Seca 727, 728 Service Manual

Service Manual

Variants:

7271321004

7271321124

7271321334

7271321614

7271321624

7271321804

7271321844

7281321009

7281321129

7281321619

7281321834

Content:

for seca 727, 728

Service Manual Number

17-05-01-260-i

Valid as of: 01.12.2010

Description:

High resolution baby scales with integrated LED-display

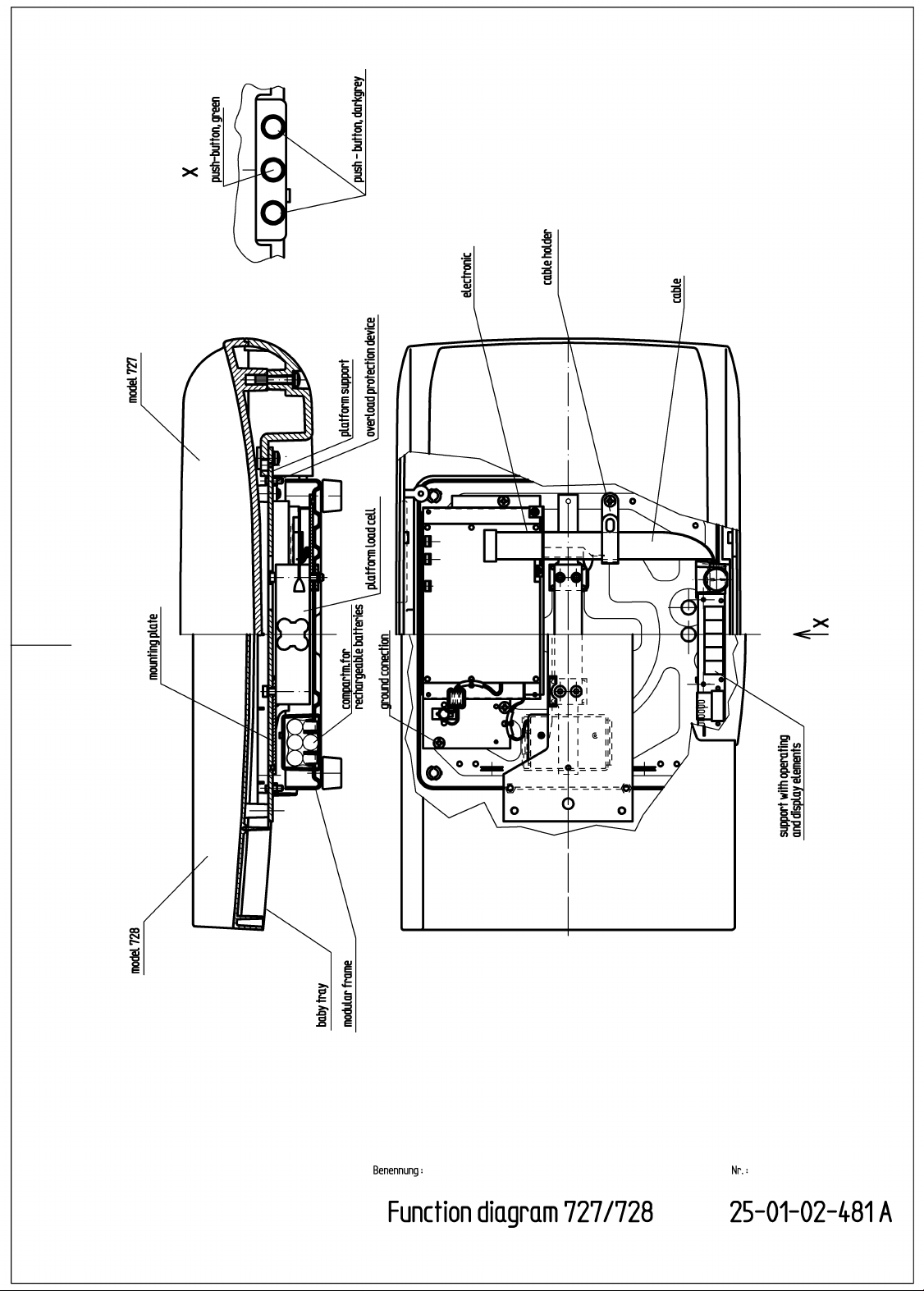

Function diagram 25-01-02-481 a

Electronics 25-01-02-467 e

Block diagram electronics 08-09-01-267 c

Description of RS232 interface 30-34-00-605 a

Description of faults 30-34-00-437 g

Replacement 30-34-00-483 e

Calibration 30-34-00-654

spare parts 30-34-00-486 k

Manual number: 17-05-01-260-i

Circuit description

Model 717,727,728,737,748,757 Blatt 1(3)

Associated circuit diagrams:

1. A/D converter circuit diagram 08-01-21-321

2. Microprocessor circuit diagram 08-01-21-322

3. Display unit circuit diagram 08-01-21-323

4. Switched-mode power supply

circuit diagram 08-01-21-354

Measuring element

A platform load cell is used as the force

measuring element. 4 wire resistance strain

gauges are attached to its surface at suitable

points which are connected in a bridge circuit.

When a load is applied, the spring body is

deformed in such a way that the two resistors

forming a half bridge are extended and

compressed. This causes the resistance to be

increased or reduced so that the bridge is

detuned, causing a change in the output signal:

=⋅ ⋅

UkUF

aS

In order to ensure a higher signal yield for the

seca 717, the measuring element and the A/D

converter are supplied with 10V; usually, a 5V

power supply is provided.

Analog to digital converter

The A/C converter directly processes the small

output signal of the strain gauge sensor. It

functions according to the principle of signaldependent pulse-width modulation. All digital

functions of the A/D converter are implemented

via software in a microcomputer. The reference

potential of the A/D converter is ≈ U/2, since the

positive input of integrator 402 is connected to a

bridge output via resistor 506. During a predefined

total time T, first the input voltage +Ue is

connected to integrator 402 via resistors 507 and

506 and then the reference voltage U/2 with FET

switch 600/1,2,13, via resistors 510, 517 (for

