Page 1

LC-13B4E

1st Edition

LC-15B4E

SERVICE MANUAL

S53A6LC-13B4E

LCD COLOUR TELEVISION

LC-13B4E

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

CONTENTS

» IMPORTANT SERVICE SAFETY PRECAUTION ........................................................................................2

» SPECIFICATIONS ........................................................................................................................................4

» OPERA TION MANUAL .................................................................................................................................5

» DIMENSIONS ...............................................................................................................................................7

» REMOVING OF MAJOR PARTS ..................................................................................................................9

» ADJUSTING PROCEDURE OF EACH SECTION .....................................................................................13

» TROUBLE SHOOTING TABLE...................................................................................................................17

» CHASSIS LA YOUT .....................................................................................................................................23

» BLOCK DIAGRAM ......................................................................................................................................24

» OVERALL WIRING DIAGRAM ...................................................................................................................26

» DESCRIPTION OF SCHEMATIC DIAGRAM .............................................................................................28

» SCHEMATIC DIAGRAM .............................................................................................................................29

» PRINTED WIRING BOARD ASSEMBLIES................................................................................................55

» REPLACEMENT PARTS LIST....................................................................................................................65

» PACKING OF THE SET ..............................................................................................................................79

LC-15B4E

Page

SHARP CORPORATION

Page 2

LC-13B4E

LC-15B4E

DESCRIPTION OF SCHEMATIC DIAGRAM

VOLTAGE MEASUREMENT CONDITION:

1. The voltages at test points are measured on

exclusive AC adaptor and the stable supply voltage

of AC 120V. Signals are fed by a color bar signal

generator for servicing purpose and the above

voltages are measured with a 20k ohm/V tester.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/16W, unless otherwise noted.

4. All resistors are Carbon type, unless otherwise

noted.

C

: Solid

S : Oxide Film T : Special

N : Metal Coating

CAPACITOR

1. All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2. All capacitors are 50V, unless otherwise noted.

3. All capacitors are Ceramic type, unless otherwise

noted.

(ML): Mylar (TA): Tantalum

(PF): Polypro Film (ST): Styrol

W

: Cement

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å” ( ) ARE

IMPORTANT FOR MAINTAINING THE SAFETY OF

THE SET. BE SURE TO REPLACE THESE PARTS

WITH SPECIFIED ONES FOR MAINTAINING THE

SAFETY AND PERFORMANCE OF THE SET.

28

Page 3

LC-13B4E

2

2

LC-15B4E

IMPORTANT SERVICE SAFETY PRECAUTION

Ë

Service work should be performed only by qualified service technicians who are thoroughly

familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CONTINUED PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE F3301(2A, 250V), F3302(1.25A, 250V),

F6500 (1.25A, 250V) AND F6501 (1.25A, 250V)

FUSE.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks:

1. Inspect all lead dress to make certain that leads are

not pinched, and check that hardware is not lodged

between the chassis and other metal parts in the

receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

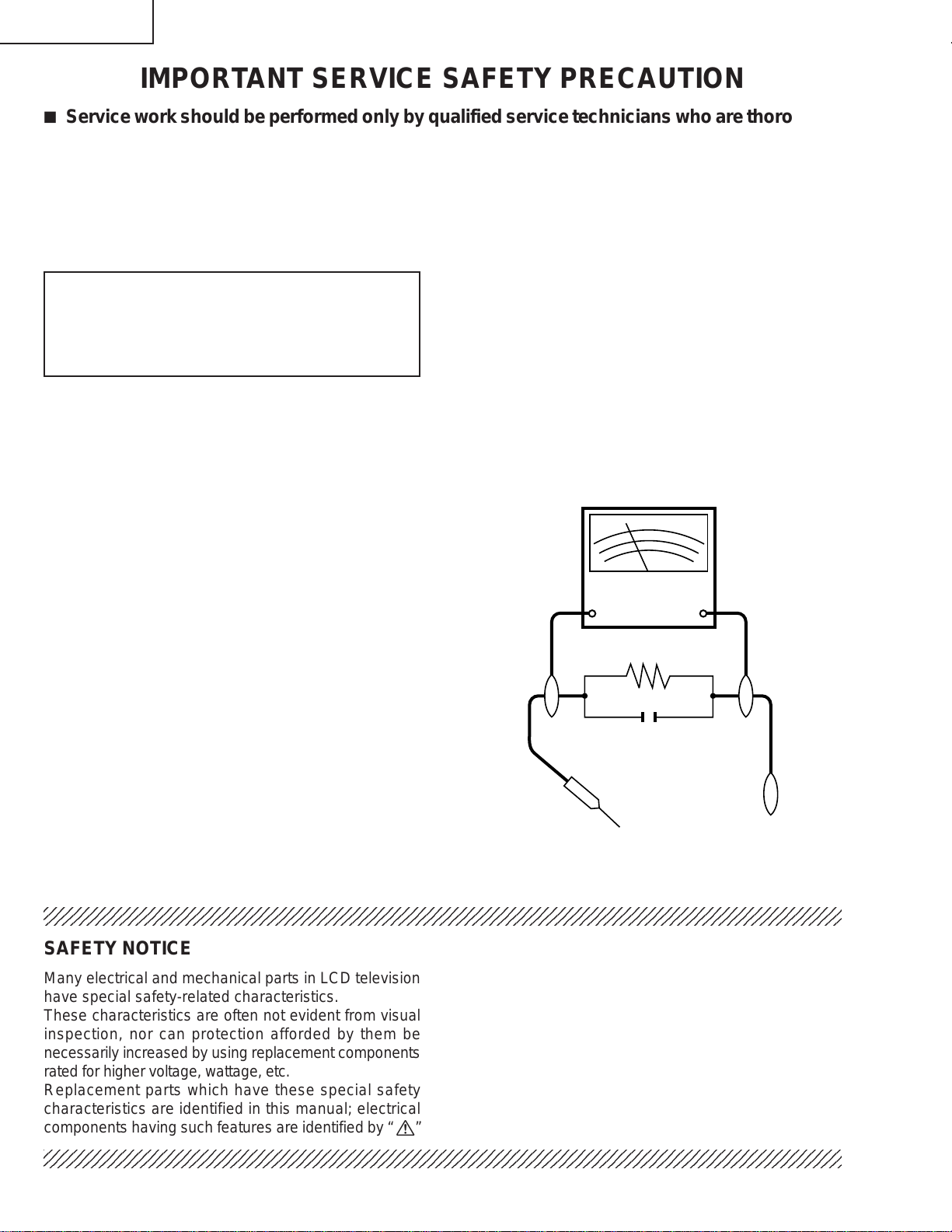

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

• Plug the AC cord directly into a 110~240 volt AC outlet,

and connect the DC power cable into the receiver's

DC jack. (Do not use an isolation transformer for this

test).

• Using two clip leads, connect a 50k ohm, 10 watt resistor

paralleled by a 0.15µF capacitor in series with all

exposed metal cabinet parts and a known earth ground,

such as electrical conduit or electrical ground connected

to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or

higher, sensitivity or measure the AC voltage drop

across the resistor.

• Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

All checks must be repeated with the AC cord plug

connection reversed. (If necessary, a nonpolarized

adaptor plug must be used only for the purpose of

completing these checks.)

Any reading of 0.75V peak (this corresponds to 0.5

mA. peak AC.) or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the monitor to the owner.

DVM

AC SCALE

50k ohm

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in LCD television

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

and shaded areas in the

Schematic Diagrams.

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of a substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock, fire or other hazards.

components having such features are identified by “ å”

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

Replacement Parts Lists and

Page 4

Precautions for using lead-free solder

1 Employing lead-free solder

"All PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on

the PWBs and service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend

you to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering

bit, contact our service station or service branch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead

solder by 40°C, and as it has poor solder wettability , you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, Since the land may be peeled off or the maximum heat-resistance

temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady soldering

condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on

and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit

after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

LC-13B4E

LC-15B4E

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No, ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

