Page 1

LC-20S4U-S

SUPPLEMENT

SERVICE MANUAL

S05P1LC20S4US

SUPPLEMENT

LCD COLOR TELEVISION

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

OUTLINE

The LCD panel of this model has been redesigned. With this redesign, the main and analog PWB unit as well

as the LCD panel-related and other mechanical parts have also been modified and these parts are not

interchangeable with those of previous LCD panel models in servicing.

This Supplement covers the modified points from the previous Supplement.

For other technical points, refer to the Service Manual for previous LCD panel model LC-20S4U-S

(S2F1LC20S4US) as well as the Supplement for LC-20S4U-S (S65K1LC20S4US).

The previous LCD panel models and the new model can be identified with the following markings.

• The

• The B character is also added at the end of the model name on the number label (barcode label) of the

• The serial product numbers (in the 5th thru 9th digits) are 81112 and on.

» IMPORTANT SERVICE SAFETY PRECAUTION .........................................................................................2

» REMOVING OF MAJOR PARTS .................................................................................................................. 5

» OVERALL WIRING DIAGRAM .....................................................................................................................8

» SCHEMATIC DIAGRAM

» REPLACEMENT PARTS LIST....................................................................................................................30

» PACKING OF THE SET ..............................................................................................................................39

B character is added at the end of the model name on the model label.

packing case.

CONTENTS

ËMAIN Unit .................................................................................................................................................10

ËANALOG Unit...........................................................................................................................................22

LC-20S4U-S

Page

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-20S4U-S

1

2

2

SUPPLEMENT

IMPORTANT SERVICE SAFETY PRECAUTION

Ë

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CONTINUED

PROTECTION AGAINST A RISK OF

FIRE REPLACE ONLY WITH SAME

A V

TYPE F3701 (2.5A, 250V) AND

F3702 (2.0A, 250V) FUSE.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks:

1. Inspect all lead dress to make certain that leads are

not pinched, and check that hardware is not lodged

between the chassis and other metal parts in the

receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields, isolation

resistor-capacitor networks, mechanical insulators, etc.

3. To be sure that no shock hazard exists, check for

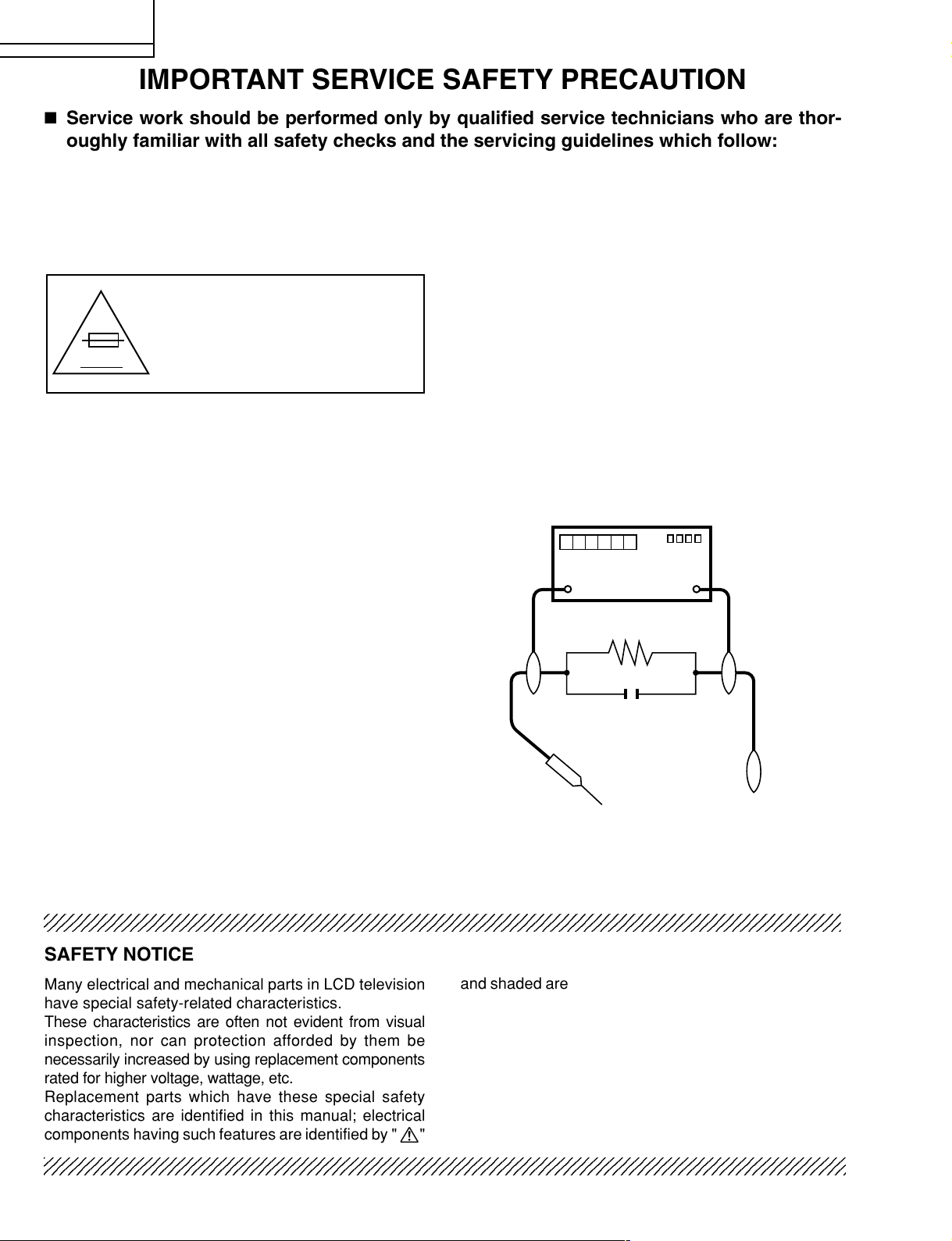

leakage current in the following manner.

• Plug the AC cord directly into a 110~240 volt AC outlet,

and connect the DC power cable into the receiver's DC

jack. (Do not use an isolation transformer for this test).

• Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as electrical conduit or electrical ground

connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or

higher, sensitivity or measure the AC voltage drop

across the resistor.

• Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

All checks must be repeated with the AC cord plug

connection reversed. (If necessary, a nonpolarized

adaptor plug must be used only for the purpose of

completing these checks.)

Any reading of 0.75V peak (this corresponds to 0.5 mA.

peak AC.) or more is excessive and indicates a potential

shock hazard which must be corrected before returning

the monitor to the owner.

DVM

AC SCALE

1.5k ohm

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

SAFETY NOTICE

Many electrical and mechanical parts in LCD television

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

and shaded areas in the

Schematic Diagrams

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock, fire or other hazards.

components having such features are identified by " å"

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

Replacement Parts Lists

.

and

Page 3

LC-20S4U-S

2

2

SUPPLEMENT

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ë

La réparation ne peut être effectuée que par un technicien spécialisé qui s'est parfaitement

accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

1. Pour la sécurité continue, n'entreprendre aucune

modification de tout circuit.

2. Débrancher l'alimentation CA avant la réparation.

PRECAUTION: POUR LA

PROTECTION CONTINUE

CONTRE LES RISQUES

D'INCENDIE, REMPLACER LE

A V

FUSIBLE PAR UN FUSIBLE DE

MEME TYPE F3701 (2.5A, 250V)

ET F3702 (2.0A, 250V).

AVANT DE RENDRE LE RECEPTEUR A

L’UTILISATEUR (Incendie et choc électrique)

Avant de rendre le récepteur à l'utilisateur, effectuer

les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour s'assurer

que les fils ne soient pas pincés ou qu'un outil ne soit

pas placé entre le châssis et les autres pièces

métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme les

boutons de commande non-métalliques, les isolants,

le dos du coffret, les couvercles ou blindages de réglage

et de compartiment, les réseaux de résistance-capacité,

les isolateurs mécaniques, etc.

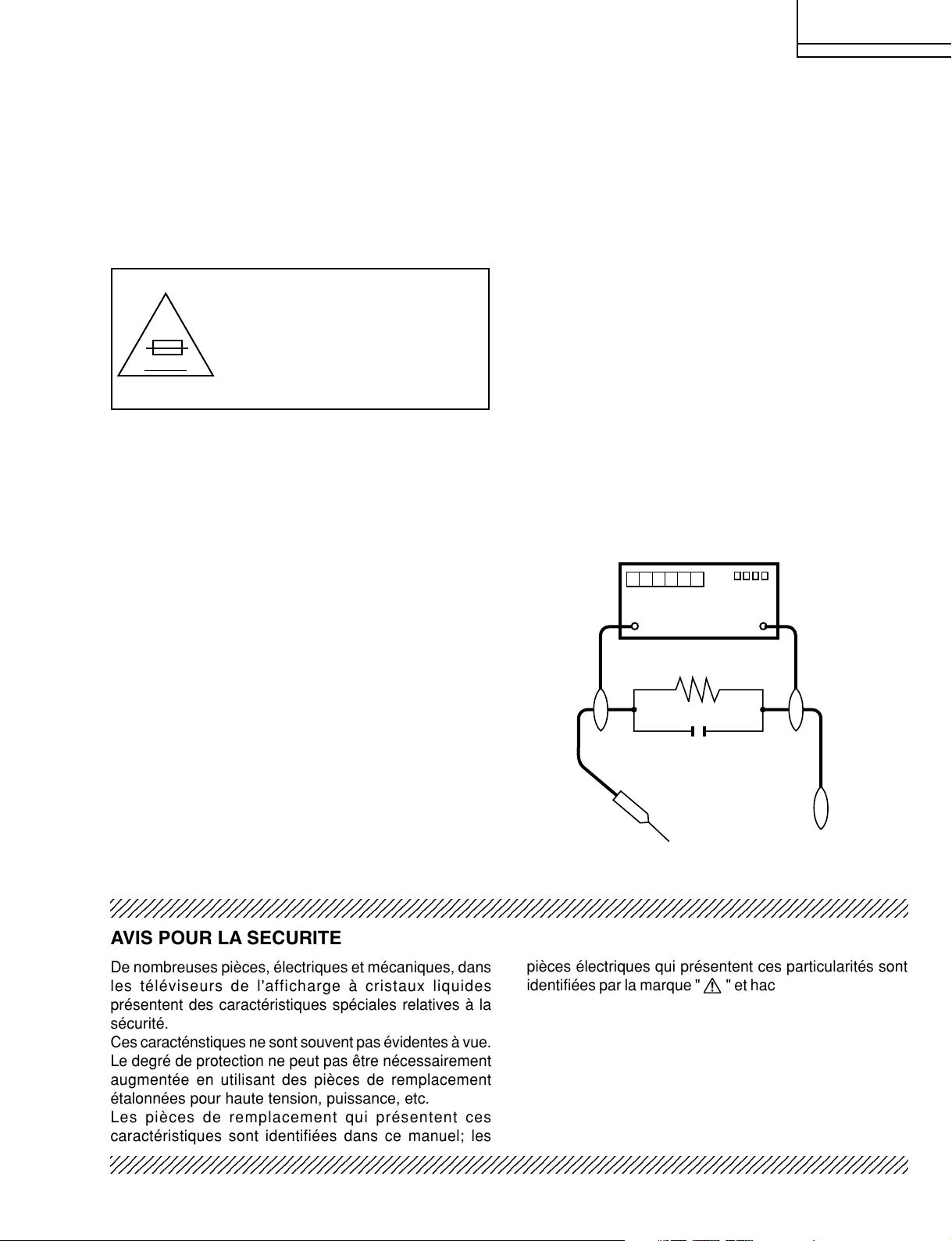

3. S'assurer qu'il n'y ait pas de danger d'électrocution en

vérifiant la fuite de courant, de la facon suivante:

• Enficher le cordon d’alimentation directement dans une

prise de 110-240V CA, et brancher le câble

d’alimentation CC à la prise CC du récepteur. (Ne pas

utiliser de transformateur d’isolation pour cet essai.)