model 727 only), 602, 604, 511, 512, 513 and 514.

The components are selected so that the

integrator integrates up during this phase

whenever an input voltage is applied until

comparator 502 reacts. The response threshold of

the comparator is determined by resistors 410 and

411. Resistor 413 causes positive feedback and

prevents the comparator oscillating. The

microcomputer detects that comparator 502 is

triggered and switches FET switch 600/1,2,13 off.

The integrator now runs down until time T has

expired. The interval between T = 0 and the

moment the comparator reacts is a measure for

the input voltage Ue.

Trimmer 602 compensates for the local gravitation

(GAL value). Trimmer 604 is used to fine-adjust

the slope. As the adjustment range for 604 has

been deliberately kept small, the slope can be

adjusted using the combination 513, 514.

∝

UF

a

Resistors 508 or 509, which can be used

alternatively, are used for coarse adjustment of

the zero point. Resistor 412 helps the output stage

of amplifier 402 to increase the negative output

range.

Resistors 515 or 516 allow characteristic curves to

be corrected.

For incubator scale 748 only:

For reasons of electromagnetic compatibility, the

analog to digital converter circuit is provided on a

separate board. Reducing the analog signal path

by mounting the board in the base plate and using

interference-suppression capacitors 400, 401,

501, 603 considerably reduce electromagnetic

susceptibility.

The 5V supply voltage for the board is fused on

the main board with a 100mA fuse to limit the

energy on the board in the event of a fault.

Temperature compensation

For temperature compensation of the strain gauge

sensor, a fixed-value resistor is connected in

parallel with a temperature-dependent resistor. To

compensate for the sensitivity's t.c. value, the

combination 511,512 is used (NTC). The positive

t.c. value of the test value can be compensated for

by the combination 405, 406 (PTC).

Zero point, sensitivity and test value are partly

interdependent. To determine these values, the

modules (electronics + sensor) are measured at

10°C and 40°C (zero point, slope, test value) and

the results are entered into a computer. The

computer uses a complex computing routine to

calculate the optimum temperature compensation.

