

3 MAIN COMP 15k

COLOR GAIN

adjustment

4 MAIN COMP 15k Cr

LEVEL adjustment

Adjust pin (1) of P801 to 0.70±0.025 Vp-p.

Adjust pin (3) of P801 to

0.70 ±0.025 Vp-p.

Adjust pin (5) of P801 to

0.70 ±0.025 Vp-p.

0.70V

0.70V

24

Page 25

(7) Component HDTV signal adjustment

Adjustment items Adjustment conditions Adjustment procedures

1 Setup 1. Input HDTV (1080i) component signal.

2. Select component source.

100% colour bar signal including 100% white, like

split field colour bar

LC-30HV4E

2 MAIN COMP HDTV

CONTRAST

adjustment

Adjust the TP815 to have 0.90 ±0.025 Vp-p from the

pedestal level.

2. Factor y settings

Adjustment item Description Adjustment procedure

1 INDUSTRY INIT

* Then turn off the AC power supply of the AVC system. (Be careful not to use the power switches of the remote control unit

and DISPLAY unit.)

It will be an end, if unite cursor with the line of

"INDUSTRY INIT", push a "VOL" button, it changes

into "ON", a "ENTER" button is pushed after that and it

is turned "OFF".

CAUTION:Before a setup is completed, please do not

shut off a power supply by any means.

25

Page 26

LC-30HV4E

Ë Ë

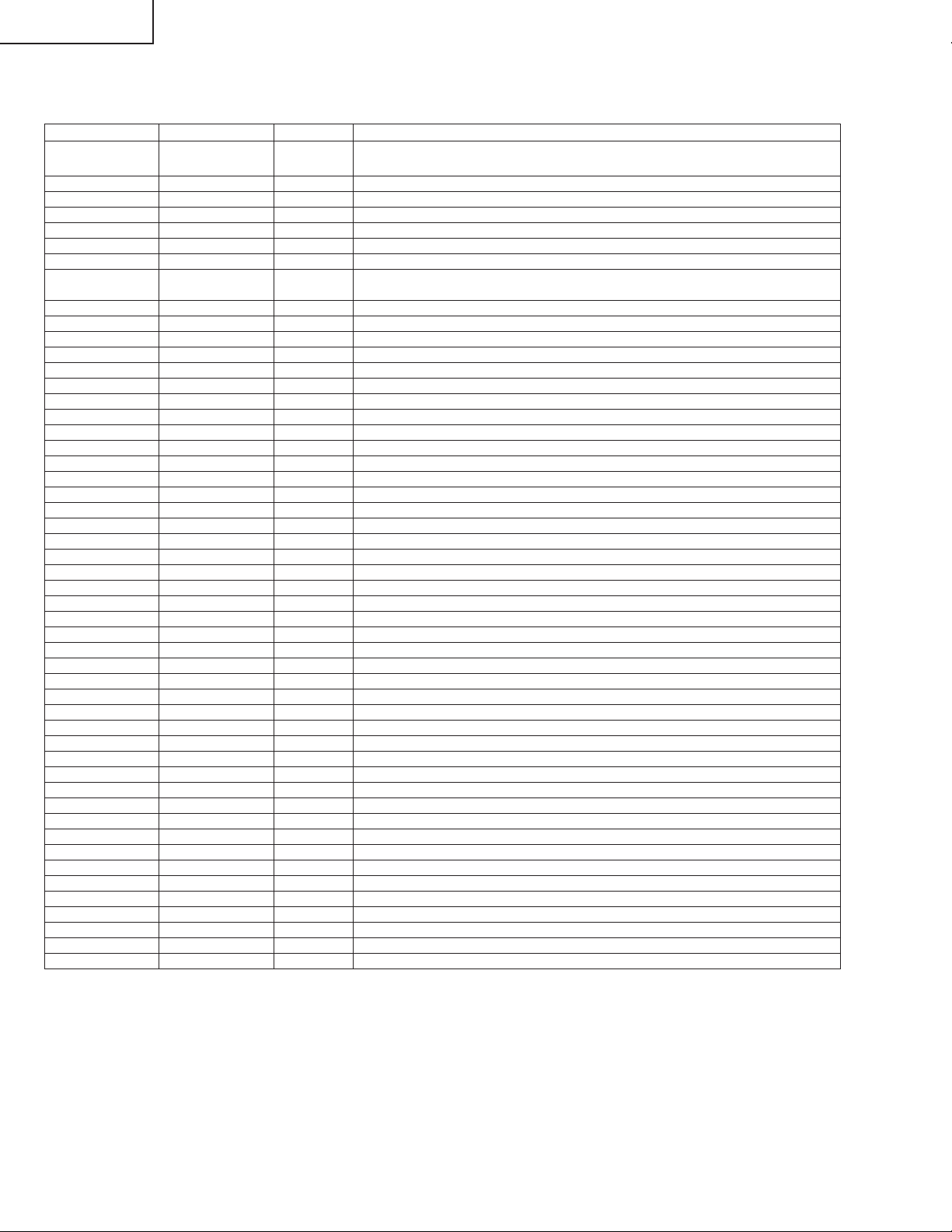

Ë Adjustment Mode Menu List (AVC System)

Ë Ë

Do not change items, the adjustment procedure of which is not described in this manual. Inadvertent changes of

such items may result in unexpected or unrecoverable errors.

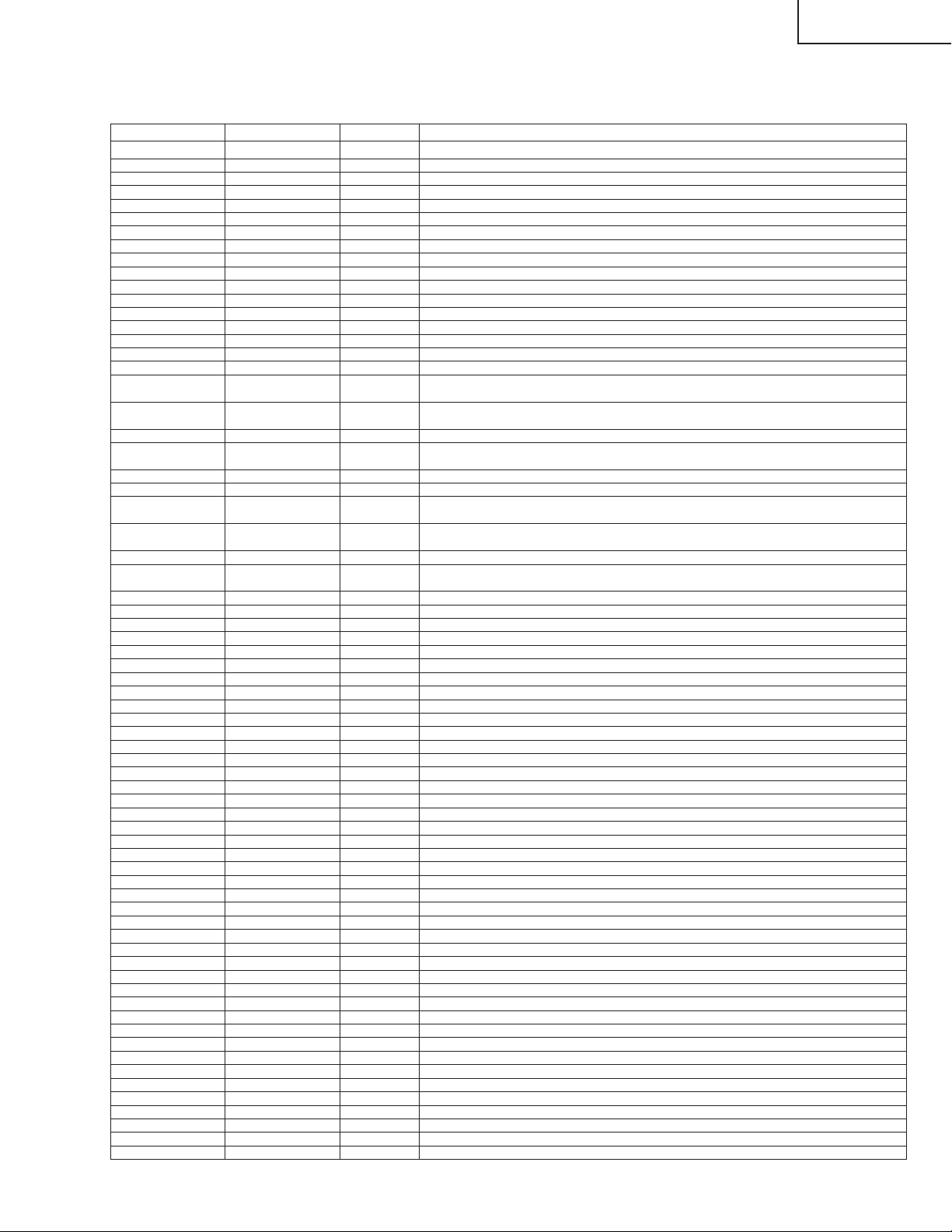

Page Item Page Item

Page 1

Page 3

Page 5

Page 7

Page 9

Page 11

Page 13

Maker Select

Ë+BAdj3.3V

Ë+BAdj1.8V(Enter: Auto)

