Page 1

LC-22SV2E

SERVICE MANUAL

S02R9LC22SV2E

LCD COLOUR TELEVISION

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

CONTENTS

» IMPORTANT SERVICE SAFETY PRECAUTION ................................................................................... 2

» SPECIFICATIONS ................................................................................................................................... 4

» OPERA TION MANUAL ............................................................................................................................ 5

» DIMENSIONS .......................................................................................................................................... 7

» REMOVING OF MAJOR PARTS............................................................................................................. 8

» ADJUSTING PROCEDURE OF EACH SECTION .................................................................................11

» TROUBLE SHOOTING TABLE ............................................................................................................. 20

» CHASSIS LAYOUT ................................................................................................................................ 26

» BLOCK DIAGRAM................................................................................................................................. 28

» OVERALL WIRING DIAGRAM .............................................................................................................. 30

» DESCRIPTION OF SCHEMATIC DIAGRAM ........................................................................................ 32

» SCHEMATIC DIAGRAM ........................................................................................................................ 33

» PRINTED WIRING BOARD ASSEMBLIES........................................................................................... 56

» REPLACEMENT PARTS LIST .............................................................................................................. 67

» PACKING OF THE SET......................................................................................................................... 83

LC-22SV2E

Page

SHARP CORPORATION

Page 2

LC-22SV2E

2

2

IMPORTANT SERVICE SAFETY PRECAUTION

Ë

Service work should be perfomed only by qualified service technicians who are thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CONTINUED

PROTECTION AGAINST A RISK OF

FIRE REPLACE ONL Y WITH SAME

TYPE F3701 (T1.6AL, 250V), F3702

(T1.6AL, 250V), F6551 (T1.25AL,

A V

250V), F6552 (T1.25AL, 250V),

F6553 (T1.25AL, 250V) AND F6554

(T1.25AL, 250V) FUSE.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks:

1. Inspect all lead dress to make certain that leads are

not pinched, and check that hardware is not lodged

between the chassis and other metal parts in the

receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

• Plug the AC cord directly into a 110~240 volt AC outlet,

and connect the DC power cable into the receiver's

DC jack. (Do not use an isolation transformer for this

test).

• Using two clip leads, connect a 50k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as electrical conduit or electrical ground

connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or

higher, sensitivity or measure the AC voltage drop

across the resisor.

• Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

All checks must be repeated with the AC cord plug

connection reversed. (If necessary, a nonpolarized

adaptor plug must be used only for the purpose of

completing these checks.)

Any reading of 0.75V peak (this corresponds to 0.5

milliamp. peak AC.) or more is excessive and indicates

a potential shock hazard which must be corrected

before returning the monitor to the owner.

DVM

AC SCALE

50k ohm

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in LCD television

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

and shaded areas in the

Schematic Diagrams

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of a substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock, fire or other hazards.

components having such features are identified by “ å”

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

Replacement Parts Lists

.

and

Page 3

LC-22SV2E

Precautions for using lead-free solder

1 Employing lead-free solder

"Inverter PWB" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached

on the PWBs and service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40ºC, we recommend

you to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldening

bit, contact our service station or service ranch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead

solder by 40°C, and as it has poor solder wettabillty, you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, Since the land may be peeled off or the maximum heat-resistance

temperature of parts may be excoeded, remove the bit from the PWB as soon as you conurm the steady soldering

condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to tum on

and off the power of the bit as required.

if a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Becareful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No, ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

3

Page 4

LC-22SV2E

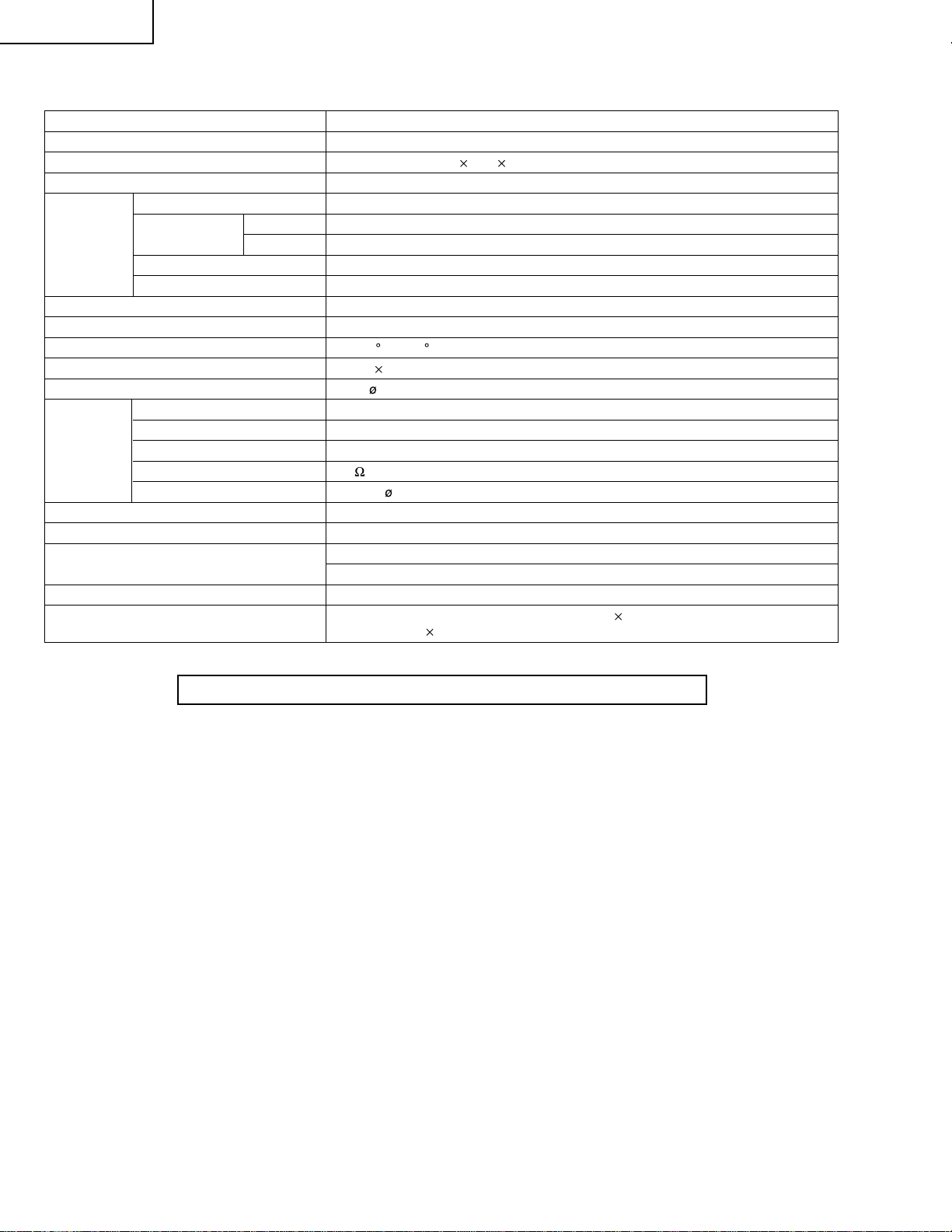

SPECIFICATIONS

Item 22" LCD COLOUR TV, Model: LC-22SV2E

LCD panel 22" Advanced Super View & BLACK TFT LCD

Number of dots 1,229,760 dots (854 480 3 dots)

Video colour system PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

TV TV-Standard (CCIR) B/G, I, D/K, L

Function Receiving VHF/UHF E2-E69 ch, I21-I69 ch, IR A-IR Jch, F2-F10 ch

Channel CATV ~ Hyper Band

TV-Tuning System Auto preset 200 ch.

STEREO/BILINGUAL NICAM, IGR

Brightness 430 cd/m

Lamp life 60,000 hours

Viewing angles H: 170 V: 170

Audio amplifier 2.5 W 2

Speakers 5 cm 2 pcs

Terminals AV-IN 1 SCART (Av in, RGB in, TV out)

AV-IN 2 S-VIDEO, VIDEO, AUDIO

OUT AUDIO

Antenna 75 Din Type

Headphones 3.5 mm jack (Rear)

OSD language English/German/French/Spanish/Italian/Swedish/Dutch

Power requirement DC 13 V, AC 110 V – 240 V, (50/60 Hz)

Power Consumption 62 W (1.0 W at Standby) (Method IEC60107) : AC 230 V (with AC Adapter)

53 W (Method IEC60107) : DC 13 V

Weight 9.3 kg w/o accessories

Accessories Operation Manual, Remote Control, Batteries ( 2), AC adapter, AC cord,

Cable clamps ( 2)

2

Specifications are subject to change without prior notice.

4

Page 5

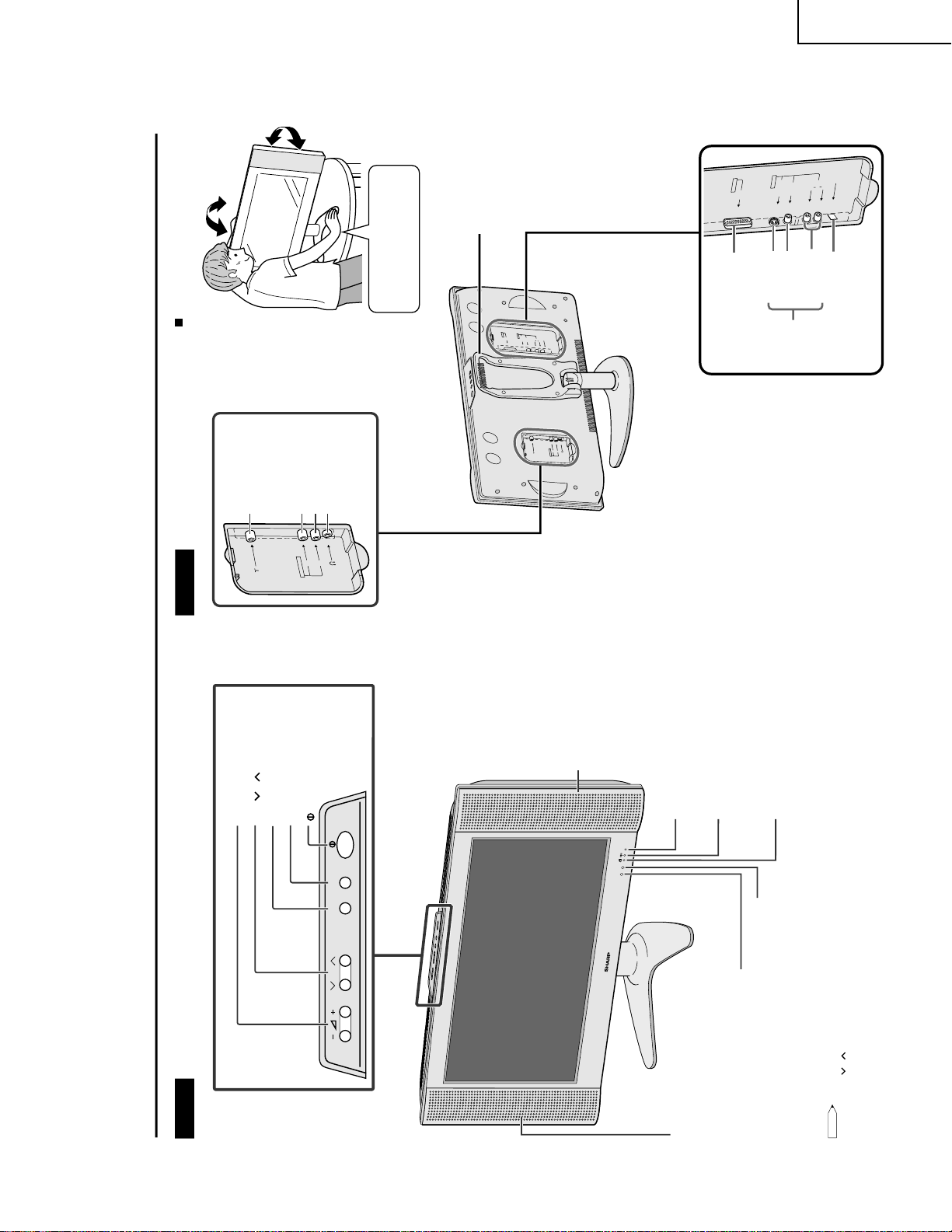

OPERATION MANUAL

Part Names of Main Unit

Controls

Note:

• TV/VIDEO CH(

)/( ) Volume (–)/(+) MENU

control.

