Page 1

HT-CN9900DVW

PRECAUTIONS FOR USING LEAD-FREE SOLDER

CHAPTER 1. GENERAL DESCRIPTION

[1] Safety Precaution For Service Manual.........1-1

[2]

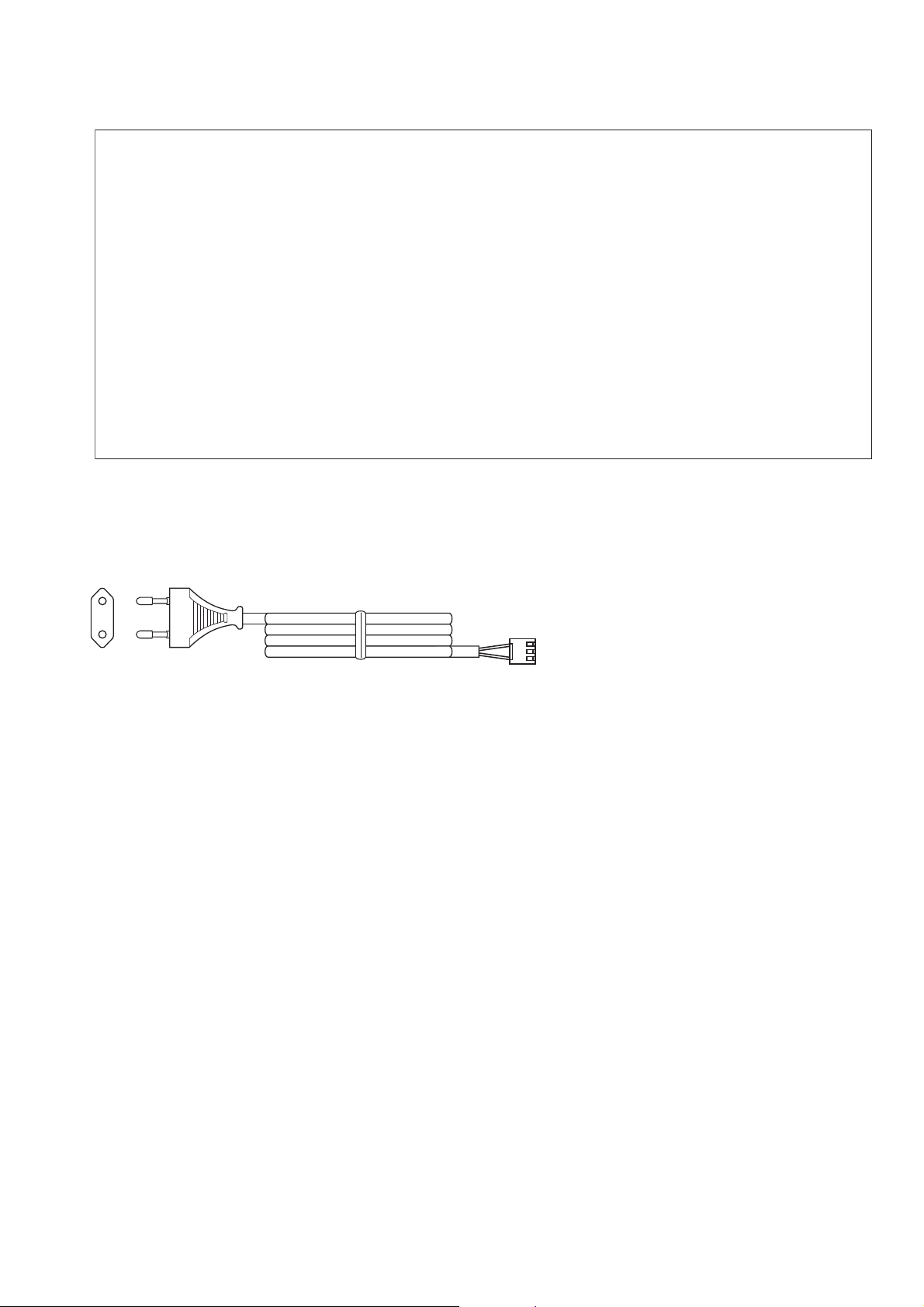

AC Power Supply Cord

..................................1-1

[3] Specifications ...............................................1-2

[4] Names Of Parts............................................1-3

CHAPTER 2. MECHANICAL DESCRIPTION

[1] Disassembly ................................................2-1

CHAPTER 3. FLOWCHART

[1] Troubeshooting ............................................3-1

CHAPTER 4. MAJOR PART DRAWING

[1] Function Table Of IC .................................... 4-1

[2] VFD Display.............................................. 4-10

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Waveforms Of Servo Circuit..........................5-1

[2] Voltage..........................................................5-3

CHAPTER 6. DIAGRAMS

[1] Block Diagram...............................................6-1

CHAPTER 7. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] Notes On Schematic Diagram ......................7-1

[2] Type Of Transistor And LED .........................7-1

[3] Schematic Diagram ......................................7-2

[4] Charts Of Connecting Wires.........................7-5

[5] Wiring Side Of PWB .....................................7-6

PARTS GUIDE

HT-CN9900DVW

!

SERVICE MANUAL

No. S7119HTC990DZ

HOME THEATER WITH DVD

MODEL

Singapore, Malaysia, Indonesia, Philippines and India]

HT-CN9900DVW Home Theater with DVD consisting of

HT-CN9900DVW (main unit), CP-CN9900F (front speakers),

CP-CN9900C (centre speaker), CP-CN9900R (surround

speakers) and CP-CN9900W (subwoofer).

• In the interests of user-safety (Required by safety

regulations in some countries) the set should be restored to

its original condition and only parts identical to those

specified be used.

CONTENTS

HT-CN9900DVW

[For Jordan, Singapore-Export,

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

HT-CN9900DVW

PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

Lead-free wire solder for servicing

Ref No.

Description

Parts No.

"MAIN/AMP, DISPLAY, USB, MIC, SMPS PWB" of this model employs lead-free solder.

The LF symbol indicates lead-free solder, and is attached on the PWB and service manuals. The alphabetical

character following LF shows the type of lead-free solder.

2. Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 C, we recommend

you to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering

bit, contact our service sta

tion or service branch in your area.

3.

Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead

solder by 40°C,and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, since the land may be peeled of for the maximum heat-resistance

temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady

soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corrected. Make sure to turn

on and off the power of the bit as required. If a different type of solder stays on the tip of the soldering bit, it is

alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sand paper.

Be careful when replacing parts with pola

rity indication on the PWB silk.

Example:

Indicates lead-free solder of tin, silver and copper.

PWB-A 92LPWB8315MANS

PWB-A 92LPWB8316MANS

PWB-A 92LPWB8327MANS

PWB-A 92LPWB8328MANS

PWB-B RUiTZA049AWZZ

MAIN/AMP (A1), DISPLAY (A2), USB (A3), MIC (A4)

[ For Jordan, Singapore-Export ]

MAIN/AMP (A1), DISPLAY (A2), USB (A3), MIC (A4)

[ For Singapore, Malaysia, Indonesia ]

MAIN/AMP (A1), DISPLAY (A2), USB (A3), MIC (A4)

[ For Philippines ]

MAIN/AMP (A1), DISPLAY (A2), USB (A3), MIC (A4)

[ For India ]

SMPS

– 1

i

Page 3

CHAPTER 1. GENERAL DESCRIPTION

This product is classified as a CLASS 1 LASER PRODUCT.

WARNINGS

THE AEL (ACCESSIBLE EMISSION LEVEL) OF LASER POWER OUTPUT FOR THIS MODEL IS SPECIFIED TO

BE LOWER THAN CLASS I REQUIREMENTS. HOWEVER, THE FOLLOWING PRECAUTIONS MUST BE OBSERVED

DURING SERVICING TO PROTECT YOUR EYES AGAINTS EXPOSURE TO THE LASER BEAM.

1- WHEN THE CABINET HAS BEEN REMOVED, THE POWER IS TURNED ON WITHOUT A COMPACT DISC,

AND THE PICKUP IS ON A POSITION OUTER THAN THE LEAD-IN POSITION, THE LASER WILL LIGHT FOR

SEVERAL SECONDS TO DETECT A DISC.

DO NOT LOOK INTO THE PICKUP LENS.

2- THE LASER POWER OUTPUT OF THE PICKUP INSIDE THE UNIT AND REPLACEMENT SERVICE PARTS

HAVE ALREADY BEEN ADJUSTED PRIOR TO SHIPPING.

3- NO ADJUSTMENT TO THE LASER POWER SHOULD BE ATTEMPTED WHEN REPLACING OR SERVICING

THE PICKUP.

4- UNDER NO CIRCUMSTANCES LOOK DIRECTLY INTO THE PICKUP LENS AT ANY TIME.

5- CAUTION - USE OF CONTROLS OR ADJUS

TMENTS, OR PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

QACCEA001AW00

[1] Safety Precaution For Service Manual

HT-CN9900DVW

[2] AC Power Supply Cord

1 – 2

1 – 1

Page 4

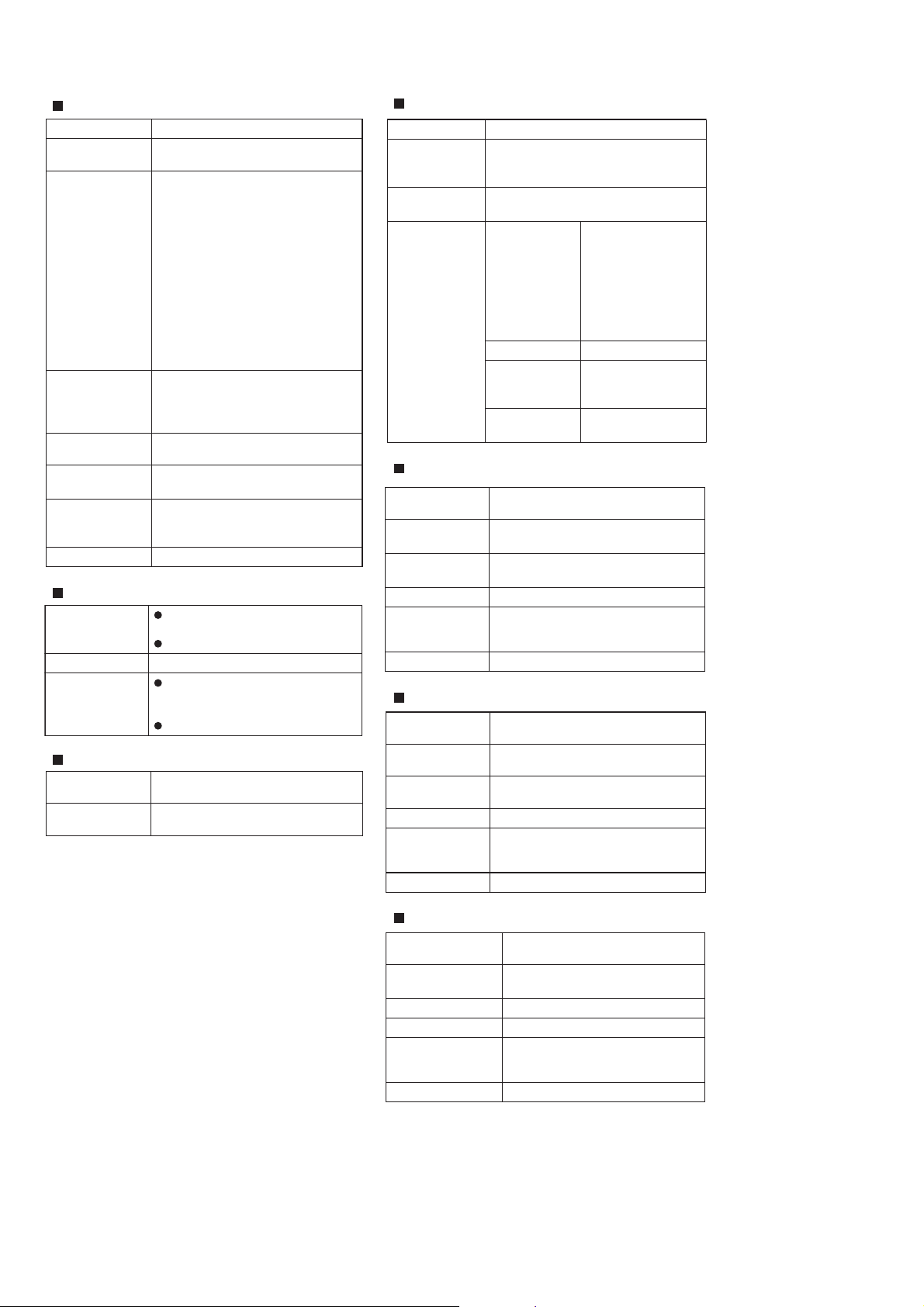

HT-CN9900DVW

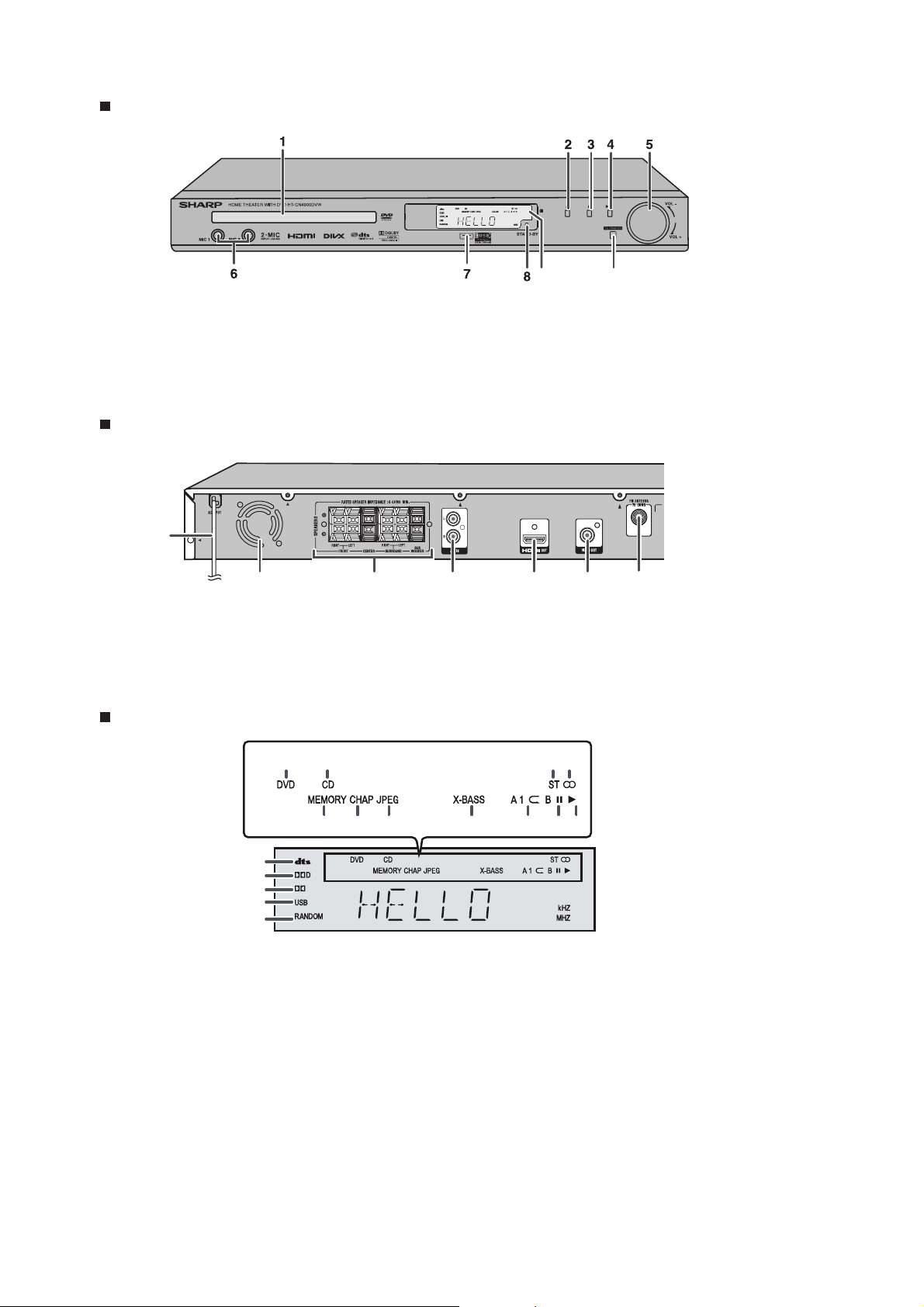

Main unit

USB

Tuner

DVD player

Subwoofer

CP-CN9900 F/R Speaker

Power source AC 220 - 240 V ~ 50/60 Hz

Power

consumption

Power on: 120 W

Output power Front speaker

(CP-CN9900):

RMS: 200 W (100 W + 100 W)

(10% T.H.D.)

Surround speaker

(CP-CN9900):

RMS: 200 W (100 W + 100 W)

(10% T.H.D.)

Centre speaker

(CP-CN9900):

RMS: 100 W (10% T.H.D.)

Subwoofer:

RMS: 100 W (10% T.H.D.)

Video output

terminals

Video output: RCA type x 1

HDMI output: HDMI x 1

Support 480p/570p/1080p output

formats.

