Page 1

HT-SB200

SERVICE MANUAL

No. S1902HTSB200W

SOUND BAR SYSTEM

is a trademark of SRS Labs, Inc.

WOW HD technology is incorporated under license

from SRS Labs, Inc.

CONTENTS

PRECAUTIONS FOR USING LEAD-FREE SOLDER

CHAPTER 1. GENERAL DESCRIPTION

[1]

AC Power Supply Cord And AC Plug Adaptor

[2] Specifications ................................................ 1-1

[3] Name Of Parts ............................................... 1-2

CHAPTER 2. ADJUSTMENTS

[1] Test Mode....................................................... 2-1

CHAPTER 3. MECHANISM BLOCKS

[1] Disassembly................................................... 3-1

CHAPTER 4. DIAGRAMS

[1] Block Diagrams.............................................. 4-1

.. 1-1

MODEL

• In the interests of user-safety the set should be restored

to its original condition and only parts identical to those

specified be used.

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] Notes On Schematic Diagram .......................6-1

[2] Types Of Transistor And LED........................ 6-1

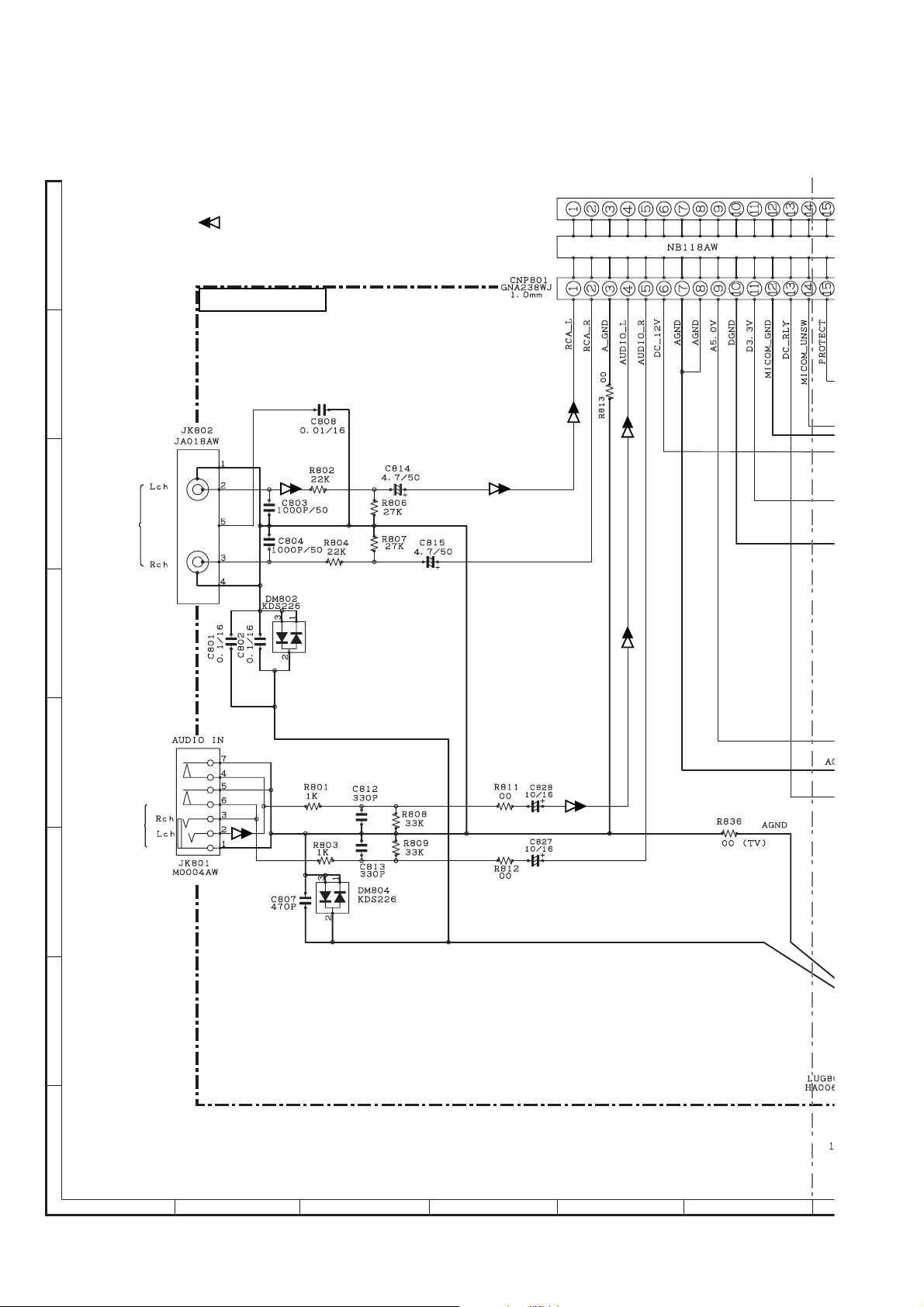

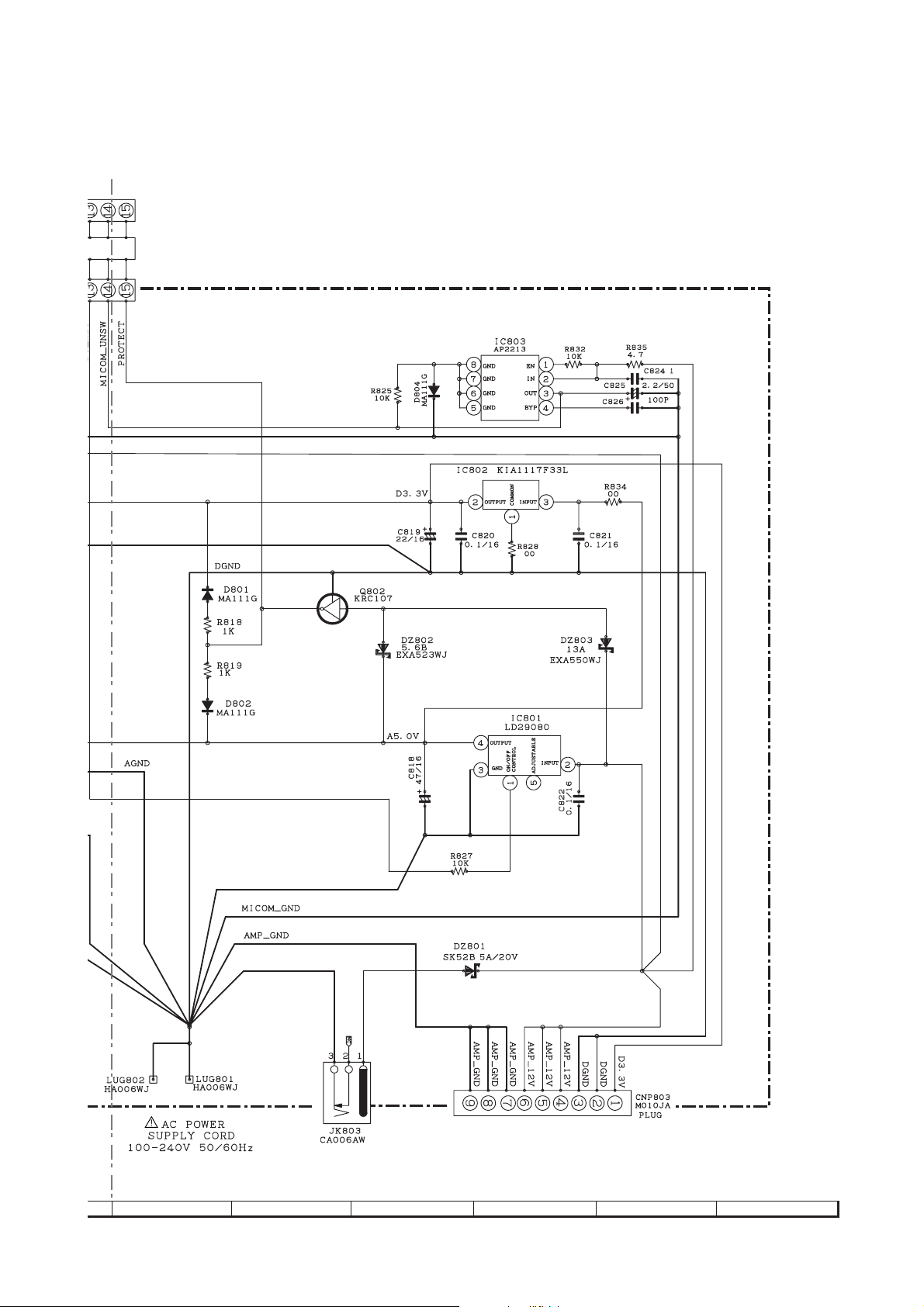

[3] Schematic Diagram .......................................6-2

[4] Chart Of Connecting Wires............................ 6-8

[5] Wiring Side Of PWB ....................................6-10

CHAPTER 7. OTHERS

[1] Function Table Of IC...................................... 7-1

PARTS GUIDE

HT-SB200

[ ASIA, EX ]

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Voltage ........................................................... 5-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

!

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

HT-SB200

PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

"MAIN, POWER, AMPLIFIER PWB" of this model employs lead-free solder. The LF symbol indicates lead-free

solder, and is attached on the PWB and service manuals. The alphabetical character following LF shows the type

of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2.

Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend

you to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering

bit, contact our service station or service branch in your area.

3.

Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead

solder by 40°C,and as it has poor solder wet ability, you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, since the land may be peeled of for the maximum heat-resistance

temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady

soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corrected. Make sure to turn

on and off the power of the bit as required. If a different type of solder stays on the tip of the soldering bit, it is

alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sand paper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Ref No.

PWB-A 92LPWB7388MANS MAIN (A1) / POWER (A2) / AMPLIFIER (A3) [ Except Indonesia, Brazil and Taiwan ]

PWB-A 92LPWB7394MANS MAIN (A1) / POWER (A2) / AMPLIFIER (A3) [ For Indonesia Only ]

Parts No.

MAIN (A1) / POWER (A2) / AMPLIFIER (A3) [ For Brazil and Taiwan Only ]PWB-A 92LPWB7387MANS

Description

– i –

Page 3

CHAPTER 1: GENERAL DESCRIPTION

CAUTION : “Danger of explosion if battery is incorrectly replaced. Replace only with the same or

equivalent type”.

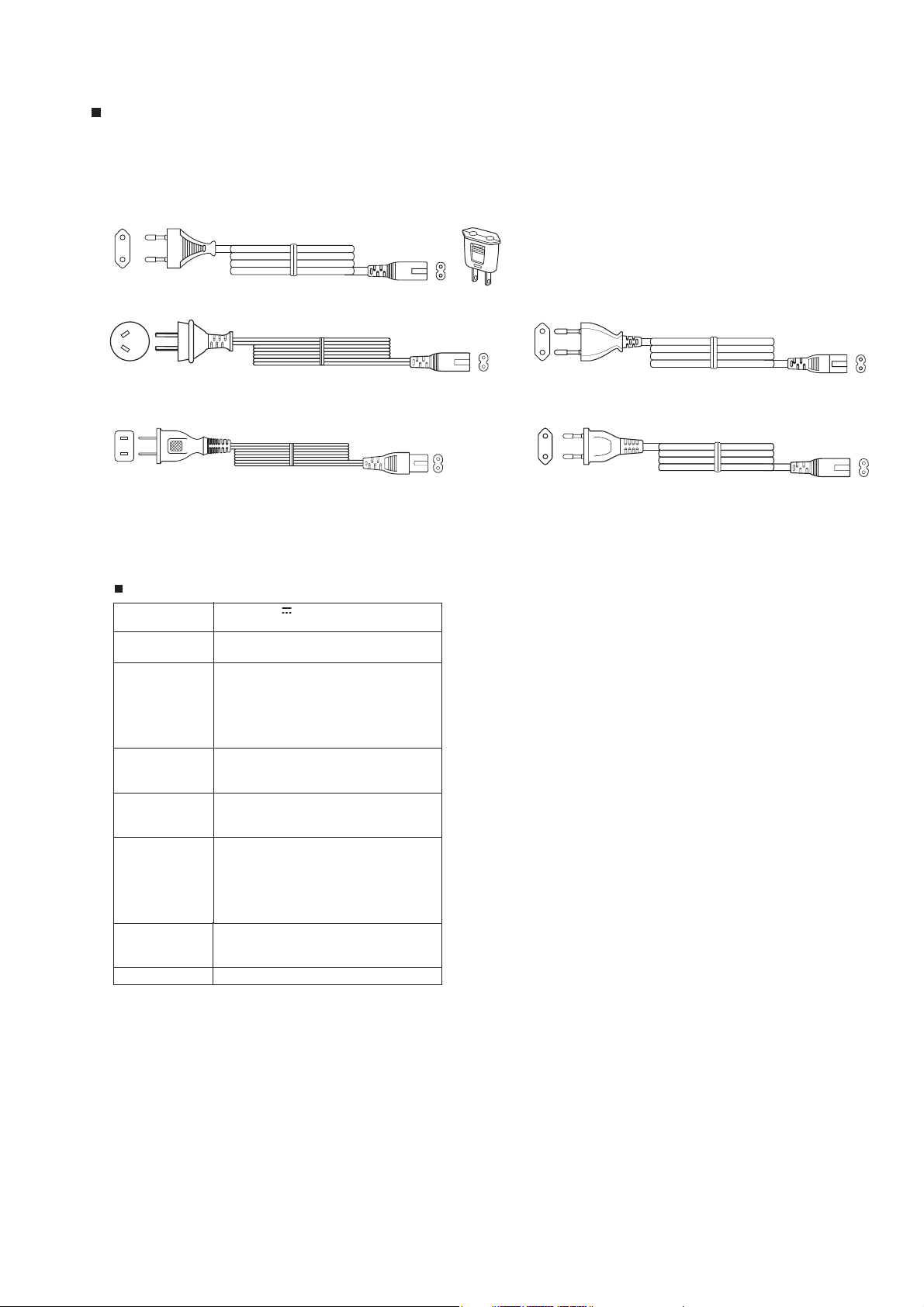

[1] AC Power Supply Cord And AC Plug Adaptor

HT-SB200

QACCEA002AW00

QACCLA002AW00

QACCZA002AW00

[2] Specifications

General

Power source DC IN 12V 4A: AC/DC adaptor

Power

consumption

Output power Front speaker:

Speaker 2.1-way Speaker System

Audio output

terminals

Input terminals Analogue input (LINE 1):

Dimensions Width: 800 mm (31-1/2")

Weight 1.75 kg (3.86 lbs.)

(*) This power consumption value is obtained when in the

power stand-by mode.

(AC 100 - 240 V ~ 50/60 Hz)

Power on: 10 W

Power stand-by: 0.6 W (*)

RMS: 12 W (6 W + 6 W) (10% T.H.D.)

RMS: 9.6 W (4.8 W + 4.8 W) (0.9% T.H.D.)

Subwoofer:

RMS: 20 W (10% T.H.D.)

RMS: 13 W (0.9% T.H.D.)