CH

MENU

TV/VIDEO

Volume (–)/(+)

POWER/STANDBY indicator

Remote sensor window

Remote sensor indicator

Upper control panel

CH (

)/( )

MENU

TV/VIDEO

(MAIN POWER)

OPC sensor window

Speaker

OPC (Optical Picture Control)

indicator

Speaker

Terminals

L

R

A

U

D

I

O

O

U

T

A

V

-I

N

1

R

G

B

A

V

-

I

N

2

S

-

V

I

D

E

O

V

I

D

E

O

L

R

A

U

D

I

O

P

O

W

E

R

I

N

P

U

T

D

C

1

3

V

L

R

AU

DIO

OU

T

AV-

IN

1

R

GB

AV-

IN

2

S

-

V

ID

E

O

V

ID

E

O

L

R

AU

DI

O

PO

W

E

R

INPU

T

D

C

1

3V

Carrying handle

Rear View

POWER INPUT DC13V

AV-IN 1

(21pin Euro-SCART)

S-VIDEO

VIDEO

AUDIO (L)

AUDIO (R)

AV-IN 2

Antenna

AUDIO OUT (L)

AUDIO OUT (R)

Headphones

To change the vertical angle of

the LCD TV set, tilt the screen

up to 5 degrees forward or 10

degrees backward. The TV set

can also be rotated 25 degrees

to right and left. Please adjust

the angle so that the TV set can

be watched most comfortably.

A red indicator blinks when the TV set

receives the remote control signal.

A green indicator lights when “Brightness” is

set to “Auto”.

, , and

Fundamentally, this operation manual provides a description based on operation using the remote

on the main unit have the same functions as the same buttons on the remote control.

A green indicator lights when the power is

on and a red indicator lights when in the

standby mode (the indicator will not light

when the main power is off).

How to adjust the angle

Tilt the display by grabbing onto

the carrying handle while securely

holding down the stand with your

other hand.

LC-22SV2E

5

Page 6

LC-22SV2E

Part Names of Remote Control

CH

MENU

E

E

N

D

M

TET

M

OK

SUBTITLE

HOLD

(Mute)

Yellow,

Timer function Menu

Cyan, Status Display

TV/VIDEO

Channel Select

MENU

Volume (+)/(

-

)

(Flashback)

Red, Picture Menu

Upwards/ Downwards

Selection, zoom display

function

END

TEXT

(Power)

SOUND

REVEAL

Right / Left Selection

SUBPAGE

ROTATE

WIDE

Green, Sound Menu

CH ( )/( )

Installing Batteries in the Remote Control

123

■

Caution!

Precautions regarding batteries

■

Preparation

■

Using Remote Control

■

Cautions regarding use of remote control

■

■

■

■

Displays the Teletext

Subtitle directly.

Temporarily holds the

current Teletext page.

Selects the wide image mode.

Switches the sound

mode.

Returns to the previous

channel.

CH

SOUND

E

N

D

MENU

R

EVE

A

L

H

O

LD

S

U

B

T

IT

L

E

SUBPAGE

R

EVE

A

L

H

O

LD

S

U

B

T

IT

L

E

SUBPAGE

TEXT

R

O

T

A

T

E

WIDE

TEXT

R

O

T

A

T

E

WIDE

T

MENUSOUND

OK

Displays the Teletext mode

screen.

Displays hidden information

such as solutions to riddles

and puzzles.

Displays the Teletext

Subpage directly.

Rotates the display in every

direction.

(Teletext mode)

Returns to normal screen.

Switches the sound on and off.

Turns on the status display

when the menu is not

displayed.

Displays the TV menu.

Displays previous/next page.

(Teletext mode)

Switches the input source

between AV1, AV2 and

TV mode.

TV/VIDEOTV/VIDEO

Open the battery cover.

Before using the LCD TV set for the first time, install the two R-03 (“AAA” size, UM/SUM-4) batteries supplied in the remote

control. When the batteries become depleted and the remote control fails to operate, replace the batteries with new R-03

(“AAA” size, UM/SUM-4) batteries.

Insert two R-03 (“AAA” size,

UM/SUM-4) batteries.

Replace the battery cover.

Slide the cover while

pressing the ( ) part.

Position the positive and

negative ends of the

batteries as indicated in

the compartment.

Engaging the lower

claw with the remote

control, close the

cover.

Improper use of batteries can result in a leakage of chemicals and/or explosion. Be sure to follow the instructions below.

Place batteries with their terminals corresponding to the (+) and (–) indications.

Different types of batteries have different characteristics. Do not mix batteries of different types.

Do not mix old and new batteries. Mixing old and new batteries can shorten the life of new batteries and/or cause old

batteries to leak chemicals.

Remove batteries as soon as they are depleted. Chemicals that leak from batteries can cause a rash. If chemical

leakage is found, wipe it off with a cloth.

The batteries supplied with the product may have a shorter life expectancy due to storage conditions.

If the remote control is not to be used for an extended period of time, remove the batteries from the remote control.

Use the remote control by pointing it towards the remote sensor

window of the main unit. Objects between the remote control and

sensor window may prevent proper operation.

Do not expose the remote control to shock. In addition, do not

expose the remote control to liquids, and do not place it in an area

with high humidity.

Do not install or place the remote control under direct sunlight. The

heat may cause deformation of the unit.

The remote control may not work properly if the remote sensor

window is under direct sunlight or strong lighting. In such a case,

change the angle of the lighting or main unit, or operate the remote

control closer to the remote sensor window.

Remote sensor indicator

OPC indicator

Power/Standby indicator

OPC sensor window

Remote sensor window

OPC

6

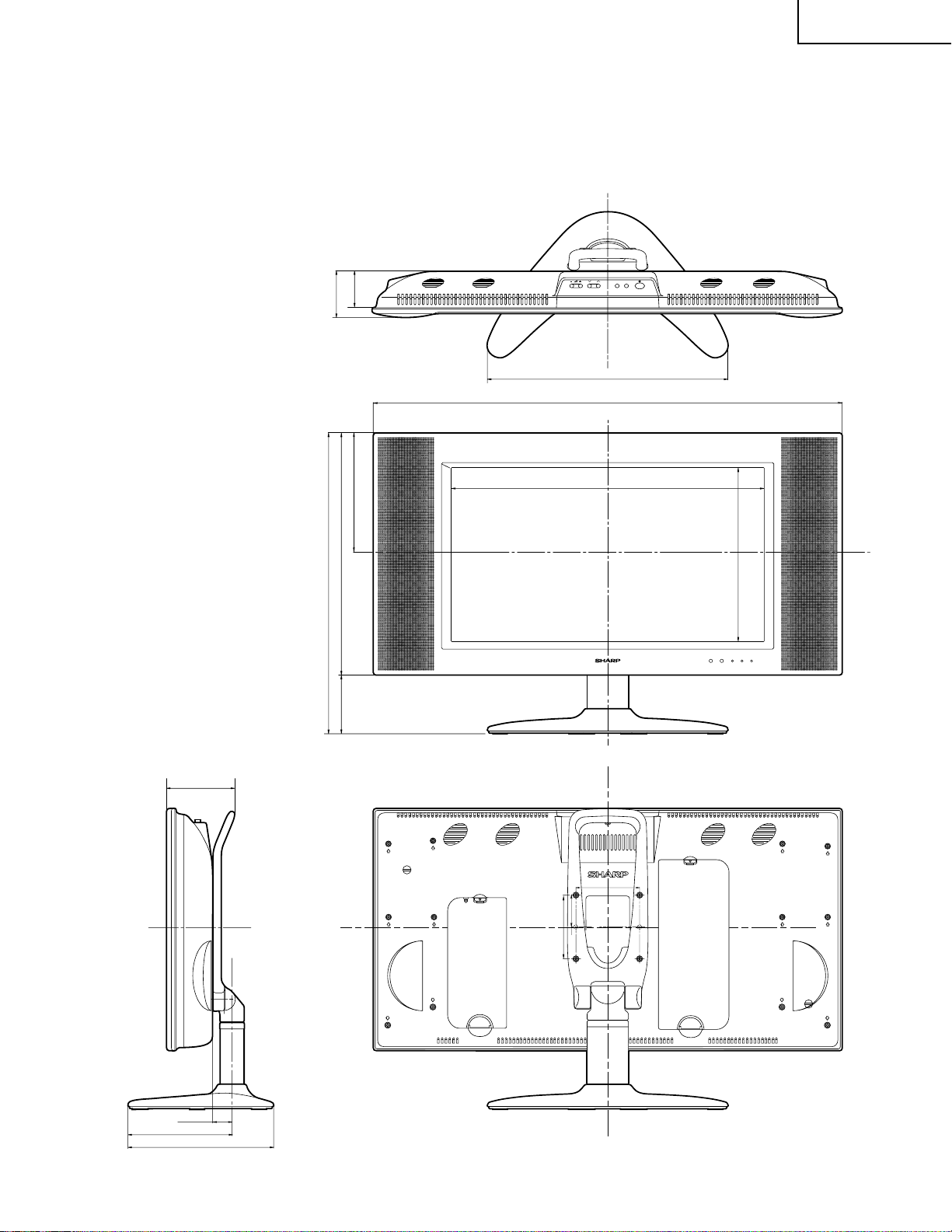

Page 7

Unit: mm

180.6

95

367

462

739

L

R

100

100

43.9

AUDIO OU T

AV-IN 1

RGB

AV-IN 2

S-VIDEO

VIDEO

L

R

AUDIO

POWER

INPUT

DC13V

59.5

72.5

420

165.4

250

31

490.62

268.32

108

CH

MENU

TV/VIDEO

DIMENSIONS

LC-22SV2E

7

Page 8

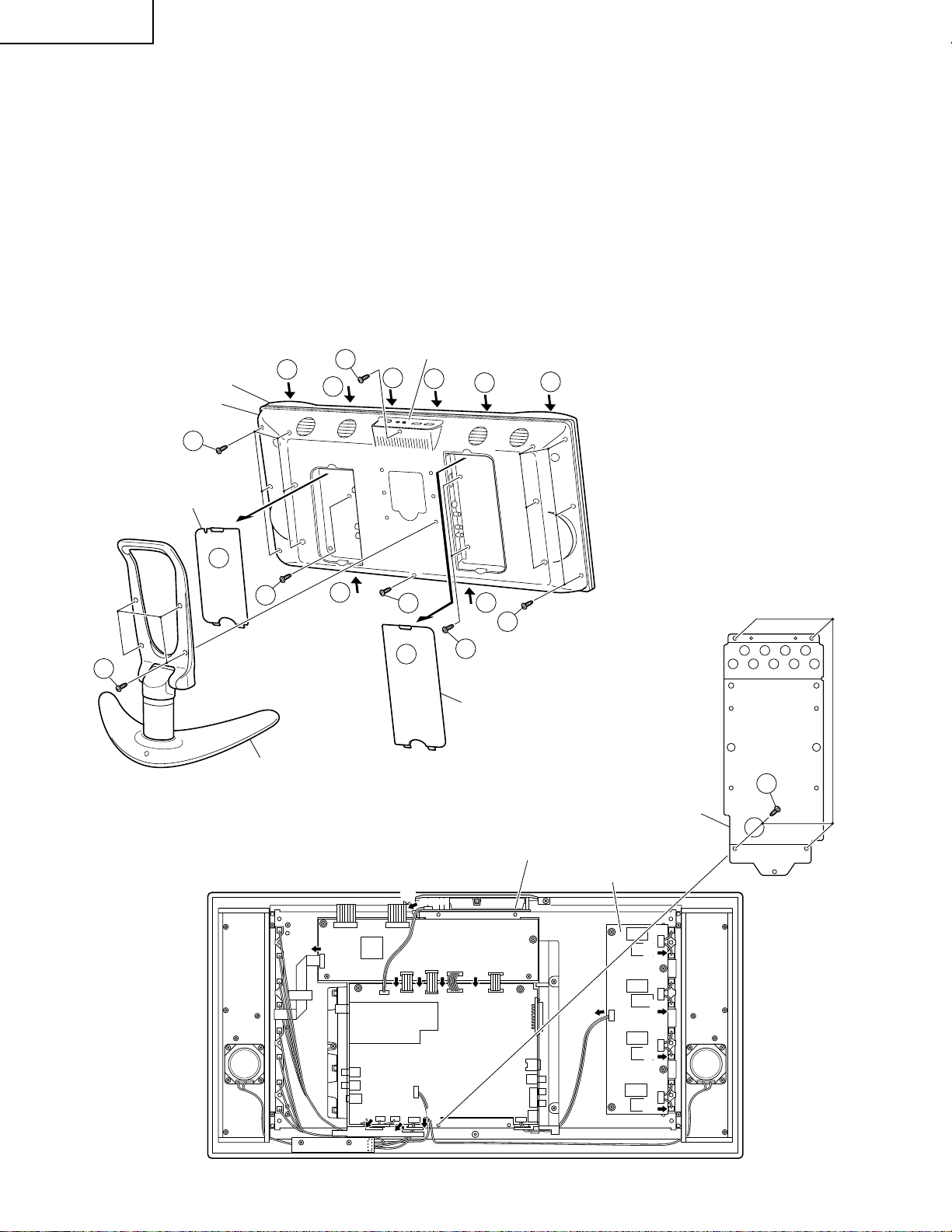

LC-22SV2E

REMOVING OF MAJOR PARTS

1. Remove the two terminal covers.

2. Remove the table stand fixing screws (4 pcs.).

3. Remove the cabinet B fixing screws (17 pcs.).

4. Remove the cabinet B after opening from the direction of an arrow.

5. Remove the reinforcement angle fixing screws (4 pcs.).

6. Detach the connector from each PWB.

Control Panel (Top Cover)