Audio input

terminals

Analogue input: 500 mV/47 k ohms

Microphone 1/2: 1 mV/600 ohms

Audio output

terminals

Speakers: 6 ohms

Subwoofer: 6 ohms

Dimensions

Width: 430 mm (16-15/16")

Height: 65.7 mm (2-19/32")

Depth: 320.3 mm (12-1/2")

Weight 3.4 kg (7.5 lbs.)

USB host

interface

Complies with USB 1.1/2.0 (Full

Speed) Mass Storage Class.

Support Bulk only and CBI protocol.

Support file JPEG

File system

support

Support USB devices with

Microsoft Windows/DOS/FAT 16/

FAT 32.

2 kbyte block length for sector.

Frequency

range

FM: 87.5 - 108 MHz

Other Maximum station can be stored is 40

preset.

Signal system PAL/NTSC colour

Supported disc

types

DVD (with the same region number at

the back of the unit), audio CD, CD-R,

CD-RW, JPEG, DivX

Video signal Horizontal resolution: 500 lines

S/N ratio: 70 dB

Audio signal Frequency

characteristic

s

Linear PCM DVD:

20 Hz to 20 kHz

(sampling rate: 48

kHz)

20 Hz to 20 kHz

(sampling rate: 96

kHz)

CD: 20 Hz to 20 kHz

S/N ratio CD: 94 dB (1 kHz)

Dynamic range Linear PCM DVD:

95 dB

CD: 94 dB

Total harmonic

distortion ratio

0.01% maximum

Type Full range speaker system

6.5 cm (2-1/2") woofer

Maximum input

power

200 W

Rated input

power

100 W

Impedance 6 ohms

Dimensions Width: 154 mm (6-1/16")

Height: 103 mm (4-1/16")

Depth: 84 mm (3-5/16")

Weight 0.5 kg (1.1 lbs.)

Type Subwoofer system

13 cm (5-1/8") subwoofer

Maximum input

power

200 W

Rated input

power

100 W

Impedance 6 ohms

Dimensions Width: 115 mm (4-1/2")

Height: 421 mm (16-9/16")

Depth: 396 mm (15-9/16")

Weight 4.3 kg (9.5 lbs.)

Type Full range speaker system

6.5 cm (2-1/2") woofer

Maximum input

power

200 W

Rated input power 100 W

Impedance 6 ohms

Dimensions Width: 250 mm (9-13/16")

Height: 1030 mm (40-9/16")

Depth: 250 mm (9-13/16")

Weight 1.5 kg (3.3 lbs.)

CP-CN9900 C Speaker

[3] Specifications

1 – 3

1 – 2

Page 5

[4] Names Of Parts

1

3 4 65 72

Main unit (front panel)

1. Disc Tray

2. Disc Tray Open/Close Button

3. Stop Button

4. Play/Pause Button

5. Volume Control

Main unit (rear panel)

