Sharp AR-205, AR-161, AR-200, AR-160 Service Manual

AR-205

CODE: 00ZAR205//A1E

DIGITAL COPIER

AR-160

AR-161

AR-200

MODEL AR-205

CONTENTS

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] EXTERNAL VIEWS AND INTERNAL STRUCTURE . . . . . . . . . . . . . . . 4-1

[ 5 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 -1

[ 7 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] USER PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

[11] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] FLASH ROM VERSION UP PROCEDURE . . . . . . . . . . . . . . . . . . . . . 12-1

[13] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safty and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

AR-205

Warning!

This product is a class A product.

If it is operated in households, offices or similar surroundings, it

can produce radio interferences at other appliances, so that the

user has to take adequate countermeasures.

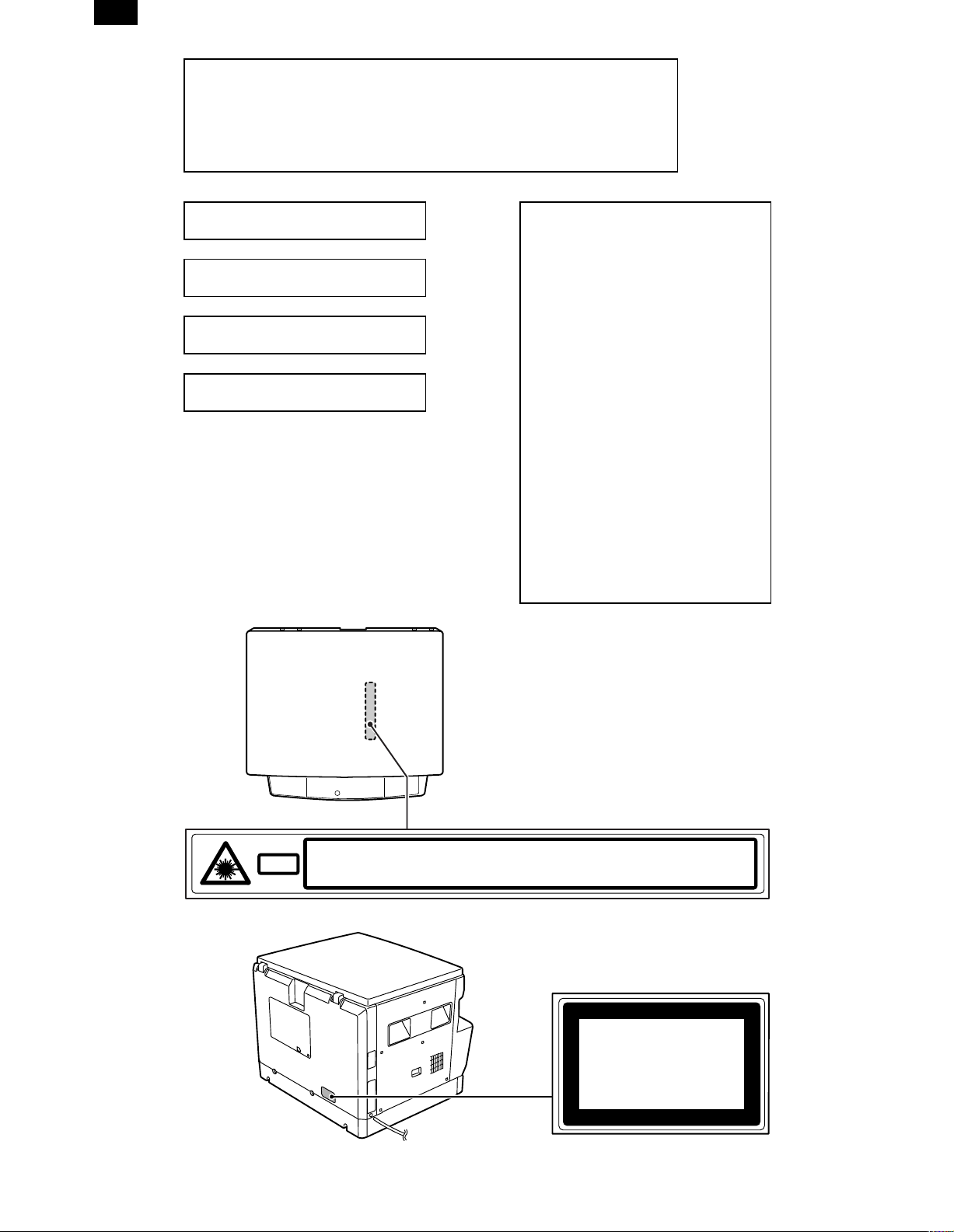

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

VAROITUS!

LAITTEEN KÄYTTÄMINEN

MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA

TAVALLA SAATTAA ALTISTAA

KÄYTTÄJÄN

TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE.

VARNING

OM APPARATEN ANVÄNDS PÅ

ANNAT SÄTT ÄN I DENNA

BRUKSANVISNING

SPECIFICERATS, KAN

ANVÄNDAREN UTSÄTTAS FÖR

OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED.

CAUTION

AVOID EXPOSURE TO BEAM.

UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET UND

VORSICHT

Laserstrahl

SICHERHEITSVERRIEGELUNG ÜBERERÜCKT. NICHT DEM STRAHL AUSSETZEN.

USYNLIG LASERSTRÅLING VED ÅBNING, NÅR SIKKERHEDSAFBRYDERE ER

ADVARSEL

UDE AF FUNKTION. UNDGA UDSAETTELSE FOR STRÅLING.

Disconnect the AC cord before servicing the unit.

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS BRYTES.

UNNGÅ EKSPONERING FOR STRÅLEN.

ADVERSEL

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRRAR ÄR

VARNING

URKOPPLADE. STRÅLEN ÄR FARLIG. BETRAKTA EJ STRÅLEN.

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTÖNTÄ

VARO!

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

CLASS 1

LASER PRODUCT

LASER KLASSE 1

CONTENTS

AR-205

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1. Note for servicing . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1. Copy mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . 3-1