4

4

4

4

Cabinet A

4

3

4

Cabinet B

3

Terminal

Cover (S)

1

3

4

3

4

3

1

3

2

Terminal

Cover (L)

Stand

5

6

SC4561

(GD)

SC4902

6

(RM)

6

(GA)

P3701

SC4901

P3504

P3504

(KK)

(KK)

6

(GB)

P3702

6

P130(KK)

6

(MC)

(MA)

SC4701

SC1401

SC1401

SC1401

SC3501

SC3501

(MA)

(MA)

(MC)

(MC)

Main PWB

P3502

(RM)

P3503

6

Operation PWB

Digital PWB

(ME)

(MB)

SC402

P4501

6

SC2202

P3706

(ME)

(MB)

P3705(PF)

8

Reinforcement

Angle

Inverter PWB

6

6

P706

(PF)

6

6

6

P6551

P6552

P6553

P6554

Page 9

7. Remove the top cover fixing screws (2 pcs.).

8. Remove the control PWB fixing screws (2 pcs.).

9. Remove the digital PWB fixing screws (4 pcs.).

10. Detatch the chassis frame cover fixing hooks (5 pcs.).

11. Remove the 21-pin terminal fixings screws (2 pcs.).

12. Remove the analog PWB fixing screws (3 pcs.).

13. Remove the inverter PWB fixing screws (4 pcs.).

14. Remove the R/C, LED PWB fixing screws (2 pcs.).

9

9

LC-22SV2E

Digital PWB

12

Main PWB

Chasis

Frame Cover

10

10

Operation PWB

Chassis Frame

8

13

Inverter PWB

11

7

Control Panel

(Top Cover)

R/C, LED PWB

14

9

Page 10

LC-22SV2E

» Precautions in handling the LCD panels

1. Work in a clean room (with humidities below 50%).

2. Be sure to wear an anti-static armband.

3. Handle the panels on an electroconductive mat.

4. Be careful not to fall, shake and shock the panels.

15. Remove the LCD panel unit fixing screws (4 pcs.).

16. Remove the reflection/deflection, prism and diffusion sheets.

17. Remove the ITO earth spring fixing screw (1 pc.).

18. Remove the ITO sheet and diffusion panel.

19. Remove the lamp fixing holder fixing screws (6 pcs.).

20. Detach the lamp clip (4 pcs.).

21. Detach the lamp unit-A/B.

22. Remove the reflection panel fixing screws. (6 pcs.).

Diffusion Panel

(PCOVU0108CEZZ)

ITO Earth Spring

(MSPRP1220CEFW)

17

22" LCD Panel

Unit

(RLCDTA011WJZZ)

Lamp Fixing Holder

(LHLDZ2184CEKZ)

16

15

Back Sheilding Plate

(PSLDM4699CEFW)

Lamp Clip

(LHLDZ2185CEZZ)

19

18

Diffusion Sheet

(PSHEP0294CEZZ)

Prism Sheet

(PSHEPA002WJZZ)

Reflection / Deflenction Sheet

(PSHEPA003WJZZ)

20

19

Lamp Fixing Holder

(LHLDZ2184CEKZ)

ITO Sheet

(PSHEP0295CEZZ)

22

21

Lamp Unit-A

(KLMP-0126CEZZ)

Lamp Unit-B

(KLMP-0127CEZZ)

Reflection Panel

(PMiR-0299CEZZ)

10

Page 11

LC-22SV2E

ADJUSTING PROCEDURE OF EACH SECTION

The best adjustment is made before shipping. If any position deviation is found or after part replace is performed,

adjust as follows.

Preparation for adjustments

Use the dedicated AC adaptor or stable DC power supply.

AC adaptor: UADP-0241CEPZ

DC power supply: 13V 5.4A

1.Entering the adjustment processing mode

• A “POWER” key is made on with pushing an “TV/VIDEO” and “MENU” keys at the same time.(K of the inspection

process mode is displayed by the upper left of the image plane.) → Next, “CH (Ù)” and “VOL (–)” keys are pushed

at the same time.(It becomes the image plane of the adjustment process mode.).....When it is canceled, it is made

to turn it off.(Even off in the “MAIN POWER” key, off with R/C are good.)

2.Key operation in the adjustment process mode

• The receiving channel UP/DOWN is performed with the “CH (ù)/(Ù)” keys.

One push ... The UP/DOWN tuning is performed per channel.

Continuous push ... The UP/DOWN search is performed until a next receivable station is found.

• Various adjustments

The adjustment is performed for each item by the “MENU”, “Menu cursor”, “CH (ù)/(Ù)” or “VOL (+)/(–)” keys

(LCD TV set and remote control).

• Adjustment item is chosen with the Menu cursor upward/downward keys.

• The adjustment item makes a toggle operation with the “MENU” key input. (Next item)

If the “MENU” key is input while the bottom item is selected, it moves to the top item on the next page.

• Press the auto preset button on the remote controller in the adjustment process mode, and the top item of the

next page will show up regardless of which item appears now.

Page 1 → Page 2 → ... → Page 23 → Page 1

• Press the manual memory button on the remote controller in the adjustment process mode, and the top item of

the same page will show up.

• UP/DOWN of each adjustment vale selected is performed with the VOL (+)/(–) keys input.

• For P16 – 17, the unit enters the register select mode with the VOL (+)/(–) keys input while NTSC/PAL is selected,

and the cursor moves to the address 01.

• The cursor moves up or down with the “CH (ù)/(Ù)” keys and moves left or right with the VOL (+)/(–) keys, and

a decision is made with the 12 key.

When the decision is made, the cursor moves to the adjustment value selected, and UP/DOWN of each adjustment

value selected by the “VOL (+)/(–)” keys input is performed.

00 ↔ 01 ↔ ... ↔ 79 ↔ 7A ↔ ... ↔ FF ↔ 00 ↔ ...

Decide with the 12 key and return to the address select. Move to the next item with the “MENU” key.

During address select, the cursor movement by the “VOL (+)/(–)” keys input is as follows:

Example: 01 ↔ 02 ↔ 03 ↔ 01 ↔ ...

The cursor movement by the “CH (ù)/(Ù)” keys input is as follows:

Example: 02 ↔ 05 ↔ ... ↔ F6 ↔ 02 ↔ ...

3.Initialization

3-1. Connect the pins (81) and (82) of IC2001 (microprocessor) to GND, and turn on the power.

3-2. Select the model name to (22SV2E/22SV2K).

11

Page 12

LC-22SV2E

4.Adjustment

4-1. +B (5V) adjustment (R3750 : Main Unit)

1) Receive the colour bar signal.

2) Adjust the voltage of the positive (+) side of C3724 to 5.00 ±0.02V.

Note: Since 5.0V is a reference voltage of all power voltage, adjust it precisely.

4-2. +B (13V) adjustment (R4657 : Digital Unit)

1) Receive the colour bar signal.

2) Connect the digital voltmeter to TP4751, and adjust to 13.00 ±0.05V.

Note: Since 13.00V is a reference voltage of all power voltage, adjust it precisely.

4-3. Counter-bias adjustment

Please perform this adjustment to each "50Hz" and "60Hz".

1) Enter the process adjustment mode.

2) Select the "14" (Dot reversal flicker pattern) of "G/A TEST PATTERN" on page 19 of the adjustment process

mode.

3) Select the "COM BIAS 60"/"COM BIAS 50" on page 2 of the adjustment process mode.

4) Adjust the flicker of a screen to be minimum.

4-4. TAMP adjustment

1) Receive the colour bar signal.

2) See if the "Y" reading on page 2 of the adjusment process mode is somewhere following. If not, make the

"PAL TAMP" adjustment to get the "Y" reading in the range of "BB" thru "CA".

3) If the adjustment of "PAL TAMP" is executed, write its adjustment value to the "SECAM TAMP" manually.

(Screen of the page 2 of the adjustment processing menu OSD)

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

2

COM B I AS 6 0

COM B I AS 5 0

PAL TAMP

SECAM TAMP

CUTOF F

RX1 GX1 BX 1

RY1 GY1 BY 1

RX2 GX2 BX 2

RYY2 GY2 BY2

TAMP H

TAMP L

45

75

021

320

57

24

24

–

45

76

021

225 320

Y Data

(White 75%)

45

86

021

C0

CA

BB

4-5. White balance adjustment

1) Receive the following signal.

Window pattern signal having left 70% white and right 40% white.

2) Adjust the "RY1, GY1, BY1" and "RY2, GY2, BY2" on page 2 of the adjustment process mode to be best

condition.

It is about "RY1, GY1, BY1" at 40% gray.

It is about "RY2, GY2, BY2" at 70% gray.

Adjusting value; x=0.257, y=0.264 (40% gray)

x=0.274, y=0.284 (70% gray)

Note:This adjustment must be done after aging for 30 minutes or longer.

5

12

Page 13

5. Lamp error detection

5-1. Functional description

This LCD colour television has a function (lamp error detection) to be turned OFF automatically for safety

when the lamp or lamp circuit is abnormal.

If the lamp or lamp circuit is abnormal, or some other errors happen, and the lamp error detection is executed,

the followings occur.

1 The main unit of television is turned OFF 5 seconds after it is turned ON. (The power LED on the front

side of TV turns from green to red.)

2 If the situation 1 happens 5 times sequentially, television can not be turned ON. (The power LED

remains red.)

5-2. Countermeasures

5-2-1.Check when turning OFF the lamp error detection

When television is turned OFF by the lamp error detection mentioned above, it enters the adjustment

process with the power LED red. Entering the adjustment process turns OFF the error detection and turns

ON TV.

This enables the operation check to detect errors in the lamp or lamp circuit.

Check whether "ERROR NO RESET" on line 7, page 1 of the adjustment process is 1 or more. If it is 1 or

more, it indicates the lamp error detection was executed.

5-2-2.Resetting of the lamp error count

After confirming that the lamp or lamp circuit is normal, reset the lamp error count. Select "ERROR NO

RESET" on line 5, page 1 of the adjustment process and set the number to 0 using the volume button.

LC-22SV2E

Page 1 of the adjustment process

M O D E L SV2E

N T S C P W M F R E Q 1DD

P A L P W M F R E Q 1DD

N T S C P W M D U T Y 0

P A L P W M D U T Y 0

T V G A I N OFF

ERROR NO RESET 0

Reset 0

P U B L I C M O D E OFF

W L D 1 3 V E R 1 . 0 0

Afterwards, perform the operation check to confirm that the lamp error detection does not function.