3

Page 5

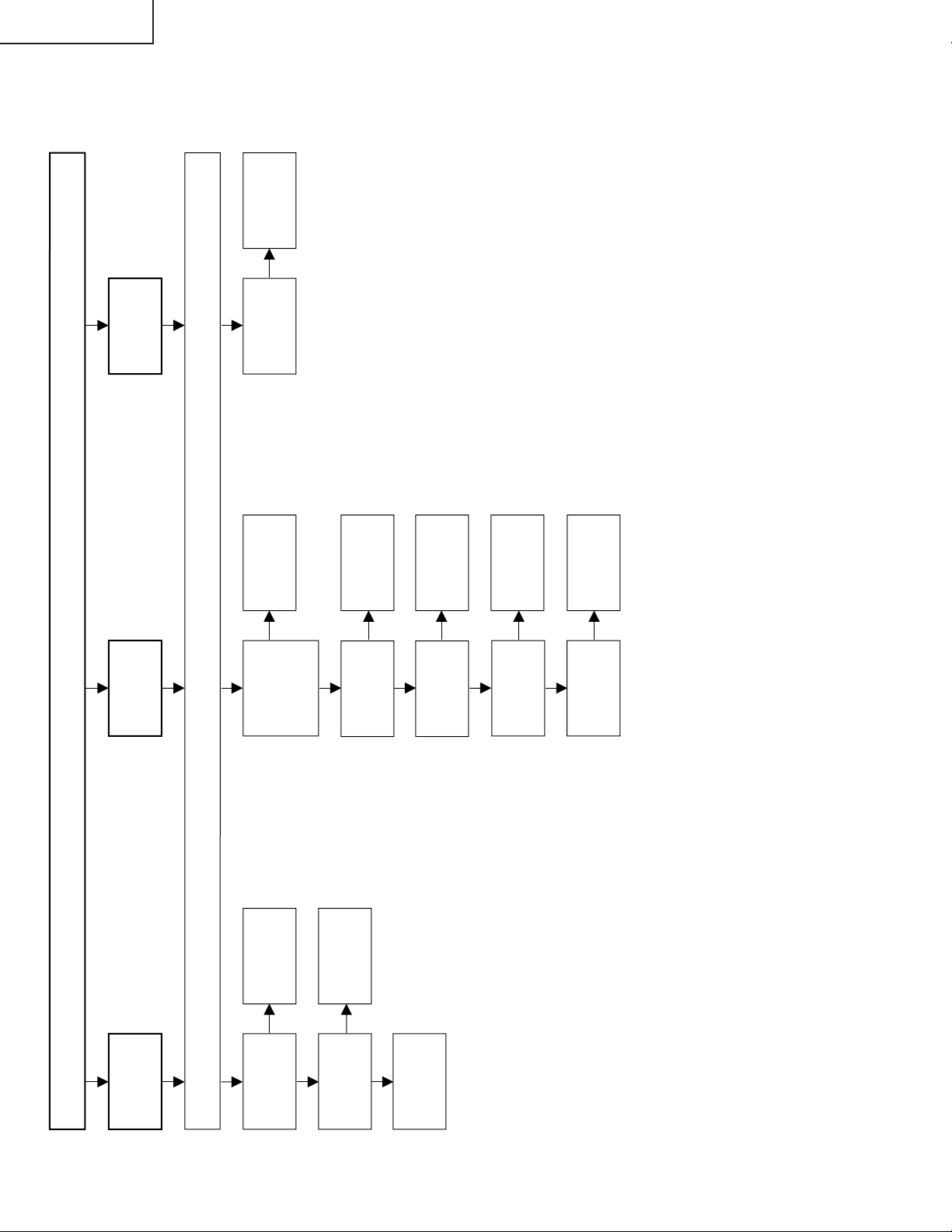

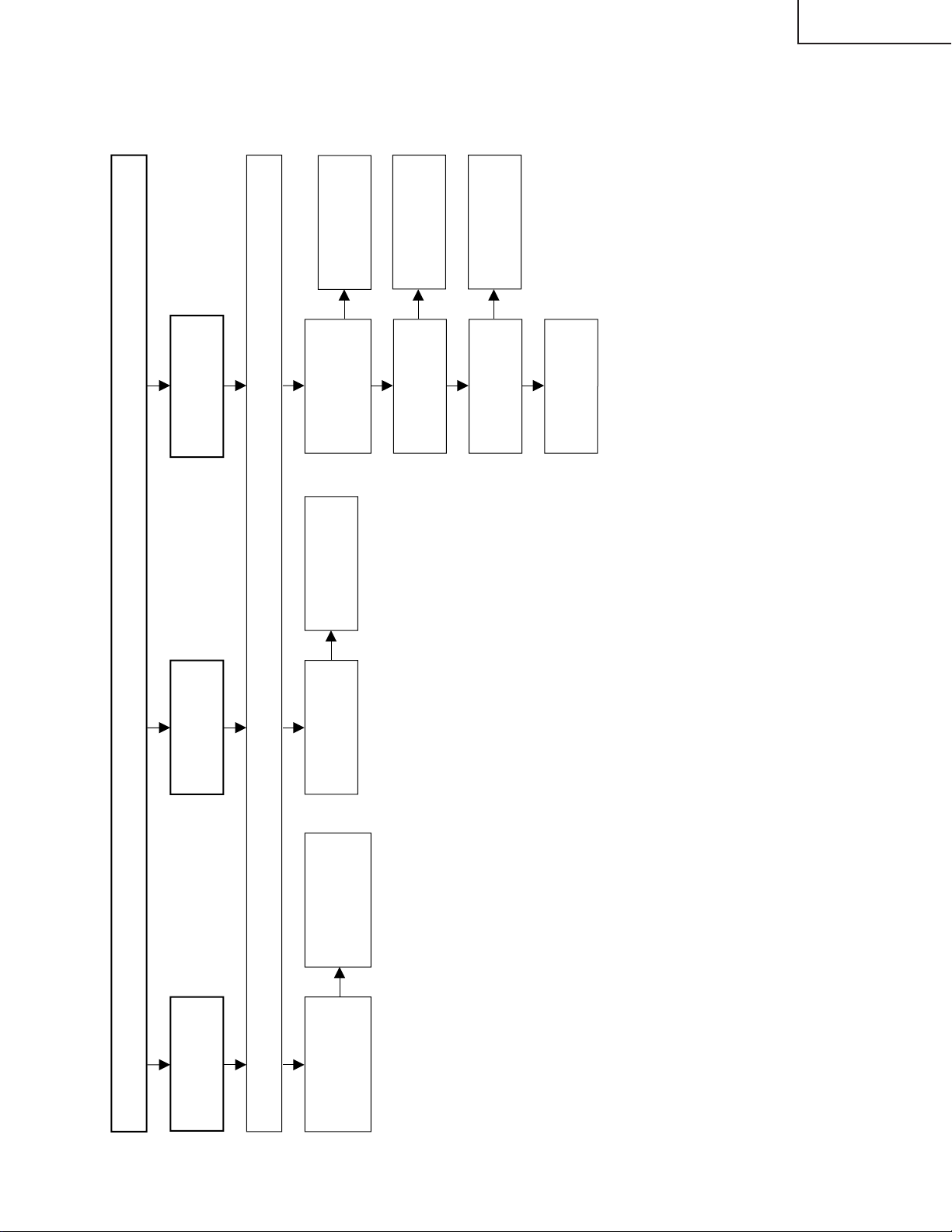

BLOCK DIAGRAM

LC-13B4E

LC-15B4E

H

SC3901

ANTENNA

SCART

TUNER

(AV1)

AUDIO IN TV_V

G

F

SC5001

AUDIO OUT

VIDEO OUT

SDA/RXD

SCL/TXD

VIDEO IN

SC_R/G/B

S

2

I

C/UART

SY

V1.SY

TV/AV

SELECTOR

IC806

SC

(AV2) INPUT

J5003

E

J5001

VIDEO

(AV2) INPUT

AUDIO

V1_V

V1.L/R

SIF1

AI_L/R

I2C

SC_L/RO

CHROMA

SELECTOR

IC803

AUDIO AMP

IC1902

AMP

IC808

AMP

IC808

(AV2) INPUT

ANA_IN1+

SC2_IN_L/R

SC1_OUT_L/R

SC1_IN_L/R

CVBS/SY_IN

R/G/B_IN

SC_IN

MSP

IC1901

VPC

IC801

V2VO

SYNC SEP

IC802

2

I

C

UART

E2PROM

IC2010

CSYNC

DACM_L/R

2

I

DACA_L/R

I2C

MICON

IC2001

C

AUDIO AMP

IC304

SC2_OUT_L/R

VPC0~7

SYNC SIGNAL

CONTROL SIGNAL

2

PROM

E

IC2008

RESET

RESET

IC2006

OSD R/G/B

L_ERR

AUDIO ACTIVE FILTER

IC1905

AUDIO AMP

IC3501

~7

YIN0

DPS

IC1201

OFL1

VPC

R/G/B/FB

LEVEL

SHIFT

Q1602,1604,1606

L/R_IN

AO_L/R

MPDA_5

MPCLK_5

DAC1CS

OUTCON

REV

AUDIO

POWER AMP

IC3301

PAVCC(+12V)

GRADATION

POWER

IC1101

FLSP/FRSP

HL/R

R0~7 G0~7 B0~7

V0 V7 V21 V64

V112 V176 V235 V255

VCOM

CSCOM

SPEAKER

HEADPHONE

JACK

AUDIO OUT

LCD

PANEL

P3301

P3302

J5002

J3901

SC1202

SC1203

SC1204

+9V

+8V

+3.3V

+32V

–11V

Q3705

+23V

+17V

VOLTAGE

CONVERTER

IC702

-16V

TEXT R/G/B /FBL

CVBS

R/G/B

TELETEXT

CPU

IC1601

OFL REVERSE

Q3606

2

C

I

SRAM 2M

IC1612

L_ERR

OFL

DC/AC

INVERTER

DRIVE

Q6500

~6505

LAMP ERROR

DETECTOR

Q3601, 3602

DC/AC

TRANS

T6500

~6503

INVVCC(+12V)

HV1/2/3

BACK

LIGHT

LAMP

P3601

P6500

~P6501

REG IC2003

D

J3701

DC12V

REG IC2004

+5V

INPUT

REG IC707

PAVCC

REG IC705

C

+3.3V

+3.4V

+34V

Q3707

IC3702

Q3708

DC/DC

CONVERTER

SIGVCC

T3701

Q3709

FLASH 4M

B

REG IC706

PWM IC3701

A

INVVCC

B12V1A

Q3703

REG IC805

REG IC704

REG IC1602

+5V

+1.8V

+3.3V

+3.3V

REG IC703

REG IC1607

REG IC1605

-8V

+5V

+3.3V

+2.5V

IC1611

P4001

KEY

P4004

REMOTE

CONTROL

RECEIVER

24

121110987654321

25

Page 6

LC-13B4E

LC-15B4E

ADJUSTING PROCEDURE OF EACH SECTION

The best adjustment is made before shipping. If any position deviation is found or after part replace is performed,

adjust as follows.

Preparation for adjustments

Use the dedicated AC adaptor or stable DC power supply.

AC adaptor: UADP-A034WJPZ

DC power supply: 12V 4.5A

1.Adjusting procedure

• Checker adjustment

Power ON (Adjustment processing mode) → +B adjustment → Counter bias adjustment → TAMP (Contrast)

adjustment → White balance adjustment

2.Entering the adjustment processing mode

There are the following two methods.

• Setting the pin (81)(KEY4) or pin (82)(KEY5) of IC2001 (microprocessor) to GND, turn on the power .

• A “POWER” key is made on with pushing an “TV/VIDEO” and “MENU” keys at the same time.(K of the inspection

process mode is displayed by the upper left of the image plane.) → Next, “CH (Ù)” and “VOL (–)” keys are pushed

at the same time.(It becomes the image plane of the adjustment process mode.).....When it is canceled, it is made

to turn it off.(Even off in the “MAIN POWER” key, off with R/C are good.)

3.Key operation in the adjustment process mode

• The receiving channel UP/DOWN is performed with the “CH (ù)/(Ù)” keys.

One push ... The UP/DOWN tuning is performed per channel.

Continuous push ... The UP/DOWN search is performed until a next receivable station is found.

• Various adjustments

The adjustment is performed for each item by the “MENU”, “Menu cursor”, “CH (ù)/(Ù)” or “VOL (+)/(–)” keys

(LCD TV set and remote control).

• Adjustment item is chosen with the Menu cursor upward/downward keys.

• The adjustment item makes a toggle operation with the “MENU” key input. (Next item)

If the “MENU” key is input while the bottom item is selected, it moves to the top item on the next page.

• Press the auto preset button on the remote controller in the adjustment process mode, and the top item of the

next page will show up regardless of which item appears now.

Page 1 → Page 2 → ... → Page 57 → Page 1

• Press the manual memory button on the remote controller in the adjustment process mode, and the top item of

the same page will show up.

• UP/DOWN of each adjustment vale selected is performed with the VOL (+)/(–) keys input.

13

Page 7

LC-13B4E

LC-15B4E

4.Initialization

When the microprocessor (IC2001) or the EEPROM (IC2008, IC2010) has been replaced or when the EEPROM

has been initialized, readjust the each adjustments.

4-1. Connect the pins (81) and (82) of IC2001 (microprocessor) to GND, and turn on the power.

4-2. Select the model name to (A522).

4-3. Select the inch size (13)~1 or (15)~2.

4-4. LED changes green from red after setting finish and about 15 seconds, initialization is completed, and it

becomes adjustment mode.

4-5. Writing the model-by-model data

For the Ver.1.10A microprocessor, get it initialized first and then make the settings, listed below, on it. (The

microprocessor version is indicated at the bottom of Adjustment Process Page 1.)

