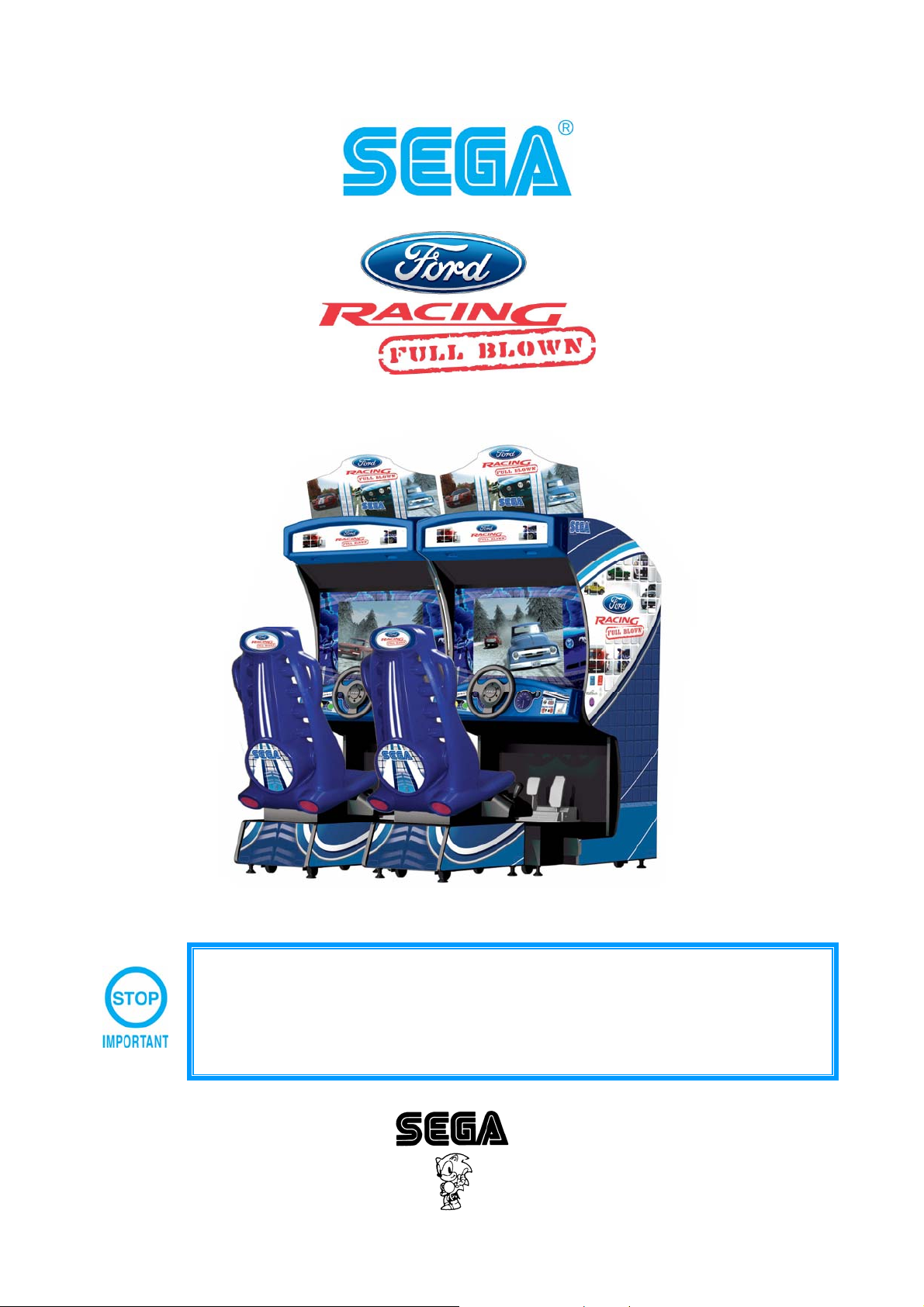

Sega FORD RACING TWIN User Manual

420-FRSM-02UK REV 2

TWIN DRIVING CABINET

• Before using this product, read this MANUAL carefully to understand the contents

stated herein.

• After reading this MANUAL, be sure to keep it available nearby the product or

Manufactured in the UK by

somewhere convenient in order to be able to refer to it whenever necessary.

SERVICE MANUAL

Amusements Europe Limited

BEFORE USING THIS PRODUCT

To ensure the safe usage of the product, be sure to read the following before using the product. The

following instructions are intended for the use of QUALIFIED SERVICE PERSONNEL ONLY

reading and sufficiently understanding the instructions should any activity be carried out on the product.

Only qualified service personnel should carry out maintenance on the product.

Terms such as WARNING!, CAUTION, and IMPORTANT! Are used where an explanation is given which

requires special attention, depending on the potential risk. SEGA is not responsible for injury or damage

caused by use in a manner contrary to the instructions stated in this document. In order to prevent

accidents warning stickers and printed instructions are applied in the places where a potentially hazardous

situation relating to the product could arise. Be sure to comply with these warnings.

Indicates that mishandling the product by disregarding this warning will cause a

potentially hazardous situation which can result in death or serious injury.

Indicates that mishandling the product by disregarding this caution will cause a

potentially hazardous situation which can result in personal injury and or material

damage.

. After carefully

This is cautionary information which should be complied with when handling the

product. Indicates that mishandling the product by disregarding this will cause a

potentially hazardous situation which may not result in personal injury but could

damage the product.

• Perform work in accordance with the instructions herein stated.

Instructions for work are explained by paying attention to the aspect of accident prevention. Failing

to perform work as per the instructions can cause accidents. In the case where only those who

have technical expertise should perform the work to avoid hazardous situations, the instructions

herein state that the service person(s) should perform such work.

• Be sure to turn off power before working on the machine.

To prevent electrical shock, be sure to turn off power before starting work in areas in which which

the service person(s) touches the interior of the product. If the work has to be performed with the

power-on status, the instructions herein will state that only a qualified service person(s) should

perform such work.

• Ensure that the Power Supply used is equipped with an Earth Leakage Breaker.

This product does not incorporate an Earth Leakage Breaker. Using a power supply which is not

equipped with an Earth Leakage Breaker may cause a fire or serious injury.

• Be sure to use fuses which meet the specified rating.

Using fuses exceeding the specified rating can cause a fire and / or cause a n electric shock.

• Specification changes, removal of equipment, conversion and/or addition, not designated by

SEGA are not permitted and will invalidate this product’s CE conformity.

The parts of the product also include any warning labels or safety covers for personal protection

etc. A potential hazard will be created if the machine is operated while any parts have been

removed. Should any doors, lids or protective covers be damaged or lost, do not operate the

product. SEGA is not liable in any whatsoever for any injury and/or damage caused by specification

changes not designated by SEGA.

• When handling the monitor, be very careful. (Applies only to product with monitor).

Some of the monitor (TV) parts are subject to high tension voltage. Even after turning off the power

some components are still occasionally subject to high tension voltage. Monito r repair and

replacement should be performed by qualified service engineers only.

i

• Install and operate the machine only in places where appropriate lighting is available,

allowing warning stickers to be clearly read.

To ensure maximum safety for both customers and operators, stickers and printed instructions

describing potentially hazardous situations are applied to places where accidents co uld occur.

Ensure that where the product is operated has sufficient lighting to allow any warnings to be read. If

any sticker or printed warning is removed or defaced, do not operate the machine, until it has been

replaced by an identical item.

Before installing the product, check for the Electrical Specification Sticker, SEGA product s have a sticker on

which the electrical specifications are detailed. Ensure that the product is compatible with the power supply

voltage and frequency requirements of the location in which the machine is to be installed.

When installing this equipment ensure the socket outlet is near the machine and is easily accessible.

In cases where commercially available monitors and printers are used only the contents relating to this

product are stated in this manual. Some commercially available equipment has functions and reactions not

stated in this manual. Read this manual in conjunction with the specific manual of such equipment.

Descriptions contained herein may be subject to change without prior notification.

The contents described herein are fully prepared with due care. However, should any question arise or

errors be found please contact SEGA.

INSPECTION IMMEDIATELY AFTER TRANSPORTING THE PRODUCT TO LOCATION

Normally, at the time of shipment, SEGA products are in a state which allow for immediate usage after

transportation to location. Nevertheless, an irregular situation may occur during transportation. Before

applying power to the product, check the following points to ensure that the procuct has been transported in

a satisfactory status.

• Is there any external damage to the machine i.e. dents, cuts or cracks?

• Are the castors or leg adjusters damaged?

• Do the power supply voltage and the frequency of the machine meet the requirements of the

location?

• Are all wiring connectors correctly connected and secure?

• Are the power cables undamaged?

• Do the fuses meet the specified rating?

• Are all accessories available?

• Can all doors be opened and closed and locked with the keys provided?

ii

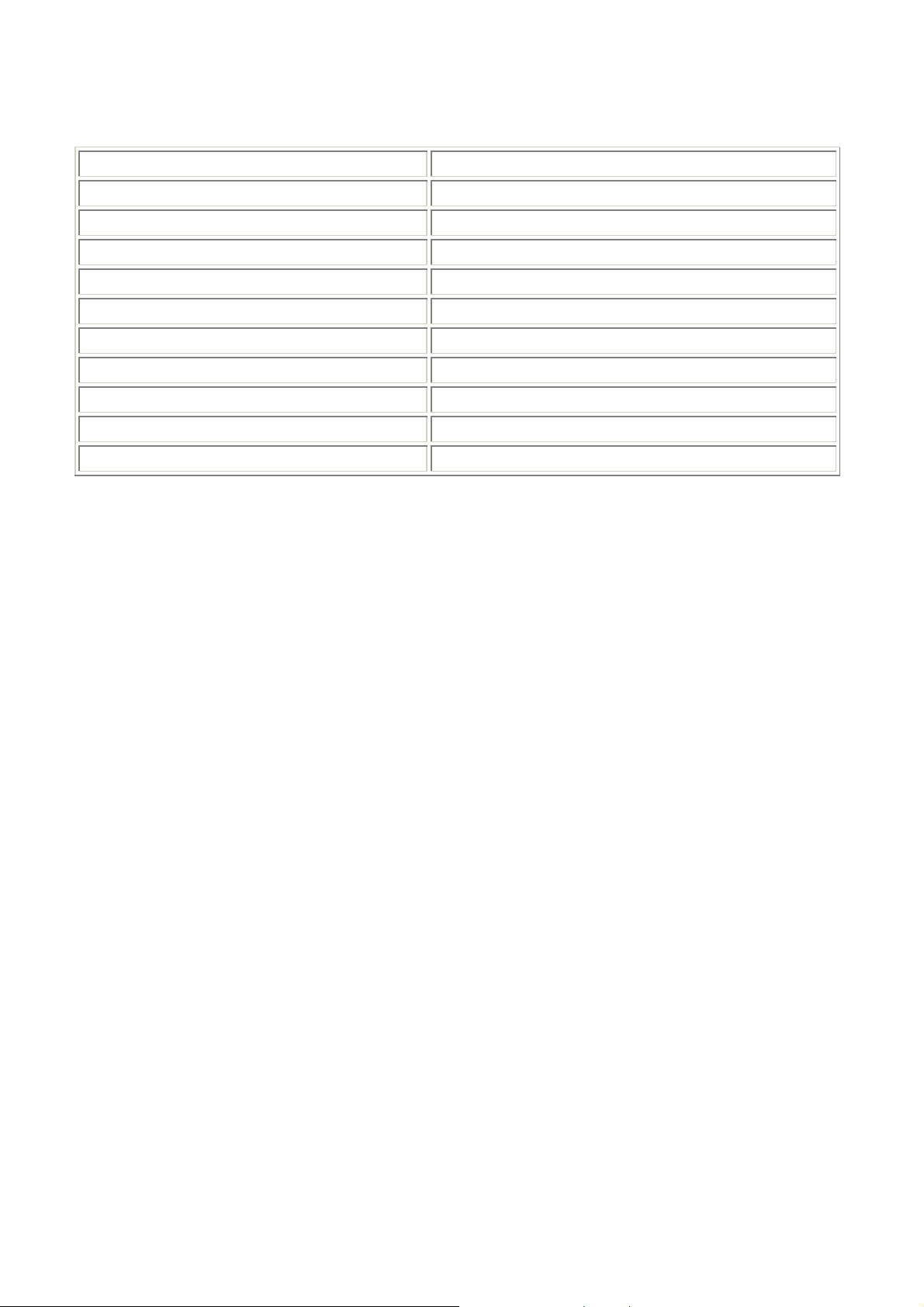

CONTENTS

SPECIFICATIONS........................................................................................................................................1

INTRODUCTION TO THIS MANUAL...........................................................................................................1

1. HANDLING PRECAUTIONS.................................................................................................................3

2. PRECAUTIONS REGARDING LOCATION AND INSTALLATION.......................................................5

3. OPERATION..........................................................................................................................................7