13

Page 14

LC-22SV2E

Pin functions of microprocessor IC (IC2001) RH-iXA380WJZZQ

No

. Pin name Function

1 N. C.

2 N. C.

3 SCL2

4 SDA2

5 VACT

6 CSYNC

7 IREM-1

8 BYTE

9 CNVSS

10 TEST_RST

11 SH_ON

12 RESET

13 XOUT

14 VSS

15 XIN

16 VDD

17 OSCIN

18 OSCOUT

19 PSWIN

20 VSYNC

21 BLK

22 N. C.

23 DAC1CS

24 DAC2CS

25 SCL1

26 SDA2

27 A_DA

28 SCK

29 SSI

30 SSO

31 N. C.

32 R

33 G

34 B

35 TEXT_OUT

36 TEXT_IN

37 SCLK

38 BUSY

39 A_ENA

40 N. C.

41

MREADY/EPM

42 L_ERR

43 N. C.

44 SSB

45 SRDYB

46 CE

47 CK

48 DA

49 PD

50 VSH_OUT

Open

Open

I2C bus clock data output

I2C bus data output/input

Scaller IC

Composite sync Signal

Remote control signal input

GND

GND/FLASH write (3.3V)

TEXT reset output

TEXT communication control

Reset input (H;Normal, L;Reset)

System clock output

GND

System clock input

Power (3.3V)

OSD frequency input

OSD frequency output

Main power input (H;OFF, L;On)

Scaller

OSD blank output

DAC1 chip select

DAC2 chip select

I2C bus clock putput

I2C bus data in/output

Autowide

Scaller clock output

Scaller data input

Scaller data output

L output fixed

OSD R signal output

OSD G signal output

OSD B signal output

TEXT data output/FLASH write

TEXT data input/FLASH write

FLASH write

FLASH write

Autowide

L output fixed

External bus mode shift input/FLASH write (H;Normal, L;External bus mode shift demand)

Lamp error detect input (H;Error, L;Normal)

L output fixed

For scaller IC

For scaller IC

FLASH write

For autowide

For autowide

For autowide

Regulator control output (H;On, L;Off)

No

. Pin name Function

51 REQ_OUT

52 HPMUTE

53 SMUTE

54 TEXT_MODE1

55 TEXT_MODE0

56 PAMUTE

57 VSH IN

58 DEF

59 STB

60 SRESET

61 N. C.

62 HSYNC

63 POWIN

64 VSYNC

65 TV/AV1

66 AV/AV2

67 EXT

68 I2/UA

69 SW_SYNC

70 VACT_CONT

71 PMUTE

72 TVPOW

73 RGBCON

74 RC_LED

75 OPC_LED

76 PRT_LED

77 MP_CS

78 MP_DA

79 MP_CLK

80 DDC_RESET

81 KEY3

82 KEY4

83 PANEL_POW

84 TEXT_H

85

TUNERMODE1

86

TUNERMODE2

87 N. C.

88 SSW

89 AFT

90 N. C.

91 KEY1

92 KEY2

93 SLOW_SW

94 OPC

95 N. C.

96 N. C.

97 N. C.

98 TVSETB

99 VCCE

100

N. C

Completion output of external bus mode shift (H;Normal, L;External bus mode)

Headphone mute output (H;On, L;off)

Audio mute output (H;On, L;Off)

TEXT microprocessor updating

TEXT microprocessor updating

Speaker standby mute output (H;Off, L;On)

Regulator power detect (H;Normal, L;Abnormal)

Extrnal output audio mute output (H;On, L;Off)

Microprosessor power supply OFF output

Multiplex reset output (H;Normal, L;Reset)

L output fixed

OSD horizontal sync signal input

DC/DC Start-up detect input (H;On, L;Off)

OSD vertical sync signal input

TV/External select (H;TV, L;External)

AV1/AV2 select (H;AV2, L;AV1)

External control change

I2C/UART change

Synchronous change control

For scaller IC

Video mute output (H;On, L;Off)

TV power control (H;On, L;Off)

SCART RGB detect

R/C receive LED output

Auto save LED output (H;On, L;Off)

Slave IC error detect output (FLASH)

G/A chip select

G/A data output

G/A clock output

Digital decoder reset (H;Normal, L;Reset)

Key input 3

Key input 4

Panel power control (H;On, L;Off)

TEXT/SCART RGB change (H;TEXT, L;SCART)

System change

System change

L output fixed

S terminal insert detect (H;Not connect, L;Connect)

AFT voltage input

L output fixed

Key input 1

Key input 2

Slow switch detect input

Auto save sensor level input

Open

Open

Pull up

GND

Power(5V)

Pull-up

14

Page 15

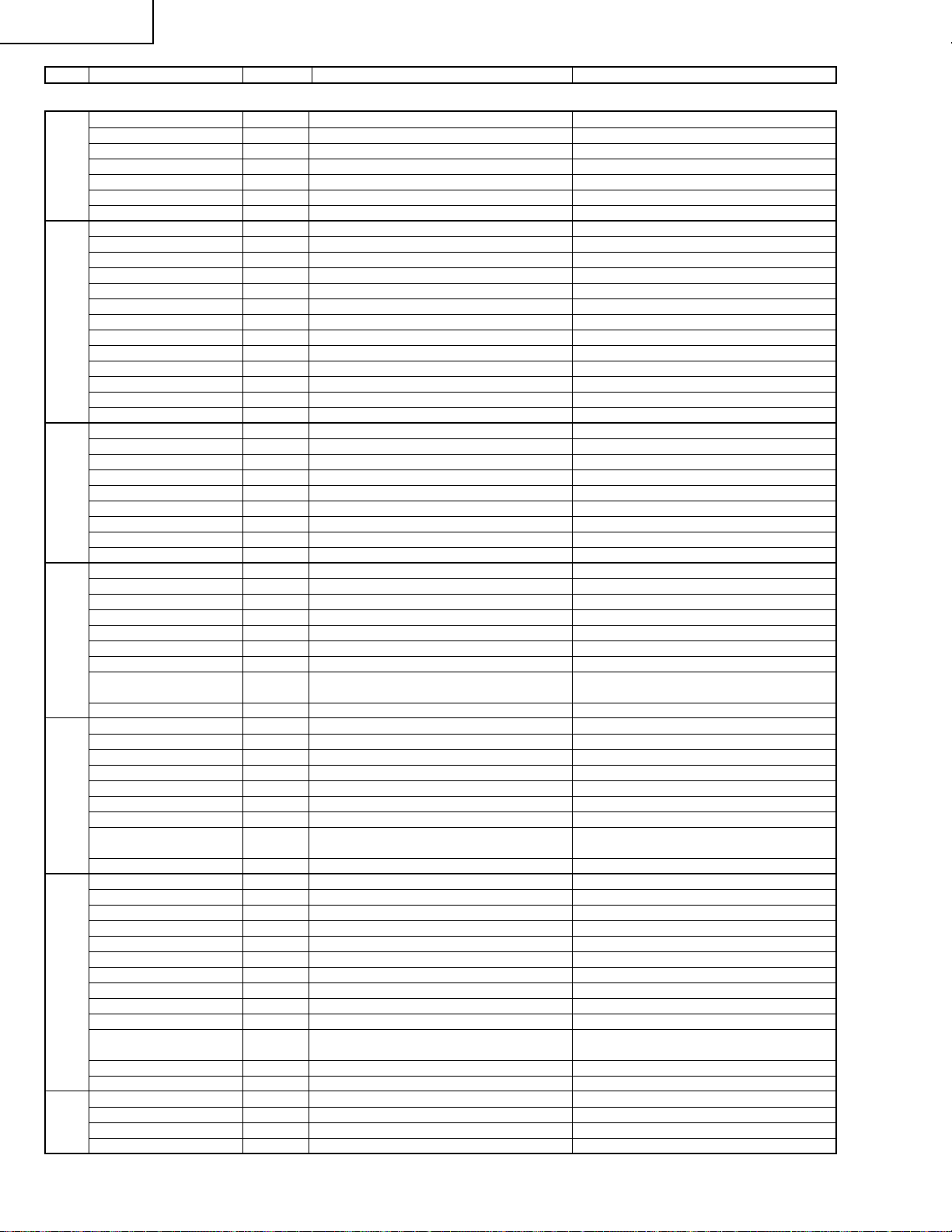

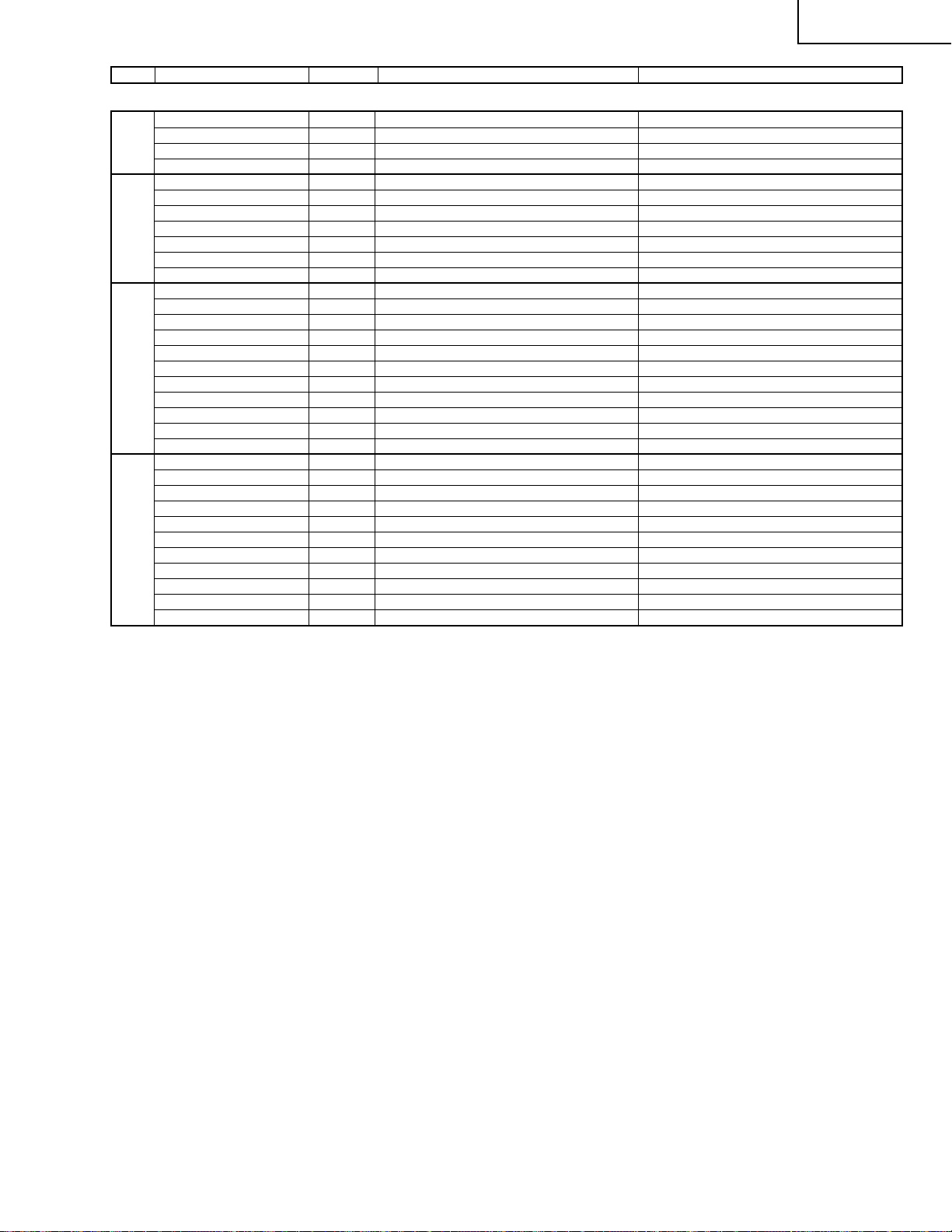

Adjustment process mode menus at a glance

Page Item

1

MODEL SV2E Model name

NTSC PWM FREQ 1DD Dimmer frequency setting

PAL PWM FREQ 1DD Dimmer frequency setting

NTSC PWM DUTY 0 Dimmer duty setting

PAL PWM DUTY 0 Dimmer duty setting

TV GAIN OFF Audio gain setting in TV mode

ERROR NO RESET 0 Lamp error count & reset

PUBLIC MODE OFF Public mode

2 COM BIAS 60 59 Counter bias adjustment (60Hz)

COM BIAS 50 39 Counter bias adjustment (50Hz)

PAL TAMP 21 TAMP adustment

SECAM TAMP 21 TAMP adustment

CUTOFF RX1, GX1, BX1 45 cutoff adjustment

CUTOFF RY1, GY1, BY1 RY1:75 cutoff adjustment

CUTOFF RX2, GX2, BX2 201 cutoff adjustment

CUTOFF RY2, GY2, BY2 RY2:230 cutoff adjustment

Y 00h Data read value at TAMP adjustment

TAMP H CA Y upper limit setting at TAMP adjustment

TAMP L BB Y lower limit setting at TAMP adjustment

3 TV PAL CONT 48 Contrast setting (TV PAL)

TV SECAM CONT 48 Contrast setting (TV SECAM)

AV NTSC CONTRAST 45 Contrast setting (external NTSC)

AV PAL CONTRAST 45 Contrast setting (external PAL)

AV SECAM CONTRAST 45 Contrast setting (external SECAM)

AV PAL-M CONTRAST 45 Contrast setting (external PAL-M)

AV PAL-N CONTRAST 45 Contrast setting (external PAL-N)

AV PAL60 CONTRAST 45 Contrast setting (external PAL-60)

V SCROLL 60 Picture size It changes with picture size.