• A l'aide de deux fils à pinces, brancher une résistance

de 1.5kΩ 10 watts en parallèle avec un condensateur

de 0.15µF en série avec toutes les pièces métalliques

exposées du coffret et une terre connue comme une

conduite électrique ou une prise de terre branchée à la

terre.

• Utiliser un voltmètre CA d'une sensibilité d'au moins

5000Ω/V pour mesurer la chute de tension CA en

travers de la résistance.

• Toucher avec la sonde d'essai les pièces métalliques

exposées qui présentent une voie de retour au châssis

(antenne, coffret métallique, tête des vis, arbres de

commande et des boutons, écusson, etc.) et mesurer

la chute de tension CA en travers de la résistance.

Toutes les vérifications doivent être refaites après avoir

inversé la fiche du cordon d'alimentation. (Si nécessaire,

une prise d'adpatation non polarisée doit être utilisée

dans le but de terminer ces vérifications.)

La tension de pointe mesurèe ne doit pas dépasser

0.75V (correspondante au courant CA de pointe de

0.5mA). Dans le cas contraire, il y a une possibilité de

choc électrique qui doit être supprimée avant de rendre

le récepteur au client.

DVM

ECHELLE CA

1.5k ohm

10W

0.15 µF

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les téléviseurs de l'afficharge à cristaux liquides

présentent des caractéristiques spéciales relatives à la

sécurité.

Ces caracténstiques ne sont souvent pas évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel; les

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

pièces électriques qui présentent ces particularités sont

identifiées par la marque " å " et hachurées dans la

des pièces de remplacement

schématiques

.

et les

diagrammes

liste

Pour assurer la protection, ces pièces doivent être

identiques à celles utilisées dans le circuit d'origine.

L'utilisation de pièces qui n'ont pas les mêmes

caractéristiques que les pièces recommandées par

l'usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

3

Page 4

LC-20S4U-S

SUPPLEMENT

Precautions for using lead-free solder

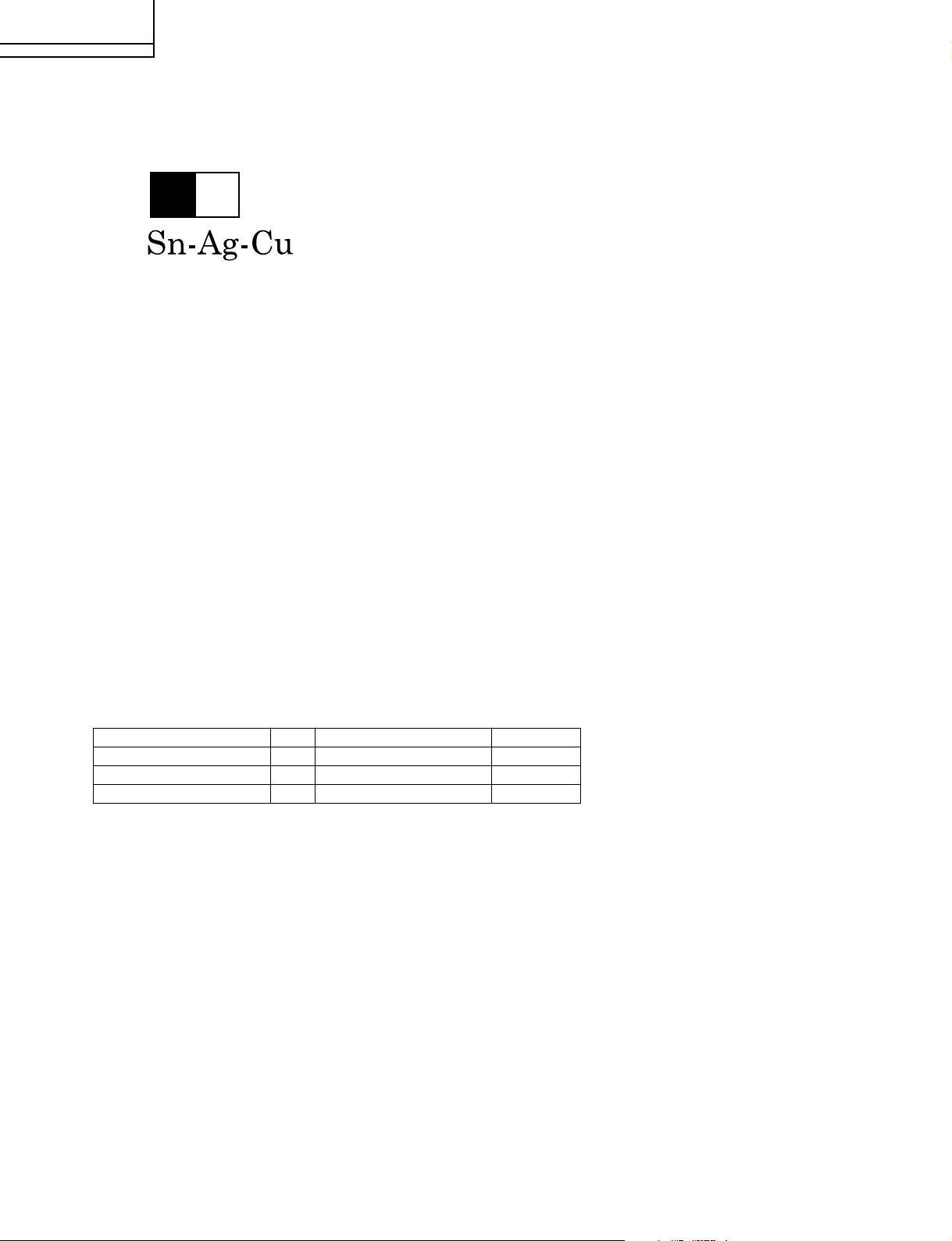

1 Employing lead-free solder

"All PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on

the PWBs and service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend

you to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit,

contact our service station or service branch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead

solder by 40°C, and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, Since the land may be peeled off or the maximum heat-resistance

temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady soldering

condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on

and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

4

Page 5

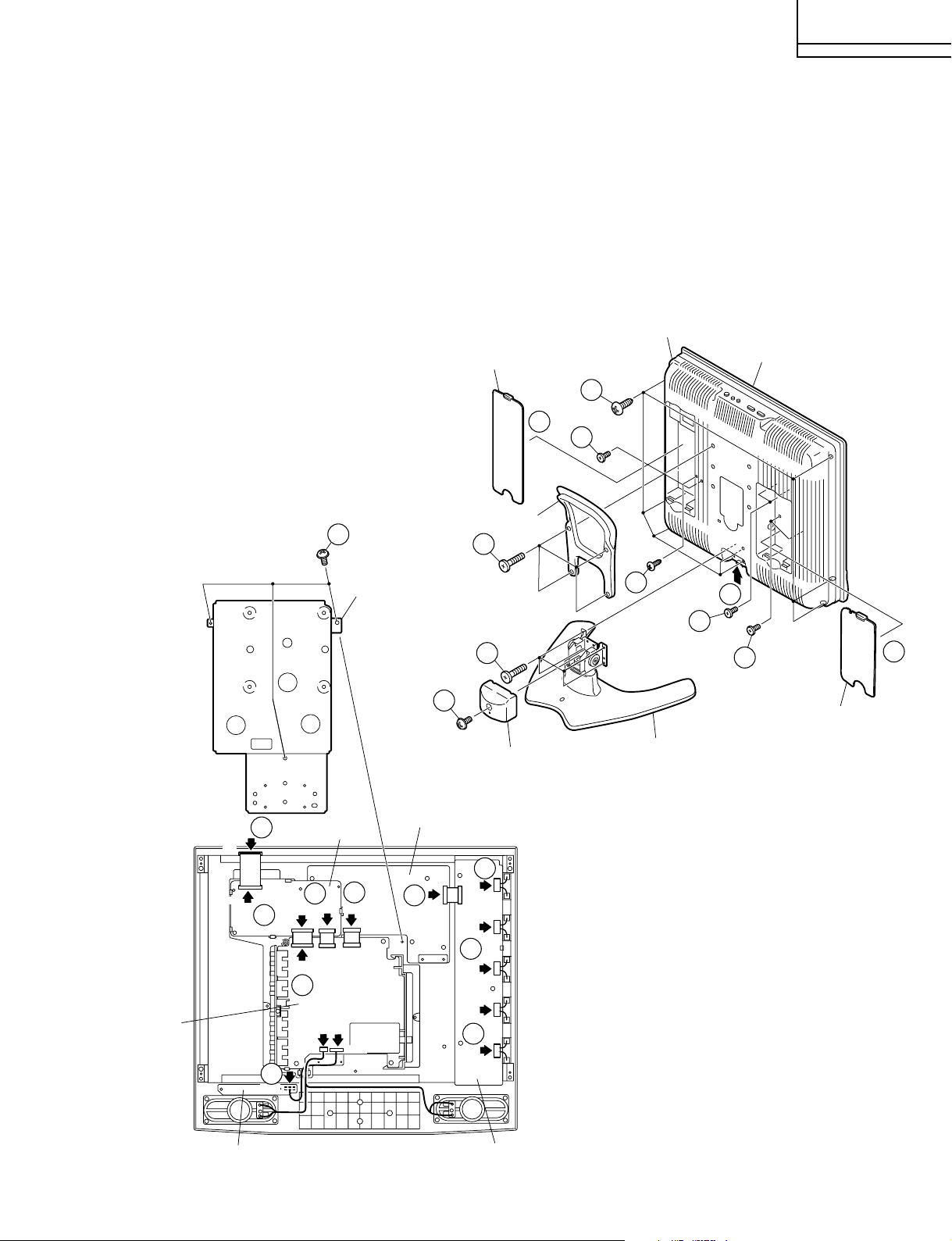

REMOVING OF MAJOR PARTS

3

6

4

4

5

5

5

5

7

1

2

Cabinet B

Carrying Handle

Cabinet A

Terminal Cover (R)

Terminal Cover (L)