1. Supply system table . . . . . . . . . . . . . . . . . . . . . 3-1

2. Environment conditions . . . . . . . . . . . . . . . . . . . 3-3

3. Production number identifi cati on . . . . . . . . . . . . 3-3

4. Consumable parts recycli ng procedure . . . . . . 3-4

[ 4 ] EXTERNAL VIEWS AND INTERNAL

STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

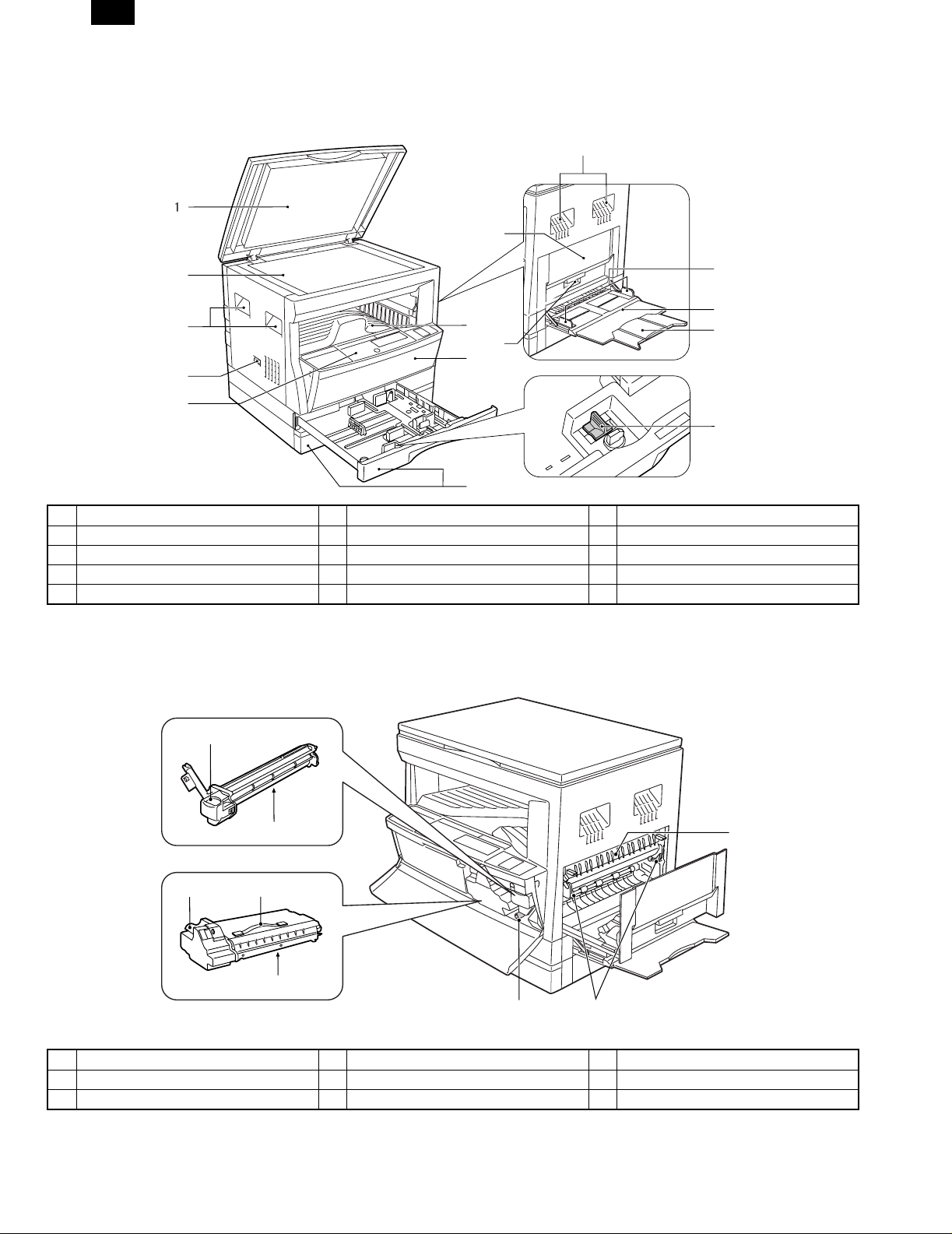

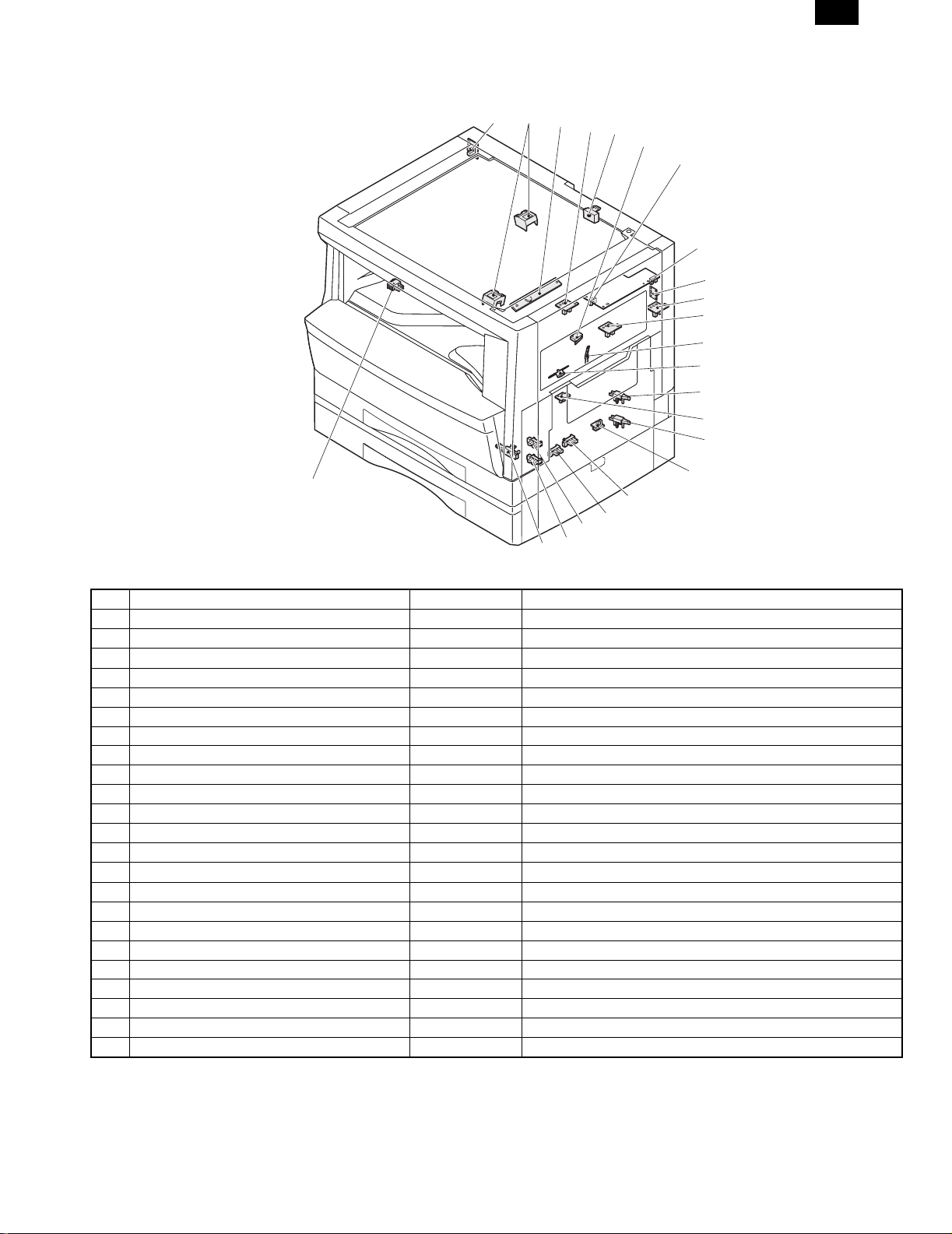

1. Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

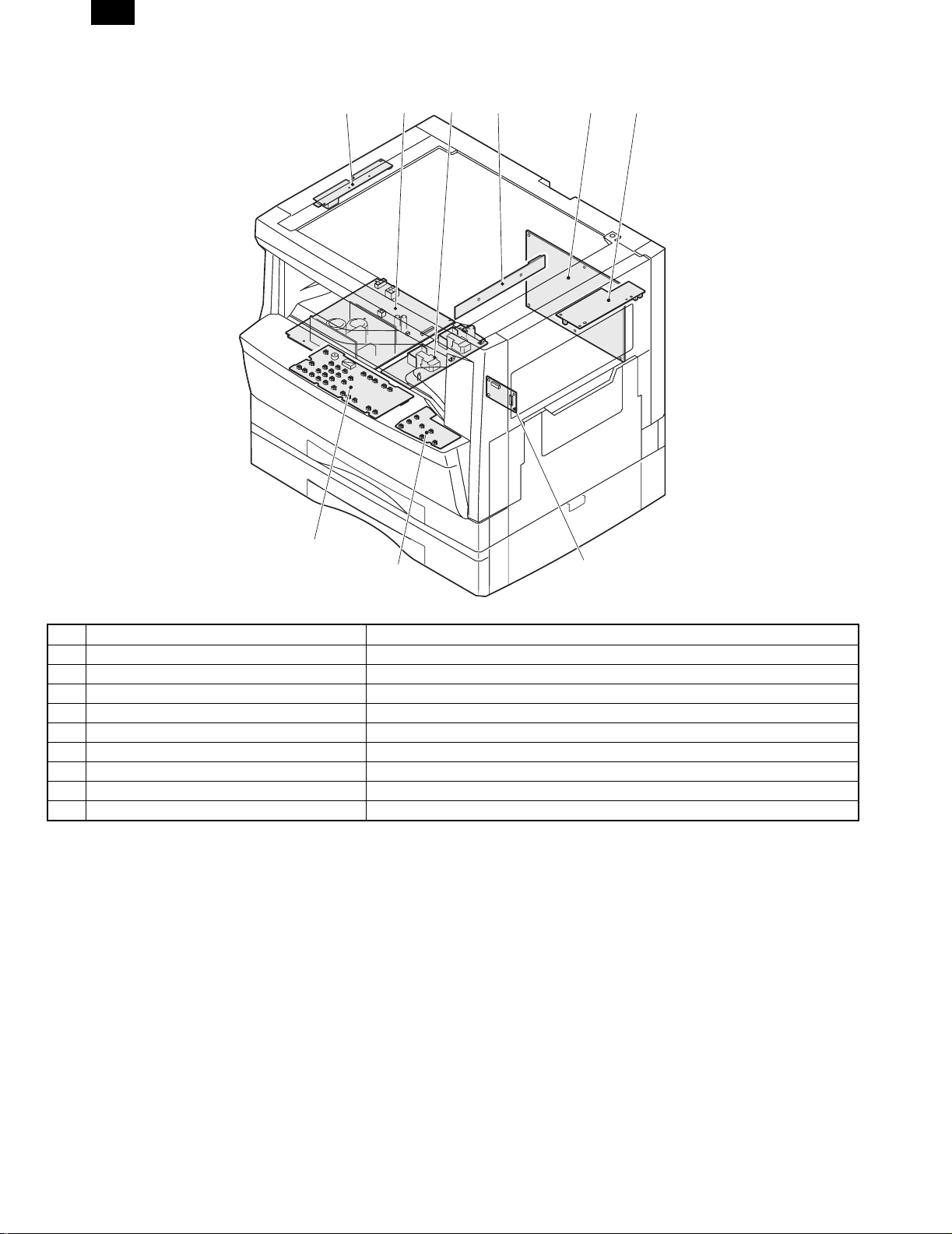

2. Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

3. Operation Section . . . . . . . . . . . . . . . . . . . . . . . 4-2

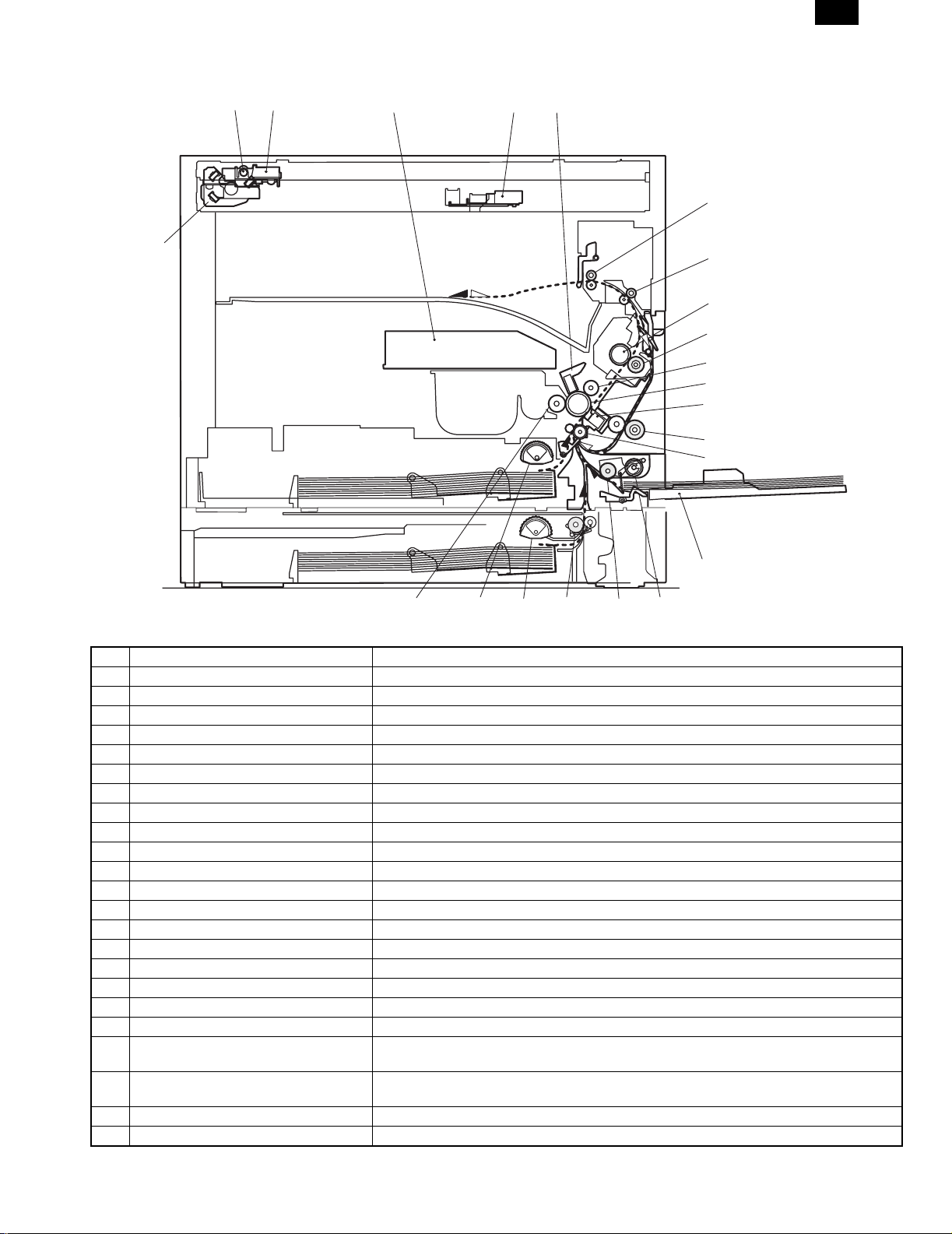

4. Motor, solenoid, clutch . . . . . . . . . . . . . . . . . . . 4-3

5. Sensor, switch . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

6. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

7. Cross sectional view . . . . . . . . . . . . . . . . . . . . . 4-6

[ 5 ] UNPACKING AND INSTALLATION . . . . . . . . . 5-1

1. Installing conditions . . . . . . . . . . . . . . . . . . . . . . 5-1

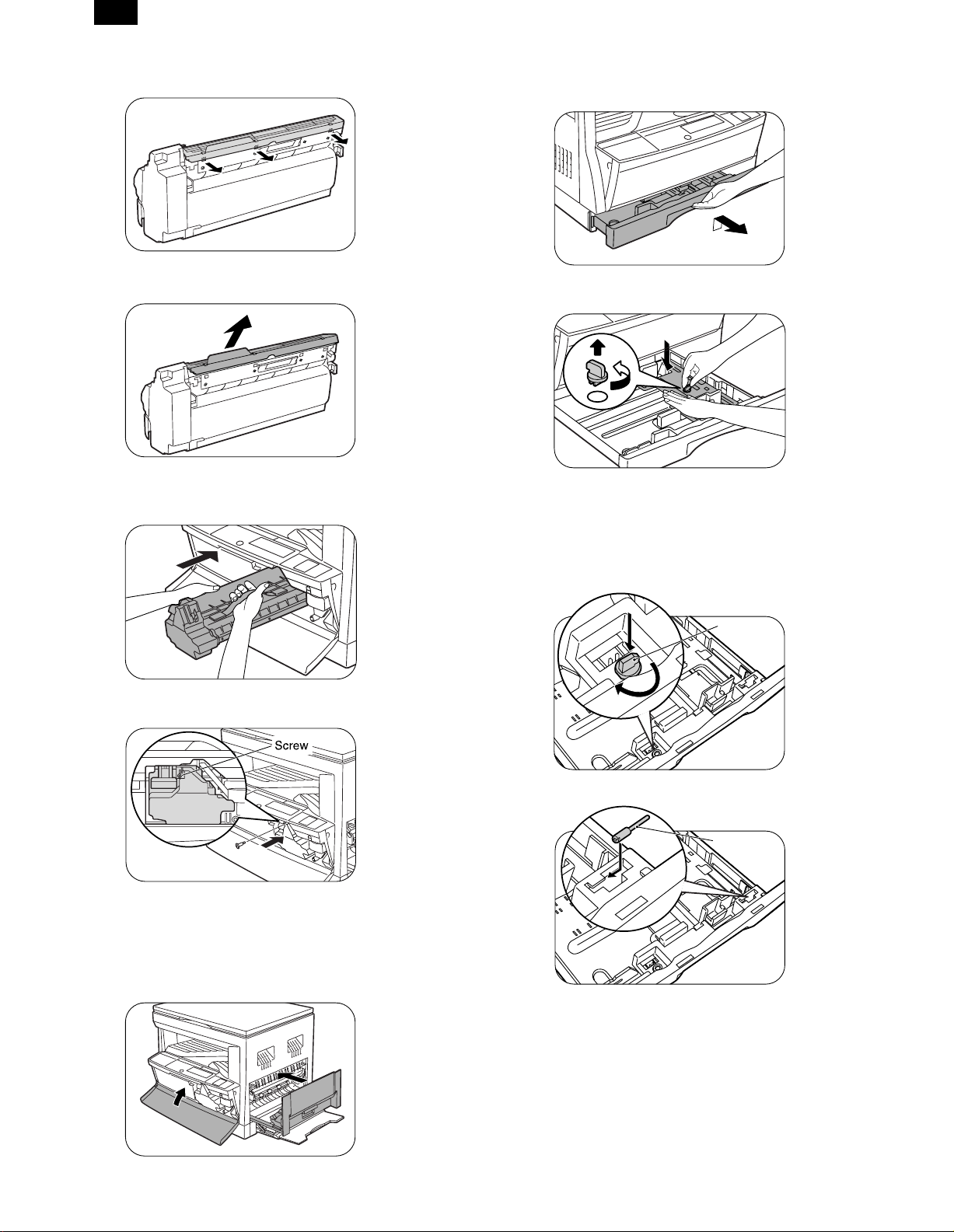

2. Removal of protectiv e m aterial and fixing screw 5-1

3. Installation of developing cart r id ge . . . . . . . . . . 5-1

4. Removal and storage of fixi ng screw . . . . . . . . 5-2

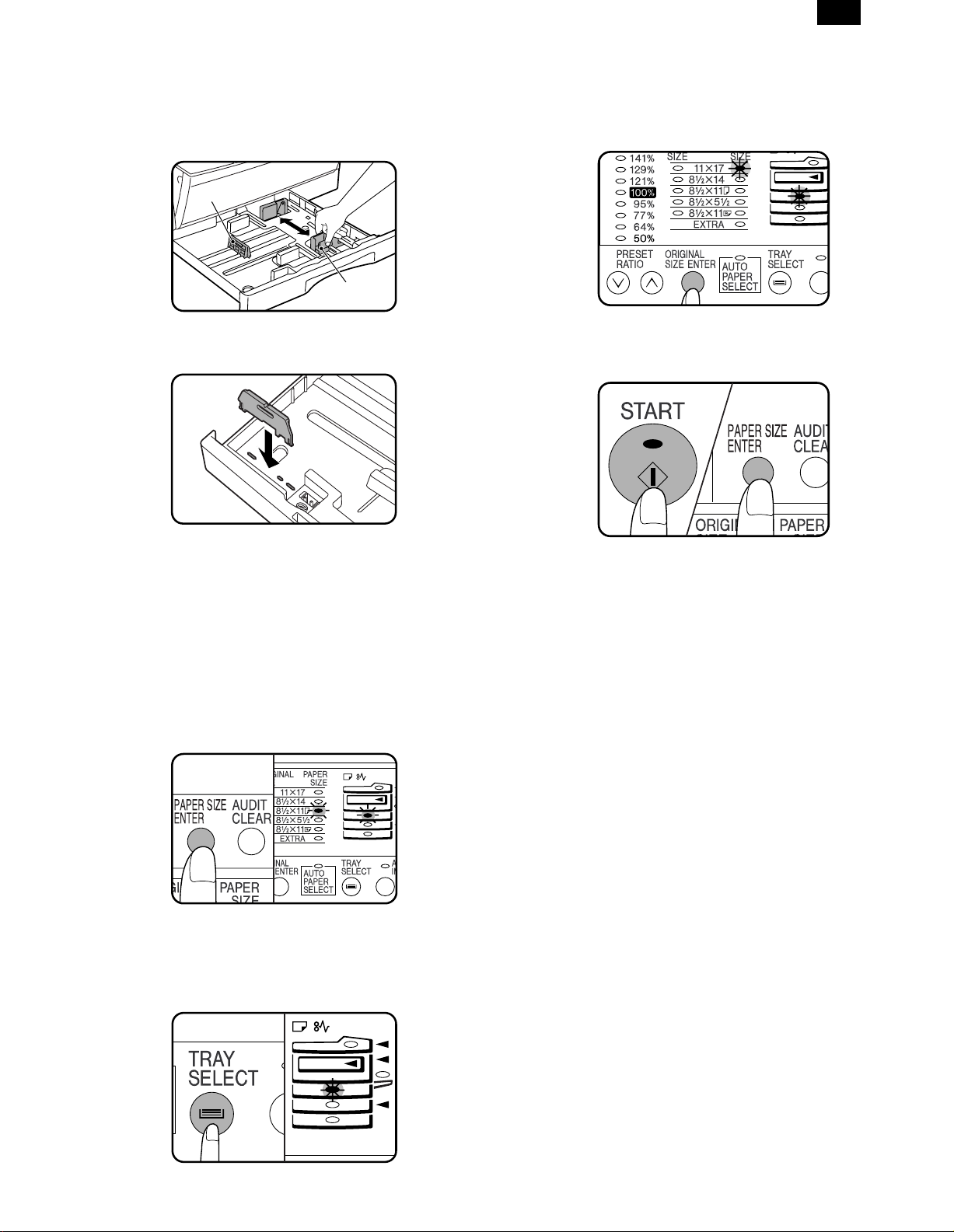

5. Changing the copy paper siz e in the tray . . . . . 5-3

[ 6 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1. Adjustment item list . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Copier adjustment . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 8 ] USER PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . 8-1

