Page 1

SERVICE MANUAL

SUPPLEMENT

LCD COLOR TELEVISION

LC-10A3U

SUPPLEMENT

SX2T7LC-10A3U

MODEL

LC-10A3U

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

OUTLINE

The 10" LCD panel used in the LC-10A3U has been redsigned as from the October 2002 production.

Accordingly, the circuitly, LCD panel and its peripheral parts have been partially changed.

This Service manual covers all the changes.

How to identify the newly designed sets

(1) The marking A is given on the model label at the bottom of the set.

(2) Serial numbers

210451112~

OCTOBER2002~

(3) The marking "A" is given on the label at the packing case.

LCD COLOR TV

MODEL

MODÉLE

ELECTRICAL RATING

DC 12V 24W

CONSOMMATION

CC 12V 24W

SERIAL NO. 210451112

N DE SERIE

MANUFACTURED OCTOBER 2002

DATE DE PRODUCTION OCTOBER 2002

SHARP CORPORATION

FABRIQUÉ AU JAPON

LC-10A3U-S A

MADE IN JAPAN

A Mark

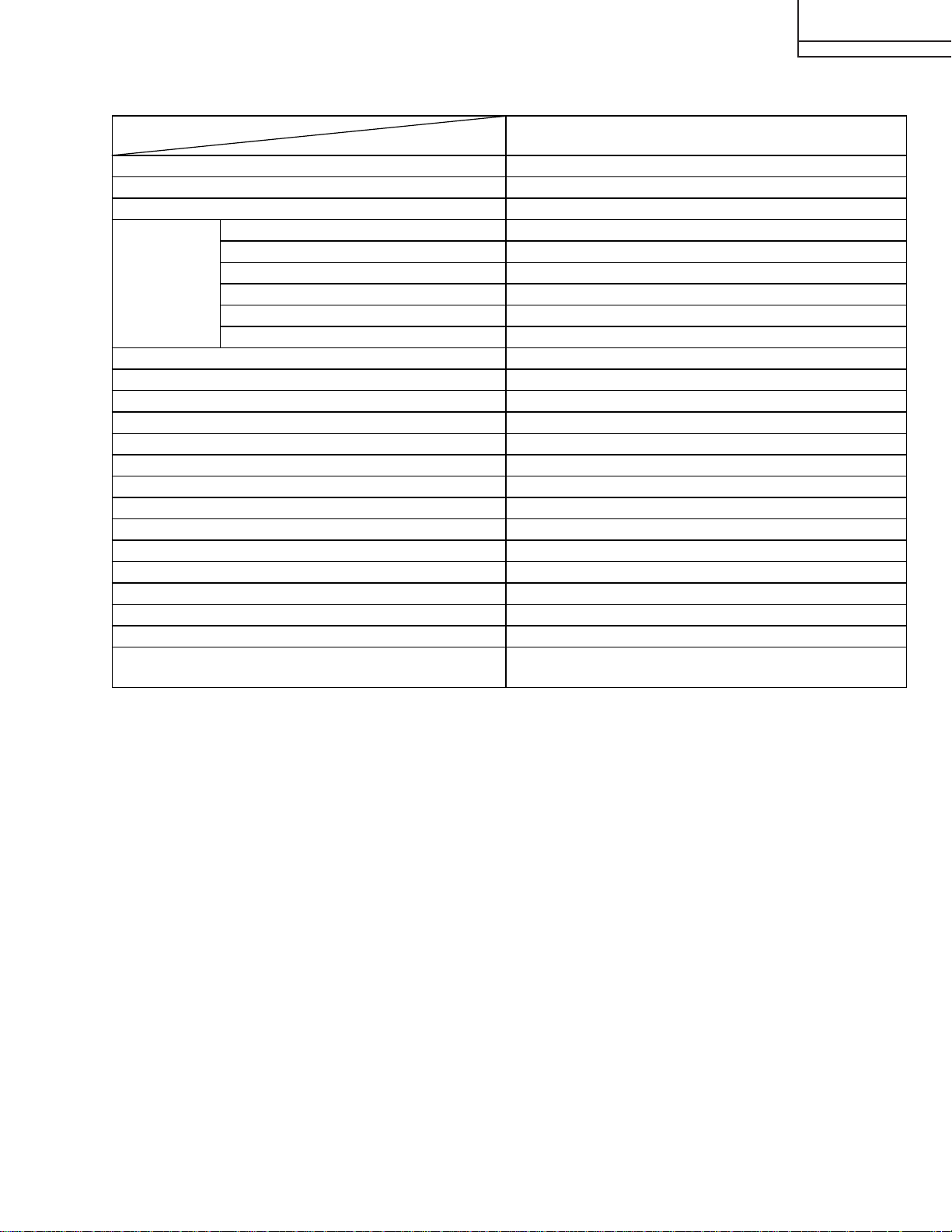

CONTENTS

Page

» IMPORTANT SERVICE SAFETY PRECAUTION.................................................................................... 2

» SPECIFICATIONS ................................................................................................................................... 5

» OPERATION MANUAL ............................................................................................................................ 6

» DIMENSIONS .......................................................................................................................................... 7

» REMOVING OF MAJOR PARTS ............................................................................................................. 8

» ADJUSTING PROCEDURE OF EACH SECTION ................................................................................ 11

» TROUBLE SHOOTING TABLE.............................................................................................................. 14

» CHASSIS LAYOUT ................................................................................................................................ 18

» BLOCK DIAGRAM ................................................................................................................................. 20

» OVERALL WIRING DIAGRAM .............................................................................................................. 22

» DESCRIPTION OF SCHEMATIC DIAGRAM ........................................................................................ 24

» SCHEMATIC DIAGRAM ........................................................................................................................ 25

» PRINTED WIRING BOARD ASSEMBLIES........................................................................................... 32

» PARTS LIST ........................................................................................................................................... 39

» PACKING OF THE SET ......................................................................................................................... 49

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-10A3U

2

2

SUPPLEMENT

IMPORTANT SERVICE SAFETY PRECAUTION

Ë

Service work should be perfomed only by qualified service technicians who are thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CONTINUED

PROTECTION A GAINST A RISK OF

FIRE REPLACE ONLY WITH SAME

TYPE F3701 (1.6A, 125V),

A V

F3702(1.6A, 125V) AND F3751

(2.5A, 125V) FUSE.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks:

1. Inspect all lead dress to make certain that leads are

not pinched, and check that hardware is not lodged

between the chassis and other metal parts in the

receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

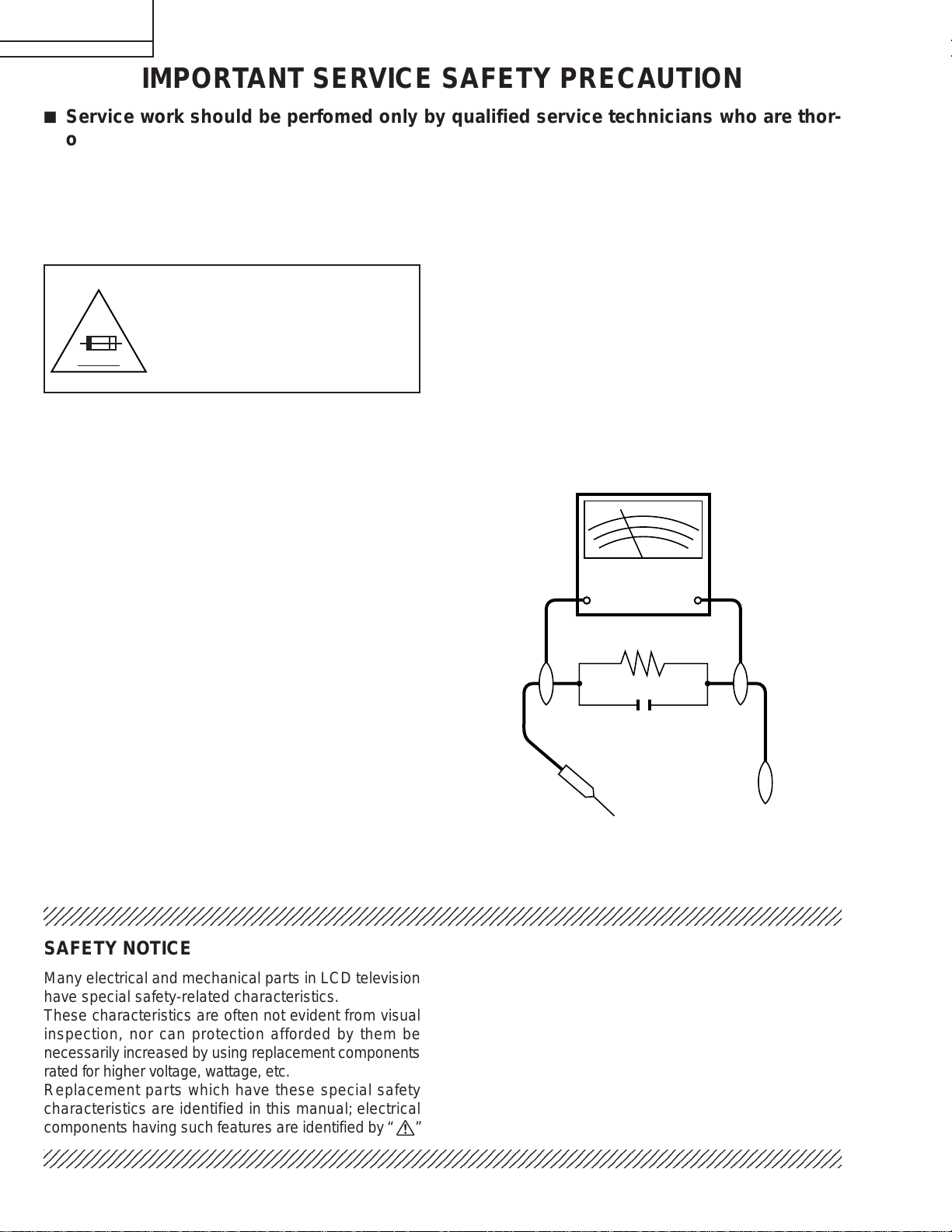

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

• Plug the AC cord directly into a 110~240 volt A C outlet,

and connect the DC power cable into the receiver's

DC jack. (Do not use an isolation transformer for this

test).

• Using two clip leads, connect a 50k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as electrical conduit or electrical ground

connected to an earth ground.

• Use an AC voltmeter ha ving with 5000 ohm per volt, or

higher, sensitivity or measure the AC voltage drop

across the resisor.

• Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

All checks must be repeated with the AC cord plug

connection reversed. (If necessar y, a nonpolarized

adaptor plug must be used only for the purpose of

completing these checks.)

Any reading of 0.75V peak (this corresponds to 0.5

milliamp. peak A C .) or more is e xcessive and indicates

a potential shock hazard which must be corrected

before returning the monitor to the owner .

DVM

AC SCALE

50k ohm

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in LCD television

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage , w attage , etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

and shaded areas in the

Schematic Diagrams

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of a substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock, fire or other hazards.

components having such features are identified by “ å”

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

Replacement Parts Lists

.

and

Page 3

LC-10A3U

2

2

2

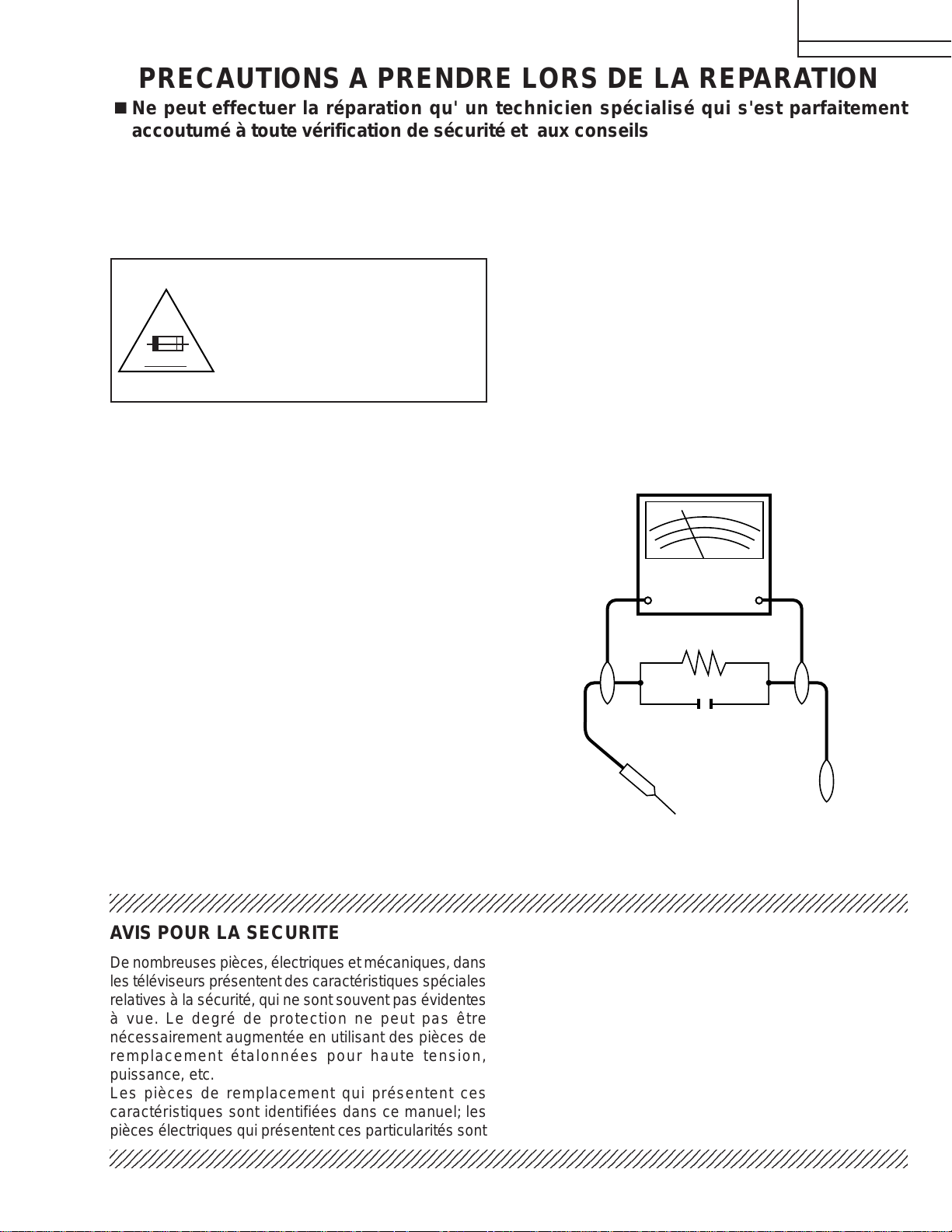

VTVM

ECHELLE CA

50k ohm

10W

0.15 µF

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

SUPPLEMENT

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ë

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement

accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

• Utiliser un voltmètre CA d'une sensibilité d'au moins

5000Ω/V pour mesurer la chute de tension en travers

1. N'entreprendre aucune modification de tout circuit.

C'est dangereux.