ËLC-13B4E

Ver.1.10A data reprogramming (INCH SIZE [13])

Adjustment process page

2

2

4

4

4

4

4

4

4

4

4

4

13

13

13

13

13

R GAIN

B GAIN

TV GEQ BAND1

TV GEQ BAND2

TV GEQ BAND3

TV GEQ BAND4

TV GEQ BAND5

EXT GEQ BAND1

EXT GEQ BAND2

EXT GEQ BAND3

EXT GEQ BAND4

EXT GEQ BAND5

SECAM TV COLOR

SECAM A V COLOR

SECAM BRIGHTNESS

SECAM TV CONTRAST

SECAM A V CONTRAST

Item

OSD settings

0 → -26

0 → -6

+1.0 → +1.5

0.0 → -0.5

0.0 → +0.5

-1.5 → +0.5

-2.0 → +1.0

+1.0 → +1.5

0.0 → -0.5

0.0 → +0.5

-1.5 → +0.5

-2.0 → +1.0

37 → 41

37 → 41

-13 → -18

54 → 58

54 → 58

ËLC-15B4E

Ver.1.10A data reprogramming (INCH SIZE [15])

Adjustment process page

2

4

4

4

4

13

13

13

13

13

4-6. Precautions in replacing the EEPROMs (IC2008 and IC2010)

When the EEPROMs (IC2008 and IC2010) have been replaced, be sure to replace also the microprocessor

(IC2001) with the one "Part No. RH-iXA522WJN1Q".

The version of the RH-iXA522WJN1Q microprocessor is 1.20A.

Note:

~1:LC-13B4E

~2:LC-15B4E

B GAIN

TV GEQ BAND4

TV GEQ BAND5

EXT GEQ BAND4

EXT GEQ BAND5

SECAM TV COLOR

SECAM A V COLOR

SECAM BRIGHTNESS

SECAM TV CONTRAST

SECAM A V CONTRAST

Item

OSD settings

0 → +14

+0.5 → 0.0

+1.5 → +1.0

+0.5 → 0.0

+1.5 → +1.0

37 → 41

37 → 41

-13 → -18

54 → 58

54 → 58

14

Page 8

5.Adjustment

5-1. +B adjustment...Page 1 +B-ADJ

Adjust the voltage of the pin (4) of P1902 to 5.00 ±0.02V with R3714.

Note: Since 5.0V is a reference voltage of all power voltage, adjust it precisely.

5-2. Counter-bias adjustment

Vary the "COM BIAS" setting on Page 2 of the adjustment process mode so that the contrast be sharpest

(black looks most sinking).

5-3. TAMP adjustment

1) Receive the upper left of 75% white half colour bar signal.

2) See if the “Y” reading on page 2 of the adjustment process mode is somewhere following. If not, make the

“PAL TAMP” adjustment to get the “Y” reading in the range of AE thru BD.

3) If the adjustment of “PAL TAMP” is executed, write its adjustment value to the “SECAM TAMP” manually.

(Screen of the page 2 of the adjustment processing menu OSD)

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

0

1

2

3

4

5

6

7

8

9

10

11

12

13

2

COM B I AS 9 0

PAL TAMP 21

SECAM TAMP 21

RCU TOF F

GCUT OF F

BCU TOF F

RGA I

GG

BGA I

TAMP

TAMP

AI

Y

N 0

N

N

H

L

B

B

A

LC-13B4E

LC-15B4E

0

0

0

0

0

6

D

E

Y Data

(White 75%)

5-4. White balance adjustment

Adjust “RCUTOFF” and “BCUTOFF” on the page 2 of the adjustment processing so as to obtain the colour

of the same level as the standard set.

15

Page 9

LC-13B4E

LC-15B4E

6. Factory Setting

6-1. Perform a factory setting after completing all adjustments.

6-2. A “POWER” keys is made on with pushing an “TV/VIDEO” and “MENU” keys at the same time.

6-3. “K” of the inspection process mode is displayed on the screen upper left.

6-4. CH (ù) and VOL (+) keys are pushed about 2 seconds at the same time.

6-5. Release keys, if “E” is displayed on the screen upper left and “COMPLETE” is displayed on the bottom of it.

6-6. After a while, a power will be in a standby mode and a setup will be finished.

Note: “First installation” serves on “Deutsch”.

7. Lamp error detection

7-1. Functional description

This LCD colour television has a function (lamp error detection) to be turned OFF automatically for safety

when the lamp or lamp circuit is abnormal.

If the lamp or lamp circuit is abnormal, or some other errors happen, and the lamp error detection is executed,

the followings occur.

1 The main unit of television is turned OFF 5 seconds after it is turned ON. (The power LED on the front side

of TV turns from green to red.)

2 If the situation 1 happens 5 times sequentially , television can not be turned ON. (The power LED remains

red.)

7-2. Countermeasures

7-2-1.Check when turning OFF the lamp error detection

When television is turned OFF by the lamp error detection mentioned above, it enters the adjustment

process with the power LED red. Entering the adjustment process turns OFF the error detection and turns

ON TV .

This enables the operation check to detect errors in the lamp or lamp circuit.

Check whether "ERROR NO RESET" on line 3, page 1 of the adjustment process is 1 or more. If it is 1 or

more, it indicates the lamp error detection was executed.

7-2-2.Resetting of the lamp error count

After confirming that the lamp or lamp circuit is normal, reset the lamp error count. Select "ERROR NO

RESET" on line 3, page 1 of the adjustment process and set the number to 0 using the volume button.

Page 1 of the adjustment process

1

M O D E L A522

INCH SIZE ~3

ERROR NO RESET 5

PUBLIC MODE OFF

EXT CONTROL OFF

EXT MODE UART

UPDATE MODE NORMAL

TEXT RESET OFF

Reset 0

V E R R O M 1 . 1 0 A

Afterwards, perform the operation check to confirm that the lamp error detection does not function.

Note:~3 LC-13B4E=13, LC-15B4E=15

16

Page 10

TROUBLE SHOOTING TABLE

No picture and No sound

Check all the settings microprocessor's adjust process menu.

Do F3301 and F3302

function?

Are T3701's secondary

outputs, +34V, +9V, +5V

and -11V normal?

Remove F3301 and F3302

and check the load side.

Is there short-circuiting?

Is there short-circuiting of

T3701 primary side periphery,

Q3703, Q3704 and S4701.

Replace F3301 and F3302.

Check S4701 and

connection cable.

Is T3701's primary oscillator

waveform normal?

Check T3701's secondary

load.

Yes Yes

No

No

No No

No

Yes

Check J3701 periphery and

connection cable.

Replace F6500~F6501.

Is the pin (120) of IC1201 in

the "H" state?

Is the output of Q3606 in the

"

L

"

state?

Yes

Yes

No

No

No

Yes

Yes

Check the OFL1 line, IC1201

and their peripheral parts.

Check the OFL line, Q3606

and their peripheral parts.

Check T6500~T6503,

Q6500~Q6505 and

connection cable.

Back light lamp failure to light up

Is the primary side of

T6500 ~T6503 periphery

short-circuiting?

Replace the back light lamp

with new one and check

again.

LC-13B4E

LC-15B4E

17

Page 11

LC-13B4E

No picture (1/3)

Check all the settings microprocessor's adjust process menu.

Is in/output of

IC801 normal?

Is in/output of

IC1201 normal?

Check IC801

and its

peripheral parts.

Check IC1201

and its

peripheral parts.

Check LCD

panel voltages

and waveform.

Yes

Yes

No

No

No picture

at all

Is voltages at

pins (6), (7) and

(18) tuner

normal?

Is output at pin

(13) of tuner

normal?

Check the

power line.

Check tuner

and its

peripheral parts.

Is input at pin

(16) of IC806

normal?

Is the pin (3) of

IC806 at "H"

state?

Yes

Yes

No

No

No

No

No

Yes

No TV output

Is the pin (48)

of IC2001 at "H"

state?

Yes

Check the its

line.

Check the its

line.

Check IC806

and its

peripheral parts.

Is input at pin

(14) of IC806

normal?

Check V1_V

line and its

peripheral parts.

No

No VIDEO 2

output

LC-15B4E

TROUBLE SHOOTING TABLE (Continued)

18

Page 12

TROUBLE SHOOTING TABLE (Continued)

No picture (2/3)

Check all the settings microprocessor's adjust process menu.

Is input at pin

(14) of IC806

normal?

Check the V2_V

line and its

peripheral parts.

No

No VIDEO 1

output

Check the SY-line,

SC-line and their

peripheral parts.

Is input at pin (9)

of IC806 and pin

(1) of IC803

normal?

No

No S-VIDEO

output

Check IC1201

and its

peripheral parts.

No

Yes

Yes

No TELETEXT

output

Is input at pins

(136), (137), (138),

and (142) of

IC1201 normal?

No

Check the R, G

and B line.

Is output at pins

(57)~(59) of IC1601

normal?

No

Yes

Check V2VO line

and its peripheral

parts.

Is input at pin (21) of

IC1601 normal?

Check IC1601 and its

peripheral parts.

LC-13B4E

LC-15B4E

19

Page 13

LC-13B4E

No picture (3/3)

Check all the settings microprocessor's adjust process menu.

Is output of

R0~R7

normal?

Is output of

G0~G7

normal?

Is output of

B0~B7

normal?

Yes

Yes

No

No

No

Colour is

unusual

Is in/output of

SPIO and

SPOI normal?

No

No picture

image

inversion

No

Gradation

defect

Is output of U/D

normal?

Yes

No

Check R1227 and

its peripheral parts.

Check R1235 and

its peripheral parts.

Check IC1202,

Q1204 and their

peripheral parts.

Check R1228 and

its peripheral parts.

Check R1232 and

its peripheral parts.

Is output V0, V7, V21,

V64, V112, V176,

V235 and V255

normal?

Check IC1101 and its

peripheral parts.

LC-15B4E

TROUBLE SHOOTING TABLE (Continued)

20

Page 14

TROUBLE SHOOTING TABLE (Continued)

No sound (1/2)

Check all the settings microprocessor's adjust process menu.

Is the pin (53) of

IC2001 in the

"L" state?

Is output at pins

(27) and (28) of

IC1901 normal?

Is output at pins

(1) and (7) of

IC1905 normal?

Yes

Yes

No

No

No

No sound

from front

speakers

Yes

Muting effect is

on. Check the

FSMUTE line.

Check IC1901

and its

peripheral parts.

Check IC1905

and its

peripheral parts.

Is the pin (52) of

IC2001 in the

"L" state?

Is output at pins

(24) and (25) of

IC1901 normal?

Is output at pins

(1) and (7) of

IC304 normal?

Yes

Yes

No

No

No

Yes

Muting effect is

on. Check the

HP_MUTE line.

Check IC1901

and its

peripheral parts.

Check IC304

and its

peripheral parts.

No sound

from

headphone

TV sound

failure

Is output at pins

(33) and (34) of

IC1901 normal?

Is output at pins

(1) and (7) of

IC3501 normal?

Check IC1901

and its

peripheral parts.

Check IC3501

and its

peripheral parts.

Yes

No

No

No

No sound

from output

line

Check the tuner

and its

peripheral parts.

Yes

No

Is output at pin

(11) of Tuner

normal?

Is input at pin

(67) of IC1901.

Check IC1901

and its

peripheral

parts.

Check

Headphone Jack

and connection

cable.

No

Is output at pins

(8) and (12) of

IC3301 normal?

Check IC3301

and its

peripheral parts.