Front Speakers: 38 mm (1-1/2") Full Range

Subwoofer: 57 mm (2-1/4") Woofer (x4)

Speakers: 12 ohms / Channel

Subwoofer: 3 ohms

(12 Ohms x 4 parallel connections)

RCA type x 1pair (L/R)

500 mV / 47 kohms

Analogue input (LINE 2):

Stereo mini socket Ø 3.5 mm

100 mV / 47 kohms

Height: 96 mm (3-3/4")

Depth: 70 mm (2-3/4")

QPLGA0004AWZZ

QACCZA007AW00

QACCZA018AW00

1 – 1

–2

Page 4

HT-SB200

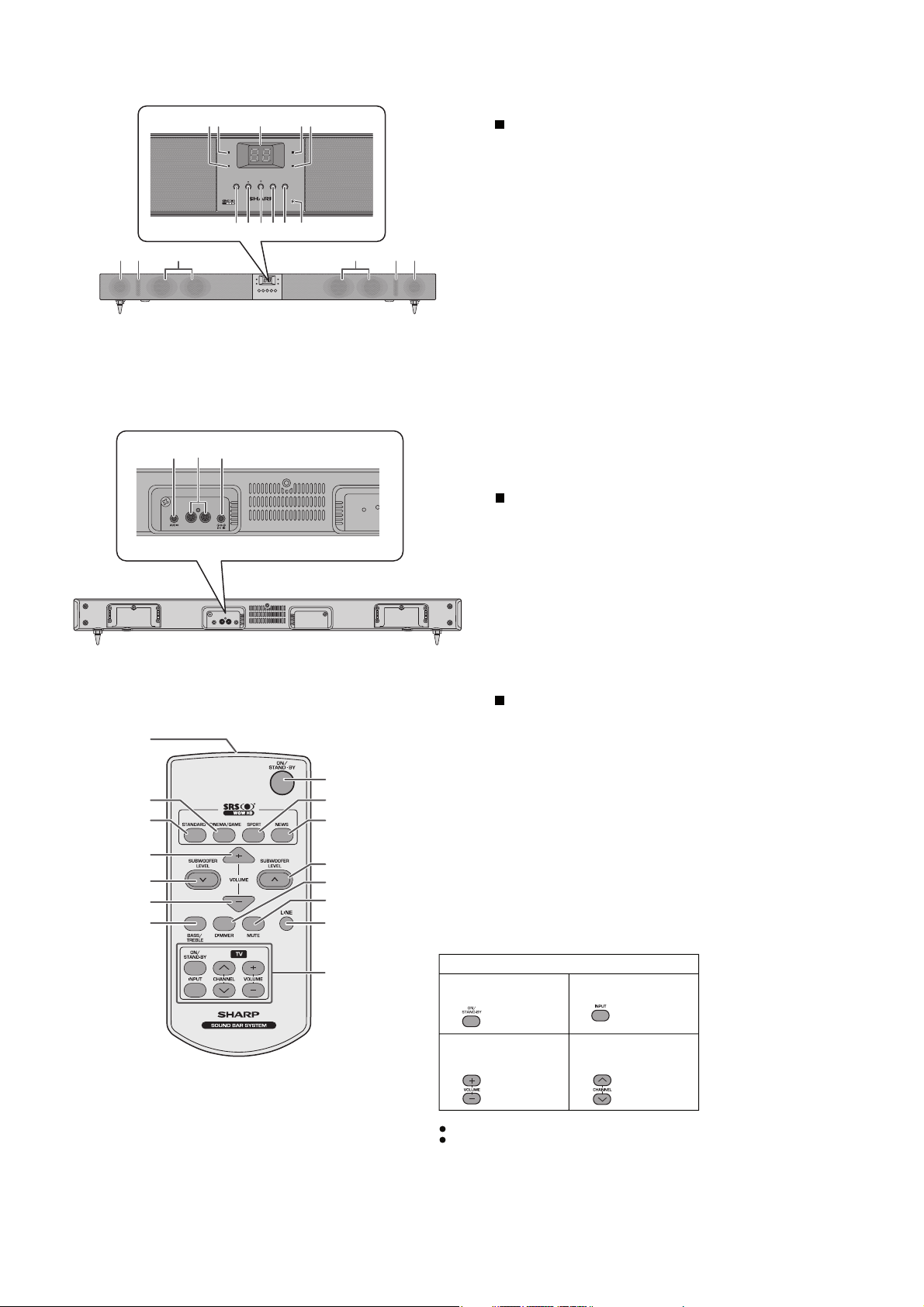

[3] Names Of Parts

2

TANDARD

S

PORT

S

TAND-BY

S

ON/

S

OUND BAR

VOL.

3

SYSTEM HT-S8200

SURROUND

FUNCTION

CINEMA / GAME

NEWS

451

Front panel

1. Sport Indicator

2. Standard Indicator

3. Information Display

4. Cinema/Game Indicator

5. News Indicator

6 7 8 9

10 11

12

13

1

14

3

1514

6. On/Stand-by Button

7. Volume Down Button

8. Volume Up Button

9. Surround Button

10. Function Button

11. Remote Sensor

12. Left Front Speaker

13. Bass Reflex Duct

14. Subwoofers

15. Right Front Speaker

123

Rear Panel

RIGHT

LEFT

LINE IN 1LINE IN 2

1. Audio Line In 2 (3.5 mm stereo/headphone) Socket

2. Line In 1 (RCA/cinch) Sockets

3. DC Input Socket

Remote Control

1. Remote Control Transmitter

1

8

2

3

4

5

6

7

9

10

11

12

13

14

15

TV Operation Buttons (Only SHARP TV):

On/Stand-by

Button

Volume Up

and Down

Buttons

Notes:

2. Cinema/Game Button

3. Standard Button

4. Volume Up Button

5. Subwoofer Level Down Button

6. Volume Down Button

7. Bass/Treble Button

8. On/Stand-by Button

9. Sport Button

10. News Button

11. Subwoofer Level Up Button

12. Dimmer Button

13. Mute Button

14. Line Button

15. TV Operation Buttons

Sets the TV

power to “ON”

or “STANDBY”.

Turn up/down

the TV

volume.

Some models of SHARP TV may not be operable.

SHARP TV remote will not work with HT-SB200 system.

Input Select

Button (TV)

Channel Up

and Down

Buttons

Press the

button to

switch the

input source.

Switch up/

down the TV

channels.

1 – 2

– 2

Page 5

CHAPTER 2. ADJUSTMENTS

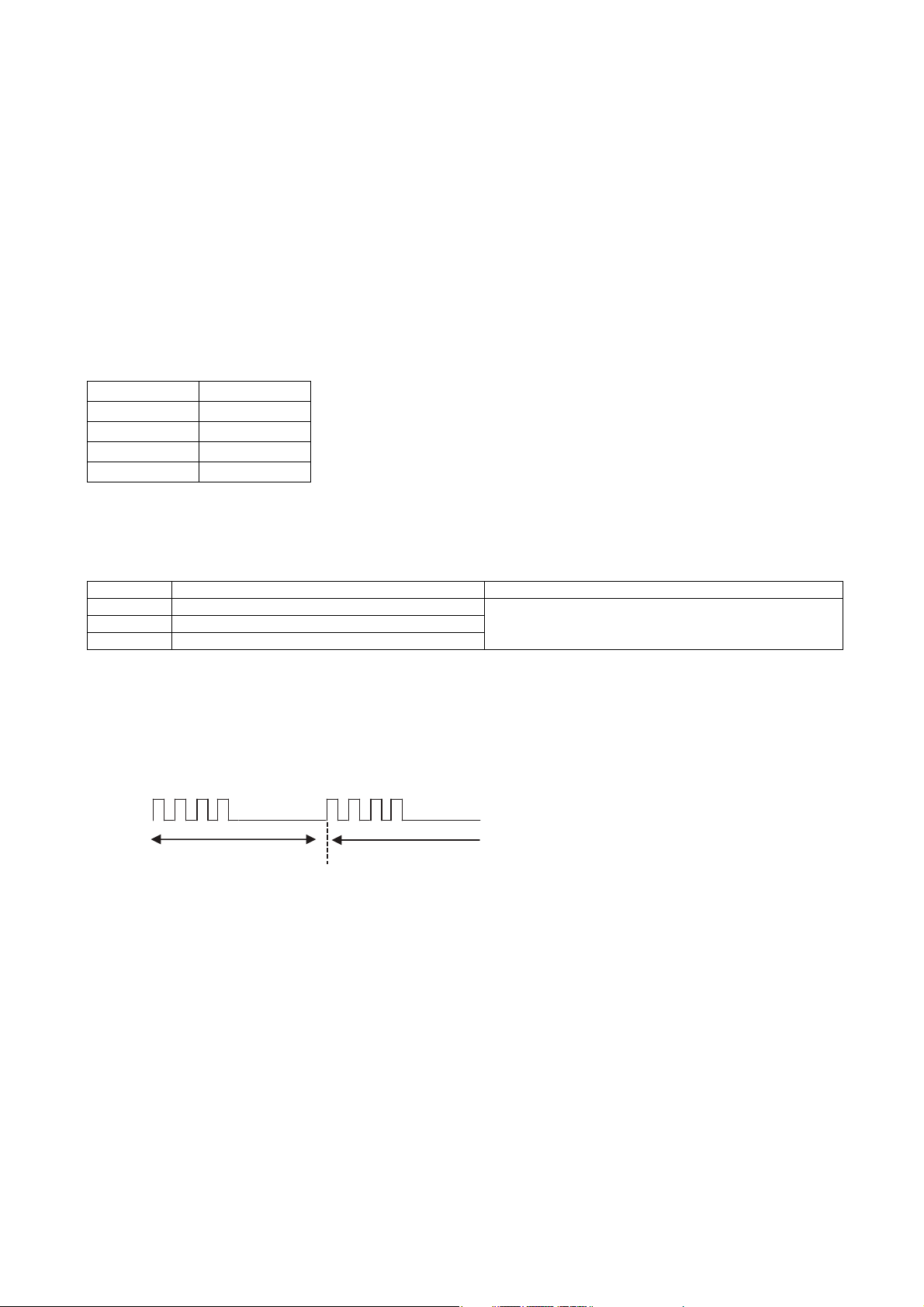

[1] Test Mode

1. Enter the Test Mode version display

While pressing down ON/STANDBY and VOL UP button, Switch ON AC supply.

Version will be display on 7 segment as below:b2 --> ** --> D

b2 = Model name, ( SB200 )

** = Software version no.

D = Destination code :- O (for Others), I (for Indonesia)

2. Enter the Test Mode version display

After enter Test Mode version display, Press VOL UP button.

1. All SOUND MODE LED will light ON

2. 7 segment display will light on if press button as below

Key 7 segment

VOL DOWN 01

VOL UP 02

SURROUND 03

FUNCTION 04

HT-SB200

3. Exit the Test Mode

While in Test Mode function, Press ON/STANDBY button to exit.

4. Error Code Description.

Display Explanation Solution

E1 Communication error between Micom and WM877

E3 Communication error between Micom and STA333

> Unplug AC cord and turn power ON again

> Check line connected between Micom and corresponding ICE2 Communication error between Micom and NJU-26040

5. System Protection indicator

In case abnormal power detection has occurred, the unit will automatically enter to stand-by mode

ON/STANDBY LED willl be flashing as below:-

Flashing

Flashing

OFF OFF

1 Frame

Unit enter Protect mode when irregular process occur on power supply line.

(Repeat)

2 – 1

Page 6

HT-SB200

CD-ES700/CD-ES77CD-ES700/CD-ES77Service ManualCD-ES700/CD-ES77MarketE

CHAPTER 3. MECHANISM BLOCKS

[1] Disassembly

Caution On Disassembly

Follow the below-mentioned notes when disassembling the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Be sure to remove the power supply plug from the wall outlet before starting to disassemble the unit.

2. Take off nylon bands or wire holders where they need to be removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were before disassembling.

3. Check that all speaker cushions (refer items 212, 214, 215 and 216 on pages 6 and 7 of Parts Guide) are properly

sealed otherwise vibration noise will be very distinct at low frequency sound.

Replace the cushions if they are found damaged during servicing.