HT-CN9900DVW

109

6. Microphone Sockets

7. USB Terminal

8. Stand-by Indicator

9. Remote Sensor

10. On/Stand-by Button

1. AC Power Lead

2. Cooling Fan

3. Speaker Terminals

4. Auxiliary Input Sockets

Display

12

13

14

15

16

1. DVD Indicator

2. CD Indicator

3. FM Stereo Mode Indicator

4. FM Stereo Receiving Indicator

5. Memory Indicator

6. Chapter Indicator

7. JPEG Indicator

8. Extra Bass Indicator

1 2

5 6 78 11109

PLII

5. HDMI Socket

6. Video Output Socket

7. FM 75 Ohms Aerial Socket

43

9. Repeat Play Indicator

10. Pause Indicator

11. Play Indicator

12. DTS Indicator

13. Dolby Digital Signal Indicator

14. Dolby Pro-Logic Indictor

15. USB indicator

16. Random Indicator

1 – 4

1 – 3

Page 6

HT-CN9900DVW

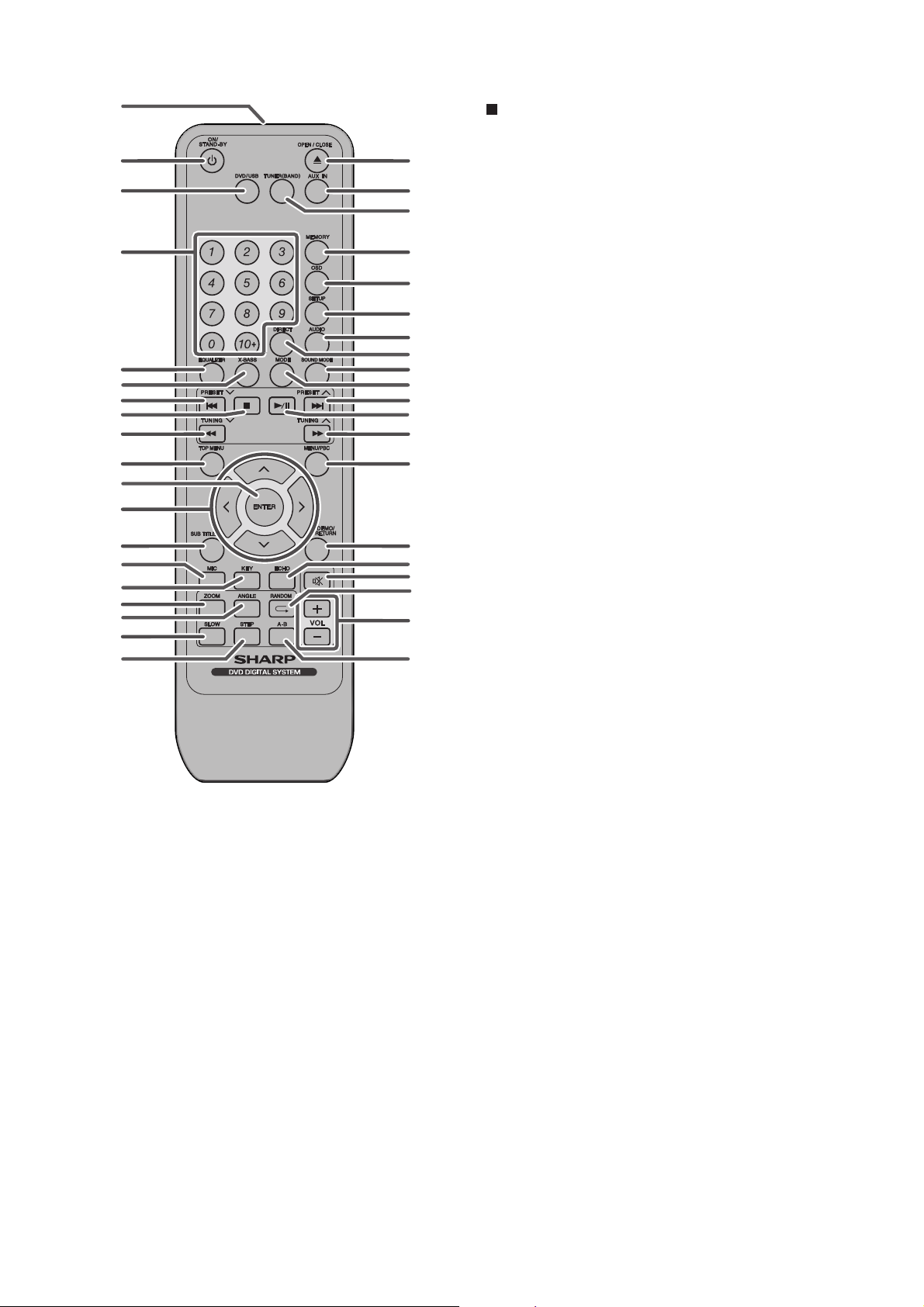

Remote control

1. Remote Control Transmitter

2. On/Stand-by Button

3. DVD/USB Button

4. Numeric Buttons

5. Equaliser Button

6. X-Bass Button

7. Chapter (Track) Skip Down or Preset Down Button

8. Stop Button

9. Fast Reverse or Tuning Down Button

10. Top Menu Button

11. Enter Button

12. Cursor Buttons

13. Subtitle Button

14. Mic Button

15. Key Button

16. Zoom Button

17. Angle Button

18. Slow Button

19. Step Button

20. Disc Tray Open/Close Button

21. AUX IN Button

22. Tuner (Band) Button

23. Memory Button

24. OSD Button

25. Setup Button

26. Audio Button

27. Direct Button

28. Sound Mode Button

29. Mode Button

30. Chapter (Track) Skip Up or Preset Up Button

31. DVD/CD Play and Pause Button

32. Fast Forward or Tuning Up Button

33. Menu/PBC Button

34. Demo/Return Button

35. Echo Button

36. Mute Button

37. Random/Repeat Button

38. Volume Up and Down Buttons

39. A-B Repeat Button

2

1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

1 – 5

1 – 4

Page 7

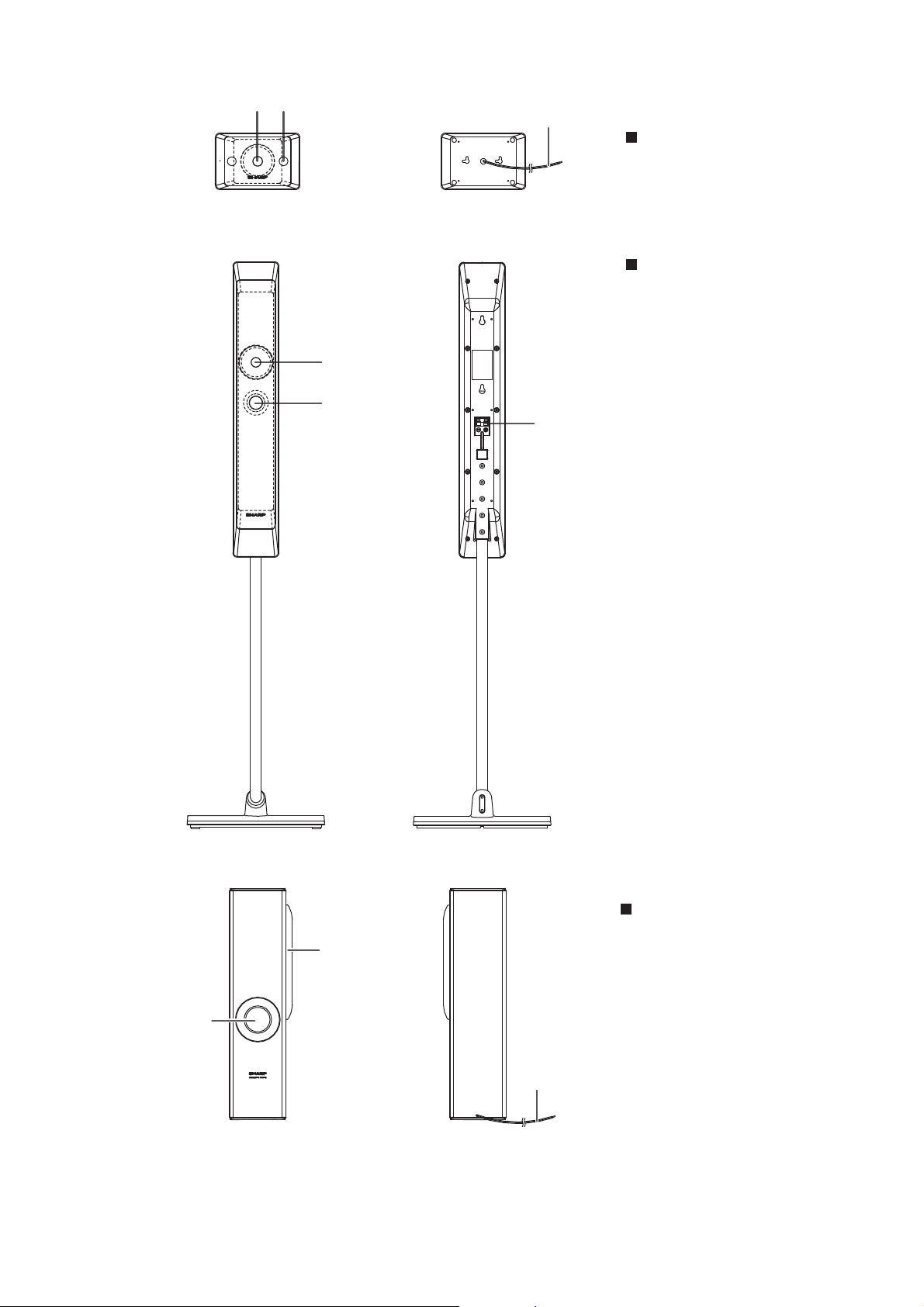

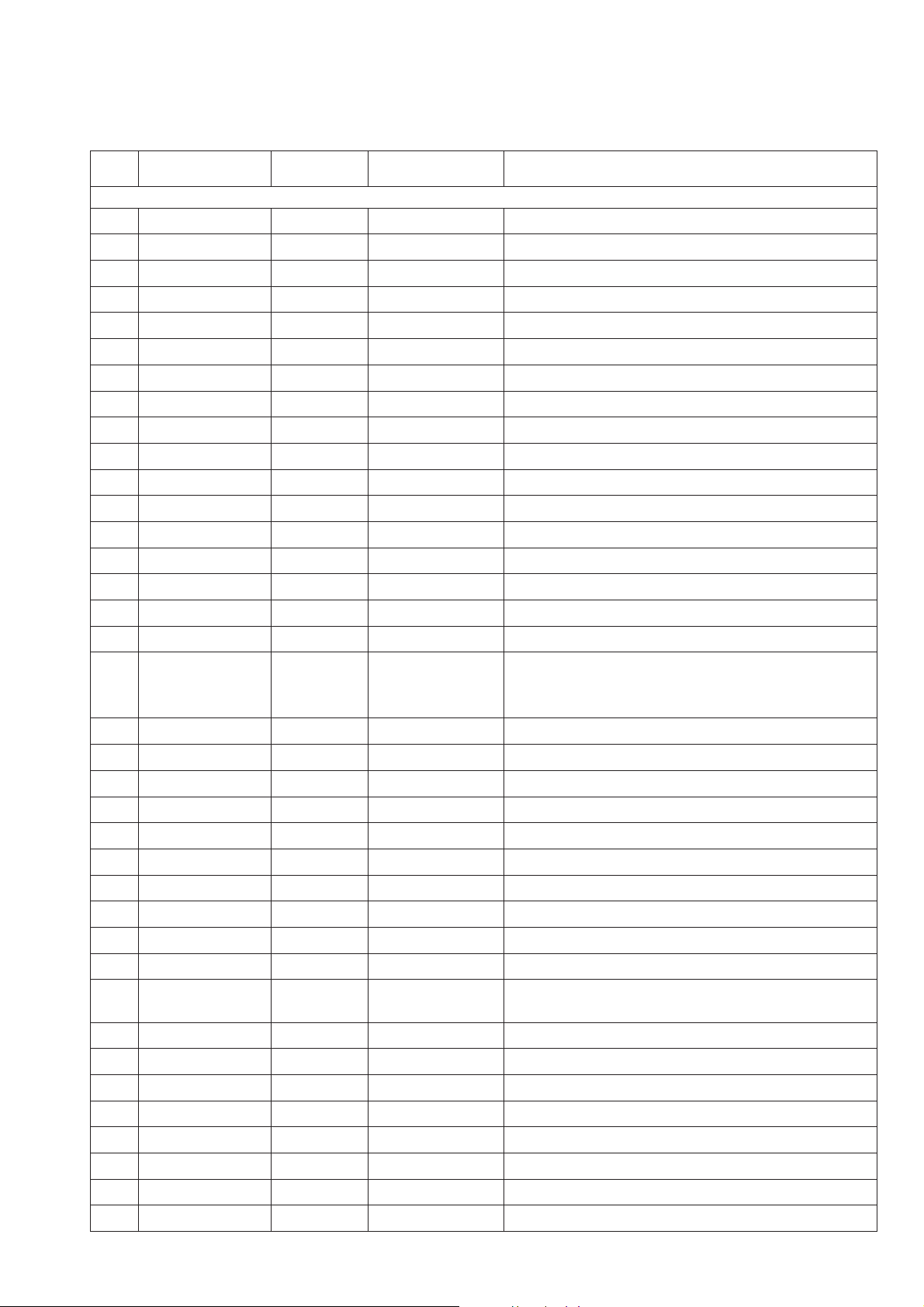

1

2

FRONT VIEW REAR VIEW

1

2

HT-CN9900DVW

3

Center speaker

1. Woofer

2. Bass Reflex Duct

3. Speaker Wire

Front/Surround speakers

1. Woofer

2. Bass Reflex Duct

3. Speaker Terminal

3

FRONT VIEW REAR VIEW

2

1

1 – 6

1 – 5

Subwoofer

1. Bass Reflex Duct

2. Subwoofer

3. Speaker Wire

3

Page 8

HT-CN9900DVW

CD-ES700/CD-ES77CD-ES700/CD-ES77Service ManualCD-ES700/CD-ES77MarketE

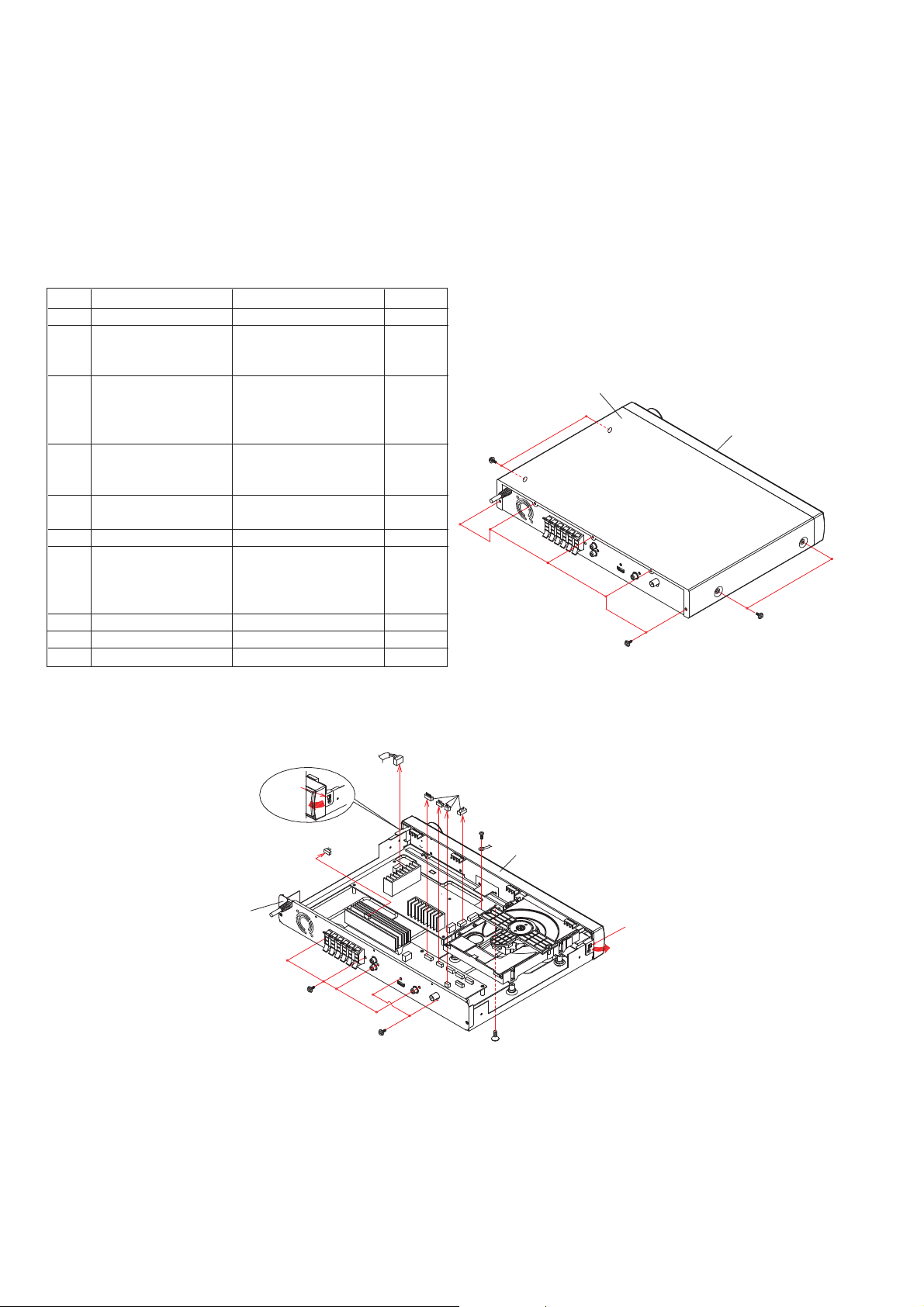

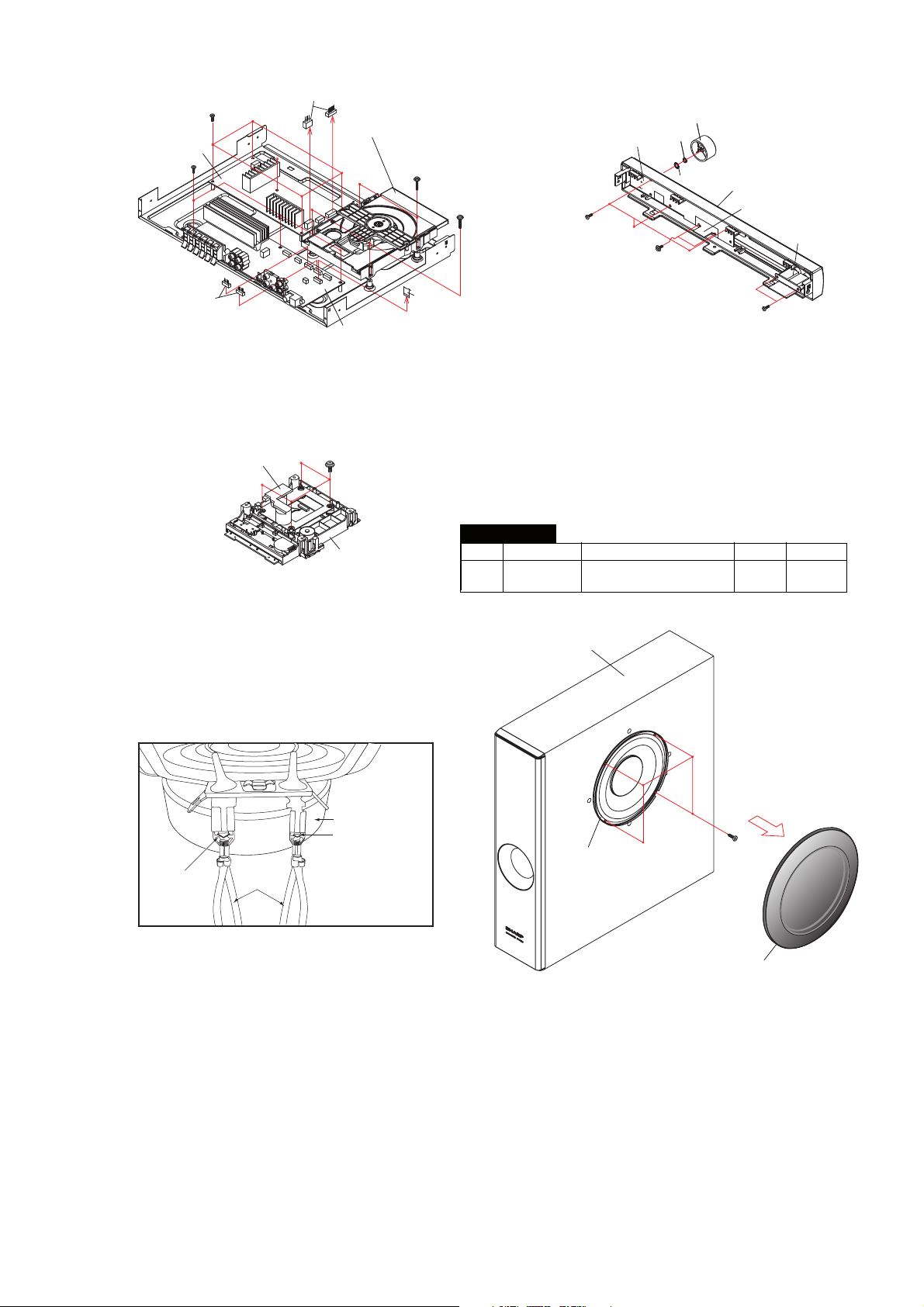

CHAPTER 2. MECHANICAL DESCRIPTION

[1] Disassembly

Caution On Disassembly

Follow the below-mentioned notes when disassembling the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need to be removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were before disassembling.

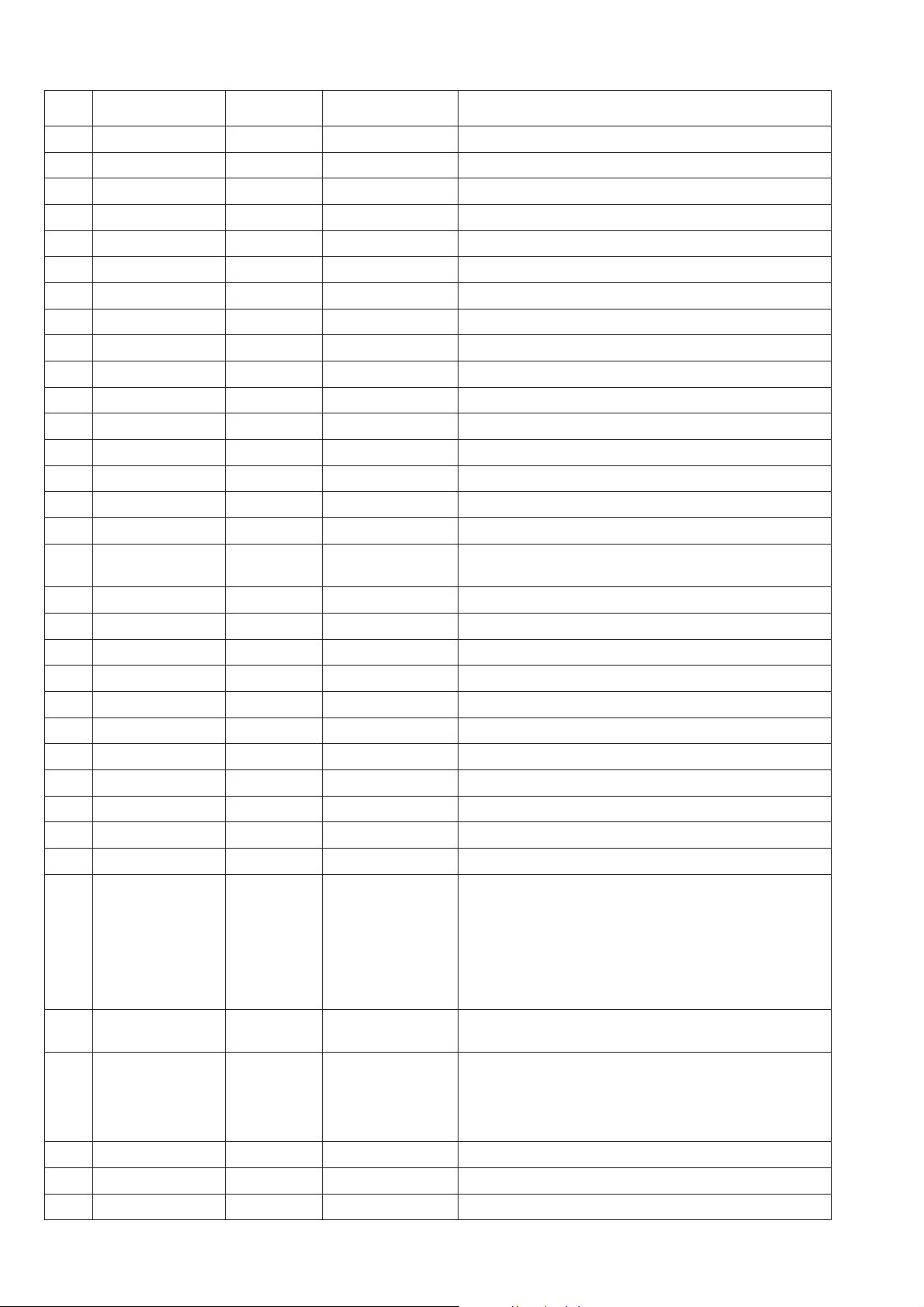

STEP REMOVAL PROCEDURE FIGURE

1 Top Cabinet

2 Rear Panel

3 Front Panel Assy

4 Loader Assy with

DVD Mechanism Unit

5 Main/Amp PWB

6 SMPS PW B

7Display PWB

8USB PWB

9Mic PWB

10 DVD Mechanism Unit

1. Screw............

1. Screw............

2. Screw............

3. Socket ..........

1. Screw............

2. Screw............

3. Socket ..........

4. Hook .............

1. Screw............

2. Flat Cable .....

3. Socket ..........

1. Screw............

2. Socket ..........

1. Screw............

1. Knob .............

2. Nut................

3. Washer .........

4. Screw............

1. Screw............

1. Screw............

1. Screw............

(A1)x9 1

(B1)x4 2

(B2)x2

(B3)x2

(C1)x1 2

(C2)x1

(C3)x4

(C4)x2

(D1)x4 3

(D2)x1

(D3)x2

(E1)x3 3

(E2)x2

(F1)x5 3

(G1)x1 4

(G2)x1

(G3)x1

(G4)x3

(H1)x2 4

(J1)x2 4

(K1)x4 5

(A1) x 2

Special Screw

Top Cabinet

(A1) x 5

Special Screw

Front Panel Assy

(A1) x 2

Special Screw

Rear Panel

Hook

(C4) x 1

PULL

(B3) x 1

(B1) x 3

M3 x 8mm

(B3) x 1

(B2) x 2

M3 x 6mm

Figure 2

(C3) x 4

(C2) x 1

Special Screw

Front Panel Assy

(C1) x 1

M3 x 6mm

PULL

Figure 1

Hook

(C4) x 1

2 – 1

Page 9

HT-CN9900DVW

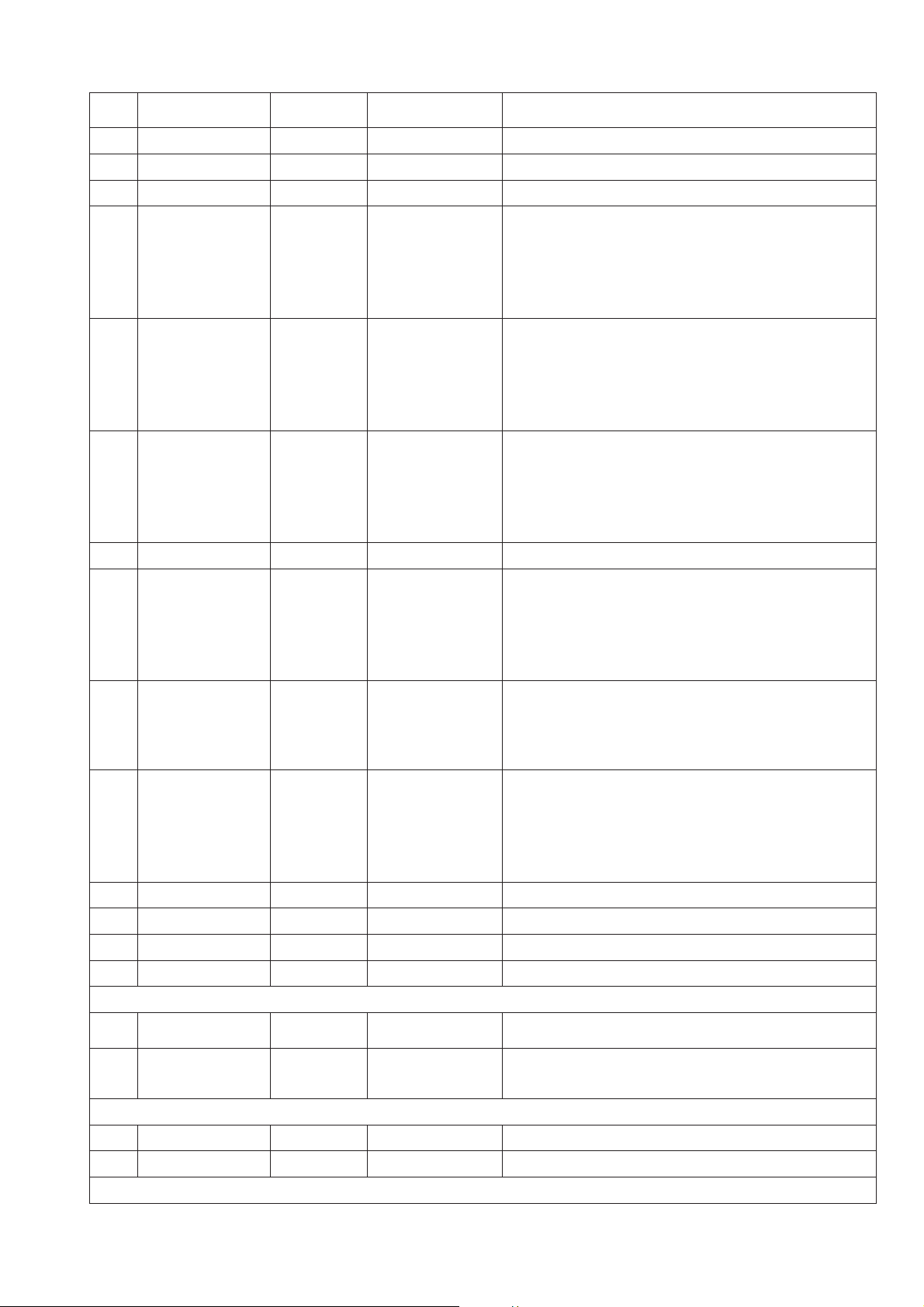

Figure 5

Figure 3 Figure 4

CAUTION:

TO REMOVE SPEAKER UNIT, PRESS THESE LOCKING TABS

TO RELEASE SPEAKER WIRES.