2. Débrancher le récepteur av ant toute réparation.

de la résistance.

• Toucher avec la sonde d'essai les pièces métalliques

exposées qui présentent une voie de retour au châssis

(antenne, coffret métallique, tête des vis, arbres de

A V

PRECAUTION: POUR LA

PRO TECTION CONTINUE CONTRE

LES RISQUES D'INCENDIE,

REMPLACER LE FUSIBLE PAR UN

FUSIBLE DE MEME TYPE F3701

(1.6A, 125V), F3702 (1.6A, 125V),

F3751(2.5A, 125V).

commande et des boutons, écusson, etc.) et mesurer

la chute de tension CA en-travers de la résistance.

Toutes les vérifications doivent être refaites après a voir

inversé la fiche du cordon d'alimentation. (Si nécessaire,

une prise d'adpatation non polarisée peut être utilisée

dans le but de terminer ces vérifications.)

Tous les courants mesurés ne doivent pas dépasser

0,5 mA.

VERIFICATIONS CONTRE L'INCEN-DIE ET

LE CHOC ELECTRIQUE

Dans le cas contraire, il y a une possibilité de choc

électrique qui doit être supprimée avant de rendre le

récepteur au client.

Avant de rendre le récepteur à l'utilisateur, effectuer

les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour s'assurer

que les fils ne soient pas pincés ou qu'un outil ne soit

pas placé entre le châssis et les autres pièces

métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme les

boutons de commande non-métalliques, les isolants,

le dos du coffret, les couvercles ou blindages de réglage

et de compartiment, les réseaux de résistancecapacité, les isolateurs mécaniques, etc.

3. S'assurer qu'il n'y ait pas de danger d'électrocution en

vérifiant la fuite de courant, de la facon suiv ante:

• Brancher le cordon d'alimentation directem-ent à une

prise de courant de 110-240V. (Ne pas utiliser de

transformateur d'isolation pour cet essai).

• A l'aide de deux fils à pinces, brancher une résistance

de 50 kΩ 10 watts en parallèle avec un condensateur

de 0,15µF en série avec toutes les pièces métalliques

exposées du coffret et une terre connue comme une

conduite électrique ou une prise de terre branchée à

la terre.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les téléviseurs présentent des caractéristiques spéciales

relatives à la sécurité, qui ne sont souvent pas évidentes

à vue. Le degré de protection ne peut pas être

nécessairement augmentée en utilisant des pièces de

remplacement étalonnées pour haute tension,

puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel; les

pièces électriques qui présentent ces particularités sont

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

identifiées par la marque " å " et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques.

Pour assurer la protection, ces pièces doivent être

identiques à celles utilisées dans le circuit d'origine.

L'utilisation de pièces qui n'ont pas les mêmes

caractéristiques que les pièces recommandées par

l'usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies, radiations X ou autres

accidents.

3

Page 4

LC-10A3U

SUPPLEMENT

Precautions for using lead-free solder

1 Employing lead-free solder

"Main PWB" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached

on the PWBs and service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40ºC, we recommend

you to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldening

bit, contact our service station or service ranch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead

solder by 40°C, and as it has poor solder wettabillty, you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, Since the land may be peeled off or the maximum heat-resistance

temperature of parts may be excoeded, remove the bit from the PWB as soon as y ou conurm the steady soldering

condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to tum on

and off the power of the bit as required.

if a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No, ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

4

Page 5

SPECIFICATIONS

ITEMS

LC-10A3U

MODEL

LCD panel 10.4” TFT LCD

Number of pixels 921,600 pixels VGA

Video color systems N358, N443, PAL, PAL-M, PAL-N, SECAM, PAL-60

Destination USA/Latin A/Twn

TV Standard (CCIR) NTSC/PAL-M/PAL-N

TV TV Tuning System PLL 181 ch.

FUNCTION STEREO AV STEREO

EZ SETUP Yes

CATV 125 ch.

4-LINE COMB FILTER Yes

Brightness 400 cd/m

2

Lamp life 60,000 Hours

Viewing angles H: 120° V: 100°

Audio amplifier 1.0 W × 2

Speakers 1-3/16 × 1-37/64 in. (3 × 4 cm), 2 pcs

Terminals AV1 AV-IN 1, S-IN

AV2 AV-IN 2

AV OUT AV-OUT

ANT F-Type

H/P Mini-jack for stereo (3.5 ø) (Rear)

OSD LANGUAGE English/French/Spanish

Power supply DC 12 V, AC110-240 V

Weight 3.97 lbs (1.8 kg) w/o accessories

Accessories R/C, Batteries, Wall mount parts, Antenna cable,

AC adapter, AC cord

■

Design and specifications are subject to change without notice.

LC-10A3U

SUPPLEMENT

5

Page 6

LC-10A3U

SUPPLEMENT

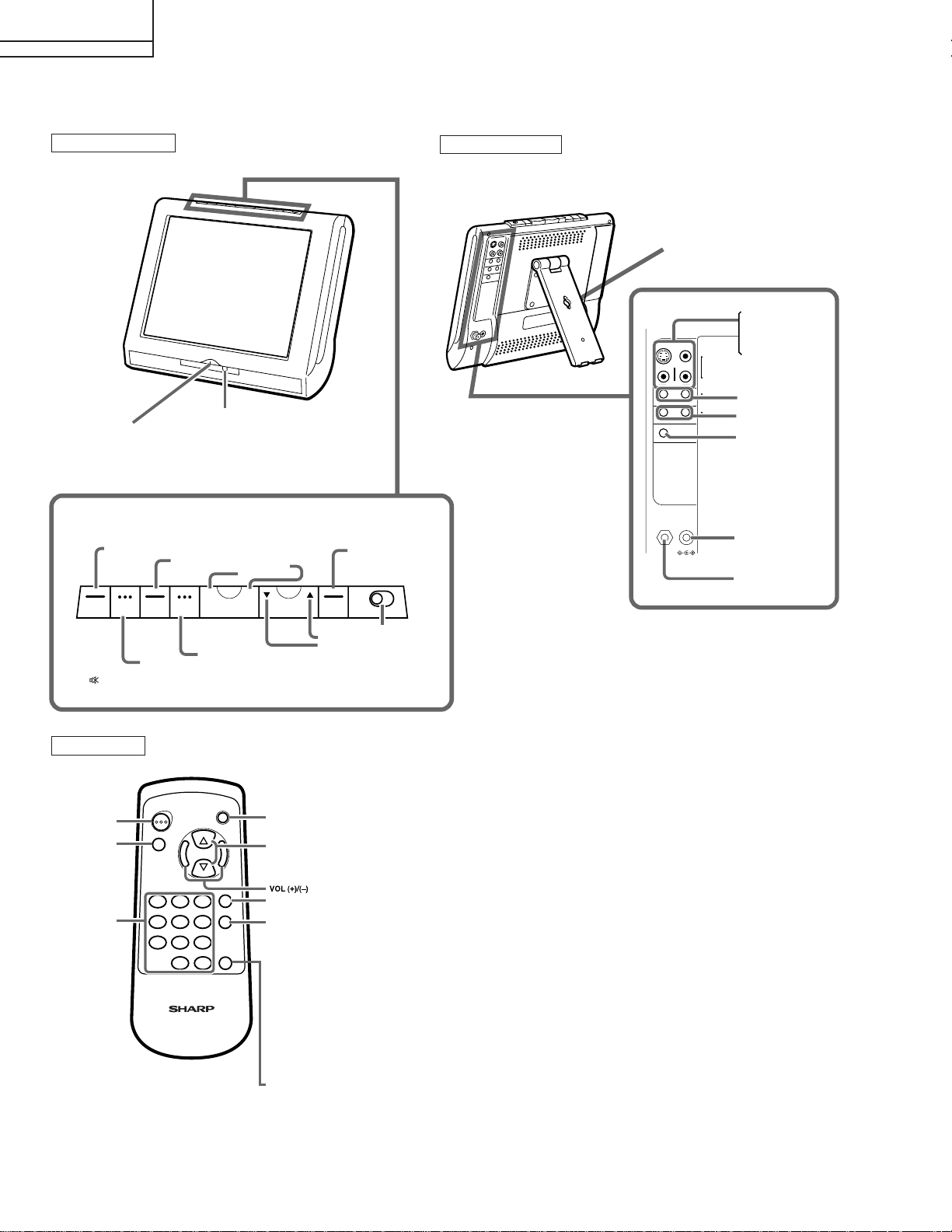

OPERATION MANUAL

Main unit (front view)

Remote sensor window

Power/standby indicator

A green indicator lights when the power is on and a red indicator

lights when in the standby mode (the indicator will not light when

the power is off).

(The actual location is not visible)

Top control panel

BRIGHT

BRIGHT

MUTE

■

The (MUTE), DISPLAY, MENU, VOLUME UP(+)/DOWN(–), CHANNEL UP(▲▲)/DOWN(▼

provide the same functions as the buttons on the remote control.

buttons

button has a slightly different function from the remote control button.)

(The

MENU

DISPLA

MUTE

Y

DISPLAY

MENU

-

VOL CH

MENU

VOLUME UP (+)/

DOWN (—)

+

TV/VIDEO

CHANNEL UP ( )

DOWN ( )

TV/VIDEO

OFF ON

MAIN POWER

▼

MAIN POWER

), and TV/VIDEO

Main unit (rear view)

Adjust the set stand to an angle so that

the screen is easily visible. The set stand

can be opened up to 80 .

Rear terminal section

AV input 1

terminal

AV-IN1

AV-IN2

AV-OUT

S-Video input

Video input

Audio R/L

AV input 2

terminal

AV output

terminal

Headphone output

terminal

DC input terminal

S

V

L

R

AUDIO

Audio

V

Audio

V

HEADPHONE

POWER

INPUT

ANT

DC12V

Antenna input terminal

Remote control

POWER

TV/VIDEO

CHANNEL SELECT

POWER

TV/VIDEO

VOL

-

1123

456

8

7

000

LCDTV

CH

CH

FLASHBACK

9

MENU

DISPLAY

MUTE

MENU

▲

CH ( )/( )

VOL

+

▼

▲

Selects next higher channel

Selects next lower channel

▼

FLASHBACK

Returns to previous channel

DISPLAY

Press....Displays receiving channel for 10 seconds.

Channel indication reduces in size after

about 10 seconds.

Press again....After the CH call is displayed in large

size, COLOR SYSTEM except N358

and is displayed for 10 seconds, and

then CH will be displayed in small

size only.

Small CH display

The above three displays can

be switched.

MUTE

Press....Stops sound.

↓

↓

No display

↓

6

Page 7

DIMENSIONS

LC-10A3U

SUPPLEMENT

Unit:inch (mm)