1. List of user programs . . . . . . . . . . . . . . . . . . . . 8-1

2. Setting the user programs . . . . . . . . . . . . . . . . . 8-1

[ 9 ] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . 9-1

1. Trouble code list . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. Details of trouble codes . . . . . . . . . . . . . . . . . . 9-1

[10] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

1. Maintenance table . . . . . . . . . . . . . . . . . . . . . . 10- 1

[11] DISASSEMBLY AND ASSEMBLY . . . . . . . . . 11-1

1. High voltage section/Duplex transport section . 11-1

2. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . 1 1-2

3. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . 11-3

4. Paper exit section . . . . . . . . . . . . . . . . . . . . . . 1 1-5

5. MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

6. Optical frame unit . . . . . . . . . . . . . . . . . . . . . . 11-7

7. LSU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

8. Tray paper feed section /

Paper transport section . . . . . . . . . . . . . . . . . . 11-8

9. Manual multi paper feed secti on . . . . . . . . . . 11-9

10. Power section . . . . . . . . . . . . . . . . . . . . . . . 11-11

11. Developing section . . . . . . . . . . . . . . . . . . . . 11-12

12. Process section . . . . . . . . . . . . . . . . . . . . . . 11-13

[12] FLASH ROM VERSION UP PROCEDURE . . 12-1

1. MCU/E-SORT . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

2. PRINTER CONTROL PWB FIRMWARE VERSION

UP 12-1

[13] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . 13-1

[ 7 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

1. Entering the simulation mode . . . . . . . . . . . . . . 7- 1

2. Cancelling the simulation mode . . . . . . . . . . . . 7-1

3. List of simulations . . . . . . . . . . . . . . . . . . . . . . . 7-1

4. Contents of simulations . . . . . . . . . . . . . . . . . . . 7-2

AR-205

[1] GENERAL

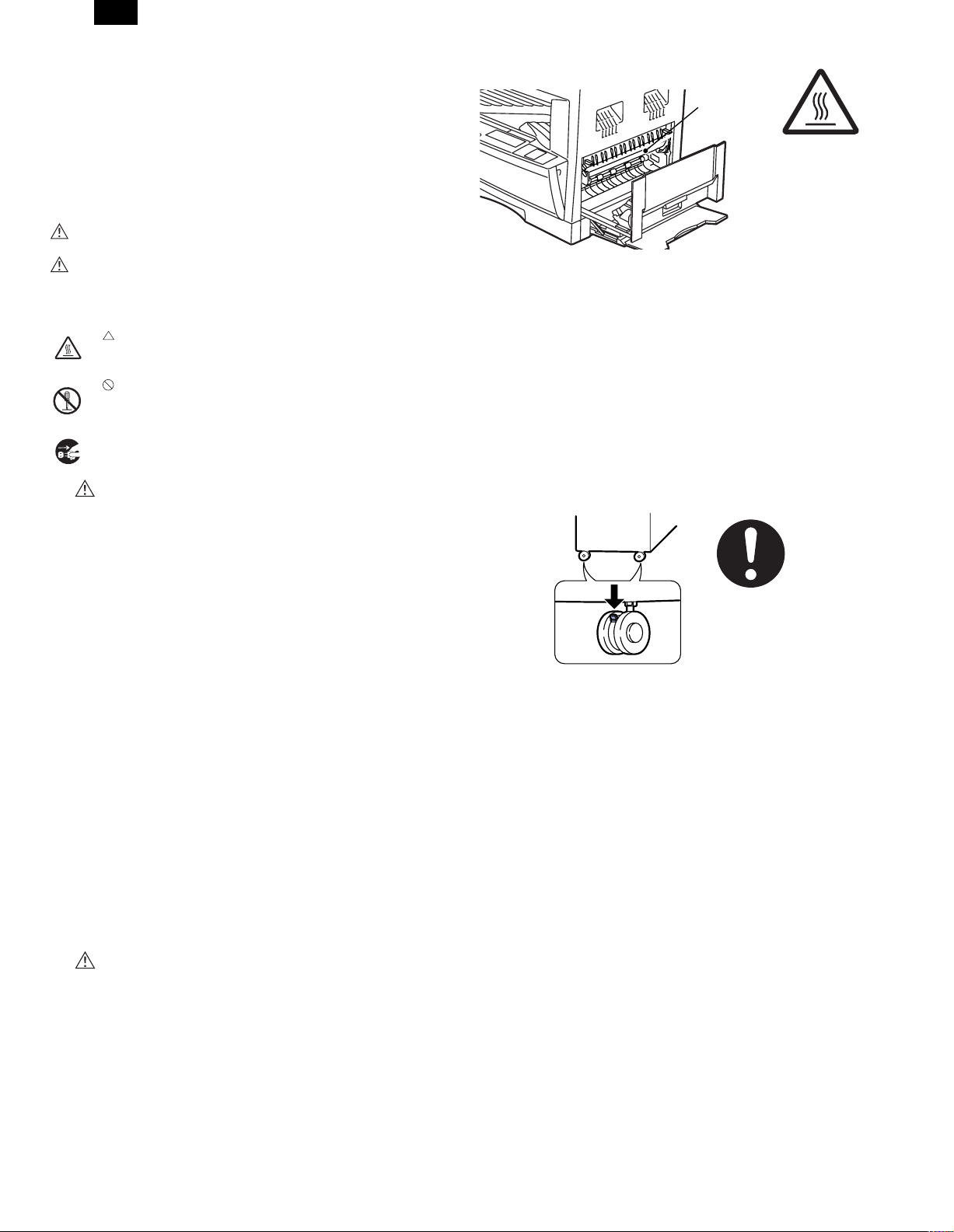

1. Note for servicing

Pictogram

This Service Manual uses some pictographs to assure safe operation.

Please understand the meanings of pictographs before servicing.

WARNING: If this WARNING should be ignored, a serious

danger to life or a serial injury would be resulted.

CAUTION: If this CAUTION should be ignored, an injury or a

damage to properties would be resulted.

Meanings of pictographs

This pic togra ph mean s tha t a care must be taken. In the

pictograph, the concrete content is drawn. (High temperature in this example)

This pictograph m ea ns inhibiti on . Th e c on cr e te content of

inhibition is shown in or near the pictograph. (Inhibition of

disassembly in this example)

●This pictograph means a thing which must be done. (Dis-

connecting the power plug from the power outlet in this

example)

A. WARNING

1) Never use a power source of more than 15A, 100V.

Avoid complex wiring, which may lead to a fire or an electric

shock.

2) When any abnormality occurs, such as smoke or bad smell, do

not use the machine. If used in abnormal conditions, a fire or an

electric shock may be resulted.

3) Be sure to connect the grounding wire. If an electric leakage

occurs without grounding, a fire or an electric shock may be

resulted. To protect the machine and the power unit from lightening, grounding must be made.

4) When removing the cabinet of the machine, use an extreme care.

There is a high voltage section inside the machine which may

cause an electric shock when touched. Do not leave the machine

with the cabinet removed. It is very dangerous for the user to

touch the inside of the machine.

5) Do not damage, brake, or work the power cord. Do not put a

heavy thing on the power cord. Do not pull or bend the power cord

extremely. Otherwise, the power cord may be damaged to cause

a fire or an electric shock.

6) Do not put a vessel with water in it on the machine. Do not put a

metal piece on the machine, which may drop into the machine,

causing a fire or an electric shock.

7) If water or a metal piece drops into the machine, turn off the

power switch, disconnect the power plug, then remove the

dropped thing.

8) Do not use a wet hand to disconnect or insert the power plug and

to operate or service the machine. It may cause an electric shock.

B. CAUTION

1) Avoid installation on an unstable surface or a slant surface. Otherwise, it may drop from the surface, resulting in an injury. It is

advisable to use the optional paper feed desk or the exclusive-use

desk.

2) Avoid installation in a humid or dusty place. Otherwise, a fire or an

elctric shock may be resulted.

3) The fusing section is very high. Be careful not to burn when

servicing.

Fusing section

4) When disconnecting the power plug from the power outlet, do not

pull the power cord. Otherwise, the cord may be damaged, resulting in exposed core or disconnection, causing a fire or an electric

shock.

5) Do not throw toner or a toner cartridge in a fire. Otherwise, toner

may pop and burn you.

6) When using the optional paper feed desk or the exclusive-use

desk, be sure to fix the adjusters on the floor, and lock the

casters.

As shown in the figure, rotate the adjuster in the fixing direction

until it makes contact with the floor. Lock the casters to fix the

machine. (If the casters are not locked, the machine may gradually move so that the SPF cable may be rubbed with the wall,

causing disconnection.

When moving the machine a little for reforming the office, turn the

adjuster to release lock of the casters. (After moving, lock the adjusters and casters to fix the machine.)

7) Do not see the light source and the laser beams. Otherwise the

eyes may be damaged.

8) When moving the machine, turn off the power switch and the

heater switch, and be sure to disconnect the power plug from the

power outlet. If not, the cord may be damaged to cause a fire or

an electric shock.

9) It is very dangerous to perform reception or printing during servicing. When servicing with the cabinet removed, pull out the

telephone line and the printer cable from the machine. (The laser

print function and the Fax function are options.)

10)There are some sharp edges inside the machine. Be careful not to

injure your fingers when servicing.