SPEAKER UNIT

LOCKING

TAB

LOCKING TAB

SPEAKER

WIRE

(F1) x 5

M3 x 8mm

(J1) x 2

M3 x 8mm

(A2) x 4

M4 x 16mm

(A1) x 1

Net Frame Ass,y

(G4) x 3

M3 x 8mm

Display PWB

(E1) x 3

M3 x 8mm

(E2) x 2

(G1) x 1

(G2) x 1

(G3) x 1

Front Panel Assy

USB PWB

Mic PWB

(D3) x 2

(D2) x 1

Main/Amp PWB

SMPS PWB

Loader Assy with

DVD Mechanism

(D1) x 2

Special Screw

(H1) x 2

Special Screw

(K1) x 4

Special Screw

DVD Mechanism Unit

Loader Assy

Wooden Box Ass’y

Subwoofer

(D1) x 2

Special Screw

Figure 6

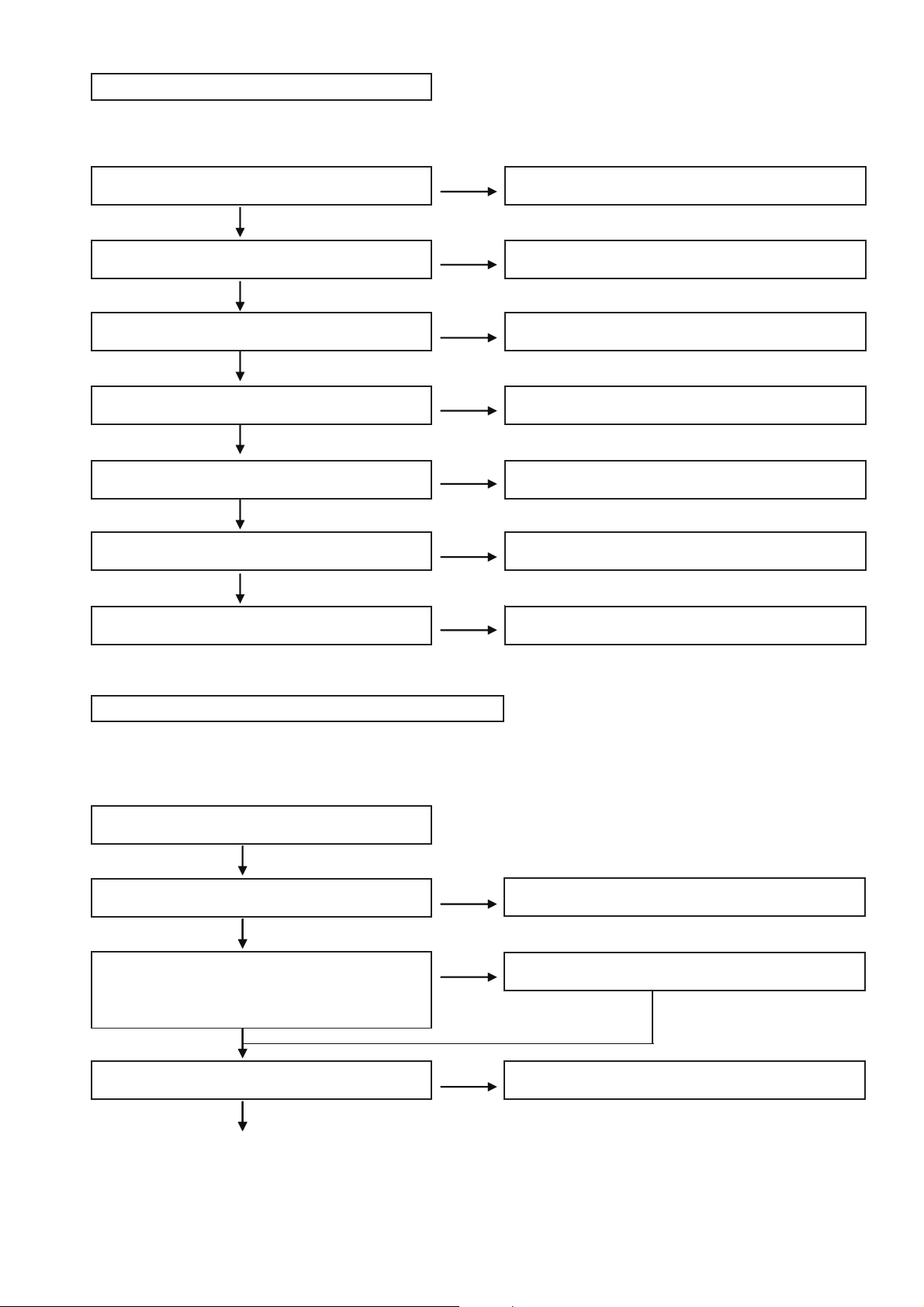

STEP REMOVAL PROCEDURE FIGURE

1 Subwoofer

1. Net Frame Ass'y ..............

(A1)x1 6

2. Screw...............................

(A2)x4

Subwoofer

2 – 2

Page 10

HT-CN9900DVW

1. When the CD/DVD does not function

The CD/DVD section may not operate when the objective lens of the optical pickup is dirty. Clean the objective lens,

and check the playback operation. When this section does not operate even after the above step is taken, check the following items.

Remove the cabinet and follow the trouble shooting instructions.

"Track skipping and/or no TOC (Table Of Contents) may be caused by build up of dust other foreign matter on the laser

pickup lens. Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned below."

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

2. When a CD/DVD cannot be played

2.1. Pressing the CD/DVD operation key is accepted, but playback does not occur.

1) Focus error system check

2) Both Video and Audio do not operate normally

Par ts code

1. CD optical pickup Lens cleaner disc UDSKA0004AFZZ

HOW TO USE

CAUTION

Cleaning fluid

Cleaner disc

Using the brush in the cleaner cap, apply 1 or 2 drops of the cleaning fluid to the

brush on the CD cleaner disc which has the mark next to it.

Place the CD cleaner disc onto the CD/DVD disc compartment with the brush side

down, then press the play button.

You will hear music for about 20 seconds and the CD/DVD player will automatically

stop. If it still play continuously, press the stop button.

1.

2.

3.

The CD lens cleaner should be effective for 30-50 operations, however if the brushes

become worn out earlier then please replace the cleaner disc.

If the CD cleaner brushes become very wet then wipe off any excess fluid with a soft

cloth.

Do not drink the cleaner fluid or allow it contact with the eyes. In the event of this

happening then drink and / or rinse with clean water and seek medical advice.

The CD cleaner disc must not be used on car CD players or on computer CD-ROM

drives.

All rights reserved. Unauthorized duplicating, broadcasting and renting this product

is prohibited by law.

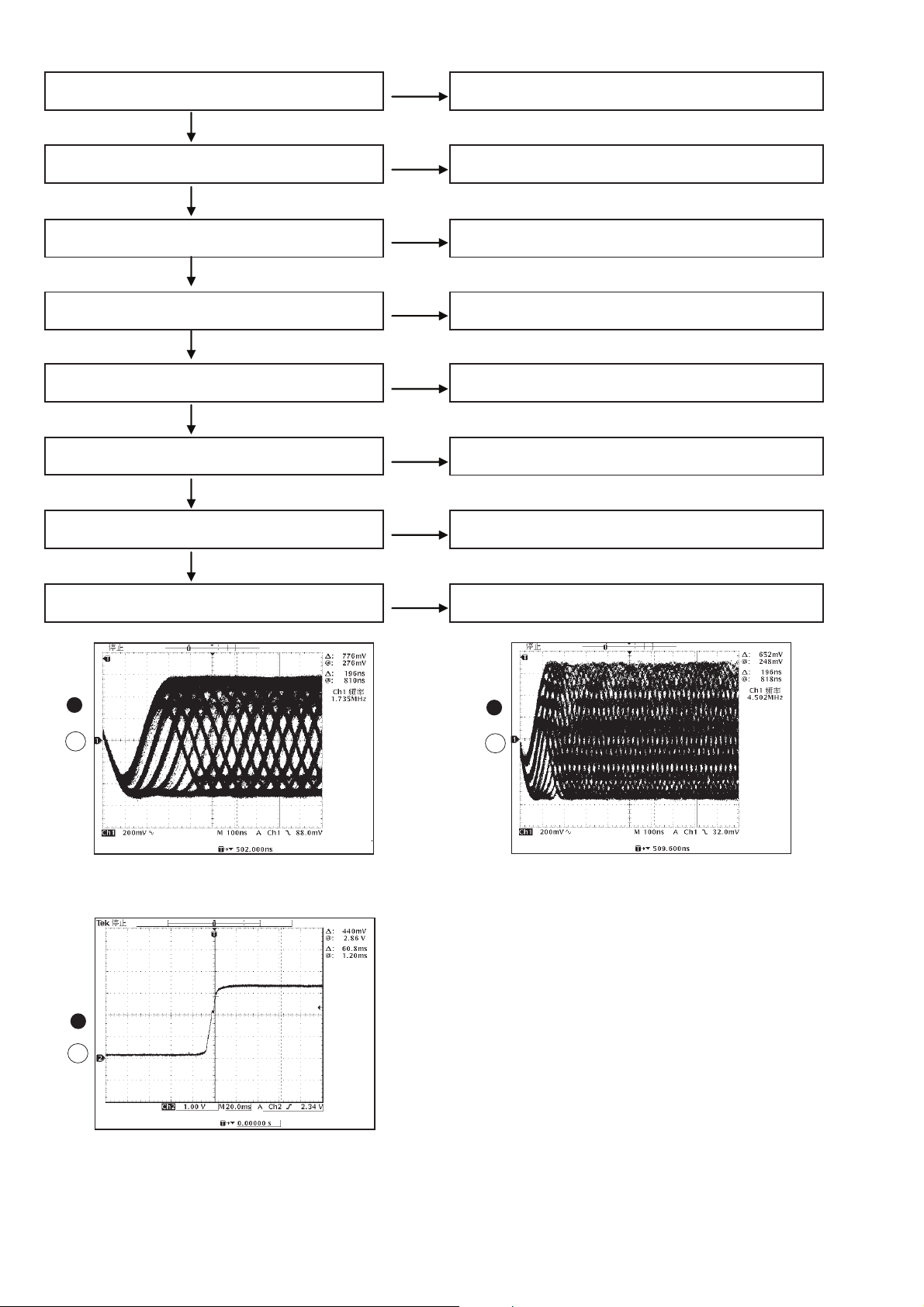

CHAPTER 3. FLOWCHART

[1] Troubleshooting

3 – 1

Page 11

( 1 ) Focus error system check.

Although a CD or DVD is inserted and the cover is closed,

" NO DISC " is displayed.

No Check incoming servo supply ( U5 ).

Yes

2. Is it Open / Close function OK ? No Check Open / Close switch.

Yes

3. Is Sled able to move to inner ? No Check Sled circuit, A5888 ( Pin 23 ).

Yes

4. Is the laser lit ? No Check Laser circuit, CD / DVD Laser circuits.

Yes

5. Does the focus ( lens ) move up and down ? No Check U5 ( Pin 18 ) and U10 ( Pin 13and 14).

Yes

6. Is the turntable rotating ? No Check U5 ( Pin 13 ) and U10 ( Pin 11 and 12 ).

Check Spindle motor.

Yes

7. Is it the CD / DVD Laser driver circuit OK ?

No Check the CD / DVD Laser driver ( Q12, Q13, Q14 &

Q15 ) peripheral circuit and U5 ( Pin 10 and 11).

( 2 ) Both Video and Audio do not operate normally

The RF waveform is normal and the time is

displayed normally, but no sound is produced.

Or the sound has dropouts.

1. Put a disc on DISC compartment.

Yes

2. When playback starts does the disc initialise ? No Repeat steps as Focus errror system check occurred.

Yes

3. Are the RF signal level output from U5 No Is the objective lens of optical pickups clean ?

pin no 168 normal?

( Waveform drawing Figure 1 for CD and

Figure 2 for DVD )

Yes

Yes

4. Replace Servo PWB. No Replace optical pickup mechanism unit.

Yes

1. Does the servo supply is + 3.3 V?

HT-CN9900DVW

3 – 2

Page 12

HT-CN9900DVW

5. Does the supply shows as + 3.3 V / + 1.8 V?

No

Check supply ( U1

2

Pin No.2 / U12 Pin No.2 ).

Yes

6. Is Reset function OK? No Check U5 pin no 44.

( Waveform drawing Figure 3 )

Yes

7. Is clock frequency shows 27MHz? No Check clock circuit ( Y2 , C169 , C170 )

Yes

1

8. Is the Flash is normal? No Check U5 pin no

4.

Yes

9. Is the SDRAM is normal? No Check U4 pin no 38.

Yes

10. Is the DSP is normal? No Check U5 Data Bus.

Yes

11. Is the Audio out is normal?

No

Check Audio out circuit ( U5 Pin No.158 and 160 ).

Yes

12. Is the Video out is normal? No

1

1

U5 168

U5 44

RF

Figure 1

1

3

RESET

Check Video out circuit ( U5 Pin no 139 )

1

2

U5 168

RF

Figure 2

Figure 3

3 – 3

Page 13

CHAPTER 4. MAJOR PART DRAWING

Pin

No.

NAME

Alternative

Function

Type Description

Analog Interface ( 66 Pins )

167 RFIP Analog Input AC coupled DVD RF signal input RFIP

168 RFIN OPOUT Analog Input AC coupled DVD RF signal input RFIN

169 RFG OPINP Analog Input Main beam, RF AC input path

170 RFH OPINN Analog Input Main beam, RF AC input path

171 RFA Analog Input RF main beam input A

172 RFB Analog Input RF main beam input B

173 RFC Analog Input RF main beam input C

174 RFD Analog Input RF main beam input D

175 RFE Analog Input RF sub beam input E

176 RFF Analog Input RF sub beam input F

1 AVDD18_2 Analog Power Analog 1.8V power

2 AVDD33_1 Analog Power Analog 3.3V power

3 XTALI Input 27MHz crystal input

4 XTALO Output 27MHz crystal output

5 AGND33 Analog Ground Analog 3.3V Ground

6 V20 Analog Output Reference Voltage 2.0V

7 V14 Analog Output Reference Voltage 1.4V

8 REXT GPO5

Analog Input /

Digital Output

1. Current reference input. It generates reference current for RF

path. Connect an external 15K resistor to this pin and AVSS.

2. GPO5

9 MDI1 Analog Input Laser power monitor input

10 LDO1 Analog Output Laser driver output

11 LDO2 Analog Output Laser driver output

12 AVDD33_2 Analog Power Analog 3.3V power

13 DMO Analog Output Disc motor control output. PWM output

14 FMO Analog Output Feed motor control. PWM output

15 TRAY_OPEN Analog Output Tray PWM output / Tray open output

16 TRAY_CLOSE Analog Output Tray PWM output / Tray close output

17 TRO Analog Output Tracking servo output. PDM output of tracking servo compensator.

18 FOO Analog Output Tracking servo output. PDM output of tracking servo compensator.

19 FG GPIO2 Analog Output

1) Motor Hall sensor input

2) GPIO2

20 USB_DP Analog Inout USB port DPLUS analog pin

21 USB_DM Analog Inout USB port DMINUS analog pin

22 VDD33_USB USB Power USB Power pin 3.3V

23 VSS33_USB USB Ground USB Ground pin 3.3V

24 PAD_VRT Analog Inout USB generating reference current

25 VDD18_USB USB Power USB Power pin 1.8V

112 AGND33_VPLL Analog Ground Analog 3.3V Ground

113 EXT_RES Analog Input External Resistor for HDMi ™ TX

[1] Function Table Of IC

U5 VHIMT1389GF-1Q : High Definition DVD Player SOC with HDMi (1/9)

HT-CN9900DVW

4 – 1

Page 14

HT-CN9900DVW

U5 VHIMT1389GF-1Q : High Definition DVD Player SOC with HDMi (2/9)

Pin

No.

114 AVDD33_VPLL Analog Power 3.3V VDD for HDMi ™ TX

115 AGND33_TX Analog Ground Analog 3.3V Ground

116 AGND18_TX2 Analog Ground Analog 1.8V Ground

117 TXCN Analog Output Negative TX CLK

118 TXCP Analog Output Positive TX CLK

119 AVDD18_TX1 Analog Power 1.8V VDD for HDMi ™ TX

120 TX0N Analog Output Negative TX CH0

121 TX0P Analog Output Positive TX CH0

122 AGND18_TX1 Analog Power 1.8V GND for HDMi ™ TX

123 TX1N Analog Output Negative TX CH1

124 TX1P Analog Output Positive TX CH1

125 AGND18_TX0 Analog Power 1.8V VDD for HDMi ™ TX

126 TX2N Analog Output Negative TX CH1

127 TX2P Analog Output Positive TX CH2

128 AGND18_TXD Analog Ground Analog 1.8V Ground

134 DACVDDC Power 3.3V Power pin for video DAC circuitry

135 VREF GPIO14

136 FS Analog Full scale adjustment (suggest to use 560 ohm)

137 DACVSSC Analog Ground Analog 3.3V Ground

138 CVBS Analog Analog CVBS or C

139 DACVDDB Power 3.3V Power pin for video DAC circuitry

140 AGNDC Analog Ground Analog 3.3V Ground

141 DACVDDA Power 3.3V Power pin for video DAC circuitry

142 Y / G Analog Green, Y, SY or CVBS

143 AGNDB Analog Ground Analog 3.3V Ground

144 B / CB / PB Analog Blue, CB / PB or SC

145 R / CR / PR Analog Red, CR / PR, CVBS or SY

146 AADVSS Analog Ground Analog 3.3V Ground

147 AKIN2 GPIO19 Analog

148 ADVCM GPIO20 Analog

149 AKIN1 GPIO21 Analog

150 AADVDD Power 3.3V Power pin for 2ch audio ADC circuitry

151 APLLVDD3 Power 3.3V Power pin for audio clock circuitry

152 APLLCAP Analog InOut APLL external capacitance connection

NAME

Alternative

Function

Type Description

Analog /

Digital Output

1.Bandgap reference voltage

2.GPO14

1. Audio ADC input 2

2. MCDATA

3. Audio Mute

4. HSYN / VSYN output

5. SPDIF output 2

6. GPIO

1.Hotplug

2.GPIO

1.Audio ADC input 1

2.Audio Mute

3.HSYN / VSYN output

4.GPIO

4 – 2

Page 15

U5 VHIMT1389GF-1Q : High Definition DVD Player SOC with HDMi (3/9)

HT-CN9900DVW

Pin

No.