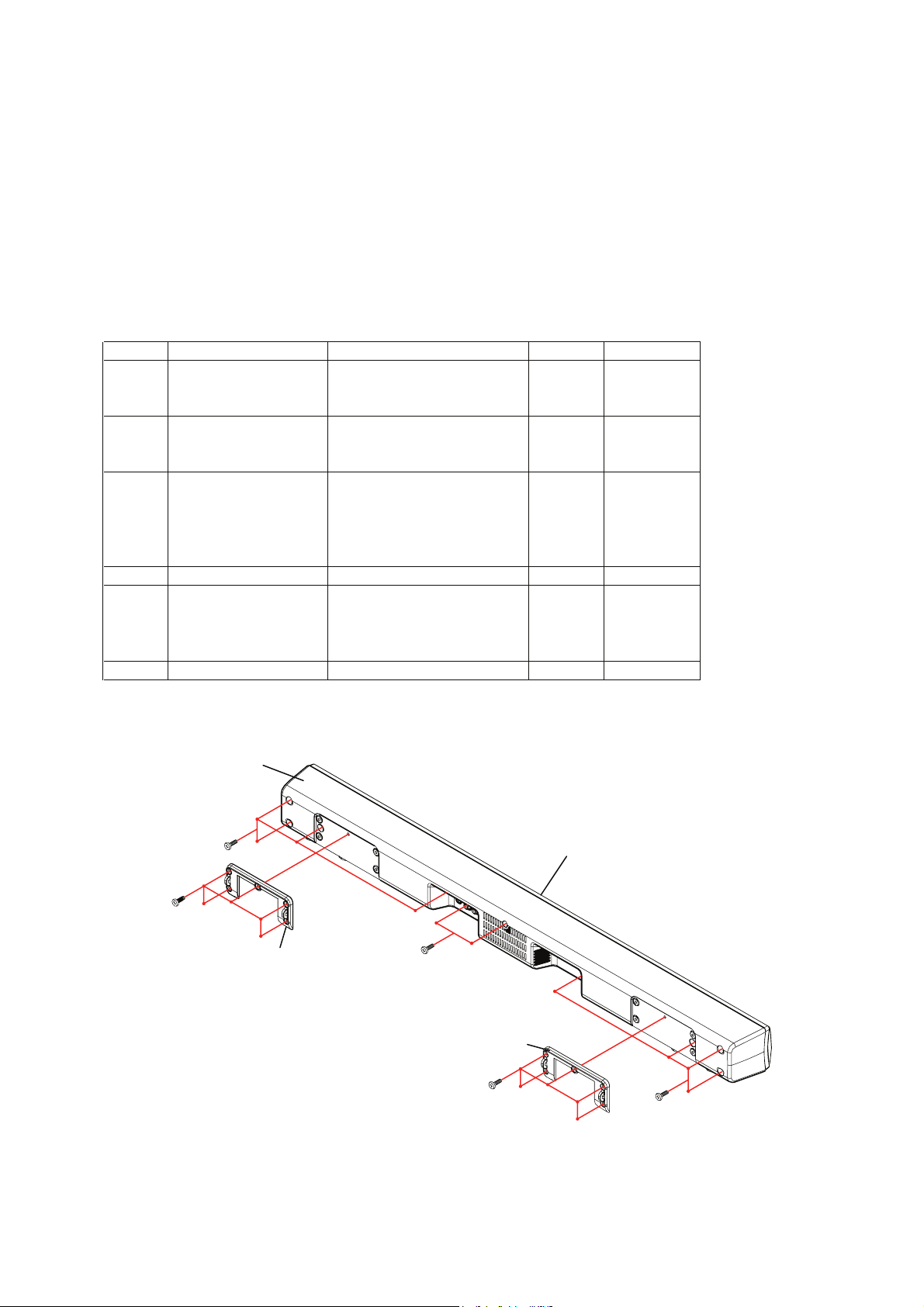

STEP REMOVAL PROCEDURE FIGURE

1 Back Cabinet Assy 1. Wall Mount Bracket…… (A1)x2 1

2. Screw…………..………. (A2)x10

3. Screw…………..………. (A3)x10

2 Amp PWB 1. Screw……….………….. (B1)x2 2

2. Connector…….……….. (B2)x1

3. Socket………………..… (B3)x2

3 Power PWB 1. Main Chassis……….…. (C1)x1 2

2. Screw………….…….…. (C2)x4

3. Screw………….…….…. (C3)x1

4. Socket………………..…

5. Screw………………...…

4 Main PWB 1. Screw………….………. (D1)x1 2

5 Woofer 1. Duct Port Holder…….… (E1)x2 3

2. Duct Port Assy………… (E2)x2 3

3. Screw………….…….…. (E3)x12 3

2. Screw………….………. (E4)x8 4

6 Speaker 1. Screw………….………. (F1)x8 4

(C4)x1

(C5)x2

Back Cabinet Ass’y

(A3)x4

M3x10mm

(A2)x5

M3.5x10mm

(A1)x1

Wall Mount Bracket

(A3)x2

M3x10mm

(A1)x1

Wall Mount Bracket

(A2)x5

M3.5x10mm

Figure 1

Front Cabinet Ass’y

(A3)x4

M3x10mm

3 – 1

Page 7

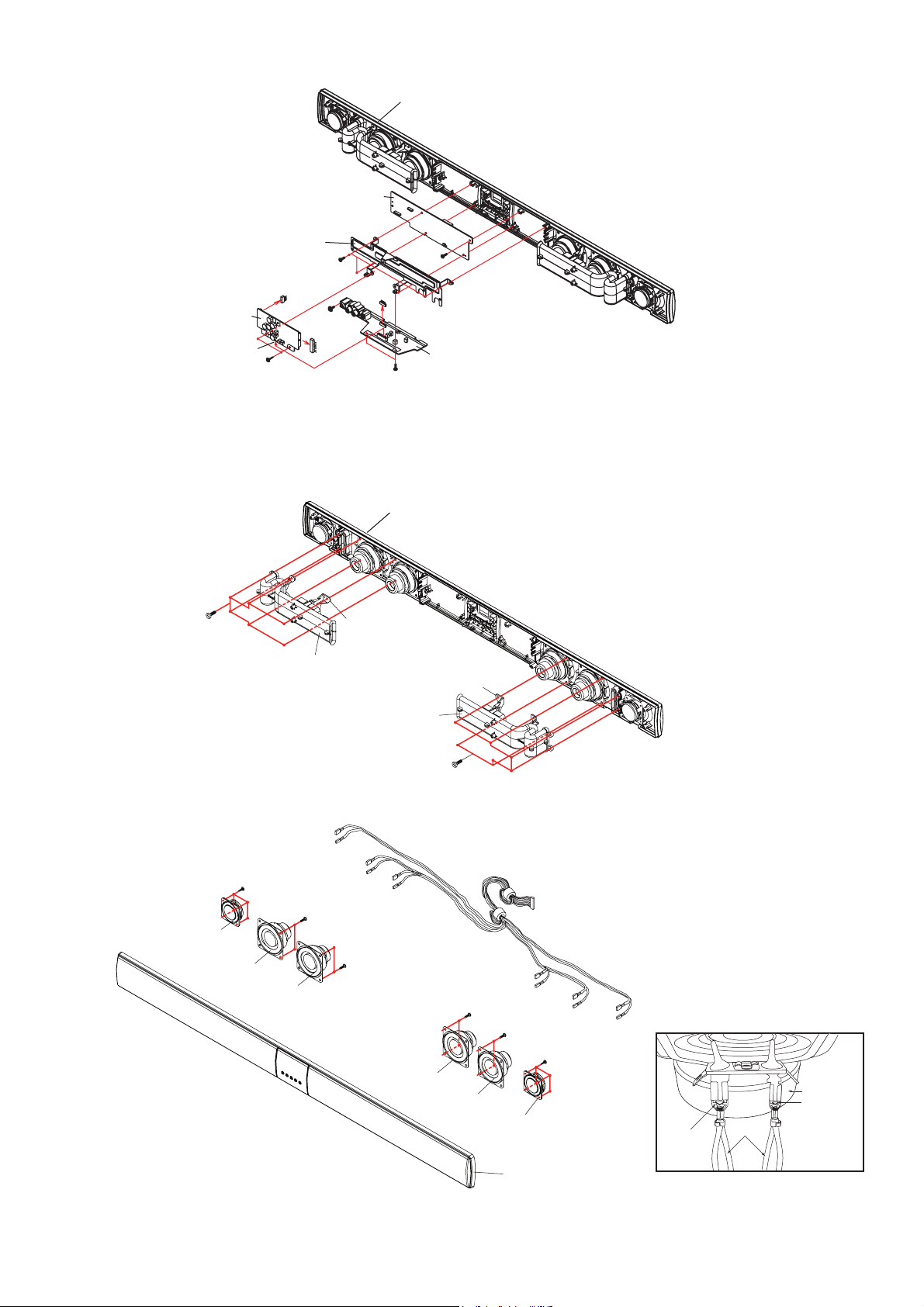

Amplifier PWB

(B2)x1

(C1)x1

Main Chassis

(C2)x4

M3x10mm

(B3)x1

(C3)x1

Special Screw

(B1)x2

Special Screw

Figure 2

Main PWB

(B3)x1

(C4)x1

Front Cabinet Ass’y

(D1)x1

M3x8mm

Power PWB

(C5)x2

M3x8mm

HT-SB200

(E3)x6

M3x10mm

Speaker

Woofer

(E2)x1

Duct Port Ass’y

(F1)x4

M2.6x8mm

Woofer

Figure 3

(E4)x2

M3x10mm

Front Cabinet Ass’y

(E1)x1

Duct Port Holder

(E1)x1

Duct Port Holder

(E2)x1

Duct Port Ass’y

(E3)x6

M3x10mm

(E4)x2

M3x10mm

Woofer

Woofer

(E4)x2

M3x10mm

(E4)x2

M3x10mm

Speaker

(F1)x4

M2.6x8mm

LOCKING TAB

SPEAKER

WIRE

SPEAKER UNIT

LOCKING TAB

Figure 4

3 – 2

Front Cabinet Ass’y

CAUTION:

TO REMOVE SPEAKER UNIT, PRESS THESE LOCKING TABS

TO RELEASE SPEAKER WIRES.

Page 8

HT-SB200

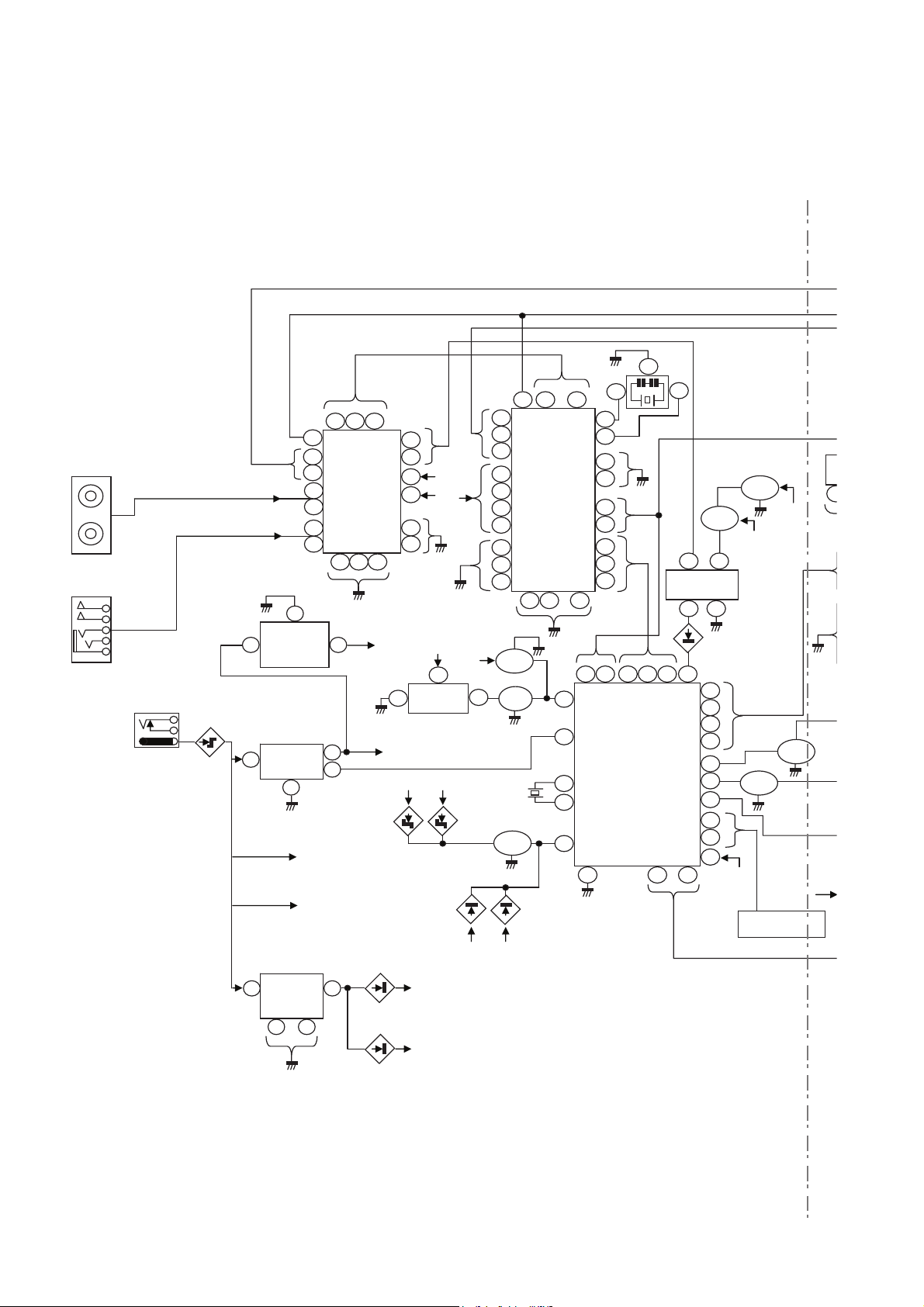

A

V

6

CHAPTER 4. DIAGRAM

[1] Block Diagram

2

1

22

5

2 4

3

JK802 (LINE IN)

hcL

L +B2

R

hcR +B5

10

11

L

R

L

R

1

28

IC601

WM8775

25

24

6 14

JK801 (AUDIO IN)

AVDD

DVDD

17

18

21

+B1

16

7

+B2

8

9

17

18

19

1

7

VDD

8

25

5

9

12

~

3

KIA1117F33L

V02/A5 B25KS

IC801

2

LD29080

1

IC802

3

+B5

+B2

2

V3.3

D

3

4

V0.5AR

1B+

1

+B1 +B4

DZ802 DZ803

5.6B 13A

2

IC605

PST8227N

DC_RLY

Q602

1

Q601

XM603

32.768kHz

Q802

FROM AC/DC

DA

OTPA

L

R 206D3B+

JK803 DZ801

NI C

D

12V 4A

DC_12V

16

14

~

~

IC602

NJU260409

SRS WOW

13 28 32

8

35

7

6

43

10

11

24

23

2

3

6

26

27

42

27 28 30

RESET

POWER

IC604

IXA229AW

SYSTEM

MICROCOMPUTER

SYS

PROTECT

10 4846

MP_12

2

IC803

AP2213

5 8

~

4B+

MICOM_UNSW

3

D604

+B3

UNSW 3.3

+B6

1

08D

+B2 +B1

208D

3

3

IC603

TJM4558CD

1

38

VREF

~

XM601

36.864MHz

Q605

8

4

L6B+

_LV

14

17

18

19

15

20

21

36

42

44

+B3

CETED

Q604

T

Q701

Q702

KEY

SW702-SW705

+B3

1

D605

Figure 4-1: BLOCK DIAGRAM (1/2)

4 – 1

Page 9

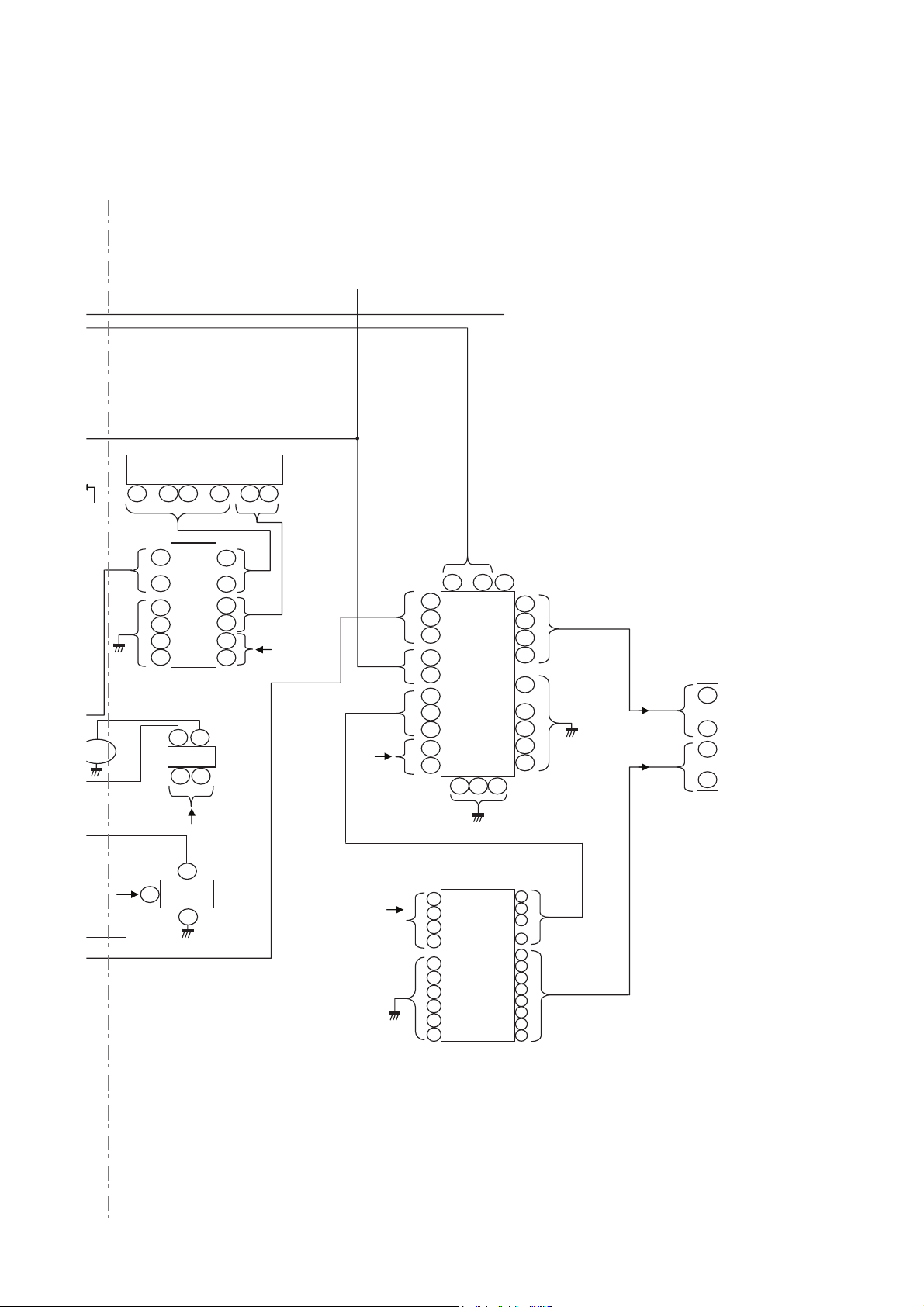

+B2

Y

LED701

SEVEN SEGMENT

616 4 5

~ ~

3

HT-SB200

1

701

5

~

2

24

26

27

30

PT6965

4 2

LED702

IC701

1

VDD

3

+B3

9

~

30 27

28

23

31

32

33

34

17

18

19

8

11

~

IC901

STA333BW

POWER IC

SDA

SCL

VCC

22

13

10

9

6

1

~

3

7

12

16

3526

L

R

1

~

L

R

FRONT = 12

4

5

~

SUBWOOFER = 3Ω

8

Ω

15

28

29

8

23

+

1B

+B4

1

2

REMOTE

SENSOR

3

+B4

7

4

12

15

1

5

6

13

14

19

VCC

IC902

STA533W

25

26

32

~

29

2

3

8

9

10

11

16

17

+B3

W705

Figure 4-2: BLOCK DIAGRAM (2/2)

4 – 2

Page 10

HT-SB200

CHAPTER 5.

VOLTAGE

[1] Voltage

IC601 IC602

PINNOVOLTAGE

(V)

1 2.45 15 2.45 1 3.28 17 1.63

2 1.64 16 4.91 2 3.27 18 1.64

3 1.62 17 0.00 3 3.13 19 0.90

4 0.81 18 2.45 4

5 1.64 19 2.45 5 0.00 21 0.00

6 0.00 20 2.45 6 3.13 22 1.62

7

8 0.00 22 2.43 8

9 0.00 23 2.43 9 0.00 25 3.28

10 1.52 24 2.44 10 1.55 26 1.65

11 1.50 25 2.44 11 1.54 27 3.12

12 0.00 26 2.43 12 0.00 28 0.00

13 2.43 27 2.43 13 0.00 29 0.00

14 0.00 28 2.45 14 0.80 30 0.00

PINNOVOLTAGE

1 2.45 16 2.45

2 1.64 17 4.91

3 1.62 18 0.00 1

4 0.81 19 2.45 2

5 1.64 20 2.45 3 0.00 29 3.07

6 0.00 21 2.45 4 3.27 30 1.93

7

8 0.00 23 2.43 6 1.43 32 0.00

9 0.00 24 2.43 7 1.07 33 0.00

10 1.52 25 2.44 8 3.10 34 0.00

11 1.50 26 2.44 9 1.43 35 3.13

12 0.00 27 2.43 10 0.00 36 3.06

13 2.43 28 2.43 11 1.56 37 0.00

14 0.00 29 2.45 12 3.13 38 0.00

15 0.00 30 0.00 13 0.00 39 0.00

PINNOVOLTAGE

1 3.05 1 0.00 19 3.28 45 0.00

2 11.75 2 3.28 20 3.10 46 3.13

3 0.00 3 4.94 21 2.96 47 3.13

4 4.94 22 0.00 48 3.27

5 0.00 23 0.00 49 0.00

3.28

IC701

(V)

3.28

IC801 IC802

(V)

PINNOVOLTAGE

(V)

21 2.45 7 3.28 23

PINNOVOLTAGE

(V)

22 2.45 5 3.13 31 0.00

PINNOVOLTAGE

(V)

IC803

PINNOVOLTAGE

(V)

1 11.41

2 11.66

3 3.84

4 2.41

5 0.54

6 0.54

7 0.54

8 0.54

PIN

VOLTAGE

NO

15 1.64 31 0.00

16 1.64 32 0.00

PINNOVOLTAGE

14 2.25 40 0.00

15 0.00 41 0.00

16 0.00 42 3.07

17 1.88 43 3.28

18 1.43 44 3.08

24 0.00 50 0.00

25 0.00 51 0.00

26 0.00 52 0.00

(V)

3.28

3.28

(V)

0.00

3.13

PINNOVOLTAGE

20 0.00

24 0.00

IC604

PINNOVOLTAGE

27 3.12

28 3.12

(V)

0.00

(V)

5 – 1

Page 11

IC901 IC902

PINNOVOLTAGE

(V)

1 0.00 19 3.26 1 0.00 19 0.00

2 0.00 20 3.22 2 0.54 20 0.00

3 0.00 21 3.26 3 0.54 21 4.83

4 8.54 22 0.00 4 11.76 22 4.83

5 11.74 23 3.29 5 0.00 23 3.29

6 0.55 24 3.29 6 0.00 24 4.84

7

8 11.76 26 0.00 8 0.54 26 3.26

9 0.55 27 1.49 9 0.54 27 3.13

10 0.55 28 1.63 10 0.54 28 0.15

11 11.76 29 1.65 11 0.54 29 0.15

12 0.00 30 0.87 12 11.76 30 0.15

13 0.55 31 3.15 13 0.00 31 0.15

14 0.00 32 3.28 14 0.00 32 0.15

15 3.34 33 3.28 15 11.76 33 6.69

16 0.00 34 3.13 16 0.54 34 6.69

17 0.15 35 0.00 17 0.54 35 11.76

18 0.15 36 3.28 18 0.00 36 11.76

0.00

PINNOVOLTAGE

(V)

25 0.00 7

PINNOVOLTAGE

(V)

11.76

PINNOVOLTAGE

(V)

25 3.27

HT-SB200

5 – 2

Page 12

HT-SB200

-MEMO-

5 – 3

Page 13

HT-SB200

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS LAYOUT

[1] Notes On Schematic Diagram

•Resistor:

To differentiate the units of resistors, such symbol as

K and M are used: the symbol K means 1000 ohm

and the symbol M means 1000 kohm and the

resistor without any symbol is ohm-type resistor.

