Page 1

LC-20D42U

N27A9LC20D42U

LCD COLOR TELEVISION

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

LC-20D42U

CONTENTS

Page

» IMPORTANT SERVICE SAFETY PRECAUTION.........................................................................................2

» SPECIFICATIONS ........................................................................................................................................5

» OPERATION MANUAL .................................................................................................................................6

» DIMENSIONS ...............................................................................................................................................9

» REMOVING OF MAJOR PARTS ................................................................................................................10

» ADJUSTING PROCEDURE OF EACH SECTION .....................................................................................15

» PUBLIC MODE SETTING PROCEDURE ..................................................................................................26

» TROUBLESHOOTING TABLE ....................................................................................................................31

» MAJOR IC INFORMATIONS ......................................................................................................................42

» BLOCK DIAGRAM ......................................................................................................................................44

» OVERALL WIRING DIAGRAM ................................................................................................................... 46

» DESCRIPTION OF SCHEMATIC DIAGRAM ............................................................................................. 48

» SCHEMATIC DIAGRAM

ËLED Unit...................................................................................................................................................49

ËMAIN Unit.................................................................................................................................................50

ËKEYUnit ...................................................................................................................................................90

» PRINTED WIRING BOARD ASSEMBLIES ................................................................................................92

» REPLACEMENT PARTS LIST .................................................................................................................. 104

» PA CKING OF THE SET ............................................................................................................................119

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-20D42U

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

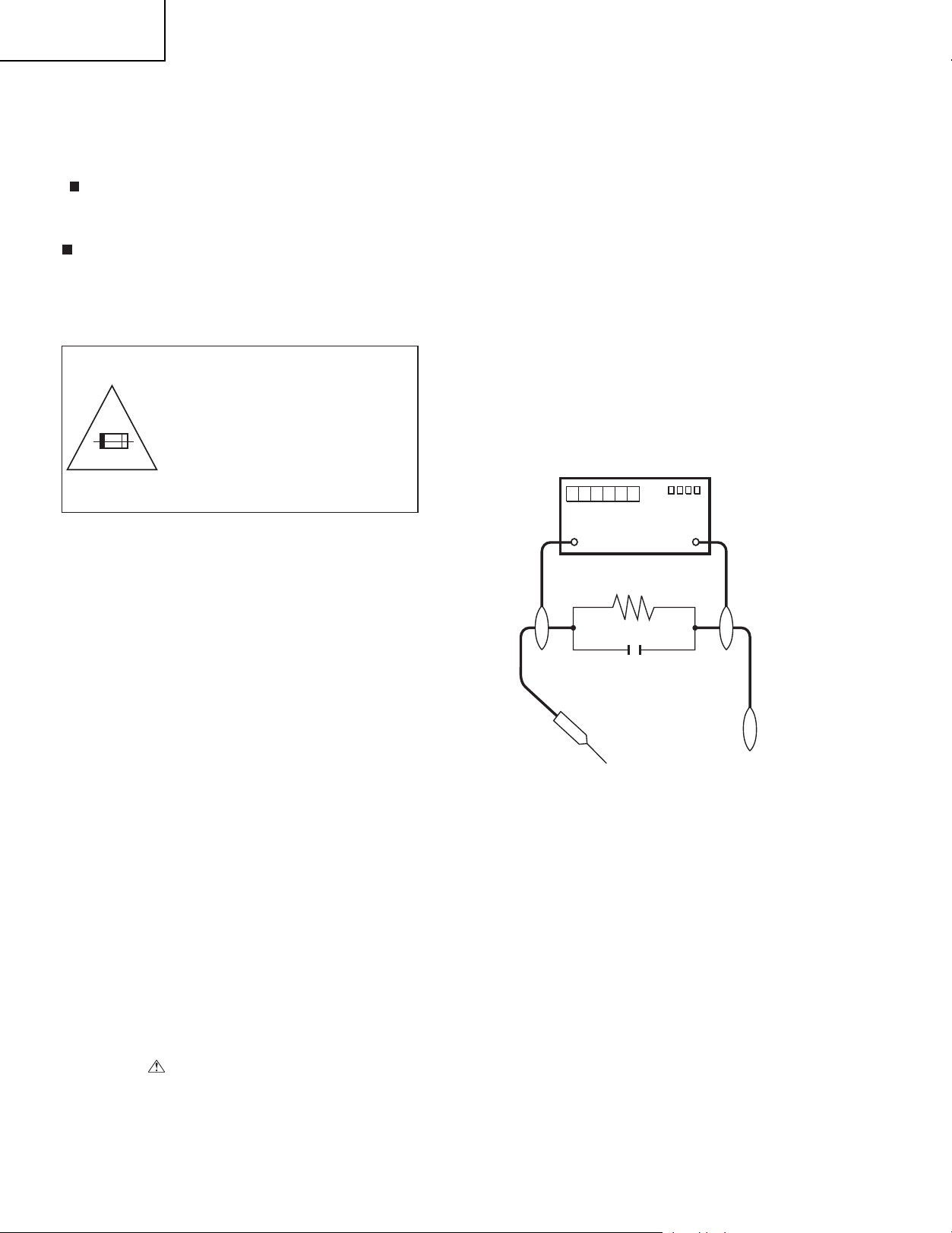

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION:FOR CONTINUED

PROTECTION AGAINST A RISK OF

FIRE REPLACE ONLY WITH SAME

TYPE FUSE.

AV

F1(250V 3.15A), F101(125V 5A)

•Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

•Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

DVM

BEFORE RETURNING THE RECEIVER (Fire &

Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

•Plug the AC cord directly into a 120 volt AC outlet.

•Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15 F capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

µ

TO EXPOSED

METAL PARTS

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

Par

ts

are identified by " " and shaded areas in the Replacement

and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Lists

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

2

Page 3

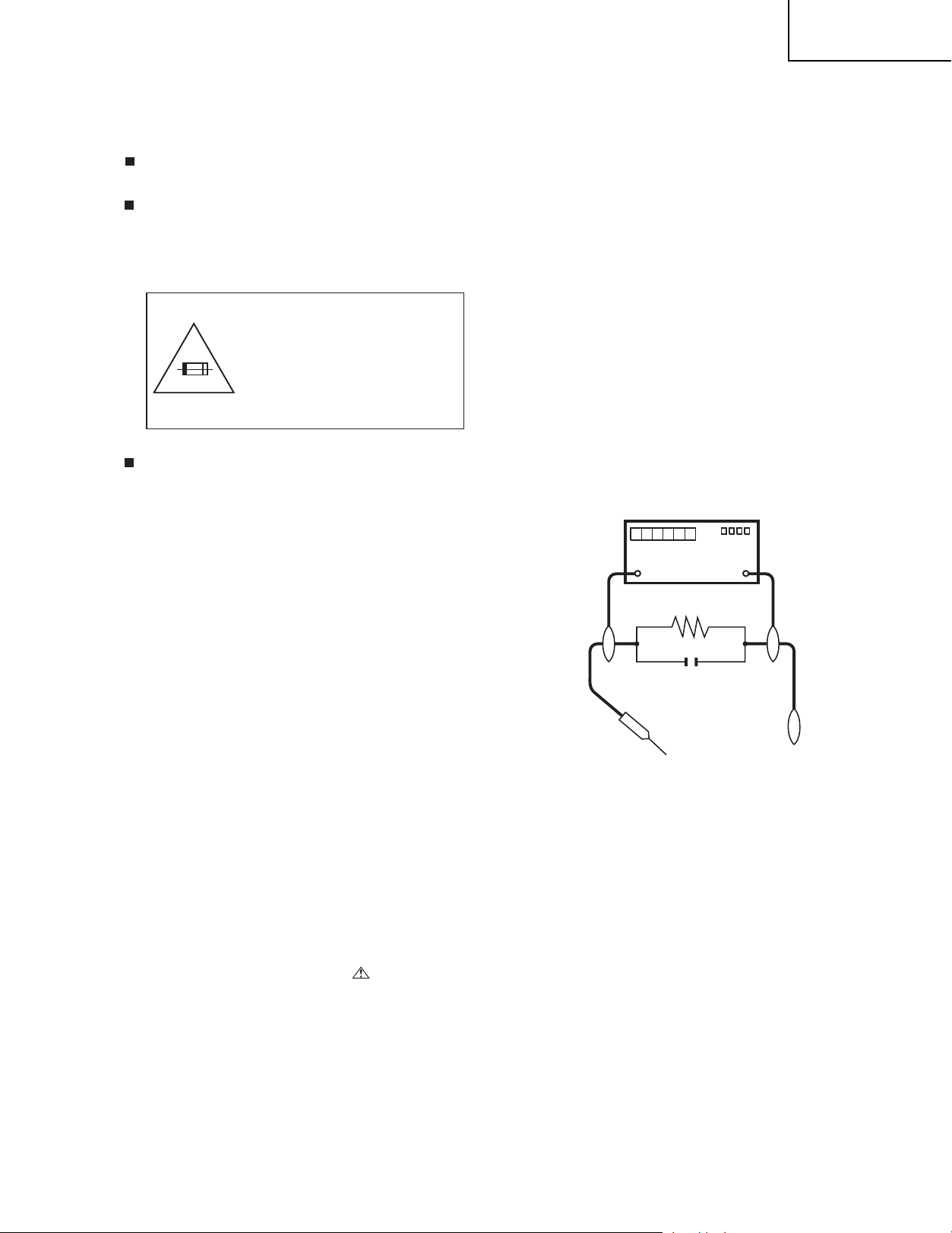

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

s

s

-

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement accoutumé à toute vérification de sécurité et aux

conseils suivants.

Al'aide de deux fils à pinces, brancher une résistance de 1.5 k

AVERTISSEMENT

1.

N'entreprendre Aaucunemodification de tout circuit. C'est dangereux.

2.

Débrancher le récepteur avant toute réparation.

PRECAUTION: POUR LA PROTECTION CONTINUE CONTRE

LES RISQUES D'INCENDIE, REMPLACER LE FUSIBLE

AV

F1(250V 3.15A), F101 (125 5A)

VERIFICATIONS CONTRE L'INCEN-DIE ET LE

CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur , effectuer les vérifications suivantes.

3.

Inspecter tous les faisceaux de câbles pour s'assurer que les fils

ne soient pas pincés ou qu'un outil ne soit pas placé entre le châssis et les autres pièces métalliques du récepteur.

4.

Inspecter tous les dispositifs de protection comme les boutons de

commande non-métalliques, les isolants, le dos du coffret, les couvercles ou blindages de réglage et de compartiment, les réseaux

de résistancecapacité, les isolateurs mécaniques, etc.

S'assurer qu'il n'y ait pas de danger d'électrocution en vérifiant la

5.

fuite de courant, de la facon suivante:

Brancher le cordon d'alimentation directem-ent à une prise de courant de 120V. (Ne pas utiliser de transformateur d'isolation pour

cet essai).

10 watts en parallèle avec un condensateur de 0.15µFensérie

avec toutes les pièces métalliques exposées du coffret et une terre

connue comme une conduite électrique ou une prise de terre

branchée à la terre.

Utiliser un voltmètre CA d'une sensibilité d'au moins 5000 /V pour

mesurer la chute de tension en travers de la résistance.

Toucher avec la sonde d'essai les pièces métalliques exposées qui

présentent une voie de retour au châssis (antenne, coffret métallique, tête des vis, arbres de commande et des boutons, écusson,

etc.) et mesurer la chute de tension CA en-travers de la résistance.

Toutes les vérifications doivent être refaites après avoir inversé la

fiche du cordon d'alimentation. (Si nécessaire, une prise

d'adpatation non polarisée peut être utilisée dans le but de terminer ces vérifications.)

La tension de pointe mesurèe ne doit pas dépasser 0.75V (correspondante au courant CA de pointe de 0.5mA).

Dans le cas contraire, il y a une possibilité de choc électrique qui

doit être supprimée avant de rendre le récepteur au client.

DVM

ECHELLE CA

1.5k ohm

10W

µ

F

0.15

SONDE D'ESSAI

LC-20D42U

AUX PIECES

METALLIQUES

EXPOSEES

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

BRANCHER A UNE

TERRE CONNUE

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans les téléviseur ACL présentent des caractéristiques spéciales relatives à la sécurité, qui ne sont souvent pas évidentes à vue. Le degré de protection ne peut pas être nécessairement augmentée en utilisant des

pièces de remplacement étalonnées pour haute tension, puissance,

etc.

Les pièces de remplacement qui présentent ces caractéristiques sont

identifiées dans ce manuel; les pièces électriques qui présentent ces

particularités sont identifiées par la marque " " et hachurées dans la

liste des pièces de remplacement et les diagrammes schématiques.

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Pour assurer la protection, ces pièces doivent être identiques à celle

utilisées dans le circuit d'origine. L'utilisation de pièces qui n'ont pa

les mêmes caractéristiques que les pièces recommandées par l'usine,

indiquées dans ce manuel, peut provoquer des électrocutions, incen

dies, radiations X ou autres accidents.

3

Page 4

LC-20D42U

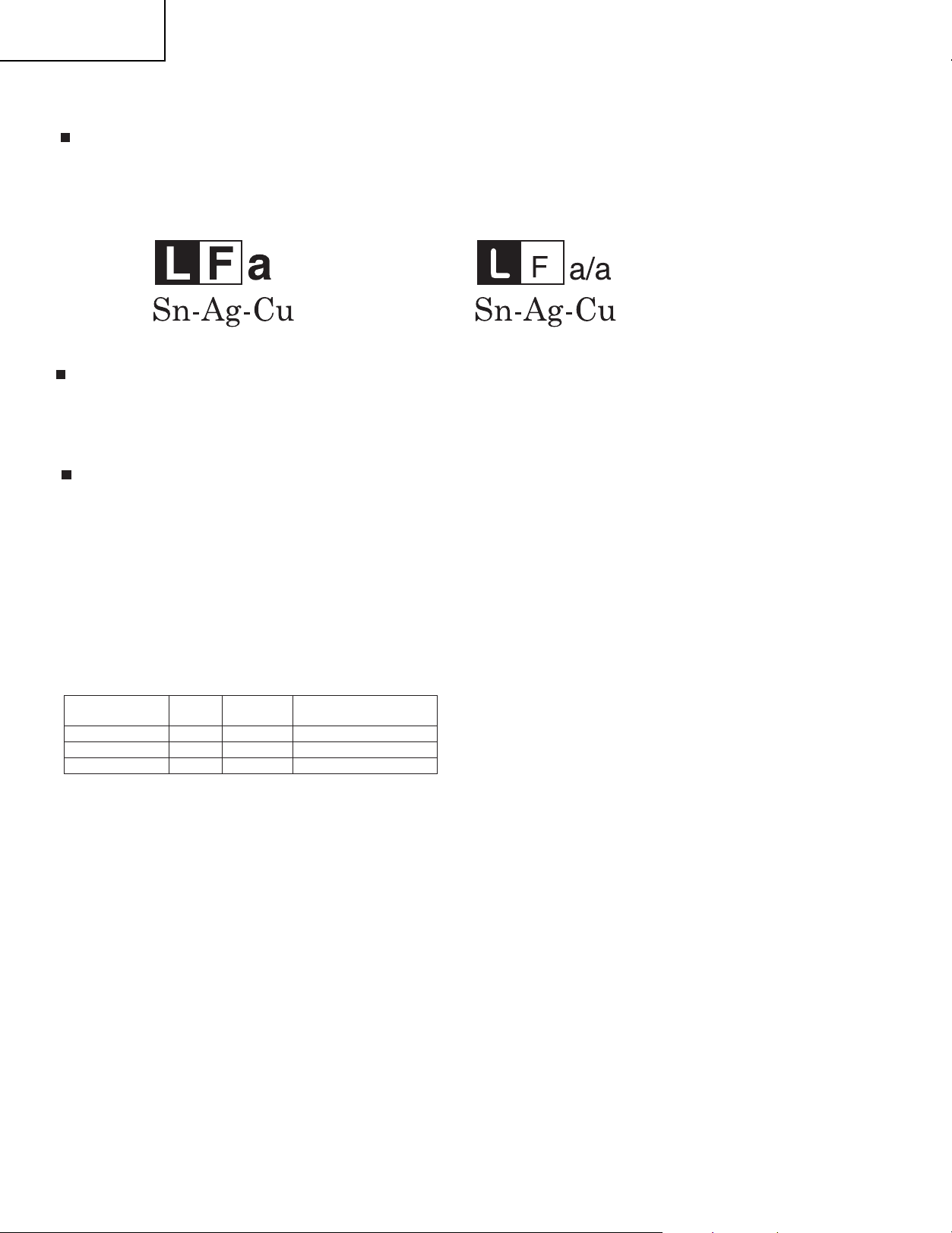

Precautions for using lead-free solder

Employing lead-free solder

•“PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper. Indicates lead-free solder of tin, silver and copper.

Using lead-free wire solder

•When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

•As the melting point of lead-free solder (Sn-Ag-Cu) is about 220

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

°C which is higher than the conventional lead solder by 40 °C, and as it has poor

°C, we recommend you to use a dedicated soldering

•Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

PARTS CODE

ZHNDAi123250E BL J 0.3mm 250g (1roll)

ZHNDAi126500E BK J 0.6mm 500g (1roll)

ZHNDAi12801KE BM J 1.0mm 1kg (1roll)

PRICE

RANK

PART

DELIVERY

DESCRIPTION

φ

φ

φ

4

Page 5

SPECIFICATIONS

LC-20D42U

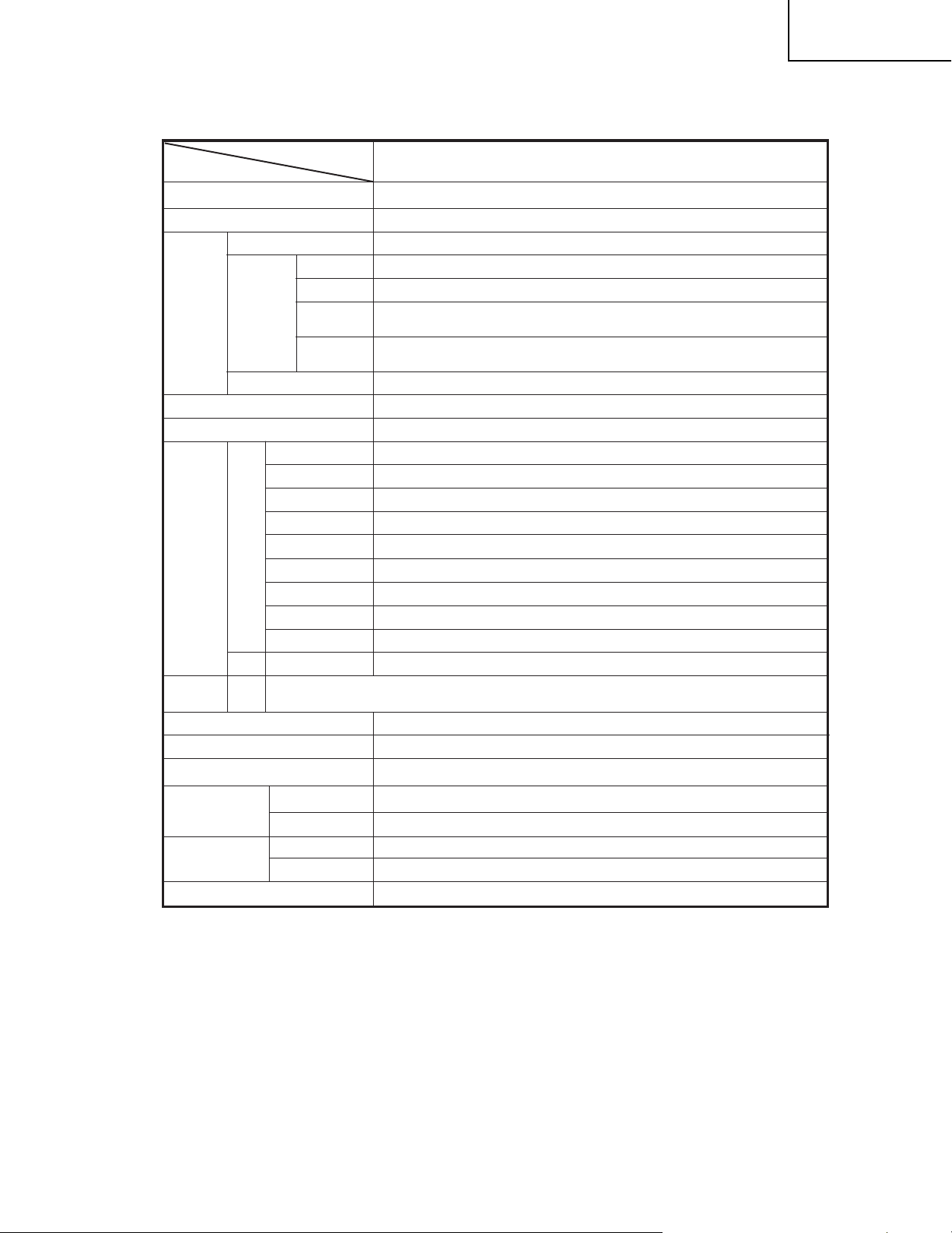

Item

LCD panel

Number of dots

TV

Function

TV-standard (CCIR)

Receiving

Channel

Audio multiplex

Backlight

Audio out

Terminals

Rear

Front

Side

USB SOFT UPDATE (When service man and products USB is used only by update of program.