1 – 1

AR-205

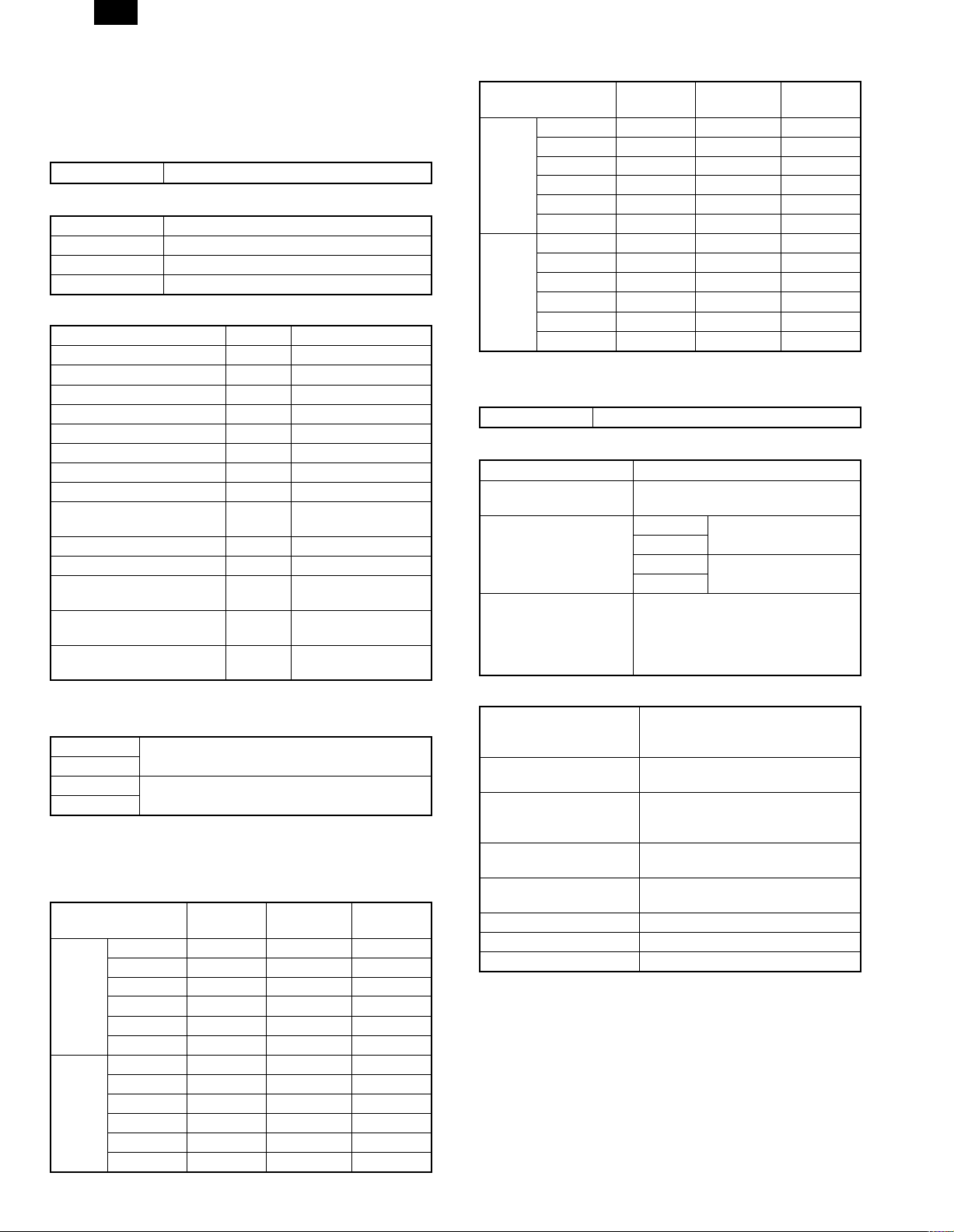

[2] SPECIFICATIONS

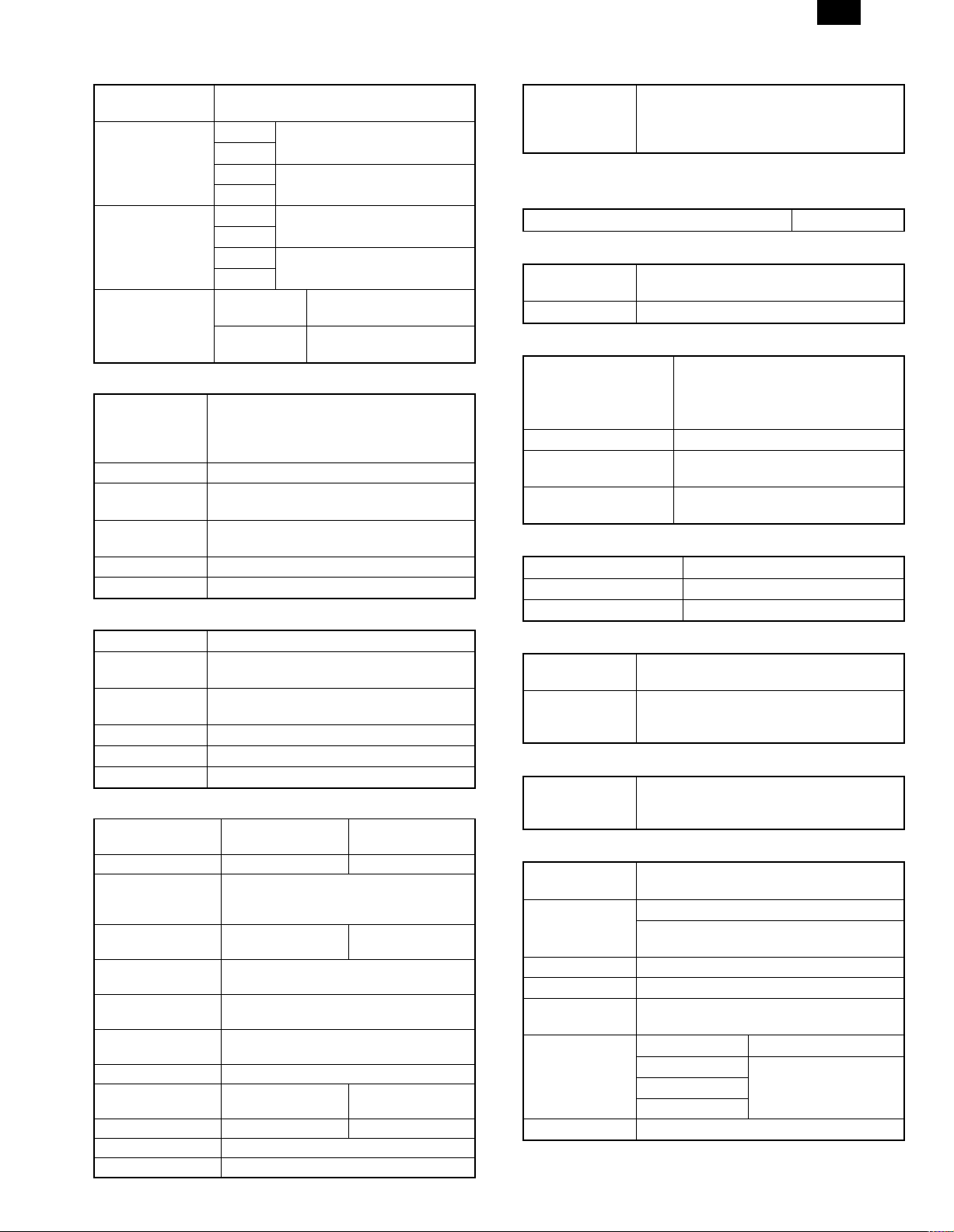

1. Copy mode

A. Type

Type Desk-top

B. Machine composition

AR-160 16-model standard model

AR-161 16-model standard model (with shifter)

AR-200 20-model standard model (with shifter)

AR-205 20-model duplex model (with shifter)

(1) Option

Machine Model Power supply

250 sheets paper feed unit AR-DE5 Supplied by the copier.

500 sheets paper feed unit AR-DE6 Supplied by the copier.

SPF AR-SP2 Supplied by the copier

RSPF AR-RP1 Supplied by the copier

Original cover AR-VR1

Electronic sorting kit AR-EB3 Supplied by the copier.

Printer expansion kit AR-PB8 Supplied by the copier.

Facsimile extension kit AR-FX2 Supplied by the copier.

LCD panel kit

(20 digits × 2 lines)

Job separator tray AR-TR2

PS2 expantion kit AR-PS1

Extension memory for FAX

(2MB)

Extension memory for FAX

(4MB)

Extension memory for FAX

(8MB)

C. Copy speed

(1) Scan One Print many

AR-160

AR-161

AR-200

AR-205

Condition: Copy speed in the normal copy from all the paper feed

ports including the manual paper feed port.

(2) Continuous copy speed (Sheets/min)

a. AR-160/161

Paper size Normal

A3 9 9 9

B4 10 10 10

AB

system

Inch

system

A4 16 16 14

A4R 12 12 12

B5 16 16 16

B5R 14 14 14

11" × 17" 9 9 9

8.5" × 14" 10 10 10

8.5" × 13" 10 10 10

8.5" × 11" 16 16 14

8.5" × 11"R 12 12 12

8.5" × 5.5" 16 16 16

(Available for AR-161 for USA/Canada)

AR-PA1 Supplied by the copier.

AR-MM5

AR-MM6

AR-MM7

Not available

Available

Enlargement

(200%)

Reduction

(50%)

b. AR-200/205

Paper size Normal

A3 11 11 11

B4 12 12 12

AB

system

Inch

system

A4 20 20 20

A4R 14 14 14

B5 20 20 20

B5R 16 16 16

11" × 17" 10 10 10

8.5" × 14" 12 12 12

8.5" × 13" 12 12 12

8.5" × 11" 20 20 20

8.5" × 11"R 15 15 15

8.5" × 5.5" 20 20 20

Enlargement

(200%)

Reduction

(50%)

D. First copy time

(1) Basic speed

First copy time 7.2sec (A4, 8.5" × 11"/1st cassette/with OC)

E. Document

Max. document size A3, 11" × 17"

Document reference

position

Detection (Platen) AR-160 None

Detection size A3, B4, A4, A4R, B5, B5R, A5

(1) SPF/R-SPF

Standard/Option Option

Document load capacity 30 sheets (56 ∼ 90g/m2 equivalent)

Document size

(Max. ∼ Min.)

Document replacement

speed

Document set/Paper feed

direction

Document weight 56 ∼ 90g/m2, 15 ∼ 23.9 lbs

Document size detection On the document feed tray

Document mixture Copy mode: Not Available

Left side center

AR-161

AR-200 Available

AR-205

11" × 17", 8.5" × 14",

8.5" × 13", 8.5" × 11",

8.5" × 11"R, 8.5" × 5.5" (8.5" × 13" is

detected by key input.)

SPF, AR-SP2

RSPF; AR-RP1 (AR-205 only)

(15 ∼ 23.9 lbs.)

A3 ∼ A5

11" × 17" ~ 8.5" × 5.5" (8.5" × 5.5",

duplex is inhibited.)

16 sheets/min (A4 × 8.5" × 11"

normal copy)

Face up, Center reference, Paper

feed from the top

2 – 1

AR-205

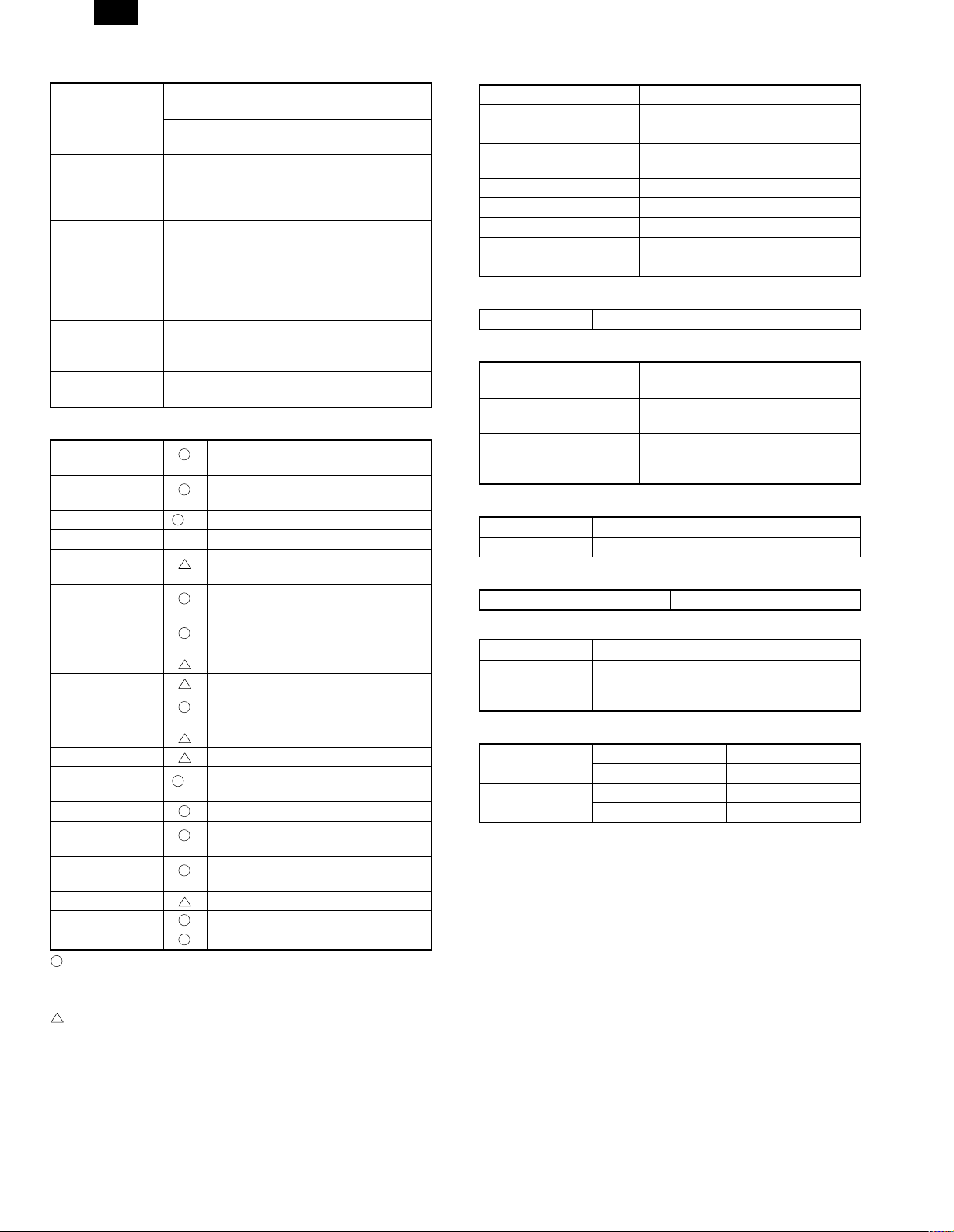

F. Paper feed

Copy size (Max. ∼

Min.)

Paper feed system AR-160 1 cassette + Multi manual paper

Paper feed

capacity

Remaining

quantity detection

(1) Paper feed section of the copier

Paper feed size A3, B4, A4, A4R, B5, B5R, A5

Side front Front

Paper feed

capacity

Detection Paper empty detection available,

Weight 56 ∼ 80g/m2 (15 lbs. ∼ 21 lbs.)

Special paper Recycled paper

(2) Manual paper feed section

Paper feed size A3 ∼ A6, 11" × 17" ∼ 8.5" × 5.5"

Paper feed

capacity

Detection Size detection not available, paper empty

Weight 56 ∼ 128g/m2 (15 ∼ 34 lbs.)

Special paper Recycled paper, OHP film, labels

Paper feed Single except for recycled paper

(3) Option paper feed unit

Model AR-DE5 AR-DE6

Paper feed size A3, B4, A4, A4R, B5, B5R

Capacity

(56 ∼ 80g/m2)

Paper weight 56 ∼ 80 g/m

Moisture preserving

heater

Detection Paper empty detection, size detection

Paper size setting User setting (by key input)

External dimensions

(W × D × H)

Weight About 5kg About 10kg

Special paper Recycled paper

Power Supplied from the machine

(A3 ∼ A6) 11" × 17" ∼ 8.5" × 5.5"

AR-161

AR-200 2 cassette + Multi manual paper

AR-205

AR-160 50 × 1 (Paper feed tray) + 100

AR-161

AR-200 250 × 2 (Paper feed tray) + 100

AR-205

Cassette

section

Manual tray Only empty detection

11" × 17", 8.5" × 14", 8.5" × 13", 8.5" × 11",

8.5" × 11"R, 8.5" × 5.5" (For A5 and 8.5" ×

5.5", only No. 1 tray available.)

250 sheets (56 ∼ 80g/m2 equivalent) (15 ∼ 21

lbs.)

size detection (by key input)

100 sheets

detection available

11" × 17", 8.5" × 14", 8.5" × 13", 8.5" × 11",

About 250 sheets ×

590 × 471 × 88mm

feed

feed

(Multi bypass feed tray)

(Multi bypass feed tray)

Empty detection available,

size detection by key input

available

1-step paper feed

unit

8.5" × 11"R

1 step

(15 ∼ 21 lbs.)

(by key input)

2-step paper feed

unit

About 250 sheets ×

2 steps

2

None

590 × 471 ×

173.5mm

G. Job speed

S-S (1st step) 100% (document replacement rate)

(AR-160/161)

80% (document replacement rate)

(AR-200/205)

Condition: With SPF

H. Multi copy

Max. number of multi copy 99 sheets

I. Warmup time

Warmup time Approx. 35 sec

Pre-heat Available

(Condition: Standard condition)

J. Copy magnification ratio

Fixed magnification ratio AB system: 50, 70, 81, 86, 100, 115,

Zooming 50 ∼ 200%

Independent

zooming/vertical

Independent zooming

(horizontal)

122, 141, 200%

Inch system: 50, 64, 77, 95, 100, 121,

129, 141, 200%

Available (50 ∼ 200%)

Available (50 ∼ 200%)

K. Print density

Density mode Auto/Manual/Photo

No. of manual adjustment 5 steps (Manual/Photo)

Toner save mode Set by the user program

L. Void width

Void area Lead edge 1 ∼ 4mm, rear edge 4mm or less

(Duplex 4mm or less), both sides 4mm or less

Image loss Max. 4mm in total of lead edge and rear edge,

max. 4mm in total of right and left edges

(Normal copy)

M. Auto duplex

Standard/Option Standard provision (AR-205 only) (D → D/D

→ S enable only when RSPF is installed)

Not available for AR-160/161/200

N. Paper exit/finishing

Paper exit

section capacity

Job separator Job separator, option (AR-TR2)

Full detection Available (Job separator upper step)

Finishing Electronic sort board: Option (AR-EB3)

Electronic sort

capacity

Offset function AR-160 None

Staple function None

Face down 250 sheets

Upper: FAX/Printer, Lower: Copier

Upper: 100sheets, Lower 150sheets

A4 (8.5" × 11") standard document 60 sheets

AR-161 Available (by the shifter)

AR-200

AR-205

2 – 2

AR-205

(1) Electronic sort board (Option)

Electronic sort Sorting 60 sheets of A4 standard

documents

Grouping 60 sheets of A4 standard

Rotation copy If there is paper of same size as the

document, the image is rotated to copy even

though the paper is set in the different

direction from the document direction.

2 in 1, 4 in 1 Copies of 2 pages or 4 pages are integrated

into one surface. Divided by solid lines,

(Selectable by the user program.)

Edge erase Images surrounding the document are erased

when copying. (Adjustable in 0 ∼ 20mm by the

user program.)

Center erase The image at the center is erased when

copying. (Adjustable in 0 ∼ 20mm by the user

program.)

Margin shift Binding margin is made at the left edge of the

set documents.

documents

P. Additional functions

*

APS

*

AMS

Duplex

Document count ✕

Sorter When the electronic sort board

Independent

zooming

1 set 2 copy Enlargement inhibited, inhibited

Binding margin Shift width 9mm

Edge erase Width 5mm (Adjustable 0 ∼ 20mm)

Black-white

reversion

2 in 1, 4 in 1

Rotation copy

Memory copy

Pre-heat function Conditions set by the user program

Auto power shut

off function

Auto tray

switching

Message display (FAX/Printer extension)

User program

Total counter

: Available

✕ : Not available

∗

: By the document size set key

: When an option is installed

(APS not available by flowing in

during use of SPF)

(AMS not available by flowing in

during use of SPF)

✕

AR-205 only available

installed.