KEY WRITE

ËDATA COPY

INDUSTRY INIT

CENTER V ersion

OSD V ersion

CVIC V ersion

TTXP V ersion

MONITOR V ersion

STANDBY TYPE

HOTEL MODE

ËSUB PAL Adjust

ËSUB PAL Y

ËSUB PAL COLOR GAIN

ËTUNER DAC ADJ

ËN358 Adjust

ËN358 Y CONTRAST

ËN358 COLOR GAIN

ËMAIN CR GAIN N358

ËN358 TINT

ËREFERENCE Adjust

ËPAL White Balance

PAL R CUTOFF

PAL R DRIVE

PAL G CUTOFF

PAL G DRIVE

PAL B CUTOFF

PAL B DRIVE

ËCOMP15K White Balance

COMP15K R CUTOFF

COMP15K R DRIVE

COMP15K G CUTOFF

COMP15K G DRIVE

COMP15K B CUTOFF

COMP15K B DRIVE

IPMODE INTERLACE

MDSW INTERLACE

PTGSW INTERLACE

IPMODE PROGRESSIVE

MDSW PROGRESSIVE

PTGSW PROGRESSIVE

IPMODE FMODEON

MDSW FMODEON

PTGSW FMODEON

IPMODE SUB

MDSW SUB

PTGSW SUB

IPMODE FMODEON PAL

MDSW FMODEON PAL

PTGSW FMODEON PAL

DEBUG PRINT SW

PIC ADJ MAKER SELECT

PIC ADJ KOUTEI SELECT

EEPROM SAVE

EEPROM RECOVER

CENTER PROG UPDATE

Page 2

Page 4

Page 6

Page 8

Page 10

Page 12

ËMAIN PAL Adjust

ËP AL Y CONTRAST

ËPAL COLOR GAIN

ËMAIN CR GAIN PAL

ËMAIN CONTRAST 15K

Center Acutime

RESET

Monitor Acutime

RESET

ËSECAM Adjust

ËSECAM Y CONTRAST

ËSECAM COLOR GAIN

ËMAIN CR GAIN SECAM

ËCOMP15K Adjust

ËCOMP15K Y CONTRAST

ËCOMP15K COLOR GAIN

ËMAIN CR GAIN COMP15K

ËCOMP HDTV Adjust

ËCOMP HDTV CONTRAST

ËCOMP HDTV SUB BRIGHT

ËPEAK ACL SW

ËN358 White Balance

N358 R CUTOFF

N358 R DRIVE

N358 G CUTOFF

N358 G DRIVE

N358 B CUTOFF

N358 B DRIVE

ËCOMP33K White Balance

COMPHDTV R CUTOFF

COMPHDTV R DRIVE

COMPHDTV G CUTOFF

COMPHDTV G DRIVE

COMPHDTV B CUTOFF

COMPHDTV B DRIVE

IPMODE PROGRESSIVE2

MDSW PROGRESSIVE2

PTGSW PROGRESSIVE2

IPMODE FMODEON2

MDSW FMODEON2

PTGSW FMODEON2

ILG LV

MD LV

VE LV

IP MODE SEL

26

Page 27

LC-30HV4E

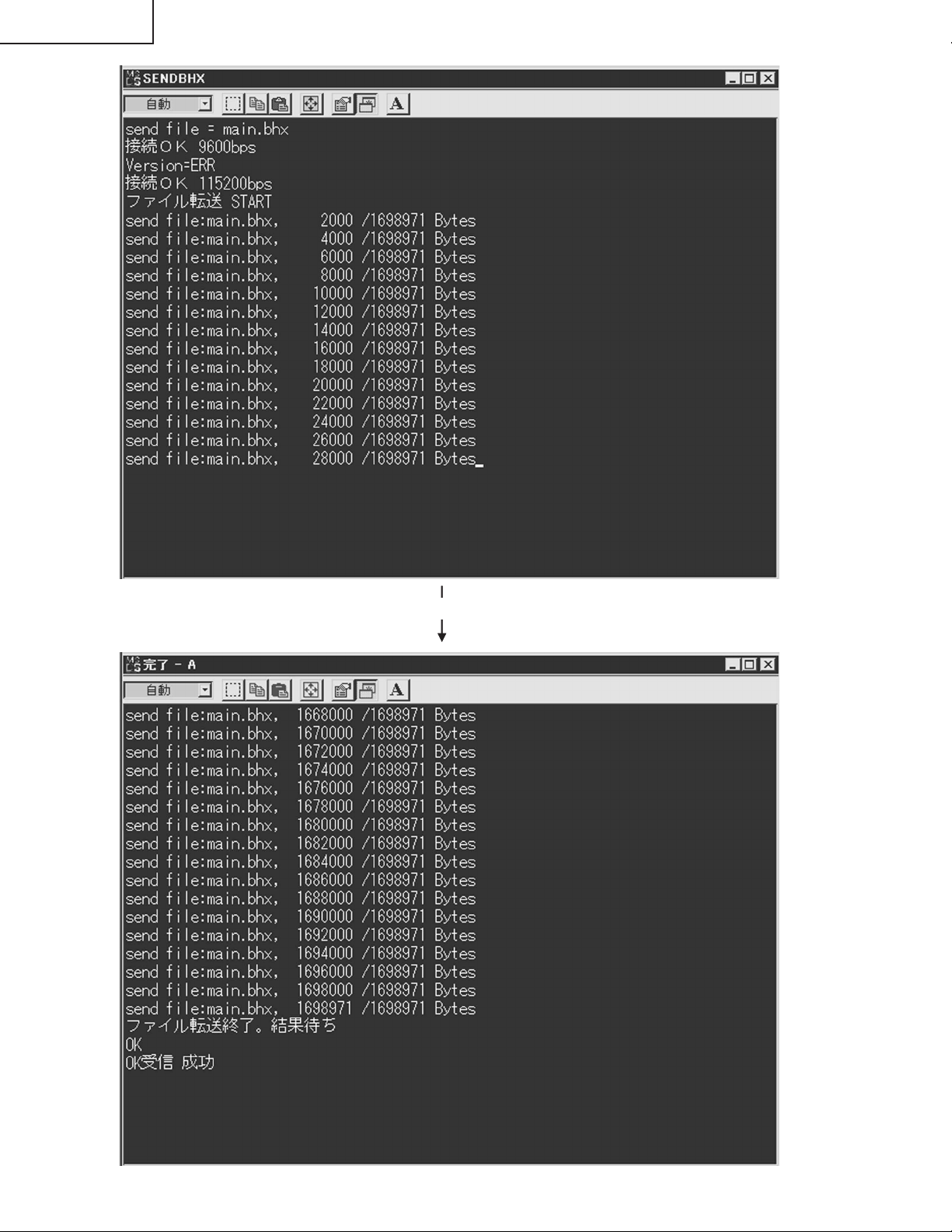

UPGRADING INSTALLED PROGRAMS

Programs installed in the product are mainly divided into the following two categories:

∫ Main programs (for AVC system)

∫ Monitoring program (for display)

CAUTON: Exercise great care to hide the procedure in entering the in-process adjustment mode from the

customer. Inadvertent setting changes in this mode may cause a fatal error resulting in a program being

unrecoverable.

[Tools required]

∫ PC

A Windows 95/98/me/2000/XP PC that has a COM port (RS-232C).

A USB-R232C converter will be acceptable provided that it is appropriately set and has PC compatibility.

∫ RS-232C cross cable

Interlink cable is also acceptable.

[Preparations]

Rewriting a program needs the product to enter the in-process adjustment mode.

1) The re writing software is supplied in the f orm of an exe file named e.g., "MAIN_2002_10_10A.exe" (provisional).

Create a directory on a HD and copy the software into the directory.

2)Double-click the file. The file will be self-extracted. Check the extracted file against the documentation

accompanying with the software.

3) Connect the AVC System and the display unit with each other and make them ready f or operation (make sure

the power LEDs of the AVC System and display unit turn red).

4) Use an RS-232C cable to connect the PC to the AVC System.

5) Exercise great care to hide the procedure in entering the in-process adjustment mode from the customer.

Press the MAIN POWER button while holding down the volume DOWN key and the INPUT key on the display

unit simultaneously.

If blue characters appear on the display, the system has entered the in-process adjustment mode successfully.

If not (the normal activation screen opens), retry.

[Rewriting the main program]

1) In the in-process adjustment mode, press the Channel Up key on the remote controller. You will move to page

("13/13" will appear on the upper left corner of the screen).

2) Make sure CENTER PROG UPDATE on page 13/13 is highlighted.

(It checks that "CENTER PROG UPDATE" on page 13/13 is chosen.)

3) Use the VOLUME -/+ keys to change OFF to ON.

4) Press the ENTER key on the remote controller. Characters on the screen will disappear and the screen blacks

out.

5) Double-click the batch file specified in the document accompanying with the software.

6) A black window (MS-DOS window) will open and rewriting starts automatically.

Rewiring of the main program is now complete. Unplug the AC cord from the AVC System and turn off the

system and then on again.

7) Enter the in-process adjustment mode and make sure the version information on the CENTER Version, OSD

Version and CVIC Version lines on page 1/13 has been updated.