OSD language

Power Requirement

Power Consumption

Model

LC-20D42U

20"Advanced Super View & BLACK TFT LCD

×

3,147,264 dots (1366 768 3 dots)

×

American TV Standard ATSC/NTSC System

VHF/UHF

CATV

Digital Terretrial

Broadcast(8VSB)

Digital cable

(64/256 QAM)

VHF 2-13ch, UHF 14-69ch

1-135ch (non-scrambled channel only)

2-69ch

*1

1-135ch (non-scrambled channel only)

BTSC System

60,000 hours (at Backlight Standard position)

×

5W 2

INPUT 1

INPUT 2

INPUT 3

INPUT 4

INPUT 5

AV in, COMPONENT in

AV in

AV in, S-VIDEO in

HDMI in with HDCP

HDMI Analog Audio in, HDMI in with HDCP

INPUT 6 15 pin mini D-sub, PC Audio in (Ø 3.5 mm jack)

ANTENNA

DIGITAL AUDIO OUTPUT

75 Ω Unbalance, F Type 1 for Analog (VHF/UHF/CATV) and Digital (AIR/CABLE)

Optical Digital audio output 1 (PCM/Dolby Digital)

×

×

OUTPUT Audio out

MOBILE AUDIO

Mobile Audio in

The ordinary user never uses it. )

English/French/Spanish

AC 120 V, 60 Hz

69 W (0.3 W Standby with AC 120V)

Weight

w/o stand

with stand

Dimension

(W H D)

*2

×

×

w/o stand

with stand

Operating temperature

*1

Emergency alert messages via Cable are unreceivable.

*2

The dimensional drawings are shown on the inside back cover.

As part of policy of continuous improvement, SHARP reserves the right to make design and speci cation changes for product

*

15.8 lbs./12.0 kg

13.2 lbs./14.5 kg

35

20

/64 1545/64 855/64 inch

35

×

/64 1419/64 533/64 inch

20

+

32˚F to 104˚F (0˚C to 40˚C)

×

×

×

+

+

improvement without prior notice. The performance speci cation gures indicated are nominal values of production units.

There may be some deviations from these values in individual units.

5

Page 6

LC-20D42U

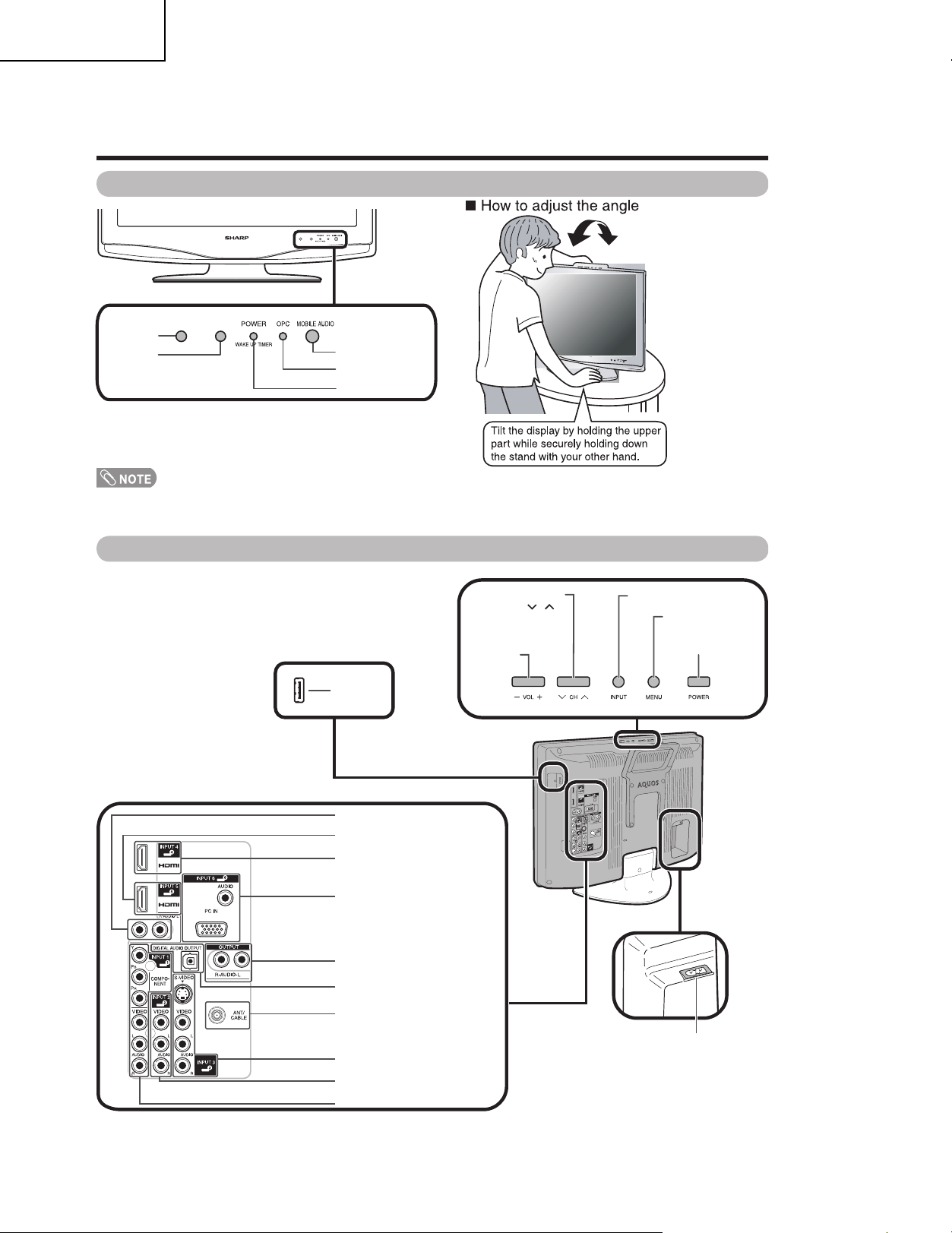

Part names

TV (Front)

Remote

control

sensor

OPC

sensor*

*OPC: Optical Picture Control

**See page 16 for TV status indicator.

TV (Rear)

OPERATION MANUAL

MOBILE

AUDIO jack

OPC indicator*

POWER

indicator**

To change the vertical angle of the LCD TV set,

tilt thescreen up to 2.5 degrees forward or 10

degrees backwards.Please adjust the angle so that

the LCD TV set can be watched most comfortably.

SOFT UPDATE

The ordinary user never

uses it.

USB

terminal

AUDIO terminals (INPUT 5)

HDMI terminal (INPUT 5)

HDMI terminal (INPUT 4)

PC IN terminals (INPUT 6)

AUDIO OUTPUT terminals

DIGITAL AUDIO OUTPUT

terminal

Antenna/Cable in

Channel buttons

(CH / )

Volume

buttons

(VOL + / - )

INPUT button

MENU button

POWER button

INPUT 3 terminals

INPUT 2 terminals

INPUT 1 terminals

AC INPUT terminal

6

Page 7

Part names

LC-20D42U

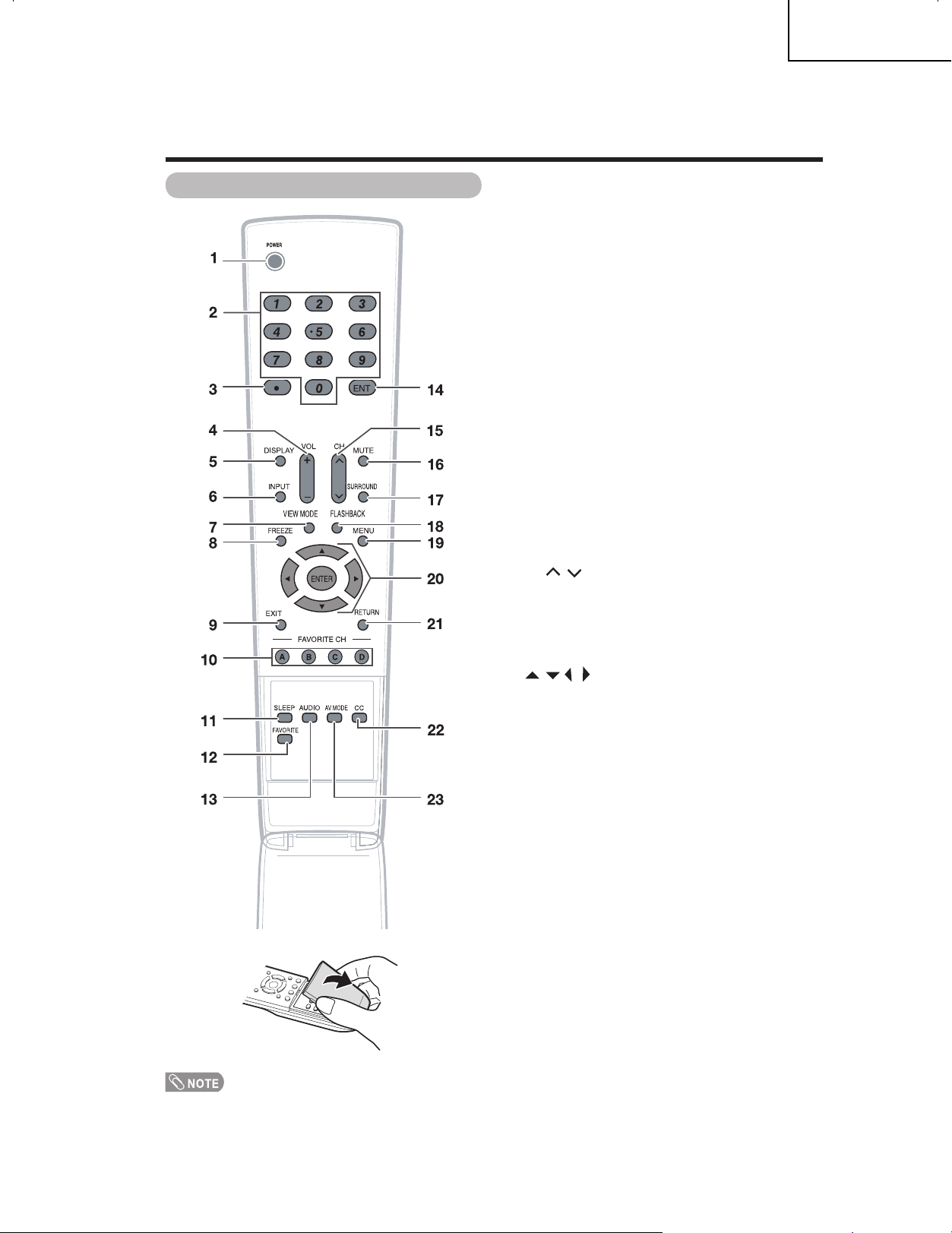

Remote control unit

1 POWER: Switch the TV power on or enters standby.

2 0 - 9: Set the channel.

3 (DOT):

»

+

4 VOL / : Set the volume.

5 DISPLAY: Display the channel and the clock

6 INPUT: Select a TV input source. (TV, INPUT 1,

7 VIEW MODE: Select the screen size.

8 FREEZE: Set the still image. Press again to return to

9 EXIT: Turn off the menu screen.

10 FAVORITE CH

A, B, C, D: Select 4 preset favorite channels in 4

While watching, you can toggle the selected channels

11 SLEEP: Set the sleep timer.

12 FAVORITE: Set the favorite channels.

13 AUDIO: Selects the MTS/SAP or the audio mode

14 ENT: Jumps to a channel after selecting with the 0 - 9

15 CH / : Select the channel.

16 MUTE: Mute the sound.

17 SURROUND: Select Surround settings.

18 FLASHBACK: Return to the previous channel or

external input mode.

MENU: Display the menu screen.

19

20 / / / /ENTER: Select a desired item on the

21 RETURN: Return to the previous menu screen.

22 CC: Display captions from a closed-caption source.

23 AV MODE: Select an audio or video setting.

-

information .

INPUT 2, INPUT 3, INPUT 4, INPUT 5, INPUT 6)

normal screen.

different categories.

by pressing A, B, C and D.

during multi-channel audio broadcasts.

buttons.

screen.

(When the input source is TV, INPUT 1, 2 or 3:

STANDARD, MOVIE, GAME, USER, DYNAMIC (Fixed),

DYNAMIC. When the input source is INPUT 4, 5 or 6:

STANDARD, MOVIE, GAME, PC, USER, DYNAMIC

(Fixed), DYNAMIC)

When using the remote control unit, point it at the TV.

7

Page 8

LC-20D42U

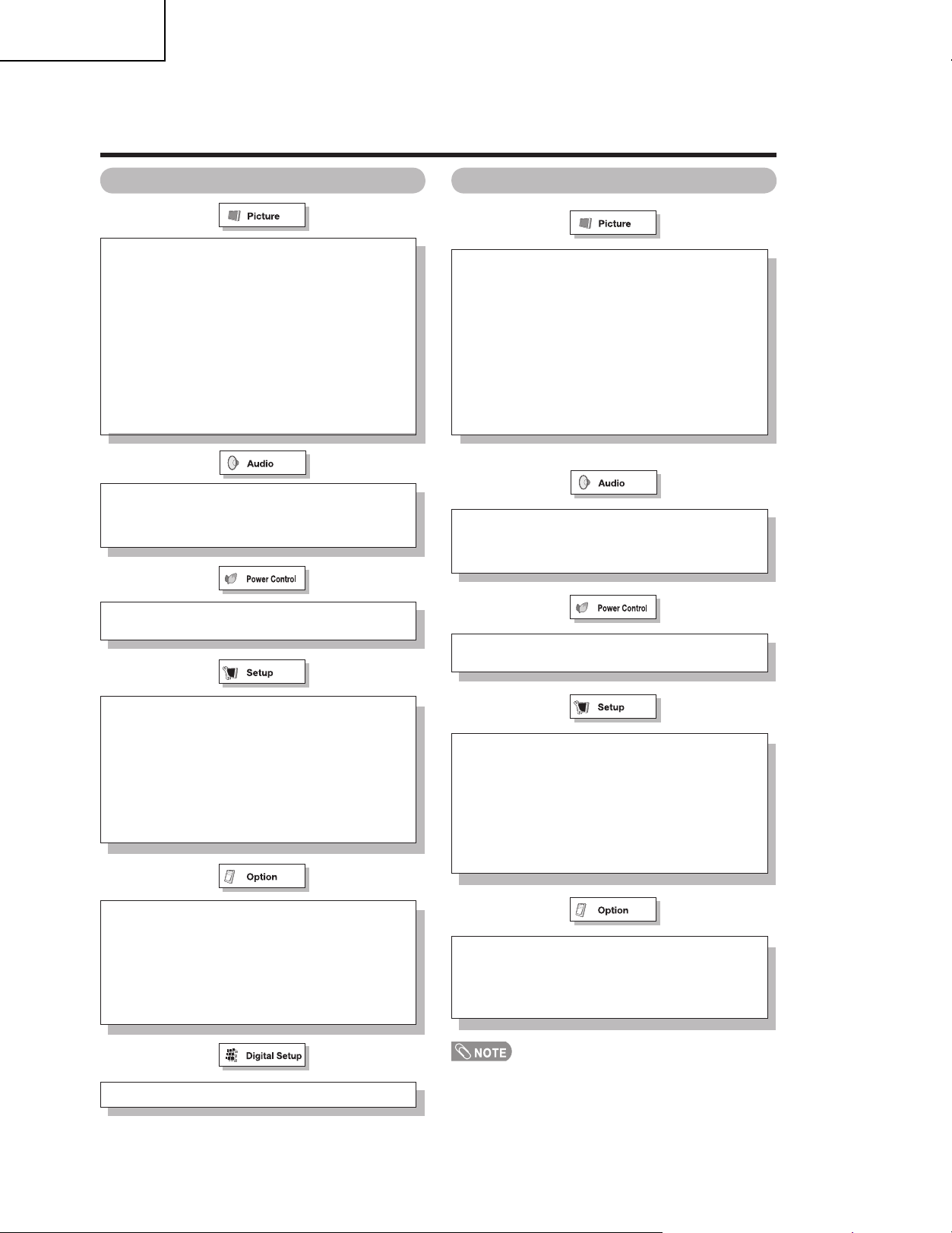

Basic adjustment sitings

Menu items for TV/INPUT 1/2/3 Menu items for HDMI/PC-IN

OPC

Backlight

Contrast

Brightness

Color

Tint

Sharpness

Advanced

Color Temp.

Black

I/P Setting

Film Mode

3D-Y/C

Monochrome

Range of OPC

Treble

Bass

Balance

Surround

No Signal Off

No Operation Off

OPC

Backlight

Contrast

Brightness

Color

Tint

Sharpness

Advanced

Color Temp.

Black

I/P Setting

Film Mode

Monochrome

Range of OPC

Treble

Bass

Balance

Surround

No Signal Off

No Operation Off

EZ Setup

CH Setup

Antenna Setup-DIGITAL

Input Skip

Input Label

Parental CTRL

Position

Language

Clock Setup

Music Player Input

Reset

Audio Only

Digital Noise Reduction

Input Select

Output Select

Color System

Caption Setup

Program Title Display

Favorite CH

Wake-up Timer Setup

Audio Setup

Input Skip

Input Signal

Auto Sync.

Input Label

Fine Sync.

Position

Language

Clock Setup

Music Player Input

Reset

Audio Only

Digital Noise Reduction

HDMI Setup

Output Select

Wake-up Timer Setup

Some menu items may not be displayed depending on the

selected input source.