153 APLLVSS Analog Ground Analog 3.3V Ground

154 ADACVSS2 Analog Ground Analog 3.3V Ground

155 ADACVSS1 Analog Ground Analog 3.3V Ground

156 ARF / LFE GPIO Analog Output

157 ARS GPIO Analog Output

158 AR GPIO Analog Output

159 AVCM Analog Audio DAC reference voltage

160 AL GPIO Analog Output

161 ALS GPIO Analog Output

162 ALF / CENTER GPIO Analog Output

163 ADACVDD1 Analog Power 3.3V Power pin for audio DAC circuitry

164 ADACVDD2 Analog Power 3.3V Power pin for audio DAC circuitry

165 AVDD18_1 Analog Power Analog 1.8V power

167 AGND18 Analog Ground Analog 1.8V Ground

79,

109

38,57,

67,92,

101

98 DVSS18 Ground 1.8V ground pin for internal digital circuitry

96 DVSS33 Ground 3.3V ground pin for internal digital circuitry

NAME

DVDD18 Power 1.8V power pin for internal digital circuitry

DVDD33 Power 3.3V power pin for internal digital circuitry

Alternative

Function

Type Description

1.Audio DAC sub-woofer channel output

2.While internal audio DAC not used

a.ACLK

b.HSYN / VSYN output

c.GPIO

1.Audio DAC right surround channel output

2.While internal audio DAC not used

a.ABCK

b.HSYN / VSYN output

c.GPIO

1.Audio DAC right channel output

2.While internal audio DAC not used

a.SDATA2

b.RXD2

c.GPIO

1.Audio DAC left channel output

2.While internal audio DAC not used

a.SDATA1

b.TXD2

c.GPIO

1.Audio DAC left surround channel output

2.While internal audio DAC not used

a.ALRCK

b.GPIO

1.Audio DAC center channel output

2.While internal audio DAC not used

a.ASDATA0

b.Audio Mute

c.GPIO

General Power (7)

General Ground (2)

Micro Controller, Flash Interface and GPIO (11)

4 – 3

Page 16

HT-CN9900DVW

U5 VHIMT1389GF-1Q : High Definition DVD Player SOC with HDMi (4/9)

Pin

No.

46 GPIO3 INT#

47 GPIO4

43 GPIO6

35 SF_CS_

36 SF_DO

37 SF_DI

39 SF_CK

40 UP1_6 SCL

41 UP1_7 SDA

44 PRST#

45 IR GPI

68 RD0

69 RD1

70 RD2

71 RD3

72 RD4

73 RD5

74 RD6

75 RD7

NAME

Alternative

Function

Type Description

InOut

8mA, SR

SMT

InOut

4mA, PD

InOut

4mA, PD

InOut

8mA, SR

PU, SMT

InOut

8mA, SR

PD, SMT

InOut

8mA, SR

PU, SMT

InOut

8mA, SR

PD, SMT

InOut

4mA, SR

PU, SMT

InOut

4mA, SR

PU, SMT

Input

4mA, SR

PU, SMT

Input

4mA, SR

SMT

Dram Interface (37) (Sorted by position)

InOut

2mA

InOut

2mA

InOut

2mA

InOut

2mA

InOut

2mA

InOut

2mA

InOut

2mA

InOut

2mA

1.General purpose IO 3

2.Microcontroller port 3-1

3.Microcontroller external interrupt 1

1.General purpose IO 4

2.SD_CLK set B

3.Microcontroller port 3-4 (Internal Pull-up)

1.General purpose IO 6

2.Microcontroller port 3-5 (Internal Pull-up)

1.Serial Flash Chip Select

2.Trap value in power-on reset:

1: Serial Flash ATMEL mode

0: Serial ST / SST mode

Serial Flash Dout

1.Serial Flash Din

2.Trap value in power-on reset:

1: Manufactory Test Mode

0: Normal Operation

Serial Flash Clock

1.Microcontroller port 1-6

2.1²C clock pin

3.Trap value in power-on reset:

1: Manufactory test mode

0: Normal operation

1.Microcontroller port 1-7

2.1²C data pin

3.Trap value in power-on reset:

1: Manufactory test mode

0: Normal operation

Power on reset input, active low

1.IR control signal input

2.GPI

DRAM data 0

DRAM data 1

DRAM data 2

DRAM data 3

DRAM data 4

DRAM data 5

DRAM data 6

DRAM data 7

4 – 4

Page 17

U5 VHIMT1389GF-1Q : High Definition DVD Player SOC with HDMi (5/9)

HT-CN9900DVW

Pin

.

No

76 DQM0

77 RD15

78 RD14

80 RD13

81 RD12

82 RD11

83 RD10

84 RD9

85 RD8

86 DQM1

87 RCLK

88 RA11

89 RA9

90 RA8

91 RD7

93 RA6

94 RA5

95 RA4

97 RWE#

99 CAS#

100 RAS#

102 BA0

103 BA1

104 RA10

105 RA0

106 RA1

107

108 RA3

NAME

RA2

Alternative

Function

Type Description

InOut

2mA, PD

InOut

2mA

InOut

2mA

InOut

2mA

InOut

2mA

InOut

2mA

InOut

2mA

InOut

2mA

InOut

2mA

InOut

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

Output

2mA, PD

Output

2mA, PD

Output

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

InOut

2mA, PD

Data mask 0

DRAM data 15

DRAM data 14

DRAM data 13

DRAM data 12

DRAM data 11

DRAM data 10

DRAM data 9

DRAM data 8

Data mask 1

DRAM clock

DRAM address bit 11

DRAM address 9

DRAM address 8

DRAM address 7

DRAM address 6

DRAM address 5

DRAM address 4

DRAM Write enable, active low

DRAM column address strobe, active low

DRAM row address strobe, active low

DRAM bank address 0

DRAM bank address 1

DRAM address 10

DRAM address 0

DRAM address 1

DRAM address 2

DRAM address 3

4 – 5

Page 18

HT-CN9900DVW

U5 VHIMT1389GF-1Q : High Definition DVD Player SOC with HDMi (6/9)

Pin

No.

66 GPIO7 CKE

65 GPIO8

64 GPIO9

111 GPIO10

42 GPIO11

38 SPDIF GPIO12

63 GPIO13

26 YCLK

27 DV_Y0

28 DV_Y1

29 DV_Y2

30 DV_Y3

31 DV_Y4

32 DV_Y5

NAME

Alternative

Function

Type Description

1. GPIO7

2. DRAM Clock Enable

I nO ut

4mA, PD

GPIO (29)

I nO ut

4mA, PD

I nO ut

4mA, PD

I nO ut

4mA, PD

InOut

4mA

I nO ut

2mA, PD

I nO ut

4mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

3. MS_CLK set A

4. SD_CLK set A

5. HSYN / VSYN input

6. Microcontroller port 1~4 (Internal Pull-Up)

1. GPIO8

2. MS_BS set A

3. SD_CMD set A

4. ASDATA2

5. ACLK

6. Audio Mute

7. HSYN / VSYN input

8. Microcontroller port 1~5 (Internal Pull-Up)

1. GPIO9

2. MS_D0 set A

3. SD_D0 set A

4. ASDATA2

5. ABCK

6. RXD1

1. GPIO10

2. ASDATA0

3. ALRCK

4. HSYN / VSYN output

5. TXD1

1. GPIO11

2. SD_CMD set B

3. MS_BS set B

4. Audio Mute

5. HSYN / VSYN output

6. Microcontroller port 3-0 (Internal Pull-Up)

1. SPDIF output

2. GPIO12

1. GPIO13

2. SD_D0 set B

3. ALRCK

4. Audio Mute

GPIO

GPIO

GPIO

GPIO

GPIO

GPIO

GPIO

4 – 6

Page 19

U5 VHIMT1389GF-1Q : High Definition DVD Player SOC with HDMi (7/9)

HT-CN9900DVW

Pin

No.

33 DV_Y6

34 DV_Y7

48 DV_C0

49 DV_C1

50 DV_C2

51 DV_C3

52 DV_C4

53 DV_C5

54 DV_C6

55 DV_C7

56 SD_MS_CLK

58 SD_MS_CMD

59 SD_MS_D0

60 SD_MS_D1

61 SD_MS_D2

62 SD_MS_D3

NAME

Alternative

Function

Type Description

I nO ut

2mA, PD

I nO ut

2mA, PD

I nO ut

4mA, PD

I nO ut

4mA, PD

I nO ut

4mA, PD

I nO ut

4mA, PD

I nO ut

4mA, PD

I nO ut

4mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

I nO ut

2mA, PD

GPIO

GPIO

GPIO

GPIO

GPIO

GPIO

1) GPIO

2) SD_D2

1) GPIO

2) SD_D3

GPIO

GPIO

1) GPIO

2) SD_CLK

3) MS_CLK

1) GPIO

2) SD_CMD

3) MS_BS

1) GPIO

2) SD_D0

3) MS_D0

1) GPIO

2) SD_D1

3) MS_D1

1) GPIO

2) SD_D2

3) MS_D2

1) GPIO

2) SD_D3

3) MS_D3

Notes:

1. The Main column is the main function, Alt. means alternative function.

2. The multi-function GPIO pins are set to green characters.

4 – 7

Page 20

HT-CN9900DVW

U5 VHIMT1389GF-1Q : High Definition DVD Player SOC with HDMi (8/9)

HDMI 1.2 Tx

HDMI Tx

DVD

PUH

Module

Motor

Drive

FLASH

ROM

DRAM

RF Amplifier

Servo IO

Spindle

Control

Memory

Controller

Debug

Port

Servo

Processor

Audio

DSP

System

Parser

CPPM/CPRM

DRM

108MHz

TV Encoder

Video

Processor

Video Decoder

Audio

Ouptut

Video DAC

interlacer

MPEG-1/2

JPEG

Audio DAC

De-

PCM

CVBS, Y/C

Component

Video

Digital Video

External

Audio DAC

GPIO

IR/VFD

System

CPU

32-bit

RISC

USB2.0

MS/SD/MMC

Controller

Figure 4-1 BLOCK DIAGRAM OF IC

SPDIF

USB

device

MS/SD/MMC

Card

4 – 8

Page 21

U5 VHIMT1389GF-1Q : High Definition DVD Player SOC with HDMi (9/9)