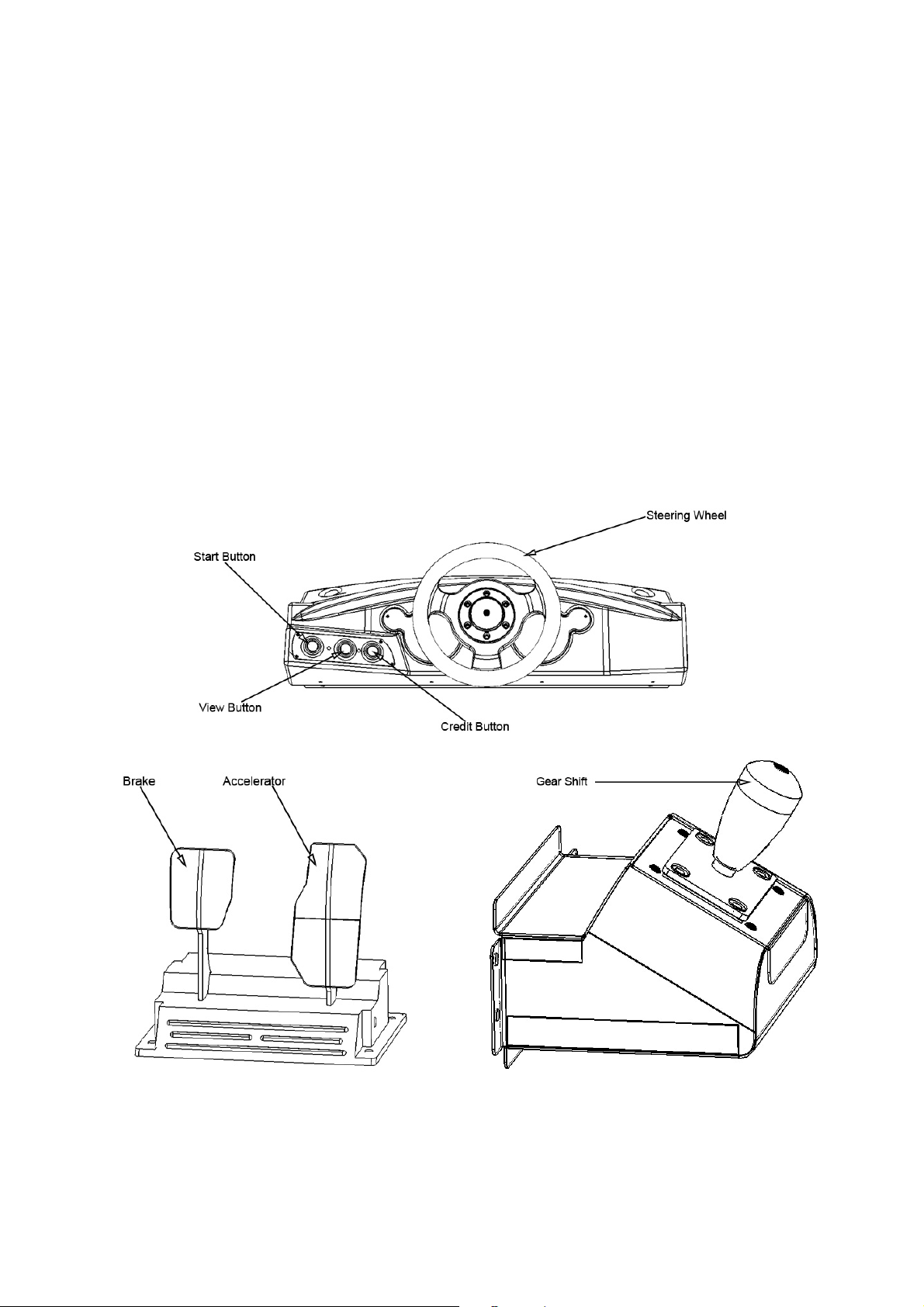

4. NAME OF PARTS..................................................................................................................................9

5. ACCESSORIES...................................................................................................................................10

6. FUSES.................................................................................................................................................11

7. ASSEMBLING WITH PRECAUTIONS................................................................................................12

8. PRECAUTIONS TO BE TAKEN WHEN MOVING THE MACHINE....................................................23

9. BASIC CONTENTS OF THE GAME ...................................................................................................24

10. EXPLANATION OF TEST AND DATA DISPLAY................................................................................25

10.1. VTS BOARD – SWITCHES AND COIN COUNTER....................................................................26

10.2. TEST MODE.................................................................................................................................27

10.3. SYSTEM INFORMATION.............................................................................................................28

10.4. UGCI TEST...................................................................................................................................29

10.5. INPUT TEST.................................................................................................................................30

10.6. CALIBRATION TEST ...................................................................................................................31

10.7. OUTPUT TEST.............................................................................................................................32

10.8. COIN TEST...................................................................................................................................33

10.9. SOUND TEST...............................................................................................................................34

10.10. CRT TEST....................................................................................................................................35

10.11. DRIVE BOARD TEST...................................................................................................................36

10.12. BOOKKEEPING ...........................................................................................................................37

10.13. CLOCK SETTINGS ......................................................................................................................40

10.14. NETWORK TEST.........................................................................................................................41

10.15. GAME TEST MODE.....................................................................................................................42

11. HOW TO PLAY....................................................................................................................................43

12. UPGRADES.........................................................................................................................................54

13. HANDLE MECHANISM.......................................................................................................................55

13.1. REMOVING THE CONTOL PANEL.............................................................................................55

13.2. REPLACING AND ADJUSTING THE HANDLE’S V.R. ...............................................................56

13.3. GREASING...................................................................................................................................57

14. SHIFT LEVER......................................................................................................................................58

14.1. REMOVING THE SHIFT LEVER..................................................................................................58

14.2. SWITCH REPLACEMENT ...........................................................................................................59

15. ACCELERATOR & BRAKE.................................................................................................................60

15.1. ADJUSTING AND REPLACING THE V.R. ..................................................................................60

16. COIN SELECTOR................................................................................................................................62

17. MONITOR............................................................................................................................................63

17.1. CAUTIONS CONCERNING THE SAFETY ISSUES WHEN HANDLING THE MONITOR..........63

17.2. CAUTIONS TO BE AWARE OF WHEN CLEANING THE CRT SURFACES..............................64

17.3. ADJUSTING THE PICTURE........................................................................................................65

18. REPLACEMENT OF FLUORESCENT LAMPS...................................................................................66

19. REPLACEMENT OF BUTTON LAMPS...............................................................................................68

20. GAME BOARD.....................................................................................................................................70

20.1. REMOVING THE GAME BD........................................................................................................70

20.2. GAME BOARD CONNECTIONS..................................................................................................72

21. UGCI BOARD......................................................................................................................................73

22. NETWORK PLAY ................................................................................................................................74

22.1. CONNECTIONS FOR NETWORK PLAY.....................................................................................76

22.2. NETWORK PLAY SETTINGS......................................................................................................77

23. COIN SETTINGS.................................................................................................................................78

23.1. VTS CREDIT BOARD OPTION SETTINGS ................................................................................80

23.2. PRICE OF PLAY SETTINGS UK .................................................................................................81

23.3. PRICE OF PLAY SETTINGS EURO............................................................................................82

24. DESIGNED RELATED PARTS ...........................................................................................................83

25. PARTS LIST ........................................................................................................................................84

25.1. TOP ASSY FORD RACING TWIN – FR00001UK.......................................................................85

25.2. ASSY MAIN 1P – FR-10001UK....................................................................................................86

25.3. ASSY CONTROL PANEL – FR-2000UK .....................................................................................88

iii

ASSY HANDLE MECHA – FR-2500UK.......................................................................................89

25.4.

25.5. ASSY SW PLATE – FR-2100UK..................................................................................................90

25.6. ASSY HEADER – FR-0200UK.....................................................................................................91

25.7. ASSY POP – FR-0270UK ............................................................................................................91

25.8. ASSY FAN UNIT DC – HDT-1530UK ..........................................................................................92

25.9. ASSY SEAT TWIN 1P – FR-5000UK...........................................................................................93

25.10. ASSY SEAT CABI – FR-5500UK.................................................................................................93

25.11. ASSY SEAT UNIT – FR-5600UK .................................................................................................94

25.12. ASSY AC BRKT MAIN – FR-0400UK ..........................................................................................95

25.13. ASSY AC BKT SUB – FR-0700UK ..............................................................................................95

25.14. ASSY PEDAL BASE L – FR-1100UK ..........................................................................................96

25.15. ASSY PEDAL BASE R – FR-1150UK..........................................................................................96

25.16. ASSY BRAKE & ACCEL – SPG-2200 .........................................................................................97

25.17. ASSY MAIN BD PC MASTER – FR-4500UK...............................................................................99

25.18. ASSY MAIN BD PC SLAVE – FR-4600UK ................................................................................100

25.19. ASSY COINCHUTE TOWER .....................................................................................................101

25.20. ASSY INSTALLATION KIT FR TWIN – FR-INST-TW................................................................102

26. APPENDIX A - ELECTRICAL SCHEMATIC .....................................................................................103

26.1. WIRE COLOURS .......................................................................................................................103

26.2. ELECTRICAL SCHEMATIC.......................................................................................................103

iv

SPECIFICATIONS

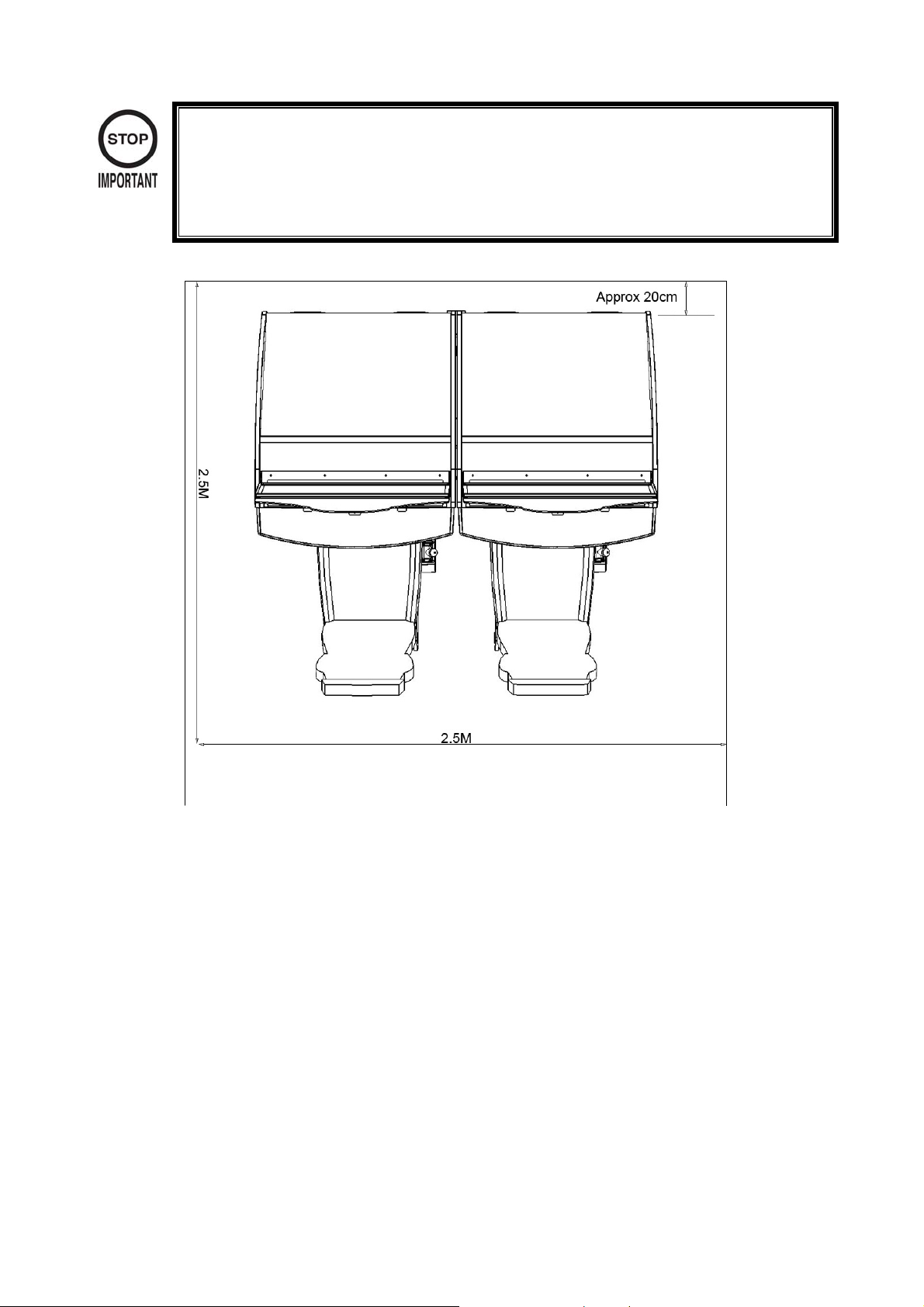

Installation space: 250cm (W) x 250cm (D)

Height: 217cm

Depth: 178cm

Width: 171cm

Weight: 500kgs (approx)

Rating: 3.5A MAX

Monitor type: SANWA 29” PFX FST

Monitor Operational Voltage: 230vac – 240vac

Display output: RGB

Operational Voltage 220vac – 240vav

Power Consumption 800W MAX

INTRODUCTION TO THIS MANUAL

This Owners Manual is intended to provide detailed descriptions together with all the necessary information

covering the general operation of electronic assemblies, electro mechanicals, servicin g control, spare parts,

etc. as regards to the product FORD RACING TWIN – FULL BLOWN.