27

Page 28

LC-30HV4E

Continued

28

Page 29

LC-30HV4E

ADJUSTMENT PROCEDURES (DISPLAY)

See "Adjusting mode" for the steps to go into adjustment process mode.

NOTE: When IC2203 is replaced, it is needed to Initialization first then Background adjustment and Common bias

adjustment.

1) +B adjustment (Digital PWB: R4648)

1. Receive PAL standard color bar signal.

2. Connect digital voltmeter to TP4602 and adjust to the specified value.

Specification: 13.00 ± 0.05V

2) Common bias adjustment

Make this adjustment each for "50 Hz", "60 Hz" and "PC". Select the input signal according to the indication onscreen.

1. Go to "Adjustment process mode".

2. On the LCD, select "14" of "PATTERN 1", dot inversion flicker pattern 2.

3. Then, select "COM BIAS" on the LCD.

4. Set the value so that the flicker on the screen is minimized.

Note: Apply this adjustment after for at least 30 min.

3) Background adjustment

1. Select video standard, and confirm the indication that the unit is preset to the standard.

2. At video input, receive the window pattern signal having left 80% WHITE and right 20% WHITE.

3. Set the screen size to the full mode.

4. Go to "Adjustment process mode".

5. Adjust "R OFFSET", "G OFFSET" and "B OFFSET" in "SIL861" so that left side 80% WHITE window pattern is

set to the specified value.

6. Adjust "R GAMMA", "G GAMMA" and "B GAMMA" in "SIL861" so that right side 20% WHITE window pattern is

set to the specified value.

Specification: x = 0.275 y = 0.273 (80% WHITE) x= 0.269 y = 0.253 (20% WHITE) [Minolta CA-110]

Note: Apply this adjustment after for at least 30 min.

4) Initialization

1. Go to "Adjustment process mode".

2. Select "1" thru "3" of "CLR MODE" in "TEST".

Setting range: 0 Normal

1 Initial setting (User clear: Factory setting)

2 Initial setting (All clear) Full initialization of EEPROM (except for ROM area)

3 Full initialization of Configuration EEPROM

3. Move the cursor down by one line.

4. Press "VOL UP" key and change the display from "WAIT" to "SEND" (write).

5. Do not shut down power while the display is "SEND".

6. When the writing is finished, the display changes from "SEND" to "WAIT".

5) Resetting lamp error counter

1. Go to "Adjustment process mode".

2. Select "L ERR RESET" in "TEST".

3. Reset the data to "0".

[L ERR RESET]

Function: Reset of fluorescent lamp error counter

It resets the times of fluorescent lamp errors and clears the last value in the memory.

Indication range: 0-5 (Fluorescent lamp errors)

(When lamp error exceeds 5 times, power supply is disabled. Resetting is required in this case.)

29

Page 30

LC-30HV4E

3.

Adjusting Mode

1. Overview

The controller IC can be adjusted in this mode.

Adjustment is done while controlling the setting of the resistor corresponding to the selected adjustment item.

When monitor is used independently, it is adjusted using the OSD simple display function incorporated in LCD

controller.

The OSD function of panel link receiver (SIL861) is used for adjustment of the independent monitor.

2. Entry to the mode

1) When cable is not connected (independent mode), follow the steps below.

a) When power switch is turned on, press the main unit INPUT and VOL DOWN keys simultaneously.

b) Press the remote controller's process adjustment key (R/C code: 40h) / process adjustment mode 2 key (R/

C code: 31h).

2) When not in independent mode, follow the steps below.

a) When power switch is turned on, press the main unit CH DOWN and VOL UP keys simultaneously.

b) Press the remote controller's process adjustment mode 2 key.

3. Exit from the mode

Turn off the power.

Press the remote controller's process adjustment mode 2 key.

4. Display

1) First layer display

The third line shows the title. The 5th line and below show the items. Microprocessor's version number

appears in the 16th line.

Example) 1.00 → 1 00

1234567891011121314

1SERVICE MODE

2OMODE 50HZ

3LCD

4SIL861

5TEST

6VERXXX

2) Second layer display (Adjustment item display)

A single page shows up to 10 adjustment items (or 14 lines).

The third line shows the title and the screen mode selected in MODE items (only when LCD is selected).

The 5th line shows the item. Microprocessor's version number appears in the 16th line.

Example) 1.00 → 1 00

Setting is shown in decimal number.

a) Adjustment on the LCD items

1234567891011121314

1LCD 50HZ

2OVL0 22 1

3REF0 209

4VL64 98

5REF64 170

6VL96 92

7REF96 184

8 VL128 85

9REF128 188

10 VL160 71

11 REF160 199

30

Page 31

b) Adjustment on the TEST items

1234567891011121314

1TEST

2OL ERR RE 0

3LCDDATA0000

4WAIT

5CLRMODE 0

6WAIT

7CNFGEEP0000

8WAIT

5. Changing data

In "adjustment item display", the items pointed by cursor can be changed using VOL UP/DOWN key.(Holding

down the key is effective.)

For the items in "LCD DATA", select the item and hit ENTER key. The ten's digit (leftmost digit) in the address

changes to red (others in green). Data change using VOL UP/DOWN key is enabled.

To move to the next digit, press CH UP key (or rightward cursor key). To go back to the previous digit, press CH

DOWN key (or leftward cursor key). Thus, 4 digits data can be entered.

When CH UP key is pressed while in rightmost digit, the cursor mov es to the leftmost digit. When CH DOWN key

is pressed while in leftmost digit, the cursor moves to the rightmost digit.

After address data adjustment, press ENTER key to exit from 4-digit adjustment and change the entire "LCD

DATA" line to red letters. (Same status as item selection)

LC-30HV4E

6. Key operation

1) Basic behaviors

Basic key behaviors are as follows.

Behavior Keys

Remote controller Main unit

Upward cursor movement Cursor up CH UP

Downward cursor movement Cursor down CH DOWN

Rightward cursor movement Cursor right

Leftward cursor movement Cursor left

Data UP VOL UP VOL UP

Data DOWN VOL DOWN VOL DOWN

Set ENTER INPUT

Back to previous layer RETURN

Back (In bottom layer only) ENTER INPUT

2) Data UP/DOWN

For the item for which OSD display is available, switch the display.

Adjust the data with UP/DOWN operation. (Any value beyond the limit is replaced by the limit value.)

Output data processing

Data transmission for every UP/DOWN operation (Data related to peripheral controller IC)

Execution of the last memory data when key is off

While the key is held down, the second step is performed approx. 500ms after the key operation and, after this,

every single step of UP/DOWN is carried out sequentially at 135ms interval.

3) Cursor UP/DOWN

Select the adjustment item by pointing it with the cursor.

When upward cursor movement is done while the cursor is at the top item, the cursor goes to the bottom item.

(In the case of multiple pages, the cursor goes to the bottom item on the previous page.)

When downward cursor mov ement is done while the cursor is at the bottom item, the cursor goes to the top item.

(In the case of multiple pages, the cursor goes to the top item on the next page.)

While the key is held down, the second step is performed approx. 500ms after the key operation and, after this,

every single step of UP/DOWN is carried out sequentially at 135ms interval.