8

Page 9

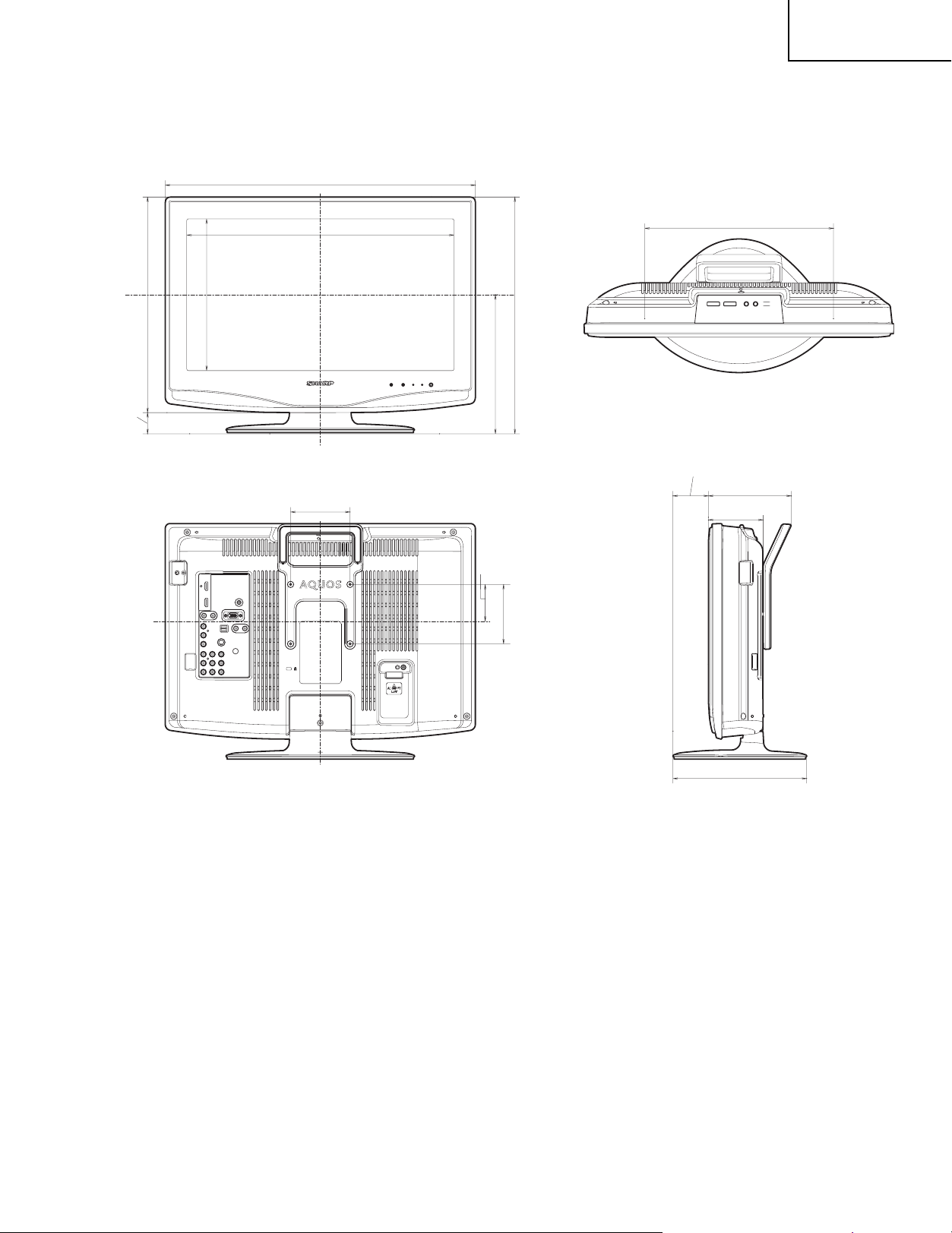

17

20

35

15

/32

/64

(522)

(443.6)

DIMENSIONS

12

LC-20D42U

33

/64

(318)

(36)

/64

27

1

(363)

/64

19

14

(249.4)

/16

13

9

(399)

/64

(234)

45

/32

7

15

9

23

2

(60)

/64

33

5

(140)

15

3

/16

(100)

(62)

/16

7

2

(100)

/16

15

3

/64

5

(92)

/8

3

55

(225)