V SCROLL 50 Picture size It changes with picture size.

H SCROLL 60 Picture size It changes with picture size.

H SCROLL 50 Picture size It changes with picture size.

4 TV GEQ BAND1 1 Equalizer setting 1(TV)

TV GEQ BAND2 -1.5 Equalizer setting 2(TV)

TV GEQ BAND3 0.5 Equalizer setting 3(TV)

TV GEQ BAND4 0.5 Equalizer setting 4(TV)

TV GEQ BAND5 1 Equalizer setting 5(TV)

EXT GEQ BAND1 1 Equalizer setting 1(external input)

EXT GEQ BAND2 -1.5 Equalizer setting 2(external input)

EXT GEQ BAND3 0.5 Equalizer setting 3(external input)

EXT GEQ BAND4 0.5 Equalizer setting 4(external input)

EXT GEQ BAND5 1 Equalizer setting 5(external input)

AVC 4SEC AVC setting

CARRIER MUTE OFF Audio output setting out of sync with TV

IGR THR 12D IGR thresh level

5 MSP DATA 0 Audio IC MSP data write & read

MSP DATA WAIT Write & read execution

PRESCALE FM/AM-M 17 Pre-scale setting (M)

PRESCALE FM/AM-B 17 Pre-scale setting (B)

PRESCALE FM/AM-D 17 Pre-scale setting (D)

PRESCALE FM/AM-I 17 Pre-scale setting (I)

PRESCALE FM/AM-L 20 Pre-scale setting (L)

PRESCALE NICAM 40 Pre-scale setting (NICAM)

PRESCALE SCART 15 Pre-scale setting (external input)

FSP TEST OFF Audio test (FS mute ON/OFF)

0018H 1D

ONTA 1

6 I2C DATA 0 I2C bus control IC data write & read

I2C DATA WAIT Write & read execution

CBW 1 Chroma band pass setting

NOSEL 3 Comb filter setting

DDR 1 Comb filter setting

HDG 3 Comb filter setting

Initial setting

GY1:76

BY1:85

GY2:225

BY2:230

Function Adjust/modify

LC-22SV2E

15

Page 16

LC-22SV2E

Page Item

6 VDG 0 Comb filter setting

VPK 0 Comb filter setting

KILVL 08 8 Color killer level setting

KILHY 05 5 Color killer hysteresis setting

VSYNC DELAY 7 Vsync delay control setting

DVC0 -720 Crystal oscillator center frequency adjustment

AUTO LCK 400 Crystal oscillator line-locked mode setting

7 VPC DATA 0 Video IC VPC data write & read

VPC DATA WAIT Write & read execution

TEST PATTERN 0 VPC test pattern select

AUTO LDLY 0 Y/C phase setting

DVD NTSC CR 18 Color density setting(component)

DVD NTSC CB 16 Color density setting(component)

DVD NTSC TINT 0 Color tone setting(component)

DVD NTSC BRIGHTNESS 71 Brightness setting(component)

DVD NTSC CONTRAST 25 Video setting(component)

DVD NTSC P FILTER 0 Peaking filter setting(component)

DVD NTSC H-PEAKING 3 Picture quality setting(component)

DVD NTSC BRIGHT2 8 Brightness setting 2(component)

DVD NTSC CONTRAST2 45 Video setting 2(component)

8 DVD PAL CR 23 Color density setting(component)

DVD PAL CB 19 Color density setting(component)

DVD PAL TINT 0 Color tone setting(component)

DVD PAL BRIGHTNESS 71 Brightness setting(component)

DVD PAL CONTRAST 25 Video setting(component)

DVD PAL P FILTER 0 Peaking filter setting(component)

DVD PAL H-PEAKING 3 Picture quality setting(component)

DVD PAL BRIGHT2 8 Brightness setting 2(component)

DVD PAL CONTRAST2 45 Video setting 2(component)

9 N358 AV COLOR 1800 Color density setting(composite,S-video)

N358 AV TINT 70 Color tone setting(composite,S-video)

N358 BRIGHTNESS 10 Brightness setting(TV,composite,S-video)

N358 PEAKING FILTER 0 Peaking filter setting(TV,composite,S-video)

N358 AV H-PEAKING 3 Picture quality setting(composite,S-video)

N358 AVO START 145 Horizontal position setting

N358 SFIF 8 Horizontal position setting

N358 SCINC1

N358 AV LDLY 0 Y/C phase setting(composite,S-video)

10 N443 AV COLOR 1800 Color density setting(composite,S-video)

N443 AV TINT 70 Color tone setting(composite,S-video)

N443 BRIGHTNESS 10 Brightness setting(TV,composite,S-video)

N443 PEAKING FILTER 0 Peaking filter setting(TV,composite,S-video)

N443 AV H-PEAKING 3 Picture quality setting(composite,S-video)

N443 AVO START 145 Horizontal position setting

N443 SFIF 8 Horizontal position setting

N443 SCINC1

N443 AV LDLY -2 Y/C phase setting(composite,S-video)

11 PAL TV COLOR 1750 Color density setting(TV)

PAL AV COLOR 1800 Color density setting(composite,S-video)

PAL TV TINT 70 Color tone setting(TV)

PAL AV TINT 70 Color tone setting(composite,S-video)

PAL BRIGHTNESS 10 Brightness setting(TV,composite,S-video)

PAL PEAKING FILTER 0 Peaking filter setting(TV,composite,S-video)

PAL TV H-PEAKING 3 Picture quality setting(TV)

PAL AV H-PEAKING 3 Picture quality setting(composite,S-video)

PAL AVO START 145 Horizontal position setting

PAL SFIF 13 Horizontal position setting

PAL SCINC1

PAL TV LDLY 0 Y/C phase setting(TV)

PAL AV LDLY -2 Y/C phase setting(composite,S-video)

12 SECAM TV COLOR 1750 Color density setting(TV)

SECAM AV COLOR 1800 Color density setting(composite,S-video)

SECAM TV TINT 70 Color tone setting(TV)

SECAM AV TINT 70 Color tone setting(composite,S-video)

Initial setting

1078(Panorama)

1600(other)

1078(Panorama)

1600(other)

1078(Panorama)

1600(other)

Function Adjust/modify

Roundness setting

Roundness setting

Roundness setting

16

Page 17

LC-22SV2E

Page Item

12 SECAM BRIGHTNESS 10 Brightness setting(TV,composite,S-video)

SECAM PEAKING FILTER 0 Peaking filter setting(TV,composite,S-video)

SECAM TV H-PEAKING 3 Picture quality setting(TV)

SECAM AV H-PEAKING 3 Picture quality setting(composite,S-video)

SECAM AVO START 145 Horizontal position setting

SECAM SFIF 13 Horizontal position setting

SECAM SCINC1

SECAM TV LDLY -2 Y/C phase setting(TV)

SECAM AV LDLY -2 Y/C phase setting(composite,S-video)

13 PAL-M AV COLOR 1800 Color density setting(composite,S-video)

PAL-M AV TINT 70 Color tone setting(composite,S-video)

PAL-M BRIGHTNESS 10 Brightness setting(TV,composite,S-video)

PAL-M PEAKING FILTER 0 Peaking filter setting(TV,composite,S-video)

PAL-M AV H-PEAKING 3 Picture quality setting(composite,S-video)

PAL-M AVO START 145 Horizontal position setting

PAL-M SFIF 8 Horizontal position setting

PAL-M SCINC1

PAL-M AV LDLY -2 Y/C phase setting(composite,S-video)

14 PAL-N AV COLOR 1800 Color density setting(composite,S-video)

PAL-N AV TINT 70 Color tone setting(composite,S-video)

PAL-N BRIGHTNESS 10 Brightness setting(TV,composite,S-video)

PAL-N PEAKING FILTER 0 Peaking filter setting(TV,composite,S-video)

PAL-N AV H-PEAKING 3 Picture quality setting(composite,S-video)

PAL-N AVO START 145 Horizontal position setting

PAL-N SFIF 0 Horizontal position setting

PAL-N SCINC1

PAL-N AV LDLY -2 Y/C phase setting(composite,S-video)

15 PAL60 AV COLOR 1800 Color density setting(composite,S-video)

PAL60 AV TINT 70 Color tone setting(composite,S-video)

PAL60 BRIGHTNESS 10 Brightness setting(TV,composite,S-video)

PAL60 PEAKING FILTER 0 Peaking filter setting(TV,composite,S-video)

PAL60 AV H-PEAKING 3 Picture quality setting(composite,S-video)

PAL60 AVO START 145 Horizontal position setting

PAL60 SFIF 13 Horizontal position setting

PAL60 SCINC1

PAL60 AV LDLY -2 Y/C phase setting(composite,S-video)

16 AFT UP 2.7

AFT DOWN 1.8

NTSC 01 0 Initial setting

NTSC 02 0 Setting

NTSC 03 1 Setting

NTSC 04 0 Start palse position

NTSC 05 0 Start palse position

NTSC 06 0 Horizontal display position

NTSC 07 0 Vertical display position

NTSC 09 10 Panel clock

NTSC 0A 0 Upper side mask

NTSC 0B 0 Lower side mask

NTSC 10 0 Test display

NTSC 11 0 Test disp data

NTSC 12 80 Flicker disp data

NTSC 13 E1 OEM low start

NTSC 14 1 OEM low start

NTSC 15 0 OEM low end

NTSC 16 10 OEM low end

NTSC 17 61 SP position

NTSC E0 0 Test setting

NTSC E1 0 Test setting

NTSC F0 7 PWM output

NTSC F3 DD PWM frequency L bit

NTSC F4 1 PWM frequency H bit

NTSC F5 0 PWM duty L bit

NTSC F6 0 PWM duty H bit

Initial setting

1078(Panorama)

1600(other)

1078(Panorama)

1600(other)

1078(Panorama)

1600(other)

1078(Panorama)

1600(other)

Function Adjust/modify

Roundness setting

Roundness setting

Roundness setting

Roundness setting

17

Page 18

LC-22SV2E

Page Item

17 PAL 01 0 Initial setting

PAL 02 0 Setting

PAL 03 1 Setting

PAL 04 0 Start palse position

PAL 05 0 Start palse position

PAL 06 0 Horizontal display position

PAL 07 0 Vertical display position

PAL 09 10 Panel clock

PAL 0A 0 Upper side mask

PAL 0B 0 Lower side mask

PAL 10 0 Test display

PAL 11 0 Test disp data

PAL 12 80 Flicker disp data

PAL 13 E1 OEM low start

PAL 14 1 OEM low start

PAL 15 0 OEM low end

PAL 16 10 OEM low end

PAL 17 61 SP position

PAL E0 0 Test setting

PAL E1 0 Test setting

PAL F0 7 PWM output

PAL F3 DD PWM frequency L bit

PAL F4 1 PWM frequency H bit

PAL F5 0 PWM duty L bit

PAL F6 0 PWM duty H bit

18 VL256 70 Gradation power referrence voltage

REF256 79 Gradation power referrence voltage

VL224 54 Gradation power referrence voltage

REF224 113 Gradation power referrence voltage

VL192 43 Gradation power referrence voltage

REF192 101 Gradation power referrence voltage

VL160 46 Gradation power referrence voltage

REF160 193 Gradation power referrence voltage

VL128 60 Gradation power referrence voltage

REF128 192 Gradation power referrence voltage

19 VL96 52 Gradation power referrence voltage

REF96 228 Gradation power referrence voltage

VL64 100 Gradation power referrence voltage

REF64 166 Gradation power referrence voltage

VL0 110 Gradation power referrence voltage

REF0 180 Gradation power referrence voltage

G/A TEST PATTERN1 0 Gradation test pattern display

G/A TEST PATTERN2 0 Gradation test pattern display

G/A DATA 0 G/A data write & read

G/A DATA WAIT Write & read execution

20 LSYNC 625 Sync ID threshold level(TV)

HSYNC 655 Sync ID threshold level(TV)