7

Page 8

LC-10A3U

SUPPLEMENT

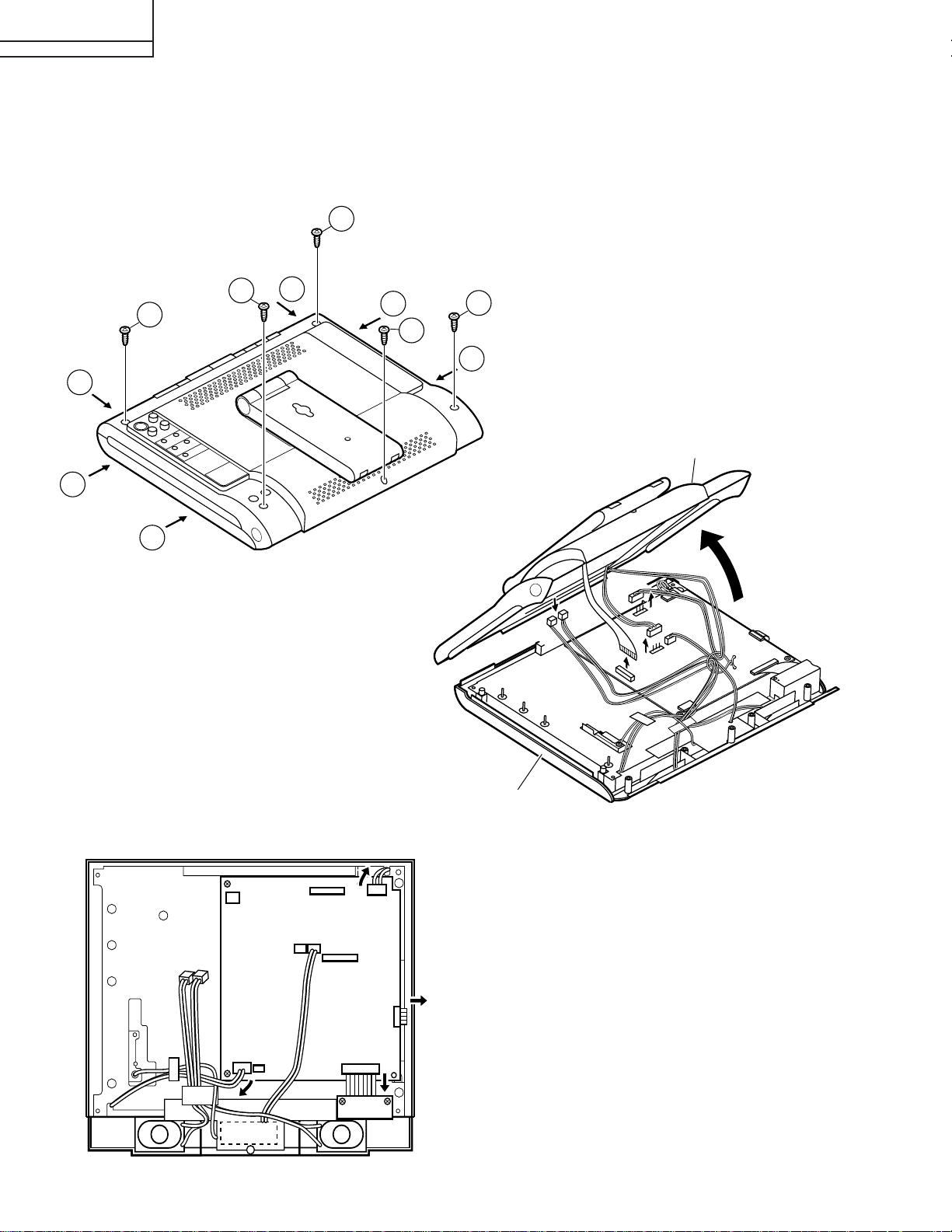

REMOVING OF MAJOR PARTS

1. Remove the five lock screws 1 off the cabinet B.

2. Push on the six hooks 2 of the cabinet B and open it slightly.

3. Disconnect all the connectors 3 from the tuner and switch PWBs. Detach the cabinet B.

4. Disconnect all the connectors 4 from the main PWB.

1

1

1

2

2

1

1

2

2

Cabinet

B

2

2

3

P3203

P3204

3

P701

P2001

SC401

3

3

P301

P2001

(Main PWB)

(Main PWB)

4

P752

P401 SC1201

P701

P2002

4

P751

SC1203

4

Cabinet A

4

8

Page 9

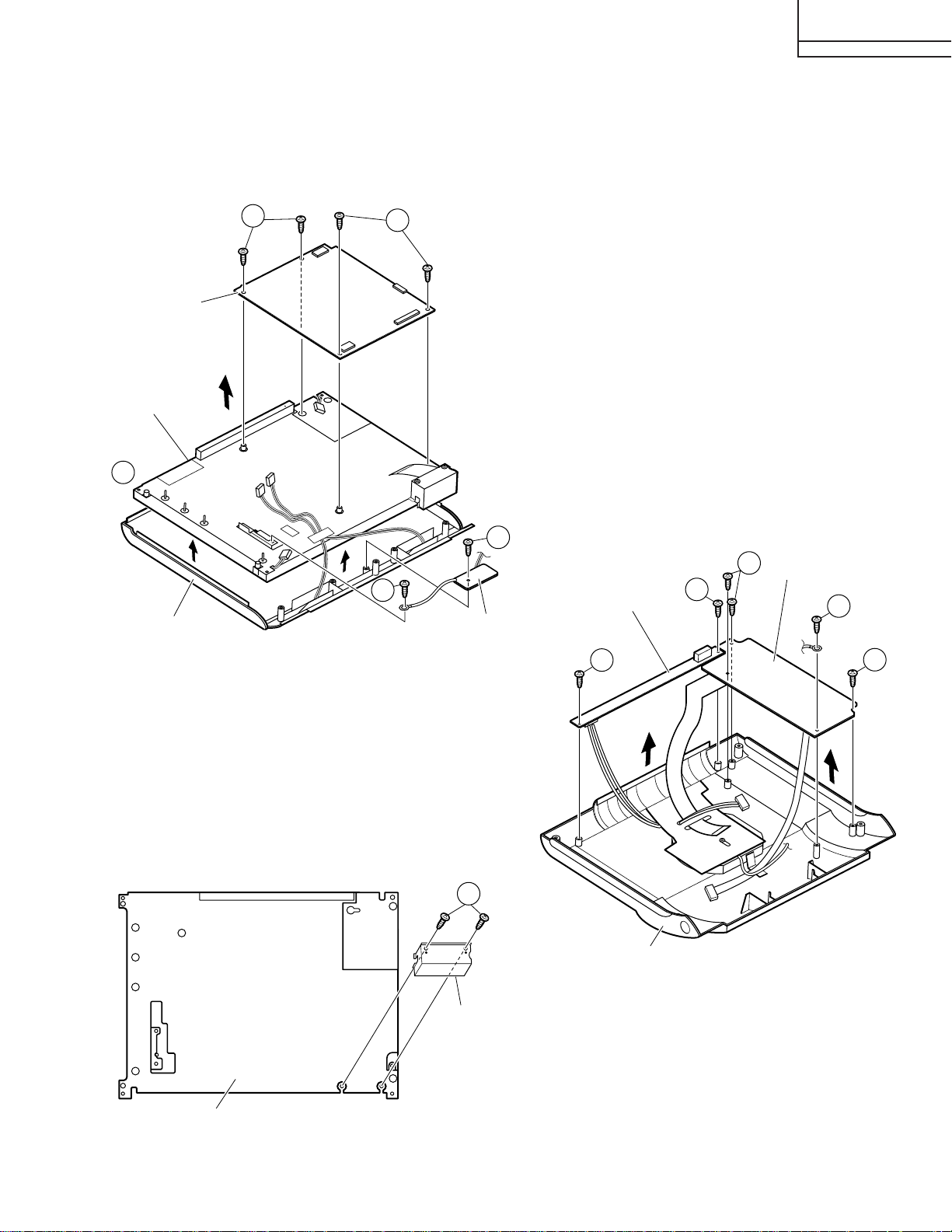

5. Remove the four lock screws 5 off the main PWB.

6. Peel off the tapes 6 and detach the LCD panel unit.

7. Remove the two lock screws 7 off the R/C, LED PWB.

8. Remove the two lock screws 8 off the terminal PWB.

9. Remove the two lock screws 9 off the switch PWB.

10.Remove the two lock screws 0 off the flexible shield.

LC-10A3U

SUPPLEMENT

Main PWB

LC display unit

6

Cabinet A

5

5

7

8

Tuner PWB

7

Switch PWB

R/C, LED PWB

9

9

8

8

10" LCD Panel unit ass’y

(Rear view)

10

Cabinet B

Flexible shield

9

Page 10

LC-10A3U

SUPPLEMENT

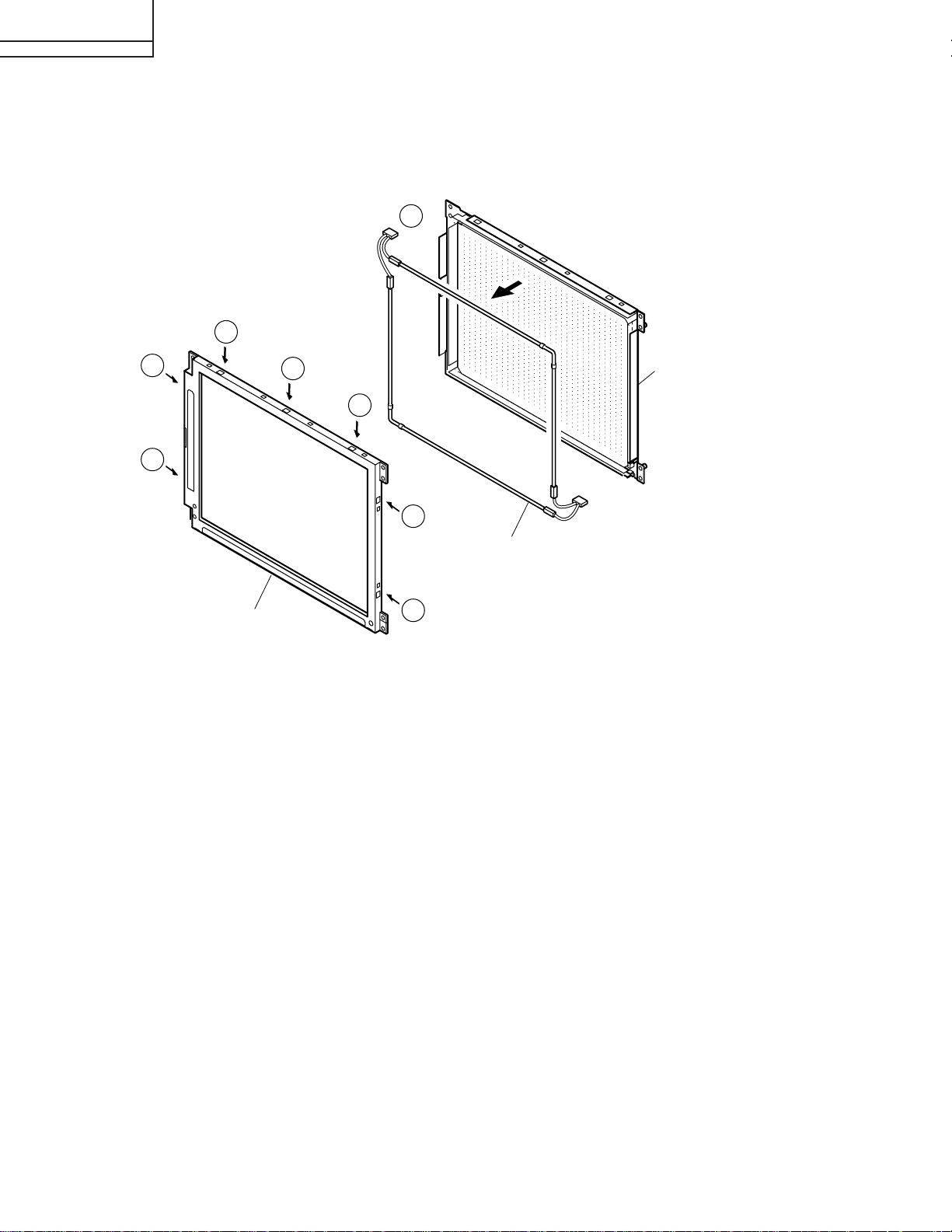

11.Undo the seven hooks q to release the unit frame.

12.Detach the fluorescent lampw.

11

12

11

11

11

10" LCD panel unit

Panel Holder

11

11

Lamp unit

11

10

Page 11

LC-10A3U

SUPPLEMENT

ADJUSTING PROCEDURE OF EACH SECTION

The best adjustment is made before shipping. If any position deviation is found or after part replace is performed, adjust

as follows.

1.Preparation for Adjustments

(1)Use the exclusive-use AC adapter or stable DC power supply.

AC adapter: UADP-0227CEPZ

DC power supply: 12 ± 0.5V

2.Special mode setting procedure

(1)After initialization of E2PROM the mode is changed to the adjustment mode.

[Procedure]

Connect TP2001 and TP2002 to GND, and turn on the power.

[Description]

» The initialization of microcomputer is as follows.

» AV position, DAC data, G/A data, sound processor data, and video chroma data adjustment values are taken as

defaults.

(2)Adjustment mode

[Procedure]

Short-circuit TP2001 to GND, and turn on the power.

Or short-circuit TP2002 to GND, and turn on the power.

Or holding down the [TV/VIDEO] key and [MENU] key, turn on the main power, and simultaneously press the

(inspection process) [CH "] key and [VOL– ] key to change the mode to the adjustment mode.

[Description]

The manual adjustment or adjustment through communication with the automatic machine is performed.

(3)Inspection mode

[Procedure]

Holding down the [TV/VIDEO] key and [MENU] key, turn on the power.

[Description]

» In the ordinary menu select “VIDEO ADJUST” with the [CH] key, and decide with the [VOL] key. Then select

“PICTURE”, “TINT (only NTSC)”, “COLOR”, “BLACK LEVEL”, “SHARPNESS”, “RED-BLUE”, “GREEN” and

“COLOR SYSTEM” with the [CH] key, and decide with the [VOL] key. After that, adjust values with the [VOL] key.

» VOLUME, PICTURE, TINT (only NTSC), COLOR, BLACK LEVEL, SHARPNESS, RED-BLUE, GREEN change

as follows.

Min. Center Max.

(4)Shipping setting mode

[Procedure]

Holding down the [TV/VIDEO] key and [MENU] key, turn on the main power, and simultaneously press the

(inspection process) [CH '] key and [VOL+] key to change the mode to the shipping setting mode.

[Description]

User adjustment and other values are taken as defaults.

If TV is indicated as SETTING COMPLETE, setting has been completed.

3.Cancel of special mode

Turn off the main unit power.

11

Page 12

LC-10A3U

SUPPLEMENT

4.Reset of lamp error

If the power LED remains red an the power is not turned on, or if repair has been performed, enter the adjustment

mode to reset the lamp error.

For the resetting procedure, refer to "No power" in the "trouble shooting Table" section.