This manual is intended for the owners, personnel and managers in charge of the operation of this product.

Only operate the product after carefully reading and sufficiently understanding the instructions. If the

product fails to function satisfactory, non-technical personnel should under no circumstances touch the

internal workings of this machine. Please contact where the product was pu rchased.

SEGA AMUSEMENTS EUROPE LIMITED

Suite 3a, Oaks house.

12-22 West Street,

Epsom.

Surrey.

KT18 7RG

Tel: +44 (0) 1372 731820

Fax: +44 (0) 1372 731849

1

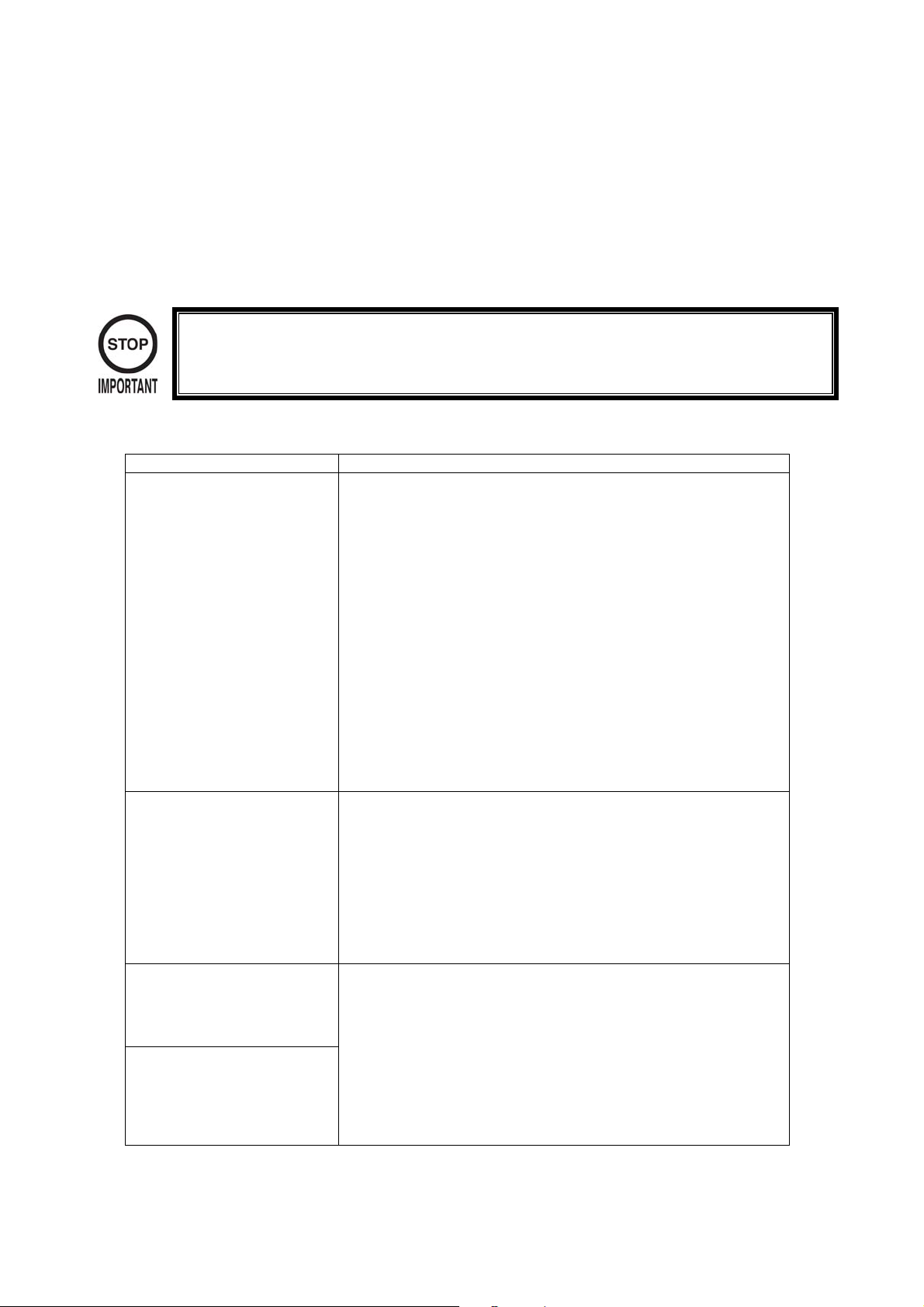

DEFINITION OF THE QUALIFIED SERVICE ENGINEER AND MAINTENANCE PERSONEL

Non-technical personnel who do not have technical knowledge and expertise sh ould refrain

from performing such work that this manual requires. Only QUALIFIED SERVICE

ENGINEERS should carry out work either inside or outside the compass of this manual.

Failure to comply with this instruction may cause a severe accident or even death.

Ensure that all service, inspection repair work and troubleshooting is carried out by a

QUALIFIED SERVICE ENGINEER.

All other work i.e. cleaning and general upkeep of the machine (supplying data cards, repairing

coin jams or re-booting a machine) can be carried out by the LOCAL MAINTENANCE

PERSONEL.

“QUALIFIED SERVICE ENGINEER”

Those who participate in the design, manufacture, inspection, maintenance or service of

equipment at an amusement equipment manufacturer.

Those who have technical expertise with qualified certification regarding electricity, electronics

and or mechanical engineering and take part in a daily service and control of amusement

equipment.

“LOCAL MAINTENANCE PERSONEL”

Those who have experience in maintenance of amusements equipment and or vending

machines and also participate in daily routine work of general maintenance of the product.

2

1. HANDLING PRECAUTIONS

When installing or inspecting the machine, be very careful of the following points and pay

attention to ensure that the player can enjoy the game in safety.

Non-compliance with the following points or inappropriate handling running counter to the

cautionary matters herein stated can cause personal injury or damage to the machine.

• Before performing the work, be sure to turn the power off. Performing the work

without turning off the power can cause electric shock or short circuit. In the case

where work should be performed in the status of power on, this manual will state to

that effect.

• To avoid electric shock or short circuit, do not apply or disconnect power to the

machine in a quick or haphazard manner.

• To avoid electric shock, do not apply power to the machine with wet hand(s).

• Do not expose Power Cords or Earth Wires on the surface, (floor, passage, etc.) If

exposed, the Power Cord or Earth Wires are sustainable to damage. Damaged

Cords or Wires can cause an electric shock or short circuit which may lead to a fire

hazard.

• To avoid causing a fire and or electric shock, do not put objects on Power Cords or

Earth Wires.

• When or after installing the product, do not unnecessarily pull the Power Cord. If

damaged the Power Cord may cause an electric shock and or fire hazard.

• In case the Power Cord is damaged, ask for a replacement through where the

product was purchased or the office stated herein. Using a damaged Power Cord can

cause and electric shock or fire hazard.

• Be sure to perform correct earth checks and make sure that the machine is correctly

earthed. Inappropriate earthing of the product may cause electric shock or fire

hazard.

• Be sure to use fuses which meet the specified rating. Using fuses which exceed the

specified rating can cause electric shock, short circuit and or fire hazard.

• Ensure all connections are made fully. Connections which are not fully made may

cause electric shock or fire hazard.

• To avoid causing a fire hazard or an electric shock, do not make any unspecified

changes to the product by replacing or changing parts or components without the

express consent of SEGA.

• Be sure to make periodic maintenance checks as stated herein.

• Only a QUALIFIED ELECTRONICS ENGINEER is allowed to perform IC BOARD

inspection or analysis using a LOGIC ANALYSER. The use of a MULTIMETER is not

permitted on IC BOARDS.

• When cleaning the CRT surfaces, use a soft dry cloth. Do not apply chemicals such

as thinners, benzene, etc.

• The electronic parts on the IC BOARD could be damaged due to human body static

electricity. Before performing IC BOARD related work, be sure to discharge physically

accumulated static by discharging on a grounded metallic surface.

3

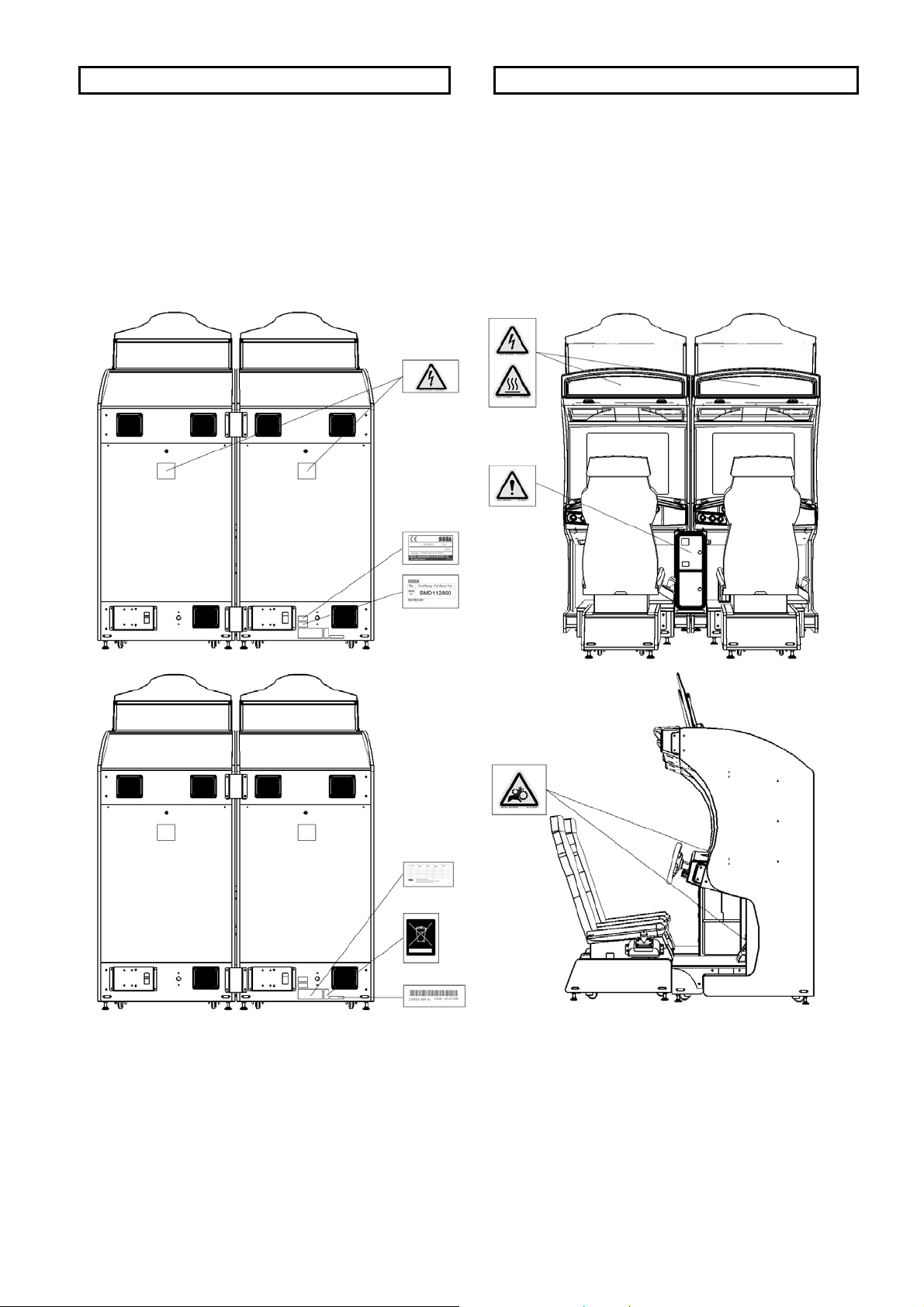

CONCERNING THE STICKER DISPLAY CONCERNING WARNING STICKERS

SEGA product has stickers describing the product

manufacture number (Serial Number) and electrical

specification. If you require service assistance you

will require the Serial Number. Identical machines

may have different parts fitted internally. Only by

quoting the Serial Number will the correct parts be

SEGA product has warning displays on stickers,

labels or printed instructions adhered/attached to

or incorporated in the places where hazardous

situations can arise. The warning displays are

intended for the accident prevention of customers

and service personnel.

identified.

4

2. PRECAUTIONS REGARDING LOCATION AND INSTALLATION

This product is an indoor amusement machine. Do not install it outside. Even indoors, avoid

installing in places mentioned below sp as not to cause a fire, electric shock, injury and or

malfunction.

