Page 1

TopPage

LC-26SA1E/RU, LC32SA1E/RU

SERVICE MANUAL

No. S66U9LC26SA1E

LCD COLOUR TELEVISION

LC-26SA1E/RU

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

LC-32SA1E/RU

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRECAUTION

Precautions for using lead-free solder ...............ii

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS .........................................1-1

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL.................................. 2-1

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS ................................................ 3-1

CHAPTER 4. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS

LC-26SA1E/RU..............................................4-1

[2] REMOVING OF MAJOR PARTS

LC-32SA1E/RU..............................................4-5

CHAPTER 5. ADJUSTMENT PROCEDURE

[1] After replacement of any PWB and/or IC for

repair, note the following................................5-1

[2] SOFTWARE UPDATING................................ 5-1

[3] Entering and exiting the adjustment pro-

cess mode.................................................... 5-11

Remote controller key operation and descrip-

[4]

tion of display in adjustment process mode

[5] Adjustment process mode menu..................5-12

[6] Special features............................................5-13

[7] Video signal adjustment procedure..............5-14

[8] White Balance Adjustment...........................5-16

.............i

....... 5-11

[9] QS Temperature NVM Data Con?rmation......5-17

[10] Initialization to factory settings.....................5-17

[11] Lamp error detection ...................................5-18

[12] Public Mode (Hotel Mode)...........................5-18

CHAPTER 6. TROUBLESHOOTING T ABLE

[1] TROBLESHOOTING TABLE.........................6-1

CHAPTER 7. MAJOR IC INFORMATIONS

[1] MAJOR IC INFORMATIONS.........................7-1

CHAPTER 8. OVERALL WIRING DIAGRAM/BLOCK

DIAGRAM

[1] OVERALL WIRING DIAGRAM......................8-1

[2] BLOCK DIAGRAM.........................................8-3

[3] POWER BLOCK DIAGRAM..........................8-5

CHAPTER 9. PRINTED WIRING BOARD

OPERATION UNIT PRINTED WIRING BOARD

[1]

R/C, LED UNIT PRINTED WIRING BOARD

[2]

[3] MAIN UNIT PRINTED WIRING BOARD........9-3

[4] AV UNIT PRINTED WIRING BOARD..........9-11

[5] POWER UNIT PRINTED WIRING BOARD......9-17

[6] TUNER UNIT PRINTED WIRING BOARD......9-21

CHAPTER 10. SCHEMATIC DIAGRAM

DESCRIPTION OF SCHEMATIC DIAGRAM

[1]

[2] SCHEMATIC DIAGRAM..............................10-2

Parts Guide

........9-1

........9-2

......10-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-26SA1E/RU, LC-32SA1E/RU

LC-26SA1E

SAFETY PRECAUTION

Service Manual

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION:

FOR CONTINUED PROTECTION AGAINST A

RISK OF FIRE REPLACE ONLY WITH SAME

TYPE FUSE.

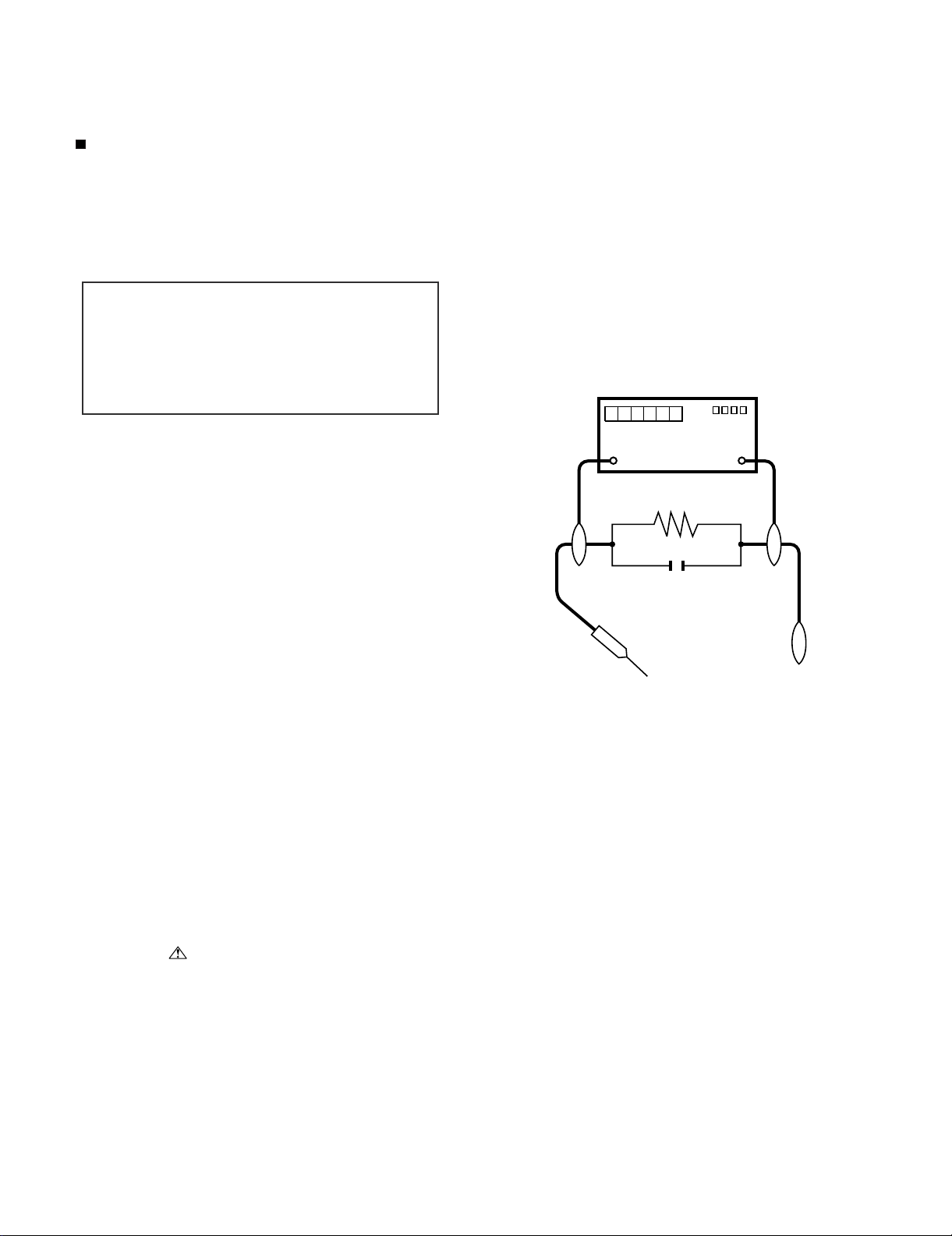

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 1.05 V peak (this corresponds to 0.7 mA peak AC.)

or more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

F701 (4A/250V)

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

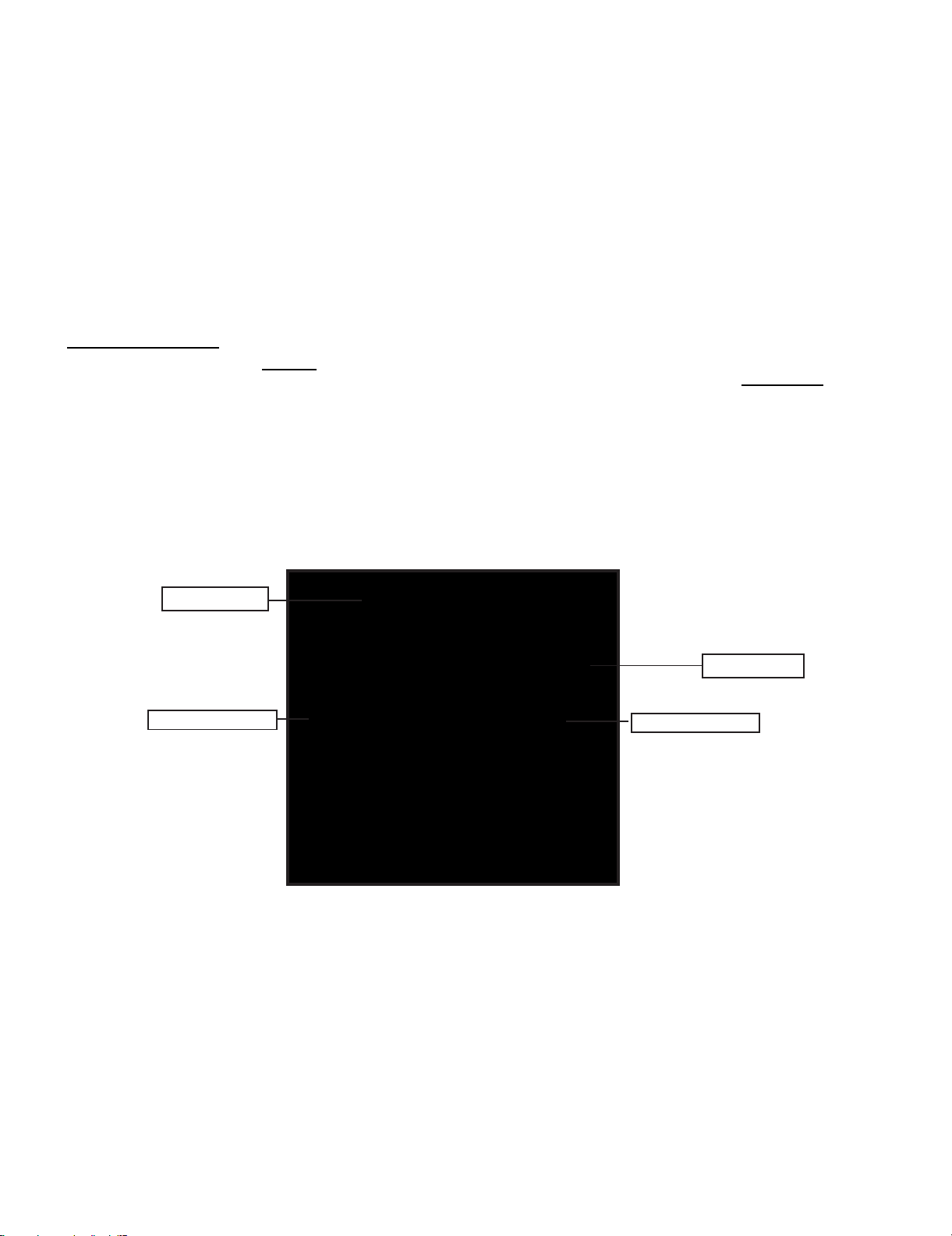

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 220~240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

TO EXPOSED

METAL PARTS

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by “ ” and shaded areas in the Replacement Parts

List and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

DVM

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

i

Page 3

LC-26SA1E/RU, LC-32SA1E/RU

Precautions for using lead-free solder

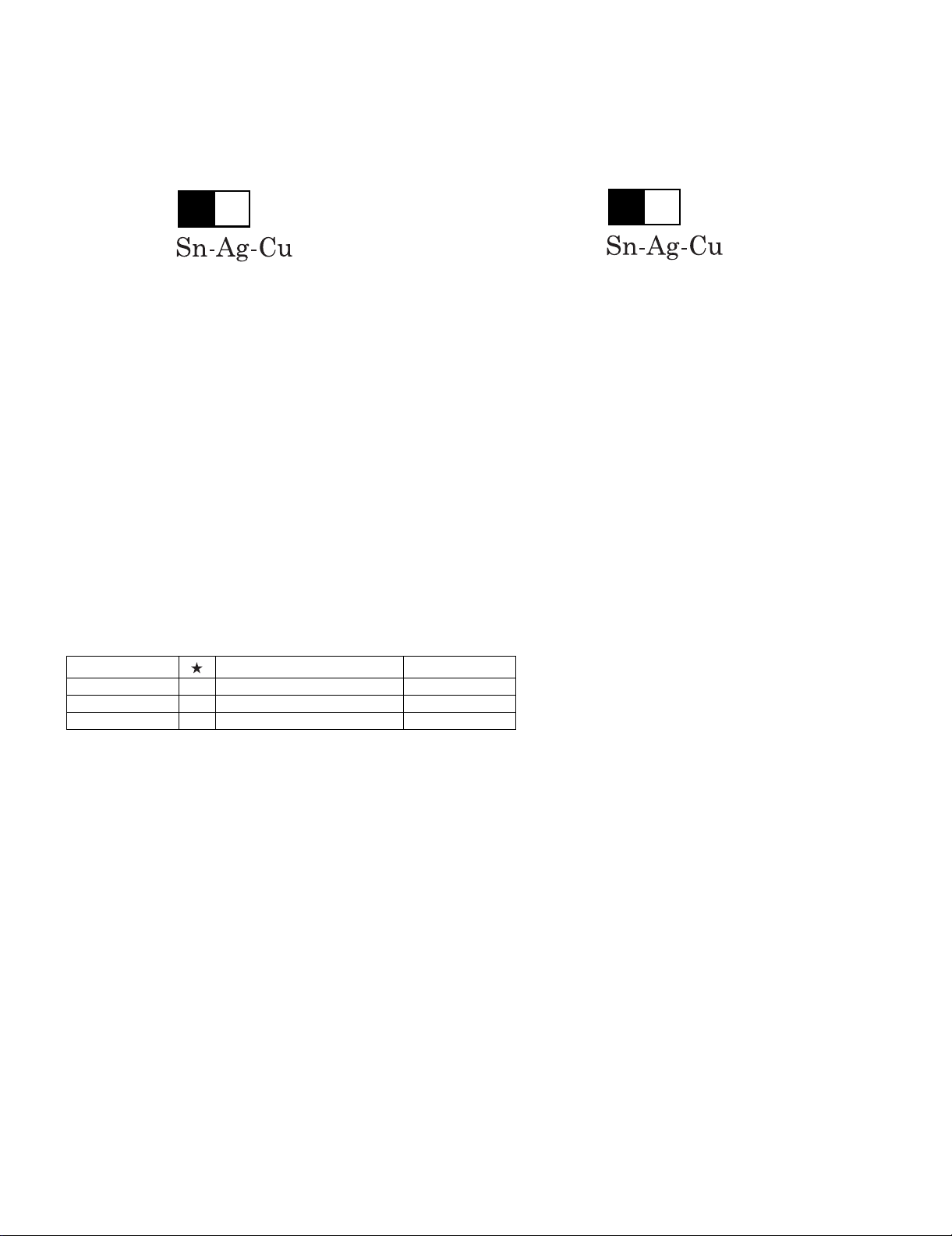

Employing lead-free solder

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Indicates lead-free solder of tin, silver and copper.

L F a/a

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g (1roll) BL

ZHNDAi126500E J φ0.6mm 500g (1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg (1roll) BM