31

Page 32

LC-30HV4E

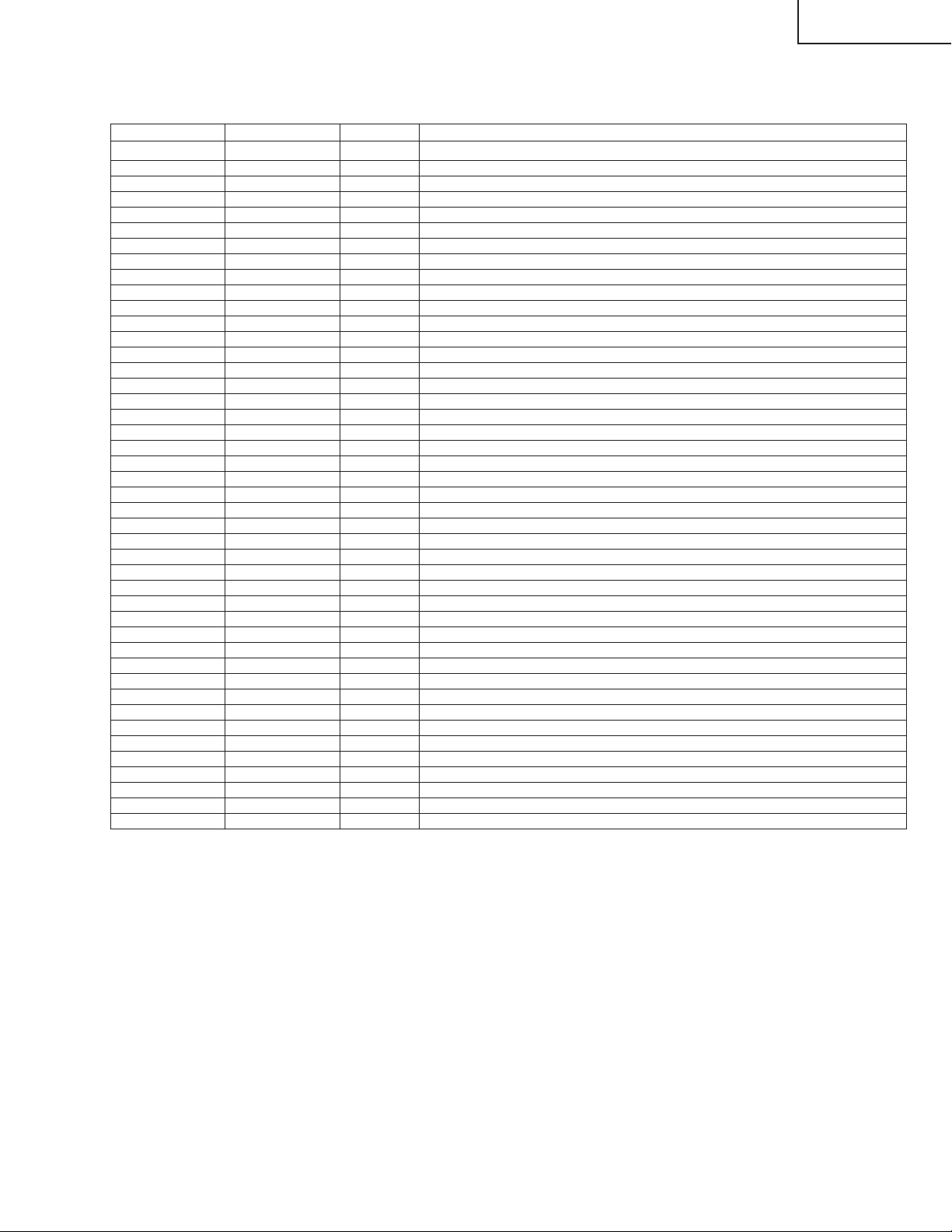

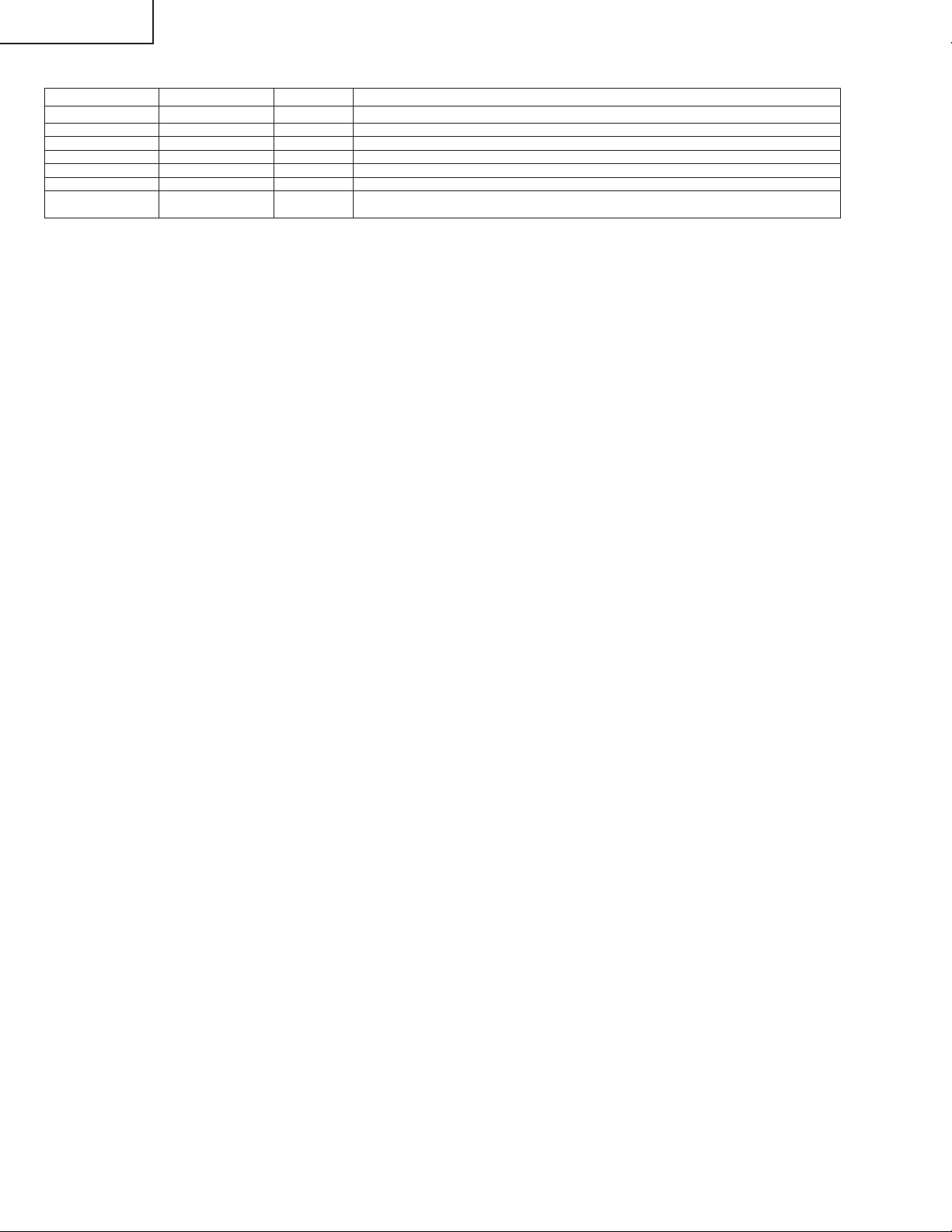

ADJUSTMENT MODE MENU LIST

First layer item PAGE ITEM SETTING RANGE INITIAL VALUE DATA SETTING

MODE 1 50HZ/60HZ/PC 50HZ Toggle

LCD 1 VL0 0 ~ 255 221 No Toggle

REF0 0 ~ 255 209 No Toggle

VL64 0 ~ 255 98 No Toggle

REF64 0 ~ 255 170 No Toggle

VL96 0 ~ 255 92 No Toggle

REF96 0 ~ 255 184 No Toggle

VL128 0 ~ 255 85 No Toggle

REF128 0 ~ 255 188 No Toggle

VL160 0 ~ 255 71 No Toggle

REF160 0 ~ 255 199 No Toggle

2 VL192 0 ~ 255 77 No Toggle

REF192 0 ~ 255 103 No Toggle

VL224 0 ~ 255 88 No Toggle

REF224 0 ~ 255 112 No Toggle

VL256 0 ~ 255 108 No Toggle

REF256 0 ~ 255 78 No Toggle

COM BIAS 0 ~ 255 70 No Toggle

PWM CTRL 0 ~ 7 Toggle

PWM FREQ 0 ~ 4095 585 No Toggle

PWM DUTY 0 ~ 4095 0 No Toggle

3 PATTERN1 0 ~ 14 0 Toggle

PATTERN2 0 ~ 12 0 Toggle

P – CLK1 0 ~ 3 0 No Toggle

P – CLK2 0 ~ 7 0 No Toggle

OS SW 0 ~ 1 0 Toggle

OS D1 0 ~ 255 138 No Toggle

OS D2 0 ~ 255 167 No Toggle

OS D3 0 ~ 255 170 No Toggle

OPC LV0 0 ~ 85 0(40) No Toggle

OPC LV1 0 ~ 85 8(44) No Toggle

4 OPC LV2 0 ~ 85 16(48) No Toggle

OPC LV3 0 ~ 85 24(52 )No Toggle

OPC LV4 0 ~ 85 32(56) No Toggle

OPC LV5 0 ~ 85 40(60) No Toggle

OPC LV6 0 ~ 85 48(64) No Toggle

OPC LV7 0 ~ 85 56(68) No Toggle

OPC LV8 0 ~ 85 64(72) No Toggle

OPC LV9 0 ~ 85 72(76) No Toggle

OPC LV10 0 ~ 85 80(80) No Toggle

SIL861 1 R GAMMA 20 ~ 180 100 No Toggle

R OFFSET 0 ~ 510 256 No Toggle

G GAMMA 20 ~ 180 100 No Toggle

G OFFSET 0 ~ 510 256 No Toggle

B GAMMA 20 ~ 180 100 No Toggle

B OFFSET 0 ~ 510 256 No Toggle

TEST 1 L ERR RESET 0 ~ 5 0 Toggle

LCD DATA Four digits 0 ~ F 0 Toggle

WAIT/SEND WAIT ———

CLR MODE One digits 0 ~ 2 0 Toggle

WAIT/SEND WAIT ———

CNFG EEP Four digits 0 ~ F 0 Toggle

WAIT/SEND WAIT ———

* Values in the parentheses are with PC.

32

Page 33

LC-30HV4E

MAJOR IC FUNCTIONS INFORMATIONS

∫ IC2501 (MSP4418G)

IC for decoding audio signals.

It serves as an S-IF audio signal decoder and an audio data selector.

∫ IC2510 (IXA385WJ)

IC for controlling audio delay.

LC-30/37HV4E uses a frame buffer to process video signals. This results in delay in outputting video signals.

The IC delays output of audio signals to synchronize output of video and audio signals.

∫ IC1301 (CXA2069Q)

7-input, 3-output selector.

This IC selects all audio and video signals received from input terminals and the tuner, except those signals

that relates to PC and components.