• Places subject to rain or water leakage, or places subject to high humidity in the

proximity of an indoor swimming pool and or shower, bath etc.

• Places subject to direct sunlight, or places subjected to high temperatures such as in

the vicinity of heating units, etc.

• Places filled with inflammable materials or chemicals or any hazardous matter.

• Dusty places.

• Sloped surfaces.

• Places subjected to any type of violent impact.

• Vicinity of anti-disaster facilities such as fire escapes and fire extinguishers.

• The operating (ambient) temperature range is from 5 degrees centigrade to 40

degrees centigrade. Only in the cases where a projector is employed then the

temperature drops from 40 to 30 degrees centigrade.

• This appliance is not suitable for installation in an area where a water jet could be

used

LIMITATIONS OF USAGE REQUIREMENTS

• Be sure to check the electrical specifications. Ensure that this product is compatible

with the locations power supply voltage and frequency requirements. A plate

describing the electrical specifications is attached to the product. Non-compliance

with the electrical specification can cause fire or electrical shock.

• This product requires a RCD as part of the location facilities. Using them in a manner

not independent can cause an electric shock or a fire.

• Ensure that the indoor wiring for the power supply is rates at 7A or higher in areas

using 220 – 240VAC. Non-compliance with this may cause electric shock or a fire.

• Be sure to independently use the power supply equipped with an Earth leakage

breaker. Using a power supply without an Earth leakage breaker can cause a fire

when earth leakage occurs.

• Putting many loads on one electrical outlet can cause a generation of heat and a fire

may result from an overload.

• When using an extension cord, ensure that the cord is rated at 7A or higher. Using a

cord rated lower than the specified rating may cause a fire or electric shock.

5

• Note that for transporting the machine to location the minimum necessary dimensions

required for opening (of doors, etc.) are 1.85M x 1.05M (without shipping pallet.).

• For the operation of this machine, secure a minimum area of 2.5M x 2.5M. For

ventilation, provide an approximately 20cm space between the rear part of the

cabinet and the wall.

6

3. OPERATION

PRECAUTIONS TO BE HEEDED BEFORE STARTING OPERATION

To avoid injury be sure to constantly give careful attention to the behaviour and manner of players and

spectators.

In order to avoid accidents, check the following before starting operation.

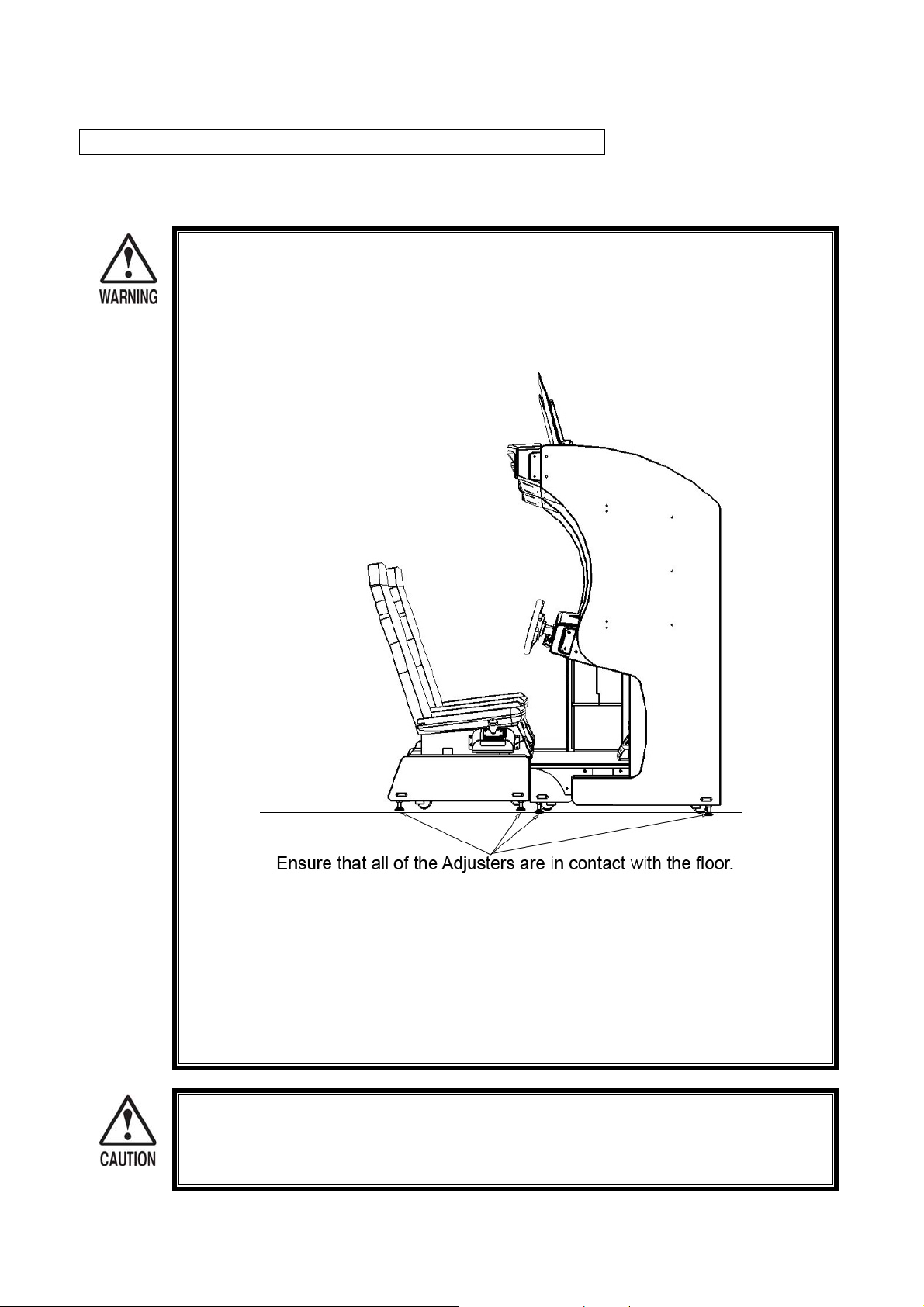

• Check if all of the adjusters are in contact with the surface. If they are not, the cabinet

may move and cause an accident.

• Do not put any heavy item on this product. Placing any heavy item on the product

can cause accidental injury.

• Do not climb on this product. Climbing on this product can cause an accident or

injury. To check the upper most part of this product, please you a step.

• To avoid electric shock, short circuit or damage, do not put the following items in the

periphery of this product.

Flower vases, flowerpots, cups or any vessels which can contain water or chemicals.

To avoid injury, be sure to provide sufficient space by considering the potentially crowde d

situation at the installation location. Insufficient installation space can cause the player to

come into contact with other resulting in injury.

7

PAYING ATTENTION TO CUSTOMERS

To avoid injury or confrontation between customers, be sure to constantly give careful attention to the

behaviour and manners of the players and visitors.

• To avoid electric shock and or short circuit, do not allow customers to put hands or

fingers or any other extraneous matter into the openings of the product.

• To avoid injury from items falling from the machine, immediately stop customers from

either putting items on top of the product or leaning against or climbing on the

product.

• To avoid electric shock and or short circuit, do not allow customers to unplug the

power cause at any cause.

• To avoid injury resulting from items falling from the machine, instruct the player not to

place items or drinks onto the product.

• Immediately stop such violent acts as hitting or kicking the product. Such violent acts

can cause damage to the product or injury to the player or observer.