ii

Page 4

LC-26SA1E/RU, LC-32SA1E/RU

LC-26SA1E

CHAPTER 1. SPECIFICATIONS

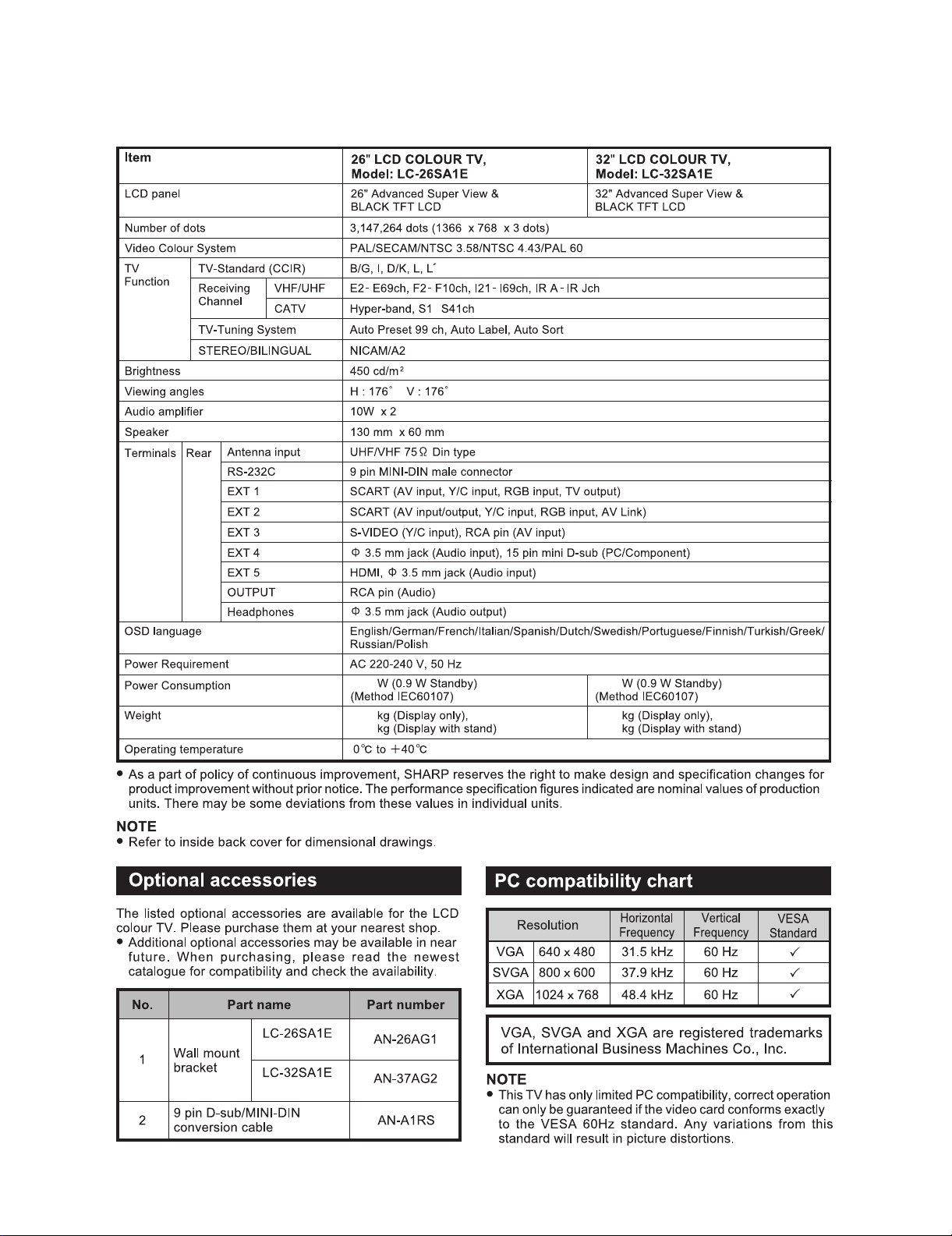

[1] SPECIFICATIONS

Service Manual

/RU /RU

-

102

13.0

15.2

125

17.9

20.1

1 – 1

Page 5

LC-26SA1E

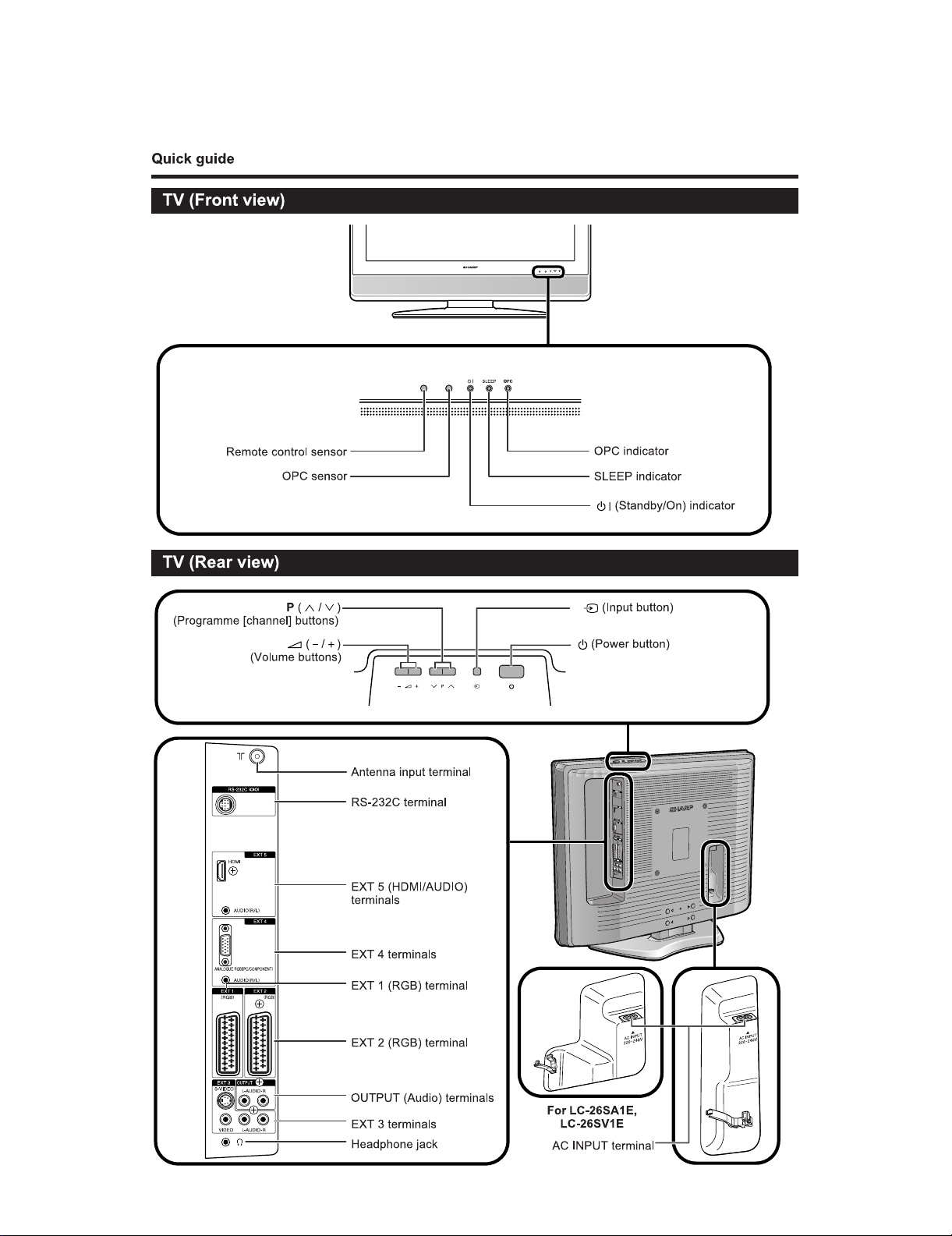

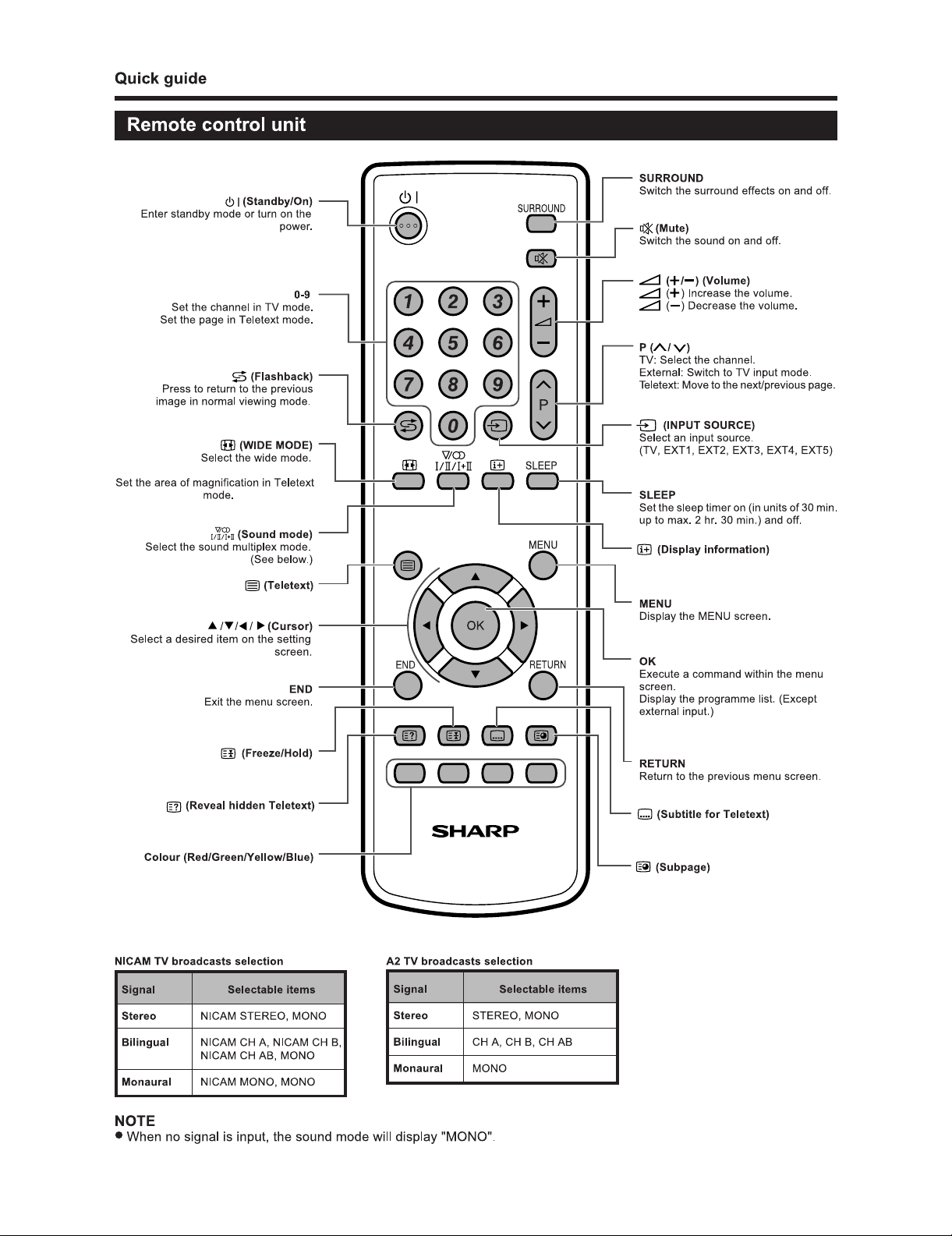

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL

LC-26SA1E/RU, LC-32SA1E/RU

Service Manual

2 – 1

Page 6

LC-26SA1E/RU, LC-32SA1E/RU

2 – 2

Page 7

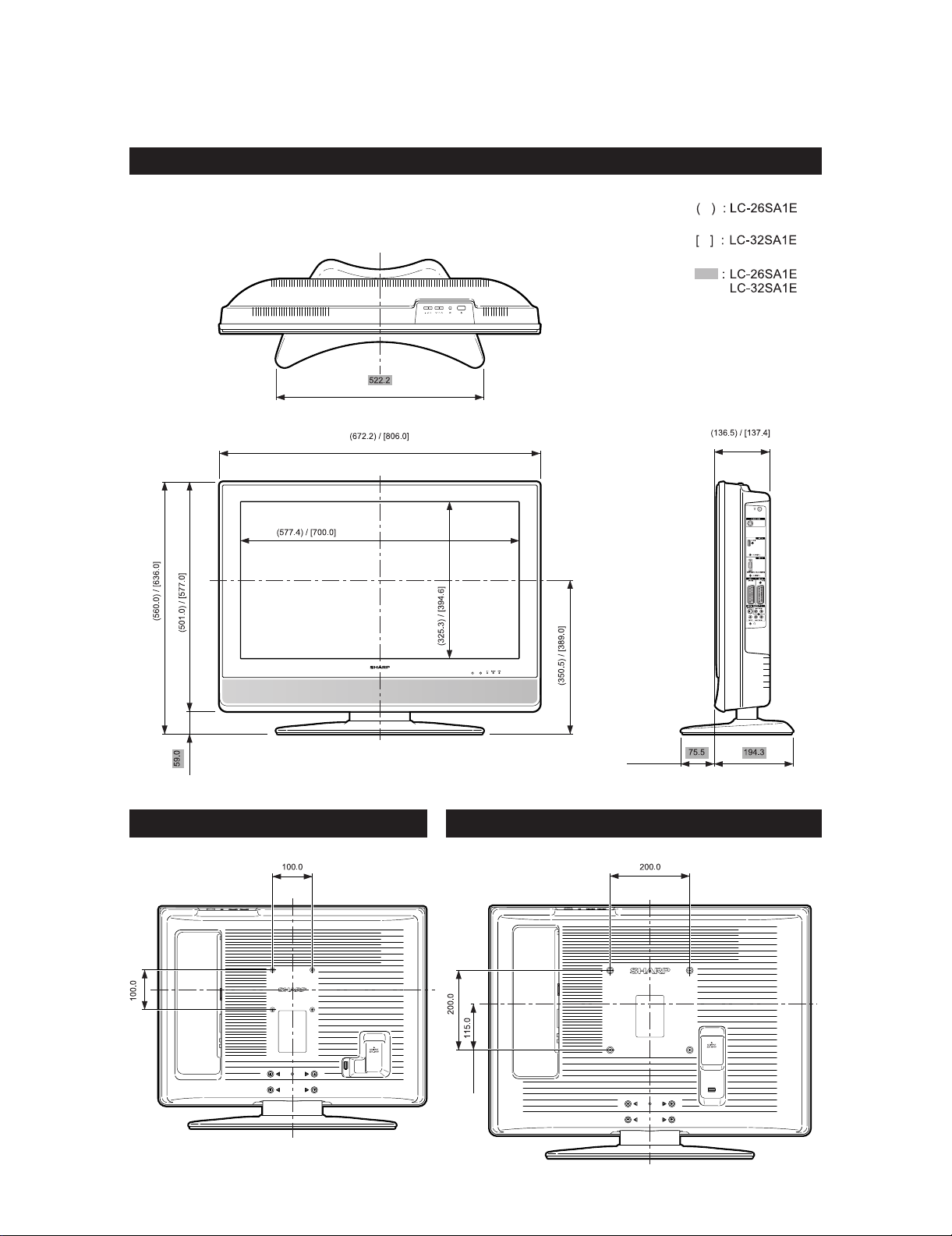

LC-26SA1E

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS

LC-26SA1E/RU / LC-32SA1E/RU

LC-26SA1E/RU, LC-32SA1E/RU

Service Manual

/RU

/RU

/RU

/RU

LC-26SA1E/RU

LC-32SA1E/RU

3 – 1

Page 8

LC-26SA1E/RU, LC-32SA1E/RU

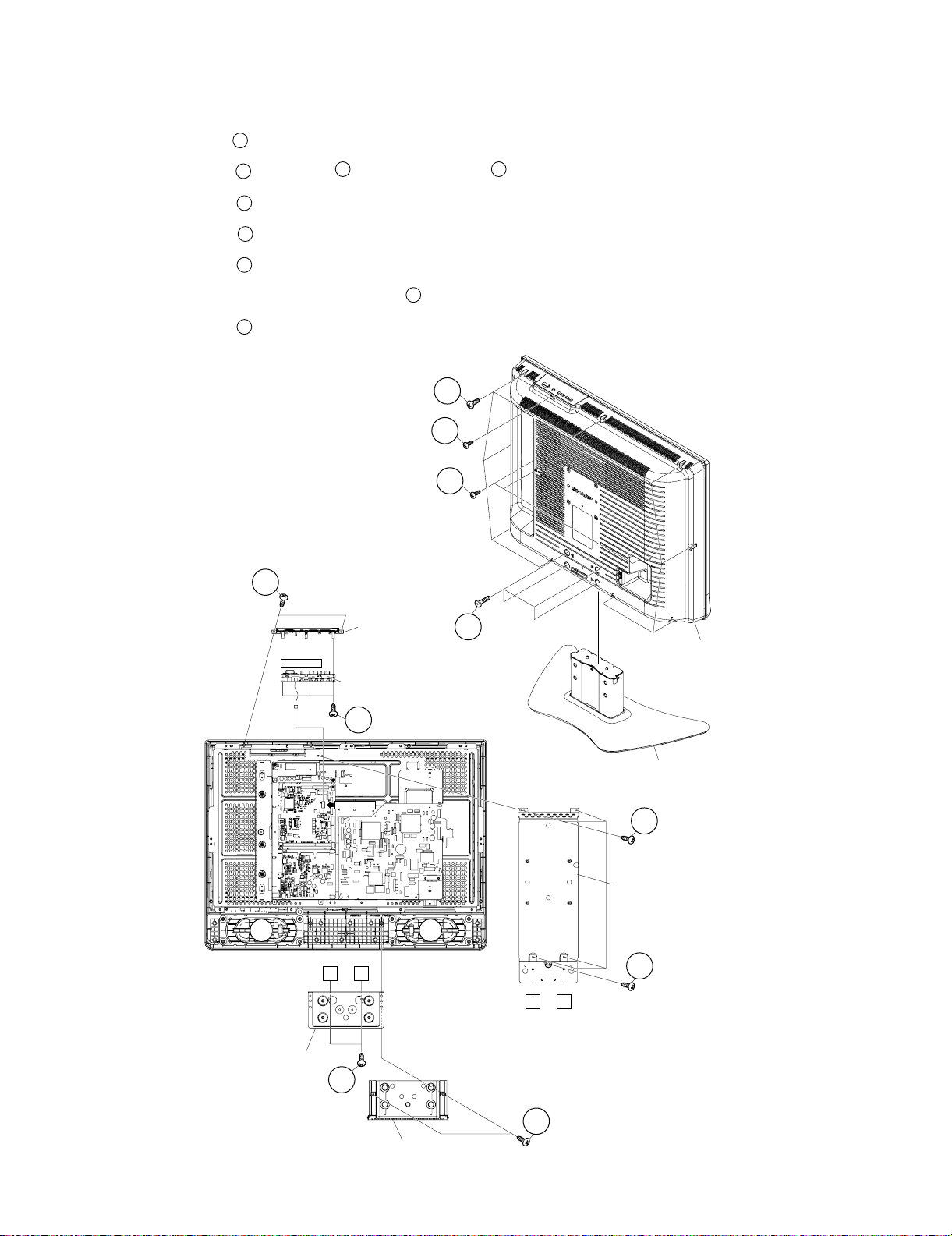

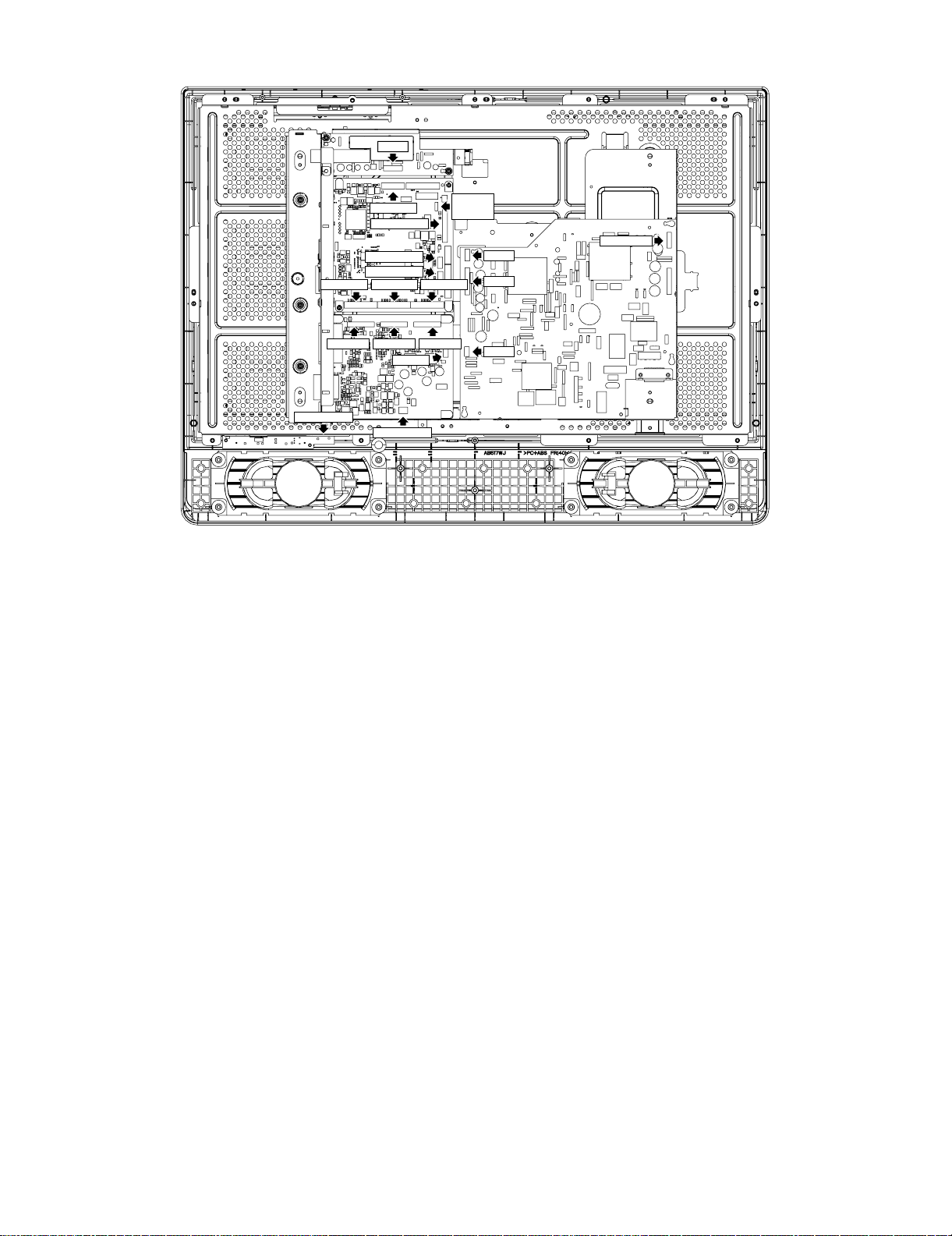

LC-26SA1E

CHAPTER 4. REMOVING OF MAJOR PARTS

Service Manual

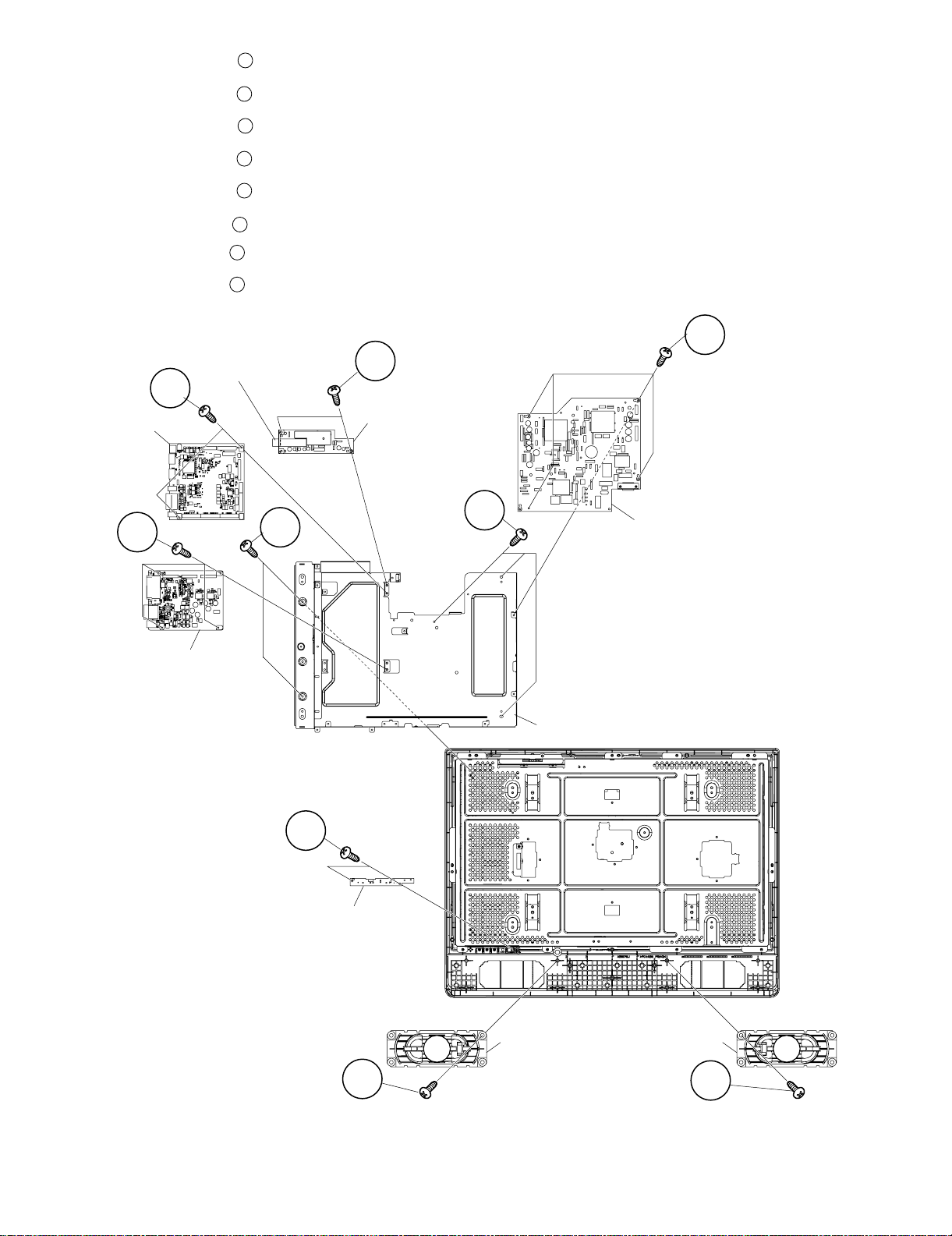

[1] REMOVING OF MAJOR PARTS LC-26SA1E/RU

1. Remove the 4 lock screws . Detach the Stand.

2. Remove the 3 lock screws . 1 lock screw and the 9 lock screws . Detach the Rear Cabinet.

3. Remove the 2 lock screws and detach the Bottom Cover.

4. Remove the 2 lock screws and detach the Stand Angle.

5. Remove the 5 lock screws and detach the Center Angle.

6. Disconnect the KM connector. Remove the 2 lock screws and detach the Top Cover Ass’y.

7. Remove the 3 lock screws and detach the KEY Unit.

1

2

5

6

7

9

3 4

8

4

3

2

8

KM(P169)

Stand Angle

Key Unit

KM(P2302)

A B

6

Top Cover Ass'y

9

1

Rear Cabinet

Stand

7

Center Angle

7

A B

Bottom Cover

5

4 – 1

Page 9

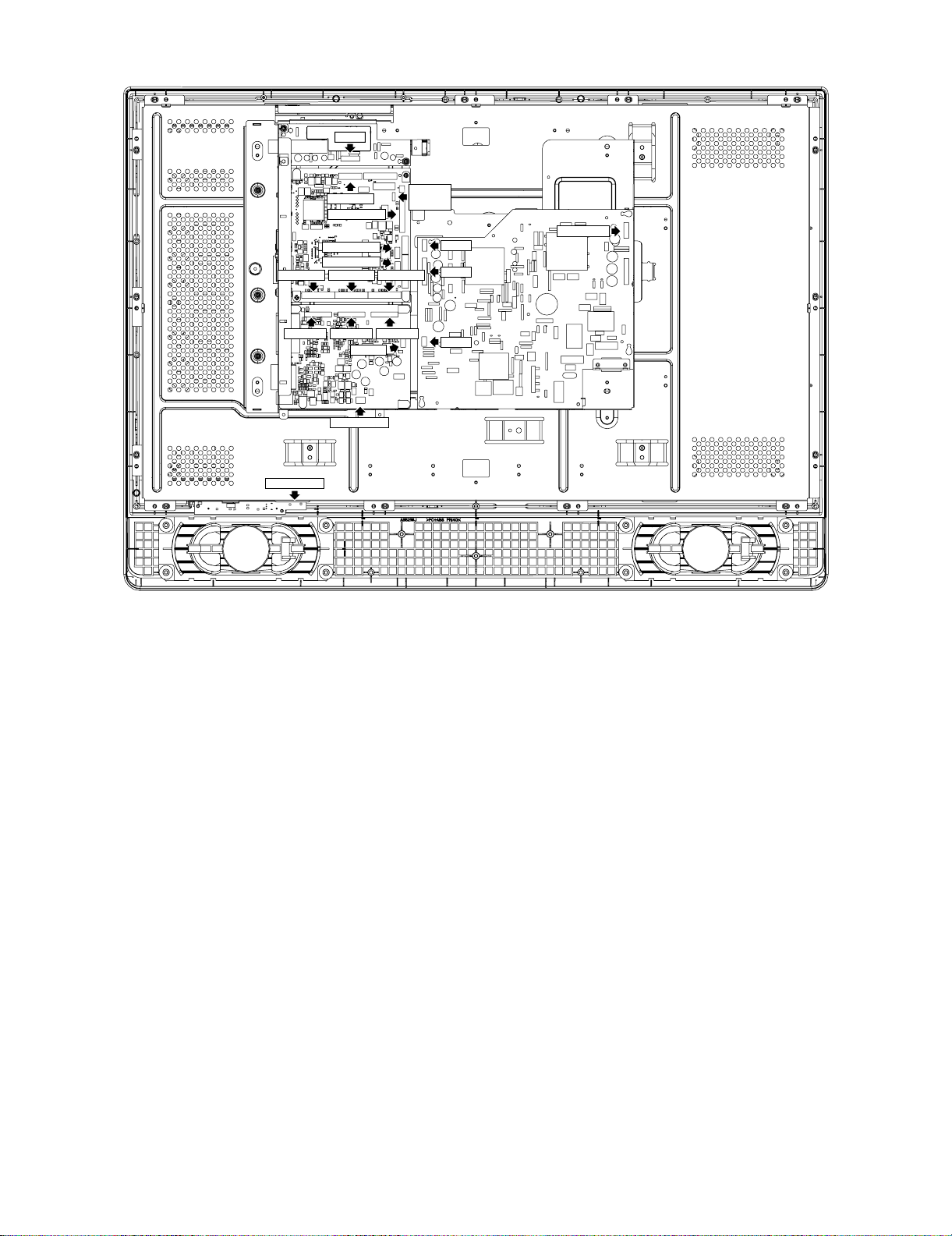

8. Remove all the connectors from PWBs.

LC-26SA1E/RU, LC-32SA1E/RU

P201

RA(P101)

SC2705

LV(P2305)

SH(P2301)

RA(P2303)