Stand

Stand Cover

1. Remove the stand cover fixing screws (1 pc.)

2. Remove the stand fixing screws (4 pcs.).

3. Remove the carrying handle fixing screws (4 pcs.).

4. Remove the terminal covers (left and right).

5. Remove the terminal screws (6 pcs.).

6. Remove the cabinet B fixing screws (8 pcs.).

7. Remove the cabinet B after opening from the direction of an arrow.

8. Remove the stand angle fixing screws (3 pcs.).

9. Disconnect all the connectors from all the PWBs.

LC-20S4U-S

SUPPLEMENT

Analog PWB

SC1201

CN1

9

9

P4001

8

Stand Angle

Operation PWB

Main PWB

9

SC2001

SC3401

9

9

SC701

P3702

SC4052

P3701

9

SC4051

SC6701

9

P6706

P6705

P6704

P6703

9

9

P3402

9

P3401

P6702

R/C, LED PWB

Inverter PWB

5

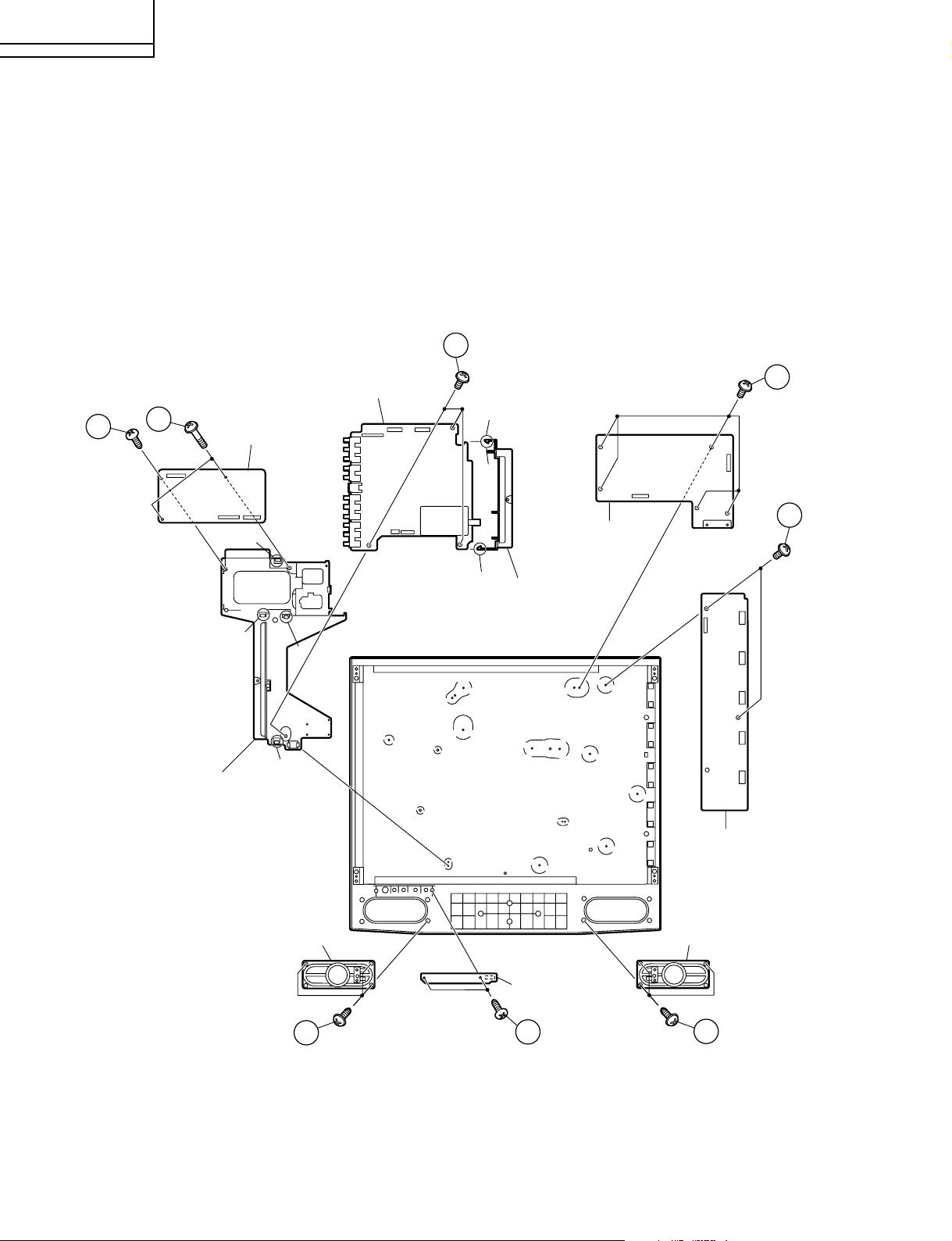

Page 6

LC-20S4U-S

SUPPLEMENT

10. Remove the 3 lock screws from the main PWB, and undo the claws a and b. Detach the main PWB by lifting the

area around the claws and pulling the PWB out.

11. Remove the 3 lock screws from the analog PWB, and undo the claws c and d. Detach the chassis frame (right)

from the analog PWB by pulling out the terminals. In the same way, undo the claws e and f, and detach the

chassis frame (left) from the analog PWB by pulling out the terminals.

Note: When detaching the main PWB and analog PWB, be careful not to break the PWB-fixing claws.

12. Remove the operation PWB fixing screws (5 pcs.)

13. Remove the inverter PWB fixing screws (2 pcs.)

14. Remove the R/C, LED PWB fixing screws (2 pcs.)

15. Remove the 3 lock screws each from the right and left speakers and take out both the speakers.

11

10

10

Main PWB

a

b

Chassis Frame (R)

Analog PWB

e

e

Operation PWB

f

Chassis Frame (L)

c

d

12

13

Speaker (R)

15

Inverter PWB

Speaker (L)

R/C, LED PWB

14

15

6

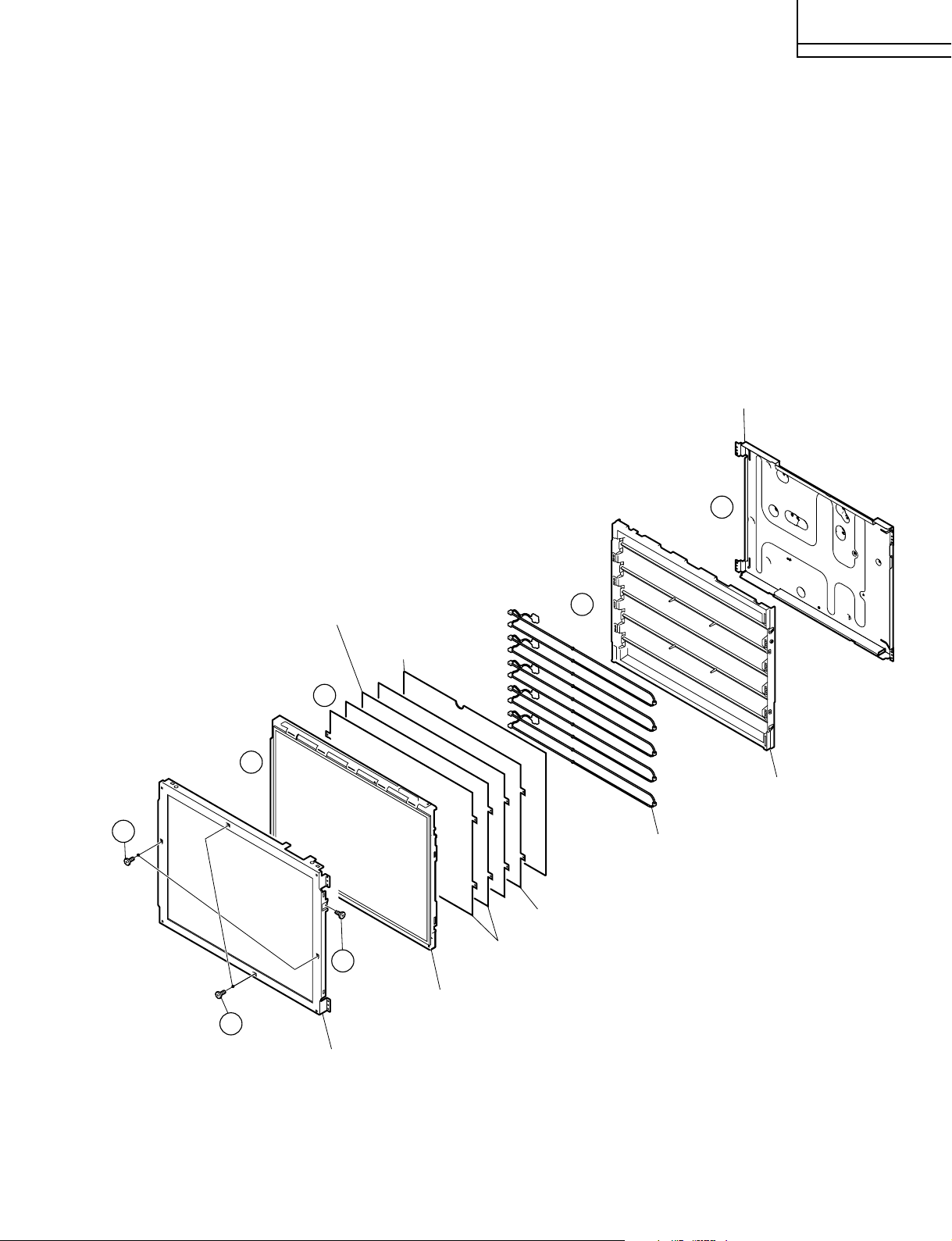

Page 7

LC-20S4U-S

SUPPLEMENT

» Precautions in handling the LCD panels

1. Work in a clean room (with humidities below 50%).

2. Be sure to wear an anti-static armband.

3. Handle the panels on an electro-conductive mat.

4. Be careful not to fall, shake and shock the panels.

16. Detach the back shield.

17. Remove the 5 lock screws from the bezel and detach the bezel.

Note: Carefully undo the hooks in the four directions.

18. Detach the LCD panel from the backlight case.

Note1: Carefully undo the hooks in the four directions.

Note2: Do not remove the LCD panel from the panel chassis. Be careful not to touch the LCD panel's glass faces,

driver IC, PWBs and other components with bare hands. (Otherwise defects may be caused in the production

line.)

19. Remove the diffusion sheets (top), lens sheet, diffusion sheet (bottom) and diffusion plate.

Note: Fit the diffusion plate and sheets tightly in the backlight casing.

If set out of position, the panel may get cracked.

20. Detach the lamp unit from the backlight case.

Back shield

(PSLDMA810WJN1)

17

Lens Sheet

(POFMA0220TPZZ)

19

18

Diffusion Plate

(PSLDK2553TPZZ)

17

16

20

Back light Case

(LHLDZ3104TPZA)

Lamp Unit, x5

(RLMPC2401TPZZ)

Diffusion Sheet (Bottom)

(PSLDK2554TPZZ)

Diffusion Sheet (Top), x2

(PSLDK2567TPZZ)

17

20" LCD Panel

Bezel

(LANGK3261TPZA)