5.Adjustments

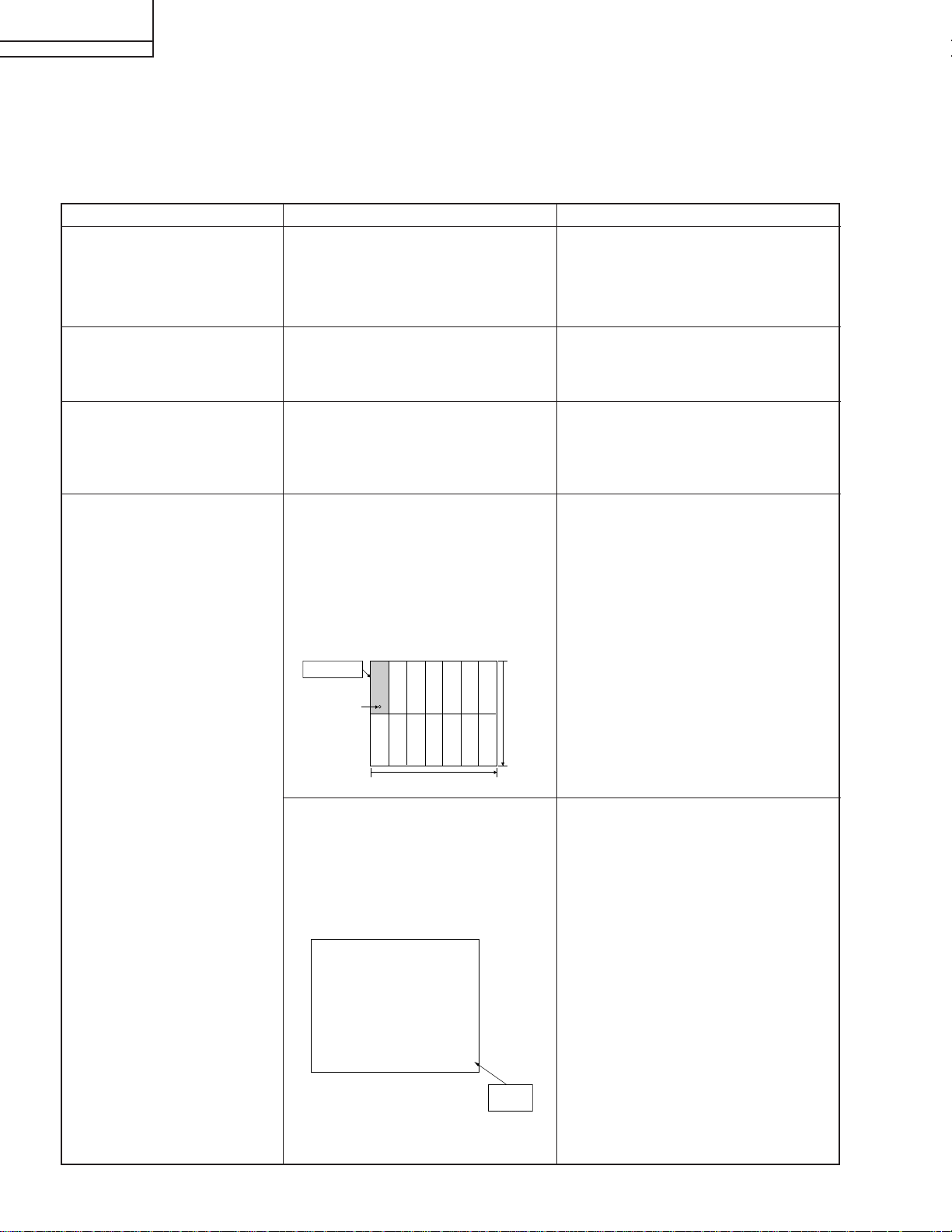

Adjustment Adjusting conditions Adjusting method

1 B+ Adjustment

(If E2PROM is replaced)

(IC2004)

2 Inch Size setup

(If E2PROM is replaced)

(IC2004)

3 Common-bias

adjustment

4 TAMP adjustment

1. Connect the DC voltmeter to pin (49)

of SC401.

1. Go to the adjustment mode.

1. Receive a B/W channel.

2. Go to the adjustment mode.

3. Select the "COM BIAS" with [MENU]

key.

1. In the TV mode, the unit receives a

picture of the half color bar signal

whose left top corner is 75% white.

The signal does not have to be the

half color bar as long as the 180th

line from the top and 46th pixel from

the left is 75% white. (Data at this

point is used for adjustment.)

Upper left 75%

1. Adjust the "B+ Adj" value to

5.0 ± 0.02V with [VOL+] or [VOL-]

key.

* The color of "+B Adj" must be yellow.

1. Select "MODEL" and adjust to "A2U"

with [VOL +] or [VOL –] key.

* The color of "MODEL" must be yellow.

1. Adjust "COM BIAS" to the darkest

screen with [VOL +] and [VOL –] key.

* The color of "COM BIAS" must be

yellow.

Vertical: 180th line

Horizontal: 46th pixel

640 pixels

480 lines

2. Adjust "NTSC TAMP" on the page 2

of the adjustment process mode so

that the "Y" value on the same page

falls between B0 - BA.

Page 2 of the adjustment process

mode

2

| COM BIAS 140

NTSC TAMP 27

SECAM TAMP 27

PAL-M TAMP 27

PAL-N TAMP 27

TV H-PEAKING 3

RCUTOFF +3

GCUTOFF 0

BCUTOFF -9

G3 B3 R3 00 00 00

G1 B4 Y DF DE B5

Y-Data

(White 75%)

3. Set the values of PAL-M TAMP and

PAL-N TAMP same.

12

Page 13

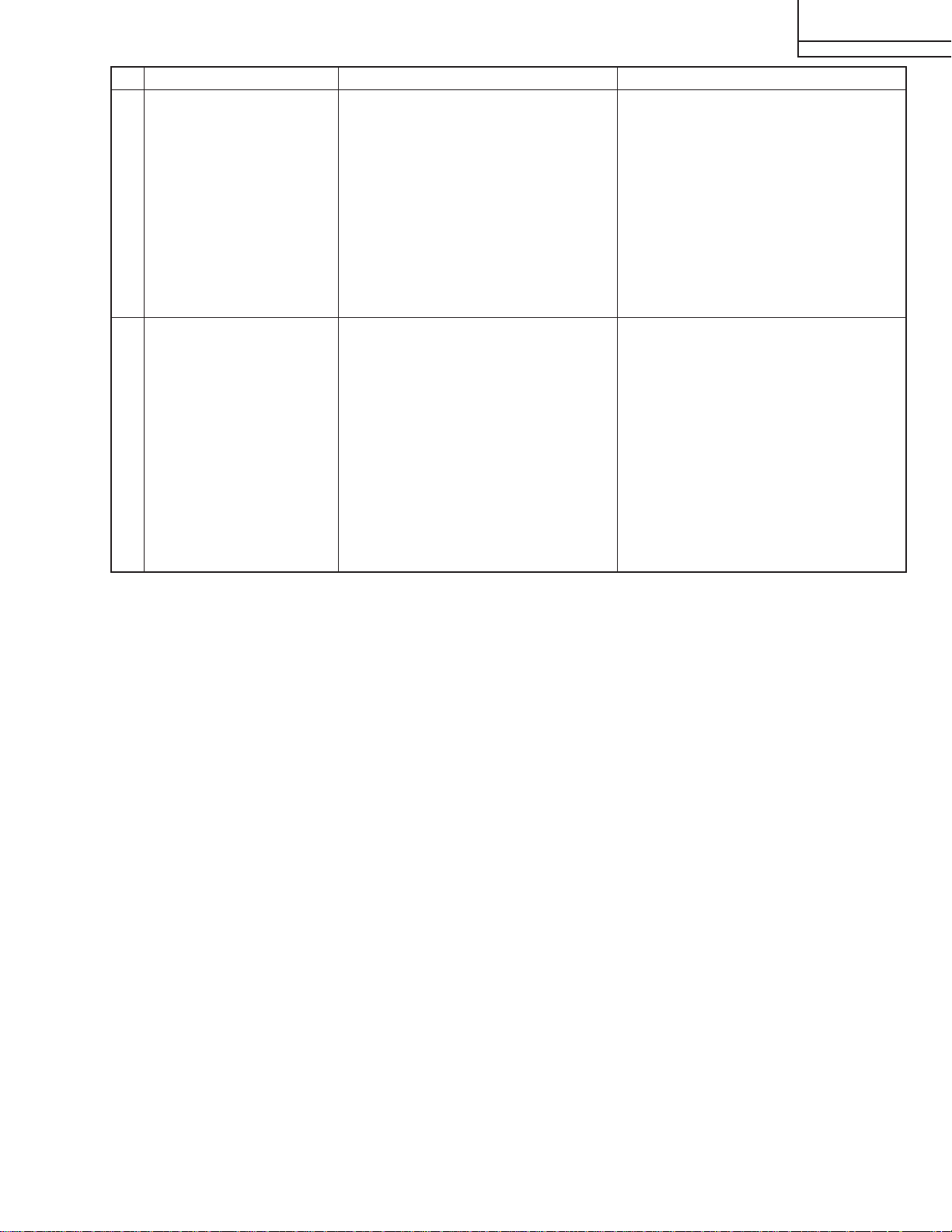

Adjustment Adjusting conditions Adjusting method

5 White balance adjustment

LC-10A3U

SUPPLEMENT

1. Receive the monoscope pattern

signal.

2. Adjust the "RCUTOFF" and

"BCUTOFF" settings on the page 2

of the adjustment process mode to

become the proper white balance.

Do not change the "GCUTOFF"

settings. (It also change the black

level.)

6 Checking and modifying

the settings

(If E2PROM is replaced)

1. Go to the adjustment mode and

check the following settings.

» V0 240

» V16 201

» V16 BIAS 127

» V32 99

» V32 BIAS 127

» V48 47

» V48 BIAS 127

» V63 0

» VGL ADJ 90

» COM 195

1.See if all the settings are as specified.

If not, select an item in question with

[VOL +] or [VOL –] key and adjust the

setting as shown at left.

* An item selected will be highlighted in

yellow.

6.Shipping setting list

Channel............................................................................................................................................... 2ch

Air/Cable ............................................................................................................................................. Air

Skip Data_CATV................................................................................................................................. All Skip

Skip Data_AIR .................................................................................................................................... All Skip

Volume................................................................................................................................................ 20

Picture................................................................................................................................................. 30

Tint ...................................................................................................................................................... 0

Color ................................................................................................................................................... 0

Black Level ......................................................................................................................................... 0

SHARP................................................................................................................................................ 0

RED-BLUE.......................................................................................................................................... 0

GREEN ............................................................................................................................................... 0

TV Color System................................................................................................................................. N358

AV Color System ................................................................................................................................ Auto

Language ............................................................................................................................................ English

Blue Screen ........................................................................................................................................ Off

EZ Setup Auto Start............................................................................................................................ On

Sleep Timer ........................................................................................................................................ None

Brightness........................................................................................................................................... Bright

Auto Power Off ................................................................................................................................... Off

Upside................................................................................................................................................. Normal

Rigth/Left ............................................................................................................................................ Normal

13

Page 14

LC-10A3U

SUPPLEMENT

TROUBLE SHOOTING TABLE

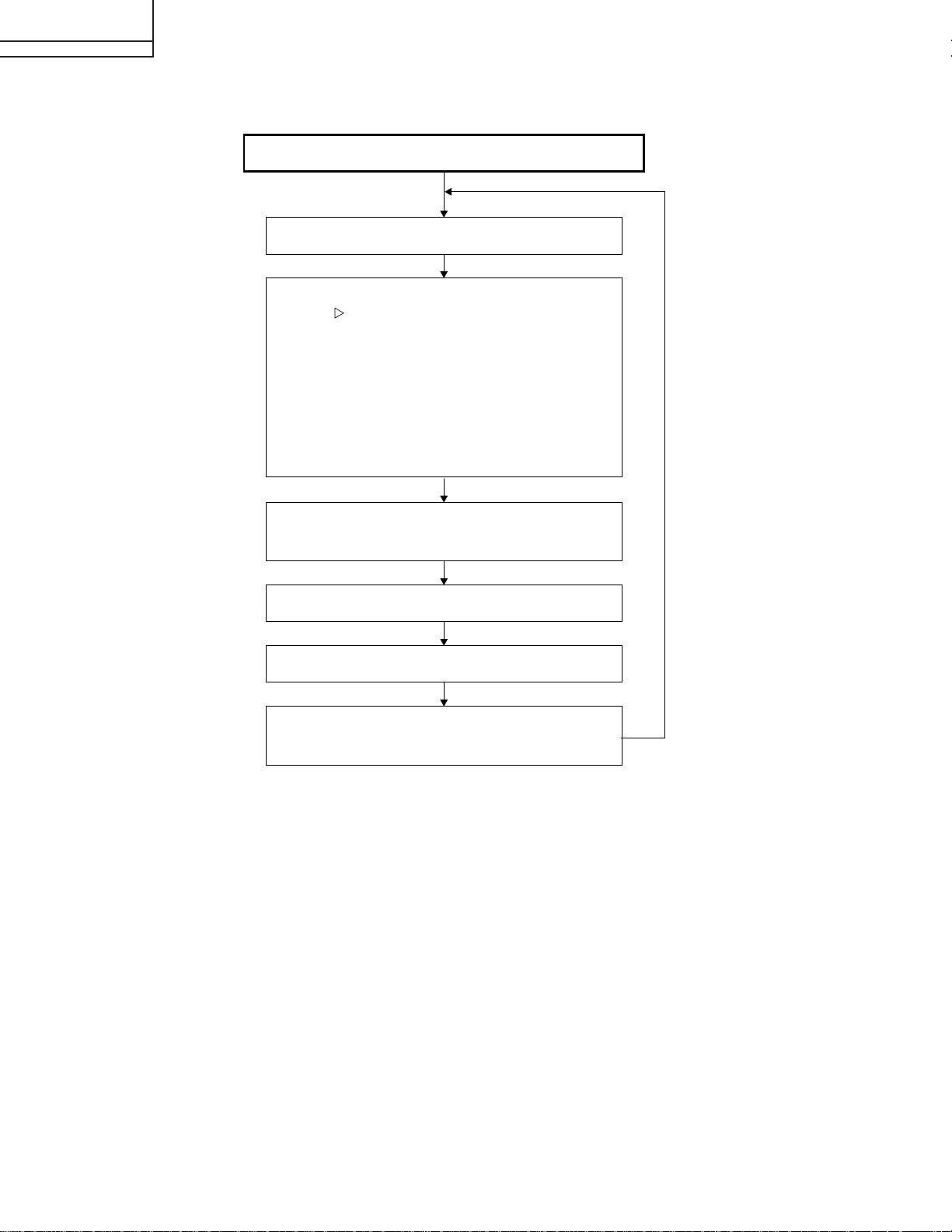

No Power (Power LED indicator still in red)

Go to the adjustment process mode.