Video signals delivered to the IC are sent to YC separation circuits IC401 (main) and IC402 (sub). Audio

signals are sent to the SR unit via IC2501 (sound processor).

∫ IC1401 (MM1519XQ)

4-input, 3-output video selector for component input.

This IC receives AV3 component input, AV1/3 RGB input and teletext RGB signals. Its output is for main, sub

and component.

∫ IC1601 (SDA5550M)

Teletext processing micro-processor.

This IC receives vide signals, decodes teletext and outputs data in RGB format.

∫ IC401/IC402 (TC90A69)

Adaptive in-field comb filter supporting both the NTSC and PAL systems. Equipped with CNR circuit, the 3-line

digital comb filter is a high-precision Y/C single chip, which provides Y/C separation of sub image signals

received from IC1301.

∫ IC403/IC404 (ML6428C1)

6.7 MHz low-pass filter.

33

Page 34

LC-30HV4E

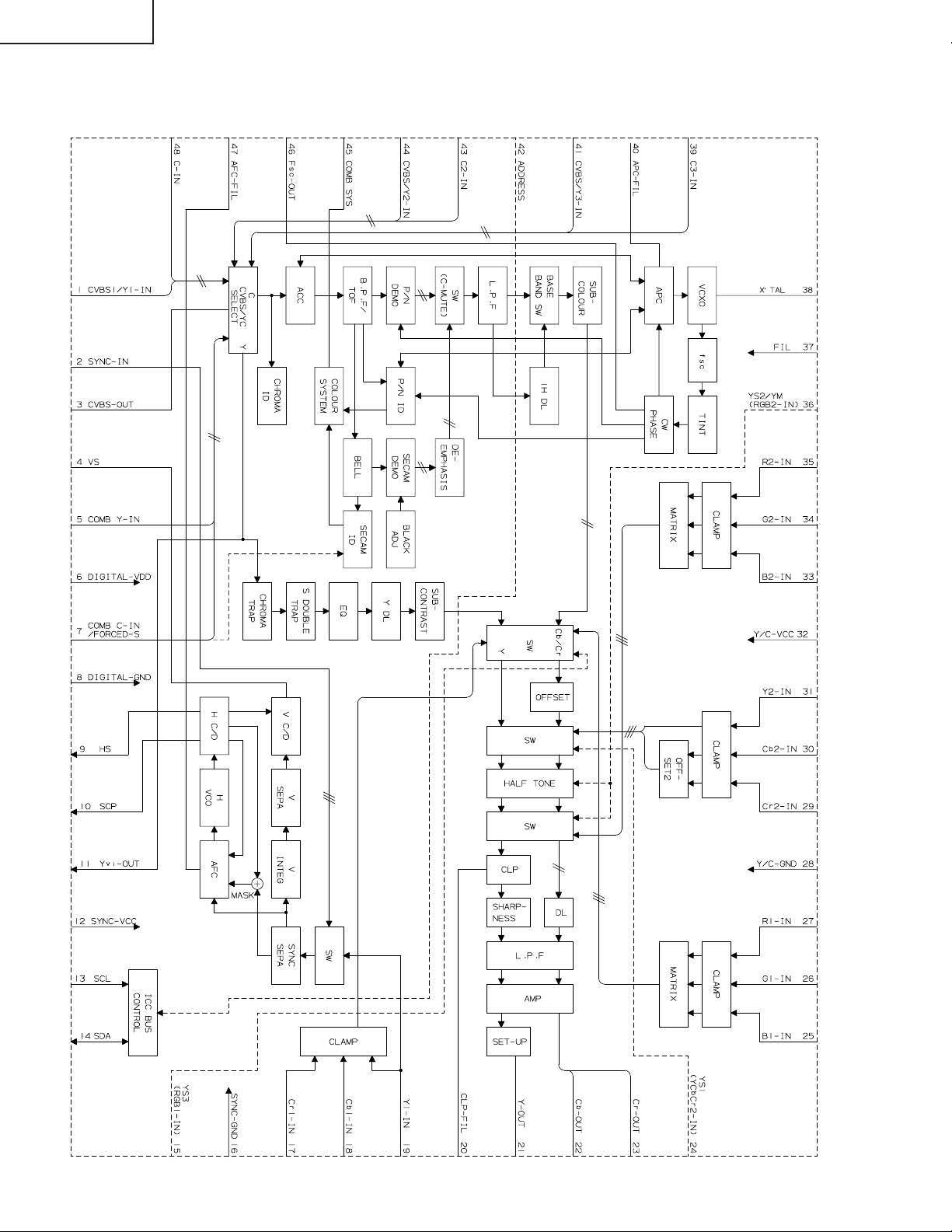

∫ IC801/IC802 (TB1274AF)

IC for synchronous processing of video and chroma demodulation for PAL/NTSC/SECAM colour TV.

Color demodulation is provided by a high-perf ormance image compensation circuit in the video section, a PAL/

NTSC/SECAM auto discrimination circuit in the chroma section, and a crystal that generates 4.43 MHz, 3.58

MHz and M/N-PAL clock signals.

This IC has a 4-channel YC signal input, 2-channel RGB signal input, and 2-channel chrominance signal input.

It receives main and sub chrominance signals from IC401 (main) and IC402 (sub) and delivers chrominance

signals via one-channel output.

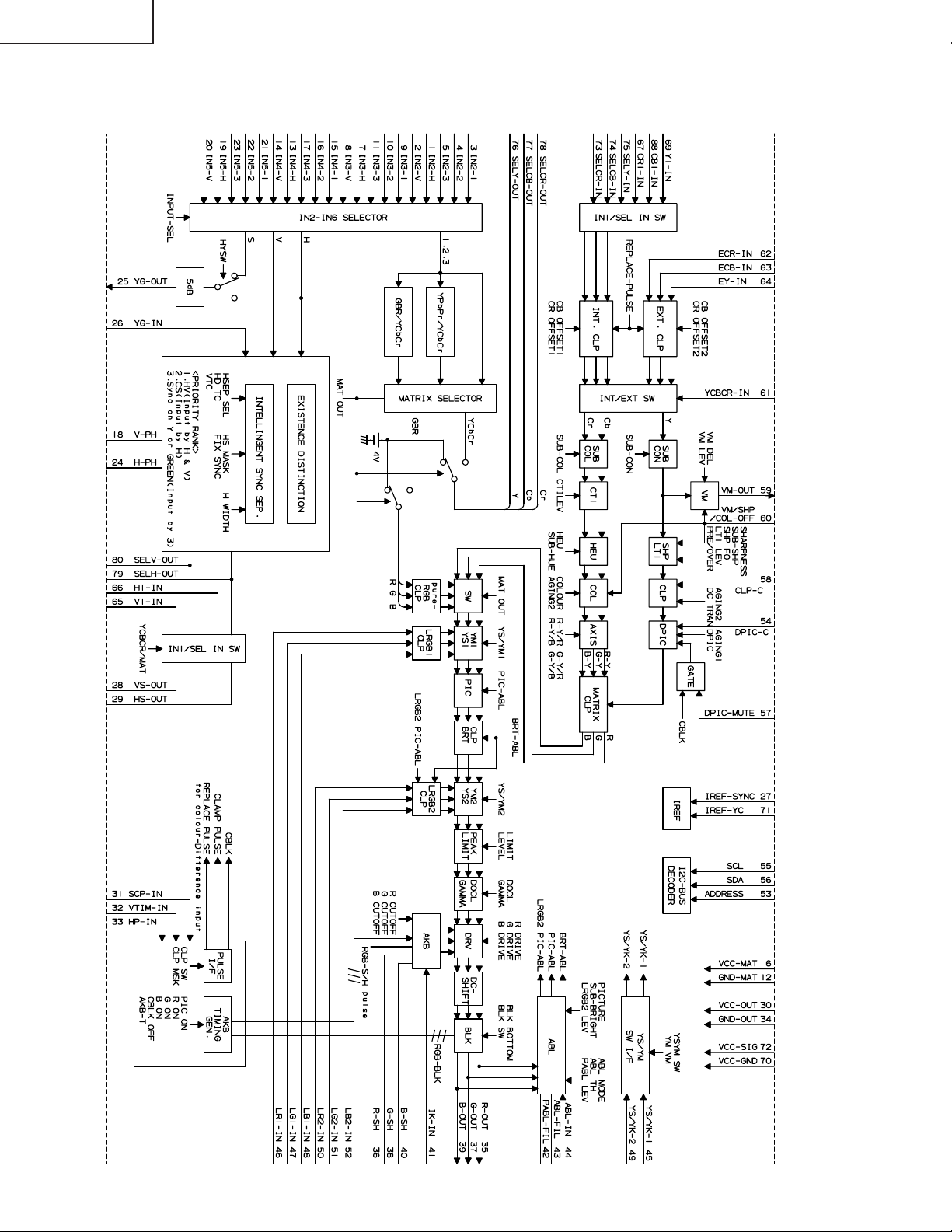

∫ IC803 (CXA2101Q)

IC having a component input integrated with a high-performance image compensation circuit. Equipped with

circuits for processing baseband signals and RGB signals and a 4-channel video switch incorporating an H/V

synchronization signal processing circuit.