7

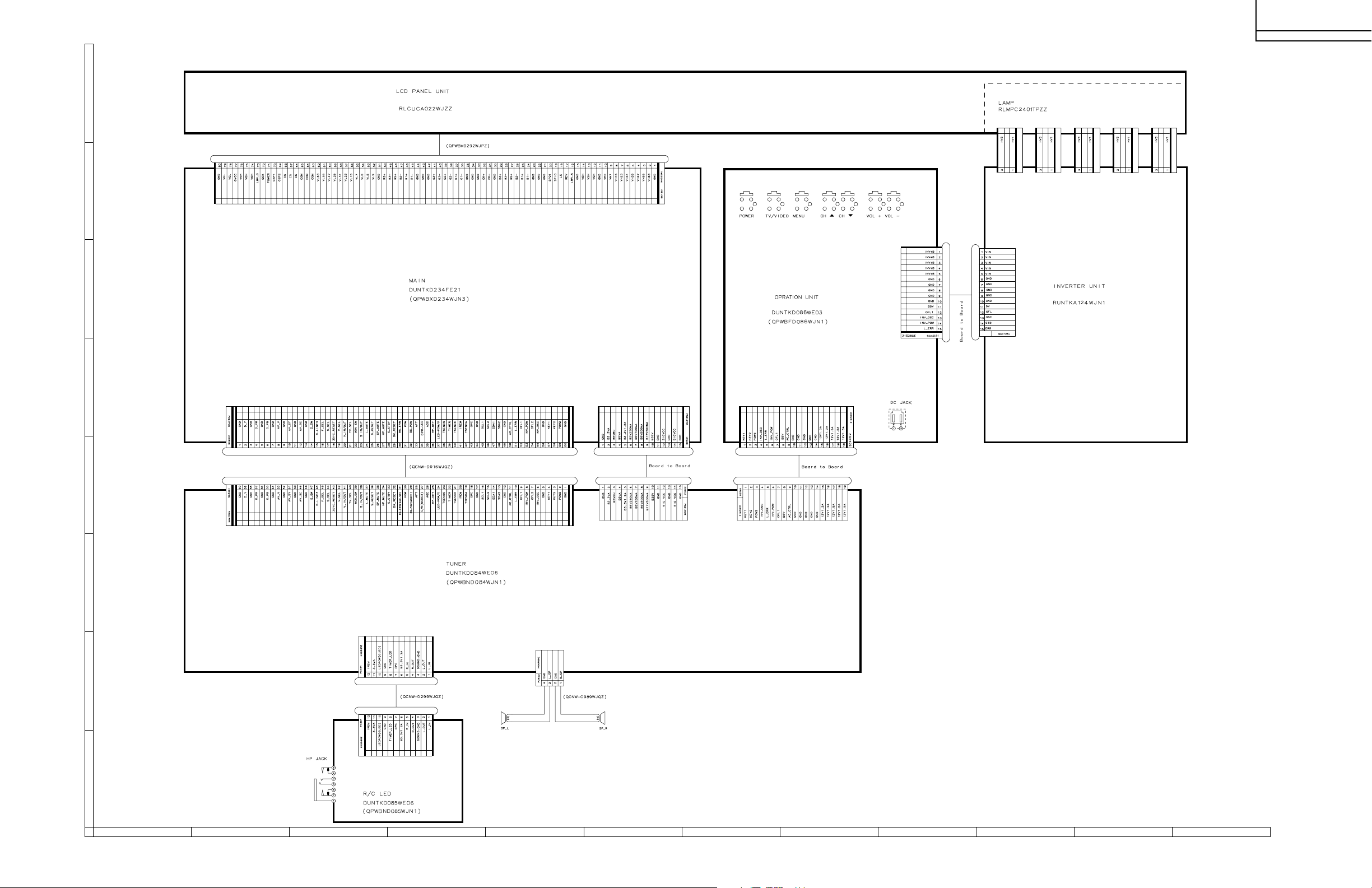

Page 8

LC-20S4U-S

121110987654321

A

B

C

D

E

F

G

H

SUPPLEMENT

OVERALL WIRING DIAGRAM

98

Page 9

LC-20S4U-S

121110987654321

A

B

C

D

E

F

G

H

SUPPLEMENT

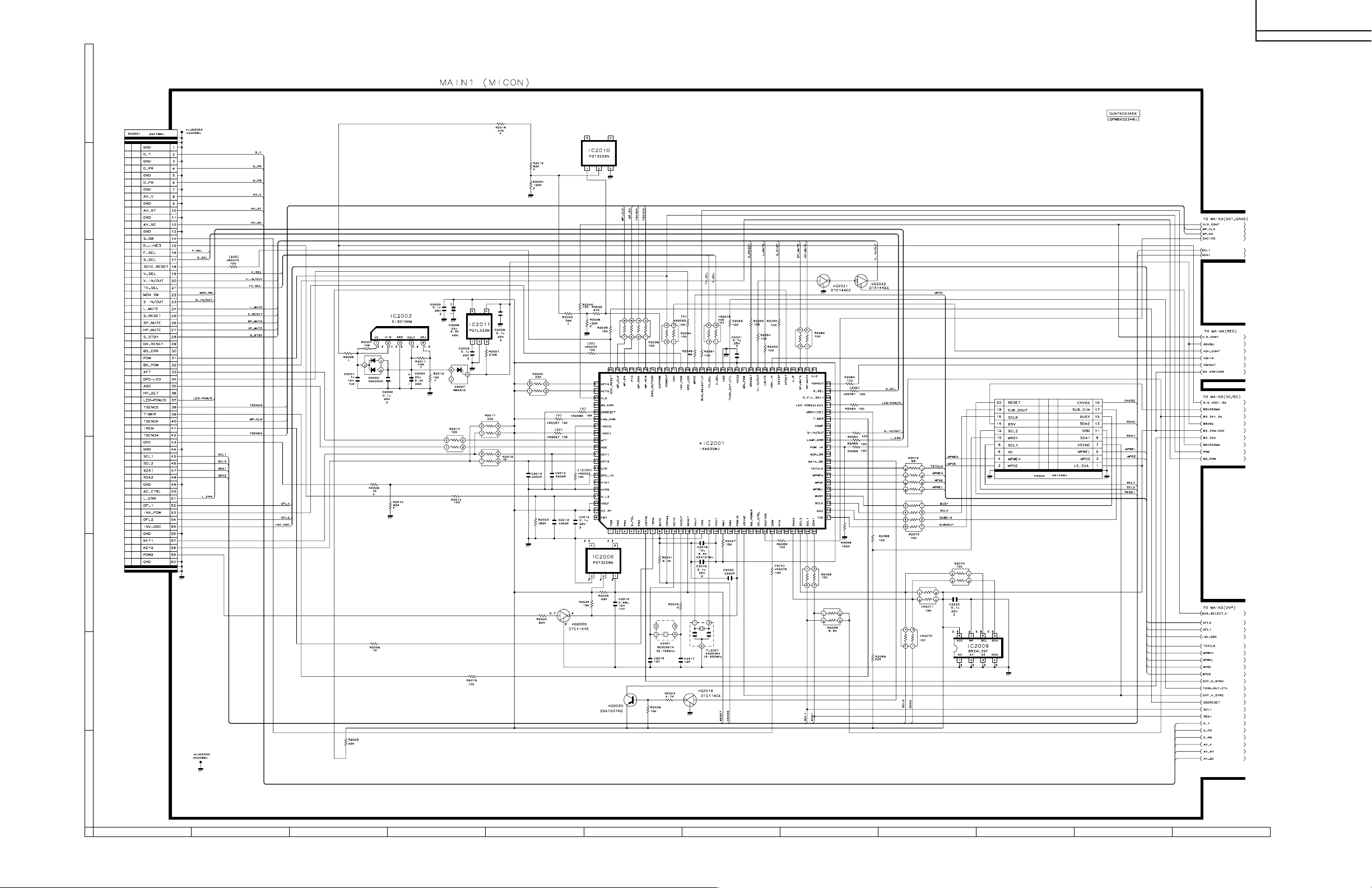

SCHEMATIC DIAGRAM

Ë

MAIN Unit-1/6

1110

Page 10

LC-20S4U-S

121110987654321

A

B

C

D

E

F

G

H

SUPPLEMENT

Ë

MAIN Unit-2/6

1312

Page 11

LC-20S4U-S

121110987654321

A

B

C

D

E

F

G

H

SUPPLEMENT

Ë

MAIN Unit-3/6

1514

Page 12

LC-20S4U-S

121110987654321

A

B

C

D

E

F

G

H

SUPPLEMENT

Ë

MAIN Unit-4/6

1716

Page 13

LC-20S4U-S

121110987654321

A

B

C

D

E

F

G

H

SUPPLEMENT

Ë

MAIN Unit-5/6

1918

Page 14

LC-20S4U-S

121110987654321

A

B

C

D

E

F

G

H

SUPPLEMENT

Ë

MAIN Unit-6/6

2120

Page 15

LC-20S4U-S

121110987654321

A

B

C

D

E

F

G

H

SUPPLEMENT

Ë

ANALOG Unit-1/4

2322

Page 16

LC-20S4U-S

121110987654321

A

B

C

D

E

F

G

H

SUPPLEMENT

Ë

ANALOG Unit-2/4

2524

Page 17

LC-20S4U-S

121110987654321

A

B

C

D

E

F

G

H

SUPPLEMENT

Ë

ANALOG Unit-3/4

2726

Page 18

LC-20S4U-S

121110987654321

A

B

C

D

E

F

G

H

SUPPLEMENT

Ë

ANALOG Unit-4/4

2928

Page 19

LC-20S4U-S

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

PARTS LIST

LISTE DES PIECES

PARTS REPLACEMENT

Replacement parts which have these special safety characteristics identified in this manual ; electrical components having such features are

identified by å and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. The use of a substitute replacement part which

does no have the same safety characteristic as the factory recommended

replacement parts shown in this service manual may create shock, fire

or other hazards.

"HOW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly, please furnish the following informations.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

in USA: Contact your nearest SHARP Parts Distributor to order. For

location of SHARP Parts Distributor, Please call Toll-Free;

1-800-BE-SHARP

★ MARK: SPARE PARTS-DELIVERY SECTION

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

PRINTED WIRING BOARD ASSEMBLIES

(NOT REPLACEMENT ITEM)

DUNTKD234FE21 – MAIN Unit —

DUNTKD084WE06 – ANALOG Unit —

Note: The R/C, LED unit, inverter unit have only their part

numbers changed. There is no change in the Schematic

Diagram, Printed Wiring Board Assemblies and Parts List.

DUNTKD085WE06 – R/C,LED Unit —

RUNTKA124WJN1 – INVERTER Unit —

LCD PANEL

NOTE: THE PARTS HERES SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDENTLY.

RLCUCA022WJZZ J 20" LCD Panel Unit Ass'y CT

DUNTKD234FE21

MAIN Unit

INTEGRATED CIRCUITS

C701 RH-iXA828WJZZY J BD9300FV-FE2 AH

IC702 RH-iXA828WJZZY J BD9300FV-FE2 AH

IC703 RH-iXA828WJZZY J BD9300FV-FE2 AH

IC705 RH-iXA828WJZZY J BD9300FV-FE2 AH

IC801 RH-iXB150WJZZQ J R8A66605A02FP BG

IC802 VHiPQ018EH1-1Y J PQ018EH01ZPH AF

IC1101 VHiBD8133FV-1Y J BD8133FV-E2 AS

IC1201 RH-iXB075WJZZQ J LR38875 AX

IC1202 VHiFSA4157+-1Y J FSA4157P6X AE

IC1703 VHiNJM2147M-1Y J NJM2147M-TE1 AF

IC2001 RH-iXA630WJZZQ J M30622MWP-245F AV

IC2003 VHiSi3010KM-1Y J SI-3010KM-TL AF

IC2006 VHiPST3229N1EY J PST3229 AD

IC2009 VHiBR24L32F-1Y J BR24L32F-WE2 AG

IC2010 VHiPST3229N1EY J PST3229 AD

IC2011 VHiPQ1L333M-1Y J PQ1L333M2SP AD

Les pi`eces de rechange qui pr élelesentent ces caract éleristiques sp

éleciales de s élecurit éle, sont identifi élees dans ce manuel : les pi`eces

élelectriques qui pr élesentent ces particularit éles, sont rep éler élee

par la marque å et sont hachur élees dans les listes de pi`eces et dans

les diagrammes sch élematiques.

La substitution d'une pi`ece de rechange par une autre qui ne pr éLesente

pas les m éoemes caract éLeristiques de s élecurit éle que la pi`ece

recommand élee parl'usine et dans ce manuel de service, peut provoquer

une éLelectrocution, un incendie ou toutautre sinistre.

"COMMENT COMMANDER LES PIECES DE RECHANGE"

Pour que votre commande soit rapidement et correctement remplie,

veuillez fournir les renseignements suivants.

1. NUMERO DU MODELE 2. NO. DE REF

3. NO. DE PIECE 4. DESCRIPTION

in CANADA: Contact SHARP Electronics of Canada Limited

★ MARQUE: SECTION LIVRAISON DES PIECES DERECHANGE

Q705 VSUML2N++++-1Y J UML2N AC

Q706 VSUML2N++++-1Y J UML2N AC

Q708 VSUML2N++++-1Y J UML2N AC

Q709 VSUML1N++++-1Y J UML1N AC

Q710 VSUML1N++++-1Y J UML1N AC

Q711 VSUML2N++++-1Y J UML2N AC

Q712 VSRTQ035P02-1Y J RTQ035P02 AD

Q713 VSRTQ035P02-1Y J RTQ035P02 AD

Q715 VSRHP020N06-1Y J RHP020N06 AD

Q716 VSRHP020N06-1Y J RHP020N06 AD

Q802 VSFMMT718//-1Y J FMMT718 AE

Q803 VS2SC3928AR-1Y J 2SC3928AR AB

Q1107 VS2SA1037KQ-1Y J 2SA1037KQ AA

Q1108 VSDTC114EE/-1Y J DTC114EE AB

Q1701 VS2SA1037KQ-1Y J 2SA1037KQ AA

Q1702 VSDTC144EE/-1Y J DTC144EE AA

Q1703 VS2SA1036K/-1Y J 2SA1036K AC

Q1706 VS2SC3928AR-1Y J 2SC3928AR AB

Q1710 VSDTC144EE/-1Y J DTC144EE AA

Q1711 VS2SA1037KQ-1Y J 2SA1037KQ AA

Q1712 VSFMMT718//-1Y J FMMT718 AE

Q1713 VSDTC144EE/-1Y J DTC144EE AA

Q2005 VSDTC114YE/-1Y J DTC114YE AB

Q2019 VSDTC114EE/-1Y J DTC114EE AB

Q2020 VS2SA1037KQ-1Y J 2SA1037KQ AA

Q2021 VSDTC144EE/-1Y J DTC144EE AA

Q2022 VSDTA144EE/-1Y J DTC144EE AA

D701 VHDRB051L40-1Y J Diode AD

D702 VHDRB051L40-1Y J Diode AD

D703 VHDRB051L40-1Y J Diode AD

D704 VHDSFPB56//2EY J Diode AC

D706 VHDRF071M2S-1Y J Diode AD

D708 VHDRB160M40-1Y J Diode AC

D709 VHD1SS355//-1Y J Diode AB

D801 VHDDAN222//-1Y J Diode AA

D1703 VHDDAN222//-1Y J Diode AA

D1706 VHDDAN222//-1Y J Diode AA

D1708 VHDRB521S30-1Y J Diode AC

D1709 VHDDAN222//-1Y J Diode AA

D2002 VHDDAN202K/-1Y J Diode AB

D2007 VHDRB491D++-1Y J Diode AD

X801 RCRSCA097WJZZY J Crystal, 54MHz AG

CHANGE DES PIECES

Phone (416) 890-2100

TRANSISTORS

DIODES

PACKAGED CIRCUITS

30

Page 20

LC-20S4U-S

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKD234FE21

MAIN Unit (Continued)