SC2703SC2702 SC2704

P1102P1101 P1201

SC301

SP(P301)

KM

P2302

LA(P704)

P702

P701

P703

4 – 2

Page 10

LC-26SA1E/RU, LC-32SA1E/RU

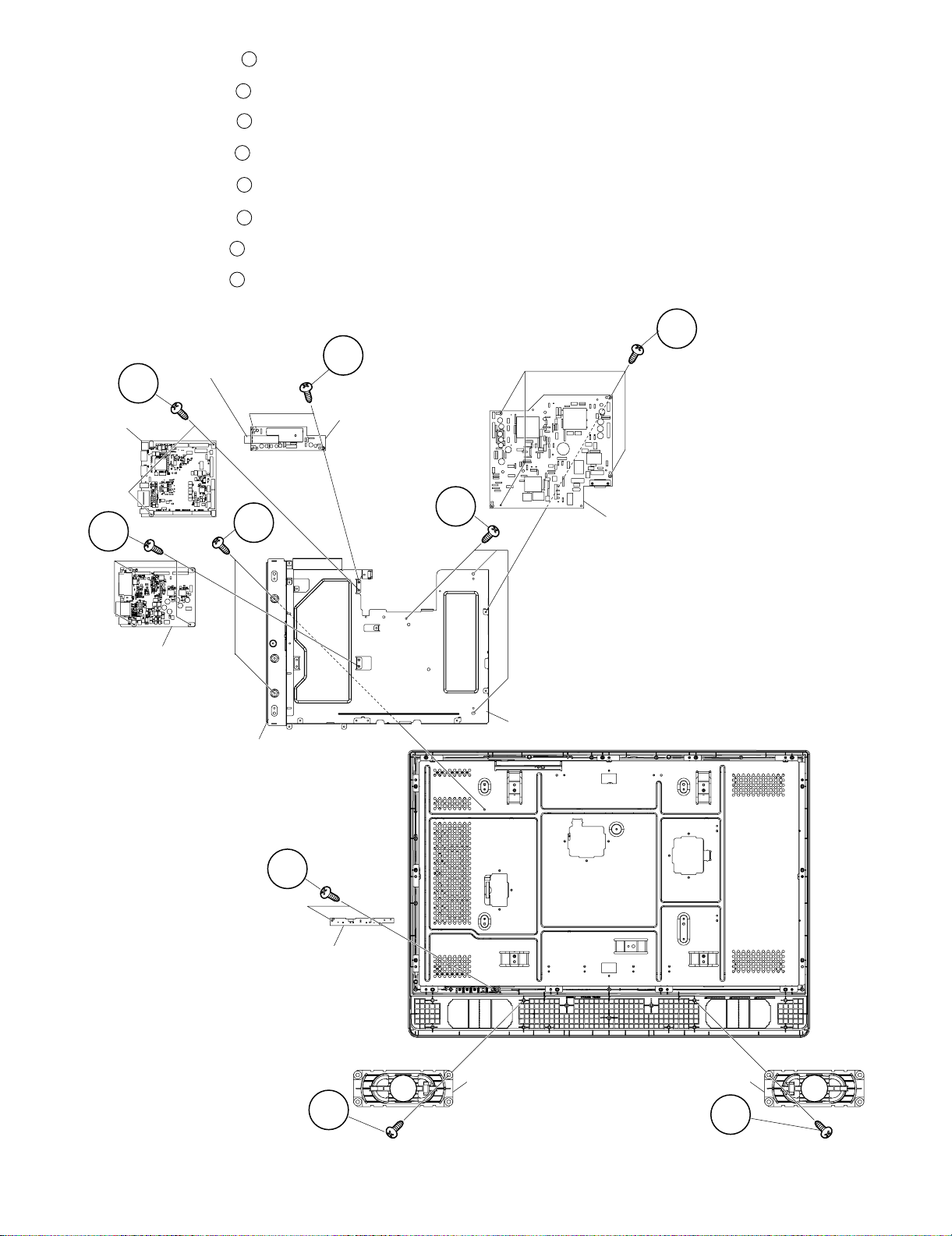

9. Remove the 4 lock screws and detach the Power Unit.

10

10.Remove the 2 lock screws and detach the Tuner Unit and Tuner Earth Plate.

11.Remove the 2 lock screws and detach the Main Unit.

12.Remove the 4 lock screws and detach the AV Unit.

13.Remove the 5 lock screws detach the Chassis Tray.

14.Remove the 2 lock screws and detach the R/C, LED Unit.

15.Remove the 1 lock screw and detach the Speaker R.

16.Remove the 1 lock screw and detach the Speaker L.

11

12

13

14

15

16

17

Tuner Earth Plate

11

12

Main Unit

Tuner Unit

14

13

14

10

Power Unit

AV Unit

15

R/C,LED Unit

16

Chassis Tray

Speaker R

Speaker L

17

4 – 3

Page 11

LC-26SA1E/RU, LC-32SA1E/RU

17.Remove the 8 lock screws and the 6 lock screws , detach the LCD Angle.

18.Remove the LCD Panel Unit from Front Cabinet.

18

19

18

19

18

LCD Angle

LCD Panel Unit Front Cabinet

18

19

18

4 – 4

Page 12

LC-26SA1E/RU, LC-32SA1E/RU

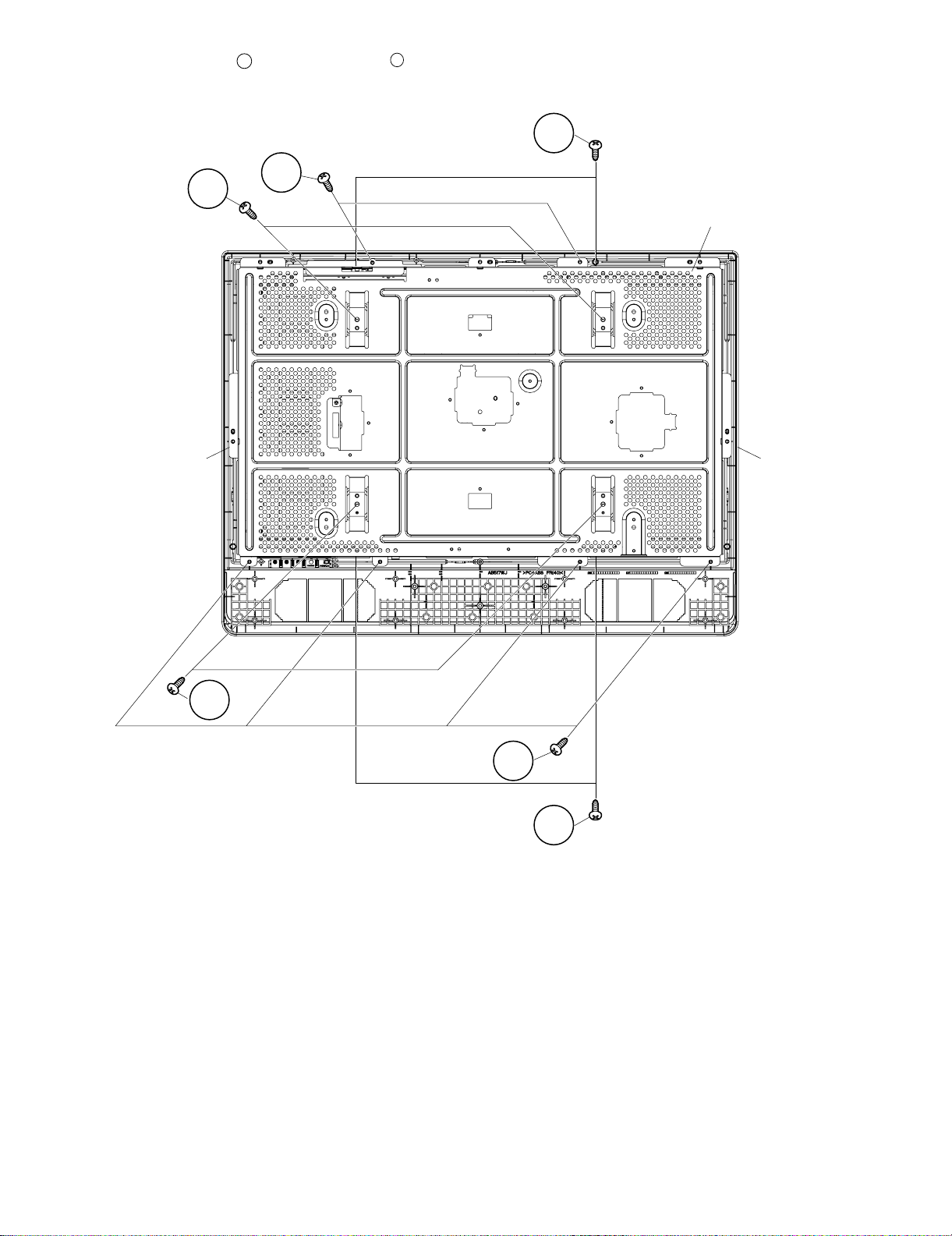

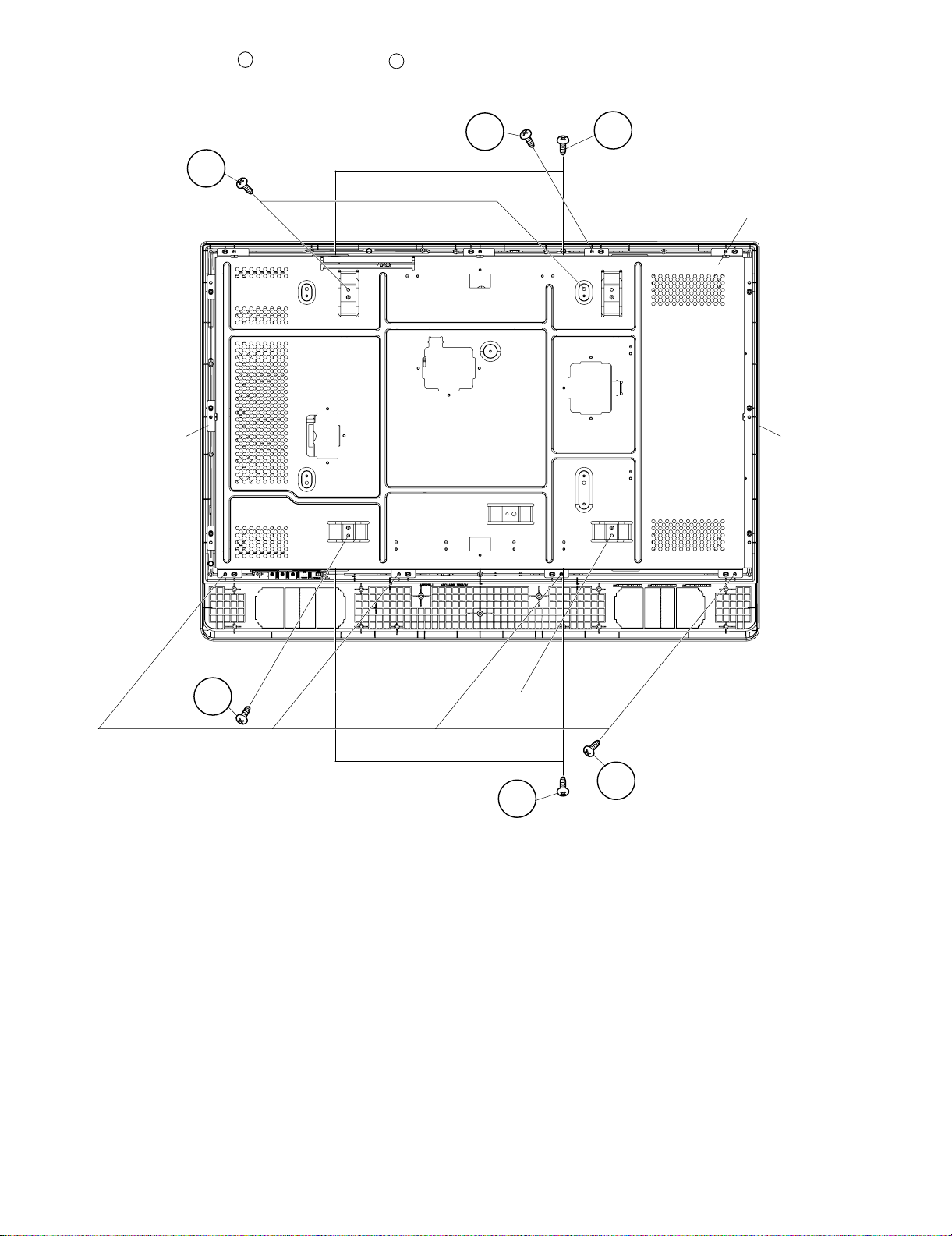

[2] REMOVING OF MAJOR PARTS LC-32SA1E/RU

1. Remove the 4 lock screws . Detach the Stand.

2. Remove the 6 lock screws . 1 lock screw and the 9 lock screws . Detach the Rear Cabinet.

3. Remove the 2 lock screws and detach the Bottom Cover.

4. Remove the 4 lock screws and detach the Stand Angle.

5. Remove the 6 lock screws and detach the Center Angle L and the Center Angle R.

6. Disconnect the KM connector. Remove the 2 lock screws and detach the Top Cover Ass’y.

7. Remove the 3 lock screws and detach the KEY Unit.

1

2

5

6

7

9

3 4

8

4

3

2

8

Center Angle R

7

Top Cover Ass'y

KM(P169)