Microcontroller and display

The central computing and control element is the

microcontroller (µC) 520.

It fulfils the following functions:

• Digital A/D conversion

• Calculation of the zero point

• Binary BCD segment conversion

• Display control using multiplex operation

• A/D converter test

• Testing the CPU and the memories (RAM and

ROM)

• Overload detection

• Monitoring the supply voltage (digital)

• Automatic zero point monitoring

• Taring function

• Hold function

All functions are implemented via software in the

programmed memory (ROM) of the µC.

Sequence of operations

08.02.98 Law 25-01-02-467 Index E

Circuit description

Model 717,727,728,737,748,757 Blatt 2(3)

When the start button is pressed, the following

steps are executed:

Starting

The µC is started with the reset logics (see below)

and the program is executed.

Self-test

A test digit is written into all of the RAM cells in

succession, then read out and compared.

The main CPU commands are checked via

computer operations to see that they function

correctly.

The sum of the digits of those memory values

which are important for the weighing result is

continuously calculated and checked for

correctness.

The µC outputs the processed 7-segment

information to the segment port. Via Darlington

driver 419 (8 transistors) and resistor network 317

(8 resistors), the cathodes of the LED's are set to

0 V. The shared anodes are connected to + 5V via

the relevant digit transistor.

Overload detection

The current measured value Mi is checked with

respect to two limit values:

a) Overranging

If F = F

(d = graduation on the display)

b) Overshooting the limit

If F = F

displayed.

+ 9d, "STOP" is displayed.

max

lim

(ca. F

+ 20 %), "EEEEE" is

max

In the event of fault, "EEEEE" is written to the

display.

Zero point determination

After starting, "SECA" is displayed for approx. 1

second. During this period, the zero point is

determined. The measured value Mo obtained is

saved and subtracted from the relevant measured

values.

For incubator scale 748 only:

After "SECA", "-UP-" flashes in the display. The

scale must be relieved by at least 0.5 kg in order

that the zero point can be determined. Once the

zero point has been determined, a sound is

emitted for approx. 1 second which signals that

the scale is ready for weighing.

Zero point follow-up

If the current measured value Mi changes only

slightly in relation to the zero point value Mo within

a given time (C = 0.5 d/sec), the current measured

value is regarded as the zero point (Mi = Mo).

Weight calculation

The weight is calculated from the current

measured value Mi minus the zero point value Mo,

divided by ne ne is the internal step count per step

displayed.

MM

()

−

0

F

Here ne = 10.

Display

The current weight F is displayed on a 7-segment

LED display. The display is controlled via multiplex

operation. Consequently, actuation faults affect all

segments and are detected immediately.

i

=

n

e

C) A/D converter limit values

If the bottom or upper limit of the A/D converter is

overshot, "EEEEE" is displayed.

Range switch-over for model 717

By pressing the weighing range switch-over

button, where normally the tare button is fitted, the

scale can be switched over between weighing

range 1 and 2:

Weighing range 1: 15kg / 5g

Weighing range 2: 6kg / 2g

Hold and tare function for model 727

The Hold/Tare button has two functions.

Tare range: up to 0.4 kg

Hold range: from 0.4 kg

Taring function for models 737 and 757

The taring function is activated by pressing the

tare button.

Hold function for models 717,737,748 and 757

The hold function is activated by pressing the hold

button.

Taring

If the taring function is activated, this is detected

by the µC, tare indicator 27 on the display board is

switched on and the weight on the scale is tared

off.

The zero point Mo is subtracted from the

measured value Mi and the result is saved as Mt.

The weight now results from:

MMM

−−()

0

F

it

=

n

e

08.02.98 Law 25-01-02-467 Index E

Circuit description

Model 717,727,728,737,748,757 Blatt 3(3)

Zero follow-up and overload detection continue to

operate as usual, whereas the measuring range is

overshot if:

M

FF d

If measured value Mi is smaller than the zero point

Mo by the value Mt, the taring function is

cancelled again.