Figure 4-2 BLOCK DIAGRAM OF IC

RFF

RFE

RFD

RFC

RFB

RFA

RFH / OPINN

RFG / OPINP

RFIN / OPOUT

RFIP

AGND1

8

AVDD18_1

ADACVDD2

ADACVDD1

CENTER / GPIO

ALS / GPIO

AL / GPIO

AVCM

AR / GPIO0

ARS

/ GPIO

LFE / GPIO

ADACVSS1

ADACVSS2

APLLVSS

APLLCAP

APLLVDD

AADVDD

AKIN1 / GPIO21

ADVCM / GPIO20

AKIN2 / GPIO19

AADVSS

R

B

AGNDC

G

DACVDDA

AGNDC

DACVDDB

CVBS

DACV

SSC

FS

VREF / GPIO14

DACVDDC

NC

176

175

174

17

3

172

171

170

169

168

167

166

165

164

163

162

161

160

159

158

157

156

155

154

15

3

152

151

150

149

148147

146

145

144

143

142

141

140

139

138137

136

1

3

5

134

1

33

AVDD18_2 1 132NC

AVDD33_1 2 131NC

XTALI 3 130NC

XTALO 4 129 NC

AGND33 5 128 AGND18_TXD

V20 6 127 TX2P

V14 7 126 TX2N

REXT / GPO5 8 125 AVDD18_TX0

MDI1 9 124 TX1P

LDO1 10 123 TX1N

LDO2 11 122 AGND18_TX1

AVDD33_2 12 121 TX0P

DMO

13 120 TX0N

FMO 14 119 AVDD18_TX1

TRAY_OPEN 15 118 TXCP

TRAY_CLOSE16 117 TXCN

TRO 17 116 AGND18_TX2

FOO 18 115 AGND33_TX

FG / GPIO2 19 114 AVDD33_VPLL

USB_DP 20 113 EXT_RES

USB_DM 21 112 AGND33_VPLL

VDD

33_USB22 111 GPIO10 / HPLG

VSS33_U

SB23 110 SPDIF / GPIO12

PAD_VRT 24 109 DVDD18

VDD18_USB25 108 RA3

YCLK 26 107 RA2

DV_Y0 27 106 RA1

DV_Y1 28 105 RA0

DV_Y2 29 104 RA10

DV_Y330 103 BA1

DV_Y4 31 102 BA0

DV_Y5 32 101 DVDD33

DV_Y6 33 100 RAS_

DV_Y7 34 99 CAS_

SF_CS_ 35 98 GND18

SF_DO 36 97 RWE_

SF_DI 37 96 GND33

DVDD33 38 95 RA4

SF_CK 3

9 94 RA5

UP1_6 / SCL 40 93 RA6

UP1_7 / SDA 41 92 DVDD33

GPIO11 42 91 RA7

GPIO6 43 90 RA8

PRS

T_ 44 89RA9

45

4647484950515253

545556

57

58

59

606162

63

64

65

666768

697071

72

73

74

75

76

77

78

79

80

81

82

83

8485

86

8788

IR

GPIO3

/ INT

GPIO4

DV_C0

DV_C1

DV_C2

DV_C

3

DV_C4

DV_C5

DV_C6

DV_C7

S

D_M

S_CLK

DVDD

33

SD_M

S

_CMD

SD_M

S_DO

SD_MS_D1

SD_M

S

_D2

SD_MS_D3

GPIO13

GPIO9

GPIO8

GPIO7 / CKE_

DVDD

33

RD0

RD1

RD2

RD3

RD4

RD5

RD6

RD7

DQM0

RD15

RD14

DVDD18

RD1

3

RD12

RD11

RD10

RD9

RD8

DQM1

RCLK

RA1

1

MT1389M

HT-CN9900DVW

4 – 9

Page 22

HT-CN9900DVW

VFD701 VVKHLD1321W-1

GRID ASSIGNMENT

OUTER DIMENSIONS

PATTERN AREA

131

[2] VFD Display

4 – 10

Page 23

CHAPTER 5. CIRCUIT DESCRIPTION

U5

U5

U5

U5

13

14

U5

U5

U5

U5

U2

U5

U2

Figure 1

Figure 2

Figure 3 Figure 4

Figure 5 Figure 6

R OUT

L OUT

TRO

FMO

FOO

MD11

Pin 15

LD01

LD02

DMO

1

2

17

18

3

4

9

15

5

6

10

11

7

8

24

9

23

10

168

11

RF

168

U5

12

44

U5

13

RF

RESET

Figure 7 Figure 8

[1] Waveform Of Servo Circuit

HT-CN9900DVW

5 – 1

Page 24

HT-CN9900DVW

14

CVBS OUT

138

U5

Figure 9

5 – 2

Page 25

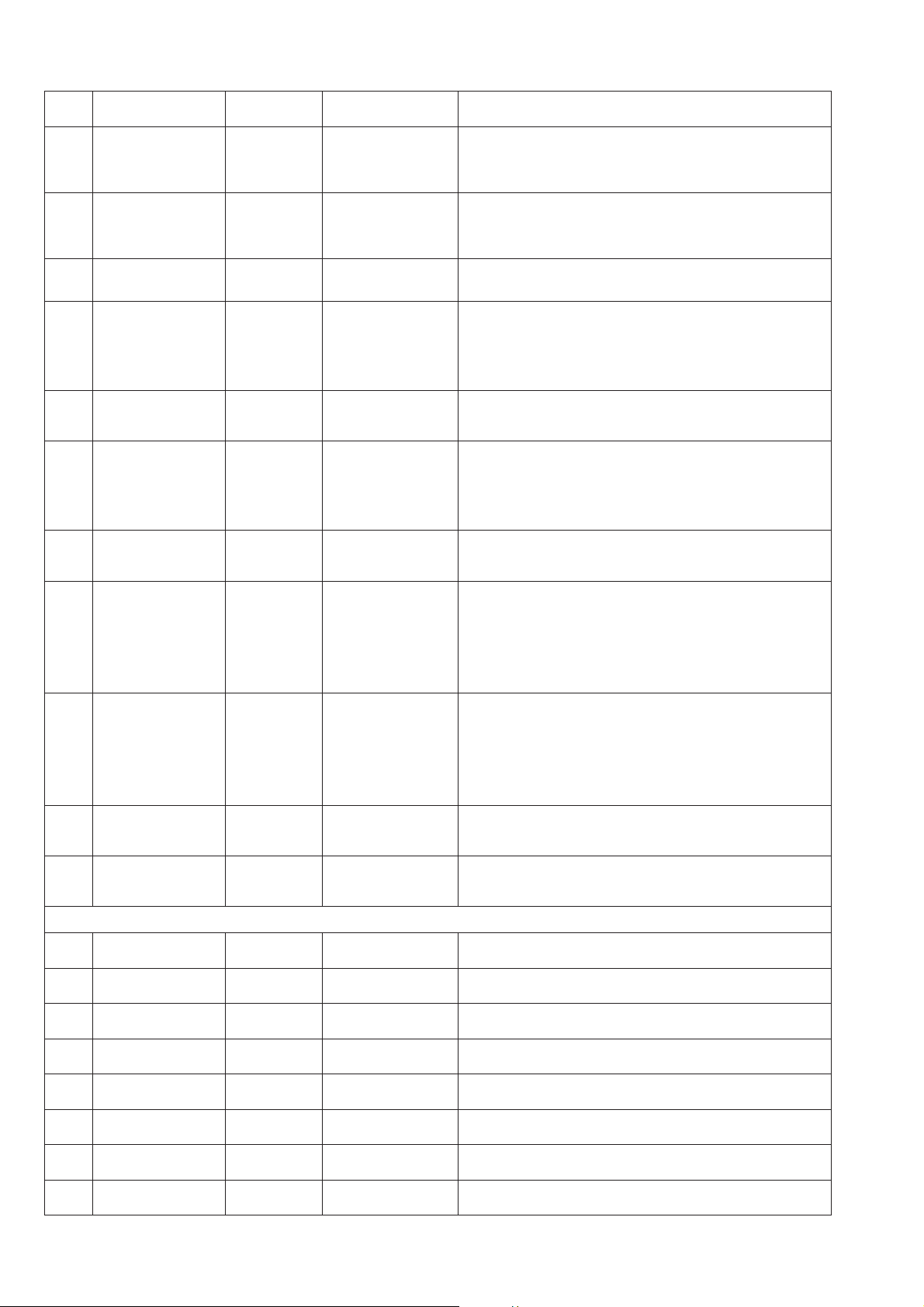

[2] Voltage

1 0.000 9 0.026

2 0.023 10 0.021

3 0.000 11 2.429

4 1.873 12 0.000

5 0.045 13 0.000

6 0.000 14 0.203

7 0.000 15 0.766

8 0.000 16 6.080

1 1.245 45 5.120 89 0.006 133 0.001

2 3.306 46 2.623 90 0.005 134 3.306

3 0.773 47 2.739 91 0.005 135 3.305

4 0.473 48 3.292 92 3.303 136 0.741

5 0.000 49 3.292 93 0.059 137 0.000

6 1.976 50 3.292 94 0.055 138 0.000

7 1.397 51 1.777 95 0.059 139 3.286

8 1.245 52 0.002 96 0.005 140 3.306

9 0.000 53 0.005 97 3.300 141 0.000

10 3.254 54 0.013 98 0.003 142 0.000

11 3.254 55 0.005 99 3.299 143 0.000

12 3.291 56 0.013 100 3.297 144 0.000

13 1.391 57 3.303 101 3.303 145 0.001

14 1.391 58 0.005 102 0.052 146 2.290

15 0.000 59 1.759 103 0.003 147 2.209

16 0.000 60 0.005 104 0.005 148 0.001

17 1.393 61 0.004 105 0.028 149 1.658

18 1.396 62 0.004 106 0.030 150 1.629

19 0.000 63 0.003 107 0.059 151 3.306

20 0.010 64 0.019 108 1.293 152 3.305

21 0.012 65 3.287 109 1.313 153 0.001

22 3.304 66 2.588 110 0.002 154 0.001

23 0.000 67 3.303 111 0.003 155 0.001

24 0.000 68 0.004 112 0.002 156 1.635

25 1.338 69 0.003 113 3.299 157 1.644

26 0.014 70 0.003 114 3.303 158 0.002

27 2.654 71 0.004 115 0.000 159 1.510

28 3.304 72 0.003 116 0.000 160 0.002

29 0.026 73 0.003 117 0.001 161 1.651

30 0.018 74 0.004 118 0.001 162 0.001

31 0.019 75 0.005 119 1.342 163 3.301

32 0.005 76 3.301 120 0.826 164 3.301

33 3.324 77 0.005 121 0.791 165 1.240

34 3.324 78 0.005 122 0.000 166 0.000

35 3.295 79 1.313 123 0.839 167 0.000

36 0.005 80 0.006 124 1.342 168 0.000

37 0.005 81 0.006 125 1.318 169 1.577

38 3.304 82 0.006 126 0.432 170 1.576

39 0.016 83 0.006 127 0.731 171 0.462

40 0.005 84 0.006 128 0.000 172 0.462

41 0.005 85 0.006 129 0.000 173 0.453

42 3.305 86 2.937 130 0.013 174 0.456

43 3.304 87 1.505 131 0.016 175 0.042

44 3.282 88 0.016 132 0.002 176 0.041

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

U2

U5

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

HT-CN9900DVW

5 – 3

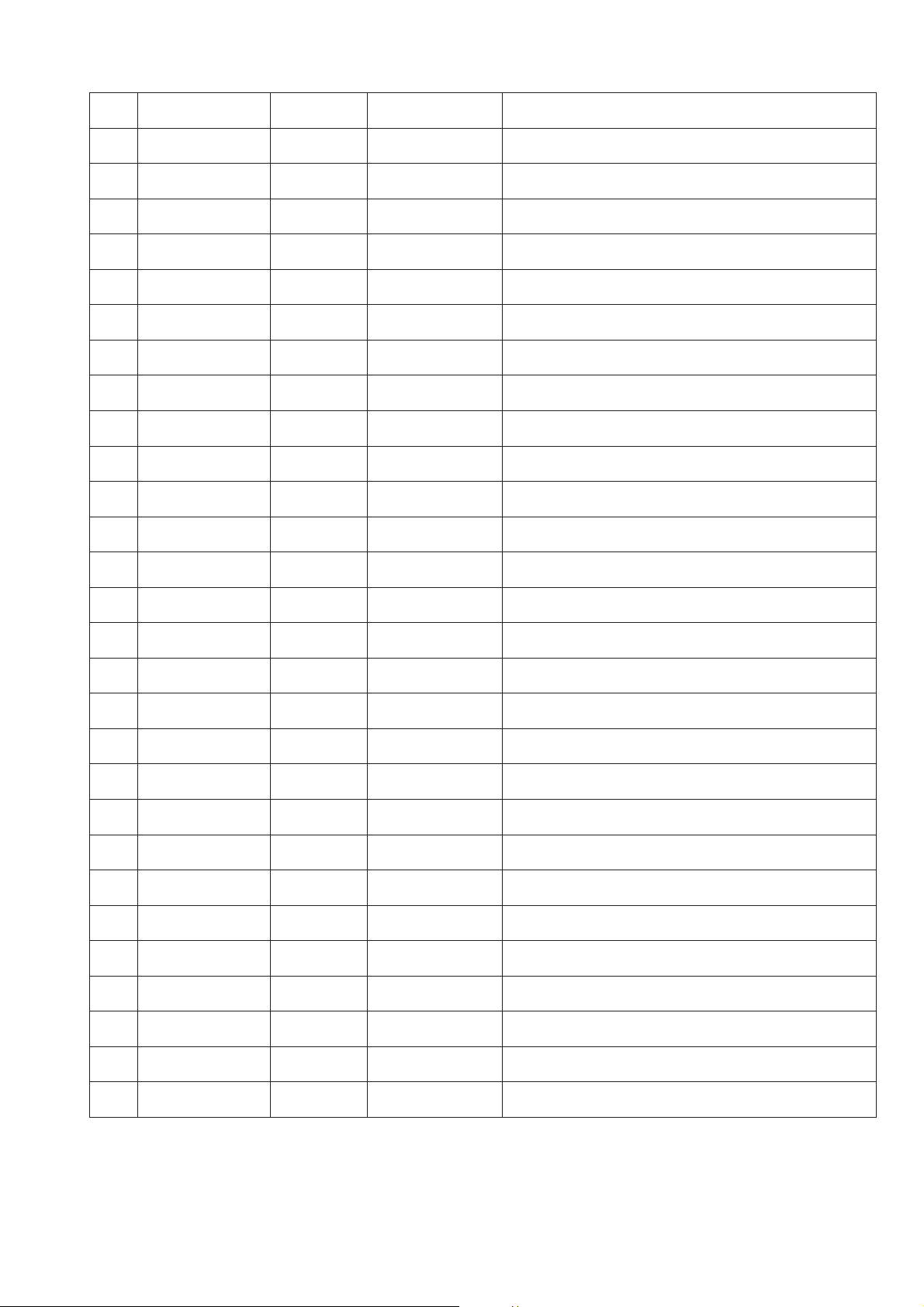

Page 26

HT-CN9900DVW

PINNOVOLTAGE

1 3.304 15 3.302 29 1.115 43 3.299

2 0.002 16 3.300 30 1.113 44 0.524

3 3.304 17 3.301 31 1.088 45 0.522

4 0.002 18 3.298 32 0.043 46 0.001

5 0.002 19 0.000 33 0.008 47 0.544

6 0.000 20 0.001 34 0.009 48 0.559

7 0.002 21 0.001 35 0.010 49 3.299

8 0.002 22 0.004 36 0.023 50 0.622

9 3.304 23 0.001 37 3.296 51 0.618

10 0.002 24 0.001 38 1.507 52 0.001

11 0.002 25 0.001 39 2.725 53 0.588

12 0.000 26 0.001 40 0.036 54 0.001

13 0.002 27 3.394 41 0.001

14 3.304 28 0.000 42 0.001

(V)

PINNOVOLTAGE

(V)

U4

PIN

NO

VOLTAGE

(V)

PINNOVOLTAGE

(V)

U10

PINNOVOLTAGE

(V)

1 1.394 1 0.000 13 0.000 25 3.301

2 5.000 2 0.000 14 0.000 26 3.307

3 1.414 3 0.000 15 36.770 27 3.307

4 1.392 4 36.770 16 0.000 28 3.310

5 1.425 5 0.000 17 0.000 29 0.012

6 0.001 6 0.000 18 0.005 30 0.009

7 0.108 7 36.770 19 0.000 31 0.001

8 0.000 8 0.003 20 0.013 32 0.001

9 5.230 9 0.003 21 4.890 33 24.980

10 0.000 10 0.000 22 4.890 34 24.980

11 0.000 11 0.000 23 3.313 35 36.770

12 1.579 12 36.770 24 0.000 36 36.770

13 1.579

14 1.475

15 1.475

16 1.475

17 1.475 1 0.000 13 0.000 25 3.301

18 1.463 2 0.000 14 0.000 26 3.307

19 1.463 3 0.000 15 36.770 27 3.307

20 5.230 4 36.770 16 0.000 28 3.310

21 1.915 5 0.000 17 0.000 29 0.012

22 5.230 6 0.000 18 0.005 30 0.009

23 0.000 7 36.770 19 0.000 31 0.001

24 0.000 8 0.003 20 0.013 32 0.001

25 0.347 9 0.003 21 4.890 33 24.980

26 5.200 10 0.000 22 4.890 34 24.980

27 5.210 11 0.000 23 3.313 35 36.770

28 0.142 12 36.770 24 0.000 36 36.770

29 0.002

30 0.002

U9

PINNOVOLTAGE

(V)

1 3.290 3 3.302 3 5.230

2 3.321 4 0.000

3 0.004 5 0.002

4 0.000 6 0.001

PIN

VOLTAGE

NO

PINNOVOLTAGE

PINNOVOLTAGE

1 3.295 1 0.000

2 0.002 2 3.306

7 3.302

8 3.306 1 0.000

(V)

(V)

U14 U12

(V)

U6

PINNOVOLTAGE

(V)

U7

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

U13

PINNOVOLTAGE

(V)

2 1.342

3 4.490

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

5 – 4

Page 27

HT-CN9900DVW

1 0.000 13 0.000 25 3.301 1

11.520

2 0.000 14 0.000 26 3.307 2

11.490

3 0.000 15 36.770 27 3.307 3

12.030

4 36.770 16 0.000 28 3.310 4

0.000

5 0.000 17 0.000 29 0.012 5

12.030

6 0.000 18 0.005 30 0.009 6

11.480

7 36.770 19 0.000 31 0.001 7

11.540

8 0.003 20 0.013 32 0.001 8

12.050

9 0.003 21 4.890 33 24.980

10 0.000 22 4.890 34 24.980

11 0.000 23 3.313 35 36.770

12 36.770 24 0.000 36 36.770

1 0.000 17 0.000 33 0.000 49 0.010

2 0.000 18 0.000 34 0.000 50 0.000

3 3.300 19 3.298 35 3.303 51 0.000

4 0.000 20 3.298 36 0.000 52 3.302

5 0.000 21 0.854 37 0.007 53 0.000

6 0.002 22 0.860 38 0.001 54 0.000

7 0.002 23 0.000 39 0.001 55 3.302

8 0.002 24 0.004 40 0.001 56 0.000

9 1.234 25 3.295 41 0.014 57 0.000

10 1.650 26 1.648 42 0.009 58 3.303

11 1.644 27 0.000 43 0.012 59 0.000

12 3.300 28 3.300 44 3.303 60 0.000

13 0.000 29 0.000 45 0.000 61 0.000

14 0.000 30 0.000 46 0.000 62 0.000

15 3.297 31 0.000 47 0.002 63 0.000

16 0.000 32 0.000 48 0.002 64 3.298

1

2.484

14

-27.290

27

-29.140

40

0.000

2

0.000

15

0.024

28

-24.740

41

0.000

3

0.000

16

-27.310

29

-27.140

42

0.000

4

0.000

17

-27.300

30

-20.050

43

0.000

5

0.000

18

1.525

31

-27.160

44

2.936

6

0.000

19

-27.28

32

-26.810

45

3.240

7

0.000

20

-30.030

33

-20.050

46

0.000

8

5.060

21

5.070

34

-27.140

47

3.389

9

-27.450

22

-29.350

35

-24.820

48

3.389

10

-27.450

23

-27.330

36

-29.530

49

1.210

11

-27.320

24

-29.700

37

-22.430

50

5.060

12

-27.320

25

-17.820

38

-17.310

51

5.060

13

-27.320

26

-22.560

39

5.070

52

1.322

1

3.270

2

0.000

3

5.050

U11

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

VOLTAGE

(V)

U701

PINNOVOLTAGE

(V)

VOLTAGE

(V)

U8

U501

PINNOVOLTAGE

(V)

PIN

NO

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

VOLTAGE

(V)

PIN

NO

PIN

NO

U702

VOLTAGE

(V)

VOLTAGE

(V)

PIN

NO

VOLTAGE

(V)

PIN

NO

PIN

NO

5 – 5

Page 28

HT-CN9900DVW

1

0.400m

11

0.300m

1

0.100m

B

2.429

2

0.300m

12

1.636

2

3.300

C

5.220

3

0.600m

13

3.286

3

5.210

E

1.737

4

0.200m

14

0.400m

5

3.066

15

1.638

6

0.600m

16

1.638

7

1.643

17

1.628

8

0.200m

18

1.637

B

0.685

G

0.029

9

1.630

19

1.633

C

0.030

D

0.000

10

1.632

20

0.000

E

0.000

S

0.000

G

2.160

B

0.014

G

5.080

B

3.289

D

5.140

C

5.100

D

0.000

C

3.290

S

3.387

E

0.000

S

0.000

E

3.303

B

0.645

B

0.030

B

3.288

B

0.648

C

20.700m

C

5.100

C

3.291

C

0.026

E

0.000

E

0.000

E

3.301

E

0.000

B

3.304

B

3.304

B

3.982

B

26.10m

C

262.50m

C

64.0m

C

5.110

C

3.298

E

3.306

E

3.306

E

3.282

E

0.000

B

5.200

G

0.001

B

0.570

C

5.040

D

2.731

C

0.026

E

0.531

S

0.525

E

0.000

Q18

PINNOVOLTAGE

(V)

Q19

PINNOVOLTAGE

(V)

Q14

PINNOVOLTAGE

(V)

Q20

PINNOVOLTAGE

(V)

Q21

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

Q17

PINNOVOLTAGE

(V)

Q16

Q3

PINNOVOLTAGE

(V)

Q12

PINNOVOLTAGE

(V)

Q13

PINNOVOLTAGE

(V)

Q7

PINNOVOLTAGE

(V)

Q9

PINNOVOLTAGE

(V)

IC2

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

PINNOVOLTAGE

(V)

IC1

PINNOVOLTAGE

(V)

PIN

NO

Q4

PINNOVOLTAGE

(V)

Q10

Q11

PINNOVOLTAGE

(V)

Q15

VOLTAGE

(V)

PINNOVOLTAGE

(V)

Q1

Q2

5 – 6

Page 29

-MEMO-

HT-CN9900DVW

5 – 7

Page 30

HT-CN9900DVW

CHAPTER 6. DIAGRAM

[1] Block Diagram

Fan

FR SPK

FM ANT

AMP

Pack

Tuner

FLASH

EN25B160

AT25FS160/

FL SPK

AMP

STA51 0

CEN SPK

P

AMP AMP

SR SPK

STA510

+30V

+3.3V

+1.2V

SL SPK

PCM

AMP

1117Y33L

1117H12E

SUB SPK

AMP

STA510

SMPS

+5.0V

IIS and DATA

OUTPUT

DATA

SW

VIDEO

HDMI

AUDIO

DATA

DATA

AUDIO

DATA

2

MIC

1

MIC

DOOR

PICK UP

HEADER

DATA

DISC

MOTOR

UX

IN

LR

A

IN

AUX

BM

WM8782

CD4052

MOTOR

MOTOR

AN5888

Motor drive

SDRAM

EM638165

Figure 6-1: BLOCK DIAGRAM

6 – 1

Page 31

HT-CN9900DVW

•Resistor:

To differentiate the units of resistors, such symbol as

K and M are used: the symbol K means 1000 ohm

and the symbol M means 1000 kohm and the

resistor without any symbol is ohm-type resistor.