8

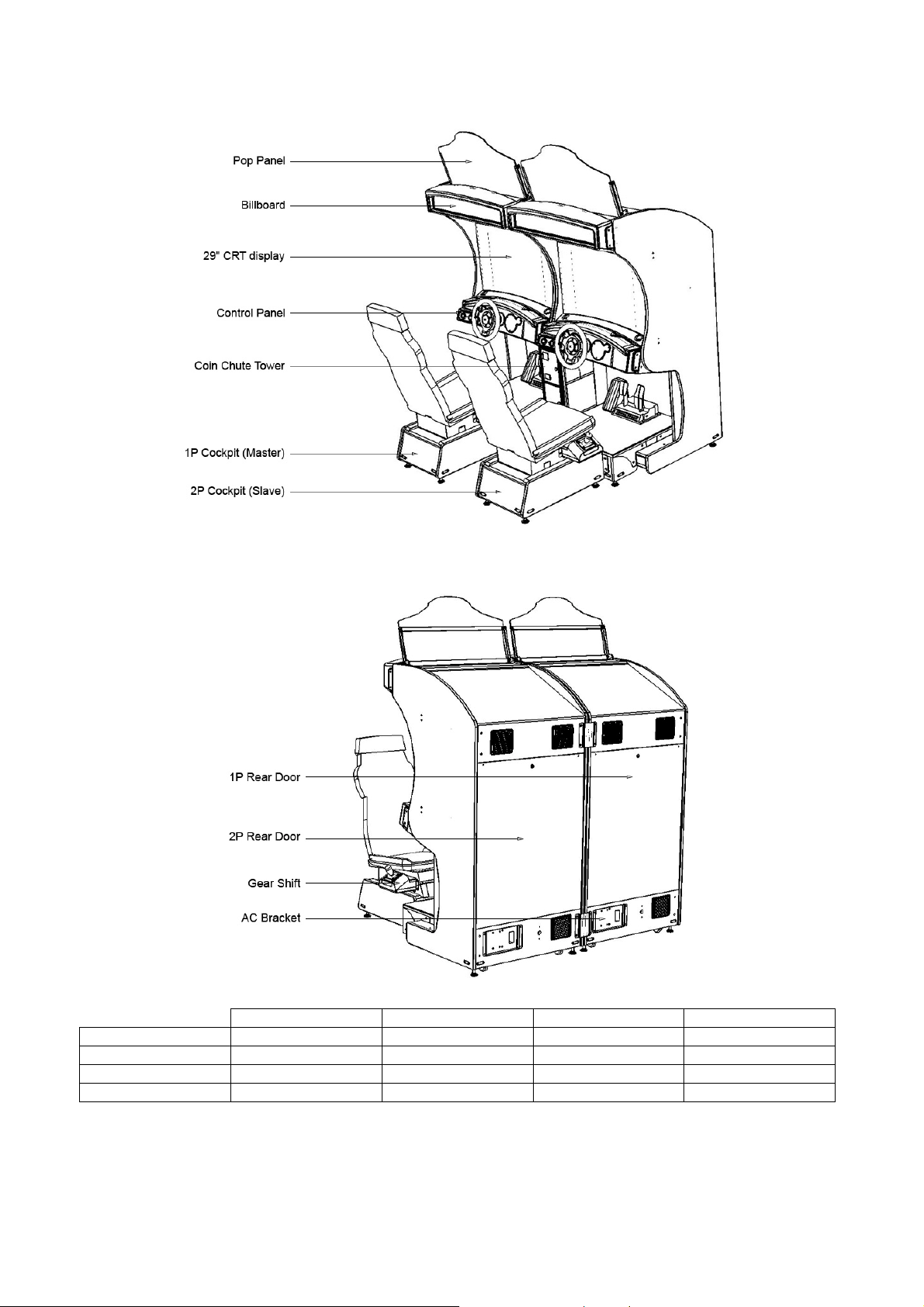

4. NAME OF PARTS

Width Depth Height Weight

Cockpit (per seat) 852mm 1630mm 1790mm

Coin Chute Tower 220mm 300mm 550mm 15kg

Pop Panel 800mm - 430mm

When Assembled 1713mm 1624mm 2200mm

9

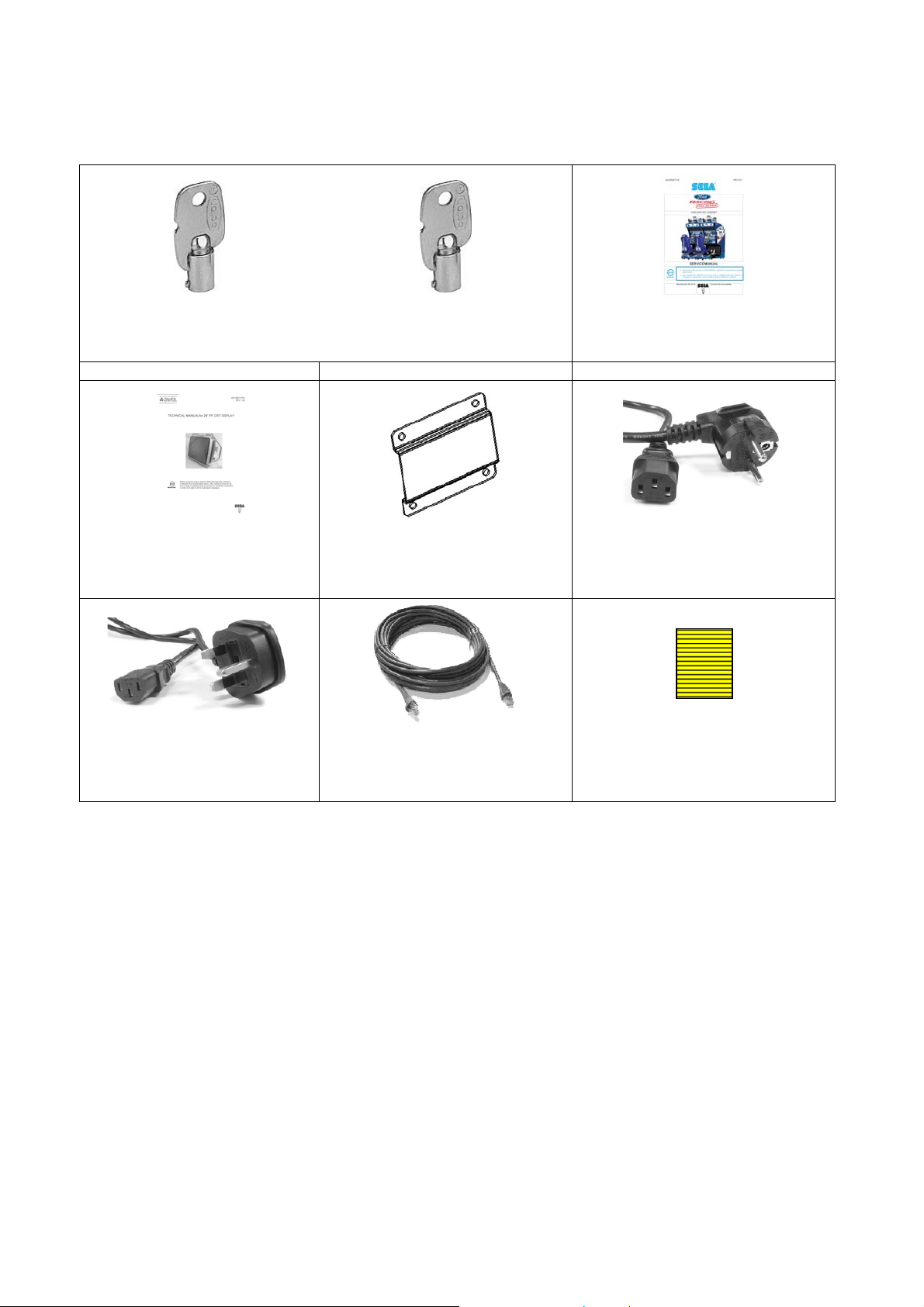

5. ACCESSORIES

When transporting the machine to location, make sure that the following parts are supplied.

KEYS MASTER 9117 KEY TO DIFFER SERVICE MANUAL FR

For opening and closing service

doors

PT No 220-5575UK PT No 220-5574-110UK PT No: 420-FRSM-02UK

SERVICE MANUAL SANWA JOINT BKT REAR X 2 POWER CORD EUROPE

Sanwa CRT Service Manual

PT No: 420-5827-91UK PT No: FR-0013UK

POWER CORD UK NETWORKING CABLE 5MTRS STICKER C EPILEPSY

Used for applying power to the

machine in UK

PT No: 600-7269-0500UK PT No: 440-CS0186UK

For opening and closing secure

For adjoining the two Display

cabinets

Used to for linking up more that

one twin cabinet

door

This Manual

Used for applying power to the

machine in Europe (not UK)

Apply to a visible area using the

location language

10

6. FUSES

• Never touch places other than those specified. Touching places other than those

specified can cause electric shock or short circuit. Disconnect the machine from the

Part Number Location Description

514-5078-3150 RND-838-001 FUSE BD CAB 1&2 3.15A T CERAMIC 20MM

514-5078-5000 RND-838-001 FUSE BD CAB 2 5A T CERAMIC 20MM

514-5078-10000 FR-0400UK AC BRKT 10A T CERAMIC 20MM

514-5079-3000 FR-838-001UK MOTOR CONT BD 3A SLO-BLO GALSS 32MM

514-XXXX-5000 838-CA-150 AUDIO AMP 5A AUTO FUSE

supply before attempting the replacement of any fuse.

• Only QUALIFIED PERSONNEL should replace fuses.

• Only replace fuses with ones of the same value and type.

There are also fuses located on the Monitor PCB. Please refer to the separate Monitor manual supplied to

reference these fuses.

11

7. ASSEMBLING WITH PRECAUTIONS

• Perform assembly work by following the procedure herein stated. Failing to comply

with the instructions can cause electric shock.

When carrying out the assembly work, follow the procedure as laid out in this manual. Do not skip any

stages as injury may occur if the machine in not installed in the correct sequence.

1. Assembling 1 and 2 player cockpit.

2. Securing the machine into location.

3. Installing the Pop panel.

• Assembling should be performed as stated in this manual. Since this is a complex

machine, erroneous assembling can cause electric shock, machine damage and or

impair functionality.

• When assembling, be sure to be accompanied by another person. Depending on the

work involved – there are some cases where two people are required. If only one

person carries out the work alone, then it is possible that injury may occur, or

damage to the product.

• Ensure that all connectors are accurately connected. Incomplete connections may

cause electric shock or fire hazard.

4. Installing Power Cables.

5. Turning power ON.

6. Assembly check.

When assembling, make sure that tools such as a Phillips type screwdriver, wrench (for M16 hex) and a

socket wrench to suit M8 (13mm) are available.

12

• Only tighten fixings when all fixing are in place. If the fixings are tightened as the

work progresses, it might not be possible to align the final fixings.

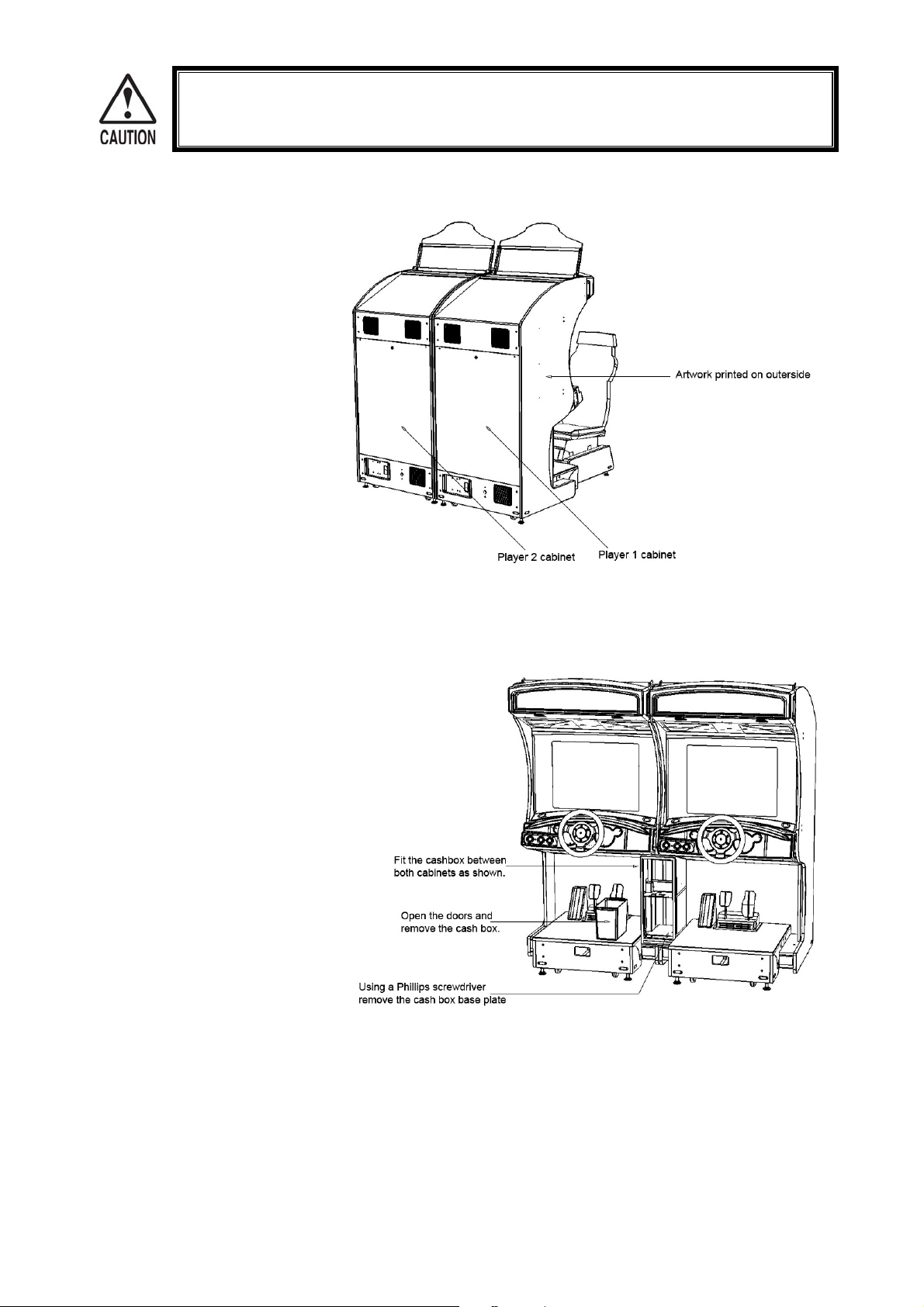

ASSEMBLING 1 AND 2

B

B

Step 1.

Place the two cockpits side by side

so that the artwork is facing

outwards on both units. The 1P

cabinet has the power cord at the

left hand side as viewed facing the

monitor.

PLAYER COCKPITS

Step 2.

Install the coin chute tower in

between both cabinets. Open both

coin doors and remove the cash

box and the cash box base plate.

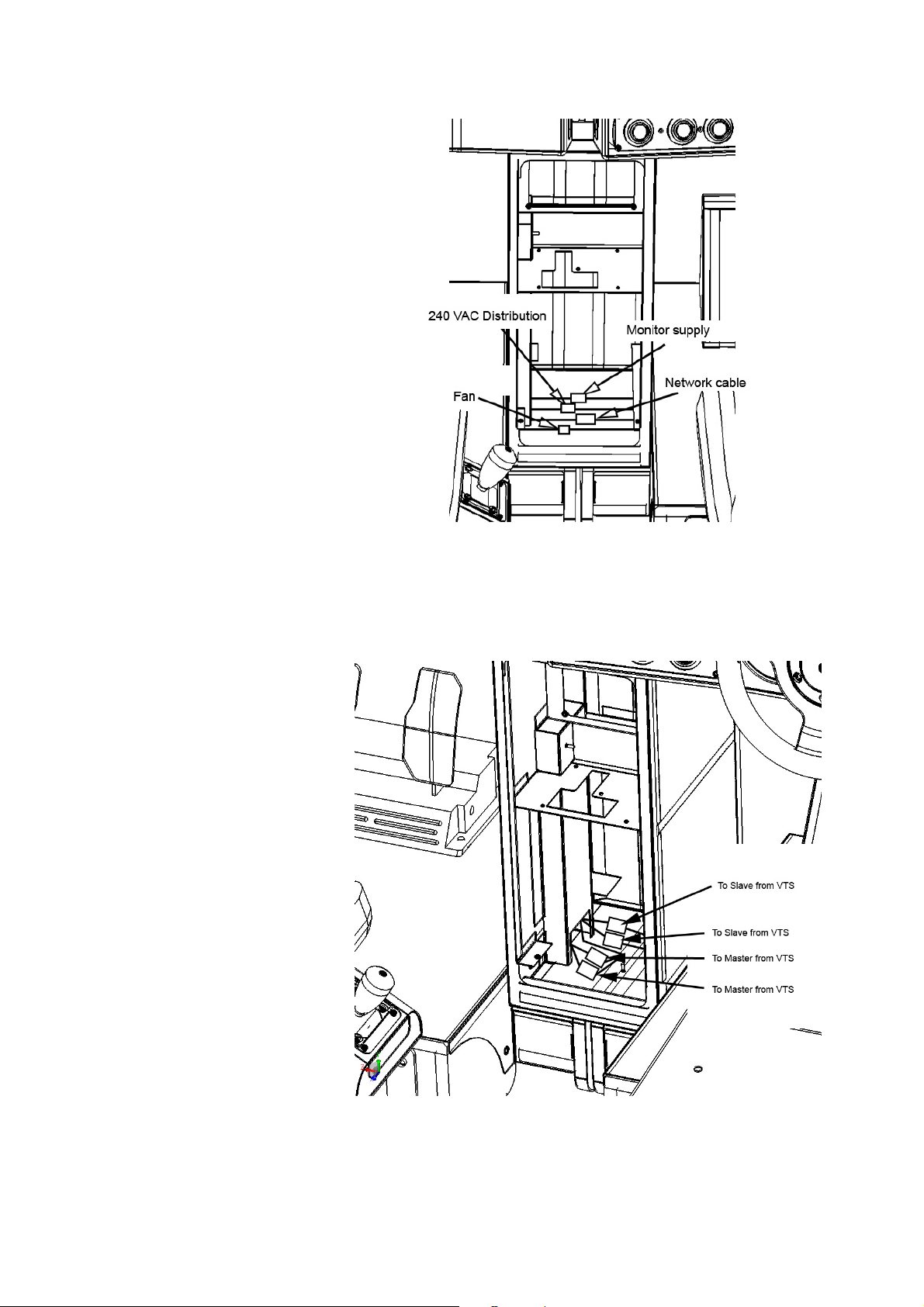

13

Step 3.