AVSYNC 5000 Sync ID threshold level(external input)

VPC FP20H VPC data read value

VPC FP21H VPC data read value

VPC FP13H VPC data read value

MSP DEMO200H MSP data read value

L ERROR WAIT 15s Lamp error detect wait time

L ERROR H TIME 1s Lamp error detect time

LR EXCHANGE 100m Sound LR exchange time

MSP ASS WAIT 1.2S Automatic sound select time

21 DENKA PORT OFF Power off mode setting

DENKA TESTP 0 Power off mode setting

DENKA TESTP2 30ms Power off mode setting

22 TEXT COMM Text IC control command setting

TEXT COMM WAIT Write & read execution

TEXT REGISTER Text IC register setting

TEXT REGISTER WAIT Write & read execution

NAME Text IC networkname setting

TEXT HEADER NAME WAIT Write & read execution

V POSITION 1F Text vertical position setting

H POSITION B0 Text horizontal position setting

Initial setting

Function Adjust/modify

18

Page 19

LC-22SV2E

Page Item

22 EXT CONTROL OFF External control select

EXT MODE UART External mode select

UPDATE MODE NORMAL Update mode select

TEXT RESET OFF Text reset

23 NR DATA OFF Noise reduction IC data sending

NR 40H EC Noise reduction IC data

NR 41H D0 Noise reduction IC data

NR 42H 00 Noise reduction IC data

NR 43H 80 Noise reduction IC data

NR 45H 08 Noise reduction IC data

NR 51H 80 Noise reduction IC data

24 50 OPC LV0 00 Opc save level 0 duty setting

50 OPC LV1 8 Opc save level 1 duty setting

50 OPC LV2 1 6 Opc save level 2 duty setting

50 OPC LV3 2 4 Opc save level 3 duty setting

50 OPC LV4 3 2 Opc save level 4 duty setting

50 OPC LV5 4 0 Opc save level 5 duty setting

50 OPC LV6 4 8 Opc save level 6 duty setting

50 OPC LV7 5 6 Opc save level 7 duty setting

50 OPC LV8 6 4 Opc save level 8 duty setting

50 OPC LV9 7 2 Opc save level 9 duty setting

50 OPC LV10 80 Opc save level 10 duty setting

25 60 OPC LV0 0 Opc save level 0 duty setting

60 OPC LV1 8 Opc save level 1 duty setting

60 OPC LV2 1 6 Opc save level 2 duty setting

60 OPC LV3 2 4 Opc save level 3 duty setting

60 OPC LV4 3 2 Opc save level 4 duty setting

60 OPC LV5 4 0 Opc save level 5 duty setting

60 OPC LV6 4 8 Opc save level 6 duty setting

60 OPC LV7 5 6 Opc save level 7 duty setting

60 OPC LV8 6 4 Opc save level 8 duty setting

60 OPC LV9 7 2 Opc save level 9 duty setting

60 OPC LV10 80 Opc save level 10 duty setting

Initial setting

Function Adjust/modify

19

Page 20

LC-22SV2E

Check all the settings microprocessor's adjust process menu.

Do F3701 and F3702

function?

Are T701's secondary

outputs, +32V, +9V,

+5V and -8V normal?

Remove F3701 and F3702

and check the load side.

Is there short-circuiting?

Is there short-circuiting of

T3701 primary side periphery,

Q3702, Q3711 and P3706?

Replace F3701 and F3702.

Check T3701's secondary

side periphery.

Check T701's secondary

load.

Check all connection of each unit. (Refer to overall wiring diagram.)

Check T701's primary side

periphery.

Check T3701's primary side

periphery, Q3711 and their

perpheral parts.

Does F3701, F3702, F6551,

F6552, F6553 and F6554

function?

Is the pin (31) of IC4561 in

the "H" state?

Are the Q6553, Q6556, Q6559

and Q6562 short-circuiting?

Is T6551~T6557's primary

oscillator waveform normal?

Replace the fluorescent

lamp with new one and

check again.

Check the OFL line, IC14561

and their peripheral parts.

Check Q6553, Q6556,

Q6559, Q6562 and their

peripheral parts.

Check Q6551, Q6554, Q6557,

Q6560, Q6552, Q6555,

Q6558, Q6561 and

connection cable.

No picture, No sound

Yes

No

Yes

Yes

Yes

No No

No

Fluorecent lamp failure to light up

Yes

Yes

No

No

No

Yes

Yes

TROUBLE SHOOTING TABLE

20

Page 21

TROUBLE SHOOTING TABLE (Continued)

Check all the settings microprocessor's adjust process menu.

Is in/output of

IC801 normal?

Is in/output of

IC4101 normal?

Check IC801

and its

peripheral parts.

Check IC4101

and its

peripheral parts.

Check IC3402

and its

peripheral parts.

Check IC801,

AV1 line and its

peripheral parts.

Is in/out of

IC4561 normal?

Check IC4561

and its

peripheral parts.

Check LCD

panel voltages

and waveform.

Is in/output of

IC3402 normal?

Is input at pin

(73) of IC801

normal?

Is voltages at

pins (6), (7)

and (18) of

tuner normal?

Is output at pin

(13) of tuner

normal?

Check the

power line.

Check tuner

and its

peripheral parts.

Is input at pin

(3) of IC3402

normal?

Is the pins (2)

and (4) of

IC3402 at "H"

and "L" state?

Check the pins

(65) and (66) of

IC2001 at "H"

and "L" state.

Check the its

line.

Check IC3402

and its

peripheral parts.

Is input at pin

(1) of IC3402

normal?

Is the pins (2)

and (4) of

IC3402 at "L"

state?

Check the its

line.

Check IC3402

and its

peripheral parts.

Check the pins

(65) and (66) of

IC2001 at "L"

state.

No picture

No picture

at all

No TV and

VIDEO 2

output

No TV output

No VIDEO 2

output

No

No

No

No

Yes

Yes

No

No

Yes

Yes

No

No

No

Yes

Yes

No

No

Yes

Yes

Yes

Yes

LC-22SV2E

21

Page 22

LC-22SV2E

Check all the settings microprocessor's adjust process menu.

Is input at pin

(74) of IC801

normal?

Check the AV1

line (SCART

INPUT) and

their peripheral

parts.

Check the

SY-line, SC-line

and their

peripheral parts.

Is input at pins

(71) and (72) of

IC801 normal?

Is input at pin

(70) of IC801

normal?

Check the

V2VO line and

their

peripheral parts.

Is input at pins

(96)~(107),

(110)~(121)

and (132)~(143)

of IC4101

normal?

Is output at pins

(57)~(60) of

IC1601

normal?

Check IC4101

and its

peripheral parts.

Check the its

line. (V2V0)

Check the its

line.

Is output at pin

(21) of IC1601

normal?

Check IC1601

and its

peripheral parts.

No picture

No VIDEO 1

output

No S-VIDEO

(VIDEO 1)

output

No line

output

No TELETEXT

output

No No No

No

No

No

Yes

Yes

Yes

TROUBLE SHOOTING TABLE (Continued)

22

Page 23

TROUBLE SHOOTING TABLE (Continued)

Check all the settings microprocessor's adjust process menu.

Is source GND

normal?

Is CSCOM

waveform

normal?

Check FB4901,

FB4902 and its

peripheral parts.

Check IC4702,

IC4711, Q4701

and their

peripheral parts.

Check FB4562

and its

peripheral parts.

Is gate GND

normal?

Is gate clock

(GCK) normal?

Check FL4572,

R4582 and gate

aray peripheral

parts.

Check IC4568

and its

peripheral parts.

Is VEE-6V being

outputted?

Is VGH+34V

being

outputted?

Check IC4565

and its

peripheral parts.

Is GSP

waveform

normal?

Check R4578

and its

peripheral parts.

Is VSH+3.3V

being

outputted?

Is source clock

normal?

Check IC4713

and its

peripheral parts.

Check R4563,

IC4561 and

their peripheral

parts.

Check IC4907

and gate aray

peripheral parts.

Is output of LBR

normal?

No picture

Becomes

dark

No

Time passes,

becomes

dark

Yes

No

No

Yes

No

Yes

No

Becomes

white.

Yes

Yes

No

No

No

Vertical line

output

Yes

No

No

LC-22SV2E

23

Page 24

LC-22SV2E

Check all the settings microprocessor's adjust process menu.

Is output of

R00~R07,

RE0~RE7

normal?

Is output of

G00~G07,

GE0~GE7

normal?

Is output of

B00~B07,

BE0~BE7

normal?

Check

FL4561~FL4564,

R4671~R4674

and their

peripheral parts.

Check

R4675~R4678,

FL4565~FL4568

and their

peripheral parts.

Check

R4679~R4682,

FL4569,

FL4510~FL4512

and their

peripheral parts.

Check IC4569,

IC4570 and

their peripheral

parts.

Is VLS +13V

being

outputted?

Is in/output of

SPIO and

SPOI normal?

Check R4571,

R4572, IC4561

and their

peripheral parts.

Is output VL0,

VL64, VL96,

VL128, VL160,

VL192, VL224,

VL256,

VH0, VH64,

VH96, VH128,

VH160, VH192,

VH224 and

VH256 normal?

Check

IC4703~IC4710

and their

peripheral parts.

No picture

Yes

Yes

No

No

Colour is

unusual

No

Picture

image is

gloomy

No

No picture

image

inversion

No

Gradation

defect

TROUBLE SHOOTING TABLE (Continued)

24

Page 25

Check all the settins microprocessor's adjust process menu.

Is the pin (53) of

IC2001 in the

"L" state?

Is output at pins

(26) and (27) of

IC1901 normal?

Is output at pins

(1) and (7) of

IC1903 normal?

Is output at pins

(8) and (12) of

IC3305 normal?

Muting effect is

on. Check the

SMUTE line.

Check IC1901

and its

peripheral parts.

Is the pin (5) of

IC3305 in the

"H" state?

Muting effect is

on. Check the

SSTBY line.

Check IC1903

and its

peripheral parts.

Check IC3305

and its

peripheral parts.

Check front

speaker and

connection

cable.

Is the pin (52) of

IC2001 in the

"L" state?

Is output at pins

(24) and (25) of

IC1901 normal?

Is output at pins

(1) and (7) of

IC304 normal?

Check J2204

(Headphones).

Muting effect is

on. Check the

MP-MUTE line.

Check IC1901

and its

peripheral parts.

Check IC304

and its

peripheral parts.

Is output at pins

(37) and (38) of

IC1901 normal?

Is output at pins

(1) and (7) of

IC1902 normal?

Check IC1901

and its

peripheral parts.

Check IC1902

and its

peripheral parts.

Check SCART

periphery parts.

Check IC1901

and its

periphery parts.

Check J3902,

J3903 and their

periphery parts.

Is output at pin

(11) of tuner

normal?

Is input at pins

(67) and (69) of

IC1901 normal?

Check the tuner

and its

peripheral parts.

Check SIF1 and

SIF2 line and

their peripheral

parts.

Is output at pins

(33) and (34) of

IC1901 normal?

Is output at pins

(1) and (7) of

IC3500 normal?

Check IC1901

and its

peripheral parts.

Check IC3500

and its

peripheral parts.