Besides, the one with “Fusible” is a fuse type

• Capacitor:

To indicate the unit of capacitor, a symbol P is used:

this symbol P means pico-farad and the unit of the

capacitor without such a symbol is microfarad. As to

electrolytic capacitor, the expression “capacitance/

withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

REF. NO DESCRIPTION POSITION

SW701 POWER ON/STAND-BY ON—OFF

SW702 VOLUME DOWN ON—OFF

SW703 VOLUME UP ON—OFF

SW704 SURROUND ON—OFF

SW705 FUNCTION ON—OFF

• Schematic diagram and Wiring Side of P.W.Board

for this model are subject to change for

improvement without prior notice.

• The indicated voltage in each section is the one

measured by Digital Multimeter between such a

section and the chassis with no signal given.

• Parts marked with “ ” are important for

maintaining the safety of the set. Be sure to replace

these parts with specified ones for maintaining the

safety and performance of the set.

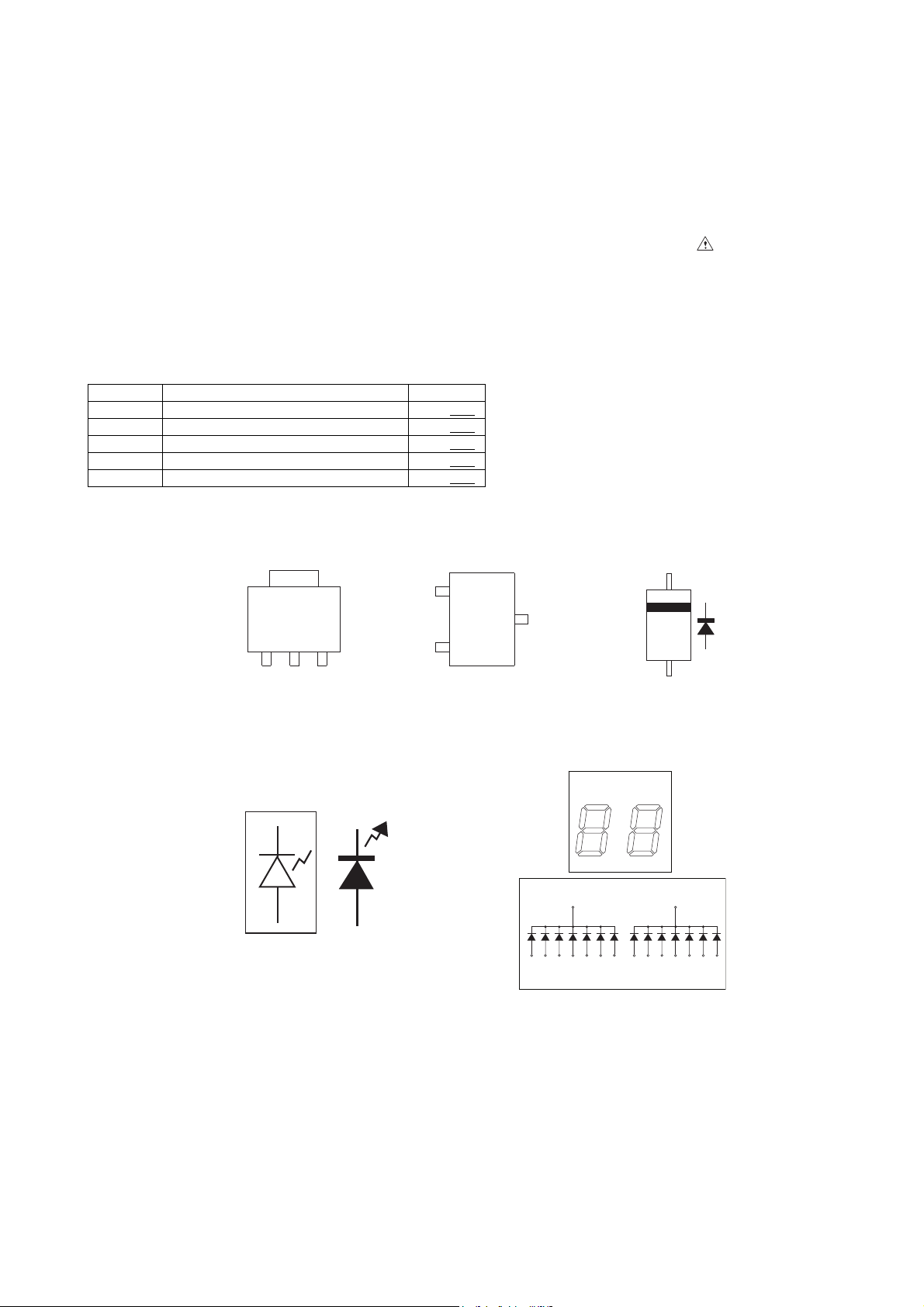

[2] Types Of Transistor And LED

TOP VIEW

B(1) C(2) E(3)

KiA1117F

PCL194H

B

(3)

E

(1)

TOP

VIEW

KRC101S

KRC107S

KRA107S

KRC104S

C

(2)

DIG 1

DIG 2 DIG 2

4

COM

DIG 1

ABCDEFG

15 13 1 3 2 14 16

TOP VIEW

MA111G

KDS226

A

G

FB

CE

D

5

COM

AB

CD E F G

10 12 8 6 7 11 9

DIG 2

6 – 1

PCL165S

Page 14

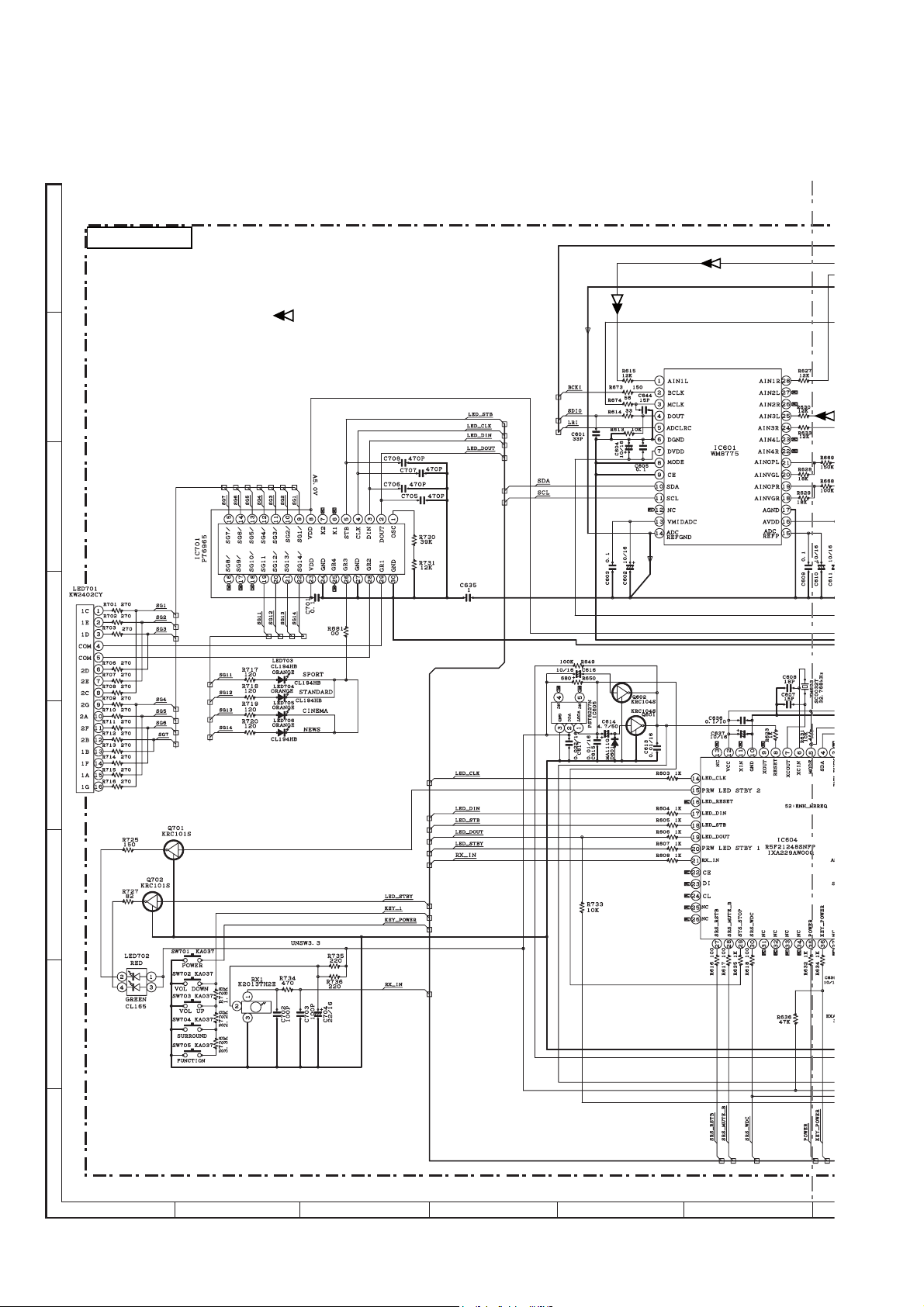

HT-SB200

[3] Schematic Diagram

MAIN PWB-A1

A

B

AUDIO SIGNAL

C

D

E

F

G

H

1

23456

Figure 6-1: MAIN SCHEMATIC DIAGRAM (1/2)

6 – 2

Page 15

TABLE 1

Remark

Dest.

Taiwan, Brazil

10KPULL DOWN R638

NIL

Indonesia Others

2.2K

10K

10K

NILPULL DOWN R645

HT-SB200

D_GND

TABLE 1

* Please refer

TAB LE 2

D_GND/PWM_IN

D_GND/PWM_IN

PWM_IN

PWM_IN

TABLE 2

Description of

CNP602 for

PIN no.9

PWM_IN

D_GND

TO AMPLIFIER SECTION

(CNP901)

TO AMPLIFIER SECTION

Taiwan,

Others

Brazil

NIL

NIL

(CNP801)

7

8 9 10 11 12

Figure 6-2: MAIN SCHEMATIC DIAGRAM (2/2)

6 – 3

Page 16

HT-SB200

A

B

TO MAIN SECTION

AUDIO SIGNAL

POWER PWB-A2

C

LINE IN 1

D

E

LINE IN 2

F

G

H

1

23456

Figure 6-3: POWER SCHEMATIC DIAGRAM (1/2)

6 – 4

Page 17

HT-SB200

DC IN

12V, 4A

TO AMPLIFIER SECTION

FROM

AC/DC ADAPTOR

7

8 9 10 11 12

Figure 6-4: POWER SCHEMATIC DIAGRAM (2/2)

6 – 5

Page 18

HT-SB200

i

AUDIO SIGNAL

TABLE 3

Description of CNP901

for PIN no. 9

PWM_IN NIL

D_GND NIL

Taiwan, Brazil

Others

A

B

C

TO MAIN SECTION

D_GND/PWM_IN

*Please refer TABLE 3

D

NOTE

C980 use for others

destination EXCEPT

Taiwan and Brazil

AMP PWB-A3

use for others destination EXCEPT Taiwan and Braz

use for others destination EXCEPT Taiwan and Brazil

E

F

G

H

TO POWER SECTION

1

23456

Figure 6-5: AMPLIFIER SCHEMATIC DIAGRAM (1/2)

6 – 6

Page 19

HT-SB200

w

SPEAKER SYSTEM (R-CH)

SPEAKER

an and Brazil

SP2

WOOFER

SP6

WOOFER

SP5

SPEAKER SYSTEM (L-CH)

WOOFER

SP4

WOOFER

SP3

SPEAKER

SP1

7

8 9 10 11 12

Figure 6-6: AMPLIFIER SCHEMATIC DIAGRAM (2/2)

6 – 7

Page 20

HT-SB200

[4] Charts Of Connecting Wires

A

RF2

CORE

RF1

CNS801-A

9 10111213141587654321

FROM

AMP PWB-A3

CNP901

910111213141587654321

CNP801

JK803

CNP803

DC INPUT

123456789

DC IN 12V , 4A

CNS801-B

BK

BK

BK

BK

BK

BK

B

910111213141587654321

CNP601

1234

CNP603

FOR

C

678912345

206PNC

01

11

9 10111213141587654321

DEVICE ONLY

EXTERNAL MICOM

1

RD

23

BK

BK

4

BK

5

BK

6

7

BK

8

BK

9

BK

01

BK

11

BK

BK

BK

BK

BK

BK

BK

BK

BK

BK

RD

D

CNS602-A

E

JK802

JK801

F

G

H

MAIN PWB-A1

(Top Side)

POWER PWB-A2

(Bottom Side)

AC / DC ADAPTOR

AC POWER SUPPLY CORD

L-CH

R-CH

AUDI O

LINE IN 2

1

2

LINE IN 1

CORE

CYLINDER CORE

(2 x TURN)

AC 100 - 240V ~ 50/60Hz

1

23456

Figure 6-7: WIRING CONNECTION (1/2)

6 – 8

Page 21

HT-SB200

123456789

CNP902

CNP901

CNS903

12345678

CNP903

9876543211011

9876543211011

WH

1

RD

2345678

BK

GY

RD

WH

GY

BK

AMP PWB-A3

(Bottom Side)

CNS602-B

RD

WH

RD

WH

RD

WH

SPEAKER

SP2

WOOFER

SP6

WOOFER

SP5

SPEAKER SYSTEM (R-CH)

RD

BK

BK

BK

BK

BK

TO

MAIN PWB-A1

CNP602

BKBKBK

BK

BK

GY

WOOFER

SP4

BK

GY

WOOFER

BK

GY

BK

SPEAKER SYSTEM (L-CH)

SP3

SPEAKER

SP1

COLOR TABLE

RD

BK

WH

RED

BLACK

WHITE

GY GREY

7

8 9 10 11 12

Figure 6-8: WIRING CONNECTION (2/2)

6 – 9

Page 22

HT-SB200

[5] Wiring Side Of PWB

MAIN PWB-A1

A

B

C

1234

56789

10

11

1234

D

E

10

1112131415

123456789

F

G

Lead-free solder indication

H

Lead-free solder is used in the MAIN PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-9(i): WIRING SIDE OF MAIN PWB (TOP VIEW) (1/2)

6 – 10

Page 23

HT-SB200

7

8 9 10 11 12

Figure 6-10(i): WIRING SIDE OF MAIN PWB (TOP VIEW) (2/2)

6 – 11

Page 24

HT-SB200

HT-SB200

for Taiwan and Brazil only.

A

MAIN PWB-A1

B

C

6

1

6C

R640

C639

CNP603

1243

C614

9

1

6C

556R

566R

C628

CNP602

C610

R679

34

6C

0

2

6C

086R

C602

386R

C621

C604

LUG601

9

86754321

10 11

146C

246C

C611

44

6

C

1

06L

C636

C637

1

R682

R641

R642

R643

6

73

36R

6

R

33

7

R

R607

R603

IC604

D

R604

R605

R606

E

64

1011121314

15

9

2

8

7

53

CNP601

1

606MD

C633

136C

3

466R

66R

F

G

Lead-free solder indication

H

Lead-free solder is used in the MAIN PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-9(ii): WIRING SIDE OF MAIN PWB (TOP VIEW) (1/2)

6 – 12

Page 25

HT-SB200

R731

C701

186R

IC701

1

037R

607C

807C

607

70

7C

C

20

7

5

3

6

C

Q

7

2

7

R

107Q

527

R

317R

217R

11

9

01

0

7

7R

7

R

R

2

3

6C

3

466R

66R

5

0

6

D

9

2

6

C

4

0

6

D

2

3

0

0

7

7

C

C

R734

6

53

3

7

7

R

R

166R

R704

807R

707R

5

4

6

1

1

1

7

7R

7

R

R

607R

1

2

307

0

0

7

7

R

R

R

7

8 9 10 11 12

Figure 6-10(ii): WIRING SIDE OF MAIN PWB (TOP VIEW) (2/2)

6 – 13

Page 26

HT-SB200

MAIN PWB-A1

A

B

C

Table of Parts Usage

Remark

Dest.

JP3

JP5

Taiwan, Brazil

USEJP1

NIL

NIL

Indonesia Others

NIL

USE NIL

NIL

NIL

USE

D

NOTE

PLEASE REFER

TABLE OF PARTS

USAGE.