X2001 RCRSC0032TAZZY J Crystal, 32.768kHz AG

FILTER AND COILS

FL2001 RFiLZA003WJPZY J Filter AD

L701 RCiLPA154WJZZY J Coil AE

L702 RCiLPA154WJZZY J Coil AE

L703 RCiLPA154WJZZY J Coil AE

L802 VPCNN220J2R9NY J Peaking 22µH AB

L1702 VPCNN470J5R4NY J Peaking 47µH AB

L1703 VPCUN100KR42NY J Peaking 10µH AB

TRANSFORMER

T701 RTRNWA141WJZZY J Transformer AG

CAPACITORS

C703 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C704 VCKYCY1EB333KY J 0.033 25V Ceramic AA

C705 VCKYCY1EB333KY J 0.033 25V Ceramic AA

C706 VCKYCY1EB333KY J 0.033 25V Ceramic AA

C707 VCKYCY1EB333KY J 0.033 25V Ceramic AA

C708 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C710 VCKYCY1HB332KY J 3300p 50V Ceramic AA

C711 VCCCCY1HH102JY J 1000p 50V Ceramic AB

C713 VCCCCY1HH102JY J 1000p 50V Ceramic AB

C714 VCCCCY1HH331JY J 330p 50V Ceramic AA

C715 VCCCCY1HH330JY J 33p 50V Ceramic AA

C719 VCCCCY1HH151JY J 150p 50V Ceramic AA

C720 VCCCCY1HH330JY J 33p 50V Ceramic AA

C721 VCCCCY1HH101JY J 100p 50V Ceramic AA

C722 VCCCCY1HH101JY J 100p 50V Ceramic AA

C723 VCCCCY1HH181JY J 180p 50V Ceramic AA

C724 VCKYTV1EB473KY J 0.047 25V Ceramic AB

C725 VCKYCY1EB123KY J 0.012 25V Ceramic AA

C726 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C727 VCKYCY1EB123KY J 0.012 25V Ceramic AA

C728 RC-KZA109WJZZY J 10 16V Ceramic AC

C729 RC-KZA109WJZZY J 10 16V Ceramic AC

C730 RC-KZA109WJZZY J 10 16V Ceramic AC

C731 VCKYCY1HB272KY J 2700p 50V Ceramic AA

C732 VCKYCY1EB223KY J 0.022 25V Ceramic AA

C733 VCCCCY1HH102JY J 1000p 50V Ceramic AB

C734 VCCCCY1HH102JY J 1000p 50V Ceramic AB

C735 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C736 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C737 RC-KZA110WJZZY J 10 25V Ceramic AD

C738 RC-KZA108WJZZY J 10 10V Ceramic AC

C739 RC-KZA108WJZZY J 10 10V Ceramic AC

C741 VCKYCY1HB562KY J 5600p 50V Ceramic AA

C742 VCEASX1CN106MY J 10 16V Electrolytic AC

C744 RC-KZA215WJZZY J 1 50V Ceramic AC

C745 RC-KZA109WJZZY J 10 16V Ceramic AC

C749 RC-KZA109WJZZY J 10 16V Ceramic AC

C801 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C802 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C803 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C804 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C805 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C806 VCKYCY1CB104KY J 0.1 16V Ceramic AB

C807 VCKYCY1CB104KY J 0.1 16V Ceramic AB

C808 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C809 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C810 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C811 VCKYCY1CB104KY J 0.1 16V Ceramic AB

C812 VCKYCY1CB104KY J 0.1 16V Ceramic AB

C813 VCKYCY1EB333KY J 0.033 25V Ceramic AA

C814 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C815 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C816 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C817 VCKYCY1HB104KY J 0.1 50V Ceramic AA

C818 VCKYCY1CB104KY J 0.1 16V Ceramic AB

C819 VCKYCY1HB104KY J 0.1 50V Ceramic AA

C820 VCKYCY1CB104KY J 0.1 16V Ceramic AB

C821 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C822 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C823 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C824 VCKYCY1HB104KY J 0.1 50V Ceramic AA

C825 VCKYCY1CB104KY J 0.1 16V Ceramic AB

C826 VCKYCY1HB104KY J 0.1 50V Ceramic AA

C827 VCKYCY1HB104KY J 0.1 50V Ceramic AA

C828 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C829 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C830 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C831 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C832 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C833 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C834 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C835 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C836 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C837 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C838 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C839 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C840 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C841 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C842 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C843 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C844 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C845 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C846 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C847 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C848 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C849 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C850 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C851 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C852 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C853 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C854 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C855 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C856 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C857 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C858 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C859 VCKYCZ1AB333KY J 0.033 10V Ceramic AB

C860 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C861 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C862 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C863 VCKYCY1HB104KY J 0.1 50V Ceramic AA

C864 VCKYCY1HB104KY J 0.1 50V Ceramic AA

C865 VCCCCY1HH5R0CY J 5p 50V Ceramic AA

C866 VCCCCY1HH5R0CY J 5p 50V Ceramic AA

C867 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C872 VCEASX0JN227MY J 220 6.3V Electrolytic AC

C874 VCKYCZ1AB104KY J 0.1 10V Ceramic AB

C875 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C876 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C877 VCEASX0JN476MY J 47 6.3V Electrolytic AC

C878 VCKYCY1AF105ZY J 1 10V Ceramic AC

C886 VCEASY1CN477MY J 470 16V Electrolytic AD

C887 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1101 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C1102 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1103 RC-KZA110WJZZY J 10 25V Ceramic AD

C1104 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1105 RC-KZA111WJZZY J 1 25V Ceramic AC

C1106 RC-KZA111WJZZY J 1 25V Ceramic AC

C1107 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C1108 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C1109 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1132 RC-KZA109WJZZY J 10 16V Ceramic AC

C1201 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1202 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1203 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1204 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1205 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1206 RC-KZA108WJZZY J 10 10V Ceramic AC

C1207 RC-KZA108WJZZY J 10 10V Ceramic AC

C1208 VCKYCY1HB104KY J 0.1 50V Ceramic AA

C1209 VCKYCY1HB104KY J 0.1 50V Ceramic AA

31

Page 21

LC-20S4U-S

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKD234FE21

MAIN Unit (Continued)

C1210 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1211 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1212 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1213 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1214 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1215 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1216 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1217 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1218 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1219 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1220 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1221 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1222 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1223 RC-KZA108WJZZY J 10 10V Ceramic AC

C1224 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1225 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1226 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1227 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1228 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1229 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1230 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1701 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1702 VCKYCY1HF104ZY J 0.1 50V Ceramic AA

C1703 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1711 RC-KZA108WJZZY J 10 10V Ceramic AC

C1714 VCEASX1HN475MY J 4.7 50V Electrolytic AC

C1715 VCKYCY1HF104ZY J 0.1 50V Ceramic AA

C1716 RC-KZ0071TAZZY J 2.2 6.3V Ceramic AD

C1717 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1719 VCKYTV1HF104ZY J 0.1 50V Ceramic AB

C1721 RC-KZA110WJZZY J 10 25V Ceramic AD

C1722 VCEASX1EN476MY J 47 25V Electrolytic AC

C2001 VCKYTV1CF105ZY J 1 16V Ceramic AB

C2002 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2004 VCEASN0JN226MY J 22 6.3V Electrolytic AB

C2005 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2006 VCEASN0JN226MY J 22 6.3V Electrolytic AB

C2008 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2009 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2010 VCKYCY1HB222KY J 2200p 50V Ceramic AA

C2012 VCKYCY1HB222KY J 2200p 50V Ceramic AA

C2013 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C2014 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2015 VCKYTV1CF684ZY J 0.68 16V Ceramic AB

C2016 VCCCCY1HH100DY J 10p 50V Ceramic AA

C2017 VCCCCY1HH120JY J 12p 50V Ceramic AA

C2018 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C2019 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2020 VCKYCY1HB222KY J 2200p 50V Ceramic AA

C2021 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2022 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

RESISTORS

R703 VRS-CY1JF333JY J 33k 1/16W Metal Oxide AA

R704 VRS-CY1JF333JY J 33k 1/16W Metal Oxide AA

R705 VRS-CY1JF333JY J 33k 1/16W Metal Oxide AA

R706 VRN-CY1JF104DY J 100k 1/16W Metal Film AA

R707 VRN-CY1JF104DY J 100k 1/16W Metal Film AA

R708 VRN-CY1JF104DY J 100k 1/16W Metal Film AA

R709 VRN-CY1JF104DY J 100k 1/16W Metal Film AA

R710 VRN-CY1JF104DY J 100k 1/16W Metal Film AA

R711 VRN-CY1JF104DY J 100k 1/16W Metal Film AA

R712 VRN-CY1JF104DY J 100k 1/16W Metal Film AA

R713 VRN-CY1JF104DY J 100k 1/16W Metal Film AA

R714 VRS-CY1JF333JY J 33k 1/16W Metal Oxide AA

R715 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R716 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R717 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R718 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R719 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R720 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R721 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R722 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R723 VRS-CY1JF243FY J 24k 1/16W Metal Oxide AA

R724 VRS-CY1JF153FY J 15k 1/16W Metal Oxide AA

R725 VRS-CY1JF333FY J 33k 1/16W Metal Oxide AA

R726 VRS-CY1JF203FY J 20k 1/16W Metal Oxide AA

R727 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R728 VRS-CY1JF753FY J 75k 1/16W Metal Oxide AA

R729 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R730 VRS-CY1JF154FY J 150k 1/16W Metal Oxide AA

R731 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R732 VRS-CY1JF333FY J 33k 1/16W Metal Oxide AA

R733 VRS-CY1JF104FY J 100k 1/16W Metal Oxide AA

R734 VRS-CY1JF562JY J 5.6k 1/16W Metal Oxide AA

R735 VRS-CY1JF134FY J 130k 1/16W Metal Oxide AA

R739 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R740 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R741 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R742 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R743 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R744 VRS-CY1JF331JY J 330 1/16W Metal Oxide AA

R745 VRS-CY1JF511JY J 510 1/16W Metal Oxide AA

R746 VRS-CY1JF511JY J 510 1/16W Metal Oxide AA

R747 VRS-CY1JF511JY J 510 1/16W Metal Oxide AA

R748 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R749 VRS-CY1JF331JY J 330 1/16W Metal Oxide AA

R750 VRS-CY1JF511JY J 510 1/16W Metal Oxide AA

R751 VRS-CY1JF511JY J 510 1/16W Metal Oxide AA

R752 VRS-CY1JF511JY J 510 1/16W Metal Oxide AA

R753 VRS-CY1JF303JY J 30k 1/16W Metal Oxide AA

R754 VRS-CY1JF303JY J 30k 1/16W Metal Oxide AA

R755 VRS-TW2HF272JY J 2.7k 1/2W Metal Oxide AA

R756 VRS-TW2HF272JY J 2.7k 1/2W Metal Oxide AA

R757 VRS-TW2HF000JY J 0 1/2W Metal Oxide AA

R759 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R760 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R765 VRS-CY1JF105JY J 1M 1/16W Metal Oxide AA