Making sure that there are no

trapped wires, make the 4 (four)

connections between both Master

and Slave cabinets.

Step 4.

Make the remaining 4 (four)

connections between the Coin

Tower and Master and Slave units.

Connect the 2 Earth ring terminals

to the M4 stud on the floor of the

Coin Tower and secure.

14

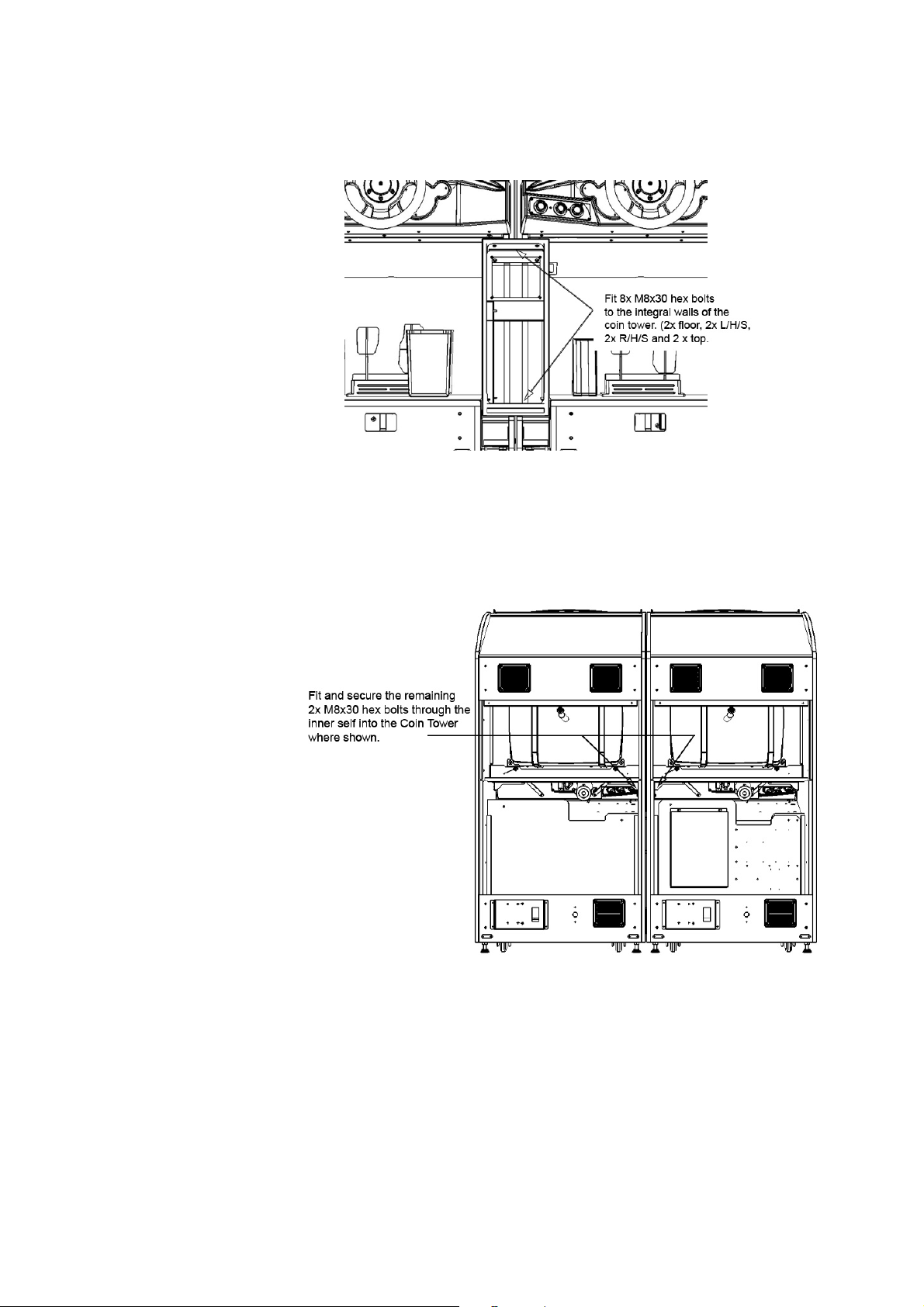

Step 5.

Fix the coin tower to both

cabinets by applying 8x

M8x30 Hex Bolts (supplied)

to the integral part of the

tower.

Step 6.

Fit and secure the

remaining 2x M8x30 Hex

Bolts into the Coin Tower

from inside both machines

as show.

15

Step 7.

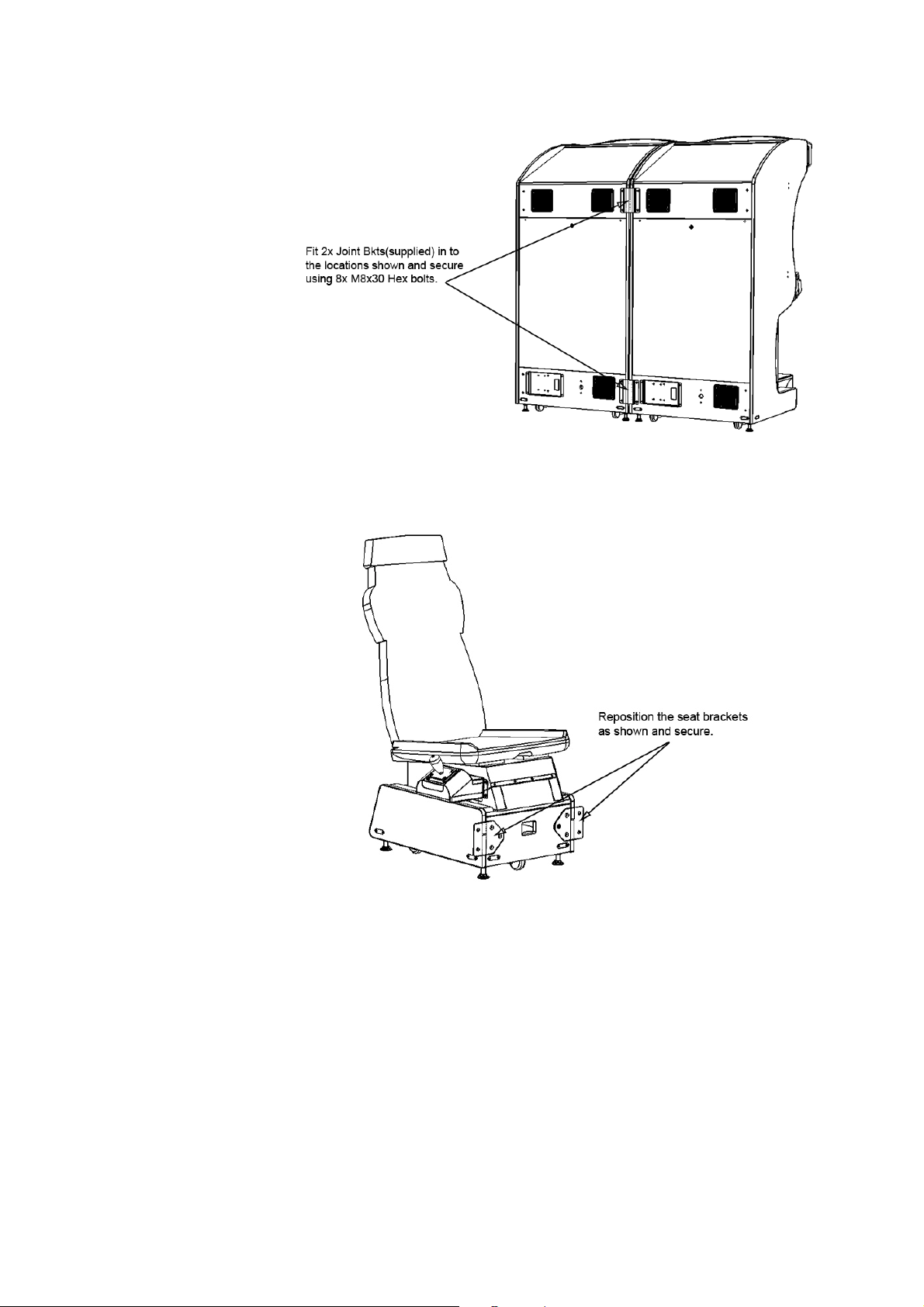

Apply the 2x Join Brackets

(FR-0013UK) to the

outside of the cabinets as

shown.

Secure using the 8x M8x30

bolts (supplied).

Step 8.

The seat brackets are

attached to the seat

cabinet but will be inverted

for transportation.

Reposition the brackets so

that they depict the figure

to the right and secure with

the same fixings.

16

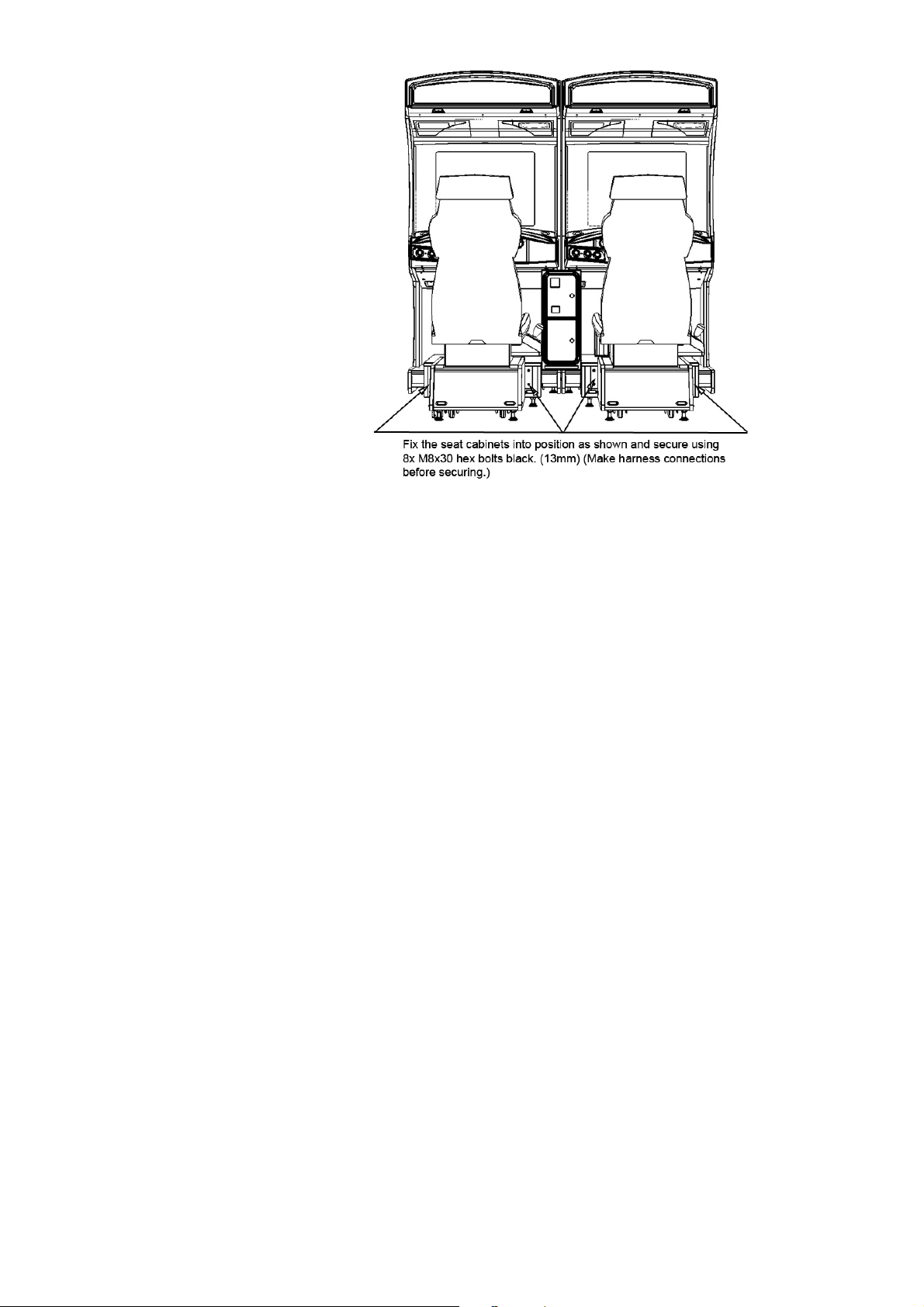

Step 9.

Offer the seat cabinet up to

the display cabinet. Before

attaching both cabinets,

make sure that the seat

harness has been

connected to the main

harness. Once connection

has been established,

secure both seat cabinets

to the main cabinets using

4x M8x30 Hex Bolts Black.