/64

8

9

Page 10

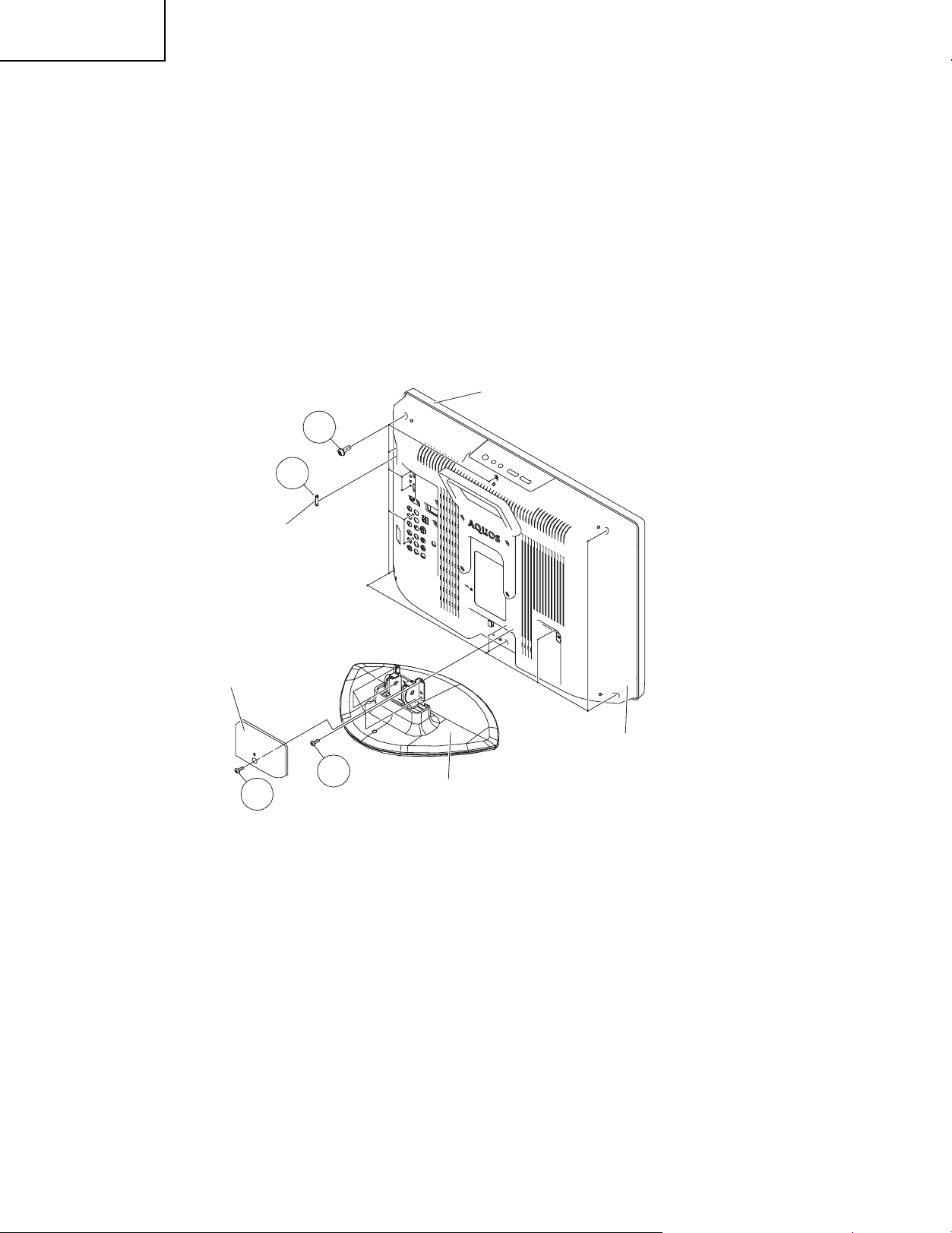

LC-20D42U

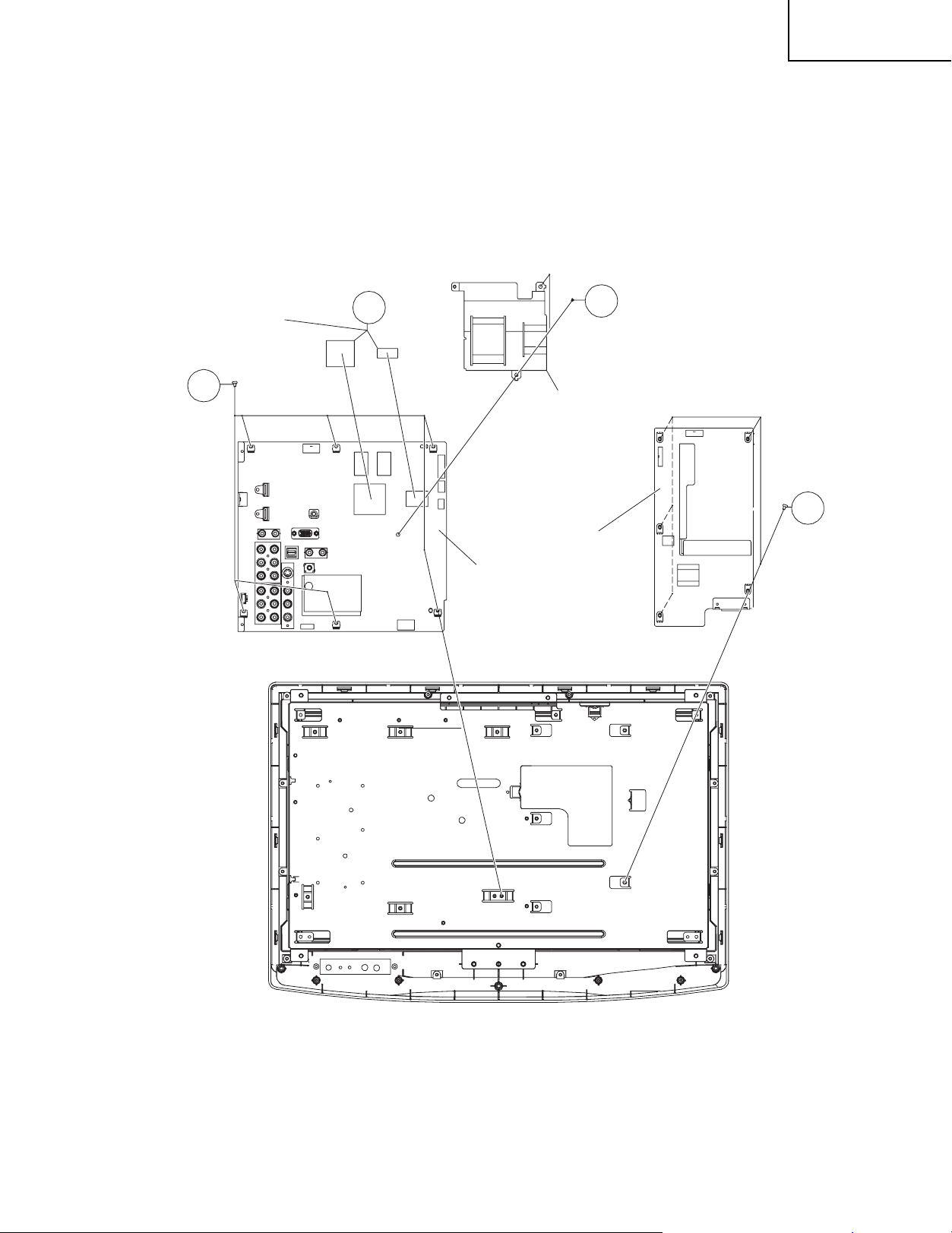

REMOVING OF MAJOR PARTS

1. Remove the lock screw and detach the Stand Cover.

2. Remove the 4 lock screw and detach the Stand Assy.

3. Remove the USB Cover.

4. Remove the 5 lock screws,4 lock screws,3 lock screws,1 lock screw and detach the Cabinet B.

Cabinet A

4

3

USB Cover

Stand Cover

1

Cabinet B

2

Stand Assy

10

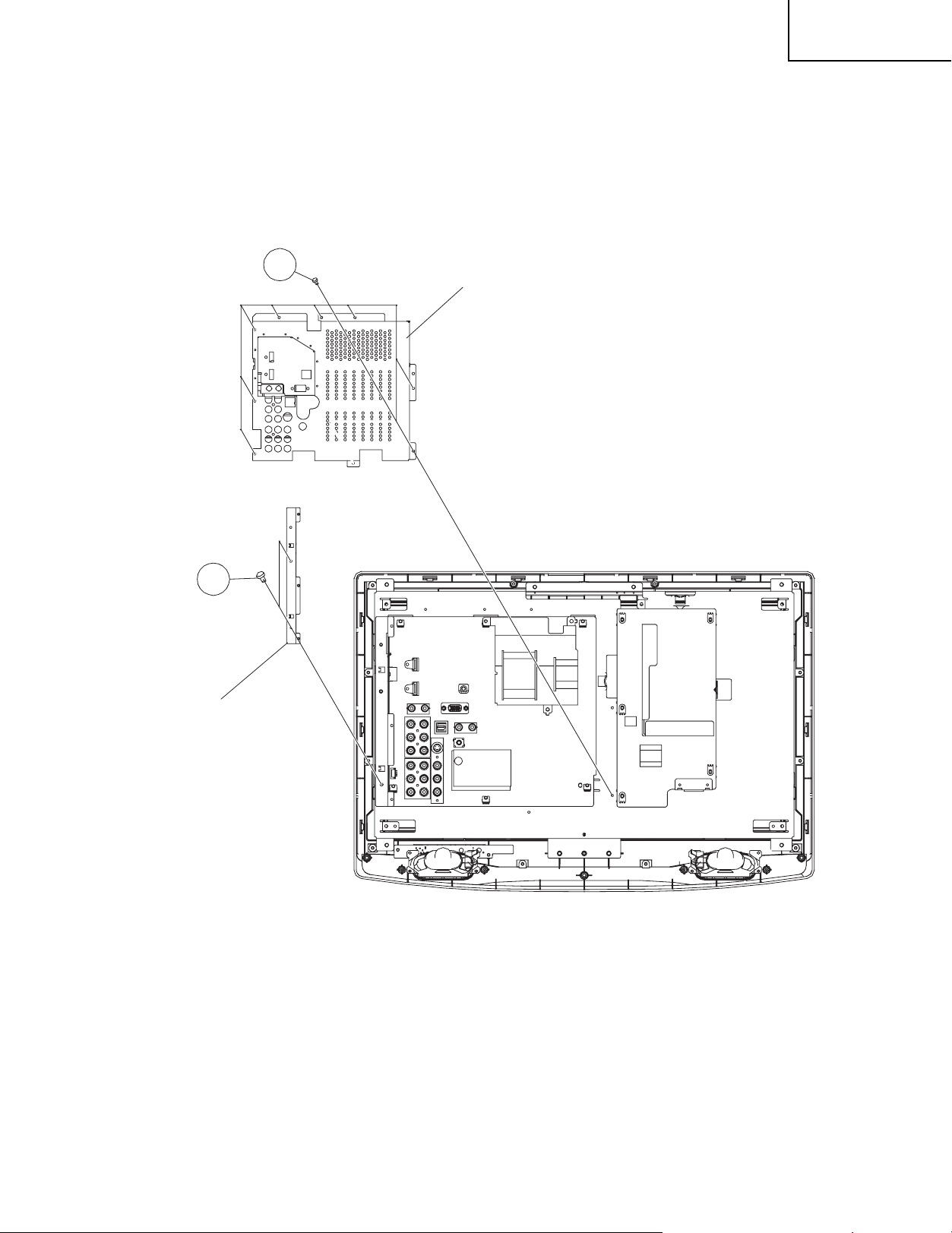

Page 11

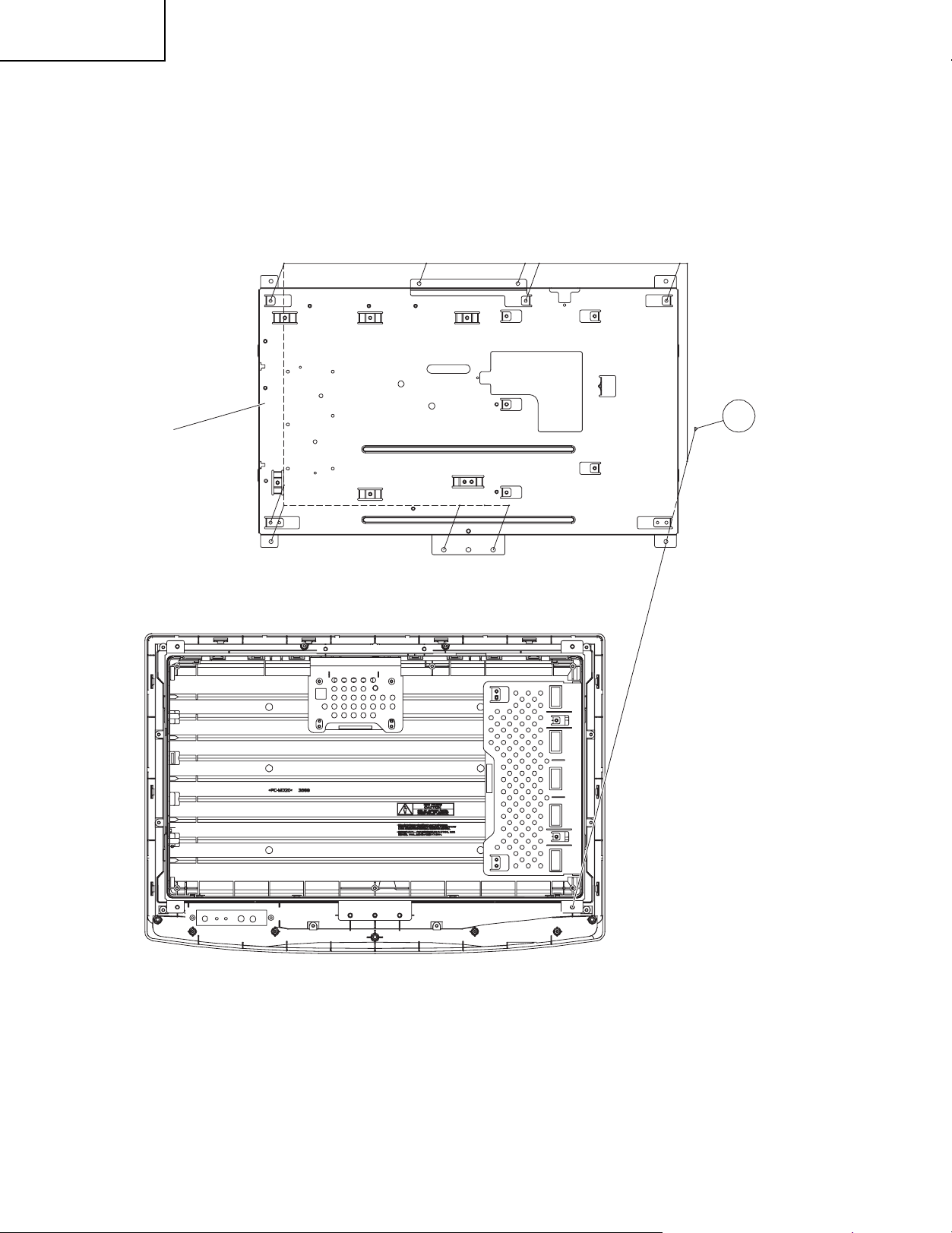

5. Remove the 6 lock screws,3 lock screws and detach the Main Shield.

6. Remove the 2 lock screws and detach the Chassis Frame.

LC-20D42U

6

5

Main Shield

Chassis Frame

11

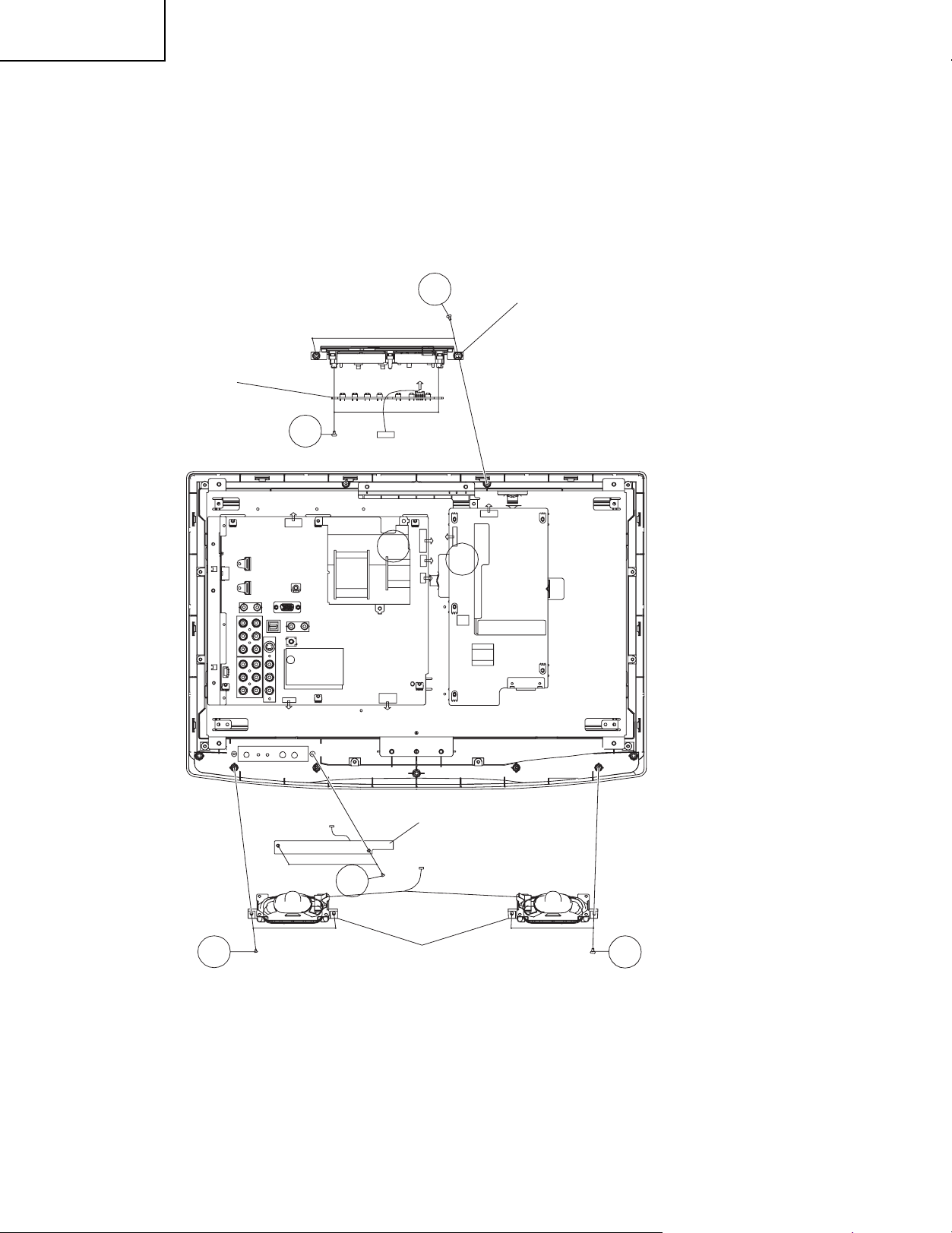

Page 12

LC-20D42U

7. Disconnect all the connectors from all he PWBs.

8. Remove the 2 lock screws and detach Top Cover Assy.

9. Remove the 2 lock screws from the Top Cover Assy and detach the KEY Unit.

10.Remove the 4 lock screws and detach the Speaker Assy L&R.

11.Remove the 2 lock screws and detach the R/C LED Unit.

8

Top Cover Assy

KEY Unit

9

10

7

7

R/C LED Unit

11

Speaker Assy L&R

10

12

Page 13

12. Remove the 5 lock screws and detach the POWER Unit.

13. Remove the 6 lock screws and detach the MAIN Unit.

14. Remove the 2 lock rivets and detach the Radiator.

15. Remove the 2 Earth Plate.

LC-20D42U

Earth Plate

13

15

14

Radiator

12

POWER Unit

MAIN Unit

13

Page 14

LC-20D42U

16.Remove the 6 lock screws,5 lock screws and detach the Back Shield.

Back Shield

16

14

Page 15

LC-20D42U

ADJUSTING PROCEDURE OF EACH SECTION

[1] ADJUSTMENT PROCEDURETME

The adjustment values are set to the optimum conditions at the factory before shipping. If a value should become improper or an adjustment is

required due to part replacement,make an adjustment according to the following procedure.

1. After replacement of any PWB unit and/or IC for repair,please note the following.

• When replacing the following units, make sure to prepare the new units loaded with updated software.

MAIN Unit:DUNKE001FMF1

2. Upgrading of each microprocessor software

Caution:Never "POWER OFF" the unit when software upgrade is on going.

Otherwise the system may be damaged beyond recovery.

2.1. Software version upgrade

The model employs the following software.

•

Main software

•Monitor microprocessor software.

The main software and the monitor microprocessor software can be upgraded by using a general-purpose USB Memory.

The followings are the procedures for upgrading,explained separately for each of the main software,the monitor microprocessor software.

2.2. Main software version upgrade

Get ready before you start

• USB Memory of 128MB or higher capacity.

• PC running on Windows 98/98SE/ME/2000/XP operating system.

• USB Memory reader/writer with USB connectivity.

Preparations

To upgrade the main software,it is necessary to get ready the USB Memory for version upgrade before you start.

Follow the steps below and create the USB Memory for version upgrade.

1. Copy the file 42LTAxxx.USB(named temporarily) for version upgrade to the root directory (folder) of the USB Momory.

NOTE:In the USB Memory drive, do not store other folders or unrelated files, or more than one files for version upgrade.

Now the USB Memory for version upgrade is ready.

How to upgrade the software

2.

Unplug the AC cord. (make sure AC power shut down more than 1 minute.)

3. Insert the USB Memory for version upgrade (prepared as above) into the service socket located Right side from center at terminals,above

HDMI4 terminal in the rear of the unit.

4. plug in the AC cord with power button pressing after 5 seconds later, unpress the power button.

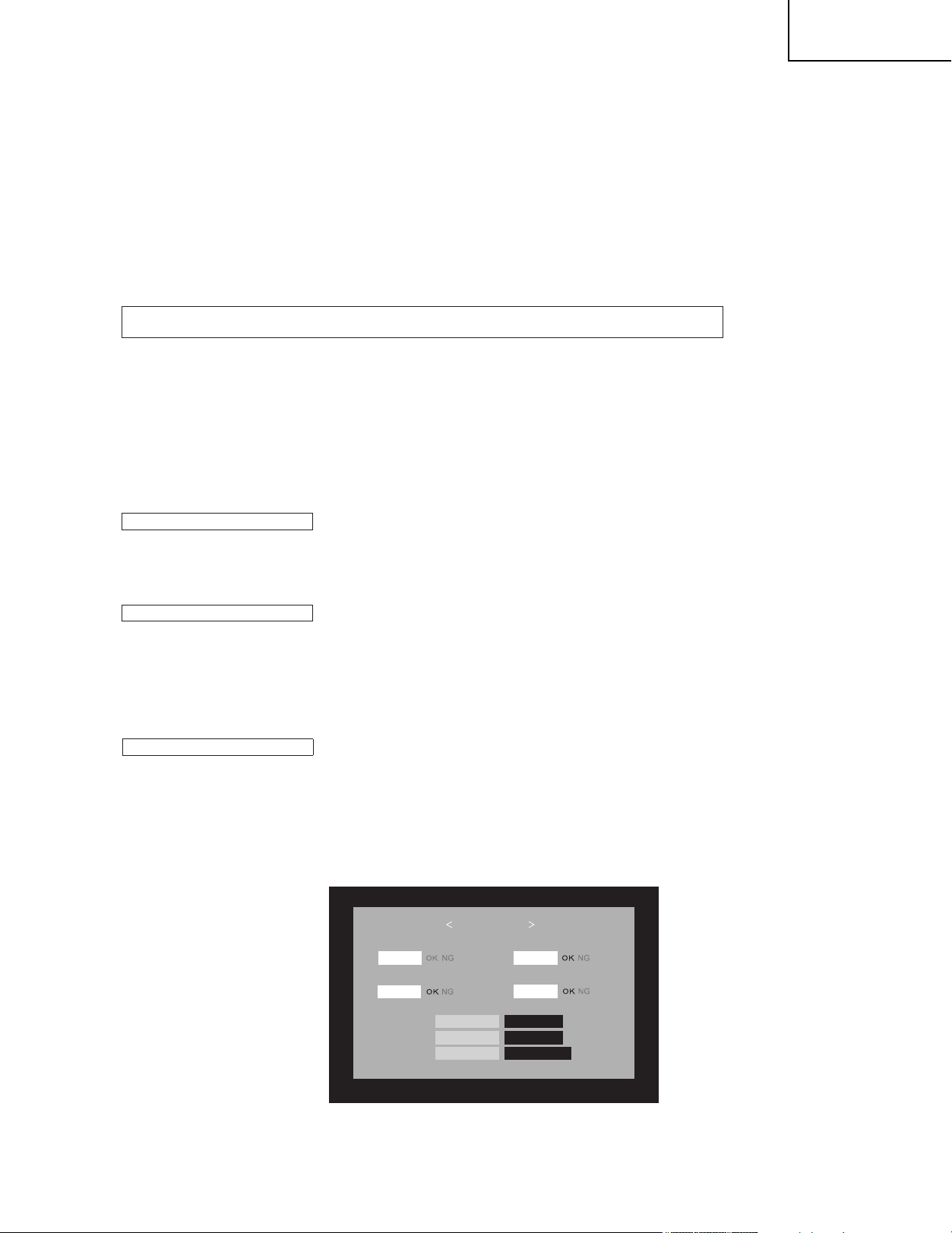

5. After the unit startup,the system upgrade screen as shown below appears within 20-40 seconds.

100%

MOISE_LITE

MAIN

45%

MONITOR

NO DATA

SYSTEM UPGRADE

EEPROM

USB - MEMORY

DETECT

U0612111 OLD Version

NEW Version U0612201

Boot Version

D42U_LITE 0.80

15

Page 16

LC-20D42U

6. Even a single failure in the process will trigger the upgrade failure screen as shown below.the word "NG" channges to red for the item failed.

NOTE: In the event of a failure, repeat the upgrading process.If the process repeatedly fails. it is likely that the hardware is troubled.

100%

100%

MOISE_LITE

MOISE_LITE

SYSTEM UPGRADE

MAIN

45%

MONITOR

NO DATA

NG

NEW Version U0612201

Boot Version

EEPROM

USB - MEMORY

DETECT

U0612111 OLD Version

D42U_LITE 0.80

7.Upon completion of the whole process,the upgrade success screen as shown below appears.You can check the new software version on this

screen. The version information appears after the upgrade is complete.

UPGRADE SUCCESS

MAIN

100%

MONITOR

NO DATA

EEPROM

USB - MEMORY

DETECT

U0612111 OLD Version

NEW Version U0612201

Boot Version

D42U_LITE 0.80

8.unplug the AC cord and remove the USB Memory for version upgrade.

9

.Now the software version upgrade is complete.

NOTE: When you are done with the software version upgrade,start the set,go to the top page of the adjustment process screen and check the main

software version information.

2.3. Monitor microprocessor software version upgrade

Create the USB memory for monitor microprocessor software version upgrade in the same manner as explained in the "Main software version upgrad".

Copy the file 42LTMxxx.USB and 42LTMxxx.BIN(named temorarily ) for monitor microprocessor software version upgrade to th USB memory.

How to upgrade the software

1. Unplug the AC cord.(make sure AC power shut down more than 1 minute.)

2. Insert the USB memory for version upgrade (prepared as above) into the service socket located Right side from center at terminals,above HDMI4

terminal in the rear of the unit.

3. plug in the AC cord with power button pressing.

4. After 5 seconds later,unpress the power botton.

CAUTION: The moment this operation is done,the upgrading of the monitor microprocessor software starts.While the upgrade is ongoing,never power

5. After the upgrade startup, the power light will flash continuous.

off the unit. Otherwise the upgrade will fail and the system may have a serious damage beyond recovery (inability to start).

After the monitor microprocessor software is upgrade, should preform the "Industry Init " by all mean.

16

Page 17

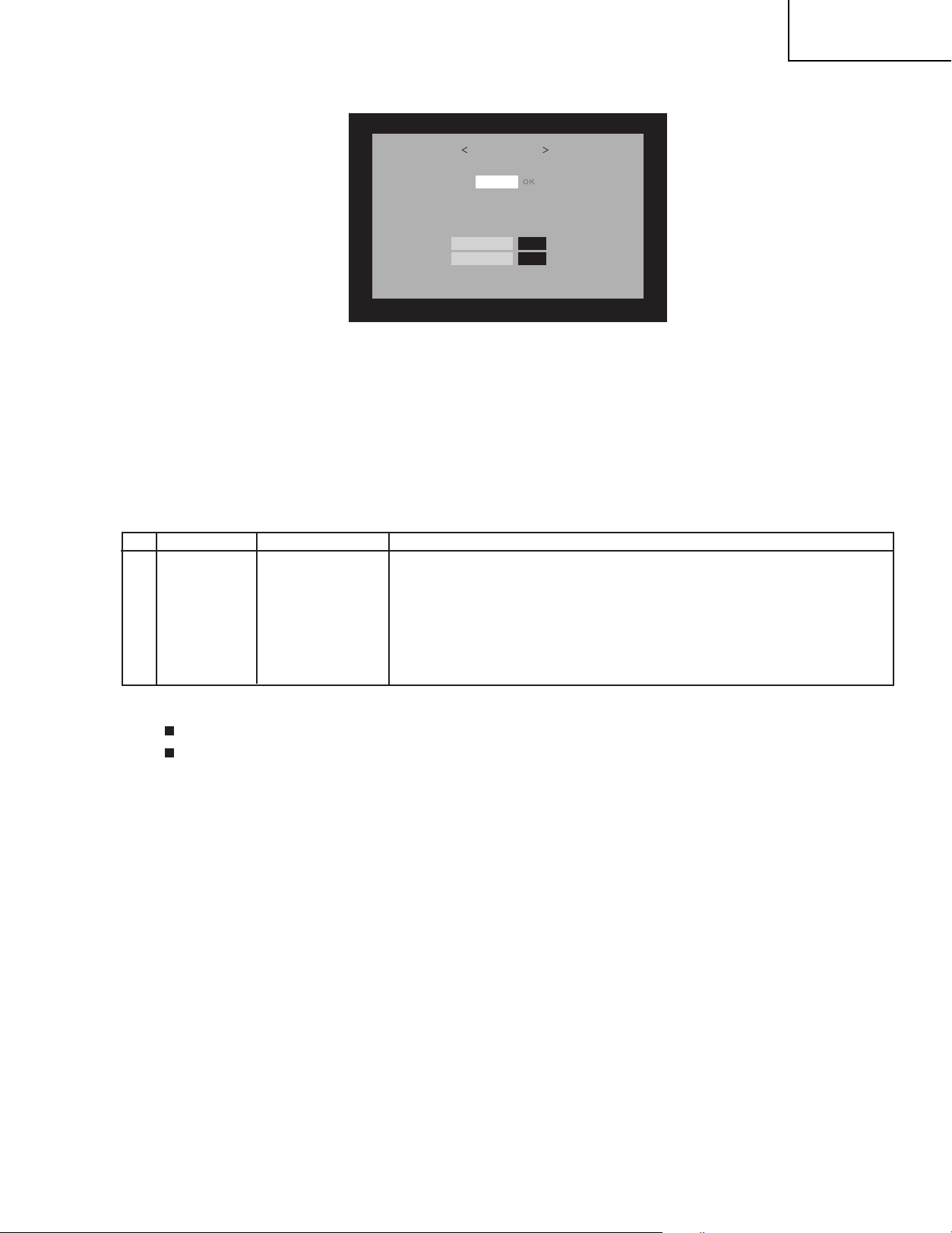

6. A failure in the process will trigger the upgrade failure screen.The word "NG" changes to red for the item failed.

UPGRADE FAILURE

MONITOR

Model err

NG

LC-20D42U

OLD Version

NEW Version

0.95

0.95

NOTE: In the event of a failure,repeat the upgrading process.If the process repeatedly fails, it is likely that the hardware is troubled.

7. Upon completion of the whole process,the set will restart autowatically.

8. Unplug the AC cord and remove the USB Memory for version upgrade.

9. Now the software versin upgrade is complete.

NOTE: When you are done with the software version upgrade,start the set,go to the top page of the adjustment process screen and check the mon-

itor microprocessor software version information and panel size information.

2.4. LCD TV Adjustment item

1.MICON SOFTWARE Writing

(1) Monitor Micon and Main Micon software writing (Main PWB : QPWBXE001WJN1)

Adjustment item

1 Software writing Inspection mode

Adjustment conditions

Connect the tool by using write MAIN soft to P9301 (TL9301,TL9302,TL9310 - TL9355,TL9357,

TL9359,TL9375,TL9378,TL9380 - TL9383) that is mounted on the main PWB,and insert USB

Memory by using MONITOR MICON to main PWB.MONITOR connect to TL8123,TL8124 that

denoted figure. Load stated voltage to MAIN PWB, write the lastest version MAIN SOFT to

file version checking

IC8451, and write the MONITOR MICON SOFT to IC2002, after all completed,turn off the AC

power.

NOTE

When the USB MEMORY cant insert to main PWB or read out is error,MAIN Miro software

must be writed anain.

2. Signal adjustment

(1) Checking the Device

Before starting the adjustment,make sure the adjustment tool and signal generator are set for Sharp LCD US.