Vertical/Horizontal: 50 ∼ 200%

during the use of SPF

Whole surface only

(AR-200/205 and AR-161 for

✕

USA/Canada: Available)

Conditions set by the user program

Q. Other specifications

Photoconductor type OPC (Organic Photo Conductor)

Photoconductor drum dia. 30mm

Copy lamp Xenon lamp

Developing system Dry 2-component magnetic brush

development

Charging system Saw teeth charging

Transfer system (+) DC corotron

Separation system (-) DC corotron

Fusing system Heat roller

Cleaning system Contact blade

R. Package form

Body Body/Accessaries

S. External view

External dimensions

(W × D × H)

Occupying area (W × D) 590 × 531mm

Weight About 32kg (AR-160/161)

590 × 531 × 470 mm (AR-160/161)

590 × 531 × 523mm (AR-200/205)

(When the manual tray is installed.)

About 35.2kg (AR-200)

About 35.7kg (AR-205)

T. Power source

Voltage AC120V, 220V, 240V ± 15%

Frequency 50/60Hz common

U. Power consumption

Max. power consumption About 1.3KWh

* EnergyStar standard (The second level conformity)

Pre-heat About 60Wh

Auto power shut

off

about 4.8wh (when FAX or the printer

expansion kit is installed)

0wh ⋅

V. Digital performance

Resolution Reading 400 dpi

Writing 600 dpi

Gradation Reading 256 gradations

Writing Binary

2 – 3

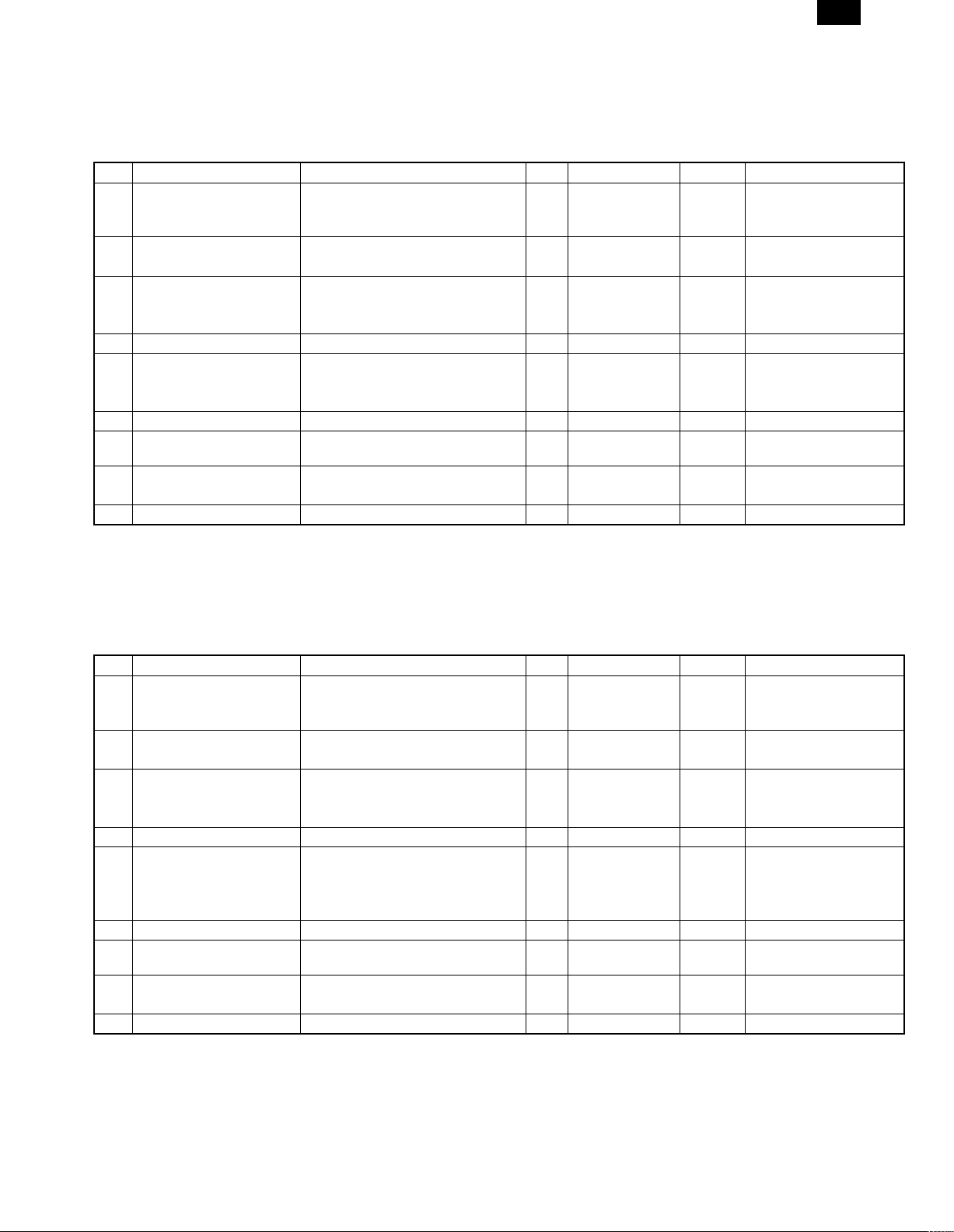

[3] CONSUMABLE PARTS

1. Supply system table

A. USA, CANADA

NO Name Content Life Model name Package Remark

1 Developer cartridge (Black) Toner/developer cartridge

(Toner 610g, Developer 395g)

Vinyl bag × 1

2 Drum cartridge Drum cartridge × 1 30K AR-200DR

Vinyl bag × 1

3 Toner kit (Black) Toner bottle (Toner 610g) × 10 150K AR-200MT

Charging hose × 1

Toner cap × 10

4 Waste toner box Waste toner box × 10 *2 AR-200TB 1

5 Developer kit (Black) Toner bottle (Developer 395g) × 10 150K AR-200MD

Developer cap × 10

DV blade × 10

6 Protective cover MG cover × 10 *3 AR-200MG 1

7 Drum kit Drum

Drum fixing plate

8 Blade kit Blade × 10 *4 AR-200CB 1

Mocket (F/R) Each × 10

9 Heat roller Upper heat roller × 1 150K AR-160UH 1

* 1: For USA government

* 2: Replace every 10 times of developer cartridge recycling (Recommendation)

* 3: Replace every 2 times of developer cartridge recycling (Recommendation)

* 4: Replace every 2 times of drum cartridge recycling (Recommendation)

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

× 1 15K AR-200TD

(*1 AR-200TD-J)

(*1 AR-200DR-J)

(*1 AR-200MT-J)

(*1 AR-200MD-J)

× 1 30K AR-200MR

(*1 AR-200MR-J)

1 Life setting by A4 (8.5" ×

11") 6% document

1

1 Life setting by A4 (8.5" ×

11") 6% document

1

1

AR-205

B. Asia, Southeast Asia

NO Name Content Life Model name Package Remark

1 Developer cartridge (Black) Toner/developer cartridge

(Toner 610g, Developer 395g)

Vinyl bag × 1

2 Drum cartridge Drum cartridge × 1 30K AR-200DR 1

Vinyl bag × 1

3 Toner kit (Black) Toner bottle (Toner 610g) × 10 150K AR-200CT 1 Life setting by A4 6%

Charging hose × 1

Toner cap × 10

4 Waste toner box Waste toner box × 10 *2 AR-200TB 1

5 Developer kit (Black) Toner bottle

(Developer 395g)

Developer cap × 10

DV blade × 10

6 Protective cover MG cover × 10 *3 AR-200MG 1

7 Drum kit Drum

Drum fixing plate

8 Blade kit Blade × 10 *4 AR-200CB 1

Mocket (F/R) Each × 10

9 Heat roller Upper heat roller × 1 150K AR-160UH 1

* 2: Replace every 10 times of developer cartridge recycling (Recommendation)

* 3: Replace every 2 times of developer cartridge recycling (Recommendation)

* 4: Replace every 2 times of drum cartridge recycling (Recommendation)

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

× 1 15K AR-200TD 1 Life setting by A4 6%

document

document

× 10 150K AR-200CD 1

× 1 30K AR-200CR 1

3 – 1

AR-205

C. Europe / Australia / New Zealand / Middle East / Africa / CIS

NO Name Content Life Model name Package Remark

1 Developer cartridge (Black) Toner/developer cartridge

(Toner 610g, Developer 395g)

Vinyl bag × 1

2 Drum cartridge Drum cartridge × 1 30K AR-200DM 1

Vinyl bag × 1

3 Toner kit (Black) Toner bottle (Toner 610g) × 10 150K AR-200LT 1 Life setting by A4 6%

Charging hose × 1

Toner cap × 10

4 Waste toner box Waste toner box × 10 *2 AR-200TB 1

5 Developer kit (Black) Toner bottle (Developer 395g) × 10 150K AR-200LD 1

Developer cap × 10

DV blade × 10

6 Protective cover MG cover × 10 *3 AR-200MG 1

7 Drum kit Drum

Drum fixing plate

8 Blade kit Blade × 10 *4 AR-200CB 1

Mocket (F/R) Each × 10

9 Heat roller Upper heat roller × 1 150K AR-160UH 1

* 2: Replace every 10 times of developer cartridge recycling (Recommendation)

* 3: Replace every 2 times of developer cartridge recycling (Recommendation)

* 4: Replace every 2 times of drum cartridge recycling (Recommendation)

× 1 15K AR-200DC 1 Life setting by A4 6%

document

document

× 1 30K AR-200LR 1

D. Hong Kong / China

NO Name Content Life Model name Package Remark

1 Developer cartridge (Black) Toner/developer cartridge

(Toner 610g, Developer 395g)

Vinyl bag × 1

2 Drum cartridge Drum cartridge × 1 30K AR-200DR-C 1

Vinyl bag × 1

3 Toner kit (Black) Toner bottle (Toner 610g) × 10 150K AR-200CT-C 1 Life setting by A4 6%

Charging hose × 1

Toner cap × 10

4 Waste toner box Waste toner box × 10 *2 AR-200TB-C 1

5 Developer kit (Black) Toner bottle (Developer 395g) × 10 150K AR-200CD-C 1

Developer cap × 10

DV blade × 10

6 Protective cover MG cover × 10 *3 AR-200MG-C

7 Drum kit Drum

Drum fixing plate

8 Blade kit Blade × 10 *4 AR-200CB-C 1

Mocket (F/R) Each × 10

9 Heat roller Upper heat roller × 1 150K AR-160UH 1

* 2: Replace every 10 times of developer cartridge recycling (Recommendation)

* 3: Replace every 2 times of developer cartridge recycling (Recommendation)

* 4: Replace every 2 times of drum cartridge recycling (Recommendation)

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

× 1 15K AR-200TD-C 1 Life setting by A4 6%

document

document

× 1 30K AR-200CR-C 1

3 – 2

AR-205

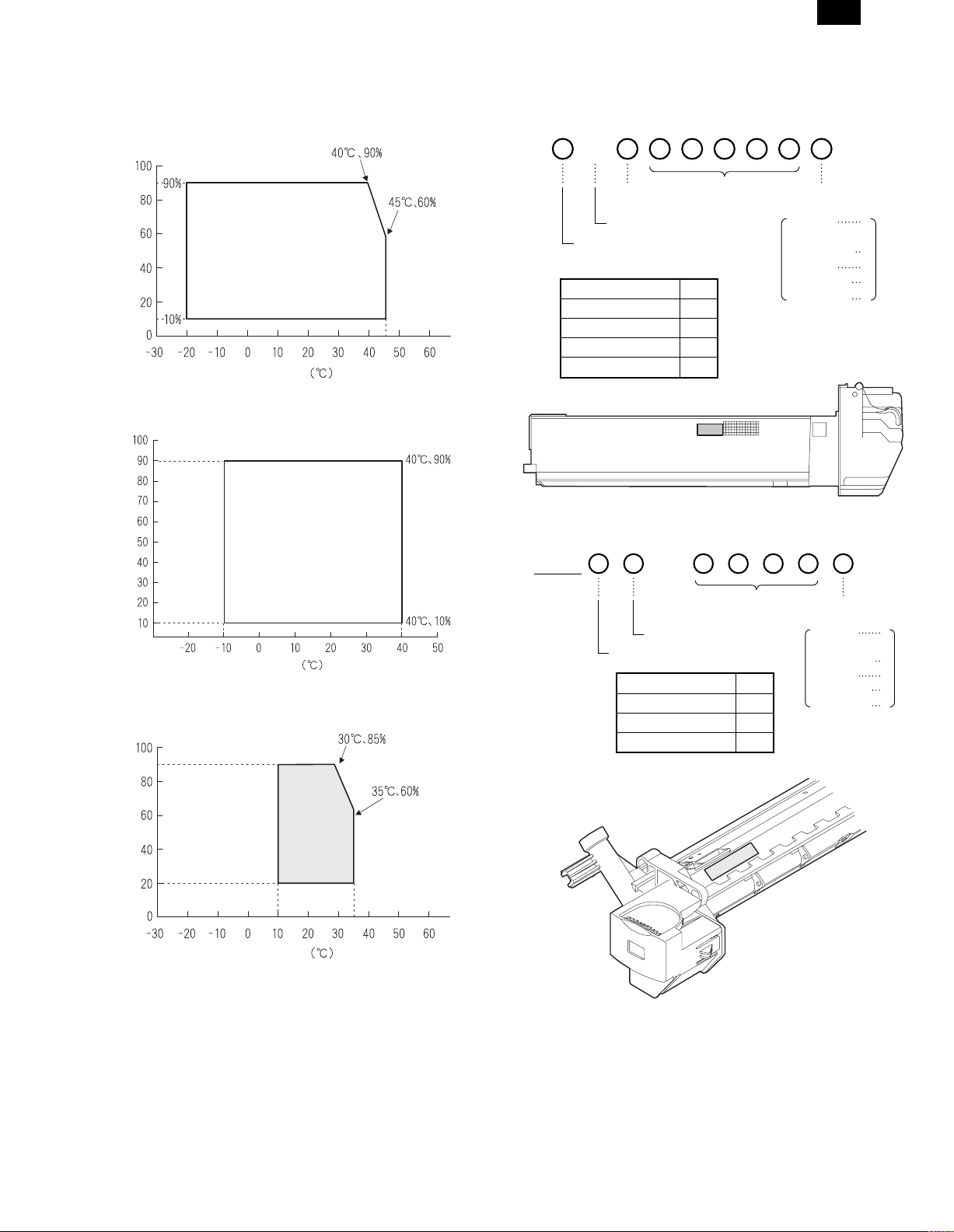

2. Environment conditions

A. Transport condition

(1) Transport conditions

Humidity (%)

Temperature

(2) Storage conditions (packed conditions)

3. Production number identification

<TD cartridge>

The label on the drum cartridge shows the date of production.