Besides, the one with “Fusible” is a fuse type

• Capacitor:

To indicate the unit of capacitor, a symbol P is used:

this symbol P means pico-farad and the unit of the

capacitor without such a symbol is microfarad. As to

electrolytic capacitor, the expression “capacitance/

withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board

for this model are subject to change for

improvement without prior notice.

• The indicated voltage in each section is the one

measured by Digital Multimeter between such a

section and the chassis with no signal given.

• Parts marked with “ ” are important for

maintaining the safety of the set. Be sure to replace

these parts with specified ones for maintaining the

safety and performance of the set.

PWB Switch Location

!

REF. NO DESCRIPTION POSITION

SW701 POWER ON/STAND-BY ON—OFF

SW702 STOP

SW703

SW704

ON—OFF

PLAY / PAUSE ON—OFF

OPEN / CLOSE

ON—OFF

TOP VIEW FRONT VIEW

KTC3875GR

KN3904S

KN3906S

SMPS8550S

SMPS8050S

PST8229U

2SK3018 (MOSFET)

BAV99

304VT

DA1010

TOP VIEW

TOP VIEW

TOP VIEW

EXA704WJ

EXA001

B

(2)

G

(2)

E

(1)

S

(1)

C

(3)

D

(3)

TOP

VIEW

TOP

VIEW

KTC4375Y

A2012

B

(1)

E

(3)

C

(2)

TOP

VIEW

1117Y33L

1117H12E

GND

Vin

Vout

TOP

VIEW

TOP

VIEW

GNDOUT

VDD NC

14

23

A

C

(1)

(2)

(3)

BAT54C

ANODE (1)

ANODE (2)

(3) CATHODE

A

C

CHAPTER 7. CIRCUIT SCHEMATICS AND PARTS LAYOUT

[1] Notes On Schematic Diagram

[2] Types Of Transistor And LED

7 – 1

Page 32

HT-CN9900DVW

FAULT

CON2

3P53254

FAULT

/FAULT

[3] Schematic Diagram

MAIN/AMP PWB-A1

A

MAIN SECTION

FAULT

B

CON2

3P53254

C

TO

MECHA ASS’Y

D

E

/FAULT

F

G

HDMI

OUT

FAULT

FROM

CD PICK-UP

UNIT

FROM

USB PWB-A4

Bi401

USB SIGNAL

AUDIO SIGNAL

VIDEO SIGNAL

H

1

2 3 456

TO

SMPS PWB-B

FROM

MIC PWB-A3

Bi501

FROM

LOADER

FROM

DISPLAY PWB-A2

7

8 9 10 11 12

CD SIGNAL

Figure 7-1: MAIN/AMP (MAIN SECTION) SCHEMATIC DIAGRAM

7 – 2

Page 33

MAIN/AMP PWB-A1

FAULT

HT-CN9900DVW

A

AMPLIFIER SECTION

B

C

D

TO

HOME THEATER

SPEAKER SYSTEM

E

F

FAULT

G

FROM

SMPS PWB-B

AUDIO SIGNAL

H

1

2 3 456

Figure 7-2: MAIN/AMP (AMP SECTION) SCHEMATIC DIAGRAM

7

8 9 10 11 12

7 – 3

Page 34

HT-CN9900DVW

B544AWPZ

C402

39P

C403

39P

0.047u

A

B

C

TO

SMPS PWB-B

DISPLAY PWB-A2

MIC PWB-A3

TO

MAIN/AMP PWB-A1

MIC IN 1MIC IN 2

0.047u

D

AUDIO SIGNAL

USB PWB-A4

E

FROM

USB EXTERNAL

F

DEVICE ONLY

USB SIGNAL

G

39P

C402

B544AWPZ

39P

C403

TO

MAIN/AMP PWB-A1

CON6

TO

H

1

2 3 456

MAIN/AMP PWB-A1

7

8 9 10 11 12

Figure 7-3: DISPLAY, MIC & USB SCHEMATIC DIAGRAM

7 – 4

Page 35

[4] Charts Of Connecting Wires

HT-CN9900DVW

SUBWOOFER

A

FM ANTENNA

VIDEO OUT

AUX IN

SURROUND

L-Ch

R-Ch

CENTER

L-Ch

FRONT

R-Ch

MIC 2 MIC 1

US B IN

HDMI IN

SW SL SR CEN FL FR

RCA3

1234

B

TU301

HA1

CON1

241

HDMI

RCA2

Bi2

RD

1234

BK

BK

BK

SP1

PK

GY

WH

BK

1234

GY

MIC502

Bi501

1234

BKWHGY

MIC501

PK

MIC PWB-A3

241

241

Bi1

1

2

RDBKBKBKBKBKBK

FROM

SMPS PWB-B

CON4

6543

89

7

BK

CNS4

RDWHBLWHBL

CN6

FROM

CD/DVD PICK-UP

UNIT

54321

6

543216

CON5 CON6

4321

4321

CNS5

WH

RDBLBK

BL

FROM

CD/DVD LOADER

CON7

5

5

BK

CNS401

BKPKWH

4321

4321

YL

4321765

4321765

CNS702

RDBKBKBKBKBKBK

CON2

MAiN / AMP PWB-A1

YLBKRD

SHIELD WIRE

C

FFC1

TO

D

MECHANISM

BK

TO

CHASSIS

(GND)

LUG402

LUG401

JK401

BI401

BKPKWH

GY

43215

YL

USB PWB-A4

COLOR TABLE

RD

BK

WH

RED

BLACK

WHITE

GY GRAY

BL BLUE

FAN

SHIELD WIRE

E

BR BROWN

PK PINK

YL YELLOW

F

DISPLAY PWB-A2

G

H

1

VOL701

CNS2

BK

BK

Bi1

BK

RD

BK

BK

BK

RD

BK

BK

BK

BK

BK

BK

BK

RD

BKBKBKBKBK

BK

1

LUG701

VFD701

3

1

BKBKBK

RD

RD

4321765

4321

Bi701

Bi702

1

FROM

MAiN / AMP PWB-A1

23456

CNS701

1

2

3

4

CNS1

1

2

3

4

8

567

1234

1

2

CN4

3

4

1

CN5CN6

2

3

4

8

567

1234

7

SMPS PWB-B

*Not Serviceable Item

BR

BL

1

2

L

1

CN1

2N

AC POWER SUPPLY CORD

AC 240V, 60Hz

8 9 10 11 12

Figure 7-4: WIRING CONNECTION

7 – 5

Page 36

HT-CN9900DVW

[5] Wiring Side Of PWB

A

MAIN/AMP PWB-A1

B

C

1234

D

E

F

123456

78

12345

1234

6

5

1234

1234

567

1234

G

Lead-free solder indication

H

Lead-free solder is used in the MAIN/AMP PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

2 3 456

Figure 7-5: WIRING SIDE OF MAIN/AMP PWB (TOP VIEW)

7

8 9 10 11 12

7 – 6

Page 37

HT-CN9900DVW

A

B

C

D

MAIN/AMP PWB-A1

E

F

G

Lead-free solder indication

H

Lead-free solder is used in the MAIN/AMP PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

2 3 456

Figure 7-6: WIRING SIDE OF MAIN/AMP PWB (BOTTOM VIEW)

7

8 9 10 11 12

7 – 7

Page 38

HT-CN9900DVW

A

DISPLAY PWB-A2

B

1

31

C

TOP VIEW

1234

D

1234567

E

F

BOTTOM VIEW

G

Lead-free solder indication

H

Lead-free solder is used in the DISPLAY PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

2 3 456

Figure 7-7: WIRING SIDE OF DISPLAY PWB

7

8 9 10 11 12

7 – 8

Page 39

HT-CN9900DVW

A

B

C

1234

D

TOP VIEW

USB PWB-A4MIC PWB-A3

12345

TOP VIEW

E

F

BOTTOM VIEW

G

BOTTOM VIEW

Lead-free solder indication

H

Lead-free solder is used in the MIC, USB PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

2 3 456

Figure 7-8: WIRING SIDE OF MIC & USB PWB

7

8 9 10 11 12

7 – 9

Page 40

PARTS GUIDE

!

CONTENTS

[1] INTEGRATED CIRCUITS

[2] TRANSISTORS

[3] DIODES

[4] COILS

[5] CRYSTALS / VIBRATORS

[6] CAPACITORS

[7] RESISTORS

[8] OTHER CIRCUITRY PARTS

[9] CABINET PARTS /

DVD MECHANISM PARTS

[10] SPEAKER BOX PARTS

[11] SUBWOOFER BOX PARTS

[12] ACCESSORIES / PACKING PARTS

[13] P.W.B. ASSEMBLY

[14] OTHER SERVICE PARTS

HOME THEATER WITH DVD

HT-CN9900DVW

MODEL

Singapore, Malaysia, Indonesia, Philippines and India]

HT-CN9900DVW Home Theater with DVD consisting of

HT-CN9900DVW (main unit), CP-CN9900F (front speakers),

CP-CN9900C (centre speaker), CP-CN9900R (surround

speakers) and CP-CN9900W (subwoofer).

HT-CN9900DVW

[For Jordan, Singapore-Export,

Explanation of capacitors/resistors parts codes

Capacitors

VCC ....................... Ceramic type

VCK ........................ Ceramic type

VCT ........................ Semiconductor type

VC • • MF ............... Cylindrical type (withoutleadwire)

VC • • MN ............... Cylindrical type (withoutleadwire)

VC • • TV ................ Square type (withoutleadwire)

VC • • TQ ............... Square type (withoutlead wire)

VC • • CY ............... Square type (withoutleadwire)

VC • • CZ ............... Square type (withoutlead wire)

VC•••••••••J..The13th character represents capacity difference.

("J" ±5%, "K" ±10%, "M" ±20%, "N" ±30%,

"C" ±0.25 pF, "D" ±0.5 pF, "Z" +80-20%.)

If there are no indications for the electrolytic capacitors,erroris ±20%.

Resi stors

VRD ....................... Carbon-film type

VRS ........................ Carbon-film type

VRN ....................... Metal-film type

VR • • MF ............... Cylindrical type (withoutleadwire)

VR • • MN ............... Cylindrical type (withoutlead wire)

VR • • TV ................ Square type (withoutlead wire)

VR • • TQ ............... Square type (withoutleadwire)

VR • • CY ............... Square type (withoutleadwire)

VR • • CZ ............... Square type (withoutleadwire)

VR•••••••••J..The13th character represents error.

("J" ±5%, "F" ±1%, "D" ±0.5%.)

If there are no indications for other parts,theresistorsare ±5%

carbon-film type.

Explanation of PWB Assembly parts code category

S Category -- Repair ( Component parts of PWB can be replace and repair, PWB no supply )

X Category -- Replacement ( PWB can not be repair. Component parts no supply )

S.X Category -- Repair and Replacement ( PWB can repair and replace )

KG Category -- Revolve repair by Business Center ( Return to Business Center and repair by manufacturer. Component parts no supply )

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones

for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 41

HT-CN9900DVW

NO. PARTS CODE

PRICE

RANK

[1] INTEGRATED CIRCUITS

IC1 VHIWM8782SR-1 AL Stereo ADC, WM8782

IC2 VHIUTC1117Y33 AD Voltage Regulator, 1117 - 3.3V

U2 VHICD4052BM-1 AE Analog Multiplexer, CD4052

U4 VHIEM638165-1 AR SDRAM 4Mx16

U5 VHIMT1389GF-1 BD DVD System-on-chip, MT1389GH

U6 VHISTA510A+-1 AT STA510LA, Amplifier IC

U7 VHISTA510A+-1 AT STA510LA, Amplifier IC

U8 VHISTA510A+-1 AT STA510LA, Amplifier IC

U9 VHIPST8229U-1 AC Reset IC, 2.9V

U10 VHISA5888TR-1 AG CD Driver, SA5888

U11 VHISTA309A+-1 AS STA309A Multi-channel Digital Audio Processor

U12 VHIUTC1117Y33 AD Voltage Regulator, 1117 - 3.3V

U13 VHIAZ1117H12E AE Voltage Regulator, 1117 - 1.2V

U14 RH-IXA317AW00 - 16M FLASH ROM (Not Replacement Item)