Check front

speaker and

connection

cable.

Yes

LC-13B4E

LC-15B4E

21

Page 15

LC-13B4E

No sound (2/2)

Check all the settings microprocessor's adjust process menu.

Yes

No

No

No sound from SCART

No

SCART sound failure

Yes

No

Check IC1901 and its

peripheral parts.

Is output at pins (36) and (37) of

IC1901 normal?

Check IC1902 and its

peripheral parts.

Is output at pins (1) and (7) of

IC1902 normal?

Check their lines and their

peripheral parts.

Is input at pins (53) and (54) of

IC1901 normal?

Check IC1901 and its

peripheral parts.

Is output at pins (27) and (28) of

IC1901 normal?

LC-15B4E

22

Page 16

OVERALL WIRING DIAGRAM

H

G

F

LC-13B4E

LC-15B4E

E

D

C

B

A

121110987654321

26

27

Page 17

SCHEMATIC DIAGRAM

Ë

R/C, LED and OPERATION Unit

H

G

F

LC-13B4E

LC-15B4E

E

D

C

B

A

654321

29

Page 18

LC-13B4E

LC-15B4E

Ë

MAIN Unit-1/7

H

G

F

E

D

C

B

A

121110987654321

30

31

Page 19

LC-13B4E

LC-15B4E

Ë

MAIN Unit-2/7

H

G

F

E

D

C

B

A

121110987654321

32

33

Page 20

LC-13B4E

LC-15B4E

Ë

MAIN Unit-3/7

H

G

F

E

D

C

B

A

121110987654321

34

35

Page 21

LC-13B4E

LC-15B4E

Ë

MAIN Unit-4/7

H

G

F

E

D

C

B

A

121110987654321

36

37

Page 22

LC-13B4E

LC-15B4E

Ë

MAIN Unit-5/7

H

G

F

E

D

C

B

A

121110987654321

38

39

Page 23

LC-13B4E

LC-15B4E

Ë

MAIN Unit-6/7

H

G

F

E

D

C

B

A

121110987654321

40

41

Page 24

LC-13B4E

LC-15B4E

Ë

MAIN Unit-7/7

H

G

F

E

D

C

B

A

121110987654321

42

43

Page 25

LC-13B4E

LC-15B4E

Ë

TUNER Unit-1/4

H

G

F

E

D

C

B

A

121110987654321

44

45

Page 26

LC-13B4E

LC-15B4E

Ë

TUNER Unit-2/4

H

G

F

E

D

C

B

A

121110987654321

46

47

Page 27

LC-13B4E

LC-15B4E

Ë

TUNER Unit-3/4 (LC-13B4E)

H

G

F

E

D

C

B

A

121110987654321

48

49

Page 28

LC-13B4E

LC-15B4E

Ë

TUNER Unit-3/4 (LC-15B4E)

H

G

F

E

D

C

B

A

121110987654321

50

51

Page 29

LC-13B4E

LC-15B4E

Ë

TUNER Unit-4/4

H

G

F

E

D

C

B

A

121110987654321

52

53

Page 30

LC-13B4E

LC-15B4E

Ë

H

G

F

INVERTER Unit

E

D

C

B

A

654321

54

Page 31

CHASSIS LAYOUT

LC-13B4E

LC-15B4E

H

MAIN Unit

G

F

E

OPERATION Unit

INVERTER Unit

TUNER Unit

D

C

B

R/C, LED Unit

A

654321

23

Page 32

LC-13B4E

LC-15B4E

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

PARTS LIST

P ARTS REPLACEMENT

Replacement parts which have these special safety characteristics

identified in this manual; electrical components having such features

are identified by

and Schematic Diagrams. The use of a substitute replacement part

which does no have the same safety characteristic as the factory

recommended replacement parts shown in this service manual may

create shock, fire or other hazards.

"HOW TO ORDER REPLACEMENT P ARTS"

To have your order filled promptly and correctly, please furnish the

following informations.

1. MODEL NUMBER 2. REF. NO.

3. P AR T NO . 4. DESCRIPTION

Ref. No. Part No. ★ Description Code

PRINTED WIRING BOARD ASSEMBLIES

å and shaded areas in the Replacement Parts Lists

★ MARK: SPARE PARTS-DELIVERY SECTION

(NOT REPLACEMENT ITEM)

LC-13B4E

DUNTKB750FE01 – MAIN Unit —

DUNTKB751DE01 – TUNER Unit —

DUNTKB752DE01 – R/C,LED Unit —

DUNTKB753DE01 – OPERATION Unit —

DUNTKB754DE01 – INVERTER Unit —

LC-15B4E

DUNTKB750FE02 – MAIN Unit —

DUNTKB751DE02 – TUNER Unit —

DUNTKB752DE02 – R/C,LED Unit —

DUNTKB753DE02 – OPERATION Unit —

DUNTKB754DE02 – INVERTER Unit —

DUNTKB750FE01:LC-13B4E

DUNTKB750FE02:LC-15B4E

MAIN UNIT

INTEGRATED CIRCUITS

IC701 VSUMX2N++++-1Y J UMX2N AB

IC702 VHiNJU7662M-1Y J NJU7662M(TE2) AL

IC703 VHiNJ79M08D-1Y J NJM79M08DL1A AF

IC704 VHiPQ1R33//-1Y J PQ1R33 AE

IC705 VHiPQ1R34++-1Y J PQ1R34 AE

IC706 VHiLM1117MJ-1Y J LM1117MPX-ADJ AF

IC707 VHiMM1573DN-1Y J MM1573DNRE AD

IC801 VHiVPC3230D1EQ J VPC3230D-QA-B3 BD

IC802 VHiBA7046F/-1Y J BA7046F AF

IC803 VHiNJM2233V-1Y J NJM2233V AE

IC805 VHiMM1563DF-1Y J MM1563DFBE AE

IC806 VHiNJM2293M-1Y J NJM2293M(TE1) AG

IC808 VHiNJM2268M-1Y J NJM2268M-TE1 AF

IC1101 VHiBD8120FP-1Y J BD8120FP AX

IC1201 VHiDPS9450+-1Q J DPS9450A-XZ-A1 BD

IC1202 VHiTC4W66U/-1Y J TC4W66FU AE

IC1601 VHiSDA5550M-1Q J SDA5550M AZ

IC1602 VHiBA05FP++-1Y J BA05FP-E2 AF

IC1603 VHiPST3228N1EY J PST3228NR AB

IC1604 VHiMM1501XN-1Y J MM1501XNRE AE

IC1605 VHiMM1562FF-1Y J MM1562FFBE AE

IC1606 VHiPST3221N1EY J PST3221NR AB

IC1607 VHiMM1563DF-1Y J MM1563DFBE AE

IC1608 VHiNC7SZ58P-1Y J NC7SZ58P6X AE

IC1609 VHiTC7SZ08U-1Y J TC7SZ08FU AE

IC1610 VHiLCX157MT-1Y J 74LCX157MTCX AE

IC1611 RH-iXA388WJZZQ J MBM29DL400TC90 AY

IC1612 VHi62S8308X-1Q J A62S8308X-70SI AY

IC1614 VHiVHC08MTC1EY J 74VHC08MTCX AD

IC1615 VHi74LVX86M-1Y J 74LVX86MTCX AD

IC2001 RH-iXA522WJZZQ J M306V3MG-102FP BB

IC2003 VHiMM1573DN-1Y J MM1573DNRE AD

IC2004 VHiPQ1L503M-1Y J PQ1L503M2SP AD

IC2005 VHiBU4052FV-1Y J BU4052BCFV-E2 AE

IC2006 VHiBD4729G+-1Y J BD4729G-TR AD

IC2007 VHiNC7S02M5-1Y J NC7S02M5 AD

IC2008 VHiBR24C32F-1Y J BR24C32F-E2 AH

IC2009 VHiTC4W66U/-1Y J TC4W66FU AE

IC2010 VHiBR2416E2-1Y J BR24C16F AK

IC2011 VHiTC4W66U/-1Y J TC4W66FU AE

LCD PANEL

NOTE: THE PARTS HERE SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDENTLY.

RLCDTA012WJN1 J 13" LCD Panel Unit CT

(LC-13B4E)

RLCDTA013WJN1 J 15" LCD Panel Unit CZ

(LC-15B4E)

Q701 VS2SA1037KQ-1Y J 2SA1037KQ AA

TRANSISTORS

Q702 VSFMMT718//-1Y J FMMT718 AE

Q703 VSDTC144EE/-1Y J DTC144EE AA

Q803 VS2SA1530AR-1Y J 2SA1530AR AB

Q804 VS2SA1530AR-1Y J 2SA1530AR AB

Q806 VS2SA1530AR-1Y J 2SA1530AR AB

Q1101 VSFMMT718//-1Y J FMMT718 AE

Q1102 VS2SC4520//-1Y J 2SC4520 AE

Q1103 VS2SA1729//-1Y J 2SA1729 AF

Q1104 VSDTC144EE/-1Y J DTC144EE AA

Q1105 VS2SC4520//-1Y J 2SC4520 AE

Q1106 VS2SA1729//-1Y J 2SA1729 AF

Q1204 VSDTC144EE/-1Y J DTC144EE AA

Q1601 VS2SA1530AR-1Y J 2SA1530AR AB

Q1602 VS2SA1530AR-1Y J 2SA1530AR AB

Q1603 VSDTC144TE/-1Y J DTC144TE AB

Q1604 VS2SA1530AR-1Y J 2SA1530AR AB

Q1605 VS2SC3928AR-1Y J 2SC3928AR AB

Q1606 VS2SA1530AR-1Y J 2SA1530AR AB

Q1607 VS2SA1530AR-1Y J 2SA1530AR AB

Q2001 VSUM5K1NTR+-1Y J UM5K1NTR AC

Q2002 VSDTC114EE/-1Y J DTC114EE AB

Q2003 VSUPA606T//-1Y J UPA606T AD

Q2005 VSUPA606T//-1Y J UPA606T AD

Q2006 VSDTC114EE/-1Y J DTC114EE AB

Q2007 VSUPA606T//-1Y J UPA606T AD

65

Page 33

LC-13B4E

LC-15B4E

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKB750FE01:LC-13B4E

DUNTKB750FE02:LC-15B4E

MAIN UNIT (Continued)