R766 VRS-CY1JF394JY J 390k 1/16W Metal Oxide AA

R801 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R809 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R810 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R811 VRS-CY1JF105JY J 1M 1/16W Metal Oxide AA

R812 VRS-CH1JF470JY J 47 1/16W Metal Oxide AA

R814 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R815 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R826 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R831 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R832 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R834 VRS-CJ1JF220JY J 22 1/16W Metal Oxide AA

R835 VRS-CH1JF470JY J 47 1/16W Metal Oxide AA

R836 VRS-CH1JF470JY J 47 1/16W Metal Oxide AA

R837 VRS-CH1JF470JY J 47 1/16W Metal Oxide AA

R838 VRS-CH1JF470JY J 47 1/16W Metal Oxide AA

R839 VRS-CH1JF470JY J 47 1/16W Metal Oxide AA

R840 VRS-CH1JF470JY J 47 1/16W Metal Oxide AA

R843 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R844 VRS-CY1JF470JY J 47 1/16W Metal Oxide AA

R845 VRS-CJ1JF270JY J 27 1/16W Metal Oxide AA

R847 VRS-CY1JF220JY J 22 1/16W Metal Oxide AA

R848 VRS-CY1JF220JY J 22 1/16W Metal Oxide AA

R849 VRS-CY1JF220JY J 22 1/16W Metal Oxide AA

R850 VRS-CY1JF220JY J 22 1/16W Metal Oxide AA

R855 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R867 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R868 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R869 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R873 VRS-CH1JF103JY J 10k 1/16W Metal Oxide AA

R874 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R876 VRS-CJ1JF100JY J 10 1/16W Metal Oxide AA

R878 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R879 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R880 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R882 VRS-CY1JF470JY J 47 1/16W Metal Oxide AA

R883 VRS-CY1JF470JY J 47 1/16W Metal Oxide AA

R893 VRS-TV1JD102JY J 1k 1/10W Metal Oxide AA

32

Page 22

LC-20S4U-S

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKD234FE21

MAIN Unit (Continued)

R894 VRS-CY1JF473JY J 47k 1/16W Metal Oxide AA

R895 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R896 VRS-CY1JF473JY J 47k 1/16W Metal Oxide AA

R1101 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1102 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1103 VRS-CY1JF333JY J 33k 1/16W Metal Oxide AA

R1104 VRS-CY1JF333JY J 33k 1/16W Metal Oxide AA

R1105 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1116 VRS-TW2ED182JY J 1.8k 1/4W Metal Oxide AA

R1117 VRS-CY1JF272JY J 2.7k 1/16W Metal Oxide AA

R1118 VRS-TQ2BD332JY J 3.3k 1/8W Metal Oxide AB

R1119 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1128 VRS-CY1JF471JY J 470 1/16W Metal Oxide AA

R1130 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1131 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1201 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1202 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1203 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1204 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1209 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R1210 VRS-CY1JF270JY J 27 1/16W Metal Oxide AA

R1211 VRS-CY1JF123FY J 12k 1/16W Metal Oxide AA

R1213 VRS-CY1JF333JY J 33k 1/16W Metal Oxide AA

R1215 VRS-CJ1JF270JY J 27 1/16W Metal Oxide AA

R1218 VRS-TW2HF361JY J 360 1/2W Metal Oxide AA

R1702 VRS-CY1JF272JY J 2.7k 1/16W Metal Oxide AA

R1703 VRS-CY1JF393FY J 39k 1/16W Metal Oxide AA

R1704 VRS-TW2ED123JY J 12k 1/4W Metal Oxide AA

R1706 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1707 VRS-CY1JF473FY J 47k 1/16W Metal Oxide AA

R1711 VRS-TW2HF330JY J 33 1/2W Metal Oxide AA

R1713 VRS-TV1JD562JY J 5.6k 1/10W Metal Oxide AA

R1714 VRS-TW2ED103JY J 10k 1/4W Metal Oxide AA

R1715 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1717 VRS-CY1JF103FY J 10k 1/16W Metal Oxide AA

R1723 VRS-CY1JF223FY J 22k 1/16W Metal Oxide AA

R1724 VRS-CY1JF303FY J 30k 1/16W Metal Oxide AA

R1729 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R1736 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1737 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1738 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R1740 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R1741 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1746 VRS-TW2ED103JY J 10k 1/4W Metal Oxide AA

R1750 VRS-TQ2BD103JY J 10k 1/8W Metal Oxide AA

R1751 VRS-CY1JF272JY J 2.7k 1/16W Metal Oxide AA

R2005 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R2006 VRS-CY1JF1R0JY J 1 1/16W Metal Oxide AA

R2007 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2008 VRS-CY1JF102FY J 1k 1/16W Metal Oxide AA

R2009 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R2010 VRS-CY1JF623FY J 62k 1/16W Metal Oxide AA

R2011 VRS-CY1JF433FY J 43k 1/16W Metal Oxide AA

R2012 VRS-CY1JF103FY J 10k 1/16W Metal Oxide AA

R2013 VRS-CJ1JF101JY J 100 1/16W Metal Oxide AA

R2014 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2015 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2016 VRS-CY1JF473FY J 47k 1/16W Metal Oxide AA

R2017 VRS-CJ1JF223JY J 22k 1/16W Metal Oxide AA

R2018 VRS-CJ1JF102JY J 1k 1/16W Metal Oxide AA

R2019 VRS-CY1JF823FY J 82k 1/16W Metal Oxide AA

R2020 VRS-CY1JF124FY J 120k 1/16W Metal Oxide AA

R2021 VRS-CY1JF274JY J 270k 1/16W Metal Oxide AA

R2022 VRS-CY1JF393FY J 39k 1/16W Metal Oxide AA

R2023 VRS-CY1JF184JY J 180k 1/16W Metal Oxide AA

R2024 VRS-CY1JF823JY J 82k 1/16W Metal Oxide AA

R2027 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2028 VRS-CY1JF124FY J 120k 1/16W Metal Oxide AA

R2029 VRS-CY1JF473JY J 47k 1/16W Metal Oxide AA

R2030 VRS-CJ1JF223JY J 22k 1/16W Metal Oxide AA

R2032 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2033 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2034 VRS-CY1JF153JY J 15k 1/16W Metal Oxide AA

R2035 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R2036 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2038 VRS-CH1JF101JY J 100 1/16W Metal Oxide AA

R2039 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2040 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2041 VRS-CY1JF512JY J 5.1k 1/16W Metal Oxide AA

R2043 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R2044 VRS-CJ1JF101JY J 100 1/16W Metal Oxide AA

R2045 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R2046 VRS-CY1JF680JY J 68 1/16W Metal Oxide AA

R2047 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2048 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2050 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2051 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2053 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2054 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2055 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2056 VRS-CJ1JF101JY J 100 1/16W Metal Oxide AA

R2058 VRS-CJ1JF682JY J 6.8k 1/16W Metal Oxide AA

R2059 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R2060 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2061 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2063 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2064 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2065 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2066 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2068 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2069 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R2070 VRS-CJ1JF101JY J 100 1/16W Metal Oxide AA

R2071 VRS-CJ1JF153JY J 15k 1/16W Metal Oxide AA

R2072 VRS-CH1JF680JY J 68 1/16W Metal Oxide AA

R2073 VRS-CH1JF101JY J 100 1/16W Metal Oxide AA

R2074 VRS-CJ1JF101JY J 100 1/16W Metal Oxide AA

R2075 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2076 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2078 VRS-CJ1JF101JY J 100 1/16W Metal Oxide AA

R2081 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2082 VRS-CJ1JF101JY J 100 1/16W Metal Oxide AA

R2085 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2086 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2087 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

MISCELLANEOUS PARTS

FB701 RBLN-0253TAZZY J Ferrite Bead AA

FB702 RBLN-0253TAZZY J Ferrite Bead AA

FB704 RBLN-0209TAZZY J Ferrite Bead AB

FB705 RBLN-0253TAZZY J Ferrite Bead AA

FB706 RBLN-0051TAZZY J Ferrite Bead AC

FB708 RBLN-0253TAZZY J Ferrite Bead AA

FB709 RBLN-0051TAZZY J Ferrite Bead AC

FB711 RBLN-0253TAZZY J Ferrite Bead AA

FB801 RBLN-0083GEZZY J Ferrite Bead AB

FB803 RBLN-0006TAZZY J Ferrite Bead AB

FB805 RBLN-0006TAZZY J Ferrite Bead AB

FB806 RBLN-0006TAZZY J Ferrite Bead AB

FB807 RBLN-0210TAZZY J Ferrite Bead AB

FB1201 RBLN-0006TAZZY J Ferrite Bead AB

FB1202 RBLN-0006TAZZY J Ferrite Bead AB

FB1203 RBLN-0006TAZZY J Ferrite Bead AB

P2002 QPLGNA144WJZZY J Plug, 20-pin AF

SC701 QCNCWA010WJZZYJ Connector, 15-pin AE

SC1201 QSOCNA222WJZZY J Socket, 80-pin AH

SC2001 QSOCNA478WJZZY J Socket, 60-pin AF

LUG2002

LUG2053

QLUGHA006WJZZY J Lug AC

QLUGHA006WJZZY J Lug AC

33

Page 23

LC-20S4U-S

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKD084WE06

ANALOG Unit

NOTE: THE PARTS HERES SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDENTLY.