Key Unit

1

Rear Cabinet

9

Stand

KM(P2302)

Center Angle L

7

D

A

D

A

6

C

B

B

C

6

Stand Angle

6

5

Bottom Cover

4 – 5

Page 13

8. Remove all the connectors from PWBs.

LC-26SA1E/RU, LC-32SA1E/RU

P201

RA(P101)

SC2705

LV(P2305)

SH(P2301)

RA(P2303)

SC2703SC2702 SC2704

P1102P1101 P1201

SC301

SP(P301)

KM

P2302

LA(P704)

P702

P701

P703

4 – 6

Page 14

LC-26SA1E/RU, LC-32SA1E/RU

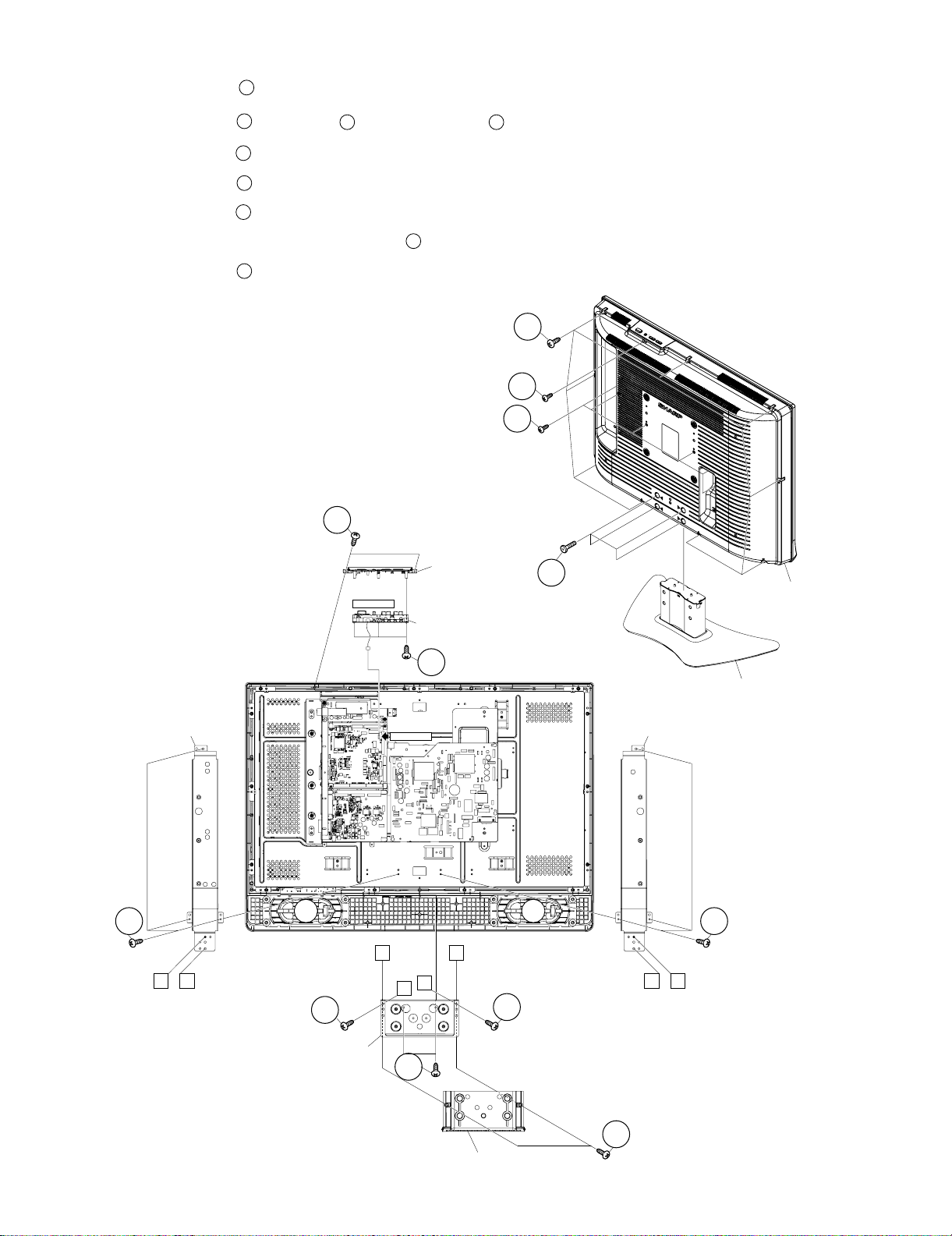

9. Remove the 4 lock screws and detach the Power Unit.

10

10.Remove the 2 lock screws and detach the Tuner Unit and Tuner Earth Plate.

11.Remove the 2 lock screws and detach the Main Unit.

12.Remove the 4 lock screws and detach the AV Unit.

13.Remove the 5 lock screws detach the Terminal Angle and the Chassis Tray.

14.Remove the 2 lock screws and detach the R/C,LED Unit.

15.Remove the 1 lock screw and detach the Sperker R.

16.Remove the 1 lock screw and detach the Sperker L.

Tuner Earth Plate

11

12

13

14

15

16

17

11

12

Main Unit

Tuner Unit

14

13

14

10

Power Unit

AV Unit

Terminal Angle

15

R/C,LED Unit

Chassis Tray

Speaker R

Speaker L

16

17

4 – 7

Page 15

17.Remove the 8 lock screws and the 5 lock screws , Detach the LCD Angle.

18.Remove the LCD Panel from Front Cabinet.

18

19

LC-26SA1E/RU, LC-32SA1E/RU

19

18

18

LCD Angle

LCD Panel Unit Front Cabinet

18

19

18

4 – 8

Page 16

LC-26SA1E/RU, LC-32SA1E/RU

LC-26SA1E

CHAPTER 5. ADJUSTMENT PROCEDURE

The adjustment values are set to their optimum at the factory before shipping.

If by any chance a value should become improper or a readjustment is required due to part replacement, make an adjustment according to the fol-

lowing procedure.

Service Manual

[1] After replacement of any PWB and/or IC for repair, note the following.

When replacing the following units, be sure to prepare the new units loaded with updated software.

MAIN-UNIT : DUNTKD890FM12 (LC-26SA1E/K/F/I/RU)

DUNTKD890FM13 (LC-32SA1E/K/F/I/RU)

• Note that an IC into which ROM data is written is available for MAIN-UNIT servicing (see below)

IC1901 VHi24LC2BiNEES EDID(HDMI)

IC2303 RH-iXB731WJZZS EDID(PC)

[2] SOFTWARE UPDATING

There are 3 methods to update software in the VCTp: I2C method, RS-232C HyperTerminal and RS-232C Tera Term method.

• RS-232C method is allowed when the TV is working properly and the action should be only software upgrade.

• I2C method is required when the VCTp fiash is empty or corrupted (it means, any software inside IC running).

1. RS-232C Method Description (HyperTerminal).

The hardware tools requirement are:

1. A Modem-null (Cross type) DB9 female to DB9 female cable.

2. An adaptor DB9 male to mini-Din 9 pin male cable (Sharp Code: QCNWGA015WJPZ)

3. Make the connections as indicated in the figure:

Computer TV set

Before using RS-232C updating method is necessary to configure a Terminal PC software. HyperTerminal has been selected as a Terminal software because it’s include in all Windows versions as an accessory, and you can find it inside “Accessories\Communications” folder. For this reason, please follow carefully the next steps:

1) First time HyperTerminal is used, it’s necessary to configure some settings. Follows next action to configure two connection: low speed

(9600bps) and high speed (115200bps).

2) Create a New Connection file with name “P55_9600bps”.

3) Select a free COM port and select the Port Settings properties as follows:

5 – 1

Page 17

4) Click on “File\Properties” menu for selecting the General and ASCII properties as follows:

5) Select “New Connection” in the File Menu.

6) Answer “Yes” to close current connection and”Yes” to save session “P55_9600bps”.

7) Create a new connection with the name “P55_115200bps”.

8) Select a the same COM port used in item 2 and select the Port Settings properties as follows:

LC-26SA1E/RU, LC-32SA1E/RU

9) Select the same General and ASCII properties as item 3.

10)Close HyperTerminal session, answering “Yes” to close current connection and “Yes” to save session “P55_115200bps”.

To start updating session, click over “P55_9600bps” icon that you can find in the “START\All programs\Accessories\ Communications\HyperTermi-

nal\HyperTerminal” folder and follow next procedure:

5 – 2

Page 18

LC-26SA1E/RU, LC-32SA1E/RU

1) Check the connection between TV set and PC, sending a wrong command, as for example: “aaa”. TV set returns an “ERR” label as an syntaxis

ERROR (Not correct order or sequence).

2) Send the command “DWMD” to enter TV set in Download Mode. The TV set answer sending same symbol continuosly. If this symbol character

doesn’t appear, please don’t worry and pass to next step.

3) Close this connection and open “P55_115200bps” connection clicking over the “P55_115200bps” that you can find in “START\All pro-

grams\Accessories\ Communications\HyperTerminal\HyperTerminal” folder.

4) Using “Transfer\Send file...” menu, select desired file (.bin format) and the transmission protocol (Xmodem) as show below.

5) After press “Send” button the updating process starts as follows:

6) When flash update process finishes, the”Flash Programming Complete” label appears in the screen.

VERY IMPORTANT NOTE:

During the updating time, please don’t use the PC for other purpouses, in order to abolish commu nication problems between TV set an d

PC. If TV set was not updated properly, the TV won’t have the software to startup again, and you must follow the “I2C method” to update

another time the TV set.

5 – 3

Page 19

2. RS-232C Method Description (Tera Term)

The hardware tools requirement are:

1. A Modem-null (Cross type) DB9 female to DB9 female cable.

2. An adaptor DB9 male to mini-Din 9 pin male cable (Sharp Code: QCNWGA015WJPZ)

3. Make the connections as indicated in the figure:

LC-26SA1E/RU, LC-32SA1E/RU

Software requirements :

To upgrade VCTp software from RS-232C external connector is necessary to use a Tera Ter m (Pro) free software.

The URL of Tera Term home page is:

http://hp.vector.co.jp/authors/VA002416/teraterm.html

(The address may be changed in future)

Tera Term (Pro) supported operating systems:

MS-Windows 95 or upper

MS-Windows NT 3.5 and 4.0 or upper

Note.- For Windows 3.1 use Tera Term version 1.X.

Copy all the distribution files to an empty floppy disk or temporary directory (for example C:\ TEMP ).

Run SETUP.EXE and follow the instruction given by it.

After the installation, the distribution ?les are no longer needed, you can delete them or may keep them in the floppy disk.

How to use Tera Term Pro :

When the Tera Term (Pro) program is used, it’s necessary to shape some settings. Follows next action to configure the connection:

5 – 4

Page 20

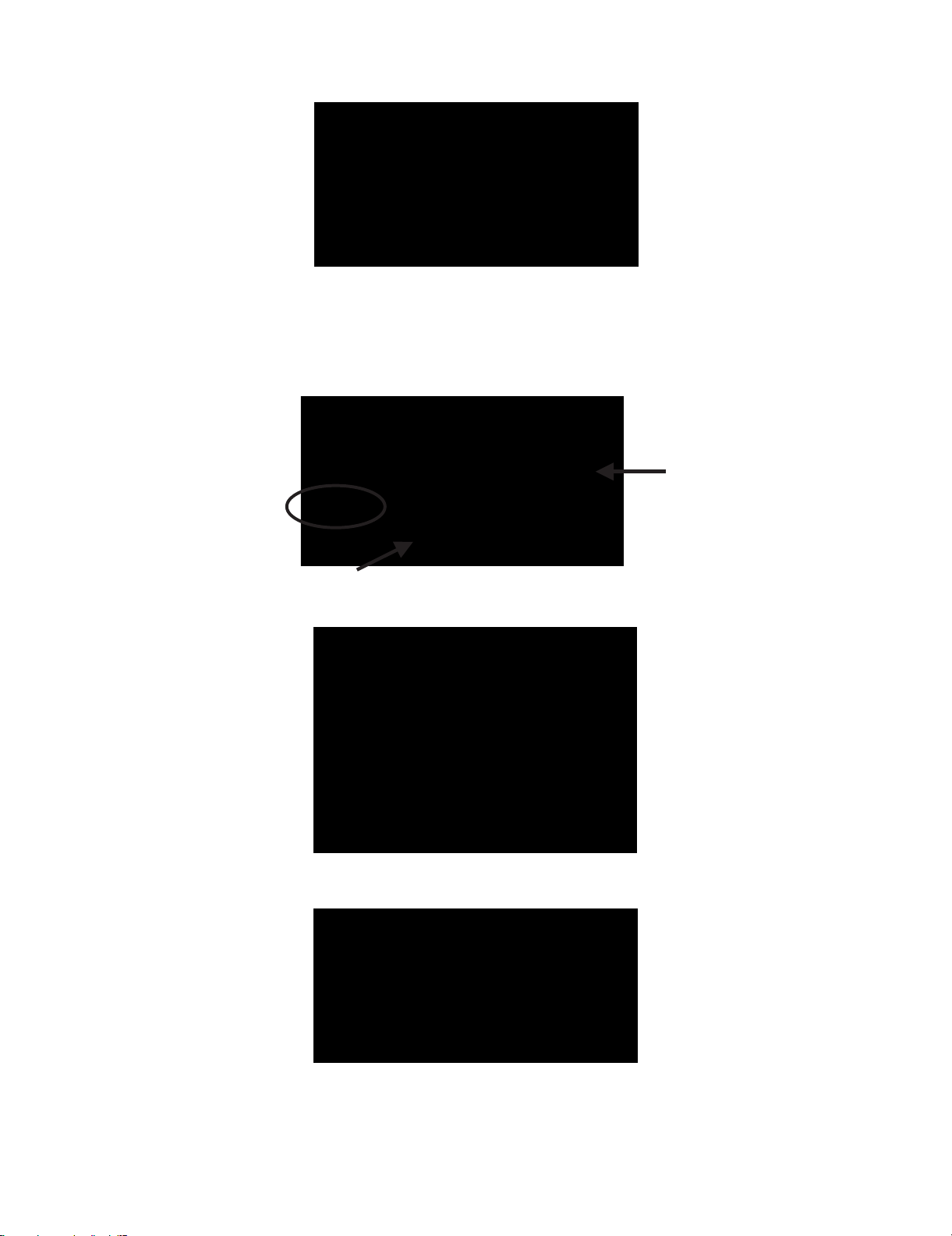

LC-26SA1E/RU, LC-32SA1E/RU

1) Select: Serial→COM X→ O.K.

2) Select: Terminal

3) Choose the same options as the above picture.

5 – 5

Page 21

4) Select: Setup → Serial port → O.K. Appear the follow screen:

5) Select follows settings:

Serial port to use: COM x

Baud rate: 9600

Data: 8 bits

Parity: none

Stop: 1 bit

Flow control: none

Enter O.K.

LC-26SA1E/RU, LC-32SA1E/RU

6) Check the connection between TV set and PC, sending a wrong command, as for example: “aaa”. TV set returns an “err” label as an syntaxes

ERROR (Not correct order or sequence).

Send a “DWMD” (capital letters) command to enter TV set in Download Mode.

Change a baud rate to 115200.

Select: Setup → Baud rate → 115200 → O.K.

5 – 6

Page 22

LC-26SA1E/RU, LC-32SA1E/RU

7) Select: File → Transfer → XMODEM → Sent

8) Choose the file for upgrade and click “Open”.

9) After select “Open” the upgrade process starts as follows:

5 – 7

Page 23

LC-26SA1E/RU, LC-32SA1E/RU

10)When flash update process finishes, the “Flash programming complete” label appear in the screen , the device automatically go to switch off, and

in a few seconds go to switch on again.

VERY IMPORTANT NOTE:

During the updating time, please don’t use the PC for other purposes, in order to abolish communication problems between TV set and PC.

If TV set was not updated properly, the TV wonÅft have the software to startup again, and you must follow the “I2C method”

another time the TV set.