B

Destination

(∗)

Indicates production in China.

The end digit of production year

∗: Destination

Division No.

Japan option 1

Ex option 2

Japan, same pack 6

Ex, same pack 7

<Drum cartridge>

The label on the drum cartridge shows the date of production.

Serial number

(00001-99999)

Production

month

January

~

September

October

November

December

1

~

9

0

X

Y

Humidity (%)

Temperature

B. Use conditions

Use environment

conditions

Humidity (%)

Temperature

C. Life (packed conditions)

Photoconductor drum (36 months from the production month)

Developer, toner (24 months from the production month)

Ver. A

1

Serial number (for each

month) (00001-99999)

Factory

The end digit of production year

Division No.

Ex production 1

Option 2

Same pack 3

Production

month

January

~

September

October

November

December

1

~

9

0

X

Y

3 – 3

AR-205

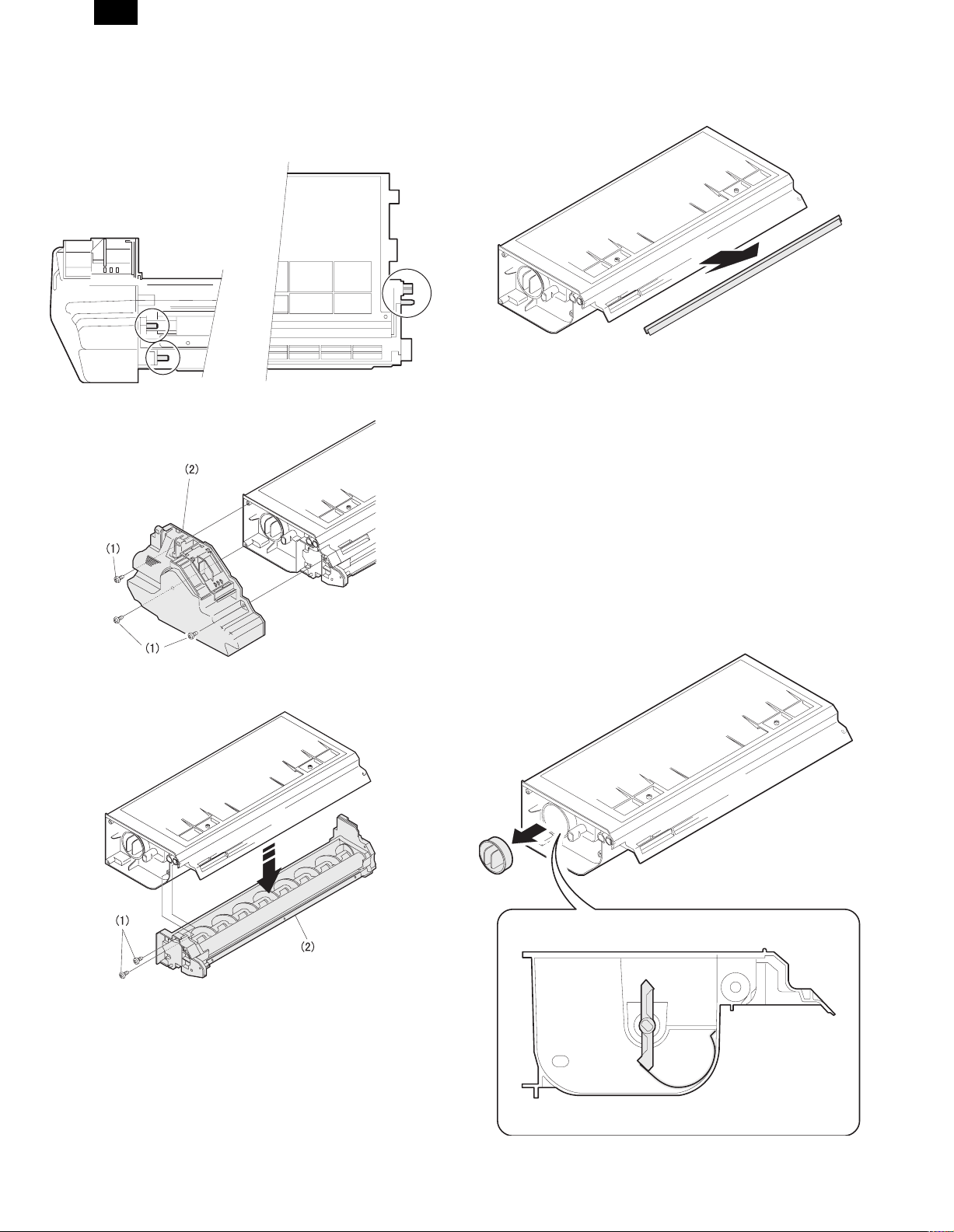

4. Consumable parts recycling procedure

A. TD cartridge

1) Check the external view.

Note: Be careful especially of breakage of the pins and the ATC

sensor connector shown below.

2) Remove the waste toner box unit.

4) Remove the DV blade.

Note: Be sure to remove adhesive completely.

Remove adhesive together with the base PET.

5) Tilt the developing unit, rotate the DV gear clockwise, and

remove developer.

6) Clean and remove developer on the MG roller and toner on the

developing doctor completely with a vacuum cleaner or an air

blower.

7) Shake the developer bottle about 10 times and supply developer

to the developing unit.

Turn the stirring roller to distribute developer evenly.

8) Install the toner box.

9) Shake the toner bottle about 20 times and install the toner supply hose to the toner bottle.

10) Remove the toner cap. While visually inspecting from the toner

supply port, stop the TH shaft at the vertical position. (The TH

mylar is on the lower side.) (Turn the gear on the back of the

toner box counterclockwise to set the TH mylar on the lower

side.)

3) Remove the developing unit.

3 – 4

AR-205

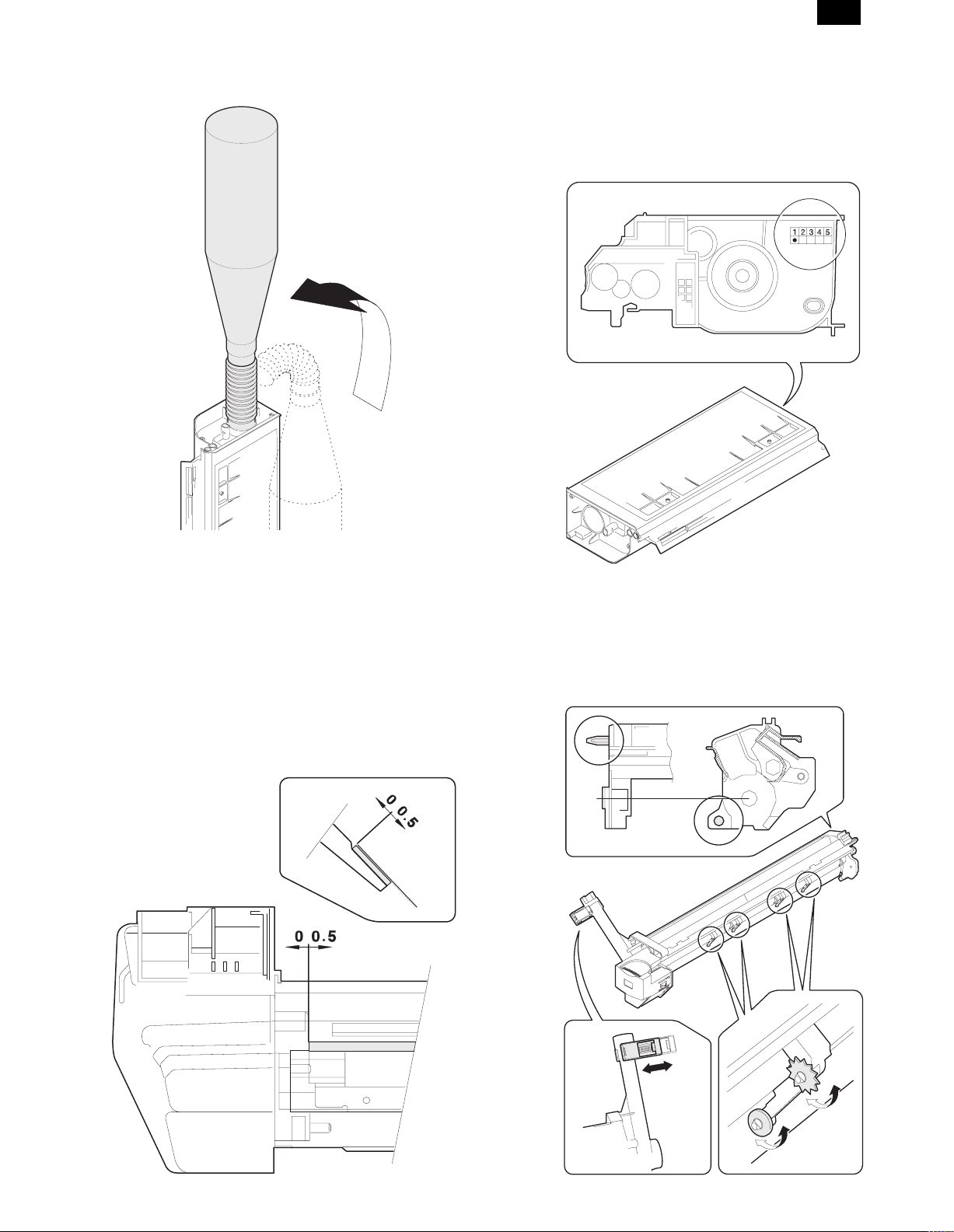

11) Face the toner supply port of the toner box upward with the

toner bottle put straight, and insert the supply hose into the toner

supply port.

17) Shake the developing unit 5 times left and right horizontally.

18) Check the distribution state of developer on the MG roller.

Rotate the MG roller and visually check for no improper distribution of developer which may be caused by foreign materials.

19) Mark the number of times of recycling on the back of the toner

box with white paint.

Max. times of recycling: 5 times

12) Lift the toner bottle and supply toner.

13) Remove the supply hose from the toner box with care not to spill

toner, and attach the toner cap.

Note: If the toner cap is not attached properly, toner splash may

occur.

14) Install the waste toner box.

15) Check the operations of the DV lever and the toner box shutter.

16) Wipe and clean the developer unit with alcohol, and attach the

DV blade to it.

(Note) • Dry alcohol completely before attaching the DV blade,

• When attaching the DV blade, be careful not to scratch it

and eliminate slack.

• After attaching, be careful not to scratch and damage the

DV blade.

B. Drum unit

1) Check the external view.

• Check for damage or cracks on the boss and the boss hole.

• Check to insure that the waste toner pipe shutter slides

smoothly.

• Check to insure that the star ring and the CRU washer rotate

smoothly.

3 – 5

AR-205

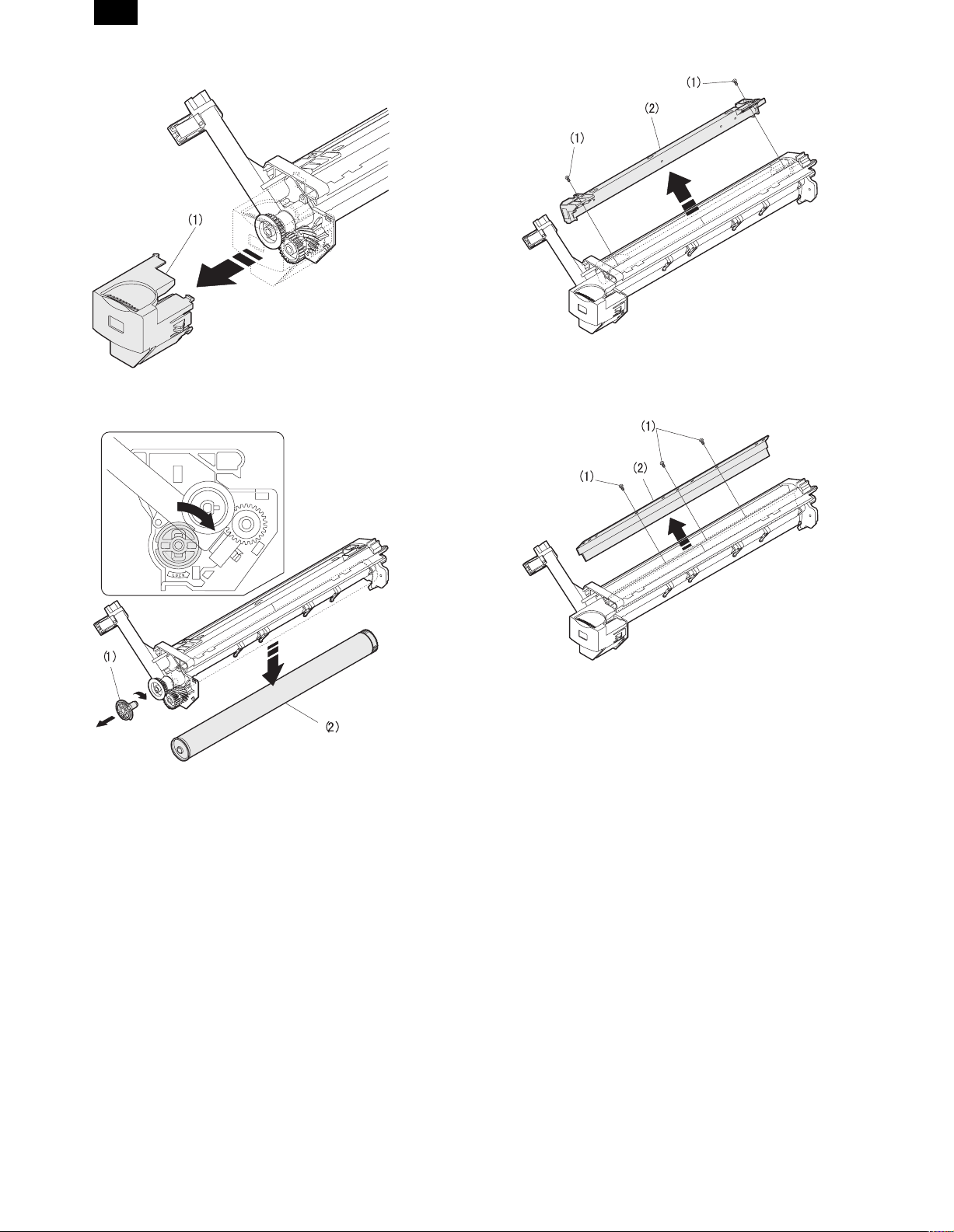

2) Remove the drum cover. (4 Lock Tabs)

3) Remove the drum fixing plate and the photoconductor drum.