TU3401 VTUVT2U5UF559 J Tuner BB

INTEGRATED CIRCUITS

IC3201 RH-iXB302WJN1Q J MSP3445G-QA-S1 AT

IC3301 VHiLA4635A+-1S J LA4635A AM

IC3401 VHiTC4053BF1EY J TC4053BF AF

IC3402 VHiNJM2246M-1Y J NJM2246M AF

IC3406 VHiNJM2283F-1Y J NJM2283M AF

IC3702 VHiSi3012LU-1Y J SI-3012LU AE

IC7001 VHiPD64084+-1Q J UPD64084GC-8EA BC

IC7002 VHiPQ1X251M-1Y J PQ1X251M2ZP AD

Q3201 VS2SC3928AR-1Y J 2SC3928AR AB

Q3202 VS2SC3928AR-1Y J 2SC3928AR AB

Q3301 VSDTC314TK/-1Y J DTC314TK AC

Q3302 VSDTC314TK/-1Y J DTC314TK AC

Q3304 VS2SC3928AR-1Y J 2SC3928AR AB

Q3401 VSDTC314TK/-1Y J DTC314TK AC

Q3402 VSDTC314TK/-1Y J DTC314TK AC

Q3403 VSDTA144EE/-1Y J DTA144EE AA

Q3405 VS2SC3928AR-1Y J 2SC3928AR AB

Q3406 VSUMG4N++++-1Y J UMG4N AB

Q3407 VS2SC3928AR-1Y J 2SC3928AR AB

Q3408 VS2SC3928AR-1Y J 2SC3928AR AB

Q3409 VS2SC3928AR-1Y J 2SC3928AR AB

Q3410 VSDTC314TK/-1Y J DTC314TK AC

Q3414 VSiMZ1A////-1Y J IMZ1A AC

Q3416 VSUM6K1NTN+-1Y J UM6K1NTN AC

Q3701 VSDTC114YE/-1Y J DTC114YE AB

Q3702 VSFMMT718//-1Y J FMMT718 AE

Q3703 VS2SA1989R/-1Y J 2SA1989R AB

Q3704 VSDTC144EE/-1Y J DTC144EE AA

Q7001 VS2SC3928AR-1Y J 2SC3928AR AB

Q7002 VS2SC3928AR-1Y J 2SC3928AR AB

Q7003 VS2SA1037KQ-1Y J 2SA1037KQ AA

Q7004 VS2SA1037KQ-1Y J 2SA1037KQ AA

Q7005 VS2SA1530AR-1Y J 2SA1530AR AB

Q7006 VS2SA1530AR-1Y J 2SA1530AR AB

Q7007 VS2SC2412KQ-1Y J 2SC2412KQ AA

Q7008 VS2SA1037KQ-1Y J 2SA1037KQ AA

Q7009 VS2SC2412KQ-1Y J 2SC2412KQ AA

Q7010 VS2SA1037KQ-1Y J 2SA1037KQ AA

D3301 VHDDAN222//-1Y J Diode AA

D3302 RH-EX1398CEZZY J Zener Diode, 8.2V AB

D3415 VHDDAN222//-1Y J Diode AA

D3703 VHDDAN222//-1Y J Diode AA

D3704 VHDRB491D++-1Y J Diode AD

D3710 RH-EXA095WJZZY J Zener Diode, 16V AB

D3711 RH-EXA095WJZZY J Zener Diode, 16V AB

PACKAGED CIRCUITS

X3201 RCRSB0250GEZZ J Crystal, 18.432MHz AG

X7001 RCRSB0258CEZZ J Crystal, 20MHz AG

L3201 VPCNN4R7J1R2NY J Peaking 4.7µH AB

L3202 VPCNN220J2R9NY J Peaking 22µH AB

L3203 VPCNN101J7R7NY J Peaking 100µH AB

L3404 RCiLPA142WJZZ J Coil AD

L3406 VPCNN1R0JR50NY J Peaking 1µH AB

L7001 VPCNN220J2R9NY J Peaking 22µH AB

L7002 VPCNN220J2R9NY J Peaking 22µH AB

L7003 VP-9N1R8KR31NY J Peaking 1.8µH AB

L7004 VP-9N1R8KR31NY J Peaking 1.8µH AB

TUNER

TRANSISTORS

DIODES

COILS

L7005 VPCNN220J2R9NY J Peaking 22µH AB

L7006 VPCNN220J2R9NY J Peaking 22µH AB

L7007 VPCNN220J2R9NY J Peaking 22µH AB

L7008 VPCNN5R6J1R2NY J Peaking 5.6µH AB

L7009 VPCNN100J1R6NY J Peaking 10µH AB

L7010 VPCNN100J1R6NY J Peaking 10µH AB

CAPACITORS

C3202 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3203 VCKYCY1AB105KY J 1 10V Ceramic AB

C3204 VCEASX0JN107MY J 100 6.3V Electrolytic AC

C3206 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C3209 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C3210 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C3211 VCKYCY1EB223KY J 0.022 25V Ceramic AA

C3212 VCKYCY1EB223KY J 0.022 25V Ceramic AA

C3214 VCEASX1CN106MY J 10 16V Electrolytic AC

C3215 VCEASX1CN107MY J 100 16V Electrolytic AC

C3216 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3217 VCEASX1HN335MY J 3.3 50V Electrolytic AB

C3218 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3223 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3224 VCCCCY1HH330JY J 33p 50V Ceramic AA

C3225 VCCCCY1HH330JY J 33p 50V Ceramic AA

C3226 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C3227 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3228 VCEASX1CN106MY J 10 16V Electrolytic AC

C3229 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3230 VCKYCY1AB105KY J 1 10V Ceramic AB

C3231 VCEASX0JN107MY J 100 6.3V Electrolytic AC

C3232 VCCCCY1HH560JY J 56p 50V Ceramic AB

C3233 VCCCCY1HH560JY J 56p 50V Ceramic AB

C3235 VCCCCY1HH5R0CY J 5p 50V Ceramic AA

C3236 VCCCCY1HH5R0CY J 5p 50V Ceramic AA

C3301 VCEASX1CN107MY J 100 16V Electrolytic AC

C3302 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C3303 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C3304 VCEASX1CN106MY J 10 16V Electrolytic AC

C3305 VCEASX1CN106MY J 10 16V Electrolytic AC

C3306 VCKYTV1CB105KY J 1 16V Ceramic AC

C3307 RC-EZA216WJZZ J 1000 16V Electrolytic AD

C3308 RC-EZA216WJZZ J 1000 16V Electrolytic AD

C3309 RC-EZA216WJZZ J 1000 16V Electrolytic AD

C3310 VCKYCY1AB105KY J 1 10V Ceramic AB

C3311 VCKYCY1AB105KY J 1 10V Ceramic AB

C3312 RC-KZA030WJZZY J 2.2 10V Ceramic AB

C3313 RC-KZA030WJZZY J 2.2 10V Ceramic AB

C3314 VCKYCY1HB153KY J 0.015 50V Ceramic AA

C3315 VCKYCY1HB153KY J 0.015 50V Ceramic AA

C3317 RC-KZA030WJZZY J 2.2 10V Ceramic AB

C3403 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3405 VCKYCY1AB105KY J 1 10V Ceramic AB

C3406 VCKYCY1AB105KY J 1 10V Ceramic AB

C3407 VCKYCY1AB105KY J 1 10V Ceramic AB

C3408 VCKYCY1AB105KY J 1 10V Ceramic AB

C3409 VCEASX1CN106MY J 10 16V Electrolytic AC

C3410 RC-KZA030WJZZY J 2.2 10V Ceramic AB

C3411 RC-KZA030WJZZY J 2.2 10V Ceramic AB

C3412 RC-KZA067WJZZY J 4.7 10V Ceramic AB

C3413 VCCCCY1HH121JY J 120p 50V Ceramic AA

C3414 RC-KZA067WJZZY J 4.7 10V Ceramic AB

C3415 VCCCCY1HH121JY J 120p 50V Ceramic AA

C3416 RC-KZA067WJZZY J 4.7 10V Ceramic AB

C3420 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3422 RC-KZA108WJZZY J 10 10V Ceramic AC

C3423 RC-KZA108WJZZY J 10 10V Ceramic AC

C3425 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3426 RC-KZA108WJZZY J 10 10V Ceramic AC

C3427 RC-KZA108WJZZY J 10 10V Ceramic AC

C3428 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3429 VCEASY1CN477MY J 470 16V Electrolytic AD

C3441 RC-KZA108WJZZY J 10 10V Ceramic AC

C3443 RC-KZA108WJZZY J 10 10V Ceramic AC

C3444 RC-KZA108WJZZY J 10 10V Ceramic AC

C3446 RC-KZA108WJZZY J 10 10V Ceramic AC

34

Page 24

LC-20S4U-S

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKD084WE06

ANALOG Unit (Continued)

C3448 RC-KZA108WJZZY J 10 10V Ceramic AC

C3451 VCAAPC0JJ226MY J 22 6.3V Electrolytic AE

C3455 VCKYCY1HF103ZY J 0.01 50V Ceramic AA

C3456 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3457 RC-EZ1351CEZZ J 3300 6.3V Electrolytic AF

C3495 VCCCCY1HH101JY J 100p 50V Ceramic AA

C3496 VCCCCY1HH101JY J 100p 50V Ceramic AA

C3497 VCCCCY1HH151JY J 150p 50V Ceramic AA

C3502 VCEASX1CN107MY J 100 16V Electrolytic AC

C3701 RC-KZ1025CEZZY J 1 10V Ceramic AB

C3702 RC-KZA108WJZZY J 10 10V Ceramic AC

C3709 RC-EZA559WJZZ J 0.33F 5.5V Electrolytic AF

C3714 VCEASX1CN476MY J 47 16V Electrolytic AC

C3715 RC-KZA111WJZZY J 1 25V Ceramic AC

C7001 VCCCCY1HH100DY J 10p 50V Ceramic AA

C7002 VCCCCY1HH180JY J 18p 50V Ceramic AA

C7003 VCCCCY1HH180JY J 18p 50V Ceramic AA

C7004 VCCCCY1HH120JY J 12p 50V Ceramic AA

C7005 VCCCCY1HH270JY J 27p 50V Ceramic AA

C7006 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C7007 VCEASX1CN107MY J 100 16V Electrolytic AC

C7008 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C7009 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7010 VCKYTV1CF105ZY J 1 16V Ceramic AB

C7011 VCCCCY1HH101JY J 100p 50V Ceramic AA

C7012 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C7013 VCCCCY1HH471JY J 470p 50V Ceramic AA

C7014 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C7015 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7016 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7017 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7019 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7020 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7021 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7022 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7023 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7024 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7025 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7026 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C7027 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7028 VCKYCY1EF473ZY J 0.047 25V Ceramic AA

C7029 VCKYCY1HB821KY J 820p 50V Ceramic AA

C7030 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7032 VCCCCY1HH561JY J 560p 50V Ceramic AB

C7033 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7034 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7035 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7037 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7038 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7039 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C7040 VCCCCY1HH180JY J 18p 50V Ceramic AA

C7041 VCCCCY1HH220JY J 22p 50V Ceramic AA

C7075 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C7076 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C7077 RC-KZA101WJZZY J 10 6.3V Ceramic AC

C7078 RC-KZA176WJZZY J 10 10V Ceramic AC

C7079 RC-KZA176WJZZY J 10 10V Ceramic AC

RESISTORS

R3201 VRS-CJ1JF101JY J 100 1/16W Metal Oxide AA

R3205 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3206 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R3207 VRS-CY1JF331JY J 330 1/16W Metal Oxide AA

R3208 VRS-CY1JF153JY J 15k 1/16W Metal Oxide AA

R3209 VRS-CY1JF332JY J 3.3k 1/16W Metal Oxide AA

R3210 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3211 VRS-CY1JF105JY J 1M 1/16W Metal Oxide AA

R3221 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3301 VRS-CY1JF122JY J 1.2k 1/16W Metal Oxide AA

R3302 VRS-CY1JF332JY J 3.3k 1/16W Metal Oxide AA

R3303 VRS-CY1JF332JY J 3.3k 1/16W Metal Oxide AA

R3304 VRS-CY1JF222JY J 2.2k 1/16W Metal Oxide AA

R3305 VRS-CY1JF222JY J 2.2k 1/16W Metal Oxide AA

R3306 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R3307 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R3308 VRS-CY1JF123JY J 12k 1/16W Metal Oxide AA

R3310 VRS-CY1JF392JY J 3.9k 1/16W Metal Oxide AA

R3311 VRS-CY1JF392JY J 3.9k 1/16W Metal Oxide AA

R3312 VRS-CY1JF183JY J 18k 1/16W Metal Oxide AA

R3313 VRS-CY1JF822JY J 8.2k 1/16W Metal Oxide AA

R3314 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3315 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R3401 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3402 VRS-TQ2BD750JY J 75 1/8W Metal Oxide AA

R3403 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3404 VRS-TQ2BD750JY J 75 1/8W Metal Oxide AA

R3405 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3406 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3407 VRS-TQ2BD750JY J 75 1/8W Metal Oxide AA

R3408 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3410 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3411 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3412 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3413 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3415 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3416 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3418 VRS-CY1JF471JY J 470 1/16W Metal Oxide AA

R3419 VRS-CY1JF471JY J 470 1/16W Metal Oxide AA

R3420 VRS-TQ2BD750JY J 75 1/8W Metal Oxide AA

R3421 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3422 VRS-TQ2BD750JY J 75 1/8W Metal Oxide AA

R3423 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3424 VRS-CY1JF562JY J 5.6k 1/16W Metal Oxide AA

R3425 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3426 VRS-TQ2BD750JY J 75 1/8W Metal Oxide AA

R3427 VRS-CY1JF153JY J 15k 1/16W Metal Oxide AA

R3428 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3432 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3434 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3439 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3440 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3443 VRS-CY1JF471JY J 470 1/16W Metal Oxide AA

R3444 VRS-TQ2BD750JY J 75 1/8W Metal Oxide AA

R3445 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R3446 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3448 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3449 VRS-CY1JF100JY J 10 1/16W Metal Oxide AA

R3450 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3451 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3452 VRS-TQ2BD221JY J 220 1/8W Metal Oxide AA

R3453 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3454 VRS-TQ2BD000JY J 0 1/8W Metal Oxide AA

R3455 VRS-CY1JF471JY J 470 1/16W Metal Oxide AA

R3456 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R3458 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3459 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3460 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3461 VRS-CY1JF471JY J 470 1/16W Metal Oxide AA

R3462 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R3465 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3466 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3467 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3468 VRS-CJ1JF331JY J 330 1/16W Metal Oxide AA

R3481 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3483 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R3485 VRS-CY1JF561FY J 560 1/16W Metal Oxide AA