E

F

G

1

JP1

JP3

JP5

Lead-free solder indication

H

Lead-free solder is used in the MAIN PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-11: WIRING SIDE OF MAIN PWB (BOTTOM VIEW) (1/2)

6 – 14

Page 27

HT-SB200

7

8 9 10 11 12

Figure 6-12: WIRING SIDE OF MAIN PWB (BOTTOM VIEW) (2/2)

6 – 15

Page 28

HT-SB200

POWER PWB-A2

A

B

C

D

DM802

C801

C804

R804

E

DM804

R801

C813

R803

R808

R809

C812

R811

R812

R807

R802

R806

C803

C808

C802

F

G

Lead-free solder indication

H

Lead-free solder is used in the POWER PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-13: WIRING SIDE OF POWER PWB (TOP VIEW) (1/2)

6 – 16

Page 29

HT-SB200

DZ803

Q802

DZ802

D801

R819 R818

D802

7

8 9 10 11 12

Figure 6-14: WIRING SIDE OF POWER PWB (TOP VIEW) (2/2)

6 – 17

Page 30

HT-SB200

POWER PWB-A2

A

B

C

123456789

D

123456789101112131415

E

F

G

Lead-free solder indication

H

Lead-free solder is used in the POWER PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-15: WIRING SIDE OF POWER PWB (BOTTOM VIEW) (1/2)

6 – 18

Page 31

HT-SB200

DC INPUT

L-CH

LINE IN 1

R-CH

LINE IN 2

AUDIO

7

8 9 10 11 12

Figure 6-16: WIRING SIDE OF POWER PWB (BOTTOM VIEW) (2/2)

6 – 19

Page 32

HT-SB200

AMP PWB-A3

A

B

C

D

E

F

G

C906

Lead-free solder indication

Lead-free solder is used in the AMPLIFIER PWB.

H

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-17(i): WIRING SIDE OF AMPLIFIER PWB (TOP VIEW)

6 – 20

Page 33

HT-SB200

HT-SB200

for Taiwan and Brazil only.

AMP PWB-A3

A

C967

C963

C966

C964

B

C965

C

C915

R906

C979

C901

C925

C941

R925

C951

C950

C926

C933

R917

L910

C943

C927

R918

C938

C936

C940

C906

L905

C937

R919

C939

C944

C928

L906

C903

D

C924

L908

C942

R923

R922

E

L907

R927

R926

C953

F

G

C948

R929

C958

C952

C959

C955

C949

C954

L913

C957

L912

L909

R928

C956

C947

C946

R924

L914

Lead-free solder indication

Lead-free solder is used in the AMPLIFIER PWB.

H

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-17(ii): WIRING SIDE OF AMPLIFIER PWB (TOP VIEW)

L911

6 – 21

L915

L916

Page 34

HT-SB200

AMP PWB-A3

A

B

C

12345678

D

E

123456789

F

G

12 3456 7891011

Lead-free solder indication

Lead-free solder is used in the AMPLIFIER PWB.

H

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-18: WIRING SIDE OF AMPLIFIER PWB (BOTTOM VIEW)

6 – 22

Page 35

HT-SB200

HT-SB200

for Taiwan and Brazil only.

A

AMP PWB-A3

12345678

B

C

D

987654321

E

F

G

1234567891011

Lead-free solder indication

Lead-free solder is used in the AMPLIFIER PWB.

H

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-19: WIRING SIDE OF AMPLIFIER PWB (BOTTOM VIEW)

6 – 23

Page 36

HT-SB200

A

A

CHAPTER 7. OTHERS

[1] Function Table Of IC

IC601 VHIWM8775++-1 : 96kHz ADC with 4 Channel I/P Multiplexer ( WM8775 ) ( 1/2 )

AINOPL

INOPR

AINVGL

INVGR

AIN1L

AIN1R

AIN2L

AIN2R

AIN3L

AIN3R

AIN4L

AIN4R

INPUT MIXER

AGND

AVDD

VMIDADC

ADCREFP

ADCREFGND

WM8775

AUDIO INTERFACE

VMID

DGND

STEREO

ADC

DVDD

CONTROL INTERFACE

AND

DIGITAL FILTERS

CL

MODE

Figure 7-1 BLOCK DIAGRAM OF IC

CE

MCLK

DOUT

ADCLRC

BCLK

DI

㪘㪠㪥㪈㪣

㪙㪚㪣㪢

㪤㪚㪣㪢

㪛㪦㪬㪫

㪘㪛㪚㪣㪩㪚

㪛㪞㪥㪛

㪛㪭㪛㪛

㪤㪦㪛㪜

㪚㪜

㪛㪠

㪚㪣

㪥㪚

㪭㪤㪠㪛㪘㪛㪚

㪘㪛㪚㪩㪜㪝㪞㪥㪛

㪈

㪉

㪊

㪋

㪌

㪍

㪎

㪏

㪐

㪈㪇

㪈㪈

㪈㪉

㪈㪊

㪈㪋

㪉㪊

㪉㪇

㪈㪐

㪉㪏

㪉㪎

㪉㪍

㪉㪌

㪉㪋

㪉㪉

㪉㪈

㪈㪏

㪈㪎

㪈㪍

㪈㪌

㪘㪠㪥㪈㪩

㪘㪠㪥㪉㪣

㪘㪠㪥㪉㪩

㪘㪠㪥㪊㪣

㪘㪠㪥㪊㪩

㪘㪠㪥㪋㪣

㪘㪠㪥㪋㪩

㪘㪠㪥㪦㪧㪣

㪘㪠㪥㪭㪞㪣

㪘㪠㪥㪦㪧㪩

㪘㪠㪥㪭㪞㪩

㪘㪞㪥㪛

㪘㪭㪛㪛

㪘㪛㪚㪩㪜㪝㪧

Figure 7-2 PIN CONFIGURATION OF IC

7 – 1

Page 37

IC601 VHIWM8775++-1 : 96kHz ADC with 4 Channel I/P Multiplexer ( WM8775 ) ( 2/2 )

PIN NAME TYPE DESCRIPTION

1 AIN1L Analogue Input Channel 1 left input multiplexer virtual ground

2 BCLK Digital Input / Output ADC audio interface bit clock

3 MCLK Digital Input Master ADC clock; 256,384,512 or 768fs (fs = word clock frequency)

4 DOUT Digital Output ADC data output

5 ADCLRC Digital Input / Output ADC left / right word clock

6 DGND Supply Digital negative supply

7 DVDD Supply Digital positive supply

8 MODE Digital Input Serial Interface Mode select

9 CE Digital Input Serial Interface Latch signal

10 DI Digital Input / Output Serial Interface data

11 CL Digital Input Serial Interface clock

12 NC NC No Connection

13 VMIDADC Analogue Output ADC midrail divider decoupling pin; 10uF external decoupling

14 ADCREFGND Supply ADC negative supply and substrate connection

15 ADCREFP Analogue Output ADC positive reference decoupling pin; 10uF external decoupling

16 AVDD Supply Analogue positive supply

17 AGND Supply Analogue negative supply and substrate connection

18 AINVGR Analogue Input Right channel multiplexer virtual ground

19 AINOPR Analogue Output Right channel multiplexer output

20 AINVGL Analogue Input Left channel multiplexer virtual ground

21 AINOPL Analogue Output Left channel multiplexer output

22 AIN4R Analogue Input Channel 4 right input multiplexer virtual ground

23 AIN4L Analogue Input Channel 4 left input multiplexer virtual ground

24 AIN3R Analogue Input Channel 3 right input multiplexer virtual ground

25 AIN3L Analogue Input Channel 3 left input multiplexer virtual ground

26 AIN2R Analogue Input Channel 2 right input multiplexer virtual ground

27 AIN2L Analogue Input Channel 2 left input multiplexer virtual ground

28 AIN1R Analogue Input Channel 1 right input multiplexer virtual ground

IC Pin Descriptions

HT-SB200

7 – 2

Page 38

HT-SB200

IC602 VHINJU260409B : SRS WOW Hardware Data Processor ( NJU26040-09B ) ( 1/2 )

SCL/SCK

SDA/SDOUT

RESETb

MCK

CLK

CLKOUT

AD1/SDIN

SERIAL

HOST

INTERFACE

TIMING

GENERATOR

AD2/SSb

DSP ARITHMETIC UNIT

PROGRAM

CONTROL

24-BIT x 24-BIT

MULTIPLIER

ALU

ADDRESS GENERATION UNIT

DATA

RAM

FIRMWARE

RAM

Figure 7-3 BLOCK DIAGRAM OF IC

SERIAL AUDIO

INTERFACE

L/R

SW

GPIO

BCKO

LRO

SDO0

SD10

SDI1

SDI2

SDO1

BCKI

LRI

PROC

MUTEb

SEL

WDC

VDD

1

RESETb

VDD

VDD

VSS

CLK

SDI2

SDI1

SDI0

LRI

BCKI

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

SDA/SDOUT

SCL/SCK

AD1/SDIN

AD2/SSb

CLKOUT

NJU26040

SSOP32

32 VSS

31

TEST0

TEST0

30

SEL

29

PROC

28

MUTEb

27

WDC

26

VDD

25

VSS

24

TEST0

23

MCK

22

TEST1

21

20

SDO1

19

SDO0

18

LRO

BCKO

17

Figure 7-4 PIN CONFIGURATION OF IC

7 – 3

Page 39

IC602 VHINJU260409B : SRS WOW Hardware Data Processor ( NJU26040-09B ) ( 2/2 )

PIN NAME Input / Output DESCRIPTION

1,7,8,25 VDD --- Power Supply + 3.3V

2 SDA/SDOUT OD I²C Input / Output / 4-Wire Serial Output. This pin rquires a pull-up resistance in

both I²C bus and 4-Wire serial mode.

3 SCL/SCK I I²C clock / Serial clock

4 AD1/SDIN I I²C Address / Serial In

5 AD2/SSb I I²C Address / Serial Enable

6 RESETb I Reset (RESETb = 'Low' : DSP Reset)

9,24,32 VSS --- GND

10 CLKOUT O OSC Output

11 CLK I OSC Clock Input

12 SDI2 I Audio Data Input 2 (L/R)

13 SDI2 I Audio Data Input 1 (L/R)

14 SDI0 I Audio Data Input 0 (L/R)

15 LRI I LR Clock Input

16 BCKI I Bit Clock Input

17 BCKO O Bit Clock Output

18 LRO O LR Clock Output

19 SDO0 O Audio Data Output 0 (L/R)

20 SDO1 O Audio Data Output 1 (SW)

21 TEST1 O for Test (Non connect)

22 MCK O Master Clock Output for A/D, D/A

23,30,31 TEST0 I - for Test (connected to VSS)

26 WDC OD Watchdog clock output (open drain output)

27 MUTEb I Master Volume level, After Reset DSP ("1" : 0dB "0" : Mute)

28 PROC I After Reset DSP ("1" : Normal "0" : Wait from Command)

29 SEL I Select I²C or Serial bus ( '1' : Serial / '0' : I²C - Bus)

HT-SB200

Note: I : I : Input

I - : Input (Pull-down)

O:Output

OD :Bi-directional (Open Drain) This pin requires a pull-up resistance.

I / O + :Bi-directional (with Pull-up resistance).

I / O - :Bi-directional (with Pull-down resistance).

7 – 4

Page 40

HT-SB200

IC604 RH-IXA229AW00 : System Microcomputer ( IXA229AW ) ( 1/3 )

NAME INPUT/

PIN

NO.

PORT_TYPE

NO USE

1

NC

SCL

2

P3_5/SCL/SSCK

NO USE

3

P3_3/SSI

SDA

4

P3_4/SDA/SCS

MODE

5

MODE

XCIN

6

P4_3/XCIN

XCOUT

7

XCOUT

RESET

8

RESET

XOUT

9

XOUT/P4_7

GND

10

VSS/AVSS

XIN

11

P4_6/XIN

VCC

12

VCC/AVCC

NO USE

13

P2_7/TRDIOD1

LED_CLK

14

P2_6/TRDIOC1

PWR_LED_STBY 2

15

P2_5/TRDIOB1

NO USE

16

P2_4/TRDIOA1

LED_DIN

17

P2_3/TRDIOD0

LED_STB

18

P2_2/TRDIOC0

LED_DOUT

19

P2_1/TRDIOB0

PWR_LED_STBY 1

20

P2_0/TRDIOA0/TRDCLK

RX_IN

21

P1_7/TRAI0/INT1

NO USE

22

P1_6/CLK0

NO USE

23

P1_5/RXD0/(TRAI0)/(INT)

NO USE

24

P1_4/TXD0

NO USE

25

P1_3/KI3/AN11

NO USE

26

NC

SRS_RSTB

27

P4_5/INT0

SRS_MUTE_B

28

P6_6/INT2/TXD1

SYS_STOP

29

P6_7/INT3/RXD1

OUTPUT

---No Use

OUTPUT

OUTPUT

OUTPUT

INPUT INPUT - Connect to VCC with 10 kohm resistor

INPUT

OUTPUT

INPUT INPUT -

OUTPUT - - -

- - - Connect to GND (VSS)

INPUT - - -

---

OUTPUT

OUTPUT

OUTPUT

OUTPUT

OUTPUT

OUTPUT

INPUT

OUTPUT

INPUT

OUTPUT

OUTPUT

OUTPUT

OUTPUT

OUTPUT - - No Use

OUTPUT

OUTPUT

INPUT

FORM

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

SOFT

PULL-UP

OFF [12C bus] Enhancer Micom IF clock, N-ch open drain.

OFF No Connect

OFF

OFF No Use

OFF No Use

OFF Fix “L”

OFF LED DRIVER CONTROL CLOCK

OFF

OFF Fix “L”

OFF

OFF LED DRIVER STROBE CONTROL

OFF

OFF

OFF [INT] SHARP format, REMOCON input

OFF Fix “L”

OFF Fix “L”

OFF Fix “L”

OFF Fix “L”

OFF SRS_Reset

OFF SRS_Mute

OFF

[12C bus] Enhancer Micom IF data Input/Output,

N-ch open drain.

Micom reset input. Active is L.

During FLASH, connect to reset at WRITER.

Micom input supply (3.3V)

Backup power supply

H setting: LED ON

L setting: LED OFF

Communication with LED DRIVER.

Command transmit (Data transfer to FLASH WRITER)

Communication with LED DRIVER.

Command received (Data transfer to FLASH WRITER)

H setting: LED ON

L setting: LED OFF

AC power fail detect.

Enter STOP mode when detect SYS_STOP “L”

FUNCTION OUTLINE

7 – 5

Page 41

IC604 RH-IXA229AW00 : System Microcomputer ( IXA229AW ) ( 2/3 )

NAME INPUT/

PIN

NO.

PORT_TYPE

SRS_WDC

30

P1_2/KI2/AN10

NO USE

31

P1_1/KI1/AN9

NO USE

32

P1_0/KI0/AN8

NO USE

33

P3_1/TRB0

NO USE

34

P3_0/TRA0

POWER (DC RELAY)

35

P6_5/CLK1

KEY POWER

36

P6_4

NO USE

37

P6_3

LVL_DETECT

38

P0_7/AN0

NO USE

39

NC

NO USE

40

NC

AREA

41

P0_6/AN1

KEY_1

42

P0_5/AN2

SYS_PROTECT

43

P0_4/AN3

VREF

44

P4_2/VREF

NO USE

45

P6_0/TRE0

AMP_PWDN

46

P6_2

AMP_RESET

47

P6_1

AMP_INT

48

P0_3/AN4

NO USE

49

P0_2/AN5

NO USE

50

P0_1/AN6

NO USE

51

P0_0/AN7

NO USE

52

P3_7/SS0

OUTPUT

INPUT

OUTPUT

OUTPUT

OUTPUT

OUTPUT

OUTPUT

INPUT

OUTPUT

INPUT ANALOG/

DIGITAL

- - - Port not connected

- - - Port not connected

INPUT ANALOG/

DIGITAL

INPUT ANALOG/

DIGITAL

INPUT ANALOG/

DIGITAL

INPUT INPUT - Reference Voltage input port (connect to VCC)

OUTPUT

OUTPUT

OUTPUT

INPUT

OUTPUT

OUTPUT

OUTPUT

OUTPUT

FORM

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

CMOS INPUT/

OUTPUT

SOFT

PULL-UP

OFF SRS_WDC

OFF Fix “L”

OFF Fix “L”

OFF Fix “L”

OFF Fix “L”

OFF

OFF MAIN SET KEY (POWER)

OFF Fix “L”

OFF LEVEL DETECT

OFF Destination setting

OFF [A/D] Main set key input

OFF System power abnormal detection

OFF Fix “L”

OFF

OFF

OFF AMP Interrupt

OFF Fix “L”

OFF Fix “L”

OFF Fix “L”

OFF Fix “L”

MAIN POWER CONTROL.