DIODES

D701 RH-EX1247CEZZY J Zener Diode, 5.6V AB

D702 VHDDAN222//-1Y J Diode AA

D703 RH-EX1245CEZZY J Zener Diode, 5.1V AB

D704 VHDDAN222//-1Y J Diode AA

D706 VHDDAN222//-1Y J Diode AA

D707 VHDDAN222//-1Y J Diode AA

D708 RH-EX1245CEZZY J Zener Diode, 5.1V AB

D709 VHDDAN222//-1Y J Diode AA

D710 VHD1SS250//1EY J Diode AB

D711 VHDDAN202K/-1Y J Diode AB

D712 VHDDAN222//-1Y J Diode AA

D713 VHDRB481K++-1Y J Diode AD

D714 VHDRB491D++-1Y J Diode AD

D1101 VHD1SS250//1EY J Diode AB

D1102 VHDDAN222//-1Y J Diode AA

D1103 VHD1SS250//1EY J Diode AB

D1104 VHD1SS250//1EY J Diode AB

D2001 RH-EX1232CEZZY J Zener Diode AB

D2002 VHDDAN202K/-1Y J Diode AB

D2003 VHDDAN202K/-1Y J Diode AB

P ACKAGED CIRCUITS

X801 RCRSC0012CEZZY J Crystal AH

X1201 RCRSC0012CEZZY J Crystal AH

X1601 RCRSCA002WJZZY J Crystal AG

FIL TER AND COILS

X2001 RFiLZ0169TAZZY J Filter AD

FL801 RCiLFA033WJZZY J Coil AG

FL802 RCiLFA033WJZZY J Coil AG

L701 RCiLPA143WJZZY J Coil AD

L702 VP-1M470J5R4NY J Peaking 47µH AC

L804 RCiLPA143WJZZY J Coil AD

L805 RCiLPA143WJZZY J Coil AD

L806 VP-9N3R3KR46NY J Peaking 3.3µH AC

L807 VP-9N3R3KR46NY J Peaking 3.3µH AC

L808 VP-9N3R3KR46NY J Peaking 3.3µH AC

L1204 VPCGM220M0R5NY J Peaking 22µH AB

L1205 VPCGM220M0R5NY J Peaking 22µH AB

L1206 VPCGM220M0R5NY J Peaking 22µH AB

L1207 VPCGM220M0R5NY J Peaking 22µH AB

L1601 VP-1M270J3R8NY J Peaking 27µH AC

CAPACITORS

C701 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C702 VCEASK1CN227MY J 220 16V Electrolytic AC

C703 RC-EZA123WJZZY J 100 6.3V Electrolytic AC

C704 VCKYTV1CB105KY J 1 16V Ceramic AC

C705 VCKYTV1CB105KY J 1 16V Ceramic AC

C706 RC-KZ0075TAZZY J 2.2 16V Ceramic AC

C707 RC-KZA041WJZZY J 10 10V Ceramic AC

C708 RC-EZA129WJZZY J 2.2 50V Electrolytic AB

C709 VCKYTV1CB105KY J 1 16V Ceramic AC

C710 VCKYTV1CB105KY J 1 16V Ceramic AC

C711 RC-EZA132WJZZY J 10 50V Electrolytic AC

C712 RC-KZA041WJZZY J 10 10V Ceramic AC

C713 RC-KZA041WJZZY J 10 10V Ceramic AC

C714 RC-KZA041WJZZY J 10 10V Ceramic AC

C715 RC-EZA132WJZZY J 10 50V Electrolytic AC

C716 RC-KZA041WJZZY J 10 10V Ceramic AC

C717 VCKYTV1CB105KY J 1 16V Ceramic AC

C718 RC-KZA041WJZZY J 10 10V Ceramic AC

C719 RC-EZA123WJZZY J 100 6.3V Electrolytic AC

C720 VCEASH0JN227MY J 220 6.3V Electrolytic AC

C721 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C722 RC-EZA131WJZZY J 4.7 50V Electrolytic AC

C723 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C724 RC-EZA132WJZZY J 10 50V Electrolytic AC

C725 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C726 RC-EZA132WJZZY J 10 50V Electrolytic AC

C727 VCKYTV1CB105KY J 1 16V Ceramic AC

C728 VCKYCY1HF103ZY J 0.01 50V Ceramic AA

C801 RC-KZA041WJZZY J 10 10V Ceramic AC

C802 RC-KZA041WJZZY J 10 10V Ceramic AC

C803 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C804 RC-KZA041WJZZY J 10 10V Ceramic AC

C805 RC-KZA041WJZZY J 10 10V Ceramic AC

C806 VCKYCY1AB105KY J 1 10V Ceramic AB

C807 VCKYCY1HB222KY J 2200p 50V Ceramic AA

C808 VCCCCY1HH101JY J 100p 50V Ceramic AA

C809 RC-KZA041WJZZY J 10 10V Ceramic AC

C810 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C812 RC-KZA041WJZZY J 10 10V Ceramic AC

C813 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C814 VCKYCY1AB105KY J 1 10V Ceramic AB

C815 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C818 RC-EZA135WJZZY J 47 6.3V Electrolytic AC

C819 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C820 RC-EZA122WJZZY J 22 6.3V Electrolytic AB

C821 VCKYTV1CF684ZY J 0.68 16V Ceramic AB

C822 RC-KZA030WJZZY J 2.2 10V Ceramic AB

C823 VCKYTV1CF684ZY J 0.68 16V Ceramic AB

C824 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C826 RC-EZA123WJZZY J 100 6.3V Electrolytic AC

C828 RC-KZ1025CEZZY J 1 10V Ceramic AB

C829 RC-EZA123WJZZY J 100 6.3V Electrolytic AC

C830 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C831 RC-KZ1025CEZZY J 1 10V Ceramic AB

C832 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C833 RC-EZA123WJZZY J 100 6.3V Electrolytic AC

C835 VCKYCY1HB331KY J 330p 50V Ceramic AA

C836 VCKYCY1HB331KY J 330p 50V Ceramic AA

C837 RC-EZA124WJZZY J 10 16V Electrolytic AB

C838 VCKYCY1HB331KY J 330p 50V Ceramic AA

C840 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C843 VCCCCY1HH7R0DY J 7p 50V Ceramic AA

C844 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C845 VCCCCY1HH7R0DY J 7p 50V Ceramic AA

C846 RC-EZA134WJZZY J 220 6.3V Electrolytic AC

C847 VCKYCY1CF224ZY J 0.22 16V Ceramic AB

C848 VCKYCY1CF224ZY J 0.22 16V Ceramic AB

C849 VCKYCY1CF224ZY J 0.22 16V Ceramic AB

C850 RC-KZ0117TAZZY J 4.7 6.3V Ceramic AD

C851 RC-KZ1025CEZZY J 1 10V Ceramic AB

C852 RC-KZ1025CEZZY J 1 10V Ceramic AB

C853 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C854 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C855 RC-KZ1025CEZZY J 1 10V Ceramic AB

C856 RC-KZ1025CEZZY J 1 10V Ceramic AB

C857 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C863 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C867 VCKYCY1EB473KY J 0.047 25V Ceramic AA

C868 VCKYCY1EB473KY J 0.047 25V Ceramic AA

C869 VCKYCY1EB473KY J 0.047 25V Ceramic AA

C870 RC-KZA030WJZZY J 2.2 10V Ceramic AB

C871 RC-KZA030WJZZY J 2.2 10V Ceramic AB

C872 VCCCCY1HH471JY J 470p 50V Ceramic AA

C873 VCKYCY1AB224KY J 0.22 10V Ceramic AB

C874 VCKYCY1AB224KY J 0.22 10V Ceramic AB

C875 VCKYCY1AB224KY J 0.22 10V Ceramic AB

C1101 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1102 RC-EZ1339CEZZY J 220 16V Electrolytic AD

C1104 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1105 VCCCCY1HH181JY J 180p 50V Ceramic AA

C1106 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1107 RC-KZA041WJZZY J 10 10V Ceramic AC

C1108 VCCCCY1HH560JY J 56p 50V Ceramic AB

C1109 RC-KZA041WJZZY J 10 10V Ceramic AC

C1110 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1111 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1112 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1113 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1114 VCCCCY1HH560JY J 56p 50V Ceramic AB

C1115 VCKYTV1CB334KY J 0.33 16V Ceramic AC

C1116 VCKYTV1CB105KY J 1 16V Ceramic AC

66

Page 34

LC-13B4E

LC-15B4E

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKB750FE01:LC-13B4E

DUNTKB750FE02:LC-15B4E

MAIN UNIT (Continued)

C1117 VCKYTV1CB105KY J 1 16V Ceramic AC

C1118 VCKYCY1EB104KY J 0.1 25V Ceramic AB

C1119 RC-KZA041WJZZY J 10 10V Ceramic AC

C1122 RC-EZ1339CEZZY J 220 16V Electrolytic AD

C1204 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1205 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1206 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1207 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1208 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1209 VCCCCY1HH7R0DY J 7p 50V Ceramic AA

C1210 VCCCCY1HH7R0DY J 7p 50V Ceramic AA

C1211 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1212 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1213 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1214 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1215 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1216 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1217 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1218 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1219 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1220 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1221 VCKYCY1CF474ZY J 0.47 16V Ceramic AB

C1222 VCKYCY1CF474ZY J 0.47 16V Ceramic AB

C1223 VCKYCY1CF474ZY J 0.47 16V Ceramic AB

C1224 VCKYCY1CF474ZY J 0.47 16V Ceramic AB

C1225 VCKYCY1CF474ZY J 0.47 16V Ceramic AB

C1226 VCKYCY1CF474ZY J 0.47 16V Ceramic AB

C1227 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1228 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1229 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1230 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1231 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1232 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1233 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1234 RC-EZA143WJZZY J 100 6.3V Electrolytic AC

C1235 RC-EZA143WJZZY J 100 6.3V Electrolytic AC

C1236 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1237 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1238 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1240 VCCCCY1HH220JY J 22p 50V Ceramic AA

C1244 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1245 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1246 RC-EZA143WJZZY J 100 6.3V Electrolytic AC

C1247 RC-EZA143WJZZY J 100 6.3V Electrolytic AC

C1601 RC-KZ0074TAZZY J 10 6.3V Ceramic AF

C1602 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1603 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1604 VCKYCY1CF334ZY J 0.33 16V Ceramic AB

C1605 RC-EZA127WJZZY J 100 6.3V Electrolytic AC

C1606 RC-EZA123WJZZY J 100 6.3V Electrolytic AC

C1607 RC-EZA199WJZZY J 10 25V Electrolytic AC

C1608 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1609 RC-EZA123WJZZY J 100 6.3V Electrolytic AC

C1610 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1611 RC-EZA123WJZZY J 100 6.3V Electrolytic AC

C1612 RC-KZA030WJZZY J 2.2 10V Ceramic AB

C1613 VCE9PF0JN226MY J 22 6.3V Elect. (N.P) AD

C1614 VCKYCY1CF334ZY J 0.33 16V Ceramic AB

C1615 RC-EZA125WJZZY J 22 16V Electrolytic AC

C1616 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C1617 RC-EZA135WJZZY J 47 6.3V Electrolytic AC

C1618 RC-KZA030WJZZY J 2.2 10V Ceramic AB

C1619 VCCCCY1HH181JY J 180p 50V Ceramic AA

C1620 VCE9PF0JN226MY J 22 6.3V Elect. (N.P) AD

C1622 RC-EZA122WJZZY J 22 6.3V Electrolytic AB

C1623 RC-EZA135WJZZY J 47 6.3V Electrolytic AC

C1624 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1625 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1626 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1627 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1628 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1629 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1630 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1631 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1632 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1633 VCKYTV1CF105ZY J 1 16V Ceramic AB

C1634 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1636 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1639 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1640 VCCCCY1HH330JY J 33p 50V Ceramic AA