1

+B-ADJ 160

MODEL A2U

INCH SIZE 10

TIMER 1

SYSTEM AUTO

NTSC PWM FREQ OCO

PAL PWM FREQ OBD

CLOSED CAPTION OFF

V-CHIP OFF

TV GAIN OFF

ERROR NO RESET 5

Move the cursor to ERROR NO RESET

and click on it (to reset to zero).

Turn off the power.

Is the power turned on again?

No

Check the back light lamp, D753, Q754, D757 and

their peripheral parts as well as pin (42) of IC2001.

Note:

This model is equipped with the lamp error detection function

that detects the current flowing into the fluorescent lamp and

protects the backlight lamp drive circuit.

If a lamp error is detected, the microprocessor interrupts the

unit and the ERROR NO RESET setting will go up.

When the ERROR NO RESET setting has reached "5", the

microprocessor turns and keeps off the unit's power. To

resume the power, take the above procedure to clear the

ERROR NO RESET setting.

14

Page 15

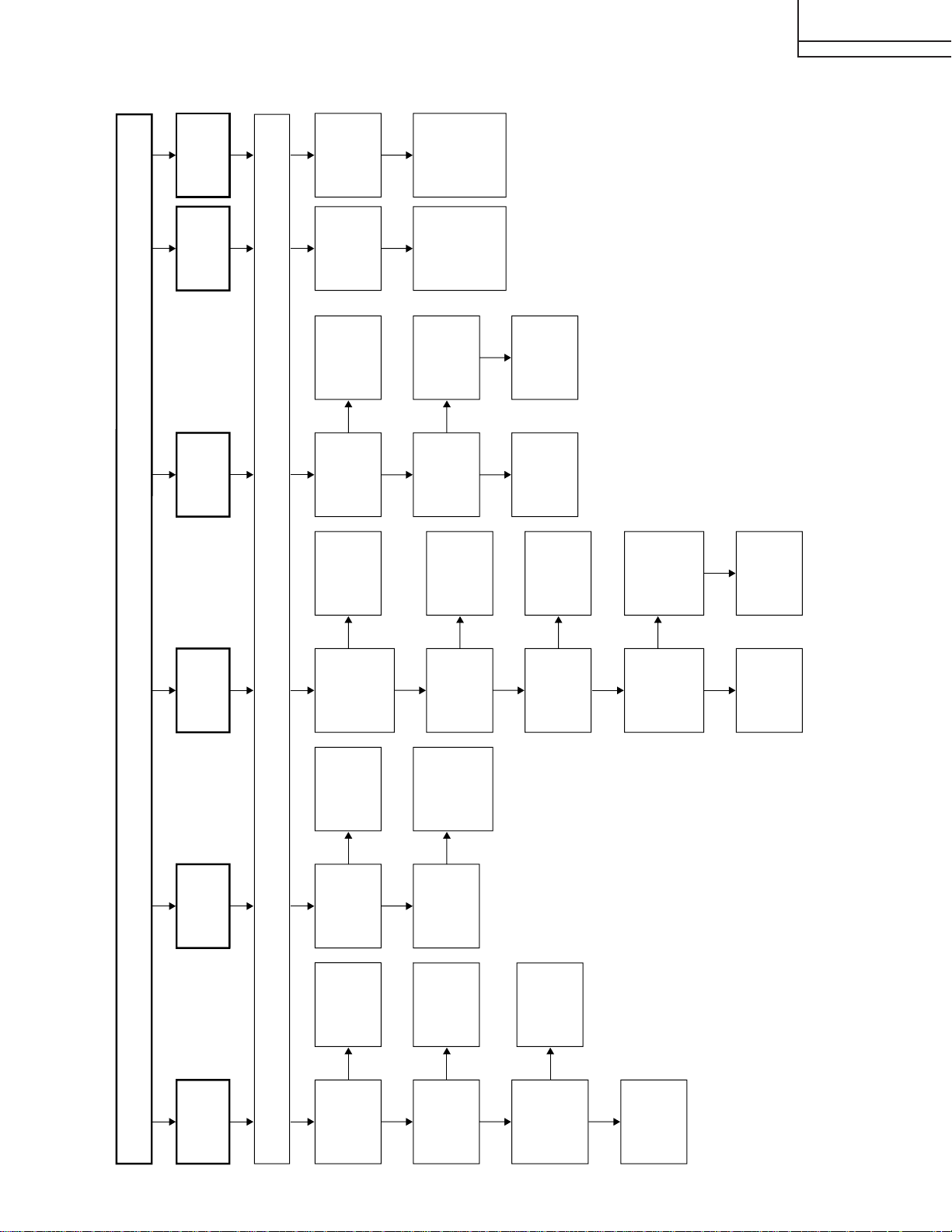

No picture

at all

Yes

No

Are inputs

and outputs

of IC802 as

specified?

Check all the settings on the microprocessor

’s adjust process menu.

No picture

Check IC802

and its

peripheral

parts.

Yes

No

Are inputs

and outputs

of IC1201 as

specified?

Check

IC1201 and

its peripheral

parts.

No

Check IC1203,

IC1204 and

their peripheral

parts.

Are inputs

and output of

IC1203 and

IC1204 as

specified?

Yes

Check LCD

panel voltage

and

waveform.

No TV and

VIDEO 1

output

Yes

No

Are inputs

and outputs

of IC402 as

specified?

Check IC402

and its

peripheral

parts.

NO

Is input at Pin

(73) of IC802

as specified?

Check IC802,

AV1 line and

their

peripheral

parts.

No TV

output

Yes

No

Are voltages

at Pins (6),

(7) and (9) of

tuner as

specified?

Check the

power line.

Yes

No

Is output at

Pin (19) of

tuner as

specified?

Check the

tuner and its

peripheral

parts.

No

Is input at Pin

(1) of IC402

as specified?

Check the

line in

question.

Yes

Check IC402

and its

peripheral

parts.

Yes

No

Are Pins (2)

and (4) of

IC402 at “H”

and “L”

respectively?

Are Pins (65)

and (66) of

IC2001 at “H”

and “L”

respectively?

No VIDEO

1 output

YES

No

Is input at Pin

(1) of IC402

as specified?

Check the

line in

question.

Yes

No

Are Pins (1)

and (4) of

IC402 both at

“L”?

No VIDEO

2 output

No

Is input at Pin

(74) of IC802

as specified?

Check J3404,

AV line and

their

peripheral

parts.

No S

VIDEO

output

No

Are inputs at

Pins (71) and

(72) of IC802

as specified?

Check

SC3301, SY

line, SC line

and

peripheral

parts.

Are Pins (65)

and (66) of

IC2001 both

at “L”?

Check IC402

and its

peripheral

parts.

Yes

Check the

line in

question.

Yes

Check the

line in

question.

TROUBLE SHOOTING TABLE (Continued)

LC-10A3U

SUPPLEMENT

15

Page 16

LC-10A3U

No picture and sound

No color

No TV color

No S-VIDEO color

Yes

No

Do F3701 and F3702

function?

Check all the settings on the microprocessor

’s adjust process menu.

No

Are secondary outputs

(+38V, +16V, +9V, +5V, -8V)

of T701 as specified?

Yes

Are the oscillation waveform

at T701’s primary side as

specified?

Yes

No

Disconnect F3701 and

F3702. Is the load side

short-circuited?

Yes

No

Is any of T701’s primary side,

Q701, Q710 and S4701

short-circuited?

Check J3701, its peripheral

parts and connection cable.

Replace F3701 and F3702.

Check S4701 and

connection cable.

Check the secondary-side

load of T701.

Fluorescent lamp failure

Yes

No

Does F3751 function?

Yes

No

Is Pin (34) of IC1201 at

“H”?

Yes

No

Are the oscillation waveforms

at the primary side of T751

and T752 as specified?

Yes

Replace F3751.

No

Is input at Pin (71) of IC802

as specified?

Check J3301, SC line and

peripheral parts.

Yes

Check the line, IC1201 and

its peripheral parts.

Check Q751, Q752, T751,

T752, Q753 and their

peripheral parts.

Replace the fluorescent lamp

and check the oscillation

waveform again.

No VIDEO color

Check all the settings on the microprocessor

’s adjust process menu.

SUPPLEMENT

TROUBLE SHOOTING TABLE (Continued)

16

Page 17

No sound

from

speakers

Yes

No

Is Pin (53) of

IC2001 at “L”?

Check all the settings on the microprocessor

’s adjust process menu.

No sound

No

Are outputs at

Pins (1) and (7)

of IC903 as

specified?

Yes

No

Are inputs and

outputs of

IC303 as

specified?

Yes

No

Are inputs at

Pins (5) and (8)

as well as

outputs at Pins

(2) and (11), all

of IC301, as

specified?

Muting effect is

on. Check the

FSMU line.

Check IC901,

IC903 and their

peripheral

parts.

Check IC303

and its

peripheral

parts.

Check the line

in question,

IC303 and its

peripheral

parts.

Yes

Check the

speakers and

their peripheral

parts.

No sound

from

headphone

Yes

No

Is Pin (55) of

IC2001 at “L”?

Check the

headphone and

its peripheral

parts.

Check Q306,

J3404 and their

peripheral

parts.

No sound

from output

line

Yes

No

Is Pin (52) of

IC2001 at “L”?

No

Are outputs at

Pins (1) and (7)

of IC902 as

specified?

Yes

Check the line

in question.

Check the

LMUTE line.

Check IC902

and its

peripheral

parts.

TV sound

failure

Yes

No

Is output at Pin

(16) of tuner as

specified?

No

Is input at Pin

(60) of IC901

as specified?

Check the

tuner and its

peripheral

parts.

Check IC901,

Q3301, Q3204,

Q3205 and

their peripheral

parts.

TROUBLE SHOOTING TABLE (Continued)

LC-10A3U

SUPPLEMENT

17

Page 18

LC-10A3U

SUPPLEMENT

CHASSIS LAYOUT

MAIN Unit (Side-A)

H

G

F

E

MAIN Unit (Side-A)

D

C

B

INVERTER

A

FIFOIC

87109654321

18

Page 19

J3701

D3301

F3751

F3701

F3702

Q3405

Q3403

Q3402 Q3401

J3404 J3302

J3403

J3305

J3401 J3402

D3402

Q3304

Q3301

Q3303

D3401

J3304 J3301

J3303

TU3201

TUNNER

Q3404

C3202

L3202

P3701

P3203

P3204

Q3204

Q3205

Q3203

SC3401

Q3201

Q3202

P4004

S4013 S4012 S4017 S4009 S4014 S4015 S4011 S4010 S4016

S4701

SC4102

RMC

4101

TUNER Unit

SWITCH Unit (Side-A)

SWITCH Unit (Side-B)

R/C, LED Unit

LC-10A3U

SUPPLEMENT

1716 1918151413121110

19

Page 20

LC-10A3U

SUPPLEMENT

BLOCK DIAGRAM

H

G

F

E

D

C

B

A

87109654321

20

Page 21

LC-10A3U

SUPPLEMENT

21

1716 1918151413121110

Page 22

LC-10A3U

SUPPLEMENT

OVERALL WIRING DIAGRAM

H

G

F

E

D

C

B

A

87109654321

22

Page 23

LC-10A3U

SUPPLEMENT

23

1716 1918151413121110

Page 24

LC-10A3U

SUPPLEMENT

DESCRIPTION OF SCHEMATIC DIAGRAM

VOLTAGE MEASUREMENT CONDITION:

1. Voltages at test points are measured at the

supply voltage of AC 120V. Signals are fed by a

color bar signal generator for servicing purpose and

the above voltages are measured with a 20k ohm/

V tester.

WAVEFORM MEASUREMENT CONDITION:

1. Wa vef orms at test points are observed at the supply

voltage of AC 120V. Signals are fed by a color bar

signal generator for servicing purpose.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “ Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/10W, unless otherwise noted.

4. All resistors are Carbon type, unless otherwise

noted.

C : Solid

S : Oxide Film T : Special

N : Metal Coating

CAPACITOR

1. All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2. All capacitors are 50V, unless otherwise noted.

3. All capacitors are Ceramic type, unless otherwise

noted.

(ML): Mylar (TA): Tantalum

(PF): Polypro Film (ST): Styrol

W

: Cement

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

SAFETY NOTES:

1. DISCONNECT THE AC PLUG FROM THE AC

OUTLET BEFORE REPLACEING PARTS.

2. SEMICONDUCTOR HEAT SINKS SHOULD BE

REGARDED AS POTENTIAL SHOCK HAZARDS

WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å” ( ) ARE

IMPORTANT FOR MAINTAINING THE SAFETY OF

THE SET. BE SURE TO REPLACE THESE PARTS

WITH SPECIFIED ONES FOR MAINTAINING THE

SAFETY AND PERFORMANCE OF THE SET.

AVIS DE SECURITE IMPORTANT:

LES PIECES MARQUEES “å” ( )SONT

IMPORTANTES POUR MAINTENIR LA SECURITE

DE L'APPAREIL.

NE REMPLACER CES PIEDES QUE PAR DES

PIECES DONT LE NUMERO EST SPECIFIE POUR

MAINTENIR LA SECURITE ET PROTEGER LE BON

FONCTIONNEMENT DE L'APPAREIL.