(Note) Dispose the drum fixing plate which was removed.

6) Remove the cleaning blade.

Note: Dispose the cleaning blade which was removed.

4) Check the cleaning blade and the red felt for no damage.

• If there is any damage, execute all procedures from item 5)

and later.

• If there is no damage, execute the procedure of item 12).

5) Remove the main charger.

(Cleaning the screen grid and the sawteeth.)

7) Clean the cleaning section and the waste toner pipe to remove

waste toner completely with a vacuum cleaner.

8) Remove the felt and duplex tape completely.

Note: Be careful not to scratch or bend the sub blade.

9) Attach the cleaning blade.

10) Attach the felt.

3 – 6

AR-205

11) Attach the main charger.

12) Attach the drum fixing plate and the photoconductor drum.

Apply grease to the inside of the photoconductor drum. (Dia. 2)

13) Attach the detection gear.

Note: • The detection gear is not installed to the drum cartridge

packed with the main body. Add a new one.

14) Attach the drum cover.

Note: After attaching the drum cover, do not make a copy.

15) Mark the number of times of recycling on the side of the cover

with white paint.

Max. times of recycling: 5 times

3 – 7

AR-205

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance

3

9

2

3

4

5

1 Original cover 2 Original table (OC table) 3 Handles

4 Power switch 5 Operation panel 6 Paper output tray

7 Front cover 8 Paper tray 9 Side cover

10 Side cover handle 11 Bypass tray guides 12 Bypass tray

13 Bypass tray extension 14 Second cassette ∗

∗ AR-200/205 only

6

10

7

8

2. Internal

11

12

13

14

1

2

3

4

5

6

1 Drum cartridge handle 2 Drum cartridge 3 TD cartridge handle

4 TD cartridge strap 5 TD cartridge 6 Roller rotating knob

7 Fusing unit release levers 8 Paper guide

7

8

4 – 1

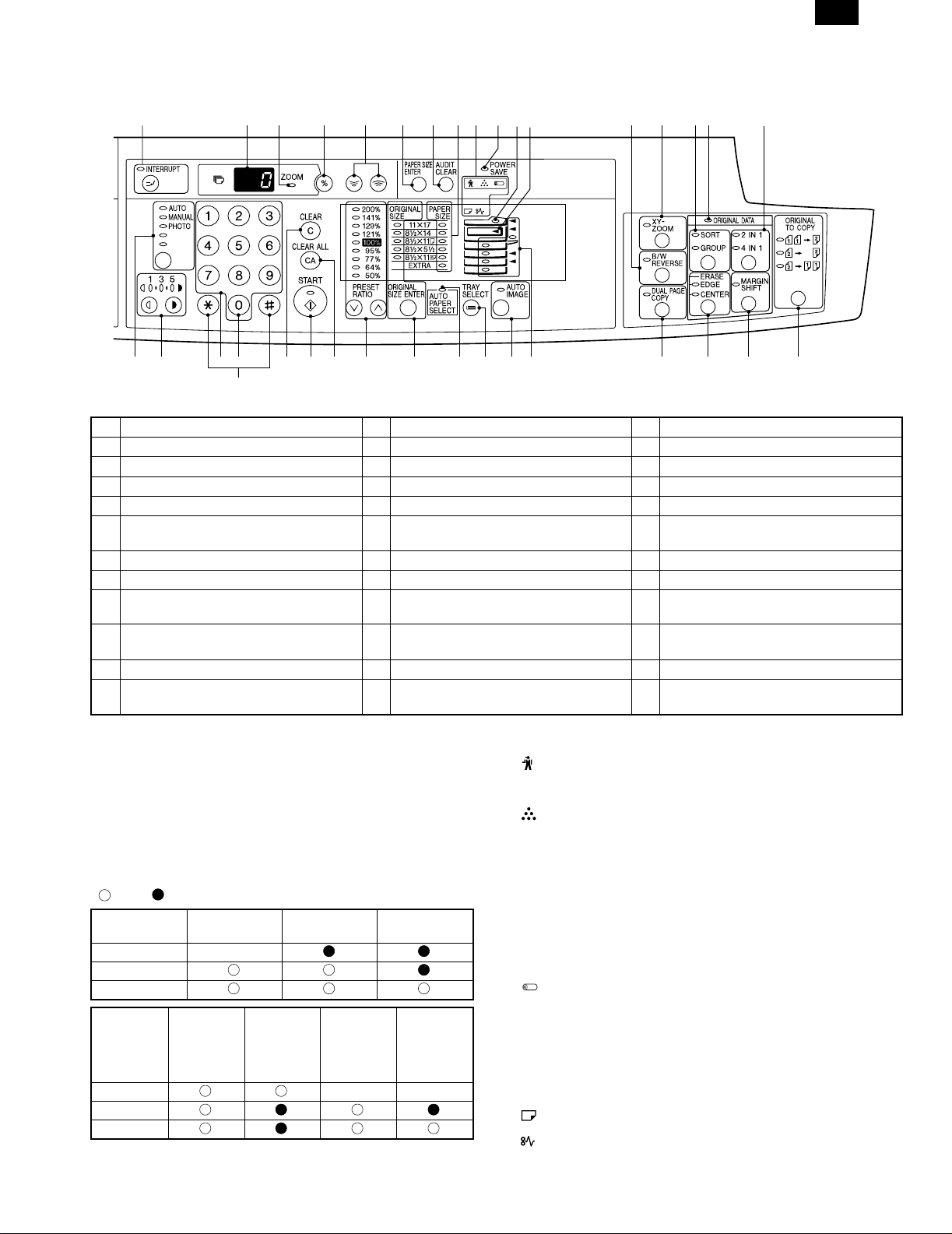

3. Operation Section

12

AR-205

9

8

10

3

4

56

7

11 12

13 14 15

16

17

18 19

Not used for the copier features.

20 21

22

23

24

25 26

27

28

29 30

31

32

33

34

1 Interrupt key and indicator 2 Copy quantity display 3 ZOOM indicator

4 Copy ratio display key 5 Zoom keys 6 PAPER SIZE ENTER key

7 AUDIT CLEAR key 8 PAPER SIZE indicators 9 Alarm indicators ∗

10 POWER SAVE indicator ∗1 11 SPF indicator 12 Output tray full indicator

13 B/W REVERSE key and indicator 14 XY-ZOOM key and indicator 15 SORT/GROUP key and indicators

16 ORIGINAL DATA indicator 17 2 IN 1 / 4 IN 1 key and indicators 18 AUTO/MANUAL/PHOTO key and

indicators

19 Light and dark keys and indicators 20 Numeric keys 21 Zero key

22 CLEAR key 23 START key and indicator 24 CLEAR ALL key

25 PRESET RATIO selector keys and

indicators

26 ORIGINAL SIZE ENTER key and

indicators

27 AUTO PAPER SELECT indicator

28 TRAY SELECT key 29 AUTO IMAGE key and indicator 30 Paper feed location/misfeed location

indicators

31 DUAL PAGE COPY key and indicator 32 ERASE key and indicators 33 MARGIN SHIFT key and indicator

34 Original → Copy key/Display lmap

<AR-205 only>

∗1

ON: Indicates that the machine is in the energy saving (pre-heat)

mode.

Blink: Indicates that the machine is in the process of resetting from

the energy saving mode or just after supplying the power.

(During warmup)

OFF: Indicates that resetting from the energy saving mode is com-

pleted and that the fusing temperature is in ready state.

The combinations of the above display lamps are as follows:

( = ON, = OFF)

Lamp

Pre-heat lamp Blink

Ready lamp

Other lamps

Lamp

Pre-heat lamp Blink Blink

Ready lamp

Other lamps

Immediately after

power ON

Energy

saving mode

(Pre-heating)

Energy

saving mode

(Auto power

shut off)

Ready Copying

Resetting

from energy

saving mode

Copy is

started during

resetting from

energy saving

mode

∗2

Maintenance lamp

When the set count number (set by the simulation) is reached,

the lamp lights up. The machine does not stop.

TD cartridge replacement required indicator

When toner density is lower than a specified level, the TONER

DEVELOPER CARTRIDGE REPLACEMENT indicator lights up

to warn the user.

If toner is not added after approximately 300 sheets are copied,

the indicator starts blinking and machine starts to supply toner.

(Toner Developer cartridge replacement indicator keeps lighting

up)

If toner density is not back to specific level after two minutes, the

READ indicator goes out and Toner Developer indicator starts

blinking, and the copier stops.

Photoconductor cartridge replacement lamp

When the copy count reaches 29,000 after installing a

Photoconductor cartridge, the lamp lights up.

When 1,000 copies are made after that, the lamp blinks instead

of lighting. The machine does not stop.

Press and hold the clear key for 5 sec in the user simulation

mode to display the remaining life of the photoconductor

cartridge in 3 digits x 2 lines on the copy quantity display.