R3487 VRS-CY1JF102FY J 1k 1/16W Metal Oxide AA

R3490 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R3491 VRS-CJ1JF000JY J 0 1/16W Metal Oxide AA

R3539 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R3540 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R3541 VRS-CY1JF105JY J 1M 1/16W Metal Oxide AA

R3542 VRS-CY1JF105JY J 1M 1/16W Metal Oxide AA

R3543 VRS-CY1JF105JY J 1M 1/16W Metal Oxide AA

R3544 VRS-TQ2BD100JY J 10 1/8W Metal Oxide AA

R3701 VRS-TQ2BD000JY J 0 1/8W Metal Oxide AA

35

Page 25

LC-20S4U-S

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKD084WE06

ANALOG Unit (Continued)

R3705 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3706 VRS-CY1JF184JY J 180k 1/16W Metal Oxide AA

R3707 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R3718 VRS-TQ2BD101JY J 100 1/8W Metal Oxide AA

R3725 VRS-CY1JF682FY J 6.8k 1/16W Metal Oxide AA

R3726 VRS-CY1JF152FY J 1.5k 1/16W Metal Oxide AA

R3727 VRS-TQ2BD1R0JY J 1 1/8W Metal Oxide AA

R3728 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3729 VRS-CY1JF132FY J 1.3k 1/16W Metal Oxide AA

R3730 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3731 VRS-TQ2BD000JY J 0 1/8W Metal Oxide AA

R7001 VRS-CY1JF122FY J 1.2k 1/16W Metal Oxide AA

R7002 VRS-CY1JF821FY J 820 1/16W Metal Oxide AA

R7003 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R7004 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R7005 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R7006 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R7007 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R7010 VRS-CY1JF911JY J 910 1/16W Metal Oxide AB

R7011 VRS-TQ2BD100JY J 10 1/8W Metal Oxide AA

R7012 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R7013 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R7014 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R7015 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R7016 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R7017 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R7018 VRS-CY1JF561JY J 560 1/16W Metal Oxide AA

R7019 VRS-CY1JF561JY J 560 1/16W Metal Oxide AA

R7020 VRS-CY1JF221JY J 220 1/16W Metal Oxide AA

R7021 VRS-CY1JF224JY J 220k 1/16W Metal Oxide AA

R7022 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R7023 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R7024 VRS-CY1JF222JY J 2.2k 1/16W Metal Oxide AA

R7025 VRS-CY1JF471JY J 470 1/16W Metal Oxide AA

R7026 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R7027 VRS-CY1JF182JY J 1.8k 1/16W Metal Oxide AA

R7028 VRS-CY1JF182JY J 1.8k 1/16W Metal Oxide AA

R7030 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R7031 VRS-CY1JF361JY J 360 1/16W Metal Oxide AA

R7032 VRS-CY1JF471JY J 470 1/16W Metal Oxide AA

R7033 VRS-CJ1JF101JY J 100 1/16W Metal Oxide AA

R7036 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R7037 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

å F3701 QFS-ZA005WJZZ J Fuse, 2.5A/250V AC

å F3702 QFS-ZA004WJZZ J Fuse, 2.0A/250V AD

FB3201 RBLN-0035TAZZY J Ferrite Bead AB

FB7005 RBLN-0061TAZZY J Ferrite Bead AD

FB7006 RBLN-0061TAZZY J Ferrite Bead AD

FB7007 RBLN-0061TAZZY J Ferrite Bead AD

FB7008 RBLN-0061TAZZY J Ferrite Bead AD

J3401 QSOCD0456CEZZ J S-VIDEO AE

J3402 QJAKGA071WJZZ X INPUT2 Terminal AC

J3403 QJAKGA071WJZZ X INPUT3/OUTPUT Terminal AC

J3404 QJAKFA034WJZZ X AUDIO(L/R)(INPUT1) AC

J3405 QJAKGA082WJZZ J Y/PB/PR(INPUT1) AC

P3401 QPLGN1358REZZY J Plug, 13-pin AD

P3402 QPLGN0478GEZZ J Plug, 4-pin AB

P3701 QPLGZ1938CEZZ J Plug, 19-pin AF

P3702 QCNCMA012WJZZ J Connector, 15-pin AD

SC3401 QSOCNA478WJZZY J Socket, 60-pin AF

LUG3401

LUG3403

LUG3404

MISCELLANEOUS PARTS

QLUGHA006WJZZY J Lug AC

QLUGHA006WJZZY J Lug AC

QLUGHA006WJZZY J Lug AC

CABINET AND MECHANICAL PARTS

1 CCABAB220WJ01 X Cabinet A Ass’y

1-1

1-2 HDECQA474WJSA J R/C,LED Cover AE

1-3 PSPAHA040WJZZ J Mask Spacer (Side), x2 AD

1-4 PSPAHA041WJZZ J

1-5 PSPAZB038WJZZ X Spacer, x2

1-6 TLABZA635WJZZ J "EnergyStar" Label AC

1-7 TLABZA875WJZZ X Material Label

2 CCABBA709WJ01 X Cabinet B Ass’y

2-1

2-2 GCOVAB085WJKA J Terminal Cover (L) AL

2-3 GCOVAB090WJKA J Terminal Cover (R) AK

2-4 JBTN-A508WJKA X Operation Button

2-5 PSPAHA663WJZZ X Spacer, x2

2-6 PSPAHA566WJZZ X Spacer, x1 AC

2-7 PSPAZA772WJZZ X Spacer, x2 AD

2-8 LANGFA085WJFW J Kensington Angle AC

2-9 LHLDWA099WJZZ X Wire Holder, x1 AB

2-10 TLABZA876WJZZ X Material Label AE

2-11 XEBSN30P10000 J Screw, x2 AA

3 CDAi-A162WJ01 J Stand Ass’y BG

3-1 GDAi-A162WJKA J Stand Base AX

3-2 GLEGGA014WJZZ J Cushion Spacer, x6 AB

3-3 LANGGA050WJF7 J Swivel Base AG

3-4 LANGHA004WJFW J Reinforcement Angle, x2 AE

3-5 LX-NZA001WJFN J Nut AD

3-6 MHNG-A091WJ01 J Tilt Hinge BA

3-7 XEBS940P08000 J Screw, x6 AB

3-8 XUSSN40P20000 J Screw, x4 AA

NOTE: The screws for the LCD panels are supplied as service parts

4 RLCUCA022WJZZ J 20" LCD Panel Unit Ass’y CT

4-1

4-2 LANGK3261TPZA J Bezel AX

4-3 PSLDK2567TPZZ J Diffusion Sheet(Top), x2 AQ

4-4 POFMA0220TPZZ J Lens Sheet BC

4-5 PSLDK2554TPZZ J Diffusion Sheet(Bottom) AN

4-6 PSLDK2553TPZZ J Diffusion Plate AX

å 4-7 RLMPC2401TPZZ J Lamp Unit, x5 AX

4-8 LHLDZ3104TPZA J Backlight Case BA

4-9 PZETE3778TPZZ J Spacer, x2 AC

4-10 LX-HZ2070TPZS J Screw, x4 (1,000 pcs.) BR

4-11 LX-HZ2055TPZS J Screw, x1 (1,000 pcs.) BP

5 GCOVAA431WJKB J Bass-Cone Cover AD

6 GCOVAB082WJKA J Stand Cover AK

7 LCHSMA164WJKA J Chassis Frame (L) AK

8 LCHSMA185WJN1 X Chassis Frame (R)

9 VSP1104PB038A J Speaker, x2 AK

10 HiNDPB535WJSA X Model Label AH

11 JHNDPA017WJKA J Carrying Handle AL

12

13 LANGTA163WJFW J Stand Angle AW

14 PSPAGA287WJZZ X Spacer, x1 AB

15 QCNW-D916WJQZ J Connecting Cord AG

16 QPWBMD292WJPZ J Connecting Cord AM

17 QCNW-D299WJQZ X Connecting Cord AL

18 QCNW-C989WJQZ J Connecting Cord AG

19 XEBSN40P10000 J Screw, x6 AB

20 LX-BZ3442CEF9 J Screw, x4 AB

21 XBBS740P08000 J Screw, x3 AA

22 XBBS930P05000 J Screw, x3 AA

23 XBBS940P08000 J Screw, x1 AB

24 XBBS940P25000 J Screw, x4 AB

25 XBPS730P10JS0 J Screw, x10 AA

26 XBPS730P20JS0 J Screw, x2 AB

27 XEBS930P08000 J Screw, x4 AA

28 XEBS940P20000 J Screw, x8 AB

Not Available

Not Available

– Cabinet A —

– Cabinet B —

in the unit of 1000 pieces.

Not Available

Not Available

– 20" LCD Panel —

– Serial No. Label —

Mask Spacer (Top-Bottom), x2

AD

36

Page 26

CABINET AND MECHANICAL PARTS

19

9

H

A

G

1-3

1-4

C

1

N

18

C

LC-20S4U-S

SUPPLEMENT

19

9

A

C

1-6

F

4

1-5

1-4

1-1

1-7

1-3

B

C

D

K

1-2

O

R/C, LED PWB

E

A

A

D

4-10

4-11

4-2

4-10

B

B

4-1

4-3

C

L

25

I

8

Operation PWB

Main PWB

14

Analog PWB

25

M

B

Inverter PWB

E

F

A

7

16

K

26

H

27

15

N

25

4-4

17

4-6

4-5

A

2-1

21

2-10

2-5

13

O

29

4-9

L

4-9

2-6

28

2-9

2-11

27

E

2-8

2-5

2

D

4-7

A

H

M

30

F

4-8

2-7

2-4

12

10

27

22

22

5

B

3-4

3

3-7

3-6

3-1

3-2

2-2

I

J

G

B

B

2-3

20

11

23

6

24

3-8

3-3

3-5

3-4

3-7

G

654321

37

Page 27

LC-20S4U-S

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

CABINET AND MECHANICAL PARTS

(Continued)

29 XEBSN30P08000 J Screw, x2 AA

30 PSLDMA810WJN1 J Back Shield AU

SUPPLIED ACCESSORIES

X1 LHLDWA002WJSA J Cable Clamp AD

å X2 QACCDA037WJPA J AC Cord AV

X3 RRMCGA293WJSA J Wireless Remote Control AT

X4 TCADEA126WJZZ X Questionnaire Card AC

X5 TiNS-B707WJZZ X Operation Manual AY

å X6 UADP-A080WJPZ X AC Adapter BC

X7

Not Available

– "AAA" size Battery, x2 —

PACKING PARTS

(NOT REPLACEMENT ITEM)

S1 SPAKCB853WJZZ – Packing Case —

S2 SPAKFA791WJZZ –

S3 SPAKFA793WJZZ – Packing Material (Partition) —

S4 SPAKPA482WJZZ – Wrapping Paper —

S5 SPAKXA767WJZZ – Buffer Material —

S6 SPAKXA923WJZZ – Buffer Material (Front Pad) —

S7 SSAKA0101GJZZ – Polyethylene Bag —

S8 TLABKA009WJZZ – No. Label —

Packing Case, for Accessory

SERVICE JIGS

(USE FOR SERVICING)

QCNW-C458WJQZ J Extension Cable 80-pin AM

QCNW-C459WJQZ J Extension Cable 60-pin AM

(SC1201-LCD)

(SC2001-SC3401)

—

Supplied Accessories

Wireless remote control

X3 X2

"AAA" size batteries (×2)

Cable clamp

X1

X6

38

AC cord

AC adapter

Operation manual

X5X7

LC-20S4U

Page 28

PACKING OF THE SET

X1

X2

X3

X4

X5

X6

X7

S7

LC-20S4U-S

SUPPLEMENT

S5

S2/S3

S5

S4

S6

S5

S1

S5

S8

39

Page 29

LC-20S4U-S

SUPPLEMENT

COPYRIGHT © 2005 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

TQ1951-S

Oct. 2005 Printed in Japan

Design and Production Information

Design : Japan

Production : SEMEX

MI. KG

SHARP CORPORATION

AV Systems Group

CS Promotion Center

Yaita, Tochigi 329-2193, Japan

Loading...

Loading...