H: POWER ON ; L: POWER OFF

AMP PWR DOWN = set L during standby

Normal operation = set H

AMP Reset Set 'L' to reset AMP

Normal operation set 'H'

HT-SB200

FUNCTION OUTLINE

7 – 6

Page 42

HT-SB200

IC604 RH-IXA229AW00 : System Microcomputer ( IXA229AW ) ( 3/3 )

NO USE

NO USE

NO USE

51

52

P3_7/SS0

NO USE 1 NC NC 39 NO USE

P3_5/SCL/SSC

SCL

NO USE 3 P3_3/SSI P6_3 37 NO USE

SDA 4

MODE

XCIN 6 P4_3/XCIN P3_0/TRA0 34 NO USE

XCOUT

RESET

XOUT

GND

XIN

VCC 12 VCC/AVCC P6_6/INT2/TXD1 28 SRS_MUTE_B

NO USE

2

K

P3_4/SDA/SC

S

5 MODE P6_5/CLK1 35 POWER (DC RELAY)

7 XCOUT P3_1/TRB0 33 NO USE

8

RESET

9

XOUT/P4_7

10

VSS/AVSS

11

P4_6/XIN

P2_7/TRDIOD

13

1

50

P0_0/AN7

P0_1/AN6

AMP_INT

AMP_RESET

NO USE

48

49

P0_2/AN5

P0_3/AN4

AMP_PWDN

NO USE

47

P6_1

IXA229A

45

46

P6_2

P6_0/TRE0

SHARP

VREF

44

P4_2/VREF

SYS_PROTECT

KEY_1

43

42

P0_4/AN3

P0_5/AN2

AREA

41

P0_6/AN1

NO USE

40

NC

P0_7/AN0

P1_0/KI0/AN8

P1_1/KI1/AN9

P1_2/KI2/AN10

P6_7/INT3/RXD

P4_5/INT0

38 LVL_DETECT

P6_4 36 KEY POWER

32

31

30

29

27 SRS_RSTB

NO USE

NO USE

SRS_WDC

SYS_STOP

P2_6/TRDIOC1

P2_5/TRDIOB1

14

15

LED_CLK

'PWR_LED_STBY 2

P1_6/CLK0

P2_4/TRDIOA1

P2_3/TRDIOD0

P2_2/TRDIOC0

17

LED_DIN

18

LED_STB

16

NO USE

P2_1/TRDIOB0

19

LED_DOUT

P2_0/TRDIOA0/TRD

CLK

20

PWR_LED_STBY 1

P1_7/TRAI0/INT1

21

RX_IN

P1_5/RXD0/(TRAI0)/

(INT)

23

22

NO USE

NO USE

Figure 7-5 BLOCK DIAGRAM OF IC

P1_3/KI3/AN11

P1_4/TXD0

24

NO USE

NC

25

26

NO USE

NO USE

7 – 7

Page 43

IC901 VHISTA333BW-1 : 2.1 Channels High Efficiency Digital Audio System ( STA333BW ) ( 1/2 )

HT-SB200

SA

SDI

LRCKI

BICKI

RESET

INT LINE

PWDN

XTI

Serial Data Input

Channel mapping

Processor

SCL

SDA

I2C

CONTROL

STATUS

EQ, Tone,

Volumes...

PLL

PLL_FILTER

Figure 7-6 BLOCK DIAGRAM OF IC

CONFIG

POWER

DDX3A

DDX3B

DDX4A/TWARNEXT

DDX4B/EAPD

OUT1A

OUT1B

OUT2A

OUT2B

GND_SUB

SA

TEST MODE

VSS

VCC_REG

OUT2B

GND2

V

cc2

OUT2A

OUT1B

V

cc1

GND1

OUT1A

GND_REG

Vdd

CONFIG

OUT3B/DDX3B

OUT3A/DDX3A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Figure 7-7 PIN CONFIGURATION OF IC

V

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

dd_DIG

GND_DIG

SCL

SDA

INT_LINE

RESET

SDI

LRCKI

BICKI

XTI

PLL_GND

PLL_FILTER

PLL_Vdd

POWRDN

GND_DIG

VDD_DIG

TWARN/OUT4B

EAPD/OUT4B

7 – 8

Page 44

HT-SB200

IC901 VHISTA333BW-1 : 2.1 Channels High Efficiency Digital Audio System ( STA333BW ) ( 2/2 )

PIN NAME TYPE DESCRIPTION

1 GND_SUB Input / Output Subtrate ground

2 SA Input I²C Select Address

3 Test_Mode Input This pin must be connected to GROUND

4 Vss Input / Output Internal reference at Vcc - 3.3V

5 Vcc_REG Input / Output Internal Vcc reference

6 OUT2B Output Output half bridge 2B

7 GND2 Input / Output Power negative supply

8 Vcc2 Input / Output Power positive supply

9 OUT2A Output Output half bridge 2A

10 OUT1B Output Output half bridge 1B

11 Vcc1 Input / Output Power positive supply

12 GND1 Input / Output Power negative supply

13 OUT1A Input / Output Output half bridge 1A

14 GND_REG Input / Output Internal Ground reference

15 Vdd Input / Output Internal 3.3V reference voltage

16 CONFIG Input Paralleled mode command

17 OUT3B/DDX3B Output PWM Out CH3B - External Bridge

18 OUT3A/DDX3A Output PWM Out CH3A - External Bridge

19 EAPD/OUT4A Output Power Down for External Bridge

20 TWARN/OUT4B Input Thermal warning from External Bridge

21 Vdd_DIG Input / Output Positive Supply Digital

22 GND_DIG Input / Output Digital Ground

23 PWRDN Input Power Down

24 PLL_Vdd Input / Output Positive Supply for PLL

25 PLL_FILTER Input Connection to PLL Filter

26 PLL_GND Input / Output Negative Supply for PLL

27 XTI Input PLL Input Clock

28 BICKI Input I²S Serial Clock

29 LRCKI Input I²S Left / Right Clock

30 SDI_12 Input I²S Serial Data Channels 1&2

31 RESET Input Reset

32 INT_LINE Output Fault Interrupt

33 SDA Input / Output I²C Serial Data

34 SCL Input I²C Serial Clock

35 GND_DIG Input / Output Digital Ground

36 Vdd_DIG Input / Output Digital Supply

7 – 9

Page 45

IC902 VHISTA533W+-1 : 2.2A QUAD POWER HALF BRIDGE ( STA533W ) ( 1/2 )

HT-SB200

GND-SUB

OUT2B

OUT2B

Vcc2B

GND2B

GND2A

Vcc2A

OUT2A

OUT2A

OUT1B

OUT1B

Vcc1B

GND1B

GND1A

Vcc1A

OUT1A

OUT1A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

VccSign

VccSign

V

ss

V

ss

IN2B

IN2A

IN1B

IN1A

TH_WAR

FAULT

TRI-STATE

PWRDN

CONFIG

L

V

V

DD

V

DD

GND-Reg

N.C.

18

19

D04AU1564

Figure 7-8 BLOCK DIAGRAM OF IC

GND-Clean

7 – 10

Page 46

HT-SB200

IC902 VHISTA533W+-1 : 2.2A QUAD POWER HALF BRIDGE ( STA533W ) ( 2/2 )

PIN NAME DESCRIPTION

1 GND_SUB Subtrate ground

2 ; 3 OUT2B Output half bridge 2B

4 Vcc2B Positive Supply

5 GND2B Negative supply

6 GND2A Negative supply

7 Vcc2A Positive Supply

8 ; 9 OUT2A Output half bridge 2A

10 ; 11 OUT1A Output half bridge 1B

12 Vcc1B Positive Supply

13 GND1B Negative supply

14 GND1A Negative supply

15 Vcc1A Positive Supply

16 ; 17 OUT1A Output half bridge 1A

18 NC Not Connected

19 GND-clean Logical Ground

20 GND-Reg Ground for regulator Vdd

21 ; 22 Vdd 5V Regulator referred to ground

23 VL Logic Reference Voltage

24 CONFIG Configuration pin

25 PWRDN Stand-by pin

26 TRI-STATE Hi-Z pin

27 FAULT Fault pin advisor

28 TH-WAR Thermal warning advisor

29 IN1A Input half bridge 1A

30 IN1B Input half bridge 1B

31 IN2A Input half bridge 2A

32 IN2B Input half bridge 2B

33 ; 34 Vss 5V Regulator referred to +Vcc

35 ; 36 Vcc Sign Signal Positive Supply

7 – 11

Page 47

Destination Table

AU Australia

BR Brazil

ID Indonesia

JO Jordan

ME Middle East/Africa/Vietnam

PH Philippines

SI Singapore

TA Taiwan

TH Thailand

PARTS GUIDE

SOUND BAR SYSTEM

MODEL

HT-SB200

HT-SB200

[ ASIA, EX ]

CONTENTS

[1] INTEGRATED CIRCUITS

[2] TRANSISTORS

[3] DIODES

[4] COILS

[5] CRYSTALS / VIBRATORS

[6] CAPACITORS

[7] RESISTORS

[8] OTHER CIRCUITRY PARTS

[9] CABINET PARTS

[10] ACCESSORIES / PACKING

PARTS

[11] P.W.B. ASSEMBLY

(Not Replacement Item)

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

!

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 48

HT-SB200

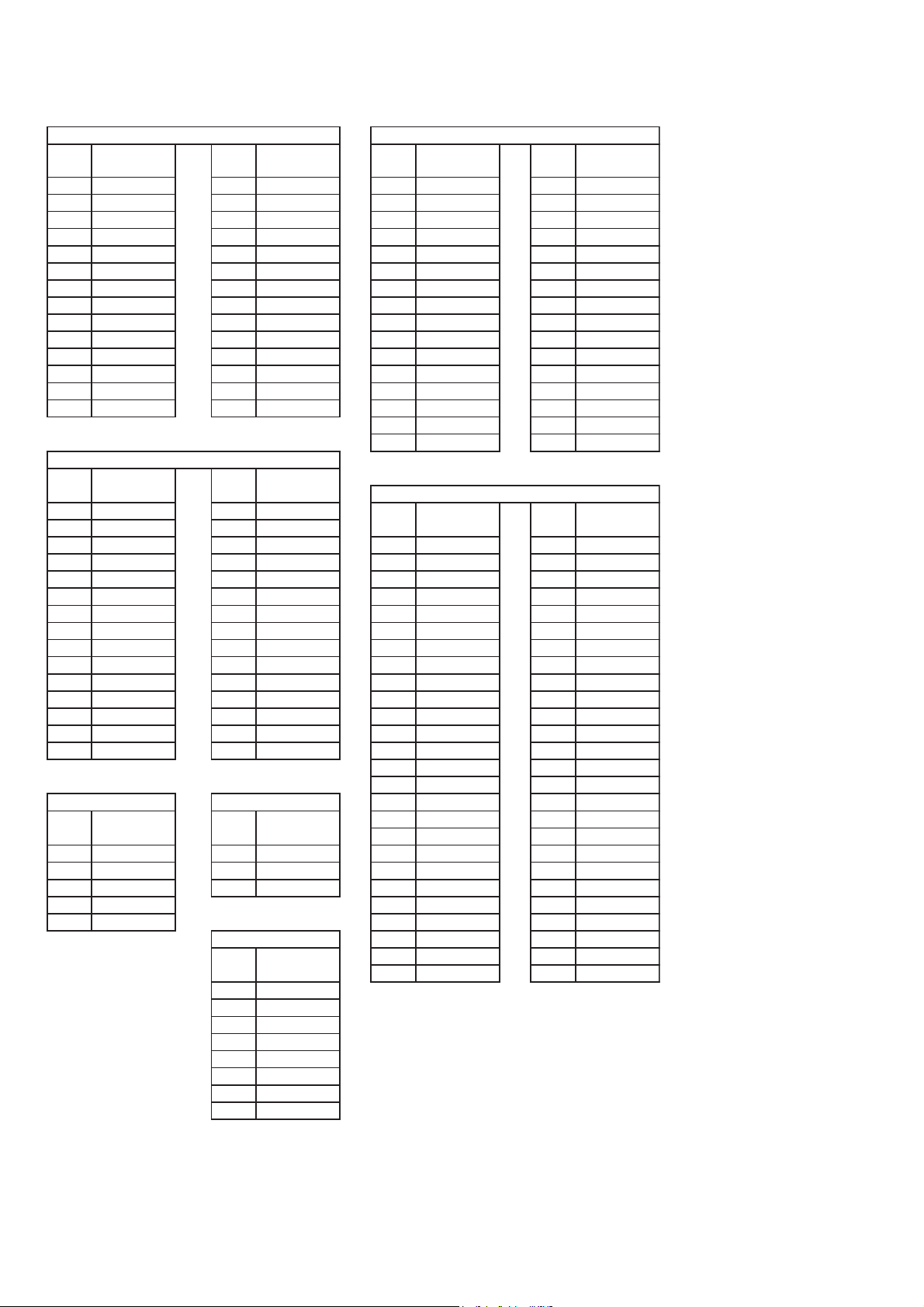

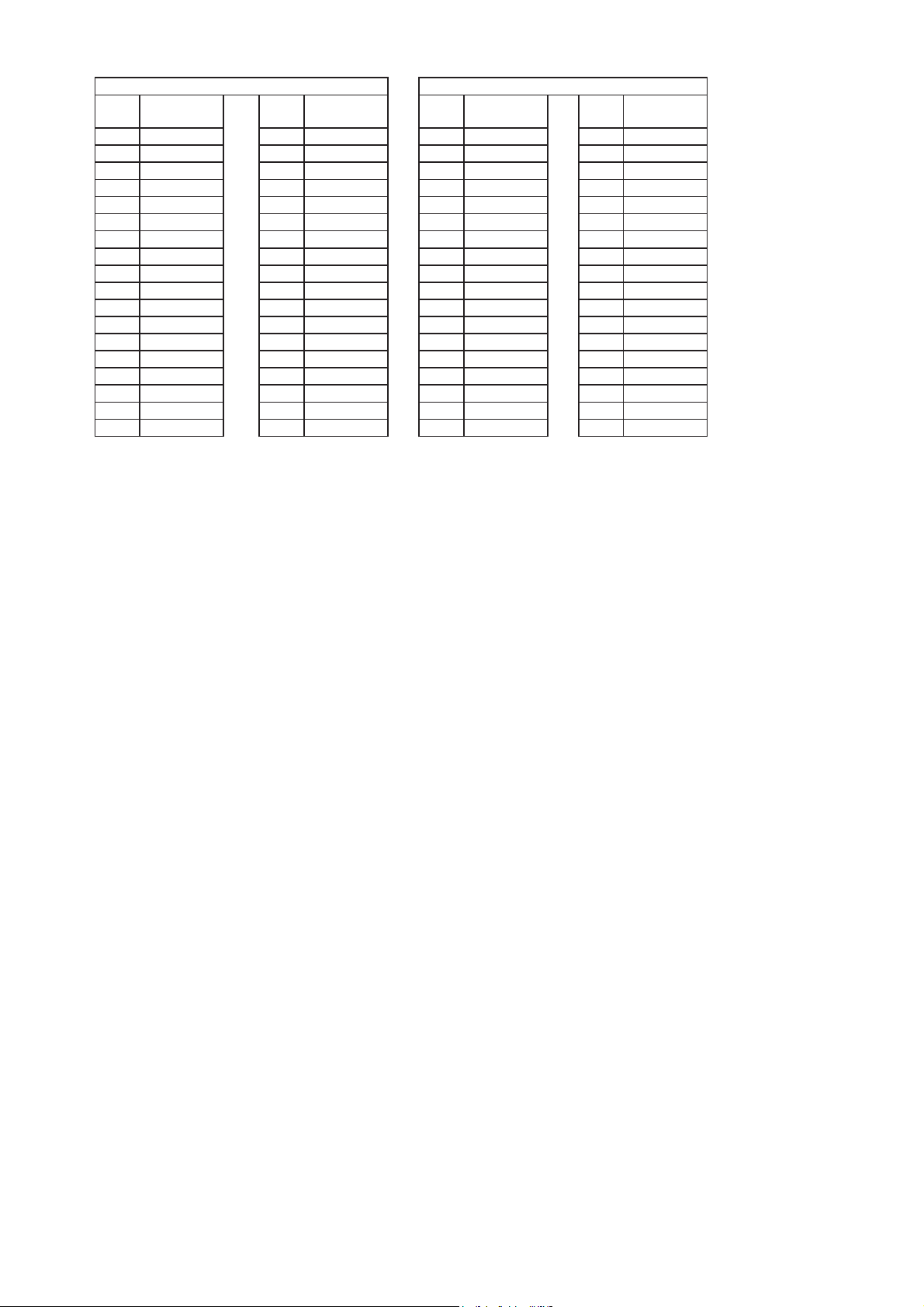

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

RANK

DESCRIPTION

[1] INTEGRATED CIRCUITS

iC601 VHiWM8775++-1 AR ADC with 4 Channel I/P Multiplexer

iC602 VHiNJU260409B AX SRS WOW Hardware Data Processor

iC603 VHiTJM4558CD1 AE Operational Amplifier

iC604 RH-iXA229AW00 AX System Microcomputer,iXA229AW

iC605 VHiPST8227N-1 AC Reset iC

iC701 VHiPT6965++-1 AK 7 Segment Driver

iC801 VHiLD29080+-1 AG Voltage Regulator, 5V

iC802 VHiKiA1117F33 AF Voltage Regulator

iC803 VHiAP2213M33E AE Voltage Regulator, 3.3V

iC901 VHiSTA333BW-1 AW Digital Amplifier

iC902 VHiSTA533W+-1 AP 2.2A Quad Power Half Bridge

[2] TRANSISTORS

Q601 VSKRC104S//-1 AC Digital,NPN,KRC104 S

Q602 VSKRC104S//-1 AC Digital,NPN,KRC104 S

Q604 VSKRC104S//-1 AC Digital,NPN,KRC104 S

Q605 VSKRA107S//-1 AB Digital,PNP,KRA107 S

Q701 VSKRC101S//-1 AB Digital,NPN,KRC101 S

Q702 VSKRC101S//-1 AB Digital,NPN,KRC101 S

Q802 VSKRC107S//-1 AB Digital,NPN,KRC107 S

Q901 VSKRC104S//-1 AC Digital,NPN,KRC104 S [Except Taiwan and Brazil]