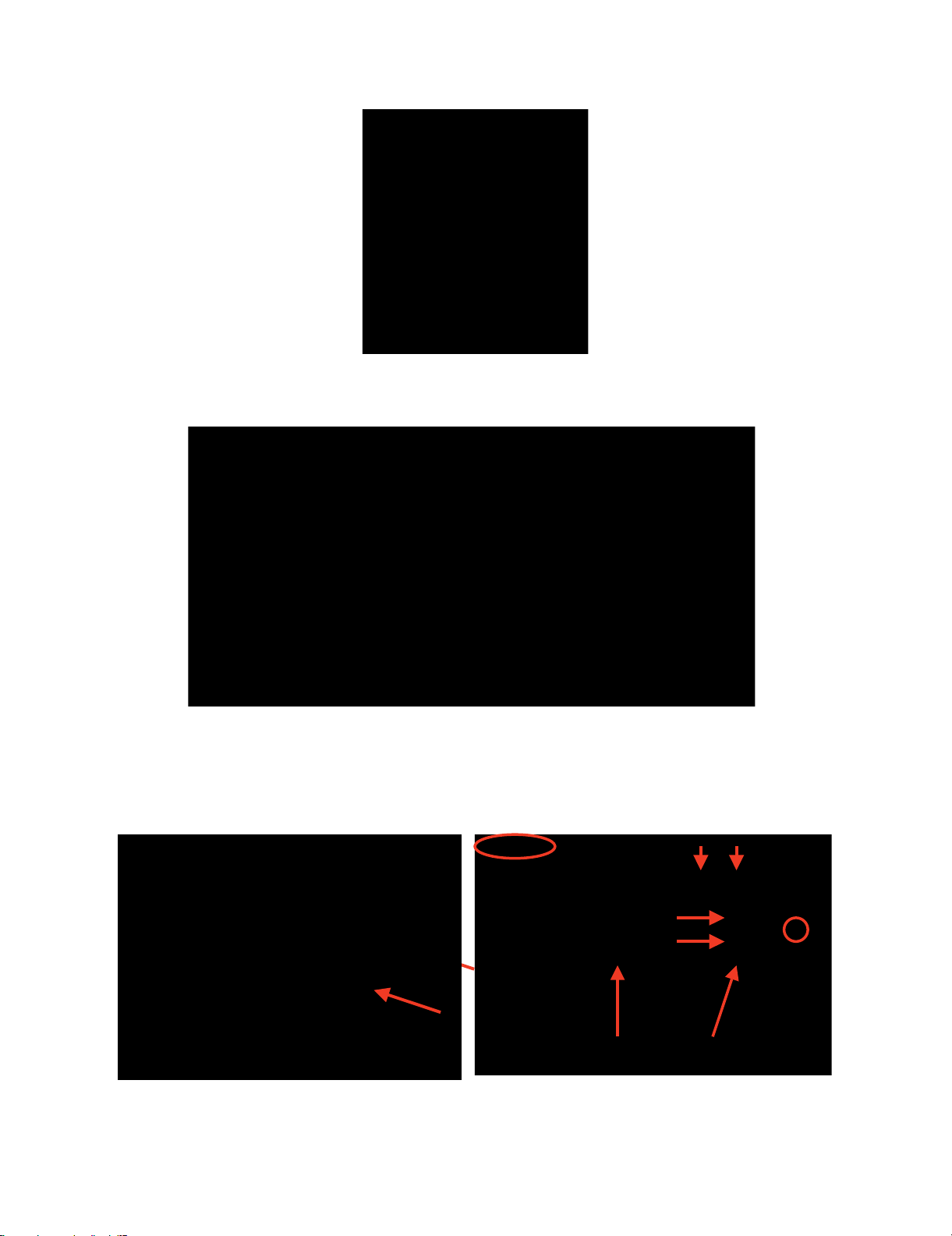

3. I2C Method Description

The hardware tools requirement are:

1. A Parallel port I2C interface with 20 pin to 3 pin cable (Sharp Code: CKIT-0004WJV0).

2. Make the connections as indicated below:

i) Connect Parallel port I2C interface to LPT port of the computer.

ii) Connect the 20 to 3 pin cable from the I2C interface to the P2306 socket in the main board (XD603).

to update

To P2306

To PC

QCNWGA100WJZZ

QPWBX0004WJZZ

I2C Interface (CKIT-0004WJV0)

Before using I2C method is necessary to install Visual I2C software following next procedure.

1. Install Visual I2C release V3.2.3b from file (“Setup_Visual_I2C_v3-2-3b8h.exe”).

• It’s strongly recommended to accept the suggested default folder (“C:\Program Files\Micronas\Visual I2C”).

2. Install Visual I2C VCTp extension from file (“Setup_VI2C_for_VCT6wxyP_v0111.exe”).

• It’s interesting to change default folder to same as Visual I2C (“C:\Program Files\Micronas\Visual I2C”).

• During this installation process is possible to install also a complementary software to manage NVM memories .

This installation is not needed, for this reason uncheck the option when the setup program ask to you. In case of installation it’s interesting to change

default folder to same as Visual I2C (“C:\Program Files\Micronas\Visual I2C”).

3. Install Parallel driver depending of your Windows version from existing files inside the Visual I2C installation folder “C:\Program Files\Micro

nas\Visual I2C\Port_Driver”, following next criteria:.

1) Windows 98/Me (“Setup_LptDrv_v0104_9x.exe”).

2) Windows NT (“Setup_LptDrv_v0104_NT_2000.exe”).

5 – 8

Page 24

LC-26SA1E/RU, LC-32SA1E/RU

3) Windows Xp/2000 (“Setup_LptDrv_v020201_XP_2000.exe”).

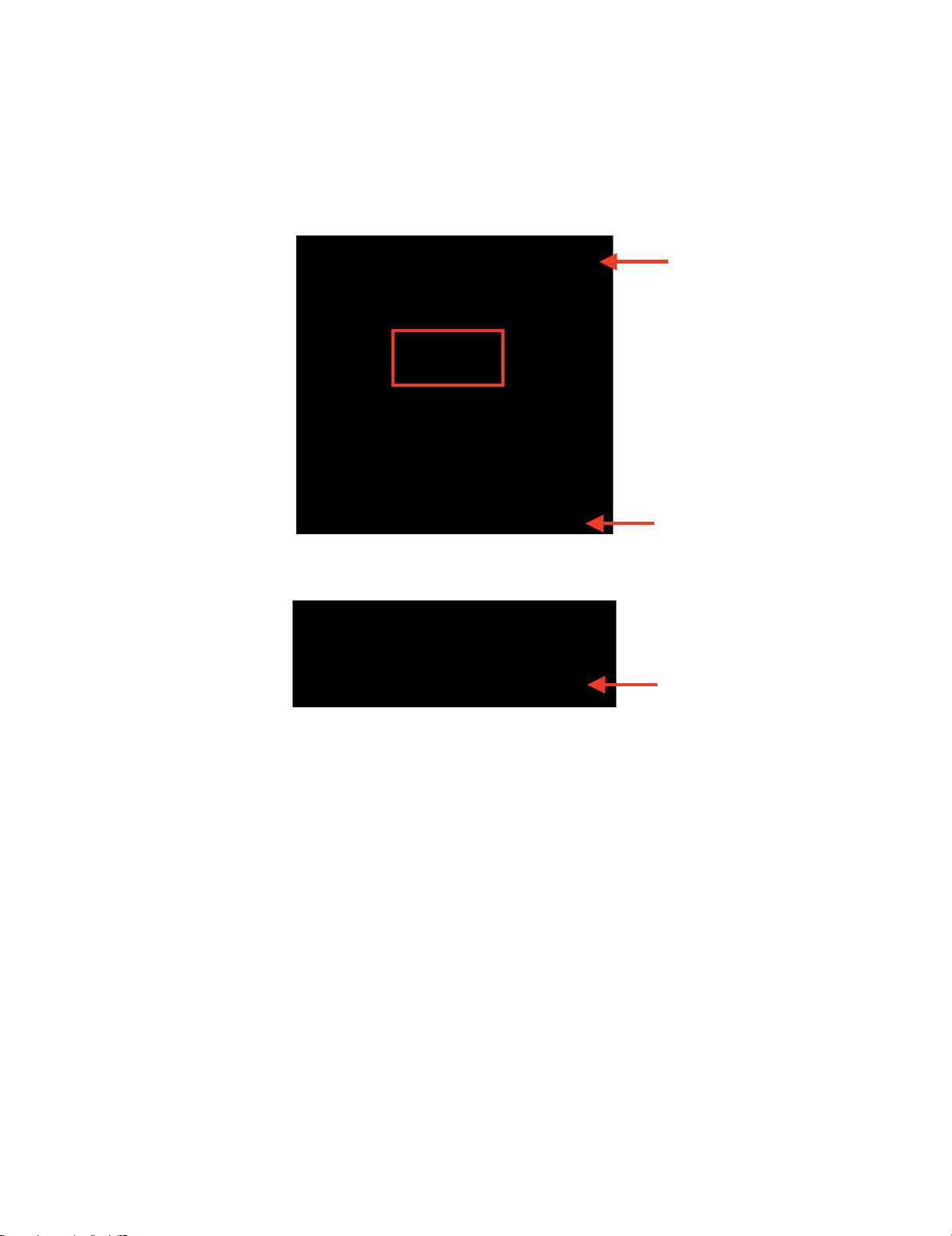

After installing Visual I2C, the new generated file structure should look like this:

4. Check installation LPT driver using “C:\Program Files\Micronas\LptDrv\LptDrvTest.exe”. After run this software, if LPT driver is installed properly

must appear this screen:

3.

• If the result is not OK, check inside PC bios: Parallel Port Mode=EPP

To run VCTp software update program, please click over “VCTP” icon from “START\All programs\Micronas\Visual I2C\IC\VCTP” and after Visual I2C

finish their starting process click on “TVT” module. As additional method, it’s possible to create a direct access to “C:\Program Files\Micronas\Visual

I2C\ic\vct6wxyP\vctq_tvt.vi2c” and launch it from Windows Desktop.

1

5

2

4

2

4

3

67

67

5 – 9

Page 25

LC-26SA1E/RU, LC-32SA1E/RU

To start updating process follow next instructions:

1. Set Autoread in ON option.

2. Click on “GO” button.

3. Wait until “40” appears in Bootloader Version field.

4. Close DOS pop up windows pressing any key (“Press any key to continue...”.).

5. Click on the “Erase flash” button and wait for a seconds and set the AutoRead to OFF.

6. Check in the desired software version is selected in the “Load BinaFlash” option. If it’s not the correct one, please double click on the file name and

select it. The first time this software is use it’s necessary to confirm write Addressing margin as from 0x0 to 0x7ffff.

7. Click on the “Load Bin → Flash” to start updating process.

8. When the updating process finishes, the “Progress” pop up window automatically closes. If appears some problem during the updating process a

error label appears in the filename information line.

If the TV has problem to enters in the”Bootloader mode”, it’s possible to force it by hardware method. This alternative method is described

below:

1. Switch off TV set or hold VCTp RESET line to GND.

2. Pull down SCL line (pin 1) to GND (pin 3) in P2306 connector.

3. Switch on TV set or release VCTp RESET line.

4. Release SCL pull down after minimum of 2 seconds.

5. Check if VCTp is in bootloader mode with Autoread setting in ON.

6. Wait until “40” appears in Bootloader Version field.

7. Follow instruction from item 5 on software method.

Sometimes, depending on the PC hardware, the progress bar runs very fast (Normal time: 1 minute) or some error message appears in the filename

information line. This means it’s necessary to modify some parameter of LPT port, for this reason select “LPT Preferences” on the “File\Preferences...” menu and increase Delay from “0” to “1” or “2” (normally, these values are the best choice).

5 – 10

Page 26

LC-26SA1E/RU, LC-32SA1E/RU

[3] Entering and exiting the adjustment process mode

1) Unplug the AC power cord of running TV set to force off the power.

2) While holding down the “VOL(-)” and ”INPUT” keys on the set at once, plug in the AC power cord to turn on the power. The letter appears on

the screen.

3) Next, hold down the ”VOL(-)” and ”P( )” keys on the set at once.

Multiple lines of orange characters appearing on the screen indicate that the set is now in the adjustment Process mode. If you fail to enter the

adjustment process mode (the display is the same as normal startup), retry the procedure.

4) To exit the adjustment process mode after the adjustment is done, unplug the AC power cord to force off the power. (When the power is turned off

with the remote controller, once unplug the AC power cord and plug it in again. In this case, wait 10 seconds or so before plugging.)

5) To remove “K” mode holding down the “VOL (-)” and “INPUT” kyes on the set at once (“K” disappears).

K

Caution : Use due care in handling the information described here lest the users should know how to enter the adjustment process mode. If the

settings are tampered with in this mode, unrecoverable system damage may result.

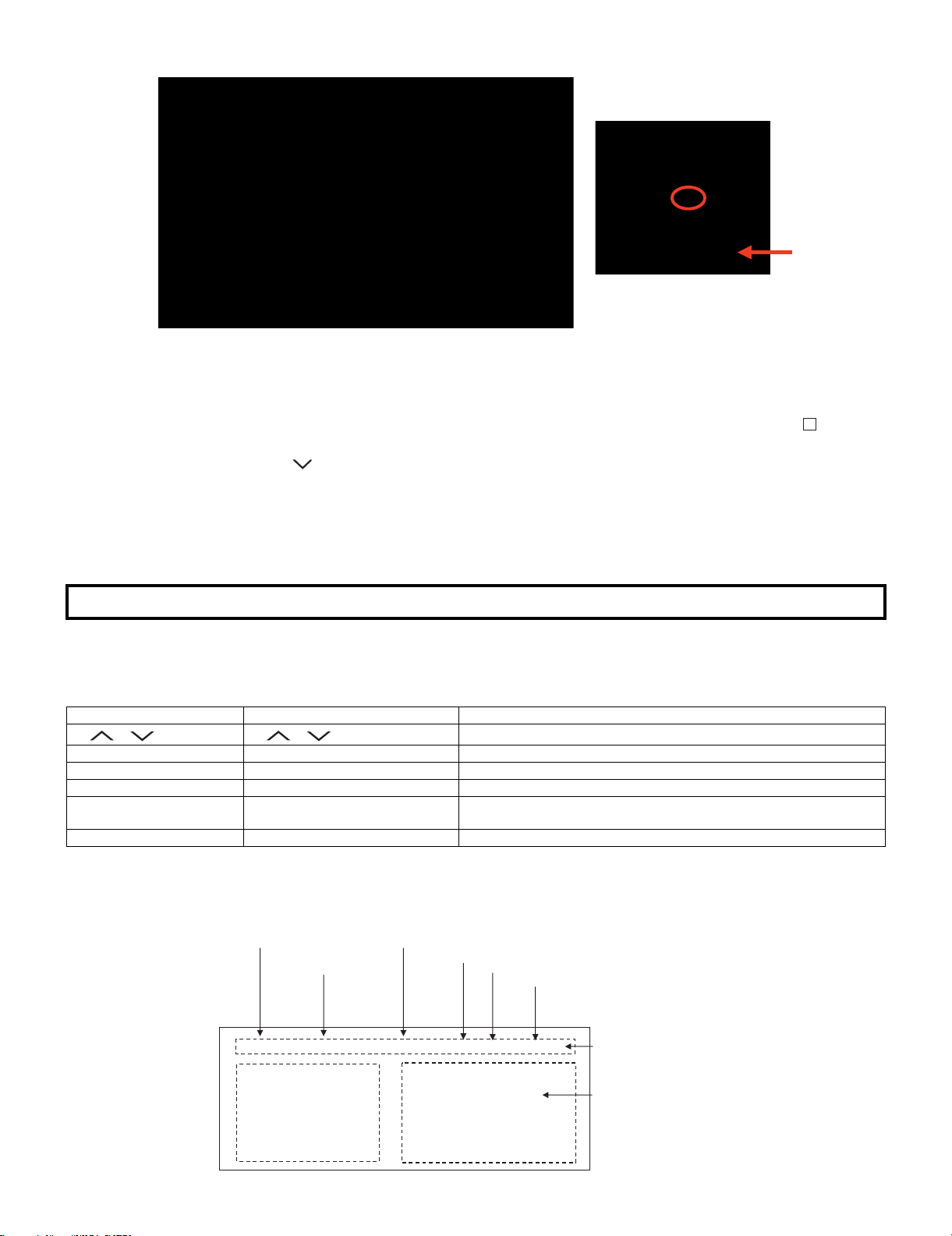

[4] Remote controller key operation and description of display in adjustment process mode.

1. key operation

Remote controller key Main unit key Function

P ( / ) P ( / )

VOL (+ / –) VOL (+ / –) Changing a selected item setting (+1/–1)

Cursor (UP/DOWN) —————— Turning a page (PREVIOUS/NEXT)

Cursor (LEFT/RIGHT) —————— Changing a selected line setting (+10/–10)

INPUT SOURCE

INPUT button Input source switching (toggle switching)

on remote controller

OK —————— Executing a function

* Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

2. Description of display

(1) Current page/Total pages (3) Currently selected input

(2) Current page title

1/11

Main Version

Dev Version

Dev Loader Version

Pic Version

TEMP SENSOR

NORMAL STANDBY CAUSE

ERROR STANDBY CAUSE

[INFO] TV AUTO 32 EURO

1.XX (XX/XX/XXX)

XX

XX

XX

XX

XX

XX

Moving an item (line) by one (UP/DOWN)

(TV→EXT1→EXT2→EXT3→EXT4→EXT5)

(4) Current colour TV system

Inch Setting (32 just as example, it may be: --/26/32)

(5)

Destination (EURO just as example.

See Factory Init,it may be EURO, UK,

ITALY, FRANCE or RUSSIA)

Adjustment process

menu header

(7) Parameters

5 – 11

Page 27

LC-26SA1E/RU, LC-32SA1E/RU

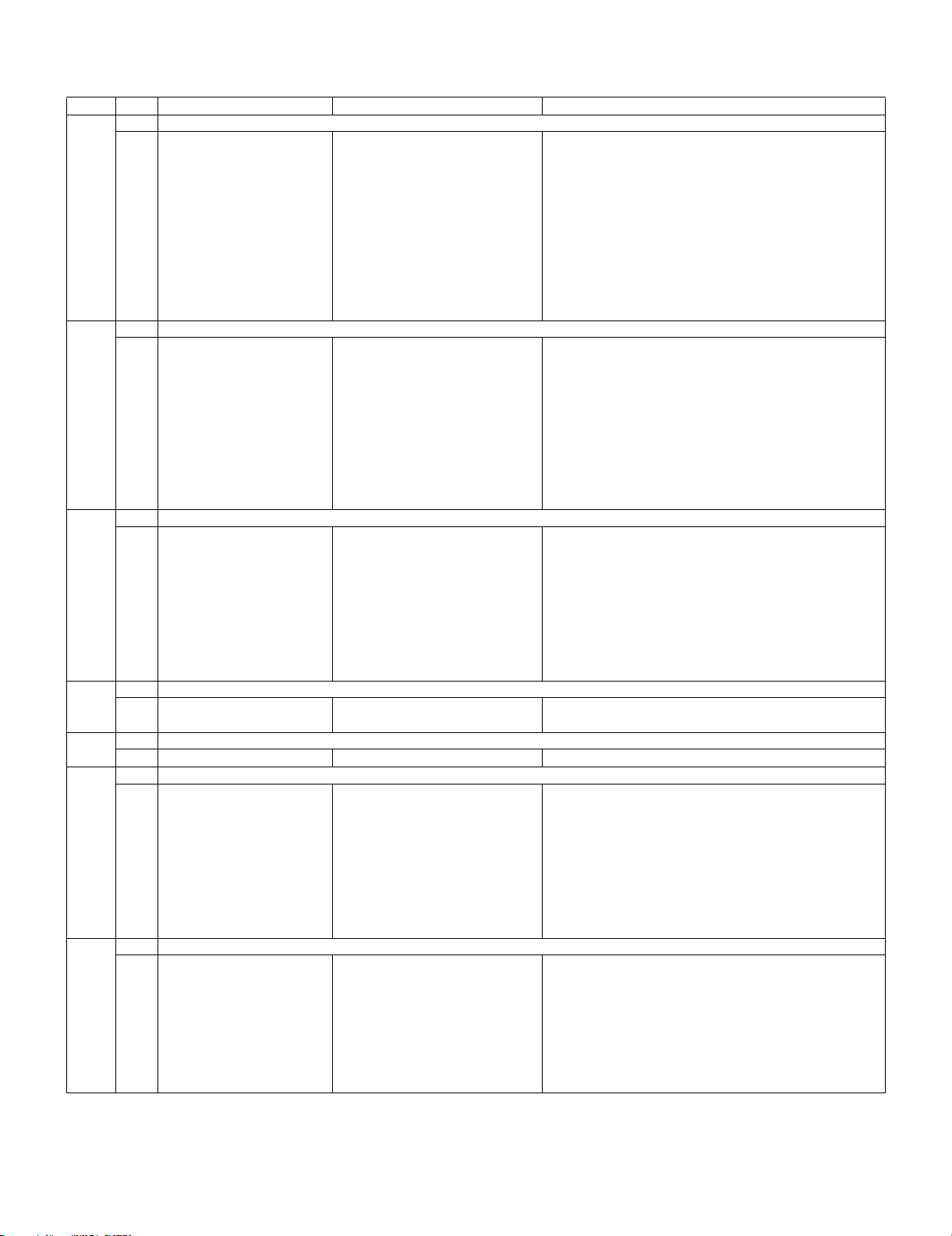

[5] Adjustment process mode menu

The character string in brackets [ ] will appear as a page title in the adjustment process menu header.