Input selection is done by INPUT-SEL (IIC BUS). Y, Pb, Pr and GBR of Ycb, Cr and HD and their H/V

synchronization signals are inputted to input pins of each channel.

Multi-scan facility permits acceptance of a horizontal scan line frequency range of 15 KHz to 60 KHz.

∫ IC1901 (IXA392WJ)

FPGA for synchronous processing

This IC selects synchronization signals and creates horizontal blanking signals.

∫ IC604 (TA1318AF)

IC for synchronous processing of TV component signals and measurement of frequency.

This IC incorporates an input signal frequency measurement feature and synchronous regeneration features.

It supports synchronous horizontal regeneration (15.75 kHz, 31.5 kHZ, 33.75 kHz and 45 kHz) and synchronous

vertical regeneration (525i, 525P, 625i and 750P).

34

Page 35

LC-30HV4E

» PC I/F unit

∫ IC10004 (CX3506R)

3-channel, 8-bit, 120 MSPS A/D converter incorporating AMP and PLL.

This IC is for video signals inputted to the PC I/F unit and used for one-screen and two-screen applications,

and for PC signals inputted to the front panel.

It provides A/D conversion of video signals (analog RGB) inputted to IN1 from CN10006 and PC signals

(analog RGB) inputted to IN2 from CN10008.

Converted digital signals are sent to IC10025.

∫ IC10310 (TLC5733A)

3-channel, 8-bit, 20 MSPS A/D converter.

This IC is for video signals inputted to the PC I/F unit and used for two-screen application.

It provides A/D conversion of video signals (analog YcbCr) inputted to IC10310 from CN10006.

Converted digital signals are sent to IC10025.

∫ IC10025 (IXA091WJ)

IC for I/P conversion and scaling of digital image according to the output resolution, and for data conversion.

There are two input channel: V0 and V1. V1 is for sub 480i/580i input processing for two-screen application. V0

is for processing all signals for main used for one and two-screen applications.

The IC generates clamp signals based on input synchronization signals.

It also performs data matrix conversion, and creates OSD signals.

Processed signals are sent to IC10413.

∫ IC10413 (SII170)

Panel link transmitter.

This IC converts 8-bit RGB image data received from IC10025 into TMDS differential signals and sends to the

display.

(Note:When replace this IC, PWB replacement correspondece.)

∫ IC10001 (IX3270CE)

One-chip RISC microprocessor.

This IC communicates with the monitor and controls the system operation.

It controls all the ICs located in the AVC system.

∫ IC10405 (µPD4721G)

RS-232 line driver/receiver conforming to EIA/TIA-232-E.

This IC enables the system to be controlled from a PC connected to the system.

It also allows IC10001 to be upgraded using the PC.

35

Page 36

LC-30HV4E

ËVHiMSP4418G-1Q (ASSY:IC2501)