Q902 VSKRC104S//-1 AC Digital,NPN,KRC104 S [Except Taiwan and Brazil]

[3] DIODES

D601 VHDMA111G++-1 AB Silicon,MA111

D602 VHDMA111G++-1 AB Silicon,MA111

D603 VHDMA111G++-1 AB Silicon,MA111

D604 VHDMA111G++-1 AB Silicon,MA111

D605 VHDMA111G++-1 AB Silicon,MA111

D801 VHDMA111G++-1 AB Silicon,MA111

D802 VHDMA111G++-1 AB Silicon,MA111

D804 VHDMA111G++-1 AB Silicon,MA111

D901 VHDMA111G++-1 AB Silicon,MA111

D902 VHDMA111G++-1 AB Silicon,MA111 [Except Taiwan and Brazil]

D903 VHDMA111G++-1 AB Silicon,MA111 [Except Taiwan and Brazil]

D904 VHDMA111G++-1 AB Silicon,MA111 [Except Taiwan and Brazil]

D905 VHDMA111G++-1 AB Silicon,MA111 [Except Taiwan and Brazil]

DM606 VHDKDS226//-1 AB Silicon,KDS226

DM802 VHDKDS226//-1 AB Silicon,KDS226

DM804 VHDKDS226//-1 AB Silicon,KDS226

DZ600 RH-EXA507WJZZ AB Zener,3.3V

DZ801 VHDGDSK52B+-1 AE Schotty

DZ802 RH-EXA523WJZZ AB Zener,5.6V

DZ803 RH-EXA550WJZZ AB Zener,13V

LED701 VHPKW2402CB-1 AT 7 Segment Blue LED

LED702 VHPCL165SRD-1 AD Dual Chip LED,Red

LED703 VHPCL194HB+-1 AD LED,Blue

LED704 VHPCL194HB+-1 AD LED,Blue

LED705 VHPCL194HB+-1 AD LED,Blue

LED706 VHPCL194HB+-1 AD LED,Blue

[4] COILS

L601 VPBNN2R2K0000 AC Coil, 2.2 µH

L901 RBLN-0061TAZZ AB Ferrite Bead

L902 RBLN-0061TAZZ AB Ferrite Bead

L903 RBLN-0061TAZZ AB Ferrite Bead

L905 RCiLPA084WJZZ AD Coil, 10 µH

L906 RCiLPA084WJZZ AD Coil, 10 µH

L907 RCiLPA762WJQZ AD Coil

L908 RCiLPA762WJQZ AD Coil

L909 RCiLPA762WJQZ AD Coil

L910 RCiLPA762WJQZ AD Coil

L911 RCiLCA022AWZZ AC Coil, 1 µH

L912 RCiLCA022AWZZ AC Coil, 1 µH

L913 RCiLCA022AWZZ AC Coil, 1 µH

L914 RCiLCA022AWZZ AC Coil, 1 µH

L915 RBLN-A007WJZZ AC Ferrite Core

L916 RBLN-A007WJZZ AC Ferrite Core

R678 RFiLN0063CFZZ AA Ferrite Bead

R907 VPCEM470M3R7N AC Coil, 47 µH

R916 VPCEM470M3R7N AC Coil, 47 µH

RF1 RCORFA016AWZZ AE Ferrite Core

RF2 RCORFA016AWZZ AE Ferrite Core

[5] CRYSTALS / VIBRATORS

XM601 RCRM-A010AWZZ AD Resonator

XM603 RCRSC0032TAZZ AE Crystal,32.768kHz

[6] CAPACITORS

C601 VCCCCZ1HH330J AB 33 pF (CH),50V

C602 VCEAPS106AF1C AB 10 µ F,16V,Electrolytic

C603 VCKYCZ1CF104Z AB 0.1 µ F,16V

C604 VCEAPS106AF1C AB 10 µ F,16V,Electrolytic

C605 VCKYCZ1CF104Z AB 0.1 µ F,16V

C607 VCCCCZ1HH150J AA 15 pF (CH),50V

C608 VCCCCZ1HH180J AA 18 pF (CH),50V

1

Page 49

HT-SB200

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

RANK

[6] CAPACITORS

C609 VCKYCZ1CF104Z AB 0.1 µ F,16V

C610 VCEAPS106AF1C AB 10 µ F,16V,Electrolytic

C611 VCEAPS106AF1C AB 10 µ F,16V,Electrolytic

C612 VCKYCZ1CF104Z AB 0.1 µ F,16V

C613 VCKYCZ1CB103K AB 0.01 µ F,16V

C614 VCEAPS475AF1H AD 4.7 µ F,50V,Electrolytic

C615 VCKYCZ1CB103K AB 0.01 µ F,16V

C616 VCEAPS106AF1C AB 10 µ F,16V,Electrolytic

C617 VCKYCZ1CB223K AB 0.022 µ F,16V

C618 RC-KZ3007AWZZ AC 2.2 µ F,16V,Electrolytic

C619 VCKYCZ1AB104K AB 0.1 µ F,10V

C620 VCEAPS106AF1C AB 10 µ F,16V,Electrolytic

C621 VCEAPS106AF1C AB 10 µ F,16V,Electrolytic

C622 VCKYCZ1CF104Z AB 0.1 µ F,16V

C623 VCKYCZ1CF104Z AB 0.1 µ F,16V

C624 VCCCCZ1HH101J AB 10 pF (CH),50V

C625 VCKYCY1EB105K AB 1 µ F,25V

C626 RC-KZ3028AWZZ AE 22 µ F,16V,Electrolytic

C627 VCKYCZ1CF104Z AB 0.1 µ F,16V

C628 VCEAPS106AF1C AB 10 µ F,16V,Electrolytic

C629 VCEASX0JN227M AC 220 µ F,6.3V,Electrolytic

C630 VCKYCY1EB105K AB 1 µ F,25V

C631 VCEASX0JN227M AC 220 µ F,6.3V,Electrolytic

C632 VCEASX0JN227M AC 220 µ F,6.3V,Electrolytic

C633 VCKYCZ1CF104Z AB 0.1 µ F,16V

C634 VCKYCY1EB105K AB 1 µ F,25V

C635 VCKYCY1EB105K AB 1 µ F,25V

C636 VCKYCZ1AB104K AB 0.1 µ F,10V

C637 VCEAPS106AF1C AB 10 µ F,16V,Electrolytic

C638 VCCCCZ1HH330J AB 33pF (CH),50v

C639 VCEAPS106AF1C AB 10 µ F,16V,Electrolytic

C641 VCCCCZ1HH390J AB 39 pF (CH),50V

C642 VCCCCZ1HH390J AB 39 pF (CH),50V

C643 VCCCCZ1HH390J AB 39 pF (CH),50V

C644 VCCCCZ1HH150J AA 15 pF (CH),50V

C645 VCKYCZ1HB102K AB 1000 p F,50V

C701 VCKYCZ1EF104Z AA 0.1 µ F,25V

C702 VCCCCZ1HH101J AB 10 pF (CH),50V

C703 VCCCCZ1HH101J AB 10 pF (CH),50V

C704 VCEAPS226AF1C AC 22 µ F,16V,Electrolytic

C705 VCKYCY1HB471K AA 470 pF,50V

C706 VCKYCY1HB471K AA 470 pF,50V

C707 VCKYCY1HB471K AA 470 pF,50V

C708 VCKYCY1HB471K AA 470 pF,50V

C801 VCKYCZ1CF104Z AB 0.1 µ F,16V

C802 VCKYCZ1CF104Z AB 0.1 µ F,16V

C803 VCKYCZ1HB102K AB 1000 p F,50V

C804 VCKYCZ1HB102K AB 1000 p F,50V

C808 VCKYCZ1CB103K AB 0.01 µ F,16V

C812 VCKYCZ1HB331K AB 330 p F,50V

C813 VCKYCZ1HB331K AB

C814 VCEAPS475AF1H AD 4.7 µ F,50V,Electrolytic

C815 VCEAPS475AF1H AD 4.7 µ F,50V,Electrolytic

C818 VCEASX1CN476M AB 47 µ F,16V,Electrolytic

C819 VCEAPS226AF1C AC 22 µ F,16V,Electrolytic

C820 VCKYCZ1CF104Z AB 0.1 µ F,16V

C821 VCKYCZ1CF104Z AB 0.1 µ F,16V

C822 VCKYCZ1CF104Z AB 0.1 µ F,16V

C824 VCKYCY1EB105K AB 1 µ F,25V

C825 VCEASX1HN225M AB 2.2 µ F,50V,Electrolytic

C826 VCCCCZ1HH101J AB 10 pF (CH),50V

C827 VCEAPS106AF1C AB 10 µ F,16V,Electrolytic

C828 VCEAPS106AF1C AB 10 µ F,16V,Electrolytic

C901 VCKYCY1EB105K AB 1 µ F,25V

C903 VCKYCZ1HB102K AB 1000 p F,50V

C904 RC-EZ3129AWZZ AF 1000 µ F,16V,Electrolytic

C906 VCKYCY1HB104K AD 0.1 µ F,50V

C908 VCKYCY1HB104K AD 0.1 µ F,50V

C909 VCKYCY1HB104K AD 0.1 µ F,50V

C910 VCEASX1CN477M AE 470 µ F,16V,Electrolytic

C912 VCKYCZ1HB472K AC 4700 p F,50V

C913 VCKYCY1HB104K AD 0.1 µ F,50V

C915 VCKYCZ1HB102K AB 1000 p F,50V

C916 VCKYCY1HB104K AD 0.1 µ F,50V

C917 VCKYCY1HB104K AD 0.1 µ F,50V

C918 VCKYCZ1HB681K AB 680 p F,50V

C919 VCKYCY1HB104K AD 0.1 µ F,50V

C920 VCCCCZ1HH101J AB 10 pF (CH),50V

C921 VCCCCZ1HH101J AB 10 pF (CH),50V

C922 VCKYCY1HB102K AA 1000 p F,50V

C923 VCKYCY1HB102K AA 1000 p F,50V

C924 VCKYCY1HB104K AD 0.1 µ F,50V

C925 VCEAPS105AF1H AB 1 µ F,50V,Electrolytic

C926 VCKYCY1HB104K AD 0.1 µ F,50V

C927 VCEAPS105AF1H AB 1 µ F,50V,Electrolytic

C928 VCKYCZ1HB102K AA 1000 p F,50V

C929 VCKYCY1HB104K AD 0.1 µ F,50V

C930 VCKYCY1HB104K AD 0.1 µ F,50V

C931 VCKYCY1HB104K AD 0.1 µ F,50V

330 p F,50V

2

DESCRIPTION

Page 50

HT-SB200

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

RANK

DESCRIPTION

[6] CAPACITORS

C932 VCKYCY1HB104K AD 0.1 µ F,50V

C933 VCKYCZ1HB681K AB 680 p F,50V

C934 VCEAPS105AF1H AB 1 µ F,50V,Electrolytic

C935 VCEAPS105AF1H AB 1 µ F,50V,Electrolytic

C936 VCKYTV1HB224K AC 0.22 µ F,50V

C937 VCKYTV1HB224K AC 0.22 µ F,50V

C938 VCKYTV1HB224K AC 0.22 µ F,50V

C939 VCKYTV1HB224K AC 0.22 µ F,50V

C940 VCKYCY1EB105K AB 1 µ F,25V

C941 VCCCCZ1HH331J AA 330 pF (CH),50V

C942 VCCCCZ1HH331J AA 330 pF (CH),50V

C943 VCCCTV1HH221J AA 220 pF,50V

C944 VCCCTV1HH221J AA 220 pF,50V

C946 VCKYCY1HB104K AD 0.1 µ F,50V

C947 VCKYCY1HB104K AD 0.1 µ F,50V

C948 VCKYCY1HB104K AD 0.1 µ F,50V

C949 VCKYCY1HB104K AD 0.1 µ F,50V

C950 VCKYCY1HB104K AD 0.1 µ F,50V

C951 VCKYCY1HB104K AD 0.1 µ F,50V

C952 VCKYCY1HB104K AD 0.1 µ F,50V

C953 VCKYCY1HB104K AD 0.1 µ F,50V

C954 VCKYTV1HB474K AC 0.47 µ F,50V

C955 VCKYTV1HB474K AC 0.47 µ F,50V

C956 VCCCTV1HH221J AA 220 pF,50V

C957 VCCCTV1HH221J AA 220 pF,50V

C958 VCCCTV1HH221J AA 220 pF,50V

C959 VCCCTV1HH221J AA 220 pF,50V

C963 VCCCCZ1HH680J AB 68 pF (CH),50V

C964 VCCCCZ1HH150J AA 15 pF (CH),50V

C965 VCKYCZ1HB472K AC 4700 pF,50V

C966 VCKYCZ1HB102K AB 1000 p F,50V

C967 VCKYCZ1HB102K AB 1000 p F,50V

C968 VCKYCY1EB105K AB 1 µ F,25V

C969 VCKYCY1HB223K AA 0.022 µ F,50V

C970 VCKYCY1HB223K AA 0.022 µ F,50V

C971 VCKYCY1HB223K AA 0.022 µ F,50V

C972 VCKYCY1HB223K AA 0.022 µ F,50V

C973 VCKYCY1HB223K AA 0.022 µ F,50V

C974 VCKYCY1HB223K AA 0.022 µ F,50V

C976 VCKYCY1VB105K AB 1 µ F,50V [Except Taiwan and Brazil]

C977 VCKYCY1HB104K AD 0.1 µ F,50V [Except Taiwan and Brazil]

C978 VCKYCY1HB104K AD 0.1 µ F,50V [Except Taiwan and Brazil]

[7] RESISTORS

C979 VRS-TV2AB000J AA 0 ohms,Jumper,1.25x2mm,Green

C980 VRS-CZ1JF000J AA 0 ohms,Jumper [Except Taiwan and Brazil]

JP1 VRS-CZ1JF000J AA 0 ohms,Jumper [Use for Taiwan and Brazil only]

JP3 VRS-CZ1JF000J AA 0 ohms,Jumper [Use for Indonesia only]

JP5 VRS-CZ1JF000J AA 0 ohms,Jumper [Except Indonesia, Taiwan and Brazil]

R601 VRS-CZ1JF102J AA 1 kohm,1/16W

R603 VRS-CZ1JF102J AA 1 kohm,1/16W

R604 VRS-CZ1JF102J AA 1 kohm,1/16W

R605 VRS-CZ1JF102J AA 1 kohm,1/16W

R606 VRS-CZ1JF102J AA 1 kohm,1/16W

R607 VRS-CZ1JF102J AA 1 kohm,1/16W

R608 VRS-CZ1JF102J AA 1 kohm,1/16W

R613 VRS-CZ1JF103J AA 10 kohm,1/16W

R614 VRS-CZ1JF330J AA 33 ohm,1/16W

R615 VRS-CZ1JF123J AA 12 kohm,1/16W

R616 VRS-CZ1JF101J AA 100 ohm,1/16W

R617 VRS-CZ1JF101J AA 100 ohm,1/16W

R618 VRS-CZ1JF101J AA 100 ohm,1/16W

R623 VRS-CZ1JF102J AA 1 kohm,1/16W

R627 VRS-CZ1JF123J AA 12 kohm,1/16W

R628 VRS-CZ1JF183J AA 18 kohm,1/16W

R629 VRS-CZ1JF183J AA 18 kohm,1/16W

R630 VRS-CZ1JF123J AA 12 kohm,1/16W

R631 VRS-CZ1JF103J AA 10 kohm,1/16W

R632 VRS-CZ1JF102J AA 1 kohm,1/16W

R633 VRS-CZ1JF123J AA 12 kohm,1/16W

R634 VRS-CZ1JF102J AA 1 kohm,1/16W

R635 VRS-CZ1JF102J AA 1 kohm,1/16W

R636 VRS-CZ1JF473J AA 47 kohm,1/16W

R637 VRS-CZ1JF102J AA 1 kohm,1/16W

R638 VRS-CZ1JF103J AA 10 kohm,1/16W [Except Indonesia]

R638 VRS-CZ1JF222J AA 2.2 kohm,1/16W [Use for Indonesia only]

R639 VRS-CZ1JF102J AA 1 kohm,1/16W

R640 VRS-CZ1JF102J AA 1 kohm,1/16W

R641 VRS-CZ1JF102J AA 1 kohm,1/16W

R642 VRS-CZ1JF102J AA 1 kohm,1/16W

R643 VRS-CZ1JF102J AA 1 kohm,1/16W

R645 VRS-CZ1JF103J AA 10 kohm,1/16W [Use for Indonesia only]