Page Line Item Description Remarks (adjustment detail, etc.)

1/11 [INFO]

1 Main Version LEW05 01.03(2006/07/15x)5 Main microprocessor version

2 Dev Version xxxxxx

3 Dev Loader Version xxxxxx

4 Pic Version xxxxxx Pic MICON version

5 TEMP SENSOR xxxxxx Temp inside the cabinet

6 NORMAL STANDBY CAUSE 1 RC_STANDBY Last status which cause standby

7 ERROR STANDBY CAUSE [1] 0 00H 00M Error standby cause Total operating time before error

[2] 0 00H 00M

[3] 0 00H 00M

[4] 0 00H 00M

[5] 0 00H 00M

2/11 [INIT]

1 Factory Init [EURO]ENTER Initialization to factory settings execution

2 Inch Setting 26/32/37/42 Inch present setting

3 Public Mode OFF/ON HOTEL MODE flag setting

4 Center Acutime xxH xxM Main operating hours

5 RESET OFF/ON Main operating hours reset

6 Backlight Acutime xxH xxM Backlight operating hours

7 RESET OFF/ON Backlight operating hours reset

8 Picture Read Pos X 0-xxx x-axis setting of picture data

9 Picture Read Pos Y 0-xxx y-axis setting of picture data

10 Picture Read ON/OFF Start/stop of picture data

3/11 [PAL.SECAM. N358]

1 RF-AGC ADJ ENTER RF-AGC auto adjustment execution

2 PAL+TUNER ADJ ENTER PAL TUNER auto adjustment execution

3 PAL ADJ ENTER PAL auto adjustment execution

4 TUNER ADJ ENTER TUNER auto adjustment execution

5 CONTRAST SD 32 PAL contrast adjustment

6 SECAM CB OFFSET 1 SECAM offset adjustment

7 SECAM CR OFFSET 1 SECAM offset adjustment

8 TUNER A DAC 32 TUNER DAC adjustment

9 RF AGC 20 RF AGC adjustment

4/11 [COMP 15K]

1 COMP 15K ADJ ENT ER COMP15K auto adjustment execcution

2 COMP 15K CONTRAST 32 Contrast adjustment

5/11 [HDTV]

1 HDTV CONTRAST 32 HDTV Contrast adjustment

6/11 [SMPTE]

1 RF-AGC ADJ ENTER RF-AGC auto adjustment execution

2 PAL+TUNER ADJ ENTER PAL TUNER auto adjustment execution

3 PAL ADJ ENTER PAL auto adjustment execution

4 TUNER ADJ ENTER TUNER auto adjustment execution

5 CONTRAST SD 32 PAL contrast adjustment

6 SECAM CB OFFSET 1 SECAM offset adjustment

7 SECAM CR OFFSET 1 SECAM offset adjustment

8 TUNER A DAC 32 TUNER DAC adjustment

9 RF AGC 20 RF AGC adjustment

7/11 [M GAMMA INFO]

1 M GAMMA IN 1 160 W/B adjustment, gradation 1 input setting

2 M GAMMA IN 2 320 W/B adjustment, gradation 2 input setting

3 M GAMMA IN 3 480 W/B adjustment, gradation 3 input setting

4 M GAMMA IN 4 640 W/B adjustment, gradation 4 input setting

5 M GAMMA IN 5 800 W/B adjustment, gradation 5 input setting

6 M GAMMA IN 6 960 W/B adjustment, gradation 6 input setting

7 M GAMMA WRITE OFF/ON EEP writing of adjustment values

8 M GAMMA RESET OFF/ON Initialization of adjustment values

5 – 12

Page 28

LC-26SA1E/RU, LC-32SA1E/RU

Page Line Item Description Remarks (adjustment detail, etc.)

8/11 [M GAMMA 1-3]

1 M GAMMA R 1 0 W/B adjustment, gradation 1R adjustment value

2 M GAMMA G 1 0 W/B adjustment, gradation 1G adjustment value

3 M GAMMA B 1 0 W/B adjustment, gradation 1B adjustment value

4 M GAMMA R 2 0 W/B adjustment, gradation 2R adjustment value

5 M GAMMA G 2 0 W/B adjustment, gradation 2G adjustment value

6 M GAMMA B 2 0 W/B adjustment, gradation 2B adjustment value

7 M GAMMA R 3 0 W/B adjustment, gradation 3R adjustment value

8 M GAMMA G 3 0 W/B adjustment, gradation 3G adjustment value

9 M GAMMA B 3 0 W/B adjustment, gradation 3B adjustment value

10 M GAMMA WRITE OFF/ON EEP writing of adjustment values

9/11 [M GAMMA 4-6]

1 M GAMMA R 4 0 W/B adjustment, gradation 4R adjustment value

2 M GAMMA G 4 0 W/B adjustment, gradation 4G adjustmnet value

3 M GAMMA B 4 0 W/B adjustment, gradation 4B adjustment value

4 M GAMMA R 5 0 W/B adjustment, gradation 5R adjustment value

5 M GAMMA G 5 0 W/B adjustment, gradation 5G adjustmnet value

6 M GAMMA B 5 0 W/B adjustment, gradation 5B adjustment value

7 M GAMMA R 6 0 W/B adjustment, gradation 6R adjustment value

8 M GAMMA G 6 0 W/B adjustment, gradation 6G adjustment value

9 M GAMMA B 6 0 W/B adjustment, gradation 6B adjustment value

10 M GAMMA WRITE OFF/ON EEP writing of adjustment values

10/11 [ETC]

1 EEP CLEAR OFF/ON Clear of all adjustment value

2 EEP CLEAR B OFF/ON Clear of setting value of B mode

3 STANDBYCAUSE RESET OFF/ON Reset of STANDBY CAUSE

4 AUTO INSTALLATION SW 0/1 1: * * * 0: * * *

5OPTION 0

6 COUNTRY (- -/EURO/UK/ITALY/FRANCE/

RUSSIA)

7 L ERR RESET 0 LAMP ERR RESET Initializatio of L_ERR

8 L ERR STOP 0/1 LAMP ERR Inhibit L_LRR detection

9 I2C-OFF ENTER BUS STOP

11/11 [LCD]

1 OSC FREQ50 62 INVERTER drive frequency setting

2 OSC FREQ60 62 INVERTER drive frequency setting

3 PWM FREQ50 0 Frequency setting for INVERTER dimmer

4 PWM FREQ60 0 Frequency setting for INVERTER dimmer

5 PWM FREQ 409 Dimmer frequency adjustment

6 PWM DUTY 227 Dimmer DUTY adjustment

7 PWM CTRL 0 Dimmer CONTROL adjustment

Destination setting

[6] Special features

* ERROR STANDBY CAUSE (Page 1/11)

The total time when the unit enters the standby due to operational error and cause of error are recorded on EEPROM as much as possible.

The values can be used to locate the fault for repair.

* EEP CLEAR (Page10/11)

Clear of process adjustment EEP value.

5 – 13

Page 29

[7] Video signal adjustment procedure

* The adjustment process mode menu is listed in Section 5.

1. Signal check

1. Signal generator level adjustment check (Adjustment to the specified level)

•Composite signal PAL : 0.7Vp-p ±0.02Vp-p (Pedestal to white level)

•15K component signal : Y level 0.7Vp-p ±0.02Vp-p (Pedestal to white level)

(50 Hz) PB, PR level 0.7Vp-p ±0.02Vp-p

2. EnterinEnter the adjustment process mode

1. Enter the adjustment process mode according to Section 3.

3. RF AGC adjustment

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

PAL

Sprit Field Colour Bar

RF signal UV

[Terminal]

TUNER

•Feed the PAL Sprit Field colour bar signal to TUNER.

Signal level: 52 dB µV +0dB , -1dB (75Ω LOAD)

LC-26SA1E/RU, LC-32SA1E/RU

[RF Signal]

2 Auto adjustment

performance

Adjustment process

Page3

Bring the cursor on [ RF AGC ADJ] and press [OK]

[ RF AGC ADJ OK] appears when finished.

4. RF AGC Adjustment (SMPTE RF SIGNAL- Alternative Method)

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

2 Auto adjustment

performance

PAL

SMPTE Field Color Bar

RF signal UV

[Terminal]

TUNER

Adjustment process

Page6

•Feed the PAL SMPTE color bar signal (E-12ch) to TUNER.

Signal level: 52 ±1dB µV (75Ω LOAD)

Bring the cursor on [ RF AGC ADJ] and press [OK].

[ RF AGC ADJ OK] appears when finished.

㸡100% white

5 – 14

Page 30

LC-26SA1E/RU, LC-32SA1E/RU

5. PAL signal & tuner adjustment

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

PAL

Full Field Color Bar

Composite or RF signal

[Terminal]

EXT3 VIDEO IN

TUNER

•Feed the PAL full field colour bar signal (75% colour saturation) to

EXT3 VIDEO IN.

•Feed the RF signal (PAL colour bar) to TUNER.

•Make sure the PAL colour bar pattern has the sync level of 7:3 with

the picture level.

㪲VIDEO IN SIGNAL]

[RF Signal]

㸡100% white

2 Auto adjustment

performance

Adjustment process

Page3

Bring the cursor on [ PAL + TUNER ADJ] and press [OK]

[ PAL + TUNER ADJ OK] appears when finished.

6. PAL Signal & Tuner Adjustment (SMPTE RF SIGNAL-Alternative Method)

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

PAL

Full Field Color Bar

Composite or RF SMPTE signal

[Terminal]

EXT3 VIDEO IN

TUNER

2 Auto adjustment

performance

Adjustment process

Page6

•Feed the PAL full field color bar signal (75% color saturation) to EXT3

VIDEO IN

•Feed the RF signal SMPTE color bar (E-12) to TUNER.

•Make sure the SMPTE color bar pattern (E-12) has the sync level of

7:3 with the picture level.

Bring the cursor on [ PAL +TUNER ADJ] and press [OK].

[ PAL+ TUNER ADJ OK] appears when finished.

㸡100% white

7. ADC adjustment (Component 15K)

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

COMP15K, 50Hz

100% Full Field Colour Bar

[Terminal]

EXT4 COMPONENT IN

2 Auto adjustment

performance

Adjustment process

Page4

•Feed the COMPONENT 15K 100% full field colour bar signal (100%

colour saturation) to EXT4 COMPONENT IN.

100% white

Bring the cursor on [ COMP15K ADJ] and press [OK]

[ COMP15K ADJ OK] appears when finished.

5 – 15

Black

Page 31

LC-26SA1E/RU, LC-32SA1E/RU

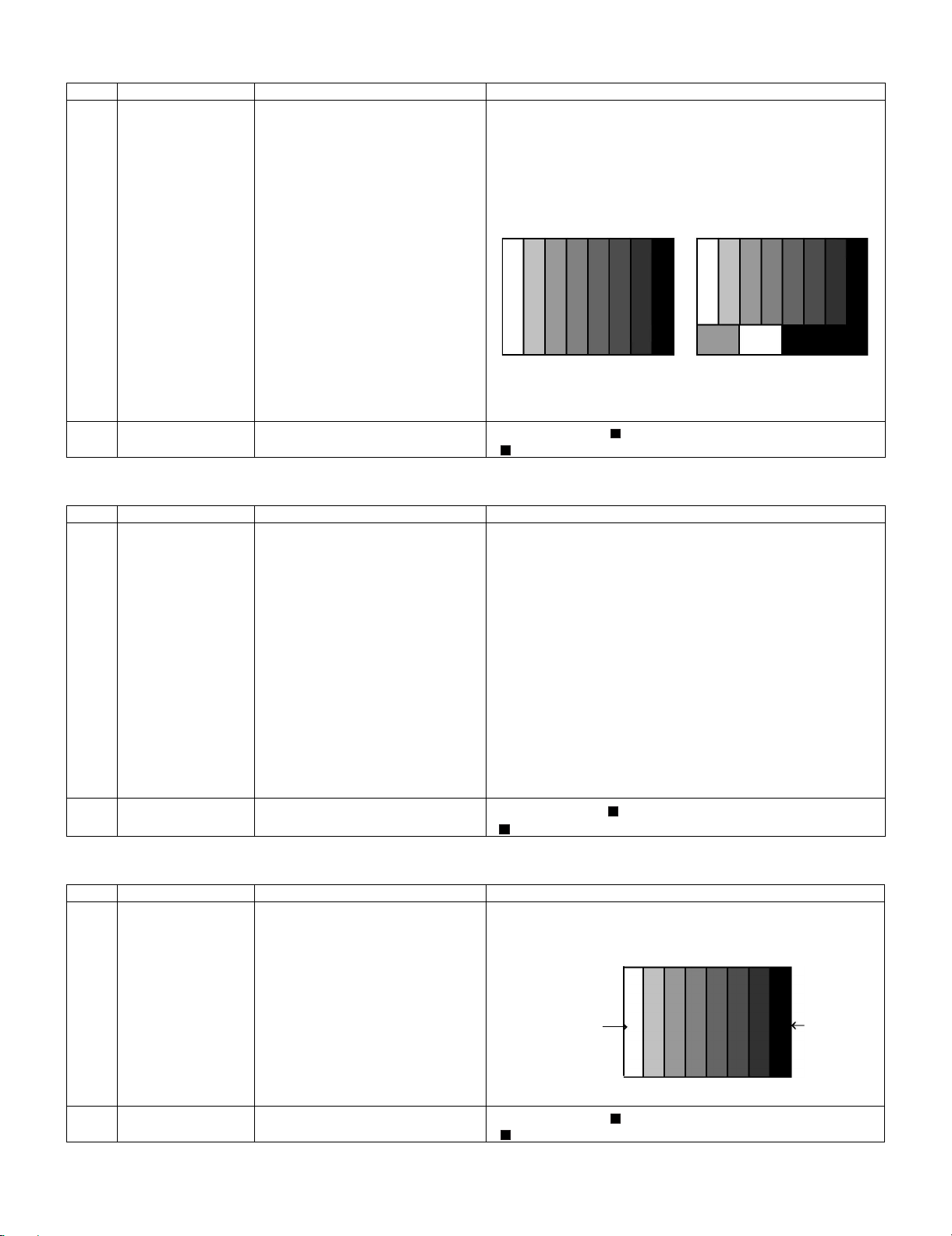

[8] White Balance Adjustment

Adjustment gradation values (IN) appear on page 7/11 of process adjustment, and adjustment initial values (offset value) appear on pages 8/11 and

9/11. For white balance adjustment, adjust the offset values on pages 8/11 and 9/11.

[Condition of the unit for inspection] Modulated light: MAX (+8)

[Adjustment reference device] Minolta CA-210

[Adjustment]

Check that the values on page 7/11 of process adjustment are set as below. If not, change them accordingly.

M GAMMA IN 1 160 M GAMMA IN 2 320

M GAMMA IN 3 480 M GAMMA IN 4 640

M GAMMA IN 5 800 M GAMMA IN 6 960

1) Display the current adjustment status at point 6. (Page 8/11 of process adjustment)

The display for checking the adjustment status is toggled by pressing the “6” button on the remote control.

(Normal OSD display → “6”→ display for check (OSD disappears) → “6” →normal OSD display → • • •)

2) Read the value of the luminance meter.

3) Change M GAMMA R6/M GAMMA B6 (Adjustment offset value) on page 9/11 of process adjustment so that the values of the luminance meter

approach x =0.272 and y =0.277.

(Basically, G is not changed. If adjustment fails with R and B, change G. When G is lowered, the weaker of R and B must be fixed.)

4) If G is changed in step 3), change the values of M GAMMA G1- M GAMMA G5 on pages 8/11 and 9/11 of process adjustment as follows. When

not changed, go to step5).

Offset value of M GAMMA G1 = (Offset value of M GAMMA G6) * (160/960)

Offset value of M GAMMA G2 = (Offset value of M GAMMA G6) * (320/960)

Offset value of M GAMMA G3 = (Offset value of M GAMMA G6) * (480/960)

Offset value of M GAMMA G4 = (Offset value of M GAMMA G6) * (640/960)

Offset value of M GAMMA G5 = (Offset value of M GAMMA G6) * (800/960)

5) Display the adjustment status of the current point 5. (Each time the “5” button on the remote control is pressed, the adjustment status check display is toggled.)

(Normal OSD display → “5” → Check display (OSD disappears) → “5” → Normal OSD display → • • •)

Change M GAMMA R5/M GAMMA B5 (adjustment offset value) on page 9/11 of process adjustment so that the values of the luminance meter

approach x = 0.272 and y = 0.277.

6) Repeat step 5) for points 4, 3, 2, and 1.

5 – 16

Page 32

LC-26SA1E/RU, LC-32SA1E/RU

[9] QS Temperature NVM Data Confirmation

During servicing of the LCD TV set , by software upgrading or by any cleaning NVM, itÅfs mandatory select the ÅgInch SettingÅh in Service Mode,

Page 2, according to the size of the TV set.

[10] Initialization to factory settings

Caution: When the factory settings have been made, all user setting data, including the channel settings, are initialized. (The adjust-

ments done in the adjustment process mode are not initialized.) Keep this in mind when initializing these settings.

Adjustment item Adjustment conditions Adjustment procedure

1 Factory settings Forcibly turn off the power

(See to below caution)

After adjustments, exit the adjustment process mode.

To exit the adjustment process mode, unplug the AC power cord from the outlet to forcibly turn off the power.

When the power is turned off with the remoto control, unpulug the AC power cord and plug it back in.