24

Page 25

SCHEMATIC DIAGRAM

Ë

SWITCH and R/C, LED Unit

H

G

F

LC-10A3U

SUPPLEMENT

E

D

C

B

A

654321

25

Page 26

LC-10A3U

SUPPLEMENT

Ë

MAIN Unit-1/2

H

G

F

E

D

C

B

A

87109654321

26

Page 27

LC-10A3U

SUPPLEMENT

27

1716 1918151413121110

Page 28

LC-10A3U

SUPPLEMENT

Ë

MAIN Unit-2/2

H

G

F

E

D

C

B

A

87109654321

28

Page 29

LC-10A3U

SUPPLEMENT

29

1716 1918151413121110

Page 30

LC-10A3U

SUPPLEMENT

Ë

TUNER Unit

H

G

F

E

D

C

B

A

87109654321

30

Page 31

LC-10A3U

SUPPLEMENT

31

1716 1918151413121110

Page 32

LC-10A3U

SUPPLEMENT

PRINTED WIRING BOARD ASSEMBLIES

H

G

F

E

D

C

B

Main Unit (Side-A)

A

654321

32

Page 33

LC-10A3U

SUPPLEMENT

H

P701

C314

G

F

E

D

C

B

P301

C712

C310

IC301

C301

C302 C312

C304

C328

C321

C322

L806

C409

L808

R406

SC401

R409

L809

L807

R411

R412

R414

R418

R420

C911

C912

C933

C915

R958

C924

R959

R960

R961

C935

C923

C926

C937

C946

IC901

X901

P752

C306

C317

C307

IC302

C324

R952

R969 C958

R967

C914

C954

R962

R964

R963

R965

C944

C905

C945

C906

R903

FB901

C902

C402

P401

C740

C736

L705

C318

C319

C308

C207

C326

C320

C330 C327

R955

C957

C901

R1144

TH401

R1143

R1145

R1146

C938

C2003

R1147

Q1101

R1127

X2001

IC1101

IC1109

C1216

C405

C739

R732

C748

C749

R750

L706

C741

R434

C403

R436

R435

C404

R2041

R2042

R2035

IC2001

C2012

R2006 R2005

X2003

C2011

C1101

R1139

R1136

R1137

R1138

R1142

R1141 R1140

R1112

C1118

R1135 R1114

R1119

C1117

Q1102

C1128

D1102

C1122

R1118 R1129

Q708

C746 R737

R738

L701

D710

C737

Q709

T701

C719

C735

C708

R310

Q306

R311

R2011

X2002

R1111

R1110

R1107

R1108

C1111

C1112

R1117

C721

Q2006

R1105

R2046

R2067

R2066

R2060

R2019

P2001

C2021

C1107

R1102

R1150

R1115

R749

R1103

C1109

R1116

FB709

C759 C713

C733

R707

C703

R769

C766 C767

C768 C769

R771

P754 P753

C751

P755

P2002

R1203

C801

R1204

C821

IC810

D802

R806

IC1201

R1206

R1205

SC1201

L804

C848

C809

C876

L805

C830

C844

C842

C1210

C1214

C1209

R1202

R1207

P751

T751

T752

C753

C755

C754

C1221

R1243

D1201

R1244

R1228

D1203

R1245

R1231

R1148

C752

SC1203

C1224

C1223

R1149

C1127

L752

C1206

C1218

C836

L1204

C1212

R1222

R1218

R1235 R1214

R1210

C1213

R1211

R1208

FB1203

R1209

Main Unit (Chip Parts Side-A)

A

654321

33

Page 34

LC-10A3U

SUPPLEMENT

H

G

F

E

D

C

B

Main Unit (Side-B)

A

654321

34

Page 35

LC-10A3U

SUPPLEMENT

H

Q307

R307

G

R756

D752

F

D753

C761

C760

R751

R752

Q751

E

FB1202

R1230

D

C

Q1202

R1241

Q1203

R1242

IC1204

C1205

R1226

R1223

R1225C1204

Q1201

R1220

R1224

R1234

C1201

R1233

R1236

Q752

C757

R754

Q753

C758

C763

C879

C817

C819

R861R827

R832

C820

L801

L803

L802

R1239

R1240

C1220

C1219

IC1203

R1232

C1203

R1217

IC1202

R831

C839R828

C840R829

C841R830

R833R834

C826

C807

R807

C835

R809

C827

R808

C811

C808

C874

C875

C825

C831

R804

R814

R811

R1221

R816

C818

C878

C822

C1202

B

C765

R766

R767

R753

Q754

C816

C814

C815

C812

R853

C810

TP801

TP 802

IC802

C813

R813

R810

D1103

D1104

Q710

C702

R701

IC701

Q701

C705R775R702

R703

L2001

C704

Q759

Q758

Q757

R768

C764

R772

R765Q756

R757

X801Q755

C802

C805

C806

R803R802R801

R819

FB801

C706

D712Q707

R740

R739

D755

D754

R770

R758

R759

IC751

D751

R851

C804C803

R860

R858

R826

L1203

L1205

C1207C1215C1211

L1202

D702

R706

C747

R774

C756

R2069

IC807

IC808

R859

FB802

IC1102

C1103

C1124

C1108

IC1106

C1110

Q702

FB708

C710

R736

FB706

FB705

FB707

FB703

FB702

D703

C722

D704

R733

R745

C707

IC704

R746

R325

R326

R726

R725

R312

TP2007

C410

TP2006

Q2005

D2001

C2008

Q2001

TP2005

R2047

R2062

R2063

IC2004

R2014

C2007

R1104

R1101

C1102

IC1105

C1113

IC2003

R2010

Q2004

R2059

R2016R2018

R2061

R2068

TP2003

R2025

R1109

C1123

IC1103

C1104

IC1110

IC1107

C1115

C714

R714

D707

FB704

C728C729D705

R734

R205

C2009

R2008

C2010

C2006

C2004

R1106

R1113

C1106

IC1108

R708

C711

R723R717

R722

C715

R705

D711

C731

D706

R735

R216

Q202

C202

R215

R210

D201

IC201

R207R202

R206

C205

R220

C206

R208

IC402

R2050

R2049R2043

Q2003

TP2001

R2003

R2004

IC2002

C2017

R2007

C2005

C1105

IC1104

R1133

R1134

C1114

R211

TP2008

TP2009

R2009

R1130

TP2002

D1101

R718

R713

C738

C701

IC702

R711

C717

C716

R720

Q703

D709

C734

R719R721R712

R709

C709

R317R316

C204

R218

Q203

R217R213R214

R212

C203

R209

R201

R204R203

R1237

Q201

C201

Q204

C406

R2044

R2048

R2051

R2052

R2028

R2082

R2031

R2033

C2015

C2016

R2045

R2002

R2083

R2032

C2001

C2023

R2001

C2002

R2057

R2058

C2018

R2053

R2054

R2055

IC2005

R1152R1151

C1116

R1123

R1121

R1122

R1120

R1125

R1124

C1120

C1119C2024

R1128C1121

R1126

R1131

R1132

Q303

R324

R219

R322

R321

Q305

R323

R966

R968

IC902

Q2007

IC303

R2056

C2022

C2019

C2020

R427

C407

R728

IC401

R428

R421

R429

C401

R426

Q301

C315

R306

C313

C311

R305

R315R314

Q304

R320

R330

C325

C932

C956

C910

C955

C907

R908

R918

R919

C940

C943

R901

L901

R438C412

C303

C305C309

R329R328

R303R304

R302

C329

C316

R308

Q302

C323

R319

C909

R909

R910

C939

R924

IC903

C959

R956

C917

C918

C960

R957

R432

R902

C931

R309

Q308R318

C411

R401

C408

R405

R407

R408

R424

R410

R413

R419

C942

R925

R920

R921

C941

R922

R923

C913

R911

R912

C929

C927

C930

C928

C925

R917

R430

C916

C961

C962

C919

C920

C921

R403

C922

R404

C963

C964

C936

R904

L902

Main Unit (Chip Parts Side-B)

A

654321

35

Page 36

LC-10A3U

SUPPLEMENT

H

G

F

E

D

C

B

A

TUNER Unit (Side-A)

654321

36

Page 37

LC-10A3U

SUPPLEMENT

H

R3324

C3306

L3201

R3204

C3205

R3321

C3207

R3322

R3205

C3204

R3206

R3208

Q3204

Q3301

R3207

Q3205

C3210

R3329 C3203

R3323 C3303

C3208

R3209 C3209

R3703

Q3203

R3201

SC3401

Q3202

Q3201

R3203

R3202

C3408

D3402

R3401

R3301

R3413

R3404

R3405

R3309 R3307

D3401

R3414

C3301

C3302

R3305

C3409

C3304

C3305

C3405

R3415

Q3402 Q3401

Q3403

R3302

R3303

R3417

R3411

C3404

R3416

C3406

R3412

C3402

R3319

Q3304

Q3303

R3306

R3314

C3309

C3310

R3310

R3402

R3304

R3308

C3407

R3334

C3201 L3401

C3313

C3308

R3328

C3202

L3202

Q3302

R3326 R3327

J3301

G

J3304

R3315

R3313

C3314

R3320

J3402

J3303

C3315 R3316

F

R3409

J3403 J3401

C3403

D3403

R3410

J3404 J3302 J3305

E

R3330

R3331

Q3405 Q3404

S3701

D

FH3703

FH3701

P3702

FH3704

FH3702

C3312

TU3201

C3311

C

FH3751 FH3752

P3701

B

D3301

J3701

R3332

R3333

R3701

R3702

A

TUNER Unit (Chip Parts Side-A)

654321

37

Page 38

LC-10A3U

SUPPLEMENT

H

G

F

R/C, LED Unit (Side-A)

E

D

R/C, LED Unit (Side-B)

C

B

A

SWITCH Unit (Side-A) SWITCH Unit (Side-B)

654321

38

Page 39

LC-10A3U

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

PARTS LIST

PARTS REPLACEMENT

Replacement parts which have these special safety characteristics

identified in this manual; electrical components having such features

are identified by

and Schematic Diagrams. The use of a substitute replacement part

which dose no have the same safety characteristic as the factory

recommended replacement parts shown in this service manual may

create shock, fire or other hazards.

"HOW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly, please furnish the

following informations.

1. MODEL NUMBER 2. REF. NO .

3. PART NO. 4. DESCRIPTION

in USA: Contact your nearest SHARP Parts Distributor to order.

Ref. No. Part No. ★ Description Code

å and shaded areas in the Replacement Parts Lists

For location of SHARP Parts Distributor, Please call TollFree; 1-800-BE-SHARP

★ MARK: SPARE PARTS-DELIVERY SECTION

LISTE DES PIECES

CHANGE DES PIECES

Les pi`eces de rechange qui pr élelesentent ces caract éleristiques

sp éleciales de s élecurit éle, sont identifi élees dans ce manuel : les

pi`eces élelectriques qui pr élesentent ces particularit éles, sont rep

éler élee par la marque å et sont hachur élees dans les listes de

pi`eces et dans les diagrammes sch élematiques.

La substitution d'une pi`ece de rechange par une autre qui ne pr

éLesente pas les m éoemes caract éLeristiques de s élecurit éle que

la pi`ece recommand élee parl'usine et dans ce manuel de service,

peut provoquer une éLelectrocution, un incendie ou toutautre sinistre.

"COMMENT COMMANDER LES PIECES DE RECHANGE"

Pour que votre commande soit r apidement et correctement remplie ,

veuillez fournir les renseignements suivants.

1. NUMERO DU MODELE 2. NO. DE REF

3. NO. DE PIECE 4. DESCRIPTION

in CANADA: Contact SHARP Electronics of Canada Limited

Phone (416) 890-2100

★MARQUE: SECTION LIVRAISON DES PIECES DE RECHANGE

Ref. No. Part No. ★ Description Code

PRINTED WIRING BOARD ASSEMBLIES

(NOT REPLACEMENT ITEM)

DUNTKA142DE01 – TUNER Unit —

DUNTKA143DE01 – SWITCH Unit —

DUNTKA144DE01 – R/C, LED Unit —

DUNTKB686FE01 – MAIN Unit —

LCD PANEL

NOTE: THE PARTS HERE SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDENTLY.

RLCDTA019WJZZ J 10" LCD Panel Unit CV

DUNTKA142DE01

TUNER UNIT

NOTE: THE PARTS HERE SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDENTLY.