Checking the signal generator level adjustment (Set to th standard level)

•

Composite signal : 0.714 Vp-p ± 0.02 (from pedestal to white)

•

15K component signal : Y level : 0.714 Vp-p ± 0.02 (from pedestal to white)

Pb, Pr LEVEL : 0.7 Vp-p ± 0.02 Vp-p

•

33K component signal : Y LEVEL : 0.7 Vp-p ± 0.02 Vp-p (from pedestal to white)

Pb, Pr LEVEL : 0.7 Vp-p ± 0.02 Vp-p

•

Analog RGB signal : RGB LEVEL : from pedestal to white)

0.7 Vp-p ± 0.02 Vp-p

Adjustment procedure

17

Page 18

LC-20D42U

(2).Process mode

Adjustment item Adjustment procedure

Process mode Enter the process adjustment mode using the process adjustment remote controller

1

(3

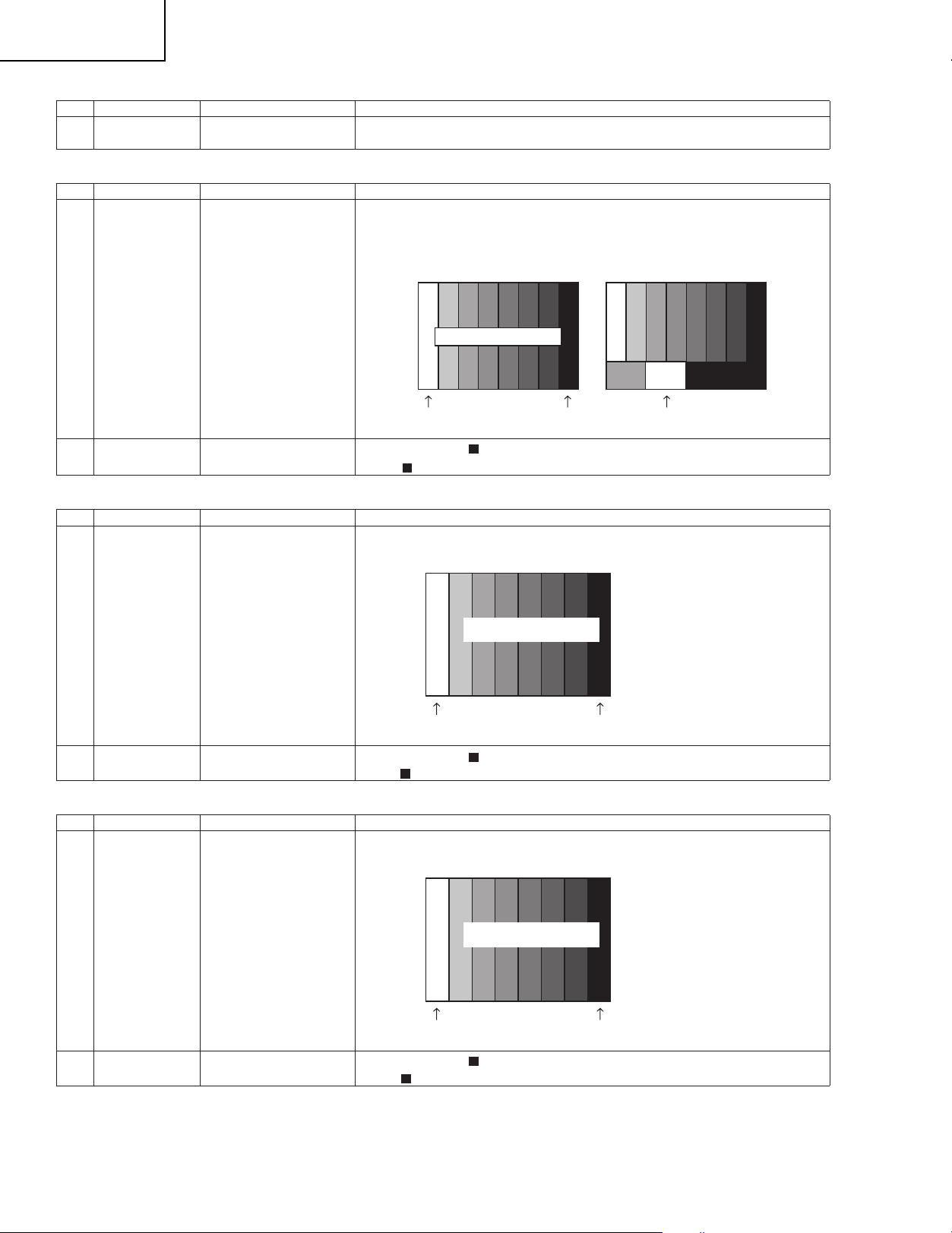

)Composite N358 signal/tuner adjustment

Adjustment item

1 Setting N358 signal

Adjustment conditions

Adjustment conditions

US-10ch

Adjustment procedure

•

Feed the N358 color bar signal(75%)to VIDEO 1 Input

•

Feed the RF signal (by use of US-10CH) to TUNER.

[Video input signal] [US-10ch]

75% Color saturation

100% white 0% black 100% white

2 Automatic adjust-

ment execution

(4) 15K COMPONENT signal adjustment

Adjustment item

1 Setting 480i signal Feed the 100% color Bar signal to VIDEO1 COMPONENT input

2 Automatic adjust-

ment execution

(5) Component 33Ksignal adjustment

Adjustment item

1 Setting 1080i signal Feed the 100% color Bar signal to VIDEO1 CIMPONENT input

Adjustment conditions

Adjustment conditions

Move the cursor to [ N358 ADJ] and press the [ENTER] key.

When [ N358 ADJ OK] appears,the adjustment is complete.

Adjustment procedure

100% Color saturation

100% white

Move the cursor t0 [ COMP 15K ALL ADJ] and press the [ENTER] key..

When [ COMP 15K ALL ADJ OK] appears, the adjustment is complete.

Adjustment procedure

480i

100% color bar

0% black

2 Automatic adjust-

ment execution

100% Color saturation

100% white

Move the cursor to [ HDTV ADJ ] and press the [ENTER] key.

When [ HDTV ADJ OK] appears, the adjustment is complete.

1080i

100% color bar

0% black

18

Page 19

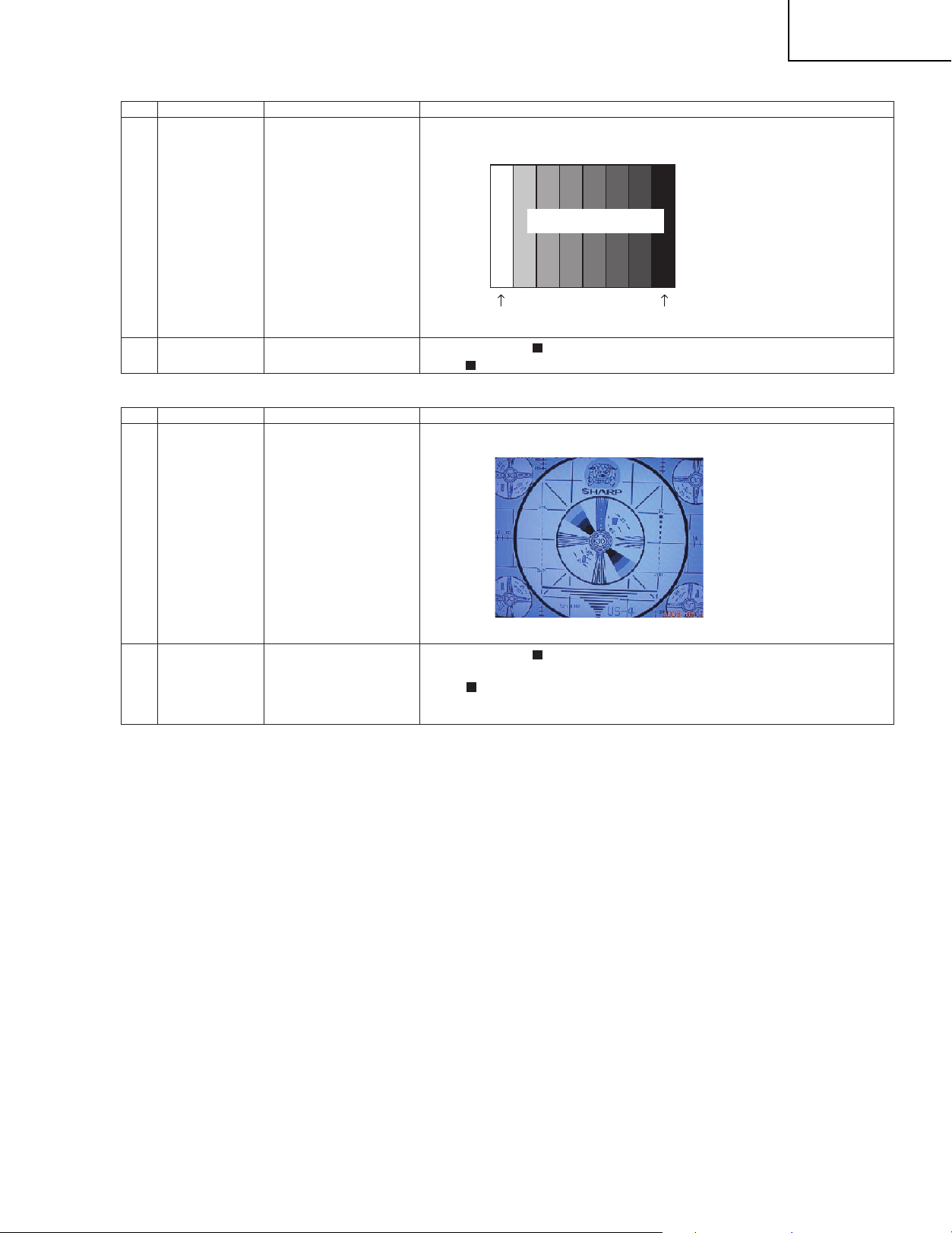

(6) Analog RGB signal adjustment

Adjustment item

1 Setting Analog RGB signal: XGA

Adjustment conditions

(1024x768) 60HZ

SYNC: HV separate

LC-20D42U

Adjustment procedure

Feed the XGA100% color bar signal to analog RGB input.

2Automatic adjust-

ment execution

) Tuner/V-Chip test

(7

Adjustment item

1 Setting NTSC RF signal

2 Automatic adjust-

ment execution

Adjustment conditions

US-4(AIR)ch

100% Color saturation

100% white

Move the cursor to [ ANALOG RGB ADJ] and press the [ENTER] key.

When [ ANALOG RGB ADJ OK] appears ,the adjustment is complete.

•

Feed the NTSC signal to RF ANTENNA.

Move the cursor to[ TUNER VCHIIP TEST(*04ch)] and press the [ENTER] key.

(* Select the channel according to RF signal.)

When [ A-OK(***.**)/VM-OK] appears in blue, the test is complete.(If [A-NG/VM-NG]

appears in yellow or red, the test is incomplete.

Make sure a displacement of ±

Adjustment procedure

0.0625MHZ from the center frequency is acceptable.

XGA

100% color bar

0% black

19

Page 20

LC-20D42U

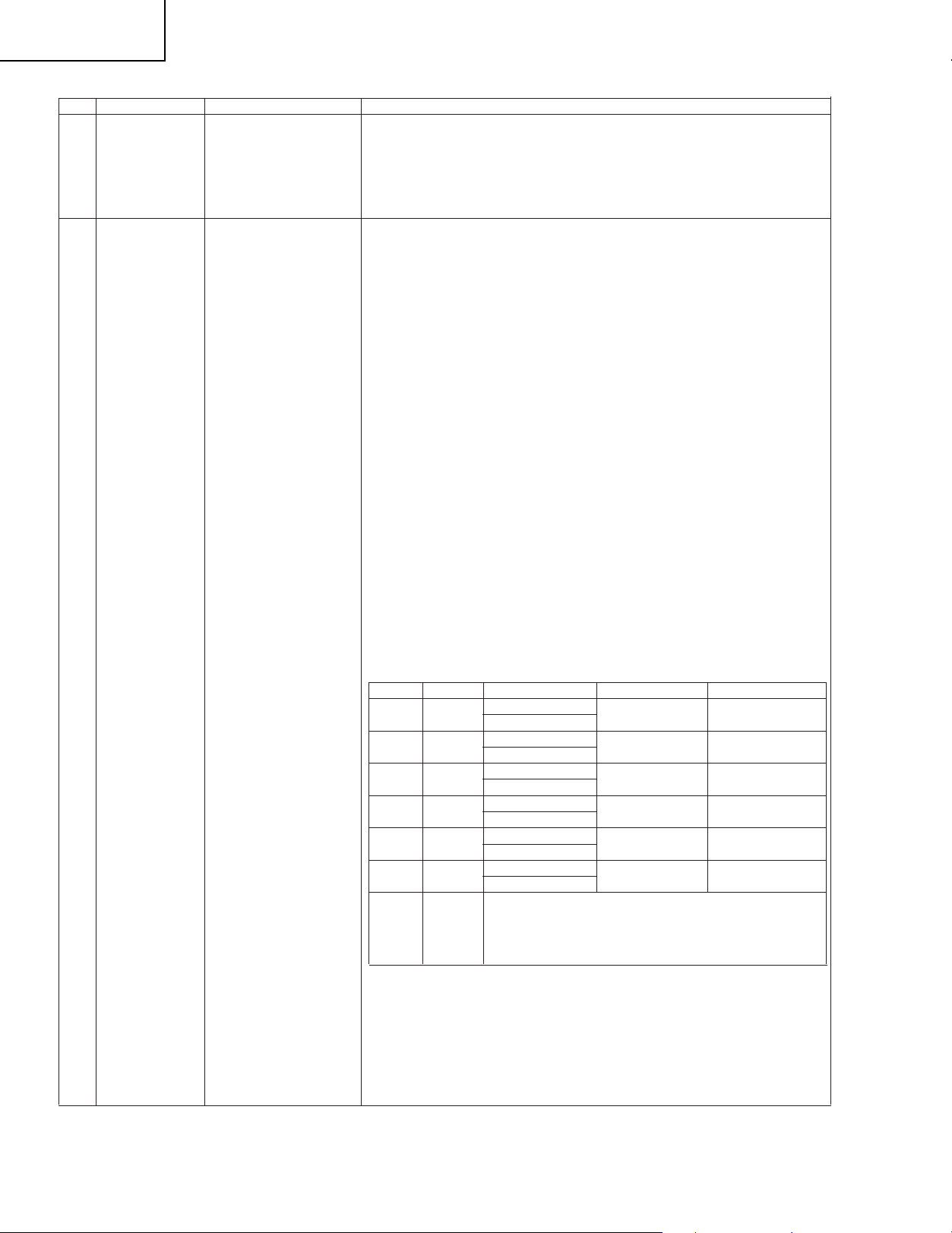

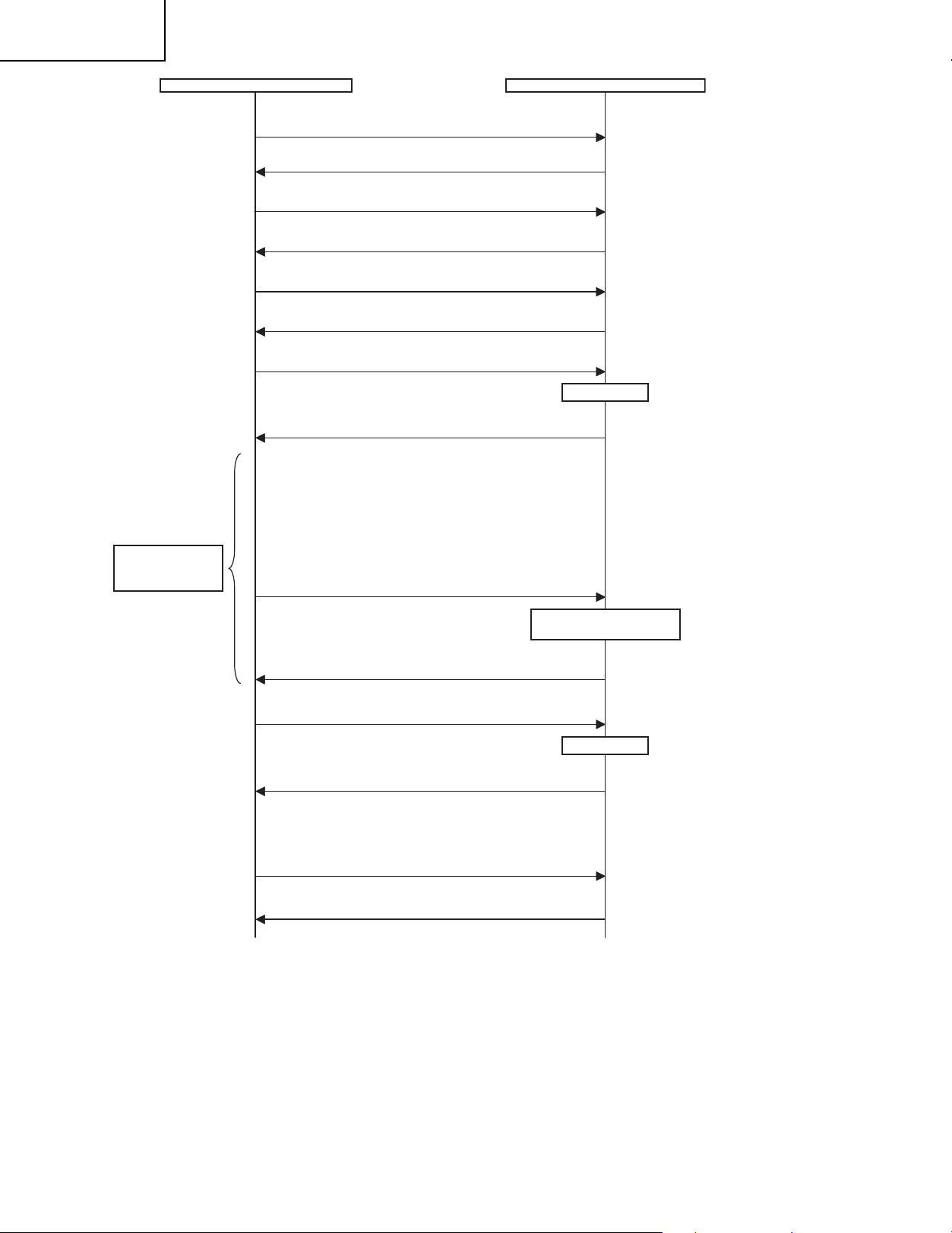

3.White balance adjustment

Adjustment item

1 Setting For detailed adjustment procedure refer to "Kameyama Model Integral WB Adjustment

2 Automatic adjust-

ment execution

Adjustment conditions

[Command]

Process mode

KRSW0001

KKT10037

Setting

KYOF0000

OSDS0001

SBSL0016

Multi-point adjustment

MSET0001

Adjustment value

initialization

MSET0004

Point 6

WBI60928

MG6G****

MG6B****

MG6R****

Point 5

WBI50800

MG5G****

MG5B****

MG5R****

Point 4

WBI40680

MG4G****

MG4B****

MG4R****

Point 3

WBI30480

MG3G****

MG3B****

MG3R****

Point 2

WBI20312

MG2G****

MG2B****

MG2R****

Point 1

WBI10168

MG1G****

MG1B****

MG1R****

Specifications V1.4".

1) Make the following settings for the set.

2) Connect the white balance adjustment tool to the set.

[Adjustment prcedure]

1) Using the remote controller,transmit the "monitor adjustment process" code.

2) Set the 6

3) Set the 5

4)

5)

6)

7)

8) With the MSET0003 command, write the adjustment values and turn off the AC

* Initial R, G and B settings at point 6: Gradation level set at 928

* Initial R and B settings at points 1 thru 5:Correct the setting same remainder of

RGB setting at each point (This is because the adjustment is made to achieve the

same remainder of RGB setting/4 at each point.

[Adjustment value]

As per the "standard set" submitted by Engineering Department

[LC-20D42U] Teaching Set.

[Adjustment reference] Instrument:[Minolta CA-210] Engineering instrument

Point 6 928 X=0.272 ±0.0012 ±0.0020

Point 5 800 X=0.272 ±0.0012 ±0.0020

Point 4 680 X=0.272 ±0.0012 ±0.0020

Point 3 480 X=0.272 ±0.0012 ±0.0020

Point 2 312 X=0.272 ±0.0020 ±0.0030

Point 1 168 X=0.272 ±0.0035 ±0.0045

Note Set conditions for inspection

AV MODE: [DYNAMIC]

Backlight: +16

Aging time: Min. 60 minutes

th

turn down the R,G and B settings to their reference levels.

Correct the G setting (800 x 6th point G setting /928) (rounded off), and make the R

and B settings to their reference levels.

Set the 4

Correct the G setting (680 x 6th point G setting /928) (rounded off), and make the R

and B settings to their reference levels.

Set the 3rd point to the specified gradation level.

Correct the G setting (480 x 6th point G setting /928) (rounded off), and make the R

and B settings to their reference levels.

Set the 2nd point to the specified gradation level.

Correct the G setting (312 x 6th point G setting /928) (rounded off), and make the R

and B settings to their reference levels.

Set the 1st point to the specified gradation level.

Correct the G setting (168 x 6th point G setting /928) (rounded off), and make the R

and B settings to their reference levels.

power.

point to the specified gradation level,With the strongest color being fixed, ,

th

point to the specified gradation level.

th

point to the specified gradation level.

Level Reference Adj. spec Ins. spec

Adjustment procedure

y=0.277

y=0.2777

y=0.277

y=0.277

y=0.277

y=0.277

AV MODE: [DYNAMIC] (Reset)

Monochro: ON

Aging Time: Min. 60 minutes

Writing

MSET0003

20

Page 21

4. Key writing

1. EDID writing (Main PWB :QPWBXE001WJZZ,Analog RGB/GDMI input terminal)

Adjustment item

1 Analog RGB

EDID writing

HDMI EDID

2

Writing

Adjustment conditions

File Version checking 1) Using the checker,write the EDID data for HDMI to

IC1505 that is mounted on the main PWB.