C1641 VCCCCY1HH330JY J 33p 50V Ceramic AA

C1642 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1643 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1644 RC-KZ0074TAZZY J 10 6.3V Ceramic AF

C1647 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1649 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1650 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1651 VCCCCY1HH471JY J 470p 50V Ceramic AA

C1652 VCCCCY1HH471JY J 470p 50V Ceramic AA

C2001 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2002 VCKYTV1CF105ZY J 1 16V Ceramic AB

C2003 RC-KZ0074TAZZY J 10 6.3V Ceramic AF

C2004 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2005 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2006 VCKYCY1AB105KY J 1 10V Ceramic AB

C2007 RC-EZA122WJZZY J 22 6.3V Electrolytic AB

C2008 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2012 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2018 VCKYTV1CF684ZY J 0.68 16V Ceramic AB

C2020 RC-EZA124WJZZY J 10 16V Electrolytic AB

C2022 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2023 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2024 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2025 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2026 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2027 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2028 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2029 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

RESISTORS

R701 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R702 VRS-CY1JF682JY J 6.8k 1/16W Metal Oxide AA

R703 VRS-CY1JF562JY J 5.6k 1/16W Metal Oxide AA

R704 VRS-CY1JF1R0JY J 1 1/16W Metal Oxide AA

R707 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R708 VRS-CY1JF272JY J 2.7k 1/16W Metal Oxide AA

R709 VRS-CY1JF272JY J 2.7k 1/16W Metal Oxide AA

R710 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R711 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R712 VRS-CY1JF680FY J 68 1/16W Metal Oxide AA

R713 VRS-CY1JF272JY J 2.7k 1/16W Metal Oxide AA

R714 VRS-CY1JF151FY J 150 1/16W Metal Oxide AA

R715 VRS-TX2HF330JY J 33 1/2W Metal Oxide AB

R716 VRS-TV1JD562JY J 5.6k 1/10W Metal Oxide AA

R717 VRS-TW2ED150JY J 15 1/4W Metal Oxide AA

R718 VRS-TX2HF472JY J 4.7k 1/2W Metal Oxide AB

R805 VRS-CY1JF561FY J 560 1/16W Metal Oxide AA

R807 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R809 VRS-CY1JF474JY J 470k 1/16W Metal Oxide AA

R811 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R812 VRS-CY1JF333JY J 33k 1/16W Metal Oxide AA

R813 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R815 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R817 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R818 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R820 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R822 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R823 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R824 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R830 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R835 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R836 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R837 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R838 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R839 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R840 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

67

Page 35

LC-13B4E

LC-15B4E

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKB750FE01:LC-13B4E

DUNTKB750FE02:LC-15B4E

MAIN UNIT (Continued)

R841 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R842 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R843 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R845 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R847 VRS-CA1JF220JY J 22 1/16W Metal Oxide AA

R849 VRS-CY1JF102FY J 1k 1/16W Metal Oxide AA

R856 VRS-CY1JF392FY J 3.9k 1/16W Metal Oxide AA

R858 VRS-CY1JF561FY J 560 1/16W Metal Oxide AA

R859 VRS-CY1JF561FY J 560 1/16W Metal Oxide AA

R860 VRS-CY1JF561FY J 560 1/16W Metal Oxide AA

R861 VRS-CY1JF105JY J 1M 1/16W Metal Oxide AA

R872 VRS-CB1JF000JY J 0 1/16W Metal Oxide AC

R873 VRS-CY1JF750JY J 75 1/16W Metal Oxide AA

R874 VRS-CY1JF750JY J 75 1/16W Metal Oxide AA

R875 VRS-CY1JF750JY J 75 1/16W Metal Oxide AA

R1101 VRS-CY1JF273FY J 27k 1/16W Metal Oxide AA

R1102 VRS-CY1JF472FY J 4.7k 1/16W Metal Oxide AA

R1103 VRS-CY1JF472FY J 4.7k 1/16W Metal Oxide AA

R1104 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R1105 VRS-CY1JF391JY J 390 1/16W Metal Oxide AA

R1106 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1107 VRS-CY1JF391JY J 390 1/16W Metal Oxide AA

R1108 VRS-TW2ED102JY J 1k 1/4W Metal Oxide AA

R1109 VRS-TW2ED5R6JY J 5.6 1/4W Metal Oxide AA

R1110 VRS-TW2ED8R2JY J 8.2 1/4W Metal Oxide AA

R1111 VRS-CY1JF103FY J 10k 1/16W Metal Oxide AA

R1112 VRS-CY1JF181JY J 180 1/16W Metal Oxide AA

R1113 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1114 VRS-CY1JF181JY J 180 1/16W Metal Oxide AA

R1115 VRS-TX2HF100JY J 10 1/2W Metal Oxide AB

R1117 VRS-TX2HF5R6JY J 5.6 1/2W Metal Oxide AB

R1118 VRS-TX2HF5R6JY J 5.6 1/2W Metal Oxide AB

R1119 VRS-CY1JF473JY J 47k 1/16W Metal Oxide AA

R1121 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1122 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1123 VRS-TX2HF000JY J 0 1/2W Metal Oxide AB

R1124 VRS-TX2HF101JY J 100 1/2W Metal Oxide AA

R1126 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1128 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1210 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1211 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1212 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R1213 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1216 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R1217 VRS-CB1JF101JY J 100 1/16W Metal Oxide AA

R1218 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R1219 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R1220 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R1221 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1222 VRS-CY1JF105JY J 1M 1/16W Metal Oxide AA

R1223 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1224 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1225 VRS-CY1JF820JY J 82 1/16W Metal Oxide AA

R1226 VRS-CY1JF220JY J 22 1/16W Metal Oxide AA

R1227 VRK-CD1JJ220JY J 22 1/16W Metal Compo AC

R1228 VRK-CD1JJ220JY J 22 1/16W Metal Compo AC

R1229 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1231 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R1232 VRK-CD1JJ220JY J 22 1/16W Metal Compo AC

R1233 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1234 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R1235 VRS-CA1JF220JY J 22 1/16W Metal Oxide AA

R1236 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1237 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1238 VRS-CY1JF220JY J 22 1/16W Metal Oxide AA

R1239 VRS-CY1JF221JY J 220 1/16W Metal Oxide AA

R1240 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1242 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1244 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R1251 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1258 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1259 VRS-CY1JF182JY J 1.8k 1/16W Metal Oxide AA

R1260 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1262 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1601 VRS-TX2HF2R2JY J 2.2 1/2W Metal Oxide AB

R1602 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R1603 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1604 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1605 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1607 VRS-CY1JF391FY J 390 1/16W Metal Oxide AA

R1608 VRS-CY1JF332JY J 3.3k 1/16W Metal Oxide AA

R1609 VRS-CY1JF681JY J 680 1/16W Metal Oxide AA

R1610 VRS-CY1JF391FY J 390 1/16W Metal Oxide AA

R1611 VRS-CY1JF132JY J 1.3k 1/16W Metal Oxide AG

R1612 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1614 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R1615 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R1616 VRS-CY1JF391FY J 390 1/16W Metal Oxide AA

R1617 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1618 VRS-CY1JF102FY J 1k 1/16W Metal Oxide AA

R1619 VRS-CY1JF102FY J 1k 1/16W Metal Oxide AA

R1620 VRS-CY1JF681FY J 680 1/16W Metal Oxide AA

R1621 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1622 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1623 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1624 VRS-CY1JF681FY J 680 1/16W Metal Oxide AA

R1625 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R1627 VRS-CY1JF333JY J 33k 1/16W Metal Oxide AA

R1628 VRS-CY1JF332JY J 3.3k 1/16W Metal Oxide AA

R1629 VRS-CY1JF332JY J 3.3k 1/16W Metal Oxide AA

R1631 VRS-CY1JF222JY J 2.2k 1/16W Metal Oxide AA

R1632 VRS-CB1JF332JY J 3.3k 1/16W Metal Oxide AC

R1635 VRS-CY1JF221JY J 220 1/16W Metal Oxide AA

R1637 VRS-CY1JF221JY J 220 1/16W Metal Oxide AA

R1639 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1642 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1645 VRS-CA1JF221JY J 220 1/16W Metal Oxide AC

R1647 VRS-CY1JF333JY J 33k 1/16W Metal Oxide AA

R1655 VRS-CY1JF102FY J 1k 1/16W Metal Oxide AA

R1656 VRS-CY1JF102FY J 1k 1/16W Metal Oxide AA

R1657 VRS-CY1JF102FY J 1k 1/16W Metal Oxide AA

R1659 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1661 VRS-CY1JF221JY J 220 1/16W Metal Oxide AA

R1664 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1665 VRS-CY1JF332JY J 3.3k 1/16W Metal Oxide AA

R2004 VRS-CY1JF333JY J 33k 1/16W Metal Oxide AA

R2006 VRS-CY1JF1R0JY J 1 1/16W Metal Oxide AA

R2007 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2008 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R2009 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R2010 VRS-CY1JF1R0JY J 1 1/16W Metal Oxide AA

R2011 VRS-CY1JF393JY J 39k 1/16W Metal Oxide AA

R2012 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R2013 VRS-CY1JF333JY J 33k 1/16W Metal Oxide AA

R2014 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R2015 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R2017 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2019 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2020 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2021 VRS-CA1JF102JY J 1k 1/16W Metal Oxide AA

R2022 VRS-CA1JF223JY J 22k 1/16W Metal Oxide AA

R2029 VRS-CA1JF223JY J 22k 1/16W Metal Oxide AA

R2032 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R2033 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2034 VRS-CY1JF512JY J 5.1k 1/16W Metal Oxide AA

R2036 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R2037 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2039 VRS-CY1JF512JY J 5.1k 1/16W Metal Oxide AA

R2041 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2042 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2043 VRS-CY1JF153JY J 15k 1/16W Metal Oxide AA

R2044 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2045 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2046 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2047 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R2049 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

68

Page 36

LC-13B4E

LC-15B4E

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKB750FE01:LC-13B4E

DUNTKB750FE02:LC-15B4E

MAIN UNIT (Continued)

R2050 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R2051 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R2052 VRS-CY1JF512JY J 5.1k 1/16W Metal Oxide AA

R2055 VRS-CB1JF101JY J 100 1/16W Metal Oxide AA

R2056 VRS-CA1JF103JY J 10k 1/16W Metal Oxide AA

R2057 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R2058 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2059 VRS-CA1JF223JY J 22k 1/16W Metal Oxide AA

R2060 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R2061 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R2063 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R2064 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2065 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2066 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R2067 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R2068 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2069 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R2070 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R2071 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2072 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R2073 VRS-CA1JF153JY J 15k 1/16W Metal Oxide AB

R2076 VRS-CB1JF101JY J 100 1/16W Metal Oxide AA

R2077 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R2078 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R2079 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R2080 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R2081 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2082 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2083 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2084 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2085 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R2086 VRS-CA1JF101JY J 100 1/16W Metal Oxide AA

R2087 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R2088 VRS-CY1JF393JY J 39k 1/16W Metal Oxide AA

R2090 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R2093 VRS-CA1JF103JY J 10k 1/16W Metal Oxide AA

R2096 VRS-CA1JF103JY J 10k 1/16W Metal Oxide AA

R2097 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2098 VRS-CY1JF512JY J 5.1k 1/16W Metal Oxide AA

R2099 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R2100 VRS-CY1JF512JY J 5.1k 1/16W Metal Oxide AA

R2101 VRS-CY1JF512JY J 5.1k 1/16W Metal Oxide AA

R2102 VRS-CY1JF512JY J 5.1k 1/16W Metal Oxide AA

R2103 VRS-CY1JF512JY J 5.1k 1/16W Metal Oxide AA

R2104 VRS-CY1JF103JY J 10k 1/16W Metal Oxide AA

R2105 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R7003 VRS-CB1JF000JY J 0 1/16W Metal Oxide AC

R7004 VRS-CB1JF000JY J 0 1/16W Metal Oxide AC

R7006 VRS-CA1JF000JY J 0 1/16W Metal Oxide AB

DUNTKB751FE01:LC-13B4E

DUNTKB751FE02:LC-15B4E

TUNER UNIT

TUNER

NOTE: THE PARTS HERE SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDENTLY.