Step 10. Tighten ALL bolts in their present location using a 13mm hex driver.

17

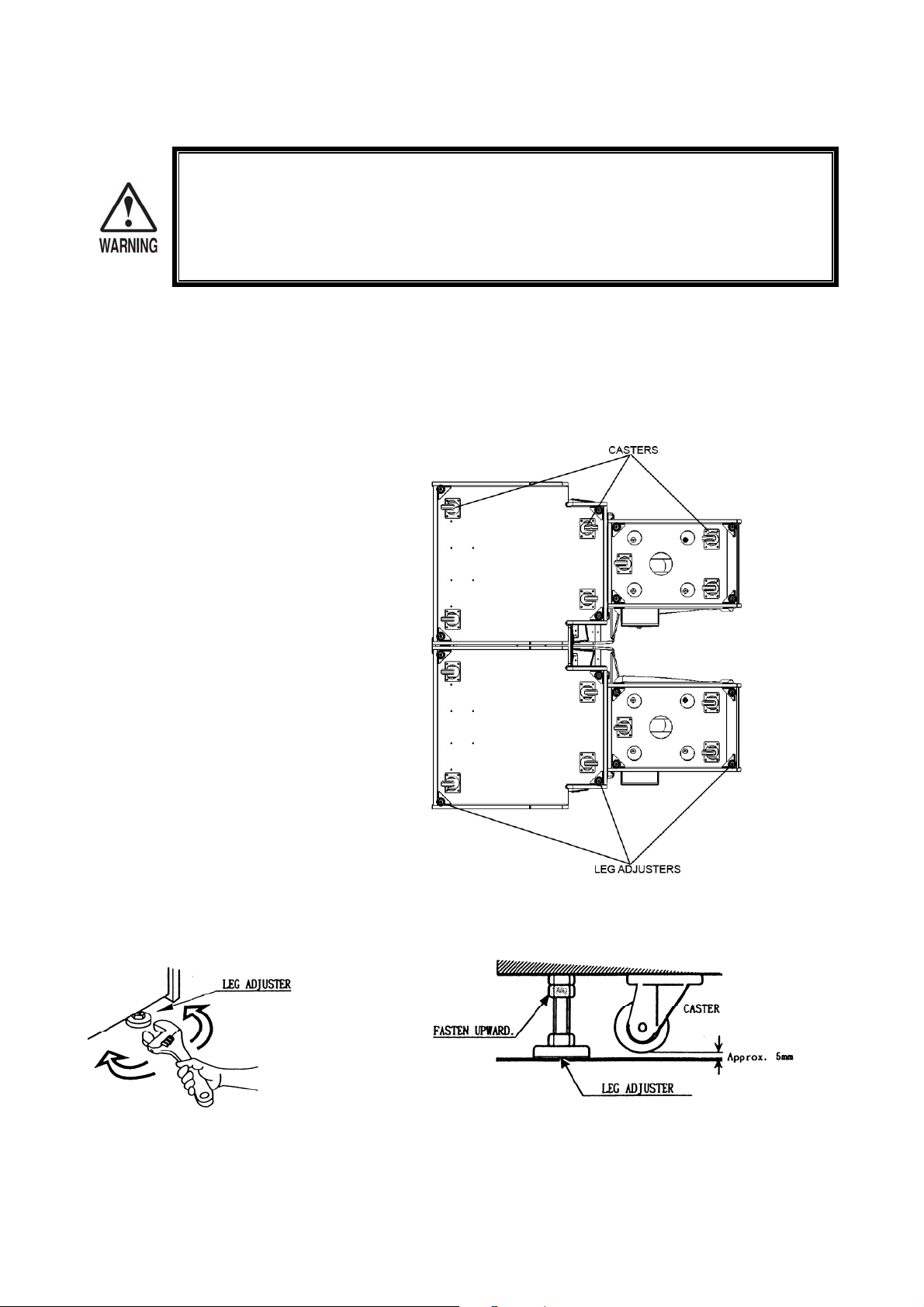

C

C

Step 1.

Move the machine to the

installation position. When

installing the machine against or

close to a wall, be sure to secure a

space to ensure player can safely

enter and exit the machine without

obstruction.

Step 2.

Bring all leg adjusters down to

make contact with the floor. Using

a Wrench or spanner adjust the

leveller so that the casters rise

approximately 5mm from the floor.

Step 3.

Once all adjusters have been

adjusted and the machine is made

level, fasten the adjuster nut

upwards to secure the height of the

adjuster.

SECURING THE MACHINE INTO LOCATION

• Make sure that all of the adjusters are in contact with the floor. If they are not, the

cabinet may move and cause an accident or injury.

• Be sure to use two people to perform this work. Depending on the specific work,

The machine has 14 casters (7 per unit) and 16 leg adjusters (8 per unit). When the

installation position is determined, bring the adjusters in contact to the floor. Make the

adjustment so that the casters rise from the floor approximately 5mm. Also make sure that

the machine positioning is level.

there are some cases in which working by one person alone may cause an accident

or injury.

After securing the height of the adjusters, tighten all of the hexagon bolts which were fastened temporarily

as per step 1.

18

D

D

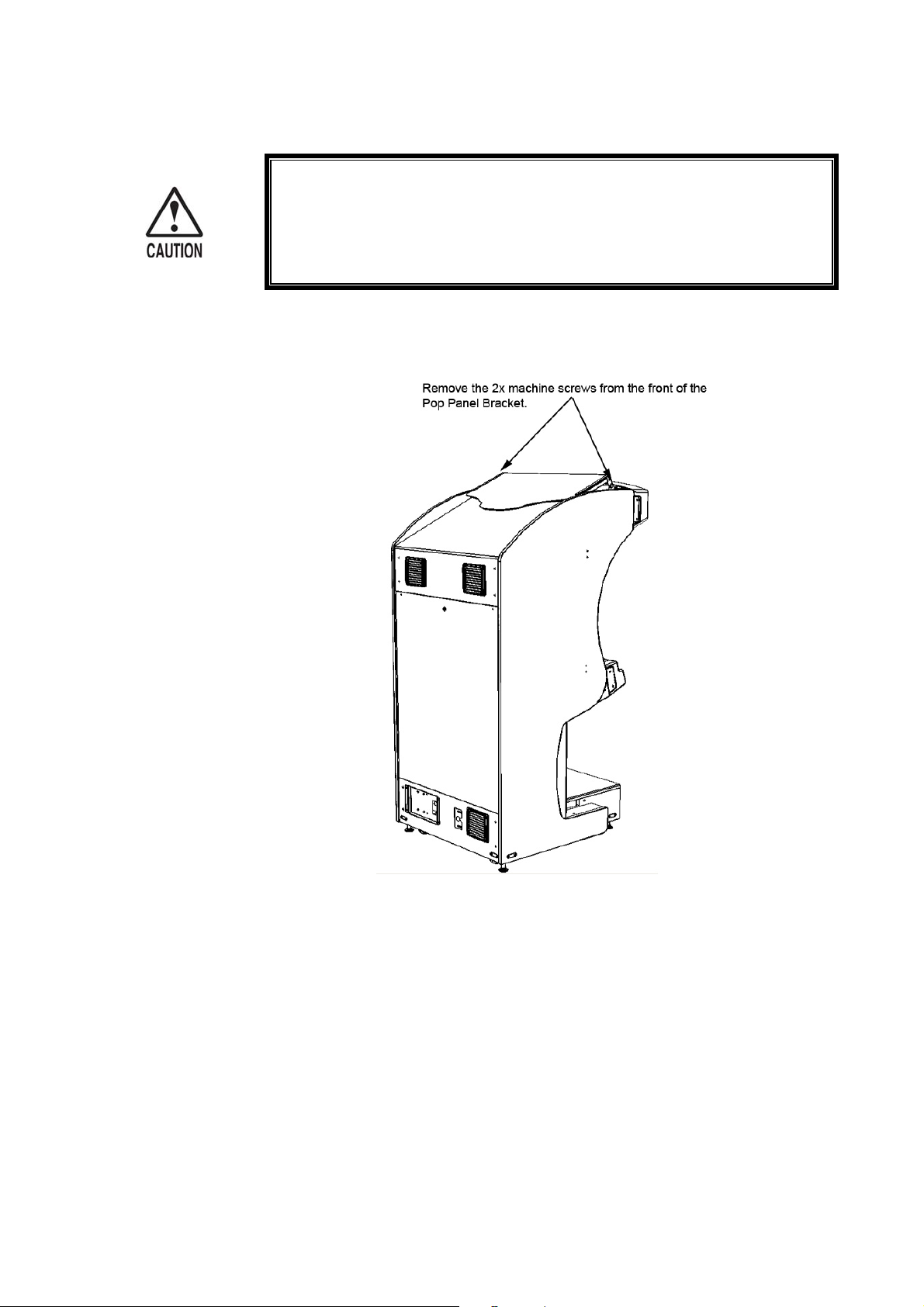

INSTALLING THE POP PANEL.

• To perform work safely and securely, be sure to use a step which is in a

secure and stable condition. Performing work without a step or a step

which is not in a suitable condition may cause and accident or injury.

Step 1.