TL1514: I2C CLODK, TL1515: 12C DATA

TL1516: 5V, TL1517: GND

TL1524: write protection (H:write enable,Low: write

protection)

2) In the analog RGB inspection,use a DDC-compatible

device. If the EDID has been written,the RGB input

does not function normally.

Inspection mode

File version checking

1)

Using the checker,write the analog HDMI EDID data to

IC1501 and IC1502 that are mounted on the main PWB.

TL15108/1510: I2C CLODK, TL1509/1511: 12C DATA

TL1512/1513: 5V, TL1519/1518: GND

TL1534/1535: write protection (H:WP,Low: write enable)

2) Write the data before the HDMI inspection with the

checker.

In the HDMI inspection, use a DDC-compatible device.If

the EDID has been written,the HDMI input does not

function normally.

LC-20D42U

Adjustment procedure

21

Page 22

LC-20D42U

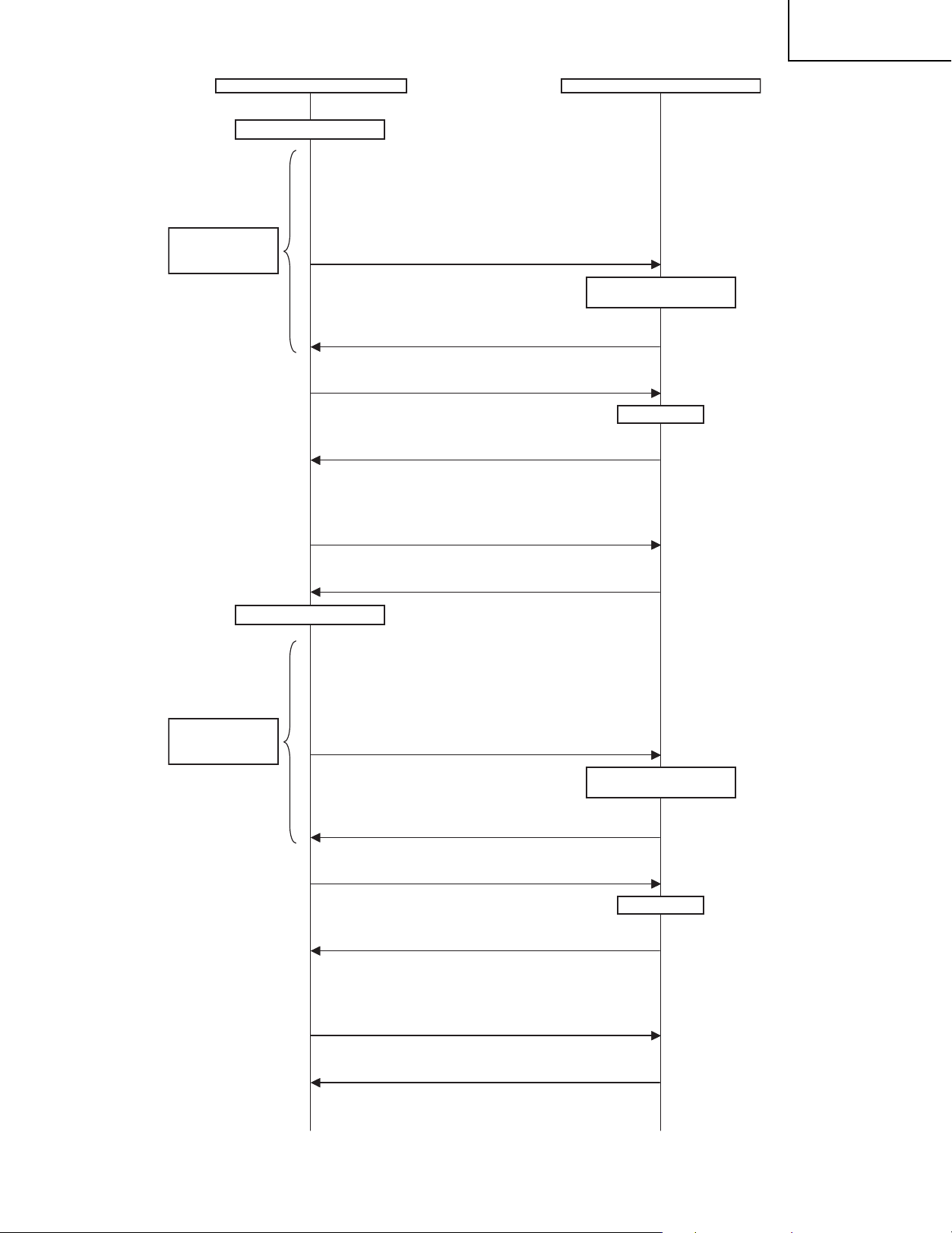

Repeat until RGB

become the target

values.

PC Set

Set the light level to MAX with the light control command

(SBSL0016 for 45).

SBSL0016

Setting is complete.

OK

Multi point adjustment mode setting

MSET0001

Multi point adjustment mode is set.

OK

Initialize adjustment values.

MSET0004

Initialization is done.

OK

Adjustment gradation setting (point 6 = 232 gradation adjustment*)

LEV60232

Pattern display

Adjustment values are set.

OK

Adjust RGB to the target xy values.

MG6RXXXX

MG6GXXXX

MG6BXXXX

* XXXX indicates the adjusted values between 0000 and 1023

(4 digit decimal number with zero fill).

* In order to adjust by reducing the value, set the strongest color

as the fixed color.

* The default adjustment value of RGB is the parameter value of

the LEV6 command multiplied by 2.

The adjustment value is

reflected in the image.

Adjustment values are set.

OK

Adjustment gradation setting (point 5 = 200 gradation adjustment*)

LEV50200

Pattern display

Adjustment values are set.

OK

Correction of G value

MG5G0800

When G is changed at gradation 6, calculate the ratio of the

change and set the following value to XXXX: (the value set with

LEV5) x 2 x (the ratio).

Adjustment values are set.

OK

22

Page 23

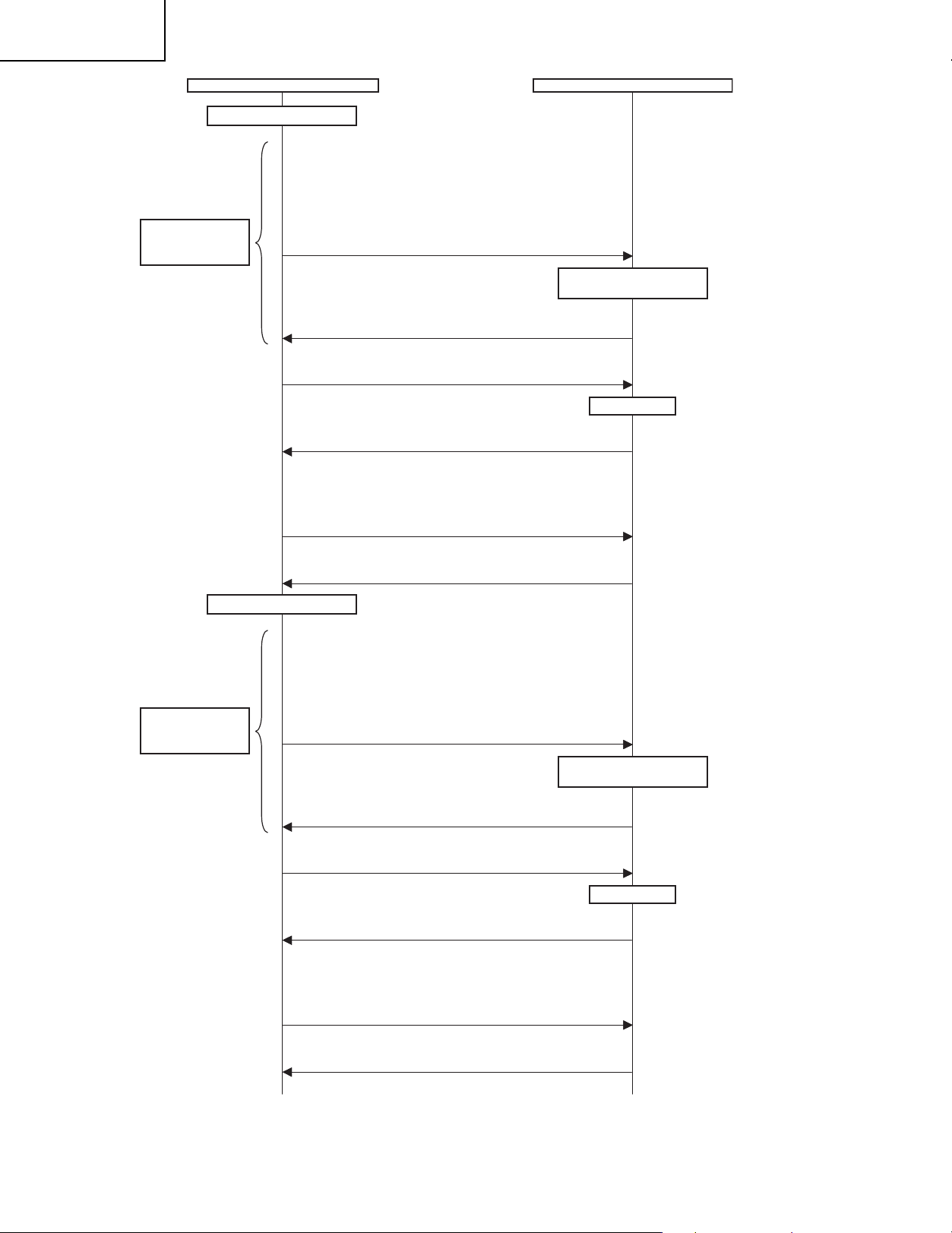

Start measurement

Repeat until RGB

become the target

values.

LC-20D42U

PC Set

Adjust RB to the target xy values.

MG5RXXXX

MG5BXXXX

* XXXX indicates the adjusted values between 0000 and 1023

(4 digit decimal number with zero fill).

* G is fixed.

* The default adjustment value of RGB is the parameter value

of the LEV5 command multiplied by 2.

The adjustment value is

reflected in the image.

Adjustment values are set.

OK

Adjustment gradation setting (point 4 = 170 gradation adjustment*)

LEV40170

Pattern display

Adjustment values are set.

OK

Correction of G value

MG4G0680

When G is changed at gradation 6, calculate the ratio of the

change and set the following value to XXXX: (the value set with

LEV4) x 2 x (the ratio).

Start measurement

Repeat until RGB

become the target

values.

Adjustment values are set.

OK

Adjust RB to the target xy values.

MG4RXXXX

MG4BXXXX

* XXXX indicates the adjusted values between 0000 and 1023

(4 digit decimal number with zero fill).

* G is fixed.

* The default adjustment value of RGB is the parameter value of

the LEV4 command multiplied by 2.

The adjustment value is

reflected in the image.

Adjustment values are set.

OK

Adjustment gradation setting (point 3 = 120 gradation adjustment*)

LEV30120

Pattern display

Adjustment values are set.

OK

Correction of G value

MG3G0480

When G is changed at gradation 6, calculate the ratio of the

change and set the following value to XXXX: (the value set with

LEV3) x 2 x (the ratio).

Adjustment values are set.

OK

23

Page 24

LC-20D42U

Start measurement

Repeat until RGB

become the target

values.

PC Set

Adjust RB to the target xy values.

MG3RXXXX

MG3BXXXX

* XXXX indicates the adjusted values between 0000 and 1023

(4 digit decimal number with zero fill).

* G is fixed.

* The default adjustment value of RGB is the parameter value of

the LEV3 command multiplied by 2.

The adjustment value is

reflected in the image.

Adjustment values are set.

OK

Adjustment gradation setting (point 2 = 78 gradation adjustment*)

LEV20078

Pattern display

Adjustment values are set.

OK

Correction of G value

MG2G0312

When G is changed at gradation 6, calculate the ratio of the

change and set the following value to XXXX: (the value set with

LEV2) x 2 x (the ratio).

Start measurement

Repeat until RGB

become the target

values.

Adjustment values are set.

OK

Adjust RB to the target xy values.

MG2RXXXX

MG2BXXXX

* XXXX indicates the adjusted values between 0000 and 1023

(4 digit decimal number with zero fill).

* G is fixed.

* The default adjustment value of RGB is the parameter value of

the LEV2 command multiplied by 2.

The adjustment value is

reflected in the image.

Adjustment values are set.

OK

Adjustment gradation setting (point 1 = 42 gradation adjustment*)

LEV10042

Pattern display

Adjustment values are set.

OK

Correction of G value

MG1G0168

When G is changed at gradation 6, calculate the ratio of the

change and set the following value to XXXX: (the value set with

LEV1) x 2 x (the ratio).

24

Adjustment values are set.

OK

Page 25

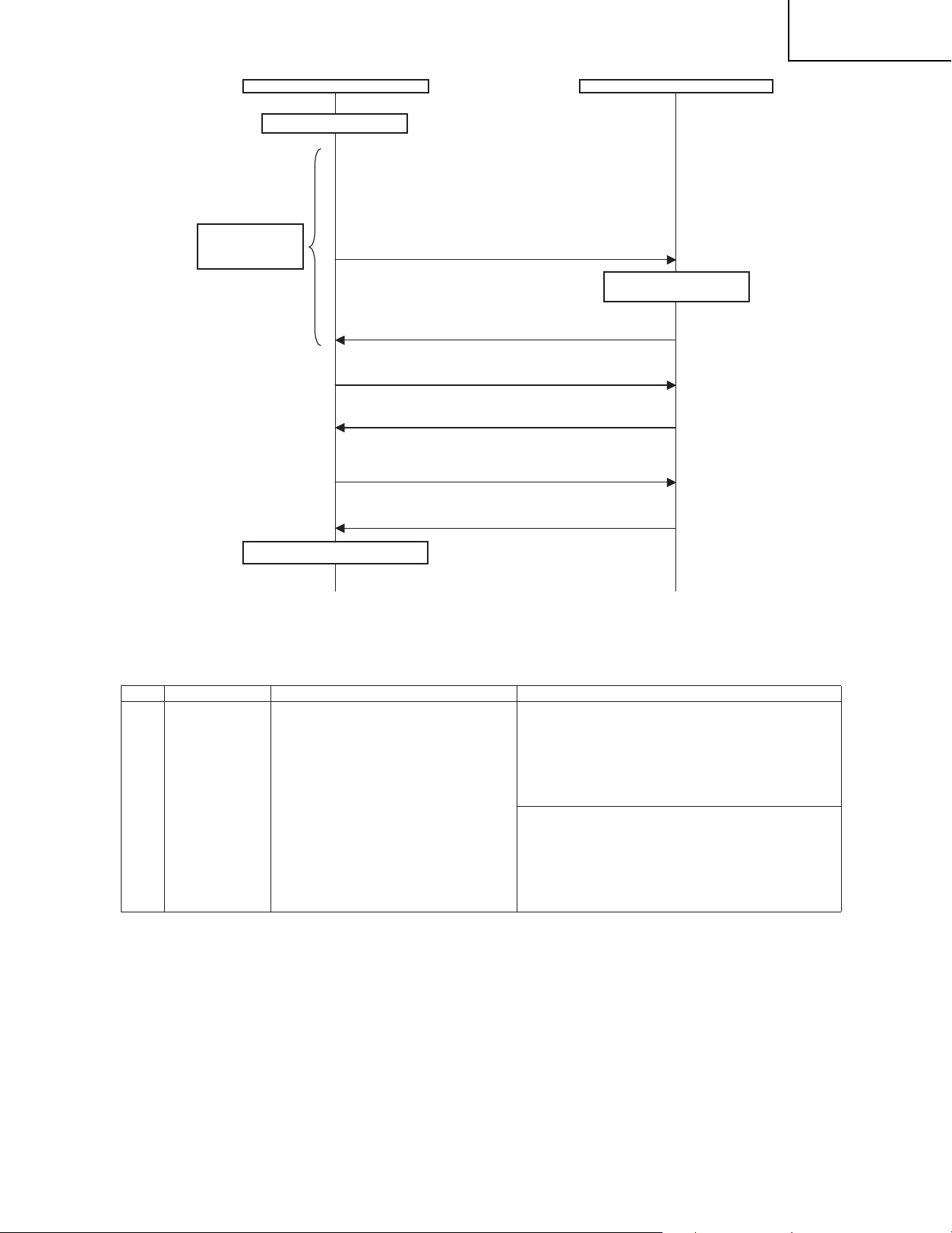

g

Start measurement

Repeat until RGB

become the target

values.

LC-20D42U

PC Set

Adjust RB to the target xy values.

MG1RXXXX

MG1BXXXX

*XXXX indicates the adjusted values between 0000 and 1023

(4 digit decimal number with zero fill).

* G is Fixed.

* The default adjustment value of RGB is the parameter value of

the LEV1 command multiplied by 2.

The adjustment value is

reflected in the image.

Adjustment values are set.

OK

Writing of adjusted values

MSET0003

Writing is complete.

OK

Deleting adjustment patterns

MSET0000

Deletion is complete.

OK

Completion of adjustment

5. Factory settings

After making the factory settings.pull off the AC cord.

NOTE: Do not turn on the power once the factory settings have been made. Otherwise the factory setting must be made again.

Adjustment item

1 Factory settings Finally pull off the AC cord. • Move the cursor to the [INDUSTRY INIT] line. Using the

Adjustment conditions

[VOL+/-] keys. set this item ON and press the [ENT] key.

The version confirm window appears on the green

screen. When [SUCCESS] appears at the top, the factory settings are complete.(If an error occurs.[ERROR]

appears on the red screen.)

• Finally turn off AC power.

The following settings are returned to the factory ones.

1) User settings

2) Channel data (broadcast frequencies,etc.)

3) Password setting

4) Operation time

5) Automatic installation flag

6) V-CHIP block setting

Adjustment procedure

6. Software version

The software version will be reported at the Conversion Judgment Meeting. Possible modifications that will follow will be reported using the Modifications Report.

* Main microprocessor

* Monitor microprocessor

* EDID data (HDMI/analo

RGB)

25

Page 26

LC-20D42U

PUBLIC MODE SETTING PROCEDURE

1. How to start Public Mode

• There are the following two ways to get the public mode setup screen displayed.

1 In the adjustment process mode, turn on "HOTEL MODE". Also press the "CH (ù)" and "VOL (+)" keys on

the set at once and turn on the power.

2 1) Press the "INPUT" and "VOL (+)" keys on the set at once and turn on the power.

2) Get the password input screen displayed.

Procedure

• The input starts with the leftmost digit.

• Use the numeric keys [1] thru [9] and [0] key on the remote controller.

The other keys are not acceptable.