TU2201 VTUVT4T5FD532 J Tuner BF

INTEGRATED CIRCUITS

IC304 VHiBH3543F+-1Y J BH3543F-E2 AE

IC1901 RH-iX1853BMZZQ J MSP3410G-QG-B8 BB

IC1902 VHiNJM4560M-1Y J NJM4560M AG

IC1905 VHiNJM4560M-1Y J NJM4560M AG

IC2202 VHiMM1506XN-1Y J MM1506XNRE AD

IC3301 VHiLA4635A+-1S J LA4635A AM

IC3501 VHiNJM4560M-1Y J NJM4560M AG

IC3701 VHiNJM2377M-1Y J NJM2377M AK

IC3702 VHiNJM2147M-1Y J NJM2147M-TE1 AF

TRANSISTORS

Q302 VSDTC144EKA-1Y J DTC144EKA AB

Q303 VSFMMT718//-1Y J FMMT718 AE

Q2201 VS2SC3928AR-1Y J 2SC3928AR AB

Q2202 VS2SC3928AR-1Y J 2SC3928AR AB

Q2203 VS2SC3928AR-1Y J 2SC3928AR AB

Q2204 VS2SC3928AR-1Y J 2SC3928AR AB

Q2205 VSiMZ1A////-1Y J IMZ1A AC

Q2206 VSiMZ1A////-1Y J IMZ1A AC

Q3301 VSDTC314TK/-1Y J DTC314TK AC

Q3302 VSDTA144EE/-1Y J DTA144EE AA

Q3303 VS2SC3928AR-1Y J 2SC3928AR AB

Q3304 VSDTC314TK/-1Y J DTC314TK AC

Q3305 VSDTC314TK/-1Y J DTC314TK AC

Q3601 VSUM5K1NTR+-1Y J UM5K1NTR AC

Q3602 VSUM5K1NTR+-1Y J UM5K1NTR AC

Q3606 VSDTC114YE/-1Y J DTC114YE AB

Q3701 VSDTC144EE/-1Y J DTC144EE AA

Q3702 VSFMMT718//-1Y J FMMT718 AE

Q3703 VSFMMT718//-1Y J FMMT718 AE

Q3704 VSDTC144EE/-1Y J DTC144EE AA

Q3705 VSFMY3/////-1Y J FMY3 AB

Q3706 VS2SK2503//-1Y J 2SK2503 AE

Q3707 VSFMMT619//-1Y J FMMT619 AE

Q3708 VS2SC3928AR-1Y J 2SC3928AR AB

Q3709 VSFMY3/////-1Y J FMY3 AB

Q3901 VS2SA1530AR-1Y J 2SA1530AR AB

Q3902 VS2SA1530AR-1Y J 2SA1530AR AB

Q3903 VSDTC314TK/-1Y J DTC314TK AC

Q3904 VS2SC3928AR-1Y J 2SC3928AR AB

Q3905 VSDTC314TK/-1Y J DTC314TK AC

Q3906 VSDTC314TK/-1Y J DTC314TK AC

Q3907 VSDTC314TK/-1Y J DTC314TK AC

FB1201 RBLN-0083GEZZY J Ferrite Bead AB

MISCELLANEOUS P ARTS

FB1601 RBLN-0006TAZZY J Ferrite Bead AB

FB1602 RBLN-0006TAZZY J Ferrite Bead AB

FB1603 RBLN-0006TAZZY J Ferrite Bead AB

FB1604 RBLN-0006TAZZY J Ferrite Bead AB

FB1605 RBLN-0006TAZZY J Ferrite Bead AB

FB1606 RBLN-0006TAZZY J Ferrite Bead AB

FB1607 RBLN-0076TAZZY J Ferrite Bead AC

FB1608 RBLN-0076TAZZY J Ferrite Bead AC

FB1609 RBLN-0076TAZZY J Ferrite Bead AC

FB1610 RBLN-0076TAZZY J Ferrite Bead AC

FB1611 RBLN-0076TAZZY J Ferrite Bead AC

P701 QPLGN0549FJZZY J Plug, 12-pin(MB) AE

P702 QPLGN0274TAZZY J Plug, 2-pin AC

P2001 QPLGN0558REZZY J Plug, 5-pin(MS) AE

SC1202 QSOCNA002WJPZY J Socket, 20-pin(LK) AD

SC1203 QSOCN0687FJZZY J Socket, 50-pin(LS) AF

SC1204 QSOCN0206FJZZY J Socket, 30-pin(LG) AF

SC2002 QSOCN0464FJZZY J Socket, 50-pin(MA) AH

TP2040 QLUGHA002WJZZ J Lug AB

PSP AHA229WJZZ J Spacer

D301 VHDMA3120WA-1Y J Diode AD

DIODES

D302 VHDMA3120WA-1Y J Diode AD

D303 VHDDAN222//-1Y J Diode AA

D1901 RH-EX1271CEZZY J Zener Diode, 12V AB

D2201 RH-EX0906CEZZY J Zener Diode AD

D2202 RH-EX1264CEZZY J Zener Diode AB

D3301 RH-EX1396CEZZY J Zener Diode AB

D3302 VHDDAN222//-1Y J Diode AA

D3601 VHDiMN10///-1Y J Diode AB

D3602 VHDiMN10///-1Y J Diode AB

D3605 VHDDAN222//-1Y J Diode AA

D3608 VHDDAN222//-1Y J Diode AA

D3701 VHDDAN222//-1Y J Diode AA

D3702 VHDDAN222//-1Y J Diode AA

D3705 VHDSFPB56//2EY J Diode AC

D3706 VHDSFPB74//2EY J Diode AD

D3707 VHDSFPB74//2EY J Diode AD

D3709 VHDDAN222//-1Y J Diode AA

D3710 VHD1SS250//1EY J Diode AB

D3711 VHDDAN222//-1Y J Diode AA

69

Page 37

LC-13B4E

LC-15B4E

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKB751FE01:LC-13B4E

DUNTKB751FE02:LC-15B4E

TUNER UNIT (Continued)

D3901 VHDDAN222//-1Y J Diode AA

D3902 VHDDAN222//-1Y J Diode AA

D3903 RH-EX1247CEZZY J Zener Diode, 5.6V AB

D3904 RH-EX1247CEZZY J Zener Diode, 5.6V AB

D3905 RH-EX1271CEZZY J Zener Diode, 12V AB

D3906 RH-EX1271CEZZY J Zener Diode, 12V AB

D3907 RH-EX1271CEZZY J Zener Diode, 12V AB

D3908 RH-EX1271CEZZY J Zener Diode, 12V AB

D3909 RH-EX1271CEZZY J Zener Diode, 12V AB

D5001 RH-EX1271CEZZY J Zener Diode, 12V AB

P ACKAGED CIRCUITS

X1901 RCRSB0250GEZZ J Crystal, 18.432MHz AG

COILS

L1901 VPCGM101M2R1NY J Peaking 100µH AB

L1902 VPCGM4R7MR13NYJ Peaking 4.7µH AB

L2201 VPCGM100MR25NY J Peaking 10µH AB

L2202 VP-1M5R6J1R2NY J Peaking 5.6µH AB

L2203 VP-1M3R3JR93NY J Peaking 3.3µH AB

L2204 VP-1M4R7J1R2NY J Peaking 4.7µH AB

L2205 VP-1M2R7JR85NY J Peaking 2.7µH AB

L2206 VP-1M4R7J1R2NY J Peaking 4.7µH AB

L2207 RCiLPA142WJZZ J Coil AD

L3701 RCiLPA026WJZZ J Coil AD

L3702 RCiLPA144WJZZY J Coil AD

L3703 RCiLPA143WJZZY J Coil AD

L3704 RCiLPA026WJZZ J Coil AD

TRANSFORMER

å T3701 RTRNWA090WJZZY J Transformer AH

CONTROL

R3714 RVR-M0111CEZZY J 1k(B) B+Adj AC

CAPACITORS

C334 VCKYTV1CF105ZY J 1 16V Ceramic AB

C335 VCKYCY1HB682KY J 6800p 50V Ceramic AA

C336 VCKYCY1HB682KY J 6800p 50V Ceramic AA

C338 VCKYTV1CF105ZY J 1 16V Ceramic AB

C339 RC-EZA135WJZZY J 47 6.3V Electrolytic AC

C340 RC-KZ1025CEZZY J 1 10V Ceramic AB

C341 RC-EZA126WJZZY J 47 16V Electrolytic AC

C342 RC-EZA126WJZZY J 47 16V Electrolytic AC

C343 RC-KZ0075TAZZY J 2.2 16V Ceramic AC

C344 RC-KZ0044TAZZY J 10 4.7V Ceramic AD

C345 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C346 RC-KZA043WJZZY J 10 6.3V Ceramic

C1901 RC-EZ0417CEZZY J 150 16V Electrolytic AD

C1902 VCCCCY1HH560JY J 56p 50V Ceramic AB

C1903 VCCCCY1HH5R0CY J 5p 50V Ceramic AA

C1904 VCCCCY1HH5R0CY J 5p 50V Ceramic AA

C1905 RC-KZA041WJZZY J 10 10V Ceramic AC

C1906 RC-KZ1025CEZZY J 1 10V Ceramic AB

C1907 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1908 VCCCCY1HH560JY J 56p 50V Ceramic AB

C1909 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C1910 RC-KZ1025CEZZY J 1 10V Ceramic AB

C1911 RC-KZ1025CEZZY J 1 10V Ceramic AB

C1912 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C1913 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C1914 RC-KZ1025CEZZY J 1 10V Ceramic AB

C1915 RC-KZ1025CEZZY J 1 10V Ceramic AB

C1916 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1917 RC-EZ0417CEZZY J 150 16V Electrolytic AD

C1918 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C1919 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1920 RC-EZA130WJZZY J 3.3 50V Electrolytic AB

C1921 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C1922 RC-KZA041WJZZY J 10 10V Ceramic AC

C1923 RC-KZA041WJZZY J 10 10V Ceramic AC

C1924 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C1925 RC-EZ0417CEZZY J 150 16V Electrolytic AD