TU3201 VTUVT2U5UF553 J Tuner BC

TRANSISTORS

Q3201 VSDTC144EE/-1Y J DTC144EE AA

Q3202 VSDTC144EE/-1Y J DTC144EE AA

Q3203 VSDTC144EE/-1Y J DTC144EE AA

Q3204 VS2SC2712Y/-1Y J 2SC2712Y AB

Q3205 VS2SC3928AR-1Y J 2SC3928AR AB

Q3301 VS2SC3928AR-1Y J 2SC3928AR AB

Q3303 VSDTC314TK/-1Y J DTC314TK AC

Q3304 VSDTC314TK/-1Y J DTC314TK AC

Q3401 VS2SC3928AR-1Y J 2SC3928AR AB

Q3402 VS2SC3928AR-1Y J 2SC3928AR AB

Q3403 VSDTC144EE/-1Y J DTC144EE AA

Q3404 VS2SK1467//-1Y J 2SK1467 AE

Q3405 VS2SK1467//-1Y J 2SK1467 AE

DIODES

D3301 VHDDE5SC4M/-1Y J Diode AF

D3401 RH-EX1271CEZZY J Zener Diode AB

D3402 RH-EX1271CEZZY J Zener Diode AB

D3403 RH-EX1271CEZZY J Zener Diode AB

COILS

L3201 VP-1M220J2R9NY J Peaking 22µH AB

L3202 RCiLC0141CEZZY J Coil AF

L3401 VP-1M101J7R7NY J Peaking 100µH AC

C3201 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3202 VCEA4U0JN338M J 3300 6.3V Electrolytic AE

C3203 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C3204 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C3205 VCCCCY1HH330JY J 33p 50V Ceramic AA

C3207 VCCCCY1HH330JY J 33p 50V Ceramic AA

C3208 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3209 VCKYCY1HB102KY J 1000p 50V Ceramic AA

39

CAPACITORS

Page 40

LC-10A3U

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKA142DE01

TUNER UNIT (Continued)

C3210 VCEAPF1HW225MY J 2.2 50V Electrolytic AB

C3301 VCE9PF1AW106MY J 10 10V Elect. (N.P) AE

C3302 VCE9PF1AW106MY J 10 10V Elect. (N.P) AE

C3303 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3304 VCKYTV1CB105KY J 1 16V Ceramic AC

C3305 VCKYTV1CB105KY J 1 16V Ceramic AC

C3306 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C3311 RC-EZ0417CEZZY J 150 16V Electrolytic AD

C3312 RC-EZ0417CEZZY J 150 16V Electrolytic AD

C3313 RC-KZ1025CEZZY J 1 10V Ceramic AB

C3314 VCKYTV1CB105KY J 1 16V Ceramic AC

C3315 VCKYTV1CB105KY J 1 16V Ceramic AC

C3402 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3403 VCEASH1CN477MY J 470 16V Electrolytic AD

C3404 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C3405 VCEAPF0JW336MY J 33 6.3V Electrolytic AB

C3406 RC-KZ1025CEZZY J 1 10V Ceramic AB

C3407 VCEAPF0JW226MY J 22 6.3V Electrolytic AB

RESISTORS

R3201 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3202 VRS-CA1JF561JY J 560 1/16W Metal Oxide AA

R3203 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3204 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3205 VRS-CY1JF153JY J 15k 1/16W Metal Oxide AA

R3206 VRS-CY1JF332JY J 3.3k 1/16W Metal Oxide AA

R3207 VRS-CY1JF152JY J 1.5k 1/16W Metal Oxide AA

R3208 VRS-CY1JF331JY J 330 1/16W Metal Oxide AA

R3209 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3301 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3302 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3303 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3304 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3305 VRS-TQ2BD750JY J 75 1/8W Metal Oxide AA

R3306 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3307 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3308 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3309 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3310 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3313 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3314 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3315 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3316 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3319 VRS-TQ2BD750JY J 75 1/8W Metal Oxide AA

R3320 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3321 VRS-CY1JF822JY J 8.2k 1/16W Metal Oxide AA

R3323 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3324 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3330 VRS-TX2HF331JY J 330 1/2W Metal Oxide AB

R3331 VRS-TX2HF331JY J 330 1/2W Metal Oxide AB

R3332 VRS-CR3AD3R9JY J 3.9 1W Metal Oxide AC

R3333 VRS-CR3AD3R9JY J 3.9 1W Metal Oxide AC

R3334 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R3401 VRS-TQ2BD750JY J 75 1/8W Metal Oxide AA

R3402 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3404 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3405 VRS-CY1JF000JY J 0 1/16W Metal Oxide AA

R3409 VRS-CY1JF104JY J 100k 1/16W Metal Oxide AA

R3410 VRS-TQ2BD750JY J 75 1/8W Metal Oxide AA

R3411 VRS-CY1JF680JY J 68 1/16W Metal Oxide AA

R3412 VRS-CY1JF680JY J 68 1/16W Metal Oxide AA

R3413 VRS-CY1JF223JY J 22k 1/16W Metal Oxide AA

R3414 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

R3415 VRS-CY1JF562JY J 5.6k 1/16W Metal Oxide AA

R3416 VRS-CY1JF272JY J 2.7k 1/16W Metal Oxide AA

R3417 VRS-CY1JF750JY J 75 1/16W Metal Oxide AA

R3701 VRS-TW2ED000JY J 0 1/4W Metal Oxide AB

R3702 VRS-TW2ED000JY J 0 1/4W Metal Oxide AB

R3703 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

å F3701 QFS-B1621GEZZ J Fuse, 1.6A 125V AD

MISCELLANEOUS PARTS

å F3702 QFS-B1621GEZZ J Fuse, 1.6A 125V AD

å F3751 QFS-B2521GEZZ J Fuse, 2.5A 125V AD

FH3701 QFSHD1002CEZZ J Fuse Holder AA

FH3702 QFSHD1002CEZZ J Fuse Holder AA

FH3703 QFSHD1002CEZZ J Fuse Holder AA

FH3704 QFSHD1002CEZZ J Fuse Holder AA

FH3751 QFSHD1002CEZZ J Fuse Holder AA

FH3752 QFSHD1002CEZZ J Fuse Holder AA

J3301 QSOCD0406GEZZ J S-Video(AV Input1) AF

J3302 QJAKJ0080CEZZ J Audio(AV Output) AF

J3303 QJAKE0166CEZZ J Audio(L)(AV Input1) AE

J3304 QJAKE0167CEZZ J Audio(R)(AV Input1) AE

J3305 QJAKJ0080CEZZ J Audio(AV Input2) AF

J3401 QJAKJ0080CEZZ J Video(AV Input2) AF

J3402 QJAKE0168CEZZ J Video(AV Inpu1) AE

J3403 QJAKJ0080CEZZ J Video(AV Output) AF

J3404 QJAKJ0080CEZZ J Headphone Terminal AF

J3701 QJAKE0165CEZZ J DC Input Terminal AE

P3203 QPLGN0280GEZZ J Plug, 2-pin AB

P3204 QPLGN0280GEZZ J Plug, 2-pin AB

P3701 QPLGN1178GEZZ J DC Input Terminal AC

SC3401 QSOCN0464FJZZY J Socket, 50-pin AH

40

Page 41

LC-10A3U

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKA143DE01

SWITCH UNIT

D4016 RH-EX1271CEZZY J Zener Diode AB

D4017 RH-EX1271CEZZY J Zener Diode AB

D4018 RH-EX1283CEZZY J Zener Diode AB

D4019 RH-EX1283CEZZY J Zener Diode AB

C4001 VCCCCY1HH471JY J 470p 50V Ceramic AA

C4002 VCCCCY1HH471JY J 470p 50V Ceramic AA

R4080 VRS-CY1JF822JY J 8.2k 1/16W Metal Oxide AA

R4081 VRS-CY1JF123JY J 12k 1/16W Metal Oxide AA

R4082 VRS-CY1JF273JY J 27k 1/16W Metal Oxide AA

R4083 VRS-CY1JF563JY J 56k 1/16W Metal Oxide AA

R4084 VRS-CY1JF822JY J 8.2k 1/16W Metal Oxide AA

R4085 VRS-CY1JF123JY J 12k 1/16W Metal Oxide AA

R4086 VRS-CY1JF273JY J 27k 1/16W Metal Oxide AA

S4009 QSW-K0088GEZZY J MENU AD

S4010 QSW-K0088GEZZY J Channel Up(')AD

S4011 QSW-K0088GEZZY J Channel Down(")AD

S4012 QSW-K0088GEZZY J MUTE AD

S4013 QSW-K0088GEZZY J BRIGHT AD

S4014 QSW-K0088GEZZY J Volume Up(+) AD

S4015 QSW-K0088GEZZY J Volume Down(-) AD

S4016 QSW-K0088GEZZY J TV/VIDEO AD

S4017 QSW-K0088GEZZY J DISPLAY AD

S4701 QSW-S0213CEZZ J MAIN POWER AE

DIODES

CAPACITORS

RESISTORS

SWITCHES

Q4106 VSDTC144EE/-1Y J DTC144EE AA

Q4107 VSUMG4/////-1Y J UMG4 AC

D4120 RH-EX1271CEZZY J Zener Diode AB

D4121 RH-EX1271CEZZY J Zener Diode AB

D4122 RH-PX0368CEZZY J Power/standby Indicator AE

C4120 VCKYTV1CF105ZY J 1 16V Ceramic AB

R4187 VRS-CY1JF331JY J 330 1/16W Metal Oxide AA

R4188 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R4189 VRS-CY1JF472JY J 4.7k 1/16W Metal Oxide AA

R4190 VRS-CY1JF101JY J 100 1/16W Metal Oxide AA

SC4102 QPLGN0464TAZZY J Plug, 4-pin AC

RMC4101

SLD4101

DUNTKA144DE01

R/C, LED UNIT

TRANSISTORS

DIODES

CAPACITORS

RESISTORS

MISCELLANEOUS PARTS

RRMCU0239CEZZ J Remote Receiver AG

PSLDM4646CEFW J Shield AD

QCNW-5710CEZZ J Connecting Cord AC

P4004 QPLGN0564TAZZY J Plug, 5-pin AC

MISCELLANEOUS PARTS

41

Page 42

LC-10A3U

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKB686FE01

MAIN UNIT

INTEGRATED CIRCUITS

IC201 VHiNJM2147M-1Y J NJM2147M-TE1 AF

IC301 VHiLA4227//-1 J LA4227 AG

IC303 VHiNJM2283F-1Y J NJM2283M AF

IC402 VHiNJM2235M-1Y J NJM2235M AE

IC701 VHiAN8005M/-1Y J AN8005M AD

IC702 VHiNJM2377M-1Y J NJM2377M AK

IC704 VHiBA033FP/-1Y J BA033FP-E2 AG

IC802 VHiVPC3230D1EQ J VPC3230D-QA-B3 BD

IC901 RH-iX3370CEN1Q J MSP3440G-QA-B8 AY

IC902 VHiNJM4560M-1Y J NJM4560M AG

IC903 VHiNJM4560M-1Y J NJM4560M AG

IC1101 VHiMB8346BV-1Y J MB88346BPFV AN

IC1102 VHiNJM4565V-1Y J NJM4565V AF

IC1103 VHiNJM4565V-1Y J NJM4565V AF

IC1104 VHiNJM4565V-1Y J NJM4565V AF

IC1105 VHiBU4053V/-1Y J BU4053BCFV-E2 AE

IC1106 VHiNJM4580V-1Y J NJM4580V AE

IC1107 VHiNJM4580V-1Y J NJM4580V AE

IC1108 VHiNJM4580V-1Y J NJM4580V AE

IC1109 VHiNJM353M/-1Y J NJM353M AG

IC1110 VHiBU4053V/-1Y J BU4053BCFV-E2 AE

IC1201 RH-iX3378CEZZQ J LR38797 AY

IC1202 VHiPD485505-2Y J UPD485505G-25 AY

IC1203 VHiSN2G04CT-1Y J SN74AHC2G04HDC AE

IC1204 VHiSN2G74CT-1Y J SN74AHC2G74HDC AE

IC2001 RH-iX3448CEZZQ J M306V0ME-119FP BA

IC2002 VHiPST529DM-1Y J PST529DMT AE

IC2003 VHiTC4W66F/-1Y J TC4W66F AE

IC2004 VHiBR24C08F-1Y J BR24C08F-E2 AF

IC2005 VHiBA7046F/-1Y J BA7046F AF

D709 VHDDAN222//-1Y J Diode AA

D710 VHDDAN222//-1Y J Diode AA

D712 VHDDAN222//-1Y J Diode AA

D753 VHDiMN10///-1Y J Diode AB

D754 VHDiMN10///-1Y J Diode AB

D1101 VHD1SS250//1EY J Diode AB

D1102 VHDDAN222//-1Y J Diode AA

D1201 VHDDAN222//-1Y J Diode AA

D1203 VHDDAN222//-1Y J Diode AA

PACKAGED CIRCUIT

X801 RCRSC0012CEZZY J Crystal AH

X901 RCRSB0250GEZZ J Crystal AG

X2002 RFiLA0110CEZZ+ J Filter AD

COILS

L701 RCiLPA026WJZZ J Coil AD

L705 RCiLC0057CEZZY J Coil AD

L706 RCiLPA026WJZZ J Coil AD

L752 RCiLC0110CEZZY J Coil AF

L803 VP-1M3R3JR93NY J Peaking 3.3µH AB

L804 RCiLC0055CEZZY J Coil AD

L805 RCiLC0055CEZZY J Coil AD

L806 VP-1M4R7J1R2NY J Peaking 4.7µH AB

L807 VP-1M4R7J1R2NY J Peaking 4.7µH AB

L901 VP-1M4R7J1R2NY J Peaking 4.7µH AB

L902 VP-1M101J7R7NY J Peaking 100µH AC

L1202 VP-1M470J5R4NY J Peaking 47µH AC

L1203 VP-1M220J2R9NY J Peaking 22µH AB

L1204 VP-1M220J2R9NY J Peaking 22µH AB

L1205 VP-1M220J2R9NY J Peaking 22µH AB

TRANSFORMERS

å T701 RTRNZ0778CEZZY J Transformer AM

å T751 RTRNZ0764CEZZ J Transformer AM

å T752 RTRNZ0764CEZZ J Transformer AM

Q201 VS2SC2712Y/-1Y J 2SC2712Y AB

TRANSISTORS

Q202 VS2SC2712Y/-1Y J 2SC2712Y AB

Q203 VSFMY3/////-1Y J FMY3 AB

Q204 VS2SC2712Y/-1Y J 2SC2712Y AB

Q302 VS2SA1162Y/-1Y J 2SA1162Y AB

Q303 VSDTC314TK/-1Y J DTC314TK AC

Q304 VSDTC314TK/-1Y J DTC314TK AC

Q308 VSDTC144EE/-1Y J DTC144EE AA

Q701 VS2SA1162Y/-1Y J 2SA1162Y AB

Q702 VS2SK2503//-1Y J 2SK2503 AE

Q703 VS2SC2712Y/-1Y J 2SC2712Y AB

Q707 VSDTC144EE/-1Y J DTC144EE AA

Q708 VSFMMT718//-1Y J FMMT718 AE

Q709 VSDTC144EE/-1Y J DTC144EE AA

Q710 VS2SA1162Y/-1Y J 2SA1162Y AB

Q751 VS2SC5707++-1Y J 2SC5707++ AE

Q752 VS2SC5707++-1Y J 2SC5707++ AE

Q753 VS2SA1162Y/-1Y J 2SA1162Y AB

Q754 VSDTC114YE/-1Y J DTC114YE AB

Q757 VSUPA606T//-1Y J UPA606T AD

Q1101 VS2SA1729//-1Y J 2SA1729 AF

Q1102 VS2SC4520//-1Y J 2SC4520 AE

Q1201 VSDTC144EE/-1Y J DTC144EE AA

Q1202 VS2SA1162Y/-1Y J 2SA1162Y AB

Q1203 VSDTC144EE/-1Y J DTC144EE AA

Q2003 VS2SC2712Y/-1Y J 2SC2712Y AB

Q2004 VSDTC144EE/-1Y J DTC144EE AA

Q2005 VSDTA144EE/-1Y J DTA144EE AA

Q2006 VSDTC144EE/-1Y J DTC144EE AA

DIODES

D201 VHDDAN222//-1Y J Diode AA

D702 VHDSFPB56//2EY J Diode AC

D703 VHD1SS250//1EY J Diode AB

D704 VHD1SS250//1EY J Diode AB

D705 VHDDAN222//-1Y J Diode AA

D706 VHDSFPB74//2EY J Diode AD

D707 VHDDAN222//-1Y J Diode AA

C201 VCKYTV1HF104ZY J 0.1 50V Ceramic AB

CAPACITORS

C202 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C204 RC-KZ1025CEZZY J 1 10V Ceramic AB