No sound

No sound

from front

speakers

No sound

from

headphone

TV sound

failure

No sound from

RCA output line

Yes

No No

No

Yes YesYes

No sound

from SCART

output line

Yes

No

No

Yes

No

Yes

Yes

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

TROUBLE SHOOTING TABLE (Continued)

LC-22SV2E

25

Page 26

LC-22SV2E

CHASSIS LAYOUT

H

DIGITAL Unit

G

F

MAIN Unit

OPERATION Unit

E

D

C

B

A

R/C, LED Unit

87109654321

26

Page 27

INVERTER Unit

LC-22SV2E

27

1716 1918151413121110

Page 28

LC-22SV2E

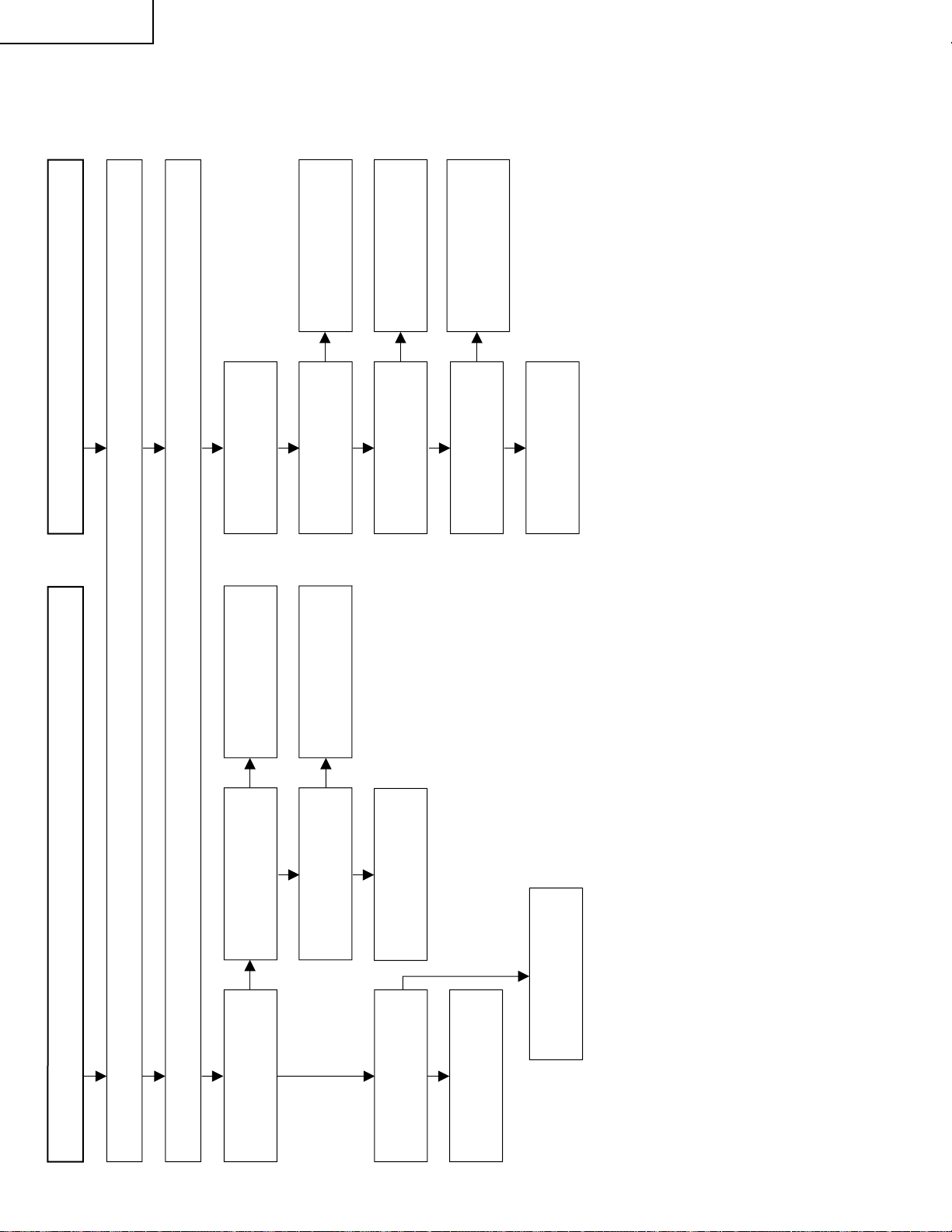

BLOCK DIAGRAM 1/2

DIGTAL BLOCK DIAGRAM

H

TO MAIN

(MA)

SC401

G

TO MAIN IC401

(ME)

SC402

OFL

SCALLER CONTROL

SCSB,SCK,SSI,SRDYB,SSO

CSYNC

SYNC

SEPARATER

V2V0V2V0

V_AV1

V1_S C

VPC SCALLER LCD LCD

IC801 IC4101 CONTROLER PANEL

Y/UV

R/G/ B

IC4561

F

E

TO MAIN

(MC)

SC4701 DAC

D

(SIG_VCC) 3.3V +3.3V (B13V1A) 3.3V +3.3V

C

B

V1_I N

V2_V

FSW1

RGB ST

TEXT RGB

OSD CONTROL

OSD R/G/B,CK,BLK,HD,VD

G/A CONTROL

MP_CS,DA,CLK

REG REG

IC4713 IC4908

6V 13V REG +2.5V

REG REG 13V IC4909

IC4557 IC4569

GRADIATION

POWER SUPPLY

IC4703~IC4710

IC4701 BIAS

IC4702 IC4711

2.5V

IC4570 5V

REG +5V

34V IC4503

REG +34V

IC4565 3.3V

-8V IC4504

REG -8V

IC4568 2.5V

COMMON

REG +3.3V

REG +2.5V

IC4104

A

654321

28

Page 29

BLOCK DIAGRAM 2/2

LC-22SV2E

H

G

F

E

MAIN BLOCK DIAGRAM

TUNER MSP SPEAKER AUDIO SPEAKER

AV2 RCA L/R AUDIO

L/R AUDIO OUT AMP OUTPUT

INPUT IC3500

J2202

AV2 AMP J2204

VIDEO IN

J2203

AV2 IC3402 SC2202

S-VIDEO IN

J2204

AV1

SCART

INPUT/

OUTPUT

R/C,LED UNIT

R/C,LED TO DIGTAL

OPC (MA)

SIF

TV_V

AV1 AUDIO

IN L/R

AV1 VIDEO IN

RGB SCART IN

RGB CONTROL

CONTROL IC2001 (MC)

BUS SW SC2001

IC3101

IC1901 OUT AMP L/R

V1_S Y

VIDEO

AMP

IC2200

AV1 VIDEO

OUT

AV1 AUDIO

OUT L/R

SCART

OUT AMP TEXT RGB

IC3402 AMP

TXD/SCL

RXD/SDA

SCL/SDA

MICON TO DIGTAL

TXD/RXD

IC1903 IC3305 OUTPUT

HEADPHONE HEADPHONE

IC304

TV/AV TO DIGTAL

SELECTER (ME)

SCART or TEXT

RGB SELECTER

IC3404

SCART or TEXT

BLANKING

SELECTER

IC3403

CSYNC

POWER AMP

J3902,J3903

IC1620,1621

TEXT RGB

TEXT

BLANKING

TELETEXT

CPU SRAM 2M

IC1601 IC1603

OSD CONTROL

OSD R/G/B,CK,BLK,HD,VD

G/A CONTRO

MP_CS,DA,CLK

SCALLER CONTROL

SCSB,SCK,SSI,SRDYB,SSO

TEXT_RGB

FLASH 4M

IC1602

V AV1

V1_IN

V1_SC

RGB_ST

V2_V

FSW1

V2V0

SC2201

OPERATION UNIT LAMP ERROR

D

C

KEY

OPERATION

E2P ROM E2P ROM RESET

IC2030 IC2030 IC2002

DC13V INV_Vcc

INPUT IC3701 +31V INVERTER

J3701 S_Vc c DRIVE

DC-DC

CONVERTER

T3701

PWM

IC3701

POWER SW 5V

Q751,Q752 REG +5V

Q753 IC751

+9V

+5V TO INVERTER

-8V P3705

B

STAND-BY

SW

Q3711,Q3712

3.3V

REG. +3.3V

IC1606

A

5V

REG

IC1610

DETECTOR

Q3705,Q3706

Q3707,Q3709

+8V Q6551-Q6562

3.3V

REG. +3.3V

IC752

+13V

B13V1A

+5V

2.5V

REG. +2.5V

IC1613

INVERTER GND

P3701,P3702

(GA,GB)

INV_VCC

BACK

LIGHT

DC/AC TRANCE

T6551-T6562

(PF)