R646 VRS-CZ1JF330J AA 33 ohm,1/16W

R647 VRS-CZ1JF472J AA 4.7 kohm,1/16W

R648 VRS-CZ1JF105J AA 1 Mohm,1/16W

R649 VRS-CZ1JF104J AA 100 kohm,1/16W

R650 VRS-CZ1JF681J AA 680 ohm,1/16W

R651 VRS-CZ1JF330J AA 33 ohm,1/16W

3

Page 51

HT-SB200

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

RANK

DESCRIPTION

[7] RESISTORS

R652 VRS-CZ1JF330J AA 33 ohm,1/16W

R653 VRS-CZ1JF822J AA 8.2 kohm,1/16W

R654 VRS-CZ1JF471J AA 470 ohm,1/16W

R655 VRS-CZ1JF103J AA 10 kohm,1/16W

R656 VRS-CZ1JF104J AA 100 kohm,1/16W

R657 VRS-CZ1JF471J AA 470 ohm,1/16W

R658 VRS-CZ1JF104J AA 100 kohm,1/16W

R659 VRS-CZ1JF103J AA 10 kohm,1/16W

R660 VRS-CZ1JF103J AA 10 kohm,1/16W

R661 VRS-CZ1JF223J AA 22 kohm,1/16W

R662 VRS-CZ1JF103J AA 10 kohm,1/16W

R663 VRS-CZ1JF151J AA 150 ohm,1/16W

R664 VRS-CZ1JF151J AA 150 ohm,1/16W

R665 VRS-CZ1JF000J AA 0 ohms,Jumper

R666 VRS-CZ1JF000J AA 0 ohms,Jumper

R668 VRS-CZ1JF104J AA 100 kohm,1/16W

R669 VRS-CZ1JF154J AA 150 kohm,1/16W

R672 VRS-CZ1JF103J AA 10 kohm,1/16W

R673 VRS-CZ1JF151J AA 150 ohm,1/16W

R674 VRS-CZ1JB560J AB 56 ohm,1/16W

R675 VRS-CZ1JF102J AA 1 kohm,1/16W

R676 VRS-CZ1JF151J AA 150 ohm,1/16W

R677 VRS-CZ1JF101J AA 100 ohm,1/16W

R679 VRS-CY1JB000J AA 0 ohms,Jumper,0.8X1.55mm,Green

R680 VRS-CY1JB000J AA 0 ohms,Jumper,0.8X1.55mm,Green [Use for Taiwan and Brazil only]

R681 VRS-CZ1JF000J AA 0 ohms,Jumper

R682 VRS-CZ1JF102J AA 1 kohm,1/16W

R683 VRS-CZ1JF103J AA 10 kohm,1/16W

R701 VRS-CZ1JF271J AA 270 ohm,1/16W

R702 VRS-CZ1JF271J AA 270 ohm,1/16W

R703 VRS-CZ1JF271J AA 270 ohm,1/16W

R706 VRS-CZ1JF271J AA 270 ohm,1/16W

R707 VRS-CZ1JF271J AA 270 ohm,1/16W

R708 VRS-CZ1JF271J AA 270 ohm,1/16W

R709 VRS-CZ1JF271J AA 270 ohm,1/16W

R710 VRS-CZ1JF271J AA 270 ohm,1/16W

R711 VRS-CZ1JF271J AA 270 ohm,1/16W

R712 VRS-CZ1JF271J AA 270 ohm,1/16W

R713 VRS-CZ1JF271J AA 270 ohm,1/16W

R714 VRS-CZ1JF271J AA 270 ohm,1/16W

R715 VRS-CZ1JF271J AA 270 ohm,1/16W

R716 VRS-CZ1JF271J AA 270 ohm,1/16W

R717 VRS-CZ1JF121J AA 120 ohm,1/16W

R718 VRS-CZ1JF121J AA 120 ohm,1/16W

R719 VRS-CZ1JF121J AA 120 ohm,1/16W

R720 VRS-CZ1JF121J AA 120 ohm,1/16W

R725 VRS-CZ1JF151J AA 150 ohm,1/16W

R726 VRS-CZ1JF332J AA 3.3 kohm,1/16W

R727 VRS-CZ1JF820J AA 82 ohm,1/16W

R728 VRS-CZ1JF182J AA 1.8 kohm,1/16W

R729 VRS-CZ1JF222J AA

R730 VRS-CZ1JF393J AA 39 kohm,1/16W

R731 VRS-CZ1JF123J AA 12 kohm,1/16W

R733 VRS-CZ1JF103J AA 10 kohm,1/16W

R734 VRS-CZ1JF471J AA 470 ohm,1/16W

R735 VRS-CZ1JF221J AA 220 ohm,1/16W

R736 VRS-CZ1JF221J AA 220 ohm,1/16W

R801 VRS-CZ1JF102J AA 1 kohm,1/16W

R802 VRS-CZ1JF223J AA 22 kohm,1/16W

R803 VRS-CZ1JF102J AA 1 kohm,1/16W

R804 VRS-CZ1JF223J AA 22 kohm,1/16W

R806 VRS-CZ1JF273J AA 27 kohm,1/16W

R807 VRS-CZ1JF273J AA 27 kohm,1/16W

R808 VRS-CZ1JF333J AA 33 kohm,1/16W

R809 VRS-CZ1JF333J AA 33 kohm,1/16W

R811 VRS-CZ1JF000J AA 0 ohms,Jumper

R812 VRS-CZ1JF000J AA 0 ohms,Jumper

R813 VRS-CZ1JF000J AA 0 ohms,Jumper

R818 VRS-CZ1JF102J AA 1 kohm,1/16W

R819 VRS-CZ1JF102J AA 1 kohm,1/16W

R825 VRS-CZ1JF103J AA 10 kohm,1/16W

R827 VRS-CZ1JF103J AA 10 kohm,1/16W

R828 VRS-CZ1JF000J AA 0 ohms,Jumper

R832 VRS-CZ1JF103J AA 10 kohm,1/16W

R834 VRS-CZ1JF000J AA 0 ohms,Jumper

R835 VRS-CZ1JF4R7J AA 4.7 ohm,1/16W

R836 VRS-TV2AB000J AA 0 ohms,Jumper,1.25x2mm,Green

R903 VRS-TQ2EF000J AA 0 ohms,Jumper

R904 VRS-CZ1JF222J AA 2.2 kohm,1/16W

R905 VRS-CZ1JF103J AA 10 kohm,1/16W

R906 VRS-CZ1JF103J AA 10 kohm,1/16W

R908 VRS-CZ1JF000J AA 0 ohms,Jumper

R909 VRS-CZ1JF151J AA 150 ohm,1/16W

R910 VRS-CZ1JF102J AA 1 kohm,1/16W

R911 VRS-CZ1JF000J AA 0 ohms,Jumper

R912 VRS-CZ1JF000J AA 0 ohms,Jumper

R913 VRS-CZ1JF000J AA 0 ohms,Jumper

R914 VRS-CZ1JF101J AA 100 ohm,1/16W

R915 VRS-CZ1JF101J AA 100 ohm,1/16W

2.2 kohm,1/16W

4

Page 52

HT-SB200

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

RANK

[7] RESISTORS

R917 VRS-TQ2EF100J AA 10 ohm,1/8W

R918 VRS-TQ2EF3R3J AA 3.3 ohm,1/8W

R919 VRS-TQ2EF3R3J AA 3.3 ohm,1/8W

R920 VRS-CZ1JF000J AA 0 ohms,Jumper

R921 VRS-CZ1JF000J AA 0 ohms,Jumper

R922 VRS-TQ2EF220J AA 22 ohm,1/8W

R923 VRS-TQ2EF220J AA 22 ohm,1/8W

R924 VRS-TQ2EF6R2J AA 6.2 ohm,1/8W

R925 VRS-TQ2EF6R2J AA 6.2 ohm,1/8W

R926 VRS-TQ2EF6R2J AA 6.2 ohm,1/8W

R927 VRS-TQ2EF6R2J AA 6.2 ohm,1/8W

R928 VRS-CZ1JF000J AA 0 ohms,Jumper

R929 VRS-CZ1JF000J AA 0 ohms,Jumper

R936 VRS-CZ1JF563J AA 56 kohm,1/16W [Except Taiwan and Brazil]

R939 VRS-CZ1JF000J AA 0 ohms,Jumper [Except Taiwan and Brazil]

R940 VRS-CZ1JF000J AA 0 ohms,Jumper [Except Taiwan and Brazil]

[8] OTHER CIRCUITRY PARTS

CNP601 QPLGNA238WJZZ AF Connector, 15 Pin

CNP602 QPLGN0061CEZZ AG Connector, 11 Pin

CNP603 QPLGN0054CEZZ AD Connector, 4 Pin

CNP801 QPLGNA238WJZZ AF Connector, 15 Pin

CNP803 QCNCM010JAWZZ AC Connector, 9 Pin

CNP901 QPLGN0061CEZZ AG Connector, 11 Pin

CNP902 QCNCW010JAWZZ AC Connector, 9 Pin

CNP903 QPLGNA164WJZZ AG Connector, 8 Pin

CNS602-A QCNWNB114AWPZ AM Connector Ass'y 11 Pin with CNS602-B

CNS801-A QCNWNB118AWPZ AS Connector Ass'y 15 Pin with CNS801-B

JK801 QJAKM0004AWZZ AK Jack, Headphone

! JK803 QJAKCA006AWZZ AK Jack, DC Input

JK802 QSOCJA018AWZZ AD Jack, Audio Line In

LUG601 QLUGHA006WJZZ AD Lug Terminal

LUG801 QLUGHA006WJZZ AD Lug Terminal

LUG802 QLUGHA006WJZZ AD Lug Terminal

LUG901 QLUGHA006WJZZ AD Lug Terminal

LUG902 QLUGHA006WJZZ AD Lug Terminal

RX1 VHLK2013TH2E1 AG Remote Sensor

SW701 QSW-KA037WJZZ AD Switch,Key Type [Power On/Standby]

SW702 QSW-KA037WJZZ AD Switch, Key Type [Volume Down]

SW703 QSW-KA037WJZZ AD Switch, Key Type [Volume Up]

SW704 QSW-KA037WJZZ AD Switch, Key Type [Surround]

SW705 QSW-KA037WJZZ AD Switch, Key Type [Function]

DESCRIPTION

5

Page 53

[9] CABINET PARTS

HT-SB200

A

B

C

D

605 x 2

605 x 2

208

PWB-A4

210

220

202

PWB-A1

PWB-A2

213 x 2

217

604

607 x 2

212

214

605 x 4

605 x 4

217

605 x 2

201

216

CNS602-A

RF1, 2

217

207

605 x 2

601

608 x 4

PWB-A3

208

209

213 x 2

220

215

218

214 x 2

602 x 2

202

210

606 x 5

215

605 x 4

228

226

608 x 2

216

224

209

214

606 x 5

225

608 x 4

212

E

603 x 4

SP1

211

F

SP3

G

205

H

1

2345

604 x 2

SP4

213

222

221

219

604 x 2

206

227

604 x 2

SP5

219

604 x 2

SP6

218

219

219

604 x 2

603 x 4

SP2

211

203

6

Page 54

HT-SB200

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

RANK

DESCRIPTION

[9] CABINET PARTS

201 CCAB-A067AW02 BG Back Cabinet Ass'y

202 CDUC-A089AW01 AP Duct Port Ass'y

203 CPNLSA089AW01 BF Front Panel Ass'y

204 GCOVAA216AWSA AL Cover, LED Top , B

205 HDECQA496AWSA AX Panel, Decoration

206 JKNBZA257AW01 AE Function Button Ass'y

206-1 GCOVAA215AWSA - Cover, LED Top , A ( Not Replacement Part )

206-2 JKNBZA257AWSA - Button, Function ( Not Replacement Part )

207 LCHSMA083AWFW AL Chassis, Main

208 LHLDZA213AWZZ AL Holder, Duct Port

209 LHLDZA214AWSA AF Bracket, Wall Mount

210 PCUSSA114AWZZ AD Cushion, Duct Port

211 PCUSSA115AWZZ AD Cushion, Front Speaker

212 PCUSSA116AWZZ AB Cushion, Speaker Sealed, A

213 PCUSSA117AWZZ AD Cushion, Support

214 PCUSSA119AWZZ AH Cushion, Speaker Sealed, B

215 PCUSSA120AWZZ AH Cushion, Sealed Speaker, C

216 PCUSSA121AWZZ AH Cushion, Sealed Speaker, D

217 PCUSSA126AWZZ AA Cushion, E

218 PCUSSA128AWZZ AB Cushion, F

219 PCUSSA130AWZZ AB Cushion, H

220 PFILSA002AWZZ AQ Module, T.B.I., A

221 PFLT-A152AWZZ AB Felt

222 QCNWNB130AW01 AX Speaker Wire Ass'y

224 TLABZA797AWZZ AB Label, Jack

225 TLABZA875AWZZ AB Label, SRS

226 TSPC-B209AWZZ Label, Specification [ For BR ]

226 TSPC-B211AWZZ AC Label, Specification [ For SI, ME ]

226 TSPC-B212AWZZ AC Label, Specification [ For AU ]

226 TSPC-B213AWZZ AC Label, Specification [ For ID ]

226 TSPC-B214AWZZ AC Label, Specification [ For JO, PH ]

226 TSPC-B215AWZZ AC Label, Specification [ For TH ]

226 TSPC-B216AWZZ AC Label, Specification [ For TA ]

227 LX-WZ7003AWZZ AB Spacer

228 92LNBAND1318A AA Nylon Band

SP 1,2 RSP-ZA303AWZZ AZ Speaker

SP 3~6 RSP-ZA304AWZZ BB Woofer

601 LX-EZ0010AWF7 AB Special Screw

602 LX-JZ0047AWF7 AB Special Screw

603 XEBY726P08000 AA Screw, M2.6 X 8mm

604 XEBY730P08000 AA Screw, M3 X 8mm

605 XEBY830P10000 AB Screw, M3 X 10mm

606 XEBY835P10000 AB Screw, M3.5 X 10mm

607 XJBY730P08000 AA Screw, M3 X 8mm

608 XJBY830P10000 AA Screw, M3 X 10mm

[10] ACCESSORIES / PACKING PARTS

1 CLEGMA004AW01 AQ Spike Leg Ass'y, A ( Length : 30 mm )

2 CLEGMA005AW01 AN Spike Leg Ass'y, B ( Length : 25 mm )

3 LANGKA167AWFW AK Bracket, Wall Mount

! 5 QACCEA002AW00 AL AC Power Supply Cord [ For JO, ID, SI, PH, ME ]

! 5 QACCLA002AW00 AQ AC Power Supply Cord [ For AU ]

! 5 QACCZA002AW00 AP AC Power Supply Cord [ For TA ]

! 5 QACCZA007AW00 AQ AC Power Supply Cord [ For TH ]

! 5 QACCZA018AW00 AC Power Supply Cord [ For BR ]

! 8 RADPAA061AW01 BG AC/DC Adaptor Ass'y [ Except TA and TH ]

! 8 RADPAA064AW01 BF AC/DC Adaptor Ass'y [ For TA ]

! 8 RADPAA065AW01 AC/DC Adaptor Ass'y [ For TH ]

4 PCUSSA118AWZZ AD Cushion, Foot

6 QCNWGA041AWPZ AQ RCA Cable

7 QPLGA0004AWZZ AF AC Plug Adaptor [ For PH Only ]

9 RRMCGA177AWSA AU Remote Control

10 SPAKAA209AWZZ AK Packing Add, Top

11 SPAKAA210AWZZ AK Packing Add, Bottom

12 SPAKCA631AWZZ AP Packing Case

13 SPAKGA121AWZZ AU Packing Carton

14 SPAKZA558AWZZ AD Packing Add, Protection

15 SSAKAA011AWZZ AB Polyethylene Bag, Accessories

16 SSAKHA147AWZZ AD Polyethylene Bag, Unit

17 TCAUHA022AWZZ AE Pattern Paper

18 TGANZA030AW04 AE Guarantee Card [ For TA Only ]

18 TGANEA009AW09 AC Guarantee Card [ For PH Only ]

19 TINSEA290AWZZ AE Operation Manual [ For ID, SI and PH ]

19 TINSTA045AWZZ AE Operation Manual [ For TH ]

19 TINSZA407AWZZ AQ Operation Manual [ For TA, JO, AU, ME ]

19 TINSZA456AWZZ Operation Manual [ For BR ]

20 TLABZ0605AWZZ AB Label, Saving Energy [ For JO, AU, ME ]

21 TLABZA806AWZZ AA Label, Pop

[11] P.W.B. ASSEMBLY ( Not Replacement Item )

! PWB-A 92LPWB7387MANS - Main (A1)/ Power (A2)/ Amplifier (A3 / Spacer (A4) [ For Brazil and Taiwan Only ]

! PWB-A 92LPWB7388MANS ! PWB-A 92LPWB7394MANS - Main (A1)/ Power (A2 / Amplifier (A3 / Spacer (A4) [ For Indonesia Only ]

Main (A1)/ Power (A2 / Amplifier (A3 / Spacer (A4) [ Except Indonesia, Brazil and Taiwan ]

7

Page 55

HT-SB200

8

Page 56

HT-SB200

COPYRIGHT 2008 BY SHARP CORPORATION