U501 VHIUTC4580E-1 AC Dual Operational Amplifier, 4580

U701 VHIPT6311LQ-1 AL FL Driver, 52 Pin

U702 VHLSIRC330M-1 AF Infrared Receiver Module

[2] TRANSISTORS

Q4 VSKN3904S//-1 AB Silicon,NPN,3904

Q5 VSKTC4375Y+-1 AE Silicon,NPN,KTC4375 Y

Q6 VS2SA2012++-1 AF Silicon,PNP,SA2012

Q7 VSKN3904S//-1 AB Silicon,NPN,3904

Q8 VSKTC3875GR-1 AB Silicon,NPN,KTC3875 GR

Q12 VSMPS8550S/-1 AB 8550S

Q13 VSMPS8550S/-1 AB 8550S

Q14 VSKN3906S//-1 AB Silicon,PNP,3906

Q15 VSKN3906S//-1 AB Silicon,PNP,3906

Q17 VS2SK3018//-1 AC N-CH MOSFET, 2SK3018

Q18 VSKN3904S//-1 AB Silicon,NPN,3904

Q19 VSKN3904S//-1 AB Silicon,NPN,3904

Q20 VSMPS8550S/-1 AB 8550S

Q21 VSMPS8050S/-1 AB S8050

[3] DIODES

D1 VHDDA1010++-1 AB Silicon,DA1010

D11 VHDBAV99///-1 AB BAV99

D16 VHDDA1010++-1 AB Silicon,DA1010

D17 VHDBAT54C//-1 AB Schottky Barrier, BAT54C

D18 VHD1N5399//-1 AC 1N5399

D21 VHDDA1010++-1 AB Silicon,DA1010

D22 VHDDA1010++-1 AB Silicon,DA1010

D27 VHDDA1010++-1 AB Silicon,DA1010

D28 VHDDA1010++-1 AB Silicon,DA1010

D501 RH-EXA001AWZZ AC Zener, 3.3V 0.5W

D701 VHDDA1010++-1 AB Silicon,DA1010

D702 VHP304VT2H1-1 AC LED, Red Color

D703 VHDDA1010++-1 AB Silicon,DA1010

D704 VHDDA1010++-1 AB Silicon,DA1010

ZD2 RH-EXA704WJQZ AB Zener

[4] COILS

FB8 RBLN-0077TAZZ AB Ferrite Bead

FB9 RBLN-0077TAZZ AB Ferrite Bead

FB10 RBLN-0077TAZZ AB Ferrite Bead

FB11 RBLN-0077TAZZ AB Ferrite Bead

FB12 RBLN-0077TAZZ AB Ferrite Bead

FB13 RBLN-0077TAZZ AB Ferrite Bead

FB14 RBLN-0081TAZZ AA Ferrite Bead, 100MHz 600

FB15 RBLN-0077TAZZ AB Ferrite Bead

FB16 RBLN-0081TAZZ AA Ferrite Bead, 100MHz 600

FB17 RBLN-0077TAZZ AB Ferrite Bead

FB18 RBLN-0077TAZZ AB Ferrite Bead

FB19 RBLN-0081TAZZ AA Ferrite Bead, 100MHz 600

L2 RBLN-A008AWZZ AB Ferrite Bead, 100MHz 1000

L6 RBLN-A008AWZZ AB Ferrite Bead, 100MHz 1000

L17 RCILZA075AWZZ AC Coil, 0.22µH

L18 RCILZA077AWZZ AC Coil 10µH

L19 RBLN-0078TAZZ AB Ferrite Bead, 10

L20 RCILZA024AWZZ AK Coil 22µH

L21 RCILZA024AWZZ AK Coil 22µH

L22 RCILZA024AWZZ AK Coil 22µH

L23 RCILZA024AWZZ AK Coil 22µH

L24 RCILZA024AWZZ AK Coil 22µH

L25 RCILZA024AWZZ AK Coil 22µH

L26 RBLN-A009AWZZ AA Ferrite Bead, 100MHz 300

L27 RBLN-0078TAZZ AB Ferrite Bead, 10

L28 RBLN-A009AWZZ AA Ferrite Bead, 100MHz 300

L29 RBLN-A008AWZZ AB Ferrite Bead, 100MHz 1000

L36 RCILZA077AWZZ AC Coil 10µH

L37 RCILZA077AWZZ AC Coil 10µH

L39 RCILZA077AWZZ AC Coil 10µH

L40 RCILZA077AWZZ AC Coil 10µH

L41 RCILZA077AWZZ AC Coil 10µH

L42 RCILZA077AWZZ AC Coil 10µH

L44 RCILZA077AWZZ AC Coil 10µH

L45 RCILZA077AWZZ AC Coil 10µH

NEW

MARK

PA RT

RANK

DESCRIPTION

1

Page 42

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PA RT

RANK

[4] COILS

L46 RCILZA077AWZZ AC Coil 10µH

L47 RBLN-A009AWZZ AA Ferrite Bead, 100MHz 300

L48 RCILZA077AWZZ AC Coil 10µH

L49 RBLN-0078TAZZ AB Ferrite Bead, 10

L50 RBLN-0078TAZZ AB Ferrite Bead, 10

L51 RCILZA077AWZZ AC Coil 10µH

L52 RCILZA077AWZZ AC Coil 10µH

L53 RCILZA077AWZZ AC Coil 10µH

L54 RCILZA077AWZZ AC Coil 10µH

L57 RBLN-A009AWZZ AA Ferrite Bead, 100MHz 300

L58 RBLN-0078TAZZ AB Ferrite Bead, 10

L59 RBLN-0078TAZZ AB Ferrite Bead, 10

L60 RBLN-0078TAZZ AB Ferrite Bead, 10

L61 RBLN-A008AWZZ AB Ferrite Bead, 100MHz 1000

L62 RBLN-A008AWZZ AB Ferrite Bead, 100MHz 1000

L65 RCILZA075AWZZ AC Coil, 0.22µH

L401 RCILZA077AWZZ AC Coil 10µH

L402 RCILZA077AWZZ AC Coil 10µH

R85 RBLN-0006TAZZ AA Ferrite Bead

R111 RBLN-0006TAZZ AA Ferrite Bead

R165 RBLN-0006TAZZ AA Ferrite Bead

[5] VIBRATORS / CRYSTALS

Y2 RCRSPA029AWZZ AD Crystal, 27MHz

[6] CAPACITORS

C2 VCKYCY1HB102K AA 1000pF 50V

C3 VCKYCY1HB104K AD 0.1µF 50V

C4 VCKYCY1EF104Z AA 0.1µF 25V

C6 VCKYCY1EF104Z AA 0.1µF 25V

C7 VCKYCY1EF104Z AA 0.1µF 25V

C8 VCKYCY1EF104Z AA 0.1µF 25V

C9 VCKYCY1EF104Z AA 0.1µF 25V

C10 VCKYCY1HB102K AA 1000pF 50V

C11 VCKYCY1EF104Z AA 0.1µF 25V

C12 VCKYCY1EF104Z AA 0.1µF 25V

C13 VCKYCY1EF104Z AA 0.1µF 25V

C14 VCKYCY1EF104Z AA 0.1µF 25V

C15 VCKYCY1EF104Z AA 0.1µF 25V

C16 VCKYCY1EF104Z AA 0.1µF 25V

C17 VCKYCY1EF104Z AA 0.1µF 25V

C18 VCCCCY1HH221J AA 220pF(CH),50V

C19 VCCCCY1HH221J AA 220pF(CH),50V

C20 VCKYTV1HB104K AB 0.1µF 50V

C21 VCKYTV1HB104K AB 0.1µF 50V

C22 VCKYTV1HB104K AB 0.1µF 50V

C23 VCKYCY1HB104K AD 0.1µF 50V

C24 VCKYTV1HB104K AB 0.1µF 50V

C25 VCKYTV1HB104K AB 0.1µF 50V

C26 VCKYTV1HB104K AB 0.1µF 50V

C27 VCKYTV1HB104K AB 0.1µF 50V

C28 VCKYTV1HB104K AB 0.1µF 50V

C29 VCKYTV1HB104K AB 0.1µF 50V

C30 VCKYTV1HB104K AB 0.1µF 50V

C31 VCKYTV1HB104K AB 0.1µF 50V

C32 VCKYTV1HB104K AB 0.1µF 50V

C34 VCKYCY1HB104K AD 0.1µF 50V

C40 VCKYCY1EF104Z AA 0.1µF 25V

C42 RC-EZ3213AWZZ AD 0.47µF 63V

C43 VCKYTV1HB104K AB 0.1µF 50V

C44 RC-EZ3213AWZZ AD 0.47µF 63V

C45 VCKYTV1HB104K AB 0.1µF 50V

C46 RC-EZ3213AWZZ AD 0.47µF 63V

C47 VCKYTV1HB104K AB 0.1µF 50V

C48 RC-EZ3213AWZZ AD 0.47µF 63V

C49 VCKYTV1HB104K AB 0.1µF 50V

C50 RC-EZ3213AWZZ AD 0.47µF 63V

C51 VCKYTV1HB104K AB 0.1µF 50V

C52 RC-EZ3213AWZZ AD 0.47µF 63V

C53 VCKYTV1HB104K AB 0.1µF 50V

C56 VCKYCY1HB104K AD 0.1µF 50V

C57 VCKYTV1HB104K AB 0.1µF 50V

C58 VCKYTV1HB104K AB 0.1µF 50V

C59 VCKYTV1HB104K AB 0.1µF 50V

C60 VCKYTV1HB104K AB 0.1µF 50V

C61 VCKYTV1HB104K AB 0.1µF 50V

C66 VCKYTV1HB104K AB

C67 VCCCCY1HH220J AA 22pF(CH),50V

C68 VCCCCY1HH221J AA 220pF(CH),50V

C69 VCCCCY1HH221J AA 220pF(CH),50V

C70 VCKYCY1HF103Z AB 0.01µF 50V

C71 VCKYCY1HF103Z AB 0.01µF 50V

C72 VCKYCY1HF103Z AB 0.01µF 50V

C73 VCKYCY1HF103Z AB 0.01µF 50V

C74 VCKYCY1HF103Z AB 0.01µF 50V

C75 VCKYCY1HF103Z AB 0.01µF 50V

C79 VCCCCY1HH681J AC 680pF(CH),50V

C80 VCCCCY1HH681J AC 680pF(CH),50V

0.1µF 50V

2

HT-CN9900DVW

DESCRIPTION

Page 43

HT-CN9900DVW

NO. PARTS CODE

PRICE

RANK

[6] CAPACITORS

C81 VCKYCY1HB104K AD 0.1µF 50V

C82 VCCCCY1HH220J AA 22pF(CH),50V

C83 VCKYCY1HB104K AD 0.1µF 50V

C84 VCKYCY1HB104K AD 0.1µF 50V

C85 VCKYCY1HB104K AD 0.1µF 50V

C87 VCCCCY1HH331J AA 330pF (CH),50V

C88 VCKYCY1HB104K AD 0.1µF 50V

C89 VCKYCY1HB104K AD 0.1µF 50V

C90 VCKYCY1HB104K AD 0.1µF 50V

C91 VCCCCY1HH681J AC 680pF(CH),50V

C92 VCKYCY1HB104K AD 0.1µF 50V

C93 VCKYCY1HB104K AD 0.1µF 50V

C94 VCCCCY1HH681J AC 680pF(CH),50V

C95 VCKYCY1HB104K AD 0.1µF 50V

C96 VCKYCY1HB104K AD 0.1µF 50V

C97 VCKYCY1HB104K AD 0.1µF 50V

C98 VCKYCY1HB104K AD 0.1µF 50V

C99 VCKYCY1HB104K AD 0.1µF 50V

C101 VCKYCY1HB104K AD 0.1µF 50V

C102 VCCCCY1HH681J AC 680pF(CH),50V

C103 RC-KZA215WJZZ AC 1µF 50V

C104 VCKYCY1HB104K AD 0.1µF 50V

C105 VCCCCY1HH681J AC 680pF(CH),50V

C106 VCKYCY1HB104K AD 0.1µF 50V

C107 VCKYCY1HB104K AD 0.1µF 50V

C108 VCKYCY1HB104K AD 0.1µF 50V

C109 VCKYCY1HB104K AD 0.1µF 50V

C110 VCKYCY1HB104K AD 0.1µF 50V

C111 VCKYCY1HB104K AD 0.1µF 50V

C112 VCCCCY1HH681J AC 680pF(CH),50V

C113 VCCCCY1HH681J AC 680pF(CH),50V

C114 VCCCCY1HH681J AC 680pF(CH),50V

C115 VCKYCY1EB105K AB 1µF 25V

C116 VCKYCY1HB104K AD 0.1µF 50V

C117 VCKYCY1HB104K AD 0.1µF 50V

C120 VCKYCY1HB104K AD 0.1µF 50V

C123 VCKYCY1HB682K AA 6800pF 50V

C124 VCKYCY1HB104K AD 0.1µF 50V

C127 VCKYCY1HB104K AD 0.1µF 50V

C128 VCCCCY1HH681J AC 680pF(CH),50V

C129 VCCCCY1HH681J AC 680pF(CH),50V

C130 VCCCCY1HH681J AC 680pF(CH),50V

C131 RC-KZA510WJPZ AC 10µF 16V

C132 RC-KZA215WJZZ AC 1µF 50V

C133 RC-KZA215WJZZ AC 1µF 50V

C134 RC-KZA215WJZZ AC 1µF 50V

C135 RC-KZA215WJZZ AC 1µF 50V

C136 RC-KZA215WJZZ AC 1µF 50V

C137 RC-KZA215WJZZ AC 1µF 50V

C138 VCKYTV1EB475K AB 4.7µF 25V

C139 VCKYCY1HB104K AD

C140 VCKYCY1HB104K AD 0.1µF 50V

C141 VCKYCY1HB104K AD 0.1µF 50V

C142 VCKYCY1HB104K AD 0.1µF 50V

C143 VCKYCY1HF224Z AB 0.22µF 50V

C144 VCKYCY1HF224Z AB 0.22µF 50V

C145 VCKYCY1HF224Z AB 0.22µF 50V

C146 VCKYCY1HF224Z AB 0.22µF 50V

C147 VCKYCY1HF224Z AB 0.22µF 50V

C148 VCKYCY1HF224Z AB 0.22µF 50V

C149 VCKYTV1EB475K AB 4.7µF 25V

C151 VCKYCY1HB104K AD 0.1µF 50V

C152 VCKYTV1EB475K AB 4.7µF 25V

C154 VCKYCY1HB104K AD 0.1µF 50V

C155 VCKYCY1HB104K AD 0.1µF 50V

C156 VCKYCY1HB104K AD 0.1µF 50V

C157 VCKYCY1HB104K AD 0.1µF 50V

C158 VCKYCY1HB104K AD 0.1µF 50V

C159 VCKYCY1HB104K AD 0.1µF 50V

C160 VCKYTV1EB475K AB 4.7µF 25V

C161 VCKYCY1HB104K AD 0.1µF 50V

C162 VCKYCY1HB104K AD 0.1µF 50V

C163 VCKYCY1HB104K AD 0.1µF 50V

C164 VCKYCY1HB104K AD 0.1µF 50V

C165 VCKYCY1HB104K AD 0.1µF 50V

C166 VCKYCY1HB104K AD 0.1µF 50V

C167 VCKYCY1HB104K AD 0.1µF 50V

C168 VCKYCY1HB104K AD 0.1µF 50V

C169 VCCCCY1HH270J AA 27pF (CH),50V

C170 VCCCCY1HH270J AA 27pF (CH),50V

C171 VCKYCY1HB104K AD 0.1µF 50V

C172 VCKYCY1HB104K AD 0.1µF 50V

C173 VCKYCY1HB104K AD 0.1µF 50V

C175 VCKYCY1HB104K AD 0.1µF 50V

C176 VCCCCY1HH150J AA 15pF (CH),50V

C177 VCKYCY1HB104K AD 0.1µF 50V

C178 VCKYCY1HB104K AD 0.1µF 50V

C179 VCKYCY1HB104K AD 0.1µF 50V

C180 VCKYCY1HB104K AD 0.1µF 50V

NEW

MARK

PA RT

RANK

DESCRIPTION

0.1µF 50V

3

Page 44

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PA RT

RANK

[6] CAPACITORS

C181 VCKYCY1HB104K AD 0.1µF 50V

C182 RC-KZA510WJPZ AC 10µF 16V

C183 VCCCCY1HH150J AA 15pF (CH),50V

C184 VCKYCY1HB104K AD 0.1µF 50V

C185 VCKYCY1HB104K AD 0.1µF 50V

C186 VCKYCY1HB104K AD 0.1µF 50V

C187 VCKYCY1HB104K AD 0.1µF 50V

C188 VCKYCY1HB104K AD 0.1µF 50V

C189 VCKYCY1HB104K AD 0.1µF 50V

C190 VCKYCY1HB104K AD 0.1µF 50V

C191 VCKYCY1HB104K AD 0.1µF 50V

C192 VCKYCY1HB104K AD 0.1µF 50V

C193 VCKYCY1HB104K AD 0.1µF 50V

C194 VCKYCY1HB104K AD 0.1µF 50V

C195 VCKYCY1HB104K AD 0.1µF 50V

C196 VCKYCY1HB104K AD 0.1µF 50V

C197 VCKYTV1EB475K AB 4.7µF 25V

C198 VCKYCY1HB104K AD 0.1µF 50V

C199 VCCCCY1HH150J AA 15pF (CH),50V

C200 VCKYCY1HB104K AD 0.1µF 50V

C201 VCKYCY1HB104K AD 0.1µF 50V

C205 VCKYCY1HB104K AD 0.1µF 50V

C206 VCCCCY1HH150J AA 15pF (CH),50V

C210 VCKYCY1HB102K AA 1000pF 50V

C211 VCKYCY1HB104K AD 0.1µF 50V

C212 VCKYCY1HB104K AD 0.1µF 50V

C213 VCCCCY1HH150J AA 15pF (CH),50V

C218 VCCCCY1HH150J AA 15pF (CH),50V

C219 VCKYCY1HB104K AD 0.1µF 50V

C220 VCKYCY1HB104K AD 0.1µF 50V

C223 VCKYCY1HB152K AA 1500pF 50V

C224 VCKYCY1HB104K AD 0.1µF 50V

C226 VCKYCY1HB104K AD 0.1µF 50V

C227 VCCCCY1HH150J AA 15pF (CH),50V

C228 VCKYCY1HB104K AD 0.1µF 50V

C229 VCKYCY1HB104K AD 0.1µF 50V

C230 VCCCCY1HH331J AA 330pF (CH),50V

C231 VCCCCY1HH331J AA 330pF (CH),50V

C232 VCKYCY1HB102K AA 1000pF 50V

C233 VCKYCY1HB102K AA 1000pF 50V

C234 VCKYCY1HB102K AA 1000pF 50V

C235 VCKYCY1HB104K AD 0.1µF 50V

C236 VCCCCY1HH150J AA 15pF (CH),50V

C237 VCCCCY1HH221J AA 220pF(CH),50V

C238 VCCCCY1HH101J AA 100pF(CH),50V

C239 VCKYCY1HB122K AA 1200pF 50V

C240 VCKYCY1HB104K AD 0.1µF 50V

C241 VCKYCY1HB104K AD 0.1µF 50V

C243 VCKYCY1HB104K AD 0.1µF 50V

C244 VCKYCY1HB104K AD 0.1µF 50V

C245 VCCCCY1HH101J AA

C246 VCCCCY1HH101J AA 100pF(CH),50V

C247 VCCCCY1HH101J AA 100pF(CH),50V

C248 VCCCCY1HH101J AA 100pF(CH),50V

C249 VCKYCY1HB104K AD 0.1µF 50V

C250 VCKYCY1HB104K AD 0.1µF 50V

C251 VCKYCY1HB104K AD 0.1µF 50V

C252 VCKYCY1HB103K AA 0.01µF 50V

C253 VCKYCY1HB104K AD 0.1µF 50V

C254 VCKYCY1HB104K AD 0.1µF 50V

C260 VCKYCY1HB104K AD 0.1µF 50V

C300 VCKYCY1HB222K AA 2200pF 50V

C301 VCKYCY1HB222K AA 2200pF 50V

C303 VCCCCY1HH221J AA 220pF(CH),50V

C304 VCCCCY1HH221J AA 220pF(CH),50V

C308 VCKYCY1HB102K AA 1000pF 50V

C401 VCKYCY1HB104K AD 0.1µF 50V

C402 VCCCCY1HH390J AA 39pF(CH),50V

C403 VCCCCY1HH390J AA 39pF(CH),50V

C501 VCCCCY1HH101J AA 100pF(CH),50V

C503 RC-KZA211WJZZ AB 2.2µF 25V

C504 RC-KZA211WJZZ AB 2.2µF 25V

C505 VCKYCY1HB473K AB 0.047µF 50V

C506 RC-KZA211WJZZ AB 2.2µF 25V

C507 VCKYCY1HB102K AA 1000pF 50V

C508 VCCCCY1HH101J AA 100pF(CH),50V

C509 RC-KZA211WJZZ AB 2.2µF 25V

C510 RC-KZA211WJZZ AB 2.2µF 25V

C511 VCKYCY1HB102K AA 1000pF 50V

C512 VCCCCY1HH101J AA 100pF(CH),50V

C513 VCKYCY1HB104K AD 0.1µF 50V

C514 VCEAZA1CW107M AC 100 µF 16V, Electrolytic

C516 VCEAZA1CW107M AC 100 µF 16V, Electrolytic