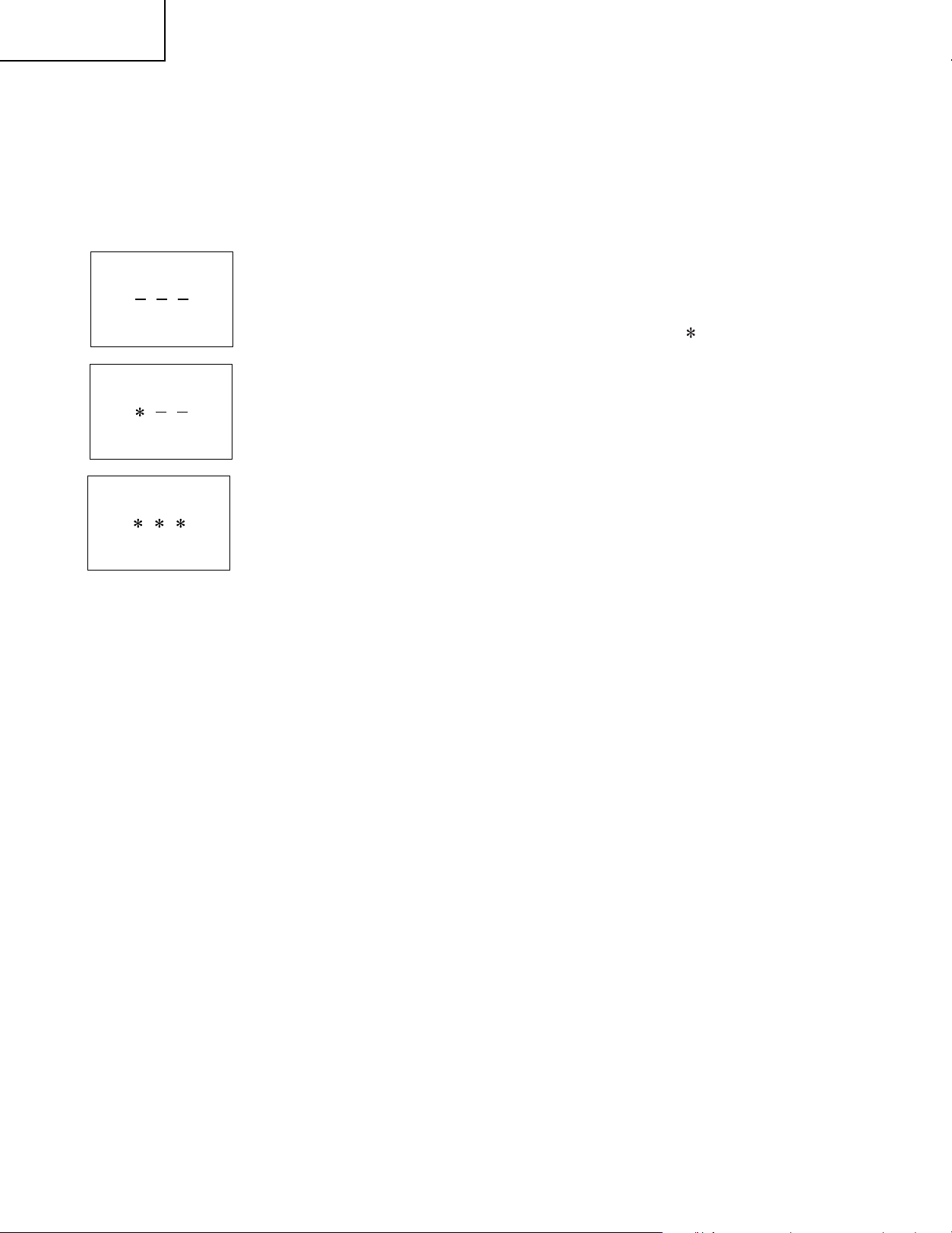

• With a numeric-key input, "–" will change to " ". The input position

will move one digit to the right.

• With all the 3 digits entered, the password will be verified.

3) The 3-digit password is now verified.

The password [0] [2] [7] provides for the public mode screen. (This screen comes on with whatever

adjustment process settings.)

With any other passwords, the screen changes to the normal mode.

26

Page 27

LC-20D42U

2. How to exit Public Mode

There are the following ways to quit the public mode setup screen.

• Tu rn off "HOTEL MODE" in the adjustment process mode. (✩) ← This way alone is not for quitting the setup

screen, but for quitting the mode itself.

• Tu rn off the power with the "POWER" key. (★)

• Select "EXECUTE". (★)

★ ... "HOTEL MODE" stays on in the adjustment process mode.

✩ ... The settings will be back to the factory ones.

3. Public Mode Setting Values

• With the factory settings made, the public mode settings get initialized. (The adjustment process remains intact.)

4. Public Mode Menu

The guidance is not displayed onscreen.

Setup procedure

• To move the cursor up and down, use the "cursor UP/DOWN" key (remote controller) and "CH (ù)/(Ù)" key

(remote controller and set).

• To change the settings, use the "cursor RIGHT/LEFT" key (remote controller) and "VOL (+)/(–)" key (remote

controller and set).

• To save new settings, keep the cursor at "EXECUTE" and use the "ENTER" key (remote controller) .

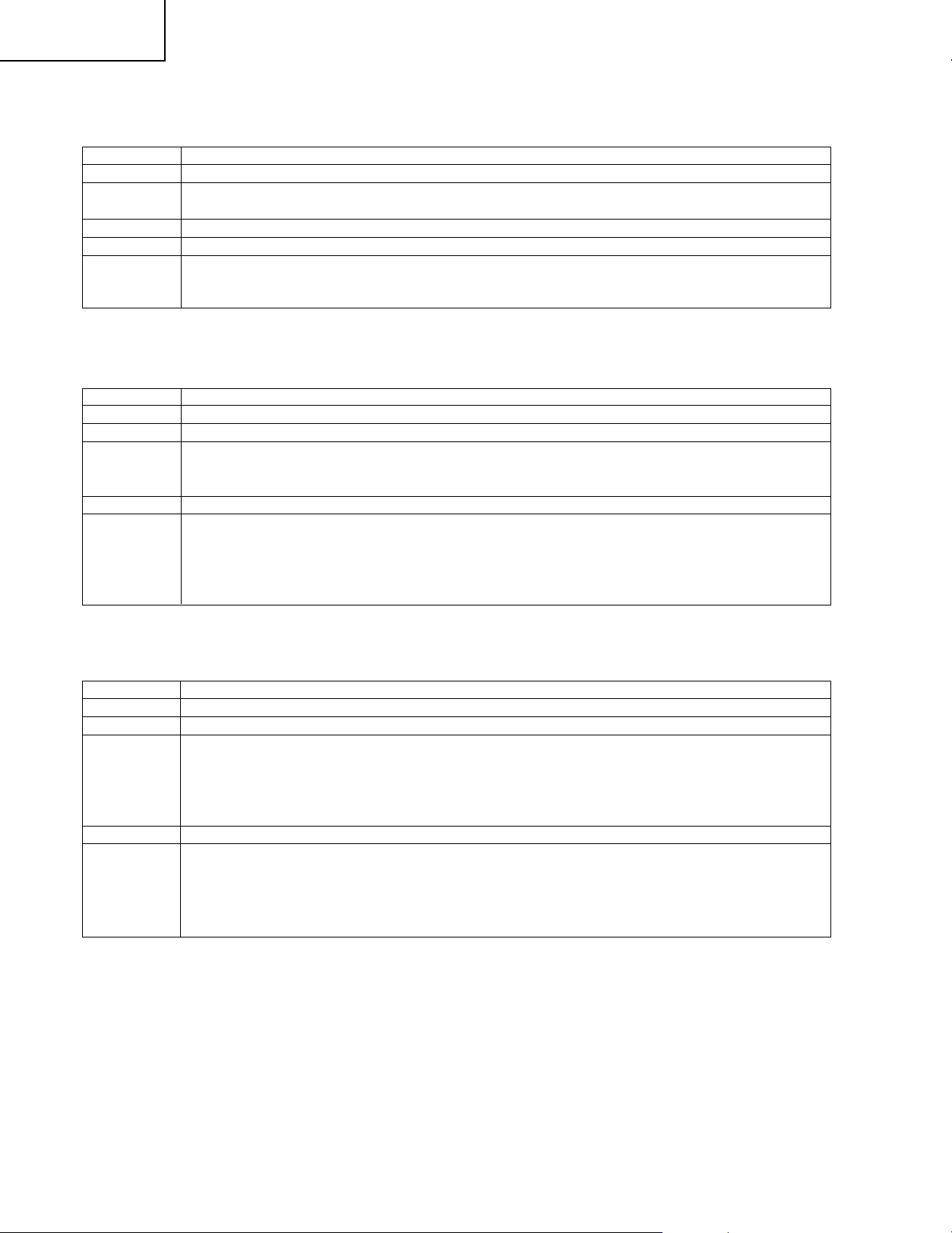

Public mode

Power on fixed [Variable ]

Maximum volume [ 60 ]

Volume fixed [Variable ]

Volume fixed level [ 60 ]

RC button [Respond ]

Panel button [Respond ]

Menu button [Respond ]

On screen display [Yes ]

Input mode start [Normal ]

Input mode fixed [Variable ]

Reset

EXECUTE

27

Page 28

LC-20D42U

5. On Setting Items

* "EZ-SETUP" discussed below indicates "EZ-SETUP after the first power-on".

(1) POWER ON FIXED

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

(2) MAXIMUM VOLUME

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Selection between

"Var iable" and "Fixed" (loop provided)

Variable

In

"Fixed" setting, the power-off by the power key of the unit is invalidated and the image is kept being

received. The power can be turned off by stopping the power supply from AC.

Refer to the

"Power-On Fixed" sheet.

None

Adjustment from 0 to 60 (no loop)

60

Sound volume can not be adjusted higher than the preset value.

•

When the sound volume is set lower than 59, only figures are displayed and the sound volume bar is not

displayed.

•

The maximum sound volume for ON-timer (Wake up timer) is limited also to the preset value.

None

•

In line output (sound volume variable), the sound volume can be adjusted from 0 to 60 irrespective of preadjusted value.

•

When the sound volume is set higher than the MAX setting by the adjusting process, the sound volume

control operation is prohibited for turn-up and the sound volume should be turned down to MAX in this

state.

(3) VOLUME FIXED

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Selection between "Variable" and "Fixed" (loop provided)

Variable

Sound volume is fixed and made invariable.

•

•

None

•

•

•

The sound volume for the ON-timer (Wake up timer) is fixed also without display of menu. Besides, the

setting is made impossible. (Basically, the menu is not displayed.)

The following keys become invalid:

•

Sound volume Up/Down (VOL +/-) [for both remote control and the unit]

•

Mute (MUTE)

In line output (sound volume variable), the sound volume can be adjusted from 0 to 60 irrespective of preadjusted value.

As for sound volume fixing and sound volume MAX level, the sound volume fixing has priority.

Once the sound volume has been changed by adjustment process, it should be set back to the sound

volume preset by sound volume fixing level when the adjustment process ends .

28

Page 29

(4) VOLUME FIXED LEVEL

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Adjustment from 1 to 60 (no loop)

60

The sound volume to be fixed by

None

None

Setting is valid only when

(5) R/C BUTTON

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Selection between

Respond

Keys acceptable by remote control are limited or reception of keys can be prohibited.

In

"No respond" setting, all the keys (including the power key) are not accepted.

•

Adjustment process, factory setting, inspection process and hotel only keys are valid irrespective of setting.

•

All the keys can be used in adjustment process, inspection mode and hotel menu irrespective of setting.

•

All the keys can be used also in the initial EZ-Setup after power-ON irrespective of setting.

(6) PANEL BUTTON

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Selection between

Respond

All the operations by keys (except the power key) of the unit can be invalidated.

•

Inspection mode and hotel menu mode can be started irrespective of setting.

•

All the keys can be used in adjustment process, inspection mode and hotel menu irrespective of setting.

•

In U.S.A model, all the keys can be used also in the initial EZ-Setup after power-ON irrespective of

setting.

LC-20D42U

"Volume fixed" is determined.

"Volume fixed" is selected for "fixed".

"Respond" and "No respond" (loop provide)

"Respond" and "No respond" (loop provide)

(7) MENU BUTTON

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Selection between "Respond" and "No respond" (loop provide)

Respond

In

unit are invalidated.

•

•

•

"No respond" setting, the menu operation by the menu key of the remote control and the menu key of the

Inspection mode and hotel menu mode can be started irrespective of setting.

All the keys can be used in adjustment process, inspection mode and hotel menu irrespective of setting.

All the keys can be used also in the initial EZ-Setup after power-ON irrespective of setting.

29

Page 30

LC-20D42U

(8) ON SCREEN DISPLAY

Selection

Default

Explanation

Limit in Setting

Others

Exception

Remarks

Selection between "Ye s " , "NO" (loop provide)

Ye s

The following OSD displays are made ineffective.

Displays of menu group, channel call, sound volume bar and direct key call

•

ON-timer (Wake-up timer) is cleared and set to "OFF".

•

Set time of the OFF-timer (SLEEP TIMER) is cleared.

•

Setting of the no-signal power-OFF (AUTO POWER OFF) is cleared to "OFF".

•

Setting of the no-operation power-OFF is cleared to "OFF".

•

Keys falling under any of the following items become invalid.

1Appearance of screen changes and the sound changes.

2Personal functions which are hard to restore.

Screen display, menu, OFF-timer, ON-timer, AV MODE, screen size switching, clock setting, treble

emphasis, AUDIO ONLY, sound changeover, LANGUAGE, CLOSED CAPTION

•

Simple input switching is generated. Those which are restored soon after leaving as they are and may be

requested for change by customer are not prohibited.

Brightness sensor (BACKLIGHT) .

•

Such a caution which is displayed independently is displayed as it is.

Non-responding signal caution.

•

When CC has already been ON, CLOSED CAPTION is displayed.

(9) INPUT MODE START

Selection

Default

Explanation

About options

Limit in Setting

Exception

Remarks

Selection between

Normal

In power-ON, the input source to be started or channel can be set.

(In standard mode, the operation follows the last memory.)

•

All the input sources in the model are made selectable.

•

When the input/output switchable input source is selected and the input source is set to output, the setting

of input/output switching is changed to input at the execution of hotel menu. In addition, the input/output

switching by menu is prohibited.

•

In TV mode, the channel to be set follows the last memory and the content of the last memory is included

in the notation by options. Ex.) TV (CH2), TV (CH4) etc.

•

The display of channel setting menu and the channel setting operation are prohibited.

None

•

In setting at "Normal", the setting of "Input mode fixed" is changed to "Variable" and selection should be

prohibited.

(10) INPUT MODE FIXED

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Selection between

– (Variable)

The input mode is fixed at the input source or the channel set at the

sources and channels can be made non-selectable.

•

With the execution of hotel mode, the input source is forced to change to that set by "Input mode start"

and the channel switching and input switching are prohibited thereafter.

•

ON-timer's (Wake-up timer) channel items are not displayed or the operation is prohibited. (Basically, they

are not displayed.)

•

The following keys are invalidated.

CH '", direct tuning button, FLASHBACK, input

~However, the keys (input switching and CH '" keys) of the unit for menu operation remain valid.

None

•

In the following case, setting is cancelled and mode is changed to "Var iable".

1When the setting of

"Normal" , "Air/Cable (CH~)", "INPUT 1/2/3","HDMI","HDMI2","DVI" (loop provide)

"Var iable" and "Fixed" (loop provide)

"Input mode start" in 9 and other input

"Input mode start" is set to NORMAL.

30

Page 31

TROUBLESHOOTING TABLE

No power supply (Front LED does not light up) and no power-up even is turned on (Front LED light up to blue)

LC-20D42U

Is the AC cord connected?

Yes

Are the harness and Cable connected

properly?

Yes

Are F1 normal?

Yes

Is the voltage of C4 approx. 160V?

Yes

Are UR12V supplied?

Yes

No

Connect the AC cord and turn on the power.

No

Connect the hamess and Cable properly.

No

If the fuse is blown when turning on the power after replacing F1.replace Q1 and

PC1.

No

Check if L1,TH1 and BD1 are normal.

No

Does AC-CTRL (pin10 of CN1) become High (approx. 3.3V)?

Yes

Check the rectifier circuit of UR12V

Is the unit set to STANDBY MODE?

Is the main unit normal?

No

Is 24V supplied?

Yes

Turn on the power again,and check if

the unit works normally.

Remarks

State of the set

STDBY

MODE1

MODE2

Power ON

PS_ON

(CN1 )

High

Low

High

10

UR12V

(CN1 )

No

Do the primary side and secondary side of T1/T1A oscillate normally?

Are D20 out of order?

UR24V

1

(CN2 )

12V

--

12V

1

24V

24V

Yes

No

Are there defective parts on the primary side?Is the output on the Secondary side short-circuited?

31

Page 32

LC-20D42U

TROUBLESHOOTING TABLE (Continued)

No audio output during UHF/VHF reception

Is SIF output from the tuner (TU1101_Pin15) normal?

Yes

Is input signal fed to pin21 (SOUNDIF 1)of IC1401(SIF

Demodulator) normal?

Yes

Are audio signals from pins 29 and 30 (SC2_OUTL/R) of

IC1401 to pins 51 and 52 of IC1404 (CODEC) normal?

Yes

Are audio outputs (A-OUT_L/R) of pins 38 and 39 of

IC1404 normal?

Yes

Is audio input from pins 38 and 39 of IC1404 to pin 3 and 5

of IC2701 (STEREO_AMP) normal?

Yes

Is audio output from IC2701 normal?

Yes

Check the connector (P2703) of AV_UNIT and around the

speakers.

No

Check the tuner and peripheral circuits.

No

Check the filter circuits (Q1102-3) and peripheral

circuits

No

Check between pins 29 and 30 (SC2_OUTL/R) of

IC1401 and pins 51 and 52 of IC1404(CODEC)

Are the DSP_LRCK,DSP_BCKIN,DSP_SDIN1,

No

DSP_MCLK,DSP_SDOUT1,DSP_SDOUT2 signals

sent from IC1404 to IC1407(DSP) normally?

Yes

Check IC1404 and peripheral circuits.

No

Check the circuits between pins 38 and 39 of

IC1404 and pins 3 and 5 of IC2701. (MUTE

cercuits:Q1307,Q1314,Q1313)

No

Check IC2701 and peripheral circuits

No monitor audio output

Is monitor audio output set to "Variable"?

No

Are audio output pins 40 and 41 of IC1404 (CODEC)

normal?

Yes

Are audio output pins 7 and 1 of IC1408 (Buffer_AMP)

normal?

Yes

Check between IC1408 and MONITOR OUTPUT terminal

(J501,J502).

Yes

Reset monitor audio output to "Fixed".

No

Check IC1404 and peripheral circuits.

No

Check IC1408 and peripheral circuits.

32

Page 33

TROUBLESHOOTING TABLE (Continued)

No audio output from external input

<<HDMI>>[INPUT-4/INPUT5 (Digital audio mode)]

Is digital audio signal (DTV_SPDIF) fed from pin E12 of IC8101 to pin 4 of IC1404?

<<HDMI>>[INPUT-5(Analog audio mode)]

Is L-ch audio signal fed from pin 3 of input terminal J1501 to pin 57 of IC1404?

Is R-ch audio signal fed from pin 2 of input terminal J1501 to pin 58 of IC1404?

PCIPUT<<INPUT-6>>

Is L-ch audio signal fed from pin 2 of input terminal J1502 to pin 55 of IC1404?

Is R-ch audio signal fed from pin 3 of input terminal J1502 to pin 56 of IC1404?

<<INPUT-1>>

Is L-ch audio signal fed from input terminal J505 to pin 12 of IC1405?

Is R-ch audio signal fed from input terminal J505 to pin 1 of IC1405?

<<INPUT-2>>

Is L-ch audio signal fed from input terminal J505 to pin 15 of IC1405?

Is R-ch audio signal fed from input terminal J505 to pin 2 of IC1405?

Is L-ch audio signal fed from pin13 of IC1405 to pin 53 of IC1404?

Is R-ch audio signal fed from pin3 of IC1405 to pin 54 of IC1404?

Yes

No audio output during digital broadcasting reception

<<INPUT-3>>

Is L-ch audio signal fed from input terminal J509 to pin 4 of IC1405?

Is R-ch audio signal fed from input terminal J509 to pin 5 of IC1405?

LC-20D42U

Are the 12S signals DAKCK,SCLK,LRCK,and DATAOUT

sect from pins B22,F13,E13 and F12 of IC8101 normally?

Yes

Are input signals of pins 24 (DAKCK),11(SCLK),10(LRCK),

32(DATA) of IC1404 normal?