INVERTER

UNIT

OFL

654321

29

Page 30

LC-22SV2E

OPERATION UNIT 1 KEY1 1 KEY1 1 VSY 1 VSY 1 VL0

2 KEY2 2 KEY2 2 HSY 2 HSY 2 VL64

DUNTKB598DE 3 POW1 3 POW1 3 VACT 3 VACT 3 VL96

4POW2 4POW2 4 VACT_CONT 4 VACT_CONT 4 VL128

5 GND 5 GND 5 SCSB 5 SCSB 5 VL160

6 SCK 6 SCK 6 VL192

ANALOG UNIT 7 SSI 7 SSI DIGTAL UNIT 7 VL224

8 SRDYB 8 SRDYB 8 VL256

DUNTKB522DE 9 SSO 9 SSO DUNTKB525DE 9 VH256

10 GND 10 GND 10 VH224

11 CSYNC 11 CSYNC 11 VH192

1 R/C 1 R/C 12 DDCRESET 12 DDCRESET 12 VH160

R/C, LED UNIT 2 +5V 2 +5V 13 GND 13 GND 13 VH128

3 GND 3 GND 14 SCL3 14 SCL3 14 VH96

DUNTKB597DE 4 TV_POW 4 TV_POW 15 SDA3 15 SDA3 15 VH64

5OPC 5OPC 16 GND 16 GND 16 VH0

6

RCIND/SLEEP

6

RCIND/SLEEP

17 OFL 17 OFL 17 GND

7 OPC_LED 7 OPC_LED 18 GND 18 GND 18 GO0

8 FLASH 8 FLASH 19 SW-SYNC 19 SW-SYNC 19 GO1

20 NC 20 NC 20 GO2

21 NC 21 NC 21 GO3

22 NC 22 NC 22 GND

23 GO4

24 GO5

25 GO6

1 SIG_VCC 1 SIG_VCC 26 GO7

2 SIG_VCC 2 SIG_VCC 27 GND

3 B13V1A 3 B13V1A 28 RO0

4 B13V1A 4 B13V1A 29 RO1

5 NC 5 NC 30 RO2

6 B9V200MA 6 B9V200MA 31 RO3

SPEAKER L 1 LSP 7 GND 7 GND 32 GND

2 GND 8 GND 8 GND 33 RO4

SPEAKER R 3 RSP 9 GND 9 GND 34 RO5

4GND 10 GND 10 GND 35 RO6

11 GND 11 GND 36 RO7

12 B-8V1A 12 B-8V1A 37 GND

38 RE0

39 RE1

40 RE2

1 GND 1 GND 41 RE3

2 LCD_CONT 2 LCD_CONT 42 GND

3 GND 3 GND 43 RE4

4 DDC_RST2 4 DDC_RST2 44 RE5

5 DAC2_CS 5 DAC2_CS 45 RE6

6 DAC1_CS 6 DAC1_CS 46 RE7

7 GND 7 GND 47 YOBI7

8 VSH_OUT 8 VSH_OUT 48 YOBI6

9 VSH_IN 9 VSH_IN 49 YOBI5

10 GND 10 GND 50 YOBI4

11 MP_CLK 11 MP_CLK 51 YOBI3

12 MP_DA 12 MP_DA 52 YOBI2

13 GND 13 GND 53 YOBI1

14 MP_CS 14 MP_CS

15 OSD_B 15 OSD_B

16 OSD_G 16 OSD_G

17 OSD_R 17 OSD_R 1 CSCOM

18 OSD_VD 18 OSD_VD 2 CSCOM

19 OSD_BLK 19 OSD_BLK 3 VCOM

20 OSD_CK 20 OSD_CK 4 VCOM

21 OSD_HD 21 OSD_HD 5 GND

22 P-MUTE 22 P-MUTE 6 VLS+13V

7 VLS+13V

8 VSH+3.3V

9 VSH+3.3V

10 LBR

11 GND

12 BO0

13 BO1

14 BO2

15 BO3

KK

RM

SA

MA

MB

MC

RM

KK

SCN2

SCN1MA

MB

MC

1 V2V0 1

2 GND 2

3 TEXT_R 3

4GND 4

5 TEXT G 5

ME

V2V0

GND

TEXT_R

GND

TEXT G

ME

OVERALL WIRING DIAGRAM

H

G

F

E

D

C

B

A

87109654321

30

Page 31

7 VLS+13V

8 VSH+3.3V

9 VSH+3.3V

10 LBR

11 GND

12 BO0

13 BO1

14 BO2

15 BO3

16 GND

17 BO4

18 BO5

19 BO6

20 BO7

21 GND

22 BE0

23 BE1

24 BE2

25 BE3

26 GND

27 BE4

28 BE5

29 BE6

1 H_GND1 30 BE7

2 H_GND2 31 GND

3 H_GND3 32 GE0

4 H_GND4 33 GE1

34 GE2

35 GE3

36 GND

1 H_GND5 1 INV_VCC 37 GE4

2 H_GND6 2 INV_VCC 38 GE5

3 H_GND7 3 INV_GND 39 GE6

4 H_GND8 4 INV_GND 40 GE7

5OFL 41 GND

42 REV

1 MRDY 1 REG 43 LS

2 BUSY 2 MRDY 44 SPIO

3 CN VSS 3 SDA1 45 SPOI

4 RESET 4 SCL2 46 GND

5 RXD 5 GND 47 CK

6 TXD 6 48 GND

7SCLK 49 POLA

8SW 50 POLB

9 VCC

10 GND

1 CS-COM

2 CS-COM

3 VGH+34V 0.5V

4 VGH+34V 0.5V

5 GSP2

6 POWER

1 HA1 INVERTER UNIT 1 INV_VCC 7GCK

2 HA2 2 INV_VCC 8 GLBR

3 HA3 DUNTKB526DE 3 INV_GND 9GND

4 INV_GND 10 GND

5OFL 11 OEM

12 NC

1HB1 13 VSH+3.3V

2HB2 14 VSH+3.3V

3HB3 15 GSP1

16 VEE-6.0V

17 VEE-6.0V

18 VGL-6.0V

1 HC1 19 VGL-6.0V

2HC2 20 GND

3 HC3 21 GND

22 GND

23 YOBI1

24 YOBI2

1HD1 25 YOBI3

2HD2 26 YOBI4

3HD3 27 YOBI5

28 YOBI6

29 YOBI7

30 VLS+13V

PFLA

LB

LC

LD

GA

TP2TP1

GB PF

GD

1 V2V0 1

2 GND 2

3 TEXT_R 3

4 GND 4

5 TEXT_G 5

6 GND 6

7 TEXT_B 7

8 GND 8

9 V_AV1 9

10 GND 10

11 B_ST 11

12 GND 12

13 G_ST 13

14 GND 14

15 R_ST 15

16 GND 16

17 V1_SC 17

18 GND 18

19 V1_IN 19

20 GND 20

21 V2_V 21

22 FSW1 22

ME

V2V0

GND

TEXT_R

GND

TEXT_G

GND

TEXT_B

GND

V_AV1

GND

B_ST

GND

G_ST

GND

R_ST

GND

V1_SC

GND

V1_IN

GND

V2_V

FSW1

ME

BACK LIGHT

LC-22SV2E

31

1716 1918151413121110

Page 32

LC-22SV2E

DESCRIPTION OF SCHEMATIC DIAGRAM

VOLTAGE MEASUREMENT CONDITION:

1. The voltages at test points are measured on

exclusive AC adaptor and the stable supply voltage

of AC 120V. Signals are fed by a color bar signal

generator for servicing purpose and the above

voltages are measured with a 20k ohm/V tester.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/16W, unless otherwise noted.

4. All resistors are Carbon type, unless otherwise

noted.

C

: Solid

S : Oxide Film T : Special

N : Metal Coating

CAPACITOR

1. All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2. All capacitors are 50V, unless otherwise noted.

3. All capacitors are Ceramic type, unless otherwise

noted.

(ML): Mylar (TA): Tantalum

(PF): Polypro Film (ST): Styrol

W

: Cement

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å” ( ) ARE

IMPORTANT FOR MAINTAINING THE SAFETY OF

THE SET. BE SURE TO REPLACE THESE PARTS

WITH SPECIFIED ONES FOR MAINTAINING THE

SAFETY AND PERFORMANCE OF THE SET.

32

Page 33

SCHEMATIC DIAGRAM

Ë

OPERATION Unit

H

G

F

LC-22SV2E

E

D

C

B

A

654321

33

Page 34

LC-22SV2E

Ë

DIGITAL Unit-1/5

H

G

F

E

D

C

B

A

87109654321

34

Page 35

LC-22SV2E

35

1716 1918151413121110

Page 36

LC-22SV2E

Ë

DIGITAL Unit-2/5

H

G

F

E

D

C

B

A

87109654321

36

Page 37

LC-22SV2E

37

1716 1918151413121110

Page 38

LC-22SV2E

Ë

DIGITAL Unit-3/5

H

G

F

E

D

C

B

A

87109654321

38

Page 39

LC-22SV2E

39

1716 1918151413121110

Page 40

LC-22SV2E

Ë

DIGITAL Unit-4/5

H

G

F

E

D

C

B

A

87109654321

40

Page 41

LC-22SV2E

41

1716 1918151413121110

Page 42

LC-22SV2E

Ë

DIGITAL Unit-5/5

H

G

F

E

D

C

B

A

87109654321

42

Page 43

LC-22SV2E

43

1716 1918151413121110

Page 44

LC-22SV2E

Ë

MAIN Unit-1/5

H

G

F

E

D

C

B

A

87109654321

44

Page 45

LC-22SV2E

45

1716 1918151413121110

Page 46

LC-22SV2E

Ë

MAIN Unit-2/5

H

G

F

E

D

C

B

A

87109654321

46

Page 47

LC-22SV2E

47

1716 1918151413121110

Page 48

LC-22SV2E

Ë

MAIN Unit-3/5

H

G

F

E

D

C

B

A

87109654321

48

Page 49

LC-22SV2E

49

1716 1918151413121110

Page 50

LC-22SV2E

Ë

MAIN Unit-4/5

H

G

F

E

D

C

B

A

87109654321

50

Page 51

LC-22SV2E

51

1716 1918151413121110

Page 52

LC-22SV2E

Ë

MAIN Unit-5/5

H

G

F

E

D

C

B

A

87109654321

52

Page 53

LC-22SV2E

53

1716 1918151413121110

Page 54

LC-22SV2E

Ë

INVERTER Unit

H

G

F

E

D

C

B

A

654321

54

Page 55

Ë

R/C, LED Unit

H

G

F

LC-22SV2E

E

D

C

B

A

654321

55

Page 56

LC-22SV2E

FB4709

1

0

PRINTED WIRING BOARD ASSEMBLIES

H

G

F

E

DIGITAL Unit (Side-A)

D

C4635

C4617

SC4902

R4676R4675

R4674R4673

R4672R4671

R4572

C4590

R4616

C4639

C4638

L4569

L4565

FL4566

FL4561 FL4562 FL4563 FL4564 FL4565

R4597

R4569

R4580

R4582

R4583

C4634

R4570

R4585

R4599

C4574 C4578

C4589

FL4572

R4584

FL4573

R4578

R4564

R4567

C4582

C4572 C4575

C4603

C4604

C4636

C4613

P4101

R4155

FB4902

FB4912

FB4116

FB4119

C4644

L4552

C

C4642

C4624

D4568

C4626

C4625

SC4561

B

C4622

C4629

FL4570

FB4566

R4562 R4604

C4605 R4601

FB4563

R4615

C4612 R4603

D4572

R4657

R4588

R4595

SC4562

FL4568FL4567

IC4561

R4586

C4562

FB4567

FL4574

R4592

R4686

C4564

R4685

R4683

C4561

R4587

C4567

C4565

C4568

C4904

FL4512FL4511FL4510FL4569

FB4561

R4568

R4563

R4565

R4566

C4591

C4581C4569 C4570 C4580 C4592 C4598

C4579

R4602

C4576

SC4901

R4679R4678R4677

R4682R4681R4680

C4915

FL4902

IC4714

C4740

SC401

FB4911

FB4901

L4901

FB4910

FB4909

C4910C4914

C4909

FL4901

C4703

FB805

L4903

C49

C49

C4912

FB4707

A

DIGITAL Unit (Chip Parts Side-A)

87109654321

56

Page 57

LC-22SV2E

C4703

L4901

L4903

C4912

C4908

C4913

FB4707

FB4709

FB4710

FB4708

FB4706

SC4701

FB4705

R4857

R4859

L4902

C4728

R4861

L4904

FB4704

FB4701

R4830

C4901

C4906

C4902

C4739

R4829

D4705

D4704

D4703

C4733

R4151

C4145

R4149

R4150

R4143

P410

R4148

R4144 R4146 R4147

R4145

R4142

R4103

R4105

R4102

R4104

R4106

C4130

C4128

C4554 C4556

R4141

C4509

X4101

IC4101

C4125

C4123

FB4109

L4508

FB4107

L4507

C4127

R4139

FB4106

R4138R4140

C4120

C4142

C4143

C4553

C4552

L4506

FB807

C4111

SC403

C4109

R810

R875 R874 R870 R869

FB803

C862

C404

Q401

R404

C401

FB806

C402

R405

R406 R408

R801 R802 R803

X801

R836 R835

C803 C804

C835

C842

FB804

SC402

C810

C801

C802

L804

C409

C4138

IC4103

C4118

C4116

FL801

C4115

C4113

C4141

L805

C838

C833

C827 C834

C826

C853

C851

C832

C831

C830

R424

R423

R4156

FB4117

P4102

C856

C854

R868

R867

R866

Z1 Z2

FDC1

FB4102

C4104

FB4111

FB4110

FB4101

C839

R816

R813

C822

C818

IC801

C812

C819 C820

C809

R422

C847

FL401

C821

R417

C843

R818

57

1716 1918151413121110

Page 58

LC-22SV2E

C4705R4746R4720C4717R4798R4772

H

G

F

E

DIGITAL Unit (Side-B)

C4108

R4127

FB4103

R4125

R4122

C4106

C4140

C4107

C4103

D

C4114C4117C4110

R4123

R4136

R4130

R4129

R4135

FB4104

C4144

C4112

FB4114

C

L808

R857

R856

L807

Z3Z4

R4112

R4113

R804

C837

L814

R820

L813

L812

R821

B

C410

FDC2

Q820R830

R829

C846

C844

C845

C4139

IC4104

IC4102

C4105

R4117

R4192

R811

C836

R814

C823

C814

R815

C840

R855L806

C855C852

C408

Q421R427

R817

R425

C850

C4101

R4191R4190

R4101R4109

C4102

C813

R826

R805

C816

R864C817

C841

R860

R421

R426

C848

R871

C805C806

R812

R837

TP802

C865C866R872C867

C815

TP801

R865

R822

R832

R833

L811

L810

R863

C860

C858

C857

R862

C861

C859

R861

Q420R428

R420

C849

IC802

R877

R878

C864

R873

C868

R876

C863

R819

FB802

FB801

R403

C403

IC401

C406

R409

R410

R401

C405

C407

R402

C869

C872C871C870

R4134

R4128

FB4115

R4152

C4119

D4101

FB4105

R4111

C4148

R4184

R4182

R4180

R4178

R4183

R4181

R4179

R4177

D4506

R4173

C4121R4110

R4174

R4168

IC4503

R880

R879R881

R4175

R4137

R4542

C4122

R4172

R4171

R4170

R4169

R4176

FB402

C4137

R4153

C4124

IC4105

R4161

R4162

R4163

R4164

R4166

R4165

R4167

C4126

FB4112

C4146

R4540R4539

FB401

C4129

IC4106

FB4113

C4555

C411

IC4504

C4134

R4544

C4136

C4135

R4131

C4133

C4132

C4131

FB4108

FB4120

FL4101

C4147

D4702

D4706

R4820

R4816

IC4713

R4853

FB4905

R4852

Q4703

R4705

D4901

IC4909