•Enter the adjustment process mode.

•Move the cursor to [Factory Init] on page 2/11.

•Use the R/C key to select a region from [EURO/UK/ITALY/

FRANCE/RUSSIA]and press the [OK] key.

“EXECUTING” appears and initialization starts.

After a while,”***OK***” appears and the setting is complete.

Note: Never turn the power off during initialization.

•The following items are initialized in the factory setting.

1. User settings

2. Channel data (e.g. broadcast frequencies)

3. Password data

5 – 17

Page 33

LC-26SA1E/RU, LC-32SA1E/RU

[1 1] Lamp error detection

1. Functional description

This LCD colour television has a function (lamp error detection) to be turned OFF automatically (Inverter unit) for safety when the lamp or lamp circuit

is abnormal.

If the lamp or lamp circuit is abnormal, or some other errors happen, and the lamp error detection is executed, the following occur.The Inverter circuit

stops but the rest of TV continues working. The power led is green.

2. Countermeasures

Proceed to repair the inverter unit to solve the problem that produces the lamp error.

3. Reset standby cause error list

For 26/32” this is not necessary because the lamp error detection is not operative by software.

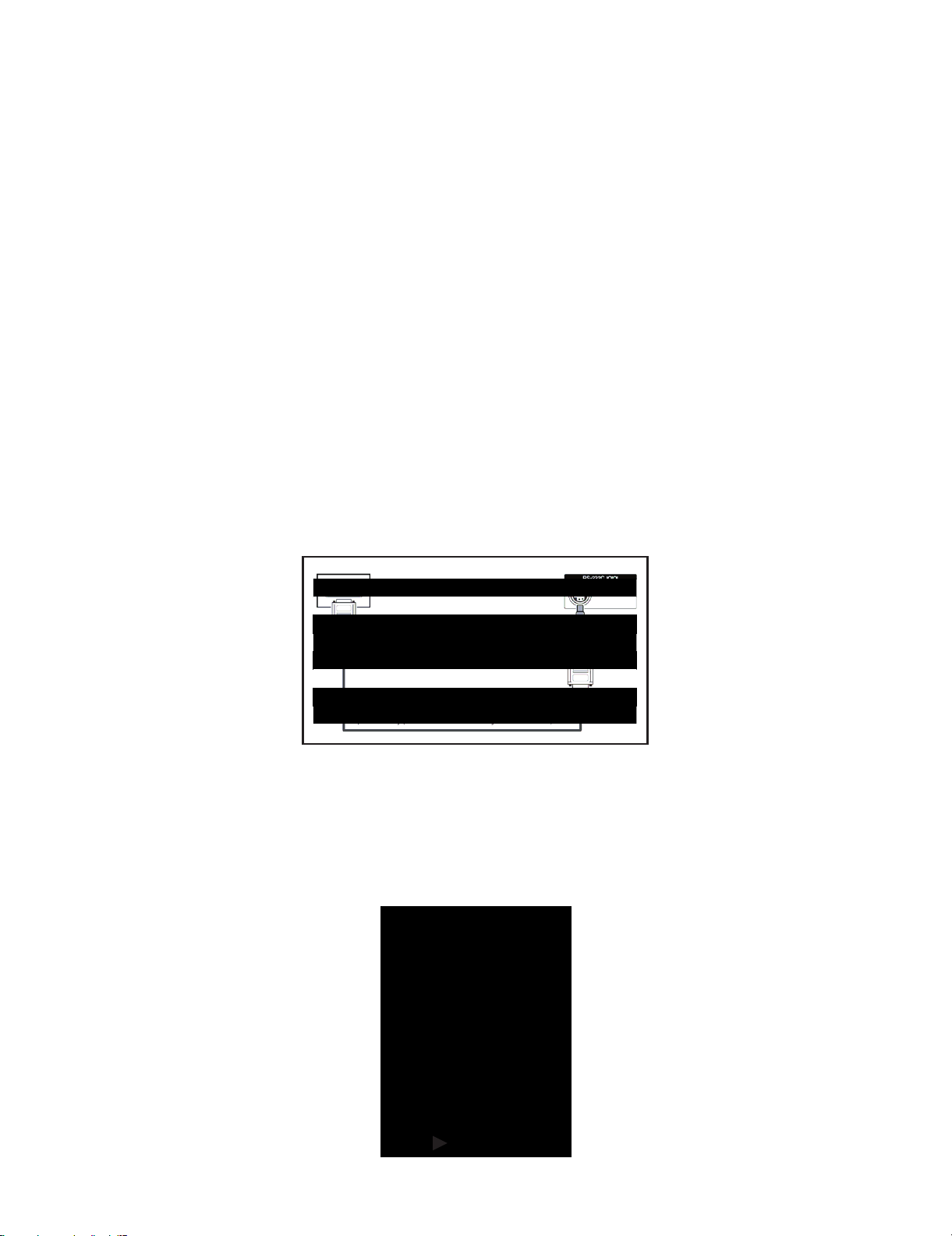

[12] Public Mode (Hotel Mode)

1. How to Enter in the Public Mode (Hotel Mode).

Turn on the power and enter in the Adjustment Process mode (ADJ1 or Service Mode) as usual.

In the [INIT], Page 2/11 of Service, turns ON the Public Mode option.

Turn off TV by pressing Main Power switch.

While pressing “VOL+” and “P^” keys at the same time, press Main Power switch for more than 2 seconds.

After this sequence the TV will turn on showing the Public Mode setting screen as follows:

Is possible to select each item of function by pressing cursor UP/DOWN keys on the remote control or CH( )( ) keys on the LCD TV.

The setting position of each item of functions is made by pressing cursor RIGHT/LEFT keys on the remote control or VOL(+)(-) keys on the LCD TV.

Select EXECUTE position after you set all function, and press cursor RIGHT/LEFT keys on the remote control or VOL(+)/(-) keys on the LCD TV for

confirmation.

2. Public Mode Settings.

1. POWER ON FIXED [VARIABLE ↔ FIXED]

When it is set to “FIXED” the TV is impossible to be switch off by Main Switch or Remote Control.

2. MAXIMUM VOLUME [0 ↔ 60]

Is possible to set the maximum volume at limited level.

3. VOLUME FIXED [VARIABLE ↔ FIXED]

Is possible to fix the sound volume at limited level.

When “FIXED” is selected the sound volume before limited is fixed.

4. VOLUME FIXED LEVEL [0 ↔ 60]

If “FIXED” has been selected, is possible to set a fixed volume at the level that is chosen.

5. RC BUTTON [RESPOND ↔ NO RESPOND]

If “NO RESPOND” is selected, the remote control keys are inoperative.

6. PANEL BUTTON [RESPOND ↔ NO RESPOND]

If “NO RESPOND” has been selected, the set’s keys remain deactivated (Except POWER key).

7. MENU BUTTON [RESPOND ↔ NO RESPOND]

5 – 18

Page 34

LC-26SA1E/RU, LC-32SA1E/RU

If “NO RESPOND” has been selected, “MENU” key, of remote control, is inoperative.

8. ON SCREEN DISPLAY [YES ↔ NO]

If “NO” has been selected, the On Screen Display does not appear.

9. INPUT MODE START [ NORMAL → TV (X) → INPUT1 → INPUT2 → INPUT3 → INPUT4 → INPUT5 ]

When any other item than “NORMAL” has been selected, the sets will start in a selected input mode at the next power-on.

10.INPUT MODE FIXED [VARIABLE → FIXED]

“FIXED” has been selected, any channels and input modes other than those selected at the start mode cannot be picked up.

11.RESET

Cancel all Public Mode settings. (It returns to the factory settings)

12.EXECUTE

Select this item, and press cursor RIGHT/LEFT keys on the remote control or VOL(+)/(-) keys on the LCD TV for confirmation the functions set-

tings.

5 – 19

Page 35

LC-26SA1E/RU, LC-32SA1E/RU

LC-26SA1E

CHAPTER 6. TROUBLESHOOTING TABLE

Service Manual

[1] TROBLESHOOTING TABLE

Power unit operation check.

Are the power cord and harness in the unit properly connected? NO Connect the power cord and harness properly, and turn on the

power.

YES

Is F701 normal? NO Are both ends of C704, C707 (26) and C705 (32) short-circuited

when checking their resistance values?

NO

Replace F701.

YES

Is a voltage of BU5V applied to pin (20) of P701?

(Set the main power SW to OFF.)

NO

Is a voltage of approx.

8 - 15V to pin (4) of

IC705?

YES

Check short circuit of 5V line (D737,

C752, etc.).

YES

Is it a symptom that the relay clatters twice as soon as the main

power SW is set to ON and the power is not supplied?

YES

Does the same symptom appear even if R858 (2.7k) is

removed and the power is supplied again?

YES

Check Q724, D731, D734, IC707, D751, D753, D754,

D741, D759 and D746.

C704 ••• Check VA701, VA702 and D701.

C707 (26)/C705 (32) ••• Check IC704 and 705.

NO Check IC705, IC708, D725 and Q724.

Check IC704, D728, D762 and D736. If there are no problems,

NO

check the resistance value between pins (1) and (6) of P704.

When the value is low (several Ω - several hundred Ω),

disconnect P704. If the value is still low, the parts of 24V line are

defective. When the resistance value is several kΩ, check the

inverter unit.

YES

NO

Does a relay noise sound? (Once) NO Are PCON1 and 2 [pins (1) and (2) of P702] at Hi (3V or more)?

YES YES

Check peripheral circuits of D738, R828 and D735. Check peripheral circuits of Q712, Q713, Q721, Q723

and RY701.

There is a possibility that control by P-CON is not performed

properly. Check whether the “PS-ON” and “PS-ON2” signals are

sent from pins (97) and (91) of IC1710 (FPGA) of MAIN-UNIT.

NO

6 – 1

Page 36

LC-26SA1E/RU, LC-32SA1E/RU

No sound (1) (during the reception of TV broadcasting)

No audio output during UHF/VHF reception

Checklist;

1) Is the volume set to MIN or MUTE on the remote control? ••• Set the desired volume.

2) Are headphones connected to HEADPHONE (J1301)? ••• Disconnect them.

3) Is ANT-CABLE disconnected or connected improperly? ••• Connect it correctly as per the operation manual.

Is the audio signal (L/R)

sent from pins (28) and

(27) of IC3002 (VCT)?

(AV-UNIT) YES NO

Is the audio signal of pins

(3) and (5) of IC303

(OP-AMP) sent properly?

YES (TUNER) NO

Is the audio signal of pin

(4) Of IC301/IC302

(AUDIO-AMP) sent

properly?

NO Check IC303 or

NO Check HEAD-PHONE

NO

peripheral circuits.

(J1301) or peripheral

circuits.

Is the SIF signal (SIF_IN+)

sent to pin (31) of IC3002

(VCT)?

Is the audio signal (SIF)

sent from pin (1) of

CONNECTOR (SC2705)?

Is the audio signal (SIF)

sent from pin (12) of IC201

(IF-DEMOD)?

Check whether +5V and

YES

YES Check pin (31) of IC3002

YES Check Q203 (AMP) and

+8V are supplied to pins

(33) and (18) of IC3002

respectively. Or, check

peripheral circuits.

(VCT) and peripheral

circuits.

peripheral circuits.

YES NO

Is the audio signal output

of pins (2) and (4) of P301

(AUDIO-CONNECTOR)

normal?

YES NO

Check Speaker (right and

left) and wire harness.

Check whether 33V and

NO Check P301 (AUDIO-

CONNECTOR) and

peripheral circuits.

Is the SIF signal sent to

pins (23) and (24) of IC201

(IF-DEMOD)?

Is the IF signal sent from

pin (11) of TUNER

(TU201)?

NO

5V are supplied to pins (9)

and (7) of TUNER (TU201)

respectively. Check SDA/

SCL and AGC signal.

YES Check IC201 and

peripheral circuits.

YES Check FL202 and

peripheral circuits.

YES Replace TUNER (TU201).

6 – 2

Page 37

No sound from external input devices (2)

No sound from an external input device connected to EXT1

(SCART1).

<EXT1>

Is IN1-L audio signal sent from pin (6) of SCART1 terminal

(J1101) to pin (14) of IC3002 (VCT)?

Is IN1-R audio signal sent from pin (2) of SCART1 terminal

(J1101) to pin (13) of IC3002 (VCT)?

YES

Is the audio signal properly sent from pins (28) and (27) of

IC3002?

YES

Is the audio signal of pins (1) and (7) of IC303 (OP-AMP) sent

properly?

YES

Is the audio output signal of pins (13) and (16) of IC302/IC301

(MAIN-AMP) normal?

LC-26SA1E/RU, LC-32SA1E/RU

NO Check pins (6) and (2) of SCART1 and connection to an external

input device.

NO Check IC3002 or peripheral circuits.

NO Check IC303 or peripheral circuits.

NO Check IC302/IC301 (MAIN-AMP), HEADPHONE and peripheral

circuits.

YES

Check CONNECTOR (P301) and Speaker (right and left).

No sound from external input devices (2)

No sound from an external input device connected to EXT2

(SCART2).

<EXT2>

Is IN2-L audio signal sent from pin (27) of SCART2 terminal

(J1101) to pin (12) of IC3002 (VCT)?

Is IN2-R audio signal sent from pin (23) of SCART2 terminal

(J1101) to pin (11) of IC3002 (VCT)?

YES

Is the audio signal properly sent from pins (28) and (27) of

IC3002?

YES

Is the audio signal of pins (1) and (7) of IC303 (OP-AMP) sent

properly?

NO Check pins (27) and (23) of SCART2 and connection to an

external input device.

NO Check IC3002 or peripheral circuits.

NO Check IC303 or peripheral circuits.

YES

Is the audio output signal of pins (13) and (16) of IC302/IC301

(MAIN-AMP) normal?

YES

Check CONNECTOR (P301) and Speaker (right and left).

NO Check IC302/IC301 (MAIN-AMP), HEADPHONE and peripheral

circuits.

6 – 3

Page 38

LC-26SA1E/RU, LC-32SA1E/RU

No sound from external input devices (2)

No sound from an external input device connected to EXT3.

<EXT3>

Is IN3-L audio signal sent from pin (3) of J1201 terminal to pin

(16) of IC3002?

Is IN3-R audio signal sent from pin (5) of J1201 terminal to pin

(15) of IC3002?

YES

Is the audio signal properly sent from pins (28) and (27) of

IC3002?

YES

Is the audio signal of pins (1) and (7) of IC303 (OP-AMP) sent

properly?

YES

Is the audio output signal of pins (13) and (16) of IC302/IC301

(MAIN-AMP) normal?

NO Check pins (3) (J1201) and (5) (J1201) of EXT3 and connection

to an external input device.

NO Check IC3002 or peripheral circuits.

NO Check IC303 or peripheral circuits.

NO Check IC302/IC301 (MAIN-AMP), HEADPHONE and peripheral

circuits.

YES

Check CONNECTOR (P301) and Speaker (right and left).

No sound from external input devices (2)

No sound from EXT4 (AUDIO) connecting an external input

device.

<EXT4>

Is D-SUB-L audio signal sent from J2702 to pin (15) of IC2704?

Is D-SUB-R audio signal sent from J2702 to pin (2) of IC2704?

YES

Is D-SUB-L audio signal sent to pin (10) of IC3002?

Is D-SUB-R audio signal sent to pin (9) of IC3002?

YES

Is the audio signal properly sent from pins (28) and (27) of

IC3002?

YES

Is the audio signal of pins (1) and (7) of IC303 (OP-AMP) sent

properly?

NO Check IC3002 or peripheral circuits.

NO Check IC303 or peripheral circuits.

YES

Is the audio output signal of pins (13) and (16) of IC302/IC301

(MAIN-AMP) normal?

YES

Check CONNECTOR (P301) and Speaker (right and left).

NO Check IC302/IC301 (MAIN-AMP), HEADPHONE and peripheral

circuits.

6 – 4

Page 39

No sound from external input devices (2)

No sound from EXT5 (AUDIO) connecting an external input

device.

<EXT5>

Is HDMI-L audio signal sent from J2701 to pin (14) of IC2704?

Is HDMI-R audio signal sent from J2701 to pin (5) of IC2704?

YES

Is HDMI-L audio signal sent to pin (10) of IC3002?

Is HDMI-R audio signal sent to pin (9) of IC3002?

YES

Check that Option-HDMI Setup-Audio select is set to “Analog”.

OK

Is the audio signal properly sent from pins (28) and (27) of

IC3002?

YES

Is the audio signal of pins (1) and (7) of IC303 (OP-AMP) sent

properly?

LC-26SA1E/RU, LC-32SA1E/RU

NO Check output of pins (13) and (3) of IC2704 and peripheral

circuits.

NO Check IC3002 or peripheral circuits.

NO Check IC303 or peripheral circuits.

YES

Is the audio output signal of pins (13) and (16) of IC302/IC301

(MAIN-AMP) normal?

YES

Check CONNECTOR (P301) and Speaker (right and left).

No sound except from speakers (3)

No audio output from the headphones.

Is there audio output on pins (2) and (3) of the headphone

terminal (J1301)?

NO

Is audio input/output signal of pins (3) and (5)/(1) and (7) of IC303

(OP-AMP) normal?

NO

Is audio output signal (SPK-OUT L/R) properly sent from pins

(28) and (27) of IC3002 (VCT)?

NO

Check audio input signal of pin (31) of IC3002 (VCT), pins (18)

and (33) of the power line, pins (84) and (83) of I2C-LINE, and

peripheral circuits.

NO Check IC302/IC301 (MAIN-AMP), HEADPHONE and peripheral

circuits.

6 – 5

Page 40

LC-26SA1E/RU, LC-32SA1E/RU

No sound except from speakers (3)

No audio output from EXT1 (SCART) terminal.

Checklist:

1) Is the MUTE button on the remote control set to ON? ••• Set to OFF.

2) Check the connection to external devices. ••• Is there any improper connection?

Is audio signal sent to pins (3) and (1) of EXT1 (J1101)? YES Check the connection to EXT1 (J1101) and external devices.

NO

Is S-MUTE-LINE [IC1710 (pin 100)] at H?

(Check Q1106/Q1105 operation.)

NO

Is audio signal sent from pins (24) and (23) of IC3002? NO Check the power supply 8/5 V pins (18) and (33) of IC3002 and

peripheral circuits.

YES

Check the audio signal output line from pins (24) and (23) of

IC3002 to pins (3) and (1) of EXT1.

No sound except from speakers (3)

No audio output from EXT2 (SCART) terminal.

Checklist:

1) Is the MUTE button on the remote control set to ON? ••• Set to OFF.

2) Check the connection to external devices. ••• Is there any improper connection?

Is audio signal sent to pins (24) and (22) of EXT2 (J1101)? YES Check the connection to EXT2 (J1101) and external devices.

NO

Is S-MUTE-LINE [IC1710 (pin 100)] or S2-MUTE-LINE [IC3003

(pin 26)] at H? (Check Q1102/Q1101 operation.)

NO

Is audio signal sent from pins (22) and (21) of IC3002? NO Check the power supply 8/5 V pins (18) and (33) of IC3002 and

peripheral circuits.