Multi Sound Processor

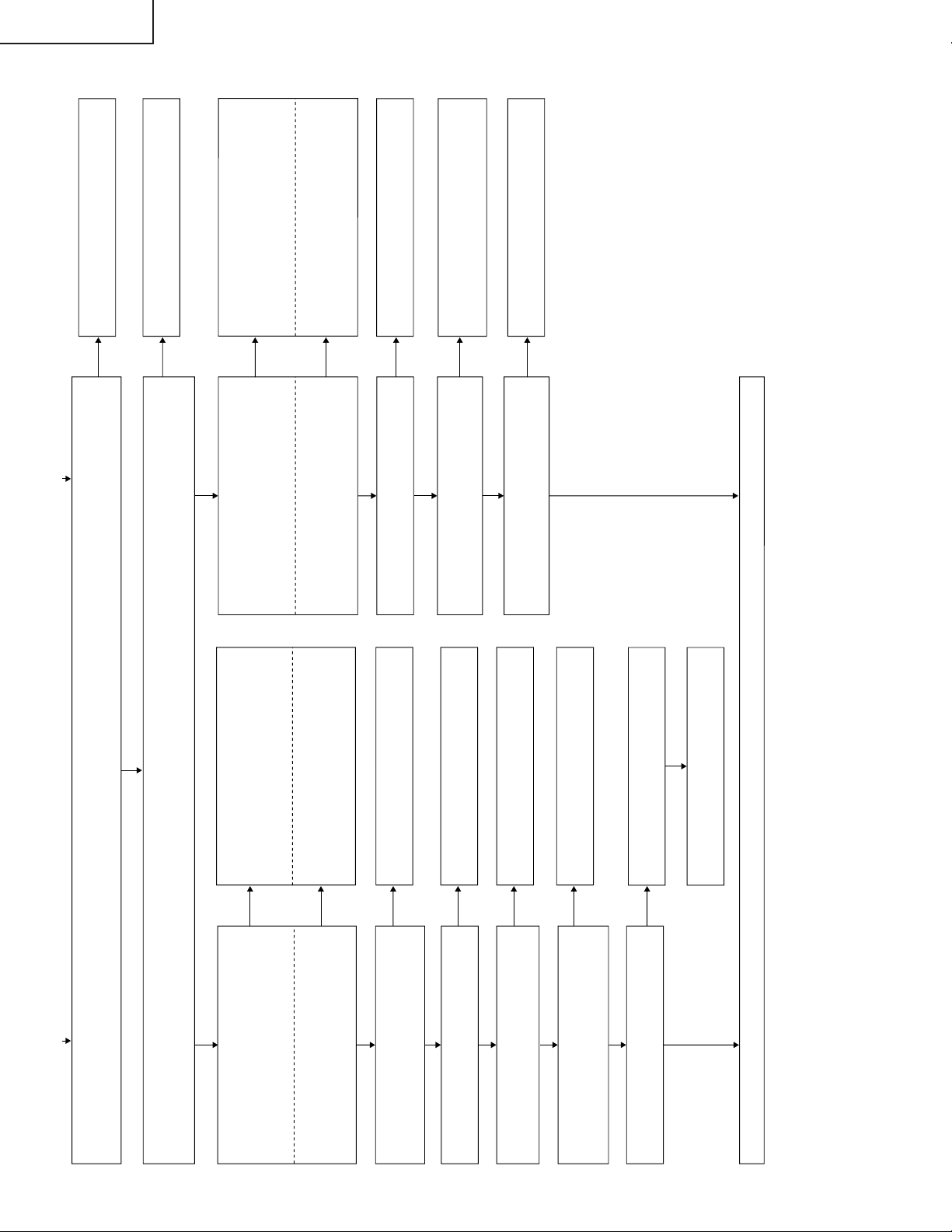

»Block diagram

36

Page 37

» Pin mapping

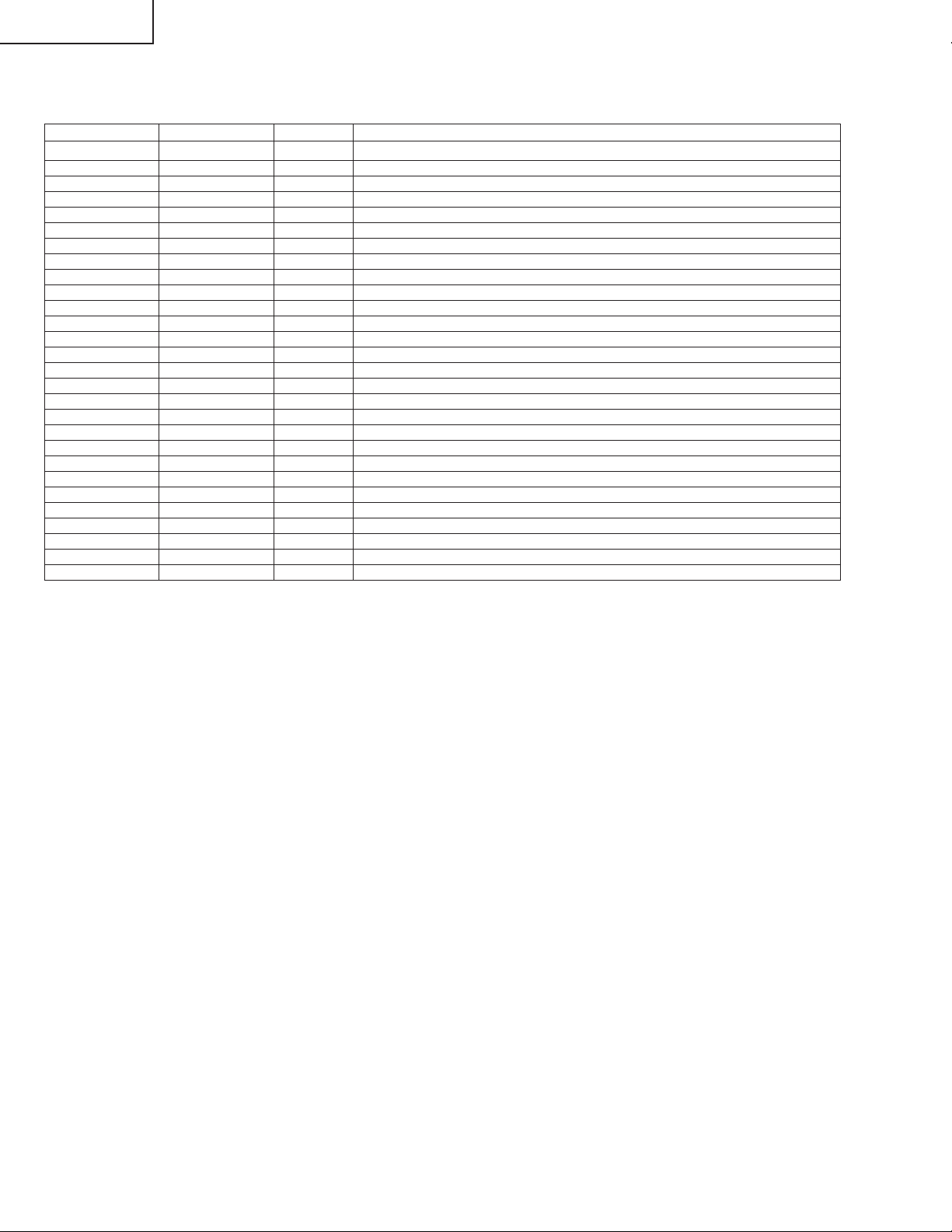

Pin No. Pin Name Type Description

1 NC –– Not connected

2 I2C_CL I/O I2C clock

3 I2C_DA I/O I2C data

4 I2S_CL I/O I2S clock

5 I2S_WS I/O I2S word strobe

6 I2S_DA_OUT O I2S data output

7 I2S_DA_IN1 I I2S1 data input

8 ADR_DA O ADR data output

9 ADR_WS O ADR word strobe

10 ADR_CL O ADR clock

11, 12, 13 DVSUP –– Digital power supply 5V

14, 15, 16 DVSS –– Digital ground

17 I2S_DA_IN2 I I2S2-data input

18 NC –– Not connected

19 I2S_CL3 I I2S3 clock

20 I2S_WS3 I I2S3 word strobe

21 RESETQ I Power-on-reset

22 I2S_DA_IN3 I I2S3-data input

23 NC –– Not connected

24 DACA_R O Headphone out, right

25 DACA_L O Headphone out, left

26 VREF2 –– Reference ground 2

27 DACM_R O Loudspeaker out, right

28 DACM_L O Loudspeaker out, left

29, 30, 31, 32 NC –– Not connected

33 SC2_OUT_R O SCART 2 output, right

34 SC2_OUT_L O SCART 2 output, left

35 VREF1 –– Reference ground 1

36 SC1_OUT_R O SCART 1 output, right

37 SC1_OUT_L O SCART 1 output, left

38 CAPL_A –– Volume capacitor AUX

39 AHVSUP –– Analog power supply 8V

40 CAPL_M –– Volume capacitor MAIN

41,42 NC –– Not connected

43,44 AHVSS –– Analog ground

45 AGNDC –– Analog reference voltage

46 NC –– Not connected

47 SC4_IN_L I SCART 4 input, left

48 SC4_IN_R I SCART 4 input, right

49 ASG –– Analog Shield Ground

50 SC3_IN_L I SCART 3 input, left

51 SC3_IN_R I SCART 3 input, right

52 ASG –– Analog Shield Ground

53 SC2_IN_L I SCART 2 input, left

54 SC2_IN_R I SCART 2 input, right

55 ASG –– Analog Shield Ground

56 SC1_IN_L I SCART 1 input, left

57 SC1_IN_R I SCART 1 input, right

58 VREFTOP –– Reference voltage IF A/D converter

59 NC –– Not connected

60 MONO_IN I Mono input

61, 62 AVSS –– Analog ground

63, 64 NC –– Not connected

65, 66 AVSUP –– Analog power supply 5V

67 ANA_IN1+ I IF input 1

68 ANA_IN- I IF common(can be left vacant, only if IF input 1 is also not in use)

69 ANA_IN2+ I IF input 2(can be left vacant, only if IF input 1 is also not in use)

70 TESTEN I Test pin

71 XTAL_IN I Crystal oscillator

72 XTAL_OUT O

73 TP –– Test pin

74 AUD_CL_OUT O Audio clock output(18.432MHz)

75, 76 NC –– Not connected

77 D_CTR_I/O_1 I/O D_CTR_I/O_1

78 D_CTR_I/O_0 I/O D_CTR_I/O_0

79 ADR_SEL I I2C Bus address select

80 STANDBYQ I Stand-by(low-active)

LC-30HV4E

37

Page 38

LC-30HV4E

ËVHiCXA2069Q-1 (ASSY:IC1301)

S2-compatible 7-input, 3-output AV switch

»Block diagram

38

Page 39

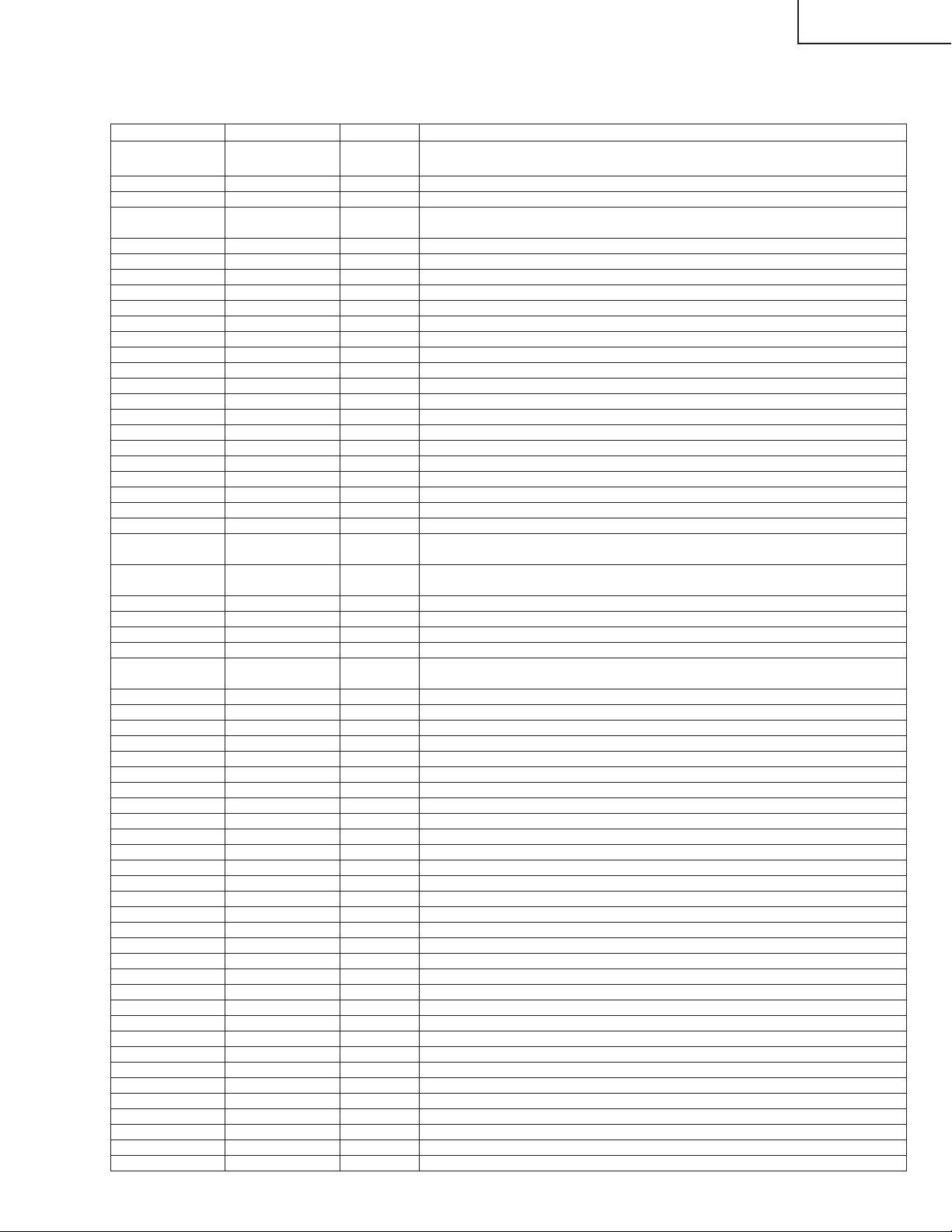

» Pin mapping

Pin No. Pin Name Type Description

63 TV I Video signal input

1 V1 I Composite video signal input

8V2 I

15 V3 I

22 V4 I

30 V4 I

60 V4 I

3 Y1 I Y/C separation signal input, used for luminance signal input

10 Y2 I YIN1: Input for signal created by Y/C separation of VOUT1 output

17 Y3 I

24 Y4 I

49 YIN1 I

5 C1 I Y/C separation signal input, used for chrominance signal input

12 C2 I CIN1: Input for signal created by Y/C separation of VOUT1 output

19 C3 I

26 C4 I

51 CIN1 I

62, 2 LTV, LV1 I Audio signal input

9, 16 LV2, LV3 I

23, 29 LV4, LV5 I

59, 64 LV6, RTV I

4, 11 RV1, RV2 I

18, 25 RV3, RV4 I

31, 61 RV5, RV6 I

53 VOUT1 O Video signal output, used for composite vide signal output

41 VOUT3 O

44 V/YOUT2 O Video signal output, controlled via I2C bus and used for composite video signal output

56 YOUT1 O Power or luminance signal output is selected.

39 YOUT3 O Video signal output, used for luminance signal output

58 COUT1 O Video signal output, used for chrominance signal output

47 COUT2 O

37 COUT3 O

52 LOUT1 O Audio signal output

43 LOUT2 O

38 LOUT3 O

54 ROUT1 O

45 ROUT2 O

40 ROUT3 O

6 S2-1 I Used for detection of S2-compatible DC that is superimposed to C signal.

13 S2-2 I 4:3 image signal is selected when voltage less than 1.3V, 4:3 letterbox signal when

20 S2-3 I 1.3V or more 2.5V or less, and 16:9 squeeze signal when voltage less than 2.5V. 4:3

27 S2-4 I image signal is selected when the pins are open because they are pulled down to

GND via 100kΩ.