The value Mt is added again to the zero point and

tare indicator 27 is switched off.

Hold operation

If the hold function is activated, the weight is

retained on display as soon as the value has

stabilized, until the hold function is activated the

next time.

Monitoring the supply voltage

A monitoring circuit for the supply voltage is

connected to pin 14 of the µC, which detects if the

operating voltage is too low. If this pin is at 0potential, the µC interrupts the normal measuring

cycle and writes "bAtt" into the display. If the scale

is operated on rechargeable batteries, the

electronics are switched off after a few seconds

via pin 8 of the µC in order to prevent exhaustive

discharge.

Switch-on time

The switch-on time is determined by the software

as standard. Continuous operation can be

achieved by soldering in jumper 618.

Power supply unit detection

If a power supply unit is connected to the scale,

transistor 109 is switched through via the battery

charging circuit (see below). This sets pin 33 of

the micro-controller to 0V and the switch-on time

is extended in accordance with the software

setting.

Power supply

The circuit has the following special features:

- Reliable function over a large input voltage

- Low power loss

Reset circuit

By connecting a power supply unit, a positive

pulse is issued via high-pass filters 116 and 117

and via diode 118. The same happens when the

start button is pressed (via 113, 114 and 115).

Resistor 112 ensures that capacitor 113 can be

discharged when the start button is open. (The

alternative connection for the start button at pin 3

=+−

range from 6 – 15 V at a controlled output

voltage of 5V or 10V.

max

1

t

n

e

of IC 126 prevents a reset when the scale is

switched on and allows a start button to be used

which is connected with the platform surface.)

The pulse from diode 115 or 118 is transferred to

the set input of flip-flop 126/B. Low-pass filter 141,

142 prevents a reset being triggered by conducted

interference. Resistor 119 is used as a pull-down

resistor for the set input.

As soon as flip-flop 126/B is set, capacitor 124 is

charged via resistor 125. The flip-flop is reset

shortly afterwards.

The pulse generated at the output of 126/B

switches on the 5V power supply via flip-flop

126/A and transfers a 5V pulse to the controller

via resistor 127 and transistor 128.

Low-pass filter 619, 620 ensures that no reset is

triggered by conducted interference.

Voltage stabilization

The reset sets flip-flop 126/A whose output sets

the shut-down input of switching controller 131 to

high. The latter generates a controlled voltage of

5V by means of diode 132, coil 133 and

capacitors 129, 130, 134 and 135. By means of

the LC combination 136, 137, this voltage is

smoothed for use in the A/D converter region.

Using resistors 139 and 140, the control threshold

is set above which the switching controller sends a

low-batt signal to the controller. Resistor 138 is

used as a pull-up resistor here.

If the voltage is to be switched off again, the

controller switches the stop signal from high to

low. Resistors 121 and 122 as well as transistor

123 perform a level conversion and inversion of

the signal, so that a positive edge is given to the

clock input of flip-flop 126/A, resetting it and

switching off the 5V voltage.

For the seca 717, the 10V in-phase regulator 451

is used which supplies the A/D converter and the

force measuring element using buffer capacitors

452, 453.

Battery charging circuit

The rechargeable batteries are charged via

stabilized power supply 103, 104, 106, 107, 108

and via diode 105. The charging current

corresponds to the float charge current of the

batteries. This current is relatively low and

increases the charging time, but the service life of

the batteries is extended considerably.

Voltage monitoring for the batteries is not

necessary. Diode 110 protects the batteries from

the unlimited current of the power supply unit.

08.02.98 Law 25-01-02-467 Index E

Circuit description

Model 717,727,728,737,748,757 Blatt 4(3)

Diode 102 is used as polarity reversal protection

and overvoltage protection. Diodes 110 and 111

protect against discharge during battery operation

and against polarity reversal.

Electrolytic and tantalum capacitors are distributed

evenly over the printed circuit board as backup

capacitors for the operating voltage.

08.02.98 Law 25-01-02-467 Index E

Loading...

Loading...