19

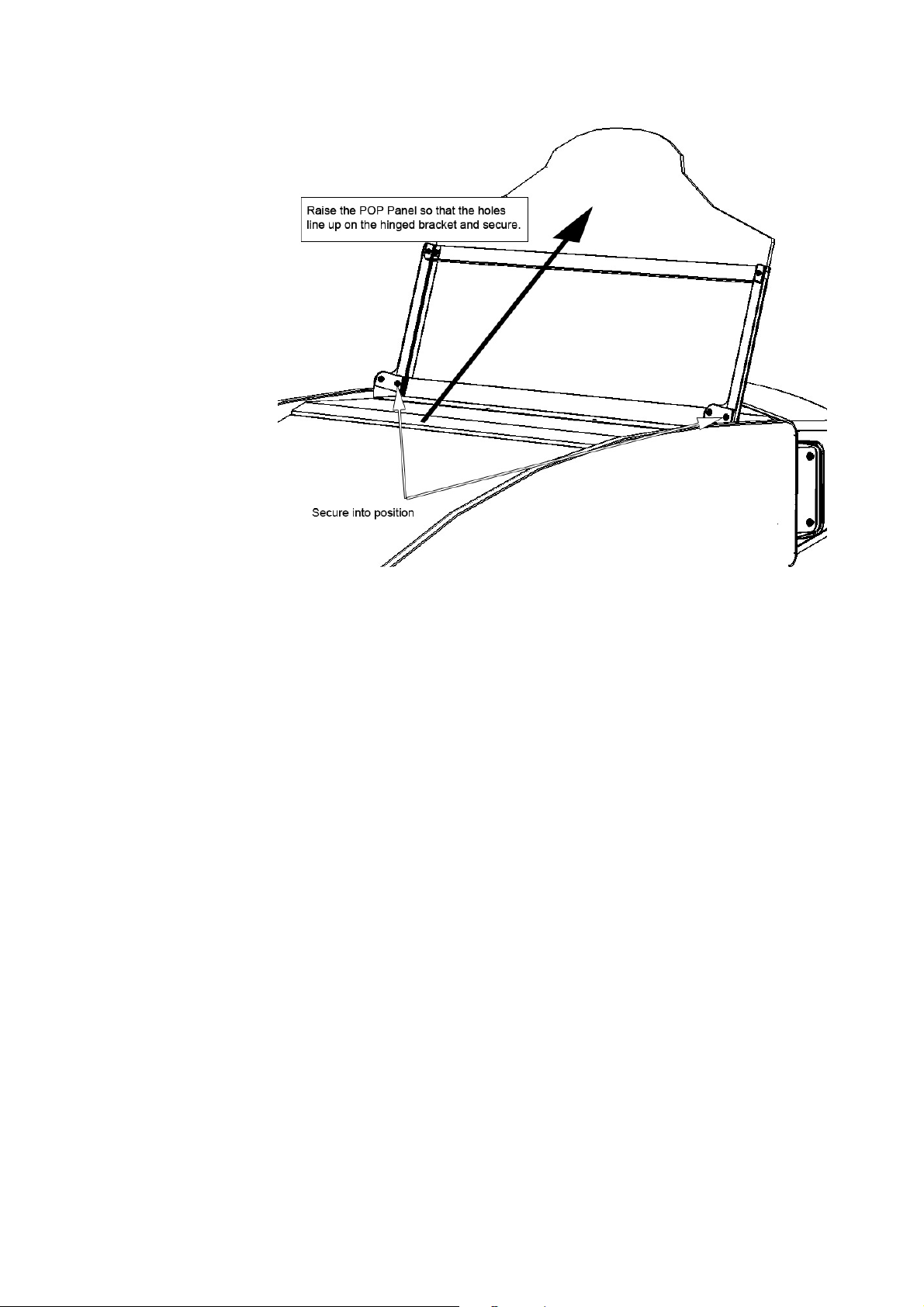

Step 2

20

E

E

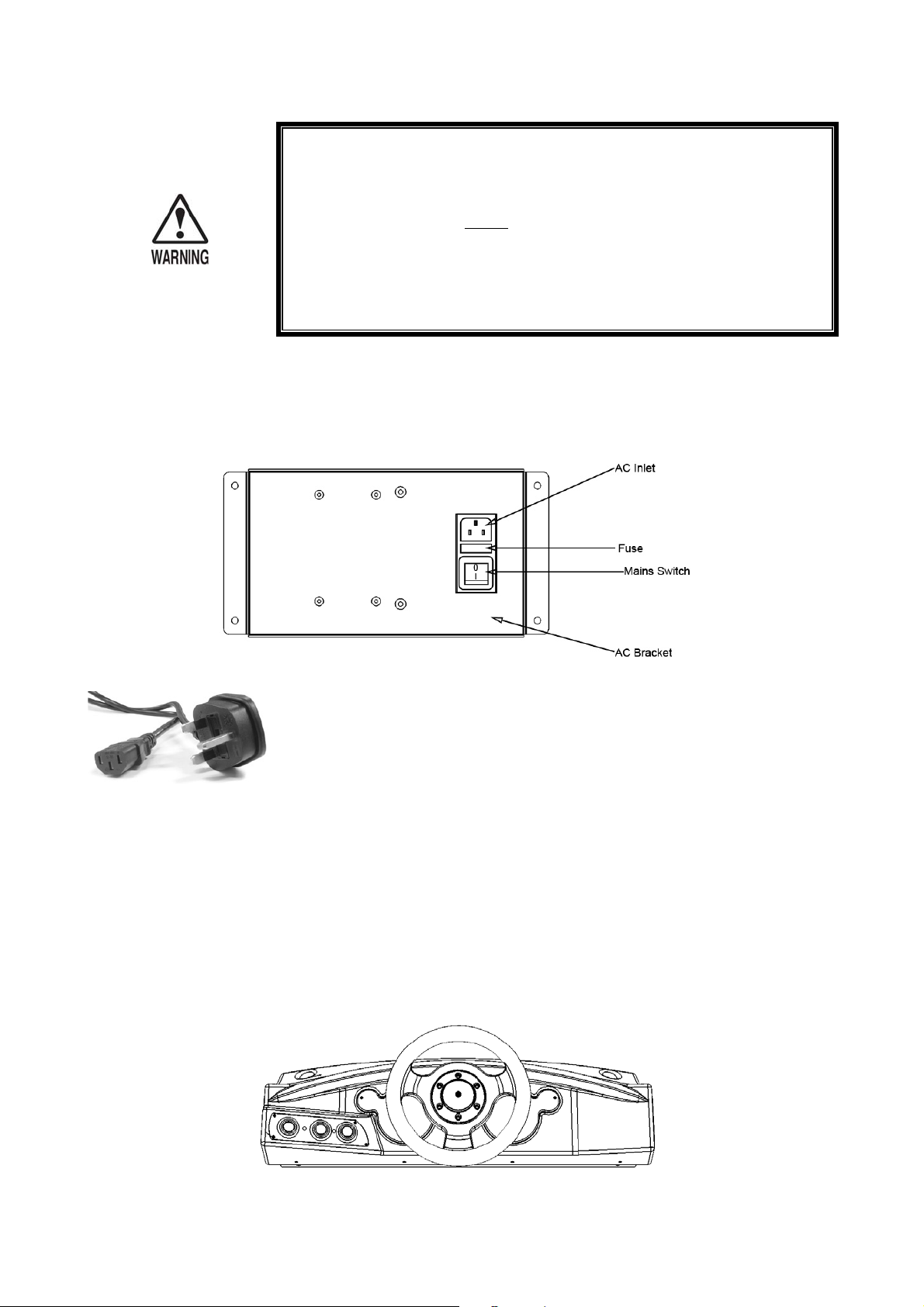

The AC unit is mounted on the 1P COCKPIT. The AC unit incorporates the Main SW, Fuse, Primary Earth

Terminal and the AC Inlet socket.

INSTALLING THE POWER CABLES

• Be sure to use an independent power supply socket equipped with an

Earth Leakage Breaker. Using a power supply without an Earth

Leakage Breaker can lead to a fire or potential shock hazard.

• THIS PRODUCT MUST

• Ensure that the power cord is not exposed on the surface. If exposed

the cord may be susceptible to damage. If damaged, the cord may

cause electric shock or fire hazard. Ensure that the power cord is not

in the customers walk way or that the cord has a protective cover.

BE EARTHED.

F

F

Firmly insert the 3 pin power plug (UK) or 2 pin power plug (EU) into the

socket outlet. Insert the opposite end of the power cord into the AC inlet of the

AC bracket.

Install suitable protective wire covering for the power cord to prevent any

accidents or injury (not supplied).

TURNING THE POWER ON

Turning the AC UNIT main switch on will cause the machine to start the POWER ON check

and NETWORK check automatically.

In the power on check the steering wheel may turn. DO NOT interrupt the steering wheel as it

moves as it may cause steering problems during the game.

During network checking “PLEASE WAIT” flashes on screen. When the network checking has

finished, the game demo mode will start. If after initialization connection has not been

established, check the network connections between cabinets and repe at process.

21

G

G

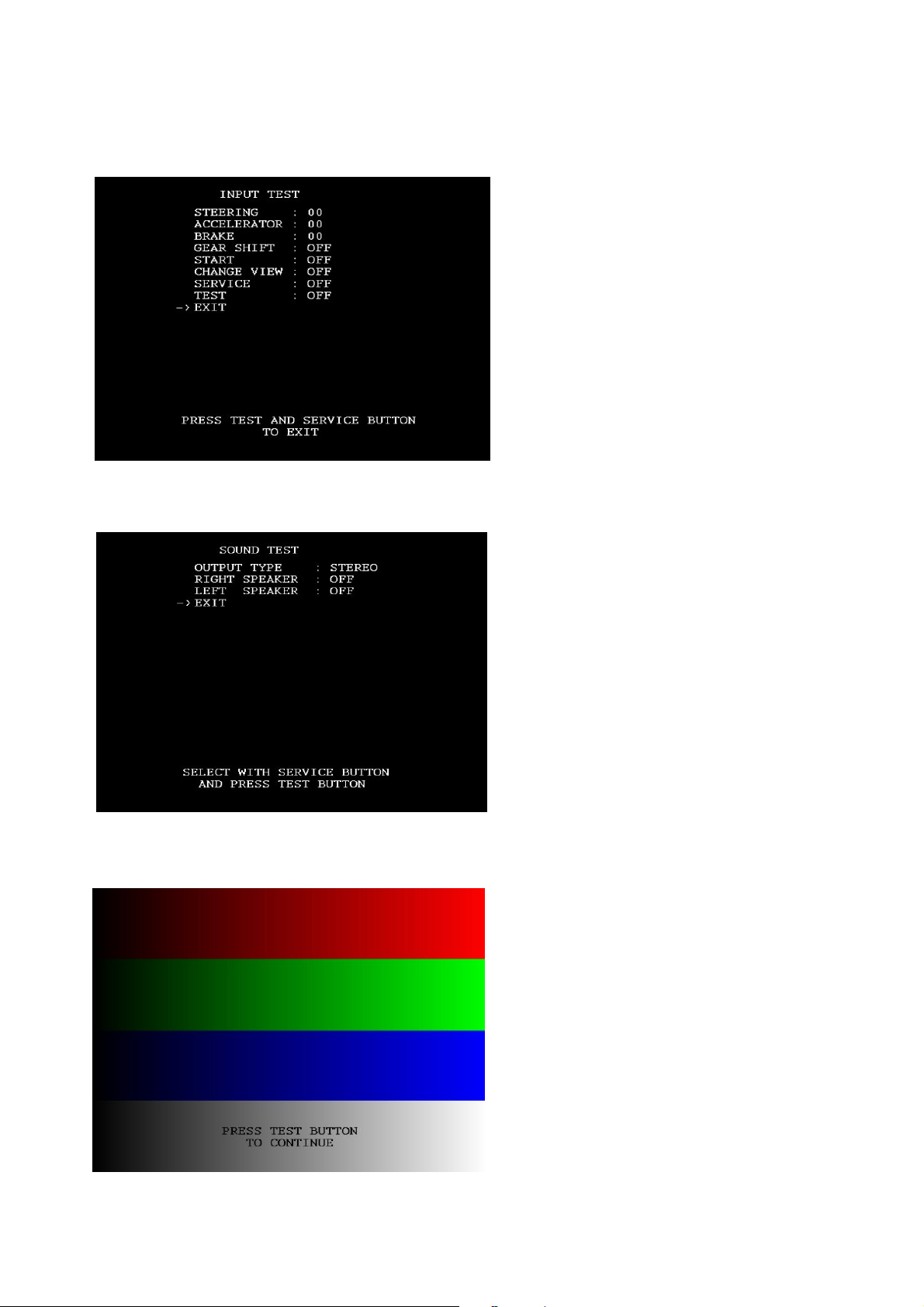

In the TEST MODE, ensure that the assembly has been made correctly and the IC BD

ASSEMBLY CHECK

is satisfactory. In the TEST MODE, perform the following tests.

Select the INPUT TEST from the SYSTEM

MENU (left screen). This screen enables the

user to test individual input to the game.

Once all input devices have been tested and

proved to be in working order, press the test

and service buttons to exit.

In the SOUND TEST, use the service switch

to access left and right speaker outputs.

Check that both speakers are working

satisfactory and that the sound levels are set

to am appropriate level.

In the SYSTEM TEST MODE MENU select

the CRT TEST. Although the monitor

adjustments have been made before

shipping, make sure that the image covers

the screen without loss of graphics. If

necessary, adjust the monitor.

Use the DEGAUSE switch if necessary to

bring the colours back into perspective.

22

8. PRECAUTIONS TO BE TAKEN WHEN MOVING THE MACHINE

• When moving the machine, be sure to unplug the power cord from both the wall and

machine ends. Moving the machine whilst either plug is inserted can cause either

and accident or injury by electric shock.

• When moving the machine along the floor, retract the Adjusters and ensure that the

casters make contact with the floor. During transportation, pay careful attention so

that the castors do not manoeuvre over power cables. Damaging power cables can

cause electric shock or a short circuit hazard.

• When moving the machine, do not push the cabinets with the seat fixed. Moving the

cabinets whilst the seat are fixed may cause damage to the fixing positions of the

seat.

• When transporting the product in places where steps are used to gain access,

disassemble the seat units from the main cabinets as damage can occur at the

adjoining positions.

When transporting the machine in places where steps have to be contended with, break the machine down

into individual parts to make transit easier.

23

9. BASIC CONTENTS OF THE GAME

The following outlines basic routines to check whether the product is functioning satisfactory. If

there is a deviation between what is explained in this section and the actual results of the machine

then immediately look into the cause of fault and eliminate the cause to ensure satisfactory

operation.

During the attract mode, the START button will flash, the BILLBOARD lamps will be lit and audio

will be emitted from both left and right speakers. (There are no speakers in the seat assembly).

1. Sit in the Cockpit. The seat can be adjusted in either a forward or reverse positions. The

lever is located on the lower right hand side in front of the seat. Pull this lever to make

adjustments to the seat.

2. Insert a coin(s). The number of credit(s) is displayed in the bottom left hand side of the

screen.

3. Press the green “CREDIT” button and the credit will transfer from the VTS BD to the

cabinet which is calling for credit. A visual indication of credits displayed at the bottom left

corner of the screen will increment by the amount of credits set. “PRESS START” will

appear on screen.

4. Press the “START” button and the game will start by employing the driver to select certain

criteria’s i.e. type of car, type of course.

24

10. EXPLANATION OF TEST AND DATA DISPLAY

By operating the buttons located on the VTS BD will enable the SYSTEM and GAME TEST

MODES. When installing the machines, collecting cash or when the machine does not perform

correctly, initiate a test sequence as explained in this section of the manual. The following outlines

each test mode and explains in detail the movement throughout the menus.

• ONLY A QUALIFIED SERVICE ENGINEER SHOULD MAKE ANY AMMENDMENTS

TO THE CRITERIAS LISTED WITHIN THE SYSTEM TEST MENU.

ITEMS DESCRIPTION

MACHINE INSTALLATION

PERIODIC SERVICING

When the machine is installed, perform the following:

1. Check that each setting is set to the factory setting as

per the time of shipment.

2. In the INPUT TEST mode, check each switch and VR

for operation.

3. In the SOUND TEST check the operation of both front

speakers.

4. In the CRT TEST check the adjustment of the picture

and adjust if necessary.

Periodically perform the following tests:

1. In the INPUT TEST mode, check the CONTROL

devices and buttons.

2. In the SOUND TEST perform a sound check.

MONITOR

DATA CHECK

In the monitor check screen, check to see if the MONITOR

adjustments are made correctly.

Check such data as game play time and histogram and adjust

difficulty levels if necessary.

25

Loading...

Loading...