Paper required indicator

Misfeed indicator

4 – 2

AR-205

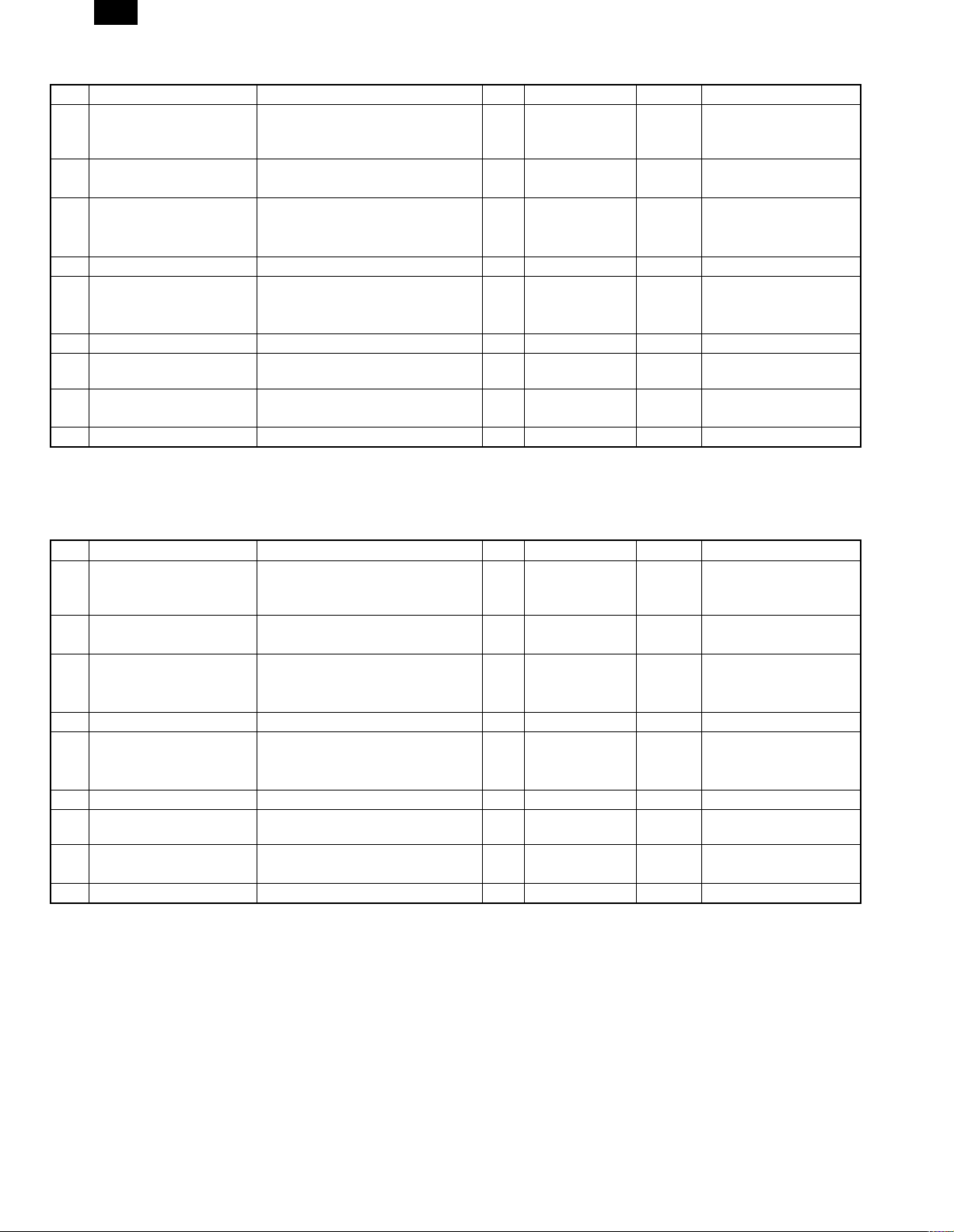

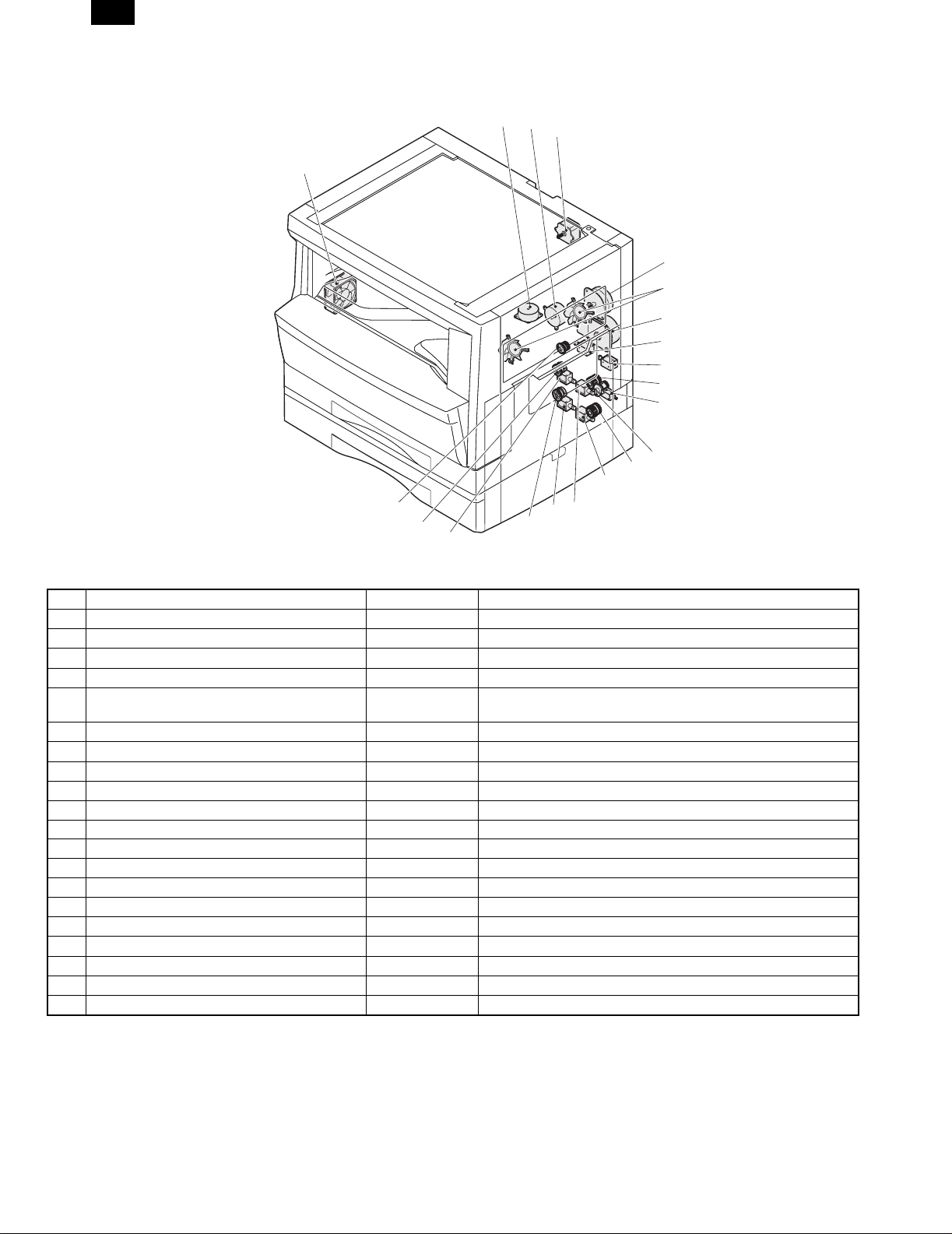

4. Motor, solenoid, clutch

2

3

4

1

5

6

7

8

9

10

11

12

13

14

20

19

18

17

16

15

No. Name Code Function, operation

1 Exhaust fan motor VFM Cools the inside of the machine.

2 Shifter motor SHTM Shifts the paper exit tray. (AR-161/200/205)

3 Toner motor TM Toner supply

4 Mirror motor MRM Drives the optical mirror base (scanner unit).

5 Duplex motor DPX Switchback operation and paper exit motor in duplex. (only

6 Cooling fan motor CFM Cools the inside of the machine.

7 Main motor MM Drives the machine.

8 Paper feed solenoid CPFS1 Solenoid for paper feed from cassette

9 Resist roller solenoid RRS Resist roller rotation control solenoid

10 Manual paper feed clutch MPFC Drives the manual paper feed roller.

11 Manual paper feed solenoid MPFS Manual paper feed solenoid

12 Manual paper transport clutch MPTC Drives the manual paper transport roller.

13 Second tray transport clutch CPFC2 Drives the second tray transport roller.

14 Second tray transport solenoid FSOL2 Second tray transport solenoid

15 First tray transport solenoid FSOL1 First tray transport solenoid

16 Second tray paper feed solenoid PSOL2 Second tray transport solenoid

17 Paper feed clutch CPFC2 Drives the cassette paper feed roller.

18 First tray paper feed solenoid PSOL1 First tray transport solenoid

19 First tray paper feed clutch CPFC1 Drives the first tray transport roller.

20 PS clutch RRC Drives the resist roller

AR-205)

4 – 3

5. Sensor, switch

AR-205

23

123

20

21

22

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

No. Name Code Function, operation

1 Mirror home position sensor MHPS Detects the mirror (scanner unit) home position.

2 Document size sensor DSIN Paper size detection

3 Toner density sensor TCS Toner quantity detection

4 Paper exit sensor (paper exit side) POD1 Detects paper exit.

5 OC open/close sensor DOC COVER

6 Right door switch DSWR Side door open/close detection

7 Paper full sensor P FULL Paper exit tray section full detection <For JOB separator>

8 Lift sensor LFTHP Paper feed tray lift up detection <For JOB separator>

9 Lower limit sensor JTRAY Job separator tray lower limit detection

10 Paper exit sensor (DUP side) PDPX Paper transport detection

11 Shifter home position sensor SFTHP Shifter home position detection

12 Thermistor RTH Fusing section temperature detection

13 Thermostat Fusing section abnormally high temperature detection

14 1st tray detection switch 1st tray detection

15 Paper in PIN Paper transport detection

16 2nd tray detection switch 2nd tray detection

17 Manual sensor MPED Manual transport detection

18 Second cassette door open/close sensor DRS2 Second cassette door open/close detection

19 Second cassette paper entry sensor PPD2 Paper transport detection

20 First tray paper empty sensor CSS1 First tray paper empty detection

21 Second tray paper empty sensor CSS2 Second tray paper empty detection

22 Drum reset switch DRST New drum detection switch

23 Power switch MAIN SW Turns ON/OFF the main power source.

4 – 4

AR-205

6. PWB unit

1234

9

8

65

7

No. Name Function, operation

1 Copy lamp invertor PWB Copy lamp control

2 Power PWB AC power input/DC power control

3 High voltage PWB High voltage control

4 CCD sensor PWB Image scanning

5 Main PWB (MCU) Machine control/Image process

6 Paper exit interface PWB Paepr exit, finishing control

7 Tray interface PWB Paper tray control

8 Electronic sort function Operation panel input/Display

9 Operation main PWB Operation panel input/Display, operation panel section control

4 – 5

7. Cross sectional view

12 3 45

AR-205

6

17

7

8

9

10

11

12

13

14

15

1819202122

16

No. Name Function/Operation

1 Copy lamp Image radiation lamp

2 Copy lamp unit Operates in synchronization with No. 2/3 mirror unit to radiate documents sequentially.

3 LSU unit Converts image signals into laser beams to write on the drum.

4 Lens unit Reads images with the lens and the CCD.

5 MC holder unit Supplies negative charges evenly on the drum.

6 Paper exit roller Used to discharge paper.

7 Transport roller Used to transport paper.

8 Upper heat roller Fuses toner on paper (with the teflon roller).

9 Lower heat roller Fuses toner on paper (with the silicon rubber roller).

10 Waste toner transport roller Transports waste toner to the waste toner box.

11 Drum unit Forms images.

12 Transfer charger unit Transfer images (on the drum) onto paper.

13 Duplex transport roller Transports paper for duplex (only AR-205).

14 Resist roller Takes synchronization between the paper lead edge and the image lead edge.

15 Manual paper feed tray Manual paper feed tray

16 Manual paper feed roller Picks up paper in manual paper feed.

17 No. 2/3 mirror unit Reflects the images from the copy lamp unit to the lens unit.

18 Manual transport roller Transports paper from the manual paper feed port.

19 2nd tray paper transport roller Transports paper from the 2nd tray.

20 2nd tray paper feed roller (semi-circular

roller)

21 1st tray paper feed roller (semi-circular

roller)

22 MG roller Puts toner on the OPC drum.

DUP transport roller Paper transport roller in duplex.

Picks up paper from the 2nd tray.

Picks up paper from the 1st tray.

4 – 6

AR-205

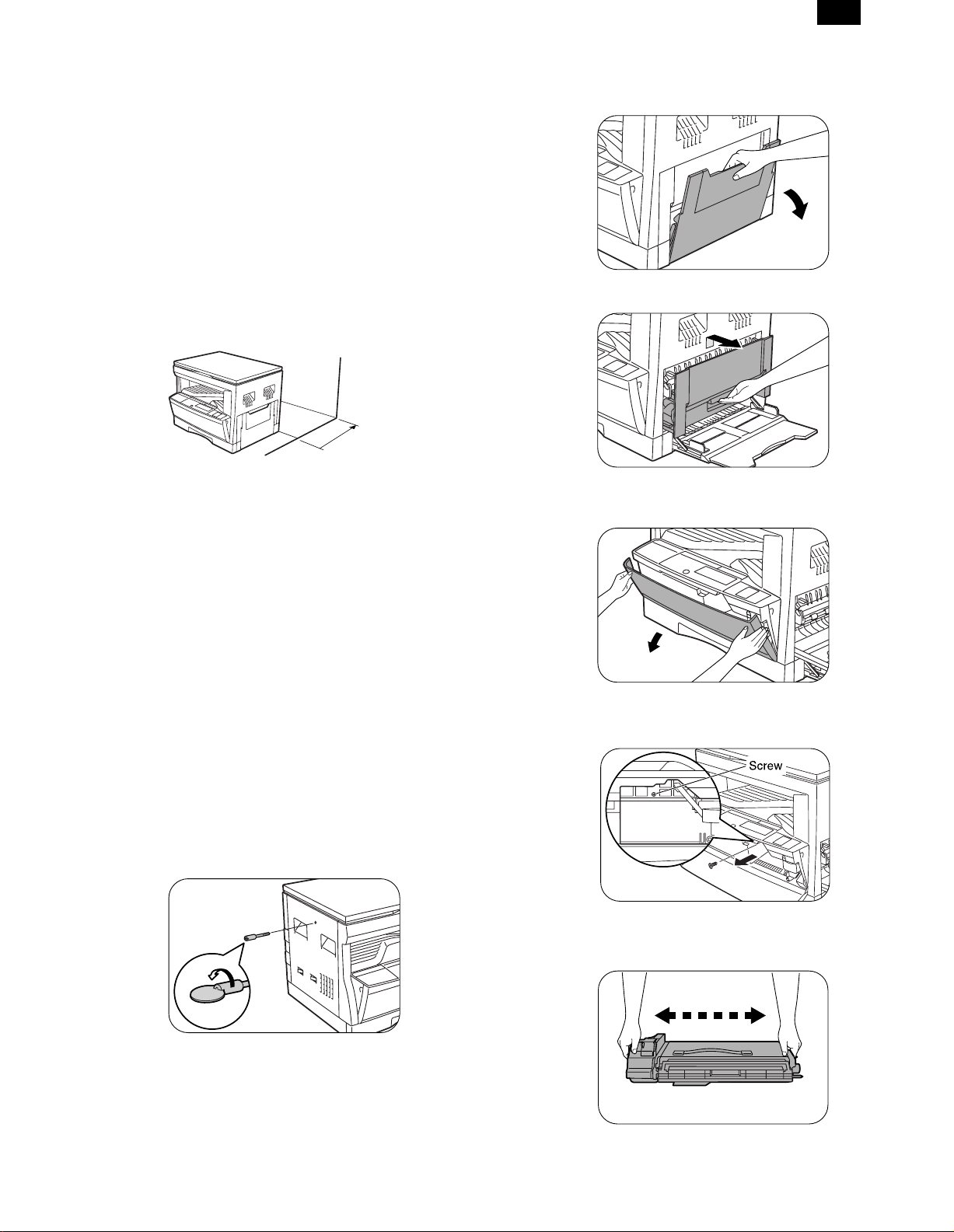

[5] UNPACKING AND

INSTALLATION

1. Installing conditions

1) Copier installation

Do not install your copier in areas that are:

• damp, humid, or very dusty

• exposed to direct sunlight

• poorly ventilated

• subject to extreme temperature or humidity changes, e.g., near an

air conditioner or heater.

• Be sure to allow the required space around the machine for servic-

ing and proper ventilation.

4" (10 cm)

2) Power source

• Use an exclusive-use power outlet. If the power plug of this

machine is inserted into a power outlet commonly used with other

illumination units, flickers of the lamp may be result. Use a power

outlet which is not used commonly with any illumination units.

• Avoid complex wiring.

3) Grounding wire connection.

• To avoid danger, be sure to connect a grounding wire. If no

grounding wire is connected and a leakage occurs, a fire or an

electric shock may be result.

3. Installation of developing cartridge

1) Open the manual paper feed tray.

2) Lift the knob and slide the side cover gently.

3) Open the front cover.

• Hold the both edge gently and open the front cover.

2. Removal of protective material and

fixing screw

1) Remove all tapes and protective material.

• Remove all tapes, then open the document cover and remove

the protective material of sheet shape

2) Remove the fixing screw.

• Use a coin to remove the fixing screw.

• The fixing screw is required when transporting the machine.

Keep it in the tray. (Refer to the later description.)

4) Remove the screw from the upper section of the insertion port of

the developer cartridge.

5) Shake a new developer cartridge a few times as shown.

• Shake it horizontally as shown with the arrow.

5 – 1

AR-205

6) Remove the pawls (3 positions) of the protective cover at the rear

side.

7) Remove the protective cover.

• Pull the cover in the arrow direction to remove.

8) Insert the developer cartridge.

• Gently insert the developer cartridge along the guide until it

locks.

4. Removal and storage of fixing screw

1) Lift the knob and gently pull out the tray.

2) Hold the paper pressure plate and turn the fixing screw in the

arrow direction.

3) Store the fixing pin and the fixing screw in the tray.

• Store the fixing screw which was removed in the above proce-

dure 2 and the fixing screw which was removed in procedure 2

of 2.

• Removal of protective material and fixing screw in the storage

place in the tray.

9) Fix the developer cartridge with the fixing screw which is packed

together with the machine.

10) Close the front cover A, then close the side cover B.

• When closing the front cover, gently press the both sides.

• When closing the side cover, hold the knob.

• When closing the covers, be sure to close the front cover first,

then close the side cover. If closed in a wrong sequence, the

covers may be broken.

B

Pressure

plate

lock

Screw

A

5 – 2

Front guide

Left guide

AR-205

5. Changing the copy paper size in the tray

1) Gently lift and pull out the paper tray until it stops.

2) Push the pressure plate down until it locks in place.

3) Squeeze the lock lever of the front guide and slide the front guide

to match the width of the paper.

4) Move the left guide to the appropriate slot as marked on the tray.

• When using 11" ×17" copy paper, store the left guide in the slot

at the left front of the paper tray.

10) Use the ORIGINAL SIZE ENTER key to select the paper size

which is set.

• Each time the ORIGINAL SIZE ENTER key is pressed, a

paper size will be indicated with a blinking paper size indicator.

11) Press the START key and then the PAPER SIZE ENTER key.

• To change the paper size setting of another tray, repeat steps

9 to 10 after pressing the START key.

5) Load copy paper into the tray.

6) Place the paper size plate in the front of the paper tray.

• The paper size indication which shows through the slot on the

front of the copier should match the selected paper size.

7) Push the paper tray firmly back into the copier.

8) To set the selected paper size, press and hold down the PAPER

SIZE ENTER key. The selected paper feed location indicator and

the corresponding paper size (which has been set) indicator will

blink. All other indicators will go out.

• For paper size setting, ensure that the COPY mode has been

selected. However, if printer or facsimile output is being performed, paper size setting cannot be made even in the COPY

mode.

9) Use the TRAY SELECT key to select the paper tray of which the

paper size has been changed.

• Each time the TRAY SELECT key is pressed, a paper tray is

indicated with a blinking paper feed location indicator. If an

optional paper feed unit is not installed, this operation is not

needed.

5 – 3

Loading...

Loading...