YES

Check the audio signal output line from pins (22) and (21) of

IC3002 to Q1103/Q1104/Q1201/Q1202.

6 – 6

Page 41

LC-26SA1E/RU, LC-32SA1E/RU

No sound except from speakers (3)

No audio output from AUDIO OUTPUT terminal.

Checklist:

1) Is the MUTE button on the remote control set to ON? ••• Set to OFF.

2) Check the connection to external devices. ••• Is there any improper connection?

Is audio signal sent to pins (13) and (15) [L/R (white) (red)] of

AUDIO OUTPUT terminal (J1201)?

NO

Is S-MUTE-LINE [IC1710 (pin 100)] at H?

(Check Q1204/Q1203 operation.)

NO

Is audio signal sent from pins (22) and (21) of IC3002? NO Check the power supply 8/5 V pins (18) and (33) of IC3002 and

YES

Check the audio signal output line from pins (22) and (21) of

IC3002 to Q1103/Q1104/Q1201/Q1202.

YES Check the connection to AUDIO OUTPUT terminal (J1201) and

external devices.

peripheral circuits.

6 – 7

Page 42

LC-26SA1E/RU, LC-32SA1E/RU

<On input of the tuner (U/V)> No picture on the display (1)

No picture appears on LCD during the tuner (U/V) reception.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “TV”.

2) Is MENU-PICTURE-Contrast/Brightness set to “MIN”? ••• Set it to an appropriate level.

3) Is ANT-CABLE disconnected or connected improperly? ••• Connect it correctly as per the operation manual.

YES

Is level of pins (4) and (5) of tuner (TU201) and pins (10) and (11)

of IC201 (IF-DEMOD) at H?

YES

Is the video signal (IF) sent from pin (11) of tuner (TU201)? NO Check the tuner (TU201) and peripheral circuits.

YES

Is video signal sent from pin (17) of IC201 (IF-DEMOD)? NO Check FL201 (SAW-FIL), IC201 and peripheral circuits.

YES

Is the video signal VIN1 (ATUNER-CVBS) sent to pin (191) of

lC3002 (VCT)?

NO These are communications lines for control (I2C). Follow the

path and check whether they are forced to L (PULL_DOWN).

NO Check IC201 (IF-DEMOD), CONNECTOR (P201 /SC2705) and

peripheral circuits.

YES

Is LVDS video signal (LVDS_0N/0P-3N/3P) sent to pins (141)/

(140) - (129)/(128) of IC3002 (VCTP), and is CLK signal

(LVDS_CN/CP) sent to pins (132)/(131)?

YES

Is LVDS video signal (LVDS_0N/0P-3N/3P) sent to pins (12)/(13)

-(24)/(25) of CONNECTOR CN1 of LCD-CONT-UNIT, and is CLK

signal (LVDS_CN/CP) sent to pins (21)/(22)?

YES

Is power (LCD5V) supplied to pins (2) - (5) of CONNECTOR CN1

in LCD-CONT-UNIT?

YES

Replace LCD-CONT-UNIT.

NO Check pins (192)/(170)/(133) of BU3.3V line of IC3002 (VCTP),

pins (185)/(169)/(142) of 1.8V line and peripheral circuits.

NO Check CONNECTOR (P2305, CN1) and HARNESS WIRE (LV).

NO Is LCD5V supplied to pins (31) - (28) of CONNECTOR (P2305)?

Check HARNESS WIRE (LV).

6 – 8

Page 43

LC-26SA1E/RU, LC-32SA1E/RU

<During external connection> No picture on the monitor (2)

SCART1:

No picture appears on EXT1 - connected monitor during the tuner

(U/V) reception.

Checklist:

1) Are input terminal on back of TV and “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and

set “INPUT SOURCE” appropriately.

2) Is the Signal Type (item) in MENU-Option-Input Select equal to Signal Type of an external device? ••• Set it to “CVBS”, “Y/C” or “RGB”.

3) Is ANT-CABLE disconnected or connected improperly? ••• Connect it correctly as per the operation manual.

4) The picture is sent to the monitor in a CVBS signal if the source during display is TV, CVBS or Y/C of EXT1-3.

When sent by component, etc., that signal is not sent to the monitor.

5) When the monitor picture is not sent and is not displayed on the monitor, refer to “No picture” for each terminal.

6) The video output from EXT1 is not the monitor output (output of the picture now watching).

The picture of the last selected TV channel is always sent to EXT1. (Specification)

Is video signal sent to pin (19) of SCART1 (J1101)? YES Check SCART1, external connection or input setting.

NO

Is video signal (V-OUT1) sent from pin (2) of IC1102 (SW)? YES Check SCART1 (J1101) and peripheral circuits.

NO

Is video signal (V-OUT1) sent from pin (195) of IC3002 (VCT)? YES Check IC1102 (SW), Connector (P1 101, SC2702) and peripheral

circuits.

NO

Is video signal (CVBS) sent to pin (191) of lC3002 (VCT)? YES Check power supply of IC3002 (VCT) and peripheral circuits.

NO

Is video signal (CVBS) sent from pin (17) of IC201 (IF-DEMOD)? YES Check CONNECTOR (P201, SC2705) and peripheral circuits.

NO

Is video signal (IF) sent from pin (11) of tuner (TU201)? YES Check IC201, FL201 (SAW-FIL), Q202 and peripheral circuits.

NO

Check 5/35 V power supply pins (7) and (9), I2C line pins (5) and

(4) of tuner (TU201) and peripheral circuits.

6 – 9

Page 44

LC-26SA1E/RU, LC-32SA1E/RU

<During external connection> No picture on the monitor (2)

SCART2:

No picture from EXT1 appears on EXT2-connected monitor.

NOTE: Normally, if the screen during display is sent to EXT2, no

picture is sent to EXT2.

Checklist:

1) Are input terminal on back of TV and “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and

set “INPUT SOURCE” appropriately.

2) Is the Signal Type (item) in MENU-Option-Input Select equal to Signal Type of an external device? ••• Set it to “CVBS”, “Y/C” or “RGB”.

3) Is ANT-CABLE disconnected or connected improperly? ••• Connect it correctly as per the operation manual.

4) The picture is sent to the monitor in a CVBS signal if the source during display is TV, CVBS or Y/C of EXT1-3.

When sent by component, etc., that signal is not sent to the monitor.

5) When the monitor picture is not sent and is not displayed on the monitor, refer to “No picture” for each terminal.

6) The video output from EXT1 is not the monitor output (output of the picture now watching).

The picture of the last selected TV channel is always sent to EXT1. (Specification)

Is video signal sent to pin (40) of SCART2 (J1101)? YES Check SCART2, external connection or input setting.

NO

Is video signal (V-OUT2) sent from pin (2) of IC1101 (SW)? YES Check SCART2 (J1101) and peripheral circuits.

NO

Is video signal (V-OUT2) sent from pin (194) of IC3002 (VCT)? YES Check IC1101 (SW), Connector (P1 102, SC2703) and peripheral

NO

Is video signal (VIN1) from EXT1 sent to pin (190) of IC3002

(VCT)?

NO

Check whether video signal is sent to pin (20) of SCART1. YES Check SCART1, IC2702 (SW), CONNECTOR (SC2702, P1101)

NO

Check SCART1, external connection or input setting.

YES Check power supply of IC3002 (VCT) and peripheral circuits.

circuits.

and peripheral circuits.

6 – 10

Page 45

LC-26SA1E/RU, LC-32SA1E/RU

<During external connection> No picture on the monitor (2)

SCART2:

No picture from EXT3 appears on EXT2- connected monitor.

Checklist:

1) Are input terminal on back of TV and “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and

set “INPUT SOURCE” appropriately.

2) Is the Signal Type (item) in MENU-Option-Input Select equal to Signal Type of an external device? ••• Set it to “CVBS”, “Y/C” or “RGB”.

3) Is ANT-CABLE disconnected or connected improperly? ••• Connect it correctly as per the operation manual.

4) The picture is sent to the monitor in a CVBS signal if the source during display is TV, CVBS or Y/C of EXT1-3.

When sent by component, etc., that signal is not sent to the monitor.

5) When the monitor picture is not sent and is not displayed on the monitor, refer to “No picture” for each terminal.

6) The video output from EXT1 is not the monitor output (output of the picture now watching).

The picture of the last selected TV channel is always sent to EXT1. (Specification)

Is video signal sent to pin (40) of SCART2 (J1101)? YES Check SCART2, external connection or input setting.

NO

Is video signal (V-OUT2) sent from pin (2) of IC1101 (SW)? YES Check SCART2 (J1101) and peripheral circuits.

NO

Is video signal (V-OUT2) sent from pin (194) of IC3002

(VCT)?

NO

Is video signal (VIN7) from EXT3 sent to pin (184) of IC3002

(VCT)?

NO

Is video signal (IN3YV) sent to pin (2) of IC1201 (SW)? YES Check pin (184) of IC3002 (VCT), CONNECTOR (SC2703,

NO

Is video signal (CVBS) sent from pin (1) of A/V-TERMINAL

(J1201=EXT3)?

NO

Check A/V-TERMINAL (J1201), external connection or input

setting.

YES Check IC1101 (SW), Connector (P1 102, SC2703) and peripheral

circuits.

YES Check power supply of IC3002 (VCT) and peripheral circuits.

P1102) and peripheral circuits.

YES Check pin (1) (IN3SW) of IC1201 (SW), power supply and

peripheral circuits.

6 – 11

Page 46

LC-26SA1E/RU, LC-32SA1E/RU

<When EXT1 is used for external input> No picture on the display (3)

No EXT1-Composite output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXIT”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is composite video signal sent to pin (20) of SCART1 (J1101)? NO Check external connection, input setting, SCART1 and

YES

Is composite video signal (VIN_1) sent to input terminal pin (6) of

IC2702 (SW)?

YES

Is composite video signal (CVBS1=VIN2) sent to input terminal

pin (190) of IC3002 (VCT)?

YES

Is LVDS signal (LVDS_0N/0P-3N/3P) sent from pins (141) and

(140) - (129) and (128) of IC3002 (VCTP), and is CLK signal

(LVDS_CN/CP) sent from pins (132) and (131)?

NO Check CONNECTOR (SC2702/P1101), SCART1 (J1101) and

NO Check IC2702 (SW) and peripheral circuits.

NO Check pins (192), (170) and (133) of BU3.3V power line and pins

peripheral circuits.

peripheral circuits.

(185), (169) and (142) of BU1.8V power line of IC3002 (VCTP),

and peripheral circuits.

YES

Is LVDS signal (LVDS_0N/0P-3N/3P) sent to pins (12) and (13) -

(24) and (25) of CONNECTOR CN1 in LCD-CONT-UNIT, and is

CLK signal (LVDS_CN/CP) sent to pins (21) and (22)?

YES

Is power (LCD5V) supplied to pins (2) - (5) of CONNECTOR CN1

in LCD-CONT-UNIT?

YES

Replace LCD-CONT-UNIT.

NO Check CONNECTOR (P2305, CN1) and HARNESS WIRE (LV).

NO Is LCD5V supplied to pins (31) - (28) of CONNECTOR (P2305)?

Check HARNESS WIRE (LV).

6 – 12

Page 47

LC-26SA1E/RU, LC-32SA1E/RU

<When EXT1 is used for external input> No picture on the display (3)

No EXT1-RGB output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXIT”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is RGB signal sent to pins (15),(11) and (7) of SCART1 (J1101)? NO Check external connection, input setting, SCART1 (J1101) and

peripheral circuits.

YES

Is RGB signal (R1/G1/B1=VIN_6/5/9) sent to input terminal pins

(187), (175) and (182) of IC3002 (VCT)?

YES

Is LVDS signal (LVDS_0N/0P-3N/3P) sent from pins (141) and

(140) - (129) and (128) of IC3002 (VCTP), and is CLK signal

(LVDS_CN/CP) sent from pins (132) and (131)?

NO Check CONNECTOR (SC2702/P1101), SCART1 (J1101) and

peripheral circuits.

NO Check pins (192), (170) and (133) of BU3.3V power line and pins

(185), (169) and (142) of BU1.8V power line of IC3002 (VCTP),

and peripheral circuits.

YES

Is LVDS signal (LVDS_0N/0P-3N/3P) sent to pins (12) and (13) (24) and (25) of CONNECTOR CN1 in LCD-CONT-UNIT, and is

CLK signal (LVDS_CN/CP) sent to pins (21) and (22)?

YES

Is power (LCD5V) supplied to pins (2) - (5) of CONNECTOR CN1

in LCD-CONT-UNIT?

YES

Replace LCD-CONT-UNIT.

NO Check CONNECTOR (P2305, CN1) and HARNESS WIRE (LV).

NO Is LCD5V supplied to pins (31) - (28) of CONNECTOR (P2305)?

Check HARNESS WIRE (LV).

6 – 13

Page 48

LC-26SA1E/RU, LC-32SA1E/RU

<When EXT1 is used for external input> No picture on the display (3)

No EXT1-Y/C output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXIT”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is Y/C signal sent to pins (20) and (15) of SCART1 (J1101)? NO Check external connection, input setting, SCART1 (J1101) and

YES

Is Y/C signal (VIN1=Y1/C1) sent to input terminal pins (190) and

(187) of IC3002 (VCT)?

YES

Is LVDS signal (LVDS_0N/0P-3N/3P) sent from pins (141) and

(140) - (129) and (128) of IC3002 (VCTP), and is CLK signal

(LVDS_CN/CP) sent from pins (132) and (131)?

YES

Is LVDS signal (LVDS_0N/0P-3N/3P) sent to pins (12) and (13) (24) and (25) of CONNECTOR CN1 in LCD-CONT-UNIT, and is

CLK signal (LVDS_CN/CP) sent to pins (21) and (22)?

NO Check CONNECTOR (SC2702/P1101), SCART1 (J1101) and

NO Check pins (192), (170) and (133) of BU3.3V power line and pins

NO Check CONNECTOR (P2305, CN1) and HARNESS WIRE (LV).

peripheral circuits.

peripheral circuits.

(185), (169) and (142) of BU1.8V power line of IC3002 (VCTP),

and peripheral circuits.

YES

Is power (LCD5V) supplied to pins (2) - (5) of CONNECTOR CN1

in LCD-CONT-UNIT?

YES

Replace LCD-CONT-UNIT.

NO Is LCD5V supplied to pins (31) - (28) of CONNECTOR (P2305)?

Check HARNESS WIRE (LV).

6 – 14

Page 49

LC-26SA1E/RU, LC-32SA1E/RU

<When EXT2 is used for external input> No picture on the display (4)

No EXT2-Composite output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXT2”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is composite video signal sent to pin (41) of SCART2 (J1101)? NO Check external connection, input setting, SCART2 (J1101) and

peripheral circuits.

YES

Is composite video signal (VIN-2) sent to input terminal pin (4) of

IC2702 (SW)?

YES

Is composite video signal (CVBS2=VIN2) sent to input terminal

pin (190) of IC3002 (VCT)?

YES

Is LVDS signal (LVDS_0N/0P-3N/3P) sent from pins (141) and

(140) - (129) and (128) of IC3002 (VCTP), and is CLK signal

(LVDS_CN/CP) sent from pins (132) and (131)?

NO Check CONNECTOR (SC2702/Pl101), SCART2 (J1101) and

peripheral circuits.

NO Check IC2702 (SW) and peripheral circuits.

NO Check pins (192), (170) and (133) of BU 3.3V power line and

pins (185), (169) and (142) of BU1.8V power line of IC3002

(VCTP), and peripheral circuits.

YES

Is LVDS signal (LVDS_0N/0P-3N/3P) sent to pins (12) and (13) (24) and (25) of CONNECTOR CN1 in LCD-CONT-UNIT, and is

CLK signal (LVDS_CN/CP) sent to pins (21) and (22)?

YES

Is power (LCD5V) supplied to pins (2) - (5) of CONNECTOR CN1

in LCD-CONT-UNIT?

YES

Replace LCD-CONT-UNIT.

NO Check CONNECTOR (P2305, CN1) and HARNESS WIRE (LV).

NO Is LCD5V supplied to pins (31) - (28) of CONNECTOR (P2305)?

Check HARNESS WIRE (LV).

6 – 15

Page 50

LC-26SA1E/RU, LC-32SA1E/RU

<When EXT2 is used for external input> No picture on the display (4)

No EXT2-RGB output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXT2”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is RGB signal sent to pins (36), (32) and (28) of SCART2

(J1101)?

YES

Is RGB signal (R2/G2/B2=VIN_15/16/17) sent to Input terminal

pins (178), (177) and (176) of IC3002 (VCT)?

YES

Is LVDS signal (LVDS_0N/0P-3N/3P) sent from pins (141) and

(140) - (129) and (128) of IC3002 (VCTP), and is CLK signal

(LVDS_CN/CP) sent from pins (132) and (131)?

NO Check external connection, input setting, SCART2 (J1101) and

peripheral circuits.

NO Check CONNECTOR (SC2702/P1101), SCART2 (J1101) and

peripheral circuits.

NO Check pins (192), (170) and (133) of BU 3.3V power line and

pins (185), (169) and (142) of BU1.8V power line of IC3002

(VCTP), and peripheral circuits.

YES

Is LVDS signal (LVDS_0N/0P-3N/3P) sent to pins (12) and (13) (24) and (25) of CONNECTOR CN1 in LCD-CONT-UNIT, and is

CLK signal (LVDS_CN/CP) sent to pins (21) and (22)?

YES

Is power (LCD5V) supplied to pins (2) - (5) of CONNECTOR CN1

in LCD-CONT-UNIT?

YES

Replace LCD-CONT-UNIT.

NO Check CONNECTOR (P2305, CN1) and HARNESS WIRE (LV).

NO Is LCD5V supplied to pins (31) - (28) of CONNECTOR (P2305)?

Check HARNESS WIRE (LV).

6 – 16

Page 51

LC-26SA1E/RU, LC-32SA1E/RU

<When EXT2 is used for external input> No picture on the display (4)

No EXT2-Y/C output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXT2”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is Y/C signal sent to pins (41) and (36) of SCART2 (J1101)? NO Check external connection, input setting, SCART2 (J1101) and

YES

Is Y/C signal (VIN1 =Y2/C2) sent to input terminal pins (190) and

(178) of IC3002 (VCT)?

YES

Is LVDS signal (LVDS_0N/0P-3N/3P) sent from pins (141) and

(140) - (129) and (128) of IC3002 (VCTP), and is CLK signal

(LVDS_CN/CP) sent from pins (132) and (131)?

NO Check CONNECTOR (SC2702/P1101), SCART2 (J1101) and

NO Check pins (192), (170) and (133) of BU 3.3V power line and

peripheral circuits.

peripheral circuits.

pins (185), (169) and (142) of BU1.8V power line of IC3002

(VCTP), and peripheral circuits.

YES

Is LVDS signal (LVDS_0N/0P-3N/3P) sent to pins (12) and (13) (24) and (25) of CONNECTOR CN1 in LCD-CONT-UNIT, and is

CLK signal (LVDS_CN/CP) sent to pins (21) and (22)?

YES

Is power (LCD5V) supplied to pins (2) - (5) of CONNECTOR CN1

in LCD-CONT-UNIT?

YES

Replace LCD-CONT-UNIT.