C1926 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1927 VCKYCY1HB682KY J 6800p 50V Ceramic AA

C1928 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1929 RC-EZ0417CEZZY J 150 16V Electrolytic AD

C1930 VCKYCY1HB682KY J 6800p 50V Ceramic AA

C1931 VCCCCY1HH101JY J 100p 50V Ceramic AA

C1932 VCKYTV1CF105ZY J 1 16V Ceramic AB

C1933 VCKYTV1CF105ZY J 1 16V Ceramic AB

C1934 RC-KZ0044TAZZY J 4.7 10V Ceramic AD

C1935 VCCCCY1HH101JY J 100p 50V Ceramic AA

C1936 RC-KZ0044TAZZY J 4.7 10V Ceramic AD

C1939 RC-KZA041WJZZY J 10 10V Ceramic AC

C1948 RC-EZA126WJZZY J 47 16V Electrolytic AC

C1950 VCCCCY1HH560JY J 56p 50V Ceramic AB

C1952 VCKYCY1EB223KY J 0.022 25V Ceramic AA

C1954 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1956 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1957 VCKYCY1HB561KY J 560p 50V Ceramic AA

C1958 VCKYCY1HB472KY J 4700p 50V Ceramic AA

C1961 VCKYCY1HB561KY J 560p 50V Ceramic AA

C1963 VCKYCY1EB223KY J 0.022 25V Ceramic AA

C1965 VCKYCY1HB472KY J 4700p 50V Ceramic AA

C1967 VCKYTV1CF105ZY J 1 16V Ceramic AB

C1968 RC-EZA129WJZZY J 2.2 50V Electrolytic AB

C1969 RC-EZA129WJZZY J 2.2 50V Electrolytic AB

C2201 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2203 RC-EZA123WJZZY J 100 6.3V Electrolytic AC

C2204 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2205 VCCCCY1HH101JY J 100p 50V Ceramic AA

C2206 VCCCCY1HH101JY J 100p 50V Ceramic AA

C2207 VCEASH1CN477MY J 470 16V Electrolytic AD

C2208 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2209 VCKYCY1HF103ZY J 0.01 50V Ceramic AA

C2210 RC-EZA128WJZZY J 1 50V Electrolytic AB

C2211 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C2212 VCCCCY1HH121JY J 120p 50V Ceramic AA

C2213 VCCCCY1HH820JY J 82p 50V Ceramic AA

C2214 VCCCCY1HH101JY J 100p 50V Ceramic AA

C2215 VCCCCY1HH180JY J 18p 50V Ceramic AA

C2216 VCCCCY1HH121JY J 120p 50V Ceramic AA

C2217 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C2218 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2219 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2220 RC-EZA124WJZZY J 10 16V Electrolytic AB

C2221 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C2222 RC-KZA041WJZZY J 10 10V Ceramic AC

C2223 VCEASH1CN477MY J 470 16V Electrolytic AD

C2224 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2225 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2226 RC-EZ1351CEZZ J 3300 6.3V Electrolytic AF

C2227 RC-EZA126WJZZY J 47 16V Electrolytic AC

C2228 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3301 RC-KZA041WJZZY J 10 10V Ceramic AC

C3302 RC-EZA129WJZZY J 2.2 50V Electrolytic AB

C3303 VCEASH1CN337MY J 330 16V Electrolytic AE

C3304 RC-EZA129WJZZY J 2.2 50V Electrolytic AB

C3305 RC-EZA127WJZZY J 100 16V Electrolytic AC

C3306 RC-EZA128WJZZY J 1 50V Electrolytic AB

C3307 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C3308 RC-EZA128WJZZY J 1 50V Electrolytic AB

C3309 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C3311 RC-EZA124WJZZY J 10 16V Electrolytic AB

C3312 VCKYTV1CF105ZY J 1 16V Ceramic AB

C3314 RC-EZ1274CEZZ J 1000 16V Electrolytic AD

C3315 RC-EZ1274CEZZ J 1000 16V Electrolytic AD

C3316 VCEASH1CN477MY J 470 16V Electrolytic AD

C3501 VCKYCY1EB223KY J 0.022 25V Ceramic AA

C3502 VCKYCY1EB223KY J 0.022 25V Ceramic AA

C3503 VCCCCY1HH101JY J 100p 50V Ceramic AA

C3504 RC-KZ0044TAZZY J 4.7 10V Ceramic AD

C3505 VCCCCY1HH101JY J 100p 50V Ceramic AA

C3506 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3507 RC-EZ0417CEZZY J 150 16V Electrolytic AD

70

Page 38

LC-13B4E

LC-15B4E

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKB751FE01:LC-13B4E

DUNTKB751FE02:LC-15B4E

TUNER UNIT

C3508 RC-KZ0044TAZZY J 4.7 10V Ceramic AD

C3509 RC-KZA041WJZZY J 10 10V Ceramic AC

C3510 VCKYTV1CF105ZY J 1 16V Ceramic AB

C3511 VCKYTV1CF105ZY J 1 16V Ceramic AB

C3512 VCKYCY1HB682KY J 6800p 50V Ceramic AA

C3513 VCKYCY1HB682KY J 6800p 50V Ceramic AA

C3601 RC-KZ0072TAZZY J 1 25V Ceramic AC

C3602 RC-KZ0072TAZZY J 1 25V Ceramic AC

C3603 RC-KZ0072TAZZY J 1 25V Ceramic AC

C3604 RC-KZ0072TAZZY J 1 25V Ceramic AC

C3702 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3703 RC-KZ1025CEZZY J 1 10V Ceramic AB

C3705 VCKYCY1EB103KY J 0.01 25V Ceramic AA

C3706 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3708 RC-EZA140WJZZY J 4.7 25V Electrolytic AB

C3709 VCEAPT1CN226MY J 22 16V Electrolytic AC

C3710 VCCCCY1HH471JY J 470p 50V Ceramic AA

C3711 VCKYCY1HB562KY J 5600p 50V Ceramic AA

C3712 RC-KZ1025CEZZY J 1 10V Ceramic AB

C3713 VCAAPF1CJ826MY J 82 16V Electrolytic AG

C3714 VCKYCY1HB562KY J 5600p 50V Ceramic AA

C3715 VCCCCY1HH181JY J 180p 50V Ceramic AA

C3716 VCEASH1HN476MY J 47 50V Electrolytic AD

C3717 VCEASH1CN337MY J 330 16V Electrolytic AE

C3718 VCKYTV1CF105ZY J 1 16V Ceramic AB

C3719 VCEASH1CN337MY J 330 16V Electrolytic AE

C3721 VCKYCY1HF104ZY J 0.1 50V Ceramic AA

C3722 VCKYTV1CF105ZY J 1 16V Ceramic AB

C3723 VCAAPF0JJ157MY J 150 6.3V Electrolytic AG

C3724 VCKYTV1CF105ZY J 1 16V Ceramic AB

C3726 VCEASH1CN477MY J 470 16V Electrolytic AD

C3727 RC-EZ1339CEZZY J 220 16V Electrolytic AD

C3728 VCKYTV1CF105ZY J 1 16V Ceramic AB

C3729 VCKYCY1HF104ZY J 0.1 50V Ceramic AA

C3730 VCKYCY1HF104ZY J 0.1 50V Ceramic AA

C3731 RC-KZ1025CEZZY J 1 10V Ceramic AB

C3732 RC-KZ1025CEZZY J 1 10V Ceramic AB

C3733 VCKYCY1HF103ZY J 0.01 50V Ceramic AA

C3734 RC-KZ0075TAZZY J 2.2 16V Ceramic AC

C3735 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3736 RC-KZ1025CEZZY J 1 10V Ceramic AB

C3737 RC-EZA127WJZZY J 100 16V Electrolytic AC

C3901 RC-EZA123WJZZY J 100 6.3V Electrolytic AC

C3902 RC-EZA126WJZZY J 47 16V Electrolytic AC

C3903 RC-KZA041WJZZY J 10 10V Ceramic AC

C3904 RC-KZA041WJZZY J 10 10V Ceramic AC

C3905 RC-EZA126WJZZY J 47 16V Electrolytic AC

C3906 VCCCCY1HH221JY J 220p 50V Ceramic AA

C3907 VCCCCY1HH101JY J 100p 50V Ceramic AA

C3908 RC-KZA041WJZZY J 10 10V Ceramic AC

C3909 RC-KZA041WJZZY J 10 10V Ceramic AC

C3910 VCCCCY1HH221JY J 220p 50V Ceramic AA

C3911 VCCCCY1HH221JY J 220p 50V Ceramic AA

C3912 VCCCCY1HH101JY J 100p 50V Ceramic AA

C3913 VCCCCY1HH221JY J 220p 50V Ceramic AA

C3914 VCCCCY1HH101JY J 100p 50V Ceramic AA

C3915 VCCCCY1HH101JY J 100p 50V Ceramic AA

C5001 VCKYCY1HB222KY J 2200p 50V Ceramic AA

C5002 VCKYCY1HB222KY J 2200p 50V Ceramic AA

C5003 RC-KZA041WJZZY J 10 10V Ceramic AC

RESISTORS

R345 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R346 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R350 VRS-CY1JF392JY J 3.9k 1/16W Metal Oxide AA

R351 VRS-CY1JF392JY J 3.9k 1/16W Metal Oxide AA

R352 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R353 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R354 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R355 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R358 VRS-CY1JF123JY J 12k 1/16W Metal Oxide AA

R361 VRS-CY1JF562JY J 5.6k 1/16W Metal Oxide AA

R362 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1901 VRS-CA1JF102JY J 1k 1/16W Metal Oxide AA

R1902 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R1903 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R1904 VRS-CY1JF105JY J 1M 1/16W Metal Oxide AA

R1907 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1908 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R1911 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1912 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R1913 VRS-CY1JF471JY J 470 1/16W Metal Oxide AA

R1914 VRS-CY1JF122JY J 1.2k 1/16W Metal Oxide AA

R1915 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R1916 VRS-CY1JF562JY J 5.6k 1/16W Metal Oxide AA

R1917 VRS-CY1JF122JY J 1.2k 1/16W Metal Oxide AA

R1918 VRS-CY1JF562JY J 5.6k 1/16W Metal Oxide AA

R1919 VRS-CY1JF471JY J 470 1/16W Metal Oxide AA

R1920 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R1921 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R1923 VRS-CY1JF473JY J 47k 1/16W Metal Oxide AA

R1924 VRS-CY1JF473JY J 47k 1/16W Metal Oxide AA

R1927 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R1928 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1932 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1933 VRS-CY1JF153JY J 15k 1/16W Metal Oxide AA

R1945 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R1947 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R1948 VRS-CY1JF102FY J 1k 1/16W Metal Oxide AA

R1950 VRS-CY1JF392FY J 3.9k 1/16W Metal Oxide AA

R1952 VRS-CY1JF123FY J 12k 1/16W Metal Oxide AA

R1953 VRS-CY1JF392FY J 3.9k 1/16W Metal Oxide AA

R1954 VRS-CY1JF123FY J 12k 1/16W Metal Oxide AA