Yes

Are audio signals from pins 29 and 30 (SC2_OUTL/R) of IC1404 to

pin 27 and 25 of IC1407 (DSP) normal?

Yes

Are audio outputs (A-OUT_L/R) of pins 38 and 39 of IC1404 normal?

Yes

Is audio input from pins 38 and 39 of IC1404 to pins 3 and 5 of

IC2701(STEREO_AMP) normal?

Yes

Is audiio output from IC2701 normal?

Yes

No

Check around IC8101 BCM3551.

No

Check the circuits between pins B22,F13,E13 and F12 of IC8101

and pins 24,11,10 and 32 of IC1404.

No

Check between pins 29 and 30 (SC2_OUTL/R) of IC1404 and pins

27 and 25 of IC1407 (DSP).

No

Are the LRCK,BICK,SDTO and SDTI signals sent from IC1404 to

IC1407 (DSP) normally?

Yes

Check IC1403 and peripheral circuits.

No

Check the Circuits between pins 38 and 39 of IC1404 and pins 3 and

5 of IC2701.(MUTE circuits:Q1307,Q1313,Q1314)

No

Check IC2701 and peripheral circuits.

Check the connector (P2703) of AV_UNIT and around the speakers

33

Page 34

LC-20D42U

TROUBLESHOOTING TABLE (Continued)

<Component video signal input> No video output (1)

No video output from extermal input <<INPUT-1>>

Is INPUT-1 selected on the input switching menu screen?

Yes

Is video signal fed to pin 21 of IC501 (AV SWITCH)?

Yes

Is video signal sent to pin 60 of IC501?

Yes

Is video signal fed to pin K25 of IC8101 (Broadcom) via

L.P.F. composed of Q2202 and Q2210?

Yes

Are digital video (LVDS) signals sent from pins 37-42 and

45-48 of IC2602?

Are digital video (COMOS) signal sent from IC8101

(DVODATA 0-23,DVOCLKO,DVODE,DVOHSYNC,

DVOVSYNC)?

Yes

Select INPUT-1 and the input signal on the input switching

menu screen.

No

When INPUT-1 cannot be selected since the characters

INPUT-1 on the menu screen are gray.

Yes

Is the video signal detection function normal?

Check between J507 and pin 38 of IC501.

No

Check between J507 and pin 21 of IC501.

No

Check IC501 (AV SWITCH) and peripheral circuits.

No

Check between IC501 and IC3301.(Q2202,Q2210,etc.)

No

Check IC2602 and peripheral circuits.

No

Check IC8101 and peripheral circuits.

Check LCD_CONTROL PWB.

34

Page 35

TROUBLESHOOTING TABLE (Continued)

<Component video signal/S-video signal input> No video output (2)

LC-20D42U

No video output from extermal input <<INPUT-3>>

Yes

Is INPUT-2 selected on the input switching menu screen?

Yes

Is video signal fed to pin 21 of IC507 (AV SWITCH)?

<Composite video signal input>

Is video signal fed to pin 3 of IC509?

<S-video signal input>

Are Y and C signals fed to pins 5 and 7 of IC501

respectively?

Yes

<Composite video signal input>

Is video signal sent to pin 60 of IC501?

<S-video signal input>

Are Y and C signals sent to pins 60 and 59 of IC501

respectively?

Yes

No

Select INPUT-3 and the input signal on the input switching

menu screen.

No

When INPUT-3 cannot be selected since the characters

INPUT-2 on the menu.

Yes

Is the video signal detection function normal?Check

between J509 and pin 42of IC501.

Is the S-video signal detection function normal?Check

between J509 and pin 2 of IC501.

No

Check between J509 and pin 3 of IC501.

Check between J509 and pin 5 and 7 of IC501.

Check IC501 (AV SWITCH) and peripheral circuits.(Q501,

No

Q502,Q503,Q504,etc.)

Check between IC501.(Q501,Q502,Q503,Q504,etc.)

<Composite video signal input>

Is video signal fed to pin K25 of IC8101 (Broadcom) via

L.P.F. composed of Q2202 and Q2210?

<S-video signal input>

Are Y and C signals fed to pins K25 and L24 of IC8101

(Broadcom) via L.P.F. composed of Q2202 and Q2210

and via L.P.F. composed of Q2203 and Q2211

respectively?

Yes

Are digital video (LVDS) signals sent from pins 37-42 and

45-48 of IC2602?

Are digital video (COMOS) signal sent from IC8101

(DVODATA 0-23,DVOCLKO,DVODE,DVOHSYNC,

DVOVSYNC)?

Yes

Check LCD_CONTROL PWB.

Check between SC1101 and IC3301.(Q2202,Q2210,etc.)/

No

(Q2203,Q2211,etc.)

No

Check IC2602 and peripheral circuits.

No

Check IC8101 and peripheral circuits.

35

Page 36

LC-20D42U

TROUBLESHOOTING TABLE (Continued)

No video output during ANALOG broadcasting reception

Is video signal sent to output terminal pin 13 of tuner

(TU1101)?

Yes

Is video signal fed to pin 7 of IC1103 (LEVEL ADJ)?

Yes

Is video signal fed to pin R26 of IC8101 (Broadcom) via L.P.F. composed of Q2204 and Q2208?

Yes

Are digital video (LVDS) signals sent from pins 37-42 and

45-48 of IC2602?

Are digital video (COMOS) signal sent from IC8101

(DVODATA 0-23,DVOCLKO,DVODE,DVOHSYNC,

DVOVSYNC)?

Yes

Check LCD_CONTROL PWB.

No

Check or repiace the tuner's peripheral circuits.

No

Is control signal for level adjustment fed from pin 1 of

IC1104 to pin 6 of IC1103?

No

Check or replace IC1104 (CONTROL) and peripheral

circuits.

No

Check between IC1103 and IC3301.(Q2204,Q2208,etc.)

No

Check IC2602 and peripheral circuits.

No

Check IC8101 and peripheral circuits.

36

Page 37

TROUBLESHOOTING TABLE (Continued)

<Component video signal input> No video output (3)

No video output from external input<<INPUT-1>>

Is INPUT-1 selected on the input switching menu screen?

Yes

No

Select INPUT-1 and the input signal on the input switching

menu screen.

When INPUT-1 cannot be selected since the characters

INPUT-1 on the menu screen are gray.

Yes

Is the component video signal detection function normal?

Check between 6 pin of J507 and pin 38 of IC501.

LC-20D42U

Are component video signals fed to pins 21,23 and 25

(Y,Pb and Pr) of IC501 (AV SWITCH)?

Yes

Are Y,Pb and Pr signals sent to pins 60,59 and 58 of

IC501 respectively?

Yes

Are component video signals sent to R574,R580,R586 Via

the Net of Q501-Q506?

Yes

Are Y,Pb and Pr signals fed to pins L26,J25 and J26 of

IC8101 (Broadcom) respectively? Via LPF composed of

Q2202,Q2203,Q2206,Q2210,Q2211 and Q2212.

Yes

Are digital video (LVDS) signals sent from pins 37-42 and

45-48 of IC2602?

Are digital video (COMOS) signal sent from IC8101

(DVODATA 0-23,DVOCLKO,DVODE,DVOHSYHC,

DVOVSYNC)?

Yes

Check LCD_CONTROL PWB.

No

Check between J507 and each input pin of IC501.

No

Check IC501 and perpheral circuits.

No

Check between IC501 and SC501. (Q501-Q506,etc.)

No

Check IC8801.(Q2210,Q2211,Q2212,etc.)

No

Check IC2602 and peripheral circuits.

Check IC8101 and peripheral circuits.

37

Page 38

LC-20D42U

TROUBLESHOOTING TABLE (Continued)

No video output from HDMI input (INPUT4)

Are signals fed from HDMI (SC1501) connector to input

terminals H_RX0

74),H_RX2

of IC1507 (TMDS_SW)?

Are signals fed from IC1507 (TMDS_SW) to input

terminals H_RX0

and B18),H_RX2

C19 and D19) of IC8101 (Broadcom)?

Are digital video (LVDS) signals sent from pins 37-42 and

45-48 of IC2602?

Are digital video (COMOS) signal sent from IC8101

(DVODATA 0-23,DVOCLKO,DVODE,DVOHSYHC,

DVOVSYNC)?

Check LCD_CONTROL PWB.

±(pins 70 and 71),H_RX1±(pins 73 and

±(pins 76 and 77) and H_RXC±(pins 67 and 68)

±(pins B19 and A19),H_RX1±(pins A18

±(pins D18 and C18) and H_RXC±(pins

Yes

Yes

Is IC1501(E2PROM) accessed with 12C when connectiong

No

HDMI device and is DDC_12C_CLOCK/DATA data read

out?

YesYes

Check IC1501 and peripheral circuits.

Are cables connected securely?

Check the setting of HDMI device.

No

Check IC1507 (TMDS_SW) and peripheral circuits.

For INPUT4,pin 21 is Low and pin 22 is High.

No

Check IC2602 and peripheral circuits.

Check IC8101 and peripheral circuits.

No

When using an old HDMI transmission device,some video formats cannot be selected or no sound is heard. Since this model

conforms to the latest HDMI standard, the HDMI transmission device does not recognize the data of the latest version

correctly.It is necessary to upgrade its firmware. Download the latest firmware from the web site of each manufacturer,or

contact the customer service center of each manufacturer.

38

Page 39

TROUBLESHOOTING TABLE (Continued)

No video output from HDMI input (INPUT5)

LC-20D42U

Are signals fed from HDMI (SC1502) connector to input

terminals H_RX0

12),H_RX2

IC1507 (TMDS_SW)?

Are signals fed from IC1507 (TMDS_SW) to input

terminals H_RX0

and B18),H_RX2

C19 and D19) of IC8101?

Are digital video (LVDS) signals sent from pins 37-42 and

45-48 of IC2602?

Are digital video (COMOS) signal sent from IC8101

(DVODATA 0-23,DVOCLKO,DVODE,DVOHSYHC,

DVOVSYNC)?

Check LCD_CONTROL PWB.

±(pins 8 and 9),H_RX1±(pins 11 and

±(pins 14 and 15) and H_RXC±(pins 5 and 6) of

±(pins B19 and A19),H_RX1±(pins A18

±(pins D18 and C18) and H_RXC±(pins

Yes

Yes

Is IC1502 (E2PROM) accessed with 12C when connecting

No

HDMI device and is DDC_12C_CLOCK/DATA data read

out?

YesYes

Check IC1502 and peripheral circuits.

Are cables connected securely?

Check the setting of HDMI device.

No

Check IC1507 (TMDS_SW) and peripheral circuits.

For INPUT5,pin 21 is High.

No

Check IC2602 and peripheral circuits.

Check IC8101 and peripheral circuits.

No

When using an old HDMI transmission device,some video formats cannot be selected or no sound is heard. Since this model

conforms to the latest HDMI standard, the HDMI transmission device does not recognize the data of the latest version

correctly.It is necessary to upgrade its firmware. Download the latest firmware from the web site of each manufacturer,or

contact the customer service center of each manufacturer.

39

Page 40

LC-20D42U

No video output from PC input (INPUT6)

TROUBLESHOOTING TABLE (Continued)

DIGITAL mode

Analog mode

IS IC1505(E

and is DDC_12C_CLOCK/DATA data read out?

Check the setting of PC.

Are signals from pins 83-76,62-55,50-43,71-68.(DATA0-23,VSYNC,HSYNC,DE,CLK) of IC3304 (ADC) toB23,A23,D22,C22,

E23,A25,D23,B24,F22,A24,C23,E22,D17,F18,E18,F17,E17,C17,B17,A17,C16,D16,F16,E16 ,F23,G22,C25,C24 of IC1801?

Are digital video (LVDS) signals sent from pins 37-42 and

45-48 of IC2602?

Are digital video (COMOS) signal sent from IC8101

(DVODATA0>23,DVOCLKO,DVODE, DVOHSYHC,

DVOVSYNC)?

Check LCD_CONTROL PWB.

2

PROM) accessed 12C when connecting PC

Yes

Check IC1505 and peripheral circuits.Are cable connected securely?

Yes

Yes

No

Are signal fed from pins 1,2,3(Analog-R/G/B),and 13,14(H

Yes

Sync/V Sync) of input terminal (SC1503) to pins 11,9,6,2,3

of IC3304 (A/DC)?

Yes

Check peripheral circuits of IC3304

Check connection of IC3304 and IC8101.

No

Check IC2602 and peripheral circuits.

No

Check IC8101 and peripheral circuits.

No

No

When using an old HDMI transmission device,some video formats cannot be selected or no sound is heard. Since this model

conforms to the latest HDMI standard, the HDMI transmission device does not recognize the data of the latest version

correctly.It is necessary to upgrade its firmware. Download the latest firmware from the web site of each manufacturer,or

contact the customer service center of each manufacturer.

[FRONT-END SECTION]

Digital broadcasting cannot be received.

Yes

Are IF_OUT_P/N signal send from

pin (20) (19) of TU1101 respectively?

No

Check the TU1101.

Yes

Are signal fed to pins U25,U26 of

IC8101?

No

Check between TU1101 and

IC8101(C1104,C1141,etc.).

Yes

Check IC8101 and its peripheral circuits.

40

Page 41

TROUBLESHOOTING TABLE (Continued)

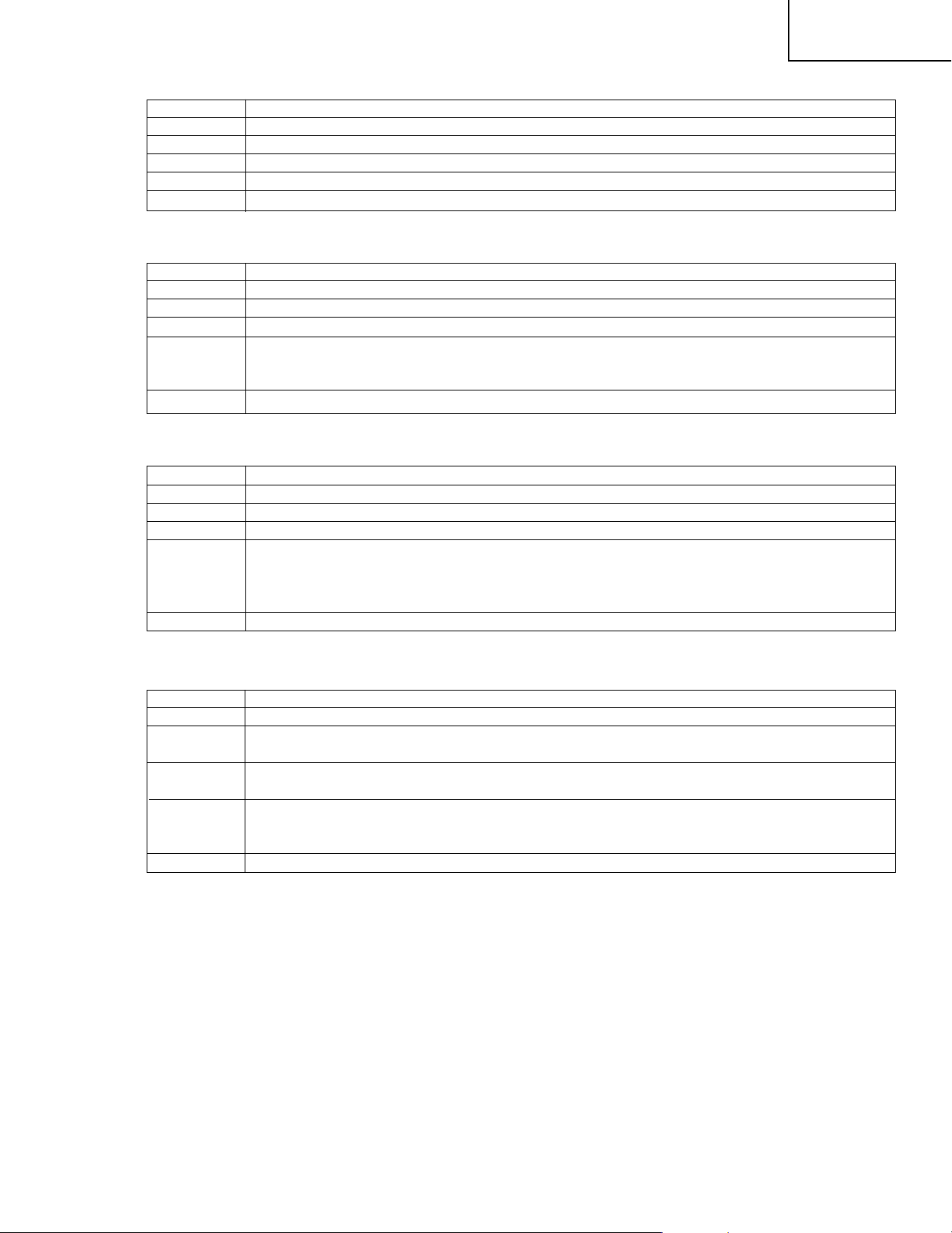

LED flashing timing chart for error notification

1) Red power LED

Remarks

Remarks

Remarks

Error type Power green LED operation (1 cycle)

Error type OPC LED operation (1 cycle)

Error type OPC LED operation (1 cycle)

Pins are monitor microprocessor pins.

H: On

L: Off

H: On

L: Off

H: On

L: Off

H: On

L: Off

H: On

L: Off

H: On

L: Off

H: On

L: Off

H: On

L: Off

H: On

L: Off

H: On

L: Off

H: On

L: Off

H: On

L: Off

Refer to "Power failure details".

Power failure

Flashes twice

communication failure

Refer to "Communication failure details".

with main CPU

Communication line failure or main CPU communication failure > Check debug statements for the main CPU.

Flashes 3 times

Vsync

failure

Flashes 4 times

Monitor temperature failure

Flashes 5 times

2) Power failure details (Power LED flashes twice and OPC LED flashes)

Pins are monitor microprocessor pins unless otherwise specified.

DET_10V failure

Flashes once

DET_D3.3V failure

Flashes twice

DET_6V failure

Flashes 3 times

Panel 5V failure

Flashes 5 times

Main failure

Flashes 7 times

3) Communication failure details (Power LED flashes 3 times and OPC LED flash

Initial communication

reception failure

Flashes once

Time-out setting reception failure

Start-up confirmation reception failure

Flashes twice

Regular communication failure

Flashes 3 times

The details are displayed in "ERROR STANDBY CAUSE" on page 1 of process A mode for the main microprocessor.

Initial communication from the main CPU is not received. (After canceling the reset, request for the monitor model No. is not received.)

Communication line failure or main CPU start-up failure

Time-out setting and start-up mode change cannot be received from the main CPU. (Start-up communication until time-out setting and

startup mode change is not received.)

Basically, communication logs are analyzed by a bus monitor or debug print logs are analyzed.

Main CPU start-up failure or monitor microprocessor's reception failure

Regular communication that is performed at 1 second intervals in the normal operation is interrupted.

Main CPU operation failure or monitor microprocessor's reception failure

Main microprocessor detection error,

DET_PNL5V (pin 58): Abnormal (L). Panel power is not applied.

If error is detected during operation, error standby is activated by polling.

EU_POW

PS_ON

PANEL_POW

D_POW

If error is detected during operation, error standby is activated by polling.

DET_6V (pin 56): Abnormal (L). D5V,A5V is not applied.

(MONITOR MAX TEMP on process A mode: Change of temperature failure AD value): Thermistor

If error is detected during operation, error standby is activated by polling.

AC_DET (pin 16): Abnormal (L), DET_10V (pin 57). Main converter A9V/UR10V is not applied.

If error is detected during operation, the power is turned on again by interrupt handling (instantaneous blackout processing).

DET_3V3 (pin 59): Abnormal (L). Main power 3.3V is not applied.

VSYNC (pin 46) failure (uninput). Video process operation failure.