C205 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C206 VCKYCY1HF103ZY J 0.01 50V Ceramic AA

C207 VCEAPF1HW335MY J 3.3 50V Electrolytic AC

C301 VCEAPF1CN106MY J 10 16V Electrolytic AD

C302 VCEAPF1CN107MY J 100 16V Electrolytic AD

C303 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C304 VCEAPF1CN476MY J 47 16V Electrolytic AD

C305 VCKYCY1EB223KY J 0.022 25V Ceramic AA

C306 VCEASH1CN477MY J 470 16V Electrolytic AD

C307 VCEAPF1HN225MY J 2.2 50V Electrolytic AD

C308 VCEAPF1HN225MY J 2.2 50V Electrolytic AD

C309 VCKYCY1EB223KY J 0.022 25V Ceramic AA

C310 VCEAPF1CN476MY J 47 16V Electrolytic AD

C311 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C312 VCEAPF1CN107MY J 100 16V Electrolytic AD

C313 VCKYTV1CF105ZY J 1 16V Ceramic AB

C314 VCEA4U1CN228M J 2200 16V Electrolytic AE

C316 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C317 VCEAPF1HN105MY J 1 50V Electrolytic AD

C318 VCEAPF1HN105MY J 1 50V Electrolytic AD

C319 VCEAPF0JW226MY J 22 6.3V Electrolytic AB

C403 VCKYTV1AB105KY J 1 10V Ceramic AC

C404 VCKYTV1AB105KY J 1 10V Ceramic AC

C406 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C408 VCCCCY1HH331JY J 330p 50V Ceramic AA

C409 VCCCCY1HH331JY J 330p 50V Ceramic AA

C411 VCCCCY1HH331JY J 330p 50V Ceramic AA

C701 VCCCCY1HH471JY J 470p 50V Ceramic AA

C702 VCKYTV1CF105ZY J 1 16V Ceramic AB

C703 VCEAPF1CN226MY J 22 16V Electrolytic AD

C704 VCKYTV1CF105ZY J 1 16V Ceramic AB

C706 VCKYCY1HB562KY J 5600p 50V Ceramic AA

C707 VCKYCY1CF334ZY J 0.33 16V Ceramic AB

C708 VCEAPF0JN226MY J 22 6.3V Electrolytic AD

C710 VCKYTV1CF105ZY J 1 16V Ceramic AB

42

Page 43

LC-10A3U

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKB686FE01

MAIN UNIT (Continued)

C711 VCKYCY1EB103KY J 0.01 25V Ceramic AA

C712 VCEAPT1CN226MY J 22 16V Electrolytic AC

C713 VCAAPD1CJ396MY J 39 16V Electrolytic AF

C716 VCKYTV1CF105ZY J 1 16V Ceramic AB

C717 VCKYTV1CF105ZY J 1 16V Ceramic AB

C719 RC-EZ0420CEZZY J 100 25V Electrolytic AE

C721 VCEASK1HN336MY J 33 50V Electrolytic AD

C722 VCKYTV1HF104ZY J 0.1 50V Ceramic AB

C728 VCKYTV1HF104ZY J 0.1 50V Ceramic AB

C729 VCKYTV1CF105ZY J 1 16V Ceramic AB

C731 VCCCCY1HH181JY J 180p 50V Ceramic AA

C733 VCEASH1CN337MY J 330 16V Electrolytic AE

C734 VCKYTV1CF105ZY J 1 16V Ceramic AB

C735 RC-EZ0416CEZZY J 330 6.3V Electroytic AD

C736 RC-EZ0416CEZZY J 330 6.3V Electroytic AD

C737 RC-EZ1339CEZZY J 220 16V Electrolytic AD

C738 RC-KZ1025CEZZY J 1 10V Ceramic AB

C740 VCEAPF1EN475MY J 4.7 25V Electrolytic AC

C741 VCKYTV1CF105ZY J 1 16V Ceramic AB

C746 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C747 VCKYCY1HB562KY J 5600p 50V Ceramic AA

C748 RC-EZ1339CEZZY J 220 16V Electrolytic AD

C749 VCAAPD0JJ127MY J 120 6.3V Electrolytic AF

C751 VCEA4U1CN228M J 2200 16V Electrolytic AE

C752 RC-FZA065WJZZ J 0.22 100V Film AE

C755 VCKYCY1HB103KY J 0.01 50V Ceramic AA

C757 VCKYCY1CB273KY J 0.027 16V Ceramic AB

C758 VCKYCY1CB273KY J 0.027 16V Ceramic AB

C759 VCEAPF0JN107MY J 100 6.3V Electrolytic AD

C760 VCKYTV1HB103KY J 0.01 50V Ceramic AA

C761 VCKYTV1HB103KY J 0.01 50V Ceramic AA

C763 VCKYCY1HB562KY J 5600p 50V Ceramic AA

C764 VCKYTV1CF105ZY J 1 16V Ceramic AB

C765 VCKYTV1CF105ZY J 1 16V Ceramic AB

C801 VCEAPF1CN106MY J 10 16V Electrolytic AD

C802 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C803 VCCCCY1HH7R0DY J 7p 50V Ceramic AA

C804 VCCCCY1HH7R0DY J 7p 50V Ceramic AA

C805 RC-KZ1025CEZZY J 1 10V Ceramic AB

C806 RC-KZ1025CEZZY J 1 10V Ceramic AB

C807 VCKYCY1HB331KY J 330p 50V Ceramic AA

C808 VCKYCY1HB331KY J 330p 50V Ceramic AA

C809 VCEASH1CN107MY J 100 16V Electrolytic AC

C810 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C811 VCKYCY1HB331KY J 330p 50V Ceramic AA

C812 RC-KZ1025CEZZY J 1 10V Ceramic AB

C813 RC-KZ1025CEZZY J 1 10V Ceramic AB

C814 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C815 VCKYTV1CF684ZY J 0.68 16V Ceramic AB

C816 VCKYTV1CF684ZY J 0.68 16V Ceramic AB

C817 VCKYTV1CF684ZY J 0.68 16V Ceramic AB

C818 RC-KZ1025CEZZY J 1 10V Ceramic AB

C819 RC-KZ1025CEZZY J 1 10V Ceramic AB

C820 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C821 VCEASH1CN107MY J 100 16V Electrolytic AC

C822 RC-KZ1025CEZZY J 1 10V Ceramic AB

C825 RC-KZ1025CEZZY J 1 10V Ceramic AB

C826 VCKYCY1CF224ZY J 0.22 16V Ceramic AB

C827 VCKYCY1CF224ZY J 0.22 16V Ceramic AB

C830 VCEAPF0GW107MY J 100 4V Electrolytic AC

C831 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C835 VCKYCY1CF224ZY J 0.22 16V Ceramic AB

C839 VCKYCY1CF224ZY J 0.22 16V Ceramic AB

C840 VCKYCY1CF224ZY J 0.22 16V Ceramic AB

C841 VCKYCY1CF224ZY J 0.22 16V Ceramic AB

C842 VCEAPF0GW107MY J 100 4V Electrolytic AC

C844 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C848 VCEAPF0JW107MY J 100 6.3V Electrolytic AC

C874 RC-KZ1025CEZZY J 1 10V Ceramic AB

C875 RC-KZ1025CEZZY J 1 10V Ceramic AB

C876 VCEAPF0GW107MY J 100 4V Electrolytic AC

C878 RC-KZ1025CEZZY J 1 10V Ceramic AB

C879 VCKYTV1CF684ZY J 0.68 16V Ceramic AB

C902 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C905 VCEAPF1CW106MY J 10 16V Electrolytic AB

C906 VCEAPF1CW106MY J 10 16V Electrolytic AB

C909 VCKYCY1HB682KY J 6800p 50V Ceramic AA

C910 VCKYCY1HB682KY J 6800p 50V Ceramic AA

C911 VCEAPF1CW106MY J 10 16V Electrolytic AB

C912 VCEAPF1CW106MY J 10 16V Electrolytic AB

C913 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C914 RC-EZ0417CEZZY J 150 16V Electrolytic AD

C915 VCEAPF0JW336MY J 33 6.3V Electrolytic AB

C916 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C919 RC-KZ1025CEZZY J 1 10V Ceramic AB

C920 RC-KZ1025CEZZY J 1 10V Ceramic AB

C921 RC-KZ1025CEZZY J 1 10V Ceramic AB

C922 RC-KZ1025CEZZY J 1 10V Ceramic AB

C923 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C924 VCEAPF1CW106MY J 10 16V Electrolytic AB

C925 RC-KZ1025CEZZY J 1 10V Ceramic AB

C927 VCCCCY1HH560JY J 56p 50V Ceramic AB

C928 VCCCCY1HH560JY J 56p 50V Ceramic AB

C929 VCCCCY1HH560JY J 56p 50V Ceramic AB

C930 VCCCCY1HH5R0CY J 5p 50V Ceramic AA

C931 VCCCCY1HH5R0CY J 5p 50V Ceramic AA

C932 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C933 RC-EZ0417CEZZY J 150 16V Electrolytic AD

C935 VCEAPF1CW226MY J 22 16V Electrolytic AB

C937 RC-EZ0417CEZZY J 150 16V Electrolytic AD

C938 RC-EZ0417CEZZY J 150 16V Electrolytic AD

C939 VCKYCY1HB561KY J 560p 50V Ceramic AA

C940 VCKYCY1HB152KY J 1500p 50V Ceramic AA

C941 VCKYCY1HB152KY J 1500p 50V Ceramic AA

C942 VCKYCY1HB561KY J 560p 50V Ceramic AA

C943 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C944 VCEAPF1CW106MY J 10 16V Electrolytic AB

C945 VCEAPF1HW225MY J 2.2 50V Electrolytic AB

C946 VCEAPF1HW225MY J 2.2 50V Electrolytic AB

C954 VCEAPF1CW106MY J 10 16V Electrolytic AB

C955 VCKYTV1CF105ZY J 1 16V Ceramic AB

C956 VCKYTV1CF105ZY J 1 16V Ceramic AB

C957 VCEAPF1EW475MY J 4.7 25V Electrolytic AB

C958 VCEAPF1EW475MY J 4.7 25V Electrolytic AB

C961 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C962 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C963 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C964 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C1101 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1102 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1103 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1104 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1105 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1106 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1107 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1108 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1109 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1110 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1111 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1112 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1113 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1114 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1115 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1116 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1117 VCCCCY1HH560JY J 56p 50V Ceramic AB

C1118 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1119 VCKYTV1CF105ZY J 1 16V Ceramic AB

C1120 VCKYTV1EF104ZY J 0.1 25V Ceramic AB

C1122 VCKYTV1CF105ZY J 1 16V Ceramic AB

C1123 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1124 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1127 VCEAPF1CN107MY J 100 16V Electrolytic AD

C1128 VCE9PF1CN106MY J 10 16V Elect. (N.P) AD

C1201 VCCCCY1HH220JY J 22p 50V Ceramic AA

C1202 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1203 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1204 VCCCCY1HH220JY J 22p 50V Ceramic AA

C1205 VCCCCY1HH220JY J 22p 50V Ceramic AA

43

Page 44

LC-10A3U

SUPPLEMENT

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

DUNTKB686FE01

MAIN UNIT (Continued)

C1206 VCEAPF1EW106MY J 10 25V Electrolytic AC

C1207 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1209 VCEAPF0JW107MY J 100 6.3V Electrolytic AC

C1210 VCEAPF0GW107MY J 100 4V Electrolytic AC

C1211 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1212 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1213 VCEAPF0JW107MY J 100 6.3V Electrolytic AC

C1214 VCEAPF0GW107MY J 100 4V Electrolytic AC

C1215 RC-KZ1025CEZZY J 1 10V Ceramic AB

C1216 VCEAPF1EW226MY J 22 25V Electrolytic AD

C1218 VCEAPF1CN106MY J 10 16V Electrolytic AD

C1219 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1220 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1221 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C1223 VCEAPF1CW106MY J 10 16V Electrolytic AB

C1224 VCEAPF1EW106MY J 10 25V Electrolytic AC

C2001 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C2002 VCCCCY1HH221JY J 220p 50V Ceramic AA

C2003 VCEAPF1HW105MY J 1 50V Electrolytic AB

C2006 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2007 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2009 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2010 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2017 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2018 VCCCCY1HH101JY J 100p 50V Ceramic AA

C2019 VCKYTV1AB105KY J 1 10V Ceramic AC

C2020 VCKYCY1HB102KY J 1000p 50V Ceramic AA

C2021 VCEAPF1AW476MY J 47 10V Electrolytic AB

C2022 VCKYCY1EF104ZY J 0.1 25V Ceramic AA

C2023 VCKYTV1AB105KY J 1 10V Ceramic AC

C2024 VCKYCY1HB222KY J 2200p 50V Ceramic AA

RESISTORS

R201 VRS-CY1JF102JY J 1k 1/16W Metal Oxide AA

R202 VRS-CY1JF103FY J 10k 1/16W Metal Oxide AA