7 S-1 I Used for selection between composite video signal and S signal.

14 S-2 I Detection result is written to the status register. S signal is selected when voltage more

21 S-3 I than 3.5V, and composite video signal when voltage less than 3.5V. Composite video

28 S-4 I signal is selected when the pins are open because they are pulled down to 5V via

100kΩ.

32 ADR I Used for selection of slave address for I2C bus.

90H is selected when voltage less than 1.5V, and 92H when more than 2.5V.

90H is selected when the pin are open.

33 SCL I I2C bus signal input

34 SDA I I2C bus signal input

36 DC OUT O Used for output of S2-compatible DC that is superimposed to COUT3.

DC superimposition is done by connecting to COUT3 via capacitor. The pin is

controlled via I2C bus.

Connection of 4.7kΩ external resistor provides output impedance of 10±3kΩ that

conforms to S2.

55 TRAP1 I Connected to trap circuit for sub carrier.

46 TRAP2 I

48 MUTE I Mute for audio signal output.

Mute is on when voltage less than 1.3V and off when voltage more than 2.5V.

Mute is off when the pin is open.

50 BIAS I Internal reference bias input.

Connected to GND via capacitor.

LC-30HV4E

39

Page 40

LC-30HV4E

ËVHiMM1519XQ-1 (IC1401)

Component Input Video Switch

»Block diagram

40

Page 41

» Pin mapping

Pin No. Pin Name Type Description

1 VIDEO 1-L1 I D-pin connection line input

2 VIDEO 1-L2 I

3 VIDEO 1-L3 I

11 VIDEO 2-L1 I

12 VIDEO 2-L2 I

13 VIDEO 2-L3 I

21 VIDEO 3-L1 I

22 VIDEO 3-L2 I

23 VIDEO 3-L3 I

4, 14, 39,45, 52, 58 VCC –– Analog power supply (9V)

51 AVCC ––

5 VIDEO 2-Y I Y signal input

15 VIDEO 3-Y I

53 TUNER-Y I

59 VIDEO 1-Y I

24 DGND ––

6, 8, 16, 18, 33,35, GND ––

37, 41, 43, 47, 49,

54, 58, 60, 62

7 VIDEO 2-Pb I Chrominance input

9 VIDEO 2-Pr I

17 VIDEO 3-Pb I

19 VIDEO 3-Pr I

55 TUNER-Pb I

57 TUNER-Pr I

61 VIDEO 1-Pb I

63 VIDEO 1-Pr I

10 VIDEO 2-SW I D-pin connection check switch line input

20 VIDEO 3-SW I

32 MONO-SW I

64 VIDEO 1-SW I

25 ADDRESS I Slave address input

26 SDA I/O I2C bus data input/output

27 SCL I I2C bus clock input

28 DVCC –– Digital power supply (5V)

29 L3 OUT O Monitor output line output

30 L2 OUT O

31 L1 OUT O

34 Pr OUT 3 O Image output

36 Pb OUT 3 O

38 Y OUT 3 O

40 Pr OUT 2 O

42 Pb OUT 2 O

44 Y OUT 2 O

46 Pr OUT 1 O

48 Pb OUT 1 O

50 Y OUT 1 O

LC-30HV4E

41

Page 42

LC-30HV4E

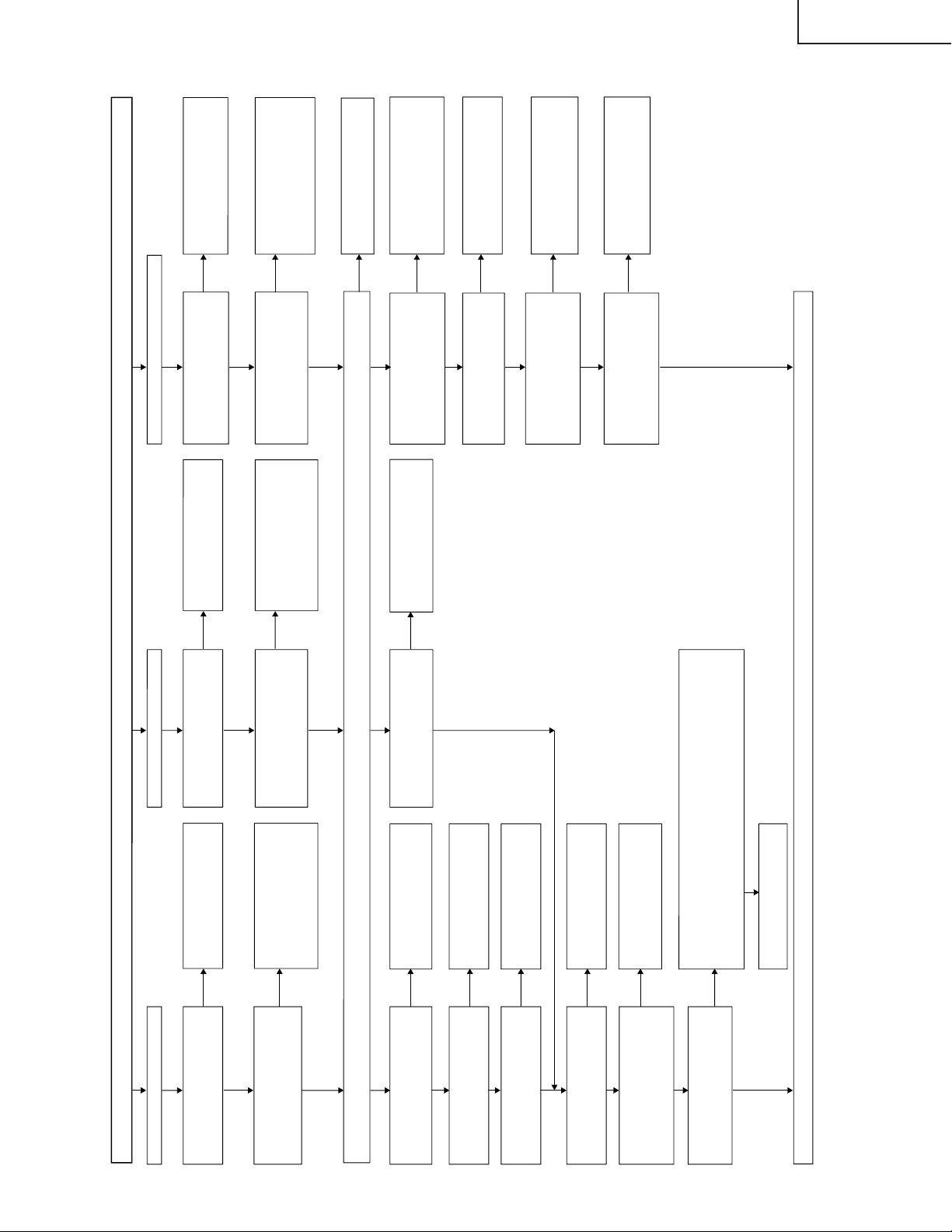

ËVHiTB1274AF-1Q (ASSY:IC801, IC802)

VIDEO/CHROMA Processor

»Block diagram

42

Page 43

» Pin mapping

Pin No. Pin Name Type Description

1 CVBS1/Y1-IN I CVBS1 or Y1-IN signal input

2 SYNC-IN I Synchronization signal input

3 CVBS-OUT O CVBS or Y+C signal output

4 VS O Output of counted-down vertical synchronization signal

5 COMB Y-IN I Input of Y signal outputted from comb filter. Open when not used

6 D-VDD –– 5 VDC power supply to DDS/BUS/V-CD/H-CD block (standard)

7 COMB C-IN I Input of C signal outputted from comb filter. Open when not used

8 D-GND –– GND for DDS/BUS/V-CD/H-CD block

9 HS O Output of horizontal synchronization signal under AFC

10 SCP O Sand castle pulse output.

Clamp pulse and horizontal blanking pulse are outputted.

11 Yvi-IN O Output of synchronous input Y signal selected using video SW

12 SYNC-VCC –– 5VDC power supply to SYNC/HVCO block (standard)

13 SCL I I2C bus SCL input

14 SDA I/O I2C bus SDA output

15 YS3 I Switch for selection between main signal and RGB1 input signal. This input is

(iRGB1-in) operative only when RGB1-ENB is enabled during bus setting.